Mitsubishi PUH-1VKA.UK, PUH-1.6VKA(1).UK, PUH-2VKA(1).UK, PUH-2.5VKA(1).UK, PUH-3VKA(1).UK Service Manual

...Page 1

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

OUTDOOR UNIT

PUH-3KA type

TECHNICAL & SERVICE MANUAL

Outdoor unit

[Model names] [Service Ref.]

PUH-1VKA PUH-1VKA.UK

1996

No.OC086

REVISED EDITION-B

PUH-1.6VKA PUH-1.6VKA.UK,PUH-1.6VKA

PUH-2VKA PUH-2VKA.UK,PUH-2VKA

1

PUH-2.5VKA PUH-2.5VKA.UK,PUH-2.5VKA

PUH-3VKA PUH-3VKA.UK,PUH-3VKA

PUH-3YKA PUH-3YKA.UK,PUH-3YKA

PUH-4YKSA PUH-4YKSA.UK,4YKSA

1

1

1

.UK

PUH-5YKSA PUH-5YKSA.UK,PUH-5YKSA

PUH-6YKSA PUH-6YKSA.UK,PUH-6YKSA

CONTENTS

1. TECHNICAL CHANGES··································2

2.

COMBINATION OF INDOOR AND OUTDOOR UNITS

3. PART NAMES AND FUNCTIONS ···················3

4. DATA ································································4

5. OUTLINES AND DIMENSIONS·······················5

6. WIRING DIAGRAM ··········································9

7.

REFRIGERANT SYSTEM DIAGRAM

8. DISASSEMBLY PROCEDURE······················23

9. PARTS LIST···················································25

10. OPTIONAL PARTS························Back cover

1

.UK

1

.UK

.UK

1

.UK

1

.UK

···············21

.UK

.UK

····2

Revision

• Parts List has been partially modified.

• Please destroy OC086 SECOND EDITION.

The Slim Line.

From Mitsubishi Electric.

Page 2

1 TECHNICAL CHANGES

PUH-1VKA.UK

1

1

.UK

1

.UK

1

.UK

1

1

1

.UK

1

.UK

.UK

.UK

.UK

PUH-1.6VKA.UK PUH-1.6VKA

PUH-2VKA.UK PUH-2VKA

PUH-2.5VKA.UK PUH-2.5VKA

PUH-3VKA.UK PUH-3VKA

PUH-3YKA.UK PUH-3YKA

PUH-4YKSA.UK PUH-4YKSA

PUH-5YKSA.UK PUH-5YKSA

PUH-6YKSA.UK PUH-6YKSA

1. The contactor have changed. (PUH-1.6/2/2.5/3VKA1,5/6YKSA1.UK)

2. Following Parts have changed in order to comply with LVD standard. (All models with

small one)

1Terminal block

2Controller board (Including the fuse)

❈ Please reter to the parts list for the new parts number

3.Color of lead wire for N phase has changed from BLK➔ BLU.

Color of lead wire for L3 phase has changed from BLU➔ BLK.

4. 4-way valve have changed. (PUH-1.6/2/2.5/3VKA1,6YKSA1.UK)

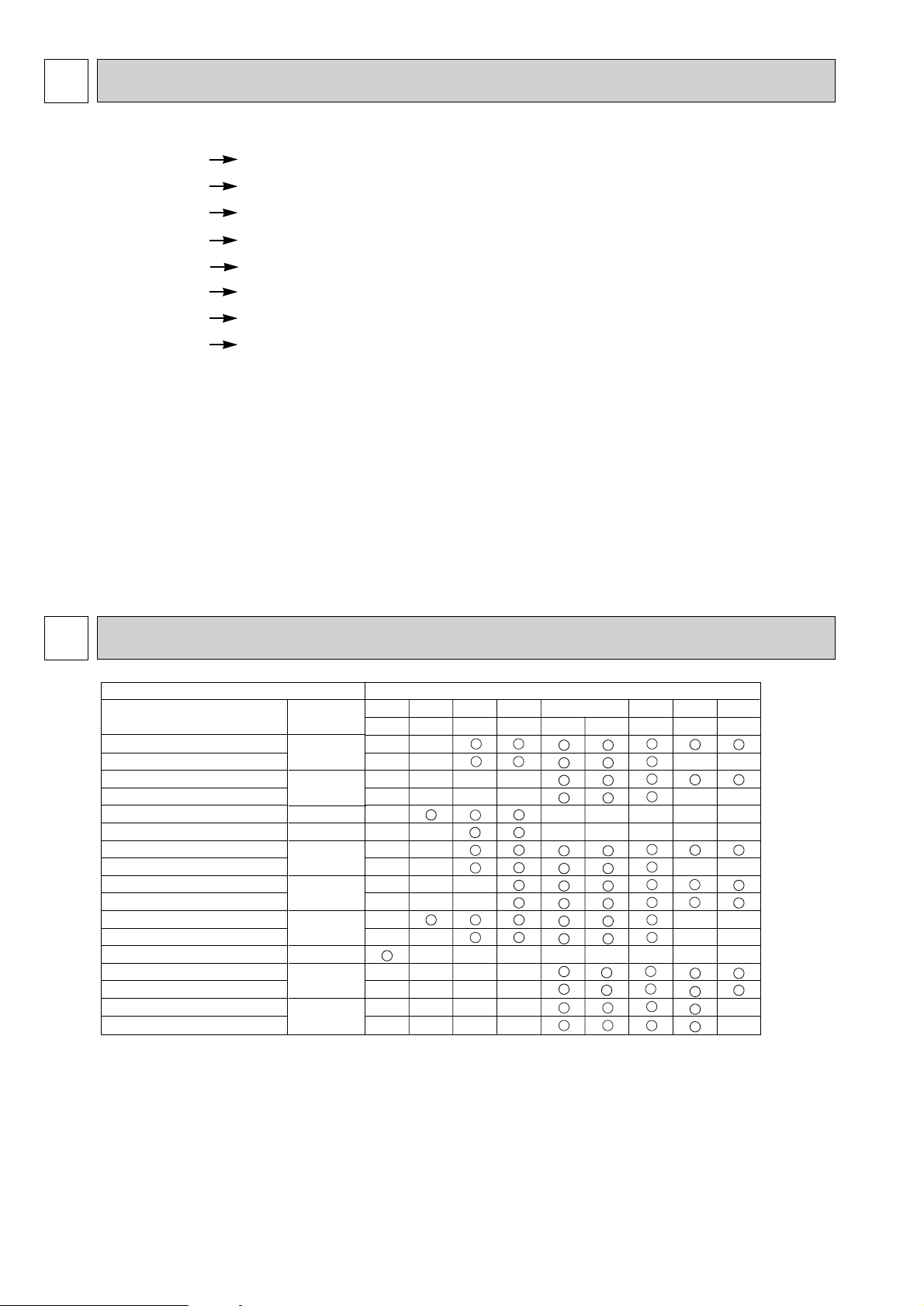

2 COMBINATION OF INDOOR AND OUTDOOR UNITS

Indoor unit Outdoor unit

Models

PLH-GKH(S)B.UK

PLH-GK(S)B.UK

PLH-GKH(S)B

PLH-GK(S)B

PLH-KKHB

PLH-KKB

PCH-GKH(S

PCH-GK(S

PEH-EKH(S

PEH-EK(S

PKH-FKH(S

PKH-FK(S

PKH-EK

PSH-GJH

PSH-GJH(S

PEHD-EKH(S

PEHD-EK(S

)A

)A

)A

)A

)A

)A

A

)

)A.UK

)A.UK

Service

Manual No.

OC091

OC096

OC099

OC098

OC094

OC068

OC069

OC070

OC075

–

1

VKA

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

VKA,VKA

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

2

1

VKA

VKA,VKA

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

1

VKA,VKA

—

—

—

341.6 2.5

1

YKA,YKA

—

—

—

1

YKSA,YKSA

—

—

—

5

1

YKSA,YKSA

—

—

—

—

—

—

—

—

6

1

YKSA,YKSA

—

—

—

—

—

—

—

—

—

—

1

2

Page 3

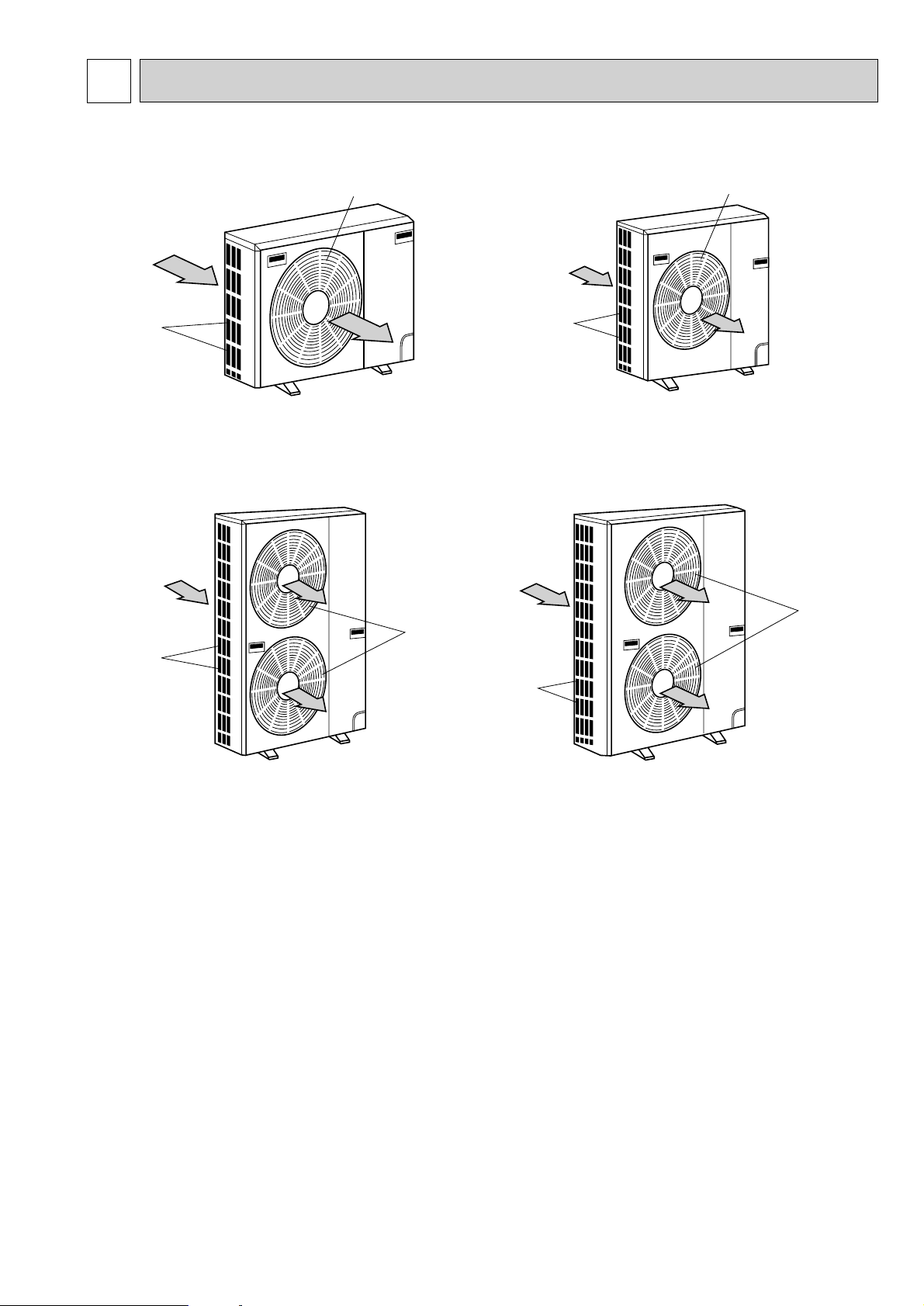

3 PART NAMES AND FUNCTIONS

PUH-1VKA.UK

1.6VKA.UK,1.6VKA

1.UK

2VKA.UK,2VKA

1·UK

Air intake

Air outlet

(Expels warm air during cooling)

PUH-4YKSA·UK

4YKSA

1·UK

Air intake

Air outlet

PUH-5YKSA·UK

5YKSA

1·UK

6YKSA·UK

6YKSA

1·UK

Air intake

Air outlet

PUH-2.5VKA.UK,2.5VKA1.UK

3VKA.UK,3VKA

1.UK

3YKA.UK,3YKA

1.UK

Air intake

Air outlet

• Outdoor unit

CHARGELESS SYSTEM

PRE-CHARGED REFRIGERANT IS SUPPLIED FOR UP TO 30m PIPING LENGTH AT SHIPMENT.

The unique refrigerant circuit and a large accumulator always control the optimal refrigerant level regardless of the length

(50m max. and 5m min.) of piping. The additional refrigerant charging work during installation often causes problems.

Therefore, it is completely eliminated. This unique system improves the quality and reliability of the work done. It also helps

to speed up the installation work.

