Mitsubishi Electric Artisan MELSEC-Q, Artisan MELSEC-A, Artisan MELSEC-QnA, Artisan MELSEC-AnS, Artisan MELSEC-QnAS Series Manual

...Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Page 2

Mitsubishi General-purpose Programmable Controllers

MELSEC-A/QnA (Large), AnS/QnAS (Small)

Transition Examples

Dec. 2014 Edition

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 3

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead

to serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this publication and keep it in a safe place for future reference.

Before using products introduced in this publication, please read this Transition

Examples and relevant manuals carefully and pay full attention to safety to handle

the product correctly.

In this publication, the safety precautions are classified into two levels:

" WARNING" and " CAUTION".

CAUTION

WARNING

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

● Configure safety circuits external to the programmable controller to ensure that the entire system operates

safely even when a fault occurs in the external power supply or the programmable controller. Failure to do

so may result in an accident due to an incorrect output or malfunction.

(1) Configure external safety circuits, such as an emergency stop circuit, protection circuit, and protective

interlock circuit for forward/reverse operation or upper/lower limit positioning.

(2) The programmable controller stops its operation upon detection of the following status, and the output

status of the system will be as shown below.

All outputs may turn on when an error occurs in the part, such as I/O control part, where the CPU module

cannot detect any error. To ensure safety operation in such a case, provide a safety mechanism or a

fail-safe circuit external to the programmable controller. For a fail-safe circuit example, refer to LOADING

AND INSTALLATION in the QCPU User's Manual (Hardware Design, Maintenance and Inspection).

(3) Outputs may remain on or off due to a failure of an output module relay or transistor. Configure an

external circuit for monitoring output signals that could cause a serious accident.

Q Series ModuleStatus

All out puts are turned off.

A/AnS Series module

All out puts are turned off.

All out puts are turned off.

Overcurrent or overvoltage protection of

the power supply module is activated.

The CPU module detects an error such as

a watchdog timer error by the self-diagnostic

function.

All outputs are held or turned

off according to the parameter

setting.

WARNING

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

Safety Precautions

● When replacing A (Large Type)/AnS (Small Type) Series with Q Series ●

Before using products introduced in this publication, please read this Transition

Examples and relevant manuals carefully and pay full attention to safety to handle

the product correctly.

In this publication, the safety precautions are classified into two levels:

" WARNING" and " CAUTION".

Indicates that incorrect handling may cause hazardous conditions,

WARNING

CAUTION

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead

to serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

Make sure that the end users read this publication and keep it in a safe place for future reference.

Design Precautions

WARNING

● Configure safety circuits external to the programmable controller to ensure that the entire system operates

safely even when a fault occurs in the external power supply or the programmable controller. Failure to do

so may result in an accident due to an incorrect output or malfunction.

(1) Configure external safety circuits, such as an emergency stop circuit, protection circuit, and protective

interlock circuit for forward/reverse operation or upper/lower limit positioning.

(2) The programmable controller stops its operation upon detection of the following status, and the output

status of the system will be as shown below.

Overcurrent or overvoltage protection of

the power supply module is activated.

The CPU module detects an error such as

a watchdog timer error by the self-diagnostic

function.

Q Series ModuleStatus

All out puts are turned off.

All outputs are held or turned

off according to the parameter

setting.

A/AnS Series module

All out puts are turned off.

All out puts are turned off.

All outputs may turn on when an error occurs in the part, such as I/O control part, where the CPU module

cannot detect any error. To ensure safety operation in such a case, provide a safety mechanism or a

fail-safe circuit external to the programmable controller. For a fail-safe circuit example, refer to LOADING

AND INSTALLATION in the QCPU User's Manual (Hardware Design, Maintenance and Inspection).

(3) Outputs may remain on or off due to a failure of an output module relay or transistor. Configure an

external circuit for monitoring output signals that could cause a serious accident.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1

Page 5

Design Precautions

WARNING

● In an output module, when a load current exceeding the rated current or an overcurrent caused by a load

short-circuit flows for a long time, it may cause smoke and fire. To prevent this, configure an external safety

circuit, such as a fuse.

● Configure a circuit so that the programmable controller is turned on first and then the external power supply.

If the external power supply is turned on first, an accident may occur due to an incorrect output or

malfunction.

● For the operating status of each station after a communication failure, refer to relevant manuals for the

network.

Incorrect output or malfunction due to a communication failure may result in an accident.

● When controlling (changing data) the running programmable controller from a peripheral connected to the

CPU module or from a personal computer connected to an intelligent function module, configure an interlock

circuit in the sequence program to ensure that the entire system will always operate safely.

For other controls for the running programmable controller (program modification and operating status

change (status control)), read relevant manuals carefully, and ensure the safety before operation.

Especially, in the case of a control from an external device to a remote programmable controller, immediate

action cannot be taken for a problem on the programmable controller due to a communication failure.

Configure an interlock circuit in the sequence program, and determine corrective actions to be taken

between the external device and CPU module in case of a communication failure.

CAUTION

● Do not install the control lines or communication cables together with the main circuit lines or power cables.

Keep a distance of 100mm (3.94 inches) or more between them.

Failure to do so may result in malfunction due to noise.

● When a device such as a lamp, heater, or solenoid valve is controlled through an output module, a large

current (approximately ten times greater than normal) may flow when the output is turned from off to on.

Take measures such as replacing the module with one having a sufficient current rating.

● The time for the CPU module to enter the RUN status after the CPU module is powered off and on or reset

will vary depending on the system configuration, parameter settings, and/or program size, etc.

Design the program so that the entire system will operate safely even if the time to reach the RUN status

varies.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2

Page 6

Installation Precautions

CAUTION

● Use the programmable controller in an environment that meets the general specifications in the QCPU

User's Manual (Hardware Design, Maintenance and Inspection).

Failure to do so may result in electric shock, fire, malfunction, or damage to or deterioration of the product.

● To mount the module, while pressing the module mounting lever located in the lower part of the module, fully

insert the module fixing projection(s) into the hole(s) in the base unit and press the module until it snaps into

place.

Incorrect mounting may cause malfunction, failure or drop of the module.

When using the programmable controller in an environment of frequent vibrations, fix the module with a

screw.

Tighten the screw within the specified torque range.

Undertightening can cause drop of the screw, short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

● When using an extension cable, connect it to the extension cable connector of the base unit securely.

Check the connection for looseness.

Poor contact may cause incorrect input or output.

● When using an SD memory card, fully insert it into the SD memory card slot.

Check that it is inserted completely.

Poor contact may cause malfunction.

● When using an extended SRAM cassette, fully insert it into the cassette connector on the CPU module.

Close the cassette cover to keep the extended SRAM cassette inserted completely.

Poor contact may cause malfunction.

● Shut off the external power supply for the system in all phases before mounting or removing the module.

Failure to do so may result in damage to the product.

A module can be replaced online (while power is on) on any MELSECNET/H remote I/O station or in the

system where a CPU module supporting the online module change function is used.

Note that there are restrictions on the modules that can be replaced online, and each module has its

predetermined replacement procedure.

For details, refer to the relevant sections in the QCPU User's Manual (Hardware Design, Maintenance and

Inspection) and in the manual for the corresponding module.

● Do not directly touch any conductive part or electronic component of the module, memory card, SD memory

card or extended SRAM cassette. Doing so can cause malfunction or failure.

● When using a motion CPU module and a motion module, make sure that proper modules are combined

before turning on power. If improper modules are used, they may be damaged. For details, refer to the

Motion CPU Module User's Manual.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3

Page 7

Wiring Precautions

WARNING

● Shut off the external power supply for the system in all phases before mounting or wiring the module.

Failure to do so may result in electric shock or damage to the product.

● After mounting or wiring, attach the included terminal cover onto the module before turning the power on or

starting operation.

Failure to do so may result in electric shock.

CAUTION

● Ground the FG and LG terminals to the dedicated conductors for the programmable controller (Class D

(Class 3) or higher grounding).

Failure to do so may result in electric shock or malfunction.

● Use applicable solderless terminals and tighten them within the specified torque range.

If any spade solderless terminal is used, it may be disconnected when the terminal screw comes loose,

resulting in failure.

● Check the rated voltage and terminal layout before wiring to the module, and connect the cables correctly.

Inputting voltage different from the rated voltage, connecting a power supply with a different voltage rating or

incorrect wiring may cause a fire or failure.

● Connectors for external connection must be crimped or pressed with the tool specified by the manufacturer,

or must be correctly soldered.

Incomplete connections could result in short circuit, fire, or malfunction.

● Fit the connectors surely to the module. Poor contact may cause malfunction.

● Do not bundle the control cable or communication cable with the main circuit or power wire, or lay them

adjacently.

Separate these by 100 mm or more.

Failure to observe this could lead to malfunctioning caused by noise.

● When connecting any cable, check the type of the interface to be connected.

Connecting to an improper interface or incorrect wiring may damage the module and external devices.

● Tightening the terminal screws within the specified torque range.

Under tightening the terminal screws can cause short circuit, a fire or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

● Prevent foreign matter such as dust or wire chips from entering the module.

Such foreign matter can cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips, from

entering the module during wiring.

Do not remove the film during wiring.

Remove it for heat dissipation before system operation.

● When disconnecting any cable from the module, do not pull the cable.

When disconnecting a cable with a connector, hold the connector of the connecting part of the module.

Before disconnecting a cable from the terminal block, loosen the terminal screw on the terminal block.

Pulling the cable with the terminal connected to the module may cause malfunction or damage to the

module or cable.

● Mitsubishi programmable controllers must be installed in control panels.

Connect the main power supply to the power supply module in the control panel through a relay terminal

block.

Wiring and replacement of a power supply module must be performed by maintenance personnel who is

familiar with protection against electric shock. (For wiring methods, refer to the QCPU User's Manual

(Hardware Design, Maintenance and Inspection)).

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

4

Page 8

Startup and Maintenance Precautions

WARNING

● Do not touch any terminal while power is on.

Doing so will cause electric shock.

● Correctly connect the battery connector.

The battery must not be charged, disassembled, heated, thrown into the fire, short-circuited, soldered,

wetted with a liquid or exposed to strong shock.

Doing so will cause the battery to produce heat, explode, or ignite, resulting in injury and fire.

● Shut off the external power supply for the system in all phases before cleaning the module or retightening

the terminal screws or module fixing screws.

Failure to do so may result in electric shock, damage to the module and malfunction.

CAUTION

● Before performing online operations (especially, program modification, forced output, and operation status

change) for the running CPU module from the peripheral connected, read relevant manuals carefully and

ensure the safety.

Improper operation may damage machines or cause accidents.

● Do not disassemble or modify the modules.

Doing so may cause failure, malfunction, injury, or a fire.

● Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone System)

more than 25cm (9.85 inches) away in all directions from the programmable controller.

Failure to do so may cause malfunction.

● Shut off the external power supply for the system in all phases before mounting or removing the module.

Failure to do so may cause the module to fail or malfunction.

A module can be replaced online (while power is on) on any MELSECNET/H remote I/O station or in the

system where a CPU module supporting the online module change function is used.

Note that there are restrictions on the modules that can be replaced online, and each module has its

predetermined replacement procedure.

For details, refer to the relevant sections in the QCPU User's Manual (Hardware Design, Maintenance and

Inspection) and in the manual for the corresponding module.

● Connection/disconnection of the module to/from the base unit and the extended SRAM cassette and

terminal block to/from the CPU module after the first use of the product shall be limited to 50 times.

(Compliant with JIS B 3502)

Exceeding the limit of 50 times may cause malfunction.

● Connection/disconnection of the SD memory card after the first use of the product shall be limited to 500

times. Exceeding the limit of 500 times may cause malfunction.

● Do not drop or apply shock to the battery to be installed in the module.

Doing so may damage the battery, causing the battery fluid to leak inside the battery.

If the battery is dropped or any shock is applied to it, dispose of it without using.

● Before handling the module, touch a grounded metal object to discharge the static electricity from the human

body.

Failure to do so may cause the module to fail or malfunction.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

5

Page 9

Disposal Precautions

CAUTION

● When disposing of this product, treat it as industrial waste.

When disposing of batteries, separate them from other wastes according to the local regulations.

