Page 1

Mitsubishi Electric Building

Air Conditioning Control System

Transmission Booster PAC-SF46EPA

GB

D

F

INSTALLATION MANUAL

• Read this manual thoroughly before using the Transmission Booster.

INSTALLATIONSHANDBUCH

• Lesen Sie dieses Handbuch gründlich durch, bevor Sie die Übertragungsverstärker (Booster).

MANUEL D’INSTALLATION

• Veuillez lire attentivement le présent manuel avant d’utiliser ce module élévateur du niveau des signaux de transmission.

INSTALLATIEHANDLEIDING

• Lees deze handleiding aandachtig door, alvorens de transmissieversterker in gebruik te nemen.

MANUALE DI INSTALLAZIONE

• Prima di utilizzare il booster di trasmissione leggere attentamente il presente manuale.

MANUAL DE INST ALACIÓN

• Lea este manual con detenimiento antes de utilizar el impulsor de transmisión

MANUAL DE INSTALAÇÃO

• Leia atentamente este manual antes de utilizar o Intensificador de Transmissão.

E°XEIPI¢IO O¢H°IøN E°KATA™TA™H™

• ¢È·‚¿ÛÙ ·˘Ùfi ÙÔ ÂÁ¯ÂÈÚ›‰ÈÔ ÙÔ˘ ¶ÔÏÏ·Ï·ÛÈ·ÛÙ‹ Ù¿Û˘ ÌÂÙ¿‰ÔÛ˘.

РУКОВОДСТВО ПО УСТАНОВКЕ

• Внимательно прочитайте данное руковоство перед установкой Усилителя передачи.

NL

I

E

P

GR

RU

TR

MONTAJ ELK‹TABI

• ‹letim güçlendiriciyi kullanmadan önce bu el kitab›n› dikkatlice okuyun.

Page 2

Contents

1 Safety Precautions................................................................................ 3

2 Product Feature .................................................................................... 4

2-1. Applicable models ........................................................................ 4

2-2. Specification ................................................................................. 4

2-3. Appearance .................................................................................. 4

3 Installation ............................................................................................ 4

3-1. Parts prepared at site ................................................................... 4

3-2. Installation space and the direction .............................................. 5

3-3. Unit installation ............................................................................. 5

4 Wiring ................................................................................................... 5

4-1. Wiring procedure .......................................................................... 5

4-2. Power Line .................................................................................... 6

4-3. M-NET transmission line .............................................................. 6

4-4. Wiring example ............................................................................. 7

5 System Limit (length of signal line, maximum number of units)............ 8

GB

2

Page 3

This manual describes the installation of the PAC-SF46EPA Transmission booster. For the information about how to install the centralized controller or

the air conditioner units, see the installation manual for them.

For your safety, first be sure to read “1 Safety Precautions” described below thoroughly and then install the PAC-SF46EPA correctly.

After reading this installation manual, keep it in a location that is easy to find, if the PAC-SF46EPA Transmission booster is going to be operated by

another person, make sure that this manual is given to him or her.

1 Safety Precautions

• Before installing this unit, make sure you read all the “Safety Precautions”.

The “Safety Precautions” provide very important points regarding safety. Make sure you follow them.

Symbols and Terms

WARNING: Statements identify condition or practices that could result in personal injury or loss of life.

CAUTION: Statements identify condition or practices that could result in damage to the unit or other property.

Symbols used in the illustrations

: Indicates a part which must be grounded.

: Beware of electric shock. (This symbol is displayed on the Transmission booster label.) <Color: Yellow>

: Please pay attention to electric shock fully because this is not Safety Extra Low-Voltage (SELV) circuit.

ELV

And at servicing, please shut down the power supply for the Transmission booster.

WARNING: Carefully read the labels affixed to the Transmission booster.

Specific Precautions

WARNING

GB

■ Ask your dealer or technical representative to install.

Any deficiency caused by your own installation may result in an electric shock or fire.

■ Install in a place which is strong enough to withstand the weight

of the unit.

Any lack of strength may cause the unit to fall down, resulting in

personal injury.

■ Wire and connect using the desired cables securely so that any

external force from the cable is imparted to the terminal connections.

Imperfect connection and fixing may result in heating or fire.

■ Never modify or repair the unit by yourself.

Any deficiency caused by your modification or repair may result in

an electric shock or fire.

Consult with your distributor for repair.

■ Make sure that the unit is powered by dedicated line.

Other appearance connected to the same line could cause an overload.

■ Make sure that there is a main power switch.

A ready accessible breaker for power source line helps reduce the

risk of electric shocks. Installation of a breaker is mandatory in same

areas.

CAUTION

■ Do not install in any place exposed to flammable gas leakage.

Flammable gases accumulated around the body of unit may cause

an explosion.

■ Do not use in any special environment.

Using in any place exposed to oil (including machine oil), steam and

sulfuric gas may deteriorate the performances significantly or give

damage to the component parts.

■ Wire so that it does not received any tension.

Tension may cause wire breakage, heating or fire.

■ Do not wash with water.

Doing so may cause an electric shock or a malfunction.

■ Do not install in any place at a temperature of more than 40°C

or less than 0°C or exposed to direct sunlight.

■ Use only a fuse of specified capacity.

A fuse of large capacity or a steel or copper wire could cause a

malfunction or fire.

■ Ensure that installation work is done correctly following this

installation manual.

Any deficiency caused by installation may result in an electric shock

or fire.

■ All electrical work must be performed by a licensed technician,

according to local regulations and the instructions given in this

manual.

Any lack of electric circuit or any deficiency caused by installation

may result in an electric shock or fire.

■ Do not move and re-install the unit yourself.

Any deficiency caused by installation may result in an electric shock

or fire.

Ask your distributor or special vendor for moving and installation.

■ This appliance must be earthed.

Make sure to install a protective earth(PE)line.

Do not connect the protective earth line to gas or water pipes, lighting conductors or telephone grounding lines.

Improper grounding may cause an electric shock.

■ The terminal block cover of each line must be firmly attached to

prevent entry of dust and moisture.

Improper mounting of cover can cause electric shock of fire.

■ Do not dispose of the PAC-SF46EPA by your self.