3

Page 4

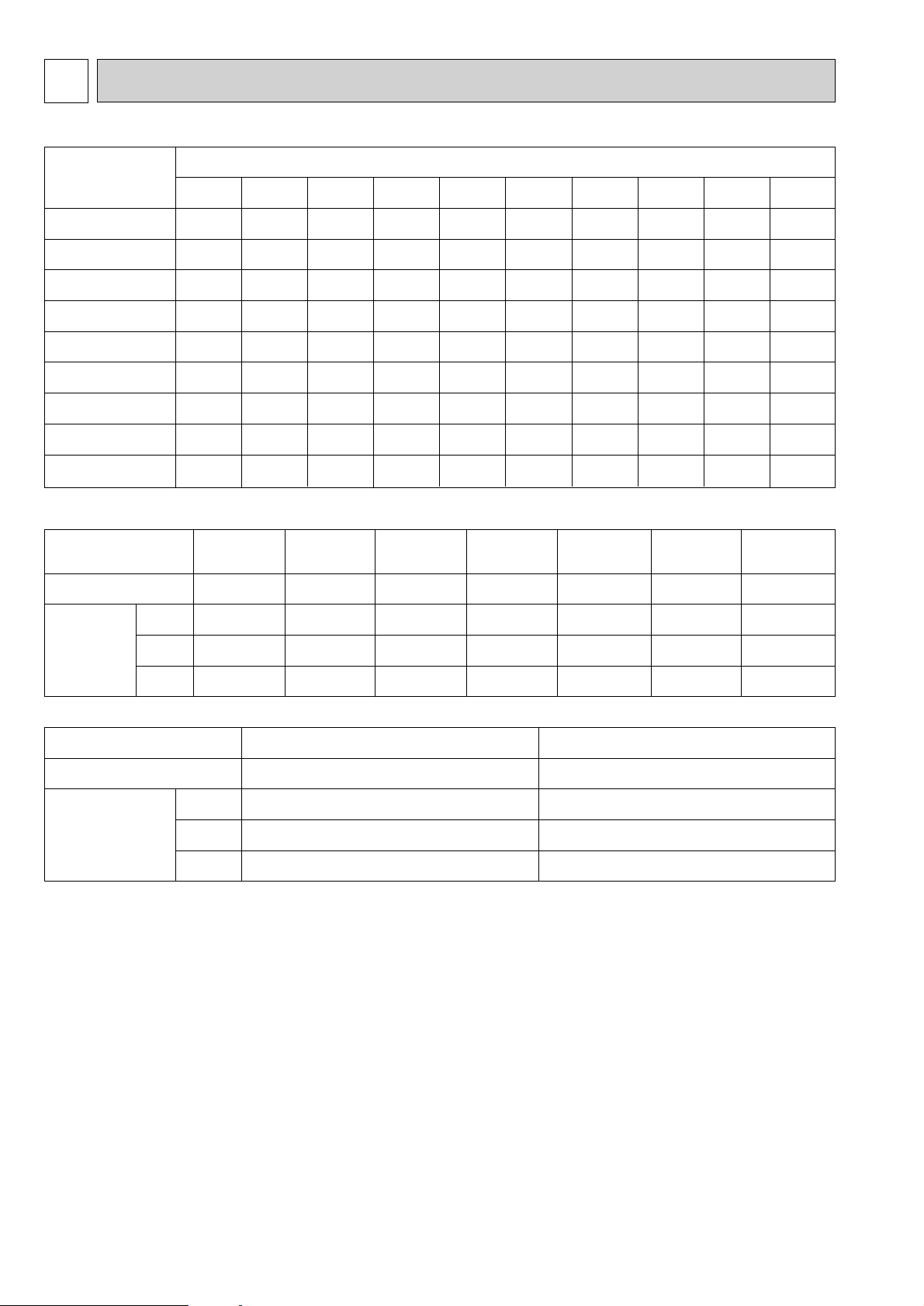

4 DATA

1. REFILLING REFRIGERANT CHARGE (R-22 : kg)

Models

PUH-1VKA1·UK

PUH-1.6VKA·UK

PUH-1.6VKA

1·UK

PUH-2VKA·UK

PUH-2VKA

1·UK

PUH-2.5VKA·UK

PUH-2.5VKA

1·UK

PUH-3VKA·UK

PUH-3VKA

1·UK

PUH-3YKA·UK

PUH-3YKA

1

·UK

PUH-4YKSA·UK

PUH-4YKSA

1

·UK

PUH-5YKSA·UK

PUH-5YKSA

1

·UK

PUH-6YKSA·UK

PUH-6YKSA

1

·UK

5m

1.7

1.5

1.5

2.1

2.5

2.5

3.5

4.7

4.3

10m

1.7

1.7

1.7

2.3

2.7

2.7

3.6

4.8

4.4

15m

1.8

1.8

1.8

2.4

2.8

2.8

3.8

5.0

4.6

2. COMPRESSOR TECHNICAL DATA

Outdoor unit

Compressor Model

Winding

Resistance

(Ω)

at 20˚C

U-V

(

R-C

U-W

(

S-C

W-V

PUH-1VKA1·UK

RH173VFC

)

)

2.85

5.55

—

PUH-1.6VKA ·UK

PUH-1.6VKA

1

RH247VFC

2.00

4.55

—

Refrigerant piping length (one way)

20m

1.8

1.9

1.9

2.5

2.9

2.9

3.9

5.1

4.7

PUH-2VKA·UK

PUH-2VKA

·UK

NH38VMD

1.05

2.23

—

25m

1.9

2.1

2.1

2.7

3.1

3.1

4.1

5.3

4.9

PUH-2.5VKA·UK

1

PUH-2.5VKA

·UK

NH41VMD

1.03

2.22

—

30m

1.9

2.2

2.2

2.8

3.2

3.2

4.2

5.4

5.0

1

·UK

PUH-3VKA

35m

—

2.3

2.3

2.9

3.3

3.3

4.4

5.6

5.2

PUH-3VKA·UK

1

·UK

NH52VND

0.83

2.03

—

40m

—

2.4

2.4

3.0

3.4

3.4

4.5

5.7

5.3

45m

—

—

—

3.1

3.6

3.6

4.6

5.9

5.5

PUH-3YKA·UK

PUH-3YKA

1

·UK

NH52YDA

3.60

3.60

3.60

50m

—

—

—

3.3

3.7

3.7

4.8

6.0

5.6

PUH-4YKSA·UK

PUH-4YKSA

1

·UK

NH56YDA

3.50

3.50

3.50

Outdoor unit

Compressor Model

Winding

Resistance

(Ω)

at 25˚C

1-T3

T

T2-T

T3-T

PUH-5YKSA/5YKSA

ZR61K3-TFD

2.53-2.91

3

1

2.53-2.91

2.53-2.91

1

·UK

PUH-6YKSA/6YKSA1·UK

ZR68KC-TFD

2.31

2.31

2.31

4

Page 5

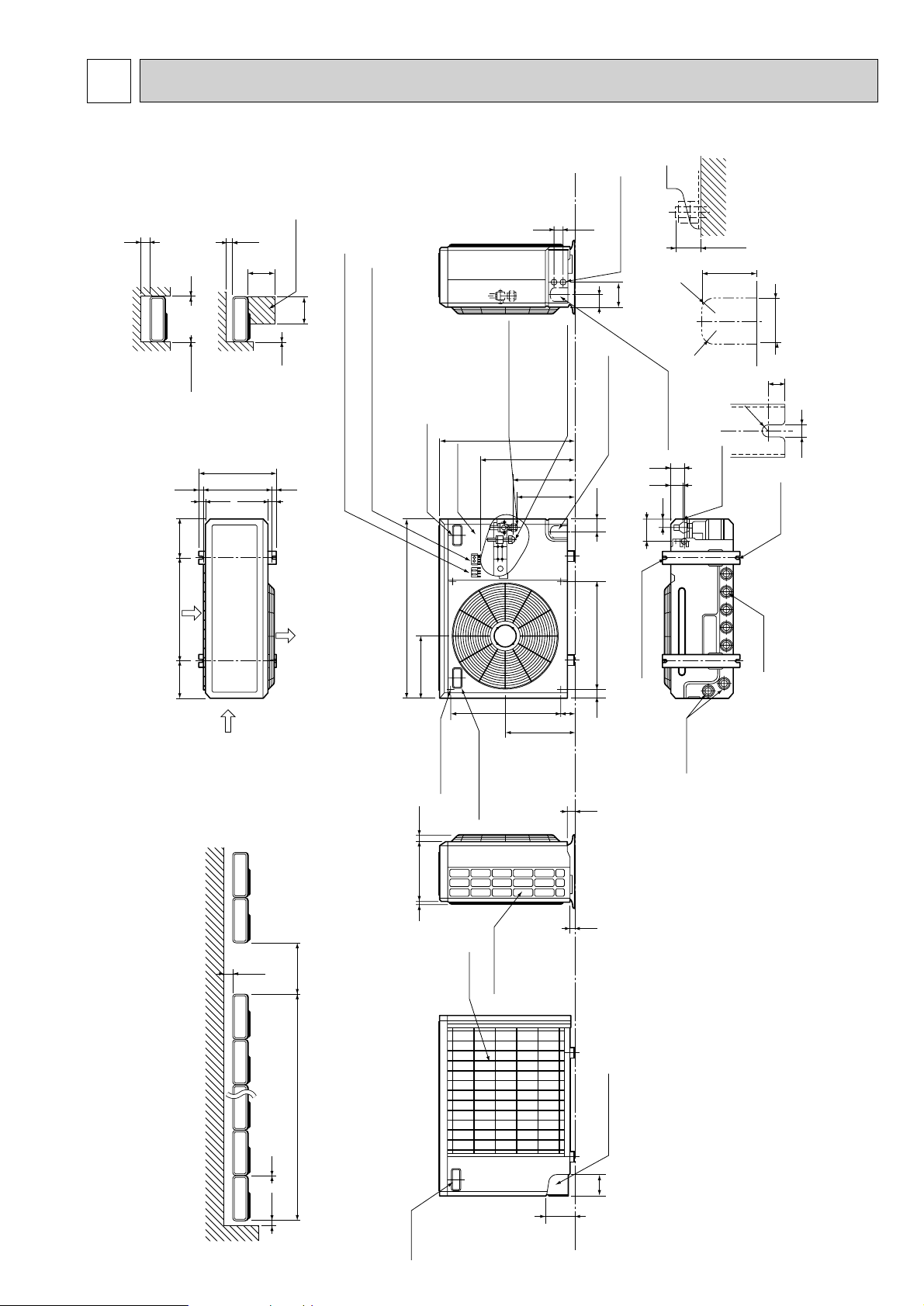

5 OUTLINES AND DIMENSIONS

100 10

1000For 10 units or less

200

Outdoor Unit-Necessary surrounding clearance

(Concentrated installation)

The upper side must be open.

Outdoor Unit-Necessary surrounding clearance

200

10

10

10

Note:Allow adequate

upper clearance

100

500

500

Service space

Front opening

Handle

for moving

138

95

Rear piping hole

23

33

Rear fresh

air intake

Side air intake

7 24(1)295(11-5/8)

Outlet guide

installation hole

302

Air intake

Air intake

Air outlet

870(34-1/4)

185

(7-9/32)

185

(7-9/32)

500(19-11/16)

330(13)

362(14-1/4)

1715

39.5 27.5

Terminal block for indoor and outdoor unit connection

Terminal block for power line and Ground terminal

Handle for moving

77

524

339

282

297

444

650 (25-5/8)

40 60524

Service panel

Refrigerant-pipe flared

connection

[15.88 3/8F

Refrigerant-pipe flared

connection

[9.52 3/8F

Knock out hole

for front piping

(refrigerant,drainage

and wiring)

Knock out hole

for right piping

(refrigerant,drainage

and wiring)

R

20

R20

60

120

4553

25 max.

Knock out holes for

power line 2-[27

Standard bolt length

65

Front right piping holes-

detail figures

80

17

42

45

12

R6

104

33

Bottom

piping hole

2-U-shaped

notched

holes

Drain hole

Drain hole

2-12o23 Oval holes

(standard bolt M10)

Handle for moving

PUH-1VKA·UK,PUH-1.6VKA·UK,PUH-2VKA·UK Unit : mm (inch)

PUH-1.6VKA1·UK,PUH-2VKA1·UK

5

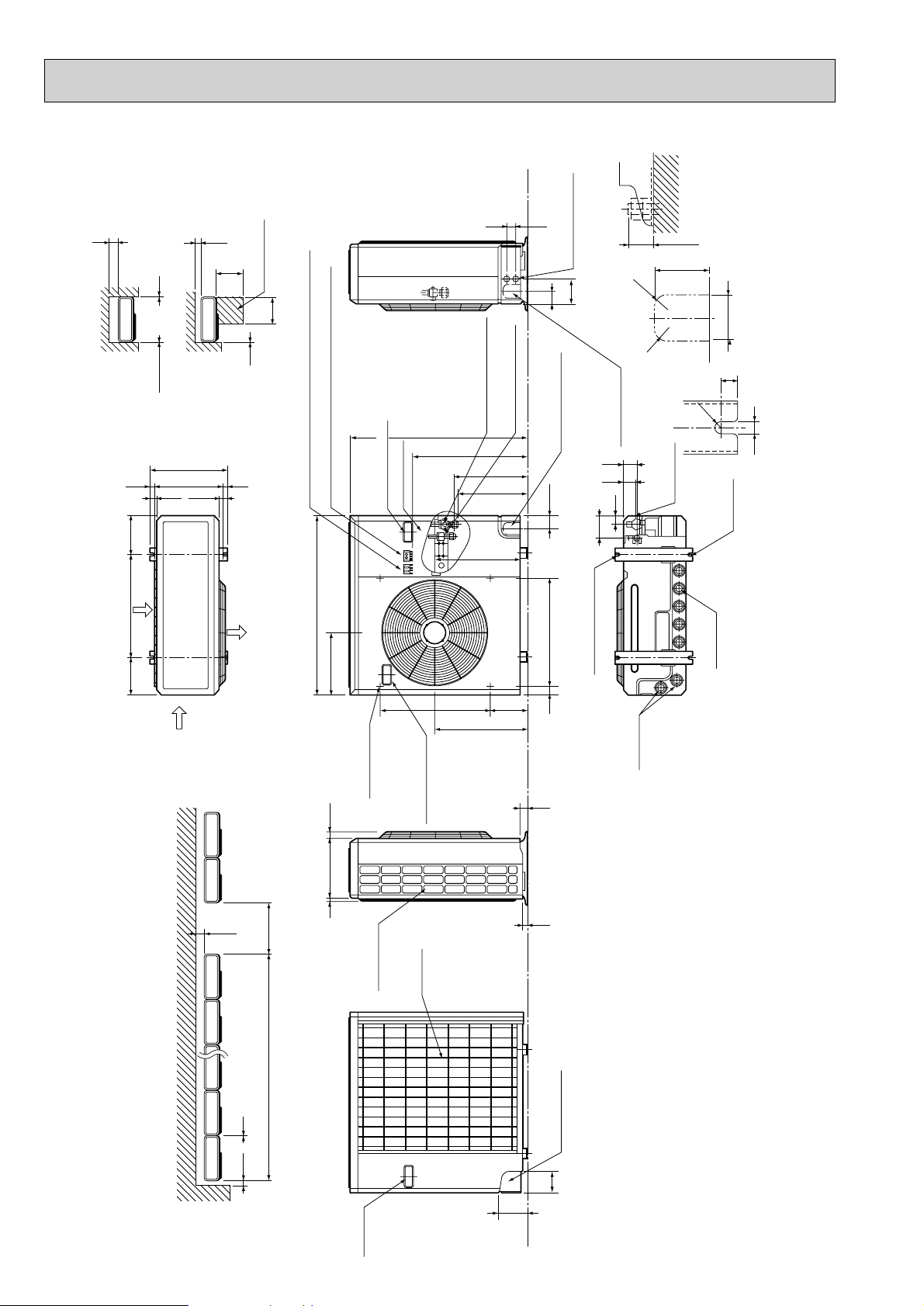

Page 6

100 10

1000For 10 units or less

200

Outdoor Unit-Necessary surrounding clearance

(Concentrated installation)

The upper side must be open.

