Page 1

INVERTER

FR-A700

PLC FUNCTION

PROGRAMMING MANUAL

PLC FUNCTION

CC-Link

COMMUNICATION

SEQUENCE

PROGRAMMING

ERROR CODE

LIST

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Page 2

CONTENTS

1. PLC FUNCTION 1

1.1 Function Block Diagram ...........................................................2

1.2 PLC Function Specifications....................................................3

1.3 System Configuration ...............................................................4

1.4 Wiring of the Inverter and Personal Computer Using

GX Developer for RS-485 Communication..............................5

1.5 Prior to Sequence Program Creation ......................................6

1.5.1 Precautions for sequence program creation .................................................6

1.5.2 Usable main GX Developer functions ...........................................................6

1.5.3 Sequence program execution key.................................................................7

1.5.4 Sequence program write............................................................................... 8

1.5.5 Setting list of built-in PLC function parameter ...............................................9

1.6 Device Map...............................................................................10

1.6.1 I/O device map............................................................................................10

1.6.2 Internal relay (M) device map......................................................................12

1.6.3 Data register (D) device map ......................................................................12

1.6.4 Special relays..............................................................................................12

1.6.5 Special registers..........................................................................................14

1.7 Inverter Status Monitoring, Special Registers for Control ..20

1.7.1 Data that can be read at all times................................................................20

1.7.2 Data that are read by controlling (OFF to ON) the read command .............23

1.7.3 How to write data by controlling (OFF to ON) the write

command....................................................................................................25

1.7.4 Inverter operation status control..................................................................31

1.7.5 Inverter parameter access error (D9150)....................................................33

1.7.6 Inverter status (D9151)................................................................................33

1.8 Inverter Parameter Read/Write Method .................................34

1.8.1 Reading the inverter parameters.................................................................34

1.8.2 Writing the inverter parameters...................................................................36

1.9 User Area Read/Write Method ................................................38

1.9.1 User parameter read/write method.............................................................. 38

1.10 Analog I/O function .................................................................39

1.10.1 Analog input ................................................................................................39

1.10.2 Analog output..............................................................................................39

1.11 Paluse train input function .....................................................40

1.12 PID control ...............................................................................41

1.13 Inverter Operation Lock Mode Setting ..................................43

CONTENTS

I

Page 3

2. CC-Link COMMUNICATION 45

2.1 System Configuration............................................................. 46

2.1.1 System configuration example.................................................................... 46

2.1.2 Function block diagram............................................................................... 47

2.2 CC-Link Parameters................................................................ 49

2.2.1 CC-Link Extended Setting (Pr. 544)............................................................ 49

2.3 CC-Link I/O Specifications ..................................................... 50

2.4 Buffer Memory......................................................................... 57

2.4.1 Remote output signals

(Master module to inverter(FR-A7NC))....................................................... 57

2.4.2 Remote input signals Pr.544=100

(Inverter(FR-A7NC) to master module)....................................................... 58

2.4.3 Remote registers Pr.544=100

(Master module to inverter(FR-A7NC))....................................................... 59

2.4.4 Remote registers Pr.544=100

(Inverter(FR-A7NC) to master module)...................................................... 60

3. SEQUENCE PROGRAMMING 61

3.1 Overview .................................................................................. 62

3.1.1 Outline of Operation Processings ............................................................... 62

3.2 RUN and STOP Operation Processings................................ 64

3.3 Program Makeup ..................................................................... 64

3.4 Programming Languages.......................................................65

3.4.1 Relay symbolic language (Ladder mode) ................................................... 65

3.4.2 Logic symbolic language (List mode).......................................................... 67

3.5 Operation Processing Method of PLC Function ..................68

3.6 I/O Processing Method ........................................................... 69

3.6.1 What is refresh system? ............................................................................. 69

3.6.2 Response delay in refresh system.............................................................. 70

3.7 Scan Time ................................................................................ 71

3.8 Numerical Values Usable in Sequence Program .................72

3.8.1 BIN (Binary Code)....................................................................................... 73

3.8.2 HEX (HEX Decimal).................................................................................... 74

3.9 Description of devices............................................................ 75

3.9.1 Device List .................................................................................................. 75

3.9.2 Inputs, Outputs X, Y.................................................................................... 76

3.9.3 Internal Relays M........................................................................................ 79

3.9.4 Timers T...................................................................................................... 80

II

Page 4

3.9.5 100ms, 10ms and 100ms retentive timers ..................................................80

3.9.6 Timer processing method and accuracy .....................................................81

3.10 Counters C ...............................................................................83

3.10.1 Count processing in refresh system............................................................84

3.10.2 Maximum counting speed of counter ..........................................................85

3.11 Data Registers D......................................................................86

3.12 Special Relays, Special Registers .........................................87

3.13 Function List............................................................................89

3.14 How to RUN/STOP the Built-in PLC Function from Outside (Re-

mote RUN/STOP) .....................................................................90

3.15 Watchdog Timer (Operation clog up monitor timer)............92

3.16 Self-diagnostic Function ........................................................93

3.16.1 Error-time operation mode .......................................................................... 94

3.17 Keyword Registration .............................................................95

3.18 Setting of Output (Y) Status at Switching from STOP Status to

RUN Status...............................................................................96

3.19 Instruction Format...................................................................97

3.20 Bit Device Processing Method...............................................99

3.20.1 1-bit processing...........................................................................................99

3.20.2 Digit designation processing .......................................................................99

3.21 Handling of Numerical Value................................................101

3.22 Operation Error......................................................................102

3.23 Instructions List ....................................................................103

3.23.1 How to use the instruction list....................................................................103

3.23.2 Sequence instruction.................................................................................105

3.23.3 Basic instructions ......................................................................................107

3.23.4 Application instructions..............................................................................109

3.24 Description of the Instructions ............................................110

3.25 Sequence Instructions ..........................................................111

3.25.1 Contact Instructions :

Operation start, series connection, parallel connection ... LD, LDI, AND, ANI,

OR, ORI.....................................................................................................111

3.25.2 Contact Instructions : Ladder block series connection, parallel connection ...

ANB, ORB ................................................................................................. 113

3.25.3 Connection Instructions :

Ladder block series connection, parallel connection ... ANB, ORB...........117

3.25.4 Connection Instructions :

Operation result, push, read, pop ... MPS, MRD, MPP.............................120

3.25.5 Output Instructions : Bit device, timer, counter ... OUT.............................123

CONTENTS

III

Page 5

3.25.6 Output Instructions : Device set, reset ... SET, RST................................. 126

3.25.7 Output Instructions : Leading edge, trailing edge differential outputs ... PLS,

PLF ........................................................................................................... 129

3.25.8 Shift Instructions : Bit device shift ... SFT, SFTP...................................... 131

3.25.9 Master Control Instructions : Master control set, reset ... MC, MCR......... 133

3.25.10End Instruction : Sequence program end ... END..................................... 137

3.25.11Other Instructions : No operation ... NOP ................................................. 138

3.26 Basic Instructions ................................................................. 140

3.26.1 Comparison Operation Instructions .......................................................... 140

3.26.2 Comparison Operation Instructions :

16-bit data comparison ... =, <>, >, <=, <, >=............................................ 142

3.26.3 Arithmetic Operation Instructions.............................................................. 144

3.26.4 Arithmetic Operation Instructions :

BIN 16-bit addition, subtraction ... +, +P, -, -P .......................................... 145

3.26.5 Arithmetic Operation Instructions :

BIN 16-bit multiplication, division ... *, *P, /, /P.......................................... 149

3.26.6 Data Transfer Instructions......................................................................... 153

3.26.7 Data Transfer Instructions :

16-bit data transfer ... MOV, MOVP.......................................................... 153

3.27 Application instructions ....................................................... 155

3.27.1 Logical Operation Instructions .................................................................. 155

3.27.2 Logical Operation Instructions :

16-bit Logical Product ... WAND, WANDP................................................ 156

3.27.3 Logical Operation Instructions :

16-bit Logical Add ... WOR, WORP .......................................................... 159

3.27.4 Logical Operation Instructions :

16-bit Exclusive Logical Add ... WXOR, WXORP..................................... 162

3.27.5 Logical Operation Instructions :

16-bit NOT Exclusive Logical Add ... WXNR, WXNRP............................. 165

3.27.6 Logical Operation Instructions :

BIN 16-bit 2’s complement ... NEG, NEGP............................................... 168

4. ERROR CODE LIST 171

4.1 How to Read the Error Code ................................................ 172

APPENDIX 175

Appendix1Instruction Processing Time ....................................... 176

IV

Page 6

1. PLC FUNCTION

This manual describes the functions and devices necessary for programming.

1.1 Function Block Diagram ...................................... 2

1.2 PLC Function Specifications............................... 3

1.3 System Configuration .......................................... 4

1.4 Wiring of the Inverter and Personal Computer

Using GX Developer for RS-485 Communication

1.5 Prior to Sequence Program Creation ................. 6

1.6 Device Map............................................................ 10

1.7 Inverter Status Monitoring, Special Registers

for Control .............................................................

1.8 Inverter Parameter Read/Write Method .............. 34

1.9 User Area Read/Write Method ............................. 38

1.10 Analog I/O function .............................................. 39

1.11 Paluse train input function .................................. 40

1.12 PID control ............................................................ 41

1.13 Inverter Operation Lock Mode Setting ............... 43

... 5

20

Chapter 1

Chapter 2

Chapter 3

Chapter 4

1

Page 7

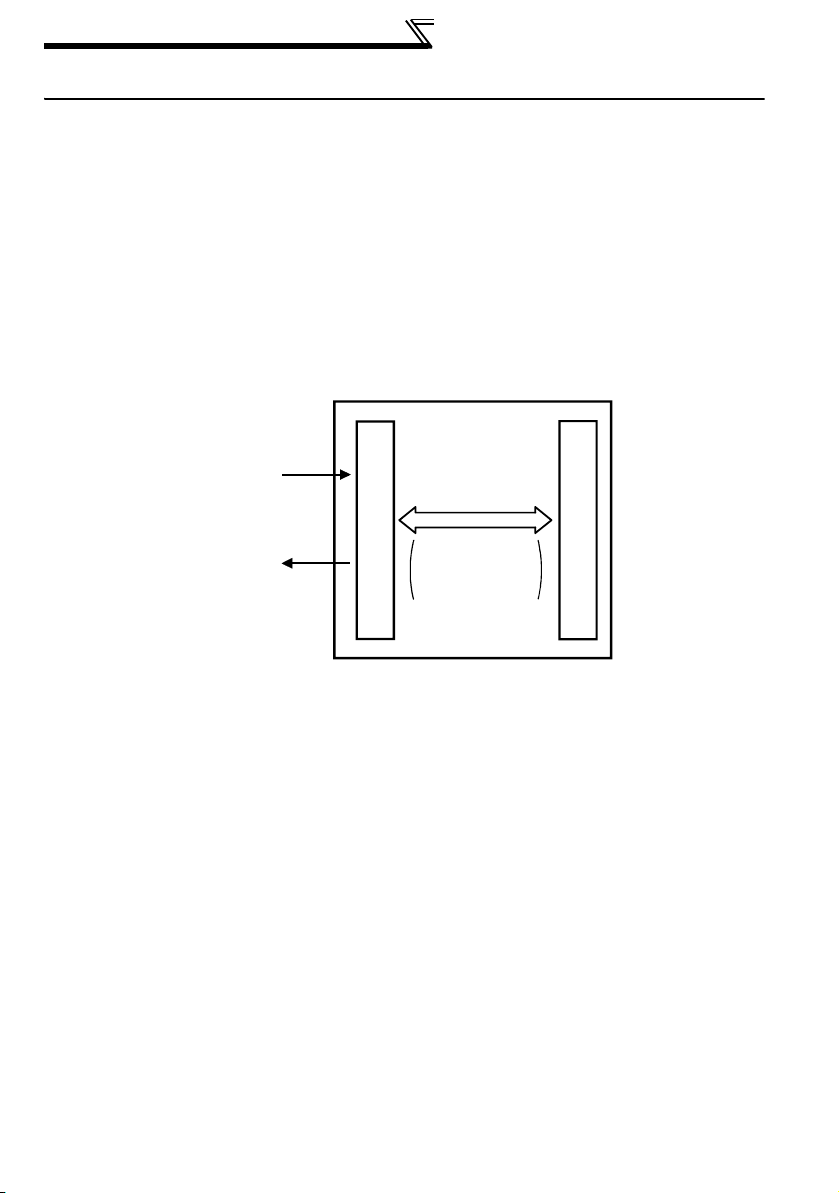

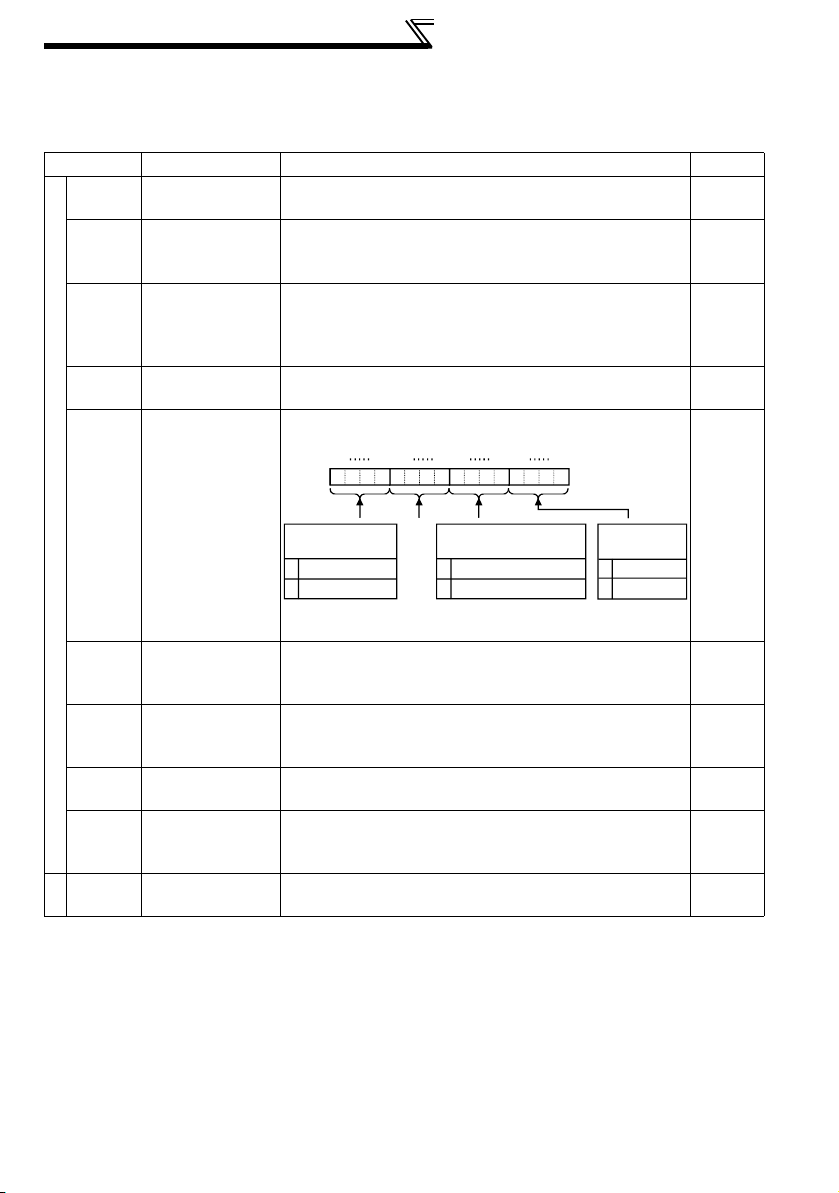

Function Block Diagram

1.1 Function Block Diagram

How I/O data are transferred to/from the inverter by the built-in PLC function is

explained using function blocks.

