Mitsubishi Electric CMB-WM-V-AA, CMB-WM-V-AB, CMB-WM108V-AA, CMB-WM108V-AB, Model name CMB-WM1016V-AB Data Book

...Page 1

AIR CONDITIONING SYSTEMS

MODEL

CMB-WM-V-AA

CMB-WM-V-AB

EIo-1

Page 2

HBC controller

CMB-WM-V-AA, CMB-WM-V-AB (for YNW/YLM-Series)

I.HBC controller

1.SPECIFICATIONS ........................................................................................................................................... 2

2.EXTERNAL DIMENSIONS .............................................................................................................................. 6

3.CENTER OF GRAVITY ................................................................................................................................. 10

4.ELECTRICAL WIRING DIAGRAMS .............................................................................................................. 11

5.SOUND LEVELS ........................................................................................................................................... 15

5-1. Sound levels ......................................................................................................................................... 15

5-2. NC curves ............................................................................................................................................. 15

6.ELECTRICAL CHARACTERISTICS.............................................................................................................. 16

Indoor units

MEES17K102

EIo-1 1

Page 3

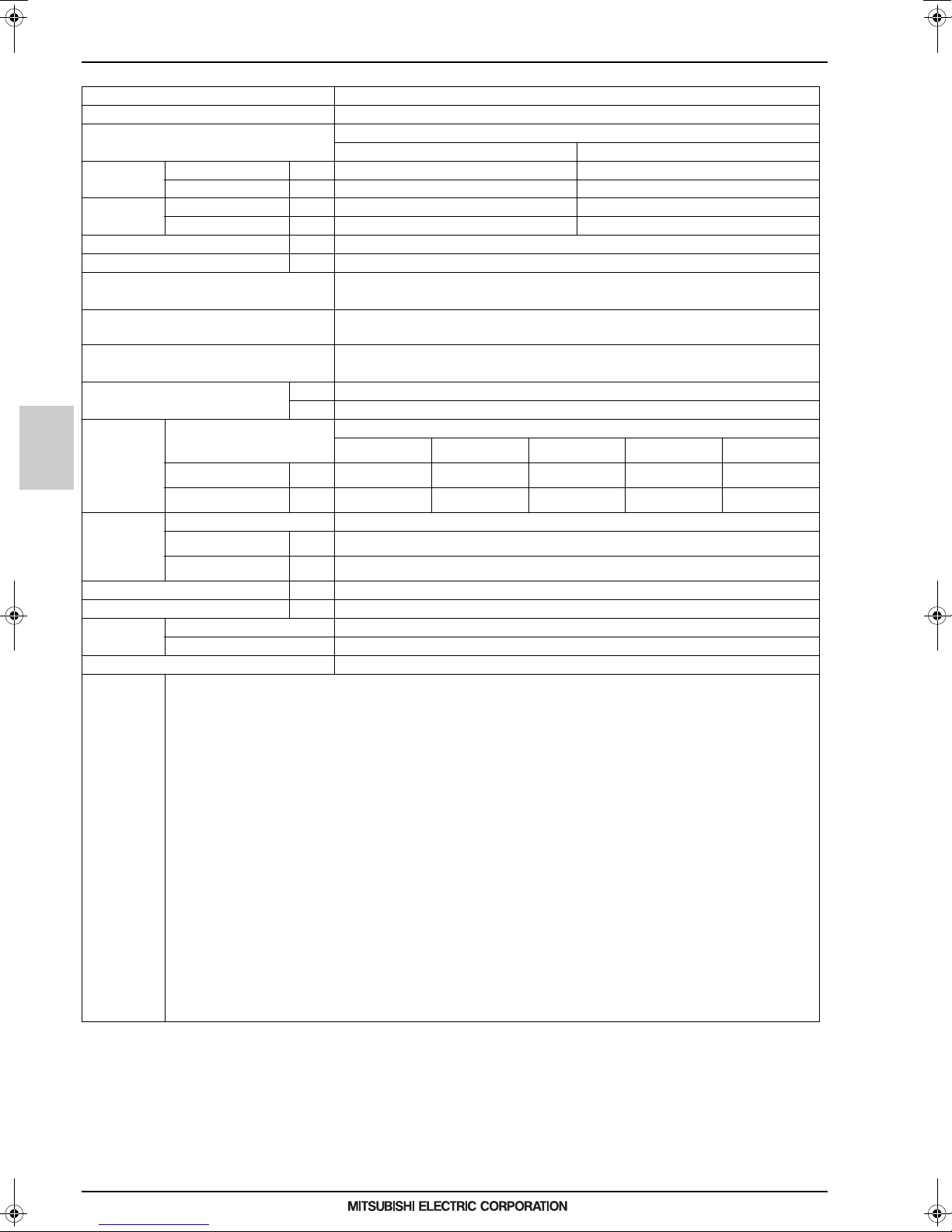

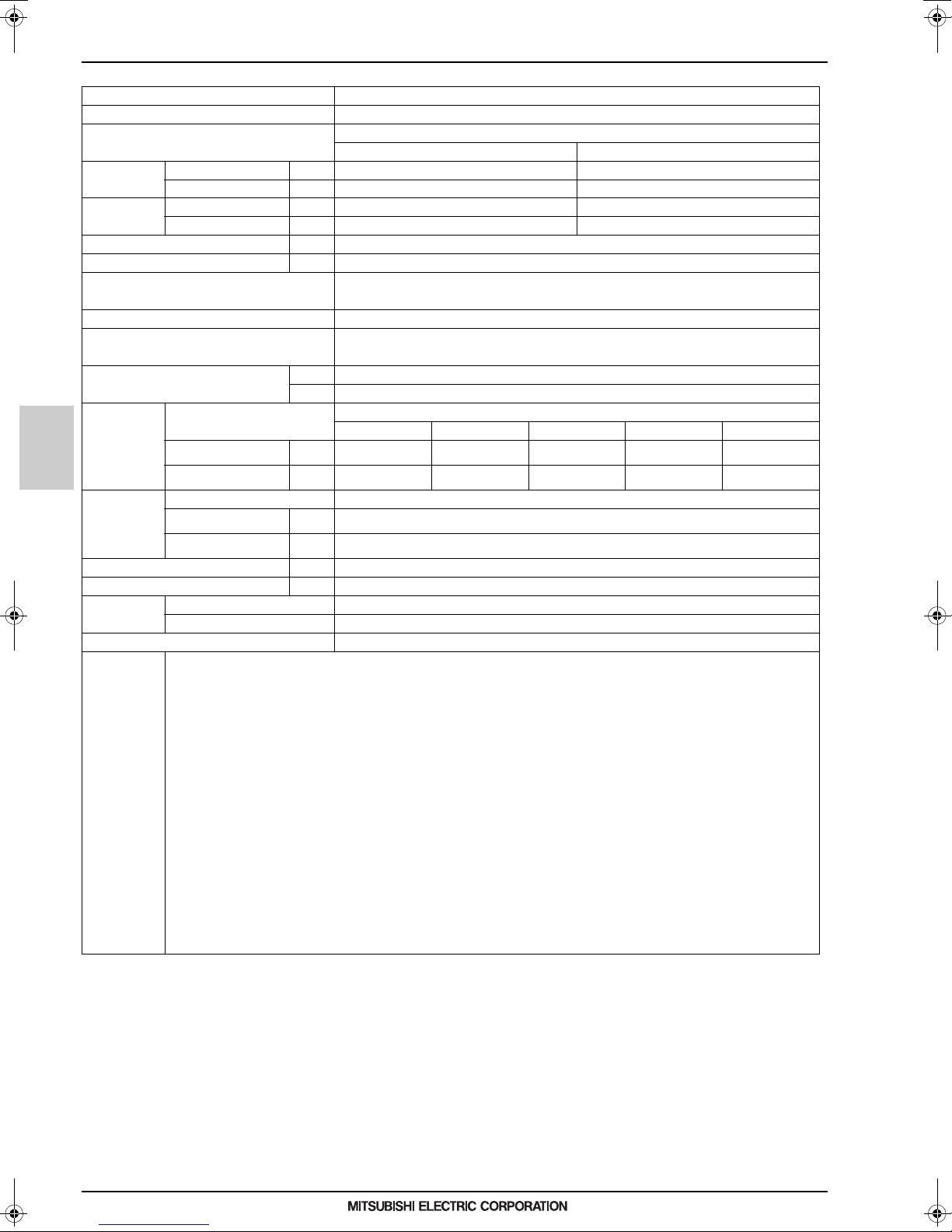

1. SPECIFICATIONS

I.HBC controller1. SPECIFICATIONS

Model name CMB-WM108V-AA

Number of branch 8

Power source 1-phase 220-230-240 V

50 Hz 60 Hz

Power input Cooling kW 0.45/0.46/0.47 0.45/0.46/0.47

(220/230/240) Heating kW 0.45/0.46/0.47 0.45/0.46/0.47

Current input Cooling A 2.89/2.83/2.79 2.89/2.83/2.79

(220/230/240) Heating A 2.89/2.83/2.79 2.89/2.83/2.79

Sound pressure level (measured in anecho ice room) dB <A> 41

Applicable temperature ra nge of installation site °C (D.B.) 0~32

External finish Galvanized steel plate

(Lower part drain pan: Pre-coated galvanized sheets + powder coating)

Connectable outdoor/heat source unit

Indoor unit capacity connectable to 1 branch

External dimension H x W x D

To outdoor/heat source unit

Refrigerant piping

diameter

Water piping

diameter

HBC controller

Field drain pipe size mm (in.) O.D. 32 (1-1/4)

Net weight kg (lbs) 86 (190) [96 (212) with water]

Standard

attachment

Optional parts

Note 1.Works not included:

High press. Pipe

Low press. Pipe

To Indoor unit

Inlet Pipe

Outlet Pipe

