Page 1

General-Purpose AC Servo

SSCNET III/H Interface

Drive Unit Instruction Manual

-MR-J4-DU_B4-RJ100

Page 2

Page 3

SAFETY INSTRUCTIONS

WARNING

Indicates that incorrect handling may cause hazardous conditions, resulting in

death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions, resulting in

minor or moderate injury or property damage.

Indicates what must not be done. For example, "No Fire" is indicated by .

Indicates what must be done. For example, grounding is indicated by .

(Please read the instructions carefully before using the equipment.)

To use the equipment correctly, do not attempt to install, operate, maintain, or inspect the equipment until you have read

through this Instruction Manual, Installation guide, and appended documents carefully. Do not use the equipment until you

have a full knowledge of the equipment, safety information and instructions.

In this Instruction Manual, the safety instruction levels are classified into "WARNING" and "CAUTION".

Note that the CAUTION level may lead to a serious consequence depending on conditions.

Please follow the instructions of both levels because they are important to personnel safety.

What must not be done and what must be done are indicated by the following diagrammatic symbols.

In this Instruction Manual, instructions at a lower level than the above, instructions for other functions, and so on are classified

into "POINT".

After reading this Instruction Manual, keep it accessible to the operator.

1

Page 4

[To prevent electric shock, note the following]

WARNING

● Before wiring, turn off the power and wait for 20 minutes or more until the charge lamp turns off. Then,

confirm that the voltage between L+ and L- is safe with a voltage tester or others. Otherwise, an

electric shock may occur. In addition, when confirming whether the charge lamp is off or not, always

confirm it from the front of the converter unit.

● Ground the converter unit, drive unit, and servo motor securely.

● Any person who is involved in wiring and inspection should be fully competent to do the work.

● Do not attempt to wire the converter unit, drive unit, and servo motor until they have been installed.

Otherwise, it may cause an electric shock.

● Do not operate the switches with wet hands. Otherwise, it may cause an electric shock.

● The cables should not be damaged, stressed, loaded, or pinched. Otherwise, it may cause an electric

shock.

● During power-on or operation, do not open the front cover of the converter unit and the drive unit.

Otherwise, it may cause an electric shock.

● Do not operate the converter unit and the drive unit with the front cover removed. High-voltage

terminals and charging area are exposed and you may get an electric shock.

● Except for wiring or periodic inspection, do not remove the front cover of the converter unit and the

drive unit even if the power is off. The converter unit and the drive unit are charged, and you may get

an electric shock.

● To prevent an electric shock, be sure to connect the protective earth (PE) terminal (marked ) of the

converter unit and the drive unit to the protective earth (PE) of the cabinet.

● To avoid an electric shock, insulate the connections of the power supply terminals.

[To prevent fire, note the following]

CAUTION

● Install the converter unit, the drive unit, the servo motor, and the regenerative resistor on

incombustible material. Installing them directly or close to combustibles will lead to smoke or a fire.

● Be sure to connect a magnetic contactor between the power supply and the main circuit power supply

(L1/L2/L3) of the converter unit, in order to configure a circuit that shuts off the power supply by the

magnetic contactor. If the magnetic contactor is not connected, a continuous flow of a large current

may cause smoke or a fire when the converter unit or the drive unit malfunctions.

● Be sure to connect a magnetic contactor for each converter unit between the power supply and the

power supply (L1/L2/L3) of the converter unit, in order to configure a circuit that shuts off the power

supply by the magnetic contactor. If a molded-case circuit breaker or fuse is not connected, a

continuous flow of a large current may cause smoke or a fire when the converter unit malfunctions.

● When using the regenerative resistor, shut the power off with an alarm signal. Otherwise, a

regenerative transistor malfunction or the like may overheat the regenerative resistor, causing smoke

or a fire.

● Provide adequate protection to prevent screws and other conductive matter, oil and other combustible

matter from entering the converter unit, the drive unit, and the servo motor.

2

Page 5

[To prevent injury, note the following]

CAUTION

● Only the power/signal specified in the Instruction Manual should be applied to each terminal.

Otherwise, it may cause an electric shock, fire, injury, etc.

● Connect cables to the correct terminals. Otherwise, a burst, damage, etc., may occur.

● Ensure that polarity (+/-) is correct. Otherwise, a burst, damage, etc., may occur.

● The heat sink of the converter unit and drive unit, the regenerative resistor, the servo motor, etc. may

be hot while power is on and for some time after power-off. Take safety measures such as providing

covers to avoid accidentally touching them by hands and parts such as cables.

[Additional instructions]

The following instructions should also be fully noted. Incorrect handling may cause a malfunction, injury, electric shock, fire,

etc.

3

Page 6

[Transportation and installation]

CAUTION

● Transport the products correctly according to their mass.

● Use the eyebolts of the converter unit and of the drive unit only for transporting. Do not use the

eyebolts for transporting with the converter unit and the drive unit mounted on a machine.

● Do not overtighten the eyebolts of the converter unit and of the drive unit. Tightening too hard may

damage the tap.

● Stacking in excess of the specified number of product packages is not allowed.

● Do not hold the front cover, cables, or connectors when carrying the converter unit and drive unit.

Otherwise, it may drop.

● Install the converter unit, the drive unit, and the servo motor in a load-bearing place in accordance

with the Instruction Manual.

● Do not get on or put heavy load on the equipment. Otherwise, it may cause injury.

● The equipment must be installed in the specified direction.

● Maintain specified clearances between the converter unit/drive unit and the inner surfaces of a control

cabinet or other equipment.

● Do not install or operate the converter unit, the drive unit, and the servo motor which have been

damaged or have any parts missing.

● Do not block the intake and exhaust areas of the converter unit and the drive unit. Otherwise, it may

cause a malfunction.

● Do not drop or apply heavy impact on the converter units, the drive units, and the servo motors.

Otherwise, it may cause injury, malfunction, etc.

● Do not strike the connector. Otherwise, it may cause a connection failure, malfunction, etc.

● When you keep or use the equipment, please fulfill the following environment.

Item Environment

Ambient

temperature

Ambient

humidity

Vibration resistance

Operation

Operation

Ambience

Altitude

Storage

Storage

Indoors (no direct sunlight), free from corrosive gas, flammable gas, oil mist, dust, and dirt

2000 m or less above sea level (Contact your local sales office for the altitude for options.)

● When the equipment has been stored for an extended period of time, contact your local sales office.

● When handling the converter unit and the drive unit, be careful with the sharp edges of the converter

unit and drive unit.

● The converter unit and the drive unit must be installed in a metal cabinet.

● When fumigants that contain halogen materials, such as fluorine, chlorine, bromine, and iodine, are

used for disinfecting and protecting wooden packaging from insects, they cause a malfunction when

entering our products. Please take necessary precautions to ensure that remaining materials from

fumigant do not enter our products, or treat packaging with methods other than fumigation, such as

heat treatment. Additionally, disinfect and protect wood from insects before packing the products.

● To prevent a fire or injury in case of an earthquake or other natural disasters, securely install, mount,

and wire the servo motor in accordance with the Instruction Manual.

0 °C to 55 °C (non-freezing)

-20 °C to 65 °C (non-freezing)

5 %RH to 90 %RH (non-condensing)

2

, at 10 Hz to 55 Hz (X, Y, Z axes)

5.9 m/s

4

Page 7

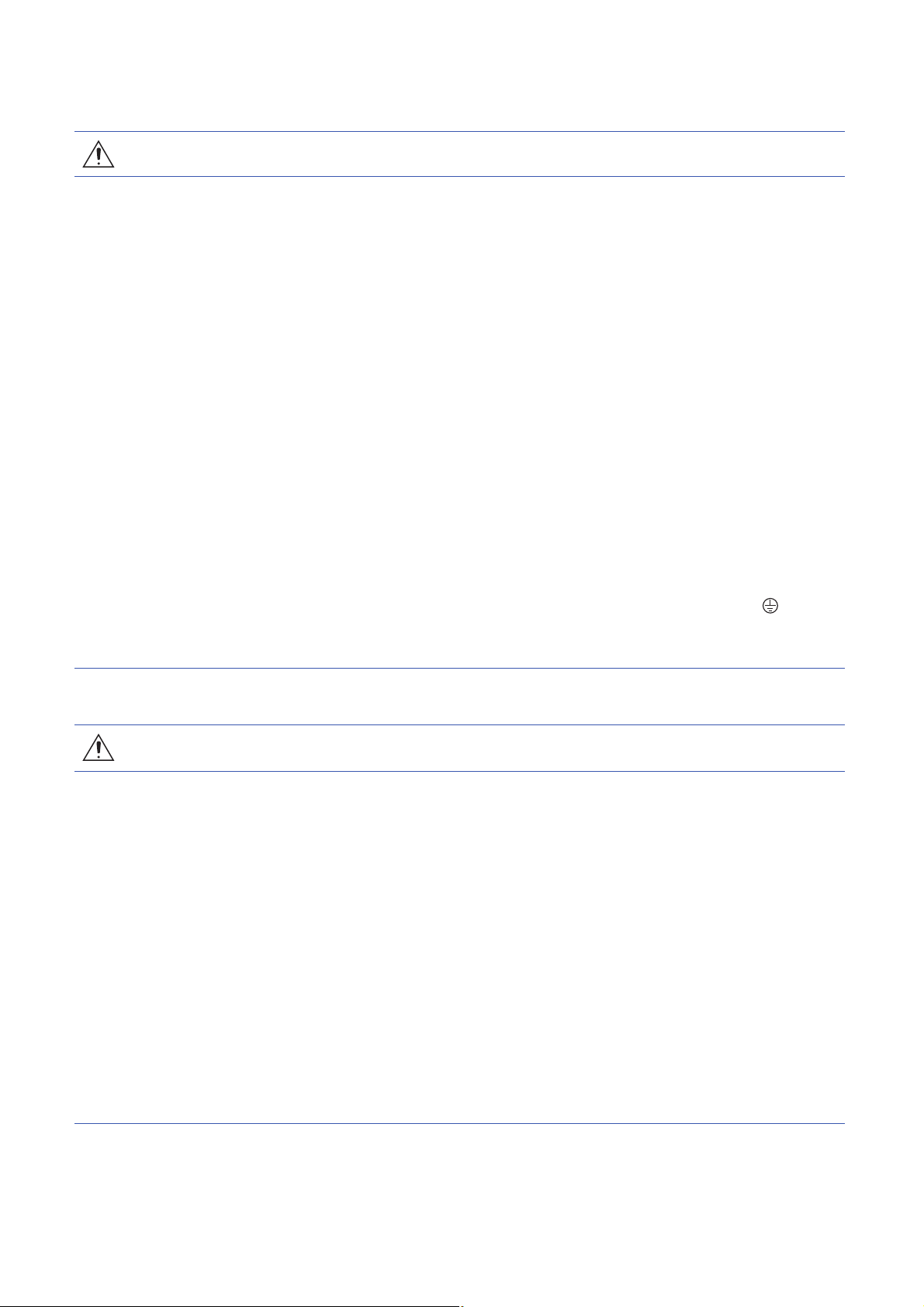

[Wiring]

