Page 1

Mitsubishi Electric Air-conditioner Network System

Central Controller

Model: G-50A

ON/OFF

CENTRAL CONTROLLER

G-50A

Installation Manual

Contents

1. Safety precautions to be observed without fail........ 1

2. Confirmation of parts .............................................. 2

3. Outline dimensions ................................................. 2

4. System diagram ...................................................... 3

5. Installation method .................................................. 4

1. Part prepared at site ........................................ 4

2. Installation method .......................................... 4

6. Initial setting ............................................................ 5

1. Address setting method................................... 5

2. Function selection method .............................. 5

3. IP address setting method............................... 6

4. Group setting ................................................... 6

5. Others.............................................................. 6

7. Test run ................................................................... 7

8. Example for system configuration ........................... 7

1. To control a K control model ............................ 7

9. External input/output usage method ....................... 7

1. External signal input function .......................... 7

2. External signal output function ........................ 8

3. LAN connection function ................................. 9

Before using the controller, please read this Installation Manual carefully to ensure proper

operation. Keep this manual for future reference.

Page 2

Page 3

This manual describes the installation of the central controller and wiring to the air conditioner. Before using the controller, read the

1 Safety precautions to be observed without fail section carefully to ensure proper installation.

1 Safety precautions to be observed without fail

Safety symbols used in this manual

The following symbols are used in this manual to indicate the type and severity of potential consequences that may result when given

instructions are not followed exactly as stated.

WARNING

CAUTION

Keep this Installation Manual and the Instruction Book for future reference. Make sure both this Installation Manual and the Instruction Book are given to the next user.

Have the controller professionally installed.

Improper installation by an unqualified person may result in

a risk of electric shock or fire.

Make sure the controller is securely mounted so that it

will not fall.

Only use specified cables. Securely connect each cable

so that the weight of the cable is not applied to the connectors.

Loose or improper connections may result in heat generation or fire.

Do not attempt to modify or repair the controller.

Modification or improper repair may result in electric shock

or fire.

Consult your dealer when repairs are necessary.

Indicates a risk of death or serious injury.

Indicates a risk of injury or damage to the controller.

WARNING

Securely install the controller according to the installation manual.

Improper installation may result in electric shock or fire.

Electric work must be perform by authorized personnel

according to the local regulations and the installation

manual.

Inadequate circuit capacity or improper installation may result in electric shock or fire.

Ask your dealer or an authorized technician to move

the controller.

Improper installation may result in electric shock or fire or

damage to the controller.

CAUTION

Do not install the controller where there is a risk of leakage of flammable gas.

If the leaked gas accumulates around the controller, it may

be ignited and result in an explosion.

Do not use the controller in an environment high in oil,

steam, or sulfuric gas.

These substances may have adverse effects on the performance of the controller or damage its parts.

When installing the controller in a hospital or communication facility, take appropriate measures to reduce noise

interference.

Inverter equipment, generators, high-frequency medical equipment, or radio communication equipment may interfere with

the normal operation of the controller, or the noise from the controller may interfere with the medical practice or cause image

distortion and static noise.

To prevent over-heating and fire, perform wiring so that

the weight of the cable will not strain the connectors.

Seal the wire lead-in port with putty to prevent the

entry of dew, water, and insects to avoid electric

shock or malfunction of the controller.

Do not wet the controller.

Water may damage the controller and cause an electric

shock.

Do not install this controller where the ambient temperature exceeds 40°C (104°F) or drops below 0°C (32°F).

To prevent deformation and malfunction, install the controller out of direct sunlight.

To avoid the risk of electric shock or malfunction of the

controller, install the controller in a non-condensing

environment.

Do not install this controller in a steamy place, such as a

bathroom or kitchen.

Do not install this controller where an acid or alkaline

solution or special chemical spray is used frequently to

avoid electric shock or malfunction.

Use specified wires with the proper current carrying

capacity to prevent current leakage, over-heating, or fire.

Do not touch the PCB (Printed Circuit Board) either with

your hand or a tool.