(1) I/O data read, write, etc. can be performed by accessing the inverter in the

predetermined method using special relays, special registers, etc.

(2) Operation, parameter read/write, etc. can be performed in accordance with the

created sequence programs (built in the inverter) using input data from the control

input terminals.

With the output signals, output data can be output to outside the inverter from the

control output terminals as not only the inverter's status signals but also pilot lamp

on/off, interlock and other control signals set freely by the user.

Inverter

Input signal

I/O data

Output signal

Special relays,

special registers,

etc.

Built-in sequence program

Inverter CPU

2

Page 8

PLC Function Specifications

1.2 PLC Function Specifications

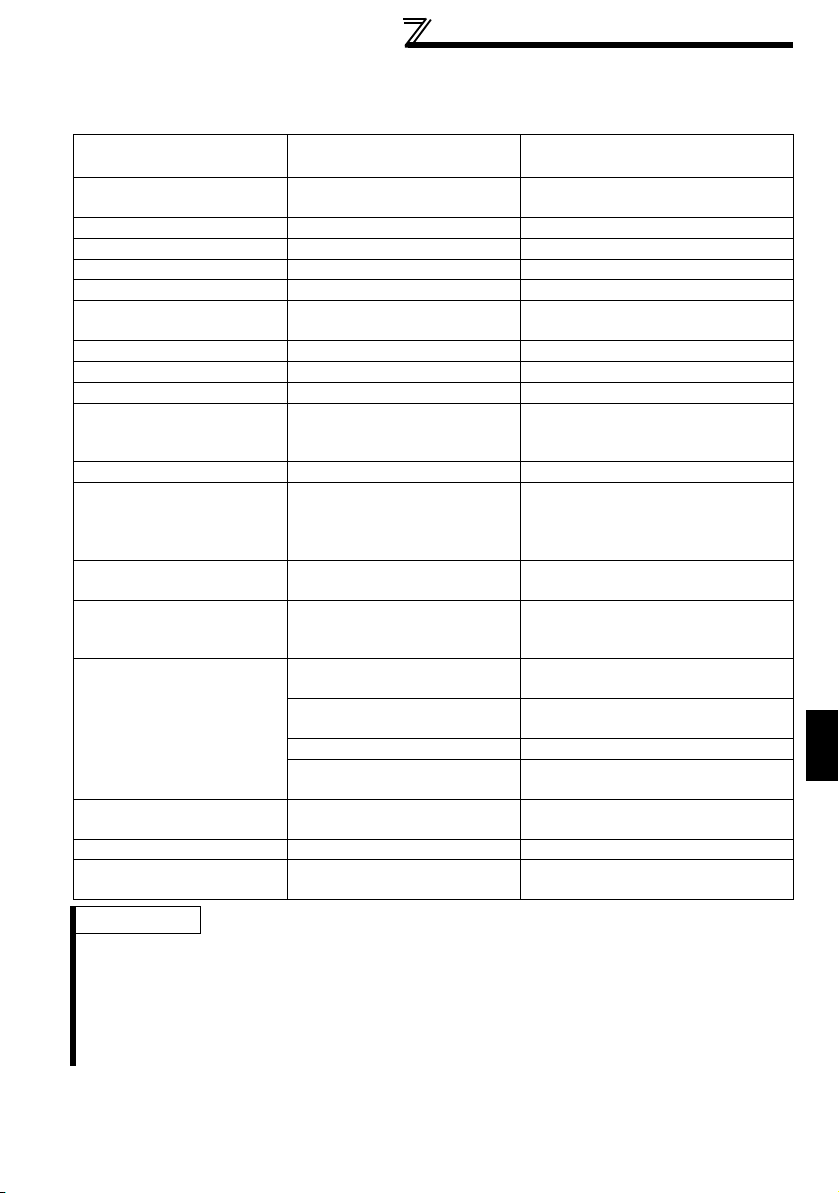

The following table indicates the program capacity and devices of the PLC function.

A700 Sequence Section

Control method Repeated operation (by stored program)

I/O control method Refresh

Programming language

PLC instructions 23

Basic instructions 32

Application instructions 18

Number of

instruction

Processing speed PLC instruction 1.9µs to 12µs/step(*2)

Number of I/O points

Number of analog I/O points

Watchdog timer 10 to 2000(ms)

Memory capacity 6k bytes used by sequence and parameters.

Program capacity 1k step

Internal relay (M) 64(M0 to M63)

Latch relay (L) None (Can be set with parameters but will not latch)

Step relay (S) None (Can be set with parameters but will operate as M)

Link relay (B) None

Timer (T)

Counter (C)

Data device (D) 120(D0 to D119)

Devices

Link register (W) None

Annunciator (F) None

File register (R) None

Accumulator (A) None

Index register (Z, V) None

Pointer (P) None

Interrupt pointer (I) None

Special relay (M) 256 (M9000 to 9255) with function limit

Special register (D) 256 (D9000 to 9255) with function limit

*1 These signals use the same terminals as used by the input and output signals given in the

common specifications of the inverter.

One point is always necessary for a sequence start (RUN/STOP).

*2 As inverter control is also performed actually, the scan time is approximately 40ms at 500 steps.

Points 16

Specifications

Points 16

Specifications

Relay symbolic language (ladder mode)

Logic symbolic language (list mode)

128 (X: 64 points, Y: 64 points)

19 points installed, X: 12 points, Y: 7 points (*1)

FR-A7AX, X: 16 points

FR-A7AY, Y: 6 points

FR-A7AR, Y: 3 points

5 points installed, Input: 3 points, Output: 2 points

FR-A7AY output: 2 points

100ms timer: Set time 0.1 to 3276.7s (T0 to T15)

10ms timer: Set time 0.01 to 327.67s

100ms retentive timer: Set time 0.1 to 3276.7s

Normal counter: Setting range 1 to 32767 (C0 to C15)

Interrupt program counter: None

1

PLC FUNCTION

3

Page 9

System Configuration

1.3 System Configuration

The following shows the system configuration for use of the PLC function.

<System configuration example>

GX Developer:

Programming tool

3-phase AC

power supply

RS-232C/

PU connector

RS-485

converter

FR-A700

Motor

Communication specifications

Set the following setting in communication parameters of the inverter.

Inverter Parameter GX Developer Setting Inverter initial setting

Pr.118 PU communication speed 96 (9600bps) 192 (19200bps)

Pr.119 PU communication stop bit length

Pr.120 PU communication parity check 1 (with odd parity check) 2 (with even parity check)

Pr.122 PU communication check time

interval

0 (data length: 8 bits, stop

bit: 1 bit)

9999 (without

communication check)

REMARKS

•For futher details, refer to the Inverter instruction manual (applied).

POINT

•Support GX Developer ver.8.0 or more

•GX Developer Setting

PLC series ACPU

PLC type A0J2H

[Project data list]→[Parameter]→[PLC parameter]→[A parameter]

→«Memory capacity» tab→"Program capacity"→"Sequence"→"main"

1 (data length: 8 bits, stop

bit: 2 bit)

9999 (without

communication check)

1k step

REMARKS

•Refer to the Inverter instruction manual (applied) for wiring.

•Refer to the GX Developer manuals for the specifications related to GX Developer and the

personal computer that uses GX Developer.

GX Developer Version xx Operating manual

GX Developer Version xx Operating manual (startup)

•The programming tool that can be used is GX Developer only. (The A6GPP, A7PHP, etc.

cannot be used.)

4

Page 10

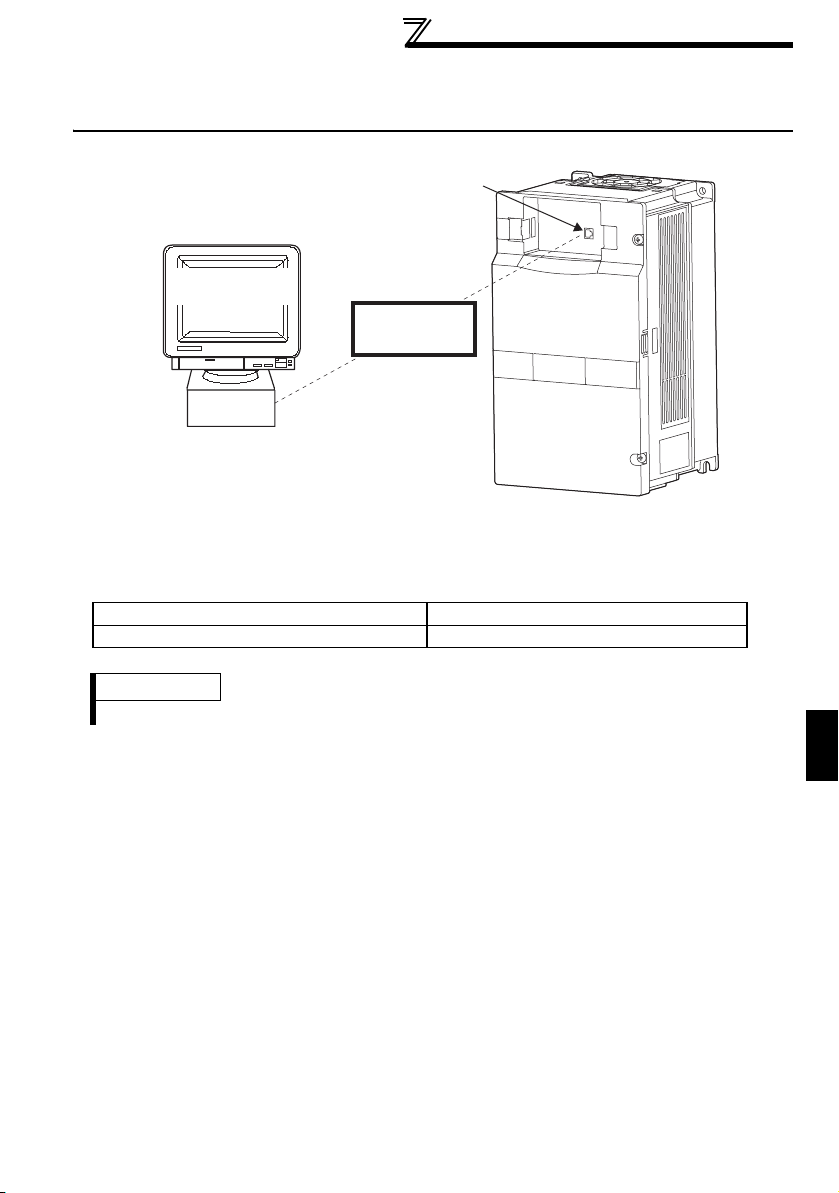

Wiring of the Inverter and Personal Computer Using

GX Developer for RS-485 Commun ication

1.4 Wiring of the Inverter and Personal Computer Using GX Developer for RS-485 Communication

PU connector

Personal computer

GX Developer :

Programming tool

RS-232C-RS-485

converter

RS-232C connector

zPersonal computer - inverter connection cable

Make connection after conversion between RS-232C and RS-485.

Examples of commercially available products (as of Sep., '05)

Type Maker

SC-FRPC BEIJERS

REMARKS

When fabricating the cable on the user side, refer to the inverter instruction manual (applied).

1

PLC FUNCTION

5

Page 11

Prior to Sequence Program Creation

1.5 Prior to Sequence Program Creation

1.5.1 Precautions for sequence program creation

POINT

•Online change of the sequence program and access to other stations are not

allowed.

In addition, program read/write from other stations and all PLC memory clear

cannot be performed.

•Back up the ladder configured with the protective function of GX Developer.

If any of the instructions (refer to page 103) and devices (refer to page 3) that cannot

be used with the built-in PLC function exists in a sequence program, an instruction

code error occurs at the execution of that instruction.

Error code D9008=10

Operation error step D9010

D9011

REMARKS

•Refer to page 22 for the error codes.

1.5.2 Usable main GX Developer functions

z Parameter or sequence program read/write

z Ladder monitor

z Device monitor

z Device test

z All device memory clear

z Remote RUN/STOP

CAUTION

Device test ([Online] - [Debug] - [Device test]) of GX Developer can be performed, but if

devices corresponding to control terminal (e.g. STF, STR) signals are tested, the

devices turn on in the sequence but the inverter does not perform the corresponding

operation.

6

Page 12

Prior to Sequence Program Creation

1.5.3 Sequence program execution key

The sequence program execution key (STOP/RUN) of the PLC is switched by turning

off/on the SQ signal.

POINT

•For the terminal used for SQ signal input, set "50" in any of Pr.178 to Pr. 189 to

assign the function.

•SQ-SD must be shorted to execute the built-in PLC function.

CAUTION

If the SQ signal is not turned on, the start signal of the inverter is designed to

become valid by the factory setting of

Open (STOP) the SQ signal-SD terminals when writing a sequence program, for

example.

When executing the sequence program, short (RUN) the SQ signal-SD terminals.

Remote run/stop of the built-in PLC function can be executed in any of the following

methods:

• Setting using the built-in PLC function parameter (contact)

• Using GX Developer

• Via CC-Link communication (refer to page 49)

REMARKS

•The validity limit of the SQ signal can be controlled using Pr.415 Inverter operation lock mode

setting. (Refer to page 43.)

CAUTION

The outputs (Y) are cleared by turning the SQ signal off (STOP) after sequence program

execution (SQ signal on).

The other devices retain the device data prior to STOP. When you want to clear the

remaining device data, power off or reset (short RES-SD for 0.1s, then open) the

inverter.

Pr.415 Inverter operation lock mode setting.

1

PLC FUNCTION

7

Page 13

Prior to Sequence Program Creation

1.5.4 Sequence program write

POINT

Sequence program write can be performed in any operation mode.

When rewriting the PLC function parameters and sequence program using GX

Developer, check the following:

1)Check that the sequence program execution key is in the STOP position (SQ signal

is off) (refer to page 7).

2)Check that the inverter is at a stop.

