Mitsubishi PUH-P25_140(VY)GAA, PU-P35_140(VY)GAA Service Manual

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

SPLIT -TYPE, AIR CONDITIONERS

SERVICE MANUAL

R407C

Outdoor unit

[model names]

PUH-P25VGAA

PUH-P35VGAA PU-P35VGAA

PUH-P35YGAA PU-P35YGAA

PUH-P50VGAA PU-P50VGAA

PUH-P50YGAA PU-P50YGAA

PUH-P60VGAA PU-P60VGAA

[Service Ref.]

Service Ref. is on page 2.

August 2005

No.OC336

• This manual describes only

service data of the outdoor

units.

PUH-P60YGAA PU-P60YGAA

PUH-P71VGAA PU-P71VGAA

PUH-P71YGAA PU-P71YGAA

PUH-P100VGAA PU-P100VGAA

PUH-P100YGAA PU-P100YGAA

PUH-P125YGAA PU-P125YGAA

PUH-P140YGAA PU-P140YGAA

CONTENTS

1. REFERENCE MANUAL··································3

2. SAFETY PRECAUTION ··································4

3. PART NAMES AND FUNCTIONS··················6

4. SPECIFICATIONS ···········································7

5. DATA ·····························································11

6. OUTLINES AND DIMENSIONS····················18

7. WIRING DIAGRAM·······································22

8. WIRING SPECIFICATIONS ··························24

9.

REFRIGERANT SYSTEM DIAGRAM

10. TROUBLESHOOTING··································30

11. FUNCTION SETTING ···································65

12. DISASSEMBLY PROCEDURE·····················71

13. PARTS LIST··················································75

··············28

[Service Ref.]

PUH-P25VGAA.UK

PUH-P35VGAA.UK PU-P35VGAA.UK

PUH-P35YGAA.UK PU-P35YGAA.UK

PUH-P50VGAA.UK PU-P50VGAA.UK

PUH-P50YGAA.UK PU-P50YGAA.UK

PUH-P60VGAA.UK PU-P60VGAA.UK

PUH-P60YGAA.UK PU-P60YGAA.UK

PUH-P71VGAA.UK PU-P71VGAA.UK

PUH-P71YGAA.UK PU-P71YGAA.UK

PUH-P100VGAA.UK PU-P100VGAA.UK

PUH-P100YGAA.UK PU-P100YGAA.UK

PUH-P125YGAA.UK PU-P125YGAA.UK

PUH-P140YGAA.UK PU-P140YGAA.UK

2

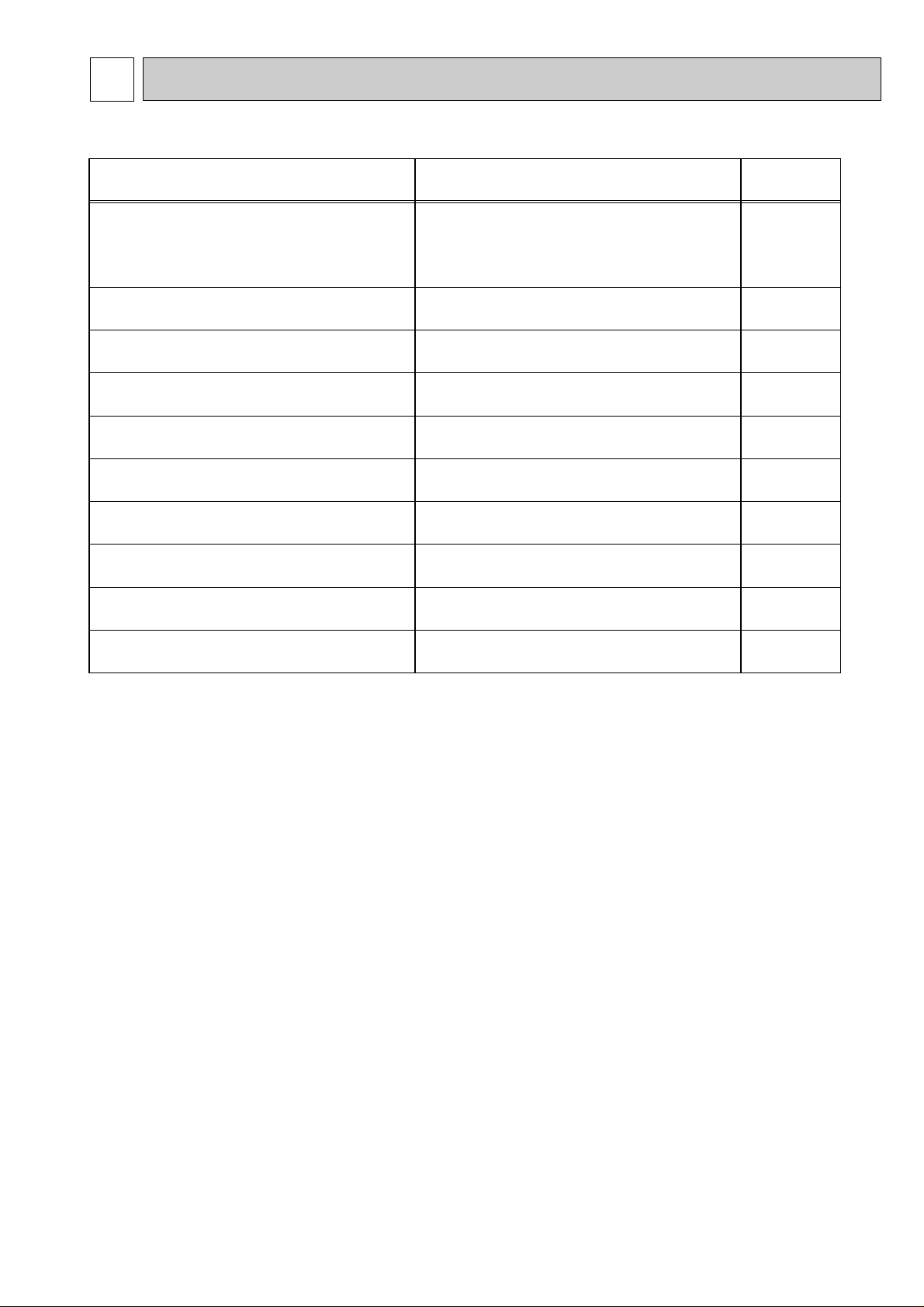

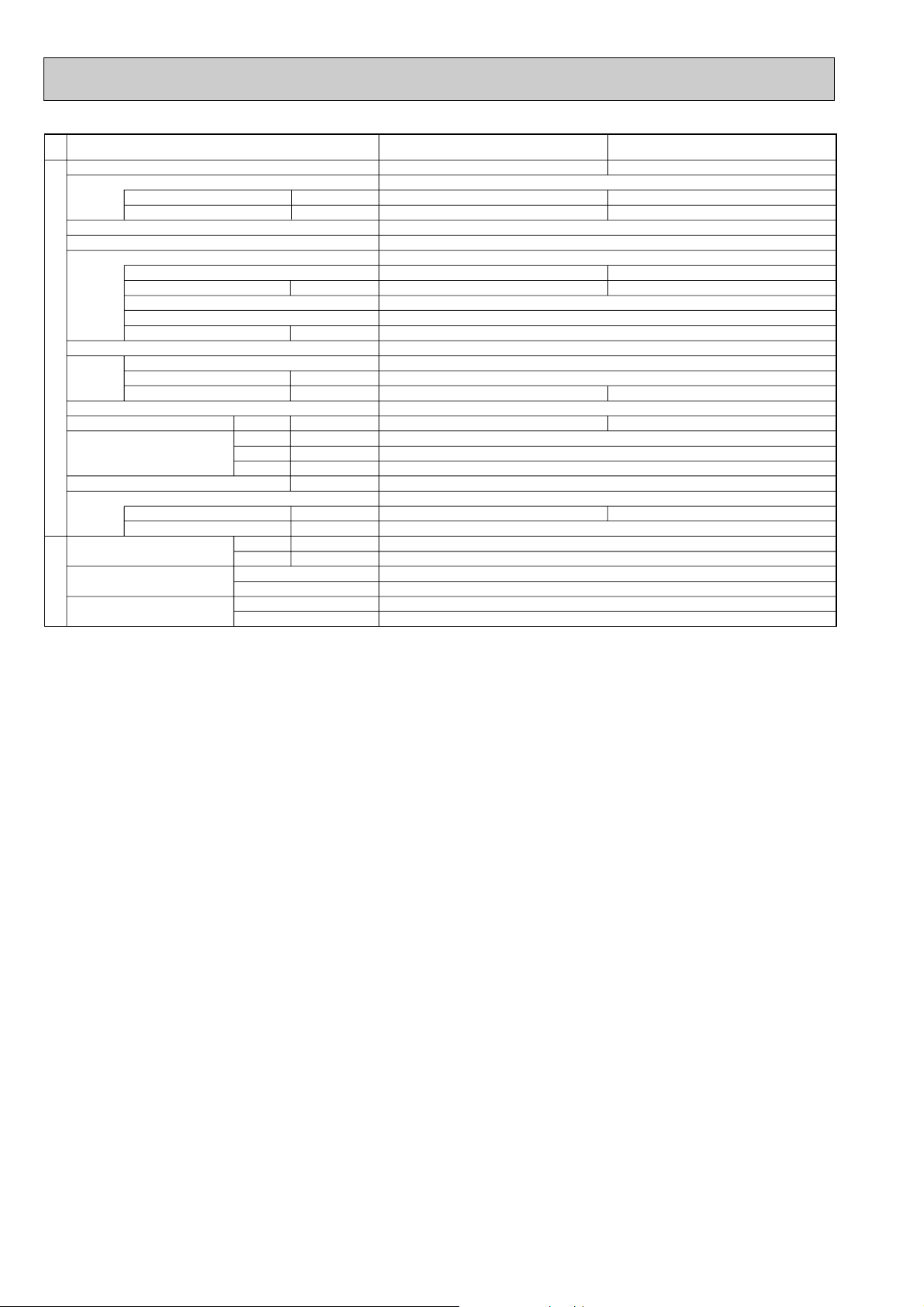

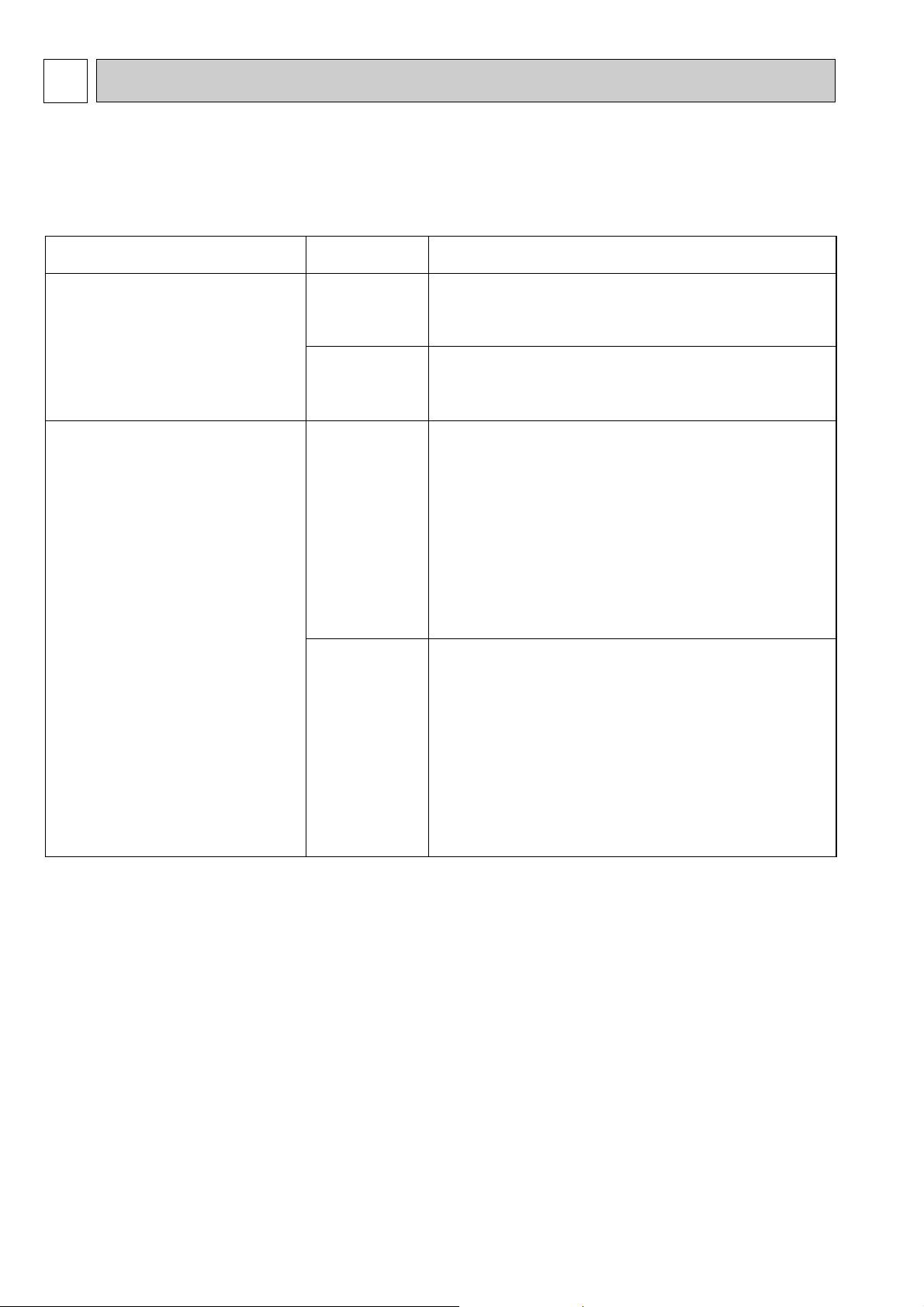

1-1. INDOOR UNIT'S SERVICE MANUAL

Model name Service Ref. Service

Manual No.

PLA-RP35/50/60/71AA PLA-RP35/50/60/71AA.UK OC335

PLA-RP100/125/140AA PLA-RP100/125/140AA.UK

PLH-P35/50/60/71AAH PLH-P35/50/60/71AAH.UK

PLH-P100/125/140AAH PLH-P100/125/140AAH.UK

PMH-P25/35/50BA PMH-P25/35/50BA OC333

PCA-RP50/60/71/100/125/140GA PCA-RP50/60/71/100/125/140GA OC328

PCH-P50/60/71/100/125/140GAH PCH-P50/60/71/100/125/140GAH

PCA-RP71/125HA PCA-RP71/125HA OC329

PKA-RP35/50GAL PKA-RP35/50GAL OC330

PKH-P35/50GALH PKH-P35/50GALH

PKA-RP60/71/100FAL PKA-RP60/71/100FAL OC331

PKH-P60/71/100FALH PKH-P60/71/100FALH

PSA-RP71/100/125/140GA PSA-RP71/100/125/140GA OC332

PSH-P71/100/125/140GAH PSH-P71/100/125/140GAH

PEAD-RP35/50/60/71EA PEAD-RP35/50/60/71EA.UK PEAD-RP100/125/140EA PEAD-RP100/125/140EA.UK

PEHD-P35/50/60/71EAH PEHD-P35/50/60/71EAH.UK PEHD-P100/125/140EAH PEHD-P100/125/140EAH.UK

PEAD-RP60/71/100GA PEAD-RP60/71/100GA.UK -

1-2. TECHNICAL DATA BOOK

1

REFERENCE MANUAL

Manual No.OCS02

3

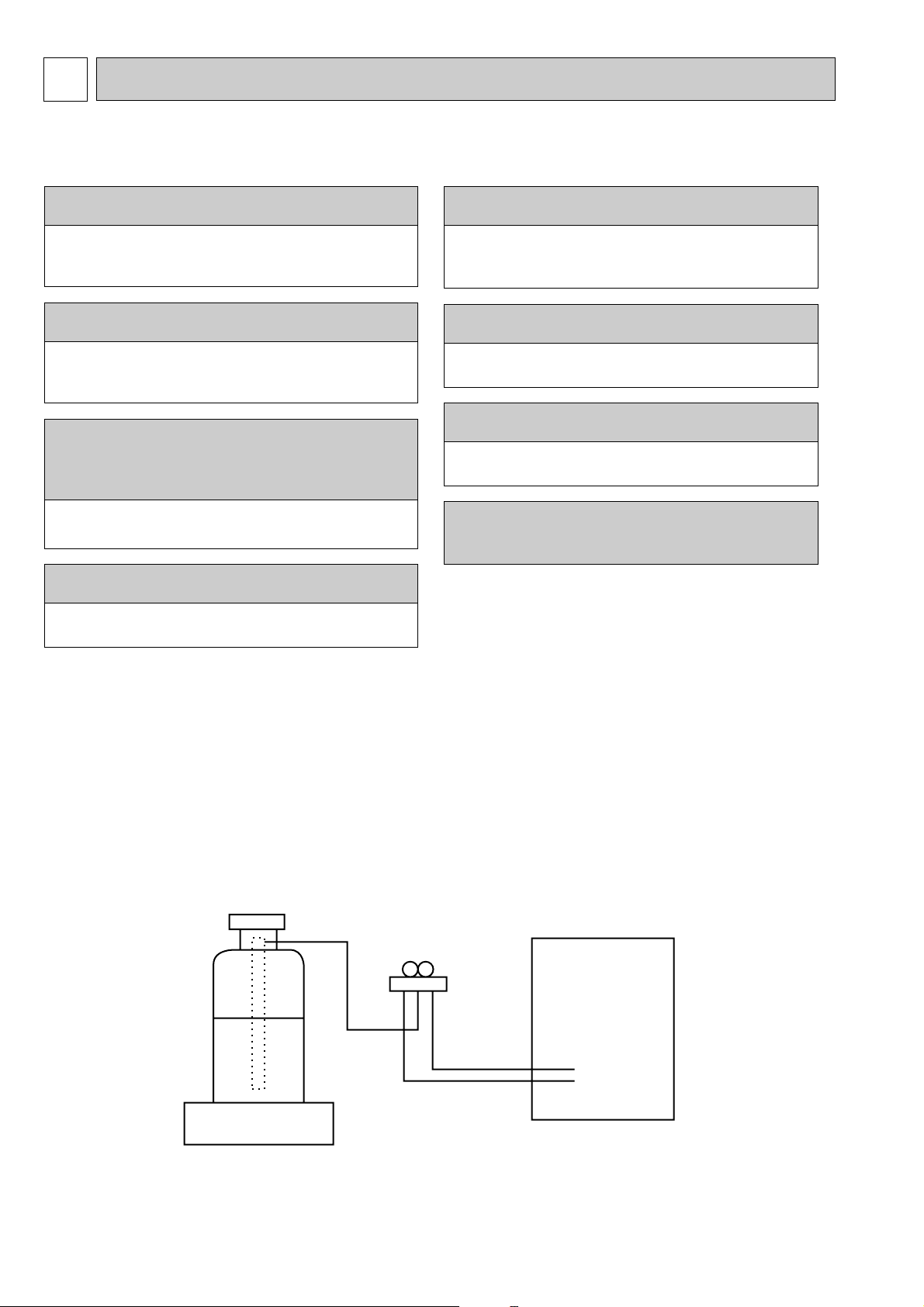

2

Do not use the existing refrigerant piping.

The old refrigerant and lubricant in the existing piping

contains a large amount of chlorine which may cause the

lubricant deterioration of the new unit.

Use “low residual oil piping”

If there is a large amount of residual oil (hydraulic oil, etc.)

inside the piping and joints, deterioration of the lubricant

will result.

Use ESTER , ETHER or HAB as the lubricant to

coat flares and flange connection parts.

If large amount of mineral oil enter, that can cause

deterioration of refrigerant oil etc.

Use liquid refrigerant to charge the system.

If gas refrigerant is used to seal the system, the composition

of the refrigerant in the cylinder will change and performance

may drop.

Do not use a refrigerant other than R407C.

If another refrigerant (R22, etc.) is used, the chlorine in the

refrigerant may cause the lubricant deterioration.

Use a vacuum pump with a reverse flow check valve.

The vacuum pump oil may flow back into the refrigerant

cycle and cause the lubricant deterioration.

Store the piping to be used during installation

indoors with keep both ends sealed until just

before brazing.

(Store elbows and other joints in a plastic bag.)

If dust, dirt, or water enters the refrigerant cycle,

deterioration of the oil and compressor trouble may result.

Ventilate the room if refrigerant leaks during

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

Gravimeter

Unit

SAFETY PRECAUTION

CAUTIONS RELATED TO NEW REFRIGERANT

Cautions for units utilising refrigerant R407C

[1] Cautions for service

·After recovering the all refrigerant in the unit, proceed to working.

·Do not release refrigerant in the air.

·After completing the repair service, recharge the cycle with the specified amount of

liquid refrigerant.

[2] Refrigerant recharging

(1) Refrigerant recharging process

1Direct charging from the cylinder.

·R407C cylinder are available on the market has a syphon pipe.

·Leave the syphon pipe cylinder standing and recharge it.

(By liquid refrigerant)

(2) Recharge in refrigerant leakage case

·After recovering the all refrigerant in the unit, proceed to working.

·Do not release the refrigerant in the air.

·After completing the repair service, recharge the cycle with the specified amount of

liquid refrigerant.

