Page 1

Mitsubishi Industrial Robot

RH-3FH-D Series

Standard Specifications Manual

CR750-D/CR751-D Controller

BFP-A8878-U

Page 2

Page 3

All teaching work must be carried out by an operator who has received special

Always read the following precautions and the separate "Safety

Manual" before starting use of the robot to learn the required

measures to be taken.

Safety Precautions

CAUTION

CAUTION

WARNING

CAUTION

DANGER

CAUTION

CAUTION

CAUTION

training. (This also applies to maintenance work with the power source turned

ON.)

Enforcement of safety training

For teaching work, prepare a work plan related to the methods and procedures

of operating the robot, and to the measures to be taken when an error occurs

or when restarting. Carry out work following this plan. (This also applies to

maintenance work with the power source turned ON.)

Preparation of work plan

Prepare a device that allows operation to be stopped immediately during

teaching work. (This also applies to maintenance work with the power source

turned ON.)

Setting of emergency stop switch

During teaching work, place a sign indicating that teaching work is in progress

on the start switch, etc. (This also applies to maintenance work with the power

source turned ON.)

Indication of teaching work in progress

Provide a fence or enclosure during operation to prevent contact of the

operator and robot.

Installation of safety fence

Establish a set signaling method to the related operators for starting work, and

follow this method.

Signaling of operation start

As a principle turn the power OFF during maintenance work. Place a sign

indicating that maintenance work is in progress on the start switch, etc.

Indication of maintenance work in progress

Before starting work, inspect the robot, emergency stop switch and other

related devices, etc., and confirm that there are no errors.

Inspection before starting work

Page 4

The points of the precautions given in the separate "Safety Manual" are given below.

DANGER

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

WARNING

WARNING

CAUTION

WARNING

CAUTION

CAUTION

CAUTION

CAUTION

Refer to the actual "Safety Manual" for details.

When automatic operation of the robot is performed using multiple control

devices (GOT, programmable controller, push-button switch), the interlocking of

operation rights of the devices, etc. must be designed by the customer.

Use the robot within the environment given in the specifications. Failure to do

so could lead to a drop or reliability or faults. (Temperature, humidity,

atmosphere, noise environment, etc.)

Transport the robot with the designated transportation posture. Transporting

the robot in a non-designated posture could lead to personal injuries or faults

from dropping.

Always use the robot installed on a secure table. Use in an instable posture

could lead to positional deviation and vibration.

Wire the cable as far away from noise sources as possible. If placed near a noise

source, positional deviation or malfunction could occur.

Do not apply excessive force on the connector or excessively bend the cable.

Failure to observe this could lead to contact defects or wire breakage.

Make sure that the workpiece weight, including the hand, does not exceed the

rated load or tolerable torque. Exceeding these values could lead to alarms or

faults.

Securely install the hand and tool, and securely grasp the workpiece. Failure to

observe this could lead to personal injuries or damage if the object comes off or

flies off during operation.

Securely ground the robot and controller. Failure to observe this could lead to

malfunctioning by noise or to electric shock accidents.

Indicate the operation state during robot operation. Failure to indicate the state

could lead to operators approaching the robot or to incorrect operation.

When carrying out teaching work in the robot's movement range, always secure

the priority right for the robot control. Failure to observe this could lead to

personal injuries or damage if the robot is started with external commands.

Keep the jog speed as low as possible, and always watch the robot. Failure to do

so could lead to interference with the workpiece or peripheral devices.

After editing the program, always confirm the operation with step operation

before starting automatic operation. Failure to do so could lead to interference

with peripheral devices because of programming mistakes, etc.

Make sure that if the safety fence entrance door is opened during automatic

operation, the door is locked or that the robot will automatically stop. Failure to

do so could lead to personal injuries.

Never carry out modifications based on personal judgments, or use nondesignated maintenance parts.

Failure to observe this could lead to faults or failures.

Page 5

When the robot arm has to be moved by hand from an external area, do not

WARNING

CAUTION

CAUTION

DANGER

DANGER

DANGER

CAUTION

CAUTION

place hands or fingers in the openings. Failure to observe this could lead to

hands or fingers catching depending on the posture.

Do not stop the robot or apply emergency stop by turning the robot controller's

main power OFF. If the robot controller main power is turned OFF during

automatic operation, the robot accuracy could be adversely affected. Moreover,

it may interfere with the peripheral device by drop or move by inertia of the arm.

Do not turn off the main power to the robot controller while rewriting the

internal information of the robot controller such as the program or parameters.

If the main power to the robot controller is turned off while in automatic

operation or rewriting the program or parameters, the internal information of the

robot controller may be damaged.

Do not connect the Handy GOT when using the GOT direct connection function

of this product. Failure to observe this may result in property damage or bodily

injury because the Handy GOT can automatically operate the robot regardless

of whether the operation rights are enabled or not.

Do not remove the SSCNET III cable while power is supplied to the controller.

Do not look directly at light emitted from the tip of SSCNET III connectors or

SSCNET III cables. Eye discomfort may be felt if exposed to the light.

(Reference: SSCNET III employs a Class 1 or equivalent light source as

specified in JIS C 6802 and IEC60825-1 (domestic standards in Japan).)

Attach the cap to the SSCNET III connector after disconnecting the SSCNET

III cable. If the cap is not attached, dirt or dust may adhere to the connector

pins, resulting in deterioration connector properties, and leading to malfunction.

Make sure there are no mistakes in the wiring. Connecting differently to the way

specified in the manual can result in errors, such as the emergency stop not

being released. In order to prevent errors occurring, please be sure to check

that all functions (such as the teaching box emergency stop, customer emergency stop, and door switch) are working properly after the wiring setup is completed.

Use the network equipments (personal computer, USB hub, LAN hub, etc)

confirmed by manufacturer. The thing unsuitable for the FA environment

(related with conformity, temperature or noise) exists in the equipments

connected to USB. When using network equipment, measures against the noise,

such as measures against EMI and the addition of the ferrite core, may be

necessary. Please fully confirm the operation by customer. Guarantee and

maintenance of the equipment on the market (usual office automa

equipment) cannot be performed.

tion

Page 6

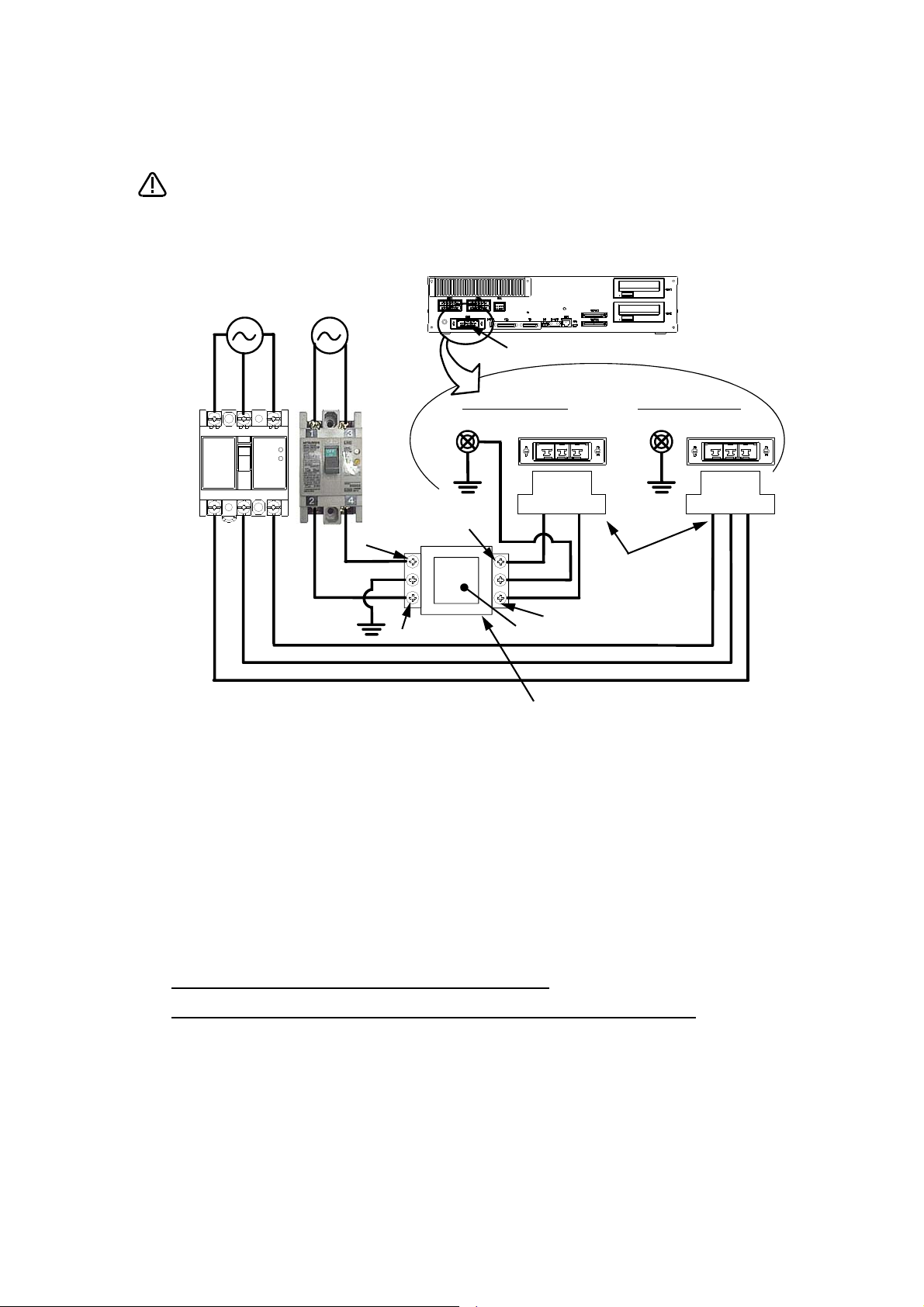

*CR751-D or CR751-Q controller

CAUTION

PE terminal

Grounding screw

Controller

ACIN connector

AC200V AC200V

Primary

Secondary

PE terminal

Grounding screw

123 123

ACIN connector

ACIN connector

Note 2)

Note 1) Crimping swage is recommended for connecting the attachment ACIN connector (soldering is also possible)

Recommendation compression tools: 234171-1(Tyco Electronics)

Note 2) The earth leakage breaker is the customer preparation. Always use the cover below.

Recommendation: For single primary power supply .........NV30FAU-2P-10A-AC100-240V-30mA, (Cover: TCS-05FA2)

For three primary power supply .......... NV30FAU-3P-10A-AC100-240V-30mA, (Cover: TCS-05FA3)

Note 3) If necessary, as shown in the figure, connects the noise filter between ACIN terminal blocks and primary power supply.

(Recommended noise filter: SUP-EL20-ER6 *OKAYA ELECTRIC INDUSTRIES)

Controller

<4> LINE/LOAD

<3> LINE/LOAD

<1> LINE/LOAD

<2> LINE/LOAD

Noise filter

Label

ACIN connector or

power cable

(Attachment)

Note 1)

For three phaseFor single phase

Three phase Single phase

Earth leak-

age breaker

(NV)

Note 3)

* The controller is an

example.

Notes of the basic component are shown.

Please install the earth leakage breaker in the primary side supply power supply

of the controller of CR751-D or CR751-Q because of leakage protection.

1) Please prepare the following: Leakage current breaker (with the terminal cover), cable for connecting the

primary power supply (AWG #14 (2mm

2

or above).

(3.5mm

The secondary power cable (with the ACIN connector) for single phase or three phase power is supplied with

the product to match the specifications. When you build a cable suitable for your environment using the ACIN

connector and the ACIN terminal supplied, prepare a secondary power cable (AWG #14 (2mm

2) Confirm that the primary power matches the specifications.

3) Confirm that the primary power is OFF and that the earth leakage breaker power switch is OFF.

4) Connect the secondary power cable.

a) When using the supplied power cable with the ACIN connector

Refer to the figure above and connect the cable from the secondary side of the earth leakage breaker.

b) When building a power cable using the ACIN connector and the ACIN terminals supplied

Connect the ACIN terminals with the secondary power cable (prepared by customers), and insert the ACIN

terminals to the ACIN connector pins with the following numbers. Crimping caulking is recommended to

connect the ACIN terminals.

For single phase: 1 and 3

For three phase: 1, 2, and 3

Refer to the figure above and connect the cable from the secondary side of the earth leakage breaker.

5) Connect this ACIN connector to the ACIN connector on the front of the controller.

6) Connect the grounding cable to the PE terminal. (M4 screw)

7) Connect the primary power cable to the primary side terminal of the earth leakage breaker.

2

or above), cables to ground the primary power supply (AWG #12

2

) or above).