Outdoor Unit-Necessary surrounding clearance

200

10

10

10

Note:Allow adequate

upper clearance

100

500

500

Service space

Front opening

Handle

for moving

138

95

Rear piping hole

23

33

Rear fresh

air intake

Side air intake

7 24(1)295(11-5/8)

Outlet guide

installation hole

302

Air intake

Air intake

Air outlet

870(34-1/4)

185

(7-9/32)

185

(7-9/32)

500(19-11/16)

330(13)

362(14-1/4)

1715

39.5 27.5

Terminal block for indoor and outdoor unit connection

Terminal block for power line and Ground terminal

Handle for moving

179 524

441

337

352

403

553

850(33-7/16)

40 60524

Service panel

Refrigerant-pipe flared

connection [15.88 5/8F

Refrigerant-pipe flared

connection [9.52 3/8F

Knock out hole

for front piping

(refrigerant,drainage

and wiring)

Knock out hole

for right piping

(refrigerant,drainage

and wiring)

R

20

R20

60

120

4553

25 max.

Knock out holes for

power line 2-[27

Standard bolt length

65

Front right piping holes-

detail figures

80

17

42

45

12

R6

104

33

Bottom

piping hole

2-U-shaped

notched

holes

Drain hole

Drain hole

2-12o23 Oval holes

(standard bolt M10)

Handle for moving

PUH-2.5VKA·UK,PUH-3VKA·UK,PUH-3YKA·UK Unit : mm (inch)

PUH-2.5VKA1·UK,PUH-3VKA1·UK,PUH-3YKA1·UK

6

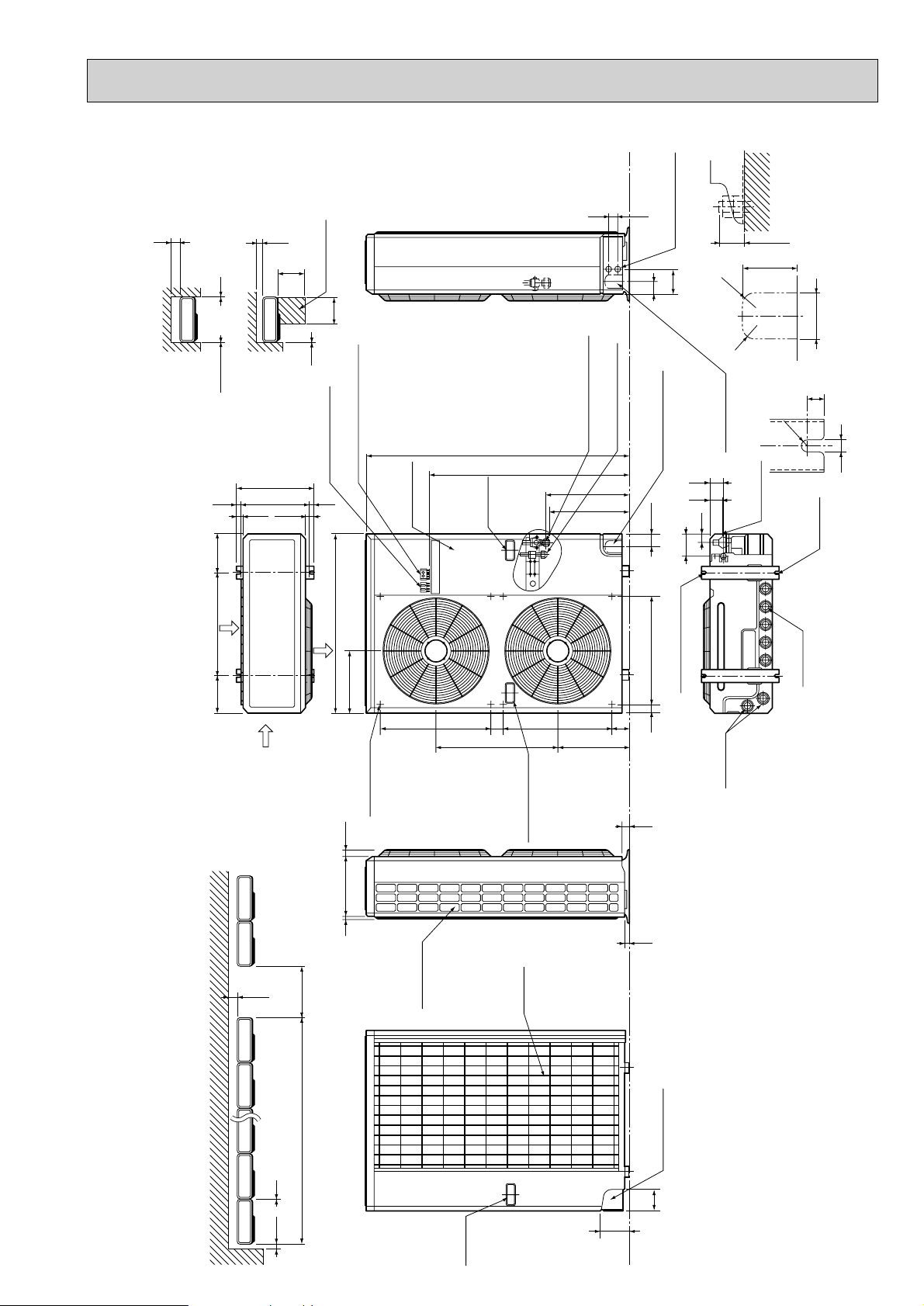

Page 7

PUH-4YKSA·UK Unit : mm (inch)

PUH-4YKSA1·UK

4553

300

Note:Allow adequate

upper clearance

10

Front opening

10

Outdoor Unit-Necessary surrounding clearance

1715

185

(7-9/32)

100

500

Service space

500

10

Terminal block for

indoor and outdoor

unit connection

362(14-1/4)

330(13)

39.5 27.5

Terminal block for power line

and Ground terminal

Service panel

Handle

for moving

Refrigerant-pipe flared

1258(49-1/2)

959

Knock out holes for

60

connection [19.05 3/4F

Refrigerant-pipe flared

connection [9.52 3/8F

Knock out hole

for front piping

403

382

power line 2-[27

120

(refrigerant,drainage

and wiring)

104

R20

20

R

Knock out hole

for right piping

(refrigerant,

57

52

Bottom

39

drainage and wiring)

25 max.

80

R6

piping hole

2-U-shaped

Standard bolt length

65

Front right piping holes-

detail figures

17

12

notched

holes

Air intake

500(19-11/16)

185

(7-9/32)

Air intake

300

1000For 10 units or less

The upper side must be open.

870(34-1/4)

302

Air outlet

Outlet guide

7 24(1)295(11-5/8)

installation hole

Side air intake

52461

585

Handle for moving

Rear fresh

air intake

345

2-12o23 Oval holes

(standard bolt M10)

83 524

40 60524

Drain hole

33

23

Drain hole

Outdoor Unit-Necessary surrounding clearance

(Concentrated installation)

150 10

Handle

for moving

Rear piping hole

95

138

7

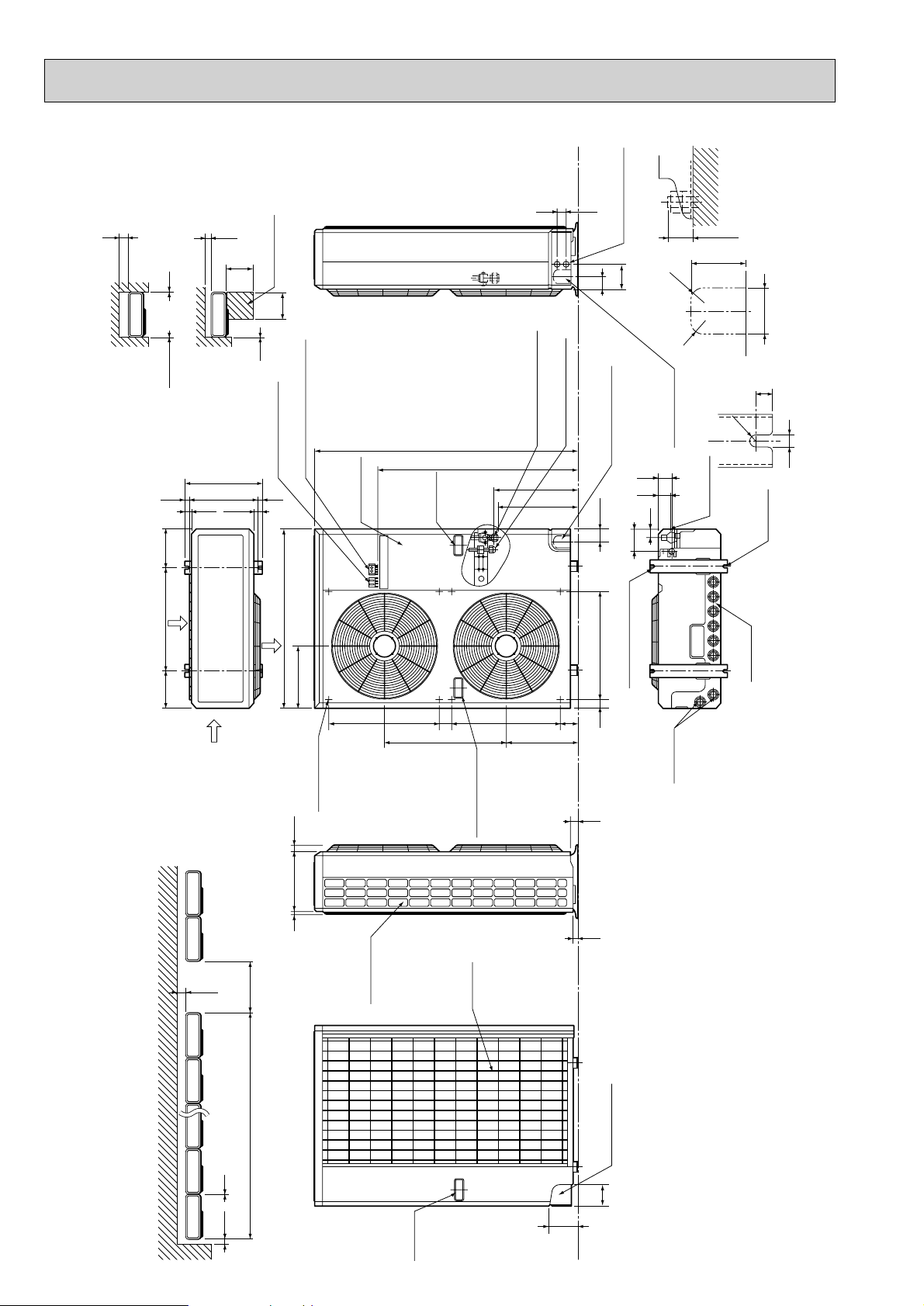

Page 8

PUH-5YKSA·UK,PUH-6YKSA·UK Unit : mm (inch)

150 10

1000For 10 units or less

300

Outdoor Unit-Necessary surrounding clearance

(Concentrated installation)

Outdoor Unit-Necessary surrounding clearance

The upper side must be open.

Handle

for moving

138

95

Rear piping hole

23

33

Rear fresh

air intake

Side air intake

7 24(1)345(13-9/16)

Outlet guide

installation hole

352

Air intake

Air intake

Air outlet

970(38-3/16)

185

(7-9/32)

185

(7-9/32)

600(23-5/8)

380(14-31/32)

412(16-1/4)

1715

39.5 27.5

Terminal block for

indoor and outdoor

unit connection

Terminal block for power line

and Ground terminal

300

10

10

10

Note:Allow adequate

upper clearance

150

500

500

Service space

Handle for moving

52461

585

83 524

345

382

403

959

1258(49-1/2)

90 60524

Service panel

Handle

for moving

Refrigerant-pipe flared

connection [19.05 3/4F

Refrigerant-pipe flared

connection [9.52 3/8F

Knock out hole

for front piping

(refrigerant,drainage

and wiring)

Knock out hole

for right piping

(refrigerant,

drainage and wiring)

R

20

R20

60

120

4553

25 max.

Knock out holes for

power line 2-[27

Standard bolt length

65

Front right piping holes-

detail figures

80

17

52

57

12

R6

104

39

Bottom

piping hole

2-U-shaped

notched

holes

Drain hole

Drain hole

2-12o23 Oval holes

(standard bolt M10)

