Page 1

AHU Controller Specifications

1. Application

This controller is used to set up a system by connecting a field-supplied Air Handling Unit (AHU) to Mitsubishi

Electric City Multi outdoor unit. This controller can be used to control the system only in cooling mode.

Applicable models: PAC-AH63, 125, 140, and 250M-G

2. System restrictions and use of range

(1) System configuration

Connectable outdoor units PUY-P250,300,350YGM-A

PUHY-P250,300,350,400,450,500YGM-A

Refrigerant type R410A

Capacity of connectable indoor units 50~100% of outdoor unit capacity

Capacity ratio between AHU and STD

(standard indoor units manufactured by

Mitsubishi) in a system with one outdoor

units to which both indoor units and AHU

controllers are connected

Number of connectable indoor units P250, 1~12; P300, 1~15; P350, 1~18

* When an AHU is grouped with the standard indoor units in a system with one outdoor unit, the

capacity of the standard indoor unit may drop depending on the operating conditions of the AHU.

A system with one AHU is recommended.

(2) Operating conditions

Operating conditions of indoor, outdoor, air handling units (cooling/heating)

Unit Type Cooling Heating

AHU (evaporator inlet air temperature) 15~24ºCWB NOT available

Outdoor unit -5~43ºCDB -20~15.5ºCWB

STD in a system with one outdoor unit to

which both indoor units and AHU

controllers are connected

* While the AHU is running in cooling mode, the operation mode of the standard indoor units cannot be

changed to heating mode, as AHU is cooling only. The operation mode of the AHU cannot be changed to

cooling mode while the other units are running in heating mode. Stop all the units in the system to change

the operation mode.

If the units are operated beyond the conditions shown above, the units may make an error stop, and in

the worst case the compressor may not function properly. To avoid this, operate the units under the

conditions shown above.

(3) Refrigerant pipe size, pipe length, and height difference restrictions

Pipe size

(Liquid / Gas)

AH63,125,140 Φ9.52 / Φ15.88

AH200 Φ9.52 / Φ19.05

Capacity of connectable AHU in a system with one outdoor units

to which both indoor units and AHU controllers are connected

must be 50% or less of outdoor unit capacity

<Example>

AHU:STD = 50%:50% Acceptable

= 70%:30% Not acceptable

= 30%:70% Acceptable

=100% : 0% Acceptable

(when only AHU is connected)