(For details of the battery directive in EU member states, refer to the QCPU User's Manual

(Hardware Design, Maintenance and Inspection).)

Transportation Precautions

CAUTION

● When transporting lithium batteries, follow the transportation regulations.

(For details of the regulated models, refer to the QCPU User's Manual (Hardware Design, Maintenance and

Inspection).)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

6

Page 10

● When replacing AnS (Small Type) Series with L Series ●

Before using products introduced in this publication, please read this Transition

Examples and relevant manuals carefully and pay full attention to safety to handle

the product correctly.

In this publication, the safety precautions are classified into two levels:

" WARNING" and " CAUTION".

Indicates that incorrect handling may cause hazardous conditions,

WARNING

CAUTION

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead

to serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

Make sure that the end users read this publication and keep it in a safe place for future reference.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

7

Page 11

WARNING

Design Precautions

●

Configure safety circuits external to the programmable controller to ensure that the entire system operates

safely even when a fault occurs in the external power supply or the programmable controller. Failure to do so

may result in an accident due to an incorrect output or malfunction.

(1) Configure external safety circuits, such as an emergency stop circuit, protection circuit, and protective

interlock circuit for forward/reverse operation or upper/lower limit positioning.

(

2) The mechanical zero return of the positioning function is controlled based on two parameters, zero

return direction and zero return speed, and deceleration is started when the near-point dog is turned

on. Therefore, if the zero return direction is set incorrectly, the positioning function may continue the

operation without deceleration. Configure an interlock circuit for prevention of mechanical damage on the

outside of the programmable controller.

(3) When the CPU module detects an error during operation of the positioning function, the function will

decelerate and stop.

(4) The programmable controller stops its operation upon detection of the following status, and the output

status of the system will be as shown below.

• When the overcurrent or overvoltage protection of the power supply module is activated, all outputs

will be turned off.

• When the CPU module detects an error such as a watchdog timer error by the self-diagnostic

function, all outputs will be held or turned off according to the parameter setting.

All outputs may turn on when an error occurs in the part, such as I/O control part, where the

CPU module cannot detect any error. To ensure safety operation in such a case, provide a safety

mechanism or a fail-safe circuit external to the programmable controller. For a fail-safe circuit

example, refer to LOADING AND INSTALLATION in the LCPU User's Manual (Hardware Design,

Maintenance and Inspection).

(5) Outputs may remain on or off due to a failure of a transistor on an output circuit. Configure an external

circuit for monitoring output signals that could cause a serious accident.

●

In an output circuit, when a load current exceeding the rated current or an overcurrent caused by a load

short-circuit flows for a long time, it may cause smoke and fire. To prevent this, configure an external safety

circuit, such as a fuse.

●

Configure a circuit so that the programmable controller is turned on first and then the external power supply.

If the external power supply is turned on first, an accident may occur due to an incorrect output or

malfunction.

●

Configure a circuit so that the external power supply is turned off before the programmable controller is

turned off.

If the programmable controller is turned off first, an accident may occur due to an incorrect output or

malfunction.

●

For the operating status of each station after a network communication failure, refer to relevant manuals for

the network. Incorrect output or malfunction due to a communication failure may result in an accident.

●

When changing data of the running programmable controller from a peripheral connected to the CPU

module, configure an interlock circuit in the program to ensure that the entire system will always operate

safely.

For other controls for the running programmable controller (program modification and operating status

change (status control)), read relevant manuals carefully, and ensure the safety before operation.

Especially, in the case of a control from an external device to a remote programmable controller, immediate

action cannot be taken for a problem on the programmable controller due to a communication failure.

Configure an interlock circuit in the program, and determine corrective actions to be taken between the

external device and CPU module in case of a communication failure.

●

If an absolute position is recovered by the positioning function, the servo ON signal may be kept off (the

servo may be kept off) for approx. 20 ms, and the motor may operate. If any problem is caused by the motor

operation when the servo ON signal is turned off, provide an electromagnetic brake so that the motor will be

locked during absolute position recovery.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

8

Page 12

CAUTION

WARNING

CAUTION

Design Precautions

WARNING

●

Do not bundle the control cable or communication cable with the main circuit or power wire, or lay them

adjacently. Separate these by 100 mm or more as a rule.

Failure to observe this could lead to malfunctioning caused by noise.

●

When a lamp load or an inductive load, such as a heater and a solenoid valve, is controlled, a large current

(approximately ten times greater than normal) may flow when the output is turned from off

module having a sufficient current rating.

●

The time for the CPU module to enter the RUN status after the CPU module is powered off and on or reset

will vary depending on the system configuration, parameter settings, and/or program size, etc. Design the

program so that the entire system will operate safely even if the time to reach the RUN status varies.

to on. Use a

Installation Precautions

●

Shut off the external power supply for the system in all phases before mounting or removing the module.

Failure to do so may cause electric shock, damage to the module or malfunction.

●

Use the programmable controller in an environment that conforms to "GENERAL SPECIFICATIONS" in the

LCPU User's Manual (Hardware Design, Maintenance and Inspection).

Failure to do so may result in electric shock, fire, malfunction, or damage to or deterioration of the product.

●

To mount modules, engage their connectors, slide them until the module connecting hook stops, and lock the

hook securely.

Incorrect mounting may cause malfunction, failure or drop of the module.

●

Do not directly touch any conductive part or electronic component of any module.

Doing so can cause malfunction or failure of the module.

●

When using an extension cable, connect it to the extension connectors of the branch module and extension

module. After connecting, check the connections for looseness.

Poor contact may cause malfunction.

●

When using an SD memory card, fully insert it into the SD memory card slot. Check that it is inserted completely.

Poor contact may cause malfunction.

●

Do not directly touch any conductive part or electronic component of the module or SD memory card.

Doing so can cause malfunction or failure.

Wiring Precautions

●

Shut off the external power supply for the system in all phases before wiring the module.

Failure to do so may result in electric shock or failure or malfunction of the module.

●

After mounting or wiring, attach the included terminal cover onto the module before turning the power on or

starting operation.

Failure to do so may result in electric shock.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

9

Page 13

CAUTION

Wiring Precautions

●

Ground the FG and LG terminals to the dedicated conductors for the programmable controller (Class D

(Class 3) or higher grounding).

Failure to do so may result in electric shock or malfunction.

●

Use applicable solderless terminals and tighten them within the specified torque range.

If any spade solderless terminal is used, it may be disconnected when the terminal screw comes loose,

resulting in failure.

●

C

heck the rated voltage and terminal layout before wiring to the module, and connect the cables correctly.

Inputting voltage different from the rated voltage, connecting a power supply with a different voltage rating or

incorrect wiring may cause a fire or failure.

●

Connectors for external connection must be crimped or pressed with the tool specified by the manufacturer,

or must be correctly soldered.

Incomplete connections could result in short circuit, fire, or malfunction.

●

Fit the connectors surely to the module.

●

Do not bundle the control cable or communication cable with the main circuit or power wire, or lay them

adjacently. Separate these by 100 mm or more as a rule.

Failure to observe this could lead to malfunctioning caused by noise.

●

The electric wires and cables connected to the module shall be installed in a duct or secured with clamps.

If such measures are not taken, the cables may sway or move or may be pulled unintentionally, and the

module and cables may be damaged, or malfunction may be caused by cable contact failure.

●

When connecting any cable, check the type of the interface to be connected.

Connecting to an improper interface or incorrect wiring may damage the module and external devices.

●

Tighten the screws on the terminal block within the specified torque range. Undertightening the screws can

cause short circuit, a fire or malfunction.

Overtightening can damage the screws and/or module, thereby causing fall, short circuit, a fire and

malfunction.

●

When disconnecting any cable from the module, do not pull the cable. When disconnecting a cable with a

connector, hold the connector of the connecting part of the module. Before disconnecting a cable from the

terminal block, loosen the terminal screw on the terminal block.

Pulling the cable with the terminal connected to the module may cause malfunction or damage to the module

or cable.

●

Prevent foreign matter such as dust or wire chips from entering the module.

Such foreign matter can cause a fire, failure, or malfunction.

●

A protective film is attached to the top of the module to prevent foreign matter, such as wire chips, from

entering the module during wiring. Do not remove the film during wiring. Remove it for heat dissipation before

system operation.

●

When using the high-speed counter function, ground the shielded wire on the encoder side (relay box).

(Class D (Class 3) grounding or higher)

Failure to do so may cause malfunction.

●

Mitsubishi programmable controllers must be installed in control panels. Connect the main power supply to

the power supply module in the control panel through a relay terminal block.

Wiring and replacement of a power supply module must be performed by maintenance personnel who is

familiar with protection against electric shock.

For wiring methods, refer to the LCPU User's Manual (Hardware Design, Maintenance and Inspection).

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

10

Page 14

WARNING

CAUTION

Startup and Maintenance Precaution

●

Do not touch any terminal while power is on.

Doing so will cause electric shock or malfunction.

●

Correctly connect the battery connector. The battery must not be charged, disassembled, heated, thrown into

the fire, short-circuited, soldered, wetted with a liquid or exposed to strong shock.

Doing so will cause the battery to produce heat, explode, or ignite, resulting in injury and fire.

●

Shut off

terminal screws or connector fixing screws.

Failure to do so may result in electric shock.

●

Before performing online operations (especially, program modification, forced output, and operation status

change) for the running CPU module from the peripheral connected, read relevant manuals carefully and

ensure the safety.

Improper operation may damage machines or cause accidents.

●

Do not disassemble or modify the modules.

Doing so may cause failure, malfunction, injury, or a fire.

the external power supply for the system in all phases before cleaning the module or retightening the

●

Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone System) more

t

han 25 cm away in all directions from the programmable controller.

Failure to do so may cause malfunction.

●

Shut off the external power supply for the system in all phases before mounting or removing the module.

Failure to do so may cause the module to fail or malfunction.

●

Tighten the screws on the terminal block and the connector mounting screws within the specified torque

range.

Undertightening the screws may cause fall of parts and wires, short circuit and malfunction.

Overtightening can damage the screws and/or module, thereby causing fall, short circuiting and malfunction.

●

Connection/disconnection of the module (including the display module) and the terminal block after the first

use of the product shall be limited to 50 times. (Compliant with JIS B 3502)

Exceeding the limit of 50 times may cause malfunction.

●

Connection/disconnection of the SD memory card after the first use of the product shall be limited to 500

times.

Exceeding the limit of 500 times may cause malfunction.

●

Do not drop or apply shock to the battery to be installed in the module.

Doing so may damage the battery, causing the battery fluid to leak inside the battery.

If the battery is dropped or any shock is applied to it, dispose of it without using.

●

Before handling the module, touch a grounded metal object to discharge the static electricity from the human

body.

Failure to do so may cause the module to fail or malfunction.

●

Before staring the test run of the positioning function, set the speed limit parameter to a low value and make

preparations to promptly stop the system in case of a hazardous situation.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

11

Page 15

CAUTION

CAUTION

Disposal Precautions

●

When disposing of this product, treat it as industrial waste.

When disposing of batteries, separate them from other wastes according to the local regulations.

(For details of the battery directive in EU member states, refer to "Handling of Batteries and Devices with

Built-in Batteries in EU Member States" in the LCPU User's Manual (Hardware Design, Maintenance and

Inspection).

Transportation Precautions

●

When transporting lithium batteries, follow the transportation regulations.

