Page 1

SPLIT -TYPE AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

Air Conditioner Optional Parts

R-Converter Unit

[Model name] [Service Ref.]

PAC-SF29LB PAC-SF29LB

2003

No.OC296

R-Converter Unit

w Refer to the technical & service manuals of the indoor

and outdoor units.

CONTENTS

1. OVERVIEW OF UNITS······································2

2. SPECIFICATIONS·············································8

3. OUTLINES AND DIMENSIONS························9

4. WIRING DIAGRAM·········································10

5.

NECESSARY CONDITIONS FOR SYSTEM CONSTRUCTION

6. TROUBLESHOOTING ····································12

7. ELECTRICAL WORK ······································19

8. REFRIGERANT PIPING··································22

9. PARTS LIST····················································23

···11

Page 2

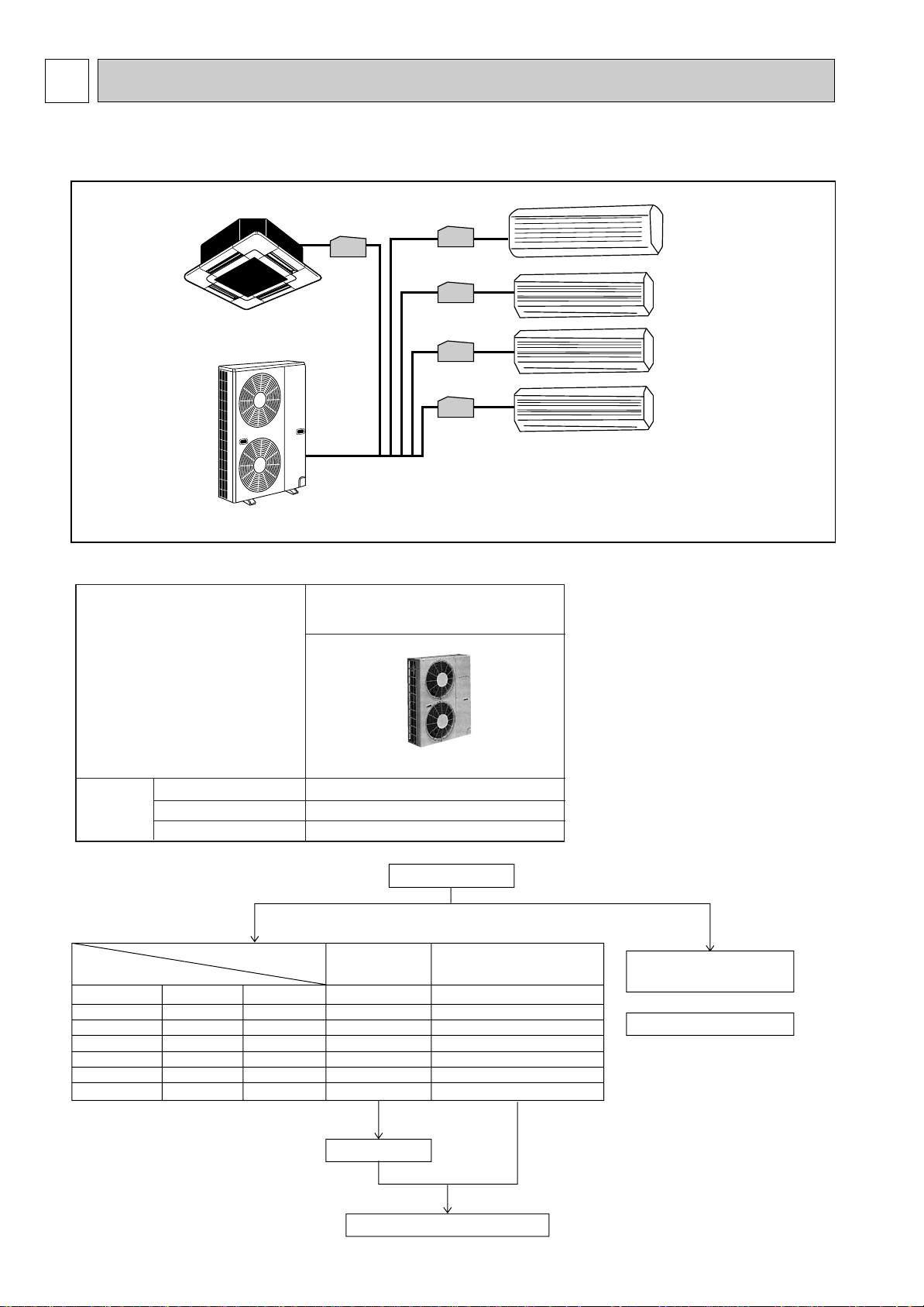

1 OVERVIEW OF UNITS

SL series

MS series

Outdoor unit

R-Converter Unit

R-Converter Unit

R-Converter Unit

R-Converter Unit

R-Converter Unit

PUMY series

Branching Pipe

Capacity type

Rated capacity

Model

20

25

32

40

50

63

Cooling (kW)

2.2

2.8

3.6

4.5

5.6

7.1

Heating (kW)

2.5

3.2

4.0

5.0

6.3

8.0

SL series

4-way folw

Cassette

Ceiling

—

SLH-1AR1.TH

—

SLH-1.6AR1.TH

SLH-2AR1.TH

—

MS series

Wall Mounted

CITY MULTI indoor Units

(P•FY series)

Remote Controller

Panel SLP-2AL

R-Converter Unit PAC-SF29LB

MSC-07RV-E5, MSH-07RV-A3

MSC-09RV-E5, MSH-09RV-A3

—

MSC-12RV-E5, MSH-12RV-A3

MSH-18RV-E2, MSH-18RV-A2

MSH-24RV-E2, MSH-24TV-A2

+

+

1-1. SYSTEM OUTLINE

1-1-1. System example

1-2. UNIT CONSTRUCTION

Outdoor unit

Indoor unit

that can be

connected

Capacity

Number of units

Total system wide capacity

50~130% of outdoor unit capacity

PUMY-P125VMA

PUMY-P125YMA

Type 20~Type 125

1~8 units

2

Page 3

PAC - SF 29 LB

(Indispensable)

Optional parts

of PAC

Symble of

factory

Lev Box

Design code No.

1-3. METHOD FOR IDENTIFYING

PUMY-P125YMA

MSH-18RV SLH-1.6AR MSC-09RV MSC-09RV MSC-07-RV

Living

R-Converter Unit

(PAC-SF29LB)

R-Converter Unit

(PAC-SF29LB)

R-Converter Unit

(PAC-SF29LB)

R-Converter Unit

(PAC-SF29LB)

R-Converter Unit

(PAC-SF29LB)

Bedroom (1) Bedroom (2) Bedroom (3)

Dining

Total rated capacity

160 163

■ R-Converter Unit

1-4. TYPICAL COMBINATION EXAMPLE

■ Verification

The rated capacity should be determined by observing the below. The unit’s quantities are limited in 1 to 8 units. For

the next step, make sure that the selected total indoor unit capacity is in a range of 63 ~ 163.

The total indoor unit capacity should be within the outdoor units. (=125 is preferred).

Combination of excessive indoor units and an outdoor unit may reduce the cooling capacity of each indoor unit.

The rated indoor capacity is as blow table.

Example:

W Capacity type of indoor units

Refer to page 2.

