Page 1

Engine

Engine Model Cat®6.6 ACERT™

Net Power – SAE J1349 128 kW 172 hp

Net Power – ISO 9249 134 kW 180 hp

• Caterpillar®engine with ACERT™ Technology –

EPA Tier III, EU Stage III Compliant.

Buckets

Bucket Capacities 2.3 - 3.0 m

3

3.0 - 4.0 yd

3

Weights

Operating Weight 15 059 kg 33,190 lb

• For 2.8 m3(3.65 yd3) general purpose bucket with

standard 20.5-R25 tires.

Operating Specifications

Static Tipping Load, Full Turn 10 076 kg 22,207 lb

• For 2.8 m3(3.65 yd3) general purpose bucket with

standard 20.5-R25 tires.

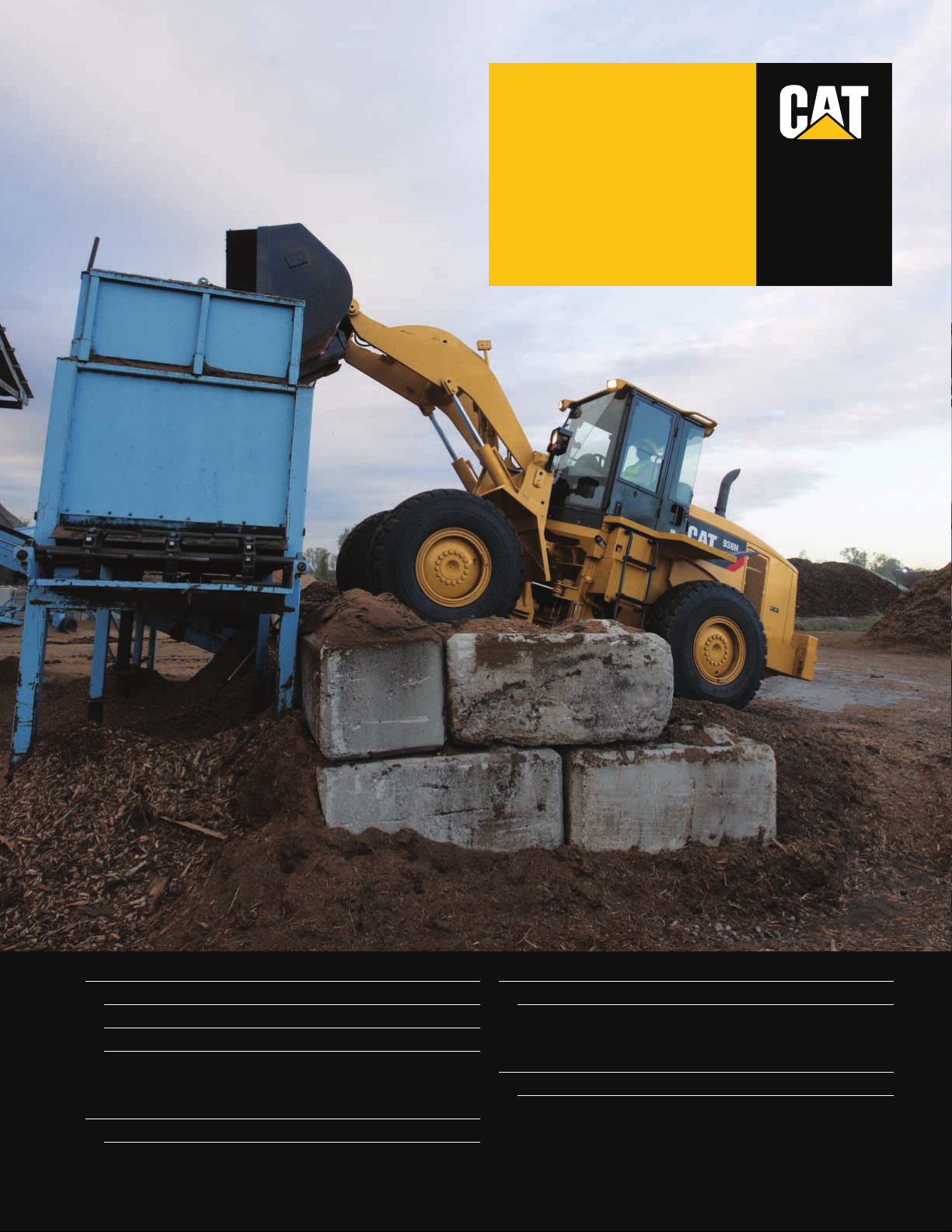

938H

Wheel Loader

®

®

Page 2

2

938H Wheel Loader

Setting the standard for wheel loader productivity, durability, versatility and comfort.

OPERATOR COMFORT

• Easy Entry and Exit

• Excellent Visibility

• Adjustable Machine Parameters to

Match Operator Preference pg. 14

✔

PRODUCTIVITY

• Improved Cycle Times with LoadSensing Hydraulic System

• Locking Differentials Provide

Superior Tractive Effort in Poor

Underfoot Conditions

• Constant Net Horsepower Through

the Operating Range pg. 8

✔

✔

DURABILITY

• ACERT™ Technology Maintains

Performance, Efficiency and Durability

While Meeting Emissions Regulations

• Heavy Duty Components Stand Up to

All Operating Conditions

• Strong, Solid Structures Built to Last

pg. 6

✔

RELIABILITY

• Proven Components and Technology

• Diagnostic Systems Monitor Product

Health to Ensure Reliability

• Unmatched Parts Availability and

Dealer Support pg. 4

Page 3

✔ New Feature

3

✔

SERVICEABILITY

• Service Centers for Convenient

Maintenance

• Exceptional Ground-Level Access

to Service Points

• Monitoring Systems and Dealer

Support Reduce Unexpected

Downtime pg. 12

✔

OWNING AND OPERATING COSTS

• Superior Maintenance

• Electronic Systems Monitor Product

Health and Performance

• Complete Dealer Support pg. 10

VERSATILITY

• Special Machine Arrangements for

