Page 1

TS100 Soldering Iron

Instruction Manual

TS100

Version 1.0.1

Please read this manual before operating

the TS100(this instruction

manual is based on APPV2.11

Page 2

WARNING:Failure to comply a

WARNING may result in serious

!

injury to the user or others.

Content

1

Safety Statement

2

!

P1

Overview

CAUTION:Failure to comply

a CAUTION may cause damage

to the product or other equipments.

NOTE:Annotations,operation

notes or additional information.

P3

3

Power Adaptor

Selection

P5

6

4

Operation

P6

5

Trouble Shooting Guide

Soldering Iron Tip

P16

7

P14

Technical Support

P18

8

Legal Statements

P20

Page 3

1

1.1 General Safety

Safety Statememt

Use only certified power source/adaptors from your region.

(please refer to 3.0 for specifications)

Do not operate in humid environment.

Do not operate in inflammable/explosive environment.

1.2 Working condition

Working condition

Temperature

Keep the surface of the product clean and dry.

Requirements

Operating Condition: from 0℃ to +50℃

Non-operating Condition: from -20℃ to +60℃

Humidity

Operating Condition: from 40℃ to 50 ℃,0% to 60% RH

Operating Condition: from 0℃ to 40 ℃,10% to 90% RH

Non-operating Condition: from 40℃ to 60℃,5% to 60%RH

Non-operating Condition: Low temperature: from 0℃ to 40℃,

5% to 90%RH

1

Page 4

1

1.3 Warnings

Safety Statememt

When using TS100,

Turn the power off when not in use,or left unattended.

When power is ON,tip temperatures will between

100℃~400℃(212℉~752℉),please be careful.

Please don’t operate TS100 when it’s wet or operate

it with wet hands,which will cause an electric shock.

1.4 Cautions

When using TS100,

• The handle is constructed with precision, dropping shall be avoided.

• After continuous use up to 40 minutes, the handle surface temperature

!

will reach 50℃~60℃.

• For the first time using, TS100 may generate a light smoke due to the

heating of heating elements, which is a normal phenomenon.

1.5 Liability Statement

Any damage of the product,or losses related to the product damage,

if it’s man-caused,or assumed to be man-caused,the liability will belong to

the user.