MSH-18 = 50

SLH-1.6 = 40

MSC-09 = 25

MSC-09 = 25

MSC-07 = 20

3

Page 4

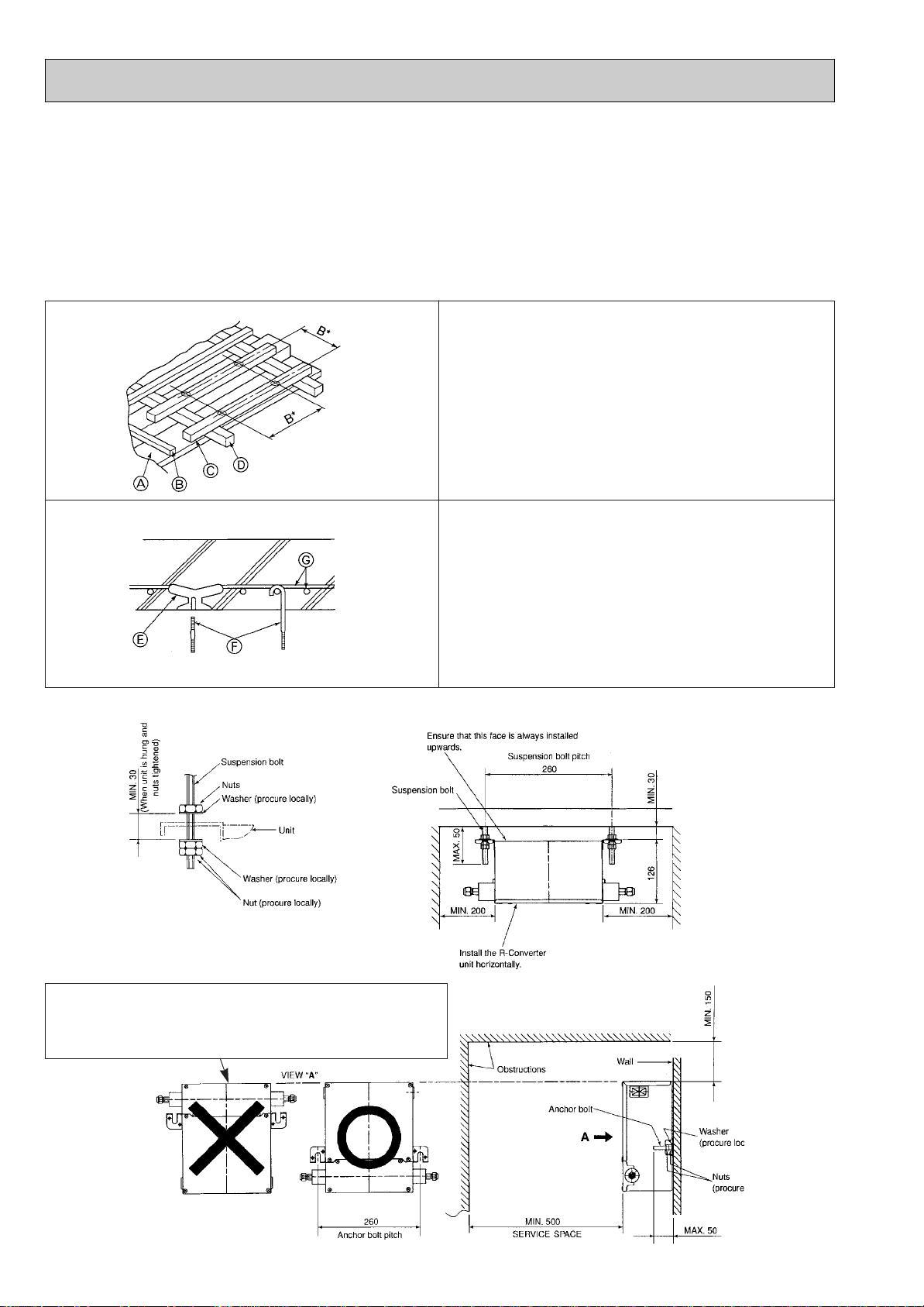

1-5. INSTALLATION

1-5-1. Installing the R-Converter Unit (mm)

Parts to procure locally

• Suspension bolts or anchor bolts : W3/8 (M10)

• Nut : W3/8 (M10)

• Washer : W3/8 (M10)

Installing the unit in a ceiling

(1) Install the suspension bolts

Wooden structures

• Use tie beams (single storied houses) or second floor

beams (two story houses) as reinforcing members.

• Wooden beams for suspending air conditioners must be

sturdy and their sides must be at least 6 cm long if the

beams are separated by not more than 90 cm. The size of

the suspension bolts should be M10 (W3/8). (The bolts are

not supplied with the unit.)

A Ceiling

B Rafter

C Beam

D Roof beam

B* Suspension bolt pitch

Ferro-concrete structures

Secure the suspension bolts using the method shown, or use

steel or wooden hangers, etc. to install the suspension bolts.

E Use inserts rated at 100-150 kg each (procure locally)

F Suspension bolts M10 (W3/8) (procure locally)

G Steel reinforcing rod

(2) Install the R-Converter unit.

Installing the unit on a wall

(1) Install the anchor bolts.

(2) Install the R-Converter unit.

Do not install the refrigerant pipes on top of the unit when

installing the unit on a wall, otherwise condensation can

enter the electrical devices, which can cause an electric

shock or a fire.

