Page 1

1

This installation manual describes how to install the MA Remote Controller for use with Mitsubishi Building Air Conditioning System, direct

expansion type CITY MULTI air conditioner indoor units (-A type and later), and Mitsubishi Mr. SLIM packaged air conditioners.

Please be sure to read this installation manual and the files on the CD-ROM that is supplied with the Remote Controller before proceeding

with the installation. Failure to follow the instructions may result in equipment damage.

For information not contained in this booklet, please refer to the files on the CD-ROM that is supplied with the Remote Controller.

If the files are not readable, please contact your dealer.

For information on how to wire and install the air conditioning units, refer to the installation manual.

After the installation, hand over this manual to users.

1. Safety Precautions

Thoroughly read the following safety precautions prior to installation.

Observe these precautions carefully to ensure safety.

After reading this manual, pass it on to the end user to retain for future reference.

Keep this manual for future reference and refer to it as necessary. This manual should be made available to those who repair or relocate

the controller. Make sure that the manual is passed on to any future users.

WARNING

CAUTION

WARNI NG

Indicates a risk of death or serious injury.

CAUTION

Indicates a risk of serious injury or structural damage.

General precautions

WT08394X01

GB

CITY MULTI Control System

and Mitsubishi Mr. SLIM Air Conditioners

MA Remote Controller PAR-33MAA

Installation Manual

For distribution to dealers and contractors

<ORIGINAL>

All electric work must be performed by qualified personnel.

Do not install the unit in a place where large amounts of oil, steam,

organic solvents, or corrosive gases, su ch as sulfuric gas, are present

or where acidic/alkaline sol utions or sprays are used frequently. These

substances can compromise the performance of the uni t or cause

certain components of the unit to corrode, which can result in electric

shock, malfunctions, smoke, or fir e.

To reduce the risk of shorting, current leakage, electric shock,

malfunctions, smoke, or fire, do not wash the controller with water

or any other liquid.

To reduce the risk of electric shock, malfunctions, smoke or fire, do

not operate the switches/buttons or touch other electrical parts with

wet hands.

To reduce the risk of injury or electric shock, before spraying a

chemical around the controller, stop the operation and cover the

controller.

To reduce the risk of injury or electric shock, stop the operatio n and

switch off the power supply before cleaning, maintai ning, or inspecting

the controller.

Properly install all required covers to keep moisture and dust out of the

controller. Dust accumulation and water can cause elect ric shock,

smoke, or fire.

To reduce the risk of injury, keep children away while installing,

inspecting, or repairing the controller.

To reduce the risk of fire or explosion, do not place flammable

materials or use flammable sprays around t he controller.

To reduce the risk of damage to the controller, do not directly spray

insecticide or other flammable sprays on the controller.

To reduce the risk of electric shock or malfunctions, do not touch

the touch panel, switches, or buttons with a pointy or sharp object.

To reduce the risk of injury and electric shock, avoid contact with

sharp edges of certain parts.

To avoid injury from broken glass, do not apply excessive force on the

glass parts.

To reduce the risk of injury, wear protective gear when working on the

controller.

Page 2

2

WARNING

CAUTION

WARNING

CAUTION

WARNING

CAUTION

Precautions during installation

Precautions during wiring

Precautions for moving or repairing the controller

Additional precautions

Do not install the controller wher e there is a risk of leaking fla mmable

gas. If flammable gas accumulates around th e controller, it may ignite

and cause a fire or explosion.

Properly dispose of the packing materials. Plastic bags pose

suffocation hazard to children.

Take appropriate safety measures against earthquakes to prevent

the controller from causing injury.

To prevent injury, install the controller on a flat surface strong

enough to support its weight.

To reduce the risk of shorting, current leakage, electric shock,

malfunctions, smoke, or fire, do not install the controller in a place

exposed to water or in a condensing envi ronment.

Controller must be installed by qualified personnel according to the

instructions detailed in the Installation Manual.

Improper installation may result in electric shock or fire.

When attaching the cover and the top casing to the bottom casing,

push it until it they click into place. If they are not properly locked

into place, they may fall, causing personal injury, controller

damage, or malfunctions.

To reduce the risk of damage to the controller, malfunctions, smoke, or

fire, do not connect the power cabl e to the signal terminal block.

Properly secure the cables in place and provide adequate slack in

the cables so as not to stress the terminals.Improperly connected

cables may break, overheat, and cause smoke or fire.

To reduce the risk of injury or electric shock, switch off the main

power before performing electrical work.

All electric work must be performed by a qualified electrician

according to the local regulations, standards, and the instructions

detailed in the Installation Manual. Capacity shortage to the power

supply circuit or improper installation may result in malfunction,

electric shock, smoke, or fire.

To reduce the risk of current leakage, overheating, smoke, or fire,

use properly rated cables with adequate current carrying capacity.

To reduce the risk of electric shock, shorting, or malfunctions, keep

wire pieces and sheath shavings out of the t erminal block.

To reduce the risk of shorting, current leakage, electric shock, or

malfunctions, keep the cables out of contact with controller edges.

To reduce the risk of electric shock, malfunctions, or fire, seal the

gap between the cables and cable access holes with putty.

The controller should be repaired or moved only by qualified

personnel. Do not disassemble or modify the controller.

Improper installation or repair may cause i njury, electric shock, or fire.

To reduce the risk of shorting, electric shock, fire, or malfunction,

do not touch the circuit board with tools or with your hands, and do

not allow dust to accumulate on the circuit board.

To avoid damage to the controller, use appropriate tools to install,

inspect, or repair the controller.

This controller is designed f or exclusive use with the Buildi ng

Management System by Mitsubishi Electric. The use of this controller

for with other systems or for other purposes may cause malfunctions.

Take appropriate measures against electrical noise interference

when installing the air conditioners in hospitals or facilities with

radio communication capabilities. Inverter, high-frequency medical,

or wireless communication equipment as well as power generators

may cause the air conditioning system to malfunction. Air

conditioning system may also adversely affect the operation of

these types of equipment by creating electrical noise.

To avoid malfunctions, do not bundle power cables and signal

cables together, or place them in the same metallic conduit.

To prevent malfunctions, do not remove the protective film or the

circuit board from the casing.

To avoid damage to the controller, do not overtighten the screws.

Use a flat-head screwdriver with a blade width of 4-7 mm (5/32-9/

32 inch). The use of a screwdriver with a narrower or wider blade

tip may damage the controller casing.

To prevent damage to the controller casing, do not force the driver

to turn with its tip inserted in the slot.

To avoid discoloration, do not use benzene, thinner, or chemical

rag to clean the controller. To clean the controller, wipe with a soft

cloth soaked in water with mild detergent, wipe off the detergent

with a wet cloth, and wipe off water with a dry cloth.

Page 3

3

To avoid damage to the controller, provide protection against static

electricity.

Do not use solderless terminals to connect cables to the terminal

block.

Solderless terminals may come in contact with t he circuit board and

cause malfunctions or damage the controller cover.

To avoid damage to the controller, do not make holes on the

controller cover.

To avoid deformation and malfunction, do not install the remote

controller in direct sunlight or where the ambient temperature may

exceed 40ºC (104ºF) or drop below 0ºC (32ºF).

