Page 1

Page 2

Page 3

MELDAS is a registered trademark of Mitsubishi Electric Corporation.

Other company and product names that appear in this manual are trademarks or registered

trademarks of the respective companies.

Page 4

Page 5

Introduction

This manual is a guide for using the MITSUBISHI CNC 700/70 Series.

Programming is described in this manual, so read this manual thoroughly before starting

programming. Thoroughly study the "Precautions for Safety" on the following page to

ensure safe use of this NC unit.

Details described in this manual

CAUTION

For items described in "Restrictions" or "Usable State", the instruction manual issued by the machine

tool builder takes precedence over this manual.

An effort has been made to note as many special handling methods in this user's manual. Items not

described in this manual must be interpreted as "not possible".

This manual has been writt e n o n t h e a ss u m p t i o n t h a t a l l o p t i on f u n c t i on s a r e added. Refer to the

specifications issued by the machine tool builder before starting use.

Refer to the Instruction Manual issued by each machine tool builder for details on each machine tool.

Some screens and functions may differ depending on the NC system or its version, and some

functions may not be possible. Please confirm the specifications before use.

General precautions

(1) Refer to the following documents for details on handling

MITSUBISHI CNC 700/70 Series Instruction Manual ................................. IB-1500042

Page 6

Page 7

Precautions for Safety

Always read the specifications issued by the machine maker, this manual, related manuals

and attached documents before installation, operation, programming, maintenance or

inspection to ensure correct use.

Understand this numerical controller, safety items and cautions before using the unit.

This manual ranks the safety precautions into "DANGER", "WARNING" and "CAUTION".

DANGER

WARNING

CAUTION

Note that even items ranked as " CAUTION", may lead to major results depending on the

situation. In any case, important information that must always be observed is described.

When the user may be subject to imminent fatalities or major injuries if

handling is mistaken.

When the user may be subject to fatalities or major injuries if handling is

mistaken.

When the user may be subject to injuries or when physical damage may

occur if handling is mistaken.

Not applicable in this manual.

Not applicable in this manual.

1. Items related to product and manual

For items described as "Restrictions" or "Usable State" in this manual, the instruction manual

issued by the machine tool builder takes precedence over this manual.

An effort has been made to describe special handling of this machine, but items that are not

described must be interpreted as "not possible".

This manual is written on the assumption that all option functions are added. Refer to the

specifications issued by the machine tool builder before starting use.

Refer to the Instruction Manual issued by each machine tool builder for details on each

machine tool.

Some screens and functions may differ depending on the NC system or its version, and some

functions may not be possible. Please confirm the specifications before use.

DANGER

WARNING

CAUTION

(Continued on next page)

Page 8

2. Items related to operation

Before starting actual machining, always carry out dry operation to confirm the machining

program, tool compensation amount and workpiece offset amount, etc.

If the workpiece coordinate system offset amount is changed during single block stop, the new

setting will be valid from the next block.

Turn the mirror image ON and OFF at the mirror image center.

Refer to the Instruction Manual issued by each machine tool builder for details on each

machine tool.

If the tool compensation amount is changed during automatic operation (including during single

block stop), it will be validated from the next block or blocks onwards.

3. Items related to programming

CAUTION

The commands with "no value after G" will be handled as "G00".

“EOB", "%", and “EOR” are symbols used for explanation. The actual codes for ISO are "CR,

LF" ("LF") and "%".

The programs created on the Edit screen are stored in the NC memory in a "CR, LF" format,

however, the programs created with external devices such as the FLD or RS-232C may be

stored in an "LF" format.

The actual codes for EIA are "EOB (End of Block)" and "EOR (End of Record)".

When creating the machining program, select the appropriate machining conditions, and make

sure that the performance, capacity and limits of the machine and NC are not exceeded. The

examples do not consider the machining conditions.

Do not change fixed cycle programs without the prior approval of the machine tool builder.

When programming a program of the multi-part system, carefully observe the movements

caused by other part systems' programs.

Page 9

Contents

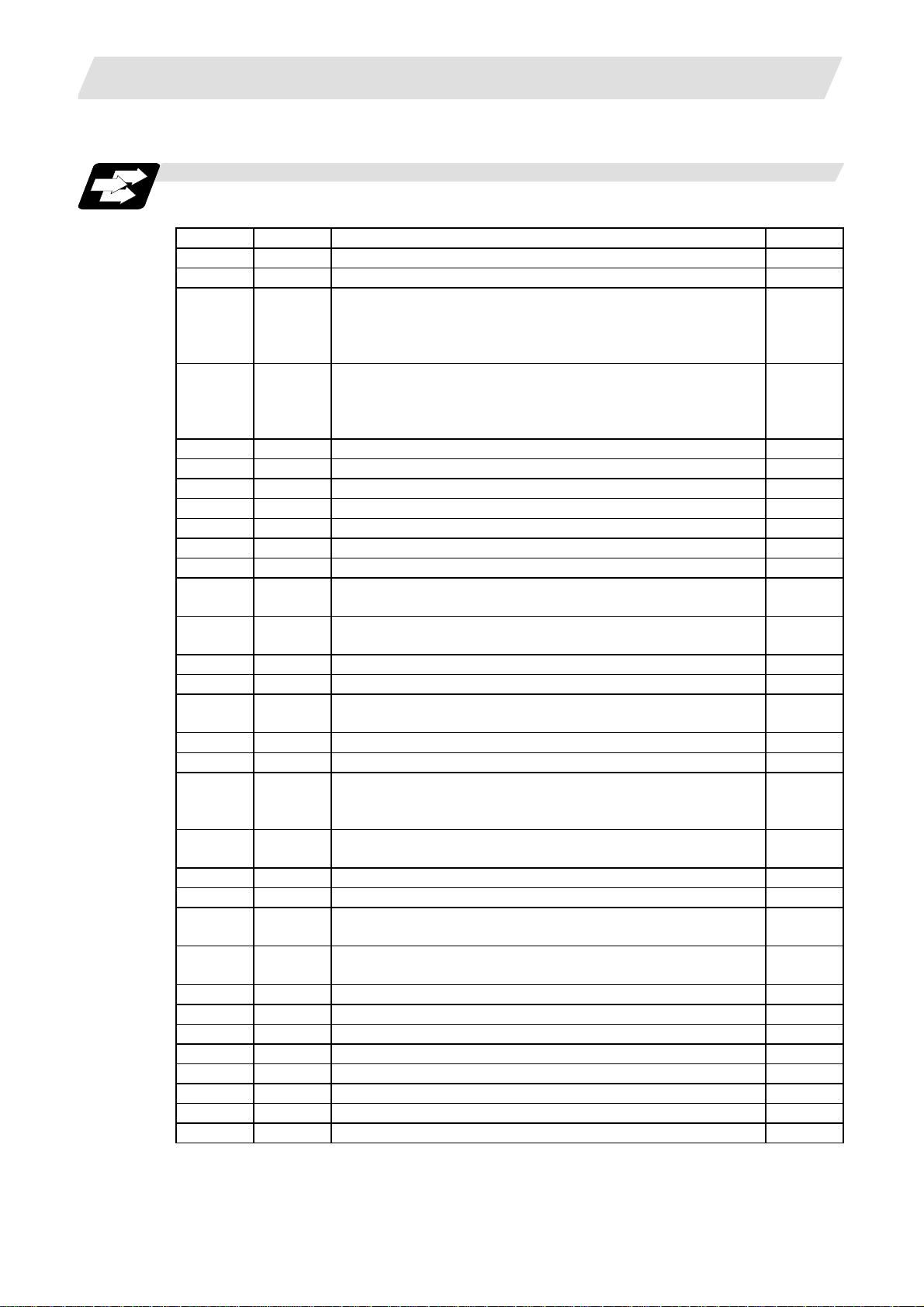

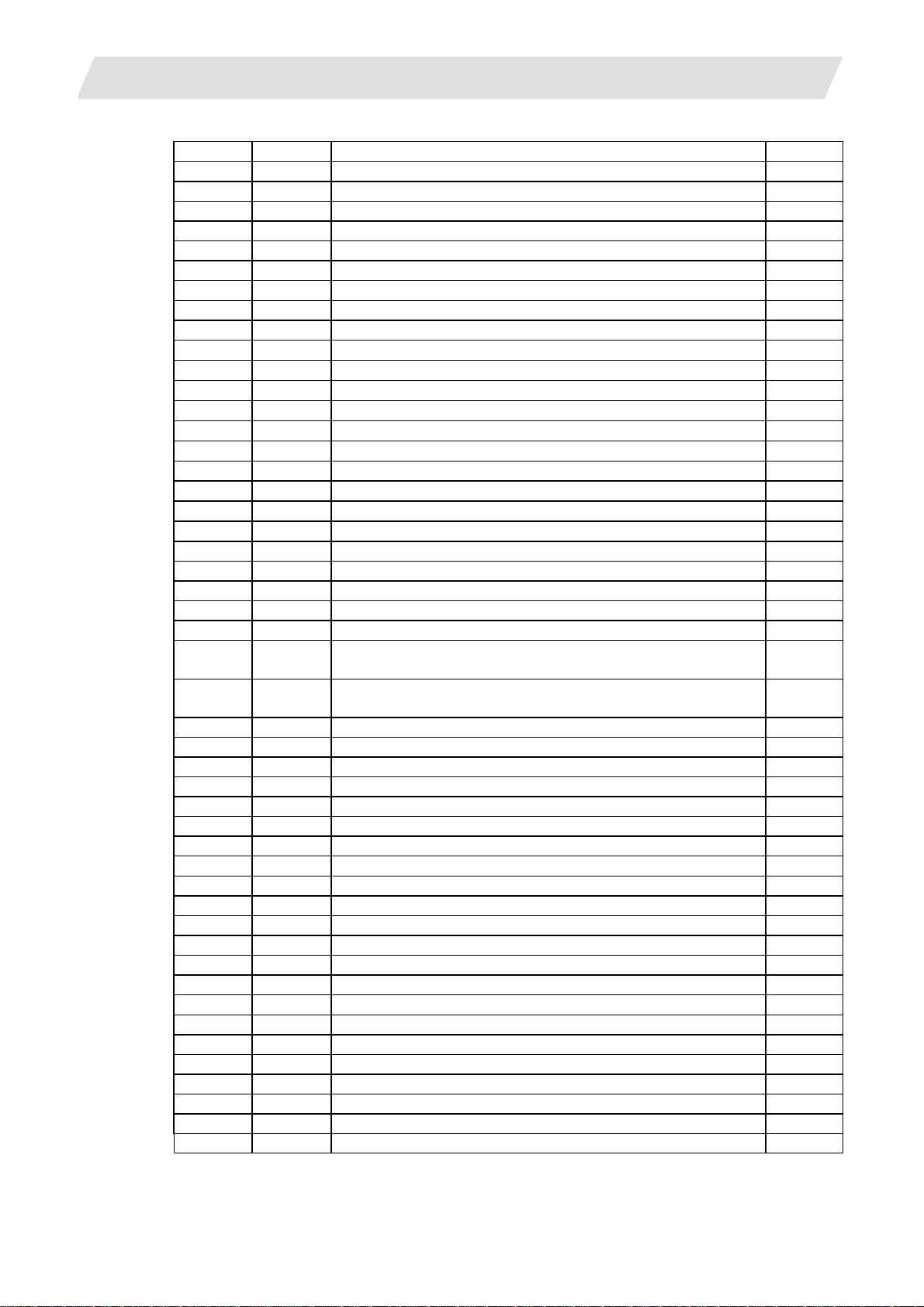

1. Control Axes..................................................................................................................................1

1.1 Coordinate Words and Control Axis........................................................................................1

1.2 Coordinate Systems and Coordinate Zero Point Symbols......................................................2

2. Least Command Increments........................................................................................................3

2.1 Input Setting Units...................................................................................................................3

2.2 Input Command Increment Tenfold.........................................................................................5

2.3 Indexing Increment..................................................................................................................6

3. Data Formats.................................................................................................................................7

3.1 Tape Codes.............................................................................................................................7

3.2 Program Formats ..................................................................................................................10

3.3 Tape Memory Format............................................................................................................13

3.4 Optional Block Skip...............................................................................................................13

3.4.1 Optional Block Skip; /......................................................................................................13

3.4.2 Optional Block Skip Addition ; /n.....................................................................................14

3.5 Program/Sequence/Block Numbers ; O, N ...........................................................................16

3.6 Parity H/V..............................................................................................................................17

3.7 G Code Lists .........................................................................................................................18

3.8 Precautions Before Starting Machining.................................................................................21

4. Buffer Register............................................................................................................................22

4.1 Input Buffer............................................................................................................................22

4.2 Pre-read Buffers....................................................................................................................23

5. Position Commands ...................................................................................................................24

5.1 Position Command Methods ; G90, G91 ..............................................................................24

5.2 Inch/Metric Command Change; G20, G21............................................................................26

5.3 Decimal Point Input...............................................................................................................28

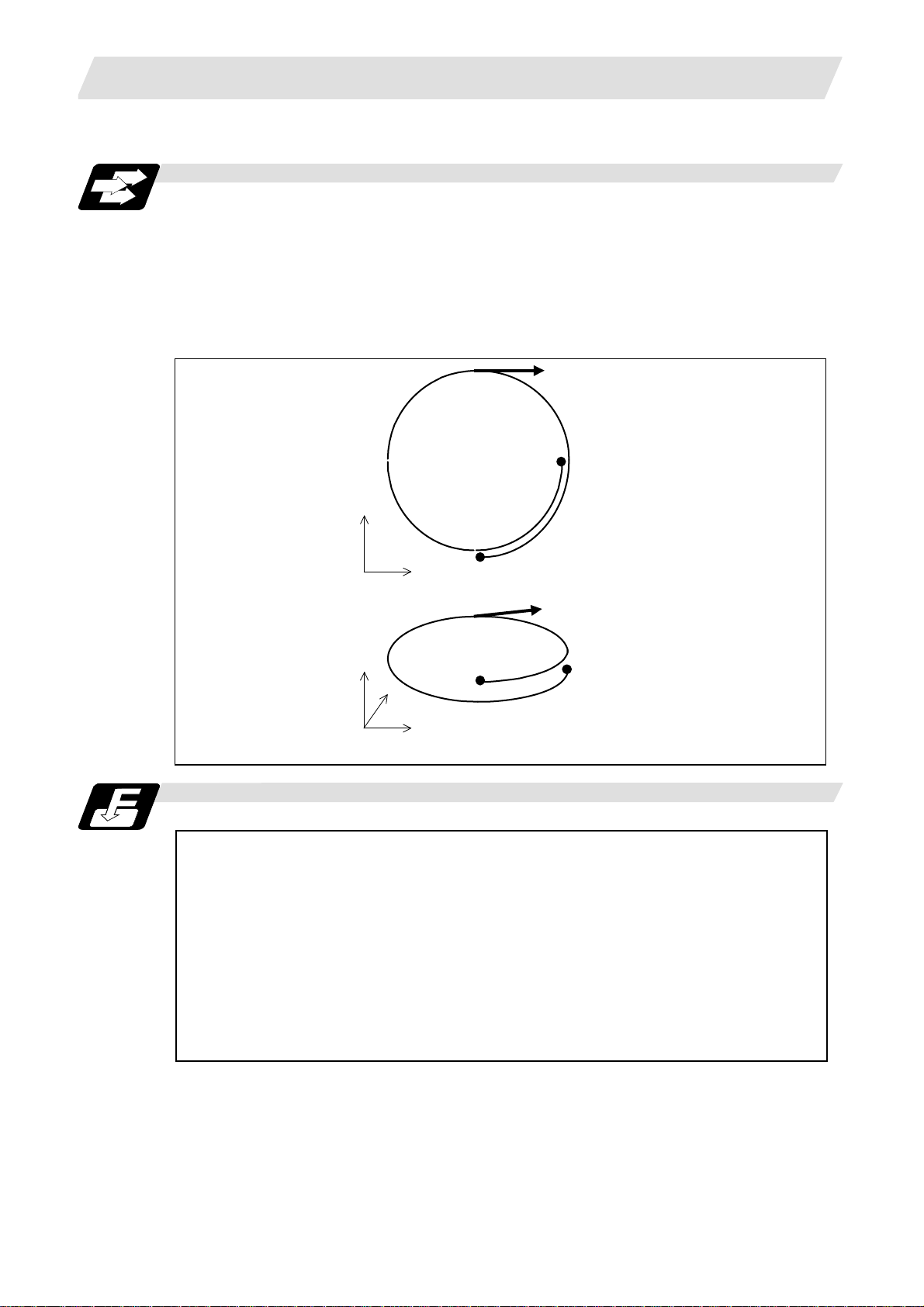

6. Interpolation Functions..............................................................................................................33

6.1 Positioning (Rapid Traverse); G00........................................................................................33

6.2 Linear Interpolation; G01.......................................................................................................40

6.3 Plane Selection; G17, G18, G19...........................................................................................42

6.4 Circular Interpolation; G02, G03...........................................................................................44

6.5 R-specified Circular Interpolation; G02, G03........................................................................49

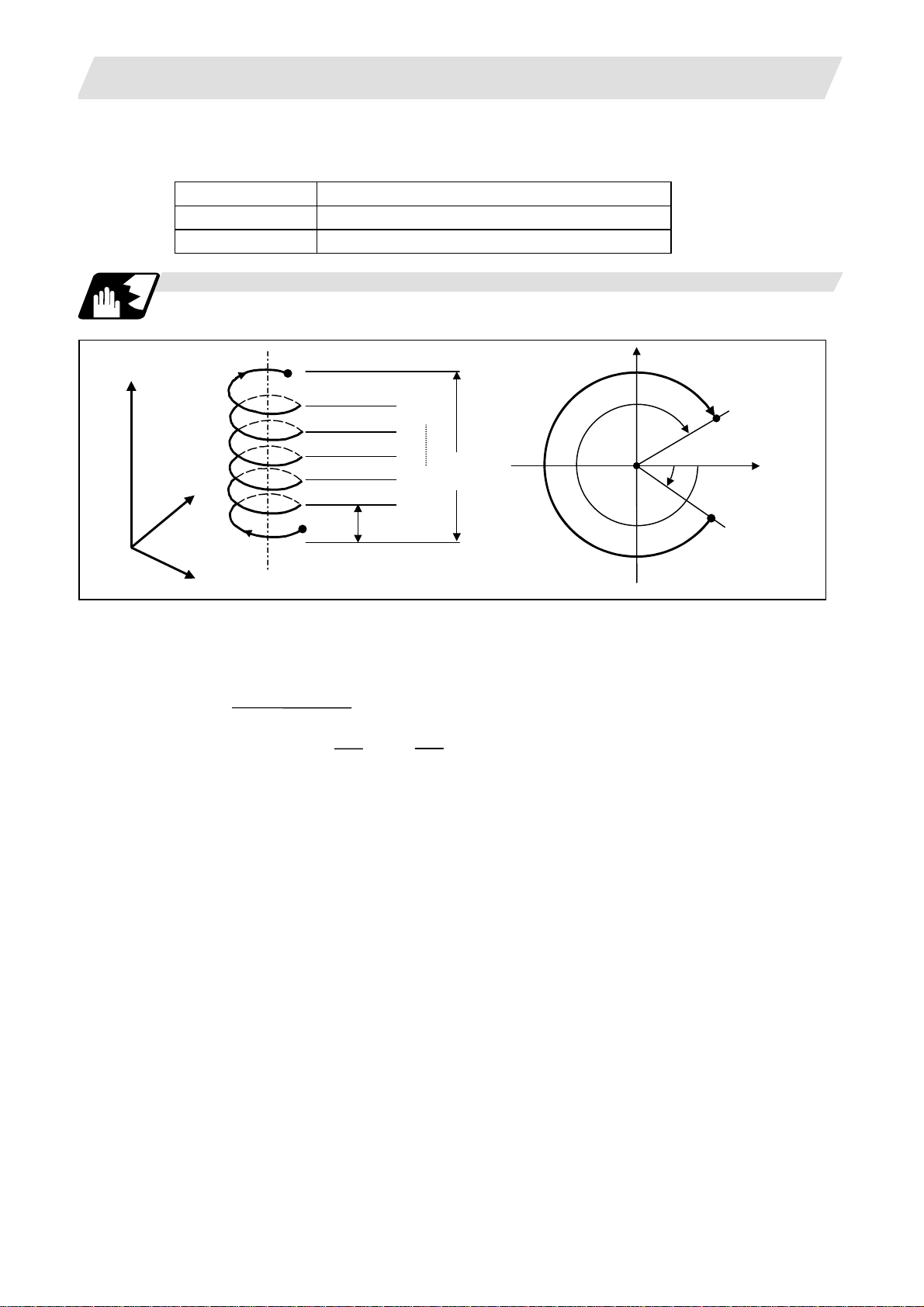

6.6 Helical Interpolation ; G17 to G19, G02, G03 .......................................................................52

6.7 Thread Cutting ......................................................................................................................56

6.7.1 Constant Lead Thread Cutting ; G33..............................................................................56

6.7.2 Inch Thread Cutting; G33................................................................................................60

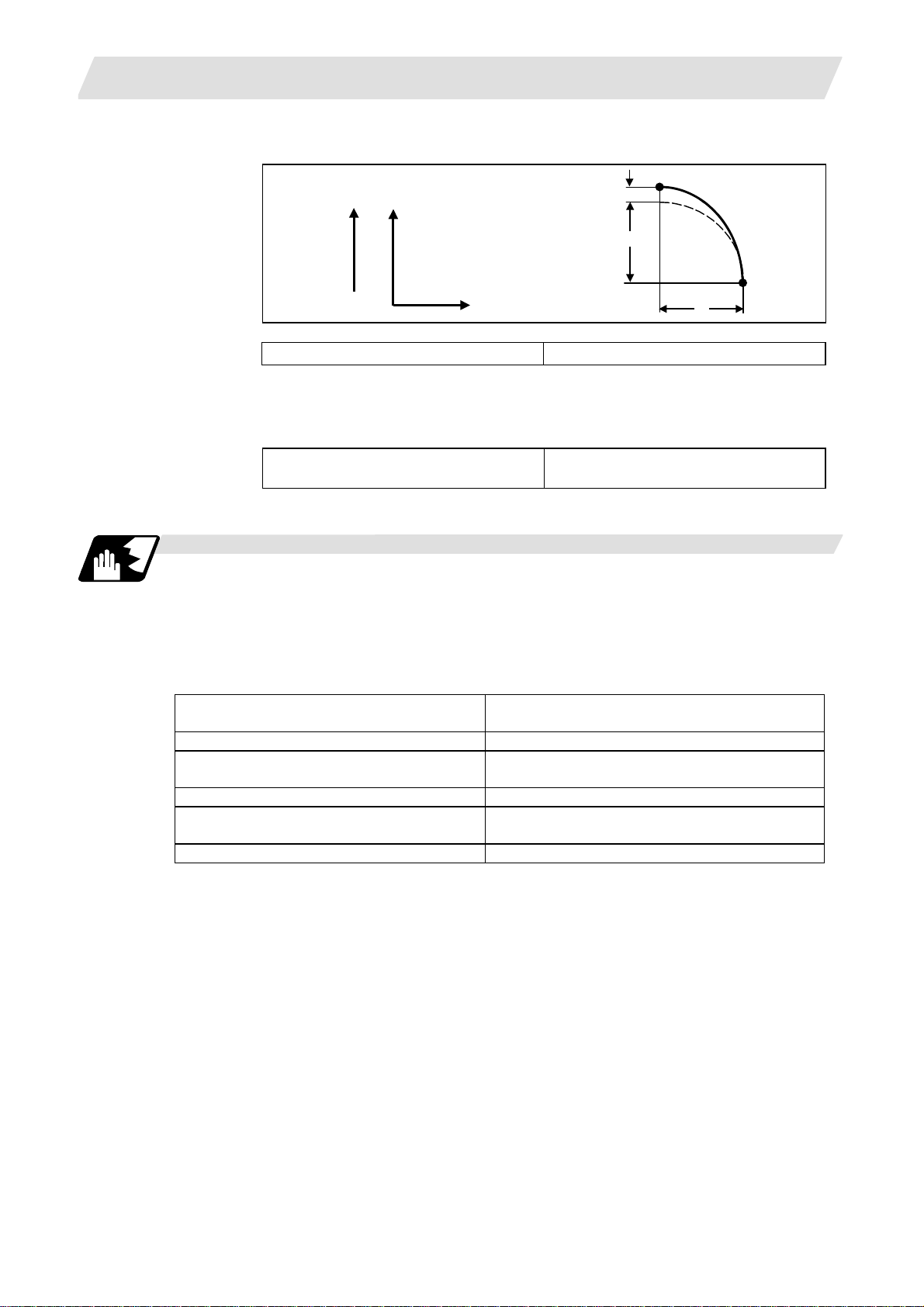

6.8 Unidirectional Positioning; G60.............................................................................................61

