Mitsubishi Electric PAR-CT01MAA-SB, PAR-CT01MAR-PB, PAR-CT01MAA-PB, PAR-CT01MAA-S, PAR-CT01MAR-SB Installation Manual

Page 1

– 1 –

GB

This installation manual describes how to install the MA Touch Remote Controller for use with

Mitsubishi Building Air Conditioning System, direct expansion type CITY MULTI air conditioner indoor

units (“-A” type and later), and Mitsubishi Mr. SLIM packaged air conditioners.

Please be sure to read this installation manual and the files on the CD-ROM that is supplied with the

Touch Remote Controller before proceeding with the installation. Failure to follow the instructions may

result in equipment damage.

For information not contained in this booklet, please refer to the files on the CD-ROM that is supplied

with the Touch Remote Controller. If the files are not readable, please contact your dealer.

For information on how to wire and install the air conditioning units, refer to the installation manual.

After the installation, hand over this manual to users.

• Thoroughly read the following safety precautions prior to installation.

• Observe these precautions carefully to ensure safety.

• After reading this manual, pass it on to the end user to retain for future reference.

• Keep this manual for future reference and refer to it as necessary. This manual should be made

available to those who repair or relocate the controller. Make sure that the manual is forwarded to

future end users.

1 Safety Precautions

WARNING

Indicates a risk of death or serious injury.

CAUTION

Indicates a risk of serious injury or structural damage.

All electric work must be performed by qualified personnel.

CITY MULTI Control System

and Mitsubishi Mr. SLIM Air Conditioners

MA Touch Remote Controller

PAR-CT01MAA-PB

PAR-CT01MAA-SB

PAR-CT01MAA-S

PAR-CT01MAR-PB

PAR-CT01MAR-SB

Installation Manual

WT08580X01

GB

For distribution to dealers and contractors

FESIPRGRTRSWDNLRUCZHGPO

<ORIGINAL>

DK

Page 2

– 2 –

GB

WARNING

CAUTION

WARNING

CAUTION

General precautions

Precautions during installation

Do not install the unit in a place where large amounts of

oil, steam, organic solvents, or corrosive gases, such

as sulfuric gas, are present or where acidic/alkaline

solutions or sprays are used frequently. These

substances can compromise the performance of the

unit or cause certain components of the unit to corrode,

which can result in electric shock, malfunctions,

smoke, or fire.

To reduce the risk of shorting, current leakage, electric

shock, malfunctions, smoke, or fire, do not wash the

controller with water or any other liquid.

To reduce the risk of electric shock, malfunctions,

smoke or fire, do not operate the switches/buttons or

touch other electrical parts with wet hands.

To reduce the risk of injury or electric shock, stop the

operation and switch off the power supply before

cleaning, maintaining, or inspecting the controller.

To reduce the risk of injury or electric shock, before

spraying a chemical around the controller, stop the

operation and cover the controller.

To reduce the risk of injury, keep children away while

installing, inspecting, or repairing the unit.

Properly install all required covers to keep moisture

and dust out of the controller. Dust accumulation and

water can cause electric shock, smoke, or fire.

To reduce the risk of electric shock or malfunctions, do

not touch the touch panel, switches, or buttons with a

pointy or sharp object.

To reduce the risk of damage to the controller, do not

directly spray insecticide or other flammable sprays on

the controller.

To reduce the risk of injury and electric shock, avoid

contact with sharp edges of certain parts.

To reduce the risk of injury, wear protective gear when

working on the controller.

Consult your dealer for the proper disposal of the

controller.

To avoid injury from broken glass, do not apply

excessive force on the glass parts.

To reduce the risk of fire or explosion, do not place

flammable materials or use flammable sprays around

the controller.

Do not install the unit where there is a risk of leaking

flammable gas.

If flammable gas accumulates around the unit, it may

ignite and cause a fire or explosion.

Take appropriate safety measures against earthquakes

to prevent the controller from causing injury.

Properly dispose of the packing materials. Plastic bags

pose suffocation hazard to children.

To prevent injury, install the controller on a flat surface

strong enough to support its weight.

To reduce the risk of shorting, current leakage, electric

shock, malfunctions, smoke, or fire, do not install the

controller in a place exposed to water or in a

condensing environment.

Controller must be installed by qualified personnel

according to the instructions detailed in the Installation

Manual.

Improper installation may result in electric shock or fire.

Install the top case into the bottom case until it clicks.

When attaching the cover and the top casing to the

bottom casing, push it until it they click into place. If

they are not properly locked into place, they may fall,

causing personal injury, controller damage, or

malfunctions.

Page 3

– 3 –

GB

WARNING

CAUTION

WARNING

CAUTION

Precautions during wiring

Precautions for moving or repairing the controller

To reduce the risk of damage to the controller,

malfunctions, smoke, or fire, do not connect the power

cable to the signal terminal block.

Properly secure the cables in place and provide

adequate slack in the cables so as not to stress the

terminals. Improperly connected cables may break,

overheat, and cause smoke or fire.

To reduce the risk of injury or electric shock, switch off

the main power before performing electrical work.

All electric work must be performed by a qualified

electrician according to the local regulations,

standards, and the instructions detailed in the

Installation Manual.

To reduce the risk of electric shock, install a breaker

and a residual current circuit breaker on the power

supply.

To reduce the risk of electric shock, smoke, or fire,

install a breaker for each controller.

Use properly rated breakers and fuses (breaker, local

switch <switch + fuse>, no-fuse breaker).

Breaker with a breaking capacity greater than the

specified capacity may cause electric shock,

malfunctions, smoke, or fire.

To reduce the risk of current leakage, overheating,

smoke, or fire, use properly rated cables with adequate

current carrying capacity.

Proper grounding must be provided by a licensed

electrician.

Do not connect the grounding wire to a gas pipe, water

pipe, lightning rod, or telephone wire.

Improper grounding may result in electric shock,

smoke, fire, or malfunction due to electrical noise

interference.

To reduce the risk of electric shock, shorting, or

malfunctions, keep wire pieces and sheath shavings

out of the terminal block.

To reduce the risk of shorting, current leakage, electric

shock, or malfunctions, keep the cables out of contact

with controller edges.

Securely seal the cable access holes with putty to

prevent condensation, water, and insects from entering

and causing electric shock, malfunctions, or fire. Water

infiltration and condensation formed inside the unit may

damage the circuit board.

The controller should be repaired or moved only by

qualified personnel.

Do not disassemble or modify the controller.

Improper installation or repair may cause injury, electric

shock, or fire.

To reduce the risk of electric shock, shorting, or

malfunctions, keep wire pieces and sheath shavings

out of the terminal block.

Page 4

– 4 –

GB

Additional precautions

To avoid damage to the unit, use appropriate tools to

install, inspect, or repair the unit.

This controller is designed for exclusive use with the

Building Management System by Mitsubishi Electric.

The use of this controller for with other systems or for

other purposes may cause malfunctions.

To avoid discoloration, do not use benzene, thinner, or

chemical rag to clean the controller.

To clean the controller, wipe with a soft cloth soaked in

water with mild detergent, wipe off the detergent with a

wet cloth, and wipe off water with a dry cloth.

To avoid damage to the controller, provide protection

against static electricity.

Take appropriate measures against electrical noise

interference when installing the air conditioners in

hospitals or facilities with radio communication

capabilities.

Inverter, high-frequency medical, or wireless

communication equipment as well as power

generators may cause the air conditioning system to

malfunction. Air conditioning system may also

adversely affect the operation of these types of

equipment by creating electrical noise.

To avoid malfunctions, do not bundle power cables and

signal cables together, or place them in the same

metallic conduit.

Leave the circuit board and its protective film on the

case.

To avoid damage to the controller, do not overtighten

the screws.

Use a flat-head screwdriver with a blade width of 3-5

mm (1/8-7/32 inch).

Do not turn the flat-head screwdriver with fitting it in the

latch strongly.

To avoid deformation and malfunction, do not install

the remote controller in direct sunlight or where the

ambient temperature may exceed 40ºC (104ºF) or

drop below 0ºC (32ºF).

Do not install the controller on the control panel door.

Vibrations or shocks to the controller may damage the

controller or cause the controller to fall.

Secure the cable with a clamp.

Do not use solderless terminals to connect cables to

the terminal block.

Solderless terminals may come in contact with the

circuit board and cause malfunctions or damage the

controller cover.

After connecting the connector, install the top case

properly.

If the supply cord is damaged, it must be replaced by

the manufacturer, its service agent or similarly qualified

persons in order to avoid a hazard.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and

knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a

person responsible for their safety.

Children should be supervised to ensure that they do

not play with the appliance.

This appliance is intended to be used by expert or

trained users in shops, in light industry and on farms,

or for commercial use by lay persons.

To avoid damage to the controller, use appropriate

tools to install, inspect, or repair the controller.

To prevent malfunctions, do not remove the protective

film or the circuit board from the casing.

Do not install the controller on the control panel door.

Vibrations or shocks to the controller may damage the

controller or cause the controller to fall.

To avoid damage to the controller, do not make holes

on the controller cover.

Hold the cables in place with clamps to prevent undue

force from being applied to the terminal block and

causing cable breakage.

Page 5

– 5 –

GB

Your computer must meet the following requirements to run Manual Navigation Software.

[PC] PC/AT compatible

[CPU] Core2 Duo 1.66 GHz or faster (Core2 Duo 1.86 GHz or faster recommended)

Pentium D 1.7 GHz or faster (Pentium D 3.0 GHz or faster recommended)

Pentium M 1.7 GHz or faster (Pentium M 2.0 GHz or faster recommended)

Pentium 4 2.4 GHz or faster (Pentium 4 2.8 GHz or faster recommended)

* Core2 Duo or faster processor is required to run Manual Navigation Software on Windows

Vista or later.

[RAM] Windows Vista or later: 1 GB minimum (2 GB or more recommended)

Windows XP: 512 MB minimum (1 GB or more recommended)

[HDD space] 1 GB minimum (available space)

* Windows Vista or later: Available space in the drive that has the Document folder

* Windows XP: Available space in the drive that has the My Document folder

[Resolution] SVGA 800 × 600 or greater

[OS] Windows8/Pro/Enterprise (Pro recommended)

Windows7 Ultimate/Enterprise/Professional/Home Premium Service Pack1 (Professional

recommended)

Windows Vista Ultimate/Business/Home Basic Service Pack1 (Business version

recommended)

Windows XP Professional/Home Edition Service Pack2 or Service Pack3 (Professional

version recommended)

[Required software] Windows8: Adobe Reader 11.0.2 or later (Windows Reader, installed by

default in Windows8, cannot be used.)

Windows7: Adobe Reader 10.1.0 or later

Windows XP and Windows Vista: Adobe Reader 8.1.3 or later

* Software to view PDF files

-----------------------------------------------------------------------------------------------------------------------------------“Windows”, “Windows XP”, “Windows Vista”, “Windows7” and “Windows8” are registered trade

marks of Microsoft Corporation.

“Adobe Reader” and “Adobe Acrobat” are registered trademarks of Adobe Systems Incorporated.

“Core2 Duo” and “Pentium” are registered trademarks of Intel Corporation.

------------------------------------------------------------------------------------------------------------------------------------

2 System Requirements

WARNING

The CD-ROM that is supplied with the unit can only be played on a CD-drive or

a DVD-drive. Do not attempt to play this CD-ROM on an audio CD player as

this may damage your ears and/or speakers.

Page 6

– 6 –

GB

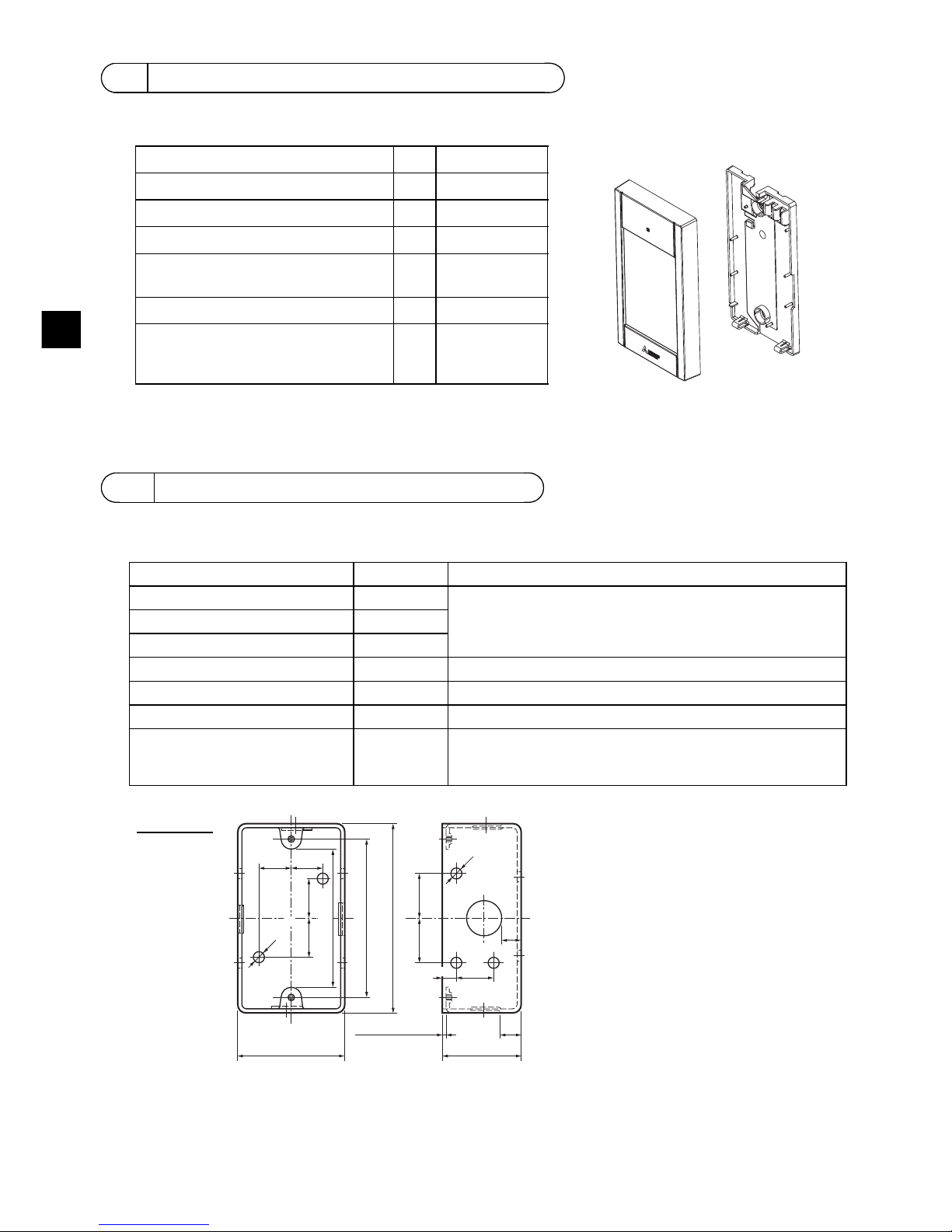

The following parts are included in the box.

(1) Field-supplied parts

The following parts are field-supplied parts.

(2) Field-supplied tools

• Flat-tip screwdriver (Width: 3 - 5 mm (1/8 - 7/32 inch))

• Nipper

• Miscellaneous tools

3 Component names and supplied parts

*3 ISO metric screw thread

*4 Remote controller cable is not included.

4 Field-supplied parts/Required tools

Parts name Qty. Notes

Single switch box 1 Not required for direct wall installation

Thin metal conduit Necessary

Lock nut and bushing Necessary

Cable cover Necessary Required for routing remote controller cable along a wall

Putty Reasonable

Molly anchor Necessary

Remote controller cable

(Use a 0.3 mm² (AWG22) 2-core

sheathed cable.)

Necessary

Parts name Qty. Appearance

Remote controller (top case) 1 Right figure *1

Remote controller (bottom case) 1 Right figure *2

Roundhead cross slot screws M4×30 2 *3

Wood screw 4.1×16

(for direct wall installation)

2*3

Simple Manual 1

CD-ROM (this manual)

Instruction Book and Installation

Manual

1

Bottom case *2

Top case *1

h

16 (5/8) 16 (5/8)

25 (1)

25 (1)

102 (4)

54 (2-1/8)

20

(13/16)

10

(3/8)

44 (1-3/4)

(3-3/8±1/32)

ø6 (1/4OD)

20 (13/16)

6

(1/4)

ø6 (1/4OD)

20 (13/16)

Switch box

unit: mm (in)

1.5 (1/16) or less

83.5±0.4

Page 7

– 7 –

GB

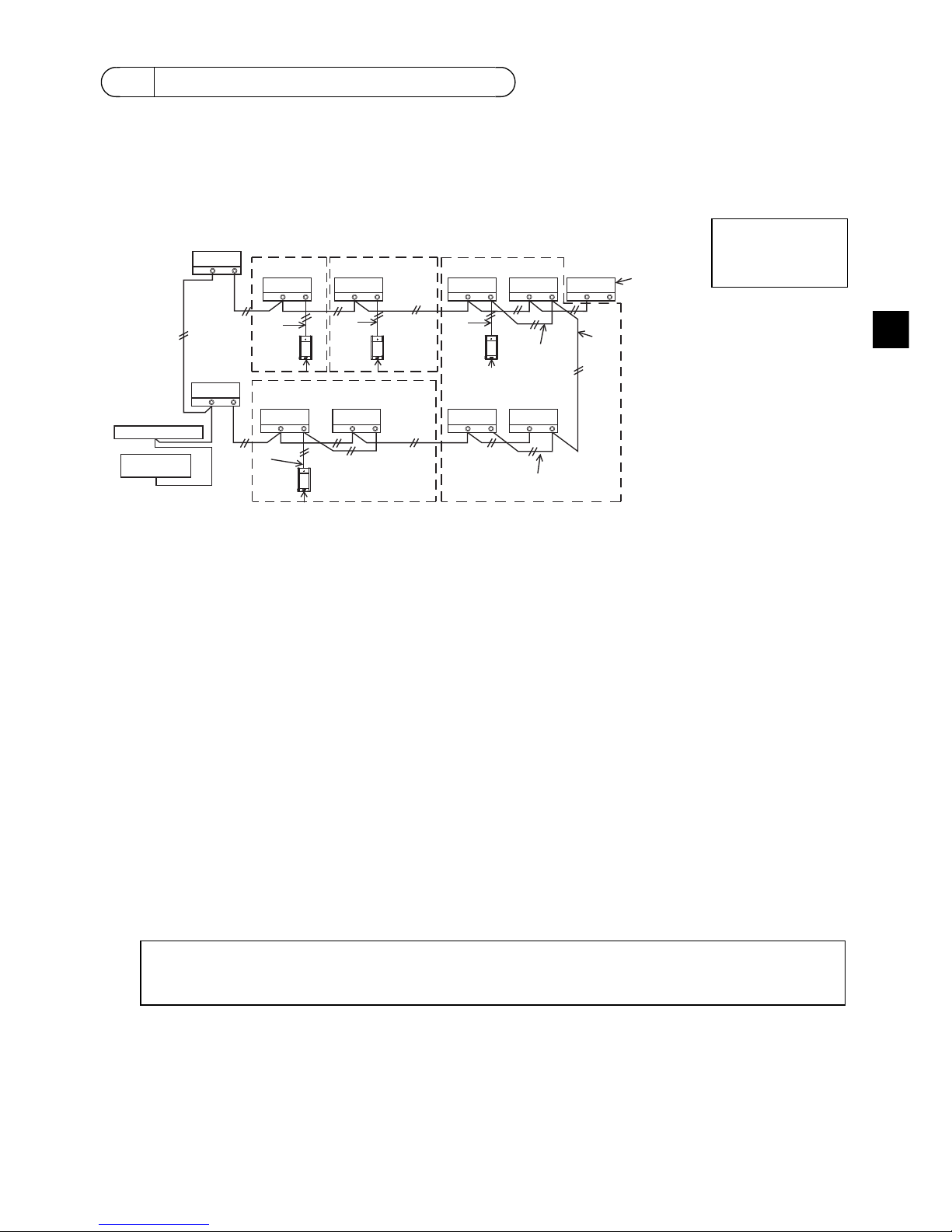

The wiring is different when the remote controller is connected to a CITY MULTI control system (“-A”

type and later) and when it is connected to a Mr. SLIM air conditioner (A control type). The wiring also

differs with the system configuration. Check the system used.

