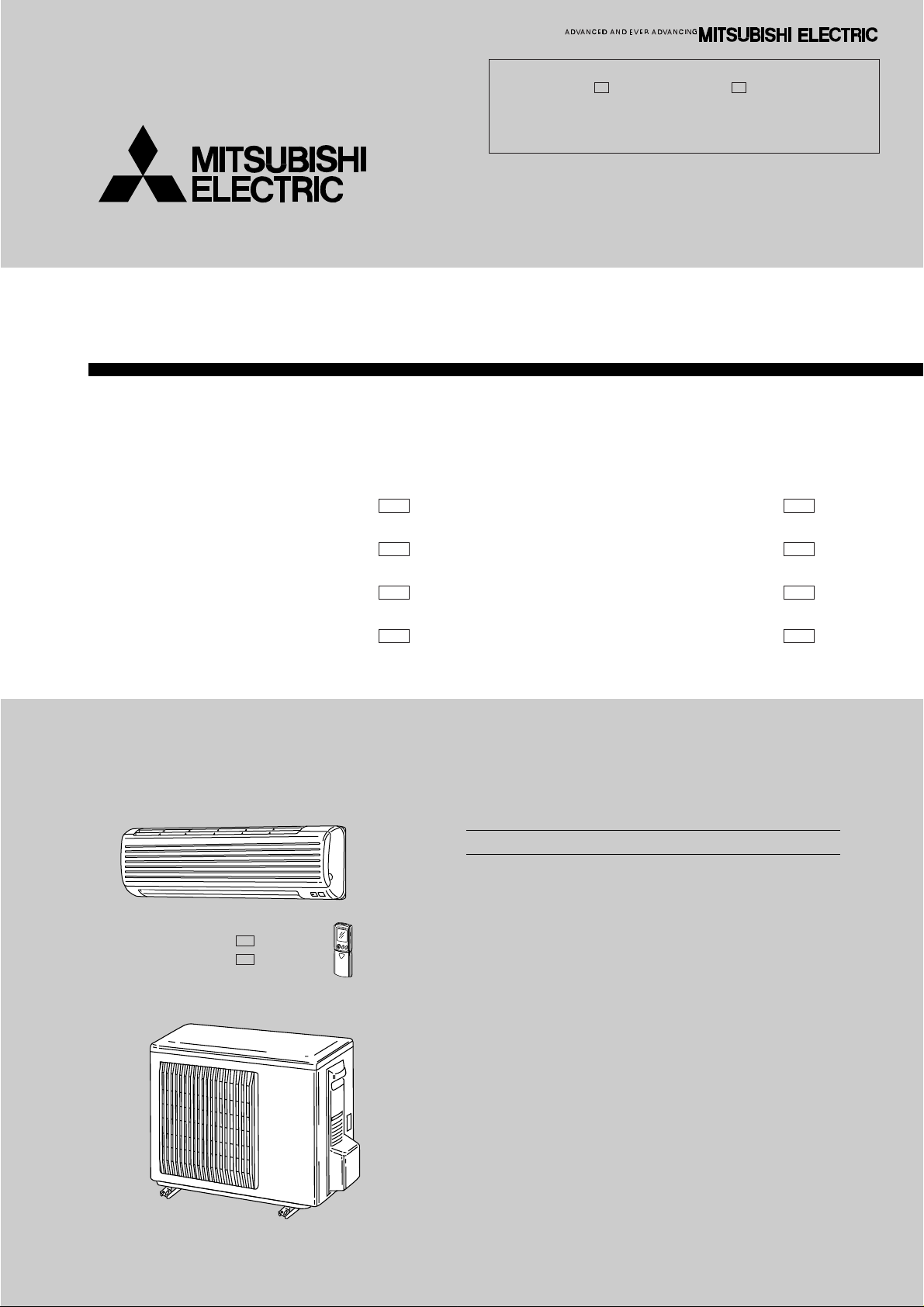

Mitsubishi MSZ-G09SV, MUZ-G09SV, MSZ-G12SV, MUZ-G12SV SERVICE MANUAL

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

SERVICE MANUAL

Wireless type

Models

Revision:

●MSZ-G09SV - and MSZ-G12SV - have been added.

●MICROPROCESSOR CONTROL, SERVICE FUNCTIONS,

and PARTS LIST have been partially modified.

●Please void OB245.

E2E2

No. OB245

REVISED EDITION-A

MSZ-G09SV -

MSZ-G09SV MSZ-G12SV MSZ-G12SV -

MSZ-G09SV MSZ-G12SV -

E2

E2

(WH) ●

(WH) ●

(WH) ●

(WH) ●

CONTENTS

1. TECHNICAL CHANGES····································2

2. PART NAMES AND FUNCTIONS······················2

3. SPECIFICATION·················································5

4. NOISE CRITERIA CURVES·······························7

5. OUTLINES AND DIMENSIONS·························8

6. WIRING DIAGRAM···········································11

7. REFRIGERANT SYSTEM DIAGRAM··············14

8. PERFORMANCE CURVES······························16

9. MICROPROCESSOR CONTROL ····················26

10. SERVICE FUNCTIONS·····································41

11. TROUBLESHOOTING ······································44

12. DISASSEMBLY INSTRUCTIONS·····················62

13. PARTS LIST······················································66

14. OPTIONAL PARTS···········································70

MUZ-G09SV MUZ-G09SV MUZ-G12SV MUZ-G12SV -

E1E1

E2E2

E1E1

E2E2

1

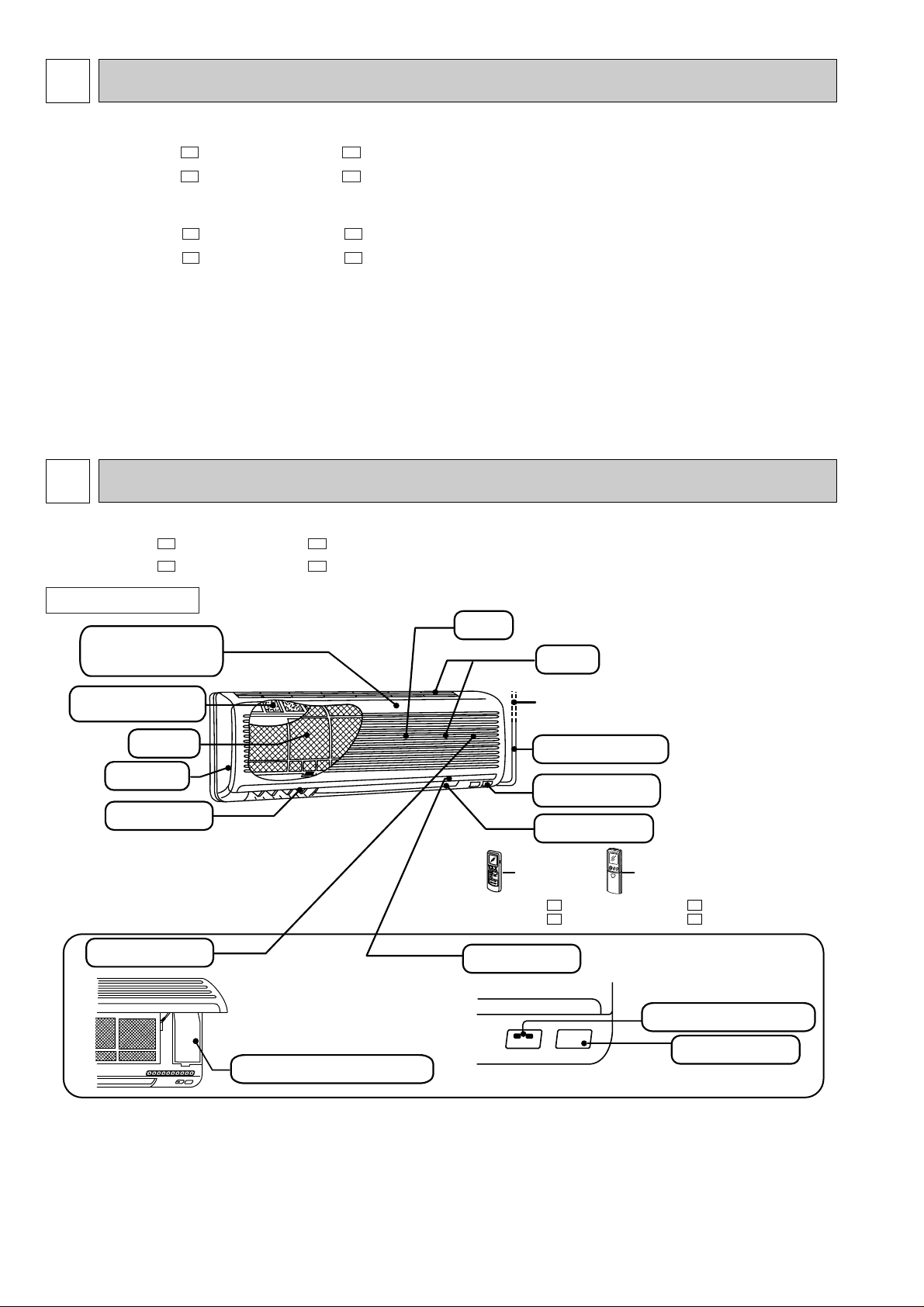

Emergency operation switch

Display section

Operation Indicator lamp

Receiving section

Grille

Air cleaning

filter(white bellows

type)

Deodorizing filter

(gray sponge type)

Air filter

Vertical vane

Air inlet

to Breaker

Remote control

receiving section

Horizontal vane

Remote

controller

Remote

controller

MSZ-G09SV MSZ-G12SV -

Operation section

(When the grille is open)

Power supply cord

Front panel

E1

E1

MSZ-G09SV MSZ-G12SV -

E2

E2

TECHNICAL CHANGES

MSZ-G09SV - ➔MSZ-G09SV -

MSZ-G12SV - ➔MSZ-G12SV -

1. Remote controller has been changed.

MUZ-G09SV - ➔MUZ-G09SV MUZ-G12SV - ➔MUZ-G12SV -

1. Only model name has changed.

2

MSZ-G09SVMSZ-G09SV-

PART NAMES AND FUNCTIONS

E1

MSZ-G12SV-

E2

MSZ-G12SV-

E2E1

E2E1

E2E1

E2E1

E1

E2

INDOOR UNIT

2

Signal transmitting section

Operation display section

OPERATE /STOP

(ON /OFF)button

OPERATION SELECT button

FAN SPEED CONTROL button

ON-TIMER button

CLOCK SET button

HR. button

MIN. button

(TIME SET button)

TEMPERATURE buttons

VANE CONTROL button

OFF-TIMER button

RESET button

ON/OFF TOO

WARM

TOO

COOL

HR. MIN.

CLOCK

RESET

CLOCK

MODE

FAN

VANE

START

STOP

ECONO COOL button

ECONO COOL

I FEEL

COOL DRY HEAT

6 00 1

1 00

AM

PM

SWING

SWING button

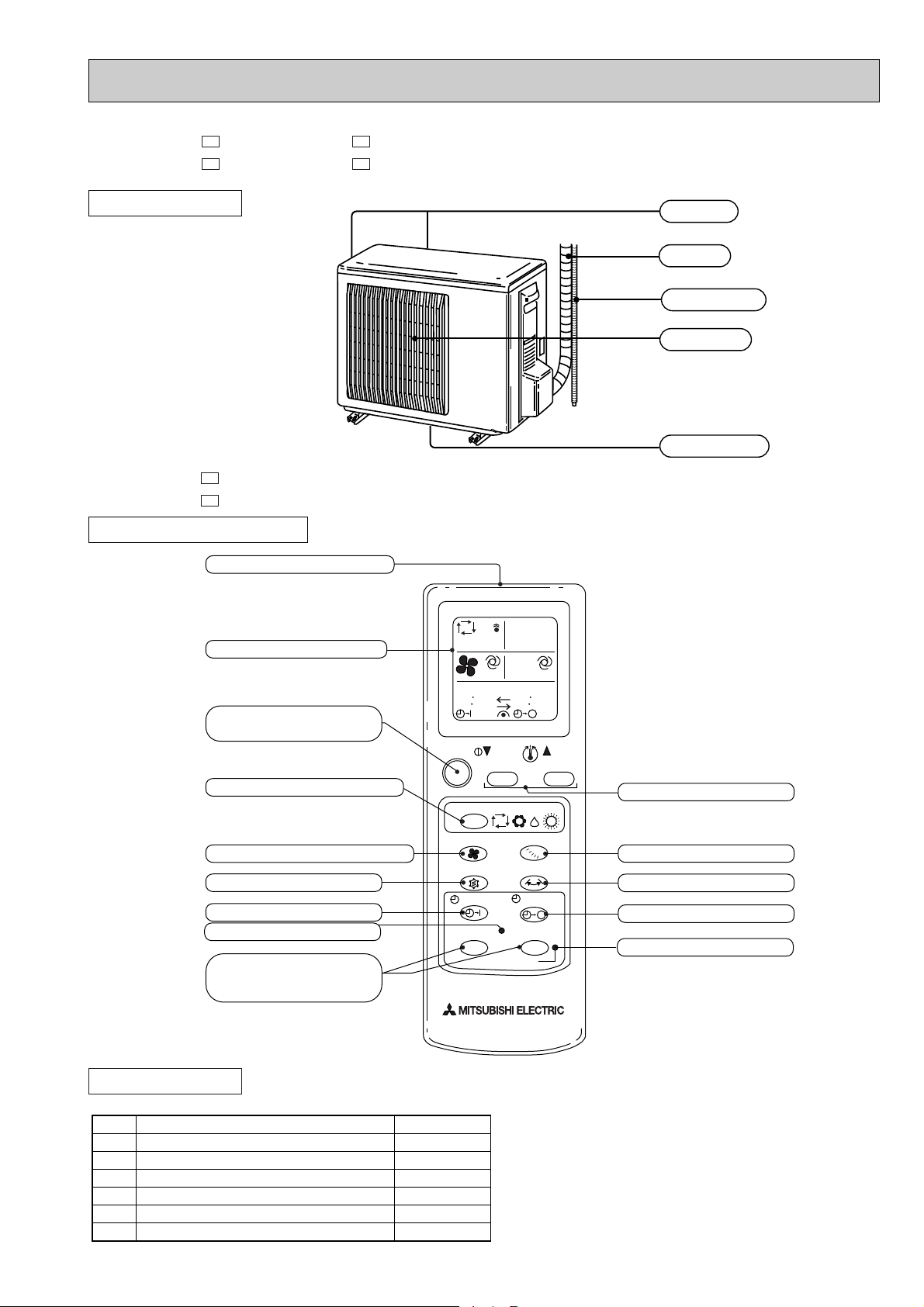

MUZ-G09SV-

Installation plate

Installation plate fixing screw 4 x 25 mm

Remote controller mounting hardware

Fixing screw for 3 3.5 x 16 mm (Black)

Battery (AAA) for remote controller

Wireless remote controller

Felt tape (Used for left or left-rear piping)