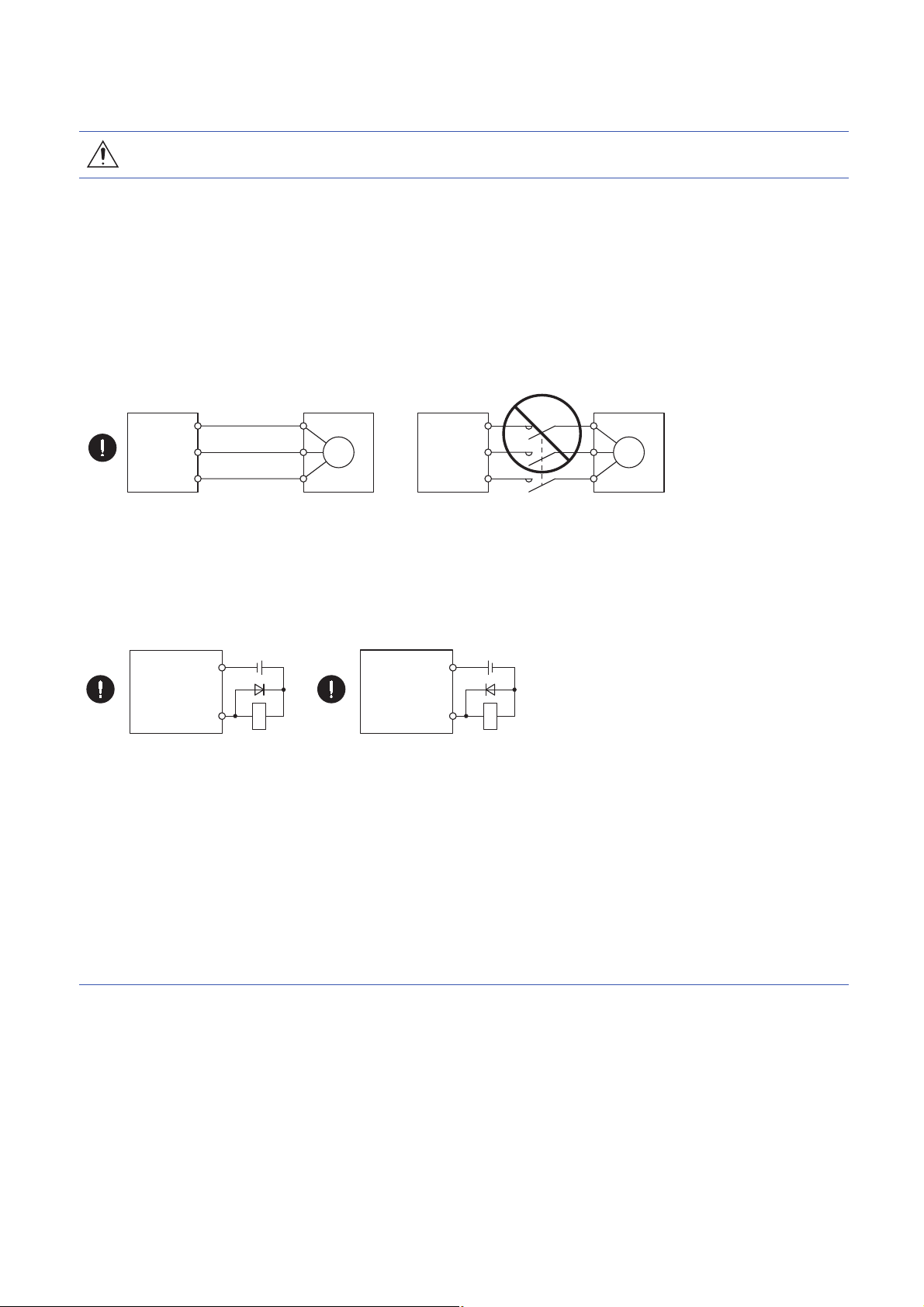

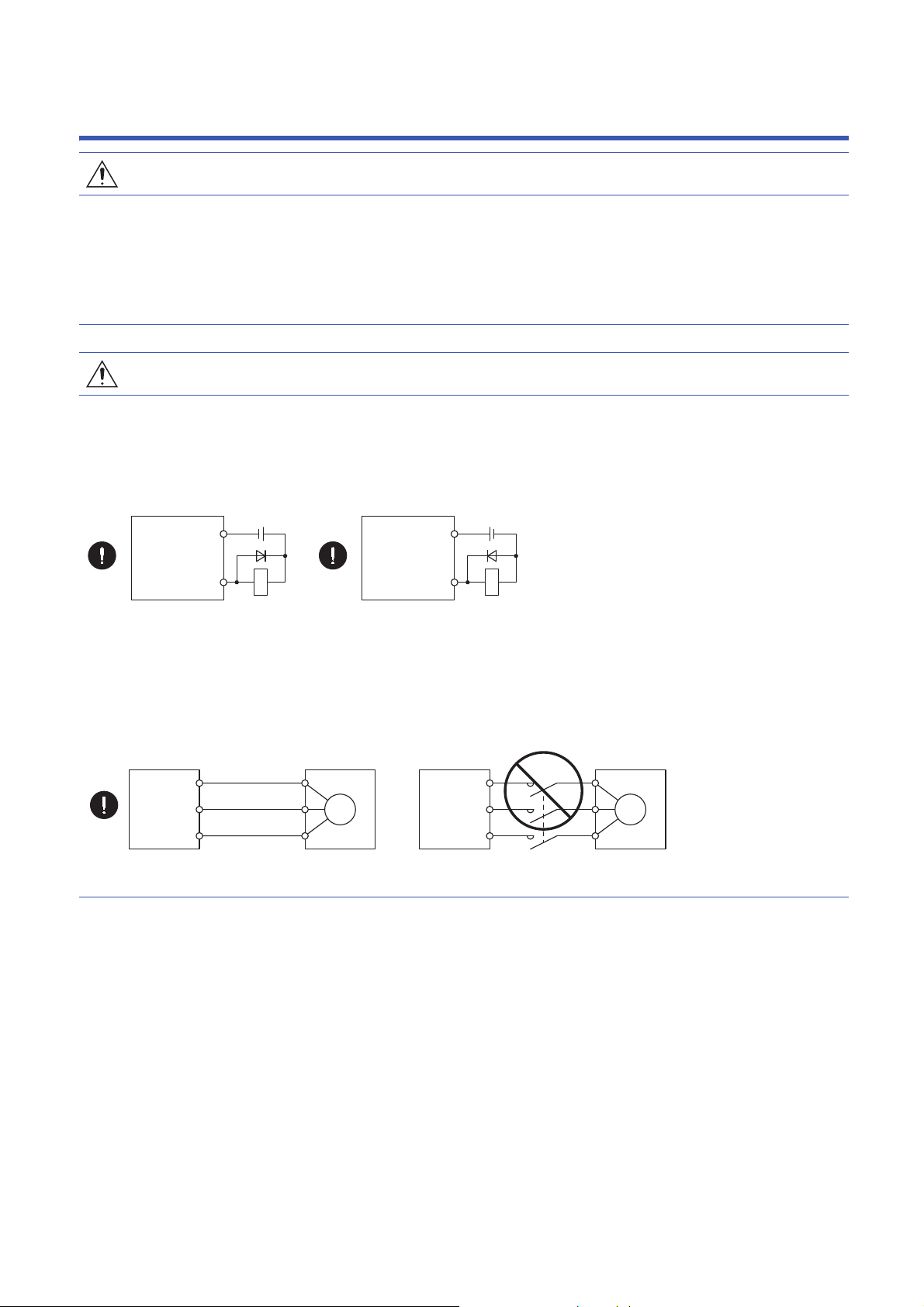

U

Servo motor

MV

W

U

V

W

Drive unit

U

Servo motor

MV

W

U

V

W

Drive unit

DOCOM

Control

output signal

Control

output signal

24 V DC

Converter unit

Drive unit

RA

For sink output interface

DOCOM

24 V DC

Converter unit

Drive unit

RA

For source output interface

CAUTION

● Wire the equipment correctly and securely. Otherwise, the servo motor may operate unexpectedly.

● Make sure to connect the cables and connectors by using the fixing screws and the locking

mechanism. Otherwise, the cables and connectors may be disconnected during operation.

● Do not install a power capacitor, surge killer, or radio noise filter (optional FR-BIF(-H)) on the drive unit

output side.

● To avoid a malfunction of the servo motor, connect the wires to the correct phase terminals (U/V/W) of

the drive unit and the servo motor.

● Connect the drive unit power outputs (U/V/W) to the servo motor power inputs (U/V/W) directly. Do not

connect a magnetic contactor and others between them. Otherwise, it may cause a malfunction.

● The connection diagrams in this Instruction Manual are shown for sink interfaces, unless stated

otherwise.

● Install the surge absorbing diode to the DC relay for control output signals in the converter unit and the

drive unit in the specified direction. Otherwise, the converter unit and the drive unit will malfunction

and will not output signals, disabling the emergency stop and other protective circuits.

● When the wires are not tightened enough to the terminal block, the wires or terminal block may

generate heat because of the poor contact. Be sure to tighten the wires with specified torque.

● Connecting a servo motor of the wrong axis to U, V, W, or CN2 of the drive unit may cause a

malfunction.

● To prevent an unexpected restart of the drive unit, configure a circuit to turn off EM2 or EM1 when the

main circuit power is turned off.

● To prevent malfunction, avoid bundling the power lines (input/output) of the converter unit and the

signal cables together or running them in parallel to each other. Separate the power lines from the

signal cables.

5

Page 8

[Test run and adjustment]

CAUTION

● When executing a test run, follow the notice and procedures in this instruction manual. Otherwise, it

may cause a malfunction, damage to the machine, or injury.

● Before operation, check and adjust the parameter settings. Improper settings may cause some

machines to operate unexpectedly.

● Never make a drastic adjustment or change to the parameter values as doing so will make the

operation unstable.

● Do not get close to moving parts during the servo-on status.

[Usage]

CAUTION

● For equipment in which the moving part of the machine may collide against the load side, install a limit

switch or stopper to the end of the moving part. The machine may be damaged due to a collision.

● Do not disassemble, repair, or modify the product. Otherwise, it may cause an electric shock, fire,

injury, etc. Disassembled, repaired, and/or modified products are not covered under warranty.

● Before resetting an alarm, make sure that the run signal of the drive unit is off to prevent a sudden

restart. Otherwise, it may cause an accident.

● Use a noise filter, etc., to minimize the influence of electromagnetic interference. Electromagnetic

interference may affect the electronic equipment used near the converter unit and the drive unit.

● Do not burn or destroy the converter unit and the drive unit. Doing so may generate a toxic gas.

● Use the converter unit and the drive unit with the specified servo motor.

● Correctly wire options and peripheral equipment, etc. in the correct combination. Otherwise, it may

cause an electric shock, fire, injury, etc.

● The electromagnetic brake on the servo motor is designed to hold the motor shaft and should not be

used for ordinary braking.

● For such reasons as incorrect wiring, service life, and mechanical structure (e.g. where a ball screw

and the servo motor are coupled via a timing belt), the electromagnetic brake may not hold the motor

shaft. To ensure safety, install a stopper on the machine side.

● If the dynamic brake is activated at power-off, alarm occurrence, etc., do not rotate the servo motor by

an external force. Otherwise, it may cause a fire.

6

Page 9

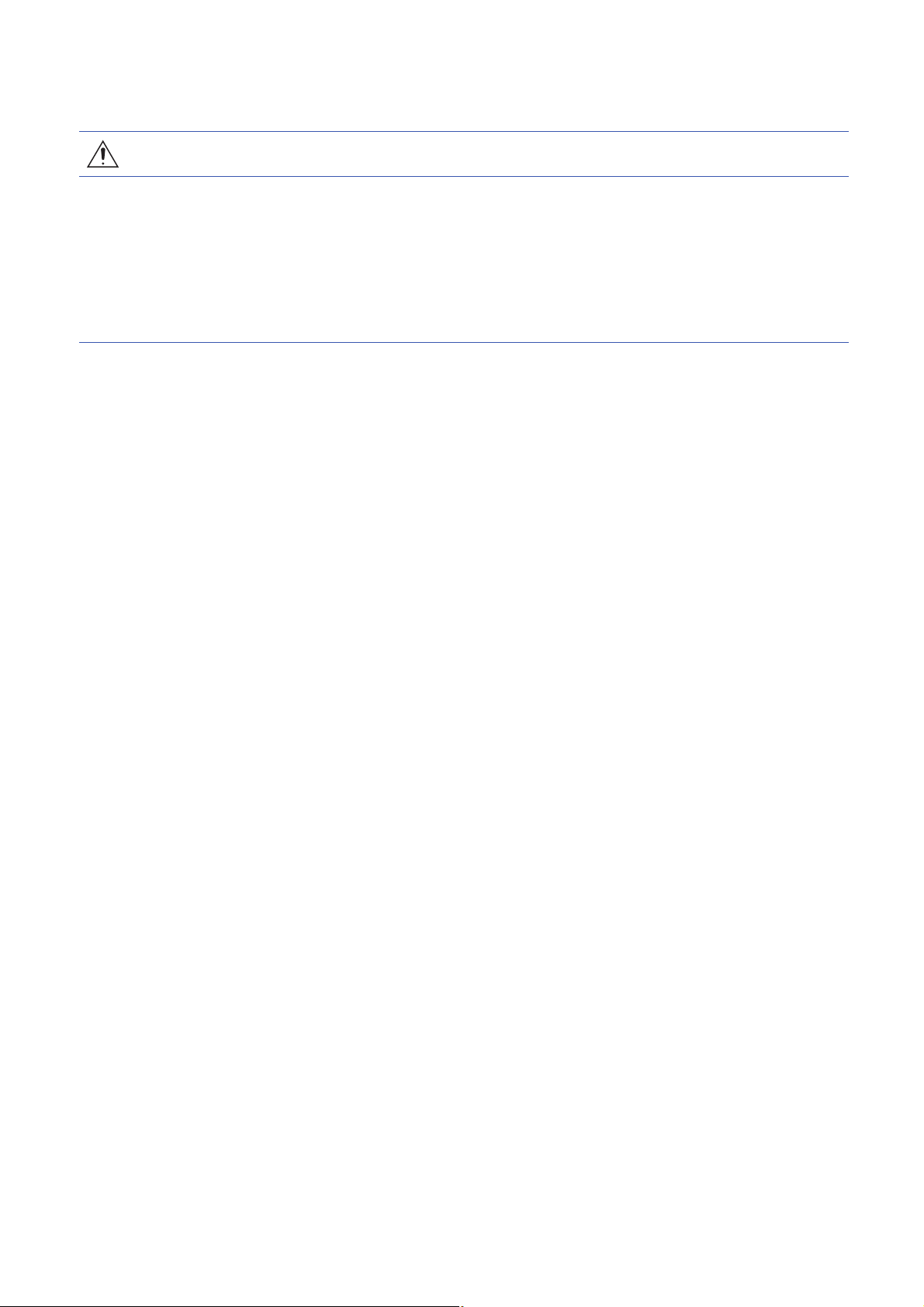

[Corrective actions]

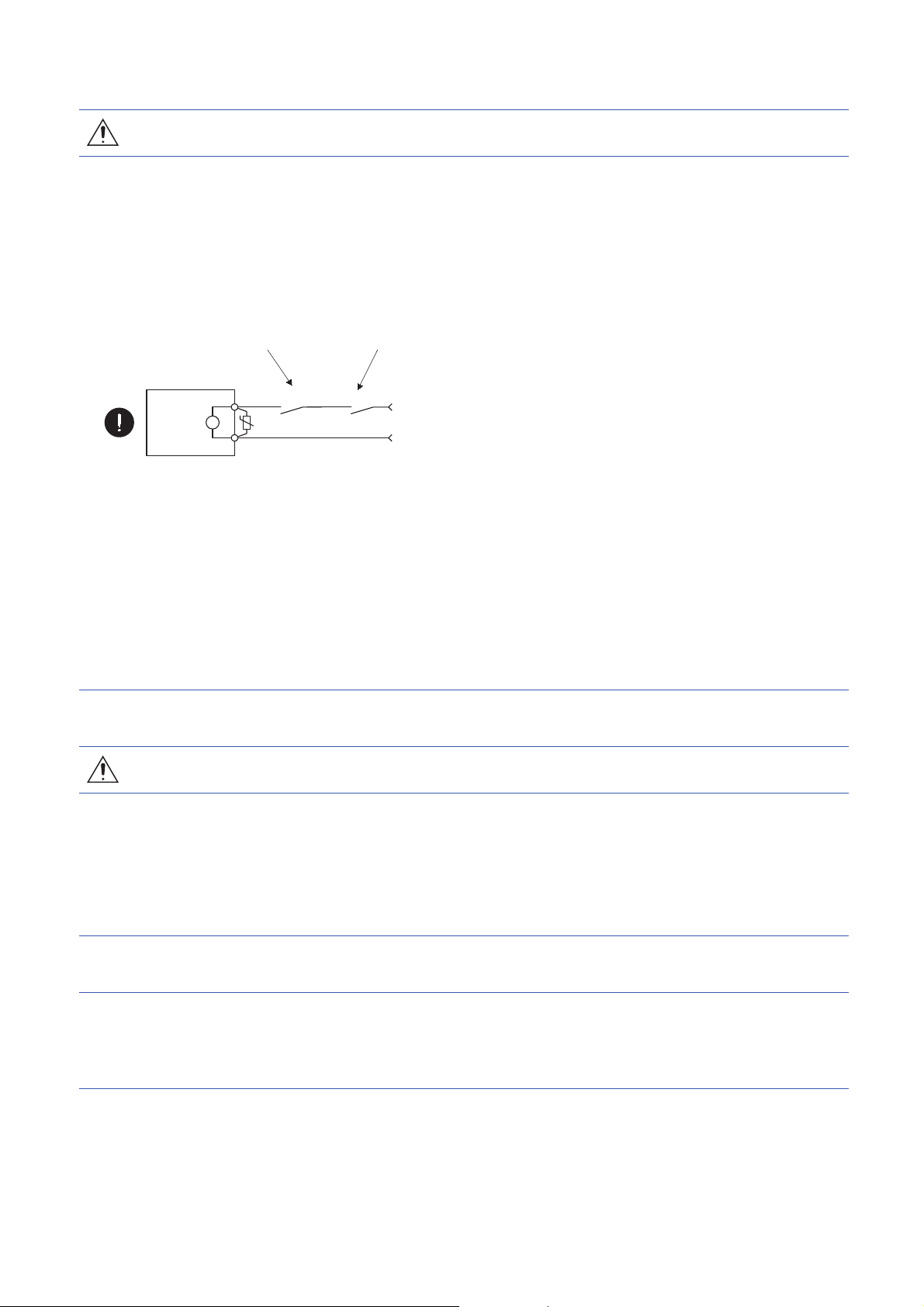

Servo motor

Electromagnetic brake

B

U

RA

Contacts must be opened with

the emergency stop switch.

Contacts must be opened when ALM

(Malfunction) or MBR (Electromagnetic

brake interlock) turns off.

24 V DC

CAUTION

● Ensure safety by confirming the power off, etc. before performing corrective actions. Otherwise, it may

cause an accident.

● If it is assumed that a power failure, machine stoppage, or product malfunction may result in a

hazardous situation, use a servo motor with an electromagnetic brake or provide an external brake

system for holding purpose to prevent such hazard.

● Configure an electromagnetic brake circuit which is interlocked with an external emergency stop

switch.

● When an alarm occurs, eliminate its cause, ensure safety, and deactivate the alarm to restart

operation.

● If the molded-case circuit breaker or fuse is activated, be sure to remove the cause and secure safety

before switching the power on. If necessary, replace the converter unit and drive unit, and recheck the

wiring. Otherwise, it may cause smoke, fire, or an electric shock.

● Provide an adequate protection to prevent unexpected restart after an instantaneous power failure.

● To prevent an electric shock, injury, or fire from occurring after an earthquake or other natural

disasters, ensure safety by checking conditions, such as the installation, mounting, wiring, and

equipment before switching the power on.

[Maintenance, inspection and parts replacement]

CAUTION

● Make sure that the emergency stop circuit operates properly such that an operation can be stopped

immediately and a power is shut off by the emergency stop switch.

● It is recommended that the converter unit and the drive unit be replaced every 10 years when it is

used in general environment.

● When using a converter unit or a drive unit whose power has not been turned on for a long time,

contact your local sales office.

[General instruction]

● To illustrate details, the equipment in the diagrams of this Instruction Manual may have been drawn

without covers and safety guards. When the equipment is operated, the covers and safety guards

must be installed as specified. Operation must be performed in accordance with this Instruction

Manual.

7

Page 10

DISPOSAL OF WASTE

• Please dispose a servo amplifier, battery (primary battery) and other options according to your local laws and regulations.

EEP-ROM LIFE

The number of write times to the EEP-ROM, which stores parameter settings, etc., is limited to 100,000. If the total number of

the following operations exceeds 100,000, the converter unit and the drive unit may malfunction when the EEP-ROM reaches

the end of its useful life.

• Write to the EEP-ROM due to parameter setting changes

• Write to the EEP-ROM due to device changes

STO FUNCTION OF THE DRIVE UNIT

When using the STO function of the drive unit, refer to chapter 13 of “MR-J4-_A_(-RJ) Servo Amplifier Instruction Manual".