6.9 Cylindrical Interpolation; G07.1.............................................................................................63

6.10 Polar Coordinate Interpolation; G12.1, G13.1/G112,G113.................................................71

6.11 Exponential Function Interpolation; G02.3, G03.3..............................................................78

6.12 Polar Coordinate Command ; G16/G15..............................................................................84

6.13 Spiral/Conical Interpolation; G02.0/G03.1(Type1), G02/G03(Type2).................................90

6.14 3-dimensional Circular Interpolation; G02.4, G03.4............................................................95

6.15 NURBS Interpolation.........................................................................................................100

6.16 Hypothetical Axis Interpolation; G07.................................................................................105

7. Feed Functions .........................................................................................................................107

7.1 Rapid Traverse Rate...........................................................................................................107

7.2 Cutting Feedrate .................................................................................................................107

7.3 F1-digit Feed.......................................................................................................................108

7.4 Feed Per Minute/Feed Per Revolution

(Asynchronous Feed/Synchronous Feed); G94, G95.........................................................110

Page 10

7.5 Inverse Time Feed; G93 .....................................................................................................112

7.6 Feedrate Designation and Effects on Control Axes............................................................116

7.7 Rapid Traverse Constant Inclination Acceleration/Deceleration.........................................120

7.8 Rapid Traverse Constant Inclination Multi-step Acceleration/Deceleration........................122

7.9 Exact Stop Check; G09.......................................................................................................131

7.10 Exact Stop Check Mode; G61...........................................................................................134

7.11 Deceleration Check...........................................................................................................134

7.11.1 G1 -> G0 Deceleration Check.....................................................................................136

7.11.2 G1 -> G1 Deceleration Check.....................................................................................137

7.12 Automatic Corner Override; G62.......................................................................................138

7.13 Tapping Mode; G63 ..........................................................................................................143

7.14 Cutting Mode ; G64...........................................................................................................143

8. Dwell...........................................................................................................................................144

8.1 Per-second Dwell ; G04......................................................................................................144

9. Miscellaneous Functions .........................................................................................................146

9.1 Miscellaneous Functions (M8-digits BCD)..........................................................................146

9.2 Secondary Miscellaneous Functions (B8-digits, A8 or C8-digits).......................................148

9.3 Index Table Indexing...........................................................................................................149

10. Spindle Functions...................................................................................................................151

10.1 Spindle Functions (S6-digits Analog)................................................................................151

10.2 Spindle Functions (S8-digits) ............................................................................................151

10.3 Constant Surface Speed Control; G96, G97.....................................................................152

10.3.1 Constant Surface Speed Control................................................................................152

10.4 Spindle Clamp Speed Setting; G92 ..................................................................................153

10.5 Spindle/C Axis Control ......................................................................................................154

10.6 Multiple Spindle Control ....................................................................................................157

10.6.1 Multiple Spindle Control II...........................................................................................158

11. Tool Functions (T command).................................................................................................160

11.1 Tool Functions (T8-digit BCD)...........................................................................................160

12. Tool Compensation Functions ..............................................................................................161

12.1 Tool Compensation...........................................................................................................161

12.2 Tool Length Compensation/Cancel; G43, G44/G49 .........................................................165

12.3 Tool Length Compensation in the Tool Axis Direction ; G43.1/G49..................................168

12.4 Tool Radius Compensation; G38, G39/G40/G41,G42......................................................175

12.4.1 Tool radius Compensation Operation.........................................................................176

12.4.2 Other Commands and Operations during Tool Radius Compensation.......................185

12.4.3 G41/G42 Commands and I, J, K Designation.............................................................194

12.4.4 Interrupts during Tool Radius Compensation.............................................................200

12.4.5 General Precautions for Tool Radius Compensation..................................................202

12.4.6 Changing of Compensation No. during Compensation Mode.....................................203

12.4.7 Start of Tool Radius Compensation and Z Axis Cut in Operation...............................205

12.4.8 Interference Check .....................................................................................................207

12.4.9 Diameter Designation of Compensation Amount........................................................214

12.4.10 Workpiece Coordinate Changing during Radius Compensation...............................216

12.5 Three-dimensional Tool Radius Compensation ; G40/G41,G42.......................................218

12.6 Tool Position Offset; G45 to G48......................................................................................229

12.7 Programmed Compensation Input ; G10, G11..................................................................236

12.8 Inputting the Tool Life Management Data; G10, G11 .......................................................241

12.8.1 Inputting the Tool Life Management Data by G10 L3 Command................................241

12.8.2 Inputting the Tool Life Management Data by G10 L30 Command..............................243

12.8.3 Precautions for Inputting the Tool Life Management Data..........................................246

13. Program Support Functions ..................................................................................................247

13.1 Fixed Cycles......................................................................................................................247

Page 11

13.1.1 Standard Fixed Cycles; G80 to G89, G73, G74, G75, G76........................................247

13.1.2 Drilling Cycle with High-Speed Retract.......................................................................274

13.1.3 Initial Point and R Point Level Return; G98, G99........................................................277

13.1.4 Setting of Workpiece Coordinates in Fixed Cycle Mode.............................................278

13.2 Special Fixed Cycle; G34, G35, G36, G37.1 ....................................................................279

13.3 Subprogram Control; M98, M99, M198.............................................................................284

13.3.1 Calling Subprogram with M98 and M99 Commands ..................................................284

13.3.2 Calling Subprogram with M198 Commands ...............................................................289

13.3.3 Figure Rotation; M98 I_ J_ K_....................................................................................289

13.4 Variable Commands..........................................................................................................292

13.5 User Macro Specifications ................................................................................................297

13.5.1 User Macro Commands; G65, G66, G66.1, G67........................................................297

13.5.2 Macro Call Command .................................................................................................298

13.5.3 ASCII Code Macro......................................................................................................307

13.5.4 Variables.....................................................................................................................311

13.5.5 Types of Variables ......................................................................................................313

13.5.6 Arithmetic Commands.................................................................................................351

13.5.7 Control Commands.....................................................................................................356

13.5.8 External Output Commands........................................................................................359

13.5.9 Precautions.................................................................................................................361

13.5.10 Actual Examples of Using User Macros....................................................................363

13.6 G Command Mirror Image; G50.1, G51.1.........................................................................367

13.7 Corner Chamfering/Corner Rounding I.............................................................................370

13.7.1 Corner Chamfering " ,C_ "..........................................................................................370

13.7.2 Corner Rounding " ,R_ ".............................................................................................372

13.8 Linear Angle Command ....................................................................................................373

13.9 Geometric Command........................................................................................................374

13.10 Circle Cutting; G12, G13.................................................................................................378

13.11 Parameter Input by Program; G10, G11.........................................................................380

13.12 Macro Interrupt; M96, M97..............................................................................................381

13.13 Tool Change Position Return; G30.1 to G30.6 ...............................................................389

13.14 Normal Line Control ; G40.1/G41.1/G42.1......................................................................392

13.15 High-accuracy Control ; G61.1, G08...............................................................................403

13.16 High-speed Machining Mode ; G05, G05.1.....................................................................417

13.16.1 High-speed Machining Mode I,II ; G05 P1, G05 P2..................................................417

13.17 High-speed High-accuracy Control ; G05, G05.1............................................................420

13.17.1 High-speed High-accuracy Control I, II.....................................................................420

13.17.2 SSS Control ..............................................................................................................427

13.18 Spline; G05.1 ..................................................................................................................432

13.19 High-accuracy Spline Interpolation ; G61.2.....................................................................439

13.20 Scaling ; G50/G51...........................................................................................................441

13.21 Coordinate Rotation by Program; G68/G69....................................................................446

13.22 Coordinate Rotation Input by Parameter; G10................................................................453

13.23 3-dimensional Coordinate Conversion ; G68/69.............................................................456

13.24 Tool Center Point Control; G43.4/G43.5.........................................................................473

13.25 Timing-synchronization between Part Systems..............................................................495

14. Coordinates System Setting Functions................................................................................498

14.1 Coordinate Words and Control Axes.................................................................................498

14.2 Basic Machine, Workpiece and Local Coordinate Systems..............................................499

14.3 Machine Zero Point and 2nd, 3rd, 4th Reference Positions..............................................500

14.4 Basic Machine Coordinate System Selection; G53...........................................................501

14.5 Coordinate System Setting ;G92.......................................................................................502

14.6 Automatic Coordinate System Setting ..............................................................................503

14.7 Reference (Zero) Position Return; G28, G29....................................................................504

14.8 2nd, 3rd and 4th Reference (Zero) Position Return; G30.................................................508

Page 12

14.9 Reference Position Check; G27........................................................................................511

14.10 Workpiece Coordinate System Setting and Offset ; G54 to G59 (G54.1).......................512

14.11 Local Coordinate System Setting; G52...........................................................................524

14.12 Workpiece Coordinate System Preset; G92.1 ................................................................528

14.13 Coordinate System for Rotary Axis.................................................................................533

15. Measurement Support Functions..........................................................................................536

15.1 Automatic Tool Length Measurement; G37 ......................................................................536

15.2 Skip Function; G31............................................................................................................540

15.3 Multi-step Skip Function; G31.n, G04...............................................................................545

15.4 Multi-step Skip Function 2; G31........................................................................................547

15.5 Speed Change Skip; G31.................................................................................................549

15.6 Programmable Current Limitation .....................................................................................552

15.7 Stroke Check before Travel; G22/G23..............................................................................553

Appendix 1. Program Error .......................................................................................................555

Appendix 2. Order of G Function Command Priority..............................................................575

INDEX.............................................................................................................................................X-1

Page 13

1. Control Axes

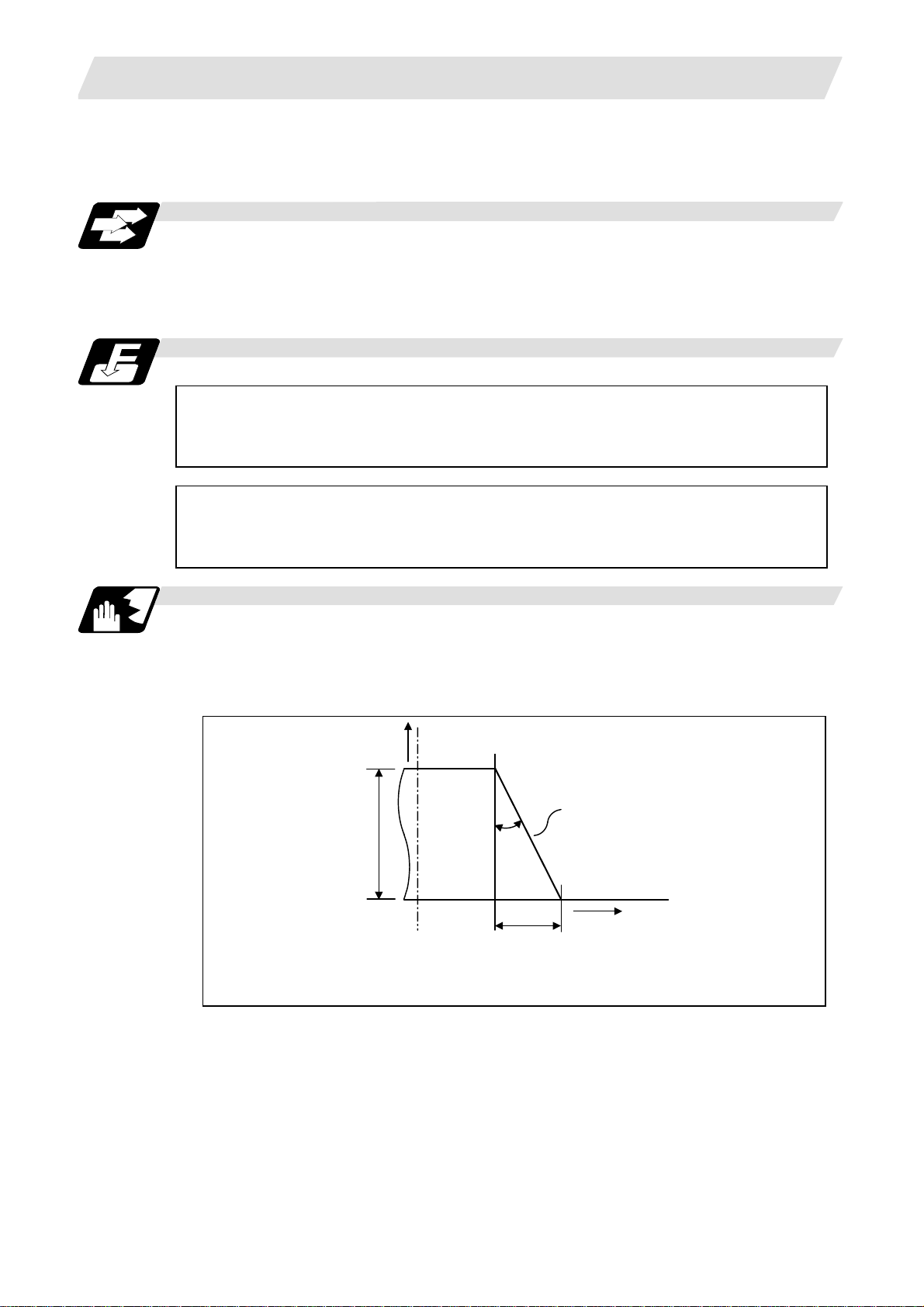

f

f

P

f

Di

1. Control Axes

1.1 Coordinate Words and Control Axis

Function and purpose

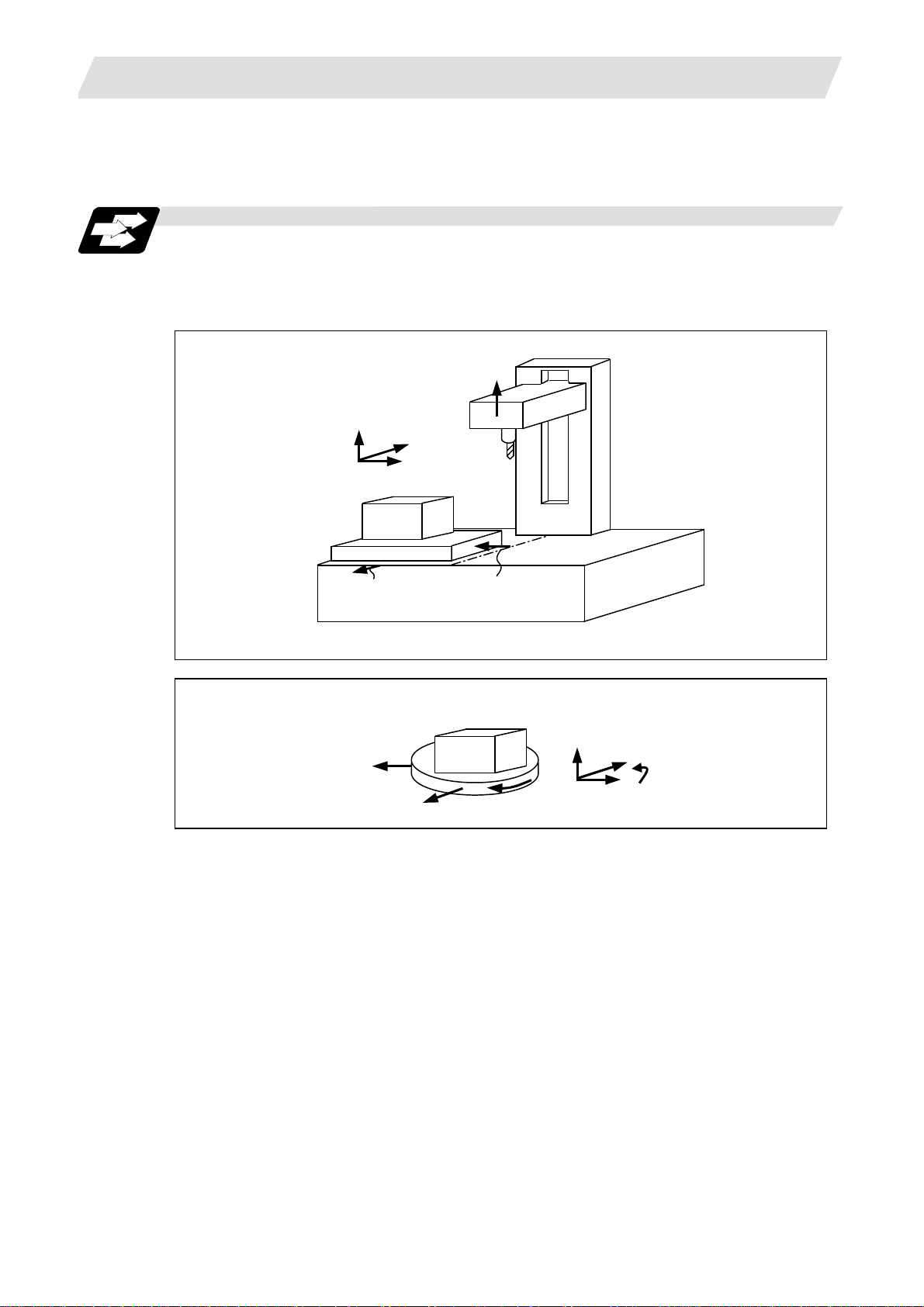

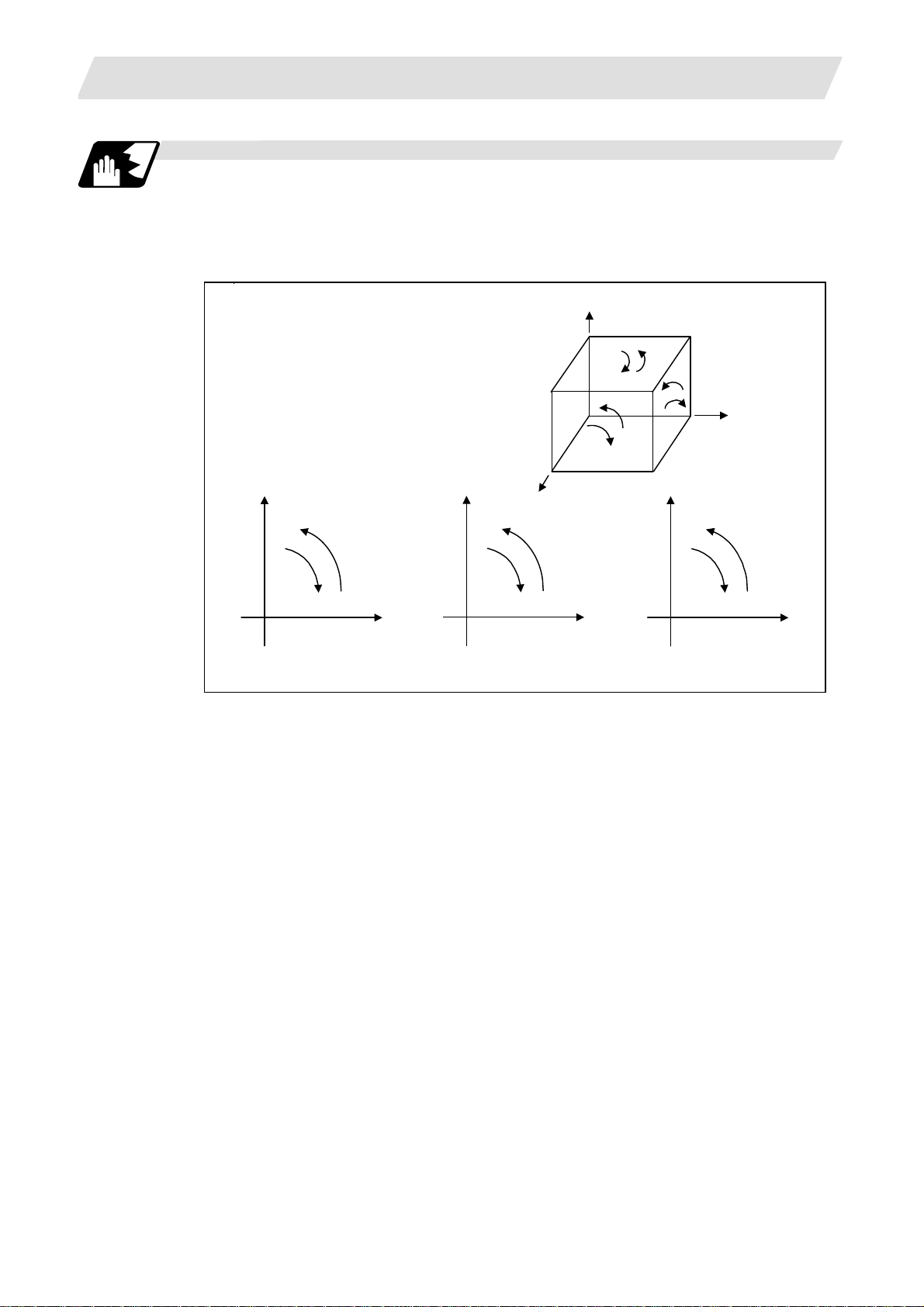

In the standard specifications, there are 3 control axes, but, by adding an additional axis, up to 4

axes can be controlled.

The designation of the processing direction responds to those axes and uses a coordinate word

made up of alphabet characters that have been decided beforehand.

