Page 1

Page 2

Page 3

MELDAS is a registered trademark of Mitsubishi Electric Corporation.

Other company and product names that appear in this manual are trademarks or

registered trademarks of the respective companies.

Page 4

Page 5

Introduction

This manual is the alarm/parameter guide required to use the MITSUBISHI CNC700/70 Series.

This manual is prepared on the assumption that your machine is provided with all of the MITSUBISHI

CNC700/70 Series functions. Confirm the functions available for your NC before proceeding to operation

by referring to the specification issued by the machine tool builder.

Notes on Reading This Manual

(1) This manual explains general parameters as viewed from the NC.

For information about each machine tool, refer to manuals issued from the machine tool builder.

If the descriptions relating to "restrictions" and "allowable conditions" conflict between this manual

and the machine tool builder's instruction manual, the later has priority over the former.

(2) This manual is intended to contain as much descriptions as possible even about special operations.

The operations to which no reference is made in this manual should be considered impossible.

(3) The "special display unit" explained in this manual is the display unit incorporated by the machine

tool builder, and is not the MITSUBISHI standard display unit.

Caution

If the descriptions relating to the "restrictions" and "allowable conditions" conflict between this

manual and the machine tool builder’s instruction manual‚ the latter has priority over the former.

The operations to which no reference is made in this manual should be considered

"impossible".

This manual is complied on the assumption that your machine is provided with all optional

functions. Confirm the functions available for your machine before proceeding to operation by

referring to the specification issued by the machine tool builder.

In some NC system versions‚ there may be cases that different pictures appear on the screen‚

the machine operates in a different way or some function is not activated.

Page 6

Page 7

Precautions for Safety

Always read the specifications issued by the machine tool builder, this manual, related manuals and attached

documents before installation, operation, programming, maintenance or inspection to ensure correct use.

Understand this numerical controller, safety items and cautions before using the unit.

This manual ranks the safety precautions into "DANGER", "WARNING" and "CAUTION".

DANGER

When the user may be subject to imminent fatalities or major injuries if handling is

mistaken.

WARNING

CAUTION

Note that even items ranked as "

case, important information that must always be observed is described.

Not applicable in this manual.

Not applicable in this manual.

When the user may be subject to fatalities or major injuries if handling is mistaken.

When the user may be subject to injuries or when physical damage may occur if

handling is mistaken.

CAUTION", may lead to major results depending on the situation. In any

DANGER

WARNING

1. Items related to product and manual

If the descriptions relating to the "restrictions" and "allowable conditions" conflict between this

manual and the machine tool builder's instruction manual‚ the latter has priority over the former.

The operations to which no reference is made in this manual should be considered impossible.

This manual is complied on the assumption that your machine is provided with all optional

functions. Confirm the functions available for your machine before proceeding to operation by

referring to the specification issued by the machine tool builder.

In some NC system versions‚ there may be cases that different pictures appear on the screen‚

the machine operates in a different way on some function is not activated.

2. Items related to faults and abnormalities

If the battery low alarm is output, save the machining programs, tool data and parameters to an

input/output device, and then replace the battery. If the BATTERY alarm occurs, the machining

programs, tool data and parameters may be damaged. After replacing the battery, reload each

data item.

CAUTION

[Continued on next page]

Page 8

CAUTION

3. Items related to maintenance

Do not replace the battery while the power is ON.

Do not short-circuit, charge, heat, incinerate or disassemble the battery.

Dispose of the spent battery according to local laws.

Do not connect or disconnect the connection cables between each unit while the power is ON.

Do not pull the cables when connecting/disconnecting it.

Do not replace cooling fan while the power is ON.

Dispose of the replaced cooling fan according to the local laws.

Do not replace backlight while the power is ON.

Dispose of the spent backlights according to the local laws.

Do not touch backlight while the power is ON. Failure to observe this could result in electric shocks

due to high voltage.

Do not touch backlight while LCD panel is in use. Failure to observe this could result in burns.

LCD panel and backlight are made of glass, so do not apply impacts or pressure on them. Failure to

observe this could result in breakage.

Incorrect connections could cause the devices to damage. Connect the cable to the designated

connector.

[Continued]

Do not replace control units while the power is ON.

Do not replace display units while the power is ON.

Do not replace keyboard units while the power is ON.

Do not replace DX units while the power is ON.

Do not replace hard disk units while the power is ON.

Dispose of the replaced hard disk unit according to the local laws.

Hard disk unit is a precision device, so do not drop or apply strong impacts on it.

4. Items related to servo parameters and spindle parameters

Do not adjust or change the parameter settings greatly as operation could become unstable.

In the explanation on bits, set all bits not used, including blank bits, to "0".

Page 9

CONTENTS

I Procedures for Starting up

1. Procedures for Starting Up 700 Series........................................................................................1

1.1 Outline of Hardware Configuration.........................................................................................1

1.2 Outline of Setup Procedures ..................................................................................................2

2. Procedures for Starting Up 70 Series..........................................................................................3

2.1 Outline of Hardware Configuration.........................................................................................3

2.2 Outline of Setup Procedures ..................................................................................................4

3. Setup Details ...............................................................................................................................5

3.1 Connecting the Control Unit and Peripheral Devices.............................................................5

3.1.1 Setting the MDS-D/DH Series Rotary Switch and DIP Switch.........................................7

3.1.2 Setting the MDS-D-SVJ3/SPJ3 Series Rotary Switch......................................................9

3.2 Erasing the Backed up Data (SRAM)...................................................................................10

3.3 Inputting the Parameters......................................................................................................12

3.3.1 When There is No Parameter File..................................................................................12

3.3.2 When a Parameter File is Available...............................................................................15

3.4 Formatting the File System...................................................................................................16

3.5 Inputting the Ladder Program...............................................................................................17

3.6 Credit System.......................................................................................................................19

3.7 Setting the Handy Terminal..................................................................................................21

3.7.1 When Connecting with PC to Input ................................................................................21

3.7.2 When Connecting with NC to Input................................................................................23

3.8 Adjustment of Dog-type Reference Position Return for Relative Position Detection............24

3.8.1 Dog-type Reference Position Return Operation.............................................................24

3.8.2 Dog-type Reference Position Return Adjustment Procedures.......................................25

3.9 Absolute Position Detection System.....................................................................................31

3.9.1 Dog-type Reference Position Return Operation.............................................................31

3.9.2 Starting up the Absolute Position Detection System......................................................32

3.10 Auxiliary Axis Operation .....................................................................................................34

3.10.1 Preparations.................................................................................................................35

3.10.2 Absolute Position Initial Setting....................................................................................36

3.10.3 Test Operation..............................................................................................................36

3.10.4 PLC device...................................................................................................................37

3.10.5 Notes............................................................................................................................40

3.11 Data Sampling....................................................................................................................41

3.12 Data backup .......................................................................................................................41

3.13 M70 SETUP INSTALLER...................................................................................................42

3.13.1 Compatible Data and CF Card Folder Configuration ...................................................42

3.13.2 Operation Method.........................................................................................................44

3.13.3 List of Error Messages .................................................................................................49

4. 700 Series H/W Replacement Methods.....................................................................................50

4.1 Durable Parts........................................................................................................................50

4.1.1 Control unit battery.........................................................................................................50

4.1.2 Cooling fan for control unit .............................................................................................52

4.1.3 Cooling fan for display unit (XP terminal).......................................................................53

Page 10

4.1.4 Backlight.........................................................................................................................54

4.2 Unit .......................................................................................................................................57

4.2.1 Control Unit.....................................................................................................................57

4.2.2 Display Unit ....................................................................................................................59

4.2.3 Keyboard unit .................................................................................................................60

4.2.4 DX Unit...........................................................................................................................62

4.2.5 Hard Disk Unit ................................................................................................................63

4.3 Compact Flash......................................................................................................................64

Control Unit Compact Flash ............................................................................................64

4.3.1

4.4 IC card..................................................................................................................................65

4.4.1

Front IC Card ..................................................................................................................65

5. 70 Series H/W Replacement Methods.......................................................................................66

5.1 Durable Parts........................................................................................................................66

5.1.1 Control unit battery.........................................................................................................66

5.1.2 Backlight.........................................................................................................................68

5.2 Unit .......................................................................................................................................70

5.2.1 Control Unit.....................................................................................................................70

5.2.2 Display Unit ....................................................................................................................72

5.2.3 Keyboard unit .................................................................................................................73

5.2.4 DX Unit...........................................................................................................................75

5.3 Compact Flash......................................................................................................................76

5.3.1 Front Compact Flash......................................................................................................76

6. Cable ......................................................................................................................................77

II Explanation of Alarms

1. List of Alarms...............................................................................................................................1

1.1 Operation Alarms....................................................................................................................1

1.2 Stop Codes...........................................................................................................................10

1.3 Servo/Spindle Alarms...........................................................................................................15

1.4 MCP Alarm ...........................................................................................................................25

1.5 System Alarms......................................................................................................................35

1.6 Absolute Position Detection System Alarms.........................................................................41

1.7 Distance-coded Reference Scale Errors ..............................................................................44

1.8 Messages during Emergency Stop.......................................................................................45

1.9 Auxiliary Axis Alarms............................................................................................................47

1.10 Computer Link Errors..........................................................................................................54

1.11 User PLC Alarms................................................................................................................55

1.12 Network Service Errors.......................................................................................................57

2. Operation Messages..................................................................................................................58

2.1 Search-related Operation Messages....................................................................................58

2.2 Graphic Display-related Operation Messages......................................................................59

2.3 Variable (Common variables, local variables) - related Operation Messages......................60

2.4 PLC Switch-related Operation Messages.............................................................................60

2.5 Compensation-related (Tool compensation, coordinate system offset) Operation Messages60

2.6 Data Input/Output-related Operation Messages...................................................................61

Page 11

2.7 Parameter-related Operation Messages ..............................................................................64

2.8 Measurement-related (Workpiece, rotation) Operation Messages.......................................65

2.9 Tool (Tool registration, tool life) -related Operation Messages.............................................67

2.10 Editing-related Operation Messages..................................................................................68

2.11 Diagnosis-related Operation Messages .............................................................................70

2.12 Maintenance-related Operation Messages.........................................................................71

2.13 Data Sampling-related Operation Messages......................................................................73

2.14 Absolute Position Detection-related Operation Messages.................................................74

2.15 System Setup-related Operation Messages.......................................................................74

2.16 Automatic Backup-related Operation Messages................................................................75

2.17 Alarm History-related Operation Messages........................................................................75

2.18 Anshin-net-related Operation Messages............................................................................76

2.19 Messages Related to Machine Tool Builder Network System............................................81

2.20 Other Operation Messages ................................................................................................83

3. Program Error............................................................................................................................84

4. Troubleshooting.......................................................................................................................104

4.1 Drive System Troubleshooting ...........................................................................................104

4.1.1 Troubleshooting at Power ON......................................................................................104

4.1.2 Troubleshooting for each alarm No..............................................................................105

4.1.3 Troubleshooting for each warning No. .........................................................................130

4.1.4 Parameter numbers during initial parameter error .......................................................132

4.1.5 Troubleshooting the spindle system when there is no alarm or warning......................133

III Explanation of Parameters

1. Outline .........................................................................................................................................1

1.1 Screen Transition Chart..........................................................................................................1

1.2 Unit.........................................................................................................................................1

2. User Parameters..........................................................................................................................2

2.1 Process Parameters...............................................................................................................2

2.2 Control Parameters ..............................................................................................................15

2.3 Axis Parameters...................................................................................................................19

2.4 Operation Parameters..........................................................................................................22

2.5 Barrier Data (For L system only) ..........................................................................................27

2.6 I/O Parameters.....................................................................................................................30

2.7 Ethernet Parameters ............................................................................................................49

2.8 Computer Link Parameters...................................................................................................56

2.9 Subprogram Storage Destination Parameters......................................................................59

2.10 Anshin-net Parameter 1......................................................................................................63

2.11 Machine Tool Builder Network System (MTB-net) Parameter 1.........................................64

3. Setting the Machine Parameters ...............................................................................................65

4. Base Specifications Parameters................................................................................................66

5. Axis Specifications Parameters...............................................................................................123

5.1 Axis Specifications Parameters..........................................................................................123

5.2 Zero Point Return Parameters............................................................................................129

Page 12

5.3 Absolute Position Parameters ............................................................................................ 134

5.4 Axis Specifications Parameters 2.......................................................................................136

6. Servo Parameters....................................................................................................................148

6.1 Details for servo parameters...............................................................................................148

6.2 List of standard parameters for each servomotor...............................................................166

6.3 Supplement.........................................................................................................................174

6.3.1 D/A Output No..............................................................................................................174

6.3.1.1 MDS-D/DH Series................................................................................................................. 174

6.3.1.2 MDS-D-SVJ3 Series............................................................................................................. 177

6.3.2 Electronic Gears...........................................................................................................180

6.3.3 Lost Motion Compensation...........................................................................................181

7. Spindle Parameters .................................................................................................................182

7.1 Spindle Base Specifications Parameters............................................................................182

7.2 Spindle Parameters............................................................................................................198

