Page 1

AUTOMATIC

TRANSMISSION

23-1

CONTENTS

SERVICE SPECIFICATIONS 2.................

LUBRICANT 2...............................

SPECIAL TOOLS 2..........................

TROUBLESHOOTING 4.......................

ON-VEHICLE SERVICE 44...................

Essential Service 44............................

A/T Control Component Location 50.............

A/T Control Component Check 51...............

23109000576

Torque Converter Stall Test 53..................

Hydraulic Pressure Test 55.....................

Hydraulic Circuit 60............................

Line Pressure Adjustment 61....................

Selector Lever Operation Check 61..............

TRANSMISSION CONTROL* 63..............

SHIFT LOCK AND KEY INTERLOCK

MECHANISMS 66...........................

TRANSMISSION ASSEMBLY 68..............

WARNING REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of a n y component of the SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the airbag) or to driver and passenger (from rendering

the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System(SRS)beforebeginningany service or maintenance ofany component of the SRS or anySRS-related

component.

NOTE

The SRS includes the following components: SRS-ECU, SRS warning lamp, air bag module, clock spring, side impact sensors and

interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection with SRS service or

maintenance) are indicated in the table of contents by an asterisk (*).

Page 2

23-2

AUTOMATIC TRANSMISSION -

Service Specifications/Lubricant/Special Tools

SERVICE SPECIFICATIONS

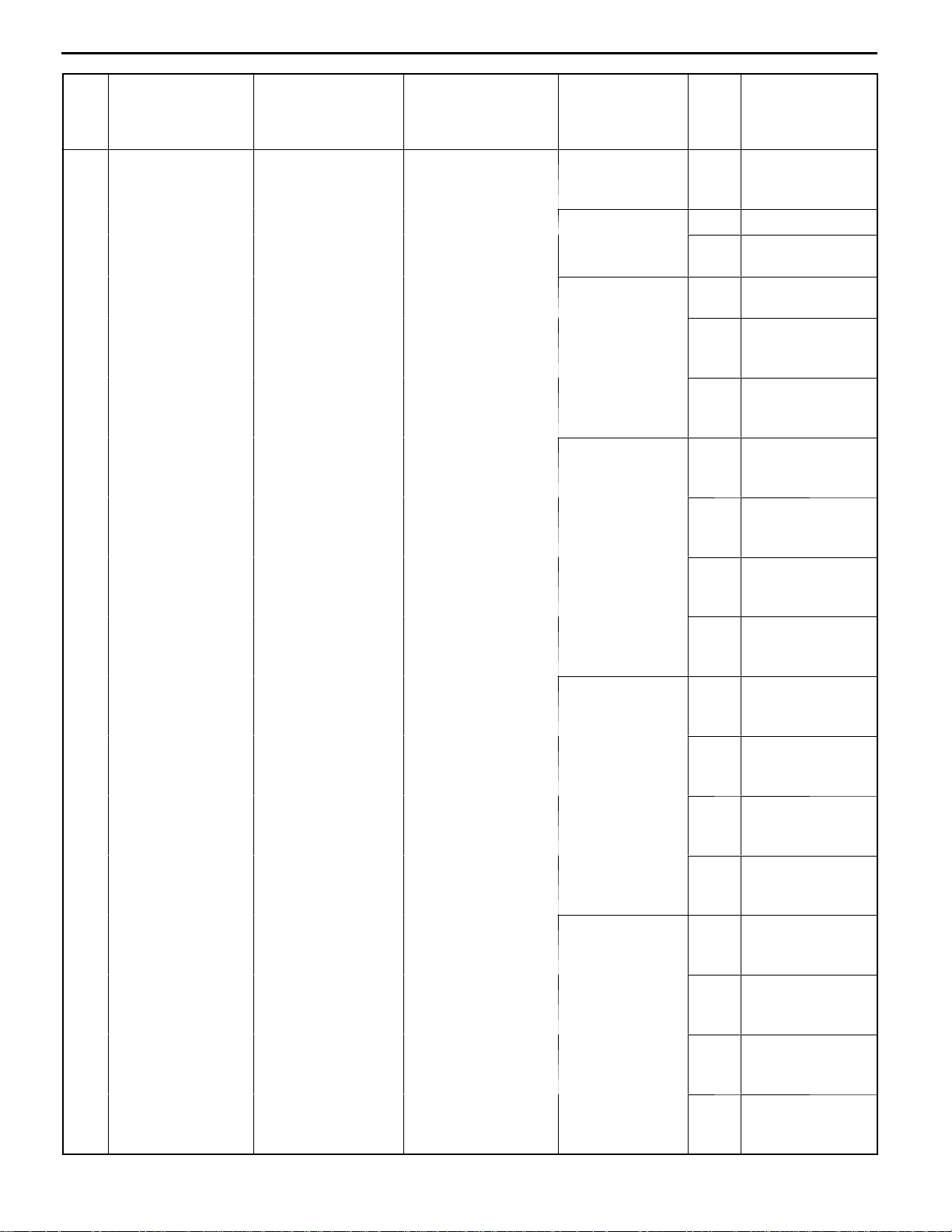

Items Standard value

Oil temperature sensor kW at 0_C 16.5 - 20.5

at 100_C 0.57 - 0.69

Resistance of damper clutch control solenoid valve coil (at 20_C) W 2.7 - 3.4

Resistance of Low-Reverse solenoid valve coil (at 20_C) W 2.7 - 3.4

Resistance of second solenoid valve coil (at 20_C) W 2.7 - 3.4

Resistance of underdrive solenoid valve coil (at 20_C) W 2.7 - 3.4

Resistance of overdrive solenoid valve coil (at 20_C) W 2.7 - 3.4

Stall speed r/min 4G93 2,200 - 2,700

4G64 2,300 - 2,800

LUBRICANT

Items Specified lubricant Quantity L

23100030284

23100040270

Transmission fluid DIA QUEEN ATF SPII, ATF SPII Mor

equivalent

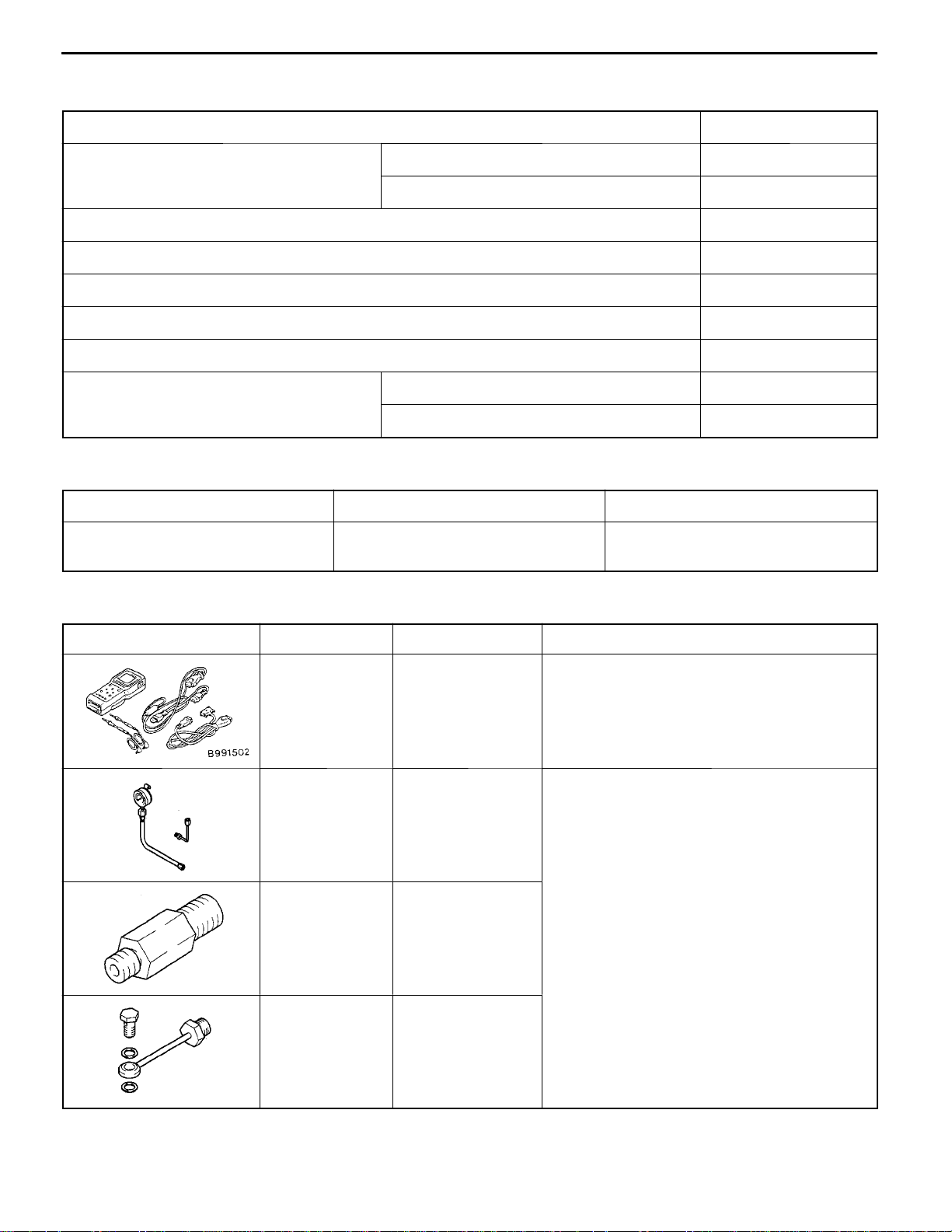

SPECIAL TOOLS

Tool Number Name Use

MB991502 MUT-II sub

assembly

MD998330

(including

MD998331)

MD998332 Adapter

Oil pressure gauge

(2,942 kPa)