Keep the PCB dust-free to prevent fire or malfunction.

To avoid the risk of electric shock or damage to the controller, do not touch the switches with wet hands.

To avoid the risk of electric shock or damage to the controller, do not press the switches with sharp objects.

Do not apply an AC voltage or a voltage higher than

30VDC to the M-NET or the Power (12VDC) terminal

blocks on the controller to avoid damage to these parts

or fire.

– 1 –

Page 4

2 Confirmation of parts

* Please confirm that in addition to this Installation Manual the following items are enclosed in the box.

No. Part name Qty.

1 Central controller 1

2 Installation plate 1

3 Wood screw 4.1✕16 (use when directly installing on the wall) 2

4 M4 round head screw for main unit installation 2

5 M3 round head screw for cover fixing 1

6 M4 countersunk screw (M4✕40) for installation plate fixing 3

7 Instruction book 1

* If the screw enclosed for installation plate fixing cannot be used because the wall is thick, prepare an M4 countersunk screw with a

length matching the wall thickness.

* Besides the above parts, purchase a power supply unit (PAC-SC50KUA) that supplies power (DC12V) to the central controller and

(DC24V) to the M-NET transmission line.

* If connected to an R410-A compatible model of CITY MULTI outdoor unit (except the S series), G-50A can be powered from the

outdoor unit. Note, however, that while the power to the connected outdoor unit is turned off, the G-50A cannot perform a schedule

operation, collect charge data, or perform energy save control.