Page 7

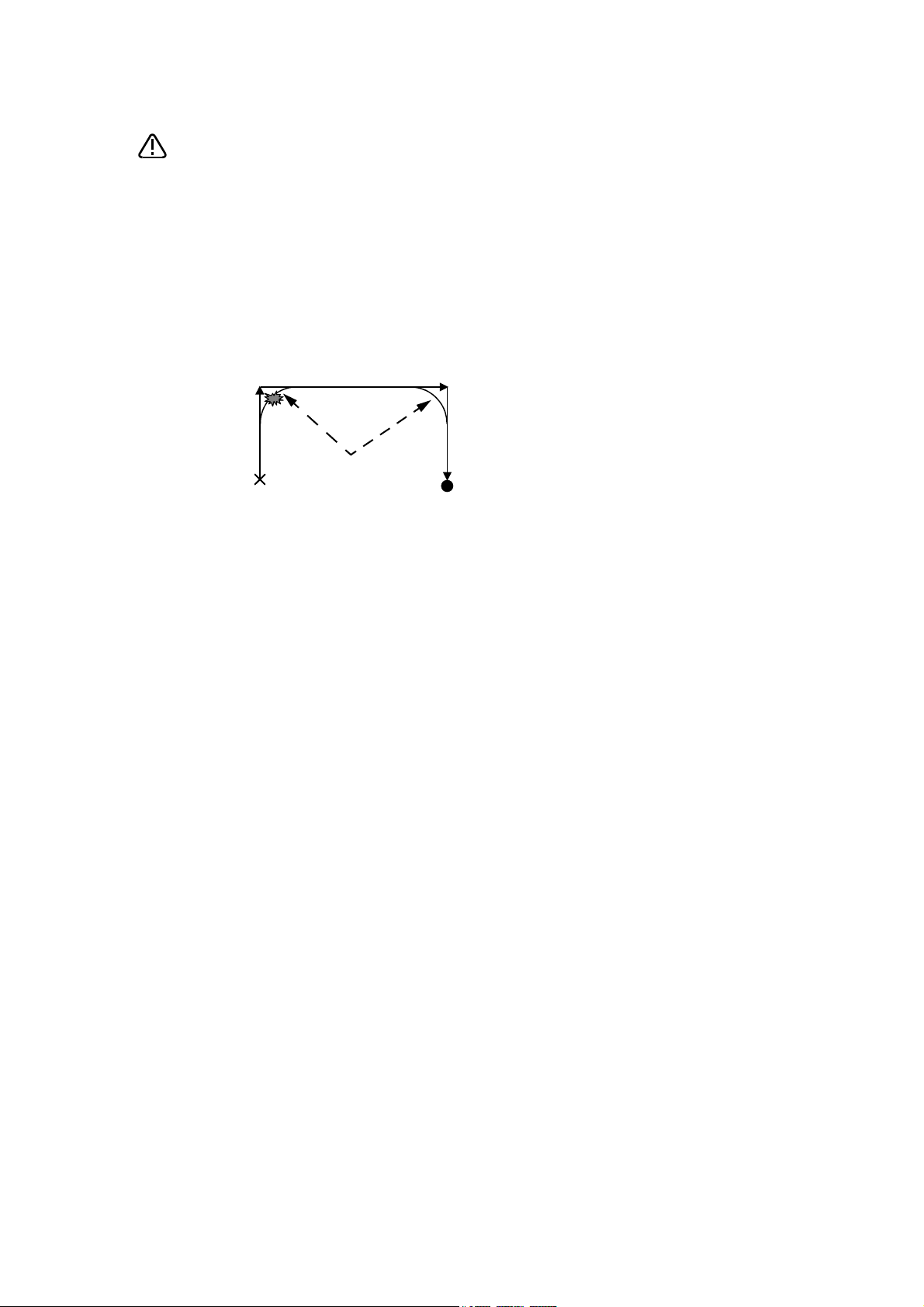

Be careful of interference with peripheral equipment.

CAUTION

Short cut

Arch movement (example)

Especially don't give a shock to the shaft (J3 axis). When you install the

hand, be careful not to knock at the shaft end by the hammer etc. The shaft

may be damaged.

Take care also of the following items.

(1)The robot's locus of movement may change with specified speed.

Especially as for the corner section, short cut distance may change. Therefore, when beginning automatic operation, moves at low speed at first, and you should gather speed slowly with

being careful of interference with peripheral equipment.

(2)It can be confirmed whether the specified position exist in the defined area by using the instruc-

tion command "Zone". It can utilize as one of the methods for collision evasion. Refer to the

"detailed description of the instructions manual/function, and operation" of the separate volume

for the details of the instruction command.

Page 8

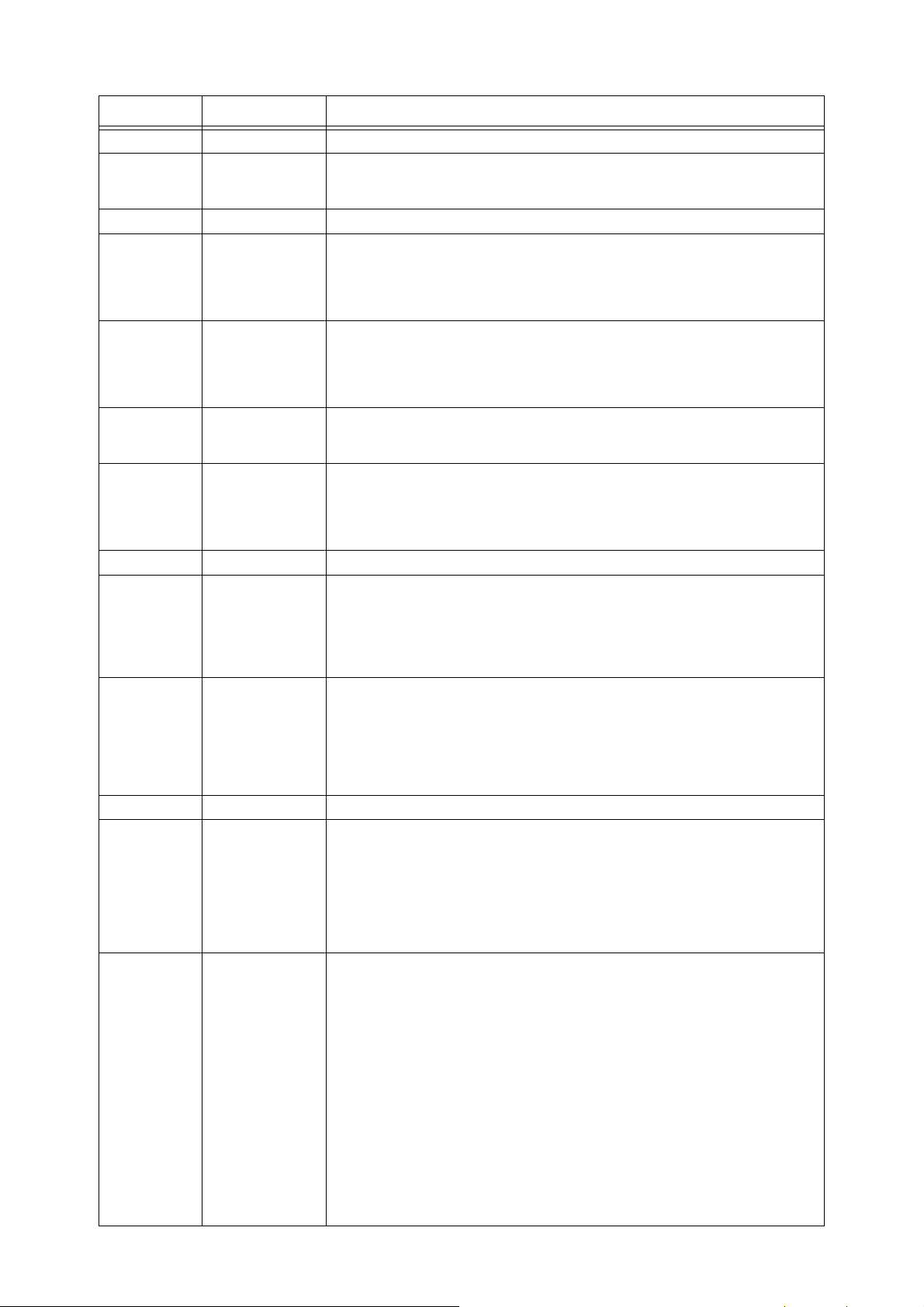

■Revision history

Date of print Specifications No. Details of revisions

2012-03-13 BFP-A8878

2012-03-21 BFP-A8878-A

2012-04-04 BFP-A8878-B

2012-05-17 BFP-A8878-C

2012-06-05 BFP-A8878-D

2012-09-03 BFP-A8878-E

2012-10-04 BFP-A8878-F

2012-10-11 BFP-A8878-G

2012-11-20 BFP-A8878-H

2013-01-11 BFP-A8878-J

2013-02-15 BFP-A8878-K

2013-07-19 BFP-A8878-M

2013-09-19 BFP-A8878-N

・First print.

・ The painting color was corrected. (Error in writing)

・ Notes were added to the example of safety measures. (The measure against the noise, The

electric specification of the output terminal)

・ CE marking specification was added.

・ The position repeatability was corrected (improvement).

・ ON voltage/ON current and OFF voltage/ OFF current of the parallel input-and-output

interface were corrected (error in writing).

・ The mechanical stopper position to change the operating range to +/-130 degree was

corrected to N12 (Error in writing)

・ Limitation of the electric current value of the relays (coil) connected to the external

emergency stop input was added.

・ The connection method of the Fig.3-27 : AXMC terminal connector (CR750) corrected to

"soldering."

・ The description of the capability value of pose repeatability was deleted.

・ The connector name of hand input signal/output signal of "Fig.2-24: Wiring and piping for

hand" was corrected.

・ The power supply capacity was corrected.

・ The notes were added to "Fig 3-24: Example of EMC noise filter installation".

・ The lithium battery (ER6) was added to The United Nations’Recommendations on the

Transport of Dangerous Goods.

・ The notes about installation of the controller and the robot arm were added. (neither direct

rays nor the heat of lighting)

・ “Table 1-1: Combination of the robot arm and the controller” was corrected.

・ The statement about trademark registration was added.

・ The notes about the input-output connected to the controller were added. (do not ground

the + side of 24V power supply prepared by customer)

・ ”Declaration of Incorporation” was updated.

・ The metal plate which fixes "Hand internal wiring and piping set (option)" was changed to

attachment of the robot arm in standard.

・ EC-Statement of Compliance was updated.

・ Note of the external emergency stop were added (opens the connector terminal at factory

shipping).

・ The connectors of RH-3FH series machine cable (AMP1, AMP2, BRK) were combined as

CN1 connector.

・ Type names of machine cables (option, special specifications) were changed. (No-CE

specification)

・ Type name of CR751 controller was corrected. (formerly: CR751-03HD-0)

・ The simple spanner for resin nuts was added to the attachments of the external wiring/

piping box (option).

・ ”Declaration of Incorporation” and “EC-Statement of Compliance” were updated.

・ ”Fig.2-28: Wiring and piping system diagram for hand and example the solenoid valve

installation” was modified.

・The cautions of operating in a low temperature environment or after a prolonged stop in ”6.3

Precautions for handling” were modified.

・ The caution about fumigation of wood packing was added to ”6.3 Precautions for handling”.

・ ”Fig.6-11: Limitations when connecting the relay etc. (CR750)” and ”Fig.6-12: Limitations

when connecting the relay etc. (CR751)” were corrected.

(Error output → Emergency stop output, Contactor controleoutput for additional axes →

Error output)

・ The descriptions of CR751-03HD1-0-S15 (CE marking specification controller) were added.

・ Type name of CR751 controller was corrected. (formerly: CR751-03HD)

・ The dimensions of screw hole position for fixing user wiring/p

・ The following descriptions of (5) in ”Fig.2-24 : Wiring and piping for hand” were corrected.

The power source wire only for the multifunctional hand → Spare wire

The connector pins name of robot side and connector name of counter side were added.

The connector pins name of counter side was corrected.

・ The descriptions of solenoid valve set were corrected, and explanations were added.

・ ”Fig.2-28 : Wiring and piping system diagram for hand and example the solenoid valve

installation” was corrected.

・ The useable length from the shaft end of Internal Wiring/Piping set for hand was corrected.

・ The descriptions about the ventilation duct which the robot of clean specification has were

corrected.

iping were added.

