Page 1

Specifications

®

Cat

TH407

Telehandler

Engine

Engine Model (Standard) Cat® C4.4 Mechanical DITAAC

Engine Model (Optional) Cat® C4.4 Electronic DITAAC-ACERT

Gross Power (Standard) 74.5 kW 100 hp

Gross Power (Optional) 93.1 kW 125 hp

Maximum Torque (Standard) 410 Nm at 1400 rpm

Maximum Torque (Optional) 496 Nm at 1400 rpm

Bore 105 mm 4.13 in

Stroke 127 mm 4.99 in

Displacement 4.4 L 268.5 in

3

Weights

Operating Weight 7700 kg 16,980 lb

Operating Specifications

Rated Load Capacity 3700 kg 8,150 lb

Maximum Lift Height 7.30 m 24 ft

Maximum Forward Reach 3.76 m 12 ft 3 in

Top Travel Speed 40 kph 25 mph

Capacity at Max Height 1800 kg 4,000 lb

Capacity at Max Reach 1500 kg 3,300 lb

Turning Radius over Tires 3.75 m 12 ft 4 in

Service Refill Capacities

Fuel Tank 150 L 39.63 gal

Hydraulic Tank 90 L 23.78 gal

Tires

Standard 15.5/80-24 16PR

Optional 400/80 R24 Power CL

440/80 R24 Power CL

460/70 R24 XMCL

500/70 R24 XMCL

15.50 x 25 SGL

Brakes

• Service brakes are inboard wet disc brakes on front axle

• Parking brakes are mechanical on front axle

Hydraulic System

Maximum System Pressure 250 bar 3,625 psi

™

Maximum Pump Flow 150 L /min 39.63 gal/min

Pump Type Variable displacement

load sensing axial piston pump

Auxiliary Hydraulic Supply 80 L/min 21.13 gal/min

(Intermittent)

Auxiliary Hydraulic Supply 60 L/min 15.85 gal/min

(Continuous)

• Auxiliary Hydraulic Circuit used for all attachments

equipped with cylinders or other hydraulic components.

Consists of valves, controls, and hydraulic lines.