For the MR-J3-D05 safety logic unit, refer to app. 5 of “MR-J4-_B_(-RJ) Servo Amplifier Instruction Manual".

COMPLIANCE WITH GLOBAL STANDARDS

For compliance with global standards, refer to "MR-CV_/MR-CR55K_/MR-J4-DU_(-RJ) Instruction Manual".

8

Page 11

ABOUT THE MANUALS

You must have this Instruction Manual and the following manuals to use this servo. Be sure to prepare all the instruction

manuals necessary to use the servo safely.

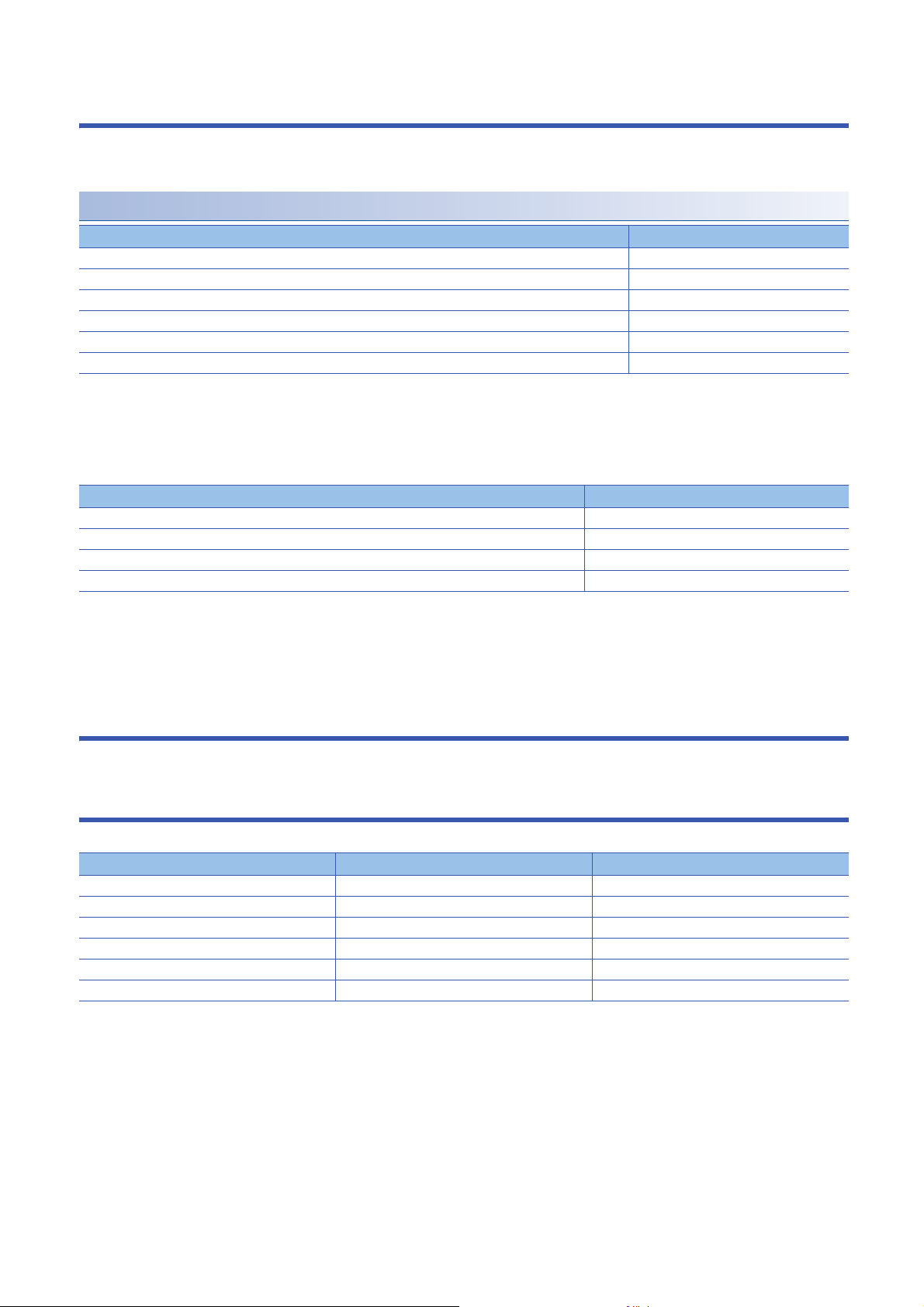

Relevant manuals

Manual name Manual No.

MELSERVO MR-J4-_B(-RJ) Servo Amplifier Instruction Manual SH(NA)030098

MELSERVO MR-CV_/MR-CR55K_/MR-J4-DU_(-RJ) Instruction Manual SH(NA)030145

MELSERVO-J4 Servo amplifier Instruction Manual (Troubleshooting) SH(NA)030108

MELSERVO MR-D30 Instruction Manual

MELSERVO Servo Motor Instruction Manual (Vol. 3) SH(NA)030099

EMC Installation Guidelines IB(NA)67310

*1 It is necessary for using an MR-D30 functional safety unit.

*1

This Instruction Manual does not describe the following items. Refer to the section of the detailed explanation field for details.

"MR-J4-_B_" means "MR-J4-_B_(-RJ) Servo Amplifier Instruction Manual". "MR-J4-DU_B_" means "MR-CV_/MR-CR55K_/

MR-J4-DU_(-RJ) Instruction Manual".

Item Detailed explanation

Normal gain adjustment

Special adjustment functions

Dimensions MR-J4-DU_B_ chapter 7

Absolute position detection system

*1

*2

*3

SH(NA)030131

MR-J4-_B_ chapter 6

MR-J4-_B_ chapter 7

MR-J4-_B_ chapter 12

*1 For parallel drive systems, the one-touch tuning is unavailable.

*2 A combination of the MR-CV55K4_ power regeneration converter unit and drive unit does not comply with SEMI-F47 standard. For the

advanced vibration suppression control II and the adaptive filter II, "Automatic setting” is invalid. Only "Manual setting" is valid.

*3 For absolute position detection systems, connect an optional battery to only the drive unit of the encoder master servo amplifier. Do not

connect the optional battery to the drive units of the encoder slave servo amplifiers.

CABLES USED FOR WIRING

Wires mentioned in this Instruction Manual are selected based on the ambient temperature of 40 .

U.S. CUSTOMARY UNITS

U.S. customary units are not shown in this manual. Convert the values if necessary according to the following table.

Quantity SI (metric) unit U.S. customary unit

Mass 1 [kg] 2.2046 [lb]

Length 1 [mm] 0.03937 [inch]

Torque 1 [N.m] 141.6 [oz.inch]

-4

Moment of inertia 1 [(× 10

Load (thrust load/axial load) 1 [N] 0.2248 [lbf]

Temperature N [] × 9/5 + 32 N []

kg.m2)] 5.4675 [oz.inch2]

9

Page 12

CONTENTS

SAFETY INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

DISPOSAL OF WASTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

EEP-ROM LIFE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

STO FUNCTION OF THE DRIVE UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

COMPLIANCE WITH GLOBAL STANDARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

ABOUT THE MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

CABLES USED FOR WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

U.S. CUSTOMARY UNITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

CHAPTER 1 FUNCTIONS AND CONFIGURATION 12

1.1 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2 Model designation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

1.3 Combinations of power regeneration converter units, drive units, and servo motors . . . . . . . . . . . . . . . 13

1.4 Compatible controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.5 Function list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.6 Configuration including peripheral equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

CHAPTER 2 INSTALLATION 16

2.1 Installation direction and clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

CHAPTER 3 SIGNALS AND WIRING 20

3.1 Connection example of power circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3.2 Alarm occurrence timing chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

When you use the forced stop deceleration function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

When you do not use the forced stop deceleration function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.3 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

CHAPTER 4 STARTUP 32

4.1 Switching power on for the first time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

4.2 Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

CHAPTER 5 PARAMETERS 35

CHAPTER 6 TROUBLESHOOTING 41

6.1 Troubleshooting for MR-CV_ power regeneration converter unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Explanation for the lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Alarm list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Warning list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.2 Troubleshooting for drive unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Explanation for the lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Alarm list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Warning list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

10

CHAPTER 7 CHARACTERISTICS 55

7.1 Overload protection characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.2 Power supply capacity and generated loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.3 Dynamic brake characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.4 Inrush currents at power-on of main circuit/control circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Page 13

Inrush currents of the power regeneration converter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Inrush current of the drive unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

CHAPTER 8 OPTIONS AND PERIPHERAL EQUIPMENT 61

8.1 MR Configurator2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Using the parallel drive system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

How to select the model name of the servo amplifier registered. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.2 AC reactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.3 External dynamic brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

CHAPTER 9 USING STO FUNCTION 72

CHAPTER 10 APPLICATION OF FUNCTIONS 74

10.1 Compatible with MR-D30 functional safety unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

CHAPTER 11 APPENDIX 78

11.1 Analog monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

REVISIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

CONTENTS

11

Page 14

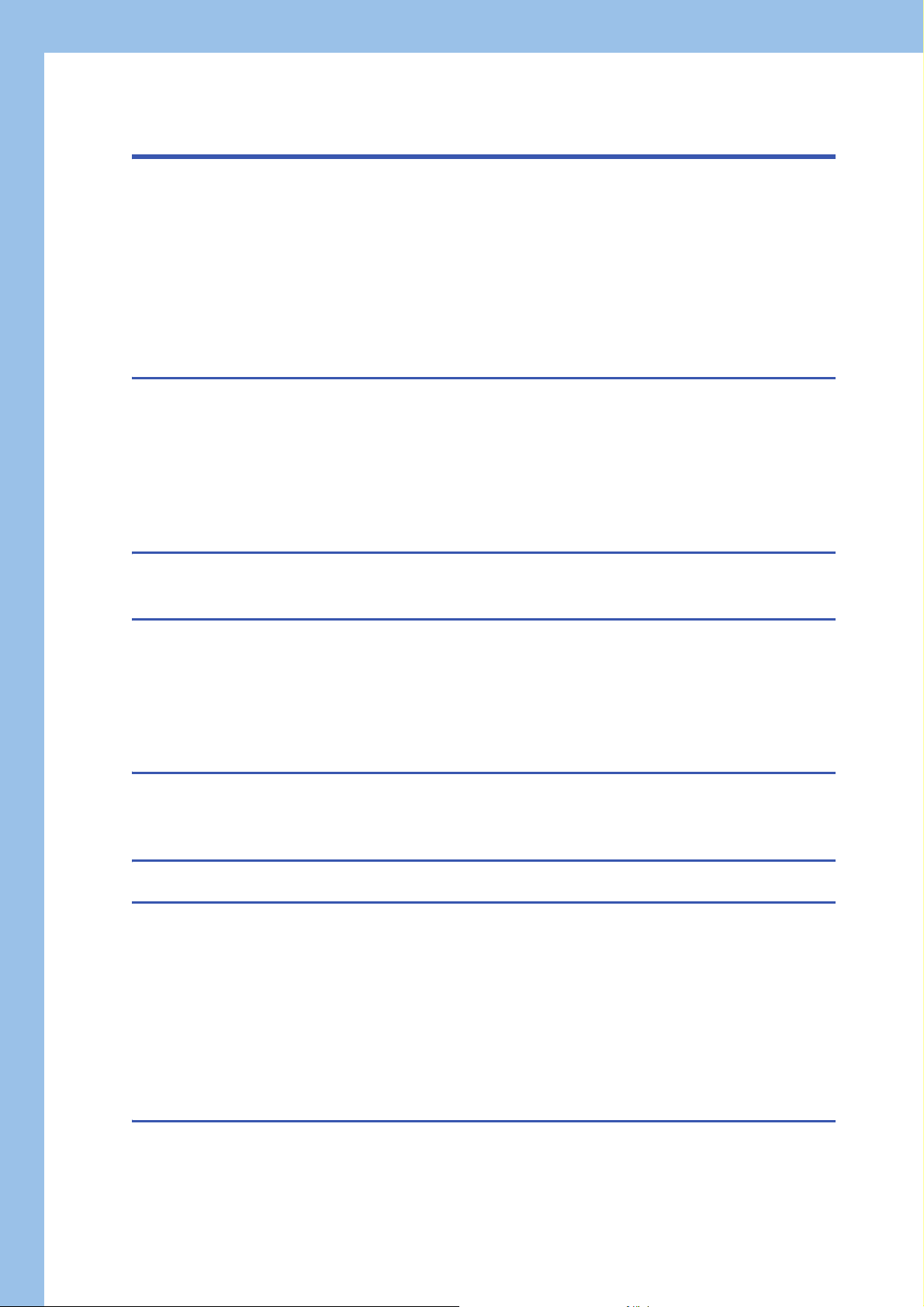

1 FUNCTIONS AND CONFIGURATION

The following items are the same as those for MR-J4-_B_(-RJ). Refer to the section of the detailed explanation field for

details. "MR-J4-DU_B_" means "MR-CV_/MR-CR55K_/MR-J4-DU_(-RJ) Instruction Manual".

Item Detailed explanation

Function block diagram MR-J4-DU_B_ section 3.1

Standard specifications MR-J4-DU_B_ section 1.4

Structure

*1 Do not connect an external encoder to the CN2L connector of the MR-J4-DU_B4-RJ100 drive unit.

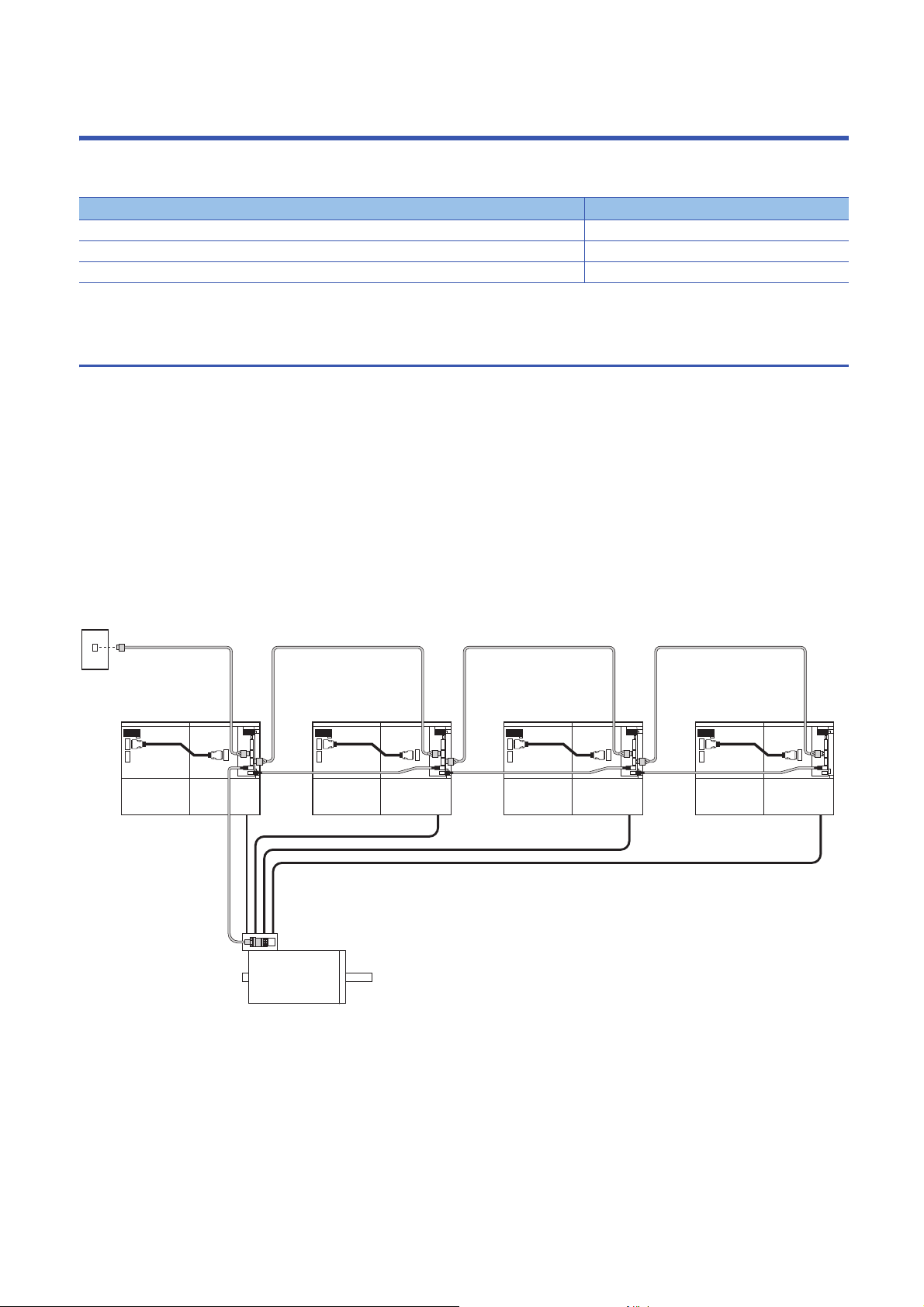

1.1 Description

This Instruction Manual describes MR-J4-DU_B4-RJ100 drive units and MR-CV55K4_ power regeneration converter units

compatible with parallel drive systems.

