Page 1

AIR-COOLED HEAT PUMP TYPE

PACKAGED AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

<Outdoor unit>

Models

PUH-8YE, PUH-10YE

(Single and Twin/Triple)

2000

For use with the R22

Page 2

Contents

Page

11

1 SAFETY PRECAUTIONS........................................................................................................... 1

11

22

2 SPECIFICATIONS ...................................................................................................................... 3

22

33

3 EXTERNAL DIMENSIONS......................................................................................................... 5

33

44

4 ELECTRICAL WIRING DIAGRAM ............................................................................................. 6

44

[1] Outdoor Unit ........................................................................................................................ 6

[2] Skelton of Indoor/Outdoor Connection ................................................................................ 7

55

5 Technical Data of PUH-8YE/10YE to Meet LVD....................................................................... 8

55

[1] Standard Operation Data..................................................................................................... 8

[2] Cooling Capacity Curves ..................................................................................................... 9

[3] Heating Capacity Curves ..................................................................................................... 9

[4] Capacity Reduction Ratio due to Changes in Piping Length ............................................. 10

[5] Center of Gravity (Outdoor unit) ........................................................................................ 11

[6] NC Curve (Outdoor unit)................................................................................................... 12

66

6 SERVICE DATA ........................................................................................................................ 13

66

[1] Appearance of Equipment ................................................................................................. 13

[2] Refrigerant Circuit.............................................................................................................. 15

[3] Limitation of Refrigerant Piping Length.............................................................................. 15

[4] Refrigerant Piping .............................................................................................................. 16

[5] Refrigerant Charge ............................................................................................................ 16

[6] Operation Rage ................................................................................................................. 16

77

7 CONTROL ................................................................................................................................ 17

77

[1] Composition of Control ...................................................................................................... 17

[2] Control specifications......................................................................................................... 17

[3] Function of switches and connectors (outdoor unit) .......................................................... 21

[4] Simple parts check method ............................................................................................... 25

[5] Reference Data.................................................................................................................. 26

[6] Self-diagnosis and troubleshooting.................................................................................... 27

[7] TEST RUN......................................................................................................................... 32

Page 3

11

1 SAFETY PRECAUTIONS

11

1. Before installation and electric work

sBefore installing the unit, make sure you read all the “Safety precautions”.

sThe “Safety precautions” provide very important points regarding safety. Make sure you follow them.

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger of injury or death to the user.

Caution:

Describes precautions that should be observed to prevent damage to the unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Beware of electric shock. (This symbol is displayed on the main unit label.) <Color: yellow>

Warning:

Carefully read the labels affixed to the main unit.

Warning:

• Use the specified cables for wiring. Make the connections securely so that the outside force of the cable is not

applied to the terminals.

- Inadequate connection and fastening may generate heat and cause a fire.

• Do not touch the heat exchanger fins.

- Improper handling may result in injury.

• If refrigerant gas leaks during installation work, ventilate the room.

- If the refrigerant gas comes into contact with a flame, poisonous gases will be released.

• Have all electric work done by a licensed electrician according to “Electric Facility Engineering Standard” and

“Interior Wire Regulations”and the instructions given in this manual and always use a special circuit.

- If the power source capacity is inadequate or electric work is performed improperly, electric shock and fire may result.

• Securely install the outdoor unit terminal cover (panel).

- If the terminal cover (panel) is not installed properly, dust or water may enter the outdoor unit and fire or electric shock

may result.

• When installing and moving the air conditioner to another site, do not charge the it with a refrigerant different

from the refrigerant (R407C or R22) specified on the unit.

- If a different refrigerant or air is mixed with the original refrigerant, the refrigerant cycle may malfunction and the unit may

be damaged.

• When moving and reinstalling the air conditioner, consult the dealer or an authorized technician.

- If the air conditioner is installed improperly, water leakage, electric shock, or fire may result.

• Do not reconstruct or change the settings of the protection devices.

- If the pressure switch, thermal switch, or other protection device is shorted and operated forcibly, or parts other than

those specified by Mitsubishi Electric are used, fire or explosion may result.

2. Precautions for devices that use R407C refrigerant

Caution:

• Do not use the existing refrigerant piping.

- The old refrigerant and refrigerator oil in the existing piping contains a large amount of chlorine which may cause the

refrigerator oil of the new unit to deteriorate.

• Use refrigerant piping made of phosphorus deoxidized copper and copper alloy seamless pipes and tubes. In

addition, be sure that the inner and outer surfaces of the pipes are c lean and free of hazardous sulphur, oxides,

dust/dirt, shaving particles, oils, moisture, or any other contaminant.

- Contaminants on the inside of the refrigerant piping may cause the refrigerant residual oil to deteriorate.

• Store the piping to be used during installation indoors and keep both ends of the piping sealed until just before

brazing. (Store elbows and other joints in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and compressor trouble may result.

–1–

Page 4

• Use ester oil, ether oil or alkylbenzene (small amount) as the refrigerator oil to coat flares and flange connections.

- The refrigerator oil will degrade if it is mixed with a large amount of mineral oil.

• Use liquid refrigerant to fill the system.

- If gas refrigerant is used to seal the system, the composition of the refrigerant in the cylinder will change and performance may drop.

• Do not use a refrigerant other than R407C.

- If another refrigerant (R22, etc.) is used, the chlorine in the refrigerant may cause the refrigerator oil to deteriorate.

• Use a vacuum pump with a reverse flow check valve.

- The vacuum pump oil may flow back into the refrigerant cycle and cause the refrigerator oil to deteriorate.

• Do not use the following tools that are used with conventional refrigerants.

(Gauge manifold, charge hose, gas leak detector, reverse flow check valve, refrigerant charge base, refrigerant

recovery equipment)

- If the conventional refrigerant and refrigerator oil are mixed in the R407C, the refrigerant may deteriorated.

- If water is mixed in the R407C, the refrigerator oil may deteriorate.

- Since R407C does not contain any chlorine, gas leak detectors for conventional refrigerants will not react to it.

• Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

• Be especially careful when managing the tools.

- If dust, dirt, or water gets in the refrigerant cycle, the refrigerant may deteriorate.

3. Electrical work

Caution:

• Ground the unit.

- Do not connect the ground wire to gas or water pipes, lightning rods, or telephone ground lines. Improper grounding ma y

result in electric shock.

• The reverse phase of L lines (L

line can be not be detected.

- The some electric parts should be damaged when power is supplied under the miss wiring.

• Use power line cables of sufficient current carrying capacity and rating.

- Cables that are too small may leak, generate heat, and cause a fire.

• Use only a circuit breaker and fuse of the specified capacity.

- A fuse or circuit breaker of a larger capacity or a steel or copper wire may result in a general unit failure or fire.

• Do not wash the air conditioner units.

- Washing them may cause an electric shock.

1, L2, L 3) can be detected (Error cord: F8), but the reverse phase of L lines and N

4. Before starting the test run

Caution:

• Turn on the power at least 12 hours before starting operation.

- Star ting operation immediately after turning on the main power switch can result in severe damage to internal parts.

Keep the power switch turned on during the operational season.

• Do not touch the switches with wet fingers.

- Touching a switch with wet fingers can cause electric shock.

• Do not touch the refrigerant pipes during and immediately after operation.

- During and immediately after operation, the refrigerant pipes are may be hot and may be cold, depending on the

condition of the refrigerant flowing through the refrigerant piping, compressor, and other refrigerant cycle parts. Your

hands may suffer burns or frostbite if you touch the refrigerant pipes.

• Do not operate the air conditioner with the panels and guards removed.

- Rotating, hot, or high-voltage parts can cause injuries.

• Do not turn off the power immediately after stopping operation.

- Always wait at least five minutes before turning off the power. Otherwise, water leakage and trouble may occur.

Note:

1. The total capacity of connected indoor unit models represents the total sum of the figures expressed in the

indoor model name.

2. Combinations in which the total capacity of the connected indoor units exceeds the capacity of the outdoor unit

will reduce the capacity of each indoor unit below the rated capacity during simultaneous operation. Theref ore,

if circumstances allows, combine indoor units within the capacity of the outdoor unit.

