Page 1

BUS CONNECTION

DIRECT CONNECTION TO CPU

COMPUTER LINK CONNECTION

ETHERNET CONNECTION

MELSECNET/H CONNECTION

MELSECNET/10 CONNECTION

CC-Link IE CONNECTION

CC-Link CONNECTION

INVERTER CONNECTION

SERVO AMPLIFIER CONNECTION

ROBOT CONTROLLER CONNECTION

CNC CONNECTION

GOT MULTI-DROP CONNECTION

MULTIPLE-GT14, GT12, GT11, GT10 CONNECTION FUNCTION

MULTI-CHANNEL FUNCTION

FA TRANSPARENT FUNCTION

Series

Connection Manual

(Mitsubishi Products)

BUS CONNECTION

BUS CONNECTION

DIRECT CONNECTION TO CPU

DIRECT CONNECTION TO CPU

COMPUTER LINK CONNECTION

COMPUTER LINK CONNECTION

ETHERNET CONNECTION

ETHERNET CONNECTION

MELSECNET/H CONNECTION

MELSECNET/H CONNECTION

MELSECNET/10 CONNECTION

MELSECNET/10 CONNECTION

CC-Link IE CONNECTION

CC-Link IE CONNECTION

CC-Link CONNECTION

CC-Link CONNECTION

INVERTER CONNECTION

INVERTER CONNECTION

SERVO AMPLIFIER CONNECTION

SERVO AMPLIFIER CONNECTION

ROBOT CONTROLLER CONNECTION

ROBOT CONTROLLER CONNECTION

for GT Works3 (ELE)

CNC CONNECTION

CNC CONNECTION

GOT MULTI-DROP CONNECTION

GOT MULTI-DROP CONNECTION

MULTIPLE-GT14, GT12, GT11, GT10 CONNECTION FUNCTION

MULTIPLE-GT14, GT12, GT11, GT10 CONNECTION FUNCTION

MULTI-CHANNEL FUNCTION

MULTI-CHANNEL FUNCTION

FA TRANSPARENT FUNCTION

FA TRANSPARENT FUNCTION

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight personal injury or physical damage.

(Always read these precautions before using this equipment.)

Before using this product, please read this manual and the relevant manuals introduced in this manual

carefully and pay full attention to safety to handle the product correctly.

The precautions given in this manual are concerned with this product.

In this manual, the safety precautions are ranked as "WARNING" and "CAUTION".

Note that the caution level may lead to a serious accident according to the circumstances.

Always follow the instructions of both levels because they are important to personal safety.

Please save this manual to make it accessible when required and always forward it to the end user.

[DESIGN PRECAUTIONS]

WARNING

● Some failures of the GOT, communication unit or cable may keep the outputs on or off.

An external monitoring circuit should be provided to check for output signals which may lead to a

serious accident.

Not doing so can cause an accident due to false output or malfunction.

● If a communication fault (including cable disconnection) occurs during monitoring on the GOT,

communication between the GOT and PLC CPU is suspended and the GOT becomes inoperative.

For bus connection : The CPU becomes faulty and the GOT becomes inoperative.

For other than bus connection : The GOT becomes inoperative.

A system where the GOT is used should be configured to perform any significant operation to the

system by using the switches of a device other than the GOT on the assumption that a GOT

communication fault will occur.

Not doing so can cause an accident due to false output or malfunction.

● Do not use the GOT as the warning device that may cause a serious accident.

An independent and redundant hardware or mechanical interlock is required to configure the device

that displays and outputs serious warning.

Failure to observe this instruction may result in an accident due to incorrect output or malfunction.

A - 1

Page 4

[DESIGN PRECAUTIONS]

WARNING

● Incorrect operation of the touch switch(s) may lead to a serious accident if the GOT backlight is gone

out.

When the GOT backlight goes out, the display section dims, while the input of the touch switch(s)

remains active.

This may confuse an operator in thinking that the GOT is in "screensaver" mode, who then tries to

release the GOT from this mode by touching the display section, which may cause a touch switch to

operate.

Note that the following occurs on the GOT when the backlight goes out.

<When using the GT1655-V, Handy GOT, GT15, GT14, GT12, GT11, or GT105 >

The POWER LED blinks (green/orange) and the monitor screen appears blank.

<When using the GT1695, GT1685, GT1675, GT1672, GT1665, or GT1662>

The POWER LED blinks (green/orange) and the monitor screen appears dimmed.

<When using the GT104 >

The monitor screen appears blank.

<When using the GT103 or GT102 >

The monitor screen appears dimmed.

● The display section of the GT16, GT1595-X, GT14, GT12 or GT1020 are an analog-resistive type

touch panel.

If you touch the display section simultaneously in 2 points or more, the switch that is located around

the center of the touched point, if any, may operate.

Do not touch the display section in 2 points or more simultaneously.

Doing so may cause an accident due to incorrect output or malfunction.

● When programs or parameters of the controller (such as a PLC) that is monitored by the GOT are

changed, be sure to reset the GOT or shut off the power of the GOT at the same time.

Not doing so can cause an accident due to false output or malfunction.

CAUTION

● Do not bundle the control and communication cables with main-circuit, power or other wiring.

Run the above cables separately from such wiring and keep them a minimum of 100mm apart.

Not doing so noise can cause a malfunction.

● Do not press the GOT display section with a pointed material as a pen or driver.

Doing so can result in a damage or failure of the display section.

● When the GOT is connected to the Ethernet network, the available IP address is restricted according

to the system configuration.

• When multiple GOTs are connected to the Ethernet network:

Do not set the IP address (192.168.0.18) for the GOTs and the controllers in the network.

• When a single GOT is connected to the Ethernet network:

Do not set the IP address (192.168.0.18) for the controllers except the GOT in the network.

Doing so can cause the IP address duplication. The duplication can negatively affect the

communication of the device with the IP address (192.168.0.18).

The operation at the IP address duplication depends on the devices and the system.

● Turn on the controllers and the network devices to be ready for communication before they

communicate with the GOT.

Failure to do so can cause a communication error on the GOT.

A - 2

Page 5

[MOUNTING PRECAUTIONS]

WARNING

● Be sure to shut off all phases of the external power supply used by the system before mounting or

removing the GOT to/from the panel.

Not switching the power off in all phases can cause a unit failure or malfunction.

● Be sure to shut off all phases of the external power supply used by the system before mounting or

removing the communication unit, option function board or multi-color display board onto/from the

GOT.

Not doing so can cause the unit to fail or malfunction.

● Before mounting an optional function board or Multi-color display board, wear a static discharge wrist

strap to prevent the board from being damaged by static electricity.

CAUTION

● Use the GOT in the environment that satisfies the general specifications described in the User's

Manual.

Not doing so can cause an electric shock, fire, malfunction or product damage or deterioration.

● When mounting the GOT to the control panel, tighten the mounting screws in the specified torque

range.

Undertightening can cause the GOT to drop, short circuit or malfunction.

Overtightening can cause a drop, short circuit or malfunction due to the damage of the screws or the

GOT.

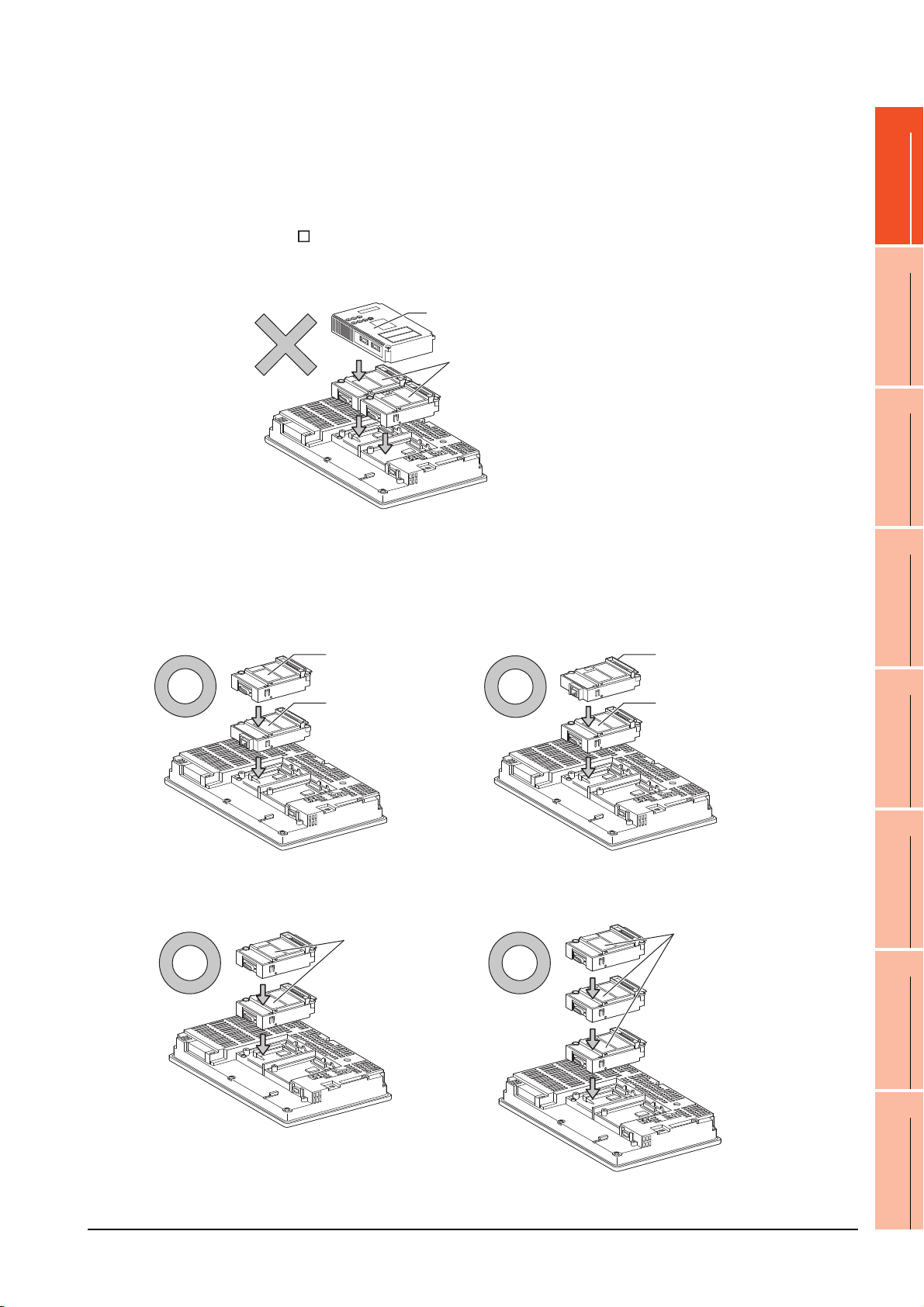

● When loading the communication unit or option unit to the GOT (GT16, GT15), fit it to the extension

interface of the GOT and tighten the mounting screws in the specified torque range.

Undertightening can cause the GOT to drop, short circuit or malfunction.

Overtightening can cause a drop, failure or malfunction due to the damage of the screws or unit.

● When mounting the multi-color display board onto the GOT (GT15), connect it to the corresponding

connector securely and tighten the mounting screws within the specified torque range.

Loose tightening may cause the unit and/or GOT to malfunction due to poor contact.

Overtightening may damage the screws, unit and/or GOT; they might malfunction.

● When mounting the option function board onto the GOT (GT16), connect it to the corresponding

connector securely and tighten the mounting screws within the specified torque range.

● When mounting an optional function board onto the GOT(GT15), fully connect it to the connector

until you hear a click.

● When mounting an optional function board onto the GOT(GT11), fully connect it to the connector.

● When inserting a CF card into the GOT(GT16, GT15, GT11), push it into the CF card interface of

GOT until the CF card eject button will pop out.

Failure to do so may cause a malfunction due to poor contact.

● When inserting/removing a SD card into/from the GOT(GT14), turn the SD card access switch off in

advance.

Failure to do so may corrupt data within the SD card.

A - 3

Page 6

[MOUNTING PRECAUTIONS]

CAUTION

● When inserting/removing a CF card into/from the GOT(GT16, GT15, GT11), turn the CF card access

switch off in advance.

Failure to do so may corrupt data within the CF card.

● When removing a SD card from the GOT(GT14), make sure to support the SD card by hand, as it

may pop out.

Failure to do so may cause the SD card to drop from the GOT and break.

● When removing a CF card from the GOT, make sure to support the CF card by hand, as it may pop

out.

Failure to do so may cause the CF card to drop from the GOT and break.