(For details of the regulated models, refer to "Precautions for Battery Transportation" in the LCPU User's

Manual (Hardware Design, Maintenance and Inspection).)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

12

Page 16

Conditions of Use for the Product

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) Where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or serious

accident; and

ii) Where the backup and fail-safe function are systematically or automatically provided outside of the

PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED TO ANY

AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT, PRODUCT

LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO PROPERTY CAUSED

BY the PRODUCT THAT ARE OPERATED OR USED IN APPLICATION NOT INTENDED OR EXCLUDED BY

INSTRUCTIONS, PRECAUTIONS, OR WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION

AND/OR SAFETY MANUALS, TECHNICAL BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any other cases in

which the public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of a special

quality assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator and

Escalator, Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for Recreation and

Amusement, and Safety devices, handling of Nuclear or Hazardous Materials or Chemicals, Mining and

Drilling, and/or other applications where there is a significant risk of injury to the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the PRODUCT in

one or more of the Prohibited Applications, provided that the usage of the PRODUCT is limited only for the

specific applications agreed to by Mitsubishi and provided further that no special quality assurance or fail-safe,

redundant or other safety features which exceed the general specifications of the PRODUCTs are required. For

details, please contact the Mitsubishi representative in your region.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

13

Page 17

Revisions

Print Date

Jul., 2008 L(NA)08121E-A First edition

Jan., 2011 L(NA)08121E-B

Sep., 2012 L(NA)08121E-C

Publication Number* Revision

Addition

CONDITIONS OF USE FOR THE PRODUCT, Replacement options

and module selection guide, Chapter 4, Section 7.3, Section 8.2,

Chapter 11, Chapter 12, Chapter 14, Chapter 15, Chapter 17,

Appendix 1, Appendix 2

Partial correction

Safety Precautions, Chapters were reorganized and contents were

revised(whole)

Addition

Section 1.2, Section 2.4, Section 4.3, Section 4.4, Chapter 5 (5),

Section 6.3

Change

Chapter 1

Chapter 6 (Title changed), Section 6.3 −> Section 6.4

Partial correction

Safety Precautions, Introduction, Replacement options and module

selection guide

Chapter 3, Section 5.1, Section 5.2, Section 6.1, Section 10.1,

Chapter 14, Appendix 2.2, Appendix 2.6

−> Section 1.1, Chapter 4 (Title changed),

Sep., 2013 L(NA) 08121E-D

Dec., 2014 L(NA) 08121E-E

* The publication number is given on the bottom left of the back cover.

Addition

Section 2.2.2, Section 2.3.4, Section 4.6, Section 5.3

Change

Table of contents

Addition

Section 1.3, Section 2.3, Section 3.2.2, Section 6.2, Section 7.5,

Section 7.6, Section 8.2, Section 8.3, Section 10.2,

Change

Table of contents, Section 2.1, Section 2.2.2,Section 2.3.2,

Section 4.6, Section 9.1, Section 10.1

This publication confers no industrial property rights or any rights of any other kind, nor does it confer any

patent licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving

industrial property rights which may occur as a result of using the contents noted in this publication.

© 2008 MITSUBISHI ELECTRIC CORPORATION

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

14

Page 18

Introduction

This publication describes case examples of transition from the large type MELSEC-A/QnA

Series, small type AnS/QnAS Series, A0J2(H) Series, and MELSECNET/MINI-S3 systems to

the MELSEC-Q or MELSEC-L Series.

Refer to these examples when considering system configurations and selecting modules during

a system upgrade.

This publication is intended to provide system configuration examples as a supplement

to the

replacement handbooks.

For specifications comparisons between A (Large Type and Small Type) and Q/L Series or

precautions for replacement, refer to the following replacement handbooks.

• Transition from MELSEC-A/QnA (Large Type) Series to Q Series Handbook (Fundamentals) 08043ENG

• Transition from MELSEC-AnS/QnAS (Small Type) Series to Q Series Handbook (Fundamentals) 08219ENG

• Transition from

• Transition from MELSEC-A/QnA (Large Type) Series to Q Series Handbook (Intelligent Function Modules) 08046ENG

• Transition from MELSEC-AnS/QnAS (Small Type) Series to Q Series Handbook (Intelligent Function Modules) 08220ENG

• Transition from MELSEC-AnS/QnAS (Small Type) Series to L Series Handbook (Intelligent Function

• Transition from MELSEC-A/QnA (Large Type), AnS/QnAS (Small Type) Series to Q Series Handbook (Network Modules) 08048ENG

• Transition from MELSEC-AnS/QnAS (Small Type) Series to L Series Handbook (Network Modules) 08260ENG

• Transition from MELSEC-A/QnA (Large Type), AnS/QnAS (Small Type) Series to Q Series Handbook (Communications) 08050ENG

• Transition from MELSEC-AnS/QnAS (Small Type

• Transition from MELSEC-A0J2H Series to Q Series Handbook 08060ENG

• Transition from MELSECNET/MINI-S3, A2C (I/O) to CC-Link Handbook 08061ENG

• Transition from MELSEC-I/OLINK to CC-Link/LT Handbook 08062ENG

MELSEC-AnS/QnAS (Small Ty

pe) Series to L Series Handbook (Fundamentals) 08258ENG

) Series to L

Modules) 0

Series Handbook (Communications) 08261ENG

8259ENG

• Transition from MELSEC-I/OLINK to AnyWire DB A20 Handbook 08263ENG

• Transition of CPUs in MELSEC Redundant System Handbook (Transition from

• Before using the products shown in the transition handbooks, catalogues, and transition examples, refer to

the relevant manuals and check the specifications, precautions, and restrictions.

For information on the products manufactured by Mitsubishi Electric Engineering Co., Ltd., Mitsubishi

Electric System & Service Co., Ltd., and other companies, refer to the relevant catalogues and check the

specifications, precautions, and restrictions.

The manuals and catalogues for our products, products manufactured by Mitsubishi Electric Engineering

Co., Ltd., and Mitsubishi Electric System & Service Co., Ltd. are shown in Appendix of each transition

handbook.

• For details on product compliance with the above standards, please contact your local Mitsubishi Electric

sales office or representative.

• Products shown in this handbook are subject to change without notice.