Checking of the diagnosis code

Measurement of oil pressure

7.8

23100060351

MD998900 Adapter

Page 3

AUTOMATIC TRANSMISSION -

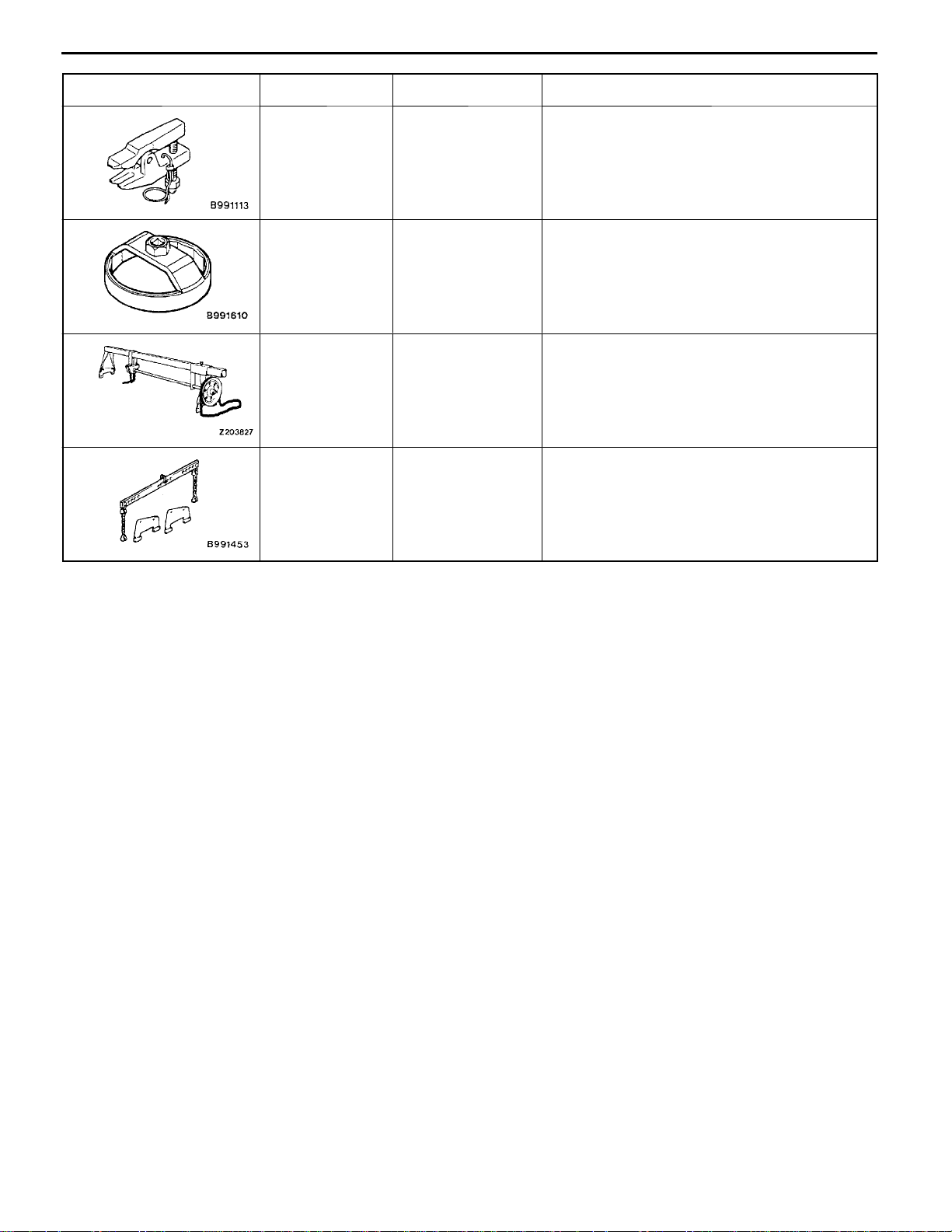

Tool Number Name Use

Special Tools

23-3

MB990635 or

MB991113

MB991610 Oil filter wrench Removal and installation of automatic trans-

GENERAL

SERVICE

TOOL

MZ203827

MB991453 Engine hanger

Steering linkage

puller

Engine lifter Supporting the engine assembly during

assembly

Ball joint disconnection

mission oil filter

removal and installation of the transmission

Supporting the engine assembly during

removal and installation of the transmission

Page 4

23-4

AUTOMATIC TRANSMISSION -

Troubleshooting

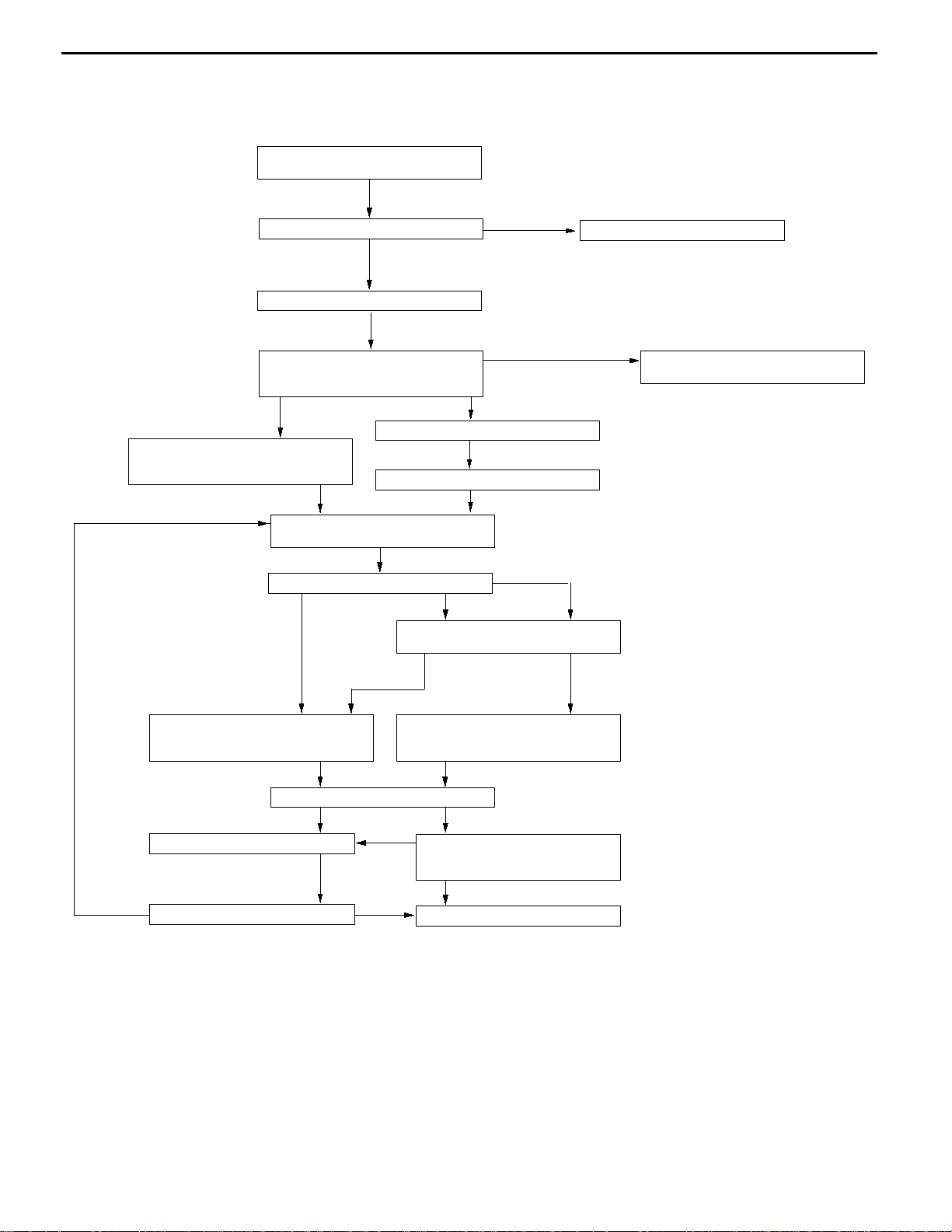

TROUBLESHOOTING

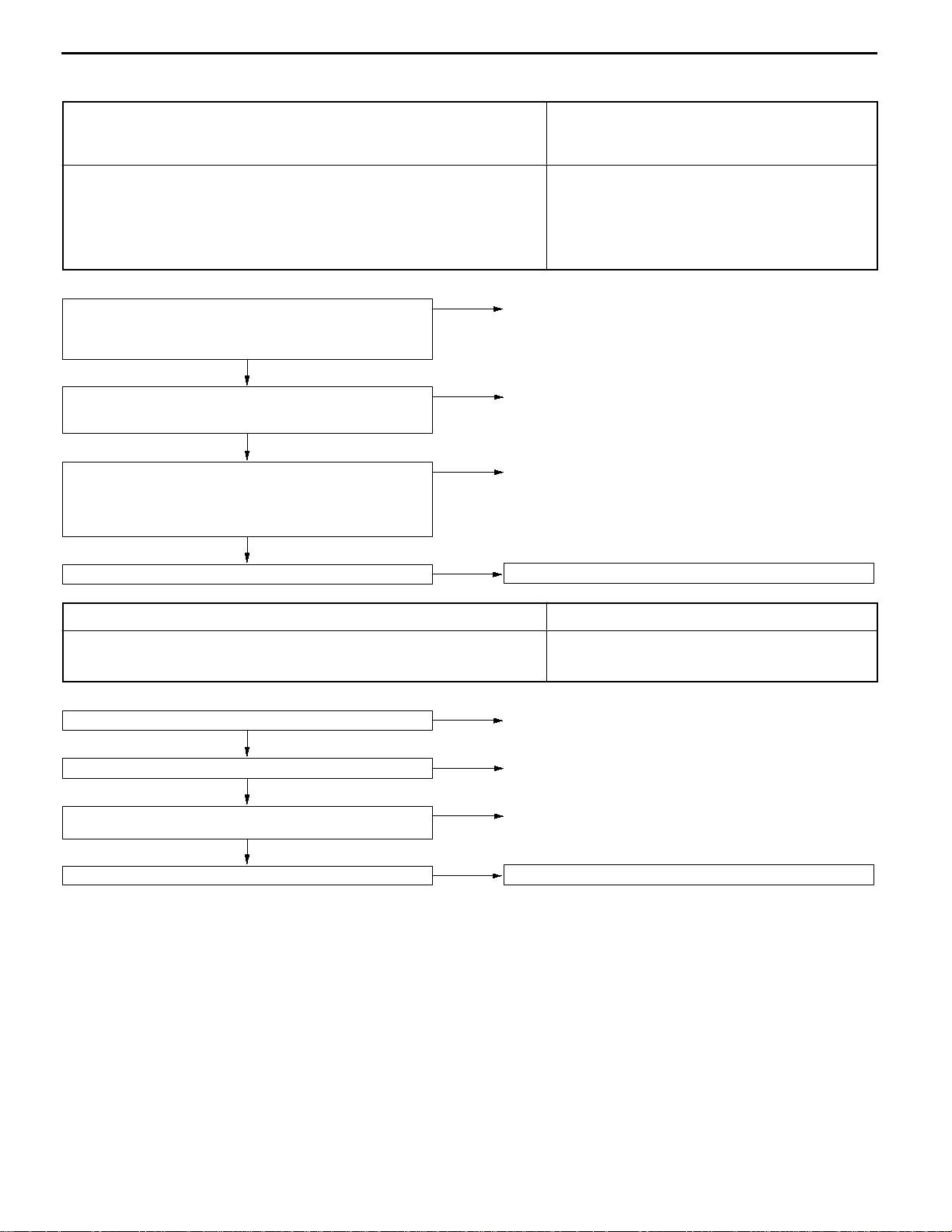

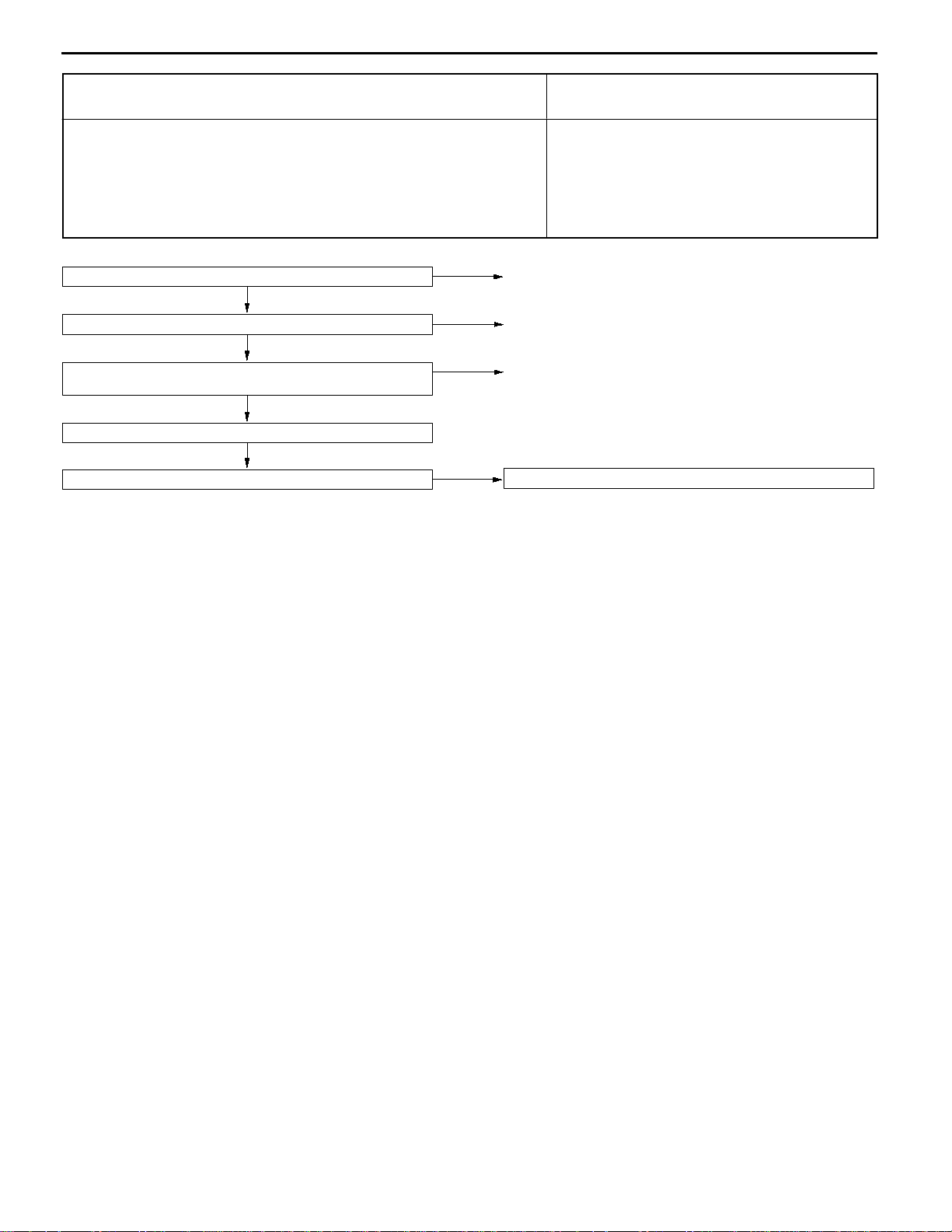

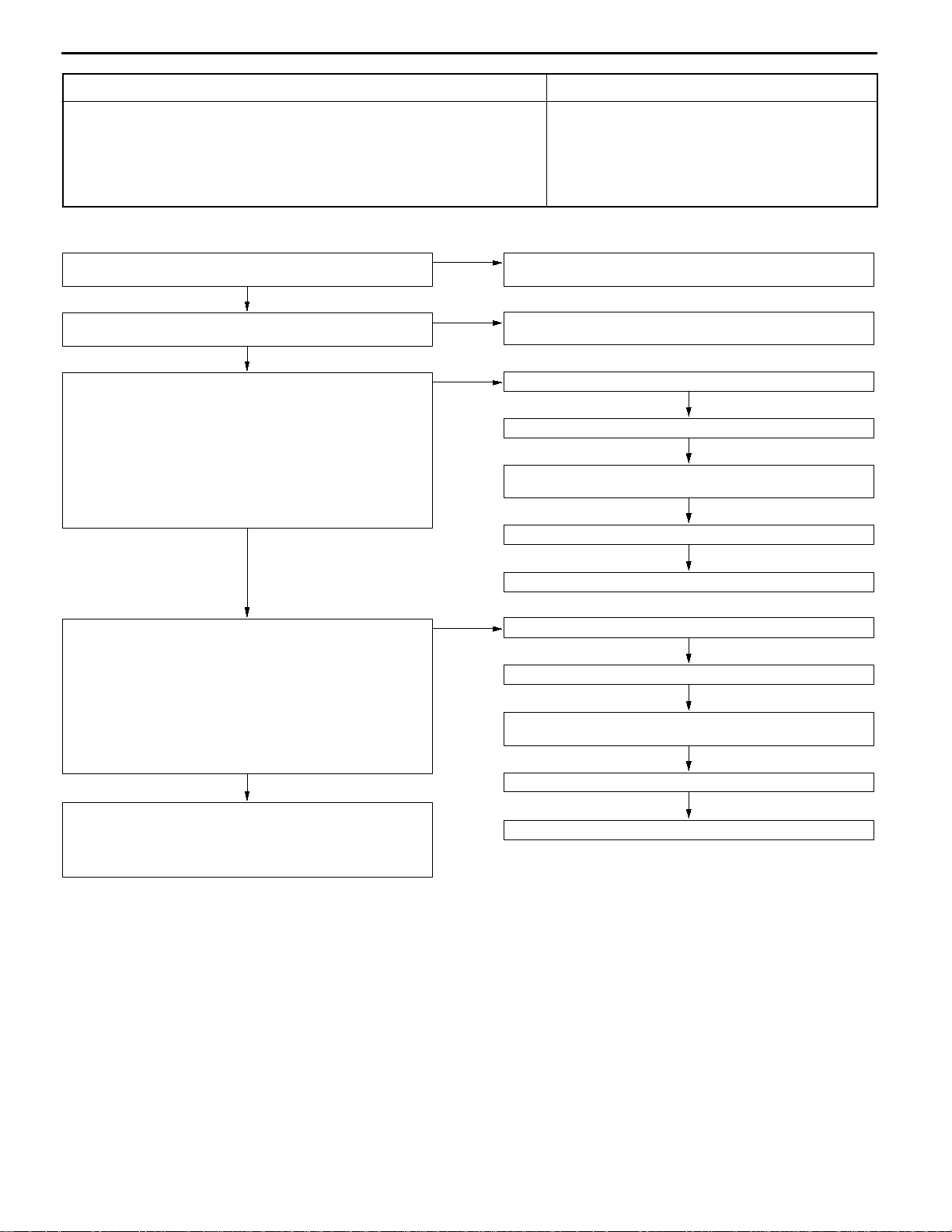

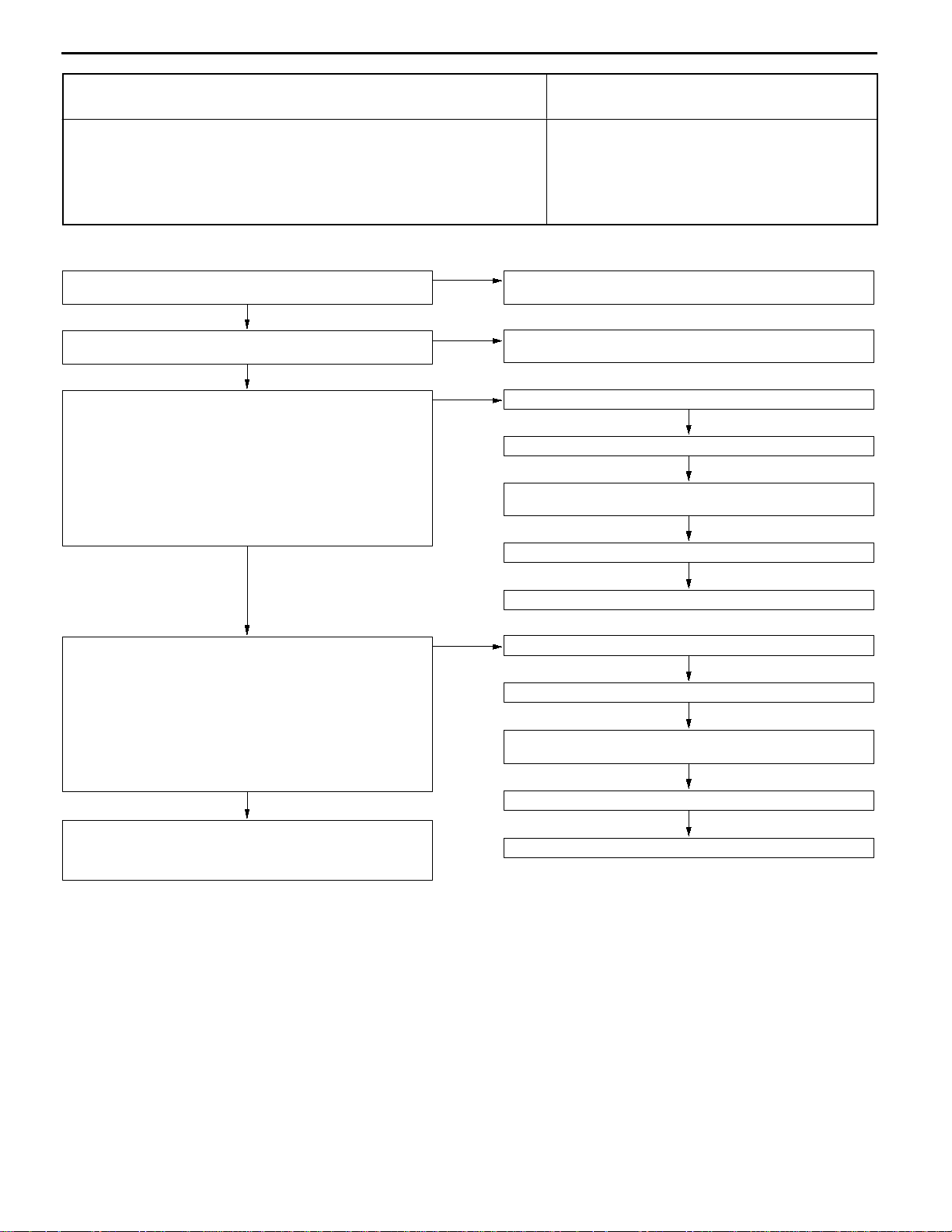

STANDARD FLOW OF DIAGNOSIS TROUBLESHOOTING

Gathering information from customer.

Check ATF .

Check trouble symptoms.

Read the diagnosis code (GROUP00

- How to Use Troubleshooting/In-

spection Service Points.)

Diagnosis code

displayed

Erase the diagnosis code (GROUP

00 - How to Use Troubleshooting/Inspection Service Points.)

Carry out the essential service

(Refer to P.23-44.)

OK

Replace the A/T-ECU.

Check trouble symptoms.

NG

Communication with

MUT-II not possible

No diagnosis code displayed

NG

Replace ATF.

23100760657

Inspection Chart For Trouble

Symptoms (Refer to P.23-24.)

Road test (Refer to P.23-6.)

Abnormality exists

(diagnosis code

present)

To INSPECTION CHART FOR

DIAGNOSIS CODES

(Refer to P.23-12.)

Search for cause.

Repair

NG

Confirmation test (road test)

No abnormality

Recheck diagnosis codes which

were read before the road test.