Page 9

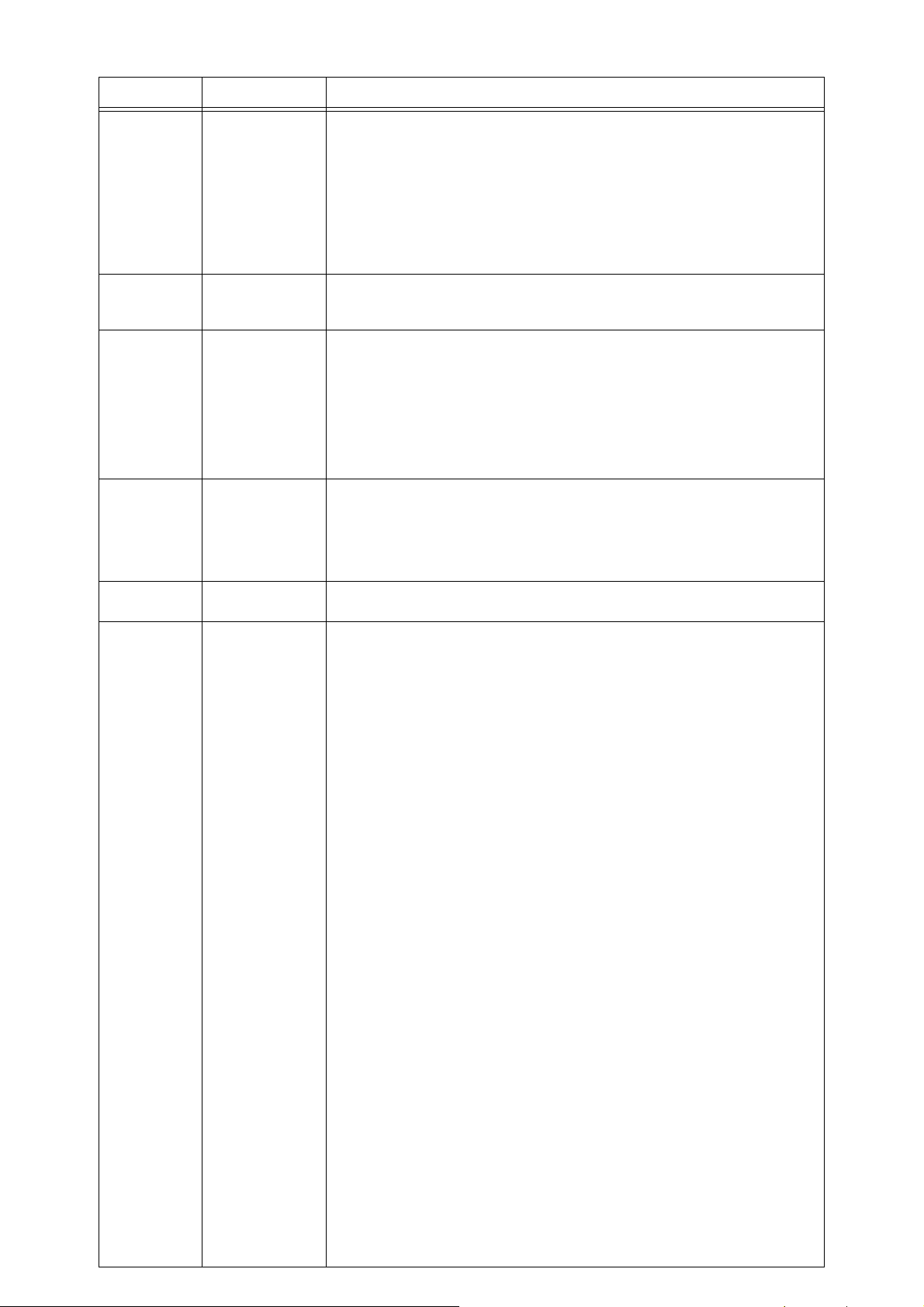

Date of print Specifications No. Details of revisions

2014-01-08 BFP-A8878-P

2014-03-31 BFP-A8878-R

2014-08-20 BFP-A8878-S

2014-12-17 BFP-A8878-T

2015-02-10 BFP-A8878-U

・ The cable fixation plate was added to ”Fig.3-4: Outside dimensions of controller (CR751)”.

・ The type name of the stopper for changing the operating range (J1 axis) in “Table 1-3: The

list of robot option equipment and special specification” was corrected. (formerly: 1S-DH-

02)

・ ”Fig. 2-5: Relationship of the offset length and maximum velocity” was corrected.

・ Conditions for the flexed type cables were corrected.

・ The note about an ambient temperature was added to “2.1.1 Basic specifications”.

・ The station numbers of the parallel I/O interface and the parallel I/O unit was corrected.

・ The description of "MELFA BASIC

controller”.

・ The grounding representation was corrected.

・ The types of the ACIN terminal were added.

・ The dimension of pilot holes for positioning pin was added.

・ The cover and corporate logo mark of this manual was changed.

・ The statement about trademark registration was modified.

・ The explanation of CR751 controller was modified.

・ The description about screw holes using for tooling wiring and piping was added.

・ The note of turning ON the power supply for control (DCcable-2) for parallel I/O unit was

added.

・ A safety relay in “example of safety measures (wiring example 5) ” both CR750 and

CR751 controller were changed.

・ ”Declaration of Incorporation” and “EC-Statement of Compliance” were updated.

・ Allowance value of the offset amount was added to "2.2.2 Mass capacity".

・ The description of how to change the operating range moved into “INSTRUCTION MAN-

UAL/ROBOT ARM SETUP & MAINTENANCE”.

・ Correction of errors in the Specifications discussion materials. (Network vision sensor: 4D-

2CG5***-PKG was deleted.)

・ The corporate logo mark of illustrations in this manual was changed.

・ The description in case the ethernet cable is used as a backup wiring for data communica-

tion was added.

IV

" was added to “Table 3-1: Specifications of

.

Page 10

■ Introduction

・ No part of this manual may be reproduced by any means or in any form, without prior consent from Mit-

subishi.

・ The contents of this manual are subject to change without notice.

・ The specifications values are based on Mitsubishi standard testing methods.

・ The information contained in this document has been written to be accurate as much as possible.

Please interpret that items not described in this document "cannot be performed." or "alarm

may occur".

Please contact your nearest dealer if you find any doubtful, wrong or skipped point.

・ This specifications is original.

・ Microsoft, Windows, Windows XP, Windows Vista, Windows 7, Windows 8, Windows 8.1 are either regis-

tered trademarks or trademarks of Microsoft Corporation in the United States and/or other countries.

・ The official name of Windows® is Microsoft®Windows®Operating System.

・ Windows®XP、 Windows Vista®、 Windows® 7、 Windows® 8、 Windows® 8.1 are either product names of

Microsoft Corporation in the United States.

・ Ethernet is registered trademarks or trademarks of Xerox Corporation in the United States.

・ All other company names and production names in this document are the trademarks or registered

trademarks of their respective owners.

Copyright(C) 2012-2015 MITSUBISHI ELECTRIC CORPORATION

This series offers small-size industrial robots developed using Mitsubishi's latest technology. They are

especially designed to handle and assemble mechanical parts. They are Mitsubishi's answer to the customer's need to achieve a compact manufacturing facility capable of highly flexible production, as necessitated by the diffusion of high-density product groups and the shorter product life cycles that have

become common-place in recent years.

However, to comply with the target application, a work system having a well-balanced robot arm, peripheral devices or robot and hand section must be structured.

When creating these standard specifications, we have edited them so that the Mitsubishi robot's characteristics and specifications can be easily understood by users considering the implementation of robots.

However, if there are any unclear points, please contact your nearest Mitsubishi branch or dealer.

Mitsubishi hopes that you will consider these standard specifications and use our robots.

Note that in this specification document the specifications related to the robot arm is described Page 9,

"2 Robot arm", the specifications related to the controllerPage 63, "3 Controller", and software functions

and a command list Page 130, "4 Software" separately.

This document has indicated the specification of the following types robot.

*RH-3FH-D series

・ About CE Marking in the automization system

The Guidelines of the measures against EMC in the automization system manufactured by the customer is shown in Page 154, "6.4 EMC installation guideline".

Please refer to it and carry out the measures against EMC of the automization system of the customer.

Page 11

Contents

Page

1 General configuration .................................................................................................................................................................... 1-1

1.1 Structural equipment ............................................................................................................................................................. 1-1

1.1.1 Standard structural equipment .................................................................................................................................. 1-1

1.1.2 Special specifications .................................................................................................................................................... 1-1

1.1.3 Options ................................................................................................................................................................................. 1-1

1.1.4 Maintenance parts ........................................................................................................................................................... 1-1

1.2 Model type name of robot .................................................................................................................................................... 1-2

1.2.1 How to identify the robot model ................................................................................................................................ 1-2

1.2.2 Combination of the robot arm and the controller .............................................................................................. 1-3

1.3 CE marking specifications .................................................................................................................................................... 1-3

1.4 Indirect export .......................................................................................................................................................................... 1-3

1.5 Instruction manuals ................................................................................................................................................................ 1-3

1.6 Contents of the structural equipment ............................................................................................................................ 1-4

1.6.1 Robot arm ........................................................................................................................................................................... 1-4

1.6.2 Controller ............................................................................................................................................................................ 1-5

1.7 Contents of the Option equipment and special specification .............................................................................. 1-6

2 Robot arm ........................................................................................................................................................................................... 2-9

2.1 Standard specifications ........................................................................................................................................................ 2-9

2.1.1 Basic specifications ........................................................................................................................................................ 2-9

(1) Standard specification ............................................................................................................................................... 2-9

(2) Clean specification ................................................................................................................................................... 2-11

2.1.2 The counter-force applied to the installation surface ................................................................................... 2-12

2.2 Definition of specifications ................................................................................................................................................ 2-13

2.2.1 Pose repeatability .......................................................................................................................................................... 2-13

2.2.2 Mass capacity .................................................................................................................................................................. 2-14

2.2.3 Relationships Among Mass Capacity, Speed, and Acceleration/Deceleration Speed ...................... 2-15

(1) Setting Load Capacity and Size (Hand Conditions) .................................................................................... 2-15

2.2.4 Vibrations at the Tip of the Arm during Low-Speed Operation of the Robot ..................................... 2-15

2.2.5 Vibration of shaft (J3 axis) position and arm end ............................................................................................ 2-16

(1) Relationship Between Mass Capacity and Speed ..............

(2) Relationship Between Height of Shaft (J3 Axis) and Acceleration/Deceleration Speed ........... 2-17

(3) Relation between offset length and the maximum speed ......................................................................... 2-18

(4) Time to reach the position repeatability ......................................................................................................... 2-19

2.2.6 Collision detection ......................................................................................................................................................... 2-19

2.2.7 Protection specifications ............................................................................................................................................ 2-20

(1) Types of protection specifications .................................................................................................................... 2-20

2.2.8 Clean specifications ...................................................................................................................................................... 2-20

(1) Types of clean specifications ............................................................................................................................... 2-20

2.3 Names of each part of the robot .................................................................................................................................... 2-22

2.4 Outside dimensions ・ Operating range diagram ........................................................................................................ 2-23

2.4.1 Outside dimensions ・ Operating range diagram ................................................................................................ 2-23

(1) Standard Specification ............................................................................................................................................ 2-23

(2) Clean Specification ................................................................................................................................................... 2-29

2.4.2 Mechanical interface and Installation surface ................................................................................................... 2-35

2.4.3 Outside dimensions of machine cables ................................................................................................................ 2-36

(1) Connection with the CR750 controller ............................................................................................................ 2-36

(2) Connection with the CR751 controller ............................................................................................................ 2-36

2.5 Tooling ........................................................................................................................................................................................ 2-37

2.5.1 Wiring and piping for hand .......................................................................................................................................... 2-37

2.5.2 Internal air piping ............................................................................................................................................................ 2-38

(1) Standard type ............................................................................................................................................................. 2-38

(2) Clean type .................................................................................................................................................................... 2-38

2.5.3 Internal wiring for the hand output cable ............................................................................................................ 2-38

2.5.4 Internal wiring for the hand input cable ................................................................................................................ 2-38

2.5.5 Ethernet cable ............................................................................................................................................................... 2-38

......................................................................... 2-16

i

Page 12

Contents

Page

2.5.6 About the Installation of Tooling Wiring and Piping (Examples of Wiring and Piping) ....................... 2-39

(1) Example of wiring and piping <1> ........................................................................................................................ 2-40

(2) Wiring and piping example <2> ............................................................................................................................. 2-40

(3) Precautions for the clean specification ........................................................................................................... 2-41

2.5.7 Wiring and piping system diagram for hand ......................................................................................................... 2-42

2.5.8 Electrical specifications of hand input/output .................................................................................................. 2-43

2.5.9 Air supply circuit example for the hand ............................................................................................................... 2-44

2.6 Shipping special specifications, options, and maintenance parts ...................................................................... 2-45

2.6.1 Shipping special specifications ................................................................................................................................. 2-45

(1) Machine cable ............................................................................................................................................................. 2-46

2.7 Options ....................................................................................................................................................................................... 2-47

(1) Machine cable extension ........................................................................................................................................ 2-48

(2) Changes J1 axis operating range ....................................................................................................................... 2-52

(3) Solenoid valve set ..................................................................................................................................................... 2-53

(4) Hand input cable ........................................................................................................................................................ 2-55

(5) Hand output cable ..................................................................................................................................................... 2-56

(6) Hand curl tube ............................................................................................................................................................ 2-57

(7) Internal Wiring/Piping set for hand .................................................................................................................... 2-58

(8) External Wiring/Piping box .................................................................................................................................... 2-59

2.8 About Overhaul ...................................................................................................................................................................... 2-61

2.9 Maintenance parts ................................................................................................................................................................. 2-62

3 Controller .......................................................................................................................................................................................... 3-63

3.1 Standard specifications ...................................................................................................................................................... 3-63

3.1.1 Basic specifications ...................................................................................................................................................... 3-63

3.1.2 Protection specifications and operating supply ................................................................................................ 3-64

3.2 Names of each part .............................................................................................................................................................. 3-65

3.2.1 Controller .......................................................................................................................................................................... 3-65

(1) CR750 controller ....................................................................................................................................................... 3-65

(2) CR751 controller ....................................................................................................................................................... 3-67

3.3 Outside dimensions/Installation dimensions .............................................................................................................. 3-69

3.3.1 Outside dimensions ....................................................................................................................................................... 3-69

(1) CR750 controller ....................................................................................................................................................... 3-69

(2) CR751 controller ....................................................................................................................................................... 3-70

3.3.2 Installation dimensions ................................................................................................................................................. 3-71

(1) CR750 controller ....................................................................................................................................................... 3-71

(2) CR751 controller ....................................................................................................................................................... 3-73

3.4 External input/output .......................................................................................................................................................... 3-75

3.4.1 Types .................................................................................................................................................................................. 3-75

3.5 Dedicated input/output ...................................................................................................................................................... 3-76

3.6 Emergency stop input and output etc. ......................................................................................................................... 3-79

3.6.1 Connection of the external emergency stop ...................................................................................................... 3-79

(1) CR750 controller ....................................................................................................................................................... 3-80

(2) CR751 controller ....................................................................................................................................................... 3-84

3.6.2 Special stop input (SKIP) ........................................................................................................................................... 3-87

(1) CR750 controller ....................................................................................................................................................... 3-87

