Page 1

Positioning Control

Training Manual

Page 2

Positioning Control

Cautions on Safety

Make sure to read the manuals and pay careful attention to safety when designi ng a system.

In practice, pay attention to the following contents and handle any products or dem onstration

units correctly.

Cautions on practice

DANGER

• Never touch any terminal while the power is supplied. If you touch a terminal,

you may get an electrical shock.

• Turn off the power before connecting / disconnecting units, or opening any

safety covers.

• Never insert your hand or any other object into a moving part.

CAUTION

• Never change the wiring or configuration of demonstration euipment without

permission or if you are unsure of how to configure a system correctly. Such

actions may cause failure, malfuncti on, injury or fire.

• If a simulation unit (such as an X-Y table) generates an abnormal smell or

sound, immediately turn off the power switch.

• If you detect any abnormality, immediately turn off the power and contact a

qualified engineer.

Page 3

Positioning Control

Positioning Control

Manual number: JY992D89901

Manual revision: A

Date : July 2000

i

Page 4

Positioning Control

ii

Page 5

Positioning Control

FAX BACK

Mitsubishi has a world wid e reputat ion for i ts ef forts i n continual ly developi ng and pushing ba ck

the frontiers of industrial automation. What is sometimes overlooked by the user is the care

and attention to detail that is taken with the documentation. However,to continue this process

of improvement, the comments of the Mitsubishi users are always welcomed. This page has

been designed for you,the reader,to fi ll in your comment s and fax them back t o us. W e look for ward to hearing from you.

Fax numbers: Your name....................................................

Mitsubishi Electric.... .....................................................................

America (01) 847-478-2253 Your company..............................................

Australia (02) 638-7072 .....................................................................

Germany (0 21 02) 4 86-1 12 Your location: ...............................................

South Africa (0 27) 11 444-0223 .....................................................................

United Kingdom (01707) 278-695

Please tick the box of your choice

What condition did the manual arrive in?

Will you be using a folder to store the manual?

What do you think to the manual presentation?

Are the explanations understandable?

Which explanation was most difficult to understand:................. ........................ .........................

....................................................................................................................................................

Are there any diagrams which are not clear?

If so,which:..................................................................................................................................

What do you think to the manual layout?

If there one thing you would like to see improved,what is it?.................................... ..................

....................................................................................................................................................

....................................................................................................................................................

Could you find the information you required easily using the index and/or the contents,if possi-

ble please identify your experience: ...........................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

Good Minor damage Unusable

Yes No

Tidy Un-friendly

Yes Not too bad Unusable

Yes No

Good Not too bad Un-helpful

Do you have any comments in general about the Mitsubishi manuals?.....................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

Thank you for taking t he time to fill out this questionnaire. We hope you found both t he

and this manual easy to use.

product

iii

Page 6

Positioning Control

iv

Page 7

Positioning Control

Introduction

This manual describes basic oper ation for those who learn positioni ng control for the first ti me,

the aim being so that they can get training using demonstration units of Mitsubishi FA

equipment.

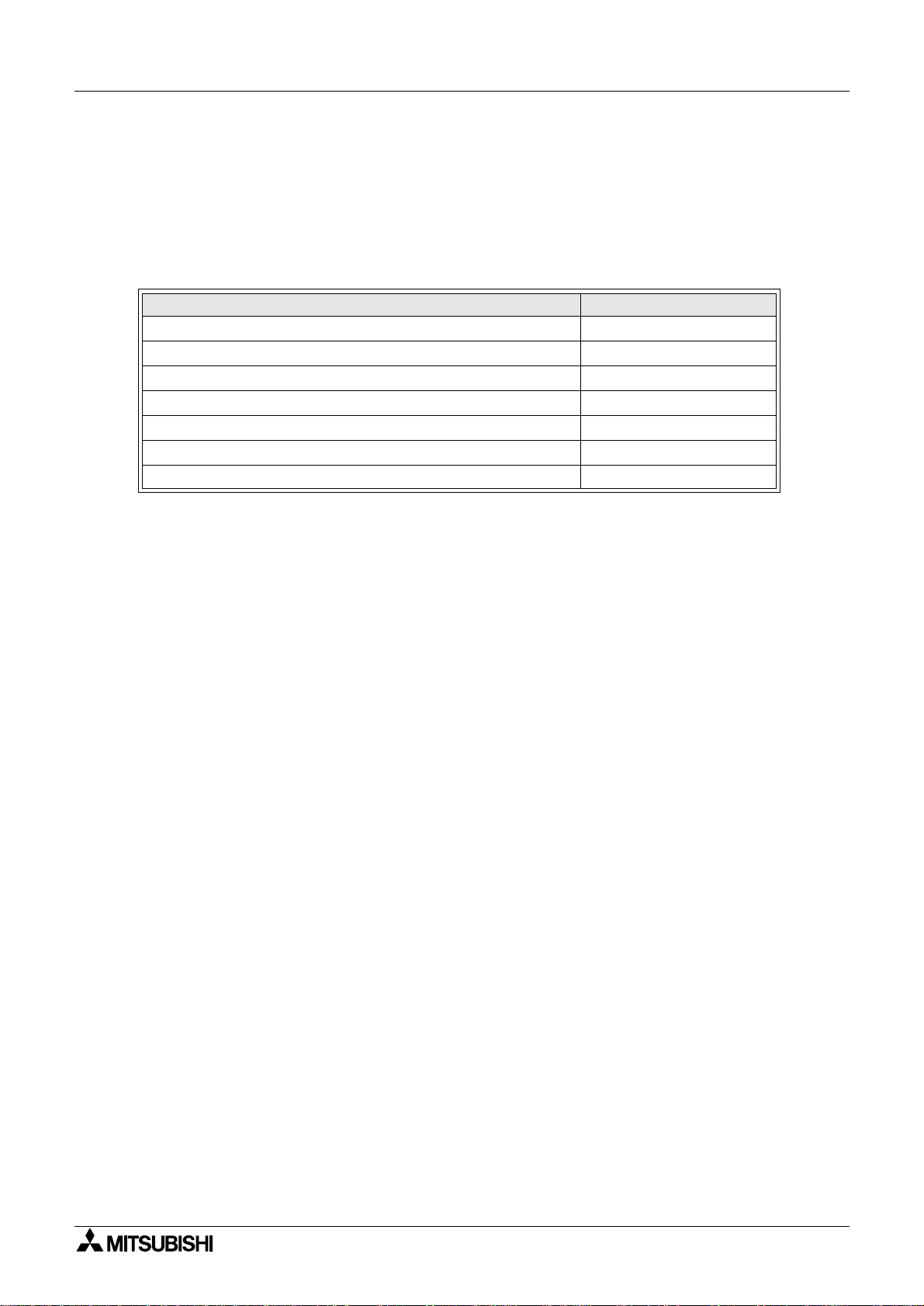

The following relevant manuals are available and should be referred to

FX-10GM/FX(E)-20GM Hardware and Programming manual JY992D60401

FX-10GM Users Guide JY992D68401

2N

-10GM/FX2N-20GM Hardware and Programming manual JY992D77801

FX

FX2N-10GM Users Guide JY992D77701

FX2N-20GM Users Guide JY992D77601

FX-PCS-VPS Win-E Software Manu al JY992D86801

2N

-10GM/FX2N-20GM Connection Manual JY992D81601

FX

Manual Name Number

v

Page 8

Positioning Control

vi

Page 9

Positioning Control Contents

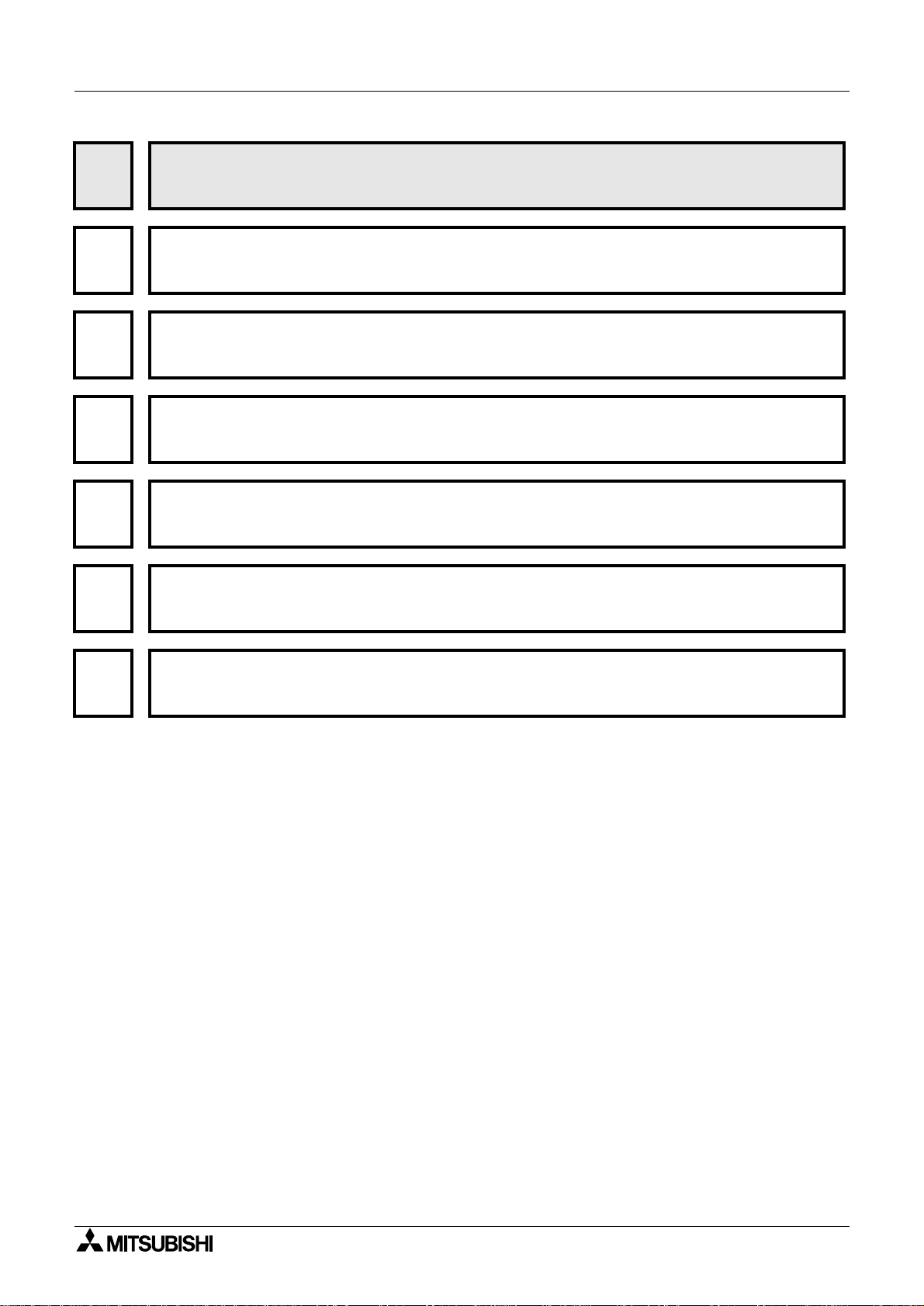

1. The World of Positioning Control...........................................................1-1

1.1 Welcome to the new world! .................................................................................1-1

1.2 Divers ifi e d a c tu a tors..................... .. .. ........................... .. .. ........................... .. .. .....1-2