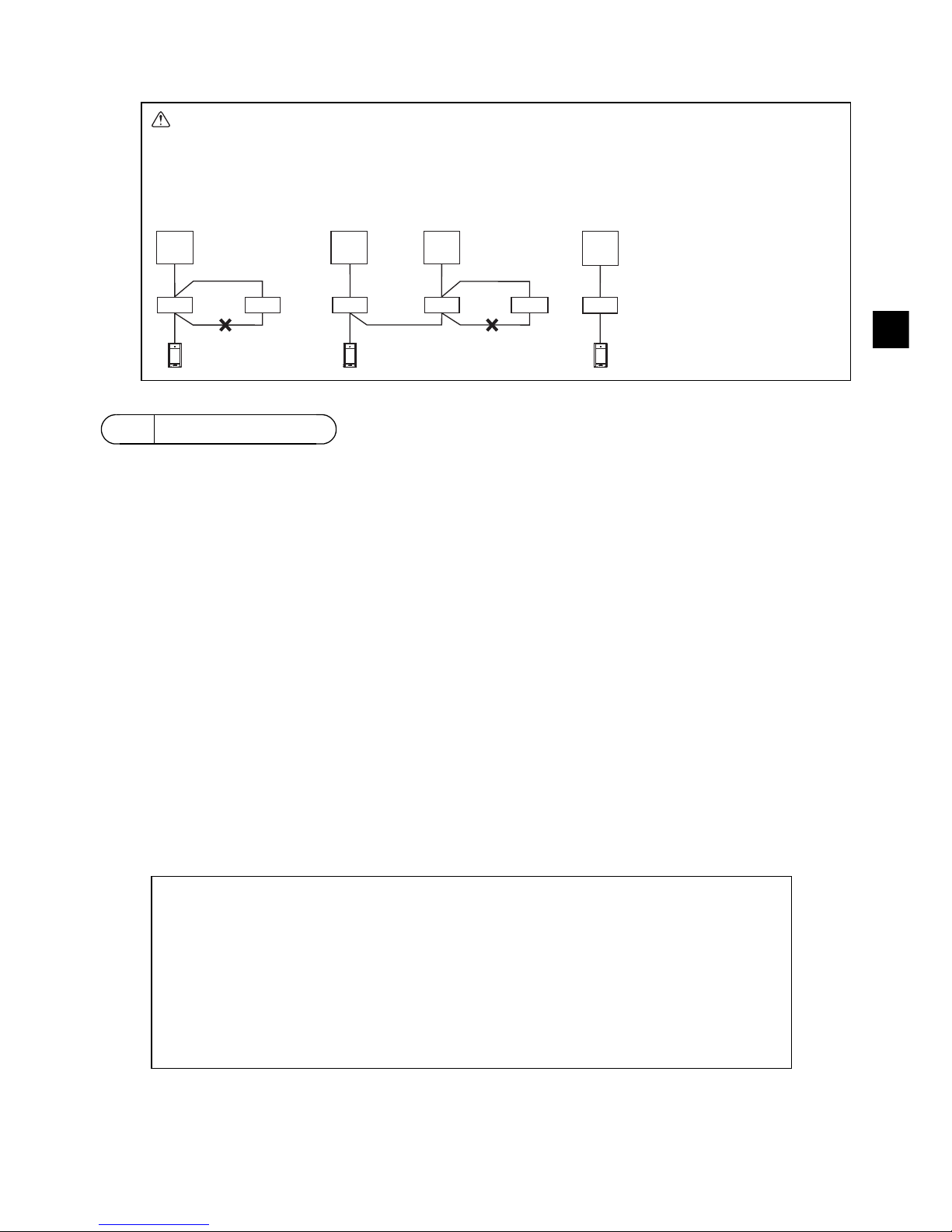

1. Connecting to CITY MULTI control system

The numbers (1) to (4) in the figure correspond to items (1) to (4) in the following description.

(1) Wiring from the remote controller

• Connect to the MA remote controller terminal block (TB15) on the indoor unit.

• The terminal block has no polarity. Connect to the terminal block at the bottom of the remote

controller case.

(2) Operating in a group (Groups 03, and 04 above)

• Interconnect the MA remote controller terminal block (TB15) of the indoor units you want to

operate as a group, and connect the MA remote controller to that point.

• When the remote controller is used in combination with the system controller as shown in the

figure above, group setting at the system controller (central controller in the figure above) is

necessary.

(3) Number of connectable remote controllers

• Only one remote controller can be connected to a group made up of indoor units.

• The MA Touch Remote Controller cannot be used in combination with other MA remote

controllers.

(4) To interlock to a LOSSNAY or OA processing unit, make the following settings using the remote

controller. (For a description of how to set an interlock, see section 11 “Service menu” (5)

“LOSSNAY setting”.)

Set the LOSSNAY or OA processing unit address and the address of all the indoor units you want

to interlock.

(5) Total length of remote controller wiring

• The MA Touch Remote Controller can be wired up to 70 m (229 ft).

5 How To Wire Transmission Line

Connect to TB15

on the indoor unit.

a Outdoor unit

b Indoor unit

c LOSSNAY or

OA processing unit

d Touch Remote Controller

e Central controller

f Power supply unit for

transmission line

TB5 TB15

TB5 TB15

bb

TB5 TB15

c

TB5 TB15

b

TB5 TB15

b

TB5 TB15

b

TB5 TB15

b

TB7 TB3

TB5 TB15

TB5 TB15

TB7 TB3

(1)

(1)

(3)

(3)

(3)

(3)

(2)

(2)

(2)

(4)

(1)

(1)

a

a

dd d

d

bb

e

f

Address = 51

Address = 01 Address = 02

Address = 55

Address = 08

Address = 07

Address = 03

Address = 04 Address = 09

Address = 06

Address = 05

Group 01 Group 02 Group 03

Group 04

NOTE: When interlocking the MA remote controller with a LOSSNAY or OA processing unit,

always set the address of all the indoor units in the group and the address of the

LOSSNAY or OA processing unit.

Page 8

– 8 –

GB

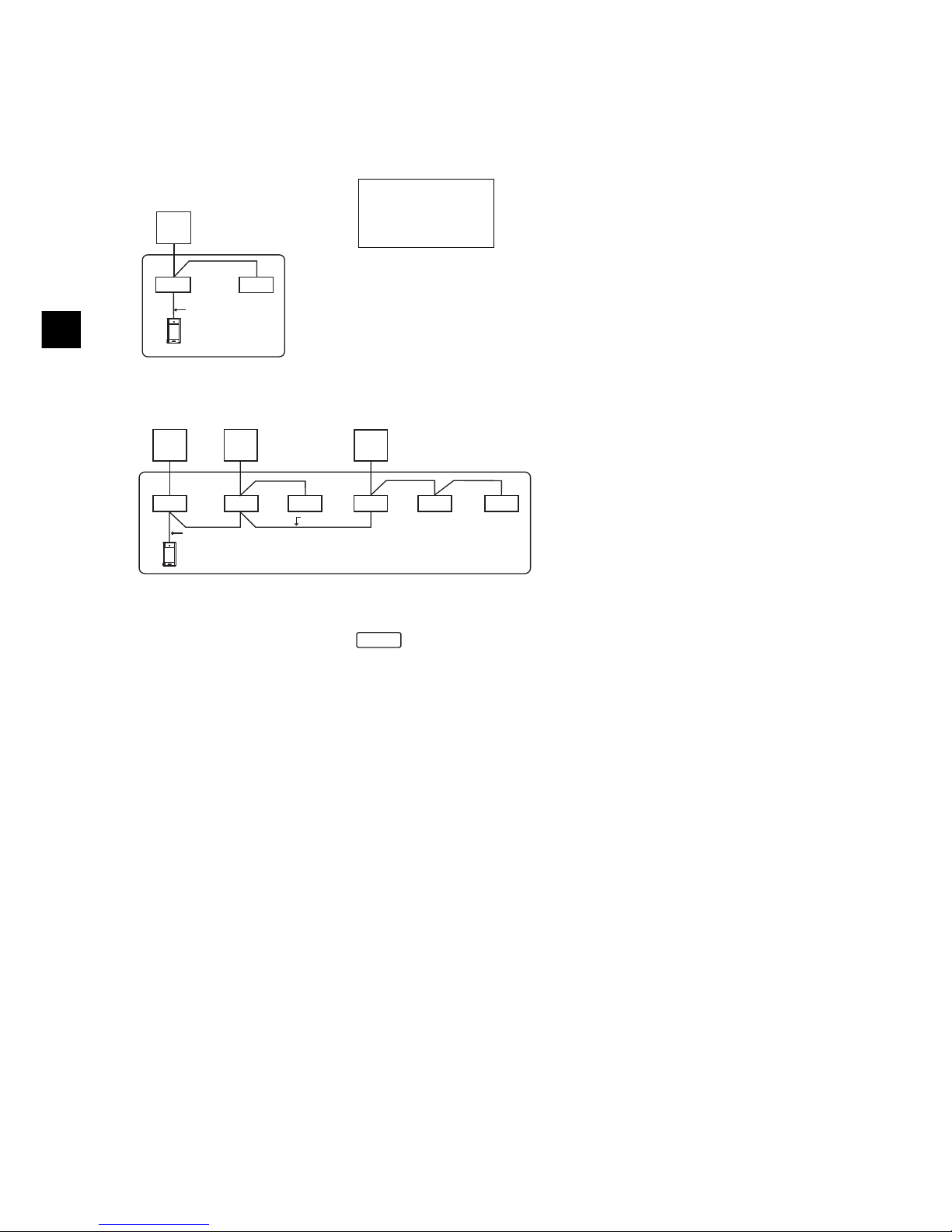

2. Connecting to Mr. SLIM air conditioner

The remote controller wiring depends on the system configuration. Check the system configuration.

Wire the remote controller as shown in the example below.

The numbers (1) to (3) in the figure correspond to items (1) to (3) in the following description.

[1] Connecting the remote controller for each refrigerant system (Standard 1:1, simultaneous twin,

simultaneous triple, simultaneous four)

[2] When grouping by different refrigerant systems

* Set the refrigerant address using the outdoor unit dip switches. (For more information, refer to the

outdoor unit installation manual.)

* All the indoor units enclosed in are controlled as one group.

(1) Wiring from remote controller

• Connect to indoor unit TB5 (remote controller terminal block). (The terminal block has no polarity.)

• For simultaneous multi type, when mixing various types of indoor units, always connect the

remote controller to the indoor unit with the most functions (wind velocity, vane, louver, etc.).

(2) When grouping with difference refrigerant systems

• Group using the remote controller wiring. Connect the remote controller to an arbitrary indoor unit

of each refrigerant system you want to group.

• When mixing different types of indoor units in the same group, always make the outdoor unit

connecting the indoor unit with the most functions (wind velocity, vane, louver, etc.) the Main unit

(refrigerant address = 00). Also, when the Main unit is the simultaneous multi type, always satisfy

the conditions of (1) above.

• The MA Touch Remote Controller can control up to 16 refrigerant systems as one group.

(3) Only one remote controller can be connected to each group. The remote controller cannot be

used in combination with other MA remote controllers.

Connect to TB5

on the indoor unit.

a Outdoor unit

b Indoor unit

d Touch Remote Controller

(1)

TB5

TB4

TB1

TB4

(3)

a

bb

d

Refrigerant

address = 00

Simultaneous twin

TB4

TB4

TB4

TB4

TB4TB4

TB1 TB1 TB1

TB5

TB5

TB5

(2)

(1)

(3)

(2)

aa a

bbbbbb

d

Standard 1:1 Simultaneous twin

Simultaneous triple

Refrigerant

address = 01

(Sub)

Refrigerant

address = 00

(Main)

Refrigerant

address = 02

(Sub)

Page 9

– 9 –

GB

(4) Total length of remote controller wiring

• The MA Touch Remote Controller can be wired up to 150 m (492 ft).

This remote controller is for the wall installation. It can be installed either in the switch box or directly

on the wall. When performing direct wall installation, wires can be thread through either back or top of

the remote controller.

(1) Selecting an installation site

Install the remote controller (switch box) on the site where the following conditions are met.

(a) For connection to the indoor unit with an Auto descending panel, a place where people can check

the Auto descending panel operation of the indoor unit while they are operating the remote

controller (Refer to the indoor unit Instructions Book for how to operate Auto descending panel.)

(b) A flat surface

(c) A place where the remote controller can measure the accurate indoor temperature

Sensors to monitor indoor temperature are on the indoor unit and on the remote controller. When

the room temperature is monitored with the sensor on the remote controller, the built-in sensor on

the remote controller monitors the room temperature. When using the sensor on the remote

controller, follow the instructions below.

• To monitor the accurate indoor temperature, install the remote controller away from direct

sunlight, heat sources, and the supply air outlet of the air conditioner.

• Install the remote controller in a location that allows the sensor to measure the representative

room temperature.

• Install the remote controller where no wires are routed around the temperature sensor on the

controller. (If wires are routed, the sensor cannot measure accurate indoor temperature.)

CAUTION - The wiring cannot be connected to TB5 of the indoor unit of the same

refrigerant system. If so connected, the system will not operate normally.

- Remote controllers cannot be wired together. Only one wire can be connected

to the remote controller terminal block.

a Outdoor unit

b Indoor unit

d Touch Remote

Controller

6How To Install

d

d

TB4

TB4

TB4

TB4

TB4

TB4

TB1

TB1 TB1

TB1

TB5

TB5

TB5

TB5 TB5 TB5

a

bbb bbb

d

aa a

Refrigerant

address = 00

Refrigerant

address = 00

Refrigerant

address = 01

Refrigerant

address = 00

Simultaneous twin Standard 1:1 Simultaneous twin Standard 1:1

■ Discrepancy between the indoor temperature measured at the wall and the actual

indoor temperature may occur.

If the following conditions are met, the use of the temperature sensor on the indoor unit is

recommended.

• Supply air does not reach to the wall easily where the remote controller is installed due to

improper airflow distribution.

• There is a great discrepancy between the wall temperature and the actual indoor

temperature.

• The back side of the wall is directly exposed to the outside air.

Note: When temperature changes rapidly, the temperature may not be detected accurately.

Important

Page 10

– 10 –

GB

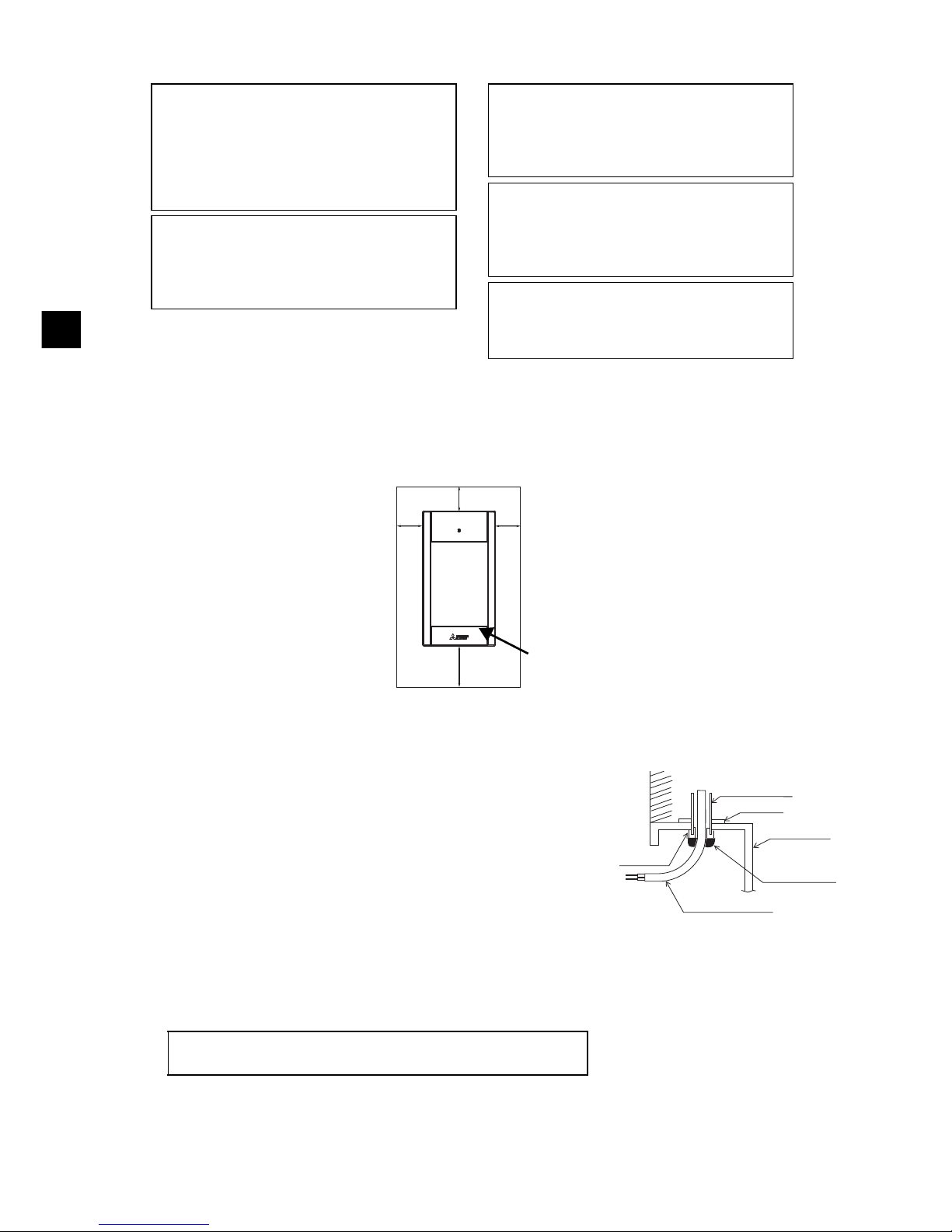

(2) Installation space

Leave a space around the remote controller as shown in the figure shown below, regardless of

whether the controller is installed in the switch box or directly on the wall. Removing the remote

controller will not be easy with insufficient space.