3)Check that the communication specification setting parameters (Pr.117 to Pr.124) are

set correctly. If any of these parameters is set incorrectly, communication with GX

Developer cannot be made.

REMARKS

Check and set the communication specification parameter (Pr. 117 to Pr. 124) using

the parameter unit (FR-PU04/FR-PU07). (Refer to the FR-PU04/FR-PU07

instruction manual for the handling of the FR-PU04/FR-PU07.) GX Developer and

the FR-PU04/FR-PU07 cannot be connected and used simultaneously.

4)Check the PLC series and sequence program capacity in the GX Developer

parameters (refer to page 4).

5) Refer to the GX Developer manual and write the sequence program.

CAUTION

•A sequence program cannot be written with its steps specified. If written,

the sequence program does not run. (The program outside the specified

range is initialized.)

•Do not read the built-in PLC function parameters and sequence program

without writing them to the inverter once using GX Developer. Since the

inverter does not have normal data, always write the built-in PLC function

parameters and sequence program once.

•Since the built-in PLC function parameters and sequence program are

written to the flash ROM, there are restrictions on the number of write times.

(Approximately 100,000 times)

8

Page 14

Function Block Diagram

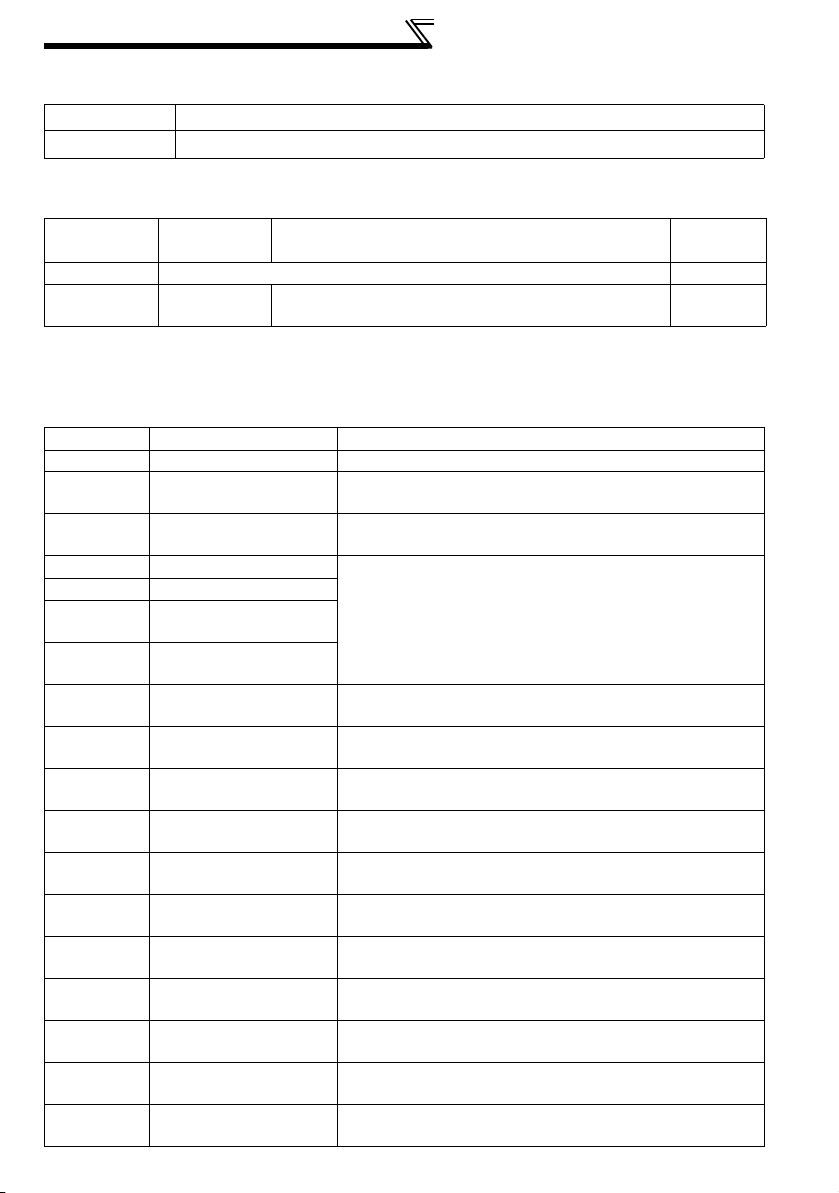

1.5.5 Setting list of built-in PLC function parameter

The built-in PLC function parameters are designed to specify the ranges of using the

PLC function, e.g. program capacity, device assignment and various functions.

Item GX Developer Default

Sequence program

capacity

File register capacity None Cannot be set (default)

Comment capacity None Cannot be set (default)

Status latch None Cannot be set (default)

Sampling trace None Cannot be set (default)

Microcomputer program

capacity

Latch range setting L1000 to L2047 Cannot be set (invalid if set)

Link range setting None Cannot be set (default)

I/O assignment None Cannot be set (default)

Internal relay, latch relay,

step relay setting

Watchdog timer setting 200ms 10 to 2000ms

Timer setting

Counter setting Without interrupt counters

Remote run/pause None

Error-time operation mode

STOP → RUN output mode

Print title registration None Cannot be set

Keyword registration None

(100ms timers since only T0 to 7

Operation error: Continued Stop/Continued

Special function module check

Operation status prior to

6k steps 1k step

None Cannot be set (default)

M0 to 999

L1000 to 2047

None for S

100ms: T0 to 199

10ms: T200 to 255

are available)

Fuse blow: Continued

I/O verify error: Stop

error: Stop

STOP is re-output.

L and S cannot be set.

(Operates as M if set)

<M0 to M63>

16 points for 100ms, 10ms and

retentive timers. Timers have

consecutive numbers.

<T0 to T15>

Cannot be set (default)

<C0 to C15>

Can be set using X0 to 1F.

Otherwise invalid. Pause does not

function.

Setting invalid (since there are no

fuses)

Setting invalid

(since there are no I/O modules)

Setting invalid (since there are no

special modules)

Prior to STOP/after operation

execution

Online setting cannot be made but

parameter setting is valid.

REMARKS

•The following functions are not supported.

1. Constant scan, 2. Latch (device data backup for power failure), 3. Pause,

4. Status latch, 5. Sampling trace, 6. Offline switch

•If parameter clear of the inverter is performed, the above built-in PLC function parameters are

not cleared.

•For the built-in PLC function parameter setting operation, refer to the GX Developer

Operating Manual.

Setting Range

<Usable device range>

1

PLC FUNCTION

9

Page 15

Device Map

1.6 Device Map

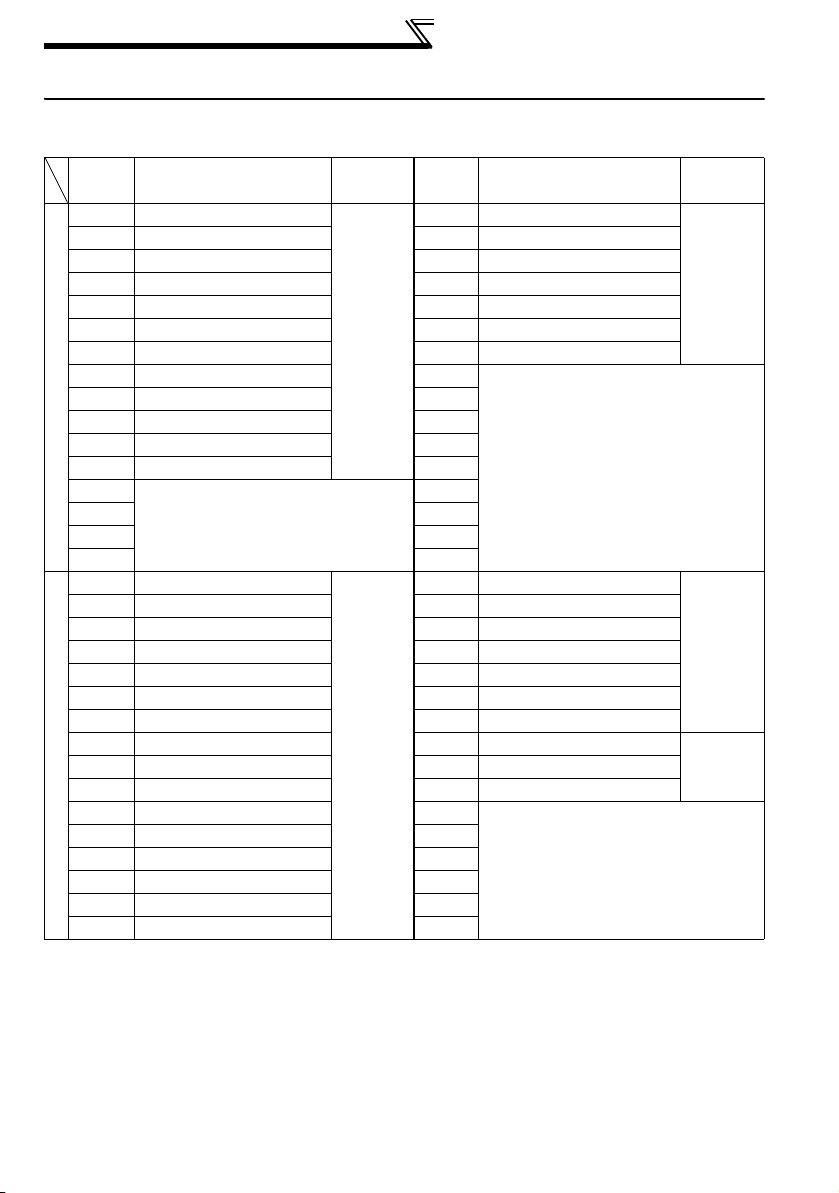

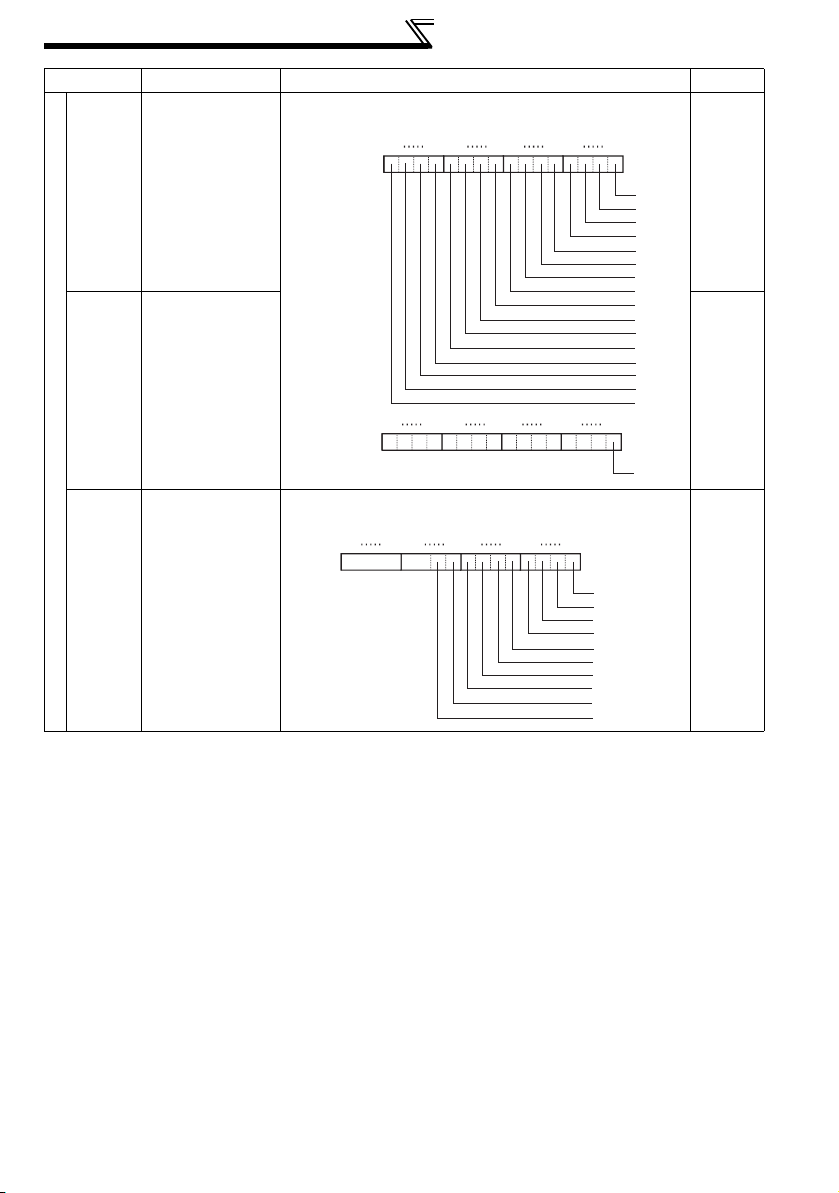

1.6.1 I/O device map

Device

No.

X00 STF terminal

X01 STR terminal Y01 SU terminal

X02 RH terminal Y02 OL terminal

X03 RM terminal Y03 IPF terminal

X04 RL terminal Y04 FU terminal

X05 JOG terminal Y05 ABC1 terminal

X06 RT terminal Y06 ABC2 terminal

X07 AU terminal Y07

X08 CS terminal Y08

X09 MRS terminal Y09

External I/O

X0A STOP terminal Y0A

X0B RES terminal Y0B

X0C

X0D Y0D

Empty

X0E Y0E

X0F Y0F

X10 X0 terminal

X11 X1 terminal Y11 DO1 terminal

X12 X2 terminal Y12 DO2 terminal

X13 X3 terminal Y13 DO3 terminal

X14 X4 terminal Y14 DO4 terminal

X15 X5 terminal Y15 DO5 terminal

X16 X6 terminal Y16 DO6 terminal

X17 X7 terminal Y17 RA1 terminal

X18 X8 terminal Y18 RA2 terminal

X19 X9 terminal Y19 RA3 terminal

X1A X10 terminal Y1A

Plug in option I/O

X1B X11 terminal Y1B

X1C X12 terminal Y1C

X1D X13 terminal Y1D

X1E X14 terminal Y1E

X1F X15 terminal Y1F

Name Remarks

External

terminal

16bit

digital

Input

FR-A7AX

Device

No.

Y00 RUN terminal

Empty

Y0C

Y10 DO0 terminal

Empty

Name Remarks

External

terminal

Dgital

output

FR-A7AY

Relay

output

FR-A7AR

10

Page 16

Device Map

Device

No.