P400, 1~20; P450, 1~22; P500, 1~25

15~24

ºCWB 15~27ºCDB

AH250 Φ9.52 / Φ22.2

WYN C0-8494

1/11

Page 2

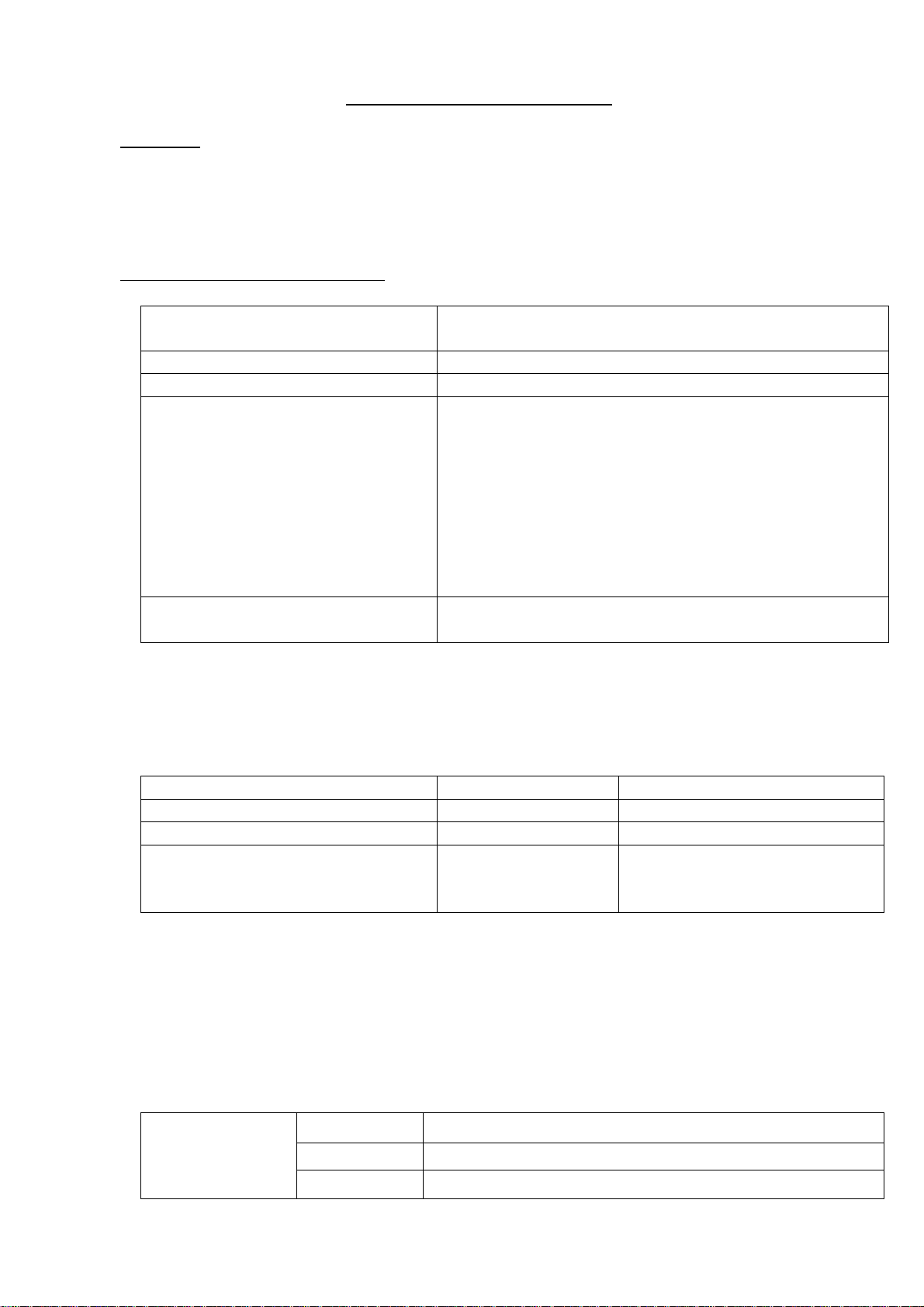

Pipe length

Height difference

(1) No further branching in the pipes is possible after the header branch.

(2) When cooling operation is performed when the outdoor temp. is 0

lower:H’=4m or less

(3) Equivalent pipes length(m):Actual pipe length + A×number of bent.

