Page 1

MELDAS Series

MITSUBISHI ELECTRIC AUTOMATION

M700 Alarm Parameter Manual

USA-E99090 -006*

USA

Page 2

List of Revisions

Rev Date of Revision Detail Author

* 10/27/04 First Edition Created TSS

Page 3

MELDAS Series

M700 Alarm Parameter Manual (IB1500038-E)

MITSUBISHI ELECTRIC AUTOMATION

USA-E99080 -061*

USA

Page 4

List of Revisions

Rev Date of Revision Detail Author

* 10/01/04 First Edition Created TSS

Page 5

MELDAS Series

MITSUBISHI ELECTRIC AUTOMATION

M700 Series Alarm Parameter Manual

USA-E01091 -004*

USA

Page 6

List of Revisions

Rev Date of Revision Detail Author

* 06/16/04 First Edition Created TSS

Page 7

MITSUBISHI CNC

700 Series

ALARM/PARAMETER MANUAL

IB(NA)1500038(ENG)*

Page 8

MITSUBISHI CNC is a registered trademark of Mitsubishi Electric Corporation.

Other company and product names that appear in this manual are trademarks or

registered trademarks of the respective company.

Page 9

PREFACE

This manual is the alarm/parameter guide required to use the MITSUBISHI 700 Series.

This manual is prepared on the assumption that your machine is provided with all of the 700 Series

functions. Confirm the functions available for your NC before proceeding to operation by referring to the

specification issued by the machine manufacturer.

Notes on Reading This Manual

(1) This manual explains general parameters as viewed from the NC.

For information about each machine tool, refer to manuals issued from the machine manufacturer.

If the descriptions relating to “restrictions” and “allowable conditions” conflict between this manual

and the machine manufacturer's instruction manual, the later has priority over the former.

(2) This manual is intended to contain as much descriptions as possible even about special operations.

The operations to which no reference is made in this manual should be considered impossible.

(3) The “special display unit” explained in this manual is the display unit incorporated by the machine

manufacturer, and is not the MITSUBISHI standard display unit.

Caution

If the descriptions relating to the “restrictions” and “allowable conditions” conflict between this

manual and the machine manufacturer’s instruction manual‚ the latter has priority over the

former.

The operations to which no reference is made in this manual should be considered

impossible.

This manual is complied on the assumption that your machine is provided with all optional

functions. Confirm the functions available for your machine before proceeding to operation by

referring to the specification issued by the machine manufacturer.

In some NC system versions‚ there may be cases that different pictures appear on the screen‚

the machine operates in a different way or some function is not activated.

Page 10

Precautions for Safety

Always read the specifications issued by the machine maker, this manual, related manuals and attached

documents before installation, operation, programming, maintenance or inspection to ensure correct use.

Understand this numerical controller, safety items and cautions before using the unit.

This manual ranks the safety precautions into "DANGER", "WARNING" and "CAUTION".

DANGER

WARNING

CAUTION

Note that even items ranked as "

important information that must always be observed is described.

When the user may be subject to imminent fatalities or major injuries if handling is

mistaken.

When the user may be subject to fatalities or major injuries if handling is mistaken.

When the user may be subject to injuries or when physical damage may occur if

handling is mistaken.

CAUTION", may lead to major results depending on the situation. In any case,

DANGER

Not applicable in this manual.

Not applicable in this manual.

1. Items related to product and manual

If the descriptions relating to the “restrictions” and “allowable conditions” conflict between this

manual and the machine manufacturer’s instruction manual‚ the latter has priority over the former.

The operations to which no reference is made in this manual should be considered impossible.

This manual is complied on the assumption that your machine is provided with all optional

functions. Confirm the functions available for your machine before proceeding to operation by

referring to the specification issued by the machine manufacturer.

In some NC system versions‚ there may be cases that different pictures appear on the screen‚

the machine operates in a different way on some function is not activated.

2. Items related to faults and abnormalities

If the BATTERY LOW alarm is output, save the machining programs, tool data and parameters

to an input/output device, and then replace the battery. If the BATTERY alarm occurs, the

machining programs, tool data and parameters may be damaged. After replacing the battery,

reload each data item.

WARNING

CAUTION

[Continued on next page]

Page 11

CAUTION

3. Items related to maintenance

Do not replace the battery while the power is ON.

Do not short-circuit, charge, heat, incinerate or disassemble the battery.

Dispose of the spent battery according to local laws.

4. Items related to servo parameters and spindle parameters

With the MDS-C1 Series, only the serial encoder is compatible as the motor end detector. The

OHE/OHA type detector cannot be used as the motor end detector.

Do not adjust or change the parameter settings greatly as operation could become unstable.

In the explanation on bits, set all bits not used, including blank bits, to “0”.

[Continued]

Page 12

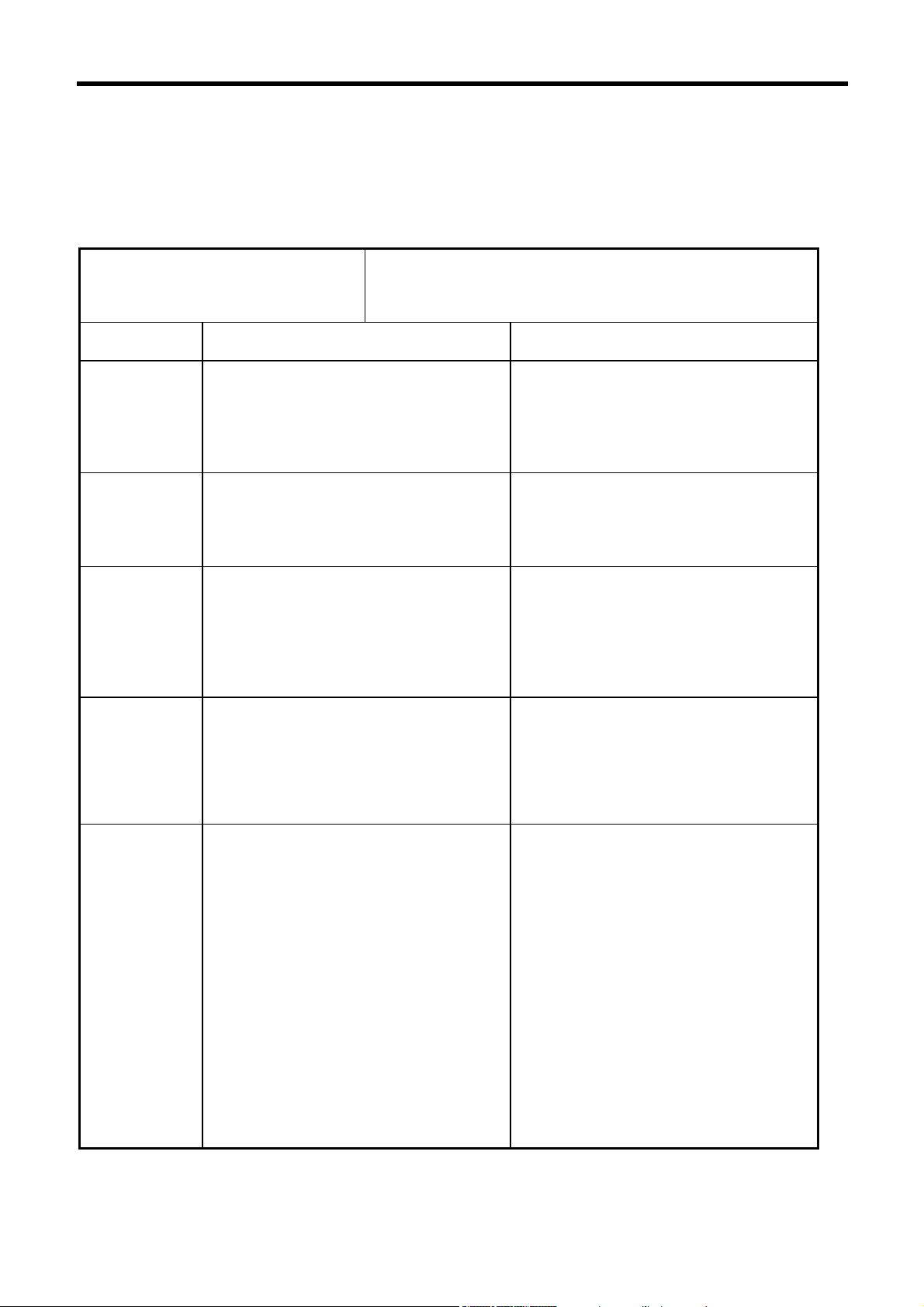

CONTENS

I EXPLANATION OF ALARMS

1. LIST OF ALARMS................................................................................................................................ 1

1.1 OPERATION ALARMS............................................................................................................... 1

1.2 STOP CODES............................................................................................................................ 9

1.3 SERVO ALARMS ..................................................................................................................... 14

1.4 SPINDLE ALARMS .................................................................................................................. 24

1.5 MCP ALARM ........................................................................................................................... 29

1.6 SYSTEM ALARMS .................................................................................................................. 32

1.7 ABSOLUTE POSITION DETECTION SYSTEM ALARMS ...................................................... 36

1.8 MESSAGES DURING EMERGENCY STOP .......................................................................... 39

1.9 AUXILIARY AXIS ALARMS...................................................................................................... 41

1.10 COMPUTER LINK ERRORS.................................................................................................... 48

1.11 USER PLC ALARMS................................................................................................................ 49

2. OPERATION MESSAGES ON SETTING AND DISPLAY UNIT....................................................... 50

2.1 OPERATION ERRORS............................................................................................................50

2.2 OPERATOR MESSAGES ........................................................................................................ 60

2.2.1 SEARCH AND OPERATION RELATED .................................................................... 60

2.2.2 MDI/EDITING RELATED ............................................................................................ 61

2.2.3 DATA INPUT/OUTPUT RELATED ............................................................................. 62

2.2.4 S-ANALOG OUTPUT ADJUSTMENT RELATED ...................................................... 63

2.2.5 AUXILIARY AXIS......................................................................................................... 63

2.2.6 PARAMETER BACKUP RELATED............................................................................. 63

2.2.7 OTHERS...................................................................................................................... 64

3. PROGRAM ERROR........................................................................................................................... 65

- i -

Page 13

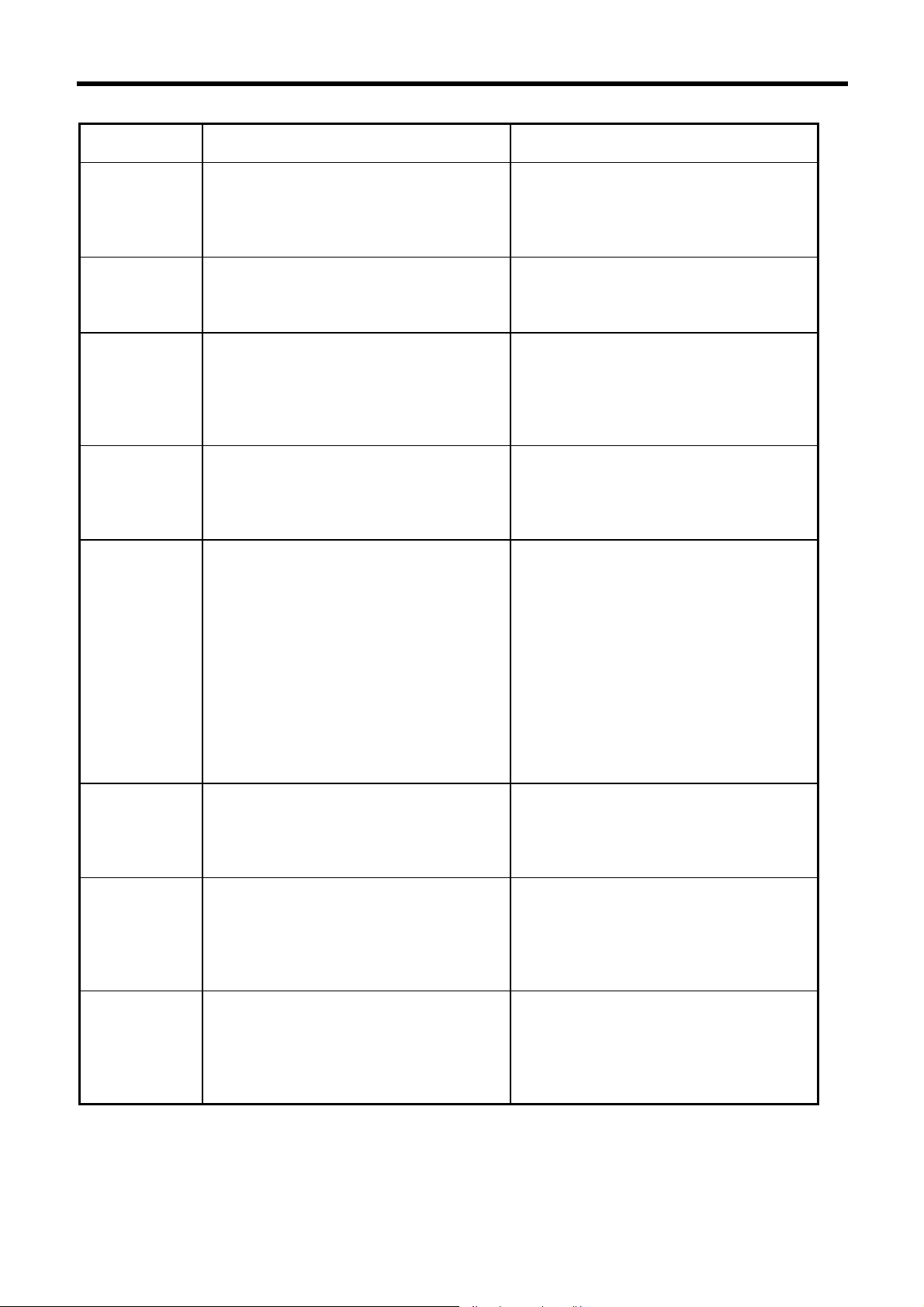

II EXPLANATION OF PARAMETERS

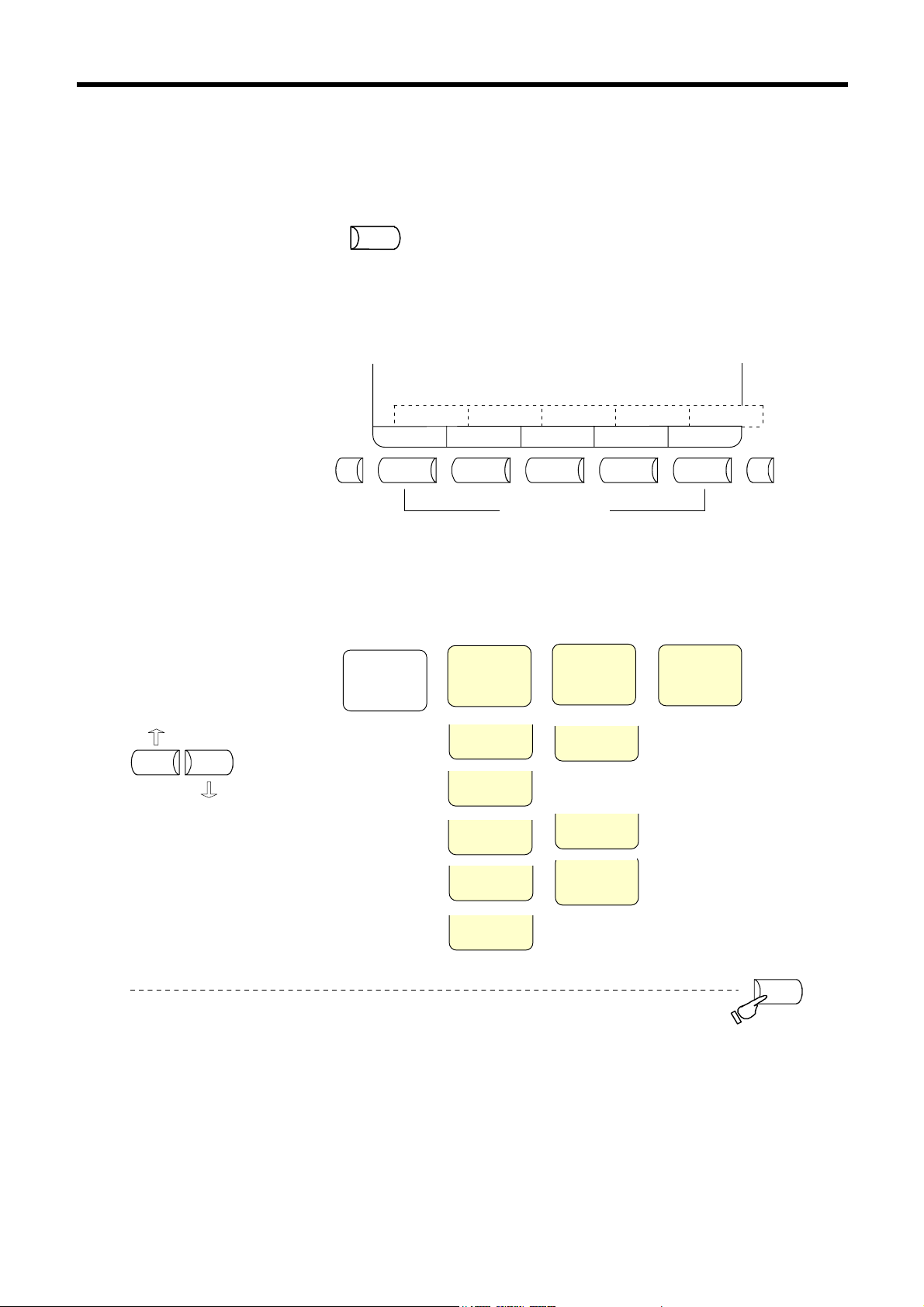

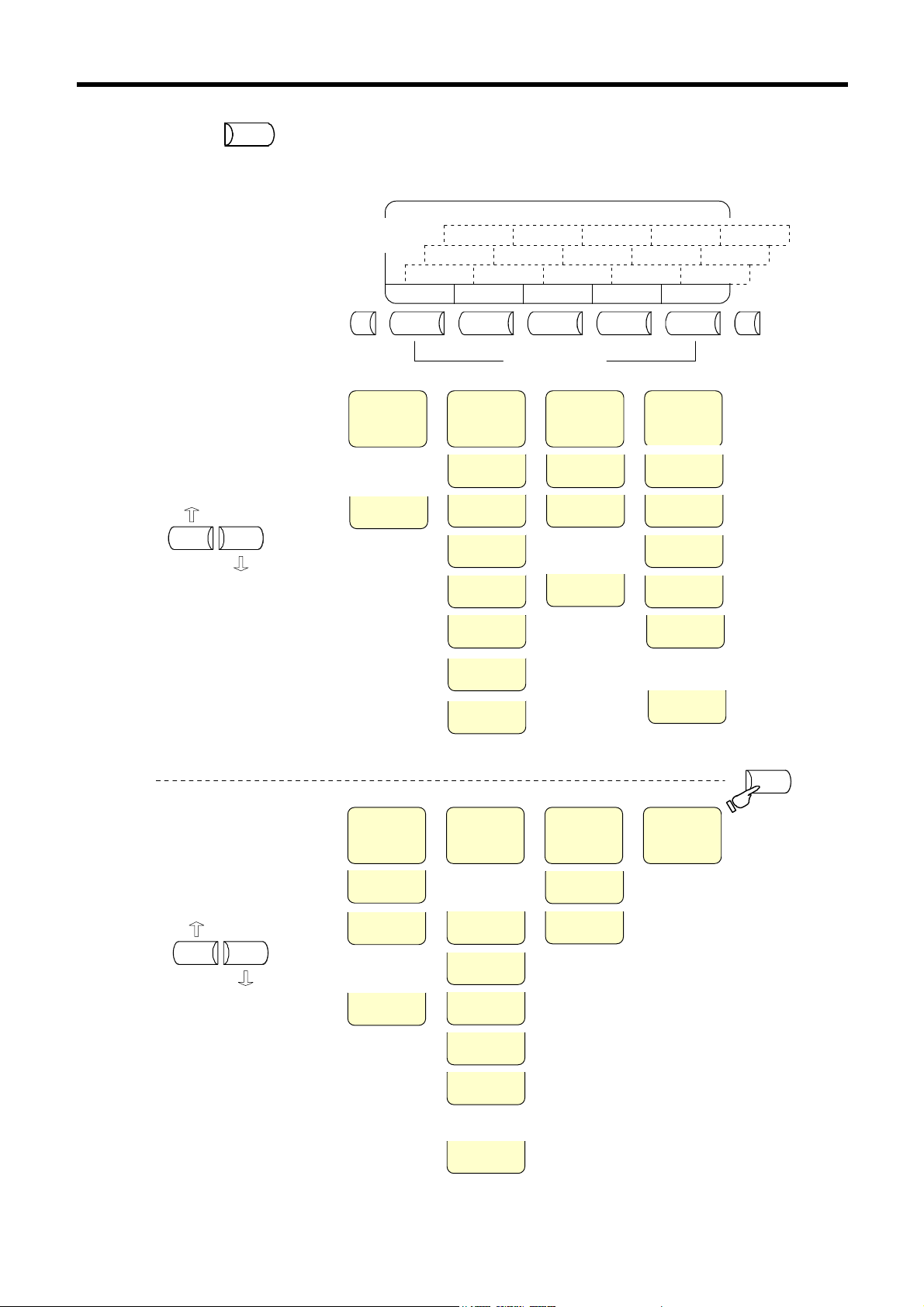

1. SCREEN CONFIGURATION ............................................................................................................... 1

1.1 SCREEN TRANSITION CHARTS.............................................................................................. 1

2. MACHINING PARAMETERS............................................................................................................... 3

2.1 PROCESS PARAMETERS ........................................................................................................ 3

2.2 CONTROL PARAMETERS ...................................................................................................... 10

2.3 AXIS PARAMETERS................................................................................................................ 12

2.4 BARRIER DATA....................................................................................................................... 14

2.5 TOOL MEASUREMENT PARAMETERS................................................................................. 16

3. I/O PARAMETERS............................................................................................................................. 17

3.1 BASE PARAMETERS .............................................................................................................. 17

3.2 I/O DEVICE PARAMETERS..................................................................................................... 18

3.3 COMPUTER LINK PARAMETERS.......................................................................................... 20

4. SETUP PARAMETERS...................................................................................................................... 22

5. BASE SPECIFICATIONS PARAMETERS ........................................................................................ 23

6. AXIS SPECIFICATIONS PARAMETERS.......................................................................................... 92

6.1 AXIS SPECIFICATIONS PARAMETERS................................................................................. 92

6.2 ZERO POINT RETURN PARAMETERS.................................................................................. 99

6.3 ABSOLUTE POSITION PARAMETERS ................................................................................ 102

6.4 AXIS SPECIFICATIONS PARAMETERS 2............................................................................ 104

7. SERVO PARAMETERS................................................................................................................... 112

7.1 MDS-B-SVJ2 .......................................................................................................................... 114

7.2 MDS-C1-Vx HIGH-GAIN (MDS-B-Vx4 COMPATIBLE).......................................................... 140

7.3 MDS-C1-Vx STANDARD SPECIFICATION (MDS-B-Vx COMPATIBLE).............................. 168

- ii -

Page 14

7.4 SUPPLEMENT ....................................................................................................................... 198

7.4.1 D/A OUTPUT SPECIFICATIONS.............................................................................. 198

7.4.2 ELECTRONIC GEARS..............................................................................................204

7.4.3 LOST MOTION COMPENSATION............................................................................ 206

8. MDS-B-SP/SPH,SPJ2 SPINDLE PARAMETERS........................................................................... 207

8.1 MDS-B-SP/SPH,SPJ2 SPINDLE BASE SPECIFICATIONS PARAMETERS........................ 207

8.2 MDS-B-SP/SPH,SPJ2 SPINDLE PARAMETERS.................................................................. 215

8.3 MDS-B-SP/SPH,SPJ2 SUPPLEMENTARY EXPLANATION

(FOR D/A OUTPUT FUNCTIONS)......................................................................................... 252

9. MDS-C1-SP, SPM SPINDLE PARAMETERS ................................................................................. 255

9.1 MDS-C1-SP SPINDLE BASE SPECIFICATIONS PARAMETERS........................................ 255

9.2 MDS-C1-SP SPINDLE PARAMETERS.................................................................................. 262

9.3 MDS-C1-SPM SPINDLE PARAMETERS............................................................................... 292

9.4 MDS-C1-SP SUPPLEMENTARY EXPLANATION................................................................. 321

9.5 MDS-C1-SPM SUPPLEMENTARY EXPLANATION.............................................................. 325

10. MACHINE ERROR COMPENSATION............................................................................................. 329

10.1 FUNCTION OUTLINE............................................................................................................. 329

10.2 SETTING COMPENSATION DATA....................................................................................... 333

10.3 EXAMPLE IN USING A LINEAR AXIS AS THE BASE AXIS.................................................335

10.4 EXAMPLE IN USING A ROTATION AXIS AS THE BASE AXIS ........................................... 339

11. PLC CONSTANTS ........................................................................................................................... 340

11.1 PLC TIMER............................................................................................................................. 340

11.2 PLC COUNTER...................................................................................................................... 340

11.3 PLC CONSTANTS.................................................................................................................. 341

11.4 SELECTING THE PLC BIT..................................................................................................... 341

12. MACRO LIST.................................................................................................................................... 344

- iii -

Page 15

13. POSITION SWITCH.......................................................................................................................... 346

13.1 OUTLINE OF FUNCTION ...................................................................................................... 346

13.2 CANCELING THE POSITION SWITCH................................................................................. 348

14. AUXILIARY AXIS PARAMETER SCREEN..................................................................................... 349