X20

X21

X22

X23

X24

X25

X26

X27

System I/O

X28

X29

X2A

X2B

Operation mode setting

read completion

Set frequency read

completion (RAM)

Set frequency read

completion (E

Operation mode setting

write completion

Set frequency write

completion (RAM)

Set frequency write

completion (E

Alarm definition batch

clear completion

Parameter clear

completion

Parameter read

completion (RAM)

Parameter write

completion (RAM)

Parameter read

completion (EEPROM)

Parameter write

completion (EEPROM)

Name Remarks

D9140 Y20

D9141 Y21

2

PROM)

D9142 Y22

D9143 Y23

D9144 Y24

2

PROM)

D9145 Y25

D9146 Y26

D9147 Y27 Parameter clear command D9147

D9241,

D9242,

D9234

D9243,

D9244,

D9235

X2C

X2D Y2D

System area

X2E Y2E

Device

No.

Y28

Y29

Y2A

Y2B

Y2C

X2F Y2F

X30 RY0

Y30 RX0

X31 RY1 Y31 RX1

X32 RY2 Y32 RX2

X33 RY3 Y33 RX3

X34 RY4 Y34 RX4

X35 RY5 Y35 RX5

X36 RY6 Y36 RX6

X37 RY7 Y37 RX7

X38 RY8 Y38 RX8

FR-A7NC

X39 RY9 Y39 RX9

X3A RYA Y3A RXA

X3B RYB Y3B RXB

CC-Link I/O remote I/O

X3C RYC Y3C RXC

X3D RYD Y3D RXD

X3E RYE Y3E RXE

X3F RYF Y3F RXF

Name Remarks

Operation mode setting

read command

Set frequency read

command (RAM)

Set frequency read

command (E

2

PROM)

Operation mode setting

write command

Set frequency write

command (RAM)

Set frequency write

command (E

2

PROM)

Alarm definition batch

clear command

Parameter read request

(RAM)

Parameter write request

(RAM)

Parameter read request

(EEPROM)

Parameter write request

(EEPROM)

System area

D9140

D9141

D9142

D9143

D9144

D9145

D9146

D9241,

D9242,

D9234

D9243,

D9244,

D9235

FR-A7NC

Device Map

1

PLC FUNCTION

11

Page 17

Device Map

1.6.2 Internal relay (M) device map

Device No. Description

M0 to M63

Use freely on user side.

1.6.3 Data register (D) device map

Data

Register (D)

D0 to D99 Use freely on user side. —

D100 to D119

Inverter Pr.

Number

Pr.506 to

Pr.515

Parameter Name

User parameters. Use freely on user side. 38

Reference

Page

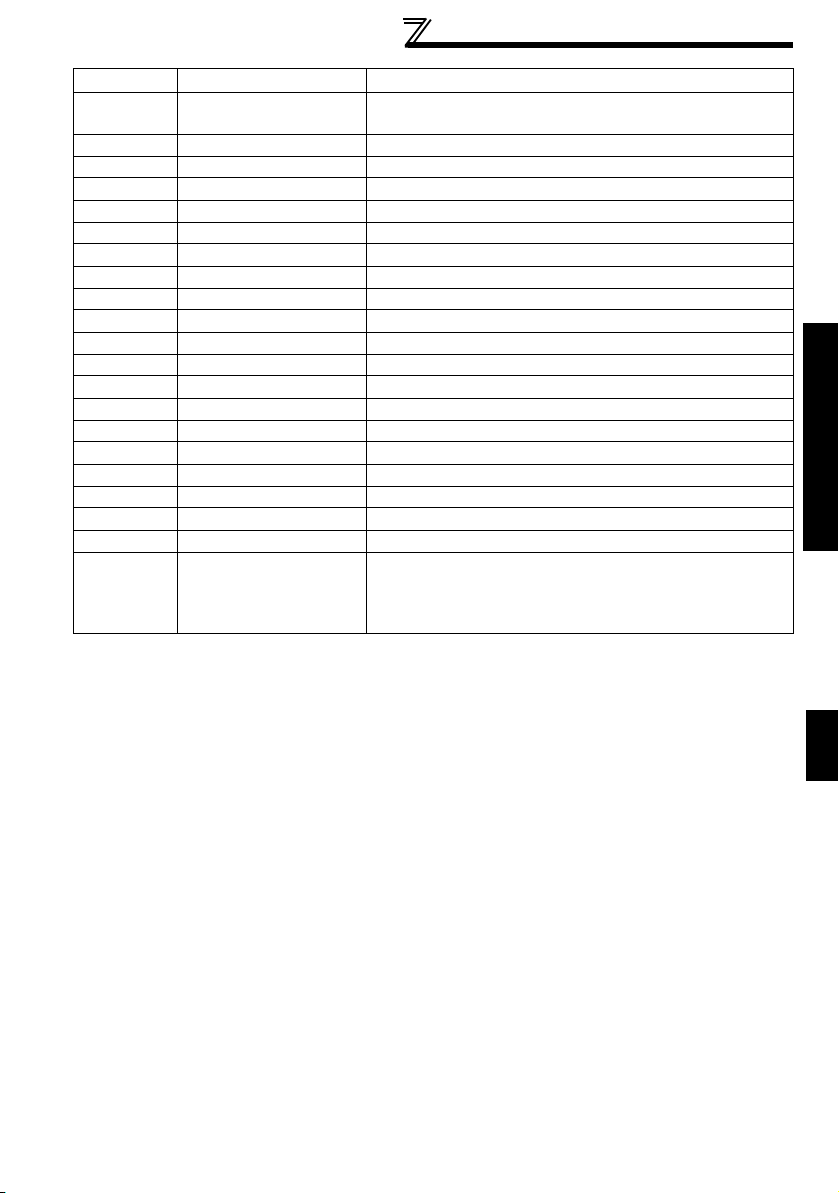

1.6.4 Special relays

The special relays are internal relays with special applications and therefore should

not be switched on-off in the program.

Number Name Description

M9008 Self-diagnostic error Turned on by self-diagnosed error.

M9010 Operation error flag

M9011 Operation error flag

M9036 Normally ON

M9037 Normally OFF

M9038

M9039

M9200

M9201

M9202

M9203

M9204

M9205

M9206

M9207

M9208

M9209

M9210

12

On only for 1 scan after

RUN

Off only for 1 scan after

RUN

Inverter operation status

control flag (STF)

Inverter operation status

control flag (STR)

Inverter operation status

control flag (RH)

Inverter operation status

control flag (RM)

Inverter operation status

control flag (RL)

Inverter operation status

control flag (JOG)

Inverter operation status

control flag (RT)

Inverter operation status

control flag (AU)

Inverter operation status

control flag (CS)

Inverter operation status

control flag (MRS)

Inverter operation status

control flag (STOP)

Turned on by an instruction execution error.

Turned off when error is removed.

Turned on by an instruction execution error.

Remains on after normal status is restored.

M9036 and M9037 are turned on and off independently

of STOP or RUN.

M9038 and M9039 change depending on the STOP or

RUN status. In other than the STOP status, M9038 is on

for one scan only and M9039 is off for one scan only.

Control the STF terminal of the inverter from PLC

function

Control the STR terminal of the inverter from PLC

function

Control the RH terminal of the inverter from PLC

function

Control the RM terminal of the inverter from PLC

function

Control the RL terminal of the inverter from PLC function

Control the JOG terminal of the inverter from PLC

function

Control the RT terminal of the inverter from PLC function

Control the AU terminal of the inverter from PLC

function

Control the CS terminal of the inverter from PLC

function

Control the MRS terminal of the inverter from PLC

function

Control the STOP terminal of the inverter from PLC

function

Page 18

Device Map

Number Name Description

M9211

M9216 Inverter status (RUN) Inverter running

M9217 Inverter status (FWD) Forward running

M9218 Inverter status (REV) Reverse running

M9219 Inverter status (SU) Up to frequency

M9220 Inverter status (OL) Overload alarm

M9221 Inverter status (IPF) Instantaneous power failure/undervoltage

M9222 Inverter status (FU) Output frequency detection

M9223 Inverter status (ALM) Alarm output

M9224 Inverter status (LF) Minor fault output

M9225 Inverter status (DO0) Status of output terminal function set in Pr. 313 is stored *1

M9226 Inverter status (DO1) Status of output terminal function set in Pr. 314 is stored *1

M9227 Inverter status (DO2) Status of output terminal function set in Pr. 315 is stored *1

M9228 Inverter status (DO3) Status of output terminal function set in Pr. 316 is stored *1

M9229 Inverter status (DO4) Status of output terminal function set in Pr. 317 is stored *1

M9230 Inverter status (DO5) Status of output terminal function set in Pr. 318 is stored *1

M9231 Inverter status (DO6) Status of output terminal function set in Pr. 319 is stored *1

M9232 Inverter status (RA1) Status of output terminal function set in Pr. 320 is stored *1

M9233 Inverter status (RA2) Status of output terminal function set in Pr. 321 is stored *1

M9234 Inverter status (RA3) Status of output terminal function set in Pr. 322 is stored *1

M9255

*1. Even if the FR-A7AY, FR-A7AR is not mounted, Pr. 313 to Pr. 322 are accessible during

Inverter operation status

control flag (RES)

Inverter operation status

control selection

PLC function operation, and status of output terminal functions are stored in each device.

(virtual output terminal)

Control the RES terminal of the inverter from PLC

function

Select the inverter status control command from M9200

to M9211 or D9148.