● When installing a USB memory to the GOT(GT16, GT14), make sure to install the USB memory to

the USB interface firmly.

Failure to do so may cause a malfunction due to poor contact.

●

Before removing the USB memory from the GOT(GT16, GT14), operate the utility screen for removal.

After the successful completion dialog box is displayed, remove the memory by hand carefully.

Failure to do so may cause the USB memory to drop, resulting in a damage or failure of the memory.

● For closing the USB environmental protection cover, fix the cover by pushing the mark on the latch

firmly to comply with the protective structure.

● Remove the protective film of the GOT.

When the user continues using the GOT with the protective film, the film may not be removed.

● Operate and store the GOT in environments without direct sunlight, high temperature, dust, humidity,

and vibrations.

● When using the GOT in the environment of oil or chemicals, use the protective cover for oil.

Failure to do so may cause failure or malfunction due to the oil or chemical entering into the GOT.

[WIRING PRECAUTIONS]

WARNING

● Be sure to shut off all phases of the external power supply used by the system before wiring.

Failure to do so may result in an electric shock, product damage or malfunctions.

CAUTION

● Please make sure to ground FG terminal and LG terminal and protective ground terminal of the GOT

power supply section by applying Class D Grounding (Class 3 Grounding Method) or higher which is

used exclusively for the GOT.

Not doing so may cause an electric shock or malfunction.

● Be sure to tighten any unused terminal screws with a torque of 0.5 to 0.8N•m.

Failure to do so may cause a short circuit due to contact with a solderless terminal.

● Use applicable solderless terminals and tighten them with the specified torque.

If any solderless spade terminal is used, it may be disconnected when the terminal screw comes

loose, resulting in failure.

A - 4

Page 7

[WIRING PRECAUTIONS]

CAUTION

● Correctly wire the GOT power supply section after confirming the rated voltage and terminal

arrangement of the product.

Not doing so can cause a fire or failure.

● Tighten the terminal screws of the GOT power supply section in the specified torque range.

Undertightening can cause a short circuit or malfunction.

Overtightening can cause a short circuit or malfunction due to the damage of the screws or the GOT.

● Exercise care to avoid foreign matter such as chips and wire offcuts entering the GOT.

Not doing so can cause a fire, failure or malfunction.

● The module has an ingress prevention label on its top to prevent foreign matter, such as wire offcuts,

from entering the module during wiring.

Do not peel this label during wiring.

Before starting system operation, be sure to peel this label because of heat dissipation.

● Plug the bus connection cable by inserting it into the connector of the connected unit until it "clicks".

After plugging, check that it has been inserted snugly.

Not doing so can cause a malfunction due to a contact fault.

● Plug the communication cable into the connector of the connected unit and tighten the mounting and

terminal screws in the specified torque range.

Undertightening can cause a short circuit or malfunction.

Overtightening can cause a short circuit or malfunction due to the damage of the screws or unit.

● Plug the QnA/ACPU/Motion controller (A series) bus connection cable by inserting it into the

connector of the connected unit until it "clicks".

After plugging, check that it has been inserted snugly.

Not doing so can cause a malfunction due to a contact fault.

[TEST OPERATION PRECAUTIONS]

WARNING

● Before performing the test operations of the user creation monitor screen (such as turning ON or

OFF bit device, changing the word device current value, changing the settings or current values of

the timer or counter, and changing the buffer memory current value), read through the manual

carefully and make yourself familiar with the operation method.

During test operation, never change the data of the devices which are used to perform significant

operation for the system.

False output or malfunction can cause an accident.

A - 5

Page 8

[STARTUP/MAINTENANCE PRECAUTIONS]

WARNING

● When power is on, do not touch the terminals.

Doing so can cause an electric shock or malfunction.

● Correctly connect the battery connector.

Do not charge, disassemble, heat, short-circuit, solder, or throw the battery into the fire.

Doing so will cause the battery to produce heat, explode, or ignite, resulting in injury and fire.

● Before starting cleaning or terminal screw retightening, always switch off the power externally in all

phases.

Not switching the power off in all phases can cause a unit failure or malfunction.

Undertightening can cause a short circuit or malfunction.

Overtightening can cause a short circuit or malfunction due to the damage of the screws or unit.

CAUTION

● Do not disassemble or modify the unit.

Doing so can cause a failure, malfunction, injury or fire.

● Do not touch the conductive and electronic parts of the unit directly.

Doing so can cause a unit malfunction or failure.

● The cables connected to the unit must be run in ducts or clamped.

Not doing so can cause the unit or cable to be damaged due to the dangling, motion or accidental

pulling of the cables or can cause a malfunction due to a cable connection fault.

● When unplugging the cable connected to the unit, do not hold and pull the cable portion.

Doing so can cause the unit or cable to be damaged or can cause a malfunction due to a cable

connection fault.

● Do not drop or apply strong impact to the unit.

Doing so may damage the unit.

● Do not drop or give an impact to the battery mounted to the unit.

Doing so may damage the battery, causing the battery fluid to leak inside the battery.

If the battery is dropped or given an impact, dispose of it without using.

● Before touching the unit, always touch grounded metal, etc. to discharge static electricity from

human body, etc.

Not doing so can cause the unit to fail or malfunction.

● Replace battery with GT15-BAT(GT16, GT15) or GT11-50BAT(GT14, GT12, GT11, GT10) by

Mitsubishi electric Co. only.

Use of another battery may present a risk of fire or explosion.

● Dispose of used battery promptly.

Keep away from children. Do not disassemble and do not dispose of in fire.

A - 6

Page 9

[TOUCH PANEL PRECAUTIONS]

CAUTION

● For the analog-resistive film type touch panels, normally the adjustment is not required. However,

the difference between a touched position and the object position may occur as the period of use

elapses. When any difference between a touched position and the object position occurs, execute

the touch panel calibration.

● When any difference between a touched position and the object position occurs, other object may be

activated. This may cause an unexpected operation due to incorrect output or malfunction.

[BACKLIGHT REPLACEMENT PRECAUTIONS]

WARNING

● Be sure to shut off all phases of the external power supply of the GOT (and the PLC CPU in the case

of a bus topology) and remove the GOT from the control panel before replacing the backlight (when

using the GOT with the backlight replaceable by the user).

Not doing so can cause an electric shock.

Replacing a backlight without removing the GOT from the control panel can cause the backlight or

control panel to drop, resulting in an injury.

CAUTION

● Wear gloves for the backlight replacement when using the GOT with the backlight replaceable by the

user.

Not doing so can cause an injury.

● Before replacing a backlight, allow 5 minutes or more after turning off the GOT when using the GOT

with the backlight replaceable by the user.

Not doing so can cause a burn from heat of the backlight.

[DISPOSAL PRECAUTIONS]

CAUTION

● When disposing of the product, handle it as industrial waste.

● When disposing of this product, treat it as industrial waste. When disposing of batteries, separate

them from other wastes according to the local regulations.

(For details of the battery directive in EU member states, refer to the User's Manual of the GOT to be

used.)

A - 7

Page 10

[TRANSPORTATION PRECAUTIONS]

CAUTION

● When transporting lithium batteries, make sure to treat them based on the transport regulations.

(For details on models subject to restrictions, refer to the User's Manual for the GOT you are using.)

● Make sure to transport the GOT main unit and/or relevant unit(s) in the manner they will not be

exposed to the impact exceeding the impact resistance described in the general specifications of the

User's Manual, as they are precision devices.

Failure to do so may cause the unit to fail.

Check if the unit operates correctly after transportation.

A - 8

Page 11

INTRODUCTION

Thank you for choosing Mitsubishi Graphic Operation Terminal (Mitsubishi GOT).

Read this manual and make sure you understand the functions and performance of the GOT thoroughly

in advance to ensure correct use.

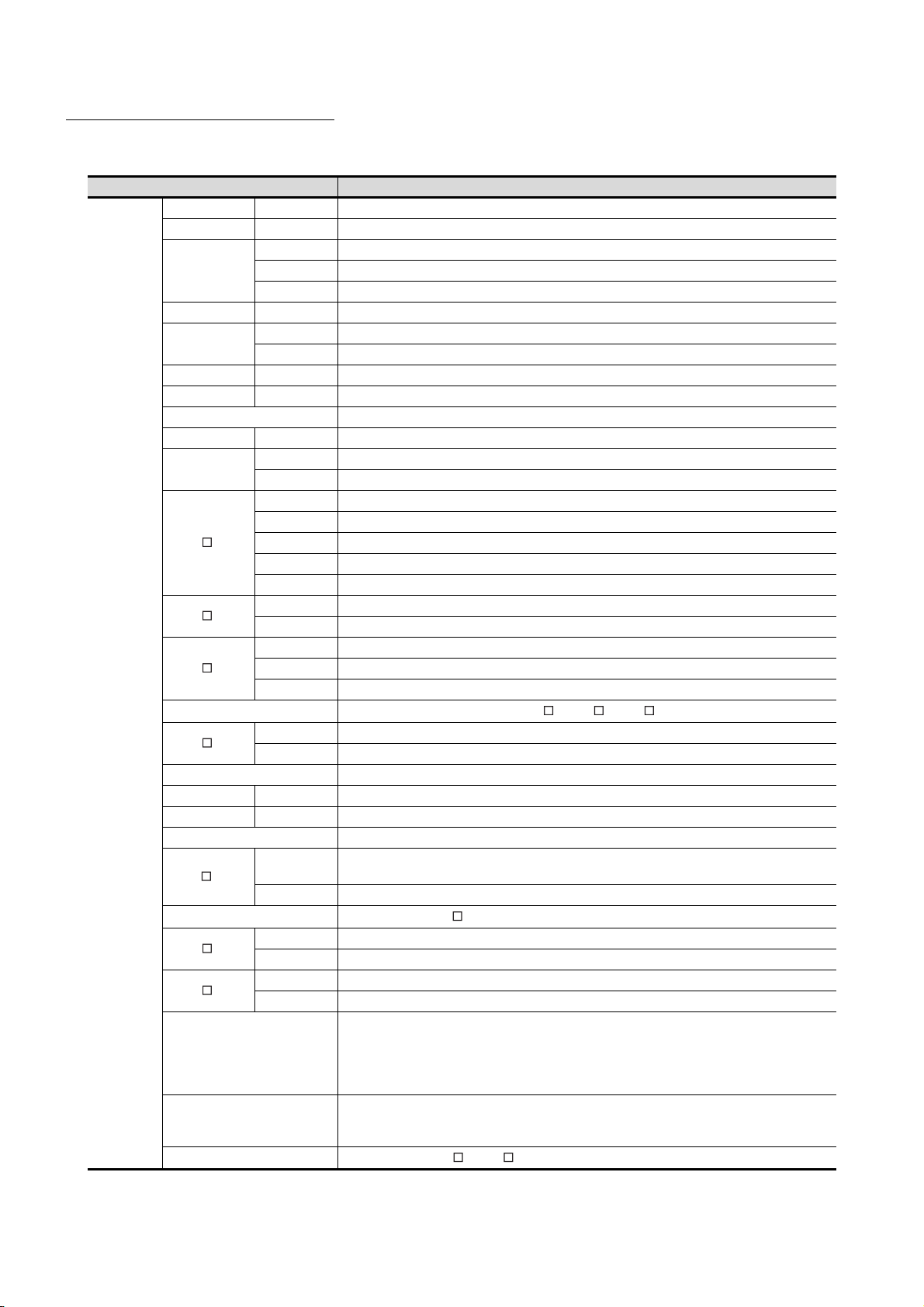

CONTENTS

SAFETY PRECAUTIONS .........................................................................................................................A - 1

INTRODUCTION ...................................................................................................................................... A - 9

CONTENTS .............................................................................................................................................. A - 9

MANUALS...............................................................................................................................................A - 20

QUICK REFERENCE .............................................................................................................................A - 22

ABBREVIATIONS AND GENERIC TERMS ...........................................................................................A - 24

HOW TO READ THIS MANUAL .............................................................................................................A - 29