7.3 Supplement.........................................................................................................................221

7.3.1 D/A Output Numbers....................................................................................................221

7.3.1.1 MDS-D/DH Series................................................................................................................. 221

7.3.1.2 MDS-D-SPJ3 Series............................................................................................................. 225

8. Rotary Axis Configuration Parameters.....................................................................................229

9. Machine Error Compensation ..................................................................................................235

9.1 Function Outline..................................................................................................................235

9.2 Setting Compensation Data................................................................................................239

9.3 Example in Using a Linear Axis as the Base Axis..............................................................241

9.4 Example in Using a Rotary Axis as the Base Axis..............................................................245

10. PLC Constants.......................................................................................................................246

10.1 PLC Timer.........................................................................................................................246

10.2 PLC Integrated Timer .......................................................................................................247

10.3 PLC Counter.....................................................................................................................247

10.4 PLC Constants..................................................................................................................248

10.5 Selecting the PLC Bit........................................................................................................248

11. Macro List ..............................................................................................................................251

12. Position Switch.......................................................................................................................253

12.1 Canceling the Position Switch ..........................................................................................255

13. Auxiliary Axis Parameter........................................................................................................256

14. Open Parameter ....................................................................................................................275

15. CC-Link Parameter ................................................................................................................276

15.1 CC-Link Parameter 1........................................................................................................276

15.2 CC-Link Parameter 2........................................................................................................287

16. Anshin-net Parameter 2 / MTB-net Parameter 2....................................................................290

17. PLC Axis Parameters.............................................................................................................303

Page 13

I Procedures for Starting Up

Page 14

Page 15

1. Procedures for Starting Up 700 Series

A

A

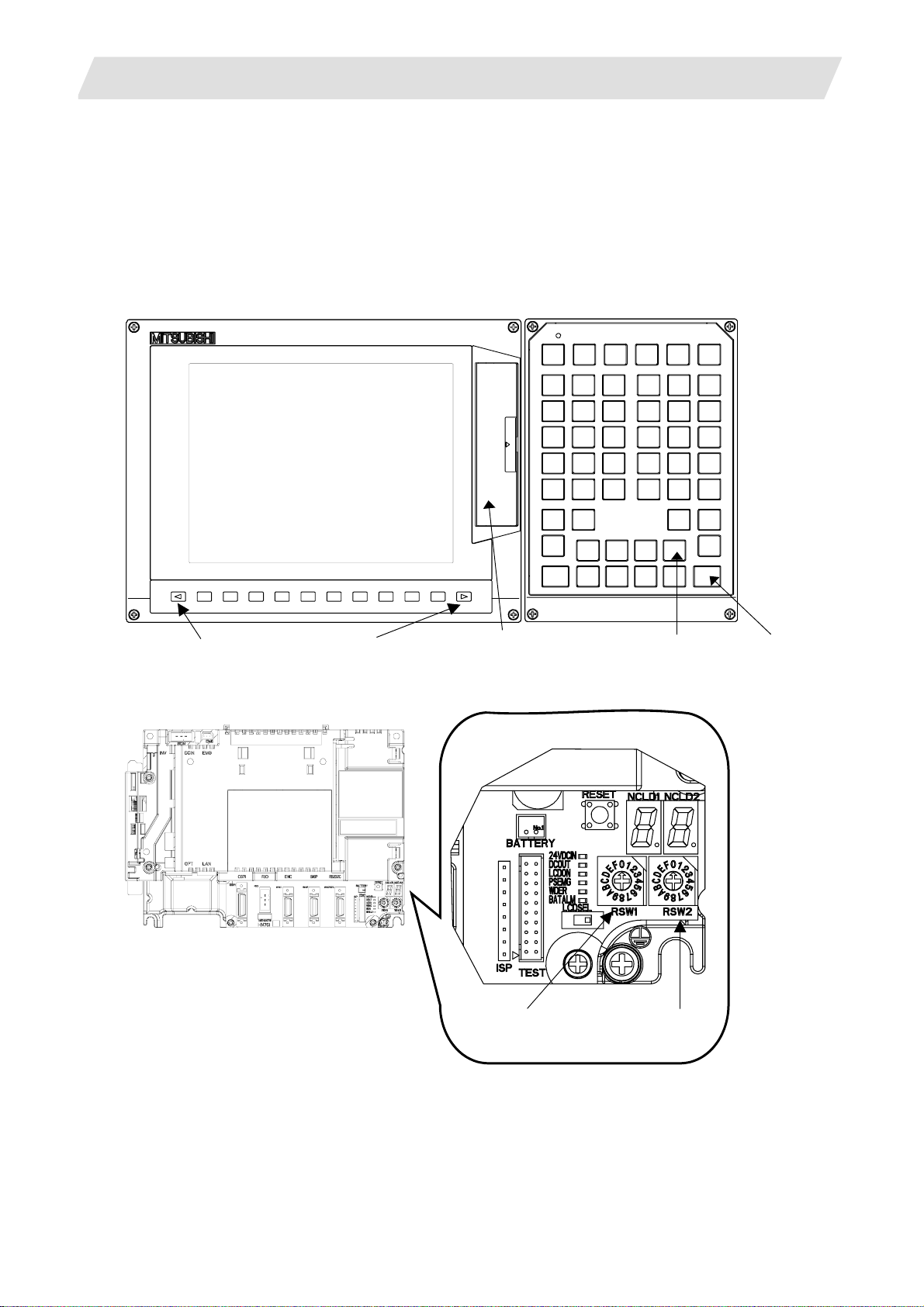

1.1 Outline of Hardware Configuration

1. Procedures for Starting Up 700 Series

This section explains the normal work required to newly start up the MITSUBISHI CNC 700 Series.

Start up the system following these setup procedures.

1.1 Outline of Hardware Configuration

The names of the hardware used in this section's explanations are explained belo w.

Display unit Keyboard

Back

Next

IC card interface on front of

display unit

Tab right

INPUT

Control unit

LED1

SW1

D

B

LED2

CS1

0

F

8

1

2 E

3

4C

5

6

79

Upper rotary switch

CS2

0

1

F

2 E

D

B

3

4C

5

6

79

8

Lower rotary switch

I - 1

Page 16

1. Procedures for Starting Up 700 Series

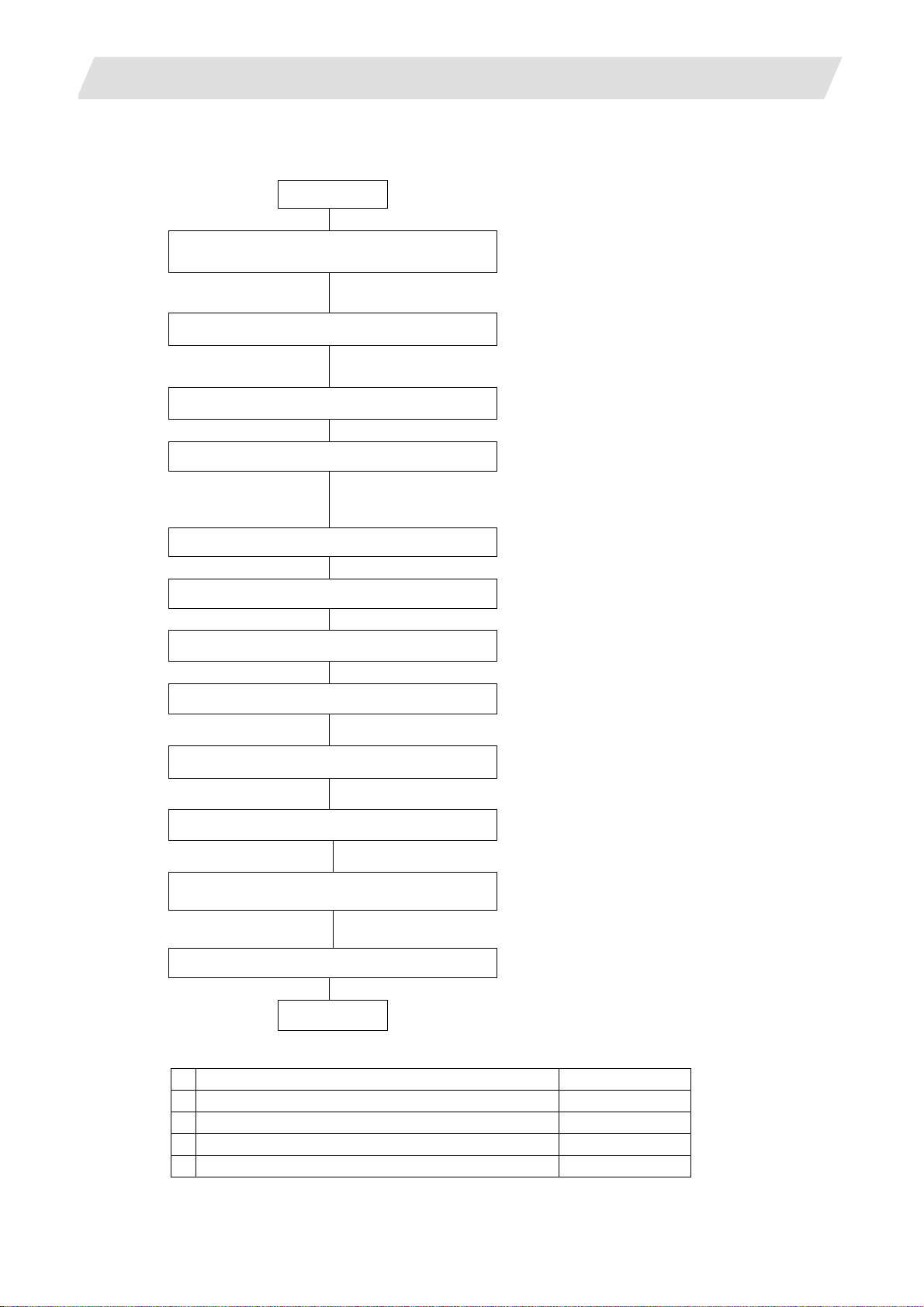

1.2 Outline of Setup Procedures

The procedures for setting up are explained with a flow chart.

Start

Connecting the control unit

and peripheral devices

Connect the control unit with the peripheral devices (servo/spindle drive,

auxiliary axis, remote I/O).

Erasing the backed up data (SRAM)

1.2 Outline of Setup Procedures

Refer to 3.1

Refer to 3.2

Turning the power ON again.

Inputting the parameters

Erase the backed up data (SRAM).

Set CS1 to "0" and CS2 to "C" to erase the SRAM.

Refer to 3.3

If there is no parameter file, input the parameters with system setup or

by manual input operation.

If there is a parameter file, input the parameters with input/output screen.

Turning the power ON again.

Formatting the file system

Refer to 3.4

Format the file system

Turning the power ON again.

Setting the data/time

Refer to 700/70 Series Instruction Manual

Set the data and time in the integrated time display pop-up window.

Inputting the ladder program

Refer to 3.5

Input the ladder program using "GX Developer" or "PLC Onboard".

Setting the credit system

Refer to 3.6

This is necessary only if the credit system is valid.

Setting the handy terminal

Input the customized data of handy terminal.

(Note) This is necessary only if the handy terminal is connected.

Refer to 3.7

Inputting the machining program

End

Carry out the procedures below if necessary.

1 Adjustment of dog-type reference position return Refer to 3.8

2 Absolute position detection system Refer to 3.9

3 Auxiliary axis operation Refer to 3.10

4 Data sampling Refer to 3.11

5 Data backup Refer to 3.12

I - 2

Page 17

2. Procedures for Starting Up 70 Series

2.1 Outline of Hardware Configuration

2. Procedures for Starting Up 70 Series

This section explains the normal work required to newly start up the MITSUBISHI CNC 70 Series.

Start up the system following these setup procedures.

2.1 Outline of Hardware Configuration

The names of the hardware used in this section's explanations are explained belo w.