- iv -

Page 16

I EXPLANATION OF ALARMS

Page 17

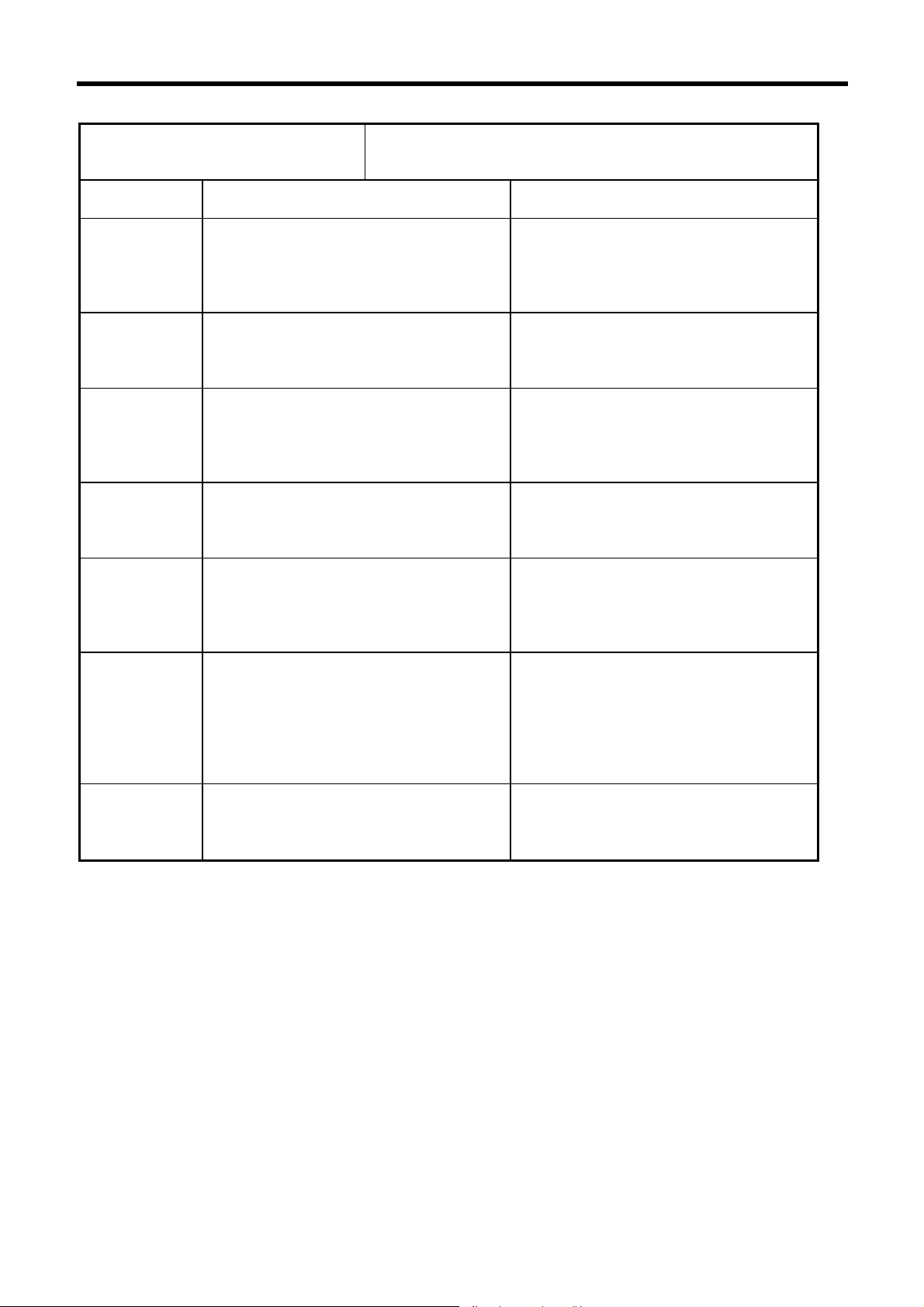

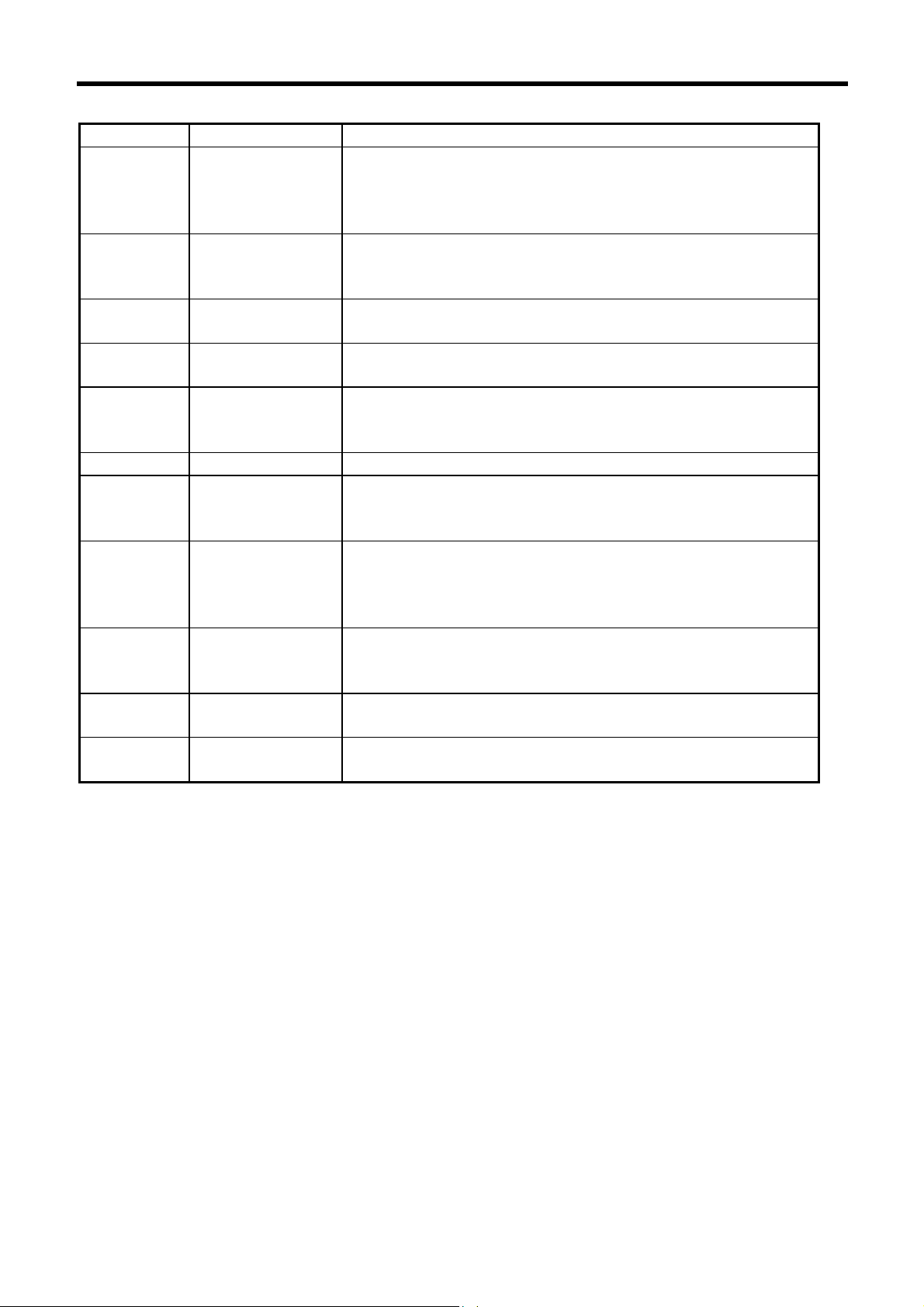

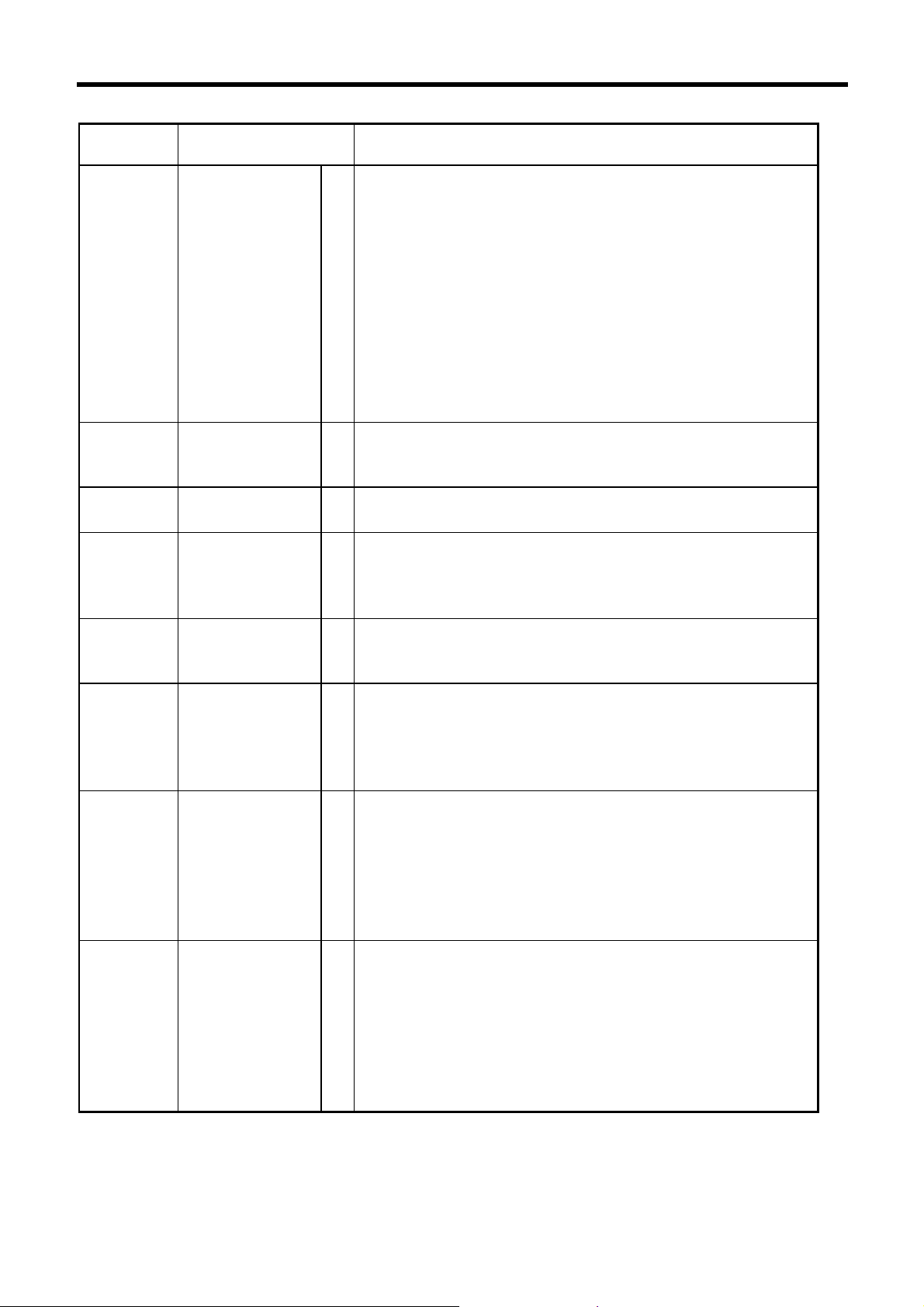

1. LIST OF ALARMS

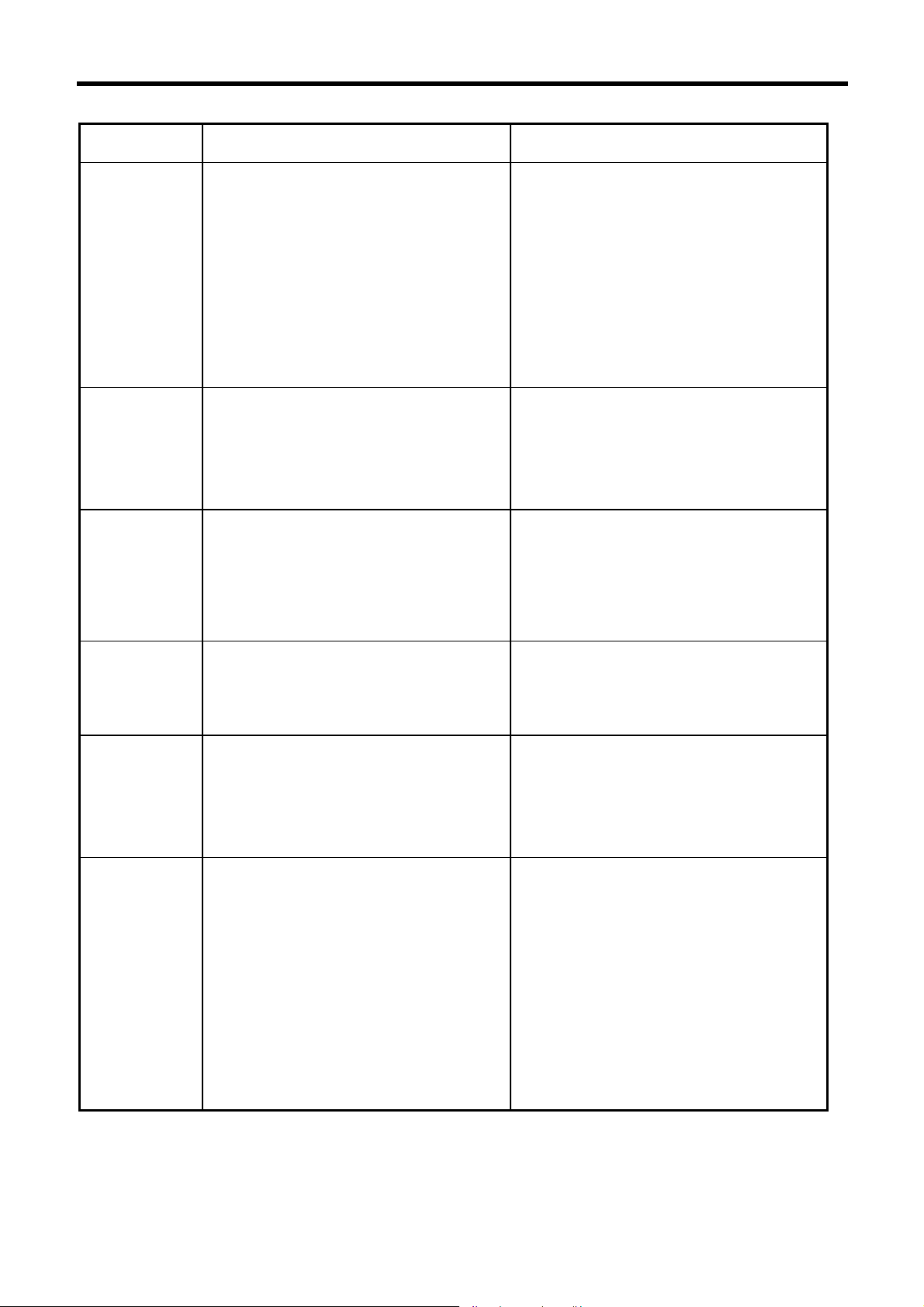

1.1 OPERATION ALARMS

1. LIST OF ALARMS

1.1 OPERATION ALARMS

(The bold characters are the messages displayed on the screen.)

M01 OPERATION ERROR

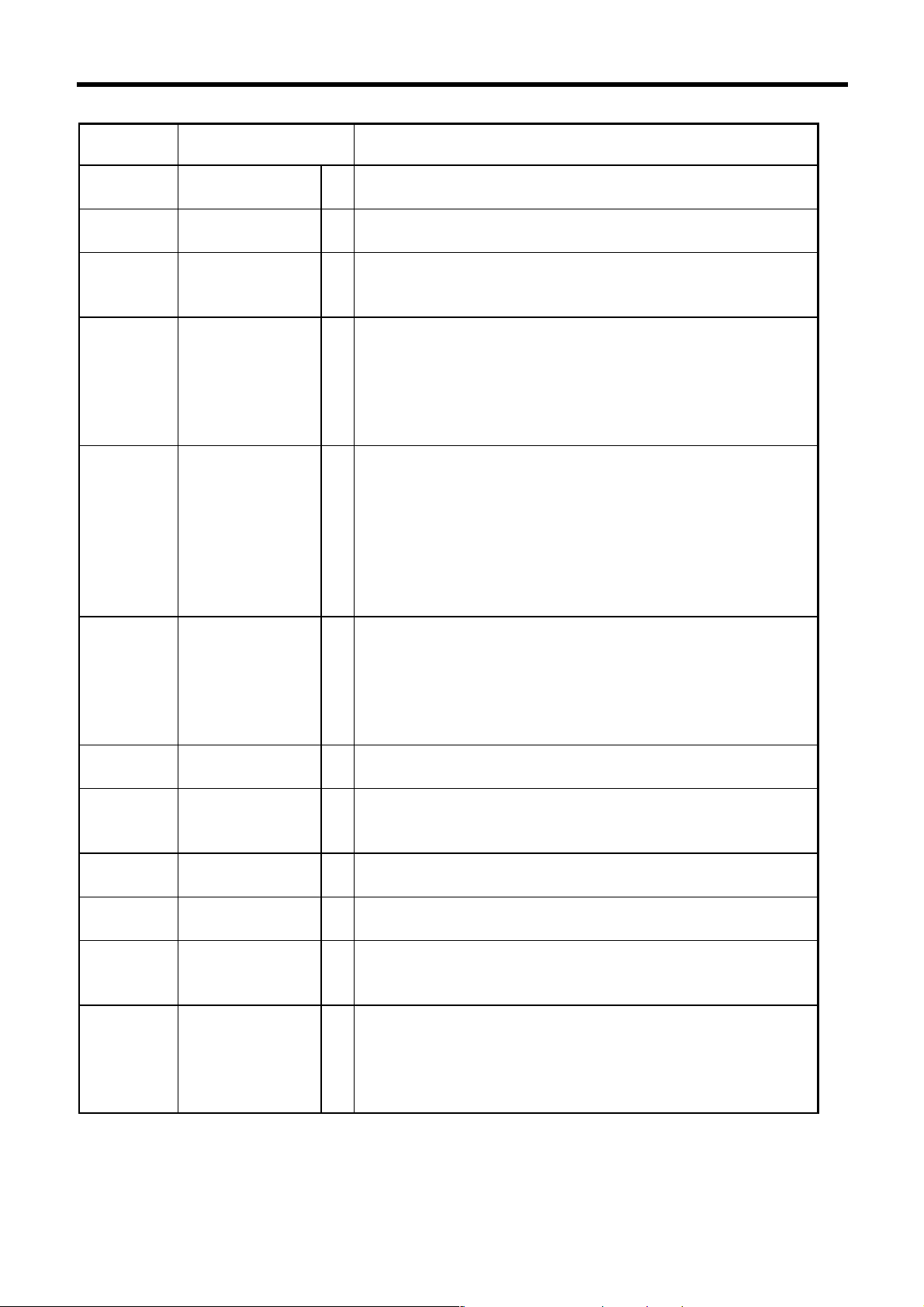

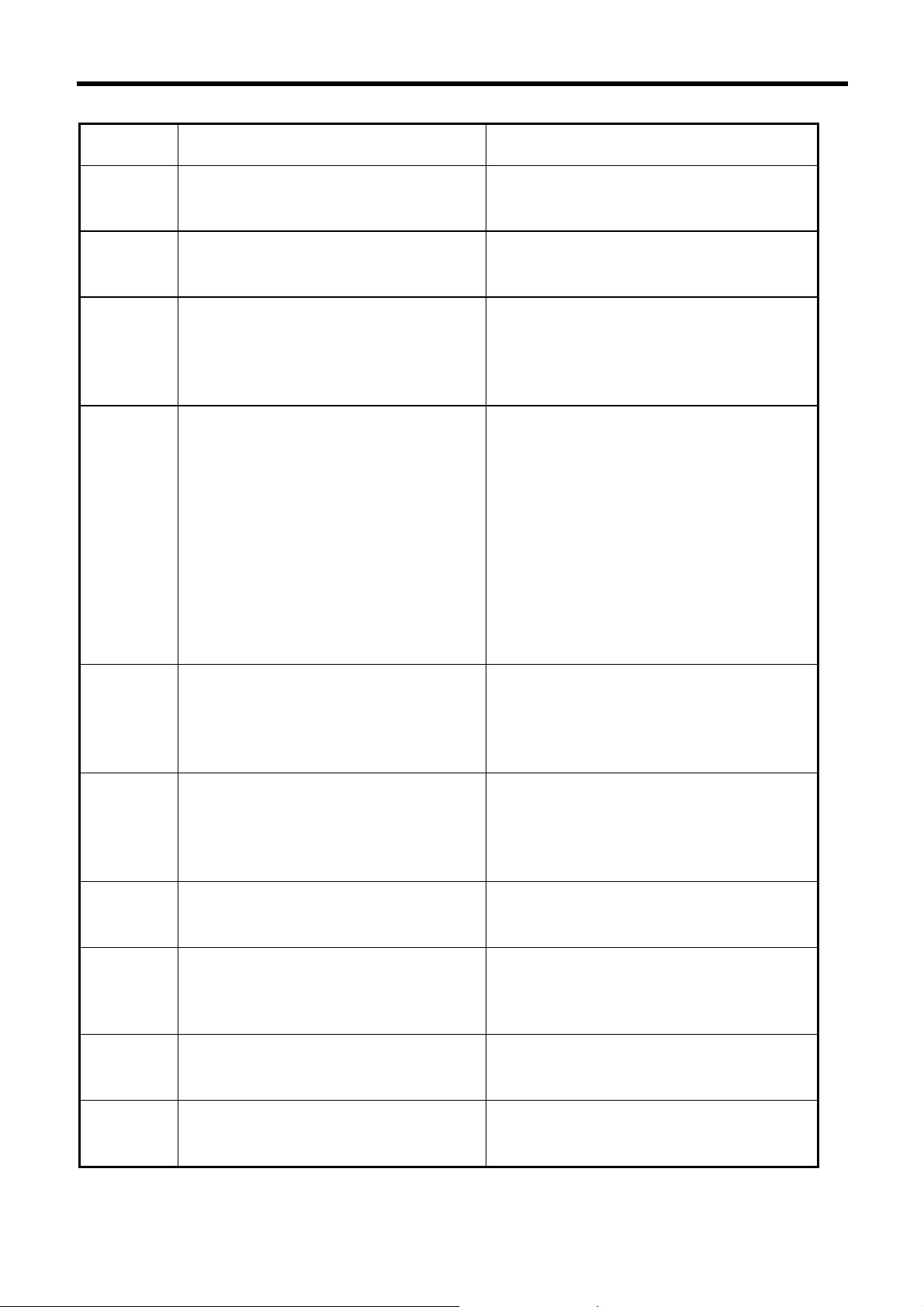

Error No. Details Remedy

0001

0002

0003

0004

DOG OVERRUN (Dog overrun)

When returning to the reference point‚

the near-point detection limit switch did

not stop over the dog‚ but overran the

dog.

Z-AX NO CRSS

One of the axes did not pass the

Z-phase during the initial reference point

return after the power was turned ON.

INVALID RET (Invalid return)

When manually returning to the

reference point‚ the return direction

differs from the axis movement direction

selected with the AXIS SELECTION

key.

EXT INTRLK (External interlock)

The external interlock function has

activated (the input signal is “OFF”) and

one of the axes has entered the interlock

state.

Alarms occurring due to incorrect operation by the operator

during NC operation and those by machine trouble are

displayed.

• Increase the length of the near-point

dog.

• Reduce the reference point return

speed.

• Move the detector one rotation or more

in the opposite direction of the reference

point‚ and repeat reference point return.

• The selection of the AXIS SELECTION

key’s +/– direction is incorrect. The error

is canceled by feeding the axis in the

correct direction.

• As the interlock function has activated‚

release it before resuming operation.

• Check the sequence on the machine

side.

• Check for broken wires in the interlock

signal line.

0005

INTRL INTRLK (Internal interlock)

The internal interlock state has been

entered.

The absolute position detector axis has

been removed.

A command for the manual/automatic

simultaneous valid axis was issued from

the automatic mode.

I - 1

• The servo OFF function is valid‚ so

release it first.

• An axis that can be removed has been

issued‚ so perform the correct

operations.

• The command is issued in the same

direction as the direction where manual

skip turned ON‚ so perform the correct

operations.

• During the manual/automatic simultaneous mode‚ the axis commanded in

the automatic mode became the manual

operation axis. Turn OFF the manual/

automatic valid signal for the

commanded axis.

• Turn ON the power again‚ and perform

absolute position initialization.

