Mitsubishi Electric FR-A8APR Instruction Manual

INVERTER

Plug-in option

FR-A8APR

INSTRUCTION MANUAL

Resolver interface

Orientation control

Resolver (encoder) feedback control

Vector control

PRE-OPERATION INSTRUCTIONS

INSTALLATION AND WIRING

PARAME TER

ORIENTATION CONTROL

RESOLVER (ENCODER) FEEDBACK

CONTROL

VECTOR CONTROL

1

2

3

4

5

6

Thank you for choosing this Mitsubishi inverter plug-in option.

Warning

Caution

Caution

This Instruction Manual provides handling information and precautions for use of this product. Incorrect handling might cause an unexpected

fault. Before using this product, always read this Instruction Manual carefully to use this product correctly.

Please forward this Instruction Manual to the end user.

Safety instructions

Do not attempt to install, operate, maintain or inspect the product until you have read through this Instruction Manual and appended

documents carefully and can use the equipment correctly. Do not use this product until you have a full knowledge of the equipment, safety

information and instructions. In this Instruction Manual, the safety instruction levels are classified into "Warning" and "Caution".

The level may even lead to a serious consequence according to conditions. Both instruction levels must be followed

because these are important to personal safety.

Electric Shock Prevention

Incorrect handling may cause hazardous conditions, resulting in death or severe injury.

Incorrect handling may cause hazardous conditions, resulting in medium or slight injury, or may cause only material

damage.

Warning

While the inverter power is ON, do not open the front cover or the wiring cover. Do not run the inverter with the front cover or the wiring cover removed. Otherwise

you may access the exposed high voltage terminals or the charging part of the circuitry and get an electric shock.

Do not remove the inverter front cover even if the power supply is disconnected. The only exception for this would be when performing wiring and periodic

inspection. You may accidentally touch the charged inverter circuits and get an electric shock.

Before wiring or inspection, LED indication of the inverter unit operation panel must be switched OFF. Any person who is involved in wiring or inspection shall wait

for at least 10 minutes after the power supply has been switched OFF and check that there is no residual voltage using a tester or the like. For some time after the

power-OFF, a high voltage remains in the smoothing capacitor, and it is dangerous.

Any person who is involved in wiring or inspection of this equipment shall be fully competent to do the work.

The plug-in option must be installed before wiring. Otherwise you may get an electric shock or be injured.

Do not touch the plug-in option or handle the cables with wet hands. Otherwise you may get an electric shock.

Do not subject the cables to scratches, excessive stress, heavy loads or pinching. Otherwise you may get an electric shock.

Injury Prevention

Caution

The voltage applied to each terminal must be the ones specified in the Instruction Manual. Otherwise a burst, damage, etc. may occur.

The cables must be connected to the correct terminals. Otherwise a burst, damage, etc. may occur.

The polarity (+ and -) must be correct. Otherwise a burst or damage may occur.

While power is ON or for some time after power OFF, do not touch the inverter as it will be extremely hot. Touching these devices may cause a burn.

2

Additional Instructions

The following instructions must be also followed. If the product is handled incorrectly, it may cause unexpected fault, an injury, or an electric

shock.

Caution

Transportation and mounting

Do not install or operate the plug-in option if it is damaged or has parts missing.

Do not stand or rest heavy objects on the product.

The mounting orientation must be correct.

Foreign conductive objects must be prevented from entering the inverter. That includes screws and metal fragments or other flammable substance such as oil.

If halogen-based materials (fluorine, chlorine, bromine, iodine, etc.) infiltrate into a Mitsubishi product, the product will be damaged. Halogen-based materials are

often included in fumigant, which is used to sterilize or disinfest wooden packages. When packaging, prevent residual fumigant components from being infiltrated

into Mitsubishi products, or use an alternative sterilization or disinfection method (heat disinfection, etc.) for packaging. Sterilization of disinfection of wooden

package should also be performed before packaging the product.

Trial run

Before starting operation, each parameter must be confirmed and adjusted. A failure to do so may cause some ma chines to make unexpected motions.

Warning

Usage

Do not modify the equipment.

Do not perform parts removal which is not instructed in this manual. Doing so may lead to fault or damage of the product.

