Page 1

General ........................

00

WORKSHOP MANUAL

SUPPLEMENT

FOREWORD

This manual outlines changes in servicing

procedures related to the chassis including vehicle

inspections, adjustments, and improvements in the

newly equipped models. Use the following manuals

in combination with this manual required.

TECHNICAL INFORMATION MANUAL

PYDE9802

WORKSHOP MANUAL

CHASSIS GROUP PWDE9803

ENGINE GROUP PWEEjjjj

(Looseleaf edition)

ELECTRICAL WIRING PHDE9802

PHDE9802-A

BODY REPAIR MANUAL PBDE9802

PARTS CATALOGUE

SPACE RUNNER B608V500Aj

SPACE WAGON B608W500Aj

Engine .........................

Fuel ...........................

Engine Cooling .................

Intake and Exhaust ............

Engine Electrical ...............

Engine and Emission Control ....

Clutch .........................

Automatic Transmission ........

Front Axle ......................

Wheel and Tyre .................

Front Suspension ...............

Service Brakes .................

Steering ........................

11

13

14

15

16

17

21

23

26

31

33

35

37

All information, illustrations and product

descriptions contained in this manual are current

as at the time of publication. We, however, reserve

the right to make changes at any time without prior

notice or obligation.

“GDI” is th e trade mark which Mitsubishi Motors

Corporation holds.

E

Mitsubishi Motors Corporation May 1999

Page 2

GENERAL

CONTENTS

00-1

HOW TO USE THIS MANUAL 2..............

Model Indications 2............................

VEHICLE IDENTIFICATION 3.................

Models 3......................................

Model Code 3.................................

Chassis Number 4.............................

Engine Model Number 5........................

New Vehicles 5................................

MAJOR SPECIFICATIONS 6..................

Page 3

00-2

GENERAL -

How to Use This Manual

HOW TO USE THIS MANUAL

MODEL INDICATIONS

The following abbreviations are used in this manual for classification of model types.

2000: Indicates models equipped with the 2,000 mL <4G63> petrol engine.

2400: Indicates models equipped with the 2,400 mL <4G64> petrol engine.

MPI: Indicates the multipoint injection, or engine equipped with the multipoint injection.

GDI: Indicates the gasoline direct injection, or engine equipped with the gasoline direct injection.

SOHC: Indicates an engine with the single overhead camshaft, or models equipped with such an

engine.

DOHC: Indicates an engine with the double overhead camshaft, or models equipped with such an

engine.

M/T: Indicates the manual transmission, or models equipped with the manual transmission.

A/T: Indicates the automatic transmission, or models equipped with the automatic transmission.

A/C: Indicates the air conditioner.

Page 4

GENERAL -

Vehicle Identification

00-3

VEHICLE IDENTIFICATION

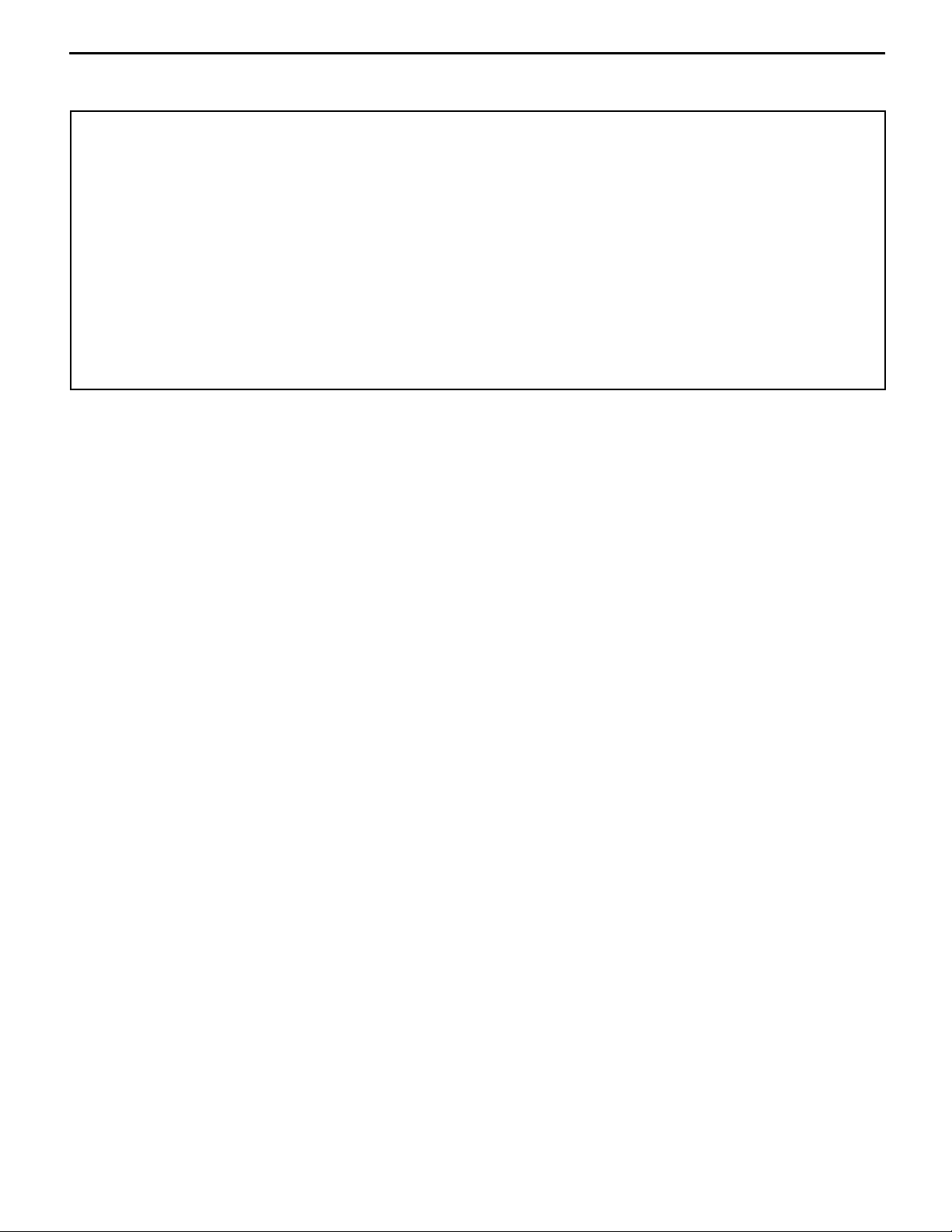

MODELS

Model code Engine model Transmission model Fuel supply system

N63W SNUEL6/R6 4G63-SOHC (1,997 mL) F5M42 (2WD-5M/T) MPI

SNFEL6

SNUJL6

SRUEL6/R6 F4A42 (2WD-4A/T)

SRFEL6

SRUJL6

N64W SNHCL6 4G64-DOHC-GDI F5M42 (2WD-5M/T) GDI

(2,351 mL)

SNGCL6

SNHGL6

SRHCL6 F4A42 (2WD-4A/T)

123456

SRGCL6

SRHGL6

7

89

MODEL CODE

No. Items Contents

1 Development N6: SPACE RUNNER

(2WD)

2 Engine type 3: 2,000 mL petrol engine

4: 2,400 mL petrol engine

3 Body type W: Wagon

4 Body style S: 3-door station wagon

5 Transmission type N: 5-speed manual

transmission

R: 4-speed automatic

transmission

6 Trim level U,F,H,G: GLX

7 Specification engine

feature

8 Steering wheel location L: Left hand

9 Destination 6: For Europe

E,J: MPI-SOHC

C,G: GDI-DOHC

R: Right hand

Page 5

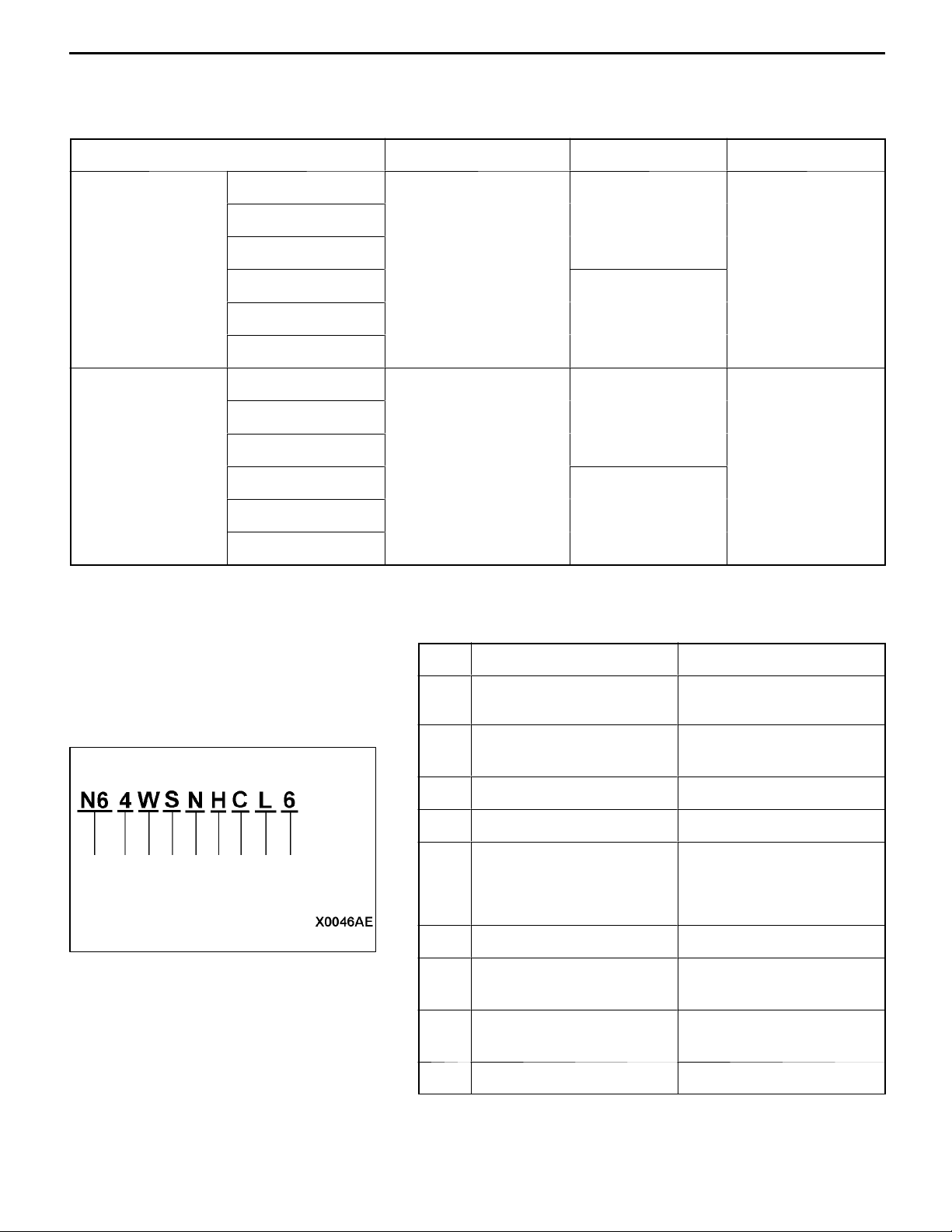

00-4

GENERAL -

CHASSIS NUMBER

Vehicle Identification

23 4

1

No. Items Contents

1 Fixed figure J Asia

2 Distribution channel M Japan channel

3 Destination A For Europe, right hand drive

4 Body style S 3-door station wagon

5 Transmission type N 5-speed manual transmission

6 Development order N6 SP ACE RUNNER (2WD)

7 Engine 3 4G63: 1,997 mL petrol engine

67891110

5

B For Europe, left hand drive

R 4-speed automatic transmission

4 4G64: 2,351 mL petrol engine

8 Sort W Station wagon

9 Model year Y 2000

10 Plant Z Okazaki Motor Vehicle Works

11 Serial number - -

Page 6

GENERAL -

Vehicle Identification

00-5

ENGINE MODEL NUMBER

1. The engine model number is stamped at the cylinder

block as shown in the following.

Engine model Engine displacement mL

4G63

4G64

1,997

2,351

2. The engine serial number is stamped near the engine

model number.

Engine serial number AA0201 to YY9999

NEW VEHICLES

New vehicles has been added as shown below.

New vehicle has been developed from the respective basic vehicle. Specification show only a particular

part of the new vehicle. For the remaining par, refer to specifications for basic vehicle.

New vehicle Basic vehicle

N63W SNUEL6 N61W SNUCL6

N63W SNUER6 N61W SNUCR6

N63W SNFEL6 N61W SNFCL6

N63W SNUJL6 N61W SNUGL6

N63W SRUEL6 N61W SRUCL6

N63W SRUER6 N61W SRUCR6

N63W SRFEL6 N61W SRFCL6

N63W SRUJL6 N61W SRUGL6

N64W SNHCL6 N61W SNUCL6

N64W SNGCL6 N61W SNFCL6

N64W SNHGL6 N61W SNUGL6

N64W SRHCL6 N61W SRUCL6

N64W SRGCL6 N61W SRFCL6

N64W SRHGL6 N61W SRUGL6

Page 7

00-6

GENERAL -

MAJOR SPECIFICATIONS

Major Specifications

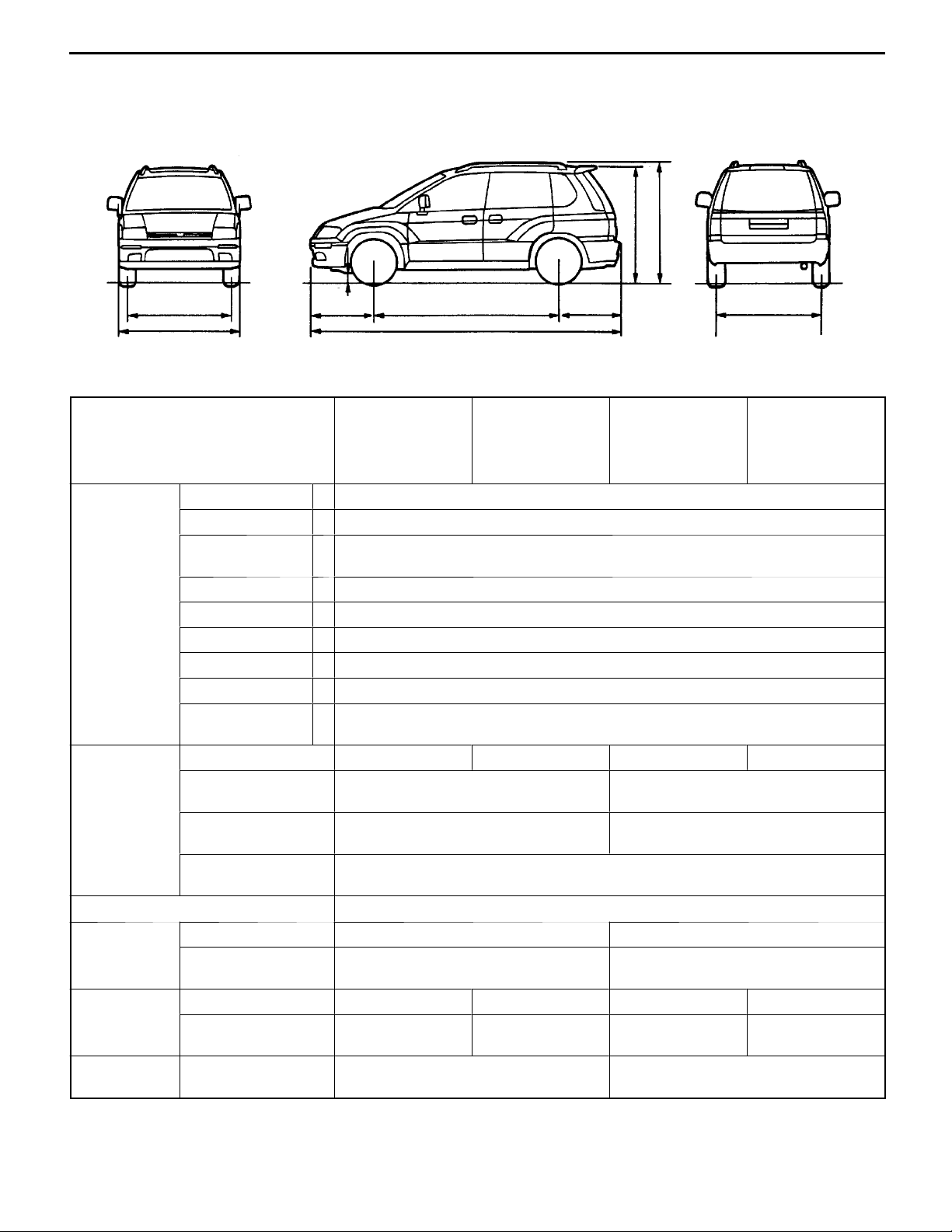

3

3*

Items

5

2

9

7

N63W

SNUEL6,

SNUER6,

SNFEL6,

SNUJL6

4

1

N63W

SRUEL6,

SRUER6,

SRFEL6,

SRUJL6

8

N64W

SNHCL6,

SNGCL6,

SNHGL6

6

N64W

SRHCL6,

SRGCL6,

SRHGL6

Vehicle Overall length 1 4,290

dimensions

mm

Overall width 2 1,695

Overall height

(unladen)

3 1,650

1,680*

Wheelbase 4 2,550

Track-front 5 1,460

Track-rear 6 1,465

Overhang-front 7 890

Overhang-rear 8 850

Ground clear-

9 155

ance (unladen)

Vehicle Kerb weight 1,360 1,380 1,400 1,420

weight kg

Max. gross vehicle

1,880 1,920

weight

Max. axle weight

1,000 1,050

rating-front

Max. axle weight

900

rating-rear

Seating capacity 5

Engine Model No. 4G63 4G64

Total displacementmL1,997 2,351

Transmis- Model No. F5M42 F4A42 F5M42 F4A42

sion

Fuel system Fuel supply system Electronically controlled multipoint

Type 5-speed manual 4-speed

automatic

5-speed manual 4-speed

automatic

Gasoline Direct Injection

injection

*: Vehicles with roof rails

Page 8

ENGINE

<4G6-MPI>

CONTENTS

11C-1

GENERAL 3.................................

Outline of Changes 3..........................

GENERAL INFORMATION 3..................