Parallel drive systems drive a servo motor with multiple MR-J4-DU_B4-RJ100 drive units and MR-CV55K4_ power

regeneration converter units connected. The encoder cables are wired by the daisy chain method. Delivering the encoder

information to all servo amplifiers, from encoder master servo amplifiers to encoder slave servo amplifiers, ensures reduced

wiring. A encoder distribution unit is not required.

The following shows a system that drives a servo motor with four MR-J4-DU_B4-RJ100 drive units and four MR-CV55K4_

power regeneration converter units connected. For the number of drive units required to be connected to one servo motor,

refer to the following.

Page 13 Combinations of power regeneration converter units, drive units, and servo motors

*1

MR-J4-DU_B_ sections 3.2 and 5.1

Servo system

controller

SSCNET III/H

Encoder master servo amplifier

Power

regeneration

converter unit 1

Drive

unit 1

Power

regeneration

converter unit 2

Servo motor

Drive

unit 2

Power

regeneration

converter unit 3

Drive

unit 3

Encoder slave servo amplifier 3Encoder slave servo amplifier 2Encoder slave servo amplifier 1

Power

regeneration

converter unit 4

Drive

unit 4

12

1 FUNCTIONS AND CONFIGURATION

1.1 Description

Page 15

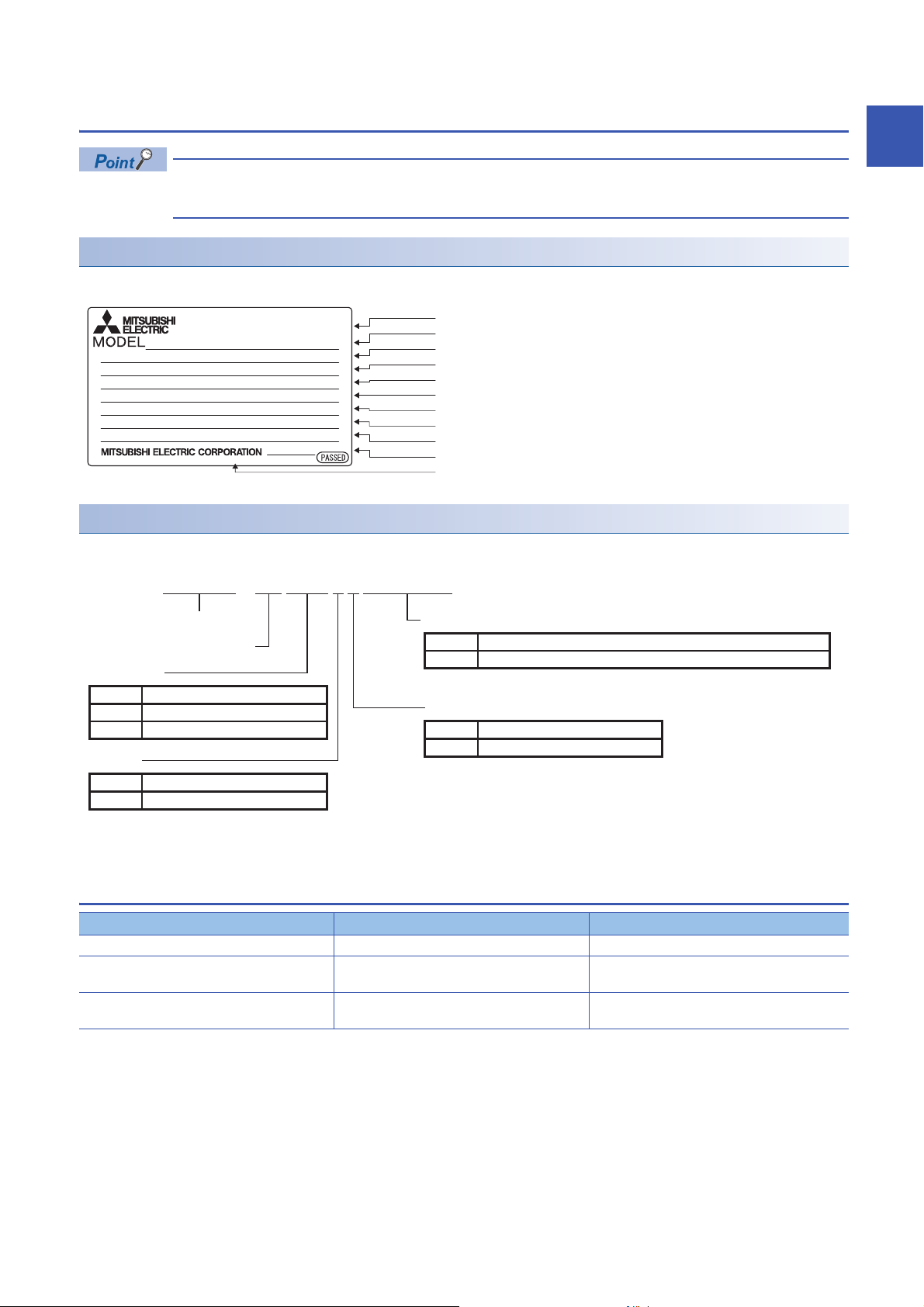

1.2 Model designation

Serial number

Model

Capacity

Applicable power supply

Rated output current

Standard, Manual number

Ambient temperature

IP rating

KC certification number

The year and month of manufacture

Country of origin

TOKYO 100-8310, JAPAN MADE IN JAPAN

DATE:

2017-12

MR-J4-DU55KB4-RJ100

SER. A7Z001001

AC SERVO

POWER

INPUT

OUTPUT

STD.: IEC/EN 61800-5-1 MAN.: IB(NA)0300228

Max. Surrounding Air Temp.: 55°C

IP20 (Terminal block IP00)

: 55kW

: DC513-648V 113.7A

: 3PH323V 0-360Hz 143.0A

MSIP-REI-MEK-TC301A013G52 BC343U843

This section describes MR-J4-DU_B4-RJ100 drive units only. For MR-CV55K4_power regeneration converter

units, refer to section 1.2 in "MR-CV_/MR-CR55K_/MR-J4-DU_(-RJ) Instruction Manual".

Rating plate

The following shows an example of the rating plate for explanation of each item.

Model

The following describes what each block of a model name indicates. Not all combinations of the symbols are available.

1

-MR - J 4 DU KB 4 - R J 15500

Series

Indicates drive unit

Rated output

Symbol Rated output [kW]

45K

55K

Interface

Symbol Interface

SSCNET III/H

B

45

55

Special specifications

Symbol Special specifications

-RJ100

Power supply

Symbol Power supply

Compatible with parallel drive system

3-phase 380 V AC to 480 V AC

4

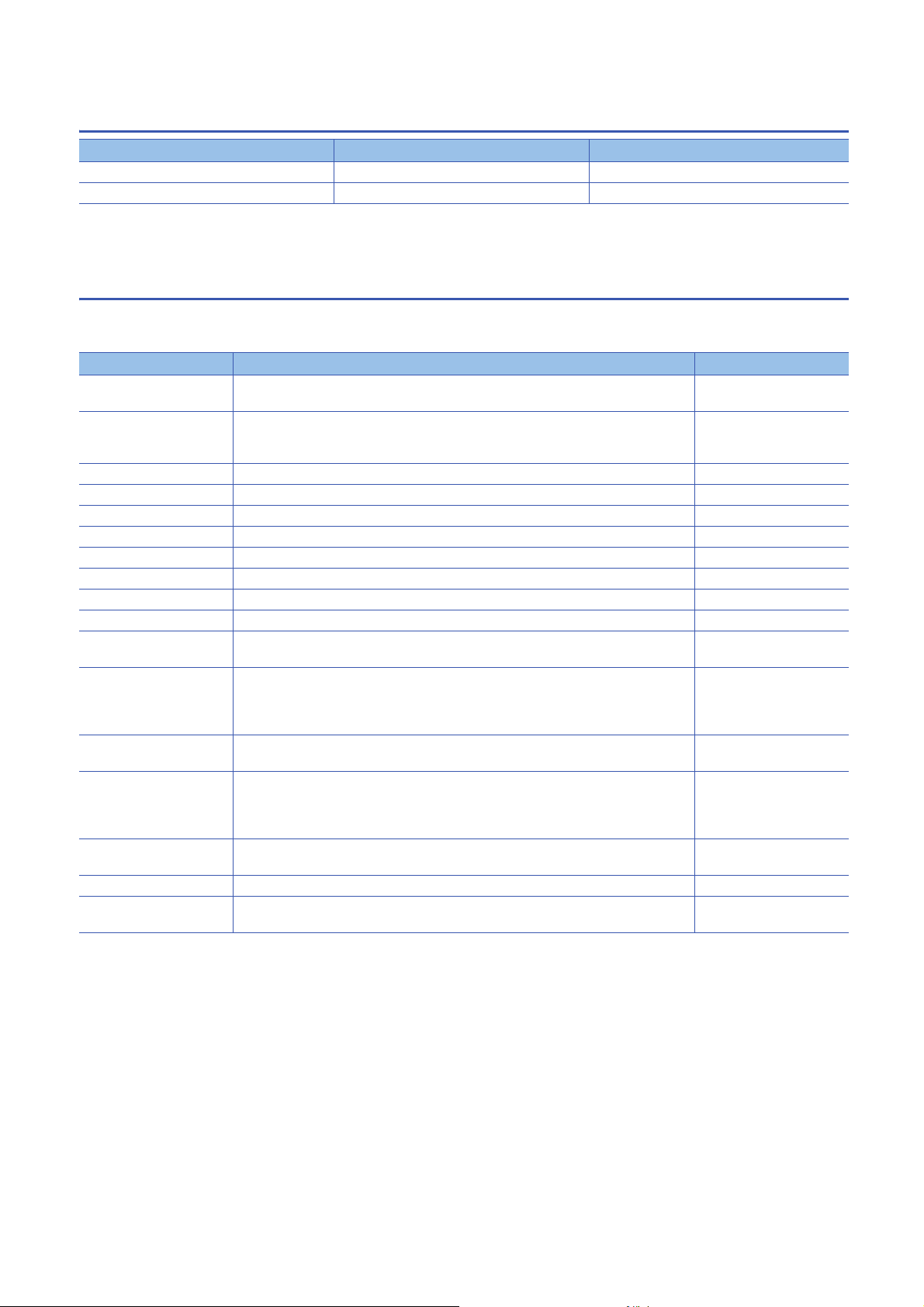

1.3 Combinations of power regeneration converter

units, drive units, and servo motors

Power regeneration converter unit Drive unit Rotary servo motor

Two units of MR-CV55K4 Two units of MR-J4-DU55KB4-RJ100 HG-JR110K24W0C

Four units of MR-CV55K4 Four units of MR-J4-DU45KB4-RJ100 HG-JR150K24W0C

HG-JR180K24W0C

Four units of MR-CV55K4 Four units of MR-J4-DU55KB4-RJ100 HG-JR200K24W0C

HG-JR220K24W0C

1 FUNCTIONS AND CONFIGURATION

1.2 Model designation

13

Page 16

1.4 Compatible controller

Motion controller Operating system Remark

Q173DSCPU SW8DNC-SV22S87QJ Special operating system

Q172DSCPU SW8DNC-SV22S87QL Special operating system

*1

*1

*1 Motion controllers with a special operating system can be used. Motion controllers with a standard operating system cannot drive

ultrahigh capacity servo motors. For details, contact your local sales office.

1.5 Function list

For the drive unit functions not mentioned in this section, refer to section 1.5 in "MR-J4-_B_(-RJ) Servo Amplifier Instruction

Manual".

Function Description Detailed explanation

Advanced vibration

suppression control II

Adaptive filter II For parallel drive systems, "Automatic setting" is invalid. Only "Manual setting" is valid.

Scale measurement function For parallel drive systems, the scale measurement function is unavailable.

J3 compatibility mode For parallel drive systems, the J3 compatibility mode is unavailable.

Machine analyzer function For parallel drive systems, the machine analyzer function is unavailable.

Test operation mode For parallel drive systems, the test operation mode is unavailable.

Linear servo system For parallel drive systems, the linear servo system is unavailable.

Direct drive servo system For parallel drive systems, the direct drive servo system is unavailable.

Fully closed loop system For parallel drive systems, the fully closed loop system is unavailable.

One-touch tuning For parallel drive systems, the one-touch tuning is unavailable.

SEMI-F47 function A combination of the MR-CV55K4_ power regeneration converter unit and drive unit does not

Tough drive function The tough drive function includes two types: the vibration tough drive and the instantaneous

STO function This function is a functional safety that complies with IEC/EN 61800-5-2. You can create a

Power monitoring function When checking the power in the parallel drive system, use the servo system controller. This

MR-D30 functional safety unit By using MR-D30 together, the safety observation function can be expanded. STO, SS1, SS2,

MR-J3-D05 safety logic unit For parallel drive systems, the MR-J3-D05 safety logic unit is unavailable.

MR-CR_ resistance

regeneration converter unit

For parallel drive systems, "Automatic setting" is invalid. Only "Manual setting" is valid.

This function suppresses vibration and residual vibration at an arm end.

The servo amplifier detects mechanical resonance and sets filter characteristics automatically

to suppress mechanical vibration.

comply with SEMI-F47 standard.

power failure tough drive. For parallel drive systems, only the vibration tough drive is available.

This function makes the equipment continue operating even under the condition that an alarm

occurs.

safety system for the equipment easily.

function calculates the power running energy and the regenerative power from the data in the

servo amplifier such as speed and current. In the SSCNET III/H system, the data are sent to a

servo system controller for analyzing and displaying the power consumption on a display.

SOS, SLS, SSM, and SBC can be used.

For parallel drive systems, the MR-CR_ resistance regeneration converter unit is unavailable.