Unique Applications

• Large Variety of Cat®Work Tools

pg. 9

Page 4

• Validated components and

technology

• Electronic systems monitor vital

machine components

• Excellent uptime from the best

dealer support network in the

industry

• Unmatched genuine Cat parts

availability

PROVEN RELIABILITY. The 938H features

many of the components designed and

proven in various Caterpillar products

– all contribute to the reliability of

the 938H:

• Frames

• Axles

• Countershaft powershift

transmission

• Individual component cooling

system

• Cab

ACERT™ TECHNOLOGY. Since March

2003, ACERT Technology has been

proving itself in on-highway trucks. More

recently it has proven itself again in field

tests of off-highway equipment.

This technology allows Cat engines

to meet durability and reliability

expectations without sacrificing

performance.

CATERPILLAR DESIGNED COMPONENTS.

Components used to build Cat Wheel

Loaders are designed and manufactured

to Caterpillar quality standards to

ensure maximum performance even

in extreme operating conditions.

Engine electronic control modules and

sensors are completely sealed against

moisture and dust. Deutsche connectors

and electrical wire braiding ensure that

electrical connections resist corrosion

and premature wear.

Hoses are engineered and manufactured

for high resistance to abrasion, excellent

flexibility and easy installation and

replacement.

Caterpillar

®

couplings use o-ring face

seals to provide positive sealing for

durable leak-free connections.

Heavy duty components reduce the risk

of leaks, corrosion and premature wear,

increasing uptime and helping to protect

the environment.

MONITORING PROGRAMS. Monitoring

product health is key to maintaining

reliability of any equipment. Many

programs are available on the 938H

to help you track machine health.

Caterpillar Messenger Display.