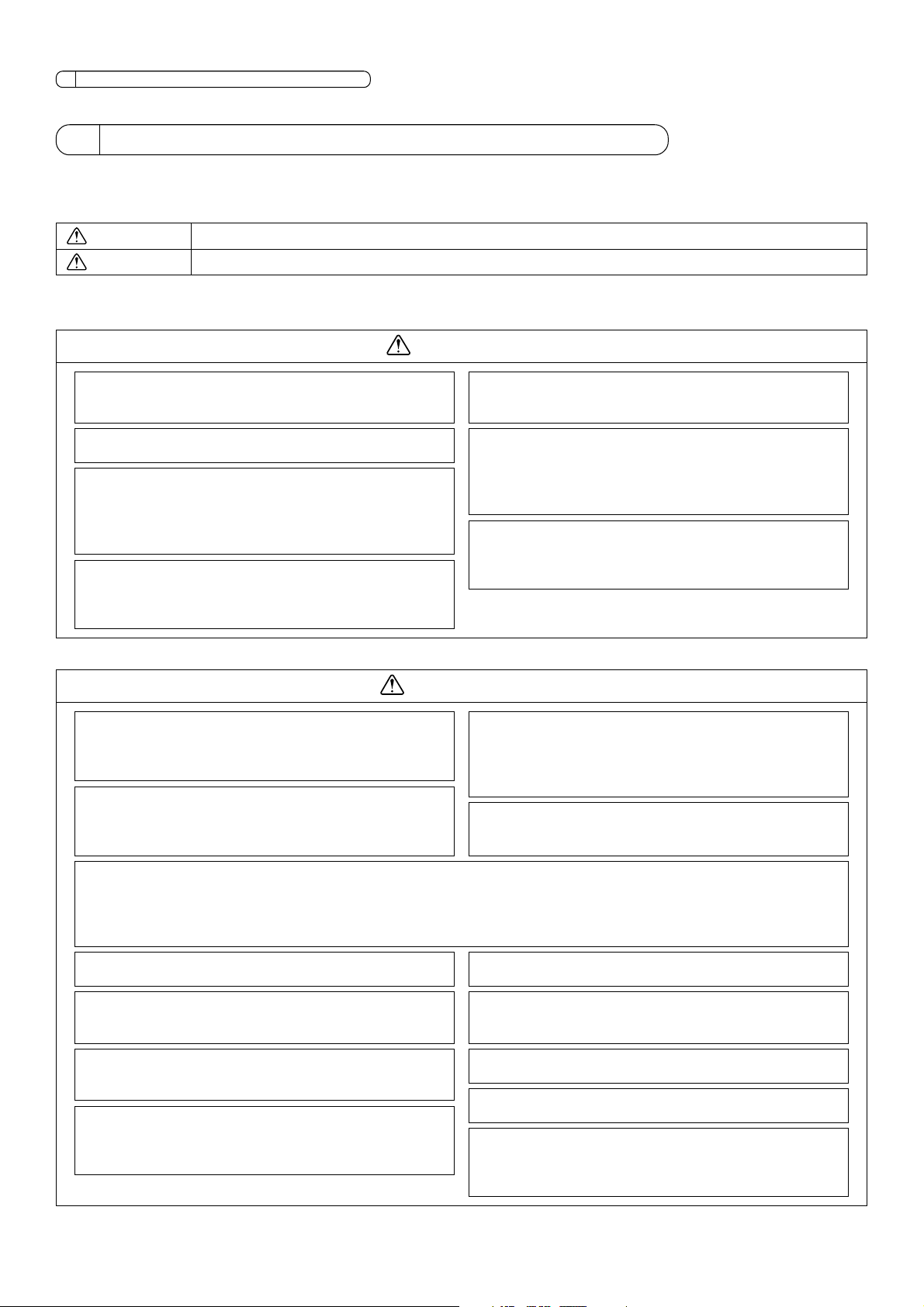

3 Outline dimensions

300 (11-13/16)

Unit: mm (in)

120 (4-3/4)

28 (1-1/8)

21 (13/16)

91

ON/OFF

CENTRAL CONTROLLER

G-50A

19 (3/4) 57 (2-1/4)

3 (1/8)

116 (4-9/16) 34 (1-5/16)104 (4-15/16)46 (1-13/16)

280 (11)

CN2

CN1

51

RS232C

GND

12VDC

ABS

POWER

M-NET

Ethernet

83.5 (3-9/32)

106 (4-3/16)

13 (1/2)

Installation plate

288 (11-11/32)

138 (5-7/16)

47 (1-27/32)

70 (2-3/4)

83 .5 (3-9/32)

91 (3-19/32)

47 (1-27/32)

– 2 –

Page 5

4 System diagram

K transmission converter

211

Model:PAC-SC25KAA

M-NET

NOTE

* This diagram does not show

the AC power supply wiring.

Only the configuration for

the transmission line is

shown.

outdoor unit

M-NET

outdoor unit

K control

outdoor unit

Group 11

KK

Group No.

BC controller

ME

Group 1 Group 2

Group 13

Group No.

Group 3 LOSSNAY

Indoor unit

Local remote controller

M-NET side: [ME] PAR-F27MEA

MA side: PAR-20/21MAA

M-NET transmission line

K transmission line

MA remote controller line

The numbers in the

indicate the address No.

[CR] PAC-SE51CRA

PAR-FA(FL)31MA

PAC-YT51CRA

LAN

Central controller

Model: G-50A

M-NET

MA

Power supply unit (optional)

Model:PAC-SC50KUA

Power(DC12V)

MA

* Address setting for each M-NET device (The same address cannot be duplicated).

* The K transmission converter (PAC-SC25KAA) and OA processing unit (LOSSNAY) are not included in systems shipped to North

America (USA & Canada).

Indoor unit

Address setting method

Set the indoor unit you want to make the master unit in the same group to the mini-

Address

1~50

mum address, and sequentially set the indoor unit addresses in the same group.

Outdoor unit

BC controller/OS controller

Min.indoor unit address in same refrigerant system + No.50 unit.

Outdoor unit address in same refrigerant system + No.1 unit.

51~100

52~100

However, for Sub-BC controller, minimum indoor unit address that connects the local refrigerant piping + 50.

K control side remote controller

M-NET remote controller

MA remote controller

OA processing unit/LOSSNAY

K transmission converter

Same address as indoor unit master unit

Set to the minimum indoor unit master address in the same group + 100.

Address setting is unnecessary.

After setting all the indoor units, set an arbitrary address.

Min.address of K control indoor unit + No.200 unit.