1.PREPARATORY PROCEDURES FOR MONITORING

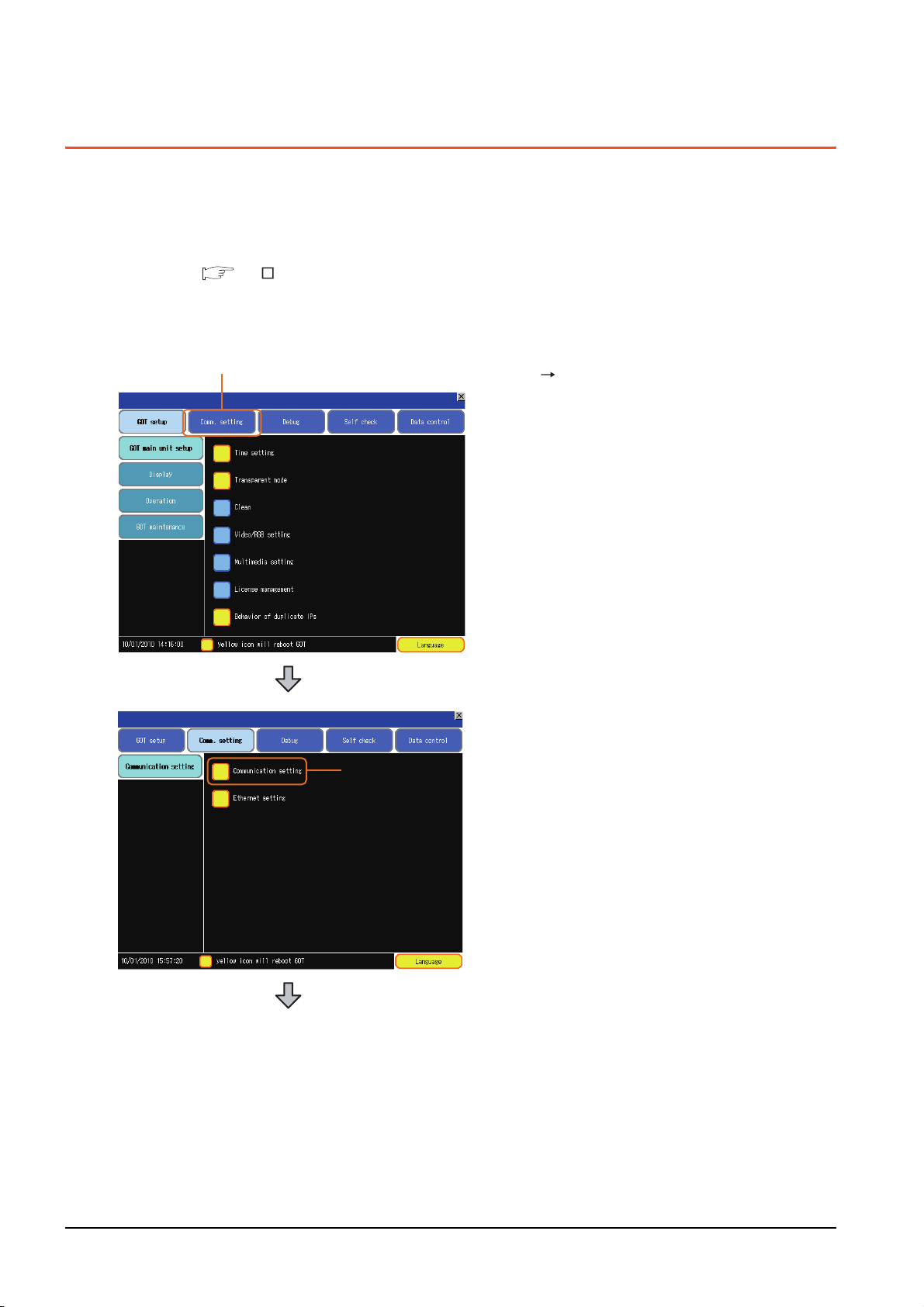

1.1 Setting the Communication Interface............................................................................................... 1 - 3

1.1.1 Setting connected equipment (Channel setting)................................................................... 1 - 4

1.1.2 I/F communication setting................................................................................................... 1 - 12

1.1.3 Precautions......................................................................................................................... 1 - 14

1.2 Writing the Project Data and OS onto the GOT............................................................................. 1 - 15

1.2.1 Writing the project data and OS onto the GOT................................................................... 1 - 15

1.2.2 Checking the project data and OS writing on GOT ............................................................ 1 - 16

1.3 Option Devices for the Respective Connection ............................................................................. 1 - 17

1.3.1 Communication module...................................................................................................... 1 - 17

1.3.2 Option unit .......................................................................................................................... 1 - 18

1.3.3 Conversion cables .............................................................................................................. 1 - 18

1.3.4 Connector conversion adapter ........................................................................................... 1 - 18

1.3.5 Serial Multi-Drop Connection Unit ...................................................................................... 1 - 18

1.3.6 RS-232/485 signal conversion adapter .............................................................................. 1 - 18

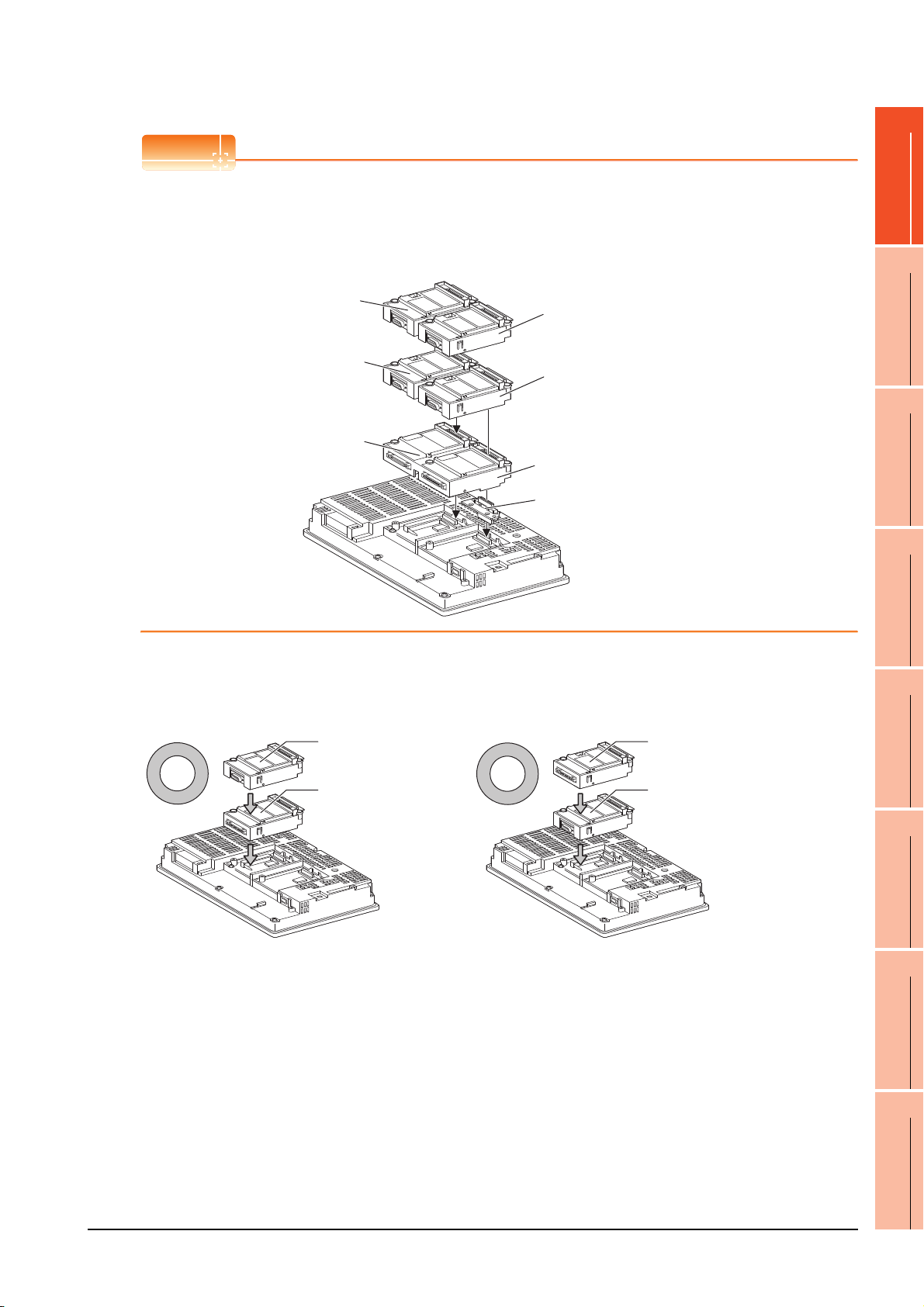

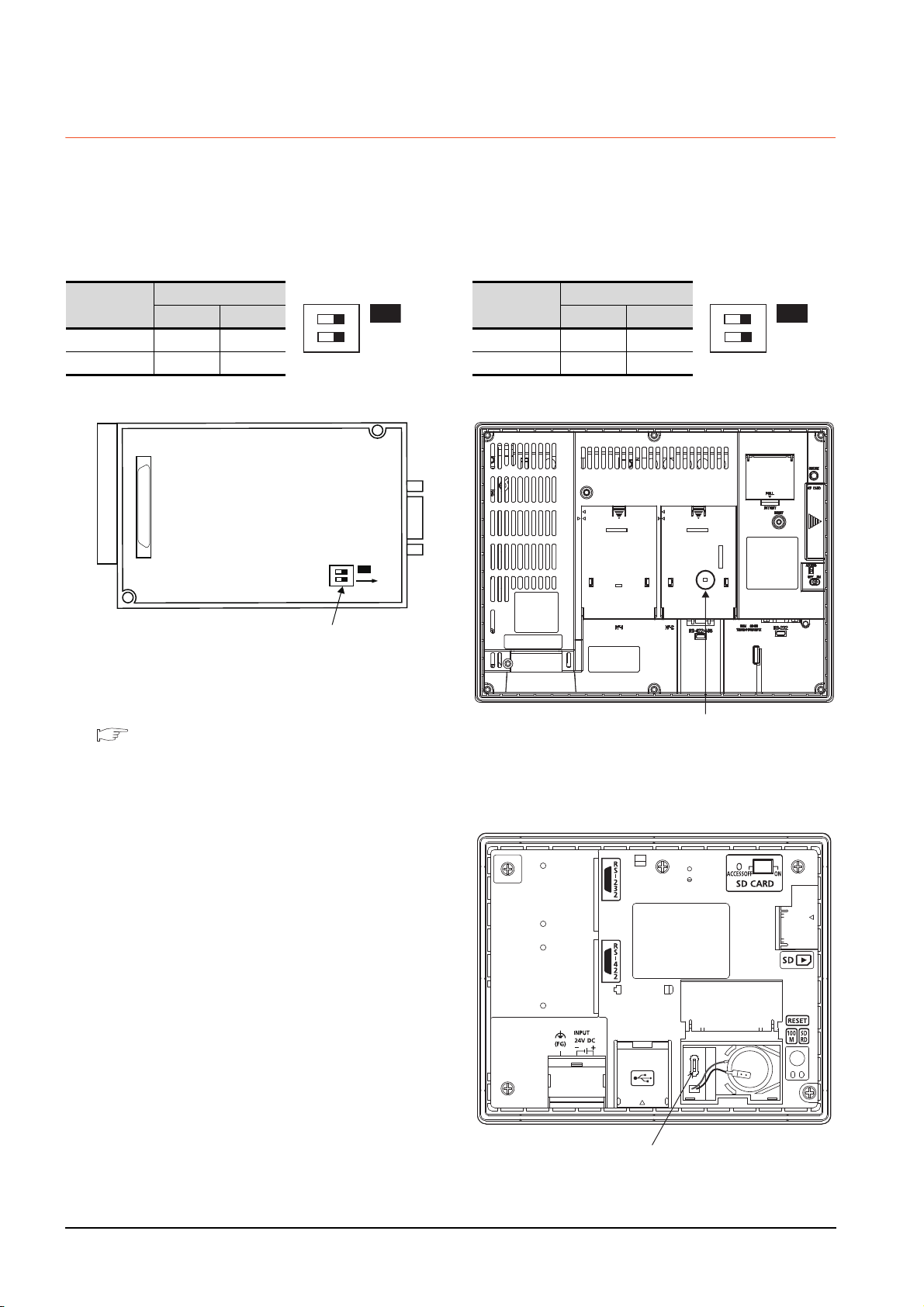

1.3.7 Installing a unit on another unit (Checking the unit installation position) ............................ 1 - 19

1.4 Connection Cables for the Respective Connection ....................................................................... 1 - 26

1.4.1 GOT connector specifications ............................................................................................ 1 - 26

1.4.2 Coaxial cable connector connection method...................................................................... 1 - 29

1.4.3 Terminating resistors of GOT ............................................................................................. 1 - 30

1.4.4 Setting the RS-232/485 signal conversion adaptor ............................................................ 1 - 33

1.5 Verifying GOT Recognizes Connected Equipment........................................................................ 1 - 34

1.6 Checking for Normal Monitoring .................................................................................................... 1 - 39