Caution

Usage

When parameter clear or all parameter clear is performed, the required parameters must be set again before starting operations. Because all parameters return to

their initial values.

Static electricity in your body must be discharged before you touch the product.

Maintenance, inspection and parts replacement

Do not carry out a megger (insulation resistance) test.

Disposal

The product must be treated as industrial waste.

Many of the diagrams and drawings in this Instruction Manual show the inverter without a cover or partially open for explanation. Never operate the inverter in this

General instruction

manner. The cover must be reinstalled and the instructions in the Instruction Manual must be followed when operating the inverter.

3

─ CONTENTS ─

1 PRE-OPERATION INSTRUCTIONS 6

1.1 Unpacking and product confirmation.......................................................................................................6

1.1.1 Product confirmation....................................................................................................................................... 6

1.1.2 SERIAL number check ...................................................................................................................................7

1.2 Component names .....................................................................................................................................8

2 INSTALLATION AND WIRING 9

2.1 Pre-installation instructions ......................................................................................................................9

2.2 Installation procedure ................................................................................................................................9

2.3 Wiring ........................................................................................................................................................12

2.4 Terminals...................................................................................................................................................15

3 PARAMETER 16

3.1 Extended parameter list...........................................................................................................................16

3.2 Function differences from the FR-A8AP ................................................................................................18

3.3 Protective function ...................................................................................................................................20

4 ORIENTATION CONTROL 21

4.1 Wiring example .........................................................................................................................................21

4.2 Terminals...................................................................................................................................................22

4.3 Specifications ...........................................................................................................................................23

5 RESOLVER (ENCODER) FEEDBACK CONTROL 24

5.1 Wiring examples .......................................................................................................................................24

5.2 Specifications ...........................................................................................................................................25

4

6 VECTOR CONTROL 26

6.1 Wiring examples .......................................................................................................................................26

6.2 Setting procedure of vector control for motor with resolver ...............................................................29

6.3 Vector control for PM motor with resolver.............................................................................................30

6.4 Offline auto tuning....................................................................................................................................31

6.5 Resolver position tuning..........................................................................................................................33

6.6 Specifications ...........................................................................................................................................36

<Notes on descriptions in this Instruction Manual>

Connection diagrams in this Instruction Manual appear with the control logic of the input terminals as sink logic, unless

otherwise specified.

5

1 PRE-OPERATION INSTRUCTIONS

1.1 Unpacking and product confirmation

Take the plug-in option out of the package, check the product name, and confirm that the product is as you ordered and intact.

This product is a plug-in option dedicated for the FR-A800 series.