1~50

101~200

-

1~50

201~250

NOTE

* The following precautions will apply when using the K transmission converter (model: PAC-SC25KAA) and controlling the M-NET

model and K control model with the same controller.

Refer to the K transmission converter installation manual for details.

1 Central controller address

Always set the controller address to “000”.

(Refer to section 6 Initial setting .)

2 Central controller function selects

Always set the No.3 function selects of the controller to “ON”

(Refer to section 6 Initial setting .)

3 Indoor unit address

Set all M-NET model indoor units from the No.1 unit, and then set the K control model addresses.

Indoor unit No.1 unit ~M-NET indoor unit max. address->K control indoor unit min. address ~50

4 K control model group No.

The min.indoor address No. of that group becomes the group No. (Same for K control side local remote controller.)

– 3 –

Page 6

5 Installation method

1. Parts prepared at site

1 Prepare an electric box.

2 Prepare lock nuts and bushing that match the conduit.

30 (1-3/16)

1 (1/32)

Center of electric box

179 (7-15/32)181 (7-1/8)

30 (1-3/16)

Unit: mm (in)

30 (1-3/16)

3 Prepare an M-NET transmission line CVVS(2-wire):

1.25mm

2

(AWG 16) or equivalent.

4 DC power supply line (3-conductor): Provide

0.75mm

2

(AWG 18) or greater.

The controller outline

Clearance around the controller

Center the controller

120

(4-23/32)

Electric box

(Shaded section)

2. Installation method

1 Secure the space shown on the right when installing the electric box.

2 When installing the controller on the electric box, the controller will be shifted by 1mm (1/32 in) to the left as shown above.

NOTE

* When installing two controllers horizontally in parallel, secure a clearance of 30mm (1-3/16 in) or more between the products.

When installing vertically with the same clearance, removing of the cover will be difficult.

* When connecting a LAN and RS-232C, a space for the connector and wiring is required. Provide this space between this unit

and the rear of the electric box.

It varies depending on the specifications of the LAN cable that is procured, but the LAN connector may protrude approximately

20mm (25/32 in) from the bottom of the unit cabinet. Provide a cable with the smallest possible connector to secure space.

Reference example) Example of installation when a 67mm (2-5/8 in) deep electric box is used with a 30mm (1-3/16 in) thick wall.

Central controller

Wall

57

(2-1/4)

mm

30mm 67mm

(1-3/16) (2-5/8)

Electric box

LAN cable

Approx. 40mm

(1-9/16)

( ): in

3 Connect the M-NET transmission line (centralized control line which is connected to TB7 of the outdoor unit) to M-NET transmis-

sion line terminal A and B. (Non Polarity)

Connect the DC power line from the power supply unit (PAC-SC50KUA) to the DC power supply terminal block of this device.

There is a 12VDC and a GND polarity.

* Type of wire. Use the cables which comply with the following specifications or equivalent.

M-NET transmission line:

CVVS 1.25mm

2

/AWG 16 (PVC-insulated, PVC-sheathed shield control cable)

CPEVS ø1.2mm/AWG 17 (PE-insulated, PVC-sheathed shield communication cable)

MVVS 1.25mm

2

/AWG 16 (PVC-insulated, PVC-sheathed shield control cable)

DC power line: 0.75mm2/AWG 18 or greater 3-conductor power line

CAUTION

Controller rear surface

M-NET

POWER

* Do not connect the AC power line to the M-NET and

POWER (DC12V) terminal blocks of this device. It may

cause a failure.

* Do not connect to the M-NET transmission line of indoor

unit control line which is connected to TB3 of the outdoor

unit.

* The conduit outlet faces only vertically. When leading the

line out from above, seal the port so that water does not

enter along the transmission line and DC power supply

line.

4 Securely seal the line lead-in port with putty to prevent the

entry of dew, water and insects, etc.

* Seal the connecting section of the electric box and conduit with

putty.

DC power line

M-NET transmission line

Bushing

M-NET transmission line

and DC power line

Wall

ABS

When not using

bridge wiring

*When using bridge wiring of the shield,

use the S-terminal as shown below.