Table A

Outdoor unit model A Outdoor unit model A

P250 0.42 P400 0.50

P300 0.42 P450 0.50

P350 0.47 P500 0.50

ºC or

WYN C0-8494

2/11

Page 3

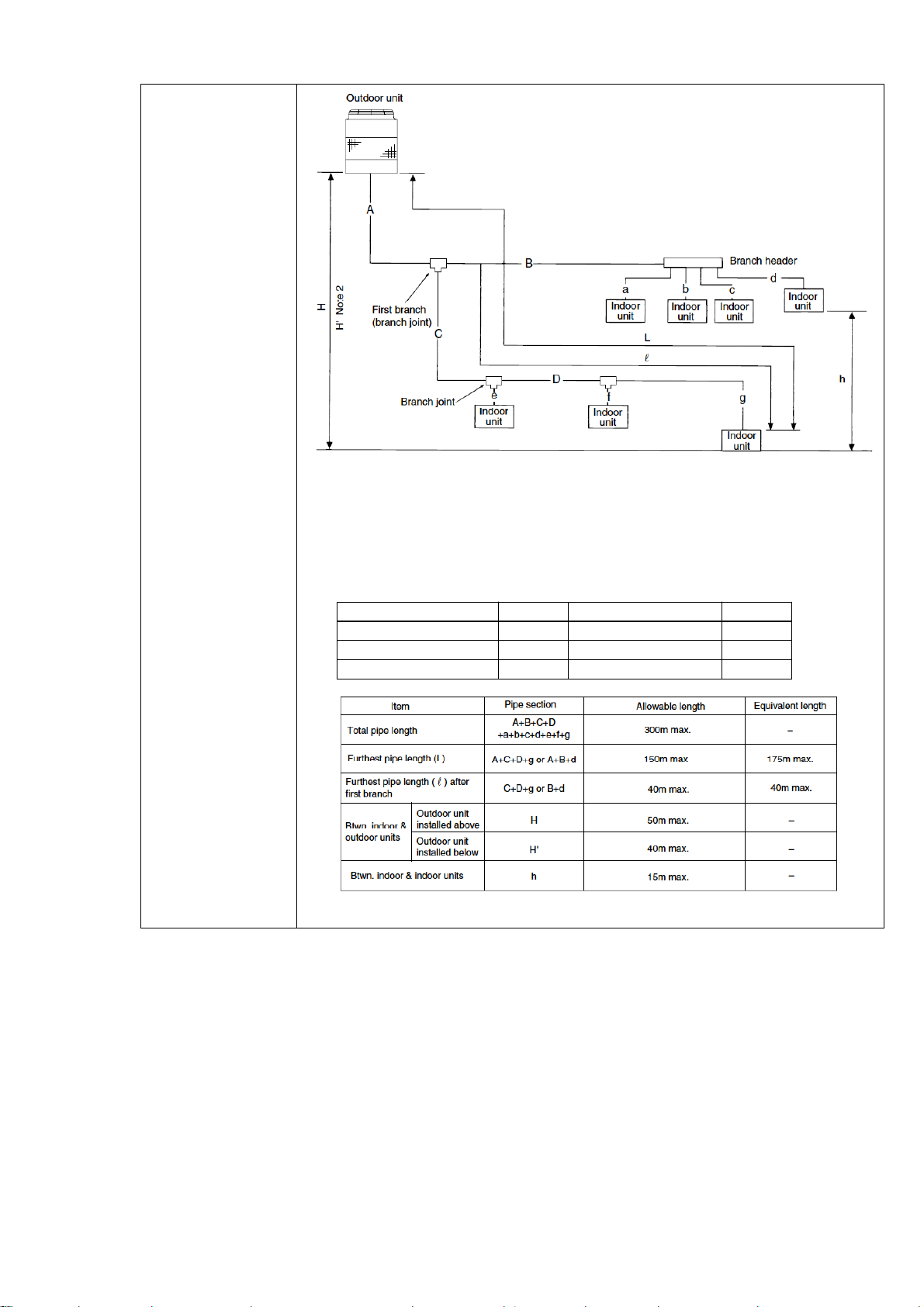

Amount of

refrigerant to be

added

(1) Original charge of refrigerant and the maximum total charge.

At factory shipment, refrigerant are charged in the outdoor unit as shown at

following Table. When extending the piping in the field, additional charge of

refrigerant is needed. Yet, the maximum total charge in the air conditioner

system should not be exceeded. The maximum additional charge varies on

models, shown as at following Table.

Ta b l e

PU(H)Y-YGM P250,300,350 P400 P450,500

Original charge A(kg) 9.5 13.0 22.0

Maximum total

charge

Maximum

additional

charge

B(kg) 40.0 40.0 67.0

C(kg) 30.5 27.0 45.0

(2) Calculate the additional charge for the air conditioner system in the field.

The additional charge (F kg) is calculated as follows. F should be round up to

0.1 digital, like 10.52→10.6kg.Yet, if F results bigger than C, the additional

charge is the maximum additional charge C.

F(kg)=(0.2×Ld)+ (0.12×Le)+ (0.06×Lf)+ (0.024×Lg)+D

Where Ld(m) : Length of liquid pipe sized Φ15.88

Le(m) : Length of liquid pipe sized Φ12.7

Lf(m) : Length of liquid pipe sized Φ9.52

Lg(m) : Length of liquid pipe sized Φ6.35

D(kg) : Additional charge of refrigerant required by the total capacity

of indoor units in the refrigerant system.

Total capacity of indoor

units connected

D(kg) 1.5 2.0 2.5 3.0

~161 161~330 331~480 481~500

3.

Product configuration

(1) Series configuration

Several types of controllers to accommodate different AHU capacities are available.

Select the appropriate controller.

Model name PAC-AH63M-G PAC-AH125M-G PAC-AH140M-G PAC-AH250M-G

Max. capacity (kW)

Min. capacity (kW)

Reference air

flow rate (m

Unit size

3

7.1 8.0 9.0 11.2 14.0 16.0 22.4 28.0

5.6 7.1 8.0 9.0 11.2 14.0 16.0 22.4

1250

/h)

1500 1750

2000 2500 3000 4000 5000

63 71 80 100 125 140 200 250

* Calculate the capacity of connectable indoor units using the “Unit size” in the table above.