The 938H is equipped with the

Caterpillar Messenger Display that

keeps watch over the health of your

loader while providing real-time

diagnostic feedback. In the event of

a system malfunction, Messenger will

provide the operator with a description

of the occurrence, and if serious enough,

sound an audible alarm in addition to

a flashing indicator light.

4

The Cat 938H – Tested and Proven – Ready to Work

RELIABILITY

Page 5

Product Link. Standard equipment on

the 938H, this state-of-the art satellite

technology enables Caterpillar dealers

and customers to keep in touch with

their machines. The system provides

a two-way information flow between

machine on-board systems and Caterpillar

dealers/customers via the Cat Dealer

Website and EquipmentManager.

EquipmentManager. EquipmentManager

is a web-based application that uses key

indicators from your equipment such

as hours, location and diagnostic codes

and combines it with powerful tools

like mapping, maintenance and repair

scheduling, and troubleshooting

instructions. This application enables

quick identification of actions required

to maximize your equipment uptime

and control owning and operating costs.

S•O•SSMServices. Keep minor repairs

from becoming major ones and avoid

complete failures. By regularly taking

samples from the ports provided, your

Cat dealer tracks wear of components

and parts, oil performance, and oil

condition and uses that data to predict

wear-related problems before they

happen. Often a simple adjustment or

replacement of a part, based on S•O•S

reports, can keep a small problem from

turning into a major repair – allowing

your machine to be running when

you need it, not waiting in the shop

for service.

DEALER SUPPORT. The Caterpillar global

network of independently-owned dealers

is the best in the world at providing

support to keep your loader up and

running. Known for parts availability

and technical expertise, Cat dealers

are partners in your business.

Service Capabilities. Cat field service

technicians have the experience and

tools necessary to service your loader

on site. Field service trucks are fully

loaded with state-of-the-art tools

and diagnostic equipment as well as

specifications and schematics for every

Cat machine. Technical experts at the

dealership and Caterpillar are available

to provide assistance to field service

technicians when needed.

When on-site repair isn’t enough,

Cat dealerships are fully-equipped

to service your loader quickly.

Parts Availability. Caterpillar provides

an unsurpassed level of personalized

service for your wheel loader. With parts

distribution centers throughout the world,

most parts can be delivered in 24 hours.

Remanufactured Parts. Cat engines

and major components are designed to

be remanufactured and provide multiple

life cycles. The Cat Reman program

is more extensive than most rebuild

programs. Components are actually

remanufactured in the factory to

original specifications with necessary

product updates.

Strict reuse guidelines and unparalleled

quality control ensure that reman products

provide the reliability and durability

that you expect from Caterpillar. Reman

products are stocked in distribution

centers around the world and are ready

to install to minimize downtime,

maintain productivity and profitability.

5

Page 6

• ACERT™ Technology maintains

engine performance, efficiency and

durability while reducing emissions

• Heavy duty components withstand

all operating conditions

• Strong, solid structures are built

to last

Cat C6.6 ACERT. The Cat C6.6 is a

6.6 liter (403 in3) displacement, in-line

six cylinder engine. The C6.6 utilizes

ACERT Technology, a series of

Caterpillar engineered innovations that

provides advanced electronic control,

precise fuel delivery and refined air

management, resulting in outstanding

performance and lower emissions.

The C6.6 with ACERT Technology

offers a compact design with big, heavy

duty engine features for outstanding

durability, reliability and performance.

The C6.6 incorporates a new cross flow

cylinder head design, 4 valve head and

an ADEM A4 electronic controller.

The C6.6 also features a proven cylinder

block, pistons and crankshaft.

Electronic Control ADEM A4.

The Advanced Diesel Engine

Management – Electronic Control

Module consistently monitors important

engine conditions and functions. It uses

sensors throughout the engine to regulate

fuel delivery and all other engine systems

that require input to manage load and

performance. The ADEM A4 controller

is the brain behind engine responsiveness,

self-diagnosis, controlling emissions

and fuel economy.

