Page 1

MANUAL

MITSUBISHI

TRACTOR

BD2G

C/

#:

28000001-UP

281 00001-UP

28200001-UP

28300001-UP

28500001-UP

28600001-UP

28700001-UP

38000001-UP

381 00001-UP

38500001-UP

38600001-UP

(v

TRACTOR

BS3G

+

I"-

SHOVEL

MITSUBISHI

HEAVY

INDUSTRIES,

LTD.

Page 2

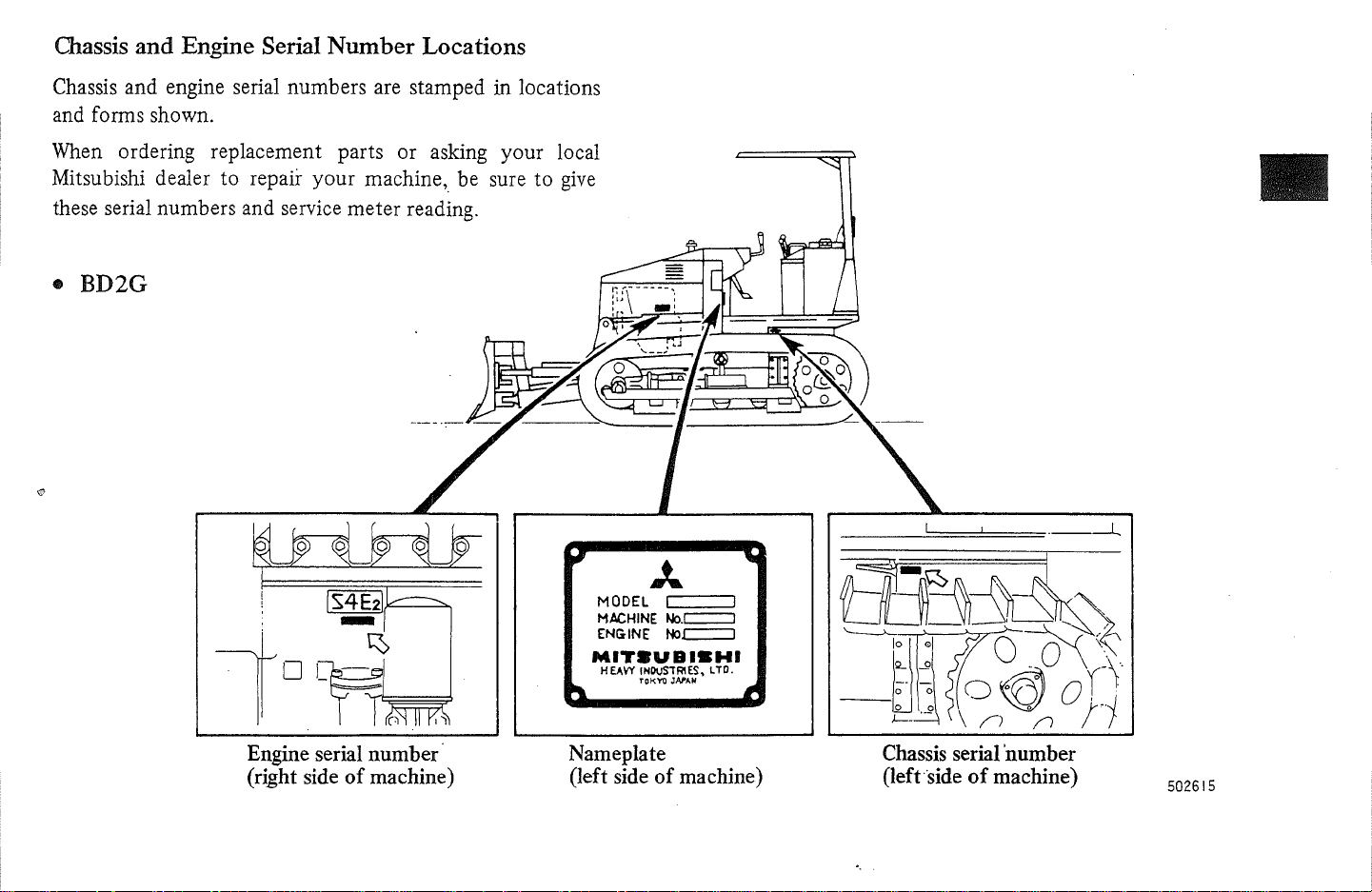

Chassis

and

Engine Serial

Number

Locations

Chassis and engine serial numbers are stamped in locations

and forms shown.

When ordering replacement parts or asking your local

Mitsubishi dealer

to

repair

your

machine, be sure

to

give

these serial numbers and service meter reading .

• BD2G

Engine serial number

(right side

of

machine)

~

MODEL I 1

MACHINE

ENG

MIT.UBISHI

HEAVY

Nameplate

(left side

No.c:::::::J

INE

No.c:::::::J

INDuSTRIES,

rCK"t1I

JAf'AH

of

LTD.

machine)

___

.!::==::!:=:==---L

Chassis serial 'number

(left-side

'.

of

machine)

502615

Page 3

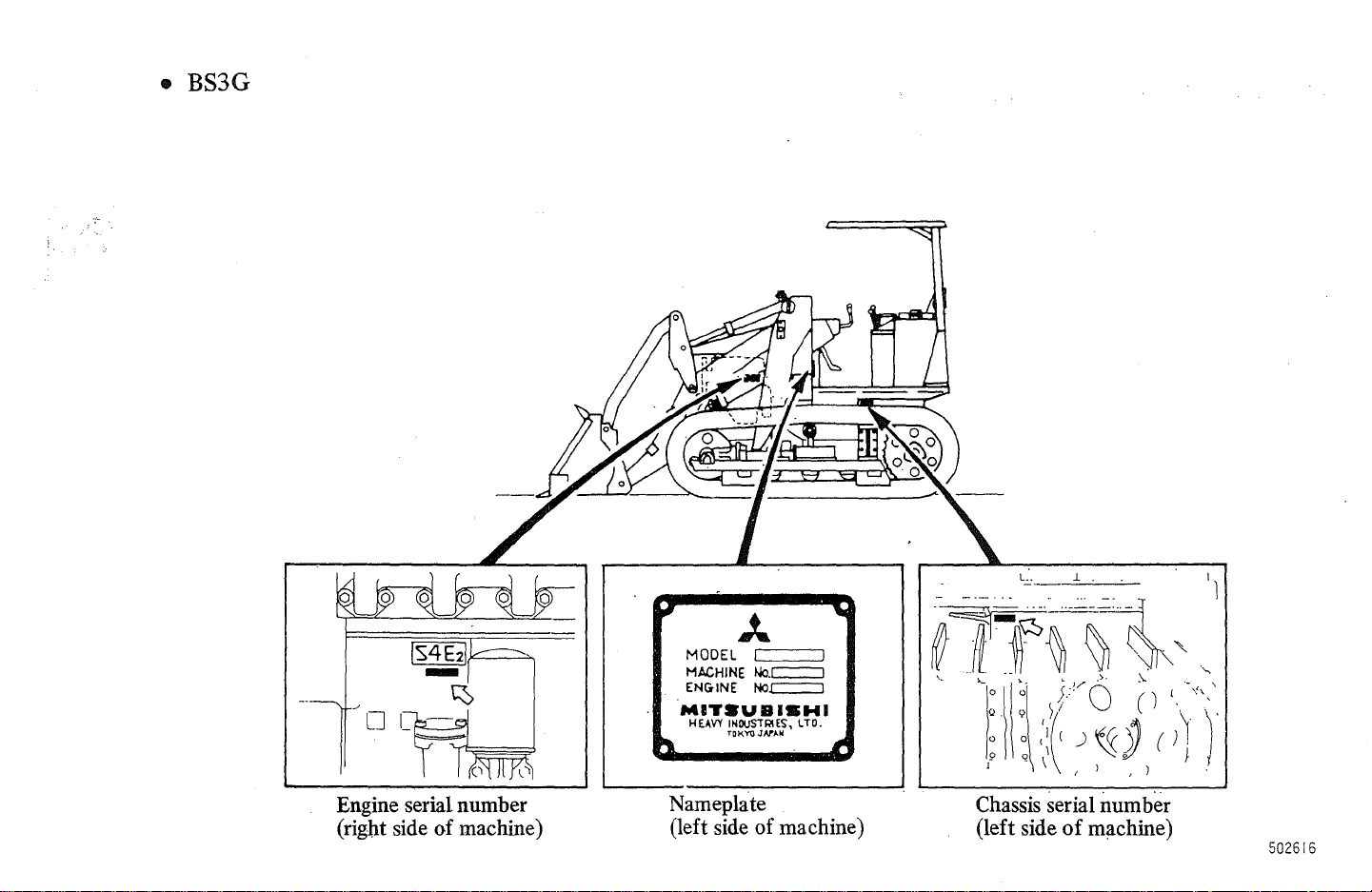

• BS3G

o

J...

MODEL I I

MACHINE

ENG

MIT.UBIBWI

HEAVY INDUSTRIES, LTD.

No.c::::::J

IN

E No.c::::=:::J

TOKYO

JAn.No

Engine serial number

of

(right side

machine)

Nameplate

(left side

of

machine)

Chassis serial number

(left side

of

machine)

502616

Page 4

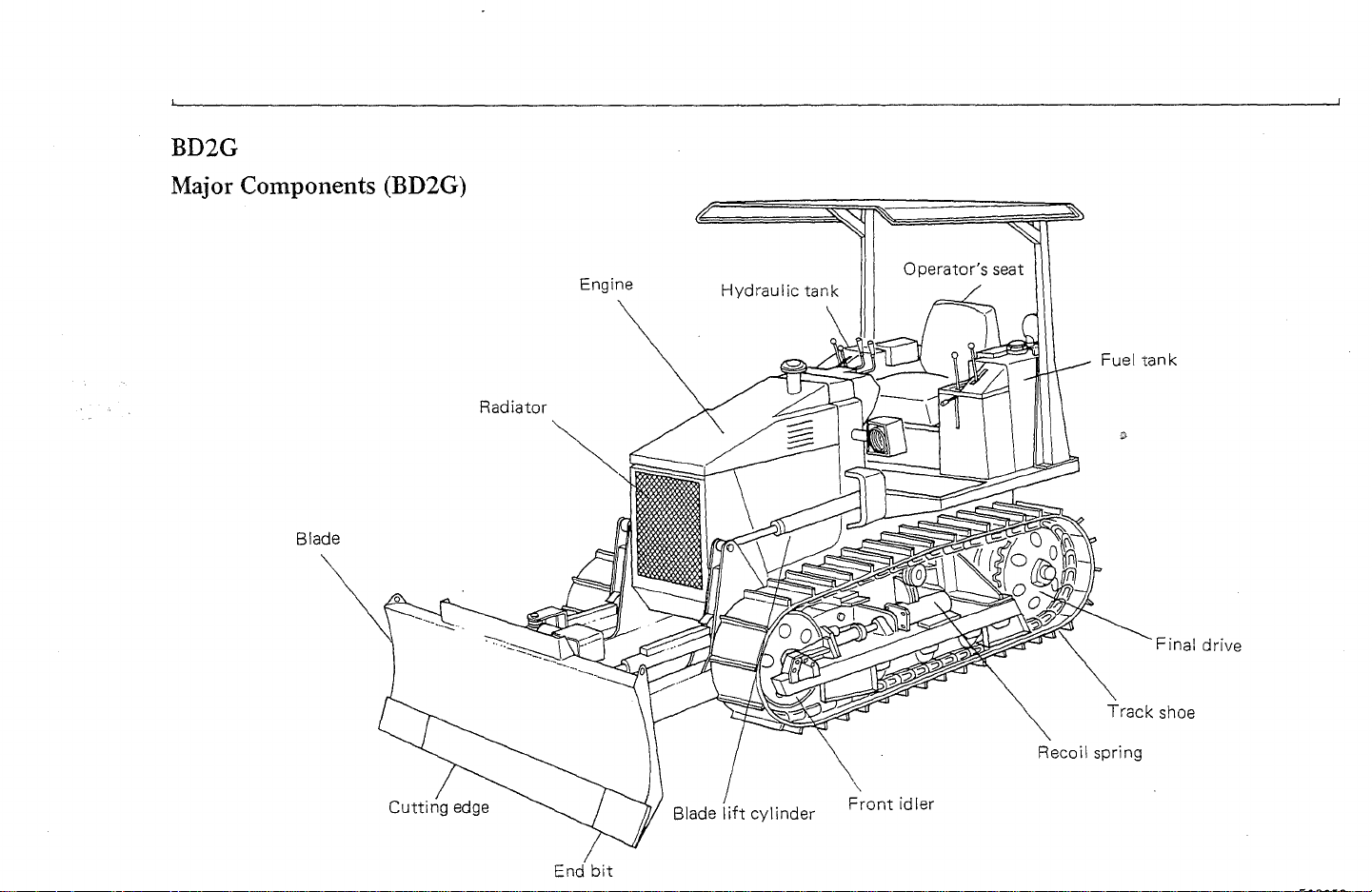

BD2G

Major

Components (BD2G)

Blade

Radiator

Engine

Fuel

Track

tank

Final drive

shoe

Cutting

edge

bit

Front

Recoil spring

idler

Page 5

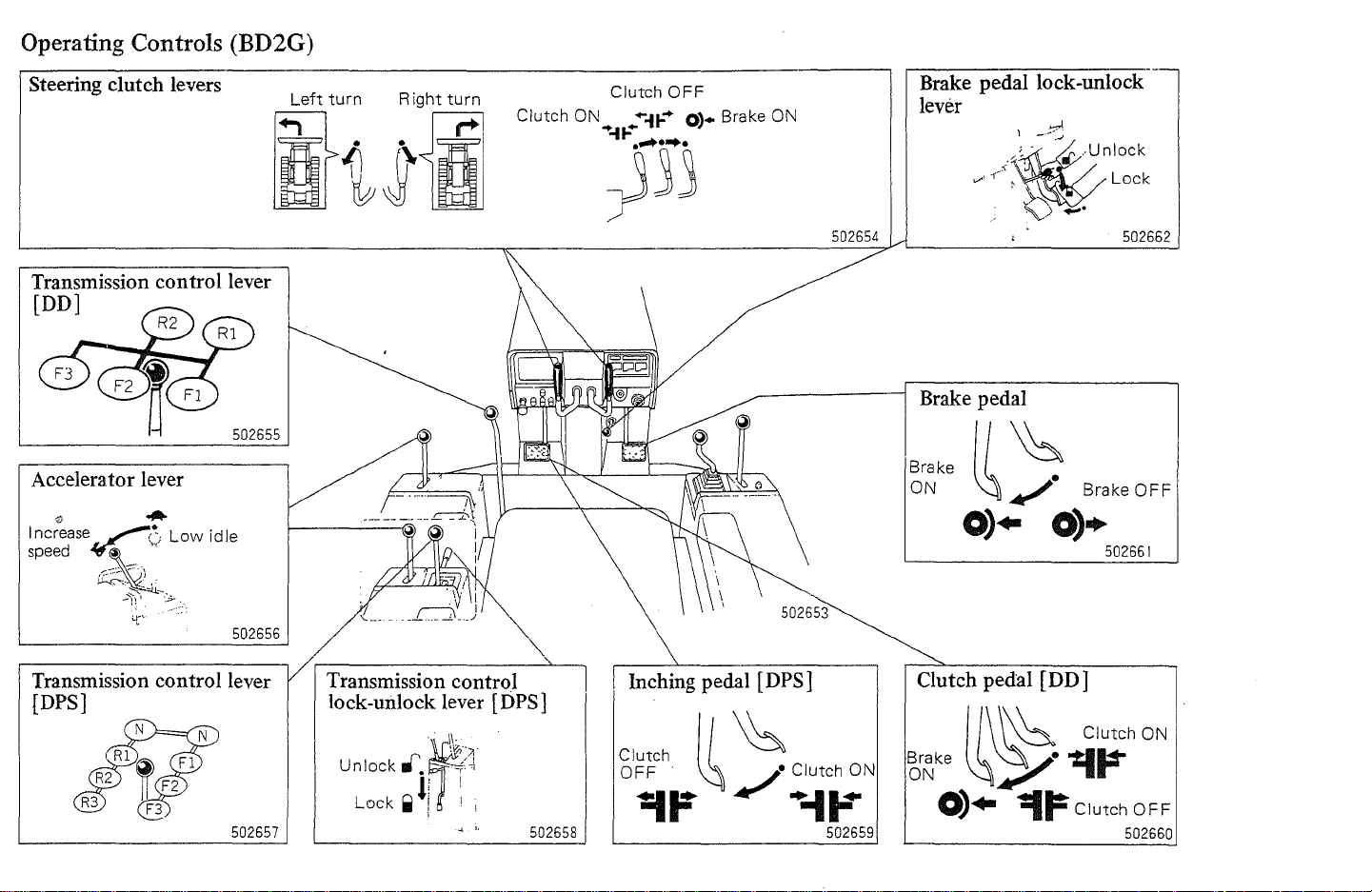

Operating Controls (BD2G)

Steering

Transmission

[DO]

Accelerator

clutch

levers

control lever

lever

Left

turn

Right

turn

Clutch ON

it~\i

502655

502656

Clutch

......