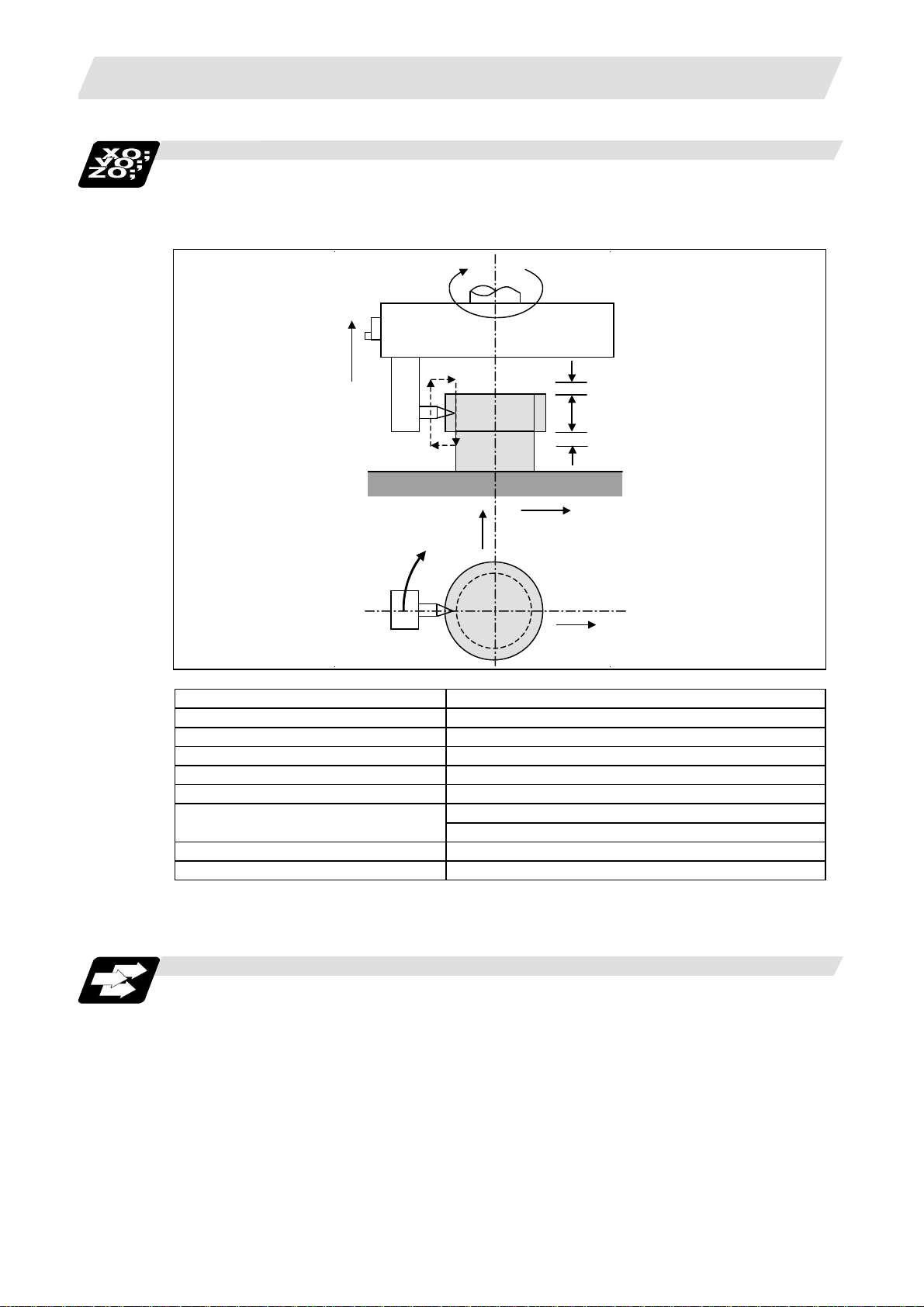

X-Y table

+Z

+Y

+X

Program coordinates

Workpiece

1.1 Coordinate Words And Control Axis

+Z

X-Y table

+Y

Direction o

table movement

Bed

+X

Direction o

table movement

X-Y and revolving table

+Z

+Y

+C

+X

rogram coordinates

+X

Direction o

movement

table

+Y

Workpiece

+C

rection of table

revolution

1

Page 14

1. Control Axes

Machi

1

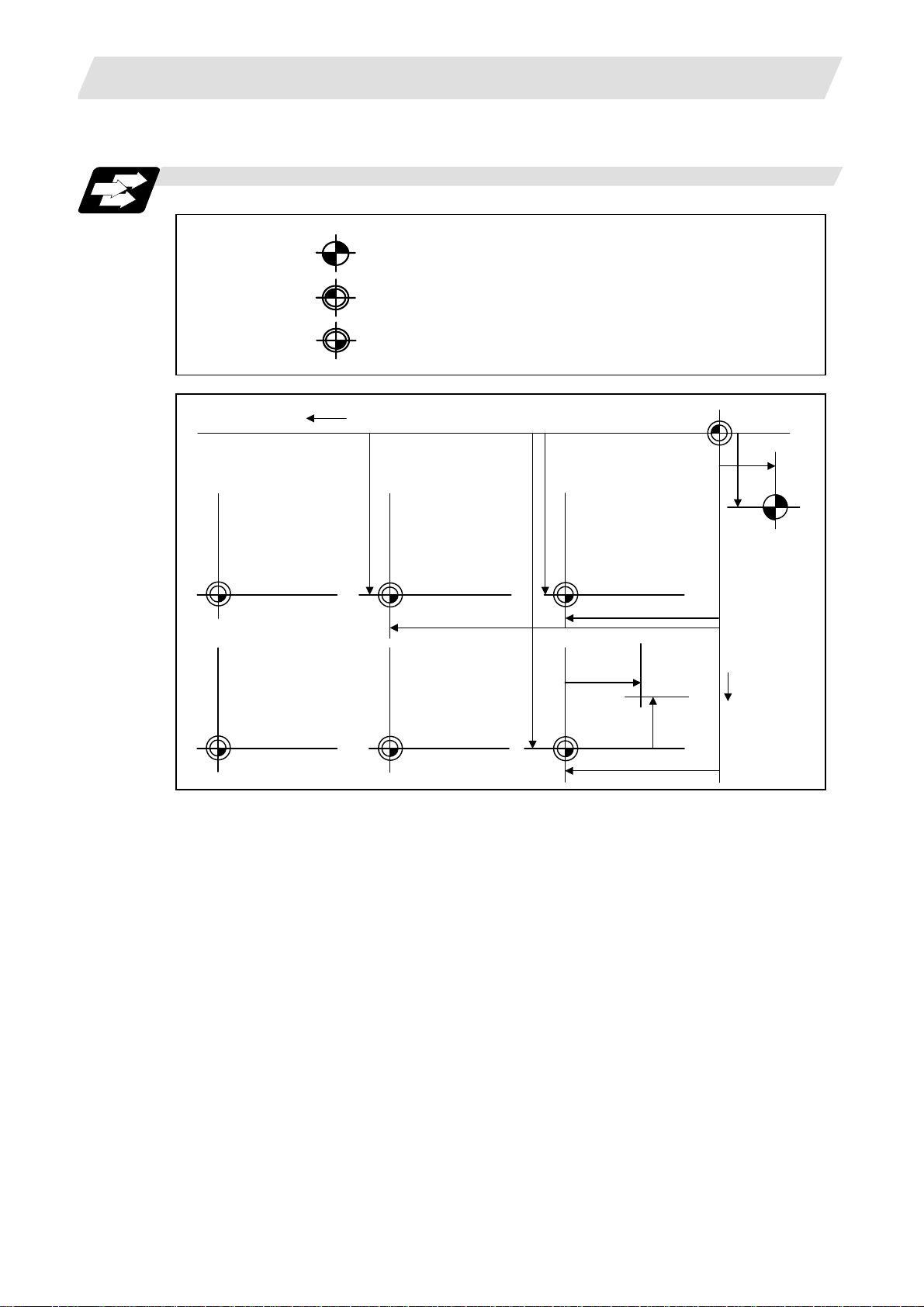

1.2 Coordinate Systems And Coordinate Zero Point Symbols

1.2 Coordinate Systems and Coordinate Zero Point Symbols

Function and purpose

Workpiece

coordinate

system 3 (G56)

-X

: Reference position

: Machine coordinate zero point

: Workpiece coordinate zero points (G54 - G59)

Basic machine coordinate system

y

3

Workpiece

coordinate

system 2 (G55)

y

2

Workpiece

coordinate

system 1 (G54)

zero point

x1

y

1

st reference

position

ne

x

2

Local

coordinate

x

5

system

(G52)

y

-Y

x

Workpiece

coordinate

system 6 (G59)

x

3

Workpiece

coordinate

system 5 (G58)

y

5

Workpiece

coordinate

system 4

(G57)

2

Page 15

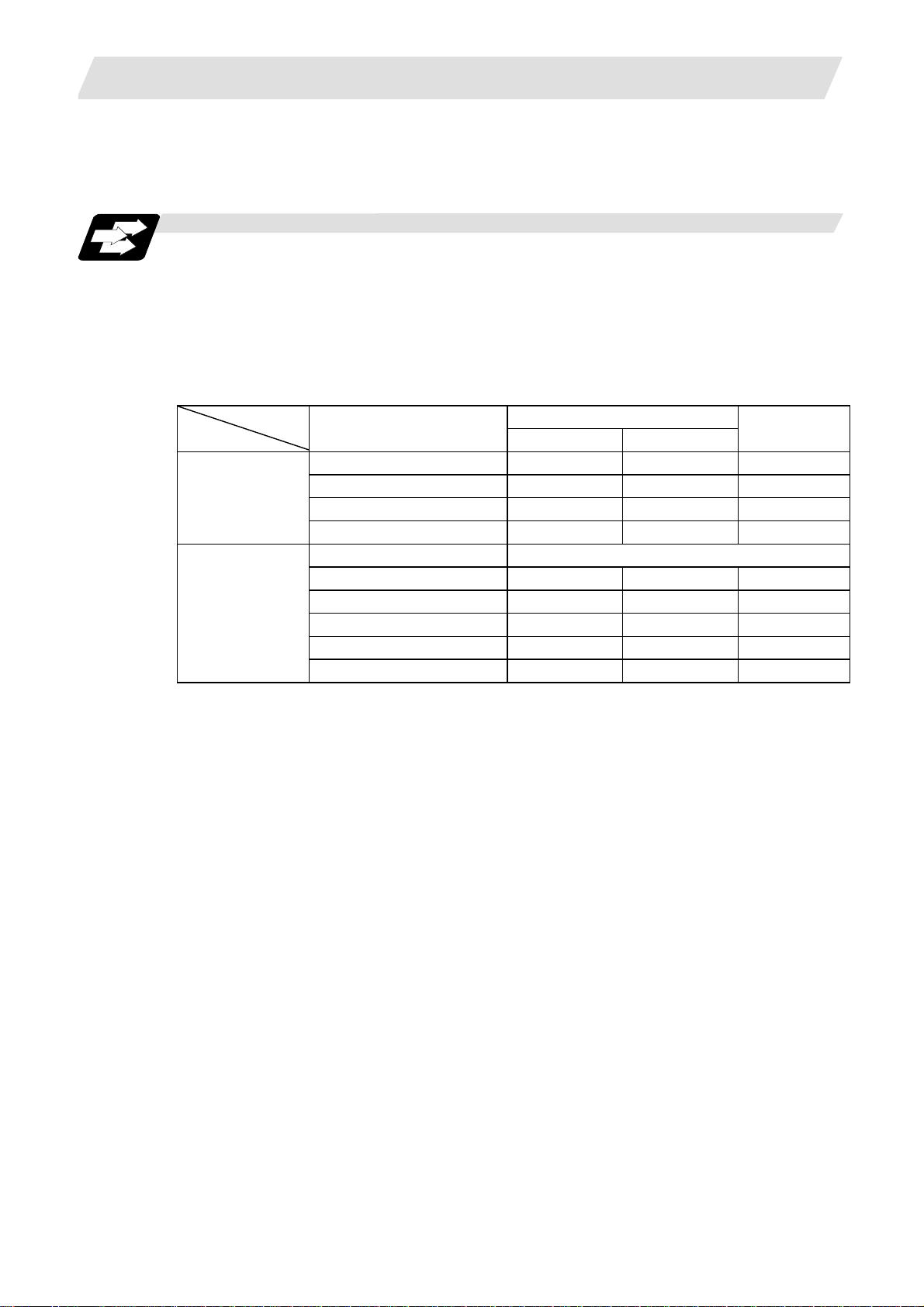

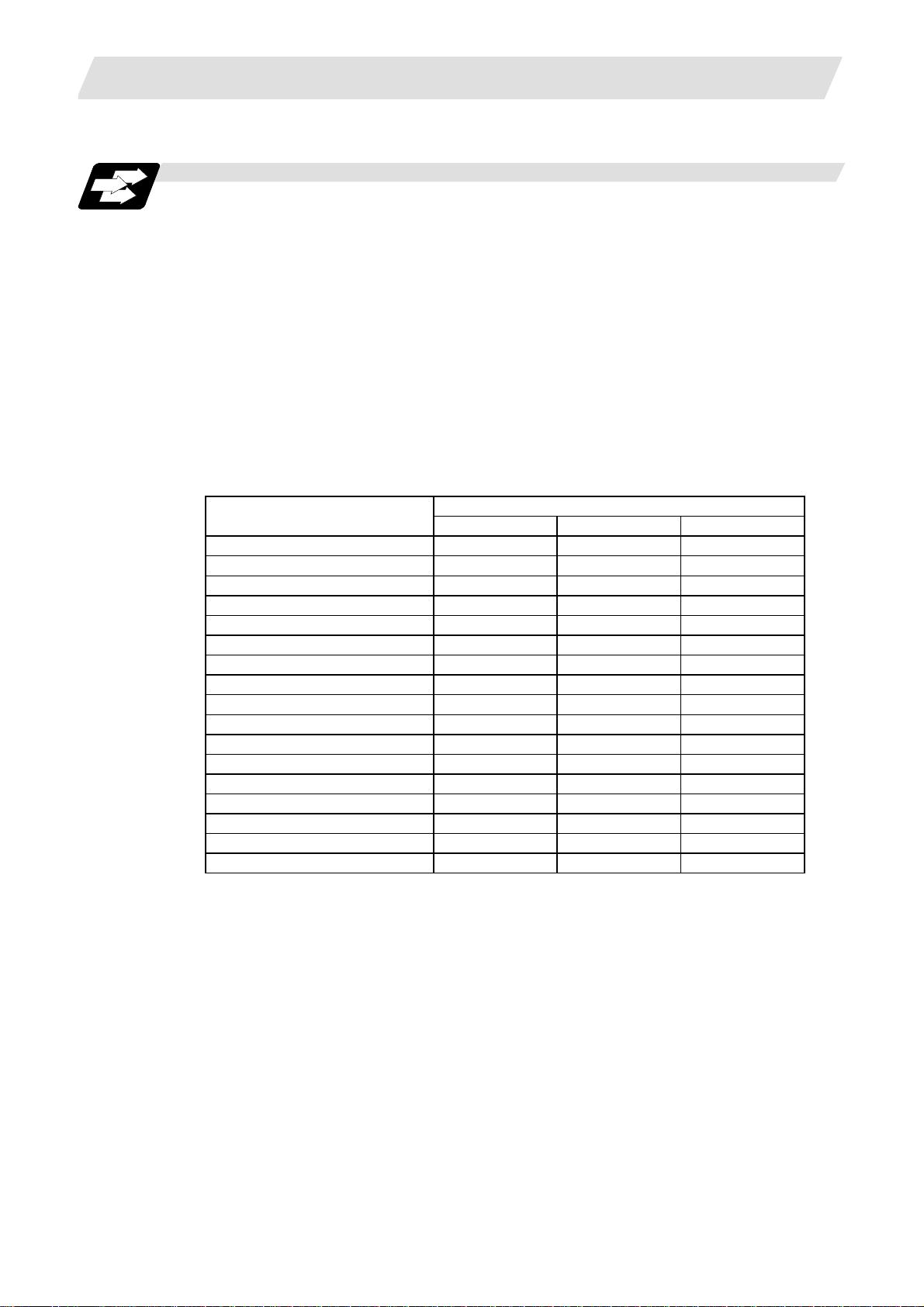

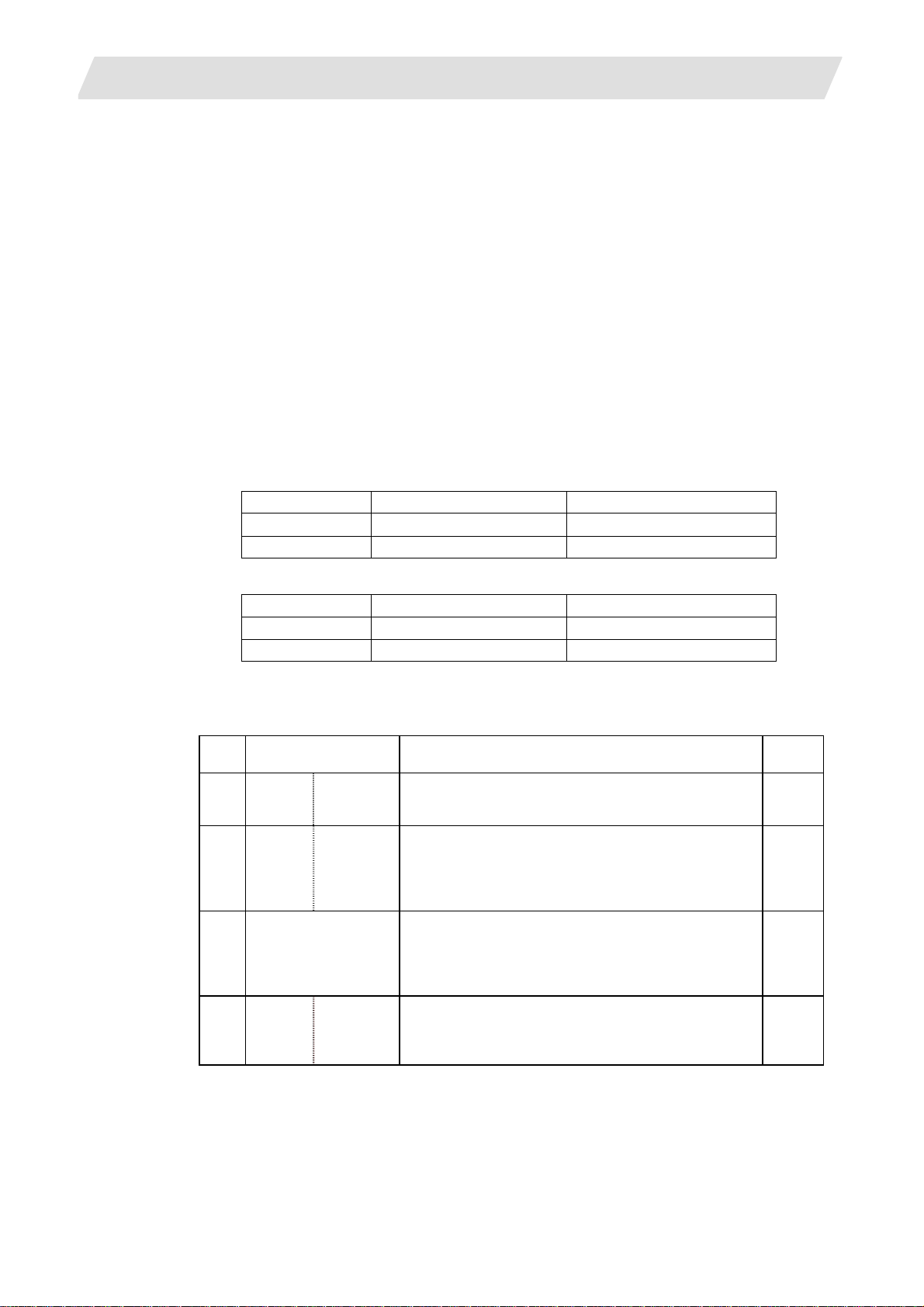

2. Least Command Increments

2. Least Command Increments

2.1 Input Setting Units

Function and purpose

The input setting units are, as with the compensation amounts, the units of setting data used in

common for all axes.

The command units are the movement amounts in the program which are commanded with MDI

inputs or command tape. These are expressed with mm, inch or degree (°) units.

With the parameters, the command units are decided for each axis, and the input setting units are

decided commonly for all axes.

#1003 iunit = B

Input setting unit

Command unit

(Note 1) Inch/metric changeover is performed in either of 2 ways: conversion from the parameter

screen (#1041 I_inch: valid only when the power is turned ON) and conversion using the

G command (G20 or G21).

However, when a G command is used for the conversion, the conversion applies only to

the input command increments and not to the input setting units.

Consequently, the tool offset amounts and other compensation amounts as well as the

variable data should be preset to correspond to inches or millimeters.

(Note 2) The millimeter and inch systems cannot be used together.

(Note 3) During circular interpolation on an axis where the input command increments are

different, the center command (I, J, K) and the radius command (R) can be designated by

the input setting units. (Use a decimal point to avoid confusion.)