■ Do not install in any steamy place such as bathroom or kitchen.

Avoid any place where moisture is condensed into dew. Doing so

may cause an electric shock or a malfunction.

■ Do not install in any place where acidic or alkaline solution or

special spray are often be used.

Doing so may cause an electric shock or malfunction.

■ Use standard wires in compliance with the current capacity.

A failure to this may result in an electric leakage, heating or fire.

■ Do not touch any PCB (Printed Circuit Board) with your hand or

tools. Do not have dust collected on the PCB.

Doing so may cause fire or an electric shock.

■ When installing the unit in a hospital, communication station,

or similar place, provide sufficient protection against noise.

The inverter equipment, private power generator, high-frequency

medial equipment, or radio communication equipment may cause

the air conditioner to operate erroneously, or fail to operate. On the

other hand, the air conditioner may affect such equipment by creating noise that disturbs medial treatment or image broadcasting.

3

Page 4

2 Product Feature

2-1. Applicable models

• Super Y Series(PUHY-YSMF-B, PUHY-YSMC)

• Lossnay unit

• Centralized controller

Do not supply power to any other models.

2-2. Specification

Source power requirement

Voltage/current of output on the

transmission booster side

Environmental condition

Dimensions

Weight

Installation Environment

GB

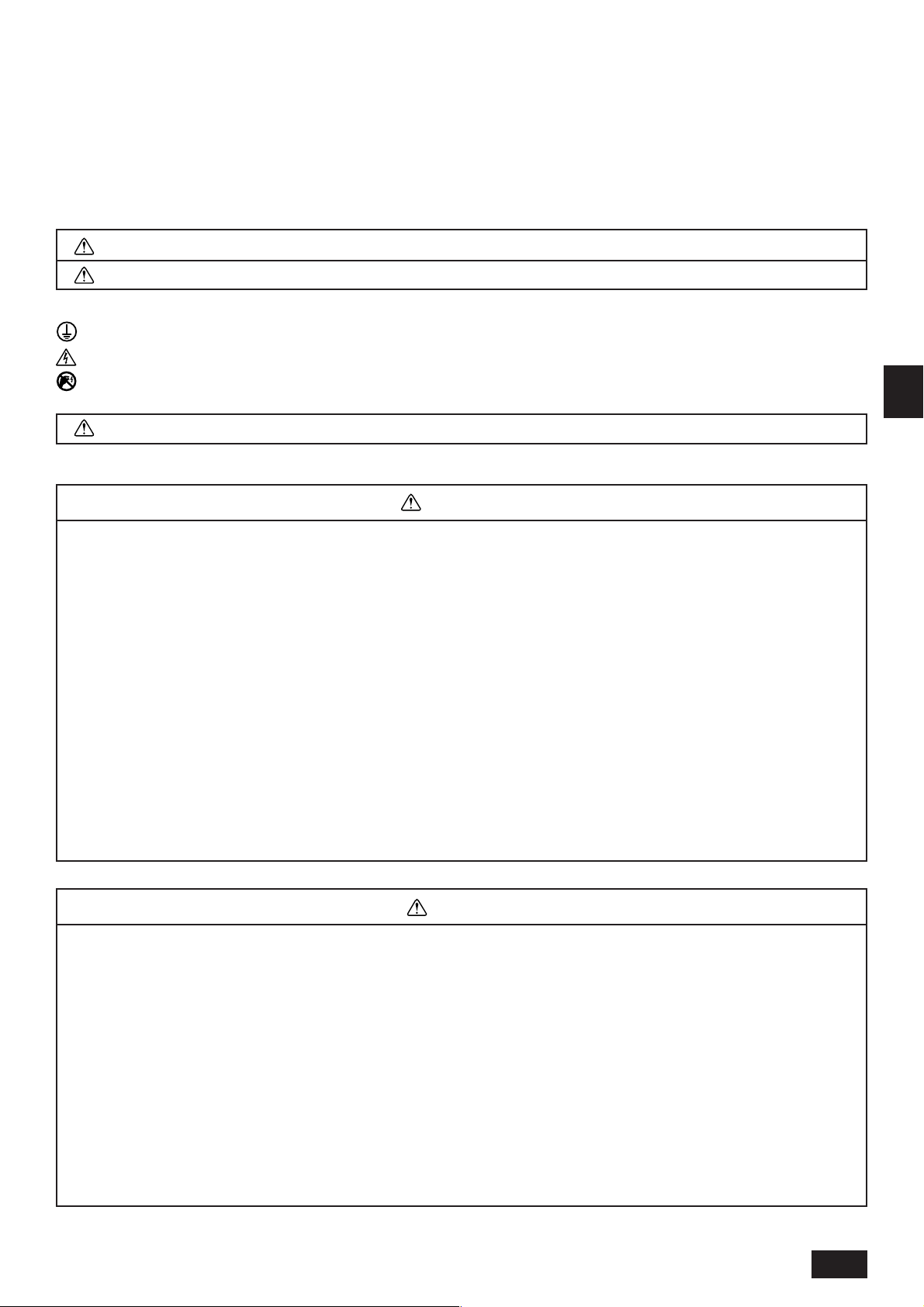

2-3. Appearance

TB1

Power line terminal

Input voltage AC220V-AC240V; 0.7A (Maximum loading) 50/60Hz Single-phase

Fuse: 2.0A F (IEC127-2)

DC28V-30V 1.7A (Maximum loading)

Temperature Operating 0-40˚C (32-104˚F)

Non operating -20-60˚C (-4-104˚F)

Humidity 30-90%RH (No condensation)

340 (High) × 360 (Width) × 59.2 (Depth) mm

3.5 kg (7.8 pounds)

Indoor

360

Cable fixture

TRANSMISSION BOOSTER

MODEL

PAC-SF46EPA

POWER RATING

WEIGHT

MADE IN JAPAN

220-240V:0.7A ~/N

50

3.4kg

240

UP

165160

340

300

TB3

M-NET Transmission

terminal block 2

TB2

M-NET Transmission

terminal block 1

3 Installation

3-1. Parts prepared at site

Please prepare the following parts before installation of the unit.