)33

....

n-

~..

OFF

....

0'.

'I

Brake ON

502654

Brake

lever

Brake

Brake

ON

pedal lock-unlock

pedal

~~

0)"

At'

~.

0)+

Brake

502662

OFF

502661

Transmission

{DPS]

control lever

502657

Transmission

lock-unlock

..

Unlock

rtf.~~~}

li

Lock

..

! ! I

;

control

lever

\\.

1

"

..

[DPS]

502658

Inching

Clutch II

OFF

.

pedal

~

~F

[DPS]

~

j.

Clutch ON

.,

+-11-"

502659

Clutch

~~ke

pedal [DO]

1/\

\h

Clutch ON

~~.~~

0)"

-=I~

Clutch

OFF

502660

Page 6

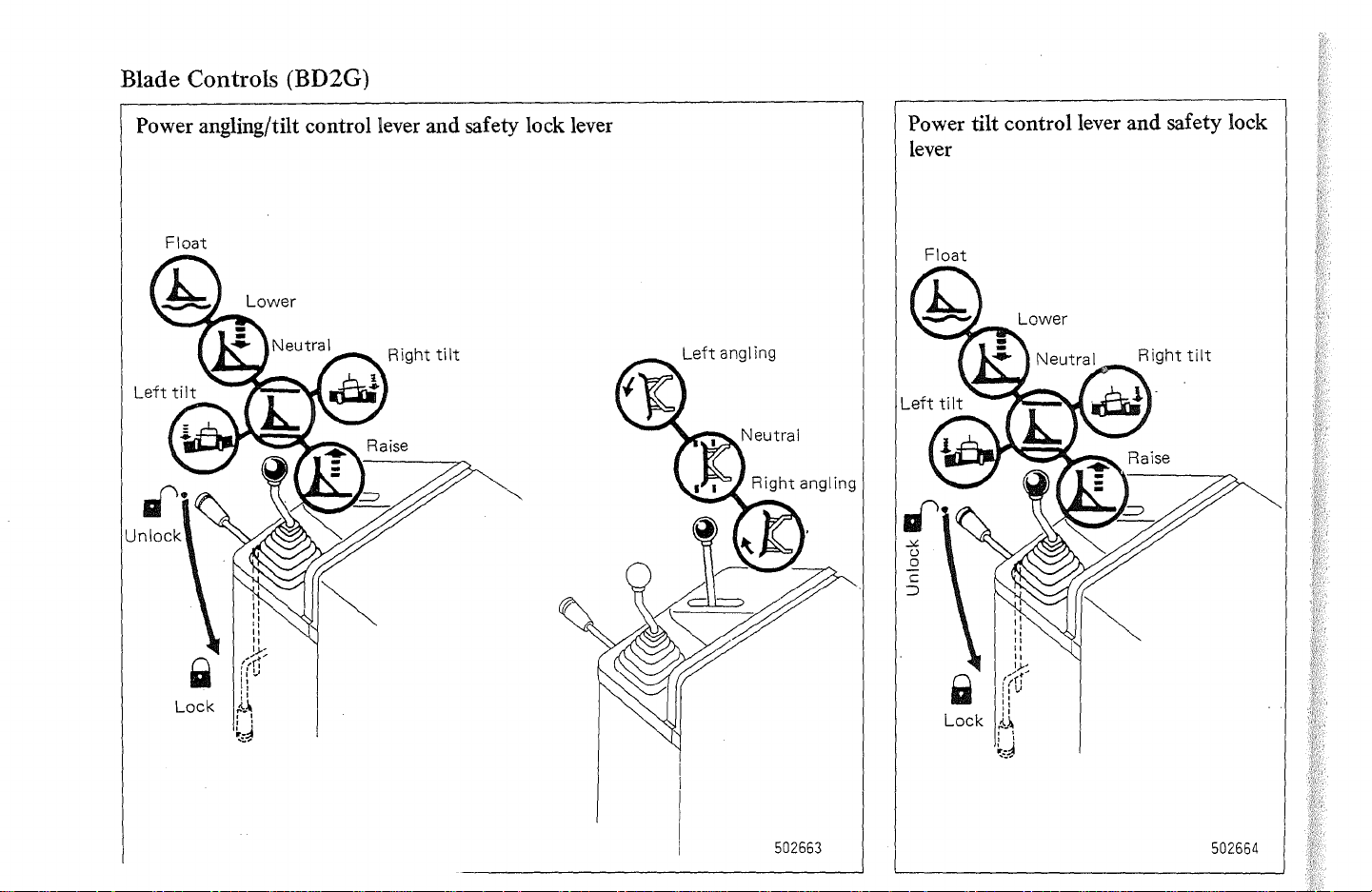

Blade Controls (BD2G)

Power angling/tilt control lever and safety lock lever

Float

Power tilt control lever and safety lock

lever

Float

502663

502664

Page 7

Indicators, Gauges and Switches (BD2G)

OK

monitor test switch

.. When this switch

with starter switch

Alternator

and engine oil pressure

warning lamps glow (with

engine stopped).

Ba

ttery

and air cleaner element

warning lamps glow (with

engine running).

electrolyte level

not

is

charging

pushed

ON:

Water

$

Normal

(green)

temperature

gauge Overheat

.--

______

TEMP

(red) .

50

1889

Service meter

hour

1

Every 6 minutes

dial advances

one number.

501887

OK

monitor

..

When any lamp glows

during operation, stop

machine soon and check

for cause. (See page 16.)

Battery switch

@i·.L-.---"------<.J

-§o-

Lighting

~I"

switch

Twist

~

1st 2nd

position

position

501959

502666

Position

Head

lamps

Working

lamp

Instrument

panel lamp

rop)

1st

Twist

2nd

'Twist

00

502665

Glow plug indicator

Glows when starter switch

turned to HEAT.

I Fuel gauge

Full

or

key.

engine.

(green)

501888

pull

501956

Empty

(red)

(l)

is

I

Starter switch

START

HEAT

OFF

ON

START

Heat engine.

I nsert

out

Keep engine

running.

Start

Page 8

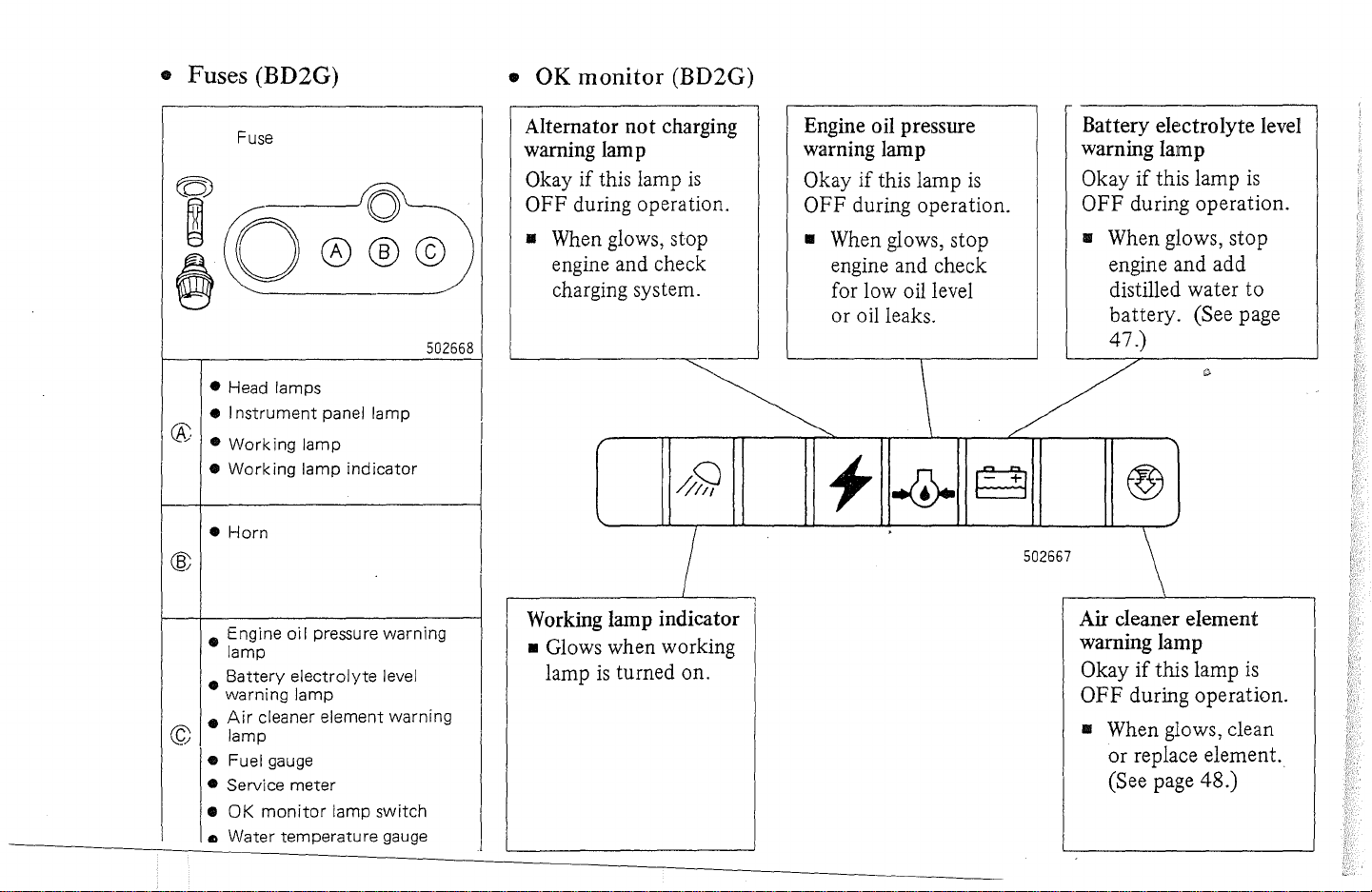

• Fuses (BD2G)

•

OK

monitor

(BD2G)

Fuse

• Head lamps

• I

nstrument

®

•

Working

•

Working

•

Horn

• Engine

lamp

•

Battery

warning lamp

•

Air

© lamp

• Fuel gauge

• Service

•

OK

III

Water

502668

panel lamp

lamp

lamp

indicator

oil

pressure warning

electrolyte

cleaner element warning

meter

monitor

temperature

lamp

level

switch

gauge

Alternator

warning lam p

Okay if this lamp

OFF during operation.

• When glows, stop

engine and check

charging system.

,--------------L-----

Working lamp indicator

• Glows when working

lamp

not

is

turned on.

charging

is

7

Engine oil pressure

warning lamp

Okay if this lamp

OFF during operation.

• When glows, stop

engine and check

for low oil level

or oil leaks.

1

is

\ /

502667

Battery electrolyte level

warning lamp

Okay

if

this lamp

OFF during operation.

• When glows, stop

engine and add

distilled water

battery. (See page

is

to

47.)

\

Air cleaner element

warning lamp

Okay

if

this lamp

OFF

during operation.

• When glows, clean

or replace element.

(See page 48.)

is

Page 9

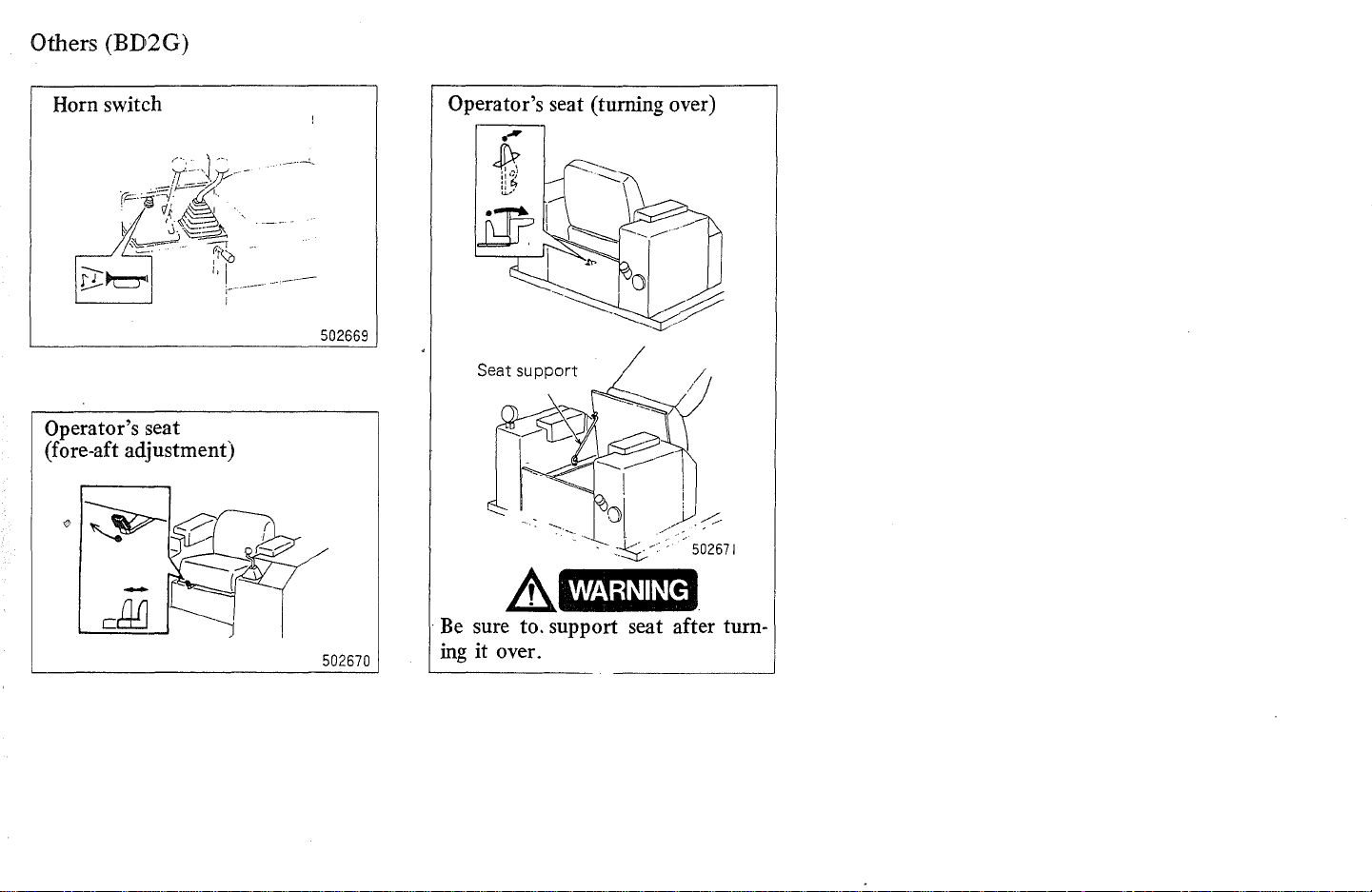

Others (BD2G)

Horn

switch

Operator's seat

(fore-aft adjustment)

502669

502670

Operator's seat (turning over)

.-

1:1

lL~

iJF

'------,--'

Seat support

A

. Be sure to. support seat after turn-

ing it over.

