Page 1

GENERAL

CONTENTS

00-1

HOW TO USE THIS MANUAL 2. . . . . . . . . . . . . .

Model Indications 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VEHICLE IDENTIFICATION 2. . . . . . . . . . . . . . . . . .

Models 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model code 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAJOR SPECIFICATIONS 4. . . . . . . . . . . . . . . . . .

Page 2

00-2

(Multi Point Fuel Injection)

(Di

l)

(G

)

GENERAL – How To Use This Manual/Vehicle Identification

HOW TO USE THIS MANUAL

MODEL INDICATIONS

The following abbreviations are used in this manual for identification of model types.

MPI: Indicates the multi point fuel injection.

GD-D: Indicates the direct injection diesel.

GDI: Indicates the gasoline direct injection.

M/T: Indicates the manual transmission, or models equipped with the manual transmission.

A/T: Indicates the automatic transmission, or models equipped with the automatic transmission.

A/C: Indicates the air conditioner.

VEHICLE IDENTIFICATION

MODELS

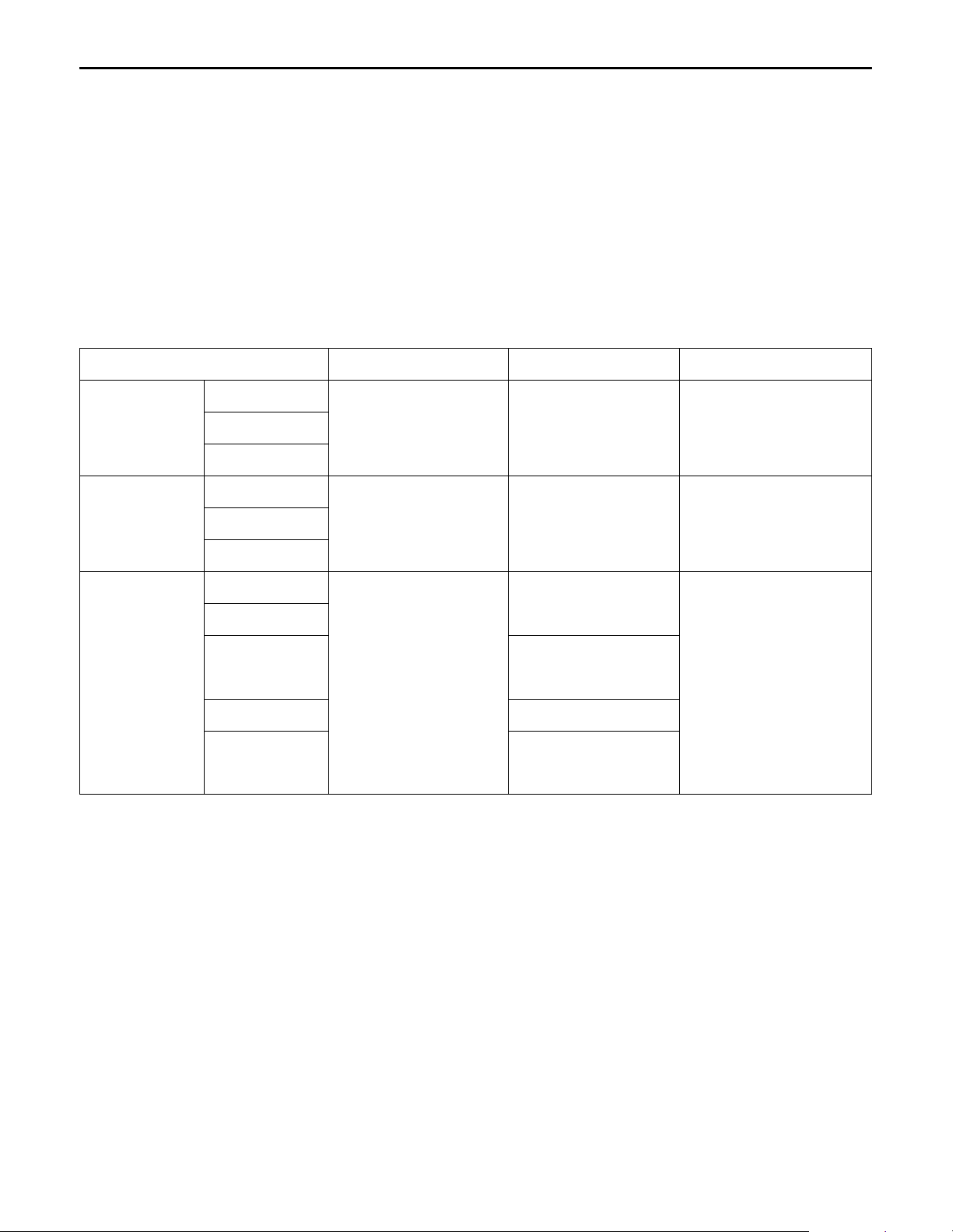

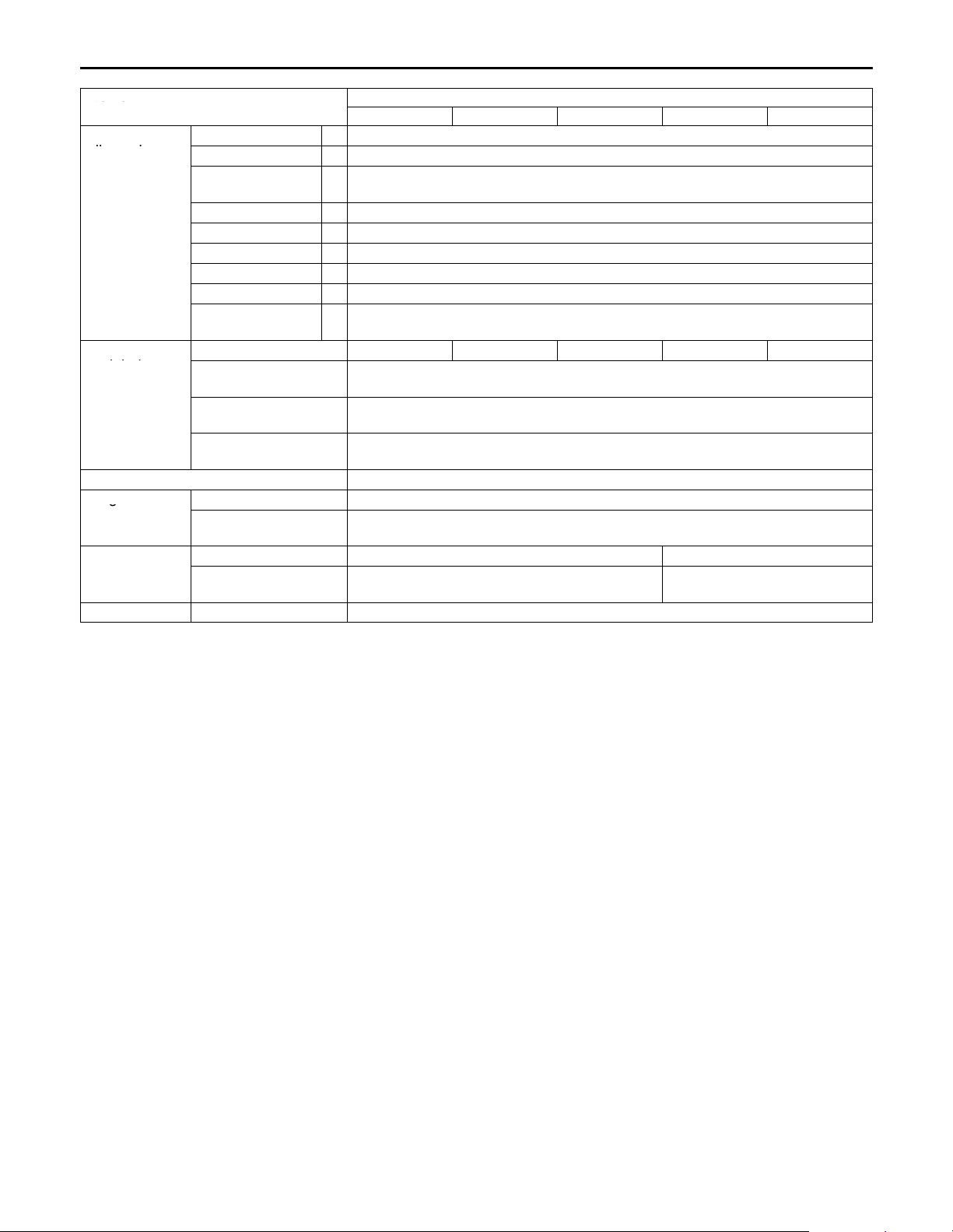

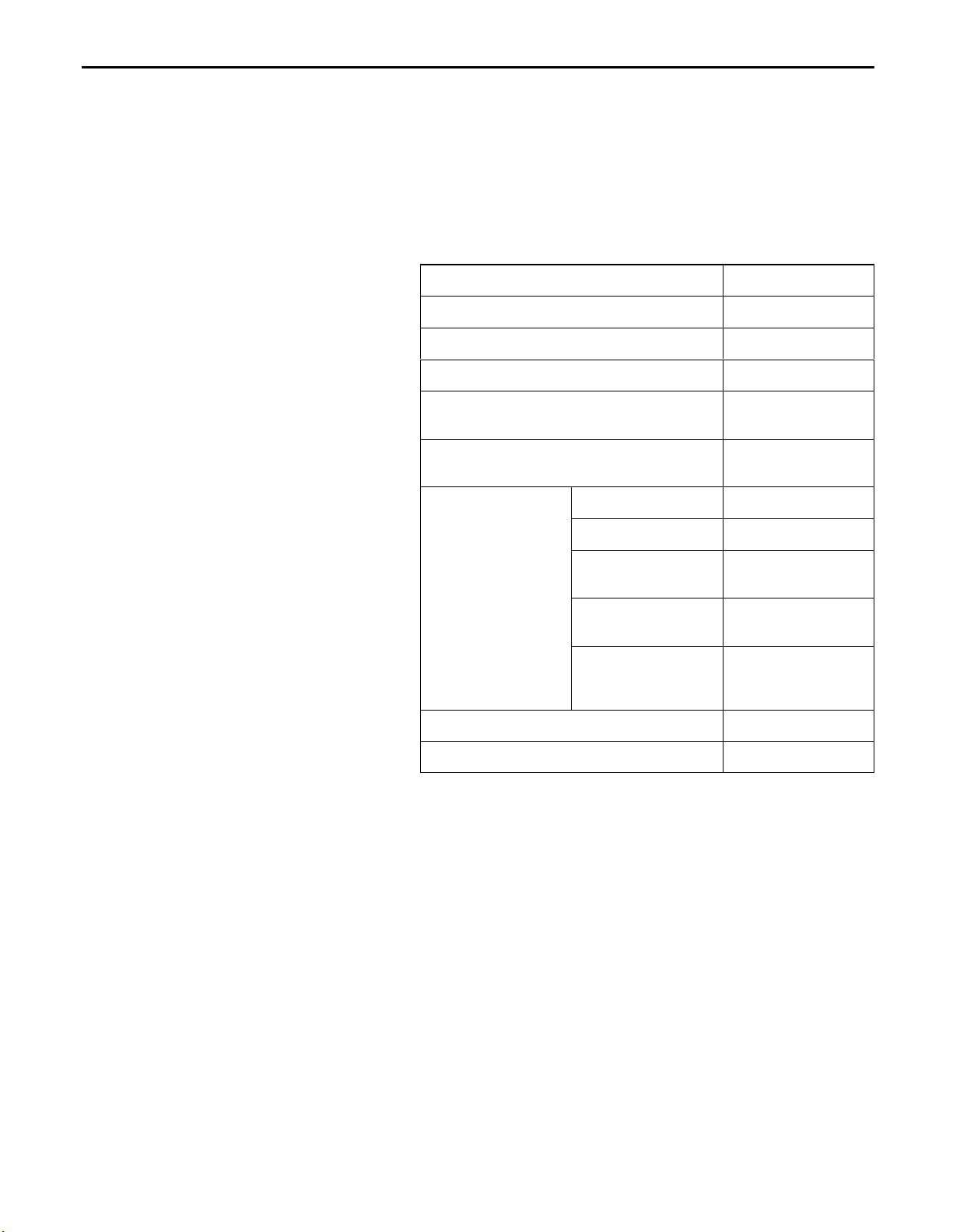

Model code Engine model Transmission model Fuel supply system

DG1A

DG4A

DG5A

LNDEL6/R6

LNJEL6/R6

LNPEL6/R6

LNDFL6/R6

LNJFL6/R6

LNPFL6/R6

LNDCL6

LNJCL6/R6

LRJCL6/R6 F4A42

LNPCL6/R6 F5M42 <5M/T>

LRPCL6/R6 F4A42

4G13 MPI (1,299 mL) F5MR1 <5M/T> MPI

F9Q1 (1,870 mL) F5MV1 <5M/T> DI-D

4G93 GDI (1,834 mL) F5M42 <5M/T> GDI

<INVECS-II 4A/T with

Sports Mode>

<INVECS-II 4A/T with

Sports Mode>

rect Injection Diese

asoline Direct Injection

Page 3

GENERAL – Vehicle Identification

2

Engine ty e

1: 1,299 mL etrol engine

,g

y

6

Trim level

D: Family

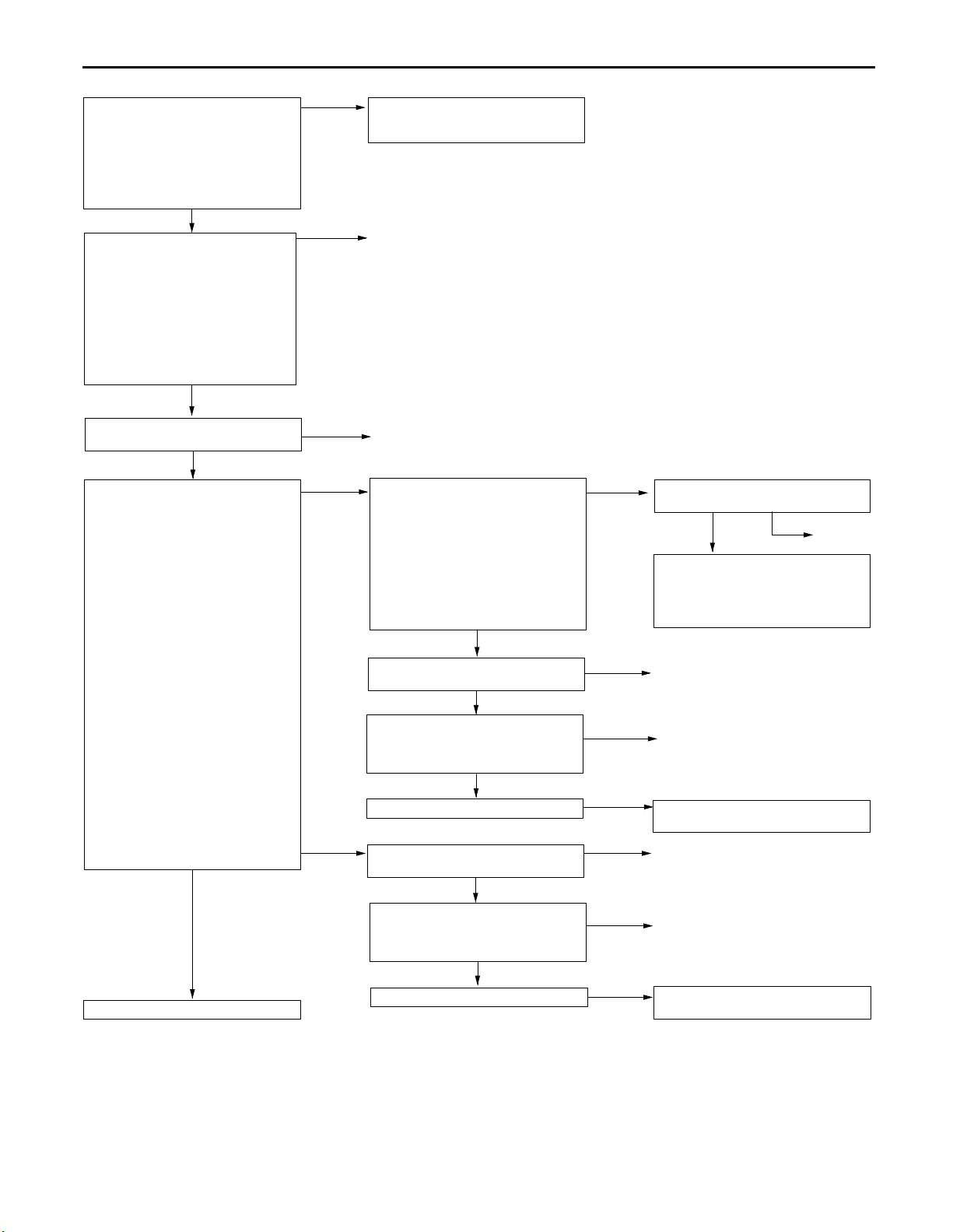

MODEL CODE

No. Items Contents

1 Development DG: MITSUBISHI SPACE STAR

2 Engine type 1: 1,299 mL petrol engine

3 Sort A: Passenger car

4 Body style L: 5-door

5 Transmission type N: 5-speed manual

6 Trim level D: Famil

00-3

4: 1,870 mL diesel engine

5: 1,834 mL petrol engine

transmission

R: 4-speed automatic

transmission

J: Comfort

P: Sport

7 Specification engine

feature

8 Steering wheel

location

9 Destination 6: For Europe

E: MPI

F: DI-D

C: GDI

L: Left hand

R: Right hand

Page 4

00-4

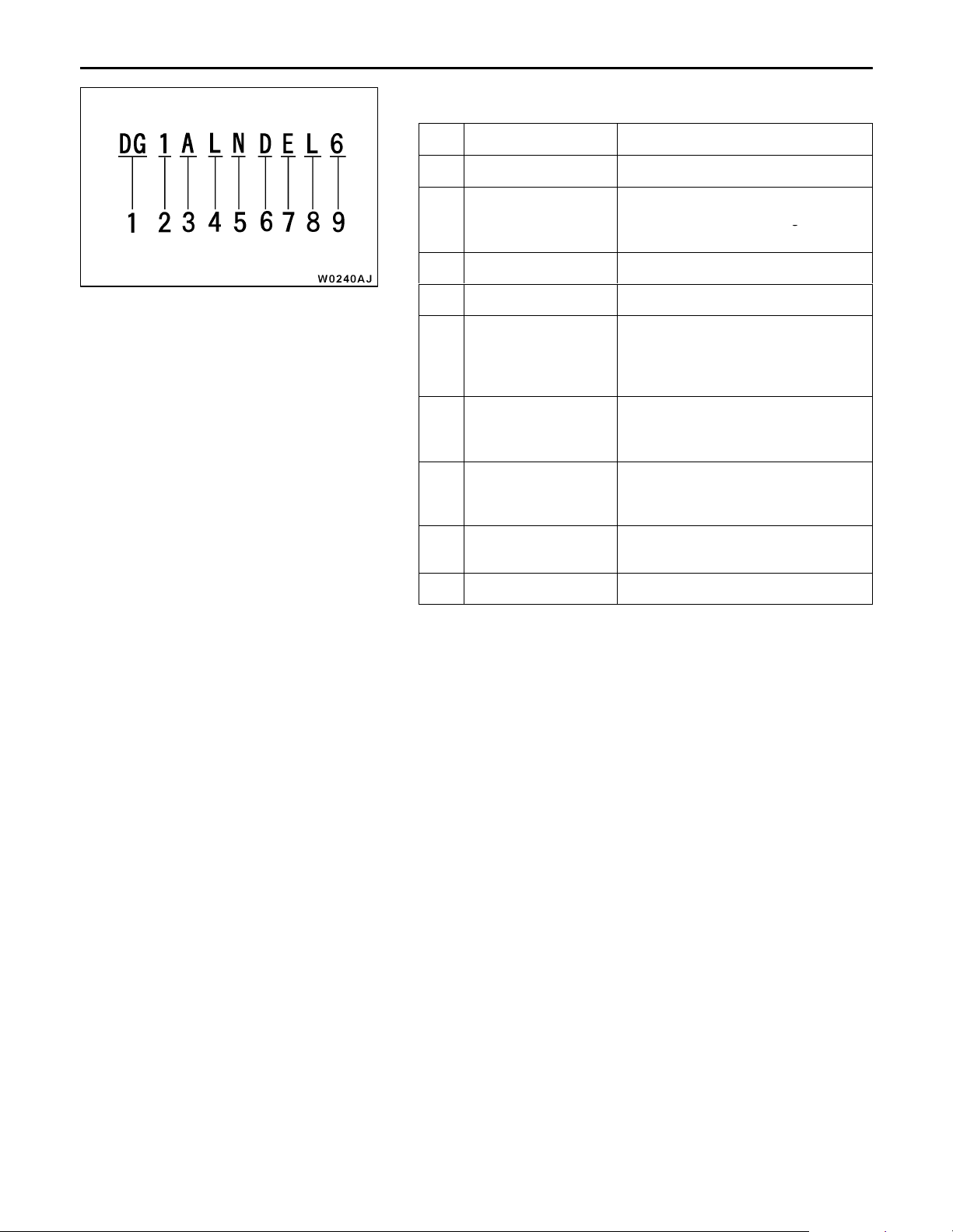

Items

g

GENERAL – Major Specifications

MAJOR SPECIFICATIONS

9

*1

3

3

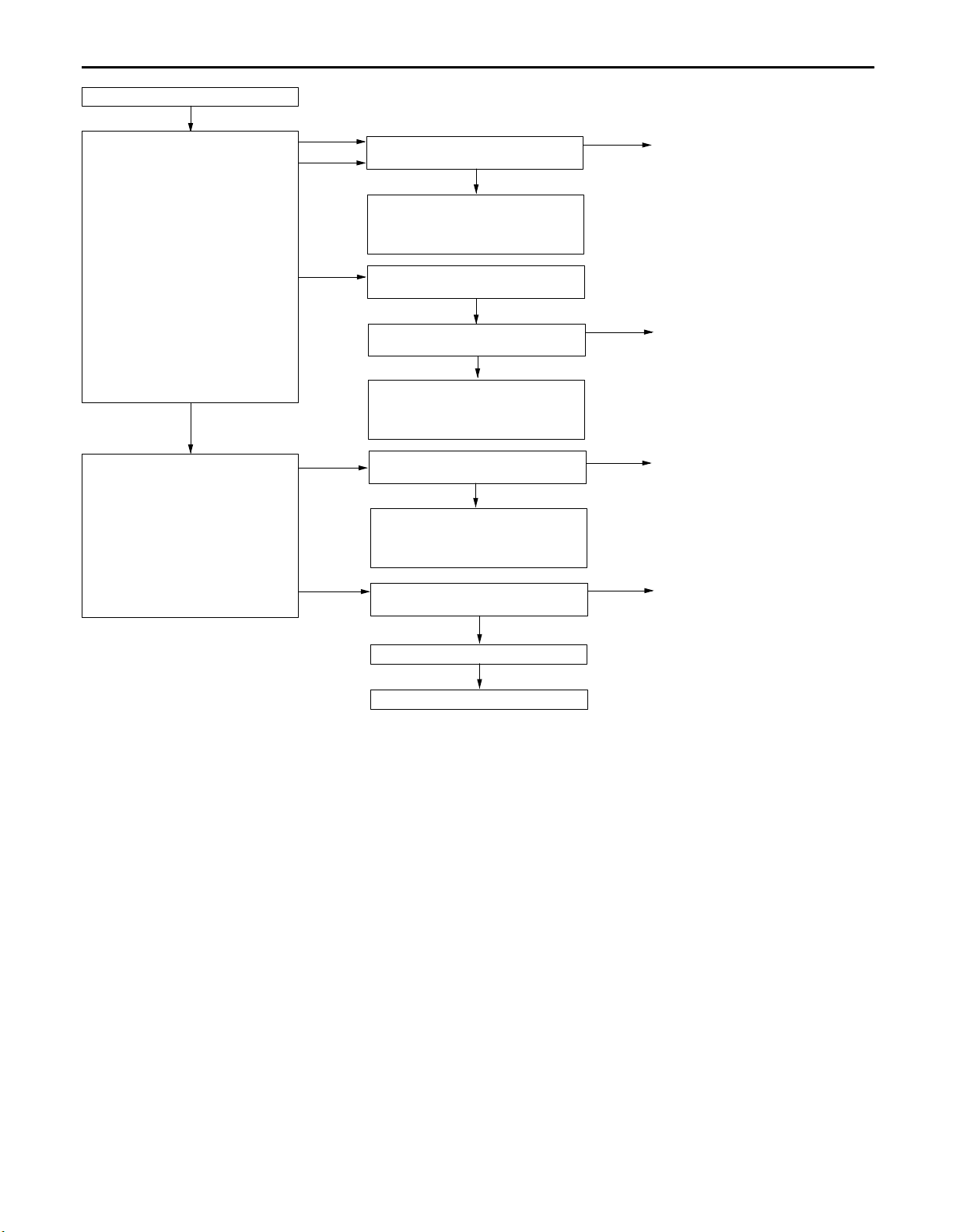

Items

Vehicle

dimensions

mm

DG1A DG4A

LNDEL6

/R6

Overall length 1 4,030

Overall width 2 1,715

Overall height

(unladen)

3 1,515,

1,555

45

12

LNJEL6

/R6

*1

LNPEL6

/R6

8

LNDFL6

/R6

LNJFL6

/R6

Wheelbase 4 2,500

Track-front 5 1,475

Track-rear 6 1,470

Overhang-front 7 835

Overhang-rear 8 695

Ground clear-

9 155

ance (unladen)

Vehicle

weight kg

Kerb weight 1,158 1,170 1,173 1,248 1,260 1,258

Max. gross vehicle

1,655 1,730

weight

Max. axle weight

855 920

rating-front

Max. axle weight

830 850

rating-rear

Seating capacity 5

Engine

Model No. 4G13 F9Q1

Total displacement

1,299 1,870

mL

Transmission

Model No. F5MR1 F5MV1

Type 5 speed-manual

Fuel system Fuel supply system Multi Point Fuel Injection Direct Injection Diesel

NOTE:

1

*

: Vehicles with roof rails

67

LNPFL6

/R6

Page 5

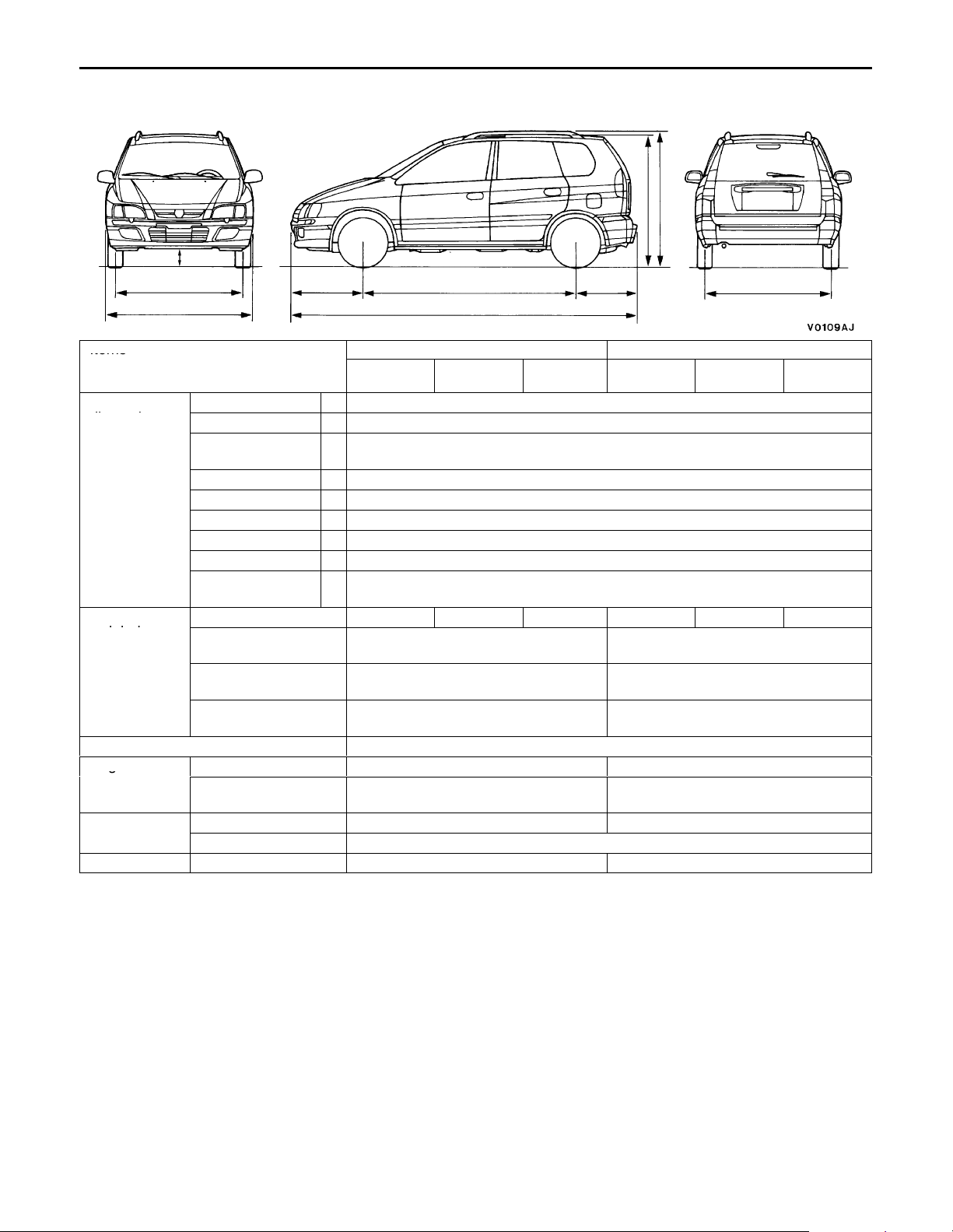

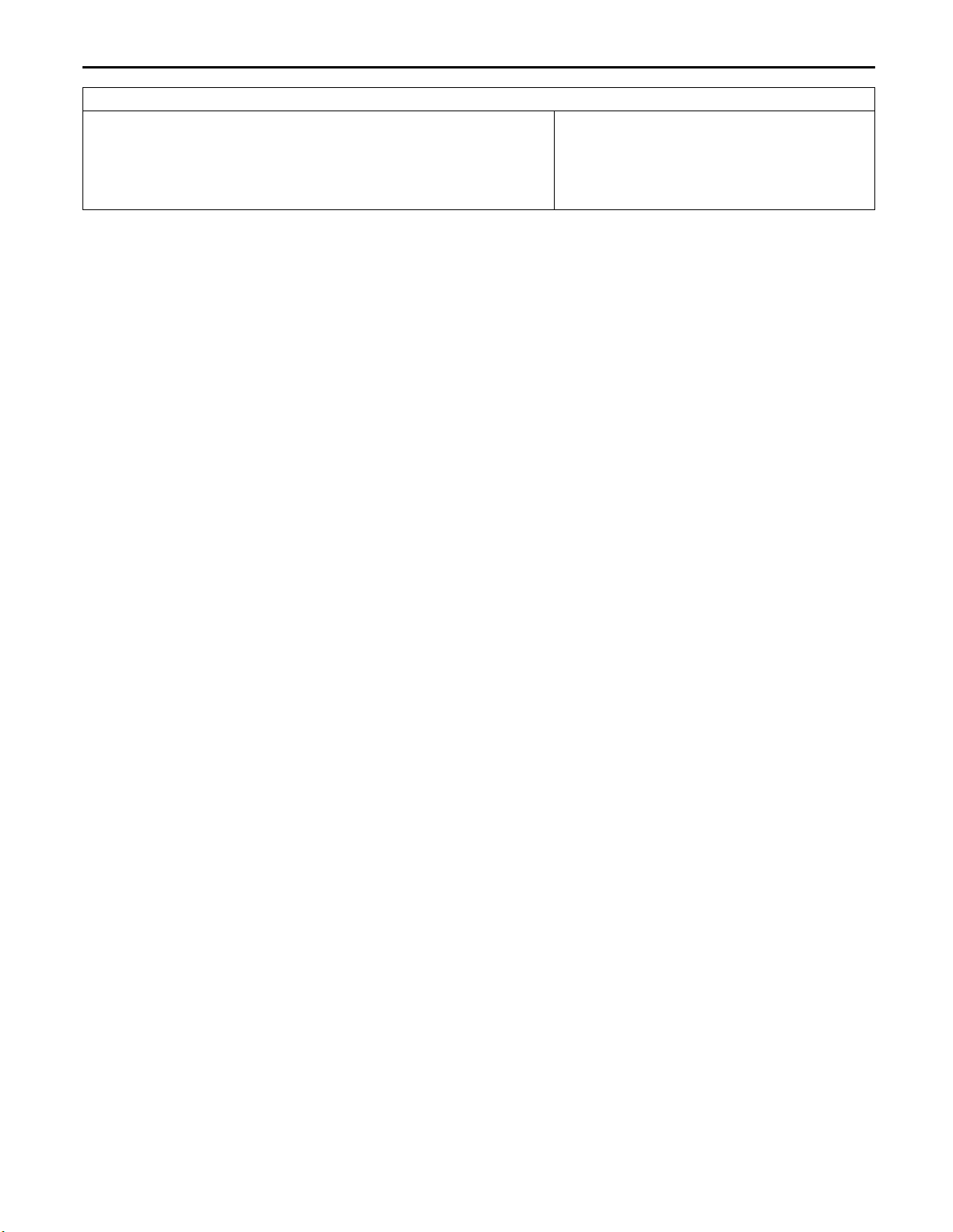

GENERAL – Major Specifications

Items

g

00-5

Items

Vehicle

dimensions

mm

Vehicle

weight kg

Seating capacity 5

Engine

Transmission

Fuel system Fuel supply system Gasoline Direct Injection

NOTE:

1

*

: Vehicles with roof rails

Overall length 1 4,030

Overall width 2 1,715

Overall height

(unladen)

Wheelbase 4 2,500

Track-front 5 1,475

Track-rear 6 1,470

Overhang-front 7 835

Overhang-rear 8 695

Ground clear-

ance (unladen)

Kerb weight 1,228 1,240 1,238 1,255 1,253

Max. gross vehicle

weight

Max. axle weight

rating-front

Max. axle weight

rating-rear

Model No. 4G93

Total displacement

mL

Model No. F5M42 F4A42

Type 5 speed-manual INVECS-II 4A/T with Sports

DG5A

LNDCL6 LNJCL6/R6 LNPCL6/R6 LRJCL6/R6 LRPCL6/R6

3 1,515,

9 150

1,555

1,730

920

850

1,834

*1

Mode

Page 6

NOTES

Page 7

ENGINE

CONTENTS

ENGINE <4G9> 11A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE <4G1> 11B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE <F9Q1> 11C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11A-1

Page 8

11A-2

ENGINE <4G9>

CONTENTS

GENERAL 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Outline of Changes 3. . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE SPECIFICATIONS 3. . . . . . . . . . . . . . . . .

SEALANTS 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIAL TOOLS 3. . . . . . . . . . . . . . . . . . . . . . . . . . .

CAMSHAFT AND CAMSHAFT OIL SEAL 5. . . .

CRANKSHAFT REAR OIL SEAL <A/T> 10. . . .

CYLINDER HEAD GASKET 12. . . . . . . . . . . . . . . .

ENGINE ASSEMBLY 15. . . . . . . . . . . . . . . . . . . . . .

Page 9

General/Service Specifications/Sealants/Special ToolsENGINE <4G9> –

11A-3

GENERAL

OUTLINE OF CHANGES

Since the resin intake manifold is adopted, the fuel system is changed, and the vehicle with A/T is added

to the lineup, the following service adjustment procedures are made.

Other service procedures are the same as before.

SERVICE SPECIFICATIONS

Items Standard value Limit

Idle speed r/min A/T 650 ± 100 –

Cylinder head bolt shank length mm – 96.4

SEALANTS

Items Specified sealants Remarks

Beam camshaft cap and cylinder

head

Camshaft position sensor support MITSUBISHI GENUINE PART

Drive plate bolt 3M Stud locking 4170 or equivalent –

3M ATD Part No.8660 or equivalent

MD970389 or equivalent

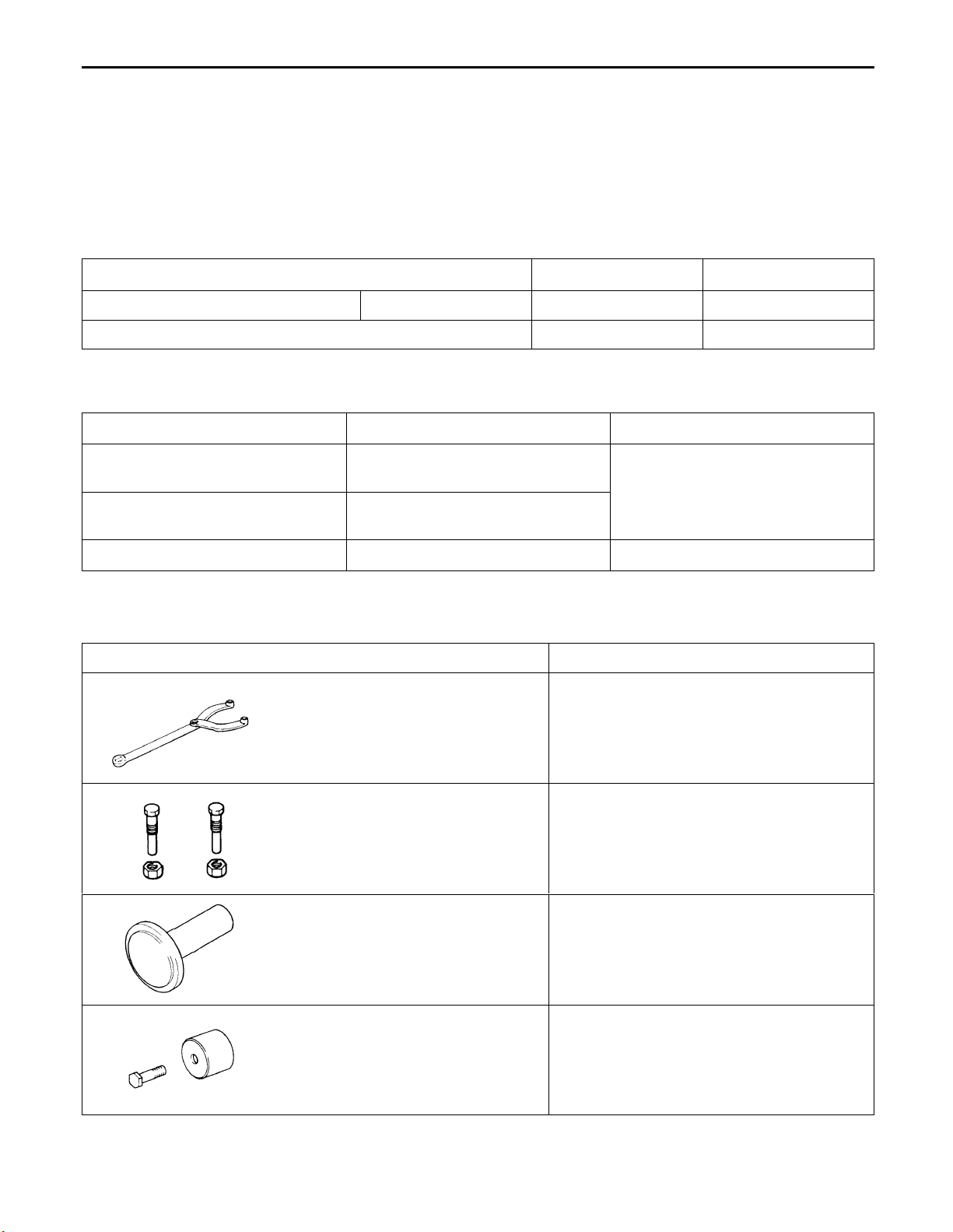

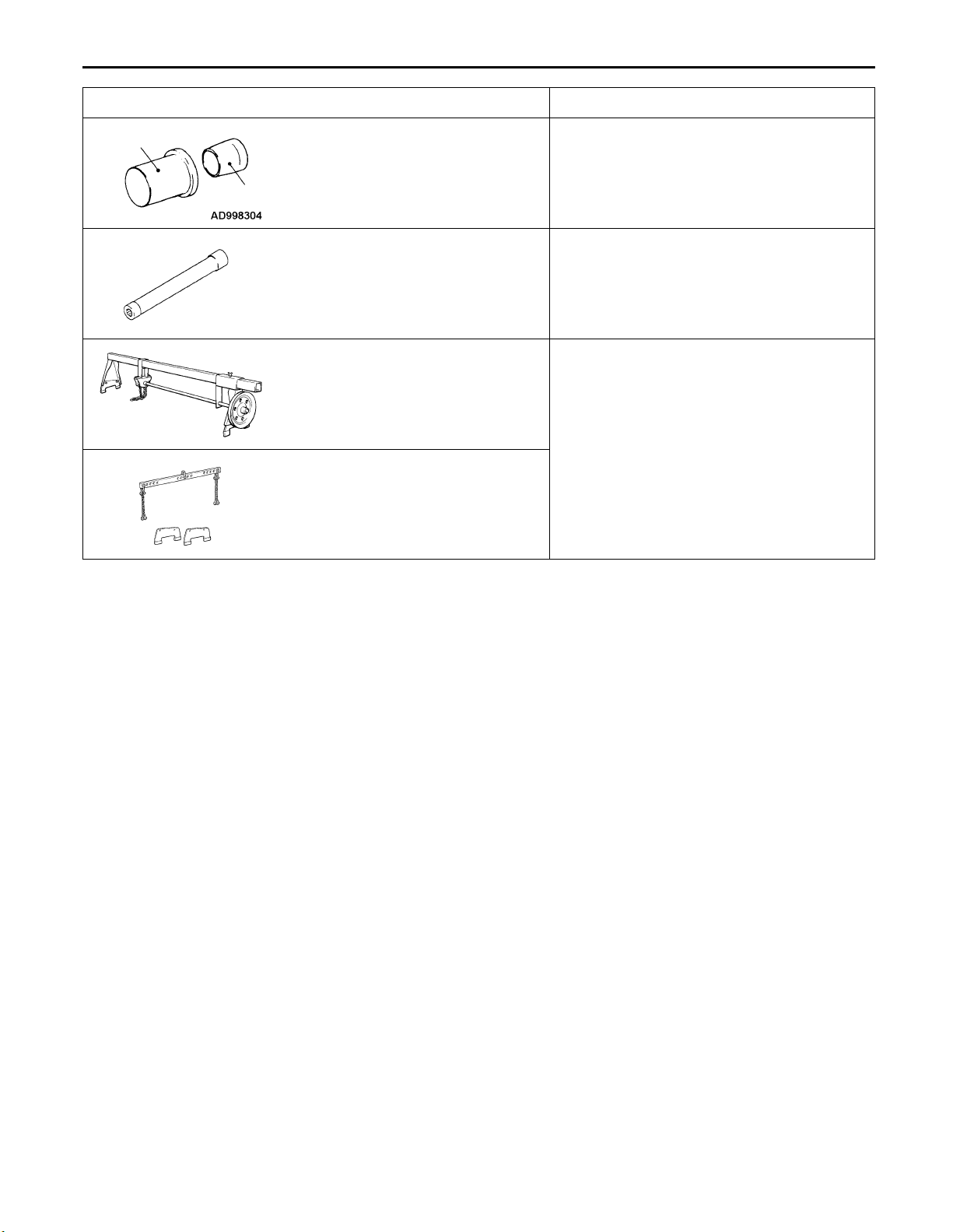

SPECIAL TOOLS

Tool Number Name Use

MB990767 End yoke holder Holding the camshaft sprocket

MD998719 Crankshaft pulley

holder pin

MD998762 Circular packing

installer

Holding the camshaft sprocket

Press-fitting the circular packing

Semi-drying sealant

MD998713 Camshaft oil seal

installer

Press-fitting the camshaft oil seal

Page 10

11A-4

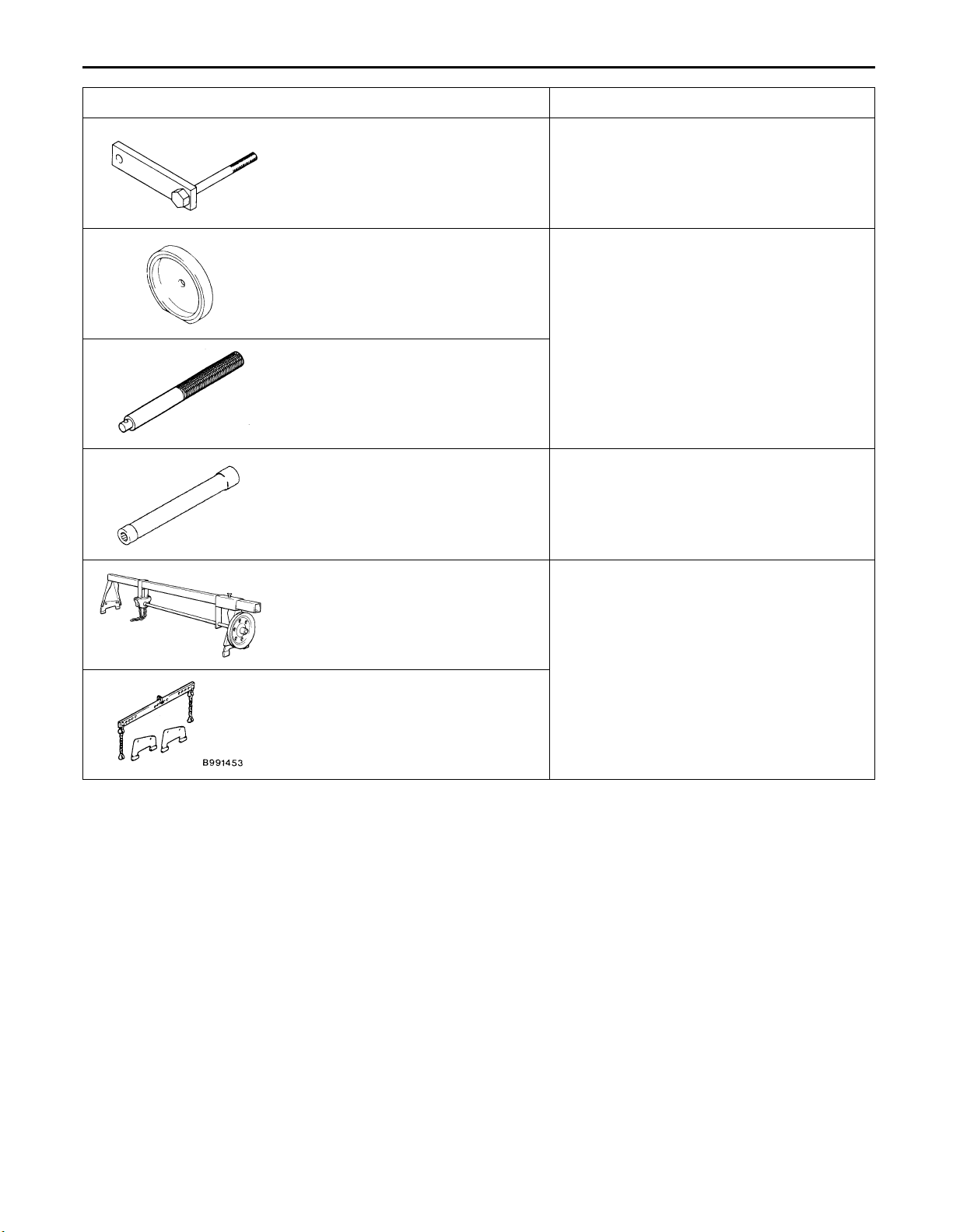

Tool UseNameNumber

MD998781 Flywheel stopper Securing the drive plate

ENGINE <4G9> – Special Tools

MD998776 Crankshaft rear oil

seal installer

MB990938 Handle

MB991653 Cylinder head bolt

wrench

GENERAL

SERVICE

TOOL

MZ203827

MB991453 Engine hanger

Engine lifter Supporting the engine assembly during

assembly

Press-fitting the crankshaft rear oil seal

Cylinder head bolt removal and installation

removal and installation of the transmission

Page 11

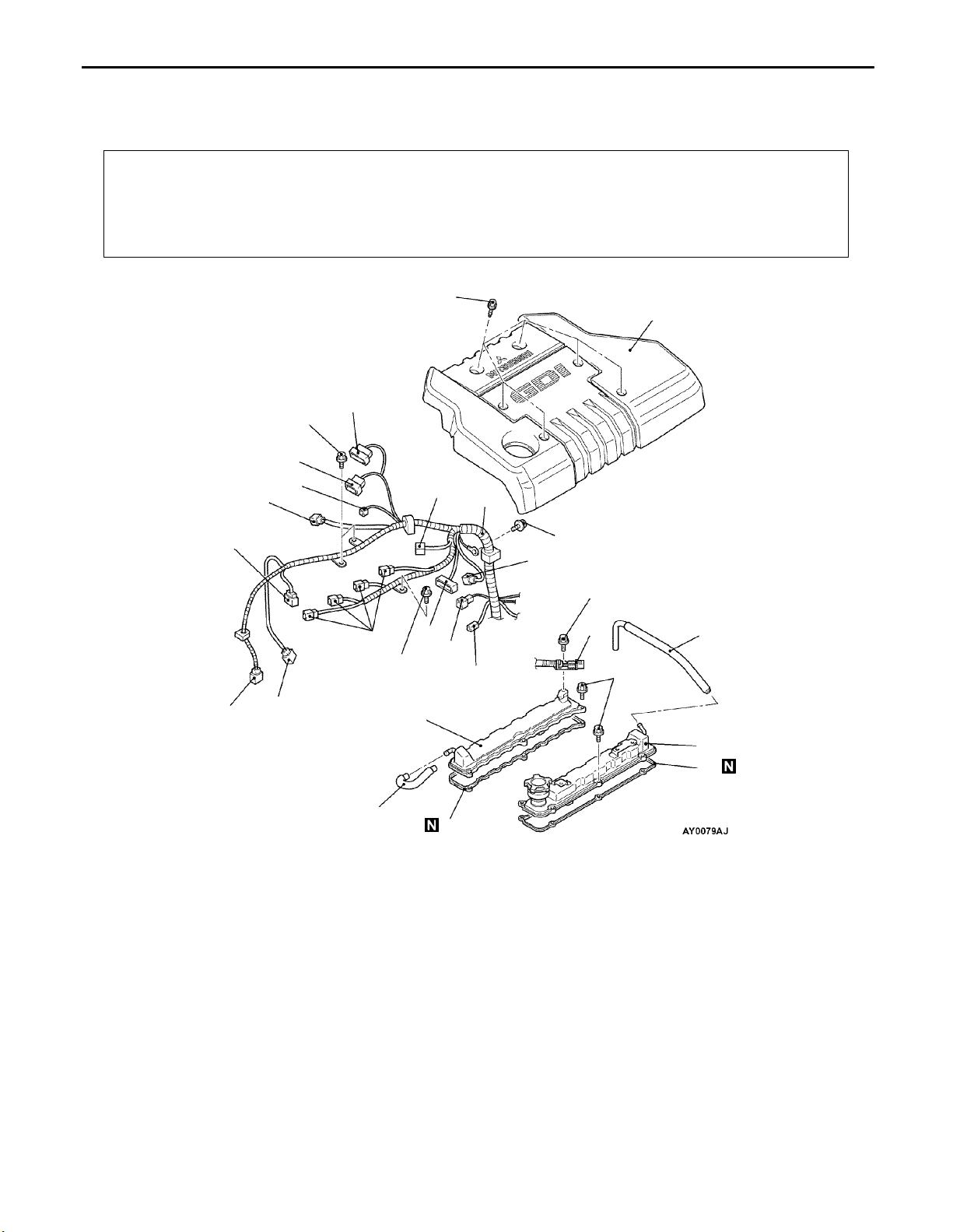

ENGINE <4G9> – Camshaft and Camshaft Oil Seal

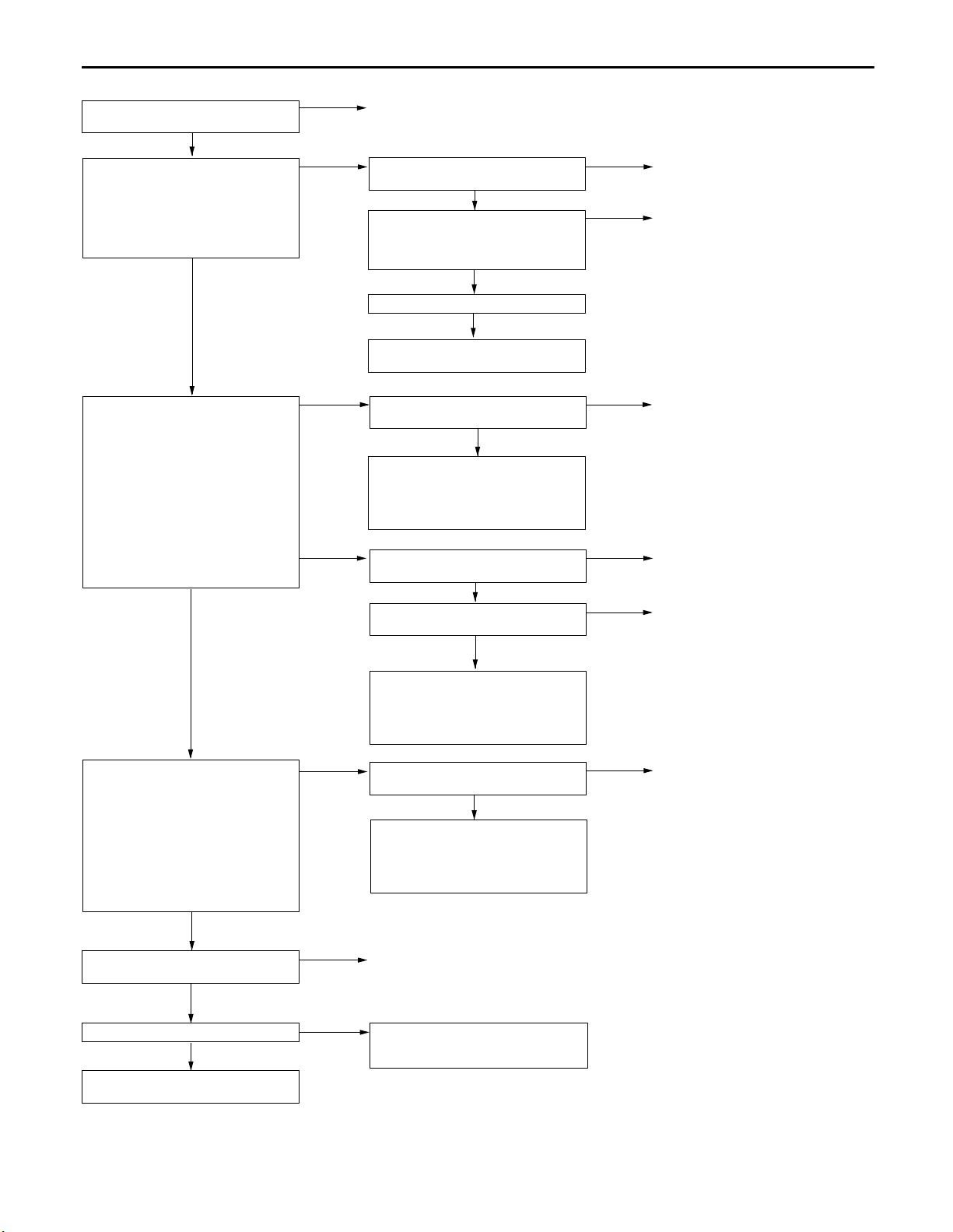

CAMSHAFT AND CAMSHAFT OIL SEAL

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

Prevention of Fuel Discharge <before removal only>

Fuel Leak Check <after installation only>

Air Bleeding the High Pressure Fuel Path

<after installation only>

[Refer to GROUP 13A – Fuel Pump (High pressure).]