SERVICE SPECIFICATIONS 3.................

SEALANTS 4................................

SPECIAL TOOLS 5..........................

ON-VEHICLE SERVICE 6.....................

Drive Belt Tension Check and Adjustment 6......

Ignition Timing Check 9........................

Idle Speed Check 10...........................

Idle Mixture Check 10..........................

Compression Pressure Check 11................

Manifold Vacuum Check 12.....................

Lash Adjuster Check 12........................

CRANKSHAFT PULLEY 15..................

CAMSHAFT AND CAMSHAFT OIL SEAL 16..

OIL PAN 19.................................

CRANKSHAFT OIL SEAL 21.................

CYLINDER HEAD GASKET 24...............

TIMING BELT 27............................

TIMING BELT B 31..........................

ENGINE ASSEMBLY 34.....................

Page 9

11C-2

NOTES

Page 10

ENGINE <4G6-MPI> -

General/General Information/

Service Specifications

11C-3

GENERAL

OUTLINE OF CHANGES

The following service procedures have been established in line with the addition of vehicles with 4G63-MPI

engine.

GENERAL INFORMATION

Items 4G63

Total displacement mL 1,997

Bore´Stroke mm 85.0´88.0

Compression ratio 10.0

Combustion chamber Pentroof type

Camshaft arrangement SOHC

Number of valve Intake 8

Exhaust 8

V alve timing Intake Opening BTDC 11

Closing ABDC 53

Exhaust Opening BBDC 63

Closing ATDC 21

Fuel system Electronically controlled multipoint fuel injection

Rocker arm Roller type

Auto-lash adjuster Equipped

_

_

_

_

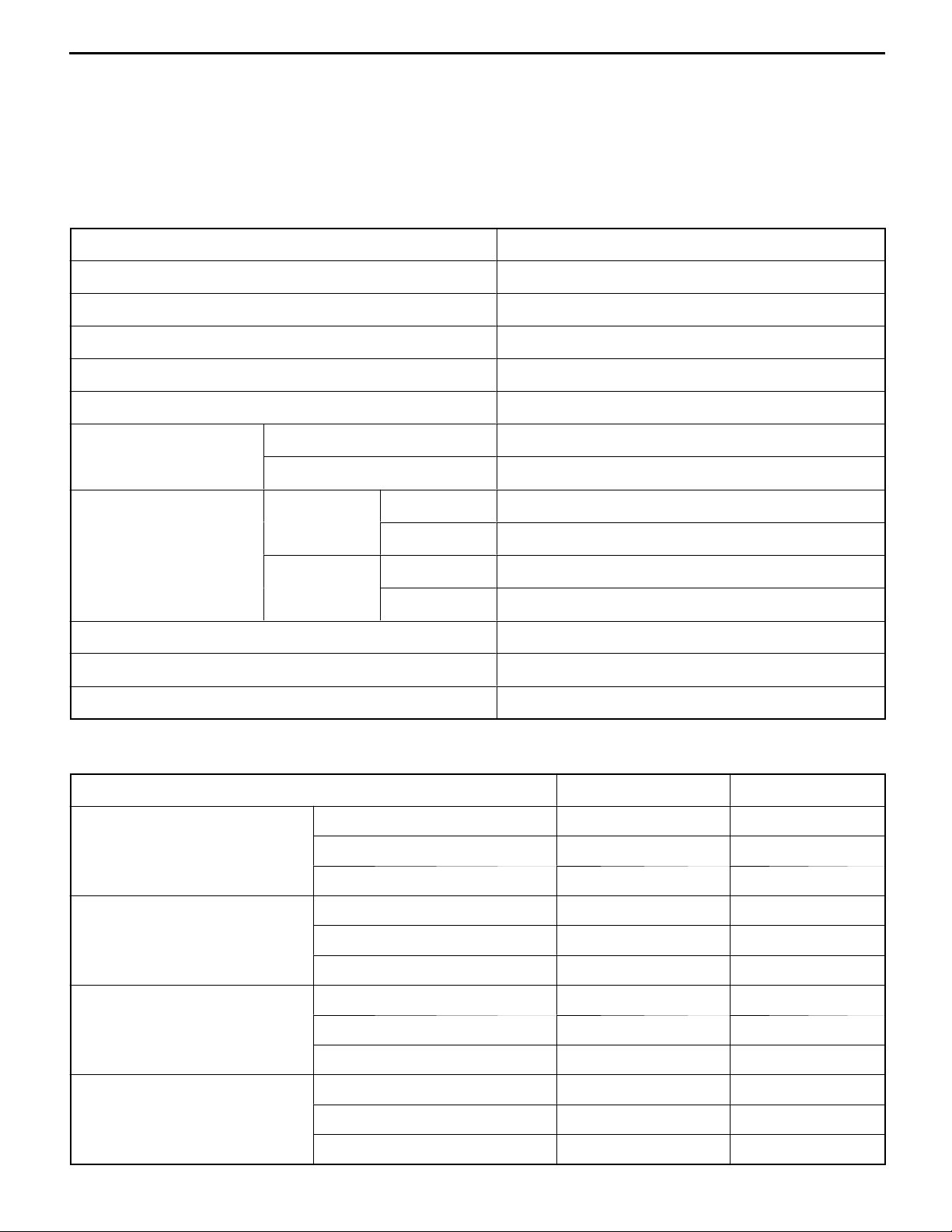

SERVICE SPECIFICATIONS

Items Standard value Limit

Alternator drive belt checked

When adjusting the alternator

drive belt

Vibration frequency Hz 177 - 232 -

Tension N 343 - 588 -

Deflection (Reference value) mm 6.7 - 9.8 -

Vibration frequency Hz 201 - 222 -

Tension N 441 - 539 -

When replacing the alternator

drive belt

Power steering oil pump and A/C

compressor drive belt tension

(When checked)

Deflection (Reference value) mm 7.2 - 8.4 -

Vibration frequency Hz 241 - 276 -

Tension N 637 - 833 -

Deflection (Reference value) mm 5.0 - 6.4 -

Vibration frequency Hz 108 - 132 -

Tension N 392 - 588 -

Deflection (Reference value) mm 11.7 - 15.3 -

Page 11

11C-4

Items LimitStandard value

ENGINE <4G6-MPI> -

Service Specifications/Sealants

Power steering oil pump and A/C

compressor drive belt tension

(When adjusted)

Power steering oil pump and A/C

compressor drive belt tension

(When replaced)

Basic ignition timing 5_ BTDC ± 3_ -

Ignition timing Approx.10_ BTDC -

Idle speed r/min 750 ± 100 -

CO contents % 0.5 or less -

HC contents ppm 100 or less -

Compression pressure kPa-r/min 1,400 Min. 1,060

Compression pressure difference of all cylinder kPa - Max. 100

Intake manifold vacuum kPa - Min. 69

Cylinder head bolt shank length mm - 99.4

Vibration frequency Hz 1 14 - 126 -

Tension N 441 - 539 -

Deflection (Reference value) mm 12.5 - 14.3 -

Vibration frequency Hz 137 - 157 -

Tension N 637 - 834 -

Deflection (Reference value) mm 8.8 - 11.0 -

Auto-tensioner push rod movement mm Within 1 -

Timing belt tension torque Nm (Reference value) 3.5 -

Auto-tensioner rod protrusion amount mm 3.8 - 4.5 -

Timing belt B tension mm 5-7 -

SEALANTS

Items Specified sealants Remarks

Rocker cover and cylinder head

Semi-circular packing

Oil pan

Thermostat case

Flywheel or drive plate bolt 3M Stud Locking 4170 or equivalent -

3M ATD Part No.8660 or equivalent -

MITSUBISHI GENUINE PART

MD970389 or equivalent

Semi-drying sealant

Page 12

ENGINE <4G6-MPI> -

Special Tools

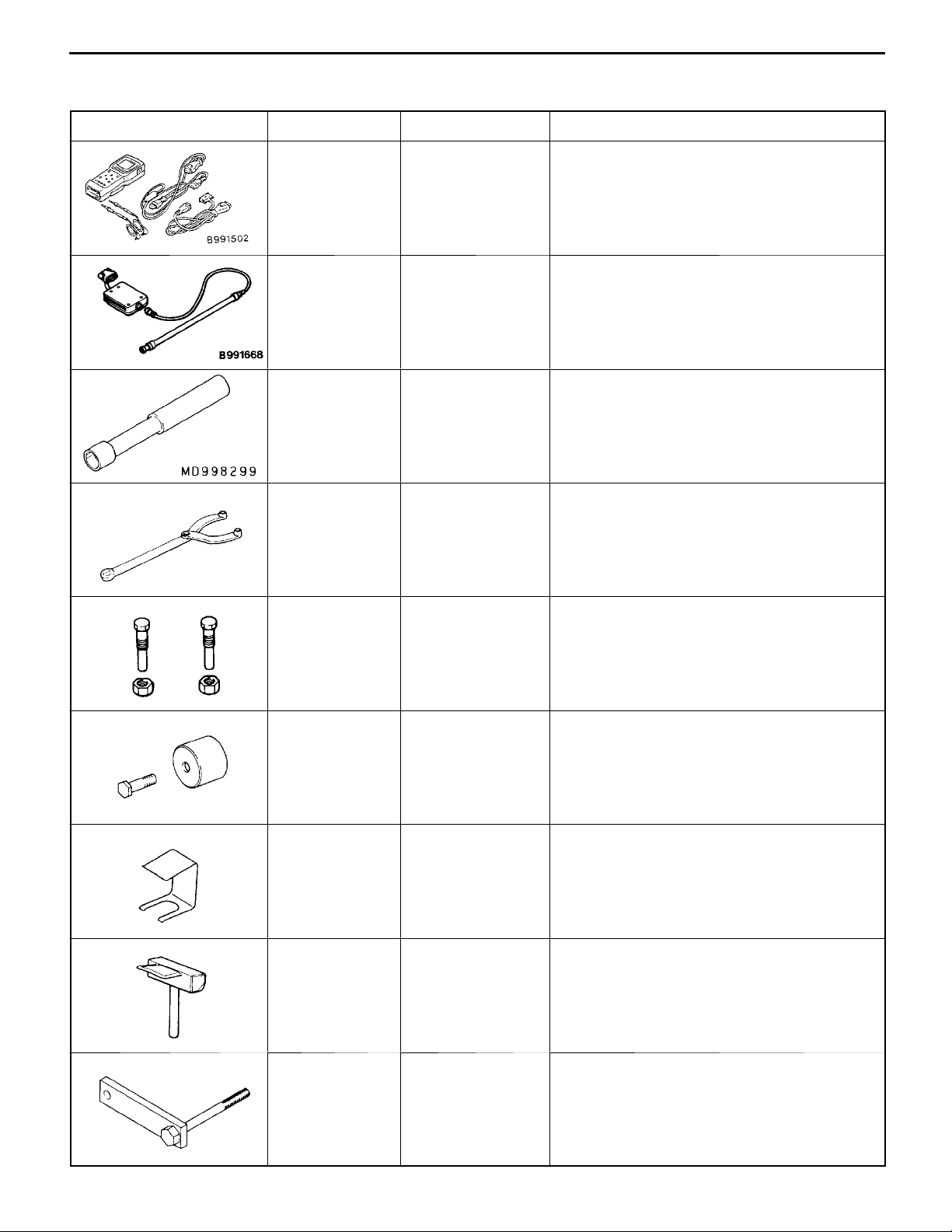

SPECIAL TOOLS

Tool Number Name Use

11C-5

MB991502 MUT-II sub assem-

bly

MB991668 Belt tension meter

set

MD998299 MAS screwdriver Adjustment of the mixture adjusting screw

MB990767 End yoke holder D Holding the camshaft sprocket

D Checking the ignition timing

D Checking the idle speed

D Erasing diagnosis code

D Measuring the drive belt tension

Measuring the drive belt tension

(used together with the MUT-II)

<Vehicles without catalytic converter>

D Holding the crankshaft sprocket

MD998719 or

MD998754

MD998713 Camshaft oil seal

MD998443 Auto-lash adjuster

MD998727 Oil pan remover Removal of oil pan

Crankshaft pulley

holder pin

installer

holder

D Holding the camshaft sprocket

D Holding the crankshaft sprocket

Press-in of the camshaft oil seal

Supporting of auto-lash adjuster

MD998781 Flywheel stopper Securing the flywheel or drive plate

Page 13

11C-6

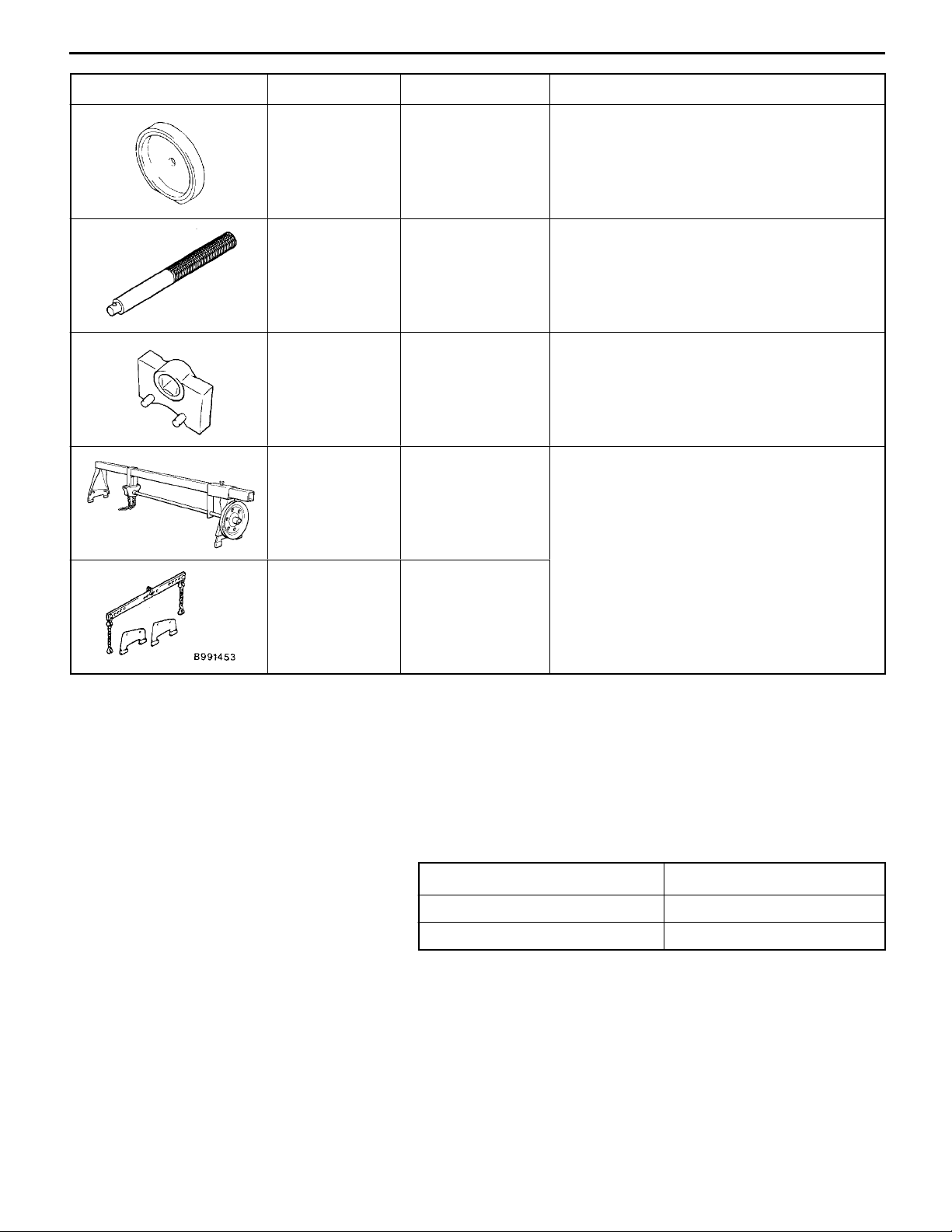

Tool UseNameNumber

ENGINE <4G6-MPI> -

Special Tools/On-vehicle Service

MD998776 Crankshaft rear oil

seal installer

MB990938 Handle Press-in of the crankshaft rear oil seal

MD998767 Tension pulley

socket wrench

GENERAL

SERVICE

TOOL

MZ203827

Engine lifter Supporting the engine assembly during

Press-in of the crankshaft rear oil seal

Timing belt tension adjustment

removal and installation of the transmission

MB991453 Engine hanger

assembly

ON-VEHICLE SERVICE

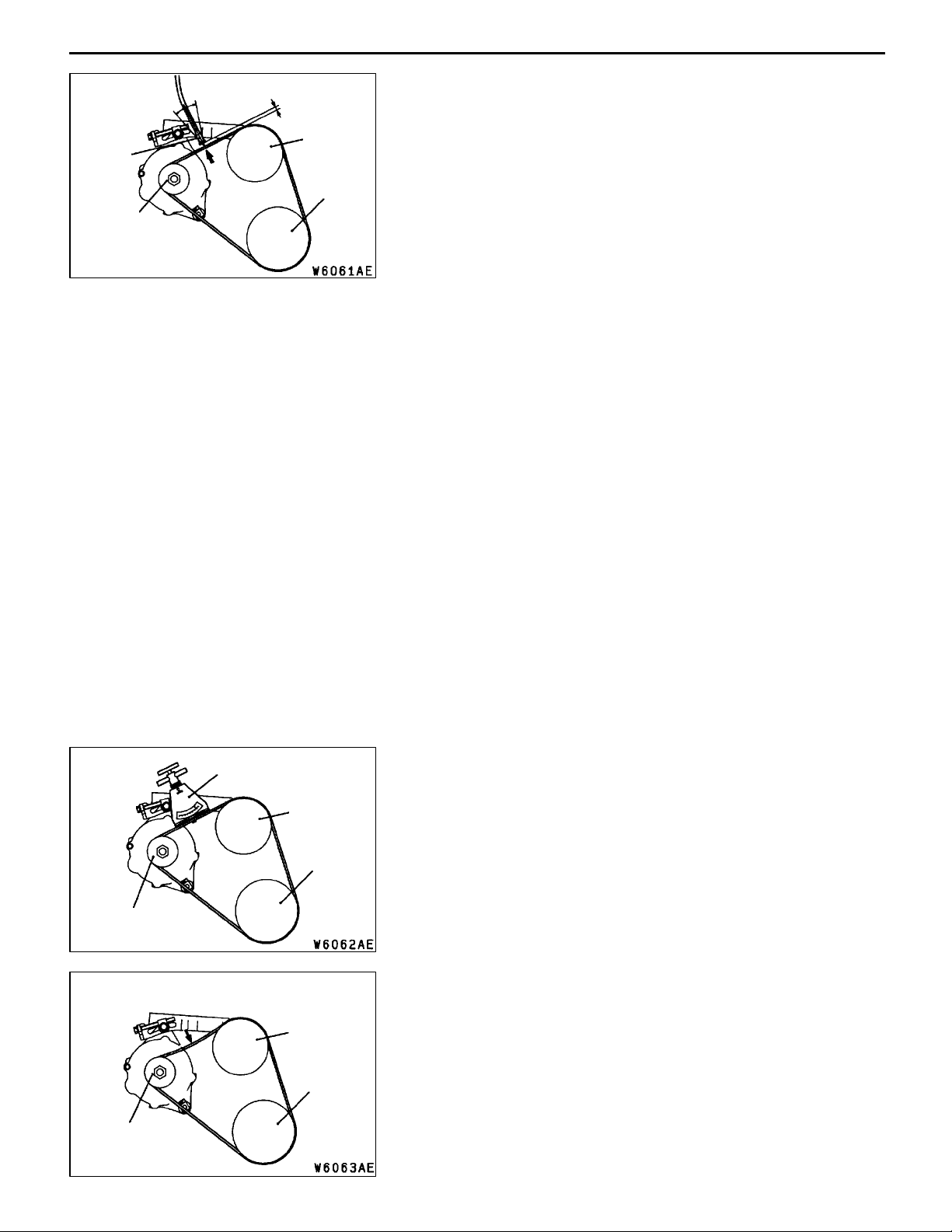

DRIVE BELT TENSION CHECK AND

ADJUSTMENT

ALTERNATOR DRIVE BELT TENSION CHECK

Check the drive belt tension in the following procedure.