Preparation parts

Unit fixing screw

Power cable/

Protective earth cable

Main power switch

(Circuit breaker)

Transmission cable

M4 screw × 4pcs

Please prepare the power cable complied with your applicable technical standard in consider with power requirement of

the unit.

*Recommend type; ø1.6mm (2.0 mm2) - ø2.0mm (3.2 mm2) (Example: H03VV-F, H03VVH2-F, H05VV-F, H05VVH2-F)

*The sticking by ring crimp terminal for wiring. (Hole diameter: M4)

Note: The power supply should comply with local specifications.

Qty.: 1pc

Type: 250VAC, Single-phase 50/60Hz, 3A

*Recommend type; CP30-BA series(MITSUBISHI ELECTRIC) or equivalent.

Note: The power supply should comply with local specifications.

Type of the cable; Sheathed vinyl cords or cable which comply with the following specifications or equivalent.

• CPEVS ø1.2mm - ø1.6mm

• CVVS 1.25mm2 - 2mm

2

*CPEV; PE insulated PVC jacketed shielded communication cable

*CVVS; PVC insulated PVC jacketed shielded control cable

*The sticking by ring crimp terminal for wiring. (Hole diameter: M3)

Cable fixture

Specification

4

Page 5

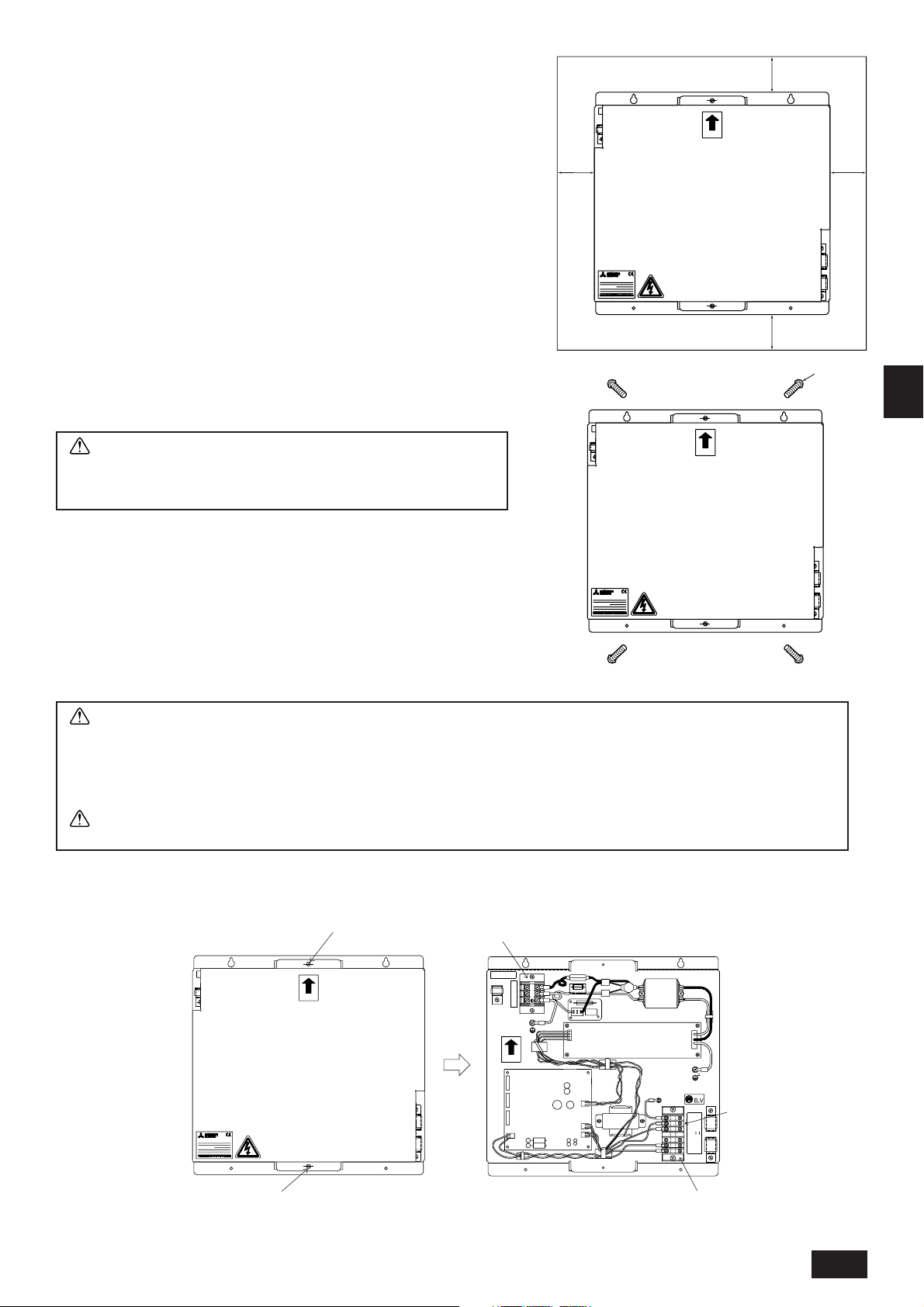

3-2. Installation space and the direction

2020

20 20

PAC-SF46EPA

TRANSMISSION BOOSTER

3.4kg

220-240V:0.7A ~/N

WEIGHT

POWER RATING

MODEL

MADE IN JAPAN

50

UP

PAC-SF46EPA Transmission booster is not waterproof type. Therefore this unit shall be

installed in a control panel box or the like. Please prepare the control panel box in consider with installation space as shown in the Fig.3-1.

The unit shall be also installed in vertical direction only indicated by the arrow making on

the cover as shown in the Fig.3-1.

Fig.3-1

3-3. Unit installation

Fix the unit to the control panel box using M4 screw as shown in the Fig.3-2.

M4

GB

CAUTION:

UP

• The unit should be fixed with 4 positions to prevent from unit falling down.

• Install the booster in a location which can withstand a load of 3.5 kg.

• Position the unit, making sure not to drop it.