= C

= D

= E

#1015 cunit = 0 Follow #1003 iunit

= 1

= 10

= 100

= 1000

= 10000

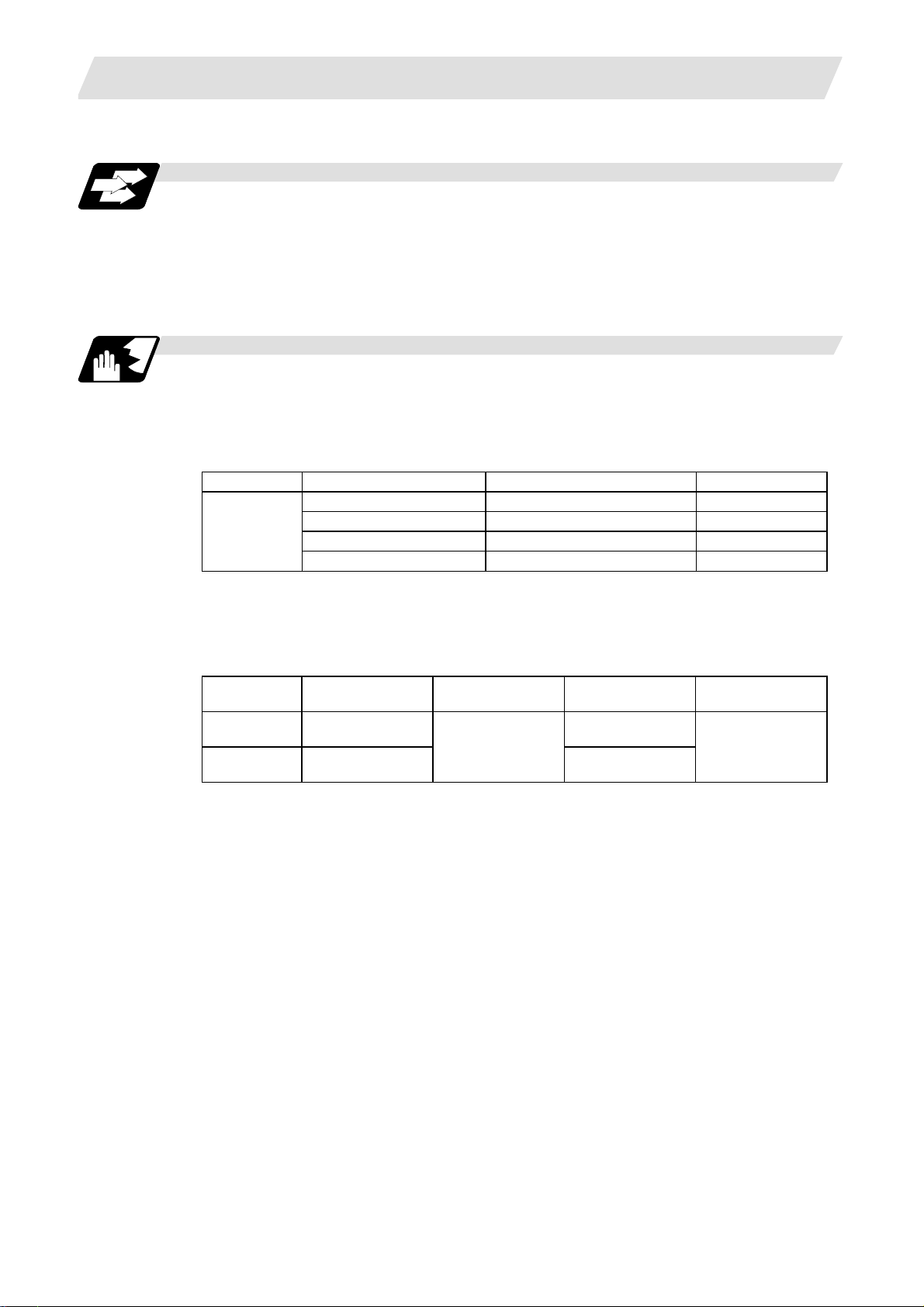

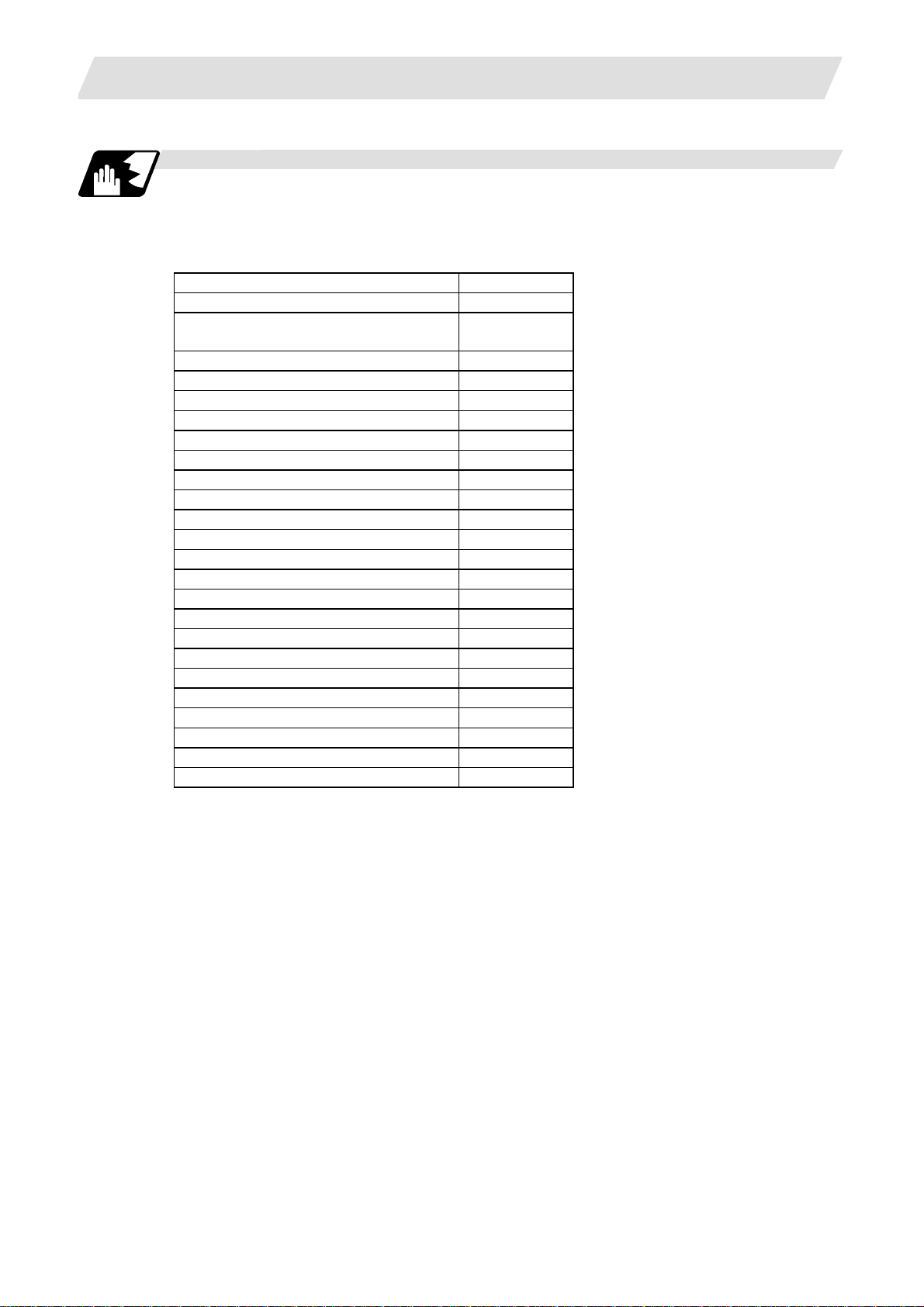

Parameters

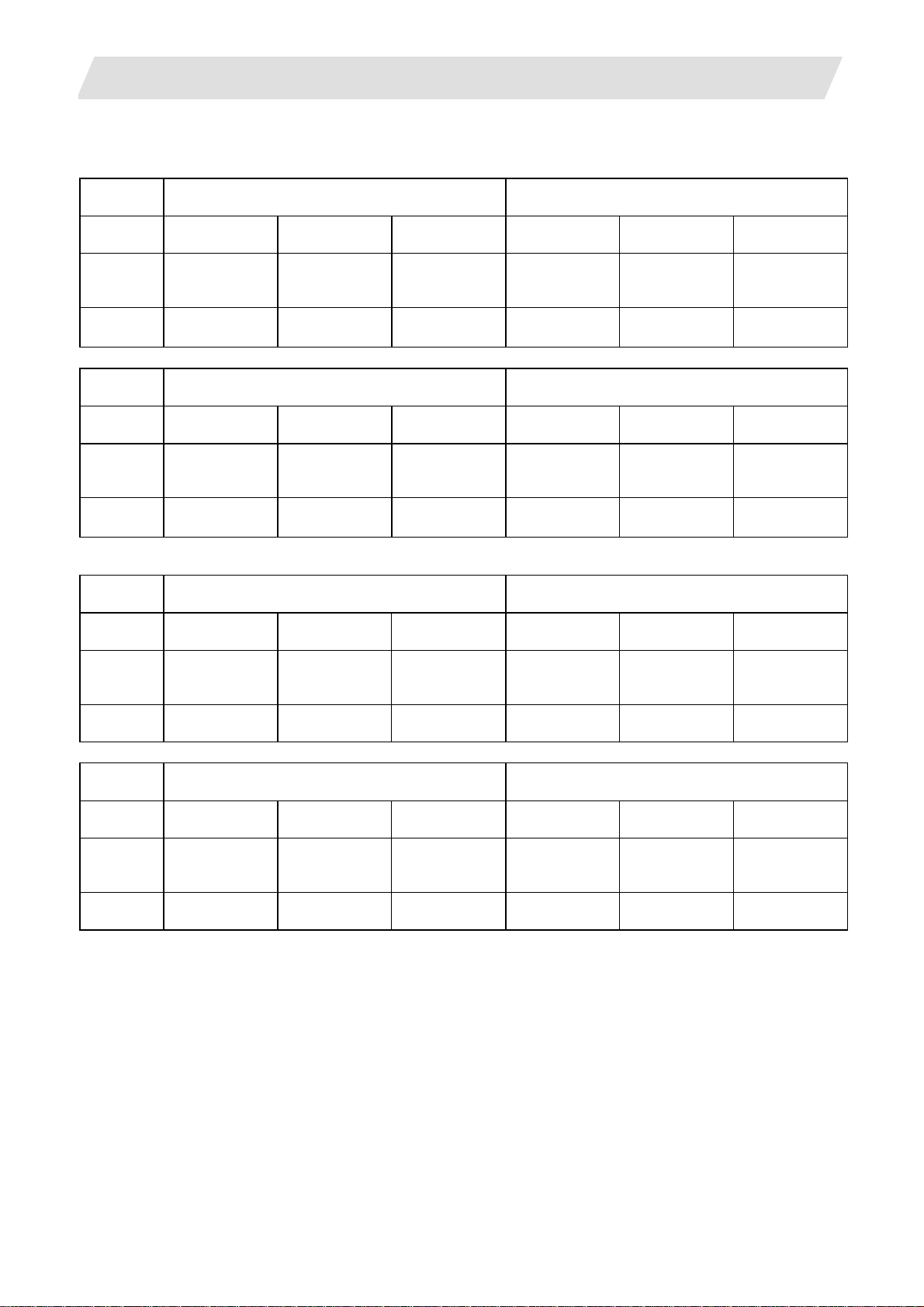

2.1 Input Setting Units

Linear axis

Millimeter Inch

0.001 0.0001 0.001

0.0001 0.00001 0.0001

0.00001 0.000001 0.00001

0.000001 0.0000001 0.000001

0.0001 0.00001 0.0001

0.001 0.0001 0.001

0.01 0.001 0.01

0.1 0.01 0.1

1.0 0.1 1.0

Rotation axis

(°)

3

Page 16

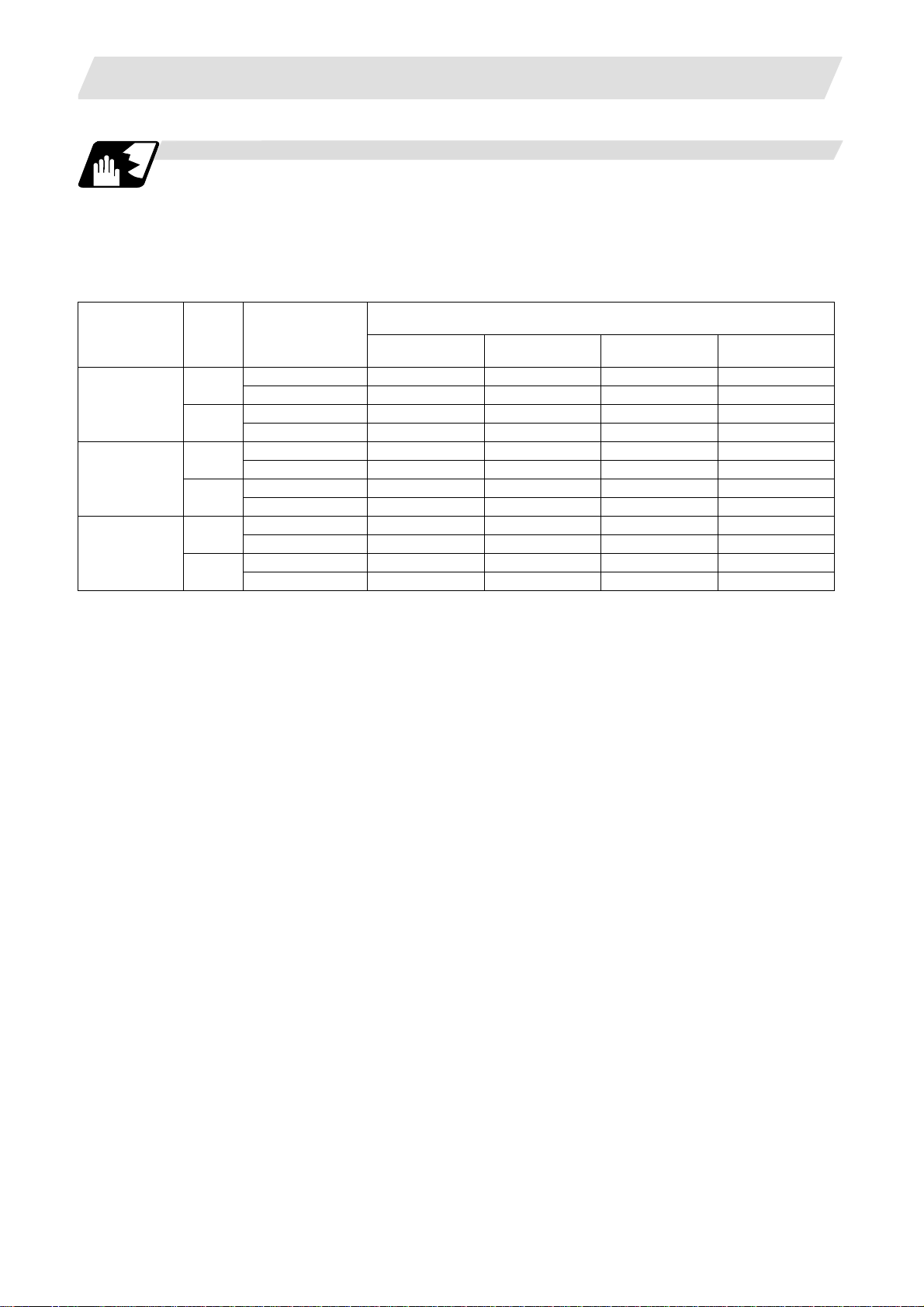

2. Least Command Increments

Detailed description

(1) Units of various data

These input setting units determine the parameter setting unit, program command unit and the

external interface unit for the PLC axis and handle pulse, etc. The following rules show how the

unit of each data changes when the input setting unit is changed. This table applies to the NC

axis and PLC axis.

2.1 Input Setting Units

Data

Speed data

Example:

rapid

Position data

Example:

SoftLimit+

Interpolation

unit data

Unit

system

metre

Inch

metre

Inch

metre

Inch

(2) Program command

The program command unit follows the above table.

If the data has a decimal point, the number of digits in the integer section will remain and the

number of digits in the decimal point section will increase as the input setting unit becomes

smaller.

When setting data with no decimal point, and which is a position command, the data will be

affected by the input setting increment and input command increment.

For the feed rate, as the input setting unit becomes smaller, the number of digits in the integer

section will remain the same, but the number of digits in the decimal point section will increase.

Setting value

1µm (B) 0.1µm (C) 10nm (D) 1nm (E)

20000 (mm/min) 20000 20000 20000 20000Milli-

Setting range 1 to 999999 1 to 999999 1 to 999999 1 to 999999

2000 (inch/min) 2000 2000 2000 2000

Setting range 1 to 999999 1 to 999999 1 to 999999 1 to 999999

123.123 (mm) 123.123 123.1230 123.12300 123.123000MilliSetting range ±99999.999 ±99999.9999 ±99999.99999 ±99999.999999

12.1234 (inch) 12.1234 12.12340 12.123400 12.1234000

Setting range ±9999.9999 ±9999.99999 ±9999.999999 ±9999.9999999

1 (µm) 2 20 200 2000Milli-

Setting range ±9999 ±9999 ±9999 ±9999

0.001 (inch) 2 20 200 2000

Setting range ±9999 ±9999 ±9999 ±9999

Input setting unit

4

Page 17

2. Least Command Increments

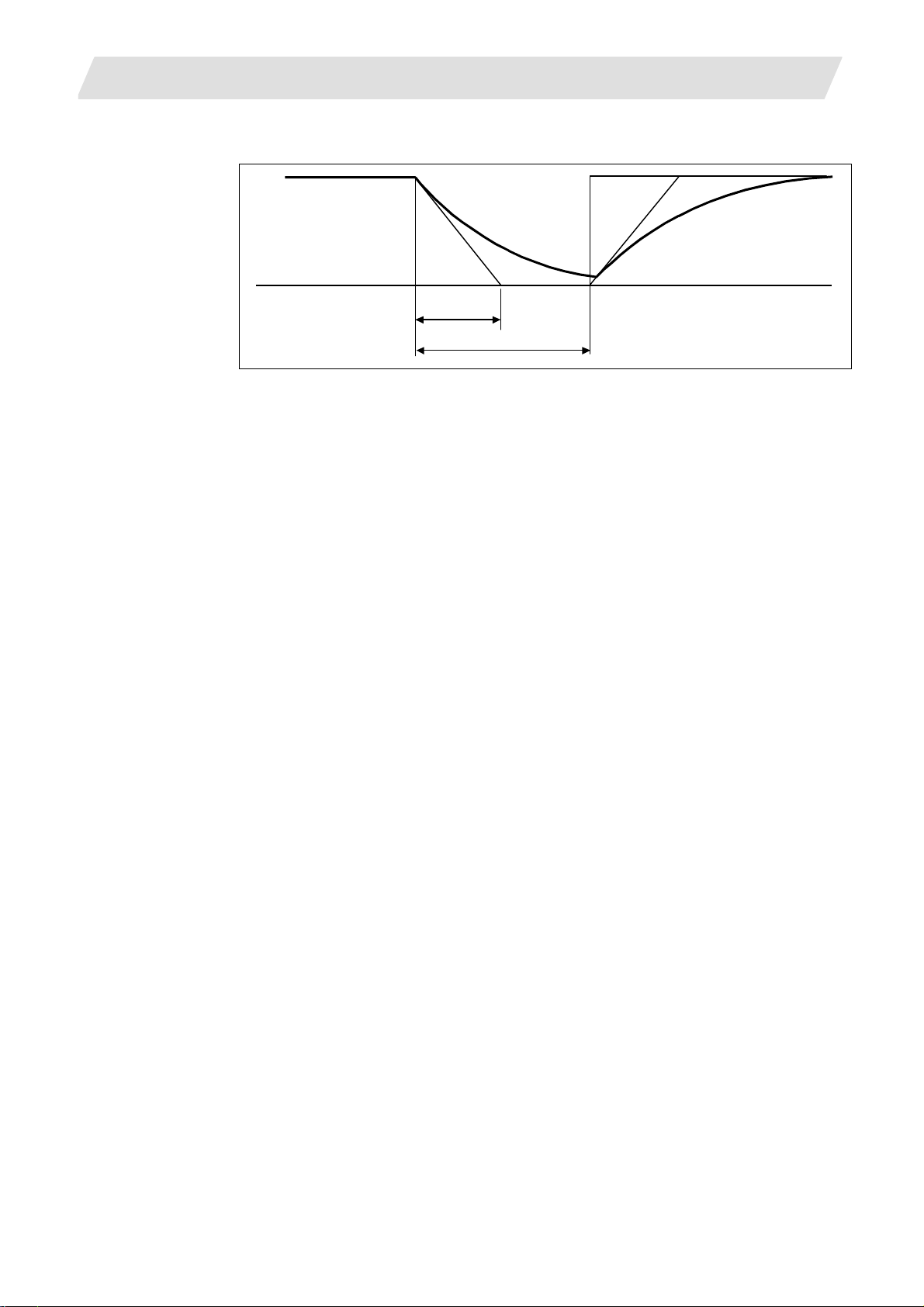

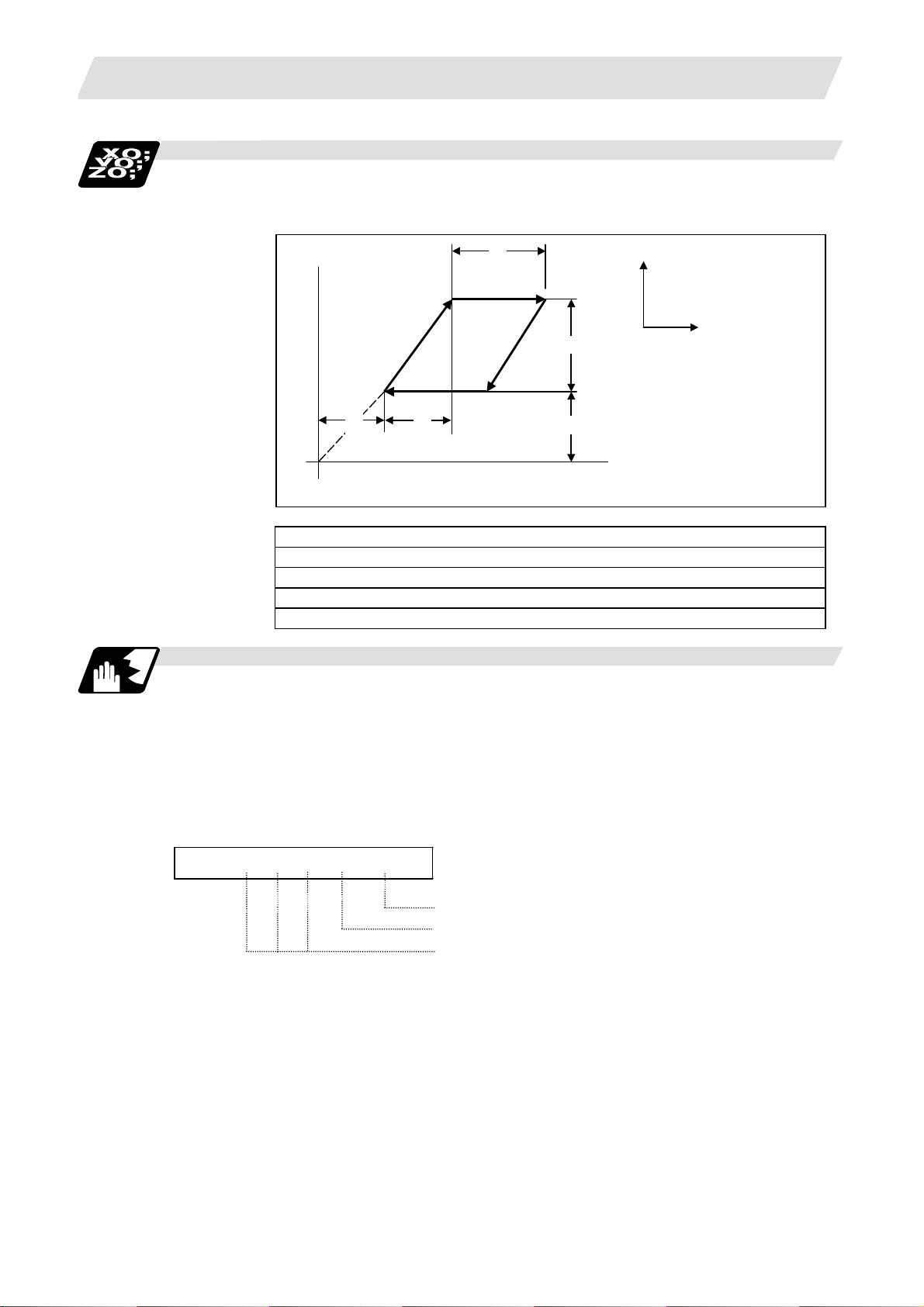

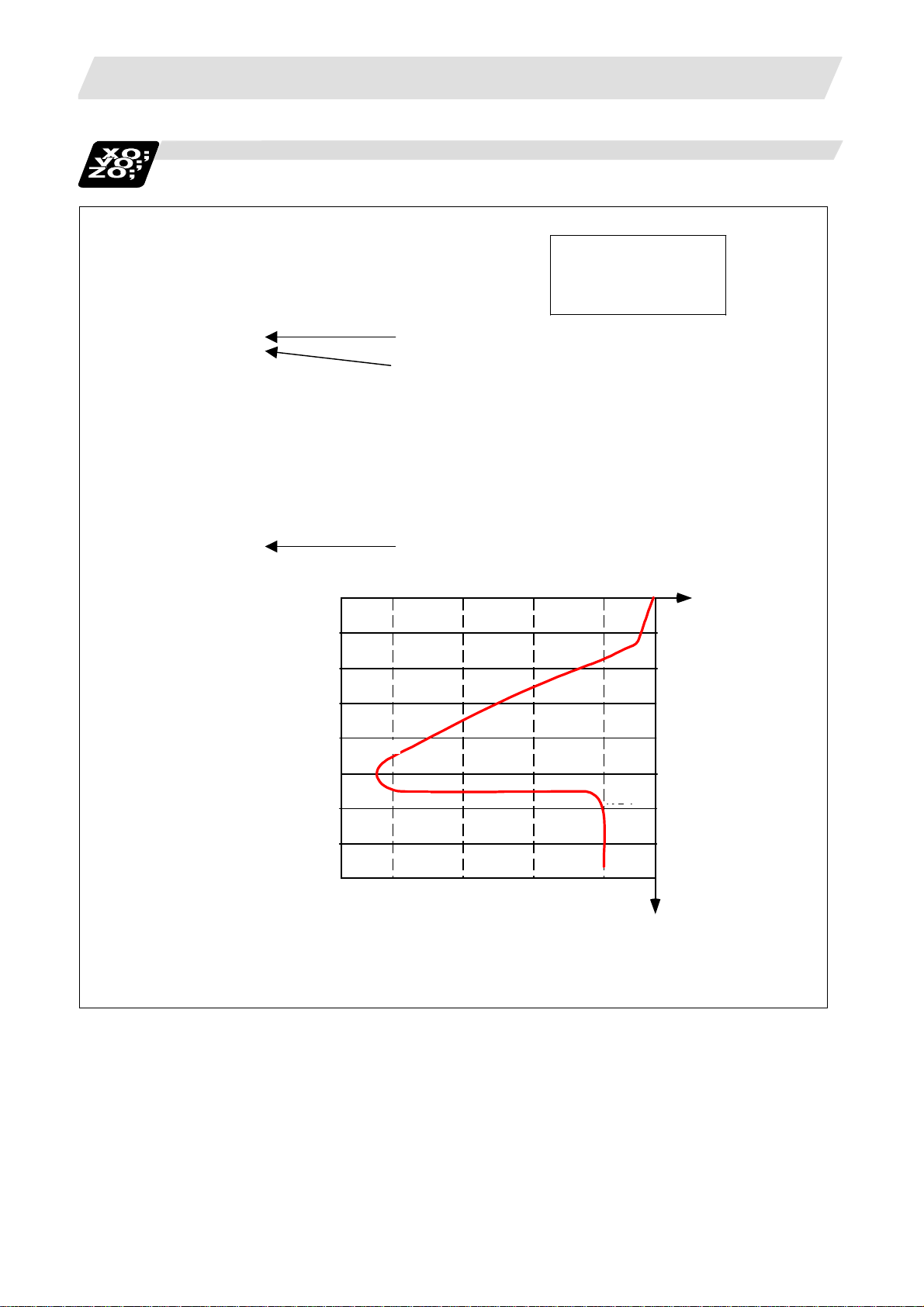

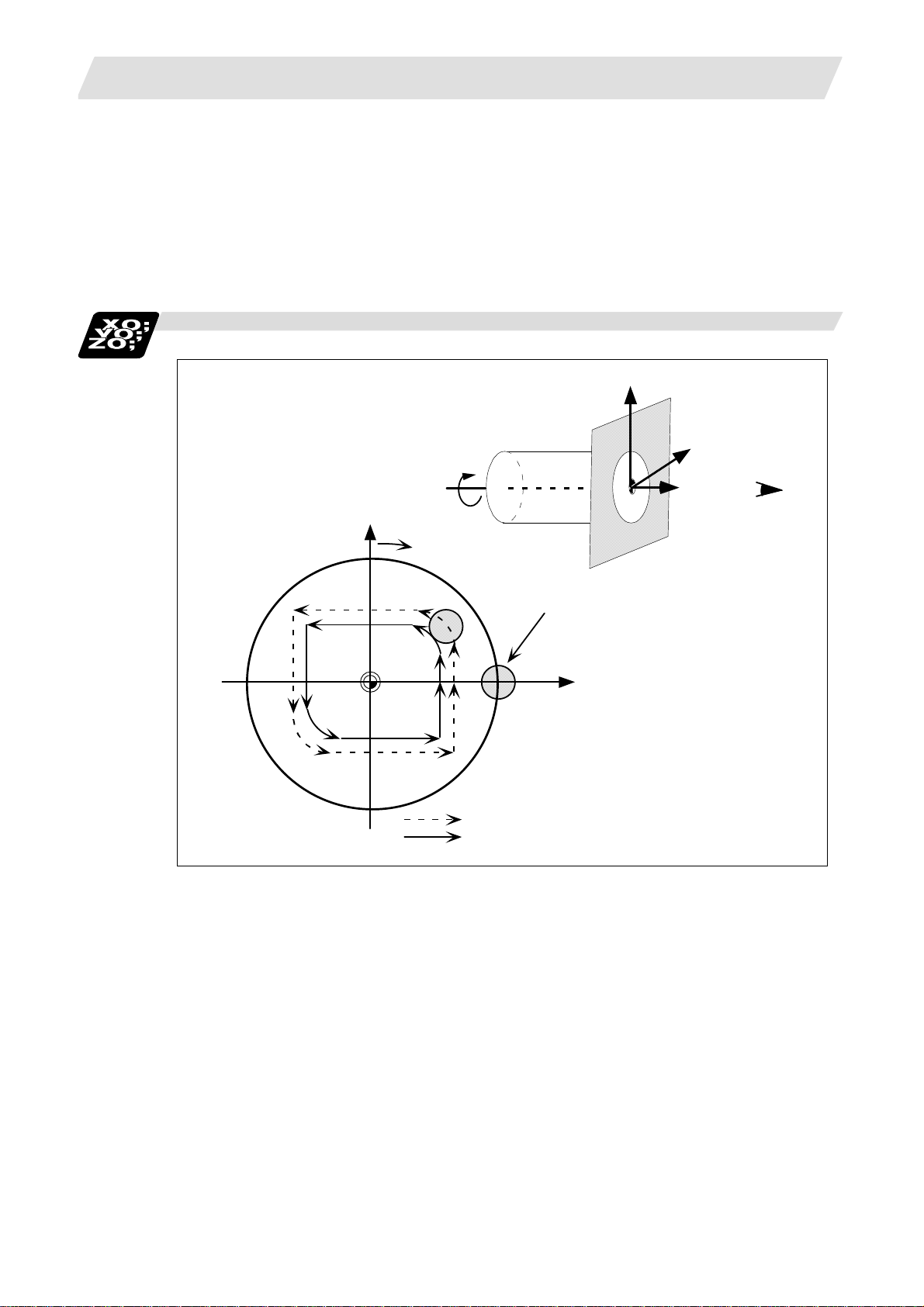

2.2 Input Command Increment Tenfold

Function and purpose

The program's command increment can be multiplied by an arbitrary scale with the parameter

designation.