Air Management. Air management

is a key concept in optimizing engine

performance and controlling emissions.

Engines must breathe clean cool air in

order to perform. To aid this, the C6.6

uses a turbocharger fitted with a smart

waste gate to give precise and reliable

control of the boost pressure. A new

cross-flow design in the cylinder head

facilitates air movement, while tighter

tolerances between the piston and

cylinder wall reduce blow by gases.

Fuel System. Through multiple injection

fuel delivery, fuel is introduced in

the combustion chamber in a number

of precisely controlled microbursts.

Injecting fuel in this way allows for

precise shaping of the combustion cycle

while reducing engine sound levels

Fuel Pump. The C6.6 uses an oillubricated high-pressure fuel pump

to feed a common fuel rail. By using

an oil-lubricated fuel pump, the C6.6

has been designed to be more tolerant

of alternative fuels.

Fuel Priming Pump. An electrical fuel

priming pump is located between the

fuel tank and the combined water

separator/primary fuel filter. The electric

priming pump eliminates the need to

pre-fill or manually prime filters after

a change, thus reducing contamination

and improving injector life.

Engine Idle Management. The Engine

Idle Management System (EIMS)

maximizes fuel efficiency and provides

flexibility in managing idle speeds

for specific application requirements.

Four idle control speeds are available.

POWERSHIFT TRANSMISSION.

The 938H continues to use powershift

transmission technology proven on

previous series. The countershaft

powershift transmission features heavyduty components to handle the toughest

applications. Built-in electronic controls

enhance productivity and durability.

Control Throttle Shifting. Control Throttle

Shifting regulates engine speed during

high-energy directional and gear changes

for smoother shifting and longer

component life.

Electronic Clutch Pressure Control.

Electronic Clutch Pressure Control

(ECPC) system modulates clutches

individually to improve shift quality,

component life and operator comfort.

Adjustment is simplified with all

solenoid valves externally mounted

on top of the transmission housing.

AXLES. The 938H axles are designed by

Caterpillar for durability in all operating

conditions. The front axle is rigidly

mounted to the frame to support the

weight of the wheel loader and withstand

internal torque loads as well as external

forces encountered throughout operation.

The rear axle is designed to allow ± 12°

oscillation. All four wheels remain on

the ground over uneven terrain providing

excellent stability and traction.

6

Built Strong and Tough

DURABILITY

Page 7

Integrated Braking System. The Cat

exclusive Integrated Braking System

reduces axle oil temperatures and

improves transmission neutralizer

smoothness. IBS has a direct impact

on durability of the axles and brakes

especially in applications involving

long distances and/or heavy braking.

RADIATOR. Brazed aluminum

construction provides a stronger joint

for maximum durability and resistance

to leaks. The 6-fins-per-inch design

decreases the chance of blockage

and plugging.

STRUCTURES. The articulated frame

design of the 938H features a durable

plate engine frame and two plate loader

tower that is robotically welded.

Robotic welding creates frame joints

with deep plate penetration welds and

excellent fusion for maximum strength

and durability.

Engine End Frame (EEF). The 938H uses

a proven solid plate engine end frame

which provides a strong, rigid structure

that resists twisting and evenly distributes

impact loads. The result is an extremely

solid mounting platform for the engine,

transmission, axle, ROPS and other

accessories.

Hitch. The distance between the upper

and lower hitch plates is an important

contributor to machine performance

and component life. The Caterpillar

hitch design provides excellent load

distribution and bearing life. Both the

upper and lower hitch pins pivot on

double tapered roller bearings –

improving durability by distributing

both vertical and horizontal loads over

a larger surface area. The wide opening

also provides excellent service access.

Non-Engine End Frame (NEEF).

The non-engine end frame provides a

solid mounting base for the front axle,

lift arms, lift cylinders and tilt cylinder.

The fabricated, two-plate loader tower

design reduces material packing under

the lift cylinders while absorbing the

forces associated with loading, twisting

and material handling.