Page 18

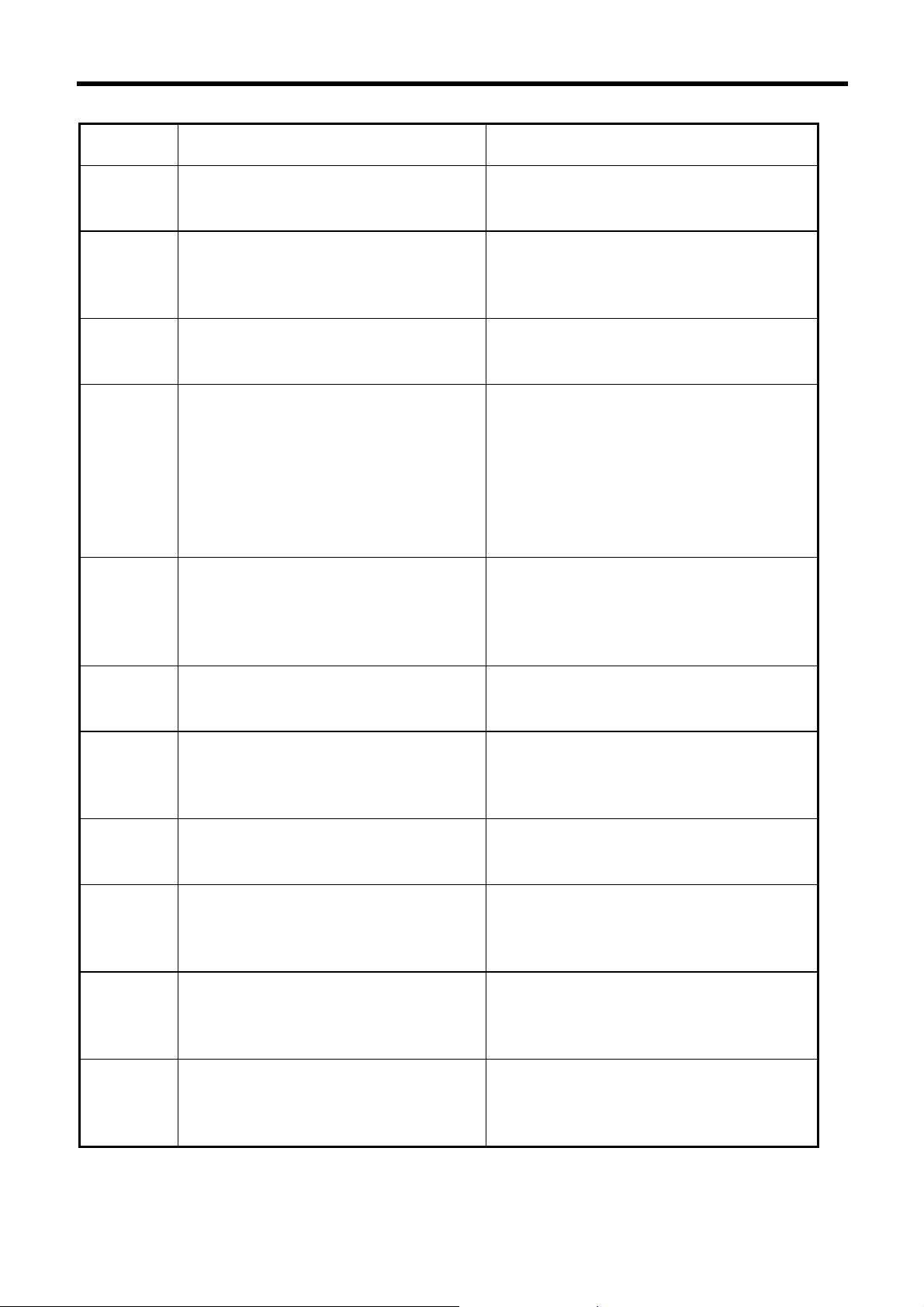

1. LIST OF ALARMS

1.1 OPERATION ALARMS

Error No. Details Remedy

0006

0007

0008

0009

0019

H/W STRK END (H/W stroke end)

The stroke end function has activated

(the input signal is “OFF”) and one of the

axes is in the stroke end status.

S/W STRK END (S/W stroke end)

The stored stroke limit I‚ II‚ IIB or IB

function has activated.

Chuck/tail-stock barrier stroke end axis

found

The chuck/tail-stock barrier function

turned ON‚ and an axis entered the

stroke end state.

Reference point return number illegal

Return to the No. 2 reference point was

performed before return to the No. 1

reference point was completed.

Sensor signal illegal ON

The sensor signal was already ON when

the tool measurement mode (TLM)

signal was validated.

The sensor signal turned ON when there

was no axis movement after the tool

measurement mode (TLM) signal was

validated.

The sensor signal turned ON at a

position within 100µm from the final

entry start position.

• Move the machine manually.

• Check for broken wires in the stroke end

signal wire.

• Check for trouble in the limit switch.

• Move it manually.

• If the stored stroke limit in the parameter

is incorrectly set‚ correct it.

• Reset the alarm with reset‚ and move

the machine in the reverse direction.

• Execute No. 1 reference point return.

• Turn the tool measurement mode signal

input OFF, and move the axis in a safe

direction.

• The operation alarm will turn OFF even

when the sensor signal is turned OFF.

Note) When the tool measurement mode

signal input is turned OFF, the axis

can be moved in either direction.

Pay attention to the movement

direction.

0020

0024

0025

Reference point return illegal

Return to the reference point was

performed before the coordinates had

not been established.

Zero point return disabled during absolute

position detection alarm

A zero point return signal was input

during an absolute position detection

alarm.

Zero point return disabled during zero

point initialization

A zero point return signal was input

during zero point initialization of the

absolute position detection system.

• Execute reference point return

• Reset the absolute position detection

alarm‚ and then perform zero point

return.

• Complete zero point initialization‚ and

then perform zero point return.

I - 2

Page 19

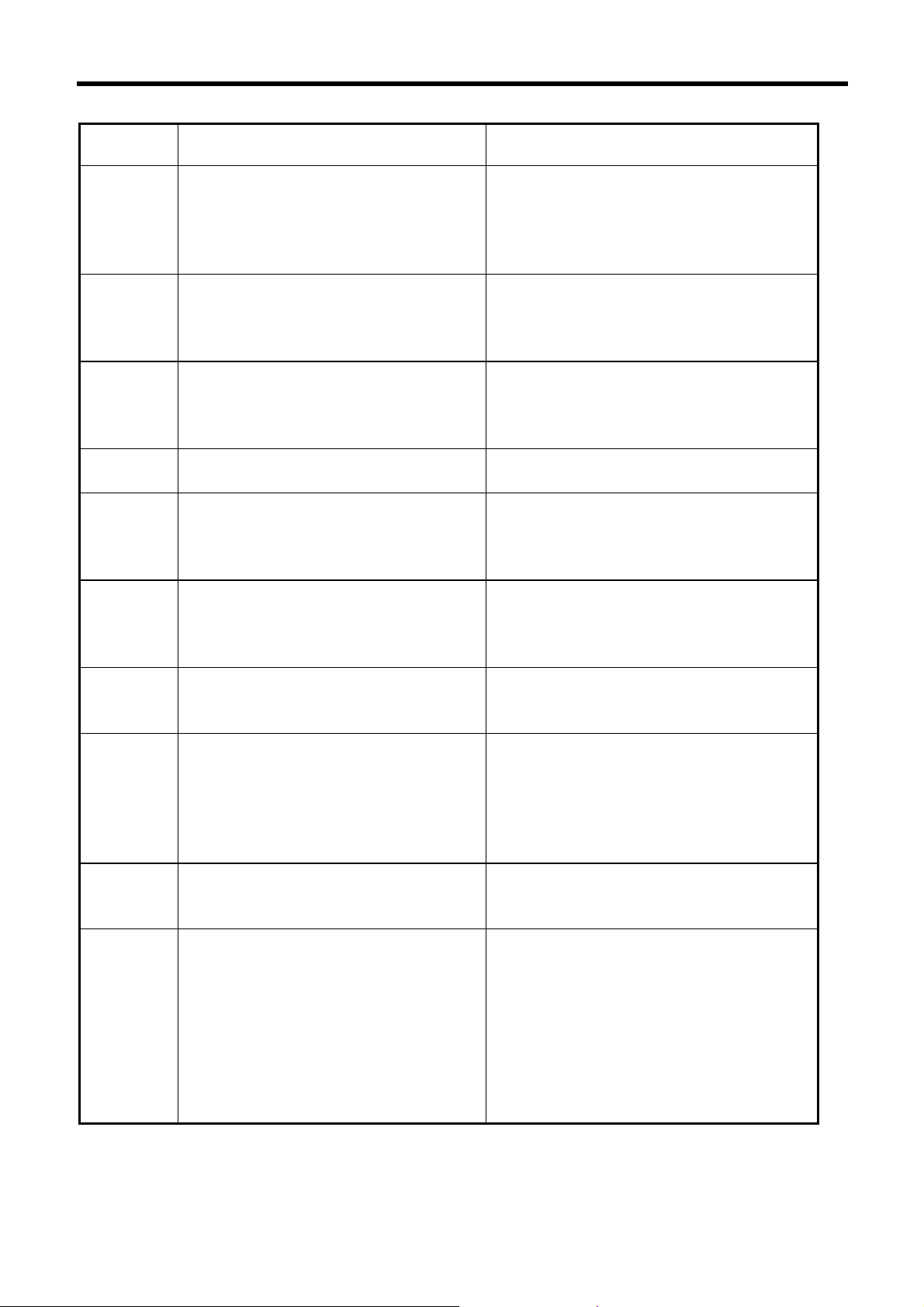

1. LIST OF ALARMS

1.1 OPERATION ALARMS

Error No. Details Remedy

0050

0051

0101

0102

Chopping axis zero point return

incomplete

• Reset or turn the chopping signal OFF,

and then carry out zero point return.

The chopping axis has not completed

zero point return before entering the

chopping mode.

All axes interlock will be applied.

Synchronization error too large

The synchronization error of the master

and slave axes exceeded the allowable

value under synchronous control.

A deviation exceeding the synchronization error limit value was found with

the synchronization deviation detection.

• Select the correction mode and move

one of the axes in the direction in which

the errors are reduced.

• Increase the allowable value or reset it

to 0 (check disabled).

• When using simple C-axis synchronous

control, set the contents of the R435

register to 0.

• Check the parameter (#2024 synerr).

NOT OP MODE (Not operation mode) • Check for a broken wire in the input

mode signal wire.

• Check for trouble in the mode selector

switch.

• Check the sequence program.

OVERRIDE ZERO (Override zero)

The cutting feed override switch on the

machine operation panel is set to zero.

• Set the switch to a value other than zero

to release the error.

• If the switch is set to a value other than

zero‚ check for a short circuit in the

signal wire.

• Check the sequence program.

0103

0104

0105

EX F SPD ZRO (External feed speed

zero)

The manual feed speed switch on the

machine operation panel is set to zero

when the machine is in the jog mode or

automatic dry run mode.

F1 SPD ZRO (F1-digit speed zero)

The F1-digit feedrate is set to zero when

the F1-digit feed command is being

executed.

SPINDLE STP (Spindle stop)

The spindle stopped during the

synchronous feed command.

• Set the switch to a value other than zero

to release the error.

• If the switch is set to a value other than

zero‚ check for a short circuit in the

signal wire.

• Check the sequence program.

• Set the F1-digit feedrate on the setup

parameter screen.

• Rotate the spindle.

• If the workpiece is not being cut‚ start dry

run.

• Check for a broken wire in the spindle

encoder cable.

• Check the connections for the spindle

encoder connectors.

• Check the spindle encoder pulse.

I - 3

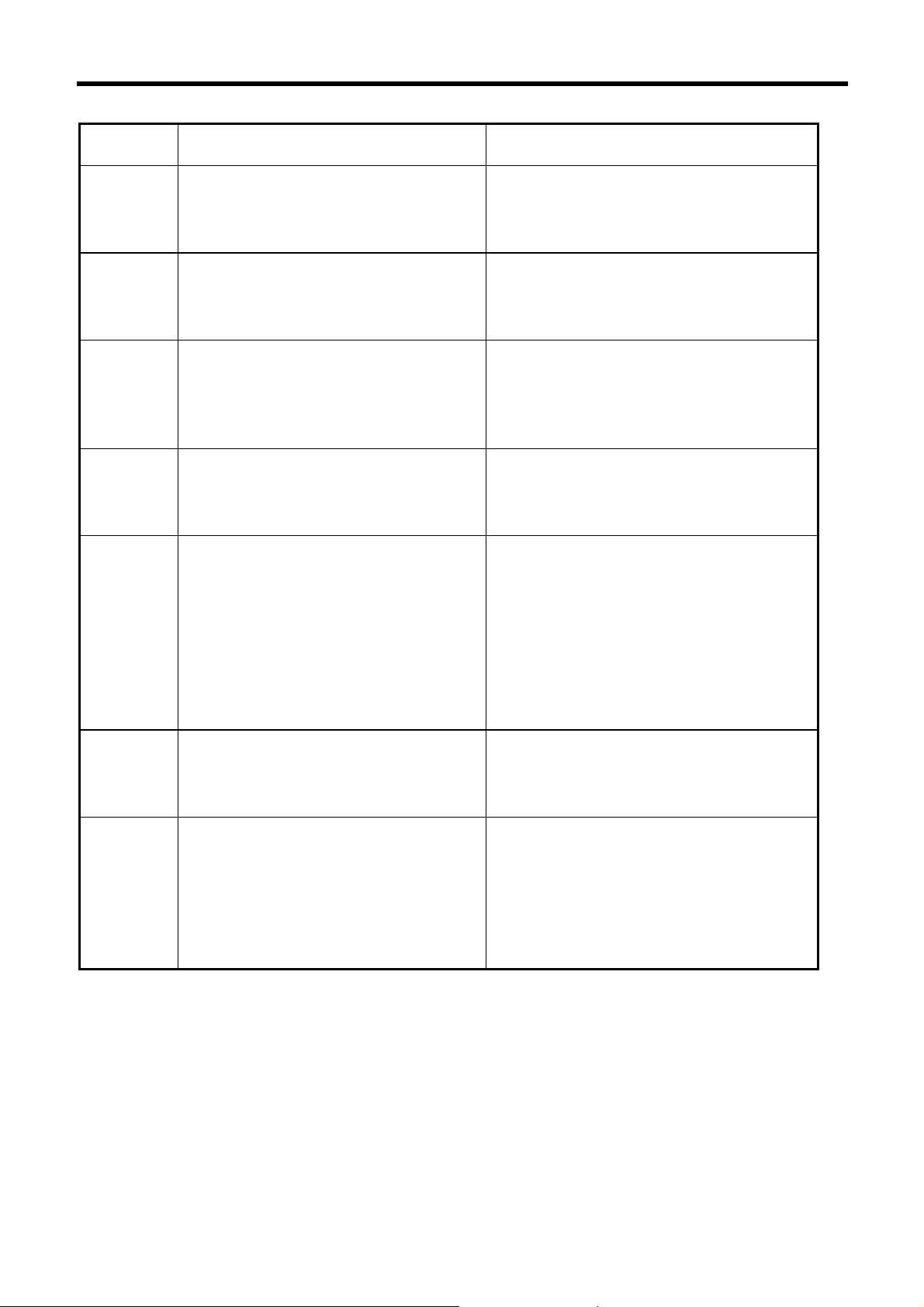

Page 20

1. LIST OF ALARMS

1.1 OPERATION ALARMS

Error No. Details Remedy

0106

0107

0108

0109

0110

HNDL FD NOW (Handle feed axis No.

illegal)

An axis not found in the specifications

was designated for handle feed or the

handle feed axis was not selected.

SPDL RPM EXS (Spindle rotation speed

excessive)

The spindle rotation speed exceeded

the axis clamp speed during the thread

cutting command.

Fixed point mode feed axis No. illegal:

An axis not found in the specifications

was designated for the fixed point mode

feed or the fixed point mode feedrate is

illegal.

BLK ST INTLK (Block start interlock)

An interlock signal that locks the start of

the block has been input.

CTBL ST INTLK (Cutting block start

interlock)

An interlock signal that locks the start of

the cutting block has been input.

• Check for broken wires in the handle

feed axis selection signal wire.

• Check the sequence program.

• Check the No. of axes listed in the

specifications.

• Lower the commanded spindle rotation

speed.

• Check for broken wires in the fixed

mode feed axis selection signal wire and

fixed point mode feedrate wire.

• Check the fixed point mode feed

specifications.

• Check the sequence program.

• Check the sequence program.

0111

0112

0113

0115

Restart switch ON

The restart switch was turned ON before

the restart search was completed, and

the manual mode was selected.

Program Check Mode

The automatic start button was pressed

during program check or in program

check mode.

Automatic start during buffer correction

The automatic start button was pressed

during buffer correction.

RESETTING

The automatic start button was pressed

during resetting or tape rewinding.

• Search the block to be restarted.

• Turn OFF the restart switch.

• Press the reset button to cancel the

program check mode.

• Press the automatic start button after

buffer correction is completed.

• When rewinding the tape‚ wait for the

winding to end‚ or press the reset button

to stop the winding‚ and then press the

automatic start button.

• During resetting‚ wait for resetting to

end‚ and then press the automatic start

button.

I - 4

Page 21

1. LIST OF ALARMS

1.1 OPERATION ALARMS

Error No. Details Remedy

0117

0118

0120

PLAYBACK NOT POSSIBLE

The playback switch was turned ON

during editing or full-character mode

(9-inch).

Block joint turn stop during normal line

control

The turning angle at the block joint

exceeded the limit during normal line

control.

Normal line control type I

The normal line control axis turning

speed (#1523 C_feed) has not been

set.

Normal line control type II

When turning in the inside of the arc, the

parameter “#8041 C-rot.R” setting value

is larger than the arc radius.

Synchronization correction mode ON

The synchronous correction mode

switch was pressed in a non-handle

mode.

• During editing‚ cancel the function by

pressing the input or previous screen key‚

and then turn ON the playback switch.

• Set the edit screen (9-inch) to the

half-character mode‚ and then turn ON

the playback switch.

• Check the program.

• Set the normal line control axis turning

speed. (Parameter “#1523 C_feed”)

• Set the C axis turning diameter smaller

than the arc radius, or check the setting

value of the C axis turning diameter.

(Parameter “#8041 C rot. R”)

• Select the handle or manual feed mode.

• Turn OFF the correction mode switch.

0121

0123

0124

0126

No synchronous control option

The synchronous control system

(register R435) was set with no

synchronous control option.

Computer link B

The cycle start was attempted before

resetting was completed.

The operation of the computer link B

was attempted in the 2nd part system of

the 2-part system.

Simultaneous axis movement prohibited

during inclined axis control valid

The basic axis corresponding to the

inclined axis was started simultaneously

in the manual mode while the inclined

axis control was valid.

Program restart machine lock

Machine lock was applied on the return

axis while manually returning to the

restart position.

• Set 0 in register R435.

• Perform the cycle start after resetting is

completed.

• Set 0 in #8109 HOST LINK, and then set

1 again before performing the cycle start.

• The operation of the computer link B

cannot be performed in the 2nd part

system of the 2-part system.

• Turn the inclined axis and basic axis start

OFF for both axes. (This also applied for

manual/automatic simultaneous start.)

• Invalidate the basic axis compensation,

or command one axis at a time.

• Release the machine lock before

resuming operations.

I - 5

Page 22

1. LIST OF ALARMS

1.1 OPERATION ALARMS

Error No. Details Remedy

0150

0151

0153

0154

0160

Chopping override zero • Check the chopping override (R135).

• Check the rapid traverse override (R134).

Command axis chopping axis

A chopping axis movement command

was issued from the program during the

chopping mode. (This alarm will not

occur when the movement amount is

• Reset, or turn OFF the chopping signal.

When the chopping signal is turned OFF,

the axis will return to the reference

position, and then the program movement

command will be executed.

commanded as 0.)

(All axes interlock state will be applied.)

Bottom dead center position zero

The bottom dead center position is set to

• Correctly set the bottom dead center

position.

the same position as the upper dead

center position.

Chopping axis handle selection axis

Chopping was started when the

chopping axis was selected as the

handle axis.

Axis with no maximum speed set for the

outside of the soft limit range

Returned from the outside of the soft

limit range for the axis with no maximum

speed set for the outside of the soft limit

• Select an axis other than the chopping

axis as the handle axis, or start chopping

after changing the mode to another

mode.

• Set the maximum speed for the outside of

the soft limit range. (Parameter “#2021

out_f”)

• Change the soft limit range.

(Parameter “#2013 OT–” “#2014 OT+”)

range.

1005

1007

1026

An attempt was made to execute G114.*

during execution of G114.*.

G51.2 was commanded when the G51.2

spindle-spindle polygon machining mode

was already entered with a separate

system.

The spindle is being used in synchronized

tapping.

Spindle C axis and other position control

were commanded simultaneously.

C axis mode command was issued for

polygon machining spindle.

C axis mode command was issued for

synchronized tapping spindle.

Polygon command was issued for

synchronized tapping spindle.

Spindle is being used as spindle/C axis.

• Issue G113 to cancel G114.*.

• Issue the spindle synchronous cancel

signal (Y2E8: SPSYC) to cancel G114.*.

• Cancel with G50.2.

• Cancel with the spindle-spindle polygon

cancel signal (Y359).

• Cancel synchronized tapping.

• Cancel the C axis command.

• Cancel the polygon machining command.

• Cancel the C axis with servo OFF.

I - 6

Page 23

1. LIST OF ALARMS

1.1 OPERATION ALARMS

Error No. Details Remedy

1030

1031

1032

Synchronization mismatch

Different M codes were commanded in

the two systems as the synchronization

M codes.

Synchronization with the "!" code was

commanded in another system during M

code synchronization.

Synchronization with the M code was

commanded in another system during

synchronization with the "!" code.

The C axis selection signal was changed

when multiple C axes could not be

selected.

An axis that cannot be controlled as the

multiple C axes selection was selected.

Tap return spindle selection illegal during

multi-spindle

Tap return was executed when a

different spindle was selected. Cutting

feed will wait until synchronization is

completed.

• Correct the program so that the M codes

match.

• Correct the program so that the same

synchronization codes are commanded.

• Check and correct the parameters and

program.

• Select the spindle for which tap cycle was

halted before the tap return signal was

turned ON.

1033

1034

1035

Spindle-spindle polygon (G51.2) cutting

interlock

Cutting feed will wait until

synchronization is completed.

Cross machining command illegal

Cross machining control exceeding the

number of control axes was attempted.

Cross machining control with duplicated

axis addresses was attempted.

Cross machining control disable modal

Cross machining control was

commanded for a system in which cross

machining control is disabled as shown

below.

• During nose R compensation mode

• During pole coordinate interpolation

mode

• During cylindrical interpolation mode

• During balance cut mode

• During fixed cycle machining mode

• During facing turret mirror image

• Wait for synchronization to end.

• Check the parameter settings for cross

machining control.

• Check the program.

I - 7

Page 24

1. LIST OF ALARMS

1.1 OPERATION ALARMS

Error No. Details Remedy

1036

1037

1038

1106

Synchronous control designation disable

The synchronous control operation

method selection (R435 register) was

set when the mode was not the C axis

mode.

The synchronous control operation

method selection (R435 register) was

set in the zero point not set state.

Mirror image disable state

The external mirror image or parameter

mirror image was commanded during

facing turret mirror image.

Synchronous control was started or

canceled when synchronous control could

not be started or canceled.

A movement command was issued to a

synchronous axis in synchronous control.

Spindle synchronous phase calculation

illegal

The spindle synchronization phase

alignment command was issued while

the spindle synchronization phase

calculation request signal was ON.

• Set the R435 register to 0.

• Check the program and parameters.

• Check the program and parameters.

• Check the program.

• Check the program.

• Check the sequence program.

(The bold characters are the messages displayed on the screen.)

M90 PARAM SET MODE

M90 Messages output when the setup parameter lock function

is enabled are displayed.

Error No. Details Remedy

—

Setup parameter lock released

The setup parameter lock is released.

Automatic start is disabled when setup

• Refer to the manual issued by the

machine manufacturer.

parameters can be set.

I - 8

Page 25

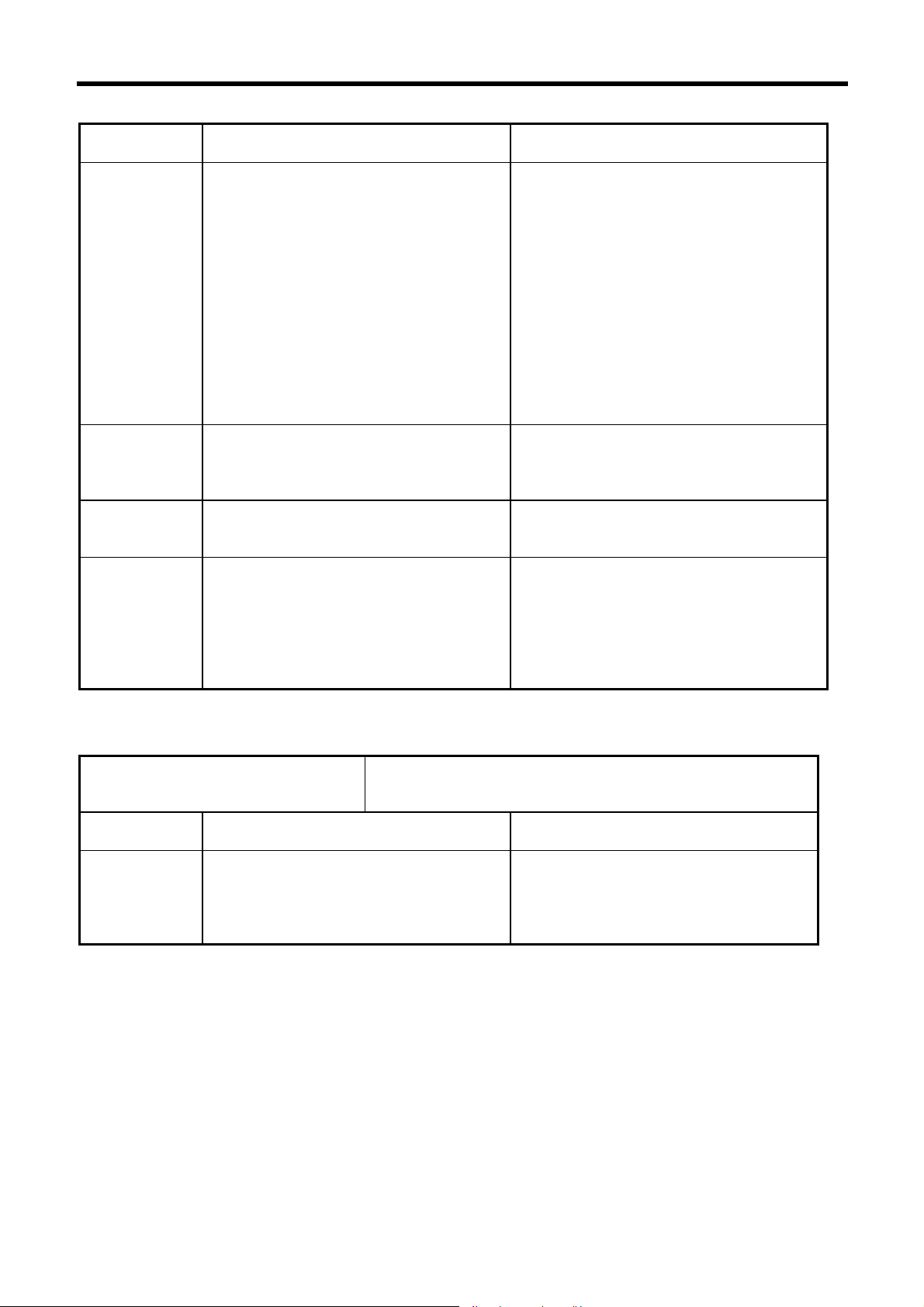

1. LIST OF ALARMS

1.2 STOP CODES

1.2 STOP CODES

These codes indicate a status that caused the controller to stop for some reason.