Also, leave an operating space in front of the remote controller.

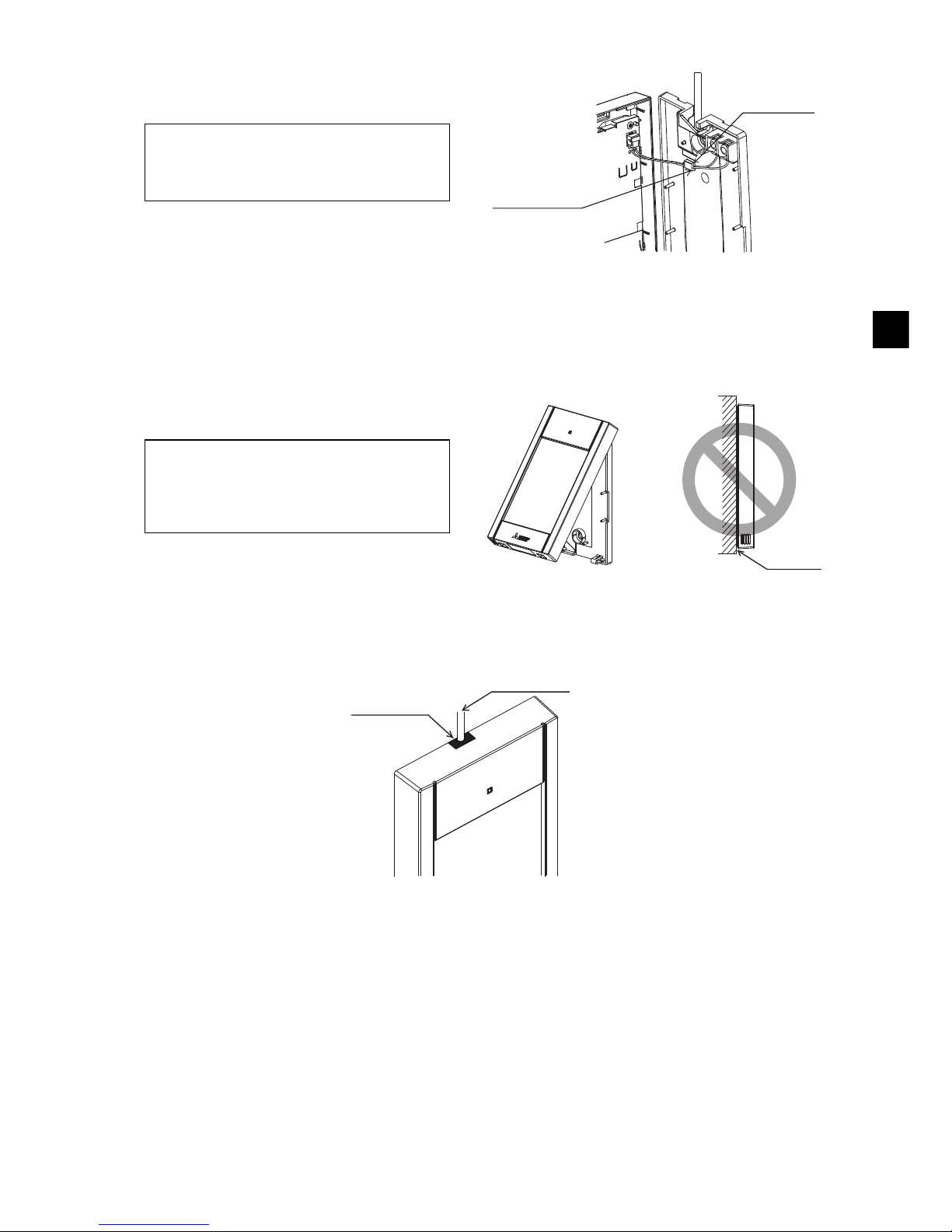

(3) Installation work

Controller can be installed either in the switch box or directly on the

wall. Perform the installation properly according to the installation

method.

1 Drill a hole in the wall.

■ Installation using a switch box

• Drill a hole in the wall, and install the switch box on the wall.

• Connect the switch box to the conduit tube.

■ Direct wall installation

• Drill a hole in the wall, and thread the cable through it.

2 Seal the cable access hole with putty.

■ Installation using a switch box

• Seal the remote controller cable access hole at the

connection of switch box and conduit tube with putty.

Do not install the controller in a place where

the difference between the remote controller

surface temperature and the actual room

temperature will be great.

If the temperature difference is too high,

room temperature may not be adequately

controlled.

To reduce the risk of malfunctions, do not

install the controller in a place where water

or oil may come into contact with the

controller, or in a condensing or corrosive

environments.

To avoid deformation and malfunction, do

not install the remote controller in direct

sunlight or where the ambient temperature

may exceed 40ºC (104ºF) or drop below 0ºC

(32ºF).

To reduce the risk of malfunctions and

damage to the controller, avoid installing the

remote controller on an electrically

conductive surface, such as an unpainted

metal sheet.

Refer to either of the following manuals for

temperature sensor setting: indoor unit

Installation Manual for CITY MULTI; this

manual for Mr. SLIM.

30

(1-3/16)

30

(1-3/16)

30 (1-3/16)

50 (1-31/32)

Temperature sensor

Unit: mm (in)

External dimensions of remote controller

Minimum required space

around the remote

controller

Wall

Conduit tube

Locknut

Switch box

Seal the gap

with putty.

Remote

controller cable

Bushing

To reduce the risk of electric shock, malfunctions, or fire, seal

the gap between the cables and cable access holes with putty.

Page 11

– 11 –

GB

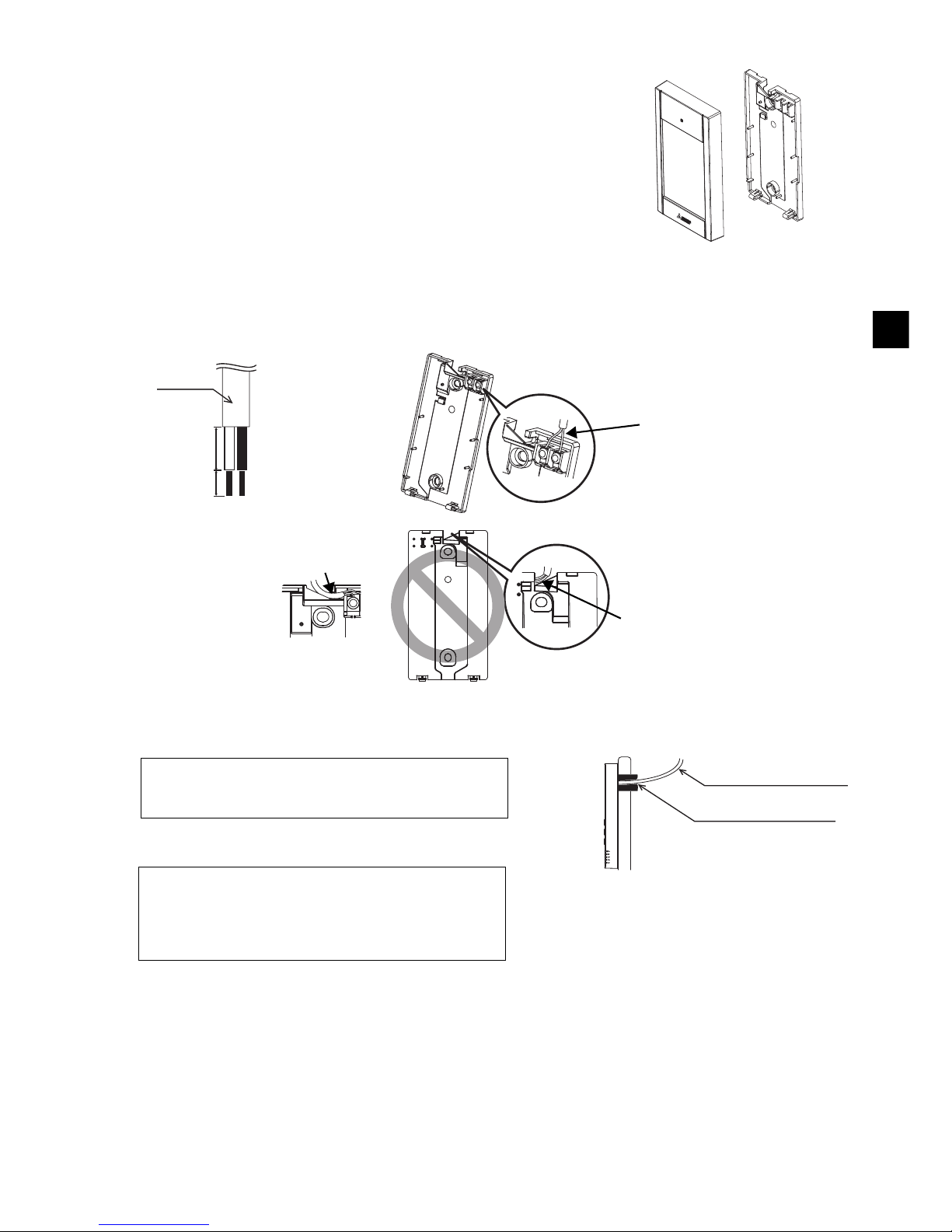

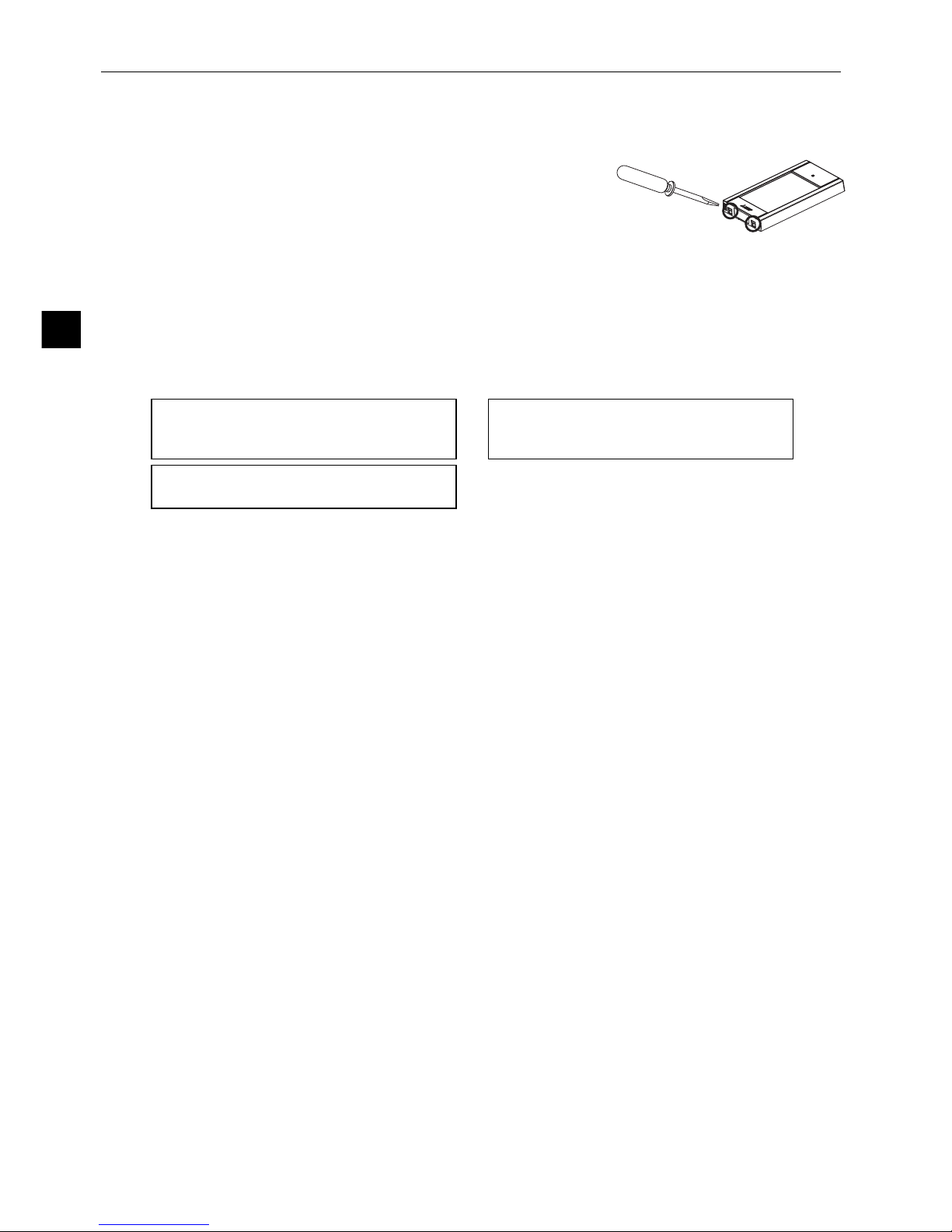

3 Prepare the bottom case of the remote controller.

4 Connect the remote controller cable to the terminal block on the bottom case.

Peel off the remote controller cable sheath as shown below to connect to the terminal block properly.

Secure the remote controller cable so that the peeled part of the cable will fit into the case.

■ Direct wall installation

• Seal the hole through which the cable is threaded with putty.

Top case Bottom case

16 (21/32)

6 (1/4)

Sheath

Unit: mm (in)

Connect the cable.

(non-polarized)

2-core wire must not be

seen on the back.

Insert the sheathed part of the cable inside

the case, and then secure the cable.

Seal the gap with putty.

Route the cable behind

the remote controller.

Remote controller cable

To reduce the risk of electric shock, shorting, or

malfunctions, keep wire pieces and sheath shavings

out of the terminal block.

Do not use solderless terminals to connect cables to

the terminal block.

Solderless terminals may come in contact with the

circuit board and cause malfunctions or damage the

controller cover.

Important

Page 12

– 12 –

GB

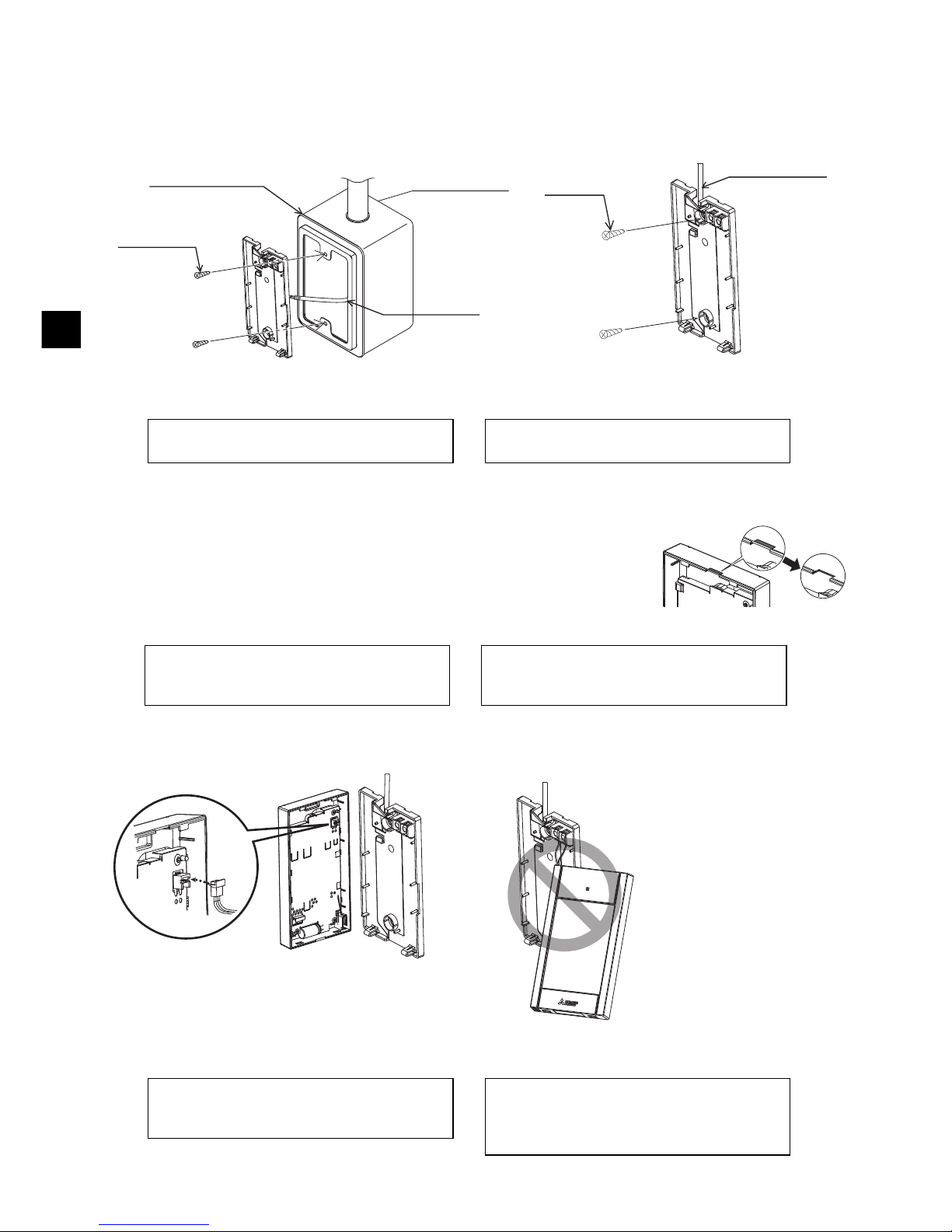

5 Install the bottom case.

Be sure to secure two places of the bottom case.