The Unit size is set to the model name at factory shipment. Change the Unit size to the appropriate value

for the selected controller using the switch on the controller board. Refer to the installation manual for

how to change the Unit size.

(2) Controller components

Name Usage

Controller board For operation control Controller

Transformer For controller board

WYN C0-8494

3/11

Page 4

LEV-kit

Thermistor

Clip

Insulation

Tie band

Tube

Installation manual

(3) Major specifications

Power supply 220~240V 50Hz

External dimension (mm) 382(430)×326×117(132)

Net weight (kg) 7

External finish(Munsel No.) 5Y 8/1

IP-class IP24

Remote controller temperature setting range

Operation

Temperature control

Terminal block For power source, for external I/O, for internal and external

communication, for remote controller, and for thermistor

Connector For remote controller and for level input switch

Relay For operation display and for error display

Electronic linear expan. valve

For detection of suction air temperature, liquid pipe

temperature, and gas pipe temperature

For mounting suction temperature thermistor

For insulating liquid pipe and gas pipe thermistor

For fixing liquid pipe and gas pipe thermistor

For fixing wiring

-

The figure in ( ) indicates mounting's.

14~30ºC

Operation by

optional remote

Press ON/OFF button on the remote controller to start/stop the

operation.

controller

Operation by

external input*

Connect the field-installed external thermostat (ON/OFF) to the

external input (ON/OFF) to start the operation when the

external thermo is ON, and stop the operation when it is OFF.

Interlock

operation with

AHU fan

Interlock setting between the error stop of AHU fan and the

external input ON/OFF must be made to close the LEV of AHU

heat exchanger when AHU fan makes an error stop. Refer to

section 5 for details.

Temperature

control by

optional remote

The thermostat will be turned off (LEV will be closed) when the

suction air temperature thermistor reading reaches the preset

temperature on the remote controller.

controller

Temperature

control by

external

thermostat

Connect the field-installed external thermostat (ON/OFF) to the

external input (ON/OFF) to start the operation when the

external thermo is ON, and stop the operation when it is OFF.

The thermostat will be turned off when the suction air

temperature thermistor reading reaches the preset temperature

on the remote controller. Refer to section 5 for details.

WYN C0-8494

4/11

Page 5

Protection function

Freeze

prevention

After 16-minute or more cooling operation, and when 1ºC or

less of the thermistor detection temperature for liquid pipe is

detected for 3 minutes in a row, the linear expansion valve will

be closed to prevent freezing. The operation will be normal

when either of the following conditions is met.

- When 3 minutes have passed after 10

ºC or more of the

thermistor detection temperature for liquid pipe is

detected.

- When 6 minutes have passed after the expansion valve

was closed to prevent freezing.

Sensor failure If a short or an open of the thermistor is detected during

operation, the error will affect the LEV, and it will be closed.

Communication

error

If the addresses overlap or the transmission line is not

connected properly, the error will affect the LEV, and it will be

closed.

Other types of

error

If the outdoor unit in the system with one outdoor unit has a

problem, the problem will affect the entire system, and the

compressor will stop.

* Default setting (operation mode setting or temperature setting) with an optional remote controller must be

made when an external input is used.