Display unit Keyboard

Back Next

Control unit

CF card interface on front

of display unit

Left rotary switch

Right rotary switch

Tab right INPUT

I - 3

Page 18

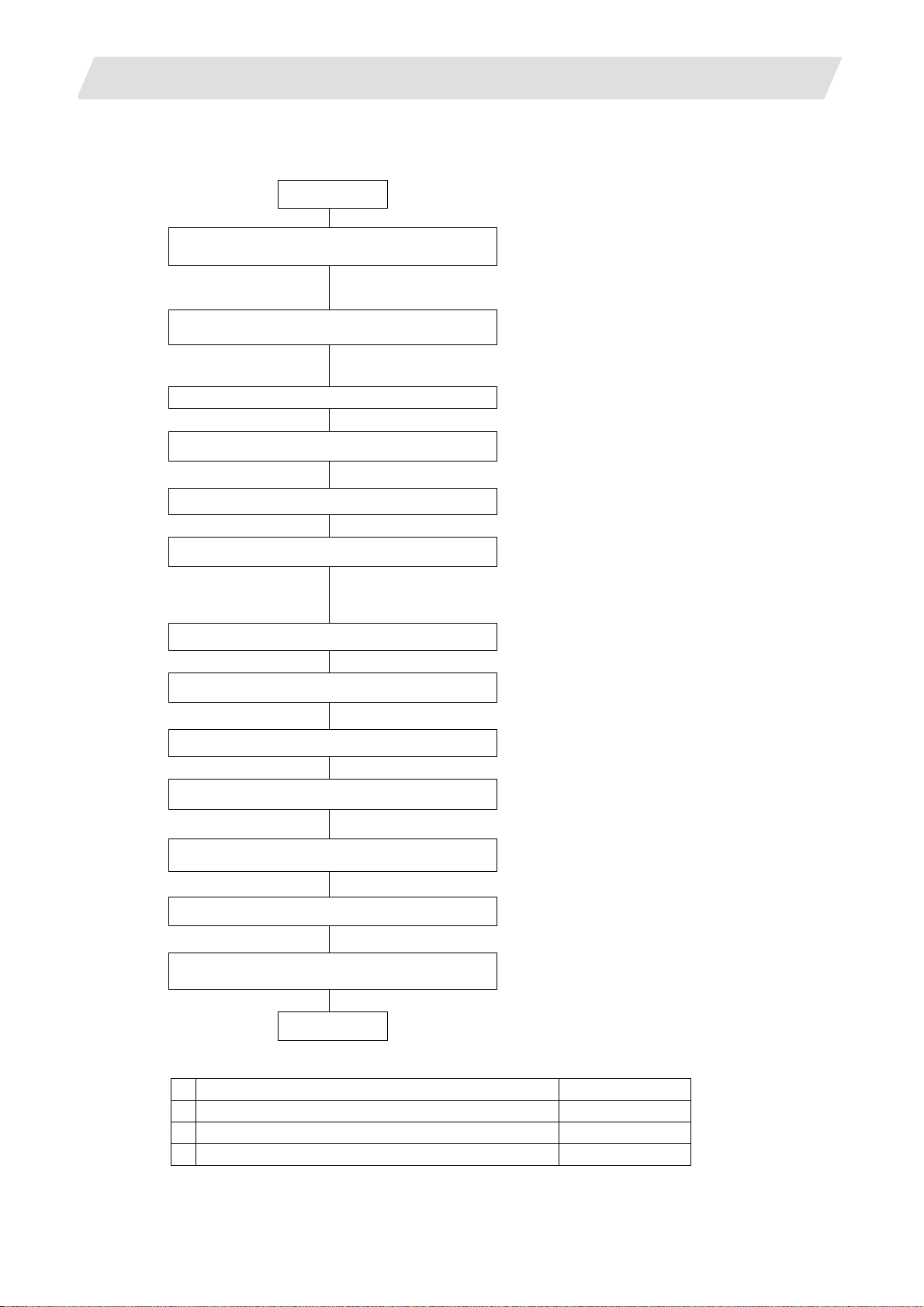

2. Procedures for Starting Up 70 Series

2.2 Outline of Setup Procedures

The procedures for setting up are explained with a flow chart.

Start

Connecting the control unit

and peripheral devices

Connect the control unit with the peripheral devices (servo/spindle drive,

and remote I/O).

Erasing the backed up data (SRAM)

2.2 Outline of Setup Procedures

Refer to 3.1

Refer to 3.2

Erase the backed up data (SRAM).

Set RSW1 to "0" and RSW2 to "C" to erase the SRAM.

Turning the power ON again.

Setting up with M70 SETUP INSTALLER

Install the language data, custom data and custom startup screen.

Turning the power ON again.

Inputting the parameters

If there is no parameter file, input the parameters with system setup or

by manual input operation.

If there is a parameter file, input the parameters with input/output screen.

Turning the power ON again.

Formatting the file system

Format the file system

Turning the power ON again.

Setting the data/time

Refer to 3.13

Refer to 3.3

Refer to 3.4

Refer to 700/70 Series Instruction Manual

Set the data and time in the integrated time display pop-up window.

Inputting the ladder program

Refer to 3.5

Input the ladder program using "GX Developer".

Setting the credit system

Refer to 3.6

This is necessary only if the credit system is valid.

Inputting the machining program

End

Carry out the procedures below if necessary.

1 Adjustment of dog-type reference position return Refer to 3.8

2 Absolute position detection system Refer to 3.9

3 Data sampling Refer to 3.11

4 Data backup Refer to 3.12

I - 4

Page 19

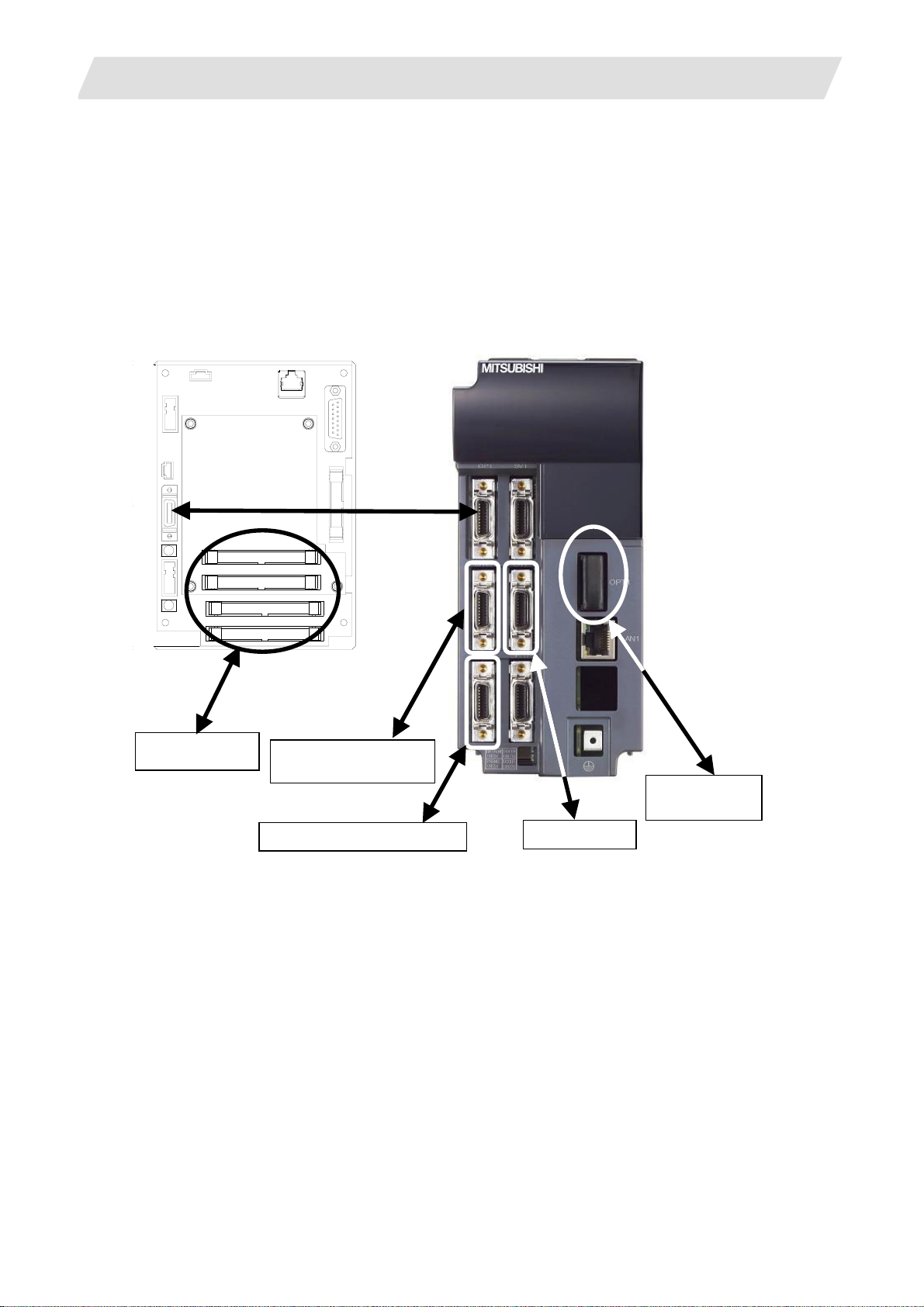

3. Setup Details

3.1 Connecting the Control Unit and Peripheral Devices

3. Setup Details

3.1 Connecting the Control Unit and Peripheral Devices

Connect the control unit with the peripheral devices (servo/spindle drive, auxiliary axis, remote IO, handy

terminal).

Refer to "Mitsubishi CNC 700 Series Connection Manual" (IB-1500034), “Mitsubishi CNC 70 Series

Connection Manual” (IB-1500254), "MDS-D Specifications Manual" (IB-15000011), and "MDS-DH

Specifications Manual" (IB-1500003) for details.

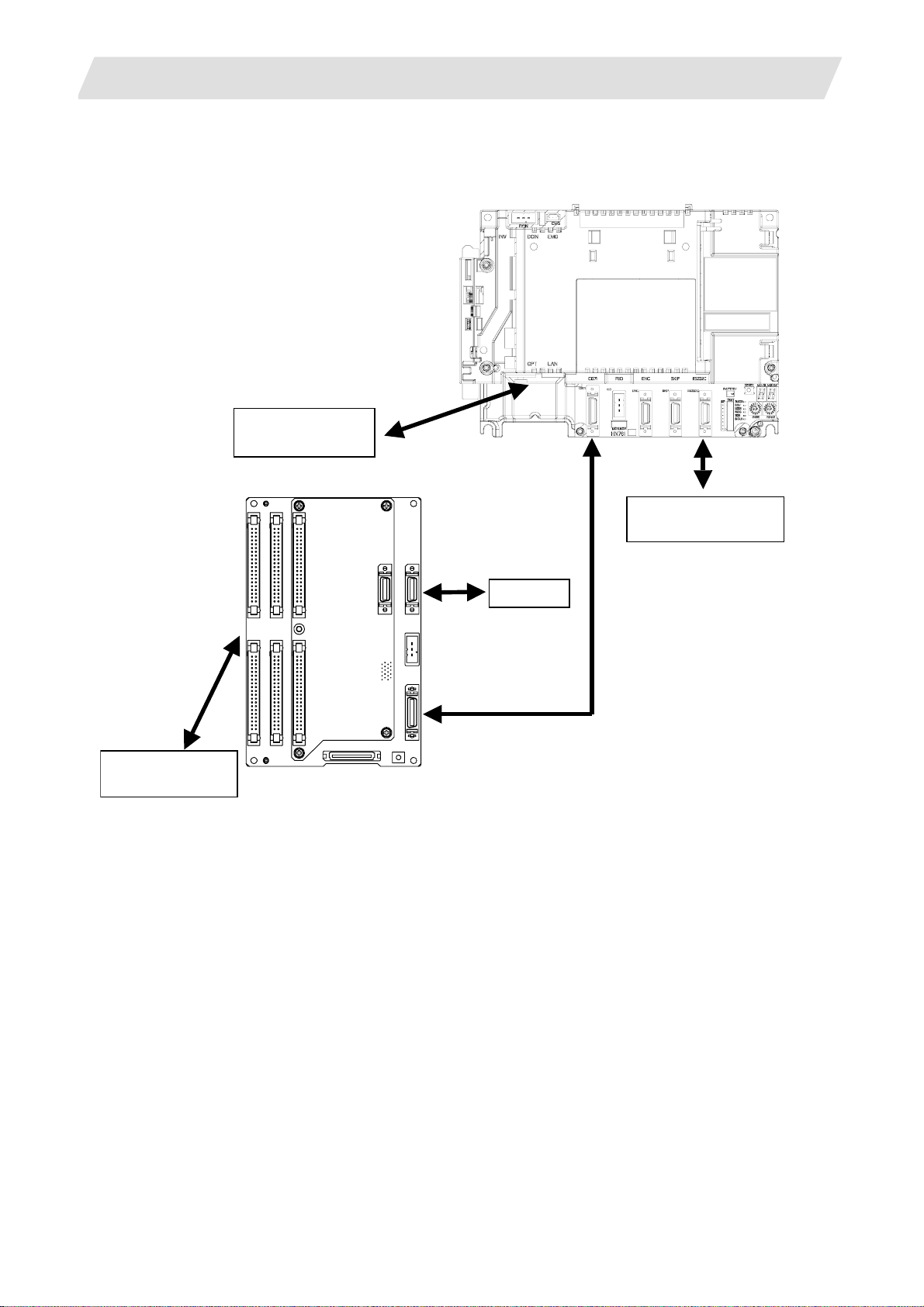

(1) 700 Series

Operation panel I/O unit

Control unit

Machine operation

panel

Handy terminal

Serial connection (RS-232C)

Handy terminal handle

Servo drive

Spindle drive

Auxiliary axis

I - 5

Page 20

3. Setup Details

(2) 70 Series

3.1 Connecting the Control Unit and Peripheral Devices

Servo drive

Spindle drive

Operation panel I/O unit

Control unit

Serial communicaton

(RS-232C)