6 Cut out the cable access hole.

■ Direct wall installation (when running the cable along the wall)

• Cut out the thin-wall part on the cover (the shaded area in the right

figure) with a nipper.

• Thread the cable from the groove behind the bottom case through

this access hole.

7 Connect the connector to the top case.

Connect the connector on the bottom case to the socket on the top case.

■ Installation using a switch box ■ Direct wall installation

Remote

controller

cable

Refer to 4.

Refer to 2.

Single switch box

Roundhead

cross slot

screws

Seal the cable

access hole

with putty.

Refer to 4.

Wood

screws

Remote

controller cable

To avoid deformation and damage to the

bottom case, do not overtighten the screws.

To avoid damage to the bottom case, do not

make holes on it.

Important

Notice

To prevent damage to the circuit board,

remove the front cover from the top case

before cutting out a cable access hole.

Note that accidentally touching the circuit

board may damage the circuit board when

cutting out a cable access hole.

Connect the connector.

To prevent malfunctions, do not remove the

protective sheet or the circuit board from the

top case.

To prevent cable breakage and

malfunctions, do not hang the top controller

casing hang by the cable as shown in the

figure above.

Important

Page 13

– 13 –

GB

8 Insert the wires into the clamp.

9 Install the top case on the bottom case.

Two mounting tabs are at the top of the top case.

Hook those two tabs onto the bottom case, and click the top case into place. Check that the case is

securely installed and not lifted.

■ Direct wall installation (when running the cable along the wall)

• Thread the cable through the access hole at the top of the remote controller.

• Seal the cut-out part of the cover with putty.

• Use a cable cover.

Clamp

Insert the wires.

Hold the wires in place with the clamp to

prevent undue force from being applied to

the terminal block and causing cable

breakage.

Important

Wall

Should not

be lifted.

When attaching the top casing to the bottom

casing, push it until it they click into place.

If they are not properly locked into place,

they may fall, causing personal injury,

controller damage, or malfunctions.

Important

Seal the gap

with putty.

Use a cable

cover.

Thread the cable through the top of the

remote controller.

Page 14

– 14 –

GB

• Uninstalling the top case

1 Uninstalling the top case

Insert a flat-tip screwdriver with a blade width of 3-5 mm (1/8-7/32

inch) into the latches at the bottom of the remote controller and lift

the latches. Then, pull up the top case.

■ At the time of factory shipment, protective sheet is on the operation interface of the front

cover. Peel off the protective sheet on the operation interface prior to use.

To prevent damage to the controller casing,

do not force the flat-tip screwdriver to turn

with its tip inserted in the slot.

Do not insert the flat-tip screwdriver too far.

Doing so will damage the circuit board.

To prevent damage to the controller casing,

use a flat-head screwdriver with a blade

width of 3-5 mm (1/8-7/32 inch).

Important

Page 15

– 15 –

GB

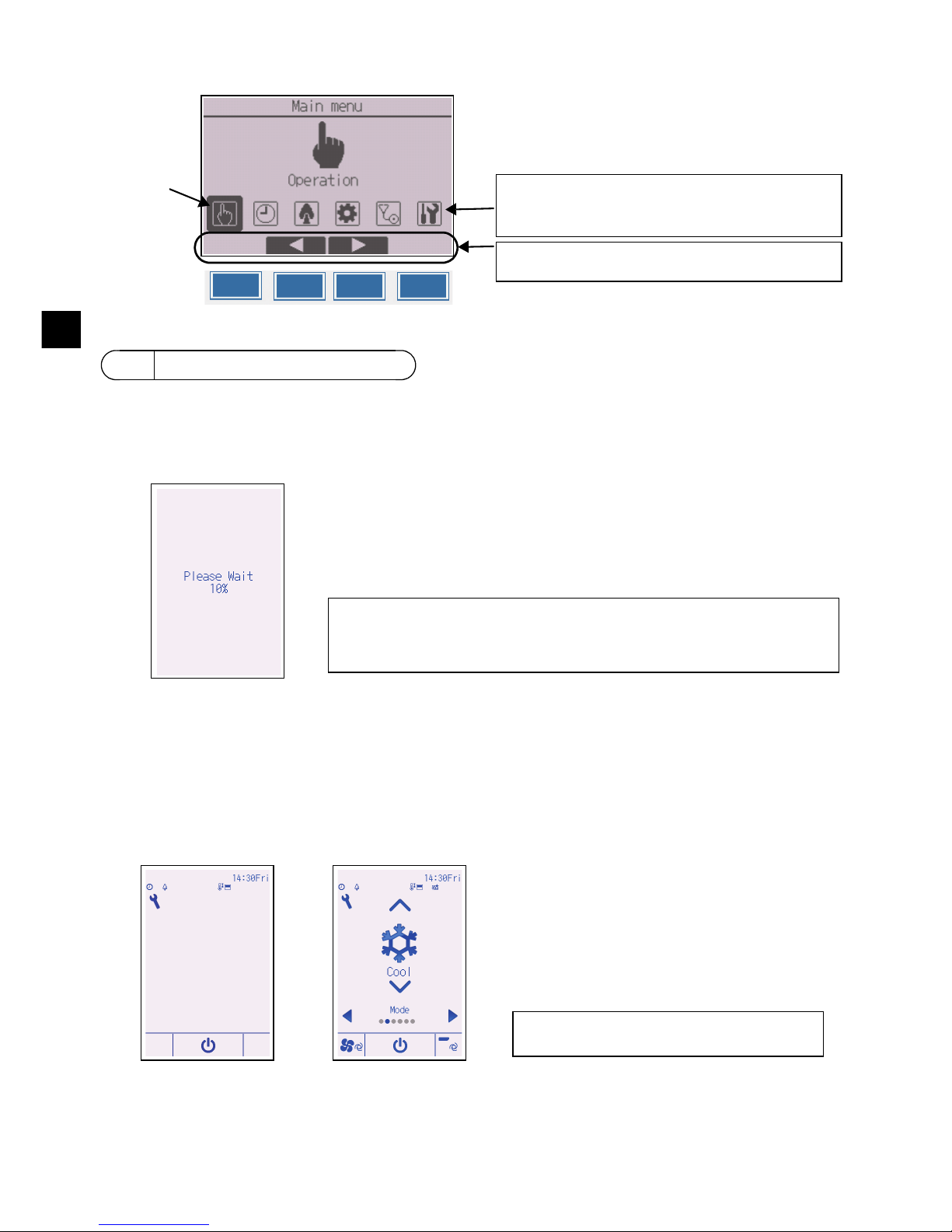

7 Remote controller button functions

(7) Touch panel & Backlit

full color LCD

(2) Function buttons

(6) Operation indicator

(11) Up/Down buttons

(4) RETURN button

(3) MENU button

(5) SELECT button

Main display Menu screen

(8) Setting button

(9) Left button

(12) Fan speed

shortcut button

(10) Right button

(13) Vane shortcut button

(1) ON/OFF button

(1) ON/OFF button

Use to turn ON/OFF the indoor unit.

(2) Function buttons

Use to select the operation mode or to set the

temperature and fan speed on the Main display.

Use to select items on other screens.

(3) MENU button

Use to bring up the Main menu.

(4) RETURN button

Use to return to the previous screen.

(5) SELECT button

Use to jump to the setting screen or to save the

settings.

(6) Operation indicator

Stays lit during normal operation. Blinks during

startup and when an error occurs.

(7) Touch panel & Backlit full color LCD

Dot display. When the backlight is off, pressing

any area turns the backlight on and it will stay lit

for a certain period of time depending on the

screen. Performing any button operation keeps

the backlight on.

(8) Setting button

Use to bring up the Main menu.

When the menu operation is locked, an

administrator password is required.

(9) Left button

Use to switch the setting items in the following

order: louver, ventilation, vane, fan speed,

operation mode, and preset temperature.

(10) Right button

Use to switch the setting items in the following

order: preset temperature, operation mode, fan

speed, vane, ventilation, and louver.

Note: When the backlight is off, pressing any area

turns the backlight on and does not perform

its function.

(11) Up/Down buttons

Use to change the contents of the setting

selected in (9) and (10) above.

(12) Fan speed shortcut button

Use to directly access the fan speed settings

screen.

(13) Vane shortcut button

Use to directly access the vane settings screen.

Pressing the Setting button will bring up the Main

menu as shown below.

Operation menu *1

Timer menu *1

Energy saving menu *1

Initial setting menu *2*3

Maintenance menu *1

Service menu *2*3

*1 Refer to the Instructions Book in the CD-ROM

for details.

*2 Explained in this manual.

*3 If no buttons are pressed for 10 minutes on the

initial setting screens, or 2 hours on the service

screens (10 minutes on some screens), the

screen will automatically return to the Main

display. Any settings that have not been saved

will be lost.

The available items on the menu depend on the

connected indoor unit model. For items not

described in the manuals that are enclosed with

the MA Touch Remote Controller, refer to the

manuals that came with the air conditioning units.

Page 16

– 16 –

GB

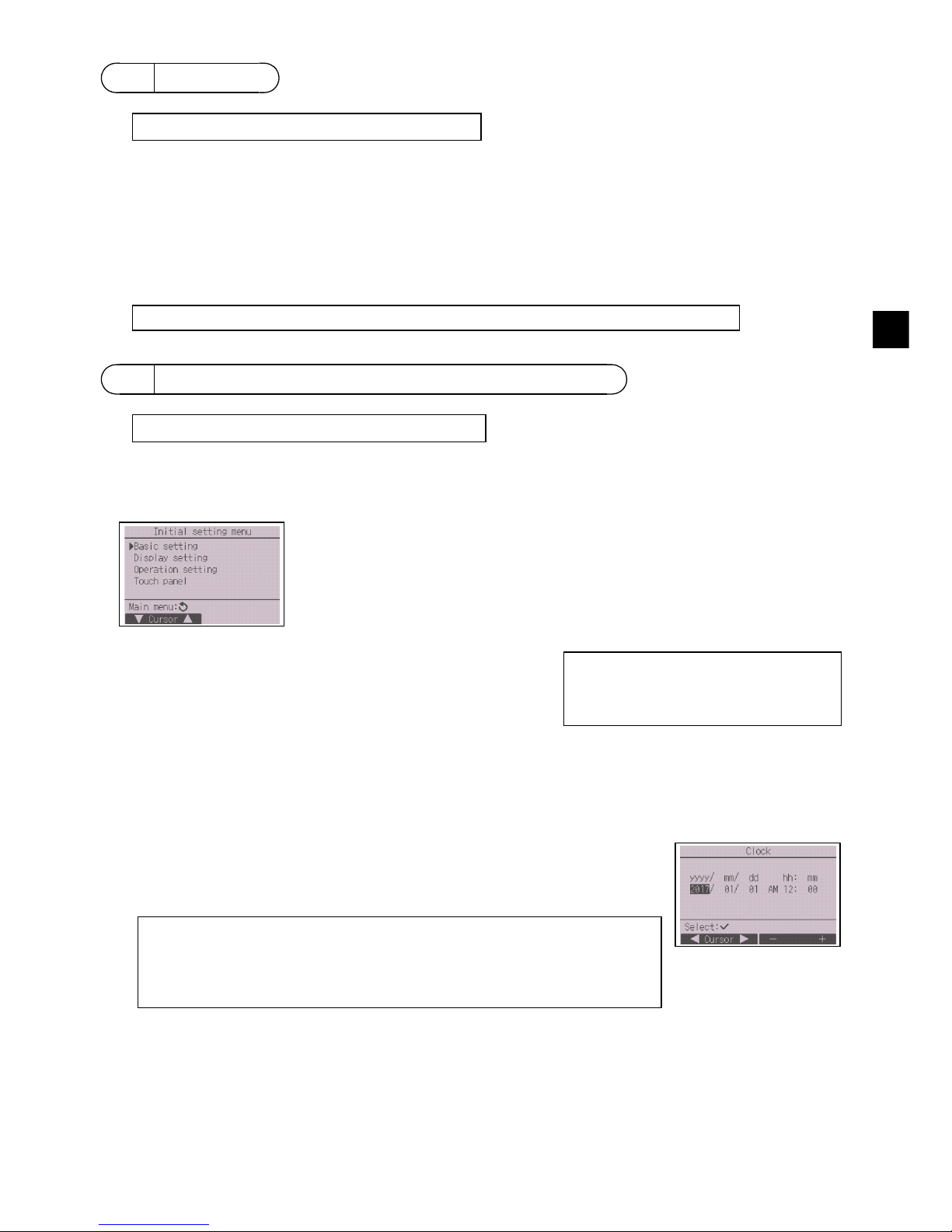

Button operations on the Main menu

Make sure that the MA remote controller is properly installed according to the instructions in the

Installation Manual and that the indoor and outdoor unit installation has been completed before

turning on the power.

(1) When the power is turned on, the following screen will appear.

(2) Main display

After the successful startup, the Status display will appear. While the Status display is displayed,

pressing any area switches the screen to the Main display. The Main display can be displayed in

two different modes: “Full” and “Basic.” Refer to section 10 “Initial settings” for how to select the

display mode. (The factory setting is “Full.”)

8 Turning on the power

Normal start up (indicating the

percentage of process completion)

Main display in the Full mode

(while the unit is not in operation)

Main display in the Full mode

(while the unit is in operation)

Cursor

Move the cursor to the desired function with the F2

and F3 buttons, and press the SELECT button to go

to the next page. Password may be required.

Button function guide will appear at the bottom of the

screens.

F1 F2 F3 F4

Note: When the power is on for the first time, the Language selection screen

will be displayed. Refer to section 10 (4) under “Display setting menu”.

Select a desired language. The system will not start-up without language

selection.

Note: Refer to the Instruction Book for the

icons on the display.

Page 17

– 17 –

GB

(1) Read the section about Test run in the indoor unit Installation Manual before performing a test

run.

(2) At the Main display, press the Setting button and select Service>Test run>Test run.

(3) Press the ON/OFF button to cancel the test run if necessary.

(4) Refer to the indoor unit Installation Manual for the detailed information about test run and for

how to handle the errors that occur during a test run.

From the Main display, select Main menu>Initial setting, and make the remote controller settings on

the screen that appears.

Basic setting menu

(1) Clock setting

[Button operation]

9 Test run

10 Initial settings (Remote controller settings)

Basic setting menu

•Clock

• Daylight saving time

• Administrator password

Display setting menu

• Main display

• Remote controller display

details setting

• Brightness

• Language selection

•Design

Operation setting menu

• Auto mode

Touch panel menu

(Refer to the Instruction Book.)

1 Move the cursor with the F1 or F2 button to the desired item.

2 Change the date and time with the F3 or F4 button, and press the

SELECT button to save the change. The change will be reflected on

the clock display on the Status display and the Main display.

Note: Clock setting is necessary for time display, weekly timer, timer setting and

error history. Make sure to perform clock setting when the unit is used for

the first time or has not used for a long time.

Note: If a given system has no system controllers, the clock time will not

automatically be corrected. In this case, periodically correct the clock time.

Note: Maintenance password is required.

Note: Refer to section 11 “Service menu” for information about the maintenance password.

Note: Administrator password is required.

Note: The initial administrator password

is “0000.” Refer to section (3)

“Administrator password setting”

for how to change the password.

Page 18

– 18 –

GB

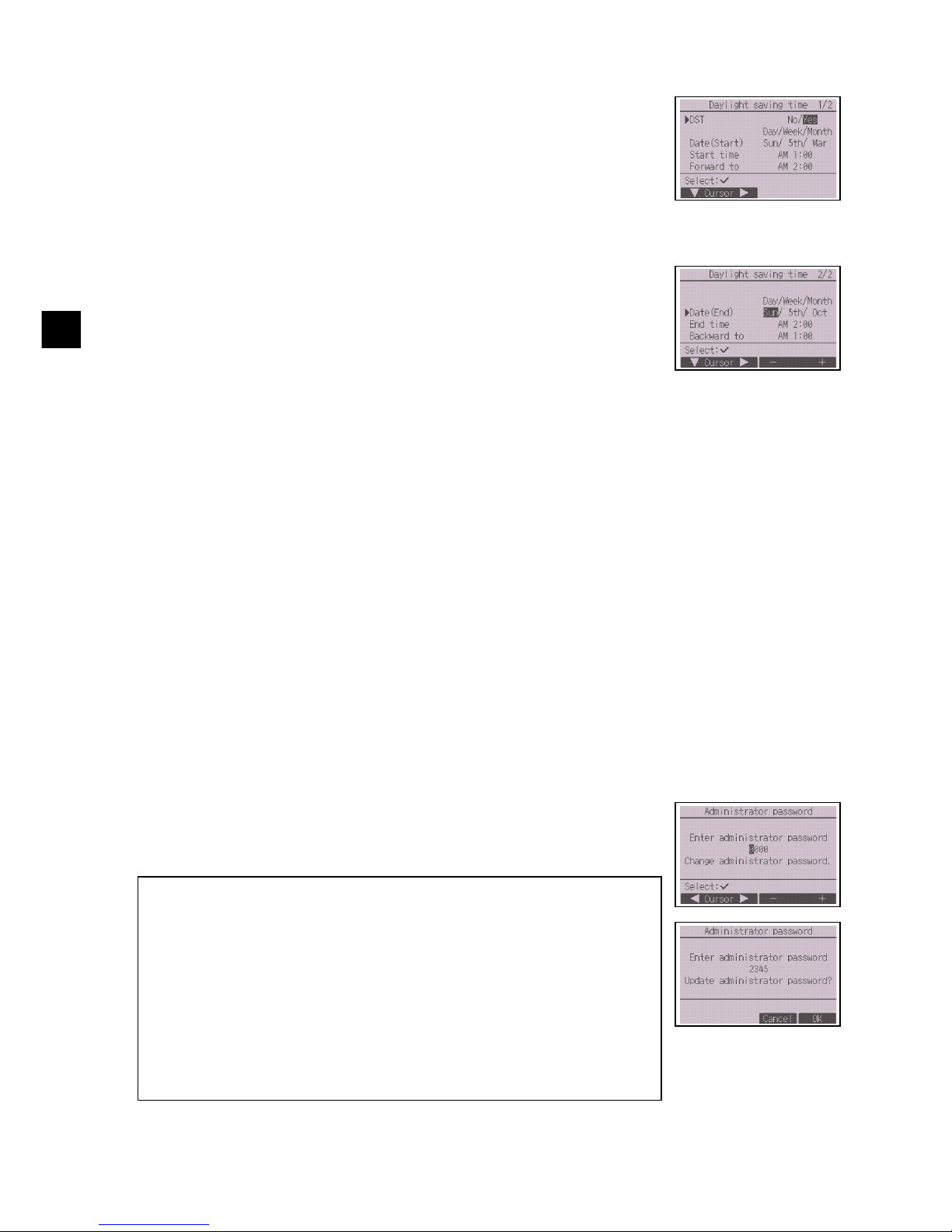

(2) Daylight saving time

[Button operation]

(3) Administrator password setting

[Button operation]

The start/end time for daylight saving time can be set. The daylight saving

time function will be activated based on the setting contents.

