Page 1

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

SPLIT -TYPE, AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

2004

No.OC301

REVISED EDITION-A

Wall MountedSeries PKA

R407C/R410A

Indoor unit

[Model names] [Service Ref.]

PKA-RP2.5FAL PKA-RP2.5FAL

PKA-RP3FAL PKA-RP3FAL

PKA-RP4FAL PKA-RP4FAL

CONTENTS

1. COMBINATION OF

INDOOR AND OUTDOOR UNITS····················2

2. SAFETY PRECAUTION····································3

3. PART NAMES AND FUNCTIONS·····················6

Indoor unit

Model name

indication

4. SPECIFICATIONS ·············································8

5. DATA································································13

6. OUTLINES AND DIMENSIONS······················33

7. WIRING DIAGRAM ·········································35

8. REFRIGERANT SYSTEM DIAGRAM·············36

9. TROUBLESHOOTING·····································37

10. DISASSEMBLY PROCEDURE ·······················47

11. PARTS LIST ····················································50

12. OPTIONAL PARTS··························Back Cover

• PKA-RP2.5FAL is added in

REVISED EDITION-A.

• This manual does not cover

outdoor units. When servicing

them, please refer to service

manual OC261 REVISED

EDITION-B, OC285, OC294

REVISED EDITION-A, OC298

and this manual in a set.

• Please void OC301.

Remote controller

Page 2

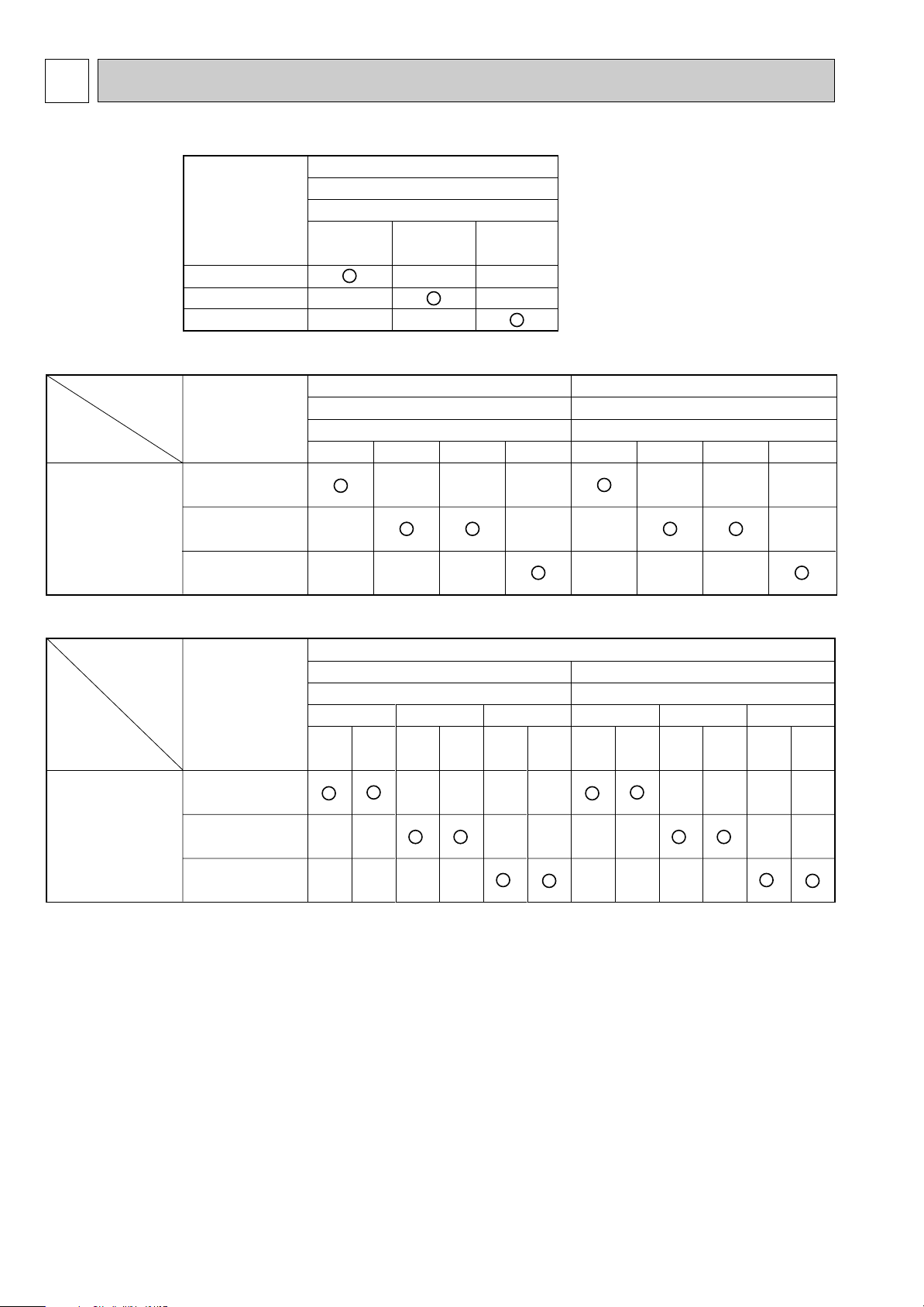

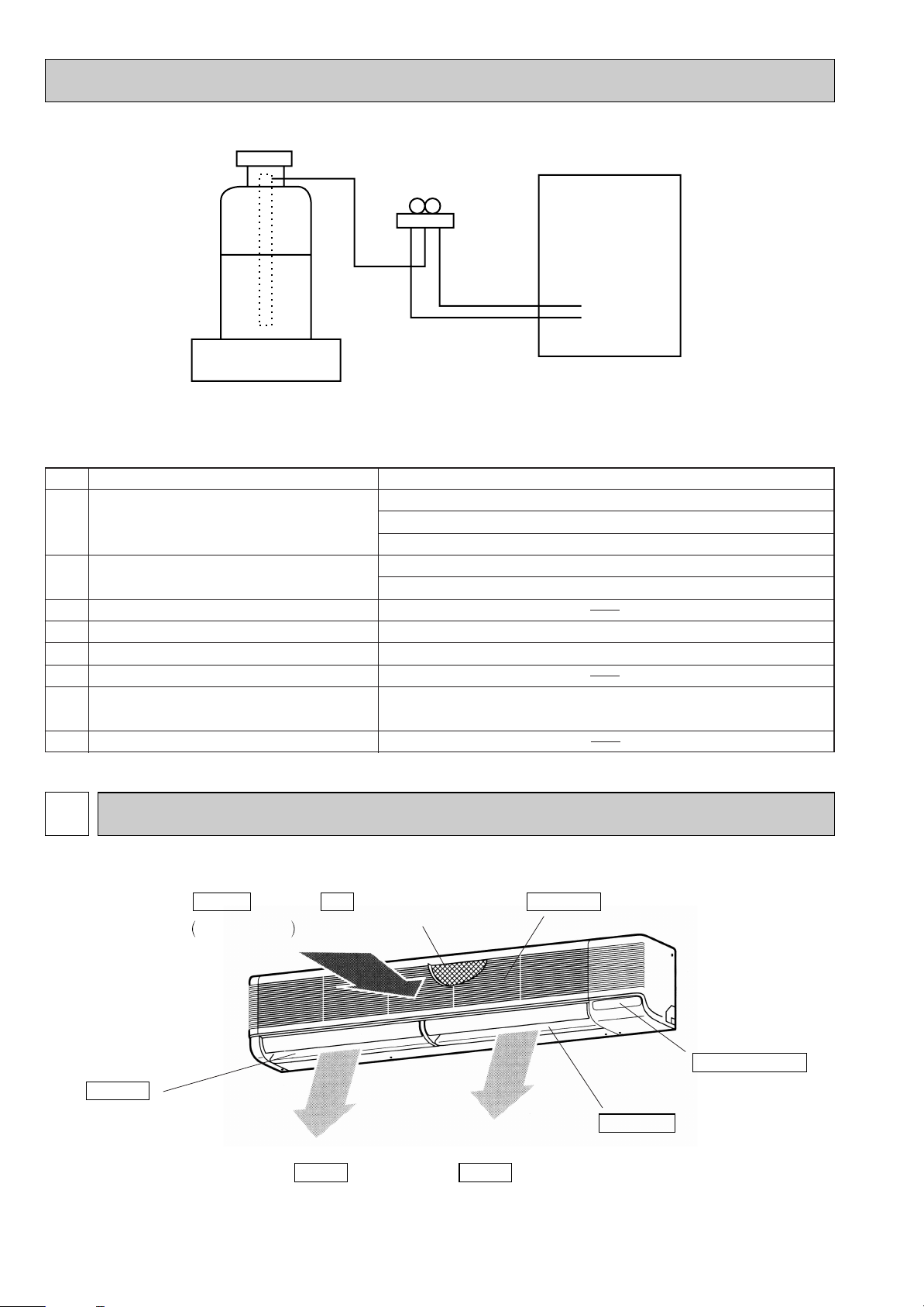

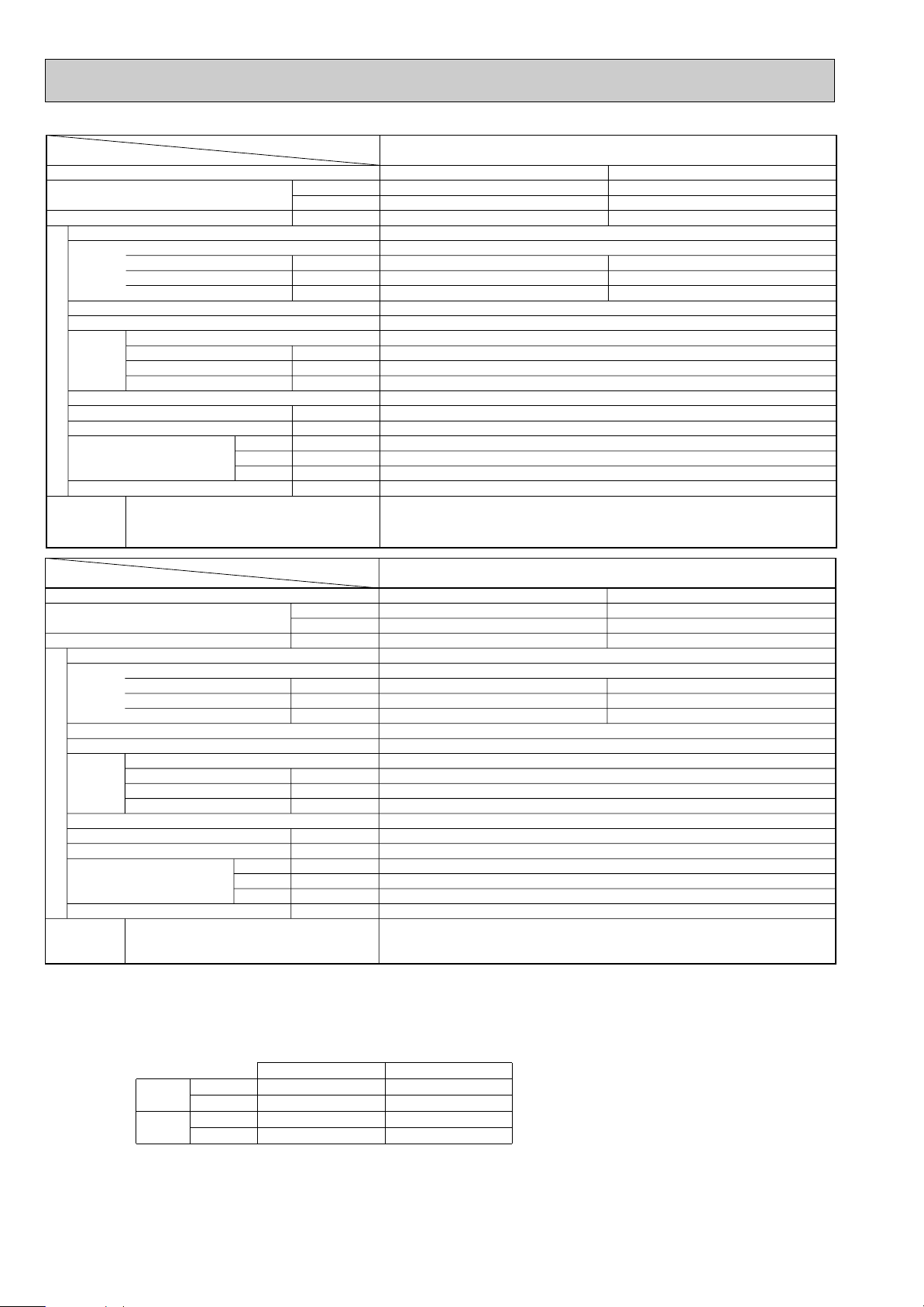

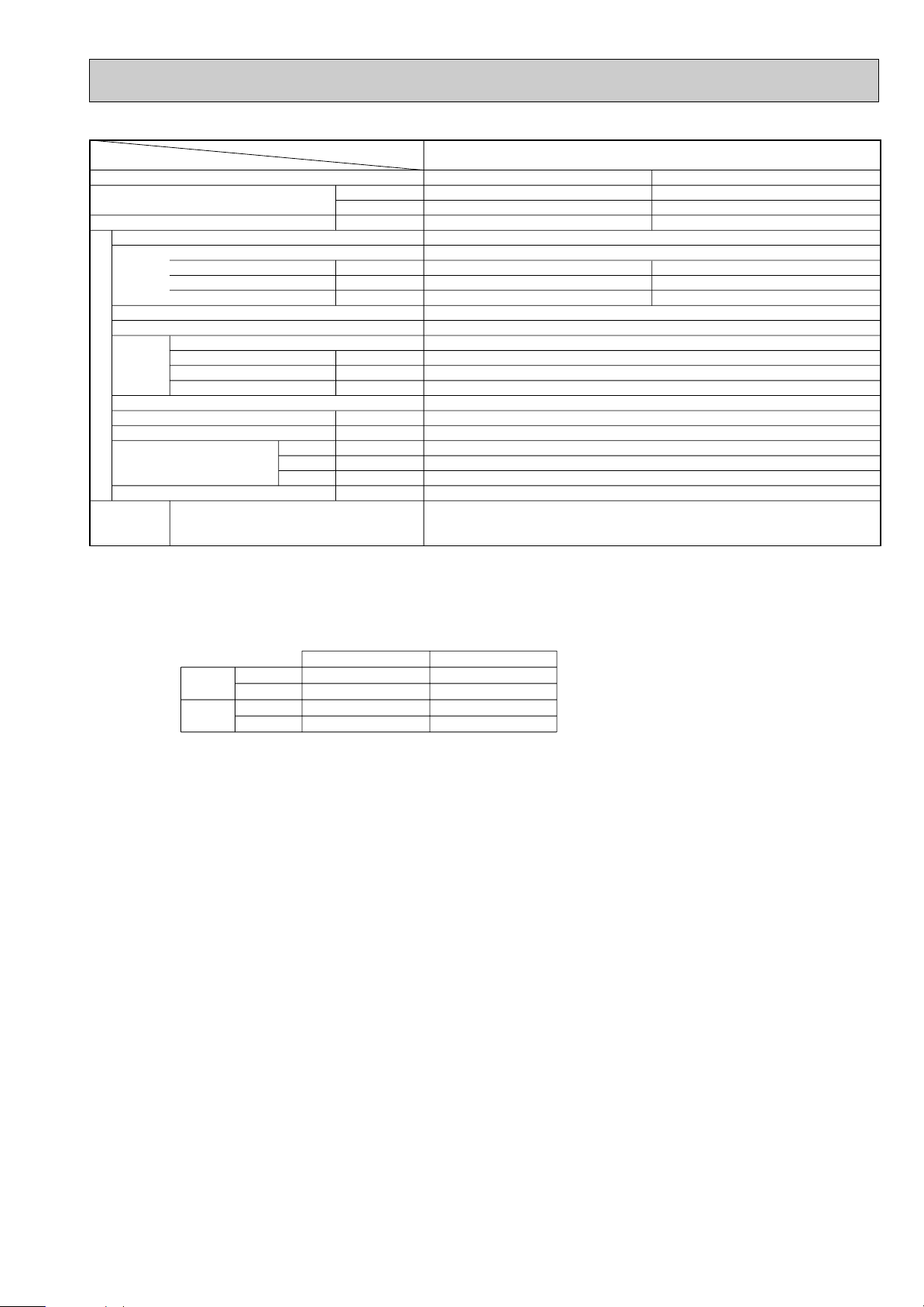

1

Outdoor unit [OC294 REVISED EDITION-A]