OFF: Special relay selection

ON : Special register selection

Device Map

13

1

PLC FUNCTION

Page 19

Device Map

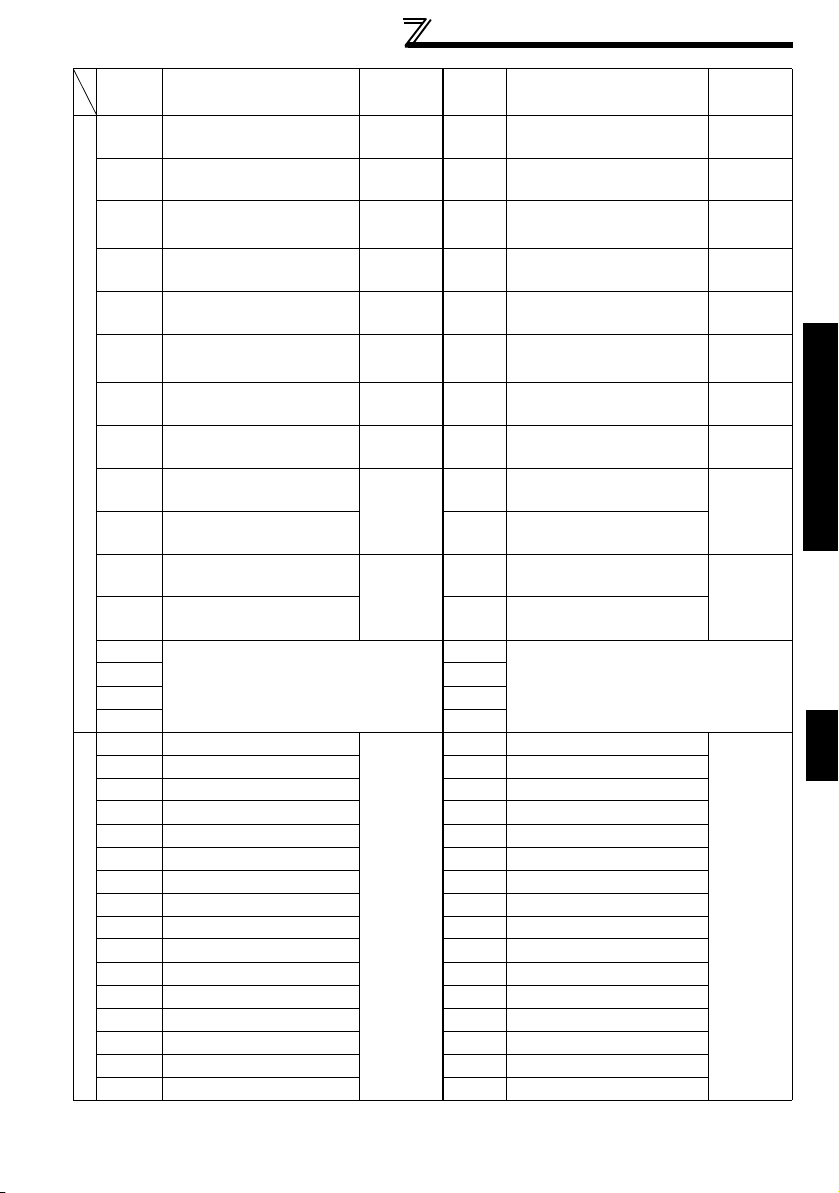

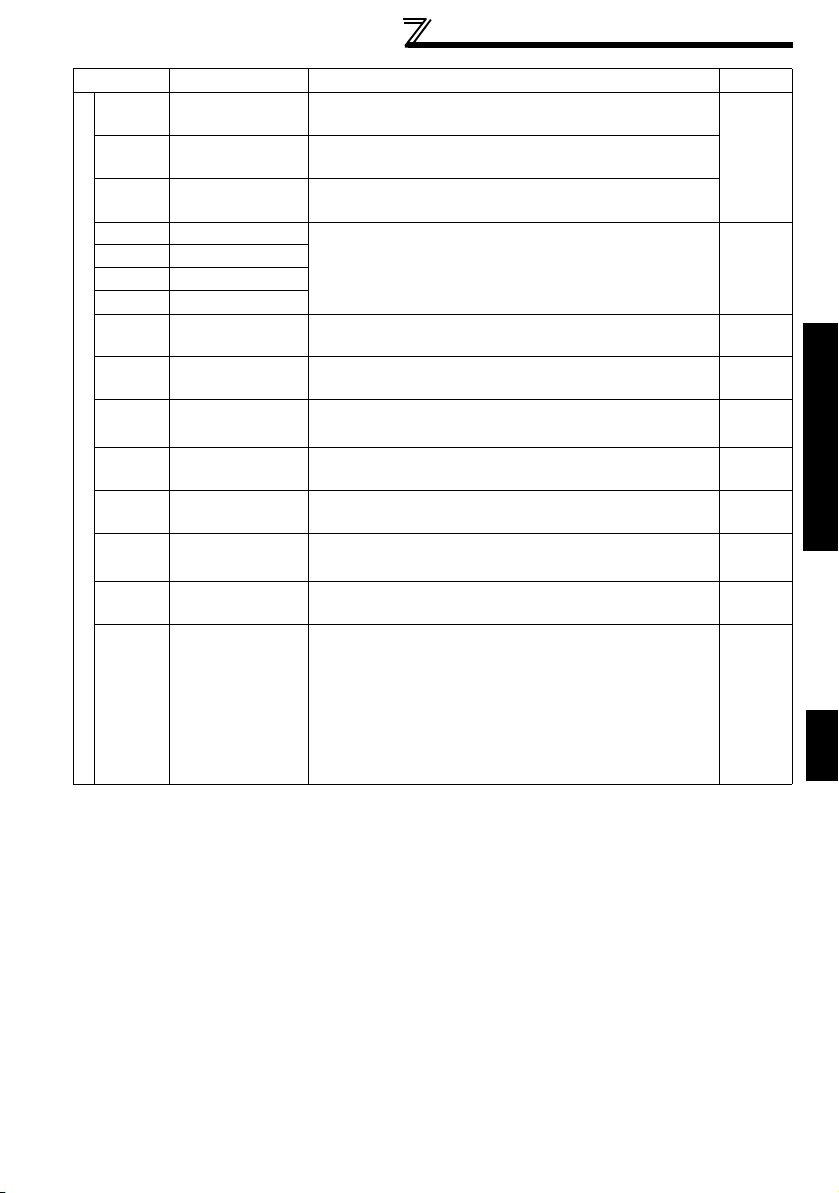

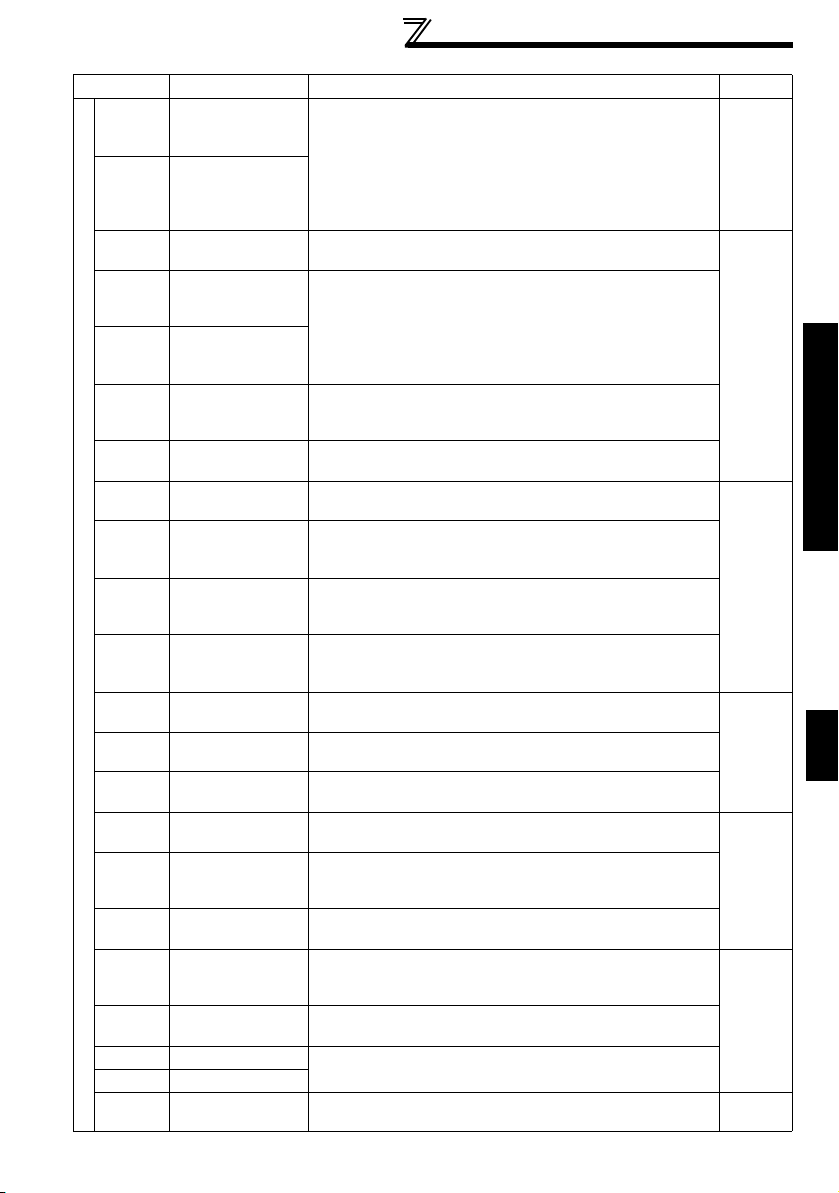

1.6.5 Special registers

The special registers are data registers with special applications and therefore data

should not be written to the special registers in the program.

Number Name Description Page

D9008

D9010

D9011

D9014

Self-diagnostic

error

Operation error

step

Operation error

step

I/O control

method

Stores the self-diagnosed error number in BIN. (Refer

to page 22 for the error codes.)

22

Stores the step number in BIN, at which an instruction

execution error occurred. After that, data is updated

—

each time operation error occurs.

Stores the step number in BIN, at which an instruction

error occurred. Since data is stored into D9011 when

M9011 turns from off to on, D9011 data is not updated

—

unless M9011 is cleared by the user program.

3 (fixed): Both input and output refreshes —

Stores the operating status of the PLC function.

B15 B12B11 B8B7 B4B3 B0

D9015

CPU operating

status

Special registers

D9016 Program number

Minimum scan

D9017

time

(10ms units)

D9018

Scan time

(10ms units)

Maximum scan

D9019

time

(10ms units)

D9062 to

D9093

Remote registers

Remote run/stop

using GX Developer

RUN

0

STOP

1

Invalid

Remote run/stop using

sequence parameter setting

RUN

0

STOP

1

Shorting/

opening SQ-SD

0

RUN

STOP

1

Stores the number that indicates which sequence

program is currently in execution.

1 (fixed): Main program (RAM)

Stores the scan time at every END that is smaller than

D9017 data, i.e. stores the minimum scan time in BIN.

Stores and updates the scan time at every END in

BIN.

Stores the scan time at every END that is greater than

D9019 data, i.e. stores the maximum scan time in

BIN.

Special registers for communication with the master

station in CC-Link.

—

—

—

—

—

50

14

Page 20

Device Map

Number Name Description Page

D9133

D9135

Output frequency

monitor

Output current

monitor

Output voltage

monitor

Stores the current output frequency.

0.01Hz units

Stores the current output current.

0.01A units

Stores the current output voltage.

0.1V units

20D9134

D9136 Error history 1, 2

D9137 Error history 3, 4

D9138 Error history 5, 6

Store the errors that occurred in the inverter in order

of occurrence.

21

D9139 Error history 7, 8

D9140

D9141

D9142

D9143

D9144

Special registers for control

D9145

D9146

Operation mode

setting read

Set frequency

read (RAM)

Set frequency

2

read (E

PROM)

Operation mode

setting write

Set frequency

write (RAM)

Set frequency

2

write (E

PROM)

Alarm definition

batch clear

Stores the current operation mode. 23

Reads and stores the set frequency (RAM). 24

Reads and stores the set frequency (EEPROM). 24

Sets a new operation mode. 26

Sets the running frequency (RAM). 27

Sets the running frequency (EEPROM). 28

Write H9696 to clear the error history. 29

H9696 write: Parameter clear

H9966 write: All clear

H5A5A write:Parameter clear except communication

D9147 Parameter clear

H55AA write:All clear except communication

parameters

30

parameters

During GX Developer communication, perform

clearing by H5A5A or H55AA.

Device Map

1

15

PLC FUNCTION

Page 21

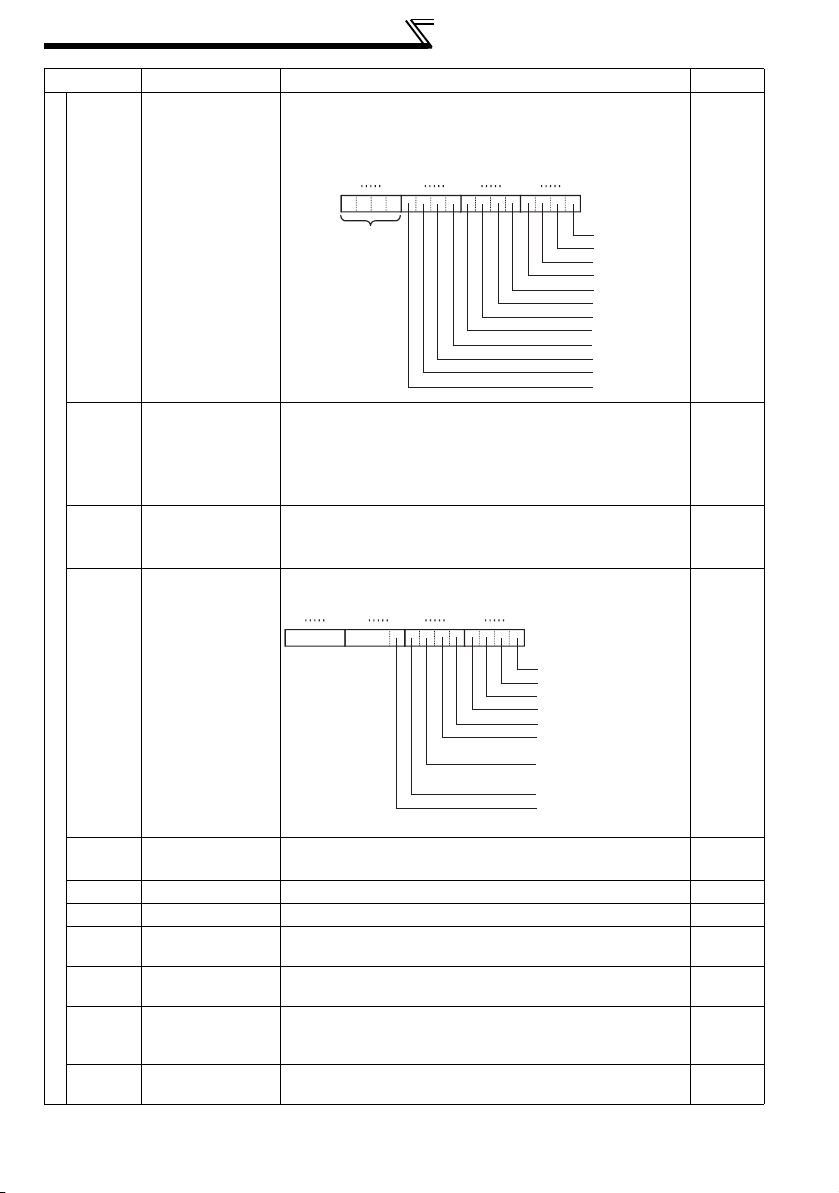

Device Map

Number Name Description Page

Turn on/off the corresponding bits to control the

inverter operation status.

The initial value: All "0". When M9255 is off, this

device does not function.

D9148

D9149

D9150

Inverter operation

status control

Inverter operation

status control

enable/disable

setting

Inverter

parameter

access error

B15 B12B11 B8B7 B4 B3 B0

Invalid

Enable/disable the inverter operation status control

using D9148 and M9200 to M9211 by turning on/off

the corresponding bits.

Bit image is the same as D9148.

The initial value: All "0" (invalid)

Stores the error No. when an error occurs because

the data stored in the parameter or special register is

not reflected on the inverter.

0:OFF

1:ON

STF

STR

RH

RM

RL

JOG

RT

AU

CS

MRS

STOP

RES

Stores the running status and operating status of the

inverter.

Special registers for control

D9151 Inverter status

B15 B8B7 B4 B3 B0

0:OFF

1:ON

Inverter running(RUN)

Forward running

Reverse running

Up to frequency(SU)

Overload alarm(OL)

Instantaneous power failure

/undervoltage(IPF)

Output frequency

detection(FU)

Alarm output(ALM)

Minor fault output(LF)

31

32

33

33

16

D9152

D9153

D9154

D9155

D9156

D9157

D9158

Frequency

setting

0.01Hz units —

Running speed 1(0.1)r/min unit —

Motor torque

Converter output

voltage

Regenerative

brake duty

0.1% units —

0.1V units —

0.1% units —

Electronic thermal

relay function load

0.1% units —

factor

Output current

peak value

0.01A/0.1A units —

Page 22

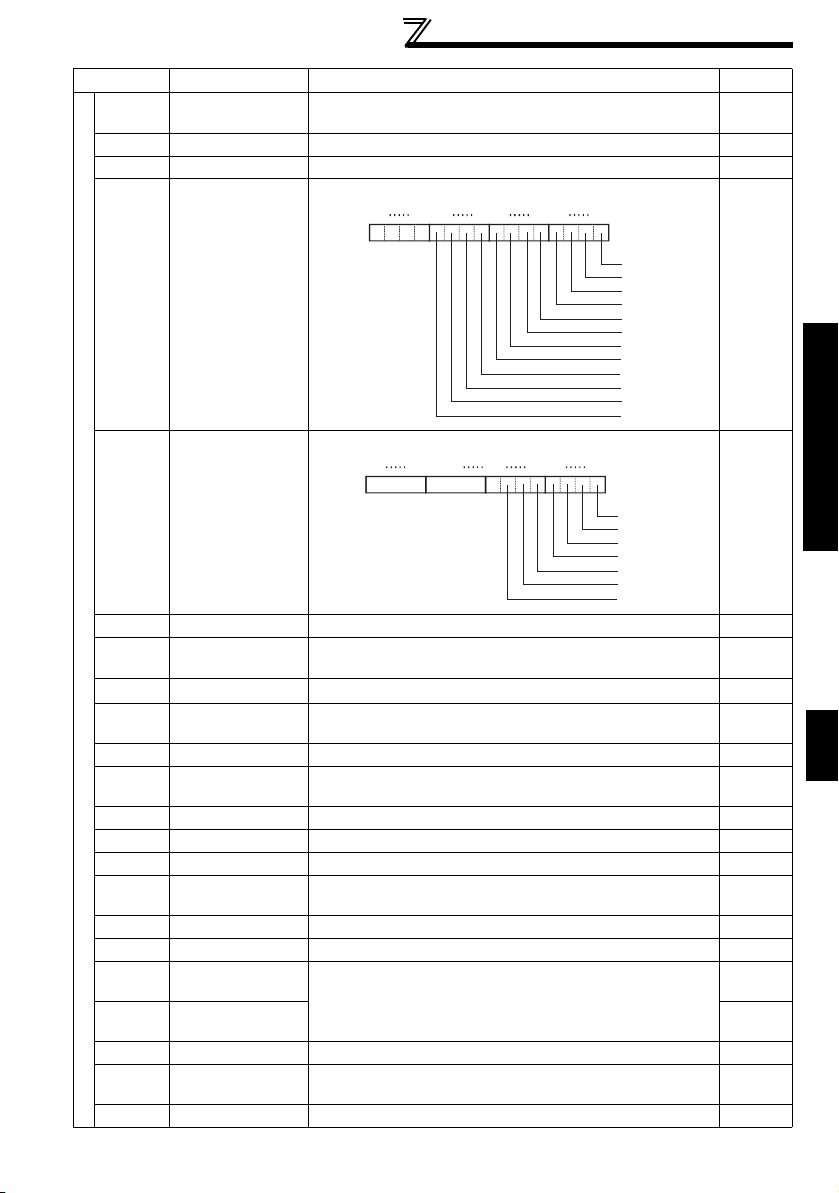

Device Map

Number Name Description Page

D9159

D9160

D9161

D9162

D9163

D9164

D9165

Converter output

voltage peak value

Input power

Output power

Input terminal

status

Output terminal

status

Load meter

Motor excitation

current

0.1V units —

0.01kW

/0.1kW units —

0.01kW

/0.1kW units —

Input terminal status

B15 B12B11 B8B7 B4 B3 B0

Output terminal status

B15 B7 B4B3 B0

0.1%

units —

details

details

0:OFF

1:ON

STF

STR

AU

RT

RL

RM

RH

JOG

MRS

STOP

RES

CS

0:OFF

1:ON

RUN

SU

IPF

OL

FU

ABC1

ABC2

—

—

0.01A/0.1A units *7 —

D9166 Position pulse —

Special registers for control

D9167

Cumulative

energization time

1h units —

D9169 — Always 0 —

D9170

Actual operation

time

1h unit —

D9171 Motor load factor 0.1% units —

D9172

Cumulative power

1kW

unit —

D9179 Torque command 0.1% units —

D9180

Torque current

command

0.1% units —

D9181 Motor output 0.01kW units —

D9182 Feedback pulse

D9197

D9198

Power saving

effect

Cumulative

saving power

1 unit —

—

Variable according to parameters

—

D9199 PID set point 0.1% units —

D9200

PID measured

value

0.1% units —

D9201 PID deviation 0.1% units —

Device Map

1

PLC FUNCTION

17

Page 23

Device Map

Number Name Description Page

The input status of the FR-A7AX is stored.