1.3 Positioning method type......................................................................................1-4

2. Positioning by AC Servo System...........................................................2-1

2.1 When an AC servo system is introduced........................ ........................ .............2-1

2.2 Examples of AC servo systems....................... .. ........................ .. ........................2-3

3. Components of Positioning Control and Their Roles ............................3-1

3.1 Positioning controller ...........................................................................................3-4

3.1.1 Command pulse and feed quantity............................................................................3-4

3.1.2 Command pulse and feed speed ..............................................................................3-4

3.1.3 Setting the acceleration/deceleration time ................................................................3-5

3.1.4 Backlash correction function ........... ...... ....... ...... ...... .................................................3-5

3.1.5 Zero point return function ..........................................................................................3-6

3.2 Servo amplifier and servo motor.......................... ................................................3-7

3.2.1 Positioning control in accordance with command pulse............................................3-7

3.2.2 Deviation counter function.........................................................................................3-7

3.2.3 Servo lock function....................................................................................................3-7

3.2.4 Regenerative brake function .....................................................................................3-8

3.2.5 Dynamic brake function...................................... ...... ....... ...... ....... .............................3-8

3.3 Drive mechanism......................................................................... ....................... .3-9

3.3.1 Concept of drive system movement quantity ............................................................3-9

3.3.2 Setting the target position........................................................................................3-11

4. Advanced Positioning............................................................................4-1

4.1 Interpolation control.............................................................................................4-1

4.2 Other con t ro ls ................................. .. ... .......................... .. .. ........................... .. .. ... 4 -3

5. Actual Positioning..................................................................................5-1

5.1 Demons tr a ti o n E q u ip me n t ..................... .. .. ........................... .. .. ...........................5-1

5.1.1 Basic Set ...................................................................................................................5-1

5.1.2 Comprehensive Set...................................................................................................5-1

5.2 Operation of the demonstration equipment .........................................................5-2

5.2.1 Program example......................................................................................................5-3

5.2.2 Writing the program...................................................................................................5-4

5.2.3 Parameters................................................................................................................5-5

5.2.4 Operation...................................................................................................................5-7

6. Product Line up .....................................................................................6-1

6.1 Position controller ................................................................................................6-1

6.2 Servo am p lif ie r... ........................... .. .. ........................... .. .. ........................... .. .. .....6-5

6.3 Servo moto r ..................... .. .. ........................... .. .. ........................... .. .. ..................6-7

Appendix A:.............................................................................................. A-1

A-1: Tentative Selection of Motor Capacity................................. ........................ .. ......A-1

A-1-1: Motor effective torque...................... ...... ....... ...... ...... ....... ...... ....... .............................A-2

A-1-2: Load inertia moment..................................................................................................A-4

vii

Page 10

Positioning Control Contents

viii

Page 11

Positioning Control The World of Positioning Control 1

1 The World of Positioning Control

2 Positioning by AC Servo Sys tem

3 Components of Positioning Control and Their Roles

4 Advanced Positioning

5 Actual Positioning

6 Product Line up

A Appendix A: Tentative Selection of Motor Capacity

Page 12

Page 13

Positioning Control

1. The World of Positioning Control

1.1 Welcome to the new world!

The positioning controller, together with the programmable controller, personal computer and

operator interface, is one of the four main units of FA (facto ry automation).

Among them, the positioning controller is important as the basis of FA, and regarded as the

center of the mechatronics field in which many senior engineers have been playing active

parts.

Positioning is all about motion, and motion often involves speed and precision. As speed can

be related to productivity, it is an area of much development. But, when the machine speed

increases, a problem with the stop precision is often generated. In order to solve this problem,

diversified grades of position controllers have been required and developed.

Improvement of the machine efficiency generates immeasurable added value, including

reduction of labour and the machine floor area for the same quantity of production.

The World of Positioning Control 1

If there are no problems related to the pos itioning aspe ct of a ma chine, it may mean that the

machine is not running most efficiently. Here is where the science of developing an optimum

positioning control system comes in.

1-1

Page 14

Positioning Control The World of Positioning Control 1

1.2 Diversified actuators

• A power source which moves an element in a system is called actuator. A unit which detects

a position of a work piece or moving part is called sensor.

• Diversified actuators and sensors, from simple ones to enhanced ones, are used in

positioning.

• This paragraph describes representat ive types, their features and weak points.

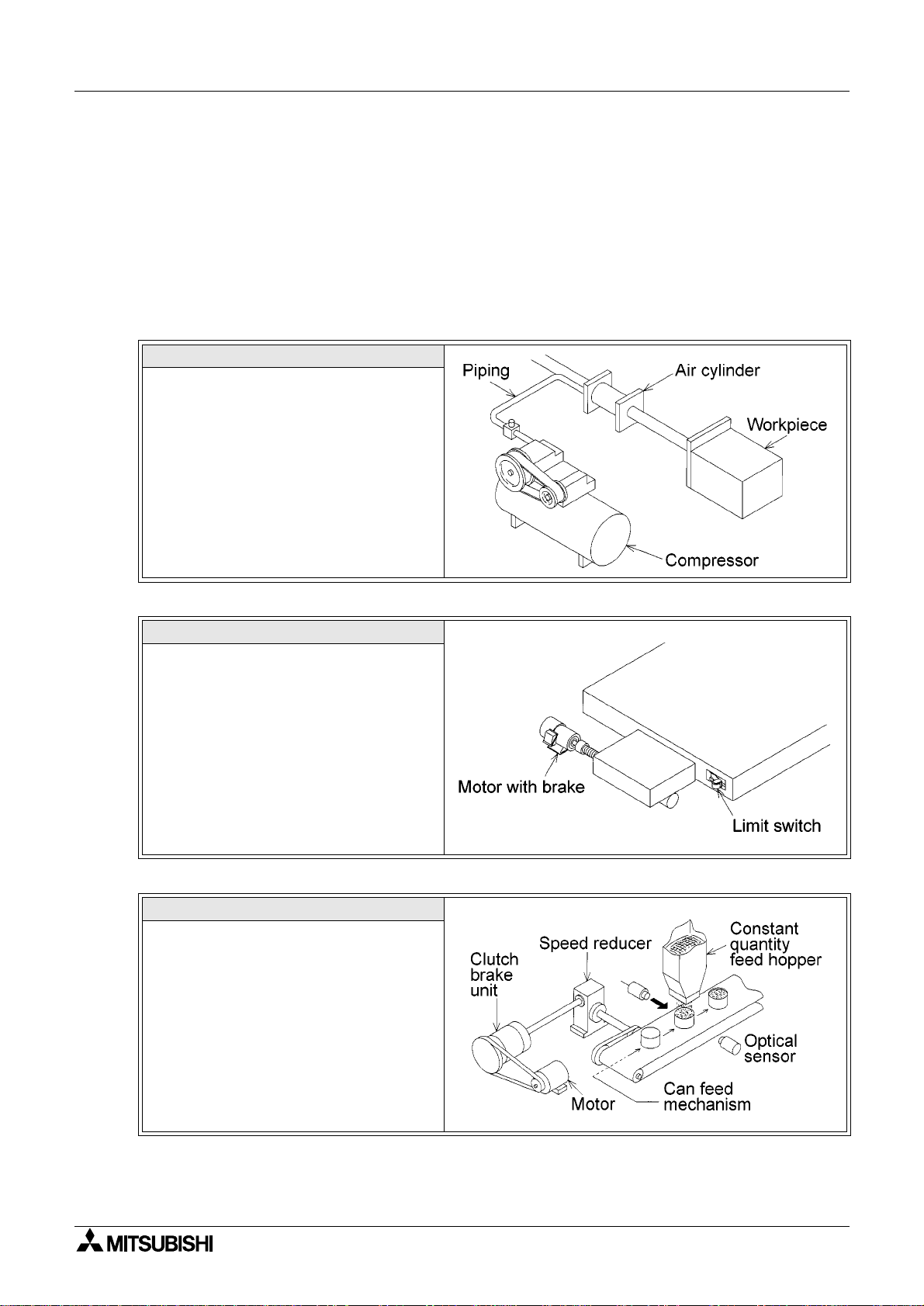

Pneumatic

• Air source and high grade piping are

required.

• High torque is not available.

• Multi-point positioning is complex and

very difficult to achieve.

• Change in pos it ion ing is difficul t.

Brake motor

• Positioning mechanism is simple.

• Repeatability is poor.

• Change in pos it ion ing is difficul t.

(When optical sensors or limit switches are

used for stop)

Clutch brake

• Frequent positioning is available.

• Life of friction plate is limited.

• Change in pos it ion ing is difficult.

(When optical sensors or limit switches are

used for stop)

1-2

Page 15

Positioning Control The World of Positioning Control 1

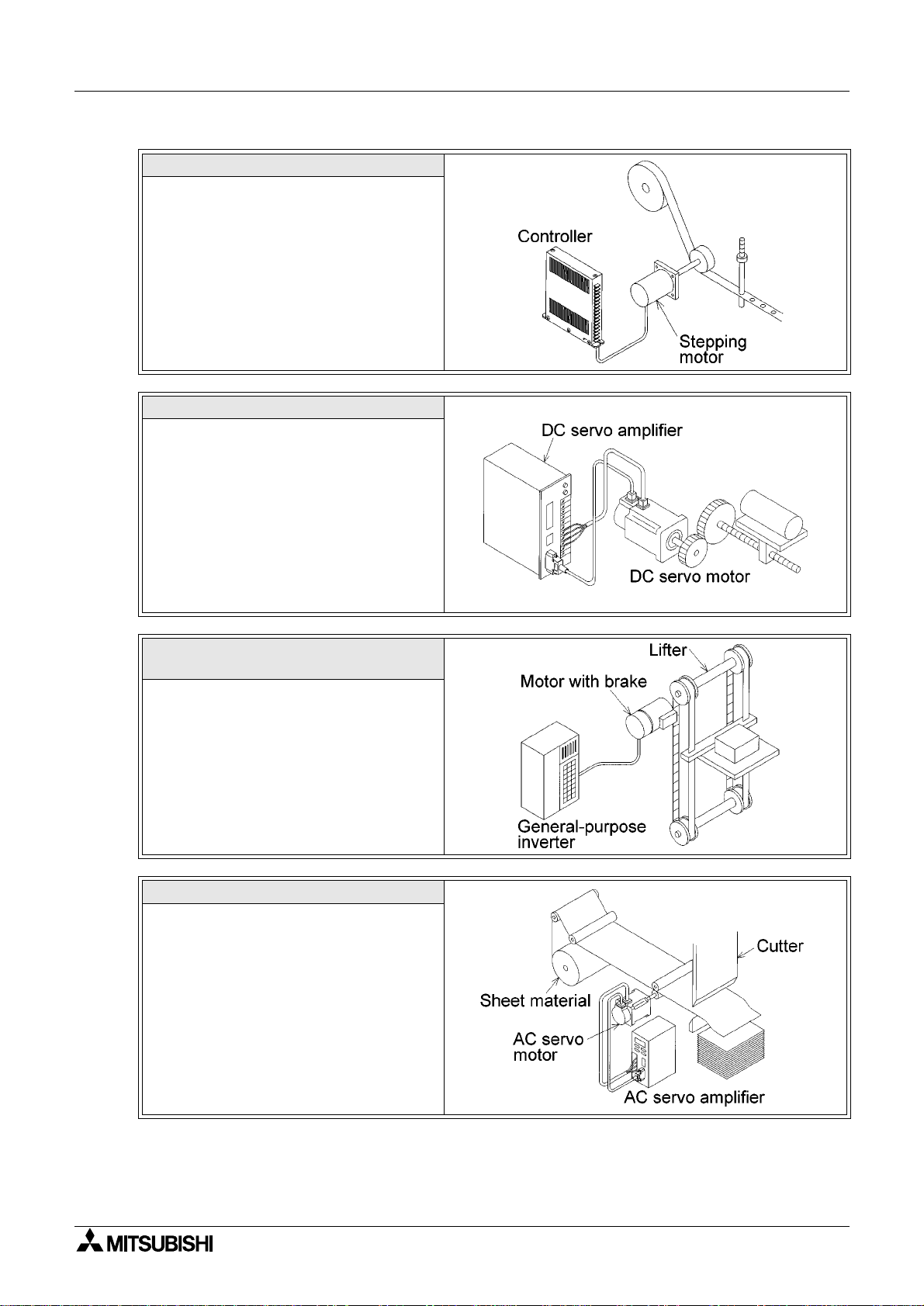

Stepping motor

• Positioning mechanism is simple.