(The bold characters are the messages displayed on the screen.)

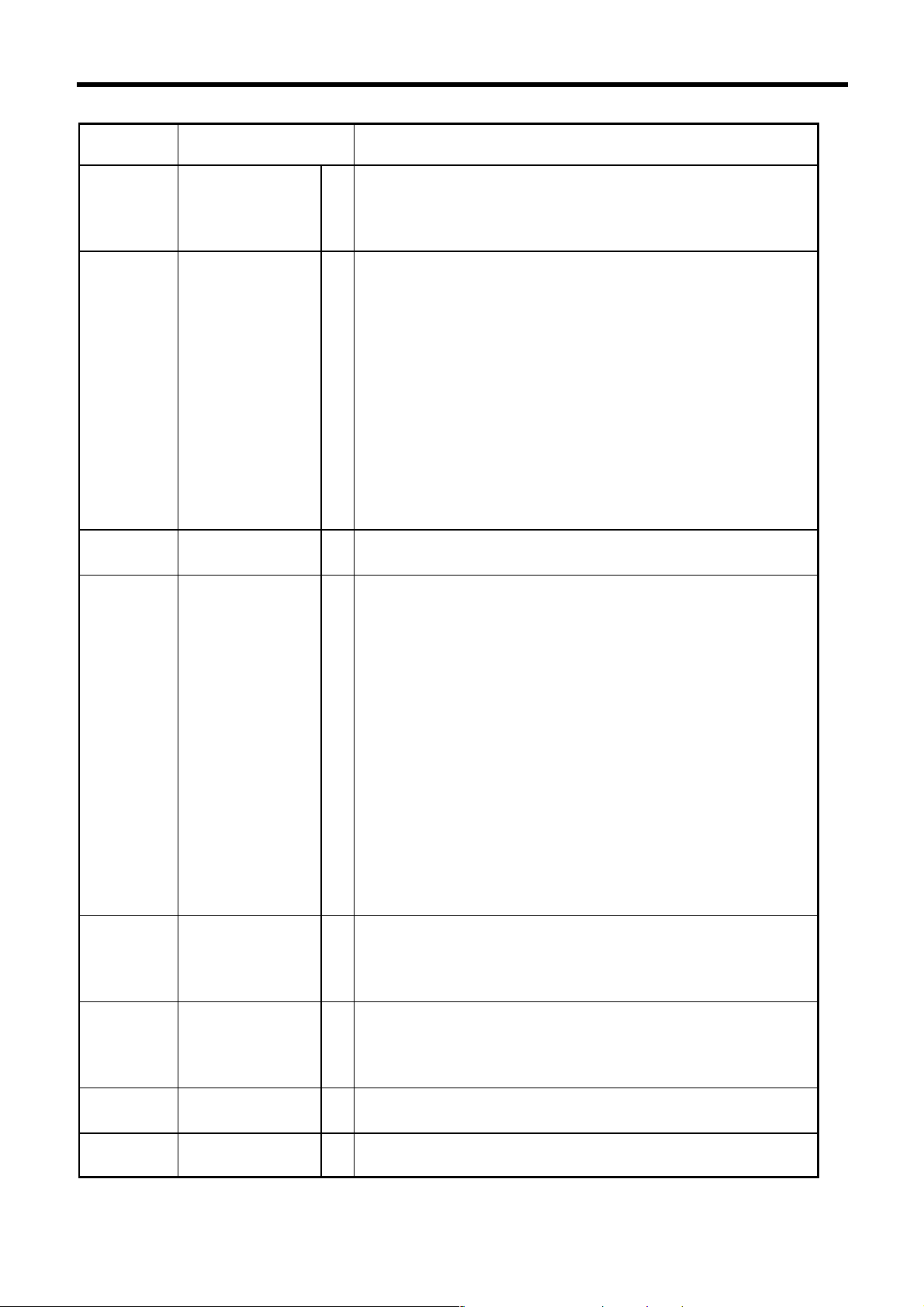

T01 CAN’T CYCLE ST

Error No. Details Remedy

0101

0102

0103

0104

AX IN MOTION (axis in motion)

Automatic start is not possible as one of

the axes is moving.

READY OFF

Automatic start is not possible as the NC

is not ready.

RESET ON

Automatic start is not possible as the

reset signal has been input.

A-OP STP SGL (Automatic operation stop

signal “ON”)

The FEED HOLD switch on the machine

operation panel is “ON” (valid).

This indicates the state where automatic operation cannot be

started when attempting to start it from the stop state.

• Try automatic start again after all axes

have stopped.

• Another alarm has occurred. Check the

details and remedy.

• Turn OFF the reset input signal.

• Check that the reset switch is not ON

constantly due to trouble.

• Check the sequence program.

• Check the FEED HOLD switch.

• The feed hold switch is the B contact.

• Check for broken wires in the feed hold

signal wire.

• Check the sequence program.

0105

0106

0107

H/W STRK END (H/W stroke end axis)

Automatic start is not possible as one of

the axes is at the stroke end.

S/W STRK END (S/W stroke end axis)

Automatic start is not possible as one of

the axes is at the stored stroke limit.

NO OP MODE (NO operation mode)

The operation mode has not been

selected.

• If one of the axis’ ends is at the stroke

end‚ move the axis manually.

• Check for broken wire in the stroke end

signal wire.

• Check for trouble in the stroke end limit

switch.

• Move the axis manually.

• If an axis is not at the end‚ check the

parameter details.

• Select the automatic operation mode.

• Check for broken wires in the automatic

operation mode (memory‚ tape‚ MDl)

signal wire.

I - 9

Page 26

1. LIST OF ALARMS

1.2 STOP CODES

Error No. Details Remedy

0108

0109

0110

0112

0113

OP MODE DUPL (Operation mode

duplicated)

Two or more automatic operation modes

are selected.

OP MODE SHFT (Operation mode shift)

The automatic operation mode changed

to another automatic operation mode.

Tape search execution

Automatic start is not possible as tape

search is being executed.

Program restart position return incomplete

Automatic start is not possible as the

axis has not been returned to the restart

position.

Thermal alarm

Automatic start is not possible because

a thermal alarm (Z53 TEMP. OVER) has

occurred.

• Check for a short circuit in the mode

selection signal wire (memory‚ tape‚

MDl).

• Check for trouble in the switch.

• Check the sequence program.

• Return to the original automatic

operation mode‚ and start automatic

start.

• Begin automatic start after the tape

search is completed.

• Manually return to the restart position.

• Turn the automatic restart valid

parameter ON, and then execute

automatic start.

• The NC controller temperature has

exceeded the specified temperature.

• Take appropriate measures to cool the

unit.

0115

0138

0139

0190

0191

In host communication

Automatic start cannot be executed as

the NC is communicating with the host

computer.

Disabled start during absolute position

detection alarm

A start signal was input during an

absolute position detection alarm.

Disabled start during zero point

initialization

A start signal was input while initializing

the absolute position detector’s zero

point.

Automatic start disabled

Automatic start is disabled because

setup parameters can be set.

Automatic start disabled

Automatic start was caused during file

deletion or writing.

• Execute automatic start after the

communication with the host computer

is completed.

• Reset the absolute position detection

alarm‚ and then input the start signal.

• Complete zero point initialization before

inputting the start signal.

• Refer to the manual issued by the

machine manufacturer.

• Cause automatic start after file deletion

or writing is completed.

I - 10

Page 27

1. LIST OF ALARMS

1.2 STOP CODES

T02 FEED HOLD

The feed hold state been entered due to a condition in the

automatic operation.

Error No. Details Remedy

0201

H/W STRK END (H/W stroke end axis)

An axis is at the stroke end.

• Manually move the axis away from the

stroke end limit switch.

• The machining program must be

corrected.

0202

S/W STRK END (S/W stroke end axis)

An axis is at the stored stroke limit.

• Manually move the axis.

• The machining program must be

corrected.

0203

RESET SIGNAL ON (Reset signal on)

The reset signal has been input.

• The program execution position has

returned to the start of the program.

Execute automatic operation from the

start of the machining program.

0204

AUTO OP STOP (Automatic operation

stop)

• Resume automatic operation by

pressing the “CYCLE START” switch.

The FEED HOLD switch is “ON”.

0205

AUTO MD CHING (Automatic mode

change)

The operation mode changed to another

mode during automatic operation.

• Return to the original automatic

operation mode‚ and resume automatic

operation by pressing the “CYCLE

START” switch.

0206

0215

Acceleration and deceleration time

constants too large

The acceleration and deceleration time

constants are too large. (This problem

occurs at the same time as system

alarm Z59.)

Absolute position detection alarm stop

An absolute position detection alarm

occurred.

• Increase the set value of the parameter

“#1206 G1bF”.

• Decrease the set value of the parameter

“#1207 G1btL”.

• Lower the cutting speed.

• Reset the absolute position detection

alarm.

I - 11

Page 28

1. LIST OF ALARMS

1.2 STOP CODES

T03 BLOCK STOP

This indicates that automatic operation stopped after executing

one block of the program.

Error No. Details Remedy

0301

SNGL BLK ON (Single block on)

The SINGLE BLOCK switch on the

• Automatic operation can be resumed by

turning the CYCLE START switch ON.

machine operation panel is ON.

The single block or machine lock switch

changed.

0302

User macro stop

The block stop command was issued in

• Automatic operation can be resumed by

turning the CYCLE START switch ON.

the user macro program.

0303

Mode change

The automatic mode changed to another

automatic mode.

• Return to the original automatic

operation mode‚ and resume automatic

operation by turning the CYCLE START

switch ON.

0304

MDI completion

The last block of MDI was completed.

• Set MDI again‚ and turn the CYCLE

START switch ON to resume MDl

operation.

0305

Block start interlock

• Check the sequence program.

The interlock signal that locks the block

start is entered.

0306

Block cutting start interlock

• Check the sequence program.

The interlock signal that locks the block

cutting start is entered.

0310

Offset change of inclined Z-axis during

program operation

• Automatic operation can be restarted by

turning ON the cycle start switch.

Whether to validate the offset of the

inclined Z-axis switched during program

operation.

T04 COLLATION STOP

Collation stop was applied during automatic operation.

Error No. Details Remedy

0401

Collation stop occurred. • Automatic operation can be restarted

with automatic start.

