Page 1

AIR-COOLED SPLIT-TYPE

PACKAGED AIR CONDITIONERS

2003

TECHNICAL & SERVICE MANUAL

<Outdoor unit>

Models

HEAT PUMP PUH-P8MYA, PUH-P10MYA

(Single and Twin/Triple/Four)

For use with the R407C

Page 2

Contents

Page

1 PRECAUTIONS FOR DEVICES THAT USE R407C REFRIGERANT ...................................... 1

[1] Storage of Piping Material ...................................................................................................2

[2] Piping Machining ................................................................................................................. 3

[3] Necessary Apparatus and Materials and Notes on Their Handling ..................................... 4

[4] Brazing................................................................................................................................. 5

[5] Airtightness Test .................................................................................................................. 6

[6] Vacuuming ........................................................................................................................... 6

[7] Charging of Refrigerant ....................................................................................................... 7

2 SPECIFICATIONS ...................................................................................................................... 8

3 EXTERNAL DIMENSIONS ....................................................................................................... 10

4 ELECTRICAL WIRING DIAGRAM ............................................................................................ 11

[1] Outdoor Unit ....................................................................................................................... 11

[2] Skelton of Indoor/Outdoor Connection .............................................................................. 12

5 Technical Data of PUH-8/10YD to Meet LVD ......................................................................... 13

[1] Standard Operation Data ................................................................................................... 13

[2] Cooling Capacity Curves ................................................................................................... 14

[3] Heating Capacity Curves ................................................................................................... 14

[4] Capacity Reduction Ratio due to Changes in Piping Length ............................................. 15

[5] Center of Gravity (Outdoor unit) ........................................................................................ 16

[6] NC Curve (Outdoor unit) ................................................................................................... 17

6 SERVICE DATA ........................................................................................................................ 18

[1] Appearance of Equipment ................................................................................................. 18

[2] Refrigerant Circuit .............................................................................................................. 20

[3] Limitation of Refrigerant Piping Length.............................................................................. 20

[4] Refrigerant Piping .............................................................................................................. 21

[5] Refrigerant Charge ............................................................................................................ 21

[6] Operation Rage ................................................................................................................. 21

7 CONTROL ................................................................................................................................ 22

[1] Composition of Control ...................................................................................................... 22

[2] Control specifications......................................................................................................... 23

[3] Function of switches and connectors (outdoor unit) .......................................................... 27

[4] Simple parts check method ............................................................................................... 35

[5] Reference Data.................................................................................................................. 36

[6] Troubleshooting of each part ............................................................................................. 37

[7] Emergency operation......................................................................................................... 40

[8] Self-diagnosis and troubleshooting.................................................................................... 42

8 Test run .................................................................................................................................... 51

Page 3

1 PRECAUTIONS FOR DEVICES THAT USE R407C REFRIGERANT

Caution

Do not use the existing refrigerant piping.

• The old refrigerant and refrigerator oil in the existing

piping contains a large amount of chlorine which may

cause the refrigerator oil of the new unit to deteriorate.

Use refrigerant piping made of C1220 (CU-DHP) phosphorus deoxidized copper as specified in the *JIS

H3300 “Copper and copper alloy seamless pipes and

tubes”. In addition, be sure that the inner and outer

surfaces of the pipes are clean and free of hazardous sulphur, oxides, dust/dirt, shaving particles, oils,

moisture, or any other contaminant.

• Contaminants on the inside of the refrigerant piping

may cause the refrigerant residual oil to deteriorate.

*JIS: Japanese Industrial Standard

Store the piping to be used during installation indoors

and keep both ends of the piping sealed until just

before brazing. (Store elbows and other joints in a

plastic bag.)

Use a vacuum pump with a reverse flow check valve.

• The vacuum pump oil may flow back into the refrigerant cycle and cause the refrigerator oil to deteriorate.

Do not use the following tools that have been used

with conventional refrigerants.

(Gauge manifold, charge hose, gas leak detector, reverse flow check valve, refrigerant charge base,

vacuum gauge, refrigerant recovery equipment)

• If the conventional refrigerant and refrigerator oil are

mixed in the R407C, the refrigerant may deteriorated.

• If water is mixed in the R407C, the refrigerator oil may

deteriorate.

• Since R407C does not contain any chlorine, gas leak

detectors for conventional refrigerants will not react to

it.

Do not use a charging cylinder.

• Using a charging cylinder may cause the refrigerant

to deteriorate.

• If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and compressor trouble may result.

Use ester oil, ether oil or alkylbenzene (small amount)

as the refrigerator oil to coat flares and flange connections.

• The refrigerator oil will degrade if it is mixed with a

large amount of mineral oil.

Use liquid refrigerant to seal the system.

• If gas refrigerant is used to seal the system, the composition of the refrigerant in the cylinder will change

and performance may drop.

Do not use a refrigerant other than R407C.

• If another refrigerant (R22, etc.) is used, the chlorine

in the refrigerant may cause the refrigerator oil to deteriorate.

Be especially careful when managing the tools.

• If dust, dirt, or water gets in the refrigerant cycle, the

refrigerant may deteriorate.

If the refrigerant leaks, recover the refrigerant in the

refrigerant cycle, then recharge the cycle with the

specified amount of the liquid refrigerant indicated

on the air conditioner.

• Since R407C is a nonazeotropic refrigerant, if additionally charged when the refrigerant leaked, the composition of the refrigerant in the refrigerant cycle will

change and result in a drop in performance or abnormal stopping.

–1–

Page 4

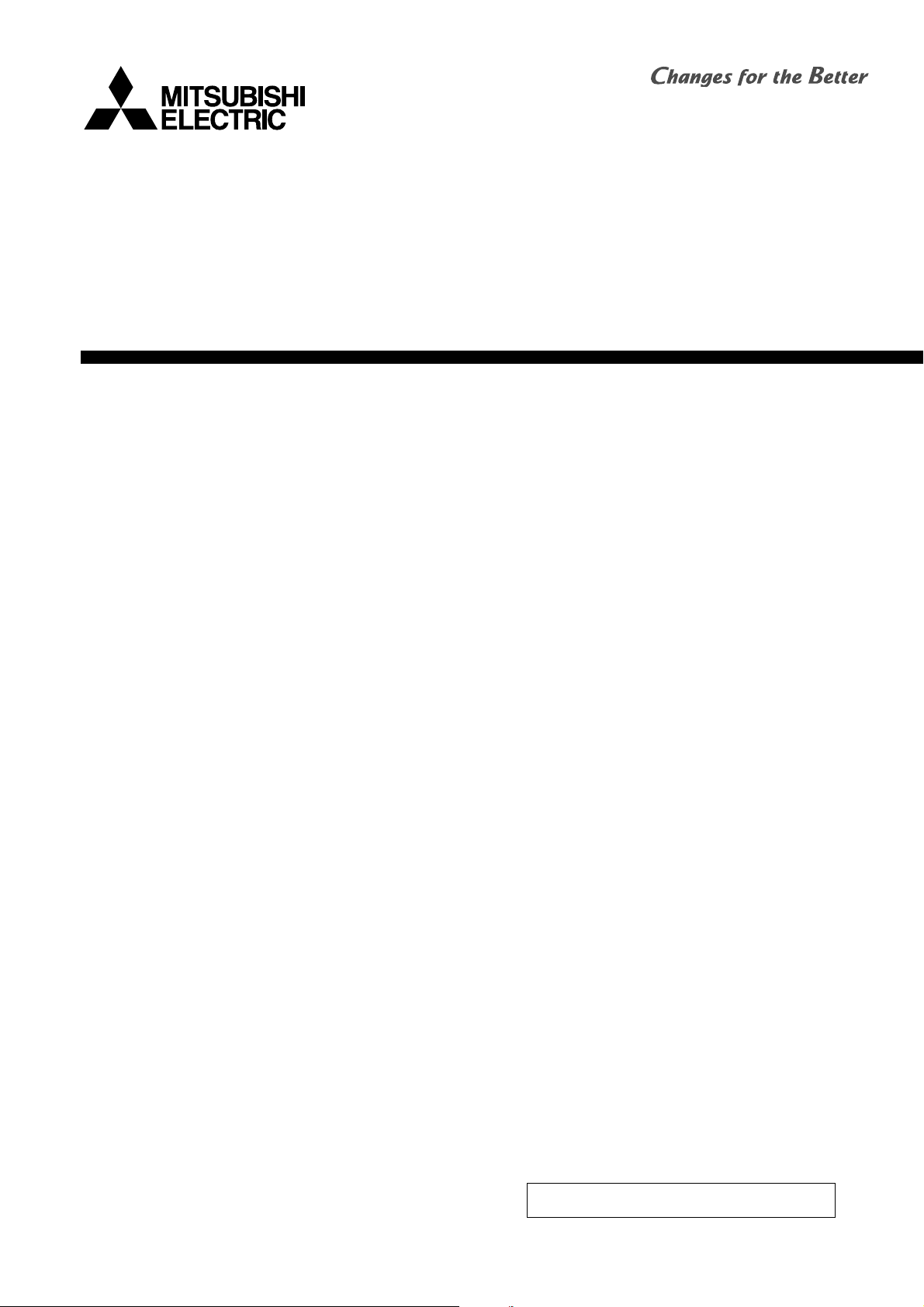

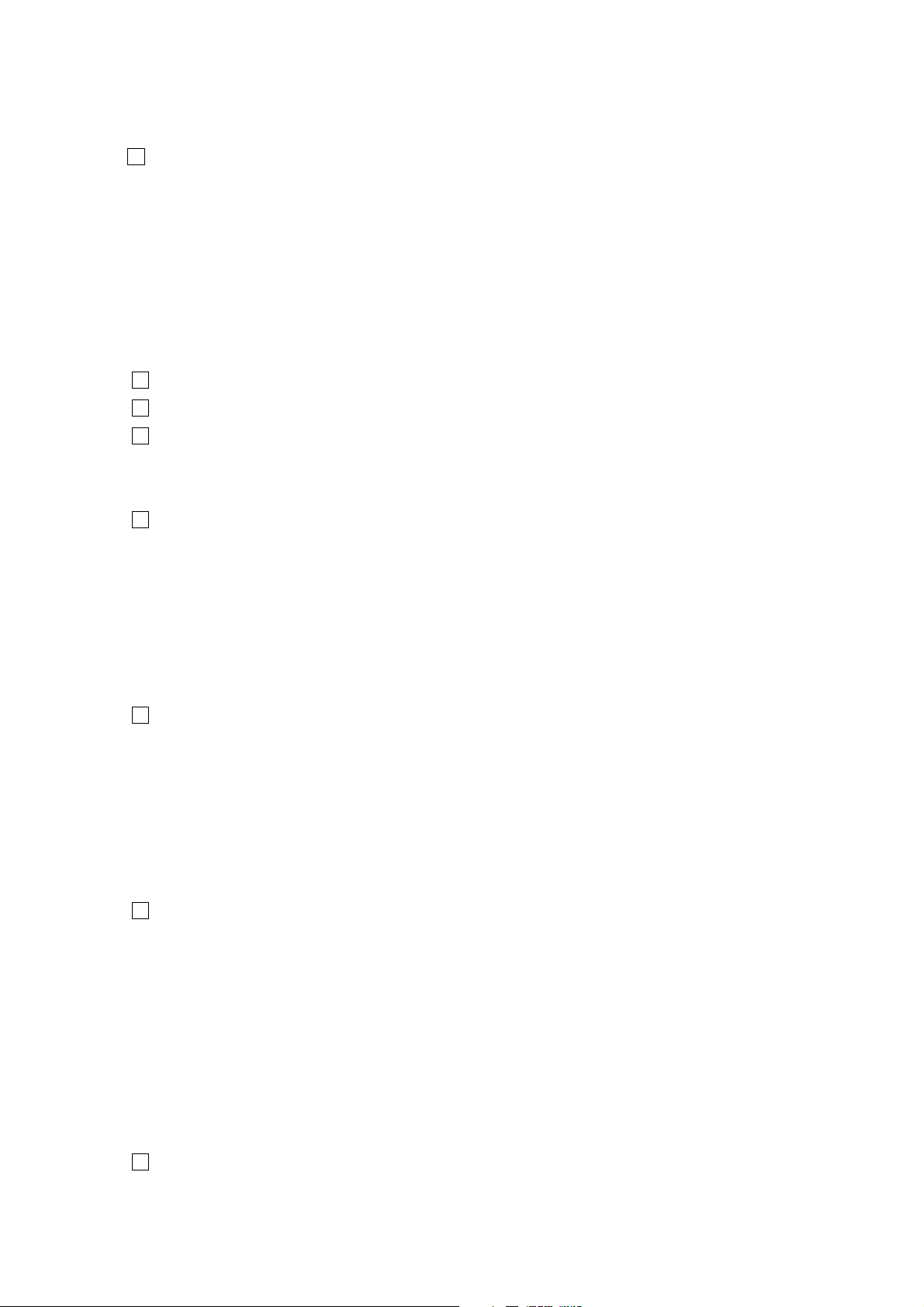

[1] Storage of Piping Material

(1) Storage location

Store the pipes to be used indoors. (Warehouse at site or owner’s warehouse)

Storing them outdoors may cause dirt, waste, or water to infiltrate.

(2) Pipe sealing before storage

Both ends of the pipes should be sealed until immediately before brazing.

Wrap elbows and T’s in plastic bags for storage.

* The new refrigerator oil is 10 times more hygroscopic than the conventional refrigerator oil (such as Suniso). Water

infiltration in the refrigerant circuit may deteriorate the oil or cause a compressor failure. Piping materials must be stored

with more care than with the conventional refrigerant pipes.

–2–

Page 5

[2] Piping Machining

Use ester oil, ether oil or alkylbenzene (small amount) as the refrigerator oil to coat flares and flange connections.

Use only the necessary minimum quantity of oil !

Reason:

1. The refrigerator oil used for the equipment is highly hygroscopic and may introduce water inside.

Notes:

• Introducing a great quantity of mineral oil into the refrigerant circuit may also cause a compressor failure.

• Do not use oils other than ester oil, ether oil or alkylbenzene.