Front opening

PUH-5YKSA1·UK,PUH-6YKSA1·UK

8

Page 9

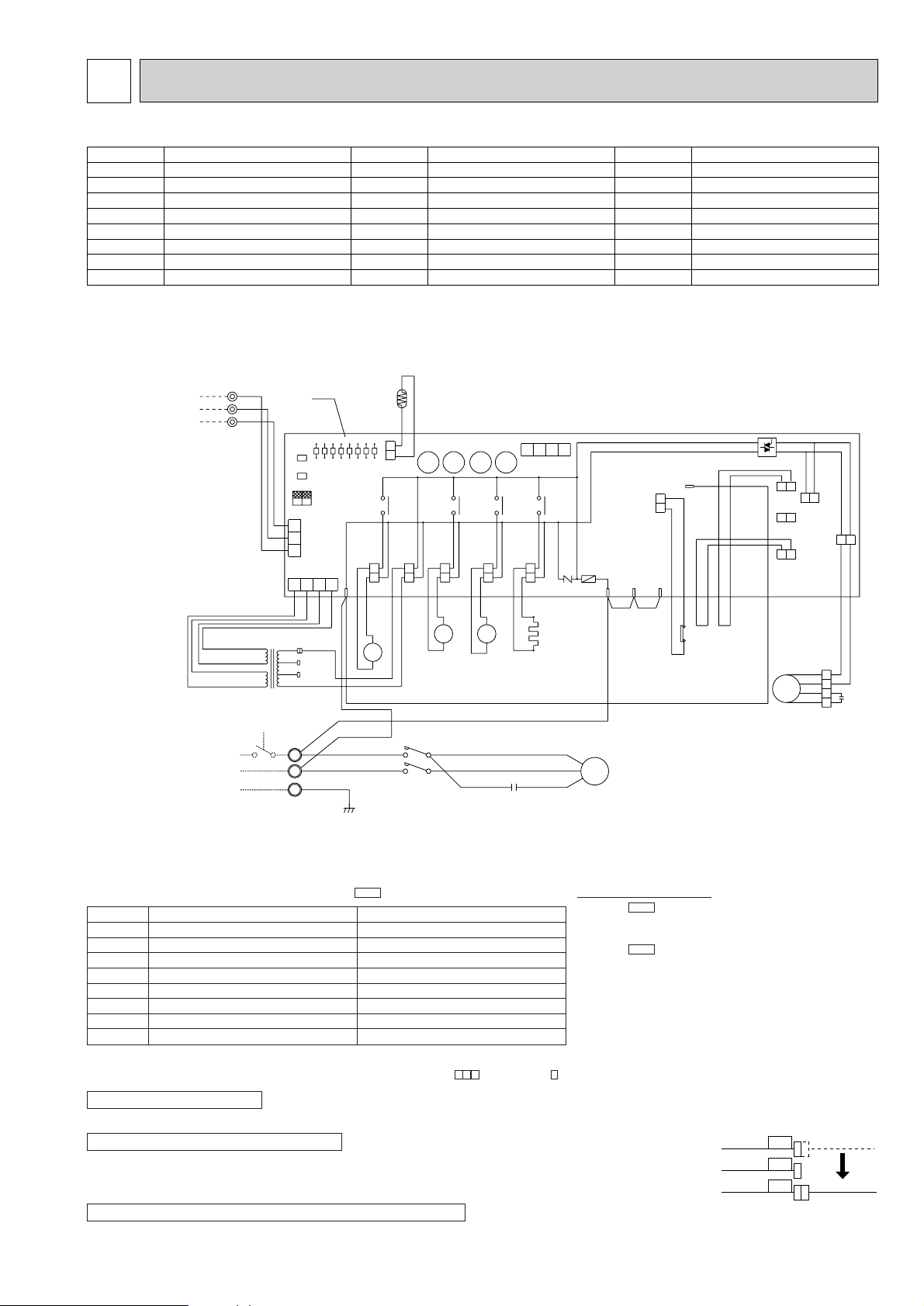

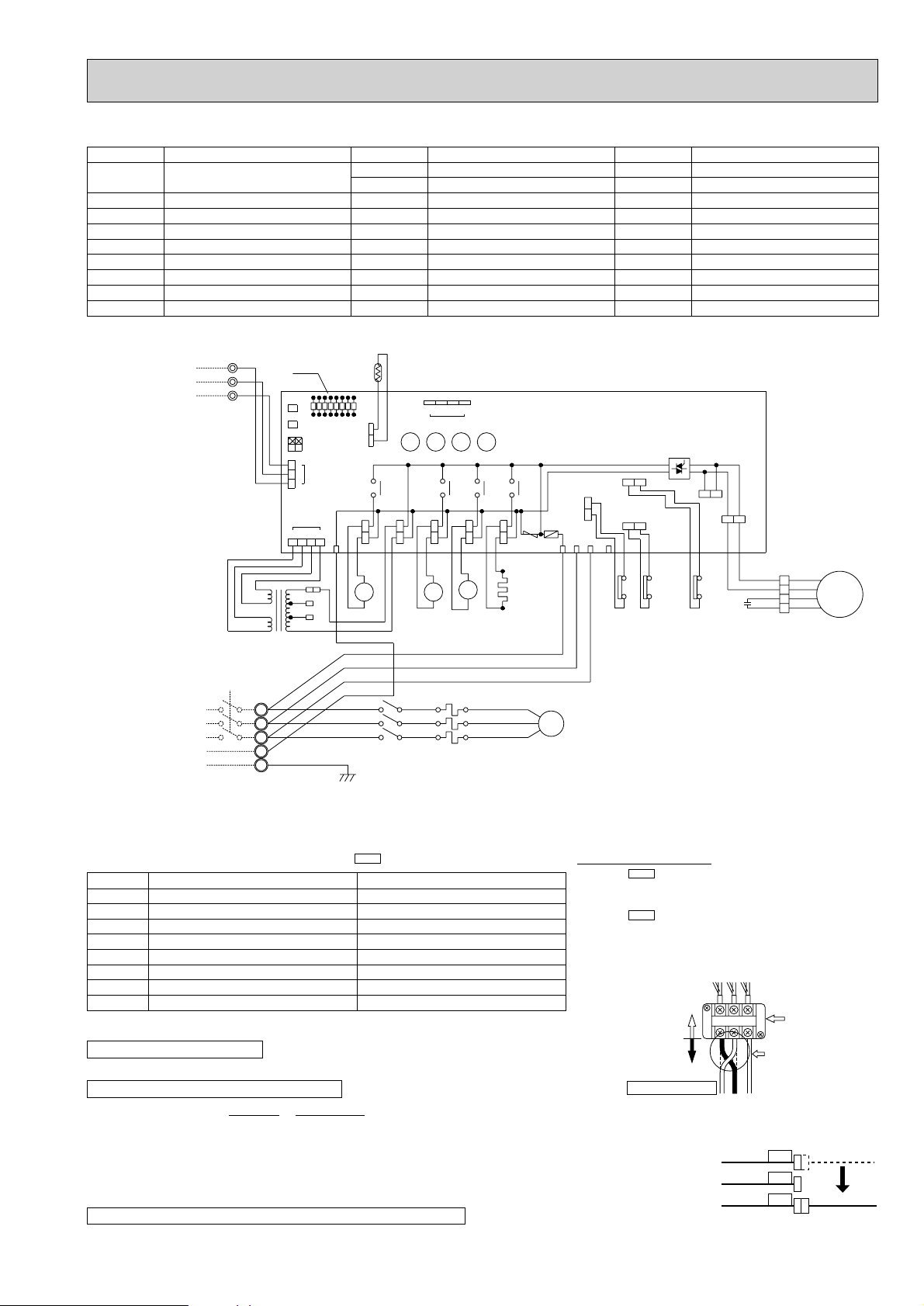

6 WIRING DIAGRAM

RED

N

E

BLU

1

230V

ORN

RED

4

3

WHT

RED

ORN

BLU

WHT

WHT

WHT

2

X11X12X13

1234

CN2

63H1

BRN

3

1

X13X14

X14

SV

RED

RED

21R

21S4

21

S4

RED

RED

MF

ORN

C1

RED

52C

R

T

W

U

BLU

WHT

BLU

C2

S

C

MC

R

63H1

BRN

BRN

GRN/YLW

T

ORN

YLW

1

2

TB3

A

RED AC12.3V

BRN AC12.3V

RED

YLW

BLK

BLK

RED

240V

220V

4

1234

CN4T

CN3

2

3

12

SW3

SW2

O.B

LED

SW1

TO INDOOR UNIT

CONNECTING WIRES

DC 12V (polar)

TB1

POWER SUPPLY

~(1PHASE)

220—240V 50Hz

ON

OFF

LD7

LD1

LD2

LD3

LD4

LD5

LD6

LD8

F

5

RT

X11X12

CN4

TRF 52C

WHT

WHT

GRY

GRY

A

B

52C

HC

CH

ZNR

R/1 S/2 T/3

BLU BLU

YLW

YLW

YLW

YLW

BLU

FC

26C

63H2

51CM

MF2

MF1

PUH-1VKA·UK,PUH-1.6VKA·UK

SYMBOL

HC

C1

C2

FC<O.B

>

F<O.B

21S4

21R

LD1~LD8

CRANKCASE HEATER

FAN MOTOR CAPACITOR

COMPRESSOR CAPACITOR

>

FAN CONTROLLER

FUSE(6A

R.V COIL

BYPASS VALVE COIL

LED(CHECK, SERVICE)

NAME

)

SYMBOL

MC

MF

O.B

SW1·2·3<O.B

T

TB1,3

RT

X11<O.B>

COMPRESSOR MOTOR(INNER THERMOSTAT)

NAME

FAN MOTOR (INNER THERMOSTAT)

OUTDOOR CONTROLLER BOARD

>

SELECT SWITCH(CHECK,SERVICE)

TRANSFORMER

TERMINAL BLOCK

OUTDOOR COIL THERMISTOR

(

0˚C/15kΩ,25˚C/5.4kΩ

)

CRANKCASE HEA TER RELA Y

SYMBOL

X12<O.B

X13<O.B

X14<O.B

ZNR<O.B>

52C

63H1

>

COMPRESSOR RELAY

>

R.V RELAY

>

B.V RELAY

VARISTOR

COMPRESSOR CONTACTOR

HIGH PRESSURE CONTROL SWITCH

NAME

Main functions of LED

LED No.

NOTES : 1. If the operation of the protection device stops to function. then check the display flashes.

CAUTIONS FOR SERVICING

●

Connect the lead wires according to the color indication of sticker on the compressor terminal.

CAUTIONS FOR POWER SUPPLY WIRING

●

Since LD8 lights when normal power is furned ”ON”, check the power supply with the ON or OFF LD8.

w

Since the transformer (T) is connected with 240V power, if 220V or 230V power is used,

change the wiring connection in the following procedure.

CAUTION FOR INDOOR AND OUTDOOR CONNECTING WIRES

●

Since the indoor and outdoor connecting wires has polarity, make sure to connect the same terminal numbers (1,2,3) for indoor and outdoor units.

LD1

LD2

LD3

LD4

LD5

LD6

LD7

LD8

Compressor indoor command

Heating indoor command

63H1 ON

Compressor ON

Outdoor fan ON

4-way valve ON

Bypass valve ON

Crankcase heater ON

2. Symblos used in wiring diagram above are.

(

when both Nos.1 and 2 of are ”OFF”

Output display (light

)

SW3

Pipe temp. sensor short/open

)

Check display (flash

—

—

—

How to use SW1 and 2

●

)

Pressing erases the past check contents loaded on the

microcomputer.

●

The output display (light) remains lit during operation but

pressing displays the past check contents in flashing

mode. Pressing the switch again returns to output display

(light).

SW1

SW2

—

26C functions

RT overheat protecyion

Defective input

/:Terminal block :Connector :PC board insertion tab.

wWhen power supply is 220V

YELLOW

ORANGE

RED

240V

230V

220V

WHITE

9

Page 10

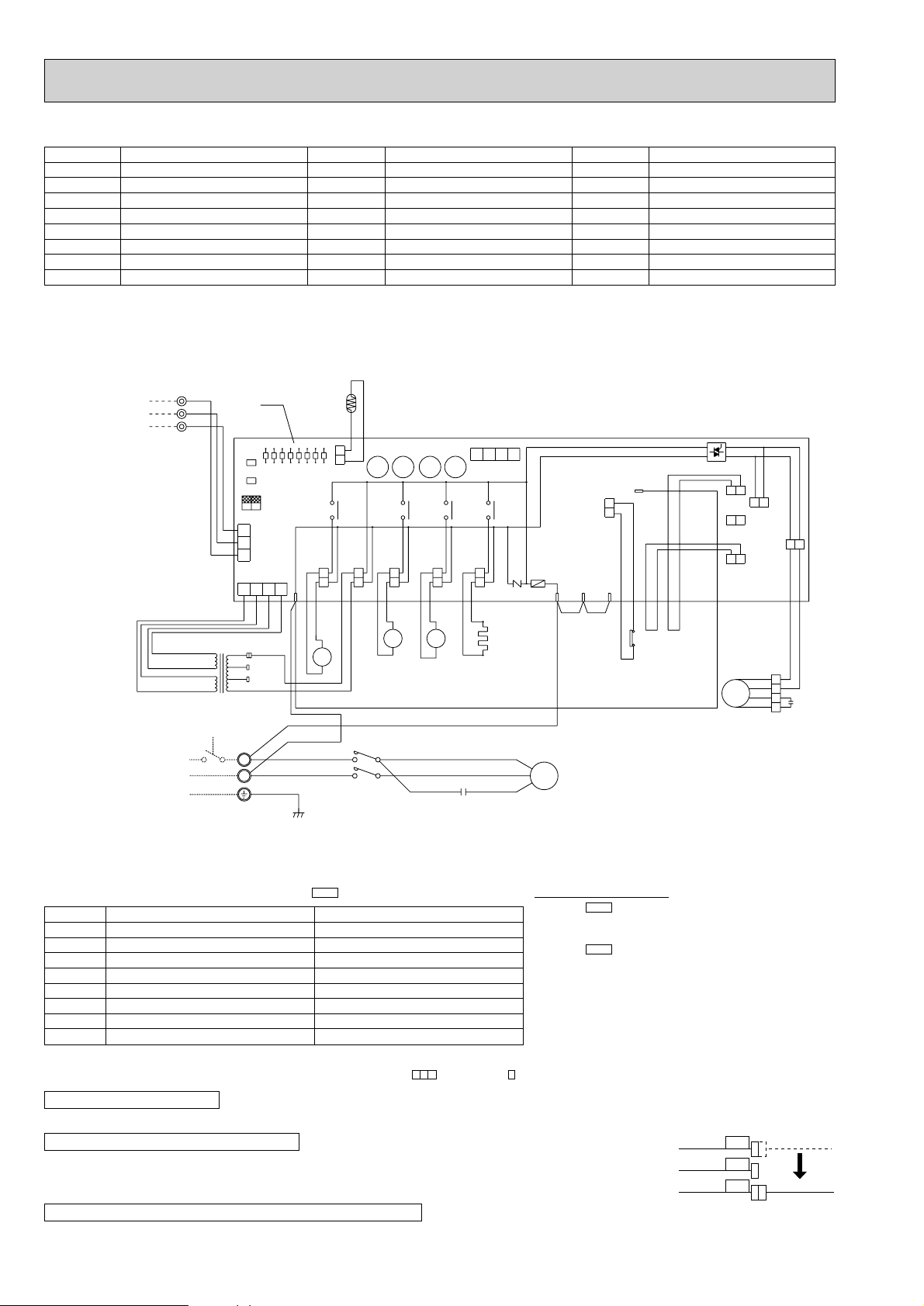

PUH-1.6VKA1·UK

RED

N

BLU

1

230V

ORN

RED

4

3

WHT

RED

ORN

BLU

WHT

WHT

WHT

2

X11X12X13

1234

CN2

63H1

BRN

3

1

X13X14

X14

SV

RED

RED

21R

21S4

21

S4

BLU

BLU

MF

ORN

C1

RED

52C

L1/1

L3/5

T3/6

T1/2

BLU

WHT

BLU

C2

S

C

MC

R

63H1

BRN

BRN

GRN/YLW

T

ORN

YLW

1

2

TB3

L

RED AC12.3V

BRN AC12.3V

RED

YLW

BLU

BLU

RED

240V

220V

4

1234

CN4T

CN3

2

3

12

SW3

SW2

O.B

SW1

TO INDOOR UNIT

CONNECTING WIRES

DC 12V (polar)

TB1

POWER SUPPLY

~(1PHASE)

220—240V 50Hz

ON

OFF

LD7

LD1

LD2

LD3

LD4

LD5

LD6

LD8

F

5

RT

X11X12

CN4

TRF 52C

WHT

WHT

GRY

GRY

A1

A2

52C

HC

CH

ZNR

R/1 S/2 T/3

BLU BLU

YLW

YLW

YLW

YLW

BLU

FC

26C

63H2

51CM

MF2

MF1

LED

SYMBOL

HC

C1

C2

FC<O.B

F<O.B

21S4

21R

LD1~LD8

CRANKCASE HEATER

FAN MOTOR CAPACITOR

COMPRESSOR CAPACITOR

>

FAN CONTROLLER

>

FUSE(6.3A

4-WAY VALVE SOLENOID COIL

BYPASS VALVE SOLENOID COIL

LED(CHECK, SERVICE)

NAME

)

SYMBOL

MC

MF

O.B

SW1·2·3<O.B

T

TB1,3

RT

X11<O.B>

COMPRESSOR MOTOR(INNER THERMOSTAT)

NAME

FAN MOTOR (INNEER THERMOSTAT)

OUTDOOR CONTROLLER BOARD

>

SELECT SWITCH(CHECK,SERVICE)

TRANSFORMER

TERMINAL BLOCK

OUTDOOR COIL THERMISTOR

(

0˚C/15kΩ,25˚C/5.4kΩ

)

CRANKCASE HEA TER RELA Y

SYMBOL

X12<O.B

X13<O.B

X14<O.B

ZNR<O.B>

52C

63H1

>

COMPRESSOR RELAY

>

21S4 RELAY

>

21R RELAY

VARISTOR

COMPRESSOR CONTACTOR

HIGH PRESSURE CONTROL SWITCH

NAME

Main functions of LED

LED No.