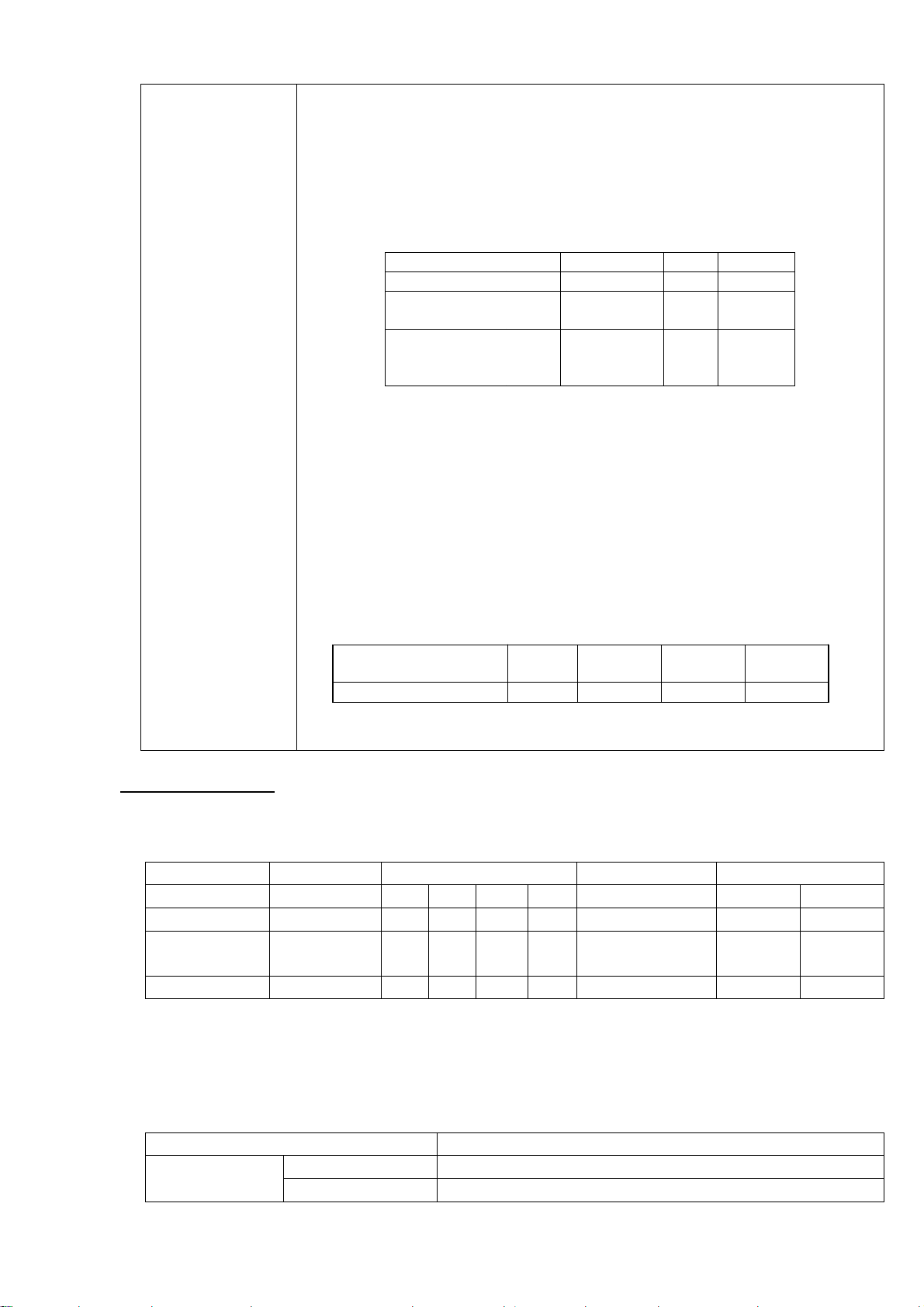

4. Requirements on AHU design

(1) Design method of heat exchanger

Model name

Unit size

Max. capacity (kW)

Min. capacity (kW)

Reference air flow

3

/h)

rate (m

Heat exchanger tube

size in evaporator

Min. volume inside

heat exchanger tube

Max. volume inside

heat exchanger tube

Standard number of paths

LEV inlet temperature

Evaporating temperature

SH

Evaporator outlet

temperature

Evaporator suction

air temperature

PAC-AH63M-G PAC-AH125M-G PAC-AH140M-G PAC-AH250M-G

63 71 80 100 125 140 200 250

7.1 8.0 9.0 11.2 14.0 16.0 22.4 28.0

5.6 7.1 8.0 9.0 11.2 14.0 16.0 22.4

1250

1500 1750

2000 2500 3000 4000 5000

Φ9.52

950

1800

3

25ºC

8.5ºC

5K

13.5ºC

27ºCDB/19ºCWB

1100 1200

2000 2250

3 3

1500 1900 2150 3000 3750

2850 3550 4050 5700 7100

4~5 4~5 5~6 6~10 8~10

Calculate the capacity of connectable indoor units using the “Unit size” in the table above.

(2) Heat exchanger manufacturing

Design pressure 4.15 MPa

Evaporator burst pressure

Compressive strength

The compressive strength of the evaporator and of other pipes must exceed

12.45MPa.

Insufficient withstand pressure may cause the pipes to crack and result in gas

WYN C0-8494

5/11

Page 6

leakage.