Counterweight. The two-piece

counterweight is integrated into the

938H design and provides added

protection for the lights by incorporating

them into the top of the structure.

Linkage. The 938H linkage is a singletilt Z-bar design. Z-bar linkage generates

excellent breakout force and good rack

back angle for better bucket loading

and load retention.

Lift arms are solid steel, providing

superior strength with an excellent front

end viewing area. The proven design

offers excellent dump clearance

and reach.

7

Page 8

• Hydraulics are easy to control with

low effort

• Differential locks provide maximum

traction in varying underfoot

conditions

• Constant net horsepower across

various applications

• Standard and optional features that

maximize productivity

LOAD SENSING HYDRAULICS. The 938H

features a load sensing hydraulic system

that supplies flow and pressure for the

implements only upon demand, and only

in the amounts necessary to perform the

needed work thus providing a more

efficient loader.

With the new S3PC Priority Proportional

Pressure Compensation Valve, implement

control is improved over the previous

system – raise/lower and rack back/dump

can be operated simultaneously.

Operators will notice enhanced ease

of operation, more rimpull into the pile

and a 16% increase in lift force.

NEW! DIFFERENTIAL LOCK. Maximize

productivity with the new hydraulic

locking front differential. This standard

feature provides operators with the

confidence to maneuver through poor

underfoot conditions with ‘on the fly’

engagement.

A Caterpillar exclusive, the optional

automatic front/rear locking differential

collects input from sensors throughout

the loader and adapts tractive effort

to meet operating requirements.

CONSTANT NET HORSEPOWER.

On many competitive machines, gross

horsepower is constant, meaning that

net engine power available for actual

work will vary based on demands made

from parasitic sources, such as air

conditioning or cooling fans.

The Cat C6.6 engine is electronically

configured to provide constant net

horsepower at full parasitic load

enhancing productivity and improving

fuel efficiency.

On-Demand Fan. With electronic control

of the variable speed on-demand fan,

temperature levels of the engine coolant,

transmission oil, hydraulic oil and air

inlet manifold are constantly monitored.

This data is used to control and maintain

fan speed at the level necessary to

maintain normal system temperatures.

Controlled fan speed improves fuel

efficiency, lowers noise levels and

reduces radiator plugging.

Isolated Cooling System. The 938H

cooling system is isolated from the

engine compartment by a non-metallic

shield. The hydraulically driven, variable

speed fan draws in clean air from the

rear of the machine and exhausts it out

the sides and top of the hood. The end

results are optimal cooling efficiency,

increased fuel efficiency, less radiator

plugging and reduced operator sound

levels.

COUNTERSHAFT POWERSHIFT

TRANSMISSION. The electronic

countershaft powershift transmission

with automatic shift capability is

designed and built by Caterpillar.

The very responsive, full-power speed

and directional changes provide excellent

cycle times and productivity.

Fuel Economy Mode. Match transmission

shifting patterns to machine application

requirements. The Fuel Economy Mode

(within Messenger) provides operators

with the ability to choose between three

different shift modes in order to maximize

shift quality and fuel efficiency.

RIDE CONTROL. The optional Ride

Control System improves ride,

performance and load retention when

traveling over rough terrain. Operators

gain confidence moving at higher

speeds in load and carry operations

decreasing cycle times and increasing

productivity.

AUTOLUBE. The optional Caterpillar

Autolube System provides precise,

automatic lubrication of pins and

bushings – during loader operation.

Automatic lubrication reduces time spent

on daily maintenance and downtime for

unplanned repairs due to inadequate

greasing – improving productivity.

8

PRODUCTIVITY

Work Smart and Move More

Page 9

• A variety of buckets and work tools

for many applications

WORK TOOLS AND QUICK COUPLERS.

A variety of buckets, work tools and

couplers are available from the factory

or from your Caterpillar dealer to

customize the 938H for your operation.