3.0 Nm

Under Cover Removal and Installation

Engine Coolant Draining and Supplying

Air Cleaner Removal and Installation

11A-5

1

7.0 Nm

8

7

6

5

3

9

15

5.0 Nm

12

10 – 12 Nm

10

5.0 Nm

11

13

14

2

4

19

18

3.4 Nm

17

21

22

16

20

Removal steps

F 1. Engine cover

2. Crank angle sensor connector

3. Fuel pressure sensor

4. Oxygen sensor (front) connector

5. Control wiring harness and EGR

wiring harness combination

connector

6. Purge control solenoid valve

connector

7. Throttle position sensor connector

8. Throttle valve control servo

connector

9. Control wiring harness and injector

wiring harness combination

connector

10. Ignition coil connector

11. Ignition failure sensor connector

12. Camshaft position sensor connector

13. Engine coolant temperature sensor

connector

14. Engine coolant temperature gauge

unit connector

15. Control wiring harness

16. PCV hose

17. Breather hose

Ignition coil (Refer to GROUP 16.

Intake manifold (Refer to GROUP 15.)

Timing belt

18. Connector bracket (injector wiring

harness)

19. Rocker cover (intake side)

20. Rocker cover gasket

21. Rocker cover (exhaust side)

22. Rocker cover gasket

Page 12

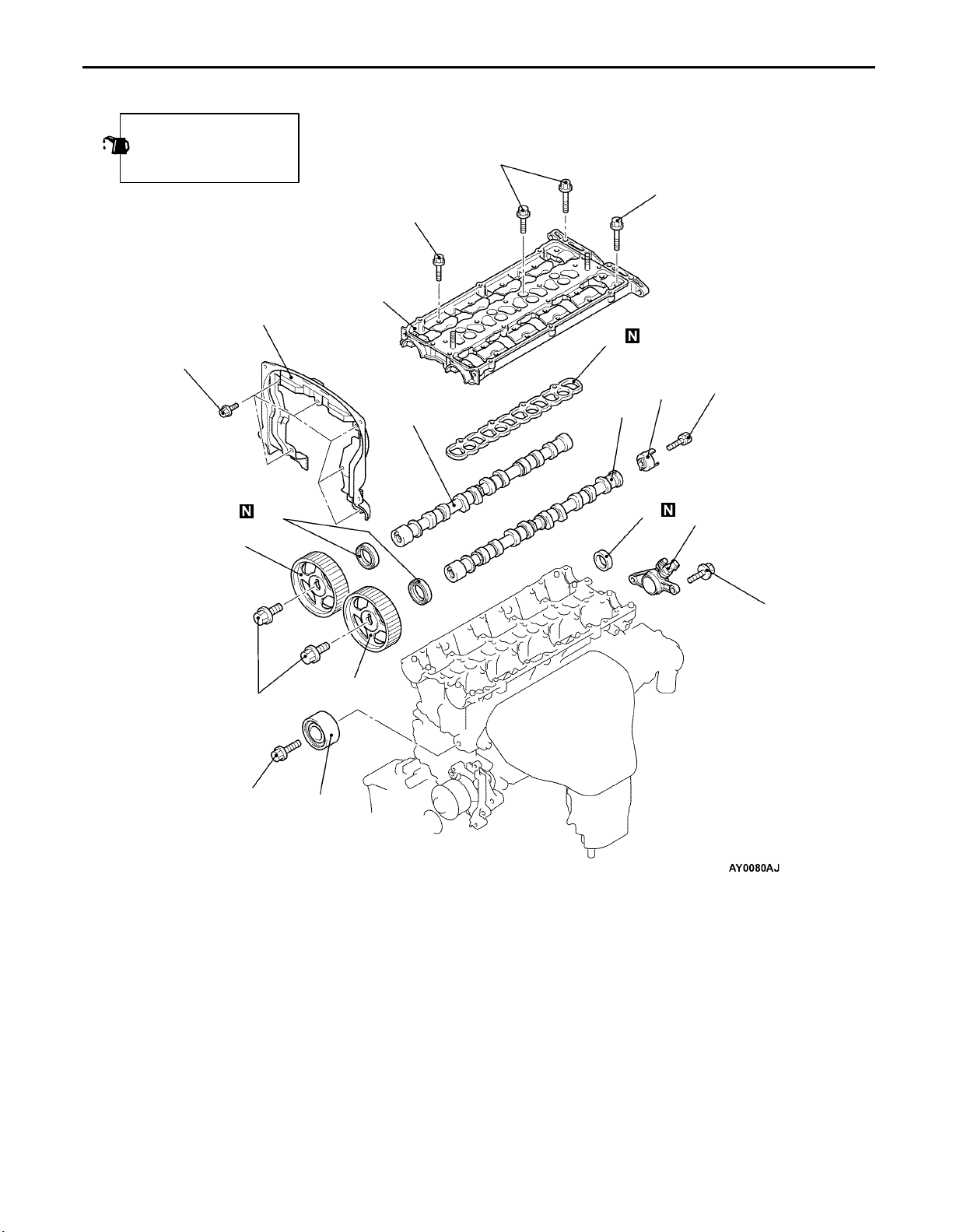

11A-6

ENGINE <4G9> – Camshaft and Camshaft Oil Seal

Apply engine oil to all

sliding parts during

installation.

25

10 – 12 Nm

21 – 25 Nm

10 – 12 Nm

29

31

30

32

21 – 25 Nm

33

22 Nm

23

88 Nm

35 Nm

26

24

23

28

27

12 – 15 Nm

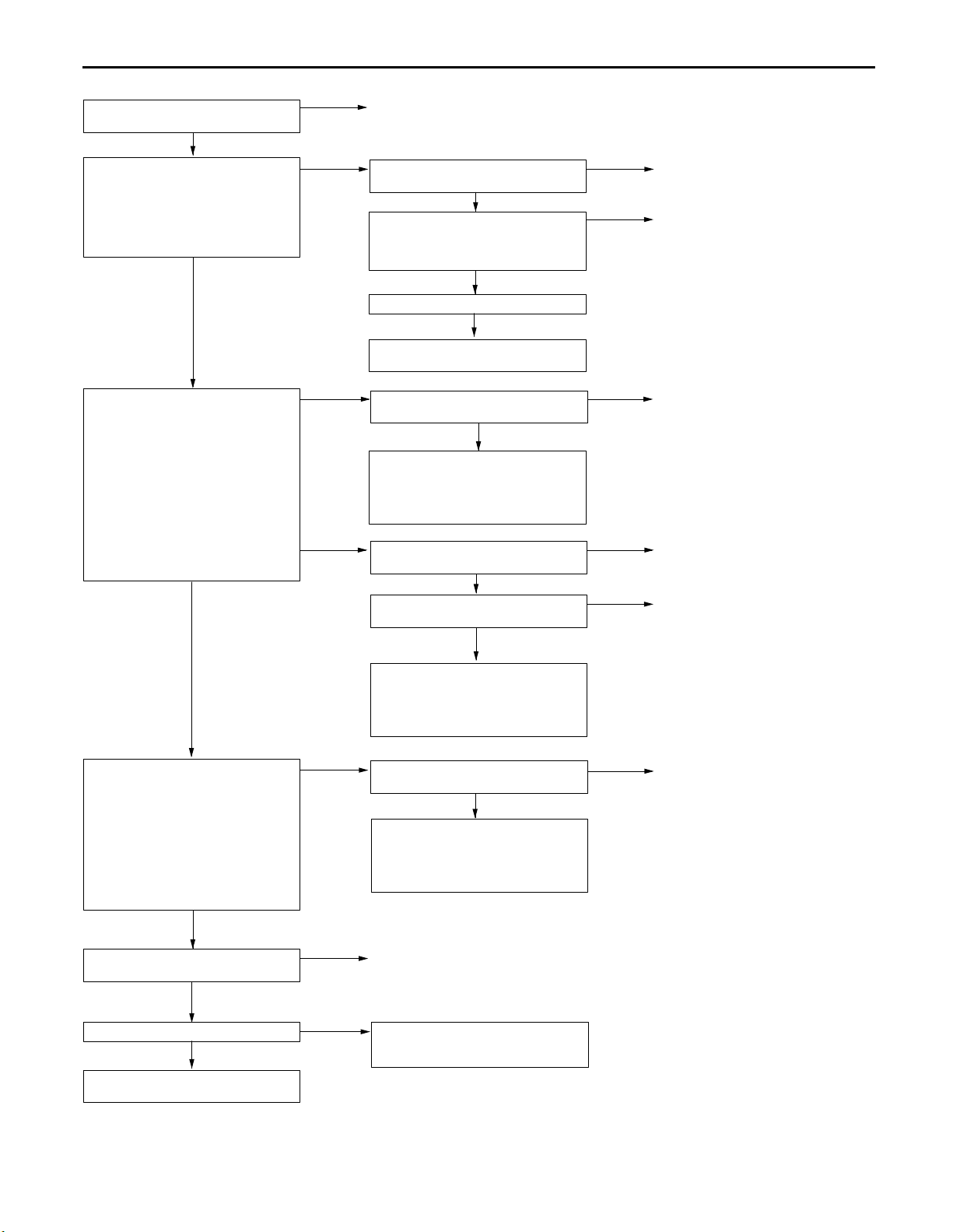

AE 23. Camshaft sprocket

24. Idler pulley

25. Timing belt rear upper cover

D 26. Camshaft oil seal

27. Camshaft position sensor support

C 28. Circular packing

Fuel pump (high pressure) assembly

(Refer to GROUP 13A.)

B 29. Beam camshaft cap

30. Beam camshaft cap gasket

A 31. Camshaft (intake side)

A 32. Camshaft (exhaust side)

33. Camshaft position sensing cylinder

Page 13

Lubrication points

Sealant: 3M ATD Part No.8660 or equivalent

ENGINE <4G9> – Camshaft and Camshaft Oil Seal

<Seen from underneath

φ3mm

beam camshaft cap>

11A-7

Sealant:

MITSUBISHI GENUINE PART

MD970389 or equivalent

Lip section

Engine oil

<Seen from above cylinder head>

Sealant: 3M ATD Part No.8660 or equivalent

Page 14

11A-8

MB990767

MD998719

ENGINE <4G9> – Camshaft and Camshaft Oil Seal

REMOVAL SERVICE POINT

A CAMSHAFT SPROCKET REMOVAL

Camshaft sprocket side

Exhaust camshaft

Approx.

106

Dowel pin

Intake side Exhaust side

28 27 31 32

20 19 23 24

12 11 15 163

Screw hole

Approx.

101

INSTALLATION SERVICE POINTS

A CAMSHAFT INSTALLATION

1. Apply engine oil to journals and cams of the camshafts.

2. Install the camshafts on the cylinder head.

Caution

Be careful not to confuse the intake camshaft with

the exhaust one. There is a screw hole for the cam

position sensing cylinder mounting bolt on the

exhaust-side camshaft.

B BEAM CAMSHAFT CAP INSTALLATION

1. Place the camshaft dowel pin as shown in the illustration.

2. Tighten the beam camshaft cap mounting bolts to the

specified torque in the order shown in the illustration.

Tightening torque:

: 10 – 12 Nm

: 21 – 25 Nm

87 561

Intake side Exhaust

14 13 9 102

22 21 17 184

30 29 25 26

Front of engine

side

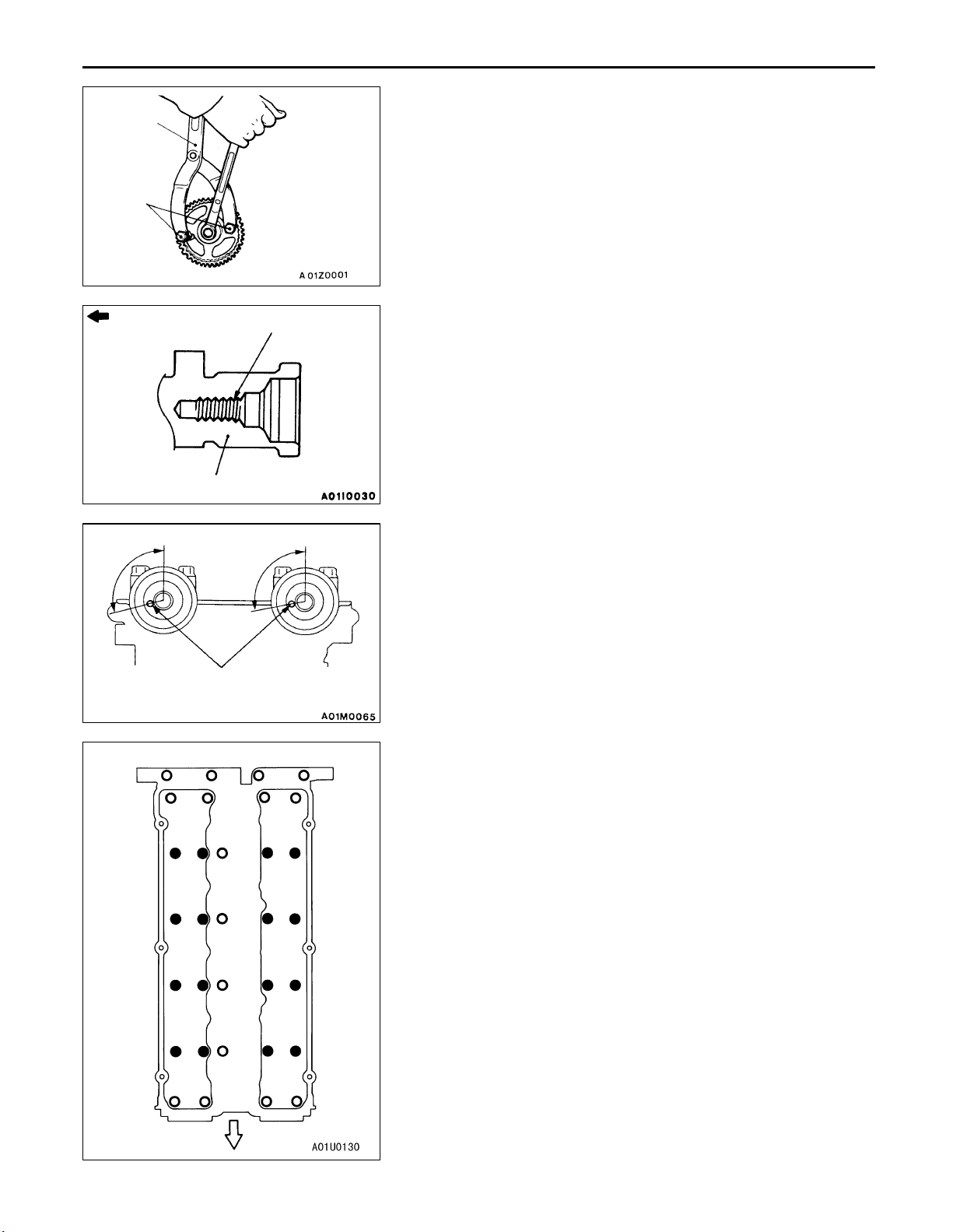

Page 15

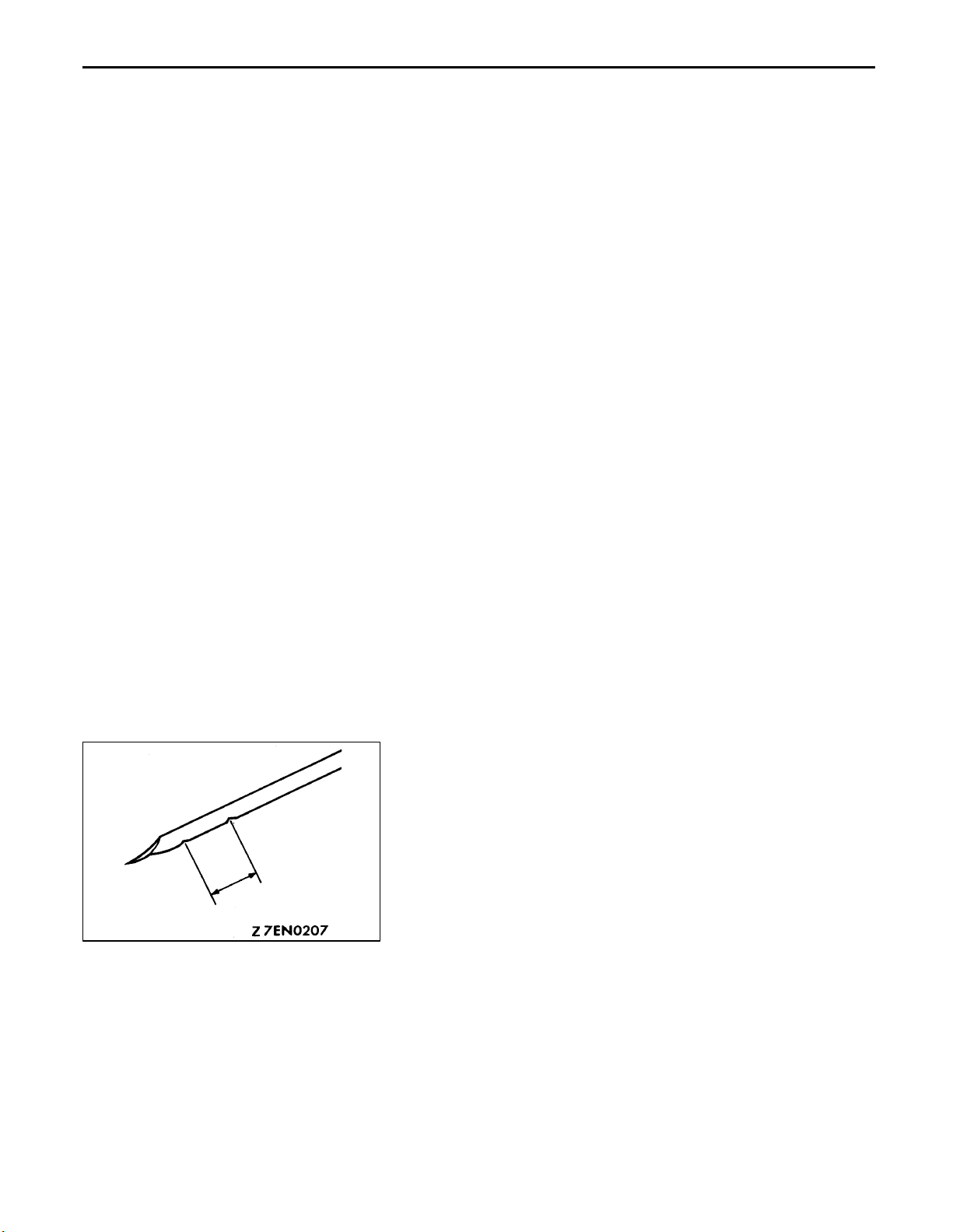

Press-fitting

depth 2 mm

MD998762

ENGINE <4G9> – Camshaft and Camshaft Oil Seal

C CIRCULAR PACKING INSTALLATION

Use the special tool to press-fit the circular packing as shown

in the illustration.

11A-9

MD998713

D CAMSHAFT OIL SEAL INSTALLATION

1. Apply engine oil to the entire circumference of the oil seal

lip.

2. Press-fit the oil seal as shown in the illustration.

E CAMSHAFT SPROCKET INSTALLATION

Use the special tool to secure the camshaft sprocket in the

same way as during removal, and then tighten the bolt to

the specified torque.

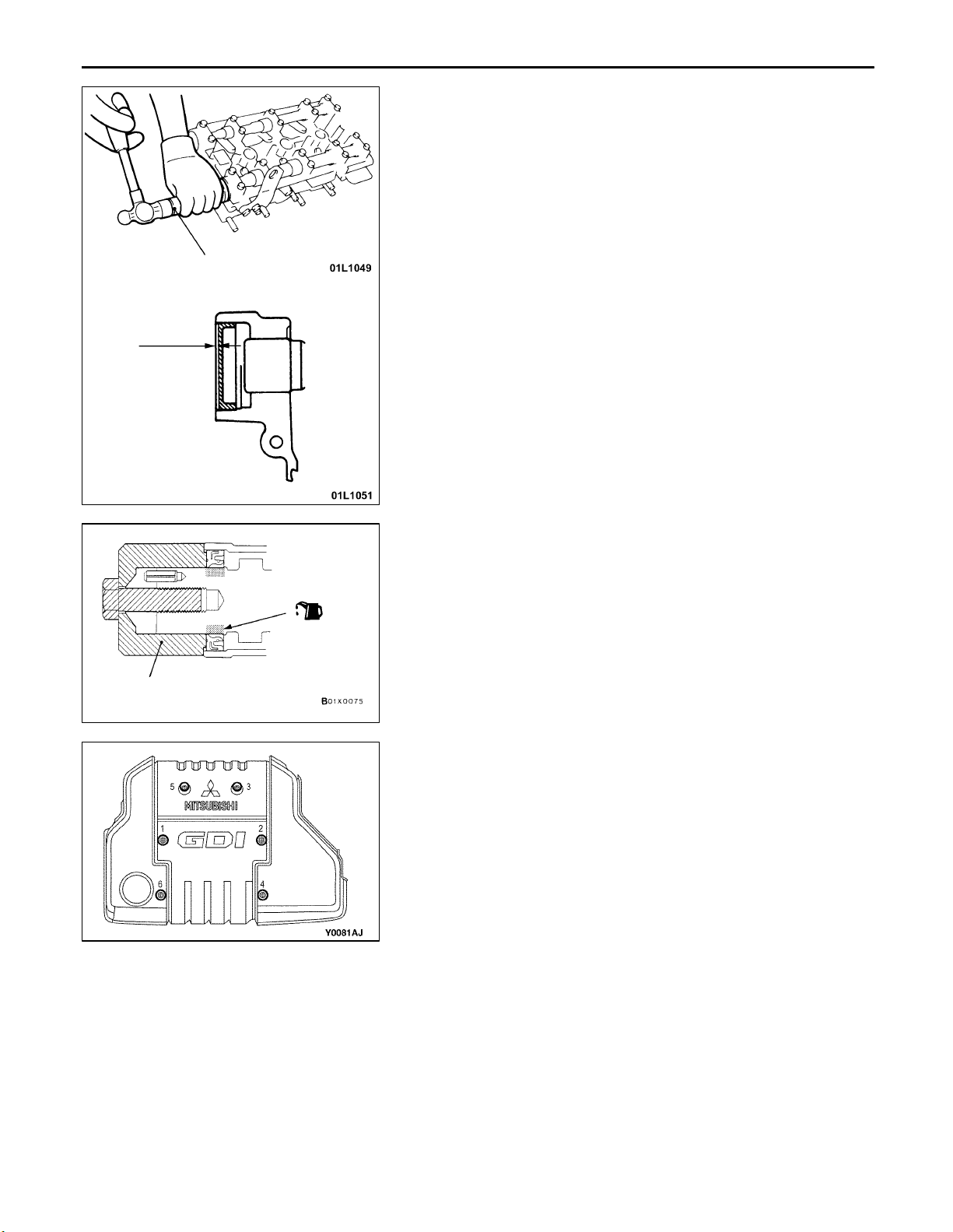

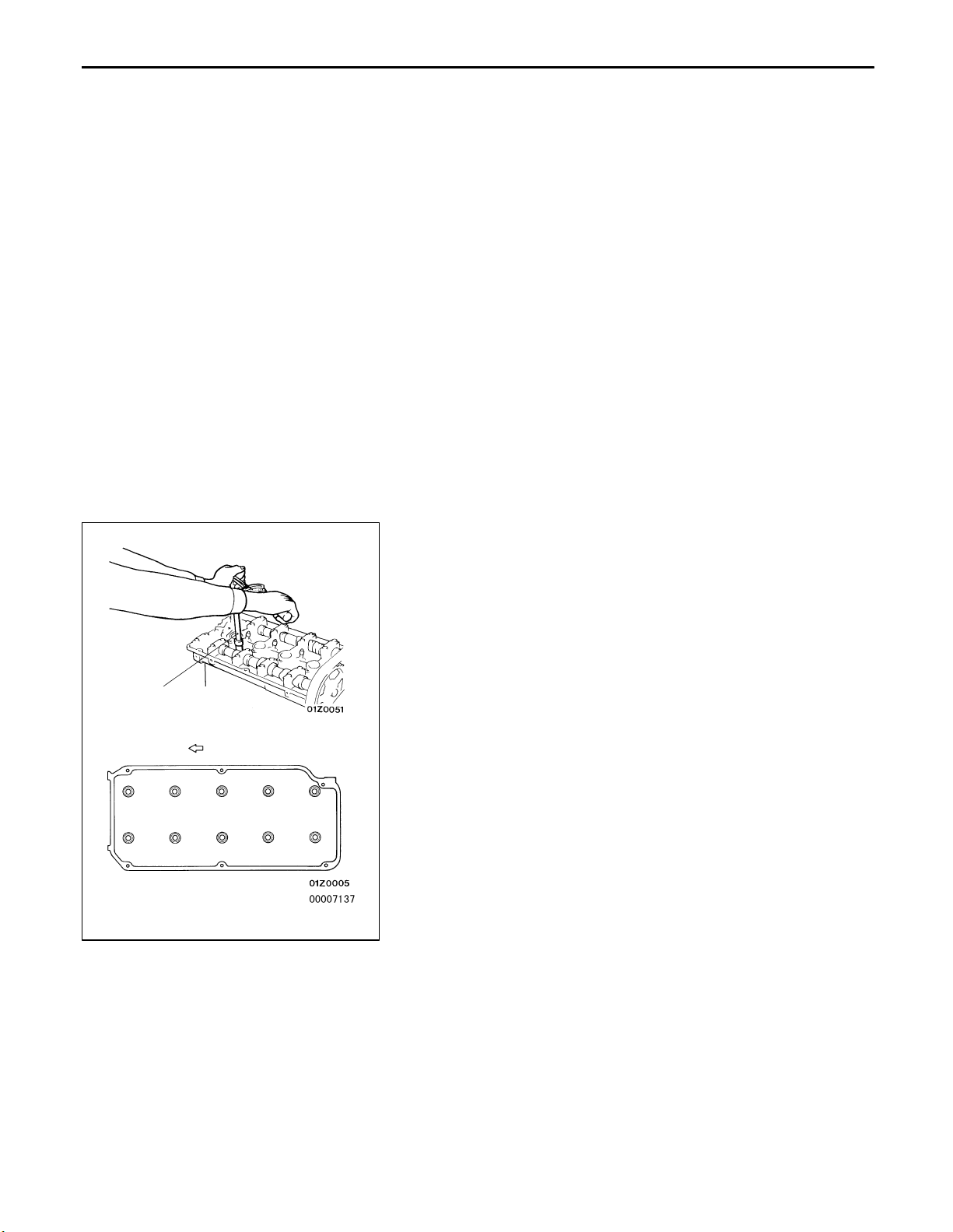

F ENGINE COVER INSTALLATION

1. Temporarily tighten the mounting bolt in the order of the

numbers shown in the illustration so that the engine cover

can move easily by hand.

2. Tighten the mounting bolt to the specified torque in the

order of the numbers shown in the illustration.

Tightening torque: 3.0 Nm

Page 16

11A-10

ENGINE <4G9> – Crankshaft Rear Oil Seal <A/T>

CRANKSHAFT REAR OIL SEAL <A/T>

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

Transmission Assembly Removal and Installation

(Refer to GROUP 23.)