Diagnosis

code displayed

To INSPECTION CHART FOR

TROUBLE SYMPTOMS

(Refer to P.23-24.)

Found Not found

OK

NG

INTERMITTENT MALFUNCTION

(GROUP 00 - Points to Note for

Intermittent Malfunctions.)

OK

Completed

Abnormality exists (no diagnosis code)

No diagnosis

code displayed

Page 5

AUTOMATIC TRANSMISSION -

Troubleshooting

23-5

DIAGNOSIS FUNCTION

1. N range lamp

The N range lamp flashes at a frequency of approximately

1 Hz if there is an abnormality in any of the items in the

table below which are related to the A/T system. Check

the diagnosis code output if the N range lamp is flashing

at a frequency of approximately 1 Hz.

N range lamp flashing items

Crank angle sensor

Input shaft speed sensor

Output shaft speed sensor

Each solenoid valve

Out of phase at each shift point

Caution

If the N range lamp is flashing at a frequency of

approximately 2 Hz (faster than at 1 Hz), it means that

the automatic transmission fluid temperature is too high.

Stop the vehicle in a safe place and wait until the N range

lamp switches off.

2. Method of reading the diagnosis code

Use the MUT-II or the N range lamp to take a reading of

the diagnosis codes. (Refer to GROUP 00 - How to Use

Troubleshooting/Inspection Service Points.)

23100770292

Page 6

23-6

AUTOMATIC TRANSMISSION -

Troubleshooting

ROAD TEST

Check by the following procedure.

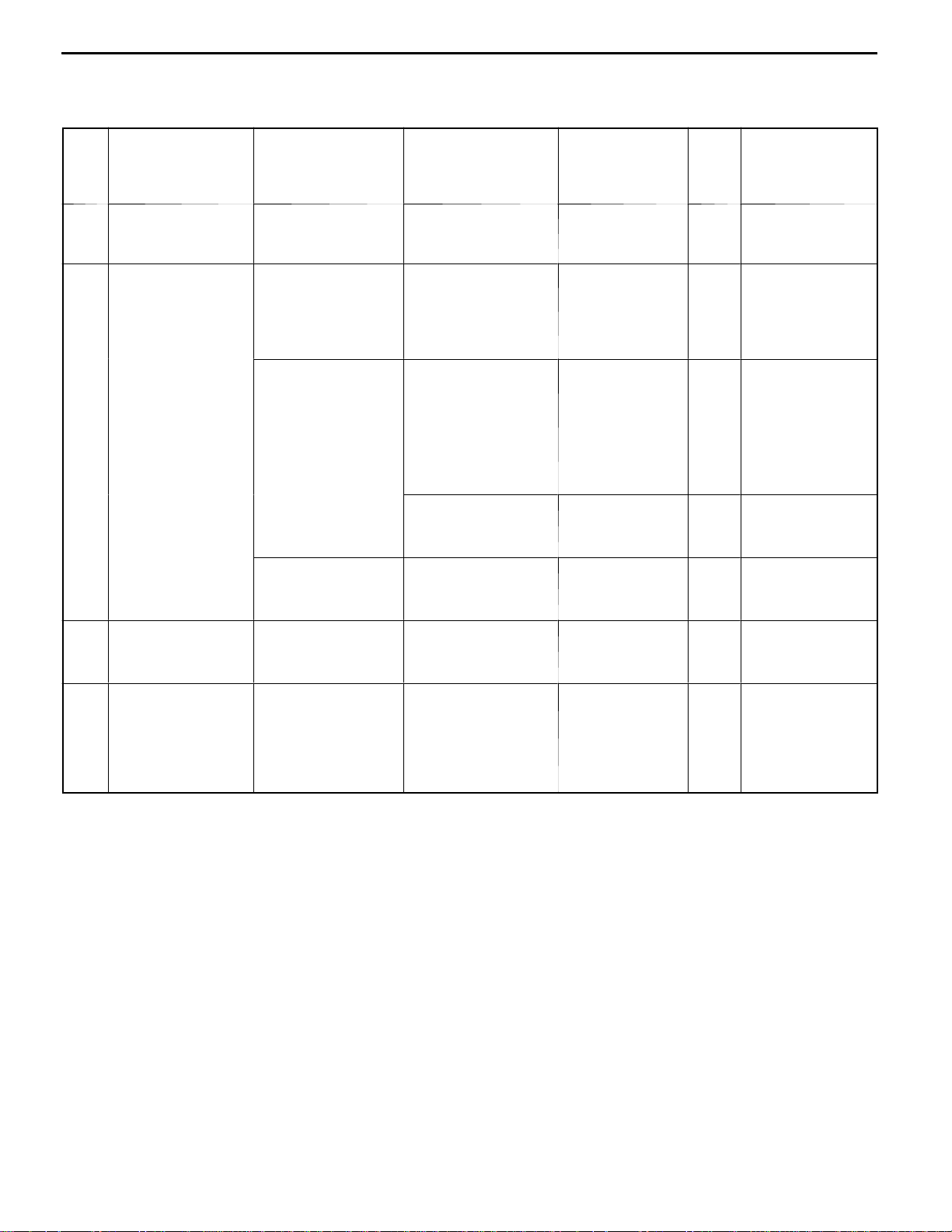

No. State prior to test

and operation

1 Ignition switch:

OFF

2 Ignition switch:

ON

Engine: Stopped

Selector lever

position: P

position: P

3 Ignition switch:

ST

Engine: Stopped

Test and operation Judgement value Check item Diag-

Ignition switch

(1) ON

Selector lever

position

(1) P, (2) R,

(3) N, (4) D,

(5) 3, (6) 2, (7) L

Accelerator pedal

(1) Released

(2) Half depressed

(3) Depressed

Brake pedal

(1) Depressed

(2) Released

Starting test with

lever P or N range

Data list No. 54

Battery voltage [V]

Data list No. 61

(1) P, (2) R, (3)N,

(4) D, (5) 3, (6) 2,

(7) L

Data list No. 11

(1) 300 - 1,000 mV

(2) Gradually rises

from (1)

(3) 4,500 - 5,500

mV

Data list No. 25

(1) OFF

(2) ON

Data list No. 26

(1) ON

(2) OFF

Starting should be

possible

23100780622

Inspection

nosis

code

No.

Control relay 54 A/T Control

Inhibitor switch - Inhibitor switch

Throttle position sensor

<4G93>

Accelerator

pedal position

sensor

<4G64>

Wide open

throttle switch

Stop lamp

switch

Starting

possible or

impossible

11

12

14

25 Wide open

26 Stop lamp switch

- Starting

procedure page

if there is an

abnormality

relay system

(23-23)

system (23-35)

Throttle

position sensor

system (23-13)

Accelerator

pedal position

sensor system

(23-13)

throttle switch

system (23-15)

system (23-16)

impossible

(23-27)

4 Warming up Drive for 15

minutes or more so

that the automatic

fluid temperature

becomes 70 90_C.

Data list No. 15

Gradually rises to

70 - 90_C

Oil temperature

sensor

15 Oil temperature

sensor system

(23-13)

Page 7

AUTOMATIC TRANSMISSION -

Troubleshooting

23-7

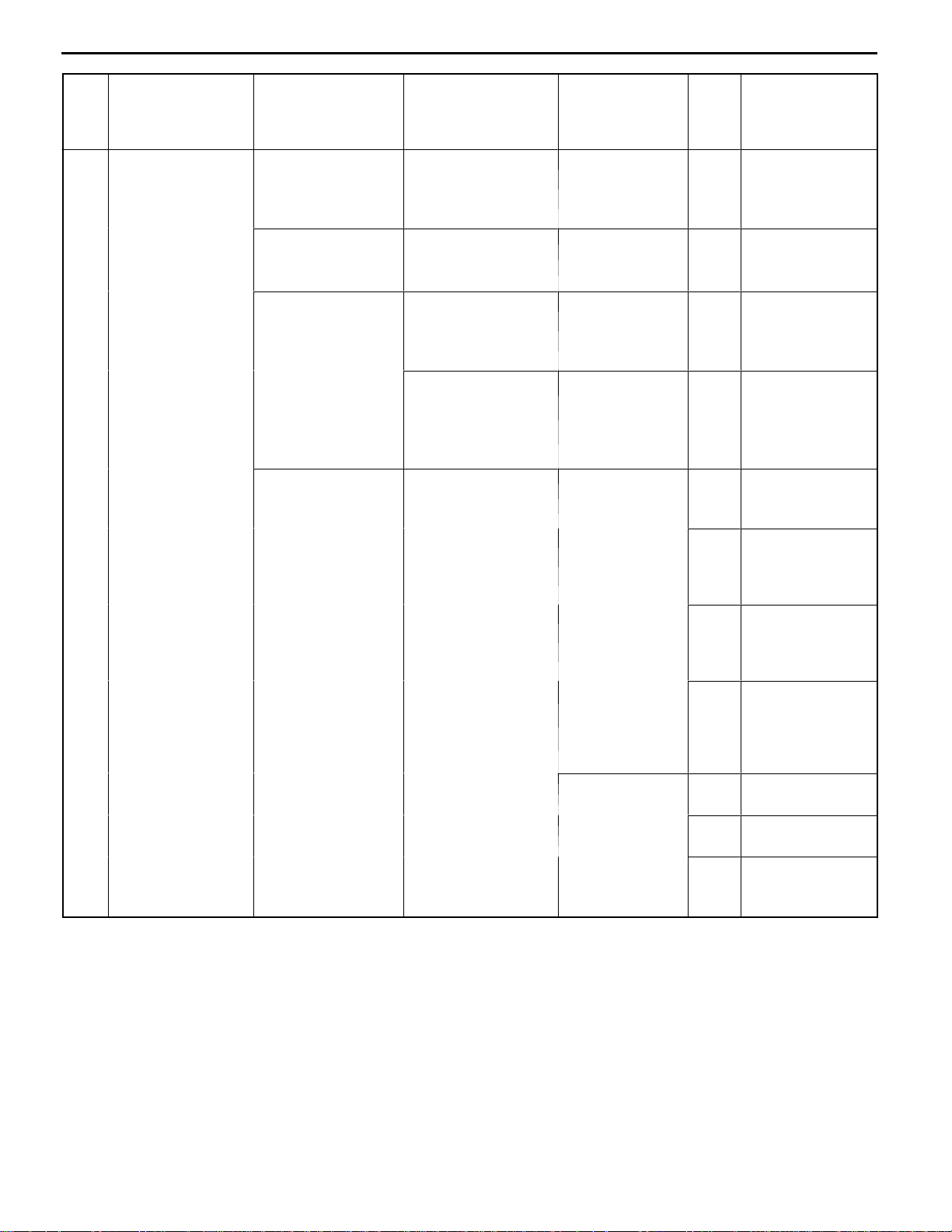

No. State prior to test

and operation

5 Engine: Idling

Selector lever

position: N

Test and operation Judgement value Check item Diag-

nosis

code

No.

Brake pedal

(Retest)

(1) Depressed

(2) Released

A/C switch

(1) ON

(2) OFF

Accelerator pedal

(1) Released

(2) Half depressed

Selector lever

position

(1) N ® D

(1) N ® D

(2) N ® R

Data list No. 26

(1) ON

(2) OFF

Data list No. 65

(1) ON

(2) OFF

Data list No. 21

(1) 550 - 850 r/min

Gradually rises

from (1)

Data list No. 57

(2) Data changes

Should be no

abnormal shifting

shocks

Time lag should be

within 2 seconds

Stop lamp

switch

Dual pressure

switch

Crank angle

sensor

Communication

with engineECU

Malfunction

when starting

Driving

impossible

26 Stop lamp switch

- Dual pressure

21 Crank angle

51 Serial

- Engine stalling

- Shocks when

- Shocks when

- Shocks when

- Does not move

- Does not

- Does not move

Inspection

procedure page

if there is an

abnormality

system (23-16)

switch system

(23-35)

sensor system

(23-14)

communication

system (23-23)

during shifting

(23-29)

changing from N

to D and large

time lag (23-29)

changing from N

to R and large

time lag (23-30)

changing from N

to D,N to R and

large time lag

(23-31)

forward (23-27)

reverse (23-28)

(forward or

reverse) (23-28)

Page 8

23-8

AUTOMATIC TRANSMISSION -

Troubleshooting

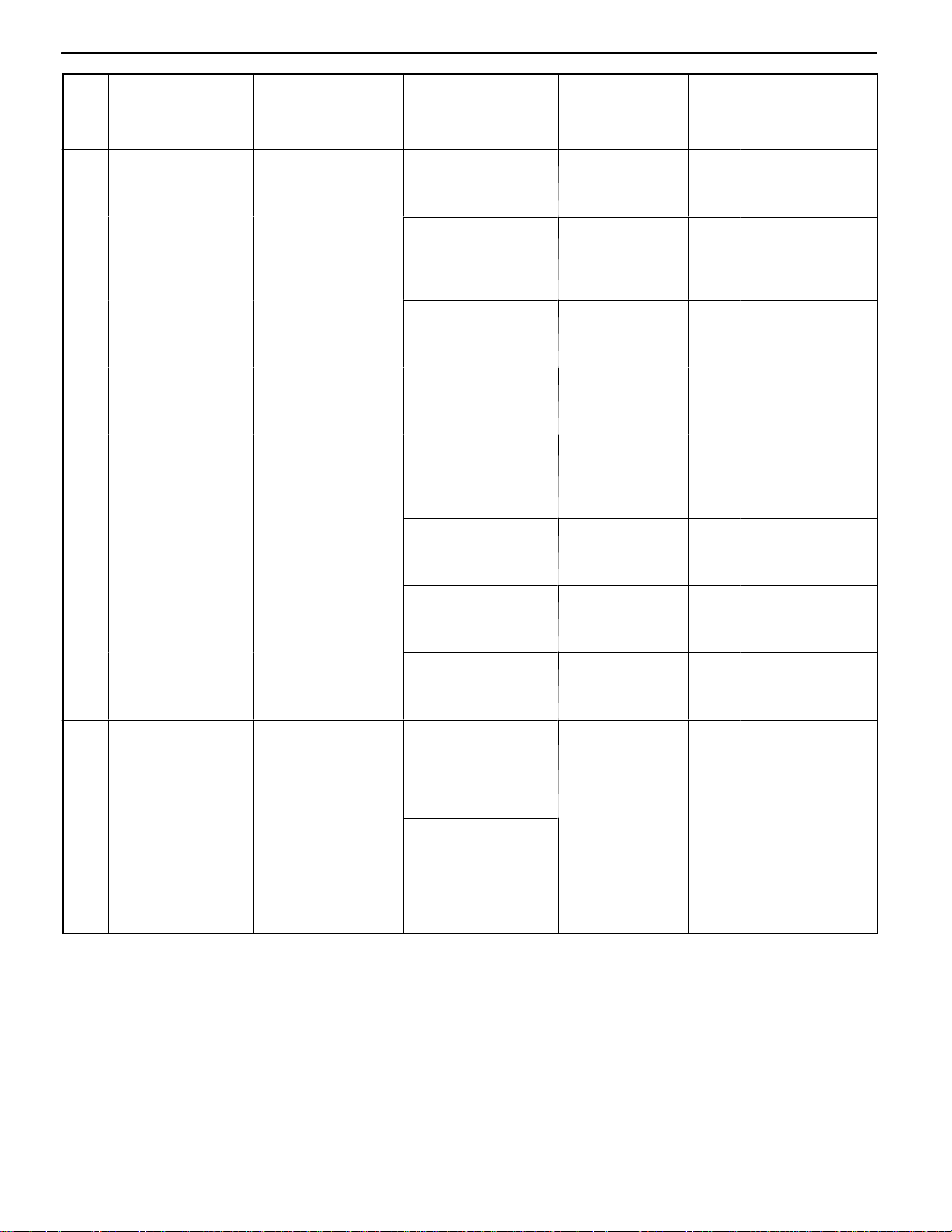

No. State prior to test

and operation

6 Selector lever

position: N

(Carry out on a

flat and straight

road.)

Test and operation Judgement value Check item Diag-

nosis

code

No.

Selector lever

position and

vehicle speed

(1) Idling in

L range

(Vehicle

stopped)

(2) Driving at

constant speed

of

10 km/h in

L position

(3) Driving at

constant speed

of

30 km/h in

2 position

(4) Driving at

50 km/h in

3 position with

accelerator fully

closed

(5) Driving at

constant speed

of

50 km/h in

D position

(Each

condition

should be

maintained for

10 seconds or

more.)