• If load is heavy, motor may step out and

displacement can occur.

• Motor capacity is small.

• Precision is poor at high speed.

DC servo system

• Positioning precision is good.

• Maintenance is required for motor

brushes.

• It is not suitable for rotation at high

speed.

General purpose inverter and general

purpose motor

• Multi-speed positioning is available

using high-speed counter.

• High precision positioning is not

available.

• Large torque is not available at start.

(Specialized inverter is required)

AC servo system

• Precision is good.

• Maintenance is not required.

• Positioning address can be easily

changed.

• It is compact, and offers high power.

1-3

Page 16

Positioning Control The World of Positioning Control 1

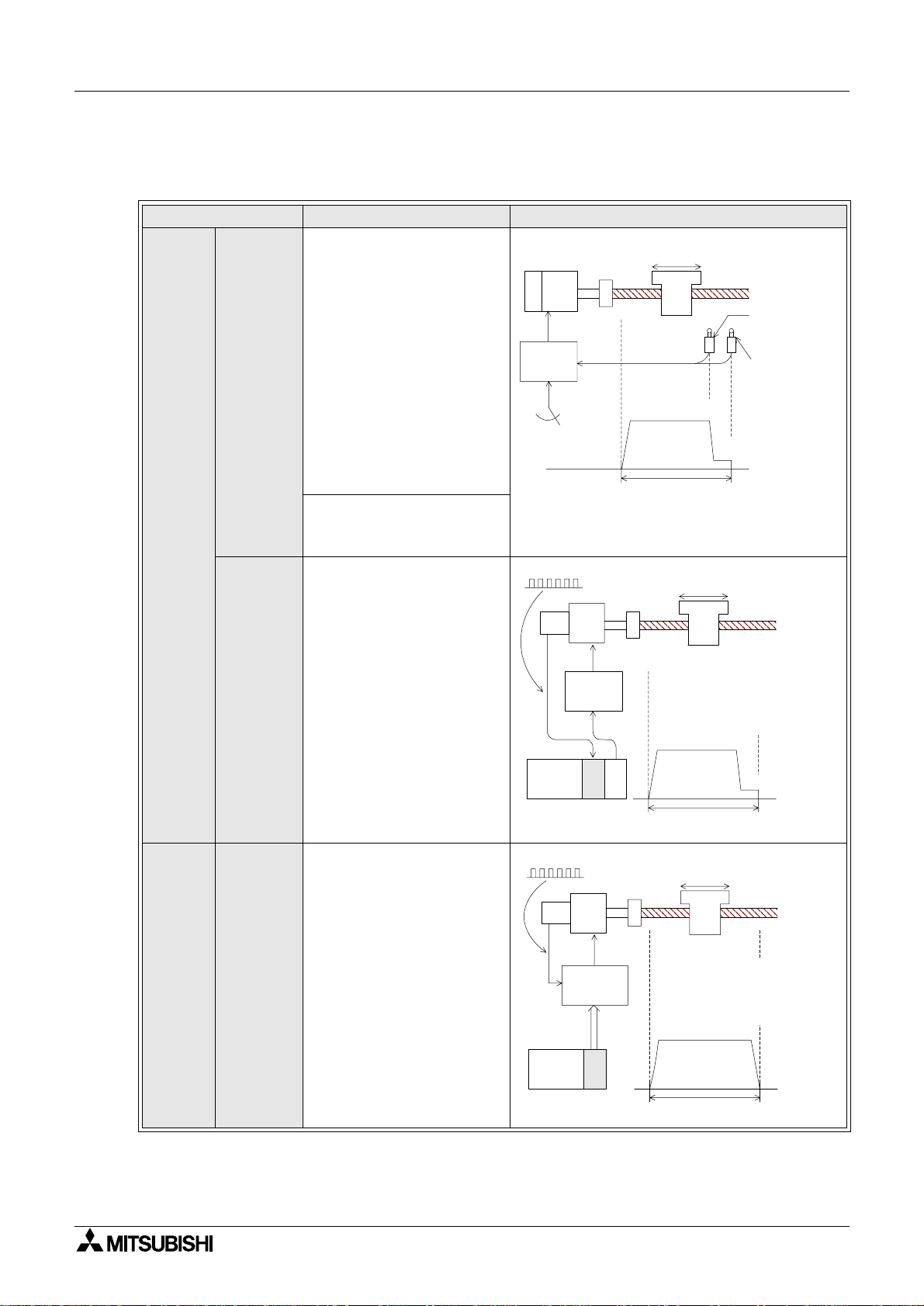

1.3 Positioning method type

1) There are three types of positioning method

Control method Description Schematic drawing

Two limit switches are

Moving part

Ball screw

Limit switch for

changeover to

low speed

Limit switch

for stop

High speed

Low speed

Movement

distance

Speed

control

Limit

switch

method

provided in places where a

systems moving part

passes. At the first limit

switch, the motor speed is

reduced. At the second limit

switch, the motor turns off

and the brake turns on, to

stop the moving part.

In this method, because

position controllers are not

required, the system

configuration can be realized

at reasonable cost.

(Guideline of stopping

precision: Approximately

±1.0 to 5.0 mm)*

B IM

INV

DC0 to 10V

IM: Inductive motor

B: Brake

INV: Inverter

Position

control

Pulse

count

method

Pulse

command

method

A position detector (such as

pulse encoder) is set up in a

motor or rotation axis. The

pulse number generated

from the position detector is

counted by a high-speed

counter. When the pulse

number reaches the preset

value, the moving part stops.

In this method, because limit

switches are not used, the

stop position can be easily

changed.

An AC servo motor which

rotates in proportion to the

input pulse number is used

as the drive motor.

When the pulse number

corresponding to the

movement distance is input

to the servo amplifier of the

AC servo motor, positioning

can be performed at high

speed in proportion to the

pulse frequency.

Pulses are

fed back.

PLG

IM

INV

DC0 to

PC

High-speed

counter unit

Pulses are

fed back.

PLG SM

Servo

amplifier

Command

pulse

PC

Position controller

Moving part

IM: Inductive motor

PLG: Pulse generator

INV: Inverter

PLC: Programmable cont rol l er

10V

High speed

Movement distanc e

Moving part

SM: Servo motor

PLG: P ul s e generator

PLC: Programmable

Movement distance

Ball screw

Low speed

Ball screw

controller

*1 The stop precision shows a value in a case where low speed is 10 to 100 mm/s.

1-4

Page 17

Positioning Control The World of Positioning Control 1

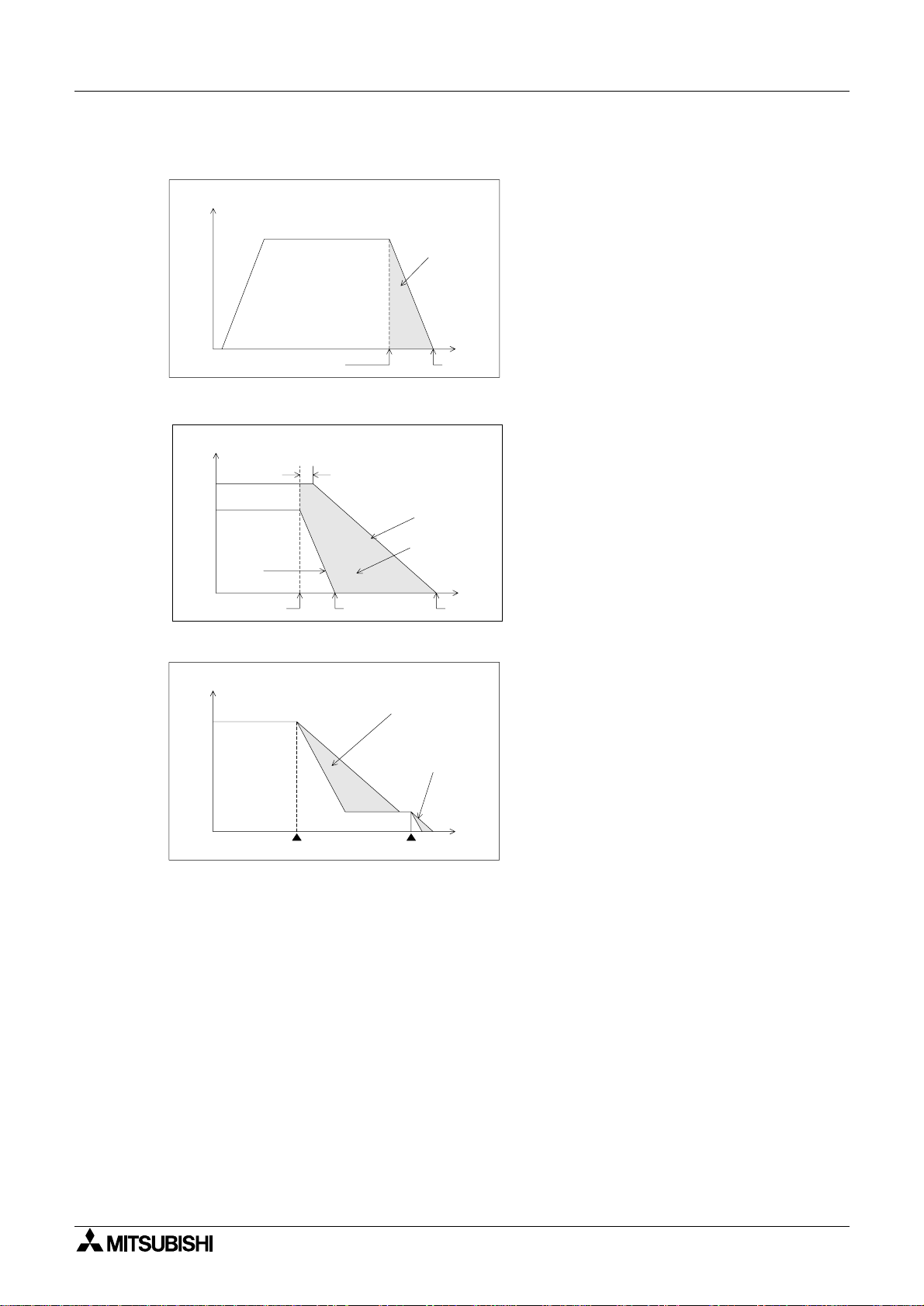

2) Positioning method and stop precision

Velocity

Stop command

Velocity

Heavy

load

Small

inertia

Stop command

Coasting

distance

Speed reduction start

Time delay

Light load

Large inertia

Dispersion

in s to p

Stop

Time

Stop

Stop

< Limit switch method >

- When automatically stopping a moving

part driven by a motor, stop the motor by a

position signal, detected by a limit switch

(in general conditions, turn on the brake at

the same time).