3

4

1

93 – 103 Nm

2

Removal steps

AB 1. Drive plate bolts

B 2. Adapter plate

B 3. Drive plate

A 4. Crankshaft rear oil seal

MD998781

REMOVAL SERVICE POINT

A DRIVE PLATE BOLTS REMOVAL

Use the special tool to secure the drive plate, and remove

the bolts.

Page 17

ENGINE <4G9> – Crankshaft Rear Oil Seal <A/T>

11A-11

Crankshaft

rear oil seal

MD990938

MD998776

Crankshaft

INSTALLATION SERVICE POINTS

A CRANKSHAFT REAR OIL SEAL INSTALLATION

1. Apply a small mount of engine oil to the entire

circumference of the oil seal lip.

2. Install the oil seal by tapping it as far as the chamfered

position of the oil seal case as shown in the illustration.

B DRIVE PLATE/ADAPTOR PLATE/DRIVE PLATE

BOLTS INSTALLATION

1. Clean off all sealant, oil and other substances which are

adhering to the threaded bolts, crankshaft thread holes

and the drive plate.

2. Apply oil to the bearing surface of the drive plate bolts.

3. Apply oil to the crankshaft thread holes.

4. Apply sealant to the threaded mounting holes.

Specified sealant: 3M Stud locking 4170 or equivalent

5. Use the special tool to secure the drive plate, and then

tighten the bolts to the specified torque.

Specified torque: 93 – 103 Nm

Page 18

11A-12

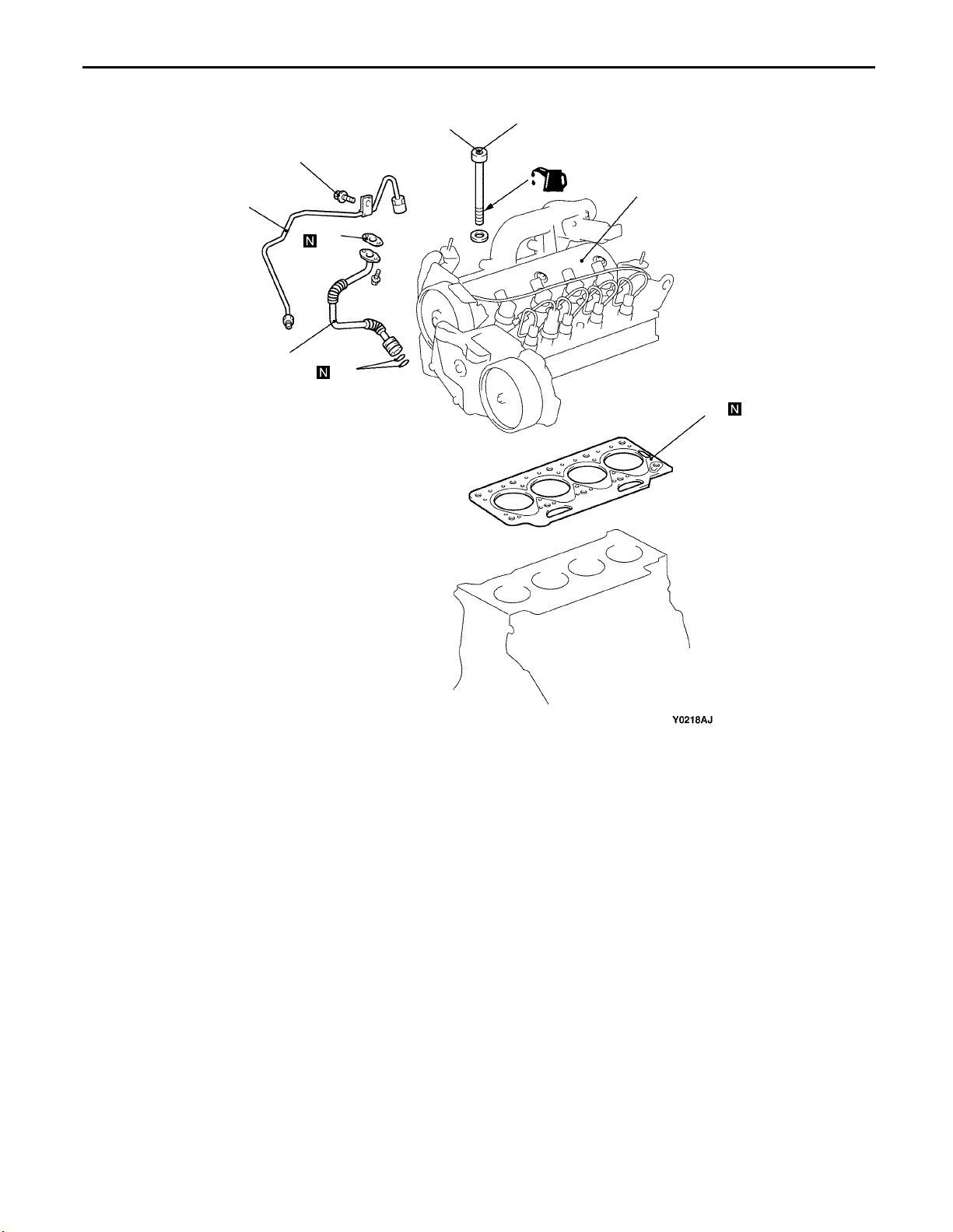

ENGINE <4G9> – Cylinder Head Gasket

CYLINDER HEAD GASKET

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

Engine Cover Removal and Installation

(Refer to P.11A-5.)

Prevention of Fuel Discharge <before removal only>

Fuel Leak Check <after installation only>

Air Bleeding the High Pressure Fuel Path<after

installation only>

[Refer to GROUP 13A – Fuel Pump (High-pressure).]

Under Cover Removal and Installation

Engine Coolant Draining and Supplying

Engine Oil Draining and Supplying

10 – 12 Nm

74 Nm → 0 Nm → 20 Nm

→ +90 → +90

12

Air Cleaner Removal and Installation

Intake Manifold Removal and Installation

(Refer to GROUP 15.)

Fuel Pump (high-pressure) Assembly Removal and

Installation (Refer to GROUP 13A.)

Timing Belt Rear Upper Cover Removal and

Installation (Refer to P.11A-5.)

Thermostat Case Assembly and Radiator upper hose

Removal and Installation

(Refer to GROUP 14 – Water Hose and Water Pipe.)

7

3.4 Nm

10

13

11

8

9

5

22 Nm

44 Nm

1

4

14

6

3

49 Nm

35 Nm

2

34 Nm

35 Nm

3

19 Nm

34 Nm

19 Nm

Page 19

ENGINE <4G9> – Cylinder Head Gasket

Removal steps

1. Injector harness connector

2. Front exhaust pipe connection

3. Exhaust manifold bracket

4. Power steering oil pump bracket

stay

A 5. Power steering oil pump and brack-

et assembly

6. Engine oil level gauge assembly

7. Connector bracket (injector wiring

harness)

REMOVAL SERVICE POINTS

A POWER STEERING OIL PUMP AND BRACKET

Remove the power steering oil pump and bracket assembly

from the engine with the hose attached.

NOTE

Place the removed power steering oil pump in a place where

it will not be a hindrance when removing and installing the

cylinder head assembly, and tie it with a cord.

11A-13

8. Rocker cover (intake side)

9. Rocker cover gasket

10. Rocker cover (exhaust side)

11. Rocker cover gasket

BB 12. Cylinder head bolt

13. Cylinder head assembly

A 14. Cylinder head gasket

ASSEMBLY REMOVAL

MB991653

Intake side Front of engine

351082

1796 4

Exhaust side

B CYLINDER HEAD BOLT REMOVAL

Use the special tool to loosen the bolts in two or three stages

in the order of the numbers shown in the illustration, and

then remove the bolts.

INSTALLATION SERVICE POINTS

A CYLINDER HEAD GASKET INSTALLATION

1. Wipe off all oil and grease from the gasket mounting

surface.

2. Install so that the shapes of the cylinder head holes match

the shapes of the respective cylinder head gasket holes.

Page 20

11A-14

ENGINE <4G9> – Cylinder Head Gasket

Burred side

Head bolt

A

Intake side Front of engine

washer

Cylinder

head

MB991653

351082

1796 4

Head bolt

(Engine

oil)

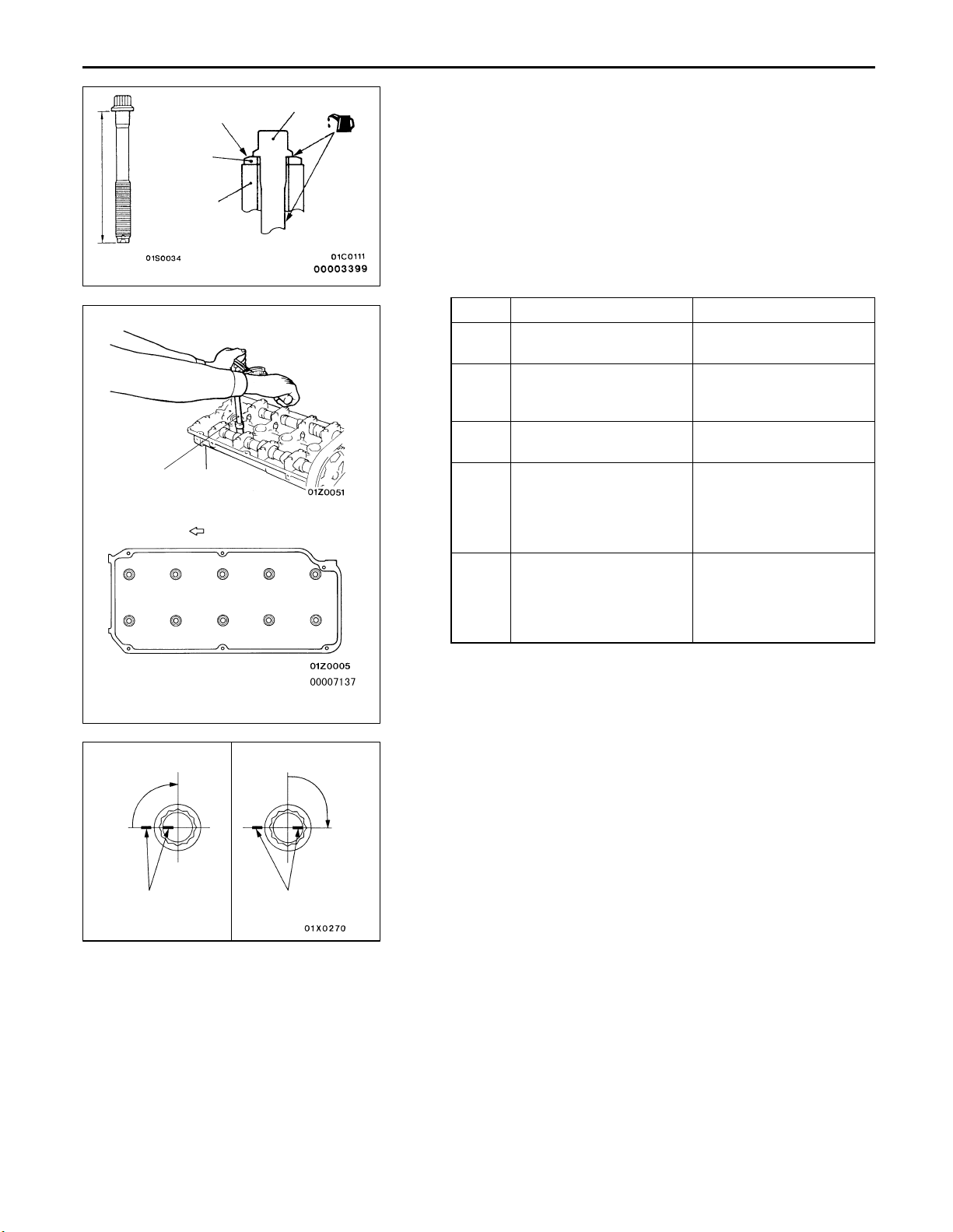

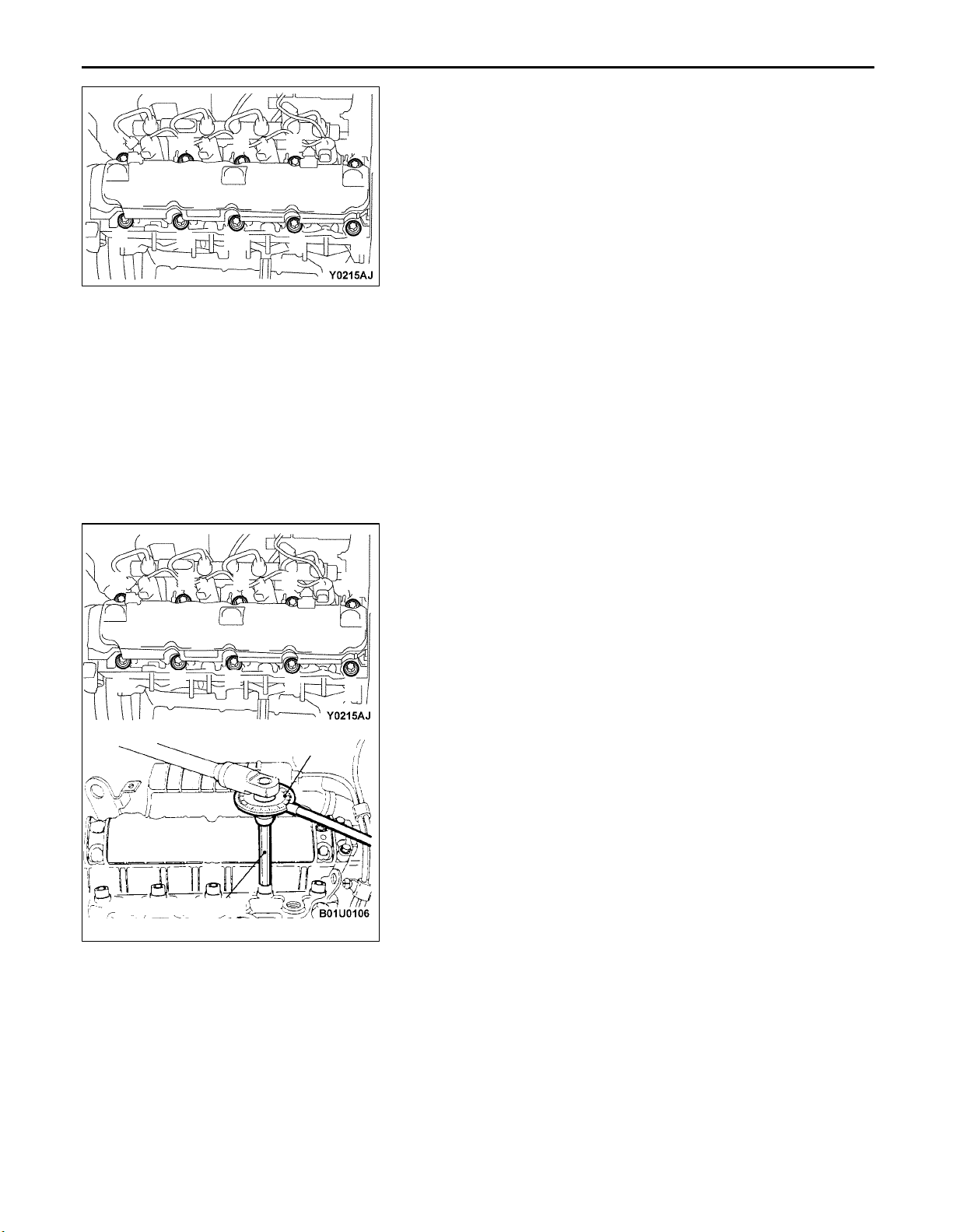

B CYLINDER HEAD BOLT INSTALLATION

1. When installing the cylinder head bolts, the length below

the head of the bolts should be within the limit.

If it is outside the limit, replace the bolts.

Limit (A): 96.4 mm

2. The head bolt washer should be installed with the burred

side caused by tapping out facing upwards.

3. Apply a small amount of engine oil to the thread section

and the washer of the cylinder head bolt.

4. Tighten the bolts by the following procedure.

Step Operation Remarks

1 Tighten to 74 Nm. Carry out in the order

shown in the illustration.

2 Fully loosen. Carry out in the reverse

order of that shown in the

illustration.

3 Tighten to 20 Nm. Carry out in the order

shown in the illustration.

4 Tighten 90 of a turn. In the order shown in the

illustration. Mark the

head of the cylinder head

bolt and cylinder head by

paint.

5 Tighten 90 of a turn. In the order shown in the

illustration. Check that

the painted mark of the

head bolt is lined up with

that of the cylinder head.

Exhaust side

Step 4

90

Painted mark

Caution

(1) Always make a tightening angle just 90. If it is

less than 90, the head bolt will be loosened.

(2) If it is more than 90, remove the head bolt and

repeat the procedure from step 1.

Step 5

90

Painted mark

Page 21

ENGINE <4G9> – Engine Assembly

ENGINE ASSEMBLY

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

Engine Cover Removal and Installation

(Refer to P.11A-5.)

Prevention of Fuel Discharge <before removal only>

Air Bleeding the High Pressure Fuel Path

<after installation only>

[Refer to GROUP 13A – Fuel Pump (High pressure).]

11A-15

Fuel Leak Check <after installation only>

Drive Belt Tension Adjustment

Under Cover Removal and Installation

Air Cleaner Removal and Installation

Hood Removal and Installation

Radiator Assembly Removal (Refer to GROUP 14.)

20

9.0 Nm

17

18

2

3

1

9.0 Nm

7.0 Nm

4

6

7

9.0 Nm

5

8

5.0 Nm

11

9

5.0 Nm

10

14

12

13

15

19

16

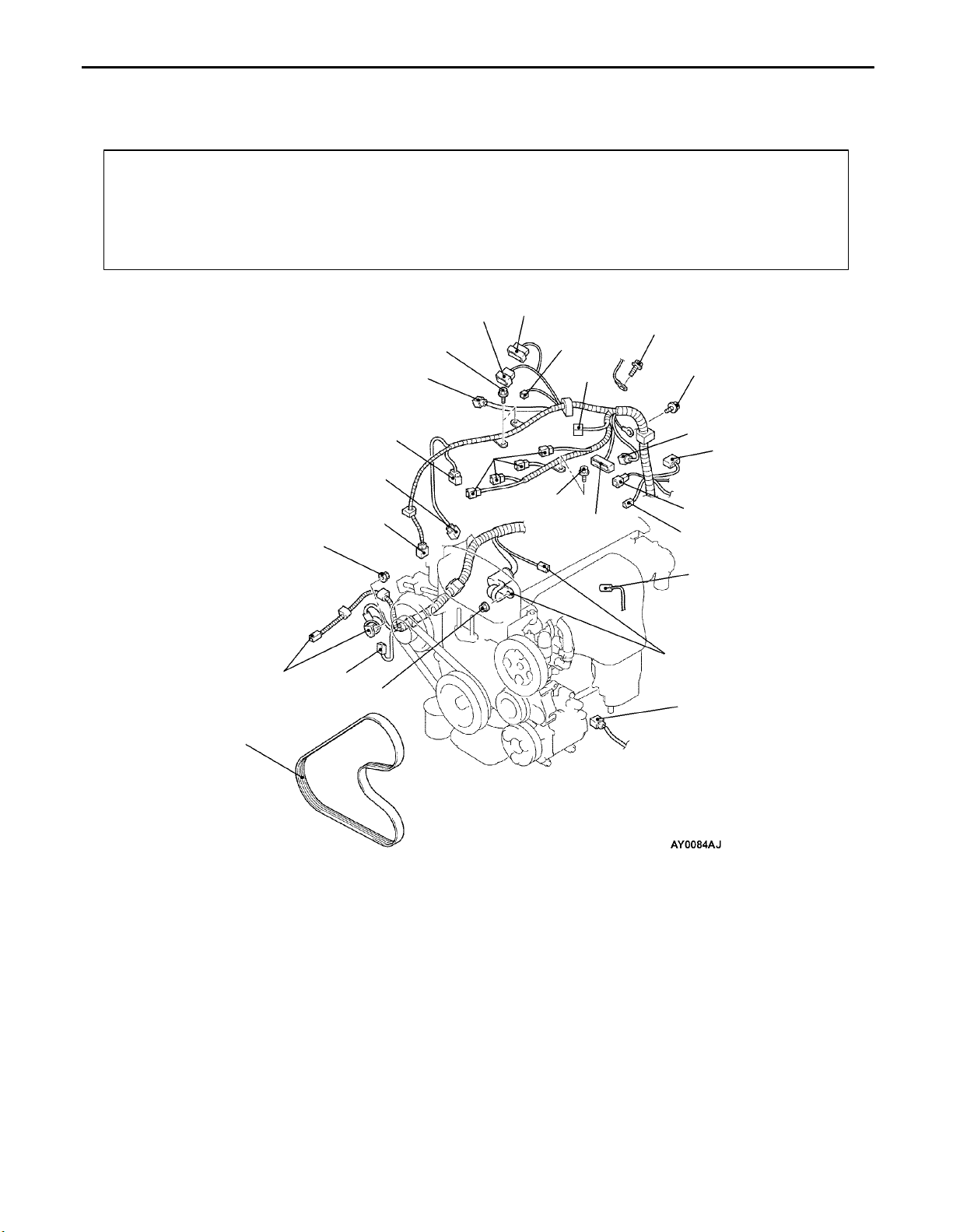

Removal steps

1. Crank angle sensor connector

2. Fuel pressure sensor

3. Oxygen sensor (front) connector

4. Control wiring harness and EGR

wiring harness combination connector

5. Purge control solenoid valve connector

6. Throttle position sensor connector

7. Throttle valve control servo connector

8. Control wiring harness and injector

wiring harness combination connector

9. Ignition coil connector

10. Ignition failure sensor connector

11. Camshaft position sensor connector

12. Engine coolant temperature sensor

connector

13. Engine coolant temperature gauge

unit connector

14. Detonation sensor connector

15. Power steering oil pressure switch

connector

16. A/C compressor connector

17. Alternator connector

18. Engine oil pressure switch connector

19. Starter connector

20. Drive belt (Power steering and A/C)

Page 22

11A-16

ENGINE <4G9> – Engine Assembly

Caution

Mounting locations marked by * should be provisionally tightened, and then fully tightened when

the body is supporting the full weight of the engine.

(Engine Oil)

12 Nm

67 Nm

29

30

23

57 Nm

24

22 Nm

28

21

26

27

5.0 Nm

25

22 Nm

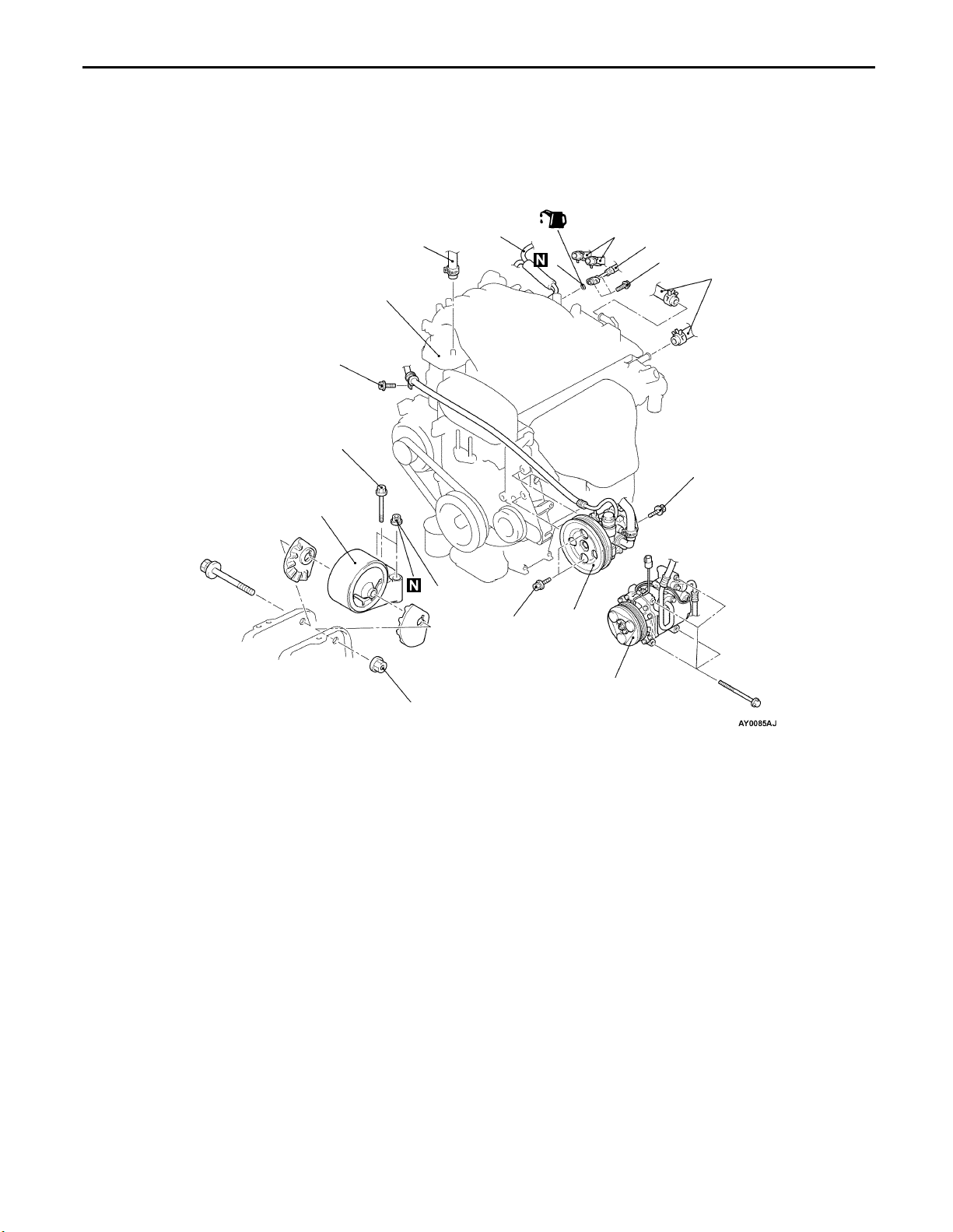

A 21. Power steering oil pump

B 22. A/C compressor

23. Brake booster vacuum hose

connection

24. Vacuum hose connection

25. Heater hoses connection

D 26. Fuel return hoses connection

C 27. High-pressure fuel hose connection

22

98 – 118 Nm*

C 28. O-ring

Transmission assembly

(Refer to ’99 SPACE STAR Workshop

Manual.)

(Refer to GROUP 23. <A/T>)

CB 29. Engine mount Bracket

DA 30. Engine assembly

Page 23

ENGINE <4G9> – Engine Assembly

REMOVAL SERVICE POINTS

A POWER STEERING OIL PUMP REMOVAL

Remove the power steering oil pump from the engine with

the hose attached.

NOTE

Place the removed power steering oil pump where it will not

be a hindrance when removing and installing the engine

assembly, and tie it with a cord.

B A/C COMPRESSOR REMOVAL

Disconnect the A/C compressor connector and remove the

compressor from the compressor bracket with the hose still

attached.

NOTE

Place the removed A/C compressor where it will not be a

hindrance when removing and installing the engine assembly,

and tie it with a cord.