LD1

LD2

LD3

LD4

LD5

LD6

LD7

LD8

Output display (light

Compressor indoor command

Heating indoor command

63H1 ON

Compressor ON

Outdoor fan ON

4-way valve ON

Bypass valve ON

Crankcase heater ON

NOTES : 1. If the operation of the protection device stops to function. then check the display flashes.

2. Symblos used in wiring diagram above are. /:Terminal block :Connector :PC board insertion tab.

CAUTIONS FOR SERVICING

●

Connect the lead wires according to the color indication of sticker on the compressor terminal.

CAUTIONS FOR POWER SUPPLY WIRING

●

Since LD8 lights when normal power is furned ”ON”, check the power supply with the ON or OFF LD8.

w

Since the transformer (T) is connected with 240V power, if 220V or 230V power is used,

change the wiring connection in the following procedure.

CAUTION FOR INDOOR AND OUTDOOR CONNECTING WIRES

●

Since the indoor and outdoor connecting wires has polarity, make sure to connect the same terminal numbers (1,2,3) for indoor and outdoor units.

10

(

when both Nos.1 and 2 of are ”OFF”

SW3

)

Check display (flash

Pipe temp. sensor short/open

26C functions

RT overheat protecyion

Defective input

)

)

—

—

—

How to use SW1 and 2

●

Pressing erases the past check contents loaded on the

microcomputer.

●

The output display (light) remains lit during operation but

pressing displays the past check contents in flashing

mode. Pressing the switch again returns to output display

(light).

SW1

SW2

—

wWhen power supply is 220V

YELLOW

240V

ORANGE

RED

230V

220V

WHITE

Page 11

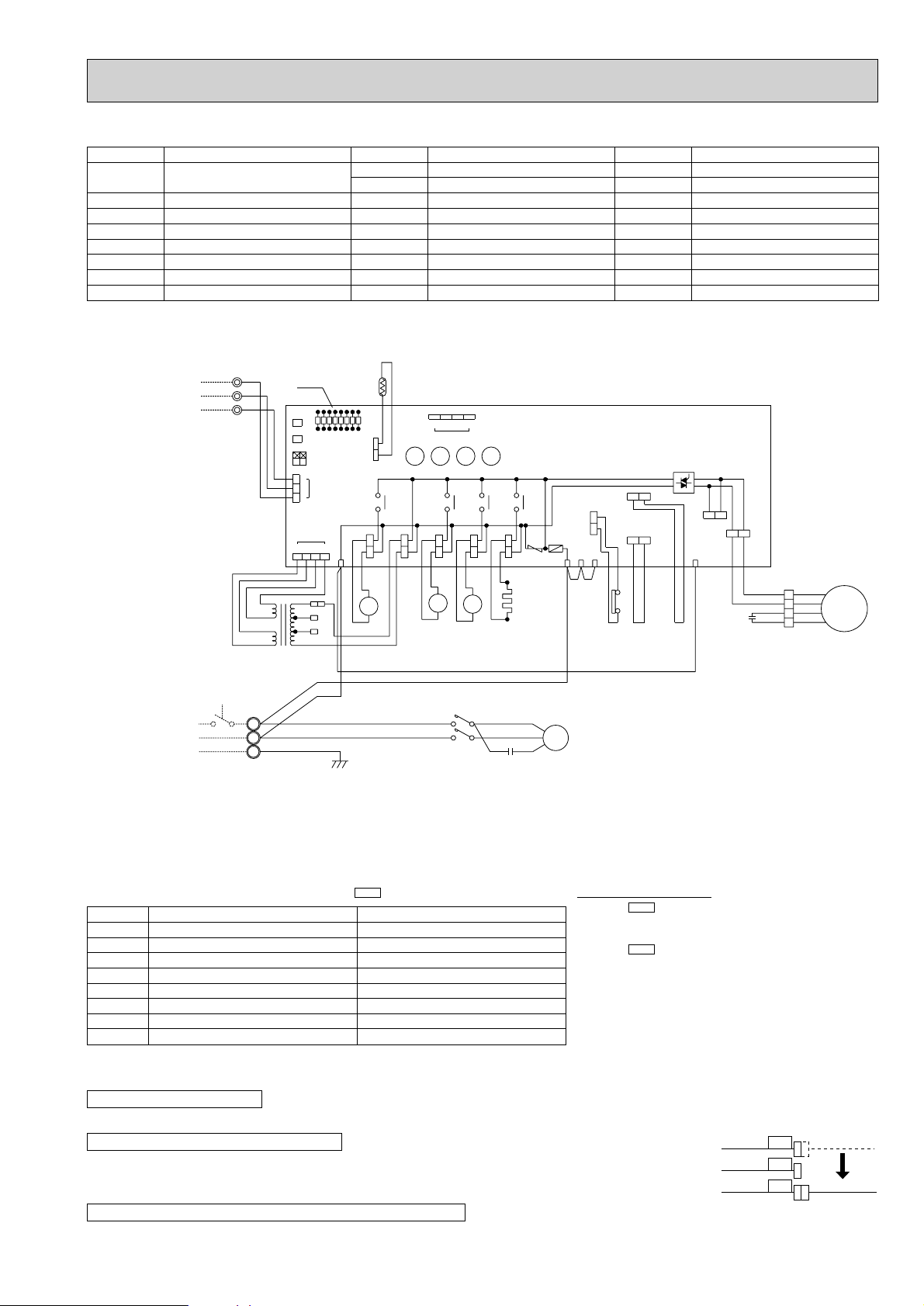

PUH-2VKA·UK,PUH-2.5VKA·UK,PUH-3VKA·UK

B

52C

A

GRY

GRY

N

E

A

RED

BLK

RED

BLK

GRN/YLW

52C

RED

C2

BLU

BLUBLU

5

MF2

RED

LED

O.B

LD8

LD7

LD6

LD5

LD4

LD3

LD2

63H1

YLW

YLW

YLW

YLW

BRN

BRN

HC

WHT

WHT

BLK

BLK

RED

RED

S

C

R

BLU

WHT

BLU

W

U

T

R

WHT

WHT

220V

230V

240V

RED

ORN

YLW

T

AC12.3V

AC

12.3V

BRN

BRN

RED

RED

C1

ORN

RED

BLU

WHT

ORN

BLU

WHT

F.C

MF1

R

ST

26C

63H1

51CM

F

ZNR

CH52C21S4TRFSV

X11X12X13X14

4

123

CN4T

4

1234

CN4

TH

LD1

CN2

CN3

1

2

3

12

ON

OFF

SW3

SW2

SW1

TB3

TB1

BRN

ORN

YLW

3

2

1

POWER SUPPLY

~(1PHASE)

220—240V 50Hz

TO INDOOR UNIT

CONNECTING WIRES

DC 12V

MF

1

2

4

3

MC

21R

21

S4

X11X12X13X14

SYMBOL

CN3(O.B

)

CN4T(O.B

HC

C1

C2

)

FC(O.B

)

F(O.B

LD1-LD8(O.B

CONNECTOR (CONNECTING)

WIRES INDOOR/OUTDOOR

)

CONNECTOR(TRANSFORMER)

CRANKCASE HEATER

FAN MOTOR CAPACITOR

RUN CAPACITOR FOR MC

FAN CONTROLLER

FUSE(6A

)

LED(CHECK,SERVICE)

NAME

)

SYMBOL

MC

MF

O.B

21R

SW1·2·3(O.B

T

TB1,3

TH

X11(O.B

)

COMPRESSOR

FAN MOTOR

OUTDOOR CONTROLLER BOARD

BYPASS VALVE SOLENOID COIL

)

SELECT SWITCH(CHECK,SERVICE)

TRANSFORMER

TERMINAL BLOCK

OUTDOOR COIL THERMISTOR

CRANKCASE HEATER RELAY

NAME

SYMBOL

X12(O.B

X13(O.B

X14(O.B

)

)

)

ZNR<O.B>

21S4

51C

52C

63H1

26C

COMPRESSOR RELAY

NAME

SOLENOID COIL RELAY

B.V COIL RELAY

SURGE ABSORBER

BYPASS VALVE SOLENOID COIL

THERMAL RELAY

CONPRESSOR CONTACTOR

HIGH PRESSURE CONTROL SWITCH

THERMAL RELAY

LD1

LD2

LD3

LD4

LD5

LD6

LD7

LD8

Compressor indoor command

Heating indoor command

63H1 ON

Compressor ON

Outdoor fan ON

4-way valve ON

Bypass valve ON

Crankcase heater ON

Main functions of LED

LED No.

NOTE : If the operation of the protection device stops to function. then check the display flashes.

CAUTIONS FOR SERVICING

●

Connect the lead wires according to the color indication of sticker on the compressor terminal.

CAUTIONS FOR POWER SUPPLY WIRING

●

Since LD8 lights when normal power is furned ”ON”, check the power supply with the ON or OFF LD8.

w

Since the transformer (T) is connected with 240V power, if 220V or 230V power is used,

change the wiring connection in the following procedure.

CAUTION FOR INDOOR AND OUTDOOR CONNECTING WIRES

●

Since the indoor and outdoor connecting wires has polarity, make sure to connect the same terminal numbers (1,2,3) for indoor and outdoor units.

(

when both Nos.1 and 2 of are ”OFF”

Output display (light

SW3

)

Pipe sensor short/open

TH overheat protecyion

Defective input

)

Check display (flash

—

—

—

—

—

How to use SW1 and 2

●

)

Pressing erases the past check contents loaded on the

microcomputer.

●

The output display (light) remains lit during operation but

pressing displays the past check contents in flashing

mode. Pressing the switch again returns to output display

(light).

SW1

SW2

wWhen power supply is 220V

YELLOW

ORANGE

RED

240V

230V

220V

WHITE

11

Page 12

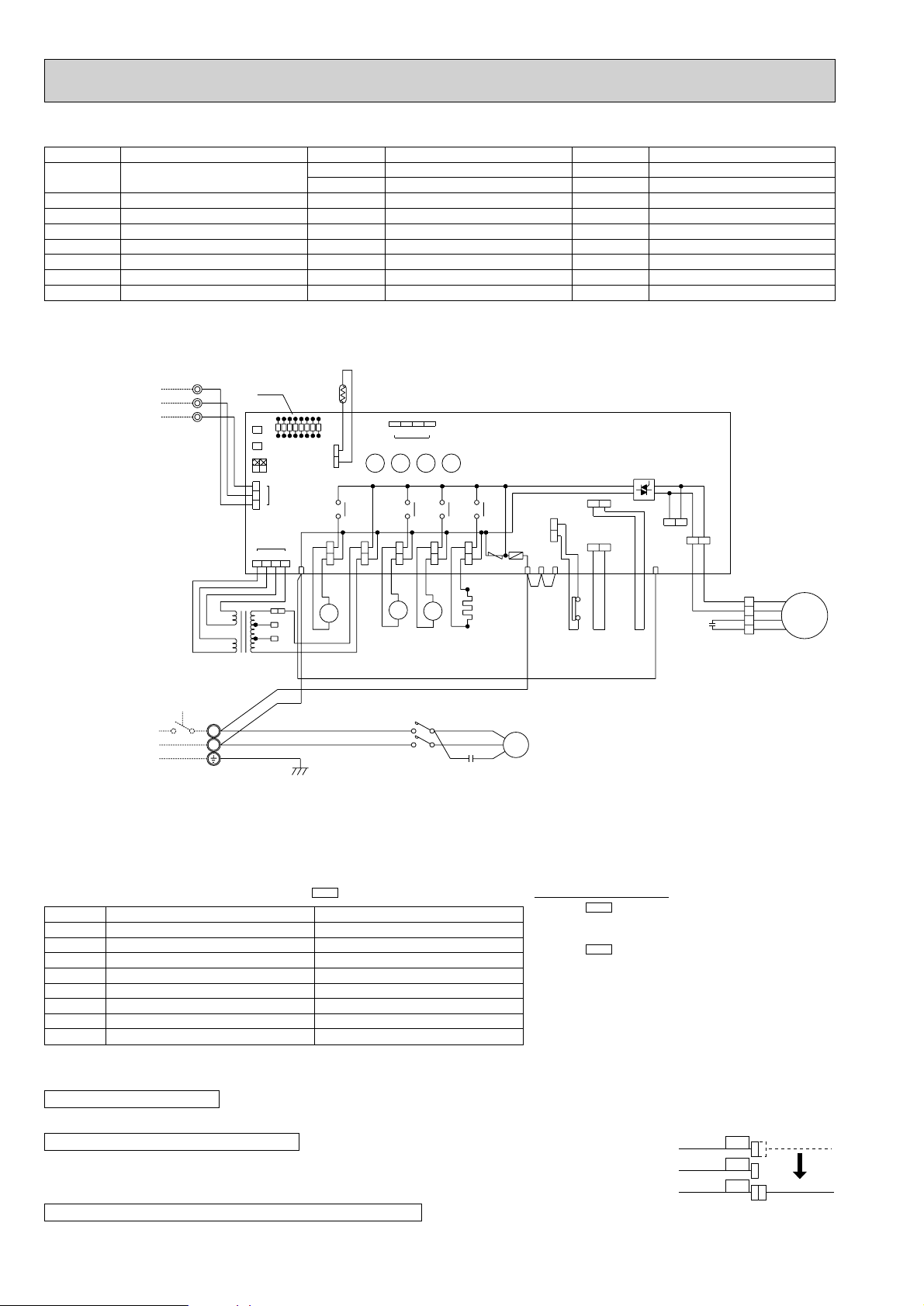

PUH-2VKA1·UK,PUH-2.5VKA1·UK,PUH-3VKA1·UK

A2

52C

A1

GRY

GRY

N

L

TB1

RED

BLU

RED

BLU

GRN/YLW

52C

RED

C2

BLU

BLUBLU

5

MF2

RED

LED

O.B

LD8

LD7

LD6

LD5

LD4

LD3

LD2

63H1

YLW

YLW

YLW

YLW

BRN

BRN

HC

WHT

WHT

BLU

BLU

RED

RED

S

C

R

BLU

WHT

BLU

T2/6

T1/2

L3/5

L1/1

WHT

WHT

220V

230V

240V

RED

ORN

YLW

T

AC12.3V

AC

12.3V

BRN

BRN

RED

RED

C1

ORN

RED

BLU

WHT

ORN

BLU

WHT

F.C

MF1

R

ST

26C

63H1

51CM

F

ZNR

CH52C21S4TRFSV

X11X12X13X14

4

123

CN4T

4

1234

CN4

TH

LD1

CN2

CN3

1

2

3

12

ON

OFF

SW3

SW2

SW1

TB3

BRN

ORN

YLW

3

2

1

POWER SUPPLY

~(1PHASE)

220—240V 50Hz

TO INDOOR UNIT

CONNECTING WIRES

DC 12V

MF

1

2

4

3

MC

21R

21

S4

X11X12X13X14

SYMBOL

CN3(O.B

)

CN4T(O.B

HC

C1

C2

FC(O.B

F(O.B

)

)

LD1-LD8(O.B

CONNECTOR (CONNECTING)

WIRES INDOOR/OUTDOOR

)

CONNECTOR(TRANSFORMER)

CRANKCASE HEATER

FAN MOTOR CAPACITOR

RUN CAPACITOR FOR MC

FAN CONTROLLER

FUSE(6.3A

)

LED(CHECK,SERVICE)

NAME

)

SYMBOL

MC

MF

O.B

21R

SW1·2·3(O.B

T

TB1,3

TH

X11(O.B

)

COMPRESSOR

FAN MOTOR

OUTDOOR CONTROLLER BOARD

BYPASS VALVE SOLENOID COIL

)

SELECT SWITCH(CHECK,SERVICE)

TRANSFORMER

TERMINAL BLOCK

PIPE TEMP. THERMISTOR

CRANKCASE HEATER RELAY

NAME

SYMBOL

X12(O.B

X13(O.B

X14(O.B

)

)

)

ZNR<O.B>

21S4

52C

63H1

COMPRESSOR RELAY

NAME

SOLENOID COIL RELAY

SOLENOID COIL RELAY

SURGE ABSORBER

4-WAY VALVE SOLENOID COIL

CONPRESSOR CONTACTOR

HIGH PRESSURE CONTROL SWITCH

Main functions of LED

LED No.