2

Page 5

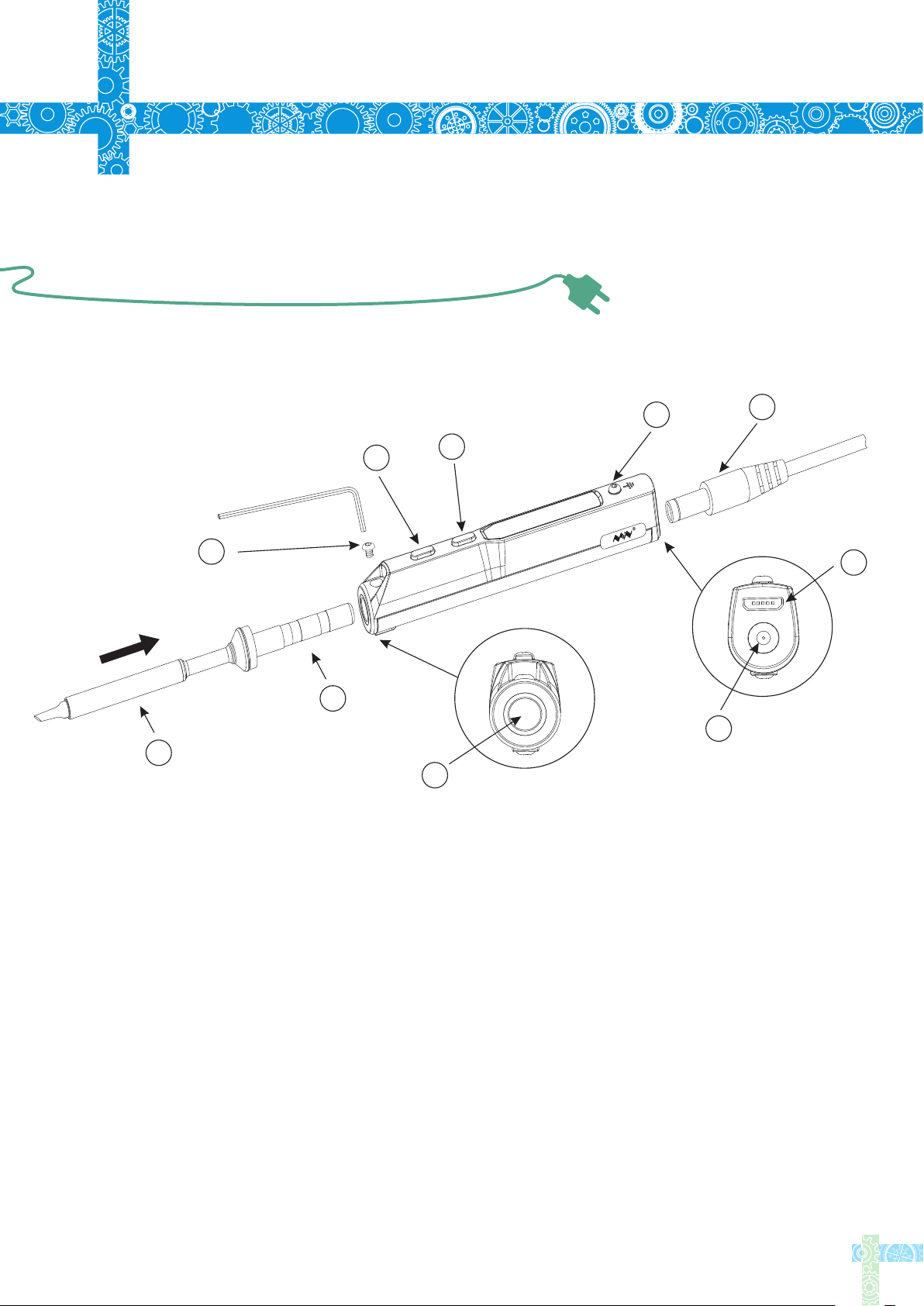

Overview

2

2.1 Ports and Control Panel Introduction

10

4

2

1

9

3

8

5

6

7

1.The tip setscrew

2.Button A

3.Button B

4.Ground cable fixing screw

5.Power c

6.Micro USB

7.DC5525

8.Soldering tip port

9.Soldering tip connector

10.Solder

onnector

12-24V port

ing tip heating end

3

Page 6

2

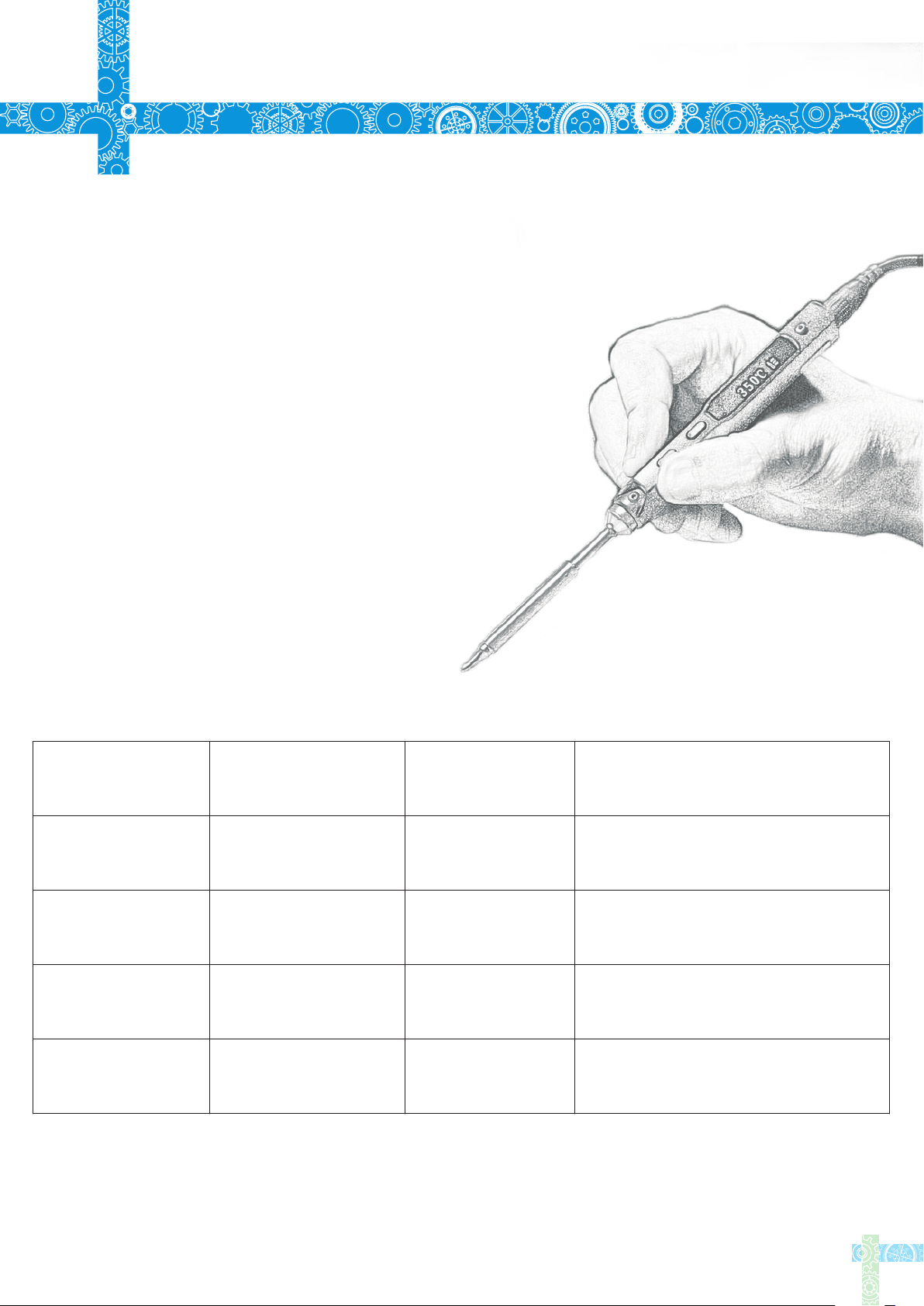

2.2 Specifications

Overview

Screen

USB port

Power port

Operation unit

Dimensions

Heating unit

Weight

2.3 Operation Specifications

OLED

Micro USB

DC5525

Length:96mm,Diameter:16.5mm

Length:72+33mm,Diameter:5.5mm

33g(power adaptor not included)