4

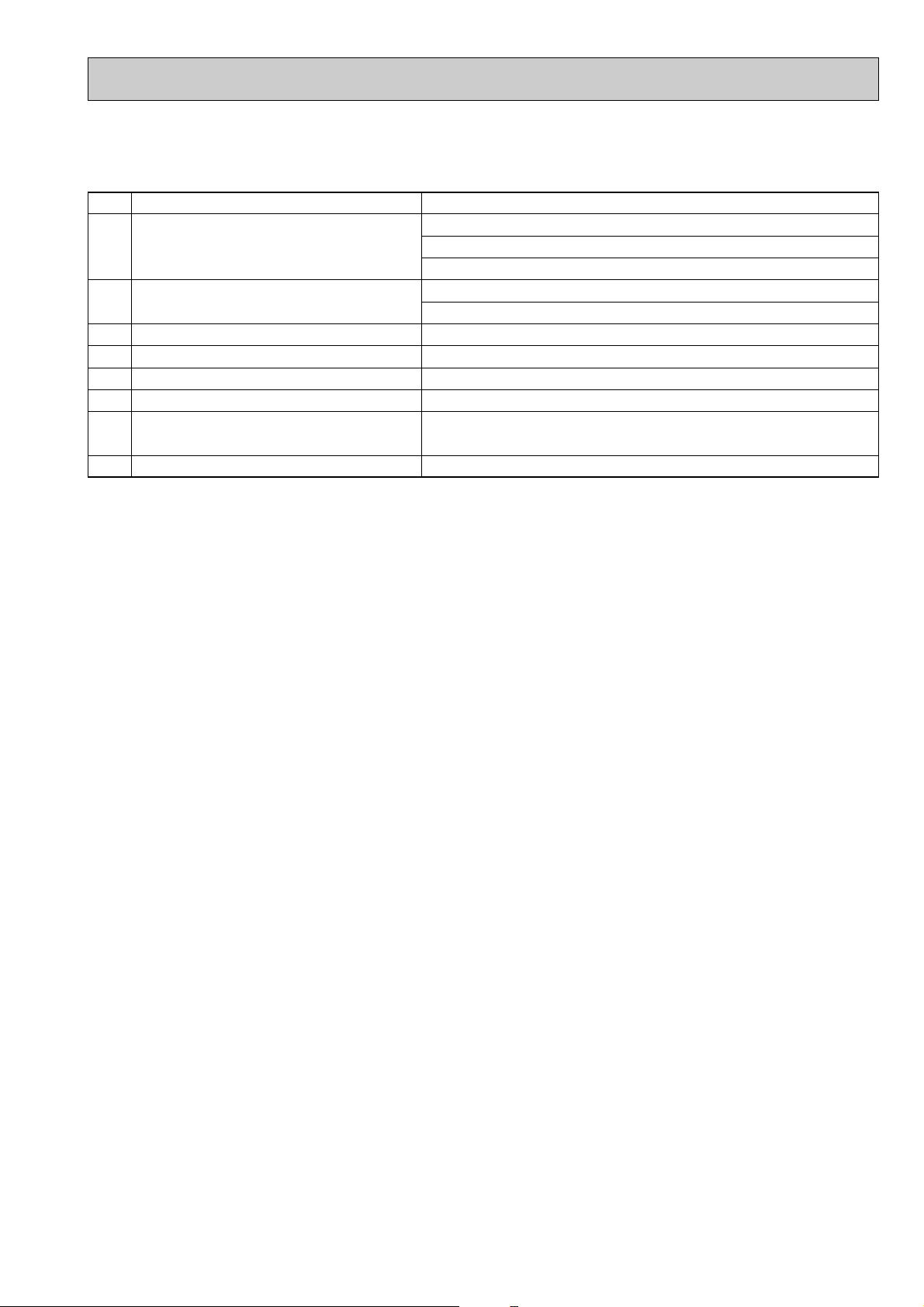

[3] Service tools

Use the below service tools as exclusive tools for R407C refrigerant.

No. Tool name Specifications

1 Gauge manifold ·Only for R407C.

·Use the existing fitting SPECIFICATIONS. (UNF7/16)

·Use high-tension side pressure of 3.43MPa·G or over.

2 Charge hose ·Only for R407C.

·Use pressure performance of 5.10MPa·G or over.

3 Electronic scale

4 Gas leak detector ·Use the detector for R134a or R407C.

5 Adapter for reverse flow check. ·Attach on vacuum pump.

6 Refrigerant charge base.

7 Refrigerant cylinder. ·For R407C ·Top of cylinder (Brown)

·Cylinder with syphon

8 Refrigerant recovery equipment.

5

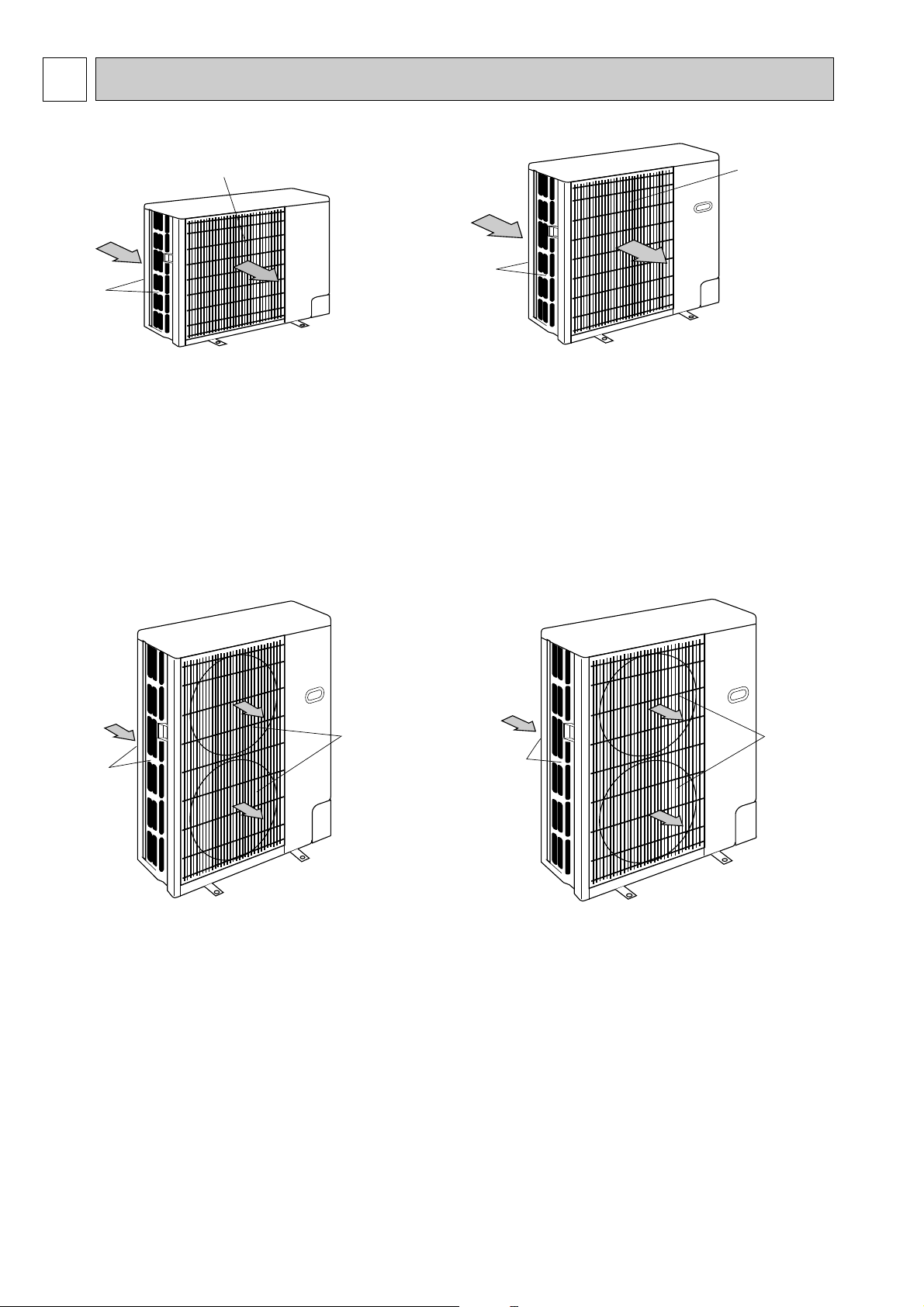

3 PART NAMES AND FUNCTIONS

Air intake

Air outlet

(Expels warm air during cooling)

Air intake

Air outlet

Air intake

Air outlet

Air intake

Air outlet

PUH-P25VGAA.UK

PUH-P35VGAA.UK

PUH-P35YGAA.UK

PU-P35VGAA.UK

PU-P35YGAA.UK

PUH-P50VGAA.UK PUH-P50YGAA.UK

PUH-P60VGAA.UK PUH-P60YGAA.UK

PUH-P71VGAA.UK PUH-P71YGAA.UK

PU-P50VGAA.UK PU-P50YGAA.UK

PU-P60VGAA.UK PU-P60YGAA.UK

PU-P71VGAA.UK PU-P71YGAA.UK

PUH-P100VGAA.UK

PUH-P100YGAA.UK

PU-P100VGAA.UK

PU-P100YGAA.UK

CHARGELESS SYSTEM

PRE-CHARGED REFRIGERANT IS SUPPLIED FOR PIPING LENGTH AT SHIPMENT.

PU/PUH-P25, P35, P50, P60 : max 20m

PU/PUH-P71, P100, P125, P140 : max 30m

The refrigerant circuit with LEV(Linear Expansion Valve) and a large accumulator always control the optimal refrigerant

level regardless of the length (20/30m max. and 5m min.) of piping. The additional refrigerant charging work during

installation often causes problems. Heretofore it is completely eliminated. This unique system improves the quality

and reliability of the work done.It also helps to speed up the installation time.

PUH-P125YGAA.UK

PUH-P140YGAA.UK

PU-P125YGAA.UK

PU-P140YGAA.UK

6

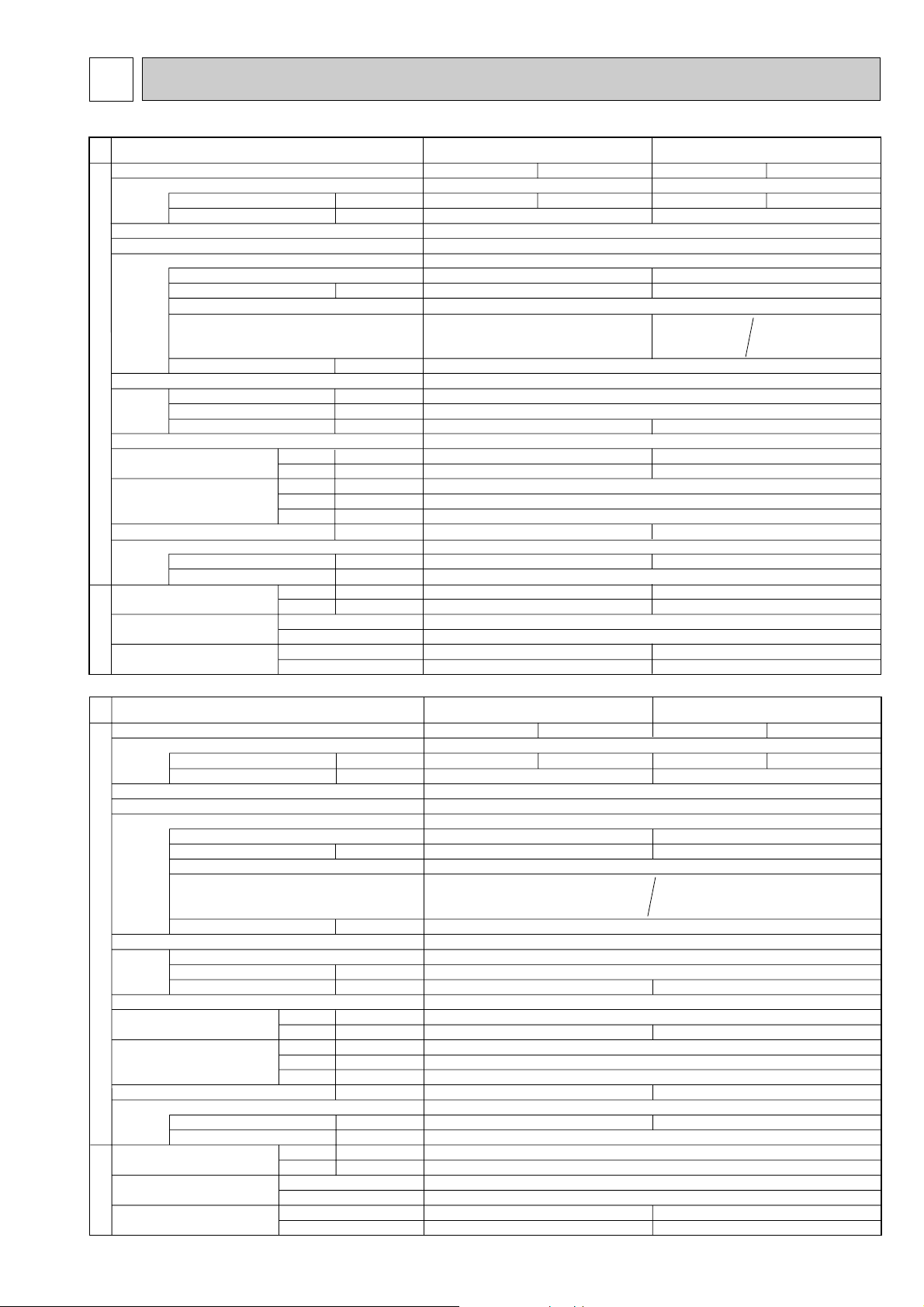

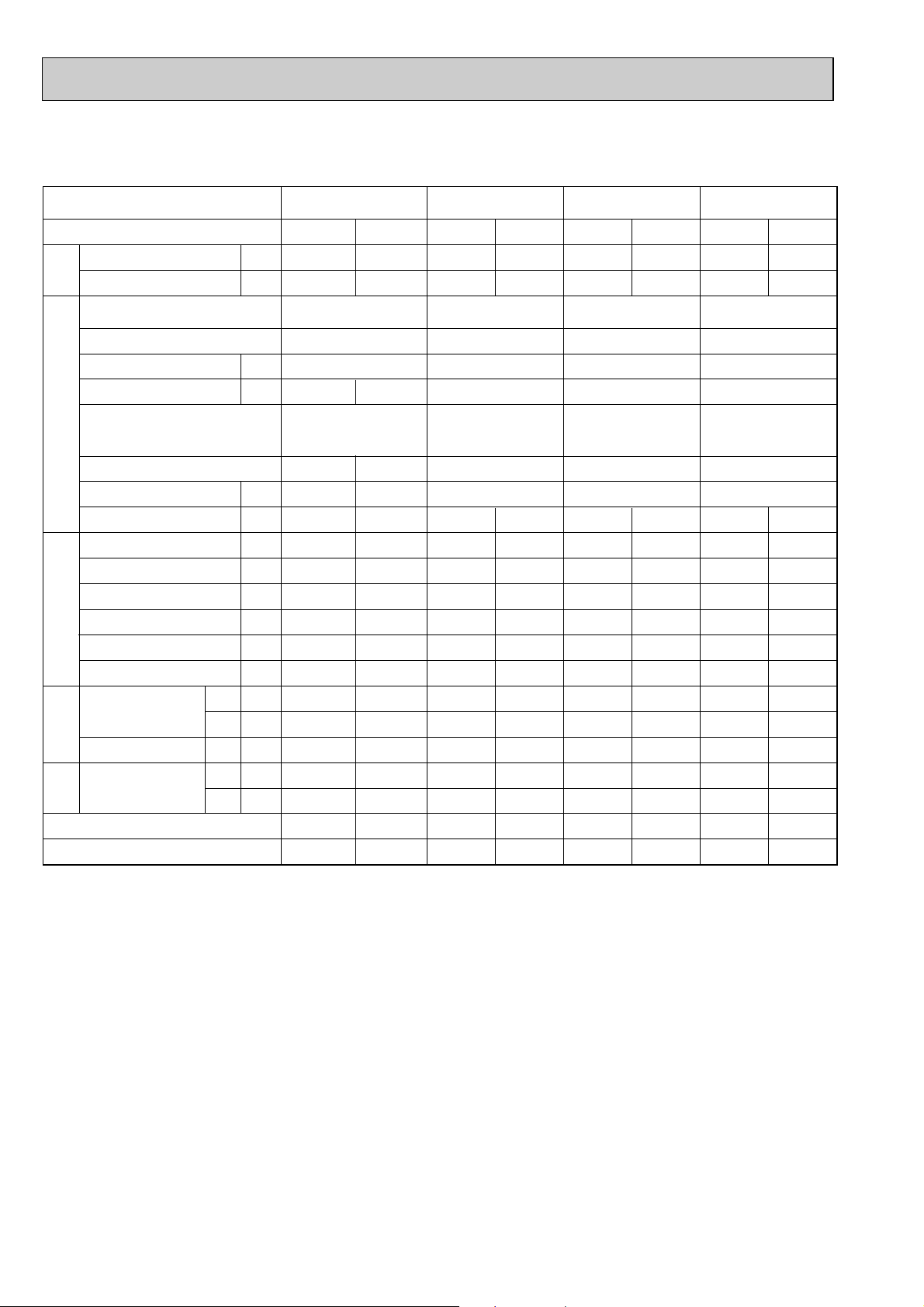

4 SPECIFICATIONS

A

A

kW

W

kW

K

/min(CFM

)

dB

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

Mode

Power supply (phase, cycle, voltage)

Running current

Max current

External finish

Refrigerant control

Compressor

Model

Motor output

Starter type

Protection devices

Crankcase heater

Heat exchanger

Fan Fan(drive) o No.

Fan motor output

Airflow

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Charge

Oil (Model)

Pipe size O.D.

Connection method

Between the indoor &

outdoor unit

OUTDOOR UNIT

REFRIGERANT PIPING

Cooling

Heating

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

Service Ref.

PUH-P25VAA.UK

PUH-P35VGAA / YGAA.UK

Cooling

5.32

Single,50Hz,230V

7.23

RE189VHSMT

0.9

45(1,590)

46

48

50(110)

1.7(3.8)

6.35(1/4)

12.7(1/2)

Max. 30m

Max. 30m

Munsell 5Y 7/1

Linear Expansion Valve

Hermetic

Line start

30

Plate fin coil

Propeller (direct) o 1

0.07

Reverse cycle

900(35-7/16)

330+20(13+3/4)

650(25-5/8)

R407C

0.57(Ester)MEL56

Flared

Flared

Heating

4.89

Cooling

7.61 / 2.54

Single,50Hz,230V / 3-ph,50Hz,400V

10.67/5.4

RE277VHSMT/RE277YFKM

1.3

45(1,590)

47

49

54(119)

2.5(5.5)

9.52(3/8)

15.88(5/8)

Max. 40m

Max. 40m

Heating

7.85 / 2.62

Internal thermostat

HP switch

Discharge thermo

Thermal relay

HP switch

Discharge thermo

Internal thermostat

HP switch

Discharge thermo

A

A

kW

W

kW

K

/min(CFM

)

dB

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

Mode

Power supply (phase, cycle, voltage)

Running current

Max current

External finish

Refrigerant control

Compressor

Model

Motor output

Starter type

Protection devices

Crankcase heater

Heat exchanger

Fan Fan(drive) o No.

Fan motor output

Airflow

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Charge

Oil (Model)

Pipe size O.D.

Connection method

Between the indoor &

outdoor unit

OUTDOOR UNIT

REFRIGERANT PIPING

Cooling

Heating

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

Service Ref.