Q4ARCPU to QnPRHCPU) 0

8117ENG

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

15

Page 19

Table of Contents

Safety Precautions 1

When replacing AnS (Small Type) Series with L Series 7

Conditions of Use for the Product 13

Revisions 14

Introduction 15

Table of Contents 16

Replacement Options and Module Selection Guide 18

Part I : Hardware

1. Comparison of base mounting area

23

24

1.1 Comparison of A/QnA (Large Type) Series and Q Series base unit mounting area 24

1.2 Comparison of AnS/QnAS (Small Type) Series and Q Series base unit mounting area 26

1.3 Comparison of AnS/QnAS (Small Type) Series and L Series mounting area 28

2. Utilizing external wiring

29

2.1 Replace A/QnA (Large Type) Series with Q Series 29

2.1.1 Install terminal block converter module and terminal module externally 29

2.1.2 Replace using Q Series large type base unit and Q Series large input/output module 36

2.1.3 Replacement utilizing A (Large Type) upgrade tool

(manufactured by Mitsubishi Electric Engineering Co., Ltd.) 43

2.2 Replace AnS/QnAS (Small Type) Series with Q Series 47

2.2.1 Replace using AnS size Q Series large type base unit 47

2.2.2 Replace using A (Small Type) upgrade tool (manufactured by Mitsubishi Electric Engineering Co., Ltd.) 48

2.2.3 Replace AnS/QnAS (Small Type) Series 200 V AC input module A1SX20 without changing I/O address 53

2.3 Replace AnS/QnAS (Small Type) Series with L Series 56

2.3.1 Replace using A (Small Type) upgrade tool (manufactured by Mitsubishi Electric Engineering Co., Ltd.) 56

2.3.2 Replace AnS/QnAS (Small Type) Series 200 V AC input module A1SX20 without changing I/O address 59

2.4 Replace A0J2 with Q Series 60

2.4.1 Replace A0J2(H) systems with Q Series using A0J2 upgrade tool 64

2.4.2 Upgrade to MELSECNET/H (remote I/O network) system using A0J2 upgrade tool 68

2.4.3 Replace MELSECNET/MINI compact type remote I/O modules with CC-Link 70

3. Replacement utilizing existing modules

72

3.1 Replace A/QnA (Large Type) Series with Q Series 72

72

3.1.2 Utilize existing I/O modules and extension base unit with Q Series CPU (Use QA conversion adapter) 74

3.2 Replace AnS/QnAS (Small Type) Series with Q Series 76

76

3.2.2 Replace main base unit with Q Series and use existing extension base unit and modules in it

(use QA1S conversion adapter) 79

3.3 Utilize existing A (Large Type) and AnS (Small Type) modules without changing I/O addresses 80

4. Replacement of MELSECNET Network System

82

4.1 Replace MELSECNET(II) with MELSECNET/10 82

4.1.1 Replace MELSECNET(II) coaxial loop with MELSECNET/10 coaxial bus system

while retaining existing A Series CPUs 82

84

4.2 Replace one of A Series stations with Q Series while retaining MELSECNET(II) 88

4.2.1 Replace A Series local station with Q Series 88

4.2.2 Replace A Series master station with Q Series 90

4.3 Replace MELSECNET containing a remote I/O station with MELSECNET/H 92

4.4 Gradual replacement of MELSECNET/10 Remote I/O Net 97

4.5 Replace MELSECNET/MINI(-S3) with CC-Link 100

4.5.1 Replace A2CCPU with Q Series CPU and CC-Link (using A2C shape CC-Link I/O modules)100

4.5.2 Replace MELSECNET/MINI(-S3) with CC-Link (using wiring conversion adapter) 102

4.5.3 Replace MELSECNET/MINI(-S3) remote I/O station (building block type: AJ72PT35)

with MELSECNET/H using the existing external wiring 104

108

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

16

Page 20

5. Replacing with replacement dedicated modules

5.1 Replace high-speed counter modules (AD61(S1)) with Q Series modules 110

5.2 Replace DC input modules with 6 mA rated input current (QX41-S2, QX81-S2) 116

5.3 Replace analog output positioning module (AD70/A1SD70) with Q Series 11 8

6. Replacement utilizing spare part

6.1 Use AnS (Small Type) modules as spare parts for existing A (Large Type) Series modules 122

6.1.1 Use AnS (Small Type) I/O modules as spare parts for A (Large Type) input/output modules123

6.1.2 Use AnS (Small Type) module as spare parts for A (Large Type) computer link module125

6.2 Use Q Series modules with AnS/QnAS Series utilizing AnS-Q module conversion adapter 127

122

110

Part

Part

: Programming

II

7. Precautions for utilizing ACPU programs in QCPU

7.1 Replace instructions with different QCPU instruction format

(excluding AnACPU/AnUCPU dedicated instructions) 131

7.1.1 Instructions that use accumulators (A0, A1)131

7.1.2 ASCII code conversion instruction "ASC"135

7.2 Replace AnACPU/AnUCPU dedicated instructions 138

7.3 Use index register as a 32-bit (2-word) device 142

7.4 Utilize SFC programs (Replace MELSAP-II with MELSAP3) 146

7.5 Method for maintaining existing addresses when replacing MELSECNET/MINI(-S3) with CC-Link 152

7.6 Replace pulse catch module 154

7.6.1 Replace with LCPU built-in I/O pulse catch function154

7.6.2 Replace with QCPU interrupt module156

: Application

III

8. Utilize existing ACPU data

8.1 Replace AD75(P/M) with QD75(P/D/M/MH) while utilizing existing positioning parameters and data 158

8.2 Procedures for replacing when file registers are used in blocks 162

8.2.1 Replace without changing file register numbers162

8.2.2 Replace by putting file registers forward 165

8.3 Copy device memory data 166

9. Utilize A/QnA -> Q conversion support tool

9.1 Utilize programs of PC type incompatible with GX Developer 168

9.2 Create a sample program for MELSECNET(II

A/QnA -> Q conversion support tool 171

10. Notes for selection of replacement modules

10.1 Select replacement module for DC input module 180

10.2 Notes for selection of replacement for Triac output module AY22 184

11. Notes for replacement of network (MELSECNET(II))

11.1 CPUs compatible with networks (MELSECNET(II), MELSECNET/10 and MELSECNET/H) 186

11.1.1 System configuration for MELSECNET/10 and MELSECNET/H (PLC to PLC network)186

11.1.2 System configuration for existing MELSECNET(II) in combination with Q Series CPU187

11.1.3 System configuration for MELSECNET/10 and MELSECNET/H (remote I/O network)187

11.1.4 System configuration for redundant system network188

129

130

157

158

168

180

186

Warranty 190

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

17

Page 21

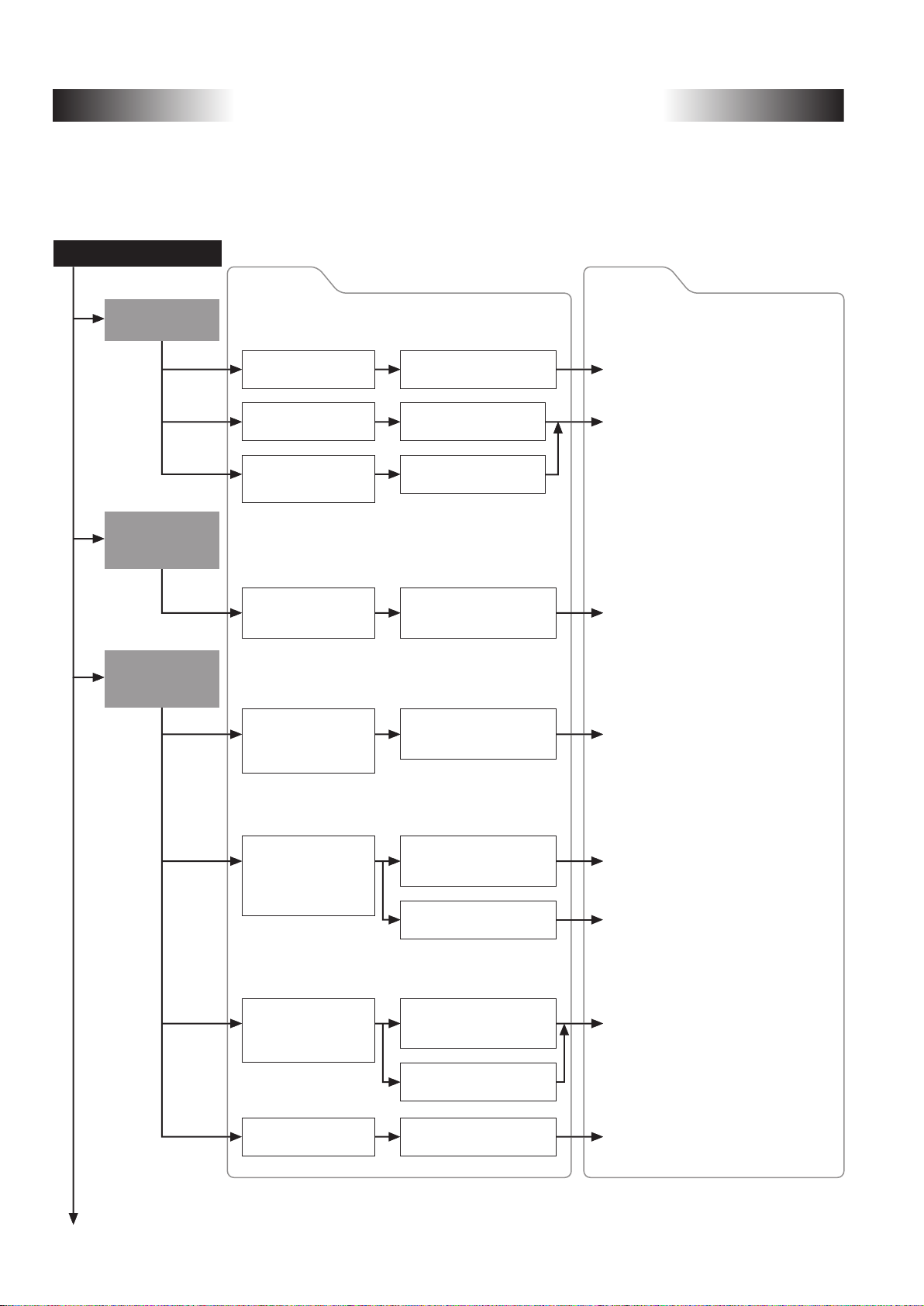

Replacement Options and

Module Selection Guide

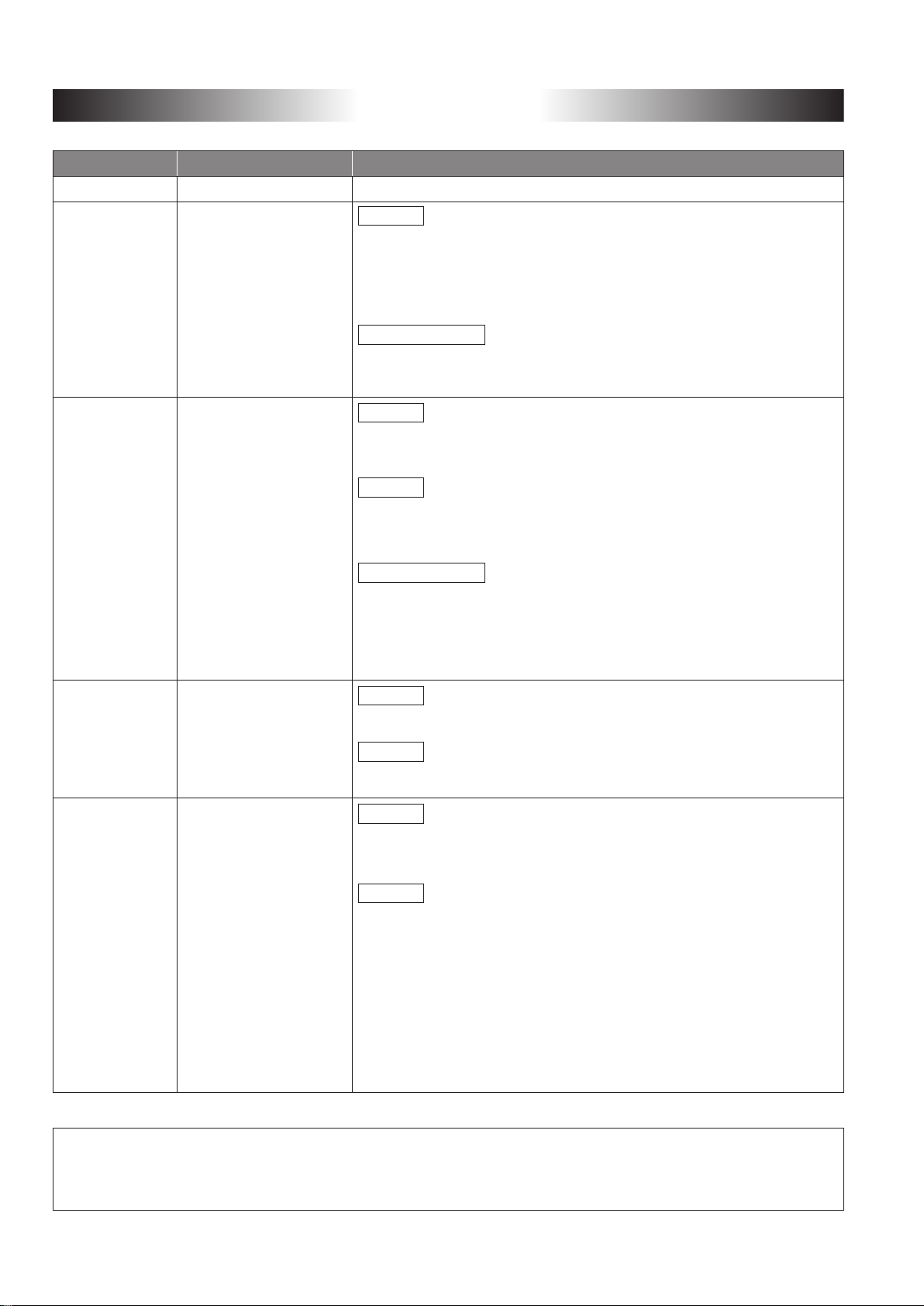

Specific modules are selected according to the transition procedure (gradually or simultaneously), module

configuration, and network configuration when replacing A/QnA (Large Type), AnS/QnAs (Small Type) Series

modules with Q/L Series modules.

The following shows module replacement options and references.

Module replacement

Replacing

A0J2HCPU

Modifying/Replacing

A (Large Type)

Series modules

Replacing

A (Large Type) Series

with Q Series

Options

To utilize existing

wiring

To replace with

Q Series I/O modules

To replace special

function modules with

Q Series modules

To add modules

to existing A (Large

Type) Series system

To only replace the CPU

module and continue using

existing A (Large Type)

Series modules

Use A0J2 renewal tool

manufactured by SC*

Select Q Series I/O

modules

Select Q Series modules

Modify/Replace modules

using A-A1S module

conversion adapter (A1ADP)

Replace modules using QA

extension base unit and

QA conversion adapter

1

References

Example: Section 2.4

Replace A0J2(H) systems with Q Series

using existing wiring

Transition from MELSEC-A0J2H Series

to Q Series Handbook

(L-08060ENG)

Example: Section 6.1

Use AnS (Small Type) modules as spare

parts for existing A (Large Type) Series

Example: Section 3.1.1

Utilize A/QnA (Large Type) Series QA6�B

extension base unit

Example: Section 3.1.2

Utilize existing I/O modules and extension

base unit with Q Series CPU

(Use QA conversion adapter)

To replace A (Large Type)

Series 32-point terminal

block type modules

without changing the

wiring configuration

To replace modules

when it is difficult to

use the Q Series

large type base unit

To replace all modules

with Q Series modules

*1: SC: Mitsubishi Electric System & Service Co., Ltd.

*2: MEE: Mitsubishi Electric Engineering Co., Ltd.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Replace modules using

Q Series large type base unit

and I/O modules

Replace modules using upgrade

tool manufactured by MEE*

Replace modules using

terminal block converter

module and terminal module

Replace modules using FA

goods manufactured by MEE*

Select Q Series modules

2

2

18

Example: Section 2.1.2

Upgrade to Q Series using Q Series large

type base unit and I/O modules

Example: Section 2.1.3

Upgrade to Q Series using Q Series large

type base unit and I/O modules

Example: Section 2.1.2 (2)

Compatibility of Q Series large type

base unit with the upgrade tool

Example: Section 2.1.1

Install terminal block converter module

and terminal module externally

Transition from MELSEC-A/QnA

(Large Type) Series to Q Series

Handbook (Fundamentals)

(L-08043ENG)