- The moving part continues by a coasting

distance until it completely stops, after the

stop command is given. The coasting

distance is shaded in the figure.

- The stop precision is equivalent to the

dispersion in the shaded area as shown in

the figure on the left.

The dispersion is affected by the speed

when the stop command is given, the load

size and the time delay since the stop

command is given, until speed reduction

actually starts.

Time

Velocity

High speed

Speed reduction command

Dispersion in

speed reduction

distance

Dispersion

in stop

Time

Stop command

- If the required stop precision is not

satisfactory when stopping from the

normal operation speed, t he most effective

method to improve the stop precision is to

reduce the operation speed.

- However, if the operation speed is simply

reduced, the machine efficiency may also

be reduced. In actual operation, the motor

speed can be reduced fro m high sp eed to

low speed once, then the motor stopped.

1-5

Page 18

Positioning Control The World of Positioning Control 1

< Pulse count method >

- When a pulse encoder is attached to a moving par t, and the mot or speed is c ontrol led by

a number steps while the pulse number is counted, the movement qu antity per pulse is

determined in accordance with the relationship between the pulse number generated by

one rotation of the encoder, and the movement quantity of the mov ing part (workpiece)

realized by one rotation of the motor. The movement quantity per pulse is regarded as

the minimum unit for the stop command.

- However, the coasting distance at stop is not eliminated.

< Pulse command method >

- In this method using a servo system, the weak points described above are improved. A

pulse encoder is attached to the servo motor, detecting the motor rotation quantity

(workpiece movement distance), to continuously and directly control the speed from the

high-speed operation to the t arget p osit ion, which all ows the wor kpiece t o stop wi th good

precision.

- As the coasting distance at stop is eliminated, the positioning precision is improved.

1-6

Page 19

Positioning Control Positioning by AC Servo System 2

1 The Wor l d of Positioning Control

2 Positioning by AC Servo System

3 Components of Positioning Control and Their Roles

4 Advanced Positioning

5 Actual Positioning

6 Product Line up

A Appendix A: Tentative Selection of Motor Capacity

Page 20

Page 21

Positioning Control

2. Positioning by AC Servo System

2.1 When an AC servo system is introduced

• Positioning can be performed by many diversified methods. Recently, AC servo methods

which offer many advantages are often introduced.

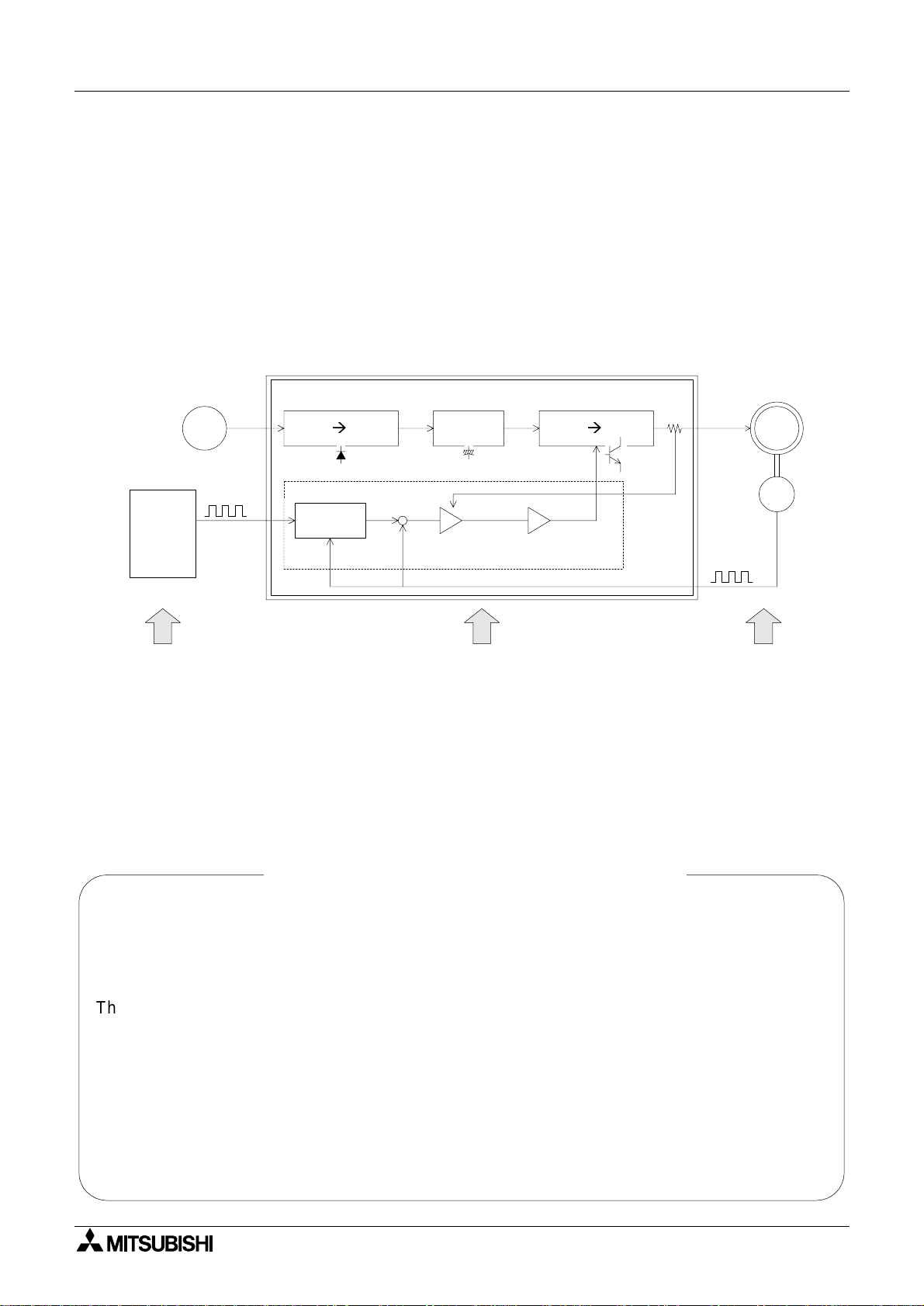

• In the positioning system of an AC servo method, a position controller, servo amplifier and

servo motor are generally required. The representative system configu ration is shown

below.

Servo amplifier

Commercial

power supply

Converter

Smoothing

circuit

Inverter

DC ACDCAC DC

Positioning by AC Servo System 2

Servo

motor

SM

Command

pulse

Position

controller

The position controller

generates a specified

quantity of forward rotation

(or reverse rotation) pulses at

a specified frequency.

Deviation

counter

Why is the AC servo system attracting attention?

Speed

command

Current

control

The command pulse number

is subtracted by the feedback

pulse number, and the speed

command to drive the servo

motor is made from the

deviation (accumulated pulse

number).

When the accumulated pulse

number becomes 0, the servo

motor stops.

PWM (pulse width

modulation) control

AC servo systems are easier to h andle than

hydraulic equipment.

Feedback

current

Feedback

The servo motor is equipped

with a built-in encoder (pulse

generator), dedicated to high

speed response, and suitable

to positioning control.

PLG

Encoder

pulse

The AC servo system satisfies the needs for

multi-model small-lot production through only

simple changes in the program.

As an AC servo system can generate large

torque, it can satisfy the needs for down sizing

and high power.

- Release from oil management

Robots in conjunction with an AC ser vo system

can satisfy the needs for labor saving and

automation.

- Release from dangerous, hard and dirty

working environments

2-1

Page 22

Positioning Control Positioning by AC Servo System 2

In the latest AC servo systems, conventional wea k points have been improved as follows.

- Though the latest systems are completely digital, they are equipped with parameters in

conformance to diversified mechanical specifications and electrical specifications so that

simple setting is possible.

- As frequent operation is enabled by a low inertia motor, the maximum torque is

increased and the system can be applied to diversified machines.

- The latest systems are equipped with an auto tuning function, with which the servo

amplifier automatically detects the load inertia moment and adjusts the gain. This is

possible even if the load inertia moment is unknown.

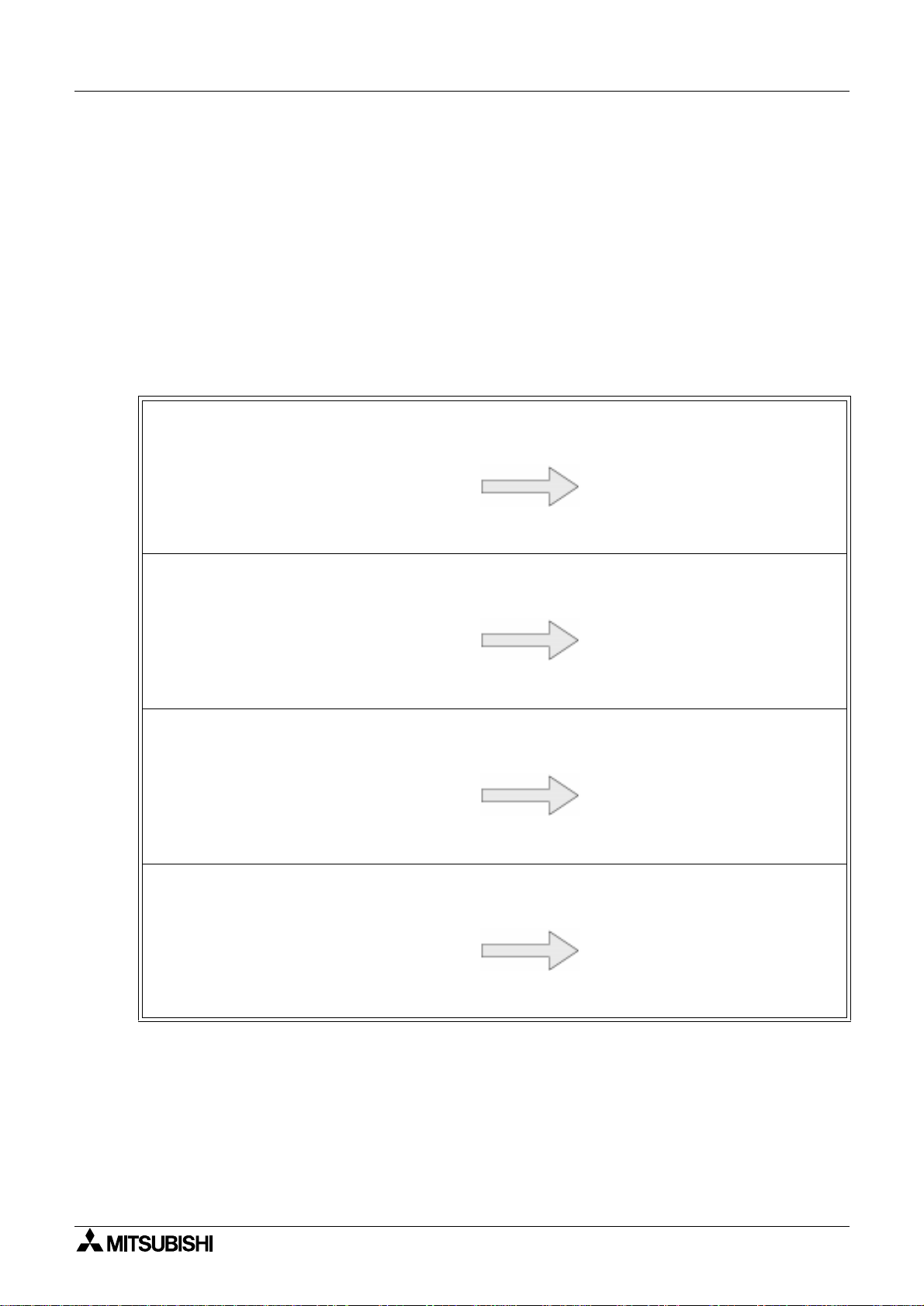

Aspects described below are now incorperated to AC serv o systems which offer marked

improvements from previous products.