PUH-P50VGAA / YGAA.UK

PUH-P60VGAA / YGAA.UK

Cooling

10.97 / 3.98

15.35 /7.0

NE36VMJMT / NE36YEKMT

1.6

55(1,940)

49

74(163)

2.6(5.7)

Max. 40m

Max. 40m

Single, 50Hz, 230V / 3-ph, 50Hz,400V(4wires)

Munsell 5Y 7/1

Linear Expansion Valve

Hermetic

Line start

38

Plate fin coil

Propeller (direct) o 1

0.07

Reverse cycle

48

900(35-7/16)

330+20(13+3/4)

855(33-5/8)

R407C

1.2 (Ester)MEL56

9.52(3/8)

15.88(5/8)

Flared

Flared

Heating

11.30 / 3.95

Cooling

13.27 / 4.43

18.03 / 7.7

NE41VMJMT / NE41YEKMT

1.9

50(1,770)

50

79(174)

3.1(6.8)

Max. 50m

Max. 50m

Heating

12.84/ 4.29

Internal thermostat

HP switch

Discharge thermo

Thermal relay

HP switch

Discharge thermo

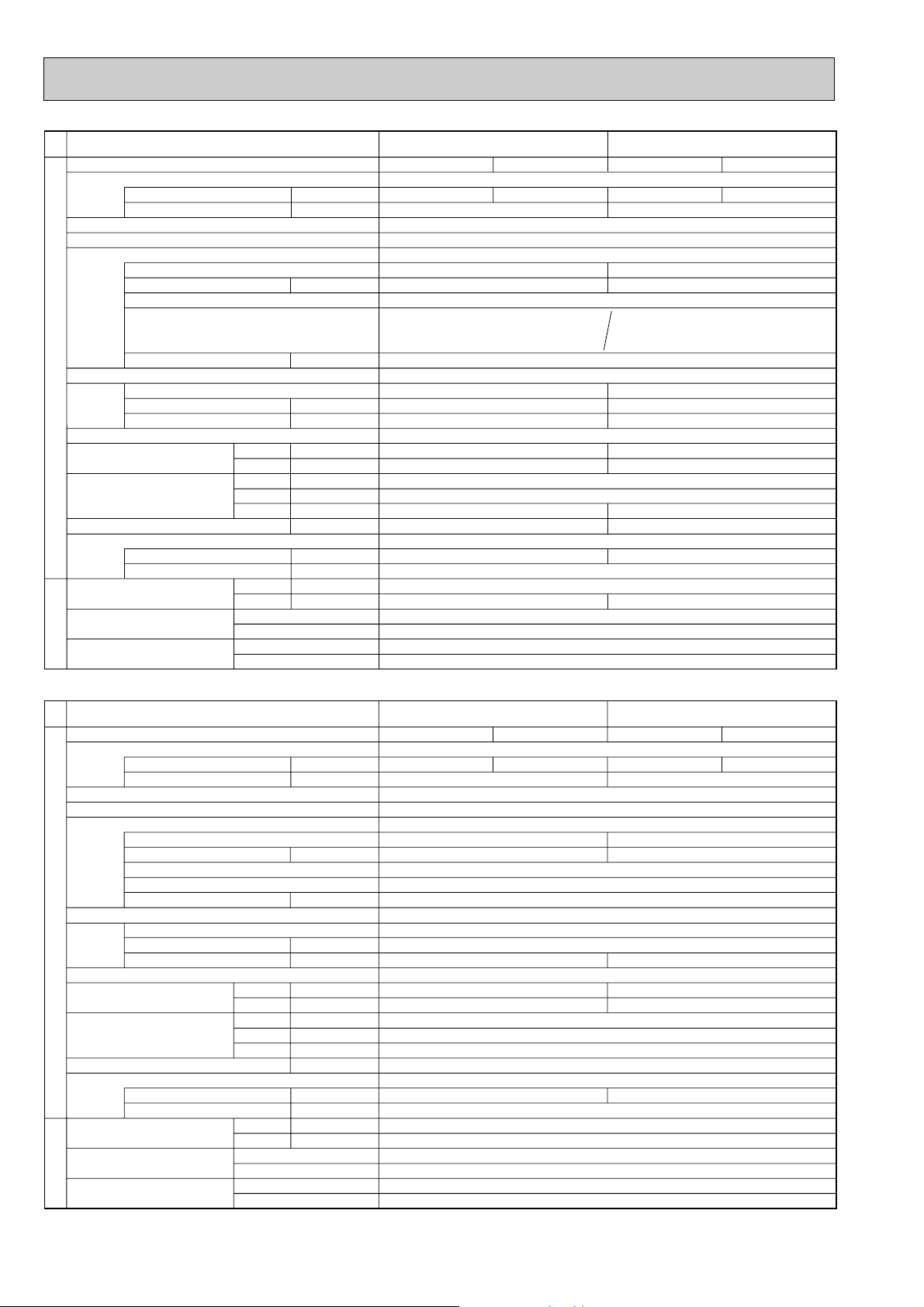

4-1. HEAT PUMP

7

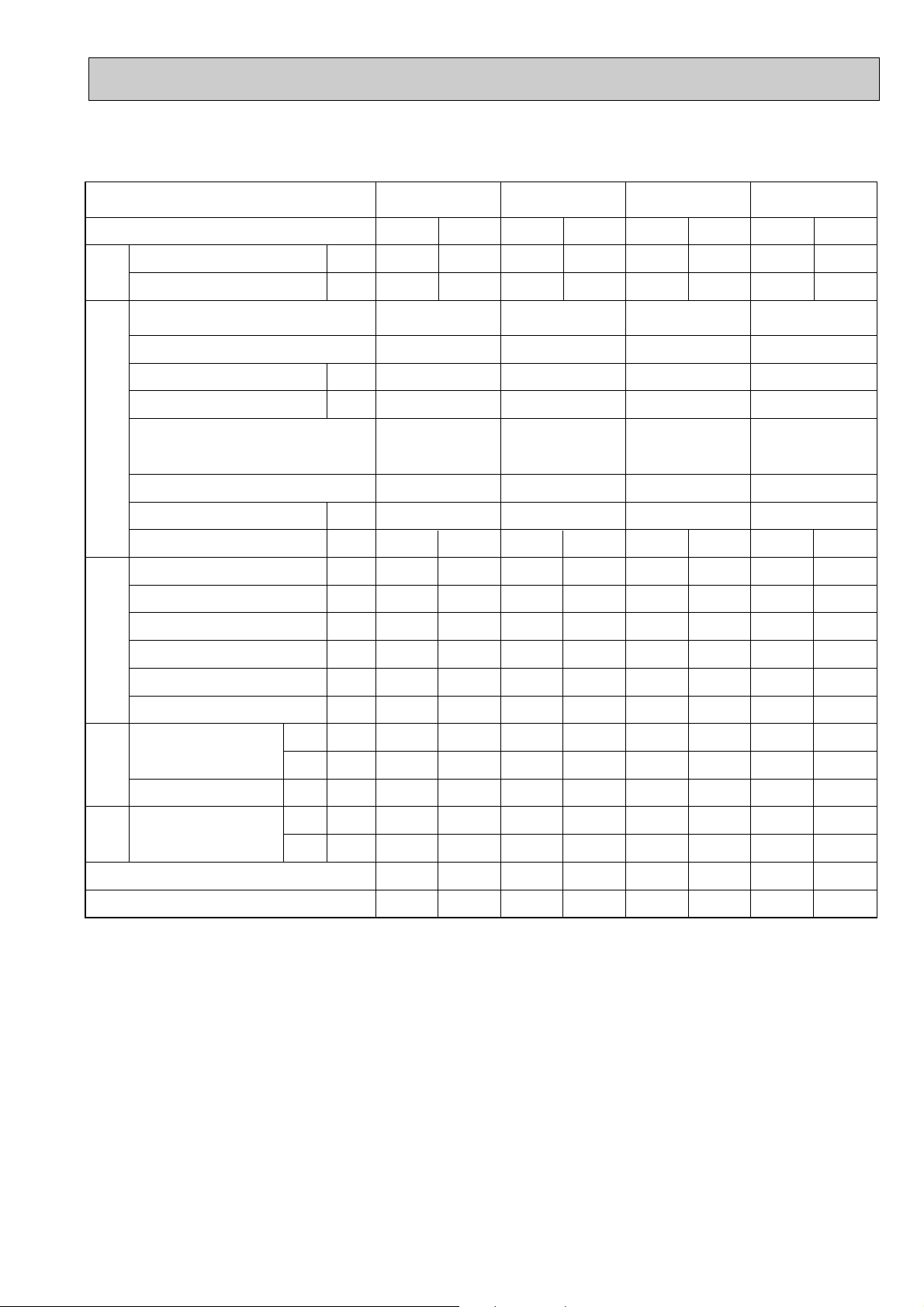

Service Ref.

Mode

Power supply (phase, cycle, voltage)

External finish

Refrigerant control

Compressor

Heat exchanger

OUTDOOR UNIT

Fan Fan(drive) o No.

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor &

outdoor unit

REFRIGERANT PIPING

Running current

Max current

Model

Motor output

Starter type

Protection devices

Crankcase heater

Fan motor output

Airflow

Charge

Oil (Model)

Indoor side

Outdoor side

Height difference

Piping length

Cooling

Heating

W

D

H

Liquid

Gas

kW

kW

K

/min(CFM

dB

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

mm(in.)

mm(in.)

PUH-P71VGAA / YGAA.UK

A

A

W

)

L

Cooling

15.66 / 5.23

NE52VNJMT / NE52YDKMT

Single, 50Hz, 230V / 3-ph, 50Hz, 400V(4wires)

22.66 / 10.8

Propeller (direct) o 1

0.07

50(1,770)

855(33-5/8)

79(174)

3.3(7.3)

15.88(5/8)

Heating

16.67 / 5.56

Munsell 5Y 7/1

Linear Expansion Valve

Hermetic

2.5

Line start

Internal thermostat

HP switch

Discharge thermo

Plate fin coil

Reverse cycle

49

51

900(35-7/16)

330+20(13+3/4)

R407C

1.3 (Ester)MEL56

9.52(3/8)

Flared

Flared

Max. 50m

Max. 50m

PUH-P100VGAA / YGAA.UK

Cooling

16.43/ 5.48

23.57 / 10.8

NE56VNJMT / NE56YDKMT

Thermal relay

HP switch

Discharge thermo

38

Propeller (direct) o 2

0.07+0.07

85(3,000)

1,260(49-5/8)

97(214)

4.0(8.8)

19.05(3/4)

Heating

17.34 / 5.79

2.7

51

53

Service Ref.

Mode

Power supply (phase, cycle, voltage)

External finish

Refrigerant control

Compressor

Heat exchanger

OUTDOOR UNIT

Fan Fan(drive) o No.

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor &

outdoor unit

REFRIGERANT PIPING

Running current

Max current

Model

Motor output

Starter type

Protection devices

Crankcase heater

Fan motor output

Airflow

Charge

Oil (Model)

Indoor side

Outdoor side

Height difference

Piping length

Cooling

Heating

W

D

H

Liquid

Gas

kW

kW

/min(CFM

K

dB(A)

dB(A)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

mm(in.)

mm(in.)

PUH-P125YGAA.UK

Cooling

A

A

W

)

L

7.52

18.0

BE82YADMT

95(3,360)

4.6(10.1)

Heating

3-ph, 50Hz, 400V(4wires)

8.06

Munsell 5Y 7/1

Linear Expansion Valve

Hermetic

3.5

Line start

Thermal relay, HP switch, Discharge thermo

38

Plate fin coil

Propeller (direct) o 2

0.07 +0.07

Reverse cycle

55

56

1,050(41-5/16)

330+20(13+3/4)

1,260(49-5/8)

125(276)

R407C

1.7 (Ester) MEL56

9.52(3/8)

19.05(3/4)

Flared

Flared

Max. 50m

Max. 50m

PUH-P140YGAA.UK

Cooling

8.92

20.4

BE96YADMT

4.2

100(3,530)

57

58

4.9(10.8)

Heating

9.45

8

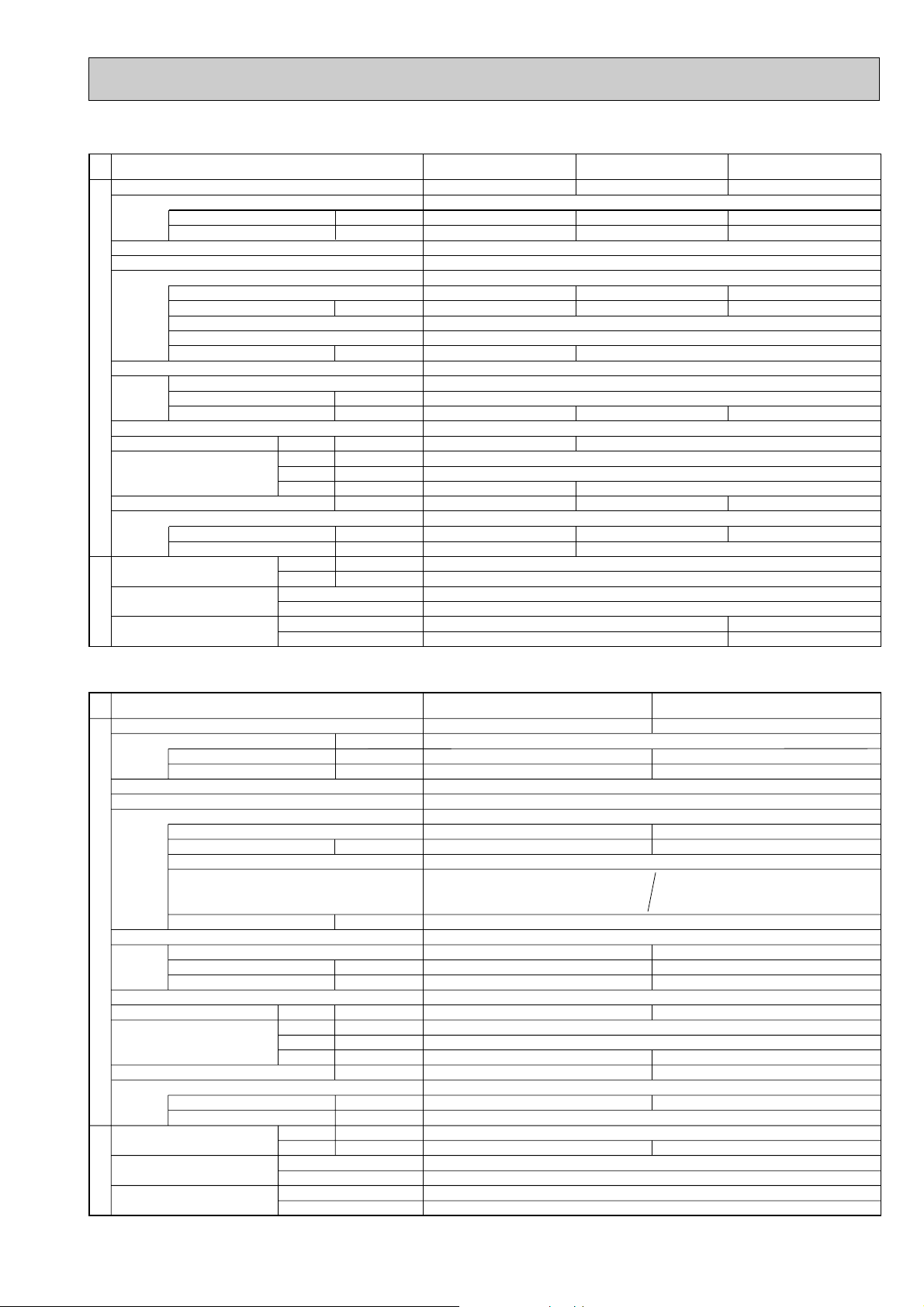

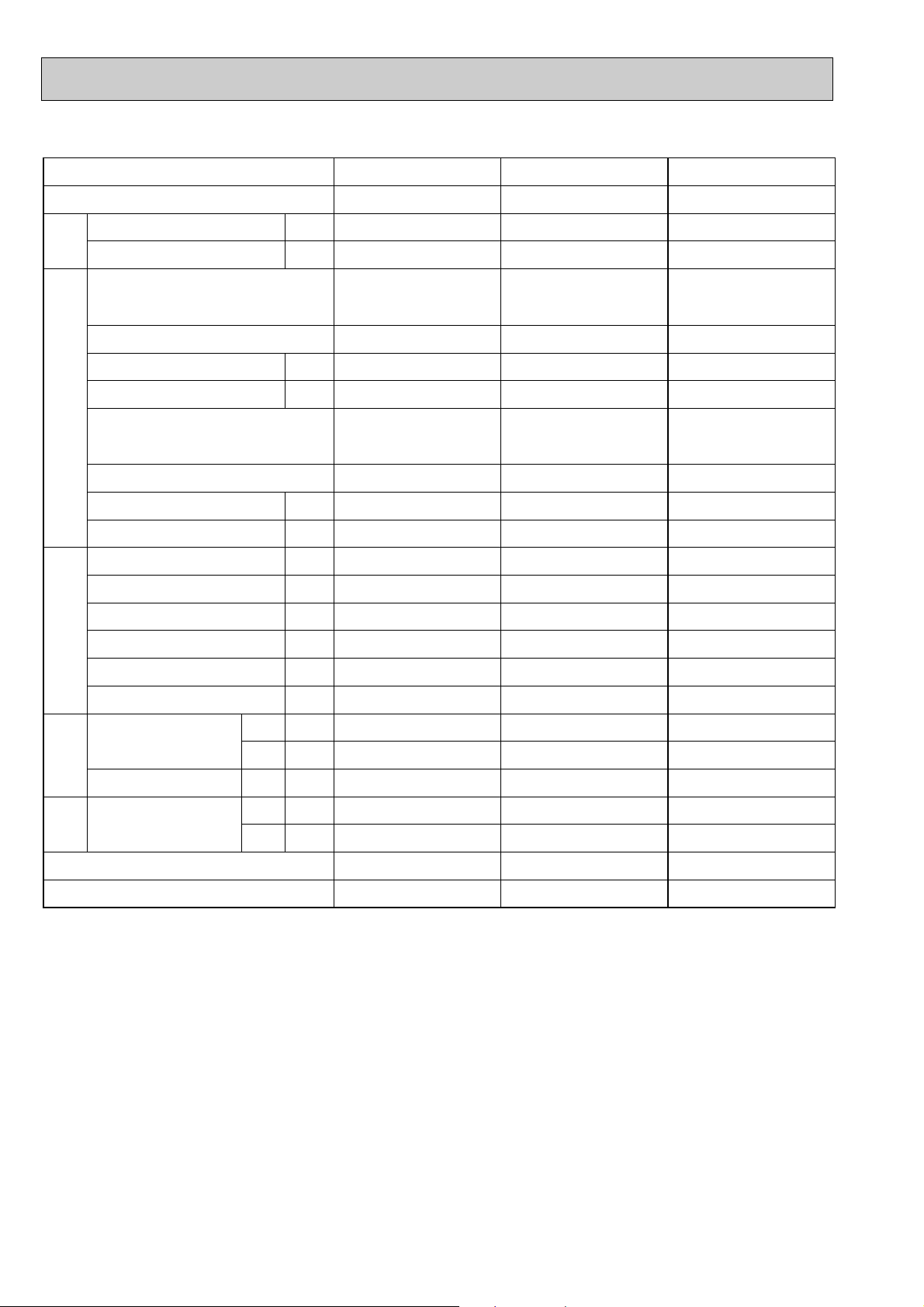

4-2. COOLING ONLY TYPE

A

A

kW

W

kW

K

/min(CFM

)

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

Mode

Power supply (phase, cycle, voltage)

Running current

Max. current

External finish

Refrigerant control

Compressor

Model

Motor output

Starter type

Protection devices

Crankcase heater

Heat exchanger

Fan Fan(drive) o No.

Fan motor output

Airflow

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Charge

Oil (Model)

Pipe size O.D.

Connection method

Between the indoor &

outdoor unit

OUTDOOR UNIT

REFRIGERANT PIPING

Cooling

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

Service Ref. PU-P71VGAA / YGAA.UK PU-P100VGAA / YGAA.UK

Cooling

15.66 / 5.23

22.66 / 10.8

NE52VNJMT / NE52YDKMT

2.5

Propeller (direct) o 1

0.07

50(1,770)

49

855(33-5/8)

79(174)

3.3(7.3)

15.88(5/8)

Single, 50Hz, 230V / 3-ph, 50Hz, 400V(4wires)

Munsell 5Y 7/1

Linear Expansion Valve

Hermetic

Line start

38

Plate fin coil

—

900(35-7/16)

330+20(13+3/4)

R407C

1.3 (Ester)MEL56

9.52(3/8)

Flared

Flared

Max. 50m

Max. 50m

Cooling

16.43/ 5.48

23.57 / 10.8

NE56VNJMT / NE56YDKMT

2.7

Propeller (direct) o 2

0.07+0.07

85(3,000)

51

1,260(49-5/8)

97(214)

4.0(8.8)

19.05(3/4)

Internal thermostat

HP switch

Discharge thermo

Thermal relay

HP switch

Discharge thermo

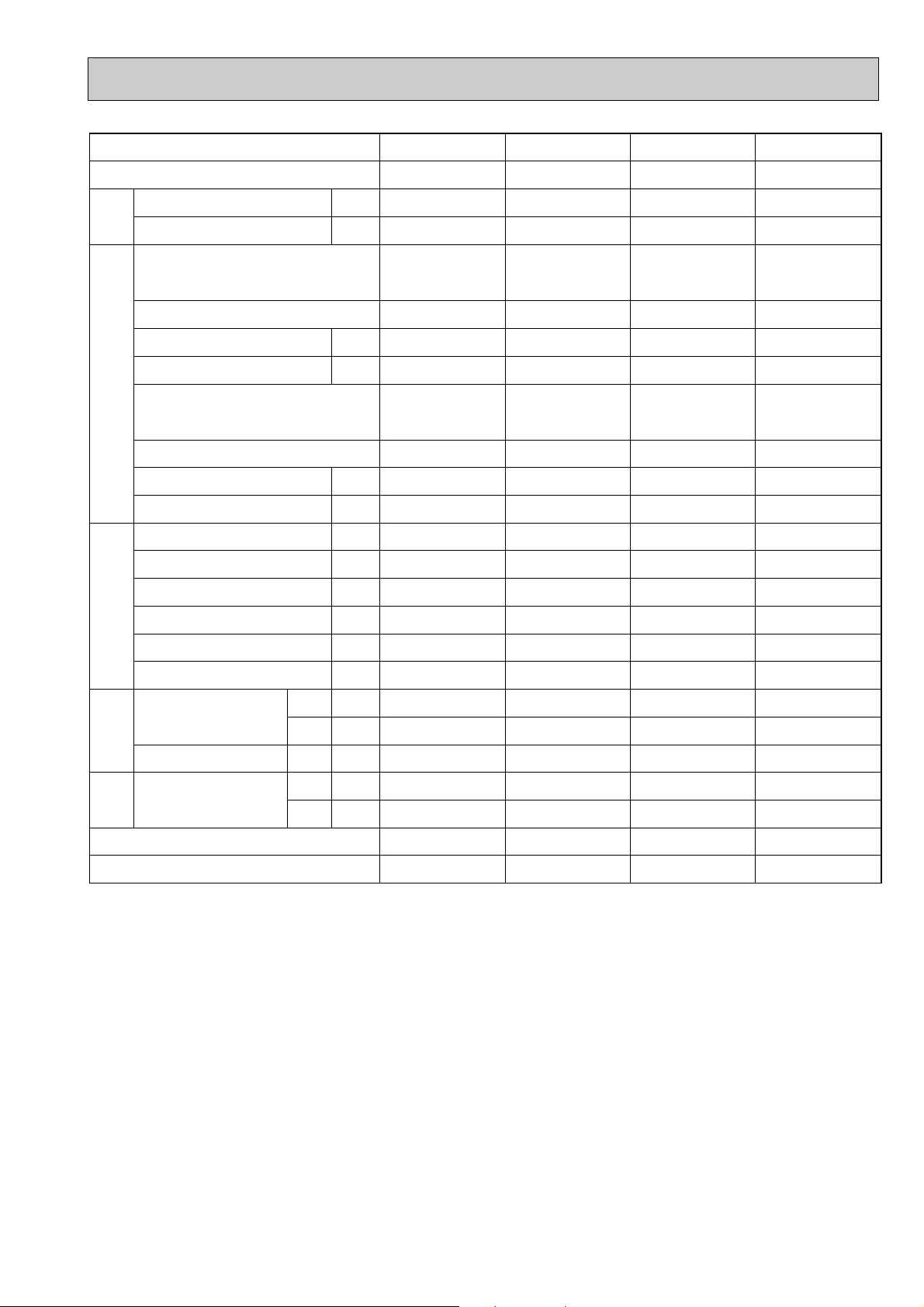

Service Ref.