11A-17

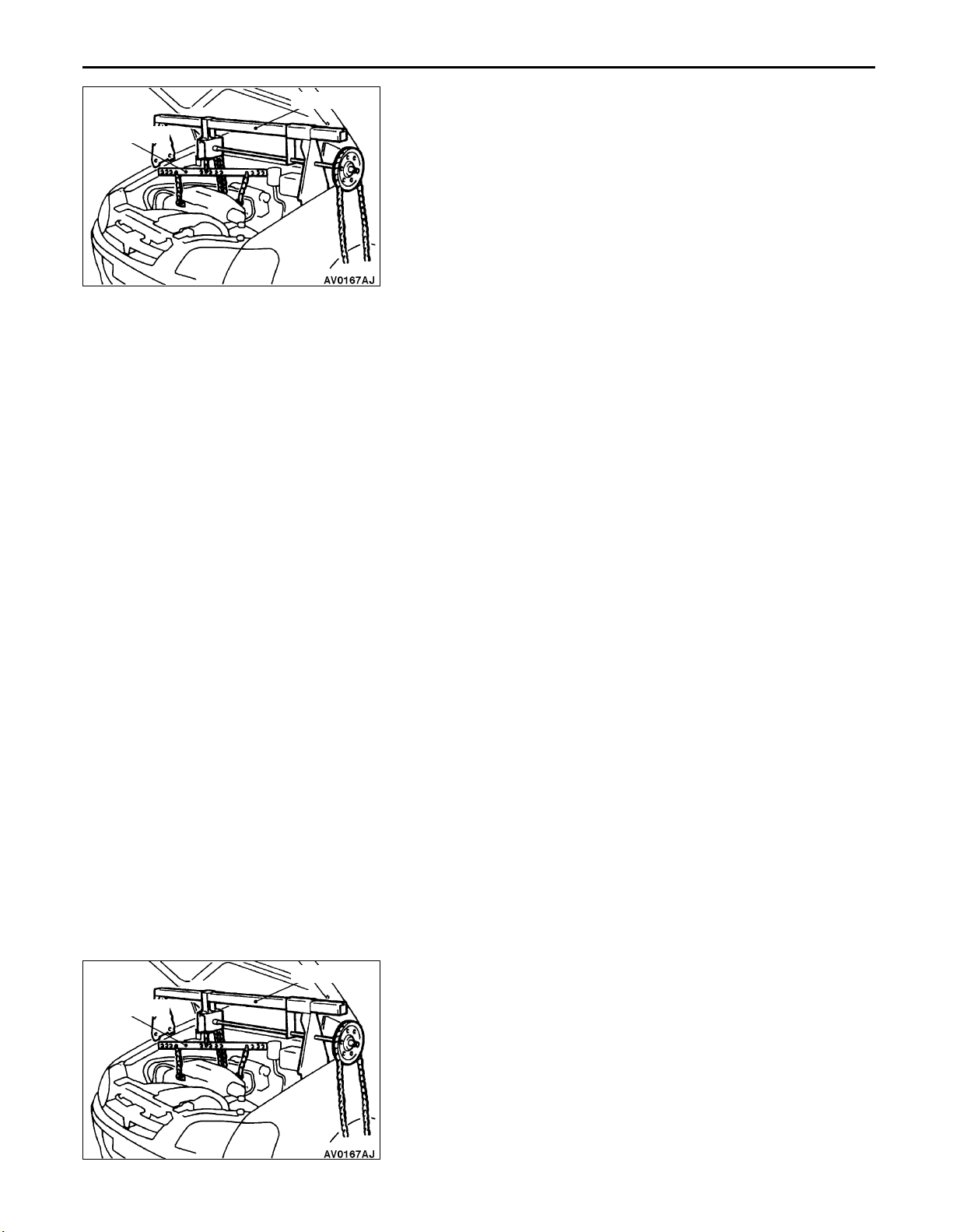

MB991453

MZ203827

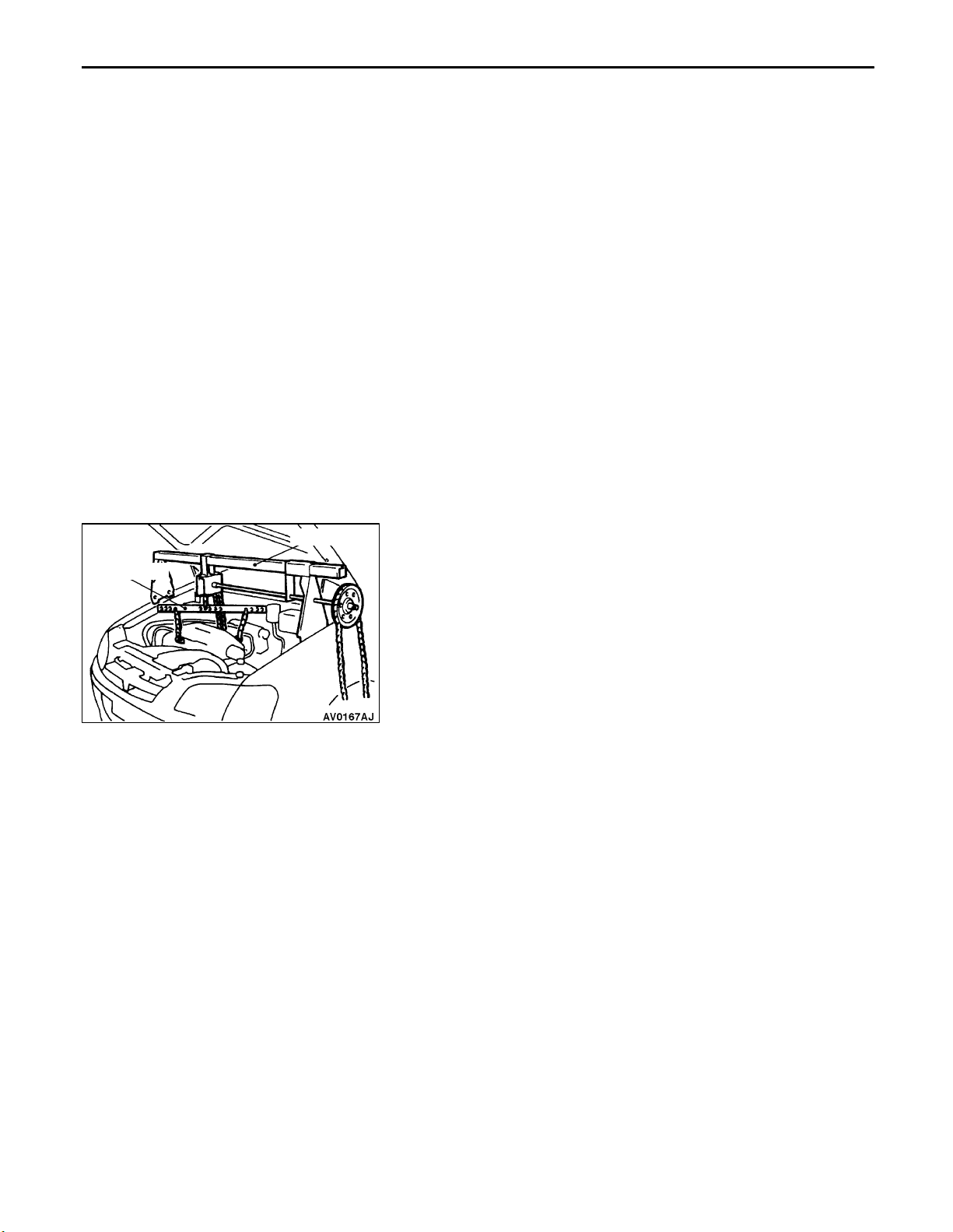

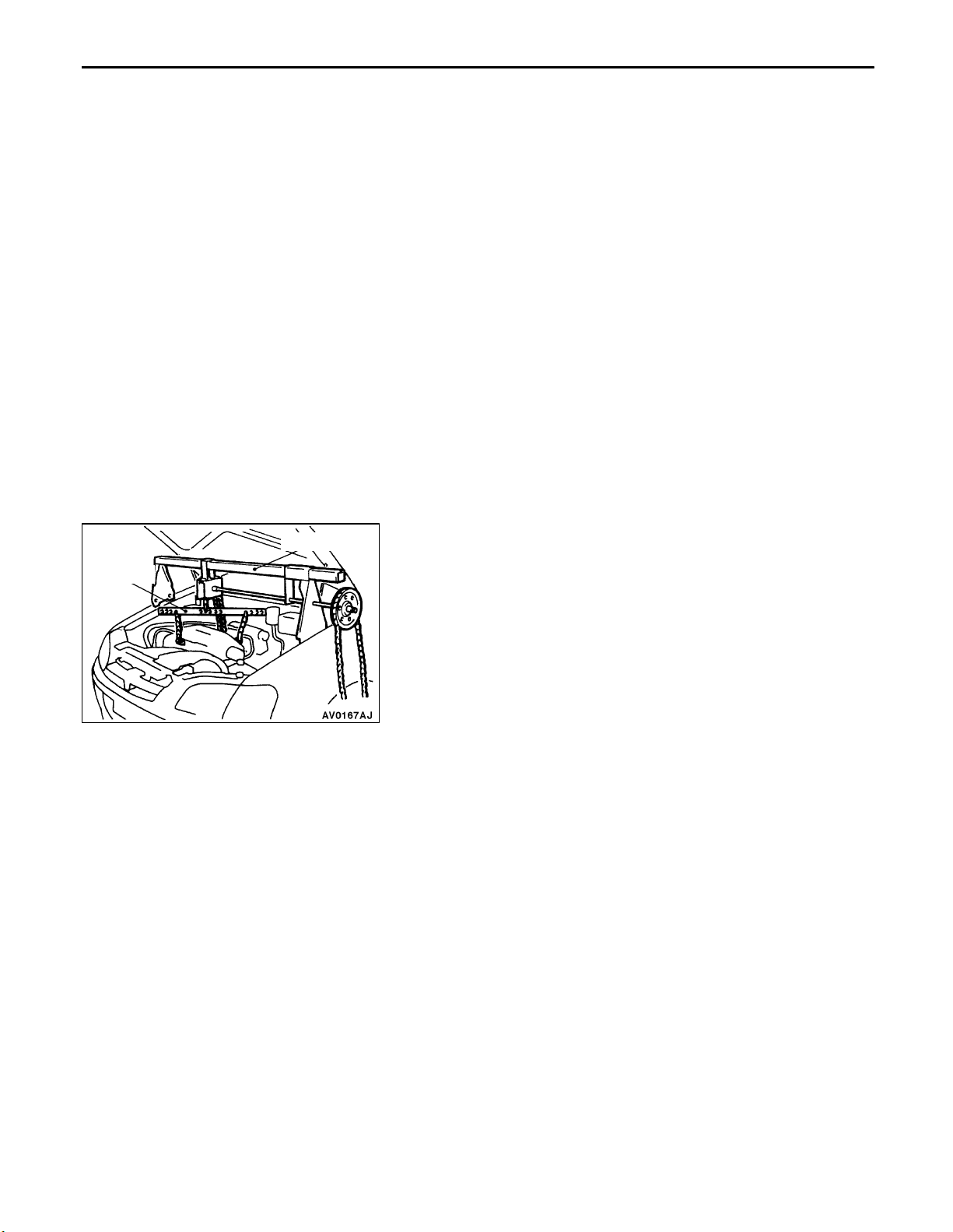

C ENGINE MOUNT BRACKET REMOVAL

1. Support the engine with a garage jack.

2. Remove the mechanical hanger (recommended tool) which

was attached when the transmission assembly was

removed.

3. Hold the engine assembly with a chain block or similar

tool.

4. Place a garage jack against the engine oil pan with a

piece of wood in between, jack up the engine so that

the weight of the engine is no longer being applied to

the engine mount bracket, and then remove the engine

mount bracket.

D ENGINE ASSEMBLY REMOVAL

After checking that all cables, hoses and harness connectors,

etc., are disconnected from the engine, lift the chain block

slowly to remove the engine assembly upward from the engine

compartment.

INSTALLATION SERVICE POINTS

A ENGINE ASSEMBLY INSTALLATION

Install the engine assembly, checking that the cables, hoses,

and harness connectors are not clamped.

Page 24

11A-18

ENGINE <4G9> – Engine Assembly

MB991453

MZ203827

B ENGINE MOUNT BRACKET INSTALLATION

1. Place a garage jack against the engine oil pan with a

piece of wood in between, and install the engine mount

bracket while adjusting the position of the engine.

2. Support the engine with the garage jack.

3. Remove the chain block and support the engine assembly

with the mechanical hanger (recommended tool).

C O-RING/HIGH-PRESSURE FUEL HOSE

INSTALLATION

1. Apply a small amount of new engine oil to the O-ring.

Caution

Do not let any engine oil get into the delivery pipe.

2. While turning the high-pressure fuel hose to the right and

left, install the delivery pipe, while being careful not to

damage the O-ring. After installing, check that the hose

turns smoothly.

3. If the hose does not turn smoothly, the O-ring is probably

being clamped. Disconnect the high-pressure fuel hose

and check the O-ring for damage. After this, re-insert the

delivery pipe and check that the hose turns smoothly.

4. Tighten to the specified torque.

Specified torque: 5.0 Nm

White mark

Blue mark

D FUEL RETURN HOSES INSTALLATION

Install so that the identification marks of the fuel return hoses

are at the positions shown in the illustration.

Page 25

ENGINE <4G1>

CONTENTS

11B-1

GENERAL 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Outline of Change 2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL INFORMATION 2. . . . . . . . . . . . . . . . . .

SERVICE SPECIFICATIONS 2. . . . . . . . . . . . . . . . .

SEALANT 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIAL TOOLS 3. . . . . . . . . . . . . . . . . . . . . . . . . . .

ON-VEHICLE SERVICE 4. . . . . . . . . . . . . . . . . . . . .

Ignition Timing Check and Adjustment 4. . . . . . . . . .

Lash Adjuster Check 5. . . . . . . . . . . . . . . . . . . . . . . . . .

CAMSHAFT AND CAMSHAFT OIL SEAL 8. . . .

CRANKSHAFT FRONT OIL SEAL 10. . . . . . . . . .

CYLINDER HEAD GASKET 12. . . . . . . . . . . . . . . .

ENGINE ASSEMBLY 15. . . . . . . . . . . . . . . . . . . . . .

Page 26

11B-2

ENGINE <4G1> –

General/General Information/Service

Specifications/Sealant

GENERAL

OUTLINE OF CHANGE

Since the catalytic converter internal-type exhaust manifold and the auto-lash adjuster are adopted, and

intake manifold and the ignition system are changed, the following service adjustment procedures are

made. Otherwise, the procedures are the same as that of the existing models.

GENERAL INFORMATION

Items 4G13

Auto-lash adjuster Equipped

SERVICE SPECIFICATIONS

Items Standard value Limit

Basic ignition timing 5 BTDC ± 3 –

Cylinder head bolt shank length mm – 103.2

SEALANT

Items Specified sealant Remarks

Camshaft position sensor support MITSUBISHI GENUINE PART

MD970389 or equivalent

Semi-drying sealant

Page 27

ENGINE <4G1> – Special Tools

SPECIAL TOOLS

Tool Number Name Use

11B-3

MB991502 MUT-II sub

assembly

MB991668 Belt tension meter

set

MD998747 Crankshaft pulley

holder

MB990767 End yoke holder Holding the camshaft sprocket

MD998719 or

MD998754

Crankshaft pulley

holder pin

Measuring the drive belt tension

Checking the idle speed

Measuring the drive belt tension

(used together with MUT-II)

Holding the crankshaft pulley

MD998713 Camshaft oil seal

installer

MD998727 Oil pan remover Removing the oil pan

MD998781 Fly wheel stopper Securing the flywheel

MD998718 Crankshaft rear oil

seal installer

Press-in of the camshaft oil seal

Press-fitting the crankshaft rear oil seal

Page 28

11B-4

Tool UseNameNumber

ENGINE <4G1> – Special Tools/On-vehicle Service

A

A: MD998304

B: MD998305

B

MB991653 Cylinder head bolt

GENERAL

SERVICE

TOOL

MZ203827

MB991453 Engine hanger as-

A: Crankshaft front

oil seal installer

B: Crankshaft front

oil seal guide

wrench

Engine lifter Supporting the engine assembly during

sembly

Press-fitting the crankshaft front oil seal

Cylinder head bolt removal and installation

removal and installation of the transmission

ON-VEHICLE SERVICE

IGNITION TIMING CHECK

1. Set the vehicle to the pre-inspection condition.

2. After turning the ignition switch to the LOCK (OFF) position,

connect the MUT-II to the diagnosis connector.

3. Connect a timing light.

4. Start the engine and run it at idle.

5. Select item No. 22 on the MUT-II and take a reading of the

engine speed. Check that the idle speed is at the standard

value.

Standard value: 750 ± 100 r/min

6. Select item No. 17 (actuator test function) on the MUT-II,

and set the ignition timing to the basic ignition timing.

7. Check the basic ignition timing.

Standard value: 5 BTDC ± 3

8. If the basic ignition timing is outside the standard value

range, check the MPI system while referring to GROUP 13B

– Troubleshooting.

9. Press the CLEAR key on the MUT-II to cancel the basic

ignition timing setting mode by the actuator test function.

Caution

If the mode is not cancelled, the basic ignition timing

setting mode will remain active for 27 minutes, and

problems with engine operation may result if the

vehicle is driven during this period.

Page 29

ENGINE <4G1> – On-vehicle Service

10. Check that the ignition timing is at the standard ignition

timing.

Standard value: Approx. 10 BTDC

NOTE

(1) There should be no problems if the ignition timing

varies within a range of about 7.

(2) At high altitudes, advance the ignition timing by about

a further 5 from the standard value.

LASH ADJUSTER CHECK

If an abnormal noise (knocking) that seems to be coming

from the lash adjuster is heard after starting the engine and

does not stop, carry out the following check.

NOTE

(1) The abnormal noise which is caused by a problem

with the lash adjusters is generated after the engine

is started, and will vary according to the engine speed.

However, this noise is not related to the actual engine

load.

Because of this, if the noise does not occur immediately

after the engine is started, if it does not change in

accordance with the engine speed, or if it changes

in accordance with the engine load, the source of

the noise is not the lash adjusters.

(2) If there is a problem with the lash adjusters, the noise

will almost never disappear, even if the engine has

been run at idle to let it warm up.

The only case where the noise might disappear is

if the oil in the engine has not been looked after properly

and oil sludge has caused the lash adjusters to stick.

1. Start the engine.

2. Check that the noise occurs immediately after the engine

is started, and that the noise changes in accordance with

changes in the engine speed.

If the noise does not occur immediately after the engine

is started, or if it does not change in accordance with

the engine speed, the problem is not being caused by

the lash adjusters, so check for some other cause of the

problem. Moreover, if the noise does not change in

accordance with the engine speed, the cause of the

problem is probably not with the engine. (In these cases,

the lash adjusters are normal.)

11B-5

Page 30

11B-6

ENGINE <4G1> – On-vehicle Service

3. While the engine is idling, check that the noise level does

not change when the engine load is varied.

If the noise level changes, the cause of the noise is probably

parts striking because of worn crankshaft bearings or

connecting rod bearings. (In such cases, the lash adjusters

are normal.)

4. After the engine has warmed up, run it at idle and check

if any noise can be heard.

If the noise has become smaller or disappeared, oil sludge

could make the lash adjusters stick. Clean the lash

adjusters. (Refer to the Engine Workshop Manual.) If not

improved, go to step 5.

5. Bleed air from the lash adjusters.

6. If the noise has not disappeared even after the air bleeding,

clean the lash adjusters. (Refer to the Engine Workshop

Manual.)

<LASH ADJUSTER AIR BLEEDING>

NOTE

(1) If the vehicle is parked on a slope for a long period

of time, the amount of oil inside the lash adjuster will

decrease, and air may get into the high pressure

chamber when starting the engine.

(2) After parking the vehicle for long periods, the oil drains

out of the oil passage, and it takes time for the oil

to be supplied to the lash adjuster, so air can get

into the high pressure chamber.

(3) If either of the above situations occur, the abnormal

noise can be eliminated by bleeding the air from inside

the lash adjusters.

Good

1. Check the engine oil and replenish or replace the oil if

necessary.

NOTE

(1) If there is a only small amount of oil, air will be drawn

in through the oil screen and will get into the oil

passage.

(2) If the amount of oil is greater than normal, then the

oil will being mixed by the crankshaft and a large

amount of air may get mixed into the oil.

(3) If the oil is degenerated, air and oil will not separate

easily in oil, and the amount of air mixed into the

oil will increase.

Page 31

ENGINE <4G1> – On-vehicle Service

(4) If the air which has been mixed in with the oil due to any

of the above reasons gets into the high pressure

chamber of the lash adjuster, the air inside the high

Highpressure

chamber

pressure chamber will be compressed when the valve

is open and the lash adjuster will over-compress,

resulting in abnormal noise when the valve closes.

This is the same effect as if the valve clearance is

adjusted to be too large by mistake. If the air inside the

lash adjusters is then released, the operation of the

lash adjusters will return to normal.

11B-7

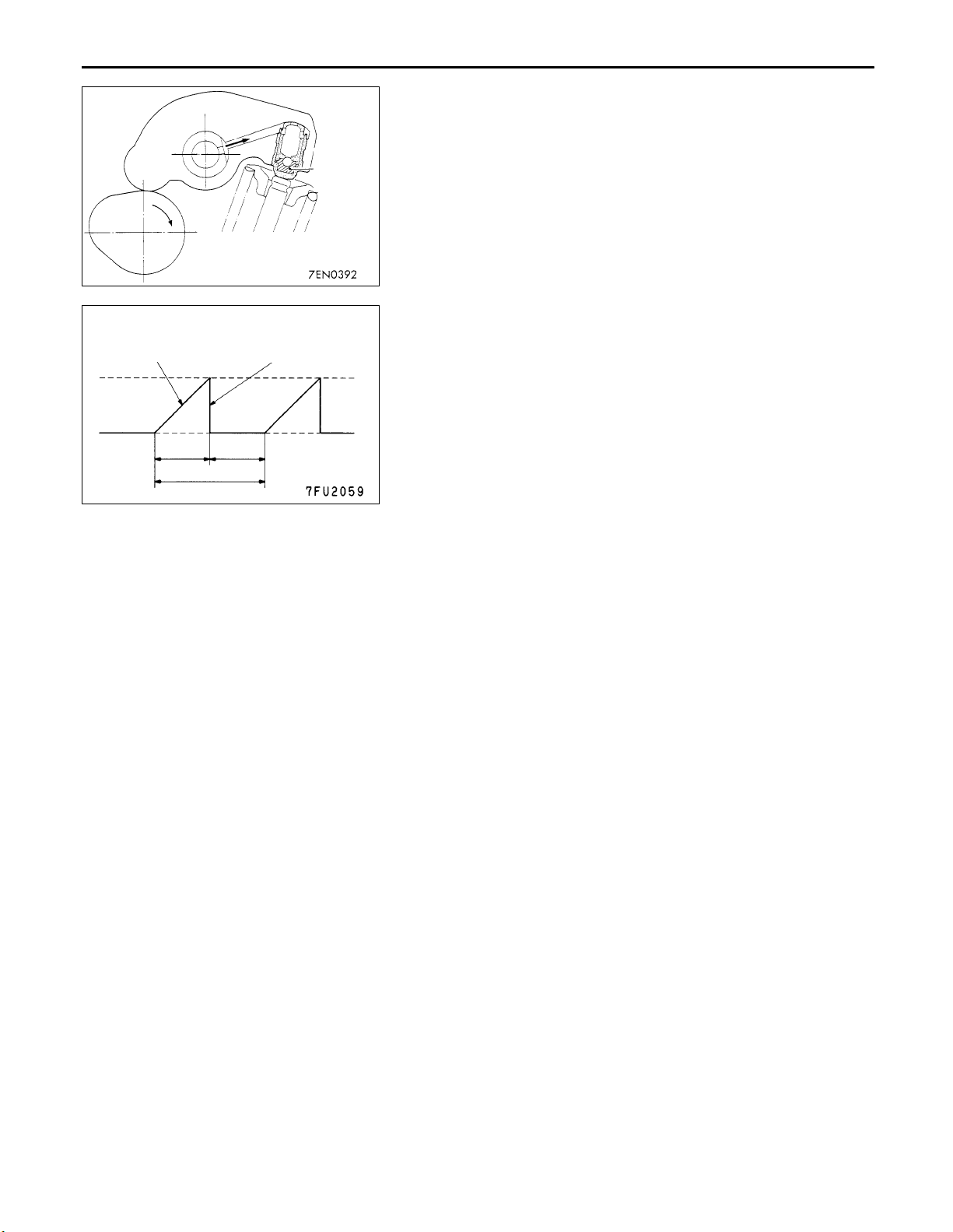

Drive pattern for air bleeding

Gradually open the

throttle valve.

Approx.

3,000 r/min

Idle speed

15

seconds

Once

Close the throttle

valve.

15

seconds

2. Run the engine at idle for 1 – 3 minutes to let it warm

up.

3. With no load on the engine, repeat the drive pattern shown

in the illustration at left and check if the abnormal noise

disappears. (The noise should normally disappear after

10 – 30 repetitions, but if there is no change in the noise

level after 30 repetitions or more, the problem is probably

not due to air inside the lash adjusters.)

4. After the noise has disappeared, repeat the drive pattern

shown in the illustration at left a further 5 times.

5. Run the engine at idle for 1 – 3 minutes and check that

the noise has disappeared.

Page 32

11B-8

ENGINE <4G1> – Camshaft and Camshaft Oil Seal

CAMSHAFT AND CAMSHAFT OIL SEAL

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

Air Cleaner Removal and Installation

Ignition Coil Removal and Installation

(Refer to GROUP16.)

Apply engine oil to all

sliding parts during

installation.

2

4

1

3.5 Nm

9.8 Nm

5.0 Nm

13

12

11

14

3

5

28 – 34 Nm

10

6

16

15

5.0 Nm

12 – 15 Nm

22 Nm

7

9.8 – 12 Nm

9.8 – 12 Nm

8

9

88 Nm

Removal steps

1. Breather hose

2. PCV hose

3. Accelerator cable clamp

4. Rocker cover

5. Rocker cover gasket

6. Spark plug guide

7. Timing belt front upper cover

14

Sealant:

MITSUBISHI GENUINE PART

MD970389 or equivalent

AB 8. Camshaft sprocket

A 9. Camshaft oil seal

10. Rocker arm and shaft assembly

11. Camshaft position sensor connector

12. Ignition failure sensor connector

13. Ignition failure sensor

14. Camshaft position sensor support

15. Camshaft

16. Camshaft position sensing cylinder

Page 33

ENGINE <4G1> – Camshaft and Camshaft Oil Seal

REMOVAL SERVICE POINT

Timing mark

Camshaft

sprocket

A CAMSHAFT SPROCKET REMOVAL

1. Turn the crankshaft in the forward direction (clockwise)

to align the timing mark so that No.1 cylinder is at the

compression TDC.

Caution

Always turn the crankshaft in the forward direction

(clockwise).

2. Secure the camshaft sprocket and the timing belt with

band cablesto prevent deviation from the relative positions

between the camshaft sprocket and the timing belt.

11B-9

MB990767

MD998719 or

MD998754

MD998713

3. Use the special tool to stop the camshaft sprocket from

turning.

4. Remove the camshaft sprocket with the timing belt

attached.

Caution

Do not turn the crankshaft after the camshaft sprocket

is removed.

INSTALLATION SERVICE POINTS

A CAMSHAFT OIL SEAL INSTALLATION

1. Apply engine oil to the camshaft oil seal lip.

2. Use the special tool to press-fit the camshaft oil seal.

B CAMSHAFT SPROCKET INSTALLATION

Use the special tool to stop the camshaft sprocket from turning

in the same way as was done during removal, and then tighten

the bolts to the specified torque.

Tightening torque: 88 Nm

Page 34

11B-10

ENGINE <4G1> – Crankshaft Front Oil Seal

CRANKSHAFT FRONT OIL SEAL

REMOVAL AND INSTALLATION

5

(Lip)

Engine oil

3

1

Removal steps

Timing belt

Crank angle sensor

(Refer to GROUP 16.)