Power

Temperature range

Temperature stability

Operation temperature under heat

Soldering tip resistance to the ground

65W

100℃~400℃(max)

±2%

40℃

<2Ω

4

Page 7

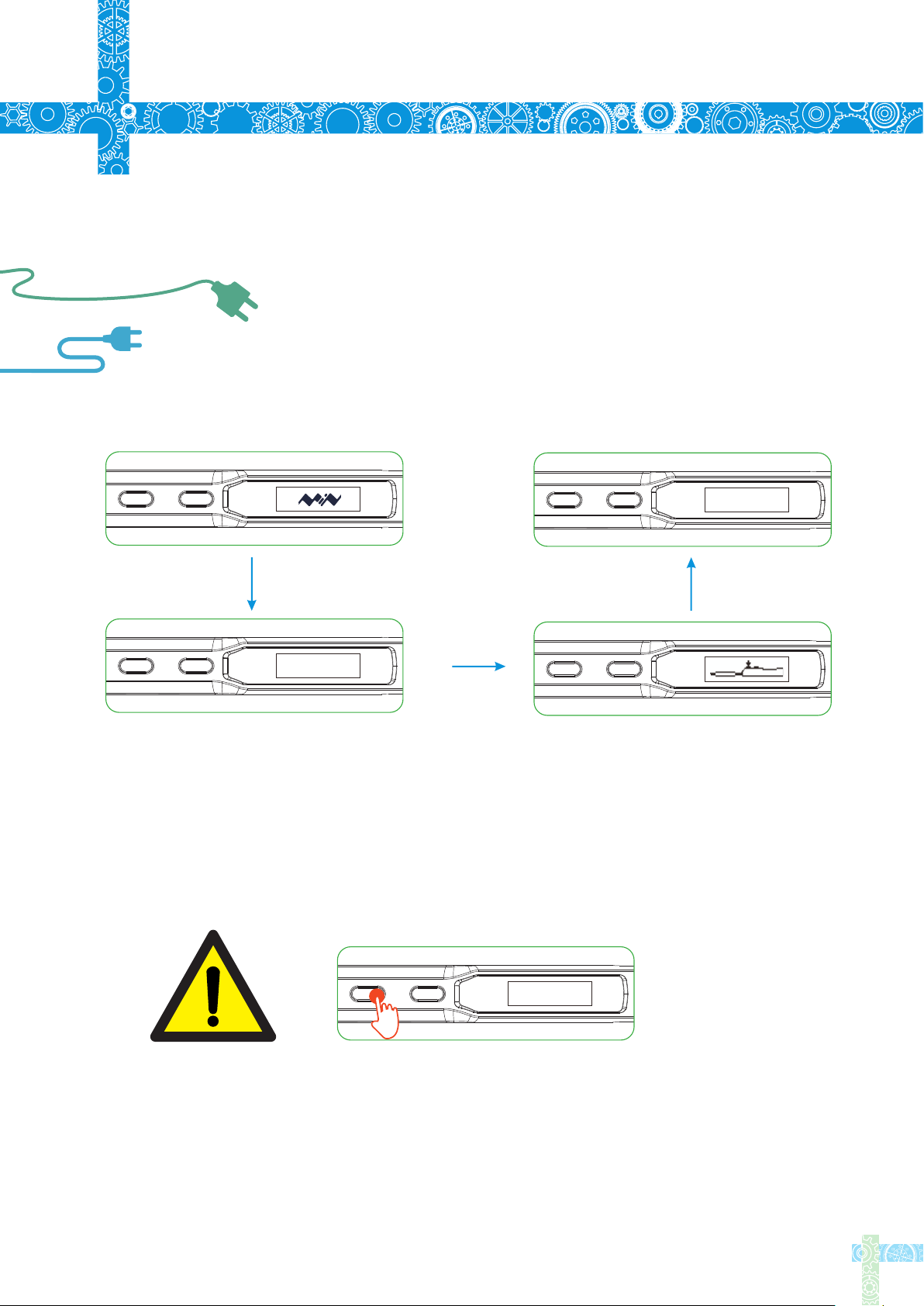

3

Power Adaptor Selection

Before connecting DC5525(12-24V)power

adaptor,check if the adaptor is in good

condition as below standard.

We would recommend the DYS404-190210V

(19V,2.1A)power supply as an accessory for

TS100.