---.::::.?\

\ \

1---

~

l~//--

I

WARNING

Page 10

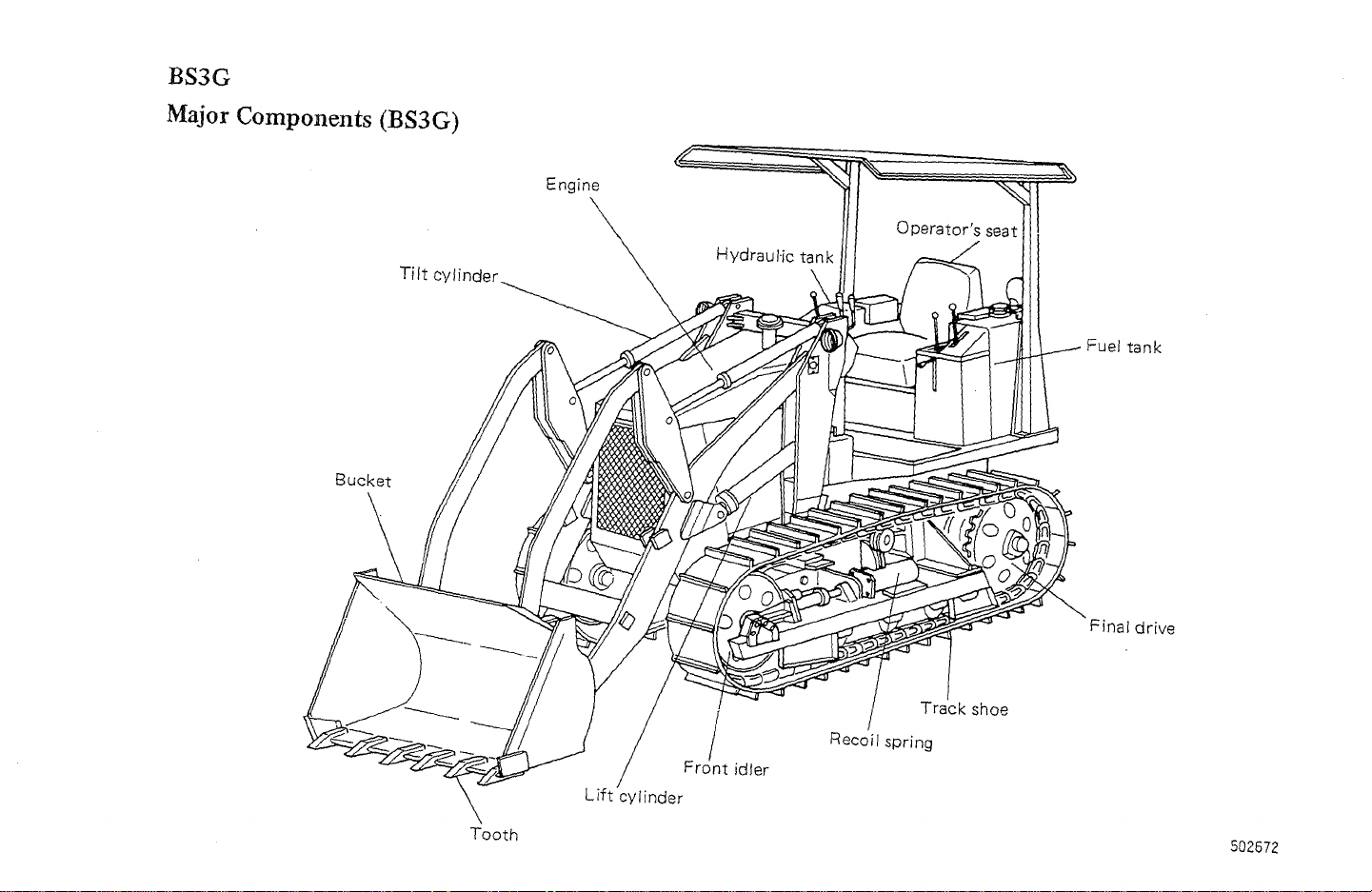

BS3G

Major Components (BS3G)

Tilt cylinder

Bucket

Engine

Fuel

Final

tank

drive

Tooth

Track

shoe

502672

Page 11

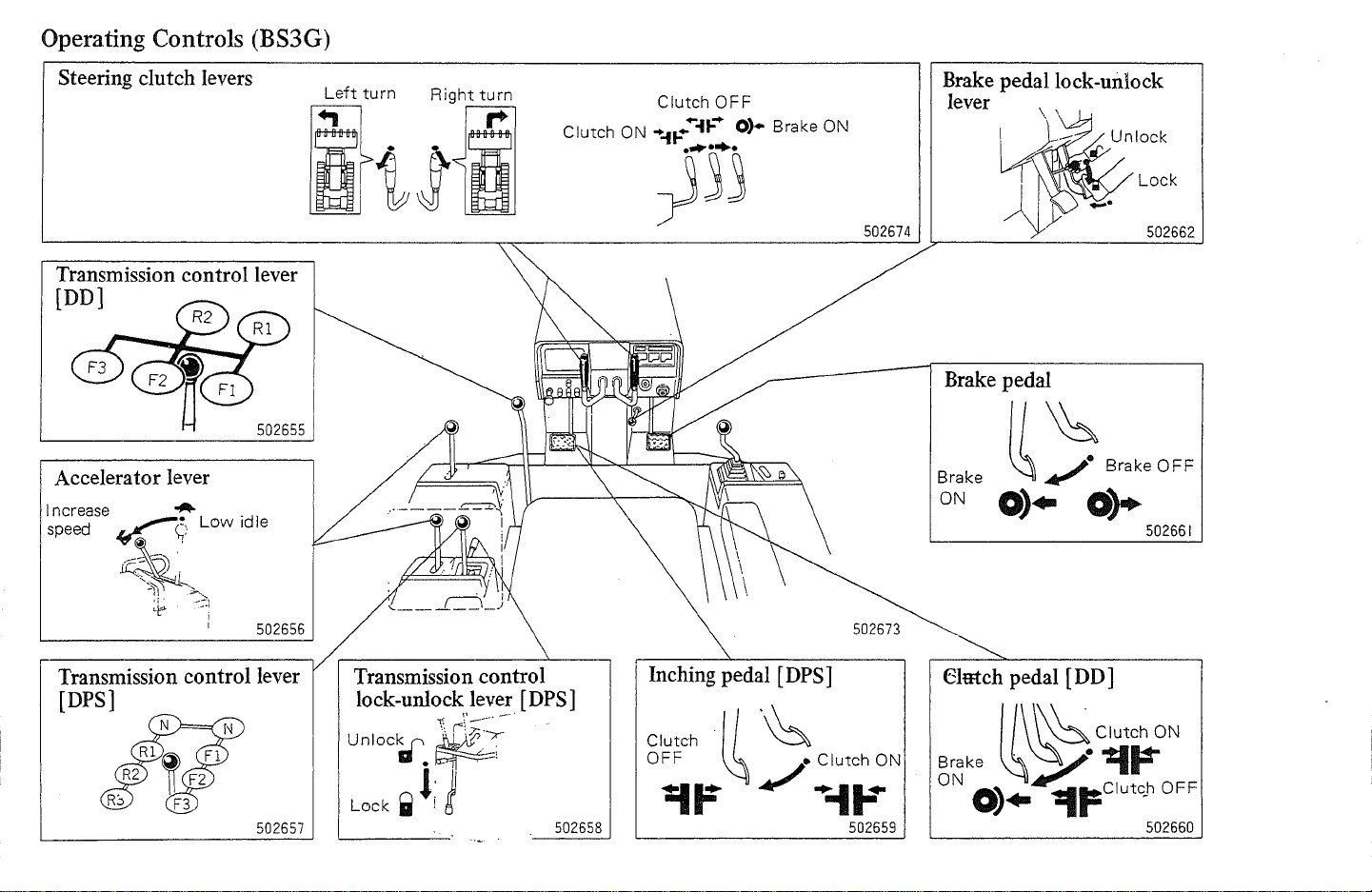

Operating Controls (BS3G)

Steering

Transmission

(DD]

Accelerator

clutch

lever

levers

control lever

502655

502656

Clutch ON

Clutch

.....

t-

.....

it-

OFF

..

0)·

Brake ON

~'Ij

502674

Brake

lever

Brake

Brake

ON

pedal lock-unlock

Lock

502662

pedal

II

~

8rnk'

OFF

~..,

0).

o~

502661

Transmission

(DPS]

control lever

502657

Transmission

lock-unlock

unIOc~.~

Lock

..

l;

control

lever

\-.

r\'

:;:~--.

-'

j

[DPS]

502658

Inching

Clutch

O~F

pedal

[DPS]

·11

'~

~/~-I;~N

502659

Elmch

Brake .

ON

~

0).

pedal

[D D ]

\

~

~'0$.../.

~~

Clutch

'=I~

lIt=Clutc,h

ON

OFF

502660

Page 12

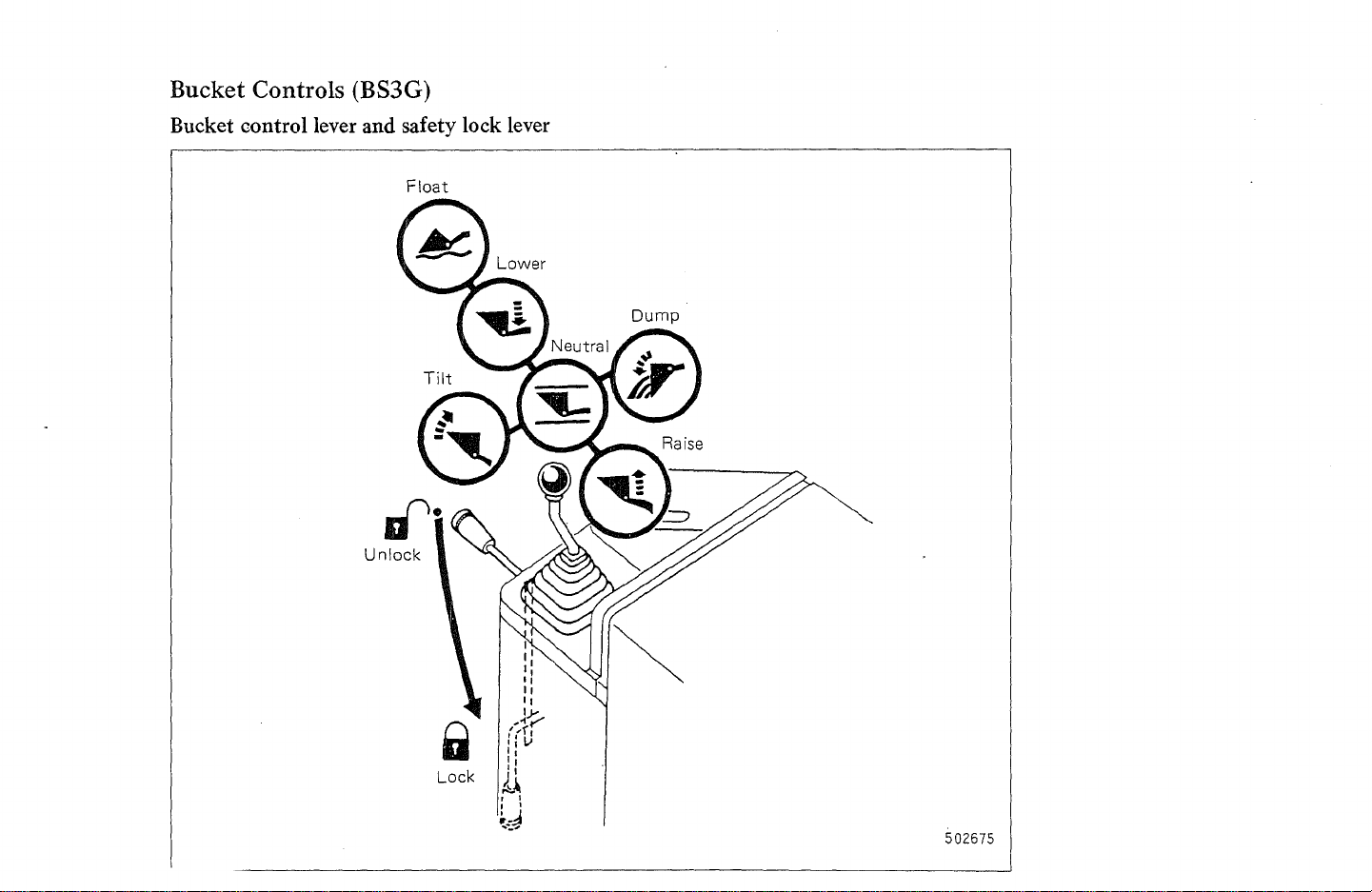

Bucket Controls (BS3G)

Bucket control lever and safety lock lever

Float

502675

Page 13

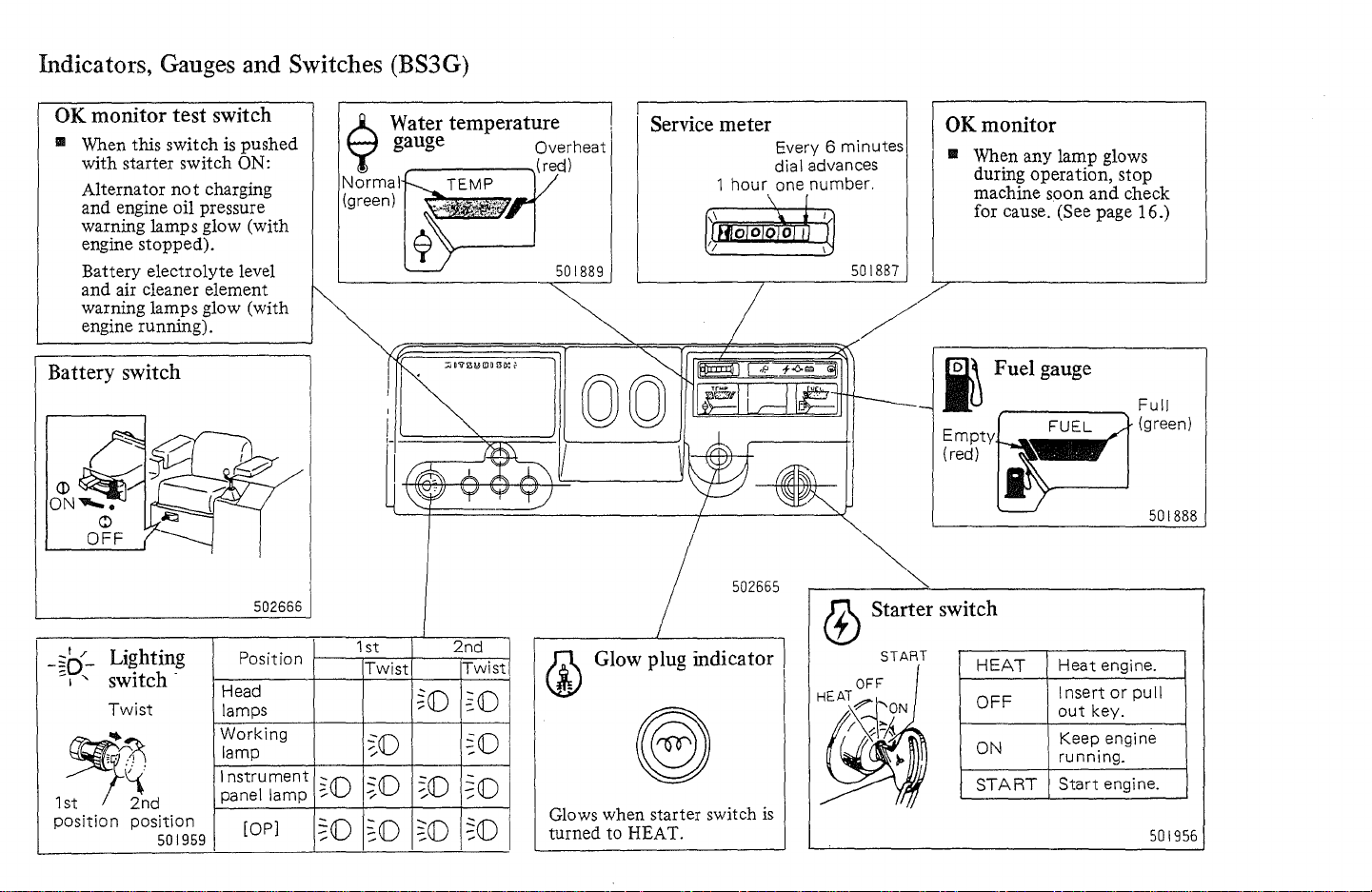

Indicators, Gauges and Switches (BS3G)

OK monitor

III When this switch

with starter switch

Alternator

and engine oil pressure

warning lamps glow (with

engine stopped).