Machine operation

panel

Handle

I - 6

Page 21

3. Setup Details

3.1 Connecting the Control Unit and Peripheral Devices

3.1.1 Setting the MDS-D/DH Series Rotary Switch and DIP Switch

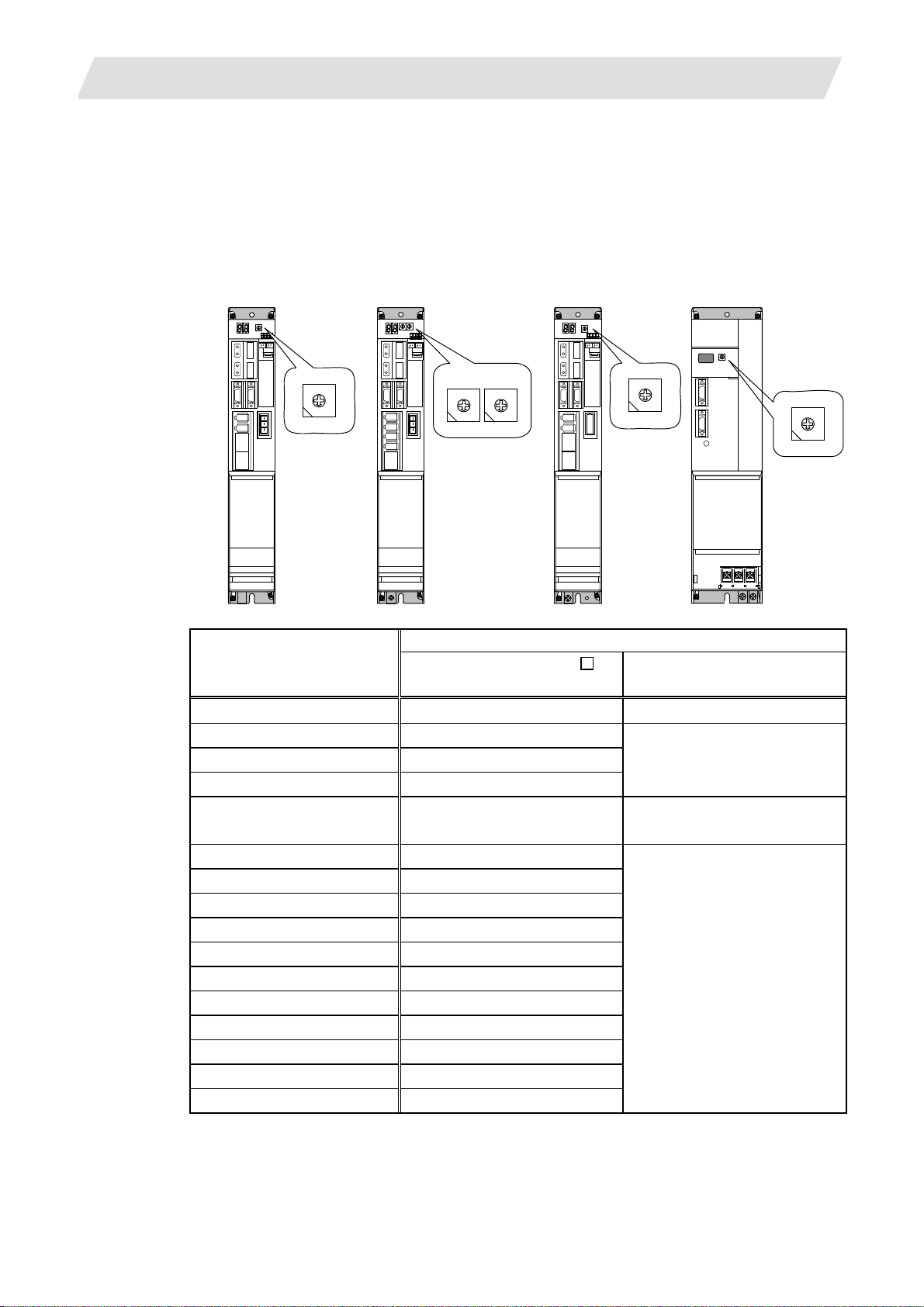

(1) Rotary switch setting

Before turning on the power, the axis No. must be set with the rotary switch. The rotary switch

settings will be validated when the drive units are turned ON.

1st axis

Servo drive unit

(MDS-D/DH-V1)

2nd axis

Servo drive unit

(MDS-D/DH-V2)

Spindle

Drive unit

(MDS-D/DH-SP□)

Power supply unit

(MDS-D/DH-CV)

8

7 9

6 A

5 B

4 C

3 D

2 E

1 F

0

8

7 9

6 A

5 B

4 C

3 D

2 E

1 F

0

8

7 9

6 A

5 B

4 C

3 D

2 E

1 F

0

L axis M axis

8

8

7 9

7 9

6 A

6 A

5 B

5 B

4 C

4 C

3 D

3 D

2 E

2 E

1 F

1 F

0

0

Details

Rotary switch setting

MDS-D/DH-V1/V2/SP

setting

MDS-D/DH-CV

setting

0 1st axis Normal setting

1 2nd axis

2 3rd axis

Setting prohibited

3 4th axis

4 5th axis

External emergency stop valid

(CN23 used)

5 6th axis

6 7th axis

7 8th axis

8 9th axis

9 10th axis

A 11th axis Setting prohibited

B 12th axis

C 13th axis

D 14th axis

E 15th axis

F 16th axis

I - 7

Page 22

3. Setup Details

(2) DIP switch setting

Setting the DIP switches is necessary prior to turning ON the power. Setting of the DIP switches at

the time of turning ON the power is validated. The DIP switches shall be as the standard setting (all

the switches OFF).

3.1 Connecting the Control Unit and Peripheral Devices

The switches are OFF when facing bottom as illustrated.

Turn this switch ON for the drive unit to which the terminator is connected.

Note that the switch must be turned OFF when the network configuration is valid.

M axis Setting unused axis

L axis Setting unused axis

Unused axis can be set by turning the switches ON.

When there is unused axis for the 2-axis drive unit,

set unused axis.

(Note) If the NC system is compatible with A1 or the prior version, set "1" to the base specifications

parameter "#1240 set12/bit4" and turn the last DIP switch ON.

I - 8

Page 23

3. Setup Details

3.1 Connecting the Control Unit and Peripheral Devices

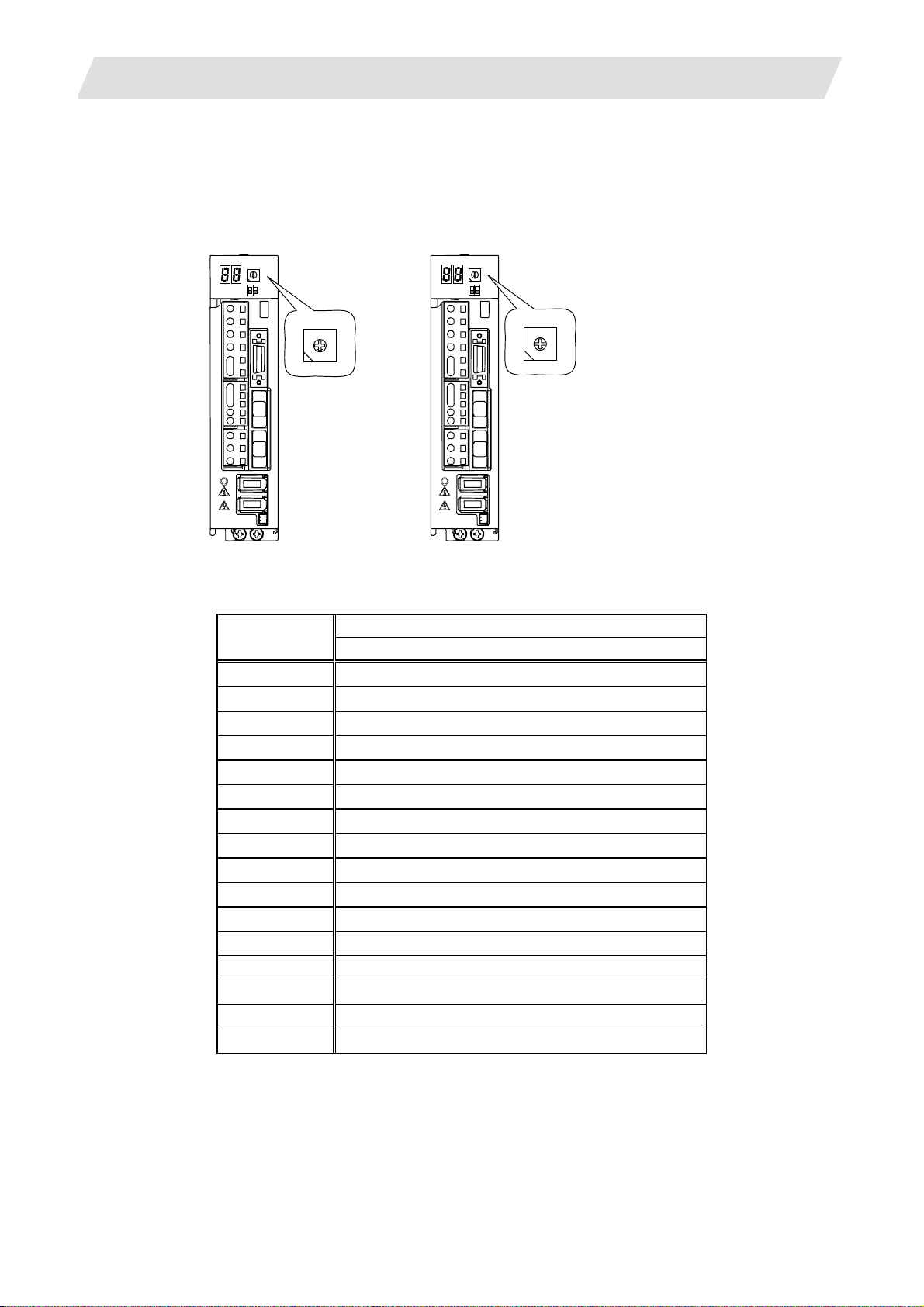

3.1.2 Setting the MDS-D-SVJ3/SPJ3 Series Rotary Switch

Before turning on the power, the axis No. must be set with the rotary switch. The rotary switch settings will

be validated when the drive units are turned ON.

Servo drive unit

(MDS-D-SVJ3)

Spindle drive unit

(MDS-D-SPJ3)

5 B

4 C

3 D

8

7 9

6 A

2 E

1 F

0

4 C

8

7 9

6 A

5 B

3 D

2 E

1 F

0

Details Setting the

rotary switch

Setting the MDS-D-SVJ3/SPJ3

0 1st axis

1 2nd axis

2 3rd axis

3 4th axis

4 5th axis

5 6th axis

6 7th axis

7 8th axis

8 9th axis

9 10th axis

A 11th axis

B 12th axis

C 13th axis

D 14th axis

E 15th axis

F 16th axis

I - 9

Page 24

3. Setup Details

A

A

A

A

3.2 Erasing the Backed up Data (SRAM)

3.2 Erasing the Backed up Data (SRAM)

Use the following procedure if the backed up data (SRAM) needs to be cleared after the control unit is

replaced, etc. (There is no influence on the option parameters even if the backup data is deleted.)

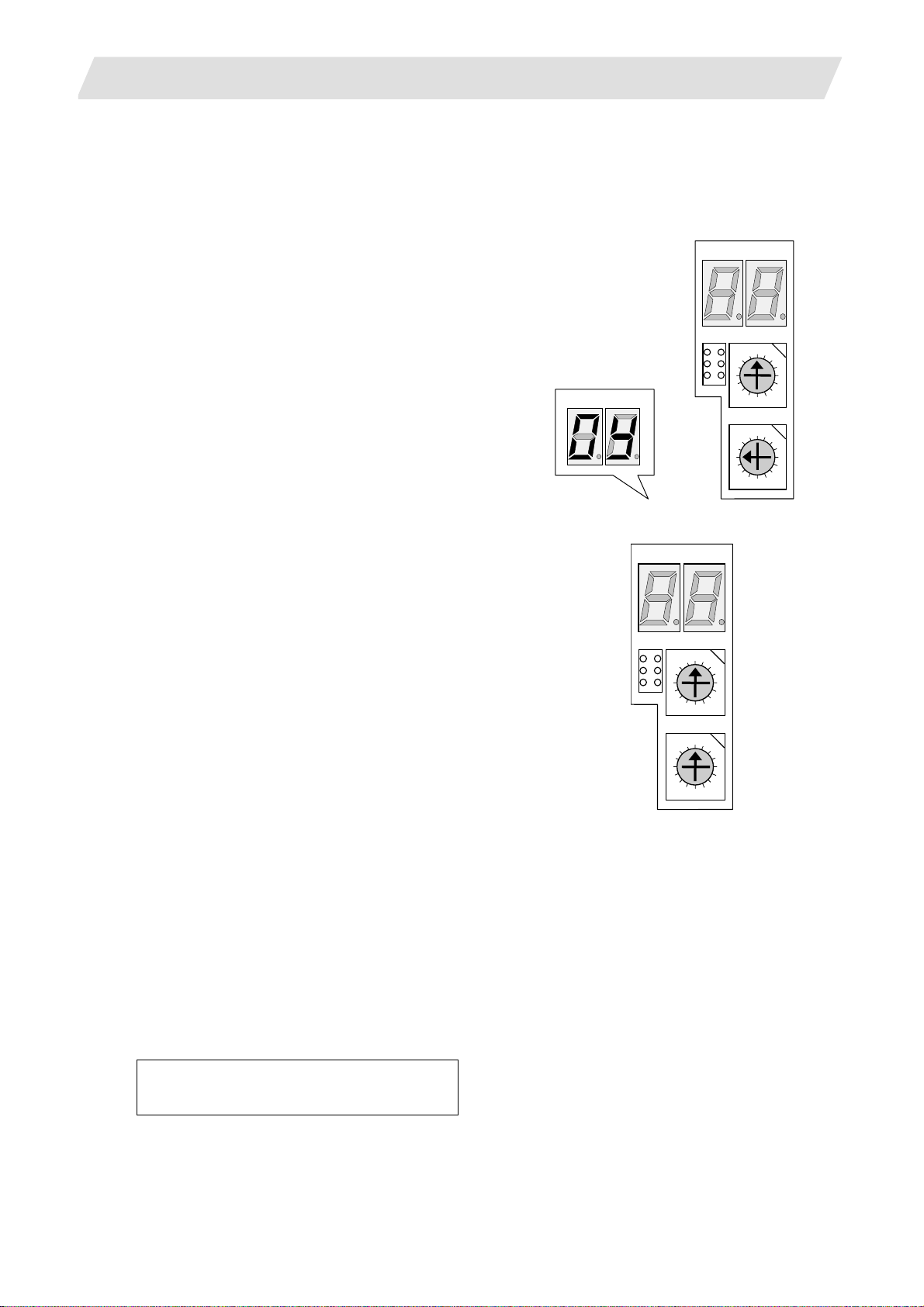

(1) 700 Series

(a) With the NC power OFF, set the upper rotary

switch (CS1) on the control unit to "0" and the

lower rotary switch (CS2) to "C". Then, turn the

power ON.