Document

Accessory Drain Connection pipe (with flexible hose and insulation)

Installation/foundation work, electrical connection work, duct work, insulation work, power source switch, and other items are not specified in this specifications.

2.The equipment is for R410A/R32 refrigerant.

3.Install this product in a location where noise (refrigerant noise) emitted by the unit will not disturb the neighbors.

(For use in quiet environments with low background noise, position the HBC CONTROLL ER at least 5 m away from any indoor units.)

4.Please install the HBC controller in a place where noise will not be an issue.

5.Please attach an expansion vessel (field supply).

6.Please use copper or plastic pipes for the water circuit. Do not use steel or stainless steel pipework.

Furthermore, when using copper pipewo rk use a non-oxidative brazing method.

Oxidation of the pipework will reduce the pump life.

7.When brazing the pipes, be sure to braze, after covering a wet cloth to the insulation pipes of the units in order to prevent it from burning and shrinking by heat.

8.Please install an air purge valve where air will gather in the water circuit.

9.Please install a pressure reducing valve and a strainer on the water supply to the HBC controller.

10.Please refer to the databook or the installation manual for the specified water quality.

11.This unit is not designed for outside installations.

12.Please always make water circulate or pull out the circulation water completely when not using it.

*Please do not use it as a drinking water.

13.Please do not use ground water and well water.

14.When installing the HBC unit in an environment which may drop below 0 °C, please add antifreez e to the circulating water.

(Refer to the databook and the installation manual).

15.R32 is flammable, and certain restrictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the Databook on installation restrictions.

mm 300 x 1,520 x 630

in.

mm (in.)

O.D.

mm (in.)

O.D.

mm (in.)

I.D.

mm (in.)

I.D.

PURY-P200~500YLM-A(1)(-BS)/PURY -EP200~500YLM-A1(-BS)/PQRY-P200~500YLM -A2/A1

To P200

To M300

15.88 (5/8)

Brazed

19.05 (3/4)

Brazed

PURY-P200~500YNW-A(-BS)/PURY-EP200~500YNW-A(-BS)

PURY-M200~300YNW-A(-BS)/PURY- EM200~300YNW-A(-BS)

Model P80 or smaller

(Use optional joint pipe combing 2 branches when the total unit capacity excee ds P81)

11-13/16 x 59-7/8 x 24-13/16

Connectable outdoor/heat source unit capacity

To P250/300 To P350 To P400 for each To P450/500 for each

19.05 (3/4)

Brazed

22.2 (7/8)

Brazed

19.05 (3/4)

Brazed

28.58 (1-1/8)

Brazed

20 (3/4)

20 (3/4)

–

–

15.88 (5/8)

Brazed

19.05 (3/4)

Brazed

Indoor units

19.05 (3/4)

Brazed

22.2 (7/8)