B 1. Crankshaft sprocket

B 2. Spring pin

B 3. Crankshaft sensing blade

B 4. Crankshaft spacer

A 5. Crankshaft front oil seal

5

4

2

MD998304

MD998305

Crankshaft

Oil seal

INSTALLATION SERVICE POINTS

A CRANKSHAFT FRONT OIL SEAL INSTALLATION

1. Apply a small amount of engine oil to the entire

circumference of the oil seal lip.

2. Tap the oil seal unit it flushes with the oil seal case.

Page 35

ENGINE <4G1> – Crankshaft Front Oil Seal

11B-11

Crankshaft

sprocket

Front of

engine

Spring pin

Crankshaft

sensing blade

Crankshaft

spacer

B CRANKSHAFT SPACER/CRANKSHAFT SENSING

BLADE/SPRING PIN/CRANKSHAFT SPROCKET

INSTALLATION

Install the crankshaft sprocket assembled with the spring pin,

the crankshaft sensing blade, and the crankshaft spacer to

the crankshaft.

Page 36

11B-12

ENGINE <4G1> – Cylinder Head Gasket

CYLINDER HEAD GASKET

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

Prevention of Fuel Discharge <before removal only>

Fuel Leak Check <after installation only>

Under Cover Removal and Installation

Engine Coolant Draining and Supplying

Engine Oil Draining and Supplying

Air Cleaner Removal and Installation

9.8 – 12 Nm

9.8 – 12 Nm

(Engine oil)

19

20

23

21

49 Nm → 0 Nm → 20 Nm → +90 → + 90 (Cold engine)

22

4

8

7

3

2

6

5

6

5

1

16

9

10

11

5.0 Nm

14

12

13

17

17

24 Nm

88 Nm

Removal steps

1. Crank angle sensor connector

2. Detonation sensor connector

3. Boost sensor connector

4. EGR solenoid valve connector

5. Ignition coil connector

6. Injector connector

7. Purge control solenoid valve connector

8. Throttle position sensor connector

9. Idle speed control servo connector

10. Ignition failure sensor connector

11. Camshaft position sensor connector

12. Engine coolant temperature sensor

connector

13. Engine coolant temperature gauge

unit connector

15

35 Nm

14. Oxygen sensor (front) connector

Rocker cover (Refer to P.11B-8.)

Intake manifold

(Refer to GROUP 15.)

Water inlet pipe (Refer to GROUP 14.)

15. Front exhaust pipe connection

16. Front exhaust pipe gasket

17. Oil level gauge assembly

18. O-ring

19. Timing belt front upper cover

AC 20. Camshaft sprocket

BB 21. Cylinder head bolts

22. Cylinder head assembly

A 23. Cylinder head gasket

18

(Engine oil)

Page 37

ENGINE <4G1> – Cylinder Head Gasket

REMOVAL SERVICE POINT

Timing mark

Camshaft

sprocket

A CAMSHAFT SPROCKET REMOVAL

1. Turn the crankshaft in the forward direction (clockwise)

to align the timing mark so that No.1 cylinder is at the

compression TDC.

Caution

Always turn the crankshaft in the forward direction

(clockwise).

2. Secure the camshaft sprocket and the timing belt with

band cablesto prevent deviation from the relative positions

between the camshaft sprocket and the timing belt.

11B-13

MB990767

MD998719 or

MD998754

Intake side

MB991653

Front of engine

3. Use the special tool to stop the camshaft sprocket from

turning.

4. Remove the camshaft sprocket with the timing belt

attached.

Caution

Do not turn the crankshaft after the camshaft sprocket

is removed.

B CYLINDER HEAD BOLT REMOVAL

Use the special tool to loosen the bolts in 2 or 3 steps in

order of the numbers shown in the illustration, and remove

the cylinder head assembly.

Caution

Because the plug guides cannot be replaced by

themselves, be careful not to damage or deform the plug

guides when removing the cylinder head bolts.

3510

1

Exhaust side

7

8

964

2

Page 38

11B-14

ENGINE <4G1> – Cylinder Head Gasket

INSTALLATION SERVICE POINTS

A CYLINDER HEAD GASKET INSTALLATION

1. Wipe off all oil and grease from the gasket mounting

surface.

2. Install so that the shapes of the cylinder head holes match

the shapes of the respective cylinder head gasket holes.

Burred side

Head bolt

A

MB991653

Intake side

washer

Cylinder

head

Front of engine

8613

4

10

257

Head bolt

(Engine

oil)

9

B CYLINDER HEAD BOLT INSTALLATION

1. When installing the cylinder head bolts, the length below

the head of the bolts should be within the limit.

If it is outside the limit, replace the bolts.

Limit (A): 103.2 mm

2. The head bolt washer should be installed with the burred

side caused by tapping out facing upwards.

3. Apply a small amount of engine oil to the thread section

and the washer of the cylinder head bolt.

4. Use the special tool to tighten the bolts by the following

procedure.

Step Operation Remarks

1 Tighten to 49 Nm Carry out in the order

shown in the illustration.

2 Fully loosen. Carry out in the reverse

order of that shown in the

illustration.

3 Tighten to 20 Nm Carry out in the order

shown in the illustration.

4 Tighten 90 of a turn. In the order shown in the

illustration. Mark the head

of the cylinder head bolt

and cylinder head by paint.

5 Tighten 90 of a turn. In the order shown in the

illustration. Check that the

painted mark of the head

bolt is lined up with that of

the cylinder head.

Exhaust side

Step 4

90

Painted mark

Step 5

Painted mark

90

Caution

1. Always make a tightening angle just 90. If it is less

than 90, the head bolt will be loosened.

2. If it is more than 90, remove the head bolt and repeat

the procedure from step 1.

C CAMSHAFT SPROCKET INSTALLATION

Use the special tool to stop the camshaft sprocket from turning

in the same way as was done during removal, and then tighten

the bolts to the specified torque.

Tightening torque: 88 Nm

Page 39

ENGINE <4G1> – Engine Assembly

ENGINE ASSEMBLY

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

Prevention of Fuel Discharge <before removal only>

Fuel Leak Check <after installation only>

Accelerator Cable Adjustment

(Refer to GROUP 17 – On-vehicle Service.)

Drive Belt Tension Adjustment

21

20

19

Under Cover Removal and Installation

Air Cleaner Removal and Installation

Hood Removal and Installation

Radiator Assembly Removal (Refer to GROUP 14.)

8

4

2

7

3

9

12

5

11B-15

11

5.0 Nm

9.0 Nm

9.0 Nm

17

18

22

Removal steps

1. Crank angle sensor connector

2. Detonation sensor connector

3. Boost sensor connector

4. EGR solenoid valve connector

5. Ignition coil connector

6. Injector connector

7. Purge control solenoid valve connector

8. Throttle position sensor connector

9. Idle speed control servo connector

10. Ignition failure sensor connector

11. Camshaft position sensor connector

12. Engine coolant temperature sensor

connector

6

6

5

12

1

15

14

13

16

13. Engine coolant temperature gauge

unit connector

14. Oxygen sensor (front) connector

15. Power steering oil pressure switch

connector

16. A/C compressor connector

17. Alternator connector

18. Oil pressure switch connector

19. Starter connector

20. Brake booster vacuum hose connection

21. Vacuum hose connection

22. Drive belt (Power steering and A/C)

Page 40

11B-16

ENGINE <4G1> – Engine Assembly

Caution

*: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle

on the ground in the unladen condition.

25

30

26

12 Nm

27

5.0 Nm

28

(Engine oil)

67 Nm

57 Nm

29

98 – 118 Nm*

A 23. Power steering oil pump and brack-

et assembly

B 24. A/C compressor

25. Heater hoses connection

26. Fuel return hose connection

39 Nm

23

39 Nm

22 Nm

24

C 27. High-pressure fuel hose connection

C 28. O-ring

Transmission assembly

CB 29. Engine mount Bracket

DA 30. Engine assembly

Page 41

ENGINE <4G1> – Engine Assembly

REMOVAL SERVICE POINTS

A POWER STEERING OIL PUMP REMOVAL

Remove the power steering oil pump and bracket with the

hose attached from the engine.

NOTE

Place the removed power steering oil pump where it will not

be a hindrance when removing and installing the engine

assembly, and tie it with a cord.

B A/C COMPRESSOR REMOVAL

Disconnect the A/C compressor connector and remove the

compressor from the compressor bracket with the hose still

attached.

NOTE

Place the removed A/C compressor where it will not be a

hindrance when removing and installing the engine assembly,

and tie it with a cord.

11B-17

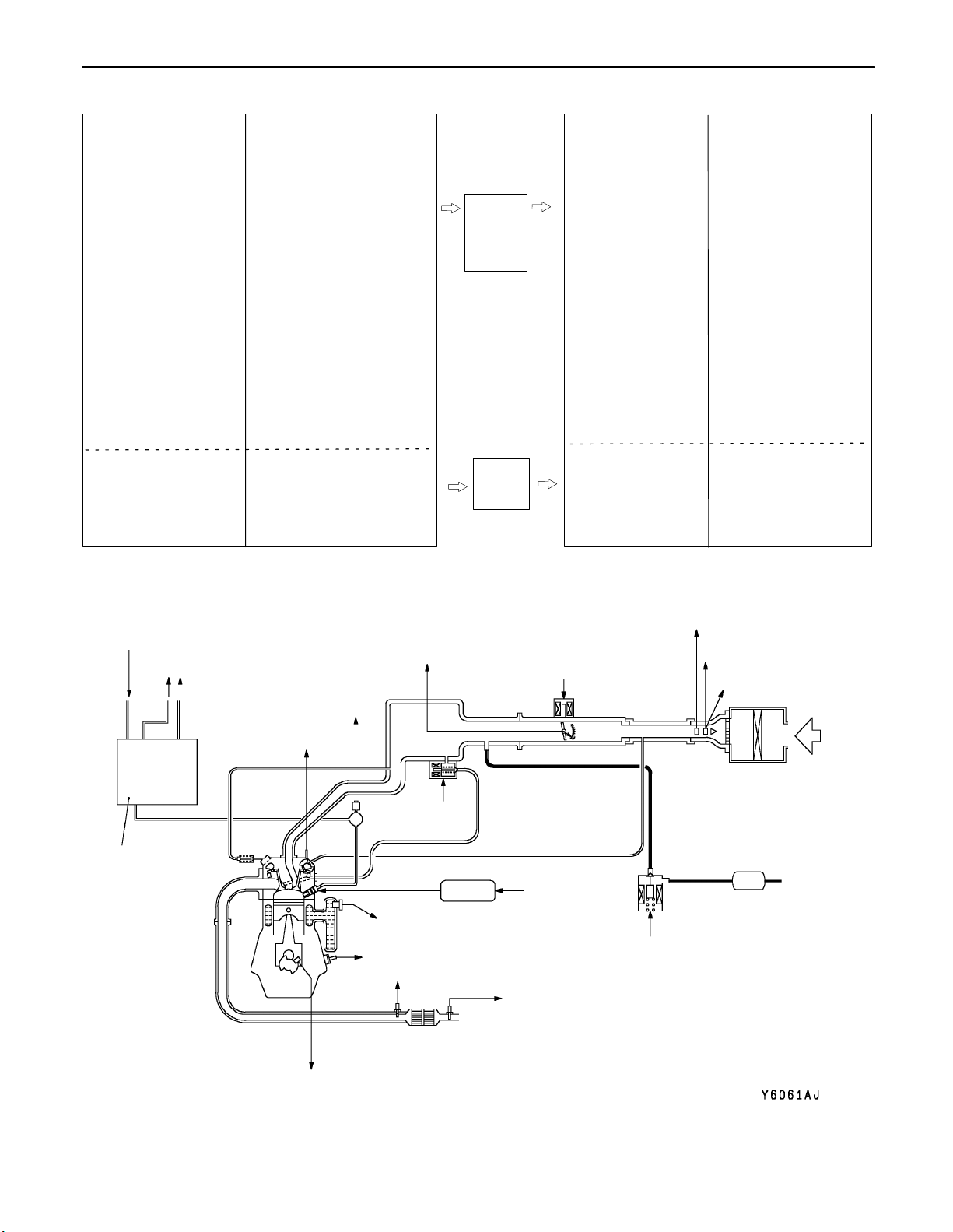

MB991453

MZ203827

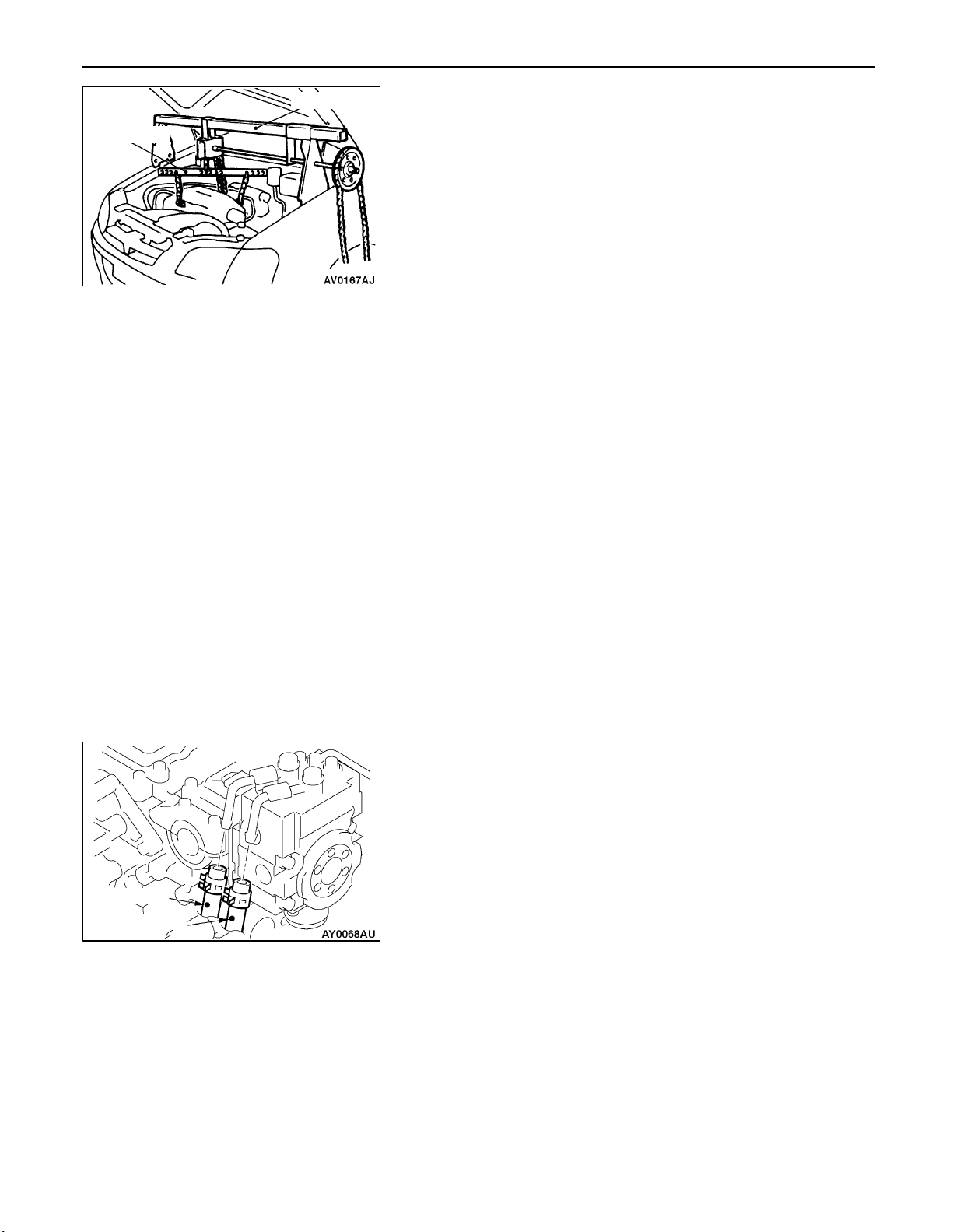

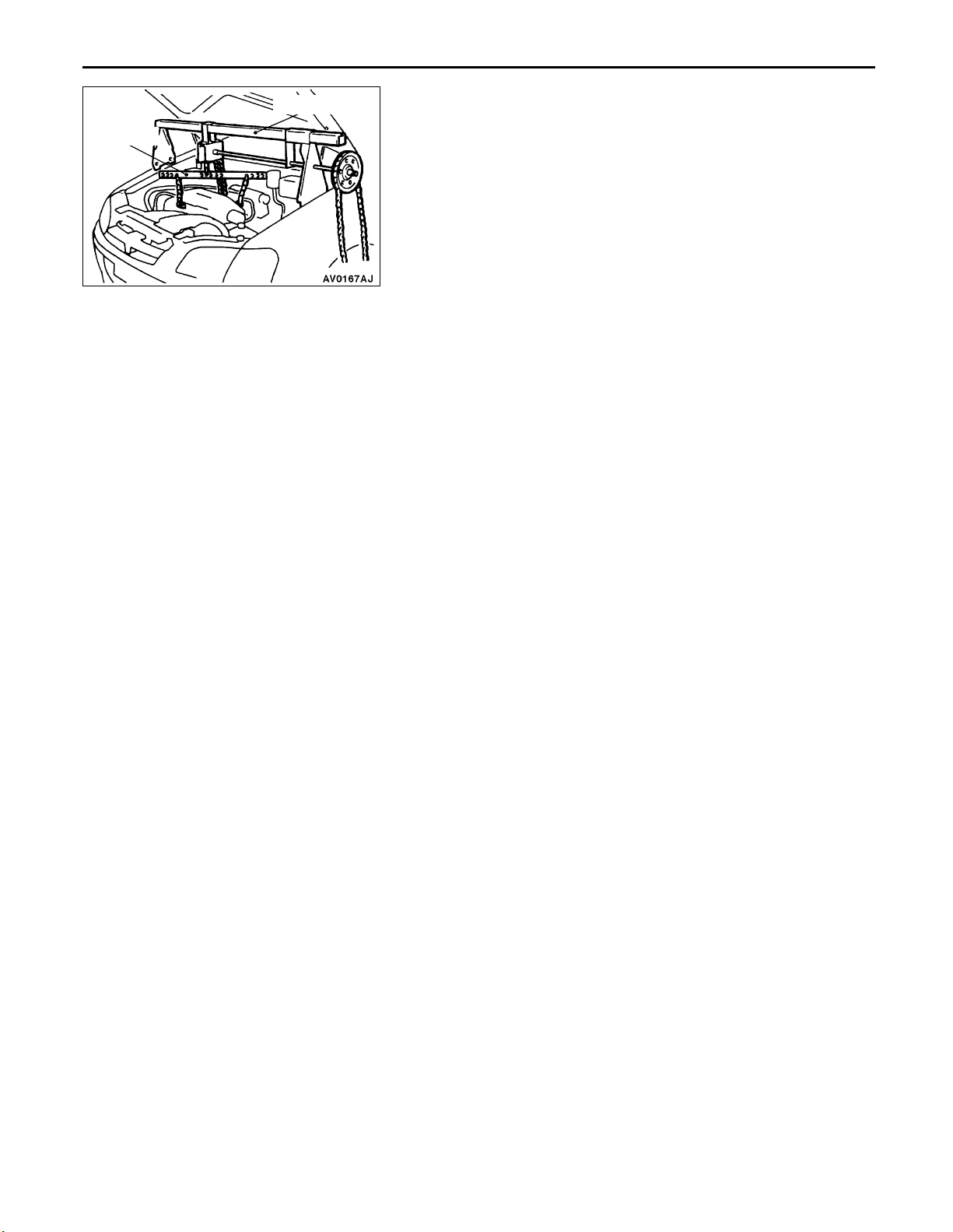

C ENGINE MOUNT BRACKET REMOVAL

1. Support the engine with a garage jack.

2. Remove the special tool which was attached when the

transmission assembly was removed.

3. Hold the engine assembly with a chain block or similar

tool.

4. Place a garage jack against the engine oil pan with a

piece of wood in between, jack up the engine so that

the weight of the engine is no longer being applied to

the engine mount bracket, and then remove the engine

mount bracket.

D ENGINE ASSEMBLY REMOVAL

After checking that all cables, hoses and harness connectors,

etc., are disconnected from the engine, lift the chain block

slowly to remove the engine assembly upward from the engine

compartment.

INSTALLATION SERVICE POINTS

A ENGINE ASSEMBLY INSTALLATION

Install the engine assembly, checking that the cables, hoses,

and harness connectors are not clamped.

Page 42

11B-18

ENGINE <4G1> – Engine Assembly

MB991453

MZ203827

B ENGINE MOUNT BRACKET INSTALLATION

1. Place a garage jack against the engine oil pan with a

piece of wood in between, and install the engine mount

bracket while adjusting the position of the engine.

2. Support the engine with the garage jack.

3. Remove the chain block and support the engine assembly

with the special tools.

C FUEL HIGH PRESSURE HOSE INSTALLATION

1. Apply a small amount of new engine oil to the O-ring.

Caution

Do not let any engine oil get into the delivery pipe.

2. While turning the fuel high-pressure hose to the right and

left, install the delivery pipe, while being careful not to

damage the O-ring. After installing, check that the hose

turns smoothly.

3. If the hose does not turn smoothly, the O-ring is probably

being clamped. Disconnect the fuel high-pressure hose

and check the O-ring for damage. After this, re-insert the

delivery pipe and check that the hose turns smoothly.

4. Tighten to the specified torque.

Tightening torque: 5.0 Nm

Page 43

ENGINE <F9Q1>

CONTENTS

11C-1

GENERAL 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Outline of Change 2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL INFORMATION 2. . . . . . . . . . . . . . . . . .

SERVICE SPECIFICATIONS 2. . . . . . . . . . . . . . . . .

SEALANTS 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIAL TOOLS 3. . . . . . . . . . . . . . . . . . . . . . . . . . .

ON-VEHICLE SERVICE 5. . . . . . . . . . . . . . . . . . . . .

Valve Clearance Check and Adjustment 5. . . . . . . .

Idle Speed Check 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compression Pressure Check 6. . . . . . . . . . . . . . . . . .

Timing Belt Tension Adjustment 7. . . . . . . . . . . . . . . .

CRANKSHAFT PULLEY 8. . . . . . . . . . . . . . . . . . . . .

CAMSHAFT AND CAMSHAFT OIL SEAL

10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OIL PAN 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CRANKSHAFT OIL SEAL 13. . . . . . . . . . . . . . . . . .

CYLINDER HEAD GASKET 15. . . . . . . . . . . . . . . .

TIMING BELT 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE ASSEMBLY 22. . . . . . . . . . . . . . . . . . . . . .

Page 44

11C-2

(at

ld)

ENGINE <F9Q1> – General/General Information/Service Specifications

GENERAL

OUTLINE OF CHANGE

The following maintenance service points have been established to correspond to the adoption of the

F9Q1 engine.

GENERAL INFORMATION

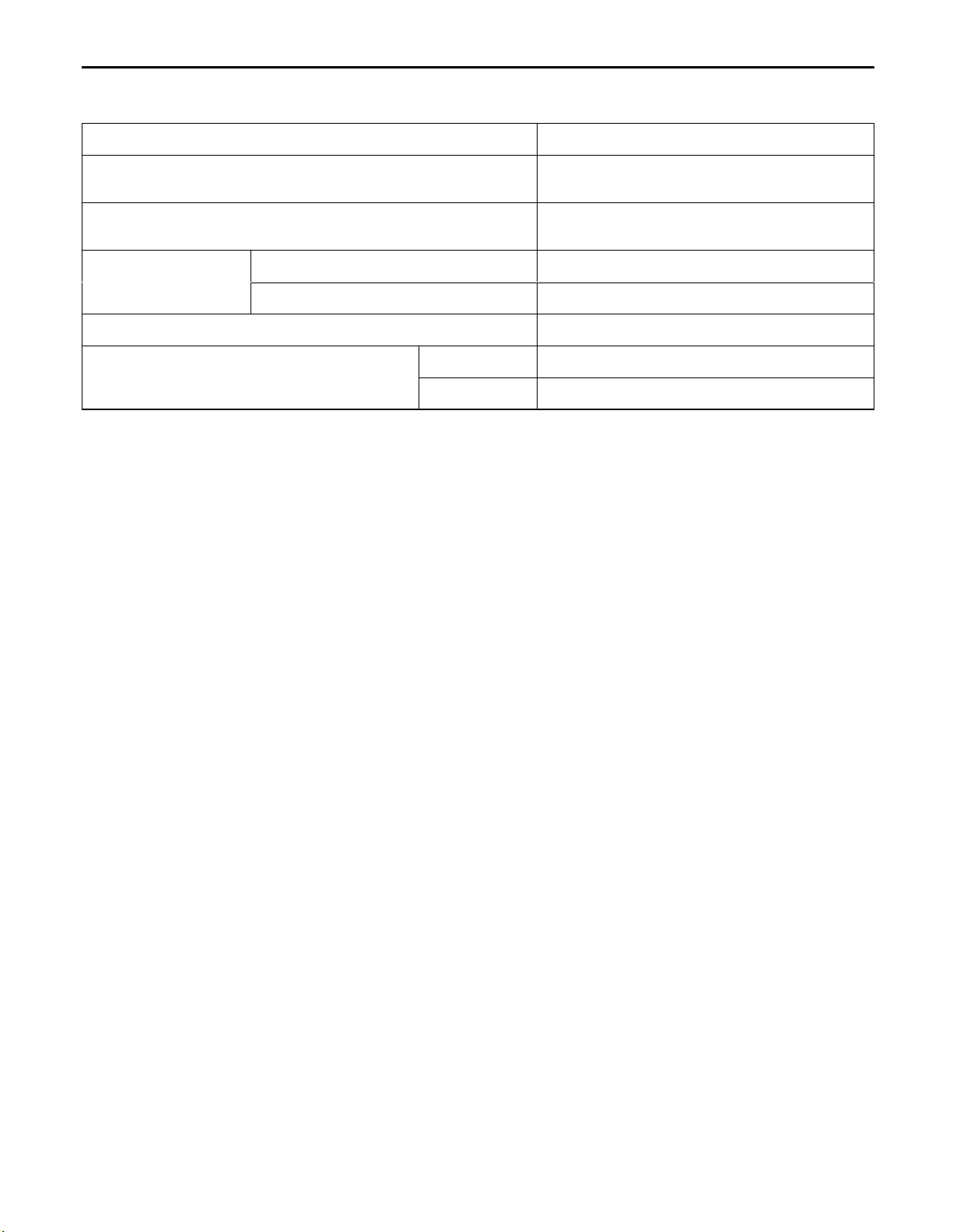

Items Specification

Total displacement mL 1,870

Bore × Stroke mm 80 × 93

Compression ratio 19

Combustion chamber Direct injection type

Camshaft arrangement SOHC

Number of valve

Valve timing Intake

Fuel system Common rail fuel injection

Intake 4

Exhaust 4

Opening 3 BTDC

Closing 21 ABDC

Exhaust

Opening 46 BBDC

Closing 6 BTDC

SERVICE SPECIFICATIONS

Items Standard value Limit

Valve clearance

co

mm checking

Idle speed r/min 750 ± 10 –

When

When

adjusting

Intake valve 0.15 – 0.25 –

Exhaust valve 0.35 – 0.45 –

Intake valve 0.20 –

Exhaust valve 0.40 –

Compression pressure (250 – 400 r/min) kPa – Min. 2,000

Compression pressure difference of all cylinder kPa – Max. 400

Timing belt frequency Hz 90 ± 15 –

Page 45

ENGINE <F9Q1> – Sealants/Special Tools

MD970389

t

SEALANTS

Item Specified sealant Remark

11C-3

Oil pan

Beam cam cap

Fly wheel bolt 3M stud locking 4170 or equivalent Anaerobic sealant

MITSUBISHI GENUINE PART

or equivalen

Semi-drying sealant

SPECIAL TOOLS

Tool Number Name Use

MB991502 MUT-II sub

assembly

MB991668 Belt tension meter

set

MD998747 Crankshaft pulley

holder

Measuring the drive belt tension

Checking the idle speed

Measuring the drive belt tension

(Used together with the MUT-II)