–2–

Page 5

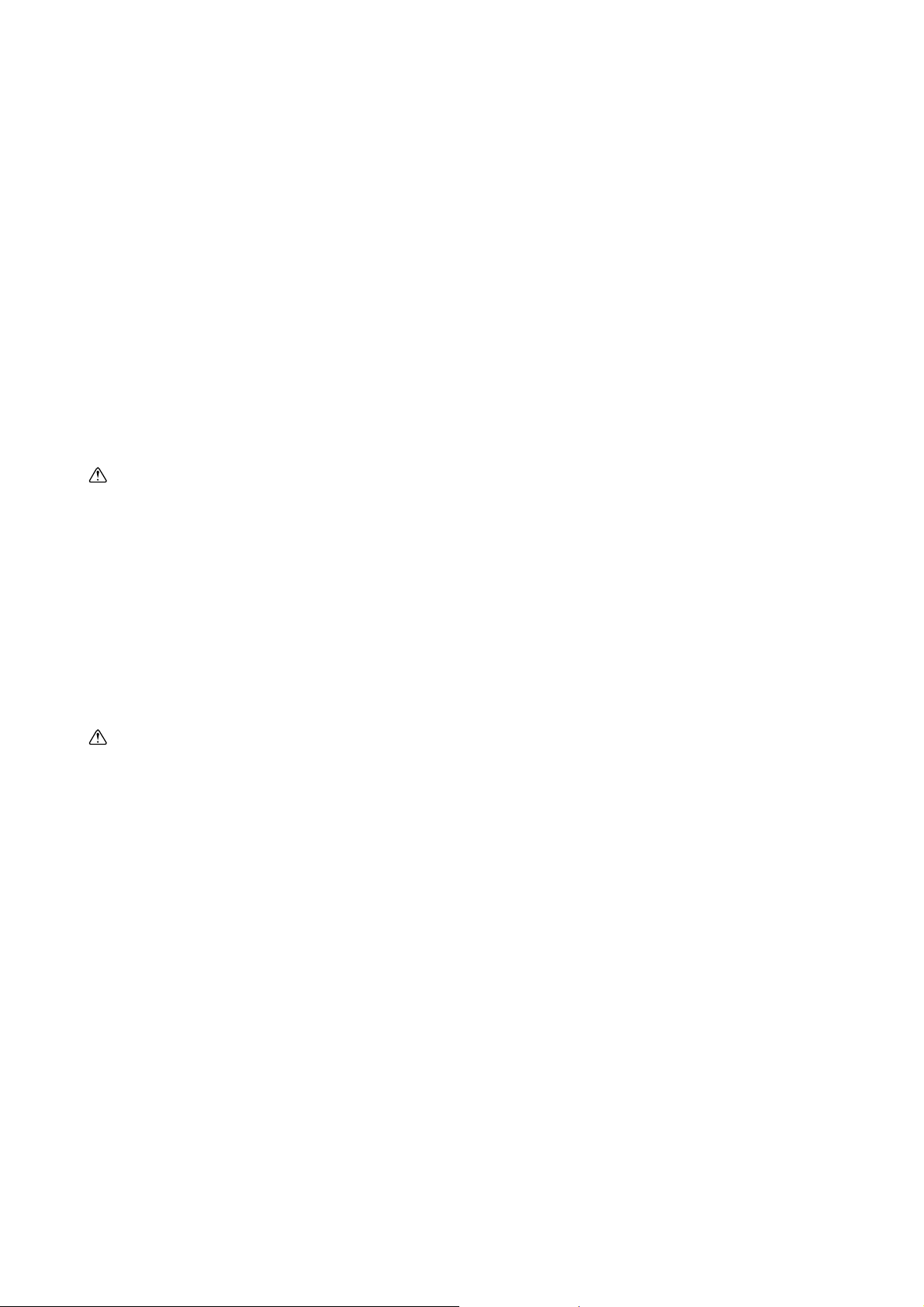

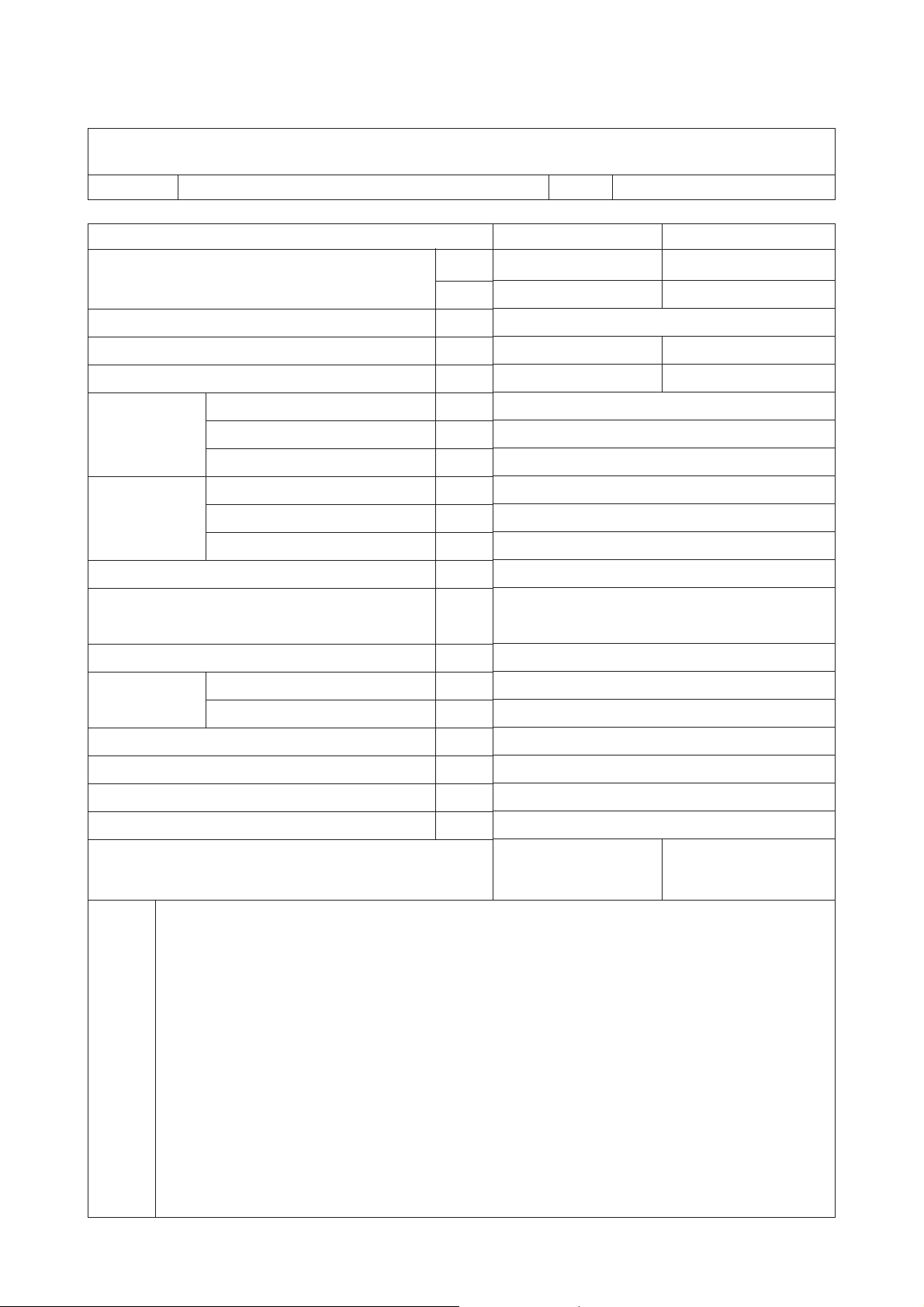

22

2 SPECIFICATIONS

22

Specifications of air-source heat pump type packaged air conditioner

(Outdoor unit)

Model name PUH-8YE Quantity

Cooling Heating

Capacity

Power source

Power input kW

Current A

Type x Quantity

Fan Airflow rate m3/min

Motor output kW

Type

Compressor Motor output kW

Crankcase heater kW

Refrigerant/Lubricant

External finish

External dimension mm

Protection

device

High pressure protection MPa

Compressor/Fan

kcal/h

kW

18,000 19,000

20.9 22.1

3N~ 380/400/415 V 50 Hz

7.62 7.17

13.5/13.6/13.7 12.3/12.4/12.5

Propeller fan × 1

185

0.38

Hermetic

5.5

0.05 (240 V)

R22/MS32(N-1)

Steel plate paintingwith polyester powder

(MUNSELL 5Y8/1 or similar)

1,715(H) × 990(W) × 840(L)

2.94

Overcurrent protection/Thermal switch

Refrigerant piping diameter Liquid/Gas mm

Indoor unit

Noise level dB (A)

Net weight kg

Operating temperature range

1. Cooling/Heating capacity indicates the maximum value at operation under the following condition.

Cooling Indoor: 27 °CDB/19 °CWB Outdoor: 35

Notes:

Heating Indoor: 20 °CDB Outdoor: 7

Pipe length: 7.5 m Height difference: 0 m

2. Works not included: Installation/Foundation work, Electrical connection work, Duct work, Insulation

work, Power source switch, and other items not specified in this specifications.

ø12.7 Flare / ø25.4 Flange

PEH-8YD

56

205

Indoor: 15 °CWB~24 °CWB Indoor: 15°CDB~27 °CDB

Outdoor: –5 °CDB~46 °CDB

Outdoor: –12 °CWB~15.5 °CWB

°

CDB

°

CDB/6 °CWB

–3–

Page 6

Specifications of air-source heat pump type packaged air conditioner

(Outdoor unit)

Model name PUH-10YE Quantity

Cooling Heating

Capacity

Power source

Power input kW

Current A

Type x Quantity

Fan Airflow rate m3/min

Motor output kW

Type

Compressor Motor output kW

Crankcase heater kW

Refrigerant/Lubricant

External finish

External dimension mm

Protection

device

High pressure protection MPa

Compressor/Fan

kcal/h

kW

22,400 24,400

26.0 28.4

3N~ 380/400/415 V 50 Hz

9.47 8.30

16.8/16.9/17.0 14.8/14.9/15.0

Propeller fan × 1

185

0.38

Hermetic

7.5

0.06 (240 V)

R22/MS-32(N-1)

Steel plate painting with polyester powder

(MUNSELL 5Y8/1 or similar)

1,715(H) × 990(W) × 840(L)

2.94

Overcurrent protection/Thermal switch

Refrigerant piping diameter Liquid/Gas mm

Indoor unit

Noise level dB (A)

Net weight kg

Operating temperature range

1. Cooling/Heating capacity indicates the maximum value at operation under the following condition.

Cooling Indoor: 27 °CDB/19 °CWB Outdoor: 35 °CDB

Notes:

Heating Indoor: 20 °CDB Outdoor: 7 °CDB/6 °CWB

Pipe length: 7.5 m Height difference: 0 m

2. Works not included: Installation/Foundation work, Electrical connection work, Duct work, Insulation

work, Power source switch,and other items not specified in this specifications.