Brazed

MEES17K102

EIo-1

2

Page 4

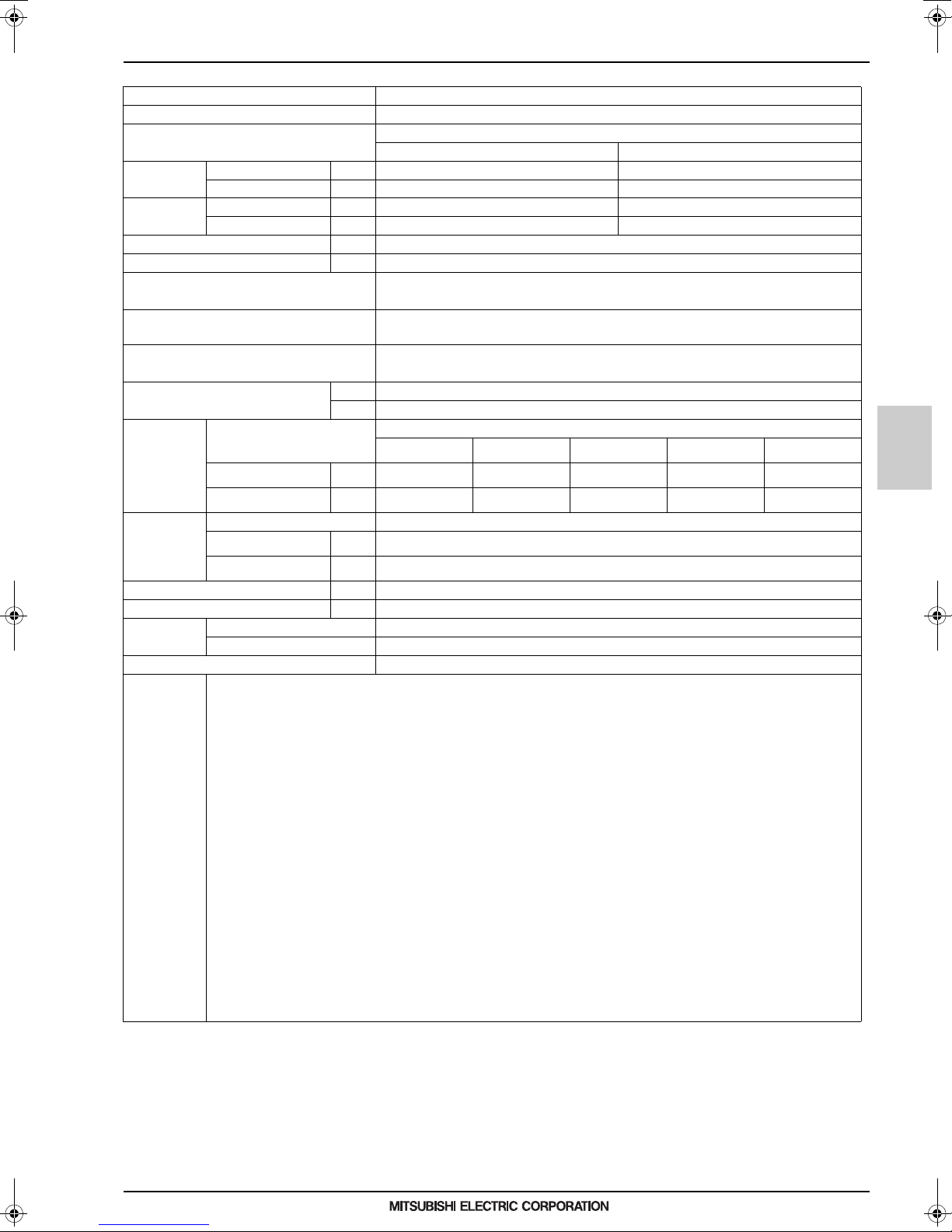

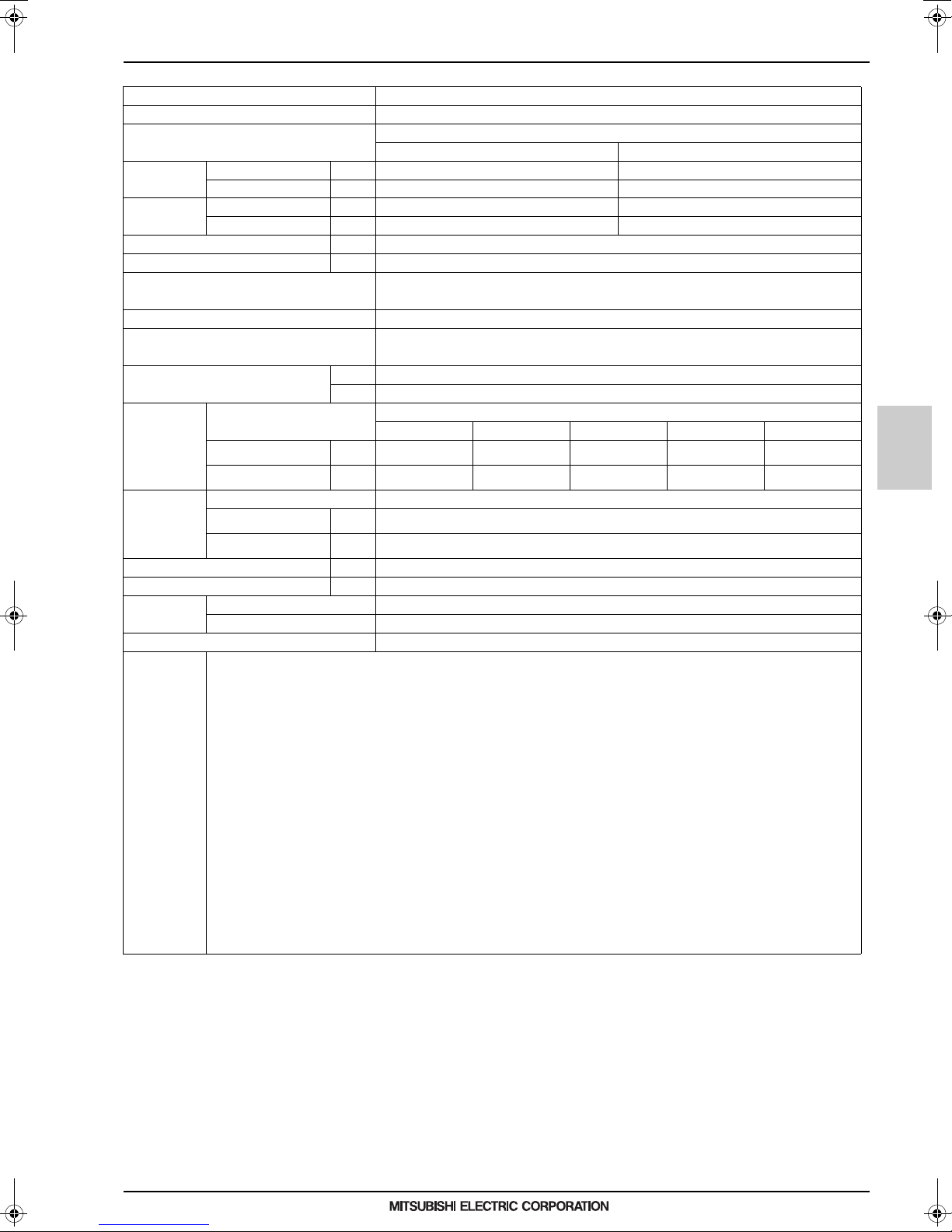

1. SPECIFICATIONS

Model name CMB-WM1016V-AA

Number of branch 16

Power source 1-phase 220-230-240 V

50 Hz 60 Hz

Power input Cooling kW 0.45/0.46/0.47 0.45/0.46 /0.47

(220/230/240) Heating kW 0.45/0.46/0.47 0.45/0.46/0.47

Current input Cooling A 2.89/2.83/2.79 2.89/2.83/2.79

(220/230/240) Heating A 2.89/2.83/2.79 2.89/2.83/2.79

Sound pressure level (measured in anechoice room) dB <A> 41

Applicable temperature range of installation site °C (D.B.) 0~32

External finish

Connectable outdoor/heat source unit

Indoor unit capacity connectable to 1 branch

External dimension H x W x D

To outdoor/heat source unit

Refrigerant piping

diameter

Water piping

diameter

Field drain pipe size mm (in.) O.D. 32 (1-1/4)

Net weight kg (lbs) 98 (217) [111 (245) with water]

Standard

attachment

Optional parts

Note 1.Works not included:

High press. Pipe

Low press. Pipe

To Indoor unit

Inlet Pipe

Outlet Pipe

Document –

Accessory Drain Connection pipe (with flexible hose and insulation)

Installation/foundation work, electrical connection work, duct work, insulation work, power source switch, and other items are not specified in this specifications.