Contamination control Wash the heat exchanger with detergent to make the allowable level of

contamination per unit length of the heat exchanger tube the following values or

less on the assumption that the heat exchanger tube size is

chlorinated detergent. Do not leave flux.

Allowable level of contamination may cause the compressor not to function

properly. Contamination amount: residual water amount 0.6 mg/m or less,

residual oil amount 0.5 mg/m or less, amount of solid contaminants 1.8 mg/m or

less

(3) Installation conditions of AHU controller

Installation

site

- Avoid locations in direct sunlight.

- Avoid locations exposed to steam or oil vapor.

- Avoid locations where combustible gas may leak, settle or be generated

- Avoid installation near machines emitting high-frequency waves.

- Avoid places where acidic solutions are frequency waves.

- Avoid places where sulfur-based or other sprays are frequently used.

- Avoid places where vibration may occur.

Ambient

temperature

Ambient

Relative humidity of 95% or less (No dew condensation is allowed)

humidity

Installation

angle

(4) Cautions on installing LEV-kit

Installation environment

Installation angle Install the motor above the horizontal.

Pipe size

Caution on brazing LEV can withstand only up to 120ºC. Cool the LEV while brazing.

Wire connection - Connect the wire according to the wire color code to avoid miswiring. In case

Avoid locations in direct sunlight.

Φ9.52 (Brazing)

Use two LEVs when installing AH250. Connect two LEVs in parallel, and

connect them to the appropriate refrigerant pipe according to the unit size.

-

- Be careful with the plate edge not to damage to the wire from being damaged.

- The wire can withstand only up to 105ºC. Keep the wire away from

- Bend the wire into "U" shape to prevent water from running down the wire and

(5) Cautions on installing thermistor

Installation site - Install the pipe thermistor properly so that it can accurately measure the pipe

- Install the liquid thermistor sensor at the evaporator inlet where the lowest

- Install the gas pipe thermistor at the junction at the evaporator outlet.

- Install the suction air temperature thermistor at a place where the average

Wire connection - Connect the wire according to the terminal number to avoid miswiring.

Φ9.52. Do not use

-20~43

ºC

Vertical installation

of AH250, connect two wires to the same terminal.

Do not strain the power supply wires.

high-temperature part.

from dripping on the electrical components or the LEV.

temperature. Protect it with the insulation material so that it is not affected by

the temperature at other places.

temperature is found, as the thermistor is used for freeze prevention.

temperature of suction air into the evaporator can be measured.

WYN C0-8494

6/11

Page 7

(6) Other cautions

- The refrigerant temperature inside the evaporator may become 0

AHU main body or on the refrigerant pipe may occur.

- Drain the AHU properly.

If the LEV of AHU does not close due to malfunction in a system with one outdoor unit to which both

indoor units and AHU controllers are connected and if the AHU is stopped and other STD are in

operation, the

temperature of AHU evaporator becomes low and dew may condense on the AHU main body.

Take appropriate measures against dew condensation to avoid serious damage to the unit.

- When a heater for heating operation is built-in and when both the heater for heating operation

and the evaporator are operated, the operation must be conducted within the evaporator inlet

temperature range.

- Install an air filter on the evaporator.

- Interlock the unit with the fan to prevent the refrigerant system from running when the fan is stopped.

- In a system with one outdoor unit to which both in indoor units and AHU controllers are connected,

the LEV of AHU will be slightly open in heating operation to prevent the refrigerant from

accumulating inside the AHU heat exchanger, and the temperature of theAHU heat exchanger will

slightly rise.

- In a system with one outdoor unit to which both indoor units and AHU controllers are connected, the

LEV will be temporarily open in heating operation to run the outdoor unit in defrost operation. In this

case, low-temperature refrigerant will run inside the AHU heat exchanger, and the heating capacity

of AHU that is running heating operation using the heater for heating operation will temporarily drop.

- Capacity control is affected by the outdoor temperature. When the outdoor temperature drops, the

discharge temperature also drops. Take proper measures to control the room temperature, to select

the outlet position, and to prevent dew condensation.