ø15.88 Flare / ø28.58 Flange

PEH-10YD

57

225

Indoor: 15 °CWB~24 °CWB Indoor: 15 °CDB~27 °CDB

Outdoor: –5 °CDB~46 °CDB

Outdoor: –12 °CWB~15.5 °CWB

–4–

Page 7

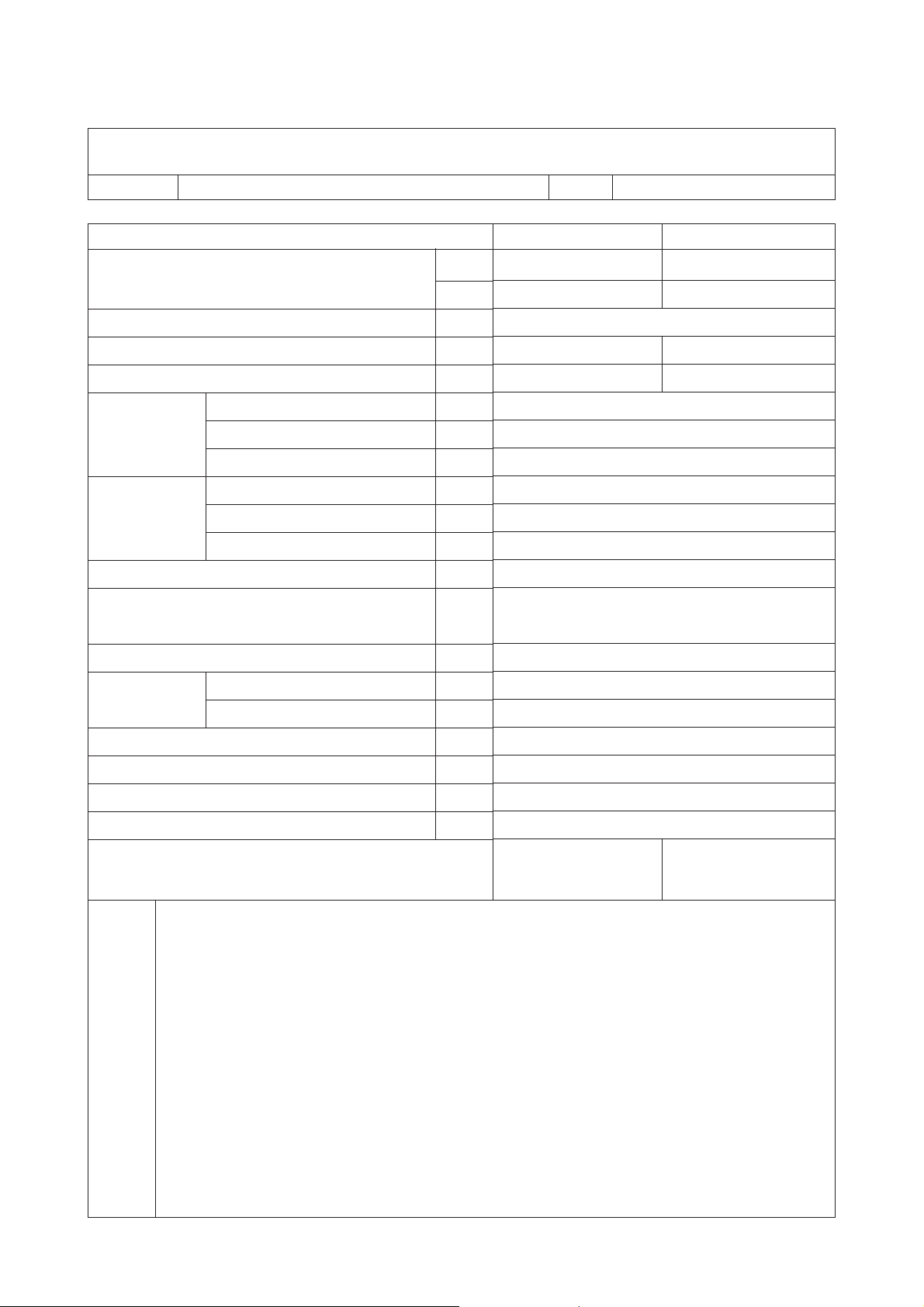

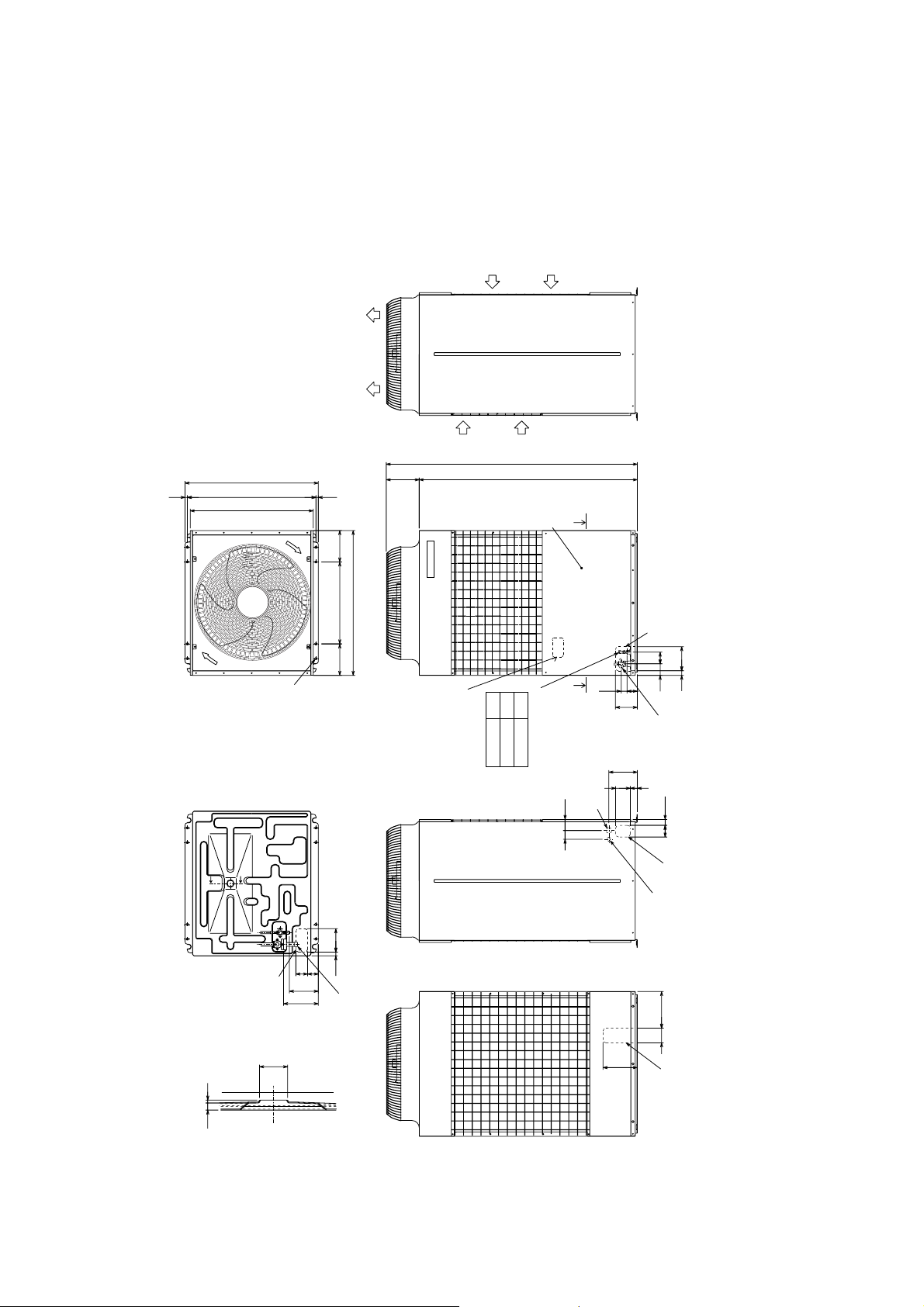

33

3 EXTERNAL DIMENSIONS

33

• Models PUH-8YE/10YE

1 pc.

1 pc.

·

···········

·················

(The connecting pipe is fixed with the unit)

(Attached near the ball valve)

< Accessory >

• Refrigerant (gas) conn. pipe

• Packing for conn. pipe

each 1pc.

4 pcs.

Air outlet

················

,

·························

27

ø

33,

ø

40,

(Painted the same color as the unit body)

ø

• Conduit mouting plate

• Tapping screw 4 ✕ 10

Note Please leave a space under the outdoor unit

910

840

of the bottom plate by the basement)

for the piping When you connect the piping

from the bottom.

(Please be careful not to close the hole

15 880 15

215

225

Unit: mm

Air

inlet

Right side view

Air

inlet

1715

1490

X

Service panel

560

990

Plane view

215

A

12.7

15.88

Oval hole

4 ✕ 2 - 14 ✕ 20

Y

Y

Knockout hole

MOOEL

PUH-8YE

PUH-10YE

X

Refrig. service

valve (liquid)

øA<flare>

40 Knockout hole

7560

ø

<Left side hole for

the power supply>

40

Knockout hole

Front piping hole

83

79

70

149

Refrig. service

194

48 100

16531

valve (gas)

<flange>

4080

Knockout hole

Left piping hole

Left side view

Front view

Cross section X-X

27 Knockout hole

<Left side hole for

the control wiring>

ø

25 160

73 80

198

Note1

Knockout hole

Bottom piping hole

50

237

25.4<brazed>

28.58<brazed>

ø

ø

8 :

10 :

Conn. pipe

251100

234

Rear view

12 5

Knockout hole

Crosss section Y-Y

–5–

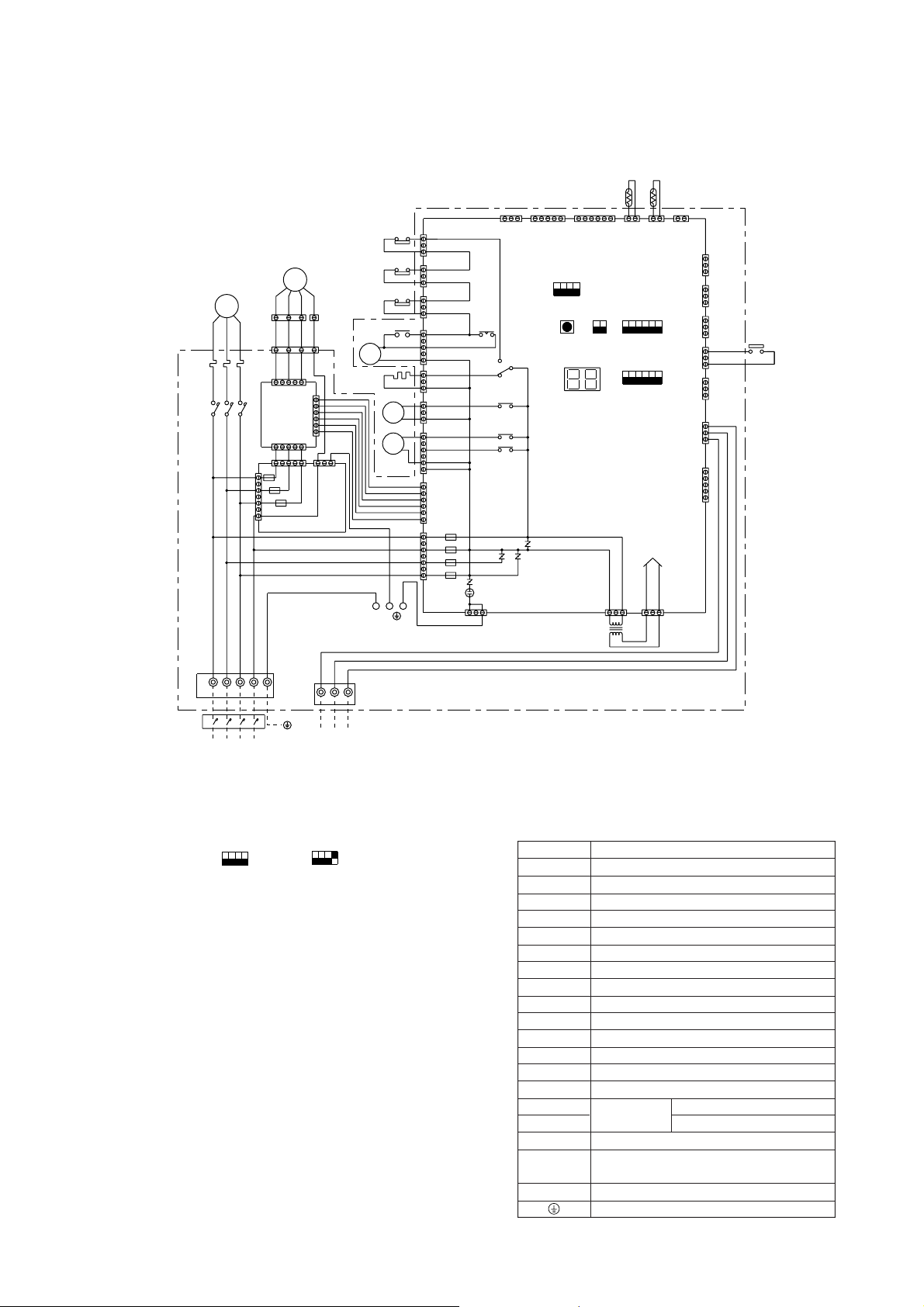

Page 8

44

4 ELECTRICAL WIRING DIAGRAM

44

[1] Outdoor Unit

• Models PUH-8YE/10YE

MC

Black

Red

White

51C

52C

Black

White

Red

(3P)

F.C.

BOARD

CNOUT1

(5P)

1

3

5

7

CNIN

(7P)

Blue

MF

1

3

4

1

1

53

CNFAN

(5P)

CNFC2

(6P)

CNPOW

(5P)

3115

F10

F20

F30

N.F.BOARD

Green/Yellow

(1P)

(4P)

1

6

3

CNOUT2

(3P)

49C

51C

63H1

52C

CH

Unit body

52C

21S4

SV1

L1

N

L2

L3

1

3

1

3

1

3

1

3

5

1

3

1

3

1

5

1

6

7

1

CN23

CN22

CN21

CN26

CN25

CN53

CN52

CNFC1

CN20

F01

F04

F02

F03

(3P)

(3P)

(3P)

(5P)

(3P)

(3P)

(6P)

(7P)

(6P)

TH1

TH2

121

CNVMNT

CNMNT

(3P)

(5P)

(6P)

ON

OFF

4

1

SW5

LED1

SW3

ON

OFF

1

SW4

CN28

(3P)

TR

2

X04

X03

X01

X02

X05

CNFG

(3P)

3

1

CN2

(2P)

ON

OFF

1

SW1

ON

OFF

1

SW2

DC power supply

CN34

(3P)

3

1

2

CN3 CN4CN40

(2P)(2P)

CN3D

(3P)

CN3S

(3P)

CN3N

(3P)

6

CN24

(3P)

CN27

(3P)

6

CN81

(3P)

CN51

(5P)

3

1

63H2

3

1

3

1

TB1

NOTE SW5-4 IS OFF IN CASE OF PUH-8YE.

SW5-4 IS ON IN CASE OF PUH-10YE.

L1 L2 L3

L1 L2 L3

Power source

3N~

380/400/415 V

50 Hz

ON

ON

OFF

OFF

1

1

SW5

N

N

4

4

PUH-8YE

TB3

23

1

To indoor unit

ON

ON

OFF

OFF

1

44

1

SW5

PUH-10YE

Note:

1. Be sure to apply earth work to the unit. (Use the earth terminal of TB1.)

Controller Box

Symbol Explanation

Symbol Name

F01~F04

F10~F30

51C

52C

63H1

63H2

TR

MC

MF

CH

X01~X05

SW1~5

21S4

SV1

TH1

TH2

TB1

TB3

49C

FUSE (6.3A 250VAC CLASS F)

FUSE (6.3A 250VAC CLASS F)

OVER CURRENT RELAY

MAGNETIC CONTACTOR (COMPRESSOR)

PRESSURE SWITCH (HIGH PRESSURE)

PRESSURE SWITCH (FOR CONTROL)

TRANSFORMER

ELECTRIC MOTOR OF COMPRESSOR

FAN MOTOR (HEAT EXCHANGER)

CRANK CASE HEATER (COMPRESSOR)

RELAY

SWITCH

4-WA Y VAL VE

SORENOID VALVE

THERMISTOR

LIQUID TEMP

DISCHARGE TEMP

POWER SOURCE TERMINAL BLOCK

INDOOR/OUTDOOR CONNECTION TERMINAL

BLOCK

THERMAL SWITCH (COMPRESSOR)

