Page 1

MITSUBISHI ELECTRIC AUTOMATION, INC

UNINTERRUPTIBLE POWER SUPPLY SYSTEM

9800A SERIES

OWNERS / TECHNICAL MANUAL

(For parallel operation possible model only.)

MITSUBISHI ELECTRIC 9800A SERIES UPS

Revision 2.01 Feb. 4, 04

ALN-H0776

Page 2

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

i

Preface

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 3

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

TABLE OF CONTENTS

LIST OF TABLES ............................................................................................... iii

LIST OF FIGURES ............................................................................................ iv

HOW TO USE THIS MANUAL ........................................................................... v

1.0 INTRODUCTION ....................................................................................... 1-1

1.1 GENERAL ..................................................................................................1-3

1.2 DEFINITIONS ............................................................................................ 1-4

1.3 OPERATION OVERVIEW ......................................................................... 1-5

1.4 SPECIFICATIONS .................................................................................... 1-12

2.0 OPERATION CONTROLS AND INDICATORS ........................................ 2-1

2.1 LED DISPLAY ........................................................................................... 2-2

ii

2.2 EPO BUTTON ........................................................................................... 2-2

2.3 LIQUID CRYSTAL DISPLAY ..................................................................... 2-3

2.4 EXTERNAL SIGNAL TERMINAL BLOCK ................................................. 2-8

2.5 EXTERNAL COMMUNICATION CONNECTOR ....................................... 2-12

3.0 INSTALLATION AND OPERATION ......................................................... 3-1

3.1 TRANSPORTATION AND INSTALLATION .............................................. 3-1

3.2 INSTALLATION PROCEDURE ................................................................. 3-1

3.3 PROCEDURE FOR CABLE CONNECTIONS ........................................... 3-2

3.4 OPERATING PROCEDURES ................................................................... 3-24

4.0 RESPONSE TO UPS FAILURE ................................................................ 4-1

5.0 PARTS REPLACEMENT .......................................................................... 5-1

6.0 FAULT CODES ......................................................................................... 6-1

7.0 WARRANTY & OUT OF WARRANTY SERVICE ..................................... 7-1

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 4

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

List of Tables

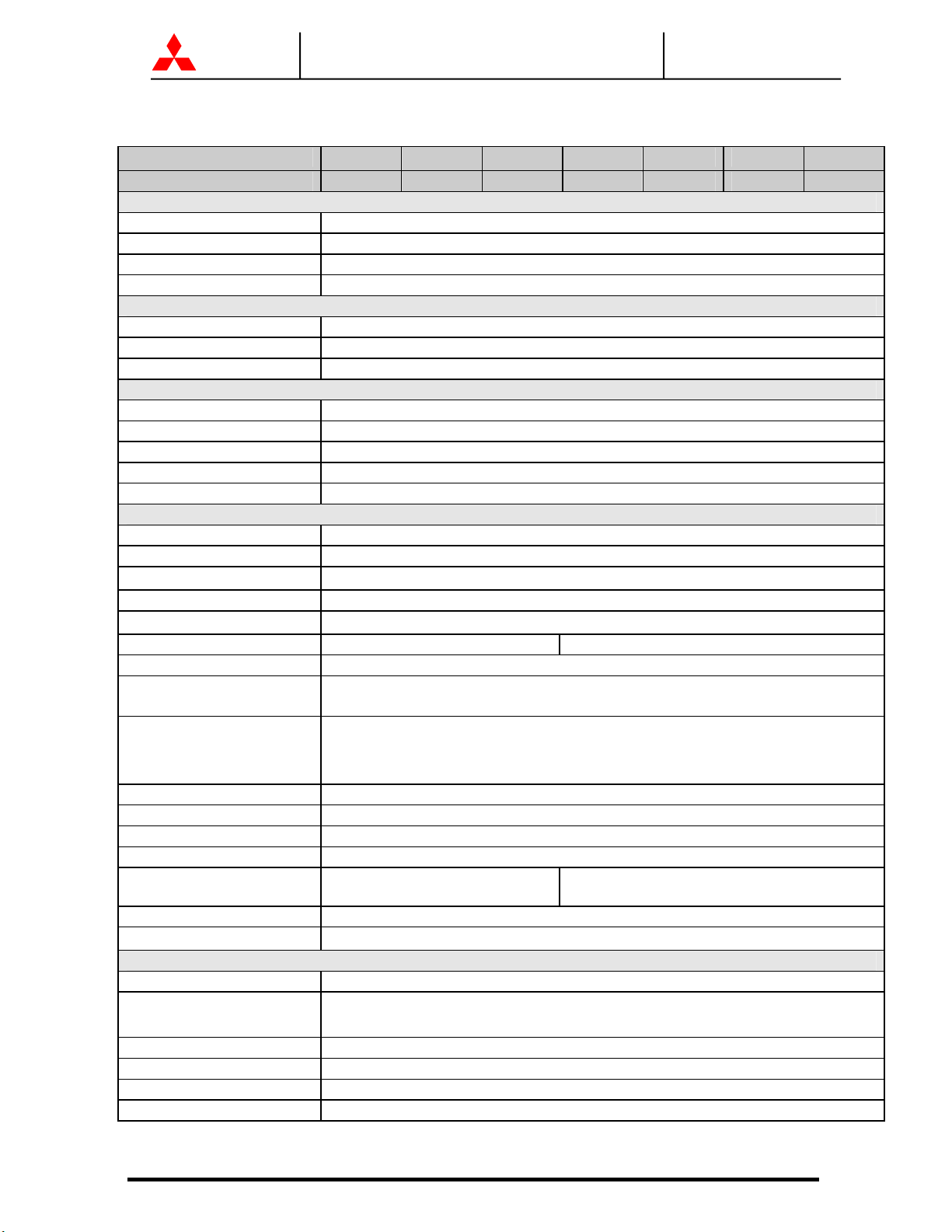

Table 1.1 Power Specifications ................................................................... 1-12

Table 1.2 UPS Module Information.............................................................. 1-12

Table 1.3 Detail of Specifications ................................................................ 1-13

Table 1.4 Rating of Contactor and Fuses .................................................... 1-14

Table 3.1 How to Transport and Install the System..................................... 3-1

Table 3.2 List of UPS Weights (lb.).............................................................. 3-1

Table 3.3 Maximum Permitted Fault Current............................................... 3-2

Table 3.4 Recommended Cable Sizes ........................................................ 3-5

Table 3.5 Crimp Type Compression Lug ..................................................... 3-6

iii

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 5

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

iv

List of Figures

Figure 1.1 Single Line Diagram-Normal Operation .................................................. 1-5

Figure 1.2 Single Line Diagram-Bypass Operation.................................................. 1-6

Figure 1.3 Single Line Diagram-Battery Operation .................................................. 1-7

Figure 1.4 UPS Parts Location ................................................................................ 1-8

Figure 1.5 UPS Parts Location (Continued)............................................................. 1-10

Figure 1.6 External I/F circuit PCB IOAU-04 .......................................................... 1-10

Figure 2.1 Operation/Display Panel ......................................................................... 2-1

Figure 2.2 Main Screen ........................................................................................... 2-3

Figure 2.3 Start/Stop Screen ................................................................................... 2-4

Figure 2.4 PIN Protection Screen ............................................................................ 2-4

Figure 2.5 Bypass Voltage Abnormal Message Screen........................................... 2-4

Figure 2.6 Measurement Screen ............................................................................. 2-4

Figure 2.7 Setup Screen.......................................................................................... 2-5

Figure 2.8 Log Select Screen .................................................................................. 2-5

Figure 2.9 Event Log Screen ................................................................................... 2-5

Figure 2.10 Battery Log Screen ............................................................................... 2-6

Figure 2.11 Main Screen (Battery Operation) .......................................................... 2-6

Figure 2.12 Measurement Screen (Battery Operation) .............................................. 2-6

Figure 2.13 Main Screen (Fault Indication) .............................................................. 2-7

Figure 2.14 Message Screen ................................................................................... 2-7

Figure 2.15 External Signal Terminal Block............................................................... 2-8

Figure 2.16 Control Wiring for External Contacts ...................................................... 2-10

Figure 2.17 Remote "Start" Contact Connections...................................................... 2-11

Figure 2.18 External communication connector......................................................... 2-12

Figure 3.1 UPS Terminal Designation .................................................................... 3-6

Figure 3.2 Diagram of input/output bus bars and terminal blocks .......................... 3-7

Figure 3.3 Diagram of Rectifier Cabinet & Inverter Cabinet Inter-connect ............. 3-19

Figure 3.4 Diagram of Power and Control Wire Connect (Parallel Connection) ...... 3-21

Figure 3.5 Operation Procedures: Start Up/Shut Down Procedure.......................... 3-24

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 6

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

v

How to use this Manual

This manual is designed for ease of use, giving the user easy and quick reference to

information.

This manual uses notice icons to draw attention to the user important information regarding the

safe operation and installation of the UPS. The notice icons used in this manual are explained

below, and should be taken into account and adhered to whenever they appear in the text of

this manual.

Warning: A warning notice icon conveys information provided to protect

the user and service personnel against hazards and/or possible equipment

damage.

Caution: A caution notice icon conveys information provided to protect

the user and service personnel against possible equipment damage.

Note: A Note notice icon indicates when the user should make a reference of

information regarding the UPS operation, load status and display status.

Such information is essential if Mitsubishi field service group assistance and

correspondence is required.

Safety Recommendations: If any problems are encountered while following this manual,

Mitsubishi field service group assistance and correspondence is recommended.

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 7

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

1-1

1.0 INTRODUCTION

Your Mitsubishi Uninterruptible Power System (UPS) is designed to provide many years of

reliable protection from power failure, brown-outs, line noise, and voltage transients. To ensure

optimum performance of the equipment, follow the manufacturer's instructions. This manual

contains descriptions required to operate the UPS. Please read this manual carefully and retain

it for future reference.

IMPORTANT SAFETY INSTRUCTIONS

RETAIN THESE INSTRUCTIONS

This manual contains important instructions for the 9800A SERIES Uninterruptible Power

Supply Systems that should be followed during installation and maintenance of the UPS and

batteries.

WARNING 1

Lethal voltages exist within the equipment during operation. Observe all

warning and cautions in this manual. Failure to comply may result in

serious injury or death. Obtain qualified service for this equipment as

instructed.