2.The equipment is for R410A/R32 refrigerant.

3.Install this product in a location where noise (refrigerant noise) emitted by the un it will not disturb the neighbors.

(For use in quiet environments with low background noise, position the HBC CONTROLLER at least 5 m away from any indoor units.)

4.Please install the HBC controller in a place where noi se will not be an issue.

5.Please attach an expansion vessel (field supply).

6.Please use copper or plastic pipes for the water circuit. Do not use steel or stainless steel pipework.

Furthermore, when using copper pipework use a non-oxidative brazing method.

Oxidation of the pipework will reduce the pump life.

7.When brazing the pipes, be sure to braze, after covering a wet cloth to the insulation pipes of the units in order to prevent it from burning and shrinking by heat.

8.Please install an air purge valve where air will gather in the water circuit.

9.Please install a pressure reducing valve and a strainer on the water supply to the HBC controller.

10.Please refer to the databook or the installation manual for the specified water quality.

11.This unit is not designed for outside installations.

12.Please always make water circulate or pull out the circulation water completely wh en not using it.

*Please do not use it as a drinking water.

13.Please do not use ground water and well water.

14.When installing the HBC unit in an environment which may drop below 0 °C, please add antifreeze to the circulating water.

(Refer to the databook and the installation manual).

15.R32 is flammable, and certain restrictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the Databook on installation restrictions.

mm 300 x 1,800 x 630

in.

To P200

mm (in.)

O.D.

mm (in.)

O.D.

mm (in.)

I.D.

mm (in.)

I.D.

To M300

15.88 (5/8)

Brazed

19.05 (3/4)

Brazed

(Lower part drain pan: Pre-coated galvanized sheets + powder coating)

PURY-P200~500YNW-A(-BS)/PURY-EP200~500YNW-A(-BS)

PURY-P200~500YLM-A(1)(-BS)/PURY -EP200~500YLM-A1(-BS)/PQRY-P200~500YLM-A2/A1

PURY-M200~300YNW-A(-BS)/PURY-EM200~300YNW-A(-BS)

(Use optional joint pipe combing 2 branches when the total unit capacity exceeds P81)

To P250/300 To P350 To P400 for each To P450/500 for each

19.05 (3/4)

Brazed

22.2 (7/8)

Brazed

Galvanized steel plate

Model P80 or smaller

11-13/16 x 70-7/8 x 24-13/16

Connectable outdoor/heat sou rce unit capacity

19.05 (3/4)

Brazed

28.58 (1-1/8)

Brazed

20 (3/4)

20 (3/4)

–

15.88 (5/8)

19.05 (3/4)

Brazed

Brazed

Indoor units

19.05 (3/4)

Brazed

22.2 (7/8)

Brazed

HBC controller

MEES17K102

EIo-1

3

Page 5

1. SPECIFICATIONS

Model name CMB-WM108V-AB

Number of branch 8

Power source 1-phase 220-230-240 V

50 Hz 60 Hz

Power input Cooling kW 0.01/0.01/0.01 0.01/0.01/0.01

(220/230/240) Heating kW 0.01/0.01/0.01 0.01/0.01/0.01

Current input Cooling A 0.05/0.05/0.05 0.05/0.05/0.05

(220/230/240) Heating A 0.05/0.05/0.05 0.05/0.05/0.05

Sound pressure level (measured in anecho ice room) dB <A> –

Applicable temperature ra nge of installation site °C (D.B.) 0~32

External finish Galvanized steel plate

(Lower part drain pan: Pre-coated galvanized sheets + powder coating)

Connectable outdoor/heat source unit –

Indoor unit capacity connectable to 1 branch

External dimension H x W x D

To outdoor/heat source unit

Refrigerant piping

diameter

Water piping

diameter

Field drain pipe size mm (in.) O.D. 32 (1-1/4)

HBC controller

Net weight kg (lbs) 44 (98) [49 (109) with water]

Standard

attachment

Optional parts

Note 1.Works not included:

High press. Pipe

Low press. Pipe

To Indoor unit

Inlet Pipe

Outlet Pipe

Document

Accessory Drain Connection pipe (with flexible hose and insulation)

Installation/foundation work, electrical connection work, duct work, insulation work, power source switch, and other items are not specified in this specifications.

2.The equipment is for water.

3.Install this product in a location where noise (refrigerant noise) emitted by the unit will not disturb the neighbors.

(For use in quiet environments with low b ackground noise, position the Sub HBC CONTROLLER at least 5 m away from any indoor units.)

4.Please install the Sub HBC controller in a place where noise will not be an issue.

5.Please attach an expansion vessel (field supply).

6.Please use copper or plastic pipes for the water circuit. Do not use steel or stainless steel pipework.

Furthermore, when using copper pipewo rk use a non-oxidative brazing method.

Oxidation of the pipework will reduce the pump life.

7.When brazing the pipes, be sure to braze, after covering a wet cloth to the insulation pipes of the units in order to prevent it from burning and shrinking by heat.

8.Please install an air purge valve where air will gather in the water circuit.

9.Please refer to the databook or the installation manual for the specified water quality.

10.This unit is not designed for outside installations.

11.Please always make water circulate or pull out the circulation water completely when not using it.

*Please do not use it as a drinking water.

12.Please do not use ground water and well water.

13.When installing the Sub HBC unit in an environment which may drop below 0 °C, please add antifreeze to the circul ating water.

(Refer to the databook and the installation manual).

14.Can't use singleness. (MAIN HBC CONTROLLER is necessary)

mm 300 x 1,520 x 630

in.

mm (in.)

O.D.

mm (in.)

O.D.

mm (in.)

I.D.

mm (in.)

I.D.

(Use optional joint pipe combing 2 branches when the total unit capacity excee ds P81)

Connectable outdoor/heat source unit capacity

–––––

–––––

–––––

Model P80 or smaller

11-13/16 x 59-7/8 x 24-13/16

20 (3/4)

20 (3/4)

–

–

Indoor units

MEES17K102

EIo-1

4

Page 6

1. SPECIFICATIONS

Model name CMB-WM1016V-AB

Number of branch 16

Power source 1-phase 220-230-240 V

50 Hz 60 Hz

Power input Cooling kW 0.01/0.01/0.01 0.01/0.01 /0.01

(220/230/240) Heating kW 0.01/0.01/0.01 0.01/0.01/0.01

Current input Cooling A 0.05/0.05/0.05 0.05/0.05/0.05

(220/230/240) Heating A 0.05/0.05/0.05 0.05/0.05/0.05

Sound pressure level (measured in anechoice room) dB <A> –

Applicable temperature range of installation site °C (D.B.) 0~32

External finish

Connectable outdoor/heat source unit –

Indoor unit capacity connectable to 1 branch

External dimension H x W x D

To outdoor/heat source unit

Refrigerant piping

diameter

Water piping

diameter

Field drain pipe size mm (in.) O.D. 32 (1-1/4)

Net weight kg (lbs) 53 (117) [62 (137) with water]

Standard

attachment

Optional parts –

Note 1.Works not included:

High press. Pipe

Low press. Pipe

To Indoor unit

Inlet Pipe

Outlet Pipe

Document –

Accessory Drain Connection pipe (with flexible hose and insulation)

Installation/foundation work, electrical connection work, duct work, insulation work, power source switch, and other items are not specified in this specifications.