1.1.1 Product confirmation

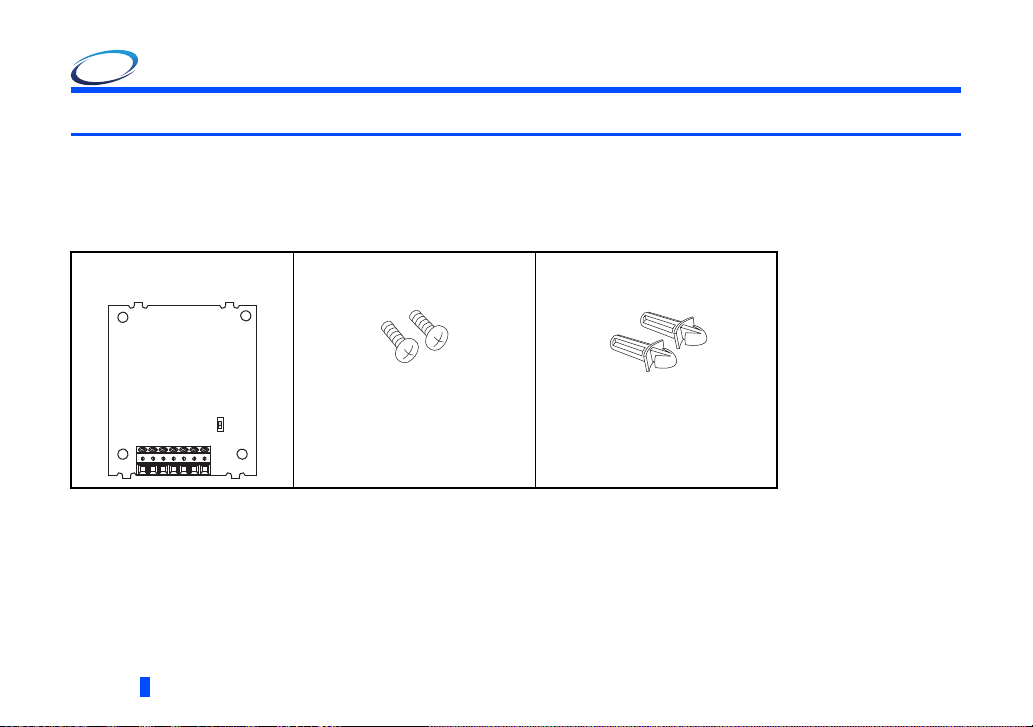

Check the enclosed items.

Plug-in option

.................................................. 1

SW1

6

PRE-OPERATION INSTRUCTIONS

Mounting screw (M3

...................... 2 (Refer to

8 mm)

page 9

Spacer

)

......................2 (Refer to

page 9

)

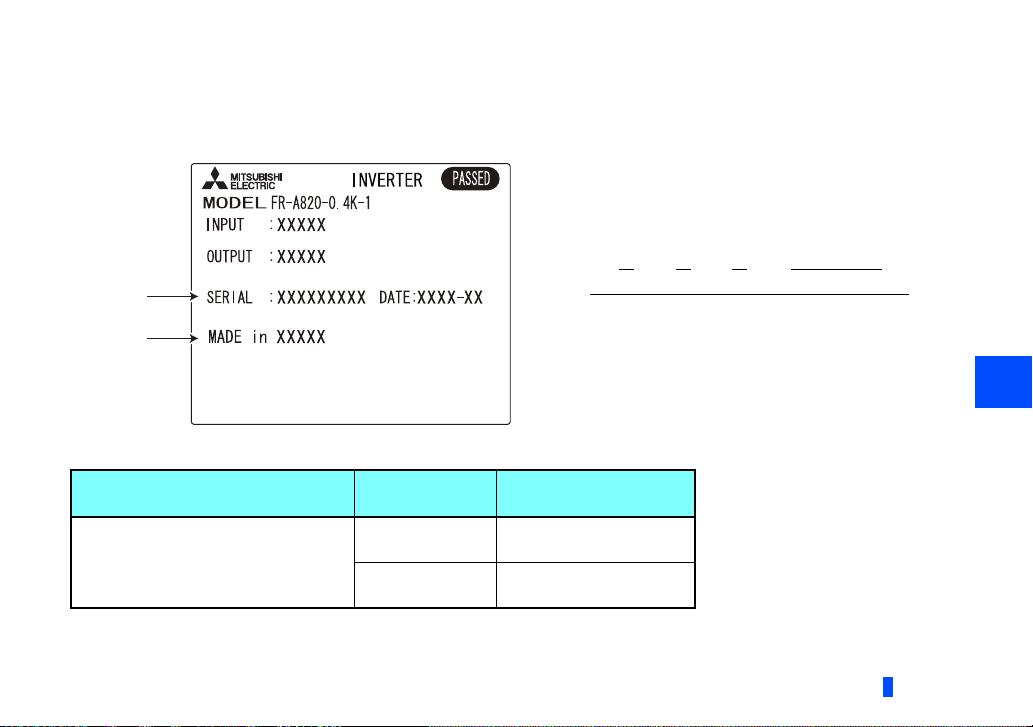

1.1.2 SERIAL number check

SERIAL

number

Country

of origin

The FR-A8APR can be used for the inverter models listed below with the following SERIAL number or later. Check the SERIAL

number indicated on the inverter rating plate or package.

Rating plate example

Symbol Year Month Control number

SERIAL

The SERIAL consists of one symbol, two characters indicating the

production year and month, and six characters indicating the

control number.

The last digit of the production year is indicated as the Year, and

the Month is indicated by 1 to 9, X (October), Y (November), or Z

(December).