Standard value:

Vibration frequency Hz 177 - 232

Tension N 343 - 588

Deflection (Reference value) mm 6.7 - 9.8

Page 14

ENGINE <4G6-MPI> -

On-vehicle Service

11C-7

MB991668

(Microphone)

Alternator

pulley

15

15

_

_

10 - 20 mm

Water pump

pulley

Crankshaft

pulley

1. Connect the special tool (belt tension meter set) to the

MUT-II.

2. Connect the MUT-II to the diagnosis connector.

3. Turn the ignition switch to ON a n d select “Belt Tension

Measurement” from th e menu screen.

4. Hold the microphone to the middle of the drive belt

between the pulleys (at the place indicated by the arrow),

about 10 - 20 mm away from the rear surface of the

belt and so that it is perpendicular to the belt (within

an angle of ± 15_).

5. Gently tap the middle of the belt between the pulleys

(the place indicated by the arrow) with your finger as

shown in the illustration, and check that the vibration

frequency of the belt is within the standard value.

Caution

(1) The temperature of the surface of the belt should

be as close as possible to normal temperature.

(2) Do not let any contaminants such as water or

oil get onto the microphone.

(3) If strong gusts of wind blow against the

microphone or if there are any loud sources of

noise nearby, the values measured by the

microphone may not correspond to actual values.

(4) If the microphone is touching the belt while the

measurement is being made, the values measured

by the microphone may not correspond to actual

values.

(5) Do not take the measurement while the vehicle’s

engine is running.

<When using the MUT-II>

Alternator

pulley

Alternator

pulley

Belt tension gauge

98 N

Water pump

pulley

Crankshaft

pulley

Water pump

pulley

Crankshaft

pulley

<When using a tension gauge>

Use a belt tension gauge to check that the belt tension is

within the standard value.

<Belt deflection check>

Apply 98 N of force to the middle of the drive belt between

the pulleys (at the place indicated by the arrow) and check

that the amount of deflection is within the standard value.

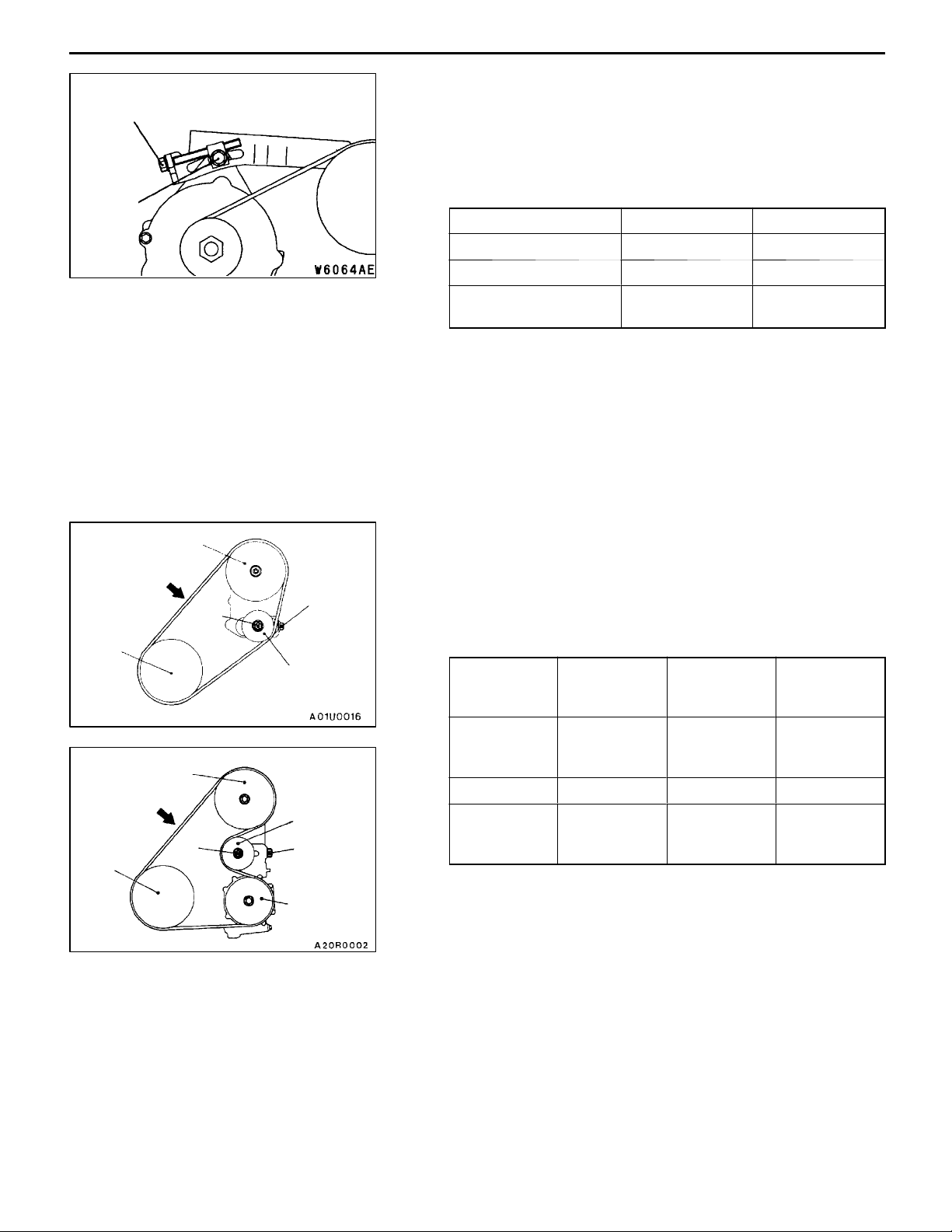

Page 15

11C-8

Adjusting bolt

Lock bolt

ENGINE <4G6-MPI> -

ALTERNATOR DRIVE BELT TENSION ADJUSTMENT

1. Loosen the nut of the alternator pivot bolt.

2. Loosen the lock bolt.

3. Use the adjusting bolt to adjust the belt tension and belt

deflection to the standard values.

Standard value:

Items When adjusting When replacing

Vibration frequency Hz 201 - 222 241 - 276

Tension N 441 - 539 637 - 833

Deflection

(Reference value) mm

4. Tighten the nut of the alternator pivot bolt.

Tightening torque: 49 Nm

5. Tighten the lock bolt.

Tightening torque: 22 Nm

6. Tighten the adjusting bolt.

Tightening torque: 5 Nm

On-vehicle Service

7.2 - 8.4 5.0 - 6.4

<Vehicles without A/C>

Oil pump pulley

98 N

Crankshaft

pulley

<Vehicles with A/C>

Oil pump pulley

98 N

Crankshaft

pulley

A

POWER STEERING OIL PUMP AND AIR CONDITIONER

COMPRESSOR DRIVE BELT TENSION CHECK AND

ADJUSTMENT

A

B

1. Check if the belt tension is within the standard value

using one of the methods below.

Standard value:

Tensioner pulley

Tensioner

pulley

B

A/C

compressor

pulley

Items When

checked

Vibration

frequency

Hz

Tension N 392 - 588 441 - 539 637 - 834

Deflection

(Reference

value) mm

108 - 132 114 - 126 137 - 157

11.7 - 15.3 12.5 - 14.3 8.8 - 11.0

When a

used belt is

installed

When a new

belt is

installed

<When measuring the vibration frequency>

With your finger tip lightly tap the centre of the belt between

the pulleys in the location shown by the arrow in t he

illustration and then measure the belt vibration frequency.

NOTE

Refer to P.11C-7 for information regarding the vibration

frequency measurement method using MUT-II.

<When measuring the tension>

Use a belt tension gauge to measure the belt tension.

Page 16

ENGINE <4G6-MPI> -

<When measuring the deflection>

Apply 98 N of pressure against the location between

the pulleys shown by the arrow in the illustration and

then measure the deflection.

2. If the tension or deflection is outside the standard value,

adjust by the following procedure.

(1) Loosen tensioner pulley fixing nut A.

(2) Adjust the amount of belt deflection using adjusting

(3) Tighten fixing nut A.

(4) Check the belt deflection amount and tension, and

On-vehicle Service

bolt B.

Tightening torque: 25 Nm

readjust if necessary.

Caution

Check after turning the crankshaft once or more

clockwise (right turn).

11C-9

IGNITION TIMING CHECK

1. Before inspection, set the vehicle to the pre-inspection

condition.

2. Connect the MUT-II to the diagnosis connector.

3. Set up a timing light.

4. Start the engine and run at idle.

5. Check that engine idle speed is within the standard value.

Standard value: 750±100 r/min

6. Select No.17 of the MUT-II Actuator test.

7. Check that basic ignition timing is within the standard

value.

Standard value: 5_BTDC±3

8. If the basic ignition timing is outside the standard value,

inspect th e MPI system while referring to GROUP 13A

- Troubleshooting.

9. Press the MUT-II clear key (Select a forced driving cancel

mode) to release the Actuator test.

Caution

If the test is not cancelled, a forced driving will

continue for 27 minutes. Driving under this condition

may damage the engine.

10. Check that ignition timing is at the standard value.

_

Standard value: approx. 10_BTDC

NOTE

1. Ignition timing is variable within about ± 7_, even

under normal operating.

2. And it is automatically further advanced by about

5_ from standard value at higher altitudes.

Page 17

11C-10

ENGINE <4G6-MPI> -

IDLE SPEED CHECK

1. Before inspection, set the vehicle to the pre-inspection

condition.

2. Turn the ignition switch to “LOCK” (OFF) position and

connect the MUT-II to the diagnosis connector.

3. Check the basic ignition timing.

Standard value: 5_BTDC±3

4. Run the engine at idle for 2 minutes.

5. Check the idle speed. Select item No. 22 and take a

reading of the idle speed.

Standard value: 750±100 r/min

NOTE

The idle speed is controlled automatically by the idle speed

control (ISC) system.

6. If the idle speed is outside the standard value, inspect

the MPI components by referring to GROUP 13A Troubleshooting.

On-vehicle Service

_

IDLE MIXTURE CHECK

1. Before inspection, set the vehicle to the pre-inspection

condition.

2. Turn the ignition switch to “LOCK” (OFF) position and

connect the MUT-II to the diagnosis connector.

3. Check that the basic ignition timing is within the standard

value.

Standard value: 5_BTDC±3

4. Run the engine at 2,500 r/min for 2 minutes.

5. Set the CO, HC tester.

6. Check the CO contents and the HC contents at idle.

Standard value

CO contents: 0.5% or less

HC contents: 100 ppm or less

7. If there is a deviation from the standard value, check

the following items:

D Diagnosis output

D Closed-loop control (When the closed-loop control

is normal, the output signal of the oxygen sensor

changes between 0 - 400 mV and 600 - 1,000 mV

at idle.)

D Fuel pressure

D Injector

D Ignition coil, spark plug cable, spark plug

D Leak in the EGR system and in the EGR valve

D Evaporative emission control system

D Compression pressure

_

Page 18

ENGINE <4G6-MPI> -

NOTE

Replace the three way catalyst when the CO and HC

contents are not within the standard value, even though

the result of the inspection is normal on all items.

COMPRESSION PRESSURE CHECK

1. Before inspection, check that the engine oil, starter and

battery are normal. In addition, set the vehicle to the

pre-inspection condition.

2. Disconnect the spark plug cables.

3. Remove all of the spark plugs.

4. Disconnect the crank angle sensor connector.

NOTE

Doing this will prevent the engine-ECU <M/T> or

engine-A/T-ECU <A/T> from carrying out ignition and fuel

injection.

5. Cover the spark plug hole with a shop towel etc., and

after the engine has been cranked, check that no foreign

material is adhering to the shop towel.

On-vehicle Service

11C-11

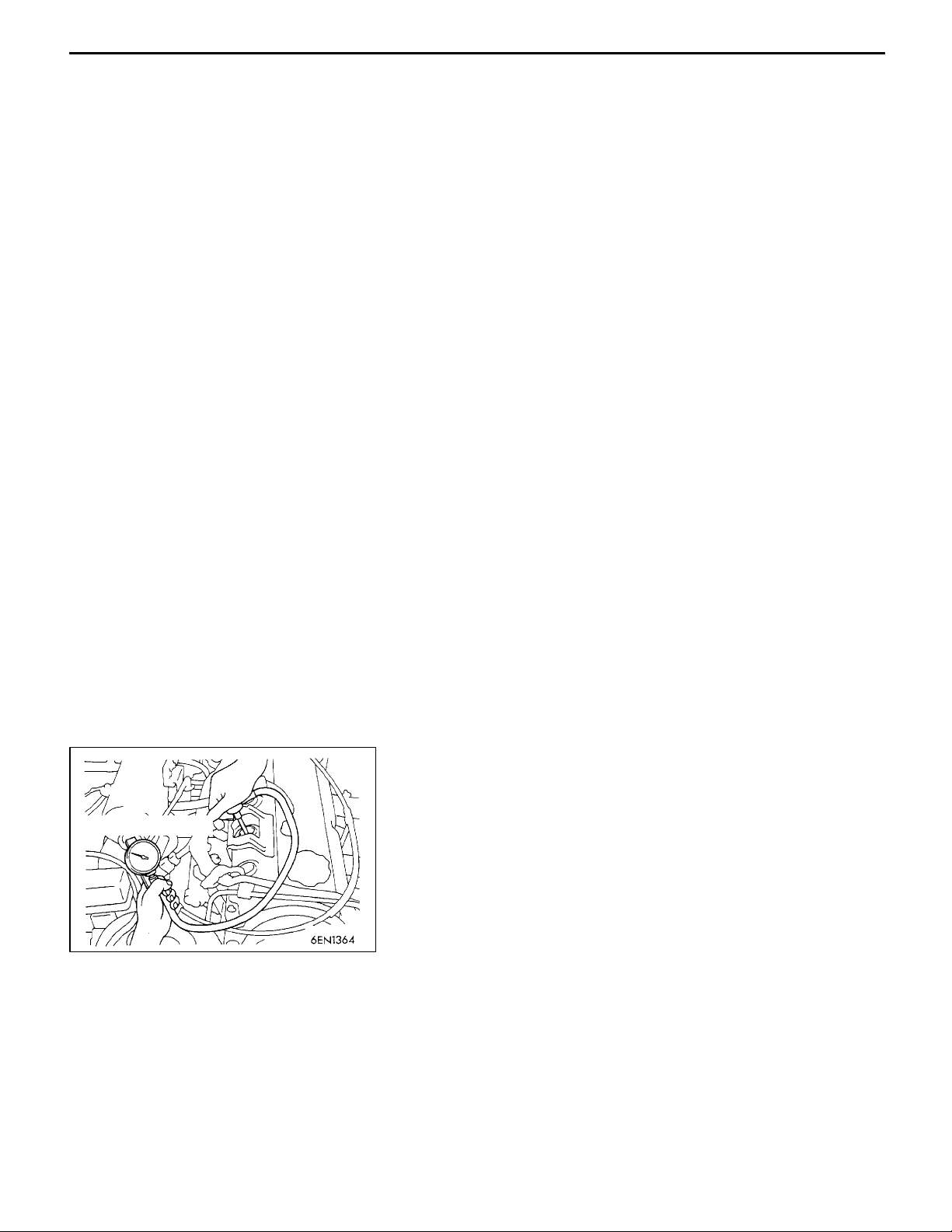

Compression gauge

Caution

1. Keep away from the spark plug hole when

cranking.

2. If compression is measured with water, oil, fuel,

etc., that has come from cracks inside the cylinder,

these materials will become heated and will gush

out from the spark plug hole, which is dangerous.

6. Set compression gauge to one of the spark plug holes.

7. Crank the engine with the throttle valve fully open and

measure the compression pressure.

Standard value (at engine speed of 250 - 400 r/min):

1,400 kPa

Limit (at engine speed of 250- 400 r/min):

Min. 1,060 kPa

8. Measure the compression pressure for all the cylinders,

and check that the pressure differences of the cylinders

are below the limit.

Limit: Max. 100 kPa

9. If there is a cylinder with compression or a compression

difference that is outside th e limit, pour a small amount

of engine oil through the spark plug hole, and repeat

the operations in steps 7 and 8.

(1) If the compression increases after oil is added, the

cause of the malfunction is a worn or damaged piston

ring and/or cylinder inner surface.