Holding the crankshaft pulley

MB991614 Angle gauge Tightening of the crankshaft pulley bolt

Tightening of the cylinder head bolts

MB990767 End yoke holder Holding the camshaft sprocket

MD998719 Crankshaft pulley

holder pin

MB996042 Oil seal installer Installation of camshaft oil seal

Page 46

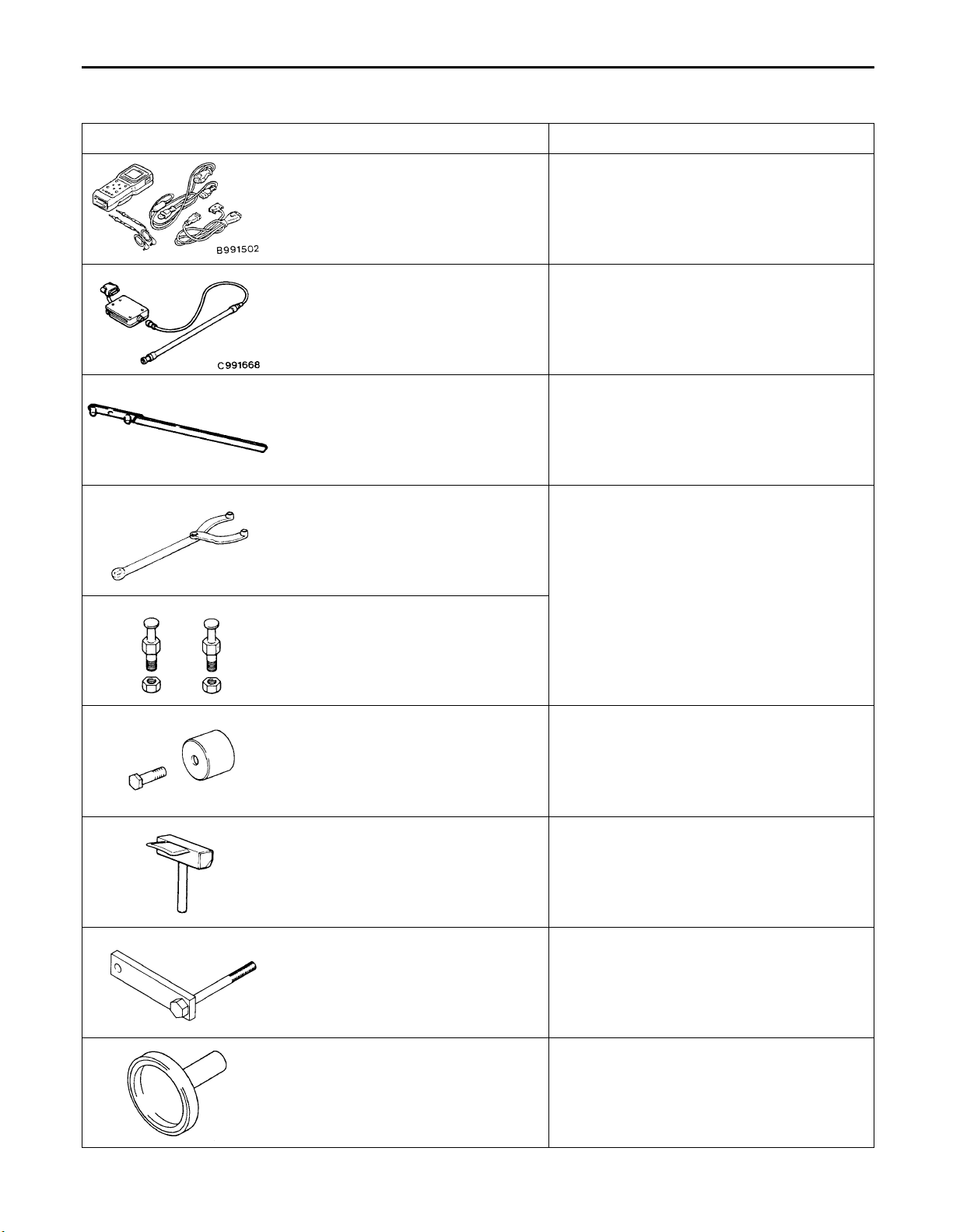

11C-4

Tool UseNameNumber

MB996015 Flywheel stopper Locking the flywheel

MB996038 Oil seal installer Installation of the crankshaft rear oil seal

MB996040 Oil seal installer Installation of the crankshaft front oil seal

ENGINE <F9Q1> – Special Tools

GENERAL

SERVICE

TOOL

MZ203827

MB991453 Engine hanger

Engine lifter Supporting the engine assembly during

assembly

removal and installation of the transmission

Page 47

ENGINE <F9Q1> – On-vehicle Service

ON-VEHICLE SERVICE

VALVE CLEARANCE CHECK AND ADJUSTMENT

1. The valve clearances have to be checked/adjusted in the

following sequence.

Cylinder at point of balance Cylinder being checked/

11C-5

adjusted

Cylinder at point

of balance

Cylinder being

checked/adjusted

1 4

2 3

3 2

4 1

2. Measure the valve clearance.

Standard value:

Cold engine Checking Adjusting

Intake valve mm 0.15 – 0.20 0.20

Exhaust valve mm 0.35 – 0.45 0.40

3. If the valve clearance is outside the standard value, adjust

by replacing the tappets using the following procedure.

4. Re-measure the places which were outside the standard

value, and make a note of the measurement value.

Adapter

Thickness

(X)

Micrometer

5. Measure the thickness of the tappet (X) with a micrometer.

6. Select a tappet which will bring the valve clearance to then

standard value based on the measurement value.

Thickness of tappet for adjustment =

Thickness of tappet installed during inspection (X)

+ (measurement value – standard value)

NOTE

(1) Measure the thickness of the tappet pad with a

micrometer.

(2) Always use new tappets.

(3) Tappets are available in thickness from 7.550 mm

to 8.150 mm, increasing by increments of 0.025 mm.

7. Remove the camshaft, and then install the selected tappet.

8. Install the camshaft.

9. After rotating the camshaft once, check that the valve

clearances are at the standard values.

Page 48

11C-6

ENGINE <F9Q1> – On-vehicle Service

IDLE SPEED CHECK

1. Before inspection, set the vehicle to the pre-inspection

condition.

2. Turn the ignition switch to the “LOCK” (OFF) position and

the connect the MUT-II to the diagnosis connector.

3. Start the engine and check that the idle speed is at the

standard value.

Standard value: 750 ± 10 r/min

4. If the idle speed is not at the standard value, refer to

GROUP 13D – Troubleshooting.

COMPRESSION PRESSURE CHECK

1. Before inspection, check that the engine oil, starter and

battery are normal. In addition, set the vehicle to the

pre-inspection condition.

2. Disconnect the all injector connector.

NOTE

Doing this will prevent carrying out fuel injection.

3. Remove all of the glow plugs.

4. Cover the glow plug hole with a shop towel etc., and after

the engine has been cranked, check that no foreign material

is adhering to the shop towel.

Caution

(1) Keep away from the glow plug hole when cranking.

(2) If compression is measured with water, oil, fuel,

etc., that has come from cranks inside the cylinder,

these materials will become heated and will gush

out from glow plug hole, which is dangerous.

5. Set compression gauge to one of the glow plug holes.

6. Crank the engine and measure the compression pressure.

Limit: Min. 2000 kPa

7. Measure the compression pressure for all cylinders, and

check that the pressure differences of the cylinders are

below the limit.

Limit: Max. 400 kPa

8. If there is a cylinder with compression or a compression

difference that is outside the limit, pour a small amount of

engine oil through the glow plug hole, and repeat the

operations in steps 6 and 7.

(1) If the compression increases after oil is added, the

cause of the malfunction is a worn or damaged piston

ring and/or cylinder inner surface.

(2) If the compression does not rise after oil is added,

the cause is a burnt or defective valve seat, or pressure

is leaking from the gasket.

9. Install the glow plugs.

10. Connect the injector connectors.

Page 49

15

15

MB991668

(Microphone)

10 – 20 mm

M6

bolt

ENGINE <F9Q1> – On-vehicle Service

TIMING BELT TENSION ADJUSTMENT

1. Connect the special tool (belt tension meter set) to the

MUT-II.

2. Connect the MUT-II to the diagnosis connector.

3. Remove the timing belt cover.

4. Turn the crankshaft clockwise to set the No. 1 cylinder to top

dead compression centre.

5. Turn the ignition switch to “ON” position and select “Belt

tension measurement” from the MUT-II menu screen.

6. Slacken the lock nut of the timing belt tensioner.

7. Tension the timing belt with the aid of an M6 bolt.

8. As shown in the illustration, keep the microphone

(MB991668) 10 to 20 mm away from the back side of the

belt perpendicularly (within an inclination of ±15 degrees).

9. With your finger tip lightly tap the centre of the belt between

the tensioner and crankshaft sprocket in the location shown

Lock nut

by the arrow in the illustration to check whether the belt

frequency in within the standard value.

Standard value: 90 ± 15 Hz

Caution

(1) Measure when the belt surface temperature is

close to room temperature.

(2) Make sure that the water or oil, etc., does not get

on the microphone.

(3) If a strong wind blows or noise is made close

to the microphone during measure, the meter will

show a value that differs from the actual value.

(4) If the measurement is taken with the microphone

touching the belt, the meter will show a value that

differs from the actual value.

(5) Do not measure while the engine is running.

11C-7

Page 50

11C-8

ENGINE <F9Q1> – Crankshaft Pulley

CRANKSHAFT PULLEY

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

Under Cover Removal and Installation

10 Nm

2

10 Nm

1

1

10 Nm

5

4

25 Nm

20 Nm → + 115 ± 15

3

Removal steps

1. A/C suction hose clump

2. Power steering pressure hose

clamp

A 3. Engine-ECU assembly

B 4. Drive belt

CA 5. Crankshaft pulley

REMOVAL SERVICE POINTS

A ENGINE-ECU ASSEMBLY REMOVAL

Remove the engine

to hold in the location where the removal of drive belt cannot

be hindered.

-ECU assembly with the harness attached

Page 51

ENGINE <F9Q1> – Crankshaft Pulley

11C-9

Belt’s automatic

pulley tensioner

MD998747

MB991614

Drive belt

Drive belt

B DRIVE BELT REMOVAL

1. Loosen the belt’s automatic pulley tensioner mounting bolt.

2. Hook 16 mm wrench to the protrusion of the belt’s automatic

pulley tensioner and turn the belt’s automatic pulley

tensioner clockwise to remove the drive belt.

Caution

Do not use the removed drive belt again. Always make

sure to replace the used drive belt with a new one.

C CRANKSHAFT PULLEY REMOVAL

Caution

1. This drive belt will get damaged. Do not use the

engine’s drive belt.

2. Never use a damaged drive belt.

INSTALLATION SERVICE POINT

A CRANKSHAFT PULLEY INSTALLATION

1. Use the special tool to hold the crankshaft pulley.

2. Tighten the crankshaft pulley mounting bolt to 20 Nm.

3. Place the special tool in a wrench to tighten the crankshaft

pulley mounting bolt to 115°±15°.

MD998747

Page 52

11C-10

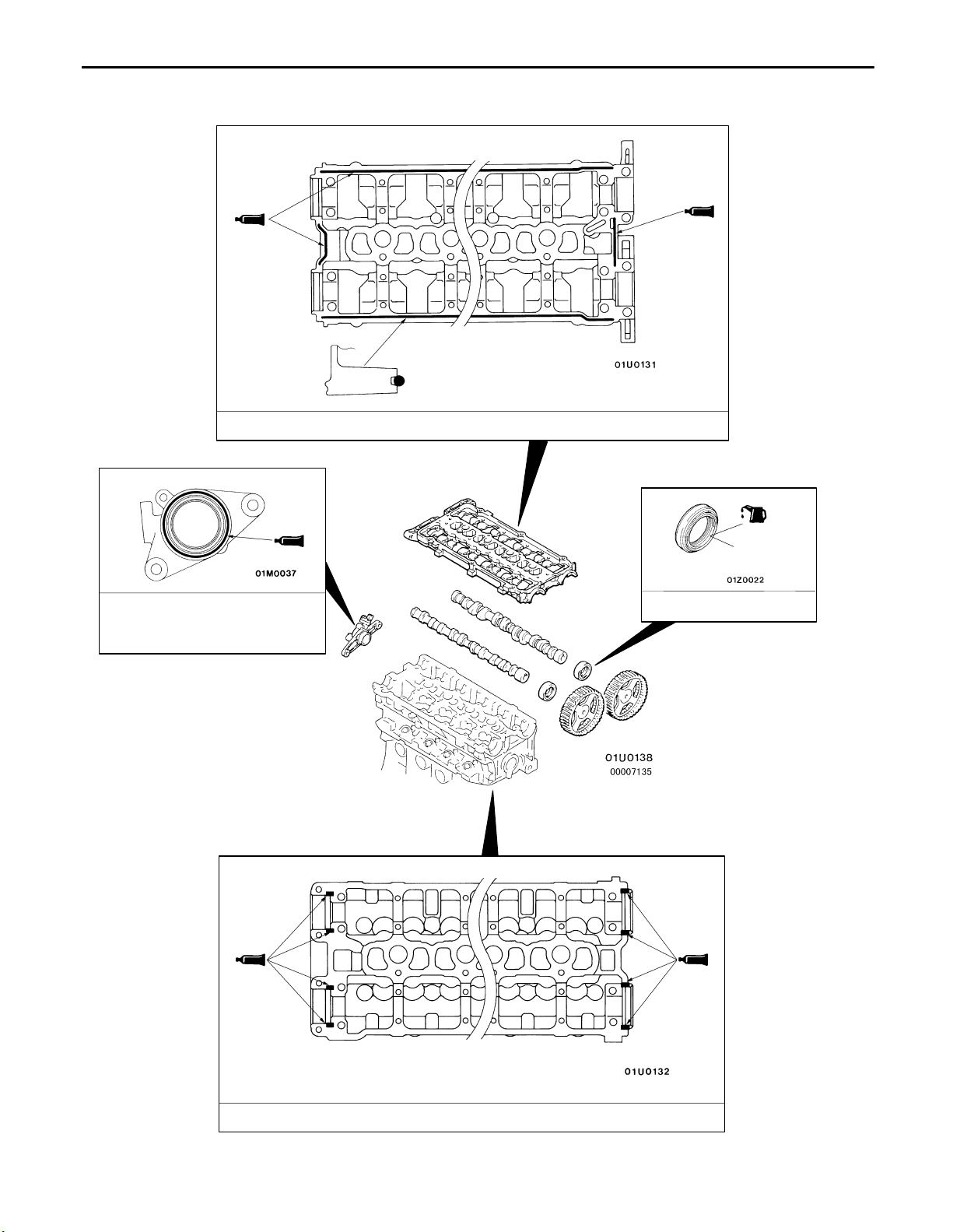

ENGINE <F9Q1> – Camshaft and Camshaft Oil Seal

CAMSHAFT AND CAMSHAFT OIL SEAL

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

Engine Coolant Draining and Supplying

(Refer to GROUP 14 – On-vehicle Service.)

Air Cleaner Removal and Installation

(Refer to GROUP 15.)

7

Timing Belt Removal and Installation

(Refer to P.11C-18.)

5 Nm

7

Sealant:

MITSUBISHI GENUINE PART

MD970389 or equivalent

1

50 Nm

10 Nm

8

11

4

22 Nm

6

13

12

2

3

5

10

10 Nm

9

3

Lip section

Removal steps

AC 1. Camshaft sprocket

2. Timing belt under cover upper

B 3. Camshaft oil seal

4. Brake booster vacuum hose

connection

5. Vacuum hose connection

6. Vacuum pump assembly

Engine oil

7. Rocker cover

8. Rocker cover gasket

9. Radiator upper hose connection

10. Water inlet fitting

A 11. Beam camshaft cap

12. Camshaft

13. Key

Page 53

MB990767

MD998719

ENGINE <F9Q1> – Camshaft and Camshaft Oil SealENGINE <F9Q1> – Camshaft and Camshaft Oil Seal

REMOVAL SERVICE POINT

A CAMSHAFT SPROCKET REMOVAL

11C-11

Front of the engine

MB996042

INSTALLATION SERVICE POINTS

A BEAM CAMSHAFT CAP INSTALLATION

Tighten the beam camshaft cap mounting bolts to the specified

torque in the order shown in the illustration.

Tightening torque: 10 Nm

B CAMSHAFT OIL SEAL INSTALLATION

1. Coat the lip of the oil seal with a thin layer of engine

oil.

2. Tape off the camshaft.

3. Locate the oil seal over the camshaft.

4. Fit the oil seal with the special tool.

C CAMSHAFT SPROCKET INSTALLATION

Use the special tool to secure the camshaft sprocket in the

same way as during removal, and then tighten the bolt to

the specified torque.

Page 54

11C-12

ENGINE <F9Q1> – Oil Pan

OIL PAN

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

Under Cover Removal and Installation

Engine Oil Draining and Supplying

(Refer to GROUP 12 – On-vehicle Service.)

3

Sealant:

MITSUBISHI GENUINE PART

MD970389 or equivalent

Oil Level Gauge Removal and Installation

Removal steps

1. Drain plug

2. Drain plug gasket

A 3. Oil pan

Oil pan

Flat-tipped

screwdriver

Notch

13 Nm

3

25 Nm

2

1

REMOVAL SERVICE POINT

A OIL PAN REMOVAL

Insert a flat-tipped screwdriver into the notch of the oil pan,

and turn it to remove the oil pan.

Caution

Because the upper oil pan used is made from aluminium,

the oil pan remover (MB998727) should not be used.

Page 55

ENGINE <F9Q1> – Crankshaft Oil Seal

CRANKSHAFT OIL SEAL

REMOVAL AND INSTALLATION

11C-13

4

53 Nm

(3M stud locking

4170 or equivalent)

5

3

2

1

Crankshaft front oil seal removal

steps

Timing belt (Refer to P.11C-18.)

1. Crankshaft sprocket

C 3. Crankshaft front oil seal

2. Key

5, 3

Lip section

Engine oil

Crankshaft rear oil seal removal

steps

Transmission assembly

Clutch cover and disc

AB 4. Flywheel assembly

A 5. Crankshaft rear oil seal

Lip section

(Refer to GROUP 22.)

7

MB996015

REMOVAL SERVICE POINT

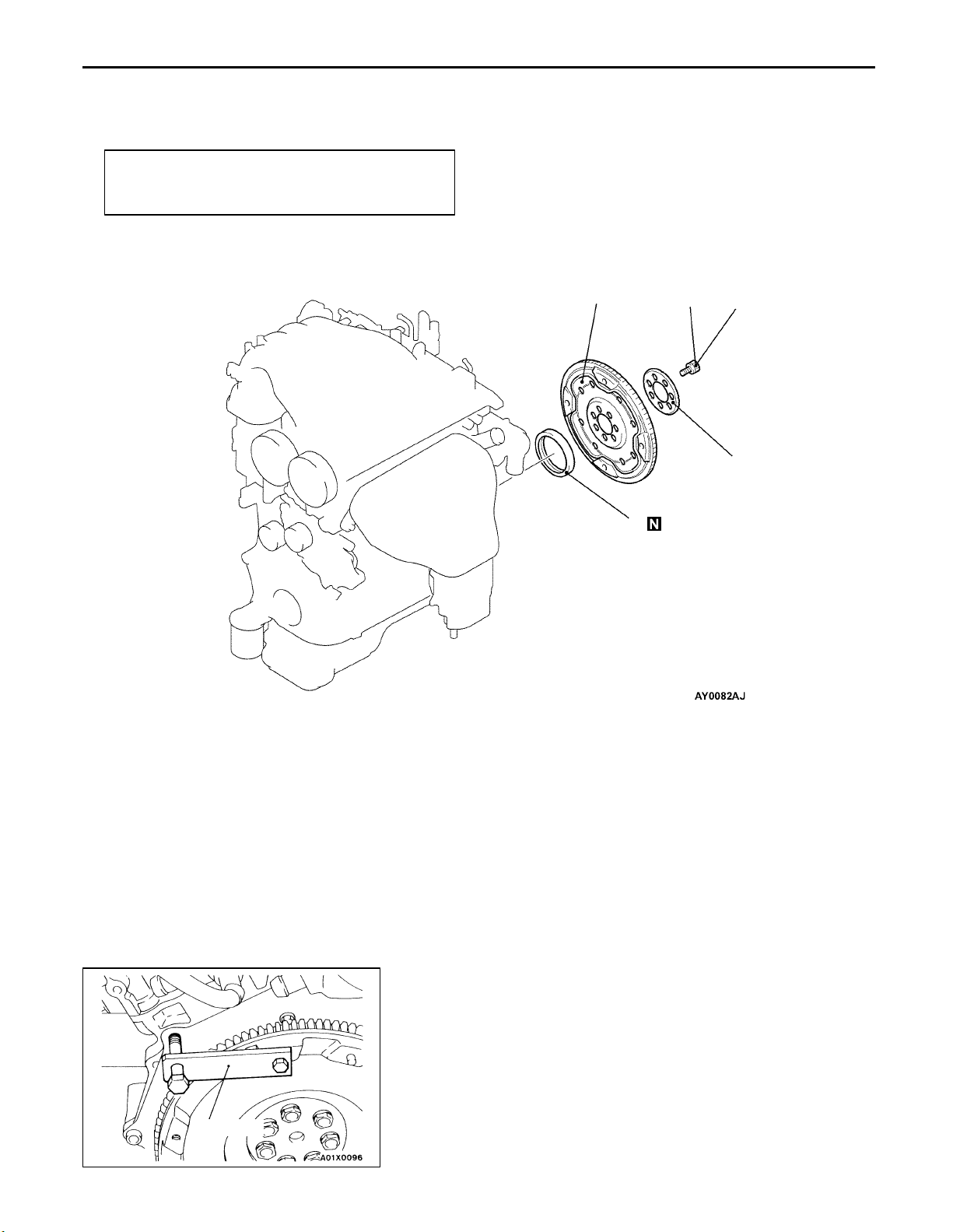

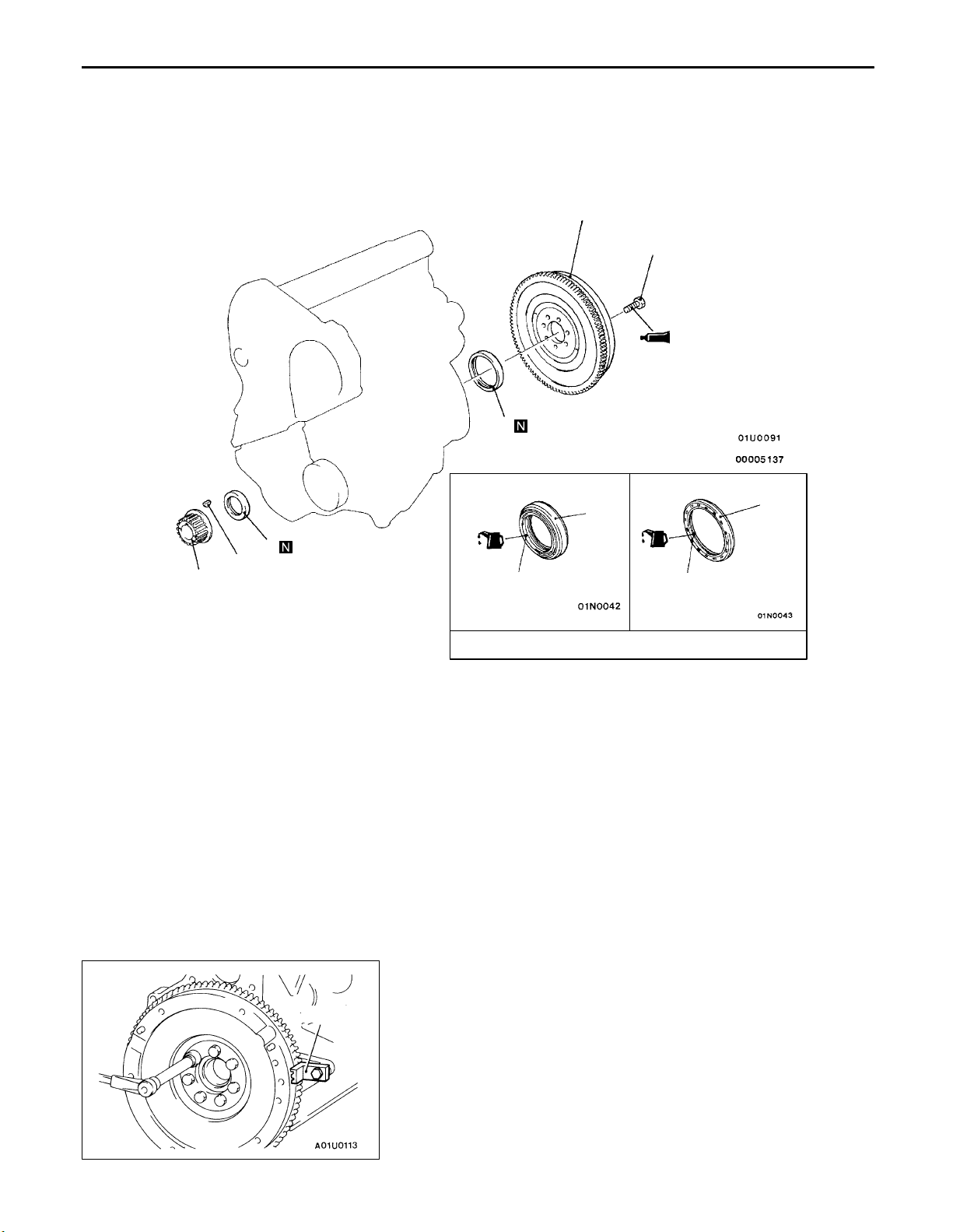

B FLYWHEEL ASSEMBLY REMOVAL

Use the special tool to secure the flywheel and remove the

bolts.