LD1

LD2

LD3

LD4

LD5

LD6

LD7

LD8

Output display (light

Compressor indoor command

Heating indoor command

63H1 ON

Compressor ON

Outdoor fan ON

4-way valve ON

Bypass valve ON

Crankcase heater ON

NOTE : If the operation of the protection device stops to function. then check the display flashes.

CAUTIONS FOR SERVICING

●

Connect the lead wires according to the color indication of sticker on the compressor terminal.

CAUTIONS FOR POWER SUPPLY WIRING

●

Since LD8 lights when normal power is furned ”ON”, check the power supply with the ON or OFF LD8.

w

Since the transformer (T) is connected with 240V power, if 220V or 230V power is used,

change the wiring connection in the following procedure.

CAUTION FOR INDOOR AND OUTDOOR CONNECTING WIRES

●

Since the indoor and outdoor connecting wires has polarity, make sure to connect the same terminal numbers (1,2,3) for indoor and outdoor units.

12

(

when both Nos.1 and 2 of are ”OFF”

)

SW3

Check display (flash

Pipe sensor short/open

TH overheat protecyion

Defective input

)

How to use SW1 and 2

●

)

—

—

—

—

—

Pressing erases the past check contents loaded on the

microcomputer.

●

The output display (light) remains lit during operation but

pressing displays the past check contents in flashing

mode. Pressing the switch again returns to output display

(light).

SW1

SW2

wWhen power supply is 220V

YELLOW

ORANGE

RED

240V

230V

220V

WHITE

Page 13

PUH-3YKA·UK

SYMBOL

CN3<O.B

CN4T<O.B

C

FC<O.B

F<O.B

HC

LD1-LD8<O.B

MC

MF

POWER SUPPLY

3N~(3PHASE 4WIRES)

380/220—415/240V 50Hz

>

CONNECTOR (CONNECTING

WIRES INDOOR/OUTDOOR)

>

CONNECTOR (TRANSFORMER)

FAN MOTOR CAPACITOR

>

FAN CONTROLLER

>

FUSE(6A

CRANKCASE HEATER

>

LED(CHECK,SERVICE)

COMPRESSOR

FAN MOTOR

TO INDOOR UNIT

CONNECTING WIRES

DC 12V

)

1

2

3

TB3

RED

NAME

YLW

ORN

BRN

RED

BRN

BRN

AC

12.3V

AC12.3V

TB1

A1

A2

A3

N

E

T

O.B

SW1

SW2

SW3

4

GRN/YLW

12

YLW

ORN

RED

LED

OFF

ON

3

2

CN3

1

CN4T

LD1

LD2

123

240V

230V

220V

LD3

SYMBOL

O.B

SW1·2·3<O.B

T

TB1,3

TH

X11<O.B

X12<O.B

X13<O.B

X14<O.B

ZNR<O.B>

TH

LD8

LD7

LD6

LD5

LD4

CN2

4

RED

RED

21R

WHT

WHT

RED

WHT

BLU

BLK

RED

WHT

BLU

OUTDOOR CONTROLLER BOARD

NAME

>

SELECT SWITCH(CHECK,SERVICE)

TRANSFORMER

TERMINAL BLOCK

SYMBOL

21R

21S4

52C

63H1

BYPASS VALVE SOLENOID COIL

NAME

R.V COIL

COMPRESSOR CONTACTOR

HIGH PRESSURE CONTROL SWITCH

OUTDOOR COIL TERMISTOR

>

CRANKCASE HEATER RELAY

>

COMPRESSOR RELAY

>

R.V COIL RELAY

>

B.V COIL RELAY

SURGE ABSORBER

1234

CN4

X11X12X13X14

63H1

ST

26C

51C

5

BRN

BRN

X11X12X13X14

ZNR

F

HC

R

U

V

MC

W

CH52C21S4TRFSV

GRY

GRY

WHT

51C

52C

WHT

A

B

RED

U

WHT

V

BLU

W

BLK

BLK

21

S4

52C

R

U

S

V

T

W

R

S

T

ORN

ORN

F.C

MF2

MF1

YLW

YLW

96

51C63H1

26C

95

WHT

WHT

3

BLU

BLU

4

RED

RED

2

C

ORN

MF

ORN

1

Main functions of LED

LED No.

LD1

LD2

LD3

LD4

LD5

LD6

LD7

LD8

Output display (light

Compressor indoor command

Heating indoor command

63H1 ON

Compressor ON

Outdoor fan ON

4-way valve ON

Bypass valve ON

Crankcase heater ON

(

when both Nos.1 and 2 of are “OFF”

SW3

)

Anti-phase detect

Missing-phase detect

Pipe sensor short/open

51C functions

26C functions

TH overheat protection

Defective input

NOTE : If the operation stops to function of the protection device, the check display flashes.

CAUTIONS FOR SERVICING

●

Connect the lead wires according to the color indication of sticker on the compressor terminal.

CAUTIONS FOR POWER SUPPLY WIRING

●

Making wiring connection in anti-phase or missing phase “A2” or “A3” causes the protection device incorporated in the

microcomputer to function resulting in LD1 or LD2 shown in the table above to flash and prevents the compressor

operation. If phase “A1” or “N” is missing it causes all displays to go out. Under normal condition LD8 light when power

is turned “ON”. If anti-phase connection is to be used, change connections of 2 out of 3 power lines (field wiring side)

contained in the power supply terminal block (TB1) of the outdoor unit as shown at the right upper.

w

Since the transformer (T) is connected with 240V power, if 220V or 230V power is used, change the wiring connection

in the following procedure.

)

Check display (flash

—

How to use SW1 and 2

●

)

Pressing erases the past check contents loaded on the

microcomputer.

●

The output display (light) remains lit during operation but

pressing displays the past check contents in flashing

mode. Pressing the switch again returns to output display

(light).

SW1

SW2

Power line reconnoction procedure

In case of reverse rotation

Unit side

wiring

A1A2A3

Field wiring

Change thie side

123

wWhen power supply is 220V

YELLOW

ORANGE

RED

Change 2 out of 1.

2 and 3.

(This example shows

reconnection of 1

and 2.)

240V

230V

220V

CAUTION FOR INDOOR AND OUTDOOR CONNECTING WIRES

●

Since the indoor and outdoor connecting wires has polarity, make sure to connect the same terminal numbers (1,2,3) for indoor and outdoor units.

Outdoor unit

terminal

WHITE

13

Page 14

PUH-3YKA1·UK

SYMBOL

CN3<O.B

CN4T<O.B

C

FC<O.B

F<O.B

HC

LD1-LD8<O.B

MC

MF

TO INDOOR UNIT

CONNECTING WIRES

DC 12V

POWER SUPPLY

3N~(3PHASE 4WIRES)

380/220—415/240V 50Hz

>

CONNECTOR (CONNECTING

WIRES INDOOR/OUTDOOR)

>

CONNECTOR (TRANSFORMER)

FAN MOTOR CAPACITOR

>

FAN CONTROLLER

>

FUSE(6.3A

CRANKCASE HEATER

>

LED(CHECK,SERVICE)

COMPRESSOR

FAN MOTOR

1

2

3

TB3

NAME

)

YLW

ORN

BRN

RED

RED

AC

12.3V

AC12.3V

BRN

BRN

TB1

L1

L2

L3

N

T

O.B

SW1

SW2

SW3

4

GRN/YLW

LED

12

3

2

1

CN4T

YLW

ORN

RED

OFF

ON

LD1

CN3

LD2

123

240V

230V

220V

LD3

4

LD4

LD5

RED

WHT

BLK

LD6

RED

RED

WHT

BLK

BLU

SYMBOL

O.B

SW1·2·3<O.B

T

TB1,3

TH

X11<O.B

X12<O.B

X13<O.B

X14<O.B

ZNR<O.B>

TH

LD8

LD7

CN2

RED

21R

WHT

WHT

L1/1

L2/3

L3/5

52C

OUTDOOR CONTROLLER BOARD

NAME

>

SELECT SWITCH(CHECK,SERVICE)

TRANSFORMER

TERMINAL BLOCK

PIPE TEMP. TERMISTOR

>

CRANKCASE HEATER RELAY

>

COMPRESSOR RELAY

>

SOLENOID COIL RELAY

>

SOLENOID COIL RELAY

SURGE ABSORBER

1234

CN4

X11X12X13X14

63H1

ST

26C

51C

5

BLU

BLU

X11X12X13X14

ZNR

F

HC

R

U

V

MC

W

CH52C21S4TRFSV

GRY

GRY

WHT

WHT

A1

21

52C

S4

A2

RED

T1/2

WHT

T2/4

BLU

T3/6

51C

SYMBOL

21R

21S4

26C

51C

52C

63H1

ORN

BRN

BRN

ORN

51C63H1

BYPASS VALVE SOLENOID COIL

NAME

4-WAY VALVE SOLENOID COIL

THERMAL SWITCH

THERMAL RELAY

COMPRESSOR CONTACTOR

HIGH PRESSURE CONTROL SWITCH

F.C

MF2

MF1

YLW

YLW

96

26C

95

WHT

WHT

3

BLU

BLU

4

RED

RED

2

C

ORN

MF

ORN

1

Main functions of LED

LED No.

LD1

LD2

LD3

LD4

LD5

LD6

LD7

LD8

Output display (light

Compressor indoor command

Heating indoor command

63H1 ON

Compressor ON

Outdoor fan ON

4-way valve ON

Bypass valve ON

Crankcase heater ON

(

when both Nos.1 and 2 of are “OFF”

SW3

)

Anti-phase detect

Missing-phase detect

Pipe sensor short/open

51C functions

26C functions

TH overheat protection

Defective input

NOTE : If the operation stops to function of the protection device, the check display flashes.

CAUTIONS FOR SERVICING

●

Connect the lead wires according to the color indication of sticker on the compressor terminal.

CAUTIONS FOR POWER SUPPLY WIRING

●

Making wiring connection in anti-phase or missing phase “L2” or “L3” causes the protection device incorporated in the

microcomputer to function resulting in LD1 or LD2 shown in the table above to flash and prevents the compressor

operation. If phase “L1” or “N” is missing it causes all displays to go out. Under normal condition LD8 light when power

is turned “ON”. If anti-phase connection is to be used, change connections of 2 out of 3 power lines (field wiring side)

contained in the power supply terminal block (TB1) of the outdoor unit as shown at the right upper.

w

Since the transformer (T) is connected with 240V power, if 220V or 230V power is used, change the wiring connection

in the following procedure.

)

Check display (flash

—

How to use SW1 and 2

●

)

Pressing erases the past check contents loaded on the

microcomputer.

●

The output display (light) remains lit during operation but

pressing displays the past check contents in flashing

mode. Pressing the switch again returns to output display

(light).

SW1

SW2

Power line reconnoction procedure

In case of reverse rotation

Unit side

wiring

L1L2L3

Field wiring

Change thie side

123

wWhen power supply is 220V

YELLOW

ORANGE

RED

Change 2 out of 1.

2 and 3.

(This example shows

reconnection of 1

and 2.)

240V

230V

220V

CAUTION FOR INDOOR AND OUTDOOR CONNECTING WIRES

●

Since the indoor and outdoor connecting wires has polarity, make sure to connect the same terminal numbers (1,2,3) for indoor and outdoor units.

14

Outdoor unit

terminal

WHITE

Page 15

PUH-4YKSA·UK

SYMBOL

CN3<O.B

CN4T<O.B

C1,2

FC<O.B

F<O.B

HC

LD1-LD8<O.B

MC

MF1,2

POWER SUPPLY

3N~(3PHASE 4WIRES)

380/220 — 415/240V 50Hz

>

CONNECTOR (CONNECTING

WIRES INDOOR/OUTDOOR)

>

CONNECTOR (TRANSFORMER)

FAN MOTOR CAPACITOR

>

FAN CONTROLLER

>

FUSE(6A

CRANKCASE HEATER

>

LED(CHECK,SERVICE)

COMPRESSOR

FAN MOTOR

TO INDOOR UNIT

CONNECTING WIRES

DC 12V

1

2

3

TB3

NAME

)

YLW

ORN

BRN

RED

RED

AC

12.3V

AC12.3V

BRN

BRN

TB1

A1

A2

A3

N

E

O.B

T

LED

SW1

SW2

SW3

12

3

2

1

CN4T

4

YLW

ORN

RED

GRN/YLW

OFF

ON

CN3

LD1

123

240V

230V

220V

LD2

LD3

LD4

4

SYMBOL

O.B

SW1·2·3<O.B

T

TB1,3

TH

X11<O.B

X12<O.B

X13<O.B

X14<O.B

ZNR<O.B>

TH3

LD8

LD7

LD6

LD5

CN2

RED

RED

21R

WHT

WHT

RED

WHT

BLU

BLK

RED

WHT

BLK

OUTDOOR CONTROLLER BOARD

NAME

>

SELECT SWITCH(CHECK,SERVICE)

TRANSFORMER

TERMINAL BLOCK

OUTDOOR COIL TERMISTOR

>

CRANKCASE HEATER RELAY

>

COMPRESSOR RELAY

>

R.V COIL RELAY

>

B.V COIL RELAY

SYMBOL

21R

21S4

26C

51C

52C

63H1

B.V COIL

NAME

R.V COIL

THERMAL SWITCH

THERMAL RELAY

COMPRESSOR CONTACTOR

HIGH PRESSURE CONTROL SWITCH

SURGE ABSORBER

1234

CN4

X11X12X13X14

63H1

26C

51C

5

BRN

BRN

X11X12X13X14

ZNR

F

HC

RST

U

V

MC

W

TRFSV

BLU

U

R

V

S

W

T

52C

21S4

BLU

21

S4

R

S

T

51C

GRY

GRY

52C

52C

CH

WHT

WHT

A

B

RED

U

WHT

V

BLU

W

ORN

ORN

F.C

MF2

MF1

YLW

YLW

96

26C51C63H1

95

WHT

WHT

3

BLU

BLU

4

RED

RED

MF1

2

ORN

WHT

BLU

BRN

YLW

ORN

1

WHT

3

BLU

4

RED

MF2

2

ORN

1

C1

C2

Main functions of LED

LED No.