1.6.1 Check on the GOT.............................................................................................................. 1 - 39

1.6.2 Confirming the communication state on the GOT side (For Ethernet connection) ............. 1 - 45

1.6.3 Confirming the communication state to each station (Station monitoring function) ............ 1 - 47

1.6.4 Check on GX Developer.................................................................................................... 1 - 50

1.6.5 Check on GX Works2 .........................................................................................................1 - 54

1.6.6 Check on the PLC ............................................................................................................. 1 - 55

A - 9

Page 12

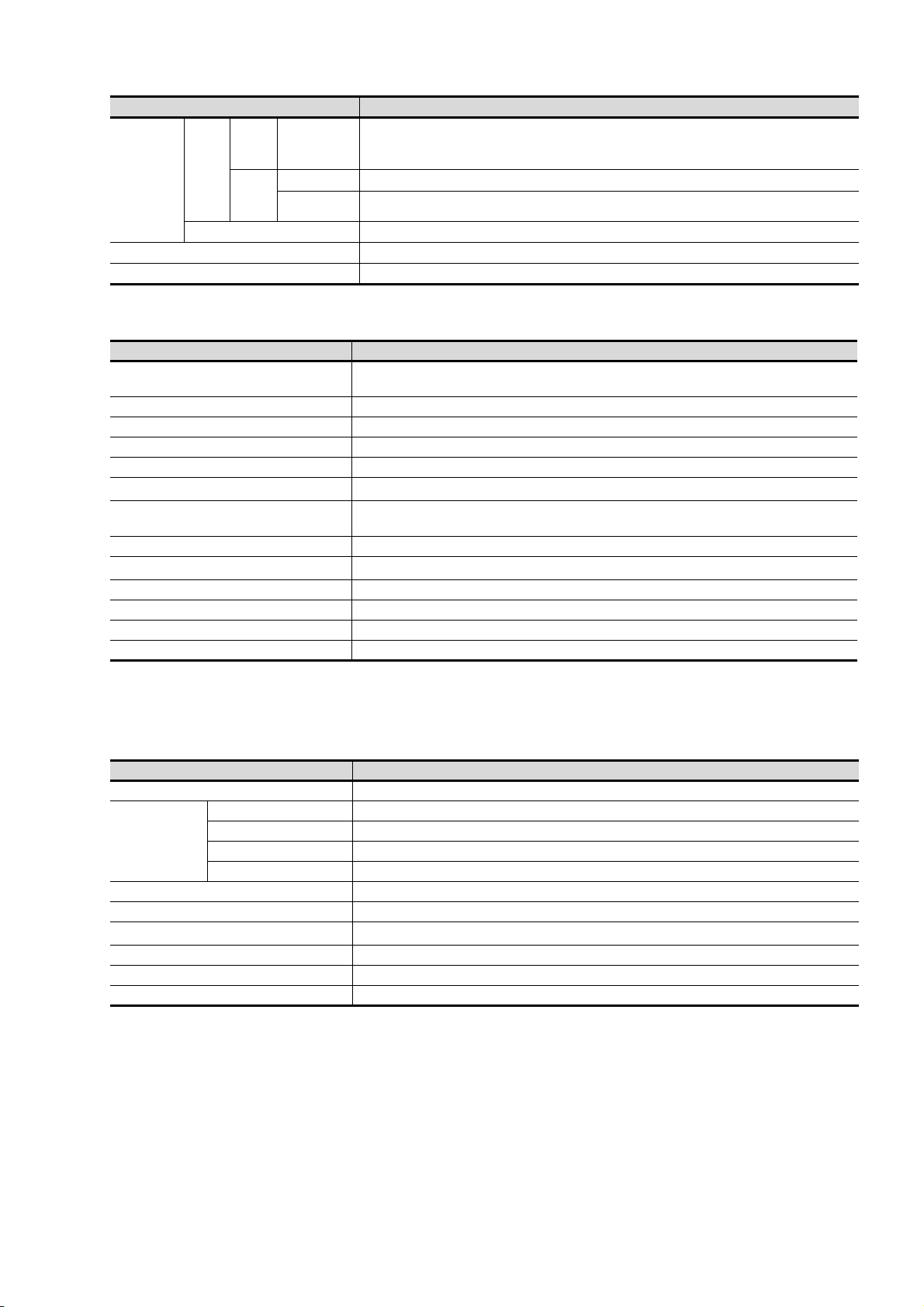

MITSUBISHI PLC CONNECTIONS

2.DEVICE RANGE THAT CAN BE SET

2.1 MELSEC-QnU/DC, Q17nD/M/NC/DR, CRnD-700........................................................................... 2 - 8

2.2 MELSEC-L ....................................................................................................................................... 2 - 9

2.3 MELSEC-QnA/Q/QS, MELDAS C6 * ............................................................................................. 2 - 10

2.4 MELSEC-Q (Multi)/Q Motion ......................................................................................................... 2 - 11

2.5 MELSEC-A .................................................................................................................................... 2 - 12

2.6 MELSEC-FX .................................................................................................................................. 2 - 13

2.7 MELSEC-WS ................................................................................................................................. 2 - 14

3.ACCESS RANGE FOR MONITORING

3.1 Access Range for Monitoring Stations on Network Systems........................................................... 3 - 2

3.1.1 MELSECNET/H, MELSECNET/10, CC-Link IE Controller Network,

CC-Link IE Field Network ..................................................................................................... 3 - 2

3.2 Access Range for Monitoring when Using Ethernet Connection ................................................... 3 - 13

3.3 CC-Link System Access Range for Monitoring.............................................................................. 3 - 14

3.4 Data Link System (MELSECNET/B, (II)) Access Range for Monitoring ........................................ 3 - 17

3.5 Access Range for Monitoring when Connecting FXCPU............................................................... 3 - 18

3.6 Connection to Remote I/O Station in MELSECNET/H Network System........................................ 3 - 19

3.7 Connection to the Head Module of CC-Link IE Field Network System .......................................... 3 - 22

4.HOW TO MONITOR REDUNTANT SYSTEM

4.1 Connection to Remote I/O Station in MELSECNET/H Network System.......................................... 4 - 8

4.1.1 Direct CPU connection (Direct CPU connection to the remote I/O station) .......................... 4 - 8

4.1.2 Computer link connection

(Connection to serial communication module mounted on remote I/O station) .................... 4 - 9

4.1.3 Ethernet connection (Connection to Ethernet module mounted on remote I/O station) ..... 4 - 10

4.2 Direct CPU Connection.................................................................................................................. 4 - 11

4.2.1 When using one GOT .........................................................................................................4 - 11

4.2.2 When using two GOTs........................................................................................................4 - 12

4.2.3 Precautions when connecting a GOT directly to a PLC CPU in the redundant system

without making Q redundant setting ................................................................................... 4 - 13

4.3 CC-Link Connection (Intelligent Device Station)............................................................................ 4 - 18

4.4 CC-Link Connection (Via G4) ........................................................................................................ 4 - 20

4.5 MELSECNET/H and MELSECNET/10 Connections (Network Systems) ...................................... 4 - 22

4.6 CC-Link IE Controller Network Connection (Network System) ...................................................... 4 - 23

4.7 Ethernet Connection ...................................................................................................................... 4 - 24

4.8 Connection to the Redundant Type Extension Base Unit.............................................................. 4 - 25

4.8.1 Computer link connection (Connection to the Serial communication module mounted

on the redundant type extension base unit)........................................................................ 4 - 25

4.8.2 Ethernet connection (Connection to the Ethernet module mounted on redundant type

extension base unit)............................................................................................................4 - 26

4.8.3 CC-Link connection (intelligent device station) (Connection to the CC-Link module

mounted on redundant type extension base unit)............................................................... 4 - 27

A - 10

Page 13

4.8.4 CC-Link connection (Via G4)

(Connection to the CC-Link module mounted on redundant type extension base unit) ..... 4 - 28

4.9 Q Redundant Setting ..................................................................................................................... 4 - 29

4.10 Switch the Monitor Target to the Control System Using the Script Function ................................. 4 - 31

4.10.1 Method for using the station number switching function..................................................... 4 - 31

4.10.2 Method for using the screen changing function .................................................................. 4 - 38

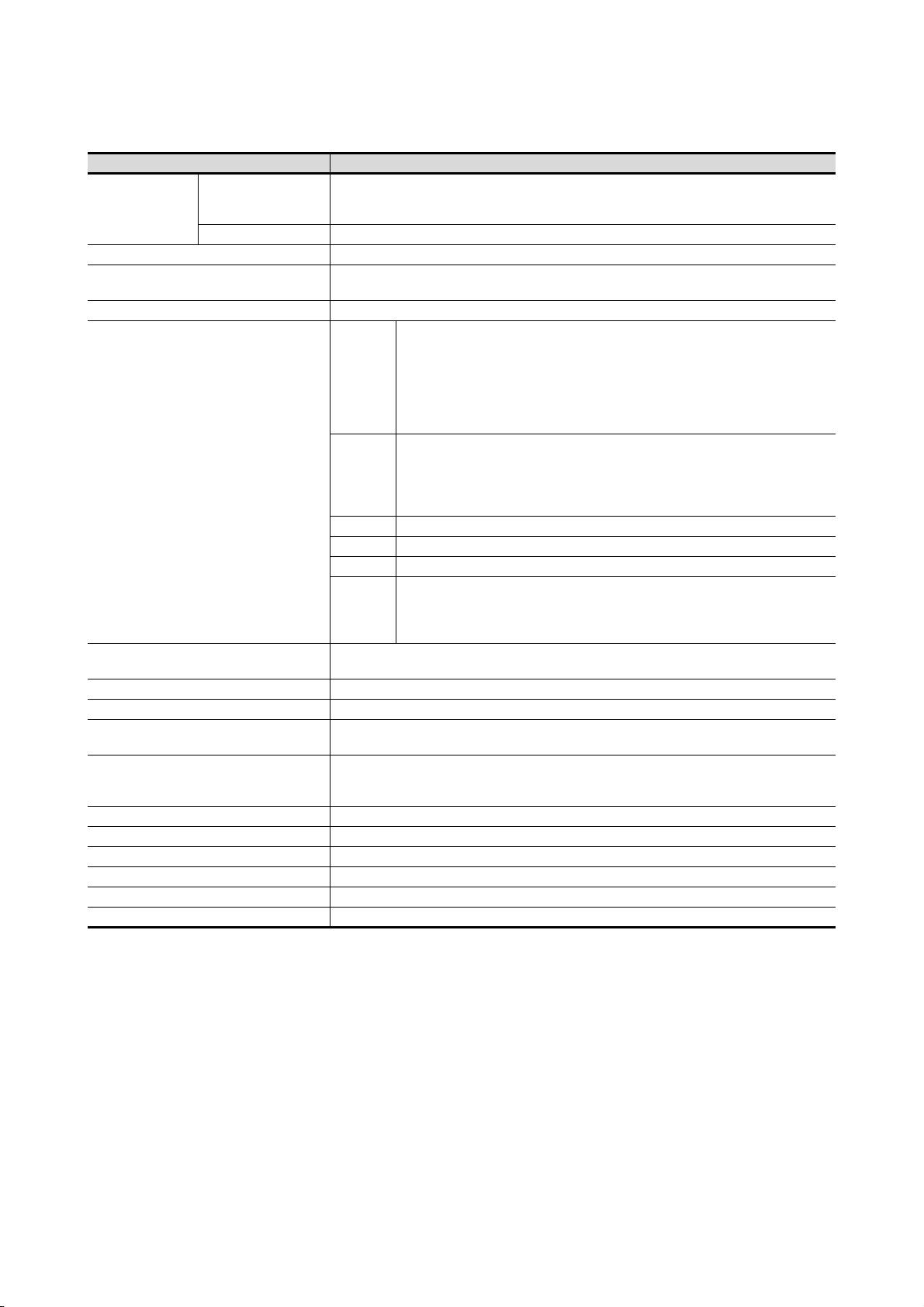

5.BUS CONNECTION

5.1 Connectable Model List ................................................................................................................... 5 - 2

5.2 System Configuration ...................................................................................................................... 5 - 5

5.2.1 Connecting to QCPU ............................................................................................................ 5 - 5

5.2.2 Connecting to QnACPU or AnCPU ...................................................................................... 5 - 9

5.2.3 Connection to QnASCPU or AnSCPU................................................................................ 5 - 12

5.2.4 Connection to A0J2HCPU .................................................................................................. 5 - 18