–3–

Page 6

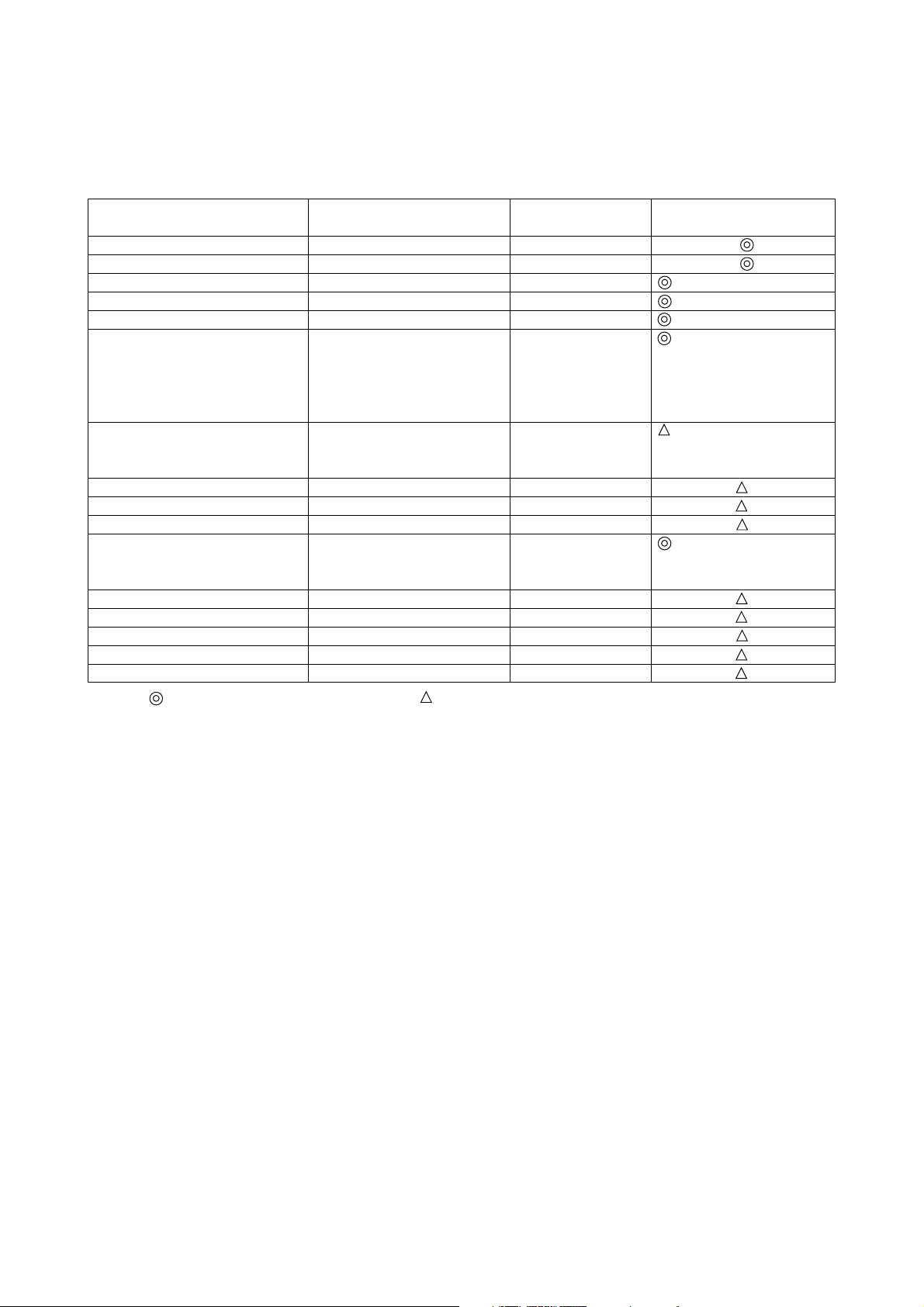

[3] Necessary Apparatus and Materials and Notes on Their Handling

The following tools should be marked as dedicated tools for R407C.

<<Comparison of apparatus and materials used for R407C and for R22>>

Apparatus Used Use R22 R407C

Gauge manifold Evacuating, refrigerant filling Current product

Charging hose Operation check Current product

Charging cylinder Refrigerant charging Current product Do not use

Gas leakage detector Gas leakage check Current product Shared with R134a

Refrigerant collector Refrigerant collection R22 For R407C use only

Refrigerant cylinder Refrigerant filling R22 Identification of dedi-

cated use for R407C:

Record refrigerant name

and put brown belt on

upper part of cylinder.

Vacuum pump Vacuum drying Current product Can be used by attach-

ing an adapter with a

check valve.

Vacuum pump with a check valve Current product

Flare tool Flaring of pipes Current product

Bender Bending of pipes Current product

Application oil Applied to flared parts Current product Ester oil or Ether oil or

Alkybenzene (Small

amount)

Torque wrench Tightening of flare nuts Current product

Pipe cutter Cutting of pipes Current product

Welder and nitrogen cylinder Welding of pipes Current product

Refrigerant charging meter Refrigerant charging Current product

Vacuum gauge Checking the vacuum degree Current product

Symbols: To be used for R407C only. Can also be used for conventional refrigerants.

Tools for R407C must be handled with more care than those for conventional refrigerants. They must not come into contact

with any water or dirt.

–4–

Page 7

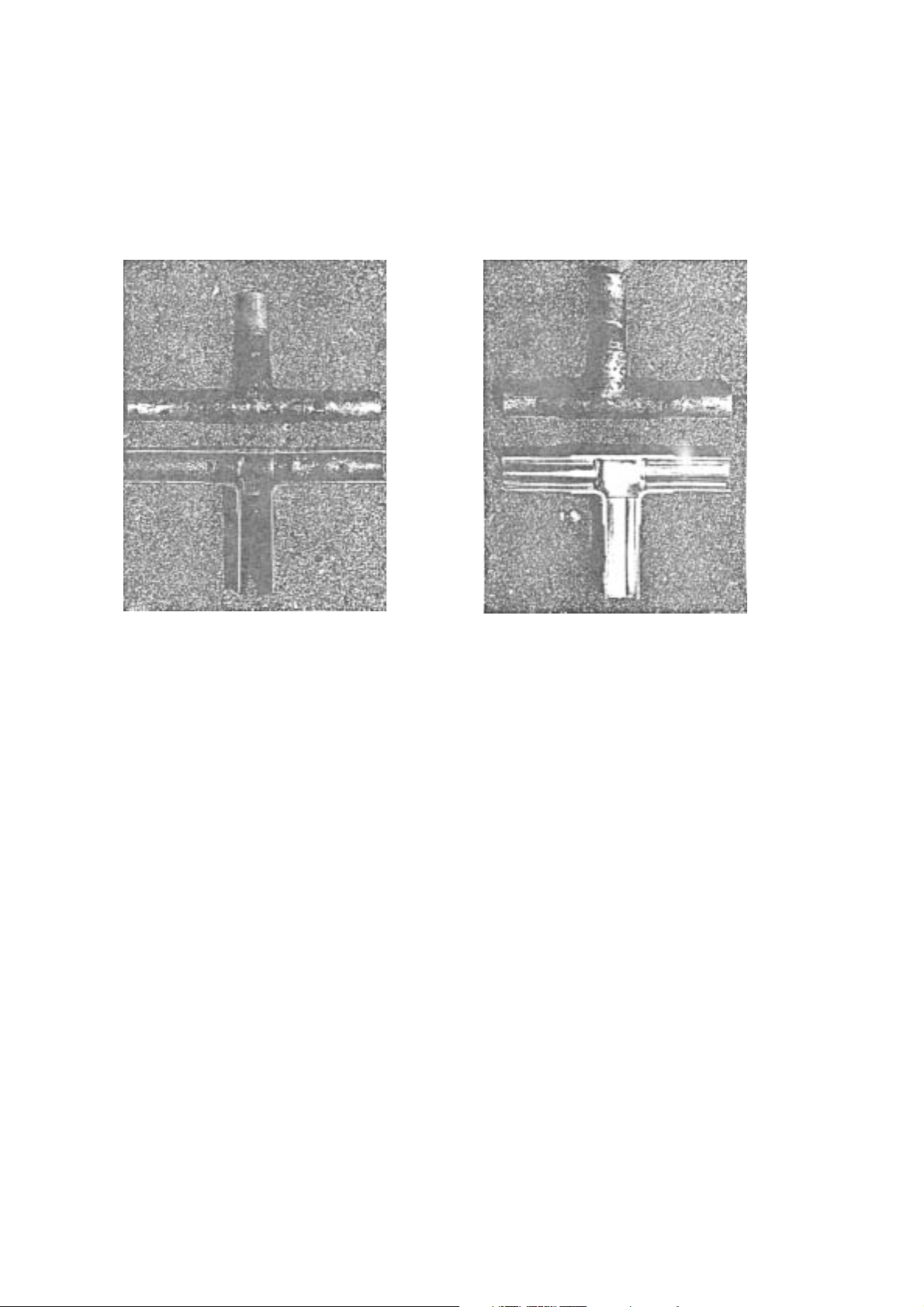

[4] Brazing

No changes from the conventional method, but special care is required so that foreign matter (ie. oxide scale, water, dirt,

etc.) does not enter the refrigerant circuit.

Example: Inner state of brazed section

When non-oxide brazing was not used When non-oxide brazing was used

Items to be strictly observed:

1. Do not conduct refrigerant piping work outdoors on a rainy day.

2. Apply non-oxide brazing.

3. Use a brazing material (Bcup-3) which requires no flux when brazing between copper pipes or between a copper

pipe and copper coupling.

4. If installed refrigerant pipes are not immediately connected to the equipment, then braze and seal both ends of them.

Reasons:

1. The new refrigerant oil is 10 times more hygroscopic than the conventional oil. The probability of a machine failure if

water infiltrates is higher than with conventional refrigerant oil.

2. A flux generally contains chlorine. A residual flux in the refrigerant circuit may generate sludge.

Note:

• Commercially available antioxidants may have adverse effects on the equipment due to its residue, etc. When

applying non-oxide brazing, use nitrogen.

–5–

Page 8

[5] Airtightness Test

No changes from the conventional method. Note that a refrigerant leakage detector for R22 cannot detect R407C leakage.

Halide torch R22 leakage detector

Items to be strictly observed:

1. Pressurize the equipment with nitrogen up to the design pressure and then judge the equipment’s airtightness, taking

temperature variations into account.

2. When investigating leakage locations using a refrigerant, be sure to use R407C.

3. Ensure that R407C is in a liquid state when charging.

Reasons:

1. Use of oxygen as the pressurized gas may cause an explosion.

2. Charging with R407C gas will lead the composition of the remaining refrigerant in the cylinder to change and this

refrigerant can then not be used.

Note:

• A leakage detector for R407C is sold commercially and it should be purchased.

[6] Vacuuming

1. Vacuum pump with check valve

A vacuum pump with a check valve is required to prevent the vacuum pump oil from flowing back into the refrigerant

circuit when the vacuum pump power is turned off (power failure).

It is also possible to attach a check valve to the actual vacuum pump afterwards.

2. Standard degree of vacuum for the vacuum pump

Use a pump which reaches 0.5 Torr (500 MICRON) or below after 5 minutes of operation.

In addition, be sure to use a vacuum pump that has been properly maintained and oiled using the specified oil. If the

vacuum pump is not properly maintained, the degree of vacuum may be too low.

3. Required accuracy of the vacuum gauge

Use a vacuum gauge that can measure up to 5 Torr. Do not use a general gauge manifold since it cannot measure a

vacuum of 5 Torr.

4. Evacuating time

• Evacuate the equipment for 1 hour after –755 mmHg (5 Torr) has been reached.

• After envacuating, leave the equipment for 1 hour and make sure the that vacuum is not lost.

5. Operating procedure when the vacuum pump is stopped

In order to prevent a backflow of the vacuum pump oil, open the relief valve on the vacuum pump side or loosen the

charge hose to drawn in air before stopping operation.

The same operating procedure should be used when using a vacuum pump with a check valve.

–6–

Page 9

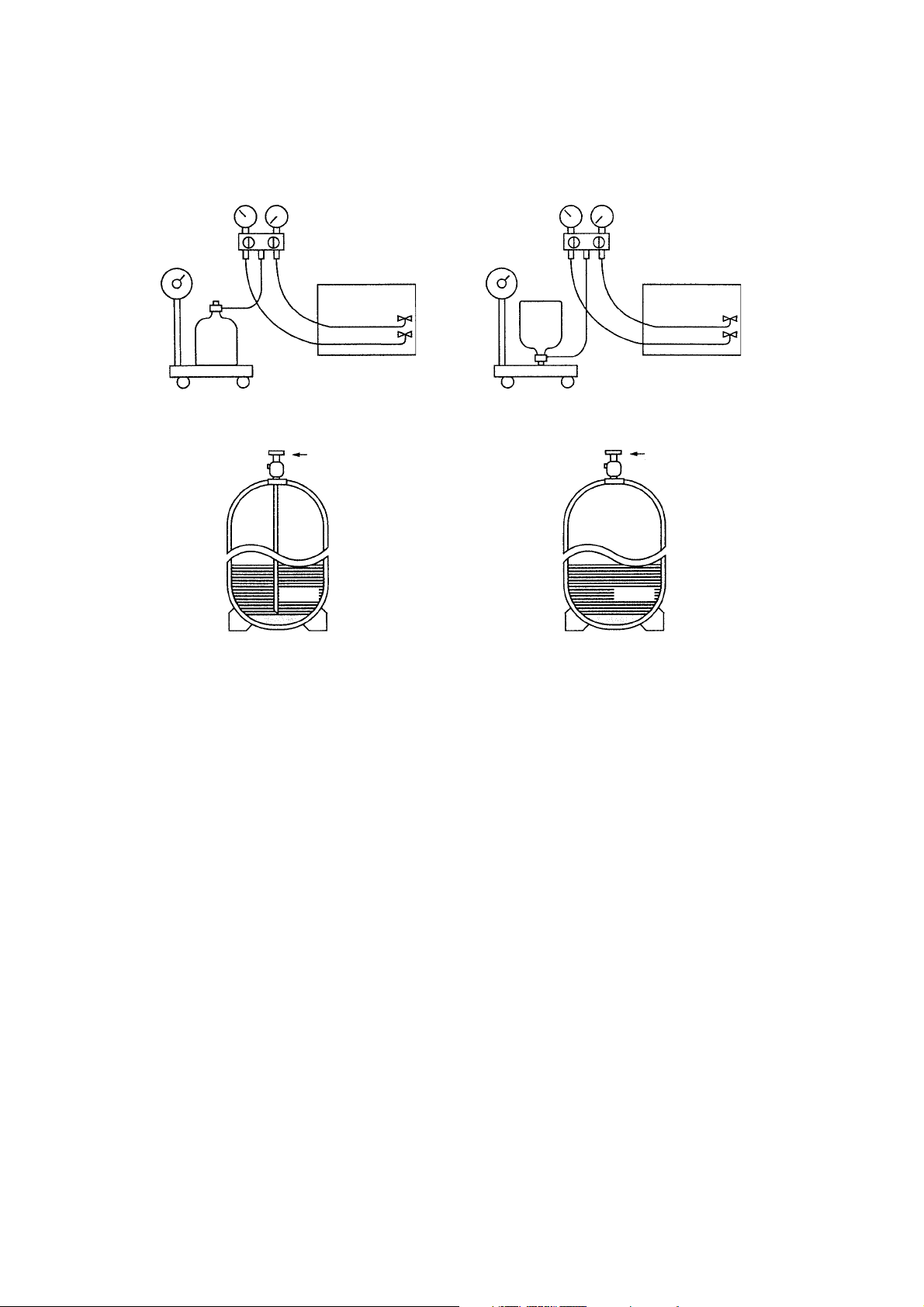

[7] Charging of Refrigerant

R407C must be in a liquid state when charging, because it is a non-azeotropic refrigerant.