TRANSMISSION BOOSTER

MODEL

PAC-SF46EPA

220-240V:0.7A ~/N

POWER RATING

50

3.4kg

WEIGHT

MADE IN JAPAN

Fig.3-2

4 Wiring

WARNING:

• All electric work must be performed according to local regulations.

Improper electrical work may result in electric shock or fire.

• Be sure to shut off the power source of the unit and the all other unit to be connected to the transmission booster before wiring.

• Firmly secure the wiring so that it does not become disconnected.

CAUTION:

• Never connect the power source to the M-NET transmission line, as this will cause a unit failure.

4-1. Wiring procedure

1. Remove the screws used to secure the cover, and then open the cover.

Remove the screws

Power line terminal

TB1

TRANSMISSION BOOSTER

MODEL

PAC-SF46EPA

POWER RATING

WEIGHT

MADE IN JAPAN

220-240V:0.7A ~/N

50

3.4kg

Remove the screws

TB1

220V-240V ~/N

L

F2.0A 250V

UP

N

UP

Fig.4-1 Fig.4-2

TB3

ABS

ABS

terminal block 2

(receiving electrical power

M-NET TRANSMISSION M-NET TRANSMISSION

(OUTDOOR UNIT SIDE)

CABLE TERMINAL BLOCK1

from the unit)

M-NET Transmission

TB3TB2

CABLE TERMINAL BLOCK2

(ADDITIONAL INDOOR UNIT SIDE)

TB2

M-NET Transmission terminal block 1

(receiving electrical power from another unit)

5

Page 6

2. Connect the power supply and transmission wiring. (Refer to 4-2 and 4-3.)

3. After connection for the each cable, fasten the each cable with the cable fixture.

4. After finishing the wiring, be sure to secure the cover with the screws before turning on the power source.

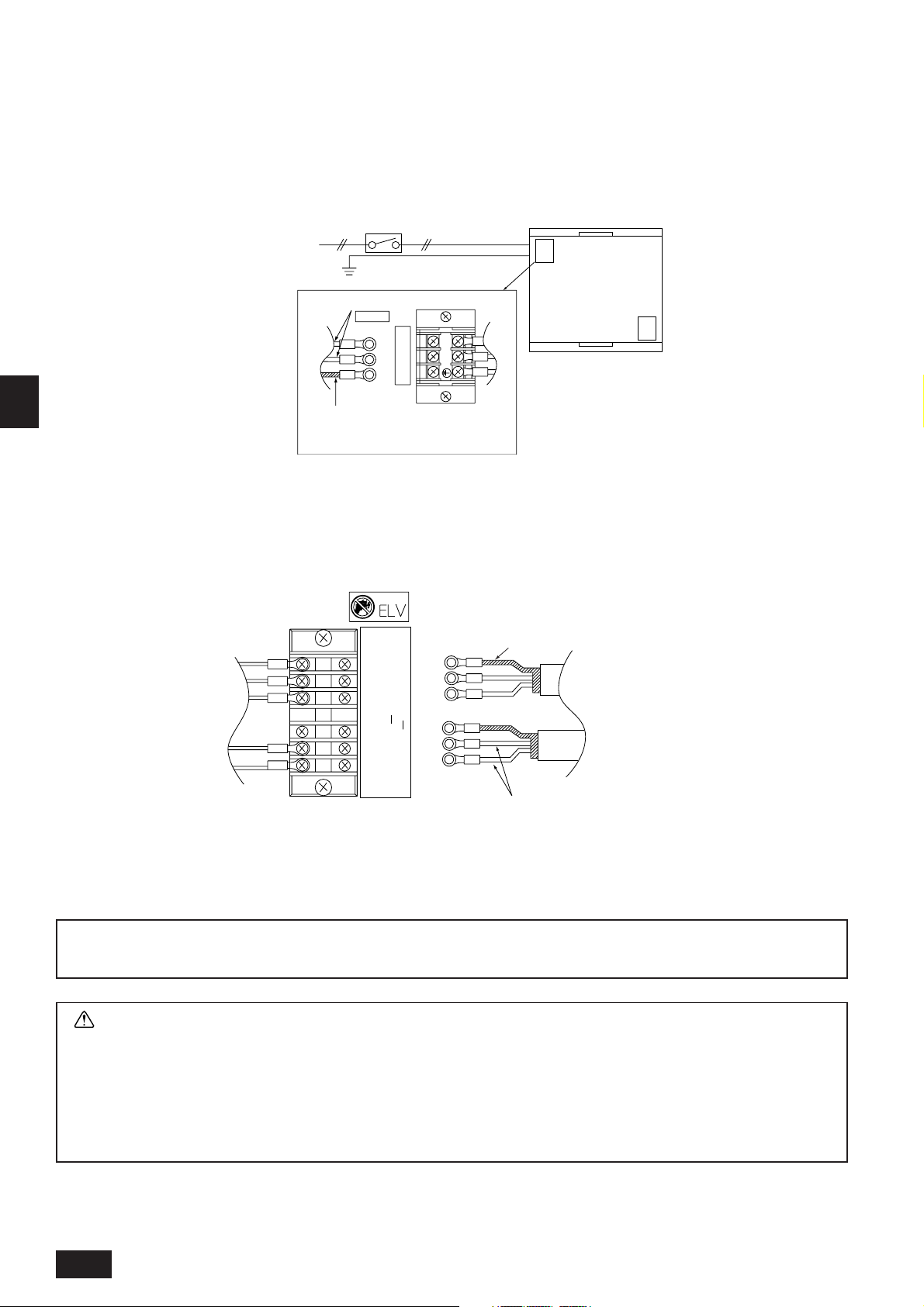

4-2. Power Line

Wire the power cable and protective earth cable to L, N and the earth line terminals on the TB1 as shown in the Fig.4-3.

Power source

AC220~AC240V

~/N 50/60Hz

Circuit breaker

Ground

Power cable

TB1

Power cable

Protective earth cable

220V-240V~/N

(L)

(N)

L

N

TB1

PAC-SF46EPA

GB

Fig.4-3

Protective

earth cable

Tightening torque: 1.4-2.0 Nm

4-3. M-NET transmission line

Wire the M-NET transmission cable to A, B(non-polarity data) and S(shield) terminals on the TB2 and TB3 as shown in the

Fig.4-4.