Mode

Power supply (phase, cycle, voltage)

External finish

Refrigerant control

Compressor

OUTDOOR UNIT

Heat exchanger

Fan Fan(drive) o No.

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor &

REFRIGERANT PIPING

outdoor unit

Running current

Max. current

Model

Motor output

Starter type

Protection devices

Crankcase heater

Fan motor output

Airflow

Charge

Oil (Model)

/min(CFM

K

Cooling

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

mm(in.)

mm(in.)

A

A

kW

W

kW

dB

L

PU-P35VGAA / YGAA.UK

Cooling

7.61 / 2.54

10.67 / 5.4

RE277VHSMT/RE277YFKM

Internal thermostat, HP switch, Discharge thermo / Thermal relay,Discharge thermo,HP switch

)

45(1,590)

650(25-5/8)

0.57 (Ester)MEL56

Single, 50Hz, 230V / 3-ph, 50Hz, 400V(4wires)

1.3

30

47

54(119)

2.5(5.5)

PU-P50VGAA / YGAA.UK

Cooling

10.97 / 3.98

15.35 / 7.0

Munsell 5Y 7/1

Linear Expansion Valve

Hermetic

NE36VMJMT/NE36YEKMT

1.6

Line start

Plate fin coil

Propeller (direct) o 1

0.07

55(1,940)

—

900(35-7/16)

330+20(13+3/4)

74(163)

R407C

2.6(5.7)

9.52(3/8)

15.88(5/8)

Flared

Flared

Max. 40m

Max. 40m

PU-P60VGAA / YGAA.UK

Cooling

13.27 / 4.43

18.03 / 7.7

NE41VMJMT/NE41YEKMT

1.9

38

50(1,770)

48

855(33-5/8)

79(174)

3.1(6.8)

1.2 (Ester)MEL56

Max. 50m

Max. 50m

9

Service Ref.

Mode

Power supply (phase, cycle, voltage)

External finish

Refrigerant control

Compressor

OUTDOOR UNIT

Heat exchanger

Fan Fan(drive) o No.

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor &

outdoor unit

REFRIGERANT PIPING

Running current

Max. current

Model

Motor output

Starter type

Protection devices

Crankcase heater

Fan motor output

Airflow

Cooling

Charge

Oil (Model)

Indoor side

Outdoor side

Height difference

Piping length

W

D

H

Liquid

Gas

kW

kW

/min(CFM

K

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

mm(in.)

mm(in.)

PU-P125YGAA.UK PU-P140YGAA.UK

Cooling

A

A

W

)

L

7.52

18.0

BE82YADMT

3.5

Thermal relay, HP switch, Discharge thermo

95(3,360)

55

4.6(10.1)

3-ph, 50Hz,400V(4wires)

Munsell 5Y 7/1

Linear Expansion Valve

Hermetic

Line start

38

Plate fin coil

Propeller (direct) o 2

0.07+0.07

—

1,050(41-5/16)

330+20(13+3/4)

1,260(49-5/8)

125(276)

R407C

1.7 (Ester) MEL56

9.52(3/8)

19.05(3/4)

Flared

Flared

Max. 50m

Max. 50m

Cooling

8.92

20.4

BE96YADMT

4.2

100(3,530)

57

4.9(10.8)

10

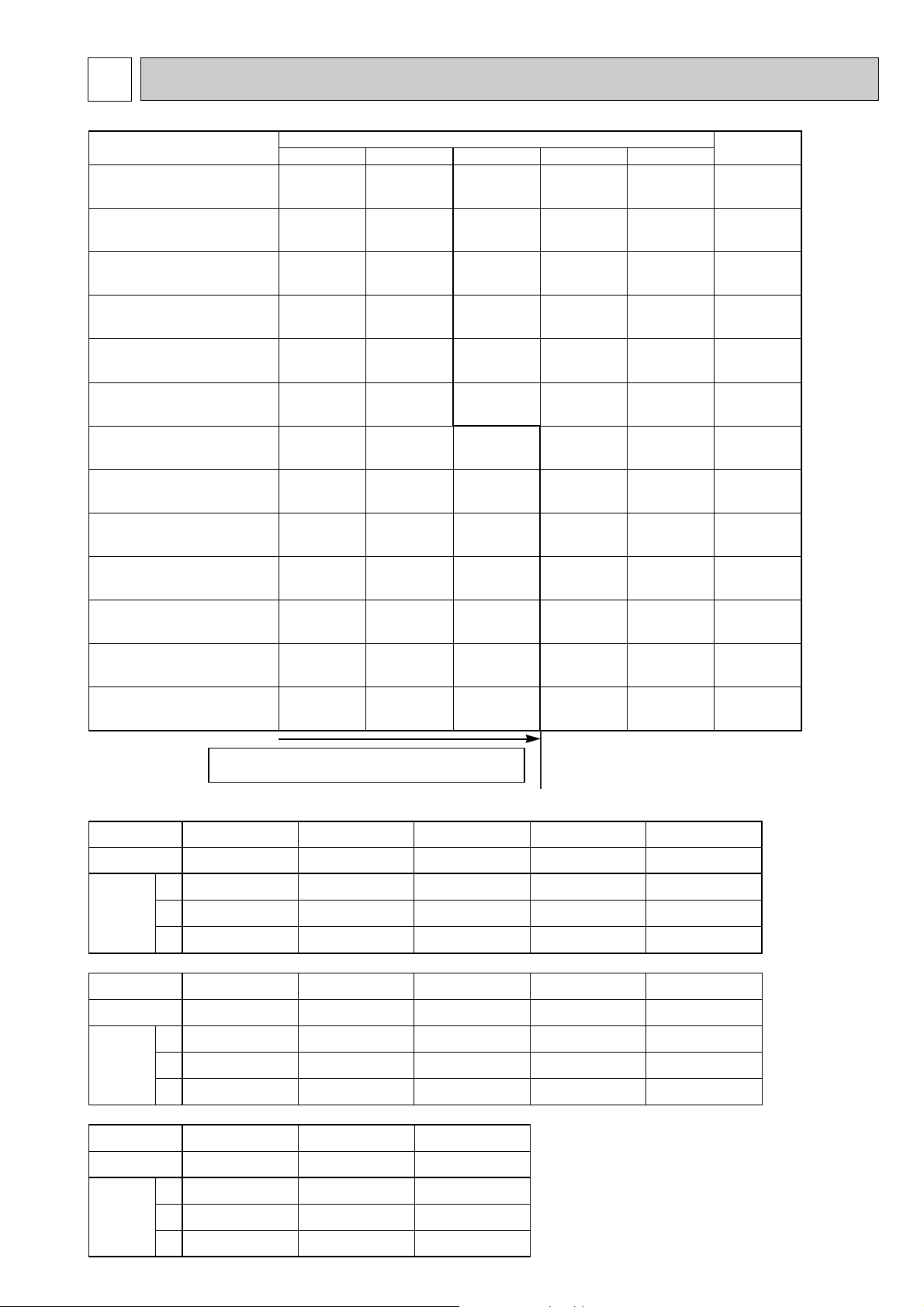

5 DATA

Piping length (one way)

10m 20m 30m

40m

50m

Factory

charged

1.6

2.4

2.4

2.5

2.5

2.9

2.9

2.9

2.9

3.4

3.4

4.0

4.3

1.7

2.5

2.5

2.6

2.6

3.1

3.1

3.1

3.1

3.7

3.7

4.3

4.6

1.8

2.6

2.6

3.1

3.1

3.3

3.3

3.3

3.3

4.0

4.0

4.6

4.9

—

3.0

3.0

3.7

3.7

3.9

3.9

3.9

3.9

4.7

4.7

5.3

5.6

—

—

—

—

—

4.5

4.5

4.5

4.5

5.4

5.4

6.0

6.3

1.7

2.5

2.5

2.6

2.6

3.1

3.1

3.3

3.3

4.0

4.0

4.6

4.9

Service Ref.

PUH-P140YGAA.UK

PU-P140YGAA.UK

PUH-P125YGAA.UK

PU-P125YGAA.UK

PUH-P100VGAA.UK

PU-P100VGAA.UK

PUH-P100YGAA.UK

PU-P100YGAA.UK

PUH-P71YGAA.UK

PU-P71YGAA.UK

PUH-P71VGAA.UK

PU-P71VGAA.UK

PUH-P60YGAA.UK

PU-P60YGAA.UK

PUH-P60VGAA.UK

PU-P60VGAA.UK

PUH-P50YGAA.UK

PU-P50YGAA.UK

PUH-P50VGAA.UK

PU-P50VGAA.UK

PUH-P35YGAA.UK

PU-P35YGAA.UK

PUH-P35VGAA.UK

PU-P35VGAA.UK

PUH-P25VGAA.UK

Compressor model

Winding

Resistance

( " )

U-V

(R-C)

U-W

(S-C)

W-V

U-V

(R-C)

U-W

(S-C)

W-V

RE277VHSMT RE277YFKM

Unit

NE36VMJMT

1.80

3.00

—

10.8

10.8

10.8

5.01

5.01

5.01

NE36YEKMT

0.89

2.03

—

Unit

Compressor model

Winding

Resistance

( " )

(at 20°C)

BE96YADMTBE82YADMT

2.123

2.123

2.123

NE52VNJMT

0.64

1.67

—

3.59

3.59

3.59

1.963

1.963

1.963

NE56YDKMT

3.32

3.32

3.32

PUH-P35VGAA.UK

PU-P35VGAA.UK

PUH-P35YGAA.UK

PU-P35YGAA.UK

PUH-P50VGAA.UK

PU-P50VGAA.UK

PUH-P50YGAA.UK

PU-P50YGAA.UK

PUH-P25VGAA.UK

PUH-P60YGAA.UK

PU-P60YGAA.UK

PUH-P60VGAA.UK

PU-P60VGAA.UK

PUH-P71VGAA.UK

PU-P71VGAA.UK

PUH-P100VGAA.UK

PU-P100VGAA.UK

PUH-P71YGAA.UK

PU-P71YGAA.UK

PUH-P125YGAA.UK

PU-P125YGAA.UK

PUH-P100YGAA.UK

PU-P100YGAA.UK

U-V

(R-C)

U-W

(S-C)

W-V

Unit

Compressor model

Winding

Resistance

( " )

NE41VMJMT

NE41YEKMT

5.00

5.00

5.00

NE56VNJMT

0.62

1.59

—

RE189VHSMT

2.79

3.36

—

0.87

2.22

—

NE52YDKMT

PUH-P140YGAA.UK

PU-P140YGAA.UK

5-1. REFILLING REFRIGERANT CHARGE (R407C : kg)

5-2. COMPRESSOR TECHNICAL DATA

PRE- CHARGED REFRIGERANT IS SUPPLIED

FOR PIPING LENGTH AT SHIPMENT.

11

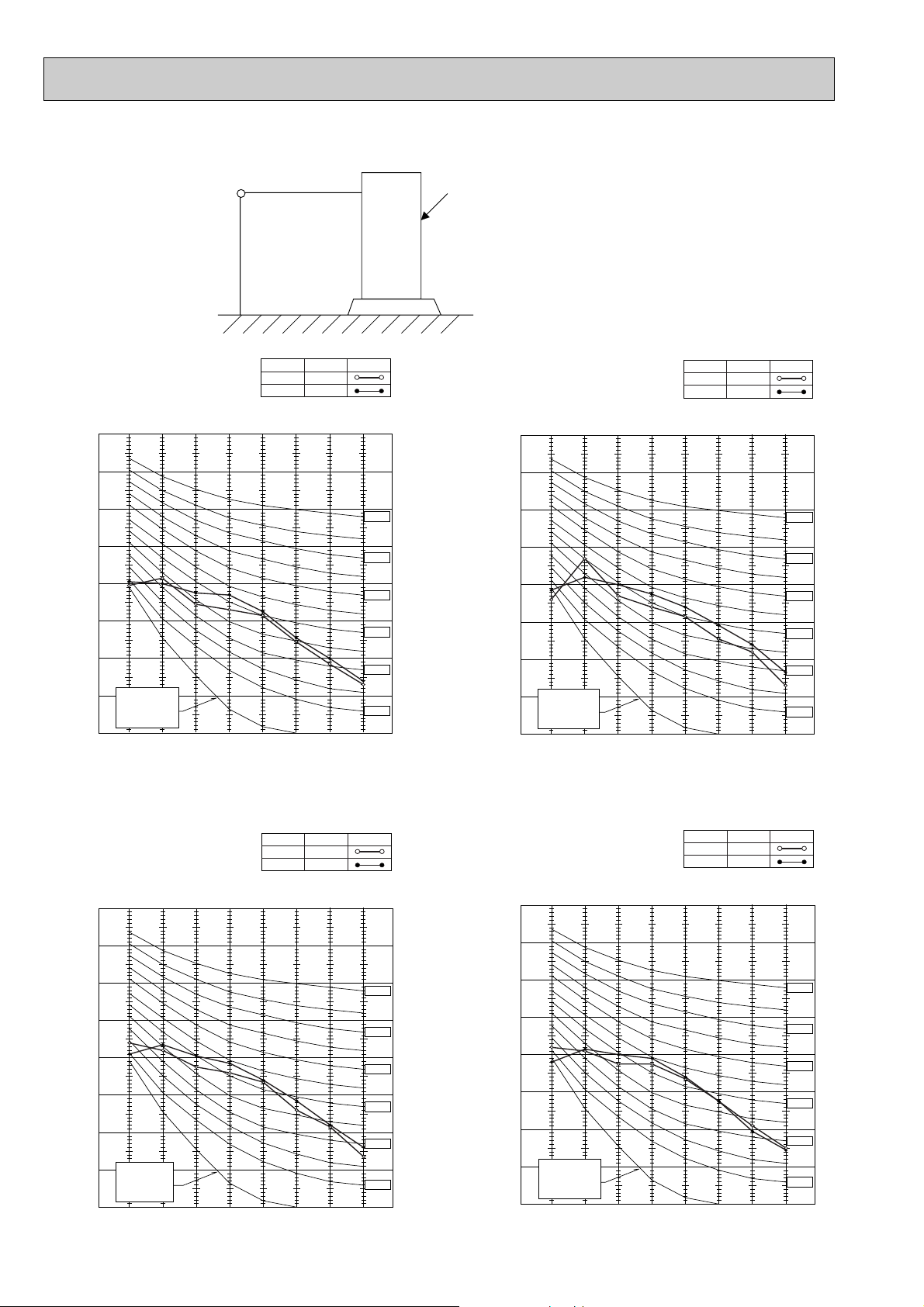

5-3. NOISE CRITERION CURVES

1m

1m

MICROPHONE

UNIT

GROUND

SPL(dB)48LINE

PUH-P25VGAA.UK

90

MODE

COOLING

HEATING

SPL(dB)49LINE

46

PUH-P35VGAA.UK

PUH-P35YGAA.UK

PU-P35VGAA.UK

MODE

COOLING

HEATING

47

PU-P35YGAA.UK

90

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

PUH-P50VGAA

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

.UK

PUH-P50YGAA.UK

PU-P50VGAA.UK

PU-P50YGAA.UK

90

MODE

COOLING

HEATING

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

SPL(dB) LINE

48

49

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

PUH-P60VGAA.UK

PUH-P60YGAA.UK

PU-P60VGAA.UK

PU-P60YGAA.UK

90

MODE

COOLING

HEATING

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

SPL(dB) LINE

48

50

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

12

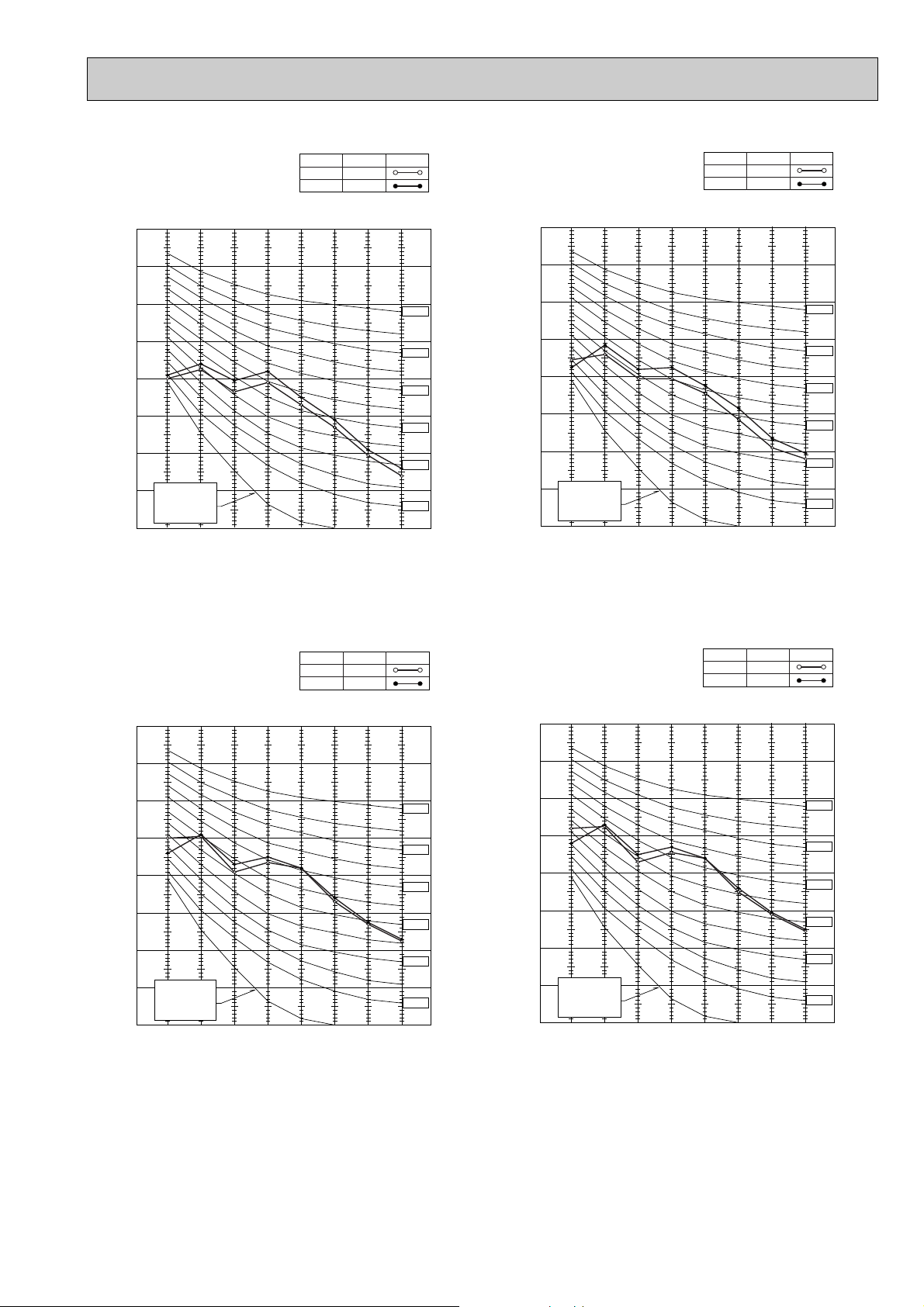

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

PUH-P71VGAA.UK

PUH-P71YGAA.UK

PU-P71VGAA.UK

PU-P71YGAA.UK

90

MODE

COOLING

HEATING

SPL(dB) LINE

49

51

PUH-P100VGAA.UK

PUH-P100YGAA.UK

PU-P100VGAA.UK

PU-P100YGAA.UK

90

MODE

COOLING

HEATING

SPL(dB)

51

53

LINE

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

10

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

PUH-P125YGAA.UK

PU-P125YGAA.UK

MODE

COOLING

HEATING

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

SPL(dB) LINE

55

56

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

PUH-P140YGAA.UK

PU-P140YGAA.UK

MODE

COOLING

HEATING

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

SPL(dB) LINE

57

58

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

90

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

90

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

13

5-4. STANDARD OPERATION DATA

Heat pump type

Representative matching

Mode

Capacity

TotalElectrical circuitRefrigerant circuitIndoor side

Input

Indoor unit

Phase , Hz

Volts

Amperes

Outdoor unit

Phase , Hz

Volts

Amperes

Discharge pressure

Suction pressure

Discharge temperature

Condensing temperature

Suction temperature

Ref. pipe length

Intake air temperature

Discharge air temperature

Intake air temperature

side

Outdoor

SHF

BF

D.B.

W.B.

D.B.

D.B.

W.B.

W

kW

V

A

V

A

MPa

MPa

°C

°C

°C

m

°C

°C

°C

°C

°C

PMH-P25BA

Cooling

3,100

1.14

PMH-P25BA

0.19

PUH-P25VGAA.UK

1, 50

230

5.13

2.01

0.55

71

48

8.0

5

27

19

13.3

35

24

0.77

0.09

Heating

3,350

1.05

1, 50

230

0.19

1, 50

230

4.72

1.85

0.44

70

44

4.0

5

20

15

41.5

7

6

—

—

PLA-RP35AA

Cooling

4,500

1.72

PLA-RP35AA PLA-RP50AA PLA-RP60AA

PUH-P35VGAA.UK

PUH-P35YGAA.UK

7.43/1.94

2.01

0.59

78

48

11

5

27

19

14.1

35

24

0.75

0.16

Heating

4,950

1.70

1 , 50

230

0.79

1/3 , 50

230/400

7.33/1.91

1.92

0.37

77

48

1

5

20

15

38.9

7

6

—

—

PLA-RP50AA

Cooling

5,600

2.53

PUH-P50VGAA.UK

PUH-P50YGAA.UK

11.30/3.23

2.48

0.59

85

55

10

5

27

19

14.6

35

24

0.82

0.12

Heating

1 , 50

230

0.79

1/3 , 50

230/400

9.72/2.70

6,350

2.20

1.96

0.38

76

45

0

5

20

15

38.9

7

6

—

—

PLA-RP60AA

Cooling

6,700

2.57

1 , 50

230

0.79

PUH-P60VGAA.UK

PUH-P60YGAA.UK

1/3 , 50

230/400

11.49/3.29

2.18

0.54

80

51

9

5

27

19

12.9

35

24

0.72

0.14

Heating

7,300

2.40

10.68/3.02

1.92

0.38

75

47

1

5

20

15

41.9

7

6

—

—

The unit of pressure has been changed to MPa based on international SI system.