For a cylinder with a syphon attached For a cylinder without a syphon attached

Cylin-

Cylin-

der

Cylinder color identification R407C-Gray Charged with liquid refrigerant

R410A-Pink

Valve

der

Valve

Liquid

Liquid

Reasons:

1. R407C is a mixture of 3 refrigerants, each with a different evaporation temperature. Therefore, if the equipment is

charged with R407C gas, then the refrigerant whose evaporation temperature is closest to the outside temperature is

charged first while the rest of refrigerants remain in the cylinder.

Note:

• In the case of a cylinder with a syphon, liquid R407C is charged without turning the cylinder up side down. Check the

type of cylinder before charging.

–7–

Page 10

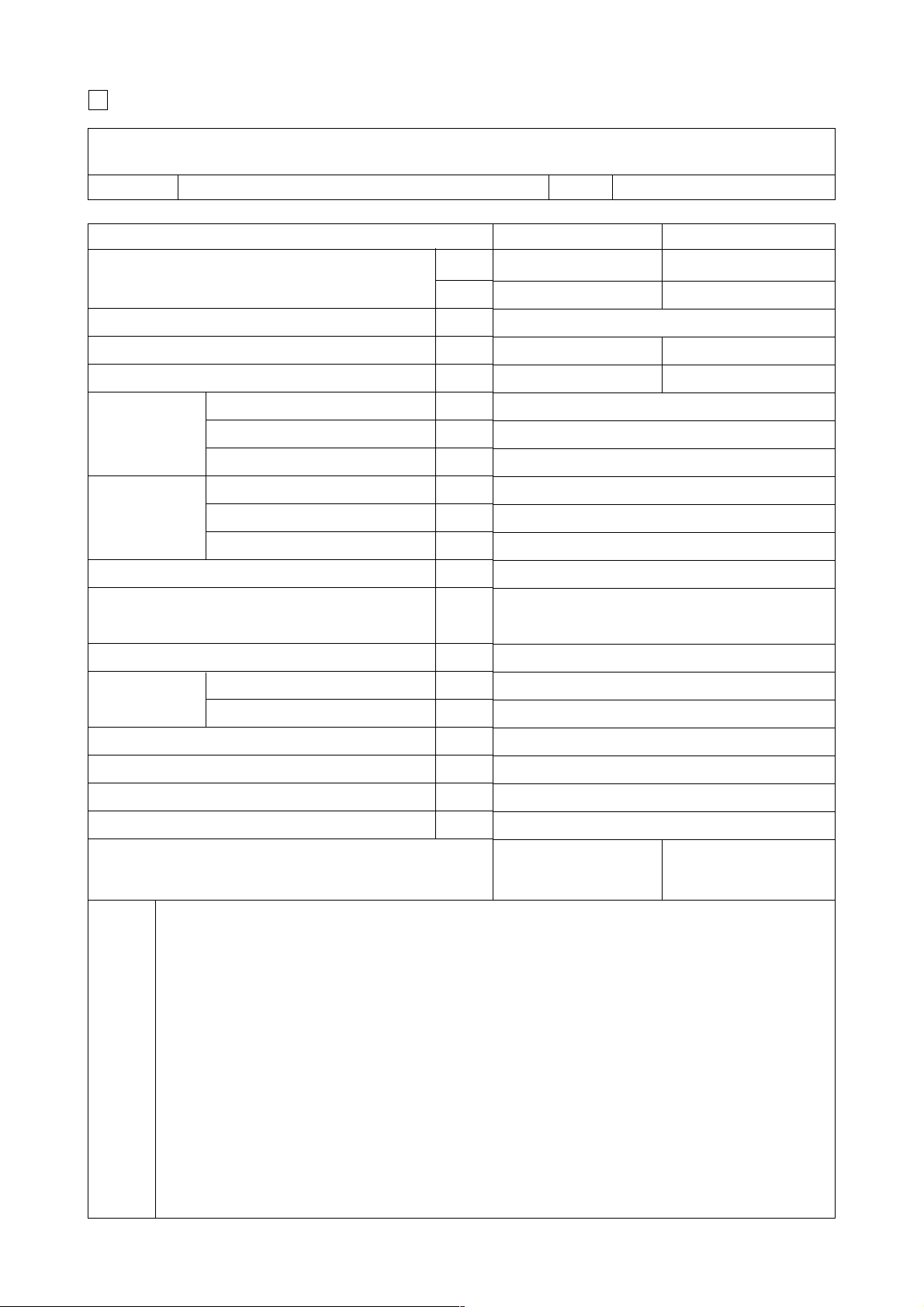

2 SPECIFICATIONS

Specifications of air-source heat pump type packaged air conditioner

(Outdoor unit)

Model name PUH-P8MYA Quantity

Cooling Heating

Capacity

Power source

Power input kW

Current A

Type x Quantity

Fan Airflow rate m3/min

Motor output kW

Type

Compressor Motor output kW

Crankcase heater kW

Refrigerant/Lubricant

External finish

External dimension mm

Protection

device

High pressure protection MPa

Compressor/Fan

kcal/h

kW

18,000 20,400

20.9 23.7

3N~ 380/400/415 V 50 Hz

7.27 7.17

13.0 12.8

Propeller fan × 1

185

0.38

Hermetic

5.5

0.05 (240 V)

R407C/FVC68D

Steel plate painting with polyester powder

(MUNSELL 5Y8/1 or similar)

1,715(H) × 990(W) × 840(L)

3.3

Overcurrent protection/Thermal switch

Refrigerant piping diameter Liquid/Gas mm

Indoor unit

Noise level dB (A)

Net weight kg

Operating temperature range

1. Cooling/Heating capacity indicates the maximum value at operation under the following condition.

Cooling Indoor: 27 °CDB/19 °CWB Outdoor: 35

Notes:

Heating Indoor: 20 °CDB Outdoor: 7

Pipe length: 7.5 m Height difference: 0 m

2. Works not included: Installation/Foundation work, Electrical connection work, Duct work, Insulation

work, Power source switch, and other items not specified in this specifications.

ø12.7 Flare / ø25.4 Flange

PEH-P8MYA

56

215

Indoor: 15 °CWB~24 °CWB Indoor: 15°CDB~27 °CDB

Outdoor: –5 °CDB~46 °CDB

Outdoor: –12 °CWB~18 °CWB

°

CDB

°

CDB/6 °CWB

–8–

Page 11

Specifications of air-source heat pump type packaged air conditioner

(Outdoor unit)

Model name PUH-P10MYA Quantity

Cooling Heating

Capacity

Power source

Power input kW

Current A

Type x Quantity

Fan Airflow rate m3/min

Motor output kW

Type

Compressor Motor output kW

Crankcase heater kW

Refrigerant/Lubricant

External finish

External dimension mm

Protection

device

High pressure protection MPa

Compressor/Fan

kcal/h

kW

22,400 26,200

26.0 30.5

3N~ 380/400/415 V 50 Hz

9.02 8.62

16.0 15.4

Propeller fan × 1

185

0.38

Hermetic

7.5

0.05 (240 V)

R407C/FVC68D

Steel plate painting with polyester powder

(MUNSEL 5Y8/1 or similar)

1,715(H) × 990(W) × 840(L)

3.3

Overcurrent protection/Thermal switch

Refrigerant piping diameter Liquid/Gas mm

Indoor unit

Noise level dB (A)

Net weight kg

Operating temperature range

1. Cooling/Heating capacity indicates the maximum value at operation under the following condition.

Cooling Indoor: 27 °CDB/19 °CWB Outdoor: 35 °CDB

Notes:

Heating Indoor: 20 °CDB Outdoor: 7 °CDB/6 °CWB

Pipe length: 7.5 m Height difference: 0 m

2. Works not included: Installation/Foundation work, Electrical connection work, Duct work, Insulation

work, Power source switch, and other items not specified in this specifications.

ø12.7 Flare / ø28.6 Flange

PEH-P10MYA

57

220

Indoor: 15 °CWB~24 °CWB Indoor: 15 °CDB~27 °CDB

Outdoor: –5 °CDB~46 °CDB Outdoor: –12 °CWB~18 °CWB

–9–

Page 12

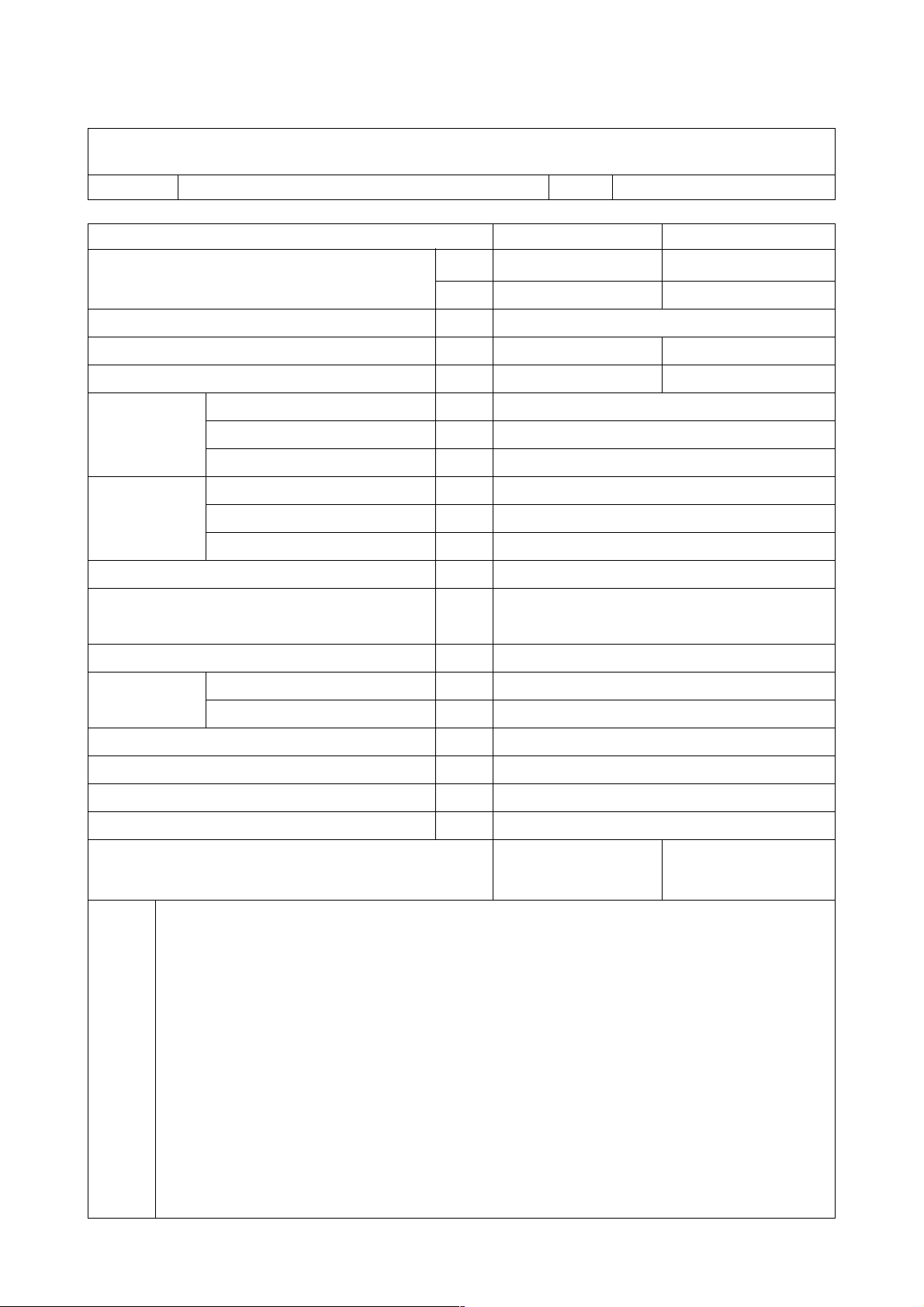

3 EXTERNAL DIMENSIONS

65

60

84

100

251

234

60

75

194

100

48

80

40

121

50

6

5

840

910

15

880

15

990

215

215

560

1715

225

1490

413

55

190

149

40

70

165

31

80

79

55

378

160

25

198

237

80

73

Service panel

4-14X20 holes

<For mounting

anchor bolt M8>

(Field supply)

Plane view

Rear view

Left side view

Front view

Right side view

Refrig. service

valve (liquid)

φ

12.7<flare>

Refrig. service

valve(gas)

<flange>

φ

38.1 Knockout hole

<Bottom side hole for

the power supply>

φ

38.1 Knockout hole

<Left side hole for

the power supply>

Knockout hole

<Front side hole for

the power supply and

control wiring>

φ

38.1 Knockout hole

<Right side hole for

the power supply>

φ

25.4 Knockout hole

<Bottom side hole for

the control wiring>

φ

25.4 Knockout hole

<Left side hole for

the control wiring>

φ

25.4 Knockout hole

<Right side hole for

the control wiring>

Knockout hole

Left piping hole

Knockout hole

Front piping hole

Knockout hole

Pressure gauge

(for option)

Knockout hole

Rear piping hole

(It is necessary

for the option)

Connecting pipe

8 :

φ

25.4<brazed>

10 :

φ

28.6<brazed>

Note 1

Note 2

Note 3

Knockout hole

Bottom piping hole

Cross section X-X

Cross section Y-Y

XX

Y

Y

Air outlet

Air

inlet

Air

inlet

• Models PUH-P8MYA/P10MYA

34 or

φ

34 by selecting

27 or

φ

φ

27 or

φ

the piping when you connected the piping from

the bottom.

(Please be careful not to close the hole of the

bottom plate by the basement.)

27 ............................................................................ 1pc.

34 ............................................................................ 1pc.

(The connecting pipe is fixed with the unit)

<Accessory>

(It is attached control box cover)

• Refrigerant connecting pipe ...................................... 1pc.

• Packing for connecting pipe ...................................... 1pc.

• Conduit mounting plate

40 ............................................................................ 1pc.