I - 12

Page 29

1. LIST OF ALARMS

1.2 STOP CODES

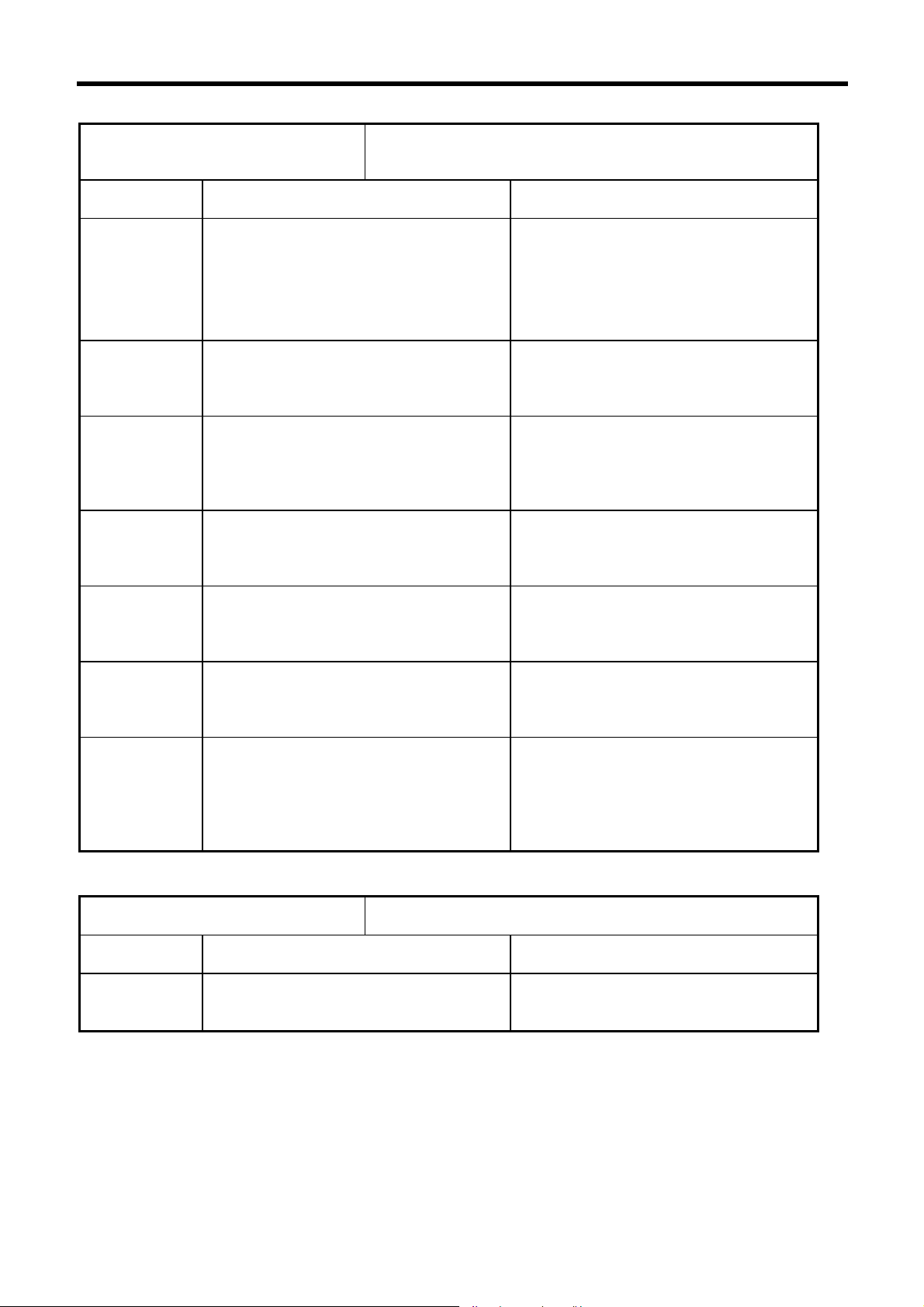

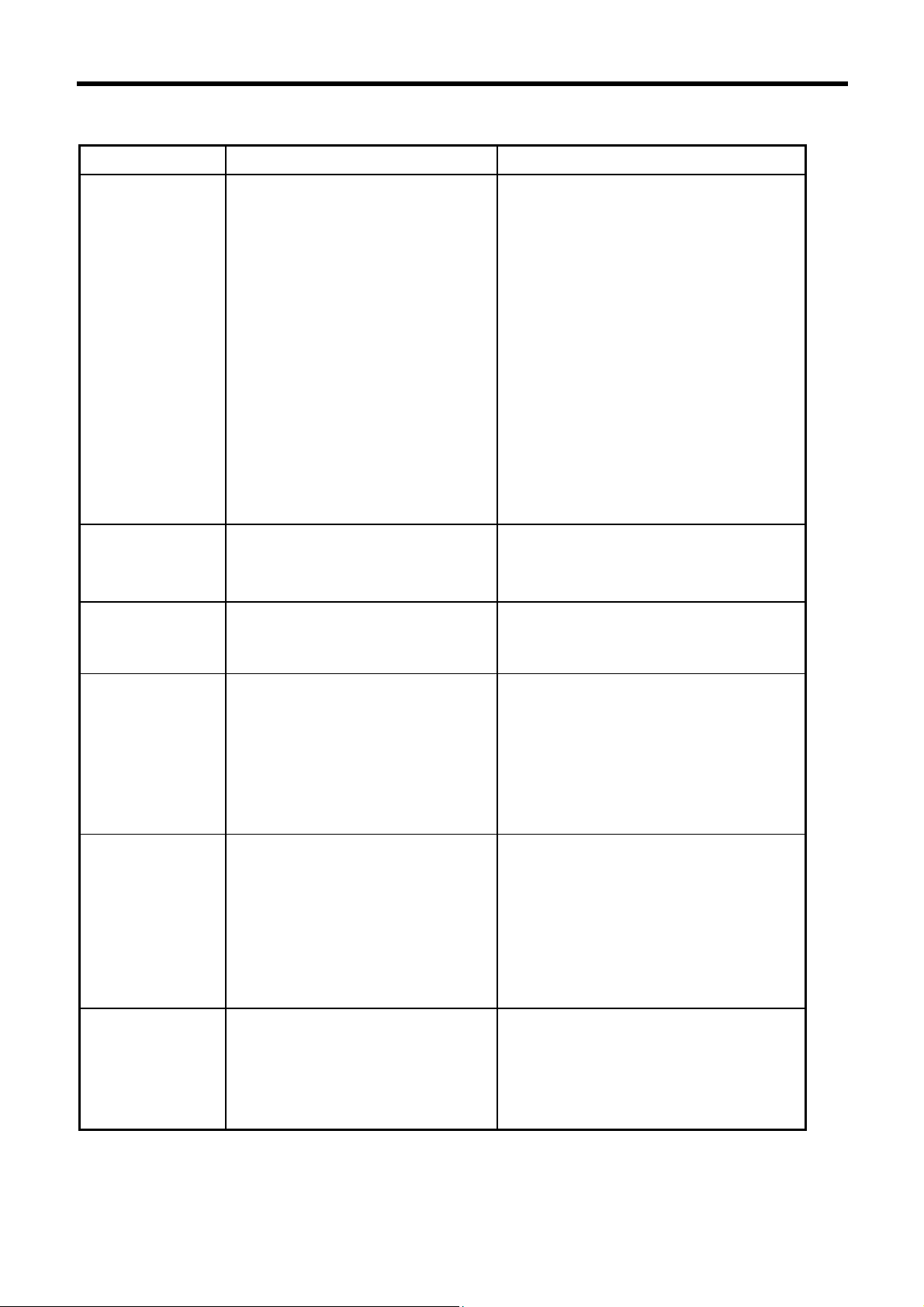

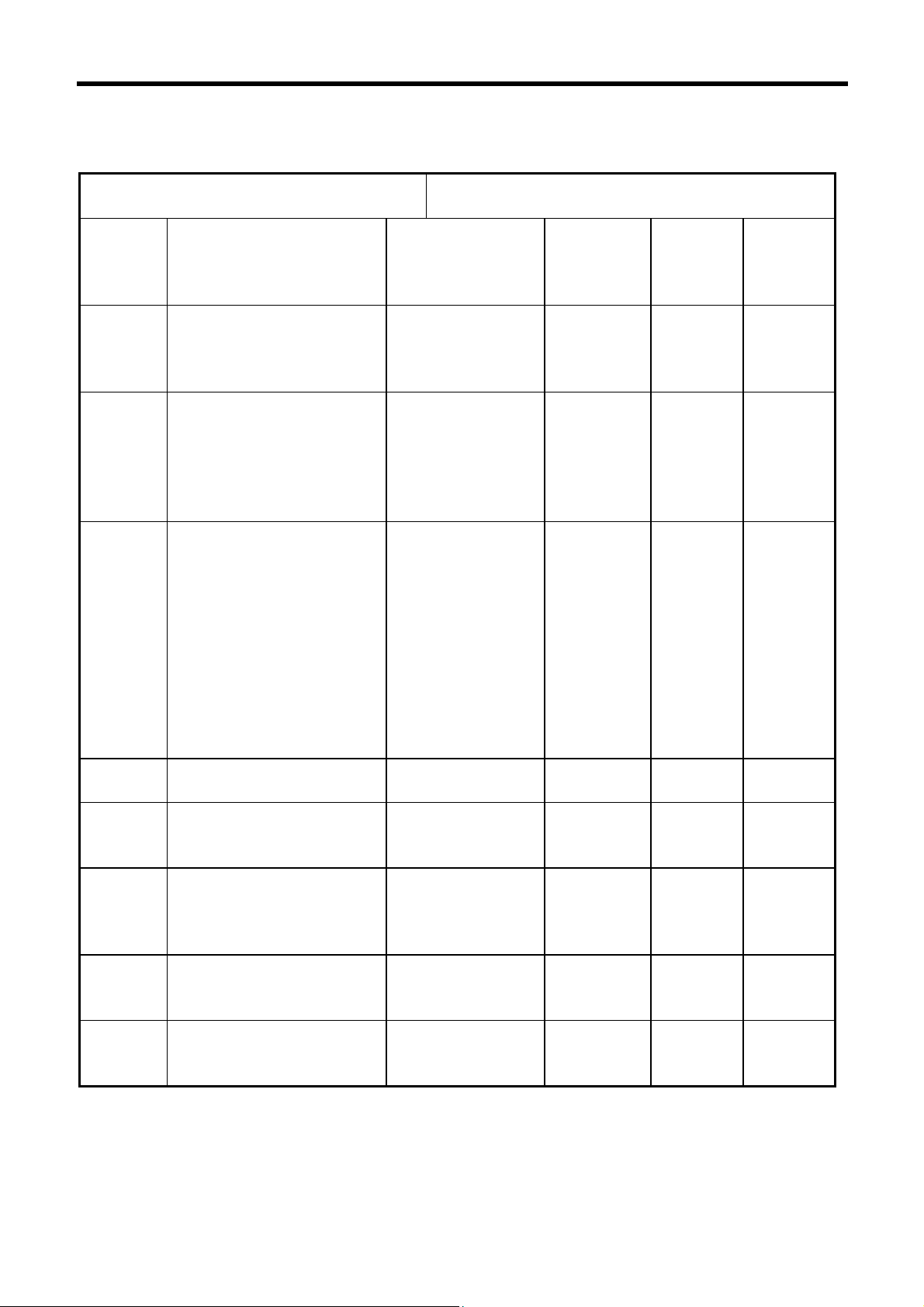

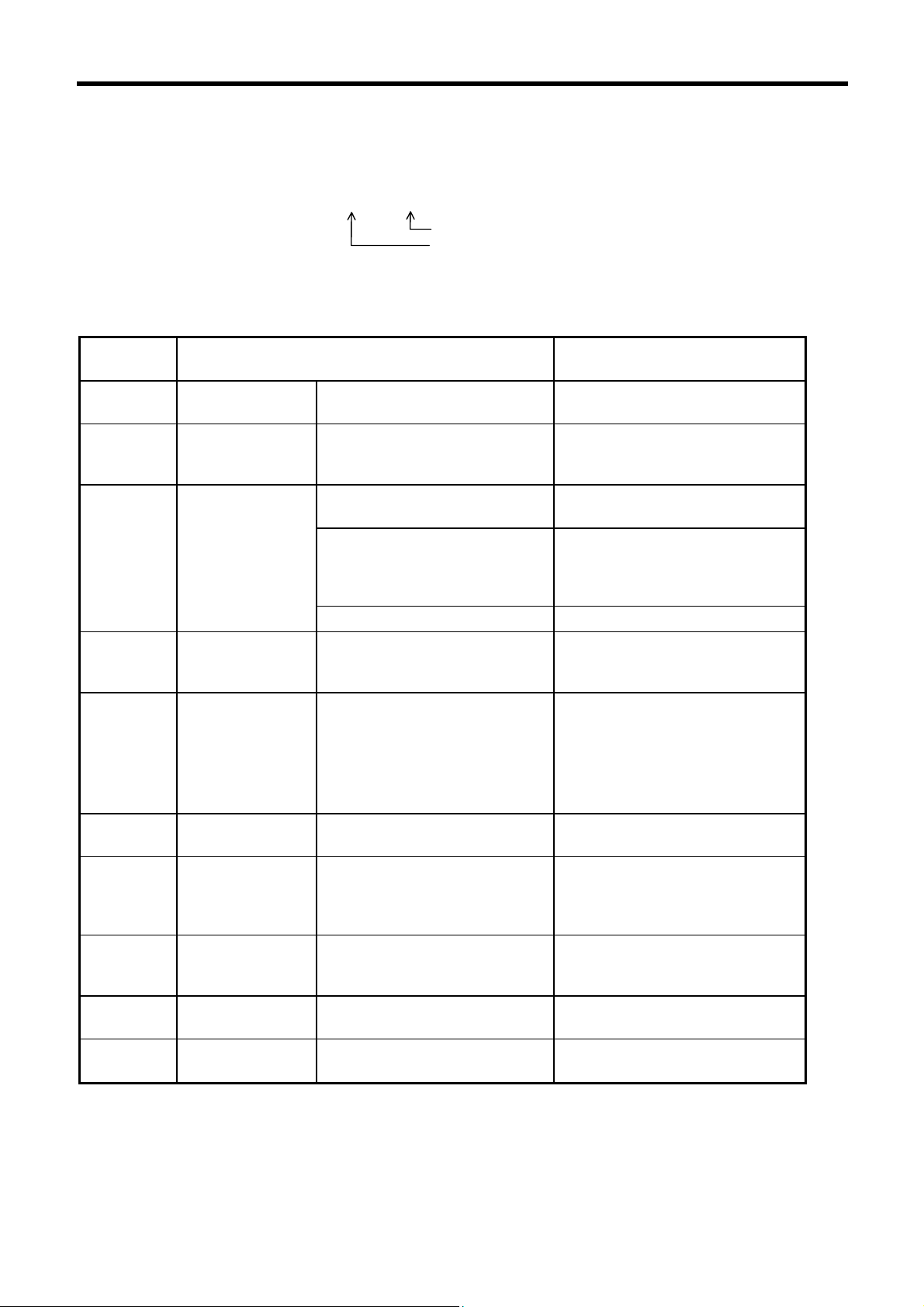

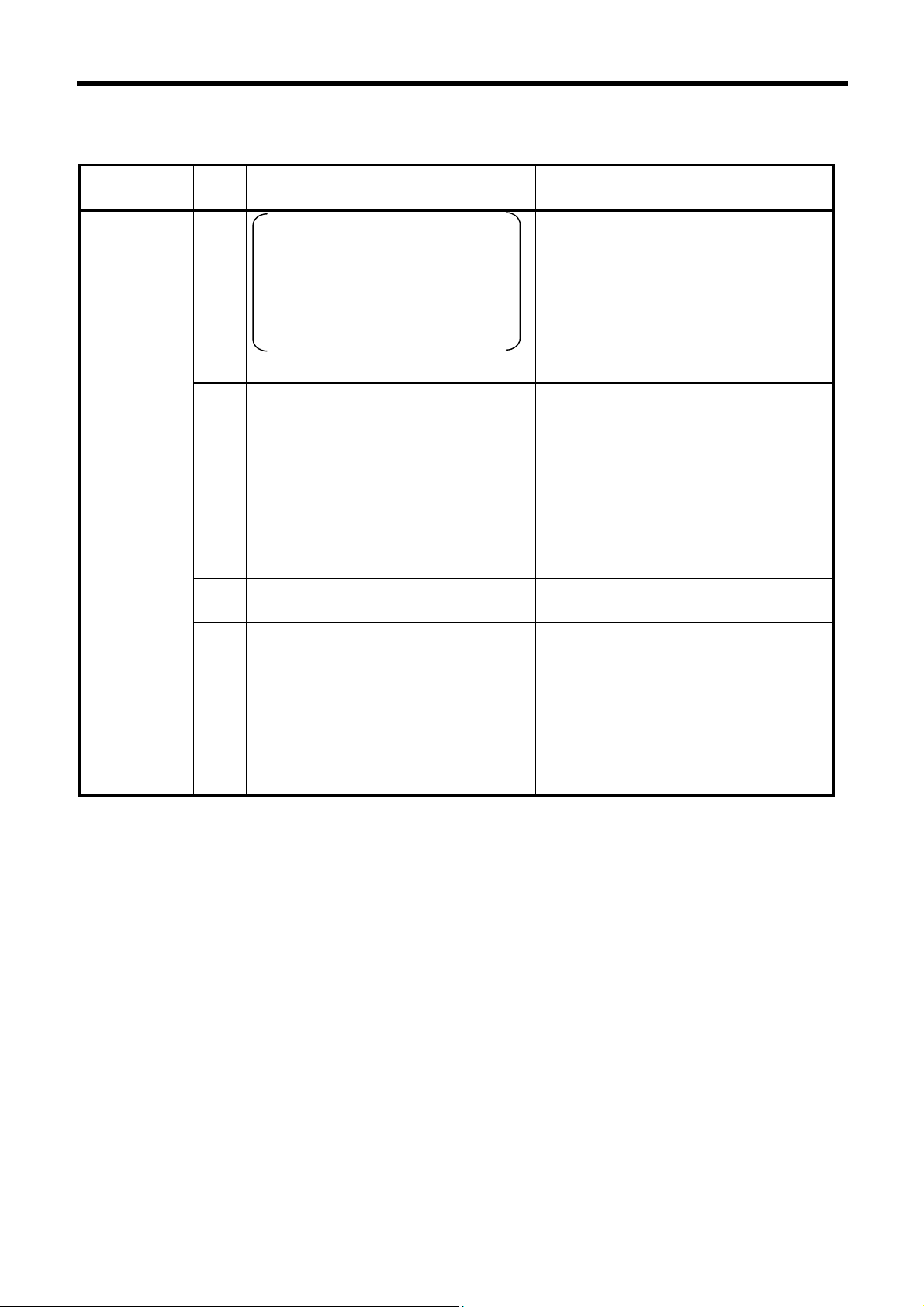

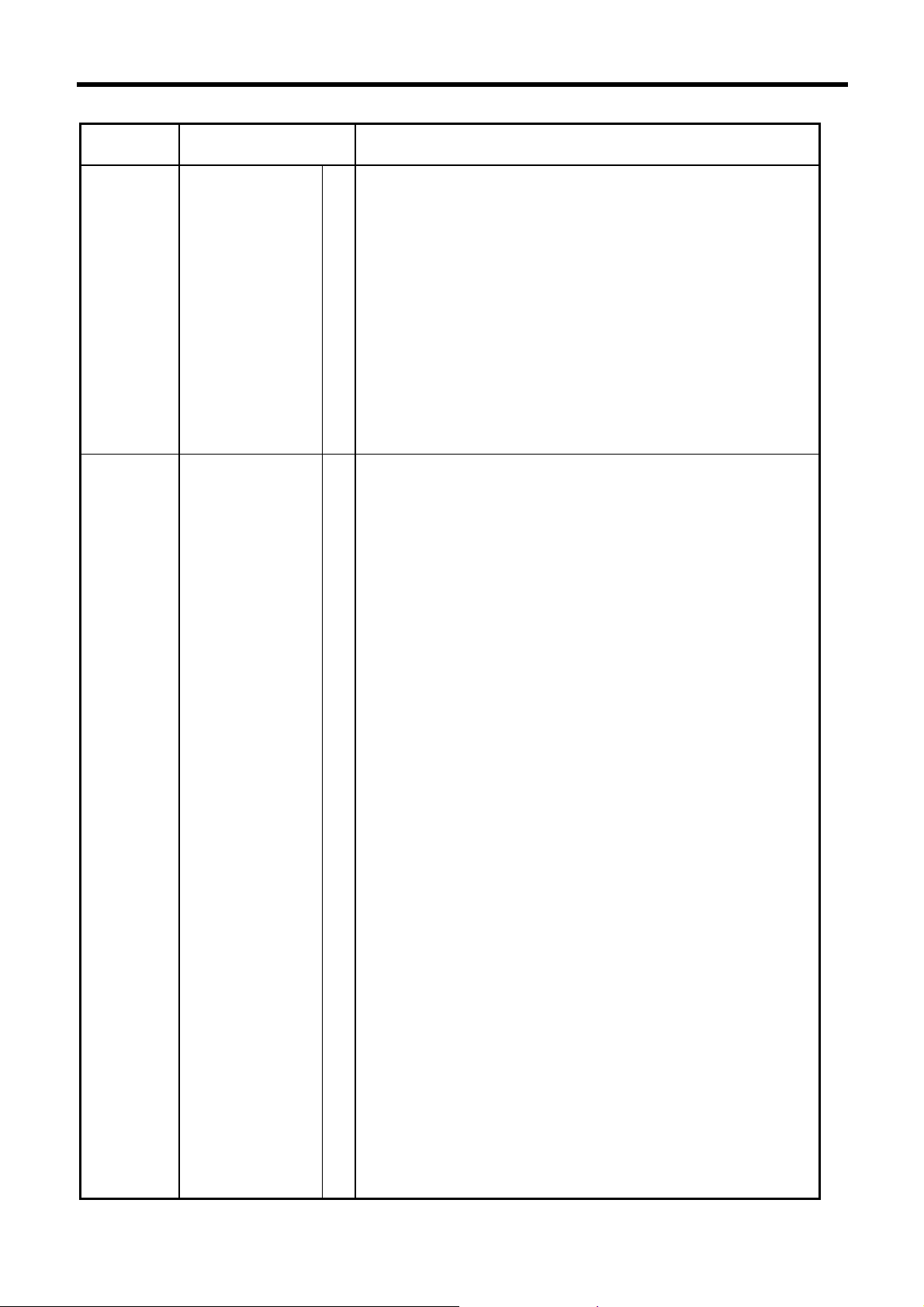

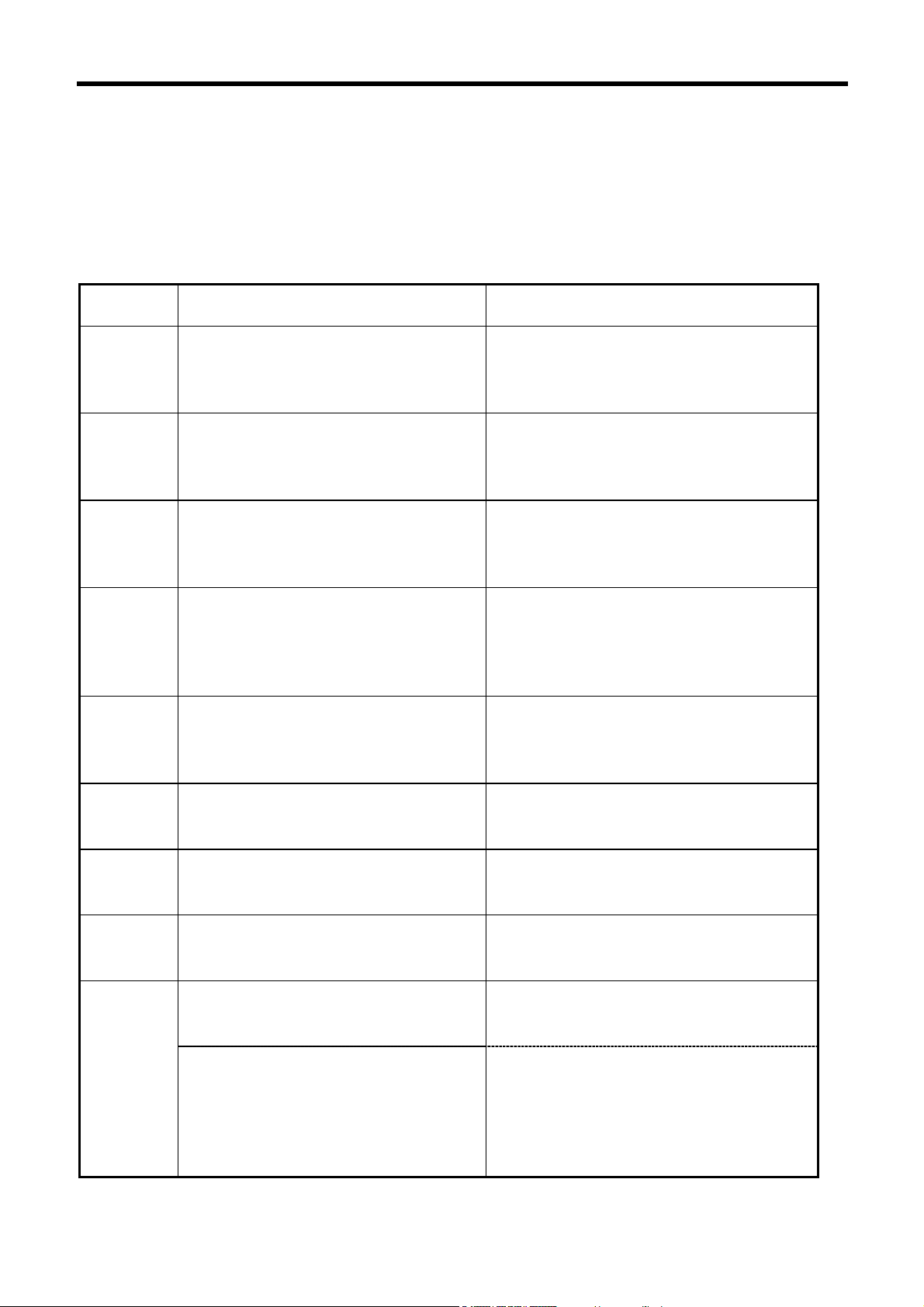

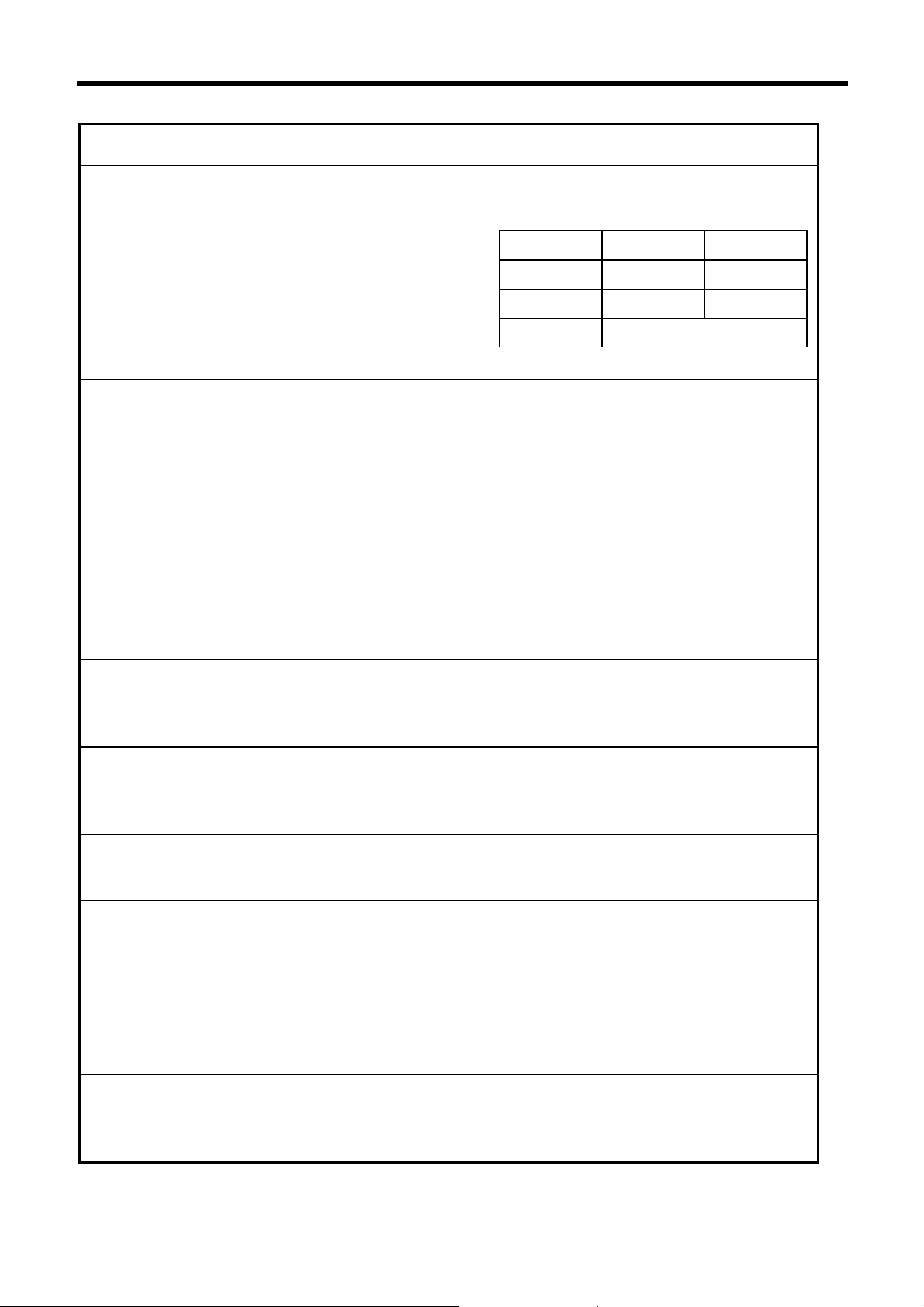

T10 FIN WAIT

This indicates the operation state when an alarm did not occur

during automatic operation‚ and nothing seems to have

happened.

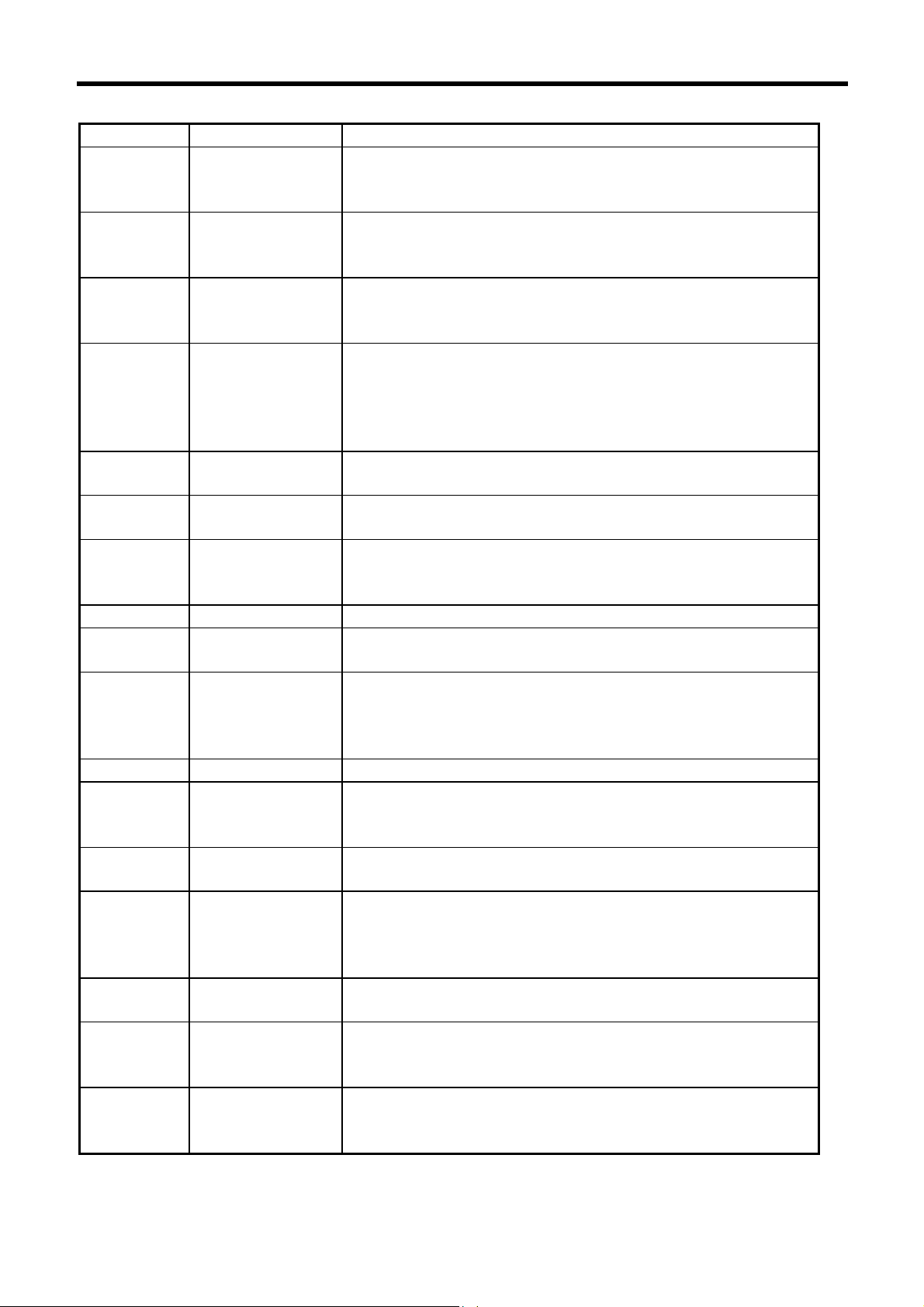

Error No. Details

0

The error number is displayed while each of the completion wait modes listed in the

table below is ON. It disappears when the mode is canceled.

0

Alarm

Unclamp

In dwell

No.

signal

wait

Note 2)

Alarm

execution

No.

Door

open

Note 1)

0 0 0

1

8

×

×

1

8

×

Waiting

Alarm

Waiting

for

spindle

position

to be

looped

×

No.

1

for

spindle

orienta-

tion to

complete

Waiting

for

cutting

speed

deceleration

2

Waiting

for rapid

traverse

deceleration

×

Waiting

for MSTB

completion

×

9

× ×

4

5

6

7

8

9

A

B

C

D

E

F

9

× ×

3

×

×

× ×

× × ×

×

×

×

×

× ×

× ×

× × ×

× × × ×

× ×

×

×

×

× ×

×

Note 1: This mode is enabled by the door interlock function.

Note 2: The system is waiting for the index table indexing unclamp signal to turn