The conversion factor is : 1(MPa)=10.2(kgf/ff)

14

Representative matching

PLA-RP71AA PLA-RP100AA

PLA-RP125AA

PLA-RP140AA

Mode

Capacity

TotalElectrical circuitRefrigerant circuitIndoor side

Input

Indoor unit

Phase , Hz

Volts

Amperes

Outdoor unit

Phase , Hz

Volts

Amperes

Discharge pressure

Suction pressure

Discharge temperature

Condensing temperature

Cooling

W

7,700

kW

V

A

V

A

MPa

MPa

°C

°C

3.42

PLA-RP71AA PLA-RP100AA

PUH-P71VGAA.UK

PUH-P71YGAA.UK

15.55/4.64

2.30

0.47

81

44

Heating

9,200

1 , 50

230

0.79

1/3 , 50

230/400

15.84/4.74

3.48

2.38

0.39

88

45

Cooling

9,600

3.68

PUH-P100VGAA.UK

PUH-P100YGAA.UK

16.33/4.59

1.98

0.54

71

42

Heating

10,500

3.91

1 , 50

230

1.25

1/3 , 50

230/400

17.43/4.96

2.12

0.42

75

47

Cooling

13,300

5.09

PLA-RP125AA

PUH-P125YGAA.UK

6.44

2.11

0.48

71

41

Heating

15,600

5.54

1 , 50

230

1.64

3 , 50

400

7.16

2.39

0.42

79

44

Cooling

14,200

5.90

PLA-RP140AA

PUH-P140YGAA.UK

7.73

2.27

0.45

81

45

Heating

17,000

6.35

1 , 50

230

1.64

3 , 50

400

8.44

2.36

0.41

84

46

Suction temperature

Ref. pipe length

Intake air temperature

Discharge air temperature

Intake air temperature

side

Outdoor

SHF

BF

D.B.

W.B.

D.B.

D.B.

W.B.

°C

m

°C

°C

°C

°C

°C

5

5

27

19

13.4

35

24

0.74

0.13

0

5

20

15

45.1

7

6

—

—

8

5

27

19

14.0

35

24

0.78

0.12

1

5

20

15

40.1

7

6

—

—

6

5

27

19

11.7

35

24

0.72

0.06

The unit of pressure has been changed to MPa based on international SI system.

The conversion factor is : 1(MPa)=10.2(kgf/ff)

0

5

20

15

48.7

7

6

—

—

2

5

27

19

11.3

35

24

0.69

0.09

-1

5

20

15

51.2

7

6

—

—

15

Cooling only type

Representative matching

Mode

Capacity

TotalElectrical circuitRefrigerant circuitIndoor side

Input

W

kW

PLA-RP35AA

Cooling

4,500

1.72

PLA-RP50AA

Cooling

5,600

2.53

PLA-RP60AA

Cooling

6,700

2.57

Indoor unit

Phase , Hz

Volts

Amperes

Outdoor unit

Phase , Hz

Volts

Amperes

Discharge pressure

Suction pressure

Discharge temperature

Condensing temperature

Suction temperature

Ref. pipe length

Intake air temperature

Discharge air temperature

Intake air temperature

side

Outdoor

SHF

BF

D.B.

W.B.

D.B.

D.B.

W.B.

V

A

V

A

MPa

MPa

°C

°C

°C

m

°C

°C

°C

°C

°C

PLA-RP35AA

1 , 50

230

0.79

PU-P35VGAA.UK

PU-P35YGAA.UK

1/3 , 50

230/400

7.43/1.94

2.01

0.59

78

48

11

5

27

19

14.1

35

24

0.75

0.16

PLA-RP50AA

1 , 50

230

0.79

PU-P50VGAA.UK

PU-P50YGAA.UK

1/3 , 50

230/400

11.30/3.23

2.48

0.59

85

55

10

5

27

19

14.6

35

24

0.82

0.12

PLA-RP60AA

1 , 50

230

0.79

PU-P60VGAA.UK

PU-P60YGAA.UK

1/3 , 50

230/400

11.49/3.29

2.18

0.54

80

51

9

5

27

19

12.9

35

24

0.72

0.14

The unit of pressure has been changed to MPa based on international SI system.

The conversion factor is : 1(MPa)=10.2(kgf/ff)

16

Representative matching

Mode

Capacity

TotalElectrical circuitRefrigerant circuitIndoor side

Input

W

kW

PLA-RP71AA PLA-RP100AA

Cooling

7,700

3.42

Cooling

9,200

3.68

PLA-RP125AA

Cooling

13,300

5.09

PLA-RP140AA

Cooling

14,200

5.90

Indoor unit

Phase , Hz

Volts

Amperes

Outdoor unit

Phase , Hz

Volts

Amperes

Discharge pressure

Suction pressure

Discharge temperature

Condensing temperature

Suction temperature

Ref. pipe length

Intake air temperature

Discharge air temperature

Intake air temperature

side

Outdoor

SHF

BF

D.B.

W.B.

D.B.

D.B.

W.B.

V

A

V

A

MPa

MPa

°C

°C

°C

m

°C

°C

°C

°C

°C

PLA-RP71AA PLA-RP100AA

1 , 50

230

0.79

PU-P71VGAA.UK

PU-P71YGAA.UK

1/3 , 50

230/400

15.55/4.64

2.30

0.47

81

44

5

5

27

19

13.4

35

24

0.74

0.13

1 , 50

230

1.25

PU-P100VGAA.UK

PU-P100YGAA.UK

1/3 , 50

230/400

16.33/4.59

1.98

0.54

71

42

8

5

27

19

14.0

35

24

0.78

0.12

PLA-RP125AA

1 , 50

230

1.64

PU-P125YGAA.UK PU-P140YGAA.UK

3 , 50

400

6.44

2.11

0.48

71

41

6

5

27

19

11.7

35

24

0.72

0.06

PLA-RP140AA

1 , 50

230

1.64

3 , 50

400

7.73

2.27

0.45

81

45

2

5

27

19

11.3

35

24

0.69

0.09

The unit of pressure has been changed to MPa based on international SI system.

The conversion factor is : 1(MPa)=10.2(kgf/ff)

17

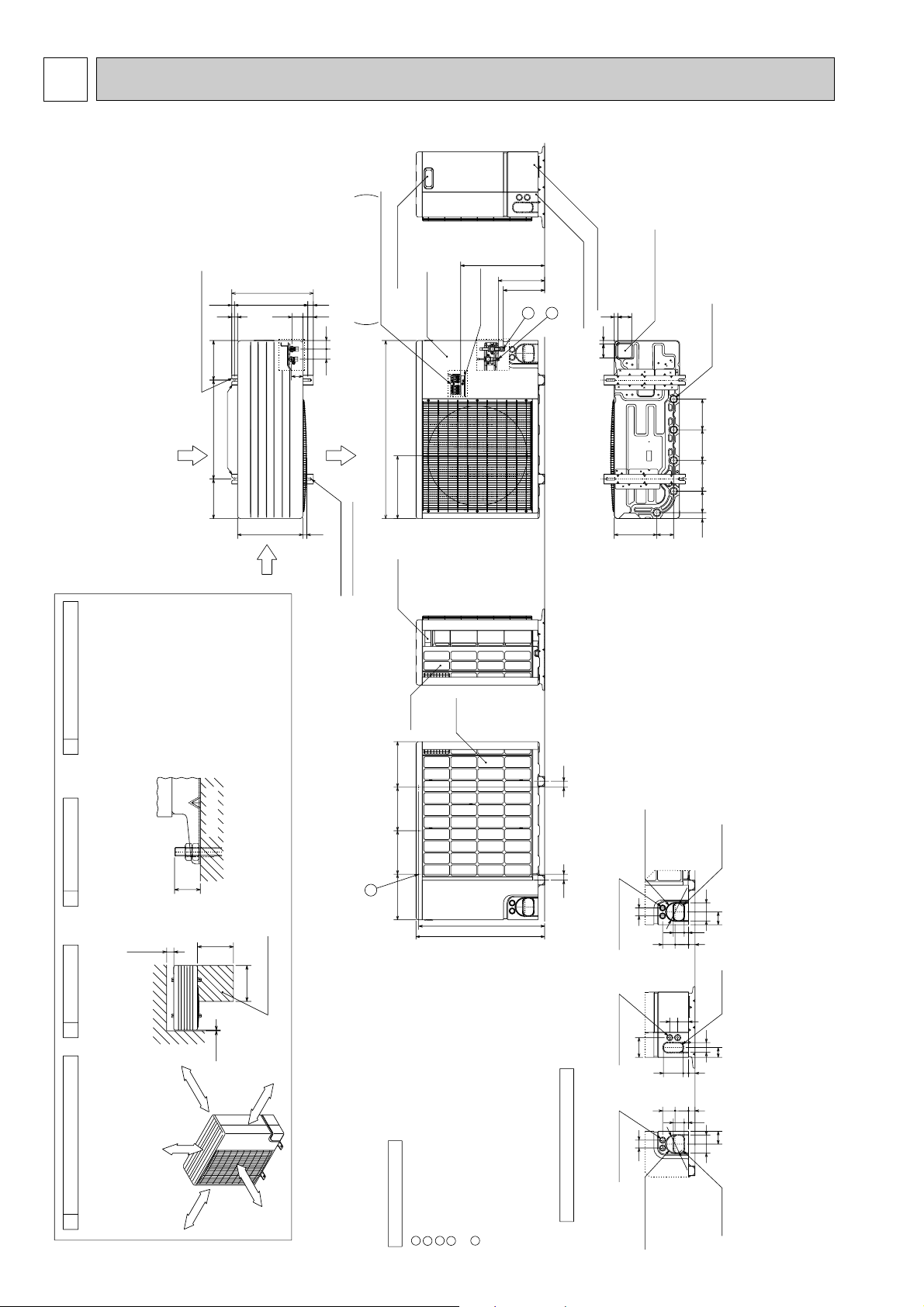

6 OUTLINES AND DIMENSIONS

321

T

SR

w1 248

w1 196

500

Power Supply Wiring Hole

(2-[27Knock-Out)

Right Piping Hole

(Knock-Out)

Power Supply Wiring Hole

(2-[27Knock-Out)

Terminal Connections

Left...Power supply Wiring

Right..Indoor/Outdoor Wiring

70

70

15515515510930

21585

Bottom Piping Hole

(Knock-Out)

Drain Hole

(5-[33holes)

18

18

424

900

318

Handle for moving

Earth Point

Service Panel

Front Piping Cover

Rear Piping Cover

1

2

Side Air

Intake

200200

53

370

(14)

412

29

330

55

4351

Rear Air Intake

Air Discharge

2-U Shaped notched holes

(Foundation Bolt M10)

2-12x40 oval holes

(Foundation Bolt M10)

20

28

58

Installation Feet

Rear

Air

Intake

Side

Air

Intake

Handle for

moving

3

230220220230

637

650

3030

Rear Trunking Hole

(Knock-Out)

< Rear Side >

Power Supply Wiring Hole

(2-[27Knock-Out)

40

33

22 55

68 63

65

92

Rear Piping Hole

(Knock-Out)

[

92

Piping Knock-Out Hole Details

. .

Refrigerant GAS pipe connection (FLARE)P35V(Y)GAA: [15.88 (5/8F)

. .

Refrigerant LIQUID pipe connection (FLARE)P35V(Y)GAA: [9.52 (3/8F)

. .

Height of STOP VALVE connection location.

1

2

< Right Side >< Front Side >

Explanation of Notes

40

68 63

22 55

65

92

33

27

100

50

50

100

33

[92

Front Piping Hole

(Knock-Out)

5540

3

. .

3-[3.6 holes (for securing the top of the unit)

These holes are provided for cases where the unit must

be secured by the base AND by the top surface.

Use Self Tapping screws 5 x L15 or less.(Obtained locally)

w1

. .

Refrigerant GAS pipe connection (FLARE)P25VGAA : [12.7 (1/2F)

. .

Refrigerant LIQUID pipe connection (FLARE)P25VGAA : [6.35 (1/4F)

1

2

O

ve

r 10m

m

FRE

E

O

ver 500m

m

Less than

30mm

FREE SPACE (Around the Unit)

Piping and wiring connections

can be made from 4 directions:

Front, Right, Rear and Below.

FOUNDATION BOLTS

1

The diagram below shows a

basic example.

Explanation of particular details are

given in the installation manuals etc.

SERVICE SPACE

Dimensions of space needed

for service access are

shown in the below diagram.

2

Over500

Over500

PIPING-WIRING DIRECTIONS

43

FOUNDATION

<Foundation bolt height>

Please secure the unit firmly

with 4 foundation (M10) bolts.

(Bolts and washers must be

purchased locally).

Service Space

O

ve

r 1

00m

m

O

ver 1

0m

m

Over10

Over100

OUTDOOR UNIT

PUH-P25VGAA.UK

PUH-P35VGAA.UK

PUH-P35YGAA.UK

PU-P35VGAA.UK

PU-P35YGAA.UK

Unit : mm

18

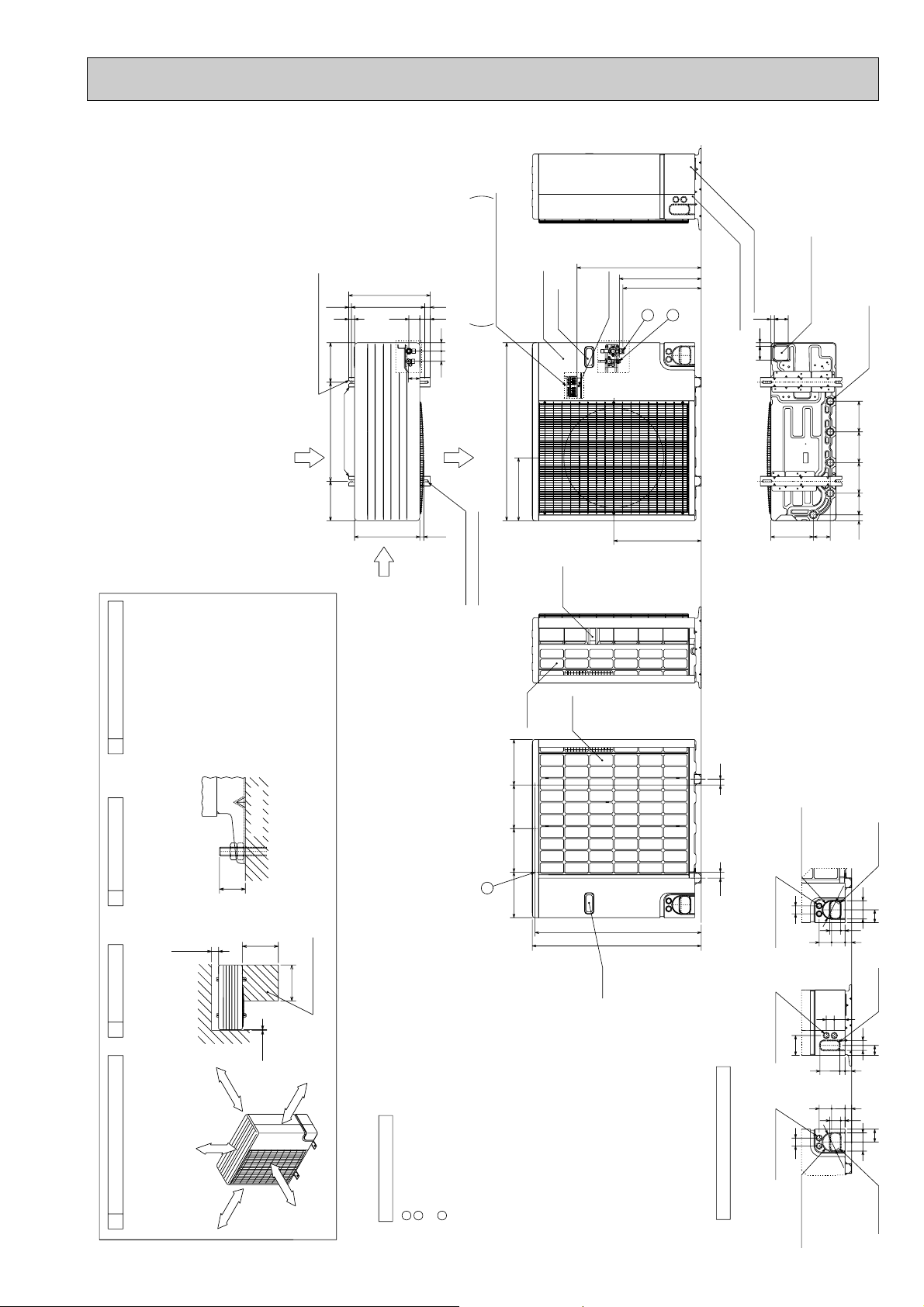

PUH-P50VGAA.UK

PUH-P50YGAA.UK

PUH-P60VGAA.UK

PUH-P60YGAA.UK

PUH-P71VGAA.UK

PUH-P71YGAA.UK

PU-P50VGAA.UK

PU-P50YGAA.UK

PU-P60VGAA.UK

PU-P60YGAA.UK

PU-P71VGAA.UK

PU-P71YGAA.UK

412

(14)

29

200500200

2-U Shaped notched holes

(Foundation Bolt M10)

370

55

28

53

43

51

58

Terminal Connections

Left...Power supply Wiring

Right..Indoor/Outdoor Wiring

Service Panel

Handle

321TSR

Earth Point

627

Unit : mm

w1 428

w1 376

Rear Piping Cover

Bottom Piping Hole

1

2

Front Piping Cover

18

70

(Knock-Out)

70

18

Drain Hole

(5-[33holes)

PIPING-WIRING DIRECTIONS

4

Piping and wiring connections

can be made from 4 directions:

Front, Right, Rear and Below.

FOUNDATION

FOUNDATION BOLTS

3

Please secure the unit firmly

with 4 foundation (M10) bolts.

(Bolts and washers must be

purchased locally).

30mm

Less than

<Foundation bolt height>

Over100

Rear Air Intake

Over500

Installation Feet

Side Air

Intake

330

Air Discharge

20

2-12x40 oval holes

(Foundation Bolt M10)

900

318

442

21585

15515515510930

Handle

Rear

Air

Intake

Intake

855

840

3030

Rear Trunking Hole

(Knock-Out)

< Rear Side >

40

Power Supply Wiring Hole

(2-[27Knock-Out)

92

[

68 63

Rear Piping Hole

(Knock-Out)

92

65

22 55

33

Side

Air

230220220230

3

SERVICE SPACE

2

Dimensions of space needed

for service access are

shown in the below diagram.

m

FRE

FREE SPACE (Around the Unit)

The diagram below shows a

basic example.

Explanation of particular details are

1

given in the installation manuals etc.

ver 10m

O

E

ver 100m

O

m

Over10

m

00m

Over500

r 10m

ve

O

ver 5

O

Service Space

m

Refrigerant LIQUID pipe connection (FLARE) [9.52 (3/8F)

Height of STOP VALVE connection location.

3-[3.6 holes (for securing the top of the unit)

Refrigerant GAS pipe connection (FLARE) [15.88 (5/8F)

. . .

. . .

. . .

These holes are provided for cases where the unit must

. . .

1w12

Explanation of Notes

be secured by the base AND by the top surface together.

3

19

Use Self Tapping screws 5 x L15 or less.