Operation voltage

12V

16V

PowerElectric current

17W

30W

>1.4A

>1.9A

Time required to increased tip

temperature from 30℃ to 300℃

40s

20s

19V

24V

40W

65W

>2.1A

>2.7A

15s

11s

5

Page 8

4

4.1 TS100 Installation

Operation

1. Loosen the tip setscrew, insert the soldering tip connector and

tighten the screw;

2. Connect the ground wire to the ground wire setscrew ;

3. Connect the DC connector to TS100, connect the power cord and turn

on the power accordingly.

Note: If the screen displays "sen-errwhen it’s plugged, means the soldering iron tip is not properly

fixed, please re-install it properly.

4.2 Default Settings

Default temperature unit

"

℃

Default temperature

Sleep mode temperature

Adjustable temperature range

300℃(Default)

200℃(Default)

100℃~400℃(Max)

6

Page 9

4

4.3 Basic Control

4.3.1 Screen Display

Operation

Press

.

Ver2 01

When plugged into DC12-24V power adaptor ,TS100 will display its logo,

Version number and its standby screen in sequence.

DFU1.0

When plugging into DC 12-24V power adaport ,pressing Button A at the sametime

will enter DFU mode,"DFU1.0" will appear on OLED screen .

To exit DFU mode: unplug and plug in the device again without pressing

any button ,then it will enter standby mode.

7

Page 10

4

4.3 Basic Control

4.3.2 Automatic Calibration

Operation

Press

Press Button B in standby mode to enter the thermometer mode

In thermometer mode, press 2 buttons at the same

time to enter the calibration mode

V

Cal_V

Display shows when calibration is succedd.

24℃

Cal_X

Display shows when calibration failed

24℃

Long press any button to exit thermometer mode

Note: Calibration shall be done when TS100 in room temperature

8

Page 11

4

4.3 Basic Control

4.3.3 Heating up

Operation

Press

When pressing Button A in standby mode,TS100 will heat up

to preset temperature

300℃

When OLED displays as picture, means it’s ready for soldering

300℃

In operation mode, holding both buttons for 3 senconds will return to standby mode

9

Page 12

4

4.3 Basic Control

4.3.4 Temperature Adjustment

Operation

300℃

In standby mode, press Button A will enter

preset temperature

246℃200℃

Release Button A when display reads the

expected temperature, and TS100 will

automatically adjust to it.

300℃

Temperature down: In temperature adjusting

mode, hold Button A for at least 2 seconds,

until display reads the temperature you want.

300℃

Temperature up: In temperature adjusting

mode, hold Button B for at least 2 seconds,

300℃

Release Button B when display reads the

expected temperature, and TS100 will

automatically adjust to it.

until display reads the temperature you want.

10

Page 13

4

4.3 Basic Control

4.3.4 Temperature Adjustment

Operation

400℃

Note: When screen displays arrow pointing to left or right (◀or▶)

which means the adjustment has already reached its upper/lower

limit temperature, settings will not be saved when power is off

Remark: Maximum temperature: 400℃

Minimum temperature:100℃

298℃

When TS100 temperature stabilizes for 60 seconds,it will automaticall yenter feedback mode,

100℃

temperature status will feedback every 5-8 seconds

The last digit on the right end of the display shown as below

Arrows up-heating arrows down-cooling

horizontal lines- temperature

stabilizeb

11

Page 14

4

4.3 Basic Control

4.3.5 Sleep Mode

Operation

200℃

In operation mode, when leaving TS100 for more than 180

seconds( 3 minutes in Default) will trigger the sleep mode,

and temperature will automactically adjust to preset sleep

temperature.

300℃

When working, TS100 will restart to operation mode and temperature

will automatically heat up to preset temperauture(300°C in Default).

Press

In sleep mode, if it’s not being operated for longer than the IDLE_TIME

setting, TS100 will then enter the standby mode.

Note:IDLE_TIME can be adjusted( 6 minutes in Default).(Preset minimum

IDLE time: 5 minutes)

12

Page 15

4

4.4 System Parameters

Operation

ParameterExplanationDefault

T_Standby

T_Work

Wait_Time

Idle_Time

T_Step

Standby mode temerature

Operating temperature

Time from operation mode

to sleep mode

Time from sleep mode

to standby mode

When preset "1",each step

will progress in 1,2,5,25;

when preset 2-25, each step

will progress according to

settings

200℃

300℃

180

seconds

360

seconds

10

Adjustable

range

100℃~400℃

100℃~400℃

60~9999

seconds

300~9999

seconds

5-25

Turn_Off_v

TempShowFlag

ZeroP_Ad

When operation voltage is

lower than default voltage

TS100 will return to stadby

mode

Temperature unit selection

Temperature calibration

parameter, TS100 automatical

adjustment

Notice: Preset parameter(s) will be updated to TS100 after saved.