FR-A800 series

Model

Country of

origin indication

SERIAL number

1

FR-A820-00046(0.4K) to 04750(90K)

FR-A840-00023(0.4K) to 06830(280K)

FR-A842-07700(315K) to 12120(500K)

FR-A846-00023(0.4K) to 03610(132K)

MADE in Japan 52 or later

MADE in China 53 or later

PRE-OPERATION INSTRUCTIONS

7

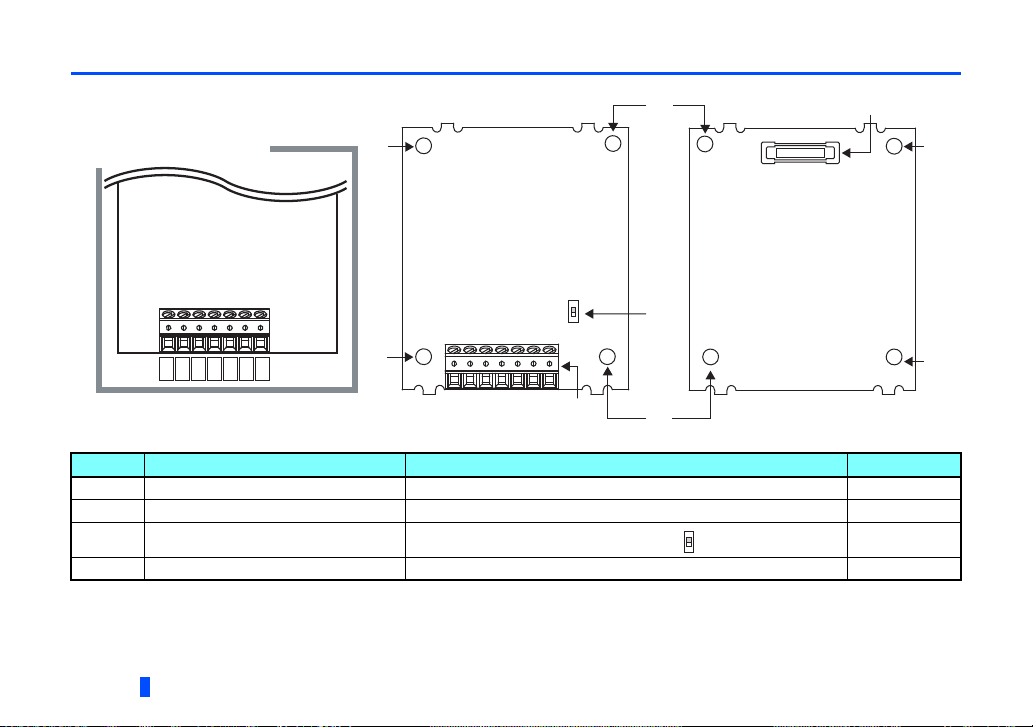

1.2 Component names

Front view Rear view

Terminal layout

(a) (d)

(a)

(b)

(a)

(a)

(a)

(a)

(c)

SW1

R1

R2

S2S4S1

S3

CM

Symbol Name Description Refer to page

a Mounting hole Fixes the option to the inverter with screws, or installs spacers. 9

b Terminal block Connected with a resolver. 15

c Switch for manufacturer setting (SW1)

d Connector Connects to the option connector of the inverter. 9

8

PRE-OPERATION INSTRUCTIONS

Do not change the initially-set status. (OFF )

―

2 INSTALLATION AND WIRING

2.1 Pre-installation instructions

Check that the inverter's input power and the control circuit power are both OFF.

Caution

With input power ON, do not install or remove the plug-in option. Otherwise, the inverter and plug-in option may be damaged.

To avoid damage due to static electricity, static electricity in your body must be discharged before you touch the product.