Quick Couplers. Quick couplers provide

unmatched versatility for wheel loaders.

Buckets and work tools can be changed

in seconds without leaving the cab for

maximum productivity.

General Purpose Buckets. General

Purpose Buckets provide good all-around

performance for stockpiling, rehandling,

excavating and bank loading. A heavy

duty General Purpose Bucket can be

used for more aggressive applications.

Material Handling Buckets. The Material

Handling Bucket is a flat-floor bucket

used for handling stockpiled materials

such as aggregates or other easy-to-load

materials requiring moderate breakout

force.

Coal Buckets. Coal Buckets maximize

productivity in loading and stockpiling

coal and other materials of similar

density.

Waste Buckets. Waste Buckets are

designed for long life in the harsh world

of refuse applications. This high-capacity

bucket is well-suited for loading, sorting

and other transfer station work.

Woodchip and Clean-Up Buckets.

Woodchip and Clean-up Buckets are

available for forestry and millyard

applications.

Multi-Purpose Buckets. Multi-Purpose

Buckets have a unique four-way action

that can load, strip topsoil, bulldoze,

clamp pipe or large chunks of concrete,

clean up debris, and many other tasks.

Side Dump Buckets. Side Dump

Buckets dump both to the front and to

the side of the machine, an advantage

when working in tight quarters, such

as street work, tunnel construction

and building levees.

Forks. Logging, Millyard and Pallet

Forks are available for forestry and

material handling applications.

Loader Rakes. Loader Rakes are

durable, high-capacity tools for land

clearing and site clean up. Rakes are

available with or without top clamps

and in quick coupler and pin-on models.

Material Handling Arms. Material

Handling Arms move pipe, concrete

blocks, highway dividers and other

construction materials quickly and

precisely.

Ground Engaging Tools (GET).

Several GET options are available from

Caterpillar for 938H buckets. Reversible

bolt on cutting edges (BOCE) as well

as bolt on teeth and segments provide

maximum performance in various

materials.

9

VERSATILITY

Built For Your Operation

Page 10

• Sight gauges, grouped maintenance

points, easy engine access, ecology

drains, maintenance-free batteries –

all simplify daily maintenance

• Electronic monitoring systems track

product health to avoid unscheduled

costly repairs

• Unsurpassed parts availability

reduces downtime

• Excellent resale value provided by

genuine Cat quality, outstanding

dealer service and unmatched dealer

support programs

• Caterpillar Financial Services and

Cat dealers understand your business

ENGINE IDLE MANAGEMENT SYSTEM.

The Engine Idle Management System

(EIMS) maximizes fuel efficiency

and provides flexibility in managing

idle speeds for specific application

requirements. Four idle control

speeds are available.

Hibernate Mode. Idle speed drops after

a preset time to provide lower fuel

consumption, reduced sound levels

and lower emissions.

Work Mode. Adjustable working idle

speeds according to customer preference

and operating conditions.

Warm-Up Mode. Keep the engine at a

consistent temperature in cold conditions.

Low Voltage Mode. Prevent battery

drain due to high electrical loads from

attachments and accessories.

MAINTENANCE. Proper maintenance

of your wheel loader can help control

expenses and lower your owning and

operating costs. The 938H provides

unmatched serviceability by offering:

• Hydraulic service center

• Electric service center

• Airborne debris-resistant, swing-out

grill provides more efficient airflow

• Well-protected, easily visible sight

gauges

• Ground level maintenance points

• Easy access to engine compartment

• Ecology drains for simple and clean

fluid drainage

• Brake wear indicators for ease of

inspection

• Maintenance-free batteries

• Extended oil and filter change

intervals

MONITORING SYSTEMS. Monitoring

product health simplifies maintenance

planning and reduces costs.

Messenger. Messenger offers the

comfort of providing real-time, visual

feedback on engine and machine

operating conditions. It displays

information on diagnostic codes,

maintenance and system parameters.