10V

℃

9-12V

0 ℃,1 is ℉is

No manual

setting required

13

Page 16

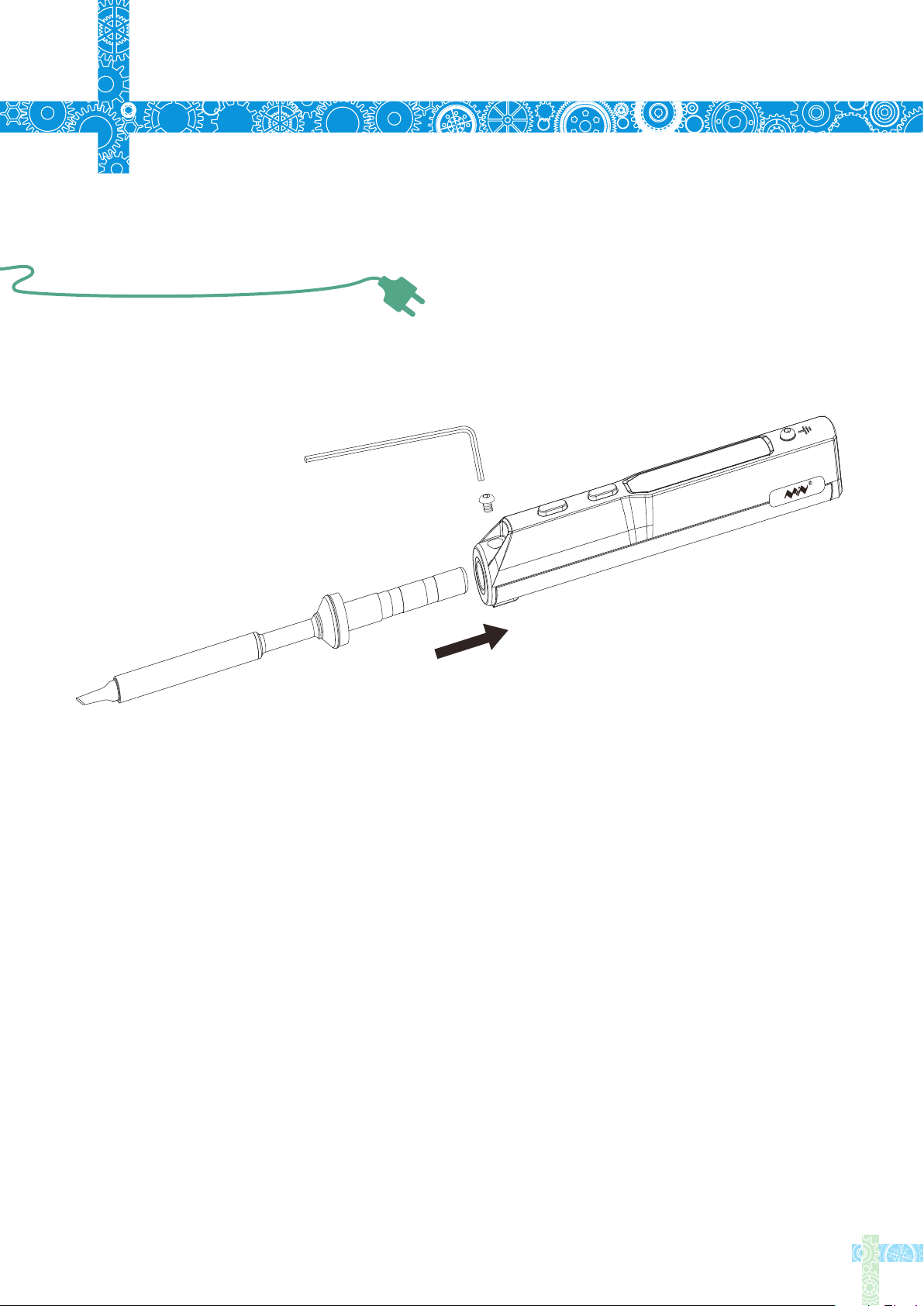

5

Soldering Iron Tip

5.1 Changing Soldering Tips

1.Unplug TS100 before changing.

2.Loosen the tip setscrew.

3.Pull out the tip, replace with another one.

4.Tighten the screw.

Note: When TS100 displays "sen-err", it means the soldering

iron tip is not installed properly.