(Painted the same color as the unit body)

φ

φ

φ

Note: 1. Please leave a space under the outdoor unit for

• Tapping screw 4 x 12 .............................................. 4pcs.

40 by selecting the conduit mounting plate.

the conduit mounting plate.

φ

2. It is possible to change to

3. The hole size can be selected to

–10–

Page 13

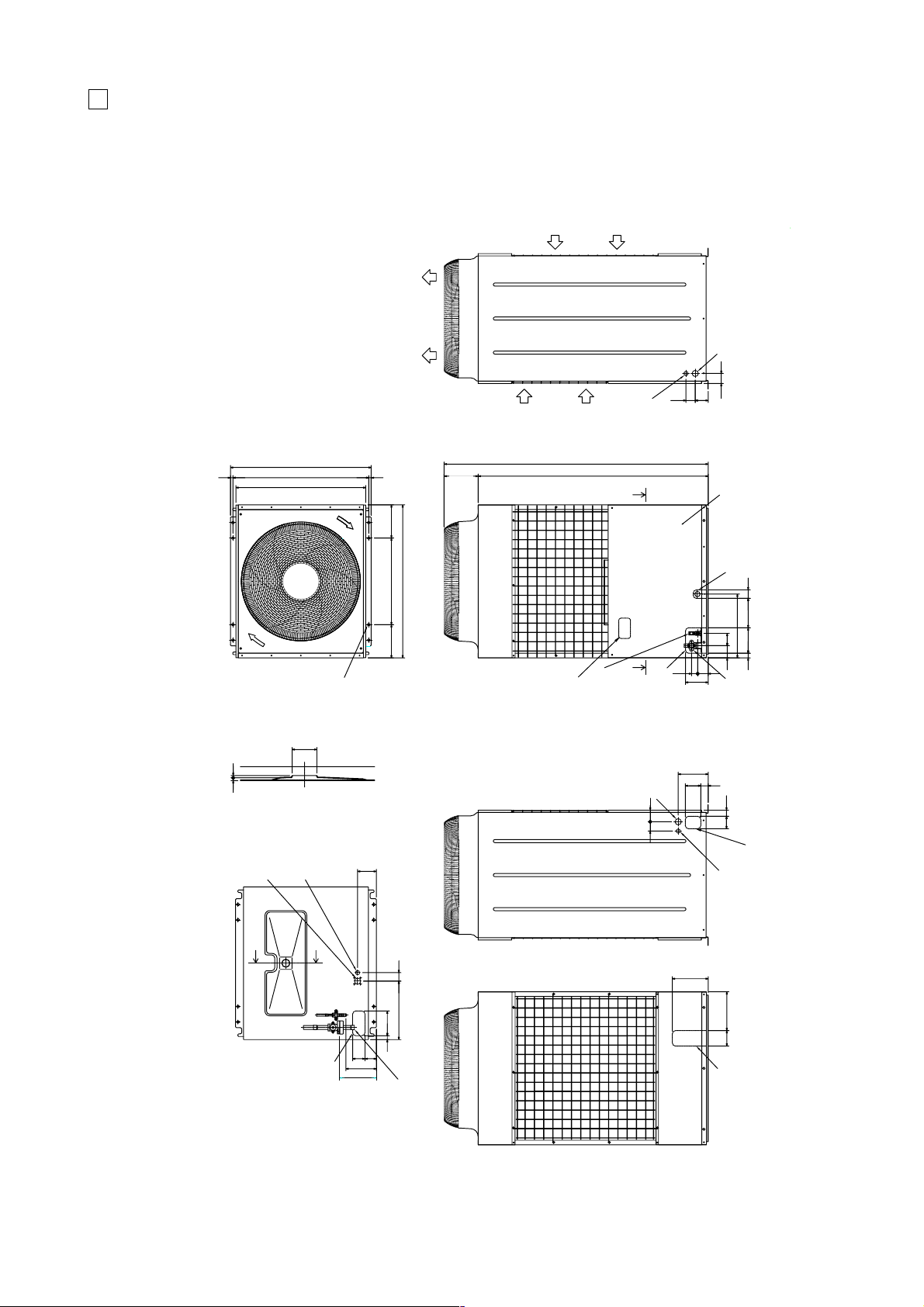

4 ELECTRICAL WIRING DIAGRAM

[1] Outdoor Unit

• Model PUH-P8MYA/P10MYA

63H1

MC

RED

51C

52C

RED

WHITE WHITE

TB1

L1

L2 L3 N PE

POWER SUPPLY

3N~PE

380/400/415V

50HZ

(*1)

BLACK

13 1

C11

(3P)

1

CNFAN

F.C.

BOARD

CNOUT1

11

(5P)

1

3

5

7

CNIN

(7P)

GREEN/YELLOW

BLACK

BLUE

PE

CIRCUIT BREAKER

(FIELD SUPPLY)

PUH-P8MYA-EU : 50A

PUH-P10MYA-EU: 60A

MF

35

(5P)

CNFC2

CNPO

(5P)

3

F10

F20

F30

F1

F2

3

1

(6P)

6

5

CNOUT2

N.F.BOARD

TB3

C12

(3P)

52C

3

(3P)

S1 S2 S3

SV1

PE

CH

21S4

51C

52C

TB8

OUT OUT ININ

TO INDOOR UNIT

CONNECTING WIRES (*2)

(POLER)

63L

CN23

1

3

CN22

1

3

CN21

1

3

CN26

1

3

5

CN25

1

3

CN53

1

3

CN52

1

3

5

6

CNFC1

1

6

(7P)

CN20

7

L1

F01

N

F04

L2

F02

L3

1

F03

X1

INDOOR UNIT

TB4

S1

S2

S3

(3P)

(3P)

(3P)

(5P)

(3P)

(3P)

(6P)

(6P)

3

CNVMNT

(3P)

X04

X01

X02

X05

CNFG

(3P)

1

TH1

TH2

1

2

CN2

(2P)

O

OFF

2

16

SW1

O

OFF

1

SW2

CN28

(3P)

3

1

TR

X03

CNMNT

(5P)

O

OFF

1

(*3)

4

SW5

SW3

LED1

Transmission

Circuit

O

OFF

CNS3

(3P)

LEV

CN40

(6P)

1

SW4

3

OUTDOOR UNIT CONTROL BOX

TH3

212

(2P) (2P)

6

DC power

supply

CN34

(3P)

131

1

CN4CN3

CN3D

(3P)

CN3S

(3P)

CN3N

(3P)

CN24

(3P)

CN27

(3P)

CN81

(3P)

CN51

(5P)

X1

3

1

63H2

2

3

1

1

C14

(2P)

Note :

1. Be sure to apply earth work to the unit.

(Use the earth terminal of TB1.)

2. The dotted lines show field wiring.

3. Color of earth wire is yellow and green

twisting.

4. This motor (*1) includes auto reset type

internal thermostat.

5. Indoor and outdoor connecting wires

(*2) are made with polarities, make

sure matching wiring and terminal.

6. SW5 (*3) is shown PUH-P10MYA setting.

In case of PUH-P8MYA setting is

shown as below.

(*3)

ON

OFF

14

SW5

Caution :

1. To protect compressor from abnormal current, over current relays is installed. Therefore, do not change factory set value of over

current relays.

Symbol Name

F1, F2 FUSE (15A 250VAC CLASS T)

F01~F04 FUSE (6.3A 250VAC CLASS F)

F10~F30 FUSE (6.3A 250VAC CLASS F)

51C OVER CURRENT RELAY (COMPRESSOR)

52C MAGNETIC CONTACTOR (COMPRESSOR)

63L PRESSURE SWITCH (LOW PRESSURE)

63H1 PRESSURE SWITCH (HIGH PRESSURE)

63H2 PRESSURE SWITCH (FOR CONTROL)

MC COMPRESSOR MOTOR

MF FAN MOTOR (OUTDOOR)

TR TRANSFORMER

X1 AUXILIARY RELAY (FOR 16, 20HP)

LED 1 LED (FOR SERVICE)

XO1~X05 AUXILIARY RELAY (MAIN BOARD)

CN2,CN20~28

CN3,34,30,3N,3S

CN4,40,51~53,81

CONNECTOR MAIN BOARD

CNFC1, FG, S3

CNMT,VMNT

Symbol Name

SW1~SW5 SWITCH (MAIN BORD)

21S4 4-WAY VALVE

SV1 SOLENOID VALVE

CH CRANK CASE HEATER (COMPRESSOR)

LEV ELECTRINIC EXPANSION VALVE

TH1 LIQUID TEMP.

TH2 THERMISTOR DISCHARGE TEMP.

TH3 COND./EVA. TEMP.

TB1 POWER SOURCE TERMINAL BLOCK

TB3, 4 OUTDOOR/INDOOR CONNECTION TERMINAL BLOCK

TB8 TERMINAL BLOCK (FOR 16, 20HP)

C11, C12 CONNECTOR (FAN MOTOR)

C14 CONNECTOR (63H2)

CAFAN, CNFC2

CNPO

CNOUT1, 2

CNIN

CONNECTOR (F. C. BOARD)

CONNECTOR (N, F. BOARD)

–11–

Page 14

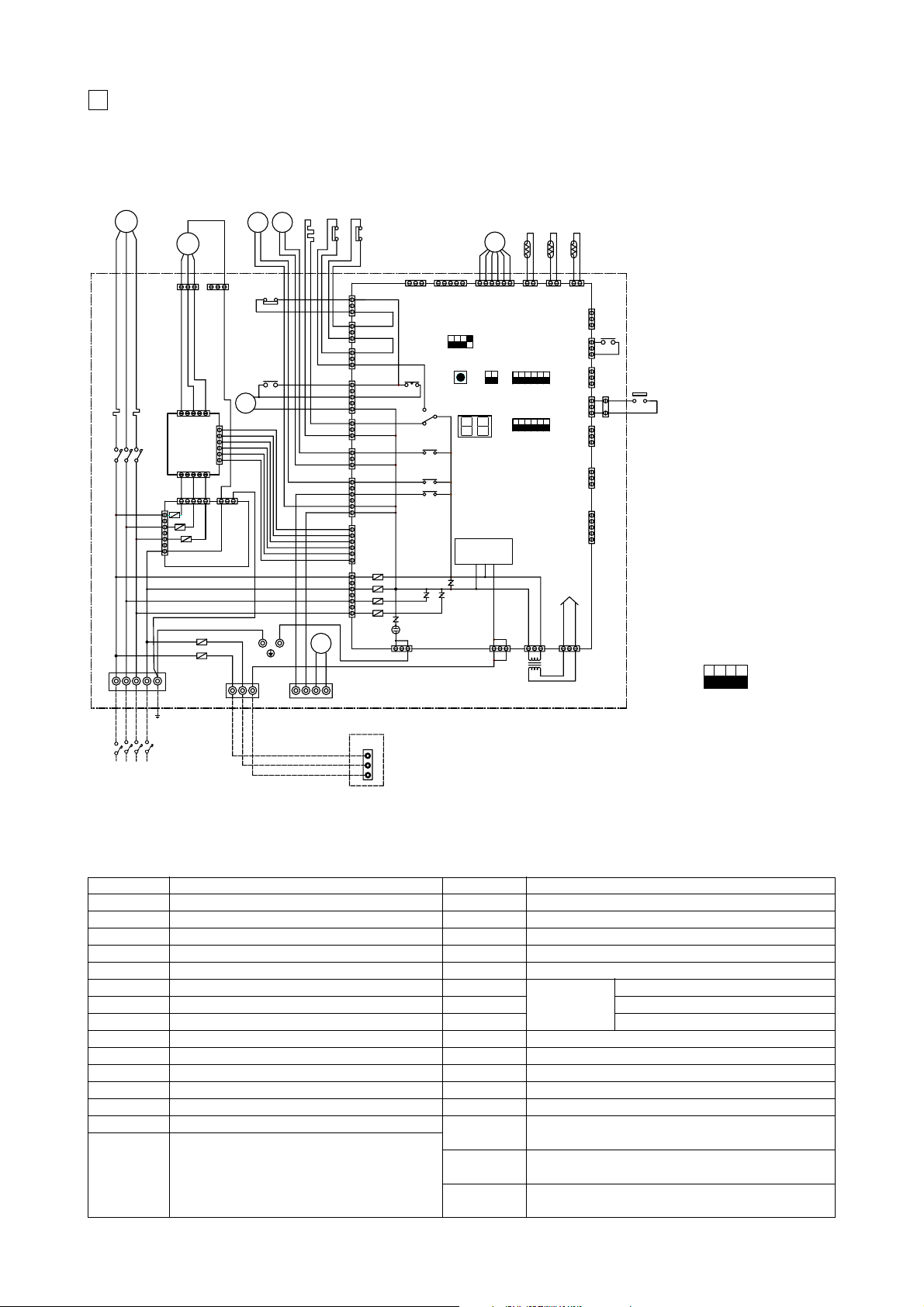

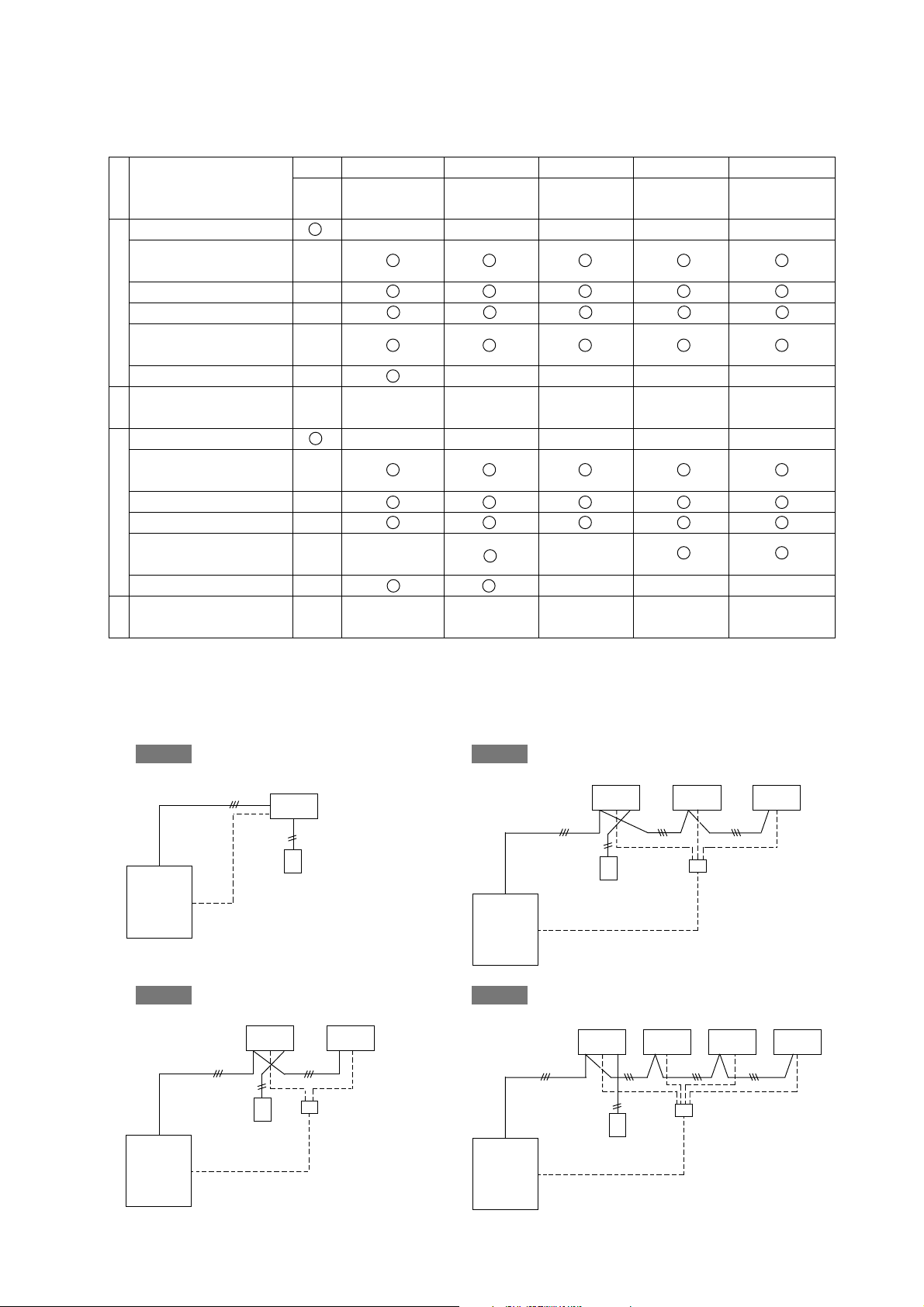

[2] Skelton of Indoor/Outdoor Connection

(1) Applicable combinations of 8 & 10HP [PUH-P8MYA/P10MYA]