2.2 Installation procedure

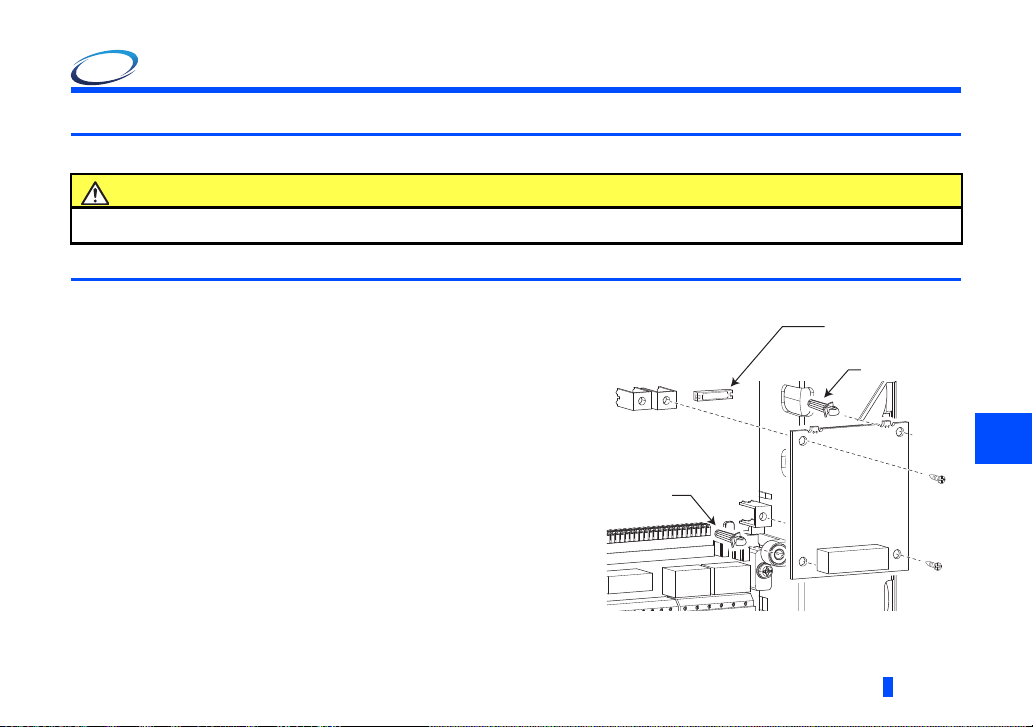

(1) Remove the inverter front cover. (Refer to Chapter 2 of

the Instruction Manual (Detailed) of the inverter for details

on how to remove the front cover.)

(2) For the two mounting holes (as shown in the next page)

that will not be tightened with mounting screws, insert

spacers.

(3) Fit the connector of the plug-in option to the guide of the

connector on the inverter unit side, and insert the plug-in

option as far as it goes.

(4) Fit the two locations, the left and right, of the plug-in

option securely to the inverter unit by screwing in the

supplied mounting screws. (tightening torque 0.33 N·m to

0.40 N·m) If the screw holes do not line up, the connector

may not be inserted deep enough. Check the connector.