This function is valid when a decimal point is not used for the command increment.

The scale is set with the parameters.

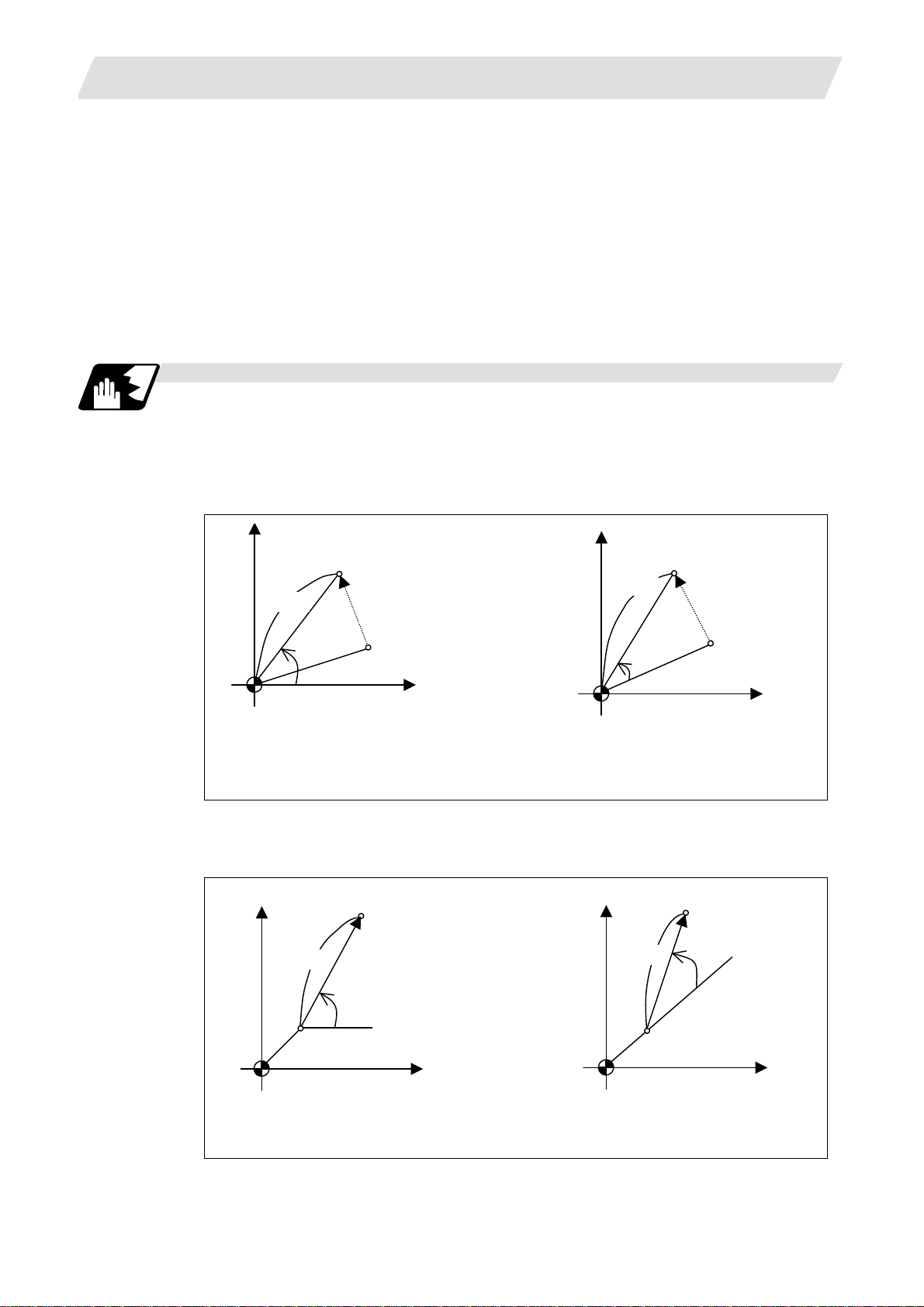

Detailed description

(1) When running a machining program already created with a 10µm input command increment

with a CNC unit for which the command increment is set to 1µm and this function's parameter

value is set to "10", machining similar to before this function is possible.

(2) When running a machining program already created with a 1µm input command increment

with a CNC unit for which the command increment is set to 0.1µm and this function's

parameter value is set to "10", machining similar to before this function is possible.

(3) This function cannot be used for the dwell function G04_X_(P_);.

(4) This function cannot be used for the compensation amount of the tool compensation input.

(5) This function can be used when decimal point type I is valid, but cannot be used when decimal

point type II is valid.

Program example

(Machining program:

programmed with 1=10µm)

(CNC unit is 1=1µm system)

X Y X Y

N1 G90 G00 X0 Y0; 0 0 0 0

N2 G91 X-10000 Y-15000; -100.000 -150.000 -10.000 -15.000

N3 G01 X-10000 Y-5000 F500; -200.000 -200.000 -20.000 -20.000

N4 G03 X-10000 Y-10000 J-10000; -300.000 -300.000 -30.000 -30.000

N5 X10000 Y-10000 R5000; -200.000 -400.000 -20.000 -40.000

N6 G01 X20.000 Y.20.000 -180.000 -380.000 0.000 -20.000

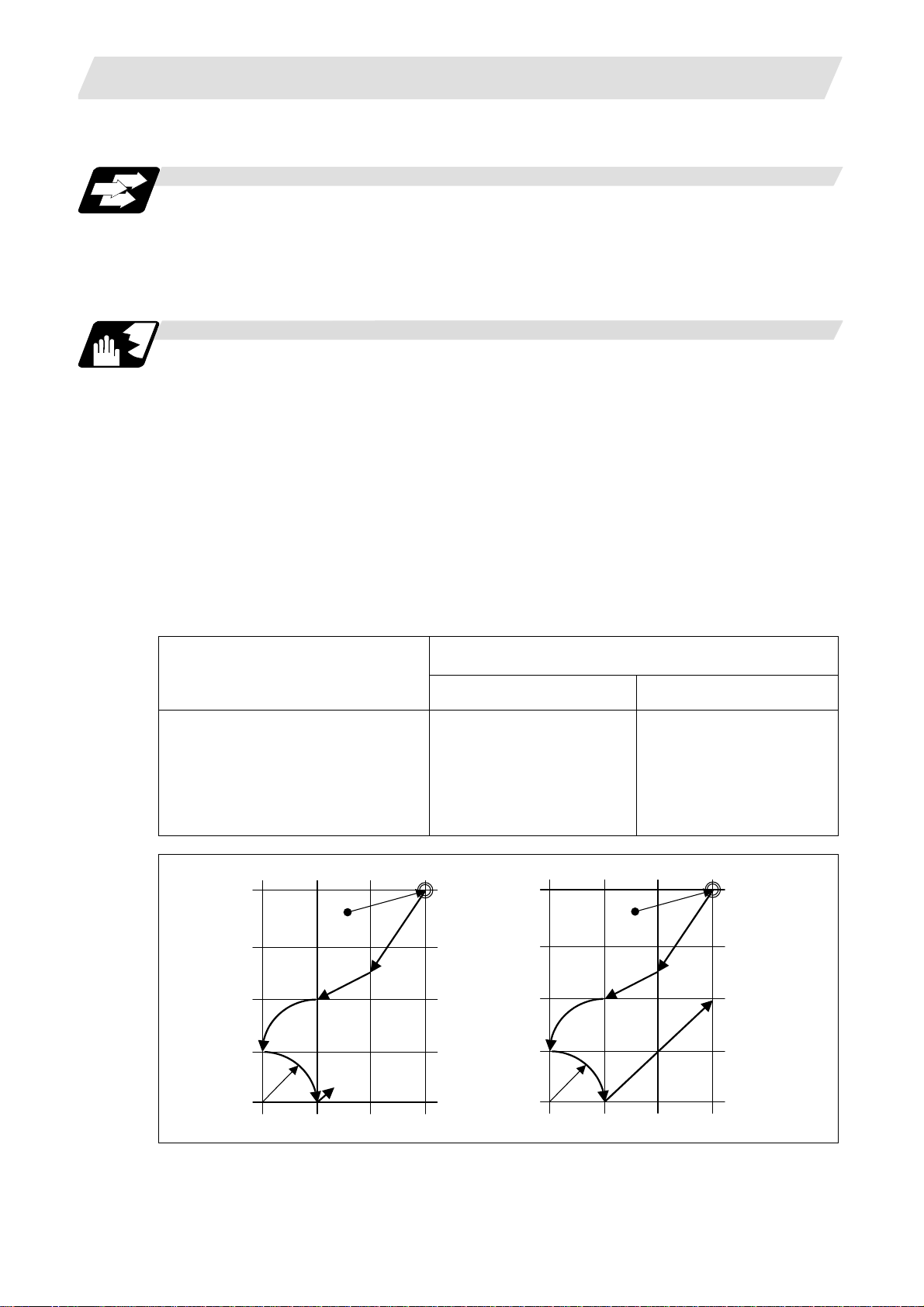

-100 -200 -300

2.2 Input Command Increment Tenfold

"UNIT*10" parameter

10 1

-10 -20 -30

N6

N2

W

-10

-20

-30

-40

N4

R

N3

N5

N6

UNIT*10 ON

N1

N2

W

-100

-200

-300

-400

N1

N3

N4

N5

R

UNIT*10 OFF

5

Page 18

2. Least Command Increments

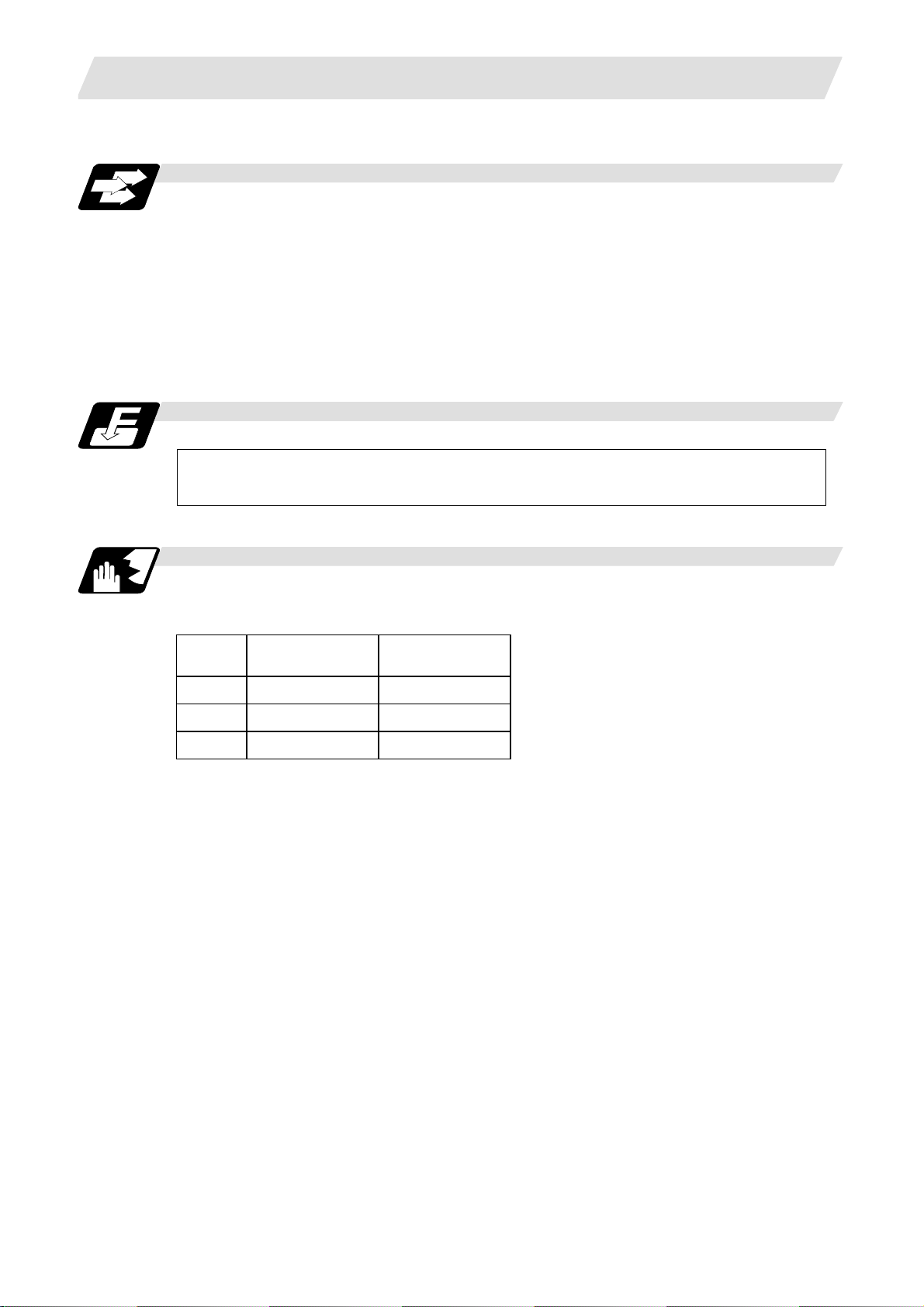

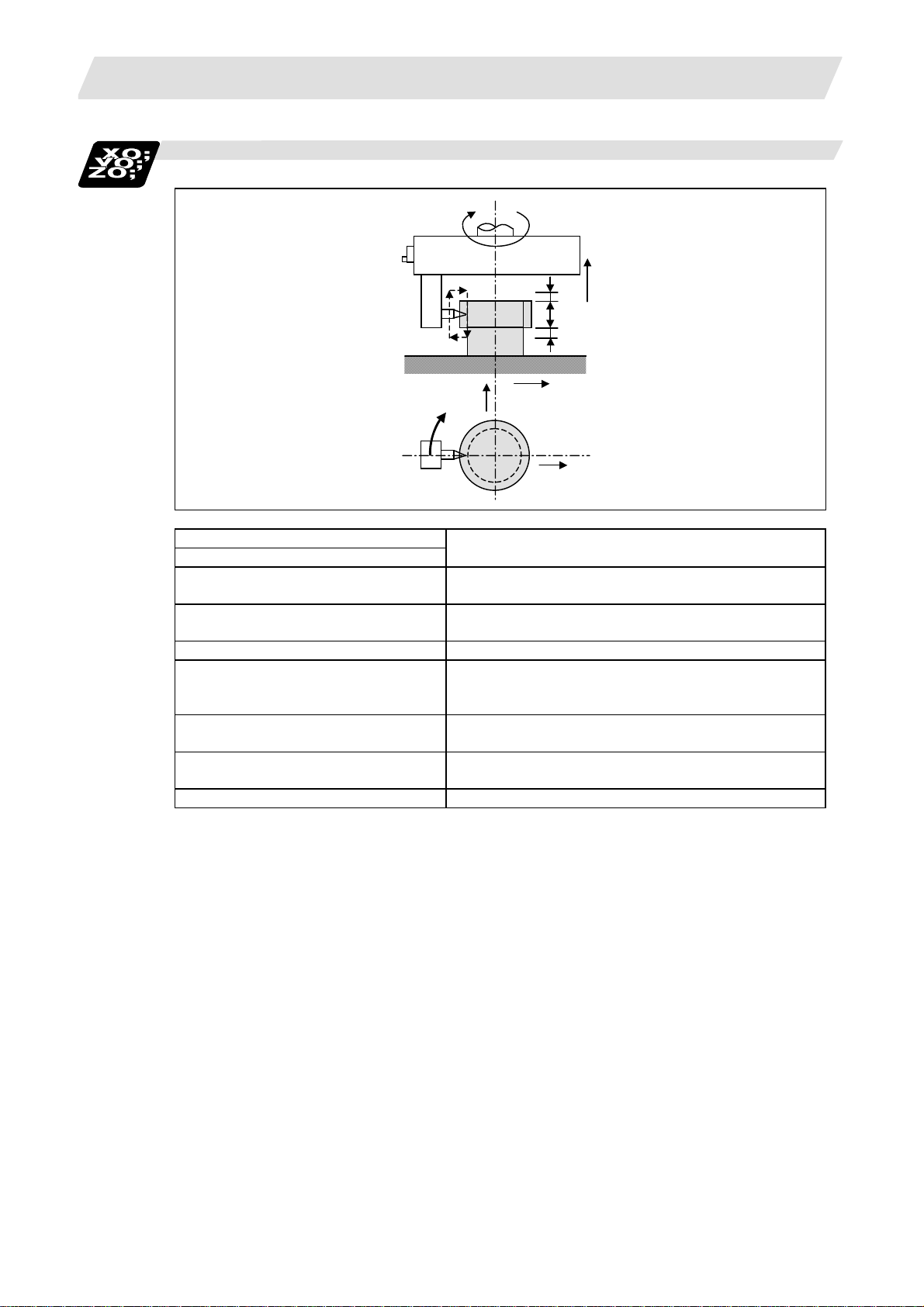

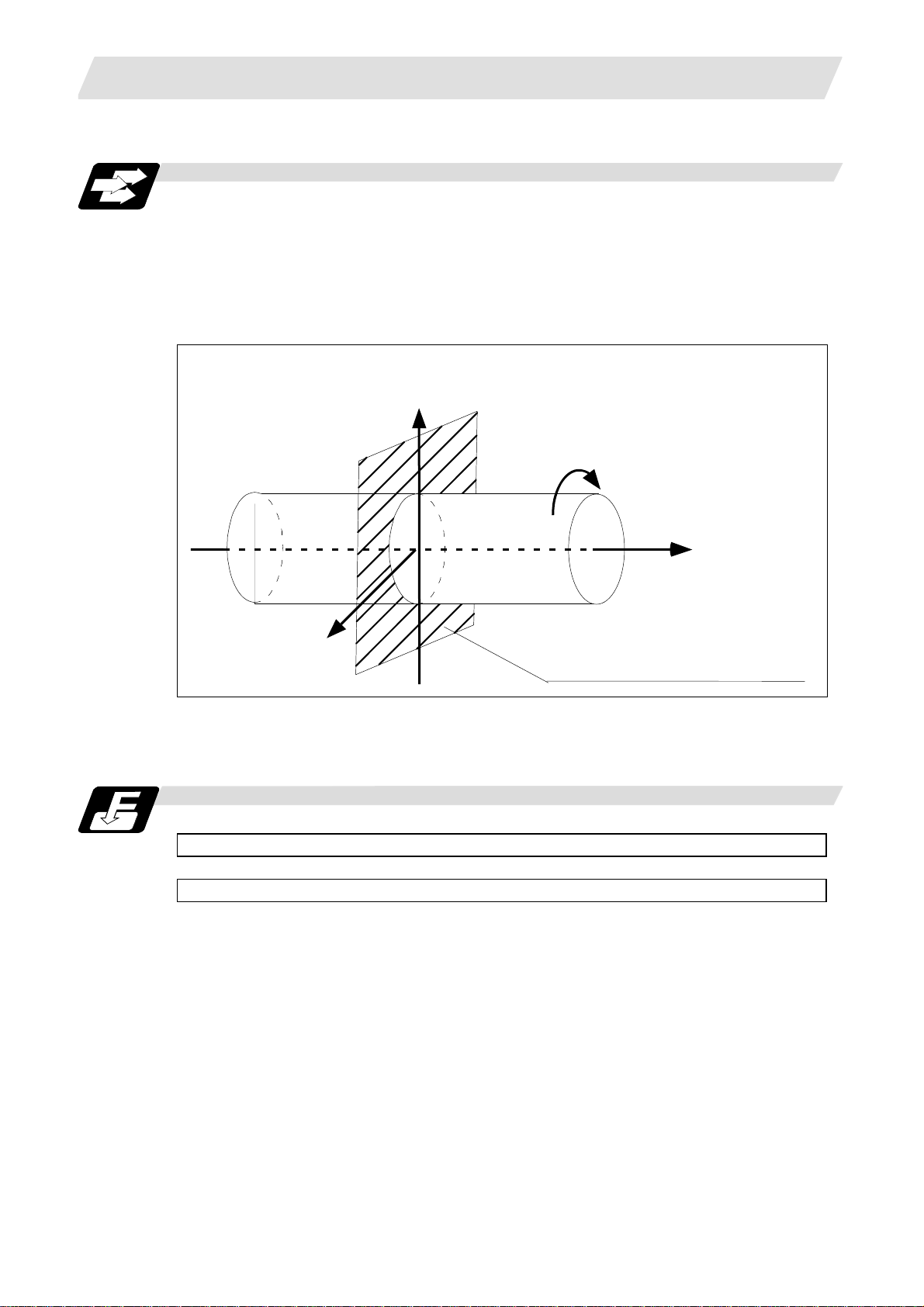

2.3 Indexing Increment

Function and purpose

This function limits the command value for the rotary axis.

This can be used for indexing the rotary table, etc. It is possible to cause a program error with a

program command other than an indexing increment (parameter setting value).

Detailed description

When the indexing increment (parameter) for limiting the command value is set, the rotary axis can

be positioned with that indexing increment. If a program other than the indexing increment setting

value is commanded, a program error (P20) will occur.

The indexing position will not be checked when the parameter is set to 0.

(Example) When the indexing increment setting value is 2 degrees, only command with the

2-degree increment are possible.

G90 G01 C102. 000 ; … Moves to the 102 degree angle.

G90 G01 C101. 000 : … Program error

G90 G01 C102 ; … Moves to the 102 degree angle. (Decimal point type II)

The following axis specification parameter is used.

# Item Contents

2106 Index unit Indexing

Precautions

• When the indexing increment is set, degree increment positioning takes place.

• The indexing position is checked with the rotary axis, and is not checked with other axes.

• When the indexing increment is set to 2 degrees, the rotary axis is set to the B axis, and the B

axis is moved with JOG to the 1.234 position, an indexing error will occur if "G90B5." or "G91B5."

is commanded.

increment

2.3 Indexing Increment

Set the indexing increment to which the rotary

axis can be positioned.

Setting range

(unit)

0 to 360 (° )

6

Page 19

3. Data Formats

3. Data Formats

3.1 Tape Codes

Function and purpose

The tape command codes used for this controller are combinations of alphabet letters (A, B, C, ...

Z), numbers (0, 1, 2 ... 9) and signs (+, -, / ...). These alphabet letters, numbers and signs are

referred to as characters. Each character is represented by a combination of 8 holes which may, or

may not, be present.

These combinations make up what is called codes.

This controller uses, the ISO code (R-840).

(Note 1) If a code not given in the tape code table in Fig. 1 is assigned during operation, program

(Note 2) For the sake of convenience, a semicolon " ; " has been used in the CNC display to

3.1 Tape Codes

error (P32) will result.

indicate the end of a block (EOB/IF) which separates one block from another. Do not use

the semicolon key, however, in actual programming but use the keys in the following

table instead.

CAUTION

“EOB", "%", and “EOR” are symbols used for explanation. The actual codes for ISO are

"CR, LF" ("LF") and "%".

The programs created on the Edit screen are stored in the NC memory in a "CR, LF" format,

however, the programs created with external devices such as the FLD or RS-232C may be

stored in an "LF" format.

The actual codes for EIA are "EOB (End of Block)" and "EOR (End of Record)".

Detailed description

EOB/EOR keys and displays

Code used

Key used

End of block LF or NL ;

End of record % %

(1) Significant data section (label skip function)

All data up to the first EOB ( ; ), after the power has been turned on or after operation has been

reset, are ignored during automatic operation based on tape, memory loading operation or

during a search operation. In other words, the significant data section of a tape extends from

the character or number code after the initial EOB ( ; ) code after resetting to the point where

the reset command is issued.

ISO Screen display

7

Page 20

3. Data Formats

G

R

•••••••

•

•••

•

•

•••••••••

•

•••••••

•

•

•••••••••••••••••

•

•

•

•••••••••••••••

•••••••••

•

(2) Control out, control in

When the ISO code is used, all data between control out "(" and control in ")" or ";" are ignored,

although these data appear on the setting and display unit. Consequently, the command tape

name, No. and other such data not directly related to control can be inserted in this section.

This information (except (B) in the tape codes) will also be loaded, however, during tape

loading. The system is set to the "control in" mode when the power is witched on.

Example of ISO code

•

3.1 Tape Codes

•

•• ••

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

•••

•••

• •

• • •• •

Operator information print-out example

L C S L

00X-85000Y-64000 (CUTTE

F R

• ••

•• •• •

••

••

•••

•••

•

•

Information in this section is ignored and nothing is executed.