Heat pump type

PUHZ-RP

Outdoor unit [OC285]

Heat pump type

PUH-P

(R407C Fixed speed)

(R407C Fixed speed)

(R410A Inverter)

Outdoor unit [OC298]

Cooling only type

PU-P

4VHA

4VHA

1

—

—

3VHA

—

—

2.5VHA

—

—

Indoor unit

PKA-RP2.5FAL

PKA-RP3FAL

PKA-RP4FAL

Heat pump without

electric heater

or

Cooling only

3VGAA

—

—

2.5VGAA

—

—

3YGAA

—

—

4YGAA

—

—

3VGAA

—

—

2.5VGAA

—

—

3YGAA

—

—

4YGAA

—

—

Indoor unit

PKA-RP2.5FAL

PKA-RP3FAL

PKA-RP4FAL

Heat pump type

PUH-P

Cooling only type

PU-P

Heat pump without

electric heater

or

Cooling only

—

—

—

—

———

—

———

—

VGAA.UK

VGAA

1.UK

YGAA.UK

YGAA1.UK

VGAA.UK

VGAA1.UK

YGAA.UK

YGAA1.UK

VGAA.UK

VGAA1.UK

YGAA.UK

YGAA1.UK

VGAA.UK

VGAA1.UK

YGAA.UK

YGAA1.UK

VGAA.UK

VGAA1.UK

YGAA.UK

YGAA1.UK

VGAA.UK

VGAA1.UK

YGAA.UK

YGAA1.UK

—

—

—

—

———

—

———

—

Indoor unit

PKA-RP2.5FAL

PKA-RP3FAL

PKA-RP4FAL

Outdoor unit [OC261 REVISED EDITION-B

]

32.5 4 32.5 4

COMBINATION OF INDOOR AND OUTDOOR UNITS

2

Page 3

2 SAFETY PRECAUTION

Do not use the existing refrigerant piping.

The old refrigerant and lubricant in the existing piping

contains a large amount of chlorine which may cause the

lubricant deterioration of the new unit.

Use “low residual oil piping”

If there is a large amount of residual oil (hydraulic oil, etc.)

inside the piping and joints, deterioration of the lubricant

will result.

Use ESTR , ETHER or HAB as the lubricant to

coat flares and flange connection parts.

If large amount of mineral oil enter, that can cause

deterioration of refrigerant oil etc.

Use liquid refrigerant to seal the system.

If gas refrigerant is used to seal the system, the composition

of the refrigerant in the cylinder will change and performance

may drop.

Do not use a refrigerant other than R407C.

If another refrigerant (R22, etc.) is used, the chlorine in the

refrigerant may cause the lubricant deterioration.

Use a vacuum pump with a reverse flow check valve.

The vacuum pump oil may flow back into the refrigerant

cycle and cause the lubricant deterioration.

Store the piping to be used during installation

indoors with keep both ends sealed until just

before brazing.

(Store elbows and other joints in a plastic bag.)

If dust, dirt, or water enters the refrigerant cycle,

deterioration of the oil and compressor trouble may result.

Ventilate the room if refrigerant leaks during

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

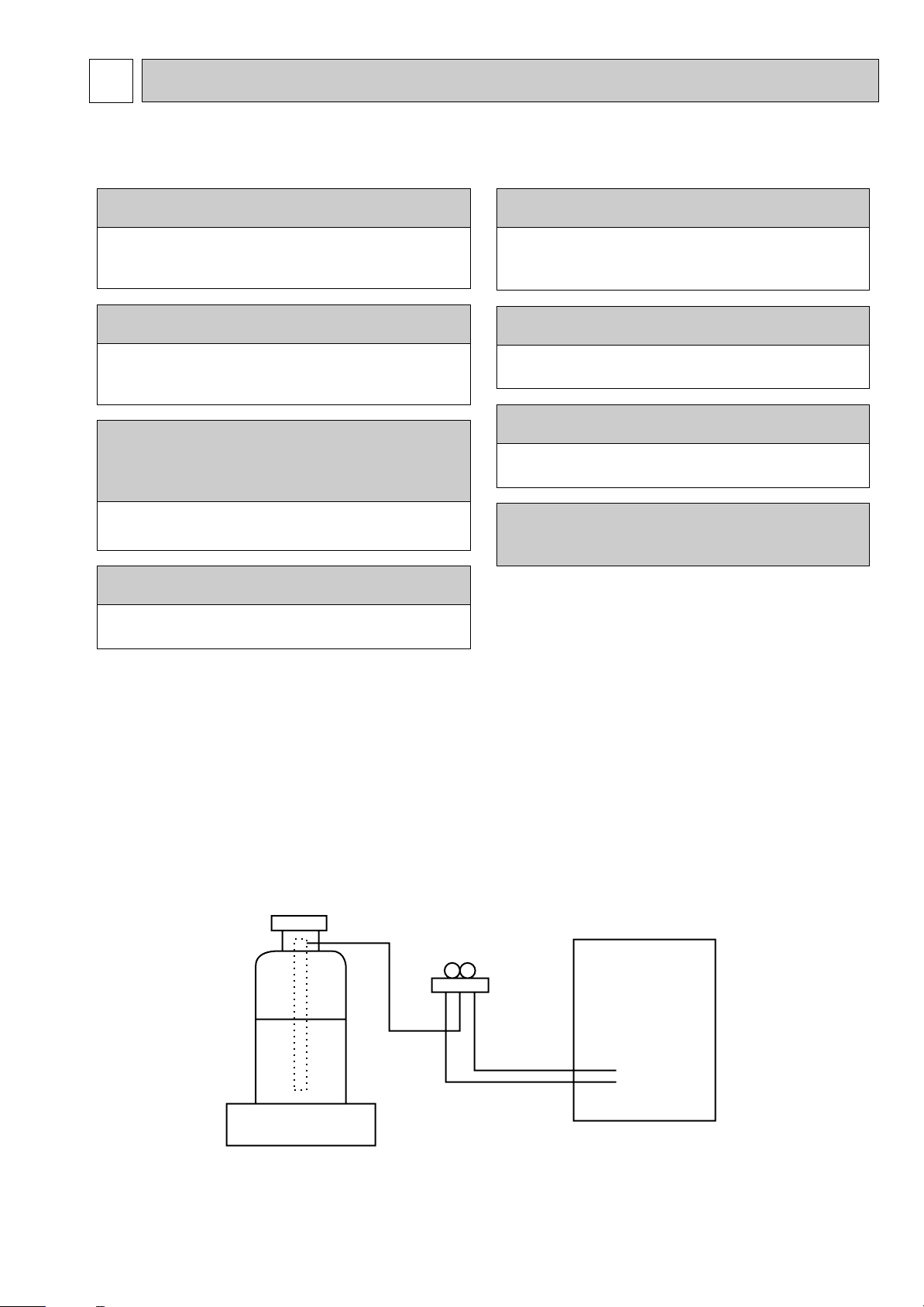

Gravimeter

Unit

CAUTIONS RELATED TO NEW REFRIGERANT

Cautions for units utilizing refrigerant R407C

[1] Cautions for service

·After recovering the all refrigerant in the unit, proceed to working.

·Do not release refrigerant in the air.

·After completing the repair service, recharge the cycle with the specified amount of

liquid refrigerant.

[2] Refrigerant recharging

(1) Refrigerant recharging process

1Direct charging from the cylinder.

·R407C cylinder are available on the market has a syphon pipe.

·Leave the syphon pipe cylinder standing and recharge it.

(By liquid refrigerant)

(2) Recharge in refrigerant leakage case

·After recovering the all refrigerant in the unit, proceed to working.

·Do not release the refrigerant in the air.

·After completing the repair service, recharge the cycle with the specified amount of

liquid refrigerant.

3

Page 4

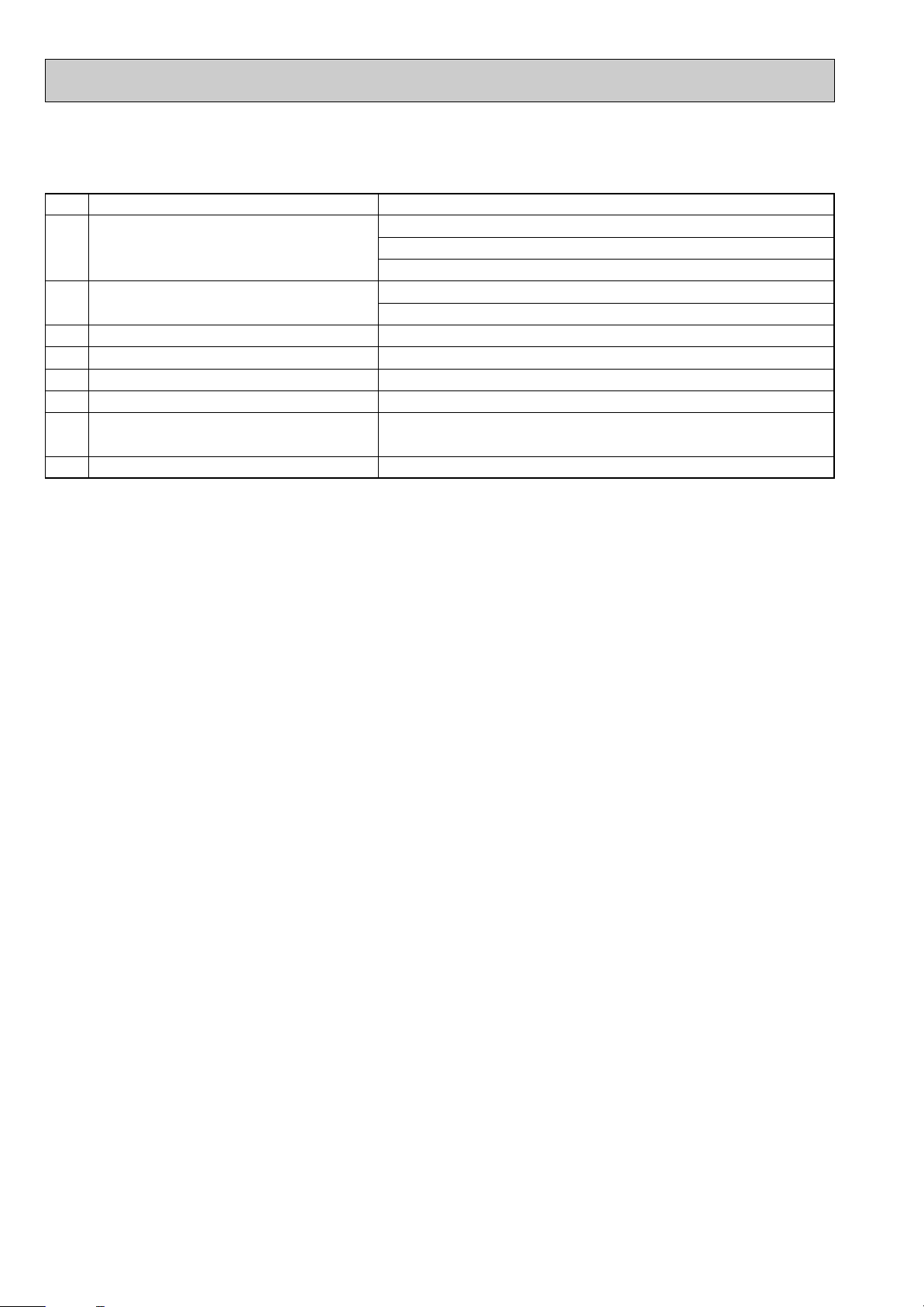

[3] Service tools

Use the below service tools as exclusive tools for R407C refrigerant.

No. Tool name Specifications

1 Gauge manifold ·Only for R407C.

·Use the existing fitting SPECIFICATIONS. (UNF7/16)

·Use high-tension side pressure of 3.43MPa·G or over.

2 Charge hose ·Only for R407C.

·Use pressure performance of 5.10MPa·G or over.

3 Electronic scale

4 Gas leak detector ·Use the detector for R134a or R407C.

5 Adapter for reverse flow check. ·Attach on vacuum pump.

6 Refrigerant charge base.

7 Refrigerant cylinder. ·For R407C ·Top of cylinder (Brown)

·Cylinder with syphon

8 Refrigerant recovery equipment.

4

Page 5

CAUTIONS RELATED TO NEW REFRIGERANT

Use new refrigerant pipes.

Make sure that the inside and outside of refrigerant piping is clean and it has no contamination

such as sulfur hazardous for use, oxides, dirt,

shaving particles, etc.

In addition, use pipes with specified thickness.

Store the piping to be used during installation

indoors and keep both ends of the piping sealed

until just before brazing. (Leave elbow joints, etc.

in their packaging.)

Use ester oil, ether oil or alkylbenzene oil (small

amount) as the refrigerant oil applied to flares

and flange connections.

In case of using the existing pipes for R22, be careful with

the followings.

· For RP4 be sure to perform replacement operation before

test run.

· Change flare nut to the one provided with this product.

Use a newly flared pipe.

· Avoid using thin pipes.

Charge refrigerant from liquid phase of gas

cylinder.

If the refrigerant is charged from gas phase, composition

change may occur in refrigerant and the efficiency will be

lowered.

Do not use refrigerant other than R410A.

If other refrigerant (R22 etc.) is used, chlorine in refrigerant can cause deterioration of refrigerant oil etc.

Use a vacuum pump with a reverse flow check

valve.

Vacuum pump oil may flow back into refrigerant cycle and

that can cause deterioration of refrigerant oil etc.

Use the following tools specifically designed for

use with R410A refrigerant.

The following tools are necessary to use R410A refrigerant.

Keep the tools with care.

If dirt, dust or moisture enter into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of refrigerant will change and the efficiency will be lowered.

Flare tool

Electronic refrigerant

charging scale

Vacuum pump adaptor

Size adjustment gauge

Gauge manifold

Torque wrench

Gas leak detector

Charge hose

Tools for R410A

Contamination inside refrigerant piping can cause deterioration of refrigerant oil etc.

If dirt, dust or moisture enter into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

If large amount of mineral oil enter, that can cause deterioration of refrigerant oil etc.

Ventilate the room if refrigerant leaks during

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

Cautions for units utilizing refrigerant R410A

[1] Cautions for service

(1) Perform service after collecting the refrigerant left in unit completely.

(2) Do not release refrigerant in the air.

(3) After completing service, charge the cycle with specified amount of refrigerant.

(4) When performing service, install a filter drier simultaneously.

Be sure to use a filter drier for new refrigerant.

[2] Additional refrigerant charge

When charging directly from cylinder

· Check that cylinder for R410A on the market is syphon type.

· Charging should be performed with the cylinder of syphon stood vertically. (Refrigerant is charged from liquid phase.)