Shield

SBABAS

(ADDITIONAL INDOOR UNIT SIDE)

(OUTDOOR UNIT SIDE)

Tightening torque: 0.6-1.0 Nm

Fig.4-4

TB3

M-NET TRANSMISSION

CABLE TERMINAL BLOCK 2

(ADDITIONAL INDOOR UNIT SIDE)

TB2

M-NET TRANSMISSION

(OUTDOOR UNIT SIDE)

CABLE TERMINAL BLOCK 1

M-NET transmission A, B line

(Non-polarity DC30V)

NOTES:

• The shield wire of M-NET transmission line shall be grounded by one point earthing method.

• The shield wire shall be connected to the S terminal of the only one unit on the common transmission line.

CAUTION:

• Do not mistake transmission line terminal block 1 (TB2) and transmission line terminal block 2 (TB3) when performing the wiring. The

transmission booster will not operate correctly if the terminal blocks are connected in reverse.

• Since the M-NET transmission line is 30V DC, do not mistake it with the power line when performing the wiring.

(The machine will be broken if the power line is connected to TB2 or TB3.)

• In order to prevent erroneous operations, do not store the power line and M-NET transmission line banded together or in the same conduit.

• Connect the ground wire certainty.

(If the ground wire is not correctly connected, there is a danger of electric shocks or incorrect operations due to the influence of the noise.)

• Never use a megohm tester on the transmission line terminal blocks (TB2 and TB3).

6

Page 7

4-4. Wiring example

Example

<Super Y series> For details, refer to the installation manual for the Super Y Series unit.

Constant capacity unit Variable capacity unit

(Shield)

TB3

S

TB3

Indoor unit

M1.M2

<Centralized controller and Lossnay units>

Centralized controller

Ground

Power

supply

unit

TB2 TB3

Transmission

booster

OUTDOOR

UNIT SIDE

Lossnay

unit

Ground

SS

Lossnay

unit

ADDITIONAL

INDOOR UNIT SIDE

Ground

Transmission

(Shield)

booster

TB2 TB3

Lossnay

remote

controller

SS

(Shield)

Lossnay

unit

Lossnay

unit

Ground

Lossnay

remote

controller

Lossnay

remote

controller

Lossnay

unit

Lossnay

remote

controller

(Shield) (Shield)

M1.M2M1.M2M1.M2M1.M2

Lossnay

unit

Lossnay

remote

controller

TB5 TB5 TB5 TB5 TB5

(Shield) (Shield) (Shield)

Remote

controller

Lossnay

remote

controller

Lossnay

remote

controller

Lossnay

unit

Lossnay

unit

Lossnay

remote

controller

Lossnay

remote

controller

Lossnay

unit

SSSSS

GB

NOTES: *This unit cannot be used to extend the transmission line.

7

Page 8

5 System Limit (length of signal line, maximum number of units)

<Super Y series>

Please read the installation manual which is included with the Super Y Series (PUHY-YSMF-B, PUHY-YSMC) unit.

<Except for Super Y series>

Centralized controller

Transmission line length limits

(1) Maximum distance between ends should be

less than 500 m

Ex.) A+B+D+E,

A+B+C+E,

C+D

(2) Maximum distance from power supply should

be less than 200 m

Ex.) B+D, B+C, A, E

GB

A

Power

supply

unit

T

T

B

B

2

3

Transmission

booster

B

C

Lossnay

unit

Lossnay

unit

D

Lossnay

remote controller

E

Lossnay

remote controller

Lossnay

unit

Lossnay

remote controller

Lossnay

unit

Lossnay

remote controller

NOTES:

• If the total length of the remote controller’s wiring is less than 10 m, use 0.75 mm2 cable, and do not add their lengths to the length

calculations made above.

• If the total length of the remote controller’s wiring is more than 10 m, use 1.25 mm2 cable or ø1.2 mm or more shielded cable for the length

of wiring exceeding 10 m, and be sure to add their lengths to the length calculations made above.

Maximum number of units that can be connected (TB3 side)

Maximum number of units

that can be connected

50 Lossnay remote controllers

(One centralized controller is equivalent to 4 Lossnay remote controllers.)

8

Page 9

65

GR

Page 10

Coдержание

1 Меры предосторожности ................................................................. 67

2 Описание изделия ............................................................................ 68

2-1. Применимые модели ................................................................ 68

2-2. Технические характеристики................................................... 68

2-3. Внешний вид ............................................................................. 68

3 Установка .......................................................................................... 68

3-1. Детали, приобретаемые на месте ........................................... 68

3-2. Пространство для установки и ориентация прибора............ 69

3-3. Установка прибора ................................................................... 69

4 Электропроводка ............................................................................. 69

4-1. Электромонтажные операции ................................................. 69

4-2. Линия питания........................................................................... 70

4-3. Линия передачи M-NET ............................................................ 70

4-4. Пример электропроводки ........................................................ 71

5 Предел системы (длина сигнальной линии,

максимальное число приборов) ...................................................... 72

RU

66

Page 11

В данном руководстве описывается установка Усилителя передачи PAC-SF46EPA. За информацией по установке центрального регулятора

или других приборов кондиционера воздуха обращайтесь к соответствующему руководству по их установке.

В целях обеспечения Вашей безопасности, обязательно прочитайте раздел “1 Меры предосторожности”, подробно изложенный ниже, затем

правильно установите прибор PAC-SF46EPA.

После прочтения данного руководства по установке, сохраните его в легко доступном месте; если с Усилителем передачи PAC-SF46EPA

будет работать другой оператор, обязательно передайте ему или ей данное руководство.

1 Меры предосторожности

• Перед установкой данного прибора обязательно прочитайте все “Меры предосторожности”.

В разделе “Меры предосторожности” содержатся чрезвычайно важные инструкции, касающаяся мер безопасности. Обязательно следуйте им.

Символика и Термины

ОСТОРОЖНО

ПРЕДУПРЕЖДЕНИЕ

: Положения, обозначающие режим или действия, которые могут привести к травме или смерти.

:

Положения, обозначающие режим или действия, которые могут привести к повреждению прибора или иного имущества.