Data list No. 63

(2) 1st, (4) 3rd, (3)

2nd, (5) 4th

Data list No. 31

(2) 0 %, (4) 100 %,

(3) 100 %, (5) 100

%

Data list No. 32

(2) 0 %, (4) 0 %,

(3) 0 %, (5) 100 %

Data list No. 33

(2)100 %, (4) 100

%, (3) 0 %, (5) 0 %

Data list No. 34

(2) 100 %, (4) 0 %,

(3) 100 %, (5) 0 %

Data list No. 29

(1) 0 km/h

(4) 50 km/h

Data list No. 22

(4) 1,800 - 2,100

r/min

Data list No. 23

(4) 1,800 - 2,100

r/min

Shift condition - -

Low and reverse

solenoid valve

Underdrive

solenoid valve

Second

solenoid valve

Overdrive

solenoid valve

Vehicle speed

sensor

Input shaft

speed sensor

Output shaft

speed sensor

31 Low and reverse

32 Underdrive

33 Second solenoid

34 Overdrive

- Vehicle speed

22 Input shaft speed

23 Output shaft

Inspection

procedure page

if there is an

abnormality

solenoid valve

system (23-16)

solenoid valve

system (23-16)

valve system

(23-16)

solenoid valve

system (23-16)

sensor system

(23-36)

sensor system

(23-14)

speed sensor

system (23-15)

7 Selector lever

position: 3

(Carry out on a

flat and straight

road.)

Selector lever

position and

vehicle speed

(1) Release the ac-

celerator pedal

fully while driving at 50 km/h

in 3rd gear.

(2) Driving at

constant speed

of 50 km/h in

3rd gear.

Data list No. 36

(1) 0 %

(2) Approx. 70 - 90

%

Data list No. 52

(1) Approx.

100 - 300 r/min

(2) Approx.

0 - 10 r/min

Damper clutch

control solenoid

valve

36

52

Damper clutch

control solenoid

valve system

(23-17)

Page 9

AUTOMATIC TRANSMISSION -

Troubleshooting

23-9

No. State prior to test

and operation

8 Use the MUT-II to

stop the INVECSII function.

Selector lever (1) Accelerate to specified output

position: D

(Carry out on a flat

and straight road.)

and straight road.)

Test and operation Judgement value Check item Diag-

Monitor data list

No. 11, 23, and 63

with the MUT-II.

4th gear at a

throttle

position

position

sensor output

of 1.5V

(accelerator

opening angle

of 30 %).

(2) Gently

(2) Gently

decelerate to a

standstill.

(3) Accelerate to

4th gear at a

throttle

position

sensor output

of 2.5 V

(accelerator

opening angle

of 50%).

(4) While driving at

60 km/h in 4th

gear, shift

down to

3 range.

(5) While driving at

40 km/h in 3rd

gear, shift

down to

2 range.

(6) While driving at

20 km/h in 2nd

gear, shift

down to

down to

L range.

For (1), (2) and (3),

the reading should

be the same as the

shaft speed and no

abnormal shocks

should occur .

should occur .

For (4), (5) and (6),

downshifting

should occur

immediately

after the shifting

operation is made.

operation is made.

Malfunction

when shifting

Displaced

shifting points

Does not shift

Does not shift

from 1 to 2 or 2

to 1

Does not shift

from 2 to 3 or 3

to 2

Does not shift

from 3 to 4 or 4

to 3

Inspection

nosis

code

No.

- Shocks and

- All points (23-32)

- Some points

- No diagnosis

22 Input shaft

23 Output shaft

31 Low and reverse

33 Second

41 1st gear ratio is

42 2nd gear ratio is

33 Second

34 Overdrive

42 2nd gear ratio is

43 3rd gear ratio is

32 Underdrive

33 Second

43 3rd gear ratio is

44 4th gear ratio is

procedure page

if there is an

abnormality

running up

(23-31)

(23-33)

code (23-33)

speed sensor

system (23-14)

speed sensor

system (23-15)

solenoid valve

system (23-16)

solenoid valve

system (23-16)

not specified

(23-18)

not specified

(23-19)

solenoid valve

system (23-16)

solenoid valve

system (23-16)

not specified

(23-19)

not specified

(23-20)

solenoid valve

system (23-16)

solenoid valve

system (23-16)

not specified

(23-20)

not specified

(23-21)

Page 10

23-10

AUTOMATIC TRANSMISSION -

Troubleshooting

No. State prior to test

and operation

9 Selector lever

position: N

(Carry out on a

(Carry out on a

flat and straight

road.)

SHIFT PATTERN

<4G93>

UPSHIFT PATTERN

Throttle opening %

100

Test and operation Judgement value Check item Diag-

Monitor data list

No. 22

and No. 23 with the

MUT-II.

(1) Move selector

lever to

The ratio between

data list No. 22 and

No. 23 should be

the same as the

gear ratio when

reversing.

Does not shift

R range, drive

at constant

speed of

10 km/h.

Thick line: Standard shift pattern

122

3

3

4

Inspection

nosis

code

No.

procedure page

if there is an

abnormality

22 Input shaft

speed sensor

system (23-14)

23 Output shaft

speed sensor

system (23-15)

46 Reverse gear

ratio is not

specified (23-22)

50

0

1,000

DOWNSHIFT PATTERN

Throttle opening %

100

122

50

1

2®3

movement

range

2,000

3

2 (L)

3®4

movement

range

3,000

Output shaft speed r/min

3

4

4,000

2

3 (L,2)

5,000

6,000

Thick line: Standard shift pattern

3

7,000

4 (L,2,3)

2¬3

movement

range

0

1,000

3¬4

movement

range

2,000

3,000 4,000 5,000 6,000 7,000

Output shaft speed r/min

Page 11

<4G64>

UPSHIFT PATTERN

AUTOMATIC TRANSMISSION -

Troubleshooting

23-11

Throttle opening %

100

1

50

0

1,000 2,000

DOWNSHIFT PATTERN

Throttle opening %

100

2

2 ® 3

movement

range

Thick line: Standard shift pattern

2

3

3,000 4,000

Output shaft speed r/min

3

3 ® 4

movement

range

4

5,000 6,000

Thick line: Standard shift pattern

7,000

50

1

2

1

0

2

2 ¬ 3

movement

range

1,000 2,000 3,000 4,000

2 (L)

3

3

3 ¬ 4

movement

range

4

2

Output shaft speed r/min

3 (L,2)

3

5,000 6,000

4 (L,2,3)

7,000

Page 12

23-12

AUTOMATIC TRANSMISSION -

Troubleshooting

INSPECTION CHART FOR DIAGNOSIS CODE

Code Diagnosis item Reference page

11 Throttle position sensor system Short circuit 23-13

12

14

15 Oil temperature sensor system Open circuit 23-13

21 Crank angle sensor system Open circuit 23-14

22 Input shaft speed sensor system Short circuit/open circuit 23-14

23 Output shaft speed sensor system Short circuit/open circuit 23-15

25 Wide open throttle switch system Short circuit 23-15

26 Stop lamp switch system Short circuit/open circuit 23-16

31 Low and reverse solenoid valve system Short circuit/open circuit 23-16

32 Underdrive solenoid valve system Short circuit/open circuit 23-16

33 Second solenoid valve system Short circuit/open circuit 23-16

<4G93>

Accelerator pedal position sensor system

Accelerator pedal position sensor system

<4G64>

Open circuit 23-13

Sensor maladjustment 23-13

23100790588

34 Overdrive solenoid valve system Short circuit/open circuit 23-16

36 Damper control clutch solenoid valve system Short circuit/open circuit 23-17

41 1st gear ratio does not meet the specification 23-18

42 2st gear ratio does not meet the specification 23-19

43 3rd gear ratio does not meet the specification 23-20

44 4th gear ratio does not meet the specification 23-21

46 Reverse gear ratio does not meet the specification 23-22

51 Abnormal communication with engine-ECU 23-23

52 Damper control clutch solenoid valve system Defective system 23-17

54 A/T Control relay system Short circuit to earth/

open circuit

56 N range lamp system Short circuit to earth 23-24

23-23

Page 13

AUTOMATIC TRANSMISSION -

Troubleshooting

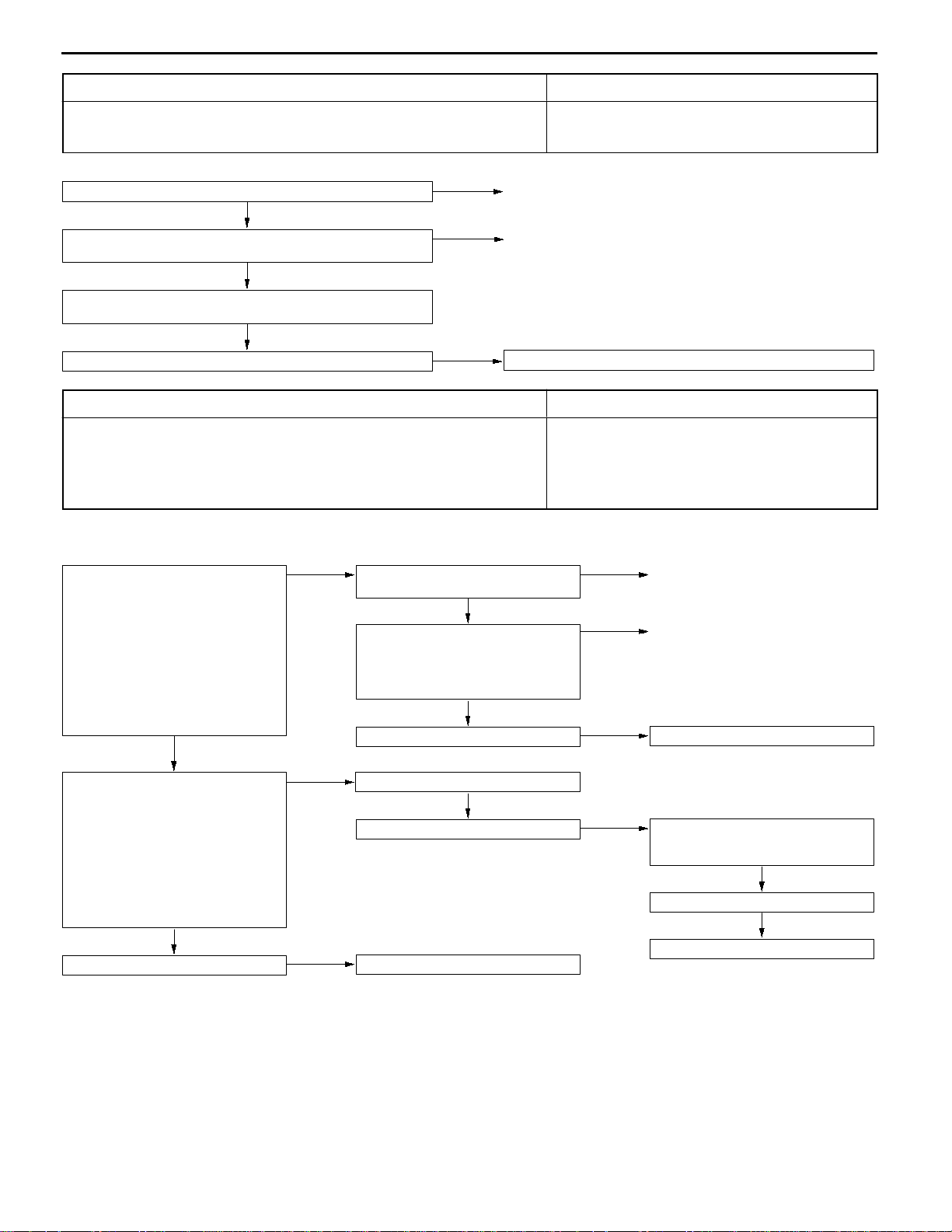

INSPECTION PROCEDURES FOR DIAGNOSIS CODES

23-13

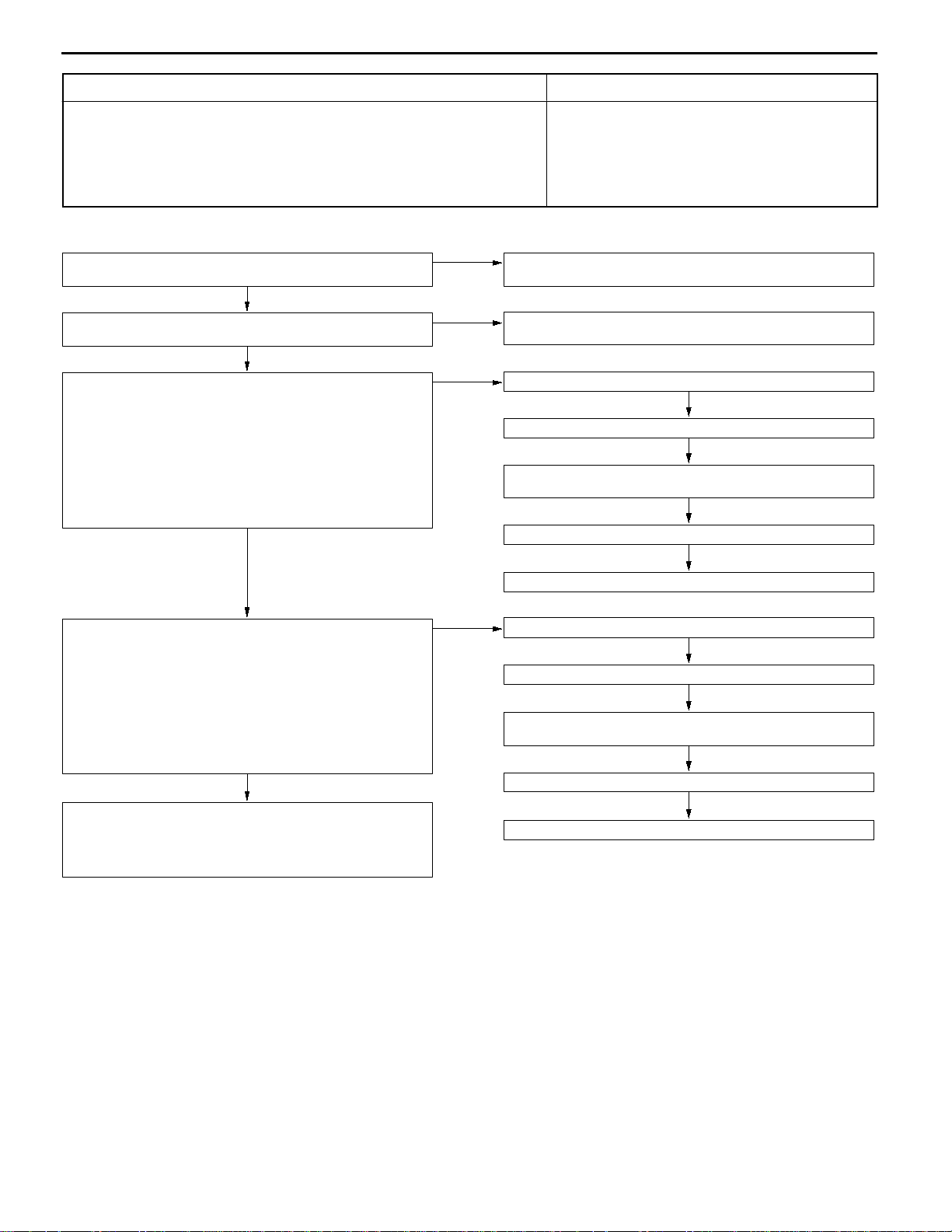

Code No. 11, 12, 14 Throttle position sensor system

<4G93>, accelerator pedal position sensor system

<4G64>

If the TPS or APS output voltage is 4.8 V or higher when the engine is idling, the

output is judged to be too high and diagnosis code No. 11 is output. If the TPS or

APS output voltage is 0.2 V or lower at times other than when the engine is idling,

the output is judged to be too low and diagnosis code No. 12 is output. If the TPS

or APS output voltage is 0.2 V or lower or if it is 1.2 V or higher when the engine

is idling, the TPS or APS adjustment is judged to be incorrect and diagnosis code

No. 14 is output.

Throttle position sensor check <4G93>

(Refer to GROUP 13B - On-vehicle Service

Accelerator pedal position sensor check<4G64>

(Refer to GROUP 13A - On-vehicle Service

OK

Check the following connectors:

D A-73, B-11 <4G93>

D A-63, A-27, B-11 <4G64>

OK

Harness check

D Between throttle position sensor and A/T-ECU

<4G93>

D Between accelerator pedal position sensor and A/T-ECU

<4G64>

OK

Check the trouble symptoms.

link=13100320030.)

link=13600430011.)

NG

NG

NG

NG

Replace

Repair

Repair

Replace the A/T-ECU.

Probable cause

D Malfunction of the throttle position sensor <4G93>

D Malfunction of the accelerator pedal position sensor

<4G64>

D Malfunction of connector

D Malfunction of the A/T-ECU

Code No. 15 Oil temperature sensor system Probable cause

If the oil temperature sensor output voltage is 2.6 V or more even after driving for

10 minutes or more (if the oil temperature does not increase), it is judged that there

is an open circuit in the oil temperature sensor and diagnosis code No. 15 is output.