LED1 LED2

SW1

LED1

D

B

D

B

E

LED2

CS1

F

CS2

F

0

1

2 E

3

4C

5

6

79

8

0

1

2

3

4C

5

6

79

8

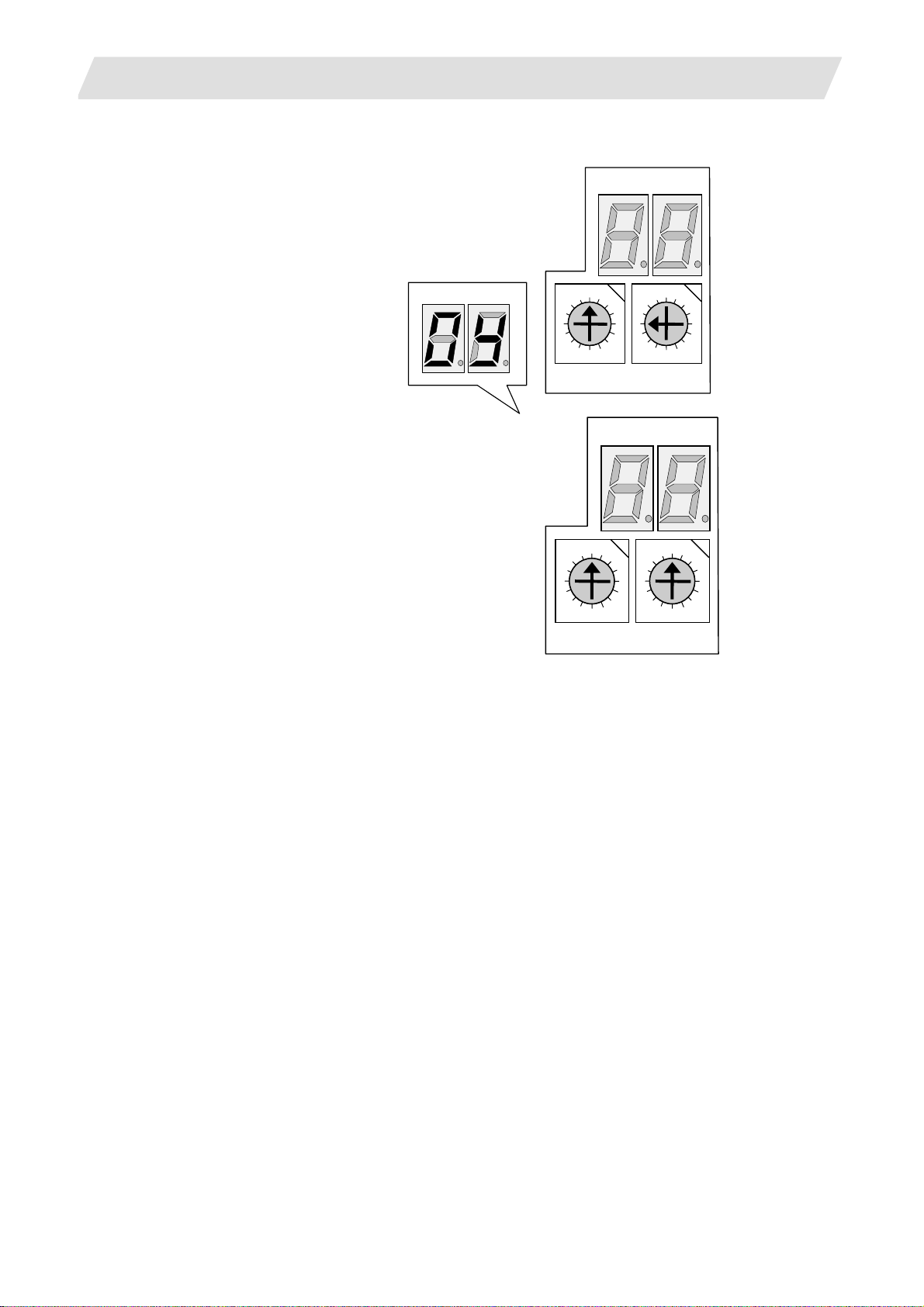

(b) The LED display will change from "08." → "00" →

LED1

LED2

"01" ... "08". The process is completed when "0Y"

is displayed. (Required time: 8 seconds)

(c) Turn the NC power OFF.

(d) Set the lower rotary switch (CS2) to "0".

SW1

D

B

D

B

CS1

0

F

8

CS2

0

F

8

1

2 E

3

4 C

5

6

7 9

1

2 E

3

4 C

5

6

7 9

(e) After turning the power OFF and O N, do nothing, and then turn the power OFF and ON again.

(Note) After the SRAM is cleared and the NC power is turned ON, the IP addresses are initialized to the

following values.

<Base common parameters>

#1934 Local IP address : 192.168.100. 1

#1935 Local Subnet mask : 255.255.255. 0

To communicate with the screen, the parameter value and the "C:\WINDOWS\melcfg.ini" setting value

must match. Confirm that "C:\WINDOWS\melcfg.ini" is set to the above value.

Last line of C:\WINDOWS\melcfg.ini

• • •

[HOSTS]

TCP1=192.168.100.1,683

I - 10

Page 25

3. Setup Details

A

A

A

A

(2) 70 Series

(a) With the NC power OFF, set the left rotary switch

(RSW1) on the control unit to "0" and the right

rotary switch (RSW2) to "C". Then, turn the power

ON.

3.2 Erasing the Backed up Data (SRAM)

NCLD1

NCLD2

NCLD1 NCLD2

0

1

F

D

B

2 E

3

4C

5

6

79

8

0

1

F

D

B

2 E

3

4 C

5

6

7 9

8

RSW2 RSW1

(b) The LED display will change from "08." → "00" →

"01" ... "08". The process is completed when "0Y"

NCLD1

NCLD2

is displayed. (Required time: 8 seconds)

(c) Turn the NC power OFF.

(d) Set the right rotary switch (RSW2) to "0".

0

1

F

D

B

2 E

3

4C

5

6

79

8

0

1

F

2 E

D

B

RSW2 RSW1

3

4 C

5

6

7 9

8

(e) After turning the power OFF and O N, do nothing, and then turn the power OFF and ON again.

I - 11

Page 26

3. Setup Details

3.3 Inputting the Parameters

3.3 Inputting the Parameters

3.3.1 When There is No Parameter File

If there is no parameter file (ALL.PRM), input the parameters with system setup or by manual input operation.

(1) Parameter input with system setup

With the system setup function, various setups necessary for the NC to initially startup are available by

simply entering the minimum required items. File formatting can be done at the same time.

Items required for setting with system setup are as follows.

● Display language, number of spindle connections, number of auxiliary axis connections

(for 700 Series only)

● Number of axes and command type for each part system

● Servo I/F connection channel and rotary switch setting for each spindle.

Also, type of converter connected with each spindle drive.

● Servo I/F connection channel and rotary switch setting for each servo axis.

Also, type of converter connected with each servo drive.

For details, refer to the section "system setup screen" in the instruction manual.

(2) Parameter input by manual input operation

(a) Select "MAINTENANCE (Mainte)" → "Mainte" → "Psswd input", and input "MPARA". Then, press

INPUT.

(b) Select the "Retn" menu

→ "Param", and set the various parameters such as the base

specifications parameters and axis specification parameters according to the machi ne configuration.

The minimum required parameters are listed below. Refer to "III Explanation of Parameters" for

details on each parameter.

(b-1) Set the number of NC axes, number of spindles and number of auxiliary axes, and then turn the

power ON again.

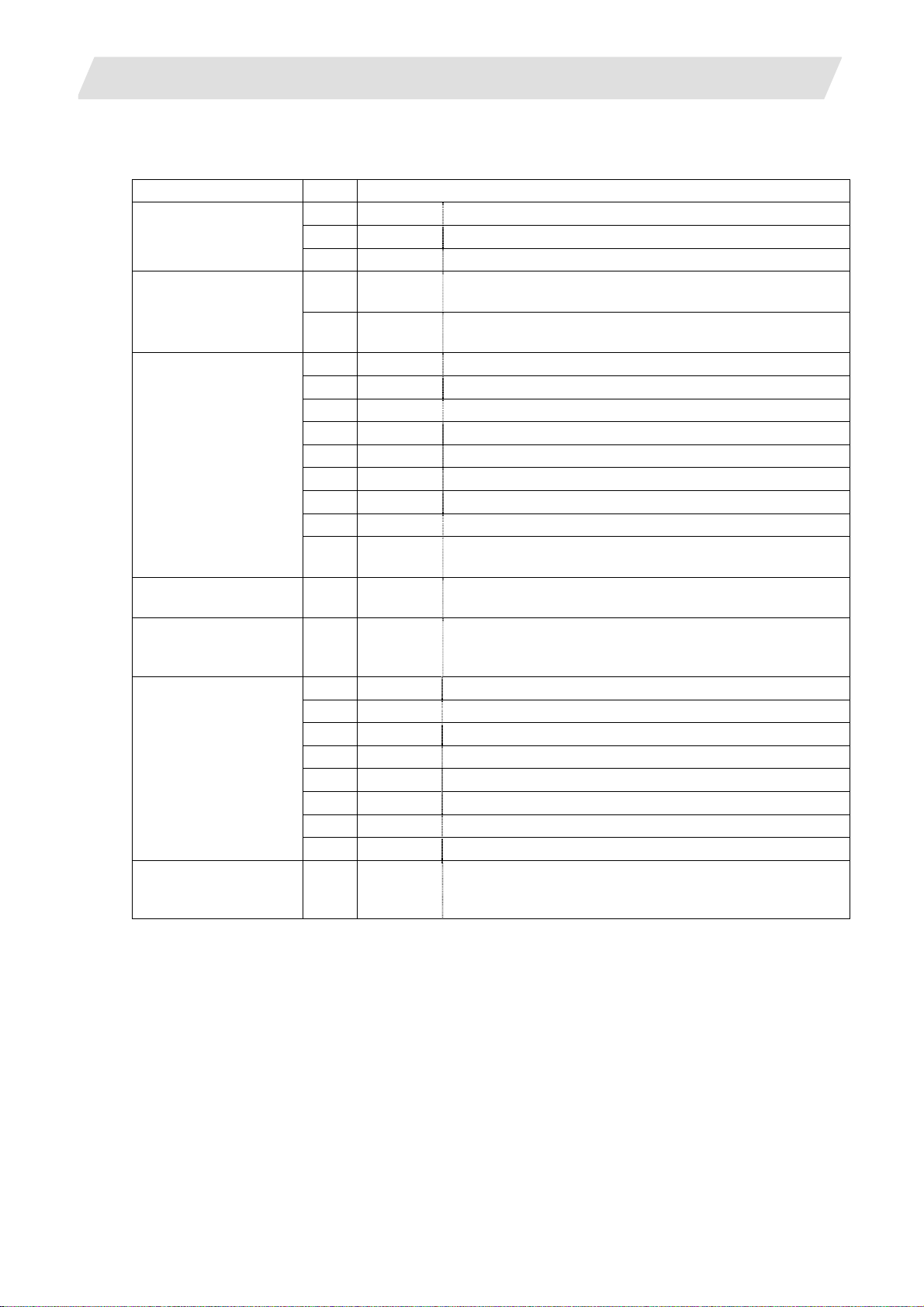

Type # Item

Base system

1002 axisno Number of axes

parameter

1039 spinno Number of spindles Base common

parameters

1044 auxno MR-J2-CT connections (for 700 Series only)

I - 12

Page 27

3. Setup Details

(b-2) Set the minimum required parameters such as the axis name.