RE T URN)

P

• •

•• •

•• • ••

•••

•

••••

• • • •

F

••

•••••

•

•

(3) EOR (%) code

Generally, the end-or-record code is punched at both ends of the tape. It has the following

functions:

(a) Rewind stop when rewinding tape (with tape handler)

(b) Rewind start during tape search (with tape handler)

(c) Completion of loading during tape loading into memory

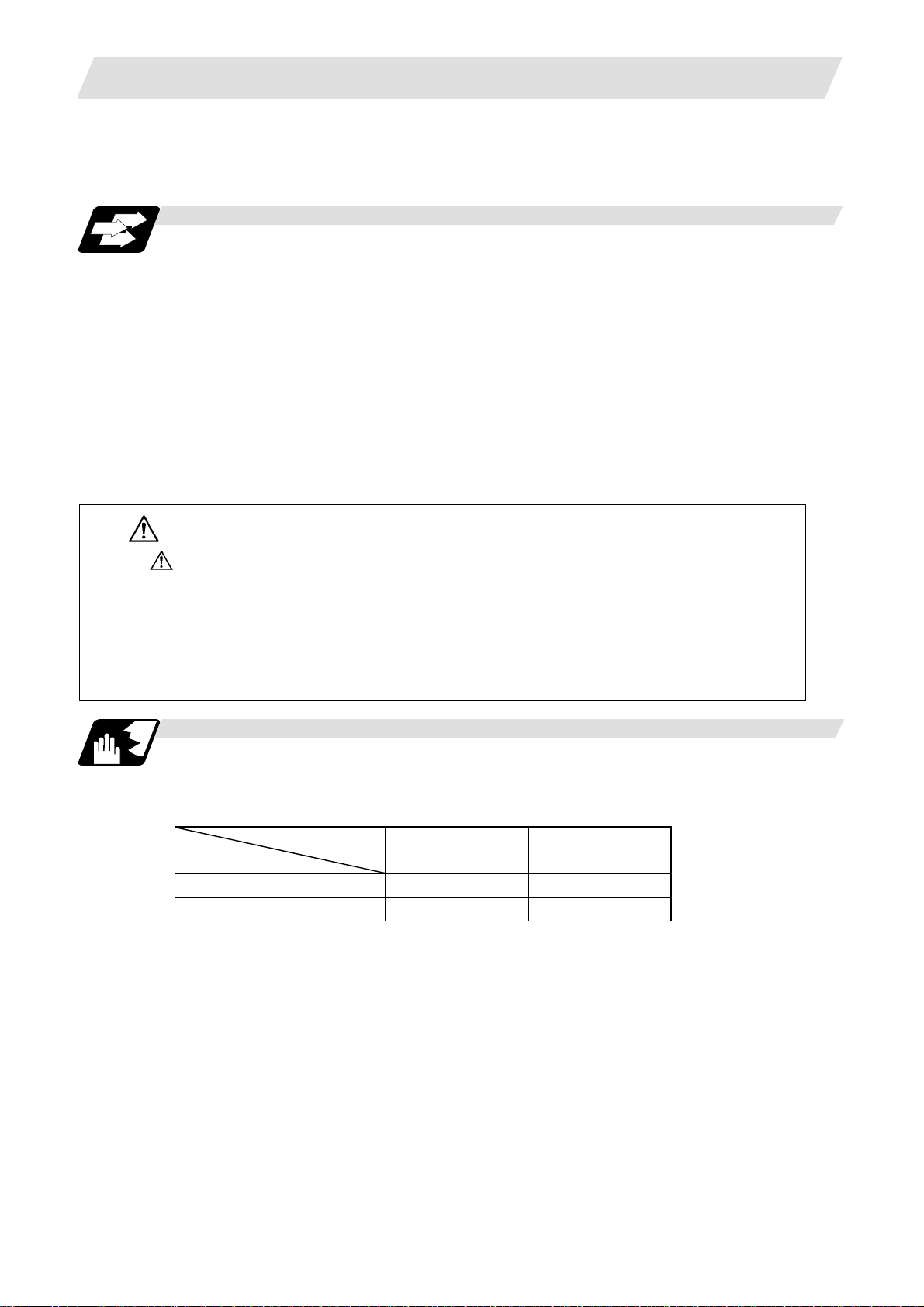

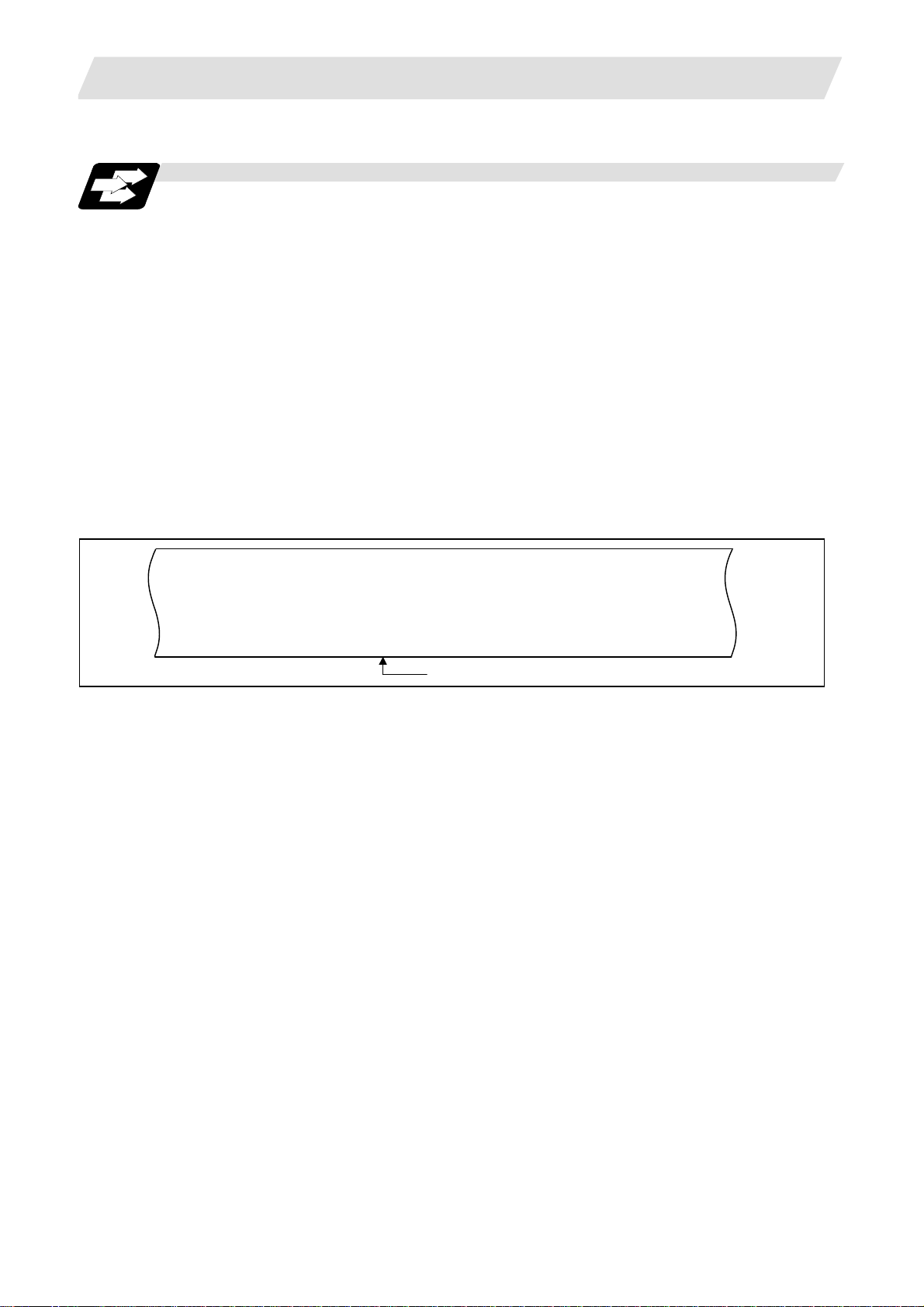

(4) Tape preparation for tape operation (with tape handler)

10cm

%

(EOR)

2m

If a tape handler is not used, there is no need for the 2-meter dummy at both ends of the tape

and for the head EOR (%) code.

• • • • • • • •

;;;;

Initial block

• • • • • • • • • • • • • • • •

(EOB)

Last block

(EOB)(EOB)

10cm %

(EOR)(EOB)

2m

8

Page 21

3. Data Formats

A

Y

( (

)

) (

)

)

)

)

@

)

)

A

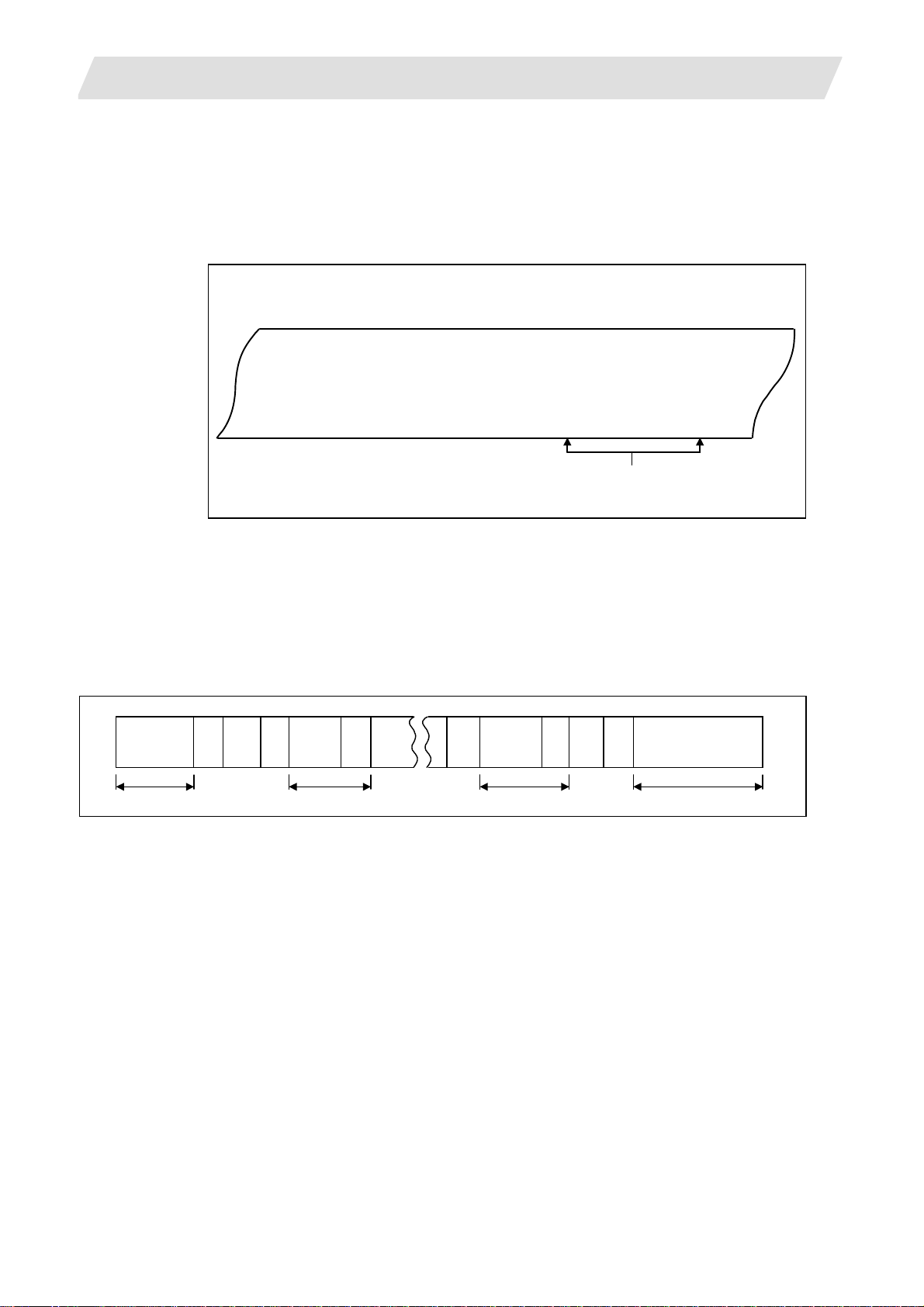

ISO code (R-840)

Feed holes

8 7 6 5 4 3 2 1

Channel No.

3.1 Tape Codes

•

•

•

•

•

•

•

••

•

••

••

•

• •

•• •

•• •• •

• •• ••

•• •• •

• •• • •

• •• ••

•• •• •••

• •

•• •

•• •

• •

•• •• •

• •• • •

• •• ••

•• •• •••

•• ••

• ••

• ••• •

•

•

•

•

•

•

•

•• ••• ••

•• ••• • •

•

• •• • •

• •

•

•

•

••

••

••

Code A are stored on tape but an error results (except when they are used in the comment

section) during operation.

The B codes are non-working codes and are always ignored. Parity V check is not executed.

•

•

•

•

•

•

•• •

•• • •

•• ••

•• •••

•

••

•

••

•

•

•

•

•

•

•

•

• •

•

••

•

•••

•

•

•

•

•

•

•

•

•• ••

•• • •

•• ••

•• •

•• •••

•• • •

•• •

•

•

•

•

••• •

•

•• •

••• • •

•

•

•

•

•

••

•

•

•

•

•••

••• ••

••• •

••• ••

••• •••

•

•

••• •••

•

••• •••

•

•

1

•

2

•

3

••

4

5

6

7

8

9

•

0

•

B

•

C

••

D

E

F

G

H

I

•

J

K

L

M

N

O

P

Q

•

R

•

S

••

T

U

V

W

X

•

Z

+

.

,

/

%

LF(Line Feed) or NL

Control Out

Control In

•

:

#

••

*

=

[

]

SP(Space

CR(Carriage Return)

BS(Back Space

HT(Horizontal Tab

•

&

!

•

$

' (Apostrophe)

;

<

>

?

"

•

DEL(Delete

NULL

DEL(Delete

• Under the ISO code, IF or NL is EOB and % is EOR.

• Under the ISO code, CR is meaningless, and EOB will not occur.

Table of tape codes

B

9

Page 22

3. Data Formats

Alp

)

3.2 Program Formats

Function and purpose

The prescribed arrangement used when assigning control information to the controller is known as

the program format, and the format used with this controller is called the "word address format".

Detailed descripti on

(1) Word and address

A word is a collection of characters arranged in a specific sequence. This entity is used as the

unit for processing data and for causing the machine to execute specific operations. Each

word used for this controller consists of an alphabet letter and a number of several digits

(sometimes with a "-" sign placed at the head of the number.).

3.2 Program Formats

Word

*

Numerals

habet (address

Word configuration

The alphabet letter at the head of the word is the address. It defines the meaning of the

numerical information which follows it.

For details of the types of words and the number of significant digits of words used for this

controller, refer to the "format details".

(2) Blocks

A block is a collection of words. It includes the information which is required for the machine to

execute specific operations. One block unit constitutes a complete command. The end of each

block is marked with an EOB (end-of-block) code.

(Example 1)

G0X - 1000 ;

G1X - 2000F500 ;

(Example 2)

(G0X - 1000 ; )

G1X - 2000F500 ;

(3) Programs

A program is a collection of several blocks.

2 blocks

Since the semicolon in the parentheses will not result

in an EOB, it is 1 block.

10

Page 23

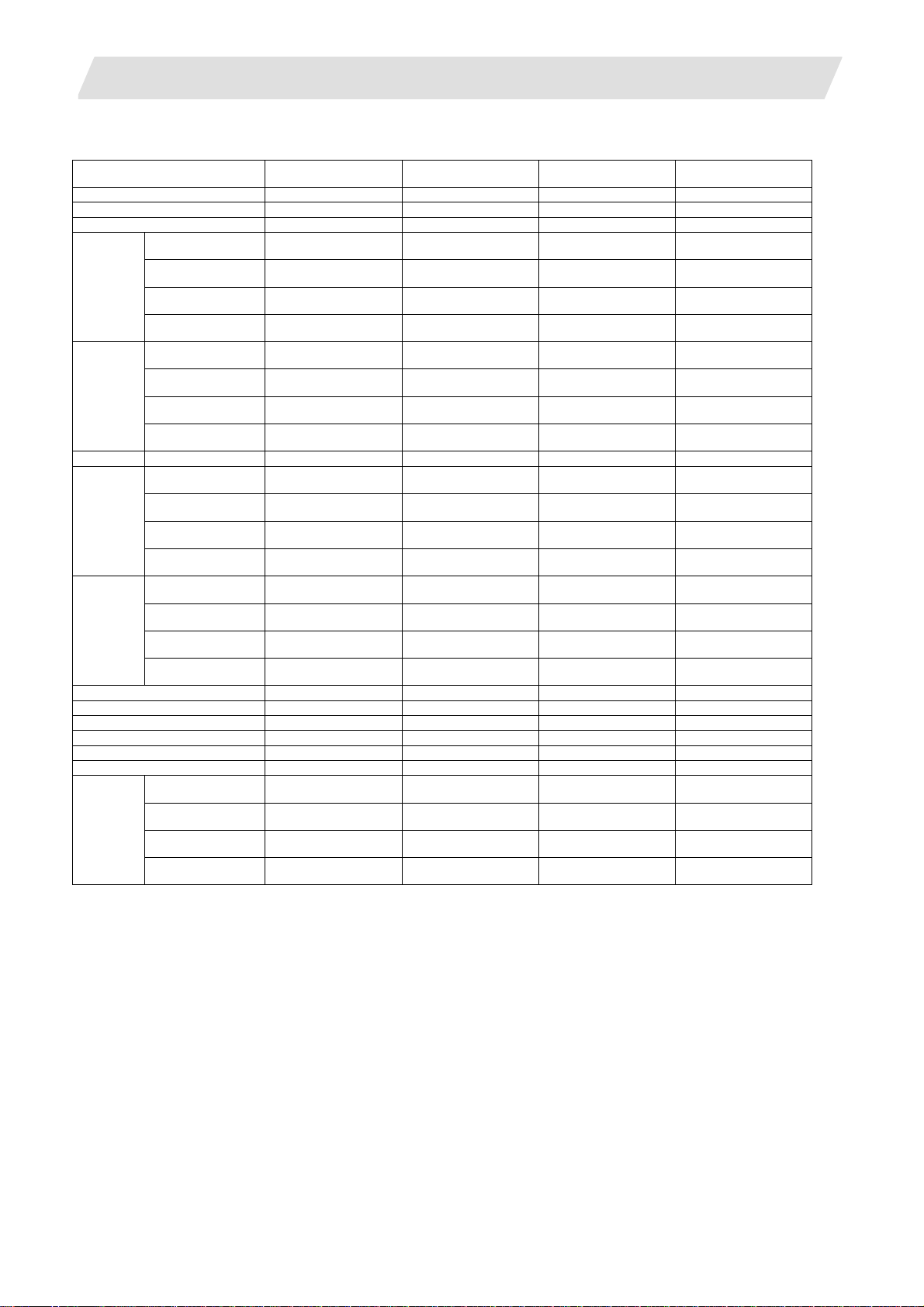

3. Data Formats

<Brief summary of format details>

Program No. 08

Sequence No. N6

Preparatory function G3/G21

Movement

axis

Arc and

cutter

radius

Dwell

Feed

function

(Feed per

minute)

Feed

function

(Feed per

revolution)

Tool compensation

Miscellaneous function (M)

Spindle function (S)

Tool function (T)

2nd miscellaneous function A8/B8/C8

Subprogram

Fixed

cycle

0.001(°) mm/

0.001 inch

0.0001(°) mm/

0.0001 inch

0.00001(°) mm/

0.00001 inch

0.000001(°) mm/

0.000001 inch

0.001(°) mm/

0.001 inch

0.0001(°) mm/

0.0001 inch

0.00001(°) mm/

0.00001 inch

0.000001(°) mm/

0.000001 inch

0.001(rev)/(s)

0.001(°) mm/

0.001 inch

0.0001 (°) mm/

0.0001 inch

0.00001 (°) mm/

0.00001 inch

0.000001 (°) mm/

0.000001 inch

0.0001(°) mm/

0.0001 inch

0.00001 (°) mm/

0.00001 inch

0.000001 (°) mm/

0.000001 inch

0.0000001 (°) mm/

0.0000001 inch

0.001(°) mm/

0.001 inch

0.0001(°) mm/

0.0001 inch

0.00001(°) mm/

0.00001 inch

0.000001(°) mm/

0.000001 inch

Metric command Inch command

X+53 Y+53 Z+53 α+53 X+44 Y+44 Z+44 α+44 X+53 Y+53 Z+53 α+53 X+53 Y+53 Z+53 α+53

X+54 Y+54 Z+54 α+54 X+45 Y+45 Z+45 α+45 X+54 Y+54 Z+54 α+54 X+54 Y+54 Z+54 α+54

X+55 Y+55 Z+55 α+55 X+46 Y+46 Z+46 α+46 X+55 Y+55 Z+55 α+55 X+55 Y+55 Z+55 α+55

X+56 Y+56 Z+56 α+56 X+47 Y+47 Z+47 α+47 X+56 Y+56 Z+56 α+56 X+56 Y+56 Z+56 α+56

I+53 J+53 K+53 I+44 J+44 K+44 I+53 J+53 K+53

I+54 J+54 K+54 I+45 J+45 K+45 I+54 J+54 K+54

I+55 J+55 K+55 I+46 J+46 K+46 I+55 J+55 K+55

I+56 J+56 K+56 I+47 J+47 K+47 I+56 J+56 K+56

X53/P8

F63 F54 F63 F54 (Note 6)

F64 F55 F64 F55 (Note 6)

F65 F56 F65 F56 (Note 6)

F66 F57 F66 F57 (Note 6)

F33 F34 F33 F34 (Note 6)

F34 F35 F34 F35 (Note 6)

F35 F36 F35 F36 (Note 6)

F36 F37 F36 F37 (Note 6)

H3 D3

M8

S8

T8

P8 H5 L4

R+53 Q53 P8 L4 R+44 Q44 P8 L4 R+53 Q53 P8 L4 R+53 Q53 P8 L4

R+54 Q54 P8 L4 R+45 Q45 P8 L4 R+54 Q54 P8 L4 R+54 Q54 P8 L4

R+55 Q55 P8 L4 R+46 Q46 P8 L4 R+55 Q55 P8 L4 R+55 Q55 P8 L4

R+56 Q56 P8 L4 R+47 Q47 P8 L4 R+56 Q56 P8 L4 R+56 Q56 P8 L4

3.2 Program Formats

Rotary axis

(Metric command)

← ← ←

← ← ←

← ← ←

← ← ←

← ← ←

← ← ←

← ← ←

← ← ←

← ← ←

← ← ←

Rotary axis

(Inch command)

I+53 J+53 K+53

I+54 J+54 K+54

I+55 J+55 K+55

I+56 J+56 K+56

(Note 5)

(Note 5)

(Note 5)

(Note 5)

(Note 1) α indicates the additional axis address, such as A, B or C.

(Note 2) The number of digits check for a word is carried out with the maximum number of digits of that address.

(Note 3) Numerals can be used without the leading zeros.

11

Page 24

3. Data Formats

3.2 Program Formats

(Note 4) The description of the brief summary is explained below:

Example 1 : 08 :8-digit program No.

Example 2 : G21 :Dimension G is 2 digits to the left of the decimal point, and 1 digit to the right.

Example 3 : X+53 :Dimension X uses + or - sign and represents 5 digits to the left of the decimal

point and 3 digits to the right.

For example, the case for when the X axis is positioned (G00) to the 45.123 mm

position in the absolute value (G90) mode is as follows:

G00 X45.123 ;

3 digits below the decimal point

5 digits above the decimal point, so it's +00045, but the

leading zeros and the mark (+) have been omitted.

G0 is possible, too.

(Note 5) If an arc is commanded using a rotary axis and linear axis while inch commands are being used, the

degrees will be converted into 0.1 inches for interpolation.

(Note 6) While inch commands are being used, the rotary axis speed will be in increments of 10 degrees.

Example: With the F1. (per-minute-feed) command, this will become the 10 degrees/minute command.

(Note 7) The decimal places below the decimal point are ignored when a command, such as an S command,

with an invalid decimal point has been assigned with a decimal point.

(Note 8) This format is the same for the value input from the memory, MDI or setting and display unit.

(Note 9) Command the program No. in an independent block. Command the program No. in the head block of

the program.

12

Page 25

3. Data Formats

3.3 Tape Memory Format

Function and purpose

(1) Storage tape and significant sections

The others are about from the current tape position to the EOB. Accordingly, under normal

conditions, operate the tape memory after resetting.

The significant codes listed in "Table of tape codes" in "3.1 Tape Codes" in the above

significant section are actually stored into the memory. All other codes are ignored and are not

stored.

The data between control out "(" and control in ")" are stored into the memory.

3.4 Optional Block Skip

3.4.1 Optional Block Skip; /

Function and purpose

This function selectively ignores specific blocks in a machining program which starts with the "/"

(slash) code.