Oil temperature sensor check (Refer to P.23-51.)

OK

Check the following connectors:

Harness check

D Between oil temperature sensor and A/T-ECU

Check the trouble symptoms.

A-88, B-11

OK

OK

NG

NG

NG

NG

Replace

Repair

Repair

D Malfunction of the oil temperature sensor

D Malfunction of connector

D Malfunction of the A/T-ECU

Replace the A/T-ECU.

Page 14

23-14

AUTOMATIC TRANSMISSION -

Troubleshooting

Code No. 21 Crank angle sensor system Probable cause

If no output pulse is detected from the crank angle sensor for 5 seconds or more

while driving at 25 km/h or more, it is judged that there is an open circuit in the

crank angle sensor and diagnosis code No. 21 is output.

D Malfunction of the crank angle sensor

D Malfunction of connector

D Malfunction of the A/T-ECU

Check the following connectors:

Harness check

D Between crank angle sensor and A/T-ECU

Crank angle sensor system check

(Refer to GROUP 13 - Troubleshooting.)

Check the trouble symptoms.

A-71, B-51, B-11

OK

OK

OK

NG

NG

NG

Repair

Repair

Replace the A/T-ECU.

Code No. 22 Input shaft speed sensor system Probable cause

If no output pulse is detected from the input shaft speed sensor for 1 second or

more while driving in 3rd or 4th gear at a speed of 30 km/h or more, there is judged

to be an open circuit or short-circuit in the input shaft speed sensor and diagnosis

code No. 22 is output. If diagnosis code No. 22 is output four times, the transmission

is locked into 3rd gear (D range) or 2nd gear as a fail-safe measure, and the N

range lamp flashes at a frequency of 1 Hz.

Measure at the input shaft speed sensor

connector A-90.

D Disconnect the connector and

measure at the harness side.

(1) Voltage between 3 and earth

(Ignition switch: ON)

OK:

(2) Voltage between 2 and earth

(3) Continuity between 1 and earth

Measure output waveform of the input

shaft speed sensor.

(using an oscilloscope)

D Engine: 2,000 r/min (approx. 50

D Transmission: 3rd gear (Voltage)

Check the trouble symptoms.

Battery voltage

(Ignition switch: ON)

OK

approx. 5 V

OK:

Continuity

OK

km/h)

OK:

Conforms to the waveform

shown at page 23-43 (Inspection procedure using an oscilloscope). There is no noise

in the output waveform.

OK

NG

NG

NG

Check the following connectors:

A-90, B-14, B-93, B-89, B-11

OK

Check the following harness:

D Between the input shaft speed

sensor and the ignition switch

D Between the input shaft speed

sensor and A/T-ECU

OK

Check the trouble symptoms.

Replace the input shaft speed sensor.

Check the trouble symptoms.

Replace the A/T-ECU.

D Malfunction of the input shaft speed sensor

D Malfunction of the underdrive clutch retainer

D Malfunction of connector

D Malfunction of A/T-ECU

L

: Refer to the Transmission Workshop Manual.

NG

NG

NG

NG

Repair

Repair

Replace the A/T-ECU.

A/T overhaul K

D Replace the underdrive clutch

Check the trouble symptoms.

Eliminate the cause of the noise.

retainer.

NG

Page 15

AUTOMATIC TRANSMISSION -

Troubleshooting

Code No. 23 Output shaft speed sensor system Probable cause

If the output from the output shaft speed sensor is continuously 50% lower than the

vehicle speed for 1 second or more while driving in 3rd or 4th gear at a speed of

30 km/h or more, there is judged to be an open circuit or short-circuit in the output

shaft speed sensor and diagnosis code No. 23 is output.

If diagnosis code No. 23 is output four times, the transmission is locked into 3rd

gear (D range) or 2nd gear as a fail-safe measure, and the N range lamp flashes

at a frequency of 1 Hz.

Measure at the output shaft speed sensor connector A-82.

D Disconnect the connector and

measure at the harness side.

(1) Voltage between 3 and earth

(Ignition switch: ON)

OK:

(2) Voltage between 2 and earth

(3) Continuity between 1 and earth

Measure output waveform of the output

shaft speed sensor.

(using an oscilloscope)

D Engine: 2,000 r/min

D Transmission: 3rd gear

Check the trouble symptoms.

Battery voltage

(Ignition switch: ON)

OK:

approx. 5 V

OK:

Continuity

OK

(approx. 50 km/h)

(Voltage)

OK:

Conforms to the waveform

shown at page 23-43 (Inspection procedure using an oscilloscope). There is no noise

in the output waveform.

OK

NG

NG

NG

Check the following connectors:

A-82, B-14, B-93, B - 89, B-11

OK

Check the following harness:

D Between the output shaft speed

sensor and the ignition switch

D Between the output shaft speed

sensor and A/T-ECU

OK

Check the trouble symptoms.

Replace the output shaft speed sensor.

Check the trouble symptoms.

Replace the A/T-ECU.

D Malfunction of the output shaft speed sensor

D Malfunction of the transfer drive gear or driven gear

D Malfunction of connector

D Malfunction of the A/T-ECU

L

: Refer to the Transmission Workshop Manual.

NG

NG

NG

NG

Repair

Repair

Replace the A/T-ECU.

A/T overhaul L

D Replace the transfer drive gear and

Check the trouble symptoms.

Eliminate the cause of the noise.

23-15

driven gear.

NG

Code No. 25 Wide open throttle switch system Probable cause

If the wide open throttle switch is on for 1 second or more with the throttle valve

opening angle at 70% or less, it is judged that there is a short circuit in the wide

open throttle switch and diagnosis code No. 25 is output.

Wide open throttle switch check (Refer to P.23-64.)

OK

Check the following connectors:

Harness check

D Between the wide open throttle switch and the A/T-ECU.

Check the trouble symptoms.

B-61, B-10

OK

OK

NG

NG

NG

NG

Replace

Repair

Repair

D Malfunction of the wide open throttle switch

D Malfunction of connector

D Malfunction of A/T-ECU

Replace the A/T-ECU.

Page 16

23-16

AUTOMATIC TRANSMISSION -

Troubleshooting

Code No. 26 Stop lamp switch system Probable cause

If the stop lamp switch is on for 5 minutes or more while driving, it is judged that

there is a short circuit in the stop lamp switch and diagnosis code No. 26 is output.

D Malfunction of the stop lamp switch

D Malfunction of connector

D Malfunction of the A/T-ECU

Stop lamp switch check (Refer to GROUP 35 - Brake Pedal.)

OK

Check the following connectors:

Harness check

D Between stop lamp switch and A/T-ECU

Check the trouble symptoms.

B-28, B-65, B-14, B-10

OK

OK

NG

NG

NG

NG

Replace

Repair

Repair

Replace the A/T-ECU.

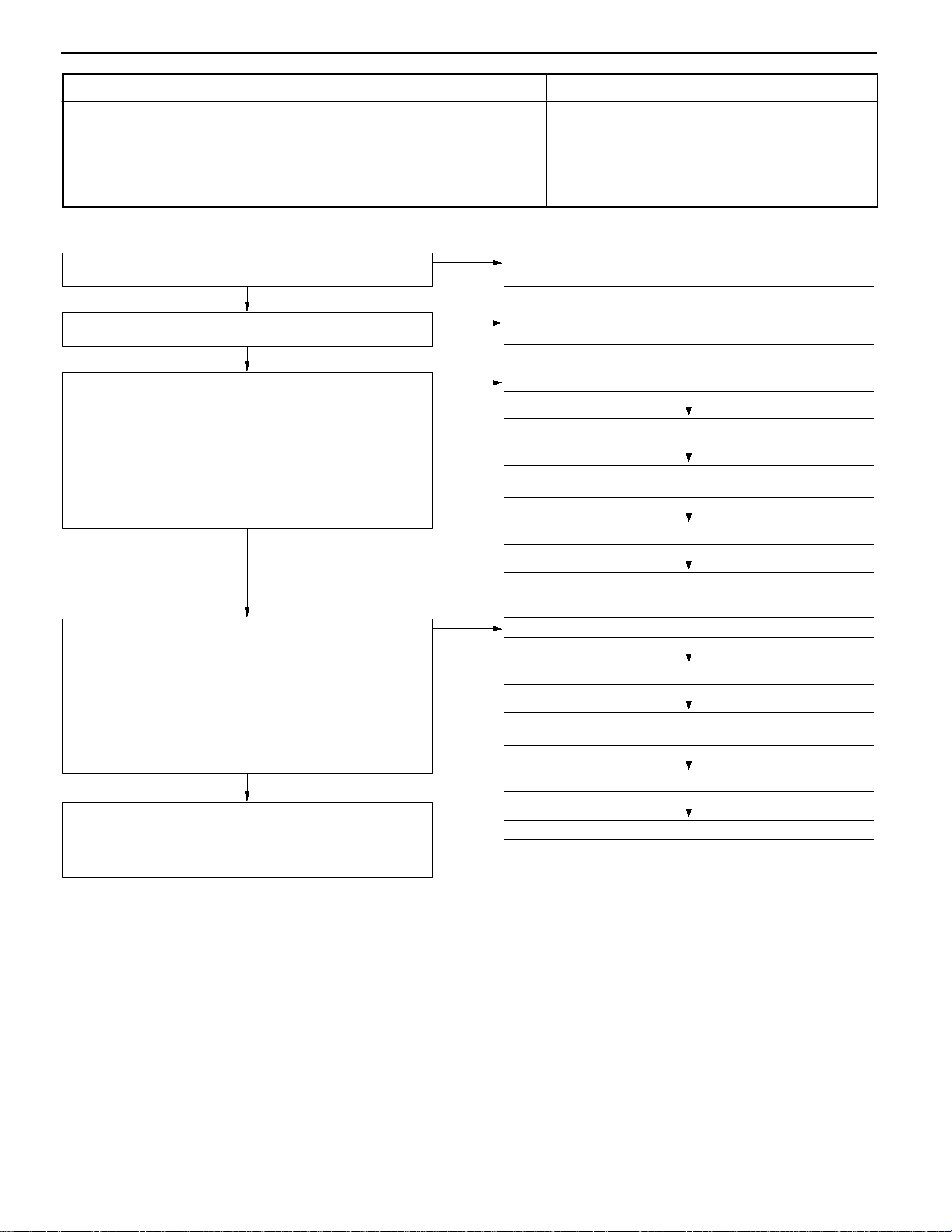

Code No. 31 Low and reverse solenoid valve system

Code No. 32 Underdrive solenoid valve system

Code No. 33 Second solenoid valve system

Code No. 34 Overdrive solenoid valve system

If the resistance value for a solenoid valve is too large or too small, it is judged

that there is a short-circuit or an open circuit in the solenoid valve and the respective

diagnosis code is output. The transmission is locked into 3rd gear as a fail-safe measure,

and the N range lamp flashes at a frequency of 1 Hz.

Solenoid valve check (Refer to P.23-52.)

OK

Check the following connectors:

Harness check

D Between solenoid valve and A/T-ECU

A-88, A -12X, B-12, B-10

OK

OK

NG

NG

NG

Replace

Repair

Repair

Probable cause

D Malfunction of solenoid valve

D Malfunction of connector

D Malfunction of the A/T-ECU

Replace the solenoid valve.

Check the trouble symptoms.

NG

Replace the A/T-ECU.

Page 17

AUTOMATIC TRANSMISSION -

Troubleshooting

23-17

Code No. 36, 52 Damper clutch control solenoid valve

system

If the resistance value for the damper clutch control solenoid valve is too large or

too small, it is judged that there is a short-circuit or an open circuit in the damper

clutch control solenoid valve and diagnosis code No. 36 is output. If the drive duty

rate for the damper clutch control solenoid valve is 100 % for a continuous period

of 4 seconds or more, it is judged that there is an abnormality in the damper clutch

control system and diagnosis code No. 52 is output. When diagnosis code No. 36

is output, the transmission is locked into 3rd gear as a fail-safe measure, and the

N range lamp flashes at a frequency of 1 Hz.

Damper clutch control solenoid valve check (Refer to P.23-52.)

OK

Check the following connectors:

Harness check

D Between damper clutch control solenoid valve and A/T-ECU

Replace the damper clutch control solenoid valve.

Check the trouble symptoms.

A-88, A-12X, B-12

OK

OK

NG

NG

NG

NG

Replace

Repair

Repair

Replace the A/T-ECU.

Probable cause

D Malfunction of the damper clutch control solenoid valve

D Malfunction of connector

D Malfunction of the A/T-ECU

Page 18

23-18

AUTOMATIC TRANSMISSION -

Troubleshooting

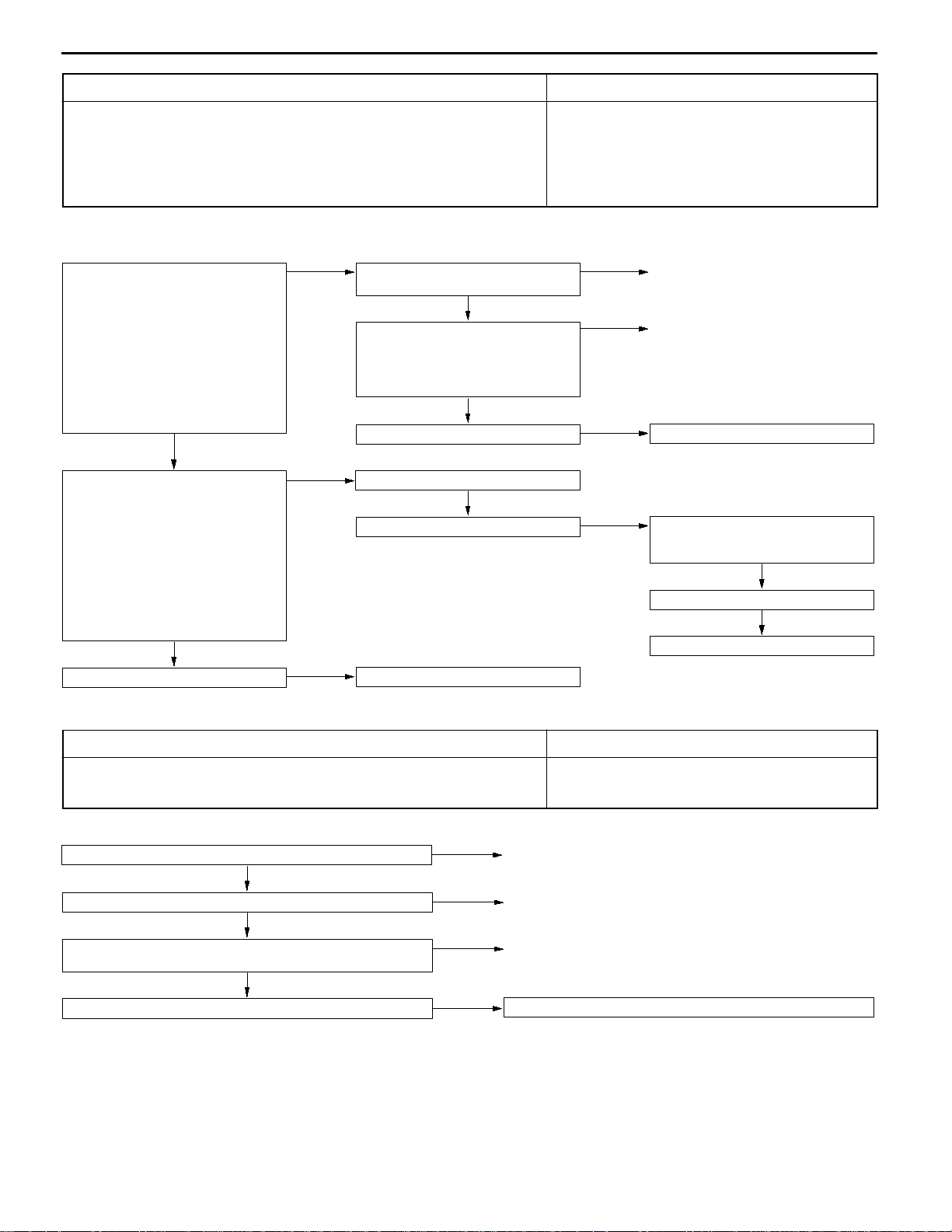

Code No. 41 1st gear ratio does not meet the specification Probable cause

If the output from the output shaft speed sensor multiplied by the 1st gear ratio is

not the same as the output from the input shaft speed sensor after shifting to 1st

gear has been completed, diagnosis code No. 41 is output. If diagnosis code No.