All off (0) when an option is not fitted.

B15

D9205

D9206

Special registers for control

D9207

Option input

terminal status 1

Option input

terminal status 2

Option output

terminal status

D9205

D9206

B12B11 B8 B7 B4 B3 B0

B15

B12B11 B8 B7 B4 B3 B0

The output status of the FR-A7AY, FR-A7AR is stored.

All off (0) when an option is not fitted.

B15 B12B11 B8B7 B4 B3 B0

0:OFF

1:ON

Y0

Y1

Y2

Y3

Y4

Y5

Y6

RA1

RA2

RA3

0:OFF

1:ON

X0

X1

X2

X3

X4

X5

X6

X7

X8

X9

X10

X11

X12

X13

X14

X15

0:OFF

1:ON

DY

—

—

—

18

Page 24

Device Map

Number Name Description Page

D9234

D9235

D9236

D9237

D9238

D9239

D9240

D9241

D9242

D9243

D9244

D9245 Terminal 1 input

Special registers for control

D9247 Terminal 4 input

D9248

D9250

D9251

D9252

D9253 AM0 output

D9254 AM1 output

D9255

Second

parameter

changing (RAM)

Second

parameter

changing

(EEPROM)

Pulse train input

sampling pulse

Pulse train input

cumulative count

value L

Pulse train input

cumulative count

value H

Reset request of

pulse train input

count

Count start of the

pulse train input

Parameter

number (RAM)

Parameter

description

(RAM)

Parameter

number

(EEPROM)

Parameter

description

(EEPROM)

PID set point /

PID deviation

PID

measurement

value

PID manipulated

variable

Ter m in a l F M

output

Ter m in a l A M

output

PID operation

control

When setting the calibration(bias/gain) parameters.

H00: Frequency(toruque)

H01: Parameter-set analog value

H02: Analog value input from terminal

The number of pulses counted in count cycle is

stored. (0 to 32767)

The cumulative value of the number of sampling

pulses is stored. (0 to 99999999)

The sampling pulses and cumulative count value are

cleared. Automatically changes to "0" after reset.

(1: count clear)

Start counting the sampling pulses and cumulative

count value. (0: count stop, 1: count start)

Set the number of parameter read or written of the

inverter.

The parameter description of the inverter (RAM value)

specified by D9241 is stored. Set the parameter

setting for parameter write.

Set the number of parameter read or written of the

inverter.

The parameter description of the inverter (EEPROM

value) specified by D9243 is stored. Set the

parameter setting for parameter write.

Analog input value of terminal 1 (0.1% increments) is

stored.

Analog input value of terminal 2 (0.1% increments) is

stored.

Analog input value of terminal 4 (0.1% increments) is

stored.

Set the PID set point or PID deviation (0.01% units)

Set the PID measurement value (0.01% units)

Stores the PID manipulated variable (0.01% units)

When Pr. 54 is set to "70", pulse train can be output

from terminal FM. High speed pulse train output can

be performed. (0.1% increments)

When Pr. 158 is set to "70", analog output can be

performed from terminal AM. (0.1% increments)

Analog output can be performed from terminal AM0

and AM1 of the FR-A7AY. (0.1% increments)

Setting 1 starts PID control. 41

34, 36

40

34, 36

39D9246 Terminal 2 input

41D9249

39

Device Map

1

PLC FUNCTION

19

Page 25

Inverter Status Monitoring, Special Registers for Control

1.7

Inverter Status Monitoring, Special Registers for Control

You can assign the data for grasping and changing the inverter's operation status to

D9133 - D9147 and read/write them from the user sequence. (Refer to page 14 for the

list.)

1.7.1 Data that can be read at all times

The following data can always be read. They are automatically refreshed every time

the END instruction is executed.

(1) Operation monitor

The following data devices are always read-enabled (write-disabled) to allow you to

monitor the output frequency, output current and output voltage of the inverter. Note

the setting units.

Device

No.

D9133

D9135

Name

Output frequency

monitor

Output current

monitor

Output voltage

monitor

CAUTION

The frequency can be set in increments of 0.01Hz but actual operation is performed in

increments of 0.1Hz.

Setting

Unit

0.01Hz Device data 6000 → 60.00Hz

0.01A Device data 200 → 2.00A

0.1V Device data 1000 → 100.0V

Data Example

Data Access Enable

Condition

AlwaysD9134

20

Page 26

Inverter Status Monitoring, Special Registers

r

for Control

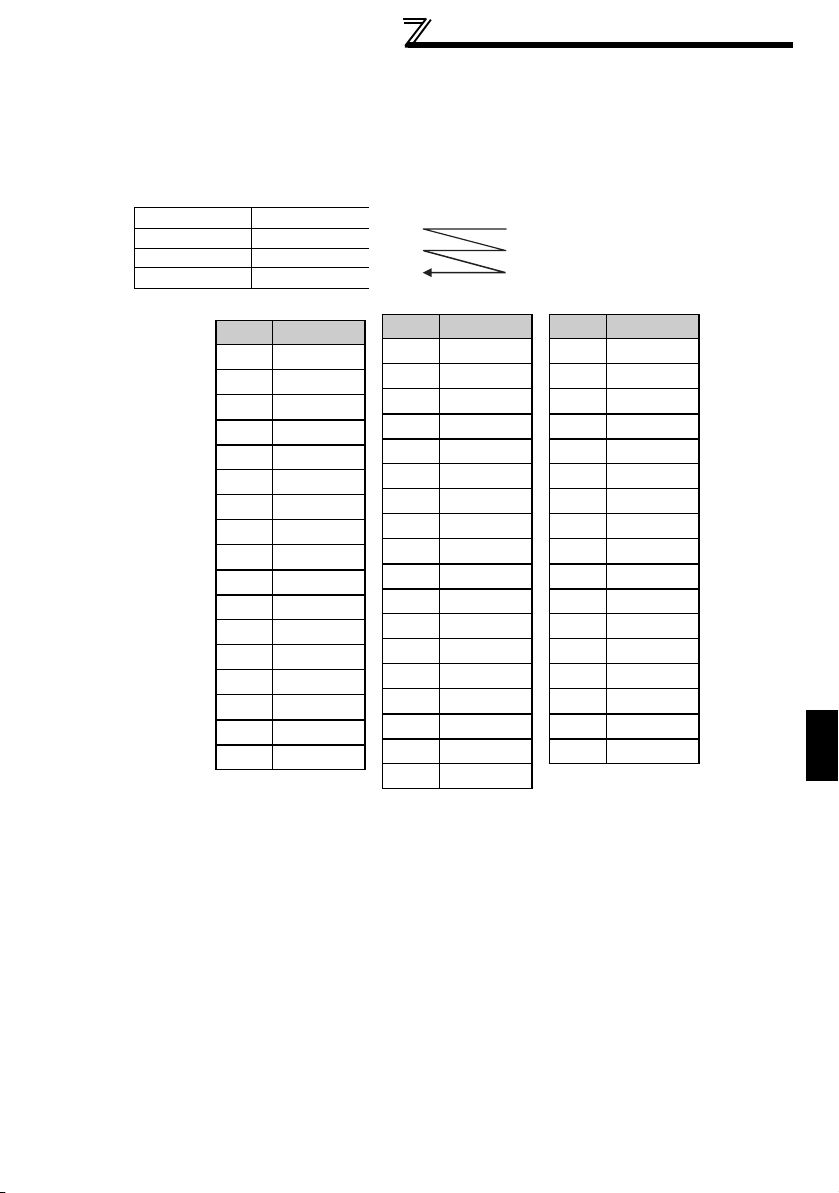

(2) Error history (error codes and error definitions)

The inverter stores the error codes of the errors that occurred.

The error codes of up to eight errors are stored in the order as shown below and are

always read-enabled (write-disabled).

<Error code storing method details>

b15 to b8 b7 to b0

D9136 Error history 2 Error history 1

D9137 Error history 4 Error history 3

D9138 Error history 6 Error history 5

D9139 Error history 8 Error history 7

Data

Description

H00 No alarm

H10 E.OC1

H11 E.OC2

H12 E.OC3

H20 E.OV1

H21 E.OV2

H22 E.OV3

H30 E.THT

H31 E.THM

H40 E.FIN

H50 E.IPF

H51 E.UVT

H52 E.ILF

H60 E.OLT

H70 E.BE

H80 E.GF

H81 E.LF

Older

Data

Description

H90 E.OHT

H91 E.PTC

HA0 E.OPT

HA3 E.OP3

HB0 E.PE

HB1 E.PUE

HB2 E.RET

HB3 E.PE2

HC0 E.CPU

HC1 E.CTE

HC2 E.P24

HC4 E.CDO

HC5 E.IOH

HC6 E.SER

HC7 E.AIE

HC8 E.USB

HD0 E.OS

HD1 E.OSD

Newe

HDA E.MB6

HDB E.MB7

HDC E.EP

HFD E.13

Data

Description

HD2 E.ECT

HD3 E.OD

HD5 E.MB1

HD6 E.MB2

HD7 E.MB3

HD8 E.MB4

HD9 E.MB5

HF1 E.1

HF2 E.2

HF3 E.3

HF6 E.6

HF7 E.7

HFB E.11

1

Refer to the Inverter instruction manual (applied) for alarm definition details.

PLC FUNCTION

21

Page 27

Inverter Status Monitoring, Special Registers

for Control

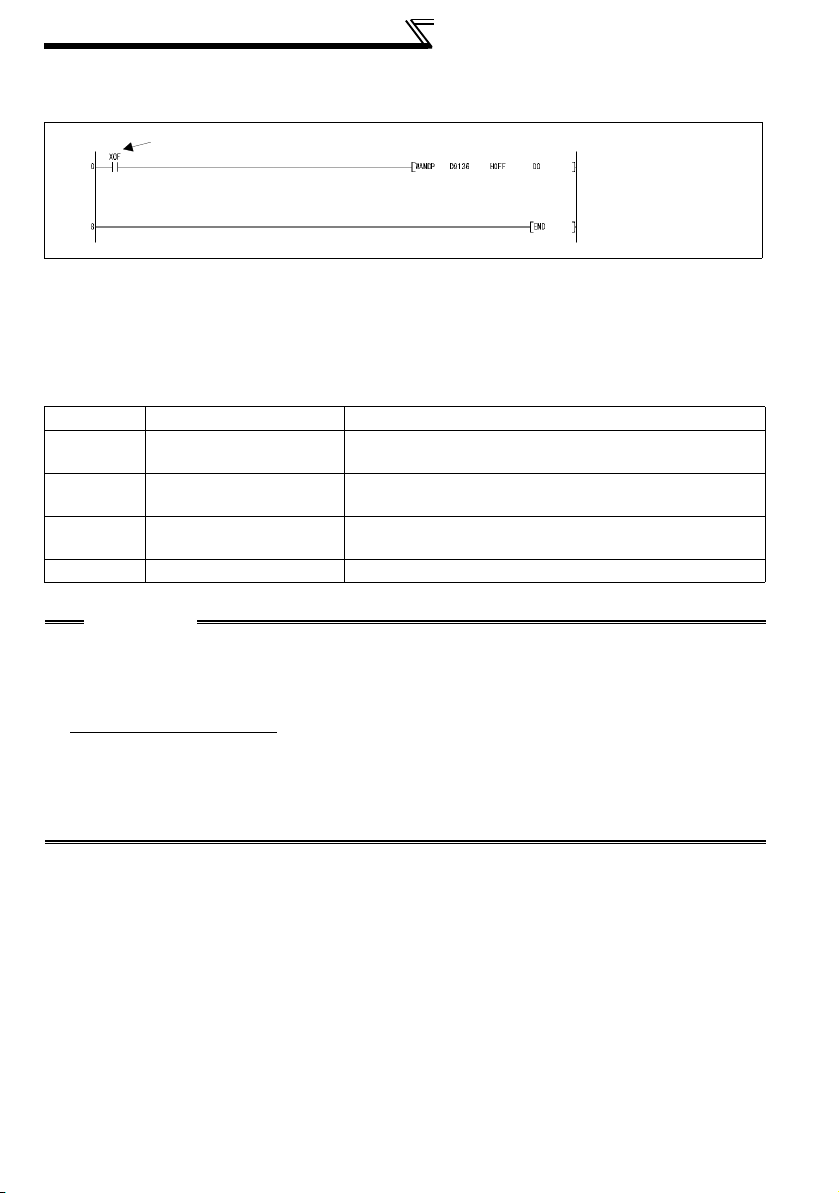

<Alarm definition read program example>

The following program reads the latest alarm definition of the inverter to D0.

Alarm definition read request

Stores only the lower 8 bits

of error history 1, 2 (D9136)

into D0.

(The latest error information

is stored into D0.)

<Regarding the error No. and details of the self-diagnostic errors>

During execution of a sequence program, any of the following error No. is stored into

D9008 due to an operation error.

At occurrence of a self-diagnostic error, the P.RUN indication (LED) flickers.

Error No. Error Name Details

10 INSTRCT CODE ERR.

11 PARAMETER ERR

22 WDT ERR

24 END NOT EXECUTE END instruction was not executed.

CAUTION

1. For the LD, AND, OR, logical comparison operation and OUT instructions,

device checks are always made. For the other instructions (SET, RST, MOV,

etc.), however, device checks are made when the execution condition holds.

2. Operation at error stop

The outputs (Y) are cleared.

The other devices hold the states prior to an error stop.

When you want to clear them, power off or reset (short RES-SD (0.1s), then

open) the inverter.