In FA work place, a downsized AC servo

system occupying less space is required!

In accordance with sever operation

conditions, a tougher AC servo system is

required!

An AC servo system anyone can handle

easily is required! Even if the

performance is good, the AC servo

system cannot be accepted if it is difficult

to handle.

Compact and light servo

system

Robust servo system

Easy servo system

An AC servo system givi ng suf f icie nt cost

performance is required!

Good cost performance servo

system

2-2

Page 23

Positioning Control Positioning by AC Servo System 2

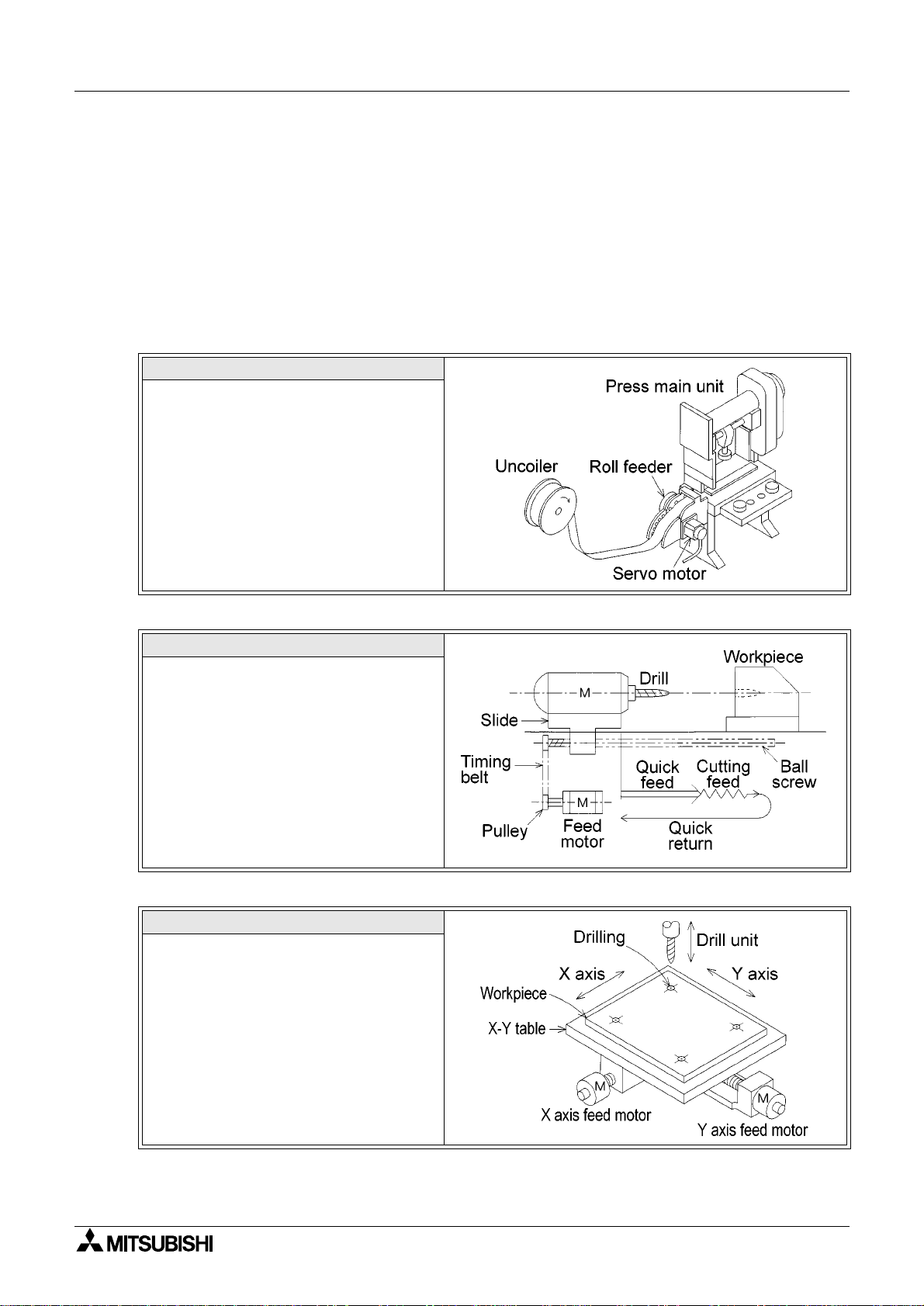

2.2 Examples of AC servo systems

• Positioning indicates the operation to move an element, such as a workpiece or tool (dril l or

cutter) from a certain position (point) to another target position (point) and stop it with high

efficiency and high precisi on.

• In other words, the principle of positioning is the control of speed in accordance with the

position, performed to promptly eliminate the remaining distance to the target position. The

flexibility to change the target position electrically and easil y is an important requirement.

• Several cases of positioning using an AC servo motor are systemati cally shown below.

Constant feed

In the press/shear process for cutting,

punching, etc., the processed material is

positioned with high precision to produce a

constant sized product.

Tapping

In order to tap a workpiece, "1. Quick

feed", "2. Cutting feed" and "3. Quick

return" are repeatedly performed.

Drilling in steel sheet

In order to perform processing on a flat

face, positioning with high precision is

performed by two motors (X axis feed

motor and Y axis feed motor).

2-3

Page 24

Positioning Control Positioning by AC Servo System 2

Index table

The position of the circular table is

indexed.

The index position is set on the outside

(digital switch) or the inside (program).

Shortcut drive is performed depending on

the index position.

Lifter moving-up/down

As negative load is applied on the servo

motor in positioning of the lifter in the

vertical direction, a regenerative option is

used also.

In order to hold the lifter stationery and

prevent drop of the lifter by power

interruption, a servo motor with

electromagnetic brake is used.

Cart travel control

A servo motor is mounted in the travel cart

as the drive source.

A mechanism such as rack and pinion is

adopted to prevent slippage between the

wheels and rails.

Carrier robot

After the conveyor stops, the 2-axis servo

system and the arm lifting mechanism

transfer workpieces to a palette.

The workpiece input positions on the

palette can be set to many points so that

setup change can be easily performed,

even if the palette position and the palette

shape change.

2-4

Page 25

Positioning Control Components of Positioning Control and Their Roles 3

1 The Wor l d of Positioning Control

2 Positioning by AC Servo Sys tem

3 Components of Positioning Control and Their Roles

4 Advanced Positioning

5 Actual Positioning

6 Product Line up

A Appendix A: Tentative Selection of Motor Capacity

Page 26

Page 27

Positioning Control

Components of Positioning Control and Their Roles 3

3. Components of Positioning Control and Their Roles

Positioning control requires a number of components such as a positioning controller, servo

amplifier, servo motor and drive mechanism. This section describes the role of each

component.

3-1

Page 28

Positioning Control Components of Positioning Control and Their Roles 3

Position controller

• Outputs the positioning speed

and the movement quantity in

command pulses to the servo

amplifier.

• Transfers signals between the

programmable controller.

• Controls return to the zero point.

Near point dog signal

In some types, the li mit switc h signal

is wired to the posit i on controller.

Main circuit

Position controller

Converter

Positioning

command

control

Command

pulse

AC DC DC DC AC

AC power

supply

Smoothing

circuit

Power board

• Improves the power factor

and cuts noise.

• Protects the power circuit.

Servo amplifier

Regenerative

brake

Inverter

Dynamic

brake

R

Parameter

Pulse

magnification

Zero point

return

control

Servo

ready

(Electronic gear)

Counter clear

Zero point signal (PG0)

Operation equipment

• Give inputs for manual/automatic

mode, start/stop, zero po int return

command, manual forward rotation/

reverse rotation and manual pulse

generator to the positioning

controller.

Deviation

counter

Speed

command

Current

control

PWM (pulse width

modulation) control

Feedback pulse

Feedback

current

Servo amplifier

• Rectifies the AC power of the main circuit into

the DC power in the converter, and smooths it in

the smoothing circuit.

When the DC power is converted into AC power

in the inverter, the current supplied to the servo

motor is changed by the P WM (pulse width

modulation) control in the contr o l circuit.

• The deviation counter receives and counts the

command pulses from the positioning controller,

subtracts the feedback pulses from them, then

drives the servo motor until the accumulated

pulse number becomes 0.

3-2

Page 29

Positioning Control Components of Positioning Control and Their Roles 3

g

g

g

g

g

g

g

g

g

Servo motor

• Dedicated to hi

positionin

maximum torque and wide variable speed ran

1/1 or more (1/1,000 to 1/5,000).

Servo motor

In the case of large motor

Cooling fan

Servo

motor

SM

Encoder

PLG

(pulse

generator)

h speed response optimal to

control, has large start torque, large

When a moving element goes beyond a limit

switch (LS), the motor stops.

Drive mechanism

Limit switch

(LS)

Speed

reducer

Near point

dog switch

e

Moving element

Ball screw

Limit switch

(LS)

When

required

Electromag

netic brake

Hand held

Programmer

Setting / display unit

• Used to write pro

position controller, allows

settin

and display of the data.

Personal

Computer

rams to the

Auxiliary device such as c huck, drill and cylinder

Sensor, actuator,

auxiliary device

• The actuator (moving part drive

mechanism) is equipped with

speed reducer, timin

screw and limit switch.

Graphic

Operator

Terminal

• Diversified auxiliary devices are

also controlled in accordance with

positionin

.

• The PLC or the positionin

controller also controls a uxiliary

devices.

• The auxiliary device operation

completed si

PLC or the position controller.

belt, ball

nal is output to the

3-3

Page 30

Positioning Control Components of Positioning Control and Their Roles 3

3.1 Positioning controller

As the positioning con troller gives position comma nds to the servo amplif ier, positioning

programs should be created, and parameters defined. The contents related to programs a nd

parameters are described below.

3.1.1 Command pulse and feed quantity

There are the following three types of command pulse output modes.

- PLS/SIGN mode

- CW/CCW mode

- A phase/B phase mode

From the three, the CW/CCW mode is picked up for explanation.

• When the servo motor encoder generates 8,192 pulses for one rotation, the command

pulse number "8,192" should be output to rotate the servo motor by 1 rotation. The

workpiece feed quantity is in proportion to the puls e number.

< Forward rotation command >

Forward rotation pulse output

Reverse rotation pulse output

< Reverse rotation command >

Forward rotation pulse output

Reverse rotation pulse output

3.1.2 Command pulse and feed speed

• When the servo motor encoder generates 8,192 pulses for one rotation, the command

pulse frequency (speed) "8,192 pulses/s" should be output to rotate the servo motor by 1

rotation per second.

Forward rotation

pulse output

R e v ers e ro ta tio n

pulse output

0

1

0

12

0

-1 -2

2

Pulse number output per

second (frequency)

(8192) pulses

(-8192) pulses

(

8192)

pulses

• Decrease the pulse frequency to rotate the servo moto r at lower speed.

• Increase the pulse frequency to rotate the servo motor at higher speed.

3-4

Page 31

Positioning Control Components of Positioning Control and Their Roles 3

3.1.3 Setting the acceleration/decelerat ion time

• When the start command is given, acceleration, operation at constant speed and

deceleration are performed for positioning. Set the accelera tion time and the deceleration

time in the parameters.