Battery electrolyte level

and air cleaner element

warning lamps glow (with

engine running).

test

not

charging

Battery switch

_I

/

-~D-

Lighting

-I

"

switch -

Twist

~

1st

position

2nd

position

501959

switch

is

pushed

ON:

502666

Position

Head

lamps

Working

lamp

Instrument

panel lamp

lOP]

6 Water temperature ,

);

gauge Overheat

Norma

(green)

1 st

Twist

~(j)

~(j)

~(j)

,-

~(j)

~O

TEMP

2nd

Twist

~(j)

~O

~O

~(j)

~O

~(j)

~(j)

Service meter

1

hour

501889

502665

Glow plug indicator

Glows when starter switch

turned to HEAT.

Every 6 minutes

dial advances

one number.

501881

(j)

is

OK

monitor

III When any lamp glows

during operation, stop

machine soon

for cause. (See page 16.)

i Fuel gauge

Empty

(red)

Starter switch

START

HEAT

OFF

ON

START

and

check

Full

(green)

Heat

engine.

Insert

or

out

Keep engine

running.

Start

pull

key.

engine.

501888

501956

Page 14

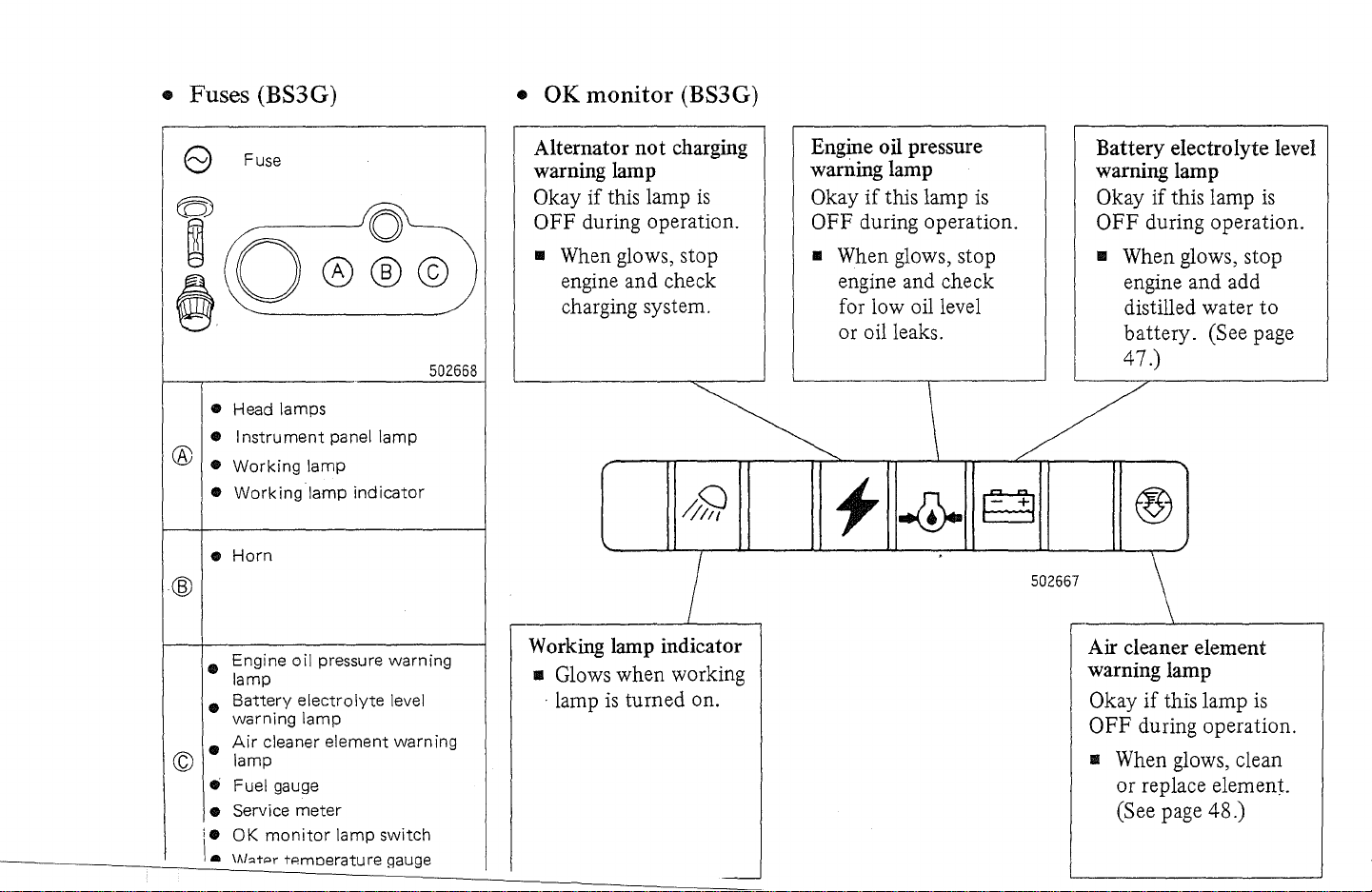

• Fuses (BS3

G)

•

OK

monitor (BS3G)

e Fuse

(Ql~

&0

• Head lamps

• I

nstrument

® •

© lamp

Working

•

Working

•

Horn

• Engine

lamp

•

Battery

warning

•

Air

cleaner element warning

• Fuel gauge

• Service

i.

OK

\.

IAbtpr

@@©)

panel

lamp

lamp

oil

pressure warning

electrolyte

lamp

meter

monitor

lamp

tAmoerature gauge

lamp

indicator

level

switch

502668

Alternator not

warning

Okay

OFF during operation.

.. When glows, stop

lamp

if

this lamp

engine and check

charging system.

charging

is

I

Working

II

. lamp

lamp

indicator

Glows when working

is

turned on.

Engine oil

warning

Okay

OFF during operation.

.. When glows, stop

engine and check

for low oil level

or oil leaks.

pressure

lamp

if

this lamp

is

Battery electrolyte level

warning

Okay if this lamp

OFF during operation.

II

lamp

is

When glows, stop

engine and add

distilled water

battery. (See page

47.)

to

\ /

f

502667

\

Air

cleaner element

warning

Okay

OFF during operation.

II

-

lamp

if

this lamp

When glows, clean

or

replace element.

(See page 48.)

is

Page 15

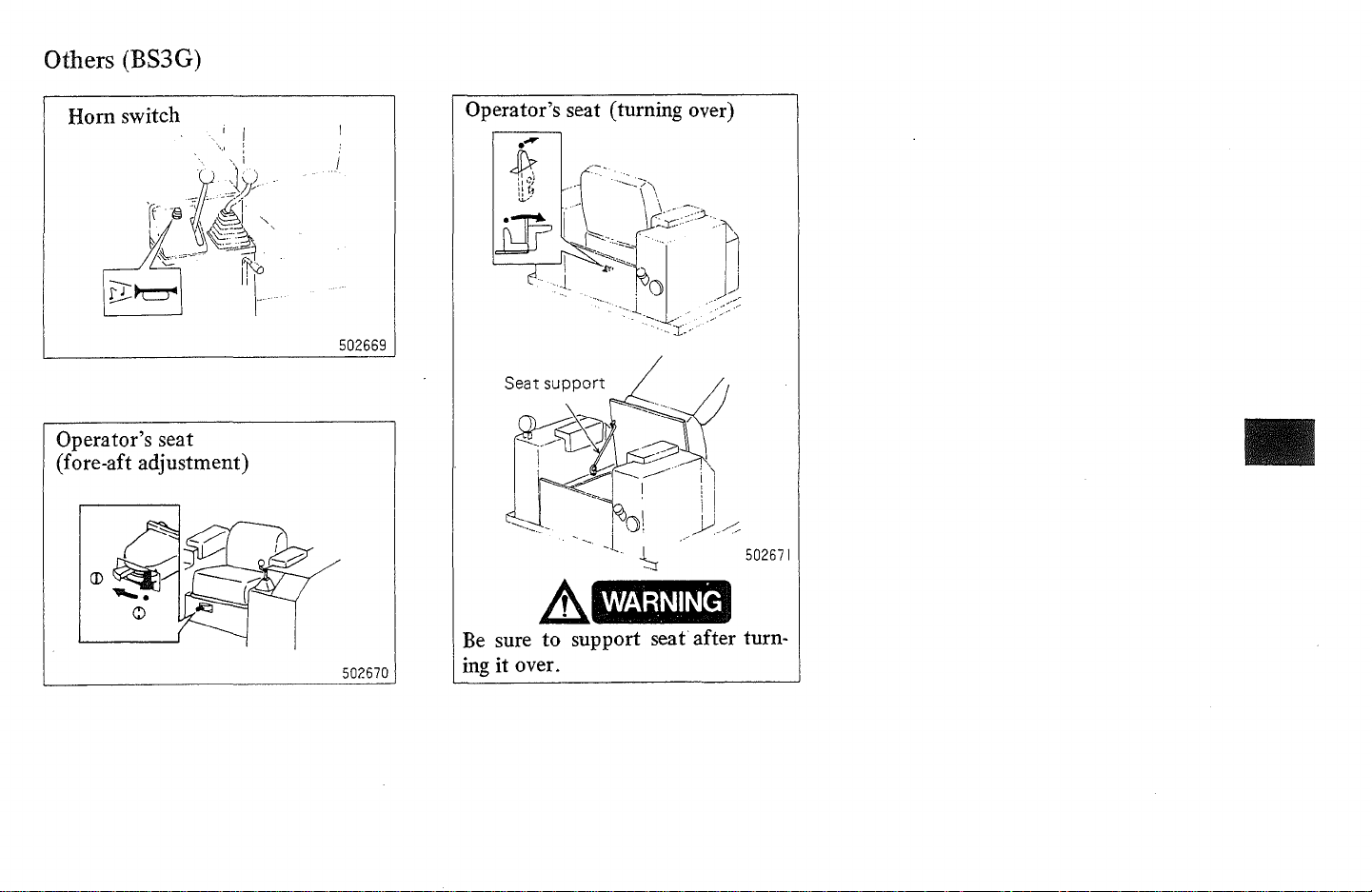

Others (BS3G)

Horn switch

Operator's seat

(fore-aft adjustment)

L-

____________________

I I

".,1

Operator's seat (turning over)

:

502669

WARNING

Be

502670

~~

sure to support

ing

it

L-

over.

______________________

seat

after turn-

__

Page 16

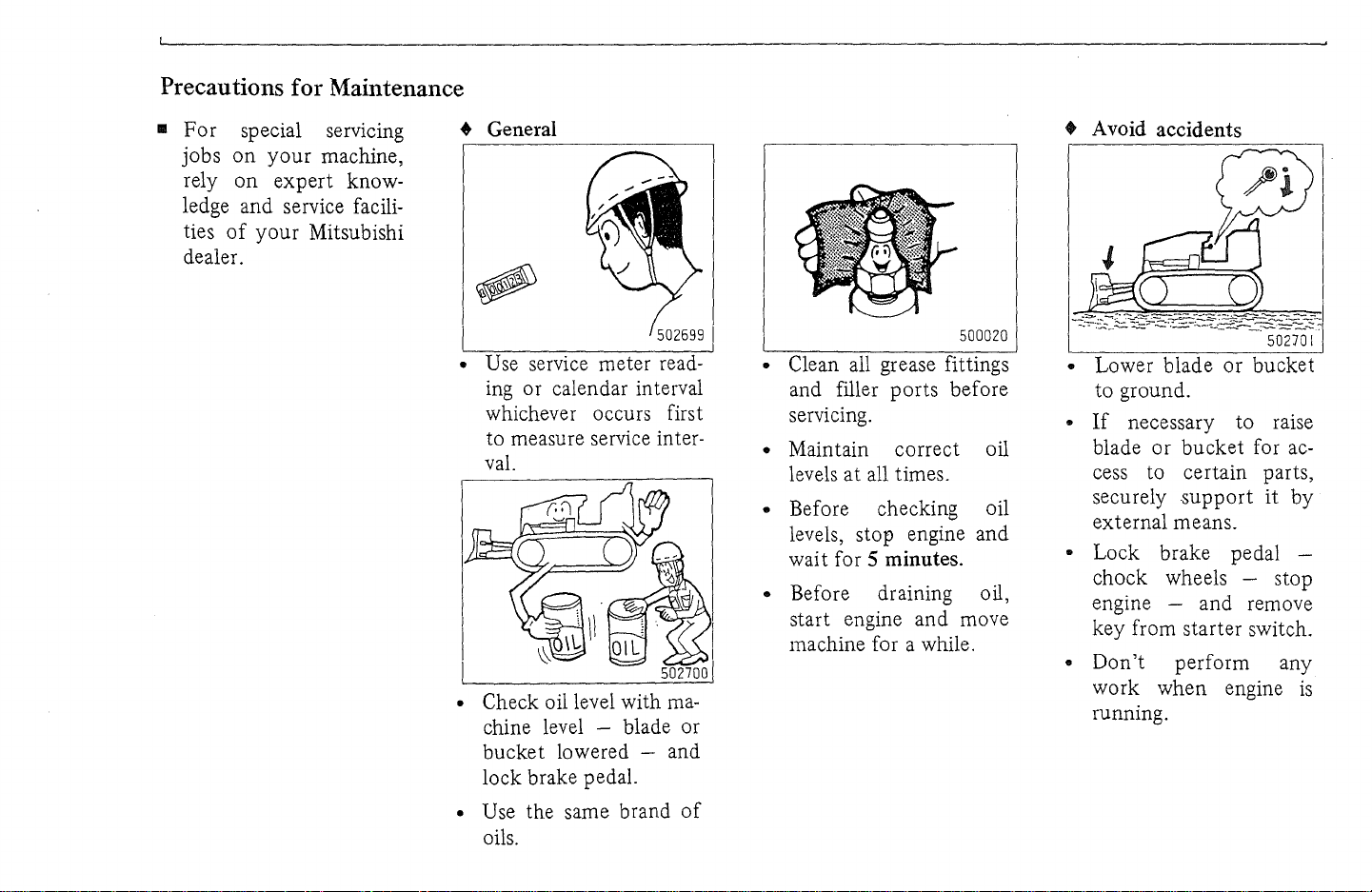

Precautions for Maintenance

..

For

special servlcmg

on

your

jobs

rely

on

machine,

expert

ledge and service facili-

of

your

ties

Mitsubishi

dealer.

know-

• General

502699

• Use service meter reading or calendar interval

whichever occurs first

to measure service interval.

• Check oil level with

machine level - blade or

bucket lowered - and

lock brake pedal.

I

• Clean all grease fittings

and filler ports before

servicing.

• Maintain correct oil

levels

at

all times.

• Before checking oil

levels, stop engine and

wai t for

5 minutes.

• Before draining oil,

start engine and move

machine for a while.

500020

• Avoid accidents

50270

• Lower blade

or

bucket

to ground.

•

If

necessary to raise

or

blade

bucket

for ac-

cess to certain parts,

securely

support

it

external means.

• Lock brake pedal chock wheels - stop

engine - and remove

key from starter switch.

•

Don't

work

perform any

when

engine

running.