4

Page 5

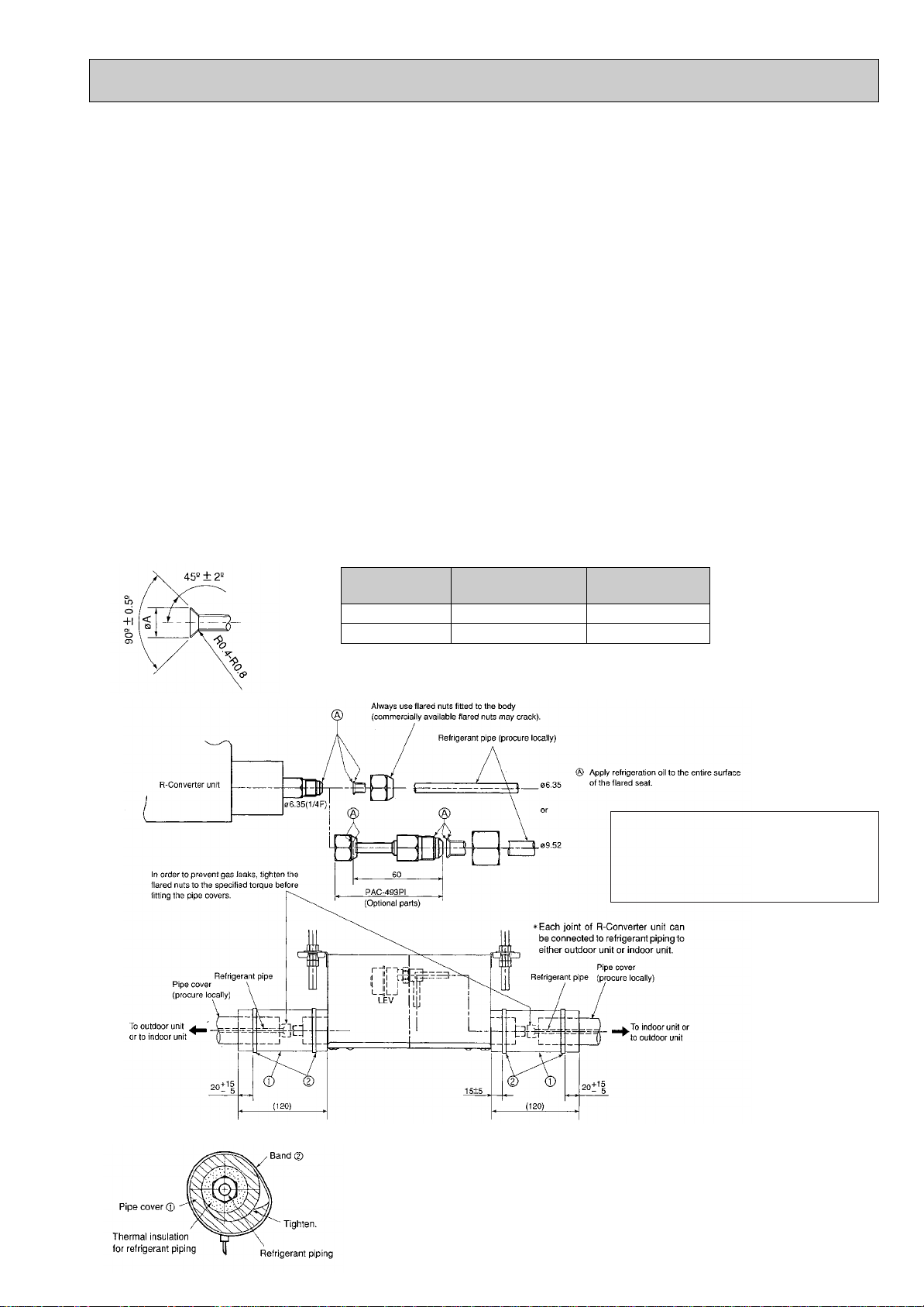

1-5-2. Installing Refrigerant Piping (mm)

Copper piping

O.D. (mm)

{6.35

{9.52

Flare dimensions

{A dimenson (mm)

8.6-9.0

12.6-13.0

Torque

N-m (kgf

•cm)

14-18 (140-180)

34-42 (340-420)

In order to prevent gas leaks, tighten the flared nut to the

specified torque even when not connecting the indoor unit

refrigerant piping.

Check the R-Converter unit accessories and parts

1 Pipe cover o 2 2 Band (long) o 4 3 Thermistor holder—[6.35 (liquid) o 1 4 Thermistor holder—[9.52 (liquid or gas) o 1

5 Thermistor holder—[12.7 (gas) o 1 6 Thermistor holder—[15.88 (gas) o 1 7 Thermistor insulation (3o150o60) o 2

8 Band (short) o 2

Connect R-Converter unit to the liquid pipe

• For identification purposes, list the indoor unit model names in the nameplate on the control box of the R-Converter

unit.

• To prevent water from dripping from the refrigerant piping, wrap both the liquid and gas piping with commercially available

thermal insulation that is at least 12 mm thick and which is able to withstand temperatures in excess of 100 °C.

• See the indoor and outdoor unit installation manual when creating a vacuum and opening or closing valves.

• Install the piping so that vibrations from the piping do not transmit to the unit.

Installing piping to the unit

(1) Remove the flared nuts and caps from the R-Converter unit.

(2) Flare the ends of the liquid and gas piping, and apply refrigeration oil (procure locally) to the flared seat.

(3) Connect the refrigerant piping immediately. Always tighten the flared nuts to the specified torque using a torque wrench and

double spanner.

(4) Press the pipe covers 1 on the liquid piping against the unit and wrap it to hold it in place.

(5) Fasten the supplied bands 2 10-20 mm from each end of the pipe covers 1 .

. Caution :

• Tighten the flare nut with a torque wrench in the specified method.

• Do not use the existing refrigerant piping, when use R407C refrigerant.

• Take precautions so that the Freon gas is not leaked during a fire.

Section of connection

Match the refrigerant piping size to

the indoor unit. If using a liquid pipe

that is [[9.52 mm, use joint pipe PAC493PI or a locally procured tandem

joint.

• Refrigerant charge :

See the outdoor unit installation manual.

Use only R407C or R22 refrigerant.

• Use the following procedures for connecting parts to

the indoor unit.

a) Tighten the flared nuts to prevent refrigerant leaks.

b) Fasten the pipe covers 1 to the pipes with the

bands 2 to prevent condensation.

5

Page 6

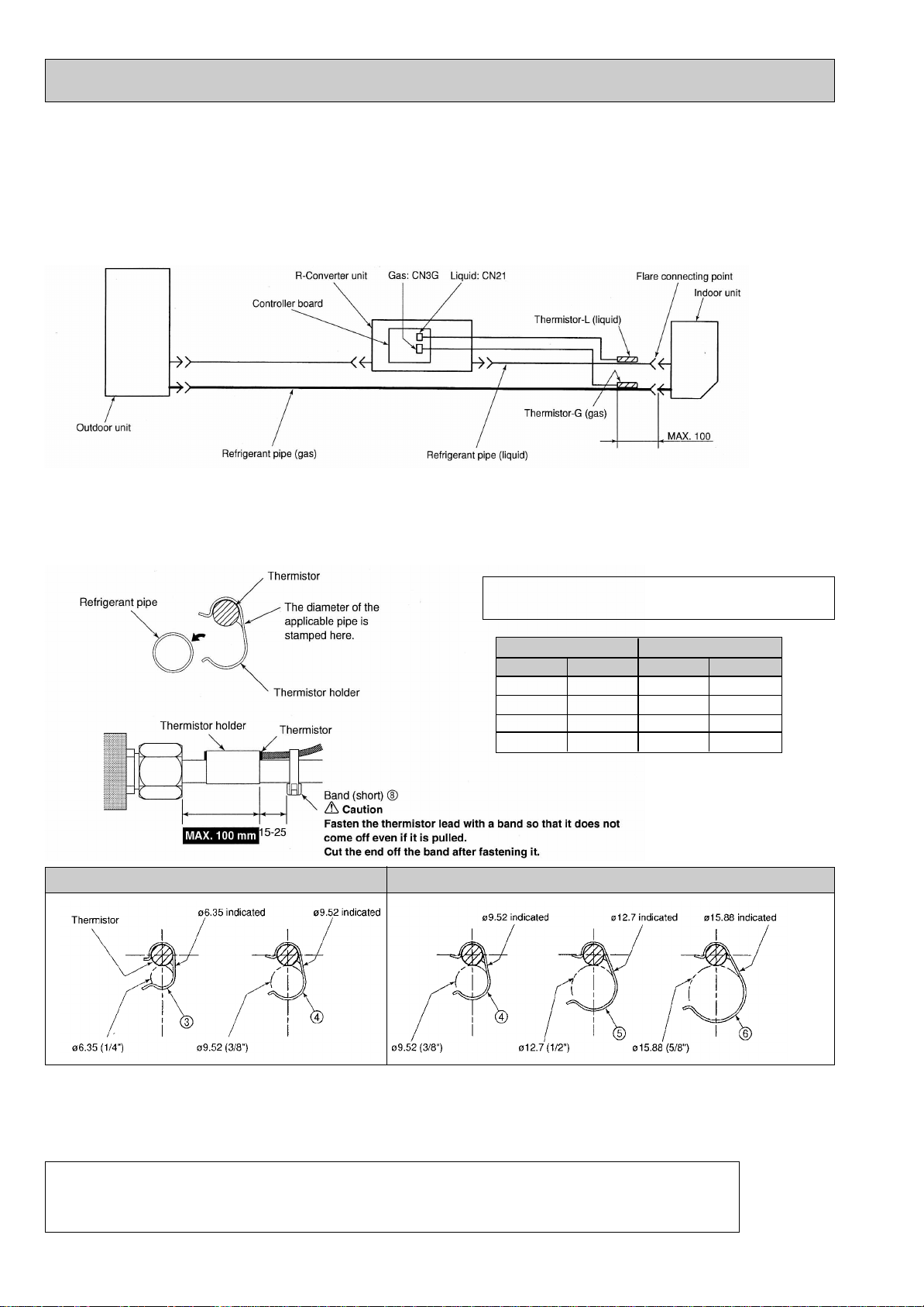

1-5-3. Installing the thermistors (mm)

Indoor unit capacity pipe size (mm)

BTU

07, 09

12, 13

18

24, 30

HP

1

1.6

2

2.5

Liquid

{6.35

{6.35

{6.35

{9.52

Gas

{9.52

{12.7

{15.88

{15.88

Be sure to install the thermistors (gas and liquid) supplied with the unit as shown in the illustration.