This appliance is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision

or instruction concerning use of the appl iance by a person responsible

for their safety.

Children should be supervised to ensur e that they do not play with the

appliance.

Do not install the controller on the control panel door.

Vibrations or shocks to the controller may damage the controller or

cause the controller to fall.

Hold the cables in place with clamps to prevent undue force from

being applied to the terminal block and causing cable breakage.

To prevent cable breakage and malfunctions, do not hang the top

controller casing hang by the cable.

This appliance is intended to be us ed by expert or trained users in

shops, in light industry and on f arms, or for commercial use by lay

persons.

If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent or similarly qualified persons in or der

to avoid a hazard.

Page 4

4

2. System Requirements

Your computer must meet the following requirements to run Manual Navigation Software.

[PC] PC/AT compatible

[CPU] Core2 Duo 1.66 GHz or faster (Core2 Duo 1.86 GHz or faster recommended)

Pentium D 1.7 GHz or faster (Pentium D 3.0 GHz or faster recommended)

Pentium M 1.7 GHz or faster (Pentium M 2.0 GHz or faster recommended)

Pentium 4 2.4 GHz or faster (Pentium 4 2.8 GHz or faster recommended)

* Core2 Duo or faster processor is required to run Manual Navigation Software on Windows Vista or later.

[RAM] Windows Vista or later: 1 GB minimum (2 GB or more recommended)

Windows XP: 512 MB minimum (1 GB or more recommended)

[HDD space] 1 GB minimum (available space)

* Windows Vista or later: Available space in the drive that has the Document folder

* Windows XP: Available space in the drive that has the My Document folder

[Resolution] SVGA 800 × 600 or greater

[OS] Windows8/Pro/Enterprise (Pro recommended)

Windows7 Ultimate/Enterprise/Professional/Home Premium Service Pack1 (Professional recommended)

Windows Vista Ultimate/Business/Home Basic Service Pack1 (Business version recommended)

Windows XP Professional/Home Edition Service Pack2 or Service Pack3 (Professional version recommended)

[Required software] Windows8: Adobe Reader 11.0.2 or later (Windows Reader, installed by default in Windows8, cannot be used.)

Windows7: Adobe Reader 10.1.0 or later

Windows XP and Windows Vista: Adobe Reader 8.1.3 or later

* Software to view PDF files

Windows, Windows XP, Windows Vista, Windows7 and Windows8 are registered trade marks of Microsoft Corporation.

Adobe Reader and Adobe Acrobat are registered trademarks of Adobe Systems Incorporated.

Core2 Duo and Pentium are registered trademarks of Intel Corporation.

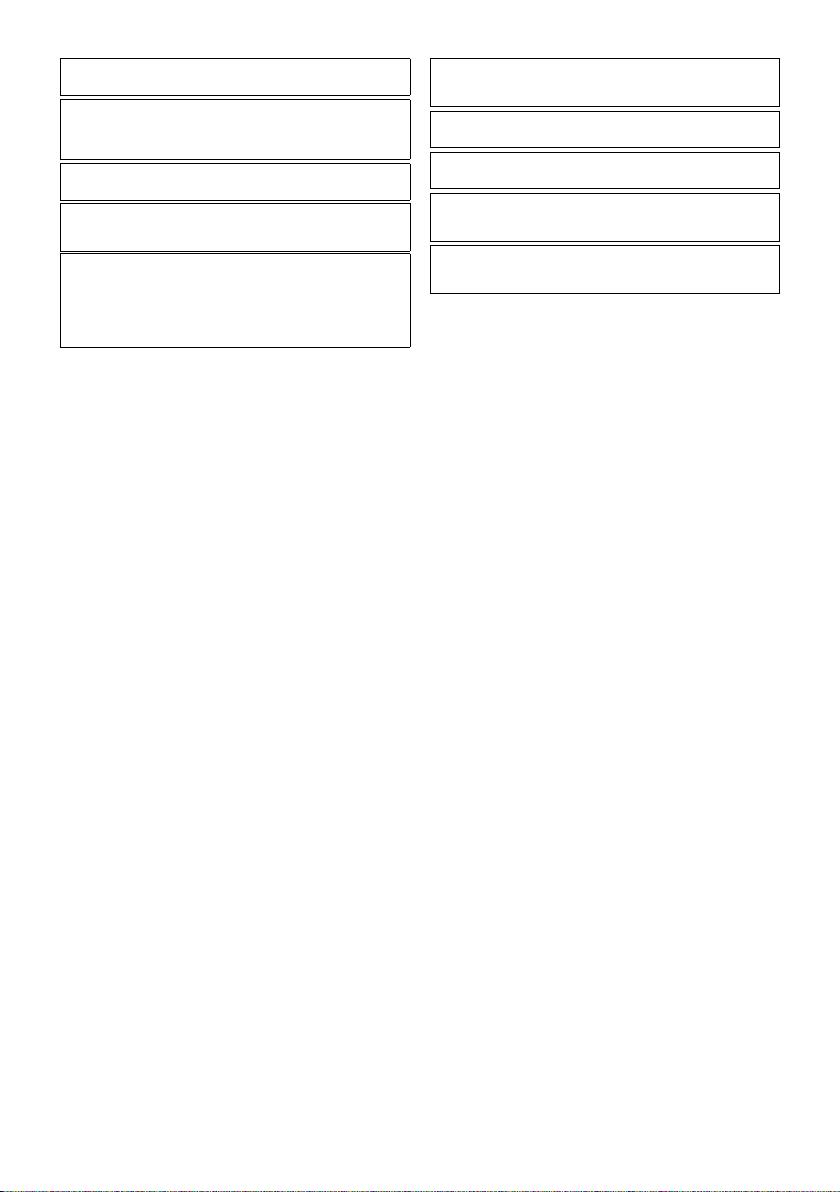

3. Component names and supplied parts

The following parts are included in the box.

WARNING

The CD-ROM that is supplied with the unit can only be played on a CD-drive or a DVD-drive. Do not attempt to play

this CD-ROM on an audio CD player as this may damage your ears and/or speakers.

*4 The front cover (*1) is already installed on the top case (*2) at factory

shipment.

*5 Remote controller cable is not included.

Parts name Qty. Appearance

Remote controller (front cover) 1 Right figure *1

Remote controller (top case) 1 Right figure *2

Remote controller (bottom case) 1 Right figure *3

Roundhead cross slot screws M4×30 2

Wood screw 4.1×16

(for direct wall installation)

2

Installation Manual (this manual) 1

Simple Operation Manual 1

CD-ROM

(Instruction Book and Installation Manual)

1

*4

Bottom case *3

Top case * 2

Front cover *1

Page 5

5

4. Field-supplied parts/Required tools

(1) Field-supplied parts

The following parts are field-supplied parts.

(2) Field-supplied tools

Flat-tip screwdriver (Width: 4-7 mm (5/32-9/32 inch)) or Plate service tool (Part No.R61008235)

Nipper

Miscellaneous tools

5. Selecting an installation site

This remote controller is for the wall installation. It can be installed either in the switch box or directly on the wall. When performing direct

wall installation, wires can be thread through either back or top of the remote controller.

(1) Selecting an installation site

Install the remote controller (switch box) on the site where the following conditions are met.