Page 56

11C-14

MB996038

ENGINE <F9Q1> – Crankshaft Oil Seal

INSTALLATION SERVICE POINTS

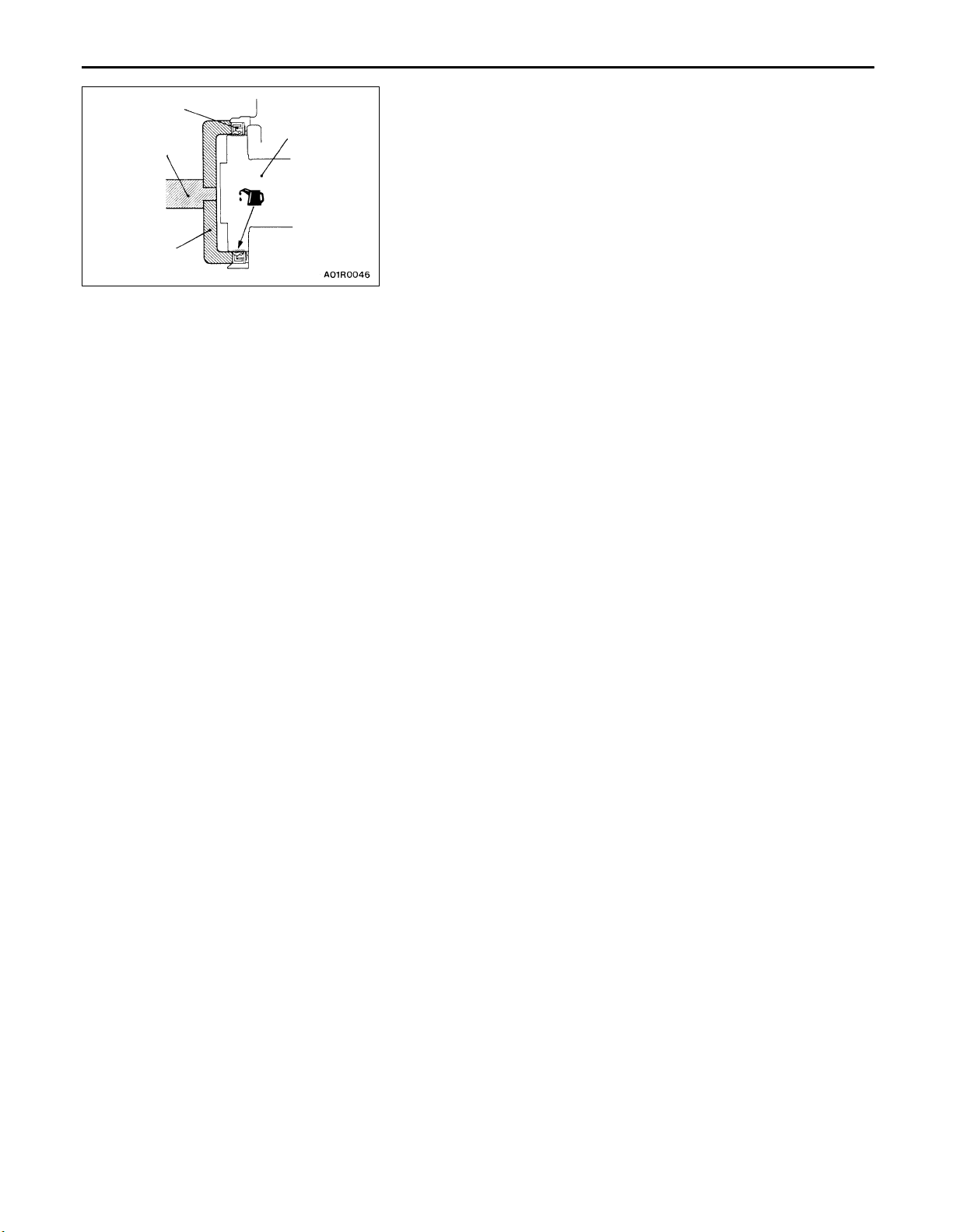

A CRANKSHAFT REAR OIL SEAL INSTALLATION

1. Coat the lip of the oil seal with a thin layer of engine

oil.

2. Locate the special tool (installer guide) over the crankshaft.

3. Locate the oil seal over the guide.

4. Fit the oil seal with special tool (installer).

MB996038

B FLYWHEEL ASSEMBLY INSTALLATION

1. Clean off all sealant, oil and other substances which are

adhering to the threaded bolts, crankshaft thread holes

and the flywheel.

2. Apply sealant to the threaded mounting bolts.

Specified sealant: 3M Stud locking 4170 or equivalent

3. Use the special tool to secure the flywheel, and then tighten

the bolts to the specified torque.

Tightening torque: 53 Nm

MB996040

MB996040

C CRANKSHAFT FRONT OIL SEAL INSTALLATION

1. Coat the lip of the oil seal with a thin layer of engine

oil.

2. Locate the special tool (installer guide) over the crankshaft.

3. Locate the oil seal over the guide.

4. Fit the oil seal with special tool (installer).

Page 57

ENGINE <F9Q1> – Cylinder Head Gasket

CYLINDER HEAD GASKET

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

Engine Coolant Draining and Supplying

(Refer to GROUP 14 – On-vehicle Service.)

Engine Oil Draining and Supplying

(Refer to GROUP 12 – On-vehicle Service.)

Timing Belt Removal and Installation

(Refer to P.11C-18.)

13

10

9

11C-15

Air Cleaner and Air Intake Hose Removal and

Installation (Refer to GROUP 15.)

Catalytic Converter Removal and Installation

(Refer to GROUP 15 – Exhaust Pipe and Main Muffler.)

Fuel Line Air Bleeding <After Installation Only>

(Refer to GROUP 13C – On-vehicle Service.)

5

6

8

5

5

6

5

6

7

14

1

11

2

3

15

9

12

4

Removal steps

1. Camshaft position sensor connector

2. Fuel pressure sensor connector

3. Fuel high pressure pump connector

4. Fuel temperature sensor connector

5. Fuel injector connector

6. Glow plug connector

7. Water temperature sensor

connector

8. EGR valve connector

9. Vacuum hose connection

10. Brake booster vacuum hose

connection

11. Radiator upper hose connection

12. Water hose connection

13. Heater hose connection

A 14. Fuel return hose connection

A 15. Fuel supply hose connection

Page 58

11C-16

ENGINE <F9Q1> – Cylinder Head Gasket

30 Nm → + 100 ± 4 → 0 N m → 25 Nm →+ 213 ± 7

20

10 Nm

(Engine oil)

16

21

18

17

19

22

16. Oil pipe assembly

17. Oil return pipe assembly

18. Oil return pipe gasket

19. O-ring

BB 20. Cylinder head bolt

21. Cylinder head assembly

A 22. Cylinder head gasket

REMOVAL SERVICE POINTS

B FUEL RETURN HOSE CONNECTION/FUEL

SUPPLY HOSE CONNECTION REMOVAL

After disconnecting the fuel return hose and the fuel supply

hose, put the cover at the end of the fuel line to prevent foreign

objects from entering.

Page 59

ENGINE <F9Q1> – Cylinder Head GasketENGINE <F9Q1> – Cylinder Head Gasket

11C-17

REMOVAL SERVICE POINTS

B CYLINDER HEAD BOLT REMOVAL

4

3

8

7

9

10

5

6

1

2

Loosen the cylinder head bolt in the order of the illustrated

numbers in two or three stages for removal.

Caution

Do not use the removed cylinder head bolt again. Always

replace the used cylinder head bolt with a new one.

INSTALLATION SERVICE POINTS

A CYLINDER HEAD GASKET INSTALLATION

1. Wipe off all oil and grease from the gasket mounting

surface.

2. Install so that the shapes of the cylinder head holes match

the shapes of the respective cylinder head gasket holes.

8

General service tool

4

B CYLINDER HEAD BOLT INSTALLATION

1. Tighten the new cylinder head bolt in the order of the

23

1

67

5

MB991614

10

9

illustrated numbers to 30 Nm.

2. Place the special tool in a wrench to tighten the cylinder

head bolt in the order of the illustrated numbers to 100°

± 4°.

3. Wait for approximately 3 minutes until the cylinder head

gasket fits in the cylinder hear and the cylinder block.

4. Loosen the illustrated number 1 and 2 bolts completely.

5. Tighten the illustrated number 1 and 2 bolts to 25 Nm.

6. Place the special tool in a wrench to tighten the illustrated

number 1 and 2 bolts to 213°± 7°.

7. Divide the rest of the bolts into pairs: Number 3 and 4

bolts, number 5 and 6 bolts, number 7 and 8 bolts, number

9 and 10 bolts. And tighten them as a pair according

to the procedures 3, 4, and 5.

Caution

The cylinder head bolt will be extended if the cylinder

head is tightened. If the cylinder head bolt is tightened

too much, replace it with a new one instead of tightening

it again.

Page 60

11C-18

ENGINE <F9Q1> – Timing Belt

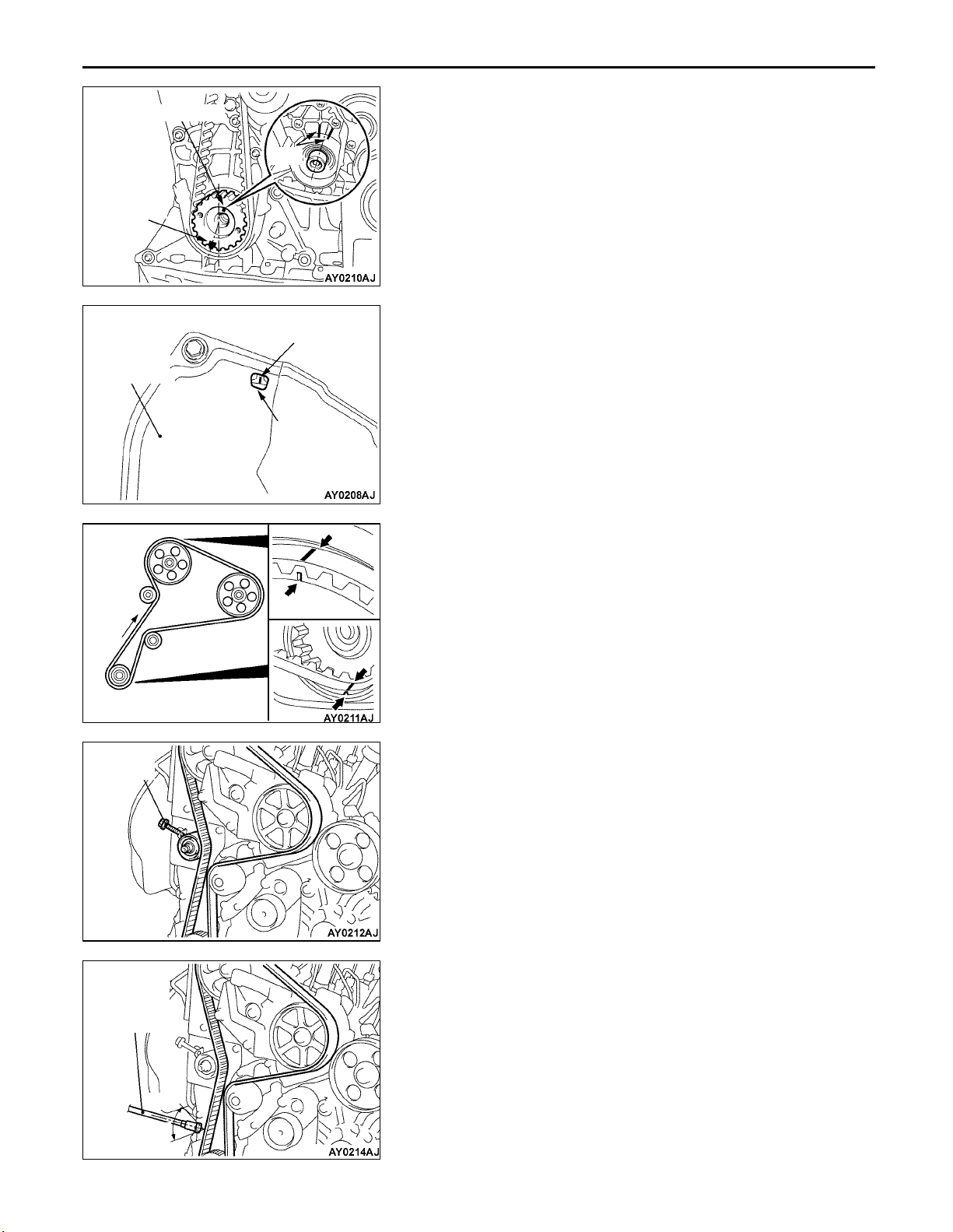

TIMING BELT

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

Under Cover Removal and Installation

Engine Mount Bracket Removal and Installation

(Refer to GROUP 32.)

10 Nm

1

9 Nm

2

10 Nm

10 Nm

6

2

8

9

7

20 Nm → + 115 ± 15

50 Nm

4

Removal steps

1. A/C suction hose clump

2. Power steering pressure hose

clamp

A 3. Engine-ECU assembly

B 4. Drive belt

25 Nm

5

3

5. Stud bolt

CB 6. Crankshaft pulley

7. Timing belt cover

DA 8. Timing belt

9. Timing belt tensioner pulley

Page 61

ENGINE <F9Q1> – Timing Belt

REMOVAL SERVICE POINTS

A ENGINE-ECU ASSEMBLY REMOVAL

Remove the engine

and hold it in the location where the removal of drive belt

cannot be hindered.

-ECU assembly with the harness attached

11C-19

Belt’s automatic

pulley tensioner

Timing belt

cover

MD998747

Timing mark

Window

Drive belt

B DRIVE BELT REMOVAL

1. Loosen the belt’s automatic pulley tensioner mounting bolt.

2. Hook 16 mm wrench to the protrusion of the belt’s automatic

pulley tensioner and turn the belt’s automatic pulley

tensioner clockwise to remove the drive belt.

Caution

Do not use the removed drive belt again. Always make

sure to replace the used drive belt with a new one.

C CRANKSHAFT PULLEY REMOVAL

1. Turn the crankshaft clockwise to align the timing mark

of the camshaft sprocket with the center of the window

of the timing belt cover.

Caution

The crankshaft must always be turned clockwise.

2. Use the special tool to hold the crankshaft pulley, loosen

the crankshaft pulley mounting bolt, and remove the

crankshaft pulley.

Caution

1. This drive belt will get damaged. Do not use the

engine’s drive belt.

2. Never use a damaged drive belt.

3. When the crankshaft pulley mounting bolt is loosened,

be careful not to miss the timing mark while turning

the crankshaft pulley.

Timing belt tensioner

pulley mounting nut

D TIMING BELT REMOVAL

Loosen the timing belt tensioner pulley mounting nut to remove

the timing belt.

Caution

Do not use the removed timing belt again. Always replace

the used timing belt with a new one.

Page 62

11C-20

ENGINE <F9Q1> – Timing Belt

Crankshaft groove

Timing mark

Timing belt

cover

Ribs

Timing mark

Window

INSTALLATION SERVICE POINTS

A TIMING BELT INSTALLATION

1. Turn the crankshaft clockwise to align the crankshaft

groove with the center of the two ribs of the crankshaft

closure cover. Furthermore, confirm that the timing mark

of the crankshaft sprocket is a tooth off to the left of the

perpendicular shaft in the engine.

2. Confirm that the timing mark of the camshaft sprocket

aligns with the center of the window of the timing belt

cover.

3. Fit the timing belt so that the lines on the belt are aligned

with the marks on the crankshaft and camshaft sprockets.

Bolt

Bolt

MB991668

(Microphone)

15

15

4. Place the bolt in the timing belt tensioner pulley to tighten

the bolt so that the timing belt tension becomes the

standard value.

Use the MUT-II to measure the timing belt tension.

Standard value: 90 ± 15 Hz

THE MEASUREMENT METHOD OF TIMING BELT

TENSION

(1) Connect the special tool (MB991668) to the MUT-II.

(2) Connect the MUT-II to the diagnosis connector.

(3) Turn the ignition switch to the on position to select

“Belt tension measurement” in the menu.

(4) Place the microphone 10 to 20 mm behind the belt

located in the center between the camshaft sprocket

and the crankshaft sprocket and hole it perpendicular

to the belt (approximate inclination of ± 15° or less).

Page 63

MB991614

MD998747

Drive belt

ENGINE <F9Q1> – Timing Belt

(5) Pluck the center position of the belt between the

camshaft sprocket and the crankshaft sprocket to

measure the vibration frequency of the belt.

B CRANKSHAFT PULLEY INSTALLATION

1. Use the special tool to hold the crankshaft pulley as shown

in the removal procedures.

2. Tighten the crankshaft pulley mounting bolt to 20 Nm.

3. Place the special tool in a wrench to tighten the crankshaft

pulley mounting bolt to 115

11C-21

°±15°.

Page 64

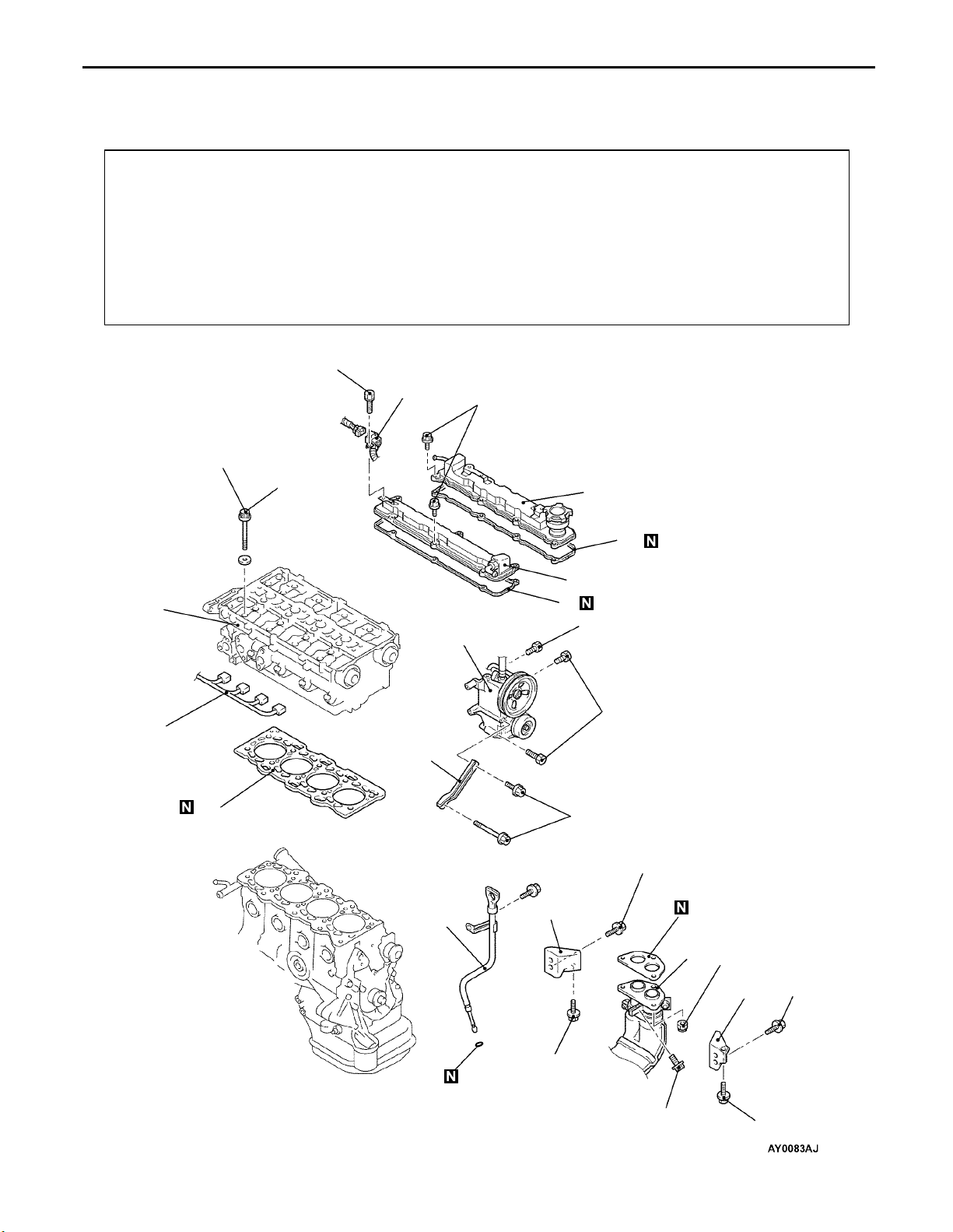

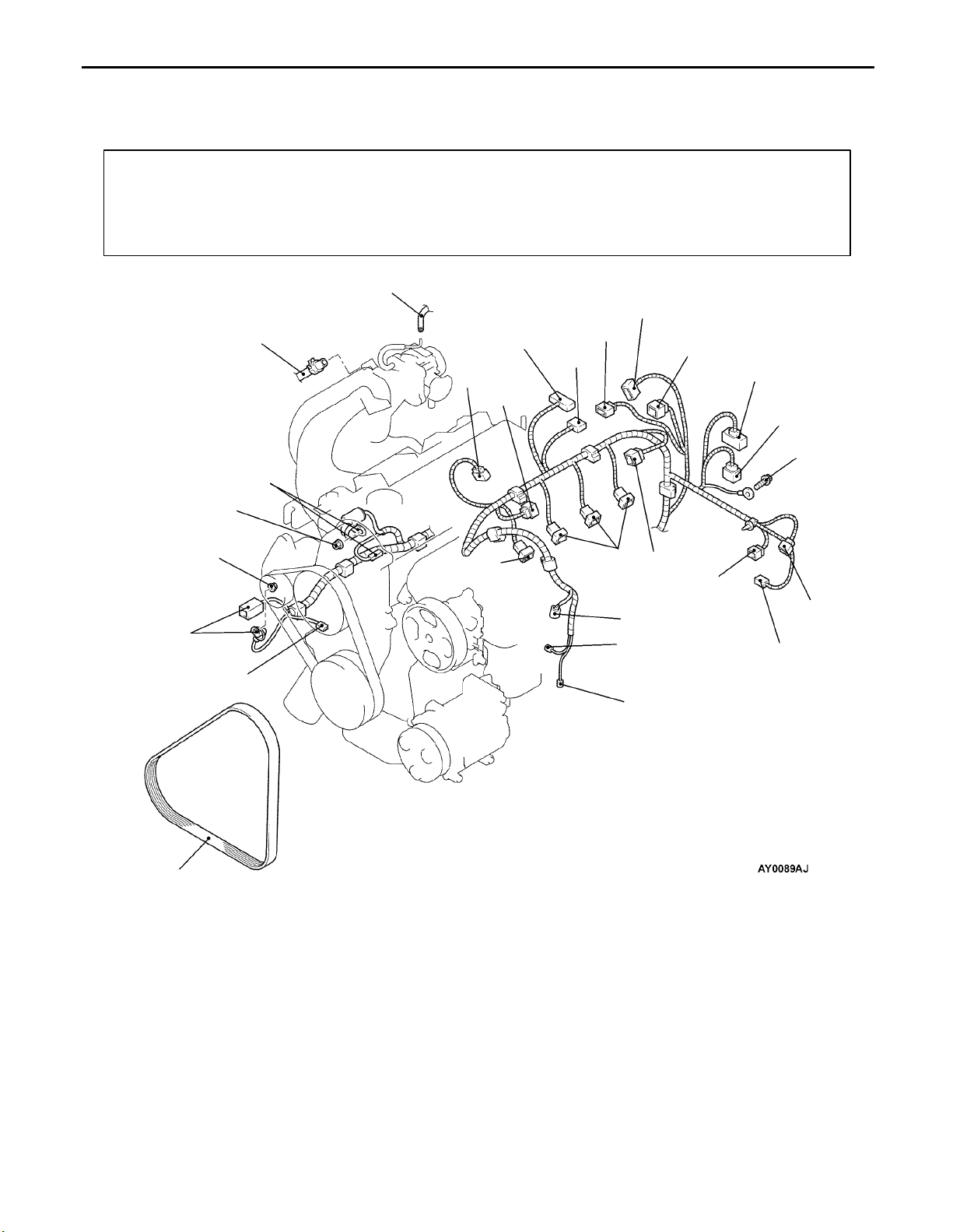

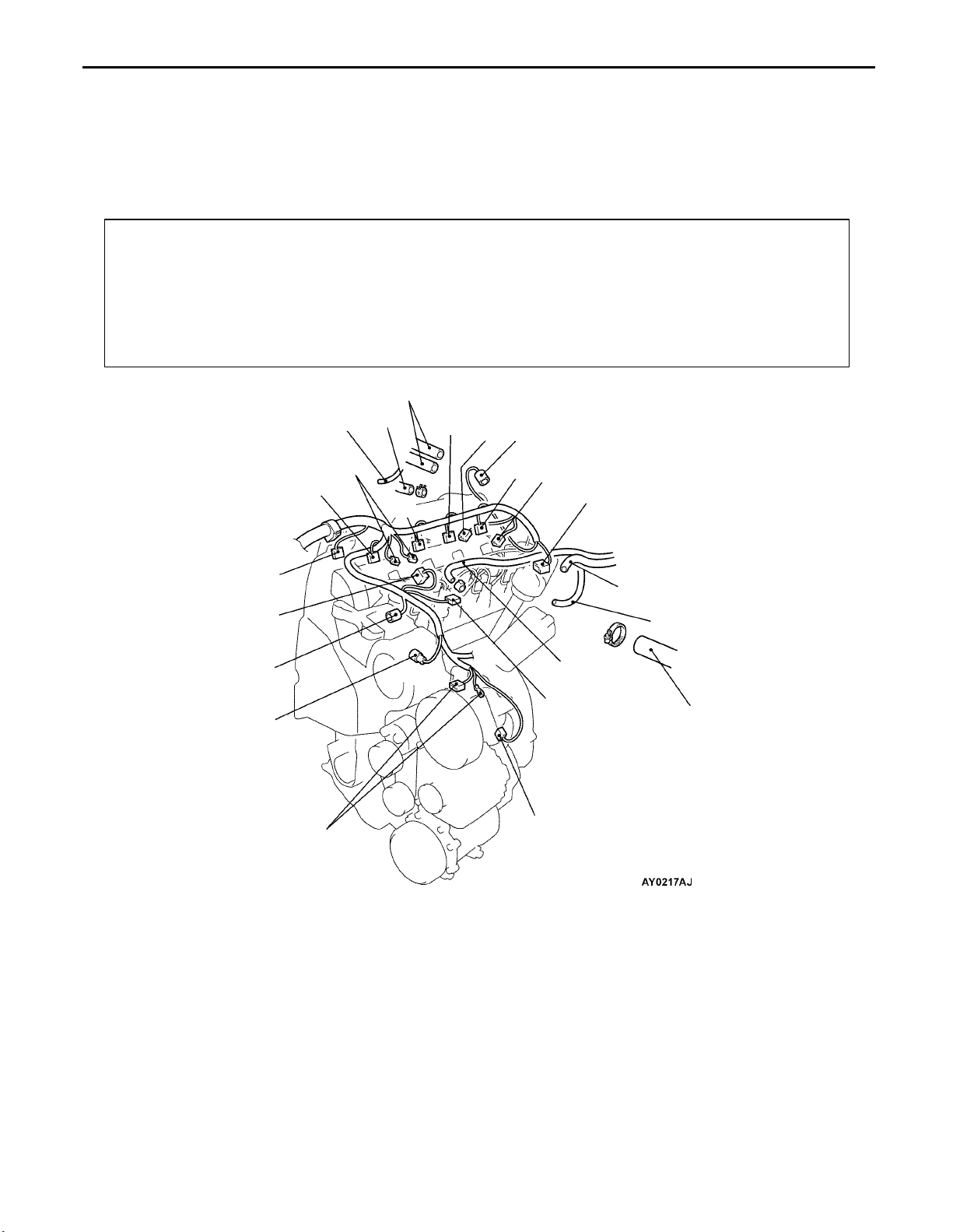

11C-22

ENGINE <F9Q1> – Engine Assembly

ENGINE ASSEMBLY

REMOVAL AND INSTALLATION

Caution

Mounting locations marked by * should be provisionally tightened, and then fully tightened when

the body is supporting the full weight of the engine.

Pre-removal and Post-installation Operation

Hood Removal and Installation

Under Cover Removal and Installation

Engine Coolant Draining and Supplying

(Refer to GROUP 14 – On-vehicle Service.)

Air Cleaner Removal and Installation

(Refer to GROUP 15.)

Inter Cooler and Inter Cooler Hose Removal and

Installation (Refer to GROUP 15.)

15

13

12

5

Front Exhaust Pipe Removal and Installation

(Refer to GROUP 15.)

Drive Belt Removal and Installation

(Refer to P.11C-8.)

Fuel Line Air Bleeding <After Installation Only>

(Refer to GROUP 13C – On-vehicle Service.)

6

8

11

6

5

5

5

6

7

1

16

2

3

17

4

10

9

12

14

Removal steps

1. Camshaft position sensor connector

2. Fuel pressure sensor connector

3. Fuel high pressure pump connector

4. Fuel temperature sensor connector

5. Fuel injector connector

6. Glow plug connector

7. Water temperature sensor

connector

8. EGR valve connector

9. A/C compressor connector

10. Alternator connector

11. Oil pressure switch connector

12. Vacuum hose connection

13. Brake booster vacuum hose

connection

14. Water hose connection

15. Heater hose connection

A 16. Fuel return hose connection

A 17. Fuel supply hose connection

Page 65

60 Nm

19

18

10 Nm