Detailed description

3.3 Tape Memory Format

(1) Provided that the optional block skip switch is ON, blocks starting with the "/" code are ignored.

They are executed if the switch is OFF.

Parity check is valid regardless of whether the optional block skip switch is ON or OFF.

When, for instance, all blocks are to be executed for one workpiece but specific block are not

to be executed for another workpiece, the same command tape can be used to machine

different parts by inserting the "/" code at the head of those specific blocks.

Precautions for using optional block skip

(1) Put the "/" code for optional block skip at the beginning of a block. If it is placed inside the block,

it is assumed as a user macro, a division instruction.

Example : N20 G1 X25./Y25. ;....NG (User macro, a division instruction; a program error

results.)

/N20 G1 X25. Y25. ;.....OK

(2) Parity checks (H and V) are conducted regardless of the optional block skip switch position.

(3) The optional block skip is processed immediately before the pre-read buffer.

Consequently, it is not possible to skip up to the block which has been read into the pre-read

buffer.

(4) This function is valid even during a sequence number search.

(5) All blocks with the "/" code are also input and output during tape storing and tape output,

regardless of the position of the optional block skip switch.

13

Page 26

3. Data Formats

3.4.2 Optional Block Skip Addition ; /n

Function and purpose

Whether the block with "/n (n:1 to 9)" (slash) is executed during automatic operation and searching

is selected.

By using the machining program with "/n" code, different parts can be machined by the same

program.

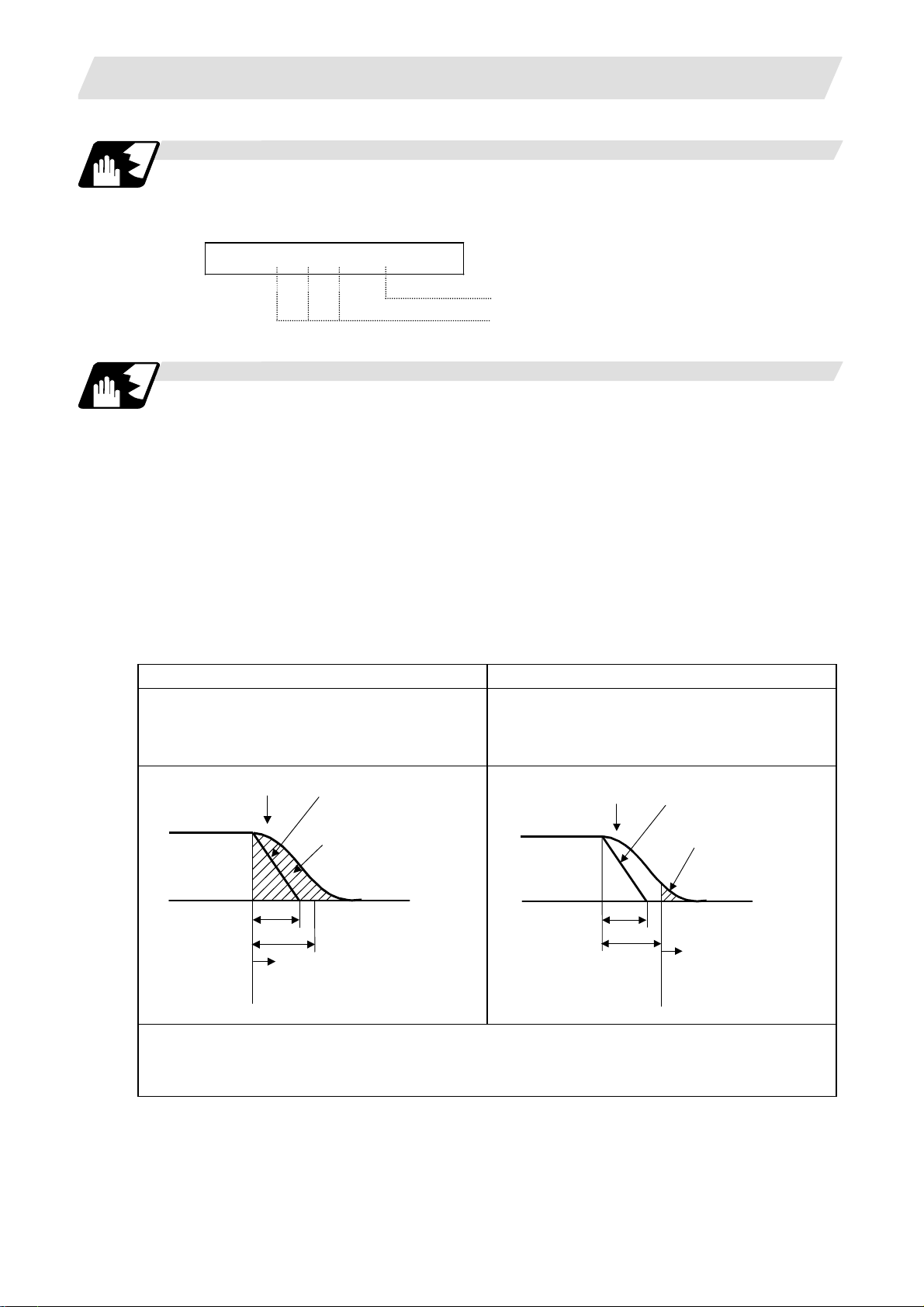

Detailed description

The block with "/n" (slash) code is skipped when the "/n" is programmed to the head of the block

and the optional block skip signal is turned ON.

For the block with the "/n" code inside the block (not the head of block), the program is operated

according to the value of the parameter "#1226 aux10/bit1" setting.

When the optional block skip signal is OFF, the block with "/n" is executed.

Example of program

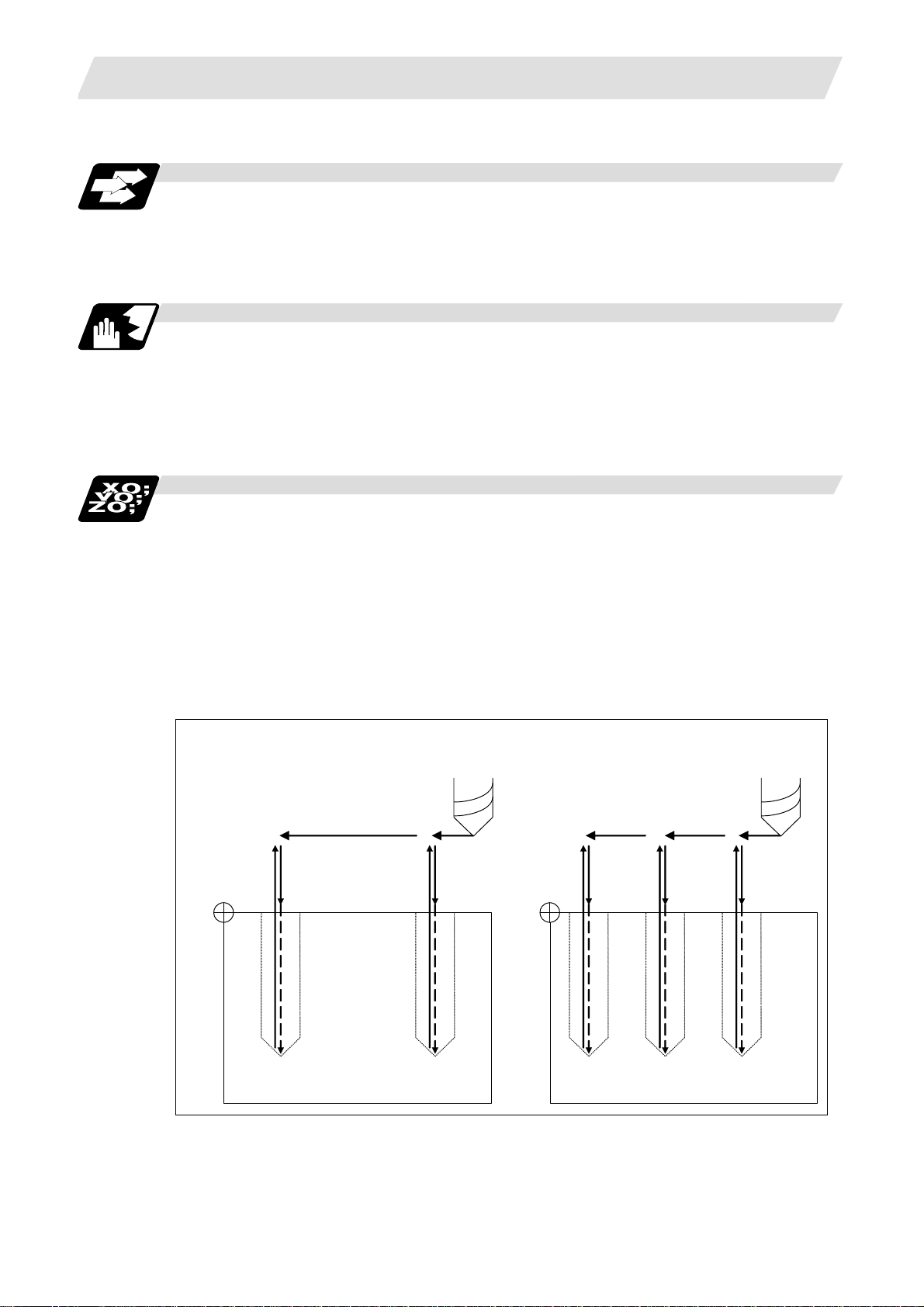

(1) When the 2 parts like the figure below are machined, the following program is used. When the

optional block skip 5 signal is ON, the part 1 is created. When the optional block skip 5 signal is

OFF, the part 2 is created.

<Program>

N1 G54;

N2 G90G81X50. Z-20. R3. F100;

/5 N3 X30.;

N4 X10.;

N5 G80;

M02;

Part 1

the optional block skip 5 signal ON

3.4 Optional Block Skip

Part 2

the optional block skip 5 signal OFF

N4 N2 N2 N3

14

N4

Page 27

3. Data Formats

3.4 Optional Block Skip

(2) When two or more "/n" codes are commanded to the head of the same block, the block is

ignored if either of the optional block skip signal corresponding to the command is ON.

<Program>

N01 G90 Z3. M03 S1000;

/1/2 N02 G00 X50.;

/1/2 N03 G01 Z-20. F100;

/1/2 N04 G00 Z3.;

/1 /3 N05 G00 X30.;

/1 /3 N06 G01 Z-20. F100;

/1 /3 N07 G00 Z3.;

/2/3 N08 G00 X10.;

/2/3 N09 G01 Z-20. F100;

/2/3 N10 G00 Z3.;

N11 G28 X0 M05;

(a) Optional block skip 1 signal ON

(Optional block skip 2, 3 signals OFF)

N01 -> N08 -> N09 -> N10 -> N11 -> N12

(b) Optional block skip 2 signal ON

(Optional block skip 1, 3 signals OFF)

N01 -> N05 -> N06 -> N07 -> N11 -> N12

(c) Optional block skip 3 signal ON

(Optional block skip 1, 2 signals OFF)

N01 -> N02 -> N03 -> N04 -> N11 -> N12

N12 M02;

(3) When the parameter "#1226 aux10/bit1" is "1", when two or more "/n" are commanded inside

the same block, the commands following "/n" in the block are ignored if either of the optional

block skip signal corresponding to the command is ON.

N01 G91 G28 X0.Y0.Z0.;

N02 G01 F1000;

N03 X1. /1 Y1. /2 Z1.;

N04 M30;

(a) When the optional block skip 1 signal is

ON and the optional block skip 2 signal is

OFF, "Y1. Z1." is ignored

(b) When the optional block skip 1 signal is

OFF and the optional block skip 2 signal is

ON, "Z1." is ignored.

15

Page 28

3. Data Formats

3.5 Program/Sequence/Block Numbers ; O, N

3.5 Program/Sequence/Block Numbers ; O, N

Function and purpose

These numbers are used for monitoring the execution of the machining programs and for calling

both machining programs and specific stages in machining programs.

(1) Program numbers are classified by workpiece correspondence or by subprogram units, and

they are designated by the address "0" followed by a number with up to 8 digits.

(2) Sequence numbers are attached where appropriate to command blocks which configure

machining programs, and they are designated by the address "N" followed by a number with

up to 6 digits.

(3) Block numbers are automatically provided internally. They are preset to zero every time a

program number or sequence number is read, and they are counted up one at a time unless

program numbers or sequence numbers are commanded in blocks which are subsequently

read.

Consequently, all the blocks of the machining programs given in the table below can be

determined without further consideration by combinations of program numbers, sequence

numbers and block numbers.

Machining program

O12345678 (DEMO, PROG) ; 12345678 0 0

G92 X0 Y0 ; 12345678 0 1

G90 G51 X-150. P0.75 ; 12345678 0 2

N100 G00 X-50. Y-25. ; 12345678 100 0

N110 G01 X250. F300 ; 12345678 110 0

Y-225. ; 12345678 110 1

X-50. ; 12345678 110 2

Y-25.; 12345678 110 3

N120 G51 Y-125. P0.5 ; 12345678 120 0

N130 G00 X-100. Y-75. ; 12345678 130 0

N140 G01 X-200. ; 12345678 140 0

Y-175. ; 12345678 140 1

X-100. ; 12345678 140 2

Y-75. ; 12345678 140 3

N150 G00 G50 X0 Y0 ; 12345678 150 0

N160 M02 ; 12345678 160 0

%

Program No. Sequence No. Block No.

Monitor display

16

Page 29

3. Data Formats

•

•

• • •

• • • • • • • • • • • • •

•

•

• •

•

•

• • •

• • •

• •

•

• • •

•

• •

•

• • • • • • • • •

•

• •

• • •

3.6 Parity H/V

Function and purpose

Parity check provides a mean of checking whether the tape has been correctly perforated or not.

This involves checking for perforated code errors or, in other words, for perforation errors. There

are two types of parity check: Parity H and Parity V.

(1) Parity H

3.6 Parity H/V

Parity H checks the number of holes configuring a character and it is done during tape

operation, tape input and sequence number search.

A parity H error is caused in the following cases.

(a) ISO code

When a code with an odd number of holes in a significant data section has been detected.

(b) EIA code

When a code with an even number of holes in a significant data section has been

detected.

Parity H error example

• • • •

•

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

• • • • • • • • • • • • • • •

•

•

• • • • • • • • •

• • •

(2) Parity V

• • • • •

• • • • • • • • • • • • • • • • •

• • • • • • • • • • • • • •

When a parity H error occurs, the tape stops following the alarm code.

A parity V check is done during tape operation, tape input and sequence number search when

the I/O PARA #9n15 (n is the unit No.1 to 5) parity V check function is set to "1". It is not done

during memory operation.

A parity V error occurs in the following case: when the number of codes from the first

significant code to the EOB (;) in the significant data section in the vertical direction of the tape

is an odd number, that is, when the number of characters in one block is odd.

When a parity V error is detected, the tape stops at the code following the EOB (;).

(Note 1) Among the tape codes, there are codes which are counted as characters for parity

(Note 2) Any space codes which may appear within the section from the initial EOB code to

• •

• • • • • • • • • •

•

•

• • • •

• • •

• • • • • • •

This character causes a parity H error.

and codes which are not counted as such. For details, refer to the "Table of tape

codes" in "3.1 Tape Codes".

the address code or "/" code are counted for parity V check.

17

Page 30

3. Data Formats

3.7 G Code Lists

Function and purpose

G code Group Function Section

Δ 00 01 Positioning 6.1

Δ 01 01 Linear interpolation 6.2

02 01 Circular interpolation CW (clockwise)

03 01 Circular interpolation CCW (counterclockwise)

02.1 01 Spiral/Conical interpolation CW (type1) 6.13

03.1 01 Spiral/Conical interpolation CCW (type1) 6.13

02.3 01 Exponential function interpolation positive rotation 6.11

03.3 01 Exponential function interpolation negative rotation 6.11

02.4 01 3-dimensional circular interpolation 6.14

03.4 01 3-dimensional circular interpolation 6.14

04 00 Dwell 8.1

05 00 High-speed machining mode

05.1 00 High-speed high-accuracy control I

06.2 01 NURBS interpolation 6.15

07 00

07.1

107

08 00 High-accuracy control 13.15

09 00 Exact stop check 7.9

10 00 Program data input (parameter /compensation data/parameter

11 00 Program data input cancel 12.7

12 00 Circular cut CW (clockwise) 13.10

13 00 Circular cut CCW (counterclockwise) 13.10

12.1

112

* 13.1

113

14

* 15 18 Polar coordinate command OFF 6.12

16 18 Polar coordinate command ON 6.12

Δ 17 02 Plane selection X-Y 6.3

Δ 18 02 Plane selection Z-X 6.3

Δ 19 02 Plane selection Y-Z 6.3

Δ 20 06 Inch command 5.2

Δ 21 06 Metric command 5.2

R-specified circular interpolation CW

Helical interpolation CW

Spiral/Conical interpolation CW (type 2)

R-specified circular interpolation CCW

Helical interpolation CCW

Spiral/Conical interpolation CCW (type 2)

High-speed high-accuracy control II

Spline

Hypothetical axis interpolation 6.16

21 Cylindrical interpolation

coordinate rotation data)

21 Polar coordinate interpolation ON

21 Polar coordinate interpolation cancel

3.7 G Code Lists

6.4

6.5

6.6

6.13

6.4

6.5

6.6

6.13

13.16

13.17

13.17

13.18

6.9

12.7

13.11

13.22

13.11

6.10

6.10

18

Page 31

3. Data Formats

3.7 G Code Lists

G code Group Function Section

22 04 Stroke check before travel ON 15.7

23 04 Stroke check before travel cancel 15.7

24

25

26

27 00 Reference position check 14.9

28 00 Reference position return 14.7

29 00 Start position return 14.7

30 00 2nd to 4th reference position return 14.8

30.1 00 Tool change position return 1 13.13

30.2 00 Tool change position return 2 13.13

30.3 00 Tool change position return 3 13.13

30.4 00 Tool change position return 4 13.13

30.5 00 Tool change position return 5 13.13

30.6 00 Tool change position return 6 13.13

31 00 Skip

Multi-step skip function 2

31.1 00 Multi-step skip function 1-1 15.3

31.2 00 Multi-step skip function 1-2 15.3

31.3 00 Multi-step skip function 1-3 15.3

32

33 01 Thread cutting 6.7

34 00 Special fixed cycle (bolt hole circle) 13.2

35 00 Special fixed cycle (line at angle) 13.2

36 00 Special fixed cycle (arc) 13.2

37 00 Automatic tool length measurement 15.1

37.1 00 Special fixed cycle (grid) 13.2

38 00 Tool radius compensation vector designation 12.4

39 00 Tool radius compensation corner arc 12.4

* 40 07 Tool radius compensation cancel

3-dimentional tool radius compensation cancel

41 07 Tool radius compensation left

3-dimentional tool radius compensation left

42 07 Tool radius compensation right

3-dimentional tool radius compensation right

* 40.1 15 Normal line control cancel 13.14

41.1 15 Normal line control left ON 13.14

42.1 15 Normal line control right ON 13.14

43 08 Tool length compensation (+) 12.2

44 08 Tool length compensation (-) 12.2

43.1 08 Tool length compensation along the tool axis 12.3

43.4 08 Tool center point control type 1 13.24

43.5 08 Tool center point control type 2 13.24

45 00 Tool position offset (extension) 12.6

46 00 Tool position offset (reduction) 12.6

47 00 Tool position offset (doubled) 12.6

48 00 Tool position offset (halved) 12.6

* 49 08 Tool length compensation cancel

Tool center point control cancel

* 50 11 Scaling cancel 13.20

51 11 Scaling ON 13.20

15.2

15.4

12.4

12.5

12.4

12.5

12.4

12.5

12.2

13.24

19

Page 32

3. Data Formats

3.7 G Code Lists

G code Group Function Section

* 50.1 19 G command mirror image cancel 13.6

51.1 19 G command mirror image ON 13.6

52 00 Local coordinate system setting 14.11

53 00 Basic machine coordinate system selection 14.4

* 54 12 Workpiece coordinate system 1 selection

55 12 Workpiece coordinate system 2 selection

56 12 Workpiece coordinate system 3 selection

57 12 Workpiece coordinate system 4 selection

58 12 Workpiece coordinate system 5 selection

59 12 Workpiece coordinate system 6 selection

54.1 12 Workpiece coordinate system selection 48 / 96 sets extended

14.10

14.10

14.10

14.10

14.10

14.10

14.10

60 00 Unidirectional positioning 6.8

61 13 Exact stop check mode 7.10

61.1 13 High-accuracy control 1 ON 13.15

61.2 13 High-accuracy spline interpolation 13.19

62 13 Automatic corner override 7.12

63 13 Tapping mode 7.13

63.1 13 Synchronous tapping mode (normal tapping)

63.2 13 Synchronous tapping mode (reverse tapping)

* 64 13 Cutting mode 7.14

65 00 User macro call 13.5.1

66 14 User macro modal call A 13.5.1

66.1 14 User macro modal call B 13.5.1

* 67 14 User macro modal call cancel 13.5.1

68 16 Programmable coordinate rotation mode ON/3-dimensional

coordinate conversion mode ON

* 69 16 Programmable coordinate rotation mode OFF/3-dimensional

coordinate conversion mode OFF

13.21

13.23

13.21

13.23

70 09 User fixed cycle

71 09 User fixed cycle

72 09 User fixed cycle

73 09 Fixed cycle (step) 13.1.1

74 09 Fixed cycle (reverse tap) 13.1.1

75 09 Fixed cycle (circle cutting cycle) 13.1.1

76 09 Fixed cycle (fine boring) 13.1.1

77 09 User fixed cycle

78 09 User fixed cycle

79 09 User fixed cycle

* 80 09 Fixed cycle cancel 13.1.1

81 09 Fixed cycle (drill/spot drill) 13.1.1

82 09 Fixed cycle (drill/counter boring) 13.1.1

83 09 Fixed cycle (deep drilling) 13.1.1

84 09 Fixed cycle (tapping) 13.1.1

85 09 Fixed cycle (boring) 13.1.1

86 09 Fixed cycle (boring) 13.1.1

87 09 Fixed cycle (back boring) 13.1.1

88 09 Fixed cycle (boring) 13.1.1

89 09 Fixed cycle (boring) 13.1.1

Δ 90 03 Absolute value command 5.1

Δ 91 03 Incremental command value 5.1

20

Page 33

3. Data Formats

g

3.8 Precautions Before Starting Machining

G code Group Function Section

92 00 Coordinate system setting / Spindle clamp speed setting 14.5

92.1 00 Workpiece coordinate system pre-setting 14.12

93 05 Inverse time feed 7.5

Δ 94 05 Feed per minute (Asynchronous feed) 7.4

Δ 95 05 Feed per revolution (Synchronous feed) 7.4

Δ 96 17 Constant surface speed control ON 10.3

Δ 97 17 Constant surface speed control OFF 10.3

* 98 10 Fixed cycle Initial level return 13.1.2

99 10 Fixed cycle R point level return 13.1.2

100 to

255

(Note 1) Codes marked with * are codes that must be or are selected in the initial state.

The codes marked with Δ are codes that should be or are selected in the initial state by

(Note 2) If two or more G codes from the same code are commanded, the latter G code will be

(Note 3) This G code list is a list of conventional G codes. Depending on the machine, movements

(Note 4) Whether the modal is initialized or not depends on each reset input.

00 User macro (G code call) Max. 10 13.5.2

the parameters.

valid.

that differ from the conventional G commands may be included when called by the G

code macro. Refer to the Instruction Manual issued by the tool builder.

(1) "Reset 1"

The modal is initialized when the reset initial parameter "#1151 rstinit" turns ON.

(2) "Reset 2" and "Reset & rewind"

The modal is initialized when the signal is input.

(3) Resetting when emergency stop is canceled

Follows "Reset 1".

(4) When modal is automatically reset at the start of individual functions such as

reference position return.

Follows "Reset & rewind".

CAUTION

The commands with "no value after G" will be handled as "G00".

3.8 Precautions Before Starting Machining

Precautions before starting machinin

CAUTION

When creating the machining program, select the appropriate machining conditions so that the

machine, NC performance, capacity and limits are not exceeded. The examples do not allow

for the machining conditions.

Before starting actual machining, always carry out dry operation to confirm the machining

program, tool compensation amount and workpiece offset amount, etc.