Page 19

11C-12

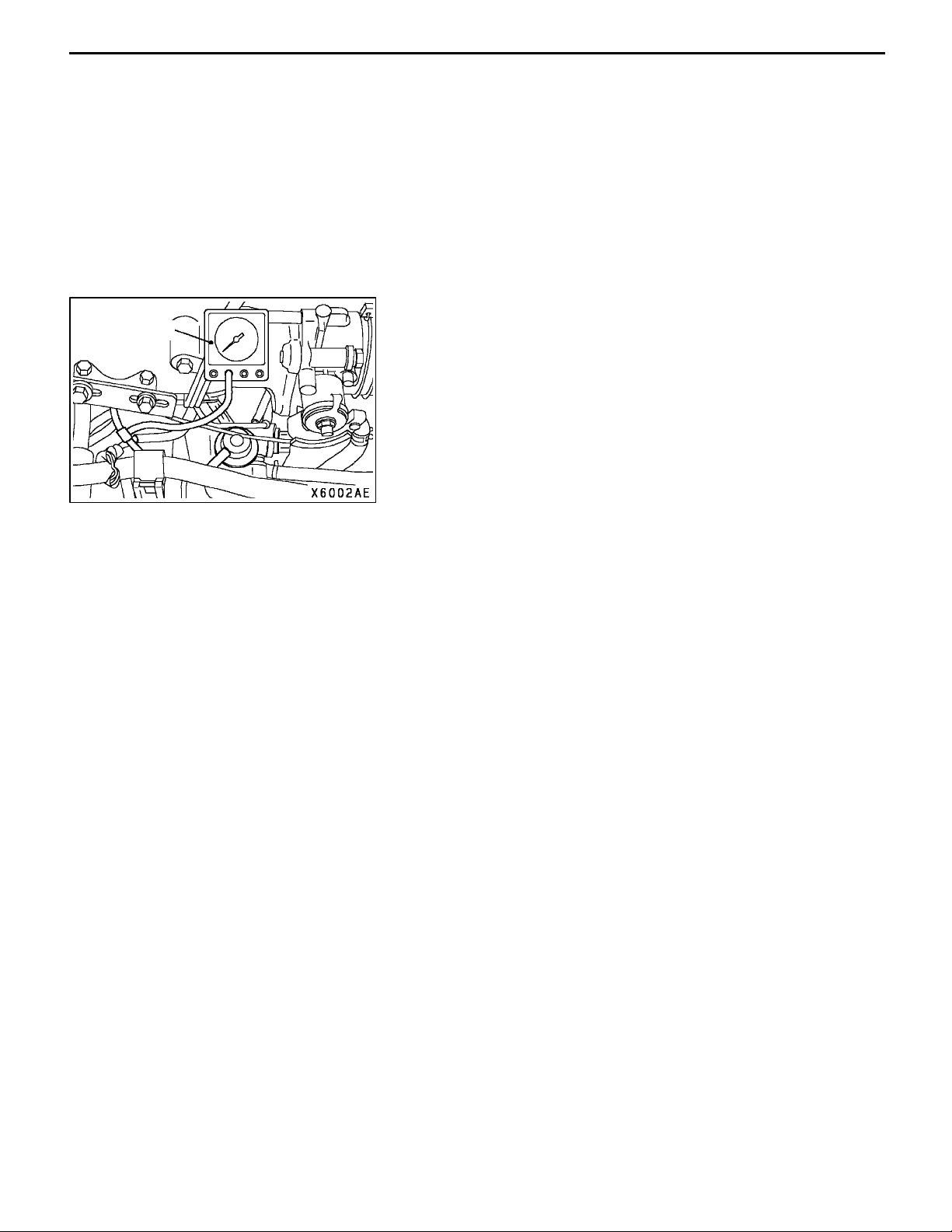

Vacuum gauge

ENGINE <4G6-MPI> -

(2) If the compression does not rise after oil is added,

10. Connect the crank angle sensor connector.

11. Install the spark plugs and spark plug cables.

12. Use the MUT-II to erase the diagnosis codes.

NOTE

This will erase the diagnosis code resulting from the crank

angle sensor connector being disconnected.

MANIFOLD VACUUM CHECK

1. Before inspection, set the vehicle to the pre-inspection

condition.

2. Attach a three-way union to the vacuum hose between

the fuel pressure regulator and the air intake plenum,

and connect a vacuum gauge.

3. Start the engine and check that idle speed is within

standard value. Then read off the vacuum gauge.

Limit: Min. 69 kPa

On-vehicle Service

the cause is a burnt or defective valve seat, or pressure

is leaking from the gasket.

LASH ADJUSTER CHECK

If an abnormal noise (knocking) that seems to be coming

from the lash adjuster is heard after starting the engine and

does not stop, carry out the following check.

NOTE

(1) The abnormal noise which is caused by a problem

with the lash adjusters is generated after the engine

is started, and will vary according to the engine speed.

However, this noise is not related to the actual engine

load.

Because of this, if the noise does not occur

immediately after the engine is started, if it does not

change in accordance with the engine speed, or if

it changes in accordance with the engine load, the

source of the noise is not the lash adjusters.

(2) If there is a problem with the lash adjusters, the noise

will almost never disappear, even if the engine has

been run at idle to let it warm up.

The only case where the noise might disappear is

if the oil in the engine has not been looked after

properly and oil sludge has caused the lash adjusters

to stick.

1. Start the engine.

2. Check that the noise occurs immediately after the engine

is started, and that the noise changes in accordance

with changes in the engine speed.

If the noise does not occur immediately after the engine

is started, or if it does not change in accordance with

the engine speed, the problem is not being caused by

the lash adjusters, so check for some other cause of

the problem. Moreover, if the noise does not change in

accordance with the engine speed, the cause of the

problem is probably not with the engine. (In these cases,

the lash adjusters are normal.)

Page 20

ENGINE <4G6-MPI> -

3. While the engine is idling, check that the noise level does

not change when the engine load is varied (for example,

by shifting from N ® D).

If the noise level changes, the cause of the noise is

probably parts striking because of worn crankshaft

bearings or connecting rod bearings. (In such cases, the

lash adjusters are normal.)

4. After the engine has warmed up, run it at idle and check

if any noise can be heard.

If the noise has become smaller or disappeared, oil sludge

could make the lash adjusters stick. Clean the lash

adjusters. (Refer to the Engine Workshop Manual.) If not

improved, go to step 5.

5. Bleed air from the lash adjusters.

6. If the noise has not disappeared even after the air

bleeding, clean the lash adjusters. (Refer to the Engine

Workshop Manual.)

<LASH ADJUSTER AIR BLEEDING>

NOTE

(1) If the vehicle is parked on a slope for a long period

(2) After parking the vehicle for long periods, the oil drains

(3) If either of the above situations occur, the abnormal

On-vehicle Service

of time, the amount of oil inside the lash adjuster

will decrease, and air may get into the high pressure

chamber when starting the engine.

out of the oil passage, an d it takes time for the oil

to be supplied to the lash adjuster, so air can get

into the high pressure chamber.

noise can be eliminated by bleeding the air from inside

the lash adjusters.

11C-13

Good

1. Check the engine oil and replenish or replace the oil

if necessary.

NOTE

(1) If there is a only small amount of oil, air will be drawn

in through the oil screen and will get into the oil

passage.

(2) If the amount of oil is greater than normal, then the

oil will being mixed by the crankshaft and a large

amount of air may get mixed into the oil.

(3) If the oil is degenerated, air and oil will not separate

easily in oil, and the amount of air mixed into the

oil will increase.

Page 21

11C-14

ENGINE <4G6-MPI> -

(4) If the air which has been mixed in with the oil due

Highpressure

chamber

On-vehicle Service

to any of the above reasons gets into the high pressure

chamber of the lash adjuster, the air inside the high

pressure chamber will be compressed when the valve

is open and the lash adjuster will over-compress,

resulting in abnormal noise when the valve closes.

This is the same effect as if the valve clearance is

adjusted to be too large by mistake. If the air inside

the lash adjusters is then released, the operation

of the lash adjusters will return to normal.

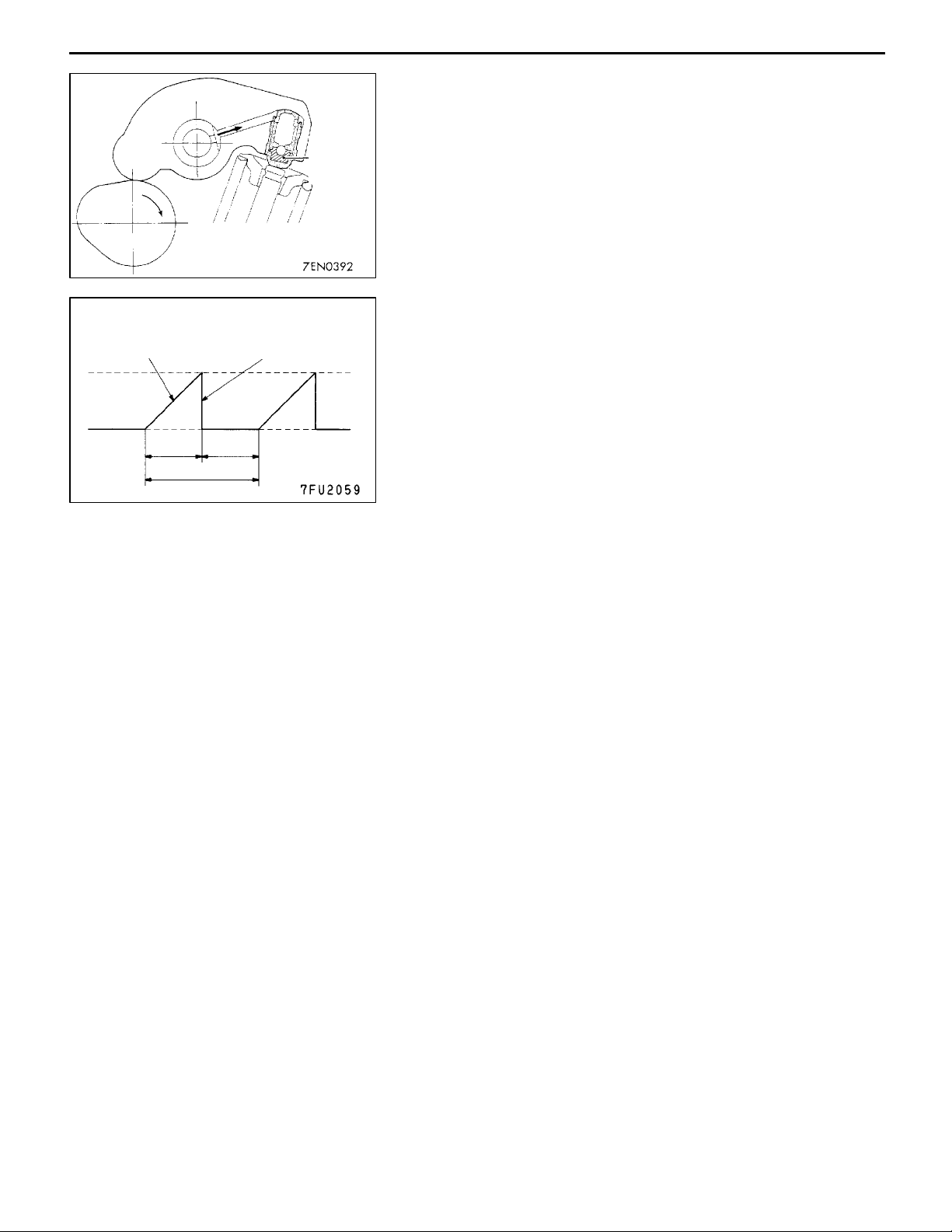

Drive pattern for air bleeding

Gradually open the

throttle valve.

Approx.

3,000 r/min

Idle speed

15

seconds

Once

Close the throttle

valve.

15

seconds

2. Run the engine at idle for 1 - 3 minutes to let it warm

up.

3. With no load on the engine, repeat the drive pattern shown

in the illustration at left and check if the abnormal noise

disappears. (The noise should normally disappear after

10 - 30 repetitions, but if there is no change in the noise

level after 30 repetitions or more, the problem is probably

not due to air inside the lash adjusters.)

4. After the noise has disappeared, repeat the drive pattern

shown in the illustration at left a further 5 times.

5. Run the engine at idle for 1 - 3 minutes and check that

the noise has disappeared.

Page 22

ENGINE <4G6-MPI> -

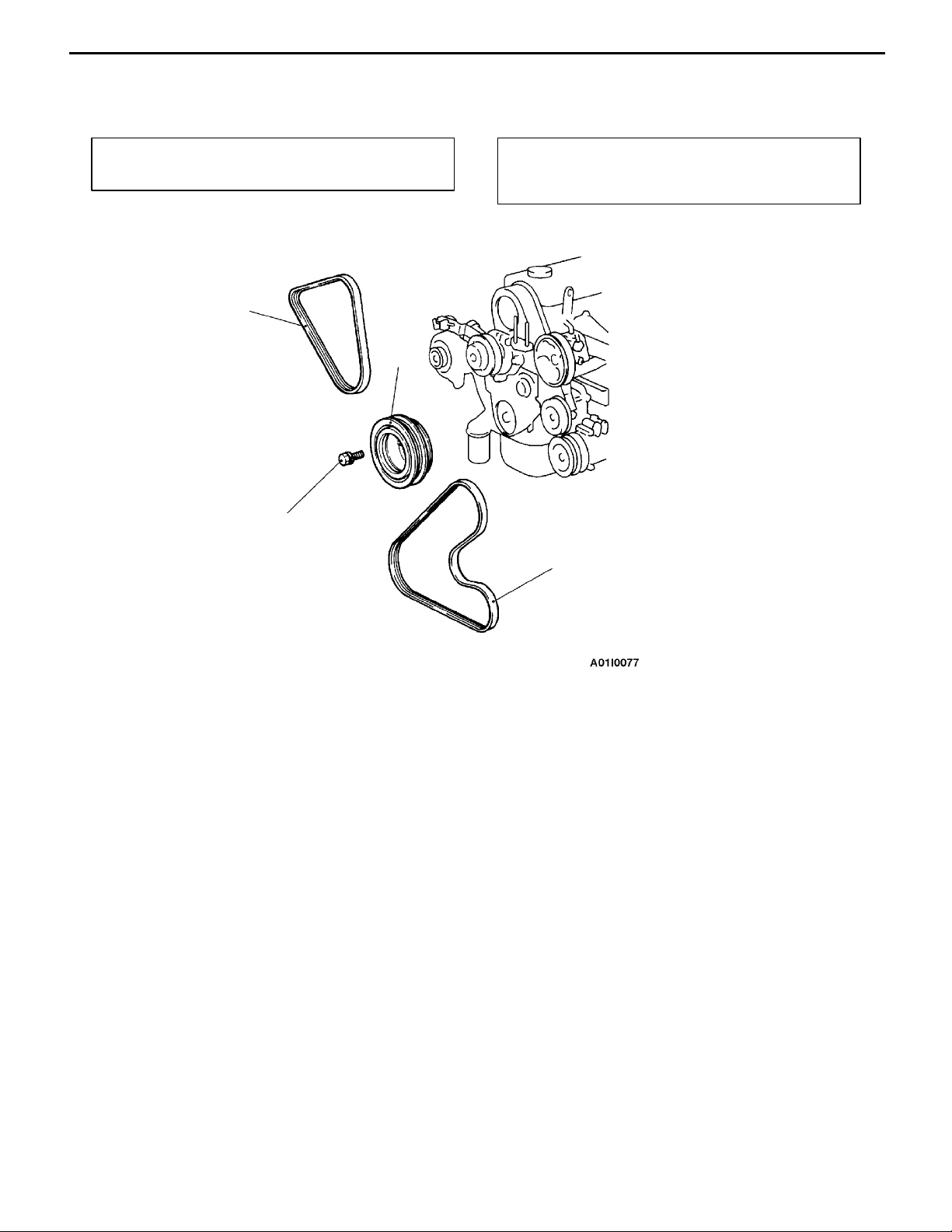

CRANKSHAFT PULLEY

REMOVAL AND INSTALLATION

Crankshaft Pulley

11C-15

Pre-removal Operation

D Under Cover Removal

2

Post-installation Operation

D Drive Belt Tension Adjustment (Refer to P.11C-6.)