(a) For connection to the indoor unit with an Auto descending panel, a place where people can check the Auto descending panel

operation of the indoor unit while they are operating the remote controller (Refer to the indoor unit Instructions Book for how to

operate Auto descending panel.)

(b) A flat surface

(c) A place where the remote controller can measure the accurate indoor temperature

Sensors to monitor indoor temperature are on the indoor unit and on the remote controller. When the room temperature is

monitored with the sensor on the remote controller, the main remote controller monitors the room temperature. When using the

sensor on the remote controller, follow the instructions below.

To monitor the accurate indoor temperature, install the remote controller away from direct sunlight, heat sources, and the supply

air outlet of the air conditioner.

Install the remote controller in a location that allows the sensor to measure the representative room temperature.

Install the remote controller where no wires are routed around the temperature sensor on the controller.

(If wires are routed, the sensor cannot measure accurate indoor temperature.)

Parts name Qty. Notes

Double switch box 1

Not required for direct wall installationThin metal conduit Necessary

Lock nut and bushing Necessary

Cable cover Necessary Required for routing remote controller cable along a wall

Putty Reasonable

Molly anchor Necessary

Remote controller cable

(Use a 0.3 mm² (AWG22) 2-core sheathed cable.)

Necessary

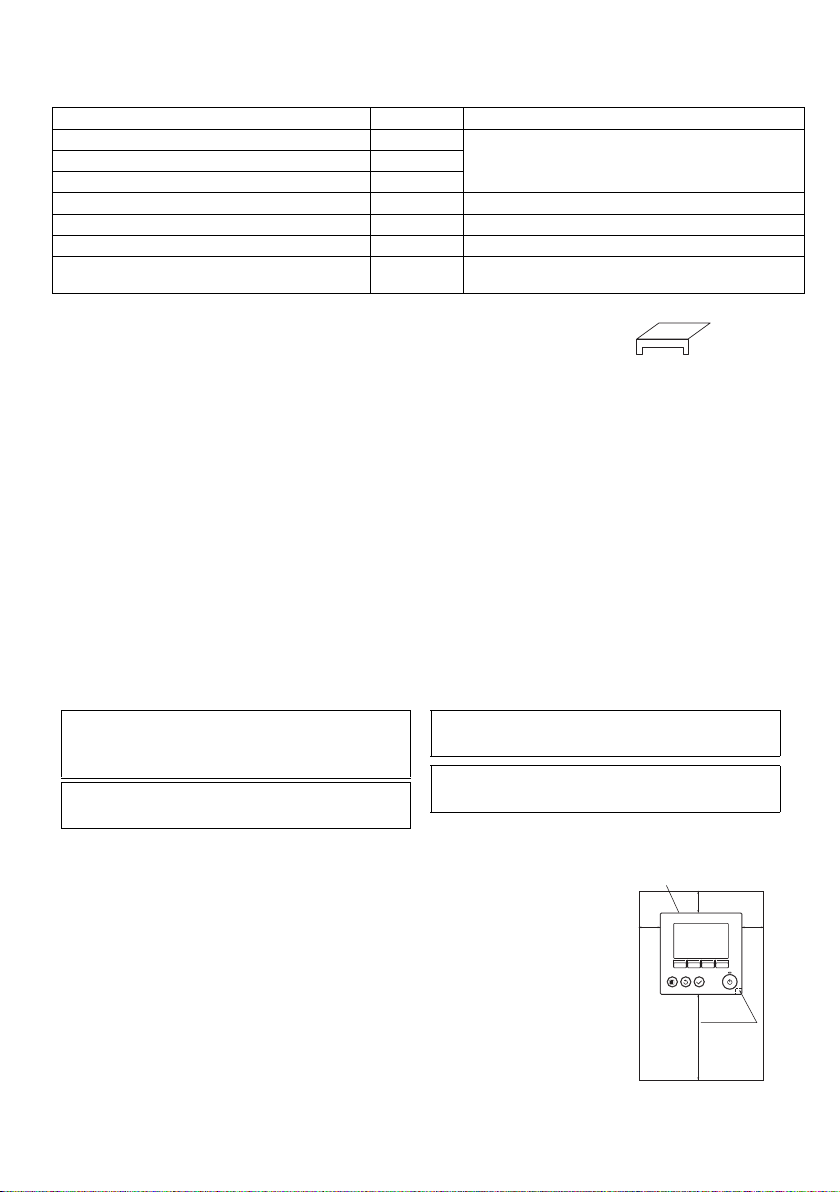

(2) Installation space

Leave a space around the remote controller as shown in the figure at right, regardless of

whether the controller is installed in the switch box or directly on the wall. Removing the

remote controller will not be easy with insufficient space.

Also, leave an operating space in front of the remote controller.

Do not install the controller in a place where the difference

between the remote controller surface temperature and the actual

room temperature will be great.

If the temperature difference is too high, room temperature may

not be adequately controlled.

To reduce the risk of shorting, current leakage, electric shock,

malfunctions, smoke, or fire, do not install the controller in a place

exposed to water or in a condensing environment.

To avoid deformation and malfunction, do not install the remote

controller in direct sunlight or where the ambient temperature may

exceed 40ºC (104ºF) or drop below 0ºC (32ºF).

To reduce the risk of malfunctions and damage to the controller,

avoid installing the remote controller on an electrically conductive

surface, such as an unpainted metal sheet.

Important

30

(1-3/16)

30

(1-3/16)

30 (1-3/16)

120 (4-3/4)

External dimensions of

remote controller

Temperature

sensor

unit: mm(in)

Minimum required space

around the remote

controller

Plate service tool

Page 6

6

6. Installation/Wiring work

4 Connect the remote controller cable to the terminal block on the bottom case.

Peel off 6 mm of the remote controller cable sheath as shown in the figure below, and thread the cable from behind the bottom

case. Thread the cable to the front of the bottom case so that the peeled part of the cable cannot be seen behind the bottom

case. Connect the remote controller cable to the terminal block on the bottom case.