(2) CR751 controller ....................................................................................................................................................... 3-88

3.6.3 Door switch function .................................................................................................................................................... 3-89

3.6.4 Enabling device function ............................................................................................................................................. 3-89

(1) When door is opening ............................................................................................................................................... 3-89

(2) When door is closing ................................................................................................................................................ 3-90

(3) Automatic Operation/Jog Operation/Brake Release and Necessary Switch Settings .............. 3-90

3.7 Mode changeover switch input ........................................................................................................................................ 3-91

(1) Specification of the key switch interface ....................................................................................................... 3-91

(2) Connection of the mode changeover switch input ..................................................................................... 3-92

3.8 Additional Axis Function ..................................................................................................................................................... 3-93

ii

Page 13

Contents

Page

3.8.1 Wiring of the Additional Axis Interface ................................................................................................................. 3-93

(1) CR750 controller ....................................................................................................................................................... 3-93

(2) CR751 controller ....................................................................................................................................................... 3-94

3.9 Magnet contactor control connector output (AXMC) for addition axes ........................................................ 3-97

(1) CR750 controller ....................................................................................................................................................... 3-98

(2) CR751 controller ....................................................................................................................................................... 3-98

3.10 Options .................................................................................................................................................................................... 3-99

(1) Teaching pendant (T/B) ...................................................................................................................................... 3-100

(2) Parallel I/O interface ............................................................................................................................................ 3-103

(3) External I/O cable .................................................................................................................................................. 3-108

(4) Parallel I/O unit ...................................................................................................................................................... 3-110

(5) External I/O cable .................................................................................................................................................. 3-121

(6) CC-Link interface .................................................................................................................................................. 3-123

(7) RT ToolBox2/RT ToolBox2 mini ...................................................................................................................... 3-126

(8) Instruction Manual (bookbinding) ..................................................................................................................... 3-128

3.11 Maintenance parts ........................................................................................................................................................... 3-129

4 Software ......................................................................................................................................................................................... 4-130

4.1 List of commands ............................................................................................................................................................... 4-130

4.2 List of parameters .............................................................................................................................................................. 4-133

5 Instruction Manual ..................................................................................................................................................................... 5-135

5.1 The details of each instruction manuals ................................................................................................................... 5-135

6 Safety .............................................................................................................................................................................................. 6-136

6.1 Safety ...................................................................................................................................................................................... 6-136

6.1.1 Self-diagnosis stop functions ................................................................................................................................ 6-136

6.1.2 External input/output signals that can be used for safety protection measures ........................... 6-137

6.1.3 Precautions for using robot .................................................................................................................................... 6-137

6.1.4 Safety measures for automatic operation ........................................................................................................ 6-138

6.1.5 Safety measures for teaching ............................................................................................................................... 6-138

6.1.6 Safety measures for maintenance and inspections, etc. ........................................................................... 6-138

6.1.7 Examples of safety measures ................................................................................................................................ 6-139

(1) CR750 controller ..........................................

(2) CR751 controller .................................................................................................................................................... 6-144

(3) External emergency stop connection [supplementary explanation] ................................................. 6-149

6.2 Working environment ......................................................................................................................................................... 6-152

6.3 Precautions for handling .................................................................................................................................................. 6-152

6.4 EMC installation guideline ............................................................................................................................................... 6-154

6.4.1 Outlines ........................................................................................................................................................................... 6-154

6.4.2 EMC directive ............................................................................................................................................................... 6-154

6.4.3 EMC measures ............................................................................................................................................................. 6-155

6.4.4 Component parts for EMC measures ................................................................................................................. 6-155

(1) Ferrite core ............................................................................................................................................................... 6-155

(2) Line noise filter ....................................................................................................................................................... 6-155

7Appendix ........................................................................................................................................................................... Appendix-156

Appendix 1 : Specifications discussion material ........................................................................................ Appendix-156

.......................................................................................................... 6-139

iii

Page 14

1General configuration

1 General configuration

1.1 Structural equipment

Structural equipment consists of the following types.

1.1.1 Standard structural equipment

The following items are enclosed as a standard.

(1) Robot arm

(2) Controller

(3) Machine cable

(4) Robot arm installation bolts

(5) Safety manual, CD-ROM (Instruction manual)

(6) Guarantee card

1.1.2 Special specifications

For the special specifications, some standard configuration equipment and specifications have to be changed

before factory shipping. Confirm the delivery date and specify the special specifications at the order.

1.1.3 Options

User can install options after their delivery.

1.1.4 Maintenance parts

Materials and parts for the maintenance use.

1-1

Structural equipment

Page 15

1General configuration

1.2 Model type name of robot

This robot has arranged the type name corresponding to load mass, arm length, and environment specification.

Details are shown below, please select the robot suitable for the customer's use.

1.2.1 How to identify the robot model

RH - 3 FH □□ △△ ○ - 1 D ▲ - Sxx

(a) (b) (c) (d) (e) (f) (g) (h) ( i ) ( j )

(a). RH..............................................Indicates the horizontal multiple-joint robot.

(b). 3..................................................Indicates the maximum load.

3: 3kg

(c). FH..............................................Indicates the FH series.

(d). □□ ..........................................Indicates the arm length.

Ex.)

35: 350mm

45: 450mm

55: 550mm

(e). △△ ..........................................Indicates the vertical stroke length.

Ex.)

12: 120mm stroke

15: 150mm stroke

(f). ○ ................................................Indicates environment specification.

Ex.)

Omitted: General specifications

C: Clean specifications

(g). 1..................................................Indicates the controller series.

Ex.)

Omitted: CR750 controller

1: CR751 controller

(h). D.................................................Indicates the controller type.

D: Stand alone type

(i). ▲.................................................Technical standard of Conformity.

Ex.)

Omitted: No conformity of technical standard.

1: Conforms to the CE Marking

(j). - S xx ....................................Indicates a special model. In order, limit special specification.

Model type name of robot

1-2

Page 16

1General configuration

1.2.2 Combination of the robot arm and the controller

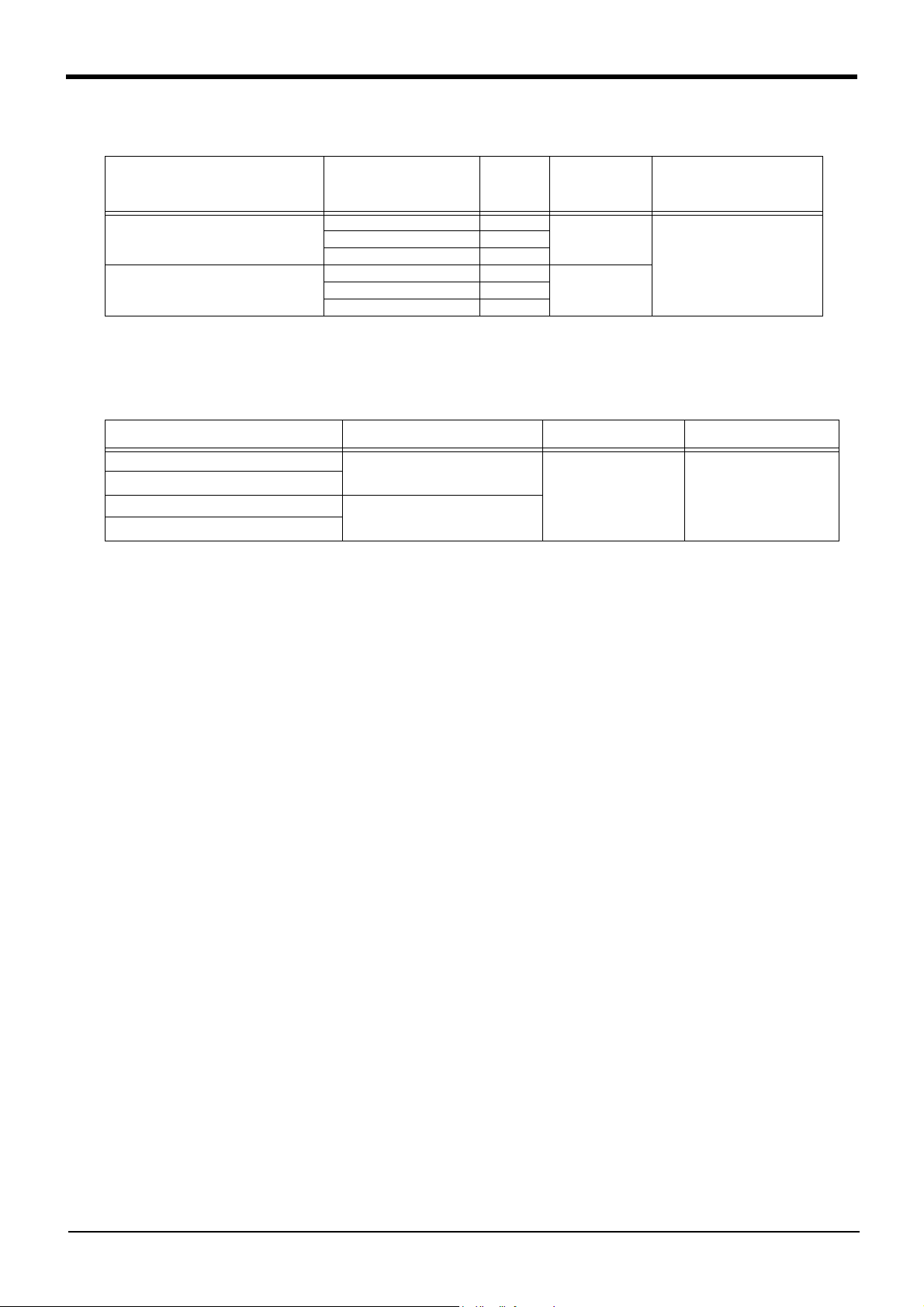

Table 1-1 : Combination of the robot arm and the controller

Protection specification

General-purpose environment RH-3FH3515-1D 350

Clean specifications RH-3FH3512C-1D 350

Robot arm

RH-3FH4515-1D 450

RH-3FH5515-1D 550

RH-3FH5512C-1D 550

1.3 CE marking specifications

The robot shown in Table 1-2 is the CE Marking specification.

Table 1-2 : Robot models with CE marking specifications

Robot type

RH-3FHxxyy-D1-S15

RH-3FHxxyyC-D1-S15

RH-3FHxxyy-1D1-S15

RH-3FHxxyyC-1D1-S15

Note1)

Note3)

Note3)

CR750-03HD1-1-S15

CR751-03HD1-0-S15

Controller External signal logic Language setting

Note2)

Note4)

Arm

length

(mm)

J3-axis stroke

(mm)

150

120RH-3FH4512C-1D 450

Source type English (ENG)

Controller

CR751-03HD-0

Note1) The "xx" indicate the arm length, "yy"indicate J3-axis stroke.

Note2) The specification and the handling method of the controller are the same as standard type controller CR750-03HD-1.

Note3) This robot is the clean specification. As long as there is no special description, refers to the contents of RH-3FHxxyyC

(clean specification).

Note4) The specification and the handling method of the controller are the same as standard type controller CR751-03HD-0.

1.4 Indirect export

The display in English is available by setting parameter LNG as "ENG."

1.5 Instruction manuals

The instruction manuals supplied in CD-ROM, except for the Safety Manual. This CD-ROM (electronic manual)

includes instruction manuals in both Japanese and English versions.

1-3

CE marking specifications

Page 17

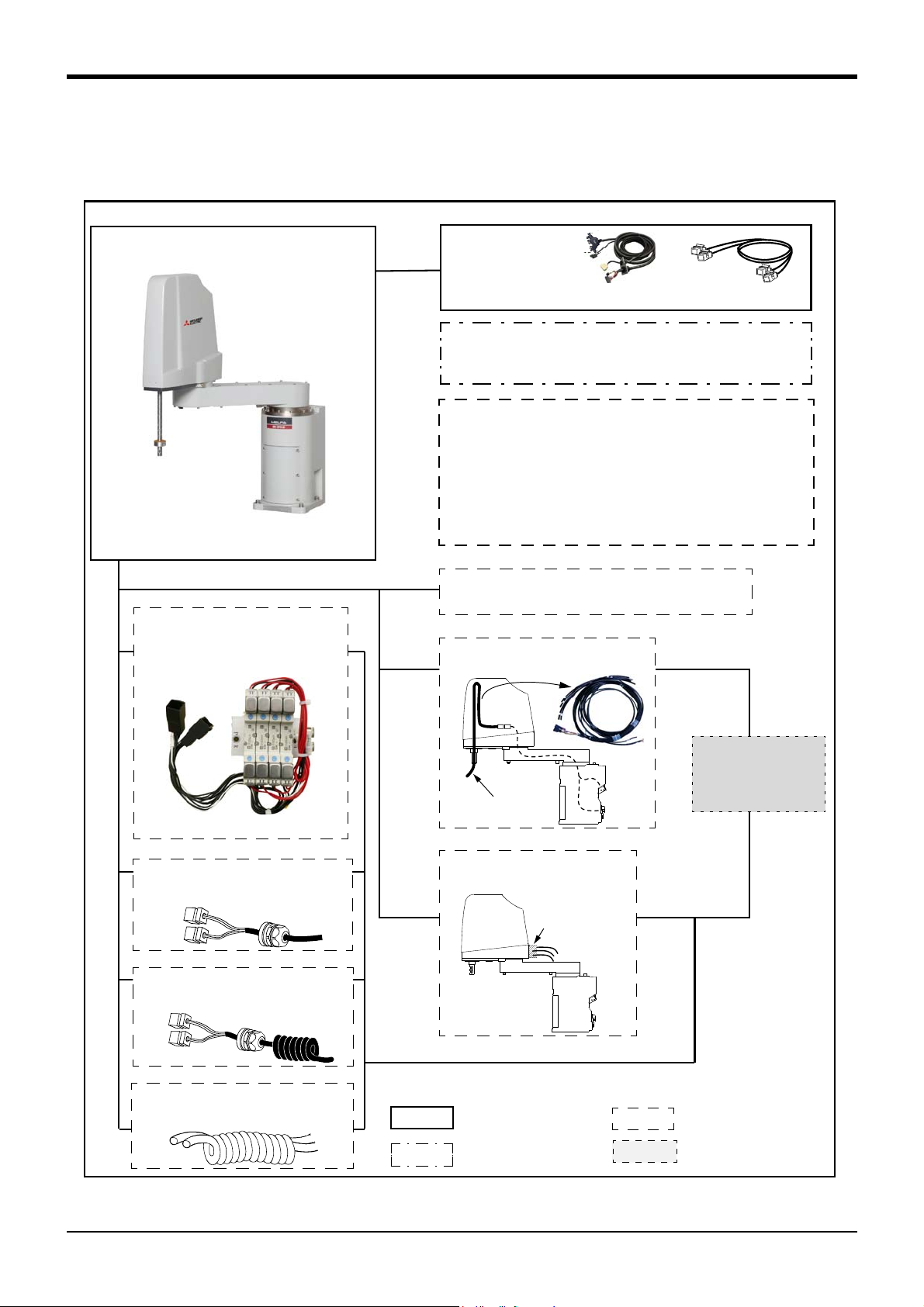

1.6 Contents of the structural equipment

* Refer to Page 9, "2.1 Standard specifica-

tions" for details on the specifications.