Indoor Units

PEH-P*MYA

PLH-P*KAH, PLH-P*AAH

PLA-P*KA, PLA-P*AA

PEHD-P*EAH, PEAD-P*EA

PCH-P*GAH, PCA-P*GA

PUH-P8MYA

PKH-P*GALH, PKH-P*FALH

PKA-P*GAL, PKA-P*FAL

PSH-P*GAH, PSA-P*GA

Indoor Units

PEH-P*MYA

PLH-P*KAH, PLH-P*AAH

PLA-P*KA, PLA-P*AA

PEHD-P*EAH, PEAD-P*EA

PCH-P*GAH, PCA-P*GA

PUH-P10MYA

PKH-P*GALH, PKH-P*FALH

PKA-P*GAL, PKA-P*FAL

PSH-P*GAH, PSA-P*GA

Multi distributor pipes

(Option)

* indicates applicable HP.

Single

8HP

–

–

–

–

–

10HP

–

–

–

–

–

–

50 : 50

4HP+4HP

–

5HP+5HP

–

–

SDD-50WSA-E

33 : 33 : 33

2.5HP+2.5HP

+2.5HP

–

–

3HP+3HP

+3HP

–

SDT-111SA-E

25 : 25 : 50

2HP+2HP

+4HP

–

–

2.5HP+2.5HP

+5HP

–

–

–

SDT-112SA-E

20 : 40 : 40

1.6HP+3HP

+3HP

–

–

–

2HP+4HP

+4HP

–

–

SDT-122SA-E

25 : 25 : 25 : 25

2HP+2HP

+2HP+2HP

–

–

2.5HP+2.5HP+

2.5HP+2.5HP

–

–

SDT-1111SA-E

(2) System

Outdoor unit

Twin

Outdoor unit

3-core cable

Pipe work

3-core cable

Transmission

line

Pipe work

Indoor unit

Remote

controller

Remote

controller

Transmission line

Indoor units

Distributor

TripleSingle

3-core cable

Outdoor unit

Four

3-core cable

Outdoor unit

Transmission

line

Transmission

line

Remote

controller

Pipe work

Remote

controller

Pipe work

Indoor units

Distributor

Indoor units

Distributor

–12–

Page 15

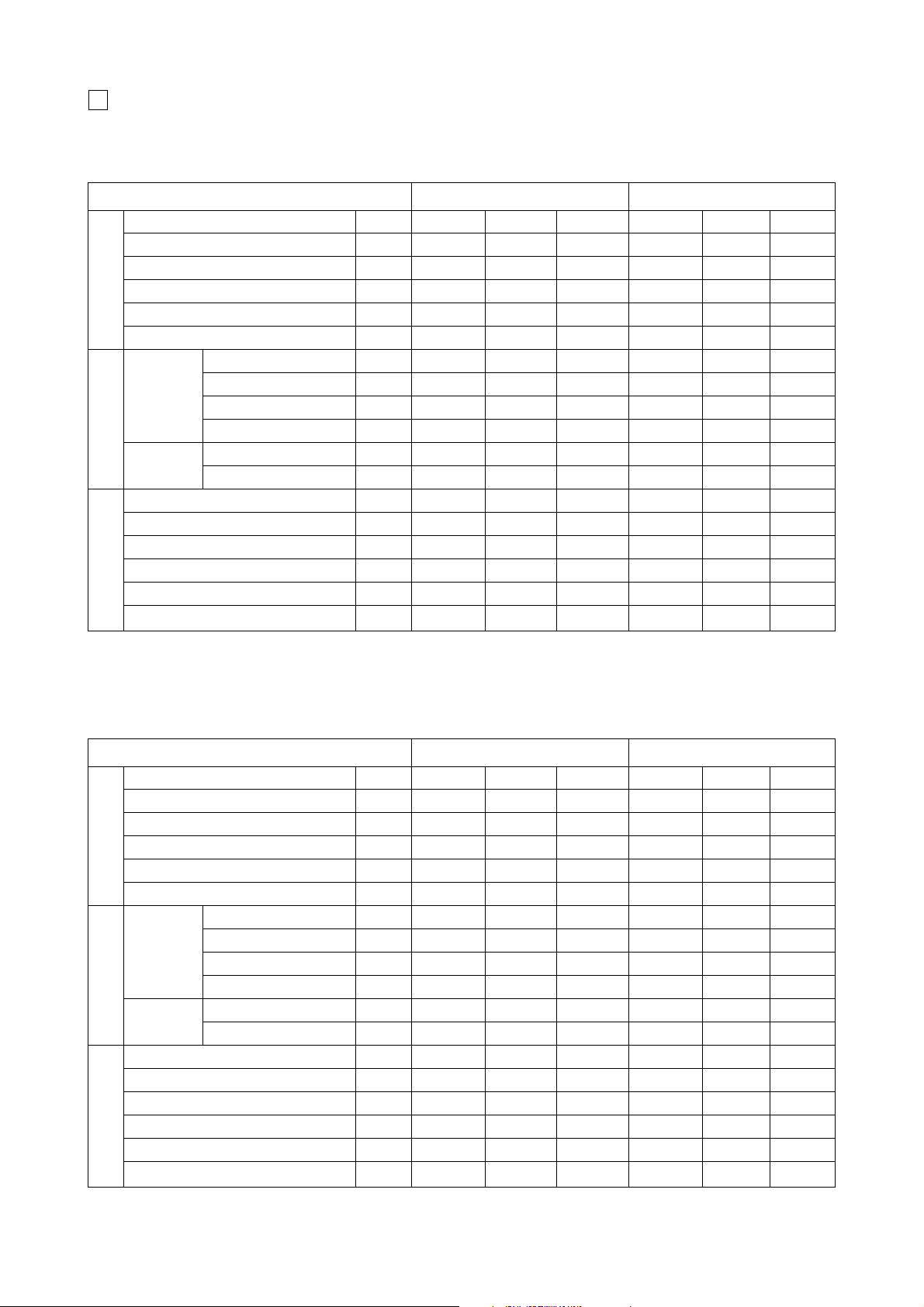

5 Technical Data of PUH-P8MYA/P10MYA to Meet LVD

[1] Standard Operation Data

(1) PUH-P8MYA

Operating condition Cooling Heating

Voltage V

Power source frequency Hz

Indoor air condition (DB/WB) °C

Outdoor air condition (DB/WB) °C

Piping length m

Operating condition

Refrigerant charge kg

Current A

Outdoor unit

Indoor unit

Electrical characteristics

Discharge pressure MPa

Suction pressure MPa

Discharge refrigerant temperature °C

Suction refrigerant temperature °C

Liquid pipe temperature

Refrigerant circuit

Compressor shell bottom temperature °C

Input kW

Compressor current A

Fan current A

Current A

Input kW

(at piping sensor)

°C

380 400 415 380 400 415

50 50 50 50 50 50

27/19 27/19 27/19 20/– 20/– 20/–

35/- 35/– 35/– 7/6 7/6 7/6

7.5 7.5 7.5 7.5 7.5 7.5

6.9 6.9 6.9 6.9 6.9 6.9

13.0 13.0 13.0 12.8 12.8 12.8

7.27 7.27 7.27 7.17 7.17 7.17

11.9 11.9 11.9 11.7 11.7 11.7

1.1 1.1 1.1 1.1 1.1 1.1

1.12 1.12 1.12 1.12 1.12 1.12

0.65 0.65 0.65 0.65 0.65 0.65

2.11 2.11 2.11 1.91 1.91 1.91

0.48 0.48 0.48 0.40 0.40 0.40

75 75 75 70 70 70

6 660 00

46 46 46 0 0 0

35 35 35 30 30 30

Note: The values listed above indicate that when connected with the indoor unit PEH-P8MYA as representative data.

(2) PUH-P10MYA

Operating condition Cooling Heating

Voltage V

Power source frequency Hz

Indoor air condition (DB/WB) °C

Outdoor air condition (DB/WB) °C

Piping length m

Operating condition

Refrigerant charge kg

Current A

Outdoor unit

Indoor unit

Electrical characteristics

Discharge pressure MPa

Suction pressure MPa

Discharge refrigerant temperature °C

Suction refrigerant temperature °C

Liquid pipe temperature

Refrigerant circuit

Compressor shell bottom temperature °C

Input kW

Compressor current A

Fan current A

Current A

Input kW

(at piping sensor)

°C

380 400 415 380 400 415

50 50 50 50 50 50

27/19 27/19 27/19 20/– 20/– 20/–

35/- 35/– 35/– 7/6 7/6 7/6

7.5 7.5 7.5 7.5 7.5 7.5

7.4 7.4 7.4 7.4 7.4 7.4

16.0 16.0 16.0 15.4 15.4 15.4

9.02 9.02 9.02 8.62 8.62 8.62

14.9 14.9 14.9 14.3 14.3 14.3

1.1 1.1 1.1 1.1 1.1 1.1

1.64 1.64 1.64 1.64 1.64 1.64

0.94 0.94 0.94 0.94 0.94 0.94

2.22 2.22 2.22 1.75 1.75 1.75

0.50 0.50 0.50 0.38 0.38 0.38

80 80 80 65 65 65

888–1–1–1

48 48 48 0 0 0

30 30 30 20 20 20

Note: The values listed above indicate that when connected with the indoor unit PEH-P10MYA as representative data.