• If the thermistors are not installed, the unit will not operate. If the thermistors are installed incorrectly, the unit will not operate

properly.

Take precaution so that condensation does contact the thermistor leads or enters the electrical devices.

Before installing thermal insulation to the frame connecting points of the indoor unit, be sure to install the thermistors

according to the procedures given on this page.

Thermistor installation order

(1) Securely fasten the thermistors (liquid and gas) supplied with the unit using the thermistor holders (3, 4, 5, 6) at the

fastening points of indoor unit refrigerant pipes.

• Set thermistor-L (liquid) in thermistor holders 3 or 4 and thermistor-G (gas) in thermistor holders 4, 5 or 6, and then

fasten the refrigerant pipes.

Select thermistor holders that match the size of the

refrigerant piping.

Liquid

Gas

. Caution :

• To prevent condensation from dripping on the thermistor fasteners, wrap them with sufficient thermal insulation.

• Install the thermistors so that the piping is on top (as shown in above illustration).

• Take out the thermistor lead from above the piping.

• Install the thermistors indoors.

• Route the following lead, line, and cable pairs so that they do not come into contact with each other.

-Thermistor lead and indoor unit-R-Converter transmission line

-Thermistor lead and power supply cable

-Transmission line and power supply cable

6

Page 7

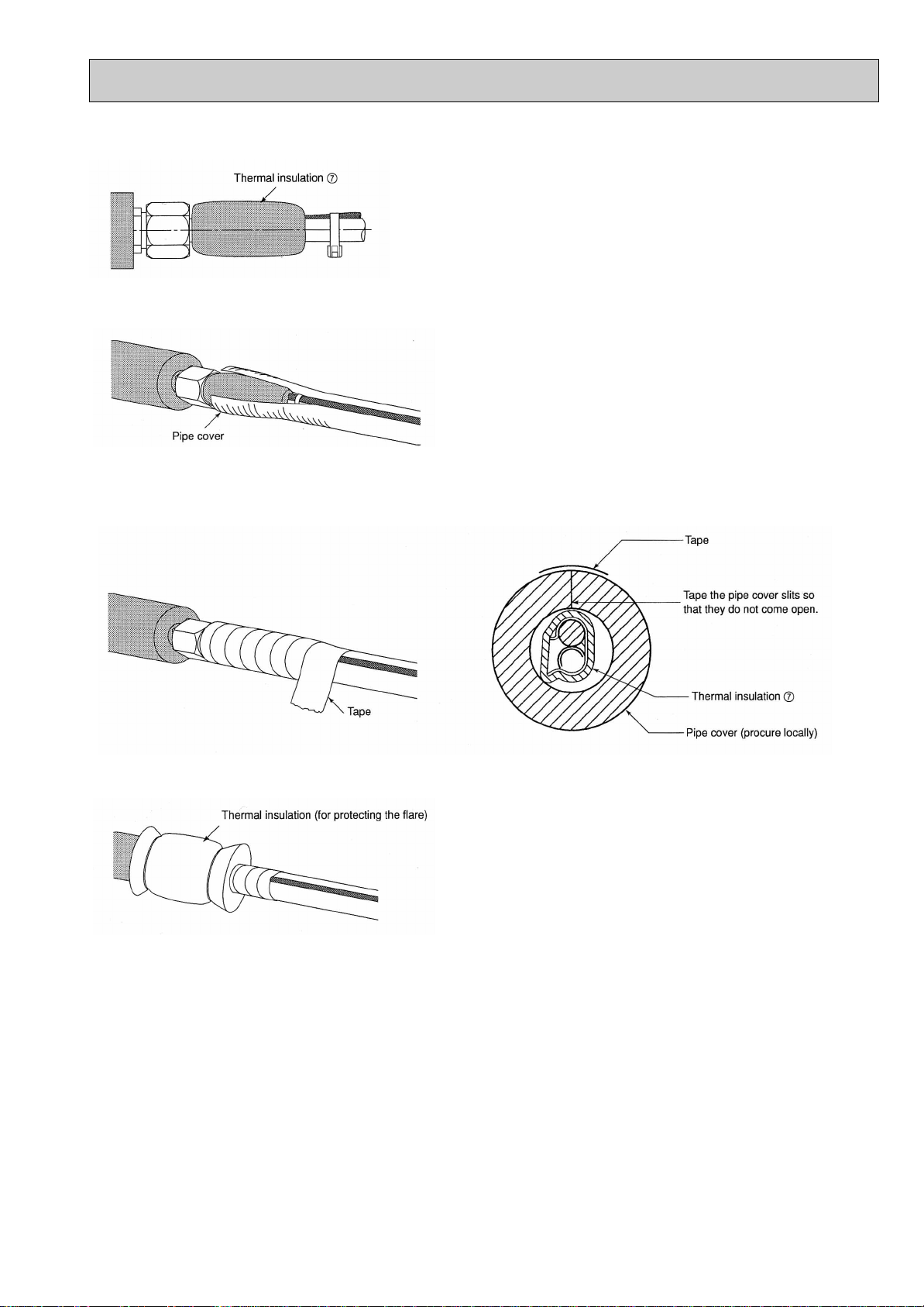

(2) Insulate the thermistors with the supplied thermal insulation 7.

(3) Cut a 100 mm slit on the top portion of the extension piping pipe covers, and then cover the thermistors with the pipe

covers.

(4) Wrap the thermal insulation covering the thermistor with tape.

. Caution :

Be sure to take out the thermistor lead from above.

(5) Cover the flare and thermistor with the thermal insulation (for protecting the flare) supplied with the indoor unit.

Bundle up the excess thermistor lead.

. Caution :

• Do not make the thermistor lead taut.

• Do not add extensions to the thermistor lead.

• Do not cut the excess thermistor lead.

• Make sure that the bundled thermistor lead does not interfere with any other wiring.