Conduit

Lock nut

Electric box

Seal with putty

GND

12VDC

12VDC : +12V

GND : 0V

– 4 –

Page 7

5 Remove the controller’s cover and install on to the electric

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

box.

(NOTE)

The cover fixing screw is

packaged with the other enclosed

screws.

Insert a flat-tip screwdriver and

rotate it to remove the cover.

<Installation on to electric box>

NOTE

* When installing the controller directly on to a wall

Installation plate

M4 countersunk

screw

Central controller

instead of using the electric box, do not use the installation plate.

* If the screw enclosed for the installation plate, fixing

cannot be used because of the wall thickness, prepare an M4 countersunk screw that matches the

Electric box

wall thickness.

* When using an LAN and external signal I/O, refer to

M4 round head screw

section 9 External input/output usage method .

6 Initial setting

NOTE

* Initial settings can be made in one of the following three ways: 1) on the unit, 2) by using the Initial Setting Web via the LAN

connection, or 3) by using the Initial Seeing Tool via the LAN connection. In this manual, how to make the initial settings on the

unit are described.

* Turn on the power supply unit (PAC-SC50KUA) power and run and initially

set this unit. When the power is first turned on, the startup screen shown at

the right is displayed.

(When changing the initially set contents after various initial settings were

performed and the system was already started, the initial setting menu

screen is displayed by pressing the

and ↓ switches simultaneously for

↑

2 seconds or longer during user operation menu screen display.)

At the end of various initial settings, return to the user operation menu

screen by pressing the

and ↓ switches simultaneously for 2 seconds

↑

or longer.

Refer to the attached instruction book section 5.Initial setting for further

information.

1. Address setting method

1 When the startup screen is displayed at power on, press the

2 Press the

3 When the

0

BACK

SCREEN

←

9

~

switches, and set the address of this unit. (000,201~250)

switch is pressed after setting, the screen returns.

1

* Always set to [000] when using K transmission converter.

* The M-NET address initial value of this unit is [000].

2. Function selection method

2

1 On the startup screen, press the

2 Switch the function by pressing the

switch to select “2 FUNCTION SETTING”.

1

~

8

switch of the same No. as the function No. you want to change.

Each time the switch is pressed, the ON/OFF state of that No. is changed.

No.1 and No.2 cannot be changed.

When Function No. 3 is set to ON, set the K transmission converter address.

Move the address and Function setting using the

<Operation example>

1) When the

3 When the

3

switch was pressed

BACK

SCREEN

switch is pressed, the screen is returned.

←

, ↓, →, and ← keys.

↑

33

ON

OFF

···

·····

·······

·······

·······

··

·······

·····

ON

OFF

(OFF) (ON)

<Function Selection Display>

No. 1

No. 2

No. 3

No. 4

No. 5

No. 6

No. 7

No. 8

OFF: Not used (Fixed to OFF)

OFF: Not used (Fixed to OFF)

OFF: K transmission converter not provided/ON: K transmission converter provided

OFF: Operation prohibit transmission valid/ON: Operation prohibit transmission invalid

OFF: Emergency stop broadcast enabled/ON: Emergency stop broadcast disabled

External input changeover

The range of a controller which the operation is prohibited.

OFF: Both of the systems controller and the local remote controller/ON: Only the local remote controller

switch to select “1 ADDRESS SETTING”.

·····

·······

··

·······

·······

·······

·····

···

1 ADDRESS SETTING

2 FUNCTION SETTING

3 IP ADDRESS SETTING

4 GROUP SETTING

PLEASE SET

INITIAL SETTING

– 5 –

Page 8

<Meanings of function selects>

Function

No.1

No.2

No.3 *1

State

Fixed to OFF

Fixed to OFF

OFF

Name

K transmission converter

Details

Not used. Always set this to “OFF”

Not used. Always set this to “OFF”

The packaged air conditioner to be used is only an M-NET model.

not provided

ON

K transmission converter

provided

K control model is included in the packaged air conditioner being used. (In

this case, set the controller address “000”.) Set the K transmission converter address at this screen.