Page 35 PARAMETERS

Page 35 PARAMETERS

Page 35 PARAMETERS

Page 35 PARAMETERS

Page 72 USING STO

FUNCTION

Page 74 APPLICATION

OF FUNCTIONS

14

1 FUNCTIONS AND CONFIGURATION

1.4 Compatible controller

Page 17

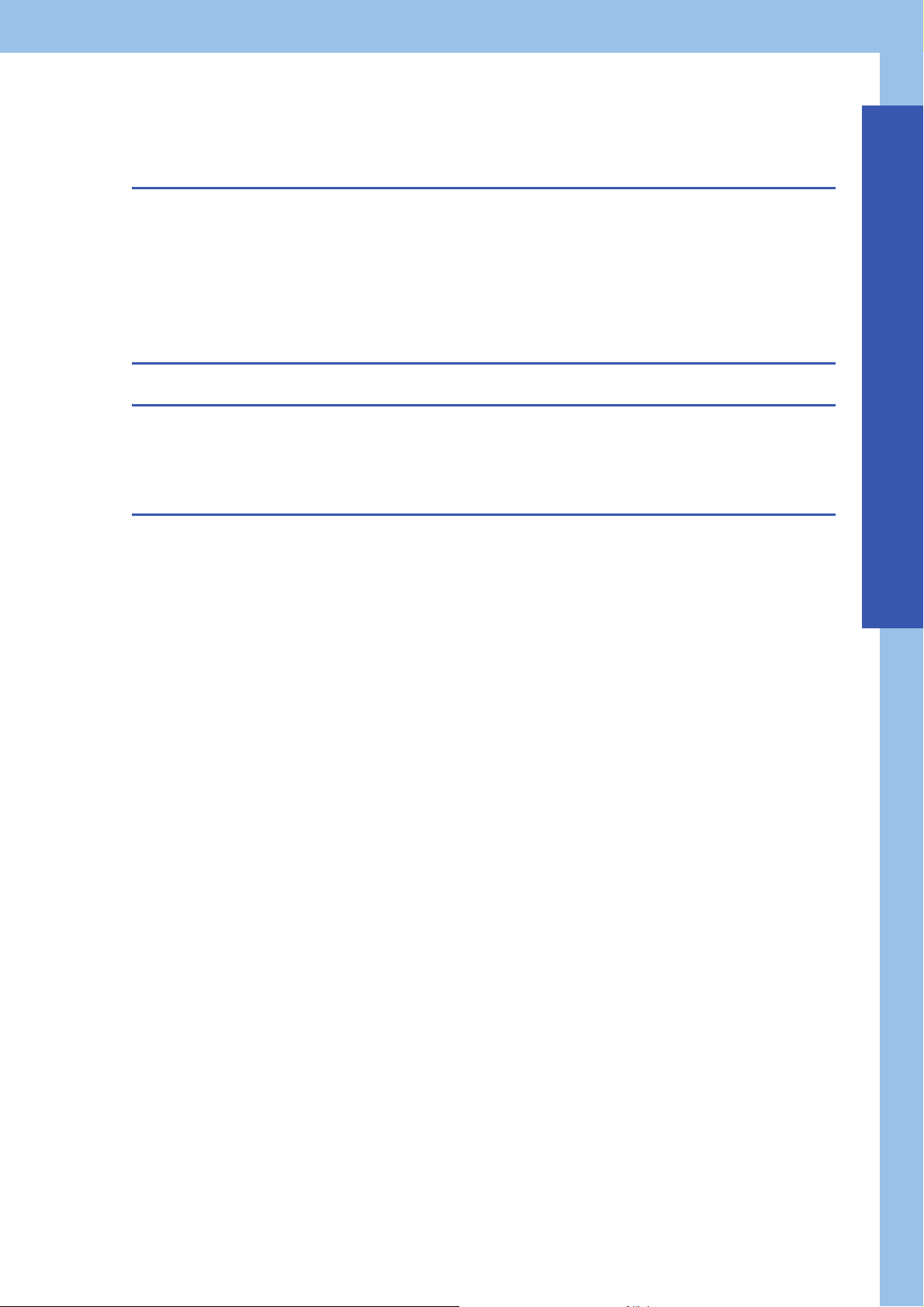

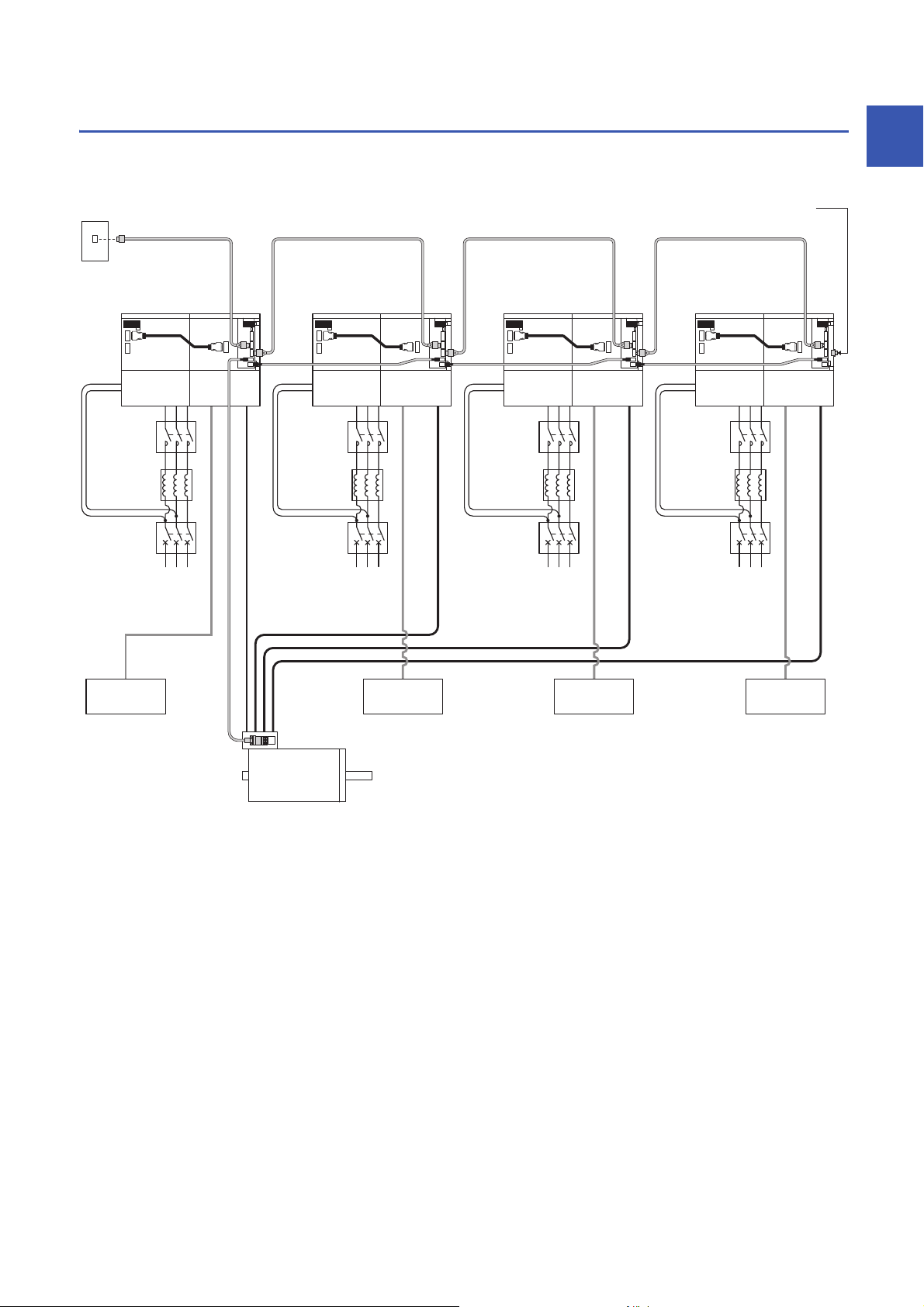

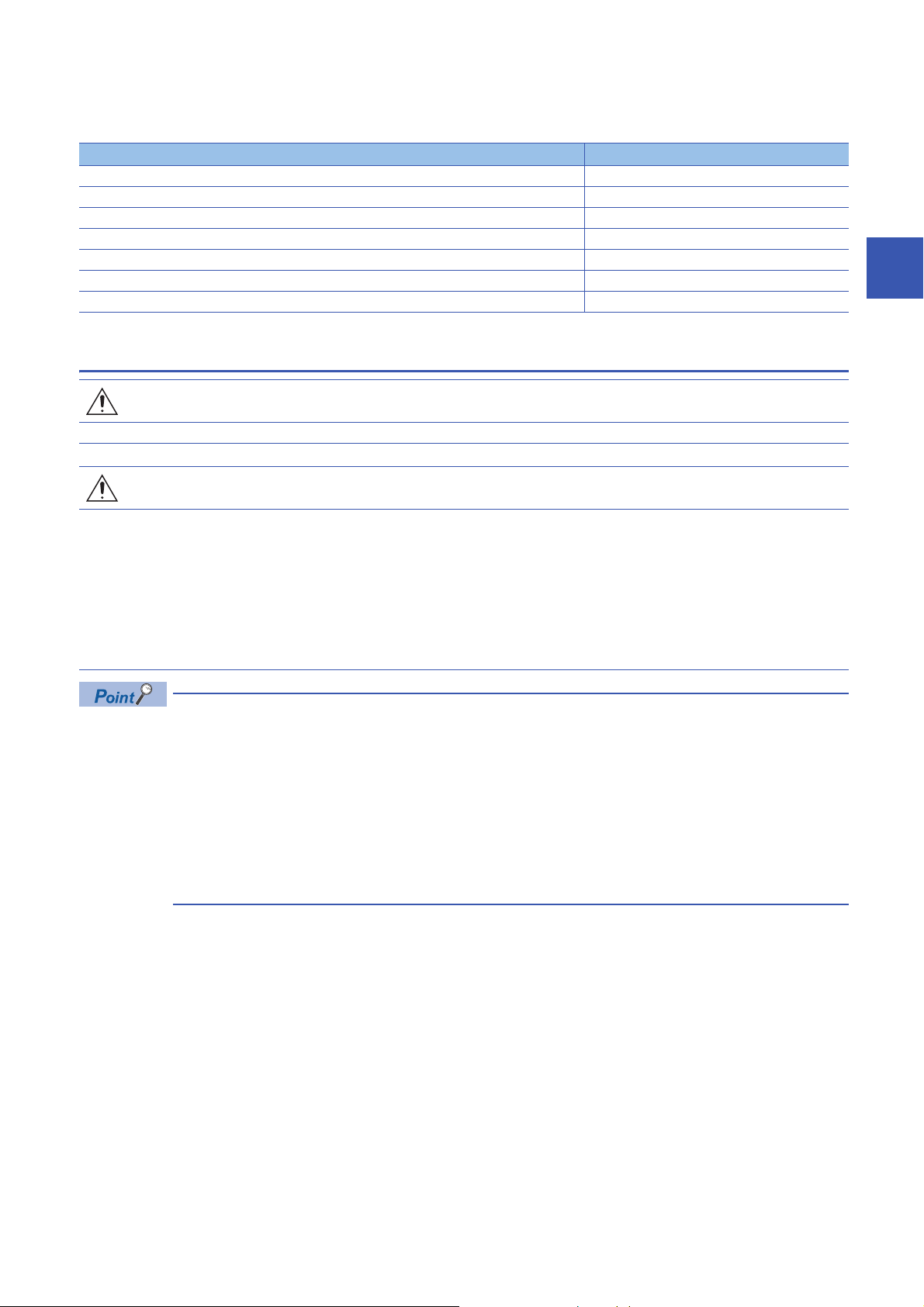

1.6 Configuration including peripheral equipment

The diagram shows a system that drives a servo motor with four MR-J4-DU_B4-RJ100 drive units and four MR-CV55K4_

power regeneration converter units connected.

1

Servo system

*8

controller

SSCNET III/H

Encoder slave

servo amplifier 1

Magnetic

contactor

(MC)

AC reactor

(MR-AL-55K4-L)

Molded-case

circuit breaker

(MCCB)

Drive

unit 1

*2, *5

*3

Encoder master servo amplifier

Power

regeneration

converter unit 1

*7 *7 *7 *7

Magnetic

contactor

(MC)

AC reactor

(MR-AL-55K4-L)

*6

Molded-case

circuit breaker

(MCCB)

Power supply

3-phase

380 V AC to

480 V AC

*3

Power

regeneration

converter unit 2

*4 *4 *4

*6

Power supply

3-phase

380 V AC to

480 V AC

Drive

unit 2

*2, *5

Encoder slave

servo amplifier 2

Power

regeneration

converter unit 3

Magnetic

contactor

(MC)

AC reactor

(MR-AL-55K4-L)

*6

Molded-case

circuit breaker

(MCCB)

Power supply

3-phase

380 V AC to

480 V AC

*3

Drive

unit 3

*2, *5

Encoder slave

servo amplifier 3

Power

regeneration

converter unit 4

Magnetic

contactor

(MC)

AC reactor

(MR-AL-55K4-L)

*6

Molded-case

circuit breaker

(MCCB)

Power supply

3-phase

380 V AC to

480 V AC

Fit a cap

(standard accessory)

on the unused connector.

*3

Drive

unit 4

*2, *5

Dynamic brake

(DBU-P55K-4-B)

*1

Servo motor

Dynamic brake

(DBU-P55K-4-B)

Dynamic brake

(DBU-P55K-4-B)

Dynamic brake

(DBU-P55K-4-B)

*1 Connect the grounding wire of the servo motor to only the first drive unit. If the grounding wire of the servo motor is connected to two or

more drive units, the circulating current may pass through the grounding wire depending on wiring conditions. When connecting

grounding wires to two or more drive units, be sure to twist the wires of the drive unit power outputs (U/V/W) for safety reasons.

*2 For the power supply, one molded-case circuit breaker, one AC reactor (MR-AL-55K4-L), and one magnetic contactor are required for

each power regeneration converter unit.

*3 Since the system is connected via SSCNET III/H, use a servo amplifier near the Motion controller as an encoder master servo amplifier,

and use the remaining servo amplifiers as encoder slave servo amplifiers. Connect the encoder master servo amplifier and slave servo

amplifiers in series to the same SSCNET III/H system.

*4 The encoder cables between drive units should be within 5 m.

*5 Supply power to all the servo amplifiers (power regeneration converter units and drive units) from the same power source. If power is

supplied from different power sources, a difference may be generated between outputs of the encoder master servo amplifier and

encoder slave servo amplifiers. This may cause the servo motor to operate unpredictably.

*6 Even if an AC reactor is installed on the power regeneration converter unit, the functions operate normally.

*7 Switch on the control circuit power supplies of all the servo amplifiers (power regeneration converter units and drive units)

simultaneously.

*8 Stop all the drive units with the emergency stop of the controller if an alarm occurs.

1 FUNCTIONS AND CONFIGURATION

1.6 Configuration including peripheral equipment

15

Page 18

2 INSTALLATION

WARNING

• To prevent electric shock, ground each equipment securely.

CAUTION

• Stacking in excess of the specified number of product packages is not allowed.

• Do not hold the front cover, cables, or connectors when carrying the converter unit and drive unit. Otherwise, it may drop.

• Install the equipment on incombustible material. Installing them directly or close to combustibles will lead to a fire.

• Install the converter unit, the drive unit, and the servo motor in a load-bearing place in accordance with the Instruction Manual.

• Do not get on or put heavy load on the equipment. Otherwise, it may cause injury.

• Use the equipment within the specified environment. For the environment, refer to section 1.4 in "MR-CV_/MR-CR55K_/MR-J4-DU_(-RJ) Instruction

Manual".

• Provide adequate protection to prevent screws and other conductive matter, oil and other combustible matter from entering the converter unit and the drive

unit.

• Do not block the intake and exhaust areas of the converter unit and the drive unit. Otherwise, it may cause a malfunction.

• Do not drop or apply heavy impact on the converter units, the drive units, and the servo motors. Otherwise, it may cause injury, malfunction, etc.

• Do not install or operate the converter unit and the drive unit which have been damaged or have any parts missing.

• When the equipment has been stored for an extended period of time, contact your local sales office.

• When handling the converter unit and the drive unit, be careful with the sharp edges of the converter unit and drive unit.

• The converter unit and the drive unit must be installed in a metal cabinet.

• When fumigants that contain halogen materials, such as fluorine, chlorine, bromine, and iodine, are used for disinfecting and protecting wooden packaging

from insects, they cause a malfunction when entering our products. Please take necessary precautions to ensure that remaining materials from fumigant do

not enter our products, or treat packaging with methods other than fumigation, such as heat treatment. Additionally, disinfect and protect wood from insects

before packing the products.

The following items are the same as those for MR-J4-_B_(-RJ). Refer to the section of the detailed explanation field for

details. "MR-J4-_B_" means "MR-J4-_B_(-RJ) Servo Amplifier Instruction Manual". "MR-J4-DU_B_" means "MR-CV_/MR-

CR55K_/MR-J4-DU_(-RJ) Instruction Manual".