5.2.5 Connection to motion controller CPU

(A273UCPU, A273UHCPU(-S3), A373UCPU(-S3)) ........................................................... 5 - 19

5.2.6 Connecting to motion controller CPU

(A171SCPU(-S3(N)), A171SHCPU(N), A172SHCPU(N), A173UHCPU(-S1))................... 5 - 24

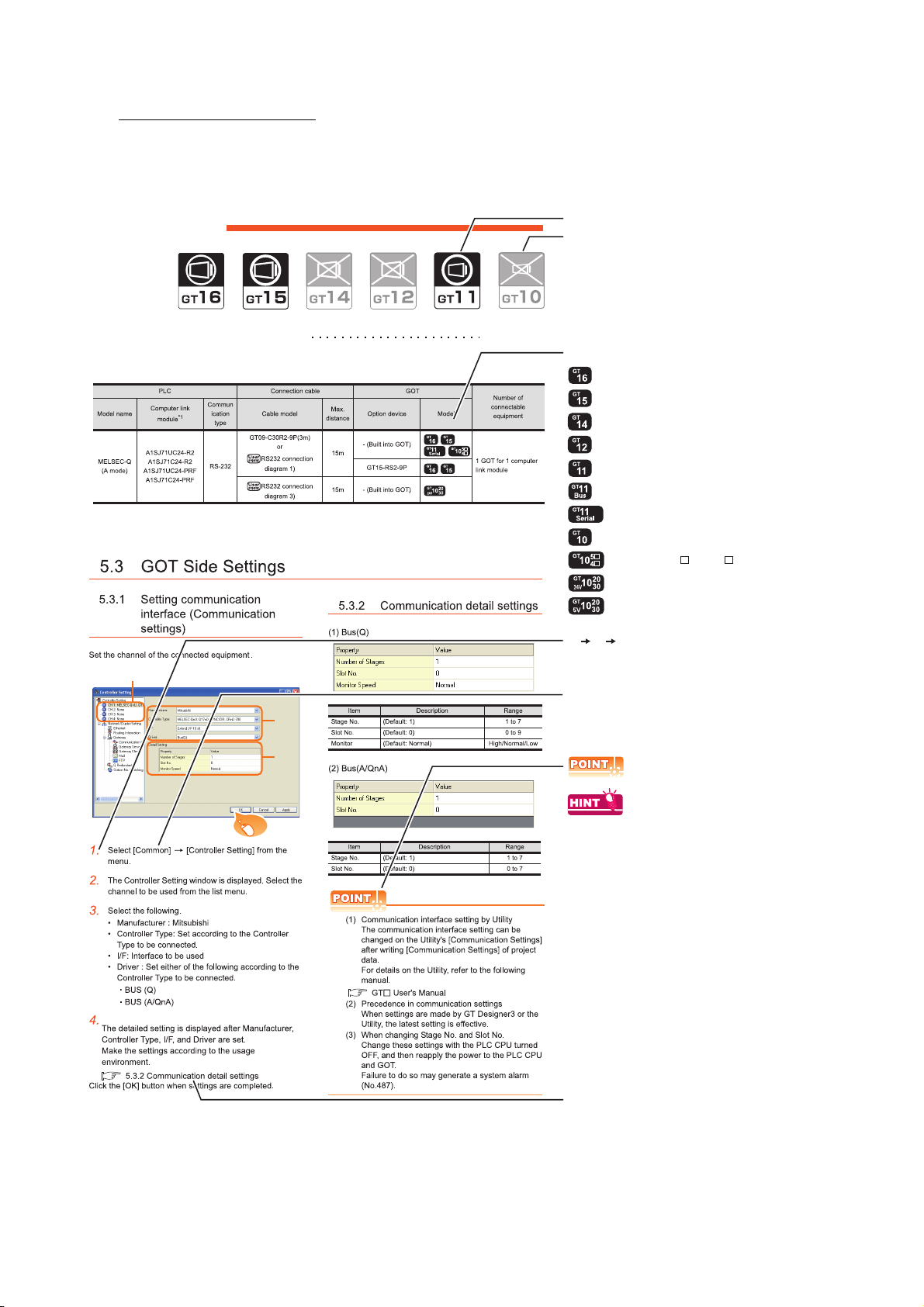

5.3 GOT Side Settings......................................................................................................................... 5 - 30

5.3.1 Setting communication interface (Communication settings)............................................... 5 - 30

5.3.2 Communication detail settings............................................................................................ 5 - 30

5.4 Precautions.................................................................................................................................... 5 - 34

5.4.1 GT15-C [ ] EXSS-1, GT15-C [ ] BS .................................................................................. 5 - 34

5.4.2 Turning the GOT ON .......................................................................................................... 5 - 34

5.4.3 Powering OFF the GOT, reapplying the power (OFF to ON) ............................................. 5 - 35

5.4.4 Reset switch on GOT ......................................................................................................... 5 - 35

5.4.5 Powering OFF or resetting the PLC ................................................................................... 5 - 35

5.4.6 Position of the GOT ............................................................................................................ 5 - 35

5.4.7 When the GOT is bus-connected to a PLC CPU without the communication driver

written ................................................................................................................................. 5 - 35

5.4.8 When designing the system ............................................................................................... 5 - 36

5.4.9 When assigning GOT I/O signals ....................................................................................... 5 - 36

5.4.10 When connecting to a QCPU (Q mode) ............................................................................. 5 - 36

5.4.11 When connecting to a QnA(S)CPU or An(S)CPU type ...................................................... 5 - 37

5.4.12 When connecting multiple GOTs ........................................................................................ 5 - 38

5.4.13 When using a PLC CPU in the direct mode ....................................................................... 5 - 38

5.4.14 When connecting to a Q4ARCPU redundant system ......................................................... 5 - 39

5.4.15 When monitoring the Q170MCPU ...................................................................................... 5 - 39

5.4.16 Troubleshooting .................................................................................................................. 5 - 39

6.DIRECT CONNECTION TO CPU

6.1 Connectable Model List ................................................................................................................... 6 - 2

6.2 System Configuration ...................................................................................................................... 6 - 6

6.2.1 Connecting to QCPU ............................................................................................................ 6 - 6

6.2.2 Connecting to LCPU............................................................................................................. 6 - 7

6.2.3 Connecting to QnACPU........................................................................................................ 6 - 8

6.2.4 Connecting to ACPU ............................................................................................................ 6 - 9

6.2.5 Connecting to FXCPU ........................................................................................................6 - 10

6.2.6 Connecting to WSCPU ....................................................................................................... 6 - 20

6.2.7 Connecting to the motion controller CPU ........................................................................... 6 - 20

A - 11

Page 14

6.3 Connection Diagram ...................................................................................................................... 6 - 22

6.3.1 RS-232 cable ...................................................................................................................... 6 - 22

6.3.2 RS-422 cable ...................................................................................................................... 6 - 23

6.4 GOT Side Settings ......................................................................................................................... 6 - 25

6.4.1 Setting communication interface (Communication settings) ............................................... 6 - 25

6.4.2 Communication detail settings ............................................................................................ 6 - 25

6.5 Precautions .................................................................................................................................... 6 - 28

7.COMPUTER LINK CONNECTION

7.1 Connectable Model List ................................................................................................................... 7 - 2

7.1.1 PLC/Motion controller CPU................................................................................................... 7 - 2

7.1.2 Serial communication module/Computer link module........................................................... 7 - 6

7.2 System Configuration ...................................................................................................................... 7 - 7

7.2.1 Connecting to QCPU (Q mode) ............................................................................................ 7 - 7

7.2.2 Connecting to LCPU ............................................................................................................. 7 - 8

7.2.3 Connecting to QCPU (A mode) ............................................................................................ 7 - 9

7.2.4 Connecting to QnACPU (QnACPU type) ............................................................................ 7 - 10

7.2.5 Connecting to QnACPU (QnASCPU type) ......................................................................... 7 - 11

7.2.6 Connecting to ACPU (AnCPU type) ................................................................................... 7 - 13

7.2.7 Connecting to ACPU (AnSCPU type, A0J2HCPU, A2CCPUC) ......................................... 7 - 14

7.3 Connection Diagram ...................................................................................................................... 7 - 15

7.3.1 RS-232 cable ...................................................................................................................... 7 - 15

7.3.2 RS-422 cable ...................................................................................................................... 7 - 17

7.4 GOT Side Settings ......................................................................................................................... 7 - 19

7.4.1 Setting communication interface (Communication settings) ............................................... 7 - 19

7.4.2 Communication detail settings ............................................................................................ 7 - 19

7.5 PLC Side Setting ........................................................................................................................... 7 - 22

7.5.1 Connecting serial communication module (Q, L Series)..................................................... 7 - 22

7.5.2 Connecting serial communication module (QnA Series) .................................................... 7 - 24

7.5.3 Connecting computer link module ...................................................................................... 7 - 25

7.6 Precautions .................................................................................................................................... 7 - 29

8.ETHERNET CONNECTION

8.1 Connectable Model List ................................................................................................................... 8 - 2

8.1.1 PLC/Motion controller CPU................................................................................................... 8 - 2

8.1.2 Ethernet module ................................................................................................................... 8 - 6

8.2 System Configuration ...................................................................................................................... 8 - 7

8.2.1 Connection to Ethernet module ............................................................................................ 8 - 7

8.2.2 Connection to Built-in Ethernet port CPU or C Controller module ...................................... 8 - 11

8.2.3 Connecting to Display I/F.................................................................................................... 8 - 12

8.2.4 Connection to CC-Link IE Field Network Ethernet Adapter Module ................................... 8 - 13

8.2.5 Connecting to PERIPHERAL I/F (Built-in Ethernet port Motion Controller CPU) ............... 8 - 14

8.3 GOT Side Settings ......................................................................................................................... 8 - 15

8.3.1 Setting communication interface (Communication settings) ............................................... 8 - 15

8.3.2 Communication detail settings ............................................................................................ 8 - 15

8.3.3 Ethernet setting................................................................................................................... 8 - 17

8.3.4 Routing parameter setting ..................................................................................................8 - 18

8.4 PLC Side Setting ........................................................................................................................... 8 - 20

8.4.1 Connecting to Built-in Ethernet port CPU (one-to-one connection) .................................... 8 - 20

A - 12

Page 15

8.4.2 Connecting to Built-in Ethernet port CPU (multiple connection)......................................... 8 - 22

8.4.3 Connecting to Ethernet module (Q/L Series)...................................................................... 8 - 24

8.4.4 Connecting to C Controller module .................................................................................... 8 - 27

8.4.5 Connecting to Ethernet module (QnA Series) .................................................................... 8 - 30

8.4.6 Connecting to Ethernet module (A Series) ......................................................................... 8 - 33

8.4.7 Connecting to Ethernet module (FX Series)....................................................................... 8 - 38

8.4.8 Connecting to Display I/F (CNC C70)................................................................................. 8 - 42

8.4.9 Connecting to CC-Link IE Field Network Ethernet Adapter Module ................................... 8 - 44

8.4.10 Connecting to PERIPHERAL I/F (Built-in Ethernet port Motion Controller CPU) ............... 8 - 46

8.5 Precautions.................................................................................................................................... 8 - 49

9.MELSECNET/H CONNECTION (PLC TO PLC NETWORK)

9.1 Connectable Model List ................................................................................................................... 9 - 2

9.1.1 PLC/Motion controller CPU ..................................................................................................9 - 2

9.1.2 MELSECNET/H network module.......................................................................................... 9 - 6

9.2 System Configuration ...................................................................................................................... 9 - 7

9.2.1 Connecting to optical loop system........................................................................................ 9 - 7

9.2.2 Connecting to the coaxial bus system .................................................................................. 9 - 7

9.3 GOT Side Settings........................................................................................................................... 9 - 9

9.3.1 Setting communication interface (Communication settings)................................................. 9 - 9

9.3.2 Communication detail settings..............................................................................................9 - 9

9.3.3 Routing parameter setting ..................................................................................................9 - 10

9.4 PLC Side Settings.......................................................................................................................... 9 - 11

9.4.1 System configuration .......................................................................................................... 9 - 11

9.4.2 Switch setting of MELSECNET/H network module ............................................................ 9 - 11

9.4.3 Parameter setting ............................................................................................................... 9 - 12

9.4.4 [Controller Setting] of GT Designer3 .................................................................................. 9 - 15

9.5 Precautions.................................................................................................................................... 9 - 16

10.MELSECNET/10 CONNECTION (PLC TO PLC NETWORK)

10.1 Connectable Model List ................................................................................................................. 10 - 2

10.1.1 PLC/Motion controller CPU ................................................................................................ 10 - 2