5

Page 6

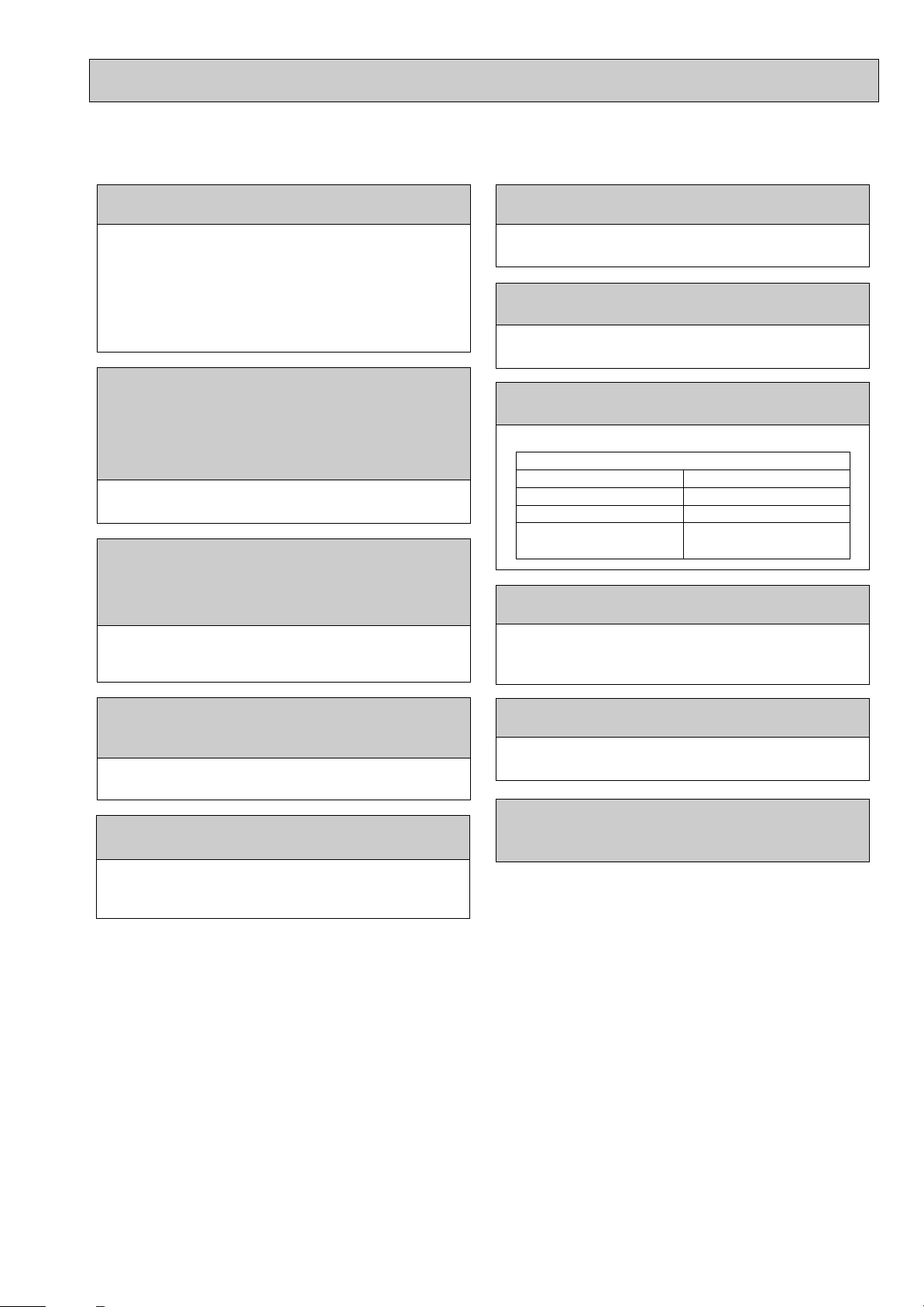

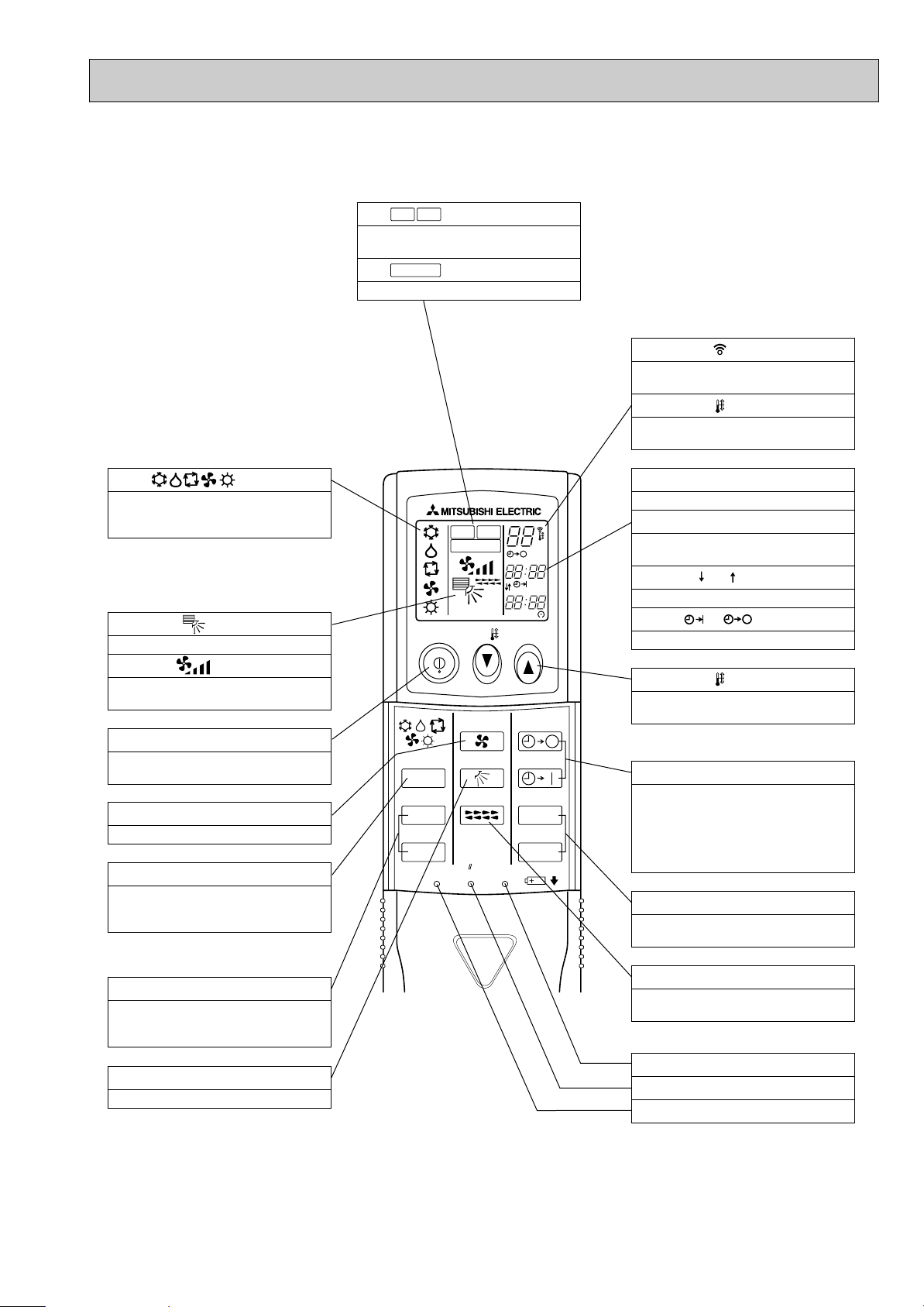

Air intake

room air is suctioned

in here.

(Removes dust and dirt from the intake air.)

Disperses airflow up and

down as well as adjusts the

angle of air flow direction.

Filter Air intake grille

Air outletAir outlet

Swing louvers

Indicator lamp section

Air flow can be changed to horizontally

by moving the Guide vane to the left or

right.

Guide vane

Gravimeter

Unit

[3] Service tools

Use the below service tools as exclusive tools for R410A refrigerant.

No. Specifications

1 Gauge manifold ·Only for R410A

·Use the existing fitting

specifications

. (UNF1/2)

·Use high-tension side pressure of 5.3MPa·G or over.

2 Charge hose ·Only for R410A

·Use pressure performance of 5.09MPa·G or over.

3 Electronic scale

4 Gas leak detector ·Use the detector for R134a, R407C or R410A.

5 Adaptor for reverse flow check ·Attach on vacuum pump.

6 Refrigerant charge base

7 Refrigerant cylinder ·Only for R410A Top of cylinder (Pink)

Cylinder with syphon

8 Refrigerant recovery equipment

3 PART NAMES AND FUNCTIONS

● Indoor Unit

6

Page 7

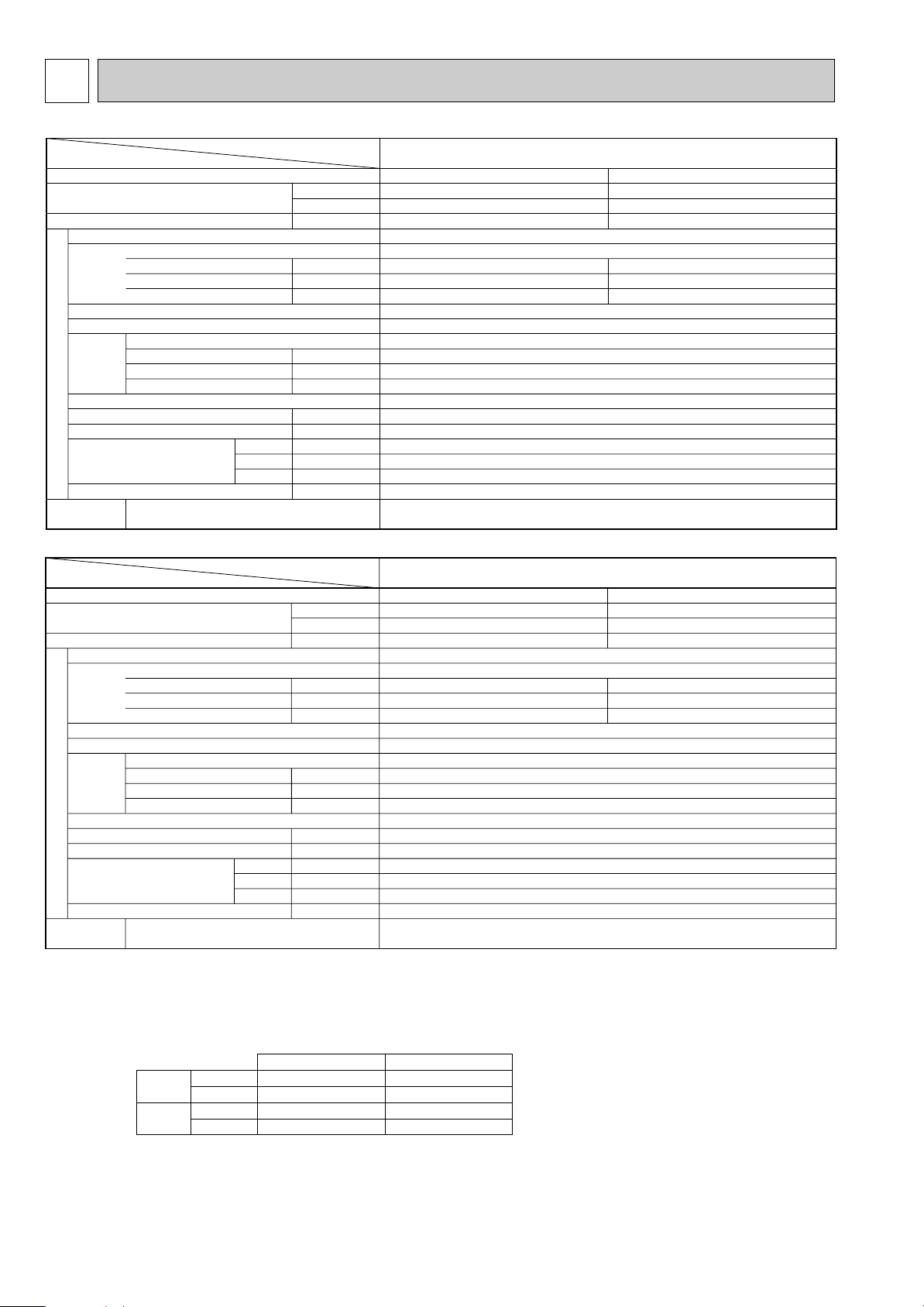

●Wireless remote controller

ON/OFF TEMP

FAN

VANE

TEST RUN

AUTO STOP

AUTO START

h

min

LOUVER

MODE

CHECK

RESETSET CLOCK

MODEL SELECT

NOT AVAILABLE

CHECK

TEST RUN

˚C

AMPM

AMPM

VANE CONTROL button

Used to change the air flow direction.

CLOCK button

RESET button

SET button

ON/OFF button

The unit is turned ON and OFF alternately

each time the button is pressed.

LOUVER button

This switch the horizontal fan motion ON

and OFF.

(Not available for this model.)

MODE SELECT button

Used to switch the operation mode between

cooling, drying, blowing, heating and auto

mode.

CHECK-TEST RUN button

Only press this button to perform an inspection check or test operation.

Do not use it for normal operation.

FAN SPEED SELECT button

Used to change the fan speed.

TIMER display

Displays when in timer operation or when

setting timer.

button

SET TEMPERATURE button sets any desired

room temperature.

CLOCK display

Displays the current time.

“ ” “ ” display

Displays the order of timer operation.

“ ” “ ” display

Displays whether timer is on or off.

w In case the outdoor unit is cool only type,

the heating mode is not available.

Buttons used to set the “hour and minute” of

the current time and timer settings.

h and min buttons

display

SET TEMP. display indicates desired temperature set.

display

FAN SPEED display indicates which fan

speed has been selected.

display

The vertical direction of air flow is indicated.

display

Blinks when model is selected.

display

Lights up while transmission to the indoor

unit is mode using switches.

display

CHECK&TEST RUN display indicates that

the unit is being checked or test-run.

display

OPERATION MODE display

Operation mode display indicates which operation mode is in effect.

TIMER CONTROL buttons

AUTO STOP (OFF timer): when this switch

is set, the air conditioner will be automatically stopped at the preset time.

AUTO START (ON timer): when this switch

is set, the air conditioner will be automatically started at the preset time.

MODEL SELECT

CHECK

TEST RUN

● When cover is open.