2.The equipment is for water.

3.Install this product in a location where noise (refrigerant noise) emitted by the un it will not disturb the neighbors.

(For use in quiet environments with low background noise, position the Sub HBC CONTROLLER at least 5 m away from any indoor units.)

4.Please install the Sub HBC controller in a place where noise will n ot be an issue.

5.Please attach an expansion vessel (field supply).

6.Please use copper or plastic pipes for the water circuit. Do not use steel or stainless steel pipework.

Furthermore, when using copper pipework use a non-oxidative brazing method.

Oxidation of the pipework will reduce the pump life.

7.When brazing the pipes, be sure to braze, after covering a wet cloth to the insulation pipes of the units in order to prevent it from burning and shrinking by heat.

8.Please install an air purge valve where air will gather in the water circuit.

9.Please refer to the databook or the installation manual for the specified water quality.

10.This unit is not designed for outside installations.

11.Please always make water circulate or pull out the circulation water completely wh en not using it.

*Please do not use it as a drinking water.

12.Please do not use ground water and well water.

13.When installing the Sub HBC unit in an environment which may drop below 0 °C, please add antifreeze to the circulating water.

(Refer to the databook and the installation manual).

14.Can't use singleness. (MAIN HBC CONTROLLER is necessary)

mm 300 x 1,520 x 630

in.

–––––

mm (in.)

O.D.

mm (in.)

O.D.

mm (in.)

I.D.

mm (in.)

I.D.

–––––

–––––

(Lower part drain pan: Pre-coated galvanized sheets + powder coating)

(Use optional joint pipe combing 2 branches when the total unit capacity exceeds P81)

Galvanized steel plate

Model P80 or smaller

11-13/16 x 59-7/8 x 24-13/16

Connectable outdoor/heat sou rce unit capacity

20 (3/4)

20 (3/4)

Indoor units

HBC controller

MEES17K102

EIo-1

5

Page 7

2. EXTERNAL DIMENSIONS

2. EXTERNAL DIMENSIONS

Indoor units

CMB-WM108V-AA

14

30

12

Y

Control box

1379

(Lifting bolt pitch)

HBC controller

Detail of Y section

543

540 90

Cutting point

(Lifting bolt pitch)

93

Z

93

31

43

51

93

200

3

Detail of Z section

224

216

157

44

272

286

1321

1391

Connection pipe from SUB HBC

[Field supply]

ø22.0(use attachment pipe)

Connection pipe to SUB HBC

[Field supply]

ø22.0(use attachment pipe)

ø22.0(use attachment pipe)

[Field supply]

Connection pipe from indoor unit

1520

70X7=490

412

ø19.05<Brazed>

Connection pipe of

outdoor/heat source unit

(High pressure)

ø22.2<Brazed>

Connection pipe of

outdoor/heat source unit

(Low pressure)

181

151

103

73

154

84

70

12345678

74

148

153

180

Unit : mm

[Field supply]

ø22.0(use attachment pipe)

Connection pipe to SUB HBC

[Field supply]

ø22.0(use attachment pipe)

Connection pipe from SUB HBC

Connection pipe to indoor unit

ø22.0(use attachment pipe)

[Field supply]

70X7=490

70

447

Water pipe(Inlet)

[Field supply]

ø22.0(use attachment pipe)

Water pipe(EXP.Tank)

[Field supply]

ø22.0(use attachment pipe)

300

Band(Accessory)

prepare in the field.

(Please give attention not to occupy service space by

letting ducts and pipes through.)

·Drain hose I.D.32(1-1/4")·····················1pc.

·Hose band········································1pc.

·Tie band···········································1pc.

·Wrench············································1pc.

<Accessories>

2. Take notice of service space as follows.

Note1. Suspension bolt(ø10),washer(M10),and nut(M10)

X

276

ø31

Detail of X section

Drain hose I.D.32(1-1/4") (Accessory)

160300

450

450

160

Access

door

Access

door

450

(700)

250

space

Service

Connection pipe from MAIN HBC

ø15.88<Brazed>

Drain piping VP-25 Connection

200

100120

Service space

Service space

Service space

MEES17K102

EIo-1

6

Page 8

2. EXTERNAL DIMENSIONS

Indoor units

CMB-WM1016V-AA

14

30

12

Detail of Y section

543

Y

Control box

1659

(Lifting bolt pitch)

Cutting point

(Lifting bolt pitch)

93

Z

93

Detail of Z section

1601

Connection pipe from SUB HBC

Connection pipe to SUB HBC

ø22.0(use attachment pipe)

[Field supply]

ø22.0(use attachment pipe)

[Field supply]

Connection pipe from indoor unit

1800

1671

181

151

103

73

[Field supply]

ø22.0(use attachment pipe)

Connection pipe from SUB HBC

154

70X15=1050412

70

1 2 3 4 5 6 7 8 9 10111213141516

84

Unit : mm

Connection pipe to SUB HBC

[Field supply]

ø22.0(use attachment pipe)

[Field supply]

ø22.0(use attachment pipe)

Connection pipe to indoor unit

ø22.0(use attachment pipe)

[Field supply]

70X15=1050

70

447

HBC controller

540 90

93

300

Band(Accessory)

prepare in the field.

(Please give attention not to occupy service space by

letting ducts and pipes through.)

2. Take notice of service space as follows.

·Drain hose I.D.32(1-1/4")·····················1pc.

·Hose band········································1pc.

·Tie band···········································1pc.

·Wrench············································1pc.

<Accessories>

Note1. Suspension bolt(ø10),washer(M10),and nut(M10)

286

272

224

216

157

31

43

44

51

200

3

276

X

ø31

Detail of X section

Drain hose I.D.32(1-1/4") (Accessory)

(High pressure)

ø22.2<Brazed>

Connection pipe of

outdoor/heat source unit

(Low pressure)

450

300300300

450450

Access

door

Access

door

74

148

153

Connection pipe of

outdoor/heat source unit

ø19.05<Brazed>

(700)

250

space

Service

180

[Field supply]

ø22.0(use attachment pipe)

Water pipe(EXP.Tank)

Connection pipe from MAIN HBC

ø15.88<Brazed>

Drain piping VP-25 Connection

200

100120

Service space

Service space

Water pipe(Inlet)

[Field supply]

ø22.0(use attachment pipe)

Service space

MEES17K102

EIo-1

7

Page 9

2. EXTERNAL DIMENSIONS

Indoor units

CMB-WM108V-AB

14

30

12

Y

1379

(Lifting bolt pitch)

HBC controller

Detail of Y section

Control box

Cutting point

(Lifting bolt pitch)

543

540 90

Detail of Z section

Z

149

93

44

200

52

3

219

1520

154

84

Connection pipe from indoor unit

ø22.0(use attachment pipe)

[Field supply]

70X7=490

70

12345678

290

73

103

141

171

Connection pipe to indoor unit

ø22.0(use attachment pipe)

[Field supply]

70X7=490

70

325

Unit : mm

300

Band(Accessory)

prepare in the field.