(Obtained Locally)

Handle

Right Piping Hole

5540

100

50

33

27

68 63

33

22 55

92

[92

< Right Side >

100

Power Supply Wiring Hole

(2-[27Knock-Out)

40

< Front Side >

Power Supply Wiring Hole

(2-[27Knock-Out)

Piping Knock-Out Hole Details

Front Trunking Hole

(Knock-Out)

Front Piping Hole

(Knock-Out)

50

65

(Knock-Out)

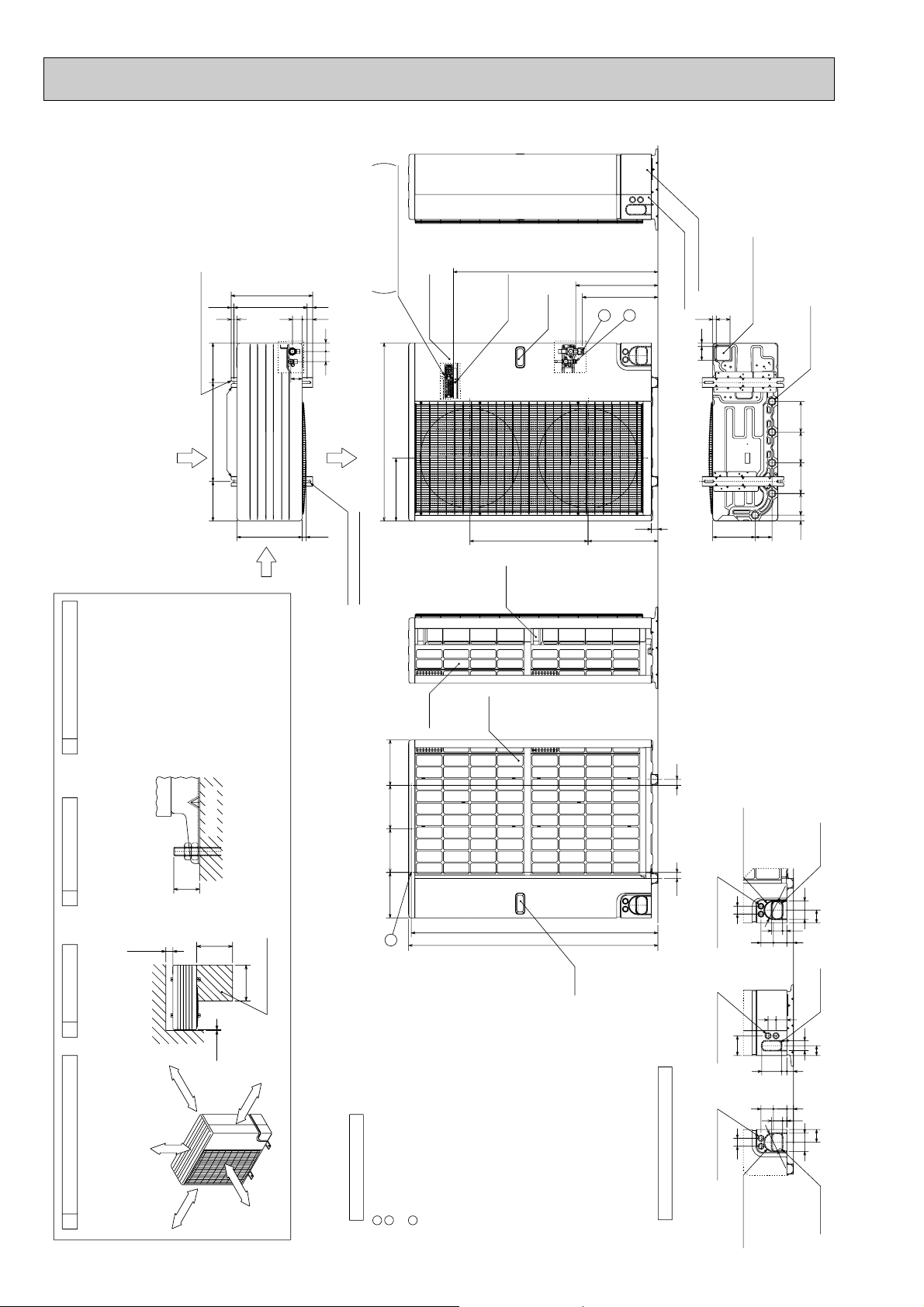

PUH-P100VGAA.UK

4

PIPING-WIRING DIRECTIONS

3

FOUNDATION BOLTS

FOUNDATION

Piping and wiring connections

can be made from 4 directions:

Front, Right, Rear and Below.

SERVICE SPACE

Please secure the unit firmly

with 4 foundation (M10) bolts.

(Bolts and washers must be

purchased locally).

30mm

<Foundation bolt height>

Less than

Over500

Over100

Service Space

Over500

1

FREE SPACE (Around the Unit)

Dimensions of space needed

for service access are

shown in the below diagram.

2

The diagram below shows a

basic example.

Explanation of particular details are

given in the installation manuals etc.

Over10

O

ver 10m

m

FRE

E

O

v

er 5

00

m

m

O

ver 100m

m

O

ver 10m

m

Explanation of Notes

. . .

Refrigerant GAS pipe connection(FLARE) [19.05 (3/4F)

. . .

Refrigerant LIQUID pipe connection(FLARE) [9.52 (3/8F)

. . .

Height of STOP VALVE connection location.

. . .

3-[3.6 holes (for securing the top of the unit)

These holes are provided for cases where the unit must

be secured by the base AND by the top surface together.

Use Self Tapping screws 5 x L15 or less.

(Obtained Locally)

3

2

w1

1

PUH-P100YGAA.UK

PU-P100VGAA.UK

PU-P100YGAA.UK

Unit : mm

29

200500200

2-U Shaped notched holes

(Foundation Bolt M10)

Installation Feet

Rear Air Intake

Side Air

Intake

370 (14)

330

412

50

58

Terminal Connections

28

53

4351

Air Discharge

20

2-12x40 oval holes

(Foundation Bolt M10)

Left...Power supply Wiring

Right..Indoor/Outdoor Wiring

Service Panel

900

318

Rear

Side

Air

Intake

Air

Intake

Earth Point

598

Handle

Handle

1033

W1 428

W1 376

1

2

33

352

Rear Piping Cover

Front Piping Cover

70

18

70 18

Bottom Piping Hole

(Knock-Out)

85 215

Drain Hole

(5-[33Holes)

30 109 155 155 155

230220220

230

3030

Rear Piping Hole

92

[

6368

5522

(Knock-Out)

92

65

33

Rear Trunking Hole

(Knock-Out)

< Rear Side >

3

1246

1260

40

Power Supply Wiring Hole

(2-[27Knock-Out)

Handle

Right Piping Hole

(Knock-Out)

4055

1002733

6368

5522

[92

50

50

33

65

92

< Right Side >

100

Power Supply Wiring Hole

(2-[27Knock-Out)

40

< Front Side >

Power Supply Wiring Hole

(2-[27Knock-Out)

Piping Knock-Out Hole Details

Front Piping Hole

Front Trunking Hole

(Knock-Out)

(Knock-Out)

20

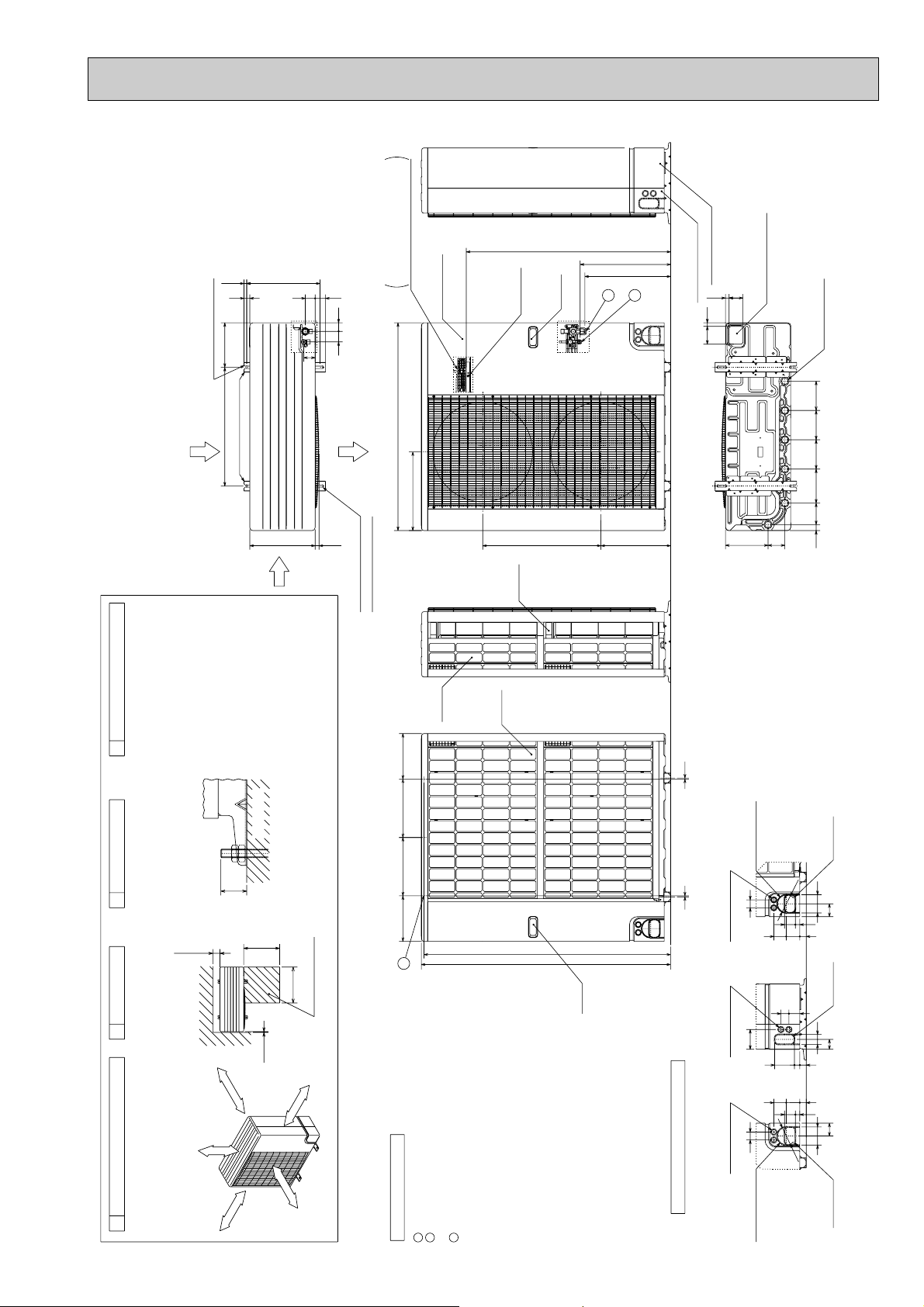

PUH-P125YGAA.UK

PUH-P140YGAA.UK

PU-P125YGAA.UK

PU-P140YGAA.UK

Unit : mm

29

225600

2-U Shaped notched holes

(Foundation Bolt M10)

Installation Feet

Rear Air Intake

Side Air

Intake

370 (14)

330

50

58

Terminal Connections

53

4453

Air Discharge

20

2-12x40 oval holes

(Foundation Bolt M10)

Left...Power supply Wiring

Right..Indoor/Outdoor Wiring

Service Panel

1050

398

Earth Point

598

Handle

1033

Handle

w1 478

w1 422

1

2

352

Rear Piping Cover

Bottom Piping Hole

70 18

Front Piping Cover

1870

21585

(Knock-Out)

Drain Hole

(5-[33Holes)

14814814817230 109

PIPING-WIRING DIRECTIONS

4

Piping and wiring connections

can be made from 4 directions:

Front, Right, Rear and Below.

FOUNDATION

FOUNDATION BOLTS

Please secure the unit firmly

with 4 foundation (M10) bolts.

(Bolts and washers must be

purchased locally).

30mm

Less than

<Foundation bolt height>

Over100

Over500

Over500

Service Space

SERVICE SPACE

23

Dimensions of space needed

for service access are

shown in the below diagram.

Over10

m

m

ver 10m

O

ver 500m

O

m

FRE

E

FREE SPACE (Around the Unit)

The diagram below shows a

basic example.

Explanation of particular details are

1

given in the installation manuals etc.

v

O

er 10m

ver 100m

O

m

Side

Air

230295295230

3

Refrigerant GAS pipe connection(FLARE) [19.05 (3/4F)

. . .

Explanation of Notes

1

Rear

Intake

Refrigerant LIQUID pipe connection(FLARE) [9.52 (3/8F)

Height of STOP VALVE connection location.

3-[3.6 holes (for securing the top of the unit)

. . .

. . .

. . .

These holes are provided for cases where the unit must

2

be secured by the base AND by the top surface together.

3

w1

Air

Intake

1246

1260

Handle

Use Self Tapping screws 5 x L15 or less.

(Obtained Locally)

55

Rear Trunking Hole

(Knock-Out)

92

92

[

< Rear Side >

40

Power Supply Wiring Hole

(2-[27Knock-Out)

< Right Side >

100

Power Supply Wiring Hole

(2-[27Knock-Out)

40

< Front Side >

Power Supply Wiring Hole

(2-[27Knock-Out)

5522

6368

4055

1002733

6368

5522

[92

33

50

33

92

Piping Knock-Out Hole Details

Front Trunking Hole

(Knock-Out)

Rear Piping Hole

(Knock-Out)

65

Right Piping Hole

(Knock-Out)

50

65

Front Piping Hole

(Knock-Out)

21

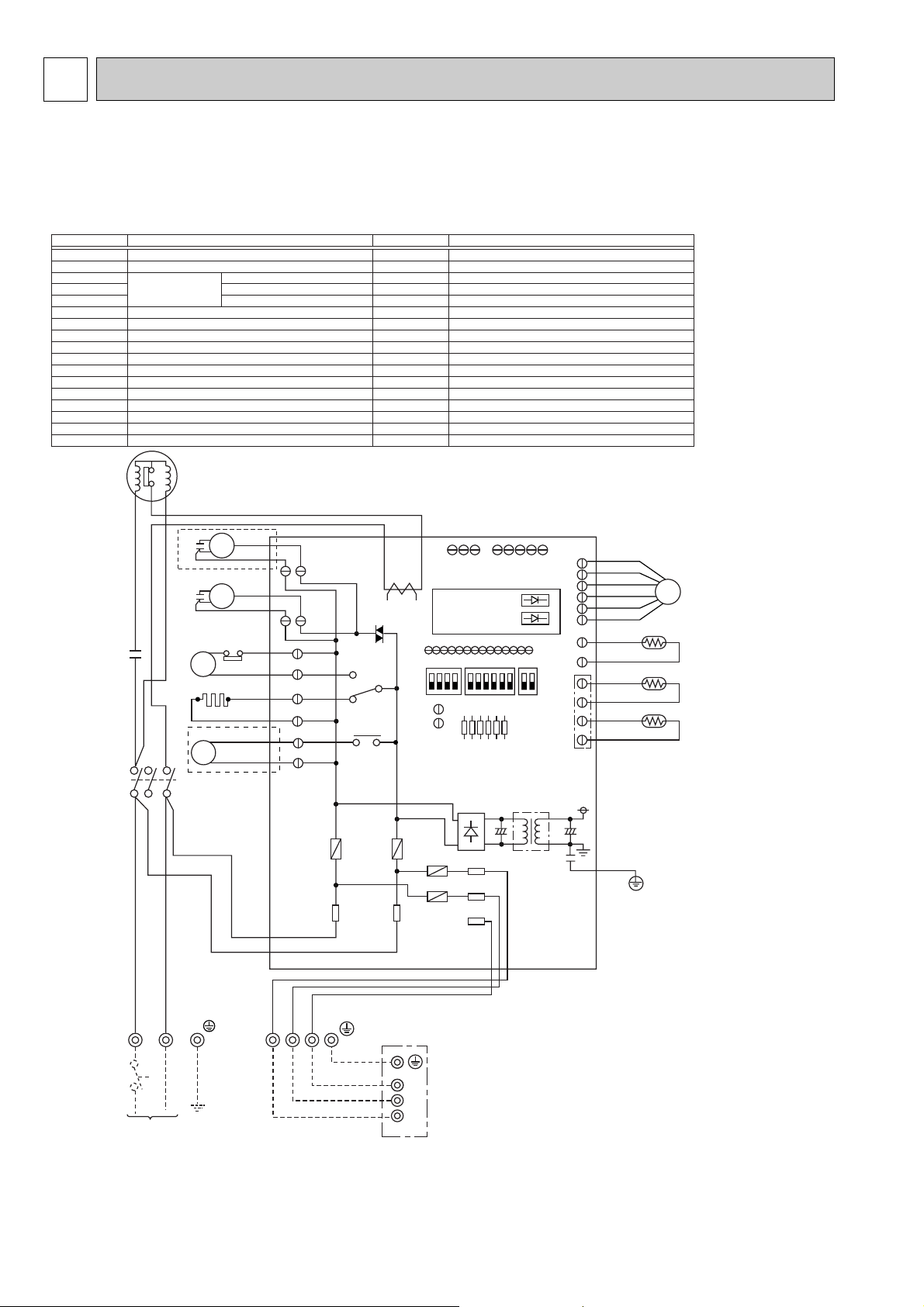

<Notes when servicing>

Some fastening terminals have a lock mechanism: When removing the fastening terminal, push the projection (locking lever) on the terminal with

your finger and pull it out.

SYMBOL NAME SYMBOL NAME

MC COMPRESSOR (INNER THERMOSTAT)

MF FAN MOTOR (INNER THERMOSTAT)

TH3 THERMISTOR LIQUID TEMP

TH4 DISCHARGE TEMP

TH6 COND. / EVA. TEMP

C3 MF CAPACITOR

C4 MF CAPACITOR

C5 MC CAPACITOR

CH CRANKCASE HEATER

52C MC CONTACTOR

21S4 4-WAY VALVE SOLENOID COIL

63H HIGH PRESSURE PROTECT SWITCH

49C INNER THERMOSTAT FOR MC

TB1 TERMINAL BLOCK

LEV LINEAR EXPANSION VALVE

TB2 TERMINAL BLOCK

O.B OUTDOOR CONTROLLER BOARD

FUSE1 (O.B) FUSE (6.3A)

FUSE2 (O.B) FUSE (6.3A)

FUSE3 (O.B) FUSE (6.3A)

FUSE4 (O.B) FUSE (6.3A)

X51 (O.B) MC/CH RELAY

X52 (O.B) 21S4 RELAY

F.C (O.B) FAN CONTROLLER

SW1 (O.B) GROUP NUMBER ADDRESS

SW4 (O.B) TEST RUN

SW5 (O.B) FUNCTION SELECTION

J1)~J6 (O.B) MODEL SELECTION

T (O.B) TRANSFORMER

CT (O.B) CURRENT TRANS

LED1 (O.B)

OPERATION CHECK DISPLAY LED

LED2 (O.B)

OPERATION CHECK DISPLAY LED

CN31 (O.B) EMERGENCY OPERATION CONNECTER

O.B

INDOOR

UNIT

SCR

MC

R

E

D

W

H

T

B

L

U

R

E

D

Y

L

W

O

R

N

B

R

N

B

L

U

C3

WHT

BLK

WHT

WHT

BRN

BRN

RED

BLU

49C

J1J2J3J4J5

J6

MF

LEV

CT

MF3

(WHT)

C4

*1

*1 PU(H)-P100VGAA MODEL ONLY

*2 PUH-P25~ P100VGAA MODEL ONLY

WHT

BLK

MF

MF4

(WHT)

52C

(PNK)

CH

(BLU)

52C

S1

S1

SW1 SW4

SW5

CNM

LED1 (GRN)

LED2 (RED)

S1

TB4

POWER SUPPLY

~/ N

230V 50Hz

S2

S2

S2

S3

S3

FUSE3

FUSE4

S3

a

b

63H

CH

52C

TB1

TB2

LN

T

OFF

ON

CNLEV

(WHT)

CNVMNT

(WHT)

CNMNT

(WHT)

TH4

(WHT)

TH3/TH6

(RED)

RED

BLU

BLK

GRY

BLK

ORN

YLW

WHT

BRN

TH4

TH6

TH3

CN31

F.C

X51

C5

2

/

T

1

6

/

T

3

1

/

L

1

5

/

L

3

4/S

R

FUSE2

FUSE1

BLU

BLU

21S4

(GRN)

21S4

X52

*2

7 WIRING DIAGRAM

PUH-P25VGAA.UK PUH-P35VGAA.UK PUH-P50VGAA.UK PUH-P60VGAA.UK

PUH-P71VGAA.UK PUH-P100VGAA.UK

PU-P35VGAA.UK PU-P50VGAA.UK PU-P60VGAA.UK PU-P71VGAA.UK

PU-P100VGAA.UK

22

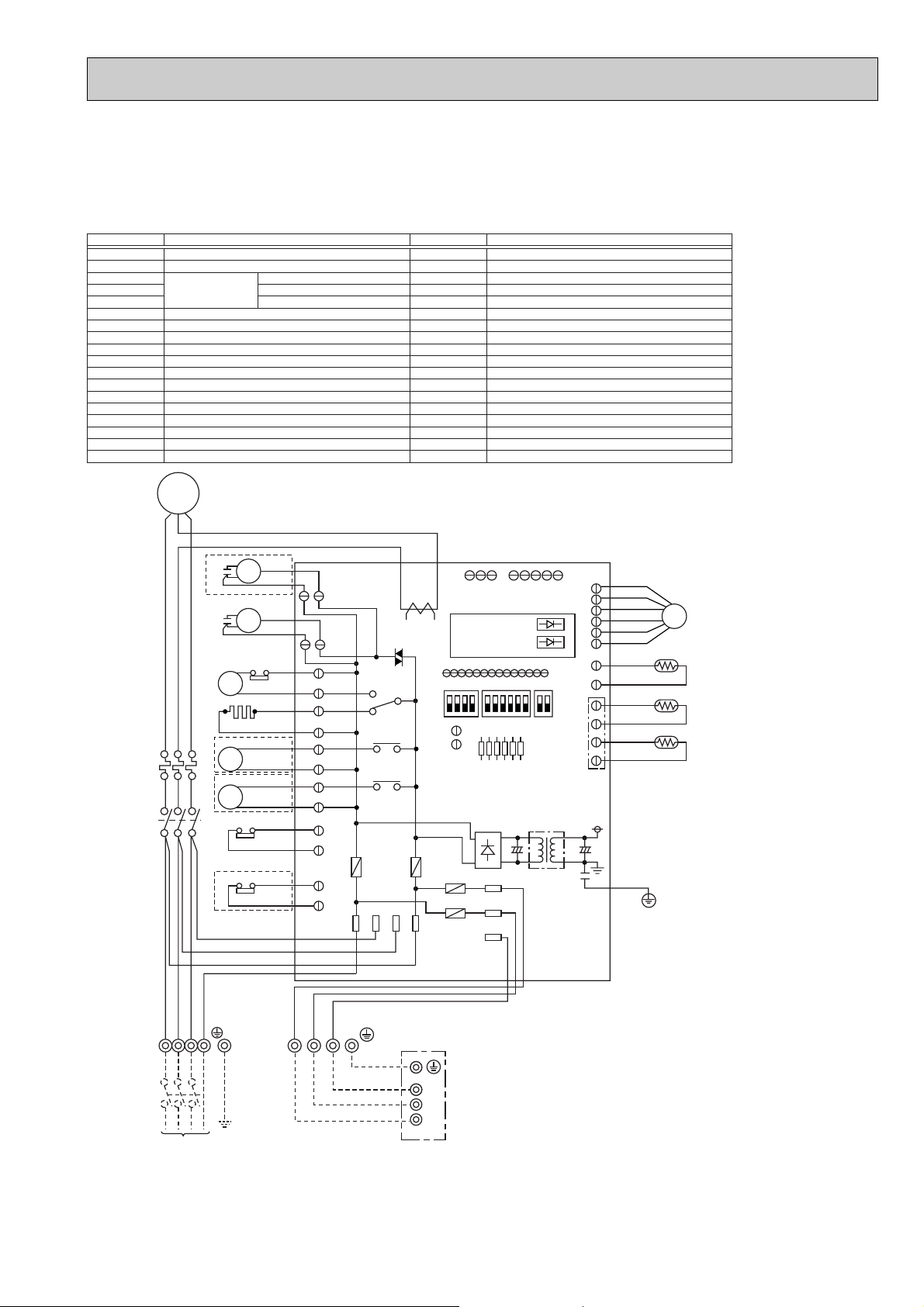

PUH-P35YGAA.UK PUH-P50YGAA.UK PUH-P60YGAA.UK PUH-P71YGAA.UK

PUH-P100YGAA.UK PUH-P125YGAA.UK PUH-P140YGAA.UK

PU-P35YGAA.UK PU-P50YGAA.UK PU-P60YGAA-UK PU-P71YGAA.UK

PU-P100YGAA.UK PU-P125YGAA.UK PU-P140YGAA.UK

SYMBOL NAME SYMBOL NAME

MC COMPRESSOR

MF FAN MOTOR (INNER THERMOSTAT)

TH3 THERMISTOR LIQUID TEMP

TH4 DISCHARGE TEMP

TH6 COND. / EVA. TEMP

C3 MF CAPACITOR

C4 MF CAPACITOR

CH CRANKCASE HEATER

52C MC CONTACTOR

21S4 4-WAY VALVE SOLENOID COIL

SV BYPASS VALVE SOLENOID COIL

63H HIGH PRESSURE PROTECT SWITCH

51C THERMAL RELAY

TB1 TERMINAL BLOCK

LEV LINEAR EXPANSION VALVE

TB2 TERMINAL BLOCK

63L LOW PRESSURE PROTECT SWITCH

MC

UVW

R

W

B

E

H

L

T

K

6

4

/

/

T

T

3

2

51C

52C

5

3

/

/

L

L

3

2

BLK

WHT

RED

W

B

B

H

L

L

T

K

U

3N~

400V 50Hz

C4

*2

C3

52C

CH

*4

21S4

*1

*3

D

2

/

T

1

1

/

L

1

R

E

D

L1 L2 L3 N

TB1

POWER SUPPLY

<Notes when servicing>

Some fastening terminals have a lock mechanism: When removing the fastening terminal, push the projection (locking lever) on the terminal with

your finger and pull it out.