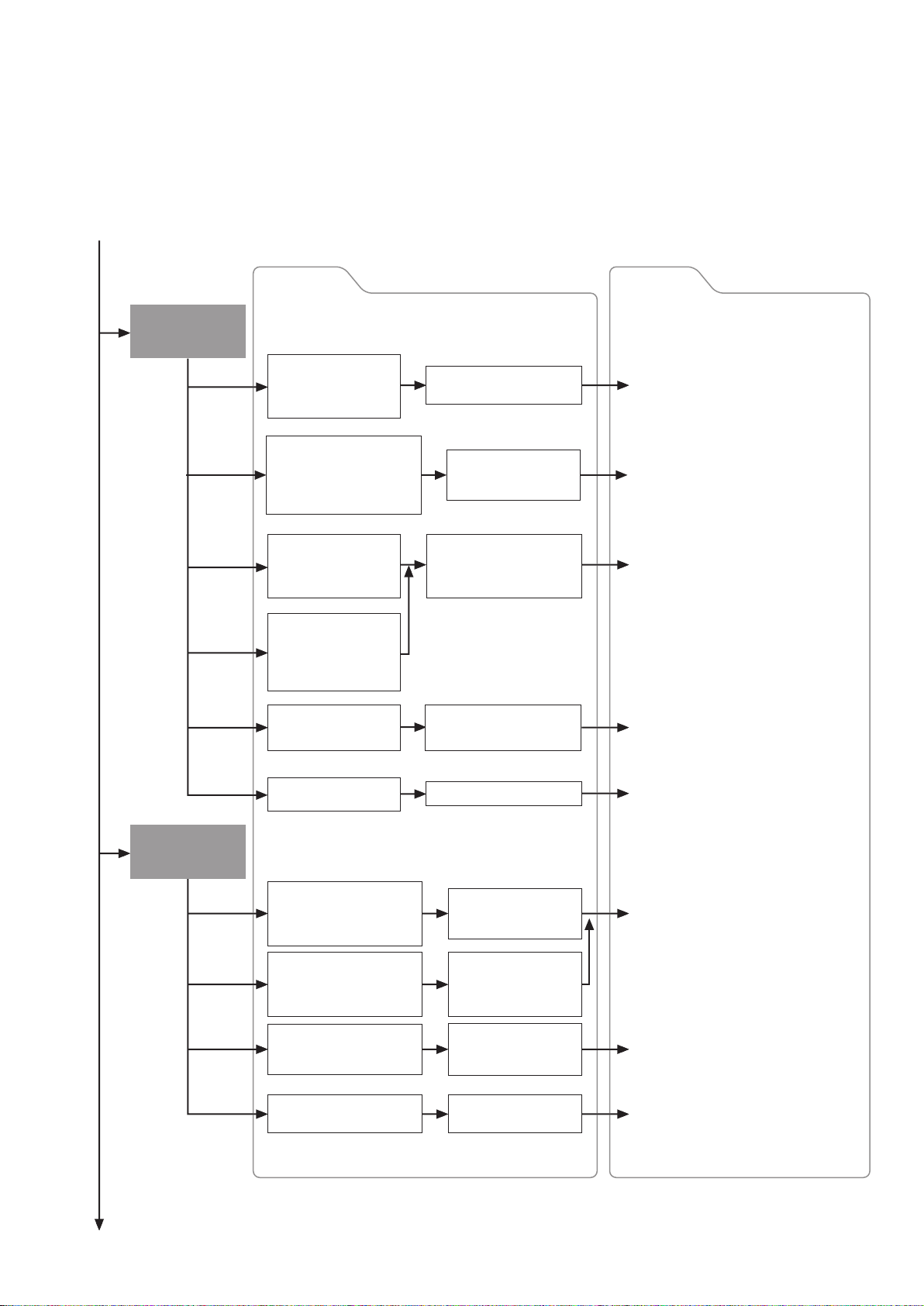

Page 22

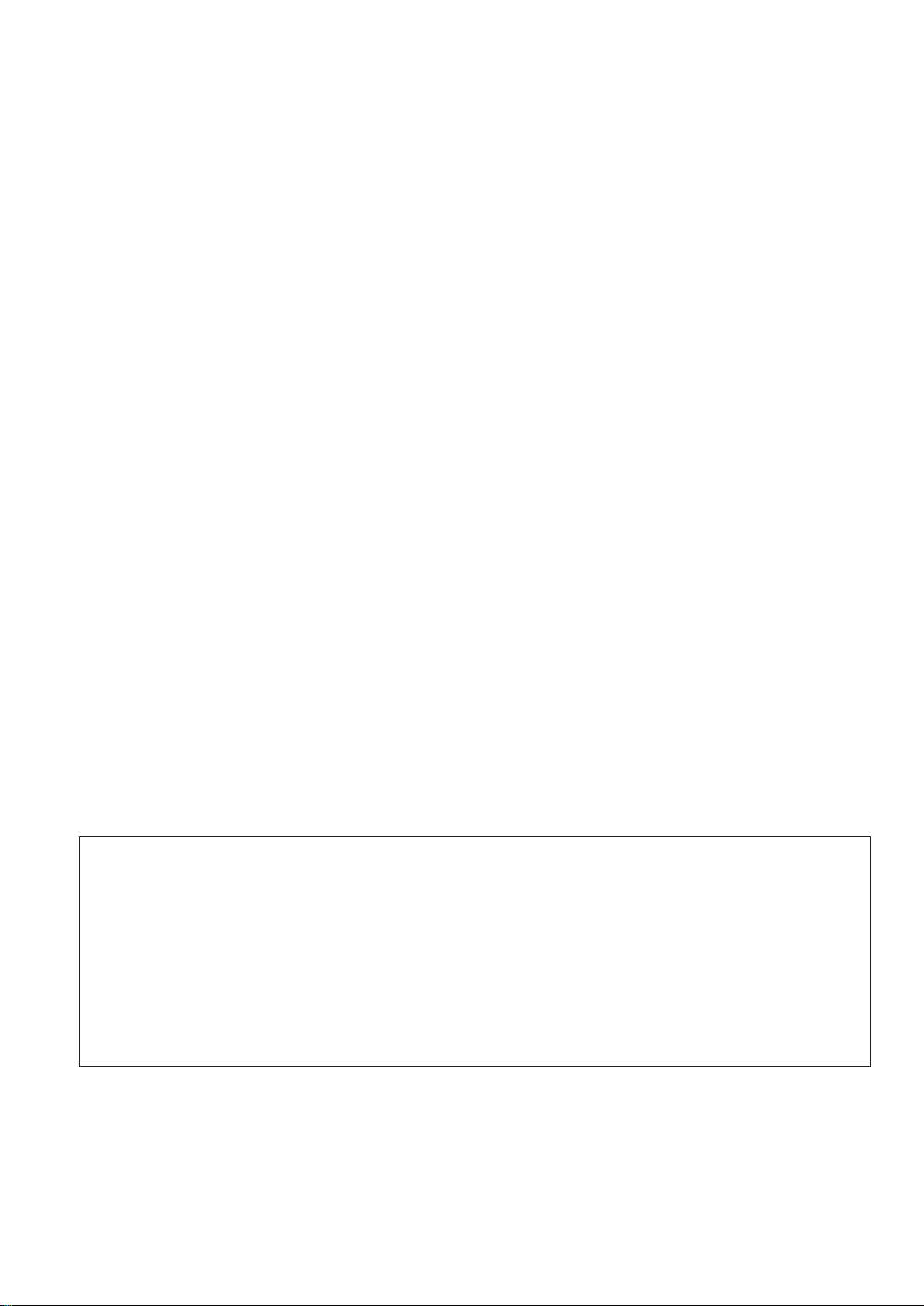

Replacing AnS

(Small Type) Series

with Q Series

Options References

To only replace the CPU

module and continue

using the existing AnS

(Small Type) module

Replace modules using

QA1S extension base

Example: Section 3.2.1

Utilize AnS/QnAS (Small Type) Series

QA1S6�B extension base unit

Replacing AnS

(Small Type) Series

with L Series

To replace only the modules

in the main base unit and

continue using the existing

AnS (Small Type) modules

in the extension base unit

To mount Q Series base

unit using existing AnS

(Small Type) base unit

mounting holes

To replace existing AnS

(Small Type) 16-point

terminal block module

without changing the

wiring configuration

To replace modules when

it is difficult to use the Q

Series large type base unit

To replace all modules

with Q Series modules

To install L Series DIN rail

using existing AnS (Small

Type) base unit mounting

holes

Replace modules

using Q-Ans base unit

conversion adapter

Replace modules using

AnS (Small Type) Series

upgrade tool manufactured

by MEE*

Replace modules using FA

goods manufactured by

MEE*

Select Q Series modules

Use base adapter

integrated with DIN

rail

Example: Item 3.2.2

Replace main base unit with Q Series

and use existing extension base unit and

modules in it

(Use QA1S conversion adapter)

Example: Section 2.2.2

Utilize AnS/QnAS (Small Type) module

replacement upgrade tool

Example: Section 2.2.3

Replace AnS/QnAS (Small Type) Series

200 V AC input module A1SX20

[Use FA goods (manufactured by

Mitsubishi Electric Engineering Co., Ltd.)]

Transition from MELSEC-AnS/QnAS

(Small Type) Series to Q Series Handbook

(Fundamentals) (L(NA)08219ENG)

Example: Item 2.3.1

Replace using upgrade tool for replacing

with L Series

To replace existing AnS (Small

Type) 16-point terminal block

type modules without changing

the wiring configuration

To obtain information on

tools other than the

upgrade tool

To replace all modules

with L Series modules

*: MEE: Mitsubishi Electric Engineering Co., Ltd.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Replace modules using

AnS (Small Type) Series

upgrade tool manufactured by MEE*

Replace modules using

FA goods manufactured

by MEE*

Select L Series

modules

19

Example: Item 2.3.2

Replace AnS/QnAS (Small Type) Series

200 V AC input module A1SX20

[Use FA goods (manufactured by

Mitsubishi Electric Engineering Co.,

Ltd.)]

Transition from MELSEC-AnS/QnAS

(Small Type) Series to L Series

Handbook (Fundamentals)

(L(NA)08258ENG)