Inverter side

option connector

Spacer

Spacer

Example of installation to connector 1

INSTALLATION AND WIRING

2

9

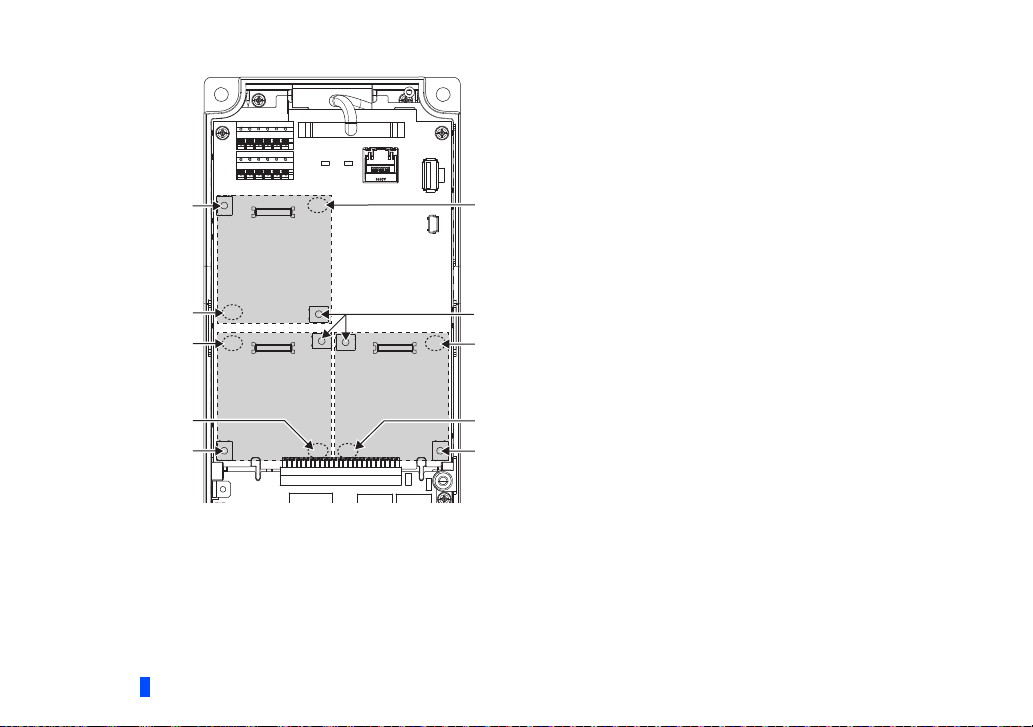

Spacer

Spacer

Spacer

Mounting screw

Mounting screw

Mounting screw

Spacer

Spacer

Spacer

Mounting screw

Connector 1Connector 2

Connector 3

Insertion positions for screws and spacers

10

INSTALLATION AND WIRING

NOTE

• When mounting/removing the plug-in option, hold the sides of the option. Do not press on the parts on the option

circuit board. Stress applied to the parts by pressing, etc. may cause a failure.

• Caution must be applied to mounting screws falling off when removing and mounting the plug-in option.

• If the FR-A8APR and the FR-A8AP are installed together, the FR-A8AP is disabled.

• Only one option can be used. When multiple options are mounted, priority is given to option connectors 1, 2 and 3 on

the inverter in this order, and options having a lower priority do not function.

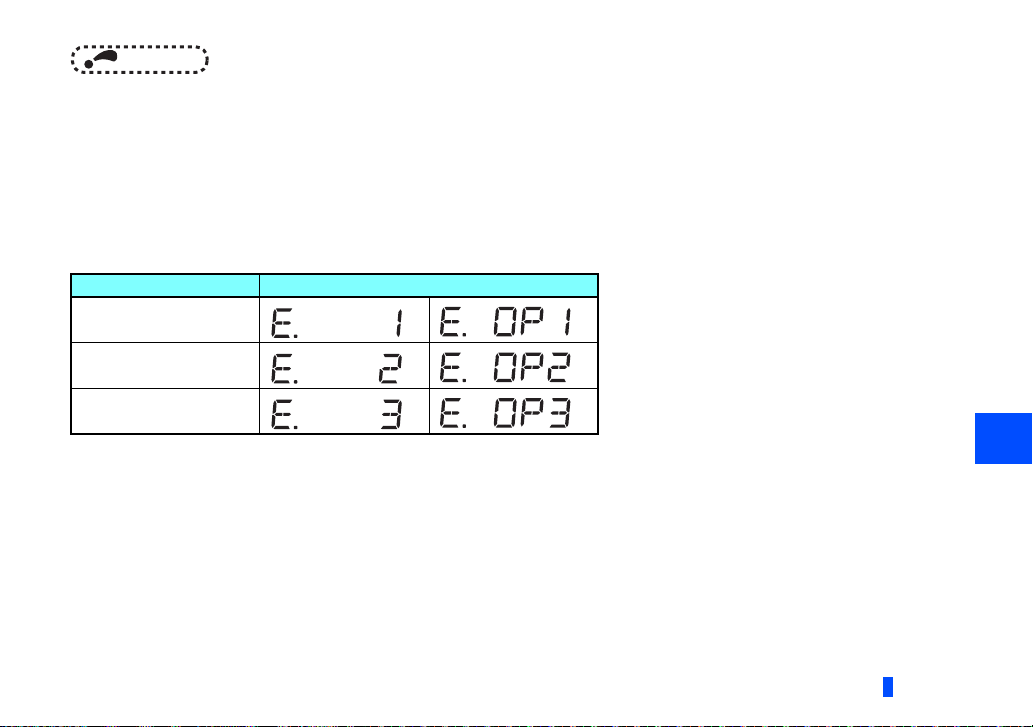

• When the inverter cannot recognize that the option unit is mounted due to improper installation, etc., or when an

option unit fault occurs, the protective function (E.1 to E.3 or E.OP1 to E.OP3) is activated and the inverter cannot be

operated. A different indication will appear according to the mounted position (option connector 1 to 3).