Символика, используемая в иллюстрациях

: Указывает на деталь, которая должна быть заземлена.

: Остерегайтесь поражения электрическим током. (Данный символ изображен на этикетке Усилителя передачи.) <Цвет: Желтый>

:

ELV

Пожалуйста внимательно соблюдайте правила защиты от поражения электротоком, так как данная цепь не является цепью Крайне Низкого Безопасного Напряжения (SELV).

А при выполнении сервисных работ, пожалуйста, отключите подачу электропитания к Усилителю передачи.

ОСТОРОЖНО

: Внимательно прочитайте этикетки, прикрепленные к Усилителю передачи.

Особые меры предосторожности

■ За установкой обратитесь к Вашему дилеру или техническому

представителю.

Любая неточность в случае вашей собственной попытки собрать систему

может привести к электрошоку или пожару.

■ Устанавливайте в месте, способном выдержать вес прибора.

Недостаточная прочность в месте установки может привести к падению

прибора, что, в свою очередь, может нанести травму.

■ При проведении проводки и соединений надежно крепите провода

с тем, чтобы любые внешние силы, действующие на кабель,

передавались на концевые соединения.

Неправильное соединение и крепление проводов может привести к их

нагреванию или пожару.

■ Запрещается самостоятельно модифицировать и ремонтировать

данный прибор.

Любая неточность в случае вашей собственной попытки исправить или

починить систему может привести к электрошоку или пожару.

Проконсультируйтесь с вашим дилером о ремонте.

■ Убедитесь в том, что питание на прибор подается с отдельной линии

питания.

Подключение других приборов к этой линии питания может привести к

перегрузке.

■ Убедитесь в том, что на линии установлен выключатель питания.

Установка в доступном месте прерывателя линии питания помогает

снизить риск поражения электротоком. В некоторых цепях установка

прерывателя является обязательной.

ОСТОРОЖНО

■ Убедитесь что вмонтирование выполнено в соответствии с

руководством.

Любая неточность в случае вашей собственной попытки собрать систему

может привести к электрошоку или пожару.

■ Все работы по электрике должны быть выполнены

лицензированным техником в соответствии с местными

требованиями и инструкциями описанными в руководстве.

Любая неточность в электрике или неисправность при сборке системы

может привести к электрошок или пожару.

■ Запрещается самостоятельно перемещать и повторно

устанавливать данный прибор.

Любая неточность при сборке системы может привести к электрошоку

или пожару. Обратитесь к вашему поставщику или специальному

представителю товара для передвигания и установки.

■ Данное устройство должно быть заземлено.

Обязательно установите защитную линию заземления (РЕ).

Запрещается подсоединять защитную линию заземления к трубам газо

и-водопровода, молниеотводам и линиям заземления телефонного

кабеля.

Неправильное заземление может привести к поражению электротоком.

■ Крышки коробок терминалов всех линий должны быть плотно

зафиксированы для предотвращения попадания пыли и влаги.

Неправильная установка крышки может привести к поражению

электротоком или пожару.

■ Запрещается самостоятельно утилизировать прибор PAC-SF46EPA.

ПРЕДУПРЕЖДЕНИЕ

■ Не устанавливайте в место открытое для утечки

легковоспламеняющихся газов.

Легковоспламеняющиеся газы аккумулируемые вокруг системы

прибора могут вызвать воспламенение.

■ Не используйте никакую специальную среду.

Использование любой поверхности экспонируемой к маслу (включая

машинное масло), пару и серному газу может значительно ухудшить

функции или вызвать повреждение компонентов системы.

■ Подсоединяте так, чтобы не создавалось никакого механического

напряжения.

Напряжение может вызвать разрыв провода, перегрев и воспламенение.

■ Не мойте с водой.

Это так же может вызвать электрошок или неисправность.

■ Не ставьте на поверхность где температура выше 40°С или ниже

чем 0°С или под воздействие прямых солнечных лучей.

■ Используйте предохранители указанного номинального тока.

Использование предохранителя высокого номинального тока или “жучка”

из стальной или медной проволоки может привести к неполадкам в

работе или пожару.

■ Не устанавливайте на поверхность подверженную парам, как

например, ванная или кухня.

Не ставьте на поверхность где конденсируется влага. Это может вызвать

электрошок или неисправность.

■ Не ставьте на поверхность где часто используются щелочь или

кислота или специальные пульвелизаторы.

Это может вызвать электрошок или неисправность.

■ Используйте стандартные провода с соответствующим

напряжением тока.

Использование некорректного напряжения может вызвать

электрическую утечку, перегрев или пожар.

■ Не прикасайтесь к печатной плате руками или инструментами. Не

допускайте скопления пыли на печатной плате.

Не допускайте загрязнения ОСП. Это может вызвать пожар или

электрошок.

■ При установке данного прибора в больнице, на станции связи или

в подобных местах обеспечьте надлежащую шумозащиту.

Инверторное оборудование, автономный электрогенератор,

высокочастотное оборудование или устройства радиосвязи могут

привести к ошибкам или отказам в работе прибора. С другой стороны,

кондиционер воздуха может воздействовать на работу подобных

устройств путем создания шумов, мешающих функционированию

медицинского оборудования или трансляции изображений.

67

RU

Page 12

2 Описание изделия

2-1. Применимые модели

• Серия Super Y (PUHY-YSMF-B, PUHY-YSMC)

• Прибор Lossnay

• Центральный регулятор

Не подключайте питание к другим моделям.

2-2. Технические характеристики

Требования к источнику

питания

Напряжение/Выход по току со

стороны усилителя передачи

Требования к окружающей

среде

Габариты

Вес

Среда для установки

2-3. Внешний вид

TB1

Терминал линии

питания

Входное напряжение 220-240В переменного тока; 0,7A (Максимальная нагрузка) 50/60Гц однофазный

Предохранитель: 2,0A F (IEC127-2)

28-30В постоянного тока 1,7A (Максимальная нагрузка)

Температура Операционная 0-40˚C (32-104˚F)

Неоперационная -20-60˚C (-4-104˚F)

Влажность 30-90% отн. влажности (Без конденсации)

340 мм (В) × 360 мм (Ш) × 59,2 мм (Г)

3,5 кг

Внутри помещения

360

Зажим кабеля

TRANSMISSION BOOSTER

MODEL

PAC-SF46EPA

POWER RATING

WEIGHT

MADE IN JAPAN

220-240V:0.7A ~/N

50

3.4kg

240

UP

165160

340

300

TB3

Передача M-NET

блок терминалов 2

TB2

Передача M-NET

блок терминалов 1

3 Установка

3-1. Детали, приобретаемые на месте

Перед установкой данного прибора необходимо приобрести следующие детали.