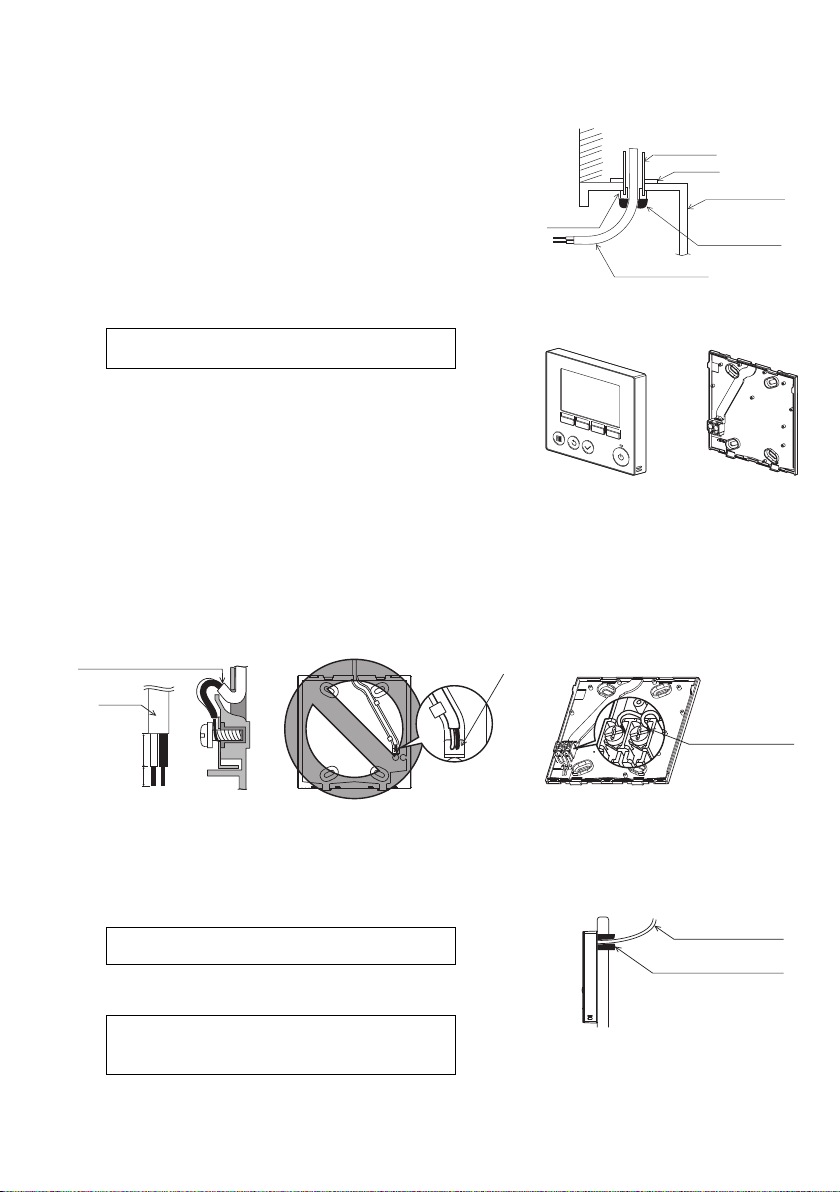

(1) Installation work

Controller can be installed either in the switch box or directly on the wall. Perform

the installation properly according to the method.

1 Drill a hole in the wall.

■ Installation using a switch box

Drill a hole in the wall, and install the switch box on the wall.

Connect the switch box to the conduit tube.

■ Direct wall installation

Drill a hole in the wall, and thread the cable through it.

2 Seal the cable access hole with putty.

■ Installation using a switch box

Seal the remote controller cable access hole at the connection of switch

box and conduit tube with putty.

3 Prepare the bottom case of the remote controller.

■ Direct wall installation

Seal the hole through which the cable is threaded with putty.

To reduce the risk of electric shock, malfunctions, or fire, seal the

gap between the cables and cable access holes with putty.

Wall

Conduit

tube

Locknut

Switch box

Seal the gap

with putty.

Remote

controller cable

Bushing

Bottom case

Front cover and top case

10 (13/32)

6 (1/4)

unit: mm(in)

Sheath

Thread the sheath part

of the cable to the front.

Thread the cable.

Front

Back

2-core wire must not

be seen on the back.

Connect the cable.

(non-polarized)

Connect the cable

so that the cable

sheath is not

pinched.

To reduce the risk of electric shock, shorting, or malfunctions, keep

wire pieces and sheath shavings out of t he terminal block.

Important

Do not use solderless terminals to connect cables to the terminal

block.

Solderless terminals may come in contact wi th the circuit board and

cause malfunctions or damage the controll er cover.

Seal the gap with putty.

Route the cable behind

the remote controller.

Remote controller

cable

Page 7

7

5 Install the bottom case.

■ Installation using a switch box

Secure at least two corners of the switch box with screws.

■ Direct wall installation

Thread the cable through the groove.

Secure at least two corners of the remote controller with screws.

Be sure to secure top-left and bottom-right corners of the remote controller (viewed from the front) to prevent it from lifting.

(Use molly anchor etc.)

6 Cut out the cable access hole.

■ Direct wall installation (when running the cable along the wall)

Insert a flat-tip screwdriver with a blade width of 47 mm (5/329/32 inch) or a

Plate service tool into either of the two latches at the bottom of the remote

controller, and move it in the direction of the arrow as shown in the figure at

right.

The top case will come loose from the front cover. Pull the top case toward

you to remove it.

Cut out the thin-wall part on the front cover (indicated with the shaded area in

the right figure) with a nipper.

(This cutout hole will be used to thread the remote controller cable through,

after the cable is threaded through the groove on the back of the bottom case.)

Place the top case onto the front cover.

7 Route the wire to the top case.

Connect the connector on the bottom case to the connector on the top case.

■ Installation using a switch box ■ Direct wall installation

Seal the cable access

hole with putty.

Double switch box

Roundhead cross

slot screws

Remote controller

cable

Wood

screw

Remote controller

cable

Thread the cable

through the groove.

Refer to 2.

Refer to 4.

Refer to 4.

To avoid damage to the controller, do not overtighten the screws. To avoid damage to the controller, do not make holes on the controller

cover.

Important

To prevent damage to the circuit board, remove the front cover from

the top case before cutting out a cabl e access hole.

Notice

or

Plate service tool

Front cover

Top case

Securely connect the

connectors.

To prevent malfunctions, do not remove the protective film or the

circuit board from the casing.

To prevent cable breakage and malfunctions, do not hang the top

controller casing hang by the cable.

Important

Protection

Sheet

Page 8

8

8 Route the wire to the top case.

9 Install the front cover and top case on the bottom case.

Two mounting tabs are at the top of the top case. (A cover is already installed on the case at the time of factory shipment.)

Hook those two tabs onto the bottom case, and click the top case into place. Check that the case is securely installed and not lifted.

Uninstalling the front cover and top case

1 Uninstalling the front cover

Insert a flat-tip screwdriver or a Plate service

tool into either of the two latches at the bottom

of the remote controller, and move it in the

direction of the arrow as shown in the figure at

right. Note that the top case may also be

removed if the driver or the tool is inserted

deeply.

2 Uninstalling the top case

Insert a flat-tip screwdriver or a Plate service

tool into either of the two latches at the bottom

of the remote controller, and move it in the

direction of the arrow as shown in the figure at

right.

Hold the cables in place with clamps to prevent undue force from

being applied to the terminal bloc k and causing cable breakage.

Important

Clamp

Insert the wire.

When attaching the cover and the top casing to the bottom casing,

push it until it they click into place.

If they are not properly locked into place, they may fall, causing

personal injury, controller damage, or malfunctions.

Important

■ Direct wall installation (when running the cable along the wall)

Thread the cable through the access hole at the top of the

remote controller.

Seal the cut-out part of the cover with putty.

Use a cable cover.

Installation is complete.

Follow the instructions below when uninstalling them.

No lifting

Wall

Seal the gap with putty.

Use a cable cover.

Thread the cable through the

top of the remote controller.

or

or

Wall

Wall

Page 9

9

7. Important

■ Discrepancy between the indoor temperature measured at the wall and the actual indoor temperature may occur.

If the following conditions are met, the use of the temperature sensor on the indoor unit is recommended.

Supply air does not reach to the wall easily where the remote controller is installed due to improper airflow distribution.