Item Detailed explanation

Keeping out of foreign materials MR-J4-DU_B_ section 2.2

Encoder cable stress MR-J4-_B_ section 2.3

SSCNET III cable laying MR-J4-_B_ section 2.4

Inspection items MR-J4-DU_B_ section 2.3

Parts having service life MR-J4-DU_B_ section 2.4

Restrictions when using this product at altitude exceeding 1000 m and up to 2000 m above sea level MR-J4-DU_B_ section 2.5

16

2 INSTALLATION

Page 19

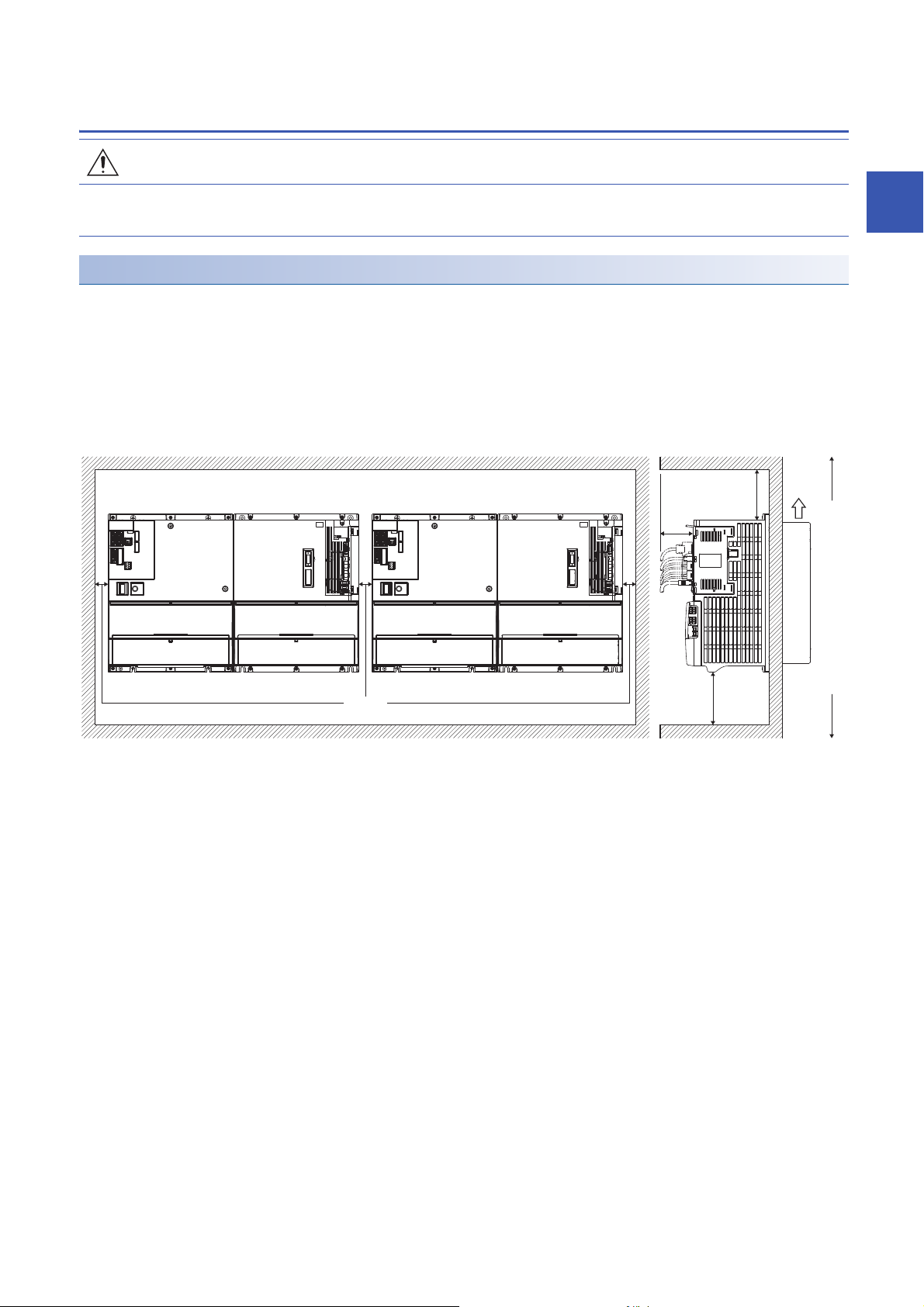

2.1 Installation direction and clearances

Cooling

fan

exhaust

80 mm

or more

SideFront

100 mm

or more

120 mm

or more

*1

Drive unitConverter unit Drive unitConverter unit

30 mm

Top

Bottom

CAUTION

• The equipment must be installed in the specified direction. Otherwise, it may cause a malfunction.

• Maintain specified clearances between the converter unit/drive unit and the inner surfaces of a control cabinet or other equipment. Otherwise, it may cause a

malfunction.

Installation

Make sure to connect a drive unit to the right side of a power regeneration converter unit. Since the units require a cooling

mechanism outside the cabinet, an opening must be provided in each mounting surface as shown below.

The TE2-1 terminal block of the drive unit and the TE2 terminal block of the power regeneration converter unit are connected

using a bus bar. Thus, remove the supplied cover on the right side of the power regeneration converter unit.

■Clearance between sets of combined power regeneration converter units and drive units

mounted side by side

2

*1 A clearance of at least 120 mm is required. Leave a clearance, taking into consideration the flexibility of the cable.

2.1 Installation direction and clearances

2 INSTALLATION

17

Page 20

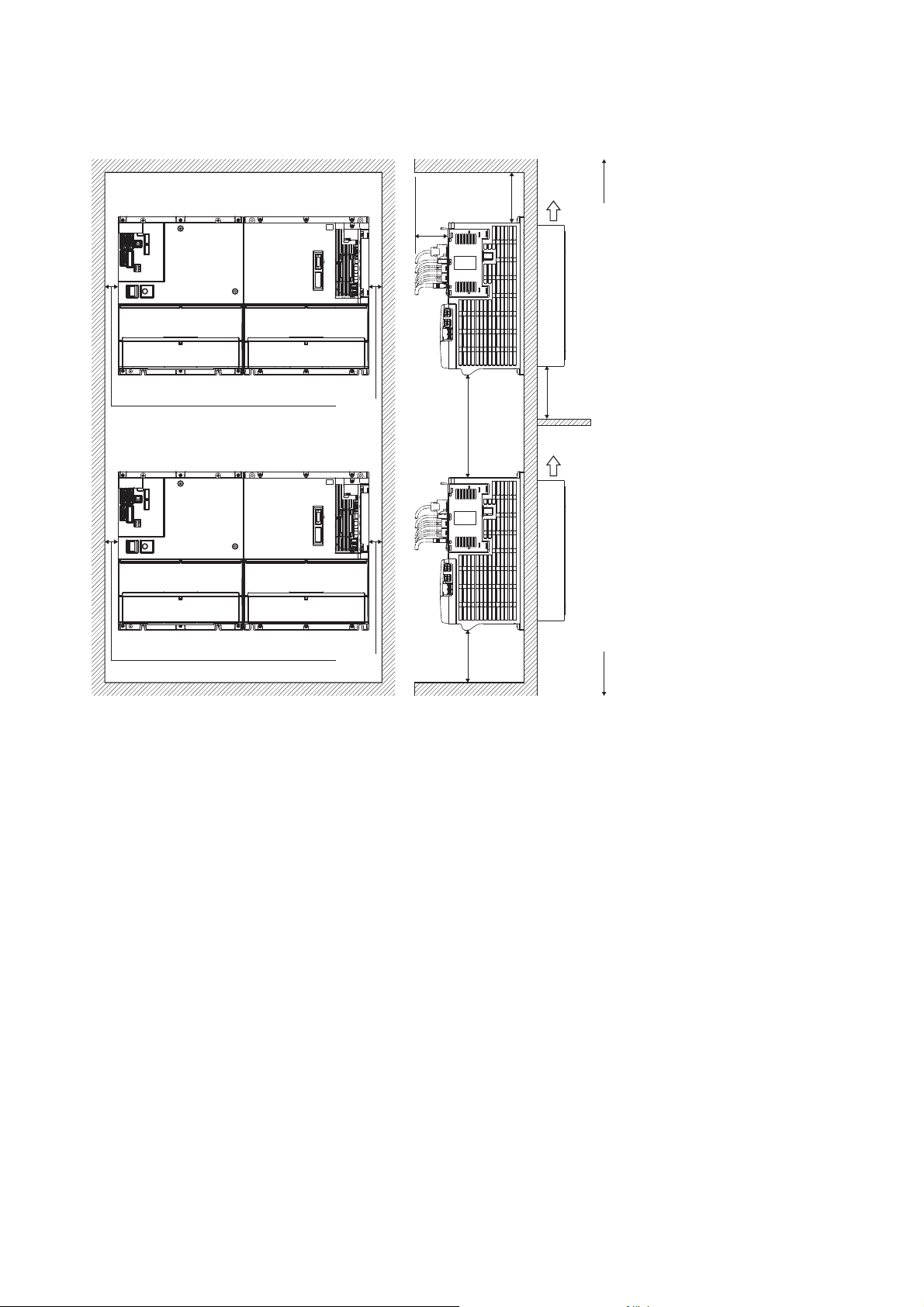

■Clearance between sets of combined power regeneration converter units and drive units

mounted above each other

220 mm

or more

Cooling

fan

exhaust

Top

*1

Cooling

100 mm

or more

Drive unitConverter unit

30 mm

Drive unitConverter unit

80 mm

or more

220 mm

or more

fan

exhaust

120 mm

30 mm

*1 Take measures, such as installing a shield, to prevent cooling fan exhaust of the lower unit from affecting the cooling fan on the upper

unit.

*2 A clearance of at least 120 mm is required. Leave a clearance, taking into consideration the flexibility of the cable.

or more

*2

Side

Bottom

18

2 INSTALLATION

2.1 Installation direction and clearances

Page 21

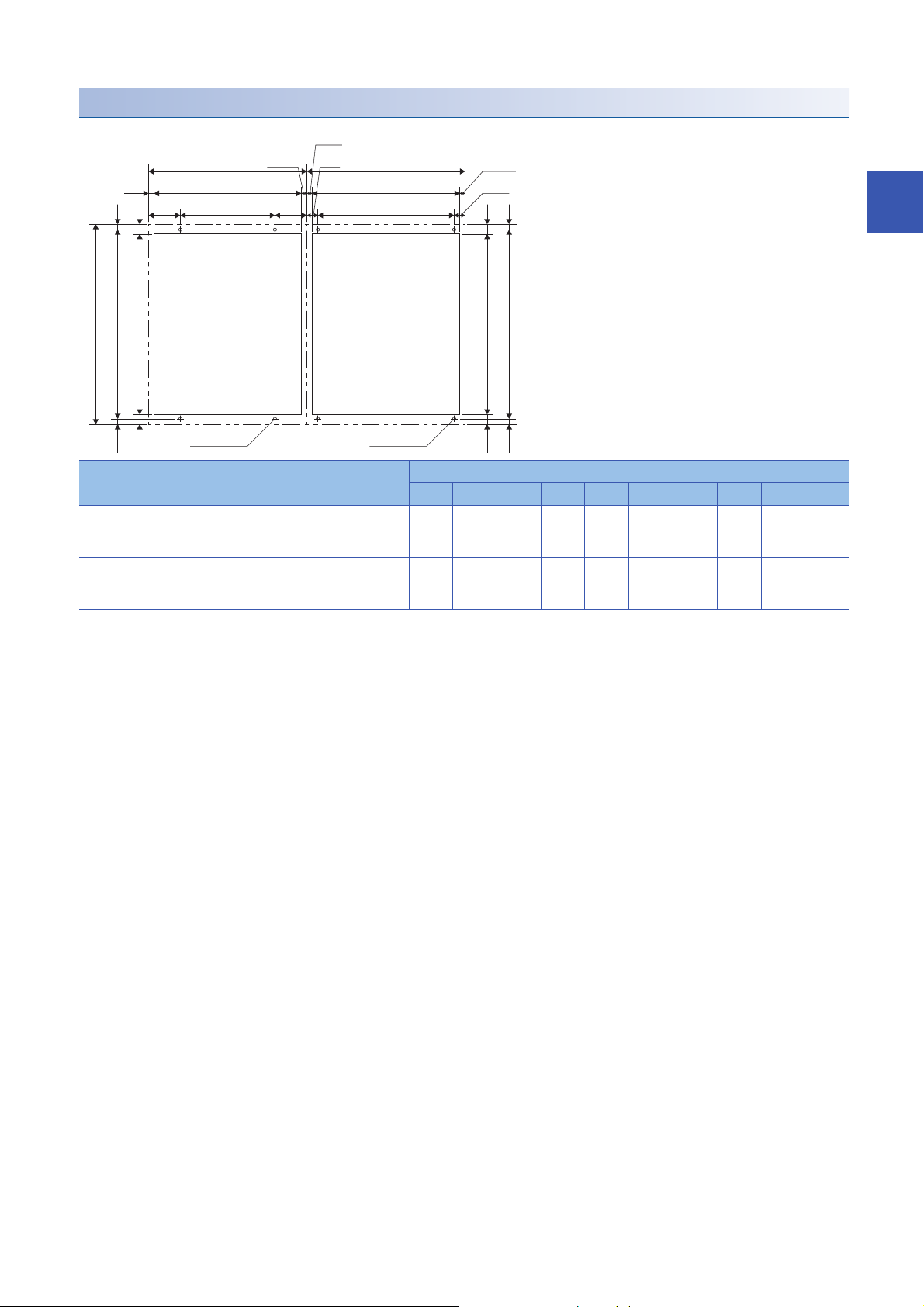

Mounting hole process drawing

Power regeneration

converter unit

Opening

Drive unit

Opening

380

360 ± 0.5 10(10)

342 19

(19)

4-M5 screw

W6

W8

W7

W9

(W10)

(W8)

W10

(W3)

360 ± 0.5 10(10)

342 19(19)

W1

W3

W4

W2

(W5)

W5

4-M5 screw

Unit Variable dimensions [mm]

W1 W2 W3 W4 W5 W6 W7 W8 W9 W10

Power regeneration converter

unit

Drive unit MR-J4-DU45KB4-RJ100

MR-CV55K4 300 180

0.5

300 260

MR-J4-DU55KB4-RJ100

60 282 9

2

20 281 9.5

0.5

2 INSTALLATION

2.1 Installation direction and clearances

19

Page 22

3 SIGNALS AND WIRING

U

Servo motor

MV

W

U

V

W

Drive unit

U

Servo motor

MV

W

U

V

W

Drive unit

WARNING

• Any person who is involved in wiring should be fully competent to do the work.

• Before wiring, turn off the power and wait for 20 minutes or more until the charge lamp turns off. Then, confirm that the voltage between L+ and L- is safe with

a voltage tester or others. Otherwise, an electric shock may occur. In addition, when confirming whether the charge lamp is off or not, always confirm it from

the front of the converter unit.

• Ground the converter unit, drive unit, and servo motor securely.

• Do not attempt to wire the converter unit, drive unit, and servo motor until they have been installed. Otherwise, it may cause an electric shock.

• The cables should not be damaged, stressed, loaded, or pinched. Otherwise, it may cause an electric shock.

• To avoid an electric shock, insulate the connections of the power supply terminals.

CAUTION

• Wire the equipment correctly and securely. Otherwise, the servo motor may operate unexpectedly, resulting in injury.

• Connect cables to the correct terminals. Otherwise, a burst, damage, etc., may occur.

• Ensure that polarity (+/-) is correct. Otherwise, a burst, damage, etc., may occur.

• The surge absorbing diode installed to the DC relay for control output should be fitted in the specified direction. Otherwise, the converter unit and the drive

unit will malfunction and will not output signals, disabling the emergency stop and other protective circuits.

Converter unit

Drive unit

DOCOM

Control

output signal

For sink output interface

• Use a noise filter, etc., to minimize the influence of electromagnetic interference. Electromagnetic interference may affect the electronic equipment used near

the converter unit and the drive unit.

• Do not install a power capacitor, surge killer, or radio noise filter (optional FR-BIF(-H)) with the power line of the servo motor.

• Do not modify the equipment.

• Connect the drive unit power outputs (U/V/W) to the servo motor power inputs (U/V/W) directly. Do not connect a magnetic contactor and others between

them. Otherwise, it may cause a malfunction.

• Connecting a servo motor of the wrong axis to U, V, W, or CN2 of the drive unit may cause a malfunction.

• Before wiring, switch operation, etc., eliminate static electricity. Otherwise, it may cause a malfunction.