Horizontal four-axis multiple-jointed type

(RH-3FH series)

Hand output cable

・ 1F-GR60S-01 (4sets)

Hand input cable

・ 1F-HC35C-01

Hand curl tube

・ 1E-ST0408C-300

Machine cable extension

CR751 controller

・ Fixed type: 1F- □□ UCBL-02 (direct type)

・Flexed type: 1F-□□LUCBL-02 (direct type)

CR750 controller

・ Fixed type: 1S- □□ CBL-03 (extension type)

・ Flexed type: 1S- □□ LCBL-03 (extension type)

・ Flexed type: 1S- □□ LUCBL-03 (direct type)

Note1) □□ refer the length. Refer to Table 1-3 for details.

Machine cable (Fix type : 2m)

・ CR751 controller: 1F-02UCBL-02

・ CR750 controller: 1S-02UCBL-03

Solenoid valve set

・ 1F-VD0*-01 (Sink type)

・ 1F-VD0*E-01 (Source type)

(*: 1 to 4 = 1 set to 4 set)

*With hand output cable.

Machine cable

(Standard product:

5m attachment)

Pneumatic hand

customer-manufactured parts

[Caution]

Standard configuration

Special specifications

Option

equipment

Prepared by customer

Changes J1 axis operating range

・ 1F-DH-01

Internal Wiring/Piping set for hand

・ 1F-HS304S-01

This option

External Wiring/Piping box

・1F-UT-BOX

Pull out Wiring/Piping

This option

For CR751 controller

For CR750 controller

1.6.1 Robot arm

The list of structural equipment is shown in below.

Fig.1-1 : Structural equipment

Contents of the structural equipment

1-4

Page 18

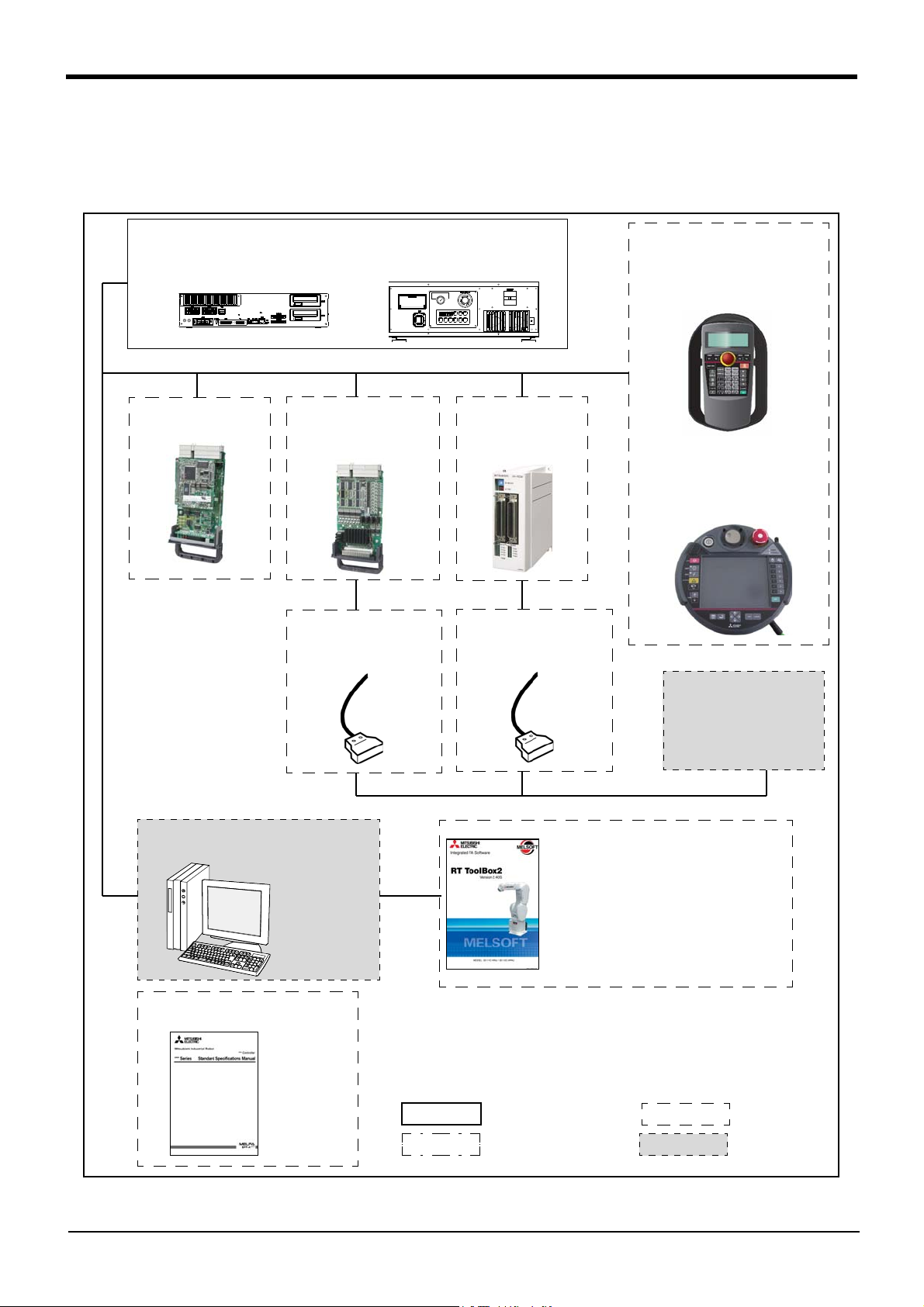

1 General configuration

Personal computer

Prepared by customer

*)Refer to Table

1-5 for USB

cable

Instruction Manual (bookbinding)

・ 5F-FA01-PE01

Parallel I/O interface

2D-TZ368(Sink)/

2D-TZ378(Source)

CC-Link interface

2D-TZ576

Teaching pendant (T/B)

Simple T/B

・ R32TB: For CR750 controller

・ R33TB: For CR751 controller

Highly efficient T/B

・ R56TB: For CR750 controller

・ R57TB: For CR751 controller

Controller

・ CR751-03HD-0

・ CR751-03HD1-0-S15

・ CR750-03HD1-1-S15

External I/O cable

・ 2D-CBL05 (5m)

・ 2D-CBL15 (15m)

Parallel I/O unit

2A-RZ361(Sink)/

2A-RZ371(Source)

External I/O cable

・ 2A-CBL05 (5m)

・ 2A-CBL15 (15m)

RT ToolBox2/RT ToolBox2 mini

RT ToolBox2

・ 3D-11C-WINE(CD-ROM)

(Windows XP、 Windows Vista、 Windows 7、

Windows 8、 Windows 8.1)

RT ToolBox2 mini

・ 3D-12C-WINE(CD-ROM)

(Windows XP、 Windows Vista、 Windows 7、

Windows 8、 Windows 8.1)

PLC (Programmable

Logic Controller)

External device

Prepared by customer

Standard configuration

Special specifications

Options

Prepared by

equipment

customer

1.6.2 Controller

The devices shown below can be installed on the controller.

The controllers that can be connected differ depending on the specification of the robot. (Refer to Page 2, "1.2

Model type name of robot".)

Fig.1-2 : Structural equipment

1-5

Page 19

1.7 Contents of the Option equipment and special specification

A list of all Optional equipment and special specifications are shown below.