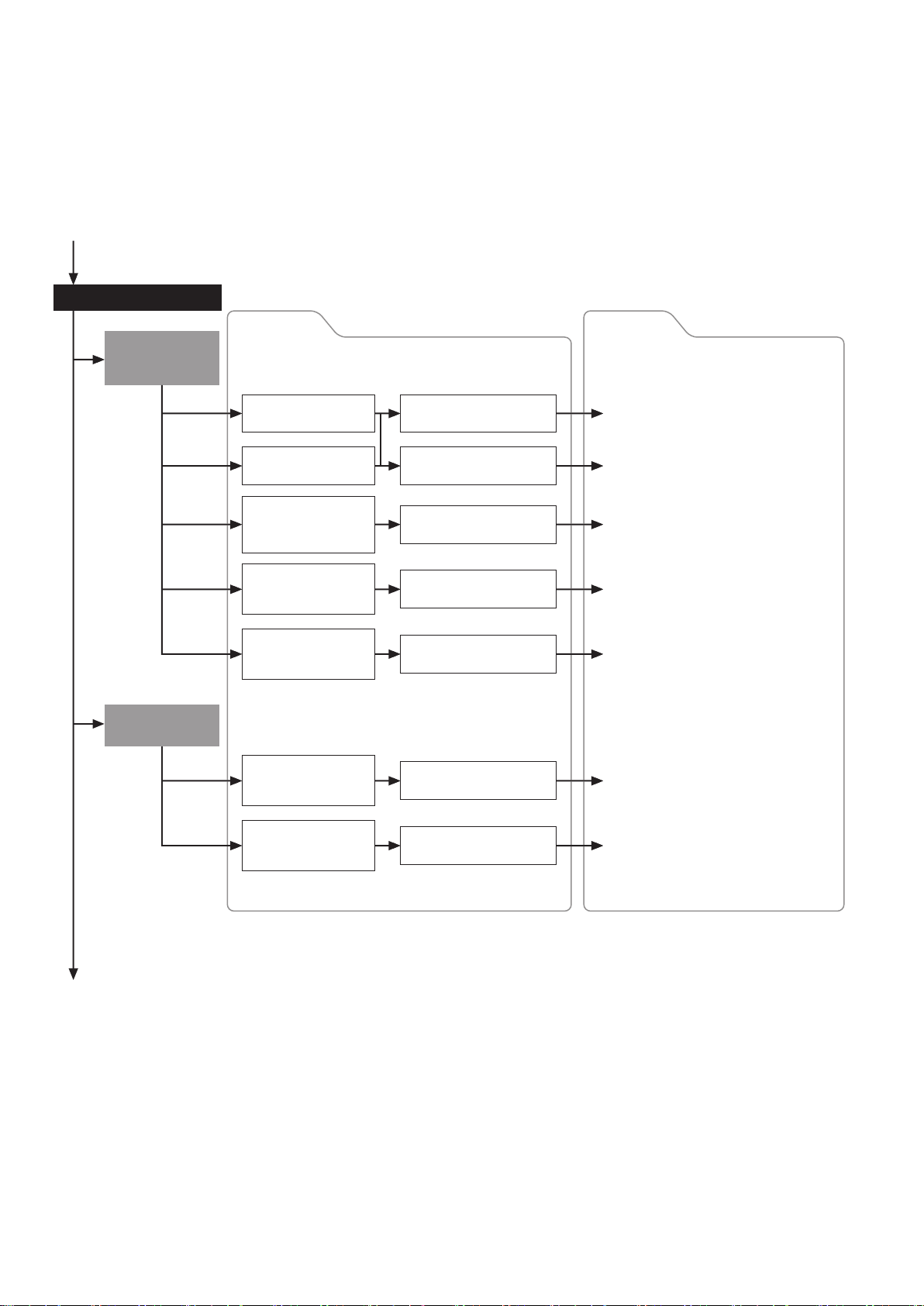

Page 23

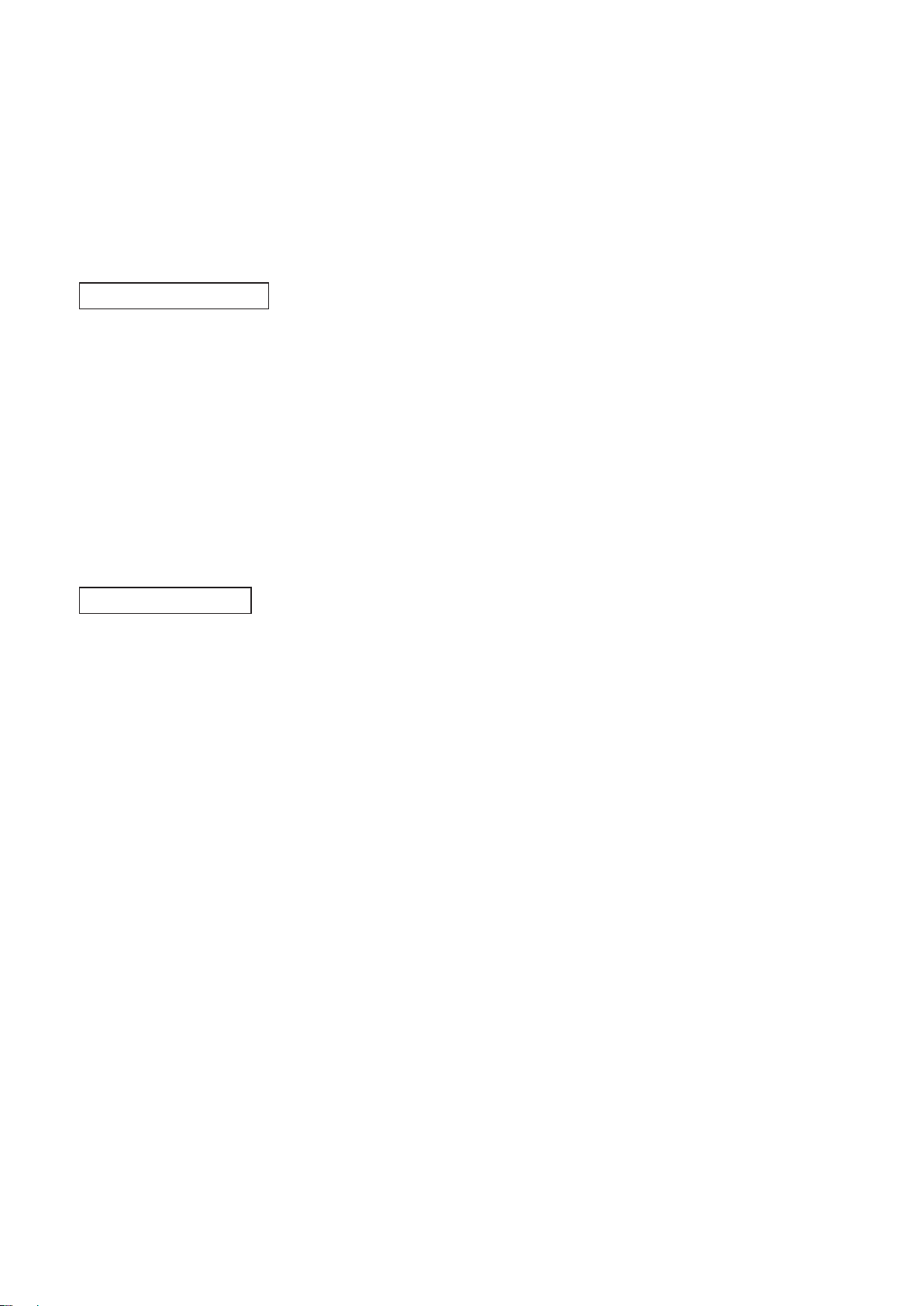

Network replacement

Replacing

MELSECNET/MINI

(S3) with CC-Link

Replacing

Replacing

MELSECNET(ΙΙ)

MELSEC-I/OLINK

Options References

To replace networks using

existing external wiring

To replace A2CCPU

To replace networks

when it is difficult to

use existing wiring

configuration

To replace

compact type remote

I/O modules

To replace building

block type remote

I/O modules

To replace networks

without changing

existing addresses

Replace network using A2C

shape I/O modules

Replace network using

wiring conversion adapter

Select CC-Link modules

Use A0J2 renewal tool

manufactured by SC*

Replace with MELSECNET/H

remote I/O network

Replace with CC-Link/LT

Example: Section 4.5.1

Replace A2CCPU with Q Series CPU

and CC-Link

Example: Section 4.5.2

Replace MELSECNET/MINI(-S3) with

CC-Link

Transition from MELSECNET/MINI-S3,

A2C(I/O) to CC-Link Handbook

(L-08061ENG)

Example: Section 2.4.3

Replace MELSECNET/MINI compact type

remote I/O modules with CC-Link

Example: Section 4.5.3

Replace MELSECNET/MINI(-S3) remote

I/O station with MELSECNET/H using the

existing external wiring

Example: Section 4.6

Replace MELSEC-I/OLINK with CC-Link/LT,

AnyWire DB A20

To replace networks

using existing

communication cables

*: SC: Mitsubishi Electric System & Service Co., Ltd.

Replace with AnyWire

DB A20

Example: Section 4.6

Replace MELSEC-I/OLINK with CC-Link/LT,

AnyWire DB A20

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

20

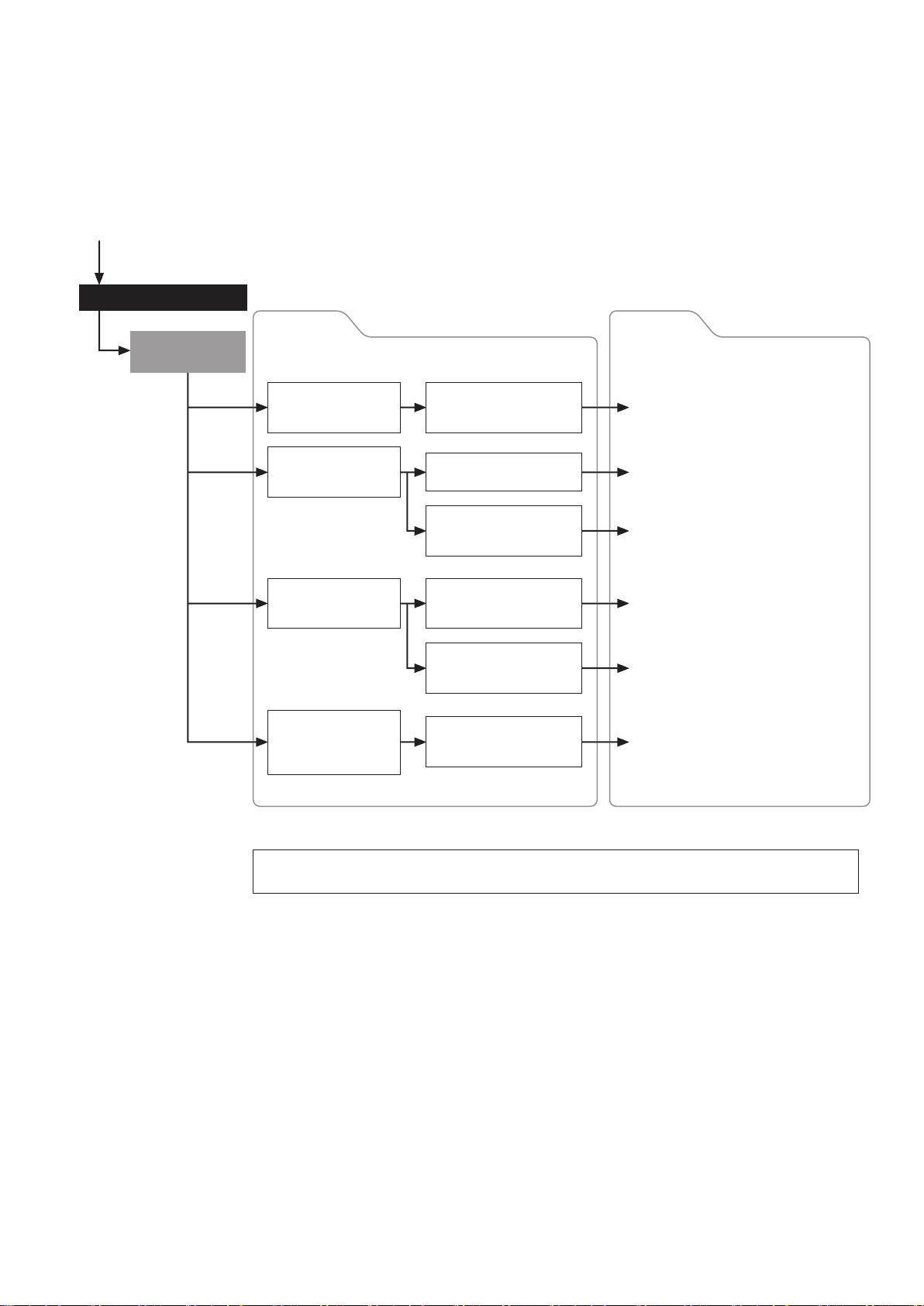

Page 24

Network replacement

Replacing

MELSECNET(ΙΙ)

Options References

To replace CPU modules

while retaining the existing

MELSECNET(ΙΙ)

To replace with

MELSECNET/10 using

existing cables

To replace networks

containing a remote

I/O station

To gradually replace

networks using existing

MELSECNET(ΙΙ) and

MELSECNET/10

Replace modules using

MELSECNET(ΙΙ) local station

data link modules

Upgrade gradually to

Q Series CPU modules

Transition to MELSECNET/H

using MELSECNET/B twisted

pair cables

Replace networks using

MELSECNET/H PLC to PLC

network and remote I/O network

Change from remote I/O station

to normal station and replace

as one single network

Use a gateway set to

configure networks with

relay stations

Example: Section 4.2

Replace one of A Series stations with

Q Series while retaining MELSECNET(ΙΙ)

Example: Section 4.1.1

Replace MELSECNET(ΙΙ) coaxial loop

with MELSECNET/10 coaxial bus system

while retaining existing A Series CPUs

Example: Section 4.1.2

Upgrade to MELSECNET/H network

system utilizing existing MELSECNET/B

twisted pair cable

Transition from MELSEC-A/QnA

(Large Type) Series to Q Series

Handbook (Network Modules)

(L-08048ENG)

Example: Chapter 4.3

Replace MELSECNET containing a remote

I/O station with MELSECNET/H

Transition from MELSEC-A/QnA

(Large Type) Series to Q Series

Handbook (Network Modules)

(L-08048ENG)

This section describes the main replacement options. If multiple options are selected or other options

are needed, comprehensive consideration is required to configure the system.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