10.1.2 MELSECNET/H (NET/10 mode), MELSECNET/10 network module ................................. 10 - 6

10.2 System Configuration .................................................................................................................... 10 - 7

10.2.1 Connecting to optical loop system...................................................................................... 10 - 7

10.2.2 Connecting to the coaxial bus system ................................................................................ 10 - 8

10.3 GOT Side Settings......................................................................................................................... 10 - 9

10.3.1 Setting communication interface (Communication settings)............................................... 10 - 9

10.3.2 Communication detail settings............................................................................................ 10 - 9

10.3.3 Routing parameter setting ................................................................................................ 10 - 10

10.3.4 Switch setting (Only when MELSECNET/10 communication unit is used)....................... 10 - 11

10.4 PLC Side Setting ......................................................................................................................... 10 - 12

10.4.1 Connecting to MELSECNET/H network module .............................................................. 10 - 12

10.4.2 Connecting to MELSECNET/10 network module (QnA Series) ....................................... 10 - 17

10.4.3 Connecting to MELSECNET/10 network module (A Series) ............................................ 10 - 21

10.5 Precautions.................................................................................................................................. 10 - 26

A - 13

Page 16

11.CC-Link IE CONTROLLER NETWORK CONNECTION

11.1 Connectable Model List ................................................................................................................. 11 - 2

11.1.1 PLC/Motion controller CPU.................................................................................................11 - 2

11.1.2 CC-Link IE Controller Network communication unit............................................................ 11 - 6

11.2 System Configuration .................................................................................................................... 11 - 7

11.2.1 Connecting to optical loop system ...................................................................................... 11 - 7

11.3 GOT side settings .......................................................................................................................... 11 - 8

11.3.1 Setting communication interface (Communication settings)............................................... 11 - 8

11.3.2 Communication detail settings ............................................................................................ 11 - 8

11.3.3 Routing parameter setting .................................................................................................. 11 - 9

11.4 PLC Side Setting ......................................................................................................................... 11 - 10

11.5 Precautions.................................................................................................................................. 11 - 16

12.CC-Link IE FIELD NETWORK CONNECTION

12.1 Connectable Model List ................................................................................................................. 12 - 2

12.1.1 PLC/Motion controller CPU.................................................................................................12 - 2

12.1.2 CC-Link IE Field Network communication unit ................................................................... 12 - 6

12.2 System Configuration .................................................................................................................... 12 - 7

12.2.1 Connecting to CC-Link IE Field Network communication unit ............................................ 12 - 7

12.3 GOT side settings .......................................................................................................................... 12 - 8

12.3.1 Setting communication interface (Communication settings)............................................... 12 - 8

12.3.2 Communication detail settings ............................................................................................ 12 - 8

12.3.3 Routing parameter setting .................................................................................................. 12 - 9

12.4 PLC Side Setting ......................................................................................................................... 12 - 10

12.5 Precautions.................................................................................................................................. 12 - 13

13.CC-Link CONNECTION (INTELLIGENT DEVICE STATION)

13.1 Connectable Model List ................................................................................................................. 13 - 2

13.1.1 PLC/Motion controller CPU.................................................................................................13 - 2

13.1.2 CC-Link module .................................................................................................................. 13 - 5

13.2 System Configuration .................................................................................................................... 13 - 6

13.2.1 Connecting with CC-Link Ver.1 compatible ........................................................................ 13 - 6

13.2.2 Connecting with CC-Link Ver.2 compatible ........................................................................ 13 - 7

13.2.3 Connecting with CC-Link Ver.1/Ver.2 compatibles mixed .................................................. 13 - 8

13.3 GOT Side Settings ......................................................................................................................... 13 - 9

13.3.1 Setting communication interface (Communication settings)............................................... 13 - 9

13.3.2 Communication detail settings ............................................................................................ 13 - 9

13.3.3 Switch setting

(Only when MODEL GT15-75J61BT13-Z CC-Link communication unit is used) ............. 13 - 11

13.4 PLC Side Setting ......................................................................................................................... 13 - 12

13.4.1 Connecting to CC-Link module (Q Series) with Ver.1 compatible .................................... 13 - 13

13.4.2 Connecting to CC-Link module (Q Series) with Ver.2 compatible .................................... 13 - 16

13.4.3 Connecting to CC-Link module (Q Series) with Ver.1/Ver.2 compatibles mixed .............. 13 - 20

13.4.4 Connecting to MELSEC-L series with CC-Link Ver.1 compatible..................................... 13 - 24

13.4.5 Connecting to MELSEC-L series with CC-Link Ver.2 compatible..................................... 13 - 25

13.4.6 Connecting to CC-Link module (QnA Series) ................................................................... 13 - 27

13.4.7 Connecting to CC-Link module (A Series)........................................................................ 13 - 31

13.5 Precautions.................................................................................................................................. 13 - 39

A - 14

Page 17

14.CC-Link CONNECTION (Via G4)

14.1 Connectable Model List ................................................................................................................. 14 - 2

14.1.1 PLC/Motion controller CPU ................................................................................................ 14 - 2

14.1.2 CC-Link module/peripheral module .................................................................................... 14 - 5

14.2 System Configuration .................................................................................................................... 14 - 6

14.2.1 Connecting to QCPU (Q mode) .......................................................................................... 14 - 6

14.2.2 Connecting to LCPU........................................................................................................... 14 - 7

14.3 Connection Diagram ...................................................................................................................... 14 - 8

14.3.1 RS-232 cable...................................................................................................................... 14 - 8

14.3.2 RS-422 cable...................................................................................................................... 14 - 8

14.4 GOT Side Settings......................................................................................................................... 14 - 9

14.4.1 Setting communication interface (Communication settings)............................................... 14 - 9

14.4.2 Communication detail settings............................................................................................ 14 - 9

14.5 PLC Side Settings........................................................................................................................ 14 - 11

14.5.1 Connecting AJ65BT-G4-S3 .............................................................................................. 14 - 11

14.5.2 Connecting AJ65BT-R2N ................................................................................................. 14 - 12

14.5.3 Switch setting of CC-Link module (Q series) .................................................................... 14 - 14

14.5.4 [Network parameter] of GX Developer ............................................................................. 14 - 14

14.5.5 Parameter setting (when connecting to C Controller module).......................................... 14 - 15

14.5.6 [Controller Setting] of GT Designer3 ................................................................................ 14 - 16

14.6 Precautions.................................................................................................................................. 14 - 17

MITSUBISHI FA DEVICE CONNECTIONS

15.INVERTER CONNECTION

15.1 Connectable Model List ................................................................................................................. 15 - 2

15.2 System Configuration .................................................................................................................... 15 - 3

15.2.1 Connecting to FREQROL-A500/A500L/F500/F500L/V500/V500L..................................... 15 - 3

15.2.2 Connecting to FREQROL-E500/S500/S500E/F500J/D700/F700PJ .................................. 15 - 7

15.2.3 Connecting to FREQROL E700........................................................................................ 15 - 10

15.2.4 Connecting to FREQROL-A700/F700/700P..................................................................... 15 - 14

15.2.5 Connecting to MD-CX522-K(-A0) ..................................................................................... 15 - 18

15.3 Connection Diagram .................................................................................................................... 15 - 21

15.3.1 RS-422 cable.................................................................................................................... 15 - 21

15.4 GOT Side Settings....................................................................................................................... 15 - 29

15.4.1 Setting communication interface (Communication settings)............................................. 15 - 29

15.4.2 Communication detail settings.......................................................................................... 15 - 29

15.5 FREQROL Series Inverter Side Settings..................................................................................... 15 - 31

15.5.1 Connecting FREQROL-S500, S500E, F500J series ........................................................ 15 - 31

15.5.2 Connecting FREQROL-E500 series................................................................................. 15 - 32

15.5.3 Connecting FREQROL-F500, F500L series..................................................................... 15 - 33

15.5.4 Connecting FREQROL-A500, A500L series .................................................................... 15 - 34

15.5.5 Connecting FREQROL-V500, V500L series .................................................................... 15 - 35

15.5.6 Connecting FREQROL-E700 series................................................................................. 15 - 36

15.5.7 Connecting FREQROL-D700 series................................................................................. 15 - 37

15.5.8 Connecting FREQROL-F700/700P series........................................................................ 15 - 38

15.5.9 Connecting FREQROL-F700PJ series............................................................................. 15 - 40

15.5.10 Connecting FREQROL-A700 series ................................................................................. 15 - 41

15.5.11 Connecting MD-CX522-K(-A0) ......................................................................................... 15 - 42

A - 15

Page 18

15.5.12 Station number setting...................................................................................................... 15 - 43

15.6 Device Range that Can Be Set .................................................................................................... 15 - 44

15.7 Precautions.................................................................................................................................. 15 - 47

16.SERVO AMPLIFIER CONNECTION

16.1 Connectable Model List ................................................................................................................. 16 - 2

16.2 System Configuration .................................................................................................................... 16 - 3

16.2.1 Connecting to the MELSERVO-J2-Super Series................................................................ 16 - 3

16.2.2 Connecting to the MELSERVO-J2M Series ....................................................................... 16 - 4

16.2.3 Connecting to the MELSERVO-J4, J3 Series..................................................................... 16 - 5

16.3 Connection Diagram ...................................................................................................................... 16 - 8

16.3.1 RS-232 cable ...................................................................................................................... 16 - 8

16.3.2 RS-422 cable ...................................................................................................................... 16 - 9

16.4 GOT Side Settings ....................................................................................................................... 16 - 12

16.4.1 Setting communication interface (Communication settings)............................................. 16 - 12

16.4.2 Communication detail settings .......................................................................................... 16 - 12

16.5 Setting on Servo Amplifier Side ................................................................................................... 16 - 14

16.5.1 Connecting to the MELSERVO-J2-Super Series.............................................................. 16 - 14

16.5.2 Connecting to the MELSERVO-J2M Series ..................................................................... 16 - 15

16.5.3 Connecting to the MELSERVO-J4,J3 Series.................................................................... 16 - 16

16.5.4 Station number setting...................................................................................................... 16 - 16

16.6 Device Range that Can Be Set .................................................................................................... 16 - 17

16.7 Precautions.................................................................................................................................. 16 - 45

17.ROBOT CONTROLLER CONNECTION

17.1 Connectable Model List ................................................................................................................. 17 - 2

17.2 System Configuration .................................................................................................................... 17 - 2

17.2.1 Connecting to robot controller (CRnD-700) ........................................................................ 17 - 2

17.3 GOT Side Settings ......................................................................................................................... 17 - 3

17.3.1 Setting communication interface (Communication settings)............................................... 17 - 3

17.3.2 Communication detail settings ............................................................................................ 17 - 3

17.3.3 Ethernet setting................................................................................................................... 17 - 5

17.4 PLC Side Settings.......................................................................................................................... 17 - 6

17.4.1 Connecting to robot controller (CRnD-700) ........................................................................ 17 - 6

17.5 Device Range that Can Be Set ...................................................................................................... 17 - 8

17.6 Precautions.................................................................................................................................... 17 - 8

18.CNC CONNECTION

18.1 Connectable Model List ................................................................................................................. 18 - 2

18.2 System Configuration .................................................................................................................... 18 - 3

18.2.1 Direct connection to CPU ................................................................................................... 18 - 3

18.2.2 MELSECNET/10 connection (PLC to PLC network) .......................................................... 18 - 4

18.2.3 CC-Link connection (intelligent device station)................................................................... 18 - 5

18.2.4 Ethernet connection............................................................................................................ 18 - 6

18.3 Connection Diagram ...................................................................................................................... 18 - 7

18.3.1 RS-232 cable ...................................................................................................................... 18 - 7

A - 16

Page 19

18.4 GOT Side Settings......................................................................................................................... 18 - 8

18.4.1 Setting communication interface (Communication settings)............................................... 18 - 8

18.4.2 Communication detail settings............................................................................................ 18 - 8

18.4.3 Ethernet setting ................................................................................................................ 18 - 13

18.4.4 Switch setting ................................................................................................................... 18 - 13

18.5 CNC Side Settings....................................................................................................................... 18 - 16

18.5.1 MELSECNET/10 connection ............................................................................................ 18 - 16

18.5.2 CC-Link (ID) connection ...................................................................................................18 - 19

18.5.3 Ethernet connection.......................................................................................................... 18 - 21

18.6 Device Range that Can Be Set.................................................................................................... 18 - 23

18.7 Precautions.................................................................................................................................. 18 - 23

18.7.1 Direct connection to CPU ................................................................................................. 18 - 23

18.7.2 MELSECNET/10 connection ............................................................................................ 18 - 23