EARTH TERMINAL

–6–

Page 9

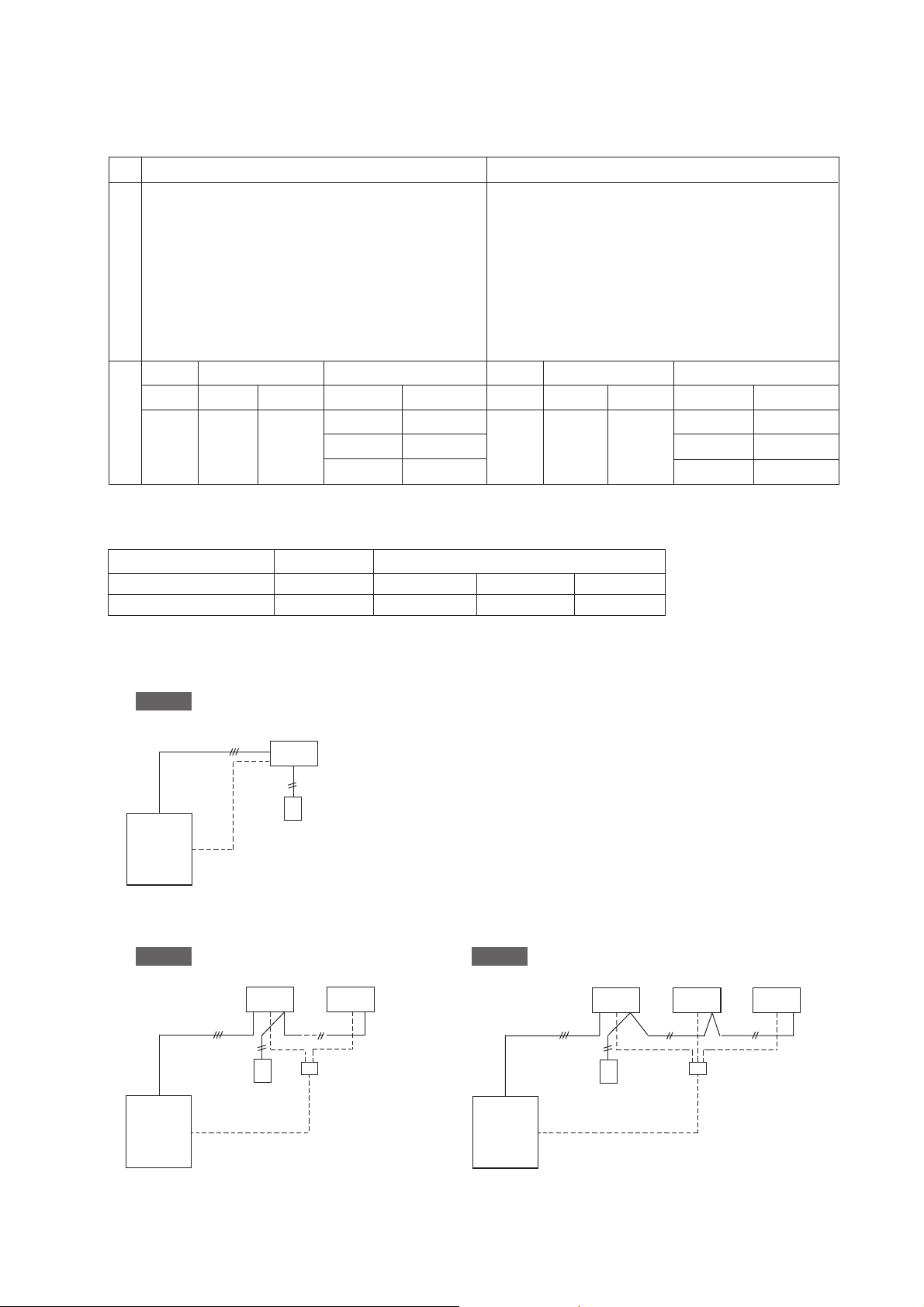

[2] Skelton of Indoor/Outdoor Connection

(1) Multiple systems combination chart

PUH-8YE PUH-10YE

PEH-8YD

PLH-1.6, 2, 2.5KK(H)B

PLH-3AK(H), PLH-4AK(H)S

PKH-1.6, 2, 2.5, 3FK(H)A, PKH-4FK(H)SA

PCH-2, 2.5, 3GK(H)A, PCH-4GK(H)SA

PEH-2.5, 3, EKHA, PEH-4EKHSA

PEHD-1.6, 2, 2.5, 3EK(H)A, PEHD-4EK(H)SA

PEH-10YD

PLH-2, 2.5KK(H)B

PLH-3AK(H), PLH-4, 5AK(H)S

PKH-2, 2.5, 3FK(H)A, PKH-4FK(H)SA

PCH-2, 2.5, 3GK(H)A, PCH-4, 5GK(H)SA

PEH-2.5, 3EKHA, PEH-4, 5EKHSA

PEHD-2, 2.5, 3EK(H)A, PEHD-4, 5EK(H)SA

Single Twin Triple Single Twin Triple

Model Ratio Model Ratio Model Model Ratio Model Ratio Model

33:33:33 2.5+2.5+2.5 33:33:33 3+3+3

Systems Indoor units

8 50:50 4+4 25:25:50 2+2+4 10 50:50 5+5 25:25:50 2.5+2.5+5

20:40:40 1.6+3+3 20:40:40 2+4+4

(2) Multiple-distributor pipes (option)

Twin Triple

Ratio of indoor units 50:50 33:33:33 25:25:50 20:40:40

Multiple-distributor SDD-50WJ-E SDT-111J-E SDT-112J-E SDT-122J-E

(3) System

Single

3-core cable (DC12V)

Outdoor unit

Pipe work

Indoor unit

Transmission line

Remote

controller

Twin Triple

Indoor units

No. 1 No. 2

3-core cable (DC12V)

Remote

controller

Distributor

Transmission

line

3-core cable (DC12V)

Indoor units

No. 1 No. 2 No.3

Remote

controller

Distributor

Transmission

line

Outdoor unit

Pipe work

–7–

Outdoor unit

Pipe work

Page 10

55

5 Technical Data of PUH-8YE/10YE to Meet LVD

55

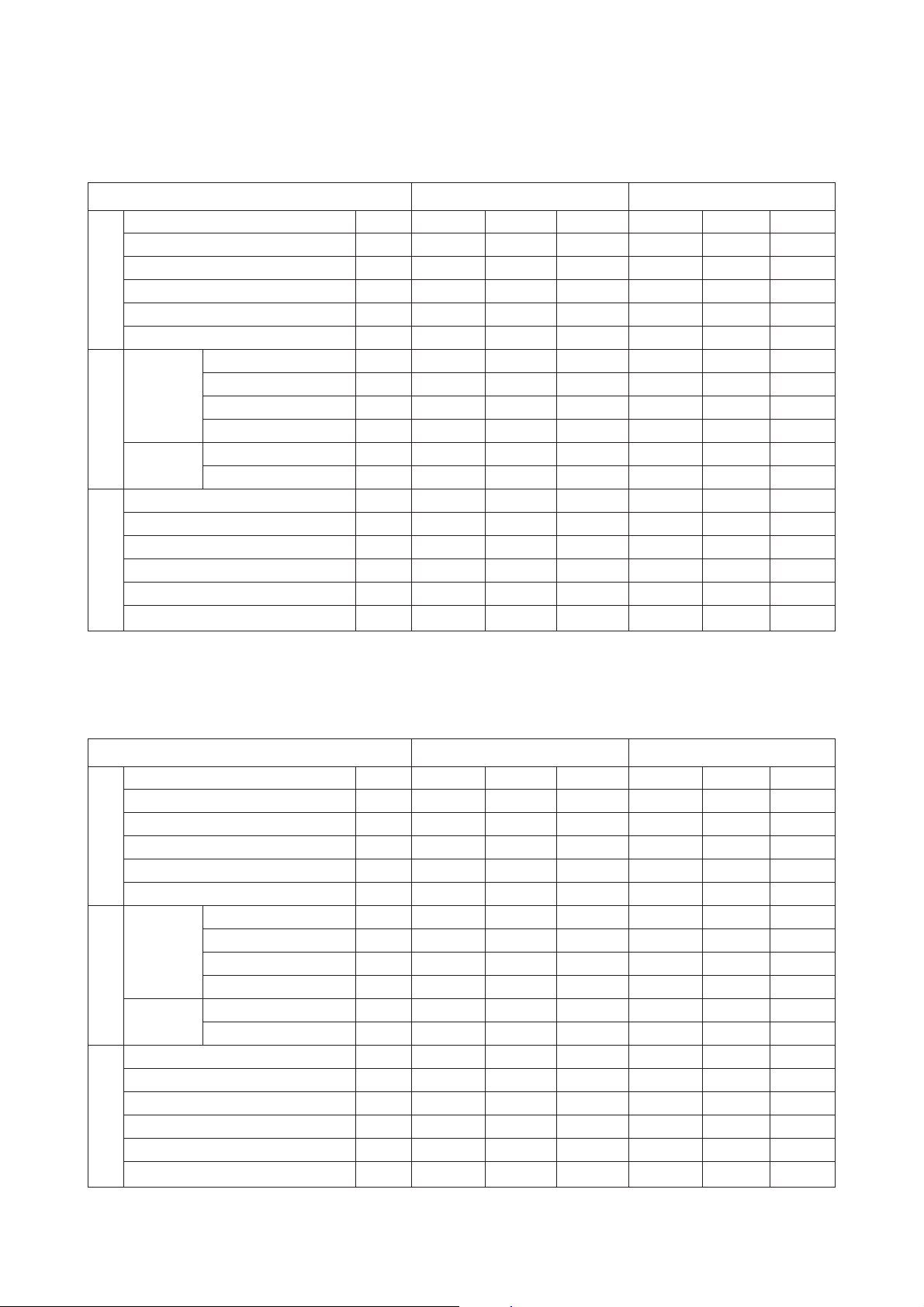

[1] Standard Operation Data

1 PUH-8YE

Operating condition Cooling Heating

Voltage V

Power source frequency Hz

Indoor air condition (DB/WB) °C

Outdoor air condition (DB/WB) °C

Piping length m

Operating condition

Refrigerant charge kg

Current A

Outdoor unit

Indoor unit

Electrical characteristics

Discharge pressure MPa

Suction pressure MPa

Discharge refrigerant temperature °C

Suction refrigerant temperature °C

Liquid pipe temperature

Refrigerant circuit

Compressor shell bottom temperature °C

Input kW

Compressor current A

Fan current A

Current A

Input kW

(at piping sensor)

°C

380 400 415 380 400 415

50 50 50 50 50 50

27/19 27/19 27/19 20/– 20/– 20/–

35/- 35/– 35/– 7/6 7/6 7/6

7.5 7.5 7.5 7.5 7.5 7.5

7.4 7.4 7.4 7.4 7.4 7.4

13.5 13.6 13.7 12.3 12.4 12.5

7.62 7.62 7.62 6.91 6.91 6.91

12.4 12.5 12.6 11.2 11.3 11.4

1.1 1.1 1.1 1.1 1.1 1.1

1.12 1.12 1.12 1.12 1.12 1.12

0.65 0.65 0.65 0.65 0.65 0.65

1.99 1.99 1.99 1.59 1.59 1.59

0.49 0.49 0.49 0.35 0.35 0.35

85 85 85 75 75 75

777–2–2–2

46 46 46 5 5 5

50 50 50 35 35 35

Note: The values listed above indicate that when connected with the indoor unit PEH-8YD as representative data.

2 PUH-10YE

Operating condition Cooling Heating

Voltage V

Power source frequency Hz

Indoor air condition (DB/WB) °C

Outdoor air condition (DB/WB) °C

Piping length m

Operating condition

Refrigerant charge kg

Current A

Outdoor unit

Indoor unit

Electrical characteristics

Discharge pressure MPa

Suction pressure MPa

Discharge refrigerant temperature °C

Suction refrigerant temperature °C

Liquid pipe temperature

Refrigerant circuit

Compressor shell bottom temperature °C

Input kW

Compressor current A

Fan current A

Current A

Input kW

(at piping sensor)

°C

380 400 415 380 400 415

50 50 50 50 50 50

27/19 27/19 27/19 20/– 20/– 20/–

35/- 35/– 35/– 7/6 7/6 7/6

7.5 7.5 7.5 7.5 7.5 7.5

7.6 7.6 7.6 7.6 7.6 7.6

16.8 16.9 17.0 14.8 14.9 15.0

9.47 9.47 9.47 8.30 8.30 8.30

15.7 15.8 15.9 13.7 13.8 13.9

1.1 1.1 1.1 1.1 1.1 1.1

1.64 1.64 1.64 1.64 1.64 1.64

0.94 0.94 0.94 0.94 0.94 0.94

2.03 2.03 2.03 1.57 1.57 1.57

0.48 0.48 0.48 0.34 0.34 0.34

95 95 95 80 80 80

888–2–2–2

47 47 47 6 6 6

60 60 60 40 40 40

Note: The values listed above indicate that when connected with the indoor unit PEH-10YD as representative data.