–13–

Page 16

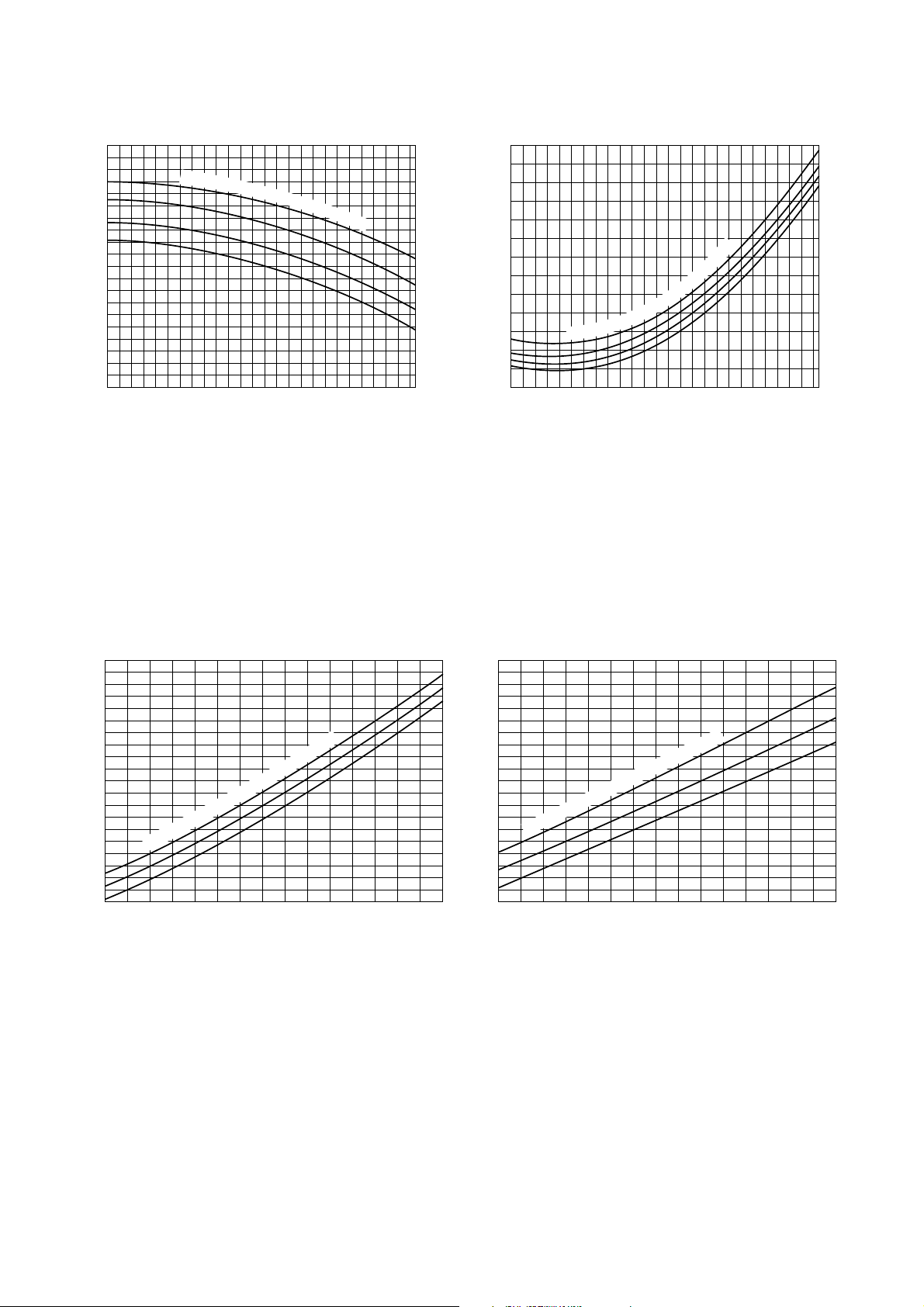

[2] Cooling Capacity Curves

• PUH-P8MYA/P10MYA

1.4

Indoor inlet air wet

1.2

bulb tem

p. <˚CW

B>

1.22

1.1

22

20

18

16

1

Capacity ratio

0.8

0.6

-5-3-113579111315171921232527293133353739414345

Outdoor air temperature <˚CDB>

[3] Heating Capacity Curves

• PUH-P8MYA/P10MYA

1.4

1.2

22

20

18

16

Input ratio

0.9

inlet air wet

Indoor

0.7

-5-3-113579111315171921232527293133353739414345

Outdoor air temperature <˚CDB>

1.4

15

20

25

1.2

bulb temp. <˚CWB>

25

20

15

1

Capacity ratio

0.8

0.6

-12-10-8-6-4-2024681012141618

Indoor inlet air dry

bulb temp. <˚CDB>

Outdoor air temperature <˚CWB>

1

Input ratio

Indoor inlet air dry

0.8

0.6

-12 -10 -8 -6 -4 -2 0 2 4 6 8 10 12 14 16 18

Outdoor air temperature <˚CWB>

bulb temp. <˚CDB>

–14–

Page 17

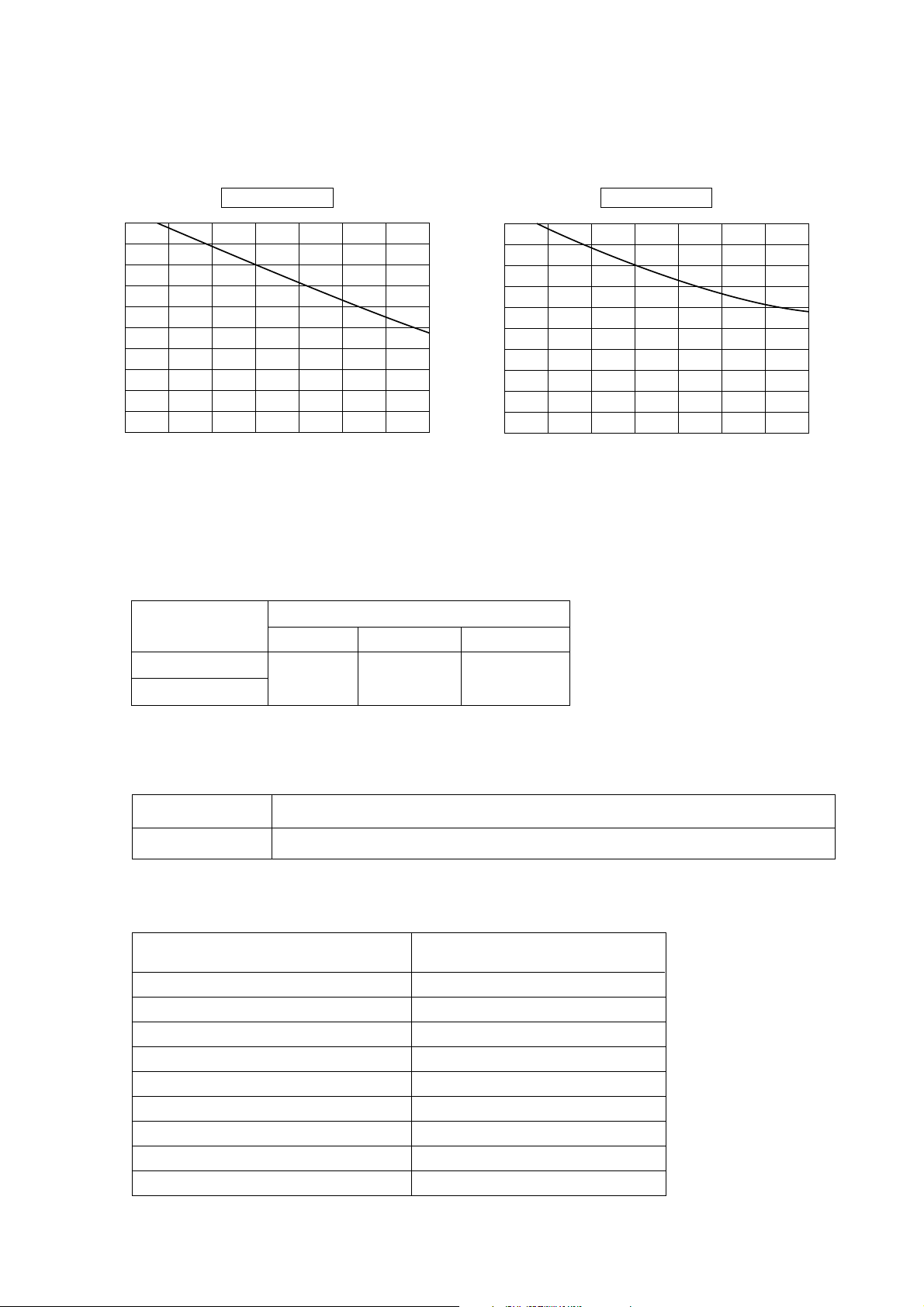

[4] Capacity Reduction Ratio due to Changes in Piping Length

(1) Cooling capacity

PUH-P8MYA

1

0.9

Capacity ratio

0.8

0 10 20 30 40 50 60 70

Equivalent piping length (m)

(2) Heating capacity

Equivalent piping length

Model name

- 30 m 30 - 50 m 50 - 70 m

PUH-P8MYA

1.0 0.995 0.99

PUH-P10MYA

PUH-P10MYA

1

0.9

Capacity ratio

0.8

0 10 20 30 40 50 60 70

Equivalent piping length (m)

(3) Calculation formula of equivalent piping length

PUH-P8MYA Equivalent piping length (m) = Actual piping length (m) + (0.47 × Number of bend)

PUH-P10MYA Equivalent piping length (m) = Actual piping length (m) + (0.5 × Number of bend)

(4) Reduction ratio by frosting

Outdoor unit inlet wet bulb temperature

(°CWB)

6 1.0

4 0.98

2 0.88

0 0.85

–2 0.86

–4 0.89

–6 0.92

–8 0.92

–10 0.92

Heating capacity reduction ratio

–15–

Page 18

[5] Center of Gravity (Outdoor unit)

(1) Caution for Lifting

Warning

Lift unit slowly by suspending rope uniformly

so that the rope will not slip off or unit will not

incline seriously.

Be careful that unit may fall down if the rope is

not in a proper position as the center or

gravity of unit is being inclined.

Protection pad

Use pads properly to

prevent the scratching of

external panel

caused by contact

with sling.

Name plate

Indicates the unit

front side.

Below 40˚

Blow 40ß

Hanger rope (Over 7m × 2)

Must be durable against unit weight.

For the lifting of unit for movement, please

be sure to suspend at four points, and not

to give any shock to unit.

Never apply two-point lifting as it is

dangerous.

Service panel

Compressor position

Suspending spot

2-point,front and rear

Model name

Item

PUH-P8MYA

PUH-P10MYA

Center of gravity

Inclining to the right

front side of unit.

G

Z

X

Center of gravity (mm)

XYZ

Y

Fasten here properly

to prevent unit from

slipping off from

the sling at lifting.

Net weight

(kg)

330 350 490 215

300 330 510 220

–16–

Page 19

[6] NC Curve (Outdoor unit)

(1) Octave Band Analysis

1) PUH-P8MYA

Measurement condition

1m

A

1m

B

Sound pressure level in anechoic room

56 dB (A)

63Hz63125Hz59250Hz56500Hz551000Hz502000Hz454000Hz428000Hz

39

70

60

50

40

30

20

OCTAVE BAND PRESSURE LEVEL< dB> 0dB = 0.0002 bar

Approximate minimum

audible limit on

continuous noise

10

63 125 250 500 1000 2000 4000 8000

OCTAVE BAND CENTER FREQUENCIES <Hz>

(dB)

NC60

NC50

NC40

NC30

NC20

Note: The measuring point is 1m from the bottom of the unit (1m from the front of the unit).

2) PUH-P10MYA

Measurement condition

1m

A

1m

B

Sound pressure level in anechoic room

57 dB (A)

63Hz63125Hz60250Hz56500Hz561000Hz512000Hz474000Hz448000Hz

40

70

60

50

40

30

20

OCTAVE BAND PRESSURE LEVEL< dB> 0dB = 0.0002 bar

Approximate minimum

audible limit on

continuous noise

10

63 125 250 500 1000 2000 4000 8000

OCTAVE BAND CENTER FREQUENCIES <Hz>

(dB)

NC60

NC50

NC40

NC30

NC20

Note: The measuring point is 1m from the bottom of the unit (1m from the front of the unit).

–17–

Page 20

6 SERVICE DATA

[1] Appearance of Equipment

• PUH-P8MYA/P10MYA Detail of Electrical Parts Box

(with cover removed) (with Main Board Panel removed)

Transformer

Power source

terminal block

Terminal block for

outdoor/indoor control

wiring connection

• PUH-P8MYA/P10MYA (with cover removed)

Terminal block for

defrosting signal

F. C.

BOARD

MAIN

BOARD

N. F.

BOARD

Relay for defrosting

signal receiving

<X1>

Overcurrent relay

<51C>

Magnetic contactor for

compressor <52C>

Outdoor unit heat exchanger

Compressor

Electrical parts box

Ball valve for refrigerant piping connection <Liquid side> Flare

Ball valve for refrigerant piping connection <Gas side> Flange

–18–

Page 21

• PUH-P8MYA/P10MYA (Detail of machine room)

Thermistor <Condenser/evaporator temp.> TH3

(At the back of the heat exchanger panel (header cover).

When this screw is removed, the header cover is removed.)

Pressure switch

(63H2)

4-way valve

Pressure switch

(63H1)

Thermistor

<Liquid temp.>

TH1

Check joint

(low pressure)

Pressure switch

(63L)

Check joint

(high pressure)

Solenoid valve(SV1)

Accumulator

Electric expansion

valve (LEV)

Thermistor

<Discharge temp.>

TH2

–19–

Page 22

H

h

L

a

b

[2] Refrigerant Circuit

Indoor

units

Indoor heat exchanger

Service port

Ball valve

Outdoor unit

Strainer

Service port

Low pressure

switch

(Protection)

Solenoid valve

Strainer

High pressure switch

(Protection)

High pressure

switch (Control)

Muffler

Outdoor heat exchanger

Service port

Accumulator

Service port

Strainer

Multiple-distributor

Ball valve

[3] Limitation of Refrigerant Piping Length

(1) Single (2) Twin

H

L ≤ 50 m

H ≤ 40 m

(3) Triple

a

h

H

PUH-P8,10

L

(4) Four

b

c

PUH-P8,10

L

Compressor

Flare connection

Flange connection

Brazing connection

h

H

Electric expansion valve

Capillary tube

<

<

Cooling operation

Heating operation

PUH-P8,10

L + a + b ≤ 70 m

L + a, L + b ≤ 50 m

a – b ≤ 8 m

H ≤ 40 m, h ≤ 1 m

a

b

c

L

d

PUH-P8,10

L + a + b + c ≤ 70 m

L + a, L + b, L + c ≤ 50 m

a – b, b – c , c – a ≤ 8 m

H ≤ 40 m, h ≤ 1 m

L + a + b + c + d ≤ 70 m

L + a, L + b, L + c, L + d ≤ 50 m

a – b , b – c , c – d, d – a ≤ 8 m

H ≤ 40 m, h ≤ 1 m

* Total bends are 15 units, and max. bends are 8 units within L + a, L + b, L + c and L + d.

–20–

Page 23

[4] Refrigerant Piping

Model Gas pipe Liquid pipe

Outdoor unit

PUH-P8MYA ø25.4 ø 12.7

PUH-P10MYA ø

28.58 ø 12.7

1.6, 2, 2.5, 3 ø 15.88 ø9.52

4, 5 ø19.05 ø 9.52

Indoor unit

8 ø 25.4 ø 12.7

10 ø28.58 ø

12.7

[5] Refrigerant Charge

Model

PUH-P8MYA

PUH-P10MYA

L: Main section actual length

Amount of infusion of

coolant at ex-factory

R407C 6.0 kg

R407C 6.5 kg

a + b + c + d: Join section actual length

0.026× L + 0.014 × ( a + b + c + d) + 1.7

× amount of indoor units. (kg)

0.026 × L + 0.014 × (

× amount of indoor units. (kg)

The value of calculation result at the second decimal place must be rounded up to the first decimal place.

(e.g. 2.22 kg must be rounded up to 2.3 kg)

Additional refrigerant charge

a + b + c + d) + 1.7

[6] Operation Rage

24

Indoor air temperature (°CWB)

15

-5 46

Outdoor air temperature (°CDB)

Cooling Heating

27

Indoor air temperature (°CDB)

15

–12 18

Outdoor air temperature (°CWB)

–21–

Page 24

7 CONTROL

[1] Composition of Control

1. Function block diagram

3N~

380/400/415 V

50 Hz

outdoor

indoor

Electrical

terminal block

Indoor/outdoor

connection terminal

block

Fuse

Indoor/outdoor

connection terminal

block

Fuse

Fuse

microcomputer

Communication

circuit

DC/DC

converter

LED1

<Power>

Transformer

DC5V for

12V

Magnetic

contractor

Fuse

Semiconductor

relay

Fan control

Over current

relay

4-way valve, LEV,

solenoid valve,

crankcase heater

Outdoor fan

Semiconductor

relay

Compressor

Louver

Vane

Drain pump

Others

Remote

controller

terminal block

Remote controller

terminal block

Remote controller

Current

detection

LED2 LED3

<Supply power>

DC5V

5V

<Indoor/outdoor units communication>

Key input

LCD

Send/receive

Communication

circuit

Fan control

Indoor fan

–22–

Page 25

[2] Control specifications

(1) Protection functions

1) The main protection devices for the outdoor unit are:

a) High pressure protection (63H1)

b) Compressor overcurrent protection (51C)

c) Liquid temp thermistor trouble (TH1)

d) Discharge temperature protection (TH2 ≥11 8 °C)

e) Discharge temp thermistor trouble (TH2)

f) Condenser/evaporater temp thermistor trouble (TH3)

g) Low pressure protection (63L)

2) When tripping of a detection device is sensed, the check mode is entered and the compressor is stopped. (After 3

minutes, the compressor restarts.) Thereafter, the compressor is stopped when the specified number of check

modes or greater is sensed within the check time.