Base axis specification

parameters

Base common

parameters

Axis specification

parameters

Zero point return

parameter

Servo parameters 2201

Spindle specification

parameters

Spindle parameters 13001

3.3 Inputting the Parameters

Type # Item

1013 axname Axis name

1021 mcp_no Drive unit I/F channel No. (Servo)

1022 axname2 2nd axis name

1155 DOOR_m Signal input device 1 for door interlock II common for part

systems

1156 DOOR_s Signal input device 2 for door interlock II common for part

systems

2001 rapid Rapid traverse rate

2002 clamp Cutting federate for clamp function

2003 smgst Acceleration/deceleration modes

2004 G0tL G0 time constant (linear)

2005 G0t1 G0 time constant (primary delay)

2007 G1tL G1 time constant (linear)

2008 G1t1 G1 time constant (primary delay)

2102 skip_tL Skip time constant linear

2103 skip_t1 Skip time constant primary delay acceleration/

deceleration by software 2nd stage

2029 grspc Grid interval

:

2456

SV001

:

SV256

Servo parameters

3001 slimt1 Limit rotation speed

3005 smax1 Maximum rotation speed

3024 sout Spindle connection

3025 enc_on Spindle encoder

3031 smcp_no Drive unit I/F channel No. (Spindle)

3105 sut Speed reach range

3107 ori_spd Orientation command speed

3109 zdetspd Z phase detection speed

:

13240

SP1001

:

SP1240

Spindle parameters

I - 13

Page 28

3. Setup Details

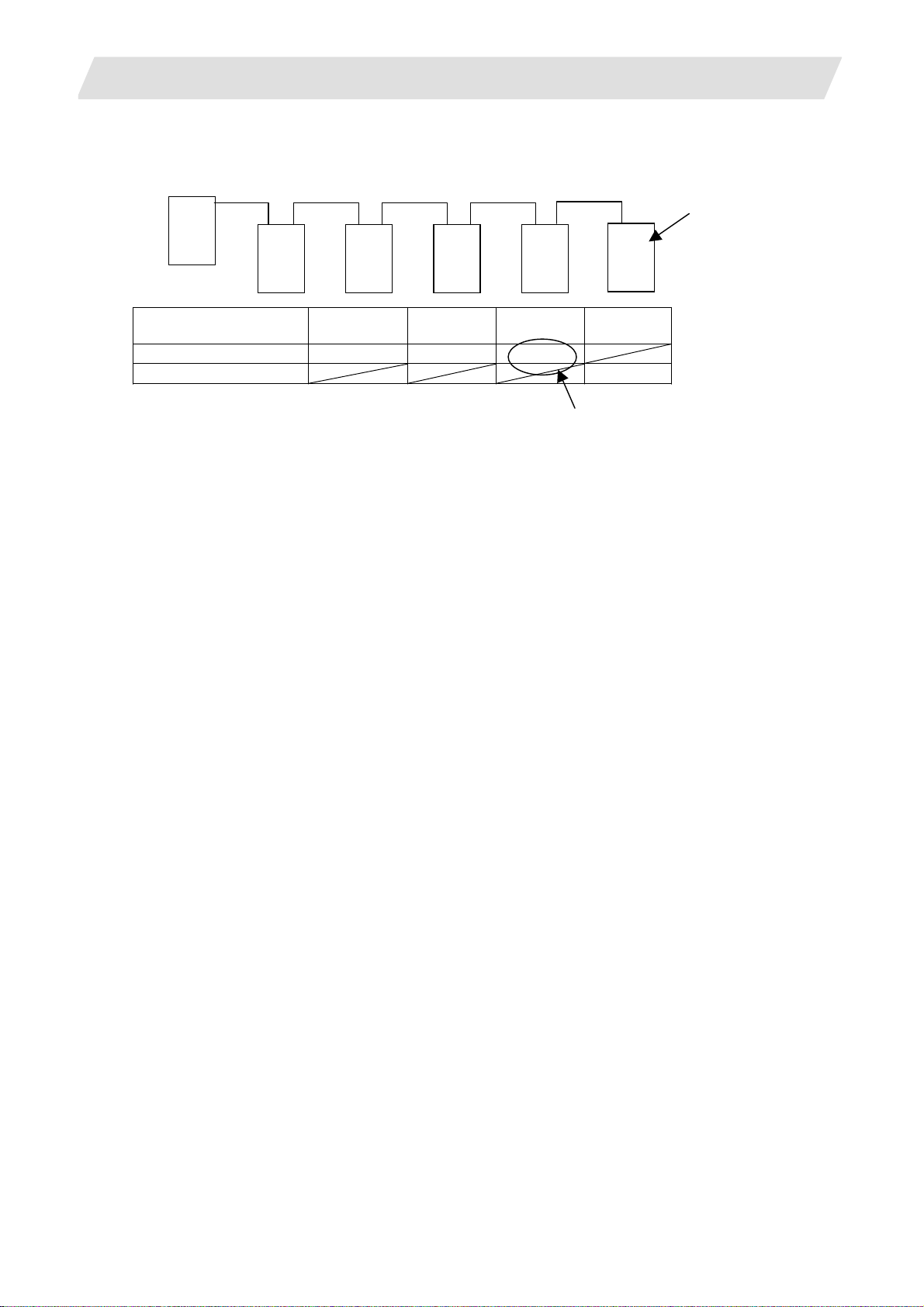

(Setting example) For 3 NC axes (X, Y, Z) and 1 spindle axis (S)

NC

X

Drive unit rotary switch

No.

#1021 mcp_no 1001 1002 1003

#3031 smcp_no 1004

Y Z S

0 1 2 3

3.3 Inputting the Parameters

Power supply

unit

P

3rd axis for 1st channel

I - 14

Page 29

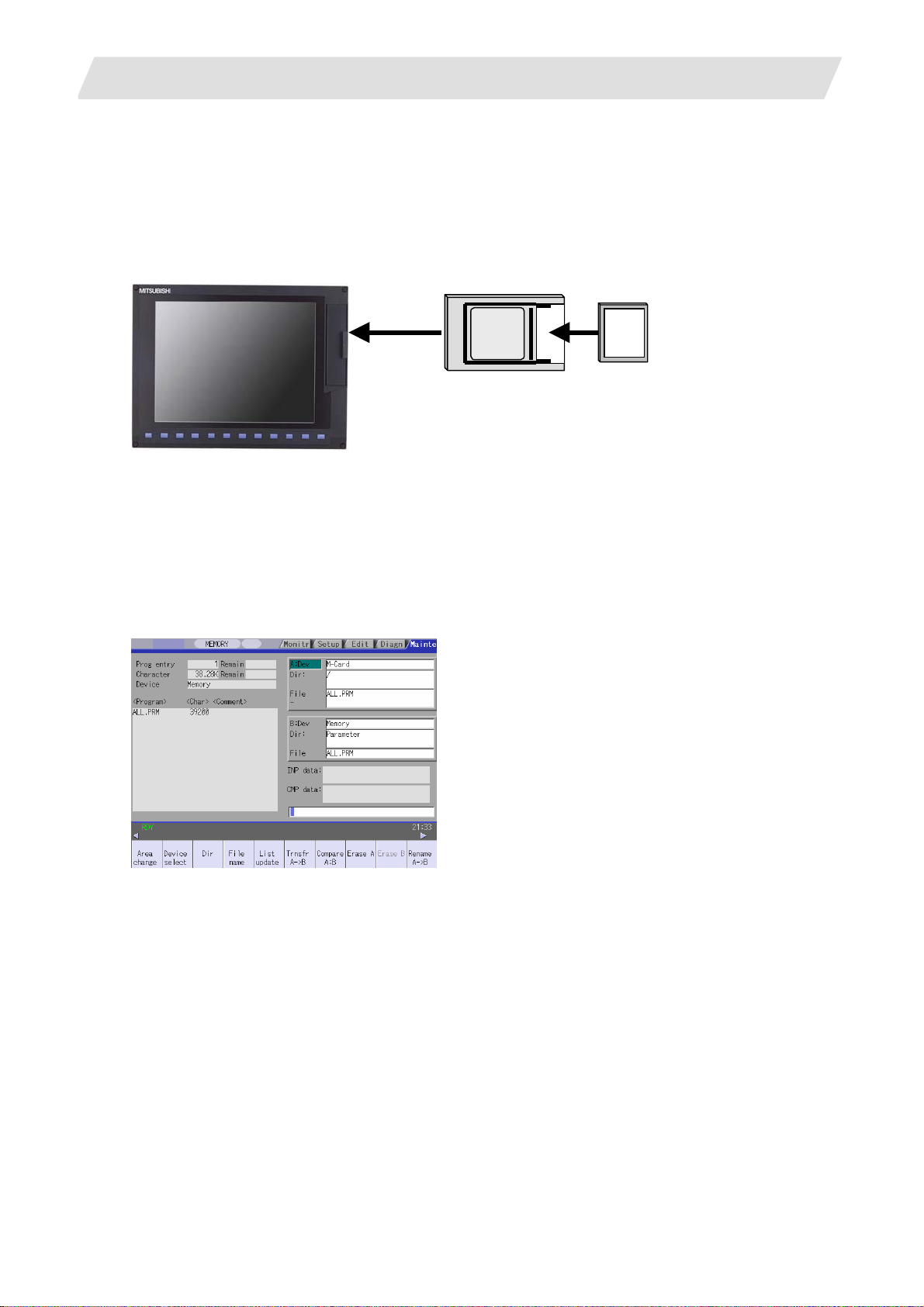

3. Setup Details

3.3 Inputting the Parameters

3.3.2 When a Parameter File is Available

If a parameter file is available, input the parameters using the input/output function.

(Example) When files are available on a compact flash (CF) card

(1) Insert the CF card into the IC card interface on the front of the display unit.

Display unit

Adapter

CF card

(Note) 70 Series, which has the CF card interface,

does not need adapter.

(2) Select "MAINTENANCE (EDIT)" → "Input/Output".

(3) Confirm that device A is selected, and then select "Device select" → "Memory card".

(4) Select "File name" → "From list" → "ALL.PRM", and then press INPUT.

(5) Press "Area change", and select device B.

(6) Select "Device select" → "Memory".

(7) Select "Dir" → "Param".

* "ALL.PRM" is directly input as the file name.

(8) Press "Transfr A → B", and execute parameter input.

I - 15

Page 30

3. Setup Details

3.4 Formatting the File System

3.4 Formatting the File System

The base specification parameter "#1037 cmdtyp" must be set before the file system is formatted.

M System specifications : Set 1 or 2 according to the tool compensation type.

L System specifications : Select and set from 3 to 8 according to the G code list.

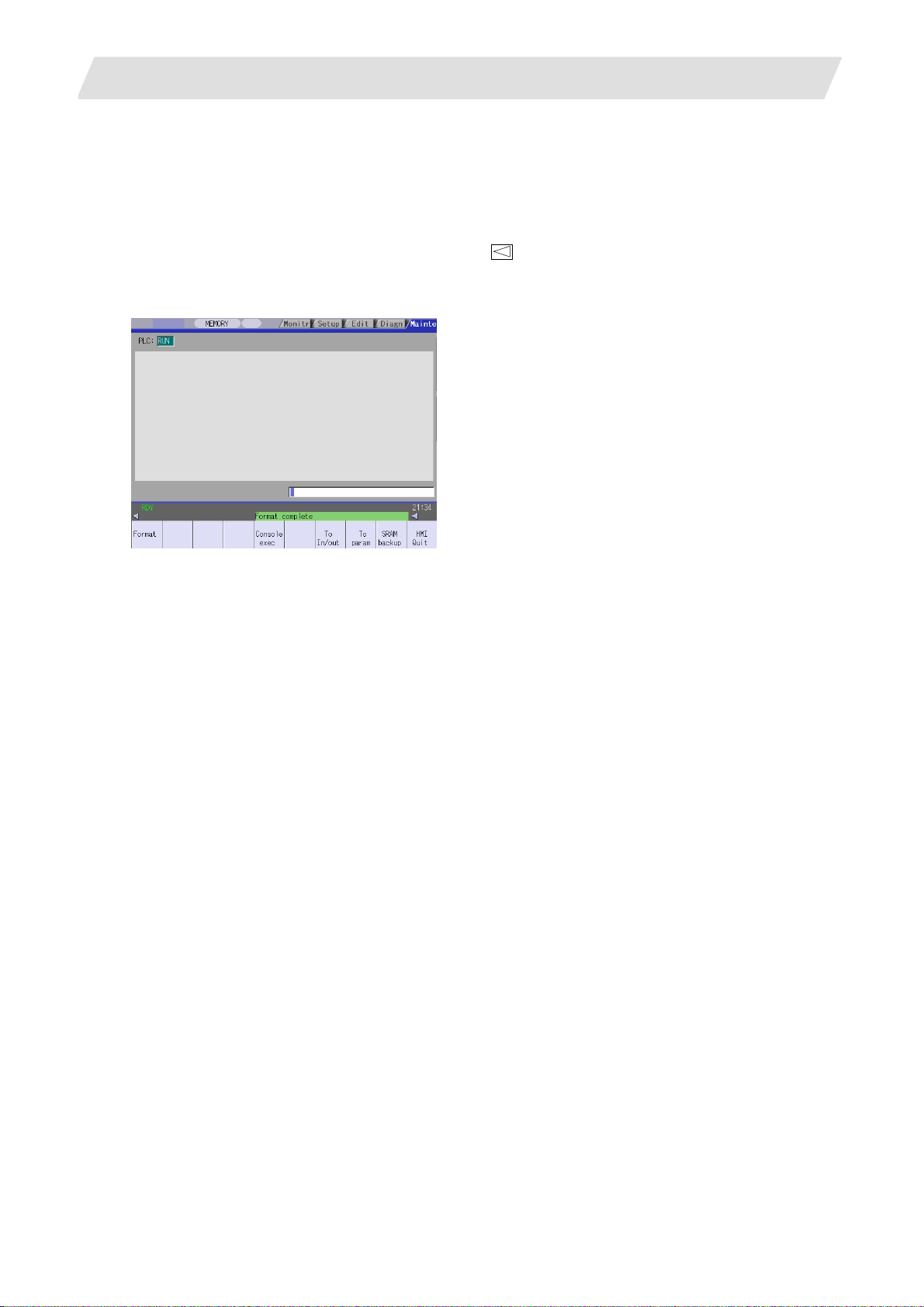

(1) Select "MAINTENANCE (Mainte)" → "NEXT" menu

(2) The message "Format NC memory (Y/N)?" will appear. Press "Y".