Parameter:

Speed

Max. speed

Positioning speed

Actual

acceleration

time

Parameter:

Acceleration

time

• This operation pattern is effective during return to the zero point, positioning and jog

operation.

3.1.4 Backlash correction functio n

• The positioning controller can output excessive pulses, only when the movement direction

is inverted so that the backlash of the mechanical system is cor rect ed.

< Backlash correction >

Backlash

Parameter:

Deceleration

time

Table

Feed screw

Actual

Time

deceleration

time

3-5

Page 32

Positioning Control Components of Positioning Control and Their Roles 3

3.1.5 Zero point return function

• There are two types of servo motor encoders, incremental type (pulse count method) and

absolute type (absolute position detection method).

• Incremental type is constructed so that the current value stored in the position controller

does not increase or decrease, even if the workpiece stop position changes by some

reason while the power is turned off, theref ore the positioning address is not assured.

• Accordingly, when the power is turned on, the machine should be moved to the reference

point to update the zero point address. This operation is called return to zero point.

• Absolute type is constructed so that the current value stored in the position controller

increases or decreases if the workpiece stop positi on changes whil e t he power i s turned of f,

thus the positioning address is assured. Accordingly, when the power is turned on, return to

the zero point is not required.

However , when the machine is used for the first time, it should be returned to the zero point

so that it recognizes the zero point address.

Zero point

Deceleration time

Creep

speed

Zero point

Dog

switch

Dog

Clear signal

*

The return point of the dog switch should be adjusted

*

to a midpoint of the zero point signal (1 pulse per

rotation of the motor).

In this example, the dog length should not be less than

the deceleration distance of the machine.

return speed

Initial position

Zero point

return direction

Dog

Backward endForward end

< Operation to return to the zero point >

• The zero point return direction, return

speed, deceleration time and creep speed

are set by parameters in th e positioning

controller.

• There are several zero point return

methods.

For example, when the forward end of the

dog reaches the dog switch, the motor

resumes its creep speed. At the first zero

point signal after the dog re aches the

backward end, the deviation counte r clear

signal is output and the motor stops.

• The zero point address set by a parameter

is written to the current value register of

the position controller.

Limit

switch

Initial

position

Escape operation

Dog

switch

Zero point

• In some models, if the zero point return

operation is performed while the work

piece is stopped beyond the dog switch,

the machine moves once until the limit

switch is actuated, inverts the direction,

then returns to the zero point again (dog

search function, zero point return retry

function).

3-6

Page 33

Positioning Control Components of Positioning Control and Their Roles 3

3.2 Servo amplifier and servo motor

The servo amplifier controls the movement quantity and the speed in accordance with

commands given by the positioning controller. The servo motor transmits rotation to the drive

mechanism after receiving a signal from the servo amplifier.

3.2.1 Positioning control in accordance with command pulse

• By PWM (pulse width modulatio n) control, performed to the servo amplifier main circuit with

regard to the position co mmand and the speed command, in accordanc e wi th the command

pulses of the position controller, the servo motor is driven. The rotation speed and the

rotation quantity are fed back from the encoder attached to t he servo motor.

3.2.2 Deviation counter function

• The difference between the command pulses and the feedback pulses counted by the

deviation counter in the servo amplifier is cal led accumulated pulses.

• While the machine is operating at a constant speed, the accumulated pulse quantity is

almost constant. During acceleration and deceleration, the accumulated pulse quantity

changes more dramatically.

• When the accumulated pulse quantity becomes equivalent to or less than the specified

quantity (in-position set value) after command pulses have stopped, the servo amplifier

outputs the positioning completed signal.

The servo motor continues operation even after that. Then, when the accumulated pulse

quantity becomes 0, the servo motor stops.

The time after the servo motor outputs th e positioning completed signal, until it stops is

called stop settling time.

Speed

Accumulated

pulses

Stop settling time

3.2.3 Servo lock function

• The servo motor is controlled so that the accumulated pulse quantity counted in the

deviation counter becomes 0.

• For example, if an external force for forward rotation is applied on the servo motor, the

servo motor performs the reverse rotati on operation to eliminate the accumulated pulses.

Command speed

Motor speed

The accumulated pulse quantity is 0, and

positioning is completed.

Time

Accumulated pulses in deviation counter Servo motor

Minus pulses Reverse rotation operation

Plus pulses Forward rotation operation

0 (zero) Stop

3-7

Page 34

Positioning Control Components of Positioning Control and Their Roles 3

3.2.4 Regenerative brake function

• During deceleration, because the servo motor rotates by the load inertia of the drive

mechanism, it functions as a generator and electric power returns to the servo amplifier.

The regenerative resistor absorbs this electric power, and functions as a brake (called a

regenerative brake.)

• The regenerative brake is required to prevent regenerative over voltage in the servo

amplifier when the load inertia is large and th e operat ion is frequently performed.

• The regenerative resistor is required when the regenerative power generation quantity

during deceleration exceeds the allowable regenerative electric power of the servo

amplifier.

3.2.5 Dynamic brake function

• When a circuit inside the servo ampl ifi er is di sabled b y a power int er rupti on in the AC po wer

of the main circuit or actuation of the protective circuit, the terminals of the servo motor are

short-circuited via resistors, the rotation energy is consumed as heat, then the motor

immediately stops without free run.

• When the motor stops by elimination of the rotation energy, the brake is not effective and

the motor runs freely.

Main

circuit

AC power

supply

NFB

Position

controller

rotations of motor

R

Converter

S

AC DC

T

Deviation

counter

Number of

Inverter

DC AC

D/A

conversion

Motor stop characteristics when the

dynamic brake is actuated

When the dynamic brake

is not actuated

U

V

W

These contacts of the

dynamic brake turn ON

when the power is

interrupted.

SM PLG

Power: OFF

Contacts of dynamic brake: ON

Time

3-8

Page 35

Positioning Control Components of Positioning Control and Their Roles 3

3.3 Drive mechanism

The drive mechanism converts the rotation motion of the servo motor into the reciprocating or

vertical motion through a speed reducer, timing belt, ball screw, etc. to move the machine.

3.3.1 Concept of drive system movement quantity

1) Representative positioning system using AC servo motor

*2 In the structure design, parameters (such as ∆ and V

advance.

V

0

Moving part

P

f

Encoder

Servo

motor

N

0

Servo

amplifier

f

0

Position

controller

Speed

reducer

1

n

P

B

: Movement quantity per pulse (mm/pulse)

D

: Moving part speed during quick feed (mm/min)

V

0

: Number of rotations of motor during quick feed (r/min)

N

0

: Lead of ball screw (mm/rev)

P

B

1

: Speed reduction ratio

n

: Feedback pulse number (pulse/rev)

P

f

: Command pulse frequency during quick feed (pulse/s)

f

0

D

S

: Movement quantity per rotation of motor (mm/rev)

) should be determined in

0

a) The servo motor stops with the precision (±∆ ) which is within ±1 pulse against the

command pulse.

b) The movement quantity of the work piece is

"Output pulses from position controller × ∆ ".

The moving part speed is

"Command pulse frequency from position controller × ∆ ".

c) Either "mm", "inch", "degree" or "pulse" can be selected as the positioning command

unit. Accordingly, when data suc h as the movement qu antity per pu lse, posit ioning speed

or the positioning address in accordance with the positioning command unit are set, the

pulse trains calculated inside the positioning controller are output for the target address,

and positioning is performed.

3-9

Page 36

Positioning Control Components of Positioning Control and Their Roles 3

2) Examples of calculation equations

a) Movement quantity per rotation of motor (mm/rev)

Movement

quantity per

Lead of ball screw (mm/rev) Speed reduction ratio=

×

rotation of motor

b) Number of rotations of motor (rev/min.)

(The maximum number of rotations is realized during quick feed.)

Number of

rotations of

motor

Note:The number of rotations of a motor during quick feed should not exceed the rated

number of rotations.

The moving part speed during quick feed should not ex ceed the parameter "speed limiting

value" of the positioning controll e r.

a) Movement quantity per pulse (mm/pulse)

Movement

quantity

per pulse

b) Command pulse frequency during quick feed (pulse/s)

Command

pulse

frequency

during

quick feed

Moving part speed during quick feed (mm/min)

=

Movement quantity per rotation of motor

Movement quantity per rotation of mot or (mm/rev)

=

Feedback pulse number (pulse/rev)

Number of rotations of motor

during quick feed (r/min)

=

60

Movement quantity per

×

rotation of motor (mm/rev)

Movement quantity per pulse

×

(mm/pulse)

Rated number of

<

rotations of

=

servo motor

Electronic

×

gear ratio

Note:The command pulse frequency during quick feed should not exceed the maximum input

pulse frequency of the servo amplifier.

a) Maximum movement distance

In each of the absolute and incremental methods, the entire movement distance should

not exceed the maximum pulse number of the positioning contro ller.

3-10

Page 37

Positioning Control Components of Positioning Control and Their Roles 3

3.3.2 Setting the target position

In positioning control, the target position can be set by the following two methods.

(Available command units are "mm", "inch", "degree" or "pulse".)

1) Absolute method

In this method, a point (absolute address) is specified for positioning while the zero point is

regarded as the reference. The start point is arbitrary.

Address

100

Address 100

Start point

End point

Address 150

Address 300

Address 150

Address 100

Address 150

0

Zero point

100

Point A

150

Point B

300

Point C

2) Incremental method

In this method, positioning is performed through specification of the m ovement direction

and the movement quantity while the current stop position is regarded as the start point.

Movement quantity

0

Zero point

+100

Movement quantity +100

Movement quantity -150

Movement quantity -100

100

Point A

Movement quantity

Movement quantity +100

Movement quantity +50

150

Point B

-100

300

Point C

Start point

End point

3-11

Page 38

Positioning Control Components of Positioning Control and Their Roles 3

3-12

Page 39

Positioning Control Advanced Positioning 4

1 The Wor l d of Positioning Control

2 Positioning by AC Servo Sys tem

3 Components of Positioning Control and Their Roles

4 Advanced Positioning

5 Actual Positioning

6 Product Line up

A Appendix A: Tentative Selection of Motor Capacity

Page 40

Page 41

Positioning Control

4. Advanced Positioning

4.1 Interpolation control

The interpolation function controls two or more axes alternately or simultaneously. Linear

interpolation and circular interpolation are usually offered.

Advanced Positioning 4

< 2-axis linear interpolation >

Y

axis

Start point

< 3-axis linear interpolation >

Z axis

Start point

X axis

Speed change in X axis

Speed

End point

End point

X axis

Y axis

< Linear interpolation >

- Linear interpolation controls two or

more axes so that the start point and

the end point (target position) are

connected in the shortest way.

- In this case, the locus is linear.

- Models applicable to 2-axis linear

interpolation control

[FX-20GM,E-20GM,FX

2N

-20GM

AD75P2/P3,AD75M2/M3,

QD75P2/P4,QD75D2/D4,

A171SH,A172SH,A173UH,A273UH]

- Models applicable to 3 or 4-axis linear

interpolation control

[A171SH,A172SH,A173UH,A273UH]

- Application examples

[Drilling on steel sheet, insertion of

parts into PCB, automatic warehouse,

automatic crane, etc.]

Time

4-1

Page 42

Positioning Control Advanced Positioning 4

< Circular interpolation

when an auxiliary point is specified >

Auxiliary

Y

line

axis

Start point

< Circular interpolation when the radius is specified >

Y

axis

Start point

< Circular interpolation when the center is specified >

Y axis

End point

X axis

End point

Radius

X axis

< Circular interpolation >

- Circular interpolation controls two or

more axes so that the start point and

the end point (target position) are

connected with circular arc.