21

Page 34

4. Buffer Register

r

y

Analysi

A

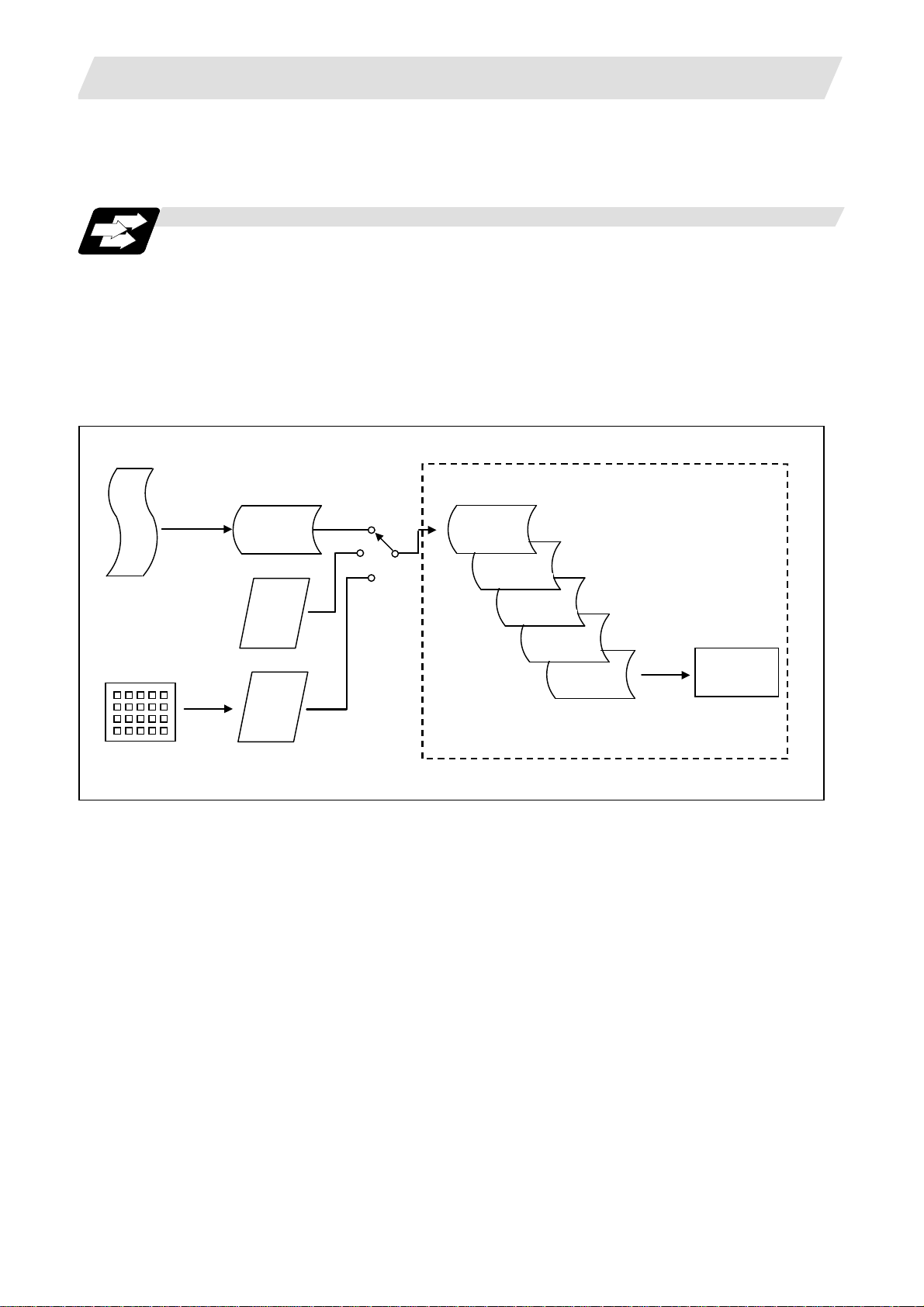

4. Buffer Register

4.1 Input Buffer

Tape

Function and purpose

When the pre-read buffer is empty during a tape operation or RS232C operation, the contents of

the input buffer are immediately transferred to the pre-read buffers and, provided that the data

stored in the input buffer do not exceed 250 x 4 characters, the following data (Max. 250

characters) are read and loaded into the input buffer.

This buffer is designed to eliminate the operational delay originating in the readout time of the tape

reader and to smooth out the block joints.

The pre-reading effects are lost, however, when the block execution time is shorter than the tape

readout time of the following block.

(Buffer size : 250 x 5 characters)

Input buffe

4.1 Input Buffer

s processing

Max. 5 execution blocks

Pre-read

buffer 5

Keyboard

Buffer 4

Memor

MDI data

Mode

switching

Note : Data equivalent to 1 block are stored in 1 pre-read buffer.

Buffer 3

Buffer 2

Buffer 1

rithmetic

processing

The input buffer has a memory capacity of 250 x 5 characters (including the EOB code).

(1) The contents of the input buffer register are updated in 250-character units.

(2) Only the significant codes in the significant data section are read into the input buffer.

(3) When codes (including "(" and ")") are sandwiched in the control in or control out mode and the

optional block skip function is ON, the data extending from the "/" (slash) code up to the EOB

code are read into the input buffer.

(4) The input buffer contents are cleared with resetting.

(Note 1) The input buffer size (250 characters) differs according to the model.

22

Page 35

4. Buffer Register

4.2 Pre-read Buffers

Function and purpose

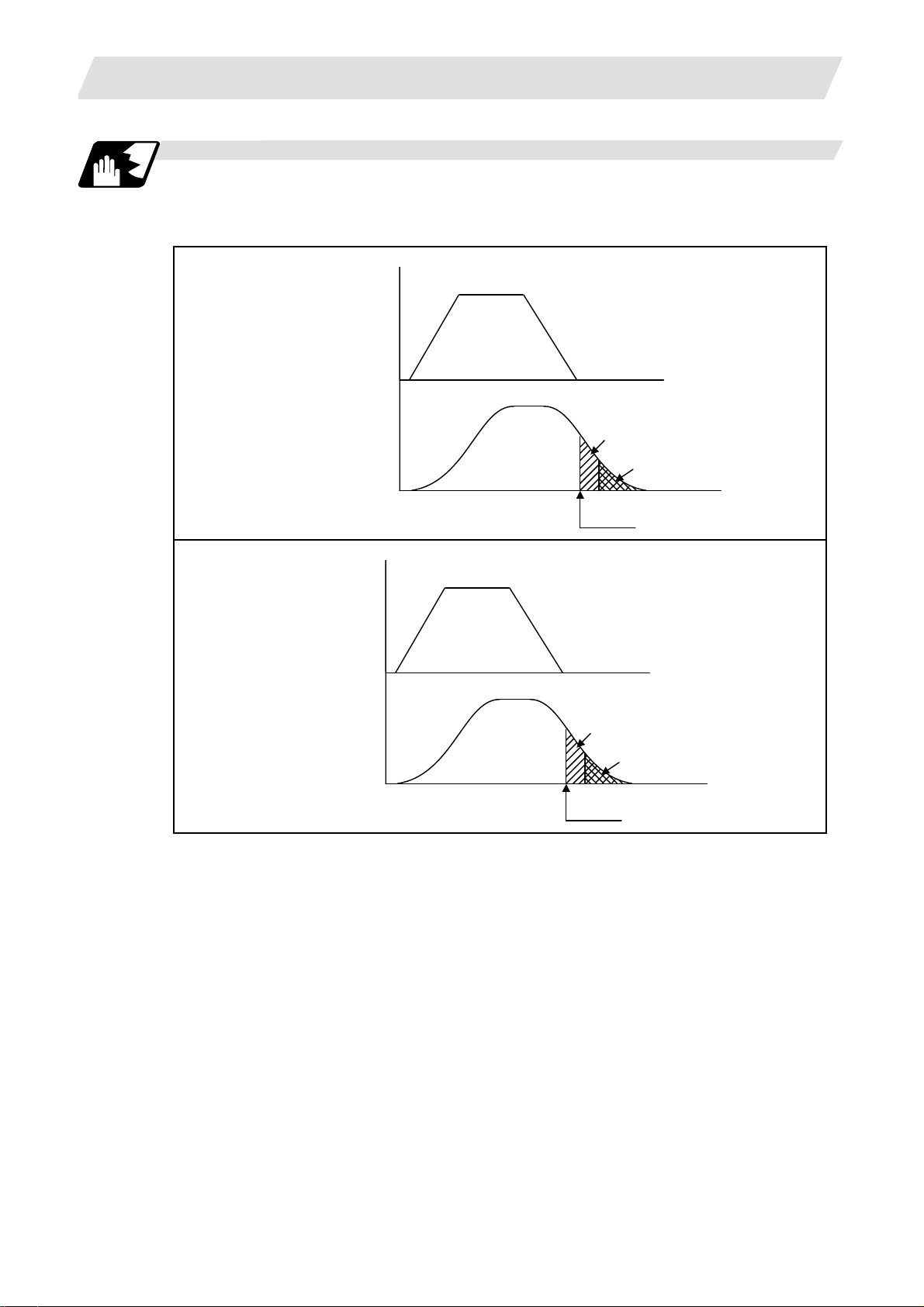

During automatic processing, the contents of 1 block are normally pre-read so that program

analysis processing is conducted smoothly. However, during tool radius compensation, a

maximum of 5 blocks are pre-read for the intersection point calculation including interference

check.

The specifications of the data in 1 block are as follows:

(1) The data of 1 block are stored in this buffer.

(2) Only the significant codes in the significant data section are read into the pre-read buffer.

(3) When codes are sandwiched in the control in and control out, and the optional block skip

function is ON, the data extending from the "/" (slash) code up to the EOB code are not read

into the pre-read buffer.

(4) The pre-read buffer contents are cleared with resetting.

(5) When the single block function is ON during continuous operation, the pre-read buffer stores

the following block data and then stops operation.

Other precautions

4.2 Pre-read Buffers

(1) Depending on whether the program is executed continuously or by single blocks, the timing of

the valid/invalid for the external control signals for the block skip and others will differ.

(2) If the external control signal such as optional block skip is turned ON/OFF with the M

command, the external control operation will not be effective on the program pre-read with the

buffer register.

(3) According to the M command that operates the external controls, it prohibits pre-reading, and

the recalculation is as follows:

The M command that commands the external controls is distinguished at the PLC, and the

"recalculation request" for PLC -> NC interface table is turned ON.

(When the "recalculation request" is ON, the program that has been pre-read is reprocessed.)

23

Page 36

5. Position Commands

5. Position Commands

5.1 Position Command Methods ; G90, G91

Function and purpose

By using the G90 and G91 commands, it is possible to execute the next coordinate commands

using absolute values or incremental values.

The R-designated circle radius and the center of the circle determined by I, J, K are always

incremental value commands.

Command format

G9D X__ Y__ Z__ α__;

G90 :Absolute command

G91 :Incremental command

α :Additional axis

Detailed description

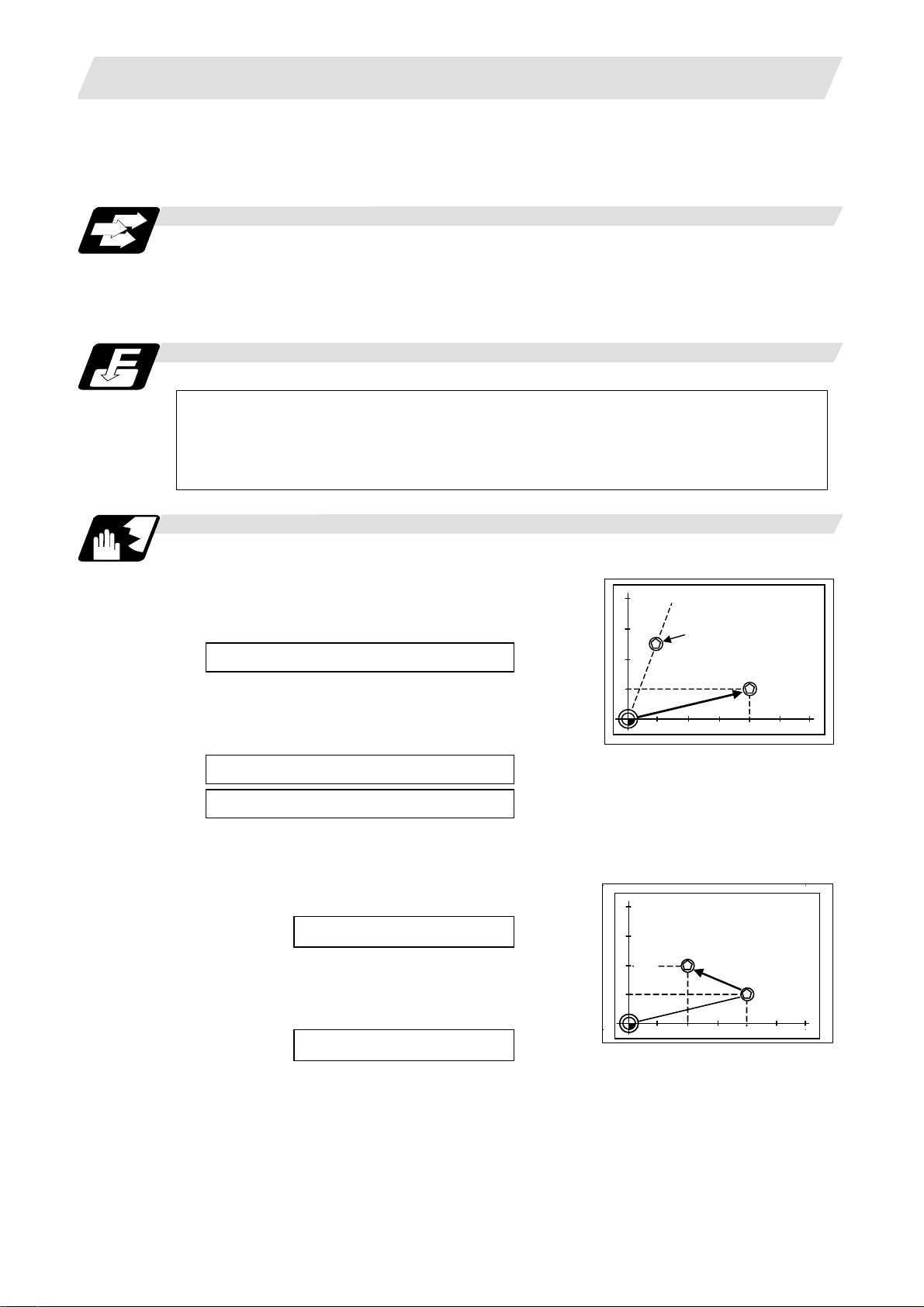

(1) Regardless of the current position, in the absolute

value mode, it is possible to move to the position of the

workpiece coordinate system that was designated in

the program.

N 1 G90 G00 X0 Y0 ;

5.1 Position Command Methods; G90, G91

Y

200.

Tool

100.

N1

In the incremental value mode, the current position is

the start point (0), and the movement is made only the

value determined by the program, and is expressed as

an incremental value.

W

100.

N2

200.

X

300.

N 2 G90 G01 X200. Y50. F100;

N 2 G91 G01 X200. Y50. F100;

Using the command from the 0 point in the workpiece coordinate system, it becomes the same

coordinate command value in either the absolute value mode or the incremental value mode.

(2) For the next block, the last G90/G91 command that

was given becomes the modal.

(G90)

N 3 X100. Y100.;

The axis moves to the workpiece

coordinate system X = 100mm and

Y

200.

100.

N3

Y = 100mm position.

(G91)

W

100.

200.

N 3 X-100. Y50.;

300.

X

The X axis moves to -100.mm and the Y axis to +50.0mm as an incremental

value, and as a result X moves to 100.mm and Y to 100.mm.

24

Page 37

5. Position Commands

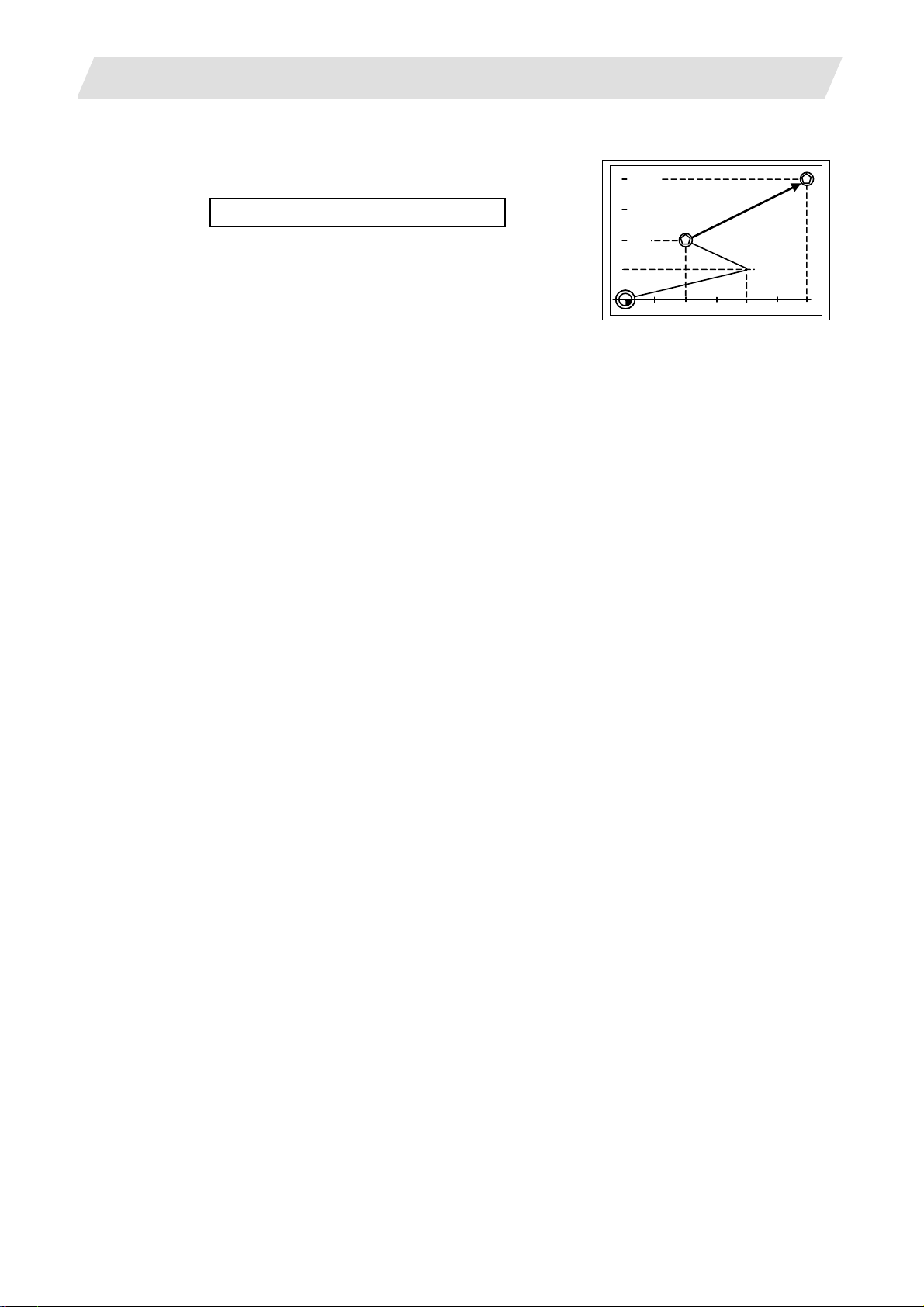

(3) Since multiple commands can be issued in the same block, it is possible to command specific

addresses as either absolute values or incremental

values.

N 4 G90 X300. G91 Y100.;

The X axis is treated in the absolute value

mode, and with G90 is moved to the workpiece

coordinate system 300.mm position. The Y

axis is moved +100.mm with G91. As a result,

Y moves to the 200.mm position. In terms of

the next block, G91 remains as the modal and

becomes the incremental value mode.

(4) When the power is turned ON, it is possible to select whether you want absolute value

commands or incremental value commands with the #1073 I_Absm parameter.

(5) Even when commanding with the manual data input (MDI), it will be treated as a modal from

that block.

5.1 Position Command Methods; G90, G91

Y

200.

100.

N4

W

200. 100.

300.

X

25

Page 38

5. Position Commands

5.2 Inch/Metric Command Change; G20, G21

5.2 Inch/Metric Command Change; G20, G21

Function and purpose

These G commands are used to change between the inch and millimeter (metric) systems.

Command format

G20/G21;

G20 : Inch command

G21 : Metric command

Detailed description

The G20 and G21 commands merely select the command units. They do not select the Input units.

G20 and G21 selection is meaningful only for linear axes and it is meaningless for rotation axes.

Output unit, command unit and setting unit

The counter or parameter setting and display unit is determined by parameter "#1041 I_inch".

For the movement/speed command, the followings will be resulted:

The movement/speed command will be displayed as metric units when "#1041 I_inch" is ON during

the G21 command mode.

The internal unit metric data of the movement/speed command will be converted into an inch unit

and displayed when "#1041 I_inch" is OFF during the G20 command mode.

The command unit for when the power is turned ON and reset is decided by combining the

parameters "#1041 I_inch", "#1151 rstint" and "#1210 RstGmd/bit5".

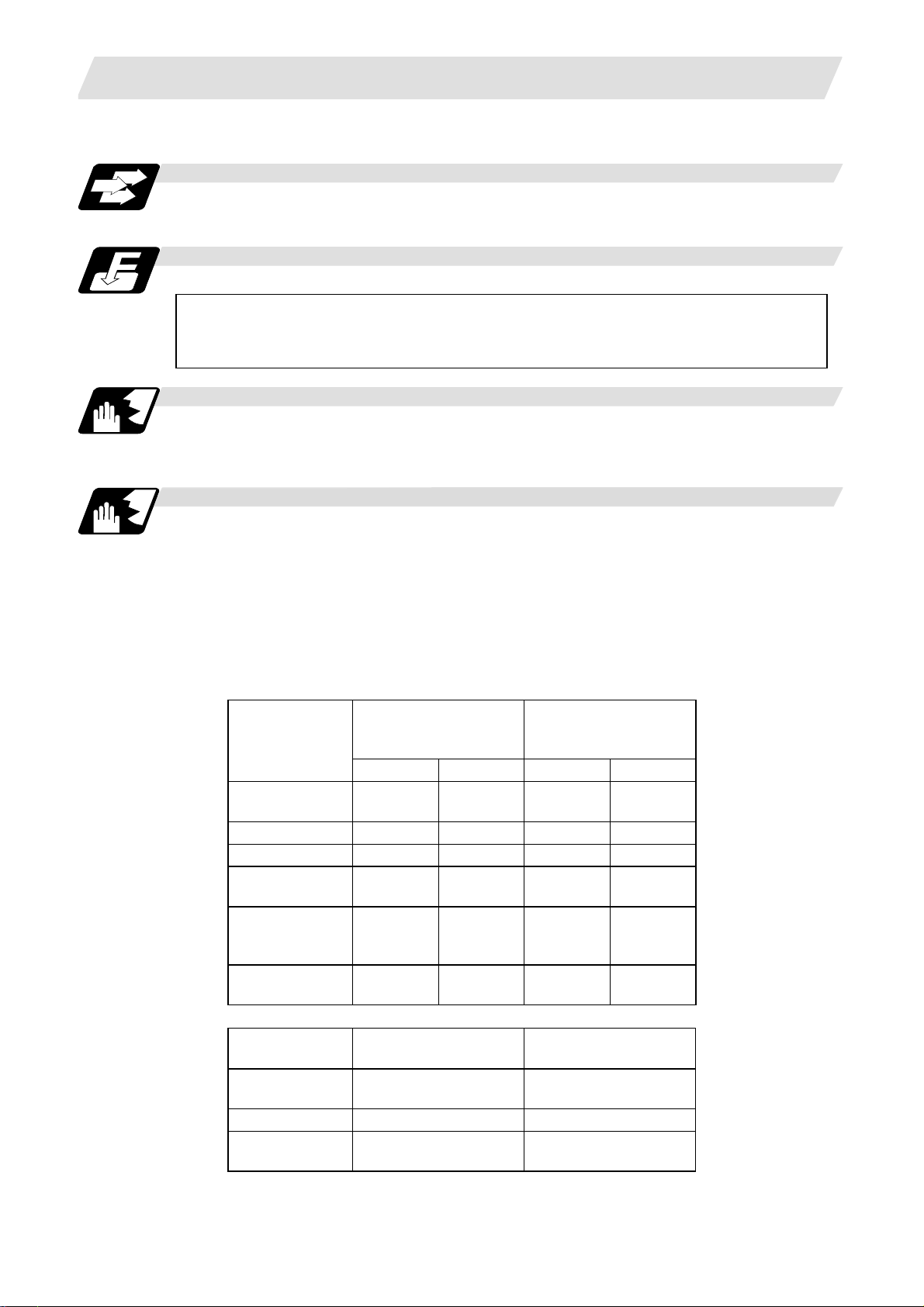

NC axis

Item

Movement/

speed command

Counter display Metric Metric Inch Inch

Speed display Metric Metric Inch Inch

User parameter

setting/display

Workpiece/

tool offset

setting/display

Handle feed

command

PLC axis

Item

Movement/

speed command

Counter display Metric Inch

User parameter