ON or OFF

I - 13

Page 30

1. LIST OF ALARMS

×

×

∆

∆

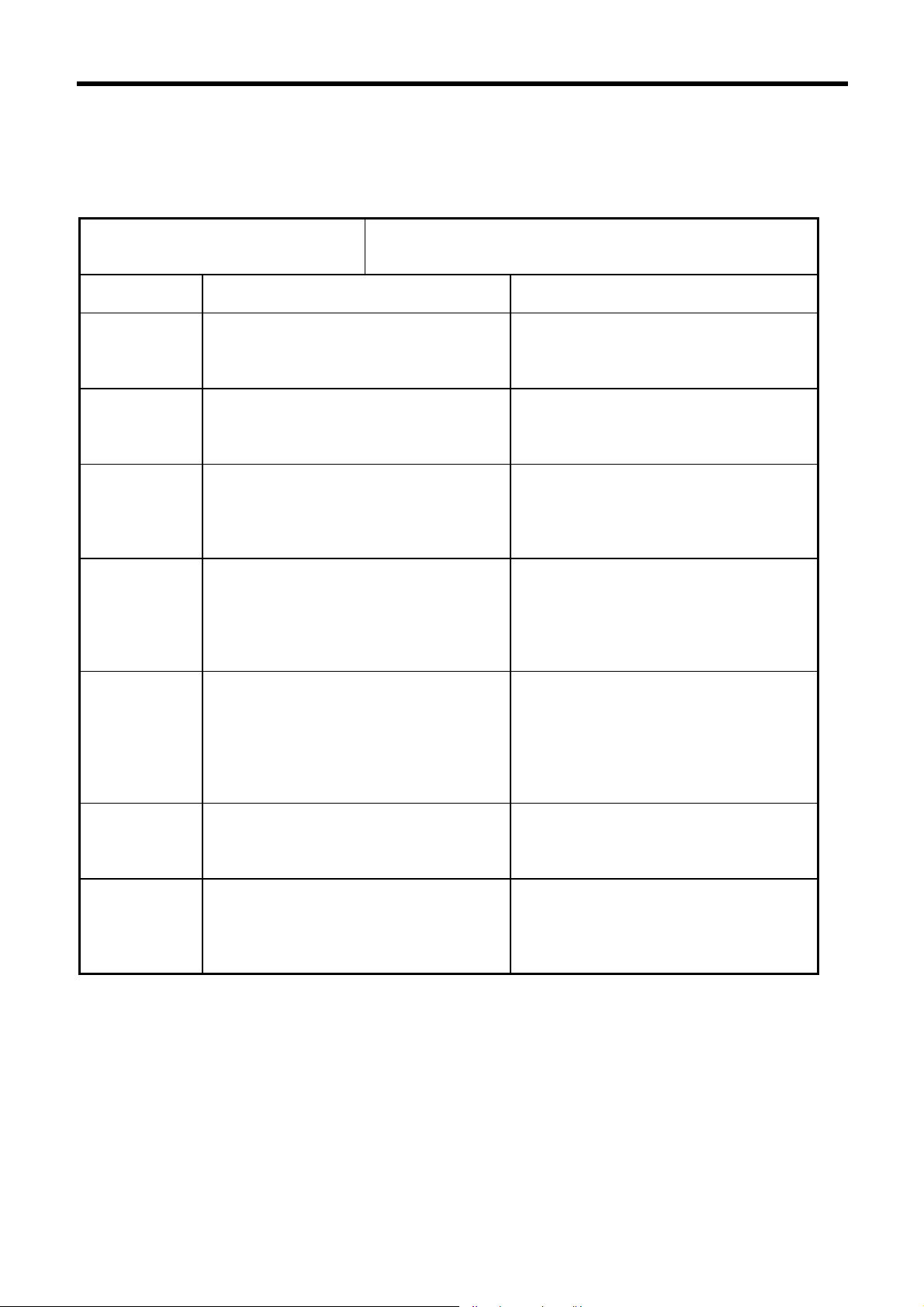

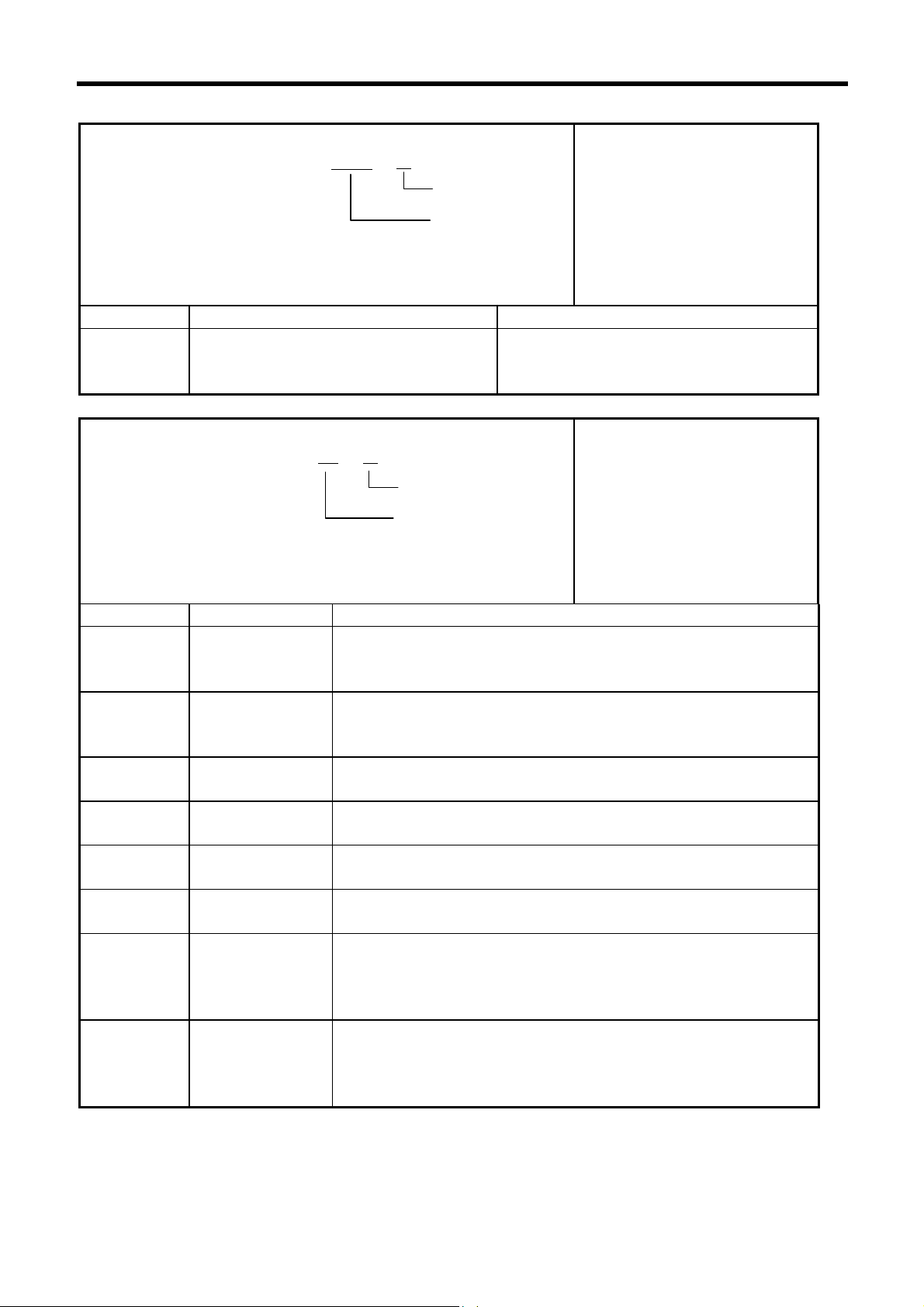

1.3 SERVO ALARMS

1.3 SERVO ALARMS

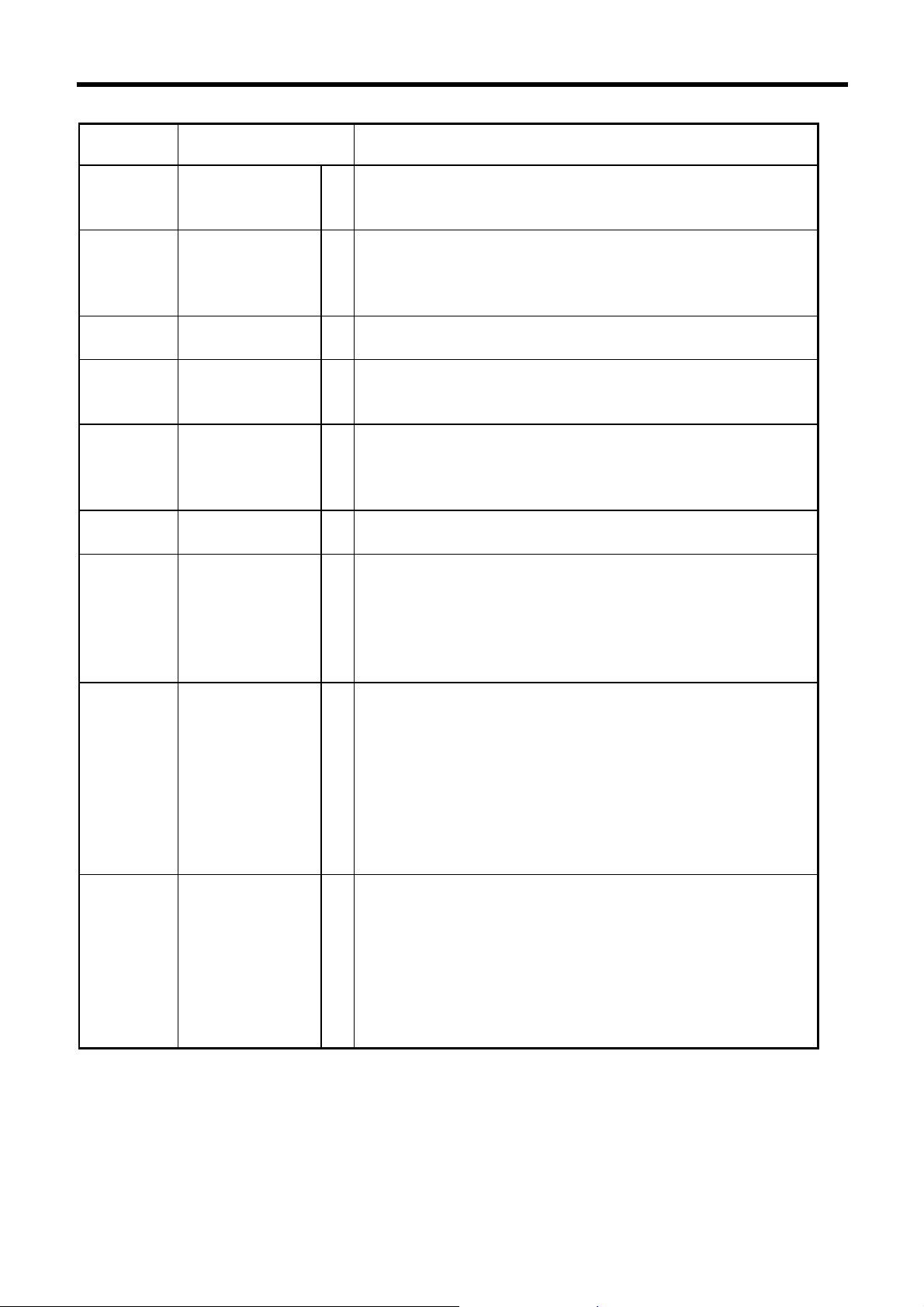

These alarms describe errors in the servo system such as the servo drive amplifier‚ motor and encoder.

The alarm message‚ alarm No. and Axis Name will display on the alarm message. The No. of the axis

where the alarm occurred and the alarm No. will also display on the servo monitor screen. If several alarms

have occurred‚ a max. of two errors per axis will display on the servo monitor screen.

If “S”, “T”, “M” or “N” is displayed as an axis name on the alarm message screen, the error is a spindle

alarm.

Refer to the section “Spindle alarms”.

(The bold characters are the messages displayed on the screen.)

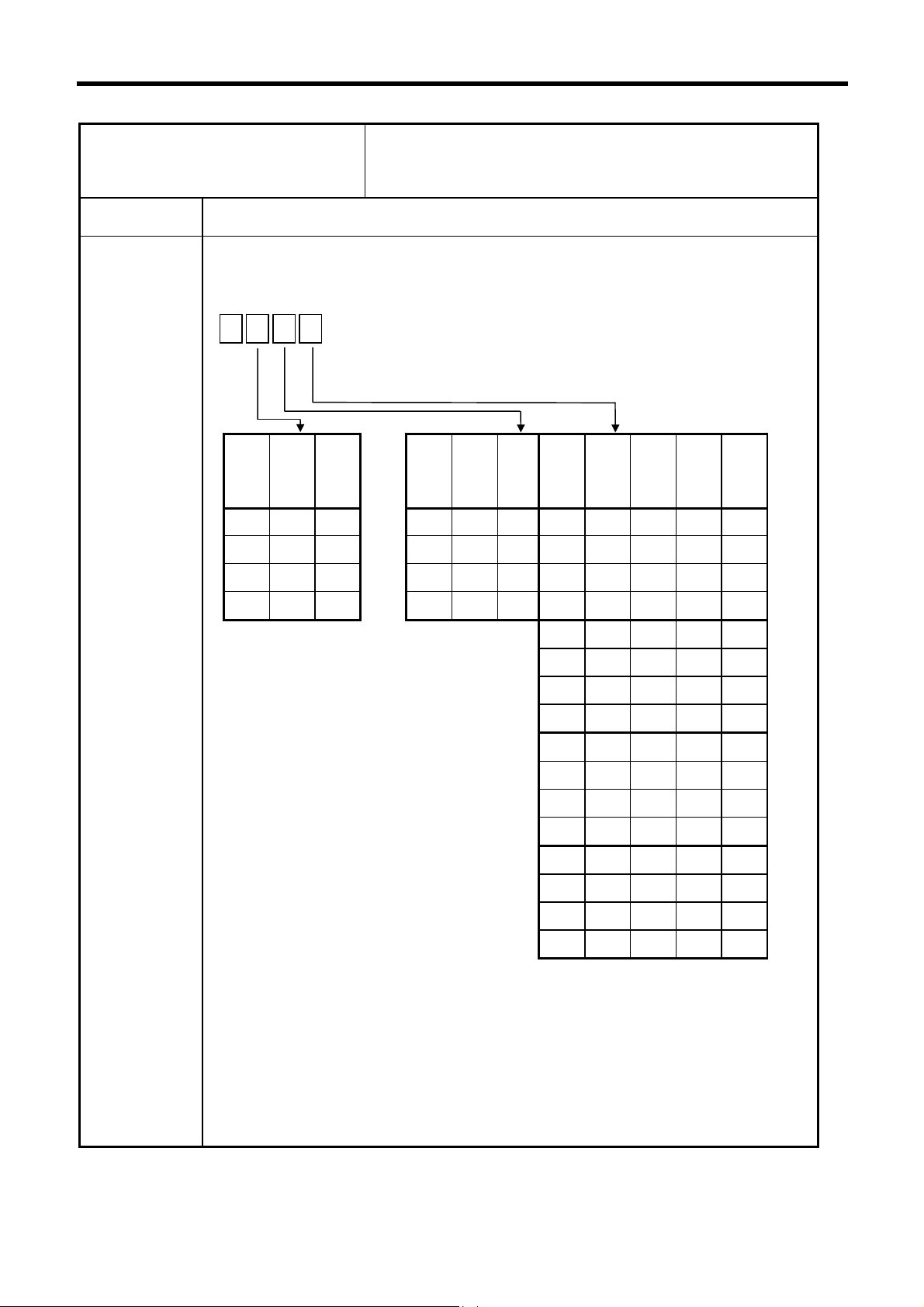

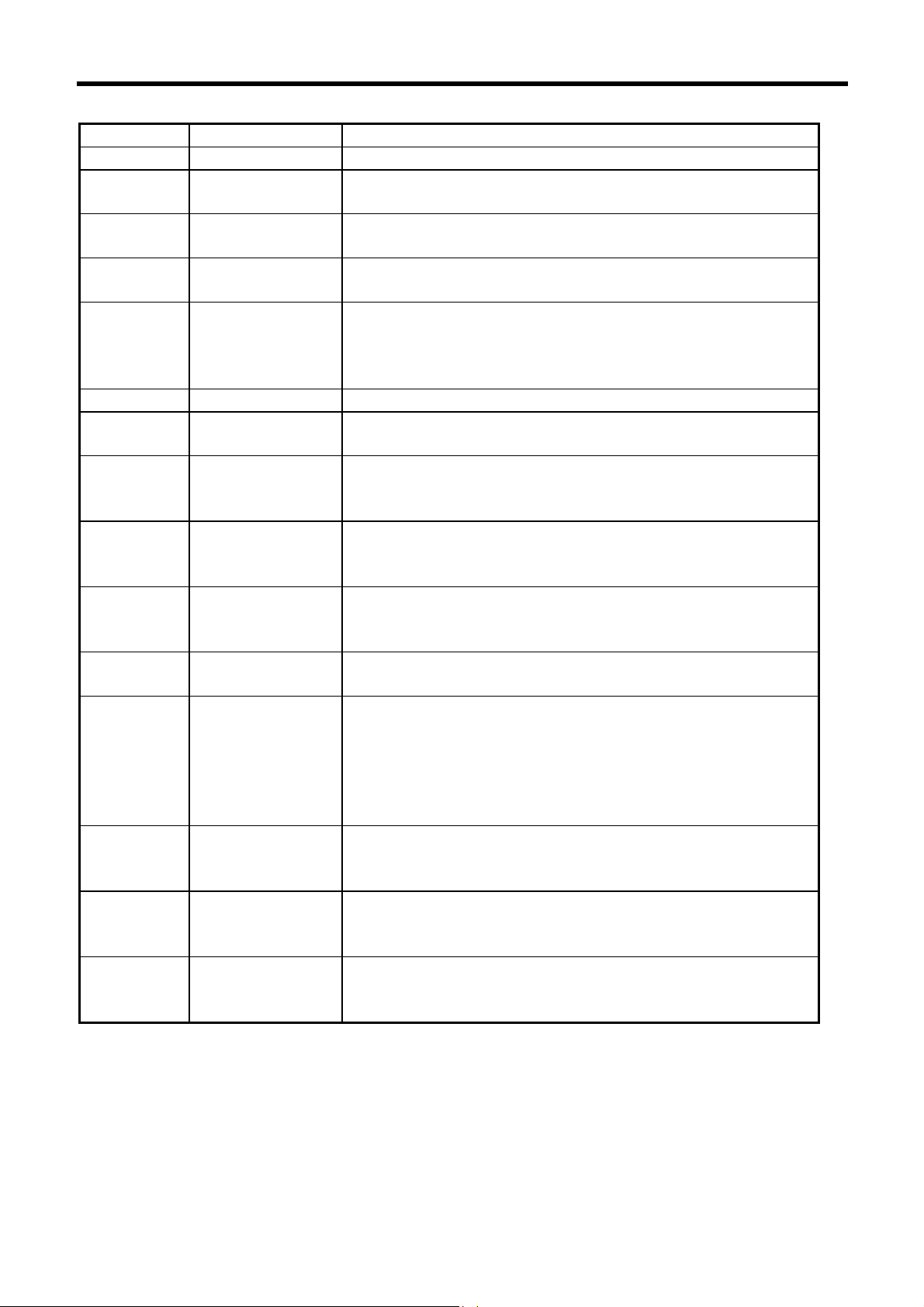

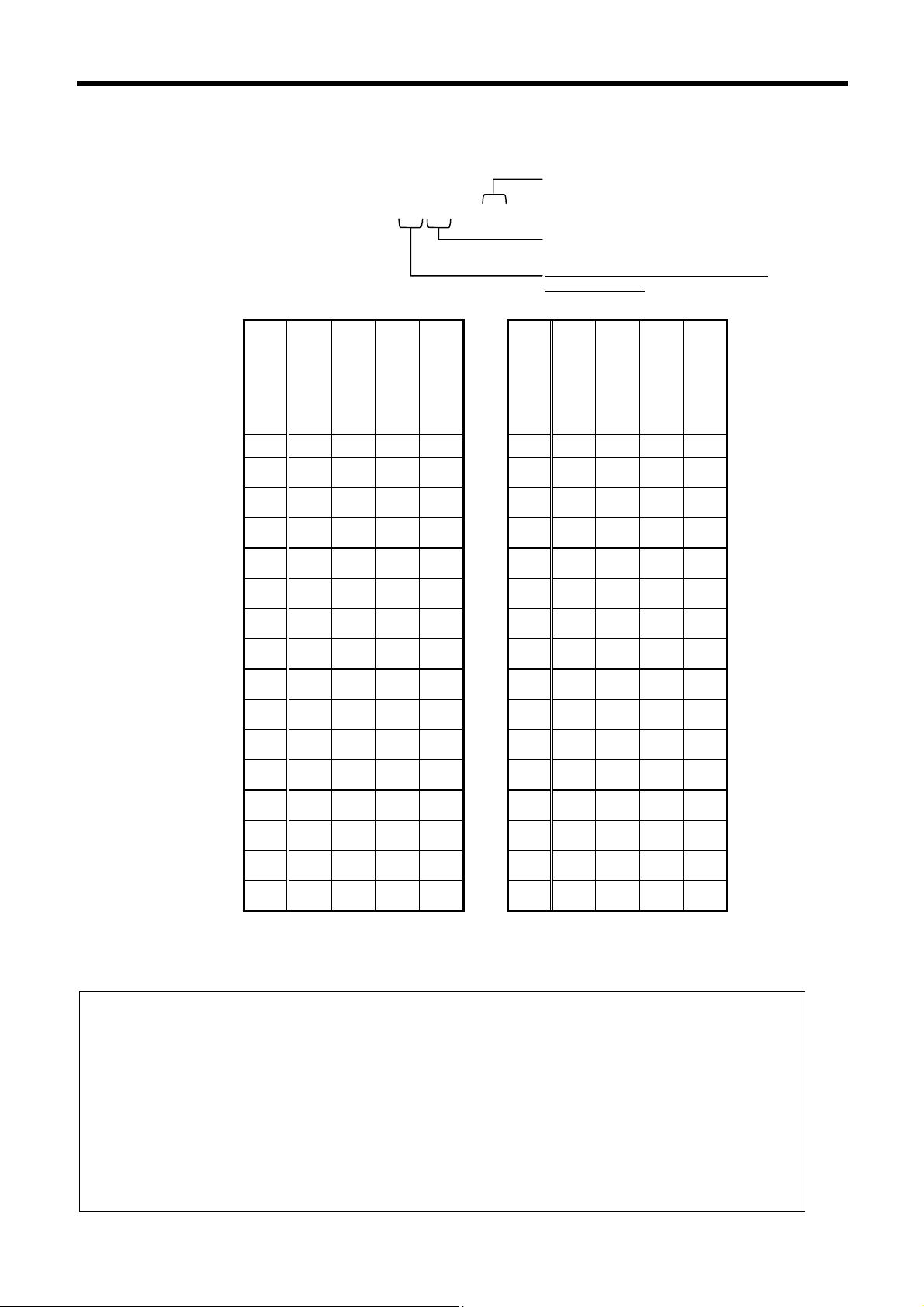

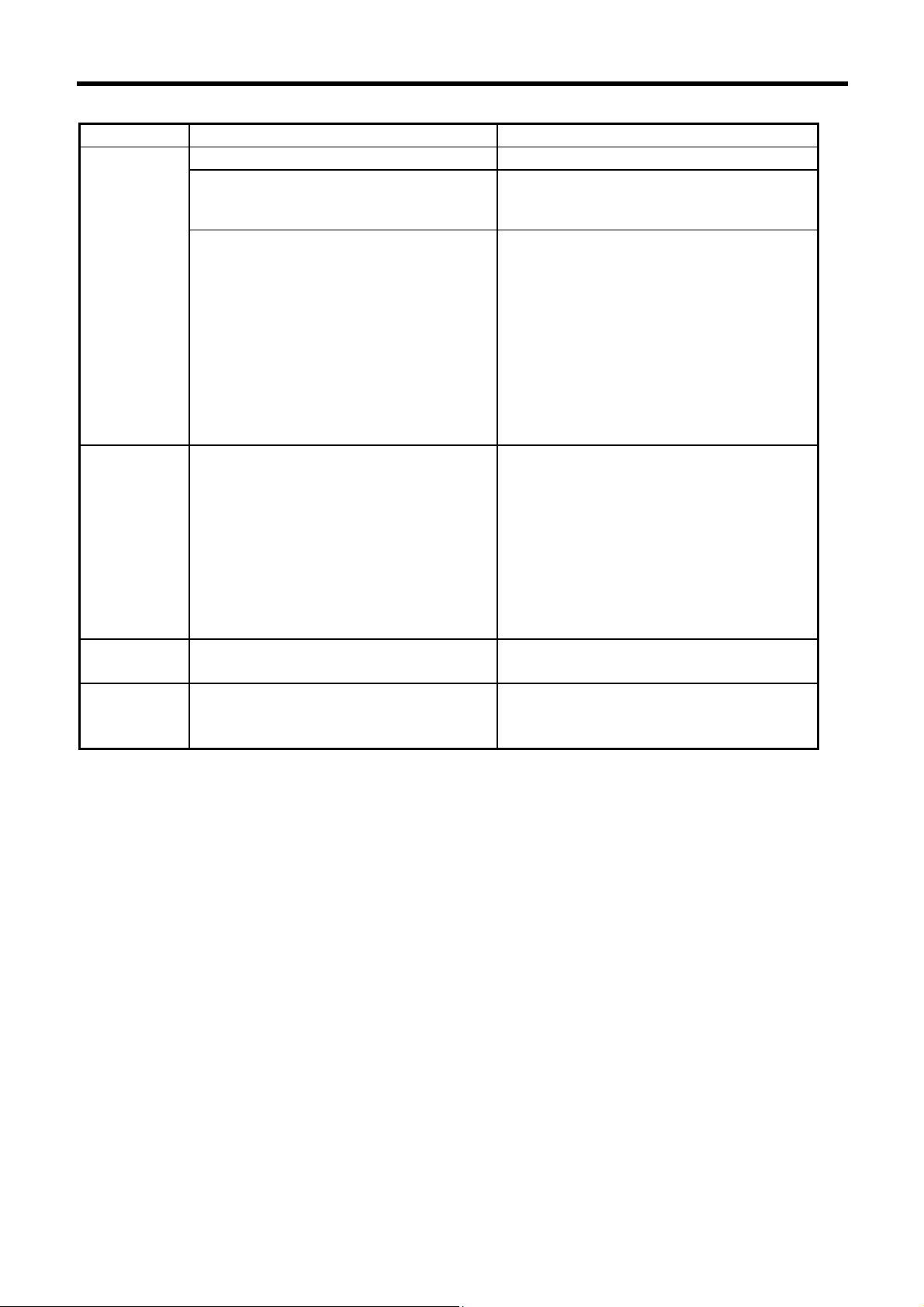

S

SERVO ALARM :

0 0

Axis name

Alarm No.

Alarm reset class

Alarm class

(Note 1) The alarm class and alarm reset class combinations are preset.

(Refer to the separate table for S02, S51 and S52.)

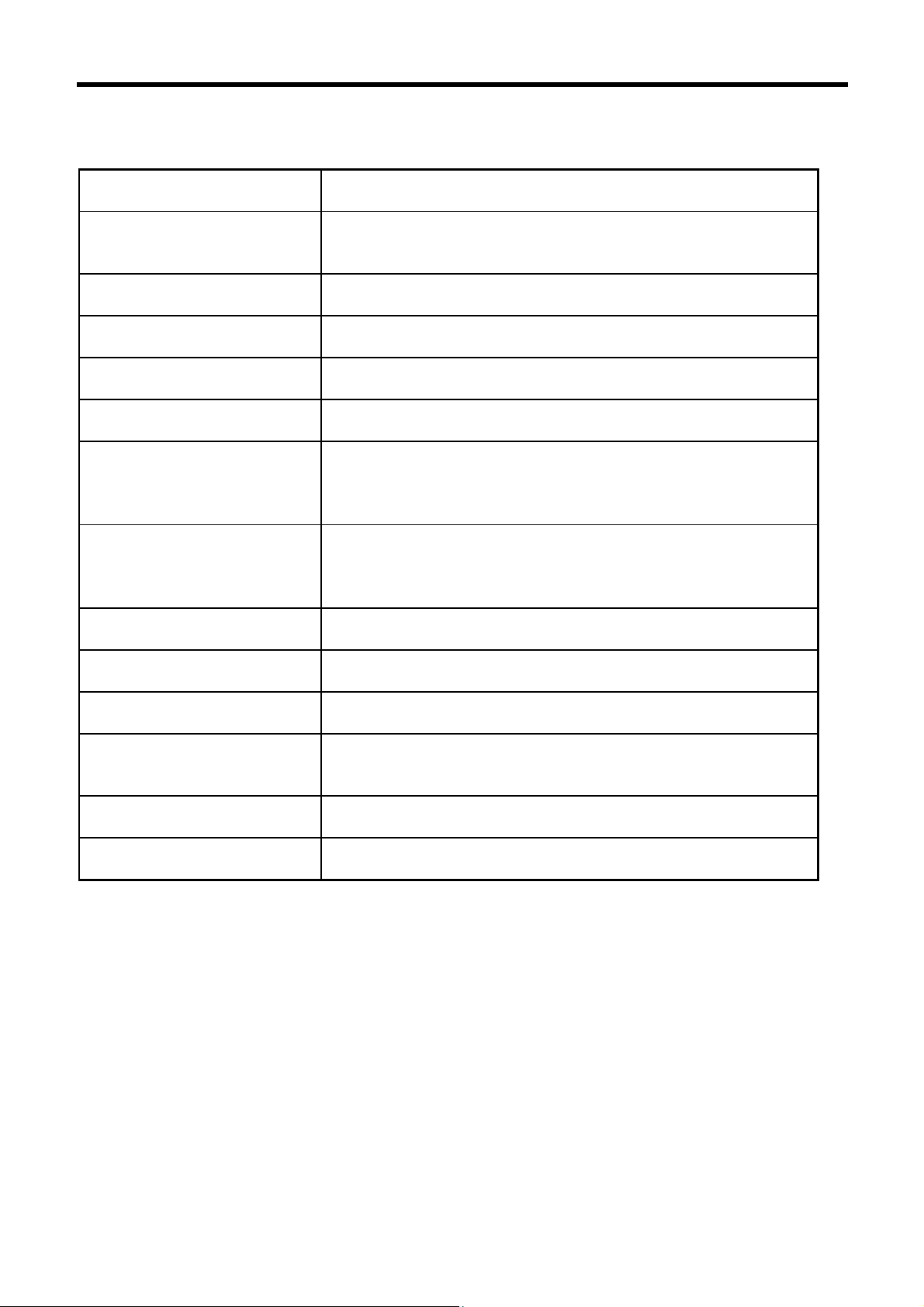

Alarm class Alarm reset class Resetting methods

S01 PR After removing the cause of the alarm, reset the

alarm by turning the NC power ON again.