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 8

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

1-2

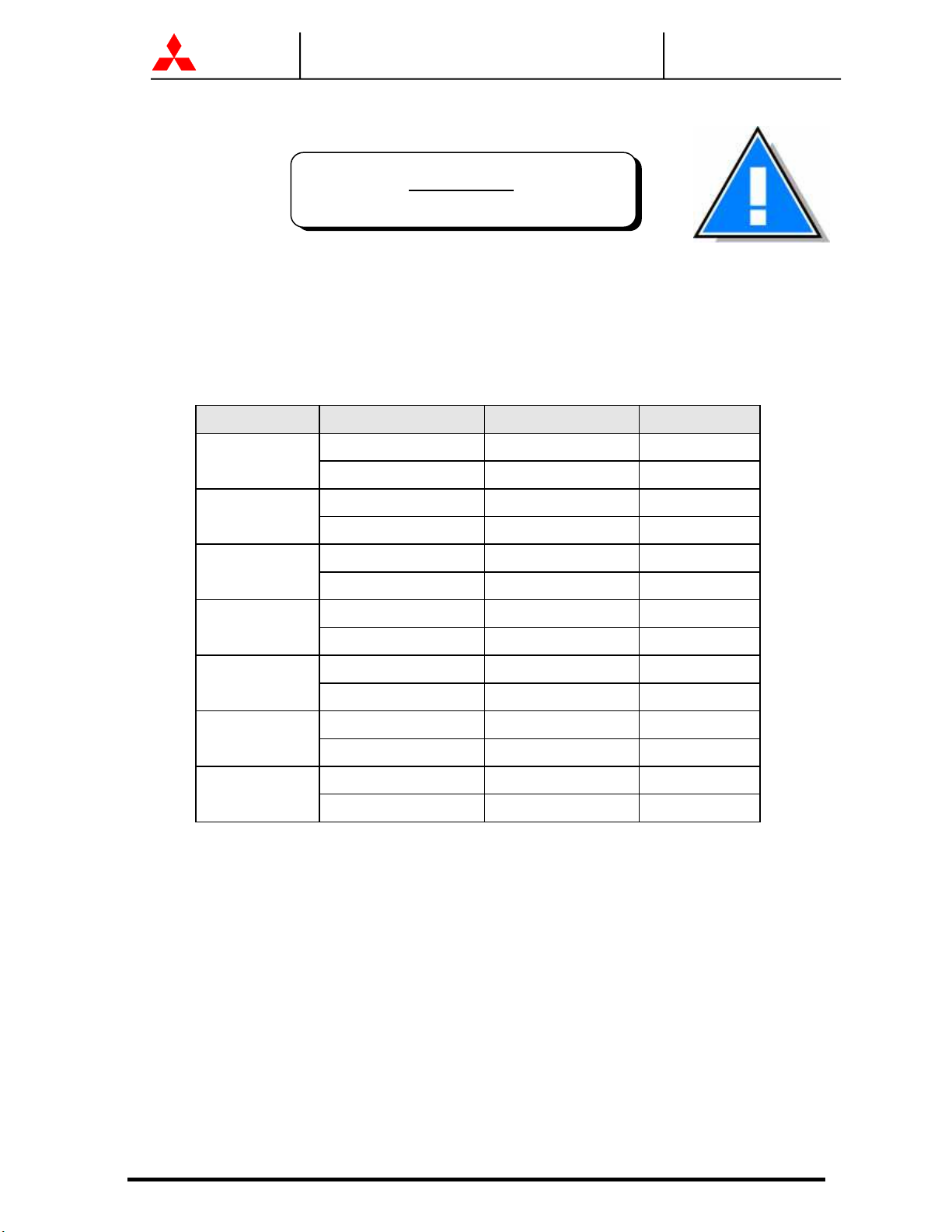

WARNING 2

This UPS does not include a Bypass input circuit breaker (MCCB) to

protect bypass circuit. The Bypass input circuit breaker (MCCB) is to be

field supplied and installed. Recommended Breaker (MCCB)'s

Specifications are as follows:

Capacity (kVA) Bypass Voltage (Vac) Bypass Rating (Aac) Breaker (A)

100 480 120 150

600 96 125

150 480 180 225

600 144 200

225 480 271 350

600 217 275

300 480 361 500

600 289 400

375 480 451 600

600 361 500

500 480 601 800

600 481 600

750 480 902 1200

600 722 900

AC input and AC output overcurrent protection and disconnect devices shall be field

supplied and installed. The DC output MCCB shall be field supplied and installed. The

overcurrent protection device should be installed in the Battery cabinet and rated as

indicated in TABLE 1.4.

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 9

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

1-3

1.1 GENERAL

The Mitsubishi 9800A SERIES UPS is designed to provide continuous and clean electrical

power to a critical load. Additionally the UPS monitors power conditions affecting the load.

In the event of an input power failure, the UPS will supply power to the critical load for the

specified battery time.

If the input power is not restored promptly, back up power from the UPS battery permits

the orderly shutdown of equipment supported by the UPS. The UPS is simple to start-up,

operate and maintain.

The 9800A SERIES UPS is available in seven kVA sizes-100, 150, 225, 300, 375, 500 and

750kVA. Specifications for each kVA model appear in Section 1.4. The principles of

operation described herein are applicable to all models.

This manual provides an overview of the 9800A SERIES components and their functions.

The appearance and purpose of operator controls and indicators is described with

procedures for operation, start-up, shutdown and basic maintenance included.

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 10

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

1-4

1.2 Definitions

UNINTERRUPTIBLE POWER SUPPLY SYSTEM (UPS) - All components within the UPS

Module Cabinet and associated batteries that function as a system to provide continuous,

conditioned AC power to a load. This is sometimes referred to as the "System".

UPS MODULE CABINET - The metal enclosure which contains the Rectifier, the Inverter,

the Chopper, the Static Transfer Switch, the Internal Bypass line, the operator controls,

and the internal control system required to provide specified AC power to a load.

UPS MODULE - The Rectifier and Inverter assemblies which, under the direction of the

internal control system and operator controls, provide specified AC power to a load.

RECTIFIER - The UPS components which contain the equipment and controls necessary

to convert input AC power to regulated DC power required for battery charging and for

supplying power to the Inverter.

INVERTER - The UPS components which contain the equipment and controls necessary

to convert DC power from the Rectifier, or the battery, to AC power required by the critical

load.

CHOPPER - The UPS components which contain the equipment and controls necessary

to charge the battery and supply power to the Inverter from battery.

STATIC TRANSFER SWITCH - The device which connects the critical load to the bypass

line when the UPS module cannot supply continuous power.

BYPASS LINE - The line which conducts electricity directly from the input power source to the

critical load during Maintenance or whenever the UPS is not completely operational.

INPUT POWER - Power provided by the electrical utility company, or auxiliary generator,

which is connected to the UPS for supplying the critical load.

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 11

put

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

1-5

1.3 Overview

The UPS provides two power paths between the utility source and the critical load.

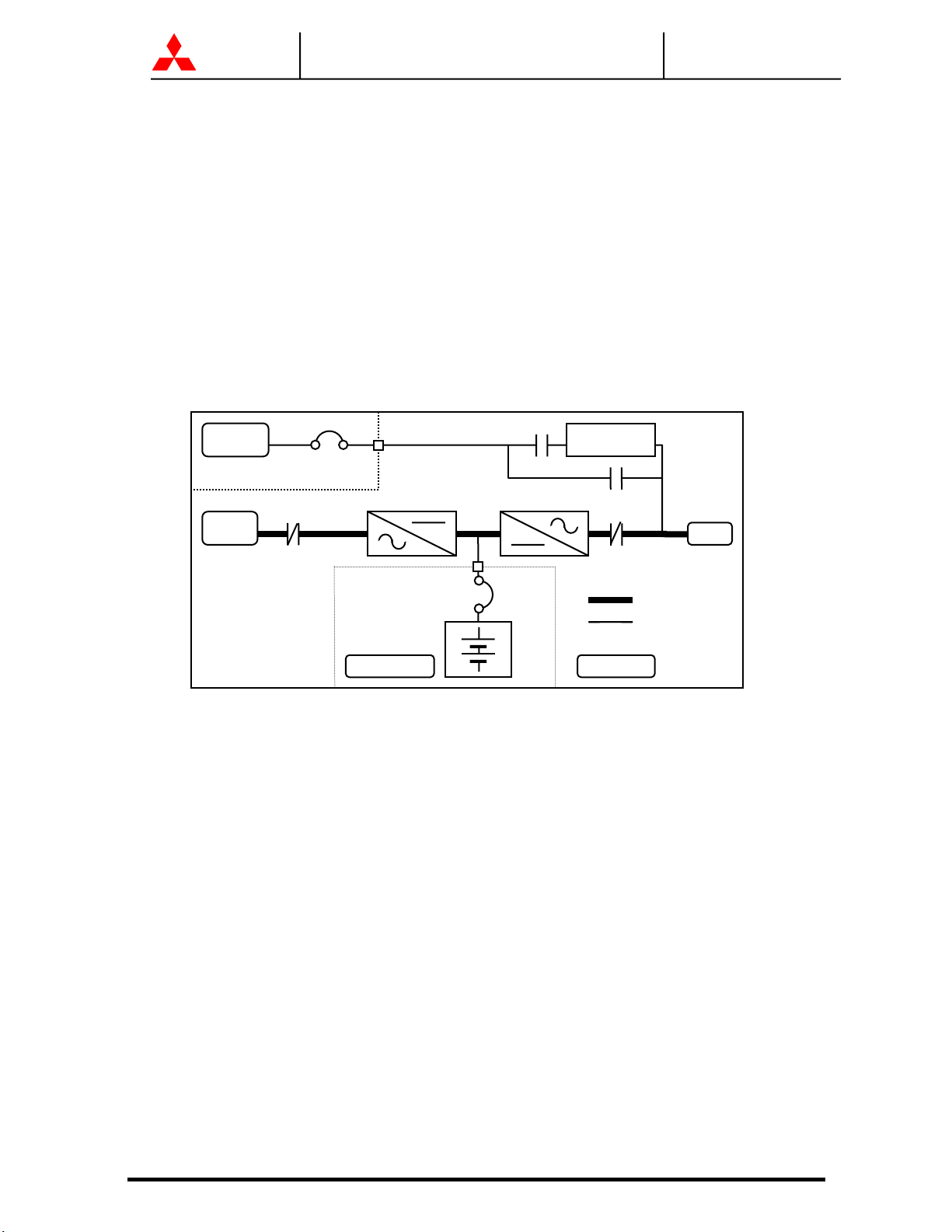

Figure 1.1 shows the path for normal operation, with the load powered from the inverter.

Figure 1.2 shows the path for bypass operation, with the load supplied through the static

bypass line.

A) Normal operation: Load power supplied by each system UPS inverter.

Figure 1.1 Single Line Diagram - Normal Operation: Load powered by UPS inverters

AC Bypass

In

AC input

CB

User supplied

MCCB

CB1

RECTIFIER

CB3

INVERTER

Static Transfer

Switch

52S

Output

52C

CB2

Power Flow

Not in Use

UPS ModuleBattery cabinet

During normal operation, the path through the UPS inverters is used to power the load.

Referring to Figure 1.1: For each system UPS, the Input AC power is converted to DC by

the Rectifier. DC power is utilized to charge the UPS battery and to provide power to the

Inverter. The Inverter converts the DC power to clean AC power to supply the critical load.

The conversion - inversion process eliminates any voltage transients or fluctuations

existing in the input power before it reaches the critical load.

The power drawn by the critical load is equally shared between all system UPS.