41 is output four times, the transmission is locked into 3rd gear as a fail-safe measure,

and the N range lamp flashes at a frequency of 1 Hz.

MUT-IISelf-Diag code

Is the diagnosis code No. 22 output?

No

MUT-IISelf-Diag code

Is the diagnosis code No. 23 output?

No

Measure output waveform from the input shaft speed sensor. (using

an oscilloscope)

D Connect the connector A-90 and measure voltage between

31 and 43 at the A/T-ECU.

D Engine: 2,000 r/min (approx. 50 km/h)

D Selector lever position: 3

(Voltage)

OK:

A waveform such as the one shown on P.23-43(Inspection

Procedure Using an Oscilloscope) is output (flashing between 0 ¨ 5V) and there is no noise appearing in

the waveform.

OK

Yes

Yes

NG

D Malfunction of the input shaft speed sensor

D Malfunction of the output shaft speed sensor

D Malfunction of the underdrive clutch retainer

D Malfunction of the transfer drive gear or driven gear

D Malfunction of the low and reverse brake system

D Malfunction of the underdrive clutch system

D Noise generated

L

: Refer to the Transmission Workshop Manual.

Code No. 22 Input shaft speed sensor system check

(Refer to P.23-14.)

Code No. 23 Output shaft speed sensor system check

(Refer to P.23-15.)

Replace the input shaft speed sensor.

Check the trouble symptoms.

A/T overhaul L

D Replace the underdrive clutch retainer.

Check the trouble symptoms.

NG

NG

Measure output waveform from the output shaft speed sensor.

(using an oscilloscope)

D Connect the connector A-82 and measure voltage between

32 and 43 at the A/T-ECU.

D Engine: 2,000 r/min (approx. 50 km/h)

D Selector lever position: 3

(Voltage)

OK:

A waveform such as the one shown on P.23-43(Inspection

Procedure Using an Oscilloscope) is output (flashing between 0 ¨ 5V) and there is no noise appearing in

the waveform.

OK

A/T overhaul L

D Underdrive clutch system check

(No. 42, No. 43, or no diagnosis code is output).

D Low and reverse brake system check

(No. 46 or no diagnosis code is output).

NG

Eliminate the cause of the noise.

Replace the output shaft speed sensor.

Check the trouble symptoms.

NG

A/T overhaul L

D Replace the transfer drive gear and driven gear.

Check the trouble symptoms.

NG

Eliminate the cause of the noise.

Page 19

AUTOMATIC TRANSMISSION -

Troubleshooting

CodeNo.422ndgear ratio does notmeet thespecification Probable cause

If the output from the output shaft speed sensor multiplied by the 2nd gear ratio

is not the same as the output from the input shaft speed sensor after shifting to

2nd gear has been completed, diagnosis code No. 42 is output. If diagnosis code

No. 42 is output four times, the transmission is locked into 3rd gear as a fail-safe

measure, and the N range lamp flashes at a frequency of 1 Hz.

MUT-IISelf-Diag code

Is the diagnosis code No. 22 output?

No

MUT-IISelf-Diag code

Is the diagnosis code No. 23 output?

No

Measure output waveform from the input shaft speed sensor. (using

an oscilloscope)

D Connect the connector A-90 and measure voltage between

31 and 43 at the A/T-ECU.

D Engine: 2,000 r/min (approx. 50 km/h)

D Selector lever position: 3

(Voltage)

OK:

A waveform such as the one shown on P.23-43(Inspection

Procedure Using an Oscilloscope) is output (flashing between 0 ¨ 5V) and there is no noise appearing in

the waveform.

OK

Yes

Yes

NG

D Malfunction of the input shaft speed sensor

D Malfunction of the output shaft speed sensor

D Malfunction of the underdrive clutch retainer

D Malfunction of the transfer drive gear or driven gear

D Malfunction of the second brake system

D Malfunction of the underdrive clutch system

D Noise generated

L

: Refer to the Transmission Workshop Manual.

Code No. 22 Input shaft speed sensor system check

(Refer to P.23-14.)

Code No. 23 Output shaft speed sensor system check

(Refer to P.23-15.)

Replace the input shaft speed sensor.

Check the trouble symptoms.

A/T overhaul L

D Replace the underdrive clutch retainer.

Check the trouble symptoms.

23-19

NG

NG

Measure output waveform from the output shaft speed sensor.

(using an oscilloscope)

D Connect the connector A-82 and measure voltage between

32 and 43 at the A/T-ECU.

D Engine: 2,000 r/min (approx. 50 km/h)

D Selector lever position: 3

(Voltage)

OK:

A waveform such as the one shown on P.23-43(Inspection

Procedure Using an Oscilloscope) is output (flashing between 0 ¨ 5V) and there is no noise appearing in

the waveform.

OK

A/T overhaul L

D Underdrive clutch system check

(No. 41, No. 43, or no diagnosis code is output).

D Second brake system check

(No. 44 or no diagnosis code is output).

NG

Eliminate the cause of the noise.

Replace the output shaft speed sensor.

Check the trouble symptoms.

NG

A/T overhaul L

D Replace the transfer drive gear and driven gear.

Check the trouble symptoms.

NG

Eliminate the cause of the noise.

Page 20

23-20

AUTOMATIC TRANSMISSION -

Troubleshooting

CodeNo.433rd gear ratio does not meet thespecification Probable cause

If the output from the output shaft speed sensor multiplied by the 3rd gear ratio is

not the same as the output from the input shaft speed sensor after shifting to 3rd

gear has been completed, diagnosis code No. 43 is output. If diagnosis code No.

43 is output four times, the transmission is locked into 3rd gear as a fail-safe measure,

and the N range lamp flashes at a frequency of 1 Hz.

MUT-IISelf-Diag code

Is the diagnosis code No. 22 output?

No

MUT-IISelf-Diag code

Is the diagnosis code No. 23 output?

No

Measure output waveform from the input shaft speed sensor. (using

an oscilloscope)

D Connect the connector A-90 and measure voltage between

31 and 43 at the A/T-ECU.

D Engine: 2,000 r/min (approx. 50 km/h)

D Selector lever position: 3

(Voltage)

OK:

A waveform such as the one shown on P.23-43(Inspection

Procedure Using an Oscilloscope) is output (flashing between 0 ¨ 5V) and there is no noise appearing in

the waveform.

OK

Yes

Yes

NG

D Malfunction of the input shaft speed sensor

D Malfunction of the output shaft speed sensor

D Malfunction of the underdrive clutch retainer

D Malfunction of the transfer drive gear or driven gear

D Malfunction of the underdrive clutch system

D Malfunction of the overdrive clutch system

D Noise generated

L

: Refer to the Transmission Workshop Manual.

Code No. 22 Input shaft speed sensor system check

(Refer to P.23-14.)

Code No. 23 Output shaft speed sensor system check

(Refer to P.23-15.)

Replace the input shaft speed sensor.

Check the trouble symptoms.

A/T overhaul L

D Replace the underdrive clutch retainer.

Check the trouble symptoms.

NG

NG

Measure output waveform from the output shaft speed sensor.

(using an oscilloscope)

D Connect the connector A-82 and measure voltage between

32 and 43 at the A/T-ECU.

D Engine: 2,000 r/min (approx. 50 km/h)

D Selector lever position: 3

(Voltage)

OK:

A waveform such as the one shown on P.23-43(Inspection

Procedure Using an Oscilloscope) is output (flashing between 0 ¨ 5V) and there is no noise appearing in

the waveform.

OK

A/T overhaul L

D Underdrive clutch system check

(No. 41, No. 42, or no diagnosis code is output).

D Overdrive clutch system check

(No. 44 or no diagnosis code is output).

NG

Eliminate the cause of the noise.

Replace the output shaft speed sensor.

Check the trouble symptoms.

NG

A/T overhaul L

D Replace the transfer drive gear and driven gear.

Check the trouble symptoms.

NG

Eliminate the cause of the noise.

Page 21

AUTOMATIC TRANSMISSION -

Troubleshooting

CodeNo. 44 4thgear ratio does not meet thespecification Probable cause

If the output from the output shaft speed sensor multiplied by the 4th gear ratio is

not the same as the output from the input shaft speed sensor after shifting to 4th

gear has been completed, diagnosis code No. 44 is output. If diagnosis code No.

44 is output four times, the transmission is locked into 3rd gear as a fail-safe measure,

and the N range lamp flashes at a frequency of 1 Hz.

MUT-IISelf-Diag code

Is the diagnosis code No. 22 output?

No

MUT-IISelf-Diag code

Is the diagnosis code No. 23 output?

No

Measure output waveform from the input shaft speed sensor. (using

an oscilloscope)

D Connect the connector A-90 and measure voltage between

31 and 43 at the A/T-ECU.

D Engine: 2,000 r/min (approx. 50 km/h)

D Selector lever position: 3

(Voltage)

OK:

A waveform such as the one shown on P.23-43(Inspection

Procedure Using an Oscilloscope) is output (flashing between 0 ¨ 5V) and there is no noise appearing in

the waveform.

OK

Yes

Yes

NG

D Malfunction of the input shaft speed sensor

D Malfunction of the output shaft speed sensor

D Malfunction of the underdrive clutch retainer

D Malfunction of the transfer drive gear or driven gear

D Malfunction of the second brake system

D Malfunction of the overdrive clutch system

D Noise generated

L

: Refer to the Transmission Workshop Manual.

Code No. 22 Input shaft speed sensor system check

(Refer to P.23-14.)

Code No. 23 Output shaft speed sensor system check

(Refer to P.23-15.)

Replace the input shaft speed sensor.

Check the trouble symptoms.

A/T overhaul L

D Replace the underdrive clutch retainer.

Check the trouble symptoms.

23-21

NG

NG

Measure output waveform from the output shaft speed sensor.

(using an oscilloscope)

D Connect the connector A-82 and measure voltage between

32 and 43 at the A/T-ECU.

D Engine: 2,000 r/min (approx. 50 km/h)

D Selector lever position: 3

(Voltage)

OK:

A waveform such as the one shown on P.23-43(Inspection

Procedure Using an Oscilloscope) is output (flashing between 0 ¨ 5V) and there is no noise appearing in

the waveform.

OK

A/T overhaul L

D Second brake system check

(No. 42 or no diagnosis code is output).

D Overdrive clutch system check

(No. 43 or no diagnosis code is output).

NG

Eliminate the cause of the noise.

Replace the output shaft speed sensor.

Check the trouble symptoms.

NG

A/T overhaul L

D Replace the transfer drive gear and driven gear.

Check the trouble symptoms.

NG

Eliminate the cause of the noise.

Page 22

23-22

AUTOMATIC TRANSMISSION -

Troubleshooting

Code No. 46 Reverse gear ratio does not meet the

specification

If the output from the output shaft speed sensor multiplied by the reverse gear ratio

is not the same as the output from the input shaft speed sensor after shifting to

reverse gear has been completed, diagnosis code No. 46 is output. If diagnosis code

No. 46 is output four times, the transmission is locked into 3rd gear as a fail-safe

measure, and the N range lamp flashes at a frequency of 1 Hz.

MUT-IISelf-Diag code

Is the diagnosis code No. 22 output?

No

MUT-IISelf-Diag code

Is the diagnosis code No. 23 output?

No

Measure output waveform from the input shaft speed sensor. (using

an oscilloscope)

D Connect the connector A-90 and measure voltage between

31 and 43 at the A/T-ECU.

D Engine: 2,000 r/min (approx. 50 km/h)

D Selector lever position: 3

(Voltage)

OK:

A waveform such as the one shown on P.23-43(Inspection

Procedure Using an Oscilloscope) is output (flashing between 0 ¨ 5V) and there is no noise appearing in

the waveform.

OK

Yes

Yes

NG

Code No. 22 Input shaft speed sensor system check

(Refer to P.23-14.)

Code No. 23 Output shaft speed sensor system check

(Refer to P.23-15.)

Replace the input shaft speed sensor.

Check the trouble symptoms.

A/T overhaul L

D Replace the underdrive clutch retainer.

Check the trouble symptoms.

Probable cause

D Malfunction of the input shaft speed sensor

D Malfunction of the output shaft speed sensor

D Malfunction of the underdrive clutch retainer

D Malfunction of the transfer drive gear or driven gear

D Malfunction of the low and reverse brake system

D Malfunction of the reverse clutch system

D Noise generated

L

: Refer to the Transmission Workshop Manual.

NG

NG

Measure output waveform from the output shaft speed sensor.

(using an oscilloscope)

D Connect the connector A-82 and measure voltage between

32 and 43 at the A/T-ECU.

D Engine: 2,000 r/min (approx. 50 km/h)

D Selector lever position: 3

(Voltage)

OK:

A waveform such as the one shown on P.23-43(Inspection

Procedure Using an Oscilloscope) is output (flashing between 0 ¨ 5V) and there is no noise appearing in

the waveform.

OK

A/T overhaul L

D Low and reverse brake system check

(No. 41 or no diagnosis code is output).

D Reverse clutch system check (No diagnosis code is output).

NG

Eliminate the cause of the noise.

Replace the output shaft speed sensor.

Check the trouble symptoms.

NG

A/T overhaul L

D Replace the transfer drive gear and driven gear.

Check the trouble symptoms.

NG

Eliminate the cause of the noise.

Page 23

AUTOMATIC TRANSMISSION -

Troubleshooting

Code No. 51 Abnormal communication with engine-ECU Probable cause

If normal communication is not possible for a continuous period of 1 second or more

when the ignition switch is at the ON position, the battery voltage is 10 V or more

and the engine speed is 450 r/min or more, diagnosis code No. 51 is output. Diagnosis

code No. 51 is also output if the data being received is abnormal for a continuous

period of 4 seconds under the same conditions.

D Malfunction of connector

D Malfunction of the engine-ECU

D Malfunction of the A/T-ECU

23-23

Check the following connectors:

D B-54, B-52, B-10 <4G93>

D B-53, B-52, B-10 <4G64>

OK

Harness check

D Between engine-ECU and A/T-ECU

OK

Check the trouble symptoms.

NG

Replace the engine-ECU.

Check the trouble symptoms.

NG

NG

NG

Repair

Repair

Replace the A/T-ECU.

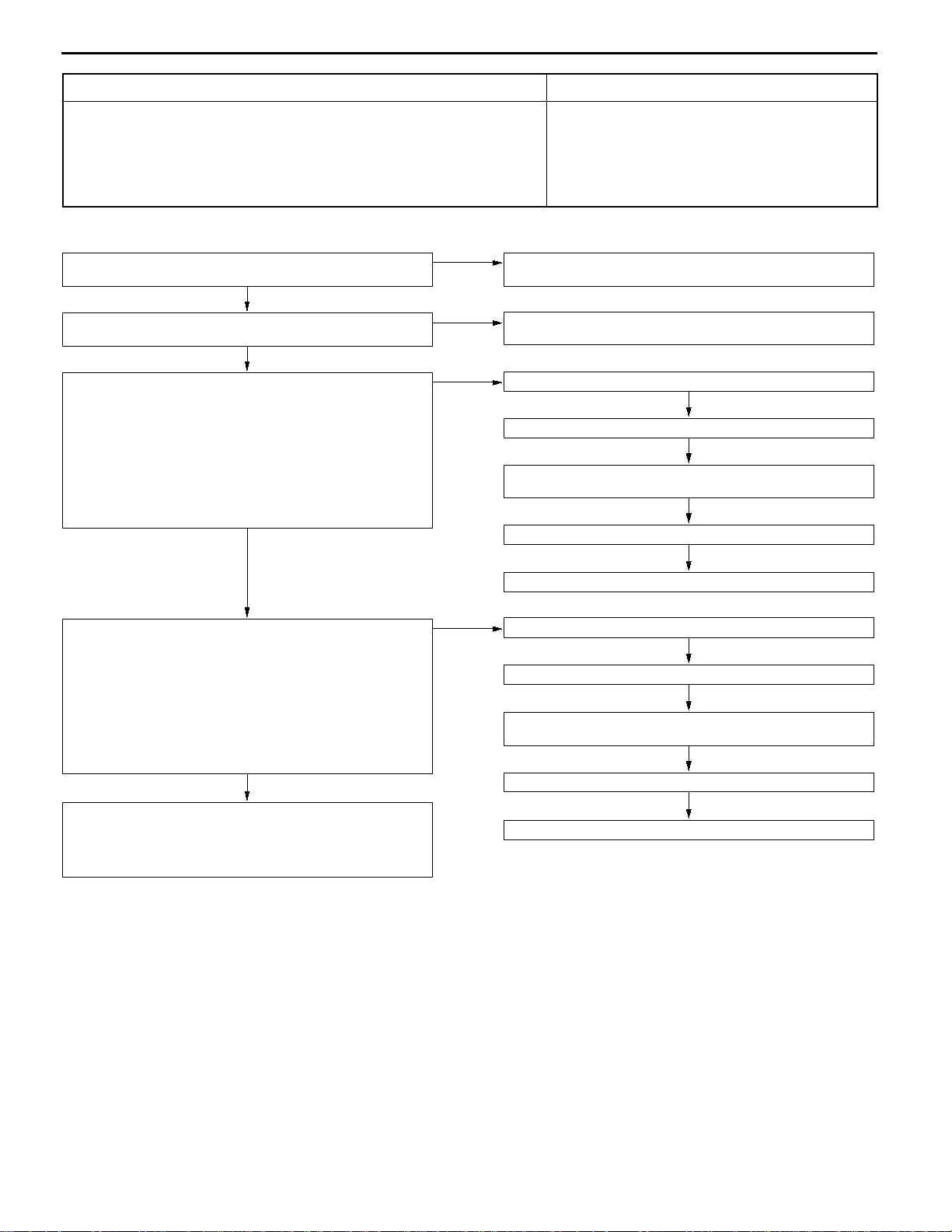

Code No. 54 A/T control relay system Probable cause

If the A/T control relay voltage is less than 7 V after the ignition switch has been

turned ON, it is judged that there is an open circuit or a short-circuit in the A/T control

relay circuit and diagnosis code No. 54 is output.