- As there are innumerable number of

arc locus connecting two points, an

auxiliary point, the arc radius, the

center or the direction should be

specified in addition to the start point

and the end point to determine the

circular arc.

- Models applicable to 2-axis circular

interpolation control

[FX-20GM,E-20GM,FX

2N

-20GM

AD75P2/P3,AD75M2/M3,

QD75P2/P4,QD75D2/D4,

A171SH,A172SH,A173UH,A273UH]

- Models applicable to 3-axis circular

interpolation control

[A171SH,A172SH,A273UH]

Speed

Center

Start point

Speed change in X axis

End point

X axis

- Application examples

[Steel sheet fusing, welder, applicator,

crane, etc.]

Time

4-2

Page 43

Positioning Control Advanced Positioning 4

4.2 Other controls

In some models, controls in accordance with diversified special needs such as speed control,

position follow-up co ntrol and three-dime nsional interpolation c ontrol shown below are

available.

< Speed control >

- After movement starts from the start

point, it then continues at the

Start point

X axis

Speed change in X axis

Speed

specified speed until the stop

command is input.

- Applicable models

[FX-1PG,FX

2N

-1PG

AD75P1/P2/P3,AD75M1/M2/M3,

QD75P1/P2/P3,QD75D1/D2/D3,

A171SH,A172SH,A173UH,A273UH]

- Application examples

[Conveyor, carrier unit, roller feed,

crane, etc.]

Speed

Constant

quantity

Start point

Speed change in X axis

End point

Time

X axis

< Constant feed >

- After start, a workpiece moves by the

specified constant quan tity, but the

current value do es not increase even

if the operation is repeated.

- Applicable models

[FX-10GM,FX-20GM,E-20GM,

2N

FX

-10GM,FX2N-20GM

AD75P1/P2/P3,AD75M1/M2/M3,

A171SH,A172SH,A273UH]

- Application examples

[Press, shear, conveyor, transfer unit,

assembly line, etc.]

Time

4-3

Page 44

Positioning Control Advanced Positioning 4

Y axis

Speed

1000

mm/min

Start point

300

mm/min

5000

mm/min

Speed

changeover point

Speed change in X axis

End

point

X axis

< Speed changeover control >

- From the start point which is the

current stop address, positioning

control is performed to the e nd point

address while the speed changes at

speed changeover points.

- The address for speed change can be

determined in advance.

- Applicable models

2N

[FX

-1PG,FX-10GM,FX-20GM,

E-20GM,FX

2N

-10GM,FX2N-10GM,

AD75P1/P2/P3,AD75M1/M2/M3,

QD75P1/P2/P4,QD75D1/D2/D4,

A171SH,A172SH,A173UH,A273UH]

- Application examples

[Conveyor, carrier unit, roller feed,

crane, etc.]

Y axis

Speed

Passing point

Start point

Radius

Passing point

Speed change in X axis

Time

End

point

X axis

< Constant speed control >

- From the start point which is the

current stop address, positioning

control is performed to the end point

address at an equal speed by way of

passing points.

- Passing points make small circular

arc.

- Applicable models

[AD75P1/P2/P3,AD75M1/M2/M3,

QD75P1/P2/P3,QD75D1/D2/D4,

A171SH,A172SH,A273UH]

- Application examples

[Steel sheet fusing, welder, applicator,

crane, transfer robot, etc.]

Time

4-4

Page 45

Positioning Control Advanced Positioning 4

Y axis

Speed

Change

point

Start

point

Speed change in X axis

Changed

end point

Original

end point

X axis

Time

< Position follow-up control >

- If the end point address is changed

while a positioning control movement

is being executed, positioning is

controlled to the new end point

address.

- Applicable models

[A171SH,A172SH,A273UH]

- Application examples

[Product follow-up type, application

line and welding line]

X axis

Speed

Z axis

Start point

Speed change in the Y axis

Time

End

point

Y axis

< Three-dimensional interpolation control >

- From the start point which is the

current stop address, 3-axis linear

interpolation control and 3-axis

circular interpolation control are

performed to the end point address by

way of passing points.

- Applicable models

[A171SH,A172SH,A273UH]

- Application examples

[Assembly robot, welding robot,

application robot and transfer robot]

4-5

Page 46

Positioning Control Advanced Positioning 4

4-6

Page 47

Positioning Control Actual Positioning 5

1 The Wor l d of Positioning Control

2 Positioning by AC Servo Sys tem

3 Components of Positioning Control and Their Roles

4 Advanced Positioning

5 Actual Positioning

6 Product Line up

A Appendix A: Tentative Selection of Motor Capacity

Page 48

Page 49

Positioning Control

5. Actual Positioning

Terms required for positioning control have been explained in the first three sections.

In this section, let’s experience actual positioning control based on the knowledge you have

learned so far.

2N

The position controller FX

can also be used in place of the FX

5.1 Demonstration Equipment

Two different levels of demonstration equipment can be u sed for this example, depend ing on

what is available. The basic set utilizes the live monitoring function of the FX-PCS-VPS

software, where as, the more comprehensive set makes use of an X Y plotting table, to

actually see the axes move, and draw the resulting locus.

5.1.1 Basic Set

The demonstration items required for the basic set up are as follows;

2N

FX

-20GM

F2-422 CAB0 Communications cable

FX-232AW(C) Converter

FX-232 CAB-1 Communications cable

Personal computer

FX-PCS-VPS\Win software

-20GM is used for the demonstration as show below. An FX-20GM

2N

-20GM.

Actual Positioning 5

MITSUBISHI

AUTO

POWER

MELSECFX2N-10GM

READY

START

ERROR

STOP

CPU-E

ZRN

SVRDY

FWD

SVEND

MANU

RVS

PGO

DOG

FP

LSF

RP

LSR

CLR

X0

X1

X2

X3

Y0

Y1

Y2

Y3

Y4

Y5

PLC EXT

I/O MOTOR

5.1.2 Comprehensive Set

The demonstration items required for the comprehensive setup are as follows;

2N

FX

-20GM

F2-422 CAB0 Communications cable

FX-232AW(C) Converter

FX-232 CAB-1 Communications cable

Personal computer

FX-PCS-VPS\Win software

Plotter Communications cable (*1 Specific to plotter)

X Y Plotting table

MITSUBISHI

AUTO

POWER

MELSECFX2N-10GM

READY

START

ERROR

STOP

CPU-E

ZRN

SVRDY

FWD

SVEND

MANU

RVS

PGO

DOG

FP

LSF

RP

LSR

CLR

X0

X1

X2

X3

Y0

Y1

Y2

Y3

Y4

Y5

PLC EXT

I/O MOTOR

FX-422CAB0 F2-232CAB-1FX-232AW(C)

Plotter

X

Y

FX-422CAB0

F2-232CAB-1FX-232AW(C) Cable *1

5-1

Page 50

Positioning Control Actual Positioning 5

5.2 Operation of the demonstration equipment

Source the required demonstration equipment, and setup as in section 5.1. If a plotter is being

used refer to the operations manual for the particular unit and setup accordingly.

Throughout this example it is assumed that you will have read and understood both the FX

20GM Hardware / Programm ing manual (JY992D77801) and the FX-P CS-VPS/Win-E

softtware manual (JY992D86801) or you will have then close at hand for reference.

2N

For this example we will use the basic setup of Personal computer and FX

Let’s draw the locus shown below dr iven by the X and Y axes simult aneously. The output Y0 is

added to imitate a pen, or other end effector.

-20GM.

2N

-

D

Start point

A

G

C

H

End Point

B

A: Start point, this point can be anywhere.

B: (0,0), Zero point, wait for 2 seconds.

C: (80,100), Output Y0 turns ON, wait for 2 seconds.

D: (110,200).

E: (200,200).

E

F

F: (200,100).

G: (150,100), Output Y0 turns OFF, wait for 2 seconds.

H: (150,70), End point.

A to B - Return to Electrical Zero.

B to C - High speed positioning.

C to D - Linear interpolation.

D to E - High speed positioning.

E to F - Clockwise circular interpolati on.

F to G - High speed positioning.

G to H - High speed positioning.

5-2

Page 51

Positioning Control Actual Positioning 5

5.2.1 Program example

The program below demonstrates basic positioning using the FX

2N

-20GM. As this program is

designed to be used without a mechanical plotter, the electrical zero point is used for

reference.

Many programs can be stored in a GM unit at one

time. This example uses program number 0.

This command is to move from the start point, to

the electrical zero point

Here the program waits for 2 seconds, using a

10ms timer.

This command indicates the rapid command to

position C.

Here Y0 is turned on, to mimic the use of an end

effector tool.

This timer allows a tool to be activate d, or an

operation executed.

This command is the start of a continuous steady

path, first using linear interpolation to position D

To position E, only the X axis need move.

For a smooth arc, circular interpolation is use d.

This example shows the start and end positions

(F), as well as the radius and a speed f.

To position G, only the X axis need move.

Here Y0 is turned off, to mimic the the end of the

end effector use.

Again a timer related to the operation above.

This command rapidly moves only the Y axis a

short distance to position H.

The end of the program, and a wait for the next

start command.

5-3

Page 52

Positioning Control Actual Positioning 5

5.2.2 Writing the program

Using FX-PCS-VPS\Win-E, re-create the flow chart program shown in section 5.2.1.

If assistance is required in the operation of the software, please refer to the Software manual

JY992D86801.

When opening a new file in VPS, choose ‘FX(2N)/E-20GM with simultaneous 2 axis’

The example program is designed to utilize the real time monitor function of VPS software. If a

mechanical plotter is being used substitute the ‘DRV Ret’ command for a ‘DRVZ’, return to

origin command. Be sure to set up the plotter in accordance with the instructions and

guidelines applicable to and supp lied with your specific plotter.

Along with the Flow chart, create a monitoring window similar to the one shown below.

All of the items on the monitoring window can be found under the insert tab on the main menu

at the top of the screen.

Items inserted include:

Current Position

Plotting (double click on plot area to change the scale)

Device Status (Y0)

Manual Operation (Start, Stop, Jog -, Jog +, for both X and Y axes, each inserted separately)

FX-GM Status

Plus, a rectangle from the drawing tool bar, to highlight the Y0 indicator .

5-4

Page 53

Positioning Control Actual Positioning 5

5.2.3 Parameters

In addition to the preparation of a positioning program, diversified parameters should be set in

the FX

2N

-20GM.

In this example, only a few parameters need be set. If a plotting table is used, the parameters

should be set in accordance with its mechanism. The se will depend upon the spe cific plotter

type, and should be found in the documentation provided with the plotter.

Below are the four positioning parameter w indows from VPS, cop y these settings into your

program.

The values for both the X and Y axes are the same for all parameters.

The system of units we will be using is both mechanical and motor, so that the position can be

controlled in mm, deg, 1/10 inch etc. while the speed can be controlled by the number o f

pulses. The system units should be set to ‘mm, and all other options left as default.

So that we can follow the path created by the FX2N-20GM, the Max speed should be set quit e

low. Intern both the JOG speed and the Interpolation value must be reduced. In practice, it is

impossible to have the JOG speed faster than the Max speed setting.

Remember to change the setting for the Y axis also.

5-5

Page 54

Positioning Control Actual Positioning 5

As we will not be connecting any mechanical hardware to the FX2N-20GM, the li mit switch and

DOG switch settings do not require setting. We do how ever need to reduce the Creep speed

and the Zero return speed.