I

by

is

• Use the same brand

oils.

of

Page 17

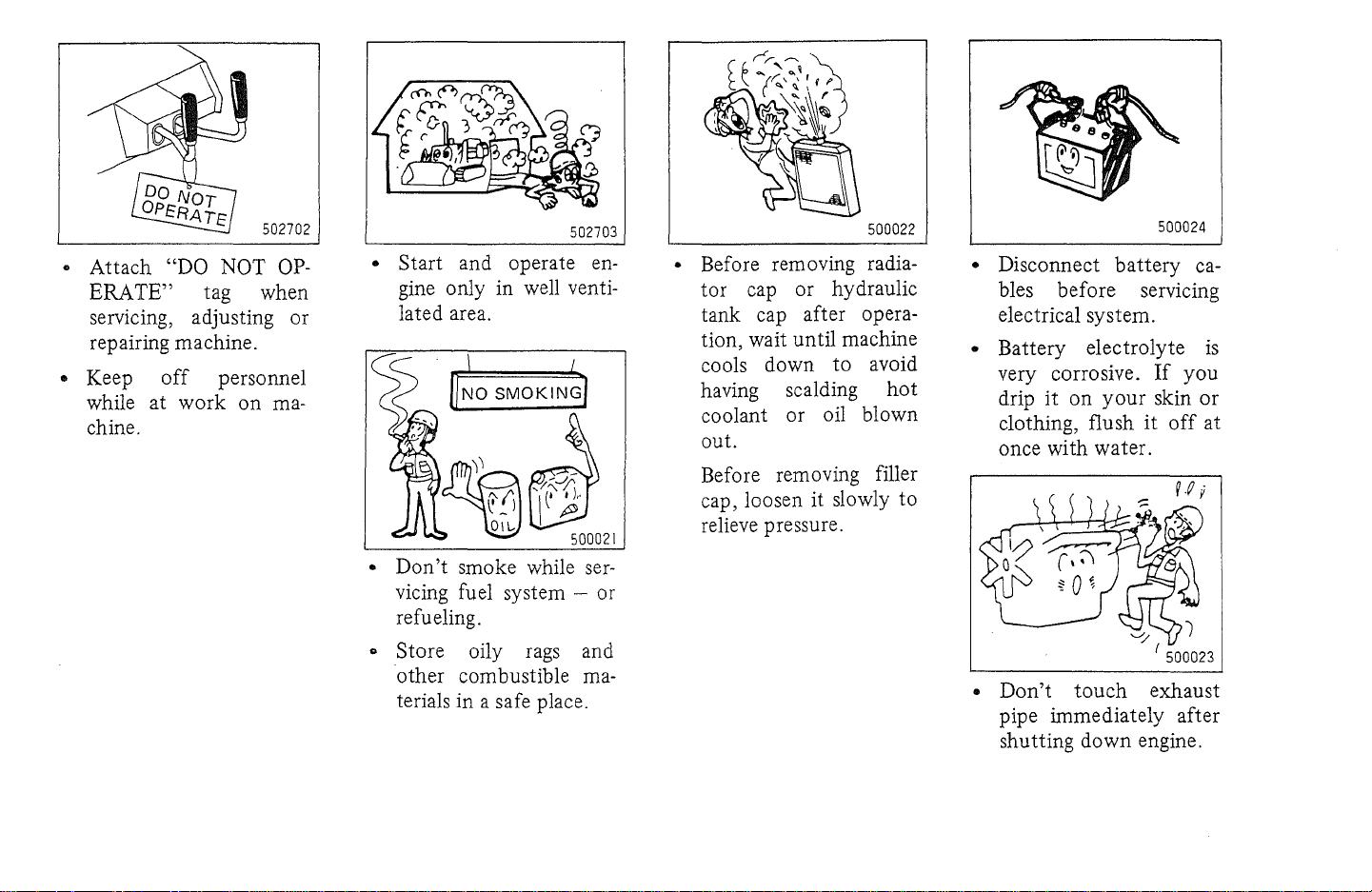

502702

502703

500022

500024

•

Attach

ERA

"DO NOT

TE"

tag when

servicing, adjusting or

repairing machine.

• Keep

while at

off

work

personnel

on

chine.

OP-

ma-

• Start and operate engine only in well ventilated area.

•

Don't

smoke while

servicing fuel system - or

refueling.

o Store oily rags and

other combustible materials in a safe place.

• Before removing radiator

cap or hydraulic

tank cap after operation, wait until machine

to

cools down

having scalding

avoid

hot

coolant or oil blown

out.

Before removing filler

cap, loosen

it

slowly to

relieve pressure.

• Disconnect

battery

bles before servicing

electrical system.

• Battery electrolyte

very corrosive.

drip

it

on

clothing, flush

your

If

skin

it

off

once with water.

•

Don't

touch

exhaust

pipe immediately after

shutting down engine.

ca-

is

you

or

at

Page 18

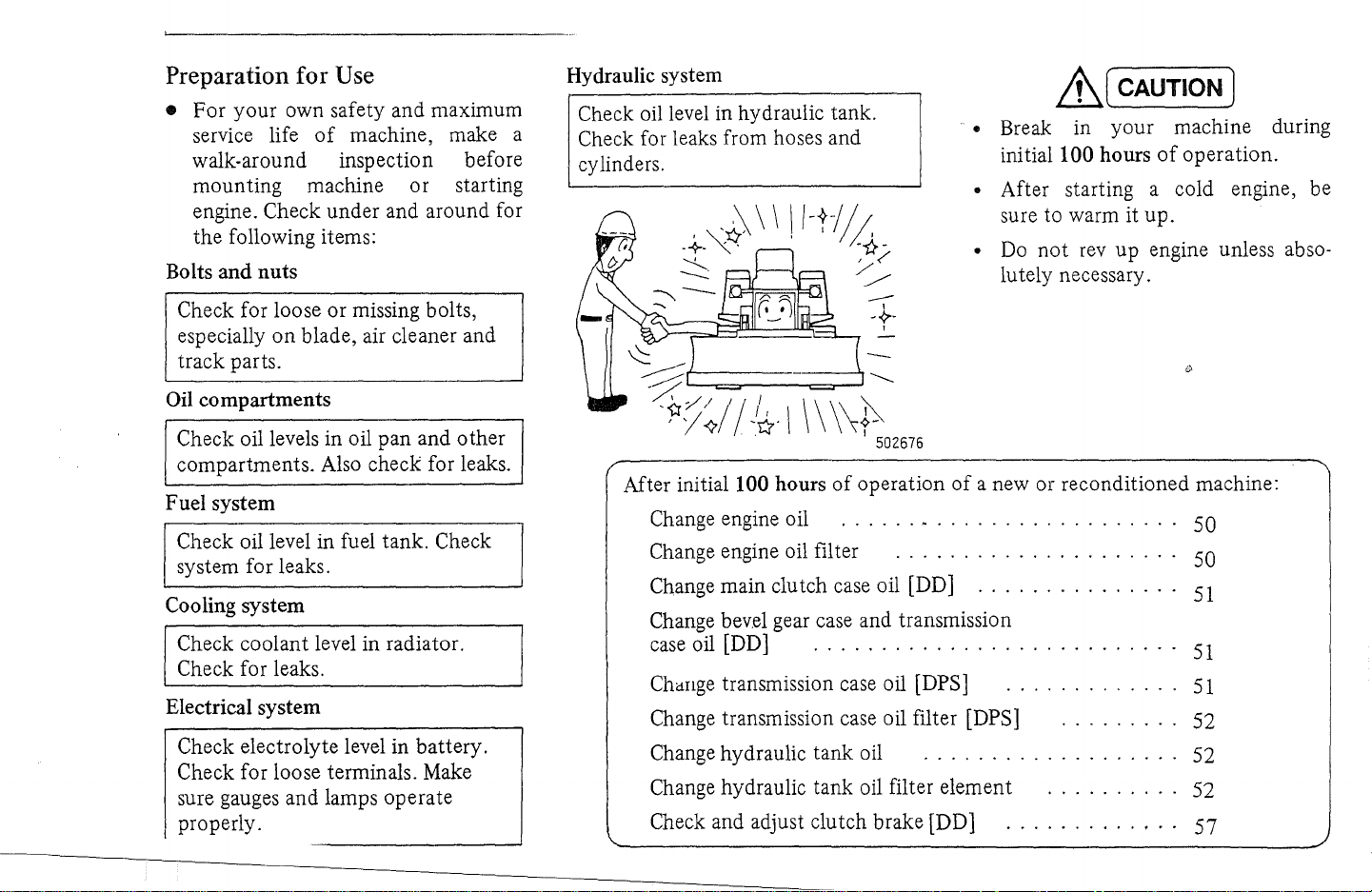

Preparation for Use

• For

Bolts and nuts

your

own safety and maximum

of

service life

walk-around inspection before

mounting machine or starting

engine. Check under and around for

the following items:

machine, make a

Hydraulic system

Check oil level in hydraulic tank .

Check for leaks from hoses and

cylinders.

~(

• Break in your machine during

initiallOO hours

• After starting a cold engine, be

sure to warm it up.

•

Do

not

lutely necessary.

CAUTION)

rev

up

engine unless abso-

of

operation.

Check for loose or missing bolts,

especially

track parts.

Oil compartments

Check oil levels in oil pan and other

compartments. Also check for leaks.

Fuel system

Check oil level in fuel tank. Check

system for leaks.

Cooling system

Check coolant level in radiator.

Check for leaks.

Electrical system

Check electrolyte level in battery.

Check for loose terminals. Make

sure gauges and lamps operate

properly.

on

blade, air cleaner and

---

>==;~~~:::L.,

\\

After

initialI00

Change engine oil

Change engine oil filter . . . . . . . . . . . . . . . . . . . 50

Change main clutch case oil [DD]

Change bevel gear case and transmission

case

oil [DD] . . . . . . . . . . . . . . . . . . . . . . . . .

ChaIlge transmission case oil [DPS]

Change transmission case oil filter [DPS]

Change hydraulic tank oil . . . . . . . . . . . . . . . . .

Change hydraulic tank oil filter element

Check and adjust clutch brake [DD]

hours

-~.

I

\\~

I 502676

of

operation

......

of

. . . . . . . . . . . . . . . . .

a new or reconditioned machine:

...............

..........

.......

..........

.............

.

..

50

51

..

51

..

51

" 52

..

52

52

57

Page 19

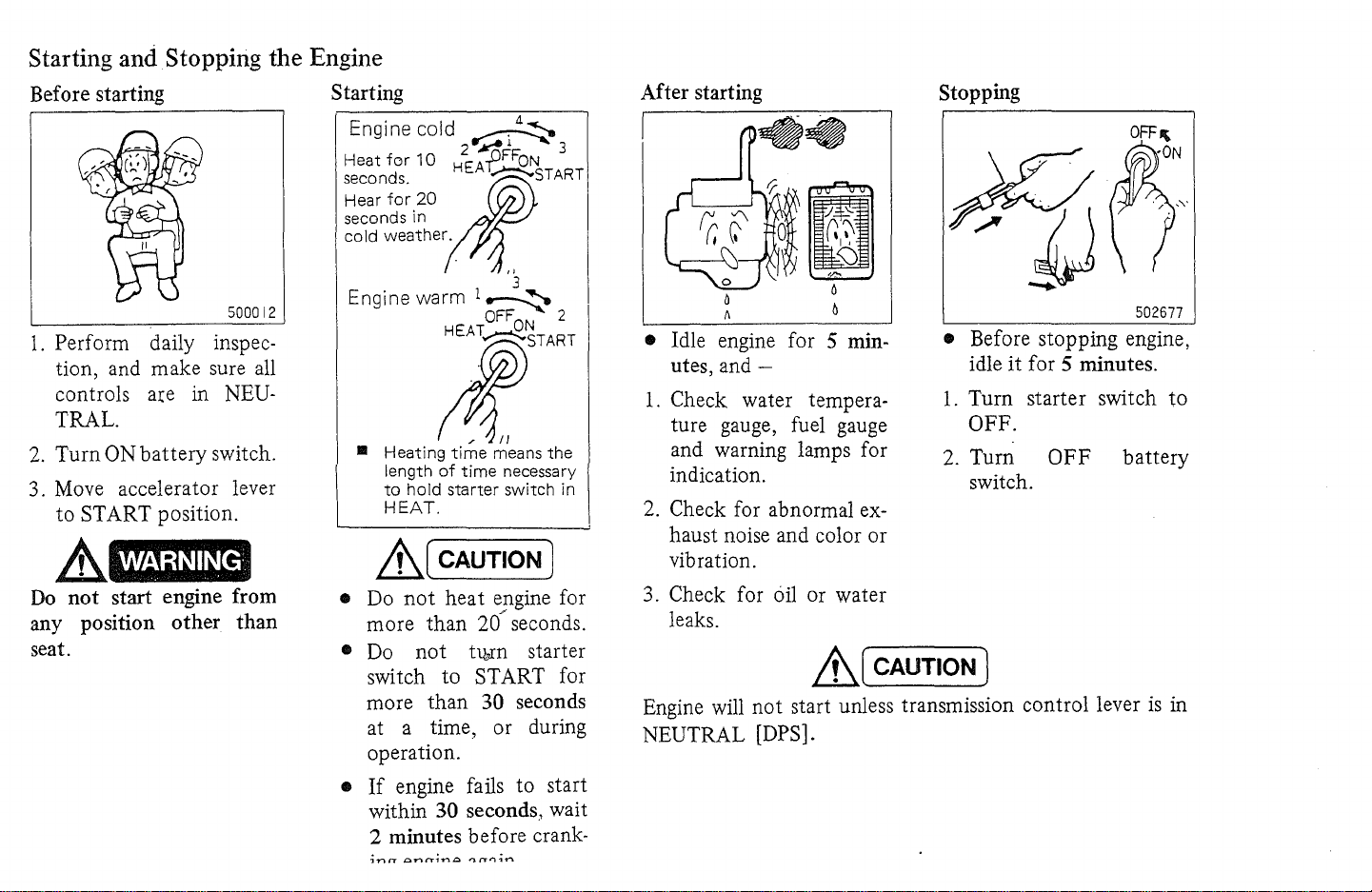

Starting and Stopping the Engine

Before starting

500012

1.

Perform daily inspec-

tion, and make sure all

a:ce

controls

in NEU-

TRAL.

2.

Turn ON battery switch.

3. Move accelerator lever

to START position.

A

Do

any position other

WARNING·

not

start engine from

than

seat.

Starting

Engine cold

Heat

for

10

seconds.

Hear

for

seconds

cold

Engine

20

in

weather.

warm

~

2"-~1

HEAfFFON

;t~START

1

~

OFF

l:START

..

Heating

length

to

HEAT.

&,,(

• Do

more than

•

Do

switch to START for

more than

at a time, or during

operation.

time

of

time

hold

starter

CAUTION)

not

heat engine for

20/ seconds.

not

tl¥n

30 seconds

means

... 3

'3

2

ON

the

necessary

switch

in

starter

After starting

• Idle engine for 5 minutes,

and-

1.

Check water tempera-

ture gauge, fuel gauge

and warning lamps for

indication.

2.

Check for abnormal

ex-

Stopping

• Before stopping engine,

it

idle

1.

Turn starter switch to

for 5 minutes.

OFF.

2.

Turn

OFF

switch.

haust noise and color or

vibration.

oil

3. Check for

or water

leaks.

&,,(

CAUTION)

Engine will not start unless transmission control lever

NEUTRAL

[DPS].