7

Page 8

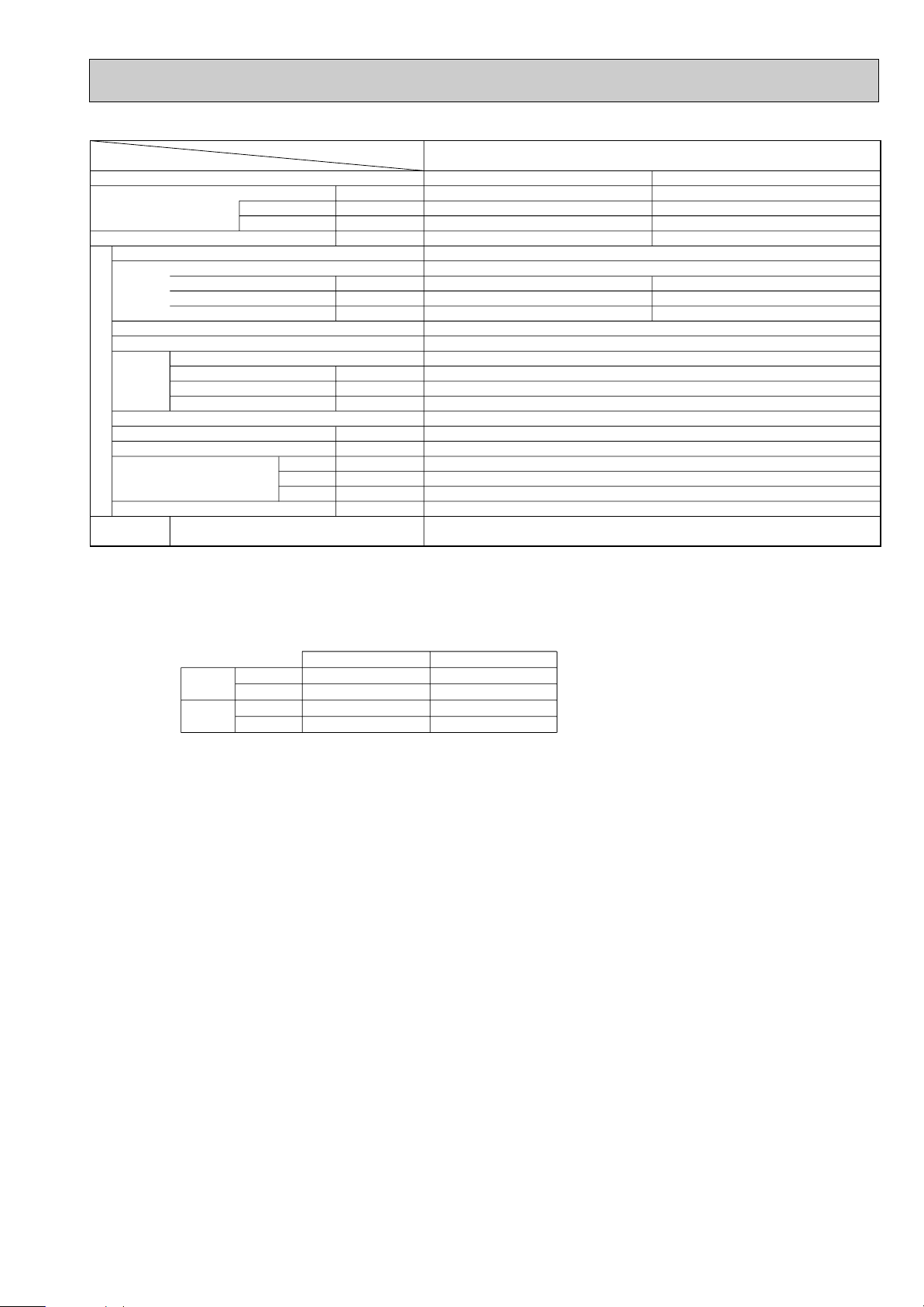

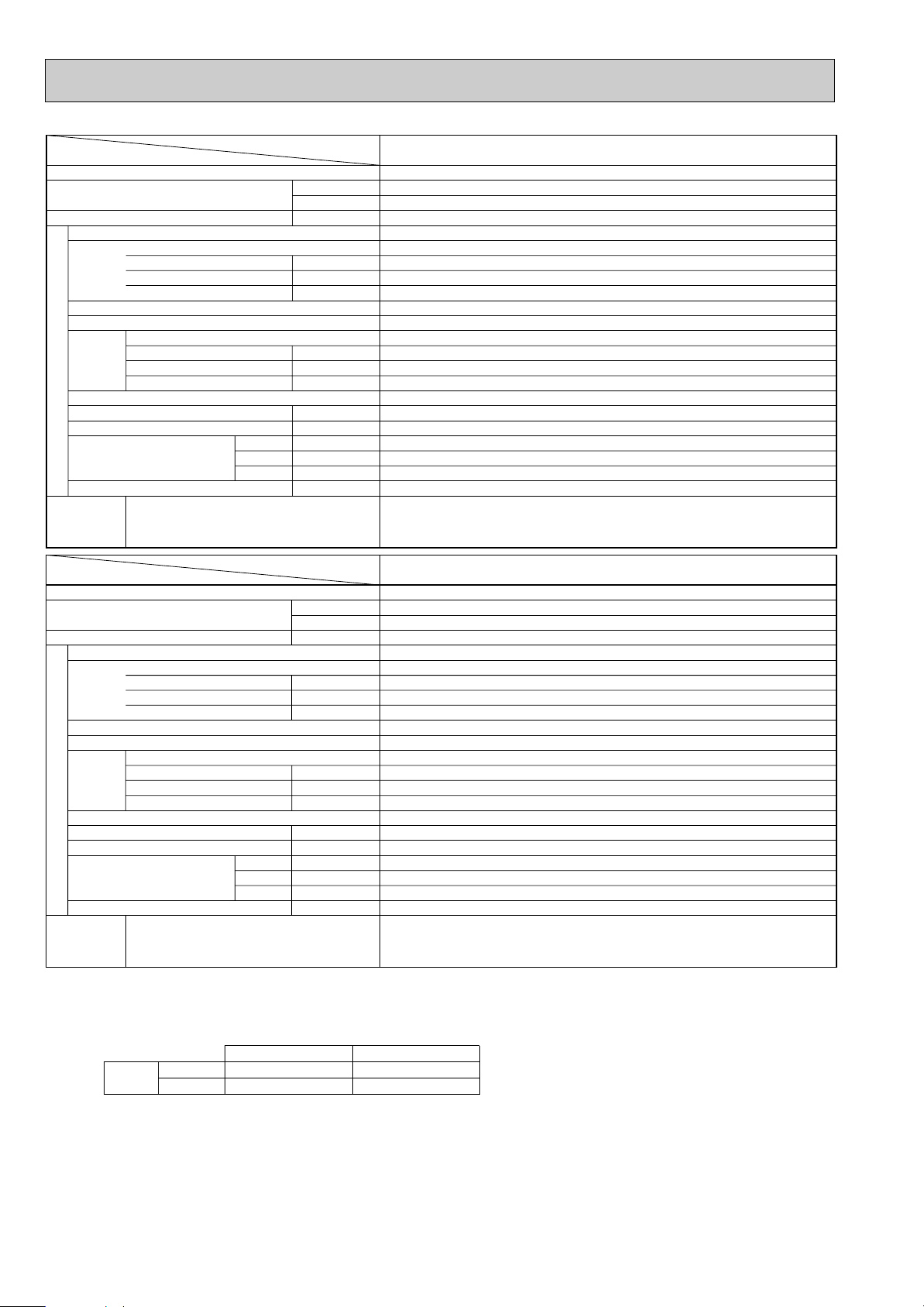

4

Service Ref.

Item

Btu/h

W

kW

kW

A

A

kW

K/min(CFM)

Pa(mmAq)

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

Function

Capacity

Total input

Service Ref.

Power supply(phase, cycle, voltage)

Input

Running current

Starting current

External finish

Heat exchanger

Fan Fan(drive) x No.

Fan motor output

Airflow(Low-High)

External static pressure

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

W

D

H

INDOOR UNIT

PKA-RP3FAL

PKA-RP3FAL

Cooling

24,200

7,100(3,300~8,100)

1.98

0.09

0.43

0.80

Heating

27,300

8,000(3,500~10,200)

2.40

0.09

0.43

0.80

Single phase, 50Hz, 220-230-240V

Munsell 3.4Y 7.7/0.8

Plate fin coil

Line flow (direct) x 2

0.040

15-20(530-706)

0(direct blow)

Wireless remote controller & built-in

39-45

26(1)

1,400(55-1/8)

235(9-1/4)

340(13-3/8)

24(53)

PUHZ-RP3VHA

Service Ref.

OUTDOOR

UNIT

Notes1. Rating Conditions (ISO T1)

Cooling : Indoor : D.B. 27˚C(80˚F), W.B. 19˚C (66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C (75˚F)

Heating : Indoor : D.B. 20˚C(68˚F) Outdoor : D.B. 7˚C(45˚F), W.B. 6˚C (43˚F)

Refrigerant piping length (one way) : 5m (16ft)

4. Above data based on indicated voltage

Indoor Unit Single phase 230V 50Hz

Outdoor Unit Single phase 230V 50Hz

2. Guaranteed operating range

Upper limit

Lower limit

Upper limit

Lower limit

Indoor

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

D.B. 28˚C

D.B. 17˚C

Outdoor

D.B. 46˚C

D.B. -5˚C

D.B. 21˚C, W.B. 15˚C

D.B. -11˚C, W.B. -12˚C

Cooling

Heating

5. Refer to the service manual of outdoor unit for the outdoor unit's specifications.

3. Guaranteed voltage

198~264V, 50Hz

Cooling

20,500

6,000(2,700~6,700)

1.55

0.09

0.43

0.80

Heating

23,900

7,000(2,800~8,200)

2.01

0.09

0.43

0.80

Single phase, 50Hz, 220-230-240V

Munsell 3.4Y 7.7/0.8

Plate fin coil

Line flow (direct) x 2

0.040

15-20(530-705)

0(direct blow)

Wireless remote controller & built-in

39-45

26(1)

1,400(55-1/8)

235(9-1/4)

340(13-3/8)

24(53)

PUHZ-RP2.5VHA

PKA-RP2.5FAL

PKA-RP2.5FAL

Service Ref.

Item

Btu/h

W

kW

kW

A

A

kW

K/min(CFM)

Pa(mmAq)

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

Function

Capacity

Total input

Service Ref.

Power supply(phase, cycle, voltage)

Input

Running current

Starting current

External finish

Heat exchanger

Fan Fan(drive) x No.

Fan motor output

Airflow(Low-High)

External static pressure

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

W

D

H

Service Ref.

INDOOR UNIT

OUTDOOR

UNIT

SPECIFICATIONS

4-1. Heat pump type (1)

8

Page 9

D

H

Service Ref.

Btu/h

W

W

kW

kW

A

A

kW

K/min(CFM)

Pa(mmAq)

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

Cooling

34,100

10,000(5,000~11,400)

10,000(4,900~11,400)

2.93

Single phase, 50Hz, 220-230-240V

0.11

0.52

0.90

Wireless remote controller & built-in

Item

Function

Capacity

Total input

Service Ref.

Power supply(phase, cycle, voltage)

External finish

Heat exchanger

Fan Fan(drive) x No.

INDOOR UNIT

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

OUTDOOR

UNIT

Notes1. Rating Conditions (ISO T1)

Input

Running current

Starting current

Fan motor output

Airflow(Low-High)

External static pressure

Service Ref.

Cooling : Indoor : D.B. 27˚C(80˚F), W.B. 19˚C (66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C (75˚F)

Heating : Indoor : D.B. 20˚C(68˚F) Outdoor : D.B. 7˚C(45˚F), W.B. 6˚C (43˚F)

Refrigerant piping length (one way) : 5m (16ft)

PUHZ-RP4VAH

PUHZ-RP4VAH1

W

PKA-RP4FAL

PKA-RP4FAL

Munsell 3.4Y 7.7/0.8

Line flow (direct) x 2

22-28(780-990)

0(direct blow)

1,680(66-1/8)

PUHZ-RP4VHA

PUHZ-RP4VHA

Heating

38,200

11,200(5,600~14,000)

11,200(4,500~14,000)

3.25

0.11

0.52

0.90

Plate fin coil

0.070

41-46

26(1)

235(9-1/4)

340(13-3/8)

28(62)

1

2. Guaranteed operating range

Cooling

Heating

3. Guaranteed voltage

198~264V, 50Hz

4. Above data based on indicated voltage

Indoor Unit Single phase 230V 50Hz

Outdoor Unit Single phase 230V 50Hz

Upper limit

Lower limit

Upper limit

Lower limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

D.B. 28˚C

D.B. 17˚C

Indoor

Outdoor

D.B. 46˚C

D.B. -5˚C

D.B. 21˚C, W.B. 15˚C

D.B. -11˚C, W.B. -12˚C

5. Refer to the service manual of outdoor unit for the outdoor unit's specifications.

9

Page 10

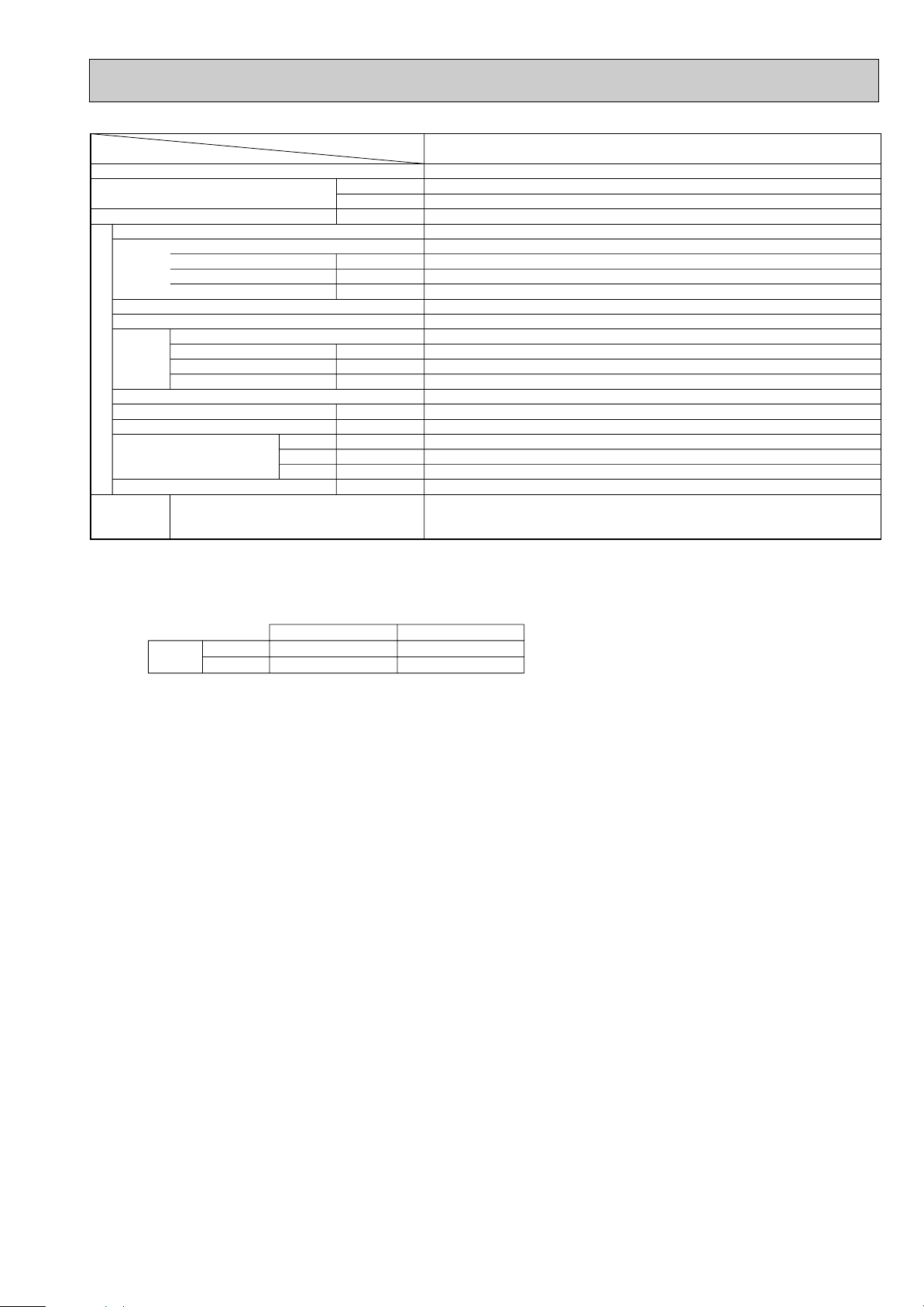

4-2. Heat pump type (2)

Service Ref.