–8–

Page 11

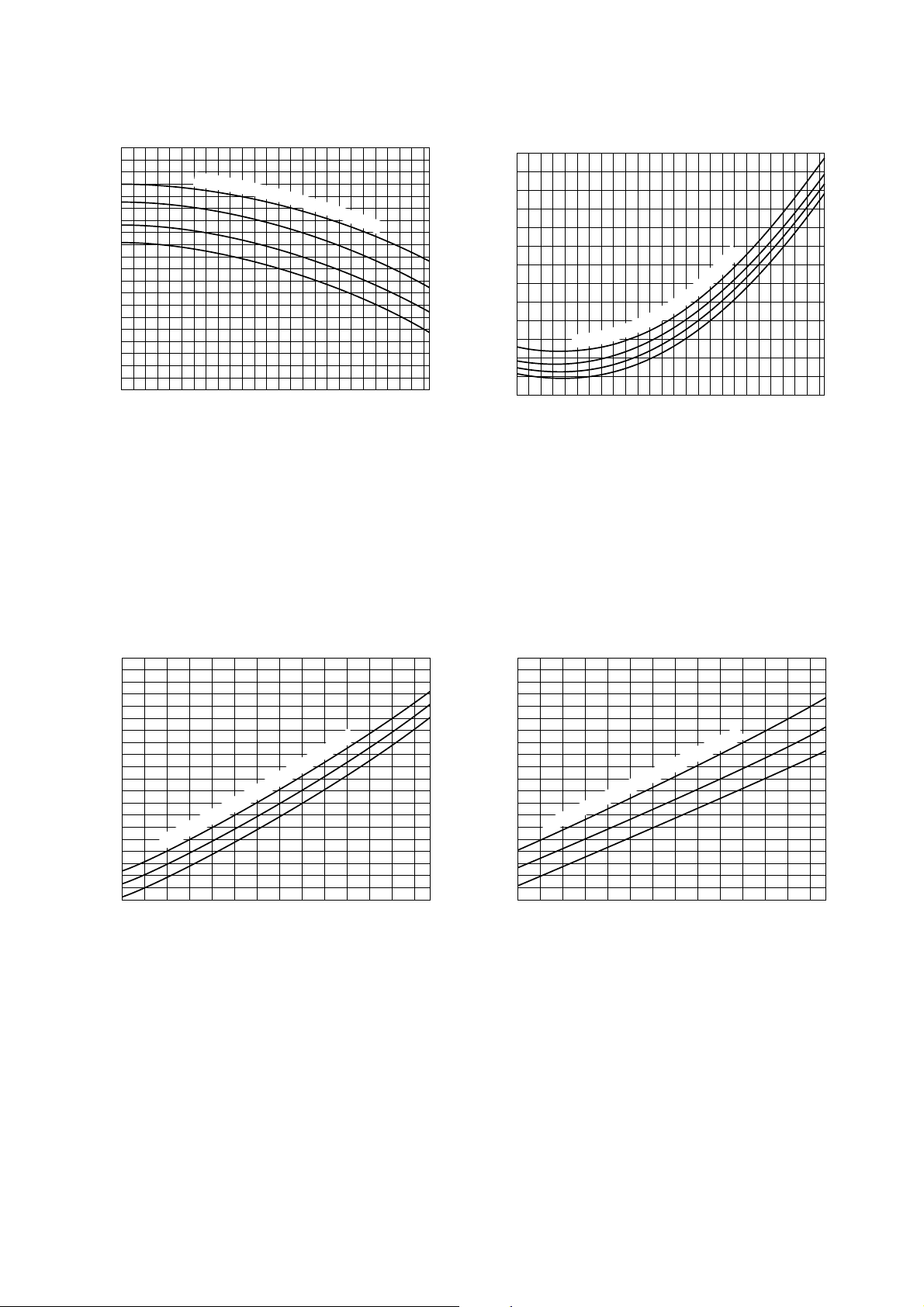

[2] Cooling Capacity Curves

• PUH-8YE/10YE

1.4

I

n

d

o

o

r

i

n

l

e

t

a

i

r

w

e

t

b

u

l

b

t

e

1.2

m

p

.

1.22

<

°

C

W

B

>

1.1

22

20

18

16

1

Capacity ratio

0.8

0.6

-5-3-113579111315171921232527293133353739414345

Outdoor air temp. <°CDB>

[3] Heating Capacity Curves

• PUH-8YE/10YE

1.4

1.2

>

B

D

C

°

<

e

r

u

t

a

r

e

p

m

e

t

b

l

u

b

y

r

Capacity ratio

0.8

1

d

r

i

a

t

e

l

n

i

r

o

o

d

n

I

22

20

18

16

15

20

25

Input ratio

0.9

i

a

t

e

l

n

i

r

o

o

d

n

I

0.7

-5-3-113579111315171921232527293133353739414345

Outdoor air temp. <°CDB>

1.4

1.2

1

Input ratio

0.8

Indoor inlet air dry bulb temperature <°CDB>

e

t

b

l

u

b

t

e

w

r

>

B

W

C

°

<

.

p

m

25

20

15

0.6

-12-10-8-6-4-202468101214

Outdoor air temperature <°CWB>

15.5

–9–

0.6

-12-10-8-6-4-202468101214

Outdoor air temperature <°CWB>

15.5

Page 12

[4] Capacity Reduction Ratio due to Changes in Piping Length

(1) Cooling capacity

PUH-8YE

1

0.9

Capacity ratio

0.8

0 10 20 30 40 50 60 70

Equivalent piping length (m)

(2) Heating capacity

Equivalent piping length

Model name

PUH-8YE

- 30 m 30 - 50 m 50 - 70 m

1.0 0.995 0.99

PUH-10YE

PUH-10YE

1

0.9

Capacity ratio

0.8

0 10 20 30 40 50 60 70

Equivalent piping length (m)

(3) Calculation formula of equivalent piping length

PUH-8YE Equivalent piping length (m) = Actual piping length (m) + (0.47 × Number of bend)

PUH-10YE Equivalent piping length (m) = Actual piping length (m) + (0.5 × Number of bend)

(4) Reduction ratio by frosting

Outdoor unit inlet wet bulb temperature

(°CWB)

6 1.0

4 0.98

2 0.88

0 0.85

–2 0.86

–4 0.89

–6 0.92

–8 0.92

–10 0.92

Heating capacity reduction ratio

–10–

Page 13

[5] Center of Gravity (Outdoor unit)

(1) Caution for Lifting

Warning

Lift unit slowly by suspending rope uniformly

so that the rope will not slip off or unit will not

incline seriously.

Be careful that unit may fall down if the rope is

not in a proper position as the center or

gravity of unit is being inclined.

Protection pad

Use pads properly to

prevent the scratching of

external panel

caused by contact

with sling.

Name plate

Indicates the unit

front side.

Blow 40˚

Hanger rope (Over 7m × 2)

Must be durable against unit weight.

For the lifting of unit for movement, please

be sure to suspend at four points, and not

to give any shock to unit.

Never apply two-point lifting as it is

dangerous.

Service panel

Compressor position

Suspending spot

2-point,front and rear

Model name

PUH-8YE

PUH-10YE

Item

Center of gravity

Inclining to the right

front side of unit.

G

Z

X

Center of gravity (mm)

XYZ

Y

Fasten here properly

to prevent unit from

slipping off from

the sling at lifting.

Net weight

(kg)

330 350 490 205

300 330 510 225

–11–

Page 14

[6] NC Curve (Outdoor unit)

(1) Octave Band Analysis

1 PUH-8YE

Measurement condition

1m

A

1m

B

Sound pressure level in anechoic room

56 dB (A)

70

60

50

40

30

20

OCTAVE BAND PRESSURE LEVEL< dB> 0dB = 0.0002µbar

Approximate minimum

audible limit on

continuous noise

10

63 125 250 500 1000 2000 4000 8000

OCTAVE BAND CENTER FREQUENCIES <Hz>

NC60

NC50

NC40

NC30

NC20

Note: The measuring point is 1m from the bottom of the unit (1m from the front of the unit)

2 PUH-10YE

Measurement condition

1m

A

1m

B

Sound pressure level in anechoic room

57 dB (A)

70

60

50

40

30

20

OCTAVE BAND PRESSURE LEVEL< dB> 0dB = 0.0002µbar

Approximate minimum

audible limit on

continuous noise

10

63 125 250 500 1000 2000 4000 8000

OCTAVE BAND CENTER FREQUENCIES <Hz>

NC60

NC50

NC40

NC30

NC20

Note: The measuring point is 1m from the bottom of the unit (1m from the front of the unit)

–12–

Page 15

66

6 SERVICE DATA

66

[1] Appearance of Equipment

• PUH-8YE/10YE Detail of Electrical Parts Box

(with cover removed) (with Main Board Panel removed)

Transformer

Terminal brock for

Power source

terminal brock

outdoor/indoor control

wiring connection

• PUH-8YE/10YE (with cover removed)

MAIN

BOARD

F. C. BOARD

Magnet contactor for

compresser <52C>

Over current relay

<51C>

N. F. BOARD

Outdoor unit

heat exchanger

Electric parts Box Compresser

Ball valve for refrigerant piping connection <Liquid side> Flare

Ball valve for refrigerant piping connection <Gas side> Flange

–13–

Page 16

• PUH-8YE/10YE (Detail of machine room)

4way valve

Pressure switch

(63H2)

Thermistor

<Liquid temp.>

TH1

Accumulater

Pressure switch

(63H1)

Check joint

(low pressure)

Check joint

(high pressure)

Thermistor

<Discharge temp.>

TH2

Solenoid valve

(SV1)

–14–

Page 17

[2] Refrigerant Circuit

Outdoor unit

Service port

Strainer

Ball valve

High pressure switch

(Protection)

Outdoor heat exchanger

Service port

Indoor heat exchanger

Indoor

units

Capillary

tube

(Heating)

Multiple-distributor

Check valve

Service port

Ball valve

Accumulator

Strainer

[3] Limitation of Refrigerant Piping Length

Pipe length Difference in height

Furthest Total pipe Difference of

pipe length length indoor to inddor

Single

L : Max. 50 m

–

Compressor

Flare connection

Flange connection

Brazing connection

–

High pressure

switch (Control)

Muffler

Service

port

Strainer

Solenoid

valve

<

<

Outdoor~Indoor Indoor~Indoor

H : Max 40 m –

Check valve

Capillary tube (Cooling)

Cooling operation

Heating operation

Amount

of bends

Max. 15

Tiwn

T riple

L+Ra : Max. 50 m

L+Rb : Max. 50 m

L+Ra : Max. 50 m

L+Rb : Max. 50 m

L+Rc : Max. 50 m

L+Ra+Rb :

Max. 70 m

L+Ra+Rb+Rc :

Max. 70 m

Ra - Rb : Max. 8 m

Ra - Rb : Max. 8 m

Ra - Rc : Max. 8 m

Rb - Rc : Max. 8 m

H : Max. 40 m h : Max. 1 m

H : Max. 40 m h : Max. 1 m

Note: 1. The number of bend shall be within 8 points between (L+Ra) (L+Rb) (L+Rc).

Single

Indoor

unit

Outdoor

unit

L

H

Twin Triple

Indoor

Outdoor

unit

L

Indoor

unit

Ra

Rb

unit

h

H

Outdoor

unit

Indoor

unit

Max. 15

(Note: 1)

Max. 15

(Note: 1)

Rc

Indoor

unit

h

H

Indoor

unit

Rb

Ra

L

–15–

Page 18

[4] Refrigerant Piping

Model Gas pipe Liquid pipe

Outdoor unit

PUH-8YE ø25.4 ø 12.7

PUH-10YE ø

28.58 ø 15.88

1.6, 2, 2.5, 3 ø 15.88 ø9.52

4, 5 ø19.05 ø 9.52

Indoor unit

8ø

10 ø28.58 ø

25.4 ø 12.7

15.88

[5] Refrigerant Charge

Model

PUH-8YE

PUH-10YE

L: Main section actual length R

Amount of infusion of

coolant at ex-factory

R22 6.5 kg

R22 6.5 kg

a +Rb +Rc +Rd: Join section actual length

0.05 × L + 0.026 × (R

× amount of indoor units. (kg)

0.08 × L + 0.026 × (Ra +Rb +Rc +Rd) + 0.5

× amount of indoor units. (kg)

The value of calculation result at the second decimal place must be rounded up to the first decimal place.