SV

PE

MF

MF

a

b

51C

63L

63H

WHT

BLK

WHT

BLK

BRN

BRN

WHT

WHT

BLU

BLU

BLK

BLK

ORN

ORN

WHT

WHT

TB2

S1

Y

L

W

(*1BLK)

(*1BLK)

O

R

N

S2

MF4

(WHT)

MF3

(WHT)

52C

(PNK)

(BLU)

21S4

(GRN)

(BLK)

51CM

(ORN)

(RED)

B

R

N

S3

CH

SV

FUSE2

63L

4/S

O.B OUTDOOR CONTROLLER BOARD

FUSE1 (O.B) FUSE (6.3A)

FUSE2 (O.B) FUSE (6.3A)

FUSE3 (O.B) FUSE (6.3A)

FUSE4 (O.B) FUSE (6.3A)

X51 (O.B) MC/CH RELAY

X52 (O.B) 21S4 RELAY

X53 (O.B) SV RELAY

F.C (O.B) FAN CONTROLLER

SW1 (O.B) GROUP NUMBER ADDRESS

SW4 (O.B) TEST RUN

SW5 (O.B) FUNCTION SELECTION

J1~J6 (O.B) MODEL SELECTION

T (O.B) TRANSFORMER

CT (O.B) CURRENT TRANS

LED1 (O.B) OPERATION CHECK DISPLAY LED

LED2 (O.B) OPERATION CHECK DISPLAY LED

CN31 (O.B) EMERGENCY OPERATION CONNECTER

O.B

X51

X52

X53

F.C

RST

CT

TB4

CNM

ON

OFF

FUSE1

S3

S2

S1

CNVMNT

SW5

CN31

FUSE4

FUSE3

INDOOR

UNIT

CNMNT

(WHT)

LED1 (GRN)

LED2 (RED)

SW1 SW4

J1J2J3J4J5

S1

S2

S3

(WHT)

J6

CNLEV

(WHT)

TH4

(WHT)

TH3/TH6

(RED)

T

*1 PUH-P125/140YGAA MODEL ONLY

*2 PU(H)-P100/125/140YGAA MODEL ONLY

*3 PU(H)-P125/140YGAA MODEL ONLY

*4 PUH-P35~ P140YGAA MODEL ONLY

BRN

RED

BLU

ORN

YLW

WHT

BLK

BLK

GRY

LEV

TH4

TH6

TH3

23

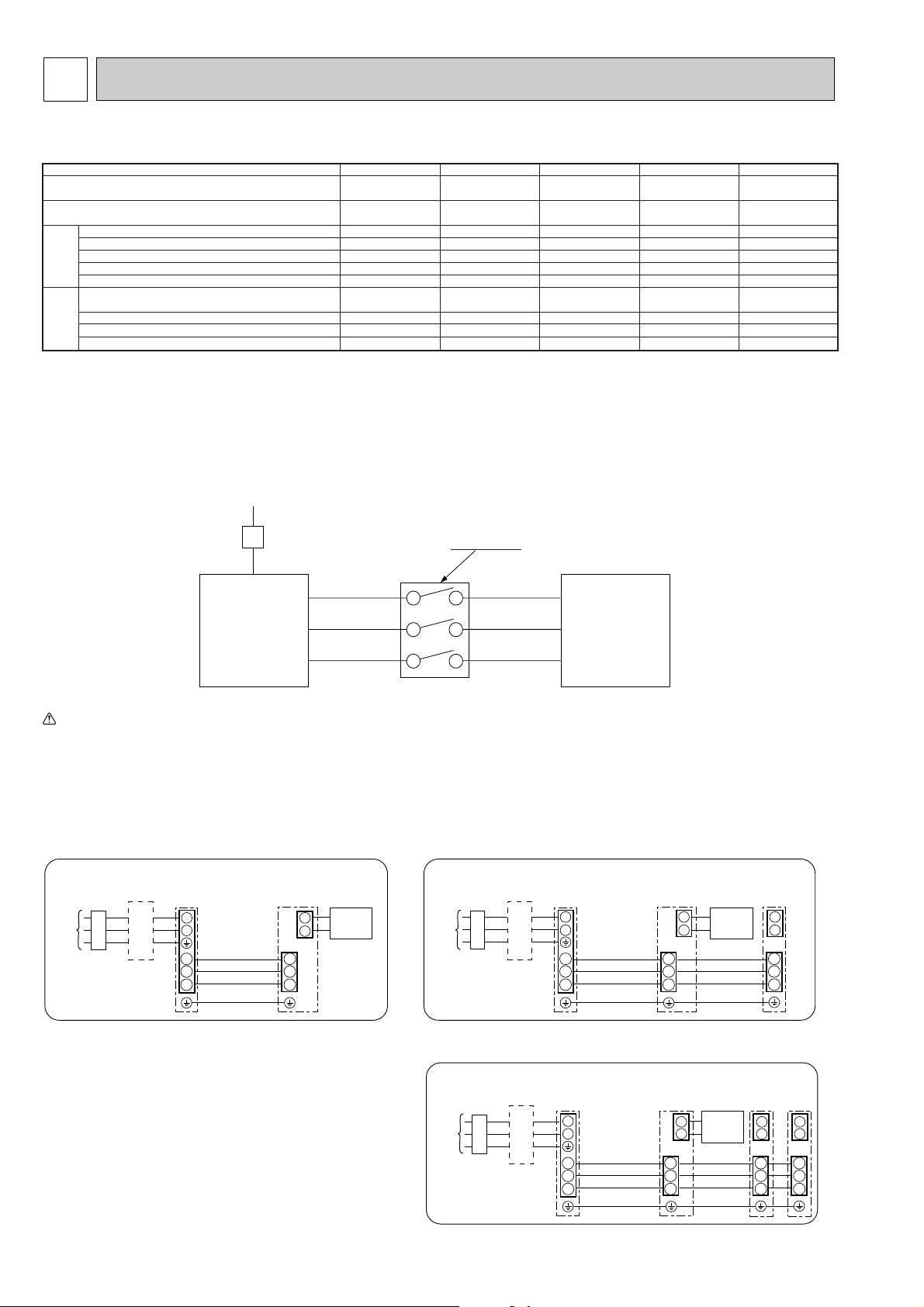

8 WIRING SPECIFICATIONS

1

2

S1

S2

S3

S1

S2

S3

Indoor/outdoor

unit connection

cable

Indoor

unit

Unit

power

supply

Outdoor

unit

Remote

controller

L

B

N

B Earth leakage breaker

C wiring circuit breaker or

isolating switch

C

B

B Earth leakage breaker

C wiring circuit breaker or

isolating switch

C

L

N

1

2

1

2

S1

Indoor

unit

S2

S3

S1

S2

S3

S1

S2

S3

Unit

power

supply

Indoor/outdoor

unit connection

cable

Indoor

unit

Outdoor

unit

Remote

controller

B

B Earth leakage breaker

C wiring circuit breaker or

isolating switch

C

1

2

1

2

1

2

S1

S2

S3

S1

S2

S3

S1

S2

S3

S1

S2

S3

Indoor/outdoor

connection cable

Indoor

unit

Unit

power

supply

Indoor

unit

Indoor

unit

Outdoor

unit

Remote

controller

L

N

8-1. FIELD ELECTRICAL WIRING (power wiring specifications)

Outdoor unit model

Outdoor unit power supply

Outdoor unit input capacity *1

Main switch (Breaker)

Outdoor unit power supply

)

2

Outdoor unit power supply earth

Indoor unit-Outdoor unit *2

Wiring

Indoor unit-Outdoor unit earth *2

Wire No. o

size (mm

Remote controller-Indoor unit *3

Outdoor unit L-N (single)

Outdoor unit L1-N, L2-N, L3-N (3 phase)

Indoor unit-Outdoor unit S1-S2 *4

Indoor unit-Outdoor unit S2-S3 *4

Circuit rating

Remote controller-Indoor unit *4

*1. A breaker with at least 3 mm contact separation in each poles shall be provided. Use non-fuse breaker (NF) or earth leakage breaker (NV).

*2. Refer to 8-2.

*3. The 10 m wire is attached in the remote controller accessory.

*4. The figures are NOT always against the ground.

S3 terminal has DC 24 V against S2 terminal. However between S3 and S1, these terminals are NOT electrically insulataed by the transformer or other device.

Notes: 1. Wiring size must comply with the applicable local and national code.

2. Power supply cords and Indoor/Outdoor unit connecting cords shall not be lighter than polychloroprene sheathed flexible cord. (Design 245 IEC 57)

3. Install an earth longer than other cables.

230V

Single phase

P25,35V P50,60V P71,100V P35,50,60,71,100Y P125, 140Y

~/N (single), 50 Hz, ~/N (single), 50 Hz, ~/N (single), 50 Hz, 3N ~ (3phase), 50 Hz,3N ~ (3phase), 50 Hz,

230 V 230 V 230 V 400 V400 V

16 A 25 A 32 A 16 A 25 A

2 o Min. 1.5 2 o Min. 2.5 2 o Min. 4 4 o Min. 1.5 4 o Min. 2.5

1 o Min. 1.5 1 o Min. 2.5 1 o Min. 4 1 o Min. 1.5 1 o Min. 1.5

3 o 1.5 (Polar) 3 o 1.5 (Polar) 3 o 1.5 (Polar) 3 o 1.5 (Polar) 3 o 1.5 (Polar)

1 o Min. 1.5 1 o Min. 1.5 1 o Min. 1.5 1 o Min. 1.5 1 o Min. 1.5

2 o 0.3 (Non-polar) 2 o 0.3 (Non-polar) 2 o 0.3 (Non-polar) 2 o 0.3 (Non-polar) 2 o 0.3 (Non-polar)

*4

AC 230 V AC 230 V AC 230 V AC 230 V AC 230 V

AC 230 V AC 230 V AC 230 V AC 230 V AC 230 V

DC 24 V DC 24 V DC 24 V DC 24 V DC 24 V

DC 12 V DC 12 V DC 12 V DC 12 V DC 12 V

A-Control

Outdoor Unit

Isolator

S1

S2

S3

3 poles isolator

S1

S2

S3

A-Control

Indoor Unit

Warning:

In case of A-control wiring, there is high v oltage potential on the S3 terminal caused by electrical circuit design that has no electrical insulation between power line

and communication signal line. Therefore, please turn off the main power supply when servicing. And do not touch the S1, S2, S3 terminals when the power is

energized. If isolator should be used between indoor unit and outdoor unit, please use 3-poles type.

1:1 system Synchronized twin and triple system Electrical wiring

• Synchronized twin

• Synchronized triple

24

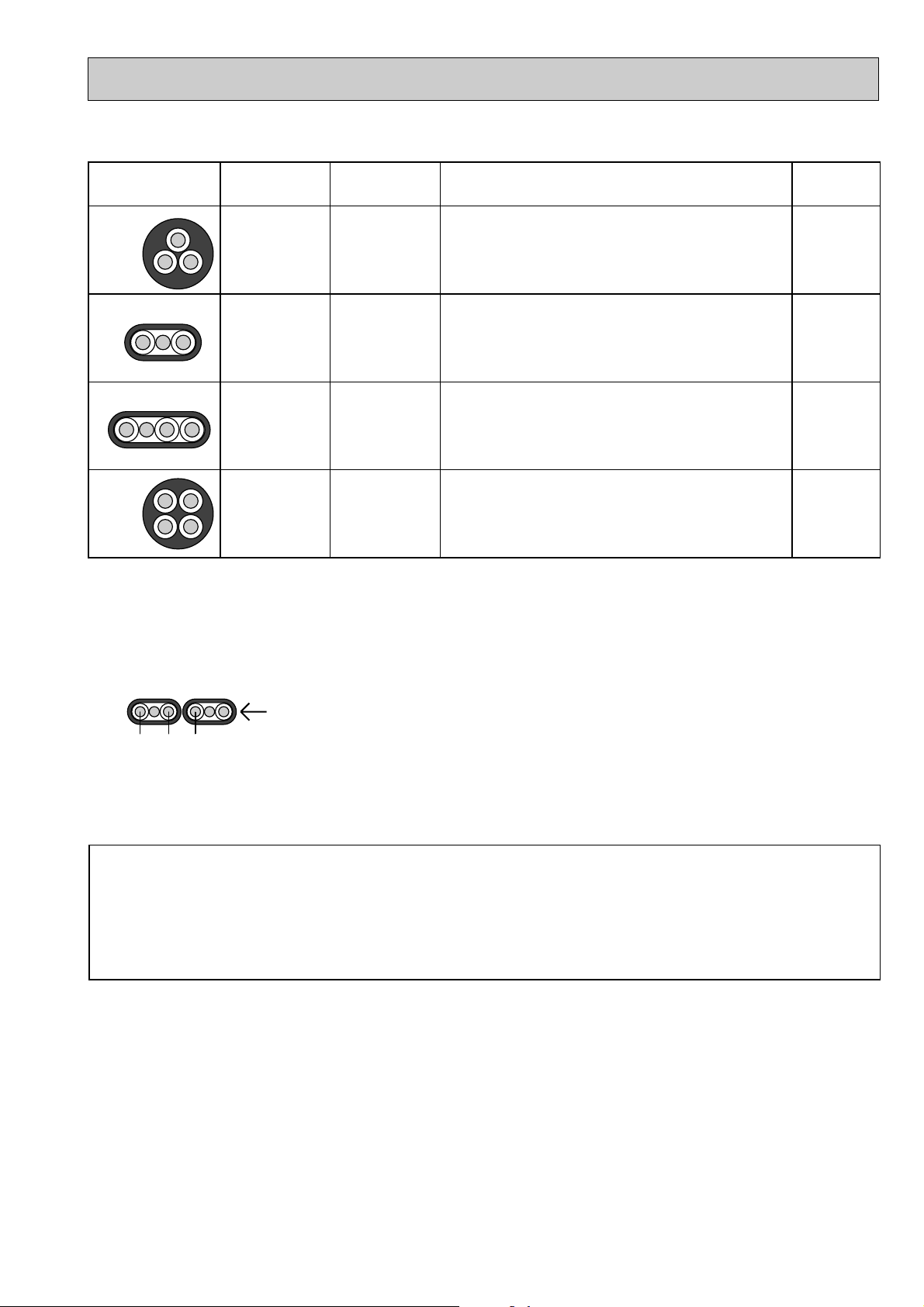

Cross section

of cable

Round

2.5

2.5

1.5

2.5

3

3

4

4

(50)

✽2

(45)

✽3

60

✽4

Not

applicable

✽5

Flat

✽1 : Power supply cords of appliances shall not be lighter than design 245 IEC or 227 IEC.

✽2 : In case that cable with stripe of yellow and green is available.

✽3 : In case of regular polarity connection (S1-S2-S3), wire size is 1.5mm

2

.

✽4 : In case of regular polarity connection (S1-S2-S3).

✽5 : In the flat cables are connected as this picture, they can be used up to 80m.

✽6 : Mentioned cable length is just a reference value.

It may be different depending on the condition of installation, Humidity or materials, etc.

Flat

Round

Wire size

(mm

2

)

Number

of wires

Clockwise : S1-S2-S3

w Pay attention to stripe of yellow and green

Clockwise : S1-S2-S3-Open

w Connect S1 and S3 to the opposite angle

Not applicable

(Because center wire has no cover finish)

From left to right : S1-Open-S2-S3

Polarity

L(m)

✽6

(3C Flat cable ✕ 2)

S1 S2 S3

Be sure to connect the indoor-outdoor connecting cables directly to the units (no intermediate

connections).

Intermediate connections can lead to communication errors if water enters the cables and causes

insufficient insulation to ground or a poor electrical contact at the intermediate connection point.

(If an intermediate connection is necessary, be sure to take measures to prevent water from entering

the cables.)

8-2. INDOOR-OUTDOOR CONNECTING CABLE

25

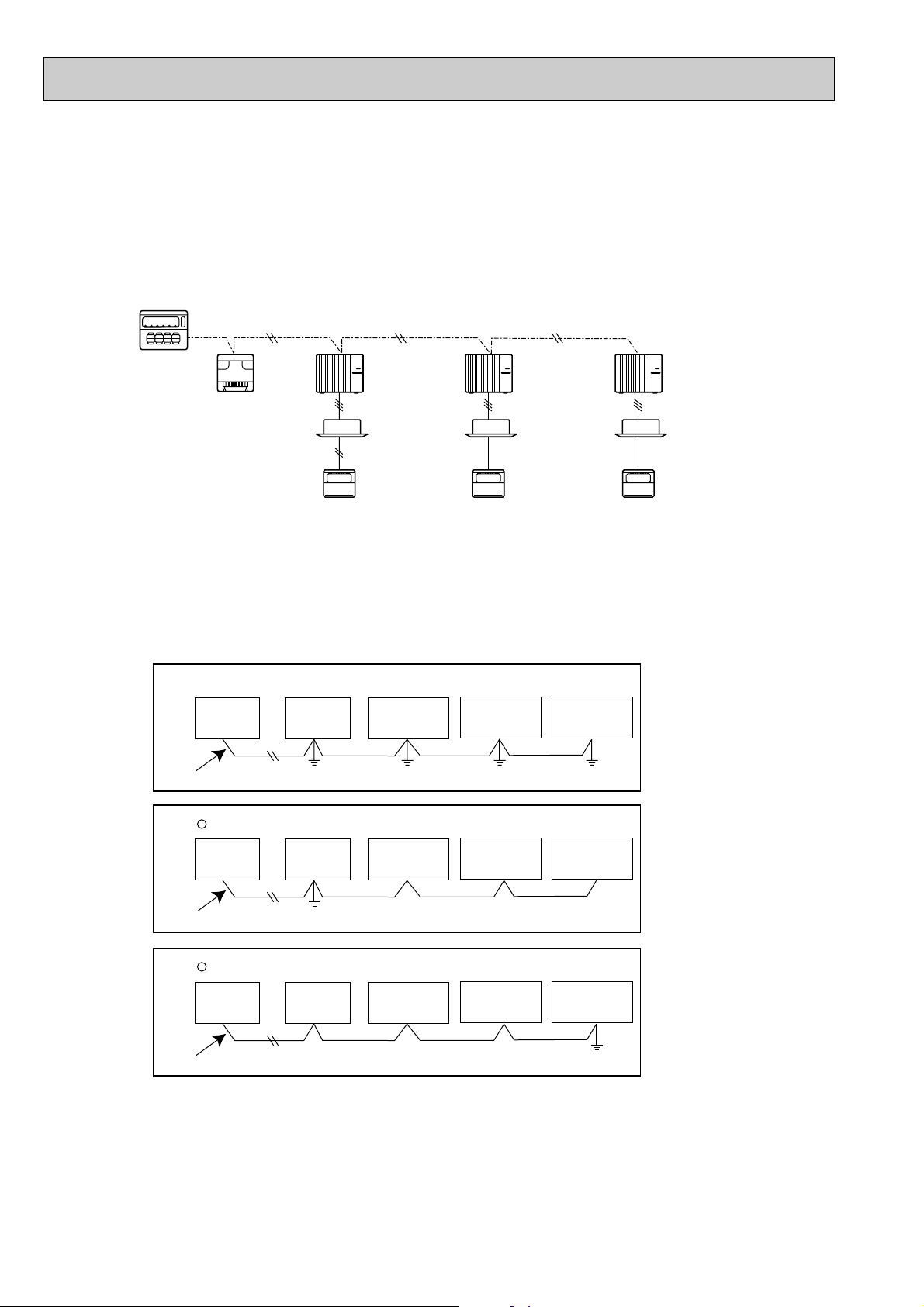

8-3. M-NET WIRING METHOD

Group

remote

controller

Refrigerant

address 00

M-NET

address 01

A-control

remote

controller

A-control

remote

controller

A-control

remote

controller

Refrigerant

address 00

M-NET

address 02

Refrigerant

address 00

M-NET

address 03

Power

supply

unit for

transmission

wire

Central

remote

controller

M-NET transmission wire

✕ Bad example (Multi spot grounding of shield wire)

Good example 1 (Single spot grounding of shield wire)

Power

supply

appliance

M-NET type

outdoor unit

Central

remote

controller

Power

supply

appliance

M-NET type

outdoor unit

M-NET type

outdoor unit

M-NET type

outdoor unit

M-NET transmission wire

M-NET type

outdoor unit

M-NET type

outdoor unit

Central

remote

controller

Power

supply

appliance

M-NET type

outdoor unit

M-NET transmission wire

M-NET type

outdoor unit

M-NET type

outdoor unit

Good example 2 (Single spot grounding of shield wire)

(Points to notice)

(1) Outside the unit, transmission wires should stay away from electric wires in order to prevent electromagnetic noise from

making an influence on the signal communication. Place them at intervals of more than 5cm. Do not put them in the same

conduit tube.