Then the transmission is locked into 3rd gear as a fail-safe measure, and the N

range lamp flashes at a frequency of 1 Hz.

Check the A/T control relay. (Refer to P.23-52.)

OK

Check the following connectors:

Harness check

D Between control relay and body earth

D Between control relay and fusible link

D Between control relay and A/T-ECU

Check the trouble symptoms.

A-12X, A-29, B-12, B-10

OK

OK

NG

NG

NG

NG

Replace

Repair

Repair

D Malfunction of the A/T control relay

D Malfunction of connector

D Malfunction of the A/T-ECU

Replace the A/T-ECU.

Page 24

23-24

AUTOMATIC TRANSMISSION -

Troubleshooting

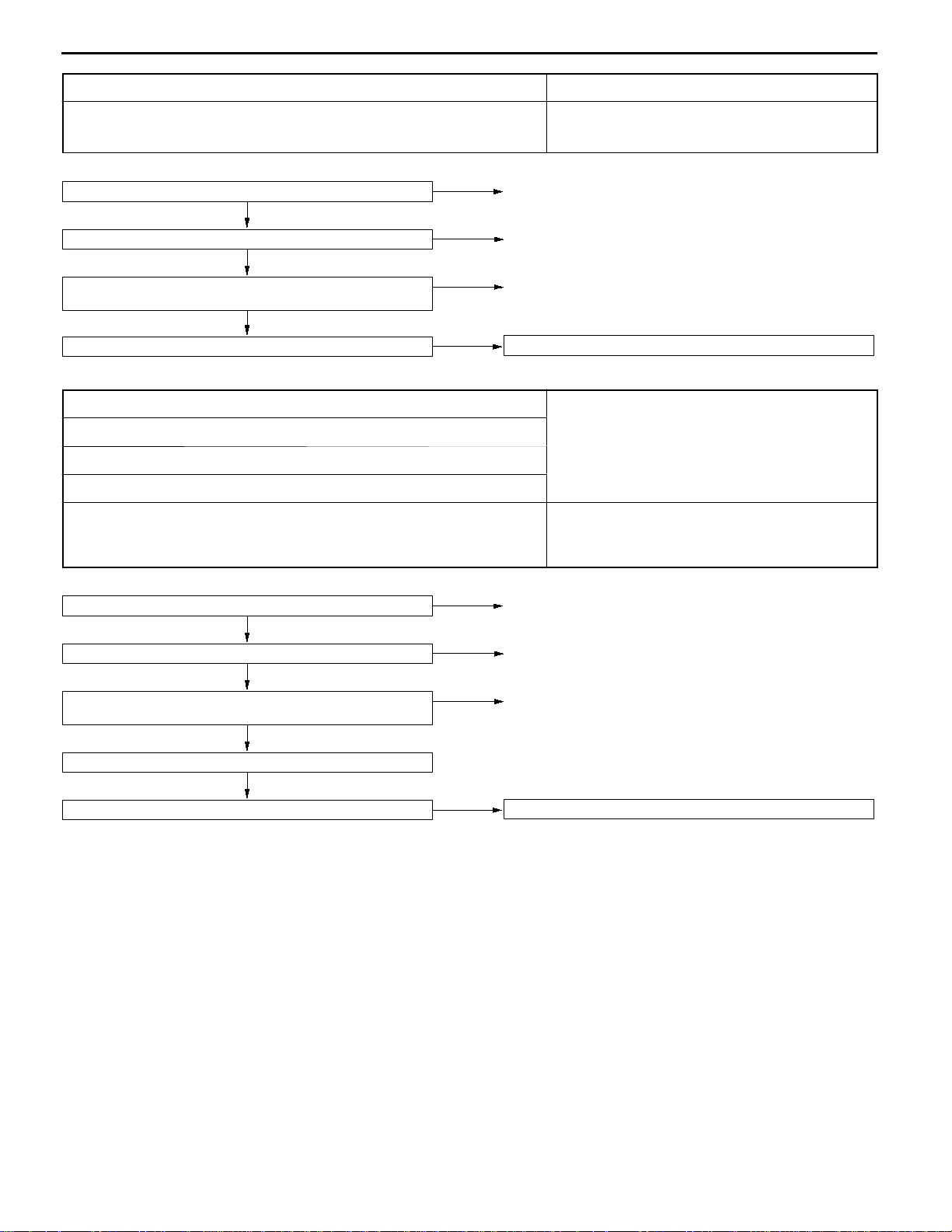

Code No. 56 N range lamp system Probable cause

If the N range signal is off after an N range lamp illumination instruction (ON instruction)

has been given, it is judged that there is a short-circuit in the N range lamp earth

and diagnosis code No. 56 is output.

D Malfunction of the N range lamp bulb

D Malfunction of connector

D Malfunction of the A/T-ECU

Check the N range lamp bulb

(Refer to GROUP 52A - Instrument Panel.)

OK

Check the following connectors:

Harness check

D Between N range lamp bulb and A/T-ECU

Check the trouble symptoms.

B-01, B-14, A-89, B-10

OK

OK

NG

NG

NG

NG

Replace

Repair

Repair

Replace the A/T-ECU.

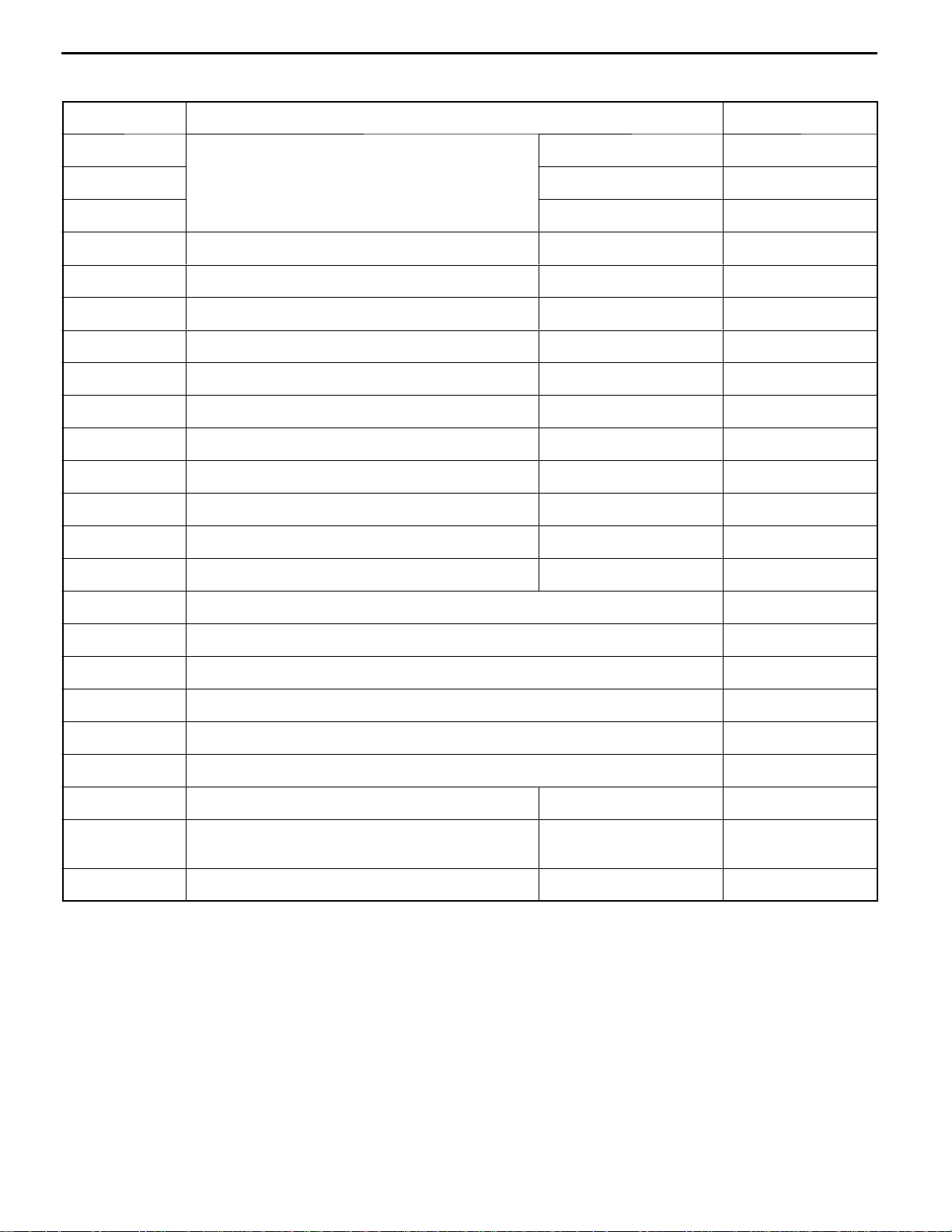

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble symptom Inspection

procedure No.

MUT-IIcan not communicate with any systems. 1 23-25

MUT-IIcan not communicate with the A/T-ECU. 2 23-26

Driving impossible Starting impossible 3 23-27

Does not move forward 4 23-27

Does not reverse 5 23-28

Reference

page

23100800588

Does not move (forward or reverse) 6 23-28

Malfunction when starting Engine stalling when shifting 7 23-29

Shocks when changing from N to D and large time lag 8 23-29

Shocks when changing from N to R and large time lag 9 23-30

Shocks when changing from N to D, N to R and large

10 23-31

time lag

Malfunction when shifting Shocks and running up 11 23-31

Page 25

AUTOMATIC TRANSMISSION -

Troubleshooting

23-25

Trouble symptom Reference

Inspection

procedure No.

page

Displaced shifting points All points 12 23-32

Some points 13 23-33

Does not shift No diagnosis codes 14 23-33

Malfunction while driving Poor acceleration 15 23-34

Vibration 16 23-34

Inhibitor switch system 17 23-35

Dual pressure switch system 18 23-35

Vehicle speed sensor system 19 23-36

INSPECTION PROCEDURE FOR TROUBLE SYMPTOMS

INSPECTION PROCEDURE 1

MUT-IIcan not communicate with any systems.

It is suspected that this malfunction is caused by a defective power supply and earth

circuits of the diagnosis connector.

Probable cause

Malfunction of diagnosis connector

D

Malfunction of harness or connector

D

Measure at diagnosis connector B-25.

Voltage between terminal No. 16 and

D

body earth

Battery voltage

OK:

OK

Measure at diagnosis connector B-25.

Continuity between terminal Nos. 4,

D

5 and body earth

Continuity

OK:

OK

Check trouble symptoms.

NG

Replace the MUT-II.

NG

NG

Check the following connectors:

B-25, B-91, B-92, B-66

OK

Check the trouble symptoms.

Check the following connector:

OK

Check trouble symptoms.

B-25

NG

NG

NG

NG

Repair

Check the harness wire between the

fusible link and the diagnosis connector,

and repair if necessary.

Repair

Check the harness wire between the

diagnosis connector and the earth, and

repair if necessary.

Page 26

23-26

AUTOMATIC TRANSMISSION -

INSPECTION PROCEDURE 2

Troubleshooting

MUT-IIcan not communicate with the A/T-ECU.

It is suspected that this malfunction is caused by an open circuit in A/T-ECU power

supply circuit or diagnosis output circuit.

Measure at diagnosis connector B-25

and A/T-ECU connectors B-12, B-10.

D Disconnect the connectors, and

measure at the harness side.

D Continuity between the following

terminals:

No. 1 (of diagnosis connector) and

23 (of B-12)

No. 7 (of diagnosis connector) and

63 (of B-10)

OK:

Continuity

OK

Measure at A/T-ECU connector B-12.

D Disconnect the connector, and

measure at the harness side.

D Ignition switch: ON

D Voltage between Nos. 11, 24 and

body earth

OK:

Battery voltage

OK

Measure at A/T-ECU connectors B-12,

B-10.

D Disconnect the connector, and

measure at the harness side.

D Continuity between terminal Nos. 12,

13, 25, 26, 72 - body earth

OK:

Continuity

OK

Check the following connectors

B-12, B-10

NG

NG

NG

NG

OK

:

Check the following connectors:

B-12, B-10, B-14, B-102, B-25

OK

Check trouble symptoms.

Check the following connectors:

B-12, B-14, B-93, B-89

OK

Check trouble symptoms.

Check the following connectors:

B-12, B-10

OK

Check trouble symptoms.

Check trouble symptoms.

Probable cause

D Malfunction of harness or connector

D Malfunction of A/T-ECU

NG

NG

NG

NG

NG

NG

NG

Repair

Check the harness wire between the

A/T-ECU and the diagnosis connector,

and repair if necessary.

Repair

Check the harness wire between the

ignition switch and the A/T-ECU, and

repair if necessary.

Repair

Check the harness wire between the

A/T-ECU and the earth, and repair if

necessary.

Replace the A/T-ECU.

Repair

Page 27

AUTOMATIC TRANSMISSION -

INSPECTION PROCEDURE 3

Troubleshooting

23-27

Starting impossible

Starting is not possible when the selector lever is in P or N range. In such cases,

the cause is probably a defective inhibitor switch system, transmission control cable

assembly, engine system, torque converter or oil pump.

Check the inhibitor switch system (Refer to P.23-35, INSPECTION

PROCEDURE 17).

OK

Check the transmission control cable assembly.

OK

Check the engine system.

D Control system, ignition system, fuel system, main engine

system

OK

Torque converter check

D Check for incorrect installation (inserted at an angle, etc.) and

for damaged splines.

OK

Replace the oil pump assembly. L

(The oil pump cannot be disassembled.)

NG

NG

NG

NG

Repair, replace

Repair, replace

Repair, replace

Repair if possible. If the splines are damaged and repairs are not

possible, replace the torque converter assembly.

Probable cause

D Malfunction of the inhibitor switch system

D Malfunction of the transmission control cable assembly

D Malfunction of the engine system

D Malfunction of the torque converter

D Malfunction of the oil pump

L

: Refer to the Transmission Workshop Manual.

INSPECTION PROCEDURE 4

Does not move (forward)

If the vehicle does not move forward when the selector lever is shifted from N to

D, 3, 2 or L range while the engine is idling, the cause is probably abnormal line

pressure or a malfunction of the underdrive clutch or valve body.

MUT-IIActuator test

D No. 2 Underdrive solenoid valve

OK:

Sound of operation can be heard.

OK

Hydraulic pressure test (Refer to P.23-55.)

D Measure the hydraulic pressure for each element when in L

range.

Standard value:

Underdrive clutch system check L

D Remove the transmission assembly, valve body cover and valve

body.

D Pistons should operate and pressure should be maintained

when air is blown through the underdrive clutch oil hole in the

transmission case.

Refer to P.23-56.

OK

NG

NG

OK

NG

Probable cause

D Abnormal line pressure

D Malfunction of the underdrive solenoid valve

D Malfunction of the underdrive clutch

D Malfunction of the valve body

L

: Refer to the Transmission Workshop Manual.

Replace the solenoid valve. L

Valve body disassembly, cleaning and reassembly L

D Pay particular attention to loosening of bolts, and to damage

and slippage of O-rings, valves and valve bodies.

D If the damage cannot be repaired, replace the valve body

assembly.

Underdrive clutch check L

D Check for burning of the facing, defective piston seal rings

and interference at the retainer.

Page 28

23-28

AUTOMATIC TRANSMISSION -

INSPECTION PROCEDURE 5

Troubleshooting

Does not reverse

If the vehicle does not reverse when the selector lever is shifted from N to R range

while the engine is idling, the cause is probably abnormal pressure in the reverse

clutch or low and reverse brake or a malfunction of the reverse clutch, low and reverse

brake or valve body.