There is an instruction code that cannot be decoded.

Unusable device is specified.

Main program capacity setting is over 1k step.

Unusable function is set.

Scan time is longer than the time that can be monitored

by the watchdog timer.

22

Page 28

Inverter Status Monitoring, Special Registers

for Control

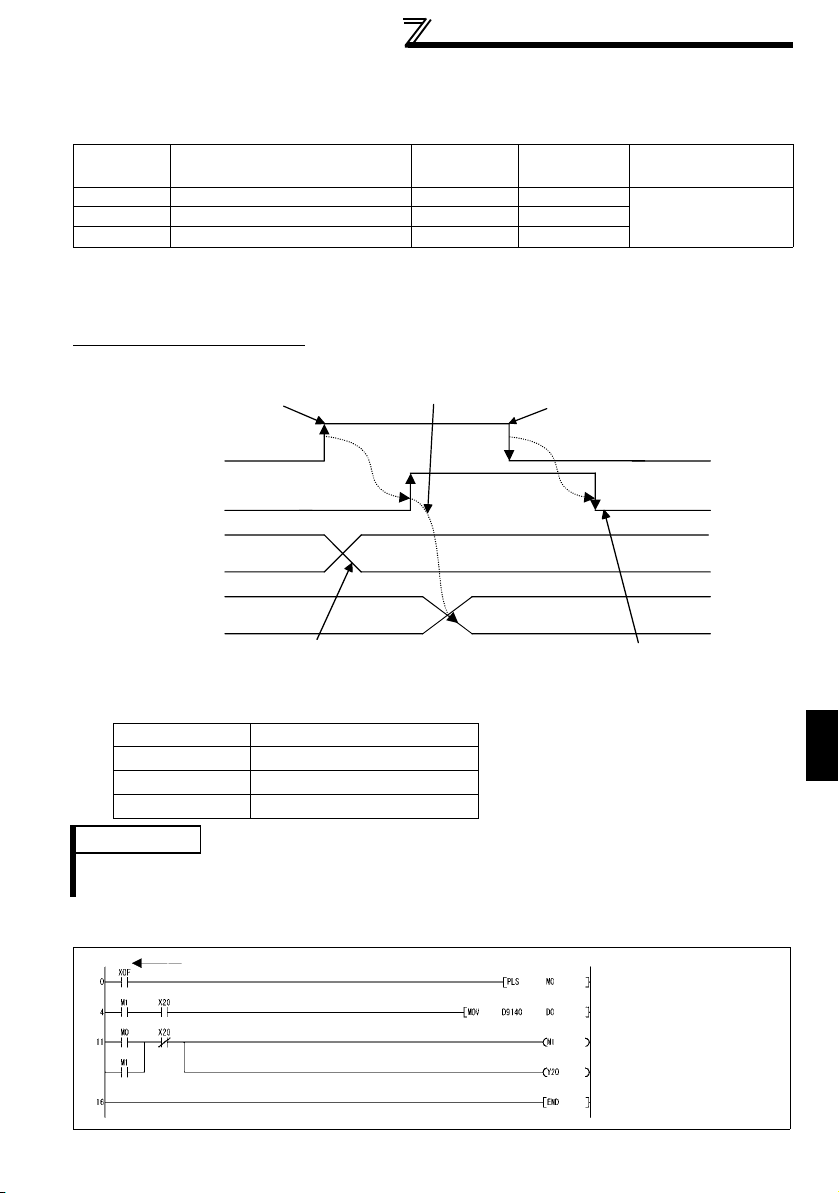

1.7.2 Data that are read by controlling (OFF to ON) the read command

You can read the operation mode and set frequency of the inverter.

Device

No.

Name

D9140 Operation mode setting read Y20 X20

D9142 Set frequency read (EEPROM) Y22 X22

Data are stored into the above data devices as soon as the read completion turns from

off to on after the read command has turned from off to on.

If the read command remains on, data is not refreshed. (Data is not updated.)

Turn the device off once, then on again to refresh data.

Data read timing chart

3) In user sequence, ON of read completion

1) Read command is turned

on in user sequence.

Y2n(n=0 to 2)

Read command

X2n(n=0 to 2)

Read completion

D914n(n=0 to 2)

Read data

is confirmed and data is read from special

register and processed.

Read

Command

Write

Completion

4) After completion of read,

read command is turned off.

Data Access

Enable Condition

AlwaysD9141 Set frequency read (RAM) Y21 X21

User sequence

processing

2) Inverter CPU stores inverter data

into special register and turns on

read completion.

5) Inverter CPU confirms that

read command is off and

turns off read completion.

(1) Operation mode setting read (D9140)

Data Setting Operation Mode

H0000

H0001

H0002

NET operation mode

External operation mode

PU operation mode

REMARKS

When the Pr. 79 "operation mode selection" setting is other than "0", the operation mode is as

set. However, when Pr. 79 = "3" or "4", the operation mode is "H0002" (PU operation mode).

<Operation mode setting read program example>

The following program reads the operation mode data to D0.

Operation mode read setting request

Turns on operation mode

read request pulse.

Stores operation mode data to D0

when operation mode setting read

completion signal turns on.

Turns on operation mode setting

read command. (Until operation

mode setting read completion

signal turns on)

1

PLC FUNCTION

23

Page 29

Inverter Status Monitoring, Special Registers

for Control

(2) Set frequency (RAM) (D9141)

The frequency set to the RAM is read to D9141. The unit is 0.01Hz.

(For example, 6000 indicates 60.00Hz.)

When the speed is set, the speed is either 1r/min or 0.1r/min.

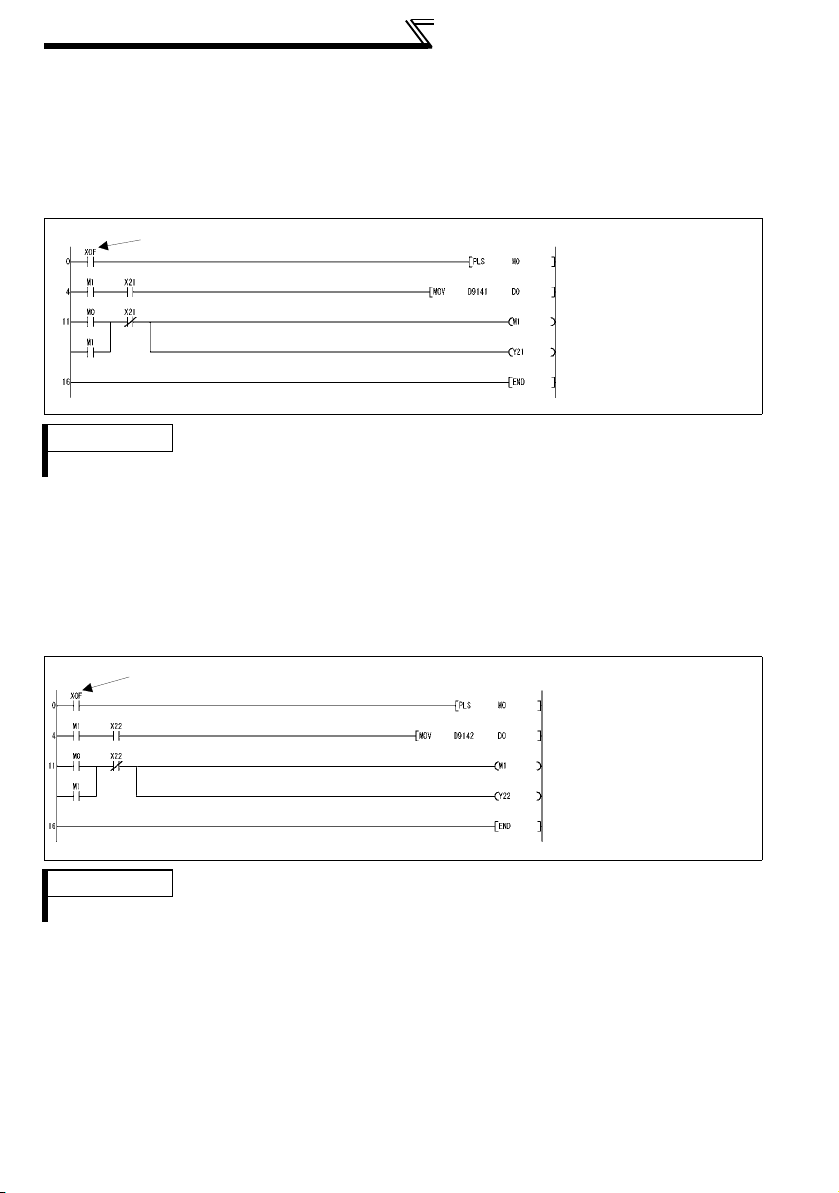

<Set frequency (RAM) read program example>

The following program reads the set frequency (RAM) to D0.

Set frequency read (RAM) setting request

Turns on set frequency

read (RAM) request pulse.

Stores data to D0 when set

frequency read (RAM)

completion signal turns on.

Turns on set frequency read (RAM)

command. (Until set frequency read

(RAM) completion signal turns on)

REMARKS

The read frequency is not the command value of the external signal.

(3) Set frequency (EEPROM) (D9142)

The frequency set to the EEPROM is read to D9142. The unit is 0.01Hz.

(For example, 6000 indicates 60.00Hz.)

When the speed is set, the speed is either 1r/min or 0.1r/min.

<Set frequency read (EEPROM) program example>

The following program reads the set frequency (E

The following program reads the set frequency (E2PROM) to D0.

2

PROM) to D0.

Set frequency read

(E

Stores data to D0 when set frequency

read (E

turns on.

Turns on set frequency read (E

command. (Until set frequency read

(E

2

PROM) setting request

2

PROM) completion signal

2

PROM) completion signal turns on)

2

PROM)

REMARKS

The read frequency is not the command value of the external signal.

24

Page 30

Inverter Status Monitoring, Special Registers

for Control

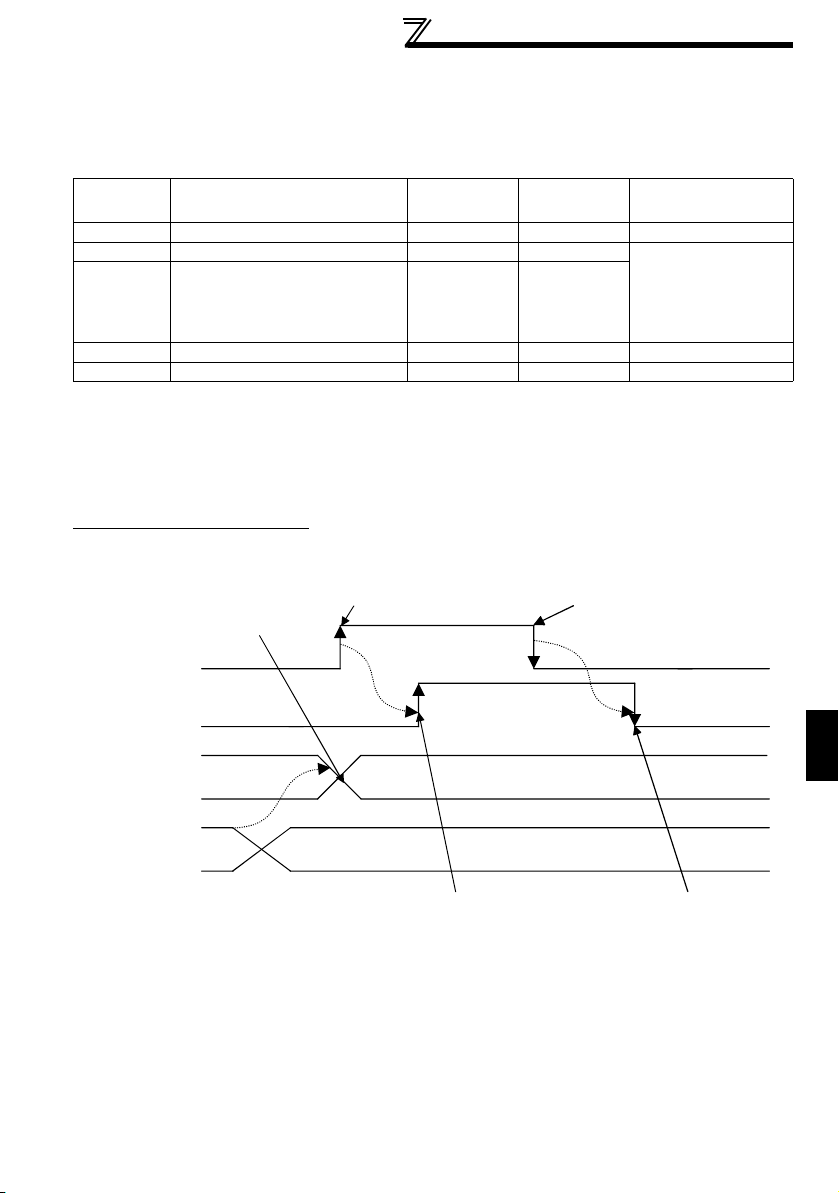

1.7.3 How to write data by controlling (OFF to ON) the write command

You can write the operation mode and set frequency to the inverter, batch-clear the

alarm definitions, and clear all parameters.

Device

No.

Name

D9143 Operation mode setting write Y23 X23 Pr.79 =0, 2

D9144 Set frequency write (RAM) Y24 X24 PU operation mode

D9145

Set frequency write

2

(E

PROM)

D9146 Alarm definition batch clear Y26 X26 Always

D9147 All parameter clear Y27 X27 As set in Pr. 77

The above data are written as soon as the write completion turns on after the write

command has turned from off to on.

(Alarm definition batch clear (D9146) and all parameter clear (D9147) turn on at

completion of clear.)

To write the data again, the write command must be turned off once, then on again.

Data write timing chart

1) In user sequence, user

data is stored into write

data area (D914n).

2) In user sequence, write

command is turned on.

Write

Command

Y25 X25

Write

Completion

Data Access

Enable Condition

(PU LED on) or CCLink operation mode

(PU and EXT LEDs

flicker slowly)

4) After confirmation of write

completion, write command

is turned off.

Y2n(n=3 to 7)

Write command

X2n(n=3 to 7)

Write completion

D914n(n=3 to 7)

Write data

User data

3) Turns on when inverter CPU completes data

write to inverter.

Alarm definition clear and parameter

clear turn on at completion of clear.

0 written to D9150 indicates normal completion.

Any value other than 0 indicates abnormal completion.

5) Inverter CPU confirms that

write command is off and

turns off write completion.

1

PLC FUNCTION

25

Page 31

Inverter Status Monitoring, Special Registers

for Control

(1) Operation mode setting write (D9143)

Data are as follows:

Data Setting Operation Mode

H0000

H0001

H0002

NET operation mode

External operation mode

PU operation mode

The operation mode switching method is as shown below when the Pr.79

Operation mode selection value is "0".