1 General configuration

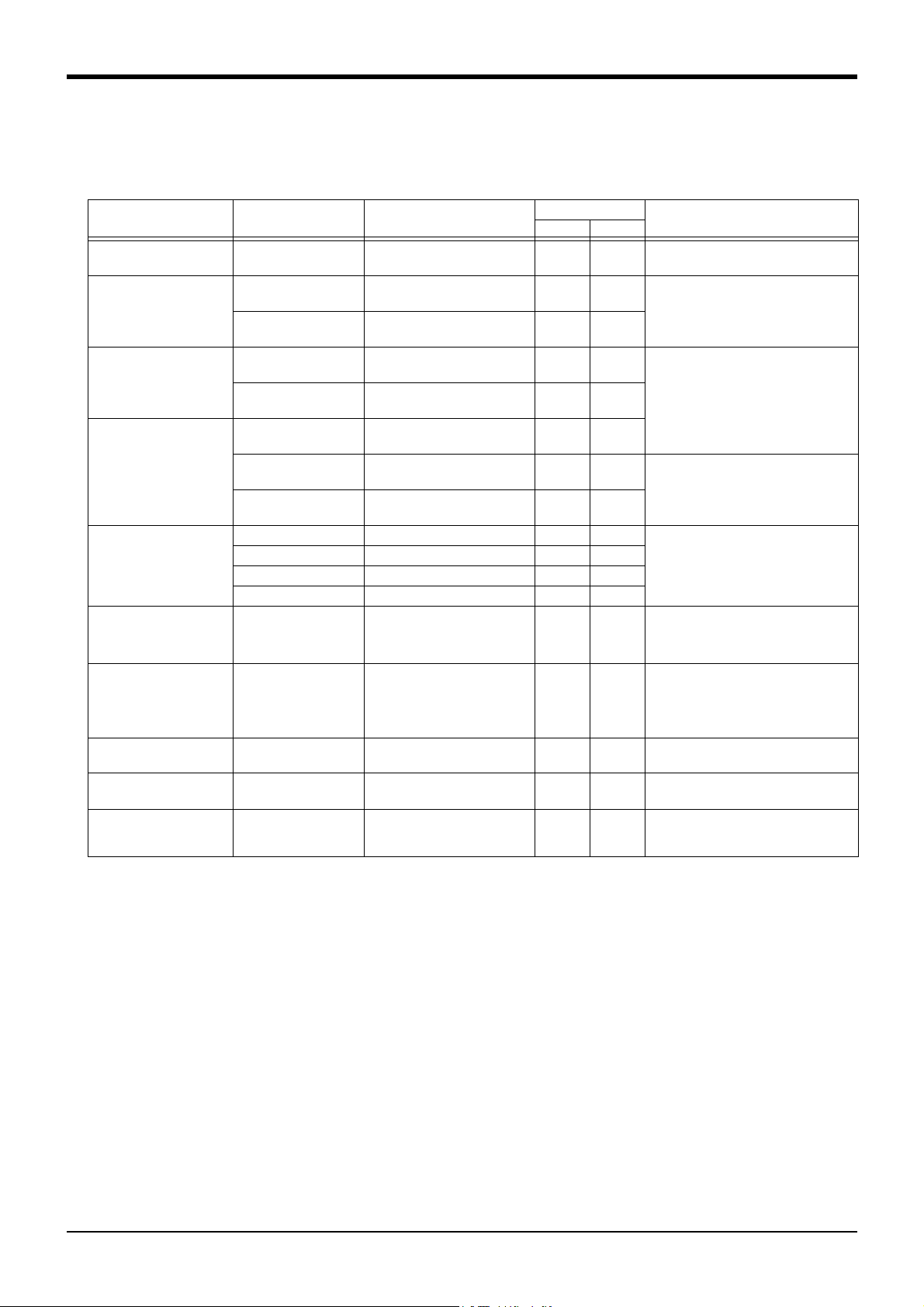

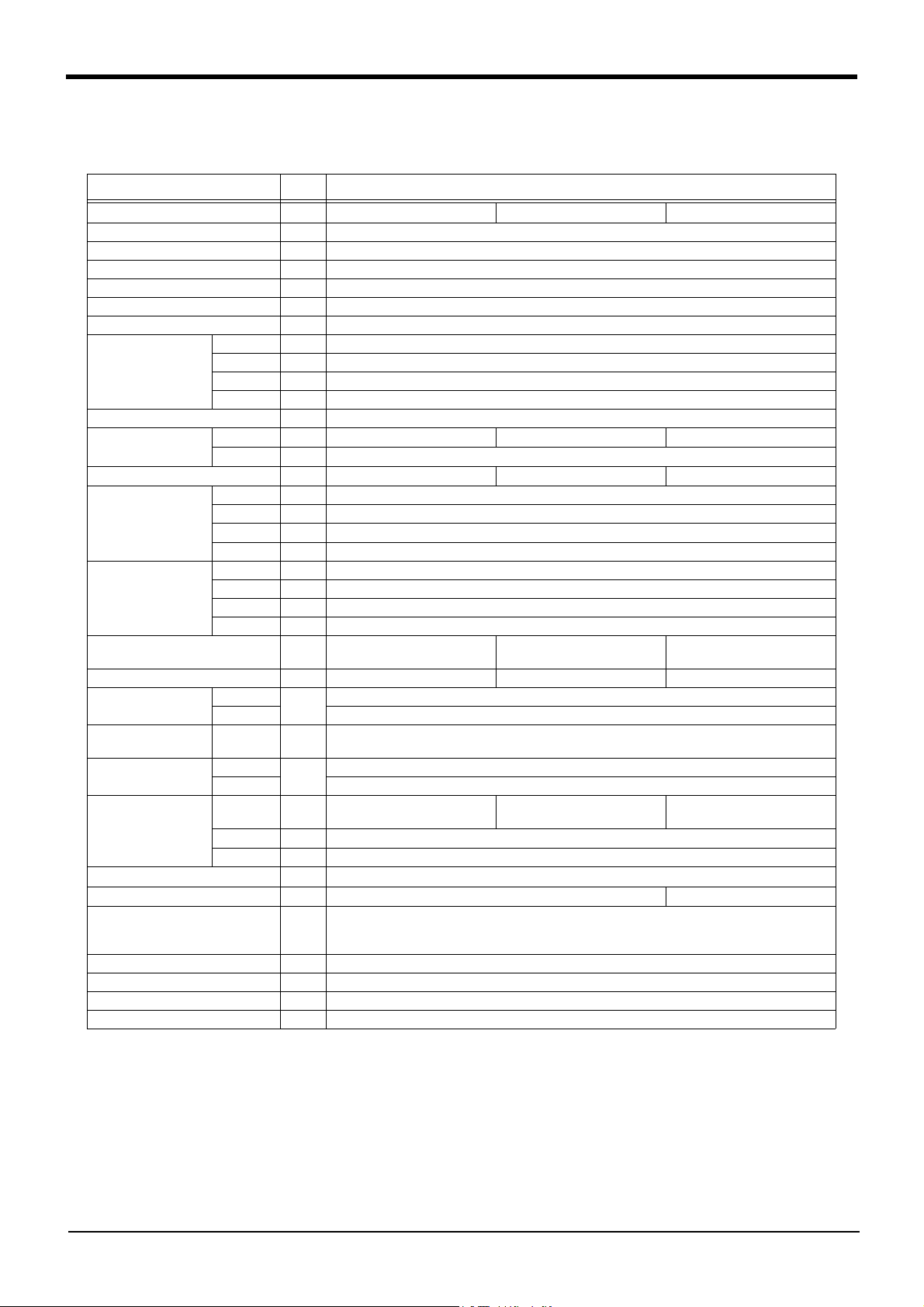

Table 1-3 : The list of robot option equipment and special specification

Item Type Specifications

Stopper for changing the

operating range (J1 axis)

Machine cable

(Replaced to shorter cable)

Machine cable extension

(extension type)

Machine cable extension

(direct type)

Solenoid valve set 1F-VD01-01/VD01E-01 1 set (Sink type)/(Source type)

Hand input cable 1F-HC35C-01 Robot side: connector.

Hand output cable

Hand curl tube 1E-ST0408C-300 For solenoid valve 4set.:Φ4x8

1F-DH-01

1S-02UCBL-03 For fixing (Set of power and sig-

1F-02UCBL-02 For fixing (Set of power and sig-

1S- □□ CBL-03 For fixing (Set of power and sig-

1S- □□ LCBL-03 For flexing (Set of power and

1S- □□ LUCBL-03 For flexing (Set of power and

1F- □□ UCBL-02 For fixing (Set of power and sig-

1F- □□ LUCBL-02 For flexing (Set of power and

1F-VD02-01/VD02E-01 2 set (Sink type)/(Source type)

1F-VD03-01/VD03E-01 3 set (Sink type)/(Source type)

1F-VD04-01/VD04E-01 4 set (Sink type)/(Source type)

1F-GR60S-01

The stopper parts for J1 axis

nal)

nal)

nal)

signal)

signal)

nal)

signal)

Hand side: wire.

Robot side: connector

Hand side: wire

Classification

Note1)

CR750 CR751

○○

○・□

-

○-

○-

○-

-○

-○

○ ○

○ ○

○ ○

○ ○

○○

○○

○○

-

○・□

Description

This must be installed by the customer.

2m

(A 2m cable is supplied instead of the

5m cable that is supplied as standard)

" □□ " in type shows the length of the

cables as follows.

05=5m, 10=10m, 15=15m

" □□ " in type shows the length of the

cables as follows.

10=10m, 15=15m, 20=20m

The solenoid-valve set for the hand of

the customer setup

1F-VD0*-01: Sink type

1F-VD0*E-01: Source type

The cable is connected to the sensor by

the customer.

Attaches the cable clamp (drip proof

type)

The cable is connected to the hand out-

put connector by the customer.

Attaches the cable clamp (drip proof

type)

Straight cable 600mm (total length)

Curl type air tube

External Wiring/Piping box 1F-UT-BOX For solenoid valve 4set.:Φ4x8

Internal Wiring/Piping set

for hand

1F-HS304S-01 Hand input cable (four signal

lines and two power lines), φ3

four hoses

○○

○○

Box which pulls out the Wire/Piping

(Hand I/O cable, Hand curl tube)

Wiring/Piping to pass in the shaft

Reducers (φ4 to φ3: 8pcs) are

Attached.

Note1) Distinction of ○ (is option) and □ (is special specification at shipping) is shown for each pair with the

controller.

Contents of the Option equipment and special specification

1-6

Page 20

1

General configuration

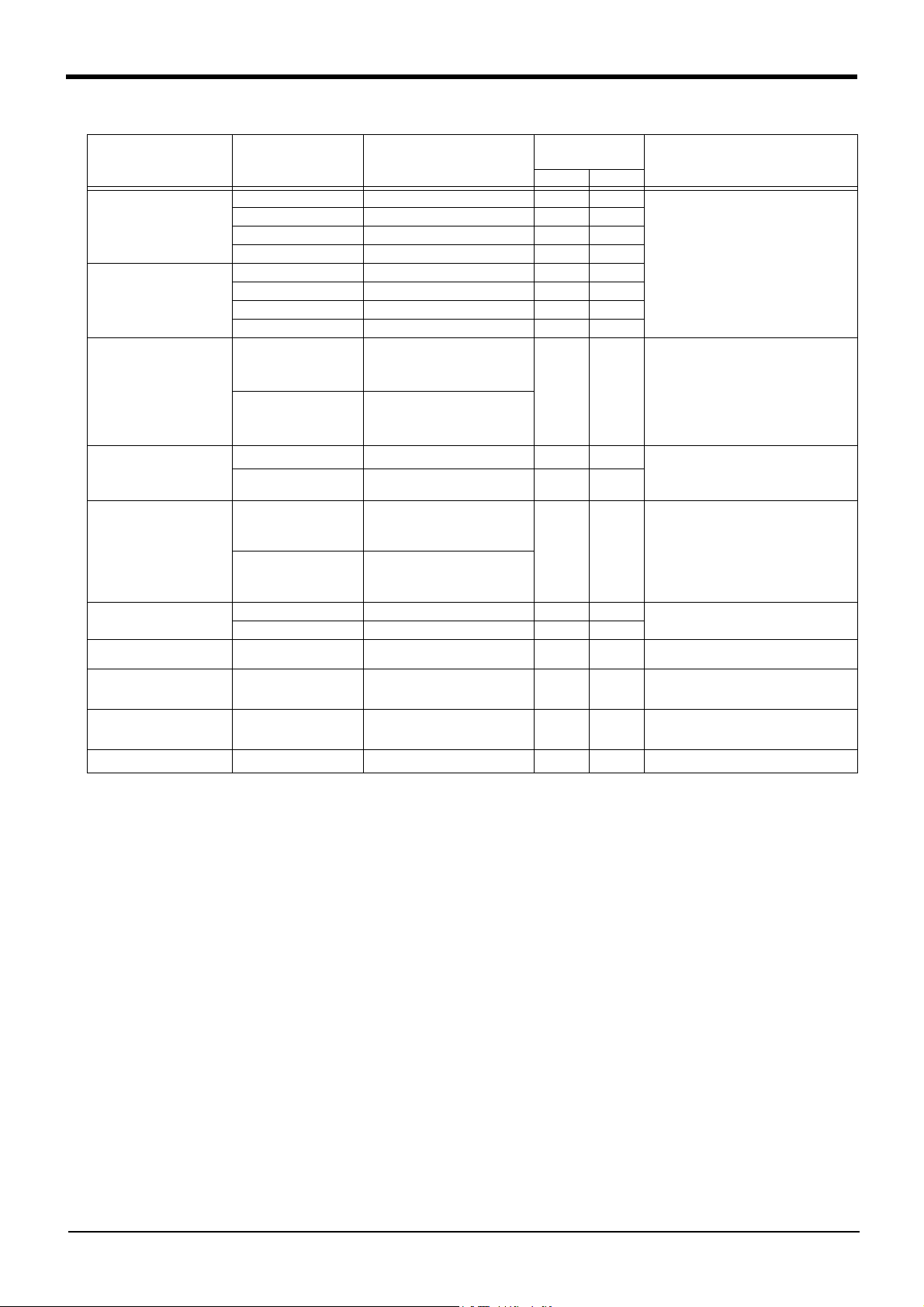

Table 1-4 : The list of controller option equipment and special specification

Classification

Item Type Specifications

Simple teaching pendant R32TB Cable length 7m ○ - With 3-position enable switch IP65

R32TB-15 Cable length 15m ○ R33TB Cable length 7m - ○

R33TB-15 Cable length 15m - ○

Highly efficient teaching

pendant

Parallel I/O Interface 2D-TZ368

External I/O cable

(For Parallel I/O Interface)

Parallel I/O Unit 2A-RZ361

External I/O cable

(For Parallel I/O Unit)

CC-Link interface 2D-TZ576 Only Intelligent device station,

RT ToolBox2

(Personal computer Sup-

port software)

RT ToolBox2 mini

(Personal computer Sup-

port software mini)

Instruction Manual

R56TB Cable length 7m ○ R56TB-15 Cable length 15m ○ R57TB Cable length 7m - ○

R57TB-15 Cable length 15m - ○

DO: 32 point

(Sink type)

2D-TZ378

(Source type)

2D-CBL05

2D-CBL15

(Sink type)

2A-RZ371

(Source type)

2A-CBL05 5m ○ ○ Use to connect the external peripheral

2A-CBL15 15m ○ ○

3D-11C-WINE CD-ROM

3D-12C-WINE CD-ROM

5F-FA01-PE01 RH-3FH-D series

DI: 32 point

Insulated type output signal

(0.1A/24V /point)

DO: 32 point/

DI: 32 point

Insulated type output signal

(9mA/ 24V /point)

5m

15m

DO: 32 point/

DI: 32 point

Insulated type output signal

(0.1A/24V /point)

DO: 32 point/

DI: 32 point

Insulated type output signal

(7mA/ 24V /point)

Local station

Note1)

CR750 CR751

○○

○○

○○

○○

○○

○○

○○

○○

Description

The card type external input-and-output.

Interface. Install to the slot of controller.

Use to connect the external peripheral

device to the parallel input/output

interface.

The unit for expansion the external

input/output.

Electrical isolated Type

(100mA/Point)

device to the parallel input/output unit

For MELSEC PLC with CC-Link connection.

Windows XP、 Windows Vista、 Windows

7、 Windows 8、 Windows 8.1

(With the simulation function)

Windows XP、 Windows Vista、 Windows

7、 Windows 8、 Windows 8.1

Note1) Distinction of ○ (is option) and □ (is special specification at shipping) is shown for each pair with the

controller.