14

Page 17

Soldering Iron Tip

5

5.2 Choosing Soldering Iron Tips

Note: Choosing the right tips will help you to work more efficient

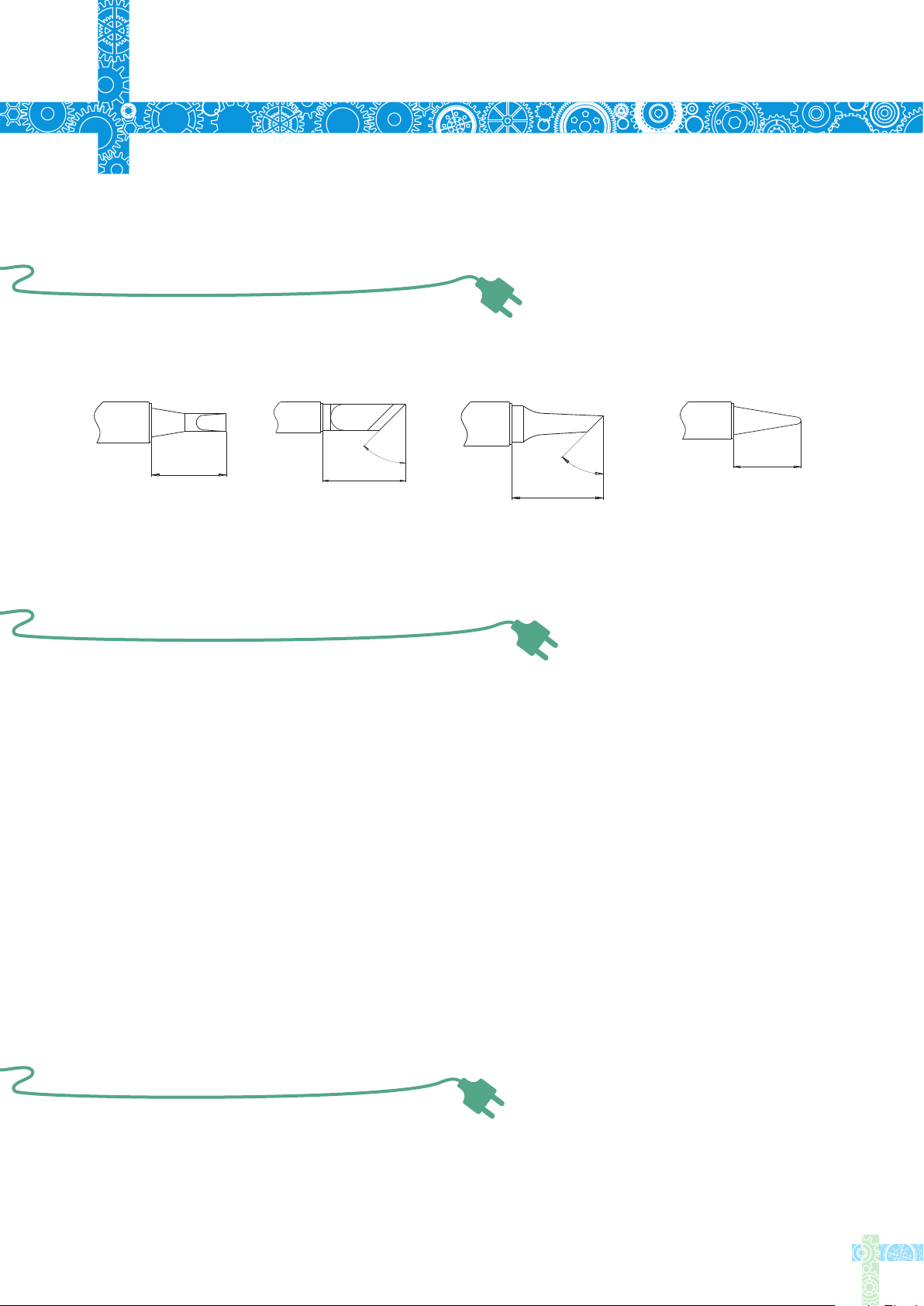

4

5

°

10.0

15.0

11.5

4

5

°

10.0

TS-D24TS-BC2TS-KTS-B2

5.3 Soldering Iron Tip Maintenance

(1) Before switching off, wipe the tip’s soldering side with some solder.

(2) Do not leave the tip in high temperature for long time, which may causeit burn out.

(3) Do not push too hard while soldering, which will damage the tip.

(4) Do not use rough material or files to clean the tip.

(5) If the tip surface is oxidized and makes it hard to apply solder on it, you may use

600~800 grit sandpaper to wipe the tip with Ethanol or Isopropyl alcohol, heat

up to 200℃ and apply solder immdeiately to avoid it oxidize again.

(6) Do not use Flux that contains high chlorine or acid, use only resin based flux.

5.4 Soldering Iron Tip Lifespan

Soldering iron tips lifespan is related to its maintenance (refer to 5.3)and use intensity.

15

Page 18

6

Trouble Shooting Guide

Problem 1:No Display

Problem 2:Every time when installing

a new tip, the temperature status display

random numbers

Problem 3:Soldering iron restart

automatically

Check:If the cable is broken

Check:Is there any data in USB mode

Check:If the screen needs to be replaced

Means the machine is checking status,which is

normal

Check 1:Is it properly plugged into the power source?

Check 2:Is the voltage too low?

(need to be set up in the config file)

Problem 4:Soldering iron is heating up

and cooling down simultaneously

Problem 5:OLED shows "Warning!"

Check 1:Is the tip first time in use?

Check 2:Is the power cord in loose or defective contact?

Check 3:Is the tip overheating?

Set the temperature in appropriate level

Check 4:Is the soldering iron clean?

refer to "Soldering iron tip maintenance"

Check 1:Is the TS100 overheating?

Is TS100 temperature higher than the maximun

operation temperature

When temperature is lower than maximum operation

temperature, the warning sign will disappear and it will

return to operation mode

16

Page 19

6

Trouble Shooting Guide

Problem 6:OLED displays"High-Vt"

Problem 7:OLED displays "Sen-err"

Problem 8: The tip doesn’t stick to the solder

Check:Is the voltage too high?(over 24V)

Check 1:Is the soldering iron installed propely?