Prepare the K transmission converter (PAC-SC25KAA) separately.

No.4

OFF

Operation prohibit valid

Set this when using as a system controller for which local remote operation

prohibit can be set.

A system controller set to this can be used only for external input.

Note that only one unit can be used in the system.

ON

Operation prohibit invalid

Set this when using as a system controller for which local remote operation

prohibit cannot be used.

Set only one unit in the system to the operation prohibit transmission valid

setting, and set all other units to the invalid setting.

No.5

OFF

ON

Emergency stop broadcast

enabled.

Emergency stop broadcast

Please be sure to make it “OFF” setting.

disabled.

No.6,7

OFF/ON

External input changeover

This changes the input when using CN3 (external input I/F).

(Refer to section 9 External input/output usage method for details.)

No.8

OFF

ON

The range of a controller

which the operation is

Both of the system controller and the local remote controller.

Only the local remote controller.

prohibited.

*1 The K transmission converter (PAC-SC25KAA) is not included in systems shipped to North America (USA & Canada) Always set

this to “OFF”.

G-50A

management range

Another system controller

management range

Unit

Unit

M-NET Gateway

management range

Management range of

G-50A

Unit

Unit

* G-50A does not

support slaves.

When G-50A controls another system controller or when the

system contains only G-50A: G-50A is set as the master system

controller.

When G-50A is controlled by another system controller:

G-50A is set as the slave system controller.

* The group setting is performed by Master system controller.

* G-50A performs the group setting in this configuration.

3. IP address setting method

When connecting an LAN to this unit, set the IP ADDRESS and MASK ADDRESS.

1 On the startup screen, press the

2 When the

3 Set both addresses using the

4 When the

→

(↓) or ← (↑) switch is pressed, the cursor moves to right or left.

BACK

SCREEN

switch is pressed, the screen is returned.

←

3

switch to select “3 IP ADDRESS SETTING”.

1

~

8

switches.

4. Group setting

* Set the group configuration with indoor units, local remote controllers (only when M-NET type used) and slave system controller to be

controlled by this unit.

* Select “4 (or 1) GROUP SETTING” on the menu screen in the initial setting mode, and set the group configuration.

* Refer to the attached instruction book section 5 Initial Setting for the initial setting method.

5. Others

* Since the screen switches from the startup screen to the initial setting menu screen after group setting, choose the menu and perform

setting and monitoring, as required.

• Interlocked setting (Sets interlocking between ventilator and indoor unit.)

• Refrigerant monitor (Outdoor unit and indoor unit refrigeration connection can be monitored.)

• Malfunction monitor (Past abnormality history can be monitored.)

• User setting (Real-time display information selection and setting.)

Refer to the attached instruction book sections 5-5 Interlocked operation setting to 6-2 Malfunction log monitor function for a detailed

description of the functions and settings.

When all the initial settings are complete, initiate startup communication by holding down the

and ↓ switches on the initial setting

↑

menu screen simultaneously for at least 2 seconds. After a while, the display shifts to the user operation menu screen.

Refer to the attached instruction book section 5 Initial setting for further information.

– 6 –

Page 9

7 Test run

* After setting the group or interlocked setting, confirm that the controller has started up, and then perform a test run.

* It may take approx. 10 minutes for local remote controller operation to be enabled after the power is turned ON. In this case, press the

ON/OFF button on the controller to enable immediate local remote controller operation.

(Test run procedure)

1. Turn ON the Power to the controller and all the units.

2. When the “INITIAL SETTING (PLEASE WAIT)” blink on the controller LCD stops, press the “1 ON/OFF switch” and the “tempera-

ture setting switch ▲” at the same time.

3. Confirm the run state (indoor unit outlet air temperature, cool air, confirmation, etc.) during the test run.

4. When each unit has been confirmed, stop the unit with the controller or local remote controller. Even if the units are not stopped, the

test run will stop automatically after approx. 2 hours.