(Please give attention not to occupy service space by

letting ducts and pipes through.)

·Drain hose I.D.32(1-1/4")·····················1pc.

·Hose band········································1pc.

<Accessories>

2. Take notice of service space as follows.

·Tie band···········································1pc.

Note1. Suspension bolt(ø10),washer(M10),and nut(M10)

X

276

ø31

Detail of X section

Drain hose I.D.32(1-1/4") (Accessory)

Connection pipe to MAIN HBC

160300160 450450

[Field supply]

ø22.0(use attachment pipe)

[Field supply]

ø22.0(use attachment pipe)

Connection pipe from MAIN HBC

(700)

450

250

Access

door

Access

door

space

Service

[Field supply]

ø22.0(use attachment pipe)

Connection pipe to MAIN HBC

[Field supply]

ø22.0(use attachment pipe)

Connection pipe from MAIN HBC

Drain piping VP-25 Connection

200

100120

Service space

Service space

Service space

MEES17K102

EIo-1

8

Page 10

2. EXTERNAL DIMENSIONS

Indoor units

CMB-WM1016V-AB

14

30

12

Detail of Y section

Y

1379

Control box

(Lifting bolt pitch)

Cutting point

(Lifting bolt pitch)

543

540 90

Detail of Z section

Z

149

93

44

200

52

3

219

1520

154

Connection pipe from indoor unit

ø22.0(use attachment pipe)

[Field supply]

84

70X15=1050

70

1 2 3 4 5 6 7 8 9 10111213141516

290

73

103

141

171

Connection pipe to indoor unit

ø22.0(use attachment pipe)

[Field supply]

70X15=1050

70

325

Unit : mm

HBC controller

300

Band(Accessory)

prepare in the field.

(Please give attention not to occupy service space by

letting ducts and pipes through.)

2. Take notice of service space as follows.

·Drain hose I.D.32(1-1/4")·····················1pc.

·Hose band········································1pc.

·Tie band···········································1pc.

Note1. Suspension bolt(ø10),washer(M10),and nut(M10)

<Accessories>

Drain hose I.D.32(1-1/4") (Accessory)

X

ø31

Detail of X section

276

[Field supply]

ø22.0(use attachment pipe)

Connection pipe to MAIN HBC

[Field supply]

ø22.0(use attachment pipe)

Connection pipe from MAIN HBC

(700)

250

450

160300160 450450

Access

door

Access

door

space

Service

[Field supply]

ø22.0(use attachment pipe)

Connection pipe to MAIN HBC

[Field supply]

ø22.0(use attachment pipe)

Connection pipe from MAIN HBC

Drain piping VP-25 Connection

200

100120

Service space

Service space

Service space

MEES17K102

EIo-1

9

Page 11

3. CENTER OF GRAVITY

CMB-WM108, 1016V-AA

CMB-WM108, 1016V-AB

xz

y

543 A

Center of gravity

Indoor unit branching point

A (mm)

x (mm)

y (mm)

z (mm)

CMB-WM108V-AA

1379

680

145

285

CMB-WM1016V-AA

1659

825

145

285

CMB-WM108 V-AB

1379

610

145

270

CMB-WM1016V-AB

1379

680

145

270

3. CENTER OF GRAVITY

Indoor units

HBC controller

MEES17K102

EIo-1

10

Page 12

4. ELECTRICAL WIRING DIAGRAMS

4. ELECTRICAL WIRING DIAGRAMS

CMB-WM108V-AA

Name

Fuse AC250V 6.3A F

Solenoid valve

F001

SV1

Symbol

Name

AC reactor

Thermister sensor

TH11~16,TH32~35,

ACL

Symbol

(Symbol explanation)

TH32

t°

Function setting connector

4 way valve

Pump

Valve blockFSFloat switch

21S4Ma,21S4Mb

WP1,WP2

VB3a~h

Z

Terminal block

(for power source)

Terminal block

Expansion valve

LEV1~3

TH31a~h

TH33

(for Transmission)

Pressure sensor

PS1,PS3

TB01

TB02

TH31g

TH16

TH15

t°

t°t°t°

1

1

2

2

3

4

5

CN509(Blue)

CN511(Red)

SW1:0

SW2:0

Never connect power line to it.

Control Board are as follows.

2. The initial set values of switch on

NOTE:1. TB02 is transmission terminal block.

TH31f

TH31e

TH31h

t°

3

4

CN508(Red)

1

t°

2

t°

3

4

TH35

t°

1

2

3

CN506(Blue)

1

2

3

4

4

5

667

CN505

dotted line are field work.

3. The wirings to TB01 and TB02 shown in

TH31a

TH34

t°

t°

1

2

5

7

CN503(Blue)

Indoor units

TH12

TH11

CN501

TH31c

TH31d

TH13

TH14

t°t°t°

t°t°t°

1

2

3

4

5

6

HBC controller

TH31b

t°

3

4

5

6

Transmission Line

Indoor/outdoor

TB02

M1

M2

S(SHIELD)

1

1

2

2

3

3

4

4

5

5

6

1

C004 C006

SV1

3

X006

CN504(Yellow)

M

LEV2

1

(Red)

CN003

ZNR001

ZNR002

6

CN502(Red)

111

333222

444

555

666

(Yellow) (Green)

(Blue)

CNLEV1 CNLEV2 CNLEV3

M

LEV1

21S4Mb 21S4Ma

653

7

6

5

X002

X003

4

3

(Blue)

CN001

2

1

2

1

CN002

(Green)

CNAC

F001

250VAC

6.3A F

(Red)

UU

DSA001

CN005

1

355371

ACL

PULL BOX

TO NEXT INDOOR UNIT

L

N

TB01

X

~220V-240V

POWER SUPPLY

50Hz/60Hz

BREAKER(16A)

FUSE(16A)

43213215432132154321321543213215

LD1:CPU in

operation

CN216 CN215

LD1:CPU in

operation

CN214 CN213

LD1:CPU in

operation

LD1:CPU in

operation

CN210 CN209 CN212 CN211

432132154321321

CN207CN208

LD1:CPU in

operation

5

CN205

LD1:CPU in

operation

CN206

5

4321321

(Red)(Red) (Yellow)(Yellow) (Red) (Red) (Yellow) (Yellow) (Red) (Red)

CN203

LD1:CPU in

operation

CN204

CN201

32132145

CN202

LD1:CPU in

operation

Detail of X section

MMMMMMMM

VB3a VB3b VB3c VB3d VB3e VB3f VB3g VB3h

11 22 33

PS1PS3

FS

Z

ON

ON

CN103

CN101

(Blue)

(Red)