Transmission Speeds

Forward — 1 7 kph 4.3 mph

Forward — 2 12 kph 7.45 mph

Forward — 3 21 kph 13 mph

Forward — 4 32 kph 19.8 mph

Forward — 5 40 kph 25 mph

Reverse — 1 7 kph 4.3 mph

Reverse — 2 12 kph 7.45 mph

Reverse — 3 21 kph 13 mph

Boom Performance

Boom Up 7.5 Seconds

Boom Down 5.1 Seconds

Tele In 4.8 Seconds

Tele Out 5.7 Seconds

Tilt Forward (dump) 3 Seconds

Tilt Backward 3 Seconds

Combined — Up and Out 11.5 Seconds

Combined — Down and In 6.6 Seconds

Drawbar Pull 83.4 kW 8500 kg 18,740 lb

Drawbar Pull 87.3 kW 8900 kg 19,620 lb

Instruments

• Engine speed, boom angle, machine speed, operation hours,

% of continuous flow selected, gear selected and direction

Page 2

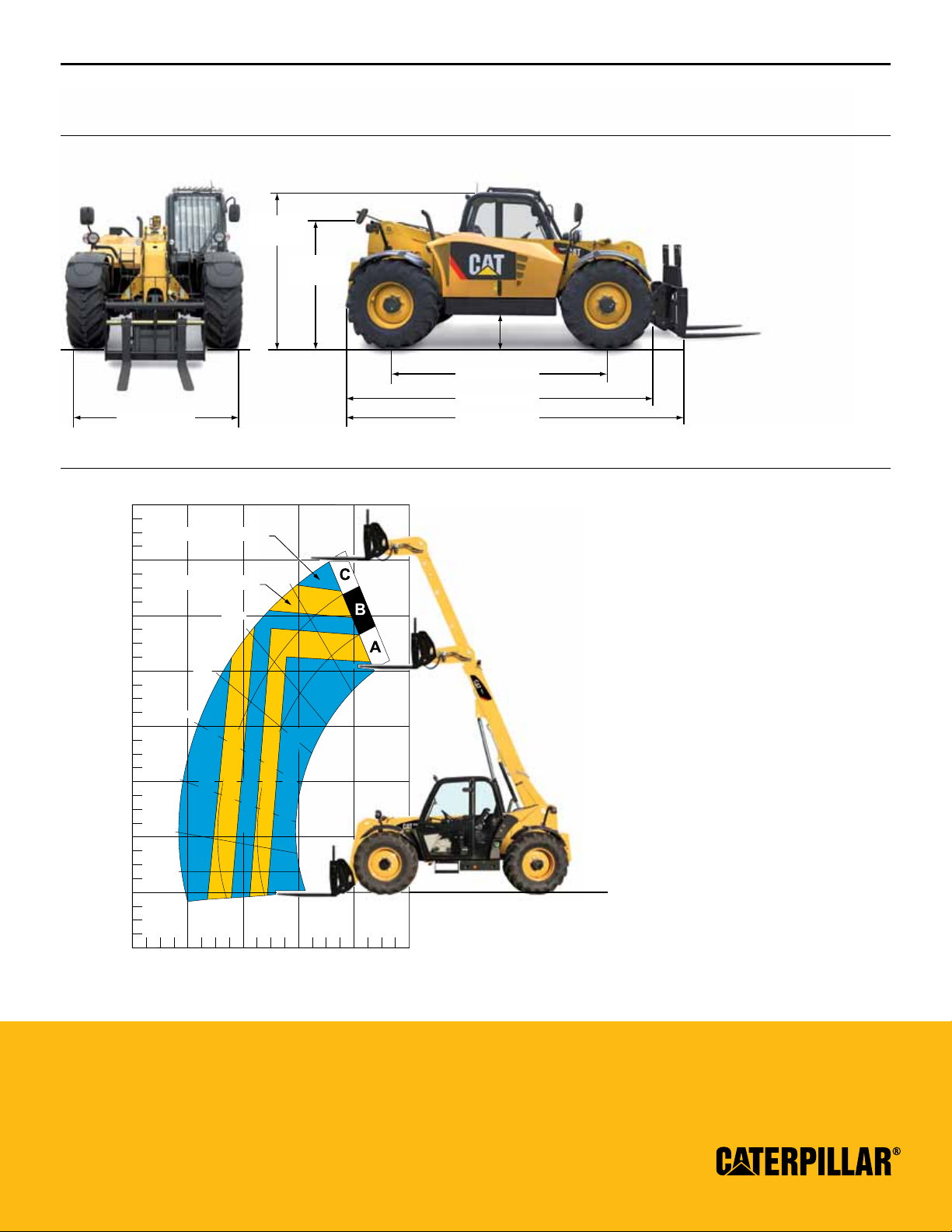

8.5 m (28 ft)

7.3 m (24 ft)

6.1 m (20 ft)

4.9 m (16 ft)

3.7 m (12 ft)

2.4 m (8 ft)

1.2 m (4 ft)

0 m (0 ft)

-1.2 m (-4 ft)

3.7 m

(12 ft)

4.9 m

(16 ft)

2.4 m

(8 ft)

1.2 m

(4 ft)

3000 kg (6,600 lb)

3700 kg (8,150 lb)

2000 kg (4,400 lb)

1500 kg (3,300 lb)

2500 kg (5,500 lb)

60°

50°

40°

30°

20°

10°

0°

1814 kg (4,000 lb)

2000 kg (4,400 lb)

TH407 Telehandler

Dimensions

All dimensions are approximate.

2400 mm(94.48 in)

Load Chart and Dimensions

238 5 mm

(93 .89 in)

1838 mm

(72.36 in)

409 mm

16.10 in

305 0 mm(120.07 in)

4679 mm(184.21 in)

5153 mm(2 02.87 in)

8.5 m (28 ft)

7.3 m (24 ft)

6.1 m (20 ft)

4.9 m (16 ft)

3.7 m (12 ft)

2.4 m (8 ft)

1.2 m (4 ft)

0 m (0 ft)

-1.2 m (-4 ft)

1800 kg (4,000 lb)

2000 kg (4,400 lb)

30°

20°

10°

0°

4.9 m

(16 ft)

(12 ft)

50°

40°

2000 kg (4,400 lb)

1500 kg (3,300 lb)

3.7 m

2.4 m

(8 ft)

67.5°

60°

3700 kg (8,150 lb)

3000 kg (6,600 lb)

2500 kg (5,500 lb)

1.2 m

(4 ft)

0 m

(0 ft)

-1.2 m

(4 ft)

IMPORTANT

Rated lift capacities shown are with machine

equipped with carriage and pallet forks. The

machine must be level on a firm surface with

undamaged, properly inflated tires. Machine

specifications and stability are based on rated

lift capacities at specific boom angles and boom

lengths. (If specifications are critical, the proposed

application should be discussed with your dealer.)

DO NOT exceed rated lif t capacity loads, as unstable

and dangerous machine conditions will result.

DO NOT tip the machine forward to determine

the allowable load.

Use only JLG approved attachments with proper

material handler model/attachment load capacity

charts displayed in the operator’s cab. OSHA

requires all rough terrain forklif t operators be

trained according to OSHA 29 CFR 1910.178 (1).

Due to continuous product improvements, machine

specifications and/or equipment changes may

be made without prior notification. This machine

meets or exceeds ANSI/ITSDF B56.6-2005 as

originally manufactured for intended applications.

For more complete information on Cat products, dealer services, and indus try solutions, visit us on t he web at

www.cat .com

© 20 09 Caterpillar

Printed in U.S.A.

All rights reserved.

CAT, CATERPILL AR, their respective logos, “Caterpillar Yellow” and t he POW ER EDGE trade dress , as well as

corporate and product identity used herein, are trademarks of Ca terpillar and may not be used w ithout permission.

AEHQ5966-05 (10-2009)

Loading...

Loading...