Приобретаемые детали

Винты для крепления прибора

Кабель питания/

Защитный провод

заземления

RU

Главный выключатель

питания

(Прерыватель цепи)

Кабель передачи

Винт M4 × 4 шт.

Пожалуйста, приобретите кабель питания, соответствующий местным техническим нормам, с учетом требований

к питанию прибора.

*Рекомендуемый тип; ø1,6мм (2,0 мм2) - ø2,0мм (3,2 мм2) (Например: H03VV-F, H03VVH2-F, H05VV-F, H05VVH2-F)

*Крепление проводов кольцевым зажимом на терминале. (Диаметр отверстия: M4)

Примечание: Электропитание должно соответствовать местным стандартам.

Кол-во: 1 шт.

Тип: 250В переменного тока, Однофазный 50/60Гц, 3A

*Рекомендуемый тип; серия CP30-BA (MITSUBISHI ELECTRIC) или эквивалентный.

Примечание: Электропитание должно соответствовать местным стандартам.

Тип кабеля; Шнуры с виниловой оболочкой или кабель, соответствующий следующим спецификациям, или ему

эквивалентный.

• CPEVS ø1,2мм - ø1,6мм

• CVVS 1,25мм2 - 2мм

2

*CPEV; Экранированный кабель связи в ПВХ-оболочке с полиэтиленовой изоляцией

*CVVS; Экранированный кабель передачи в ПВХ-оболочке с поливинилхлоридной изоляцией

*Крепление проводов кольцевым зажимом на терминале. (Диаметр отверстия: M3)

Зажим кабеля

Техническое описание

68

Page 13

3-2. Пространство для установки и ориентация

2020

20 20

PAC-SF46EPA

TRANSMISSION BOOSTER

3.4kg

220-240V:0.7A ~/N

WEIGHT

POWER RATING

MODEL

MADE IN JAPAN

50

UP

прибора

Усилитель передачи PAC-SF46EPA не принадлежит к моделям водонепроницаемого

типа. Поэтому данный прибор следует устанавливать внутри коробки панели

управления или подобного приспособления. Пожалуйста подготовьте коробку панели

управления с учетом необходимого пространства для установки, как изображено

на Рис. 3-1.

Данный прибор необходимо устанавливать только в вертикальном положении,

указанном стрелкой на крышке прибора, как изображено на Рис. 3-1.

Рис.3-1

3-3. Установка прибора

Прикрепите прибор к коробке панели управления с помощью винтов М4, как показано

на Рис. 3-2.

ПРЕДУПРЕЖДЕНИЕ

• Прибор необходимо закрепить в 4 точках для предотвращения его

падения.

• Установите усилитель в таком месте, которое способно выдержать

нагрузку в 3,5 кг.

• Закрепите прибор, следя за тем, чтобы не уронить его.

:

M4

UP

TRANSMISSION BOOSTER

MODEL

PAC-SF46EPA

220-240V:0.7A ~/N

POWER RATING

50

3.4kg

WEIGHT

MADE IN JAPAN

4 Электропроводка

ОСТОРОЖНО

:

Рис.3-2

• Все электромонтажные работы должны проводиться в соответствии с местными нормами.

Неправильная электропроводка может привести к поражению электротоком или пожару.

• Перед проведением электромонтажных работ обязательно отключите питание данного прибора и всех других приборов, которые

подсоединяются к усилителю передачи.

• Надежно закрепляйте провода, чтобы не произошло их отсоединение.

ПРЕДУПРЕЖДЕНИЕ

:

• Никогда не подсоединяйте источник питания к линии передачи M-NET, так как это приведет к отказу в работе прибора.

4-1. Электромонтажные операции

1. Снимите винты, с помощью которых крепится крышка, затем снимите саму крышку.

Снимите винты

UP

Терминал линии питания

TB1

TB1

220V-240V ~/N

L

F2.0A 250V

N

RU

TRANSMISSION BOOSTER

MODEL

PAC-SF46EPA

220-240V:0.7A ~/N

POWER RATING

50

3.4kg

WEIGHT

MADE IN JAPAN

Снимите винты

UP

Рис.4-1 Рис.4-2

TB3

ABS

ABS

блок терминалов 2

(получение

M-NET TRANSMISSION M-NET TRANSMISSION

(OUTDOOR UNIT SIDE)

CABLE TERMINAL BLOCK1

электропитания от

прибора)

Передача M-NET

TB3TB2

CABLE TERMINAL BLOCK2

(ADDITIONAL INDOOR UNIT SIDE)

TB2

Передача M-NET блок терминалов 1

(получение электропитания от другого

прибора)

69

Page 14

2. Подсоедините провода электропитания и передачи. (См. 4-2 и 4-3.)

3. После соединения всех кабелей, закрепите кабели с помощью кабельных зажимов.

4. После завершения электромонтажных работ и перед включением электропитания обязательно с помощью винтов закрепите на месте

крышку.

4-2. Линия питания

Подсоедините кабель питания и защитный кабель заземления соответственно к L, N и к терминалам линии заземления на TB1, как

показано на Рис. 4-3.

Источник питания

AC220~AC240V

~/N 50/60Hz

Рис.4-3

Прерыватель цепи

Заземление

Кабель питания

Защитный

кабель

заземления

TB1

(L)

(N)

Кабель питания

Защитный кабель

заземления

220V-240V~/N

L

N

TB1

PAC-SF46EPA

Момент вращения при затягивании: 1,4-2,0 Н/м

4-3. Линия передачи M-NET

Подсоедините кабель передачи M-NET к терминалам A, B (неполяризованные данные) и к терминалу S (экран) на TB2 и TB3, как показано

на Рис. 4-4.