Item

Btu/h

W

kW

kW

A

A

kW

K/min(CFM)

Pa(mmAq)

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

Function

Capacity

Total input

Service Ref.

Power supply(phase, cycle, voltage)

Input

Running current

Starting current

External finish

Heat exchanger

Fan Fan(drive) x No.

Fan motor output

Airflow(Low-High)

External static pressure

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

W

D

H

INDOOR UNIT

PKA-RP3FAL

PKA-RP3FAL

Cooling

26,800

7,850

3.43

0.09

0.43

0.80

Heating

32,100

9,400

3.61

0.09

0.43

0.80

Single phase, 50Hz, 220-230-240V

Munsell 3.4Y 7.7/0.8

Plate fin coil

Line flow (direct) x 2

0.040

15-20(530-705)

0(direct blow)

Wireless remote controller & built-in

39-45

26(1)

1,400(55-1/8)

235(9-1/4)

340(13-3/8)

24(53)

Service Ref.

OUTDOOR

UNIT

PUH-P3VGAA / PUH-P3YGAA

PUH-P3VGAA.UK / PUH-P3YGAA.UK

PUH-P3VGAA

1.UK / PUH-P3YGAA1.UK

Notes1. Rating Conditions (ISO T1)

Cooling : Indoor : D.B. 27˚C(80˚F), W.B. 19˚C (66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C (75˚F)

Heating : Indoor : D.B. 20˚C(68˚F) Outdoor : D.B. 7˚C(45˚F), W.B. 6˚C (43˚F)

Refrigerant piping length (one way) : 5m (16ft)

4. Above data based on indicated voltage

Indoor Unit Single phase 230V 50Hz

Outdoor Unit 3 phase 400V 50Hz

2. Guaranteed operating range

Upper limit

Lower limit

Upper limit

Lower limit

Indoor

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

D.B. 28˚C

D.B. 17˚C

Outdoor

D.B. 46˚C

D.B. -5˚C

D.B. 24˚C, W.B. 18˚C

D.B. -11˚C, W.B. -12˚C

Cooling

Heating

5. Refer to the service manual of outdoor unit for the outdoor unit's specifications.

3. Guaranteed voltage

198~264V, 50Hz

Cooling

22,000

6,450

2.65

0.09

0.43

0.80

Heating

25,100

7,350

2.63

0.09

0.43

0.80

Single phase, 50Hz, 220-230-240V

Munsell 3.4Y 7.7/0.8

Plate fin coil

Line flow (direct) x 2

0.040

15-20(530-706)

0(direct blow)

Wireless remote controller & built-in

39-45

26(1)

1,400(55-1/8)

235(9-1/4)

340(13-3/8)

24(53)

PKA-RP2.5FAL

PKA-RP2.5FAL

Service Ref.

Item

Btu/h

W

kW

kW

A

A

kW

K/min(CFM)

Pa(mmAq)

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

Function

Capacity

Total input

Service Ref.

Power supply(phase, cycle, voltage)

Input

Running current

Starting current

External finish

Heat exchanger

Fan Fan(drive) x No.

Fan motor output

Airflow(Low-High)

External static pressure

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

W

D

H

Service Ref.

INDOOR UNIT

OUTDOOR

UNIT

PUH-P2.5VGAA

PUH-P2.5VGAA.UK / PUH-P2.5YGAA.UK

PUH-P2.5VGAA

1.UK/ PUH-P2.5YGAA1.UK

10

Page 11

D

H

Service Ref.

Btu/h

W

kW

kW

A

A

kW

K/min(CFM)

Pa(mmAq)

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

Cooling

32,100

9,400

3.59

Single phase, 50Hz, 220-230-240V

0.11

0.52

0.90

Wireless remote controller & built-in

PUH-P4YGAA

PUH-P4VGAA.UK / PUH-P4YGAA.UK

PUH-P4VGAA

Item

Function

Capacity

Total input

Service Ref.

Power supply(phase, cycle, voltage)

External finish

Heat exchanger

Fan Fan(drive) x No.

INDOOR UNIT

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

OUTDOOR

UNIT

Notes1. Rating Conditions (ISO T1)

Input

Running current

Starting current

Fan motor output

Airflow(Low-High)

External static pressure

W

Service Ref.

Cooling : Indoor : D.B. 27˚C(80˚F), W.B. 19˚C (66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C (75˚F)

Heating : Indoor : D.B. 20˚C(68˚F) Outdoor : D.B. 7˚C(45˚F), W.B. 6˚C (43˚F)

Refrigerant piping length (one way) : 5m (16ft)

PKA-RP4FAL

PKA-RP4FAL

Munsell 3.4Y 7.7/0.8

Line flow (direct) x 2

22-28(775-990)

0(direct blow)

1,680(66-1/8)

Heating

36,800

10,800

3.77

0.11

0.52

0.90

Plate fin coil

0.070

41-46

26(1)

235(9-1/4)

340(13-3/8)

28(62)

1.UK / PUH-P4YGAA1.UK

2. Guaranteed operating range

Cooling

Heating

3. Guaranteed voltage

198~264V, 50Hz

4. Above data based on indicated voltage

Indoor Unit Single phase 230V 50Hz

Outdoor Unit 3 phase 400V 50Hz

Upper limit

Lower limit

Upper limit

Lower limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

D.B. 28˚C

D.B. 17˚C

Indoor

Outdoor

D.B. 46˚C

D.B. -5˚C

D.B. 24˚C, W.B. 18˚C

D.B. -11˚C, W.B. -12˚C

5. Refer to the service manual of outdoor unit for the outdoor unit's specifications.

11

Page 12

4-3. Cooling only type

Cooling

22,000

6,450

2.65

0.09

0.43

0.80

Single phase, 50Hz, 220-230-240V

Munsell 3.4Y 7.7/0.8

Plate fin coil

Line flow (direct) x 2

0.040

15-20(530-706)

0(direct blow)

Wireless remote controller & built-in

39-45

26(1)

1,400(55-1/8)

235(9-1/4)

340(13-3/8)

24(53)

PKA-RP2.5FAL

PKA-RP2.5FAL

Service Ref.

Item

Btu/h

W

kW

kW

A

A

kW

K/min(CFM)

Pa(mmAq)

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

Function

Capacity

Total input

Service Ref.

Power supply(phase, cycle, voltage)

Input

Running current

Starting current

External finish

Heat exchanger

Fan Fan(drive) x No.

Fan motor output

Airflow(Low-High)

External static pressure

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

W

D

H

Service Ref.

INDOOR UNIT

OUTDOOR

UNIT

PU-P2.5VGAA

PU-P2.5VGAA.UK /PU-P2.5YGAA.UK

PU-P2.5VGAA

1.UK/ PU-P2.5YGAA1.UK

Service Ref.

Item

Btu/h

W

kW

kW

A

A

kW

K/min(CFM)

Pa(mmAq)

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

Function

Capacity

Total input

Service Ref.

Power supply(phase, cycle, voltage)

Input

Running current

Starting current

External finish

Heat exchanger

Fan Fan(drive) x No.

Fan motor output

Airflow(Low-High)

External static pressure

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

W

D

H

Service Ref.

INDOOR UNIT

OUTDOOR

UNIT

PKA-RP3FAL

Cooling

26,800

7,850

3.43

PKA-RP3FAL

Single phase, 50Hz, 220-230-240V

0.09

0.43

0.80

Munsell 3.4Y 7.7/0.8

Plate fin coil

Line flow (direct) x 2

0.040

15-20(530-705)

0(direct blow)

Wireless remote controller & built-in

39-45

26(1)

1,400(55-1/8)

235(9-1/4)

340(13-3/8)

24(53)

PU-P3VGAA / PU-P3YGAA

PU-P3VGAA.UK / PU-P3YGAA.UK

PU-P3VGAA

1.UK / PU-P3YGAA1.UK

Notes1. Rating Conditions (ISO T1)

Cooling : Indoor : D.B. 27˚C(80˚F), W.B. 19˚C (66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C (75˚F)

Refrigerant piping length (one way) : 5m (16ft)

4. Above data based on indicated voltage

Indoor Unit Single phase 230V 50Hz

Outdoor Unit 3 phase 400V 50Hz

2. Guaranteed operating range

3. Guaranteed voltage

198~264V, 50Hz

Upper limit

Lower limit

Indoor

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

Outdoor

D.B. 46˚C

D.B. -5˚C

Cooling

5. Refer to the service manual of outdoor unit for the outdoor unit's specifications.

12

Page 13

D

H

Indoor

Service Ref.

Btu/h

W

kW

Single phase, 50Hz, 220-230-240V

kW

A

A

kW

K/min(CFM)

Pa(mmAq)

Wireless remote controller & built-in

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

PU-P4VGAA.UK / PU-P4YGAA.UK

PU-P4VGAA1.UK / PU-P4YGAA1.UK

Outdoor

D.B. 46˚C

D.B. -5˚C

Item

Function

Capacity

Total input

Service Ref.

Power supply(phase, cycle, voltage)

External finish

Heat exchanger

Fan Fan(drive) x No.

INDOOR UNIT

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

OUTDOOR

UNIT

Notes1. Rating Conditions (ISO T1)

2. Guaranteed operating range

Input

Running current

Starting current

Fan motor output

Airflow(Low-High)

External static pressure

W

Service Ref.

Cooling : Indoor : D.B. 27˚C(80˚F), W.B. 19˚C (66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C (75˚F)

Refrigerant piping length (one way) : 5m (16ft)

Cooling

Upper limit

Lower limit

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

PKA-RP4FAL

PKA-RP4FAL

Munsell 3.4Y 7.7/0.8

Plate fin coil

Line flow (direct) x 2

22-28(775-990)

0(direct blow)

1,680(66-1/8)

Cooling

32,100

9,400

3.59

0.11

0.52

0.90

0.070

41-46

26(1)

235(9-1/4)

340(13-3/8)

28(62)

PU-P4YGAA

3. Guaranteed voltage

198~264V, 50Hz

4. Above data based on indicated voltage

Indoor Unit Single phase 230V 50Hz

Outdoor Unit 3 phase 400V 50Hz

5. Refer to the service manual of outdoor unit for the outdoor unit's specifications.

13

Page 14

5 DATA

Outdoor intake air D.B.(°C)

20 25 30

Indoor

Intake air

D.B.(°C)

Indoor

Intake air

W.B.(°C)

20

20

20

22

22

22

24

24

24

24

26

26

26

26

27

27

27

27

28

28

28

28

30

30

30

30

32

32

32

32

34

34

34

34

16

18

20

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

CA

5,940

6,360

6,840

5,940

6,360

6,840

5,940

6,360

6,840

7,290

5,940

6,360

6,840

7,290

5,940

6,360

6,840

7,290

5,940

6,360

6,840

7,290

5,940

6,360

6,840

7,290

5,940

6,360

6,840

7,290

5,940

6,360

6,840

7,290

SHC(W)

4,336

3,880

3,352

4,811

4,388

3,899

5,287

4,897

4,446

3,864

5,762

5,406

4,993

4,447

5,940

5,660

5,267

4,739

5,940

5,915

5,540

5,030

5,940

6,360

6,088

5,613

5,940

6,360

6,635

6,197

5,940

6,360

6,840

6,780

SHF

0.73

0.61

0.49

0.81

0.69

0.57

0.89

0.77

0.65

0.53

0.97

0.85

0.73

0.61

1.00

0.89

0.77

0.65

1.00

0.93

0.81

0.69

1.00

1.00

0.89

0.77

1.00

1.00

0.97

0.85

1.00

1.00

1.00

0.93

SHF

0.73

0.61

0.49

0.81

0.69

0.57

0.89

0.77

0.65

0.53

0.97

0.85

0.73

0.61

1.00

0.89

0.77

0.65

1.00

0.93

0.81

0.69

1.00

1.00

0.89

0.77

1.00

1.00

0.97

0.85

1.00

1.00

1.00

0.93

SHF

0.73

0.61

0.49

0.81

0.69

0.57

0.89

0.77

0.65

0.53

0.97

0.85

0.73

0.61

1.00

0.89

0.77

0.65

1.00

0.93

0.81

0.69

1.00

1.00

0.89

0.77

1.00

1.00

0.97

0.85

1.00

1.00

1.00

0.93

P.C.

1.24

1.26

1.30

1.24

1.26

1.30

1.33

1.24

1.26

1.30

1.24

1.26

1.30

1.33

1.24

1.26

1.30

1.33

1.24

1.26

1.30

1.33

1.24

1.26

1.30

1.33

1.24

1.26

1.30

1.33

1.24

1.26

1.30

1.33

CA

5,760

6,180

6,690

5,760

6,180

6,690

7,140

5,760

6,180

6,690

5,760

6,180

6,690

7,140

5,760

6,180

6,690

7,140

5,760

6,180

6,690

7,140

5,760

6,180

6,690

7,140

5,760

6,180

6,690

7,140

5,760

6,180

6,690

7,140

SHC(W)

4,205

3,770

3,278

4,666

4,264

3,813

5,126

4,759

4,349

3,784

5,587

5,253

4,884

4,355

5,760

5,500

5,151

4,641

5,760

5,747

5,419

4,927

5,760

6,180

5,954

5,498

5,760

6,180

6,489

6,069

5,760

6,180

6,690

6,640

P.C.

1.31

1.33

1.36

1.31

1.33

1.36

1.31

1.33

1.36

1.41

1.31

1.33

1.36

1.41

1.31

1.33

1.36

1.41

1.31

1.33

1.36

1.41

1.31

1.33

1.36

1.41

1.31

1.33

1.36

1.41

1.31

1.33

1.36

1.41

CA

5,580

5,970

6,510

5,580

5,970

6,510

5,580

5,970

6,510

6,960

5,580

5,970

6,510

6,960

5,580

5,970

6,510

6,960

5,580

5,970

6,510

6,960

5,580

5,970

6,510

6,960

5,580

5,970

6,510

6,960

5,580

5,970

6,510

6,960

SHC(W)

4,073

3,642

3,190

4,520

4,119

3,711

4,966

4,597

4,232

3,689

5,413

5,075

4,752

4,246

5,580

5,313

5,013

4,524

5,580

5,552

5,273

4,802

5,580

5,970

5,794

5,359

5,580

5,970

6,315

5,916

5,580

5,970

6,510

6,473

P.C.