21

Page 25

MEMO

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

22

Page 26

PartⅠ: Hardware

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

23

Page 27

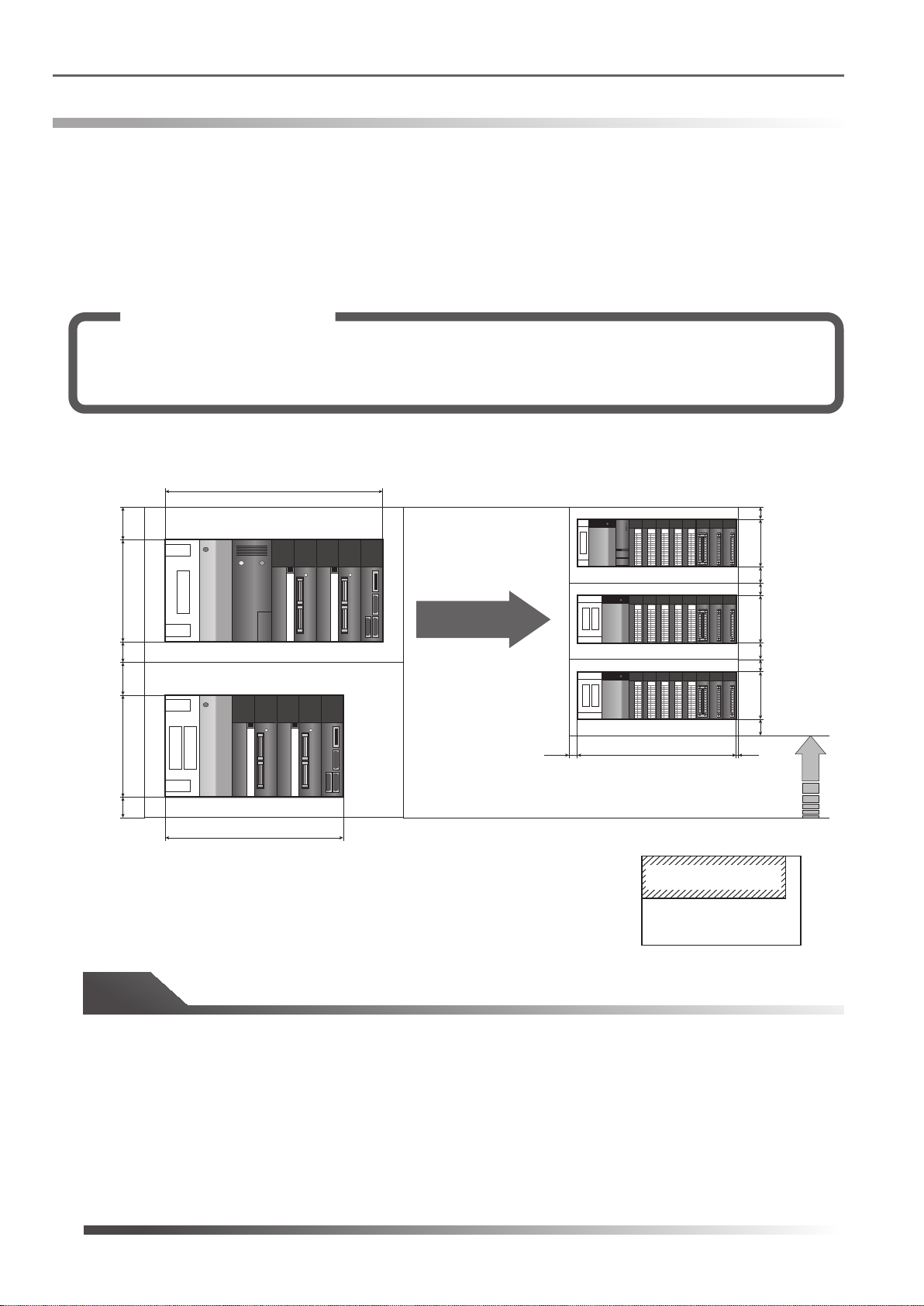

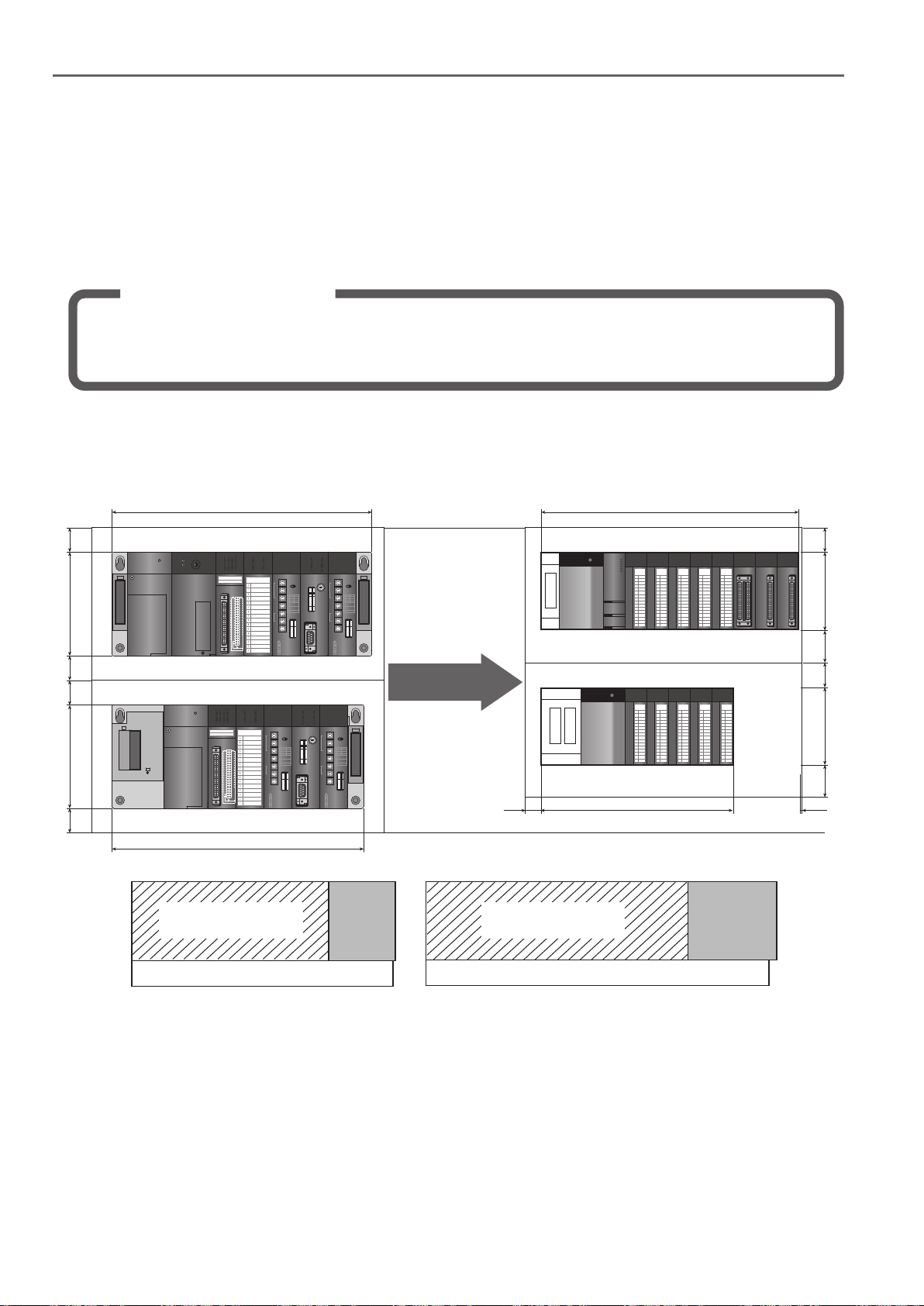

1.1 Comparison of A/QnA (Large Type) Series and Q Series base unit mounting area

Comparison of base mounting area

1.

1.1 Comparison of A/QnA (Large Type) Series and Q Series base unit mounting area

When upgrading existing A/QnA systems, there are cases where the number of modules increases due to

specification differences. For instance, to replace an A/QnA (Large Type) Series 32-point terminal block type I/O

module, two Q Series 16-point terminal block type I/O modules are used. Despite increase in the number of I/O

slots and extension base stages, the Q Series footprint is smaller than that of the A/QnA (Large Type) Series.

The following example shows a comparison of the mounting areas when the A/QnA (Large Type) Series system

is upgraded to the Q Series.

Solution and Benefit

When replacing each 32-point terminal block type module with two 16-point terminal block type

modules, an additional extension base unit is required due to an increase in the number of modules.

However, the Q Series system fits inside the existing control panel because it is compact in size.

(1) When the A/QnA (Large Type) Series main base unit A35B and the A65B extension base unit are

replaced

250

250

382

80

A35B

Q38B/Q68B

0

0

0

0

1

1

1

1

2

2

2

2

3

3

3

3

4

4

4

4

5

5

5

5

6

6

6

6

7

7

7

7

8

8

8

8

9

9

9

9

A

A

A

A

B

B

B

B

C

C

C

C

D

D

D

D

E

E

E

E

F

F

F

F

30

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

98

40

30

0

0

0

0

1

2

3

4

5

6

7

Replace

8

9

A

B

C

D

E

F

50

0

1

1

1

1

2

2

2

2

3

3

3

3

4

4

4

4

5

5

5

5

6

6

6

6

7

7

7

7

8

8

8

8

9

9

9

9

A

A

A

A

B

B

B

B

C

C

C

C

D

D

D

D

E

E

E

E

F

F

F

F

98

40

30

80

A65B

0

0

0

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

1

1

1

2

2

2

2

3

3

3

3

4

4

4

4

5

5

5

5

6

6

6

6

7

7

7

7

8

8

8

8

9

9

9

9

A

A

A

A

B

B

B

B

C

C

C

C

D

D

D

D

E

E

E

E

F

F

F

F

98

40

20 5

50

352

328

Downsized

Unit: mm

Q38B/Q68B

A35B

Base unit size comparsion

Tip

The A/QnA (Large Type) Series main base unit and extension base unit differ in size:

• A35B main base unit: 382 mm (W) x 250 mm (H)

• A65B extension base unit: 352 mm (W) x 250 mm (H)

Whereas the Q Series main base unit and extension base unit are the same size:

• Q38B main base unit/Q68B extension base unit: 328 mm (W) x 98 mm (H)

Even with the extra I/O slots and base units, the base unit installation area for Q Series is smaller than that for

A/QnA (Large Type) Series.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

24

Page 28

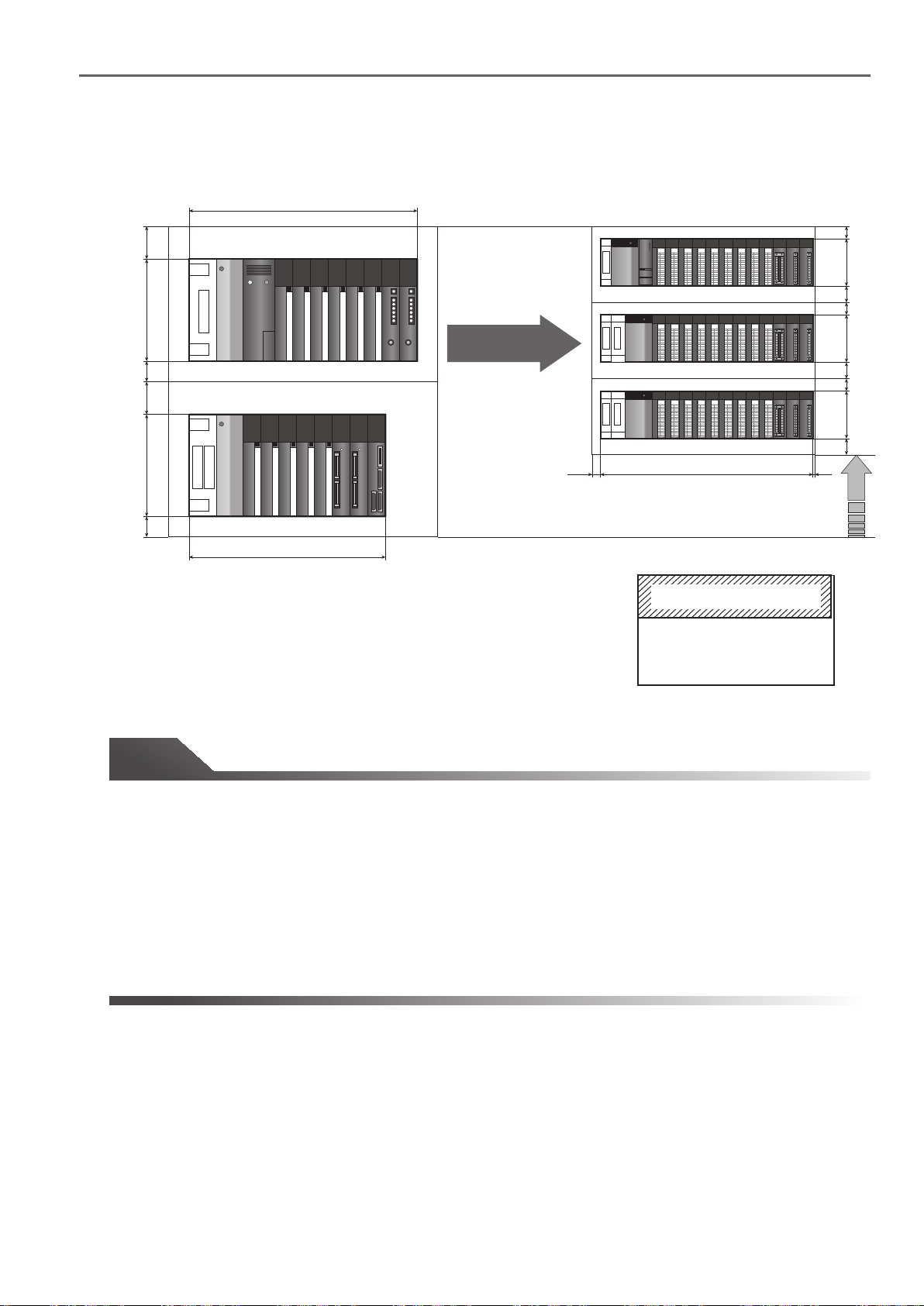

1.1 Comparison of A/QnA (Large Type) Series and Q Series base unit mounting area

(2) When the A/QnA (Large Type) Series main base unit A38B and the A68B extension base unit are