Экран

Рис.4-4

SBABAS

TB3

M-NET TRANSMISSION

TB2

M-NET TRANSMISSION

CABLE TERMINAL BLOCK 2

(ADDITIONAL INDOOR UNIT SIDE)

(OUTDOOR UNIT SIDE)

CABLE TERMINAL BLOCK 1

Линия А, В передачи M-NET

(Неполяризованная, 30В постоянного тока)

(СТОРОНА ДОПОЛНИТЕЛЬНОГО

ВНУТРЕННЕГО ПРИБОРА)

(СТОРОНА НАРУЖНОГО ПРИБОРА)

Момент вращения при затягивании: 0,6-1,0 Н/м

ПРИМЕЧАНИЯ:

• Провод экрана линии передачи M-NET должен быть заземлен методом заземления в одной точке.

• Провод экрана должен подсоединяться к терминалу S только одного прибора на общей линии передачи.

RU

ПРЕДУПРЕЖДЕНИЕ

• При проведении электропроводки не перепутайте блок терминалов линии передачи 1 (TB2) и блок терминалов линии передачи

2 (TB3). В случае обратного подсоединения блоков терминалов усилитель передачи не будет функционировать правильно.

• Учитывая тот факт, что напряжение в линии передачи M-NET составляет 30В постоянного тока, при проведении

электромонтажных работ не перепутайте эту линию с линией питания.

(Если линию питания подсоединить к TB2 or TB3, устройство сломается.)

• Чтобы избежать ошибки при проведении электромонтажных операций, не оставляйте линию питания и линию передачи M-NET

в одной связке или в одном кабелепроводе.

• Правильно подсоединяйте провод заземления.

(Если провод заземления подсоединен неправильно, возникает опасность поражения электротоком или неправильного

функционирования прибора под влиянием шумов.)

• Никогда не используйте мом-тестер на терминалах (TB2 и TB3) линии передачи.

:

70

Page 15

4-4. Пример электропроводки

Пример

<Серия Super Y> Более подробное описание содержится в руководстве по установке прибора серии Super Y.

Прибор постоянной

мощности

Прибор переменной

мощности

(Экран)

TB3

S

TB3

Внутренний прибор

TB5 TB5 TB5 TB5 TB5

M1.M2

(Экран)

Пульт

дистанционного

управления

<Центральный регулятор и приборы Lossnay>

Центральный регулятор

Заземление

Прибор

электропитания

TB2 TB3

Усилитель

передачи

СТОРОНА НАРУЖНОГО

ПРИБОРА

Прибор

Lossnay

Заземление

SS

Прибор

Lossnay

СТОРОНА

ДОПОЛНИТЕЛЬНОГО ВНУТРЕННЕГО ПРИБОРА

Заземление

Прибор

Lossnay

Пульт

дистанционного

управления

прибора Lossnay

Прибор

Lossnay

Пульт

дистанционного

управления

прибора Lossnay

(Экран)

(Экран) (Экран)

Прибор

Lossnay

Пульт

дистанционного

управления

прибора Lossnay

Пульт

дистанционного

управления

прибора Lossnay

Усилитель

передачи

TB2 TB3

SS

Прибор

Lossnay

Пульт

дистанционного

управления

прибора Lossnay

Прибор

Lossnay

Заземление

Прибор

Lossnay

Пульт

дистанционного

управления

прибора Lossnay

Пульт

дистанционного

управления

прибора Lossnay

M1.M2M1.M2M1.M2M1.M2

(Экран) (Экран) (Экран)

Прибор

Lossnay

Пульт

дистанционного

управления

прибора Lossnay

SSSSS

Пульт

дистанционного

управления

прибора Lossnay

ПРИМЕЧАНИЯ: *Данный прибор не может быть использован для удлинения линии передачи.

RU

71

Page 16

5 Предел системы (длина сигнальной линии, максимальное

число приборов)

<Серия Super Y>

Пожалуйста прочитайте руководство по установке, прилагаемое к прибору серии Super Y (PUHY-YSMF-B, PUHY-YSMC).

<За исключением серии Super Y>

Пределы длины линии передачи

(1) Максимальное расстояние между концами

должно быть менее 500 м

Напр.) A+B+D+E,

A+B+C+E,

C+D

(2) Максимальное расстояние от источника

питания должно быть менее 200 м

Напр.) B+D, B+C, A, E

A

Центральный регулятор

B

Прибор

электропитания

T

B

2

Усилитель

передачи

Прибор

Lossnay

T

B

3

Прибор

Lossnay

C

Пульт дистанционного

управления прибора Lossnay

Пульт дистанционного

управления прибора Lossnay

D

E

Прибор

Lossnay

Пульт дистанционного

управления прибора Lossnay

Прибор

Lossnay

Пульт дистанционного

управления прибора Lossnay

ПРИМЕЧАНИЯ:

• Если общая длина электропроводки пульта дистанционного управления менее 10 м, используйте кабель 0,75 мм2, и при этом не

прибавляйте их длину к расчетам длин, приведенным выше.

• Если общая длина электропроводки пульта дистанционного управления более 10 м, используйте кабель1,25 мм2 или

экранированный кабель не менее ø1,2 мм для проведения электропроводки длиной более 10 м, и при этом обязательно прибавьте

их длину к расчетам длин, приведенным выше.

Максимальное число приборов, которые можно подсоединить (сторона TB3)

Максимальное число

приборов, которые можно

подсоединить

50 пультов дистанционного управления Lossnay

(Один центральный регулятор эквивалентен 4 пультам дистанционного управления

Lossnay.)

RU

72

Page 17

89

Page 18

This product is designed and intended for use in the residential,

commercial and light-industrial environment.

The product at hand is

based on the following

EU regulations:

• Low Voltage Directive 73/23/EEC

• Electromagnetic Compatibility Directive 89/

336/EEC

HEAD OFFICE MITSUBISHI DENKI BLDG MARUNOUCHI TOKYO 100-8310 TELEX J24532 CABLE MELCO TOKYO

WT02986X01

Loading...

Loading...