1

5

1

2

2

1

1

1

2

3

4

5

6

7

MUZ-G09SV-

E1

MUZ-G12SV-

E2

MUZ-G12SV-

E1

E2

OUTDOOR UNIT

MSZ-G09SVMSZ-G12SV-

E1

E1

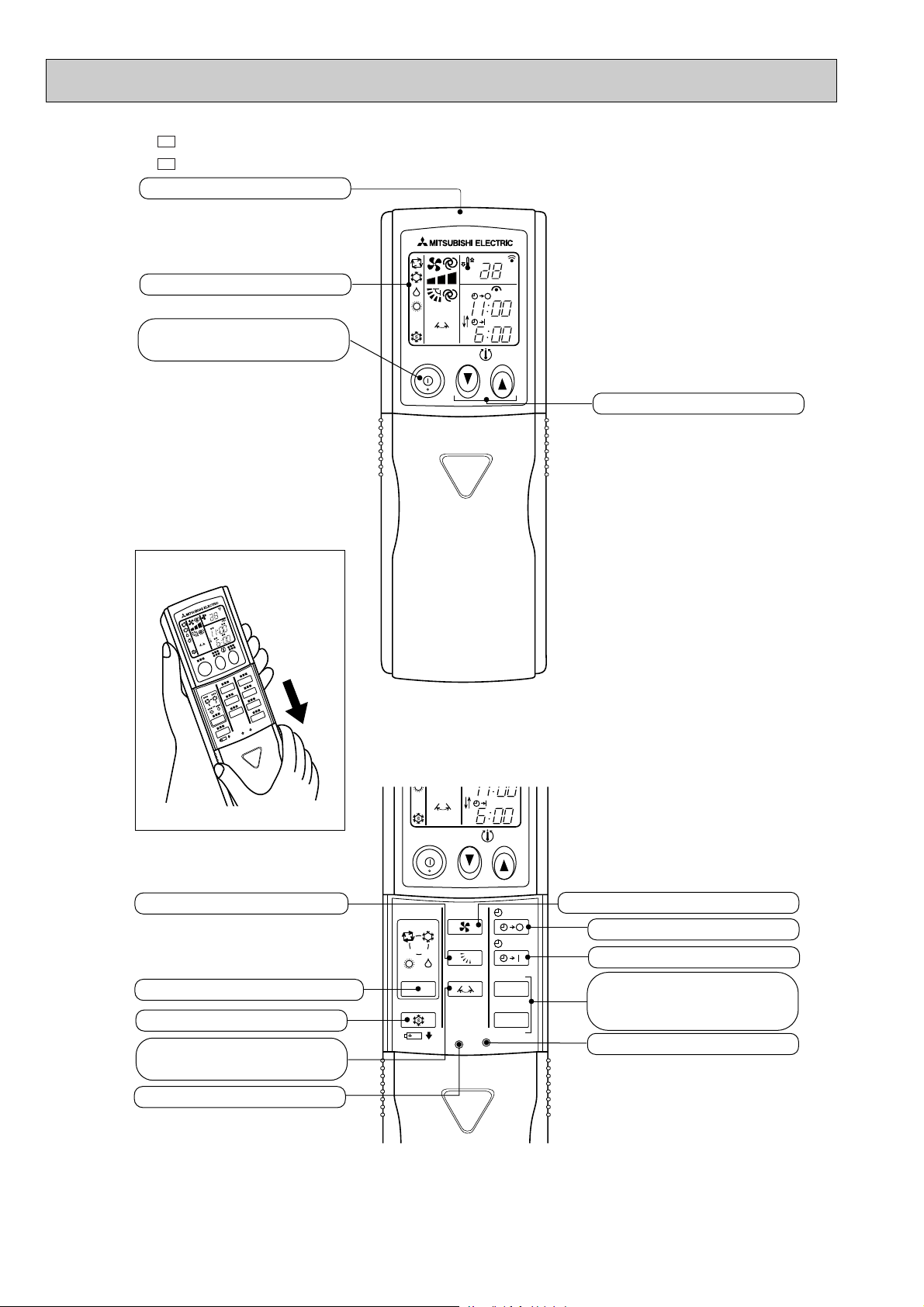

REMOTE CONTROLLER

Air inlet

Piping

Drain hose

Air outlet

Drain outlet

ACCESSORIES

Check the following parts before installation.

3

ON/OFF

TOO

COOL

AMPM

AMPM

CLOCK

TOO

WARM

ON/OFF

FAN

TOO

WARM

TOO

COOL

VANE

MODE

ECONO COOL

STOP

START

HR.

MIN.

SWING

I FEEL

COOL

HEAT

DRY

PM

CLOCK

AMPM

RESET CLOCK

:

:

Open the front lid.

Signal transmitting section

Operation display section

OPERATE /STOP

(ON /OFF)button

TEMPERATURE buttons

OPERATION SELECT button

FAN SPEED CONTROL button

OFF-TIMER button

HR. button

MIN. button

(TIME SET button)

ON-TIMER button

RESET button

ECONO COOL button

VANE control button

CLOCK SET button

Vertical vane

swing button

MSZ-G09SVMSZ-G12SV-

E2

E2

4

3

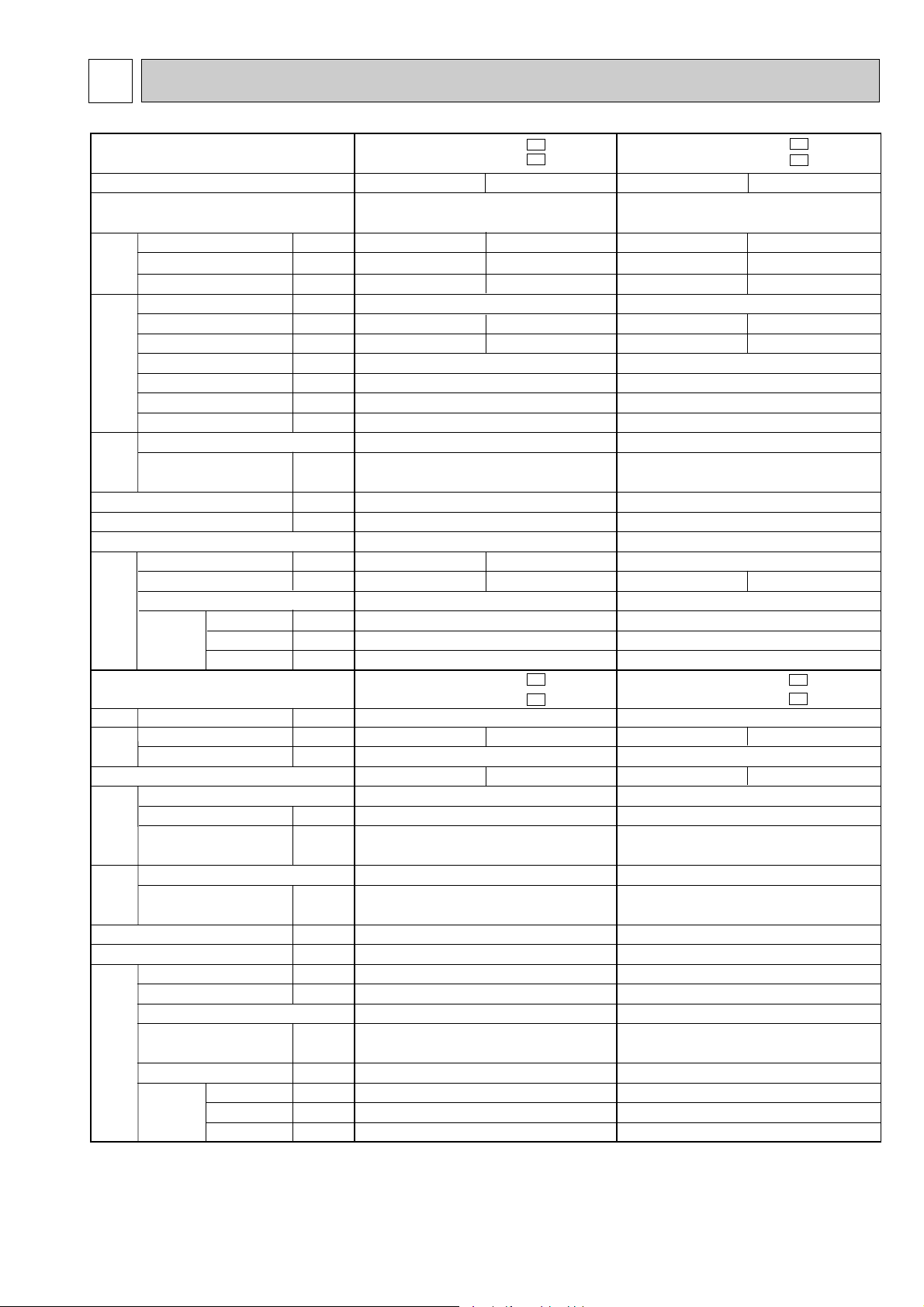

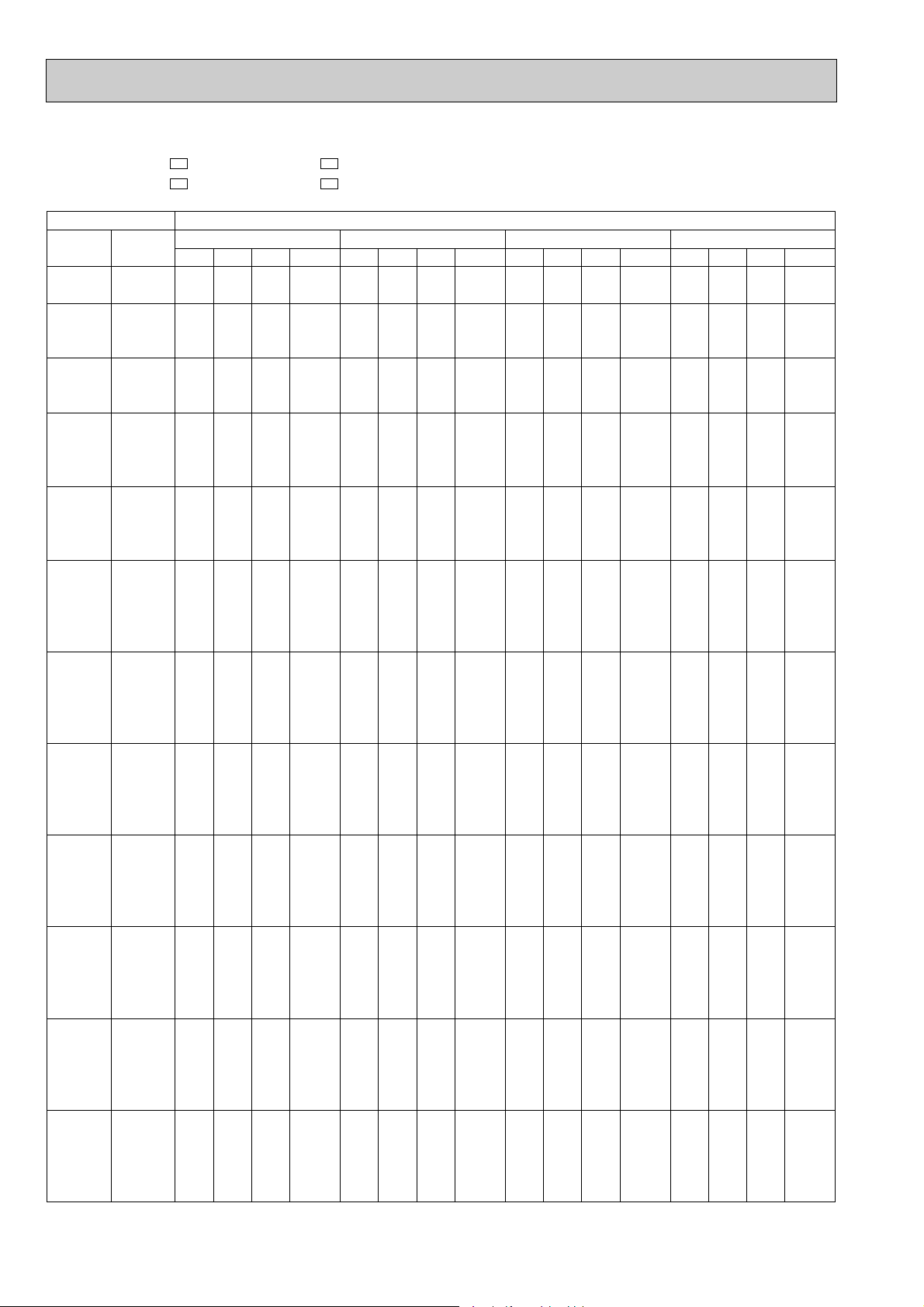

Indoor model

Function

Power supply

Capacity

Air flow(High)

Dehumidification

Power outlet

Running current

Power input

Auxiliary heater

Power factor

Starting current

Fan motor current

Model

Winding

resistance(at20:)

Dimensions WOHOD

Weight

Air direction

Sound level (High)

Fan speed (High)

Fan speed regulator

RT11(at25:)

Thermistor RT12(at25:)

RT13(at25:)

Outdoor model

Outdoor air flow

Compressor motor current

Fan motor current

Model

Output

Winding

resistance(at20:)

Model

Winding

resistance(at20:)

Dimensions WOHOD

Weight

Sound level

Fan speed

Fan speed regulator

Refrigerant filling

capacity(R22)

Refrigerating oil (Model)

RT61(at0:)

Thermistor RT62(at100:)

RT64(at70:)

kW

K /h

R/h

A

A

W

A(kW)

%

A

A

"

mm

kg

dB(A)

rpm

k"

k"

k"

K /h

A

A

W

"

"

mm

kg

dB(A)

rpm

kg

cc

k"

k"

k"

Single phase

230V,50Hz

10

—

90

5.50

0.17

RC4V19-BA

WHT-BLK 292

BLK-RED 325

850O278O191

9

5

3

10

10

10

MUZ-G09SV -

E1

MUZ-G09SV -

E2

1500

0.25

KHV-104FGK

900

U-V 2.14 U-W 2.14

V-W 2.14

RA6V18-AA

WHT-BLK 279

BLK-RED 198

710(+69)o540o255

28

45

600

1

0.75

270 (MS56)

33.2

13.4

7.9

Cooling

2.6 (1.3-3.1)

474

1.2

4.54

940 (440 - 1120)

36

950

4.12

2.77

Heating

3.6 (1.4-5.1)

504

—

5.50

1140 (430 - 1300)

35

1000

5.08

3.16

Electrical

data

Fan

motor

Special

remarks

Compressor

Electrical

data

Fan

motor

Special

remarks

Coefficient of performance(C.O.P)

Capacity

Capacity

MSZ-G09SV -

E1

MSZ-G09SV -

E2

MSZ-G12SV -

E1

MSZ-G12SV -

E2

Single phase

230V,50Hz

10

—

90

7.40

0.19

RC4V19-BA

WHT-BLK 292

BLK-RED 325

850O278O191

10

5

39

3

10

10

10

MUZ-G12SV -

E1

MUZ-G12SV -

E2

1560

0.34

SHV-130FEA

1100

U-V 0.45 U-W 0.45

V-W 0.45

RA6V28-DA

WHT-BLK 201

BLK-RED 350

710(+69)o540o255

34

48

720

1

1.10

350 (MS56)

33.2

13.4

7.9

Cooling

3.5 (0.9-4.0)

588

1.6

6.20

1290 (290 - 1390)

1020

5.67

2.71

Heating

4.8 (0.9-6.7)

642

—

7.40

1540 (290 - 2090)

1100

6.87

3.12

SPECIFICATION

NOTE : Test conditions are based on ISO 5151 (Refrigerant piping length (one way): 5m)

Cooling : Indoor DB27: WB19:

Heating : Indoor DB 20: WB15:

Outdoor DB35: WB(24:)

Outdoor DB 7: WB 6:

5

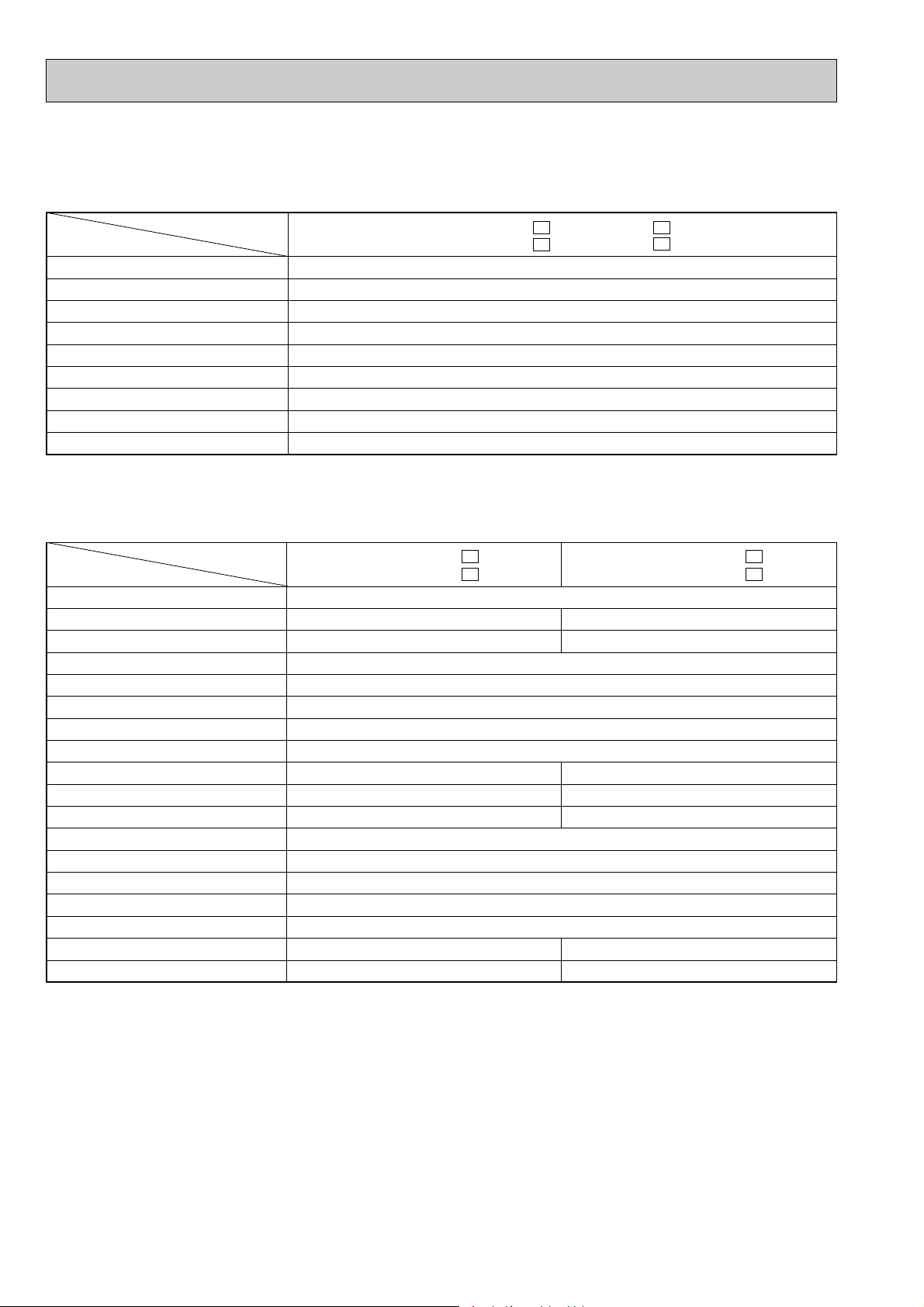

1.5+ 440V

250V 3.15A

93:5A 250V

MP20GA 12V 300"