(e.g. 2.22 kg must be rounded up to 2.3 kg)

Additional refrigerant charge

a +Rb +Rc +Rd) + 0.5

[6] Operation Rage

24

Indoor air temperature (°CWB)

15

-5 46

Outdoor air temperature (°CDB)

Cooling Heating

27

Indoor air temperature (°CDB)

15

–12 15.5

Outdoor air temperature (°CWB)

–16–

Page 19

77

3N~

380/400/415 V

50 Hz

outdoor

Fuse

Fuse

DC5V for

microcomputer

Electrical

terminal block

Over current

relay

Magnetic

contractor

4-way valve, Gas

bypass solenoid

valve, crankcase

heater

Communication

circuit

Transformer

Fan control

Auxiliary relay

Compressor

Outdoor fan

Indoor/outdoor

connection terminal

block

7 CONTROL

77

[1] Composition of Control

1 Function block diagram

[2] Control specifications

(1) Protection functions

1) The main protection devices for the outdoor unit are:

1 High pressure protection (63H1)

2 Compressor overcurrent protection (51C)

3 Inner thermostat (49C, compressor)

4 Liquid temp thermistor trouble (TH1)

5 Discharge temperature protection (TH2

6 Discharge temp thermistor trouble (TH2)

2) When tripping of a detection device is sensed, the check mode is entered and the compressor is stopped. (After 3

minutes, the compressor restarts.) Thereafter, the compressor is stopped when the specified number of check

modes or greater is sensed within the check time.

>

135 °C)

=

Protection functions

1 High pressure protection

(63H1)

2 Compressor overcurrent

protection (51C)

3 Inner thermostat (49C,

compressor)

4 Liquid temp thermistor

trouble (TH1)

5 Discharge temperature

protection (TH2

>

135 °C)

=

6 Discharge temp ther-

mistor trouble (TH2)

3) Check mode is released by stopping operation, changing the operation mode, or check mode time up. A check

mode is also released by stopping of operation by remote controller.

Operation value

2.94 MPa

8YE: 22 A

10YE: 27 A

105 ± 5 °C

Less than –39 °C or

greater than 88 °C

Greater than 135 °C

Less than 0 °C or

greater than 216 °C

Detection condition

Compressor operating

Compressor operating

Compressor operating

Compressor operating except for

10 minutes at end of defrosting, 7

minutes while compressor starting

Compressor operating

Compressor operating except for

10 minutes at end of defrosting, 5

minutes while compressor starting

Number of

check modes

0

1 time

1 time

1 time

2 times

1 time

Check time

–

30 minutes

30 minutes

30 minutes

30 minutes

30 minutes

4) Detected check mode history (newest) and abnormality history (last 2 times) are memorized and are displayed on

the segment by circuit board DIP switch setting.

The operation mode when the newest abnormality was generated, the thermistor temperature (TH1,2), and the

thermostat ON time can also be displayed.

–17–

Page 20

(2) Compressor, 4-way valve, and crankcase heater control

1) Determines the operation mode based on the indoor/outdoor communication data and operates the air conditioner.

2) Compressor control has a function which prevents the compressor from restarting within 3 minutes.

3) The 4-way valve is always ON during heating (except during defrosting). In other modes, it is OFF. However, when

the operation mode was changed from heating to stop, the 4-w ay valv e is turned off 10 minutes after the compressor

was stopped.

4) While the compressor is stopped, the crankcase heater remains ON. (OFF while the compressor is operating.)

5) When the operation mode is changed while the compressor is operating, the compressor stops and 3 minutes later

restarts in the new mode.

(3) Fan control

Controls the fan speed based on the piping temperature (TH1) to perf orm cooling at low outdoor temperatures and heating

at high outdoor temperatures.

1) Control at cooling

1 When the compressor stops, the fan stops (fan output=0%).

2 When the power is turned on, or when the compressor is restated after it has been stopped for 30 minutes or

longer, the piping temperature ( TH1) determines the fan output.

When TH

>

25 °C Fan output = 100 %

=

When TH < 25 °C Fan output = 60 %

3 When the compressor is restarted within 30 minutes after it has been stopped, the fan step before the compres-

sor was stopped is selected. Ho wever, when the fan output w as under 30% when the fan was stopped, 30 % is

selected.

4 When the mode was changed from heating to cooling, the fan step conforms to item 2.

5 T w o minutes after the fan is started, the fan step (number of units) is controlled every 30 seconds based on the

piping temperature (TH1).

6 When TH1 reaches 50 °C or higher, or when the control high pressure switch (63H2) tripped, the fan output

becomes 100 %.

7 Fan output while the compressor is operating is within the 20 % to 100 % range.

• FAN step

The following expression determines the next fan step count nj+1:

nj+1 = nj+∆nj nj: Current fan step, ∆nj: Displacement step amount

nj control

• If nj+1

• If nj+1

• If TH1

>

100 % nj+1 = 100 %

=

<

20 % nj+1 = 20 %

=

>

50 °C or 63H2 is “OFF” nj+1 = 100 %

=

FAN ∆nj Outputs are all %.

Condensation temperature TH1

Target condensation

temperature 31 °C

<

20

nj < 50

=

<

<

nj

Current

output

50

100

=

=

t > 49 °C

10

t = 49

t = 46

t = 43

t = 40

t = 36

t = 33

t = 29

t = 26

~

~

t > 46

~

t > 43

t > 40

5

3

2

2

4

3

2

~

t > 36

2

2

~

t > 33

1

1

~

t > 29

0

0

~

t > 26

–1

–1

~

t > 23

–2

–2

t = 23

t > 20

–3

–4

<

~

t

20 °C

=

–5

–10

* IN the night mode, the maximum value of nj is 80%. (When TH1 < 50 °C)

–18–

Page 21

2) Control at heating

1 When the compressor is stopped and during defrosting, the fan is stopped.

2 When the power is turned on, or when the compressor is restarted after being stopped for 30 minutes or longer,

the piping temperature (TH1) determines the fan step.

TH1 > 8 °C Fan output = 60 %

<

TH1

8 °C Fan output = 100 %

=

3 When the compressor is restarted within 30 minutes, the fan step is the step before the compressor was stopped.

4 When the mode is changed from cooling to heating, the fan step conforms to item 2.

5 When returning from defrosting, the fan step is the step before defrosting.

6 Two minutes after the fan was restarted, the fan step is controlled every 30 seconds based on the piping tem-

perature (TH1).

7 When TH1 is –5 °C or lower, the fan output is made 100 %.

• FAN step

The following expression determines the next fan step count nj+1:

nj+1 = nj+∆nj nj: Current fan step, ∆nj: Displacement step amount

nj control

• If nj+1

• If nj+1

>

100 % nj+1 = 100 %

=

<

20 % nj+1 = 20 %

=

• If TH1 < –5 °C nj+1 = 100 %

FAN ∆nj Outputs are all %.

Evaporation temperature TH1

Target evaporation

temperature 12 °C

T > 19 °C

T = 19

~

T > 17

T = 17

~

T > 15

T = 15

~

T > 13

T = 13

~

T > 11

T = 11

~

T > 8

T = 8

~

T > 6

T = 6

~

T > 4

T = 4

~

T > 2

T = 2

~

T > 0

T

<

0 °C

=

nj + 1

<

100

=

–10

–4

–2

20

Current

output

<

=

(4) Defrosting control

1) When the following conditions are satisfied, defrosting starts:

1 When the integrated compressor operation time has exceeded T

temperature (TH1) is below –2 °C

2 When the integrated compressor operation time has exceeded 30 minutes and the piping differential tempera-

ture is ∆TH1

>

8, TH1

=

<

–2 °C

=

Piping differential temperature ∆TH1 = TH10 – TH1

2) The defrosting prohibit time T

<

T

2

3 (minutes) T1 120 (minutes)

=

3 < T

2

7 < T

2

2 < 15 40

10 < T

T

2 = 15 30

1 is set as following based on the defrosting time T2:

<

780

=

<

10 60

=

Note: When the compressor was stopped during defrosting, T1 = 30 min utes is set to recognize the stop as defrost-

ing end.

–1

0

1

2

2

3

1 (initial setting 50 minutes) and the piping

4

Current piping temperature

Piping temperature 10 minutes after starting or

10 minutes after returning from defrosting

Note: T1 is reset at the end of defrosting, or by cooling

ON command.

10

3) During defrosting, all the outdoor fans are stopped and the bypass solenoid valve (SV1) is turned ON and the 4-wa y

valve (21S4) is turned OFF.

4) When the following conditions are satisfied, defrosting ends:

1 T

2

2 2 < T

3 T

2 =15 minutes

<

2 mins TH1

=

2 < 15 minutes TH1

>

40 °C

=

>

8 °C continuous 2 minutes

=

5) When the fan and 4-way valv e (21S4) are turned ON at the end of defrosting, the heating mode is reset. Two minutes

after defrosting reset, the bypass solenoid valve (SV1) turns OFF.

–19–

Page 22

(5) Bypass solenoid valve control (SV1)

1) Control at cooling

1 While the compressor is stopped, the solenoid valve is OFF.

2 When the power is turned on, or when the compressor is restarted after it has been stopped for 30 minutes or

longer, if the Liquid temperature (TH1) is 25 °C or higher then the solenoid valve turns ON for 2 minutes.

3 When the mode is changed from heating to cooling, solenoid valve operation conforms to item 2.

2) Control at heating

1 While the compressor is stopped, the solenoid valve is OFF.

2 When the power is turned on, or the compressor is restarted after it has been stopped for 30 minutes or longer,

the solenoid valve turns ON for 2 minutes.

3 When the mode is changed from cooling to heating, the solenoid valve turns ON for 2 minutes at starting.

4 When the control pressure switch (63H2) trips, the solenoid valve turns ON.

5 If 63H2 resets 15 minutes after tripping, the solenoid valve turns OFF.

6 During defrosting, the solenoid valve turns ON.

(6) Service functions

1) Abnormality history clear

1 When DIP SW1-2 is turned ON while the compressor is operating or stopped, the abnormality history is cleared.

–20–

Page 23

[3] Function of switches and connectors (outdoor unit)

(1) Function of switches

1) Function of switches

(Normal mode)

Kind of

switch

DIP SW

Tact SW

DIP SW

DIP SW

Switch

SW1

CN33

When

open

(Normal)

SW2

SW3

SW4

SW5

Pole

1

2

Abnormality history clear

Function

None

3

4

None

5

6

1

2

3

Self diagnosis

4

5

6

Mode input register

1

2

1

3-phase power source

2

3

Cooling only switching

4

None

detection

Model setting

–

–

Normal mode

SW3 = Unrelated

Operation by switch operation

ON OFF

––

Clear Normal

See pages 22 to 24.

Register Normal

––

––

Do not Do

Cooling only Heat pump

PUH-10YE PUH-8YE

Switch effec-

tive timing

–

Running or

stopped

–

–

Running or

stopped

stopped

–

–

–

–

When power

turned on

When power

turned on

2) Switch functions at set mode change

Set input mode

1

8 °C continuous 2 minutes

Switch effective

timing

stopped

stopped

stopped

Kind of

switch

DIP SW

Switch

SW1

When

CN33

shorted

(mode

switching)

Pole

1

2

3

4

Defrosting end switching

5

6

Function

None

Night mode

Defrosting prohibit time

switching

None

CN33 = short SW3 = ON*

Operation by switch operation

ON OFF

––

Night mode Normal mode

12 °C continuous 2 minutes

Fixed Training

––

*1 Mode input is entered by SW3 OFF→ON change (___↑). Press and hold do wn SW3 f or about 2 seconds. The set

mode can be registered according to the outdoor unit setting information on page 24.

Remarks

Note: After changing the mode by CN33 shorting (mode switching), return to the normal mode by opening CN33.

3) Connector function assignment

Type

Connector

Connector

CN31

CN32

CN33

Function

None

Function test

DIP switch mode switching

Operation by open/short

short open

––

Function mode Normal

Mode switching Normal

Switch effec-

tive timing

At initialization

stopped

–

–

–

–21–

Page 24

<Outdoor unit operation monitoring function>

The operation status and check code contents can be ascertained by means of the 2-digit number and symbol on digital

display light emitting diode LED2 by operating DIP switch SW2.