1.39

1.43

1.46

1.39

1.43

1.46

1.50

1.39

1.43

1.46

1.39

1.43

1.46

1.50

1.39

1.43

1.46

1.50

1.39

1.43

1.46

1.50

1.39

1.43

1.46

1.50

1.39

1.43

1.46

1.50

1.39

1.43

1.46

1.50

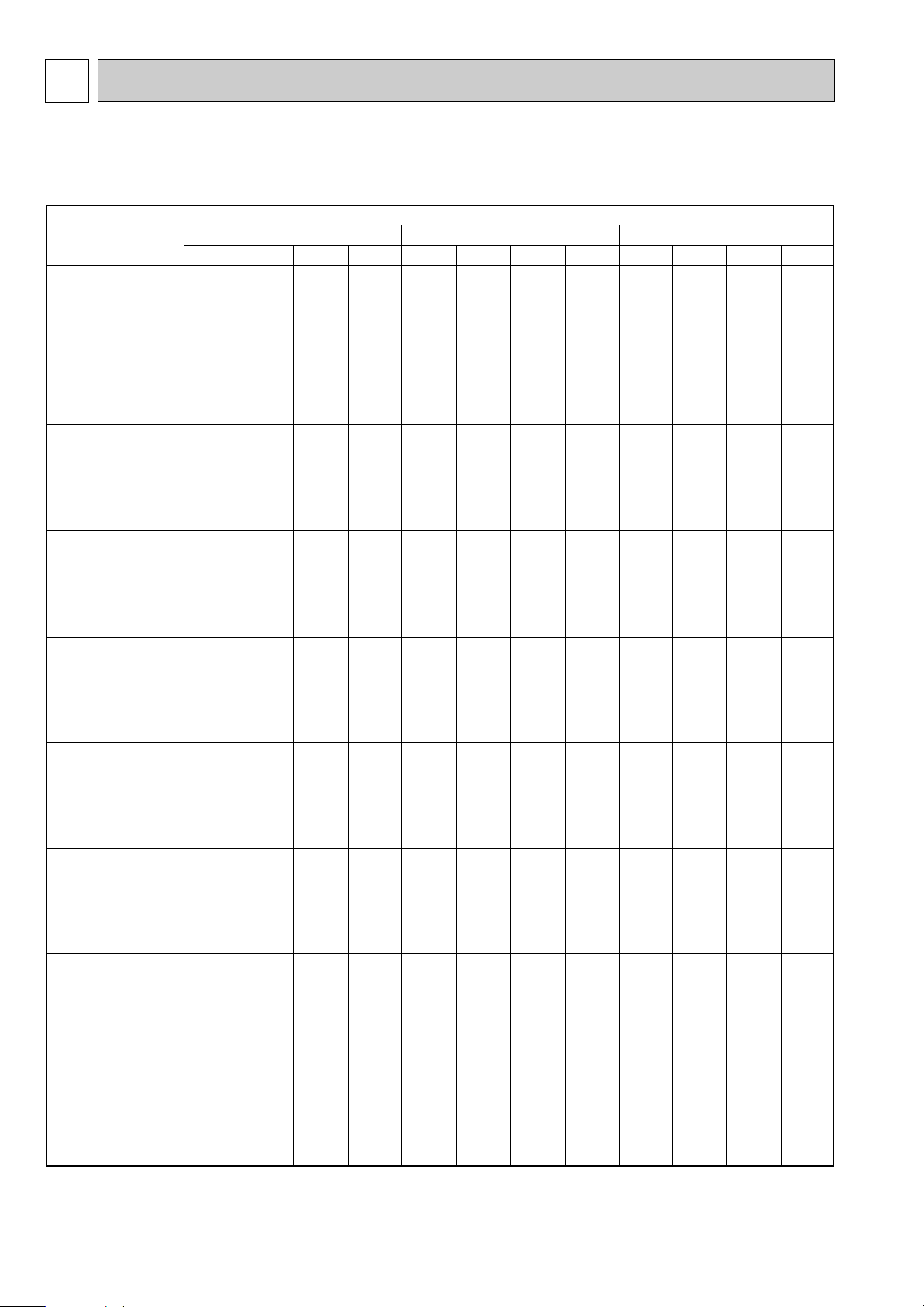

5-1. PERFORMANCE DATA

COOLING CAPACITY(1)

PKA-RP2.5FAL / PUHZ-RP2.5VHA

(230V)

CA : Capacity (W) SHC(W) :Sensible heat capacity

P.C. : Power consumption (kW) SHF : Sensible heat factor

14

Page 15

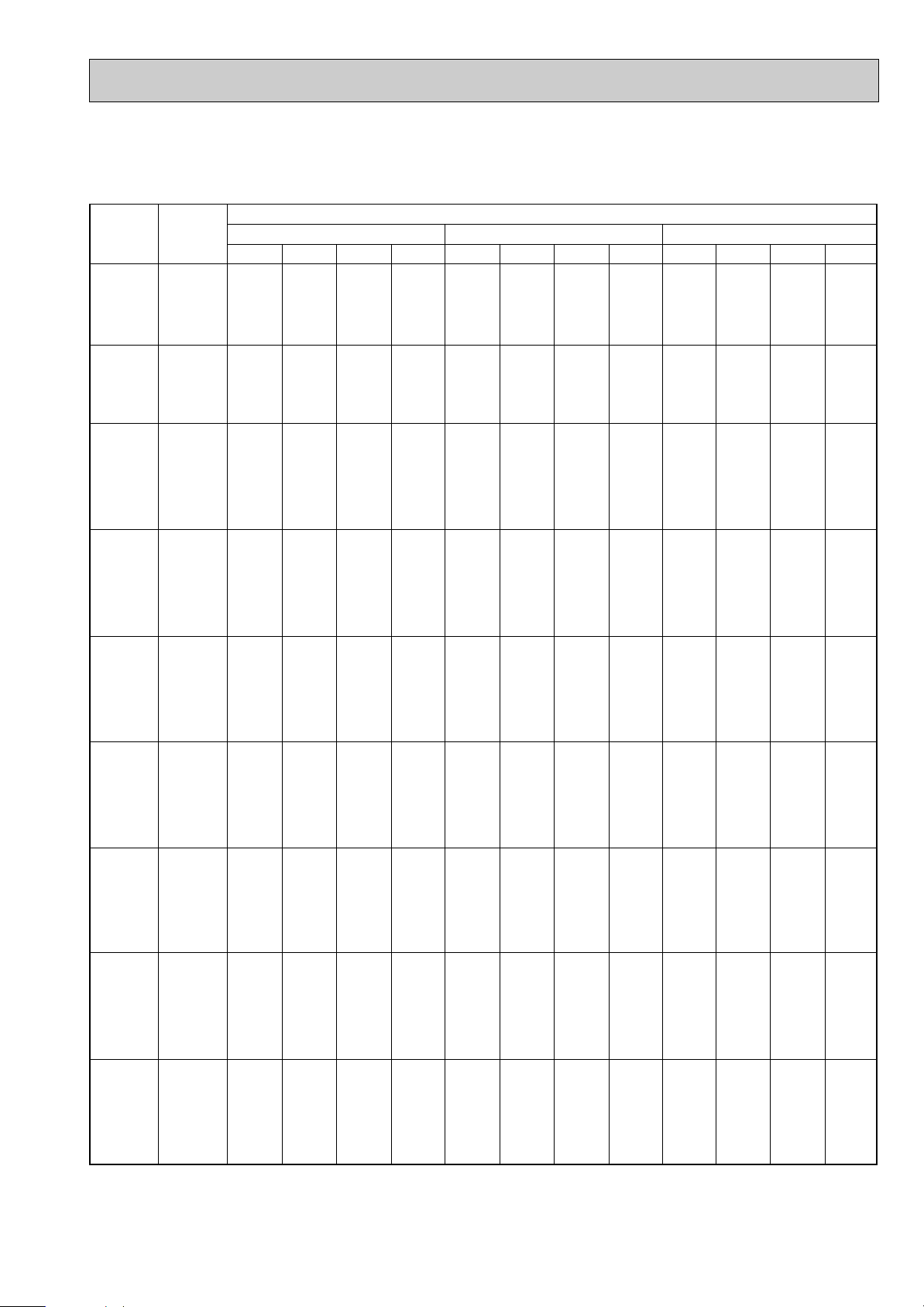

COOLING CAPACITY(2)

Outdoor intake air D.B.(°C)

35 40 45

Indoor

Intake air

D.B.(°C)

Indoor

Intake air

W.B.(°C)

20

20

20

22

22

22

24

24

24

24

26

26

26

26

27

27

27

27

28

28

28

28

30

30

30

30

32

32

32

32

34

34

34

34

16

18

20

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

CA

5,340

5,760

6,240

5,340

5,760

6,240

5,340

5,760

6,240

6,720

5,340

5,760

6,240

6,720

5,340

5,760

6,240

6,720

5,340

5,760

6,240

6,720

5,340

5,760

6,240

6,720

5,340

5,760

6,240

6,720

5,340

5,760

6,240

6,720

SHC(W)

3,898

3,514

3,058

4,325

3,974

3,557

4,753

4,435

4,056

3,562

5,180

4,896

4,555

4,099

5,340

5,126

4,805

4,368

5,340

5,357

5,054

4,637

5,340

5,760

5,554

5,174

5,340

5,760

6,053

5,712

5,340

5,760

6,240

6,250

SHF

0.73

0.61

0.49

0.81

0.69

0.57

0.89

0.77

0.65

0.53

0.97

0.85

0.73

0.61

1.00

0.89

0.77

0.65

1.00

0.93

0.81

0.69

1.00

1.00

0.89

0.77

1.00

1.00

0.97

0.85

1.00

1.00

1.00

0.93

SHF

0.73

0.61

0.49

0.81

0.69

0.57

0.89

0.77

0.65

0.53

0.97

0.85

0.73

0.61

1.00

0.89

0.77

0.65

1.00

0.93

0.81

0.69

1.00

1.00

0.89

0.77

1.00

1.00

0.97

0.85

1.00

1.00

1.00

0.93

SHF

0.73

0.61

0.49

0.81

0.69

0.57

0.89

0.77

0.65

0.53

0.97

0.85

0.73

0.61

1.00

0.89

0.77

0.65

1.00

0.93

0.81

0.69

1.00

1.00

0.89

0.77

1.00

1.00

0.97

0.85

1.00

1.00

1.00

0.93

P.C.

1.49

1.53

1.57

1.49

1.53

1.57

1.49

1.53

1.57

1.60

1.49

1.53

1.57

1.60

1.49

1.53

1.57

1.60

1.49

1.53

1.57

1.60

1.49

1.53

1.57

1.60

1.49

1.53

1.57

1.60

1.49

1.53

1.57

1.60

CA

5,100

5,580

6,000

5,100

5,580

6,000

5,100

5,580

6,000

6,480

5,100

5,580

6,000

6,480

5,100

5,580

6,000

6,480

5,100

5,580

6,000

6,480

5,100

5,580

6,000

6,480

5,100

5,580

6,000

6,480

5,100

5,580

6,000

6,480

SHC(W)

3,723

3,404

2,940

4,131

3,850

3,420

4,539

4,297

3,900

3,434

4,947

4,743

4,380

3,953

5,100

4,966

4,620

4,212

5,100

5,189

4,860

4,471

5,100

5,580

5,340

4,990

5,100

5,580

5,820

5,508

5,100

5,580

6,000

6,026

P.C.

1.60

1.64

1.67

1.60

1.64

1.67

1.60

1.64

1.67

1.72

1.60

1.64

1.67

1.72

1.60

1.64

1.67

1.72

1.60

1.64

1.67

1.72

1.60

1.64

1.67

1.72

1.60

1.64

1.67

1.72

1.60

1.64

1.67

1.72

CA

4,860

5,220

5,640

4,860

5,220

5,640

4,860

5,220

5,640

6,120

4,860

5,220

5,640

6,120

4,860

5,220

5,640

6,120

4,860

5,220

5,640

6,120

4,860

5,220

5,640

6,120

4,860

5,220

5,640

6,120

4,860

5,220

5,640

6,120

SHC(W)

3,548

3,184

2,764

3,937

3,602

3,215

4,325

4,019

3,666

3,244

4,714

4,437

4,117

3,733

4,860

4,646

4,343

3,978

4,860

4,855

4,568

4,223

4,860

5,220

5,020

4,712

4,860

5,220

5,471

5,202

4,860

5,220

5,640

5,692

P.C.

1.73

1.77

1.80

1.73

1.77

1.80

1.73

1.77

1.80

1.83

1.73

1.77

1.80

1.83

1.73

1.77

1.80

1.83

1.73

1.77

1.80

1.83

1.73

1.77

1.80

1.83

1.73

1.77

1.80

1.83

1.73

1.77

1.80

1.83

PKA-RP2.5FAL / PUHZ-RP2.5VHA

(230V)

CA : Capacity (W) SHC(W) :Sensible heat capacity

P.C. : Power consumption (kW) SHF : Sensible heat factor

15

Page 16

Outdoor intake air D.B.(°C)

20 25 30

Indoor

Intake air

D.B.(°C)

Indoor

Intake air

W.B.(°C)

20

20

20

22

22

22

24

24

24

24

26

26

26

26

27

27

27

27

28

28

28

28

30

30

30

30

32

32

32

32

34

34

34

34

16

18

20

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

CA

7,029

7,526

8,094

7,029

7,526

8,094

7,029

7,526

8,094

8,627

7,029

7,526

8,094

8,627

7,029

7,526

8,094

8,627

7,029

7,526

8,094

8,627

7,029

7,526

8,094

8,627

7,029

7,526

8,094

8,627

7,029

7,526

8,094

8,627

SHC(W)

4,709

4,139

3,480

5,272

4,741

4,128

5,834

5,343

4,775

4,054

6,396

5,946

5,423

4,745

6,678

6,247

5,747

5,090

6,959

6,548

6,071

5,435

7,029

7,150

6,718

6,125

7,029

7,526

7,366

6,815

7,029

7,526

8,013

7,505

SHF

0.67

0.55

0.43

0.75

0.63

0.51

0.83

0.71

0.59

0.47

0.91

0.79

0.67

0.55

0.95

0.83

0.71

0.59

0.99

0.87

0.75

0.63

1.00

0.95

0.83

0.71

1.00

1.00

0.91

0.79

1.00

1.00

0.99

0.87

SHF

0.67

0.55

0.43

0.75

0.63

0.51

0.83

0.71

0.59

0.47

0.91

0.79

0.67

0.55

0.95

0.83

0.71

0.59

0.99

0.87

0.75

0.63

1.00

0.95

0.83

0.71

1.00

1.00

0.91

0.79

1.00

1.00

0.99

0.87

SHF

0.67

0.55

0.43

0.75

0.63

0.51

0.83

0.71

0.59

0.47

0.91

0.79

0.67

0.55

0.95

0.83

0.71

0.59

0.99

0.87

0.75

0.63

1.00

0.95

0.83

0.71

1.00

1.00

0.91

0.79

1.00

1.00

0.99

0.87

P.C.

1.58

1.61

1.66

1.58

1.61

1.66

1.58

1.61

1.66

1.70

1.58

1.61

1.66

1.70

1.58

1.61

1.66

1.70

1.58

1.61

1.66

1.70

1.58

1.61

1.66

1.70

1.58

1.61

1.66

1.70

1.58

1.61

1.66

1.70

CA

6,816

7,313

7,917

6,816

7,313

7,917

6,816

7,313

7,917

8,449

6,816

7,313

7,917

8,449

6,816

7,313

7,917

8,449

6,816

7,313

7,917

8,449

6,816

7,313

7,917

8,449

6,816

7,313

7,917

8,449

6,816

7,313

7,917

8,449

SHC(W)

4,567

4,022

3,404

5,112

4,607

4,037

5,657

5,192

4,671

3,971

6,203

5,777

5,304

4,647

6,475

6,070

5,621

4,985

6,748

6,362

5,937

5,323

6,816

6,947

6,571

5,999

6,816

7,313

7,204

6,675

6,816

7,313

7,837

7,351

P.C.

1.67

1.70

1.74

1.67

1.70

1.74

1.67

1.70

1.74

1.80

1.67

1.70

1.74

1.80

1.67

1.70

1.74

1.80

1.67

1.70

1.74

1.80

1.67

1.70

1.74

1.80

1.67

1.70

1.74

1.80

1.67

1.70

1.74

1.80

CA

6,603

7,065

7,704

6,603

7,065

7,704

6,603

7,065

7,704

8,236

6,603

7,065

7,704

8,236

6,603

7,,065

7,704

8,236

6,603

7,065

7,704

8,236

6,603

7,065

7,704

8,236

6,603

7,065

7,704

8,236

6,603

7,065

7,704

8,236

SHC(W)

4,424

3,885

3,313

4,952

4,451

3,929

5,480

5,016

4,545

3,871

6,009

5,581

5,161

4,530

6,273

5,864

5,469

4,859

6,537

6,146

5,778

5,189

6,603

6,711

6,394

5,848

6,603

7,065

7,010

6,506

6,603

7,065

7,626

7,165

P.C.