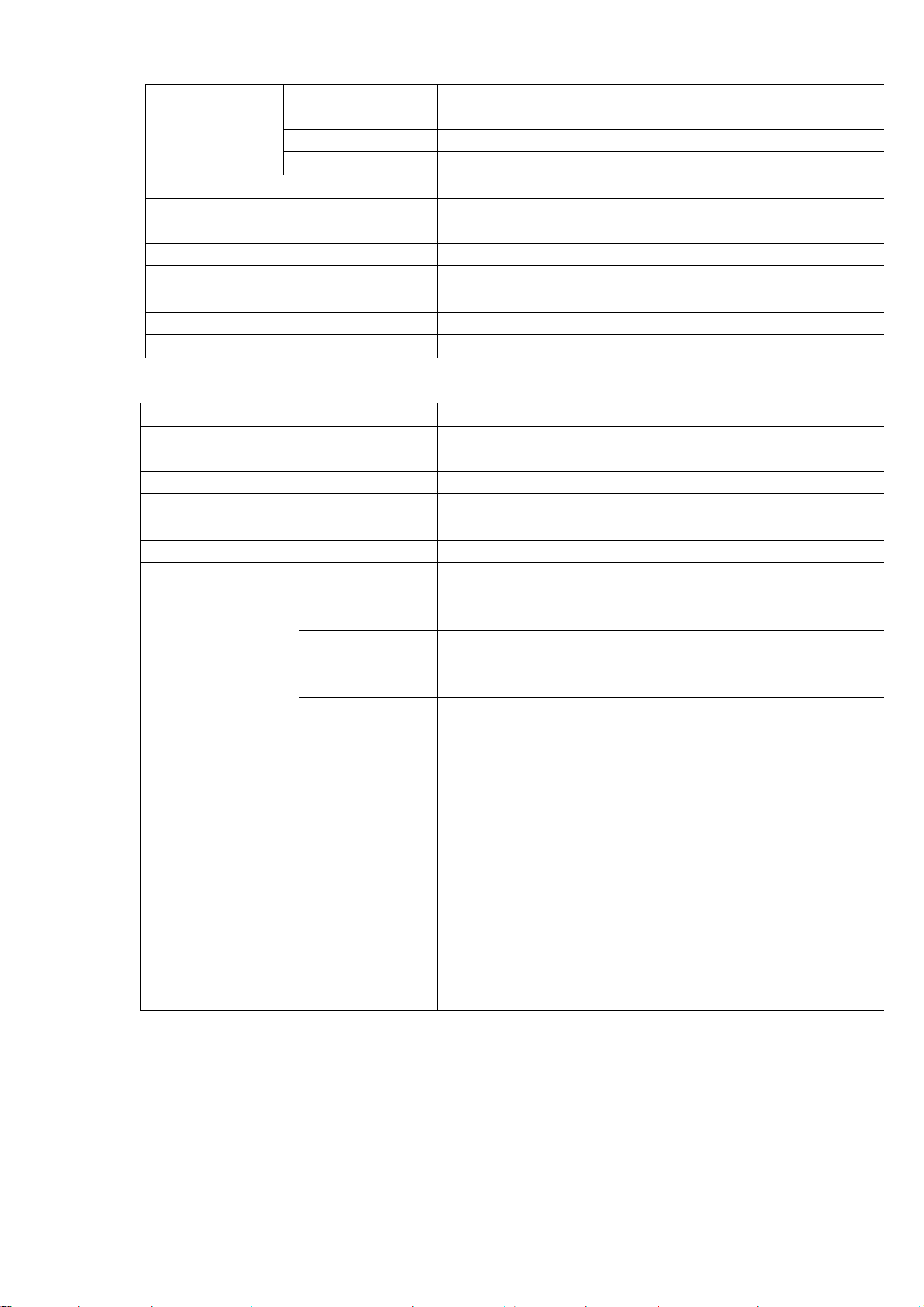

5.

Requirements on interface with controller

Item Connection circuit

Operation

■Operation contact specifications

■Use a relay when the electrical wire exceeds 10m.

- Do not strain the power supply wires.

- Be careful with the plate edge not to damage to the wire from being damaged.

- The wire can withstand only up to 105ºC. Keep the wire away from

high-temperature part.

- Bend the wire into "U" shape to prevent water from running down the wire and

from dripping on the electrical components or the thermistor.

ºC. Note that dew condensation on

SW1: Operation command

(field supply)

Minimum applicable load

DC5V, 1mA

X: Relay(field supply)

Minimum applicable load

DC5V, 1mA

SW2: Operation command

(field supply)

WYN C0-8494

7/11

Page 8

■Interlock operation with fan error and connection example of field-installed thermostat

Interlock the unit so that the unit stops when an error occurs on the fan (field supply).