(3) When the memory is correctly formatted, the message "Format complete" will appear.

→ "Format".

(Note) When the parameter is set with system setup, the file system does not need to be formatted.

I - 16

Page 31

3. Setup Details

3.5 Inputting the Ladder Program

3.5 Inputting the Ladder Program

The ladder program can be created and input using the GX Developer installed in an external personal

computer or with the PLC onboard editing screen.

Refer to the "MITSUBISHI CNC 700 Series PLC Programming manual" (IB-1500036) for details.

The ladder program creation and input procedures are explained below with a flow chart.

(1) 700 Series

Start

Creation methods

Write with GX Developer

Connection method

Write to NC temporary

memory with Ethernet

communication

Create with GX Developer

Writing method

Write to NC temporary

memory with RS-232-C

Create with PLC onboard

Write to NC temporary

memory

Write with PLC onboard

Save ladder program on

IC card

Open ladder program in IC

card with PLC onboard

Write to NC temporary

memory

Write ladder program to NC ROM

End

I - 17

Page 32

3. Setup Details

(2) 70 Series

Start

Create with GX Developer

Write with GX Developer

3.5 Inputting the Ladder Program

Write to NC temporary

memory with Ethernet

communication

Write ladder program to NC ROM

Connection method

End

Write to NC temporary

memory with RS-232-C

I - 18

Page 33

3. Setup Details

3.6 Credit System

Encryption key and decryption code need to be set in order to validate credit system.

(1) Enter code key in the input/output

screen.

(a) Set the device name, directory and

file name in [A:Dev].

(b) Set "Memory" in device section and

"/CRE" in directory section of

[B:Dev].

Contens in directory section/file name

section will be written over.

Directroy section "Encryption Key"

File name section "ENCKEY.DAT"

3.6 Credit System

(c) Press the menu key [Trnsfr A→B].

(2) Enter cancel code in the input/output

screen.

(a) Set the device name, directory and

file name in [A:Dev].

(b) Set "Memory" in device section and

"/RLS" in directory section of [B:Dev].

Contens in directory section/file name

section will be written over.

Directory section "Decryption Code"

File name section "PASSCODE.DAT"

(c) Press the menu key [Trnsfr A→B].

I - 19

Page 34

3. Setup Details

(3) Turn the power ON again.

3.6 Credit System

Confirm that the expiration date (time limit)

is indicated in [DIAGN]-[Self diag] screen.

I - 20

Page 35

3. Setup Details

3.7 Setting the Handy Terminal

3.7 Setting the Handy Terminal

It is necessary to customize the display part composition, the key input, and the communication condition

with NC, etc. to connect the handy terminal (HG1T-SB12UH-MK1346-L*).

Create the customized data by "NC Designer HT", and download to the handy terminal.

There are two inputting methods of the handy terminal's costomaized data.

(1) Connecting PC and the handy terminal, the data is input from "NC Designer HT".

(2) Connecting NC and the handy terminal, the data is input from CF (Compact Flash).

3.7.1 When Connecting with PC to Input

Project data (*.p1t) h andled as customized data is cr eated by customized data cr eation tool "NC Designer

HT" and download to the handy terminal.

(1) Start the customized data creating tool "NC Designer HT" and create the project data (*.p1t).

(2) Connect PC and the handy terminal with serial (RS-232C).

(3) Select [Online] - [Communication setting] from the menu of "NC Designer HT", confirm the

communication condition is as follows.

Port : Set the PC side port.

Transmission :19200 [bps]

Data : 8 [bit]

Stop bit : 1

Parity : None

I - 21

Page 36

3. Setup Details

(4) Select [Online] - [Download] from the menu of "NC Designer HT".

(5) The following dialog box is displayed, so press the "Yes".

3.7 Setting the Handy Terminal

(6) If the passward is set to the downloaded costomazed data, the "Input password" dialog box is displayed.

So input the passward, press the "OK".

(7) The costomaized data is downloaded to the handy terminal.

(8) When the download has been completed, the following dialog box is displayed.

I - 22

Page 37

3. Setup Details

3.7 Setting the Handy Terminal

3.7.2 When Connecting with NC to Input

Download data (handy.cod) is created from project data (*.p1t) created by customized data creation tool "NC

Designer HT", and the customized data is downloaded to the handy terminal.

(1) Start the customized data creating tool "NC Designer HT" and create the project data (*.p1t).

(2) Select [File] - [Writing download data] from the menu of "NC Designer HT", and save the download data

named as "handy.cod" in the root directory of CF.

(3) Insert the CF created in the step (2) to the control unit.

(4) Set the passward which has been set to the handy terminal to "#11011 Handy TERM. PW."

(Note) When downloading the data for the first time, nothing is set to the parameter.

(5) NC power supply is turned OFF, and the handy terminal is connected with NC.

I - 23

Page 38

3. Setup Details

t

3.8 Adjustment of Dog-type Reference Position Return for Relative Position Detection

3.8 Adjustment of Dog-type Reference Position Return for Relative Position Detection

There are two types for the position detection system, the relative position detection and the absolute position

detection. The methods of returning to the reference position include the dog-type reference position return

and the dogless-type reference position return.

This section describes the method to adjust the dog-type reference position return for the relative position

detection. Refer to the section "3.9 Absolute Position Detection System" for the method of adjusting the

absolute position detection.

3.8.1 Dog-type Reference Position Return Operation

(1) Executes dog-type reference position

return.

(2) Detects near-point dog while travelling. -> Decelerates to a stop, then resumes moving in G28

(3) Reaches the first grid point leaving

near-point dog.

This grid point where the axis stops with (3) is called the electrical zero point. Normally, this electrical

zero point position is regarded as the reference position.

Progress state Operation of axis

-> Starts moving in G28 rapid traverse rate.

approach speed.

-> Stops.

(1)

Reference position

G28 rapid traverse rate

Grid point

(2)

-

Grid space

Limit switch for

near-point detection

Direction of reference position return

G28 approach speed

(3)

+

Near-point dog

Grid amoun

Electrical zero point

The first reference position return after turning the power ON is carried out with the dog-type reference

position return. The second and following returns are carried out wi th either the dog-type reference

position return or the high-speed reference position return, depending on the parameter.

High-speed reference position return is a function that directly positions to the reference position saved

in the memory without decelerating at the near-point dog.

(Note) If reference position return has not been executed even once afte r turning the power ON, the program

error (P430) will occur when movement commands other than G28 are executed.

I - 24

Page 39

3. Setup Details

3.8 Adjustment of Dog-type Reference Position Return for Relative Position Detection

3.8.2 Dog-type Reference Position Return Adjustment Procedures

Adjust the dog-type reference position return with the following steps.

Refer to the next page and followings for details of parameters an d the calculation method for grid mask

amount.

Procedures

(1) Set the following parameter to "0".

・Reference position shift amount (#2027 G28sft).

・Grid mask amount (#2028 grmask).

(2) Turn the power OFF and ON, and then execute reference position return.

(3) Confirm the grid space and grid amount values on DRIVE MONITOR screen.

(4) Calculate the grid mask amount with the calculation method for grid mask amount.

(5) Set the grid mask amount.

(6) Turn the power OFF and ON, and then execute reference position return.

(7) Confirm the grid space and grid amount values on DRIVE MONITOR screen.

If the grid amount value is approx. half of the grid space, the grid mask amount has been set

correctly.

If the value is not approx. half, repeat the procedure from step (1).

(8) Set the reference position shift amount (#2027 G28sft).

(9) Turn the power OFF and ON, and then execute reference position return.

(10) Set the machine coordinate system offset amount (#2037 G53ofs).

I - 25

Page 40

3. Setup Details

p

)

r-p

g

p

p

3.8 Adjustment of Dog-type Reference Position Return for Relative Position Detection

Reference position return operation and parameter related drawing

Basic machine coordinate

system zero point

#2025 G28rap

(G28 rapid traverse rate)

#2030 dir(-) (Reference position return direction)

(Position returned to with the reference

#2026 G28crp (G28 approach speed)

Electrical zero point

Reference position

osition return command

-

Grid point

The grid located at the near-point dog or

the grid mask area is not the electrical

Reference point

Grid point

Grid amount

zero

The reference position is positioned when the dog-type reference position return is executed. Note that

the other method is available for the absolute position detection.

The reference position is positioned with the manual reference position return or G28 command in the

machining program.

Using parameters, the reference position can be shifted from the electrical zero point position.

The position detector has a Z-phase that generates one pulse per rotation. The 0-point position of this

Z-phase is the grid point. Thus, there is a grid point per rot ation of the po sition d etector, and the machine

has many grid points at a regular pitch.

The grid point can be set at intervals of grid space by setting the grid space (#2029 grspc). Thus, multiple

grid points can be set per detector rot ation.

The grid amount is the distance from where the near-point detection limit switch leaves the near-point

dog to the grid point (electrical zero point) while the dog-type reference position return.

The grid amount can be confirmed on DRIVE MONITOR screen.

After setting the grid mask, the grid amount shows the dist ance fro m the grid ma sk OFF to the grid point.

oint.

#2029 grspc

(Grid space)

Nea

oint do

#2037 G53ofs

(Machine zero point offset)

Grid amount is displayed on

the drive monitor screen.

Grid

mask

#2028

grmask

(Grid mask

amount)

#2027

G28sft

Grid

amount

(Reference

position shift

amount)

The first grid out of the grid

mask is the electrical zero

oint.

+

I - 26

Page 41

3. Setup Details

f

3.8 Adjustment of Dog-type Reference Position Return for Relative Position Detection

G28 rapid traverse rate (#2025 G28rap)

Set the feedrate for dog-type reference position return in manual operation and automatic operation.

The rapid traverse rate (#2001 rapid) is applied for the feedrate during high-speed reference positio n

return.

G28 approach speed (#2026 G28crp)

Set the approach speed (creep speed) to the reference position after decelerating to a stop by the

near-dog detection. Since the creep speed is accelerated and decelerated in steps

(no-acceleration/deceleration), the mechanical shock, etc., could occur if the speed is too large.

The creep speed should be set between 100 and 300 mm/min., or within 500 mm/min. at the fastest.

Reference position shift amount (#2027 G28sft)

Set the shift amount to shift the reference position from the electrical zero point.

The shift direction can be set only in the reference position return direction.

If the reference position shift amount is "0", the grid point (electrical zero point) will be the reference

position.

Grid mask amount (#2028 grmask)

The first grid point after the dog OFF is regarded as the electrical zero point.

If the grid point is at the position where the near-point dog is kicked OFF, the position of electrical zero

point may differ because of the delay of the limit switch operation, at the grid point where the dog is

kicked OFF or the next grid point. This causes a deviation of reference position by the amou nt of the grid

space.

The position that the dog is kicked OFF should be at the approximate center of the grid space.

Reference position

Dog

Electrical zero point shits

depending on the speed o

limit switch delay.

Adjustments can be made by changing the near-point dog or by setting the grid mask amount.

Setting the grid mask has the same effect as lengthening the near-point dog.

If the grid amount is approximate the grid space or 0, the grid point may be at the position of near-point

dog OFF, so set a grid mask.

Set the grid mask amount so that the grid amount is one-half of the grid space.

The grid mask amount can be set only in the reference position return direction.