ERZV10D471

S201DH1Y

5P

JM1aN-ZTMP-DC12V

136:i3: 2A

100+ 420V

1500+ 420V

8A 8mH

70m" 5W

10" 15W

EM43261

QM15TG-9B

INDOOR UNIT

OUTDOOR UNIT

Item

Model

Model

Item

Indoor fan capacitor

Fuse

Thermal fuse

Vane motor

Varistor

Solid state relay

Terminal block

Contactor

Indoor fan motor thermal fuse

Current transformer

Power-facrtor capacitor

Smoothing capacitor

Outdoor fan capacitor

Diode stack

Fuse

Fuse

Expansion valve coil

Reactor

Current-detecting resistor

Current-limiting resistor

Solid state relay

Terminal block

Outdoor fan relay

Current-limiting relay

R.V. coil

Noise filter

Transistor module

MSZ-G09SV -

E1

MSZ-G12SV -

E1

MUZ-G12SV -

E1

MSZ-G09SV -

E2

MSZ-G12SV -

E2

165+ 420V

2500+ 420V

15A 4.3mH

100m" 5W

10" 20W

EM43262

QM20TG-9B

MUZ-G09SV -

E1

MUZ-G12SV -

E2

MUZ-G09SV -

E2

RR-18

1.8+ 440V

S25VB80

250V 2A

250V 1A

LAM-MD12ME 12VDC

TLP3506

4P

G5S-1

G4A-1A

LB8 220-240V AC

(CT61)

(C61)

(C63)

(C65)

(DS61, DS62)

(F801)

(F901)

(LEV)

(L61)

(R61, R62)

(R64)

(SSR61)

(TB2)

(X61)

(X64)

(21S4)

(C11)

(F11)

(F12)

(MV1, MV2)

(NR11)

(SR141)

(TB)

(52C)

Specifications and rating conditions of main electric parts

6

4

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

Test conditions,

Cooling : DB 27: WB 19:

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

COOLING

FUNCTION

36

SPL(dB(A)) LINE

High

SPEED

HEATING

Heating : DB 20: WB 15:

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

Test conditions,

Cooling : DB 35: WB (24:)

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

COOLING

FUNCTION

45

SPL(dB(A)) LINE

High

SPEED

HEATING

Heating : DB 7: WB 6:

NOISE CRITERIA CURVES

MSZ-G09SVMSZ-G09SV-

E1

E2

MUZ-G09SVMUZ-G09SV-

E1

E2

MSZ-G12SVMSZ-G12SV-

90

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

CONTINUOUS

NOISE

10

E1

E2

SPEED

High

FUNCTION

COOLING

HEATING

Test conditions,

Cooling : DB 27: WB 19:

Heating : DB 20: WB 15:

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

SPL(dB(A)) LINE

39

MUZ-G12SVMUZ-G12SV-

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

7

E1

E2

SPEED

High

FUNCTION

COOLING

HEATING

SPL(dB(A)) LINE

Test conditions,

Cooling : DB 35: WB (24:)

Heating : DB 7: WB 6:

90

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

48

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

5

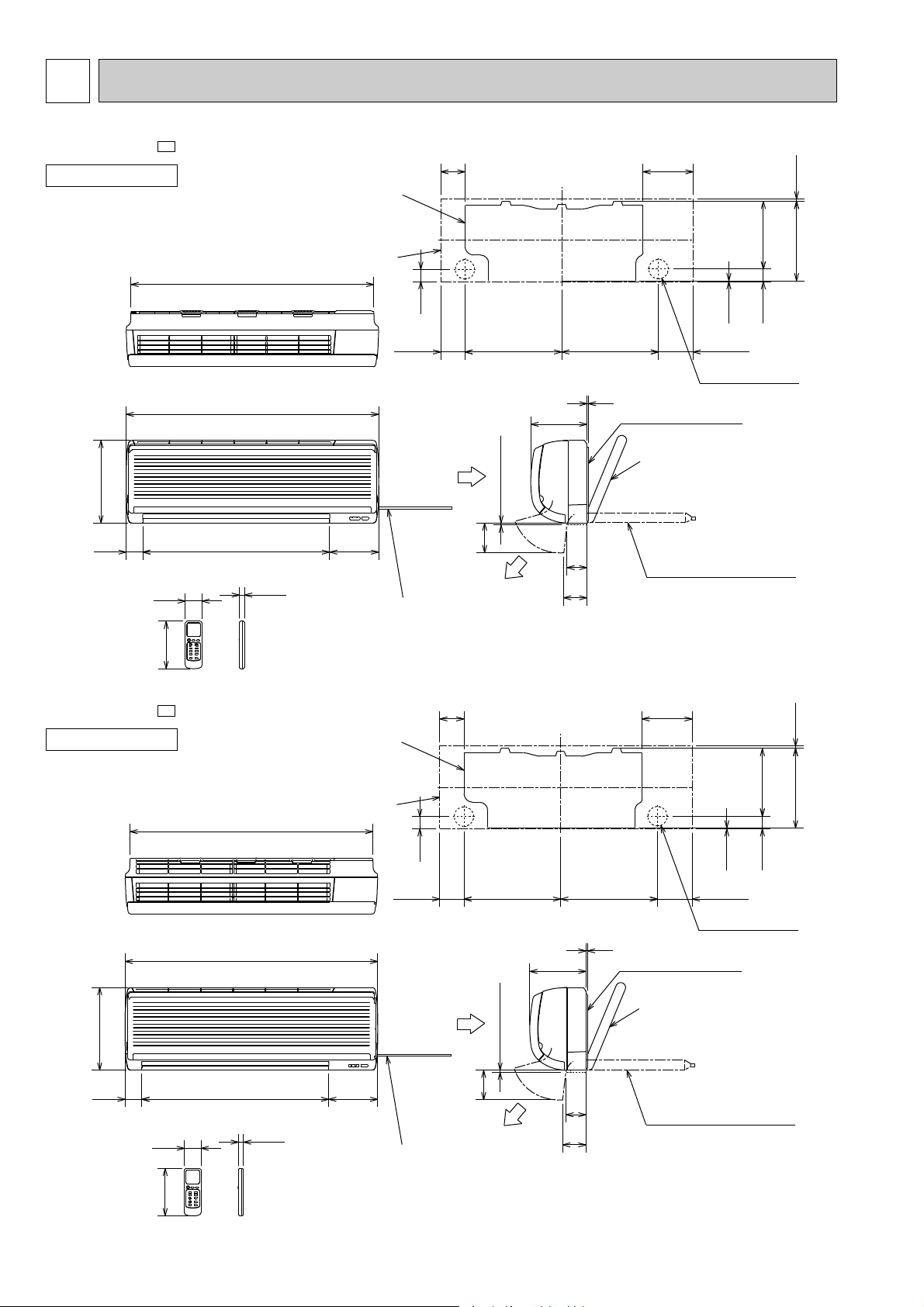

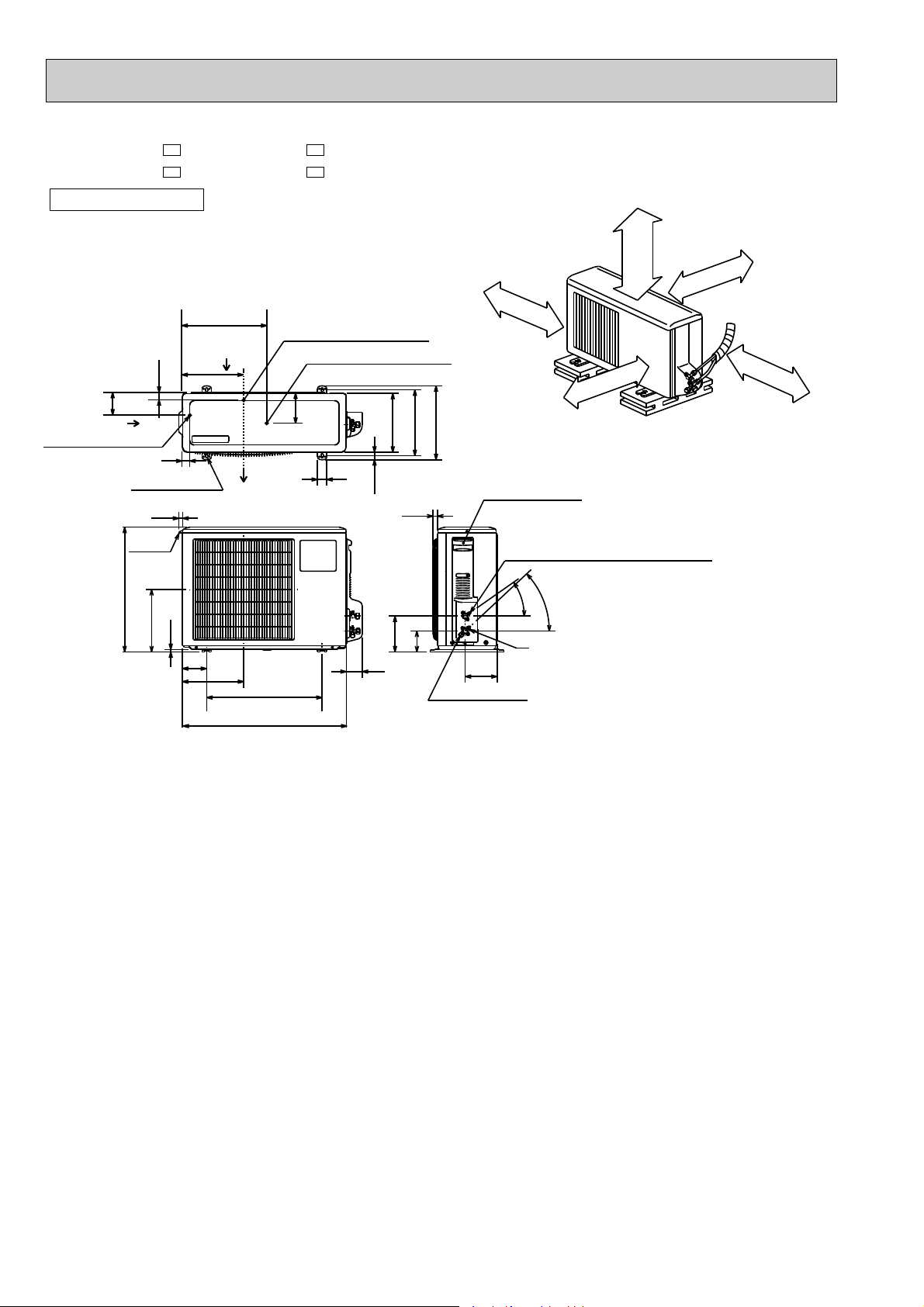

OUTLINES AND DIMENSIONS

MSZ-G09SV-

INDOOR UNIT

Unit: mm

E1

82 169

Installation plate

271 4.5

Indoor unit

818

231.5

278

Wireless remote controller

MSZ-G12SV-

INDOOR UNIT

56

160

E1

850

17.5

16562956

Power supply cord

Lead to right 1.0m

Lead to left 0.3m

Installation plate

41

Air in

82

326 326

189

7 or more

100

Air out

67

78

5

Installation plate

Liquid line [6.35-0.5m

Gas line [9.52-0.43m

{

Insulation [37 O.D.

Drain hose [16

(Connected part O.D.)

Insulation [28

169

42

2.5

116.581.5

Wall hole [65

[21 I.D.

278

56

160

Wireless remote controller

818

850

17.5

Indoor unit

16562956

Power supply cord

Lead to right 1.0m

Lead to left 0.3m

41

Air in

326 326

189

or more

7

100

Air out

67

78

5

Installation plate

Liquid line [6.35-0.5m

Gas line [9.52-0.43m

{

Insulation [37 O.D.

Drain hose [16

(Connected part O.D.)

Insulation [28

231.5

42

2.5

116.581.5

Wall hole [65

[21 I.D.

271 4.5

8

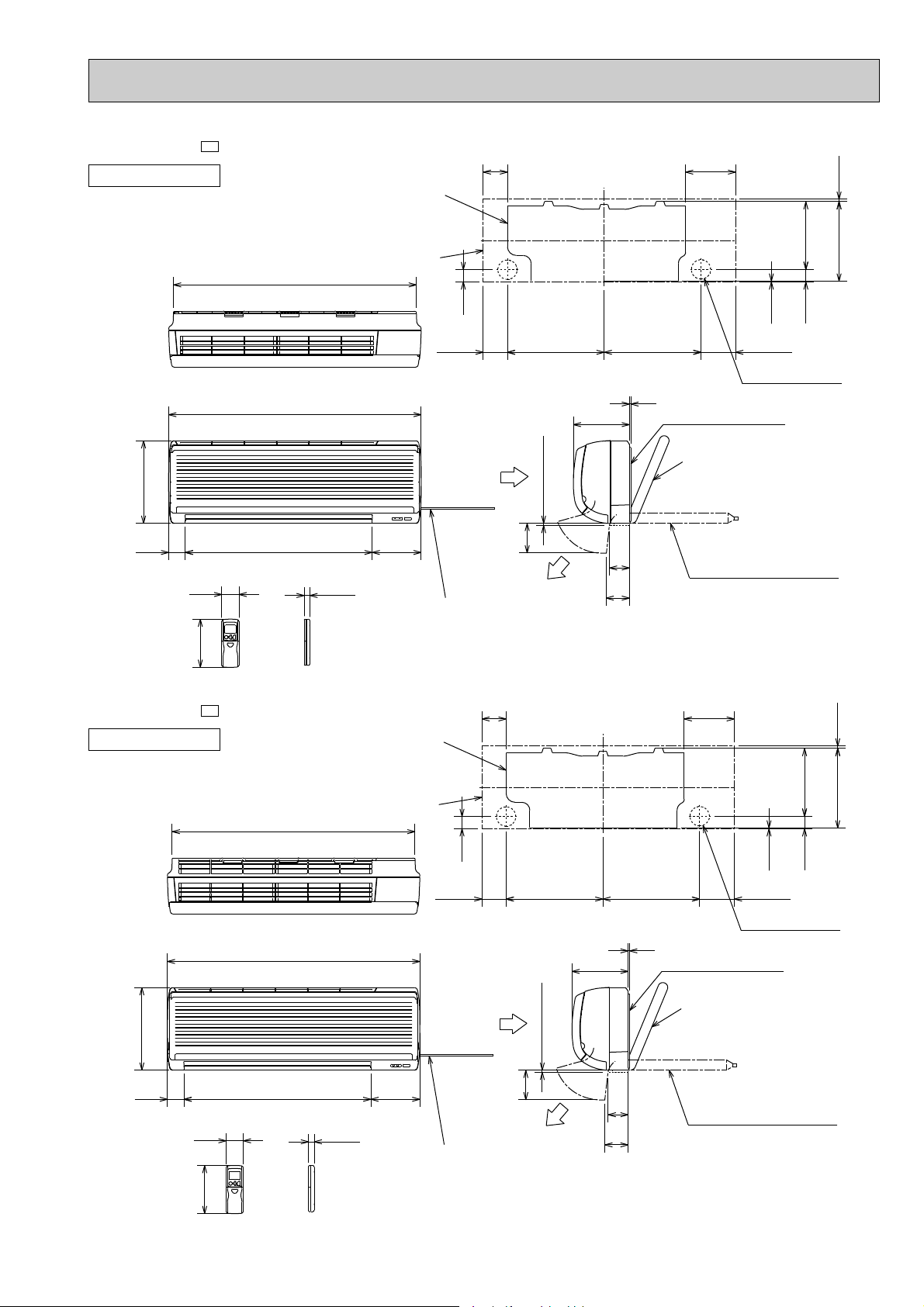

MSZ-G09SV-

INDOOR UNIT

Unit: mm

E2

82 169

Installation plate

271 4.5

Indoor unit

818

231.5

278

58

162

Wireless remote controller

MSZ-G12SV-

INDOOR UNIT

41

326 326

67

78

5

Installation plate

Liquid line [6.35-0.5m

Gas line [9.52-0.43m

{

Insulation [37 O.D.