Check 2:If check 1 passes, then replace the

soldering iron tip

1.Tip temperature is over 400℃

2.The soldering side of the tip is not applied

with solder properly

3.Lack of flux during operation

4.Rub the tip against dry or high sulfur sponge

or fabric

5.Tip touched organic material like plastic,silicone

oil or other chemicals

Problem 9:TS100 return to standby mode

during operation

6.Using impure solder or solder that contains low

proportion of tin

Checl:Is the voltage lower than default(10V)

Wait until voltage recovers , it could work

normally when the voltage is over 10V

17

Page 20

Technical Support

7

7.1 Standard service

1 year of warranty will be provided for one year, if the damage was not caused by false

manipulation by the user.Plesae contact your retailer for warranty detail

Tips are consumables, once it’s used, no replacement will be provided.

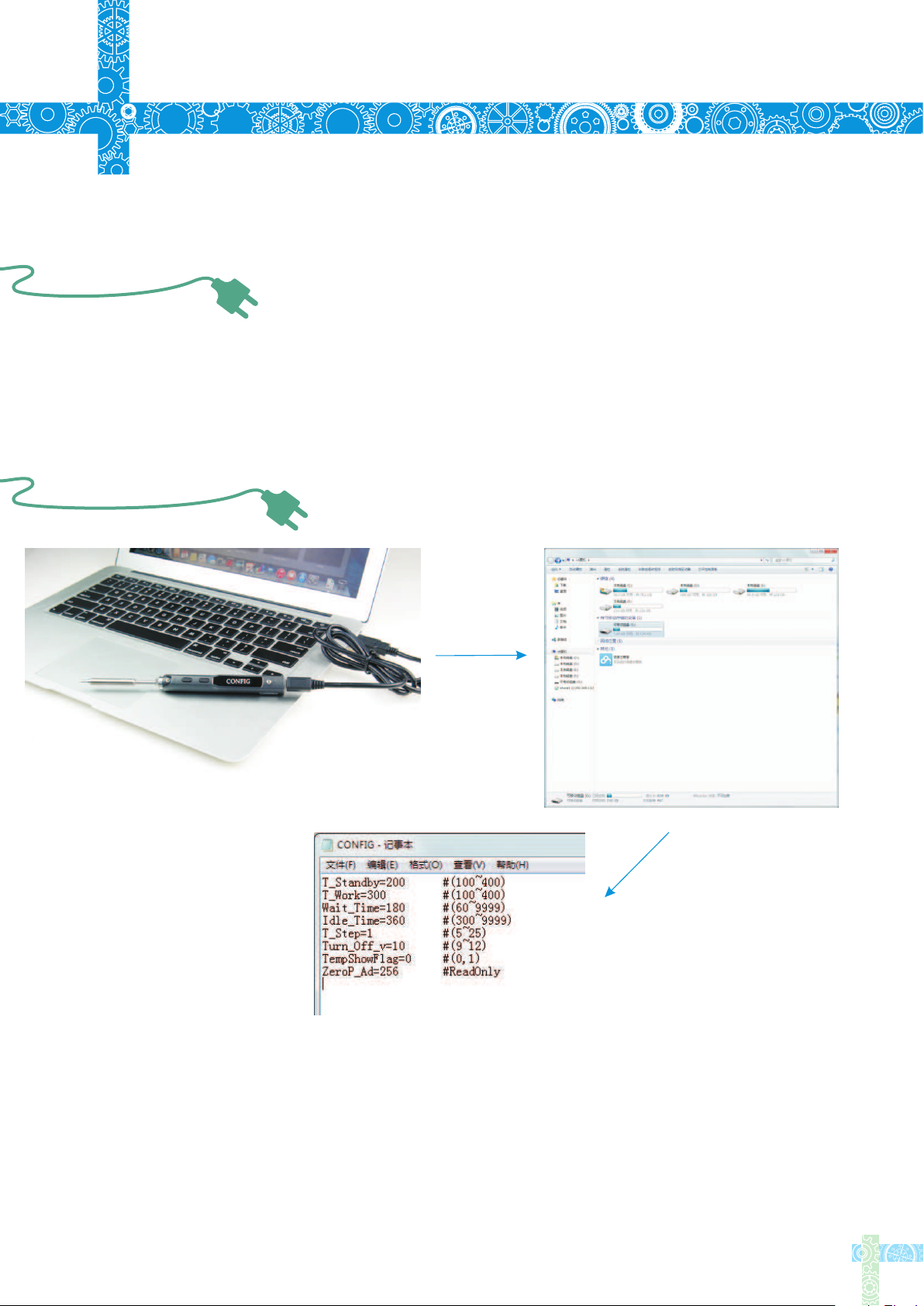

7.2 Default Parameter Setting

Connect TS100 to your PC with USB data cord, OLED will display "CONFIG"

and means it's in setting mode. Open config.txt file from the USB drive, set the

default parameters.

18

Page 21

7

Technical Support

7.3 Firmware Update

1.Visit www.miniware.com.cn and download the latest TS100 firmware to your PC.

2.Connect TS100 to your PC with USB data cord,meanwhile,press TS100’s Button A

to enter DFU mode once a “DFU1.0” notice appears on the screen. A virtual disk with

8 serial numbers will appear on your PC.