The grid amount and grid space can be confirmed on the DRIVE MONITOR screen.

Refer to "calculation method for the grid mask amount" on the next page for the grid mask amount

values.

I - 27

Page 42

3. Setup Details

g

3.8 Adjustment of Dog-type Reference Position Return for Relative Position Detection

Calculation method for grid mask amount

When

Grid space Grid space

2

< Grid amount

Grid mask amount = Grid amount

Reference position (Position returned to with

the reference position return command)

Electrical zero point

−

2

-

Near-point dog

Grid mask

Grid mask

amount

#2016

Grid amount

Grid space

2

+

When

Grid space Grid space

2

> Grid amount Grid mask amount = Grid amount +

2

-

This will not be the electrical

zero point due to the grid mask.

Reference position

before

rid mask i s se t.

Reference position after

grid mask is set.

+

Near-point dog Grid mask

Grid space

Grid amount

Grid mask amount

#2016

2

Grid amount after

grid mask is set.

I - 28

Page 43

3. Setup Details

3.8 Adjustment of Dog-type Reference Position Return for Relative Position Detection

Grid space (#2029 grspc)

Set the distance between grids.

The normal grid space is the ball screw pitch value (#2218 PIT) or the movement amount per motor

rotation set as a mm unit.

To make the grid space smaller, set a divisor of the grid space.

Calculation method for movement amount per motor rotation

(1) When linear feed mechanism is ball screw:

Movement amount per

motor rotation =

(2) When linear feed mechanism is rack & pinion:

Motor side gear ratio

Machine side gear ratio

Ball screw pitch

∗

Movement amount per

motor rotation =

(3) For rotary axis:

motor rotation= Machine side gear ratio

PC1

N =

PC2

∗ PIT

Motor side gear ratio

Machine side gear ratio

Motor side gear ratio Movement angle per

= Movement amount per motor rotation

N

= Motor side gear ratio

PC1

= Machine side gear ratio

PC2

= Ball screw pitch

PIT

Number of pinion gear teeth ∗ Rack pitch

∗

360

∗

I - 29

Page 44

3. Setup Details

3.8 Adjustment of Dog-type Reference Position Return for Relative Position Detection

Reference position return direction (#2030 dir (−))

Set the direction to move after the limit switch kicks the dog causing a deceleration stop during dog-type

reference position return. The direction is either positive "0" or negative "1".

Set "0" if the reference position is in the positive direction from the near-point dog.

Set "1" if the reference position is in the negative direction from the near-point dog.

(a) When reference position return direction is positive (+ )

To move in

+ direction

(-)

Dog

(b) When reference position return direction is negative (−)

To move in

- direction

(+)

Reference position

To move in

+ direction

(-)

Dog

Reference position

Axis with no reference position (#2031 noref)

Set "0" for the axis to carry out dog-type reference position return and the axis for absolute position

detection.

Set "1" for the axis without carrying out reference position return during relative position detection.

Machine coordinate system offset (#2037 G53ofs)

Set the amount to shift the basic machine coordinate system zero point position from the referen ce

position.

When "0" is set, the reference position will be the position of the basic machine coordinate system zero

point.

In “G53ofs” parameter, set the position of the reference position looking from the basic machine

coordinate system zero point with the coordinates of basic machine coordin ate system. By the reference

position return after the power is turned ON, the machine position will be set an d the basic machine

coordinate system will be established.

Selection of grid display type (#1229 set01/bit6)

Select the grid display type on DRIVE MONITOR screen during dog-type refe ren ce po sition re turn.

0: Distance from dog OFF to electric zero point (including grid mask amount)

1: Distance from dog OFF to electric zero point (excluding grid mask amount)

To move in

- direction

(+)

I - 30

Page 45

3. Setup Details

A

3.9 Absolute Position Detection System

3.9 Absolute Position Detection System

The absolute position detection function detects the machine movement amount while the power is OFF. This

allows automatic operation to be started without carrying out reference position return after the power is

turned ON. This function is extremely reliable as it carries out a mutual check of the feedback amount from

the detector, and checks the absolute position unique to the machine, etc.

To carry out the absolute position detection, the machine zero point must be determined, and the absolute

position must be established. Following two methods are available depending on how the ab solute position is

established.

(1) Dogless-type absolute position detection

The absolute position is established by setting an arbitrary coordinate at an arbitrary position without

using the dog.

The absolute position basic point can be determined with the following three methods.

・Machine end stopper method

・Marked point alignment method

・Marked point alignment method II

For the machine end stopper method, the manual initialization and automatic initialization methods ca n

be used.

(2) Dog-type absolute position detection

The absolute position is established by executing dog-type reference position ret urn.

The validity and method of the absolute position detection system can be selected with parameters for each

axis. Note that the servo drive unit and detector must have the specifications compatible for the absolute

position detection.

3.9.1 Dog-type Reference Position Return Operation

Using the mechanical basic position (machine end or marked point) or the electri cal ba sic position (grid

point immediately before the machine end or marked point) as the absolute position basic point, the

basic machine coordinate system zero point will be set at the position "ZERO" value far from the absolute

position basic point in the direction of reversed “ZERO” sign.

The reference position is set at the position "G53ofs" value far from the basic machine coordin ate

system's zero point.

bsolute position

Basic machine

coordinate system

"G53ofs"

Reference position

Dogless absolute position coordinate system

"ZERO"

basic point

ZERO : Coordinate position of absolute position basic point looking from basic machine

coordinate system zero point. (ABS. POSITION PARAMETER screen "#2 ZERO")

G53ofs : Coordinate position of reference position loo king fro m basic machine coordinate

system zero point. (axis specifications parameter "#2037 G53ofs")

(Note) Select with the parameter "#2059 zerbas" whether to use the mechanical basic position or electrical

basic position as the absolute position basic point for the machine end sto pper method.

I - 31

Page 46

3. Setup Details

3.9 Absolute Position Detection System

3.9.2 Starting up the Absolute Position Detection System

The zero point initialization should be carried out before the absolute position detection system is st arted

up. The coordinate system is established and operation is enabled by zero point initialization.

In this section, only the outline is introduced. (Refer to the Instruction Manual for details.)

Refer to the chapter "III Parameters" for the parameter details.

Operation when absolute position is not established

If the zero point has not been initialized even once or if the absolute position is lost, the following alarm

and non-initialized axis will be output. The coordinate system is unstable in this point, so the limitations

given in following table will be applied to each mode. Initialize the zero point and establish the coo rdinate

system. Refer to the Instruction Manual for details.

Alarm: Z70 (Absolute position data error)

Z71 (Absolute position encoder failure)

Operation in each mode

Operation

mode

Memory/MDI Movement command invalid

(Note 1) (Including G28)

JOG feed Valid Valid

Rapid traverse Valid Valid

Handle Valid Valid

Step Valid Valid

Zero point return Starting not possible (Note 2) Starting possible

(Note 1) The program error (P430) will occur.

(Note 2) If the axis before the absolute position establish is started, the error "M01 OPERATION ERROR

0024" will occur.

(This mode is valid for an axis for which the absolute position has been est ablished.)

Selecting the zero point initialization method

Select the zero point initialization method with the following parameter.

#2049 type 1: Dogless type Machine end stopper method

2: Dogless type Marked point alignment method

3: Dog type

4: Dogless type Marked point alignment method II

Absolute position detection method

Dogless-type Dog-type

Movement command invalid

(Note 1) (G28 is valid)

I - 32

Page 47

3. Setup Details

Dogless-type zero point initialization

The zero point is initialized using the ABS POSITION SET screen and JOG or handle.

The operation methods differ according to the zero point initialization method. Re fer to the Instructio n

Manual for details.

(1) Machine end stopper method

The machine end stopper method includes the manual initialization and automatic initialization

methods.

(a) Manual initialization

Dog-type zero point initialization

With this method, the axis is pushed against the machine end stopper using handle or JOG.

(b) Automatic initialization

With this method, the axis is pushed against the machine end stopper, and can be used when the

"INIT-SET" mode is selected. This method has the following features compared to the manual

initialization method.

・The axis is pushed with the same conditions (feedrate, distance) each time, so inconsistencies in

the zero point position can be reduced.

・Part of the operations is automated to simplify the zero point initialization.

(2) Marked point alignment method

With this method, the axis is aligned to the machine's basic point (marked point) using handle or

JOG. The first grid point where the axis reaches upon retraction in the opposite direction after

alignment to the marked point is regarded as the basic point.

(3) Marked point alignment method II

With this method, the axis is aligned to the machine's basic point (marked point) using handle or

JOG. The machine’s basic position (marked point) is regarded a s th e basi c poi nt.

By executing dog-type reference position return with the manual reference position return mode or

automatic reference position return command (G28), the zero point will be initialized.

3.9 Absolute Position Detection System

I - 33

Page 48

3. Setup Details

3.10 Auxiliary Axis Operation

3.10 Auxiliary Axis Operation

Auxiliary axis absolute position initial setting and test run are carried out on the auxiliary axis test screen.

In this section, only the outline is introduced. Refer to the Instruction Manual and "MR-J2-CT Specifications

and Instruction Manual (BNP-B3944)" for details.

Also, refer to "13. Auxiliary Axis Parameter" in "III Parameter" for details on the auxiliary axis parameters.

I -

34

Page 49

3. Setup Details

3.10 Auxiliary Axis Operation

3.10.1 Preparations

Before the screen is switched to auxiliary axis test screen, prepare the following things.

(1) Parameter settings

Set the following parameters.

No. Name Setting details

50102 Cont2

50120 ABS

Type

Control

parameter 2

Absolute

position

detection

parameter

bit7 = 1 (Absolute position detection)

Turn the NC power ON again after this parameter is set.

The alarm "Z70 Abs data error" occurs after the power

(Note)

ON again.

bit1/bit2 : Select the absolute position detection method.

Method bit2 bit1 Details

Dog-type method

Mechanical end

stopper method

Marked point

alignment method

When bit1 is "1", dog-type method is selected regardless of

(Note)

(Note)

0 0 This decides the basic point by

1 0 This decides the basic point by

1 This decides the reference

position by the near point dog.

pushing an axis to machine end

etc. when the torque (current)

limit is set.

aligning an axis to machine origin

point.

bit2 setting.

bit3 : Select the electrical basic position direction at marked point

alignment method.

Direction bit3

Electrical basic position direction + 0

Electrical basic position direction - 1

(2) Release servo OFF/interlock for auxiliary axis.

(3) Turn J2CT operation adjustment mode valid signal (R9998/bit0) ON.

I -

35

Page 50

3. Setup Details

3.10 Auxiliary Axis Operation

3.10.2 Absolute Position Initial Setting

The coordinate system is established and operation is enabled when the absolute position is initially set.

Carry this out when absolute position is not established.

Refer to the Instruction Manual for detailed operations.

3.10.3 Test Operation

Disconnect the auxiliary axis control from PLC and startup in a forward/reverse run by menu operation to

carry out a test operation.

Refer to the Instruction Manual for detailed operations.

I -

36

Page 51

3. Setup Details

3.10 Auxiliary Axis Operation

3.10.4 PLC device

Devices that are used for auxiliary axis operation adjustment and control are as follows.

Refer to "MR-J2-CT Specifications and Instruction Manual (BNP-B3944)" for details.

(1) Operation adjustment mode

Device No.

bit

R9998 bit0 J2CT Operation adjustment mode valid (Common for all axes)

R9948 bit0 J2CT 1st axis in operation adjustment mode

bit1 J2CT 2nd axis in ope ration adjustment mode

bit2 J2CT 3rd axis in operation adjustment mode

bit3 J2CT 4th axis in operation adjustment mode

(2) Auxiliary axis control command

Signal name J2CT

Abbrev. CTCM4 CTCM3 CTCM2 CTCM1 CTCML CTCMH

J2CT

1st axis

J2CT

2nd axis

J2CT

3rd axis

J2CT

4th axis

(a) CTCM1 (J2CT Control command 1)

bit Details

0 *SVF Servo OFF

1 QEMG PLC emergency stop

2 *PRT1 Data protect

3 MRST MC reset

4 *IT+ Interlock +

5 *IT- Interlock 6 RDF Ready OFF

7 H Handle mode

8 AUT Automatic operation mode

9 MAN Manual operation mode

A J Jog mode

B ZRN Reference position mode

C

D AZS Zero point initialization mode

E ZST Basic position set

F S Incremental mode

Abbrev. Signal name

J2CT

Control

command L

Control

command 4

J2CT

Control

command 3

J2CT

Control

command 2

J2CT

Control

command 1

R9950 R9951 R9952 R9953 R9954 R9955

R9956 R9957 R9958 R9959 R9960 R9961

R9962 R9963 R9964 R9965 R9966 R9967

R9968 R9969 R9970 R9971 R9972 R9973

(b) CTCM2 (J2CT Control command 2)

bit Details

0 ST Operation start

1 DIR Rotation direction

2 STS Arbitrary point feed command valid

3 PUS Stopper positioning command valid

4 MP1 Incremental feed magnification 1

5 MP2 Incremental feed magnification 2

6 PR1 Operation parameter selection1