18.7.3 CC-Link (ID) connection ...................................................................................................18 - 23

18.7.4 Ethernet connection.......................................................................................................... 18 - 24

MULTIPLE GOT CONNECTIONS

19.GOT MULTI-DROP CONNECTION

19.1 CPU that can be Monitored ........................................................................................................... 19 - 2

19.2 Connectable Model List ................................................................................................................. 19 - 3

19.3 System Configuration .................................................................................................................. 19 - 14

19.4 Connection Diagram .................................................................................................................... 19 - 15

19.4.1 RS-485 cable.................................................................................................................... 19 - 15

19.5 GOT Side Settings....................................................................................................................... 19 - 23

19.5.1 Setting communication interface (communication settings) ............................................. 19 - 23

19.5.2 Communication detail settings.......................................................................................... 19 - 23

19.6 Setting of Serial Multi-Drop Connection Unit ............................................................................... 19 - 24

19.6.1 Write the OS ..................................................................................................................... 19 - 24

19.6.2 Setting communication interface (Communication settings)............................................. 19 - 24

19.6.3 Setting switches................................................................................................................ 19 - 28

19.7 Setting of connection conversion adapter....................................................................................19 - 29

19.7.1 Setting switches................................................................................................................ 19 - 29

19.8 Precautions.................................................................................................................................. 19 - 30

20.MULTIPLE-GT14, GT12, GT11, GT10 CONNECTION FUNCTION

20.1 Connectable Model List ................................................................................................................. 20 - 2

20.2 System Configuration .................................................................................................................... 20 - 2

20.2.1 Connecting the GOT to PLC via RS-232 interface ............................................................. 20 - 2

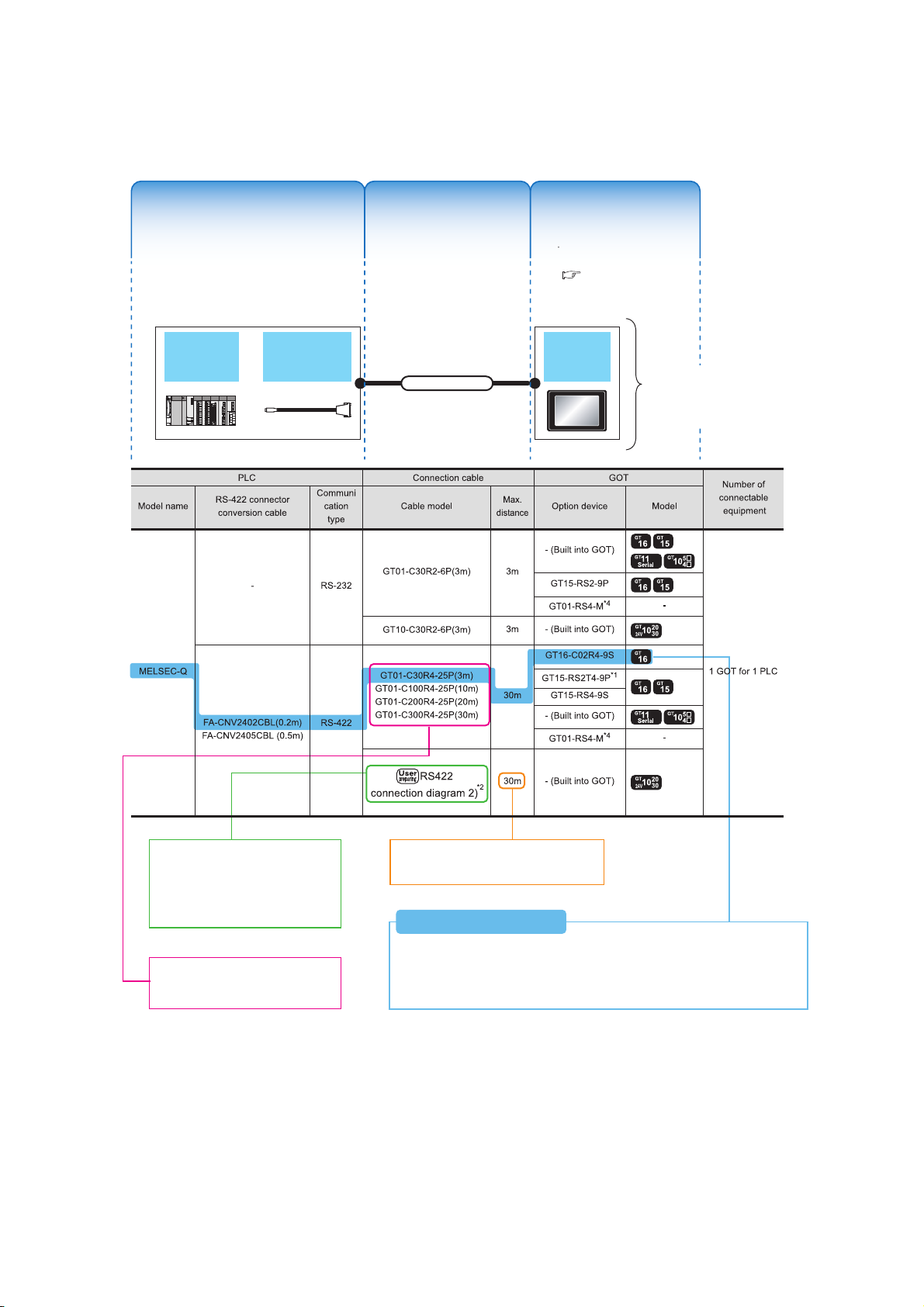

20.2.2 Connecting the GOT to PLC via RS-422 interface ............................................................. 20 - 4

20.3 Connection Diagram ...................................................................................................................... 20 - 5

20.3.1 RS-232 Cable ..................................................................................................................... 20 - 5

20.3.2 RS-422 cable...................................................................................................................... 20 - 6

20.4 GOT Side Settings......................................................................................................................... 20 - 7

20.4.1 Setting communication interface (Communication settings)............................................... 20 - 7

20.4.2 Communication detail settings............................................................................................ 20 - 9

20.5 Precautions.................................................................................................................................. 20 - 11

A - 17

Page 20

MULTI-CHANNEL FUNCTION

21.MULTI-CHANNEL FUNCTION

21.1 What is Multi-channel Function?.................................................................................................... 21 - 2

21.2 System Configuration .................................................................................................................... 21 - 4

21.2.1 Bus connection and serial connection ................................................................................ 21 - 4

21.2.2 Ethernet multiple connection ..............................................................................................21 - 6

21.3 GOT Side Settings ......................................................................................................................... 21 - 7

21.3.1 Basics of interface selection ............................................................................................... 21 - 7

21.3.2 General flow from system selection to drawing ................................................................ 21 - 12

21.3.3 Determining the connection type and channel No. (System selection) ............................ 21 - 13

21.3.4 Determining the GOT side interface (Interface selection)................................................. 21 - 23

21.3.5 Setting for communication settings................................................................................... 21 - 35

21.3.6 Items to be checked before starting drawing .................................................................... 21 - 39

21.4 Precautions.................................................................................................................................. 21 - 41

21.4.1 Precautions for hardware..................................................................................................21 - 41

21.4.2 Precautions for use........................................................................................................... 21 - 41

21.5 Multi-channel Function Check Sheet ........................................................................................... 21 - 42

FA TRANSPARENT FUNCTION

22.FA TRANSPARENT FUNCTION

22.1 FA Transparent Function ............................................................................................................... 22 - 2

22.2 Compatible Software ..................................................................................................................... 22 - 2

22.3 List of Models that Can Be Monitored.......................................................................................... 22 - 11

22.4 System Configuration .................................................................................................................. 22 - 26

22.4.1 GX Developer, GX Works2, GX LogViewer, MX Component, MX Sheet, LCPU Logging

Configuration Tool, Setting/Monitoring tool for C Controller module ................................ 22 - 26

22.4.2 PX Developer, GX Configurator........................................................................................ 22 - 29

22.4.3 MT Developer, MT Works2............................................................................................... 22 - 30

22.4.4 MR Configurator, MR Configurator2 ................................................................................. 22 - 32

22.4.5 FR Configurator ................................................................................................................ 22 - 34

22.4.6 FX Configurator-FP, FX Configurator-EN ......................................................................... 22 - 34

22.4.7 RT ToolBox2..................................................................................................................... 22 - 35

22.4.8 NC Configurator................................................................................................................ 22 - 35

22.5 GOT Side Settings ....................................................................................................................... 22 - 36

22.5.1 Setting communication interface....................................................................................... 22 - 36

22.6 Personal Computer Side Setting ................................................................................................. 22 - 39

22.6.1 Accessing the PLC by the GX Developer, PX Developer, GX Configurator ..................... 22 - 39

22.6.2 Accessing by GX Works2 ................................................................................................. 22 - 43

22.6.3 Accessing by GX LogViewer ............................................................................................ 22 - 52

22.6.4 Accessing PLC by GX Configurator-QP ........................................................................... 22 - 53

22.6.5 Accessing by the MT Developer ....................................................................................... 22 - 54

22.6.6 Accessing by the MT Works2 ........................................................................................... 22 - 55

22.6.7 Accessing the servo amplifier by the MR Configurator..................................................... 22 - 58

22.6.8 Accessing the servo amplifier by the MR Configurator2................................................... 22 - 58

22.6.9 Accessing the inverter by the FR Configurator ................................................................. 22 - 58

22.6.10 Accessing PLC by FX Configurator-FP ............................................................................ 22 - 59

22.6.11 Accessing by FX Configurator-EN .................................................................................... 22 - 60

A - 18

Page 21

22.6.12 Accessing by RT ToolBox2 .............................................................................................. 22 - 61

22.6.13 Accessing by NC Configurator ......................................................................................... 22 - 63

22.6.14 Accessing by MELSOFT Navigator .................................................................................. 22 - 63