7

Page 8

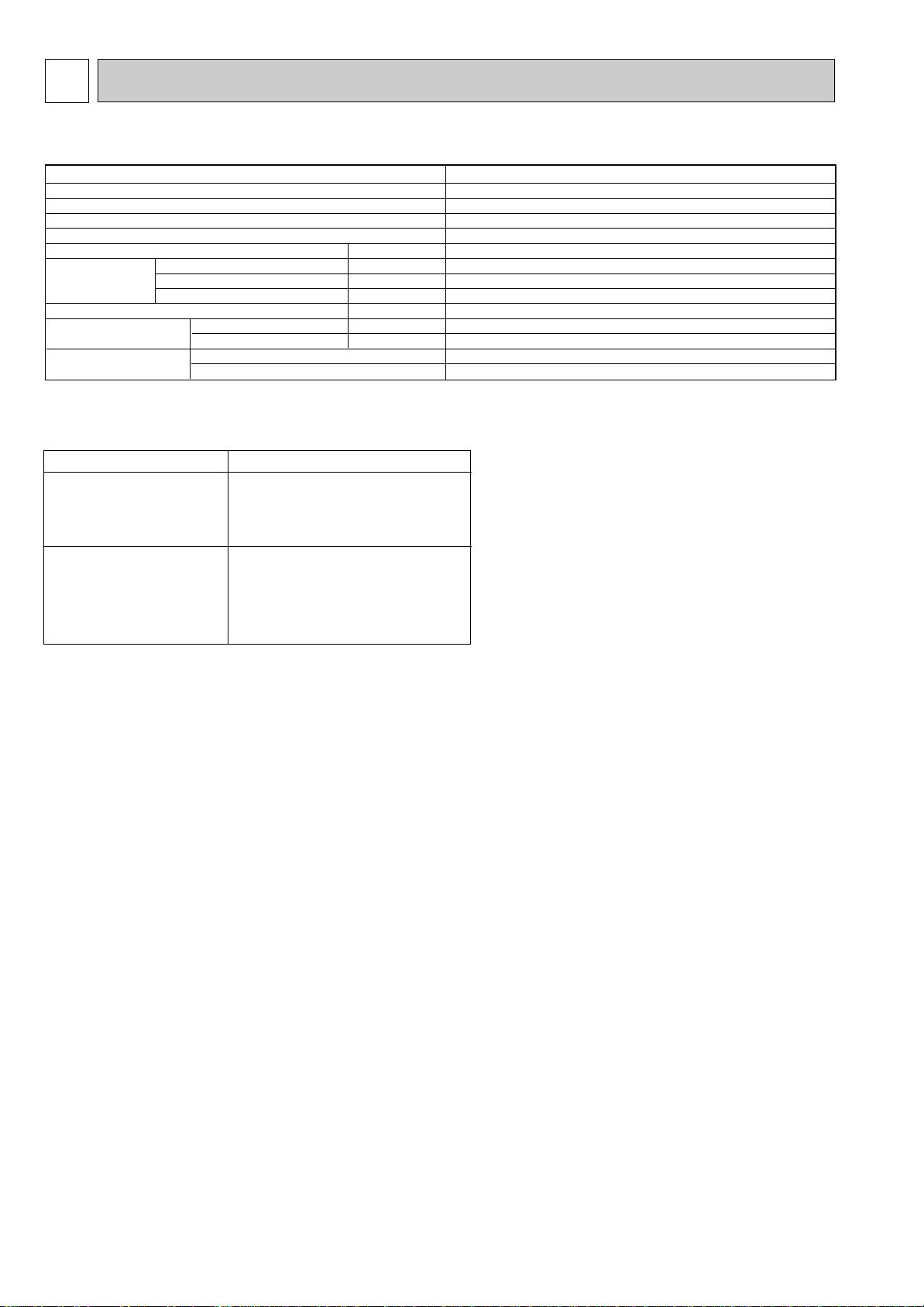

2 SPECIFICATIONS

mm

mm

mm

mm

kg

mm(in.)

mm(in.)

Model name

Connectable number of indoor units

Total capacity index of indoor units to be connected

Power supply

External finish

Drain hose size (on site)

Dimensions

Weight

Piping connection (Flare)

Wiring

Width

Depth

Height

Liquid

Gas

To indoor unit

To outdoor unit

PAC-SF29LB

1

Type 20-63

Single phase, 220/230/240V, 50Hz, Single phase, 220V, 60Hz

Hot-dip Zinc - coated steel (No external finish)

—

280

220

126

2.8

6.35 (1/4)W

—

2-core cable

2-core shield cable (Non-polarized)

Model Name (series)

Connectable indoor units

Connectable outdoor units

Wall mounted MS series*

Cassette Ceiling SL series*

PUMY series *

* See page 2 for detail model name.

R-Converter Unit : PAC-SF29LB

W If using on indoor unit with [9.52 piping connection and using a [9.52 refrigerant pipe, use joint pipe “PAC-493PI” (optional

parts) or a locally procured tandem joint ([6.35

➝[9.52)

8

Page 9

3 OUTLINES AND DIMENSIONS

MIN.150

MAX.50

Suspension bolt

MAX50

3

103

LEV

126

MIN.200

126 MIN.30

(220)

MIN.100

CEILING MOUNT

(280)

MAX.50

MIN.100

MIN.50

Obstructions

WALL MOUNT

450

Anchor bolt

MAINTENANCE HOLE

Suspension bolt

450

VIEW "A"

MAINTENANCE HOLE

"A"

MIN.500

SERVICE SPACE

Obstructions

<mm>

S=1:4

280

Wiring

Terminal block

Band

1/4F

110

40

Electric cover

12

GAS

CN3G

CN21

LIQUID

1/4F

24

8

18

Band

FUSE

26 40

85

3.15A 250V

Suspension bolt pitch

260

300

2✕2- [6 hole

Wiring

Wiring

50/60Hz

2

NL

Band

3N

SM1

M2

2-Electric wire inlet

/N 220-240V/220V

<POWER SUPPLY>

Terminal block:TB2

Controller board

DC12V

Terminal block:TB3

<TO INDOOR UNIT>

* V = 126H * 280W * 220D = 0.0078 m

* Weight : 2.8kg

* Suspension bolt or Anchor bolt : M10(W3/8)

DC24V-30V

Terminal block:TB5

<TO OUTDOOR UNIT>

9

Page 10

4 WIRING DIAGRAM

10

Page 11

5

Capillary tube

in R-Converter Unit

1 : {3.6 o {2.4 o L95

2 : {3.6 o {2.4 o L150

Liquid (mm)

Gas (mm)

{6.35w (IN/OUT)

Indoor unit capacity pipe size (mm)

BTU

07, 09

12, 13

18

24, 30

HP

1

1.6

2

2.5

Liquid

{6.35

{6.35

{6.35

{9.52

Gas

{9.52

{12.7

{15.88

{15.88

<Reference>

Conversion formula

1/4F

3/8F

1/2F

5/8F

3/4F

{6.35

{9.52

{12.7

{15.88

{19.05

Model name

Connected pipes diametermmDiameter AmmDiameter B

mm

{6.35 → {9.52 {6.35 {9.52PAC-493PI

Outdoor unit capacity pipe size (mm)

kcal/h

12500

kW

14.0

Liquid

{9.52

Gas

{19.05

TH23j

R-Converter Unit1

R-Converter Unit2

Indoor Unit2

Indoor Unit1

Outdoor Unit

Capillary tube

LEV1

HIC

TH1

TH5

TH6

Comp

Acc

SV

O/S

THHS

21S4

63HS

TH2

LEV2j

LEV2j

TH23j

HEX

HEX

HEX

TH22j

TH22j

Functioal Parts

<Outdoor Unit>

<R-Converter Unit>

Compressor

Oil Separator

High Pressure Sensor

4-way Valve

Heat Exchenger

Overcooling Heat Exchenger

Electronic Expansion Valve

Accumulator

Electronic Expansion Valve

Comp

O/S

63HS

21S4

HEX

HIC

LEV1

Acc

LEV2j

Thermistor

<Outdoor Unit>

<R-Converter Unit>

Discharge Temperature Sensor

Saturation Temperature of Suction Pressur

Piping Temperature

Outdoor Air Temperature

Liquid Pipe Temperature

Gas Pipe Temperature

TH1

TH2

TH5

TH6

Th22j

Th23j

NECESSARY CONDITIONS FOR SYSTEM CONSTRUCTION

5-1. REFRIGERANT SYSTEM DIAGRAM

• Piping connection size of R-Converter Unit

W If using a [9.52 refrigerant pipe, use joint pipe

“PAC-493PI” (optional parts) or a locally

procured tandem joint ([6.35➝[9.52)

• Piping connection size of indoor unit

Select piping that match the size of the Indoor Unit

piping connection.