* Refer to the installation manual for the connected indoor unit for details on the test run method.

8 Example for system configuration

1. To control a K control model

* Set G-50A address to “000” When a K transmission converter is con-

nected. Always set to the master system controller when the address is

“000”.

* Make the address of the K-control models of indoor units larger than that

of the M-transmission models of indoor units.

* When using a group setting for the K control model, set only the indoor

unit that belongs to that group.

G-50A

(Master system controller)

DC12V

M-NET

Power supply unit

(Model PAC-SC50KUA)

20 indoor units

Indoor unit address 01~20

Group 1 to Group 20

20 indoor units (for control)

Indoor unit address 21~40

Group 21 to Group 40

K transmission converter

(Model: PAC-SC25KAA)

* Set the min.indoor unit address in the group for the K control model group

No.

* When connected to a K-transmission converter, set the function setting

switch No.3 to “ON” (with connection to K-transmission converter).

* Set the master system controller function select No.4 to “OFF” (operation

prohibit transmission valid) when the K transmission controller is connected.

9 External input/output usage method

1. External signal input function

* External signal input requires the external I/O adapter (Model: PAC-YG10HA-E) sold separately.

(1)External input

Emergency stop/normal, run/stop and prohibit/enable of local remote controller operation can be controlled for all air conditioners being

controlled by using a voltage (DC12V or DC24V) contact signal from an external source. (Select with the function select setting.)

No.

1

External signal input function

Do not use external input signal

(factory setting)

Execute emergency stop/normal with

2

level signal

3

Perform ON/OFF with level signal

4

Perform ON/OFF, prohibit/enable with

pulse signals.

Function

No.6 No.7

OFF

OFF

ON

ON

OFF

ON

OFF

ON

Remarks

The local remote controller ON/OFF operations, and the

controller ON/OFF operation and prohibit/enable change

operations will be prohibited during emergency stop. Timer

operation will also be prohibited.

The local remote controller ON/OFF operations, and the

controller ON/OFF operations and prohibit/enable change

operations will be prohibited. Timer operation will also be

prohibited.

Set the pulse width while the contact is ON to 0.5 to 1 sec.

(2)Level signal and pulse signal (DC12V or DC24V)

(A) Level signal

Contact ON

Contact OFF

Contact ON

Contact OFF

Stop

Normal

Run

Emergency stop

Stop

Normal

(B) Pulse signal

– 7 –

(Example) for ON/OFF

Signal 1(run)

Signal 2(stop)

Contact ON

Contact OFF

Contact ON

Contact OFF

0.5 to 1 sec

0.5 to 1 sec

OFF

*The prohibit/enable input is the same.

ON

OFF

Page 10

(3)External input specifications

CN2 Lead wire Emergency stop/normal level signal ON/OFF, level signal ON/OFF, prohibit/enable pulse signal

No.5 Orange Emergency stop/normal input ON/OFF input ON input

No.6 Yellow Not used Not used OFF input

No.7 Blue Not used Not used Local remote controller operation prohibit input

No.8 Gray Not used Not used Local remote controller operation enable input

No.9 Red External DC source “+ DC12V” or “+ DC24V”

(A) For level signal

1 When the emergency stop/normal signal is selected, the status will change from normal to emergency stop when the

external input signal contact changes from OFF to ON, and will change from emergency stop to normal when the contact

changes from ON to OFF. Air conditioning units that came to an emergency stop will remain stopped after the emergency

stop is cancelled. Manually start up each unit to restore the previous operation.

2 When the ON/OFF signal is selected, the status will change from OFF to ON when the external input signal contact

changes from OFF to ON, and will change from ON to OFF when the contact changes from ON to OFF.

(B) For pulse signal

1 Even if the ON signal is input during ON, the status will remain ON.

2 If the local remote controller is prohibited, the ON/OFF operation mode and temperature setting operations by the local

remote controller will be prohibited.