Drain hose [16

(Connected part O.D.)

Insulation [28

169

850

Air in

7 or more

16562956

19

Power supply cord

Lead to right 1.0m

Lead to left 0.3m

E2

Installation plate

100

Air out

82

189

116.581.5

Wall hole [65

42

2.5

[21 I.D.

278

818

850

58

162

Wireless remote controller

19

Indoor unit

16562956

Power supply cord

Lead to right 1.0m

Lead to left 0.3m

41

Air in

271 4.5

231.5

42

2.5

326 326

5

189

or more

7

100

Air out

9

67

78

Installation plate

Liquid line [6.35-0.5m

Gas line [9.52-0.43m

{

Insulation [37 O.D.

Drain hose [16

(Connected part O.D.)

Insulation [28

116.581.5

Wall hole [65

[21 I.D.

Liquid refrigerant pipe joint

Refrigerant pipe (flared) [6.35

Service panel

Gas refrigerant pipe joint

Refrigerant pipe (flared)

[9.52 (MUZ-G09SV

)

Service port

Bolt pitch for installation

Handle

Air out

Air in

Drainage holes [28

4 holes 10o21

18

500

710

265

105

69

138

20

40

However, either the

left/ right sides or

back side should

be unobstructed.

Air in

265

REQUIRED SPACE

Even if the right/ left sides or

back side are vacant, the top

has to be at least 100mm

unobstructed.

Drainage holes [28

127

32.4

92

367

Drainage holes [28

33

32.5

255

285

320

155

90

43-

35-

540

270

10

350mm or more

100mm or more

100mm or more

100mm or more

Basically

unobstructed

[12.7 (MUZ-G12SV

)

W A

W A

W B

W A In case of poorly-ventilated place, the front or the back

has to be at least 200 mm unobstructed.

W B The wall may get dirty in case the air is discharged

toward it.

MUZ-G09SV- MUZ-G12SVMUZ-G09SV- MUZ-G12SV-

OUTDOOR UNIT

E1E1

E2E2

Unit: mm

10

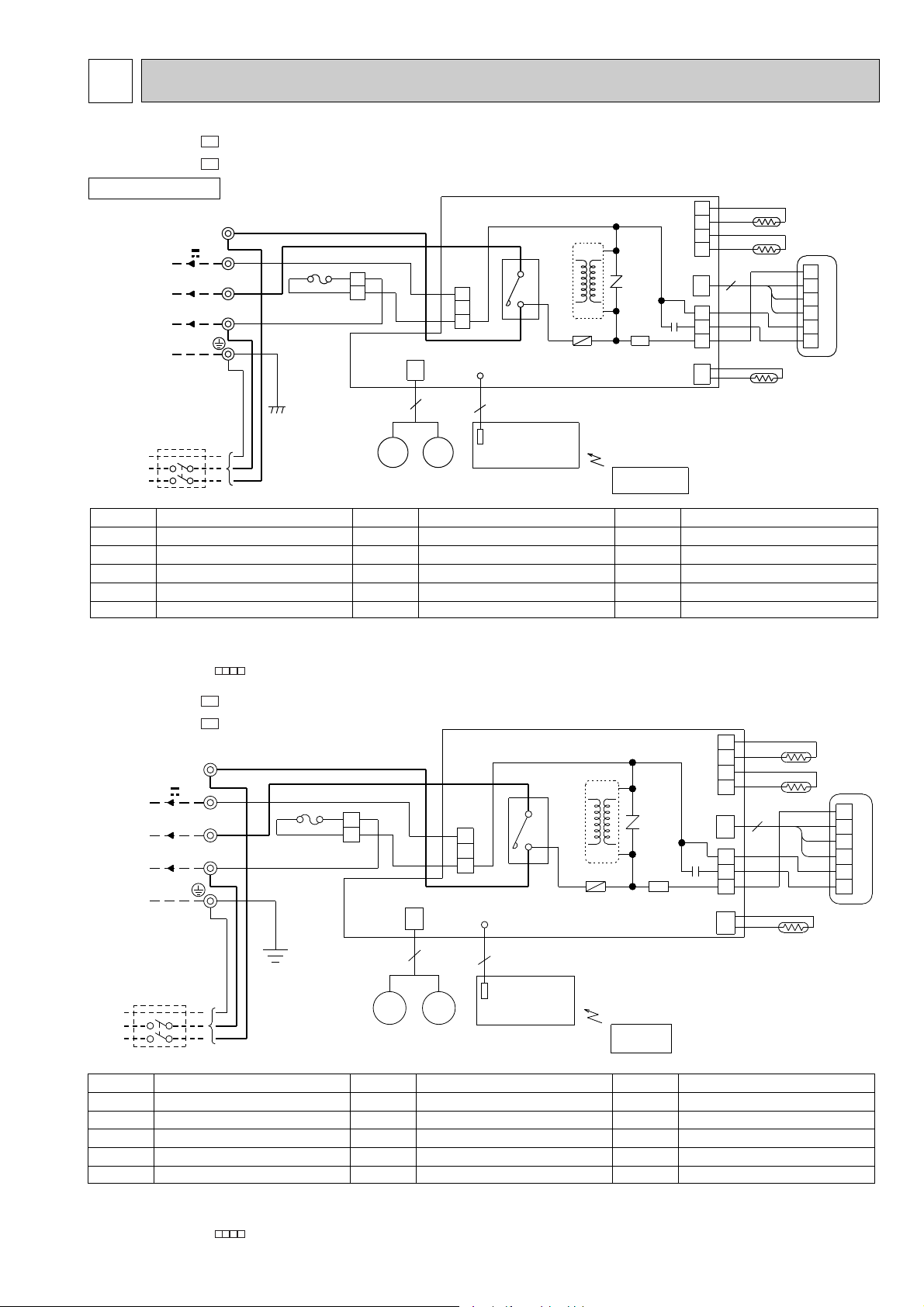

6 WIRING DIAGRAM

POWER

SUPPLY

CORD

~/N 230V

50Hz

GRN/YLW

BLK

GRY

YLW

BRN

WHT

RED

MF

1

2

3

4

5

6

3

SR141

3

2

1

CN

121

C11

HIC1

TRANS

MV2

RT13

4

3

2

1

CN112

151

CN

MV1

10

RT12

RT11

111

CN

CN211

NR11

ELECTRONIC CONTROL P.C. BOARD

F11

230V~

BRN

TB

L

3

2

N

BLU

BRN

WHT

BLU

F12

RED

BLU

BLU

1

2

BLU

1

2

3

CN201

3

4

52C

PE

CIRCUIT BREAKER

12V

TO OUTDOOR

UNIT

CONNECTING

REMOTE

CONTROLLER

POWER MONITOR,

RECEIVER

P.C. BOARD

5

LD101T

SYMBOL

C11

F11

F12

HIC1

MF

SYMBOL

MV1

MV2

NR11

RT11

RT12

SYMBOL

RT13

SR141

TB

52C

NAME

INDOOR FAN CAPACITOR

FUSE (3.15A)

THERMAL FUSE (93:)

DC/DC CONVERTER

INDOOR FAN MOTOR(INNER FUSE)

NAME

VANE MOTOR (HORIZONTAL)

VANE MOTOR (VERTICAL)

VARISTOR

ROOM TEMPERATURE THERMISTOR

INDOOR COIL THERMISTOR (MAIN)

NAME

INDOOR COIL THERMISTOR (SUB)

SOLID STATE RELAY

TERMINAL BLOCK

CONTACTOR

GRN/YLW

GRN/YLW

LD101T

5

POWER MONITOR,

RECEIVER

P.C.BOARD

REMOTE

CONTROLLER

TO OUTDOOR

UNIT

CONNECTING

12V

CIRCUIT BREAKER

PE

52C

4

3

CN201

3

2

1

BLU

2

1

BLU

BLU

RED

F12

BLU

WHT

BRN

BLU

N

2

3

L

TB

BRN

230V~

F11

ELECTRONIC CONTROL P.C. BOARD

NR11

CN211

CN

111

RT11

RT12

10

MV1

CN

151

CN112

1

2

3

4

RT13

MV2

TRANS

HIC1

C11

121

CN

1

2

3

SR141

3

6

5

4

3

2

1

MF

RED

WHT

BRN

YLW

GRY

BLK

GRN/YLW

POWER

SUPPLY

CORD

~/N 230V

50Hz

SYMBOL

C11

F11

F12

HIC1

MF

SYMBOL

MV1

MV2

NR11

RT11

RT12

SYMBOL

RT13

SR141

TB

52C

NAME

INDOOR FAN CAPACITOR

FUSE (3.15A)

THERMAL FUSE (93:)

DC/DC CONVERTER

INDOOR FAN MOTOR(INNER FUSE)

NAME

VANE MOTOR (HORIZONTAL)

VANE MOTOR (VERTICAL)

VARISTOR

ROOM TEMPERATURE THERMISTOR

INDOOR COIL THERMISTOR (MAIN)

NAME

INDOOR COIL THERMISTOR (SUB)

SOLID STATE RELAY

TERMINAL BLOCK

CONTACTOR

MSZ-G09SVMSZ-G12SV-

INDOOR UNIT

E1

E1

MODELS WIRING DIAGRAM

NOTE:1. About the outdoor side electric wiring refer to the outdoor unit electric wiring diagram for servicing.

2. Use copper conductors only. (For field wiring)

3. Symbols below indicate.

/: Terminal block, : Connector

E2

E2

MODELS WIRING DIAGRAM

11

MSZ-G09SVMSZ-G12SV-

NOTE:1. About the outdoor side electric wiring refer to the outdoor unit electric wiring diagram for servicing.

2. Use copper conductors only. (For field wiring)

3. Symbols below indicate.

/: Terminal block, : Connector

SG79B727H01

SG79J166H01

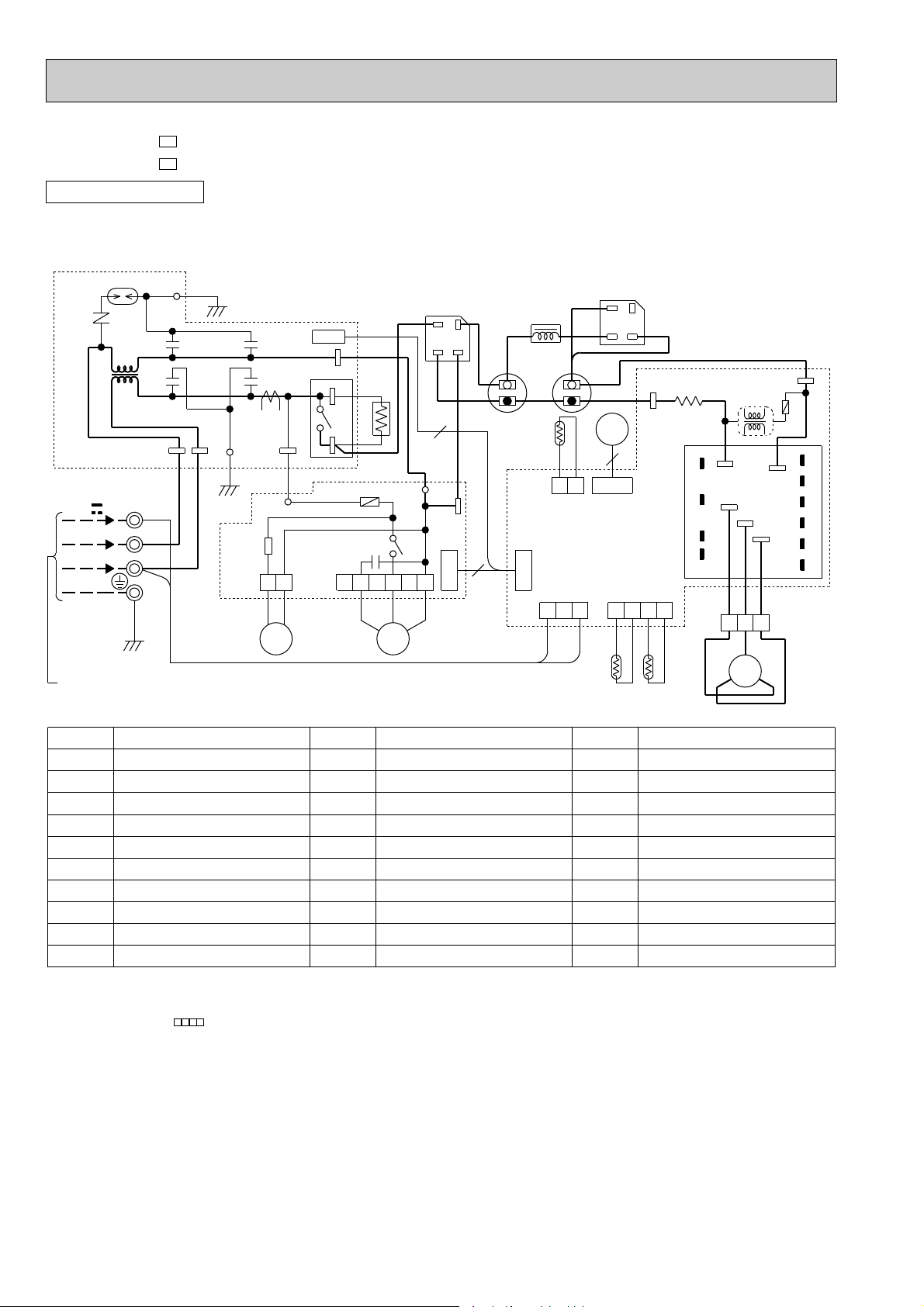

MUZ-G09SVMUZ-G09SV-

E1

E2

OUTDOOR UNIT

MODELS WIRING DIAGRAM

DSA61

NR61

NOISE FILTER

P.C. BOARD

12V

230V ~

GRN/YLW

FROM INDOOR UNIT

CONNECTING

L62

3

2

N

TB2

LDE2

TAB66

RED

WHT

BLU

CY61

CY62

GRN

LDE1

TAB65

GRN

CN721

21S4: heating ON

CY63

CT61

CY64

LD64

SSR61

21S4 MF61

CN725

TAB69

X64

TAB68

BLU

RELAY

P.C. BOARD

CN771

12

3

4

6 5 4 3 2 1

WHT

BLU

ORN

F901

C65

RED

R64

ORN

LD62

BLK

X61

DS61

(

(-)

4

WHT

~

)

+)

(

(

~

WHT

TAB

67

CN723

BLK

)

YLW

DS62

RED

(~)

+)

(

(-)

(~)

BLK

+

YLW

-

RED

TAB64

R61

RED

TAB63

T801

F801

LEV

BUN

BVN

N

U

P

BUP

TR

V

EUPEVP

BVP

6

CN724

2

+

-

C61

BLK

L61

C63

YLW

RED

RT64

1

CN642

W

3

ELECTRONIC

CONTROL

P.C. BOARD

CN722

CN601

2

1

3

BLU

RED

1

RT61

CN641

2

3

RT62

BWN

EUN

RED

WHT

4

BLK

1

WHT

W

2

MC

3

V

U

BWP

EWP

REDBLK

SYMBOL

CT61

C61

C63

C65

CY61~64

DSA61

DS61,62

F801

F901

LEV

NOTE:1. About the indoor side electric wiring refer to the indoor unit electric wiring diagram for servicing.