NET mode

(CC-Link)

H0001

H0000

External

operation mode

H0002

H0000

H0002

H0001

PU operation

mode

When Pr. 79 =2, switching is performed as shown below.

NET mode External

(CC-Link)

H0001

operation mode

H0000

REMARKS

When Pr. 79 is other than 0, the mode is fixed.

There are no restrictions on operation mode switching.

On normal completion of operation mode setting, the write completion signal

(X23) turns on, and at the same time, 0 is set to D9150.

If the value written is other than H0000 to H0002 or write is performed during

inverter operation, HFFFF is set to D9150 as soon as the write completion signal

(X23) turns on, resulting in abnormal completion.

If abnormal completion occurs, the operation mode is not changed.

<Operation mode setting write program example>

The following program changes the operation mode to the NET mode.

Operation mode write setting request

Normal write

Abnormal write

Turns on operation mode

setting write request pulse.

Check whether operation mode

setting write completion signal

turned on to judge whether write

was performed normally or not.

Stores 0 (CC-Link operation mode)

to D9143 and turns on operation

mode setting write command.

(Until completion signal turns on)

26

Page 32

Inverter Status Monitoring, Special Registers

for Control

(2) Set frequency (RAM) (D9144)

The D9144 data is written to the RAM as a set frequency. The unit is 0.01Hz.

(For example, 6000 indicates 60.00Hz.)

When the speed is set, the speed is either 1r/min or 0.1r/min.

The range where the frequency can be set is 0 to 12000 (0 to 120.00Hz).

When the frequency setting is written normally, the write completion signal (X24)

turns on, and at the same time, 0 is set to D9150.

If any value outside the range is written, HFFFF is set to D9150 as soon as the

write completion signal (X24) turns on, resulting in abnormal completion. If

abnormal completion occurs, the set frequency is not changed.

POINT

• The frequency can be set in the PU operation mode and NET operation

mode. Refer to the inverter instruction manual (applied).

<Set frequency write (RAM) program example>

The following program changes the set frequency (RAM) to 30Hz.

Set frequency write (RAM) setting request

Normal write

Abnormal write

Turns on set frequency

write (RAM) command pulse.

Check whether set frequency

write (RAM) completion signal

turned on to judge whether write

was performed normally or not.

Stores 3000 (30Hz) into D9144,

and turns on set frequency write

(RAM) command.

(Until completion signal turns on)

1

PLC FUNCTION

27

Page 33

Inverter Status Monitoring, Special Registers

for Control

(3) Set frequency (EEPROM) (D9145)

The D9145 data is written to the EEPROM as a set frequency. The unit is 0.01Hz.

(For example, 6000 indicates 60.00Hz.)

When the speed is set, the speed is either 1r/min or 0.1r/min.

The range where the frequency can be set is 0 to 12000 (0 to 120.00Hz).

When the frequency setting is written normally, the write completion signal (X25)

turns on, and at the same time, 0 is set to D9150.

If any value outside the range is written, HFFFF is set to D9150 as soon as the

write completion signal (X25) turns on, resulting in abnormal completion. If

abnormal completion occurs, the set frequency is not changed.

POINT

• Setting is enabled in the PU operation mode and NET operation mode.

(Refer to the Inverter instruction manual (applied).)

<Set frequency write (EEPROM) program example>

The following program changes the set frequency (EEPROM) to 10Hz.

Set frequency write (E2PROM) setting request

Normal write

Abnormal write

1000

Turns on set frequency write

2

PROM) request pulse.

(E

Check whether set frequency

2

write (E

PROM) completion signal

turned on to judge whether write

was performed normally or not.

Stores 1000 (10Hz) into D9145,

and turns on set frequency write

2

(E

PROM) command.

(Until completion signal turns on)

CAUTION

When rewriting the set frequency frequently, use device D9144 "set frequency (RAM)".

There are restrictions on the number of write times of the EEPROM. (Approximately

100,000 times)

28

Page 34

Inverter Status Monitoring, Special Registers

(4) Alarm definition batch clear (D9146)

Writing H9696 to D9146 batch-clears the alarm definitions.

At completion of clear, the write completion signal (X26) turns on, and at the

same time, 0 is set to D9150. If any value outside the setting range is written or

write is performed during inverter operation, HFFFF is set to D9150 as soon as

the write completion signal (X26) turns on, resulting in abnormal completion.

If abnormal completion occurs, the alarm definitions are not cleared.

<Alarm definition batch clear program example>

The following program batch-clears the alarm history.

for Control

Alarm definition batch clear request

Normal write

Abnormal write

Turns on alarm definition

batch clear request pulse.

Check whether alarm definition

batch clear signal turned on to

judge whether write was

performed normally or not.

Stores H9696 (batch clear code)

to D9146 and turns on alarm

definition batch clea r command.

(Until completion signal turns on)

1

29

PLC FUNCTION

Page 35

Inverter Status Monitoring, Special Registers

for Control

(5) Parameter clear (D9147)

Writing H9696 or H9966 to D9147 clears all parameters. Writing H5A5A or

H55AA to D9147 clears the parameters other than the communication

parameters (Refer to the Inverter instruction manual (applied)).

Device No. Setting Description Details

Terminal functions are not

cleared.

Terminal functions are

cleared.

Terminal functions are not

cleared.

Terminal functions are

cleared.

D9147

H9696

All parameter clear

H9966

H5A5A Parameters other than

communication parameters

H55AA

are cleared.

At completion of clear, the write completion signal (X27) turns on, and at the

same time, 0 is set to D9150. If any value outside the setting range is written or

write is performed during inverter operation, HFFFF is set to D9150 as soon as

the write completion signal (X27) turns on, resulting in abnormal completion. If

abnormal completion occurs, the parameters are not cleared.

REMARKS

Check the terminal function parameters and communication-related parameters in the

parameter list (Refer to the Inverter instruction manual (applied)).

POINT

Setting is enabled in the PU operation mode and NET operation mode. Refer to

the inverter instruction manual (applied).

<All parameter clear program example>

The following program clears all parameters.

All parameter clear request

Related device

Device D9150: Parameter access error code (refer to page 33)

30

Normal write

Abnormal write

Turns on all parameter

clear request pulse.

Check whether all parameter

clear signal turned on to judge

whether write was performed

normally or not.

Stores H9696 (all parameter

clear code) to D9146 and turns

on alarm definition batch clear

command.

(Until completion signal turns on)

Page 36

Inverter Status Monitoring, Special Registers

for Control

1.7.4 Inverter operation status control

Device No. Name Data Access Enable Condition

D9148 Inverter operation status control

D9149

Inverter operation status control

enable/disable

(1) Inverter operation status control (D9148)

Device for inverter operation status control. The operation of the inverter can be

controlled by turning on/off (1, 0) bits b0 to b11 of D9148.

All bits are factory-set to "0".

Example: When 5 is set to D9148, bits b0 and b2 are 1 (ON), and STF and RH

therefore turn on to give a high-speed forward rotation command.

Always

Note that this function is enabled in

the external/NET operation mode.

(Not enabled in the PU

operation mode.)

B15 B12B11 B8B7 B4 B3 B0

Invalid

0:OFF

101000000000

1:ON

STF (Pr.178)

STR (Pr.179)

RH (Pr.182)

RM (Pr.181)

RL (Pr.180)

JOG (Pr.185)

RT (Pr.183)

AU (Pr.184)

CS (Pr.186)

MRS (Pr.187)

STOP (Pr.188)

RES (Pr.189)

CAUTION

As in the external input terminals, functions can be assigned to the bits of

D9148 using Pr.178 to Pr.189. However, no function can be assigned to SQ

(sequence RUN setting: 50).

1

PLC FUNCTION

31

Page 37

Inverter Status Monitoring, Special Registers

r

for Control

(2) Inverter operation status control enable/disable setting (D9149)

You can enable or disable D9148 "inverter operation status control". The controls

of the corresponding bits of D9148 are enabled by turning on/off (1, 0) bits b0 to

b11 of D9149. All bits are factory-set to "0".

Example: When H1F is set to D9149, bits b0 to b11 are 1 (ON), the external terminal

inputs are therefore all disabled, and operation control using the inverter

operation status control (D9148) can be performed.

B15 B12B11 B8B7 B4 B3 B0

Invalid

0:OFF

111111111111

1:ON

STF (Pr.178)

STR (Pr.179)

RH (Pr.182)

RM (Pr.181)

RL (Pr.180)

JOG (Pr.185)

RT (Pr.183)

AU (Pr.184)

CS (Pr.186)

MRS (Pr.187)

STOP (Pr.188)

RES (Pr.189)

CAUTION

•When D9148 "inverter operation status control" is enabled using D9149,

the control performed by external terminal inputs and the control

performed by CC-Link remote inputs are disabled for the enabled bits.

(Same as when "No functions" are set to Pr.178 to Pr.189.)

•When the terminal is made valid from PLC function, control from external

terminal is made invalid.

<Operation command setting program example>

The following program example runs the inverter at high speed in forward rotation

direction.

Operation start

Turns on operation start pulse.

HFFF

Operation stop

Enables all inverter operation status

control enable/disable bits, and

disables external terminal inputs.

Self-holds operation start, and turns

on bits 0 (STF) and 2 (RH) of inverte

operation status control, D9148.

At input of stop signal, clears inverter

operation status control, D9148,

to 0 and decelerates inverter to stop.

32

Page 38

Inverter Status Monitoring, Special Registers

for Control

1.7.5 Inverter parameter access error (D9150)

Device No. Name

D9150 Inverter parameter access error Always

If any value outside the setting range is written during parameter write, set frequency

write, parameter clear, etc. from the sequence program of the inverter, or if write is

performed when write is disabled, a write alarm occurs and the corresponding alarm

code is stored into D9150.

<Parameter>

The parameter No. + H8000 is stored into D9150.

Example: If an error occurs during write of Pr.0 Torque boost, H8000 (H0 + H8000) is

stored into D9150.

If an error occurs during write of Pr.10 DC injection brake operation frequency,

H800A is stored into D9150.

<Operation mode, set frequency, alarm definition batch clear, all parameter

clear>

HFFFF is stored into D9150. (Normal 0)

POINT

If write is completed normally after error occurrence, D9150 is not cleared

(D9150 data is held at error occurrence). When using D9150 to stop operation,

etc., the user must clear it.

Data Access Enable

Condition

1.7.6 Inverter status (D9151)

Device No. Name

D9151 Inverter status Always

The running status and operating status of the inverter are stored.

The corresponding bits are set according to the inverter status.

B15 B8B7 B4 B3 B0

0:OFF

1:ON

Inverter running(RUN)

Forward running

Reverse running

Up to frequency(SU)

Overload alarm(OL)

Instantaneous power failure

/undervoltage(IPF)

Output frequency

detection(FU)

Alarm output(ALM)

Minor fault output(LF)

Data Access Enable

Condition

1

PLC FUNCTION

33

Page 39

Inverter Parameter Read/Write Method

1.8 Inverter Parameter Read/Write Method

1.8.1 Reading the inverter parameters

Data Access Enable

Device No. Name Command

D9241 Parameter number (RAM)

D9242 Parameter description (RAM)

D9234

D9243 Parameter number (EEPROM)

D9244

D9235

Second parameter changing

(RAM)

Parameter description

(EEPROM)

Second parameter changing

(EEPROM

Y28 X28 Always

Y2A X2A

Completion

When reading the parameter, the parameter description is stored to D9242(D9244) by

storing the parameter number to D9241(D9243) and turning Y28 (Y2A) on. When

reading is completed, X28 (X2A) turns ON to notify the completion. (The device

number within parentheses is used to read the parameter setting value from

EEPROM.)

When reading the calibration parameter (Pr. 902 to Pr. 939), set the following value to

D9234 (D9235) to read each calibration parameter value.

0: Setting value (Frequency/Toruque)

1: Parameter-set analog value

2: Analog value input from terminal

When access error occurs such as "parameter does not exist", value obtained by adding the

parameter number and 8000H is stored to D9150. (Refer to page 33)

Condition

(Operation mode)

PU, NET operation mode

(as in Pr.77)

34

Page 40

Inverter parameter data read timing chart

3) In user sequence, ON of read completion

is confirmed and data are read from data

registers D9242(D9243) and processed.

1) Read command is turned

on in user sequence.

Y28(Y2A)

Parameter read

command

X28(X2A)

Parameter read

completion

Inverter

parameter

D9242(D9243)

Parameter

read data

User sequence

processing

2) Inverter CPU stores inverter parameter

data into data registers D9242(D9243),

and turns on read completion.

Inverter Parameter Read/Write Method

4) After completion of read,

read command is turned off.

5) Inverter CPU confirms that read

command is off and turns off

read completion.

35

1

PLC FUNCTION

Page 41

Inverter Parameter Read/Write Method

1.8.2 Writing the inverter parameters

Data Access Enable

Device No. Name Command

D9241 Parameter number (RAM)

D9242 Parameter description (RAM)

D9234

D9243 Parameter number (EEPROM)

D9244

D9235

Second parameter changing

(RAM)

Parameter description

(EEPROM)

Second parameter changing

(EEPROM

Y29

Y2B X2B

Completion

X29 Always

Parameter writing is performed when the parameter number is stored to D9241

(D9243) and parameter writing value to D9242 (D9244), and turns ON the Y29 (Y2B).

When writing is completed, X29 (X2B) turns ON to notify the completion. (The device

number within parentheses is used to write the parameter setting value to EEPROM.)

When writing the calibration parameter (Pr. 902 to Pr. 939), set the following value to

D9234 (D9235) to write each calibration parameter value.

0: Setting value (Frequency/Toruque)

1: Parameter-set analog value

2: Analog value input from terminal

As soon as the inverter parameter write completion (X29 (RAM) or X2B (EEPROM))

turns on, 0 is set to D9150 on normal completion.

If an error occurs during access to the parameters, e.g. if any value outside the setting

range is written or write is performed during inverter operation, the value of parameter

No. + H8000 is set to D9150 as soon as the write completion signal (X29 (RAM) or

X2B (EEPROM)) turns on, resulting in abnormal completion. If abnormal completion

occurs, the parameters are not written. (For example, if an error occurs in the torque

boost, H8000 is written to D9150.)

For whether inverter parameter write can be performed or not, refer to Pr.77 Parameter

write selection .

Condition

(Operation mode)

PU, NET operation mode

(as in Pr.77)

POINT

Inverter parameter write must be performed in the PU operation mode or NET

operation mode. (Refer to the inverter instruction manual (applied).)

36

Page 42

Inverter parameter data write timing chart

Inverter Parameter Read/Write Method

1) In user sequence, user data

are stored into parameter write

data area (D9242(D9244)).

Y29(Y2B)

Parameter

write command

X29(X2B)

Parameter

write completion

Inverter parameter

D9242(D9244)

Parameter write

data

User sequence

data