MUT-IIActuator test

D No. 1 Low and reverse solenoid valve

OK:

Sound of operation can be heard.

OK

Hydraulic pressure check (Refer to P.23-55.)

D Measure the reverse clutch pressure in R range.

Standard value:

Hydraulic pressure check (Refer to P.23-55.)

D Measure the low and reverse brake pressure in R range.

Standard value:

Reverse clutch system and low and reverse brake system check

L

D Remove the transmission assembly, valve body cover and valve

body.

D Pistons should operate and pressure should be maintained

when air is blown through the reverse clutch oil hole and the

low reverse brake oil hole in the transmission case.

Refer to P.23-56.

OK

Refer to P.23-56.

OK

NG

NG

NG

OK

NG

Replace the low and reverse solenoid valve. L

Valve body disassembly, cleaning and reassembly L

D Pay particular attention to loosening of bolts, and to damage

D If the damage cannot be repaired, replace the valve body

Reverse clutch and low and reverse brake check L

D Check for burning of the facing, defective piston seal rings

Probable cause

D Abnormal reverse clutch pressure

D Abnormal low and reverse brake pressure

D Malfunction of the low and reverse solenoid valve

D Malfunction of the reverse clutch

D Malfunction of the low and reverse brake

D Malfunction of the valve body

L

: Refer to the Transmission Workshop Manual.

and slippage of O-rings, valves and valve bodies.

assembly.

and interference at the retainer.

INSPECTION PROCEDURE 6

Does not move (forward or reverse)

If the vehicle does not move forward or reverse when the selector lever is shifted

to any position while the engine is idling, the cause is probably abnormal line pressure,

or a malfunction of the power train, oil pump or valve body.

Hydraulic pressure check (Refer to P.23-55.)

D Measure the hydraulic pressure for each element when moving

forward and back.

Standard value:

Replace the oil pump assembly. L

(The oil pump cannot be disassembled.)

Refer to P.23-56.

NG

OK

NG

Probable cause

D Abnormal line pressure

D Malfunction of power train

D Malfunction of the oil pump

D Malfunction of the valve body

L

: Refer to the Transmission Workshop Manual.

Power train check L

D Disassemble the transmission, check the condition of the

planetary carrier, output shaft and differential, etc.

Valve body disassembly, cleaning and reassembly L

D Pay particular attention to loosening of bolts, and to damage

and slippage of O-rings, valves and valve bodies.

D If the damage cannot be repaired, replace the valve body

assembly.

Page 29

AUTOMATIC TRANSMISSION -

INSPECTION PROCEDURE 7

Troubleshooting

23-29

Engine stalling when shifting

If the engine stalls when the selector lever is shifted from N to D or R range while

the engine is idling, the cause is probably a malfunction of the engine system, damper

clutch solenoid valve, valve body or torque converter (damper clutch malfunction).

Engine system check

D Check the control system, ignition system, fuel system and

main system.

OK

Replace the damper clutch control solenoid valve.

Valve body disassembly, cleaning and reassembly L

D Pay particular attention to loosening of bolts, and to damage

and slippage of O-rings, valves and valve bodies.

D If the damage cannot be repaired, replace the valve body

assembly.

NG

NG

INSPECTION PROCEDURE 8

Shocks when changing from N to D and large time lag

If abnormal shocks or a time lag of 2 seconds or more occur when the selector

lever is shifted from N to D range while the engine is idling, the cause is probably

abnormal underdrive clutch pressure or a malfunction of the underdrive clutch, valve

body, TPS <4G93> or APS <4G64>.

Probable cause

D Malfunction of the engine system

D Malfunction of the damper clutch control solenoid valve

D Malfunction of the valve body

D Malfunction of the torque converter (Malfunction of the

damper clutch)

L

: Refer to the Transmission Workshop Manual.

Repair, replace

Replace the torque converter.

Probable cause

D Abnormal underdrive clutch pressure

D Malfunction of the underdrive solenoid valve

D Malfunction of the underdrive clutch

D Malfunction of the valve body

D Malfunction of the idle position switch

D Malfunction of the TPS <4G93>

D Malfunction of the APS <4G64>

MUT-IIActuator test

D No. 2 Underdrive solenoid valve

OK:

Sound of operation can be heard.

OK

When does the shock occur?

When shifting

Hydraulic pressure test (Refer to P.23-55.)

D Measure the underdrive clutch pressure when shifting from

NtoD.

Standard value:

Underdrive clutch system check L

D Remove the transmission assembly, valve body cover and valve

body.

D Pistons should operate and pressure should be maintained

when air is blown through the underdrive clutch oil hole in the

transmission case.

Underdrive clutch check L

D Check for burning of the facing, defective piston seal rings

and interference at the retainer.

Refer to P.23-56.

OK

NG

NG

When starting

NG

OK

L

: Refer to the Transmission Workshop Manual.

Replace the underdrive solenoid valve. L

Shocks sometimes occur

No Yes

MUT-IIData list

D No. 11 TPS/APS

OK:

Increases in proportion to accelerator pedal opening

angle.

OK NG

Code Nos. 11, 12, 14 TPS/APS system check (Refer to P.23-13.)

Valve body disassembly, cleaning and reassembly L

D Pay particular attention to loosening of bolts, and to damage

and slippage of O-rings, valves and valve bodies.

D If the damage cannot be repaired, replace the valve body

assembly.

Page 30

23-30

AUTOMATIC TRANSMISSION -

INSPECTION PROCEDURE 9

Troubleshooting

Shocks when changing from N to R and large time lag

If abnormal shocks or a time lag of 2 seconds or more occurs when the selector

lever is shifted from N to R range while the engine is idling, the cause is probably

abnormal reverse clutch pressure or low and reverse brake pressure, or a malfunction

of the reverse clutch, low and reverse brake, valve body, TPS <4G93> or APS <4G64>.

MUT-IIActuator test

D No. 1 Low and reverse solenoid valve

OK:

Sound of operation can be heard.

OK

When does the shock occur?

When shifting

Hydraulic pressure test (Refer to P.23-55.)

D Measure the reverse clutch pressure in R range.

Standard value:

Hydraulic pressure test (Refer to P.23-55.)

D Measure the low and reverse brake pressure in R range.

Standard value:

Reverse clutch system and low reverse brake system check L

D Remove the transmission assembly, valve body cover and valve

body.

D Pistons should operate and pressure should be maintained

when air is blown through the reverse clutch oil hole and low

and reverse brake oil hole in the transmission case.

Refer to P.23-56.

OK

Refer to P.23-56.

OK

NG

NG

When starting

NG

NG

OK

Replace the low and reverse solenoid valve. L

Shocks sometimes occur

MUT-IIData list

D No. 11 TPS/APS

Code No. 11, 12, 14 TPS/APS system check (Refer to P.23-13.)

Valve body disassembly, cleaning and reassembly L

D Pay particular attention to loosening of bolts, and to damage

D If the damage cannot be repaired, replace the valve body

Probable cause

D Abnormal reverse clutch pressure

D Abnormal low and reverse brake pressure

D Malfunction of the low and reverse solenoid valve

D Malfunction of the reverse clutch

D Malfunction of the low and reverse brake

D Malfunction of the valve body

D Malfunction of the idle position switch

D Malfunction of the TPS <4G93>

D Malfunction of the APS <4G64>

L

: Refer to the Transmission Workshop Manual.

No Yes

OK:

Increases in proportion to accelerator pedal opening

angle.

OK NG

and slippage of O-rings, valves and valve bodies.

assembly.

Reverse clutch and low reverse brake check L

D Check for burning of the facing, defective piston seal rings

and interference at the retainer.

Page 31

AUTOMATIC TRANSMISSION -

INSPECTION PROCEDURE 10

Troubleshooting

23-31

Shocks when changing from N to D, N to R and large time

lag

If abnormal shocks or a time lag of 2 seconds or more occur when the selector

lever is shifted from N to D range and from N to R range while the engine is idling,

the cause is probably abnormal line pressure or a malfunction of the oil pump or

valve body.

Hydraulic pressure test (Refer to P.23-55.)

D Measure the hydraulic pressure for each element when in D

range and R range.

Standard value:

When does the shock occur?

Replace the oil pump assembly. L

(The oil pump cannot be disassembled.)

Refer to P.23-56.

OK

When shifting

NG

When

starting

INSPECTION PROCEDURE 11

Shocks and running up

If shocks occur when driving due to upshifting or downshifting and the transmission

speed becomes higher than the engine speed, the cause is probably abnormal line

pressure or a malfunction of a solenoid valve, oil pump, valve body or of a brake

or clutch.

Probable cause

D Abnormal line pressure

D Malfunction of the oil pump

D Malfunction of the valve body

L

: Refer to the Transmission Workshop Manual.

Adjust the line pressure. (Refer to P.23-61.)

NG

Valve body disassembly, cleaning and reassembly L

D Pay particular attention to loosening of bolts, and to damage

and slippage of O-rings, valves and valve bodies.

D If the damage cannot be repaired, replace the valve body

assembly.

Probable cause

D Abnormal line pressure

D Malfunction of each solenoid valve

D Malfunction of the oil pump

D Malfunction of the valve body

D Malfunction of each brake or each clutch

MUT-IIActuator test

D No. 1 Low and reverse solenoid valve

D No. 2 Underdrive solenoid valve

D No. 3 Second solenoid valve

D No. 4 Overdrive solenoid valve

OK:

Sound of operation can be heard.

OK

Adjust the line pressure. (Refer to P.23-61.)

OK

Clutch and brake check L

D Check for burning of the facing, defective piston seal rings

and interference at the retainer.

NG

NG

L

: Refer to the Transmission Workshop Manual.

Replace the solenoid valve.

Replace the oil pump assembly. L

(The oil pump cannot be disassembled.)

NG

Valve body disassembly, cleaning and reassembly L

D Pay particular attention to loosening of bolts, and to damage

and slippage of O-rings, valves and valve bodies.

D If the damage cannot be repaired, replace the valve body

assembly.

Page 32

23-32

AUTOMATIC TRANSMISSION -

INSPECTION PROCEDURE 12

Troubleshooting

All points (Displaced shifting points)

If all shift points are displaced while driving, the cause is probably a malfunction of

the output shaft speed sensor, TPS or of a solenoid valve.

MUT-IIData list

D No. 23 Output shaft speed sensor

OK:

Increases in proportion to vehicle speed.

OK

MUT-IIData list

D No. 11 TPS/APS

OK:

Increases in proportion to accelerator pedal opening angle

OK

MUT-IIData list

D No. 31 Low and reverse solenoid valve duty %

D No. 32 Underdrive solenoid valve duty %

D No. 33 Second solenoid valve duty %

D No. 34 Overdrive solenoid valve duty %

OK:

Refer to the table below.

OK

Adjust the line pressure. (Refer to P.23-61.)

NG

NG

NG

NG

Code No. 23 - Output shaft speed sensor system (Refer to P.23-15.)

Code No. 11, 12, 14 TPS/APS system check (Refer to P.23-13.)

Replace the solenoid valve. L

Replace the A/T-ECU.

Valve body disassembly, cleaning and reassembly L

D Pay particular attention to loosening of bolts, and to damage

D If the damage cannot be repaired, replace the valve body

Probable cause

D Malfunction of the output shaft speed sensor

D Malfunction of the throttle position sensor

D Malfunction of each solenoid valve

D Abnormal line pressure

D Malfunction of the valve body

D Malfunction of the A/T-ECU

L

: Refer to the Transmission Workshop Manual.

NG

and slippage of O-rings, valves and valve bodies.

assembly.

No. 31 No. 32 No. 33 No. 34

Driving at constant speed in 1st gear 0% 0% 100 % 100 %

Driving at constant speed in 2nd gear 100 % 0% 0% 100 %

Driving at constant speed in 3rd gear 100 % 0% 100 % 0%

Driving at constant speed in 4th gear 100 % 100 % 0% 0%

Page 33

AUTOMATIC TRANSMISSION -

INSPECTION PROCEDURE 13

Troubleshooting

23-33

Some points (Displaced shifting points)

If some of the shift points are displaced while driving, the cause is probably a malfunction

of the valve body, or it is related to control and is not an abnormality.

INVECS-IICANCEL COMMAND

D Use the MUT-II to stop the

INVECS-II function.

Does standard shifting occur normally?

Yes

No

Does the problem occur only when the

automatictransmissionfluidtemperature

is - 29_C or lower or 125_C or higher?

Yes

It is related to control and is not an abnormality.

INSPECTION PROCEDURE 14

No diagnosis codes (Does not shift)

If shifting does not occur while driving and no diagnosis codes are output, the cause

is probably a malfunction of the inhibitor switch, or A/T-ECU.

Does the transmission remain in 3rd

gear with selector lever in position

D?

Yes

Is backup power being supplied to the

A/T-ECU?

No

Is power being supplied to the

A/T-ECU?

Power supply circuit check

D Pay particular attention to open

circuits in the harnesses, poor

connector connections and open

circuits in fuses.

D If there is a blown fuse, investigate

why a short-circuit has occurred and

then replace the fuse.

Yes

No

No

Yes

MUT-IIData list

D No. 61 Inhibitor switch

OK:

A/T-ECU input signal and selector lever position should

match.

OK

Replace the A/T-ECU.

Probable cause

D Malfunction of the valve body

L

: Refer to the Transmission Workshop Manual.

No

Valve body disassembly, cleaning and

reassembly L

D Pay particular attention to loosening

of bolts, and to damage and slippage

of O-rings, valves and valve bodies.

D If the damage cannot be repaired,

replace the valve body assembly.

Probable cause

D Malfunction of the inhibitor switch

D Malfunction of the A/T-ECU

NG

Inhibitor switch check

D INSPECTION PROCEDURE 17 -

Inhibitor switch system check.

(Refer to P.23-35.)

Page 34

23-34

AUTOMATIC TRANSMISSION -

INSPECTION PROCEDURE 15

Troubleshooting

Poor acceleration

If acceleration is poor even if downshifting occurs while driving, the cause is probably

a malfunction of the engine system or of a brake or clutch.

Engine system check

D Check the control system, ignition system, fuel system and

main system.

OK

Brake or clutch check L

D Check for burning of the facing, defective piston seal rings

and interference at the retainer.

NG

INSPECTION PROCEDURE 16

Vibration

If vibration occurs when driving at constant speed or when accelerating and deceleration

in top range, the cause is probably abnormal damper clutch pressure or a malfunction

of the engine system, damper clutch control solenoid valve, torque converter or valve

body.

MUT-IIActuator test

D No. 6 Damper clutch control solenoid valve

OK:

Sound of operation can be heard.

OK

Does the problem occur even when the oil temperature sensor

connector is disconnected?

No

Hydraulic pressure test (Refer to P.23-55.)

D Measure the damper clutch pressure.

Standard value:

Replace the torque converter assembly.

Refer to P.23-56.

OK

NG

Yes

NG

Probable cause

D Malfunction of the engine system

D Malfunction of the brake or clutch

L

: Refer to the Transmission Workshop Manual.

Replace, repair

Probable cause

D Abnormal damper clutch pressure

D Malfunction of the engine system

D Malfunction of the damper clutch control solenoid valve

D Malfunction of the torque converter

D Malfunction of the valve body

L

: Refer to the Transmission Workshop Manual.

Replace the damper clutch control solenoid valve. L

Engine system check

D Check the control system, ignition system, fuel system and

main system.

Valve body disassembly, cleaning and reassembly L

D Pay particular attention to loosening of bolts, and to damage

and slippage of O-rings, valves and valve bodies.

D If the damage cannot be repaired, replace the valve body

assembly.

Page 35

AUTOMATIC TRANSMISSION -

INSPECTION PROCEDURE 17

Troubleshooting

23-35

Inhibitor switch system

The cause is probably a malfunction of the inhibitor switch circuit, ignition switch

circuit or a defective A/T-ECU.

Inhibitor switch check (Refer to P.23-48.)

OK

Check the voltage of the inhibitor switch

connector A-89.

D Disconnect the connector and

measure at the harness side.

D Voltage between terminal No. 8 and

earth

OK:

Battery voltage

OK

Check the following connectors:

A-89, B-10

OK

Harness check

D Between inhibitor switch and

A/T-ECU connector

OK

Check the trouble symptoms.

NG

NG

NG

NG

NG

Replace

Repair

Repair

Check the following connectors:

B-14, B-93, B-89

Harness check

D Between inhibitor switch and

ignition switch

Check the trouble symptoms.

Ignition switch check

(Refer to GROUP54 - Ignition Switch.)

Replace the A/T-ECU.

Probable cause

D Malfunction of the inhibitor switch