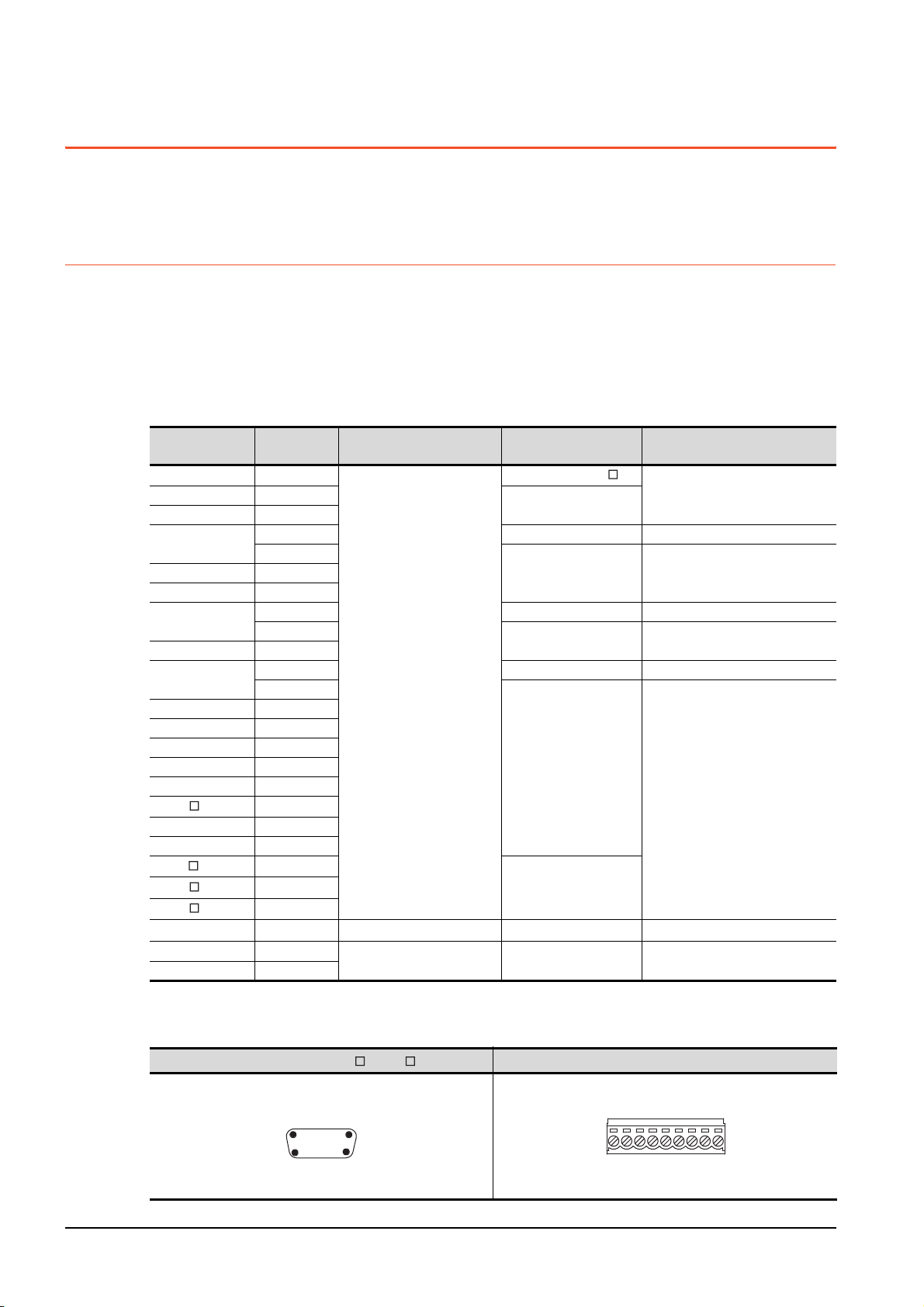

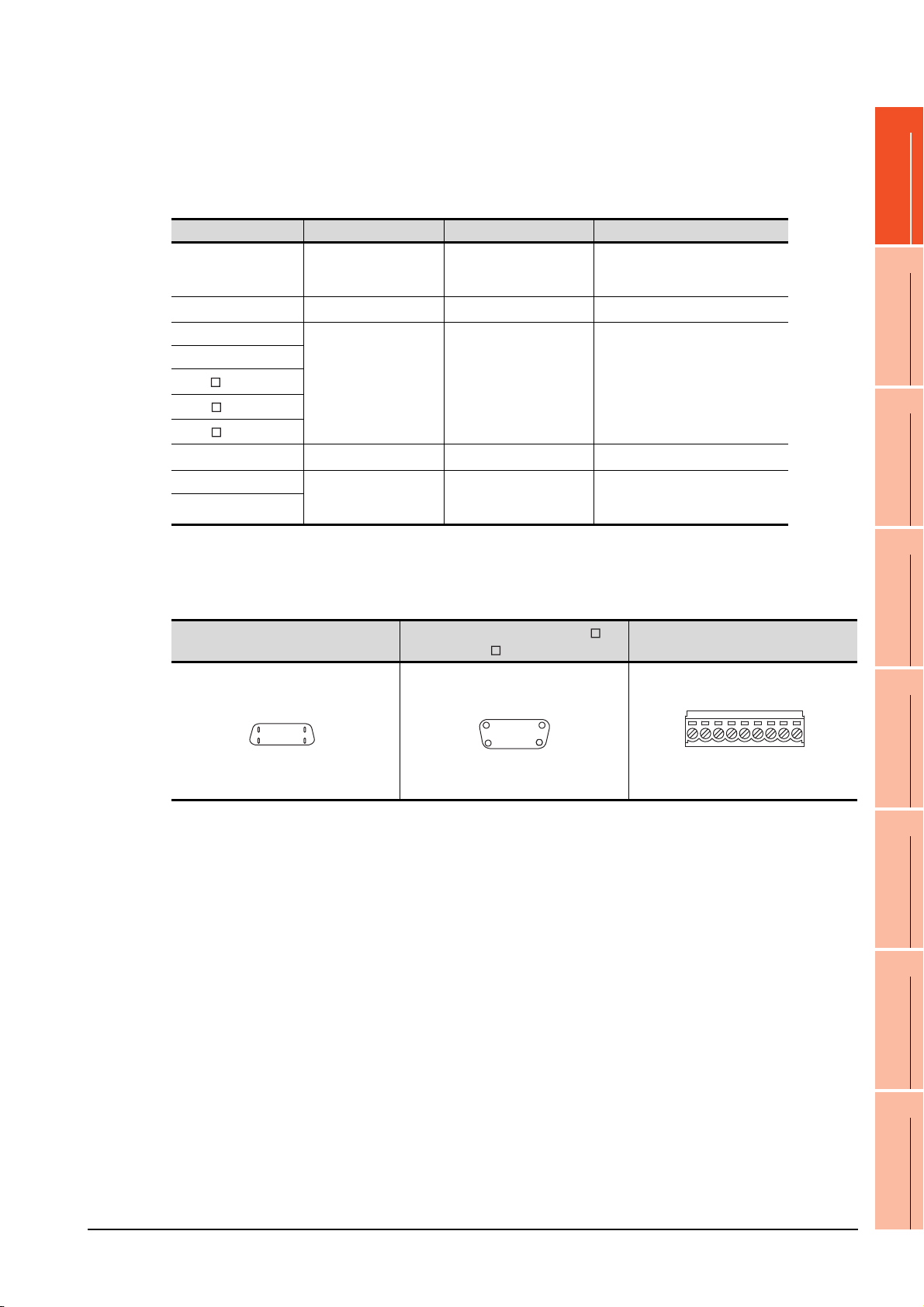

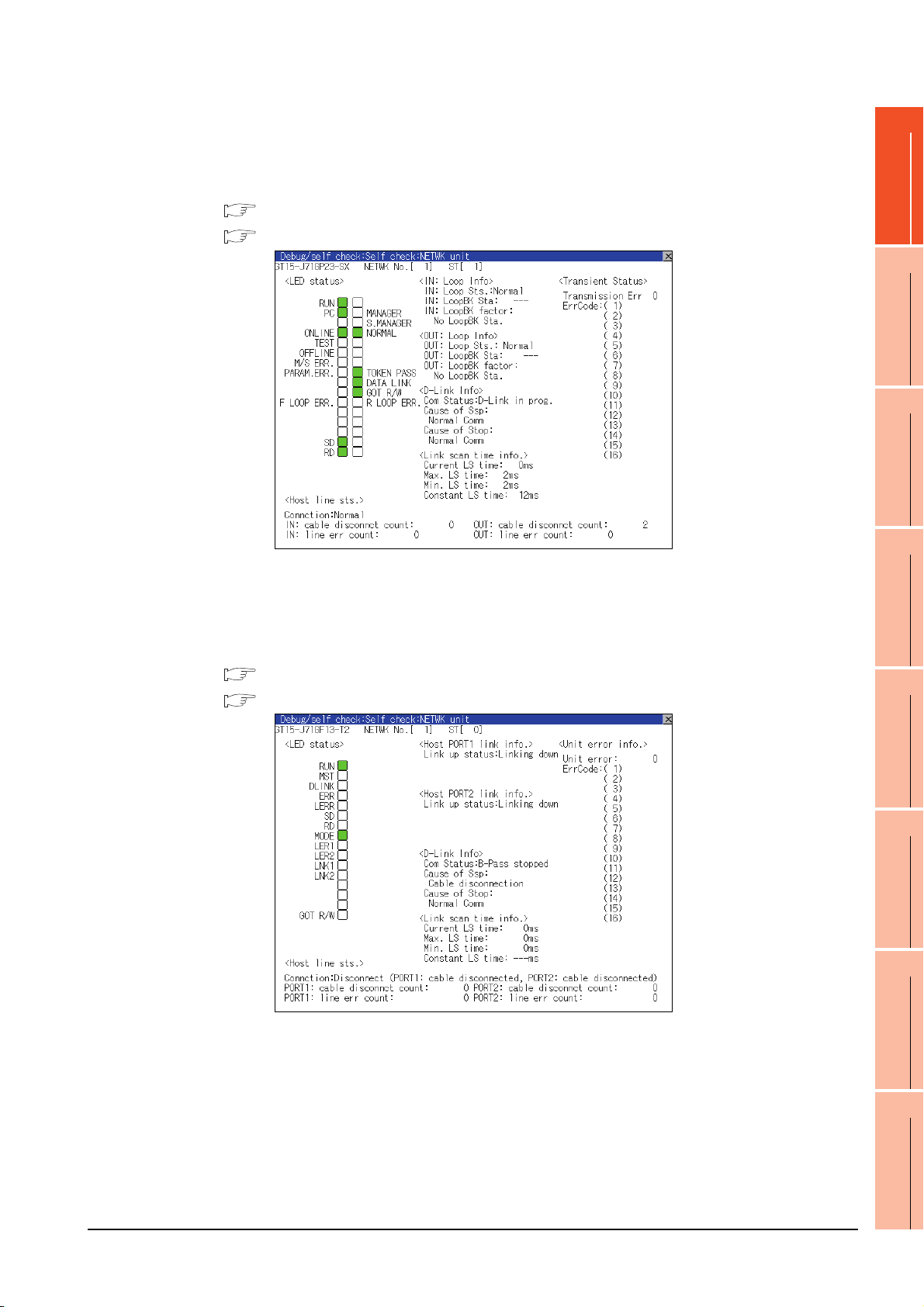

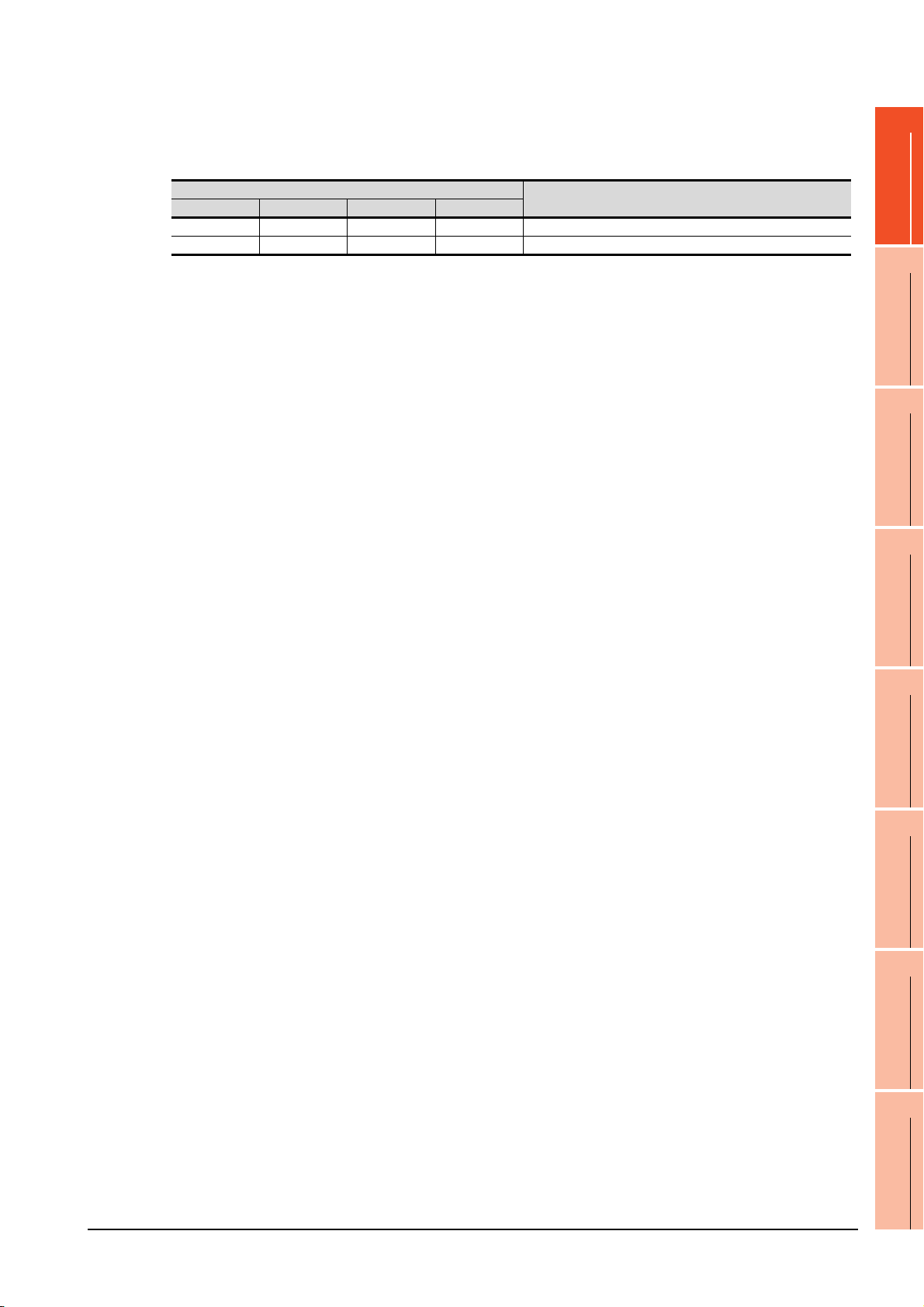

22.6.15 Accessing by LCPU Logging Configuration Tool.............................................................. 22 - 64