Product Link. With Product Link

customers and dealers can remotely

obtain machine diagnostics. The system

provides updates on service meter

hours, machine health and equipment

location.

EquipmentManager. EquipmentManager

uses key indicators from equipment such

as hours, location and diagnostic codes

and combines them with powerful tools

like mapping, maintenance and repair

scheduling as well as troubleshooting

instructions. This application enables

quick identification of actions required

to maximize equipment uptime and

control owning and operation costs.

Machine Security System. Stolen

equipment equates to lost production

and increased costs. Eliminate machine

theft and unauthorized usage with the

Cat Machine Security System (MSS).

MSS is integrated into the machine’s

electronic system and can protect most

brands of equipment by requiring a

uniquely coded key to start the machine.

S

•O•

S Services. Managing component

life and machine availability decreases

downtime while improving your

productivity and efficiency. S•O•S

Services can help you do that. Regular

fluid sampling is used to track what

is going on inside the equipment.

Wear-related problems are predictable

and easily and quickly repairable.

Maintenance can be done according

to your schedule, resulting in increased

uptime and flexibility in maintenance

and repair before failure.

10

The 938H – Best Value for Your Operation

OWNING AND OPERATING COSTS

Page 11

PARTS AVAILABILITY. Caterpillar

provides an unsurpassed level of

personalized service for your wheel

loader. With parts distribution centers

worldwide, most parts can be delivered

in 24 hours. Easy access to parts

reduces downtime.

RESALE VALUE. Owning quality

equipment is a very important factor in

maintaining resale value. Cat not only

supplies quality equipment but also

provides product and dealer support to

maintain the reliability and durability

of your machine.

CUSTOMER SUPPORT AGREEMENTS.

A Customer Support Agreement (CSA)

is any arrangement between you and your

Cat dealer that helps you lower your

total cost per unit of production. CSAs

are flexible, allowing them to be tailored

to your business. They can range from

simple Preventive Maintenance Kits to

sophisticated Total Cost Performance

Guarantees. Having a CSA with your

Cat dealer allows you more time to do

what you do best – run your business.

CATERPILLAR EQUIPMENT TRAINING

SOLUTIONS. A thorough understanding

of machine systems and a high level

of skill in operation helps achieve

maximum efficiency and improves return

on investment. Caterpillar Equipment

Training Solutions programs help

provide operators with high levels of

proficiency and confidence. Contact your

Cat Dealer for more information on

Caterpillar Equipment Training

Solutions programs.

CATERPILLAR FINANCIAL SERVICES

CORPORATION. Cat Financial understands

your business, your industry and the

challenges you face. That’s why they

can provide payment plans to fit your

unique needs – and to help you achieve

your goals.

11

Page 12

• Grouped service points and sight

gauges for easy daily maintenance

• Convenient access to engine

compartment for excellent

serviceability

• Swing-out grill and cooling cores

for easy cleaning

• Electronic systems to monitor

product health

HYDRAULIC SERVICE CENTER.

Transmission and hydraulic oil filters

are located in the Hydraulic Service

Center, behind the hinged, right-side

access ladder. The hydraulic oil tank

can be drained from this location

using the access port.

ELECTRIC SERVICE CENTER. A lockable

compartment located just below the

left side access platform contains key

electrical components such as the remote

jump-start receptacle, battery disconnect

switch, circuit breakers and hood

actuation switch. The maintenance free

batteries are conveniently located under

the electric service center.

NEW! MULTI-PIECE AXLE. With the

introduction of Caterpillar’s new multipiece axles, service brakes and final

drives are located outboard and provide

easy access when service is required.

GROUND LEVEL GREASE POINTS.

Grease fittings are grouped on the right

side of the machine in two convenient

locations thus facilitating easy lubrication

of vital components throughout the

machine.