• Piping connection size of outdoor unit

• Different-diameter joint (Optional parts)

11

Page 12

6 TROUBLESHOOTING

6-1. Test Run

. Caution :

Before operating the unit, check that the wiring, piping, and thermistors are installed and that the switches have been

set.

Refer to the "Test run" section of the indoor units and outdoor unit installation manuals.

After installation of an indoor unit, R-Converter unit, and outdoor unit, begin a test run to check water leaks in the R-Converter

unit.

Be sure to perform a test run in cooling mode for each indoor unit installed. Make sure that each indoor unit operates

properly following the installation manual supplied with the unit.

If a test run is performed on all indoor units at once, improper connection of the refrigerant pipes and the indoor and outdoor

unit connecting wires cannot be detected.

. Caution :

• Always use the remote controller to operate the indoor unit.

• When using an R-Converter unit, operation from the outdoor unit is not possible.

• The following symptoms are not malfunctions.

Symptom

Indoor unit does not operate

even if set to cooling (heating )

operation

Indoor unit fan stops during

heating operation

W See the operation manual of indoor units for details.

WW This mode is activated for approximately 1 minute to help avoid an insufficient supply of refrigerant during heating opera-

tion when refrigerant is stored in an indoor unit that has been turned off or thermo-off.

• A hissing noise can be heard immediately after the air conditioner is started or stopped. This is the sound of the refrigerant

flowing inside R-Converter unit. The problem is insignificant.

The cooling (heating) operation cannot be operated when the

cooling (heating) operation of another indoor unit is operating.

The fan stops during defrosting operation.

Fan stops when the refrigerant collecting mode WW is activated.

When this occurs, the vanes close.

Cause

Indoor unit LED display W

Stand by

(For Multi System)

—

Stand by

(For Multi System)

12

Page 13

6-2. Self-diagnosis and Remedy (Display on Outdoor controller board)

Error code Error codeTrouble Trouble

1102

1108

1302

1500

1501

1505

2502

2503

4115

4116

4220

4230

4250

5101

5102

5103

5105

5106

5110

Discharge temperature trouble

Compressor's inner thermal sensor trouble

High pressure trouble

Excessive refrigerant replenishment

Insufficient refrigerant

Vacuum operation protection

Drain pump trouble

Drain sensor trouble (THd)

Power synchronization signal trouble

Indoor unit fan rotation trouble

Inverter main voltage drop

Overheat protection of radiator panel

Multiple IPM errors

Intake thermistor trouble (TH21) or discharge

thermistor trouble (TH1)

Liquid pipe thermistor trouble (TH22) or intake pressure

saturation pressure thermistor trouble (TH2)

Gas pipe temperature sensor trouble (TH23)

Piping temperature sensor trouble (TH5)

Outdoor temperature sensor trouble (TH6)

IPM heat sink thermistor trouble (THHS)

Pressure sensor trouble (63HS)

Duplicated unit address setting

Transmission error (Transmission processor

hardware error)

Transmission error (Transmission route BUSY)

Transmission and reception error

(Communication trouble with transmission processor)

Transmission and reception error (No ACK error)

No response

MA communication receive signal error

(no receive signal)

MA communication send signal error

(starting bit detection error)

MA communication send error (H/W error)

MA communication receive error

(Synchronous recovery error)

total capacity error

Capacity code error

Connecting unit number error

Address set error

Remote controller sensor trouble

5201

6600

6602

6603

6606

6607

6608

6831

6832

6833

6834

7100

7101

7102

7105

7111

Display

7101

7103

1110

Meaning and detecting method Causes Check points

Capacity code error

1Abnormal if capacity code SW of R Converter unit is set to "0".

2Abnormal if capacity code setting

of R-Converter unit is not the same

as that of indoor unit.

1No setting or setting mistakes of

capacity code SW.

2Mis-wiring connection between

indoor unit and R-Converter unit

(Converse wiring).

1Check capacity code setting.

2Check if there is no mis-wiring

connection.

Combination error

1Abnormal if R-Converter unit is

connected to the indoor unit which

is not designed for connecting to R Converter type.

2Abnormal if system remote

controller (SC) remote controller is

connected to R-Converter unit.

1The indoor unit is not designed for

connecting to R-Converter unit.

2System remote controller (SC)

remote controller is connected to

R-Converter unit.

1Check if the model name of the

indoor unit is listed up on page 2.

2Check if system remote controller

(SC) remote controller is a part of

R-Converter

Converse connection error

1Abnormal if the equation below is

continuously detected for 10

minutes during cooling operation.

Intake temperature - piping

temperature (TH22 or TH23) [

3deg

2Abnormal if the equation below is

continuously detected for 10

minutes during cooling operation.

Indoor main pipe temperature -

gas pipe temperature (TH23) ]

25deg

1Converse connection of extension

pipe between indoor unit and R Converter unit

2Converse connection of

communication wire between

indoor unit and R-Converter unit.

3Disconnection of sensor,

No installation or installation

mistakes of sensor

4Shortage or leakage of refrigerant,

Clogged refrigerant circuit

1Check if the connection of

extension pipe is converse.

2Check if the communication wire is

converse.

3Check if sensor is correctly

installed.

4Check piping temperature by test

run.

<Abnormalities detected with the power on>

Error codes will be displayed in LD1 on the outdoor controller board if abnormalities occur while unit is running. Therefore,

check LD1 on the outdoor controller board first in that case. If no code is displayed in LD1, check LED on the indoor controller

board.

<List of error codes in LD1>

W Read the technical manual of outdoor unit if codes listed up above are displayed.

13

Page 14

Switch

SW1 1

2

3

4

5

6

7

8

SW2

SW4 1

2

3

4

5

6

SW11

SW12

Pole Function

Operation by Switch

When to set Remarks

ON OFF

Converse connection error (1110) detection

No Function

Correction of liquid pipe temperature in

heating operation

Change of LEV opening pulse

Change of Remote display

Humidifier control

Correction of liquid pipe temperature in

cooling operation (1)

Correction of liquid pipe temperature in

cooling operation (2)

No Function

No Function

No Function

Correction of LEV opening pulse in dry

operation

Solutions for refrigerant flowing sound after

defrosting operation

Solutions for refrigerant flowing sound

during defrosting operation

Capacity code setting

During stopping the

operation

Setting made at the factory

R-Converter unit controller board

Set the capacity setting of

the R-Converter unit equal

to the capacity setting of

the indoor unit.

Before turning the

power on

Before turning the

power on

Before turning the

power on

Inactive

Active

Change

On signal of thermostat

Always in heating

Active

Inactive

No change

Output from Fan

Thermo-on in heating

Active

Active

Active

Inactive

Inactive

Inactive

Capability

description

Btu HP

Capability

description

Btu HP

SW2 SW2

07

ON

OFF

-

1

1.6

15

2

2.5

-

17

18

24

30

08

09

10

12

13

1 23456

1 23456

1 23456

ON

OFF

ON

OFF

ON

OFF

1 23456

ON

OFF

1 23456

ON

OFF

1 2345678

1 23456

1 23456

ON

OFF

ON

OFF

Setting made at the factory

ON

OFF

1 23456

Setting made at the factory

Addresses setting on board

Setting made at the factory

6-3. Internal Switch Function Table

R-Converter Unit

(1) Before turning on the power of the indoor unit, be sure to set the SW2. If the switches are not set or if the setting are

incorrect, the device will not operate properly.