Protection functions

a) High pressure protection

(63H1)

b) Compressor overcurrent

protection (51C)

c) Liquid temp thermistor

trouble (TH1)

d) Discharge temperature

protection (TH2

>

118 °C)

=

e) Discharge temp ther-

mistor trouble (TH2)

f) Condenser/evaporater

temp thermistor trouble

(TH3)

g) Low pressure protection

(63L)

Operation value

3.3 MPa

P8MYA: 22 A

P10MYA: 27 A

Less than –39 °C or

greater than 88 °C

Greater than 118 °C

Less than 0 °C or

greater than 216 °C

Less than –39 °C or

greater than 88 °C

0 MPa

Detection condition

Compressor operating

Compressor operating

Compressor operating except for

10 minutes at end of defrosting

and 7 minutes while compressor

starting

Compressor operating

Compressor operating except for

10 minutes at end of defrosting

and 5 minutes while compressor

starting

Compressor operating except for

10 minutes at end of defrosting

and 7 minutes while compressor

starting

Compressor operating except for

defrosting, 10 minutes at end of

defrosting

Number of

check modes

0

1 time

1 time

2 times

1 time

1 time

2 times

Check time

–

30 minutes

30 minutes

30 minutes

30 minutes

30 minutes

30 minutes

3) Check mode is released by stopping operation, changing the operation mode, or check mode time up. A check

mode is also released by stopping of operation by remote controller.

4) Detected check mode history (newest) and abnormality history (last 2 times) are memorized and are displayed on

the segment by circuit board DIP switch setting.

The operation mode when the newest abnormality was generated, the thermistor temperature (TH1,2,3), and the

thermostat ON time can also be displayed.

(2) Compressor, 4-way valve, and crankcase heater control

1) Determines the operation mode and operates the compressor based on the indoor/outdoor communication or MNET communication data.

2) Compressor control has a function which prevents the compressor from restarting within 3 minutes.

3) The 4-way valve is always ON during heating (except during defrosting). In other modes, it is OFF. However, when

the operation mode was changed from heating to stop, the 4-way valve is turned off 10 minutes after the compressor was stopped.

4) While the compressor is stopped, the crankcase heater remains ON. (OFF while the compressor is operating.)

5) When the operation mode is changed while the compressor is operating, the compressor stops and 3 minutes later

restarts in the new mode.

–23–

Page 26

(3) Fan control

Controls the fan speed based on the piping temperature (TH1) to perform cooling at low outdoor temperatures and heating

at high outdoor temperatures.

1) Control at cooling

a) When the compressor stops, the fan stops (fan output=0%).

b) When the power is turned on, or when the compressor is restated after it has been stopped for 30 minutes or

longer, the piping temperature ( TH1) determines the fan output.

When TH ≤ 25˚C Fan output = 100 %

When TH < 25˚C Fan output = 60 %

c) When the compressor is restarted within 30 minutes after it has been stopped, the fan step before the compres-

sor was stopped is selected. However, when the fan output was under 30% when the fan was stopped, 30 % is

selected.

d) When the mode was changed from heating to cooling, the fan step conforms to item 2.

e) Two minutes after the fan is started, the fan step (number of units) is controlled every 30 seconds based on the

piping temperature (TH1).

f) When TH1 reaches 50˚C or higher, or when the control high pressure switch (63H2) tripped, the fan output

becomes 100 %.

g) Fan output while the compressor is operating is within the 20 % to 100 % range.

• FAN step

The following expression determines the next fan step count nj+1:

nj + 1 = nj + ∆nj nj: Current fan step, ∆nj: Displacement step amount

nj control

• If nj + 1 ≥ 100 % nj + 1 = 100 %

• If nj + 1 ≥ 20 % nj + 1 = 20 %

• If TH1 ≥ 50 °C or 63H2 is “OFF” nj + 1 = 100 %

FAN ∆nj Outputs are all %.

Target condensation

temperature 31 °C

20 ≤ nj < 50

50 ≤ nj 100

Current

output

t > 49 °C

5

10

t = 49

t = 46

~

t > 46

t > 43

3

4

* In the night mode, the maximum value of nj is 80%. (When TH1 < 50˚C)

Condensation temperature TH1

t = 43

t = 40

~

~

t > 40

2

2

3

2

~

t > 36

2

2

t = 36

~

t > 33

2

2

t = 33

~

t > 29

0

0

t = 29

~

t > 26

–2

–2

t = 26

~

t > 23

–2

–2

t = 23

~

t > 20

–3

–4

t≤ 20 ˚C

–5

–10

–24–

Page 27

2) Control at heating

a) When the compressor is stopped and during defrosting, the fan is stopped.

b) When the power is turned on, or when the compressor is restarted after being stopped for 30 minutes or longer,

the piping temperature (TH1) determines the fan step.

TH1 > 8˚C Fan output = 60 %

TH1 ≤ 8˚C Fan output = 100 %

c) When the compressor is restarted within 30 minutes, the fan step is the step before the compressor was stopped.

d) When the mode is changed from cooling to heating, the fan step conforms to item b).

e) When returning from defrosting, the fan step is the step before defrosting.

f) Two minutes after the fan was restarted, the fan step is controlled every 30 seconds based on the piping

temperature (TH1).

g) When TH1 is –5˚C or lower, the fan output is made 100 %.

• FAN step

The following expression determines the next fan step count nj + 1:

nj + 1 = nj + ∆nj nj: Current fan step, ∆nj: Displacement step amount

nj control

• If nj + 1 ≤ 100 % nj + 1 = 100 %

• If nj + 1 ≤ 20 % nj + 1 = 20 %

• If TH1 < –5 °C nj + 1 = 100 %

FAN ∆nj Outputs are all %.

Evaporation temperature TH1

Target evaporation

temperature 10 °C

T > 19 °C

T = 19

~

T > 17

T = 17

~

T > 15

T = 15

~

T > 13

T = 13

~

T > 11

T = 11

~

T > 8

T = 8

~

T > 6

T = 6

~

T > 4

T = 4

~

T > 2

T = 2

~

T > 0

T≤ 0˚C

20 ≤ nj + 1 ≤ 100

Current

output

–10

–4

–3

(4) Defrosting control

1) When the following conditions are satisfied, defrosting starts:

a) When the integrated compressor operation time has exceeded T

temperature (TH1) is below –10 C

b) When the integrated compressor ˚C

Piping differential temperature ∆TH1 = TH10 – TH1

2) The defrosting prohibit time T

1 is set as following based on the defrosting time T2:

T2 ≤ 3 (minutes) T1 60 (minutes)

3 < T2 < 15 40

T

2 = 15 30

Note: T

Note: When the compressor was stopped during defrosting, T1 = 20 minutes is set to recognize the stop as

defrosting end.

–2

–2

0

2

2

3

4

10

1 (initial setting 50 minutes) and the piping

Current piping temperature

Piping temperature 10 minutes after starting or

10 minutes after returning from defrosting

1 is reset at the end of defrosting, or by cooling ON command.

3) During defrosting, all the outdoor fans are stopped and the bypass solenoid valve (SV1) is turned ON and the 4-way

valve (21S4) is turned OFF.

4) When the following conditions are satisfied, defrosting ends:

a) T

2 ≤ 2 mins TH1 ≤ 30°C

b) 2 < T

2 < 15 minutes TH1 ≤ 8°C continuous 2 minutes

c) T2 =15 minutes

5) When the fan and 4-way valve (21S4) are turned ON at the end of defrosting, the heating mode is reset. Two

minutes after defrosting reset, the bypass solenoid valve (SV1) turns OFF.

–25–

Page 28

(5) Bypass solenoid valve control (SV1)

1) Control at cooling

a) While the compressor is stopped, the solenoid valve is OFF.

b) When the power is turned on, or when the compressor is restarted after it has been stopped for 30 minutes or

longer, if the liquid temperature (TH1) is 25˚C or higher then the solenoid valve turns ON for 2 minutes.

c) When the power is turned on, or when the compressor restarted after it has been stopped for 30 minutes or

longer, the solenoid valve turns ON for 5 minutes if the liquid temperature (TH1) is staying below 25˚C.

d) The item b) or c) is applied to the mode change from heating to cooling.

e) When the previous operation mode is cooling and the compressor restarted within 30 minutes after it’s stopping

by the tripping of 63H2, the solenoid valve turns ON for 2 minutes.

2) Control at heating

a) While the compressor is stopped, the solenoid valve is OFF.

b) When the power is turned on, or when the compressor restarted after it has been stopped for 30 minutes or

longer, the solenoid valve turns ON for 2 minutes if the liquid temperature (TH1) is staying above 8˚C.

c) When the power is turned on, or when the compressor restarted after it has been stopped for 30 minutes or

longer, the solenoid valve turns ON for 5 minutes if the liquid temperature (TH1) is staying below 8˚C.

d) The item b) or c) is applied to the mode change from cooling to heating.

e) When the control pressure switch (63H2) trips, the solenoid valve turns ON.

f) If 63H2 resets 15 minutes after tripping, the solenoid valve turns OFF.

g) During defrosting, the solenoid valve turns ON.

h) When the previous operation mode is heating and the compressor restarted within 30 minutes after it’s stopping

by the tripping of 63H2, the solenoid valve turns ON for 2 minutes.

i) When the previous operation mode is heating, and the compressor restarted within 30 minutes after the tripping

of 63L, the solenoid valve turns ON for 2 minutes.

(6) Electronic expansion valve (LEV)

1) Initial processing after power turned on

After the power is turned on, full close processing is performed as initial drive processing.

a) A 2200 pulses down is output from power on.

b) At the end of 2200 pulse down output, 60 pulses up is output.

c) Sixty pulses up output ends initial processing. At this point, the valves are fully closed.

2) Control contents

At compressor starting

At compressor stopping

At defrosting

Normal

3) Normal LEV control

a) The operation frequency when the compressor is started (including after defrosting reset) determines the stan-

dard opening angle.

b) After a) above, sub cool (SC) shown below controls the LEV opening angle.

<Definition of SC>

Cooling: SC = TH3 (outdoor unit)-TH1 (outdoor unit)

Heating: SC = TH5 (indoor unit)-TH2 (indoor unit)

* When there are multiple indoor units, the value of TH2 and TH5 is the average value of TH2 and TH5 of all

the indoor units.

<LEV control>

LEV is controlled so that SC is equal to SCm.

SC < SCm: LEV opening angle is made smaller

SC > SCm: LEV opening angle is made larger

SC = SCm: LEV opening angle remains unchanged

SCm = 5~15 (SCm is different with Indoor Units.)

4) Transient LEV control

a) When outlet temperature (outdoor unit TH2) rises

When the outlet temperature (outdoor unit TH2) exceeds 115 °C, the LEV opening angle is made larger.

LEV output opening angle

Initial opening angle

1000 pulses

2000 pulses (full close)

See next item

Opening angle control range

Approx. 1000 to 2000 pulses

–

–

1000 to 1500 pulses

(7) Service functions

1) Abnormality history clear

a) When DIP SW1-2 is turned ON while the compressor is operating or stopped, the abnormality history is cleared.

–26–

Page 29

[3] Function of switches and connectors (outdoor unit)

(1) Function of switches

1) Function of switches

Kind of

switch

DIP SW

Tact SW

DIP SW

DIP SW

(Normal mode)

Switch

SW1

CN33

When

open

(Normal)

SW2

SW3

SW4

SW5

Pole

1

Abnormality history clear

2

Function

None

3

4

5

Refrigerant system

address setting

6

1

2

3

Self diagnosis

4

5

6

Mode input register

1

Trial run mode switching

2

1

2

3

4

Trial run

Inlet temp. re-reading

3-phase power source

detection

Cooling only switching

Model setting

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

Normal mode

SW3 = Unrelated

Operation by switch operation

ON OFF

––

Clear Normal

123456

ON

OFF

01234

123456

ON

OFF

56789

123456

ON

OFF

10 11 12 13 14

→

Shows that Nos. 3, 4, 5 , and 6 of

15

SW1 are ON.

OFF

OFF

OFF

ON

ON

ON

123456

123456

123456

See pages 29 to 34.

Register Normal

Operate Stop

Heat Cool

Do Do not

Do not Do

Cooling only Heat pump

PUH-P10MYA PUH-P8MYA

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

OFF

OFF

OFF

ON

ON

ON

123456

123456

123456

Switch effec-

tive timing

–

Running or

stopped

When power

turned on

Running or

stopped

stopped

stopped*

1

stopped

–

When power

turned on

When power

turned on

2) Switch functions at set mode change

Set input mode

2

8 °C continuous 2 minutes

Switch effec-

tive

stopped

stopped

stopped

Kind of

switch

DIP SW

Switch

SW1

When

CN33

shorted

(mode

switching)

Pole

1

2

3

4

Defrosting end switching

5

6

Function

None

Night mode

Defrosting prohibit time

switching

None

CN33 = short SW3 = ON*

Operation by switch operation

ON OFF

––

Night mode Normal mode

12 °C continuous 2 minutes

Fixed Training

––

*1 Trial run performs trail run processing by input change while stopped. (For details, see the trail run section)

*2 Mode input is entered by SW3 OFF→ON change (___↑). Press and hold down SW3 for about 2 seconds. The set

mode can be registered according to the outdoor unit setting information on page 31.

Remarks

Note: After changing the mode by CN33 shorting (mode switching), return to the normal mode by opening CN33.

3) Connector function assignment

Type

Connector

Connector

CN31

CN32

CN33

Function

Emergency operation

Function test

DIP switch mode switching

Operation by open/short

short open

Start Normal

Function mode Normal

Mode switching Normal

Switch effec-

tive timing

At initialization

At initialization

stopped

timing

–

–

–27–

Page 30

<Outdoor unit operation monitoring function>

The operation status and check code contents can be ascertained by means of the 2-digit number and symbol on digital

display light emitting diode LED2 by operating DIP switch SW2.

<Description of operation of digital display light emitting diode (LED2)>

• When ON (normal operation): Displays the operation mode.