CURRENT TRANSFORMER

POWER-FACTOR CAPACITOR

SMOOTHING CAPACITOR

OUTDOOR FAN CAPACITOR

CAPACITOR

SURGE ABSORBER

DIODE STACK

FUSE (2A)

FUSE (1A)

EXPANSION VALVE COIL

2.Use copper conductors only. (For field wiring)

3. Symbols below indicate.

/: Terminal block, : Connector

NAME

SYMBOL

L61

L62

MC

MF61

NR61

RT61

RT62

RT64

R61

R64

NAME

REACTOR

CMC COIL

COMPRESSOR

OUTDOOR FAN MOTOR(INNER PROTECTOR)

VARISTOR

DEFROST THERMISTOR

DISCHARGE TEMPERATURE THERMISTOR

FIN TEMPERATURE THERMISTOR

CURRENT-DETECTING RESISTOR

CURRENT-LIMITING RESISTOR

SYMBOL

SSR61

TB2

TR

T801

X61

X64

21S4

NAME

SOLID STATE RELAY

TERMINAL BLOCK

POWER TRANSISTOR MODULE

TRANSFORMER

OUTDOOR FAN RELAY

CURRENT-LIMITING RELAY

R.V. COIL

SG79B710H03

12

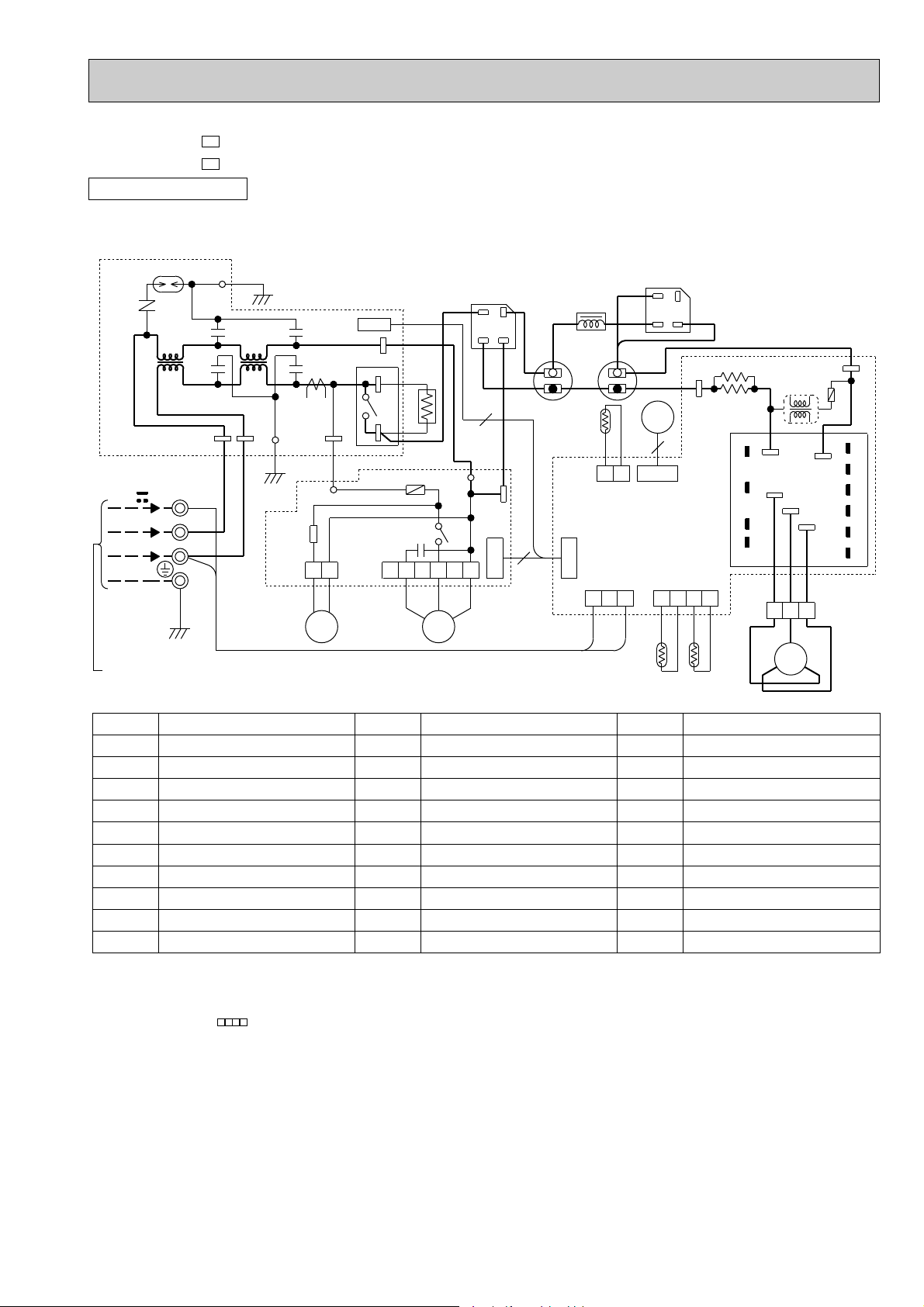

MUZ-G12SVMUZ-G12SV-

E1

E2

OUTDOOR UNIT

MODELS WIRING DIAGRAM

DSA61

NR61

L62

NOISE FILTER

P.C. BOARD

12V

230V ~

GRN/YLW

FROM INDOOR UNIT

CONNECTING

N

3

2

TB2

TAB66

RED

WHT

BLU

LDE2

CY61

CY62

GRN

L63

TAB65

CN721

CN725

CY63

CY64

LDE1

GRN

21S4: heating ON

TAB69

CT61

X64

TAB68

BLU

LD64

RELAY

SSR61

P.C BOARD

12

CN771

21S4 MF61

ORN

WHT

3

BLU

R64

4

ORN

LD62

F901

C65

X61

6 5 4 3 2 1

BLK

RED

DS61

(

~

(

4

WHT

-

)

)

TAB

67

+)

(

(

)

~

YLW

WHT

CN723

BLK

3

+

-

C61

BLK

L61

C63

YLW

CN722

DS62

RED

(~)

(-)

BLK

RED

+

YLW

-

RT64

CN642

LEV

6

1

CN724

2

ELECTRONIC

CONTROL

P.C. BOARD

CN601

1

2

3

BLU

1

RED

RT61

+)

(

(~)

TAB64

CN641

2

RED

3

RT62

RED

R62

R61

N

BUN

BVN

BWN

EUN

4

BLK

W

U

BLK

1

WHT

T801

V

WHT

2

MC

TR

V

TAB63

W

RED

3

U

P

RED

F801

BUP

EUPEVP

BVP

BWP

EWP

SYMBOL

CT61

C61

C63

C65

CY61~64

DSA61

DS61,62

F801

F901

LEV

NOTE:1. About the indoor side electric wiring refer to the indoor unit electric wiring diagram for servicing.

CURRENT TRANSFORMER

POWER-FACTOR CAPACITOR

SMOOTHING CAPACITOR

OUTDOOR FAN CAPACITOR

CAPACITOR

SURGE ABSORBER

DIODE STACK

FUSE (2A)

FUSE (1A)

EXPANSION VALVE COIL

2.Use copper conductors only. (For field wiring)

3. Symbols below indicate.

/: Terminal block, : Connector

NAME

SYMBOL

L61

L62, 63

MC

MF61

NR61

RT61

RT62

RT64

R61, 62

R64

NAME

REACTOR

CMC COIL

COMPRESSOR

OUTDOOR FAN MOTOR(INNER PROTECTOR)

VARISTOR

DEFROST THERMISTOR

DISCHARGE TEMPERATURE THERMISTOR

FIN TEMPERATURE THERMISTOR

CURRENT-DETECTING RESISTOR

CURRENT-LIMITING RESISTOR

SYMBOL

SSR61

TB2

TR

T801

X61

X64

21S4

NAME

SOLID STATE RELAY

TERMINAL BLOCK

POWER TRANSISTOR MODULE

TRANSFORMER

OUTDOOR FAN RELAY

CURRENT-LIMITING RELAY

R.V. COIL

SG79B873H03

13

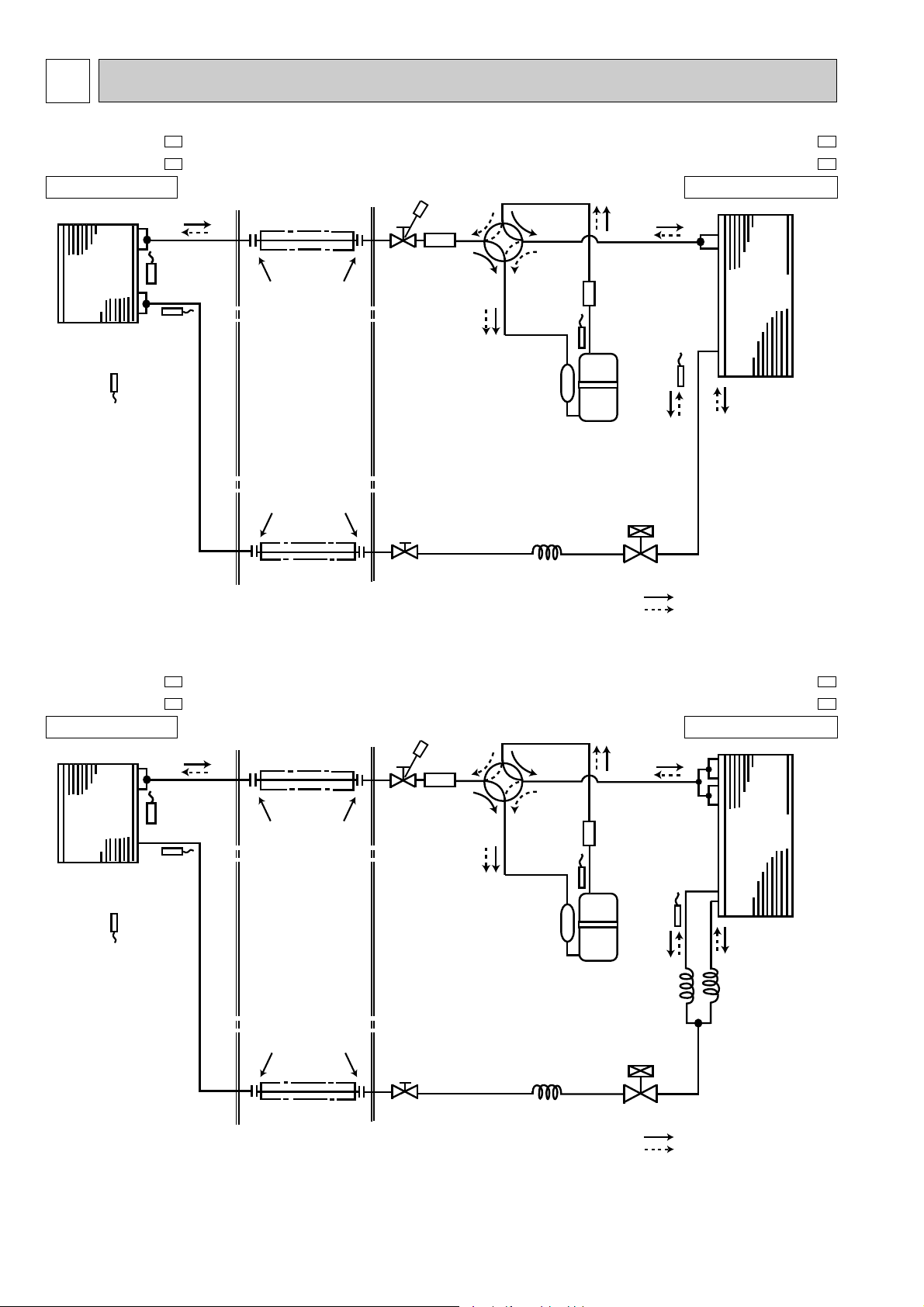

7

Indoor

heat

exchanger

Outdoor

heat

exchanger

Flared connection

Room temperature

thermistor

RT11

Indoor coil

temperature

thermistor

RT13(sub)

Defrost

temperatuer

thermistor

RT61

Discharge

temperatuer

thermistor

RT62

Flared connection

Stop valve

(with strainar)

Stop valve

(with service port)

Capillary tube

[3.0✕[1.8✕400

Refrigerant flow in cooling

Compressor

Accumulator

Muffler

Muffler

4-way valve

Refrigerant flow in heating

Refrigerant pipe [9.52

(with heat insulator)

Refrigerant pipe

[6.35

(with heat insulator)

Indoor coil

temperature

thermistor

RT12(main)

Expansion

valve

R.V. coil

heating ON

cooling OFF

Indoor

heat

exchanger

Outdoor

heat

exchanger

Flared connection

Room temperature

thermistor

RT11

Indoor coil

temperatuer

thermistor

RT13(sub)

Defrost

temperature

thermistor

RT61

Discharge

temperature

thermistor

RT62

Flared connection

Stop valve

(with strainar)

Stop valve

(with service port)

Capillary tube

[3.0✕[2.0✕200

Capillary

tube

[3.0✕[2.0✕300

Refrigerant flow in cooling

Compressor

Accumulator

Muffler

Muffler

4-way valve

Refrigerant flow in heating

Refrigerant pipe [12.7

(with heat insulator)

Refrigerant pipe

[6.35

(with heat insulator)

Capillary

tube

[3.0✕[2.0✕300

Indoor coil

temperatuer

thermistor

RT12(main)

Expansion

valve

R.V. coil

heating ON

cooling OFF

REFRIGERANT SYSTEM DIAGRAM

MSZ-G09SV MSZ-G09SV -

INDOOR UNIT

Unit : mm

E1

E2

MUZ-G09SV MUZ-G09SV -

E1

E2

OUTDOOR UNIT

MSZ-G12SV MSZ-G12SV -

INDOOR UNIT

E1

E2

Unit : mm

MUZ-G12SV MUZ-G12SV -

OUTDOOR UNIT

E1

E2

14

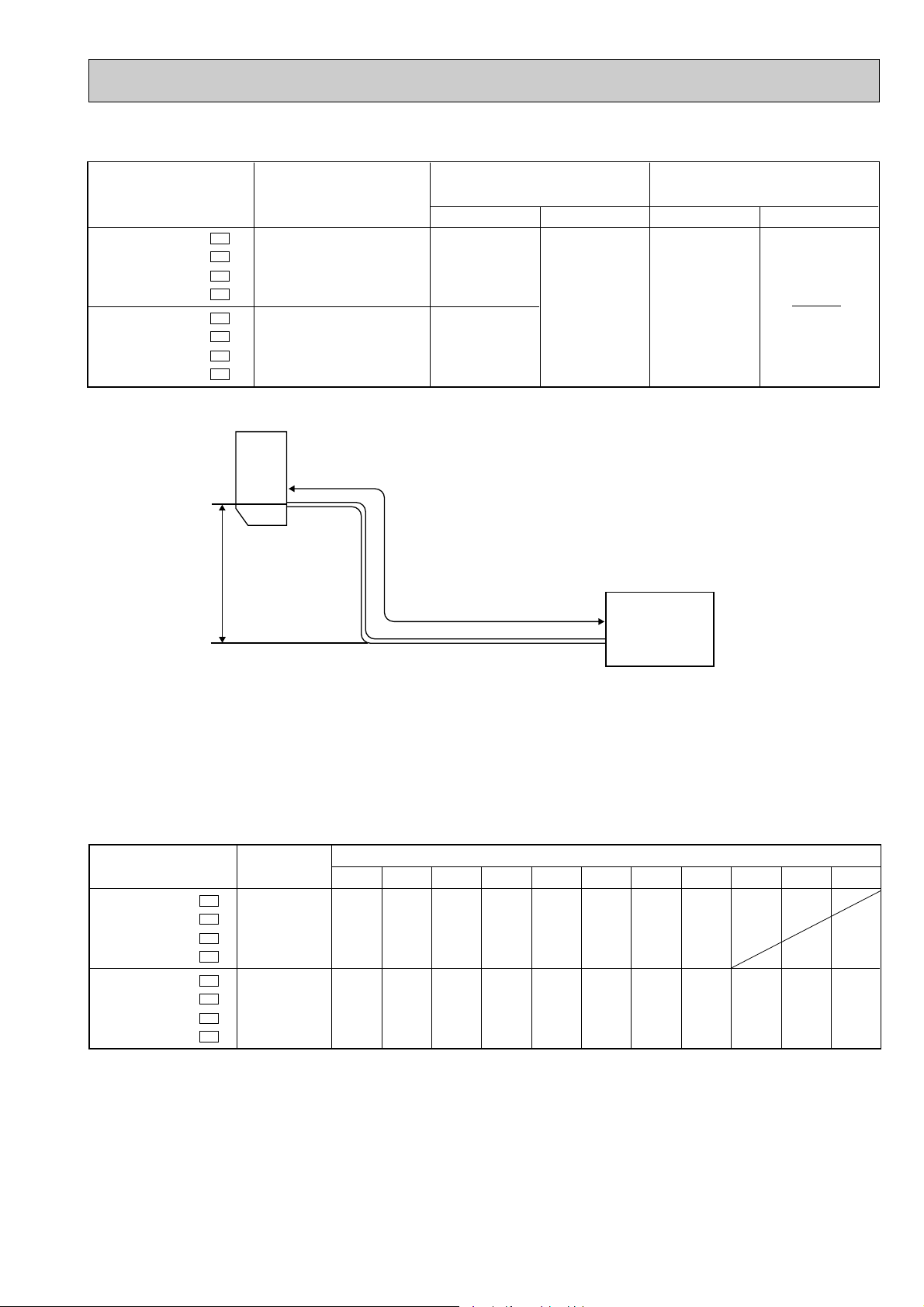

MAX. REFRIGERANT PIPING LENGTH

Refrigerant Piping

Max. length

A

w Height difference should be within

8m(MSZ-G09SV)/ 10m(MSZ-G12SV)

regardless of which unit,

indoor or outdoor position is high.