1-7

Contents of the Option equipment and special specification

Page 21

Caution

Caution

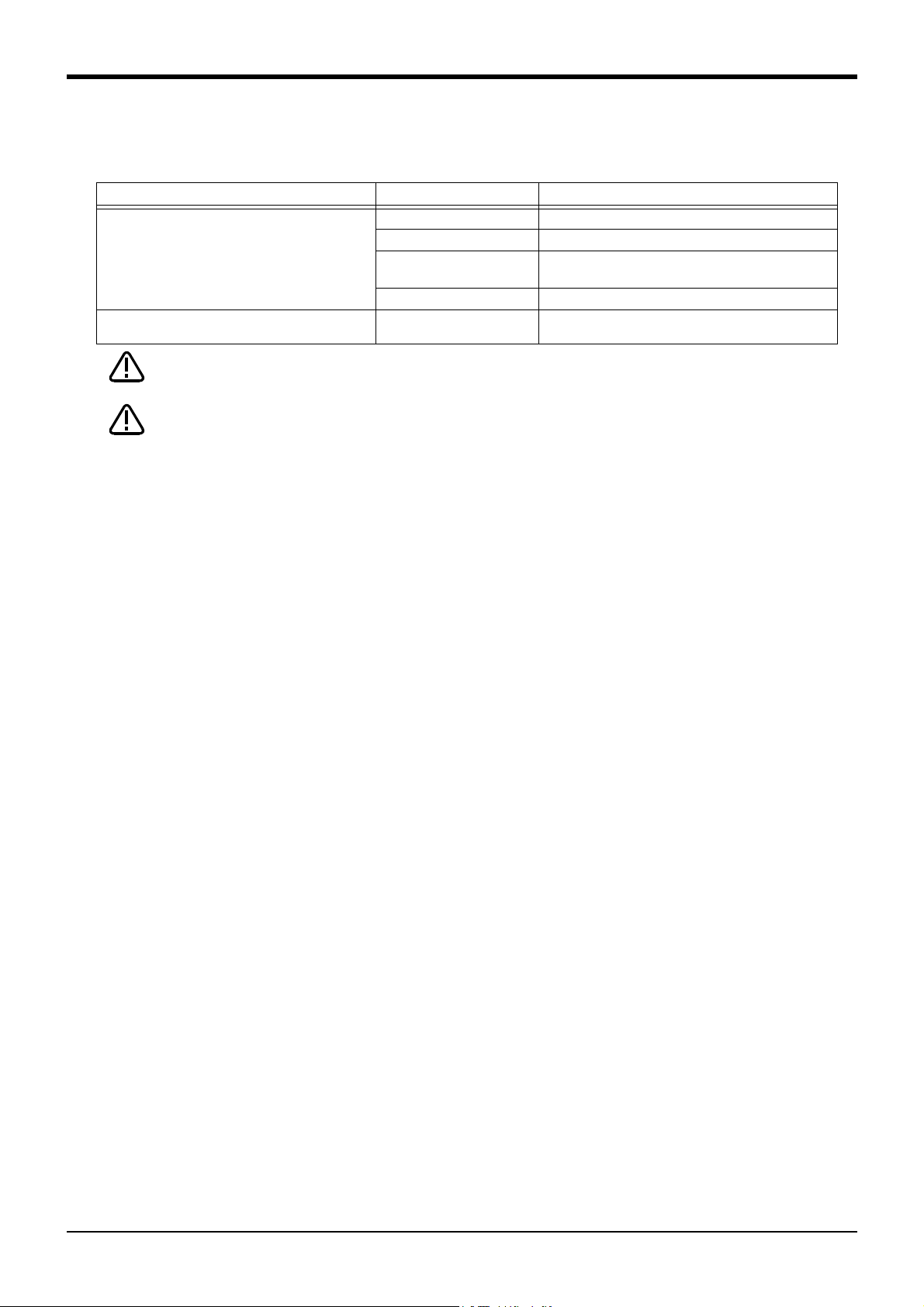

[Reference]:The recommendation products of the USB cable are shown below

Table 1-5 : Recommendation article of the USB cable

Name Type name Supplier

USB cable

(USB A type-USB mini B type)

USB adapter

(USB B type-USB mini B type)

Be careful to the USB cable to apply neither the static electricity nor the noise.

Otherwise, it becomes the cause of malfunction.

Use the network equipments (personal computer, USB hub, LAN hub, etc) confirmed by manufacturer.

The thing unsuitable for the FA environment (related with conformity, temperature or noise) exists in

the equipments connected to USB. When using network equipment, measures against the noise, such

as measures against EMI and the addition of the ferrite core, may be necessary. Please fully confirm

the operation by customer. Guarantee and maintenance of the equipment on the market (usual office

automation equipment) cannot be performed.

KU-AMB530 SANWA SUPPLY INC.

USB-M53 ELECOM CO., LTD.

GT09-C30USB-5P

MR-J3USBCBL3M MITSUBISHI ELECTRIC CO., LTD.

AD-USBBFTM5M ELECOM CO., LTD.

MITSUBISHI ELECTRIC SYSTEM & SERVICE CO.,

LTD.

1 General configuration

Contents of the Option equipment and special specification

1-8

Page 22

2Robot arm

2 Robot arm

2.1 Standard specifications

2.1.1 Basic specifications

(1) Standard specification

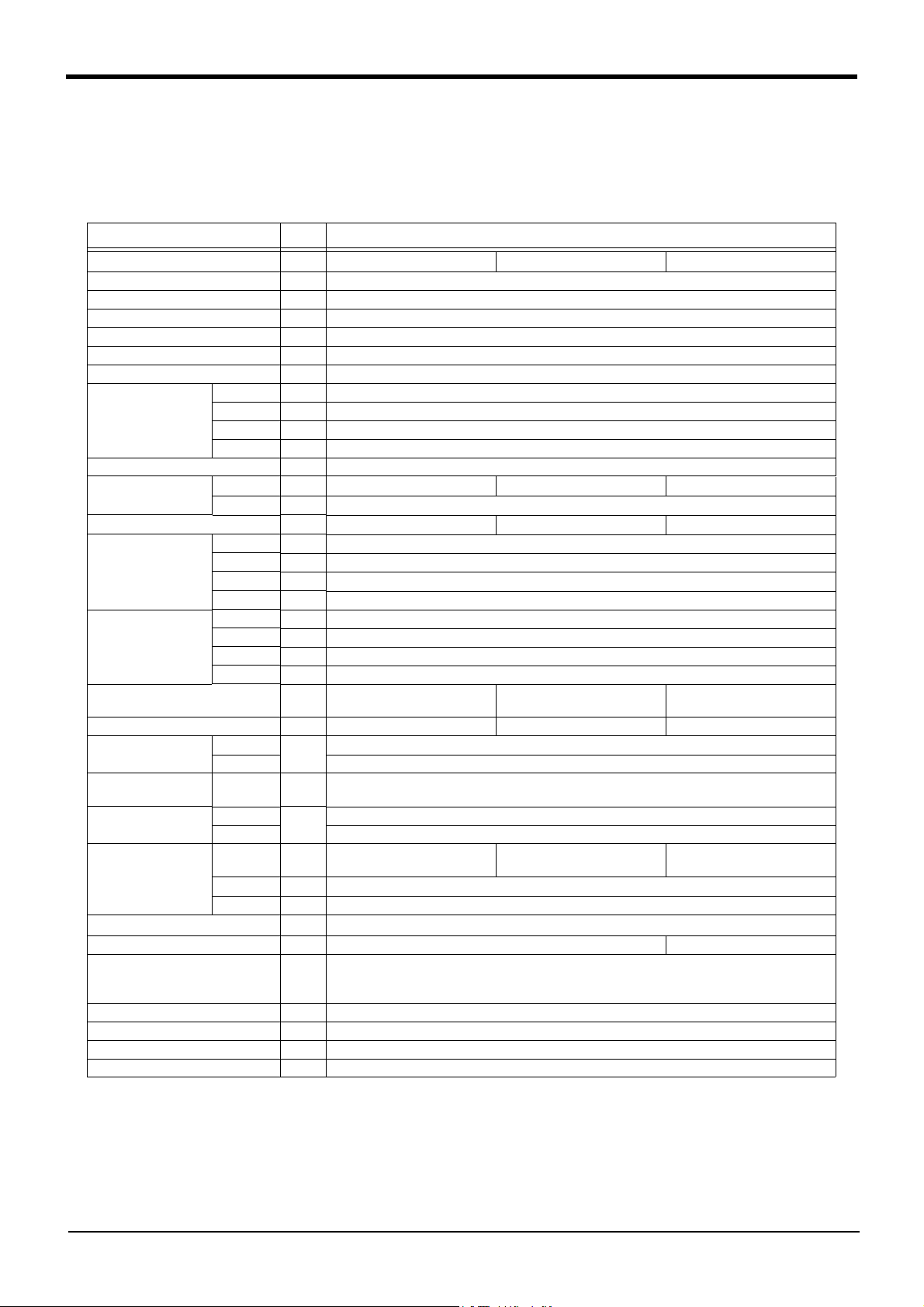

Table 2-1 : Standard specifications of robot arm

Item Unit

Type

Environment Standard specification

Installation posture On floor

Degree of freedom 4

Structure Horizontal, multiple-joint type

Drive system AC servo motor

Position detection method Absolute encoder

Motor capacity J1 W 200

J2 W 100

J3 (Z) W 100

J4 (θaxis) W 50

Brake J1, J2, J4: no brake, J3: with brake

Arm length № 1 arm

№2 arm

Max.reach radius( № 1+ № 2)

Operating range J1 deg ±170

J2 deg ±145

J3 (Z)

J4 (θaxis) deg ±360

Note1)

Speed of motion

Maximum horizontal composite speed

Note2)

Cycle time

Load

Z axis pressing force

Note4)

Allowable inertia Rating

Pose repeatability

Ambient temperature

Mass

Tool wiring ・ Input 8 points/Output 8 points, (total 20 cores)

Tool pneumatic pipes Primary: φ6 x two hoses, Secondary: φ4 x eight hoses

Supply pressure MPa 0.5±10%

Protection specification

Painting color Light gray (Equivalent to Munsell: 0.6B7.6/0.2)

Note3)

J1 deg/s 400

J2 deg/s 720

J3 (Z) mm/s 1,100

J4 (θaxis) deg/s 3,000

Rating

Maximum 3

Maximum N 82

Maximum 0.06

Note5)

X-Y

direction

J3 (Z)

J4 (θaxis) deg ±0.004

Note6)

Note9)

mm

mm

mm

mm

mm/s

sec 0.41 0.46 0.51

kg

(N)

2

kg ・ m

mm

mm

℃0 to 40

k

RH-3FH3515 RH-3FH4515 RH-3FH5515

125

350

6,800 7,500 8,300

±0.010 ±0.010 ±0.012

29

・ Dedicated signal cable for multifunctional hand (Two cores + Power cable two cores)

・ Ethernet cable one cable (100BASE-TX, eight cores)

Note1) The maximum speed is the value which applied MvTune2 (high-speed movement mode).

Note2) At the maximum speed on the X-Y flat surface in the robot's control point, it is obtained with each speed of J1, J2,

and J4. The control point is the position offset by the rated inertia from the flange.

Specifications

225 325

225

450 550

150

1

0.005

±0.010

32

Note7)

Note8)

IP20

2-9

Standard specifications

Page 23

300

25

Note3) The value of the following movement which applied MvTune2 (high-speed movement mode) with the carrying mass of

2kg.

・ The cycle time may increase with the case where the positioning accuracy of the work etc. is necessary, or by the

moving position.

Note4) This is the downwards pressing force that occurs at the end of the load when the maximum load is on board and the

J1, J2 and J4 axis are in their resting state. Please operate at this level or below. When pressing for long periods of

time, an excess load error may occur. Please operate in a manner that does not cause errors.

Note5) The pose repeatability details are given in Page 13, "2.2.1 Pose repeatability".

Note6) Sets the robot's operating environmental temperature as parameter OLTMX. Corresponding to the environment, the con-

tinuous control action performance and the overload-protection function are optimized. (Refers to "Optimizing the overload level" described in "Chapter 5 Functions set with parameters" of separate instruction manual/ Detailed

explanations of functions and operations for details.)

Note7) The 8-wire cable designated for LAN wiring can also be used for backup wiring.

Note8) The φ4 secondary piping can be obtained with the electromagnetic valve (option). Details regarding the electromag-

netic valve (optional) are shown on Page 53, "(3) Solenoid valve set".

Note9) The protection specification details are given in Page 20, "2.2.7 Protection specifications".

2Robot arm

Standard specifications

2-10

Page 24

2Robot arm

(2) Clean specification

Table 2-2 : Standard specifications of robot arm (Clean specification)

Item Unit

Type

Environment Standard specification

Installation posture On floor

Degree of freedom 4

Structure Horizontal, multiple-joint type

Drive system AC servo motor

Position detection method Absolute encoder

Motor capacity J1 W 200

J2 W 100

J3 (Z) W 100

J4 (θaxis) W 50

Brake J1, J2, J4: no brake, J3: with brake

Arm length № 1 arm

№2 arm

Max.reach radius( № 1+ № 2)

Operating range J1 deg ±170

J2 deg ±145

J3 (Z)

J4 (θaxis) deg ±360

Note1)

Speed of motion

Maximum horizontal composite speed

Note2)

Cycle time

Load

Z axis pressing force

Note4)

Allowable inertia Rating

Pose repeatability

Ambient temperature

Mass

Tool wiring ・ Input 8 points/Output 8 points, (total 20 cores)

Tool pneumatic pipes Primary: φ6 x two hoses, Secondary: φ4 x eight hoses

Supply pressure MPa 0.5±10%

Protection specification

Painting color Light gray (Equivalent to Munsell: 0.6B7.6/0.2)

Note3)

J1 deg/s 420

J2 deg/s 720

J3 (Z) mm/s 1,100

J4 (θaxis) deg/s 3,000

Rating

Maximum 3

Maximum N 82

Maximum 0.06

Note5)

X-Y

direction

J3 (Z)

J4 (θaxis) deg ±0.004

Note6)

Note9)

mm

mm

mm

mm

mm/s

sec 0.41 0.46 0.51

kg

(N)

2

kg ・ m

mm

mm

℃0 to 40

k

RH-3FH3512C RH-3FH4512C RH-3FH5512C

125

350

6,800 7,500 8,300

±0.010 ±0.010 ±0.012

29

・ Dedicated signal cable for multifunctional hand (Two cores + Power cable two cores)

・ Ethernet cable one cable (100BASE-TX, eight cores)

Note1) The maximum speed is the value which applied MvTune2 (high-speed movement mode).

Note2) At the maximum speed on the X-Y flat surface in the robot's control point, it is obtained with each speed of J1, J2,

and J4. The control point is the position offset by the rated inertia from the flange.