In the event of a UPS module failure, the critical load power will be continually supplied

and shared by all other system UPS.

In the event of a load overcurrent, all system UPS will transfer to bypass without

interruption to the critical load.

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 12

put

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

1-6

The Bypass Input circuit breaker (MCCB) for protection of the UPS and cables are field

supplied and field installed. (See WARNING 2 on page 1-2)

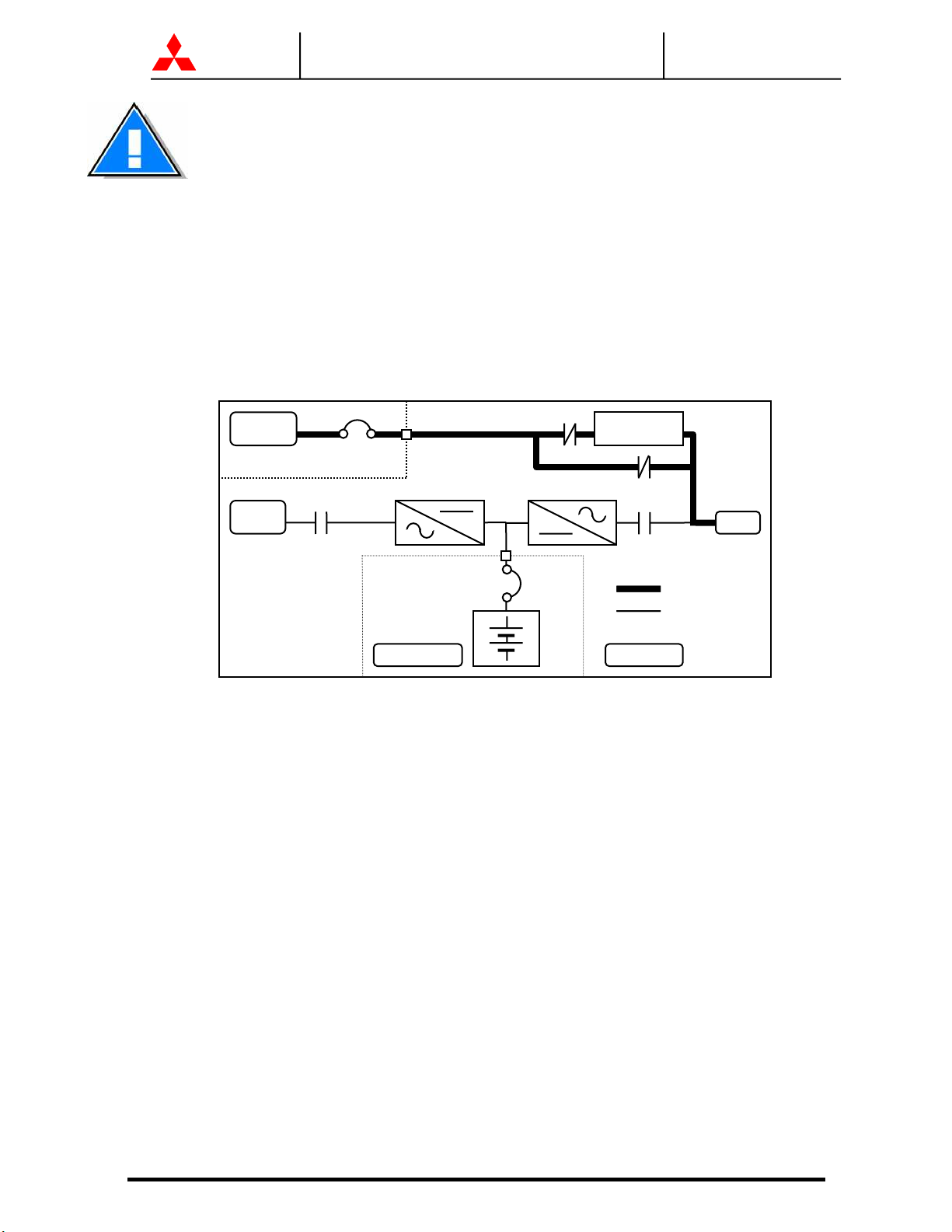

B) Bypass Operation: Load Power supplied through each system UPS internal static

bypass line.

FIGURE 1.2 Single Line Diagram - Bypass Operation: Load fed through Internal static

bypass line.

AC Bypass

In

AC input

CB

User supplied

MCCB

CB1

Static Transfer

Switch

CB3

RECTIFIER

INVERTER

CB2

52S

Output

52C

Power Flow

Not in Use

UPS Module Battery cabinet

Referring to Figure 1.2: The Internal Static Bypass line is a Hard wired line through CB3

and contactor 52S which supplies the critical load with unconditioned input power.

Each system UPS internal static bypass line will equally share the power supplied to the

critical load.

The internal static bypass line will route power to the critical load while the UPS module is

de-energized during Start-up and before the system is fully operational.

Bypass operation will occur In the event of a load overcurrent, with all system UPS

transferring to bypass without interruption to the critical load.

The internal control system determines the operation of the two paths, with the load

powered from the inverter being the normal operation.

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 13

put

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

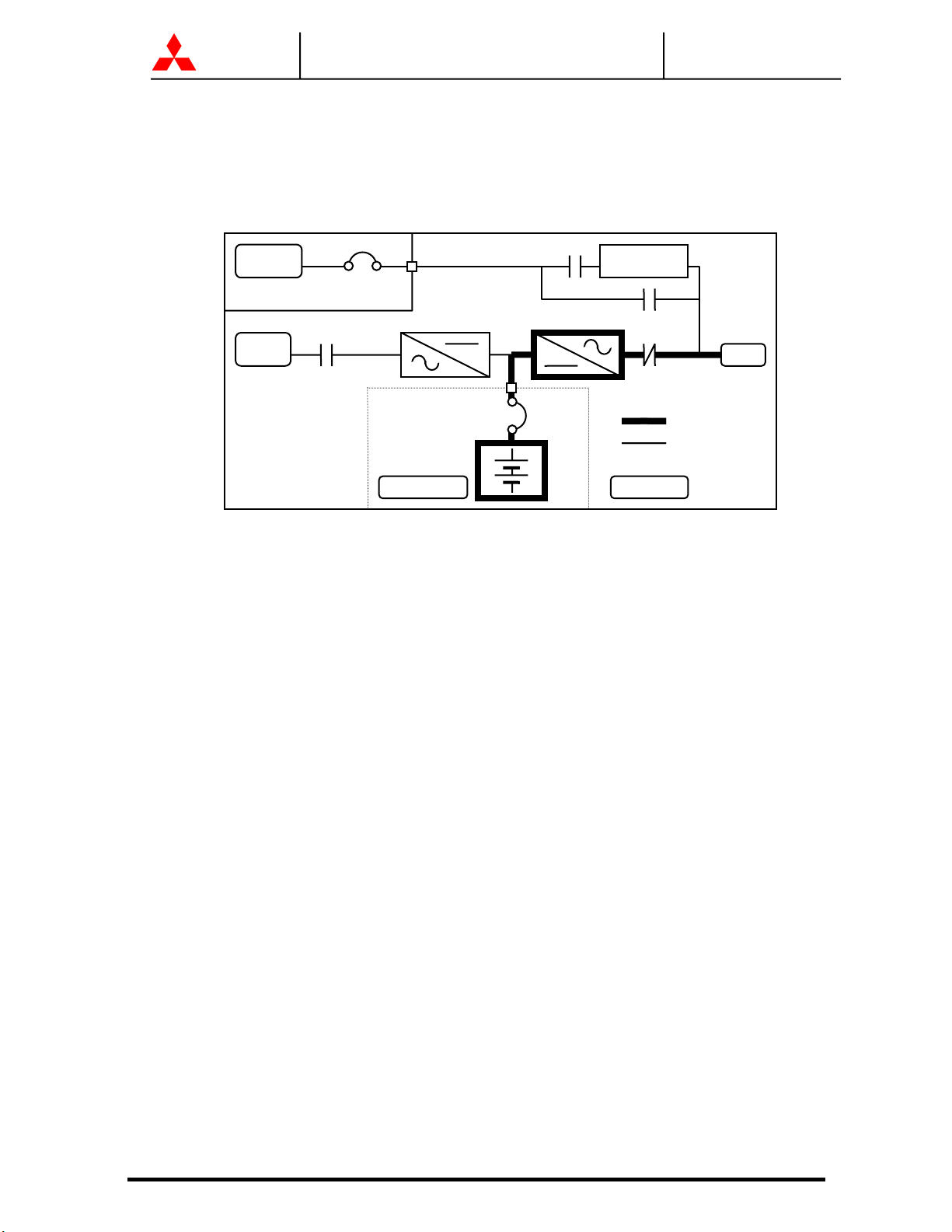

C) Battery operation: Load Power supplied by each system UPS battery and inverter.

FIGURE 1.3 Single Line Diagram - Battery Operation

1-7

AC Bypass

In

AC input

CB

User supplied

MCCB

CB1

Static Transfer

Switch

CB3

RECTIFIER INVERTER

CB2

52S

Output

52C

Power Flow

Not in Use

UPS Module Battery cabinet

Referring to Figure 1.3: In the event of AC input source failure or interruption, each

system UPS rectifier will de-energize and each UPS battery will immediately discharge

and supply DC power to the Inverter to maintain continuous AC power to the load. This

operation will continue until:

a) The battery capacity expires and the inverter turns off, or

b) Input power is restored after which the rectifier will power the inverter and critical load

and simultaneously recharge the batteries.

A fully charged battery will provide power for the specified time at the rated load, or longer,

at a reduced load.

When power is restored after a low battery shutdown, each system UPS Rectifier

automatically restarts operation, recharges the batteries and the Inverter is automatically

restarted without operator intervention. Load is automatically assumed by the inverter

without operator intervention.

The power drawn by the load is equally shared between all system UPS during battery

operation.