w Max. Height

difference 8m

(MSZ-G09SV

)

Indoor

unit

Outdoor unit

w Max. Height

difference 10m

(MSZ-G12SV

)

Refrigerant piping

Max. length : m

A

12

15

Indoor unit

Gas 0.43

Liquid 0.5

Gas

9.52

12.7

Liquid

6.35

Outdoor unit

Piping size O.D : mm Length of connecting pipe : m

Model

MSZ-G09SV -

E1

MUZ-G09SV -

E1

MSZ-G09SV -

E2

MUZ-G09SV -

E2

MSZ-G12SV -

E1

MUZ-G12SV -

E1

MSZ-G12SV -

E2

MUZ-G12SV -

E2

Outdoor unit

precharged

750

1100

14m

270

7m

60

60

6m

30

30

5m

0

0

11m

180

180

Model

Refrigerant piping length (one way)

Calculation : Xg=30g/mo(Refrigerant piping length(m) - 5)

8m

90

90

9m

120

120

10m

150

150

12m

210

210

13m

240

15m

300

MSZ-G09SV -

E1

MUZ-G09SV -

E1

MSZ-G09SV -

E2

MUZ-G09SV -

E2

MSZ-G12SV -

E1

MUZ-G12SV -

E1

MSZ-G12SV -

E2

MUZ-G12SV -

E2

MAX. HEIGHT DIFFERENCE

ADDITIONAL REFRIGERANT CHARGE (R22:g)

15

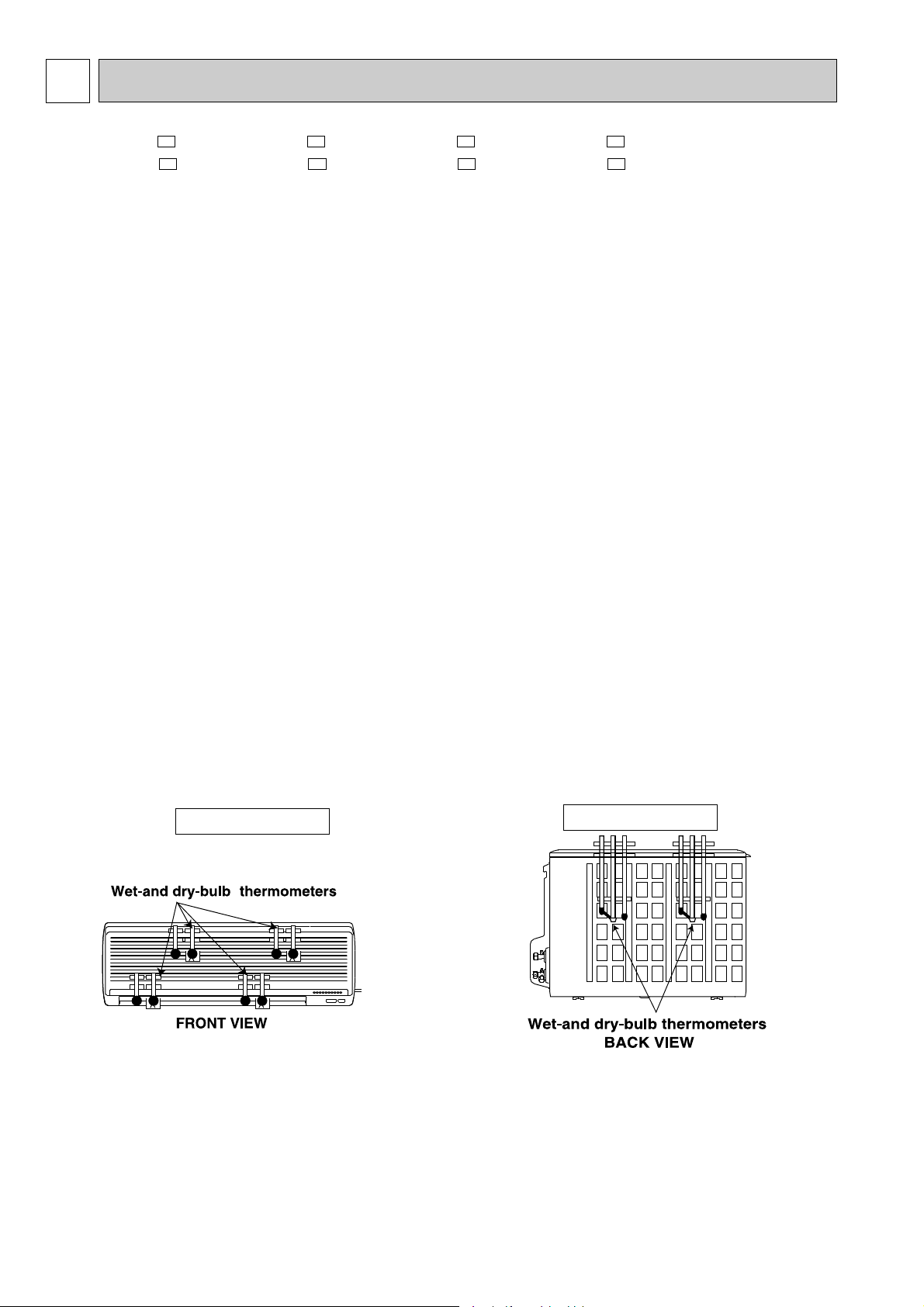

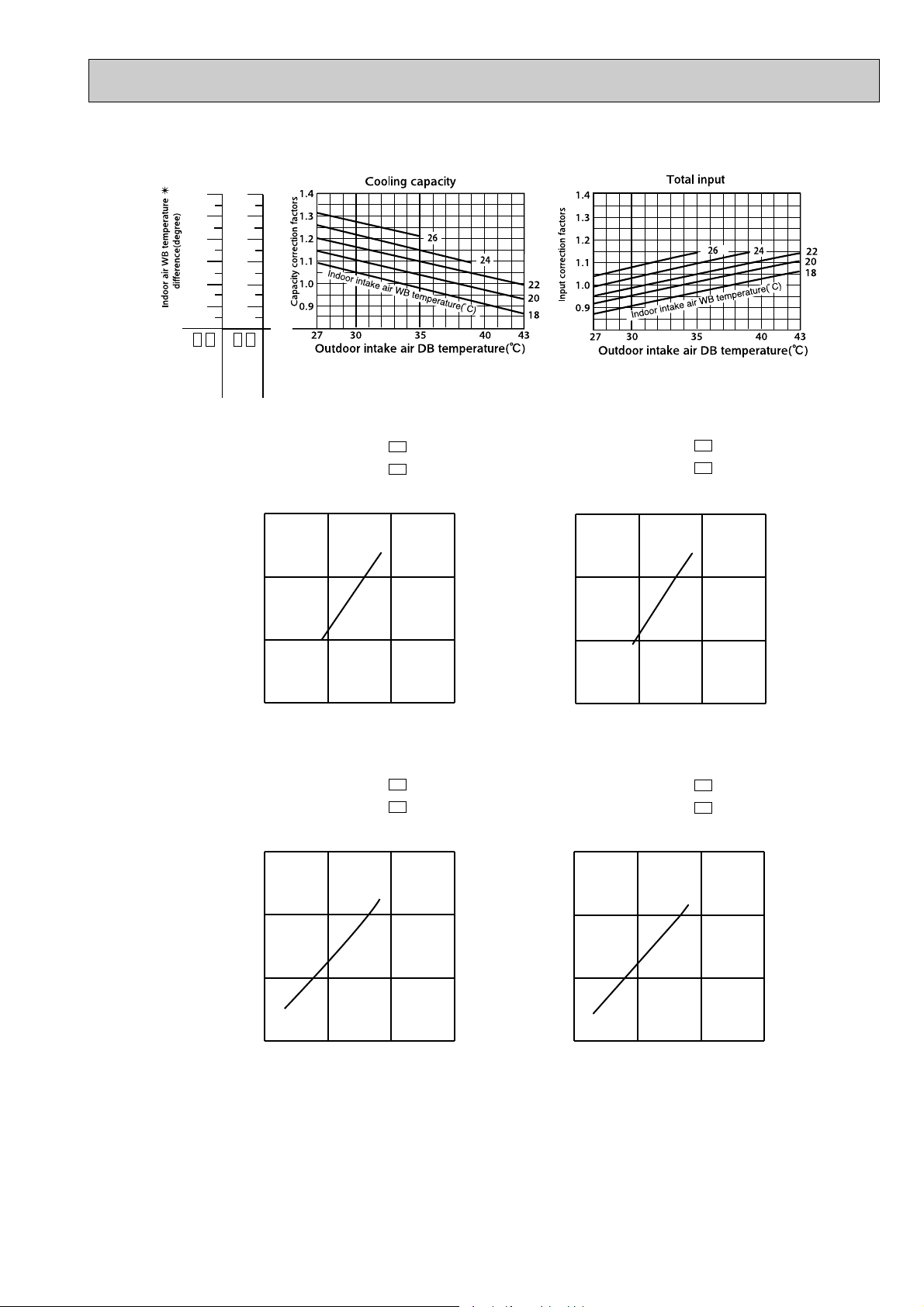

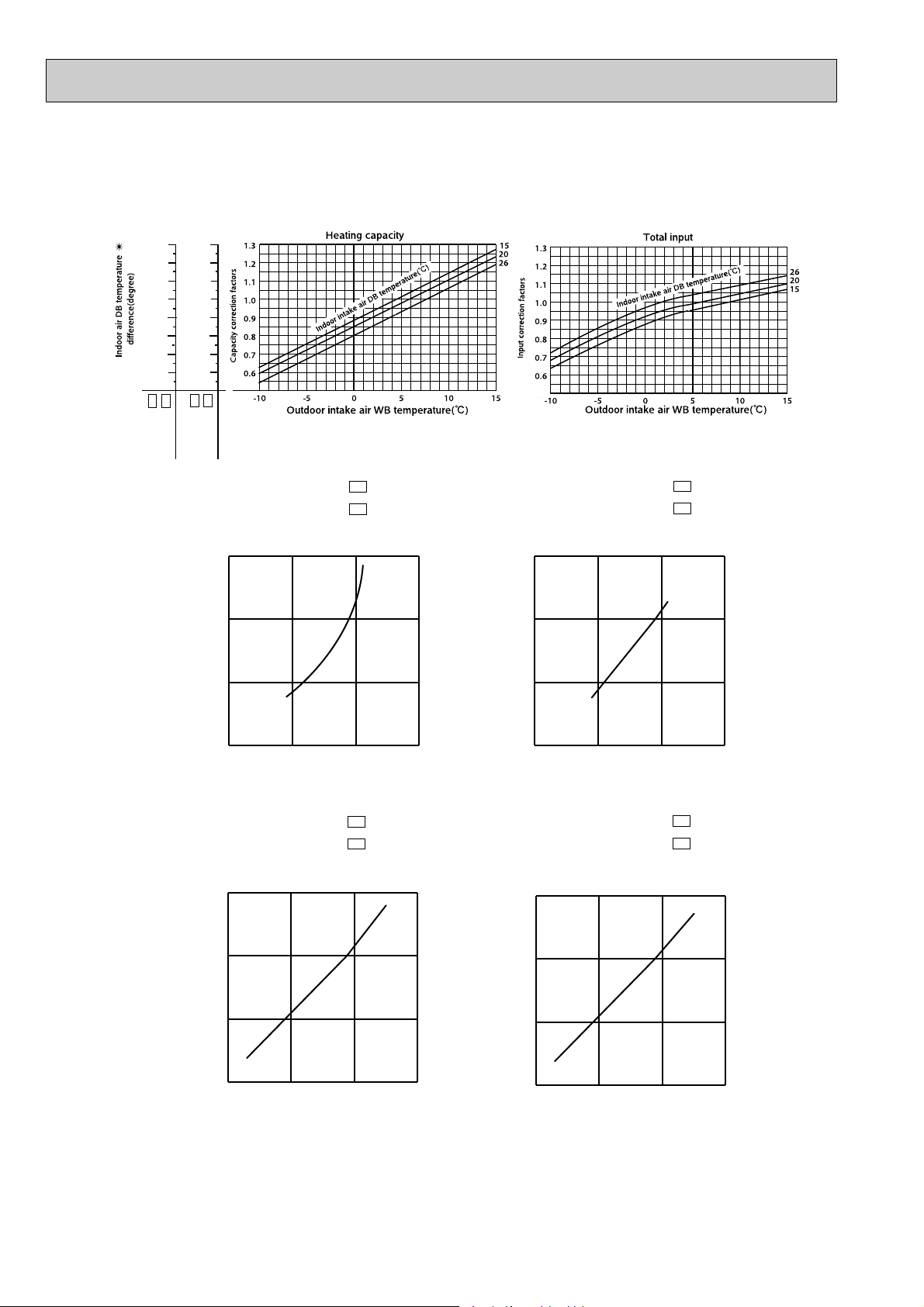

PERFORMANCE CURVES8

MSZ-G09SVMUZ-G09SV-

The standard data contained in these specifications apply only to the operation of the air conditioner under normal conditions.

Since operating conditions vary according to the areas where these units are installed. The following information has been

provided to clarify the operating characteristics of the air conditioner under the conditions indicated by the performance curve.

(1) GUARANTEED VOLTAGE

207 ~ 253V, 50Hz

(2) AIR FLOW

Air flow should be set at MAX.

(3) MAIN READINGS

(1) Indoor intake air wet-bulb temperature ::WB

(2) Indoor outlet air wet-bulb temperature ::WB

(3) Outdoor intake air dry-bulb temperature ::DB

(4) Total input :W

(5) Indoor intake air dry-bulb temperature ::DB

(6) Outdoor intake air wet-bulb temperature ::WB

(7) Total input :W

Indoor air wet/dry-bulb temperature difference on the left side of the chart on page 15 and 16 shows the difference

between the indoor intake air wet/dry-bulb temperature and the indoor outlet air wet/dry-bulb temperature for your reference at service.

E1

MSZ-G09SV-

E1

MUZ-G09SV-

E2

MSZ-G12SV-

E2

MUZ-G12SV-

Cooling

}

Heating

}

E1

MSZ-G12SV-

E1

MUZ-G12SV-

E2

E2

How to measure the indoor air wet-bulb/ dry-bulb temperature difference

1. Attach at least 2 sets of wet-and dry-bulb thermometers to the indoor air intake as shown in the figure, and at least 2 sets

of wet-and dry-bulb thermometers to the indoor air outlet. The thermometers must be attached to the position where air

speed is high.

2. Attach at least 2 sets of wet-and dry-bulb thermometers to the outdoor air intake.

Cover the thermometers to prevent direct rays of the sun.

3. Check that the air filter is cleaned.

4. Open windows and doors of room.

5. Press the EMERGENCY OPERATION switch once (twice) to start the EMERGENCY COOL (HEAT) MODE.

6. When system stabilizes after more than 15 minutes, measure temperature and take an average temperature.

7. 10 minutes later, measure temperature again and check that the temperature does not change.