(2) After setting the switches, turn the indoor unit, R-Converter unit, and outdoor unit on in that order.

(3) In case capacity code setting or address setting is mistaken, reset it, turn off power supply of the outdoor unit, R-Converter

unit and indoor unit for 2 minutes or more at the same time and turn on power supply again in the order of (2).

14

Page 15

6-4. How to check the parts PAC-SF29LB

Parts name

Liquid pipe thermistor (TH22)

Gas pipe thermistor (TH23)

Disconnect the connector then measure the resistance using a tester.

(Surrounding temperature 10

°

C-30°C)

Check points

(Refer to the thermistor)

Normal

4.3k"-9.6k"

Abnormal

Open or short

<Thermistor Characteristic graph>

Thermistor for

lower temperature

Thermistor R0 = 15k" i 3%

B constant = 3480k" i 1%

0°C

10°C

20°C

25°C

Rt = 15exp {3480( )}

Liquid pipe thermistor (TH22)

Gas pipe temperature thermistor (TH23)

273+t 273

11

15k"

9.6k"

6.3k"

5.2k"

30°C

40°C

4.3k"

3.0k"

0

10

20

30

40

50

-20 -10 0 10 20 30 40 50

Temperature (:)

Resistance (K")

6-4-1. Thermistor

15

Page 16

6-4-2. Linear Expansion Valve

M

LEV

Blue

{4

{3

{2

{1

{4

{3

{2

{1

6

5

4

3

2

1

BRN

RED

BLU

ORN

YLW

WHT

Brown

Yellow

Red

White

Orange

1

5

2

3

6

4

Controller board

DC12V

Drive circuit

Connector (CN60)

A

E

D

C

B

Closing

Opening

Completely sealed (80-100 pulses)

Number of pulses

Valve fully open

at 2,000 pulses

Valve position (volume)

Parts name

Linear expansion valve

Disconnect the connector then measure the resistance valve using a tester.

Refer to the next page for a detail.

Check points

Normal

150k" i10%

Abnormal

Open or short

(1)-(5)

White-Red

(2)-(6)

Yellow-Brown

(3)-(5)

Orange-Red

(4)-(6)

Blue-Brown

Blue

1

2

4

1

5

3

2

6

4

3

5

6

Brown

Yellow

Orange

Red

White

M

Linear expansion valve

11

Operation summary of the linear expansion valve.

• Linear expansion valve open/close through stepping motor after receiving the pulse signal from the indoor controller board.

• Valve position can be changed in proportion to the number of pulse signal.

<Connection between the indoor controller board and the linear expansion valve.>

Note : Since the number of the connector at the controller board side and the relay connector are different, follow the color of

the lead wire.

22

Output pulse signal and valve action

Valve closing:1➔2➔3➔4➔1

Valve opening:4➔3➔2➔1➔4

The address of the pulse output is shifted using the procedures

mentioned earlier.

w1. All output phase will turn OFF when the LEV stops

operating.

2. When the output phase is terminated or when the phase

Output(phase)

{1

{2

{3

{4

(a) LEV action

1

ON

ON

OFF

OFF

Output

23

OFF

ON

ON

OFF

OFF

OFF

ON

ON

4

ON

OFF

OFF

ON

shift is not according to frequency, the motor rotation will

become irregular, causing the motor to vibrate or lockup.

w When the power supply is on, the closing signal of 2,200

pulse will be transmitted to decide the position of the valve.

The valve position can be determined when point A is

reached.

The LEV will not vibrate or make noise when the valve is

operating smoothly. However, when the number of pulses

change from E to A ,or if the valve lockup, there may be

more noise than under normal circumstances.

• The noise can be heard by resting your ear on the handle

of a screwdriver that is pressed against the top of the

LEV valve.

16

Page 17

3 Troubleshooting

Problem Check point Corrective measure

Remove the connector from the controller board and connect diagnostic

LEDs.

Pulses will be issued for 10 seconds when the power is turned on.

It indicates that there is an abnormality in the operating circuit if

any LEDs don't turn on or off.

If the linear expansion valve becomes locked and the motor is still operating,

the motor will emit a clicking noise and will not function. This clicking noise

indicates an abnormality.

Use an all-purpose electrical meter to measure the resistance between the

different coils (red-white, red-orange, brown-yellow, brown-blue). Normal

resistance is within a range of 150'±10%.

In order to check the linear expansion valve, operate one indoor unit in the

fan mode and another in the cooling mode. Then, use the outdoor multi

controller board to operate the monitor and check the pipe temperature of the

indoor unit (RT12). The linear expansion valve should be fully closed when

the fan is operating. The temperature measured by the temperature sensor

will drop if there is any leakage.

If the measured temperature is significantly lower than that on the remote

controller, this indicates that the valve is not closed. It is not necessary to

replace the linear expansion valve if the leak of refrigerant is small and does

not cause a malfunction.

1 Check improperly connected connector terminals and the wire colors.

2 Remove the connector on the controller board side and check electrical

conductance

Malfunction in

microprocessor

operating circuit

Locked expansion

valve

Short circuit or broken

circuit in expansion

valve motor coil

Valve does no close

completely

Incorrect connection

or connection failure

Replace the R-Converter

controller board

Replace the linear

expansion valve

Replace the linear

expansion valve

Replace the linear

expansion valve if there

is a major leak of

refrigerant.

Continuity check of

wrong part.

6

5

4

3

2

1

1k" LED

17

Page 18

6-5. Monitoring Function

Operating status

LED1

Green

LED2

Red

LED3

Red

When power supply is turned on.

Operating status of the indoor unit.

Error occurring on R-Converter Unit

When main supply for R-Converter unit is OFF.

(220V~240V 50Hz/220V 60Hz)

During start-up

Completion on start-up

During operation

Under suspension

Lighting

Lighting

Lighting

Lighting

—

OFF

Blinking

(ever 1.0 sec.)

OFF

Blinking

(ever 0.2 sec.)

Blinking

(ever 0.2 sec.)

—

—

OFF

OFF

Lighting

OFF

Blinking

—

Note LED2 blinks ever 0.2 secs, all the time once after the indoor unit is operated.

6-5-1. R-Converter Unit

18

Page 19

7 ELECTRICAL WORK

Model

Minimum wire thickness (mm

2

)

Breaker for wiring (NFB)

15A

Breaker for current leakage

15A

Branch GroundMain cable

1.5 1.51.5R-Converter unit

7-1. Caution

(1) Follow local regulations and ordinances for technical

standards related to electrical equipment, wiring, and

specifications of each electric power company.

(2) Wiring for control (hereinafter referred to as transmission

line) must be situated at least 5 cm from the power source

wiring so that it is not influenced by electrical noise. (Do not

insert transmission line and power source wire in the same

conduit.)

(3) Be sure to provide designated grounded work to outdoor

unit.

(4) Never connect the main power source to the terminal block

of a transmission line. If connected, electrical parts will be

burnt out.

(5) Use a 2-core shield cable for connecting a transmission line

to TB5 of the R-Converter unit. If transmission of different

systems are wired with the same multiplecore cable, which

can result in poor transmission and receipt and can cause

incorrect operation.

(6) The system will not operate if connected improperly.