<Description of operation of digital display light emitting diode (LED2)>

• When ON (normal operation): Displays the operation mode.

SW2

LED2

[Tens digit: Operation mode]

Display Operation mode

O stopped

C Cooling/Dry

H Heating

d Defrost

ON

[Units digit: Relay output]

Display Compressor 4-way valve Bypass solenoid valve

0– – –

1– – ON

2 – ON –

3 – ON ON

123456

ON

OFF

(Load status)

4ON – –

5ON – ON

6ON ON –

7ON ON ON

• When blinking (Operation stopped by tripping protection device): Displays the check mode

• PUH-8YE/10YE

Display Check contents (operating)

U2 49C trip, Compressor discharge temperature abnormal

U3 Compressor discharge temp thermistor (TH2) open/short

U4 Liquid temp thermistor (TH1) open/short

U6 Compressor overcurrent protection trip (51C trip)

UE High pressure protection (63H1 trip)

Self diagnosis by SW2

• PUH-8YE/10YE

SW2 setting Display contents Description of display Unit

–39 - 88

(When 0 °C or lower, “–”and temperature are displayed

alternately.)

<Example> When –10,

°C

123456

ON

OFF

Liquid temperature

(TH1)

–39 - 88

every other second

–

←→ 10

123456

ON

OFF

Discharge temperature

0 - 216

0 - 216

(When 100 °C or higher, 100s digit and 10s and units

digits are displayed alternately.)

<Example> When 115,

°C

every other second

1

←→ 15

123456

ON

OFF

FAN output

0 - 100

0 - 100

(When 100 or higher, 100s digit and 10s and units digits

are displayed alternately.)

<Example> When 100,

%

every other second

1

←→ 00

–22–

Page 25

SW2 setting Display contents Description of display Unit

0 - 999

(When 100 or higher, 100s digit and 10s and units digits

are displayed alternately.)

<Example> When 425,

100 times

123456

ON

OFF

Number of compressor

ON/OFF

0 - 999

every other second

4

←→ 25

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

Compressor integrated operation time

0 - 999

Newest check code

Newest outdoor unit

abnormality

Check display

Operation mode when

abnormality occurred

Liquid temperature

(TH1) when abnormality occurred

– 39 - 88

0 - 999

(When 100 or higher, 100s digit and 10s and units digits

are displayed alternately.)

<Example> When 245,

every other second

2

←→ 45

When no check mode,“00”

<Example> When piping thermistor abnormal U4

Operation mode when abnormally stopped

<Example> Comp only ON at cooling operation C4

–39 - 88

(When 0 °C or lower, “–” and temperature are displayed

alternately.)

<Example> When –15,

every other second

–

←→ 15

10 hours

Code display

Code display

°C

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

COMP discharge

temperature (TH2)

when abnormality

occurred

0 - 216

Check code history (1)

(newest)

Abnormal unit No. and

check code inverted

display

Check code history (2)

(One before newest)

Abnormal unit No. and

check code inverted

display

0 - 216

(When 100 or higher, 100s digit and 10s and units digits

are displayed alternately.)

<Example> When 130,

every other second

1

←→ 30

When no abnormality history

“0”, “←→”, “–”

When no abnormality history

“0”, “←→”, “–”

°C

Code display

Code display

–23–

Page 26

SW2 setting Display contents Description of display Unit

0 - 999

(When 100 or higher, 100s digit and 10s and units digits

are displayed alternately.)

<Example> When 245,

Minutes

123456

ON

OFF

Current thermostat

ON time

0 - 999

every other second

2

←→ 45

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

Outdoor unit set

information 1

Outdoor unit set

information 2

FAN output at abnormal stop

0 - 100

Thermostat ON time

until abnormal stop

0 - 999

Outdoor unit capacity is displayed as function code.

Model name function code

PUH-8YE 20

PUH-10YE 25

Outdoor unit set information 1 Function setting (display valves)

3-phase power source detection Do (1) Do not (0)

Cooling only switching Cooling only (2) H/P (0)

Tens digitUnits digit

Night mode Night mode (1) Normal mode (0)

Defrosting end time

Defrosting prohibit time Fixed (4) Training (0)

Set information display values are added and displayed at each position.

12 °C continuous 2 minutes

(2)

8 °C continuous 2 minutes

0 - 100

(When 100 or higher, 100s digit and 10s and units digits

are displayed alternately.)

<Example> When 100,

every other second

1

←→ 00

0 - 999

(When 100 or higher, 100s digit and 10s and units digits

are displayed alternately.)

<Example> When 245,

every other second

2

←→ 45

(0)

Code display

Code display

%

Minutes

–24–

Page 27

[4] Simple parts check method

• PUH-8YE/10YE

Part name

Thermistor (TH1) <Liquid

temperature detection>

Thermistor (TH2) <Discharge temperature detection>

Fan motor

Thermal protector

trip temperature

135 ± 5 °C

White

Red

Black

Blue

Compressor

Judgment instructions

Disconnect the connector and measure the resistance value with a multimeter.

(Ambient temperature 10 °C to 30 °C)

Abnormal

Open or short

TH1

TH2

Normal

4.3 kΩ~9.6 kΩ

160 kΩ~410 kΩ

(Based on thermistor characteristic table (next page))

Measure the resistance value across the terminals with a multimeter. (Winding

temperature 20 °C)

Motor lead wire

Between 2 phases

Normal

22.8 Ω

Abnormal

Open or short

Measure the resistance value across the terminals with a multimeter. (Winding

temperature 20 °C)

Normal

PUH-8YE

Each phase 1.51 Ω

PUH-10YE

Each phase 1.03 Ω

Abnormal

Open or short

Open or short

–25–

Page 28

[5] Reference Data

50

40

30

20

10

0

–20 –10 10 20 30 40 500

25

20

15

10

5

0

90 100 110 120

<Thermistor characteristic table>

Low temperature thermistor Thermistor <Liquid temperature detection> (TH1)

Thermistor <Liquid temperature detection> (TH1)

Thermistor Ro = 15 kΩ ± 3 %

B constant = 3,460 kΩ ± 2 %

Rt = 15 exp {3,460 (–––––– – ––––)}

11

273 + t 273

0 °C: 15 kΩ

10 °C: 9.7 kΩ

20 °C: 6.4 kΩ

25 °C: 5.3 kΩ

30 °C: 4.3 kΩ

40 °C: 3.1 kΩ

<Low temperature thermistor>

Resistance

Temperature

High temperature thermistor Thermistor <Discharge temperature detection> (TH2)

Thermistor (Discharge temperature detection) (TH2)

<High temperature thermistor>

Thermistor R120 = 7.465 kΩ ± 2 %

B constant = 4,057 kΩ ± 2 %

Rt = 7.465 exp {4,057 (–––––– – ––––)}

11

273 + t 393

20 °C: 250 kΩ 70 °C: 34 kΩ

30 °C: 160 kΩ 80 °C: 24 kΩ

40 °C: 104 kΩ 90 °C: 17.5 kΩ

50 °C: 70 kΩ 100 °C: 13.0 kΩ

60 °C: 48 kΩ 110 °C: 9.8 kΩ

Resistance

Temperature

–26–

Page 29

[6] Self-diagnosis and troubleshooting

<Abnormality detected during unit operation: Outdoor unit>

(1) PUH-8YE/10YE

Outdoor

unit LED

display

U2

U3

U4

U6

UE

Meaning of abnormality display and

abnormality troubleshooting

Discharge temperature abnormal

(comp)

When the discharge thermistor temperature (TH2) exceeds 135 °C while

the compressor is operating, an abnormality is recognized.

49C trip

When connector (49C) opens while

the compressor is operating, an abnormality is recognized.

49C Inner thermostat (Comp)

105 ± 5 °C

Discharge temp thermistor (TH2)

open or shorted.

When an open (0 °C or lower) or

short (216 °C or higher) is detected

while the compressor is operating, an

abnormality is recognized.

(Detection is disabled for 5 minutes

at compressor starting.)

Liquid temp thermistor (TH1) open

or shorted.

When an open (–39 °C or lower) or

short (88 °C or higher) is detected

while the compressor is operating, an

abnormality is recognized. (Detection

is disabled for 7 minutes beginning

from 10 seconds after the compressor starts and for 10 minutes after

return from defrosting.)

Compressor overcurrent trip

When the current value reaches the

overload set value or higher while the

compressor is operating, an abnormality is recognized.

PUH-8YE............................... 22 A

PUH-10YE............................. 27 A

High pressure abnormal (63H1

trip)

Detected (2.94+0

MPa) by 63H1 trip

-0.15

while compressor is operating.

63H1:Pressure switch (high pres-

sure)

OFF: 2.94

+0

-0.15

(MPa)

ON: 2.35 ± 0.2 (MPa)

1 Compressor overheating due to insuf-

ficient refrigerant.

2 Thermistor faulty. (TH2)

3 Outdoor controller board faulty.

1 Compressor overheating operation due

to insufficient refrigerant.

2 Connector (49C) on indoor controller

board dislodged or contact faulty.

3 49C disconnected, or contact faulty.

4 RST not connected properly.

5 Missing phase.

6 Outdoor controller board faulty.

1 Connector (CN3) dislodged or connect

faulty .

2 Thermistor faulty. (TH2)

3 Outdoor controller board faulty.

1 Connector (CN2) dislodged or contact

faulty.

2 Thermistor faulty.

3 Outdoor controller board faulty.

1 Overload operation exceeding unit us-

age range limit.

2 Power supply terminal voltage low.

3 Power supply missing phase.

4 Compressor motor faulty.

5 Compressor locked.

6 Connector (CN22) on outdoor control-

ler board dislodged or contact faulty.

7 51C disconnected or contact faulty.

1 Started with ball valve closed.

2 Connector (CN21) on outdoor control-

ler board dislodged or contact faulty.

3 63H1 disconnected or contact faulty.

4 Indoor filter clogged. Power reset de-

tected during heating overload operation (Heating).

5 Low indoor unit air flow (heating).

6 Low outdoor unit air flow (cooling).

7 Part faulty.

Cause

Judgment method and remedy

1 Check input super heat.

Check for refrigerant leakage and check

piping length.

Charge with additional refrigerant.

23

T urn off power and restart operation and

check if “U3” is displayed within 8 min-

utes.

When “U3” is displayed, carry out “U3”

processing.

(Do not replace board at “U2” display

only.)

1 Check intake super heating.

Check for refrigerant leakage.

Charge additional refrigerant.

23

After checking connection, restart and

check operation.

45

Check power supply connections.

6 Replace outdoor controller board.

1 Check connector contact and thermistor

wire.

2 Check thermistor resistance value, or

check temperature by microcomputer.

(Check using SW2 self-diagnosis func-

tion.)

See page 26.

3 Replace outdoor controller board.

(Replace board after sufficiently check-

ing 1 and 2.)

1 Check connector contact and thermistor

wire.

2 Check thermistor resistance value or

check temperature by microcomputer.

(Check using SW2 self-diagnosis func-

tion.)

See to page 26.

3 Replace outdoor controller board.

(Replace board after sufficiently check-

ing 1 and 2)

1 Check usage conditions.

(Check for short cycle operation.)

2 Check power supply voltage.

3 Check wiring for breaks and faulty con-

tact.

4 Check motor winding resistance (See

page 25.)

5 Replace compressor.

67

After checking connections, restart and

check operation.

1 Check if ball valve is fully open.

2

Repair connector.

3

4 Check indoor filter.

5 Check flow duct static pressure and for

faulty fan motor.