There is a great discrepancy between the wall temperature and the actual indoor temperature.

The back side of the wall is directly exposed to the outside air.

■ Refer to the section on initial setting in this Manual for remote controller main/sub setting.

■ Refer to either of the following manuals for temperature sensor setting: indoor unit Installation Manual for CITY MULTI; this

manual for Mr. Slim.

■ At the time of factory shipment, protective sheet is on the operation interface of the front cover.

Peel off the protective sheet on the operation interface prior to use.

3 Installing the cover and top case

Two mounting tabs are at the top of the top case.

Hook those two tabs onto the bottom case, and

click the top case into place.

Install the cover on the top case in the same way

as with the top case.

Check that the top case is securely installed and

not lifted.

Note: When temperature changes rapidly, the temperature may not be detected accurately.

Use a flat-head screwdriver with a blade width of 4-7 mm (5/32-9/

32 inch). The use of a screwdriver with a narrower or wider blade

tip may damage the controller casing.

To prevent damage to the controller casing, do not force the driver

to turn with its tip inserted in the slot.

To prevent damage to the control board, do not insert the driver

into the slot strongly.

Important

When attaching the cover and the top casing to the

bottom casing, push it until it they click into place.

If they are not properly locked into place, they may fall,

causing personal injury, controller damage, or

malfunctions.

Important

No lifting

Wall

Top case

Top case

Front cover

Page 10

10

8. Remote controller button functions

Button operations on the Main menu

(7) Backlit LCD

(2) Function buttons

F1, F2, F3, and F4 from the left

(6) Operation indicator

(1) ON/OFF button

(4) RETURN button

(3) MENU button

(5) SELECT button

(1) ON/OFF button

Use to turn ON/OFF the indoor unit.

(2) Function buttons

Use to select the operation mode or to set the temperature and fan speed

on the Main display.

Use to select items on other screens.

(3) MENU button

Use to bring up the Main menu.

(4) RETURN button

Use to return to the previous screen.

(5) SELECT button

Use to jump to the setting screen or to save the settings.

(6) Operation indicator

Stays lit during normal operation. Blinks during startup and when an error

occurs.

(7) Backlit LCD

Dot display.

When the backlight is off, pressing any button turns the backlight

on and i

t will stay lit for a certain period of time depending on the screen.

Performing any button operation keeps the backlight on.

Note: When the backlight is off, pressing any button turns the backlight on and

does not perform its function. (except for the ON/OFF button)

F1 F2 F3 F4

Main

Main display:

Cursor Page

Main menu

Vane·Louver·Vent. (Lossnay)

High power

Timer

Weekly timer

OU silent mode

Page

Cursor

Move the cursor to the desired function with the F1

and F2 buttons, and press the SELECT button to

go to the next page. Password may be required.

The function of the MENU, SELECT, and RETURN

buttons will appear on the setting screens.

Button function guide will appear at the bottom of

the screens.

Pressing the MENU button will bring up the Main menu as

shown below.

(Refer to section 9.(2) "Main display" for details.)

1/3 Vane

·

Louver·Vent. (Lossnay)

High power

Timer

Weekly timer

OU silent mode

2/3 Restriction

Energy saving

Night setback

Filter information

Error information

3/3 Maintenance

Initial setting

Service

*1 Refer to the Instructions Book in the CD-ROM for details.

*2 Explained in this manual.

*3 If no buttons are pressed for 10 minutes on the initial

setting screens, or 2 hours on the service screens (10

minutes on some screens), the screen will automatically

return to the Main display. Any settings that have not

been saved will be lost.

The available items on the menu depend on the connected

indoor unit model. For items not described in the manuals

that are enclosed with the MA remote controller, refer to the

manuals that came with the air conditioning units.

*1

*1

*1

*1

*1

*1

*1

*1

*1

*1

*1

*2 *3

*2 *3

Page 11

11

9. Turning on the power

Make sure that the MA remote controller is properly installed according to the instructions in the Installation Manual and that the indoor and

outdoor unit installation has been completed before turning on the power.

(1) When the power is turned on, the following screen will appear.

(2) Main display

After the successful startup, the Main display will appear. The Main display can be displayed in two different modes: "Full" and "Basic."

Refer to section 11 "Initial settings" for how to select the display mode. (The factory setting is "Full.")

10. Test run <Maintenance password is required.>

(1) Read the section about Test run in the indoor unit Installation Manual before performing a test run.

(2) At the Main display, press the MENU button and select Service>Test run>Test run.

(3) Press the ON/OFF button to cancel the test run if necessary.

(4) Refer to the indoor unit Installation Manual for the detailed information about test run and for how to handle the errors that occur during

a test run.

11. Initial settings (Remote controller settings)

<Administrator password is required.>

From the Main display, select Main menu>Initial setting, and make the remote controller settings on the screen that appears.

(1) Main/Sub setting

When connecting two remote controllers, one of them needs to be designated as a sub controller.

Notes

· When the power is on for the first time, the Language selection screen will be displayed. Refer

to section 11 (8). Select a desired language. The system will not start-up without language

selection.

· Some models of CITY MULTI cannot have more than one remote controller connected. Refer

to relevant documents (e.g., catalogs) for usage compatibility.

Normal start up (indicating the

percentage of process completion)

Notes

· When connecting two remote controllers, be sure

to designate one as a main and the other as a sub

controller. Refer to section 11 "Initial settings" for

how to make the Main/Sub setting.

· Refer to the Instructions Book for the icons on the

display.

Main display in the Full mode

(while the unit is not in operation)

Main display in the Full mode

(while the unit is in operation)

Note: Refer to section 12 "Service menu" for information about the maintenance password.

Initial setting menu (1/2)

· Main/Sub

· Clock

· Main display

· Contrast

· Display details

-Clock

-Temperature

-Room temp.

-Auto mode

Initial setting menu (2/2)

· Auto mode

· Administrator password

· Language selection

· Daylight saving time

Note: The initial administrator password is "0000." Refer

to section (7) "Administrator password setting" for

how to change the password.

[Button operation]

[1] When the F3 or F4 button is pressed, the currently selected setting will appear highlighted.

Select "Sub", and press the SELECT button to save the change.

[2] Press the MENU button to return to the Main menu screen. (This button always brings up the

Main menu screen.)

Please Wait

10%

Fri Fri

Cool

Room

AutoSet temp.

Mode Temp. Fan

Initial setting menu

Main menu:

Cursor Page

Main/Sub

Clock

Main display

Contrast

Display details

Main/Sub

Main / Sub

Select:

Cursor

Page 12

12

(2) Clock setting

(3) Main display setting

Use the F3 or F4 button to select the display mode "Full" or "Basic." (The factory setting is "Full.")

(4) Display contrast

(5) Remote controller display details setting

[1] Clock display

[2] Temperature unit setting

[Button operation]

[1] Move the cursor with the F1 or F2 button to the desired item.

[2] Change the date and time with the F3 or F4 button, and press the SELECT button to save the

change. The change will be reflected on the clock display on the Main display.

Note: Clock setting is necessary for time display, weekly timer, timer setting and error history.

Make sure to perform clock setting when the unit is used for the first time or has not used

for a long time.

Note: If a given system has no system controllers, the clock time will not automatically be

corrected. In this case, periodically correct the clock time.