• If a given system has a system controller, disable this setting to keep

the correct time.

• At the beginning and the end of daylight saving time, the timer may go

into action twice or not at all.

• This function will not work unless the clock has been set.

1 The daylight saving time function can be activated/deactivated or the

start/end times can be set by using the F1 through F4 buttons.

•DST

Select “Yes” to activate the daylight saving time, or select “No” to

deactivate.

• Date(Start)

Set the start day of the week, week number, and month for daylight

saving time.

• Start time

Set the start time for daylight saving time.

• Forward to

Set the time when the clock is to be set forward to at the start time

above.

• Date(End) (2nd page)

Set the end day of the week, week number, and month for daylight

saving time.

• End time (2nd page)

Set the end time for daylight saving time.

• Backward to (2nd page)

Set the time when the clock is to be set backward to at the end time

above.

2 Press the SELECT button to save the setting.

* If “5th” is selected for the week number and the 5th week does not exist in the

selected month of the year, the setting is considered to be “4th.”

1 A window to enter a new password will appear. Enter a new password,

and press the SELECT button.

2 Press the F4 button (OK) on the password change confirmation screen

to save the change. Press the F3 button (Cancel) to cancel the change.

Note: The initial administrator password is “0000.” Change the default password

as necessary to prevent unauthorized access. Have the password

available for those who need it.

Note: If you forget your administrator password, you can initialize the password

to the default password “0000” by pressing and holding the F1 button for

ten seconds on the administrator password setting screen.

Note: The administrator password is required to make the settings for the

following items.

· Timer setting · Weekly timer setting · Energy-save setting

· Outdoor unit silent mode setting · Restriction setting

· Night setback setting · Initial setting

Refer to the Instruction Book that came with the remote controller for the

detailed information about how to make the settings for these items.

Page 19

– 19 –

GB

Display setting menu

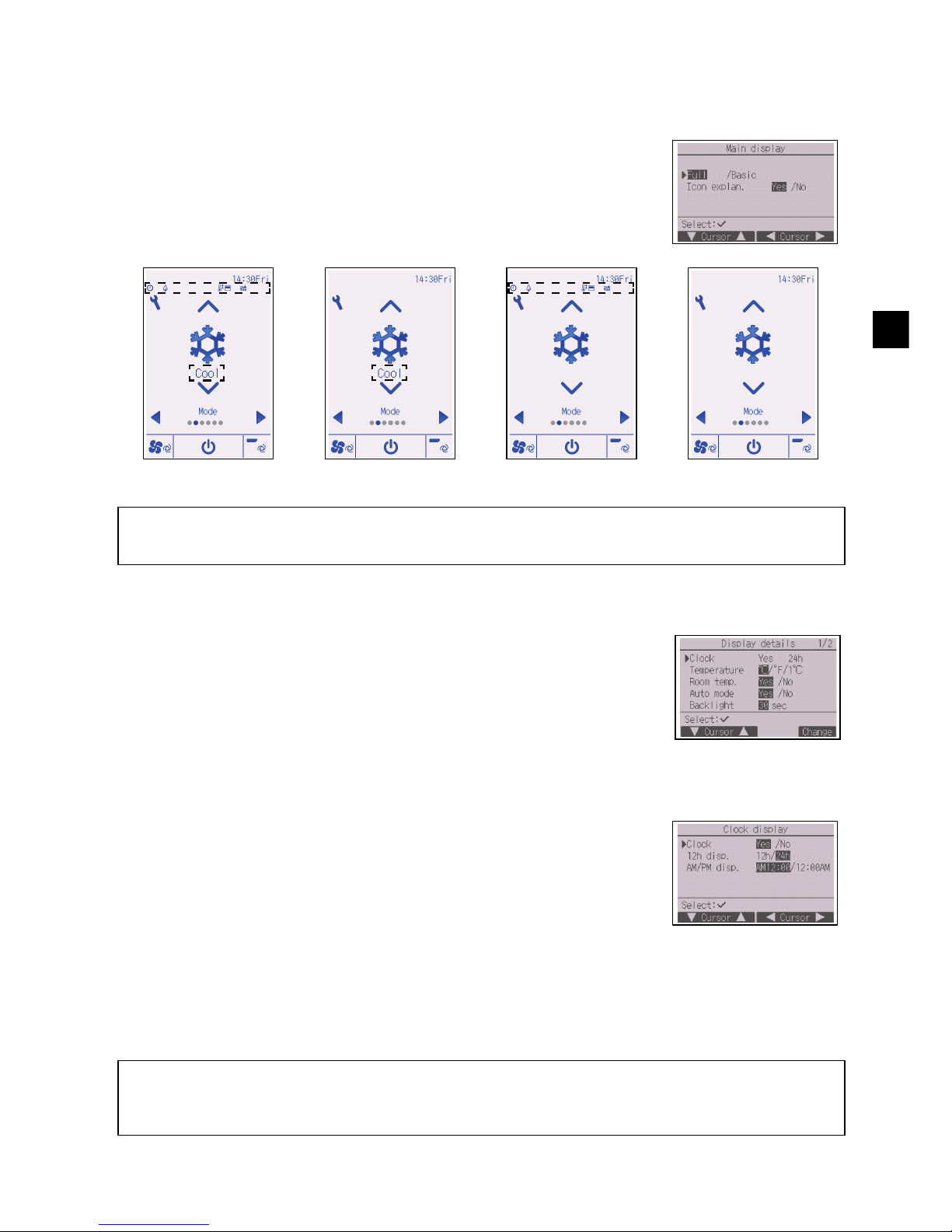

(1) Main display setting

[Button operation]

(2) Remote controller display details setting

[1] Clock display

[Button operation]

1 Move the cursor to “Full/Basic,” and use the F3 or F4 button to select

the display mode “Full” or “Basic.” (The factory setting is “Full.”)

2 Move the cursor to “Icon explan.” and use the F3 or F4 button to select

the display mode “Yes” or “No.” (The factory setting is “Yes.”)

Example: Full mode

(Icon explanation enabled)

Example: Basic mode

(Icon explanation enabled)

Example: Full mode

(Icon explanation disabled)

Example: Basic mode

(Icon explanation disabled)

Note: This setting is only for the Main display. In the Basic mode, icons that indicate control status on timer and

schedule settings will not appear on the display. When “No” is selected, the explanation of the setting

contents on the Main display will not appear.

Make the settings for the remote-controller-related items as necessary.

Press the SELECT button to save the changes.

1 Select “Clock” from the display details setting screen, and press the

F4 button (Change) to bring up the clock display setting screen.

2 Use the F1 through F4 buttons to select “Yes” (display) or “No” (non-

display) and its format for the Status display and the Main display.

3 Save the settings with the SELECT button. (The factory settings are

“Yes” (display) and “24 h” format.)

Clock display: Yes (Time is displayed on the Status display and the Main display.)

No (Time is not displayed on the Status display and the Main display.)

Display format: 24-hour format

12-hour format

AM/PM display (Effective when the display format is 12-hour): AM/PM before the time

AM/PM after the time

Note: Time display format will also be reflected on the timer and schedule setting display. The time is displayed

as shown below.

12-hour format: AM12:00 ~ AM1:00 ~ PM12:00 ~ PM1:00 ~ PM11:59

24-hour format: 0:00 ~ 1:00 ~ 12:00 ~ 13:00 ~ 23:59

Page 20

– 20 –

GB

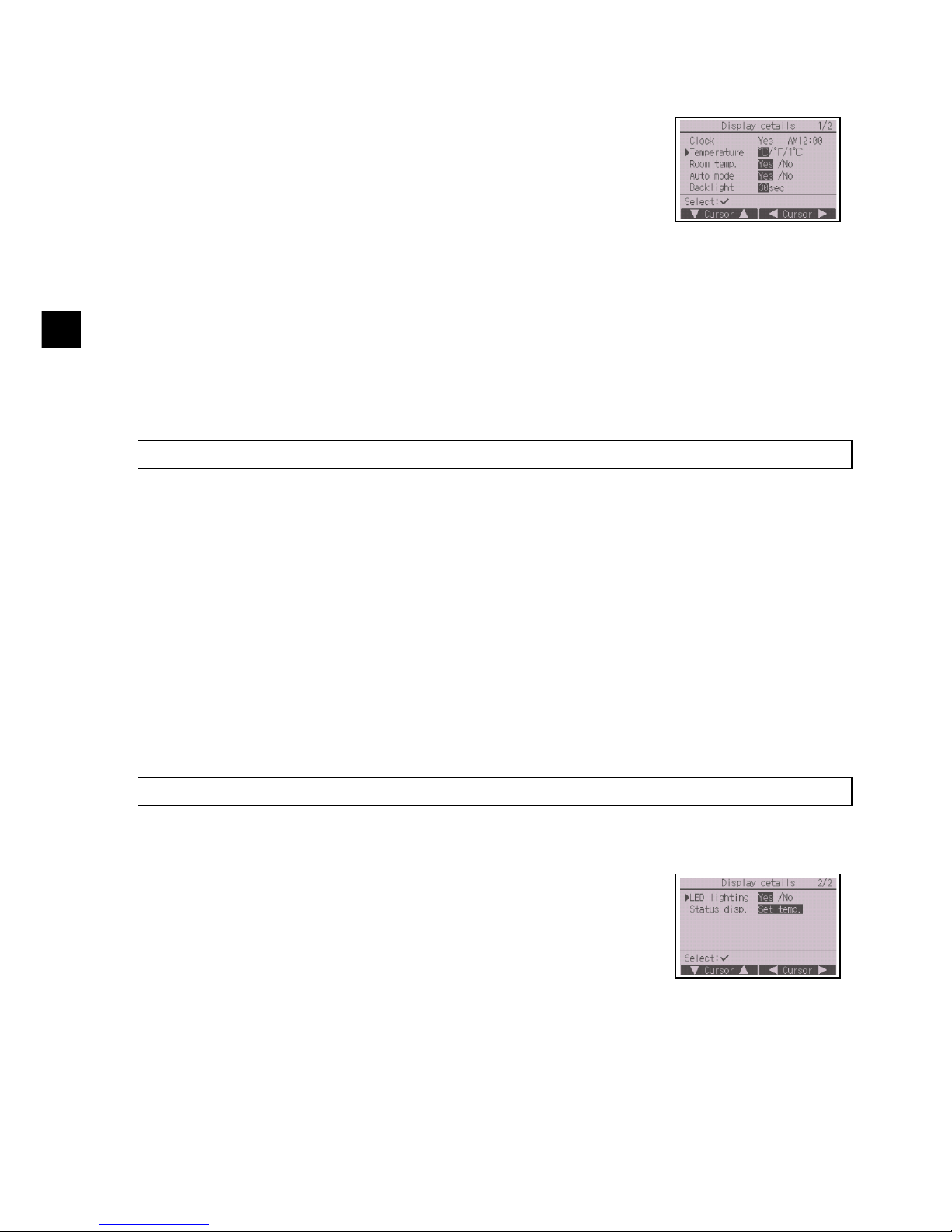

[2] Temperature unit setting

[Button operation]

[3] Room temperature display

[Button operation]

[4] Auto (single set point) mode display setting

[Button operation]

[5] Backlight

The backlight lighting-up time can be set.

[Button operation]

[6] LED lighting

Move the cursor to “Temperature” from the display details setting screen,

and select the desired temperature unit with the F3 or F4 button. (The

factory setting is Centigrade (ºC).)

• ºC: Temperature is displayed in Centigrade. Temperature is displayed

in 0.5- or 1-degree increments, depending on the model of indoor

units.

• ºF: Temperature is displayed in Fahrenheit.

• 1 ºC: Temperature is displayed in Centigrade in 1-degree increments.

Move the cursor to “Room temp.” on the display details setting screen, and select the desired

setting with the F3 or F4 button.

(The factory setting is “Yes”.)

• Yes: Room temperature appears on the Main display.

• No: Room temperature does not appear on the Main display.

Note: Even when “Yes” is set, the room temperature is not displayed on the Main display in the “Basic” mode.

Move the cursor to “Auto mode” from the display details setting screen, and select the desired

mode with the F3 or F4 button. (The factory setting is “Yes.”)

• Yes: “Auto Cool” or “Auto Heat” is displayed during operation in the Auto (single set point) mode.

• No: Only “Auto” is displayed during operation in the Auto (single set point) mode.

Move the cursor to “Backlight” from the display details setting screen, and select the desired time

(5/10/20/30/60 seconds) with the F4 button. (The factory setting is “30” seconds.)

Note: This setting is effective on the Status display and the Main display.

The LED lighting can be set to either “Yes” (On) or “No” (Off). (The

factory setting is “Yes”.)

When “No” is selected, the LED will not light up even during the normal

operation.

Page 21

– 21 –

GB

[7] Status display

Make the settings for the temperature to be displayed on the Status display.

[Button operation]

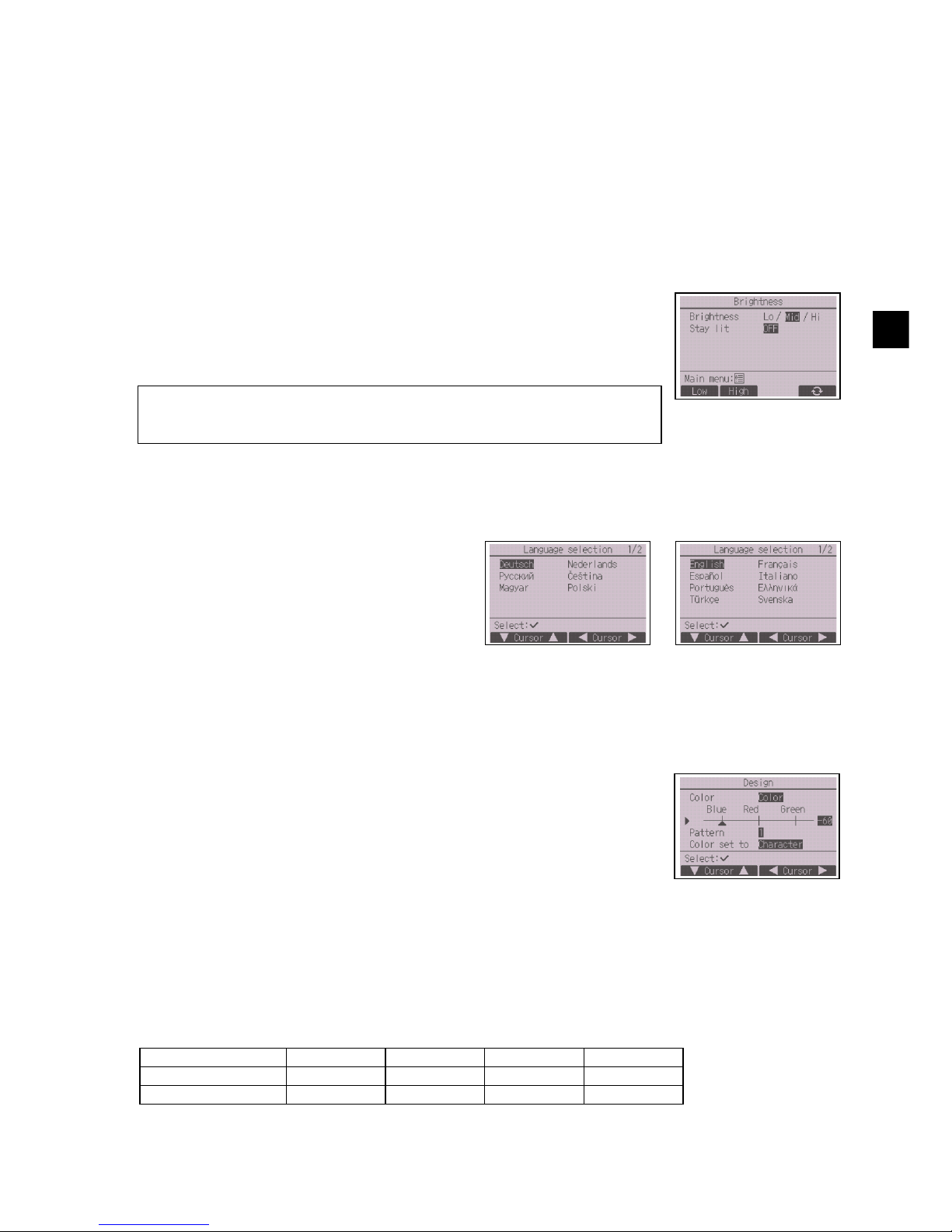

(3) Brightness

[Button operation]

(4) Language selection

[Button operation]

(5) Design setting

The screen design can be set.

[Button operation]

* At factory shipment, these items are set as follows.