D Under Cover Installation

3

25 Nm

1

Removal steps

1. Drive belt (Power steering and

A/C)

2. Drive belt (Alternator)

3. Crankshaft pulley

Page 23

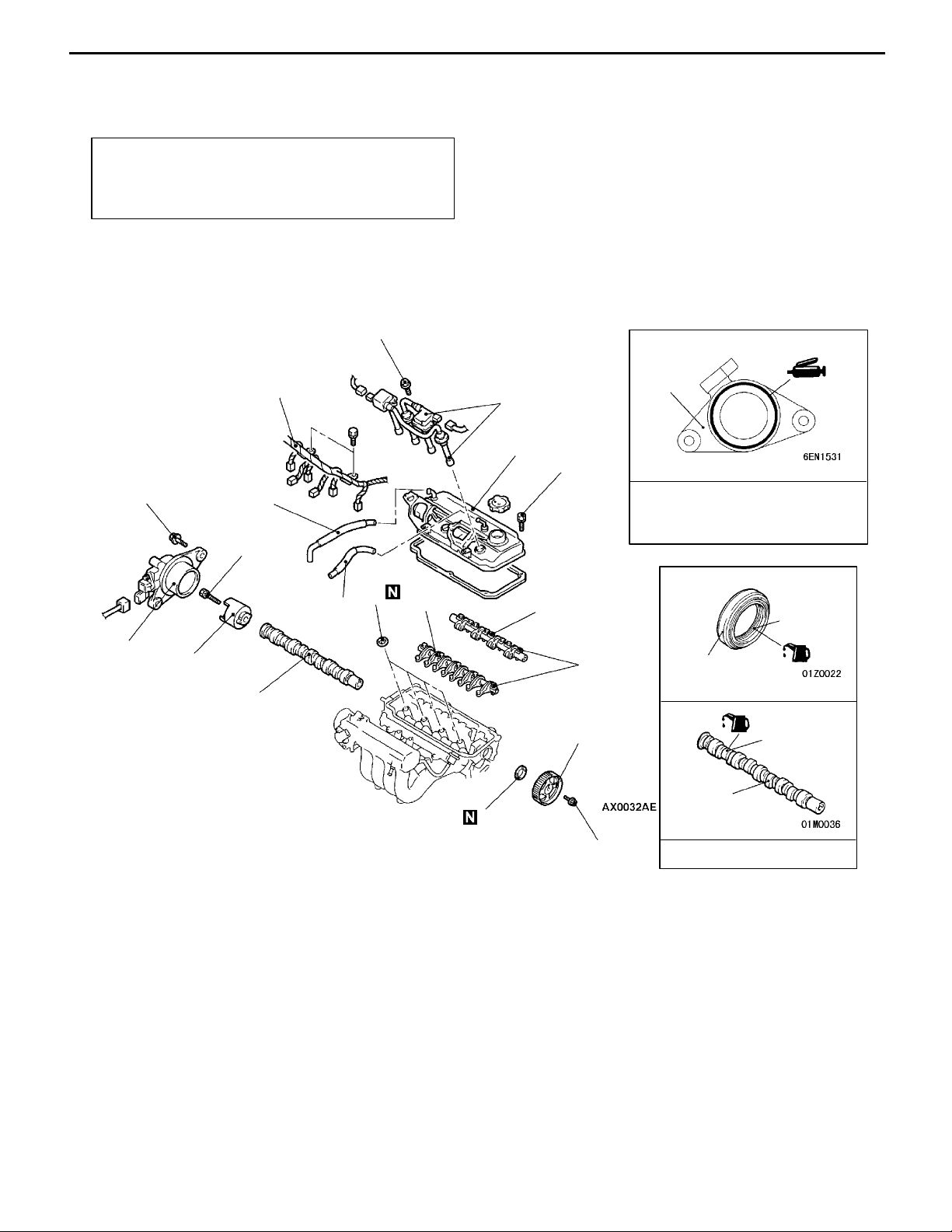

11C-16

ENGINE <4G6-MPI> -

Camshaft and Camshaft Oil Seal

CAMSHAFT AND CAMSHAFT OIL SEAL

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

D Air Cleaner Removal and Installation

D Timing Belt Removal and Installation (Refer to

P.11C-27.)

10 Nm

(f 3 ± 1 mm)

14 Nm

6

1

2

6

5

3.4 Nm

4

22 Nm

10

3

7

12

11

28 - 34 Nm

Sealant:

MITSUBISHI GENUINE PART

MD970389 or equivalent

Lip section

9

13

8

Cam section

and journal

section

13

9

AA""CA

Removal steps

1. Control harness connection

2. Spark plug cable and ignition coil

3. PCV hose connection

4. Breather hose

5. Rocker cover

6. Camshaft position sensor support

7. Camshaft position sensing cylinder

8. Camshaft sprocket

"BA

AB""AA

AB""AA

88 Nm

9. Camshaft oil seal

10. Spark plug guide oil seal

11. Rocker arm and shaft assembly

12. Rocker arm and shaft assembly

13. Camshaft

Engine oil

(intake side)

(exhaust side)

Page 24

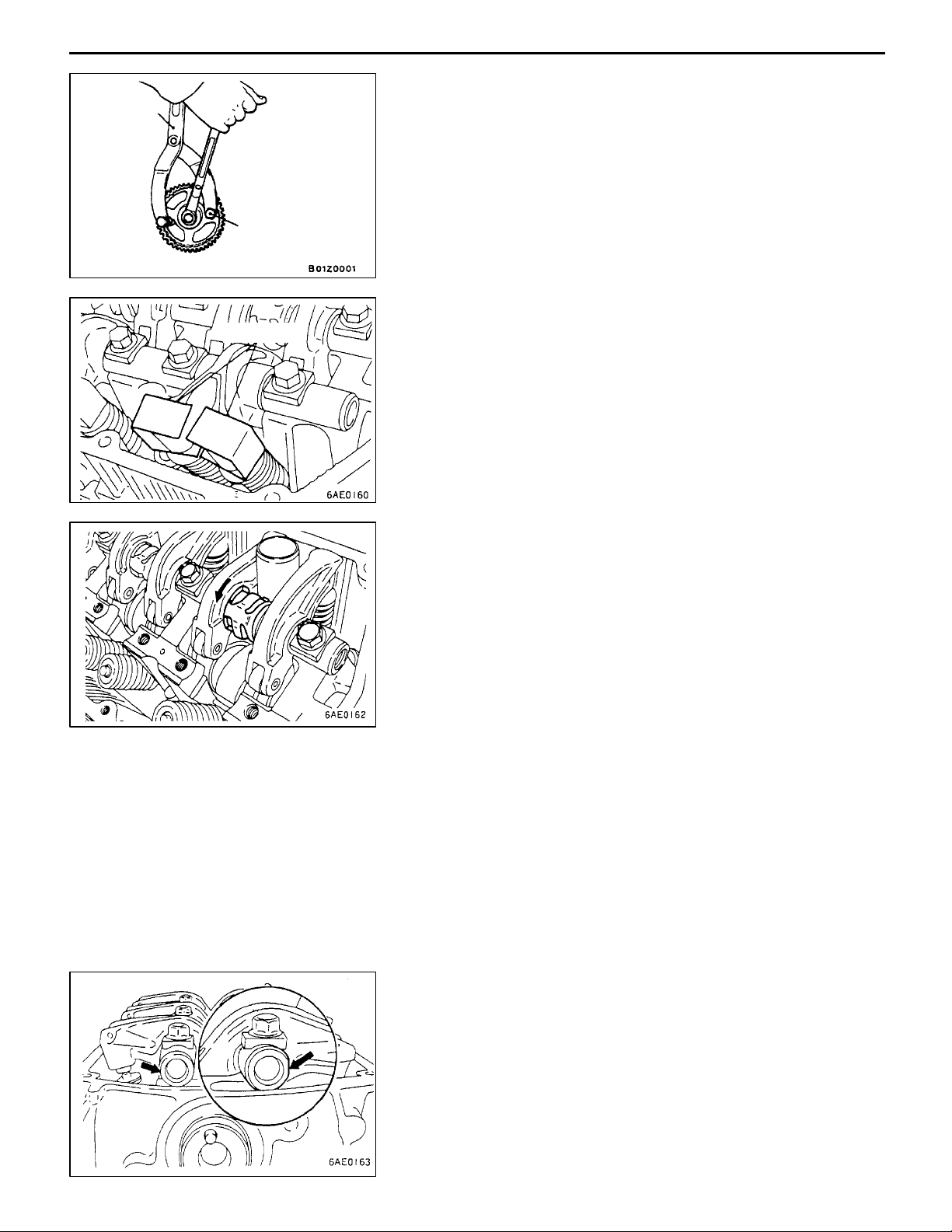

MB990767

ENGINE <4G6-MPI> -

MD998719 or

MD998754

Camshaft and Camshaft Oil Seal

REMOVAL SERVICE POINTS

AA"

CAMSHAFT SPROCKET REMOVAL

11C-17

MD998443

AB"

Before removing the rocker arm an d shaft assembly, install

the special tools as shown in the illustration so that the lash

adjusters will not fall out.

ROCKER ARM AND SHAFT ASSEMBLY

REMOVAL

INSTALLATION SERVICE POINTS

"AA

1. Temporarily tighten the rocker shaft with the bolt so that

2. Fit the rocker shaft spring from the above and position

3. Remove the special tool for fixing the lash adjuster.

ROCKER ARM AND SHAFT ASSEMBLY

INSTALLATION

all rocker arms on the inlet valve side do not push the

valves.

it so that it is right angles to the plug guide.

NOTE

Install the rocker shaft spring before installing the rocker

arm and rocker arm shaft on the exhaust side.

4. Confirm that the rocker shaft notch is in the direction

shown in the diagram.

Page 25

11C-18

ENGINE <4G6-MPI> -

Camshaft and Camshaft Oil Seal

MD998713

"BA

1. Apply engine oil to the camshaft oil seal lip.

2. Use the special tool to press-fit the camshaft oil seal.

"CA

Use the special tool to stop the camshaft sprocket from turning

in the same way as was done during removal, and then tighten

the bolts to the specified torque.

CAMSHAFT OIL SEAL INSTALLATION

CAMSHAFT SPROCKET INSTALLATION

Page 26

ENGINE <4G6-MPI> -

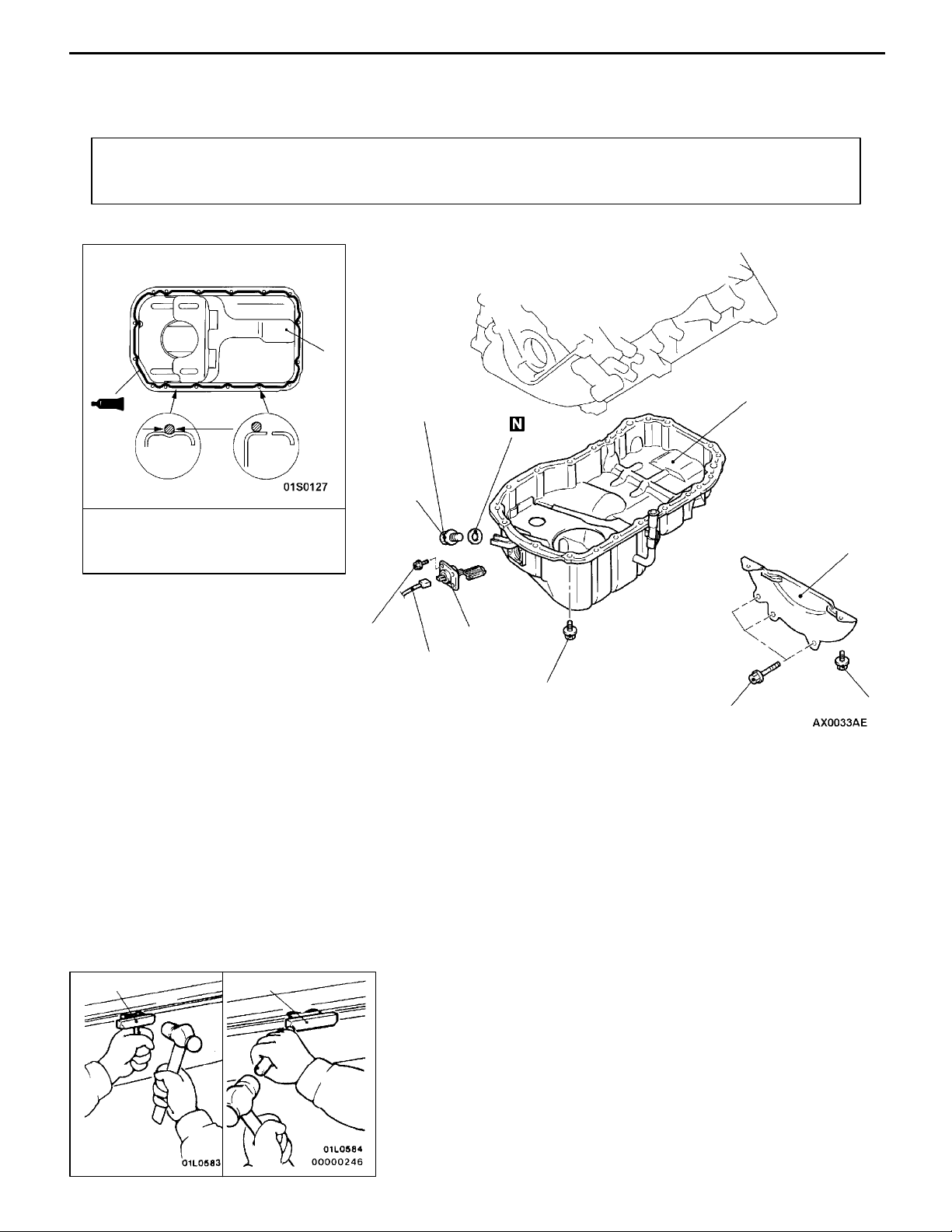

OIL PAN

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

D Under Cover Removal and Installation

D Engine Oil Draining and Supplying

5

Oil Pan

D Oil Level Gauge Removal and Installation

D Front Exhaust Pipe Removal and Installation

11C-19

f 4 ± 1mm

Groove

Sealant:

MITSUBISHI GENUINE PART

MD970389 or equivalent

Removal steps

"AA

1. Drain plug

2. Drain plug gasket

3. Harness connector

Bolt

hole

9Nm

39 Nm

1

3

6

2

AA"

9Nm

44 Nm

4. Bell housing cover

5. Oil pan

6. Oil level sensor

5

4

9Nm

MD998727

MD998727

REMOVAL SERVICE POINT

AA"

After removing the oil pa n mounting bolts, remove the oil

pan with the special tool and a brass bar.

Caution

Perform this slowly to avoid deformation of the oil pan

flange.

OIL PAN REMOVAL

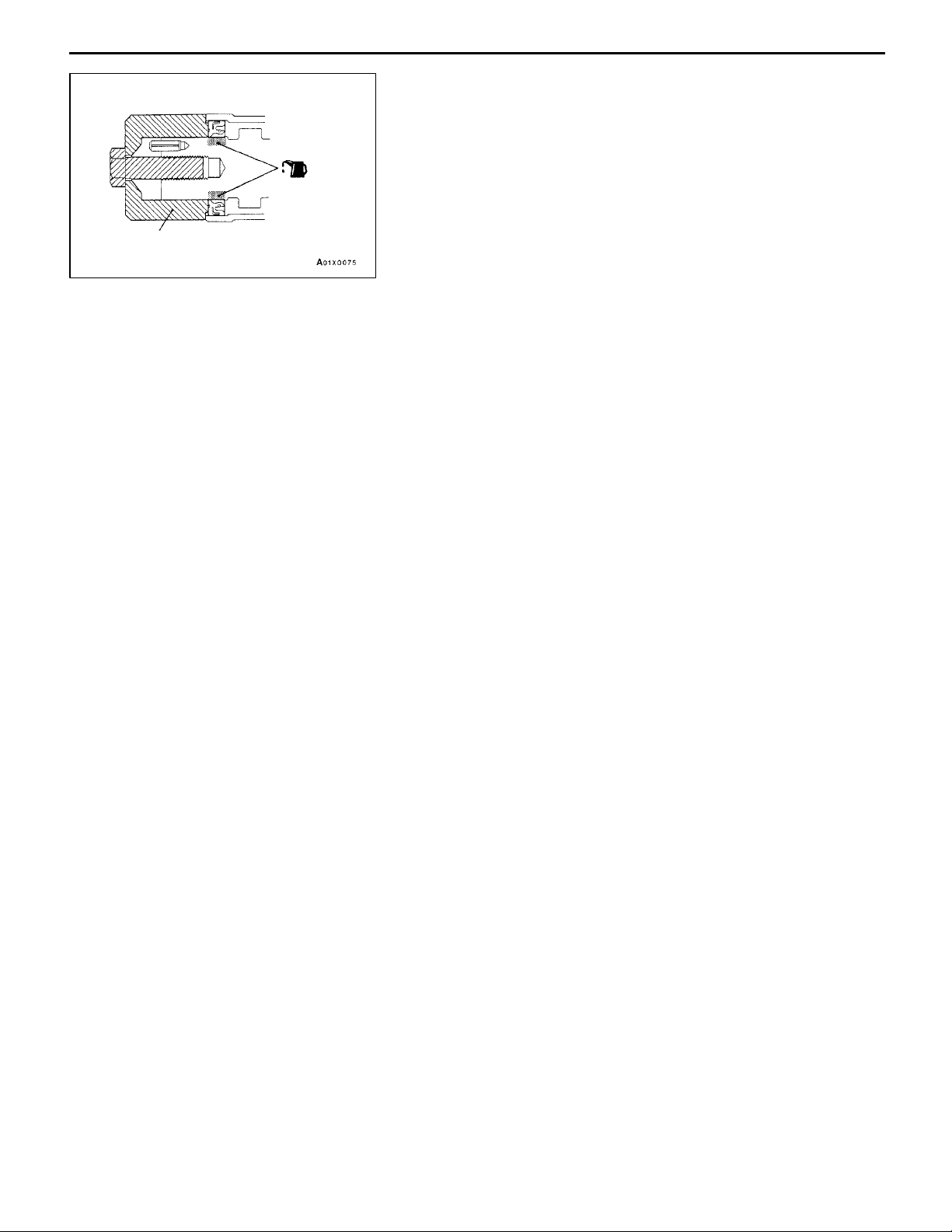

Page 27

11C-20

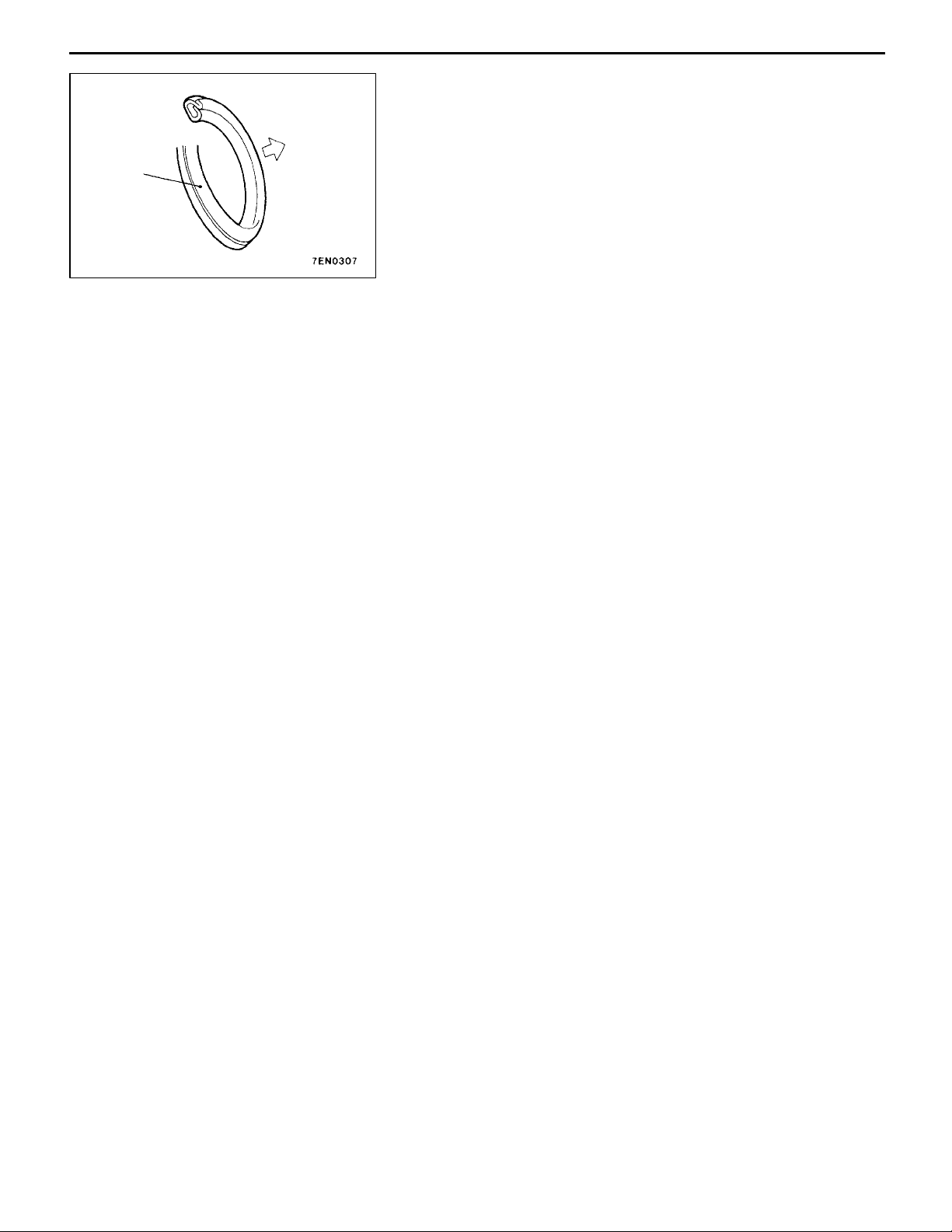

Drain plug

gasket

ENGINE <4G6-MPI> -

INSTALLATION SERVICE POINT

"AA

Oil pan side

Install the drain plug gasket in the direction so that it faces

as shown in the illustration.