6 Check for faulty outdoor fan motor.

7 Replace pressure switch.

–27–

Page 30

(2) Setting method of system

Single

Remote

controller

Twin

Remote

controller

Triple

CN40

CN40

OFF

OFF

ON

ON

SW6

1 2 3 4

SW6

1 2 3 4

Outdoor unit

Outdoor unit

OFF

•Setting of SW6

All set to OFF (at factory shipment)

SW6

ON

1 2 3 4

•Setting of SW6

No. 1 indoor unit SW6-1 : ON

No. 2 indoor unit SW6-2 : ON

No. 1 No. 2 No. 3

Remote

controller

CN40

OFF

SW6

ON

1 2 3 4

Outdoor unit

DIP SW6 for Single, Twin, Triple setting (Indoor circuit board)

ON

Single Twin Triple

SW6–1 OFF ON: No. 1 indoor unit only ON: No.1 indoor unit only

1234

OFF

SW6–2 OFF ON: No. 2 indoor unit only ON: No. 2 indoor unit only

SW6–3 OFF OFF ON: No. 3 indoor unit only

SW6-4 OFF OFF ON

OFF

ON

SW6

1 2 3 4

•Setting of SW6

No. 1 indoor unit SW6-1, 4: ON

No. 2 indoor unit SW6-2, 4: ON

No. 3 indoor unit SW6-3, 4: ON

ON

OFF

SW6

1 2 3 4

Removable of CN40

• Please remove the CN40 of No. 2 indoor unit at Twin system and remove the CN40 of No. 3 indoor unit at Triple system.

–28–

Page 31

(3) Judgment by setting of trial run mode

Symptom Causes Service procedures

The “CENTRALLY CONTROL” display does not disappear, and the

switch is ineffective.

A

Faulty receiving circuit of remote

controller, or faulty indoor tr ansmission circuit.

Address is being set to DIP-SW17

of remote controller, or to DIP-SW2

of indoor unit.

Remote controller is being connected with timer adapter.

(1) Check for the correct setting of DIP SW17 of re-

mote controller.

(2)

a) Turn DIP SW17-7 of remote controller for ser-

vices ON (acting as subordinate remote controller), and connect it to remote controller terminal bed.

b) Turn local switch ON, and check whether the

display of “CENTRALLY CONTROL” has been

disappeared.

•Replace the remote controller if it is disappeared.

•When it has not been disappeared, check DIPSW2 for correct setting, and replace indoor controller if the setting is correct.

At turning the operation SW of remote

controller on, “E0” is displayed for 2

~ 4 seconds after operation display.

B

Turning operation switch of remote

controller ON generates operation

display with electronic sound, but disappears soon.

Faulty remote controller transmission/receiving circuit, or faulty indoor unit transmission/receiving

circuit.

Erroneous wiring of indoor/outdoor

connecting line, or reset function is

being effective by overcurrent

deection due to the short circuit of

drain sensor.

(1) Turn DIP SW17-7 of remote controller for services

ON (acting as subordinate remote controller), and

connect it to remote controller terminal bed.

(2) Turn local switch ON, and after 5 seconds, con-

firm the liquid crystal display has been distinguished. If “CENTRALLY CONTROL” is lighting,

return to the item A.

(3) Turn the operation switch of subordinate remote

controller, and check the display of both remote

controllers after 5 seconds elapsed.

1

Operation

display

2

Operation

display

3

No display

4

No display

Remote

controller

Subordinate

remote controller

E0 display

Operation display

E0 display

Operation display

Faulty spot

Faulty indoor unit

Faulty remote

controller

Faulty indoor unit/

remote controller

Faulty remote

controller

(1) Check for the wiring connection of indoor/outdoor

connecting line.

a)

1

2

Indoor Outdoor

3

1

2

3

C

and heating trial operation

b)

Reset by cooling trial operation

1

2

Indoor Outdoor

3

1

2

3

Reset at heating trial operation

–29–

Page 32

Symptom Causes Service procedures

c)

1

2

Indoor Outdoor

3

Reset by cooling trial operation

and heating trial operation

1

2

3

C

T urning the operation SW of remote

controller ON keeps all lights being

distinguished, and generates no

electronic sound.

D

The piping temperature code of liquid crystal display does not change,

or “P8” is displa yed at about 10 min-

E

utes after operation start.

Short circuit of remote controller

wiring.

Faulty power source circuit of indoor controller, or improper contact

of CN40.

Disconnection of transformer, or

improper contact of CN40

Blown fuse (F)

Local switch OFF

d)

1

2

Indoor Outdoor

3

1

2

3

Reset at heating trial operation

(2) Measure the resistance value between 1~3 of

drain sensor connector (CN50). Normal if it is

about 82 Ω.

* When both (1) and (2) are normal, replace indoor

controller.

(1) Check for remote controller terminal voltage

a) At no voltage found,

Remove the wiring of remote controller terminal, and check the voltage between wiring.

•If the voltage shows DC6V ~ DC12V, replace

remote controller as it is faulty. (Short circuit

inside remote controller)

•If no voltage is found, check for indoor side.

1) AC380 ~ 415V check

2) Fuse (F)

3) Transf ormer connector CN4T

4) Connector CN40

* When no trouble is found for the items 1) ~ 4)

above, replace indoor controller.

Please refer to ” ” on the next page.

–30–

Page 33

(4) Check mode display and description

Display

of liquid

crystal

Symptom Causes Remedy

Transmission/receiving

error

No reply of indoor to

the signal of remote

controller

Inlet sensor trouble

Piping sensor trouble

Transmission/receiving

error

No reply of remote controller to the signal of indoor unit

Drain sensor trouble

•Faulty transmission line

•Faulty signal transmission/receiving circuit

• No existence of the unit address designated

•Faulty thermister

•Improper contact of connector

•Faulty thermister

•Improper contact of connector

•Improper contact of transmission line

•Faulty signal transmission/receiving circuit

•Faulty thermister

•Improper contact of connector

•Conduct self-diagnosis with another remote

controller.

E0 display → Replace indoor microcomputer

board.

Display other than E0 → Replace remote controller.

•Connector check

•Thermister check

→ No problem → Replace indoor microcomputer board.

•Connector check

•Thermister check

→ No problem → Replace indoor microcomputer board.

•Check for transmission line

•Check for transmitting/receiving circuit

•Connector check

•Thermister check

→ No problem → Replace indoor microcomputer board.

Tripping of drain overflow

protection

Tripping of frost/over heat

protection device

System error

Outdoor unit trouble

•Faulty drain water lifting up mechanism

•Improper mounting of drain level detecting

sensor

•Short cycle of airflow route

•Clogging of air filter

•Faulty indoor fan

•Erroneous setting of unit address (indoor)

•Faulty transmission circuit of remote controller

• Erroneous wiring of indoor/outdoor connecting line

•Detection of reverse phase

•Tripping of outdoor unit protection device

•Faulty piping sensor

•Faulty outdoor circuit board

•Not effective to PEH-YD

• Improper contact of CN50 may be considered inside the indoor controller board of indoor unit.

As some indoor units connected are

equipped with this function in the case of twin/

triple specification, confirm it with the service

manual of indoor units.

•Remove blocking matter.

•Check for air filter.

•Check for indoor fan.

•Check for indoor unit address

•Check for transmitting/receiving circuit

•Check for remote controller power source.

•Check for wiring and outdoor circuit board.

•Check outdoor unit protection device for tripping.

–31–

Page 34

[7] TEST RUN

1. Checking before Getting Test Run

1 Check to see whether there are refrigerant leakage, and slack of power or transmission cable.

2 Confirm that 500 V megger shows 1.0 MΩ or more between power supply terminal block and ground. Do not

operate in the case of 1.0 MΩ or less.

Note: Never carry out megohm check over the terminal control board.

Otherwise the control board would be broken.

3 Check to see whether both gas and liquid valves are fully open.

Note: Be sure to tighten the caps.

4 Turn on universal power supply at least 12 hours before getting test run in order to carry current to the

crankcase heater. If current-carrying hours are too short, it may result in a malfunction of the compressor.

2. Test Run Method

˚C

ON/OFF

CHECK MODE

TEST RUN

CHECK

TEST RUN

(A) Display panel

(B) Control panel

(C) Cooling/Heating select button (3), (4)

(D) Check code indicator (See Note 1.)

(E) Test run remaining time indicator (See note 3.)

(A)

MITSUBISHI ELECTRIC

CENTRALLY CONTROLLED

CHECK

STAND BY

DEFROST

ON OFF

CLOCK

˚C

(F) ON/OFF LED (Lights up in operation.)

(G) ON/OFF button (7)

CLOCK ON OFF

(H) Test run indicator

(I) Test run button

(J) Room temperature display

(B)

REMOTE CONTROLLER

PAR-JH030KA

TEMP.

TIMER SET

(C)

Operation procedure

(1) Turn on universal power supply at least 12 hours before getting started.

(2) Press [TEST RUN] button twice

(3) Press [Cooling/Heating] select button

→ displaying “TEST RUN” on display panel.

→ make sure that air is blowing out.

(4) Press [Cooling/Heating] select button to change from cooling to heating operation, and vice versa

warm or cold air is blowing out.

(5) → Make sure that indoor unit fans operate normally.

(6) Make sure that interlocking devices such as ventilator operate normally if any.

(7) Press [ON/OFF] button to cancel test run → Stop operation.

(D)

(E)

(J)

(F)

(G)

(H)

( I )

→ make sure that

Note: 1. If check code is displayed on remote controller or remote controller does not operate normally, find the cause.

2. Test run automatically stops the operation after two hours by activation of timer set to two hours.

3. During test run, test run remaining time is displayed on time display section.

A piping temperature code is displayed on the room temperature display section (J) during test run.

Note: Piping temperature codes 1 to 15 (–15 °C to 80 °C) are available. Code No. reduces during cooling and increases

during heating, thus operation state of the compressor can be checked by observing the code displayed.

Code 1 2 3 4 5 6 7 8

Indoor coil temp. –15 °C~2 °C3 °C~10 °C 11 °C~15 °C 16 °C~20 °C 21 °C~25 °C 26 °C~30 °C 31 °C~35 °C 36 °C~40 °C

Code 9 10 11 12 13 14 15

Indoor coil temp. 41 °C~45 °C 46 °C~50 °C 51 °C~55 °C 56 °C~60 °C 61 °C~70 °C 71 °C~80 °C Sensor malfunction

–32–

Page 35

3. Corrective Actions in Case of Trouble During Test Run

(1) Trouble codes displayed on remote controller and feature of the trouble

Code Trouble

P1 Intake sensor trouble, thermister trouble, contact failure

P2 Piping sensor trouble, thermister trouble, contact failure

P4 Drain sensor trouble

P5 Drain pump trouble, drain overflow protection activated

P6 Anti-freezing/overheat function activated

P7 System error, address setting error

P8 Outdoor unit trouble

E0 Transmission/reception error, contact failure, etc.

U8 Indicates no trouble so far.

(2) Troubleshooting table

Symptom Cause

1. No display on the remote controller, and no electric sound

is generated even if the switch is pressed.

(1) Check if the power is ON.

Check the voltage (12VDC) at the remote controller terminal.

Check the main circuit voltage.

(2) Check the transmission line for short-circuit.

(3) Check for blown fuse, improper contact of connector/terminal block.

2. “Centrally control” is displayed on the remote controller, and

no switches are operable.

3. “E0” is displayed on the remote controller when operation

is started.

4. “P7” is displayed on the remote controller.

5. “P8” is displayed on the remote controller.

(1) Check if address is correct (indoor unit PCB, remote controller)

(2) Check if your remote controller has been disabled by the central-

ized remote controller.

(1) Check the transmission line for contact failure.

(1) Check if the address for the indoor unit is correct.

(1) Check the cables between the indoor and outdoor units for incorrect

wiring.

(2)

Check if the protective device of the outdoor unit has been activated.

–33–

Page 36

Certificate Number FM33568

Certificate Number EC97J1227

HEAD OFFICE MITSUBISHI DENKI BLDG. MARUNOUCHI TOKYO 100-0005 TELEX J24532 CABLE MELCO TOKYO

The Air Conditioning & Refrigeration Systems Works acquired ISO 9001 certification under Series 9000 of the International Standard Organization (ISO) based on a review of Quality

warranties for the production of refrigeration and air conditioning equipment.

ISO Authorization System

The ISO 9000 series is a plant authorization system relating to quality warranties as stipulated by the ISO. ISO 9001 certifies quality warranties based on the “design, development,

production, installation and auxiliary services” for products built at an authorized plant.

The Air Conditioning & Refrigeration Systems W orks acquired en vironmental management

system standard ISO 14001 certification.

The ISO 14000 series is a set of standards applying to envir onmental pr otection set by the

International Standard Organization (ISO). ISO 14001 certifies the plant’s environmental

protection system and activities.

MEE00K035

Printed in Japan