(2) Terminal block (TB7) for transmission wires should never be connected to 220~240V power supply. If it is connected,

electronic parts on M-NET p.c. board may be burn out.

(3) Use 2-core x 1.25mm2shield wire (CVVS, CPEVS) for the transmission wire. Transmission signals may not be sent or

received normally if different types of transmission wires are put together in the same multi-conductor cable. Never do this

because this may cause a malfunction.

It would be ok if M-NET wire (non-polar, 2-cores) is arranged in addition to the wiring for A-control.

(4) Ground only one of any appliances through M-NET transmission wire (shield wire). Communication error may occur due to

the influence of electromagnetic noise.

“Ed” error will appear on the LED display of outdoor unit.

“0403” error will appear on the central-control remote controller.

If there are more than two grounding spots on the shield wire, noise may enter into the shield wire because the ground wire

and shield wire form one circuit and the electric potential difference occurs due to the impedance difference among grounding spots. In case of single spot grounding, noise does not enter into the shield wire because the ground wire and shield

wire do not form one circuit.

To avoid communication errors caused by noise, make sure to observe the single spot grounding method described in the

installation manual.

26

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

12

~

50

M-NET Address No.

<Setting example>

Switng

setting

SW11

ones

digit

SW12

tens

digit

OFF

ON

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

0

Refrigerant

address

OFF

ON

8

OFF

ON

1

OFF

ON

9

OFF

ON

10

OFF

ON

11

OFF

ON

12

OFF

ON

13

OFF

ON

14

OFF

ON

15

OFF

ON

2

OFF

ON

3

OFF

ON

4

OFF

ON

5

OFF

ON

6

OFF

ON

7

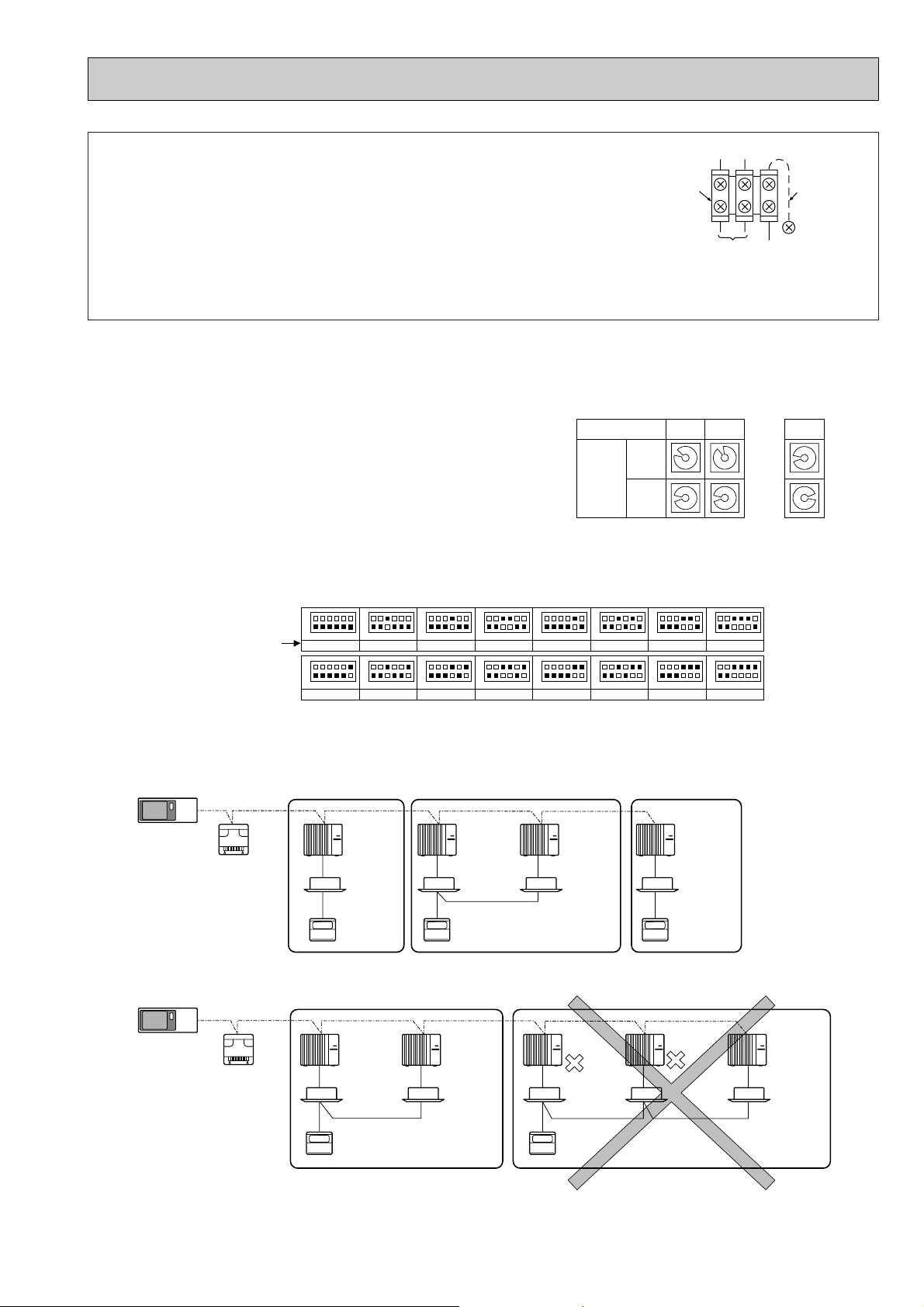

System

controller

A-control

remote

controller

Group A Group B Group C

A-control

remote

controller

TB5

A-control

remote

controller

Refrigerant

address 00

M-NET

address 01

Refrigerant

address 00

M-NET

address 02

Refrigerant

address 01

M-NET

address 03

Refrigerant

address 00

M-NET

address 04

Power

supply

unit for

transmission

wire

A-control

remote

controller

A-control

remote

controller

TB5

Group A Group B

Refrigerant

address 00

M-NET

address 01

Refrigerant

address 01

M-NET

address 02

Refrigerant

address 00

M-NET

address 04

Refrigerant

address 01

M-NET

address 03

Refrigerant

address 02

M-NET

address 05

System

controller

Power

supply

unit for

transmission

wire

● M-NET wiring

(1) Use 2-core x 1.25mm

2

shield wire for electric wires.

(Excluding the case connecting to system controller.)

(2) Connect the wire to the M-NET terminal block.Connect one core of the

transmission wire (non-polar) to Aterminal and the other to B. Peel the

shield wire, twist the shield part to a string and connect it to S terminal.

(3) In the system which several outdoor units are being connected, the terminal

(A, B, S) on M-NET terminal block should be individually wired to the other

M-NET

terminal

block

ABS

Transmission

wire

Ground

wire

Shield

part

outdoor unit’s terminal, i.e. Ato A, B to B and S to S.In this case, choose one of those outdoor units and drive a screw

to fix an ground wire on the plate as shown on the right figure.

8-3-1. M-NET address setting

In A-control models, M-NET address and refrigerant address should be set only for the outdoor unit. Similar to Free Combo

system, there is no need to set the address of outdoor unit and remote controller. To construct a central control system, the

setting of M-NET address should be conducted only upon the outdoor unit. The setting range should be 1 to 50 (the same as

that of the indoor unit in Free Combo system), and the address number should be consecutively set in a same group.

Address number can be set by using rotary switches

(SW11 for ones digit and SW12 for tens digit), which

is located on the M-NET board of outdoor unit.

(Factory setting: all addresses are set to “0”.)

8-3-2. Refrigerant address setting

In case of multiple grouping system (multiple refrigerant circuits in one group), indoor units should be connected by remote

controller wiring (TB5) and the refrigerant address needs to be set. Leave the refrigerant addresses to “00” if the group setting is not conducted. Set the refrigerant address by using DIP SW1-3 to -6 on the outdoor controller board. [Factory setting:

all switches are OFF. (All refrigerant addresses are “00”.)]

8-3-3. Regulations in address settings

In case of multiple grouping system, M-NET and refrigerant address settings should be done as explained in the above section. Set the lowest number in the group for the outdoor unit whose refrigerant address is “00” as its M-NET address.

w Refrigerant addresses can be overlapped if they are in the different group.

w In group B, M-NET address of the outdoor unit whose refrigerant address is “00” is not set to the minimum in the group. As

“3” is right for this situation, the setting is wrong. Taking group A as a good sample, set the minimum M-NET address in

the group for the outdoor unit whose refrigerant address is “00”.

27

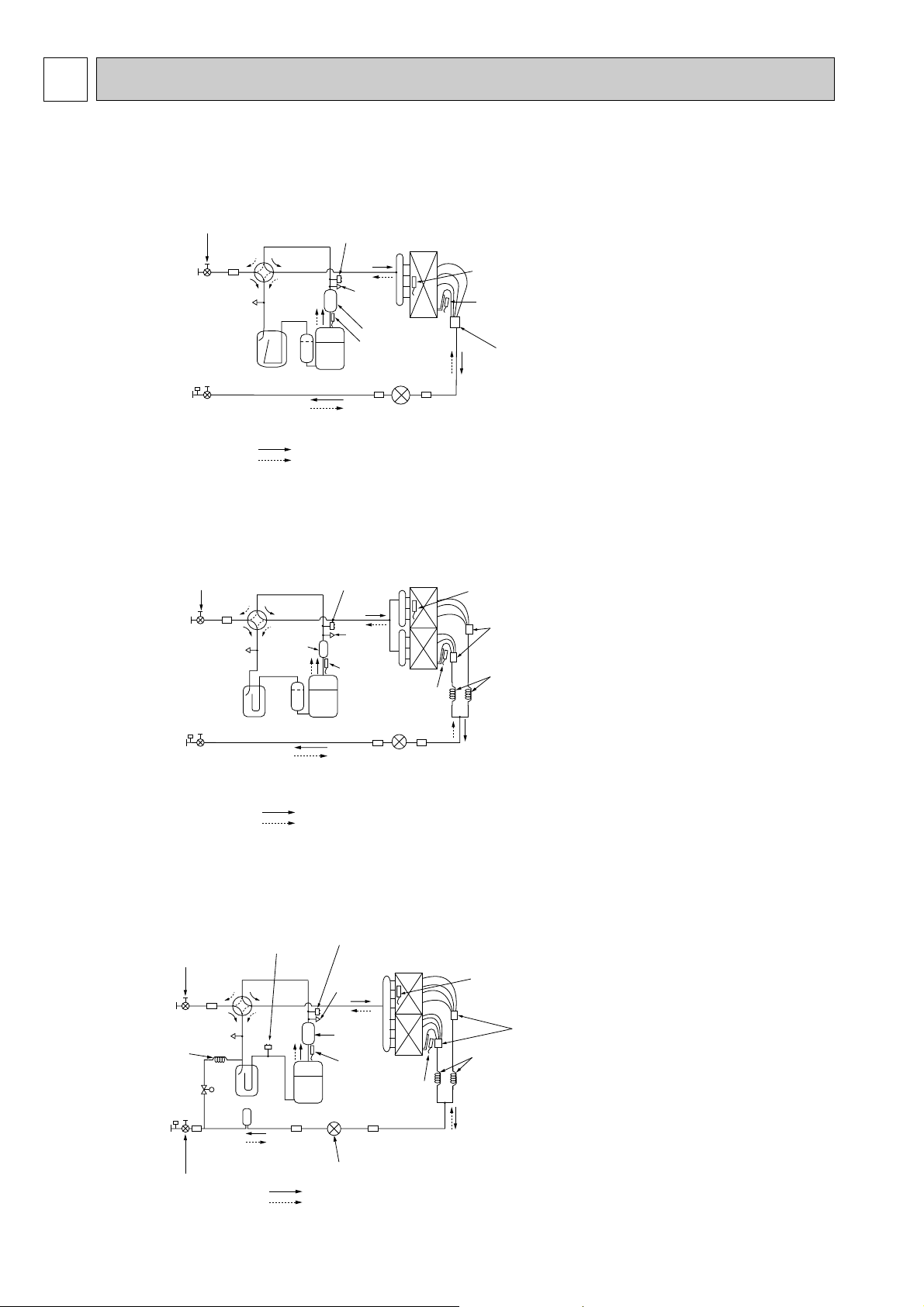

9

Service

port

Accumulator

Compressor

Refrigerant GAS pipe

19.05A({3/4")

Refrigerant LIQUID pipe

9.52A({3/8")

Stop valve

(with service port)

4-way valve

Service

port

High pressure

protect switch

Thermistor

(TH3)

Capillary tube

(O.D.4.0✕I.D.3.0-L350)✕2pcs

Refrigerant flow in cooling

Refrigerant flow in heating

Liner expansion valve

Thermistor

(TH4)

Muffler

Thermistor

(TH6)

Distributor

with

strainer

Ball valve

(#50)

Strainer

(#100)

Strainer

(#100)

Strainer

Service

port

Accumulator

Ball valve

Compressor

Refrigerant GAS pipe

P25···12.7A({1/2")

P35~P71···15.88A({5/8")

Refrigerant LIQUID pipe

P25···6.35A({1/4")

P35~P71···9.52A({3/8")

Stop valve

(with service port)

4-way valve

Service

port

High pressure

protect switch

Outdoor heat exchanger

Thermistor

(TH3)

Thermistor

(TH6)

Distributor

with

strainer

Muffler

Thermistor(TH4)

Linear expansion valve

Refrigerant flow in cooling

Refrigerant flow in heating

(#50)

Strainer

(#100)

Strainer

(#100)

Strainer

Service

port

Accumulator

Compressor

Refrigerant GAS pipe

19.05A({3/4")

Refrigerant LIQUID pipe

9.52A({3/8")

4-way

valve

Service

port

High pressure protect switch

Thermistor

(TH3)

Capillary tube

(O.D.4.0✕I.D.3.0-L200)✕2pcs

Drier

Liner expansion valve

Muffler

Thermistor

(TH4)

Thermistor

(TH6)

Distributor

with

strainer

Refrigerant flow in cooling

Refrigerant flow in heating

w1 : O.D.4.0✕I.D.2.0-L400(PUH-P125)

O.D.4.0✕I.D.3.0-L450(PUH-P140)

Ball valve

(#50)

Strainer

Strainer

(#100)

Strainer

(#100)

Strainer

(#50)

Low pressure protect

switch

Stop valve

(with service port)

Capillary

tube w1

REFRIGERANT SYSTEM DIAGRAM

PUH-P25VGAA.UK PUH-P35VGAA.UK PUH-P50VGAA.UK PUH-P60VGAA.UK

PUH-P71VGAA.UK

PUH-P35YGAA.UK PUH-P50YGAA.UK PUH-P60YGAA.UK PUH-P71YGAA.UK

<4-way valve solenoid coil>

Heating : ON

Cooling : OFF

PUH-P100VGAA.UK

PUH-P100YGAA.UK

PUH-P125YGAA.UK

PUH-P140YGAA.UK

28

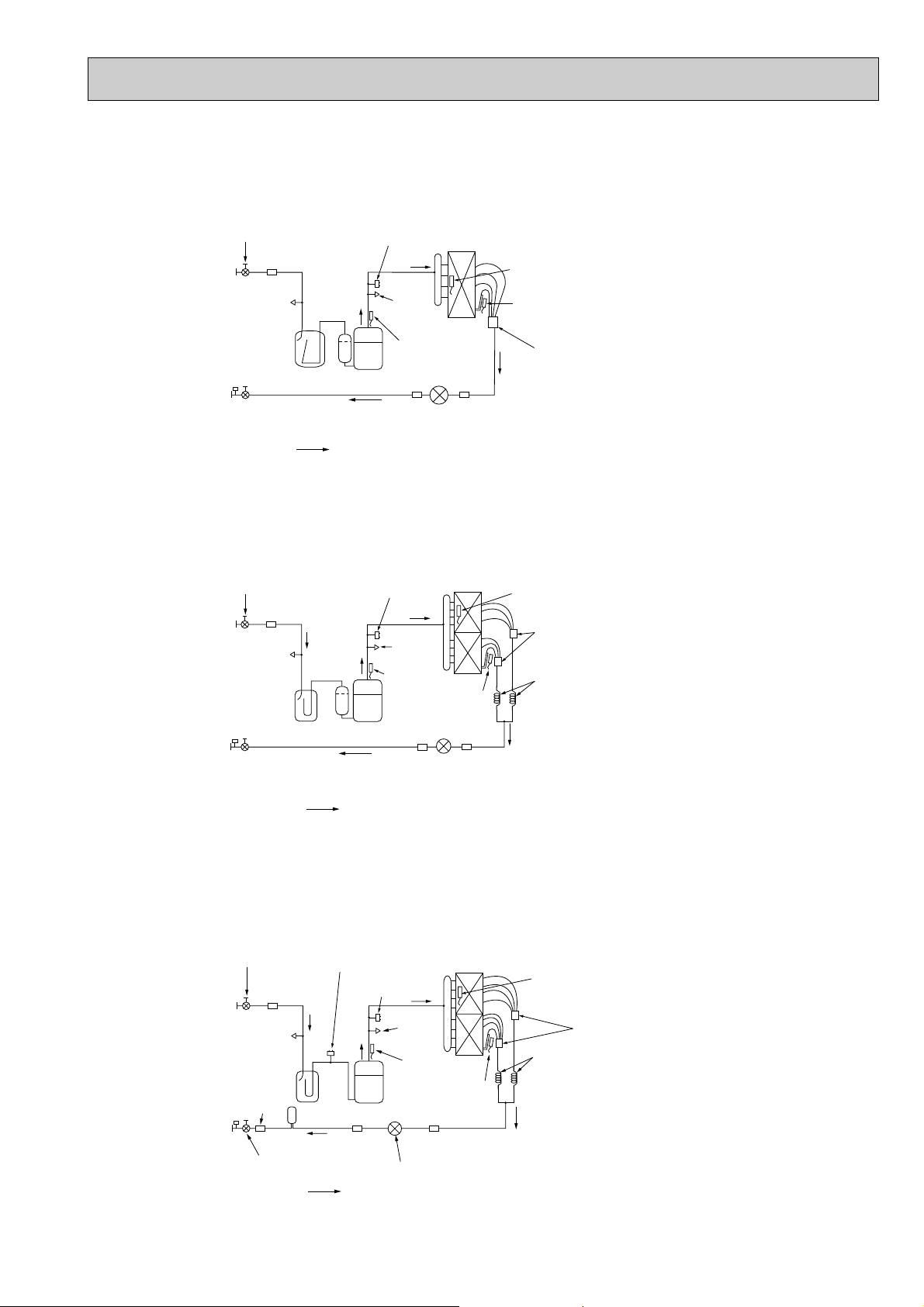

Service

port

Accumulator

Compressor

Refrigerant GAS pipe

19.05A({3/4")

Refrigerant LIQUID pipe

9.52A({3/8")

Stop valve

(with service port)

Service

port

High pressure

protect switch

Thermistor

(TH3)

Capillary tube

(O.D.4.0✕I.D.3.0-R350)✕2pcs

Refrigerant flow in cooling

Liner expansion valve

Thermistor

(TH4)

Thermistor

(TH6)

Distributor

with

strainer

Ball valve

(#50)

Strainer

(#100)

Strainer

(#100)

Strainer

PU-P35VGAA.UK PU-P50VGAA.UK PU-P60VGAA.UK PU-P71VGAA.UK

Service

port

Accumulator

Compressor

Refrigerant GAS pipe

15.88A({5/8")

Refrigerant LIQUID pipe

9.52A({3/8")

Stop valve

(with service port)

Service

port

High pressure

protect switch

Outdoor heat exchanger

Thermistor

(TH3)

Thermistor

(TH6)

Distributor

with

strainer

Thermistor(TH4)

Linear expansion valve

Refrigerant flow in cooling

Ball valve

(#50)

Strainer

(#100)

Strainer

(#100)

Strainer

Service

port

Accumulator

Compressor

Refrigerant GAS pipe

19.05A({3/4")

Refrigerant LIQUID pipe

9.52A({3/8")

Service

port

High pressure

protect switch

Thermistor

(TH3)

Capillary tube

(O.D.4.0✕I.D.3.0-L200)✕2pcs

Drier

Thermistor

(TH4)

Thermistor

(TH6)

Distributor

with