Oil Pan

DRAIN PLUG GASKET INSTALLATION

Page 28

ENGINE <4G6-MPI> -

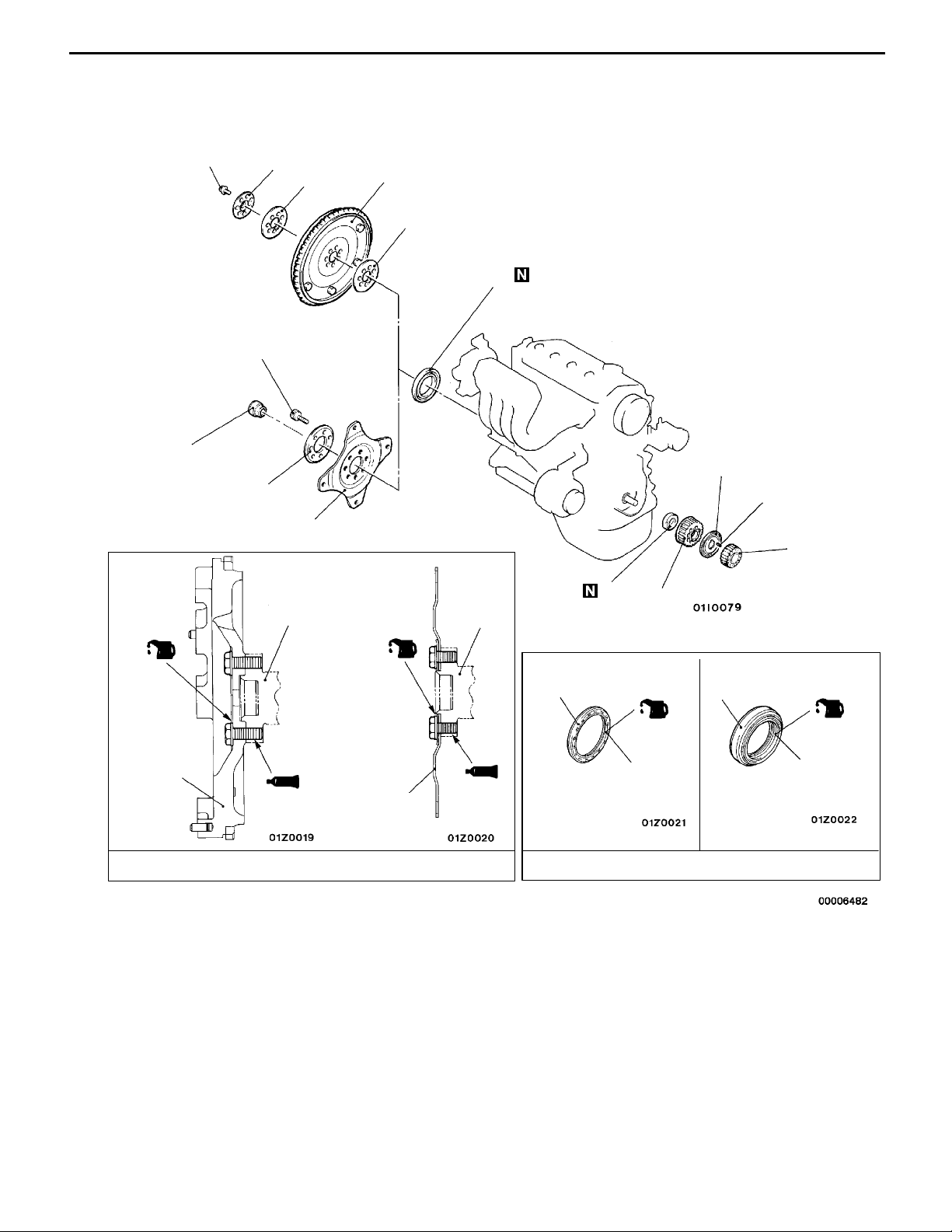

CRANKSHAFT OIL SEAL

REMOVAL AND INSTALLATION

Crankshaft Oil Seal

11C-21

127 - 137 Nm

<M/T>

<M/T>

7

8

9

11

12

127 - 137 Nm

<A/T>

6

2

8

4

10

1

<A/T>

Crankshaft

Crankshaft

5

3

(Engine oil:

(Engine oil:

bolt washer surface)

bolt washer

surface)

9

10

Sealant: 3M Stud locking 4170 or equivalent

Crankshaft front oil seal removal

steps

D

Timing belt (Refer to P.11C-27.)

D

Timing belt B (Refer to P.11C-31.)

D

Crank angle sensor

(Refer to GROUP 16.)

1. Crankshaft sprocket

2. Flange

3. Crankshaft sprocket B

"CA

4. Key

5. Crankshaft front oil seal

12

Lip section

Engine oil

Crankshaft rear oil seal removal

steps

D

AA"D

AB""BA

AB""BA

AB""BA

AB""BA

AB""BA

"AA

Oil pan (Refer to P.11C-19.)

Transmission assembly

D

Clutch cover and disc <M/T>

6. Crankshaft bushing <A/T>

7. Plate <M/T>

8. Adapter plate

9. Flywheel <M/T>

10. Drive plate <A/T>

11. Adapter plate <M/T>

12. Crankshaft rear oil seal

5

Lip section

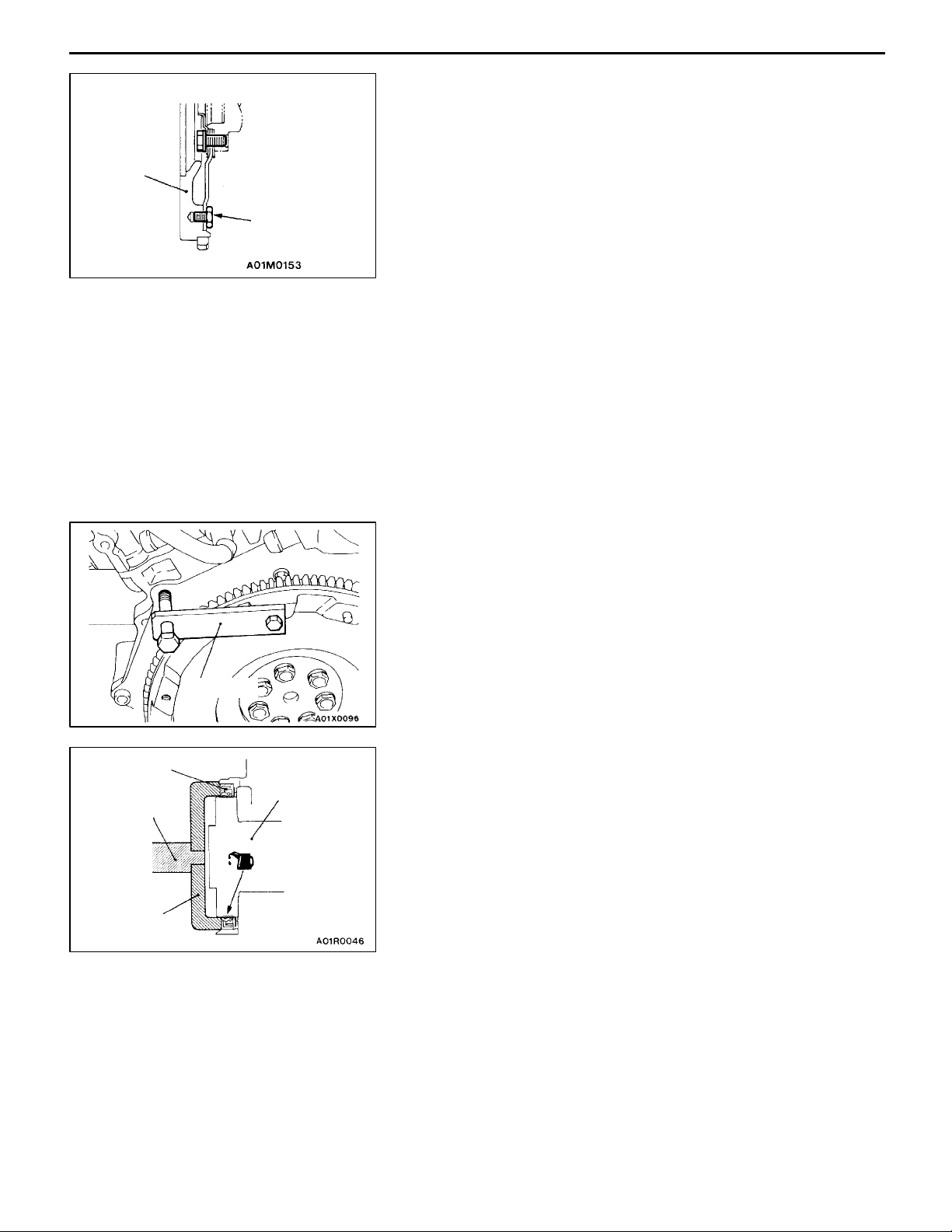

Page 29

11C-22

ENGINE <4G6-MPI> -

Crankshaft Oil Seal

<M/T>

Flywheel

Bolt

REMOVAL SERVICE POINTS

AA"

<M/T>:

Refer to ’99 SPACE RUNNER/SPACE WAGON Workshop

Manual (Pub. No. PWDE9803) GROUP 22.

Caution

Do not remove the flywheel mounting bolt shown by the

arrow. If this bolt Is removed, the flywheel will become

out of balance and damaged.

<A/T>:

Refer to ’99 SPACE RUNNER/SPACE WAGON Workshop

Manual (Pub. No. PWDE9803) GROUP 23.

AB"

Use the special tool to secure the flywheel or drive plate,

and remove the bolts.

TRANSMISSION ASSEMBLY REMOVAL

PLATE <M/T>/ADAPTER PLATE/FLYWHEEL

<M/T>/DRIVE PLATE <A/T> REMOVAL

Crankshaft

rear oil seal

MD990938

MD998776

MD998781

Crankshaft

INSTALLATION SERVICE POINTS

"AA

1. Apply a small mount of engine oil to the entire

2. Install the oil seal by tapping it as far as the chamfered

"BA

1. Clean off all sealant, oil and other substances which are

CRANKSHAFT REAR OIL SEAL INSTALLATION

circumference of the oil seal lip.

position of the oil seal case as shown in the illustration.

DRIVE PLATE <A/T>/FLYWHEEL <M/T>/ADAPTER

PLATE/PLATE <M/T> INSTALLATION

adhering to the threaded bolts, crankshaft thread holes

and the flywheel or drive plate.

Page 30

ENGINE <4G6-MPI> -

2. Apply oil to the bearing surface of the flywheel or drive

plate bolts.

3. Apply oil to the crankshaft thread holes.

4. Apply sealant to the threaded mounting holes.

Specified sealant: 3M Stud locking 4170 or equivalent

5. Use the special tool to hold the flywheel or drive plate

in the same manner as removal, and install the bolt.

Crankshaft Oil Seal

11C-23

"CA

1. Apply a small amount of engine oil to the entire

2. Press-fit the oil seal unit it is flush with the oil seal case.

CRANKSHAFT FRONT OIL SEAL INSTALLATION

circumference of the oil seal lip.

Page 31

11C-24

ENGINE <4G6-MPI> -

CYLINDER HEAD GASKET

REMOVAL AND INSTALLATION

Cylinder Head Gasket

Pre-removal and Post-installation Operation

D Fuel Discharge Prevention (Refer to GROUP 13D

- On-vehicle Service.) <Pre-removal only>

D Engine Coolant Draining and Supplying

D Engine Oil Draining and Supplying

1

78 Nm®0Nm®20 Nm®+90

_ ®

+90

9

(Engine oil)

3

10

D Intake Manifold Removal and Installation (Refer to

GROUP 15.)

D Thermostat Case Assembly Removal and Installation

(Refer to GROUP 14 - Water Hose and Pipe.)

D Timing Belt Removal and Installation (Refer to

P.11C-27.)

10 Nm

2

1

_

7

8

3.4 Nm

AA"

11

Removal steps

1. Ignition coil connector

2. Ignition coil assembly

3. Camshaft position sensor connector

4. Power steering oil pump and

bracket assembly

5. Front exhaust pipe connection

4

34 Nm

AB""BA

"AA

49 Nm

6

5

44 Nm

6. Engine oil level gauge

7. Breather hose

8. Rocker cover

9. Cylinder head bolt

10. Cylinder head assembly

11. Cylinder head gasket

Page 32

ENGINE <4G6-MPI> -

REMOVAL SERVICE POINTS

AA"

Remove the power steering oil pump and bracket assembly

from the engine with the hose attached.

NOTE

Place the removed power steering oil pump in a place where

it will not be a hindrance when removing and installing the

cylinder head assembly, and tie it with a cord.

Cylinder Head Gasket

11C-25

POWER STEERING OIL PUMP AND BRACKET

ASSEMBLY REMOVAL

Intake side

351082

17964

Exhaust side

A

Burred side

Head bolt

washer

Cylinder

head

Front of engine

Head bolt

(Engine

oil)

AB"

CYLINDER HEAD BOLT REMOVAL

Loosen the bolts in 2 or 3 steps in order of the numbers

shown in the illustration, and remove the cylinder head

assembly.

Caution

Because the plug guides cannot be replaced by

themselves, be careful not to damage or deform the plug

guides when removing the cylinder head bolts.

INSTALLATION SERVICE POINTS

"AA

1. Wipe off all oil an d grease from the gasket mounting

2. Install so that the shapes of the cylinder head holes match

"BA

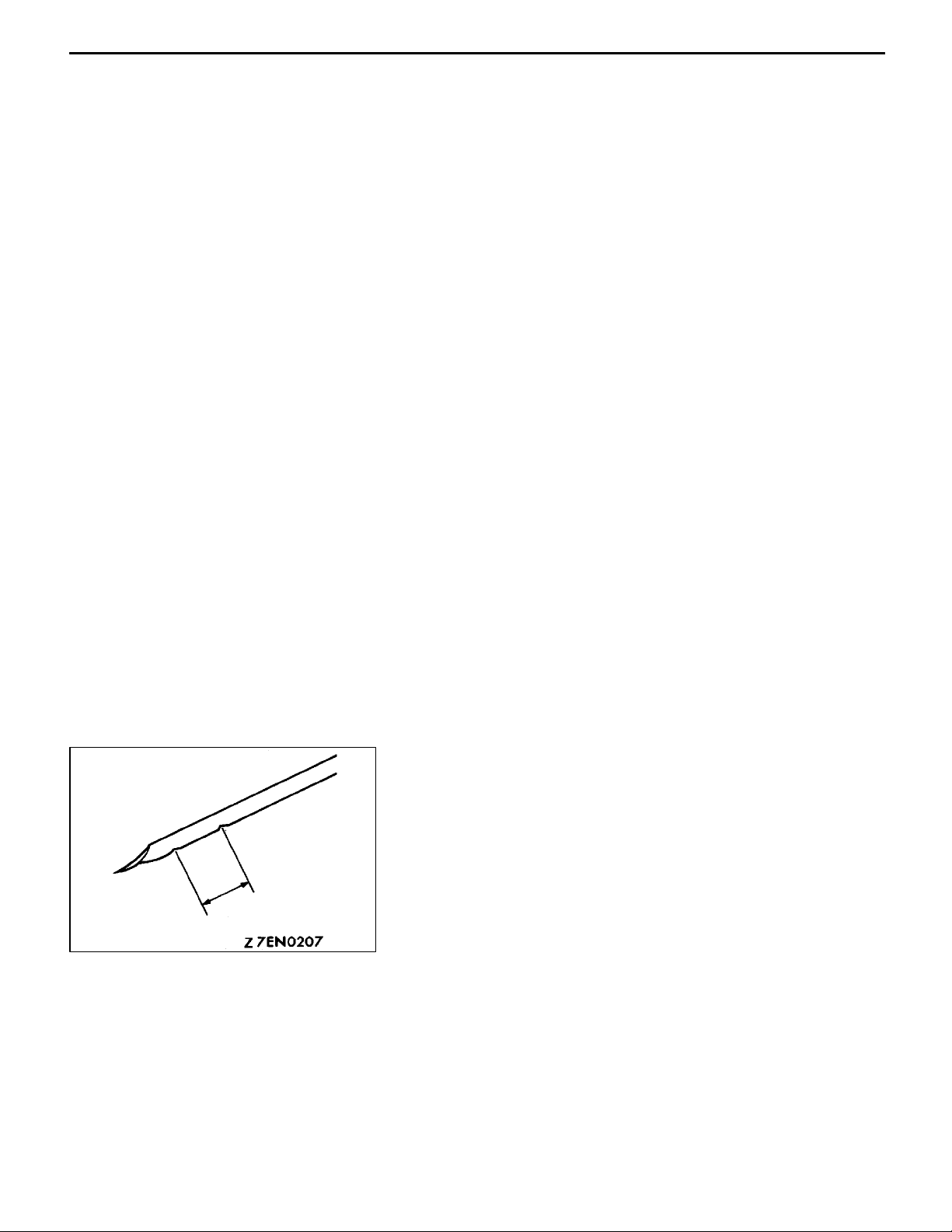

1. When installing the cylinder head bolts, the length below

2. The head bolt washer should be installed with the burred

3. Apply a small amount of engine oil to the thread section

CYLINDER HEAD GASKET INSTALLATION

surface.

the shapes of the respective cylinder head gasket holes.