1.77

1.82

1.86

1.77

1.82

1.86

1.77

1.82

1.86

1.92

1.77

1.82

1.86

1.92

1.77

1.82

1.86

1.92

1.77

1.82

1.86

1.92

1.77

1.82

1.86

1.92

1.77

1.82

1.86

1.92

1.77

1.82

1.86

1.92

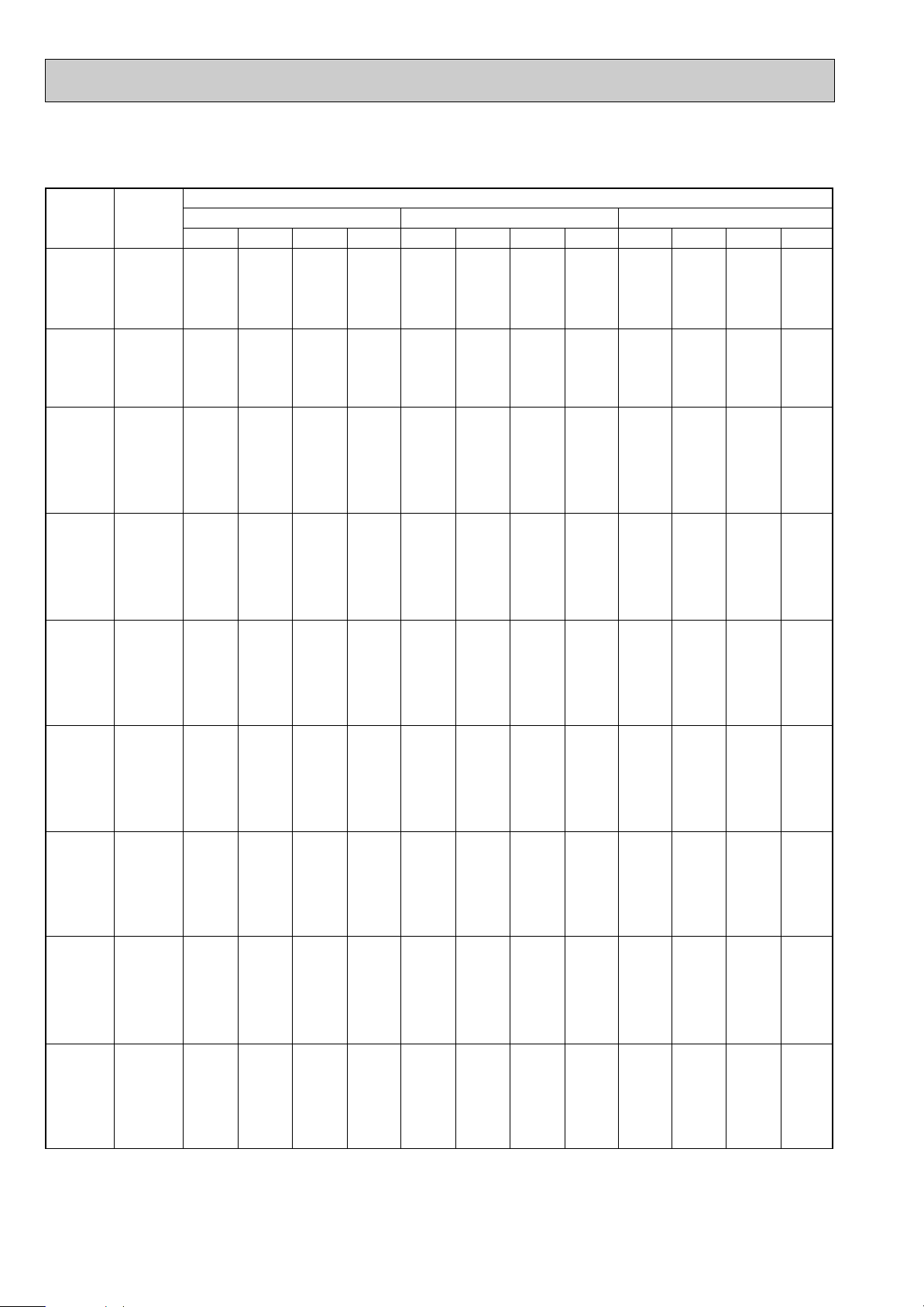

COOLING CAPACITY(3)

PKA-RP3FAL / PUHZ-RP3VHA

(230V)

CA : Capacity (W) SHC(W) :Sensible heat capacity

P.C. : Power consumption (kW) SHF : Sensible heat factor

16

Page 17

Outdoor intake air D.B.(°C)

35 40 45

Indoor

Intake air

D.B.(°C)

Indoor

Intake air

W.B.(°C)

20

20

20

22

22

22

24

24

24

24

26

26

26

26

27

27

27

27

28

28

28

28

30

30

30

30

32

32

32

32

34

34

34

34

16

18

20

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

CA

6,319

6,816

7,384

6,319

6,816

7,384

6,319

6,816

7,384

7,952

6,319

6,816

7,384

7,952

6,319

6,816

7,384

7,952

6,319

6,816

7,384

7,952

6,319

6,816

7,384

7,952

6,319

6,816

7,384

7,952

6,319

6,816

7,384

7,952

SHC(W)

4,234

3,749

3,175

4,739

4,294

3,766

5,245

4,839

4,357

3,737

5,750

5,385

4,947

4,374

6,003

5,657

5,243

4,692

6,256

5,930

5,538

5,010

6,319

6,475

6,129

5,646

6,319

6,816

6,719

6,282

6,319

6,816

7,310

6,918

P.C.

1.90

1.95

2.00

1.90

1.95

2.00

1.90

1.95

2.00

2.04

1.90

1.95

2.00

2.04

1.90

1.95

2.00

2.04

1.90

1.95

2.00

2.04

1.90

1.95

2.00

2.04

1.90

1.95

2.00

2.04

1.90

1.95

2.00

2.04

CA

6,035

6,603

7,100

6,035

6,603

7,100

6,035

6,603

7,100

7,668

6,035

6,603

7,100

7,668

6,035

6,603

7,100

7,668

6,035

6,603

7,100

7,668

6,035

6,603

7,100

7,668

6,035

6,603

7,100

7,668

6,035

6,603

7,100

7,668

SHC(W)

4,043

3,632

3,053

4,526

4,160

3,621

5,009

4,688

4,189

3,604

5,492

5,216

4,757

4,217

5,733

5,480

5,041

4,524

5,975

5,745

5,325

4,831

6,035

6,273

5,893

5,444

6,035

6,603

6,461

6,058

6,035

6,603

7,029

6,671

P.C.

2.04

2.10

2.14

2.04

2.10

2.14

2.04

2.10

2.14

2.20

2.04

2.10

2.14

2.20

2.04

2.10

2.14

2.20

2.04

2.10

2.14

2.20

2.04

2.10

2.14

2.20

2.04

2.10

2.14

2.20

2.04

2.10

2.14

2.20

CA

5,751

6,177

6,674

5,751

6,177

6,674

5,751

6,177

6,674

7,242

5,751

6,177

6,674

7,242

5,751

6,177

6,674

7,242

5,751

6,177

6,674

7,242

5,751

6,177

6,674

7,242

5,751

6,177

6,674

7,242

5,751

6,177

6,674

7,242

SHC(W)

3,853

3,397

2,870

4,313

3,892

3,404

4,773

4,386

3,938

3,404

5,233

4,880

4,472

3,983

5,463

5,127

4,739

4,273

5,693

5,374

5,006

4,562

5,751

5,868

5,539

5,142

5,751

6,177

6,073

5,721

5,751

6,177

6,607

6,301

P.C.

2.21

2.26

2.30

2.21

2.26

2.30

2.21

2.26

2.30

2.34

2.21

2.26

2.30

2.34

2.21

2.26

2.30

2.34

2.21

2.26

2.30

2.34

2.21

2.26

2.30

2.34

2.21

2.26

2.30

2.34

2.21

2.26

2.30

2.34

SHF

0.67

0.55

0.43

0.75

0.63

0.51

0.83

0.71

0.59

0.47

0.91

0.79

0.67

0.55

0.95

0.83

0.71

0.59

0.99

0.87

0.75

0.63

1.00

0.95

0.83

0.71

1.00

1.00

0.91

0.79

1.00

1.00

0.99

0.87

SHF

0.67

0.55

0.43

0.75

0.63

0.51

0.83

0.71

0.59

0.47

0.91

0.79

0.67

0.55

0.95

0.83

0.71

0.59

0.99

0.87

0.75

0.63

1.00

0.95

0.83

0.71

1.00

1.00

0.91

0.79

1.00

1.00

0.99

0.87

SHF

0.67

0.55

0.43

0.75

0.63

0.51

0.83

0.71

0.59

0.47

0.91

0.79

0.67

0.55

0.95

0.83

0.71

0.59

0.99

0.87

0.75

0.63

1.00

0.95

0.83

0.71

1.00

1.00

0.91

0.79

1.00

1.00

0.99

0.87

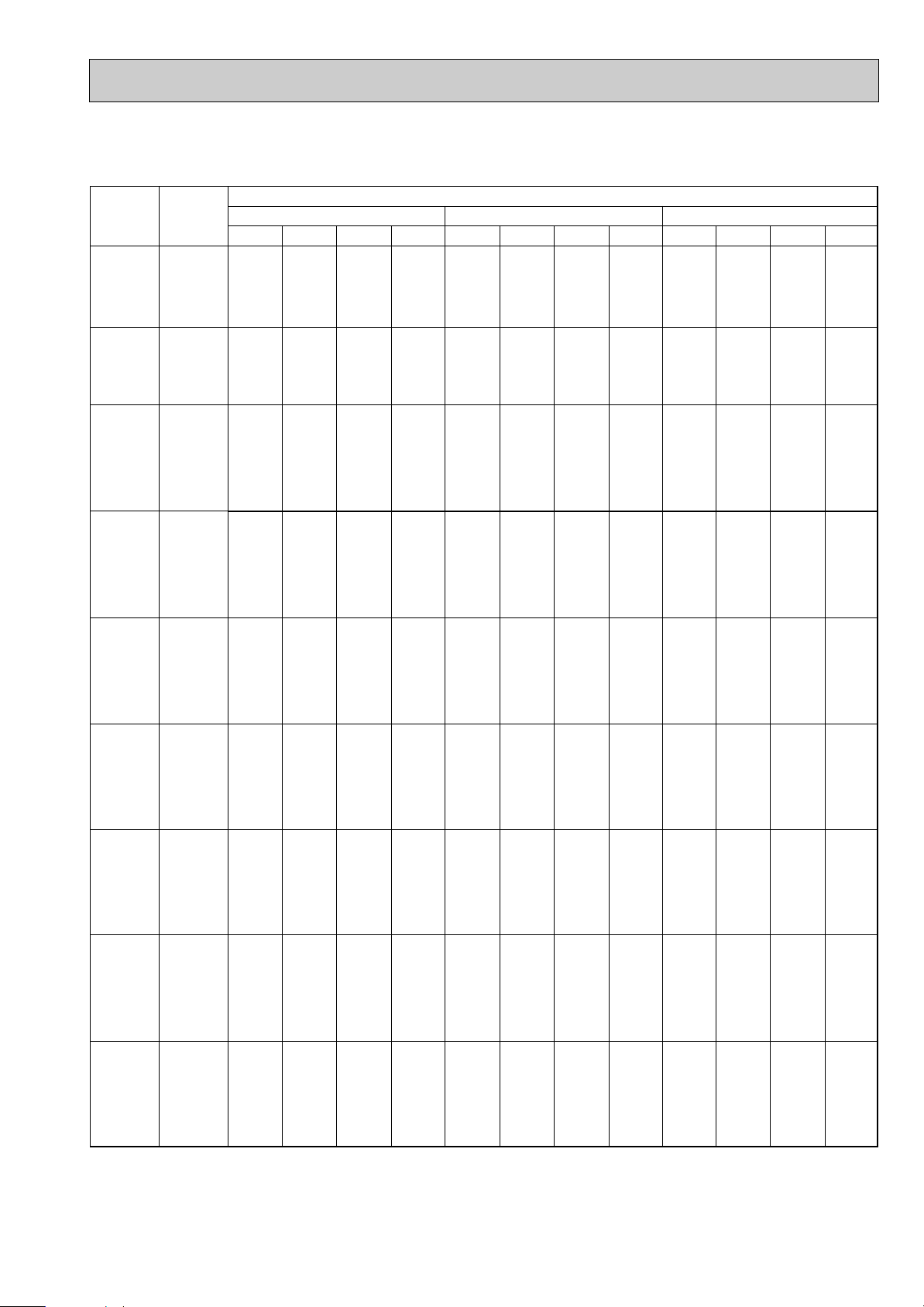

COOLING CAPACITY(4)

PKA-RP3FAL / PUHZ-RP3VHA

(230V)

CA : Capacity (W) SHC(W) :Sensible heat capacity

P.C. : Power consumption (kW) SHF : Sensible heat factor

17

Page 18

Outdoor intake air D.B.(°C)

20 25 30

Indoor

Intake air

D.B.(°C)

Indoor

Intake air

W.B.(°C)

20

20

20

22

22

22

24

24

24

24

26

26

26

26

27

27

27

27

28

28

28

28

30

30

30

30

32

32

32

32

34

34

34

34

16

18

20

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

CA

9,900

10,600

11,400

9,900

10,600

11,400

9,900

10,600

11,400

12,150

9,900

10,600

11,400

12,150

9,900

10,600

11,400

12,150

9,900

10,600

11,400

12,150

9,900

10,600

11,400

12,150

9,900

10,600

11,400

12,150

9,900

10,600

11,400

12,150

SHC(W)

6,039

5,194

4,218

6,831

6,042

5,130

7,623

6,890

6,042

4,982

8,415

7,738

6,954

5,954

8,811

8,162

7,410

6,440

9,207

8,586

7,866

6,926

9,900

9,434

8,778

7,898

9,900

10,282

9,690

8,870

9,900

10,600

10,602

9,842

SHF

0.61

0.49

0.37

0.69

0.57

0.45

0.77

0.65

0.53

0.41

0.85

0.73

0.61

0.49

0.89

0.77

0.65

0.53

0.93

0.81

0.69

0.57

1.00

0.89

0.77

0.65

1.00

0.97

0.85

0.73

1.00

1.00

0.93

0.81

SHF

0.61

0.49

0.37

0.69

0.57

0.45

0.77

0.65

0.53

0.41

0.85

0.73

0.61

0.49

0.89

0.77

0.65

0.53

0.93

0.81

0.69

0.57

1.00

0.89

0.77

0.65

1.00

0.97

0.85

0.73

1.00

1.00

0.93

0.81

SHF

0.61

0.49

0.37

0.69

0.57

0.45

0.77

0.65

0.53

0.41

0.85

0.73

0.61

0.49

0.89

0.77

0.65

0.53

0.93

0.81

0.69

0.57

1.00

0.89

0.77

0.65

1.00

0.97

0.85

0.73

1.00

1.00

0.93

0.81

P.C.