502677

battery

is

in

•

If

engine fails to start

within

30 seconds, wait

2 minutes before crank-

Page 20

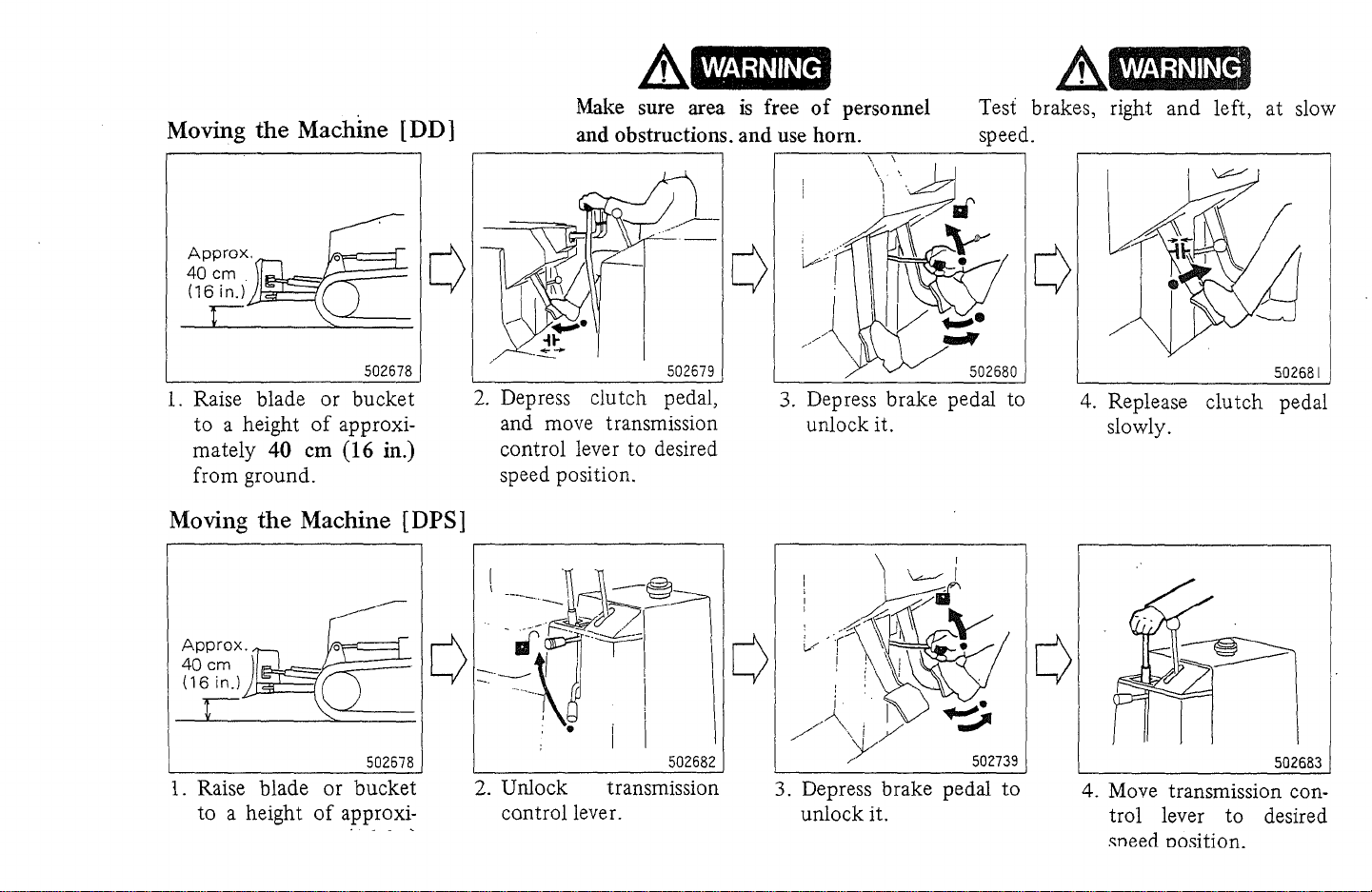

Moving the Machine [D D ]

WARNING

Make

and obstructions. and use horn.

sure

area

is

free

of

personnel

.&

Test brakes, right

speed.

and

left,

at

slow

502678

1.

Raise blade

to

a height

mately

from ground.

40

or

of

em

bucket

approxi-

(16

in.)

Moving the Machine [DPS]

502678

1.

Raise blade

to

a height

or

of

approxi-

bucket

502679

2.

Depress clutch pedal,

and move transmission

control lever to desired

speed position.

502682

2. Unlock transmission

control lever.

3.

Depress brake pedal to

unlock it.

j . I

/--\.

i

./

3. Depress brake pedal

unlock

,.

)V

/'

it.

./

502739

to

4. Replease

slowly.

clutch

If!

4.

Move transmission control lever

."need Dosition.

to

502681

pedal

502683

desired

Page 21

WARNING

WARNING

LtJ

CAUTION)

Avoid sharp starts, stops or turns

whenever possible for your own safety,

for maximum service life

machine.

Steering

• Right

or

left turns

.,

of

r+

your

• •

fi

Loft

tom

L-

________________________

t1

Righttum

fi fi

__

502684

A void sidehill travel whenever possible.

Drive up and down a slope. The danger

of

tipping is always present. Sidehill

travel can also cause uneven wear

track parts.

• Moderate

~

Moderate

turns

or

sharp turns

Steering

clutch

OFF

Steering

clutch

brake

'--11-"

0)·

.-'j-h

j

j_

ON

r-------,

~~

ii

Sharp

turns

of

502685

When shifting

clutch pedal

clutch brake, and try again [DD].

&J

Do

not

drive your machine with your

foot resting on clutch or brake pedal.

&[

Avoid sharp turns, especially

speeds.

wear

case, cause track

Such turns cause premature

of

track parts and,

is

difficult, depress

all

the way

CAUTION)

CAUTION)

to

get

out

in

the

of

to

apply

at

worst

place.

high

1.

To make moderate turns, pull steering clutch lever slowly and accordingly.

2. To make sharp turns, pull steering

clutch lever quickly

all

the way.

Page 22

"

Changing Speed or Direction [DD]

1.

Reduce machine speed

by

moving accelerator

lever back, and depress

clutch pedal.

Stop

Move

and

change speed

2, Depress brake pedal,

and move transmission

control lever to desired

position.

Move

502686

Changing Speed or Direction [DPS]

• It

Move transmission con-

trollever

to desired

postion.

is

depress inching pedal.

not

necessary to

Move

forward

3. Release clutch pedal to

start your machine moving again.

Stop

and Move

change

direction

backward

• When changing direction, be sure to come

to a complete stop

avoid damage

to

trans-

mission.

502687

to

Lt(

CAUTION)

• When changing speed or

be

sure

direction,

to

come to a complete stop

by depressing brake

pedal to avoid damage

to transmission.

• When shifting

is

difficult, depress clutch

pedal all the way

to

apply clutch brake, and

try

again

[DD]

.

Page 23

~topping

1. Reduce machine

speed by moving

accelerator lever back

back.

l D D 1

Stopping [DPS]

1.

Reduce machine

speed by moving

accelerator lever back.

2. Depress clutch pedal

and, at the same

time, -

2.

Move

transmission

control lever to

NEUTRAL

3.

Depress brake pedal

gently to stop your

machine.

3. Depress brake pedal

gently to stop your

machine.

4.

Move

transmission

control lever to

NEUTRAL, and

release clutch pedal.

WARNING

When leaving your machine unattended, be sure to:

1. Lower blade or bucket to ground. Lock blade control

lever with safety lock lever on machine equipped

with power angling-tilt control.

2. Make sure transmission control lever

On

DPS

machine, lock transmission control with

lock-unlock lever.

3. Lock brake pedal.

4.

Shut

off

engine, and remove key from starter switch.

5.

Turn OFF battery switch.

is

in NEUTRAL.

WARNING

When

right angles to the slope - chock tracks - and penetrate

blade into ground.

parking your machine on a slope, position

it

at

Page 24

Operating Techniques

• Going up slopes

• Going down slopes

• Going over obstacles

502635

•

Drive

Sidehill travel can cause machine to

slip

•

Do

effect becomes more effective than

when on level surfaces.

• Shifting on slopes

• When shifting on a slope, depress

brake pedal to stop machine,

press clutch pedal and move transmission control lever to desired

position.

too late, shifting would

In such a case, move machine

ward just a little and try again.

up

as

straight

sideways or track to slip off.

not make quick turns. Steering

If

clutch pedal

as

possible.

is

depressed

be

difficult.

de-

for-

502689

• In steep downhill operation,

allow engine to overspeed. Select

proper speed before starting

chine downgrade.

• Steering controls sometimes reverse

is

when machine

or being pushed by a load.

steering clutch

way, for instance, .machine would

make a right turn.

~

Never

TRAL. Always stay in gear .

free wheel downgrade in

WARNING

coasting downhill '

lever

is

do

not

ma-

If

left

pulled half-

NEU-

Alert

for

jolt

502690

•

Go

over an obstacle with extreme

an

angle

care at

machine speed, and ease up to

"breakover".point - balance slowly

on an obstacle

the other side, being alert for jolt

of contact.

~

Do

not exceed maximum limit

chine stability indicated on nameplate

attached to machine.

if possible. Reduce

- .and ease down to

WARNING

of

ma-

Page 25

• Operating in deep

mud

or

water

• Operating in

rocky

terrain

•

Super

swamp

swamp models

and

ultra

super

• Drive

Avoid sharp

..

Make sure drain plugs

compartments

..

When starting

do

saw"

by

tion

your

machine at low speeds.

or

frequent

are tight in place.

to

mire

down

not

spin

your

track

machine.

or

dropping load, changing direc-

or

placing planks

for recovery.

..

Check oil in final. drives for

of

mud

or

water

with new oil

foreign

matter

more

upon

in oil.

502691

turns.

of

all gear

in

try

to

Get

traction

under

tracks

entry

often.

Refill

discovery

mud,

"see-

of

• On rocky footing,

track

parts are

subject to excessive stress and strain.

When operating in such a terrain,

loosen

4

track

to

6 em (1-1/2

Refer to page

track

adjustment.

• Operating

adjustment to obtain

to

2-3/8

54

of

this manual for

on

snow

in.) sag.

• Use snow-and-ice shoes whenever

possible. These shoes are designed

for good

penetration

and

traction

on ice or hard packed snow.

•

At

end

of

operating period, clean

or

mud

from

snow

around

track

links, sprockets, idlers, rollers and

to

guards

orevent freezin!:!

of

trllch

..

Track shoes

of

are designed for use

areas. Avoid operating

in

rocky

hard

damage

terrain

surfaces

to

the

shoes.

the

swamp

only

or

going over rough,

to

prevent

in

these

models

swampy

models

costly

Page 26

• Stripping or leveling

A[

When stripping or leveling by driving

machine forward, do

fully; otherwise bucket, bucket linkage

and frame would suffer costly damage.

• When moving one job site to

other, be sure to lock bucket

control lever to avoid accidents.

CAUTION)

not

dump bucket

an-

Page 27

Transporting

JIll

Check regulations covering transportation

ment

including tractors.

Loading

the

Machine

of

construction equip-

4

..

Drive up machine forward when

loading. Drive it backward when

unloading.

5.

Be

sure

to

block truck wheels.

1.

Loading platform

than overall width

thoroughly compacted along its

length.

If

loading platform

2.

use ramps. Ramps must be strong

enough to load machine safely.

Support each ramp

from underside to prevent it from

being weighed down

3.

Platform or ramps

gradient

of

10

to

15 deg.

must

of

is

be wider

machine and

not

available,

with

by

machine.

must

have a

blocks

&.(

Drive up and down without steering.

If

machine starts slipping sideways,

drive it down to ground immediately,

and try again.

6.

Upon loading, block tracks on

front and rear sides, and secure

machine with tie-downs such

chains or ropes to prevent side slip.

7. Lower blade or bucket, lock brake

pedal, and place all controls in

NEUTRAL.

8. Plan travel route by checking state

and local laws, weight limits,

pass clearance, etc.

CAUTION)

both

as

over-

Page 28

Special Conditions

Operating

• Lubricants

in

cold weather

and

diesel fuels

• Coolant

Engine cooling system

•

machine shipped from factory

filled with coolant containing 30%

of

Mitsubishi Long Life Coolant

(antifreeze containing rust inhibitor).

of

a new

is

• Long Life Coolant is highly flammable; keep

flame.

• Starting in cold

it

away

weather

from

open

• Use lube oils

See

the

FUELS AND LUBRICATNS, in

page 59.

• Use diesel fuels having lower

point.

MENDED FUELS AND LUBru-

CANTS, in page 59.

• Battery

• Add distilled water to

fore starting engine for the day's

run.

• Always keep

so

is

20°C

See

that

electrolyte specific gravity

higher

than

(68°F).

of

lower viscosity.

chart, RECOMMENDED

the

chart, RECOM-

battery

battery

1.28

fully charged

as

corrected

pour

be-

to

• Long Life Coolant

sub-zero temperatures down

-ISoC (SOF).

When using Long Life Coolant

•

temperatures below -ISOC

rely

on

the following chart for

correct percentage.

Starting

temperature

°c

(OF)

Percentage

of

Long Life

Coolant

• Change Long Life Coolant every

2 years. When changing, flush cooling system thoroughly.

• Use Long Life Coolant

water.

~

• Long Life Coolant is poisonous;

be careful

drip

it

on

-20

(-4)

35

WARNING·

not

your

is

effective for

-30

(-22) (-40)

45

with

to

drink it.

skin, flush it

(SOF),

-40

55

soft

If

you

o,ff

to

at

at

•

Turn

starter switch

tion

to

heat

After starting engine, warm it up

thoroughly.

•

After

operating

• Clean snow or

your

machine

on

Park

or logs

• Wipe dirt

rods

• Drain

tank.

dry concrete floor, planks

to

avoid freezing.

and

of

hydraulic cylinders.

water

and sediment from fuel

to

HEAT posi-

engine thoroughly.

in

cold

weather

mud

from around

to

prevent freeZing.

moisture from piston

Page 29

vpt:raung

III

nor wearner

engine cool. Check radiator for low

coolant level, leaks or trash buildup.

502698

• Lubricants

Use lube oils

the chart,

of

higher viscosity. See

RECOMMENDED FUELS

AND LUBRICANTS, in page 59.

• Battery

Check electrolyte level more often

Add

than in cold weather.

water

to

batteries whenever level

distilled

is

low.

• Coolant

Engine

especially in heavy

hours

is

likely

or

in ascending a long, steep

to

get overheated,

duty

operation for

slope. Whenever water temperature

gauge registers near

slow down

or

or

in RED range,

stop machine, and let

• After operating

• Before stopping engine, let

just longer

in

hot

weather

than

in cold weather for

it

idle

cooling.

• Check coolant level in radiator and

electrolyte level in batteries.

Operating in extremely dusty

conditions

• Check air cleaner element and

change it more often.

• Clean air breathers

fuel

tank

to help prevent premature

wear

of

pistons and cylinders.

of

engine and

• Remove dust accumulated inside

alternator and starter covers. Clean

radiator core. Wash machine from

as

clean

time to time to keep it

as

possible.

Page 30

I\..t;;l:UHHW.::uueu r UeTh

auu

LUUnCanr

s

"

Refill

capacity

liter (U.S. gal)

60 (15.S)

7

(I.S)

5.5 (1.5)

3.5 (0.9)

9.5(2.5)

11

(2.9)

(l.S)

7

Each side:

6.S

(1.7)

*1

9.5 (2.5)

*2

13

(3.4)

33 (S.7)

13

(3.4)

.

,

Fuel

*

Engine

*

Main

Compartment

tank Diesel fuel

clutch [DD] Engine oil

. :

j'

:,)

ii'

t.,.,·.

,:.,:"

;.'

','

i'

,:'

i;

* Damper case [DPS] Engine oil

I"

* Transmission case

'.

".,

[DD]

{

},

* Transmission case

r:,'

[DPS]

I'.

* Transfer/bevel gear

case

[DPS]

I,

"

t'

* Final drive gear

cases

[.

~;.

i

* Hydraulic tank Engine oil

fi.

Grease

various

t:,

I:;,

Radiator

fi'

11'.

1""

I~

i:

I""

fittings on

points

Mitsubishi Toughness Multi engine oil can be used in compartments marked *.