Operation signal

Error signal

Electrical wiring

X: Relay

(field supply)

Minimum applicable load

DC5V, 1mA

SW2: Operation command

(field supply)

Error: Error of fan sections

(field supply)

Thermo: Thermistor

(field supply)

L1: Operation display lamp

(field supply)

Display power source:

DC30V 1A, AC100V/200V 1A

L2: Error display lamp

(field supply)

Display power source:

If error resets (stop operation) and restart operations are repeatedly performed, the

Compressor may be damaged seriously. Install an error lamp, and contact the service

firm or the dealer when an error occurs. Installation of the remote controller is

recommended so that the error details can be checked.

DC30V 1A, AC100V/200V 1A

- Power supply cords of appliances shall not be lighter than design 245 IEC 57 or 227

IEC 57.

- A switch with at least 3mm contact separation in each pole shall be provided by the Air

conditioner installation.

- The diameter of the power supply wire to the AHU controller must be 1.5mm

- Use an earth leakage breaker with a sensitivity of 30 mA 0.1s or less.

- Use a separate wire for AHU’s main circuit from that for the circuit shown above. Select

the appropriate wire or the protection device on site, according to the AHU

specifications.

Transmission cables - Type of cable : Shielding wire (2-core) CVVS or CPEVS or MVVS

- Cable diameter : 1.25mm

M-NET Remote controller

cables

MA Remote controller

cables

- Type of cable : Sheathed wire 2-core cable(unshielded) CVV

- Cable diameter: 0.3~1.25mm

(0.75~1.25mm

* When 10m is exceeded, use cables with the same specification as transmission cables.

- Type of cable : Sheathed wire 2-core cable(unshielded) CVV

- Cable diameter: 0.3~1.25mm

(0.75~1.25mm

- Max length : 200m

2

2

2

: connected with simple remote controller)

2

2

: connected with simple remote controller)

2

or larger.

WYN C0-8494

8/11

Page 9

CVVS, MVVS : PVC insulated PVC jacketed shielded control cable

CPEVS : PE insulated PVC jacketed shielded communication cable

CVV : PV insulated PVC sheathed control cable

6. Related cautions

(1) Installation work

- Secure enough service space for replacement of the LEV and the thermistor.

- After an AHU controller is installed, address setting and unit size setting on the switch on the

controller board are necessary. Refer to the installation manual for the setting method.

- Refer to the outdoor unit installation manual or the data book for installation of the outdoor unit.

(2) Test run

- Turn on the main power to the unit at least 12 hours before test run to power the crankcase heater.

Insufficient powering time may result in compressor damage.

- As the temperature setting and the operation mode setting are made at initial setting, a remote

controller is necessary. Remove the remote controller after making the initial settings if it is used.

In case of PAR21MAA, remove the remote controller after turning off the power of the indoor and

outdoor units. In case of PAR-27MEA, remove it after deleting the address of the remote

controller.

(Refer to the installation manual for remote controller for more details.)

(3) Operation control

- Remove the connector inside the AHU controller when a local remote controller is used. When the

connector is connected, the controller will be in the remote operation mode, and the operation by the

local remote controller will be prohibited.

- If the error lamp lights or the error display appears on the remote controller, do not make an error

reset by yourself. Contact the service firm or the dealer.

- Refer to the data book for system controller when using the system controller.

(4) Service

- Establish a regular maintenance routine to prolong the life of the units. It is recommended that the

maintenance contract be concluded with a maintenance firm.

7.

Warranty

- Specifications of AHU and compatibility with regulations must be confirmed by your company.

- Selection of an appropriate AHU (with appropriate specifications to match those of units connected

to the AHU such as configuration, dimension, lifetime, vibration, noise, or characteristic) must be

made by your company.

- Mitsubishi Electric shall not be liable for any damage to the entire system or the AHU main body

caused by connected AHU with wrong specification or wrong usage of AHU.

- Mitsubishi Electric shall not be liable for any damage to the outdoor units or the indoor units

connected caused by AHU damage.

WYN C0-8494

9/11

Page 10

EE

External Dimension

PAC-AH63/125/140/250M-G

R3.5

R7.5

Φ7.0

WYN C0-8494

10/11

Page 11

Electrical Wiring Diagram

WYN C0-8494

11/11

Loading...

Loading...