2.34

2.39

2.46

2.34

2.39

2.46

2.34

2.39

2.46

2.52

2.34

2.39

2.46

2.52

2.34

2.39

2.46

2.52

2.34

2.39

2.46

2.52

2.34

2.39

2.46

2.52

2.34

2.39

2.46

2.52

2.34

2.39

2.46

2.52

CA

9,600

10,300

11,150

9,600

10,300

11,150

9,600

10,300

11,150

11,900

9,600

10,300

11,150

11,900

9,600

10,300

11,150

11,900

9,600

10,300

11,150

11,900

9,600

10,300

11,150

11,900

9,600

10,300

11,150

11,900

9,600

10,300

11,150

11,900

SHC(W)

5,856

5,047

4,126

6,624

5,871

5,018

7,392

6,695

5,910

4,879

8,160

7,519

6,802

5,831

8,544

7,931

7,248

6,307

8,928

8,343

7,694

6,783

9,600

9,167

8,586

7,735

9,600

9,991

9,478

8,687

9,600

10,300

10,370

9,639

P.C.

2.48

2.52

2.58

2.48

2.52

2.58

2.48

2.52

2.58

2.67

2.48

2.52

2.58

2.67

2.48

2.52

2.58

2.67

2.48

2.52

2.58

2.67

2.48

2.52

2.58

2.67

2.48

2.52

2.58

2.67

2.48

2.52

2.58

2.67

CA

9,300

9,950

10,850

9,300

9,950

10,850

9,300

9,950

10,850

11,600

9,300

9,950

10,850

11,600

9,300

9,950

10,850

11,600

9,300

9,950

10,850

11,600

9,300

9,950

10,850

11,600

9,300

9,950

10,850

11,600

9,300

9,950

10,850

11,600

SHC(W)

5,673

4,876

4,015

6,417

5,672

4,883

7,161

6,468

5,751

4,756

7,905

7,264

6,619

5,684

8,277

7,662

7,053

6,148

8,649

8,060

7,487

6,612

9,300

8,856

8,355

7,540

9,300

9,652

9,223

8,468

9,300

9,950

10,091

9,396

P.C.

2.62

2.70

2.75

2.62

2.70

2.75

2.62

2.70

2.75

2.84

2.62

2.70

2.75

2.84

2.62

2.70

2.75

2.84

2.62

2.70

2.75

2.84

2.62

2.70

2.75

2.84

2.62

2.70

2.75

2.84

2.62

2.70

2.75

2.84

COOLING CAPACITY(5)

PKA-RP4FAL / PUHZ-RP4VHA

PUHZ-RP4VHA1

(230V)

CA : Capacity (W) SHC(W) :Sensible heat capacity

P.C. : Power consumption (kW) SHF : Sensible heat factor

18

Page 19

COOLING CAPACITY(6)

PKA-RP4FAL / PUHZ-RP4VHA

PUHZ-RP4VHA1

Indoor

Intake air

D.B.(°C)

20

20

20

22

22

22

24

24

24

24

26

26

26

26

27

27

27

27

28

28

28

28

30

30

30

30

32

32

32

32

34

34

34

34

CA : Capacity (W) SHC(W) :Sensible heat capacity

P.C. : Power consumption (kW) SHF : Sensible heat factor

Indoor

Intake air

W.B.(°C)

16

18

20

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

CA

8,900

9,600

10,400

8,900

9,600

10,400

8,900

9,600

10,400

11,200

8,900

9,600

10,400

11,200

8,900

9,600

10,400

11,200

8,900

9,600

10,400

11,200

8,900

9,600

10,400

11,200

8,900

9,600

10,400

11,200

8,900

9,600

10,400

11,200

35 40 45

SHC(W)

5,429

4,704

3,848

6,141

5,472

4,680

6,853

6,240

5,512

4,592

7,565

7,008

6,344

5,488

7,921

7,392

6,760

5,936

8,277

7,776

7,176

6,384

8,900

8,544

8,008

7,280

8,900

9,312

8,840

8,176

8,900

9,600

9,672

9,072

SHF

0.61

0.49

0.37

0.69

0.57

0.45

0.77

0.65

0.53

0.41

0.85

0.73

0.61

0.49

0.89

0.77

0.65

0.53

0.93

0.81

0.69

0.57

1.00

0.89

0.77

0.65

1.00

0.97

0.85

0.73

1.00

1.00

0.93

0.81

P.C.

2.81

2.89

2.96

2.81

2.89

2.96

2.81

2.89

2.96

3.02

2.81

2.89

2.96

3.02

2.81

2.89

2.96

3.02

2.81

2.89

2.96

3.02

2.81

2.89

2.96

3.02

2.81

2.89

2.96

3.02

2.81

2.89

2.96

3.02

Outdoor intake air D.B.(°C)

SHC(W)

CA

8,500

9,300

10,000

8,500

9,300

10,000

8,500

9,300

10,000

10,800

8,500

9,300

10,000

10,800

8,500

9,300

10,000

10,800

8,500

9,300

10,000

10,800

8,500

9,300

10,000

10,800

8,500

9,300

10,000

10,800

8,500

9,300

10,000

10,800

5,185

4,557

3,700

5,865

5,301

4,500

6,545

6,045

5,300

4,428

7,225

6,789

6,100

5,292

7,565

7,161

6,500

5,724

7,905

7,533

6,900

6,156

8,500

8,277

7,700

7,020

8,500

9,021

8,500

7,884

8,500

9,300

9,300

8,748

SHF

0.61

0.49

0.37

0.69

0.57

0.45

0.77

0.65

0.53

0.41

0.85

0.73

0.61

0.49

0.89

0.77

0.65

0.53

0.93

0.81

0.69

0.57

1.00

0.89

0.77

0.65

1.00

0.97

0.85

0.73

1.00

1.00

0.93

0.81

P.C.

3.02

3.11

3.16

3.02

3.11

3.16

3.02

3.11

3.16

3.25

3.02

3.11

3.16

3.25

3.02

3.11

3.16

3.25

3.02

3.11

3.16

3.25

3.02

3.11

3.16

3.25

3.02

3.11

3.16

3.25

3.02

3.11

3.16

3.25

CA

8,100

8,700

9,400

8,100

8,700

9,400

8,100

8,700

9,400

10,200

8,100

8,700

9,400

10,200

8,100

8,700

9,400

10,200

8,100

8,700

9,400

10,200

8,100

8,700

9,400

10,200

8,100

8,700

9,400

10,200

8,100

8,700

9,400

10,200

SHC(W)

4,941

4,263

3,478

5,589

4,959

4,230

6,237

5,655

4,982

4,182

6,885

6,351

5,734

4,998

7,209

6,699

6,110

5,406

7,533

7,047

6,486

5,814

8,100

7,743

7,238

6,630

8,100

8,439

7,990

7,446

8,100

8,700

8,742

8,262

SHF

0.61

0.49

0.37

0.69

0.57

0.45

0.77

0.65

0.53

0.41

0.85

0.73

0.61

0.49

0.89

0.77

0.65

0.53

0.93

0.81

0.69

0.57

1.00

0.89

0.77

0.65

1.00

0.97

0.85

0.73

1.00

1.00

0.93

0.81

(230V)

P.C.

3.27

3.34

3.40

3.27

3.34

3.40

3.27

3.34

3.40

3.46

3.27

3.34

3.40

3.46

3.27

3.34

3.40

3.46

3.27

3.34

3.40

3.46

3.27

3.34

3.40

3.46

3.27

3.34

3.40

3.46

3.27

3.34

3.40

3.46

19

Page 20

COOLING CAPACITY(7)

Outdoor intake air D.B.(°C)

20 25 30

Indoor

Intake air

D.B.(°C)

Indoor

Intake air

W.B.(°C)

20

20

20

22

22

22

24

24

24

24

26

26

26

26

27

27

27

27

28

28

28

28

30

30

30

30

32

32

32

32

34

34

34

34

16

18

20

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

CA

6,386

6,837

7,353

6,386

6,837

7,353

6,386

6,837

7,353

7,837

6,386

6,837

7,353

7,837

6,386

6,837

7,353

7,837

6,386

6,837

7,353

7,837

6,386

6,837

7,353

7,837

6,386

6,837

7,353

7,837

6,386

6,837

7,353

7,837

SHC(W)

4,470

3,965

3,382

4,981

4,512

3,971

5,492

5,059

4,559

3,918

6,002

5,606

5,147

4,545

6,258

5,880

5,441

4,859

6,386

6,153

5,735

5,172

6,386

6,700

6,324

5,799

6,386

6,837

6,912

6,426

6,386

6,837

7,353

7,053

SHF

0.70

0.58

0.46

0.78

0.66

0.54

0.86

0.74

0.62

0.50

0.94

0.82

0.70

0.58

0.98

0.86

0.74

0.62

1.00

0.90

0.78

0.66

1.00

0.98

0.86

0.74

1.00

1.00

0.94

0.82

1.00

1.00

1.00

0.90

SHF

0.70

0.58

0.46

0.78

0.66

0.54

0.86

0.74

0.62

0.50

0.94

0.82

0.70

0.58

0.98

0.86

0.74

0.62

1.00

0.90

0.78

0.66

1.00

0.98

0.86

0.74

1.00

1.00

0.94

0.82

1.00

1.00

1.00

0.90

SHF

0.70

0.58

0.46

0.78

0.66

0.54

0.86

0.74

0.62

0.50

0.94

0.82

0.70

0.58

0.98

0.86

0.74

0.62

1.00

0.90

0.78

0.66

1.00

0.98

0.86

0.74

1.00

1.00

0.94

0.82

1.00

1.00

1.00

0.90

P.C.

2.12

2.16

2.23

2.12

2.16

2.23

2.12

2.16

2.23

2.28

2.12

2.16

2.23

2.28

2.12

2.16

2.23

2.28

2.12

2.16

2.23

2.28

2.12

2.16

2.23

2.28

2.12

2.16

2.23

2.28

2.12

2.16

2.23

2.28

CA

6,192

6,644

7,192

6,192

6,644

7,192

6,192

6,644

7,192

7,676

6,192

6,644

7,192

7,676

6,192

6,644

7,192

7,676

6,192

6,644

7,192

7,676

6,192

6,644

7,192

7,676

6,192

6,644

7,192

7,676

6,192

6,644

7,192

7,676

SHC(W)

4,334

3,853

3,308

4,830

4,385

3,884

5,325

4,916

4,459

3,838

5,820

5,448

5,034

4,452

6,068

5,713

5,322

4,759

6,192

5,979

5,610

5,066

6,192

6,511

6,185

5,680

6,192

6,644

6,760

6,294

6,192

6,644

7,192

6,908

P.C.

2.24

2.28

2.33

2.24

2.28

2.33

2.24

2.28

2.33

2.41

2.24

2.28

2.33

2.41

2.24

2.28

2.33

2.41

2.24

2.28

2.33

2.41

2.24

2.28

2.33

2.41

2.24

2.28

2.33

2.41

2.24

2.28

2.33

2.41

CA

5,999

6,418

6,998

5,999

6,418

6,998

5,999

6,418

6,998

7,482

5,999

6,418

6,998

7,482

5,999

6,418

6,998

7,482

5,999

6,418

6,998

7,482

5,999

6,418

6,998

7,482

5,999

6,418

6,998

7,482

5,999

6,418

6,998

7,482

SHC(W)

4,199

3,722

3,219

4,679

4,236

3,779

5,159

4,749

4,339

3,741

5,639

5,263

4,899

4,340

5,879

5,519

5,179

4,639

5,999

5,776

5,459

4,938

5,999

6,289

6,018

5,537

5,999

6,418

6,578

6,135

5,999

6,418

6,998

6,734

P.C.

2.37

2.44

2.49

2.37

2.44

2.49

2.37

2.44

2.49

2.57

2.37

2.44

2.49

2.57

2.37

2.44

2.49

2.57

2.37

2.44

2.49

2.57

2.37

2.44

2.49

2.57

2.37

2.44

2.49

2.57

2.37

2.44

2.49

2.57

PKA-RP2.5FAL / PUH-P2.5VGAA

PUH-P2.5VGAA.UK PUH-P2.5YGAA.UK

PUH-P2.5VGAA1.UK PUH-P2.5YGAA1.UK

PU-P2.5VGAA

PU-P2.5VGAA.UK PU-P2.5YGAA.UK

PU-P2.5VGAA1.UK PU-P2.5YGAA1.UK

(230V)

CA : Capacity (W) SHC(W) :Sensible heat capacity

P.C. : Power consumption (kW) SHF : Sensible heat factor

20

Page 21

COOLING CAPACITY(8)

Outdoor intake air D.B.(°C)

35 40 45

Indoor

Intake air

D.B.(°C)

Indoor

Intake air

W.B.(°C)

20

20

20

22

22

22

24

24

24

24

26

26

26

26

27

27

27

27

28

28

28

28

30

30

30

30

32

32

32

32

34

34

34

34

16

18

20

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

CA

5,741

6,192

6,708

5,741

6,192

6,708

5,741

6,192

6,708

7,224

5,741

6,192

6,708

7,224

5,741

6,192

6,708

7,224

5,741

6,192

6,708

7,224

5,741

6,192

6,708

7,224

5,741

6,192

6,708

7,224

5,741

6,192

6,708

7,224

SHC(W)

4,018

3,591

3,086

4,478

4,087

3,622

4,937

4,582

4,159

3,612

5,396

5,077

4,696

4,190

5,626

5,325

4,964

4,479

5,741

5,573

5,232

4,768

5,741

6,068

5,769

5,346

5,741

6,192

6,306

5,924

5,741

6,192

6,708

6,502

SHF

0.70

0.58

0.46

0.78

0.66

0.54

0.86

0.74

0.62

0.50

0.94

0.82

0.70

0.58

0.98

0.86

0.74

0.62

1.00

0.90

0.78

0.66

1.00

0.98

0.86

0.74

1.00

1.00

0.94

0.82

1.00

1.00

1.00

0.90

SHF

0.70

0.58

0.46

0.78

0.66

0.54

0.86

0.74

0.62

0.50

0.94

0.82

0.70

0.58

0.98

0.86

0.74

0.62

1.00

0.90

0.78

0.66

1.00

0.98

0.86

0.74

1.00

1.00

0.94

0.82

1.00

1.00

1.00

0.90

SHF

0.70

0.58

0.46

0.78

0.66

0.54

0.86

0.74

0.62

0.50

0.94

0.82

0.70

0.58

0.98

0.86

0.74

0.62

1.00

0.90

0.78

0.66

1.00

0.98

0.86

0.74

1.00

1.00

0.94

0.82

1.00

1.00

1.00

0.90

P.C.

2.54

2.61

2.68

2.54

2.61

2.68

2.54

2.61

2.68

2.73

2.54

2.61

2.68

2.73

2.54

2.61

2.68

2.73

2.54

2.61

2.68

2.73

2.54

2.61

2.68

2.73

2.54

2.61

2.68

2.73

2.54

2.61

2.68

2.73

CA

5,483

5,999

6,450

5,483

5,999

6,450

5,483

5,999

6,450

6,966

5,483

5,999

6,450

6,966

5,483

5,999

6,450

6,966

5,483

5,999

6,450

6,966

5,483

5,999

6,450

6,966

5,483

5,999

6,450

6,966

5,483

5,999

6,450

6,966

SHC(W)

3,838

3,479

2,967

4,276

3,959

3,483

4,715

4,439

3,999

3,483

5,154

4,919

4,515

4,040

5,373

5,159

4,773

4,319

5,483

5,399

5,031

4,598

5,483

5,879

5,547

5,155

5,483

5,999

6,063

5,712

5,483

5,999

6,450

6,269

P.C.

2.73

2.81

2.86

2.73

2.81

2.86

2.73

2.81

2.86

2.94

2.73

2.81

2.86

2.94

2.73

2.81

2.86

2.94

2.73

2.81

2.86

2.94

2.73

2.81

2.86

2.94

2.73

2.81

2.86

2.94

2.73

2.81