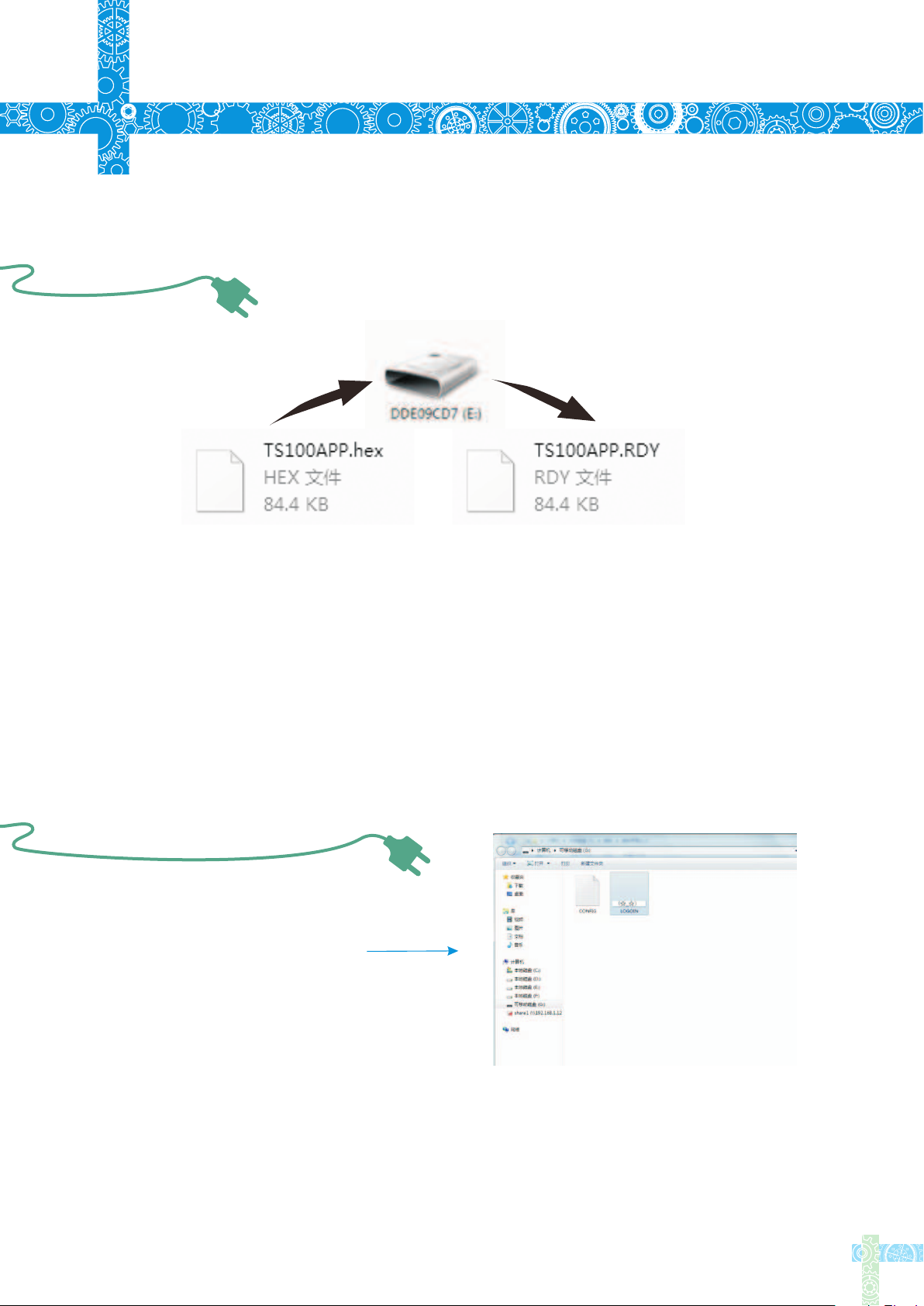

3.Copy the hex firmware to the root directory of that disk. When the extension of the

firmware changes from “hex” to “rdy”, disconnect USB and the firmware is upgraded.

7.4 Changing Boot Up Screen

Create your own 96*16 pixel

image save as BMP in single

color bitmap

Copy the file to soldering iron’s USB

drive, change file name to "LOGOIN"

Note:When the "LOGOIN.BMP" exists in the USB drive, the boot up logo will be

using the file, if the file doesn’t exist, it will be using the default logo instead

19

Page 22

8

8.1 Disposal

Legal Statements

Do not dispose this product with domestic waste

Handling and recycle:Disposal of the product shall be

manipulated according to laws and regulations in your

area.

8.2 Statement of Fulfilling FCC Standard

This device fulfills part 15 of the FCC regulations Device must fulfill below 2

conditions:

(1) Device must not generate interference

(2) Device must be able to resist any interferences

on it, including interferences that could cause dangerous

manipulation

8.3 Statement of Fulfilling CE Standard

This is a trademark of Europe Union

This product with CE logo on it fulfills related

Euro Union laws and regulations

20

Loading...

Loading...