SW2

12345 6

ON

OFF

(Load status)

LED2

[Tens digit: Operation mode]

Display Operation mode

O stopped

C Cooling/Dry

H Heating

d Defrost

ON

[Units digit: Relay output]

Display Compressor 4-way valve Bypass solenoid valve

0 –– –

1 –– ON

2 – ON –

3 – ON ON

4ON ––

5ON – ON

6ON ON –

7ON ON ON

• When blinking (Operation stopped by tripping protection device): Displays the check mode

Display Check unit

0 Outdoor unit

1 Indoor unit 1

2 Indoor unit 2

3 Indoor unit 3

4 Indoor unit 4

Display Check contents (at power on)

E8 Indoor-outdoor communication receive abnormal (outdoor unit)

E9 Indoor-outdoor communication send abnormal (outdoor unit)

EA

Eb

Indoor/outdoor connection erroneous wiring, number of indoor

units mismatch

Indoor/outdoor connection erroneous wiring (indoor unit power

failure, disconnection)

Ed Serial communication abnormal (M-NET)

E0-E7 Communication other than outdoor unit abnormal

F8 Input circuit faulty

• PUH-P8MYA/P10MYA

Display Check contents (operating)

U2 Compressor discharge temperature abnormal, CN23 short-circuit connector unplugged

U3 Compressor discharge temp thermistor (TH2) open/short

U4 Liquid temp thermistor (TH1), Condenser/evaporater temp thermistor (TH3) open/short

U6 Compressor overcurrent protection trip (51C trip)

UE High pressure protection (63H1 trip)

UL Low pressure protection (63L trip)

P1-P8 Indoor unit abnormal

A0-A8 M-NET communication abnormal

–28–

Page 31

Self diagnosis by SW2

• PUH-P8MYA/P10MYA

SW2 setting Display contents Description of display Unit

–39 - 88

(When 0 °C or lower, “–”and temperature are displayed

alternately.)

<Example> When –10,

°C

123456

ON

OFF

Liquid temperature

(TH1)

–39 - 88

every other second

–

←→ 10

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

Discharge temperature (TH2)

0 - 216

FAN output

0 - 100

Number of compressor

ON/OFF

0 - 999

Compressor integrated operation time

0 - 999

0 - 216

(When 100 or higher, 100s digit and 10s and units digits

are displayed alternately.)

<Example> When 115,

every other second

1

←→ 15

0 - 100

(When 100 or higher, 100s digit and 10s and units digits

are displayed alternately.)

<Example> When 100,

every other second

1

←→ 00

0 - 999

(When 100 or higher, 100s digit and 10s and units digits

are displayed alternately.)

<Example> When 425,

every other second

4

←→ 25

0 - 999

(When 100 or higher, 100s digit and 10s and units digits

are displayed alternately.)

<Example> When 245,

every other second

2

←→ 45

°C

%

100 times

10 hours

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

Current check mode

code 1

Current check mode

code 2

LEV opening angle

(/5)

0 - 400

Check mode segment display

method

Segment and bit correspondence

bit 2 bit 3

bit 1

bit 5

bit 6 bit 7

bit 4

bit 8

Check mode 1 display method

bit 1 ..... Compressor discharge temperature

abnormal

bit 2 ..... Compressor discharge temp thermistor

abnormal (TH2)

bit 3 ..... CN23 short-circuit connector un-

plugged

bit 5 ..... Liquid temp thermistor abnormal (TH1)

Check mode 2 display method

bit 1 ..... Overcurrent trip (Comp)

bit 2 ..... Low pressure protection

0 - 400

(When 100 or higher, 100s digit and 10s and units digits

are displayed alternately.)

<Example> When 200 ,

every other second

2

←→ 00

–29–

5 pulses

Page 32

SW2 setting Display contents Description of display Unit

When no check mode,“00”

<Example> When piping thermistor abnormal U4

Code display

123456

ON

OFF

Newest check code

Newest outdoor unit

abnormality

Check display

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

Operation mode when

abnormality occurred

Liquid temperature

(TH1) when abnormality occurred

– 39 - 88

COMP discharge

temperature (TH2)

when abnormality

occurred

0 - 216

Check code history (1)

(newest)

Abnormal unit No. and

check code inverted

display

Operation mode when abnormally stopped

<Example> Comp. only ON at cooling operation C4

–39 - 88

(When 0 °C or lower, “–” and temperature are displayed

alternately.)

<Example> When –15,

every other second

–

←→ 15

0 - 216

(When 100 or higher, 100s digit and 10s and units digits

are displayed alternately.)

<Example> When 130,

every other second

1

←→ 30

When no abnormality history

“0”, “←→”, “–”

Code display

°C

°C

Code display

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

Check code history (2)

(One before newest)

Abnormal unit No. and

check code inverted

display

Current thermostat

ON time

0 - 999

Number of indoor

units connected

0 - 4

When no abnormality history

“0”, “←→”, “–”

0 - 999

(When 100 or higher, 100s digit and 10s and units digits

are displayed alternately.)

<Example> When 245,

every other second

2

←→ 45

0 - 4

Code display

Minutes

Units

–30–

Page 33

SW2 setting Display contents Description of display Unit

123456

ON

OFF

Outdoor unit set

information 1

Outdoor unit capacity is displayed as function code.

Model name function code

PUH-P8MYA 20

PUH-P10MYA 25

Code display

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

Outdoor unit set

information 2

Indoor unit piping

temperature (TH2)

Indoor 1

–39 - 88

Indoor unit piping

temperature (TH2)

Indoor 2

–39 - 88

Indoor unit piping

temperature (TH2)

Indoor 3

–39 - 88

Outdoor unit set information 1 Function setting (display valves)

3-phase power source detection Do (1) Do not (0)

Cooling only switching Cooling only (2) H/P (0)

Tens digitUnits digit

Night mode Night mode (1) Normal mode (0)

Defrosting end time

Defrosting prohibit time Fixed (4) Training (0)

Set information display values are added and displayed at each position.

12 °C continuous 2 minutes

(2)

8 °C continuous 2 minutes

–39 - 88

(When 0 °C or lower, “–”and temperature are displayed

alternately.)

When there are no indoor units, “00” is displayed.

–39 - 88

(When 0 °C or lower, “–”and temperature are displayed

alternately.)

When there are no indoor units, “00” is displayed.

–39 - 88

(When 0 °C or lower, “–”and temperature are displayed

alternately.)

When there are no indoor units, “00” is displayed.

(0)

Code display

°C

°C

°C

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

Indoor unit piping

temperature (TH2)

Indoor 4

–39 - 88

Indoor intake temperature

8 - 39.5

Indoor set temperature

17 - 30

–39 - 88

(When 0 °C or lower, “–”and temperature are displayed

alternately.)

When there are no indoor units, “00” is displayed.

8 - 39.5

When there are no indoor units, “00” is displayed.

17 - 30

When there are no indoor units, “00” is displayed.

°C

°C

°C

–31–

Page 34

SW2 setting Display contents Description of display Unit

Indoor unit control

Control mode display system

status

123456

ON

OFF

123456

ON

OFF

Indoor 1, 2

Indoor unit control

status

Indoor 3, 4

Indoor unit No.2

Indoor unit No.4

Indoor unit No.1

Indoor unit No.3

Display

0

1

2

3

4

Freeze prevention

5

6

Compressor OFF

7

Control mode

Indoor unit

Ordinary

Hot adjustment

Defrosting

—

Heater ON

Surge prevention

Outdoor unit

←

←

←

←

←

←

←

←

–

–

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

Condenser/evaporater

temperature (TH3)

Outdoor unit control

status

Discharge super heat

SHd

0 - 216

Cooling: Outdoor TH2 -

Outdoor TH3

Heating: Outdoor TH2

- Indoor TH3

(Average)

–39 - 88

(When 0 °C or lower, “–”and temperature are displayed

alternately.)

<Example> When –10,

every other second

–

←→ –10

Control mode display system

Indoor unit No.2

Indoor unit No.4

Indoor unit No.1

Indoor unit No.3 Outdoor unit

Display

0

1

2

3

4

5

6

7

Freeze prevention

Surge prevention

Compressor OFF

Control mode

Indoor unit

Ordinary

Hot adjustment

Defrosting

—

Heater ON

Outdoor unit

←

←

←

←

←

←

←

←

0 - 216

(When 100 or higher, 100s digit and 10s and units digits

are displayed alternately.)

<Example> When 150,

every other second

1

←→ 50

°C

–

°C

123456

ON

OFF

123456

ON

OFF

Sub cool Sc

0 - 130

Cooling: Outdoor TH3

- Outdoor

TH1

Heating: Indoor TH3

(Average) Indoor TH2

(Average)

Target sub cool step N

1 - 5

0 - 130

(When 100 or higher, 100s digit and 10s and units digits

are displayed alternately.)

<Example> When 100,

every other second

1

←→ 00

1 - 5

–32–

°C

–

Page 35

SW2 setting Display contents Description of display Unit

0 - 255

When communication demand not set: 100 %

(When 100 or higher, 100s digit and 10s and units digits

are displayed alternately.)

123456

ON

OFF

Communication demand capacity

0 - 255

<Example> When 100,

every other second

1

←→ 100

%

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

Abnormal thermistor

display

1 - 3, –

FAN output at abnormal stop

0 - 100

LEV opening angle (/5)

at abnormal stop

0 - 400

Outdoor Condenser/

evaporater temp temperature at abnormal

stop

–39 - 88

1 - 3, –

1: Outdoor liquid temp thermistor (TH1)

2: Outdoor discharge temp thermistor (TH2)

3: Outdoor condenser/evaporater temp thermistor (TH3)

–: No abnormal thermistor

0 - 100

(When 100 or higher, 100s digit and 10s and units digits

are displayed alternately.)

<Example> When 100,

every other second

–

←→ 00

0 - 400

(When 100 or higher, 100s digit and 10s and units digits

are displayed alternately.)

<Example> When 200,

every other second

2

←→ 00

–39 - 88

(When 0 °C or lower, “–”and temperature are displayed

alternately.)

<Example> When –10,

every other second

–

←→ –10

–

%

5 pulses

°C

123456

ON

OFF

123456

ON

OFF

Discharge super heat

SHd at abnormal stop

0 - 216

Cooling: Outdoor TH2-

Outdoor TH3

Heating: Outdoor TH2-

Indoor TH3

(average)

Sub cool Sc at abnormal stop

0 - 130

Cooling: Outdoor TH3-

Outdoor TH1

Heating: Indoor TH3

(average) -Indoor TH2 (average)

0 - 216

(When 100 °C or higher, 100s digit and 10s and units

digits are displayed alternately.)

<Example> When 150,

every other second

–

←→ 50

0 - 130

(When 100 °C or higher, 100s digit and 10s and units

digits are displayed alternately.)

<Example> When 100,

every other second

1

←→ 00

°C

°C

–33–

Page 36

SW2 setting Display contents Description of display Unit

0 - 999

(When 100 or higher, 100s digit and 10s and units digits

are displayed alternately.)

<Example> When 245,

Minutes

123456

ON

OFF

Thermostat ON time up

to abnormal stop

0 - 999

every other second

2

←→ 45

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

LEV regular control

count n

1 - 5

Indoor unit condenser/

evaporater temp temperature (TH3)

Indoor 1

–39 - 88

Indoor unit condenser/

evaporater temp temperature (TH3)

Indoor 2

–39 - 88

Indoor unit condenser/

evaporater temp temperature (TH3)

Indoor 3

–39 - 88

1 - 5

–39 - 88

(When 0 ˚C or lower, “–”and temperature are displayed

alternately.)

When there are no indoor units, “00” is displayed.

–39 - 88

(When 0 ˚C or lower, “–”and temperature are displayed

alternately.)

When there are no indoor units, “00” is displayed.

–39 - 88

(When 0 ˚C or lower, “–”and temperature are displayed

alternately.)

When there are no indoor units, “00” is displayed.

–

˚C

˚C

˚C

123456

ON

OFF

Indoor unit condenser/

evaporater temp temperature (TH3)

Indoor 4

–39 - 88

–39 - 88

(When 0 ˚C or lower, “–”and temperature are displayed

alternately.)

When there are no indoor units, “00” is displayed.

˚C

–34–

Page 37

[4] Simple parts check method

• PUH-P8MYA/P10MYA

Part name

Thermistor (TH1) <Liquid

temperature detection>

Thermistor (TH2)

<Dischargetemperature

detection>

Thermistor (TH3) <Condenser/

evaporater temperature

detection>

Fan motor

Thermal protector

trip temperature

135 ± 5˚C : ON

88 ± 5˚C : OFF

White

Red

Black

Blue

Compressor

Judgment instructions

Disconnect the connector and measure the resistance value with a multimeter.

(Ambient temperature 10 ˚C to 30 ˚C)

TH1, 3

TH2

Normal

4.3 kΩ~9.6 kΩ

160 kΩ~410 kΩ

Abnormal

Open or short

(Based on thermistor characteristic table (next page))

Measure the resistance value across the terminals with a multimeter. (Winding

temperature 20 ˚C)

Motor lead wire

Between 2 phases

Normal

45.5 Ω

Abnormal

Open or short

Measure the resistance value across the terminals with a multimeter. (Winding

temperature 20 ˚C)

Normal

PUH-P8MYA

Each phase 1.574 Ω

PUH-P10MYA

Each phase 1.263 Ω

Abnormal

Open or short

Open or short

–35–

Page 38

[5] Reference Data

<Thermistor characteristic table>

Low temperature thermistor Thermistor <Liquid temperature detection> (TH1)

Thermistor <Condenser/evaporater temperature detection> (TH3)

Thermistor <Liquid temperature detection> (TH1)

Thermistor <Condenser/evaporater temperature detection> (TH3)

Thermistor Ro = 15 kΩ ± 3 %

B constant = 3,460 kΩ ± 2 %

Rt = 15 exp {3,460 (–––––– – ––––)}

11

273 + t 273

50

<Low temperature thermistor>

0 °C: 15 kΩ

40

10 °C: 9.7 kΩ

20 °C: 6.4 kΩ

25 °C: 5.3 kΩ

30

30 °C: 4.3 kΩ

40 °C: 3.1 kΩ

Resistance

20

10

0

—20 —10 10 20 30 40 500

High temperature thermistor Thermistor <Discharge temperature detection> (TH2)

Thermistor (Discharge temperature detection) (TH2)

Thermistor R120 = 7.465 kΩ ± 2 %

B constant = 4,057 kΩ ± 2 %

Rt = 7.465 exp {4,057 (–––––– – ––––)}

11

273 + t 393

25

Temperature

<High temperature thermistor>

20 °C: 250 kΩ 70 °C: 34 kΩ

30 °C: 160 kΩ 80 °C: 24 kΩ

40 °C: 104 kΩ 90 °C: 17.5 kΩ

50 °C: 70 kΩ 100 °C: 13.0 kΩ

60 °C: 48 kΩ 110 °C: 9.8 kΩ

20

15

Resistance

10

5

0

90 100 110 120

Temperature

–36–

Page 39

[6] Troubleshooting of each part

(1) LEV

1) Overview of LEV operation

LEV (electronic expansion valve) receives pulse signals from the outdoor unit main circuit board and drives a valve

by means of a servomotor.

The valve opening angle changes in proportion to the number of pulses.

<Outdoor controller board and LEV>

Blue

Brown

Yellow

White

Red

Orange