24 V DC

RA

Converter unit

Drive unit

24 V DC

DOCOM

Control

output signal

For source output interface

RA

20

3 SIGNALS AND WIRING

Page 23

The following items are the same as those for MR-J4-_B_(-RJ). Refer to the section of the detailed explanation field for

details. "MR-J4-_B_" means "MR-J4-_B_(-RJ) Servo Amplifier Instruction Manual". "MR-J4-DU_B_" means "MR-CV_/MR-

CR55K_/MR-J4-DU_(-RJ) Instruction Manual".

Item Detailed explanation

I/O signal connection example MR-J4-_B_ section 3.2

Explanation of power supply system MR-J4-DU_B_ sections 3.3 and 5.2

Connectors and pin assignment MR-J4-DU_B_ sections 3.3 and 5.2

Signal (device) explanations MR-J4-_B_ section 3.5

Forced stop deceleration function MR-J4-_B_ section 3.6

Interface MR-J4-DU_B_ section 3.3

SSCNET III cable connection MR-J4-_B_ section 3.9

3.1 Connection example of power circuit

WARNING

• Insulate the connections of the power supply terminals. Otherwise, an electric shock may occur.

CAUTION

• Be sure to connect a magnetic contactor between the power supply and the main circuit power supply (L1/L2/L3) of the power regeneration converter unit, in

order to configure a circuit that shuts off the power supply by the power regeneration converter unit. If a magnetic contactor is not connected, continuous flow

of a large current may cause a fire when the power regeneration converter unit or the drive unit malfunctions.

• Use ALM (Malfunction) to shut the power off. Not doing so may cause a fire when the power regeneration converter unit malfunctions and causes the AC

reactor to overheat.

• The power regeneration converter unit has a built-in surge absorber (varistor) to reduce exogenous noise and to suppress lightning surge. Exogenous noise

or lightning surge deteriorates the varistor characteristics, and the varistor may be damaged. To prevent a fire, use a molded-case circuit breaker or fuse for

the input power supply.

• Check the power regeneration converter unit model, and then input proper voltage to the power regeneration converter unit power supply. If input voltage

exceeds the upper limit, the power regeneration converter unit and the drive unit will break down.

3

For drive units, EM2 has the same function as EM1 in the torque control mode.

Even if alarm has occurred, do not switch off the control circuit power supply. When the control circuit power

supply is shut off, an optical module does not operate, and optical transmission of SSCNET III/H

communication is interrupted. Therefore, the next servo amplifiers and drive units show "AA" on the display

and shut off the base circuit, stopping the servo motor with the dynamic brake.

For the magnetic contactor control connector (CN23), refer to section 3.3 in "MR-CV_/MR-CR55K_/MR-J4-

DU_(-RJ) Instruction Manual".

If the control axis No. is not be set correctly, or an SSCNET III cable is not be connected, the relay may switch

on and off repeatedly. Check the control axis No. setting and SSCNET III cable connection.

3 SIGNALS AND WIRING

3.1 Connection example of power circuit

21

Page 24

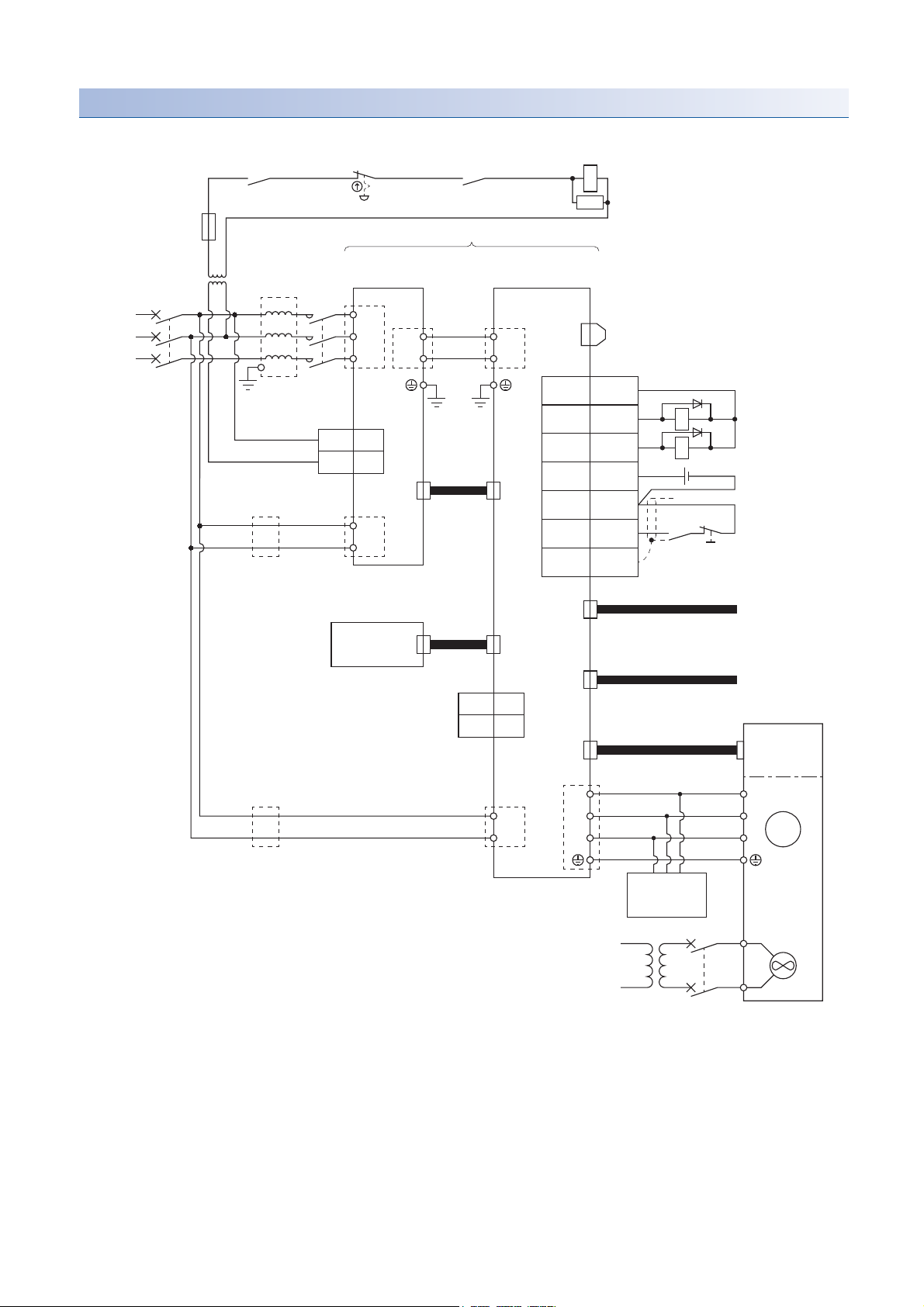

Connection example of encoder master servo amplifier

Drive unit

malfunction

*10

RA1

Operation ready

OFF/ON

Emergency

stop switch

MCCB

Power

supply

3-phase

380 V AC to

480 V AC

*16

Power regeneration

converter unit 1

MR-CV55K4

1MC1

3

MC2

CN23

TE3

CN4

1BAT

2LG

CN40A

CN1A

CN1B

CN4

CN2L

CN2

L1

L2

L3

L+

L-

AC

reactor

*14

MC

*5

L11

L21

L+

L-

Protection

coordination

cable

*11

Main circuit

power supply

*1

M

Encoder

Servo motor

BV

BU

Cooling

fan

V1

U1

W1

V

U

W

Dynamic

brake

(optional)

CN3

CN8

MR-ENE4CBL_M-H-MTH

*19

To CN1A on

drive unit 2 of

encoder slave

servo amplifier 1

To CN2 on

drive unit 2 of

encoder slave

servo amplifier 1

*8

TE2-2

TE2-1

TE1

Servo system

controller

TE3

TE1

L11

L21

MCCB

Encoder master servo amplifier

Step-down

transformer

*15

*13

*13

*2, *17

*2, *17

*4

*7

*3

*9

*4

*4

*10

*12

*4

MR-J4CN2CBL_M-H

SSCNET III cable

SSCNET III

cable

Bus bar

24 V DC

RA3

RA1

EM2

3

20

SD

Plate

DICOM10

ALM15

DOCOM

*18

DB

5 DICOM

Drive unit 1

MR-J4-DU_KB4-RJ100

MC

SK

Power supply

*6

22

3 SIGNALS AND WIRING

3.1 Connection example of power circuit

Page 25

*1 To prevent an unexpected restart of the drive unit, configure a circuit to turn off EM2 (Forced stop 2) in the drive unit when the main

circuit power is turned off.

*2 Always match the phases of the power supply connected to L11 and L21 on the power regeneration converter unit and the drive unit with

the phases connected to L1 and L2. Otherwise, the drive unit and the power regeneration converter unit may malfunction.

*3 Always supply power to the cooling fan terminal. For specifications of the cooling fan power supply and how to detect a failure, refer to

"Servo Motor Instruction Manual (Vol. 3)".

*4 Connect the grounding wire from the servo motor to the protective earth (PE) terminal of the drive unit. Put the grounding wires of the

drive unit and the power regeneration converter unit together

into one on the protective earth (PE) terminal of the cabinet, and then connect to the ground. Connect the grounding wire of the servo

motor to only the drive unit of the encoder master servo amplifier. If the grounding wire of the servo motor is connected to two or more

drive units, the circulating current may pass through the grounding wire depending on wiring conditions. When connecting grounding

wires to two or more drive units, be sure to twist the wires of the drive unit power outputs (U/V/W).

*5 Use a magnetic contactor with an operation delay time (interval between current being applied to the coil until closure of contacts) of 80

ms or less.

*6 For absolute position detection systems, connect an optional battery to only the drive unit of the encoder master servo amplifier. Do not

connect the optional battery to the drive units of the encoder slave servo amplifiers.

*7 Use an external dynamic brake (option) together. Failure to do so will cause an accident, such as machine collision because the servo

motor does not stop immediately but coasts at emergency stop. For wiring of the dynamic brake, refer to the following.

Page 69 External dynamic brake

*8 Encoder signals are distributed to all the drive units in the system via each drive unit.

*9 This diagram shows sink I/O interface. For source I/O interface, refer to section 3.8.3 in MR-J4-_B_(-RJ) Servo Amplifier Instruction

Manual.

*10 Configure a sequence that will shut off the main circuit power when an alarm occurs.

*11 Configure a circuit to simultaneously turn on or off EM2 (Forced stop 2) in the drive units of the encoder master servo amplifier and

encoder slave servo amplifiers.

*12 When not using the STO function, always attach the short-circuit connector supplied with the drive unit.

*13 If the wire size used for the branch circuit is smaller than that used for L1, L2, and L3, install an overcurrent protection device (molded-

case circuit breaker, fuse, or others) to protect the circuit.

*14 Even if an AC reactor is installed on the power regeneration converter unit, the functions operate normally.

*15 A step-down transformer is required when the coil voltage of the magnetic contactor is 200 V class.

*16 Supply power to all the servo amplifiers (power regeneration converter units and drive units) from the same power source. If power is

supplied from different power sources, a difference may be generated between outputs of the encoder master servo amplifier and that of

encoder slave servo amplifiers. This may cause the servo motor to operate unpredictably.

*17 Switch on the control circuit power supplies of all the servo amplifiers (power regeneration converter units and drive units)

simultaneously.

*18 The dynamic brake must be controlled by the drive unit of the encoder master servo amplifier. Assign DB (Dynamic brake interlock) in

[Pr. PD07] to [Pr. PD09].

*19 The encoder cable has a thermistor signal wire. Wiring the thermistor signal is unnecessary.

3

3 SIGNALS AND WIRING

3.1 Connection example of power circuit

23

Page 26

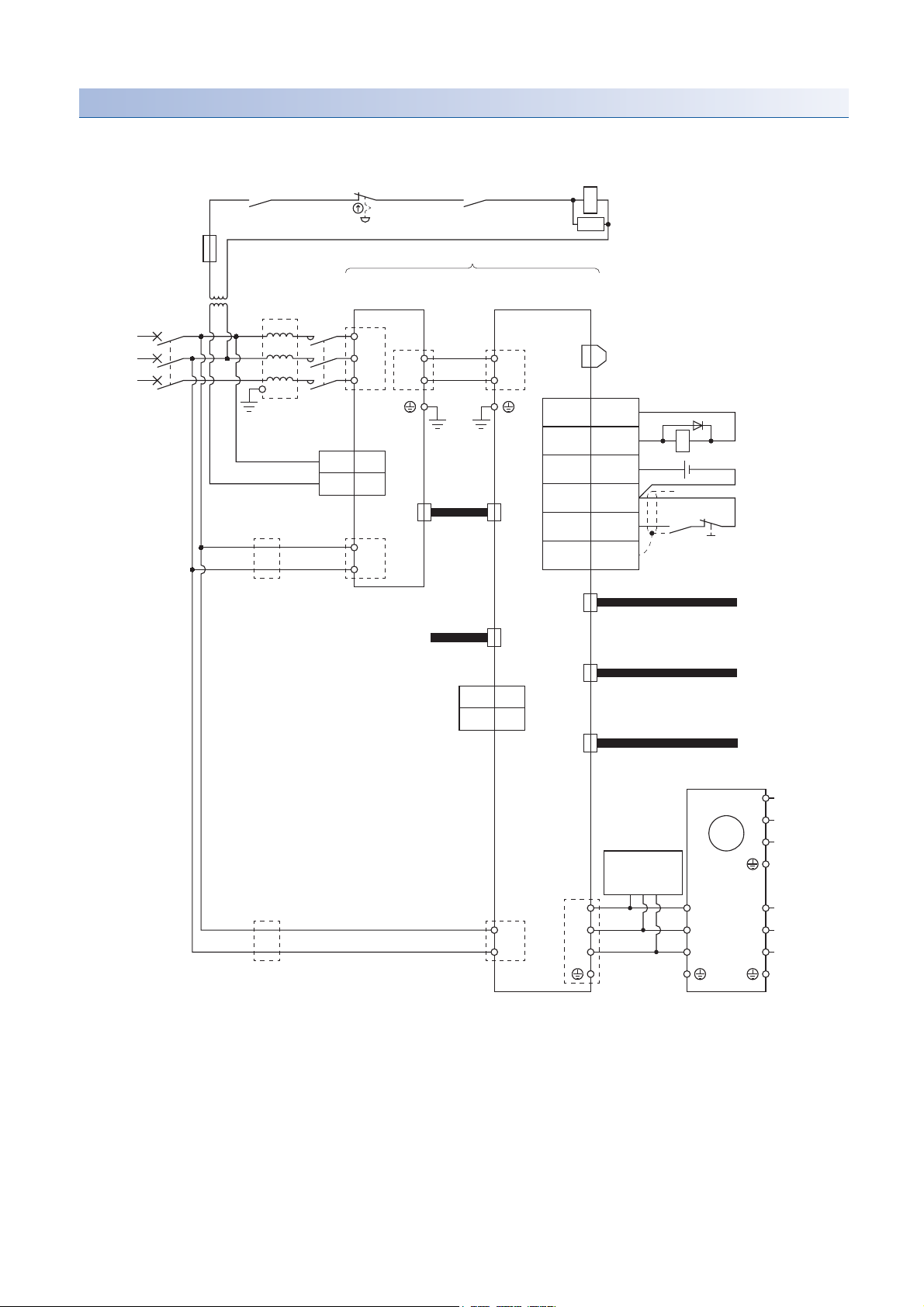

Connection example of encoder slave servo amplifier

This example is the connection for the encoder slave servo amplifier 1.