TB2 : Terminal block for power supply

TB3 : Terminal block for transmission line to indoor unit

TB5 : Terminal block for transmission line to outdoor unit

(7) Before turning the indoor unit and the R-Converter unit

on, be sure to set the switches. (See page 14).

(8) To turn the power on, turn on the indoor unit,

R-Converter unit, then the outdoor unit, in that order.

(9) For identification purposes, list the indoor unit model names

in the nameplate on the control box of the R-Converter unit.

7-2. Connecting the R-Converter unit, indoor unit and outdoor unit transmission cables

• Connect the outdoor unit (TB3) to the R-Converter unit (TB5). (Non-polarized 2-wire) The "S" terminal on the R-Converter unit

(TB5) is a shielding wire connection. For connecting cable specifications, refer to the outdoor unit installation manual.

• Connect the indoor unit (TB) to the R-Converter unit (TB3). For connecting cable specifications, refer to the indoor unit

installation manual.

Permissible Length

1 "Indoor unit - R-Converter unit"

Maximum transmission cable length : r

2 "Outdoor unit - R-Converter unit" + "R-Converter unit - R-Converter unit"

Maximum transmission cable length : (L

1

and r2, r3[ 10 m (2-Core 1.0 mm2)

1

+ L2) or (L1 - L3 + L4) or (L2 + L3 + L4) [ 200 m

7-3. Wiring of main power supply and equipment capacity

Thickness of wire for main power supply and on/off capacities

1. Use separate power supplies for the outdoor unit and R-Converter unit.

2. Consider the ambient conditions (ambient temperature, direct sunlight, rain, etc.) when wiring and making connections.

3. The wire size is the minimum value for metal conduit wiring. The power cord size must be 1 rank thinker in consideration of

voltage drops.

Make sure that the power supply voltage does not drop more than 10%.

4. Select non-fuse breaker (NFB) or earth leakage breaker (NV).

(A means for the disconnection of the supply with an isolation switch, or similar device, in all active conductors shall be

incorporated in the fixed wiring.)

5. Power supply codes of appliance must not be lighter than design 245 IEC 53 or 227 IEC 53.

6. Aswitch with at least a 3 mm contact separation in each pole must be provided by the air conditioner installation.

Power cable size : more than 1.5 mm

2

.

19

Page 20

. Warning :

• Be sure to use the specified wires for connection so that no external force is imparted to the terminal connections.

If the wires are not securely connected, a fire can occur.

• Be sure to use the appropriate type of overcurrent protection switch. Note that generated overcurrent may include

some amount of direct current.

. Caution :

• Some installation sites may require a ground-fault interrupter. If a ground-fault interrupter is not installed, an electric

shock can occur.

• Use only a circuit breaker and fuse of he specified capacity. Using a fuse and copper wire with excessive capacity

can cause a malfunction or a fire.

When connected to a CITY MULTI indoor unit in a system

M-NET system remote controllers cannot be used to operate the indoor unit that is connected to the R-Converter.

(1) Example of setting an address automatically

A Outdoor unit

B R-Converter unit

C Indoor unit

D Remote controller

E CITY MULTI indoor unit

F Unit remote controller (MA)

G M-NET transmission cable

(3) Group setting including R-Converter units are not possible.

(2) Example of a group setting not including R-Converter units

A Outdoor unit

B R-Converter unit

C Indoor unit

D Remote controller

E CITY MULTI indoor unit

G M-NET transmission cable

H Network remote controller (NR)

(4) Connecting to a system remote controller is not possible.

A Outdoor unit

B R-Converter unit

C Indoor unit

D Remote controller

E CITY MULTI indoor unit

G M-NET transmission cable

H Network remote controller (NR)

A Outdoor unit

B R-Converter unit

C Indoor unit

D Remote controller

E CITY MULTI indoor unit

G M-NET transmission cable

H Network remote controller (NR)

I System remote controller (SC)

20

Page 21

7-4. Wiring (mm)

(1) Remove the electrical cover.

(2) Insert the wiring and each thermistor into the unit, and then fasten them with the bands on the inside of the unit.

(3) Connect each wire to the terminal block securely.

(4) Connect each thermistor to the controller board.

• Thermistor (liquid) ➝ CN21

• Thermistor (gas) ➝ CN3G

(5) After installing the unit, install the electric cover.

21

Page 22

8 REFRIGERANT PIPING

Indoor unit capacity

*R-Converter unit

Liquid pipe size (mm)

BTU

07

09

12, 13

18

24, 30

HP

-

1

1.6

2

2.5

{6.35 o 0.8

{9.52 o 0.8

{6.35 o 0.8

Indoor unit connection example

• Connect one R-Converter unit per indoor unit.

• Connect the R-Converter unit the liquid pipe.

• The thermistor-L (liquid) is installed close to the connecting

point of the extension piping (liquid) for the indoor unit.

• The thermistor-G (gas) is installed close to the connecting

point of the extension piping (gas) for the indoor unit.

Piping connection size

Refrigerant piping system

W For details, see PUMY series technical & service manual.

Install sections a, b, c, d and e as shown in the illustration to

the R-Converter unit.

W If using a liquid pipe that is [9.52 mm, use joint pipe

“PAC-493PI” (optional parts) or a locally procured tandem

joint ([6.35➝[9.52 mm)

Additional refrigerant quantity

• If necessary, add additional refrigerant to the unit by

following the calculation method given in the outdoor unit

(PUMY) manual.

• When calculating the refrigerant quantity, be sure to include

the R-Converter unit-to-indoor unit liquid pipe length.

• The installation condition for the R-Converter unit-to-indoor

unit are as shown in the illustration below.

• The refrigerant pipe length from the indoor unit to the

R-Converter unit must be less than 10 m and its height

difference less than 8 m.

• Install the R-Converter unit within an indoor-unit-to-indoorunit height difference of 12 m.

• Match the refrigerant piping size to the indoor unit.

22

Page 23

9 PARTS LIST

1

2

3

4

5

6

7

8

9

10

11

12

Part No. SpecificationNo.

Wiring

Diagram

Symbol

Recommended

Q,ty

Price

Unit

Amount

Part Name

Q,ty/set

PAC-SF29LB

Remarks

(Drawing No.)

LEV BOX

CONTROLLER BOARD

TERMINAL BLOCK

TH. HOLDER ASSY

THERMISTOR-L

THERMISTOR-G

CONT COVER

BOX COVER

LEV ASSY

TERMINAL BLOCK

TERMINAL BLOCK

FUSE

(M1, M2, S)

(Liquid)

(Gas)

(3, N)

(L, N, )

250V 3.15A

(RG02A916G05)

(RG02T534H04)

(RG02T533H04)

1

1

1

1

1

1

1

1

1

1

1

1

R.C

TB5

TH22

TH23

LEV

TB3

TB2

FUSE

T7W E17 315

T7W E00 716

T7W E00 241

T7W E34 202

T7W E35 202

T7W E12 401

T7W E20 716

T7W 509 716

T7W E04 239

PAC-SF29LB

1

2

12

11

3

10

9

4

5

6

8

7

23

Page 24

HEAD OFFICE : MITSUBISHI DENKI BLDG., 2-2-3, MARUNOUCHI, CHIYODA-KU, TOKYO100-8310, JAPAN

cCopyright 2003 MITSUBISHI ELECTRIC ENGINEERING CO., LTD.

Distributed in Jun. 2003 No.OC296 PDF

Made in Japan.

New publication, effective Jun. 2003

Specifications subject to change without notice.

Loading...

Loading...