All of the parameter settings o n this screen window can be left as their def ault values, they are

already optimized for our program.

If a plotter table is be ing used, all o f the above p arameters will need to be checke d before

power ON, or operation.

5-6

Page 55

Positioning Control Actual Positioning 5

5.2.4 Operation

Now that your program has been written, check the communication cables between the FX

20GM and PC, then download your program to the FX

2N

-20GM. Make sure that the GM unit is

2N

in ‘MANU’ mode before download, or it will be impossible to communicate.

In VPS, start the Monitor mode by clicking the Monitor icon on the tool bar, shown below.

Monitor icon

The Monitor mode screen will appear. Here, the flow icon menu and program map have been

removed. Three windows are displayed;

2N

Monitoring window: This is the window you c reated, and will use to cont rol t he FX

-20GM and

view the resulting locus.

Sub-task - Monitor mode: This window in not needed as we do not use any sub rout ines in our

programs, it can be minimized to create more space on the screen.

X-axis and Y-axis - Monitor mode - At first this window will be empty, but as soon as you start

your program, the flow chart will appear, and scroll through, keeping the live instruction

highlighted in red.

After minimizing the Sub-task monitor window, resize the Monitoring window and then the Xaxis and Y-axis window.

-

Now you are ready to begin.

Firstly set the start point, thi s can be done be either using the X and Y axis JOG buttons, or by

double clicking on the current position display.

Double clicking the current position display brings

up this window;

For X, replace 0 with 50, and click on the ‘Write to

FX-GM’ button.

For Y, replace 0 with 125, and click on the ‘Write to

FX-GM’ button.

As you write that data to the GM, you will see a

red line being draw n on th e plot in the M onitoring

window. This shows the current position.

We want a clean plot area to begi n with , so double

click on the plotting area, and click on the clear button.

5-7

Page 56

Positioning Control Actual Positioning 5

The next step, it to switch the FX2N-20GM to ‘AUTO’ mode, so that the program can be

executed.

Finally, on the Monitor screen click on either the X or Y axis start buttons. It does not matter

which one, as both will start the program. Sit back and see what you have produced.

Your screen should look similar to the one shown below, the plot should be identical.

To run the program again, set a new start position (or let it start from where it is), clean the plot

area, and press start.

If your plot does not look the same as the one above, check yo ur program against the one in

section 5.2.1.

If it does, now is the time to experiment some more. Try a new program, perhaps include subtasks and multiple flow charts . Only a sample of the functionality available in VPS has be used

in this example program, try using some of the other programming aspects.

5-8

Page 57

Positioning Control Product Line up 6

1 The Wor l d of Positioning Control

2 Positioning by AC Servo Sys tem

3 Components of Positioning Control and Their Roles

4 Advanced Positioning

5 Actual Positioning

6 Product Line up

A Appendix A: Tentative Selection of Motor Capacity

Page 58

Page 59

Positioning Control

6. Product Line up

We are offering diversified position controllers, servo amplifiers and servo motors. You can

select desired units in accordance with your system and application.

For the derails, refer to the catalog of each product.

6.1 Position controller

1) Outline of position controller models

In the position controller, the positioning function is built in or extended. For some position

controllers, an PLC executes positioning programs. Other position contro llers execute

programs using their unique positioning language without regard to any PLC.

Product Line up 6

FX Series

A Series

Q Series

Model name/unit

name

1S

/FX1N Series

FX

PLC

1-axis position

controller FX-10GM

2N

FX

-10GM

2-axis position

controller FX-20GM

2N

FX

-20GM

2-axis position

controller E-20GM

1-axis pulse output

block FX

1- to 3-axis position

controller AD75P1

to AD75P3

1- to 3-axis position

controller AD75M1

to AD75M3

1- to 4-axis position

controller QD75P1

to QD75P4

1- to 4-axis position

controller QD75D1

to QD75D4

2N

-1PG

Positioning

language

FX sequence

language

Dedicated

language

FX sequence

language

A sequence

language

+

Positioning

data

Q sequence

language

+

Positioning

data

Outline

Pulse output type for independent 2 axes

Through application instructions in the PLC main unit,

absolute position detection, return to mechanical zero

point and one-speed constant positioning are

available.

Pulse output type for 1

axis

Pulse output type for 2

axes

Independent 2 axes or

simultaneous 2 axes

(linear interpolation,

circular interpolation)

Pulse output block for FX

Used as an extension block

Pulse output type for 1 to 3 axes

Simultaneous 1 to 3 axes, independent 1 to 3 axes, 2axis linear interpolation, 2-axis circular interpolation

SSC net connection type for 1 to 3 axes

Simultaneous 1 to 3 axes, independent 1 to 3 axes, 2axis linear interpolation, 2-axis circular interpolation

Pulse output type for 1 to 4 axes (open collector

output)

Simultaneous 1 to 4 axes, independent 1 to 4 axes, 2

to 4-axis linear interpolation, 2-axis circular

interpolation

Pulse output type for 1 to 4 axes (differential output)

Simultaneous 1 to 4 axes, independent 1 to 4 axes, 2

to 4-axis linear interpolation, 2-axis circular

interpolation

Easy sequence function is

provided.

Bus connection to FX

Series PLC is available.

(Position controller can be

used independently also. )

Easy sequence function is

provided.

(Position controller can be

used independently also. )

2N

Series PLC

6-1

Page 60

Positioning Control Product Line up 6

Motion

controller

Model name/

unit name

A171SH

A172SH

A173SH

A273UH

Positioning language Outline

Language dedicated to servo system

[4-, 32-axis independent control, 2- to 4axis linear interpolation control, 2-axis circular interpolation control, speed control,

equal speed control, position follow-up

control]

NC language

[Control using G codes]

Dedicated robot

[Three-dimensional linear/circular interpolation control]

Mechanical support language

[Synchronous operation control]

A171UHCPU (512 I/O points):

4-axis control

A172SHCPU (512 I/O points):

8-axis control

A173UHCPU (2,048 I/O

points): 32-axis control

Servo amplifier

(0.05 to 55 kw are dedicated to

SSC net connection.)

A3UCPU (2,048 I/O points):

32-axis control

Servo amplifier

(0.05 to 0.6 kw allow built-in

type also.)

(0.05 to 55 kw are dedicated to

SSC net connection.)

Mechanical support language in motion controller

A new world of synchronous mechanism is open.

Programming in virtual world

By simply connecting and laying out a

transmission module and an output

module to a virtual main shaft on the

screen, while regarding diversified

synchronous mechanism as software

mechanical modules, you can easily

program a synchronous system.

6-2

Page 61

Positioning Control Product Line up 6

1) When and which position controller?

In addition to the PLC series, take into account the following contents to determine the

position controller to be used.

a) Determine the position controller to be used in accordance with the number of controlled

axes (motors).

1-axis control

2-axis control

3-axis control

Control of 4-

axes or more

Position controller dedicated to 1 axis

2N

FX-10GM, FX

-10GM, FX2N-1PG

AD75P1, AD75M1, QD75P1, QD75D1

Only 1 axis of 2-axis position controller

FX-20GM, E-20GM, FX

2N

-20GM, FX1S/FX1N Series PLC

AD75P2, AD75M2, QD75P2, QD75D2

2-axis position controller

2N

FX-20GM, E-20GM, FX

-20GM, FX1S/FX1N Series PLC

AD75P2, AD75M2, QD75P2, QD75D2

3-axis position controller

AD75P3, AD75M3

Combination of 1-axis position controller and 2-axis position controller

For 1-axis control, for 2-axis control

4-axis position controller

QD75P4, QD75D4, A171SH

Position controller for 4 axes or more

A171SH, A172SH, A173UH, A273UH -----

Combination of 1-axis position controller, 2-axis position controller

and 3-axis position controller

for 1-axis control, for 2-axis control, for 3-axis control

6-3

Page 62

Positioning Control Product Line up 6

b) Determine the position controller to be used in accordance with the output pulse

frequency.

However, the pulse frequency actually used inside the servo amplifier can be increased

by electronic gearing.

100kp/sec

200kp/sec

When the required command pulse is 100 kpps or less

2N

FX

-1PG, FX1S/FX1N Series PLC

When the required command pulse is 200 kpps or less

FX-10GM, FX-20GM, E-20GM, FX2N-10GM, FX2N-20GM

400kp/sec

1Mkp/sec

AD75P

When the required command pulse is 400 kpps or less

AD75P

When the required command pulse is 1 Mpps or less

AD75M

, QD75P

, QD75P

, A171SH, A172SH, A173UH, A273UH

c) Determine the position controller to be used in accordance with handli ng of the feedback

pulse.

Position

controller

Command

pulse

To servo amplifier

Servo

amplifier

Servo

motor

SM

The position controller only outputs pulses,

and does not check feedback pulses.

Accordingly, it is not confirmed whether or

not rotation in accordance with command

pulses is actually performed.

Position

controller

SSC net

Feedback

pulse

PLG

Encoder

To position controller

Servo

motor

Servo

amplifier

Feedback

pulse

SM

PLG

Encoder

FX-10GM, FX-20GM, FX

E-20GM, FX

1S

/FX1N Series PLC

FX

AD75P

2N

-10GM, FX2N-20GM,

, QD75P, QD75D

2N

-1PG,

The position controller checks feedback

pulses. Accordingly, it is confirmed whether

or not rotation in accordance with command

pulses is actually performed.

AD75M

, A171SH A172SH,

A173UH, A273UH

6-4

Page 63

Positioning Control Product Line up 6

6.2 Servo amplifier

1) Outline of serve amplifier models

Model name Outline

• DC 24V

• Size is extremely small, and capacity is small.

MR-J2-Jr Series

MR-C Series

MR-J2/J2S Series

MR-H Series

MR-H-ACN Series

• Applicable to 10 to 30 w.

• Used for semiconductor manufacturing unit and small robots.

• Setup so ftware by per s ona l com pute r is availab le.

• General-purpose type optimal to use instead of stepping motor

(dedicated to position control).

• Size is extremely small.

• Applicable to 30 to 400 w.

• Real-time auto tuning eliminates adjustment in setup.

• Inertia is extremely low.

• Speed can increase at constant torque without step out until high

speed area, and operation is smooth even at low speed.

• Setup so ftware by per s ona l com pute r is avai lab le.

• General-purpose type in compact body easy to use.

• Applicable to 50 w to 7 kw. 100 VAC input type is offered as a series.

• Real-time auto tuning eliminates adjustment in setup.

• Convenient test run function and diagnosis function are provided.

• Applicable to low noise operation.

• Setup so ftware by per s ona l com pute r is avai lab le.

• General-purpose type of high performance and high response.

• Applicable to 50 w to 55 kw.

• Real-time auto tuning eliminates adjustment in setup.

• Applicable to low noise operation.

• Interactive parameters facilitate maintenance.

• Setup so ftware by per s ona l com pute r is avai lab le.

• 1-axis positioning function is built in.

• Applicable to 50 w to 55 kw.

• Frequent operation of high precision is available.

• Real-time auto tuning eliminates adjustment in setup.

• Applicable to low noise operation, absolute value and diversified ways

of return to zero point.

6-5

Page 64

Positioning Control Product Line up 6

2) When and which servo amplifier?

In addition to the series, take into account the following contents to determine the servo

amplifier to be used.

a) Determine the servo amplifier to be used in accordance with the ra ted output of the servo

motor.

400w or less

7kw or less

55kw or less

Extremely small capacity type servo amplifier

MR-J2-Jr, MR-C

Small capacity type servo amplifier

MR-J2

Medium or large capacity type servo amplifier

MR-H-