Step-down

transformer

Power

supply

3-phase

380 V AC to

480 V AC

Drive unit

malfunction

RA2

*10

Emergency

stop switch

Operation ready

OFF/ON

MC

SK

Encoder slave servo amplifier 1

Power regeneration

*15

MCCB

*16

AC

reactor

*14

MC

converter unit 2

TE1

*20

L1

L2

L3

MR-CV55K4

TE2-2

L+

L-

Bus bar

*4

Drive unit 2

MR-J4-DU_KB4-RJ100

TE2-1

L+

L-

*4

CN8

CN3

*12

*9

DICOM10

CN23

1MC1

CN4

Protection

coordination

cable

CN40A

Plate

3

MC2

*13

*2, *17

TE3

L11

ALM15

5 DICOM

DOCOM

3

EM2

20

SD

RA2

24 V DC

Main circuit

power supply

*10

*11

*1

L21

To CN1A on

drive unit 3 of

encoder slave

servo amplifier 2

To CN2 on

drive unit 3 of

encoder slave

servo amplifier 2

To CN2L on

drive unit 1 of

encoder master

servo amplifier

*5

*5, *8

*8

To CN1B on drive unit 1 of

encoder master servo amplifier

SSCNET III

cable

*6

CN1A

CN4

1BAT

2LG

CN1B

SSCNET III cable

MR-J4CN2CBL_M-H

CN2L

MR-J4CN2CBL_M-H

CN2

Servo motor

U3

To drive unit 3

of encoder

slave

V3

W3

*4

U4

V4

W4

*4

servo

amplifier 2

To drive unit 4

of encoder

slave

servo

amplifier 3

*5

*5

M

Dynamic

*7

brake

TE1

*13

*2, *17

TE3

L11

L21

U

V

W

*4

(optional)

U2

V2

W2

*4

24

3 SIGNALS AND WIRING

3.1 Connection example of power circuit

Page 27

*1 To prevent an unexpected restart of the drive unit, configure a circuit to turn off EM2 (Forced stop 2) in the drive unit when the main

circuit power is turned off.

*2 Always match the phases of the power supply connected to L11 and L21 on the power regeneration converter unit and the drive unit with

the phases connected to L1 and L2. Otherwise, the drive unit and the power regeneration converter unit may malfunction.

*3 Use a magnetic contactor with an operation delay time (interval between current being applied to the coil until closure of contacts) of 80

ms or less.

*4 Connect the grounding wire from the servo motor to the protective earth (PE) terminal of the drive unit. Put the grounding wires of the

drive unit and the power regeneration converter unit together

into one on the protective earth (PE) terminal of the cabinet, and then connect to the ground. Connect the grounding wire of the servo

motor to only the drive unit of the encoder master servo amplifier. If the grounding wire of the servo motor is connected to two or more

drive units, the circulating current may pass through the grounding wire depending on wiring conditions. When connecting grounding

wires to two or more drive units, be sure to twist the wires of the drive unit power outputs (U/V/W).

*5 This is for connecting four drive units and four power regeneration converter units to the servo motor.

*6 For the absolute position detection system, connect an optional battery to only the drive unit of the encoder master servo amplifier. Do

not connect the optional battery to the drive units of the encoder slave servo amplifiers.

*7 Use an external dynamic brake (option) together. Failure to do so will cause an accident, such as machine collision because the servo

motor does not stop immediately but coasts at emergency stop. For wiring of the dynamic brake, refer to the following.

Page 69 External dynamic brake

*8 Encoder signals are distributed to all the drive units in the system via each drive unit.

*9 This diagram shows sink I/O interface. For source I/O interface, refer to section 3.8.3 in MR-J4-_B_(-RJ) Servo Amplifier Instruction

Manual.

*10 Configure a sequence that will shut off the main circuit power when an alarm occurs.

*11 Configure a circuit to simultaneously turn on or off EM2 (Forced stop 2) in the drive units of the encoder master servo amplifier and

encoder slave servo amplifiers.

*12 When not using the STO function, always attach the short-circuit connector supplied with the drive unit.

*13 If the wire size used for the branch circuit is smaller than that used for L1, L2, and L3, install an overcurrent protection device (molded-

case circuit breaker, fuse, or others) to protect the circuit.

*14 Even if an AC reactor is installed on the power regeneration converter unit, the functions operate normally.

*15 A step-down transformer is required when the coil voltage of the magnetic contactor is 200 V class.

*16 Supply power to all the servo amplifiers (power regeneration converter units and drive units) from the same power source. If power is

supplied from different power sources, a difference may be generated between outputs of the encoder master servo amplifier and that of

encoder slave servo amplifiers. This may cause the servo motor to operate unpredictably.

*17 Switch on the control circuit power supplies of all the servo amplifiers (power regeneration converter units and drive units)

simultaneously.

3

3 SIGNALS AND WIRING

3.1 Connection example of power circuit

25

Page 28

3.2 Alarm occurrence timing chart

Power

regeneration

converter unit 4

Drive

unit 4

Encoder slave servo amplifier 3

Power

regeneration

converter unit 3

Drive

unit 3

Encoder slave servo amplifier 2

Power

regeneration

converter unit 2

Drive

unit 2

Encoder slave servo amplifier 1

SSCNET III/H

Servo system

controller

Power

regeneration

converter unit 1

Drive

unit 1

Encoder master servo amplifier

Servo motor

Alarm non-occurrence axis Alarm occurrence axis Alarm non-occurrence axis Alarm non-occurrence axis

Alarm occurrence

CAUTION

• When an alarm has occurred, remove its cause, make sure that the operation signal is not being inputted, ensure safety, and reset the alarm before

restarting operation.

When SSCNET III/H communication is shut off, the servo motor stops with the dynamic brake.

In the torque control mode, the forced stop deceleration function is unavailable.

This section describes MR-J4-DU_B4-RJ100 drive units only. For MR-CV55K4_power regeneration converter

units, refer to section 3.3 in "MR-CV_/MR-CR55K_/MR-J4-DU_(-RJ) Instruction Manual".

To deactivate the alarm, cycle the control circuit power or give the error reset or CPU reset command from the servo system

controller. However, the alarm cannot be deactivated unless its cause is removed.

Timing charts in this section show that an alarm occurs in any axis in the four axis of the parallel drive system.

3 SIGNALS AND WIRING

26

3.2 Alarm occurrence timing chart

Page 29

When you use the forced stop deceleration function

Set [Pr. PA04] to "2 _ _ _" (initial value).

Time constant setting

When you use the forced stop deceleration function, set the same value in the forced stop deceleration time constant [Pr.

PC24] of the drive unit and the rapid stop deceleration time set with the Motion controller.

■Difference between the deceleration time constant and the deceleration time

The following shows the difference between the forced stop deceleration time constant and the rapid stop deceleration time.

• Forced stop deceleration time constant (Drive unit)

The time for the servo motor to stop from the rated speed

[r/min]

Servo motor rated speed

Command speed

[ms]

Time required for the

servo motor to stop

Forced stop deceleration

time constant [Pr. PC24]

• Rapid stop deceleration time (Motion controller)

Time for the servo motor to stop from the speed limit value of the Motion controller

3

Speed limit value

Command speed

[pulse/s]

[ms]

Time required for the

servo motor to stop

Rapid stop deceleration time

3 SIGNALS AND WIRING

3.2 Alarm occurrence timing chart

27

Page 30

■Formula for calculating the rapid stop deceleration time

Rapid stop deceleration time [ms] =

Forced stop deceleration time constant [ms] × Speed limit value [pulse/s]

*1

× 60 [s]

Servo motor rated speed [r/min] × 4194304 [pulse]

Rapid stop deceleration time [ms] =

1000 × 2097152 × 60

2000 × 4194304

= 15 [ms]

*1 In addition to [pulse/s], [mm/min], [inch/min], and [degree/min] are used for the control unit of the Motion controller. When a control unit

other than [pulse/s] is used, convert the unit into [pulse/s] to calculate the rapid stop deceleration time.

■Setting example of the rapid stop deceleration time

Condition

Servo motor rated speed: 2000 [r/min] (Depends on the servo motor)

Speed limit value: 2097152 [pulse/s] (Depends on users, setting by the motion controller)

Forced stop deceleration time constant: 1000 [ms] (Depends on users, setting by the drive unit)

Therefore, set the rapid stop deceleration time of the motion controller to 1 ms.

If an alarm subject to the forced stop deceleration function occurs

The following timing chart shows that an alarm occurs in any axis in the parallel drive system.

Alarm occurrence

Model speed command is 0,

and the speed is equal to

or less than zero speed

Servo motor speed

*1

Alarm occurrence axis

Alarm non-occurrence axis

Base circuit

(Energy supply to

the servo motor)

Drive unit display

ALM (Malfunction)

Servo motor speed

Base circuit

(Energy supply to

the servo motor)

Drive unit display

ALM (Malfunction)

0 r/min

ON

OFF

ON (no alarm)

OFF (alarm)

0 r/min

ON

OFF

ON (no alarm)

OFF (alarm)

No alarm

The command from the

controller is not received.

Alarm No.No alarm

The command from the

controller is not received.

Alarm E7

Model speed command is 0,

and the speed is equal to

or less than zero speed

*1

*1 The model speed command is a speed command generated in the servo amplifier for forced stop deceleration of the servo motor.

28

3 SIGNALS AND WIRING

3.2 Alarm occurrence timing chart

Page 31

If an alarm not subject to the forced stop deceleration function occurs

ON

OFF

0 r/min

Braking by the dynamic brake

Braking by the dynamic brake

ON

OFF

0 r/min

ON (no alarm)

OFF (alarm)

Base circuit

(Energy supply to

the servo motor)

Base circuit

(Energy supply to

the servo motor)

Drive unit display

Servo motor speed

ALM (Malfunction)

ON (no alarm)

OFF (alarm)

Drive unit display

Servo motor speed

ALM (Malfunction)

Alarm occurrence axis

Alarm non-occurrence axis

Alarm occurrence

Alarm No.No alarm

No alarm

When the dynamic brake is used, a brake operation delay time occurs. For details, refer to the specifications

of the magnetic contactor you use.

The following timing chart shows that an alarm occurs in any axis in the parallel drive system.

3

3.2 Alarm occurrence timing chart

3 SIGNALS AND WIRING

29

Page 32

When SSCNET III/H communication is shut off

Axis in which SSCNET III/H

communication shut-off

has not occurred

Occurrence of SSCNET III/H communication shut-off

AA

ON

OFF

0 r/min

Axis in which SSCNET III/H

communication shut-off

has occurred

ON

OFF

0 r/min

Ab

Base circuit

(Energy supply to

the servo motor)

ON (no alarm)

OFF (alarm)

ON (no alarm)

OFF (alarm)

Drive unit display

Servo motor speed

ALM (Malfunction)

Base circuit

(Energy supply to

the servo motor)

Drive unit display

Servo motor speed

ALM (Malfunction)

Braking by the dynamic brake

No alarm

Braking by the dynamic brake

No alarm

When an SSCNET III/H communication shut-off occurs in a servo amplifier, the servo amplifier and

subsequent servo amplifiers show "AA" on the display.

When you do not use the forced stop deceleration function

Set [Pr. PA04] to "0 _ _ _". The operation status of the servo motor during an alarm is the same as that of when the forced stop

deceleration function is used.

Page 27 When you use the forced stop deceleration function

30

3 SIGNALS AND WIRING

3.2 Alarm occurrence timing chart

Page 33

3.3 Grounding

Converter

unit

Drive

unit

Converter

unit

Drive

unit

Converter

unit

Drive

unit

Converter

unit

Drive

unit

Copper bar

Converter

unit

Drive

unit

Other

device

Converter

unit

Drive

unit

Other

device

Good example Bad example

WARNING

• Ground the power regeneration converter unit, drive unit, and servo motor securely.

• To prevent an electric shock, be sure to connect the protective earth (PE) terminal (marked ) of the power regeneration converter unit and the drive unit to

the protective earth (PE) of the cabinet.

For items other than the ones described in this section, refer to section 3.3 in "MR-CV_/MR-CR55K_/MR-J4-

DU_(-RJ) Instruction Manual".

Capacitances exist between input/output lines of the servo and other lines or the ground, and in the servo motor, through

which a leakage current flows. For a servo with a large capacity, a leakage current including a high-frequency of several 100

mA may flow.

Note the following.

• To prevent an electric shock, be sure to ground the drive unit, power regeneration converter unit, and servo motor.

• To lower the impedance of the grounding wire, use the wire of the size equal to or greater than that shown in section 8.4 in

"MR-CV_/MR-CR55K_/MR-J4-DU_(-RJ) Instruction Manual", and make the wire as short as possible. Stranded wires or

braided wires are helpful to lower impedance.

• Prevent multiple points from being grounded. Ground one point. Grounding multiple points may generate a potential

difference between the grounded points by the impedance of the grounding wires. If the units cannot be grounded to one

point, connect the grounding wires to a copper bar and ground it to one point.

3

• Leakage currents including high-frequency components flow through the grounding wires of the drive unit, power

regeneration converter unit, and servo motor. Route the grounding wires of noise-sensitive devices separately.

• Route the grounding wires as far away from the input/output lines of noise-sensitive devices as possible, and run the

grounding wires in parallel to each other as short as possible.

• Connect the grounding wire from the servo motor to the protective earth (PE) terminal of the drive unit. Put the grounding

wires of the drive unit and the power regeneration converter unit together into one on the protective earth (PE) terminal of

the cabinet, and then connect to the ground. Connect the grounding wire of the servo motor to only the drive unit of the

encoder master servo amplifier. If the grounding wire of the servo motor is connected to two or more drive units, the

circulating current may pass through the grounding wire depending on wiring conditions. When connecting grounding wires

to two or more drive units, be sure to twist the wires of the drive unit power outputs (U/V/W).

3 SIGNALS AND WIRING

3.3 Grounding

31

Page 34

4 STARTUP

WARNING

• When executing a test run, follow the notice and procedures in this instruction manual. Otherwise, it may cause a malfunction, damage to the machine, or

injury.

• Do not operate the switches with wet hands. Otherwise, it may cause an electric shock.

CAUTION

• Before starting operation, check the parameters. Improper settings may cause some machines to operate unexpectedly.

• The heat sink of the power regeneration converter unit and drive unit, and the servo motor, etc. may be hot while power is on and for some time after poweroff. Take safety measures such as providing covers to avoid accidentally touching them by hands and parts such as cables.

• During operation, never touch the rotor of the servo motor. Otherwise, it may cause injury.

• Before wiring, switch operation, etc., eliminate static electricity. Otherwise, it may cause a malfunction.

For parallel drive systems, test operation cannot be performed with MR Configurator2. Perform test operation

with the controller.

The following items are the same as those for MR-J4-_B_(-RJ). Refer to the section of the detailed explanation field for

details. "MR-J4-_B_" means "MR-J4-_B_(-RJ) Servo Amplifier Instruction Manual". "MR-J4-DU_B_" means "MR-CV_/MR-

CR55K_/MR-J4-DU_(-RJ) Instruction Manual".

Item Detailed explanation

Switch setting and display of the drive unit MR-J4-_B_ section 4.3

Switch setting and operation section of power regeneration converter unit MR-J4-DU_B_ section 3.4

32

4 STARTUP

Page 35

4.1 Switching power on for the first time

Start up the parallel drive system in the following procedure. Once settings are made, they do not need to be reset. When

changes are made to the system settings of the Motion controller, and the drive unit is replaced, start up the system in the

following procedure again.

"MR-J4-_B_" means "MR-J4-_B_(-RJ) Servo Amplifier Instruction Manual". "MR-J4-DU_B_" means "MR-CV_/MR-CR55K_/

MR-J4-DU_(-RJ) Instruction Manual".

Setting

classification

Servo amplifier

Controller

Servo amplifier

Step Description Reference

1. Wiring check

2. Surrounding environment

check

3. Controller setting

4. Controller power on

5. System setting

6. Servo data setting

7. Controller reset

8. MR-CV55K4_ power

Check whether the power regeneration converter unit, drive

unit, and servo motor are wired correctly.

Check the surrounding environment of the power

regeneration converter unit, the drive unit and the servo

motor.

Make the controller settings (normal and the following

settings specific to the parallel drive system).

The parallel drive system is identified as the one axis of the

servo amplifier in the SSCNET configuration of MT

Developer2.

Set the system settings with the encoder master servo

amplifier.

When the system is set with the encoder slave servo

amplifier, an error may occur.

Set the following servo parameters with MR Configurator2 of

MT Developer2. Set the servo parameter for the drive unit of

the encoder master servo amplifier.

• [Pr. PA02 Regenerative option]

• [Pr. PA17 Servo motor series setting]

• [Pr. PA18 Servo motor type setting]

• [Pr. PC04 Function selection C-1]

• [Pr. PF37 Parallel drive - Encoder ID setting 1]

• [Pr. PF40 Parallel drive - Servo motor side system setting]