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 14

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

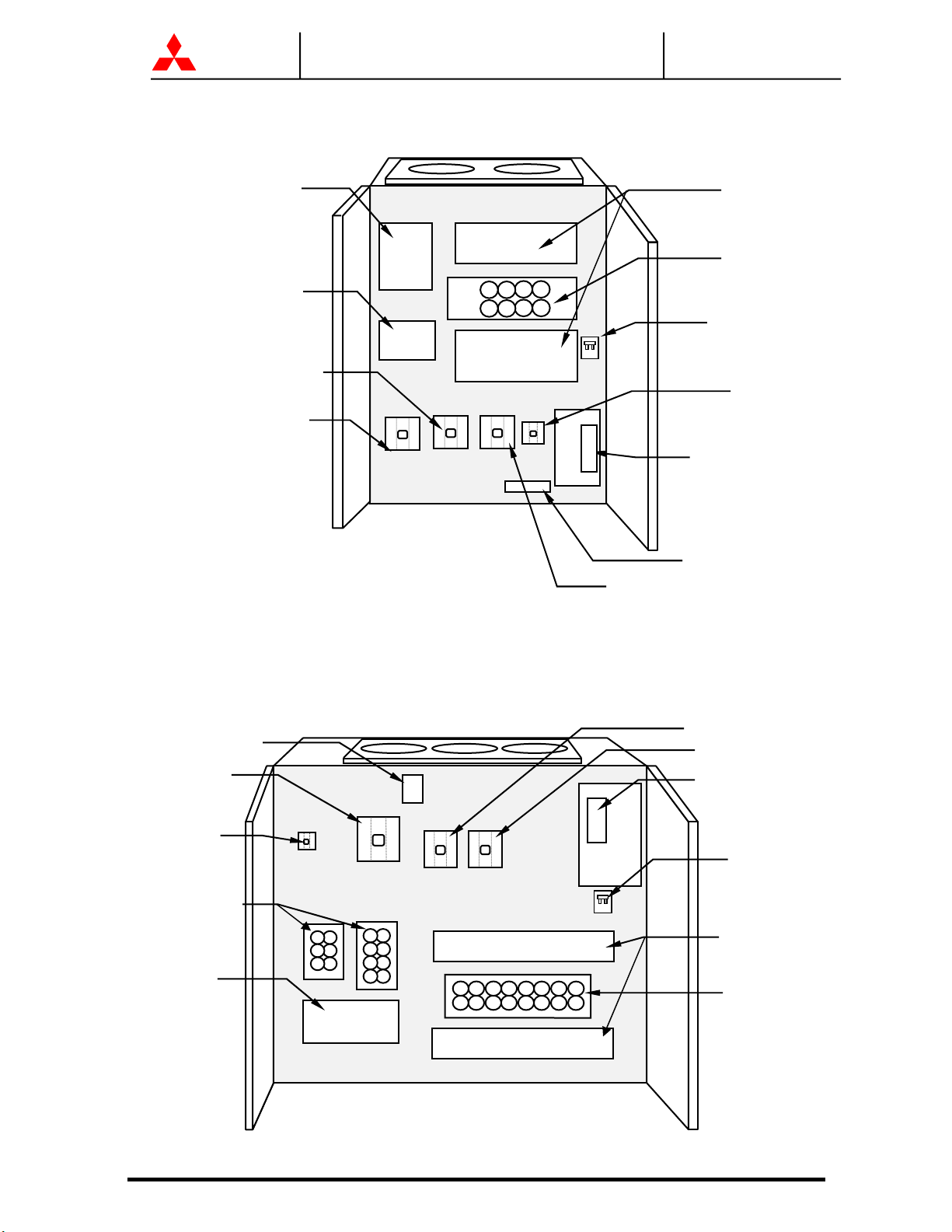

FIGURE 1.4-a UPS Parts Location (100kVA, 150kVA, 225kVA)

Page Number:

1-8

AC capacitors

UPS module

FRONT VIEW

Inverter

Chopper

unit

DC

Rectifier unit

capacitors

1. CPM

52S

CB3

CB1

2. External I/F

circuit PCB

IOAU-04

52C

3. Grounding Bar

FIGURE 1.4-b UPS Parts Location (300kVA,375kVA)

3. Grounding

UPS module

FRONT VIEW

Bar

CB1

CB3

AC capacitors

Rectifier

unit

52S

52C

2. External I/F

circuit PCB

IOAU-04

1.CPM

Inverter

Chopper

unit

DC

capacitors

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 15

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

FIGURE 1.4-c UPS Parts Location (500kVA)

Page Number:

1-9

4. Grounding Bar

CB1

Rectifier

unit

AC capacitors

1.CPM

UPS module

FRONT VIEW

2. External I/F circuit PCB

IOAU-04

52S

AC capacitors

52C

CB3

Capacitors

DC

Inverter

Chopper

unit

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 16

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

FIGURE 1.4-d UPS Parts Location (750kVA)

Page Number:

1-10

5. Grounding Bar

52S

CB1

1.CPM

CB3

AC capacitors

UPS module

FRONT VIEW

3. External I/F circuit PCB

IOAU-04

AC capacitors

52C

Rectifier

unit

DC

Capacitors

Inverter

Chopper

unit

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 17

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

FIGURE 1.5 UPS Parts Location (Continued)

UPS module

REAR OF FRONT DOOR (Right side)

6

INVERTER

START

|

SYNC.LED

INVERTER

STOP

Page Number:

1-11

7

|

FIGURE 1.6 External I/F circuit PCB IOAU-04

|

FAULT

RESET

8

|

MAINTENANCE

SWITCH

9

|

TEST

SWITCH

10

4. External contact signal terminal

|

BOOT

SWITCH

11

IOAU-04

5. RS232C D-sub connector

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 18

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

1-12

Description of Figures 1.4, 1.5, and 1.6:

1. CPM - Circuit protector for control power supply.

2. Switches on IFGR-G board : FOR SERVICE PERSONNEL ONLY (FIGURE 1.6):

- (4) External contact signal terminal

- (5) RS232C communication connector

3. Grounding bar (G)

4. External contact signal terminal block - Terminal block to connect contact signal

input/output lines to and from the external devices. Refer to Figure 2.15 section 2.4 for

details.

5. RS232C communication connector - Refer to Figure 2.18 section 2.5 for details.

6. Inverter start switch - This switch is used to transfer the UPS from static bypass to

inverter during maintenance purposes. Transfers will lock-out if the bypass voltage is

more than +12%,-12% of nominal.

* Uninterrupted switching is made at the time of synchronous operation. Switching is impossible at

the time of asynchronous operation.

7. “INVERTER STOP” switch - This switch is used to transfer the UPS from inverter to

static bypass during maintenance purposes. Do not operate it under normal operation.

Transfers will lock-out if the bypass voltage is more than +12%,-12% of nominal.

* Uninterrupted switching is made at the time of synchronous operation. Switching is impossible at

the time of asynchronous operation.

8. “FAULT RESET” switch (FOR SERVICE PERSONNEL ONLY) - This switch resets errors

resulting from alarm conditions. (Do not operate this switch while inverter and converter are

in operation.)

9. Maintenance (Set) button (FOR SERVICE PERSONNEL ONLY) - This switch sets the

UPS menu parameters.

10. “Test mode” switch (FOR SERVICE PERSONNEL ONLY) - This switch changes system

operation to the test-mode. (This switch should not be operated by personnel other than

an Authorized Service Engineer).

11. “BOOT” switch (FOR SERVICE PERSONNEL ONLY) - This switch boots the processor

in the main control circuit resulting from alarm conditions. (Do not operate this switch

while inverter and converter are in operation).

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 19

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

1-13

1.4 Specifications

The UPS name plate displays the rated kVA as well as nominal voltages and currents. The

name plate is located on the inside of the UPS front door.

TABLE 1.1 Power Specifications

Rated output

Power

100kVA / 80kW

150kVA / 120kW

225kVA / 180kW

300kVA / 270kW

375kVA / 338kW

500kVA / 450kW

750kVA / 675kW

Input voltage

3 phase / 3 wire

480V

480V

480V

480V

480V

480V

480V

Bypass input voltage

3 phase / 4 wire

480V or 600V

480V or 600V

480V or 600V

480V or 600V

480V or 600V

480V or 600V

480V or 600V

Output voltage

3 phase / 3 or 4 wire

480V or 600V

480V or 600V

480V or 600V

480V or 600V

480V or 600V

480V or 600V

480V or 600V

TABLE 1.2 UPS Module Information

UPS

[kVA]

CABLE

ENTRY

WIDTH

[in / mm]

DEPTH

[in / mm]

HEIGHT

[in / mm]

WEIGHT

[lb./ kg]

HEATING

[kBTU/h]

100 BOTTOM 43.3 / 1100 29.8 / 758 79.7 / 2025 2100 / 950 22.0

150 BOTTOM 47.2 / 1200 29.8 / 758 79.7 / 2025 2820 / 1275 33.0

225 BOTTOM 55.1 / 1400 29.8 / 758 79.7 / 2025 3310 / 1500 45.0

300 TOP 76.8 / 1950 37.7 / 958 79.7 / 2025 4990 / 2260 68.0

375 TOP 76.8 / 1950 37.7 / 958 79.7 / 2025 5250 / 2380 84.0

500 TOP 114.2 / 2900 37.7 / 958 79.7 / 2025 6930 / 3140 98.0

750 TOP 129.9 / 3300 49.5 / 1258 79.7 / 2025 9655 / 4380 136.1

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 20

TABLE 1.3 Detail of Specifications

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

1-14

Rated Output kVA 100 150 225 300 375 500 750

Rated Output kW 80 120 180 270 338 450 675

AC INPUT

Configuration 3 phase, 3 wire

Voltage 277/480 V, 346/600 V +15% to -15%

Frequency 60 Hz +/-5%

Reflected Current THD 6% max. at 100% load; 9% max. at 50% load

STATIC BYPASS INPUT

Configuration 3 phase, 4 wire

Voltage 277/480 V, 346/600 V +/-10%

Frequency 60 Hz

BATTERY

Type Lead Acid

Ride Through Application Specific

Nominal Voltage 480 Vdc

Minimum Voltage 400 Vdc

Number of Cells 240

AC OUTPUT

Configuration 3 phase, 4 wire

Voltage 277/480 V, 346/600 V

Voltage Stability

+/-1%

Frequency 60 Hz

Frequency Stability

+/-0.05% in free running mode

Power Factor 0.8 nominal 0.9 nominal

Power Factor range 0.8 to 1.0 lagging (within output kW rating)

Voltage THD 2% maximum THD at 100% Linear Load

5% maximum THD at 100% non-linear load

Transient Response

+/-2% maximum at 100% load step

+/-1% maximum at loss/return of AC power

+/-5% maximum at load transfer to/from static bypass

Transient Recovery Less than 20ms

Voltage Unbalance 1% maximum at 100% unbalanced load

Phase Displacement 1deg. maximum at 100% load

Inverter Overload 125% for 10 minutes; 150% for 1 minute

System Overload 1000% for 1 cycle

(with bypass available)

500% for 1 cycle

(with bypass available)

Bypass Overload 125% for 10 minutes

Withstand Rating 65kA* * : with optional fuse

ENVIRONMENTAL

Cooling Forced Air

Operating Temperature

32゚F to 104゚F ( 0゚C to 40゚C).