CYLINDER HEAD BOLT INSTALLATION

the head of the bolts should be within the limit.

If it is outside the limit, replace t h e bolts.

Limit (A): 99.4 mm

side caused by tapping out facing upwards.

and the washer of the cylinder head bolt.

Page 33

11C-26

ENGINE <4G6-MPI> -

Cylinder Head Gasket

Intake side

86139

104257

Exhaust side

Step 4

90

_

Painted mark

Front of engine

Step 5

Painted mark

90

4. Tighten the bolts by the following procedure.

Step Operation Remarks

1 Tighten to 78 Nm. Carry out in the order

shown in the illustration.

2 Fully loosen. Carry out in the reverse

order of that shown in the

illustration.

3 Tighten to 20 Nm. Carry out in the order

shown in the illustration.

4 Tighten 90_of a turn. In the order shown in the

illustration. Mark the head

of the cylinder head bolt

_

5 Tighten 90_of a turn. In the order shown in the

and cylinder head by paint.

illustration. Check that the

painted mark of the head

bolt is lined up with that of

the cylinder head.

Caution

1. Always make a tightening angle just 90_. If it is less

than 90_, the head bolt will be loosened.

2. If it is more than 90_, remove the head bolt and repeat

the procedure from step 1.

"CA

HIGH-PRESSURE FUEL HOSE INSTALLATION

1. Apply a small amount of new engine oil to the O-ring.

Caution

Do not let any engine oil get into the delivery pipe.

2. While turning the high-pressure fuel hose to the right

and left, install the delivery pipe, while being careful not

to damage the O-ring. After installing, check that the hose

turns smoothly.

3. If the hose does not turn smoothly, the O-ring is probably

being clamped. Disconnect the high-pressure fuel hose

and check the O-ring for damage. After this, re-insert

the delivery pipe and check that the hose turns smoothly.

Page 34

ENGINE <4G6-MPI> -

TIMING BELT

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

D Crankshaft Pulley Removal and Installation (Refer

to P.11C-15.)

D Engine Mount Bracket Removal and Installation

Timing Belt

3

11C-27

10 - 12 Nm

"CAD

AA""BA

"AA

1

5

9Nm

Removal steps

1. Timing belt upper cover

2. Timing belt lower cover

Timing belt tension adjustment

3. Timing belt

4. T ension pulley

5. Auto tensioner

48 Nm

4

24 Nm

2

Page 35

11C-28

ENGINE <4G6-MPI> -

Timing Belt

Timing mark (Top

of cylinder head)

Timing mark

Timing mark

Crankshaft

sprocket

B

A

Auto tensioner

Timing mark

98 - 196N

Camshaft sprocket

Timing mark

Oil pump

sprocket

Centre bolt

Movement

Push rod

REMOVAL SERVICE POINT

AA"

1. Turn the crankshaft clockwise (right turn) to align each

2. Loosen the tension pulley centre bolt.

3. Move the tension pulley to the water pump side, and

TIMING BELT REMOVAL

timing mark and to set the No. 1 cylinder at compression

top dead centre.

Caution

The crankshaft should always be turned only

clockwise.

then remove the timing belt.

Caution

If the timing belt is to be re-used, use chalk to mark

(on its flat side) an arrow indicating the clockwise

direction.

INSTALLATION SERVICE POINTS

"AA

1. Apply 98 - 196 N force to the auto tensioner by pressing

2. If it is out of the standard value, replace the auto tensioner.

AUTO TENSIONER INSTALLATION

it against a metal (cylinder block, etc.), and measure the

movement of the push rod.

Standard value: Within 1 mm

A: Length when it is free (not pressed)

B: Length when it is pressed

A - B: Movement

AB

3. Use a press or vice to gently compress the auto tensioner

push rod until pin hole A of the push rod and pin hole

B of the tensioner cylinder are aligned.

Caution

If the compression speed is too fast, the rod may

become damaged, so be sure to carry out this

operation slowly.

Page 36

ENGINE <4G6-MPI> -

Timing Belt

11C-29

Timing mark (Top

of cylinder head)

Timing mark

Timing mark

Crankshaft

sprocket

Plug

Set pin

Timing mark

Camshaft sprocket

Timing mark

60 mm or

more

Counterbalance

shaft

Oil pump

sprocket

Screwdriver

Cylinder

block

8mm

4. Once the holes are aligned, insert the set pin.

NOTE

When replacing the auto tensioner with a new part, the

pin will be in the auto tensioner.

5. Install the auto tensioner to the engine.

"BA

TIMING BELT INSTALLATION

1. Align the timing marks on the camshaft sprocket,

crankshaft sprocket and oil pump sprocket.

2. After aligning the timing mark on the oil pump sprocket,

remove the cylinder block plug and insert a Phillips

screwdriver with a diameter of 8 mm, and check to be

sure that the screwdriver goes in 60 mm or more. If

the screwdriver will only go in 20 - 25 mm before striking

the counterbalance shaft, turn the sprocket once, realign

the timing mark and check that the screwdriver goes in

60 mm or more. The screwdriver should not be taken

out until the timing belt is installed.

Fixing bolt

Pin hole

Belt tension side

Belt tension side

3. Install the belt to the crankshaft sprocket, oil pump

sprocket and camshaft sprocket in that order, so that

there is no slackness in the belt tension.

Caution

If the timing belt is re-used, install so that the arrow

marked on it at time of removal is pointing in the

clockwise direction.

4. Set the tension pulley so that the pin holes are at the

top, press the tension pulley lightly against the timing

belt, and then provisionally tighten the fixing bolt.

5. Adjust the timing belt tension.

Page 37

11C-30

ENGINE <4G6-MPI> -

Timing Belt

50 Nm

MD998767

A

Auto tensioner

Tension

direction

"CA

TIMING BELT TENSION ADJUSTMENT

1. After turning the crankshaft 1/4 of a revolution in the

anticlockwise direction, turn it in the clockwise direction

until the timing marks are aligned.

2. Loosen the tension pulley fixing bolt, and then use the

special tool and a torque wrench to tighten the fixing

bolt to the specified torque while applying tension to the

timing belt.

Standard value: 3.5 Nm <Timing belt tension torque>

Caution

When tightening the fixing bolt, make sure that the

tension pulley does not turn with the bolt.

3. Turn the crankshaft two revolutions in the clockwise

direction so that the timing marks are aligned. After leaving

it for 15 minutes, measure the amount of protrusion of

the auto tensioner.

Standard value (A): 3.8 - 4.5 mm

4. If the amount of protrusion is outside the standard value,

repeat the operation in steps (1) to (3).

5. Check again to be sure that the timing marks of each

sprocket are aligned.

Page 38

ENGINE <4G6-MPI> -

TIMING BELT B

REMOVAL AND INSTALLATION

1

19 Nm

4

Timing Belt B

11C-31

5

Removal steps

1. Timing belt (Refer to P.11C-27.)

AA""CA 2. Crankshaft sprocket

"BA 3. Flange

Crankshaft

sprocket

MD998719 or MD998754

MB990767

2

108 - 127 Nm

REMOVAL SERVICE POINTS

AA"

3

4. Timing belt B tensioner

AB""AA 5. Timing belt B

CRANKSHAFT SPROCKET REMOVAL

AB"

TIMING BELT B REMOVAL

Caution

If timing belt “B” is to be re-used, use chalk to mark

it with an arrow on its flat side indicating the turning

direction (to the right).

Page 39

11C-32

ENGINE <4G6-MPI> -

Timing Belt B

Counterbalance shaft sprocket

Timing

marks

Crankshaft

sprocket B

Centre of

tensioner

pulley

Centre of installation

bolt

Shaft

Belt tension side

Timing marks

INSTALLATION SERVICE POINTS

"AA

1. Install timing belt “B” by the following procedure.

2. Adjust the tension of timing belt “B” by the following

TIMING BELT B INSTALLATION, ADJUSTMENT

(1) Ensure that crankshaft sprocket “B” timing mark and

the counterbalance shaft sprocket timing mark are

aligned.

(2) Fit timing belt “B” over crankshaft sprocket “B” an d

the counterbalance shaft sprocket. Ensure that there

is no slack in the belt.

procedure.

(1) Temporarily fix the timing belt “B” tensioner such that

the centre of the tensioner pulley is to the left a nd

above the centre of the installation bolt, and

temporarily attach the tensioner pulley so that the

flange is toward the front of the engine.

(2) Holding the timing belt “B” tensioner up with your

finger in th e direction of the arrow, place pressure

on the timing belt so that the tension side of the

belt is taut. Now tighten the bolt to fix the tensioner.

Caution

When tightening the bolt, ensure that the tensioner

pulley shaft does not rotate with the bolt. Allowing

it to rotate with the bolt can cause excessive

tension on the belt.

Centre of

tensioner

pulley

Centre of

installation

bolt

Crankshaft

sprocket

A

Flange

Crankshaft

Crankshaft

sprocket “B”

3. To ensure that the tension is correct, depress the belt

(point A) with a finger. I f not, adjust.

Standard value: 5 - 7 mm

"BA

FLANGE INSTALLATION

When installing, make sure the direction is correct. See figure.

Page 40

ENGINE <4G6-MPI> -

Timing Belt B

11C-33

Crankshaft

sprocket

MD998719 or MD998754

MB990767

"CA

CRANKSHAFT SPROCKET INSTALLATION

NOTE

Apply the minimum amount of engine oil to the bearing surface

and thread of the crankshaft bolt.

Page 41

11C-34

ENGINE <4G6-MPI> -

Engine Assembly

ENGINE ASSEMBLY

REMOVAL AND INSTALLATION

Caution

Mounting locations marked by * should be provisionally tightened, and then fully tightened after

placing the vehicle horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal and Post-installation Operation

D Fuel Discharge Prevention (Refer to GROUP 13D

- On-vehicle Service.) <Pre-removal only>

D Engine Cover Removal and Installation

D Under Cover Removal and Installation

D Engine Coolant Draining and Supplying

3

5Nm 39Nm

9

13

12

4

2

67 Nm

11

16

57 Nm

10

16

D Hood Removal and Installation

D Transmission Assembly Removal and Installation

D Drive Belt Tension Adjustment (Refer to P.11C-6.)

<Post-installation only>

D Accelerator Cable Adjustment <Post-installation only>

2

5

17

6

39 Nm

8

7

1

AA"

AB"

15

14

98 - 118 Nm*

Removal steps

1. Drive belt (Power steering and

A/C)

2. Engine harness connector

3. Earth cable connection

4. Accelerator cable connection

5. Alternator connector

6. Power steering hose clamp

7. A/C compressor

8. Power steering oil pump

9. Vacuum hose connection

AC""CA

"BA

AD""AA

10. Brake booster vacuum hose

connection

11. Heater hose connection

12. Fuel return hose connection

13. Fuel pressure hose connection

14. Power steering oil reservoir

15. Engine mount bracket

16. Engine mount stopper

17. Engine assembly

Page 42

ENGINE <4G6-MPI> -

REMOVAL SERVICE POINTS

AA"

Disconnect the A/C compressor connector and remove the

compressor from the compressor bracket with the hose still

attached.

NOTE

Place the removed A/C compressor where it will not be a

hindrance when removing and installing the engine assembly,

and tie it with a cord.

A/C COMPRESSOR REMOVAL

Engine Assembly

11C-35

MB991453

MZ203827

AB"

Remove the power steering oil pump and bracket assembly

from the engine with the hose attached.

NOTE

Place the removed power steering oil pump in a place where

it will not be a hindrance when removing and installing the

engine assembly, and tie it with a cord.

AC"

1. Support the engine with a garage jack.

2. Remove the special tool which was attached when the

3. Hold the engine assembly with a chain block or similar

4. Place a garage jack against the engine oil pan with a

AD"

After checking that all cables, hoses and harness connectors,

etc., are disconnected from the engine, lower the chain block

slowly to remove the engine assembly downward from the

engine compartment.

POWER STEERING OIL PUMP REMOVAL

ENGINE MOUNT BRACKET REMOVAL

transmission assembly was removed.

tool.

piece of wood in between, jack up the engine so that

the weight of the engine is no longer being applied to

the engine mount bracket, and then remove the engine

mount bracket.

ENGINE ASSEMBLY REMOVAL

Page 43

11C-36

ENGINE <4G6-MPI> -

INSTALLATION SERVICE POINTS

"AA

Install the engine assembly, checking that the cables, hoses,

and harness connectors are not clamped.

ENGINE ASSEMBLY INSTALLATION

Engine Assembly

Engine

mount

stopper

Engine mount bracket

Engine side

Arrow

"BA

ENGINE MOUNT STOPPER INSTALLATION

Clamp the engine mount stopper so that the arrow points

in the direction as shown in the diagram.

"CA

ENGINE MOUNT BRACKET INSTALLATION

1. Place a garage jack against the engine oil pan with a

piece of wood in between, and install the engine mount

bracket while adjusting the position of the engine.

2. Support the engine with the garage jack.

3. Remove the chain block and support the engine assembly

with the special tool.

Page 44

FUEL

CONTENTS

GASOLINE DIRECT INJECTION (GDI) 13A..................................

MULTIPOINT FUEL INJECTION (MPI) <4G6> 13D............................

13A-1

Page 45

13A-2

GASOLINE

DIRECT

INJECTION (GDI)

CONTENTS

GENERAL 3.................................

Outline of Change 3...........................

SERVICE SPECIFICATIONS 3.................

TROUBLESHOOTING 3.......................

ON-VEHICLE SERVICE 11....................

Accelerator Pedal Position Switch and Accelerator

Pedal Position Sensor Adjustment 11............

Accelerator Pedal Position Sensor Inspection 11..

Accelerator Pedal Position Switch Inspection 12..

FUEL PUMP (HIGH PRESSURE) AND FUEL

PRESSURE REGULATOR

(HIGH PRESSURE) 14.......................

INJECTOR 18...............................

Page 46

GDI <4G6> -

General/Service Specification/Troubleshooting

13A-3

GENERAL

OUTLINE OF CHANGES

The following service procedures for items which are different from before have been established to

correspond to the addition of vehicles with 4G6-GDI engine.

Other service procedures are the same as before.

D An integrated-type accelerator pedal position sensor has been adopted.

D A GDI ECO indication lamp has been adopted.

D The fuel feed pipe and fuel return pipe shapes have been changed.

SERVICE SPECIFICATIONS

Items Standard value

Adjustment voltages (1) and (2) of accelrator pedal position sensor V 0.5 - 0.9

Resistance (1) and (2) of accelerator pedal position sensor k

W

3.5 - 6.5

TROUBLESHOOTING

INSPECTION CHART FOR DIAGNOSIS CODES

Diagnosis code Nos. 77 and 78 have been changed in line with the adoption of an integrated-type accelerator

pedal position sensor. Other items are the same as before.

Code No. Diagnosis item Reference page

77 Accelerator pedal position sensor (2nd channel) system 13A - 4

78 Accelerator pedal position sensor (1st channel) system 13A-5

Page 47

13A-4

GDI <4G6> -

Troubleshooting

INSPECTION PROCEDURE FOR DIAGNOSIS CODES

Code No.77 Accelerator pedal position sensor (2nd

channel) system

Range of check

D Accelerator pedal position sensor (1st channel) system is normal.

D Communication between the engine-ECU and throttle valve controller is normal.

Set conditions

D Output voltage of accelerator position sensor (2nd channel) system is 0.2 V or

less for one second.

or

D Output voltage of the accelerator pedal position sensor (1st channel) is 2.5 V

or less, and output voltage of the accelerator pedal position sensor (2nd channel)

is 4.5 V or more for one second.

or

D Difference between the accelerator pedal position sensor output voltages (1st

and 2nd channels) exceeds 1.0 V (i.e. when the throttle valve opening angle changes

slightly).

Check the accelerator pedal position

sensor (2nd channel). (Refer to P.13A-

11.)

OK

Measure at accelerator pedal position

sensor connector A-103.

D Disconnect the connector, and

measure at the harness side.

D Voltage between terminal 8 and

earth

(Ignition switch: ON)

OK:

earth

OK:

4.8 - 5.2 V

Continuity

OK

D Continuity between terminal 7 and

NG

NG

Replace the accelerator pedal position

sensor assembly.

Check the following connectors:

A-27, B-50

OK

Check trouble symptom.

Probable cause

D Malfunction of the accelerator pedal position sensor

(2nd channel)

D Open circuit or short-circuited harness wire in the

accelerator pedal position sensor (2nd channel)

system, or poor connector contact

D Malfunction of the throttle valve controller

D Malfunction of the engine-ECU

NG

NG

Repair

Check the harness wire between the

throttle valve controller and the accelerator pedal position sensor (2nd channel).

OK

Replace the throttle valve controller.

NG

Repair

Measure at throttle valve controller connector B-50.

D Connect the connector.

D Voltage between terminal 20 and

earth (Ignition switch: ON)

OK:

0.3 - 1.0 V

(Accelerator pedal: fully released)

4.2 - 5.5 V

(Accelerator pedal: fully depressed)

OK

MUT-IIData list

78 Accelerator pedal position sensor

(1st channel). (Refer to P.13A-9.)

OK

Replace the throttle valve controller.

NG

NG

Check the following connectors:

A-27, A-103

OK

Check trouble symptom.