Move the cursor to “Status disp.” from the display details setting screen, and select the desired

setting with the F4 button.

Each pressing the F4 button will toggle through the following options: Set temp., Room temp., and

Hide.

Select the desired brightness for the remote controller LCD with the F1

and F2 buttons.

The ON/OFF of the Stay lit mode can be switched with the F4 button.

When “ON” is selected, the backlight will remain lit dimly even after the

specified time has elapsed.

Note: Adjust the brightness to improve viewing in different lighting conditions or

installation locations. This setting can not improve viewing from all

directions.

Move the cursor to the language you desire with

the F1 through F4 buttons.

Press the SELECT button to save the setting.

Select the color option with the F4 button.

• Color: The display color can be selected.

• White: Monochrome display (white basis)

• Black: Monochrome display (black basis)

When “White” or “Black” is selected, press the SELECT button. When

“Color” is selected, select the following item with the F1 or F2 button, and

set the desired display color for each item.

• Color shade: Set the color shade with the F3 or F4 button. (The

settable range is -90 to 89.)

• Pattern: Set the color with the F4 button.

• Color set to: Select “Character” or “BG” (Background) as a target to

which the color is applied with the F4 button.

Color option Color shade Pattern Color set to

CT01MAA(R)-S, SB Color -70 1 Character

CT01MAA(R)-PB Color -90 2 Character

Page 22

– 22 –

GB

Operation setting menu

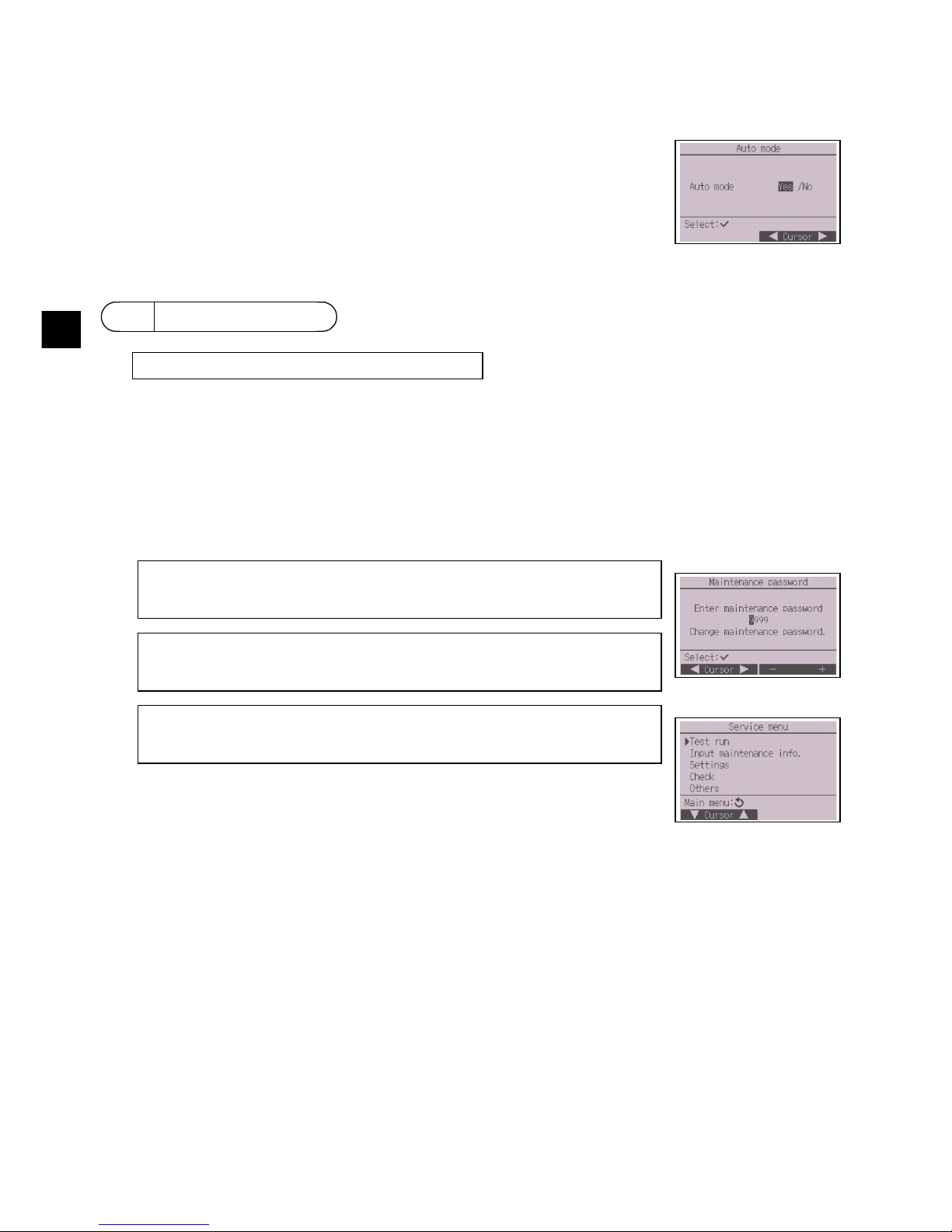

(1) Auto mode setting

[Button operation]

At the Main display, press the Setting button and select “Service” to make the maintenance settings.

When the Service menu is selected, a window will appear asking for the password.

To enter the current maintenance password (4 numerical digits), move the cursor to the digit you want

to change with the F1 or F2 button, and set each number (0 through 9) with the F3 or F4 button. Then,

press the SELECT button.

Whether or not to use the Auto (single set point) or Auto (dual set points)

mode can be selected by using the F3 or F4 button. This setting is valid

only when indoor units with the Auto mode function are connected.

(The factory setting is “Yes”.)

Press the SELECT button to save the changes made.

• Yes: The Auto mode can be selected in the operation mode setting.

• No: The Auto mode cannot be selected in the operation mode setting.

11 Service menu

Note: The initial maintenance password is “9999.” Change the default password

as necessary to prevent unauthorized access. Have the password

available for those who need it.

Note: If you forget your maintenance password, you can initialize the password

to the default password “9999” by pressing and holding the F1 button for

ten seconds on the maintenance password setting screen.

Note: Air conditioning units may need to be stopped to make certain settings.

There may be some settings that cannot be made when the system is

centrally controlled.

Note: Maintenance password is required.

Page 23

– 23 –

GB

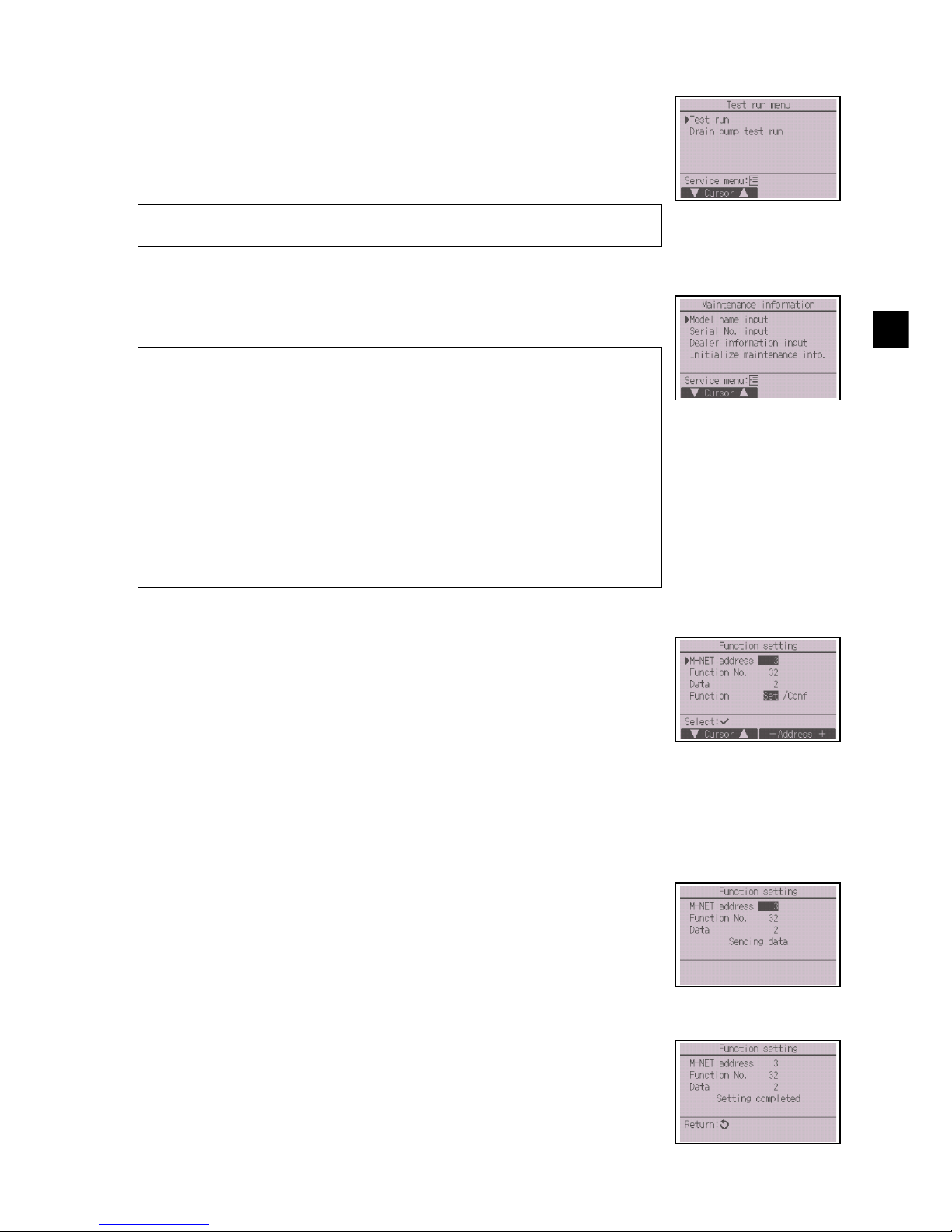

(1) Test run (CITY MULTI and Mr. SLIM)

(2) Input maintenance information (CITY MULTI and Mr. SLIM)

(3) Function setting (CITY MULTI)

[Button operation]

Select “Test run” from the Service menu to bring up the Test run menu.

• Test run: Select this option to perform a test run.

• Drain pump test run: Select this option to perform a test run on the

drain pump on the indoor unit.

Applicable only to the type of indoor units that support the test run

function.

Note: Refer to the indoor unit Installation Manual for the detailed information

about test run.

Select “Input maintenance info.” from the Service menu to bring up the

Maintenance information screen. Refer to the indoor unit Installation

Manual for how to make the settings.

Note: The following settings can be made from the Maintenance information

screen.

·Registering model names and serial numbers

Enter the model names and serial numbers of outdoor and indoor units.

The information entered will appear on the Error information screen.

Model names can have up to 18 characters, and the serial numbers can

have up to 8 characters.

·Registering dealer information

Enter phone number of a dealer. The entered information will appear on

the Error information screen. Phone number can have up to 13

characters.

·Initializing maintenance information

Select the desired item to initialize the model name, serial number, and

dealer information settings.

Make the settings for the indoor unit functions via the remote controller as

necessary.

Select “Function setting” from the Settings menu to bring up the Function

setting screen.

1 The Function setting screen will appear.

Press the F1 or F2 button to move the cursor to one of the following: M-NET address, function

setting number, or setting value. Then, press the F3 or F4 button to change the settings to the

desired settings.

2 Once the settings have been completed, press the SELECT button.

A screen will appear that indicates that the settings information is being

sent.

To check the current settings of a given unit, enter the setting for its MNET address and function setting number, select Conf for the Function,

and press the SELECT button.

A screen will appear that indicates that the settings are being searched

for. When the search is done, the current settings will appear.

3 When the settings information has been sent, a screen will appear that

indicates its completion.

To make additional settings, press the RETURN button to return to the

screen shown in Step 2 above. Set the function numbers for other

indoor units by following the same steps.

Page 24

– 24 –

GB

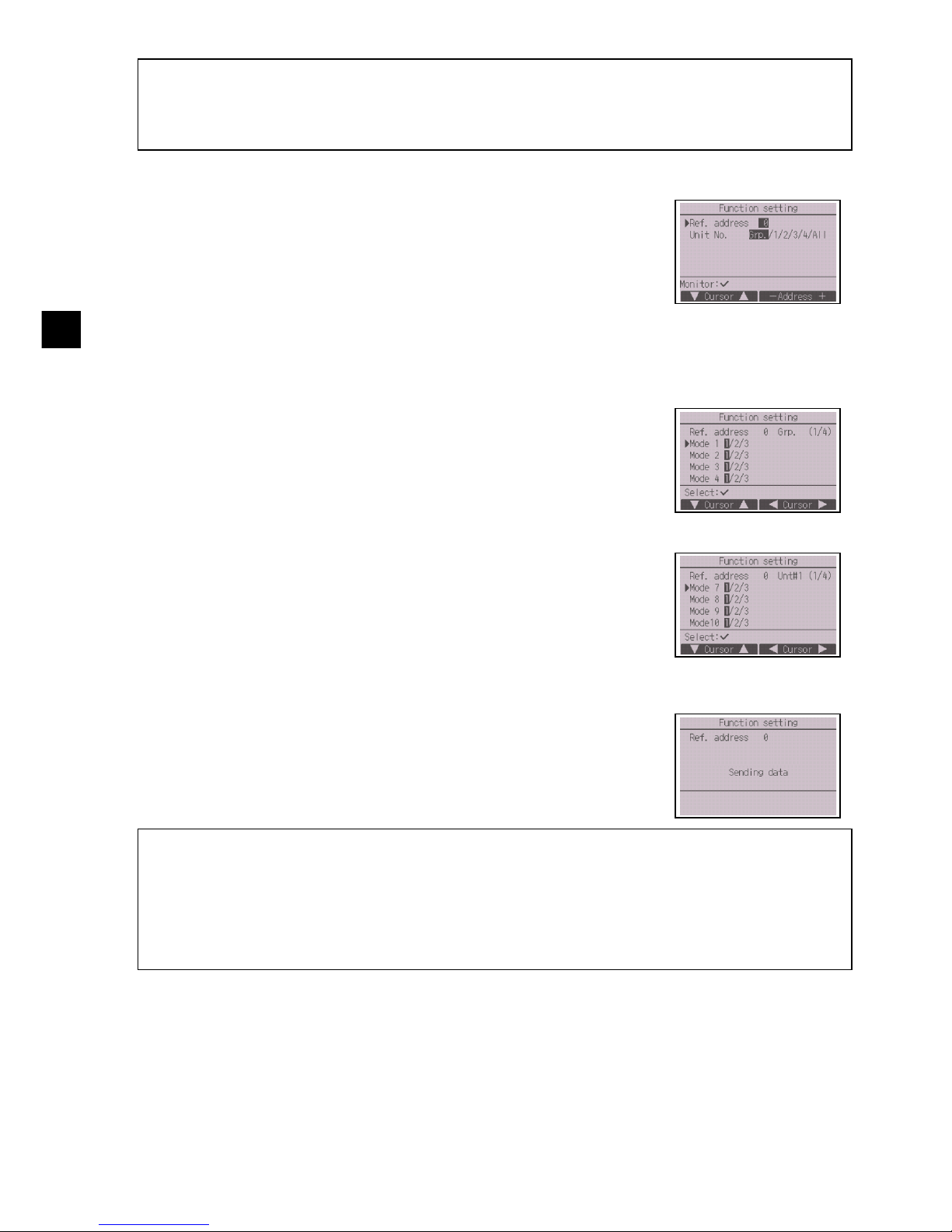

(4) Function setting (Mr. SLIM)

[Button operation]

Note:

· Refer to the indoor unit Installation Manual for information about the factory settings of indoor units,

function setting numbers, and setting values.

· Be sure to write down the settings for all functions if any of the initial settings has been changed after the

completion of installation work.

Make the settings for the indoor unit functions via the remote controller as

necessary.

Select “Function setting” from the Settings menu to bring up the Function

setting screen.

1 Set the indoor unit refrigerant addresses and unit numbers with the F1 through F4 buttons, and

then press the SELECT button to confirm the current setting.

2 When data collection from the indoor units is completed, the current

settings appears highlighted. Non-highlighted items indicate that no

function settings are made. Screen appearance varies depending on

the “Unit No.” setting.

Common items

3 Use the F1 or F2 button to move the cursor to select the mode number,

and change the setting number with the F3 or F4 button.

Individual items

(Unit No. 1 through 4)

4 When the settings are completed, press the SELECT button to send the

setting data from the remote controller to the indoor units.

5 When the transmission is successfully completed, the screen will return

to the Function setting screen.

Note:

· Make the function settings shown in Table 1 on Mr. SLIM units as necessary.

· Refer to the Instructions Book when it is necessary to set the settings for CITY MULTI units.

· Table 1 summarizes the setting options for each mode number. Refer to the indoor unit Installation

Manual for the detailed information about initial settings, mode numbers, and setting numbers for the

indoor units.

· Be sure to write down the settings for all functions if any of the initial settings has been changed after the

completion of installation work.