Recommended : 68゚F to 86゚F ( 20゚C to 30゚C)

Relative Humidity 5% ~ 95% Non Condensing

Altitude 0 to 9000 feet No Derating

Location Indoor (free from corrosive gases and dust)

Paint Color Munsell 5Y7/1 (Beige)

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 21

MITSUBISHI

ELECTRIC

TABLE 1.4 Rating of Contactors and Fuses

9800A SERIES UPS

OWNERS / TECHNICAL MANUAL

Page Number:

1-15

NUMBER APPLICATION

100kVA 150kVA 225kVA 300kVA 375kVA 500kVA 750kVA

480V 600V 480V 600V 480V 600V 480V 600V 480V 600V 480V 600V 480V 600V

F

U

S

E

S

CB1 AC input contactor 135A 200A 350A 450A 660A 660A 910A

CB2 Battery disconnect

breaker

CB3 STS contactor 135A 260A

52C Inverter output

contactor

52S Bypass contactor 135A 200A 350A 450A 450A 660A 910A

88RC Control circuit contactor 90A

FCU, FCV, FCW AC input fuse 200A/660V 250A/660V 315A/660V

FIU, FIV, Inverter output fuse 250A/660V 200A/660V 315A/660V 315A/660V 315A/660V 315A/660V 315A/660V

FUA, FUB, FUC Control power fuse 30A/600V

(OPTION)

FSU, FSV, FSW

FZS1, 2, 3 Bypass input ZNR fuse 16A/500V

FBS1, 2, 3 Control power fuse 10A/600V

FZR1, 2, 3 AC input ZNR fuse 16A/500V

FPU, FPV, FPW Parallel control

Bypass input fuse 200A/

circuit fuse

400A 600A 800A 1200A 1600A (MEAU) (MEAU)

135A 200A 350A 450A 450A 660A 910A

660V

- 315A/

660V

- 250A/

OUTPUT CAPACITY OF EQUIPMENT

660V

- 250A/

660V

10A/600V

- 315A/

660V

- 315A/

660V

*Rating would be changed.

315A/

660V

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 22

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

2.0 OPERATOR CONTROLS AND INDICATORS

The 9800A Series operator controls and indicators are located as follows:

Circuit breakers and contactors: Inside the module

UPS status indicators: Outside of front door

FIGURE 2.1 Operation/Display Panel (Front panel)

3

2

1

LOAD ON

INVERTER

BATTERY

OP.

LOAD ON

BYPASS

LCD

FAULT

UPS

FAULT

Page Number:

2-1

4

5

6

7

EMRG.STOP

540V

8

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 23

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

2.1 LED Display

1) Load on inverter [ LOAD ON INVERTER ](green)

Illuminates when power is supplied from inverter to the critical load.

(Indicates the state of inverter transfer switch "52C".)

2) Battery operation [ BATTERY OP. ](yellow)

Illuminates when power is supplied from batteries following a power failure.

3) Load on bypass [ LOAD ON BYPASS ](green)

Illuminates when power is supplied to load devices by static bypass.

(Indicates the state of bypass transfer switch "52S".)

4) Overload [ OVERLOAD ](red)

Illuminates in overload condition.

5) LCD fault [ LCD FAULT ](red)

Illuminates when an error occurs.

Page Number:

2-2

6) UPS fault [ UPS FAULT ](red) [Annunciator: intermittent or constant tones]

Illuminates when an error occurs in the system. In this case, the details of the error are

indicated on the display panel.

2.2 EPO button (Emergency Power Off button) (7)

When activated, the Emergency Power Off (EPO) function shuts down the UPS module.

The critical load will lose power and also shutdown. The EPO function can be performed

both locally or remotely.

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 24

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

2-3

2.3 Liquid Crystal Display (8)

The Liquid Crystal Display (LCD) panel indicates power flow, measured values,

operational guidance, data records and error messages. The LCD panel has a back-light

which facilitates viewing in different ambient lighting conditions. The LCD will automatically

clear and turn off, if the screen is not activated within 3 minute period. The LCD is turned

back on when it is touched again. The ERROR indicator is cleared after 24 hours and can

be reproduced by pressing any key on the panel.

2.3.1 Menu

A) MAIN MENU (FIGURE 2.2)

The LCD panel indicates power flow and measured values, while also operating the

start/stop function. The LCD panel also allows the user to verify the status and operation

of the UPS Module.

FIGURE 2.2 Main screen

540V

The following will be displayed when the START/STOP key on the LCD panel is

pressed:

1) Start/Stop screen (FIGURE 2.3)

The display indicates the start and stop operations for the UPS system. If this

operation is PIN protected, the user is required to enter the security PIN before the

screen can be accessed. Refer to (FIGURE 2.4).

When in remote mode, the message “REMOTE operating model” will appear on this

Screen. The user cannot operate the start and stop functions without changing the

setup from remote mode to local mode.

When bypass voltage is abnormal, the message “Bypass voltage abnormal” will appear.

-Start: When the bypass voltage is abnormal, the LCD asks the operator if an

interrupted transfer is acceptable (Load may be lost). (FIGURE 2.5)

-Stop: When the bypass voltage is abnormal, the user cannot transfer from inverter

to bypass line.

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 25

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

2-4

FIGURE 2.3 Start/Stop screen

FIGURE 2.4 PIN protection screen FIGURE 2.5 Bypass voltage abnormal

message screen

B) MEASUREMENT MENU (FIGURE 2.6)

This screen shows details of measured values. Bypass voltage, input voltage, output

line to line voltage and output frequency are displayed. Output currents are displayed as

RMS values.

FIGURE 2.6 Measurement screen

540V

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 26

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

2-5

C) SETUP MENU (FIGURE 2.7)

This screen prompts the user to select: (a) whether the start & stop operation will be

performed by local or remote operation; (b) date & time adjustment; (c) battery

equalizing charge. The battery equalizing charge operation key will appear when battery

equalizing charge is set up (Setup is based on battery type).

FIGURE 2.7 Setup screen

D) LOG MENU (FIGURE 2.8)

This menu shows operation / failure and battery discharge records.

FIGURE 2.8 Log select screen

1.) Event log (FIGURE 2.9)

Operation and failure records are indicated. Maximum of 50 events are displayed.

FIGURE 2.9 Event log screen

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 27

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

2.) Battery log (FIGURE 2.10)

This screen displays the cumulative battery discharging record.

FIGURE 2.10 Battery log screen

2.3.2 INPUT POWER FAILURE

During an Input Power Failure, the UPS inverter will be powered by the UPS batteries.

9800A SERIES UPS

Page Number:

2-6

The following will be displayed on the main and measurement screen (Indication of

battery operation and remaining battery life).

FIGURE 2.11 Main screen FIGURE 2.12 Measurement screen

(Battery operation) (Battery operation)

480V

480V

The LCD will display a battery low voltage message when the battery capacity is near

depletion. The End of Battery Discharge announcement is displayed when the battery

end voltage is reached. At this time, the inverter will perform an electronic shutdown to

prevent battery loss of life typical from extreme deep discharge conditions. When the

input power is restored, the inverter will automatically restart to power the load, and

the batteries will be simultaneously recharged. The End of Battery announcement is

shown at the bottom of the screen.

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 28

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

2.3.3 FAULT INDICATION (FIGURE 2.13)

“MESSAGE” and “SILENCE ALARM” buttons will appear on the main menu when

UPS failure condition has occurred.

FIGURE 2.13 Main screen (Fault indication)

Page Number:

2-7

540V

The following will be displayed when the message key on the LCD panel is pressed.

1)

Message (FIGURE 2.14)

The display shows a fault code, the description of the fault and a guidance of what

action is to be taken by the user. A maximum of 10 faults is displayed at one time. If

an input power failure occurs during a fault condition, the fault indication and input

power failure announcement are alternatively displayed at 5 second intervals.

FIGURE 2.14 Message screen

2) Silence alarm

This key will appear when a failure occurs. The audible alarm (announcing the failure)

can be silenced by pressing this key.

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 29

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

2-8

2.4 External Signal Terminal Block

The UPS is equipped with a series of input/output terminals for external annunciation of

alarms and for remote access of certain UPS functions. The layout of terminals is shown in

Figure 2.15. with a functional description of the input/output port presented. OUT1 to

OUT6 are user programmable, but are factory default set being also shown in Figure 2.15.

FIGURE 2.15-1 External Signal Terminal Block (NEC Class2)

TN1

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

2

4

6

8

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

FAULT

OUT1: LOAD ON BYPASS

OUT2: LOAD ON INVERTER

OUT3: BATTERY OPERATION

OUT4: RECTIFIER OPERATION

OUT5: BATTERY LOW VOLTAGE

OUT6: OVERLOAD

OUT7: SPARE

OUT8: SPARE

OUT9: SPARE

UPS

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 30

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

2-9

FIGURE 2.15-2 External Signal Terminal Block (NEC Class2)

TN2

10

12

14

16

18

20

22

24

26

28

30

2

4

6

8

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

IN1: REMOTE INVERTER START

IN2: REMOTE INVERTER STOP

IN3: BATTERY TEMP. HIGH

IN4: POWER DEMAND

IN5: SPARE

IN6: SPARE

IN7: SPARE

IN8: SPARE

IN9: SPARE

REMOTE EPO

CB2 UVT

CB2 AX

52L AX

52C AX

(User supplied dry

contact)

(User supplied sensor

and dry contact)

(User supplied dry

contact)

(User supplied dry

contact)

UPS

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 31

N

MITSUBISHI

ELECTRIC

A) Output Contacts (for external alarm annunciation)

Output contacts consist of form “A” dry type contacts. Rated capacity of all output

contacts is NEC Class2 (30Vdc/1Adc). All dry contacts should be operated at their

rated values or lower. Figure 2.16 illustrates a typical installation. The external relay

can also be a lamp, LED, computer, etc.

FIGURE 2.16 Control Wiring for External Contacts

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

2-10

UPS Cabinet

Terminal

Relay

Contact

Details of output alarm contacts : TN1

Terminals 1 to 2

Terminals 5 to 6

Terminals 9 to 10

, 3 to 4 "UPS failure" contact

Activated when a major fault has occurred with the system.

, 7 to 8 "Load on Bypass" contact (OUT1)

Activated when the power is supplied from the static bypass input.

, 11 to 12 "Load on Inverter" contact (OUT2)

Activated when the power is supplied by the inverter.

Terminal

User supplied

External to UPS

Cabinet

Relay

Coil

EC Class 2

Power Source

Terminals 13 to 14

Activated when the battery is operating following an AC power failure.

Terminals 17 to 18

Activated when the rectifier is operating.

Terminals 21 to 22

Activated when the battery voltage drops below discharge end voltage level

during inverter operation (i.e. During AC fail condition).

Terminals 25 to 26

Activated when an overload has occurred to the system.

Terminals 29 through 40

, 15 to 16 "Battery Operation" contact (OUT3)

, 19 to 20 "Rectifier Operation" contact (OUT4)

, 23 to 24 "Battery Low Voltage" contact (OUT5)

, 27 to 28 "Overload" contact (OUT6)

"Spare" contact (OUT7 through OUT9)

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 32

t

y

y

t

t

y

t

MITSUBISHI

ELECTRIC

NOTE: The UPS is equipped with a selectable output contact feature. The

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

2-11

above alarms are the default settings. Contact MITSUBISHI

ELECTRIC AUTOMATION, INC. for setup information.

B) Input Contacts (for remote access of UPS)

External contacts are provided by the user of the UPS system. Terminal voltage at the

UPS is 24Vdc. Provide external dry contact accordingly.

NOTE:

Do not apply voltages to remote access input terminals. Damage to

UPS may result.