replaced

250

250

480

80

A38B

Q312B/Q612B

0

0

0

0

0

0

1

1

1

2

2

2

3

3

3

4

4

4

5

5

5

6

6

6

7

7

7

8

8

8

9

9

9

A

A

A

B

B

B

C

C

C

D

D

D

E

E

E

F

F

F

0

1

1

1

1

2

2

2

2

3

3

3

3

4

4

4

4

5

5

5

5

6

6

6

6

7

7

7

7

8

8

8

8

9

9

9

9

A

A

A

A

B

B

B

B

C

C

C

C

D

D

D

D

E

E

E

E

F

F

F

F

30

0

0

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

A

A

B

B

C

C

D

D

E

E

F

F

98

40

30

0

0

0

0

0

0

0

0

1

1

1

1

1

2

2

2

2

2

3

3

3

3

3

4

4

4

4

4

5

5

5

5

5

6

6

6

6

6

7

7

7

7

7

8

8

8

8

8

9

9

9

9

9

A

A

A

A

Replace

B

C

D

E

F

A

B

B

B

B

C

C

C

C

D

D

D

D

E

E

E

E

F

F

F

F

50

0

1

1

1

1

2

2

2

2

3

3

3

3

4

4

4

4

5

5

5

5

6

6

6

6

7

7

7

7

8

8

8

8

9

9

9

9

A

A

A

A

B

B

B

B

C

C

C

C

D

D

D

D

E

E

E

E

F

F

F

F

98

40

30

80

A68B

0

0

0

0

0

0

0

0

1

1

1

1

1

2

2

2

2

2

3

3

3

3

3

4

4

4

4

4

5

5

5

5

5

6

6

6

6

6

7

7

7

7

7

8

8

8

8

8

9

9

9

9

9

A

A

A

A

A

B

B

B

B

B

C

C

C

C

C

D

D

D

D

D

E

E

E

E

E

F

F

F

F

F

0

1

1

1

1

2

2

2

2

3

3

3

3

4

4

4

4

5

5

5

5

6

6

6

6

7

7

7

7

8

8

8

8

9

9

9

9

A

A

A

A

B

B

B

B

C

C

C

C

D

D

D

D

E

E

E

E

F

F

F

F

98

40

20

50

466

439 5

Downsized

Unit: mm

Q312B/Q612B

A38B

Base unit size comparsion

Tip

The A/QnA (Large Type) Series main base unit and extension base unit differ in size:

• A38B main base unit: 480 mm (W) x 250 mm (H)

• A68B extension base unit: 466 mm (W) x 250 mm (H)

Whereas the Q Series main base unit and extension base unit are the same size:

• Q312B main base unit/Q612B extension base unit: 439 mm (W) x 98 mm (H)

Even with the extra I/O slots and base units, the base unit installation area for Q Series is smaller than that for

A/QnA (Large Type) Series.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

25

Page 29

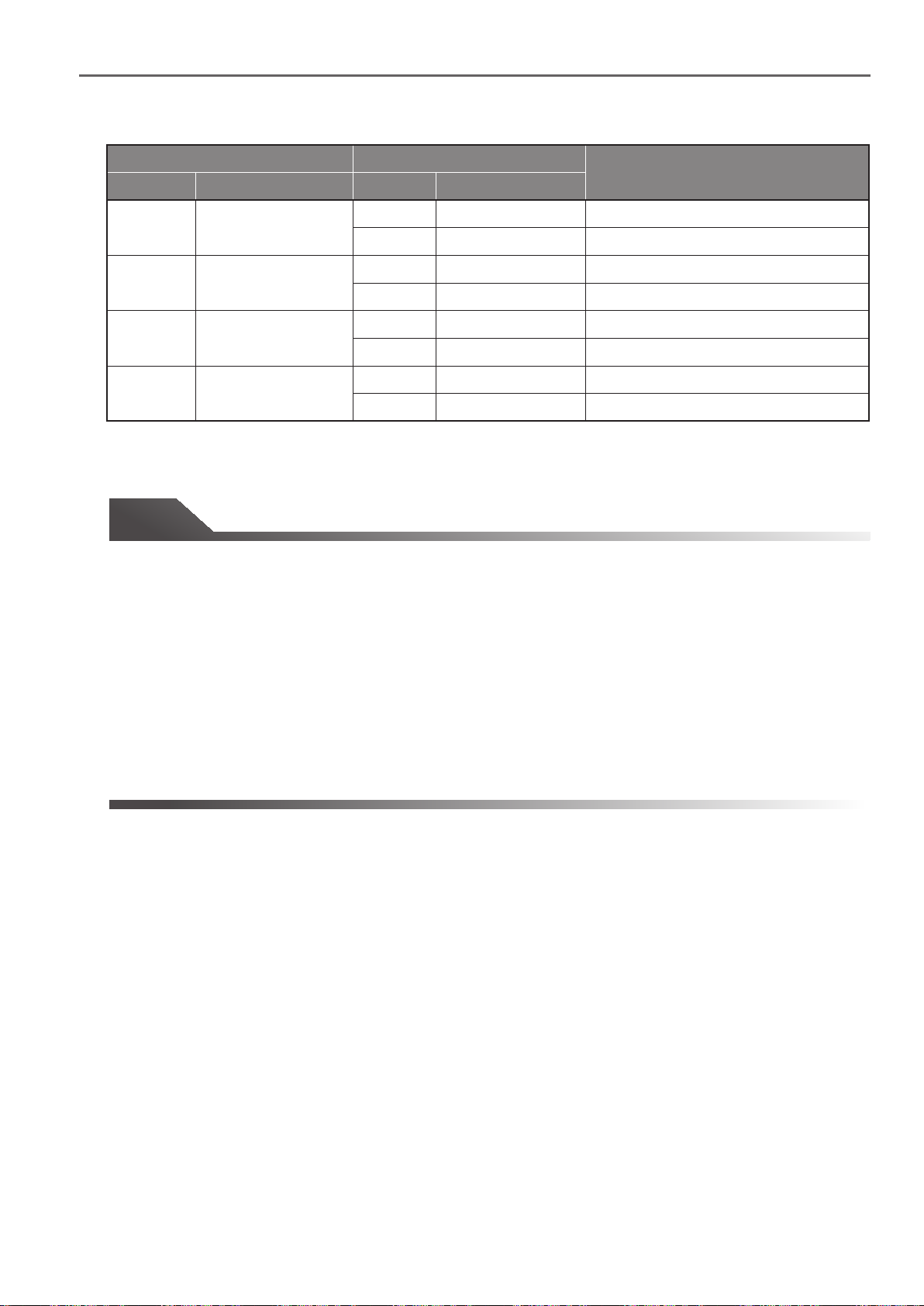

1.2 Comparison of AnS/QnAS (Small Type) Series and Q Series base unit mounting area

1.2 Comparison of AnS/QnAS (Small Type) Series and Q Series base unit mounting area

The Q Series is compact, and has a smaller mounting area.

It can be mounted within the AnS/QnAS (Small Type) mounting area.

The following example shows a comparison of the mounting areas when the AnS/QnAS (Small Type) Series

system is upgraded to the Q Series.

Solution and Benefit

Using the “AnS to Q Series conversion adapter” (manufactured by Mitsubishi Electric Engineering

Co., Ltd.), the 16-point terminal block type module can fit into the existing space without changing

the wiring.

(1) When the AnS/QnAS (Small Type) Series main base unit A1S35B and the A1S65B extension base

unit are replaced

30

130

30

30

130

30

325

A1S35B

A1S65B

315

Q35B/Q65B Q38B/Q68B

Q38B

/Q68B

Replace

328

Q38B/Q68B

0

0

0

0

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

A

A

B

B

C

C

D

D

E

E

F

F

0

1

1

1

2

2

2

3

3

3

4

4

4

5

5

5

6

6

6

7

7

7

8

8

8

9

9

9

A

A

A

B

B

B

C

C

C

D

D

D

E

E

E

F

F

F

Q35B/Q65B

0

0

0

0

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

A

A

B

B

C

C

D

D

E

E

F

F

0

1

1

1

2

2

2

3

3

3

4

4

4

5

5

5

6

6

6

7

7

7

8

8

8

9

9

9

A

A

A

B

B

B

C

C

C

D

D

D

E

E

E

F

F

F

24520 5

Q312B

/Q612B

30

98

40

30

98

40

Unit: mm

A1S38BA1S35B

Base unit size comparsion

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

26

Page 30

1.2 Comparison of AnS/QnAS (Small Type) Series and Q Series base unit mounting area

Existing base unit Replacement base unit

Model Outline dimensions Outline dimensionsModel

A1S35B

A1S38B

A1S65B

A1S68B

325(W)×130(H)

430(W)×130(H)

315(W)×130(H)

420(W)×130(H)

Q35B

Q38B

Q38B

Q312B

Q65B

Q68B

Q68B

Q612B

245(W)×98(H)

328(W)×98(H)

328(W)×98(H)

439(W)×98(H)

245(W)×98(H)

328(W)×98(H)

328(W)×98(H)

439(W)×98(H)

Width is 80 mm narrower

Width is 3 mm wider

Width is 102 mm narrower

Width is 9 mm wider

Width is 70 mm narrower

Width is 13 mm wider

Width is 92 mm narrower

Width is 19 mm wider

Tip

The AnS /QnA (Small Type) Series main base unit and extension base unit differ in size:

• A1S35B main base unit: 325 mm (W) x 130 mm (H)

• A1S65B extension base unit: 315 mm (W) x 130 mm (H)

Remarks

Whereas the Q Series main base unit and extension base unit are the same size:

• Q38B main base unit/Q68B extension base unit: 328 mm (W) x 98 mm (H)

The width will increase if the number of modules increases, i.e., A1S35B to Q68B will increase 3 mm, and

A1S38B to Q312B will increase by 9 mm.

However, this increase can be handled. Confirm the in-panel layout and space and determine whether the

extra modules can be mounted.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

27

Page 31

299

325

1.3 Comparison of AnS/QnAS (Small Type) Series and L Series mounting area

1.3 Comparison of AnS/QnAS (Small Type) Series and L Series mounting area

The L Series modules are designed to be installed directly on the DIN rails. The modules can be

mounted freely according to the in-panel space.

When replacing AnS/QnAS (Small Type) Series modules with L Series, examine the mounting method

in consideration of the in-panel space.

Solution and Benefit

(1) Using the "AnS to L Series conversion adapter" (manufactured by Mitsubishi Electric

Engineering Co., Ltd.), the module to be mounted has a wiring connector incompatible with

the terminal block of the terminal block type module can fit into the existing space without

changing the wiring.

(2) The number of modules to be newly mounted can be reduced by using various built-in

functions of the CPU.

unit are replaced

30

130

30

30

130

30

A1S35B

A1S65B

■ Built-in functions of CPU

315

General-purpose input function Interrupt input function Pulse catch function

General-purpose output function

Replace

30

90

30

90

30

229

Unit: mm

Positioning function

Ethernet function

CC-Link function

High-speed counter function

*1

*1: The CC-Link function can

be used on L26CPU-BT and

L26CPU-PBT.

Tip

Although the external dimensions of AnS/QnAS (Small Type) Series are determined by the base unit to be

used, the width of L Series varies depending on the number of selected modules.

For the method for calculating the required width, refer to "Transition from MELSEC-AnS/QnAS (Small Type)

Series to L Series Handbook."

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

28

Page 32

2.1 Replace A/QnA (Large Type) Series with Q Series

Utilizing external wiring

2.

2.1 Replace A/QnA (Large Type) Series with Q Series

2.1.1 Install terminal block converter module and terminal module externally

(1) Replace 32-point terminal block type module using connector/terminal block converter module

Solution and Benefit

• The connector/terminal block converter module can support up to 2mm2 wires, allowing the use

of existing thick wires without modification.

• Using a connector/terminal block converter module, an existing 32-point terminal block type

module can be replaced with a 32-point connector type module without increasing the number of

modules.