*1: Super swamp

model

Lubricants,

Engine oil

etc

CD

CD

CD

Gear oil GL-4'

Engine oil

CD

Gear oil GL-4

Gear oil GL-4

CD

Grease

Soft water

*2: Ultra super swamp model

-25

(-13)

SAEIOW 0

SAE5Wf

NLGINo.O

Soft water with antifreeze

-15

(5)

I

SAE5W

SAE5W

SAE80

SAE5W

SAE 80

SAE80

~NLGINo.l#

Ambient

I

Consult

AE

207

L

£

£

temRerature

-5

(23) (32) (41)

0 5 '

°c

(oF)

I

your Mitsubishi dealer

,

,

SAE

SAE

SAE

lOW

SAE 30

lOW

lOW

SAE90

lOW

SAE 90

SAE 90

§

J

J

,

,

I

I

I

I

I

I

,

I

I

SAE

,

NLGINo.2

I

Soft

//

water

15

(59)

25

(77)

I

..

Page 31

Factory-Filled Lubricants

The following list shows brands

tractor shovels shipped from the factory:

Compartment Brand name

Engine

Main clutch case [DD]

Damper case [DPS]

Transmission case [DD]

Transmission case [DPS]

Transfer/bevel gear case

[DPS]

Final drive gear cases

Hydraulic tank SAE

of

lubricants used in Mitsubishi tractors and

SAE 30 (Diamond HD30 special)

SAE

lOW

(Diamond

lOW

SAE

SAE

SAE

.

SAE 90 (Apolloi! Gear HE90)

SAE

(Diamond

90

(Apolloi! Gear HE90)

lOW

(Diamond

90

(Apolloi! Gear HE90)

lOW

(Diamond HDIOWspecial)

(NOTE)

• These brands are subject to change without notice.

• Avoid mixing lubricants.

with each

brand

other

at

successive service intervals.

and deteriorate when mixed.

In

some cases, different brands

It

HD

S-3

lOW)

HD

S-3

lOW)

HD

S-3

lOW)

of

lubricants are

is

best to stick with one and the same

not

compatible

• Temperature range

of

Mitsubishi Toughness Multi engine oil is -20

to

40°C (-4

to

104°F).

Page 32

Inspection and charging

• Removal and installation

Removal

Installation

A battery

charged gives

.

plosive

that

is

being

off

high ex-

gases. Never light a

match or a cigarette near

such

a battery.

x

Don't connect a tester

battery during charging.

to

Don't

cable from a

is

disconnect charger

battery

being charged.

that

• Disconnect cables from negative

minals in

that

order when removing

cables to positive (+) and negative

(-)

and positive

battery.

(-)

terminals in

(+)

ter-

Connect

that

order when installing it.

• Never place a metal object across terminals.

• Jump-starting

Good

battery

500029

a

Don't

touch battery ter-

Dead

battery

minals immediately after

operation.

o

Connecting

sequence 0

Disconnecting

sequence

502376

Page 33

Storage

• Short-duration storage

• Store machine in a

if

it

is

to

be left standing for a short

of

period

left outdoors, cover engine room

and operator's seat

the like.

• Renew oil film once a week by running engine until it

warm. This will circulate oil and

prevent rusting from condensation.

• Drain cooling system

will be below freezing and no

freeze

the system is drained, attach

Coolant"

time.

is

used in the system. When

tag to starter switch.

dry

garage even

If

machine has to be

with

canvas

is

thoroughly

if

temperature

anti-

"No

or

• Long-duration storage

o Care

..

•

•

• Lubricate all grease fittings and

• Apply a thick coat

of

machine to be stored

If

machine

period

Wash

a dry garage.

left outdoors, place

level ground and cover it for protection against dust and moisture.

If

preservative oil

engine, attach a tag reading

Engine Oil" at an easy-to-recognize

place.

change oils in all compartments.

oil

to exposed sliding surfaces

hydraulic cylinder piston rods' and

control1inkages.

is

to be stored for a long

of

time, proceed

machine clean,

If

machine has

is

of

as

follows:

and

store

it

to

be

it

on blocks

to be used in

rust-preventive

on

"No

of

in

II

In

freezing weather, drain

system, or refill it with coolant con-

taining more anti-freeze.

o Care

•

• When moving implement, wipe

• Recharge

o Care

• Remove drain plug from each com- '

of

machine during storage

At

least once a

and move machine and implement.

This will circulate oil and prevent

rusting from condensation.

grease

rods. After moving, apply grease.

month.

from storage

partment,

sediment to drain. Check oil level,

adding oil

off

of

machine

month,

hydraulic cylinder piston

battery

and allow moisture and

if

necessary.

at lease once a

to

be released

CQoling

start engine,

..

'1'1//

502750

• Disconnect battery cables and cover

battery, or dismount

store it in a dry, cool place.

• Lock

TRAL, and place accelerator lever

in IDLING position.

• Block tracks instead

brake pedal.

all

control levers in

battery

of

and

NEU-

locking

• Wipe

•

Start

ventilated area.

off

rust-preventive grease.

Start

engine, and warm it up thor-

oughly to circulate oil.

A

and

WARNING"

operate engine only in well

Page 34

Starter

will

not

crank engine

or

cranks slowly.

Check

if

transmission control lever

is

in NEUTRAL [DPS]

Check

l-.-

____

With starter switch

electrical system

--,-

____

Engine oil pressure

warning lamp glows

ON

.-------'---------,

'-------,.-----~

*Starter, starter relay defective

Battery dead

Battery-starter switch

circuit defective

r------10.K.l------.I

----'

Engine oil pressure

warning lamp

Battery-battery switch

circuit defective

<?

Check and adjust alternator belt tension

<?

Recharge or replace (Measure

electrolyte specific gravity)

<>

Repair or replace

Consult your Mltsubishi dealer

OFF

Check lubricating

system

'----------'

;L,

\r'

.

RepaIr or replace

1.

2.

Check engine

* Running parts defective

~Change

For

causes indicated

other than those cited here, consult

dealer.

When communicating with

for replacement part supply

sure to

serial number and service meter reading.

give

them the vehicle serial

oil * Valves come in contact

with pistons

* Foreign

Consult

dealer

by

an' asterisk (*) or any cause

your

matter

your

Mitsubishi

your

Mitsubishi dealer

or

any

other

number,

in cylinders

Mitsubishi

service, be

engine

Page 35

• Starter will crank engine, but engine

will

not

start.

Check fuel system

Check fuel

tank

No

fuel in

Fuel left in tank

Refill

* Check for leaks

tank

¢ and defective

Moisture

sediment

Air in system

Wrong type

fuel

or

.Check electrical system

pipes

¢ Drain

. out

9 Prime

of

Q Change

not

Engine

Low battery voltage

Defective circuit

heated

Check air intake

system

Air cleaner dirty

<?

Heat engine properly

Check and adjust

¢5

alternator belt tension

and recharge battery

<?

* Repair

or

~Clean

replace

Check engine

element

* Low compression

pressure

* Cylinders, pistons and

piston rings worn

'------.-------'

Consult

Mitsubishi dealer

your

Restriction in

fuel line

- Dirty

filter?

Clean

* Clean clogged pipe,

or repair leaky pipe

* Fuel injection pump defective Consult your Mitsubishi dealer

Page 36

Engine

White

smoke

lacks

power

or

blue exhaust

°';

r'

r·~

, .

(J

ib

500041

Wrong grade

of

oil

+ Change oil and follow lubrication recommenda-

tions.

Wrong type

of

fuel

Air cleaner restricted

Overcooling

Overheating

Abnormal coolant temperature

+ Change fuel.

+ Clean

+ Cover up radiator

+ Flush cooling system

+ * Replace thermostat.

or

replace element.

or

replace parts.

or

replace parts.

(due to defective thermostat)

Fuel injection quantity decreased

Valve clearance maladjusted

injection pump defective

Fuel

Poor fuel spray from injection nozzles

Fuel injection mistimed.

Compression pressure too low (due to

+ Replace clogged fuel filter.

+ * Readjust.

+ * Readjust or replace.

+ * Readjust

+ * Retime.

7-

* Repair or replace.

or

replace.

worn cylinders, piston rings)

r-

Too much oil in crankcase

r-

Low viscosity grade

of

oil

+ Fill only to correct level.

+ Change oil and follow lubrication recommenda-

tions.

f--

f-.-

Overcooling

f-

Fuel injection mistimed

'-

Compression pressure too low

7- Cover up radiator

+ * Retime.

+ * Repair

or

replace.

or

replace parts.

"

Page 37

Black or gray exhaust

smoke

500042

High fuel consumption

Fuel

Tank

High oil consumption

500043

~

~

500044

Wrong type

Valve clearance maladjusted

Air cleaner restricted

Fuel injection pump defective

Compression pressure too low

Air cleaner restricted

Fuel leaks

Fuel injection pump defective

Poor fuel spray from injection nozzles

Compression pressure too low

,-

Too much oil in crankcase

f-

Low

viscosity grade

f-

Oil leaks

'-

Cylinders and/ or piston rings worn

of

fuel

of

oil

.,.

Change fuel.

.,.

* Readjust.

.,.

Clean

or

change element.

.,.

* Readjust or replace.

.,.

* Repair or replace.

.,.

Clean

.,.

.,.

.,.

.,.

.,.

.,.

.,.

.,.

or

change element.

Retighten or replace.

* Readjust or replace.

* Readjust or replace.

* Repair

Fill only

Change oil and follow lubrication recommenda- :.

tions .

or

replace.

to

correct level.

* Retighten or replace.

* Repair or replace.

Page 38

Engine

oil

warning

pressure

lamp

glows

- Low oil level

- Low viscosity grade

-

-

Oil

filter clogged

-

Oil

pump

-

Oil

pressure reguiating

defective

of

oil

valVe

defective

+ Fill only to correct level.

+ Change oil and follow lubrication recommenda-

tions.

-7 Change element.

-7 * Readjust

-7 * Readjust or replace.

or

replace.

Page 39

Chassis

• Main clutch

Slips

[DD]

081)

~

Drags

<{0J}

~

Abnormal

temperature rise

~

~

oil

500073

500074

r-

Clutch pedal free play too small

J-

Clutch facing worn

J-

Clutch disc friction surfaces fouled with

- oil

f-

'-

,-

t-

_I-

- Clutch shifter or clutch disc binding

- Friction surfaces dirty

or

dirt

Clutch facing burnt, resulting in reduced

friction

Clutch springs weak

Clutch pedal stroke too small

Clutch pedal free play too iarge

Clearance unequal in clutch

on drive shaft

~

Readjust.

~

* Replace.

~

* Wash

~

* Replace.

~

* Replace.

~

Readjust.

~

Readjust.

~

* Readjust.

~

* Disassemble

"*

. * Wash.

or

replace

and

repair or replace.

502751

Oil level too high

"*

Lower oil level.

Page 40

·

Chatters

when

disengaged

'.

Transmission

500075

[DD]

500076

Release bearing seized, worn or pooly

lubricated

High viscosity grade

of

oil

Clutch brake maladjusted or worn

Clutch drags

Shift fork and shift rail worn or damaged

Gears worn or damaged

7- * Lubricate or replace.

7- Change oil and follow lubrication recommenda-

tions.

7- * Readjust.

7- Readjust clutch control.

7- * Repair or replace.

7- * Replace.

Page 41

'.

Gears slip

Noisy

out

of

mesh

500077

500078

r-

I--~

-

Gear meshing incomplete

Gear

teeth

unevenly worn

Gear shaft splines worn

Detent

Bearings or bushings worn

Gear teeth worn

Bearings

Oil level too low or low viscosity grade

of

springs weak

or

oil

or

improperly meshing

bushings worn

....

* Repair

....

* Replace.

....

* Replace .

....

* Replace.

....

* Replace.

...

* Repair

....

* Replace.

....

Change oil and follow lubrication recommendations.

or

replace .

or

replace,

Page 42

•

Transmission

[DPS

500050

500051

J

Oi1level

Gauge defective

Oil filter clogged

Hydraulic pressure

Clutch drags

Bearings

Air

Water in oil

Oil lines restricted

Oil level

Oil pressure

Control

Forward

simultaneously

Clutch seized

Clu

Shaft

too

high

worn

or

entrapped

too

low

too

low

linkage maladjusted

and

reverse clutches engaged

tch

oil passage restricted

splines

worn

too

seized

low

+ Lower oil level.

+ * Replace.

+ Wash

+ * Readjust

+ * Replace clutch plates.

+ * Repair

+ * Retighten

+ Change oil.

+ * Repair

+

+ * Repair

+ * Readjust.

+ * Repair

+ * Replace clutch plates.

+ * Wash

+ * Replace.

Add

or

oil.

replace.

or

or

replace.

or

or

replace.

or

replace oil

or

replace.

or

replace.

repair.

replace gasket.

pump.

Noisy

' "

(,

'

CJ

ltJ

?

'1

500052

Oil level

of

Gears damaged

Bearings

Clu

Shaft

oil

tch

too

worn

seized

splines

low

worn

or

low viscosity grade

or

seized

+

Add

up

to

level

or

change oil.

+ * Replace.

+ * Replace.

+ * Replace clutch plates.

+ * Replace.

Page 43

• Steering clutches

Slip

500073

Drag

I--t-

.-

Control linkage maladjusted

Clutch plates worn

'-

Clutch springs weak or broken

+ Readjust.

+ * Replace.

+ * Replace.

r-

I--l-

'-

500074

Clutch brake slips

t---

If

~~

~

~

502752

Clearance unequal in clutch

Control linkage maladjusted

Booster pressure too low

Control linkage maladjusted

+ * Readjust.

+ Readjust.

+ Repair or replace main clutch pump.

DPS

Repair or replace

Repair oil leaks from

+ Readjust.

transmission pump.

lines or steering cylinder.

Page 44

• Final drives

Sprocket

wear

on

side faces

..•

Tracks

Slip

off

• Implement

Blade

or

bucket

will

not

rise

rise

too slowly

teeth

or

501416

501417

r---

Tracks

- Tracks

.

r-

Low oil level in hydraulic

I--f-

Hydraulic

'-- Oil lines

too

too

bent

loose

loose

pump

tank

internally worn

-7 Readjust.

-7 Readjust.

-7

Add oil.

-7

* Replace.

-7

* Repair or replace.

502753

Page 45

Periodical Change

of

Safety Parts

To prevent personal injury and damage to machine,

change parts listed below

at

recommended intervals.

These parts are made

deteriorate or

difficult

to

determine

age

they have expired in safe service life. This

of

for the need

such periodical change.

Change these parts whenever suspected

or aging even

if

change periods have

Periodical change

Warranty.

Ref.

No.

1

2

Fuel hoses

High-pressure hydraulic hoses

of

materials which are apt to

in the course

by

visual inspection whether or

of

time. Moreover,

is

of

deterioration

not

come yet.

of

these parts are

not

covered by

Change Every

it

not

the reason

2 years

2 years

For parts to be replaced, see page 39.

III When replacing parts, be sure to use genuine Mitsubishi

parts.

is

Page 46

BD2G

BS3G

~---.

2 (2 pes on

pes

2

on

left

right

side,

side)

.,-----------_._-------

2 (2

pes

on

left

right

side,

side)

pes

on

2

(2

pes

on

on

left

right

2

pes

side,

side)

2

___

.....r--.-----

502745

'-

Page 47

Maintenance Schedule

• Perform previous interval items at multiples

original requirement. For example, at

or

monthly, also perform those items listed under

"Every 10 service hours or daily."

Ref.

,

No.

Walk-around checks

CD

Engine oil pan

®

Radiator

®

Main clutch case

@

[DD]

Transmission case Check oil level

®

[DPS]

Bevel gear case/trans- Check oil level

®

mission case [DD]

(j)

Hydraulic tank

Bevel gear case/trans- Check oil level

®

fer case [DPS] and add.

Fuel tank

®

Item

EVERY

10

(BEFORE

SERVICE

OPERATION)

Service Remarks

"

HOURS

Check oil level

and add.

Check coolant

level and add.

Check oil level

and add.

and add.

and add.

Check oil level

and add.

Check oil level

and add; drain

moisture and

(,Clrl-i....-n.on+

250 service

OR

DAILY

of

hours

the

Page

43

44

44

44

44

44

44

45

45

Ref.

No.