S03 NR After removing the cause of the alarm, reset the

alarm by inputting the NC RESET key.

S04 AR After removing the cause of the alarm, reset the

alarm by turning the servo drive unit power ON

again.

(Note 2) The resetting method may change according to the alarm class.

For example, even if “S03 Servo error: NR” is displayed, it may be necessary to turn the NC

power ON again.

(Note 3) Refer to the spindle alarms if the axis name is “S”, “T”, “M” or “N”.

Alarm No. Name Meaning

10

11

12

13

14

15

Insufficient voltage PN bus voltage dropped to 200 V or lower.

Axis selection error The rotary switches for both axes are set to the same axis number

when using the 2-axis integrated amplifier. Otherwise, the switches

are set to an illegal value.

Memory error 1 An error occurred in a memory or FB IC by self-check to be made

during driver power-ON.

Software processing

error 1

Software processing

error 2

Memory error 2 Amplifier self-diagnosis error

The S/W process did not end within the specified time. (S/W

operation sequence or timing error)

The control IC is not operating correctly.

(The amplifier LED display will be “-”.)

I - 14

Page 31

1. LIST OF ALARMS

1.3 SERVO ALARMS

Alarm No. Name Meaning

16

Magnetic pole

position detection

An error occurred in the U, V, and W phases for polarity position

detection.

error

17

A/D converter error An error occurred in the A/D converter for current detection by

self-check to be made during driver power-ON.

A/D converter variables contain an abnormal value.

18

1A

Motor side detector:

Initial

communication error

Machine side

detector: Initial

The absolute position data was not sent properly with serial data

when the power was turned ON.

Initial communication with the detector could not be performed.

Initial communication with the detector cannot be performed in the

system that uses OHA25K-ET in the machine end detector.

communication error

1B

Machine side

detector: CPU error

In the high-speed serial detector connected to the machine end, an

error occurred in the data stored in an EEROM.

1

1C

Machine side

detector:

In the high-speed serial detector connected to the machine end, a

deteriorated LED was detected.

EEPROM/LED error

1D

1E

Machine side

detector: Data error

Machine side

detector: Memory

In the high-speed serial detector connected to the machine end, an

error occurred in a position within one rotation.

In the high-speed serial detector connected to the machine end, the

built-in thermal protector functioned.

error

1F

Machine side

detector:

In the high-speed serial detector connected to the machine end,

communication with the detector stopped.

Communication

error

20

21

22

24

Motor side detector:

No signal 1

Machine side

detector: No signal 2

LSI error LSI operation error

Grounding A grounded motor cable was detected. (Detected only in Ready ON

An abnormality was detected in the ABZ or UVW phase for the motor

end detector.

An abnormality was detected in the ABZ phase in a closed-loop

system.

state)

25

Absolute position

data lost

The absolute position data in the detector was lost.

(The backup voltage in the absolute position detector dropped. The

absolute position cannot be corrected.)

26

Unused axis error A power module error occurred in the axis set as [F] in the rotary

switch.

(Alarm issued only for 2-axis amplifier.)

27

Machine side

detector: CPU error

The CPU in the machine end absolute position detection linear scale

is malfunctioning.

2

I - 15

Page 32

1. LIST OF ALARMS

1.3 SERVO ALARMS

Alarm No. Name Meaning

28

Machine side

detector: Overspeed

The absolute position linear scale moved more than 45 mm/s during

initialization after the NC power was turned ON.

(Alarm output by linear scale.)

29

2A

2B

Machine side

detector: Absolute

position data error

Machine side

detector: Relative

position data error

Motor side detector:

CPU error 1

An error occurred in the scale or scale circuit for the absolute value

linear scale.

(Alarm is output from the linear scale.)

The absolute position linear scale has exceeded the maximum

movement speed.

(Alarm is output from the linear scale.)

Detector circuit error

In the motor end high-speed serial detector, an error occurred in the

data stored in an EEROM.

The scale CPU doesn’t operate properly.

(Alarm is output from the linear scale.)

2C

Motor side detector:

A deteriorated LED was detected in the detector.

EEPROM/LED error

2D

Motor side detector:

A detector position data error was detected.

Data error

2F

Motor side detector:

Communication

Communication with the detector stopped or receive data was

abnormal.

error

30

31

Over regeneration Overheating was detected in the regenerative resistor.

Overspeed A speed exceeding the motor’s tolerable rotation speed was

detected.

32

Power module

overcurrent

The overcurrent protector in the power module functioned.

An error occurred in the IPM used in the inverter. One of the

following factors can be considered.

(1) Overcurrent‚ (2) Overheat‚ (3) Drop in control power voltage‚ etc.

33

34

Overvoltage The PN bus voltage exceeded 400 V.

NC-DRV

An error occurred in the communication data from the NC.

communication:

CRC error

35

NC command error The movement command data from the NC is abnormally large in

amount.

36

NC-DRV

Communication from the NC stopped.

communication:

Communication

error

37

38

Initial parameter

error

NC-DRV

communication:

The servo parameter sent from the controller during initialization by

NC power-ON was illegal.

There was a protocol error in the communication with the NC.

(Frame error)

Protocol Error 1

39

NC-DRV

communication:

There was a protocol error in the communication with the NC.

(Information error)

Protocol Error 2

I - 16

Page 33

1. LIST OF ALARMS

1.3 SERVO ALARMS

Alarm No. Name Meaning

3A

3B

3C

Overcurrent The motor drive current is too large.

Power module

overheat

Regeneration circuit

An overheat in the IPM used for the servo drive’s main circuit was

detected.

A regeneration transistor or resistor error was detected.

error

42

Feedback error 1 A feedback pulse skip or Z-phase error occurred in the position

detector.

43

Feedback error 2 There is an excessive difference in the feedback amount between

the motor end detector and the machine end detector during a

closed loop. An FB IC error was also detected during semi-closed

loop.

46

48

49

Motor overheat The motor overheated.

Motor side detector:

CPU error 2

Motor side detector:

Overspeed

When using the linear servo system, the CPU in the absolute

position linear scale is malfunctioning.

When using the linear servo system, the absolute position linear

scale detected a speed exceeding 45m/s when the CNC power was

turned ON.

4A

Motor side detector:

Absolute position

When using the linear servo system, the absolute position linear

scale detected an error in the scale or scale circuit.

data error

4B

4F

Motor side detector:

Relative position

data error

Instantaneous

When using the linear servo system, the absolute position linear

scale detected a speed exceeding the maximum movement speed of

the absolute position scale.

A momentary power interrupt of 50 ms or longer was detected.

power interruption

50

Overload 1 Excessive loads were applied for an interval exceeding the specified

time.

The load level of the servomotor or servo driver can be calculated

from the motor current. This load level has reached the overload

level that is specified by the overload detection level (sv022: OLL)

and overload-time constant (sv021: OLT).

51

Overload 2 Excessive loads are applied, exceeding the specified time.

A current command exceeding 95% of the maximum driver capacity

continued for 1.0 second or more.

52

Excessive error 1 The difference between the ideal and actual positions has exceeded

parameter setting value

sv023: OD1 (or sv053: OD3) when the servo was turned ON.

53

Excessive error 2 The difference between the ideal and actual positions has exceeded

parameter setting value

sv026: OD2 when the servo was turned OFF.

I - 17

Page 34

1. LIST OF ALARMS

1.3 SERVO ALARMS

Alarm No. Name Meaning

54

Excessive error 3 When an excessive error or alarm 1 is detected, no motor current

flows. This error occurs when the power cable is loose or

disconnected or no voltage is applied to the bus.

55

External emergency

stop error

No contactor interrupt command is issued in 30 seconds after an

external emergency stop signal is input.

Check the settings for the emergency stop input signal and sv036

external emergency stop.

58

59

5A

5F

Collision detection 1:

G0

Collision detection 1:

G1

Collision detection 2 An interference or system 2 error was detected.

External contactor

An interference or system 1 error was detected in G0 modal (rapid

traverse feed) mode.

An interference or system 1 error was detected in G1 modal (cutting

speed) mode.

An outside contact fused.

welding

61

62

Power module

overcurrent

Frequency error A “power frequency error” was detected in the power supply unit.

The “regenerative overcurrent” alarm was generated on the power

supply unit side. (Alarm “1” on the power supply unit.)

(Alarm “2” on the power supply unit.)

63

65

Supplementary

regeneration error

Rush relay error The “rush current error” alarm was generated on the power supply

The “compensating regenerative error” alarm was generated on the

power supply unit side. (Alarm “3” on the power supply unit.)

unit side. (Alarm “5” on the power supply unit.)

67

Phase interruption The “open phase alarm” was generated on the power supply unit

side. (Alarm “7” on the power supply unit.)

68

Watchdog The “watch dog” alarm was generated on the power supply unit side.

(Alarm “8” on the power supply unit.)

69

Grounding The “motor ground fault” alarm was generated on the power supply

unit side. (Alarm “9” on the power supply unit.) For details refer to the

descriptions for the power supply unit’s alarms.

6A

External contactor

welding

“External contactor deposition” was detected on the power supply

unit side. (Alarm “A” on the power supply unit.)

I - 18

Page 35

1. LIST OF ALARMS

1.3 SERVO ALARMS

Alarm No. Name Meaning

6B

Rush relay welding “Rush relay deposition” was detected on the power supply unit side.

(Alarm “b” on the power supply unit.)

6C

Main circuit error “Main circuit error” was detected on the power supply unit side.

(Alarm “c” on the power supply unit.)

6D

Parameter error “Parameter value abnormal” was detected on the power supply unit

side. (Alarm “d” on the power supply unit.)

6E

Power supply PCB

combination error

Memory error “Memory error” was detected on the power supply unit side. (Alarm

An incorrect power PCB and control PCB combination was detected.

(Alarm “d” on the power supply unit.) (MDS-CH-CV Series only)

“E” on the power supply unit.)

6F

Power supply error • “AD converter error” was detected on the power supply unit side.

• It was recognized that the power supply is not connected. (Alarm

“F” on the power supply unit.)

71

Instantaneous

power

“Momentary power failure detection” alarm is generated on the

power supply unit side. (Alarm “H” on the power supply unit.)

interruption/External

emergency stop

73

Over regeneration “Overregeneration” alarm is generated on the power supply unit

side. (Alarm “J” on the power supply unit.)

74

75

Regenerative

resistor overheat

Overvoltage “Overvoltage” alarm is generated on the power supply unit side.

“Regeneration resistor overheated” alarm is generated on the power

supply unit side. (Alarm “K” on the power supply unit.)

(Alarm “L” on the power supply unit.)

76

77

7F

External emergency

stop setting error

Power module

overheat

Drive unit power

supply reclose

request

“External emergency stop setting abnormal” alarm is generated on

the power supply unit side. (Alarm “M” on the power supply unit.)

“Power module or PC board overheated” alarm is generated on the

power supply unit side. (Alarm “n” on the power supply unit.)

An error was detected when the high-gain mode and normal mode

was selected.

Turn the amplifier power ON again.

If this alarm is detected even after the amplifier power is turned ON

again after the alarm 7F is detected, there is an error in the

EEPROM.

Refer to the MELDAS AC Servo Maintenance Manual for details.

80

Detector converting

unit 1: Connection

The MDS-B-HR connected to the motor end detected an incorrect

connection or broken cable.

error

I - 19

Page 36

1. LIST OF ALARMS

1.3 SERVO ALARMS

Alarm No. Name Meaning

81

Detector converting

unit 1:

The MDS-B-HR connected to the motor end detected an error in the

communication with the absolute position detection scale.

Communication

error

83

Detector converting

unit 1: Judgment

The MDS-B-HR connected to the motor end could not judge the

connected scale's analog wave cycle.

error

84

85

86

Detector converting

unit 1: CPU error

Detector converting

unit 1: Data error

Detector converting

unit 1: Magnetic Pole

The CPU for the MDS-B-HR connected to the motor end is not

operating correctly.

An error was detected in the analog interpolation data for the

MDS-B-HR connected to the motor end.

An error was detected in the magnetic pole data of the MDS-B-HR

connected to the motor end.

error

88

89

Watchdog Servo system operation is abnormal.

Detector converting

unit 2: Connection

The MDS-B-HR connected to the machine end detected an incorrect

connection or broken cable.

error

8A

Detector converting

unit 2:

The MDS-B-HR connected to the machine end detected an error in

the communication with the absolute position detection scale.

Communication

error

8C

Detector converting

unit 2: Judgment

The MDS-B-HR connected to the machine end could not judge the

connected scale's analog wave cycle.

error

8D

8E

Detector converting

unit 2: CPU error

Detector converting

unit 2: Data error

The CPU for the MDS-B-HR connected to the machine end is not

operating correctly.

An error was detected in the analog interpolation data for the

MDS-B-HR connected to the machine end.

I - 20

Page 37

1. LIST OF ALARMS

A

A

1.3 SERVO ALARMS

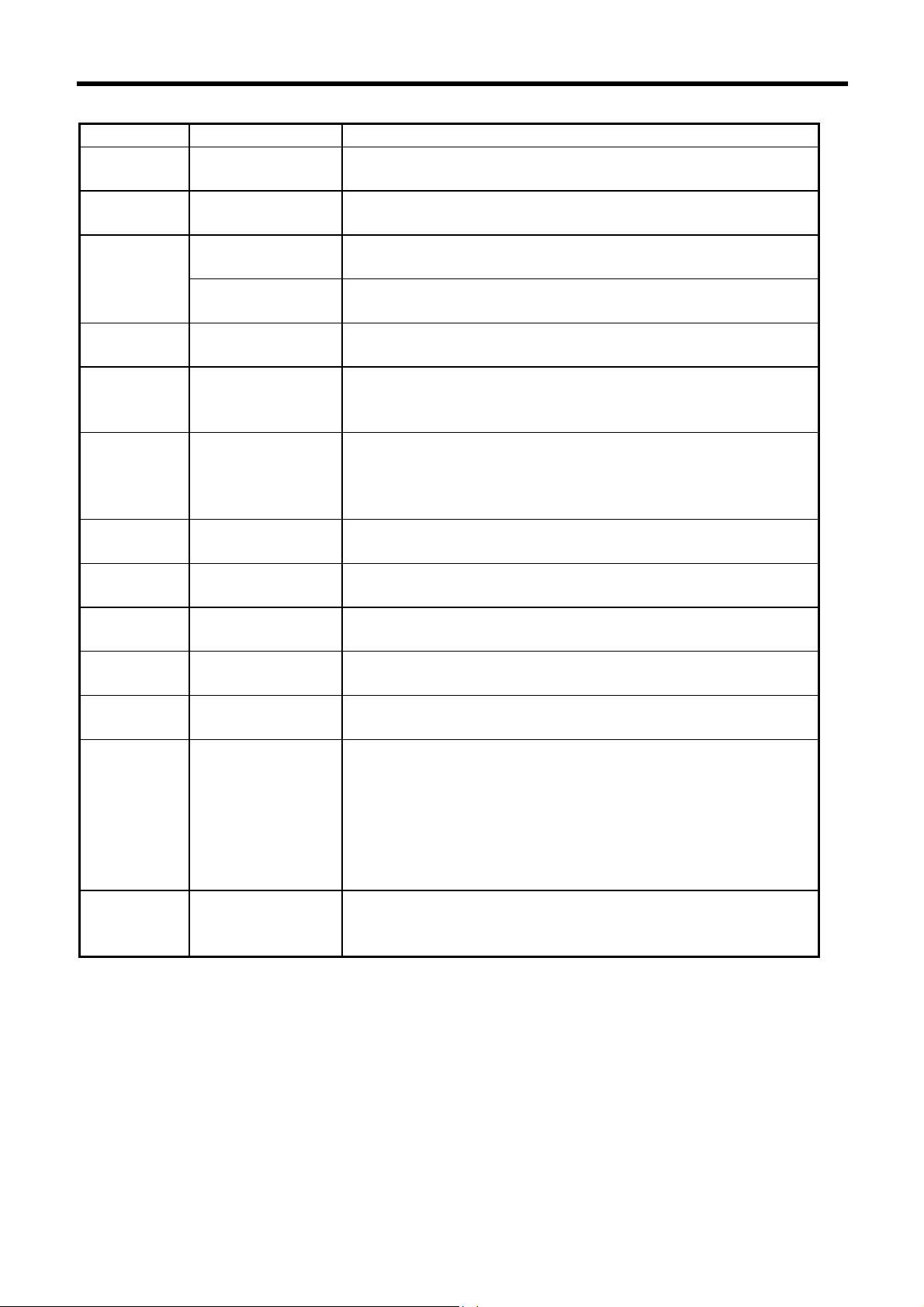

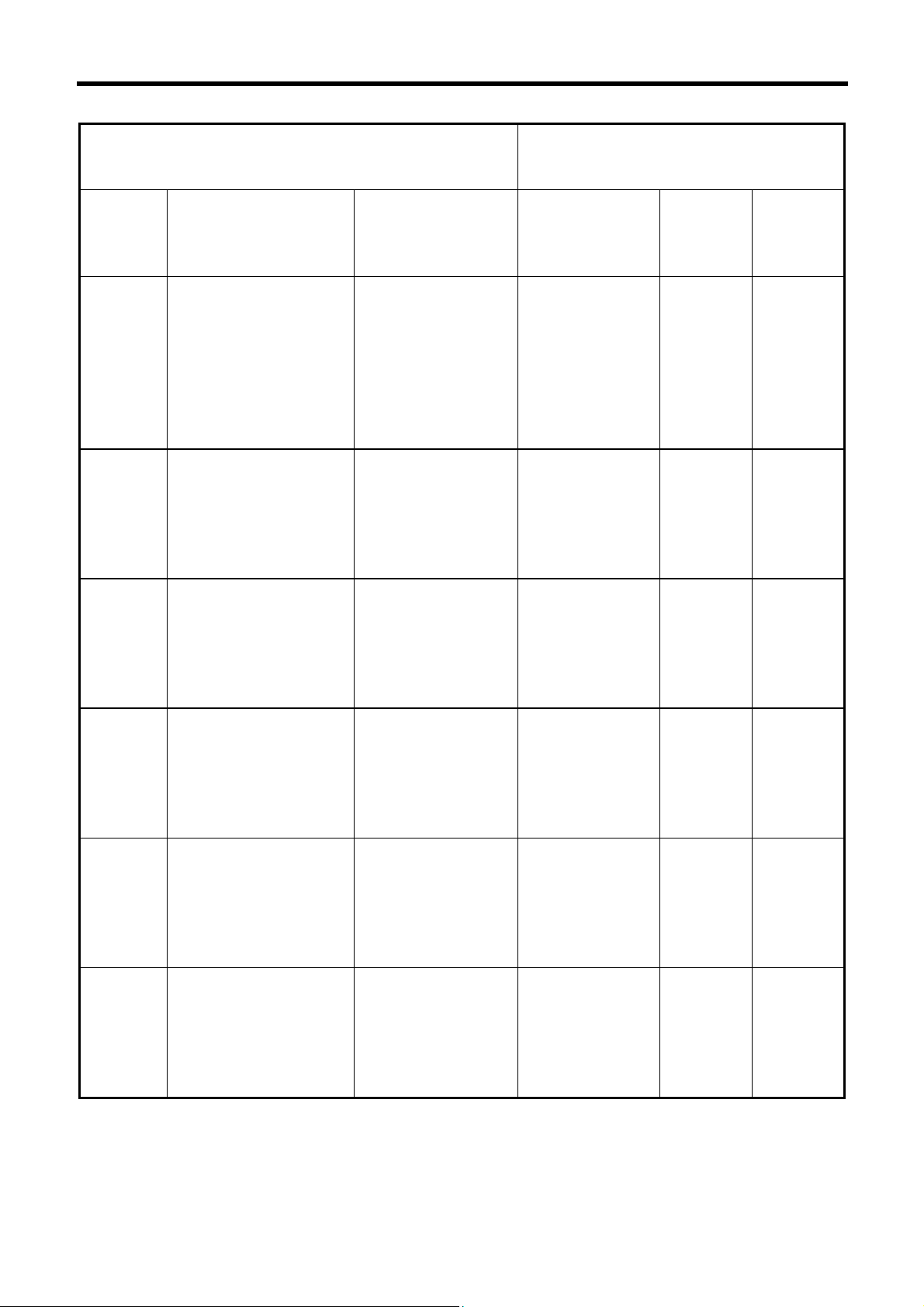

An error was found in the

S02 INIT PARAM ERR

∆∆∆∆

xis name

larm No. (parameter No.)

(Note) Refer to the spindle alarms if the axis name is “S”, “T”, “M” or

“N”.

Alarm No. Details Remedy

2201 – 2264

2301

2302

2303

2304

2305

The servo parameter setting data is illegal.

The alarm No. is the No. of the servo

parameter where the error occurred.

The number of constants to be used in the

following functions is too large:

• Electronic gears

• Position loop gain

• Speed feedback conversion

High-speed serial incremental detector

Parameters for absolute position detection

are set to ON during OSE104 and OSE105

connection.

Set the parameters for absolute position

detection to OFF.

To detect an absolute position, replace the

incremental specification detector with an

absolute position detector.

No servo option is found.

The closed loop (including the ball screwend detector) or dual feedback control

function is an option.

No servo option is found.

The SHG control function is an option.

No servo option is found.

The adaptive filtering function is an option.

Check the descriptions for the appropriate

parameters and correct them.

Check that all the related parameters are

specified correctly.

sv001:PC1, sv002:PC2, sv003:PGN1

sv018:PIT, sv019:RNG1, sv020:RNG2

Check that all the related parameters are

specified correctly.

sv017:SPEC, sv025:MTYP

Check that all the related parameters are

specified correctly.

sv025:MTYP/pen

sv017:SPEC/dfbx

Check that all the related parameters are

specified correctly.

sv057:SHGC

sv058:SHGCsp

Check that all the related parameters are

specified correctly.

sv027:SSF1/aflt

parameters transmitted from the

controller to the spindle amplifier

when the power was turned ON.

Remove the cause of the alarm,

and then reset the alarm by

turning the controller power OFF

once.

I - 21

Page 38

1. LIST OF ALARMS

A

A

A

A

1.3 SERVO ALARMS

A warning appears if a

S51 PARAMETER ERROR

∆∆∆∆

xis name

larm No.

(parameter No.)

(Note) Refer to the spindle alarms if the axis name is “S”, “T”, “M” or

“N”.

Alarm No. Details Remedy

2201 – 2264

Servo parameter setting data is illegal.

The alarm No. is the No. of the servo

parameter where the warning occurred.

Check the descriptions for the appropriate

parameters and correct them.

parameter set outside the

tolerable range is set.

Illegal settings will be ignored.

This alarm will be reset when the

correct value is set.

The servo warning is displayed.

S52 SERVO WARNING 0 0 ∆∆

xis name

larm No.

(Warning No.)

(Note) Refer to the spindle alarms if the axis name is “S”, “T”, “M” or

“N”.

Alarm No. Name Meaning

90

91

92

93

96

97

9B

9C

Detector: Initial

communication

error

Detector:

Communication

error

Detector: Protocol

error

Initial absolute

position fluctuation

Scale feedback

error

Scale offset error An error occurred in the offset data to be read during initialization by

Detector

converting unit:

Magnetic pole shift

warning

Detector

converting unit:

Magnetic pole

warning

Initial communication with the absolute position linear scale cannot be

performed.

An error occurred in communication with the detector in the absolute

position detector.

An error occurred in the data from the detector in the absolute position

detector.

The absolute position data fluctuated when the power was turned ON

so the absolute value counter could not be set.

There is an excessive difference in the feedback amount between the

motor end detector and the MP scale in the absolute position detector.

NC power-ON in the absolute position detector of the MP scale.

When using the linear servo system, an error was detected in the

magnetic pole shift amount set in sv028.

When using the linear servo system, an error was detected in the

magnetic pole data of the MDS-B-HR connected to the MAIN side

after the Z phase was passed.

I - 22

Page 39

1. LIST OF ALARMS

1.3 SERVO ALARMS

Alarm No. Name Meaning

9E

9F

E0

E1

Absolute position

detector:

Revolution counter

error

Battery voltage

drop

Over regeneration

warning

Overload warning An 80% level of the overload 1 alarm was detected. This is not an

An error occurred in the rotation counter in the detector. An error

occurred in the rotation counter in

OSE104/OSA104/OSE105/OSA105/OSE104-ET/OSA104-ET/OSE1

05-ET/OSA105-ET. The absolute position cannot be corrected.