INDOOR UNIT

OUTDOOR UNIT

16

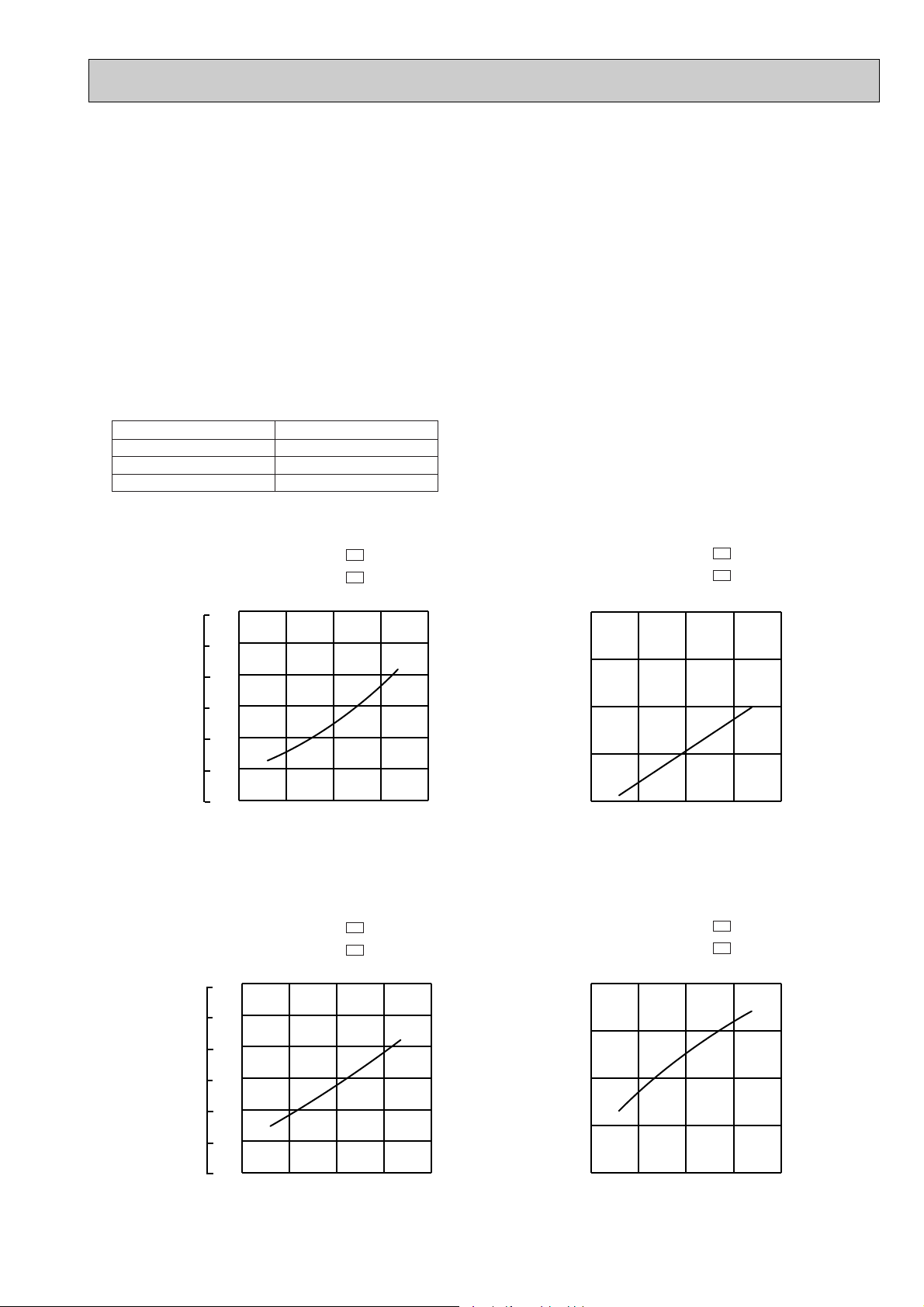

11.5

10.5

9.6

8.6

7.7

6.8

MSZ-G09SV- E1

MSZ-G09SV- E2

11.6

10.6

9.6

8.7

7.8

6.9

MSZ-G12SV- E1

MSZ-G12SV- E2

0 50 100 150(Hz)

0.0

0.5

1.0

1.5

Correction of Cooling capacity

Capacity correction factors

The operational frequency of compressor

Cooling capacity

✴ These values are under rated (frequency).

MUZ-G09SV MUZ-G09SV -

MUZ-G12SV MUZ-G12SV -

E1

E2

E1

E2

Correction of Cooling capacity

1.5

MUZ-G09SV MUZ-G09SV -

E1

E2

Correction of total input

1.5

1.0

0.5

Input correction factors

0.0

0 50 100 150(Hz)

The operational frequency of compressor

MUZ-G12SV MUZ-G12SV -

E1

E2

Correction of total input

1.5

1.0

0.5

Capacity correction factors

0.0

0 50 100 150(Hz)

The operational frequency of compressor

17

1.0

0.5

Input correction factors

0.0

0 50 100 150

The operational frequency of compressor

28.0

25.9

23.7

21.6

19.4

17.2

15.1

12.9

MSZ-G09SV- E1

MSZ-G09SV- E2

29.3

27.1

24.8

22.6

20.3

18.1

15.8

13.5

MSZ-G12SV- E1

MSZ-G12SV- E2

Heating capacity

0 50 100 150(Hz)

0.0

0.5

1.0

1.5

Correction of Heating capacity

Capacity correction factors

The operational frequency of compressor

Correction of total input

Input correction factors

The operational frequency of compressor

0 50 100 150(Hz)

0.0

0.5

1.0

1.5

NOTE:The following curves are for the heating operation without any frost.

✴ These values are under rated (frequency).

MUZ-G09SV MUZ-G09SV -

MUZ-G12SV MUZ-G12SV -

E1

E2

E1

E2

Correction of Heating capacity

1.5

MUZ-G09SV MUZ-G09SV -

MUZ-G12SV MUZ-G12SV -

Correction of total input

1.5

E1

E2

E1

E2

Capacity correction factors

1.0

0.5

0.0

0 50 100 150(Hz)

The operational frequency of compressor

18

1.0

0.5

Input correction factors

0.0

0 50 100 150(Hz)

The operational frequency of compressor

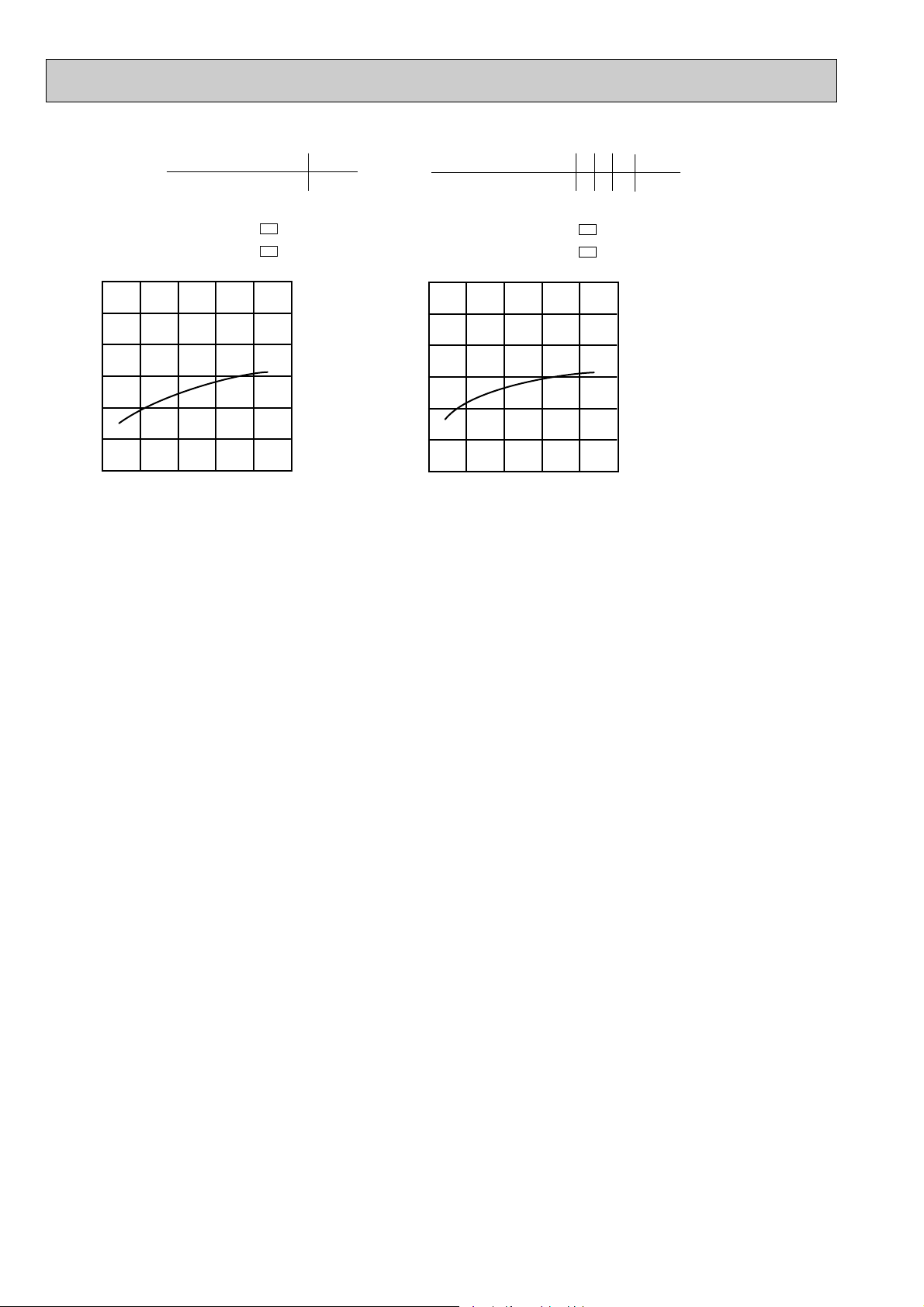

OUTDOOR LOW PRESSURE AND OUTDOOR UNIT CURRENT

(MPa [Gauge])

(kgf/F [Gauge])

18 32

15 20

50

25

60

30

70(%)

35(:)

0.2

0.3

0.4

0.5

0.6

0.7

79Hz

2

3

4

5

6

7

8

0.8

15 20

50

25

60

30

70(%)

35(:)

3

4

5

6

7

79Hz

32

18

(MPa [Gauge])

(kgf/F [Gauge])

18 32

15 20

50

25

60

30

70(%)

35(:)

0.2

0.3

0.4

0.5

0.6

0.7

85Hz

2

3

4

5

6

7

8

0.8

15 20

50

25

60

30

70(%)

35(:)

3

4

5

6

7

85Hz

32

18

How to operate with fixed operational frequency of the compressor.

1. Press the EMERGENCY OPERATION switch on the front of the indoor unit , and select either EMERGENCY COOL

mode or EMERGENCY HEAT mode before starting to operate the air conditioner.

2. The compressor starts up.

The operational frequency of the compressor is G09: 79Hz, G12: 85Hz in EMERGENCY COOL mode and 58Hz in

EMERGENCY HEAT mode.

3. The fan speed of the indoor unit is High.

4. This operation continues for 30minutes.

5. In order to release this operation, press the EMERGENCY OPERATION switch twice or once, or press any button on the

remote controller.

NOTE : The unit of pressure has been changed to MPa on the international system of units(SI unit system).

ff

The conversion factor is: 1(MPa [Gauge]) =10.2(kgf/

[Gauge])

COOL operation

1 Both indoor and outdoor unit are under the same temperature/humidity condition.

Dry-bulb temperature

20

25

30

2 Air flow should be set at High.

3 Operational frequency : 79Hz

MUZ-G09SV MUZ-G09SV -

Relative humidity(%)

50

60

70

E1

E2

MUZ-G09SV MUZ-G09SV -

E1

E2

Outdoor low pressure

Operational frequency : 85Hz

Outdoor low pressure

Ambient temperature(:)

Ambient humidity(%)

MUZ-G12SV MUZ-G12SV -

Ambient temperature(:)

Ambient humidity(%)

Outdoor unit current (A)

Ambient temperature(:)

Ambient humidity(%)

E1

E2

MUZ-G12SV MUZ-G12SV -

E1

E2

Outdoor unit current (A)

Ambient temperature(:)

Ambient humidity(%)

19

6.0

5.5

5.0

4.5

4.0

3.5

3.0

2 5 10 15 20 25

58Hz

HEAT operation

6.0

5.5

5.0

4.5

4.0

3.5

3.0

2 5 10 15 20 25

58Hz

Condition Indoor : Dry bulb temperature 20.0:

Wet bulb temperature 14.5:

Outdoor : Dry bulb temperature 2 7 15 20.0:

Wet bulb temperature 1 6 12 14.5:

MUZ-G09SV MUZ-G09SV -

Outdoor unit current (A)

Ambient temperature(:)

E1

E2

MUZ-G12SV MUZ-G12SV -

E1

E2

Outdoor unit current (A)

Ambient temperature(:)

20

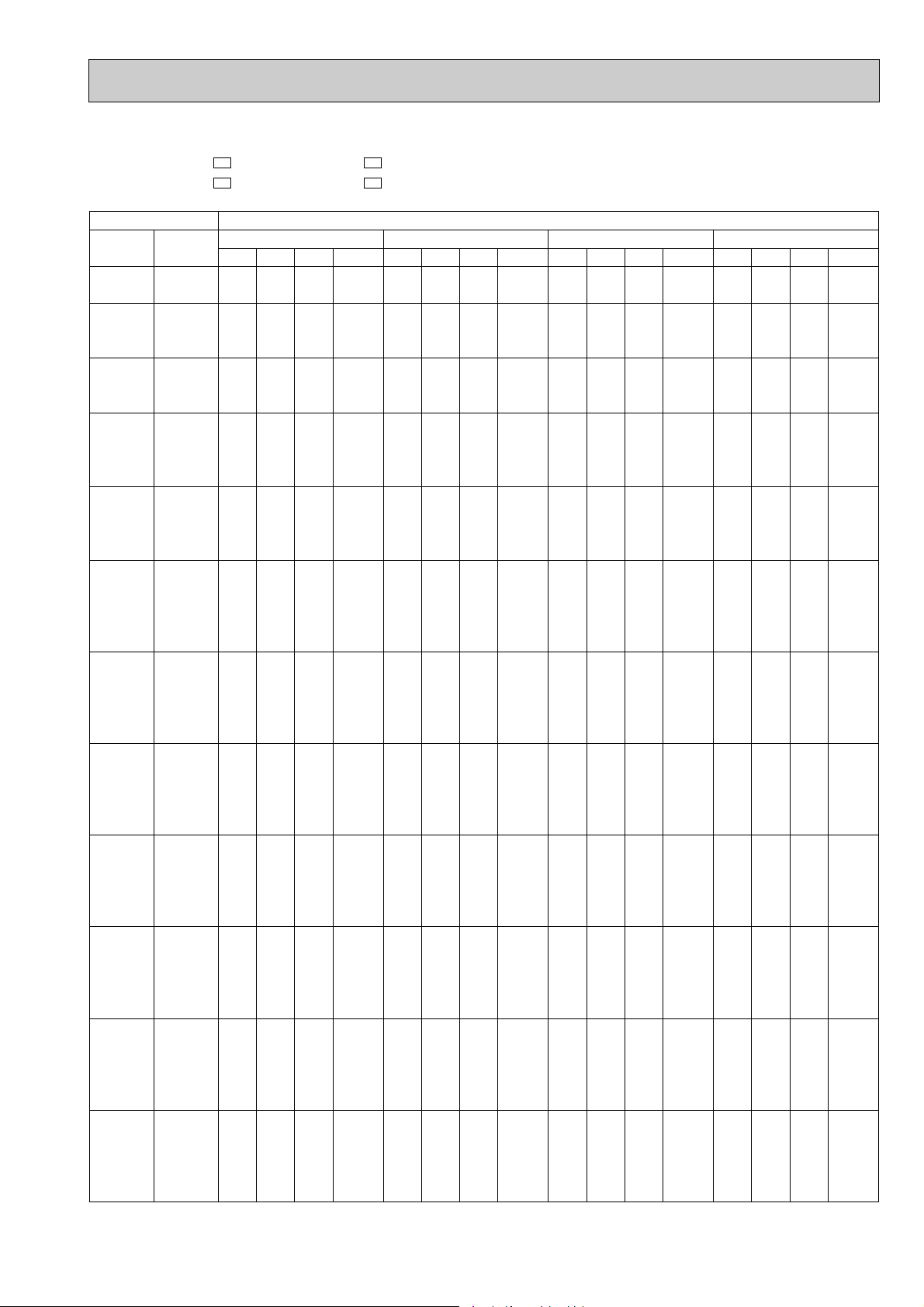

PERFORMANCE DATA COOL operation

MSZ-G09SV - MUZ-G09SV MSZ-G09SV - MUZ-G09SV -

CAPACITY:2.6(KW)