3 Set the pulse width (contact ON time) to 0.5 to 1 sec.

(4)Recommended circuit example

(A) For level signal

CN2

This unit

Red

9

8

7

6

Orange

5

1

Max.10m

(32 ft)

X1

X1

Run/stop or

Emergency stop

Power supply(*1)

(DC12V or DC24V)

Use relays X1, X2, Y1, and Y2 that meet the

following specifications.

Operating coil

Rated voltage : DC12V, DC24V

(B) For pulse signal

CN2

9

8

7

6

Orange

5

1

Max.10m

This unit

Red

Gray

Blue

Yellow

(32 ft)

Y2

Y1

X2

X1

Power supply(*1)

(DC12V or DC24V)

X1 X2 Y1 Y2

Run Stop Prohibit Enable

Power consumption: 0.9 W or less

(*1) Prepare a power supply separately accord-

ing to the relay being used. (DC12V or

DC24V)

1 The contact relay, DC power source, extension cable, etc., must be prepared separately at the site.

2

2 The connection cable can be extended up to 10m (32 ft). (Use a 0.3mm

(AWG 22) or larger wire.)

3 Strip the extra cable near the connector, and securely insulate the exposed section with tape, etc.

2. External signal output function

* External signal output requires the external I/o adapter (Model: PAC-YG10HA-E) sold separately.

(1)External output

When one or more air conditioners are running, the “ON” signal will be output and if a malfunction occurs in one or more air

conditioners, the “Malfunction” signal will be output.

(2)External output specifications

CN 2 Lead wire Details of each terminal

No.1 Green Common (External ground)

1 The “ON” signal is output even while the “Malfunction” sig-

nal is being output.

No.2 Black ON/OFF

No.3 Brown Malfunction/normal

– 8 –

Page 11

POWER

GND

12VDC

91

CN2

51

CN1

RS232C

Ethernet

ABS

M-NET

(3)Recommended circuit example

CN2

9

This unit

4

Brown

3

Black

2

Green

1

Max.10m

(32 ft)

Diode(*2)

Z1

Power (*1)

Supply

1 Each element will turn on while ON operation or a malfunction occurs.

2 The connection cable can be extended up to 10m (32 ft).

3 The relays, lamps, diodes and extension cables, etc, must be prepared separately at the site.

Z1

L1

Z2

Z2

L2

L1: Run display lamp

L2: Malfunction display lamp

Use Z1 and Z2 relays that meet the following specifications.

Operation coil

Rated voltage : DC12V, DC24V

Power Consumption: 0.9W or less

(*1) Prepare a power supply separately according to the relay

being used. (DC12V or DC24V)

(*2) Always insert a diode on both ends of the relay coil.

NOTE

Peel off the label

* When connecting the external input/output cables to connector CN2

on the controller, Peel off the label on the controller connector

section.

3. LAN connection function

When using the LAN connection function, connect the LAN cable to the Ethernet connector of this device.

* Procure the LAN cable at the site, and use 10 BASE-T Straight cable.

* For a description of the IP address setting method, refer to section 6 Inital setting .

* LAN is 10 BASE-T Specification.

Ethernet

M-NET

ABS

POWER

12VDC

91

GND

RS232C

51

CN1

CN2

CAUTION

* Perform the LAN wiring before installation, and wire up to the body by the same method as wiring the M-NET transmission line.

* When a LAN is already connected, decide the IP address by consultation with the system administrator and connect to the LAN

body after changing the IP address.

* When connecting an LAN connector, space for the connector and wiring is required. Provide this space at this unit and the rear

of the electric box. Refer to section 5 Installation method .

* When the G-50A cover is opened, the LAN status lamp and LAN changeover switch are accessed. For detailed information, refer

to sections 3-2 and 5-9 of the Instruction Book.

– 9 –

Page 12

This product is designed and intended for use in the residential,

commercial and light -industrial environment.

The product at hand is

based on the following

EU regulations:

• Low Voltage Directive 73/23/EEC

• Electromagnetic Compatibility Directive 89/

336/EEC

HEAD OFFICE: TOKYO BLDG., 2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

WT03944X02

Printed in Japan

Recycled Paper

Loading...

Loading...