Specifications

225 325

225

450 550

120

1

0.005

±0.010

32

Note7)

Note8)

Clean specification: ISO class 3

2-11

Standard specifications

Page 25

300

25

Note3) The value of the following movement which applied MvTune2 (high-speed movement mode) with the carrying mass of

2kg.

・ The cycle time may increase with the case where the positioning accuracy of the work etc. is necessary, or by the

moving position.

Note4) This is the downwards pressing force that occurs at the end of the load when the maximum load is on board and the

J1, J2 and J4 axis are in their resting state. Please operate at this level or below. When pressing for long periods of

time, an excess load error may occur. Please operate in a manner that does not cause errors.

Note5) The pose repeatability details are given in Page 13, "2.2.1 Pose repeatability".

Note6) Sets the robot's operating environmental temperature as parameter OLTMX. Corresponding to the environment, the con-

tinuous control action performance and the overload-protection function are optimized. (Refers to "Optimizing the overload level" described in "Chapter 5 Functions set with parameters" of separate instruction manual/ Detailed

explanations of functions and operations for details.)

Note7) The 8-wire cable designated for LAN wiring can also be used for backup wiring.

Note8) The φ4 secondary piping can be obtained with the electromagnetic valve (option). Details regarding the electromag-

netic valve (optional) are shown on Page 53, "(3) Solenoid valve set".

Note9) The details of the clean specifications are described in Page 20, "2.2.8 Clean specifications". The conditions neces-

sary to guarantee cleanliness are as follows: clean room down flow greater then 0.3 m/s, robot internal suction of 30

to 50 L/min, and installation of an exhaust duct at the rear of the robot’s main base. A φ8 joint has been prepared

at the rear of the base for suction.

The protection specification details are given in Page 20, "2.2.7 Protection specifications".

2Robot arm

2.1.2 The counter-force applied to the installation surface

The counter-force applied to the installation surface for the strength design of the robot installation surface is

shown.

Table 2-3 : Value of each counter-force

Item Unit Value

Falls moment: M

Torsion moment: M

Horizontal translation force: F

Vertical translation force: F

L

T

V

H

N ・ m 240

N ・ m 255

N 810

N 380

Standard specifications

2-12

Page 26

2 Robot arm

2.2 Definition of specifications

The accuracy of pose repeatability mentioned in catalogs and in the specification manual is defined as follows.

2.2.1 Pose repeatability

For this robot, the pose repeatability is given in accordance with JIS B 8432 (Pose repeatability). Note that the

value is based on 100 measurements (although 30 measurements are required according to JIS).

[Caution] The specified "pose repeatability" is not guaranteed to be satisfied under the following conditions.

[1] Operation pattern factors

1) When an operation that approaches from different directions and orientations are included in relation to the teaching position during repeated operations

2) When the speed at teaching and the speed at execution are different

[2] Load fluctuation factor

1) When work is present/absent in repeated operations

[3] Disturbance factor during operation

1) Even if approaching from the same direction and orientation to the teaching position, when the

power is turned OFF or a stop operation is performed halfway

[4] Temperature factors

1) When the operating environment temperature changes

2) When accuracy is required before and after a warm-up operation

[5] Factors due to differences in accuracy definition

1) When accuracy is required between a position set by a numeric value in the robot's internal coordinate system and a position within the actual space

2) When accuracy is required between a position generated by the pallet function and a position

within the actual space

2-13

Definition of specifications

Page 27

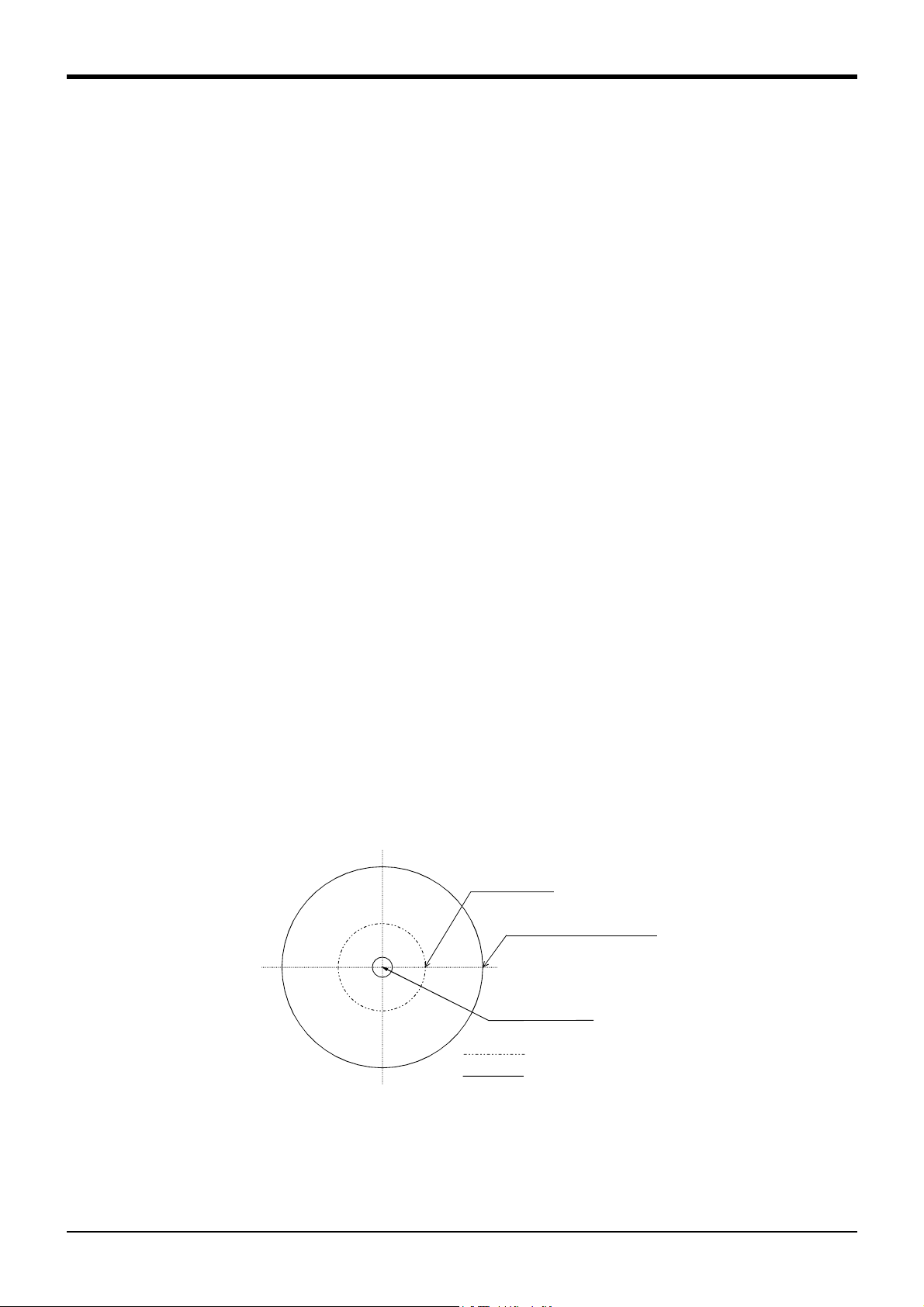

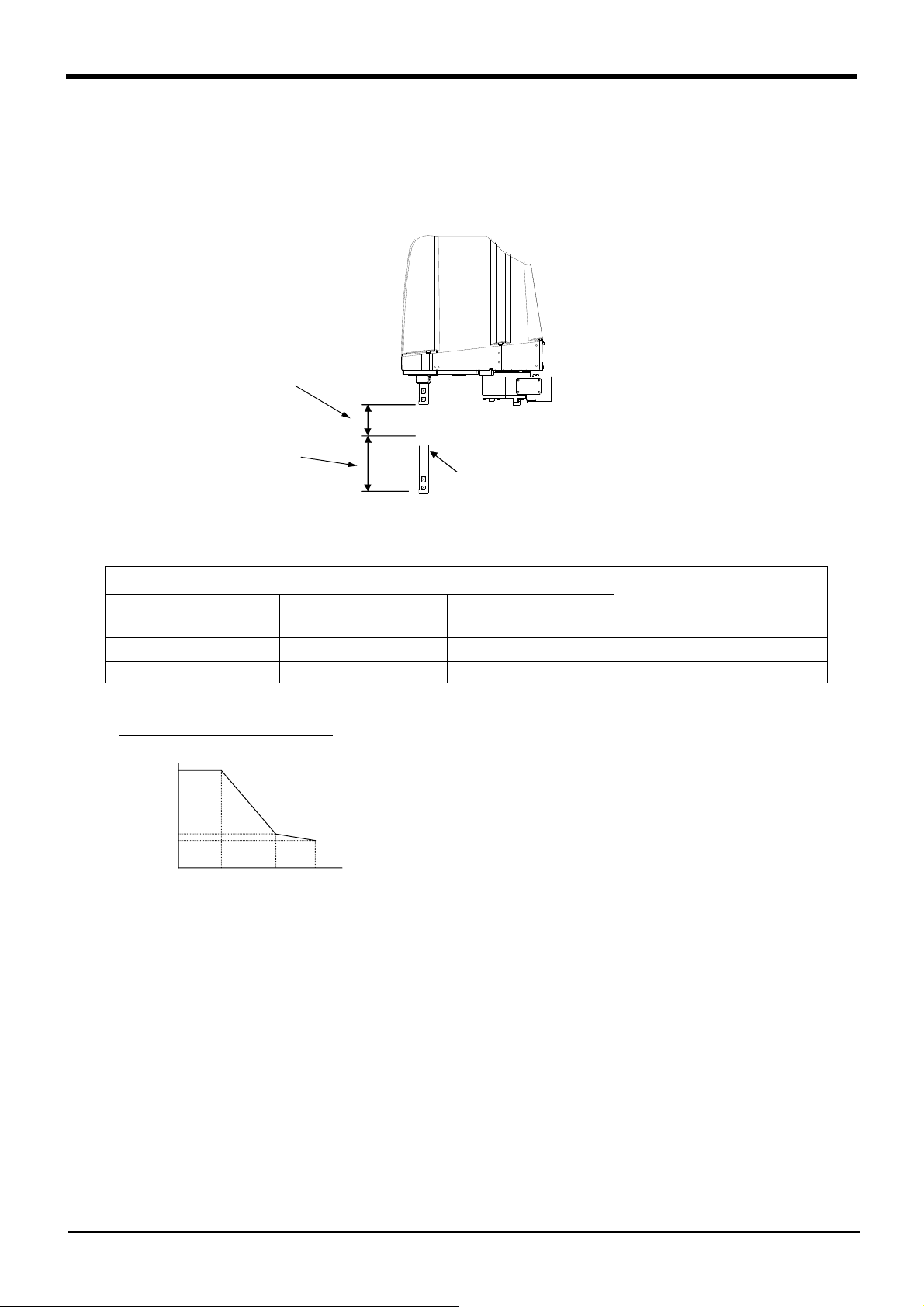

定格慣性モーメント

最大慣性モーメント

シャフト中心

単位:mm

20mm(1kg)

100mm(3kg以下)

Unit: mm

Shaft center

Allowable moment of inertia

Maximum

Rating

100mm (less than 3kg)

2 Robot arm

2.2.2 Mass capacity

The robot's mass capacity is expressed solely in terms of mass, but even for tools and works of similar mass,

eccentric loads will have some restrictions When designing the tooling or when selecting a robot, consider the following issues.

(1) The tooling should have the value less or equal than the smaller of the allowable moment of inertia found in

Page 9, "2.1.1 Basic specifications".

(2) Fig. 2-1 shows the distribution dimensions for the center of gravity in the case where the volume of the

load is relatively small. Use this figure as a reference when designing the tooling.

Please use the robot in the allowable moment of inertia of maximum moment of inertia shown in Fig. 2-1.

[Caution]The mass capacity is greatly influenced by the operating speed of the robot and the motion posture.

Even if you are within the allowable range mentioned previously, a vibration, an overload or generate an

overcurrnt alarm could occur. In such cases, please reduce acceleration and deceleration (Accel command) speeds and movement speed (Ovrd command). Although the standard value to reduce is 50% for

each command, please adjust corresponding to the movement posture. Refer to separate "Instruction

Manual/Detailed Explanation of Functions and Operations" for details of each command.

Moreover, if hand/workpiece parameters are not set exactly, the similar phenomenon will be easier to

occur.

[Caution] Refer to Page 15, "2.2.3 Relationships Among Mass Capacity, Speed, and Acceleration/Deceleration

Speed", and set the values of the mass, magnitude, and distance to the centroid of a tool and a workpiece

to parameters.

If parameters are not set exactly, the lifetime of reduction gears, a belt, etc. is affected.

[Caution] The overhang amount of the load, such as the mass capacity and the allowable moment of inertia

defined in this section, are dynamic limit values determined by the capacity of the motor that drives axes

or the capacity of the speed reducer. Therefore, it does not guarantee the accuracy on all areas of tooling.

Guaranteed accuracy is measured from the center point of the mechanical interface surface. Please note

that if the point of operation is kept away from the mechanical interface surface by long and low-rigid

tooling, the positioning accuracy may deteriorate or may cause vibration.

Note that the allowable offset value (Z direction) from the lower edge of the shaft to the position of center

of gravity is 100 mm.

[Caution] Even within the allowable range previously mentioned, an overload alarm may be generated if an ascend-

ing operation continues at a micro-low speed. In such a case, it is necessary to increase the ascending

speed.