Refer to Figure 2.17 for a typical wiring configuration. Although this figure applies to

the remote start/stop terminals, the same wiring arrangement is used for emergency

stop; battery liquid low; and battery temperature high.

FIGURE 2.17 Remote "Start" Contact Connections

UPS Cabine

Rela

External to UPS

Cabine

Star

Coil

Common

24 VDC

Relay Coil current : 8.3mA

Details of input contacts for remote access : TN2

Terminals 1 to 2 Remote "Inverter Start" input terminal (IN1)

Used to start inverter from a remote location. UPS must be programmed for

remote operation. Refer to Operations Menu for procedure.

Terminals 3 to 4 Remote "Inverter Stop" input terminal (IN2)

Used to stop inverter from a remote location. UPS must be programmed for

remote operation. Refer to Operations Menu for procedure.

Terminals 5 to 6 "Battery Temp. High" contact input (IN3)

Input fed by a thermocouple that monitors battery temperature. The

Use Momentar

User supplied

Star

Switch

0.5S - 4S

ON

OFF

Switches Onl

converter float voltage level is reduced for battery over-temperature

conditions. External thermocouple is user supplied

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 33

)

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

2-12

Terminals 7 to 8 "Power Demand Command" contact input (IN4)

This contact is used to control the input power. Power demand is turned ON

when the contact is closed, and power demand is turned OFF when the

contact is open.

Terminals 9 to 18 "Spare" contact input (IN5 through IN9)

Terminals 19 to 20 "Remote EPO" contact input

Used to perform a remote UPS Emergency Power Off (EPO).

The load will be dropped.

NOTE:

The UPS is equipped with a selectable output contact item. The above

items are the default settings. Contact MITSUBISHI ELECTRIC

NOTE :

AUTOMATION, INC. for setup information.

In all cases, a switch having a protective cover is recommended in

order to reduce the possibility of accidental operation.

2.5 External communication connector

This is an RS232C port for “DiamondLink”* monitoring software.

The layout of connector is shown in Figure 2.18.

FIGURE 2.18 External communication connector (NEC Class2)

D-SUB 9Pin (male

Pin 1. : Not used

Pin 2. RXD : Receive data

6

7

8

9

1

2

3

4

Pin 3. TXD : Transmit data

Pin 4. : Not used

Pin 5. GND : Signal ground

Pin 6. : Not used

Pin 7. : Not used

Pin 8. : Not used

Pin 9. : Not used

PCB IOAU-04

“

* Consult MITSUBISHI ELECTRIC AUTOMATION, INC. for details on

DiamondLink”

monitoring software and its capabilities.

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 34

3

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

3.0 INSTALLATION AND OPERATION

3.1 Transportation and Installation

TABLE 3.1 How to transport and install the system

Transportation Installation

Page Number:

-1

Transport unit with forklift.

Carry with overhead crane using

eyebolts provided.

Using the pre drilled holes (4 - 24) in the

UPS channel base, anchor the unit using

appropriate hardware. (Not provided)

Note :

Do not transport in a horizontal position. Cabinets must be maintained

upright within +/- 15° of the vertical during handling.

3.2 Installation Procedure

UPS Capacity (kVA) 100 150 225 300 375 500 750

A) Note the load tolerance of the floor

Refer to Table 3.2 for list of UPS weights.

TABLE 3.2 List of UPS weights

Weight (lb.) 2100 2820 3310 4990 5250 6930 9655

B) Minimum clearance required for ventilation

Right side

Left side

Back side

Top side

25 mm (not required when sidecars are used)

25 mm (not required when sidecars are used)

0.0 mm

600 mm (for air flow)

C) Space requirement for routine maintenance

Allow for the following space at the time of installation.

Front

1000 mm 100kVA, 150kVA, 225kVA

1075 mm 300kVA, 375kVA, 500kVA, 750kVA

Sides

Rear

0.0 mm

0.0 mm

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 35

3

MITSUBISHI

ELECTRIC

D) External Battery Supply

Please refer to the following when installing and maintaining batteries:

1. The customer shall refer to the battery manufacturer's installation manual for

battery installation and maintenance instructions.

2. The maximum permitted fault current from the remote battery supply, and the

DC voltage rating of the battery supply over-current protective device are

shown in Table 3.3.

TABLE 3.3 Maximum Permitted Fault Current

9800A SERIES UPS

OWNERS / TECHNICAL MANUAL

Page Number:

-2

UPS CAPACITY

(kVA)

DC VOLTAGE

RATING (V)

MAXIMUM PERMITTED

FAULT CURRENT (A)

100 480 25000

150 480 25000

225 480 25000

300 480 25000

375 480 25000

500 480 25000

750 480 25000

3.3 Procedure for Cable Connections *

i. Confirm the capacity of the UPS being installed. Identify the input/output power

terminal blocks as shown in the appropriate Figures 3.1 through 3.2-a~g,Figure 3.3. and

Figure 3.4a~c. (Note *

Figure 3.4a~c shows power and control wire for parallel system.)

ii. Connect the internal control wire and power wire.

(1) Control wire Inter-connect

1. CB2 Auxiliary to terminal 1, 2.

2. CB2-UVT to terminal 3, 4.

3. Parallel configuration Wiring (Refer to Figure 3.4a~c )

- CLC CB 52L1-AX, 52L2-AX …. 52Ln-AX to UPSn TB1 (1,2 terminals)

- Parallel Control CN92, CN93, In, Out cables between UPS modules

(2) Power wire Inter-connect

a.) From user’s distribution panel

1. X1 (A-phase) to A bus bar in UPS rectifier section.

2. X2 (B-phase) to B bus bar in UPS rectifier section.

3. X3 (C-phase) to C bus bar in UPS rectifier section.

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 36

3-3

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

b.) DC Input to UPS

1. Positive cable to BP bus bar in UPS rectifier section.

2. Negative cable to BN bus bar in UPS rectifier section.

c.) From UPS AC Output Terminals to Critical Load Cabinet (CLC) UPS AC

Output Terminals (Refer to Figure 3.4a~c)

iii. Connect the grounding conductor from the input service entrance to the UPS ground

bar.

iv. Two (2) sources feeding the UPS

:

(1) Connect the rectifier input power cables from the input service entrance to the

rectifier input power terminals, identified as A, B, C in Figures 3.2-a~g. Input

cables must be sized for an ampere rating larger than the maximum input drawn

by the rectifier. (Refer to equipment nameplate for current ratings.) Confirm that

an external bypass input circuit breaker (MCCB) is installed (refer to WARNING 2,

page 1-2). Connect the bypass input power cables from the input service entrance

to the bypass input power terminals, identified as A40, B40, C40 and N40 in

Figures 3.2-a~g. Bypass input cables must be sized for an ampere rating larger

than the maximum output current capacity of the UPS. Refer to Table 3.4 for

recommended cable sizes.

(2) Connect the external signal terminal block as desired. Refer to section 2.4 and

2

Figure 2.15 for functional description. 2mm

, or less, shielded conductor is

recommended.

v. One (1) source feeding the UPS

:

(1) Confirm that an external input circuit breaker sized to protect both the rectifier

input and the bypass line is installed. (Refer to equipment nameplate for current

ratings.) Connect the bypass input power cables from the input service entrance

to the bypass input power terminals, identified as A40, B40, C40 and N40 in

Figures 3.2-a~g Input cables must be sized for an ampere rating larger than the

maximum current capacity of the UPS. Refer to Table 3.4 for recommended cable

sizes.

(2) Using adequately sized conductors and referring to the appropriate figure

identified in Figures 3.2-a~g, connect jumper bypass terminals A40, B40, C40 to

rectifier input power terminals A, B, C as identified in Figures 3.2-a~g.

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 37

3

MITSUBISHI

ELECTRIC

(3) Connect the external signal terminal block as desired. Refer to section 2.4 and

Figure 2.15 for functional description. 2mm

recommended.

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

2

, or less, shielded conductor is

Page Number:

-4

NOTES:

1. Confirm that all UPS internal contactors (breakers) "CB1", "CB2", and

"CB3" are open before energizing UPS.

2. UPS power terminals are supplied with stud type fittings. It is recommended

that compression lugs be used to fasten all input/output power cables.

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 38

3-5

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

TABLE 3.4 Recommended Cable Sizes

kVA

Capacity

100kVA 480V 480V 1 AWG

150kVA 480V 480V 3/0 AWG

225kVA 480V 480V 300 MCM

300kVA 480V 480V 2x4/0 AWG

375kVA 480V 480V 3x300 MCM

500kVA 480V 480V 3x250 MCM

600V 600V 2x350 MCM

750kVA 480V 480V 3x500 MCM

Input

Voltage

600V 600V 2 AWG

600V 600V 2/0 AWG

600V 600V 250 MCM

600V 600V 2x3/0 AWG

600V 600V 2x4/0 AWG

600V 600V 3x350 MCM

Output

Voltage

Input Side * 1, 2 Output Side * 1, 2 Bypass Side * 1, 2 DC Input Side * 1, 2

Cable

Size

or larger

or larger

or larger

or larger

or larger

or larger

or larger

or larger

or larger

or larger

or larger

or larger

or larger

or larger

Torque

in. lbs

200 - 269

in. lbs

200 - 269

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 – 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

Cable

Size

1 AWG

or larger

2 AWG

or larger

3/0 AWG

or larger

2/0 AWG

or larger

350 MCM

or larger

250 MCM

or larger

2x3/0 AWG

or larger

400 MCM

or larger

2x250 MCM

or larger

2x3/0 AWG

or larger

2x400 MCM

or larger

2x300 MCM

or larger

3x500 MCM

or larger

3x350 MCM

or larger

Torque

in. lbs

200 - 269

in. lbs

200 - 269

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

2x250 MCM

2x400 MCM

2x300 MCM

3x500 MCM

3x350 MCM

*1 - The cables must be selected to be equal to or larger than the sizes listed in the table.

*2 - Voltage drop across power cables not to exceed 2% of nominal source voltage.

*3 - Allowable ampere-capacities based on 90゚C insulation at ambient temperature of 30゚C.

Not more than 3 conductors in a raceway without de-rating.

Note: Copper conductors assumed.