Full mode (Example) Basic mode (Example)

Note: This setting is only for the Main display. In the Basic mode, icons that indicate control status on timer and schedule

settings will not appear on the display. Vane, louver, and ventilation settings or room temperature will not appear, either.

[Button operation]

Adjust LCD contrast with the F3 or F4 button.

The current level is indicated with a triangle.

Note: Adjust the contrast to improve viewing in different lighting conditions or installation

locations. This setting can not improve viewing from all directions.

Make the settings for the remote-controller-related items as necessary.

Press the SELECT button to save the changes.

[Button operation]

· Select "Clock" from the remote controller display details setting screen, and press the F4 button

(Change) to bring up the clock display setting screen.

· Use the F1 through F4 buttons to select "Yes" (display) or "No" (non-display) and its format for

the Main display.

· Save the settings with the SELECT button.

(The factory settings are "Yes" (display) and "24 h" format. )

Clock display: Yes (Time is displayed on the Main display.)

No (Time is not displayed on the Main display.)

Display format: 24-hour format

12-hour format

AM/PM display (Effective when the display format is 12-hour): AM/PM before the time

AM/PM after the time

Note: Time display format will also be reflected on the timer and schedule setting display. The time is displayed as shown below.

12-hour format: AM12:00 ~ AM1:00 ~ PM12:00 ~ PM1:00 ~ PM11:59

24-hour format: 0:00 ~ 1:00 ~ 12:00 ~ 13:00 ~ 23:59

[Button operation]

Move the cursor to the "Temperature" on the display details setting screen, and select the desired

temperature unit with the F3 or F4 button. (The factory setting is Centigrade (C).)

· C: Temperature is displayed in Centigrade. Temperature is displayed in 0.5- or 1-degree

increments, depending on the model of indoor units.

· F: Temperature is displayed in Fahrenheit.

· 1 C: Temperature is displayed in Centigrade in 1-degree increments. This item will not appear

on a sub remote controller.

Clock

Select:

Cursor

2017/ 01/ 01 00: 00

yyyy/ mm/ dd hh: mm

Fri Fri

Cool

Mode Temp. Fan Mode Temp. Fan

Room

AutoSet temp.

Cool Auto

Set temp.

Full / Basic

Main display

Cursor

Select:

DarkLight

Contrast

Main menu:

Display details

/ 1

Cursor

Change

Select:

Clock

Temperature

Room temp.

Auto mode

No 24h

Yes / No

Yes / No

Clock display

Cursor Cursor

Select:

Clock

12h disp.

AM/PM disp.

Yes No

Display details

Cursor

Cursor

Select:

Clock

Temperature

Room temp.

Auto mode

No 24h

Yes / No

Yes / No

/ 1

Page 13

13

[3]Room temperature display

[4]Auto (single set point) mode display setting

(6) Auto mode setting

(7) Administrator password setting

(8) Language selection

[Button operation]

Move the cursor to the "Room temp." on the display details setting screen, and select the desired setting with the F3 or F4 button.

(The factory setting is "Yes".)

· Yes: Room temperature appears on the Main display.

· No: Room temperature does not appear on the Main display.

Note: Even when "Yes" is set, the room temperature is not displayed on the Main display in the "Basic" mode.

[Button operation]

Move the cursor to the "Auto mode" on the display details setting screen, and select the desired mode with the F3 or F4 button.

(The factory setting is "Yes".)

· Yes: "AUTO COOL" or "AUTO HEAT" is displayed during operation in the AUTO (single set point) mode.

· No: Only "AUTO" is displayed during operation in the AUTO (single set point) mode.

[Button operation]

Whether or not to use the Auto (single set point) or Auto (dual set points) mode can be selected by

using the F3 or F4 button. This setting is valid only when indoor units with the AUTO mode

function are connected.

(The factory setting is "Yes".)

Press the SELECT button to save the changes made.

· Yes: The AUTO mode can be selected in the operation mode setting.

· No: The AUTO mode cannot be selected in the operation mode setting.

[Button operation]

[1] To enter the current Administrator password (4 numerical digits), move the cursor to the digit

you want to change with the F1 or F2 button, and set each number (0 through 9) with the F3 or

F4 button.

[2] Press the SELECT button.

Note: The initial administrator password is "0000." Change the default password as necessary to

prevent unauthorized access. Have the password available for those who need it.

Note: If you forget your administrator password, you can initialize the password to the default

password "0000" by pressing and holding the F1 and F2 buttons simultaneously for three

seconds on the administrator password setting screen.

[3] If the password matches, a window to enter a new password will appear. Enter a new password

in the same way as explained above, and press the SELECT button.

[4] Press the F4 button (OK) on the password change confirmation screen to save the change.

Press the F3 button (Cancel) to cancel the change.

Note: The administrator password is required to make the settings for the following items.

· Timer setting · Weekly timer setting · Energy-save setting

· Outdoor unit silent mode setting · Restriction setting

Refer to the Instruction Book that came with the remote controller for the detailed

information about how to make the settings for these items.

[Button operation]

Move the cursor to the language you desire with the F1 through F4 buttons.

Press the SELECT button to save the setting.

Auto mode

Auto mode Yes / No

Select:

Cursor

Administrator password

Enter administrator password

Select:

Cursor

Administrator password

Enter administrator password

Change administrator password.

Select:

Cursor

Administrator password

Enter administrator password

Update administrator password?

Cancel OK

Cursor

Select:

Français

Italiano

Ελληνικά

Svenska

Language selection

Cursor

English

Español

Português

Türkçe

Page 14

14

(9) Daylight saving time

The start/end time for daylight saving time can be set. The daylight saving time function will be

activated based on the setting contents.

If a given system has a system controller, disable this setting to keep the correct time.

At the beginning and the end of daylight saving time, the timer may go into action twice or not at

all.

This function will not work unless the clock has been set.

[Button operation]

[1] The daylight saving time function can be activated/deactivated or the start/end times can be set

by using the F1 through F4 buttons.

DST

Select "Yes" to activate the daylight saving time, or select "No" to deactivate.

Date(Start)

Set the start day of the week, week number, and month for daylight saving time.

Start time

Set the start time for daylight saving time.

Forward to

Set the time when the clock is to be set forward to at the start time above.

Date(End) (2nd page)

Set the end day of the week, week number, and month for daylight saving time.

End time (2nd page)

Set the end time for daylight saving time.

Backward to (2nd page)

Set the time when the clock is to be set backward to at the end time above.

[2]Press the SELECT button to save the setting.

* If "5th" is selected for the week number and the 5th week does not exist in the selected

month of the year, the setting is considered to be "4th."

No / Yes

Day

/

Week / Month

Sun

/

5th / Mar

1:00

2:00

Day

/

Week / Month

2:00

1:00

Sun / 5th / Oct

Cursor

Select:

Date(End)

End time

Backward to

Cursor

Select:

DST

Date(Start)

Start time

Forward to

Daylight saving time

Daylight saving time

Page 15

15

12. Service menu (Maintenance password is required.)

At the Main display, press the MENU button and select "Service" to make the maintenance settings.

When the Service menu is selected, a window will appear asking for the password.