CN512CN513

LED1

10 12345678910

123456789

CN101

CN401

1 1

2 2

3 3

CN201

32 1

11 24 45 56 6

SW3

SW4

(Red)

CN003

(Red)

(Red)

1

10

ON

CN001

CN002

3

1

Power Board

CN510

1

2

34

SWP2SWP1 SWP3

SW5

12345678

(Green)

(Blue)

1

CN518

SW1SW2

1

2

1

2

3

4

5

6

7

CN204

2

CN203

(Red)

3

4

5

123

(Blue)

CN514

Control Board

M

LEV3

WP1

WP2

11

22

33

55

77

99

CN006

(Yellow)

L001

C003 C005

C002 C007

MEES17K102

EIo-1

11

Page 13

4. ELECTRICAL WIRING DIAGRAMS

CMB-WM1016V-AA

Name

Fuse AC250V 6.3A F

Solenoid valve

4 way valve

Pump

Valve block

Function setting connector

Float switch

F001

SV1

21S4Ma,21S4Mb

WP1,WP2

VB3a~p

Z

Symbol

Name

AC reactor

FS

Pressure sensor

Thermister sensor

Expansion valve

Terminal block

(for power source)

Terminal block

(for Transmission)

SW1:0

SW2:0

Control Board are as follows.

Never connect power line to it.

2.The initial set values of switch on

dotted line are field work.

3.The wirings to TB01 and TB02 shown in

Indoor units

ACL

LEV1~3

TH11~16,TH32~35,

TH31a~p

Symbol

(Symbol explanation)

PS1PS3

FS

HBC controller

Indoor/outdoor

Transmission Line

TB02

M1

M2

S(SHIELD)

PS1,PS3

TB01

TB02

TH31h

TH31g

TH16

TH33

TH15

TH32

t°t°t°

t°

1

1

2

2

3

3

4

4

5

CN508(Red)

CN509(Blue)

CN511(Red)

1

2

3

CN512

CN510

1

2

3

4

5

1

2

3

CN518

4

110

SW1SW2

LED1

1

SW3

123456789

10 10

SW4

123456789

O

CN101

(Red)

(Red) (Red)

CN201 CN003

3

SWP2SWP1 SWP3

SW5

12345678

1

2

CN001

(Green)

1

2

3

4

5

(Blue)

CN002

6

7

1

CN203

(Red)

CN204

Power Board

2

3

11

22

Z

ON

ON

1

2

3

CN513

CN401

1 1

2 2

3 3

(Blue)

CN103

CN101

(Red)

32 1

11 24 45 56 6

NOTE:1.TB02 is transmission terminal block.

TH31b

TH31f

TH31e

TH35

TH31k

TH31l

t°

t°t°t°

t°t°t°

CN505

1

1

2

2

3

3

4

4

5

667

CN506(Blue)

(Blue)

CN514

Control Board

WP1

WP2

33

55

77

99

L001

TH31a

TH34

TH31i

TH31j

t°

t°

t°t°t°

1

1

2

2

3

3

4

4

5

5

7

6

CN503(Blue)

1

2

3

4

5

6

CN504(Yellow)

1

2

3

4

CN507

CN516

11

22

33

(Red)

CN515

M

M

LEV2

LEV3

SV1

21S4Mb 21S4Ma

1

3

1

CN006

(Red)

(Yellow)

CN003

X002

X006

X003

ZNR001

UU

ZNR002

C004 C006

C003 C005

C002 C007

TH12

TH11

TH31c

TH31d

TH13

TH14

t°t°t°

t°t°t°t°t°

CN501

1

2

3

4

5

6

1

2

3

4

5

6

CN502(Red)

111

3

444

555

666

33222

(Yellow) (Green)

(Blue)

CNLEV1 CNLEV2 CNLEV3

M

LEV1

653

7

6

5

4

3

(Blue)

CN001

2

1

2

1

CN002

(Green)

CNAC

F001

250VAC

6.3A F

(Red)

DSA001

CN005

1

355371

ACL

TH31m

TH31n

t°

TO NEXT INDOOR UNIT

TH31p

TH31o

t°

LD1:CPU in

operation

LD1:CPU in

operation

443322113322115544332211332211554321321

CN216 CN218CN215 CN217

LD1:CPU in

operation

CN214 CN220CN213 CN219

LD1:CPU in

operation

LD1:CPU in

operation

LD1:CPU in

operation

LD1:CPU in

operation

LD1:CPU in

operation

LD1:CPU in

operation

LD1:CPU in

operation

CN210 CN209 CN212 CN211

CN205

CN206

CN203

CN204

CN207CN208

CN201

CN202

54

5

321321

54321321

4321321

Detail of X section

5

5

4321321

(Red)(Red) (Yellow)(Yellow) (Red) (Red) (Yellow) (Yellow) (Red) (Yellow)(Red) (Yellow)

32145

321

87654321

LD1:CPU in

operation

87654321

X

~220V-240V

POWER SUPPLY

50Hz/60Hz

FUSE(16A) BREAKER(16A)

PULL BOX

TB01

L

N

LD1:CPU in

operation

LD1:CPU in

operation

LD1:CPU in

operation

LD1:CPU in

operation

LD1:CPU in

operation

CN805(Red)

87654321

CN804

87654321

CN803(Yellow) CN806(Yellow)

87654321

CN802(Red)

8765432

CN801

1

MEES17K102

MM MMMMMMMMMMM MMM

VB3k VB3a VB3bVB3l VB3cVB3m VB3dVB3n VB3eVB3o VB3fVB3p VB3g VB3jVB3h VB3i

EIo-1

12

Page 14

4. ELECTRICAL WIRING DIAGRAMS

CMB-WM108V-AB

Name

Valve block

Float switch

Thermister sensor

TH31a~h,TH32,TH33

Symbol

VB3a~h

FS

(Symbol explanation)

Fuse AC250V 6.3A F

Terminal block

TB01

Function setting connector

(for power source)

Terminal block

(for Transmission)

TB02

F001

Z

SW1:0

SW2:0

Never connect power line to it.

2. The initial set values of switch on

dotted line are field work.

Control Board are as follows.

3. The wirings to TB01 and TB02 shown in

NOTE:1. TB02 is transmission terminal block.