Mounted position Fault indication

Option connector 1

Option connector 2

Option connector 3

• When removing the plug-in option, remove the two screws on the left and right, then pull it straight out. Pressure

applied to the connector and to the option board may break the option.

2

INSTALLATION AND WIRING

11

2.3 Wiring

NOTE

5 mm

Wire

Sleeve

0 to 0.5 mm

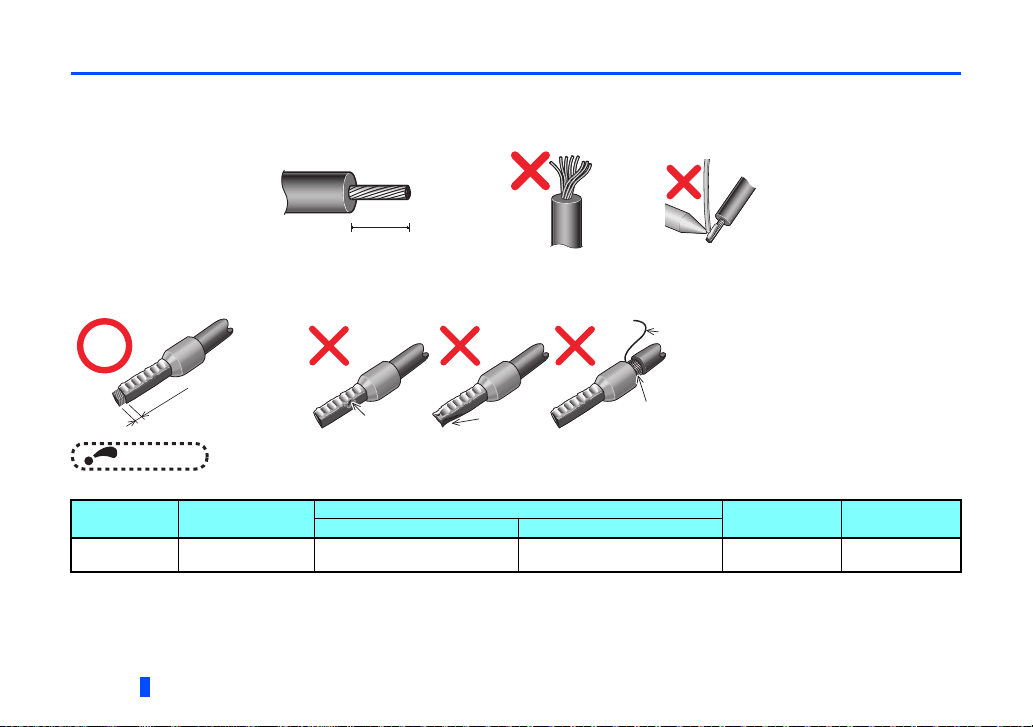

(1) Strip off the sheath of the signal cable from the resolver for the below length. If the length of the sheath peeled is too long,

a short circuit may occur with neighboring wires. If the length is too short, wires might come off.

Wire the stripped signal cable after twisting it to prevent it from becoming loose. In addition, do not solder it.

Cable stripping length

For connecting the FR-A8APR, use a blade terminal as necessary.

When using the blade terminal, use care so that the twisted wires do not come out.

Unstranded

Wire

Sleeve

wires

0 to 0.5 mm

Damaged

Crumpled tip

• Blade terminals commercially available (as of January 2015. The product may be changed without notice.)

Ter min al

screw size

Wire size (mm2)

Ferrule terminal model

M2 0.3 to 0.5 Al 0,5-6WH A 0,5-6

12

INSTALLATION AND WIRING

Wires are not inserted

into the sleeve

Manufacturer

Phoenix Contact

Co.,Ltd.

Crimping tool

nameWith insulation sleeve Without insulation sleeve

CRIMPFOX 6

Loading...

Loading...