To enter the current maintenance password (4 numerical digits), move the cursor to the digit you want to change with the F1 or F2 button,

and set each number (0 through 9) with the F3 or F4 button. Then, press the SELECT button.

If the password matches, the Service menu will appear.

The type of menu that appears depends on the connected indoor units type (CITY MULTI or Mr. Slim).

(1) Test run (CITY MULTI and Mr. Slim)

(2) Input maintenance Info. (CITY MULTI and Mr. Slim)

(3) Function setting (Mr. Slim)

Note: The initial maintenance password is "9999." Change the default password as necessary to

prevent unauthorized access. Have the password available for those who need it.

Note: If you forget your maintenance password, you can initialize the password to the default

password "9999" by pressing and holding the F1 and F2 buttons simultaneously for three

seconds on the maintenance password setting screen.

<Mr. Slim> <CITY MULTI>

Note: Air conditioning units may need to be stopped to make

certain settings. There may be some settings that

cannot be made when the system is centrally

controlled.

Select "Test run" from the Service menu to bring up the Test run menu.

· Test run: Select this option to perform a test run.

· Drain pump test run: Select this option to perform a test run on the drain pump on the indoor unit.

Applicable only to the type of indoor units that support the test run function.

Note: Refer to the indoor unit Installation Manual for the detailed information about test run.

Select "Input maintenance Info." from the Service menu to bring up the Maintenance information

screen. Refer to the indoor unit Installation Manual for how to make the settings.

Note: The following settings can be made from the Maintenance Information screen.

Registering model names and serial numbers

Enter the model names and serial numbers of outdoor and indoor units. The information

entered will appear on the Error information screen. Model names can have up to 18

characters, and the serial numbers can have up to 8 characters.

Registering dealer information

Enter phone number of a dealer. The entered information will appear on the Error information

screen. Phone number can have up to 13 characters.

Initializing maintenance information

Select the desired item to initialize the model name, serial number, and dealer information

settings.

Make the settings for the indoor unit

functions via the remote controller

as necessary.

Select "Function setting" from the

Service menu to bring up the

Function setting screen.

[Button operation]

[1] Set the indoor unit refrigerant addresses and unit numbers with

the F1 through F4 buttons, and then press the SELECT button

to confirm the current setting.

[2] When data collection from the

indoor units is completed, the

current settings appears

highlighted. Non-highlighted items

indicate that no function settings

are made. Screen appearance

varies depending on the "Unit No."

setting.

Common items

Service menu

Cursor

Select:

Enter maintenance password

Service menu Service menu

Cursor Cursor

Main menu: Main menu:

Test run

Input maintenance info.

Function setting

Check

Self check

Maintenance password

Remote controller check

Service menu Service menu

Cursor Cursor

Main menu: Main menu:

Test run

Input maintenance info.

Lossnay

Check

Self check

Maintenance password

Remote controller check

Service menu Service menu

Service menu: Service menu:

Not available.

Please stop the unit.

Not available.

Centrally controlled.

Test run menu

Cursor

Service menu:

Test run

Drain pump test run

Maintenance information

Cursor

Service menu:

Model name input

Serial No. input

Dealer information input

Initialize maintenance info.

Function setting

Cursor Address

Monitor:

Ref. address

Unit No.

Grp./1/2/3/4/All

Function setting

Cursor Cursor

Request:

Ref. address

Mode 1

Mode 2

Mode 3

Mode 4

Grp.

Page 16

16

Table1. Function setting options

(4) LOSSNAY setting (CITY MULTI only)

This setting is required only when the operation of CITY MULTI units is interlocked with LOSSNAY units. This setting is not available for

the Mr. Slim units. Interlock settings can be made for the indoor unit to which the remote controller is connected. (They can also be

confirmed or deleted.)

[3] Use the F1 or F2 button to move

the cursor to select the mode

number, and change the setting

number with the F3 or F4 button.

[4] When the settings are completed,

press the SELECT button to send

the setting data from the remote

controller to the indoor units.

[5] When the transmission is

successfully completed, the screen

will return to the Function setting

screen.

Individual items

(Unit No. 1 through 4)

Note:

Make the function settings shown in Table 1 on Mr. Slim units as necessary.

Refer to the Instructions Book when it is necessary to set the settings for CITY MULTI units.

Table 1 summarizes the setting options for each mode number. Refer to the indoor unit Installation Manual for the

detailed information about initial settings, mode numbers, and setting numbers for the indoor units.

Be sure to write down the settings for all functions if any of the initial settings has been changed after the completion of

installation work.

Mode No. Mode Settings Setting No. Unit numbers

01 Automatic recovery after power failure Disable 1

Set "Grp." for the Unit number.

These settings apply to all the connected

indoor units.

Enable (Four minutes of standby time is required after the restoration of power.) 2

02

Thermistor selection

(indoor temperature detection)

Average temperature reading of the indoor units in operat ion 1

Thermistor on the indoor unit to which the remote controller is connected (fixed) 2

Built-in sensor on the remote controller 3

03 LOSSNAY connection Not connected 1

Connected (without outdoor air intake by the indoor units ) 2

Connected (with outdoor air intake by the indoor units ) 3

04 Power voltage 240 V 1

220 V, 230 V 2

05 AUTO mode Enable (Automatically the unit achieves effective energy saving operation.) 1

Disable 2

07 Filter sign 100 hours 1

Set "1, 2, 3, 4, or All" for the Unit number.

These settings apply to each indoor unit.

If "1, 2, 3, or 4" is set for the Unit number,

the settings apply only to the specified

indoor unit regardless of the number of

connected indoor units (one through four

units).

If "ALL" is set for the Unit number, the

settings apply to all the connected indo or

units regardless of the number of

connected indoor units (one through four

units).

2500 hours 2

Not displayed 3

08 Fan speed Silent mode (or standard) 1

Standard (or High ceiling 1) 2

High ceiling (or High ceiling 2) 3

09 Outlet 4 directional 1

3 directional 2

2 directional 3

10 Optional parts No 1

(High-efficiency filter) Yes 2

11 Vane No vanes (or the vane setting No.3 is effective.) 1

Equipped with vanes (The vane setting No.1 is effective.) 2

Equipped with vanes (The vane setting No.2 is effective.) 3

Note:

Use the centralized controller to make the settings if it is connected.

To interlock the operation of the indoor units with the LOSSNAY units, be sure to interlock the addresses of ALL indoor

units in the group and that of the LOSSNAY unit.

[Button operation]

[1] When "Lossnay" on the Service

menu is selected, the remote

controller will automatically begin

searching for the registered

LOSSNAY addresses of the

currently connected indoor unit.

[2] When the search is completed,

the smallest address of the

indoor units that are connected

to the remote controller and the

address of the interlocked

LOSSNAY unit will appear. "--"

will appear if no LOSSNAY unit

is interlocked with the indoor

units.

If no settings need to be made, press the RETURN button to go

back to the Service menu.

To make LOSSNAY interlock setting

[3] Enter the addresses of the indoor unit and the LOSSNAY unit to be

interlocked, with the F1 through F4 buttons, select "Set" in the

"Function", and press the SELECT button to save the settings.

"Sending data" will appear on the screen. If the setting is

successfully completed, "Setting completed" will appear.