Cable

Size

1 AWG

or larger

2 AWG

or larger

3/0 AWG

or larger

2/0 AWG

or larger

350 MCM

or larger

250 MCM

or larger

2x3/0 AWG

or larger

400 MCM

or larger

or larger

2x3/0 AWG

or larger

or larger

or larger

or larger

or larger

Page Number:

Torque

in. lbs

200 - 269

in. lbs

200 - 269

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

Cable

Size

3/0 AWG

or larger

3/0 AWG

or larger

350 MCM

or larger

350 MCM

or larger

2x4/0 AWG

or larger

2x4/0 AWG

or larger

2x400 MCM

or larger

2x400 MCM

or larger

3x350 MCM

or larger

3x350 MCM

or larger

3x500 MCM

or larger

3x500 MCM

or larger

5x500 MCM

or larger

5x500 MCM

or larger

Torque

in. lbs

200 - 269

in. lbs

200 - 269

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

347 - 469

in. lbs

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 39

3-6

put

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

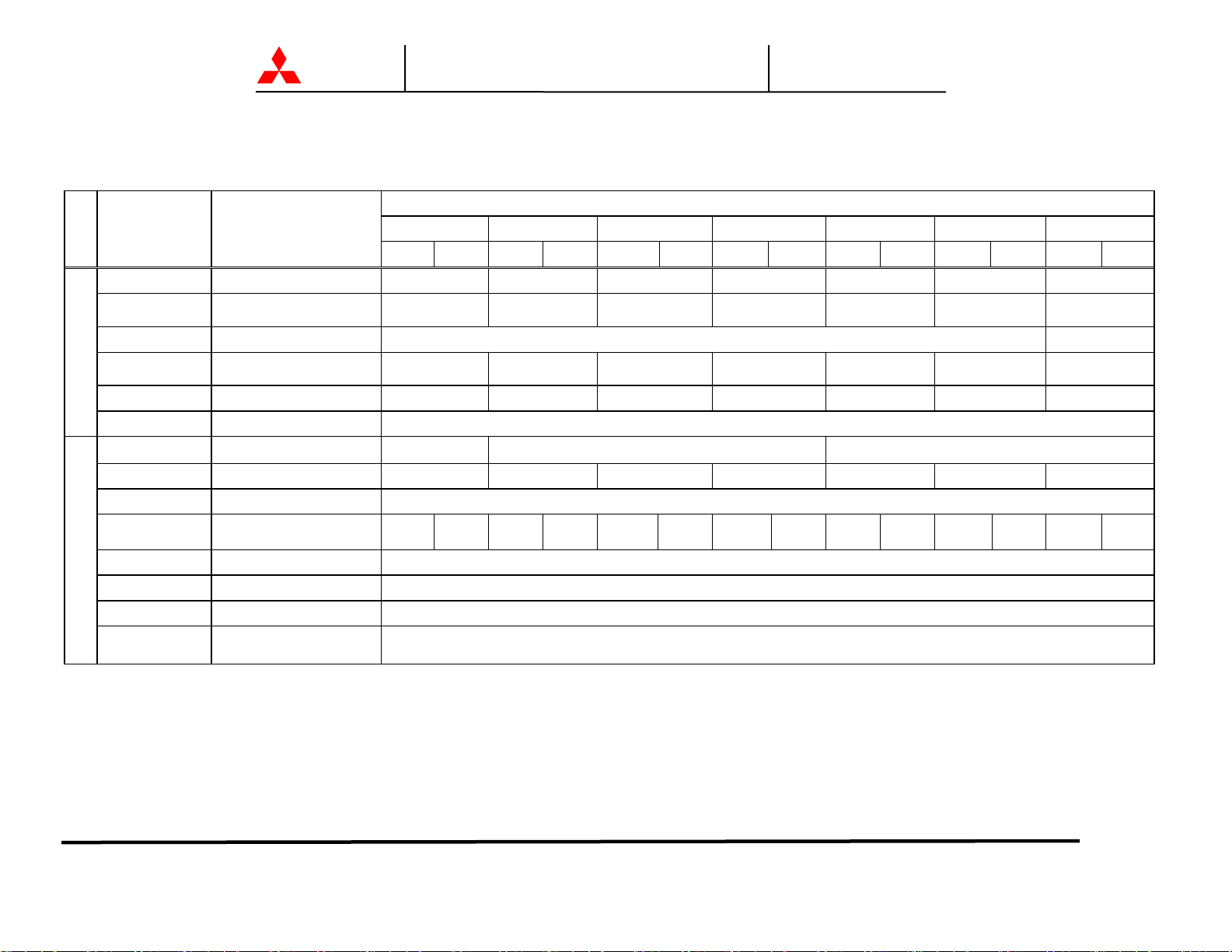

TABLE 3.5 Crimp Type Compression Lug

Page Number:

WIRE

SIZE

WIRE

STRAND

RECOMMENDATION CRIMP TOOL REQUIRED

BURNDY TYPE Y35 OR Y46

(CODE) CLASS VENDOR CAT. NO. COLOR KEY DIE INDEX

1 B

I

1/0 B

I

2/0 B

I

3/0 B

I

4/0 B

I

250 MCM B

I

300 MCM B

I

350 MCM B

I

400 MCM B

I

500 MCM B

I

BURNDY

ILSCO

BURNDY

BURNDY

ILSCO

BURNDY

BURNDY

ILSCO

BURNDY

BURNDY

ILSCO

BURNDY

BURNDY

ILSCO

BURNDY

BURNDY

ILSCO

BURNDY

BURNDY

ILSCO

BURNDY

BURNDY

ILSCO

BURNDY

BURNDY

ILSCO

BURNDY

BURNDY

ILSCO

BURNDY

YA1C

CRA-1L

YA25-LB

YA25

CRA-1/OL

YA25-LB

YA26

CRA-2/OL

YA27-LB

YA27

CRB-3/OL

YA28-LB

YA28

CRB-4/OL

YA29-LB

YA29

CRA-250L

YA30-LB

YA30

CRA-300L

YA32-LB

YA31

CRA-350L

YA34-LB

YA32

CRA-400L

YA36-LB

YA34

CRA-500L

YA38-LB

GREEN

GREEN

--PINK

PINK

---

BLACK

BLACK

---

ORANGE

ORANGE

---

PURPLE

PURPLE

---

YELLOW

YELLOW

---

WHITE

WHITE

---

RED

RED

---

BLUE

BLUE

---

BROWN

BROWN

---

11 / 375

11 / 375

1019

12 / 348

12 / 348

1020

13

13

1021

14 / 101

14 / 101

1022

15

15

1023

16

16

1024

17 / 298

17 / 298

1026

18 / 324

18 / 324

1027

19 / 470

19 / 470

1027

20 / 299

20 / 299

1029

NOTE: When using crimp type lugs, the lugs should be crimped to the specifications given in the

manufacturer's instructions for both crimp tool and lug.

FIGURE 3.1 UPS Terminal Designation

AC input

Terminals:

A, B, C

AC Bypass

In

Terminals:

A40,B40,C40,N40

CB1

CB3

Terminals:

BP,BN

CB2

Static Transfer

Switch

52S

52C

Output

Terminals:

A50,B50,C50,

N50

UPS ModuleBattery cabinet

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 40

3

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

-7

FIGURE 3.2-a-1 Diagram of input/output bus bars and terminal blocks (100kVA, 150kVA, 225kVA UPS, Input voltage 480Vac)

Location of bus bars and terminal blocks Detailed Terminals

External

wiring block

100kVA : 43.3” (1100mm)

150kVA : 47.2” (1200mm)

225kVA : 55.1” (1400mm)

UPS module

AC

Input

A,B,C

AC

Output

A50,B50,C50

Bypass

Input

A40,B40,C40

H=79.7” (2025mm)

D=29.9” (760mm)

N40,N50

Battery

Input

BN,BP

For power terminals, use 3/8” (10mm) Diameter bolts.

UPS module

AC Input

A B C

AC Output

A50 B50 C50

Bypass Input

A40 B40 C40

N40

N50

DC Input

BN BP

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 41

3-8

r

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

FIGURE 3.2-a-2 Diagram of Power Wire & Control Wire Inter-Connect (100kVA, 150kVA, 225kVA UPS, Input voltage 480Vac)

DC circuit breake

UVT

External signal terminal

IOAU-04 – [TN2]

Auxiliary

24

23

22

21

BN

BP

“+”Positive“-“Negative

User supplied

User supplied

UPS module

Wall mounted DC breaker

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 42

3-9

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

FIGURE 3.2-b-1 Diagram of input/output bus bars and terminal blocks (100kVA, 150kVA, 225kVA UPS, Input voltage 600Vac)

Location of bus bars and terminal blocks Detailed Terminals

100kVA : 79.3” (2014mm)

150kVA : 83.2” (2113mm)

225kVA : 99.1” (2520mm)

Input

cabinet

External

wiring block

UPS module

AC

Input

H1,H2,H3

H=79.7” (2025mm)

D=29.9” (760mm)

AC

Output

A50,B50,C50

N40,N50

Bypass

Input

A40,B40,C40

Battery

Input

BN,BP

For power terminals, use 3/8” (10mm) Diameter bolts.

Input

UPS module

cabinet

AC Input

H1 H2 H3

AC Output

A50 B50 C50

Bypass Input

A40 B40 C40

N40

N50

DC Input

BN BP

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 43

3-10

C circu

er

pu

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

FIGURE 3.2-b-2 Diagram of Power Wire & Control Wire Inter-Connect (100kVA, 150kVA, 225kVA UPS, Input voltage 600Vac)

User supplied

X1 X2 X3

H1 H2 H3

t transformer

In

Input Cabinet

External signal terminal

IOAU-04 – [TN2]

24

23

22

21

A B C

UPS module

BPBN

User supplied

D

it break

UVT

Auxiliary

“+”Positive“-“Negative

User supplied

Wall mounted DC breaker

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 44

3

y

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

-11

FIGURE 3.2-c-1 Diagram of input/output bus bars and terminal blocks (300kVA, 375kVA UPS, Input voltage 480Vac)

Location of bus bars and terminal blocks Detailed Terminals

Battery

Input

BN,BP

76.8” (1950mm)

N50

AC

Input

A,B,C

Bypass

Input

A40,B40,C40

UPS module

H=79.7” (2025mm)

D=37.8” (960mm)

External

wiring block

AC

Output

A50,B50,C50

DC Input

BN BP

AC Input

A B C

B

pass Input

A40 B40 C40

UPS module

N50

AC Output

A50 B50 C50

UPS Power Terminals use 1/2” (13mm) Diameter bolts.

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 45

3

er

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

-12

FIGURE 3.2-c-2 Diagram of Power Wire & Control Wire Inter-Connect (300kVA, 375kVA UPS, Input voltage 480Vac)

External signal terminal

IOAU-04 – [TN2]

BPBN

24

23

22

21

DC circuit break

UVT

Auxiliary

“-“Negative

“+”Positive

User supplied

User supplied

UPS module

Wall mounted DC breaker

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 46

3-13

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

FIGURE 3.2-d-1 Diagram of input/output bus bars and terminal blocks (300kVA, 375kVA UPS, Input voltage 600Vac)

Location of bus bars and terminal blocks Detailed Terminals

H=79.7” (2025mm)

D=37.8” (960mm)

300kVA : 120.8” (3068mm)

375kVA : 130.8” (3322mm)

DC Input

BN BP

Bypass Input

A40 B40 C40

N50

AC Output

A50 B50 C50

Input

cabinet

N50

Battery

Input

BN,BP

AC Input

H1,H2,H3

Bypass

Input

A40,B40,C40

UPS module

External

wiring block

AC

Output

A50,B50,C50

AC Input

H1 H2 H3

Input cabinet

UPS module

UPS Power Terminals use 1/2” (13mm) Diameter bolts.