INDOOR INDOOR

DB(;) WB(;)

21 18 3.06 1.53 0.50 752 2.93 1.46 0.50 790 2.81 1.40 0.50 827 2.70 1.35 0.50 865

21 20 3.19 1.21 0.38 790 3.06 1.16 0.38 837 2.96 1.13 0.38 855 2.86 1.09 0.38 893

22 18 3.06 1.65 0.54 752 2.93 1.58 0.54 790 2.81 1.52 0.54 827 2.70 1.46 0.54 865

22 20 3.19 1.34 0.42 790 3.06 1.28 0.42 837 2.96 1.24 0.42 855 2.86 1.20 0.42 893

22 22 3.32 0.99 0.30 818 3.20 0.96 0.30 870 3.12 0.94 0.30 893 2.99 0.90 0.30 931

23 18 3.06 1.77 0.58 752 2.93 1.70 0.58 790 2.81 1.63 0.58 827 2.70 1.57 0.58 865

23 20 3.19 1.47 0.46 790 3.06 1.41 0.46 837 2.96 1.36 0.46 855 2.86 1.32 0.46 893

23 22 3.32 1.13 0.34 818 3.20 1.09 0.34 870 3.12 1.06 0.34 893 2.99 1.02 0.34 931

24 18 3.06 1.89 0.62 752 2.93 1.81 0.62 790 2.81 1.74 0.62 827 2.70 1.68 0.62 865

24 20 3.19 1.59 0.50 790 3.06 1.53 0.50 837 2.96 1.48 0.50 855 2.86 1.43 0.50 893

24 22 3.32 1.26 0.38 818 3.20 1.22 0.38 870 3.12 1.19 0.38 893 2.99 1.14 0.38 931

24 24 3.48 0.91 0.26 855 3.35 0.87 0.26 902 3.28 0.85 0.26 931 3.17 0.82 0.26 978

25 18 3.06 2.02 0.66 752 2.93 1.93 0.66 790 2.81 1.85 0.66 827 2.70 1.78 0.66 865

25 20 3.19 1.72 0.54 790 3.06 1.65 0.54 837 2.96 1.60 0.54 855 2.86 1.54 0.54 893

25 22 3.32 1.39 0.42 818 3.20 1.34 0.42 870 3.12 1.31 0.42 893 2.99 1.26 0.42 931

25 24 3.48 1.05 0.30 855 3.35 1.01 0.30 902 3.28 0.98 0.30 931 3.17 0.95 0.30 978

26 18 3.06 2.14 0.70 752 2.93 2.05 0.70 790 2.81 1.97 0.70 827 2.70 1.89 0.70 865

26 20 3.19 1.85 0.58 790 3.06 1.77 0.58 837 2.96 1.72 0.58 855 2.86 1.66 0.58 893

26 22 3.32 1.52 0.46 818 3.20 1.47 0.46 870 3.12 1.44 0.46 893 2.99 1.38 0.46 931

26 24 3.48 1.18 0.34 855 3.35 1.14 0.34 902 3.28 1.11 0.34 931 3.17 1.08 0.34 978

26 26 3.59 0.79 0.22 902 3.48 0.77 0.22 949 3.43 0.76 0.22 978 3.33 0.73 0.22 1006

27 18 3.06 2.26 0.74 752 2.93 2.16 0.74 790 2.81 2.08 0.74 827 2.70 2.00 0.74 865

27 20 3.19 1.97 0.62 790 3.06 1.89 0.62 837 2.96 1.84 0.62 855 2.86 1.77 0.62 893

27 22 3.32 1.66 0.50 818 3.20 1.60 0.50 870 3.12 1.56 0.50 893 2.99 1.50 0.50 931

27 24 3.48 1.32 0.38 855 3.35 1.27 0.38 902 3.28 1.24 0.38 931 3.17 1.21 0.38 978

27 26 3.59 0.93 0.26 902 3.48 0.91 0.26 949 3.43 0.89 0.26 978 3.33 0.87 0.26 1006

28 18 3.06 2.38 0.78 752 2.93 2.28 0.78 790 2.81 2.19 0.78 827 2.70 2.11 0.78 865

28 20 3.19 2.10 0.66 790 3.06 2.02 0.66 837 2.96 1.96 0.66 855 2.86 1.89 0.66 893

28 22 3.32 1.79 0.54 818 3.20 1.73 0.54 870 3.12 1.68 0.54 893 2.99 1.61 0.54 931

28 24 3.48 1.46 0.42 855 3.35 1.41 0.42 902 3.28 1.38 0.42 931 3.17 1.33 0.42 978

28 26 3.59 1.08 0.30 902 3.48 1.05 0.30 949 3.43 1.03 0.30 978 3.33 1.00 0.30 1006

29 18 3.06 2.51 0.82 752 2.93 2.40 0.82 790 2.81 2.30 0.82 827 2.70 2.22 0.82 865

29 20 3.19 2.23 0.70 790 3.06 2.14 0.70 837 2.96 2.07 0.70 855 2.86 2.00 0.70 893

29 22 3.32 1.92 0.58 818 3.20 1.85 0.58 870 3.12 1.81 0.58 893 2.99 1.73 0.58 931

29 24 3.48 1.60 0.46 855 3.35 1.54 0.46 902 3.28 1.51 0.46 931 3.17 1.46 0.46 978

29 26 3.59 1.22 0.34 902 3.48 1.18 0.34 949 3.43 1.17 0.34 978 3.33 1.13 0.34 1006

30 18 3.06 2.63 0.86 752 2.93 2.52 0.86 790 2.81 2.41 0.86 827 2.70 2.33 0.86 865

30 20 3.19 2.36 0.74 790 3.06 2.26 0.74 837 2.96 2.19 0.74 855 2.86 2.12 0.74 893

30 22 3.32 2.06 0.62 818 3.20 1.98 0.62 870 3.12 1.93 0.62 893 2.99 1.85 0.62 931

30 24 3.48 1.74 0.50 855 3.35 1.68 0.50 902 3.28 1.64 0.50 931 3.17 1.59 0.50 978

30 26 3.59 1.36 0.38 902 3.48 1.32 0.38 949 3.43 1.30 0.38 978 3.33 1.26 0.38 1006

31 18 3.06 2.75 0.90 752 2.93 2.63 0.90 790 2.81 2.53 0.90 827 2.70 2.43 0.90 865

31 20 3.19 2.48 0.78 790 3.06 2.38 0.78 837 2.96 2.31 0.78 855 2.86 2.23 0.78 893

31 22 3.32 2.19 0.66 818 3.20 2.11 0.66 870 3.12 2.06 0.66 893 2.99 1.97 0.66 931

31 24 3.48 1.88 0.54 855 3.35 1.81 0.54 902 3.28 1.77 0.54 931 3.17 1.71 0.54 978

31 26 3.59 1.51 0.42 902 3.48 1.46 0.42 949 3.43 1.44 0.42 978 3.33 1.40 0.42 1006

32 18 3.06 2.87 0.94 752 2.93 2.75 0.94 790 2.81 2.64 0.94 827 2.70 2.54 0.94 865

32 20 3.19 2.61 0.82 790 3.06 2.51 0.82 837 2.96 2.43 0.82 855 2.86 2.35 0.82 893

32 22 3.32 2.32 0.70 818 3.20 2.24 0.70 870 3.12 2.18 0.70 893 2.99 2.09 0.70 931

32 24 3.48 2.02 0.58 855 3.35 1.95 0.58 902 3.28 1.90 0.58 931 3.17 1.84 0.58 978

32 26 3.59 1.65 0.46 902 3.48 1.60 0.46 949 3.43 1.58 0.46 978 3.33 1.53 0.46 1006

NOTE Q :Total capacity (kW) SHF :Sensible heat factor

SHC :Sensible heat capacity (kW) INPUT :Total power input (W)

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

INPUT:940(W)SHF:0.68

21 25 27 30

E1E1

E2E2

OUTDOOR DB(;)

21

CAPACITY:2.6(KW)

INPUT:940(W)SHF:0.68

OUTDOOR DB(;)

INDOOR INDOOR

35 40 43 46

DB(;) WB(;)

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

21 18 2.55 1.27 0.50 921 2.34 1.17 0.50 978 2.25 1.12 0.50 996 2.16 1.08 0.50 1015

21 20 2.68 1.02 0.38 959 2.50 0.95 0.38 1006 2.41 0.91 0.38 1034 2.31 0.88 0.38 1062

22 18 2.55 1.38 0.54 921 2.34 1.26 0.54 978 2.25 1.21 0.54 996 2.16 1.17 0.54 1015

22 20 2.68 1.12 0.42 959 2.50 1.05 0.42 1006 2.41 1.01 0.42 1034 2.31 0.97 0.42 1062

22 22 2.83 0.85 0.30 996 2.65 0.80 0.30 1053 2.56 0.77 0.30 1072 2.47 0.74 0.30 1090

23 18 2.55 1.48 0.58 921 2.34 1.36 0.58 978 2.25 1.30 0.58 996 2.16 1.25 0.58 1015

23 20 2.68 1.23 0.46 959 2.50 1.15 0.46 1006 2.41 1.11 0.46 1034 2.31 1.06 0.46 1062

23 22 2.83 0.96 0.34 996 2.65 0.90 0.34 1053

2.56 0.87 0.34 1072

2.47 0.84 0.34 1090

24 18 2.55 1.58 0.62 921 2.34 1.45 0.62 978 2.25 1.39 0.62 996 2.16 1.34 0.62 1015

24 20 2.68 1.34 0.50 959 2.50 1.25 0.50 1006 2.41 1.20 0.50 1034 2.31 1.16 0.50 1062

24 22 2.83 1.08 0.38 996 2.65 1.01 0.38 1053 2.56 0.97 0.38 1072 2.47 0.94 0.38 1090

24 24 2.99 0.78 0.26 1034 2.81 0.73 0.26 1081 2.73 0.71 0.26 1105 2.65 0.69 0.26 1128

25 18 2.55 1.68 0.66 921 2.34 1.54 0.66 978 2.25 1.48 0.66 996 2.16 1.42 0.66 1015

25 20 2.68 1.45 0.54 959 2.50 1.35 0.54 1006 2.41 1.30 0.54 1034 2.31 1.25 0.54 1062

25 22 2.83 1.19 0.42 996 2.65 1.11 0.42 1053 2.56 1.08 0.42 1072 2.47 1.04 0.42 1090

25 24 2.99 0.90 0.30 1034 2.81 0.84 0.30 1081 2.73 0.82 0.30 1105 2.65 0.80 0.30 1128

26 18 2.55 1.78 0.70 921 2.34 1.64 0.70 978 2.25 1.57 0.70 996 2.16 1.51 0.70 1015

26 20 2.68 1.55 0.58 959 2.50 1.45 0.58 1006 2.41 1.39 0.58 1034 2.31 1.34 0.58 1062

26 22 2.83 1.30 0.46 996 2.65 1.22 0.46 1053 2.56 1.18 0.46 1072 2.47 1.14 0.46 1090

26 24 2.99 1.02 0.34 1034 2.81 0.95 0.34 1081 2.73 0.93 0.34 1105 2.65 0.90 0.34 1128

26 26 3.15 0.69 0.22 1072 2.96 0.65 0.22 1119 2.87 0.63 0.22 1142 2.78 0.61 0.22 1166

27 18 2.55 1.89 0.74 921 2.34 1.73 0.74 978 2.25 1.66 0.74 996 2.16 1.60 0.74 1015

27 20 2.68 1.66 0.62 959 2.50 1.55 0.62 1006 2.41 1.49 0.62 1034 2.31 1.43 0.62 1062

27 22 2.83 1.42 0.50 996 2.65 1.33 0.50 1053 2.56 1.28 0.50 1072 2.47 1.24 0.50 1090

27 24 2.99 1.14 0.38 1034 2.81 1.07 0.38 1081 2.73 1.04 0.38 1105 2.65 1.01 0.38 1128

27 26 3.15 0.82 0.26 1072 2.96 0.77 0.26 1119 2.87 0.75 0.26 1142 2.78 0.72 0.26 1166

28 18 2.55 1.99 0.78 921 2.34 1.83 0.78 978 2.25 1.75 0.78 996 2.16 1.68 0.78 1015

28 20 2.68 1.77 0.66 959 2.50 1.65 0.66 1006 2.41 1.59 0.66 1034 2.31 1.53 0.66 1062

28 22 2.83 1.53 0.54 996 2.65 1.43 0.54 1053 2.56 1.38 0.54 1072 2.47 1.33 0.54 1090

28 24 2.99 1.26 0.42 1034 2.81 1.18 0.42 1081 2.73 1.15 0.42 1105 2.65 1.11 0.42 1128

28 26 3.15 0.94 0.30 1072 2.96 0.89 0.30 1119 2.87 0.86 0.30 1142 2.78 0.83 0.30 1166

29 18 2.55 2.09 0.82 921 2.34 1.92 0.82 978 2.25 1.84 0.82 996 2.16 1.77 0.82 1015

29 20 2.68 1.87 0.70 959 2.50 1.75 0.70 1006 2.41 1.68 0.70 1034 2.31 1.62 0.70 1062

29 22 2.83 1.64 0.58 996 2.65 1.54 0.58 1053 2.56 1.49 0.58 1072 2.47 1.43 0.58 1090

29 24 2.99 1.38 0.46 1034 2.81 1.29 0.46 1081 2.73 1.26 0.46 1105 2.65 1.22 0.46 1128

29 26 3.15 1.07 0.34 1072 2.96 1.01 0.34 1119 2.87 0.98 0.34 1142 2.78 0.95 0.34 1166

30 18 2.55 2.19 0.86 921 2.34 2.01 0.86 978 2.25 1.93 0.86 996 2.16 1.86 0.86 1015

30 20 2.68 1.98 0.74 959 2.50 1.85 0.74 1006 2.41 1.78 0.74 1034 2.31 1.71 0.74 1062

30 22 2.83 1.76 0.62 996 2.65 1.64 0.62 1053 2.56 1.59 0.62 1072 2.47 1.53 0.62 1090

30 24 2.99 1.50 0.50 1034 2.81 1.40 0.50 1081 2.73 1.37 0.50 1105 2.65 1.33 0.50 1128

30 26 3.15 1.20 0.38 1072 2.96 1.13 0.38 1119 2.87 1.09 0.38 1142 2.78 1.06 0.38 1166

31 18 2.55 2.29 0.90 921 2.34 2.11 0.90 978 2.25 2.02 0.90 996 2.16 1.94 0.90 1015

31 20 2.68 2.09 0.78 959 2.50 1.95 0.78 1006 2.41 1.88 0.78 1034 2.31 1.80 0.78 1062

31 22 2.83 1.87 0.66 996 2.65 1.75 0.66 1053 2.56 1.69 0.66 1072 2.47 1.63 0.66 1090

31 24 2.99 1.61 0.54 1034 2.81 1.52 0.54 1081 2.73 1.47 0.54 1105 2.65 1.43 0.54 1128

31 26 3.15 1.32 0.42 1072 2.96 1.24 0.42 1119 2.87 1.21 0.42 1142 2.78 1.17 0.42 1166

32 18 2.55 2.40 0.94 921 2.34 2.20 0.94 978 2.25 2.11 0.94 996 2.16 2.03 0.94 1015

32 20 2.68 2.20 0.82 959 2.50 2.05 0.82 1006 2.41 1.97 0.82 1034 2.31 1.90 0.82 1062

32 22 2.83 1.98 0.70 996 2.65 1.86 0.70 1053 2.56 1.79 0.70 1072 2.47 1.73 0.70 1090

32 24 2.99 1.73 0.58 1034 2.81 1.63 0.58 1081 2.73 1.58 0.58 1105 2.65 1.54 0.58 1128

32 26 3.15 1.45 0.46 1072 2.96 1.36 0.46 1119 2.87 1.32 0.46 1142 2.78 1.28 0.46 1166

PERFORMANCE DATA COOL operation

MSZ-G09SV - MUZ-G09SV MSZ-G09SV - MUZ-G09SV -

E1E1

E2E2

NOTE Q :Total capacity (kW) SHF :Sensible heat factor

SHC :Sensible heat capacity (kW) INPUT :Total power input (W)

22

Loading...

Loading...