The voltage of the battery supplying to the absolute value detector

dropped.

An 80% level of the regeneration alarm was detected. (The

regeneration alarm may occur if operation is continued.)

alarm so the servo will not turn OFF‚ but if operation is continued‚

overload 1 alarm may occur.

E3

Absolute position

There is a difference between absolute and relative position data.

counter warning

E4

Set parameter

A parameter setting exceeding the setting range was set.

warning

E6

Control axis

A control axis removal command has been issued. (Status display)

detachment

warning

E8

Excessive

supplementary

The auxiliary regeneration cycle was too high in the power supply unit.

(Alarm “o” from the power supply unit)

regeneration

frequency

E9

Instantaneous

power interruption

A momentary power interrupt of 25 to 50 ms occurred. (Alarm “p” from

the power supply unit.)

warning

EA

In external

emergency stop

The power supply enters an emergency stop state by receiving the

stop signal from the NC. (Alarm “q” from the power supply unit)

state

EB

Over regeneration

warning

An excessive-regeneration alarm was generated from the power

supply unit. (Alarm “r” from the power supply unit.)

I - 23

Page 40

1. LIST OF ALARMS

×

×

∆

∆

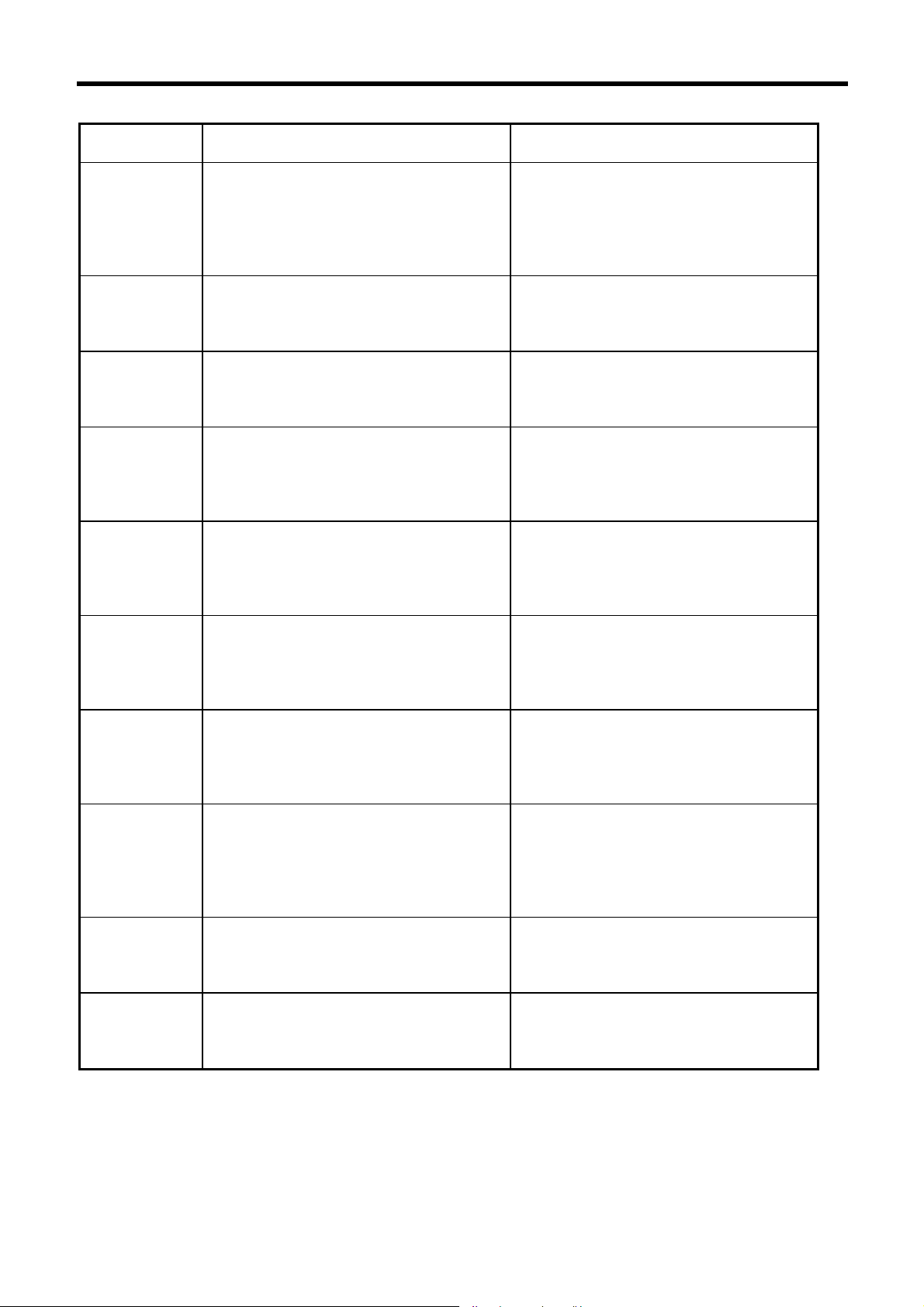

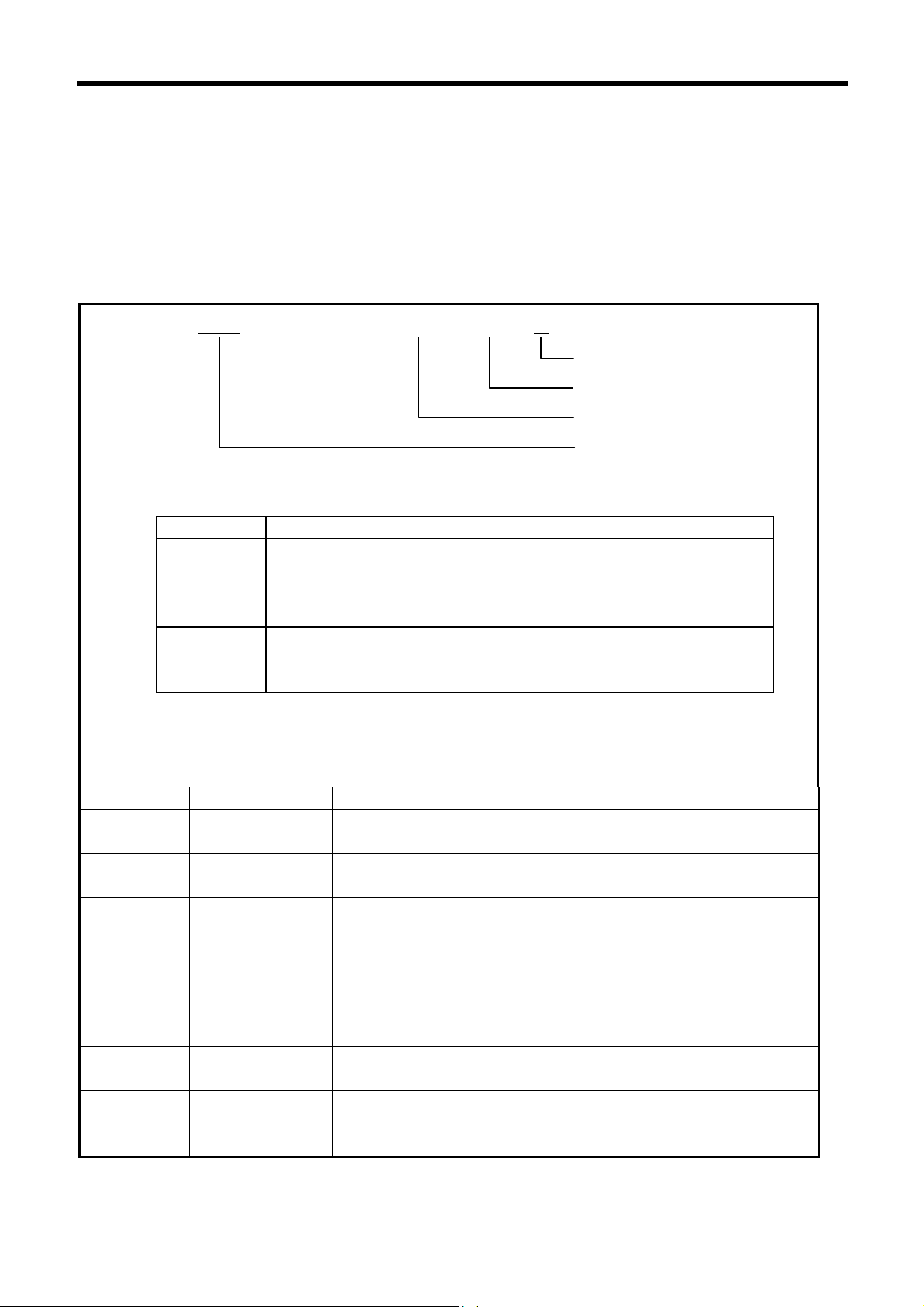

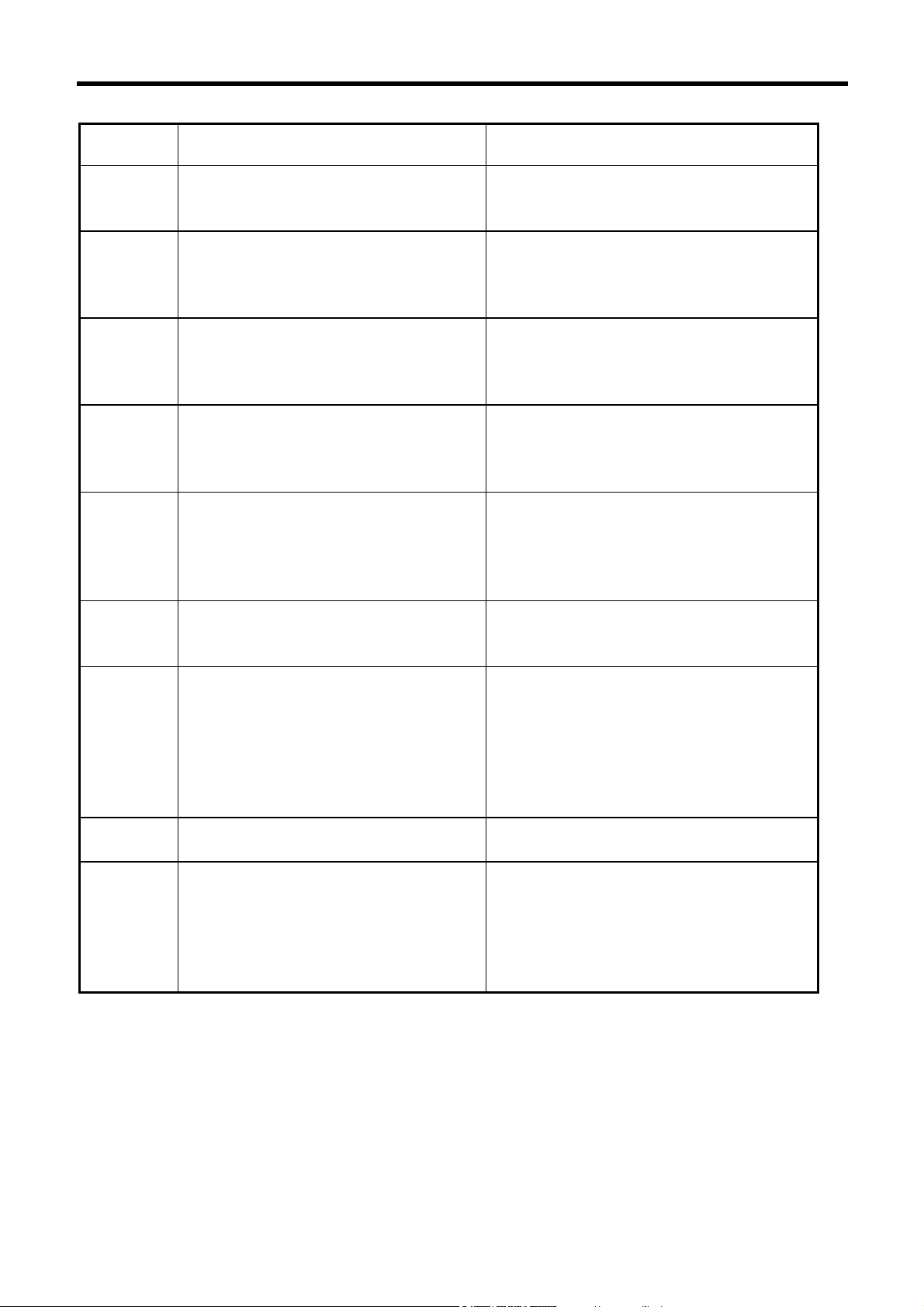

1.4 SPINDLE ALARMS

1.4 SPINDLE ALARMS

These alarms describe errors in the spindle system such as the spindle amplifier‚ motor and encoder.

The alarm message, alarm number, and axis name (S: 1st spindle, T: 2nd spindle, M: 3rd spindle, N: 4th

spindle) will display on the alarm message screen. If several alarms have occurred, the number of the

alarm that occurred last and the other alarm numbers will display on the spindle monitor screen for

confirmation. If an axis name other than “S”, “T”, “M” and “N” is displayed, the alarm is a servo alarm.

Refer to the section “Servo alarms”. (The bold characters are the messages displayed on the screen.)

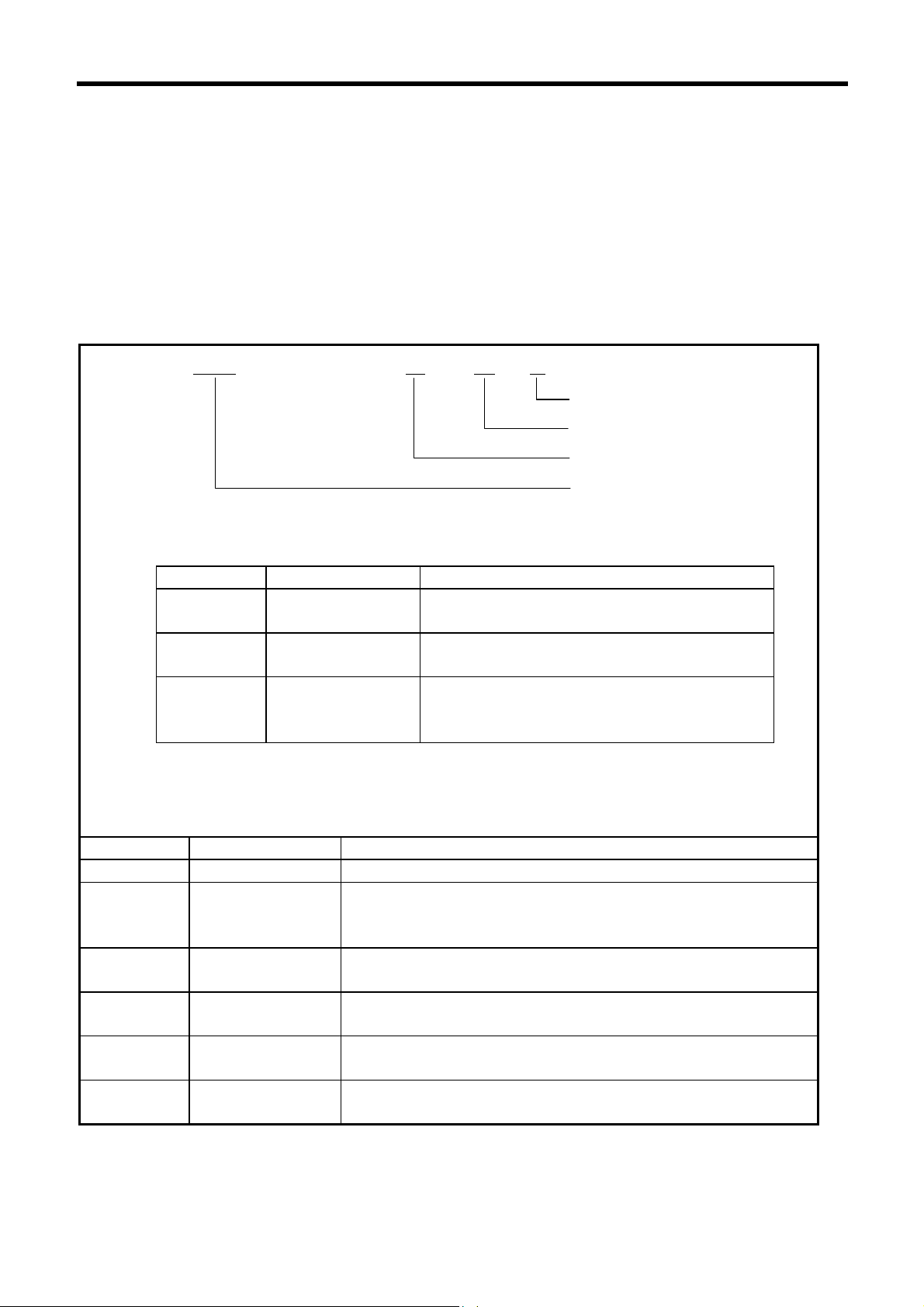

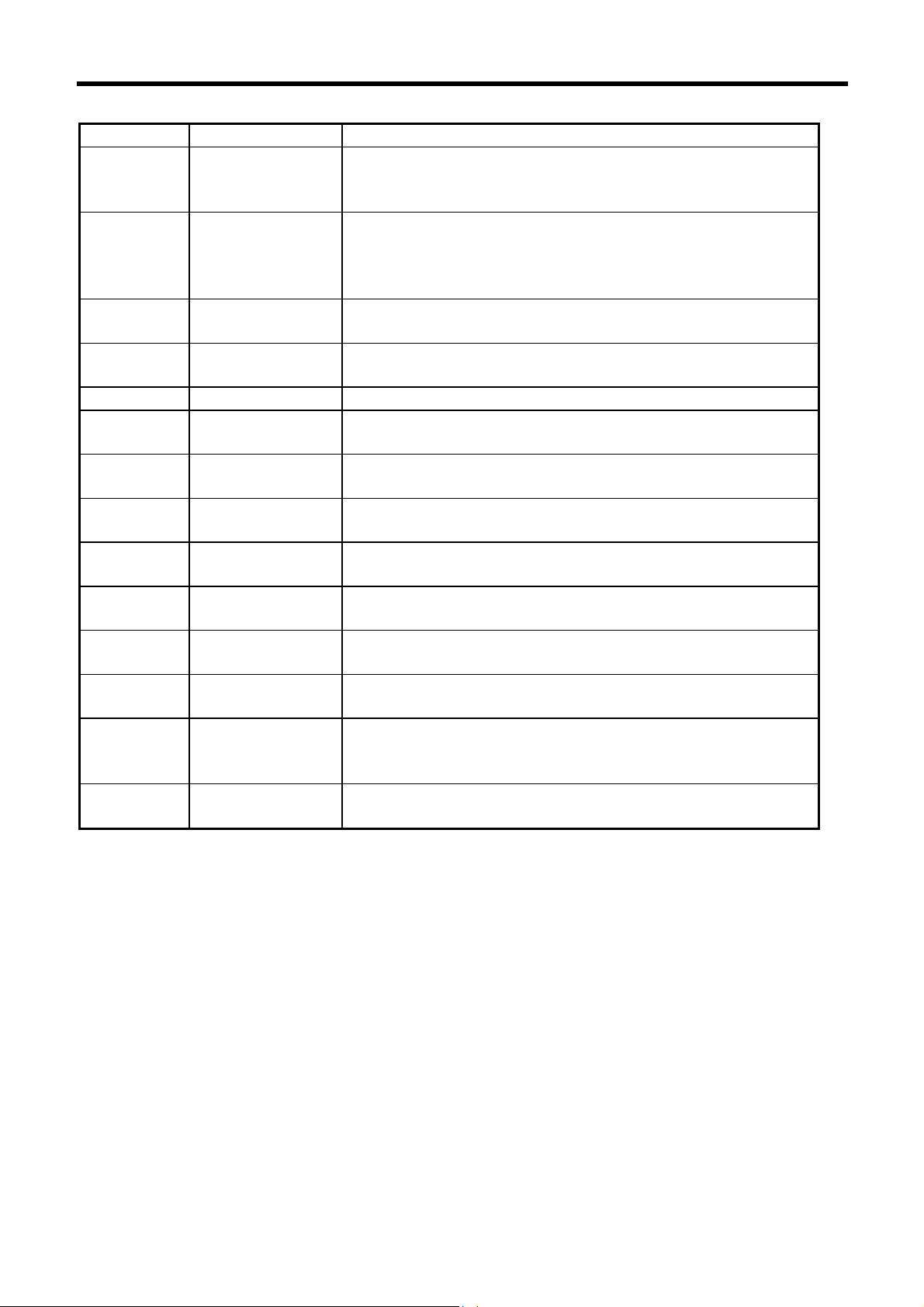

S

SERVO ALARM :

0 0

Axis name

Alarm No.

Alarm reset class

Alarm class

(Note 1) The alarm class and alarm reset class combinations are preset.

(Refer to the separate table for S02, S51 and S52.)

Alarm class Alarm reset class Resetting methods

S01 PR After removing the cause of the alarm, reset the

alarm by turning the NC power ON again.

S03 NR After removing the cause of the alarm, reset the

alarm by inputting the NC RESET key.

S04 AR After removing the cause of the alarm, reset the

alarm by turning the servo drive unit power ON

again.

(Note 2) The resetting method may change according to the alarm class.

For example, even if “S03 Servo error: NR” is displayed, it may be necessary to turn the NC

power ON again.

(Note 3) Refer to the servo alarms if the axis name is other than “S”, “T”, “M” and “N”.

Alarm No. Name Meaning

12

13

16

17

20

Memory error 1 A check sum or RAM check error occurred in the ROM of the spindle

drive’s control card.

Software

processing error 1

Magnetic pole

position detection

error

A/D converter error The AD converter for current detection did not function normally

Motor side

detector: No signal

1

The S/W process did not end within the specified time.

The start signal was input before the Z-phase of the magnetic pole

position was automatically adjusted.

Or, the number of initial magnetic pole estimation retry times (10 times

or more) was exceeded.

(After replacing the spindle amplifier, set parameter (SP205: ZCHS) to

1 from 0, carry out Z phase automatic adjustment, and then turn the

power ON again.)

during initialization.

A signal was not input from the PLG‚ or was not at a normal level.

I - 24

Page 41

1. LIST OF ALARMS

1.4 SPINDLE ALARMS

Alarm No. Name Meaning

21

Machine side

detector: No signal

A signal was not input from the spindle encoder (for orient‚ C axis)‚ or

was not at a normal level.

2

23

Excessive speed

error 1

The command speed and motor speed difference was above the

specified value‚ and the state continued for the specified time.

This may also occur when the coil changeover contactor is not the

specified contactor.

30

31

32

Over regeneration Overheating was detected in the regenerative resistor.

Overspeed The motor speed exceeded 115% of the set max. speed.

Power module

overcurrent

A current exceeding the specified value flowed to the spindle drive’s

main circuit.

This may also occur when the coil changeover contactor is not the

specified contactor.

33

Overvoltage The bus voltage in the driver exceeded 400V.

This may also occur when the coil changeover contactor is not the

specified contactor.

34

NC-DRV

A CRC error occurred in the communication data from the controller.

communication:

CRC error

35

NC command error The movement command data from the controller is abnormally high

during position control.

36

NC-DRV

The periodic data transmission from the controller was stopped.

communication:

Communication

error

37

38

Initial parameter

error

NC-DRV

communication:

The servo parameter sent from the controller during initialization of the

driver was illegal.

There was a protocol error in the communication with the controller.

(Frame error)

Protocol error 1

39

NC-DRV

communication:

There was a protocol error in the communication with the controller.

(Information error)

Protocol error 2

3A

Overcurrent The command current reached the spindle drive's maximum output

current and continued for one second or more.

3B

Power module

An overheat in the IPM used for the driver’s main circuit was detected.

overheat

3D

Spindle motor

locked

A state in which the motor speed did not reach 45r/min or more even

when the maximum torque command value reached the time set in the

parameter SP239 (3 seconds when set to 0) was detected.

3E

Spindle speed

overrun

1. A state in which the motor was continuously accelerated even

when the speed feedback exceeded 112.5% (detection speed) of

the commanded speed was detected. (Note that if a speed less

than the parameter SP237 (1000r/min when set to 0) setting is

commanded, the detection speed will be the speed command

value + SP237∗1.125.)

2. Motor rotation exceeding the value set with parameter SP206

(when set to 0: 10 deg.) was detected even though the speed

command was 0 (including when stopped during position control).

I - 25

Page 42

1. LIST OF ALARMS

1.4 SPINDLE ALARMS

Alarm No. Name Meaning

3F

Excessive speed

error 2

The state in which the speed range set by parameter SP238 (30%

when set to 0) was exceeded while rotating at a constant speed with

speed control exceeded the time set in parameter SP239 (3 seconds

when set to 0).

40

41

Detector selection

unit switching error

Detector selection

unit

The procedure for changing the signal during use of the TK unit is

wrong.

Communication with the TK unit during use of the TK unit was

incorrect.

communication

error

42

Feedback error 1 1. A PLG error was detected during PLG automatic compensation.

2. The correct Z phase was not detected even when the motor

rotated several times during Z phase automatic adjustment.

3. An abnormal number of feedback pulses was continuously

detected during normal operation.

43

Feedback error 2 A deviation occurred in the feedback from the spindle encoder and

motor built-in encoder.

44

Inappropriate

winding selected

When using the coil changeover motor, the C axis mode was entered

when the H coil or M coil was selected.

for C axis

46

Motor overheat The motor overheated and the thermal protector functioned during an

overload or when the motor cooling blower stopped.

4E

NC command

mode error

The spindle control mode was selected several times.

(If the input was unexpected, the mode will return to the speed control