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 47

3

C circu

er

pu

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

-14

FIGURE 3.2-d-2 Diagram of Power Wire & Control Wire Inter-Connect (300kVA, 375kVA UPS, Input voltage 600Vac)

External signal terminal

A B C

IOAU-04 – [TN2]

BPBN

24

23

22

21

D

Auxiliary

it break

UVT

X1 X2 X3

User supplied

H1 H2 H3

In

t transformer

Input Cabinet

UPS module

MITSUBISHI ELECTRIC 9800A SERIES UPS

“-“Negative

“+”Positive

User supplied

User supplied

Wall mounted DC breaker

Page 48

3-15

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

FIGURE 3.2-e-1 Diagram of input/output bus bars and terminal blocks (500kVA, 750kVA UPS, Input voltage 480Vac)

Location of bus bars and terminal blocks Detailed Terminals

51.2” (1300mm)

Battery

Input

BN,BP

AC Input

A,B,C

N40,N50

AC Output

A50,B50,C50

UPS module

H=79.7” (2025mm)

D=37.8" (960mm)

63.0” (1600mm)

External

wiring block

Bypass Input

A40,B40,C40

AC Input

A B C

DC Input

BN BP

UPS module

AC Output

A50B50C

50

N40N

50

A40B40C

40

Bypass

Input

UPS Power Terminals use 1/2” (13mm) Diameter bolts.

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 49

3-16

r

r

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

FIGURE 3.2-e-2 Diagram of Power Wire & Control Wire Inter-Connect (500kVA, 750kVA UPS, Input voltage 480Vac)

External signal terminal

BP BN

IOAU-04 – [TN2]

24

23

22

21

DC circuit breake

UVT

Auxiliary

User supplied

UPS module

User supplied

Floor mounted DC breaker

MITSUBISHI ELECTRIC 9800A SERIES UPS

Positive

Bus Bar

Negative

Bus Ba

Page 50

3

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

-17

FIGURE 3.2-f-1 Diagram of input/output bus bars and terminal blocks (500kVA, 750kVA UPS, Input voltage 600Vac)

Location of bus bars and terminal blocks Detailed Terminals

Input

cabinet

AC Input

H1,H2,H3

168.2” (4270mm)

N40,N50

AC Output

Battery

A50,B50,C50

Input

BN,BP

UPS module

H=79.7” (2025mm)

D=37.8" (960mm)

External

wiring block

Bypass Input

A40,B40,C40

AC Input

A B C

Input cabinet

DC Input

BN BP

UPS module

AC Output

A50B50C

50

N40N

50

A40B40C

40

Bypass

Input

UPS Power Terminals use 1/2” (13mm) Diameter bolts.

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 51

3-18

r

C circu

er

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

FIGURE 3.2-f-2 Diagram of Power Wire & Control Wire Inter-Connect (500kVA, 750kVA UPS, Input voltage 600Vac)

User supplied

X1 X2 X3

H1 H2 H3

Input transformer

External signal terminal

IOAU-04 – [TN2]

D

24

BPBN

A B C

23

22

21

Auxiliary

it break

UVT

User supplied

Positive

Bus Bar

Negative

Bus Ba

User supplied

Input Cabinet

UPS module

MITSUBISHI ELECTRIC 9800A SERIES UPS

Floor mounted DC breaker

Page 52

3-19

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

FIGURE 3.3-a Diagram of Rectifier Cabinet & Inverter Cabinet Inter-Connect 1 (500kVA, 750kVA UPS)

MITSUBISHI ELECTRIC 9800A SERIES UPS

N50

Page 53

3-20

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

FIGURE 3.3-b Diagram of Rectifier Cabinet & Inverter Cabinet Inter-Connect 2 (500kVA, 750kVA UPS)

Ground Bus Bar

Ground Bus Bar

Rectifier Cabinet

CON2

CON1

CON3

CON4

CON5

CN1

CN3

CN11 CN4 CN5

Inverter Cabinet

RYER-E

CN9

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 54

3

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

-21

CRITICAL LOAD CABINET

FIGURE 3.4-a Diagram of Power Wire Connect ( Parallel connection )

52MB

input

AC

UPS-1

Bypass

CB1

Converter

Inverter

52S

AC output

52L

1

52C

UPS-2

Bypass

CB2

Battery

52S

52CS

input

AC

CB1

Converter

Inverter

AC output

52L

2

CB2

52C

Battery

Bypass

*1

52S

UPS-n

AC

input

CB1

Converter

Inverter

AC output

52L

*1

n

52C

CB2

Battery

*1 n : Maximum = 8

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 55

3

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

-22

FIGURE 3.4-b Diagram of Power Wire & Control Wire Connect ( Parallel connection )

UPS-1

CN92

CN93

IN

OUT

AC Output

A50

B50

C50

N40/N50

IOAU-04

TN2

25

26

UPS-2

CN92

CN93

IN

OUT

AC Output

A50

B50

IOAU-04

TN2

25

26

Critical Load Cabinet

1

2

3

4

5

6

7

8

UPS-1 AC Output

A

B

C

N

UPS-2 AC Output

A

B

52L1-AX

52L2-AX

C50

N40/N50

C

N

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 56

3-23

UPS-1

IOAU-04

TN2

CN92

CN93

IN

OUT

25 26

MITSUBISHI

ELECTRIC

9800A SERIES UPS

OWNERS / TECHNICAL MANUAL

Page Number:

FIGURE 3.4-c Diagram of Power Wire & Control Wire Connect ( Parallel connection )

AC Output

UPS-1

UPS-2

CN92

CN93

IN

OUT

UPS-n

25 26

IOAU-04

TN2

*2

UPS-3 CN93

UPS-(n-1)CN92

UPS-3 OUT

UPS-(n-1) IN

*1

25 26

IOAU-04

TN2

CN92

CN93

IN

OUT

UPS-2

A

B

C

N

A

B

C

N

Critical Load Cabinet

TB1

1

2

3

4

15

16

52L1-AX

52L2-AX

*1

52Ln-AX

AC Output

A50

B50

C50

N40/N50

N40/N50

AC Output

A50

B50

C50

AC Output

A50

B50

C50

N40/N50

MITSUBISHI ELECTRIC 9800A SERIES UPS

UPS-n

A

B

C

N

*1

*1 n : Maximum = 8

*2 Return from the last

UPS module to the first UPS

module (continuous loop).

Page 57

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

3.4 Operating Procedures

A) Start-up Procedure

a) Verify that Critical Load Cabinet (CLC) Circuit Breakers 52L1, 52L2…and 52Ln are

closed.

b) Verify that the External Bypass Input Circuit Breaker for each unit is closed

(Breaker is user supplied.)

c) If a dual source is feeding the UPS, close the External AC Rectifier Input Circuit

Breaker manually (user supplied).

Start-up of UPS-1

1. Verify that Control Circuit Breakers (CPM) is closed.

(When Inverter is stopped, the Control Circuit Breaker is not normally opened)

2. The pre-charging cycle will begin and Input Contactor (CB1) will close automatically.

3. Close Battery Disconnect Circuit Breaker (CB2).

4. The inverter can now be started.

Note: When "REMOTE OPERATION MODE" is displayed on the LCD panel, the inverter

start operation can only be performed remotely. If local inverter start operation is required

(at the UPS), select "LOCAL" in "Remote/Local" selection in setup page. Select “LOCAL”

mode for the purpose of this start up procedure.

5. On the LCD panel, select “START/STOP MENU” and press the “START” key.

6. The Inverter will start within 5 seconds. Start up is complete.

Start-up of next UPS

The next UPS can be started in the same way as UPS-1.

FIGURE 3.5-a Start-up Procedure

540V

Page Number:

3-24

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 58

B) Shut-down Procedure

Shut-down of UPS-1

MITSUBISHI

ELECTRIC

If a total UPS shutdown is required, verify that the critical load is OFF.

1. Press the "START/STOP MENU" from the Main Menu on the LCD.

Note: When "REMOTE OPERATION MODE" is displayed on the LCD panel, the

inverter stop operation can only be performed remotely. If local inverter stop operation is

required (at the UPS), select "LOCAL" in "Remote/Local" selection in setup page. Select

“LOCAL” mode for the purpose of this stop procedure.

2. Press both "STOP" keys simultaneously on the LCD.

3. In general, only the Inverter will be stopped and the Rectifier will remain energized to

charge the batteries.

Opening the user supplied External Input AC Circuit Breaker (if dual source

used), the External Bypass Input Circuit Breaker and the DC Disconnect Circuit

Breaker, CB2, will shut down the load.

4. If stopping both the Rectifier and Charger is required, open the Battery Disconnect

circuit breaker (CB2) manually.

5. If a dual source is feeding the UPS, open the External AC Rectifier Input Circuit

Breaker (user supplied) manually.

6. If turning off all power to the critical load is desired, open the External Bypass Input

Circuit Breaker (user supplied) manually.

Shut-down of next UPS

The next UPS can be shut down in the same way as UPS-1.

The parallel UPS system will be in bypass operation when all inverters stops.

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

3-25

FIGURE 3.5-b Shut-down Procedure

540V

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 59

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

C) Bypass Operation Procedure

UPS-1

1. Check for “SYNC” on the LCD.

2. Press the "START/STOP MENU" from the LCD Main Menu.

3. Press the "STOP" key on the LCD.

Next UPS

Stop the next UPS in the same way as UPS-1.

The paralleling UPS system will be in bypass operation when all inverters stop.

** Transfer from bypass to inverter.

UPS-1

1. Press the "START/STOP MENU" from the LCD Main Menu.

2. Press the "START" key on the LCD.

Next UPS

Start the next UPS in the same way as UPS-1.

The paralleling UPS system will be in inverter operation when all inverters start.

Note: When "REMOTE OPERATION MODE" is displayed on the LCD panel, the inverter

start or stop operation can only be performed remotely. If local inverter start or stop operation

is required (at the UPS), select "LOCAL" in "Remote/Local" selection in setup page. Select

“LOCAL” mode for the purpose of this stop procedure.

Page Number:

3-26

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 60

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

4.0 RESPONSE TO UPS FAILURE

UPS FAULT

Page Number:

4-1

Annunciator Silence

Recording of Fault

Primary Action

Information to Service Center

Note

The error code indicated on the LCD display panel at the time of

a UPS alarm condition is very important.

In order to reduce repair time, please include this information,

along with the operation status and load status for all

correspondence with Mitsubishi’s field service group.

Depress “SILENCE ALARM” key on MAIN menu.

Refer to the list of fault codes in section 6.0 for error

description.

Take necessary action according to display guidance.

When a faults occur, contact the Authorized Mitsubishi

Service Representative or call Mitsubishi at

1-800-887-7830.

MITSUBISHI ELECTRIC 9800A SERIES UPS

Page 61

MITSUBISHI

ELECTRIC

OWNERS / TECHNICAL MANUAL

9800A SERIES UPS

Page Number:

5-1

5.0 PARTS REPLACEMENT

Contact Mitsubishi or its Authorized Service Center on all issues regarding the replacement

of parts.

A) Battery