LD1

LD2

LD3

LD4

LD5

LD6

LD7

LD8

Output display (light

Compressor indoor command

Heating indoor command

63H1 ON

Compressor ON

Outdoor fan ON

4-way valve ON

Bypass valve ON

Crankcase heater ON

(

when both Nos.1 and 2 of are “OFF”

SW3

)

Anti-phase detect

Missing-phase detect

Pipe sensor short/open

51C functions

26C functions

TH overheat protection

Defective input

NOTE : If the operation stops to function of the protection device, the check display flashes.

CAUTIONS FOR SERVICING

●

Connect the lead wires according to the colo indication of sticker on the compressor terminal.

CAUTIONS FOR POWER SUPPLY WIRING

●

Making wiring connection in anti-phase or missing phase “A2” or “A3” causes the protection device incorporated in the

microcomputer to function resulting in LD1 or LD2 shown in the table above to flash and prevents the compressor

operation. If phase “A1” or “N” is missing it causes all displays to go out. Under normal condition LD8 light when power

is turned “ON”. If anti-phase connection is to be used, change connections of 2 out of 3 power lines (field wiring side)

contained in the power supply terminal block (TB1) of the outdoor unit as shown at the right upper.

w

Since the transformer (T) is connected with 240V power, if 220V or 230V power is used, change the wiring connection

in the following procedure.

)

Check display (flash

—

How to use SW1 and 2

●

)

Pressing erases the past check contents loaded on the

microcomputer.

●

The output display (light) remains during operation but

pressing displays the past check contents in flashing

mode. Pressing the switch again returns to output display

(light).

SW1

SW2

Unit side

wiring

Field wiring

Change thie side

Power line reconnoction procedure

In case of reverse rotation

A1A2A3

Change 2 out of 1.

2 and 3.

(This example shows

reconnection of 1

123

and 2.)

wWhen power supply is 220V

YELLOW

ORANGE

RED

240V

230V

220V

CAUTION FOR INDOOR AND OUTDOOR CONNECTING WIRES

●

Since the indoor and outdoor connecting wires has polarity, make sure to connect the same terminal numbers (1,2,3) for indoor and outdoor units.

Outdoor unit

terminal

WHITE

15

Page 16

PUH-4YKSA1·UK

SYMBOL

CN3<O.B

CN4T<O.B

C1,2

FC<O.B

F<O.B

HC

LD1-LD8<O.B

MC

MF1,2

TO INDOOR UNIT

CONNECTING WIRES

DC 12V

POWER SUPPLY

3N~(3PHASE 4WIRES)

380/220 — 415/240V 50Hz

>

CONNECTOR (CONNECTING

WIRES INDOOR/OUTDOOR)

>

CONNECTOR (TRANSFORMER)

FAN MOTOR CAPACITOR

>

FAN CONTROLLER

>

FUSE(6.3A

CRANKCASE HEATER

>

LED(CHECK,SERVICE)

COMPRESSOR

FAN MOTOR

1

2

3

TB3

YLW

ORN

BRN

RED

RED

AC12.3V

NAME

)

BRN

BRN

AC

12.3V

TB1

L1

L2

L3

N

O.B

T

LED

SW1

SW2

SW3

12

3

2

1

CN4T

4

YLW

ORN

RED

GRN/YLW

OFF

ON

CN3

LD1

123

240V

230V

220V

LD2

LD3

4

LD4

RED

WHT

BLK

LD5

LD6

RED

RED

WHT

BLK

BLU

LD7

CN2

RED

WHT

WHT

SYMBOL

O.B

SW1·2·3<O.B

T

TB1,3

TH

X11<O.B

X12<O.B

X13<O.B

X14<O.B

ZNR<O.B>

TH3

LD8

TRFSV

21R

L1/1

L2/3

L3/5

52C

OUTDOOR CONTROLLER BOARD

NAME

>

SELECT SWITCH(CHECK,SERVICE)

TRANSFORMER

TERMINAL BLOCK

PIPE TEMP. TERMISTOR

>

CRANKCASE HEATER RELAY

>

COMPRESSOR RELAY

>

SOLENOID COIL RELAY

>

SOLENOID COIL RELAY

SURGE ABSORBER

1234

CN4

X11X12X13X14

X11X12X13X14

63H1

ZNR

F

RST

5

BLU

BLU

21S4

21

S4

51C

GRY

GRY

52C

52C

A1

A2

T1/2

T2/4

T3/6

WHT

WHT

RED

WHT

BLU

CH

HC

GRY

U

V

MC

W

26C

51C

BRN

BRN

SYMBOL

21R

21S4

26C

51C

52C

63H1

ORN

ORN

96

95

BYPASS VALVE SOLENOID COIL

NAME

4-WAY VALVE SOLENOID COIL

THERMAL SWITCH

THERMAL RELAY

COMPRESSOR CONTACTOR

HIGH PRESSURE CONTROL SWITCH

F.C

MF2

MF1

YLW

YLW

26C51C63H1

WHT

WHT

3

BLU

BLU

4

RED

RED

MF1

2

ORN

WHT

BLU

BRN

YLW

ORN

1

WHT

3

BLU

4

RED

MF2

2

ORN

1

C1

C2

Main functions of LED

LED No.

LD1

LD2

LD3

LD4

LD5

LD6

LD7

LD8

Output display (light

Compressor indoor command

Heating indoor command

63H1 ON

Compressor ON

Outdoor fan ON

4-way valve ON

Bypass valve ON

Crankcase heater ON

(

when both Nos.1 and 2 of are “OFF”

SW3

)

Anti-phase detect

Missing-phase detect

Pipe sensor short/open

51C functions

26C functions

TH overheat protection

Defective input

NOTE : If the operation stops to function of the protection device, the check display flashes.

CAUTIONS FOR SERVICING

●

Connect the lead wires according to the colo indication of sticker on the compressor terminal.

CAUTIONS FOR POWER SUPPLY WIRING

●

Making wiring connection in anti-phase or missing phase “L2” or “L3” causes the protection device incorporated in the

microcomputer to function resulting in LD1 or LD2 shown in the table above to flash and prevents the compressor

operation. If phase “L1” or “N” is missing it causes all displays to go out. Under normal condition LD8 light when power

is turned “ON”. If anti-phase connection is to be used, change connections of 2 out of 3 power lines (field wiring side)

contained in the power supply terminal block (TB1) of the outdoor unit as shown at the right upper.

w

Since the transformer (T) is connected with 240V power, if 220V or 230V power is used, change the wiring connection

in the following procedure.

)

Check display (flash

—

How to use SW1 and 2

●

)

Pressing erases the past check contents loaded on the

microcomputer.

●

The output display (light) remains during operation but

pressing displays the past check contents in flashing

mode. Pressing the switch again returns to output display

(light).

SW1

SW2

Unit side

wiring

Field wiring

Change thie side

Power line reconnoction procedure

In case of reverse rotation

L1L2L3

Change 2 out of 1.

2 and 3.

(This example shows

reconnection of 1

123

and 2.)

wWhen power supply is 220V

YELLOW

ORANGE

RED

240V

230V

220V

CAUTION FOR INDOOR AND OUTDOOR CONNECTING WIRES

●

Since the indoor and outdoor connecting wires has polarity, make sure to connect the same terminal numbers (1,2,3) for indoor and outdoor units.

16

Outdoor unit

terminal

WHITE

Page 17

PUH-5YKSA·UK

SYMBOL

MC

MF1,2

C1,2

TH

HC

49C

52C

21S4

21R

T

TO INDOOR UNIT

CONNECTING WIRES

DC 12V

POWER SUPPLY

3N~(3PHASE 4WIRES)

380/220—415/240V 50Hz

COMPRESSOR

FAN MOTOR

FAN MOTOR CAPACITOR

OUTDOOR COIL THERMISTOR

CRANKCASE HEATER

INTERNAL THERMOSTAT FOR MC

COMPRESSOR CONTACTOR

R.V COIL

BYPASS VALVE COIL

TRANSFORMER

1

2

3

TB3

RED

AC12.3V

NAME

YLW

ORN

BRN

RED

BRN

BRN

AC

12.3V

TB1

A1

A2

A3

N

E

O.B

T

LED

SW1

SW2

SW3

12

3

2

1

CN4T

4

YLW

ORN

RED

GRN/YLW

OFF

ON

LD1

CN3

240V

230V

220V

LD2

123

LD3

SYMBOL

TB1,3

26C

O.B

ZNR<O.B>

F<O.B

FC<O.B

X11<O.B

X12<O.B

X13<O.B

X14<O.B

TH

LD8

LD7

LD6

LD5

LD4

CN2

4

RED

RED

13

52C

21R

14

RED

WHT

WHT

RED

WHT

BLU

BLK

RED

WHT

BLU

TERMINAL BLOCK

NAME

THERMAL SWITCH (DIS.CHARGE)

OUTDOOR CONTROLLER BOARD

SURGE ABSORBER

>

FUSE(6A

>

FAN CONTROLLER

>

CRANKCASE HEATER RELAY

>

COMPRESSOR RELAY

>

R.V COIL RELAY

>

B.V COIL RELAY

CN4

BLU

BLU

21

S4

U

R

V

S

W

T

52C

)

1234

X11X12X13X14

X11X12X13X14

63H1

ZNR

F

CH52C21S4TRFSV

GRY

GRY

BLK

BLK

A1

52C

A2

RED

WHT

BLU

RST

HC

SYMBOL

CN3<O.B

CN4T<O.B

SW1,2,3<O.B

LD1-LD8<O.B

51CM<O.B

63H1

26C

51CM

5

BRN

BRN

63H1

49C

T1

T2

T3

MC

>

CONNECTOR (CONNECTING

WIRES INDOOR/OUTDOOR

NAME

>

CONNECTOR (TRANSFORMER)

>

SELECT SWITCH (CHECK,SERVICE)

>

LED (CHECK,SERVICE)

>

JUMPER CONNECTOR

HIGH PRESSURE CONTROL SWITCH

F.C

MF2

MF1

BLK

BLK

26C

WHT

WHT

3

BLU

BLU

4

RED

RED

2

C1

ORN

WHT

BLU

BRN

C2

YLW

MF1

ORN

1

WHT

3

BLU

4

RED

2

MF2

ORN

1

Main functions of LED

LED No.

LD1

LD2

LD3

LD4

LD5

LD6

LD7

LD8

Output display (light

Compressor indoor command

Heating indoor command

63H1 ON

Compressor ON

Outdoor fan ON

4-way valve ON

Bypass valve ON

Crankcase heater ON

(

when both Nos.1 and 2 of are “OFF”

SW3

)

Anti-phase detect

Missing-phase detect

Pipe sensor short/open

26C functions

TH overheat protection

Defective input

NOTE : If the operation stops to function of the protection device, the check display flashes.

CAUTION FOR SERVICING

●

Connect the lead wires accordling to the color indication of sticker on the compressor terminal.

CAUTIONS FOR POWER SUPPLY WIRING

●

Making wiring connection in anti-phase or missing phase “A2” or “A3” causes the protection device incorporated in the

microcomputer to function resulting in LD1 or LD2 shown in the table above to flash and prevents the compressor

operation. If phase “A1” or “N” is missing it causes all displays to go out. Under normal condition LD8 light when power

is turned “ON”. If anti-phase connection is to be used, change connections of 2 out of 3 power lines (field wiring side)

contained in the power supply terminal block (TB1) of the outdoor unit as shown at the right upper.

w

Since the transformer (T) is connected with 240V power, if 220V or 230V power is used, change the wiring connection

in the following procedure.

)

Check display (flash

—

—

How to use SW1 and 2

●

)

Pressing erases the past check contents loaded on the

microcomputer.

●

The output display (light) remains lit during operation but

pressing displays the past check contents in flashing

mode. Pressing the switch again returns to output display

(light).

SW1

SW2

Power line reconnoction procedure

In case of reverse rotation

Unit side

wiring

A1A2A3

Field wiring

Change thie side

123

wWhen power supply is 220V

YELLOW

ORANGE

RED

Change 2 out of 1.

2 and 3.

(This example shows

reconnection of 1

and 2.)

240V

230V

220V

CAUTION FOR INDOOR AND OUTDOOR CONNECTING WIRES

●

Since the indoor and outdoor connecting wires has polarity, make sure to connect the same terminal numbers (1,2,3) for indoor and outdoor units.