@

Brake pedal

Clutch pedal

@

Inching pedal Check stroke

(@

[DPS]

Transmission con-

@

trollever

@

Tracks

Implement

Q~'

Steering clutch

(Jji

levers

EVERY

@

Fan belt

@

Battery

Implement

C®

Item

[DPS]

250

Cheek free

play/stroke

and adjust. Stroke:

Check free

play/stroke

and adjust.

and adjust.

Check clearance

in guide.

Check adjustment (sag). (3/4 to 1-3/16 in.)

Check for

damage or wear.

Check stroke.

SERVICE

Check tension.

Check e1ectrolyte level.

Lubricate.

Service

HOURS

Remarks

Free play: 0.5 to

0.5 to 1 cm

(3/16 to

8 cm (3-1/8

Free play:

1.5 cm (9/16 in.)

Stroke:

16

Stroke: 14.5

(5-11/16 in.)

Clearance:

0.5 to 2 mm

(0.02 to 0.08 in.)

Sag: 2 to 3'cm

Stroke: 20 to

22

8-11/16

OR

Sag: 1 to 1.5

(3/8 to 9/16 in.)

3/8

cm

(6-5/16 in.)

em

(7-7/8 to

in.)

MONTHLY

in.)

in.)

cm

cm

!Page

45

45

45

45

46

46

46

47

47

48

Page 48

Ref.

No.

Item Service

]EVERY

500

SERVICE

HOURS

Remarks

OR 3 MONTHS

Page

Ref.

No,

Damper case [DPS)

@

Item

Service Remarks

Change oil.

3.5 liters

(0.9 U.S. gal)

Page

51

@J)

Fuel tank

Final drive gear Check oil level

(?])

cases and add.

([7)

Fuel feed pump

Air cleaner Clean element.

@

Steering clutch cases Drain moisture.

@

(2j)

Engine oil pan Change oil.

EVERY 1000

i2j)

Engine oil filter

Fuel filter

®

@

Universal

joint

Wash

Wash

SERVICE

Change.

Change element.

Lubricate.

EVERY 2000 SERVICE

Main clutch case

@

[DD]

Change oiL

strainer,

filter.

HOURS

HOURS

7 liters:

(1.8 U.S. gal)

OR 6 MONTHS

2 fittings

OR I YEAR

5.5 liters

(1.5

U.S. gal)

49

49

49

49

49

49

50

50

50

51

Bevel

($~

@

C@

(3])

(@

'@

@

@)

@)

gear case/trans-

mission case [DD)

Bevel

gear case/trans-

fer case

Transmission case

[DPS]

Transmission case

[DPS]

Hydraulic tank

Hydraulic tank

Final drive gear

cases

Radiator

Air cleaner

[DPS]

Change oil.

Change

Change oil.

Change oil filter;

wash strainer.

Change

Change oil

filter element.

Change oil.

Flush; change

coolant.

Change element.

oiL

oiL

9,5 liters

(2.5

U.S. gal)

7 liters

(1.8 U.S. gal)

11

liters

(2.9 U,S. gal)

33 liters

(8.7 U.S. gal)

Standard: 6.5

liters (1.7

Super swamp: 9.5

liters (2.5

Ultra swamp: 13

liters (3.4 U.S.gal)

(Each side)

13 liters

(3.4

U.S.gal)

U.S.gal)

U.S. gal)

51

51

51

52

52

52

52

52

52

Main clutch case

@

[DD]

Wash

strainer.

51

"

Page 49

Ref.

No.

Item

Service

Remarks

Page

AFTER

NEW

Engine oil pan

®

@

Engine oil filter

Main clutch case

(~

[DD]

Bevel gear case/trans-

®I

mission case [DD] (2.5 U.S. gal)

Transmission case

@

[DPS] (2.9 U.S. gal)

Transmission case

~3§)

[DPS]

@

Hydraulic

@ Hydraulic

Clutch brake [DD]

INITIAL

OR

RECONDITIONED

tank

tank

100

Change oil.

Change.

Change oil.

Change oil.

Change oil.

Change oil filter;

wash strainer.

Change oil.

Change oil filter

element.

Adjust.

SERVICE

MACHINE

HOURS

5.5 liters

(1.5 U.S. gal)

9.5 liters

11

33 liters

(8.7 U.S. gal)

OF

7 liters

(1.8 U.S. gal)

liters

50

50

51

51

51

52

52

52

57

Page 50

_

.............

__

.......... "-&.

...

J.'

....

U

...

.l1.L\",.,~lall\..-c

Legend

-:r

6

LU

~

.

-4IIIIIIIIIt"\

~1

i

CHECK

LEVEL

DRAIN

ADD

LUBRICATE

OIL

GAUGE

FUEL

OIL

OIL

LEVEL

Every 10 service hours

Walk-around checks

CD

Cooling system

Check

for

leaks,

e

O

hoses

Engine

(])

Check

leaks.

Hydraulic

Check

~

hoses

Gear

Check

or

trash

compartment

for

for

or

damaged lines.

cases

for

buildup.

oil

or

system

leaks,

oil

leaks.

worn

fuel

worn

or

daily (I) (before operation)

a

Implement

Check

for

damage.

wear

~

Sprockets

Check

for

0

ir.

f

damage.

Engine

Check

exhaust

or

vibration.

Electrical system

Check

connections

wires.

wear

operation

for

abnormal

color,

for

loose

or

or

or

sound

wire

broken

• Make sure defects found during

all been repaired.

the

previous day have

502688

Page 51

Every 10 service hours or daily (ll) (before operation)

@ Engine oil pan - Check oil level and

add.

® Radiator - Check coolant level and

add.

.

--.----~-

._-------,

@

Main

clutch case

[DD}

- Check oil

level and add.

® Transmission case [DPS] - Check

oil

level and add.

® Bevel gear case/transmission case

[DD]

OJ

Hydraulic tank - Check oil level and

add .

- Check oil level and add.

502705

~

502709

Page 52

Every

10

service

hours

or

daily

(ill)

(before

operation)

®

Bevel

gear case/transfer case [DPS]

- Check oil level and add.

® Fuel

tank

- Check oil level and

add; drain moisture and sediment.

'. _ EL---:

11--;:

I I

I

-r-

® Brake pedal - Check free play /

stroke and adjust.

Free

play:

0.5

to

(3/16

@ Clutch pedal [DD] - Check free

play/stroke and adjust.

1 em

to

3/8

in.)

@ Inching pedal [DPS] - Check

stroke and adjust.

@ Transmission control lever [DPS] -

Check clearance

in guide.

-

----j-:-----__

I

k=:l

t..:::::.J::il

•

W

502711

(..------

.

~

-

-.

.--~

I I

I I

,,---\

-0,

~~'-

~.~-----

;::;;;

Stroke:

(6-5/16 in.)

~

Free play: 1.5 ern

~

(9/16

in.!

16

em

502713

Clearance:

0.5

(0.02

to

to

2 mm

0.08

in.)

502715

Page 53

Every 10 service hours or daily

(N)

(before operation)

® Tracks - Check adjustment (sag).

Sag: 2 to

@ Implement - Check for damage or

wear.

(3/4

3 em

to

1-3/16

in.)

502716

@ Steering clutch levers - Check

stroke.

Stroke:

20

to

(7-7/8

22

em

to

8-11/16

~

502718

in.)

502717

Page 54

Every

@

@

250

service hours or monthly (I)

Fan

belt - Check tension.

Battery

- Check electrolyte level

502359

(battery electrolyte level warning lamp

of

OK

monitor).

Upper

limit

..c..t:U:l.O...,..-

1I111111111r-

Lower

limit

502720 I

Page 55

Every

250

service hours or monthly

@ Implement - Lubricate.

\

3 strokes

grease

from

gun

(IT)

BS3G

18

fittings

Straight

blade 5

fittings

502725

Page 56

Every

500

service hours or 3 months

® Fuel tank - Wash strainer.

~Strainer

®)

Final drive gear cases -

level and

add.

Check

502721

oil

@ Fuel feed pump - Wash filter.

@)

Air cleaner - Clean element.

500318

1~2~)

Steering clutch cases -

moisture.

Drain

® Engine oil pan - Change oil.

cQ)

LU

502724 1

(l)

-r-

502726

Page 57

Every

(~

1000

Engine oil filter - Change.

Filter

service hours or 6 months

wrench

(~)

Universal

joint

- Lubricate.

EJ

2

fittings

Installation

rtf)

Fuel filter - Change element.

Element

500320

502361

\

502727

Page 58

Every 2000 service

hours

or

1 year

(I)

~J)

Main

®

Main

strainer.

dutch

clutch case [DD] - Wash

case [DD] - Change oil.

502728

(@

Damper case [DPS] - Change oil.

;g

•

W

502730

® Bevel gear case/transmission case

- Change oil.

[DD]

© Bevel gear case/transfer case [DPS J

- Change oil.

502732

@ Transmission case [DPS] - Change

oil.

(;)

,....

.

(l

( @

Strainer

"~

~.~

~~

502729

502731

502733

".

Page 59

Every

!~9;

2000

service

hours

or

Transmission case [DPS] - Change

oil filter; wash strainer.

~~'

1 year

(n)

(iJ)

Hydraulic tank - Change oil filter

element.

@)

Radiator - Flush; change coolant.

~

~.

C:{6J

Hydraulic

Strainer

tank

- Change oil.

502734

502735

(@

Final drive gear cases - Change oil.

502736

502737

502738

@ Air cleaner - Change element.

502723

tJ

•

L!.J

Page 60

When

Required

Cleaning air cleaner element

1.

Use

pressure air - 7

psi [0.7 MPaJ maximum

- 3 kg/cm2 (40 psi)

maximum when cleaning dry dirty

element.

2.

If

element is dirty with soot or oily

substance, immerse it in warm

water and non-sudsing household

detergent for approximately

minutes, and rinse it with clean

water.

3.

After cleaning, insert light inside

element and check for pinholes

tears.

kg/cm2 (100

or

[0.3

water

MPaJ

30

or

500025

.. Have spare elements

use while cleaning used

Dry element in breeze

..

from an electric fan. Do

elements by bumping

WARNING

~

Wear safety goggles and protective

clothing when using pressure air.

'.

on

hand to

element;

or

not

or

tapping.

.

current

clean

Priming fuel system

1.

Unlock priming

ing it counterclockwise.

2. Loosen air vent plug (2)

fIlter. Operate priming

fuel flows from vent

bles,

then

tighten

3. Loosen air vent plugs

tion

pump,

the same

4.

After completing priming operation,

lock priming

clockwise while depressing

ward.

manner

pump

the

and prime

as

for fuel filter.

pump

(1)

pump

without

plug.

(3)

the

pump

by

turning it

it

by

of

of

turn-

fuel

until

bub-

injec-

in

down-

Page 61

Adjusting tracks

2to3,,;m

(3/4

to

1-3/16

in.)

CD

When properly adjusted, tracks should

have a

in.)

between carrier roller and front idler,

as

• To adjust:

1.

sag

of

2 to 3 em

as

measured

shown .

Remove cover, and apply grease,

with a grease gun, into

until dimension (A) (between flange

and rigid bar)

(17-3/4 in.).

at

ct:=o

(3/4

to 1-3/16

a point half way

fill

valve

is

within 45

(1)

em

• To loosen:

valve

Turn fill

and allow grease to escape from vent

hole (2).

&

Keep your face away from fill valve

when making an adjustment.

(1) counterclockwise

WARNING

2.

Operate machine backward and

ward to equalize adjustment.

III

If

it

is

difficult to set dimension (A)

within 45 em (17-3/4 in.), consult

your Mitsubishi dealer.

for-

Page 62

Adjusting

Adjust

through (D):

steering clutches

the following four items (A)

(A)

Released position

clutch levers

of

J

(B)

Clearance between brake band

and drum

J

(C)

Stroke of steering clutch levers

t

(D)

Adjustment after connection

to steering

valve

steering

(A)

Released position

clutch levers

1.

Reposition stopper bolt (2)

of

position

(3-9/16 to

right and left lever positions.)

2.

To

adjust released position

(3), loosen lock nut (4) and turn

lever (3) in either direction.

should be 6.5 to 7.5 em (2-9/16 to

8-11/16 in.)

of

face

(B)

Clearance between brake band

and drum

in

Run

and back

that position.

I

(C)

Adjust length

clevis

22

when pulled

adjusting

Stroke steering clutch levers

(7)

em

(7-7/8 to 8-11/16 in.) stroke

lever (1)

3-3/4/ in.). (Equalize

as

instrument panel.

it

off 2-2/3 rotations from

of

so

that levers (3) have 20 to

all

the way.

of

steering

is

9 to 9.5 em

of

measured from end

nut

(5)

all

the way,

.

rod (6) by means

so

that

lever

It

of

• When making a connection to lever

(8), lightly push lever (8) forward.

Page 63

Adjusting brake pedal

Adjusting inching pedal

[DPS]

-----~

502742

(D) Adjustment

to

steering valve

Adjust length

after

connection

of

rod (11) to bring

steering valve plunger (9) into contact

with roller

II

Do

(10).

not

push in plunger (9).

----

II

There

of

is

no need

of

adjusting stroke

this pedal after steering clutch

adjustment has been made properly.

To be adjusted

1.

Reposition stopper

pedal

is

is

its free play.

bolt

(1)

so

20 cm (7-7/8 in.)

measured from dashboard wall. .

of

2. Adjust length

play

of

pedal

to

3/8 in.).

II

Make sure right and left brakes

rod (2)

is

0.5

to

so

that free

1 em

move simultaneously when

start depressing pedal.

502743

that

(3/16

you

as

;..-->.:--.;-~

1.

Reposition stopper bolt (1)

inching pedal

20 em (7-7/8 in.)

is

20

em (7-7/8 in.)

so

measured from dashboard wall.

2. Adjust length

of

rod (3)

so

lever (2) starts moving soon when

pedal

is

depressed.

3. Reposition stopper

pedal stroke

bolt

(4)

so

is

14.5 em (5-11/16

in.).

502744

that

as

that

that

Page 64

Adjusting clutch pedal

[DD]

CD

20

em

1.

Reposition stopper bolt (1)

clutch pedal

measured from dashboard wall.

2.

Adjust length

of

play

3.

Reposition stopper

pedal stroke

pedal

is

20 cm (7-7/8 in.)

of

rod (2)

is

1.5 cm (9/16 in.).

so

bolt

is

16 cm (6-5/16 in.).

(7-7/8 in.)

Free

play

1.5

em

(9/16

in.)

502746

so

that

(3)

so

that

as

free

that

Adjusting clutch brake

[DD]

• This brake should be capable

stopping a rotating universal

joint

in about 2.5 seconds when clutch

pedal

engine running at maximum

1.

Adjust as-installed length

is

depressed

all

the way with

of

speed_

spring

(1) to 4 cm (1-5/8 in.).

2.

Loosen lock nuts (2) (3), and run in

adjusting bolt

(4) until brake band

(5) comes in full-face contact with

drum (6).

3. Back

off

adjusting bolt (4) 2.5

3 rotations from that position to

obtain correct clearance between

band and drum.

of

to

Adjusting transmission

control

lever

[DPS]

• Clearance (a) between guide (1) and

(2) should be 0.5

lever

to 2 mm

(0.02 to 0.08 in.) in any position.

Loosen lock

nuts

(3), and

turn

rods (4)

(5) to adjust clearance (a).

•

If

it

is

difficult to

obtain

correct

clearance, lever parts would be

badly worn. In such a case, consult

your

Mitsubishi dealer.

Page 65

Adjusting tip angle (straight blade)

II

To vary tip angle

of

blade for giving

blade a better digging action,

making for quick, plow-like penetration into ground or for giving

dirt a rolling action ahead

as

proceed

1.

Set blade at large angle by turning

follows:

of

left brace (1) counterclockwise with

handle (2).

blade,

2. Set blade at smaller angle by

turn-

ing left brace (1) clockwise with

handle (2).

&['--C-AU-T-IO-N )

Do

not

increase exposed length (A)

eye bolt (3) more than 10.5 em (4 in.).

c::o

of