Page 25

– 25 –

GB

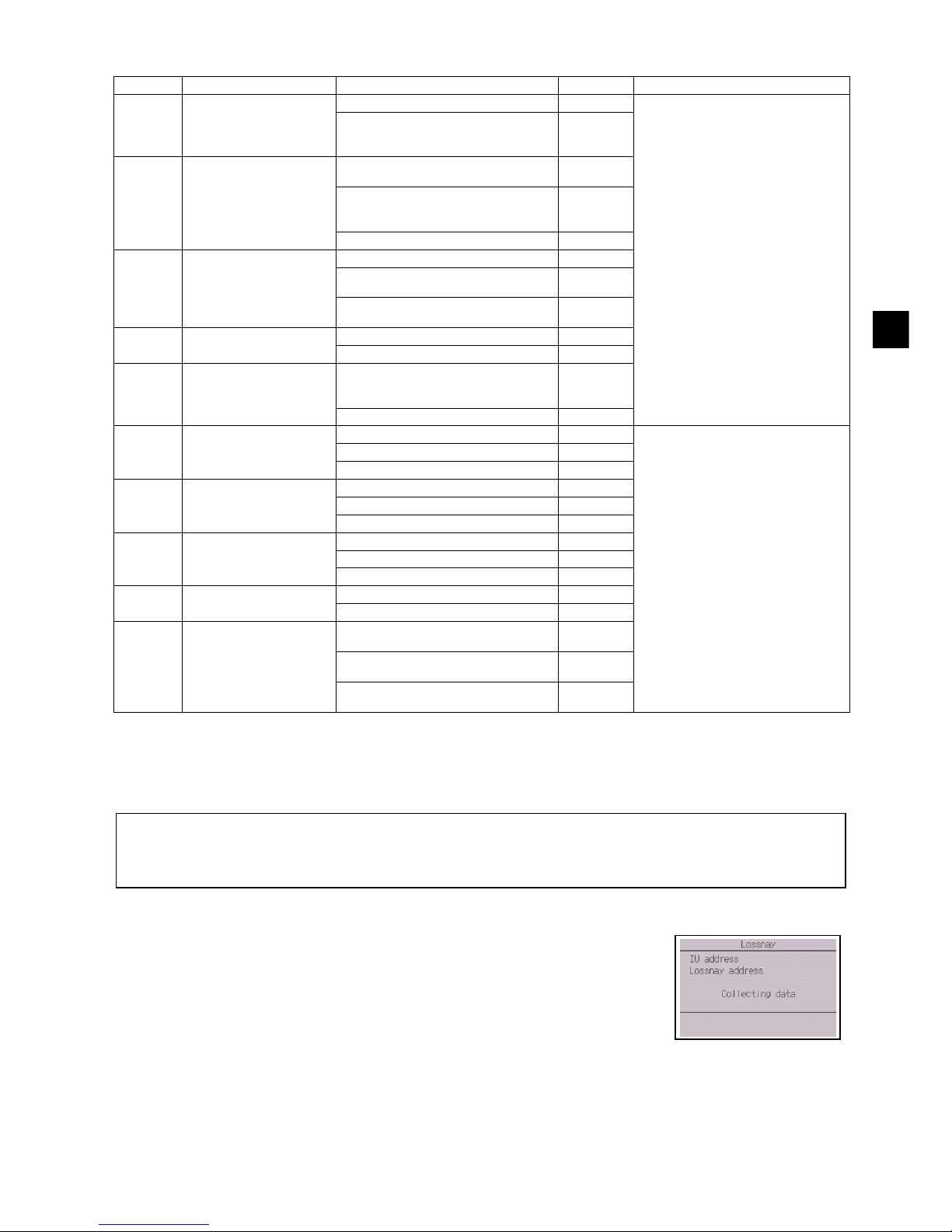

Table1. Function setting options

(5) LOSSNAY setting (CITY MULTI only)

This setting is required only when the operation of CITY MULTI units is interlocked with LOSSNAY

units. This setting is not available for the Mr. SLIM units. Interlock settings can be made for the indoor

unit to which the remote controller is connected. (They can also be confirmed or deleted.)

[Button operation]

Mode No. Mode Settings Setting No. Unit numbers

01 Automatic recovery after

power failure

Disable 1 Set “Grp.” for the Unit number.

These settings apply to all the

connected indoor units.

Enable (Four minutes of standby time

is required after the restoration of

power.)

2

02 Thermistor selection

(indoor temperature

detection)

Average temperature reading of the

indoor units in operation

1

Thermistor on the indoor unit to which

the remote controller is connected

(fixed)

2

Built-in sensor on the remote controller 3

03 LOSSNAY connection Not connected 1

Connected (without outdoor air intake

by the indoor units )

2

Connected (with outdoor air intake by

the indoor units )

3

04 Power voltage 240 V 1

220 V, 230 V 2

05 Auto mode Enable (Automatically the unit

achieves effective energy saving

operation.)

1

Disable 2

07 Filter sign 100 hours 1 Set “1, 2, 3, 4, or All” for the Unit

number.

These settings apply to each indoor

unit.

·If “1, 2, 3, or 4” is set for the Unit

number, the settings apply only to

the specified indoor unit regardless

of the number of connected indoor

units (one through four units).

·If “All” is set for the Unit number, the

settings apply to all the connected

indoor units regardless of the

number of connected indoor units

(one through four units).

2500 hours 2

Not displayed 3

08 Fan speed Silent mode (or standard) 1

Standard (or High ceiling 1) 2

High ceiling (or High ceiling 2) 3

09 Outlet 4 directional 1

3 directional 2

2 directional 3

10 Optional parts

(High-efficiency filter)

No 1

Ye s 2

11 Vane No vanes (or the vane setting No.3 is

effective.)

1

Equipped with vanes (The vane

setting No.1 is effective.)

2

Equipped with vanes (The vane

setting No.2 is effective.)

3

Note:

· Use the centralized controller to make the settings if it is connected.

· To interlock the operation of the indoor units with the LOSSNAY units, be sure to interlock the addresses of ALL

indoor units in the group and that of the LOSSNAY unit.

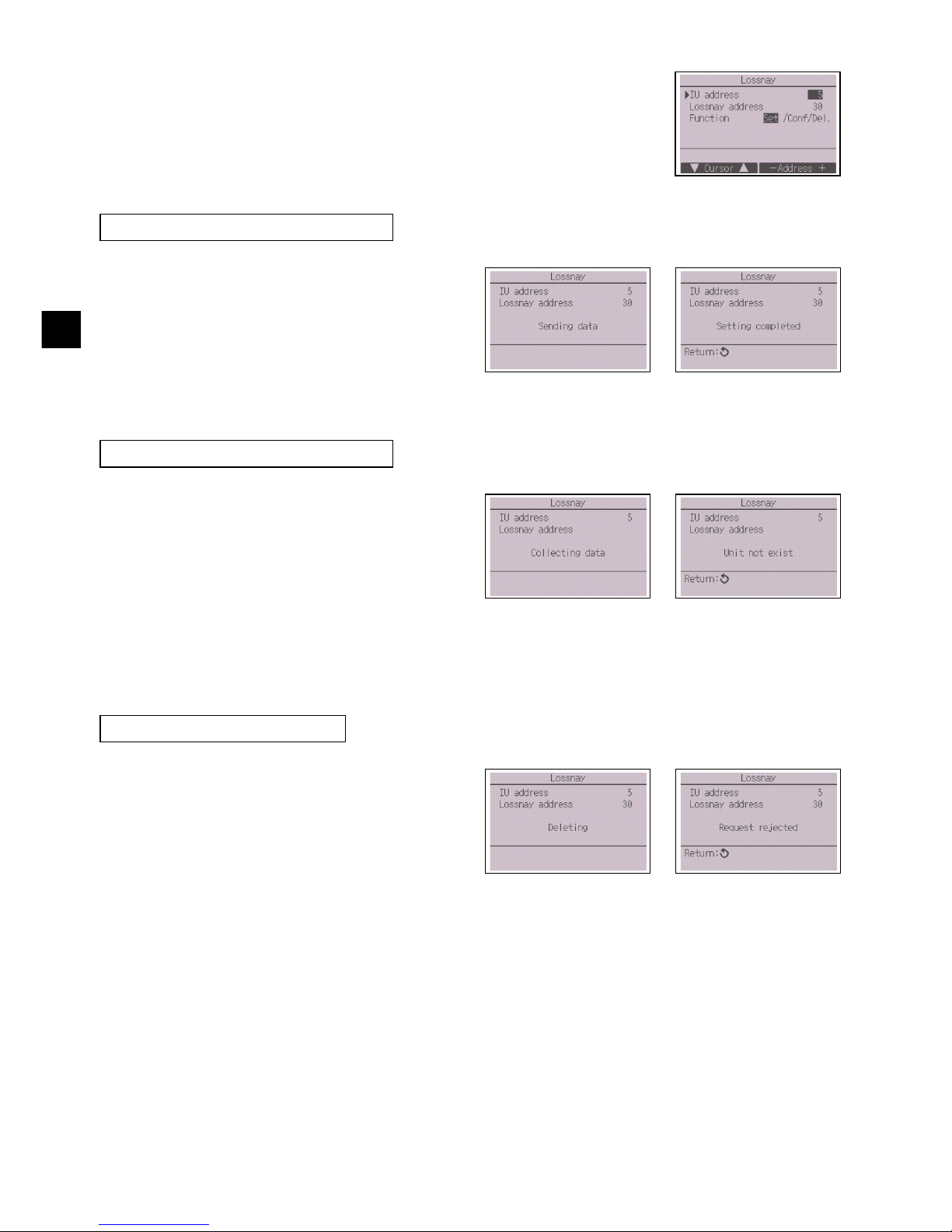

1 When “Lossnay” on the Settings menu is selected, the remote controller

will automatically begin searching for the registered LOSSNAY

addresses of the currently connected indoor unit.

Page 26

– 26 –

GB

2 When the search is completed, the smallest address of the indoor units

that are connected to the remote controller and the address of the

interlocked LOSSNAY unit will appear. “--” will appear if no LOSSNAY

unit is interlocked with the indoor units.

If no settings need to be made, press the RETURN button to go back to

the Settings menu.

To make LOSSNAY interlock setting

3 Enter the addresses of the indoor unit and the

LOSSNAY unit to be interlocked, with the F1

through F4 buttons, select “Set” in the

“Function”, and press the SELECT button to

save the settings. “Sending data” will appear

on the screen. If the setting is successfully

completed, “Setting completed” will appear.

To search for the LOSSNAY address

4 Enter the address of the indoor unit to which

the remote controller is connected, select

“Conf” in the “Function”, and press the

SELECT button. “Collecting data” will appear

on the screen. If the signal is received

correctly, the indoor unit address and

LOSSNAY address will appear. “--” will

appear when no LOSSNAY unit is found.

“Unit not exist” will appear if no indoor units

that are correspond to the entered address

are found.

To delete the interlock setting

5 To delete the interlocked setting between

LOSSNAY unit and the indoor units to which

the remote controller is connected, enter the

indoor unit address and LOSSNAY address

with the F1 through F4 buttons, select “Del.”

in the “Function”, and press the SELECT

button. “Deleting” will appear. The screen will

return to the search result screen if the

deletion is successfully completed. “Unit not

exist” will appear if no indoor units that are

correspond to the entered address are found.

If deletion fails, “Request rejected” will

appear on the screen.

Page 27

– 27 –

GB

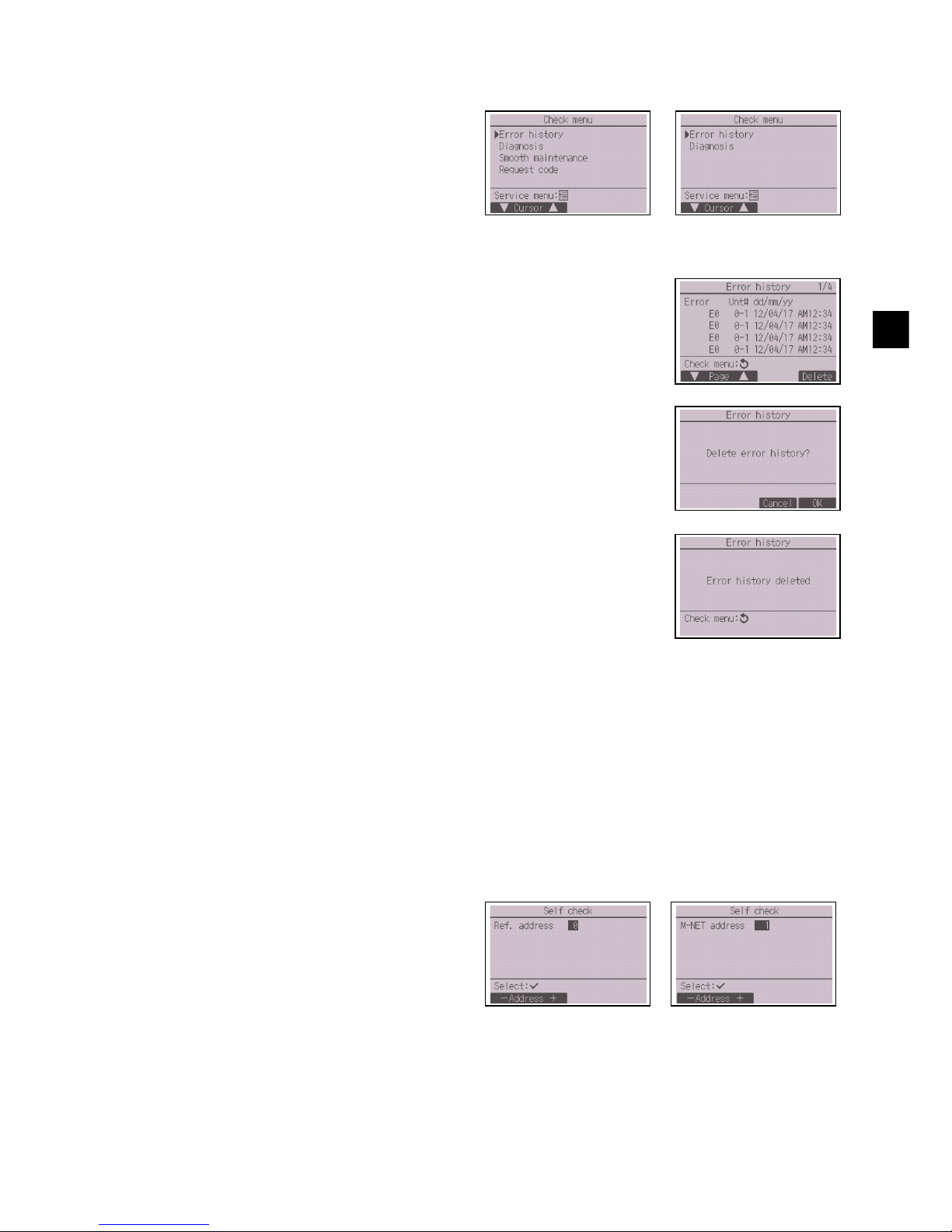

(6) Check

[Button operation]

(7) Diagnostic function

Error history of each unit can be checked via the remote controller.

[Button operation]

Select “Check” on the Service menu to bring up

the Check menu screen.

The type of menu that appears depends on the

type of indoor units that are connected (CITY

MULTI or Mr. SLIM).

(When CITY MULTI is connected, only “Error

history” will appear in the menu.)

<Mr. SLIM> <CITY MULTI>

1 Error history

Select “Error history” from the Check menu, and press the SELECT

button to view up to 16 error history records. Four records are shown

per page, and the top record on the first page indicates the latest error

record.

[Deleting the error history]

To delete the error history, press the F4 button (Delete) on the screen

that shows error history. A confirmation screen will appear asking if you

want to delete the error history.

Press the F4 button (OK) to delete the error history.

“Error history deleted” will appear on the screen. Press the RETURN

button to go back to the Check menu screen.

2 Other options in the Check menu (Mr. SLIM only)

The following options are also available on the Mr. SLIM units in the Check menu.

• Smooth maintenance

• Request code

These options are available only on the Mr. SLIM units. Refer to the indoor unit Installation Manual

for details.

1 Select “Self check” from the Diagnosis menu,

and press the SELECT button to view the

Self check screen.

2 With the F1 or F2 button, enter the refrigerant

address (Mr. SLIM) or the M-NET address

(CITY MULTI), and press the SELECT

button.

3 Error code, unit number, attribute, and indoor

unit demand signal ON/OFF status at the

contact (CITY MULTI only) will appear. “-” will

appear if no error history is available.

<Mr. SLIM> <CITY MULTI>

Page 28

– 28 –

GB

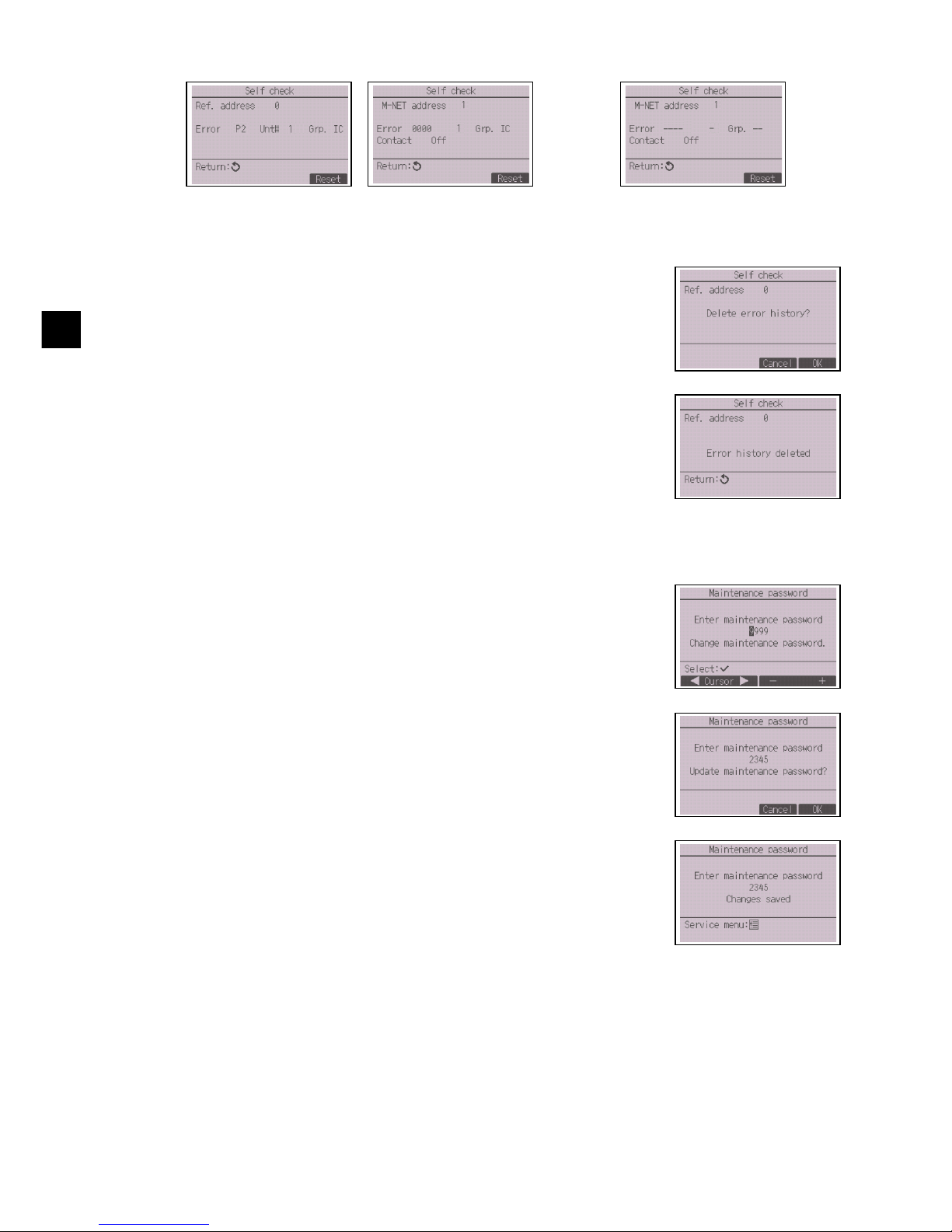

[Resetting the error history]

(8) Changing the maintenance password

[Button operation]

<Mr. SLIM> <CITY MULTI>

When there is no error history

1 Press the F4 button (Reset) on the screen that shows the error history.

A confirmation screen will appear asking if you want to delete the error

history.