Outdoor unit

terminal

WHITE

17

Page 18

PUH-5YKSA1·UK

SYMBOL

MC

MF1,2

C1,2

TH

HC

49C

52C

21S4

21R

T

TO INDOOR UNIT

CONNECTING WIRES

DC 12V

POWER SUPPLY

3N~(3PHASE 4WIRES)

380/220—415/240V 50Hz

COMPRESSOR

FAN MOTOR

FAN MOTOR CAPACITOR

PIPE TEMP. THERMISTOR

CRANKCASE HEATER

INTERNAL THERMOSTAT FOR MC

COMPRESSOR CONTACTOR

4-WAY VALVE SOLENOID COIL

BYPASS VALVE SOLENOID COIL

TRANSFORMER

1

2

3

TB3

RED

NAME

YLW

ORN

BRN

RED

AC

12.3V

AC12.3V

TB1

BRN

BRN

L1

L2

L3

N

T

O.B

SW1

SW2

SW3

4

GRN/YLW

12

YLW

ORN

RED

LED

OFF

ON

3

2

CN3

1

CN4T

LD1

240V

230V

220V

LD2

123

LD3

LD6

LD5

LD4

4

RED

13

52C

14

RED

RED

WHT

BLK

BLU

RED

WHT

BLK

SYMBOL

TB1,3

26C

O.B

ZNR<O.B>

>

F<O.B

FC<O.B

X11<O.B

X12<O.B

X13<O.B

X14<O.B

TH

LD8

LD7

CN2

RED

21R

WHT

WHT

L1/1

L2/3

L3/5

52C

TERMINAL BLOCK

NAME

THERMAL SWITCH (DIS.CHARGE)

OUTDOOR CONTROLLER BOARD

SURGE ABSORBER

1234

GRY

52C

)

X11X12X13X14

X11X12X13X14

63H1

ZNR

F

CH52C21S4TRFSV

BLK

BLK

A1

A2

RED

WHT

BLU

RST

HC

FUSE(6.3A

>

FAN CONTROLLER

>

CRANKCASE HEATER RELAY

>

COMPRESSOR RELAY

>

SOLENOID COIL RELAY

>

SOLENOID COIL RELAY

CN4

GRY

BLU

BLU

21

S4

T1/2

T2/4

T3/6

SYMBOL

CN3<O.B

CN4T<O.B

SW1,2,3<O.B

LD1-LD8<O.B

51CM<O.B

63H1

26C

51CM

5

BRN

BRN

63H1

49C

T1

T2

T3

MC

>

CONNECTOR (CONNECTING

WIRES INDOOR/OUTDOOR

NAME

>

CONNECTOR (TRANSFORMER)

>

SELECT SWITCH (CHECK,SERVICE)

>

LED (CHECK,SERVICE)

>

JUMPER CONNECTOR

HIGH PRESSURE CONTROL SWITCH

F.C

MF2

MF1

BLK

BLK

26C

WHT

WHT

3

BLU

BLU

4

RED

RED

2

C1

ORN

WHT

BLU

BRN

C2

YLW

MF1

ORN

1

WHT

3

BLU

4

RED

2

MF2

ORN

1

Main functions of LED

LED No.

LD1

LD2

LD3

LD4

LD5

LD6

LD7

LD8

Output display (light

Compressor indoor command

Heating indoor command

63H1 ON

Compressor ON

Outdoor fan ON

4-way valve ON

Bypass valve ON

Crankcase heater ON

(

when both Nos.1 and 2 of are “OFF”

SW3

)

Anti-phase detect

Missing-phase detect

Pipe sensor short/open

26C functions

TH overheat protection

Defective input

NOTE : If the operation stops to function of the protection device, the check display flashes.

CAUTION FOR SERVICING

●

Connect the lead wires accordling to the color indication of sticker on the compressor terminal.

CAUTIONS FOR POWER SUPPLY WIRING

●

Making wiring connection in anti-phase or missing phase “L2” or “L3” causes the protection device incorporated in the

microcomputer to function resulting in LD1 or LD2 shown in the table above to flash and prevents the compressor

operation. If phase “L1” or “N” is missing it causes all displays to go out. Under normal condition LD8 light when power

is turned “ON”. If anti-phase connection is to be used, change connections of 2 out of 3 power lines (field wiring side)

contained in the power supply terminal block (TB1) of the outdoor unit as shown at the right upper.

w

Since the transformer (T) is connected with 240V power, if 220V or 230V power is used, change the wiring connection

in the following procedure.

)

Check display (flash

—

—

How to use SW1 and 2

●

)

Pressing erases the past check contents loaded on the

microcomputer.

●

The output display (light) remains lit during operation but

pressing displays the past check contents in flashing

mode. Pressing the switch again returns to output display

(light).

SW1

SW2

Power line reconnoction procedure

In case of reverse rotation

Unit side

wiring

L1L2L3

Field wiring

Change thie side

123

wWhen power supply is 220V

YELLOW

ORANGE

RED

Change 2 out of 1.

2 and 3.

(This example shows

reconnection of 1

and 2.)

240V

230V

220V

CAUTION FOR INDOOR AND OUTDOOR CONNECTING WIRES

●

Since the indoor and outdoor connecting wires has polarity, make sure to connect the same terminal numbers (1,2,3) for indoor and outdoor units.

18

Outdoor unit

terminal

WHITE

Page 19

PUH-6YKSA·UK

SYMBOL

MC

MF1,2

C1,2

TH

HC

49C

52C

21S4

21R

T

TO INDOOR UNIT

CONNECTING WIRES

DC 12V

POWER SUPPLY

3N~(3PHASE 4WIRES)

380/220—415/240V 50Hz

COMPRESSOR

FAN MOTOR

FAN MOTOR CAPACITOR

OUTDOOR COIL THERMISTOR

CRANKCASE HEATER

INTERNAL THERMOSTAT FOR MC

COMPRESSOR CONTACTOR

R.V COIL

B.V COIL

TRANSFORMER

1

2

3

TB3

RED

RED

AC12.3V

NAME

YLW

ORN

BRN

BRN

BRN

AC

12.3V

TB1

A1

A2

A3

N

E

SYMBOL

TB1,3

26C

O.B

ZNR<O.B

F<O.B

FC<O.B

X11<O.B

X12<O.B

X13<O.B

X14<O.B

LED

O.B

SW1

SW2

LD1

SW3

OFF

ON

12

3

2

CN3

1

CN4T

4

YLW

240V

ORN

230V

RED

220V

T

GRN/YLW

TH

LD8

LD7

LD6

LD5

LD4

LD3

LD2

CN2

123

4

WHT

RED

RED

13

52C

21R

14

3

5

RED

RED

X15

RED

WHT

BLU

BLK

RED

R

WHT

S

BLU

T

52C

TERMINAL BLOCK

THERMAL SWITCH (DIS,CHARGE)

OUTDOOR CONTROLLER BOARD

>

SURGE ABSORBER

>

FUSE (6.3A)

>

FAN CONTROLLER

>

CRANKCASE HEATER RELAY

>

COMPRESSOR RELAY

>

R.V COIL RELAY

>

B.V COIL RELAY

CN4

BLK

BLK

WHT

BLK

7

21

X15

S4

8

BLK

U

V

W

NAME

SYMBOL

X15

CN3<O.B

BYPASS VALVE RELAY

NAME

>

CONNECTOR (CONNECTING

WIRES INDOOR/OUTDOOR)

MC

>

CONNECTOR(TRANSFORMER)

>

SELECT SWITCH(CHECK,SERVICE)

>

LED (CHECK,SERVICE)

>

JUMPER CONNECTOR

HIGH PRESSURE CONTROL SWITCH

F.C

MF2

MF1

BLK

BLK

26C

WHT

WHT

3

BLU

BLU

4

RED

RED

2

C1

ORN

WHT

BLU

BRN

C2

YLW

MF1

ORN

1

WHT

3

BLU

4

RED

2

MF2

ORN

1

CN4T<O.B

SW1,2,3<O.B

LD1-LD8<O.B

51CM<O.B

63H1

1234

X11X12X13X14

63H1

RST

26C

51CM

5

T1

T2

T3

BRN

BRN

63H1

49C

X11X12X13X14

ZNR

F

CH52C21S4TRFSV

GRY

GRY

BLK

BLK

A

52C

HC

B

RED

WHT

BLU

Main functions of LED

LED No.

LD1

LD2

LD3

LD4

LD5

LD6

LD7

LD8

Output display (light

Compressor indoor command

Heating indoor command

63H1 ON

Compressor ON

Outdoor fan ON

4-way valve ON

Bypass valve ON

Crankcase heater ON

(

when both Nos.1 and 2 of are “OFF”

SW3

)

Anti-phase detect

Missing-phase detect

Pipe sensor short/open

26C functions

TH overheat protection

Defective input

NOTE : If the operation stops to function of the protection device, the check display flashes.

CAUTION FOR SERVICING

●

Connect the lead wires accordling to the color indication of sticker on the compressor terminal.

CAUTIONS FOR POWER SUPPLY WIRING

●

Making wiring connection in anti-phase or missing phase “A2” or “A3” causes the protection device incorporated in the

microcomputer to function resulting in LD1 or LD2 shown in the table above to flash and prevents the compressor

operation. If phase “A1” or “N” is missing it causes all displays to go out. Under normal condition LD8 light when power

is turned “ON”. If anti-phase connection is to be used, change connections of 2 out of 3 power lines (field wiring side)

contained in the power supply terminal block (TB1) of the outdoor unit as shown at the right upper.

w

Since the transformer (T) is connected with 240V power, if 220V or 230V power is used, change the wiring connection

in the following procedure.

)

Check display (flash

—

—

How to use SW1 and 2

●

)

Pressing erases the past check contents loaded on the

microcomputer.

●

The output display (light) remains lit during operation but

pressing displays the past check contents in flashing

mode. Pressing the switch again returns to output display

(light).

SW1

SW2

Power line reconnoction procedure

In case of reverse rotation

Unit side

wiring

A1A2A3

Field wiring

Change thie side

123

wWhen power supply is 220V

YELLOW

ORANGE

RED

Change 2 out of 1.

2 and 3.

(This example shows

reconnection of 1

and 2.)

240V

230V

220V

CAUTION FOR INDOOR AND OUTDOOR CONNECTING WIRES

●

Since the indoor and outdoor connecting wires has polarity, make sure to connect the same terminal numbers (1,2,3) for indoor and outdoor units.

Outdoor unit

terminal

WHITE

19

Page 20

PUH-6YKSA1·UK

SYMBOL

MC

MF1,2

C1,2

TH

HC

49C

52C

21S4

21R

T

TO INDOOR UNIT

CONNECTING WIRES

DC 12V

POWER SUPPLY

3N~(3PHASE 4WIRES)

380/220—415/240V 50Hz

COMPRESSOR

FAN MOTOR

FAN MOTOR CAPACITOR

PIPE TEMP. THERMISTOR

CRANKCASE HEATER

INTERNAL THERMOSTAT FOR MC

COMPRESSOR CONTACTOR

4-WAY VALVE SOLENOID COIL

BYPASS VALVE SOLENOID COIL

TRANSFORMER

NAME

1

2

3

TB3

RED

RED

AC12.3V

YLW

ORN

BRN

AC

12.3V

BRN

BRN

TB1

L1

L2

L3

N

SYMBOL

TB1,3

26C

O.B

ZNR<O.B

F<O.B

FC<O.B

X11<O.B

X12<O.B

X13<O.B

X14<O.B

LED

O.B

SW1

SW2

LD1

SW3

OFF

ON

12

3

2

CN3

1

CN4T

4

YLW

240V

ORN

230V

RED

220V

T

GRN/YLW

TH

LD8

LD7

LD6

LD5

LD4

LD3

LD2

CN2

123

4

WHT

RED

RED

13

52C

21R

14

3

5

RED

RED

X15

RED

WHT

BLK

BLU

RED

L1/1

WHT

L2/3

BLK

L3/5

TERMINAL BLOCK

THERMAL SWITCH (DIS,CHARGE)

OUTDOOR CONTROLLER BOARD

>

SURGE ABSORBER

>

FUSE (6.3A)

>

FAN CONTROLLER

>

CRANKCASE HEATER RELAY

>

COMPRESSOR RELAY

>

SOLENOID COIL RELAY

>

SOLENOID COIL RELAY

CN4

BLU

BLU

WHT

BLU

7

21

X15

S4

8

BLU

T1/2

T2/4

T3/6

52C

NAME

SYMBOL

X15

CN3<O.B

BYPASS VALVE RELAY

NAME

>

CONNECTOR (CONNECTING

WIRES INDOOR/OUTDOOR)

49C

MC

>

CONNECTOR(TRANSFORMER)

>

SELECT SWITCH(CHECK,SERVICE)

>

LED (CHECK,SERVICE)

>

JUMPER CONNECTOR

HIGH PRESSURE CONTROL SWITCH

F.C

MF2

MF1

BLK

BLK

26C

WHT

WHT

3

BLU

BLU

4

RED

RED

2

C1

ORN

WHT

BLU

BRN

C2

YLW

MF1

ORN

1

WHT

3

BLU

4

RED

2

MF2

ORN

1

CN4T<O.B

SW1,2,3<O.B

LD1-LD8<O.B

51CM<O.B

63H1

1234

X11X12X13X14

63H1

RST

26C

51CM

5

T1

T2

T3

BRN

BRN

63H1

X11X12X13X14

ZNR

F

CH52C21S4TRFSV

GRY

GRY

BLK

BLK

A1

52C

HC

A2

GRY

RED

WHT

BLU

Main functions of LED

LED No.

LD1

LD2

LD3

LD4

LD5

LD6

LD7

LD8

Output display (light

Compressor indoor command

Heating indoor command

63H1 ON

Compressor ON

Outdoor fan ON

4-way valve ON

Bypass valve ON

Crankcase heater ON

(

when both Nos.1 and 2 of are “OFF”

SW3

)

Anti-phase detect

Missing-phase detect

Pipe sensor short/open

26C functions

TH overheat protection

Defective input

NOTE : If the operation stops to function of the protection device, the check display flashes.

CAUTION FOR SERVICING

●

Connect the lead wires accordling to the color indication of sticker on the compressor terminal.

CAUTIONS FOR POWER SUPPLY WIRING

●

Making wiring connection in anti-phase or missing phase “L2” or “L3” causes the protection device incorporated in the

microcomputer to function resulting in LD1 or LD2 shown in the table above to flash and prevents the compressor

operation. If phase “L1” or “N” is missing it causes all displays to go out. Under normal condition LD8 light when power

is turned “ON”. If anti-phase connection is to be used, change connections of 2 out of 3 power lines (field wiring side)

contained in the power supply terminal block (TB1) of the outdoor unit as shown at the right upper.

w

Since the transformer (T) is connected with 240V power, if 220V or 230V power is used, change the wiring connection

in the following procedure.

)

Check display (flash

—

—

How to use SW1 and 2

●

)

Pressing erases the past check contents loaded on the

microcomputer.

●

The output display (light) remains lit during operation but

pressing displays the past check contents in flashing

mode. Pressing the switch again returns to output display

(light).

SW1

SW2

Power line reconnoction procedure

In case of reverse rotation

Unit side

wiring

L1L2L3

Field wiring

Change thie side

123

wWhen power supply is 220V

YELLOW

ORANGE

RED

Change 2 out of 1.

2 and 3.

(This example shows

reconnection of 1

and 2.)

240V

230V

220V

CAUTION FOR INDOOR AND OUTDOOR CONNECTING WIRES

●

Since the indoor and outdoor connecting wires has polarity, make sure to connect the same terminal numbers (1,2,3) for indoor and outdoor units.

20

Outdoor unit

terminal

WHITE

Page 21

7 REFRIGERANT SYSTEM DIAGRAM

Indoor unit

Outdoor unit

Indoor

heat

exchanger

Thermistor

TH2

Strainer

Flared

connection

Flexible tube

Service

port

Accumulator

Ball valve

Strainer

Compressor

Refrigerant pipe

(option)