Check the accelerator pedal position

sensor (1st channel) system. (Refer to

P.13A-5, INSPECTION PROCEDURE

FOR DIAGNOSIS CODE 78.)

NG

NG

Repair

Check the harness wire between the

accelerator pedal position sensor (2nd

channel) and throttle valve controller.

OK

Adjust the accelerator pedal position

sensor. (Refer to P.13A-11.)

Check trouble symptom.

NG

Replace the throttle valve controller.

NG

Repair

Page 48

GDI <4G6> -

Troubleshooting

13A-5

Code No.78 Accelerator pedal position sensor (1st

channel) system

Range of check

D Accelerator pedal position sensor (2nd channel) system is normal.

D Communication between the engine-ECU and throttle valve controller is normal.

Set conditions

D Output voltage of accelerator position sensor (1st channel) system is 0.2 V or

less for one second.

or

D Output voltage of the accelerator pedal position sensor (2nd channel) is 2.5 V

or less, and (1st channel) output voltage of the accelerator pedal position sensor

is 4.5 V or more for one second.

or

D Difference between the accelerator pedal position sensor (1st and 2nd channels)

output voltages exceeds 1.0 V (i.e. when the throttle valve opening angle changes

slightly).

or

D Although the accelerator pedal position switch is on, 1st-channel output voltage

of the accelerator pedal position sensor exceeds 1.1 V for one second.

MUT-IIData list

26 Accelerator pedal position switch

(P.13A-9.)

OK

Check the accelerator pedal position

sensor (1st channel). (Refer to P.13A-

11.)

OK

Measure at the accelerator pedal position sensor connector A-103.

D Disconnect the connector, and

measure at the harness side.

D Voltage between terminal 2 and

earth (Ignition switch: ON)

OK:

D Continuity between terminal 1 and

Measure at the engine-ECU B-51.

D Connect the connector.

D Voltage between terminal 87 and

MUT-IIData list

78 Accelerator pedal position sensor

(2nd channel). (Refer to P.13A-9.)

Replace the engine-ECU.

4.8 - 5.2 V

earth

OK:

Continuity

OK

earth

(Ignition switch: ON)

OK:

0.3 - 1.0 V

(Accelerator pedal: fully released)

4.2 - 5.5 V

(Accelerator pedal: fully depressed)

OK

OK

NG

NG

NG

NG

NG

Check the accelerator pedal position

switch system. (Refer to P.13A-7, INSPECTION PROCEDURE 27.)

Replace the accelerator pedal position

sensor assembly.

Check the following connectors:

A-27, B-51

OK

Check trouble symptom.

Check the following connectors:

A-27, A-103

OK

Check trouble symptom.

Check the accelerator pedal position

sensor (2nd channel) system. (Refer

to P.13A-4, INSPECTION PROCEDURE FOR DIAGNOSIS CODE 77.)

Probable cause

D Malfunction of the accelerator pedal position sensor

(1st channel)

D Open circuit or short-circuited harness wire in the

accelerator pedal position sensor (1st channel) system,

or poor connector contact

D ON-seizure of the accelerator pedal position switch

D Malfunction of the throttle valve controller

D Malfunction of the engine-ECU

NG

NG

NG

NG

Repair

Check the harness wire between the

accelerator pedal position sensor (1st

channel) and engine-ECU.

OK

Replace the engine-ECU.

Repair

Check the harness wire between the

accelerator pedal position sensor (1st

channel) and engine-ECU.

OK

Adjust the accelerator pedal position

sensor. (Refer to P.13A-11.)

Check trouble symptom.

NG

Replace the engine-ECU.

NG

Repair

NG

Repair

Page 49

13A-6

GDI <4G6> -

Troubleshooting

INSPECTION CHART FOR TROUBLE SYMPTOMS

Inspection procedure No. 27 has been changed in line with the adoption of an integrated-type accelerator

pedal position sensor. Inspection procedure Nos. 36 and 37 have been added in line with the adoption

of a GDI indication lamp. Other items are the same as before.

Trouble symptom Inspection

procedure No.

GDI ECO indication The GDI ECO indication lamp does not illuminate. 36 13A- 8

lamp system

The GDI ECO indication lamp remains on (does not

extinguish).

37 13A-8

Reference page

Page 50

GDI <4G6> -

GDI <4G6> -

Troubleshooting

Troubleshooting

INSPECTION PROCEDURE FOR TROUBLE SYMPTOMS

INSPECTION PROCEDURE 2 7

13A-7

Accelerator pedal position switch system

The accelerator pedal position switch detects that the accelerator pedal is fully closed,

and sends a signal to the engine-ECU. The engine-ECU controls idle speed, based

on this signal.

Check the accelerator pedal position switch. (Refer to P.13A-11.)

OK

Measure at accelerator pedal position sensor connector A-103.

D Disconnect the connector, and measure at the harness side.

D Voltage between terminal 4 and earth

(Ignition switch: ON)

OK:

OK:

4 V or more

Continuity

OK

A-103

OK

D Continuity between terminal 5 and earth

Check the following connector:

Check trouble symptom.

NG

NG

NG

NG

Replace the accelerator pedal position sensor assembly.

Check the following connectors:

Check trouble symptom.

Check the harness wire between the engine-ECU and accelerator

pedal position sensor 1 (1st channel).

Repair

Replace the engine-ECU.

Probable cause

D Maladjustment of the accelerator cable

D Maladjustment of the accelerator pedal position switch

D Open circuit or short-circuited harness wire in the

accelerator pedal position switch system, or poor

connector contact

D Malfunction of the engine-ECU

A-27, B-51, B-52

OK

NG

OK

NG

Repair

NG

Repair

Page 51

13A-8

INSPECTION PROCEDURE 3 6

GDI <4G6> -

Troubleshooting

The GDI ECO indication lamp does not illuminate.

If the GDI ECO indication lamp does not illuminate after turning on the ignition switch,

the causes listed in the right column are suspected.

MUT-IIData list

16 System voltage (Refer to P.13A-76*.)

OK

Measure at engine-ECU connector B-54.

D Disconnect the connector, measure at the harness side.

D Earth terminal 19

(Ignition switch: ON)

OK:

The GDI ECO indication lamp illuminates.

NG

Check a burned-out bulb.

OK

Measure at combination meter B-01.

D Disconnect the connector, measure at the harness side.

D Voltage between terminal 42 and earth

(Ignition switch: ON)

OK:

System voltage

NG

Check the GDI ECO indication lamp circuit, and repair if necessary.

NG

Replace

NG

OK

OK

Check the engine-ECU power supply and earth circuits system.

(Refer to P.13A-64*, INSPECTION PROCEDURE 23.)

Check the following connector:

Check trouble symptom.

Replace the engine-ECU.

Check the following connectors:

Check trouble symptom.

Probable cause

D Burned-out GDI ECO indication lamp bulb

D Open circuit or short -circuited harness wire in the

GDI ECO indication lamp circuit

D Malfunction of the engine-ECU

B-54

OK

NG

OK

NG

NG

Repair

B-02, B-15, B-54

NG

Repair

Check the harness wire between the combination meter and engineECU, and repair if necessary.

NOTE

*: Refer to the ’99 SPACE RUNNER/SPACE WAGON Workshop Manual (Pub. No. PWDE9803)

INSPECTION PROCEDURE 37

The GDI ECO indication lamp remains on (does not

Probable cause

extinguish).

If the GDI ECO indication lamp does not extinguish during high load operation, the

causes listed int right column are suspected.

Measure at combination meter connector B-02.

D Disconnect the connector, measure at the harness side.

D Disconnect the engine-ECU connector.

D Continuity between terminal 19 and earth.

OK:

No continuity

OK

Replace the engine-ECU.

NG

D Short circuit between the GDI ECO indication lamp

and engine-ECU

D Malfunction of the engine-ECU

Check the harness wire between the combination meter and engineECU, and repair if necessary.

Page 52

GDI <4G6> -

Troubleshooting

13A-9

DATA LIST REFERENCE TABLE

Caution

When shifting the select lever to D range, the brakes should be applied so that vehicle does not

move forward.

NOTE

1.*1: When the accelerator pedal position sensor (1st channel) output is 500 - 900 mV, the accelerator

pedal position switch should normally change from ON to OFF. If this does not happen, adjust the

accelerator pedal position sensor.

2.*2: Check if the difference in output between *2 and *3 is 4 V or more.

Item

No.

Check

items

Requirements Normal condition Inspection

procedure No.

Reference

page

26 Accelera-

tor pedal

position

switch

77 Accelera-

tor pedal

position

sensor

(2nd

channel)

78 Accelera-

tor pedal

position

sensor (1st

channel)*

ignition switch: ON

Depress and release

the accelerator pedal

several times)

ignition switch: ON

ignition switch: ON

1

Release the accelerator pedal.

Depress the accelerator pedal slightly.

Release the accelerator pedal.

Depress the accelerator pedal gradually.

Depress the accelerator pedal fully.

Release the accelerator pedal.

Depress the accelerator pedal gradually.

Depress the accelerator pedal fully.

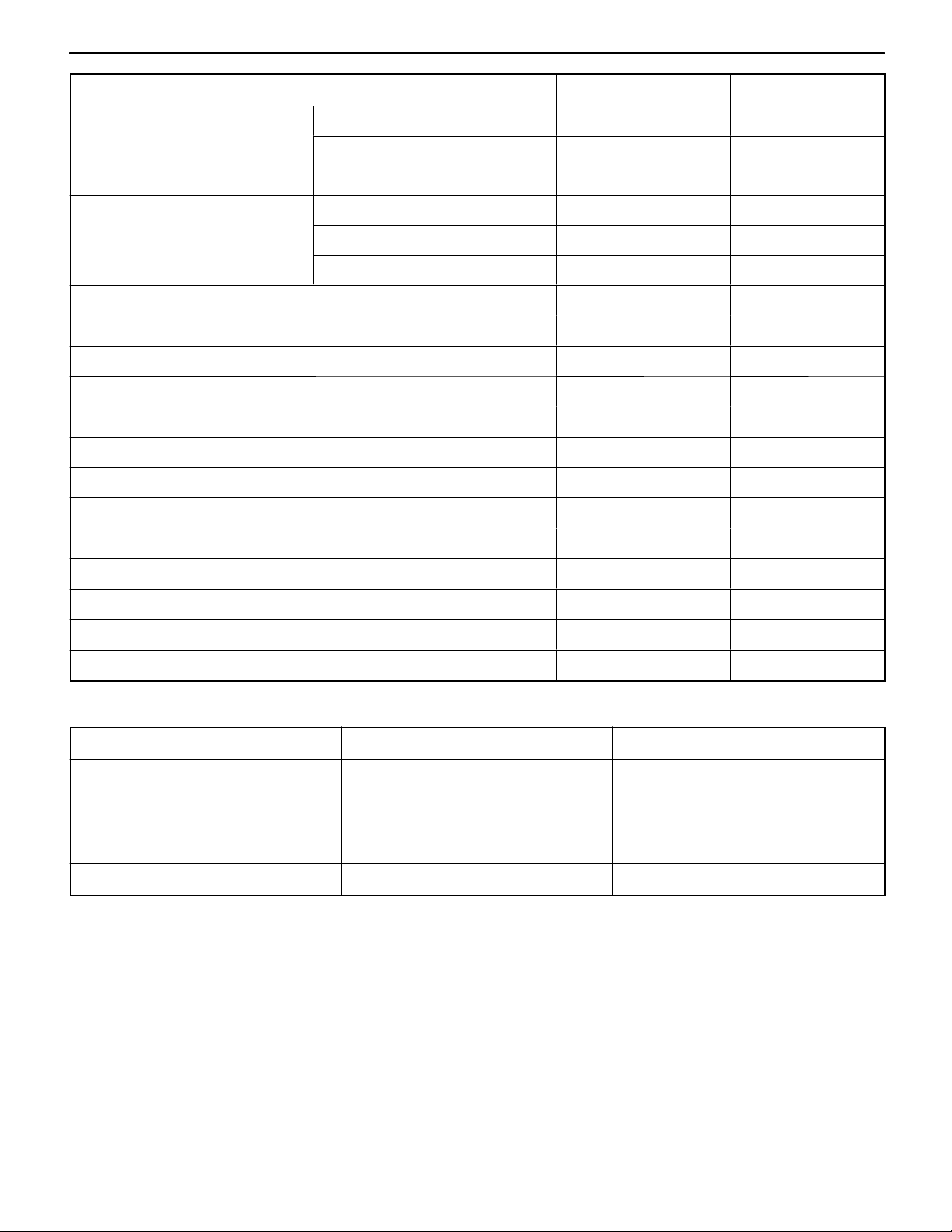

CHECK AT THE ENGINE-ECU TERMINALS

TERMINAL VOLTAGE CHECK CHART

Engine-ECU Connector Terminal Arrangement

ON

OFF

300-1,000 mV*

Increases in response to the pedal

depression stroke.

4,200-5,500 mV*

300-1,000 mV*

Increases in response to the pedal

depression stroke.

4,200-5,500 mV*

2

2

Procedure

No. 27

Code No. 77 13A-4

3

Code No. 78 13A-5

3

13A-7

Terminal No. Check items Check requirements (engine condition) Normal condition

3 GDI ECO indication

lamp

57 Accelerator pedal Ignition switch:

position switch ON

81 Power supply to accel-

erator pedal position

sensor (1st channel)

87 Accelerator pedal Ignition switch:

position sensor

(1st channel)

Engine: idling 0-3 mV

Engine: When the accelerator pedal is suddenly

depressed while the engine is idling

Release the accelerator pedal. 0-1 V

Depress the accelerator pedal slightly. 4 V or more

Ignition switch: ON 4.5 - 5.5 V

Release the accelerator pedal. 0.3-1.0 V*

ON

Depress the accelerator pedal fully. 4.2- 5.5 V*

System voltage

1

2

NOTE

Check if the difference in output between *1 and *2 is 4 V or more.

Page 53

13A-10

GDI <4G6> -

Troubleshooting

Engine-ECU Connector Terminal Arrangement

Terminal No. Check items Standard value, Normal condition (Check require-

ments)

57-53 Accelerator pedal position switch Continuity (when the accelerator pedal is

released)

No continuity (when the accelerator pedal is

slightly depressed)

CHECK AT THE THROTTLE VALVE CONTROLLER TERMINALS

TERMINAL VOLTAGE CHECK CHART

Throttle Valve Controller Connector Terminal Arrangement

Terminal No. Check items Requirements Normal value

20 Accelerator pedal Ignition switch: ON Release the accelerator pedal. 0.3-1.0 V*

position sensor

(2nd channel)

Depress the accelerator pedal

fully.

4.5-5.5 V*

NOTE

Check if the difference in output between *1 and *2 is 4 V or more.

1

2

Page 54

GDI <4G6> -

ON-VEHICLE SERVICE

On-Vehicle Service

13A-11

Accelerator pedal

position sensor

Power steering

reservoir tank

Thickness

gauge

Accelerator pedal position sensor

Fully-closed stopper

Terminal (4)

Accelerator

lever

1. ACCELERATOR PEDAL POSITION SWITCH AND

ACCELERATOR PEDAL POSITION SENSOR

ADJUSTMENT

Caution

(1) The accelerator pedal position sensor is adjusted

correctly at the time of shipment from the factory,

and so it should not normally be moved.

(2) If adjustment does become necessary, use the

following procedure.

<When using t h e MUT-II>

(1) Connect the MUT-II to the diagnosis connector.

(2) Remove the two accelerator pedal position sensor

assembly mounting bolts, and then insert a thickness

gauge with a thickness of 0.60 mm in between the

accelerator lever and the fully-closed stopper.

(3) Turn the ignition switch to ON (without starting the engine).

(4) Loosen the accelerator pedal position sensor mounting

bolt, and then turn the accelerator pedal position sensor

anti-clockwise as far as it will go.

(5) Check that the idle switch turns on at this time.

(6) Turn the accelerator pedal position sensor clockwise until

the point is found where the idle switch turns off. Securely

tighten the accelerator pedal position sensor mounting

bolt at this point.

(7) Check that the accelerator pedal position sensor (1st

channel) output at this time is within the standard value

range.

Standard value: 0.5 - 0.9 V

Power steering

reservoir tank

Terminal (5)MB991658

Accelerator pedal

position sensor

(8) Turn the ignition switch to the LOCK (OFF) position.

(9) Remove the thickness gauge and then install the

accelerator pedal position sensor assembly.

(10)Remove th e MUT-II.

2. ACCELERATOR PEDAL POSITION SENSOR

INSPECTION

(1) Disconnect the accelerator pedal position sensor

connector.

Page 55

13A-12

GDI <4G6> -

(2) Measure the resistance between accelerator pedal

On-Vehicle Service

position sensor connector terminal (1) [accelerator pedal

position sensor (1st channel) earth] and terminal (2)

[accelerator pedal position sensor (1st channel) power

supply], and between terminal (7) [accelerator pedal

position sensor (2nd channel) earth] and terminal (8)

[accelerator pedal position sensor (2nd channel) power

supply].

Accelerator pedal position sensor

(1st channel) power supply

Accelerator

pedal position

sensor (1st

channel) earth

Accelerator pedal

position sensor (1st

channel) output

Accelerator pedal

position sensor (2nd

channel) earth

Accelerator pedal

position sensor

(2nd channel)

power supply

Accelerator pedal

position sensor (2nd

channel) output

Standard value: 0.5 - 0.9 k

W

(3) Measure the resistance between accelerator pedal

position sensor connector terminal (2) [accelerator pedal

position sensor (1st channel) power supply] and terminal

(3) [accelerator pedal position sensor (1st channel)

output], and between terminal (8) [accelerator pedal

position sensor (2nd channel) power supply] and terminal

(6) [accelerator pedal position sensor (2nd channel)

output].

Normal condition:

When accelerator pedal is

gently depressed

Changes comparatively

smoothly in proportion to the

accelerator pedal depression

amount

(4) If the measured values are outside the standard value

range, or if the resistance does not change smoothly,

replace the accelerator pedal position sensor.

NOTE

After replacement, adjust the accelerator pedal position

sensor. (Refer to P.13A - 11.)

Power steering

reservoir tank

Accelerator pedal

position switch

3. ACCELERATOR PEDAL POSITION SWITCH

INSPECTION

(1) Disconnect the accelerator pedal position sensor