2 Press the F4 button (OK) to delete the error history. If deletion fails,

“Request rejected” will appear, and “Unit not exist” will appear if no

indoor units that are correspond to the entered address are found.

1 Select “Maintenance password” on the Others menu, and press the

SELECT button to bring up the screen to enter a new password.

2 Move the cursor to the digit you want to change with the F1 or F2

button, and set each digit to the desired number (0 through 9) with the

F3 or F4 button.

3 Press the SELECT button to save the new password.

4 A confirmation screen will appear asking if you want to change the

maintenance password. Press the F4 button (OK) to save the change.

Press the F3 button (Cancel) to cancel the change.

5 “Changes saved” will appear when the password is updated.

6 Press the MENU button to return to the Service menu or press the

RETURN button to go back to the “Maintenance password” screen.

Page 29

– 29 –

GB

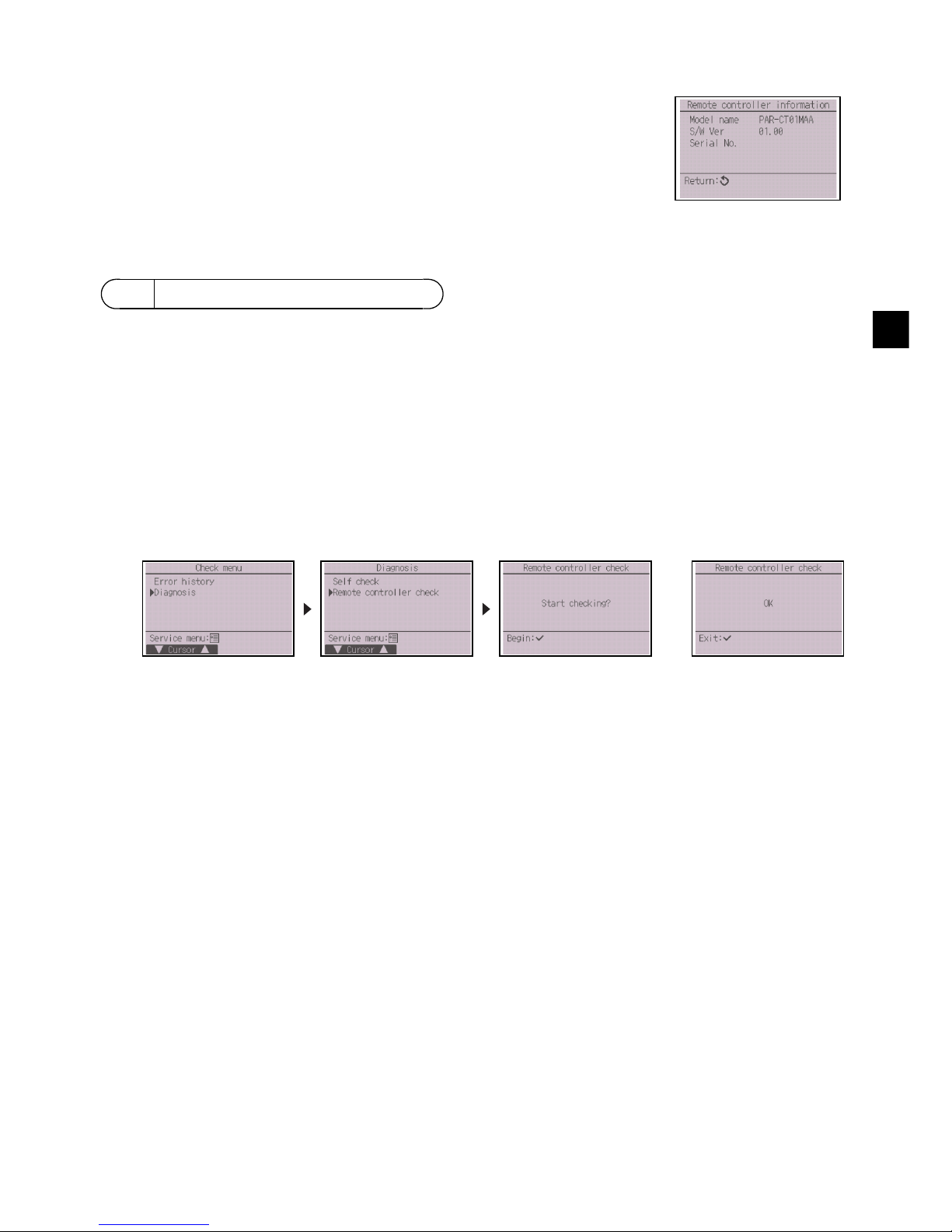

(9) Remote controller information

When the remote controller does not work properly, use the remote controller checking function to

troubleshoot the problem.

(1) Check the remote controller display and see if anything is displayed (including lines). Nothing will

appear on the remote controller display if the correct voltage (8.5-12 VDC) is not supplied to the

remote controller. If this is the case, check the remote controller wiring and indoor units.

[Button operation]

OK: No problems are found with the remote controller. Check other parts for problems.

E3, 6832: There is noise on the transmission line, or the indoor unit or another remote controller is faulty. Check

the transmission line and the other remote controllers.

NG (ALL0, ALL1): Send-receive circuit fault. Remote controller needs replacing.

ERC: The number of data errors is the discrepancy between the number of bits in the data transmitted from the

remote controller and that of the data that was actually transmitted over the transmission line. If data errors

are found, check the transmission line for external noise interference.

The following information of the remote controller in use can be checked.

• Model name

• Software version

• Serial number

[Button operation]

1 Select “Others” from the Service menu.

2 Select “Remote controller information”.

12 Remote controller check

1 Select “Remote controller check” from the Diagnosis menu, and press the SELECT button to start

the remote controller check and see the check results. To cancel the remote controller check and

exit the Remote controller check menu screen, press the MENU or the RETURN button. The

remote controller will not reboot itself.

Select “Remote

controller check”.

Remote controller check

results screen

2 If the SELECT button is pressed after the remote controller check results are displayed, remote

controller check will end, and the remote controller will automatically reboot itself.

Page 30

– 30 –

GB

Page 31

– 1 –

F

Ce manuel d’installation décrit comment installer la Télécommande tactile MA en vue de son utilisation

avec le Système de climatisation de bâtiment Mitsubishi, les unités intérieures de climatiseurs CITY

MULTI de type extension directe (type « -A » et ultérieurs), et les climatiseurs autonomes Mitsubishi

Mr. SLIM.

Assurez-vous de lire ce manuel d’installation et les fichiers sur le CD-ROM fourni avec la

Télécommande tactile avant de procéder à l’installation. Le non-respect de cette prescription peut

entraîner des dommages pour les appareils.

Reportez-vous aux fichiers sur le CD-ROM fourni avec la Télécommande tactile pour les informations

qui ne figurent pas dans ce livret. Si les fichiers sont illisibles, veuillez contacter votre revendeur.

Pour des informations sur le câblage et l’installation des climatiseurs, reportez-vous au manuel

d’installation.

Après l’installation, remettez ce manuel aux utilisateurs.

• Lisez attentivement les consignes de sécurité ci-après avant de procéder à l’installation.

• Respectez scrupuleusement ces consignes pour assurer votre sécurité.

• Après avoir lu ce manuel, remettez-le à l’utilisateur final pour qu’il puisse le consulter en cas de

besoin.

• Conservez ce manuel pour pouvoir le consulter en cas de besoin. Il convient que ce manuel soit

accessible aux personnes chargées de réparer ou de déplacer le contrôleur. Assurez-vous que le

manuel est bien transmis à tout futur utilisateur final.

1 Consignes de sécurité

AVERTISSEMENT

Signale un risque de blessure grave, voire mortelle.

ATTENTION

Signale un risque de blessure grave ou de dommage matériel.

Seul un personnel qualifié est autorisé à réaliser les travaux électriques.

Système de contrôle CITY MULTI

et Climatiseurs Mitsubishi Mr. SLIM

Télécommande tactile MA

PAR-CT01MAA-PB

PAR-CT01MAA-SB

PAR-CT01MAA-S

PAR-CT01MAR-PB

PAR-CT01MAR-SB

Manuel d’installation

WT08580X01

F

Pour distribution aux distributeurs et aux sous-traitants

<Traduction des instructions d’origine>

Page 32

– 2 –

F

AVERTISSEMENT

ATTENTION

AVERTISSEMENT

ATTENTION

Précautions générales

Précautions pendant l’installation

N’installez pas l’unité en un endroit où se trouvent de

grandes quantités d’huile, de vapeur, de solvants

organiques ou de gaz corrosifs tels du gaz sulfurique ou

encore là où sont fréquemment utilisés des aérosols ou des

solutions acides/alcalines. Ces substances peuvent affecter

les performances de l’unité ou provoquer la corrosion de

certains de ses composants, ce qui peut donner lieu à des

défauts de fonctionnement, des dégagements de fumée ou

même une électrocution ou un incendie.

Ne lavez pas le contrôleur avec de l’eau ou tout autre

liquide afin de prévenir tout risque de court-circuit, de

fuite électrique, d’électrocution, de dysfonctionnement,

de fumée ou d’incendie.

N’utilisez pas les commutateurs/boutons ou d’autres

parties électriques avec les mains mouillées afin de

prévenir tout risque d’électrocution, de

dysfonctionnement, de fumée ou d’incendie.

Pour éviter tout risque de blessure ou d’électrocution,

éteignez le contrôleur et coupez l’alimentation

électrique avant de le nettoyer, de l’examiner ou avant

toute opération d’entretien de celui-ci.

Pour éviter tout risque de lésion ou d’électrocution,

éteignez le contrôleur et couvrez-le avant de pulvériser

un quelconque produit chimique dans l’environnement

de celui-ci.

Pour prévenir tout risque de blessure, tenez les enfants

éloignés pendant l’installation, l’inspection ou la

réparation de l’unité.

Installez correctement toutes les protections requises

pour protéger le contrôleur contre l’humidité et la

poussière. L’accumulation de poussière et d’eau peut

provoquer des électrocutions, de la fumée ou un

incendie.

Ne touchez pas l’écran tactile, les commutateurs ou les

boutons avec un objet pointu ou tranchant afin de prévenir

tout risque d’électrocution ou de dysfonctionnement.

Pour prévenir tout risque d’endommager le contrôleur,

ne pulvérisez pas d’insecticide ou tout autre aérosol

inflammable directement dessus.

Évitez le contact avec les bords tranchants de

certaines parties afin de prévenir tout risque de

blessure et d’électrocution.

Pour prévenir tout risque de blessure, portez un

équipement de protection lors de toute intervention sur

le contrôleur.

Contactez votre revendeur pour la mise au rebut du

contrôleur.

N’exercez pas une force excessive sur les parties en

verre pour éviter qu’elles se brisent et provoquent des

blessures.

Pour prévenir tout risque d’incendie ou d’explosion, ne

placez pas de matériaux inflammables et ne pulvérisez

pas de substances inflammables dans l’environnement

du contrôleur.

N’installez pas l’unité dans un endroit où peut se

produire une fuite de gaz inflammable.

Si du gaz inflammable s’accumule autour de l’unité, il

peut s’enflammer et provoquer un incendie ou une

explosion.

Prenez des mesures de sécurité appropriées contre

les tremblements de terre pour éviter que le contrôleur

provoque des blessures.

Mettez les matériels d’emballage au rebut

conformément à la réglementation. Les enfants

risquent de s’étouffer avec les sachets en plastique.

Pour prévenir tout risque de blessure, installez le

contrôleur sur une surface plane suffisamment solide

pour supporter son poids.

Pour prévenir tout risque de court-circuit, de fuite

électrique, d’électrocution, de dysfonctionnement, de

fumée ou d’incendie, n’installez pas le contrôleur en un

endroit exposé à l’eau ou à la condensation.

Le contrôleur doit être installé par du personnel qualifié

en suivant les instructions décrites dans le Manuel

d’installation.

Une installation incorrecte peut être la cause d’une

électrocution ou d’un incendie.

Installez le boîtier supérieur dans le boîtier inférieur

jusqu’à ce que vous entendiez un clic

d’enclenchement.

Quand vous fixez le couvercle et le boîtier supérieur au

boîtier inférieur, poussez-les jusqu’à ce qu’ils

s’enclenchent en place. S’ils ne sont pas correctement

verrouillés en place, ils peuvent tomber, et provoquer

des blessures, des dommages au contrôleur, ou des

dysfonctionnements.

Page 33

– 3 –

F

AVERTISSEMENT

ATTENTION

AVERTISSEMENT

ATTENTION

Précautions pendant le câblage

Précautions pour le déplacement ou la réparation du contrôleur

Pour prévenir tout risque de dommage au contrôleur,

de dysfonctionnement, de dégagement de fumée ou

d’incendie, ne branchez pas le câble d’alimentation au

bornier des signaux.

Fixez correctement les câbles en place et laissez

assez de mou aux câbles pour ne pas exercer de

contrainte sur les bornes. Des câbles mal connectés

peuvent se casser, surchauffer, et provoquer de la

fumée ou un incendie.

Pour prévenir tout risque de blessure et

d’électrocution, coupez l’alimentation générale avant

d’effectuer un travail électrique.

Tous les travaux électriques doivent être effectués par

un électricien qualifié conformément à la

réglementation et aux normes locales et en suivant les

instructions décrites dans le Manuel d’installation.

Pour prévenir tout risque d’électrocution, installez un

disjoncteur ainsi qu’un interrupteur à courant

différentiel résiduel sur l’alimentation électrique.

Pour prévenir tout risque d’électrocution, de fumée ou

d’incendie, installez un disjoncteur pour chaque

contrôleur.

Utilisez des disjoncteurs et fusibles correctement

calibrés (disjoncteur, commutateur local <commutateur

+ fusible>, disjoncteur sans fusible).

Les disjoncteurs à capacité de coupure supérieure à

celle spécifiée peuvent provoquer un

dysfonctionnement, une électrocution, un dégagement

de fumée ou un incendie.

Pour prévenir tout risque de fuite électrique, de

surchauffe, de dégagement de fumée ou d’incendie,

utilisez des câbles de section appropriée pour le

courant nominal spécifié.

Une mise à la terre appropriée doit être assurée par

un électricien agréé.

Ne raccordez pas le câble de mise à la terre à une

conduite de gaz, à une arrivée d’eau, au paratonnerre

ou au câble téléphonique.

Une mise à la terre incorrecte peut être la cause d’une

électrocution, d’un dégagement de fumée, d’un

incendie ou d’un dysfonctionnement en raison

d’interférences électromagnétiques.

Pour réduire les risques d’électrocution, de court-circuit

ou de dysfonctionnement, retirez toutes les chutes de

fil et de gaine du bornier.

Pour prévenir tout risque de court-circuit, de fuite

électrique, d’électrocution ou de dysfonctionnement,

ne laissez pas les câbles entrer en contact avec les

bords vifs du contrôleur.

Bouchez soigneusement les trous d’accès des câbles

avec du mastic pour éviter toute condensation,

infiltration d’eau et d’insectes qui pourrait provoquer

des dysfonctionnements, une électrocution ou un

incendie. L’infiltration d’eau et la formation de

condensation à l’intérieur de l’unité peuvent

endommager la carte de circuit imprimé.

Seul un personnel qualifié doit être autorisé à réparer

le contrôleur ou à le changer de place.

N’essayez pas de démonter ou de modifier le

contrôleur vous-même.

Une installation ou une réparation non conforme peut

entraîner des blessures, une électrocution ou un

incendie.

Pour réduire les risques d’électrocution, de court-circuit

ou de dysfonctionnement, retirez toutes les chutes de

fil et de gaine du bornier.

Page 34

– 4 –

F

Précautions supplémentaires

Pour prévenir tout dommage à l’unité, utilisez des

outils appropriés pour son installation, son inspection

ou sa réparation.

Ce contrôleur est exclusivement destiné à être utilisé

avec le Système de gestion d’immeuble de Mitsubishi

Electric.

L’utilisation de ce contrôleur avec d’autres systèmes

ou à d’autres fins peut entraîner des

dysfonctionnements.

N’utilisez pas de benzène, de diluant ou d’abrasif

chimique pour nettoyer le contrôleur afin d’éviter de le

décolorer.

Pour nettoyer le contrôleur, essuyez-le avec un chiffon

doux imbibé d’un mélange d’eau et d’un détergent

doux, rincez les restes de détergent avec un chiffon

humide, puis essuyez l’eau avec un chiffon sec.

Protégez le contrôleur contre l’électricité statique pour

éviter de l’endommager.

Prenez des dispositions appropriées contre les

interférences électromagnétiques lorsque les

climatiseurs sont installés dans des hôpitaux ou à

proximité d’équipements de radiocommunication.

Les onduleurs ainsi que les équipements médicaux à

haute fréquence ou de communication sans fil et les

générateurs d’énergie peuvent être la cause de

dysfonctionnements du système de climatisation. Le

système de climatisation peut également affecter le

bon fonctionnement de ces types d’équipement en

créant du bruit électrique.

Pour prévenir tout dysfonctionnement, n’attachez pas

les câbles d’alimentation et de signaux ensemble et

faites-les passer dans des chemins de câbles

différents.

Laissez le circuit imprimé et son film de protection sur

le boîtier.

Ne serrez pas trop les vis pour éviter d’endommager le

contrôleur.

Utilisez un tournevis à tête plate avec une lame de

3-5 mm (1/8-7/32 pouce).