Indoor units

Indoor/outdoor

Transmission Line

TB02

M1

M2

S(SHIELD)

TH31b

TH31f

TH31e

TH31h

ON ON

CN103

CN101

(Blue)

(Red)

CN401

32 1

11 2

LED1

SW3

SW4

12345678910 12345678910

CN101

(Red)

TH31g

1

CN509(Blue)

CN510

1234

110

SWP2SWP1 SWP3

SW5

ON

12345678

CN001

(Green)

3

1

Power Board

2

1

CN518

SW1SW2

1

2

3

4

2

3

123

t°t°t°t°t°

1

2

3

CN508(Red)

4

5

(Blue)

CN514

4

Control Board

L001

TH33

TH32

t°

t°

FS

Z

TH31a

t°

t°

1

2

3

4

5

CN503(Blue)

1

2

3

4

5

66

CN504(Yellow)

ZNR001

UU

ZNR002

C004 C006

C003 C005

C002 C007

TH31c

TH31d

t°

2

1

CN002

(Green)

(Red)

CNAC

F001

250VAC

6.3A F

DSA001

CN005

1

355371

POWER SUPPLY

PULL BOX

TO NEXT INDOOR UNIT

L

N

TB01

X

~220V-240V

50Hz/60Hz

FUSE(16A) BREAKER(16A)

43213215432132154321321543213215

LD1:CPU in

operation

CN216 CN215

LD1:CPU in

operation

CN214 CN213

LD1:CPU in

operation

LD1:CPU in

operation

CN210 CN209 CN212 CN211

432132154321321

CN207CN208

LD1:CPU in

operation

5

CN205

LD1:CPU in

operation

CN206

5

4321321

(Red)(Red) (Yellow)(Yellow) (Red) (Red) (Yellow) (Yellow) (Red) (Red)

CN203

LD1:CPU in

operation

CN204

CN201

32132145

CN202

LD1:CPU in

operation

HBC controller

Detail of X section

MMMMMMMM

VB3a VB3b VB3c VB3d VB3e VB3f VB3g VB3h

MEES17K102

EIo-1

13

Page 15

4. ELECTRICAL WIRING DIAGRAMS

CMB-WM1016V-AB

Name

Valve block

Function setting connector

Float switch

Thermister sensor

Terminal block

(for power source)

Terminal block

(for Transmission)

Fuse AC250V 6.3A F

SW1:0

SW2:0

Never connect powerline to it.

ControlBoardare asfollows.

dotted line are field work.

3.The wirings to TB01 and TB02 shown in

TH31b

TH31a

TH31j

°

°

t°t

Z

FS

TH31a~p,TH32,TH33

Symbol

(Symbol explanation)

TH32

°

TH33

t°t

TB01

VB3a~p

TH31g

°

TB02

TH31h

F001

TH31e

t°t°t

2.The initial set valuesof switch on

NOTE:1.TB02 is transmissionterminal block.

TH31k

TH31l

TH31f

°

t

TH31i

°

t°t

t°t

TH31c

°

t

TH31d

°

t

TH31m

°

t

TH31n

t°t°t

TH31p

Indoor units

TH31o

°

2

2

3

4

1

CN509(Blue)

CN510

3

4

2

1

FS

1

2

3

4

CN518

110

SW1SW2

LED1

Z

HBC controller

Indoor/outdoor

Transmission Line

TB02

M1

M2

S(SHIELD)

SW3

SWP2SWP1 SWP3

123456789 10

ON

SW4

SW5

123456789 1010

12345678

ON

ON

1

2

CN001

(Green)

CN101

1

3

(Red)

CN401

3

4

1

CN508(Red)

5

1

2

3

(Blue)

CN514

3

4

5

667

2

1

CN506(Blue)

Control Board

1

CN505

Power Board

(Blue)

CN103

L001

CN101

(Red)

32 1

11 2

2

3

3

4

4

5

5

7

6

1

2

CN503(Blue)

LD1:CPU in

operation

3

4

5

6

2

1

CN504(Yellow)

CN507

1

2

3

4

LD1:CPU in

operation

44332211332211554 43 32 21 13 32 21 15 54321321

CN216 CN218CN215 CN217

LD1:CPU in

operation

CN516

11

22

33

(Red)

CN515

X

~220V-240V

POWER SUPPLY

50Hz/60Hz

FUSE(16A) BREAKER(16A)

PULL BOX

2

1

CN002

(Green)

(Red)

CNAC

F001

250VAC

6.3A F

ZNR001

UU

ZNR002

C004 C006

C003 C005

C002 C007

DSA001

CN005

1

355371

TO NEXT INDOOR UNIT

TB01

L

N

87654321

LD1:CPU in

operation

87654321

CN805(Red)

LD1:CPU in

operation

87654321

CN804

LD1:CPU in

operation

87654321

CN803(Yellow) CN806(Yellow)

LD1:CPU in

operation

87654321

CN802(Red)

LD1:CPU in

operation

8765432

CN801

1

LD1:CPU in

operation

CN214 CN220CN213 CN219

LD1:CPU in

operation

54321321

LD1:CPU in

operation

5

CN210 CN209 CN212 CN211

LD1:CPU in

operation

54321321

4321321

CN207CN208

LD1:CPU in

operation

5

CN205

LD1:CPU in

operation

CN206

5

4321321

(Red)(Red) (Yellow)(Yellow) (Red) (Red) (Yellow) (Yellow) (Red) (Yellow)(Red) (Yellow)

CN203

CN204

LD1:CPU in

operation

32145

CN201

321

CN202

LD1:CPU in

operation

Detail of X section

MEES17K102

MM MMMMMMMMMMM MMM

VB3k VB3a VB3bVB3l VB3cVB3m VB3dVB3n VB3eVB3o VB3fVB3p VB3g VB3jVB3h VB3i

EIo-1

14

Page 16

5. SOUND LEVELS

5. SOUND LEVELS

5-1. Sound levels

(Measured point)

CMB-WM108V-AA

CMB-WM1016V-AA

1.5m

Measurement location

Measured in anechoic room.

*

5-2. NC curves

CMB-WM108V-AA,CMB-WM1016V-AA

Power Source: 230V, 50Hz

70.0

65.0

60.0

55.0

50.0

45.0

40.0

35.0

30.0

25.0

20.0

Approximate minimum

audible limit on

15.0

continuous noise

Octave band pressure level (dB) 0dB=20μPa

10.0

63 125 250 500 1k 2k 4k 8k

Octave band center frequencies (Hz)

Indoor units

HBC controller

NC-60

NC-50

NC-40

NC-30

NC-20

MEES17K102

EIo-1

15

Page 17

6. ELECTRICAL CHARACTERISTICS

6. ELECTRICAL CHARACTERISTICS

Symbols: MCA: Max. Circuit Amps, MFA: Max. Fuse Amps, RLA: Rated Load Amps

HBC controller

CMB-WM108V-AA

CMB-WM1016V-AA

CMB-WM108V-AB

CMB-WM1016V-AB

Hz Volts Range+-10% MCA(A) MFA(A)

220

50/60

230 2.83

240 2.79

220

50/60

230 0.05

240 0.05

Power supply

Max.: 264V

Min.: 198V

Max.: 264V

Min.: 198V

Indoor units

RLA(A)

2.89

3.49 15

0.05

0.06 15

HBC controller

MEES17K102

EIo-1

16

Page 18

Warning

■

Do not use refrigerant other than the type indicated in the manuals provided with the unit and on the nameplate.

- Doing so may cause the unit or pipes to burst, or result in explosion or fire during use, repair, or at the time of disposal of the unit.

- It may also be in violation of applicable laws.

- MITSUBISHI ELECTRIC CORPORATION cannot be held responsible for malfunctions or accidents resulting from the use of the wrong

type of refrigerant.

■

Our air conditioning equipment and heat pumps contain a fluorinated greenhouse gas, R410A/R32.

MEES17K102

New publication effective Mar. 2018

Specifications subject to change without notice

Loading...

Loading...