Function setting

Cursor Cursor

Request:

Ref. address

Mode 7

Mode 8

Mode 9

Mode11

Unt # 1

Function setting

Ref. address

Sending data

Lossnay

IU address

Lossnay address

Collecting data

Lossnay

Cursor Address

Select:

IU address

Lossnay address

Function Set/Conf/Del.

LossnayLossnay

Return:

IU address

Lossnay address

IU address

Lossnay address

Sending data Setting completed

Page 17

17

(5) Check

(6) Diagnostic function.

To search for the LOSSNAY address

[4] Enter the address of the indoor unit to which the remote controller is

connected, select "Conf" in the "Function", and press the SELECT button.

"Collecting data" will appear on the screen. If the signal is received correctly,

the indoor unit address and LOSSNAY address will appear. "--" will appear

when no LOSSNAY unit is found. "Unit not exist" will appear if no indoor units

that are correspond to the entered address are found.

To delete the interlock setting

[5] To delete the interlocked setting between LOSSNAY unit and the indoor units

to which the remote controller is connected, enter the indoor unit address and

LOSSNAY address with the F1 through F4 buttons, select "Del." in the

"Function", and press the SELECT button. "Deleting" will appear. The screen

will return to the search result screen if the deletion is successfully

completed. "Unit not exist" will appear if no indoor units that are correspond

to the entered address are found. If deletion fails, "Request rejected" will

appear on the screen.

Select "Check" on the Service menu to bring up the Check menu screen.

The type of menu that appears depends on the type of indoor units that are

connected (CITY MULTI or Mr. Slim).

(When CITY MULTI is connected, only "Error history" will appear in the menu.)

<Mr. Slim>

[1] Error history

Select "Error history" from the

Check menu, and press the

SELECT button to view up to 16

error history records. Four records

are shown per page, and the top

record on the first page indicates

the latest error record.

"Error history deleted" will appear on

the screen. Press the Return button to

go back to the Check menu screen.

[2] Other options in the Check menu

(Mr. Slim only)

The following options are also

available on the Mr. Slim units in the

Check menu.

[Deleting the error history]

To delete the error history, press the

F4 button (Delete) on the screen

that shows error history. A

confirmation screen will appear

asking if you want to delete the error

history.

Press the F4 button (OK) to delete

the history.

Refrigerant volume check

Refrigerant leak check

Smooth maintenance

Request code

These options are available only on the Mr. Slim units.

Refer to the indoor unit Installation Manual for details.

Error history of each unit can be checked via the remote controller.

[Procedures]

[1] Select "Self check" from the Service menu, and press the SELECT button to

view the Self check screen.

[2] With the F1 or F2 button, enter the refrigerant address (Mr. Slim) or the M-

NET address (CITY MULTI), and press the SELECT button.

[3] Error code, unit number, attribute, and indoor unit demand signal ON/OFF

status at the contact (CITY MULTI only) will appear. "-" will appear if no error

history is available.

<Mr. Slim> <CITY MULTI>

<Mr. Slim> <CITY MULTI>

When there is no error history

LossnayLossnay

Return:

IU address

Lossnay address

IU address

Lossnay address

Collecting data Unit not exist

LossnayLossnay

Return:

IU address

Lossnay address

IU address

Lossnay address

Deleting

Request rejected

Check menu

Cursor

Service menu:

Error history

Refrigerant volume check

Refrigerant leak check

Smooth maintenance

Request code

Error history

Page

Delete

Check menu:

Error Unt# dd/mm/yy

Error history

Check menu:

Error history deleted

Error history

Cancel OK

Delete error history?

Self check Self check

Select: Select:

Ref. address M-NET address

Address Address

Self check Self check

Ref. address

Contact

Return:Return:

Reset Reset

M-NET address

Error Unt # ErrorGrp.IC Grp.IC

Self check

Contact

Return:

Reset

M-NET address

Error Grp.

---- ---

Page 18

18

(7) Setting the maintenance password

Take the following steps to change the maintenance password.

13. Remote controller check

When the remote controller does not work properly, use the remote controller checking function to troubleshoot the problem.

(1) Check the remote controller display and see if anything is displayed (including lines). Nothing will appear on the remote controller

display if the correct voltage (8.5-12 VDC) is not supplied to the remote controller. If this is the case, check the remote controller wiring

and indoor units.

[Procedures]

[1] Select "Remote controller check" from the Service menu, and press the SELECT button to start the remote controller check and see

the check results. To cancel the remote controller check and exit the Remote controller check menu screen, press the MENU or the

RETURN button. The remote controller will not reboot itself.

OK: No problems are found with the remote controller. Check other parts for problems.

E3, 6832: There is noise on the transmission line, or the indoor unit or another remote controller is faulty. Check the transmission line and

the other remote controllers.

NG (ALL0, ALL1): Send-receive circuit fault. Remote controller needs replacing.

ERC: The number of data errors is the discrepancy between the number of bits in the data transmitted from the remote controller and that

of the data that was actually transmitted over the transmission line. If data errors are found, check the transmission line for external

noise interference.

[2] If the SELECT button is pressed after the remote controller check results are displayed, remote controller check will end, and the

remote controller will automatically reboot itself.

[Resetting the error history]

[1] Press the F4 button (Reset) on

the screen that shows the error

history. A confirmation screen

will appear asking if you want to

delete the error history.

[2] Press the F4 button (OK) to

delete the error history. If

deletion fails, "Request rejected"

will appear, and "Unit not exist"

will appear if no indoor units that

are correspond to the entered

address are found.

[Procedures]

[1] Select "Maintenance password" on the Service menu, and press the SELECT button to bring up

the screen to enter a new password.

[2] Move the cursor to the digit you want to change with the F1 or F2 button, and set each digit to the

desired number (0 through 9) with the F3 or F4 button.

[3] Press the SELECT button to save the new password.

[4] A confirmation screen will appear asking if you want to change the maintenance password. Press

the F4 button (OK) to save the change. Press the F3 button (Cancel) to cancel the change.

[5] "Changes saved" will appear when the password is updated.

[6] Press the MENU button to return to the Service menu or press the RETURN button to go back to

the "Maintenance password" screen.

Select "Remote controller check". Remote con troller check results screen

Self check

Delete error history?

Ref. address

Cancel OK

Self check

Return:

Ref. address

Error history deleted

Maintenance password

Cursor

Select:

Enter maintenance password

Change maintenance password.

Maintenance password

Cancel OK

Enter maintenance password

Update maintenance password?

Maintenance password

Service menu:

Enter maintenance password

Changes saved

Service menu Remote controller check Remote controller check

Cursor

Main menu: Begin: Exit:

Maintenance password

Remote controller check

Start checking?

Page 19

Page 20

WT08394X01

This product is designed and intended for use in the residential,

commercial, and light-industrial environment.

The product at hand is based on the following EU regulations:

Restriction of Hazardous Substances 2011/65/EU

Electromagnetic Compatibility Directive 2014/30/EU

HEAD OFFICE: TOKYO BLDG., 2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

MANUFACTURER: MITSUBISHI ELECTRIC CORPORATION Air-conditioning & Refrigeration Systems Works

5-66, Tebira 6 Chome, Wakayama-city, 640-8686, Japan

Loading...

Loading...