AUTOLUBE. Reduce time spent on daily

maintenance and downtime for unplanned

repairs due to inadequate greasing with

the optional Caterpillar Automatic

Lubrication System. Precise lubrication

of pins and bushings at specific intervals

improves component wear and reduces

ground contamination from excessive

greasing.

S

•O•

S SERVICES. Sampling valves on

the 938H allow quick access to engine,

transmission and hydraulic oils for

S•O•S analysis. Oil change intervals

and other services can be optimized

according to your work schedule,

reducing downtime and managing

expenses.

REMOTE PRESSURE TAPS. Pressure taps

for key systems are grouped and centrally

located throughout the machine and

help facilitate quick diagnostics.

BRAKE WEAR INDICATORS. Axles are

equipped with standard brake wear

indicators, allowing a technician to

easily determine when it is necessary

to service the brakes.

SIGHT GAUGES. Well-protected,

yet easily visible sight gauges for the

transmission, hydraulic oil and radiator

coolant allow easy daily checks while

reducing the risk of contaminants

entering the systems.

12

Easy to Maintain – Easy to Service

SERVICEABILITY

Page 13

ENGINE COMPARTMENT ACCESS.

A single mechanical lift cylinder

with manual back-up opens the hood.

The tilting hood provides excellent

access to the engine and cooling

compartments and if necessary, the

entire hood can be removed with

the built-in lift points.

With the hood closed, quick checks of

the engine oil level, coolant site gauge

and air inlet indicator can be completed

through the side service door.

ECOLOGY DRAINS. Engine, transmission

and hydraulic oils can be easily drained

with standard-equipment ecology drains.

An axle oil ecology drain is optional.

ELECTRIC PRIMING PUMP. An electric

fuel priming pump located on the primary

fuel filter base eliminates the need to

pre-fill or manually prime filters after a

change, eliminating engine contamination.

COOLING SYSTEM. Cooling system

access for clean-out and maintenance

is outstanding. The perforated and

corrugated grill minimizes debris buildup and swings out for easy cleaning

and access to the cooling cores.

The full-width air conditioning condenser

and oil cooler cores swing out 45° to

allow easy cleaning of the rear radiator

face. An access panel located on the

right side of the radiator support structure

provides access to the front face of the

radiator and ATAAC cores for easy

cleaning.

COMPLETE CUSTOMER SUPPORT.

Cat field service technicians have the

experience and tools necessary to

service your loader on site. Technical

experts at the dealership and Caterpillar

can provide additional assistance to

field service technicians as needed.

When on-site repair isn’t enough, Cat

dealerships are fully equipped to service

your loader quickly.

13

Page 14

• Comfortable operation

• Excellent visibility

• Easy entry and exit

• Low effort steering

OPERATING ENVIRONMENT. The 938H

provides operators with a comfortable

operating environment with generous

storage space and excellent visibility.

Seat. The durable seat adjusts 6-ways

to accommodate all sized operators.

The seat features an automotive style

lumbar support for maximum comfort.

The Cat C-500 Series Comfort airsuspension seat is optional as is a

heated backrest and seat cushion.

Implement Pod. The newly restyled

implement pod provides superior comfort

through the full length adjustable

armrest. Standard transmission F-N-R

switch allows operators to keep their

hand on the implement control levers

while making directional shifts.

An optional joystick with integrated

F-N-R switch is available and replaces

the lift and tilt levers.

VISIBILITY. The 938H offers excellent

visibility to the front and rear of the

machine. Distortion-free flat glass

stretches to the floor of the cab for

excellent visibility to the bucket.

Wet-arm wipers on both front and back

keep the windows clean in any condition.

Rear Vision Camera. An optional rear

vision camera is available to clearly

monitor movement behind the wheel

loader.

Lighting Packages. In addition to the

standard roading lights, optional lighting

packages are available for low-light

applications. Optional auxiliary halogen

or High Intensity Discharge (HID) cab

lights provide exceptional lighting for

night work. A rotating beacon is

available as a safety feature.

ENTRY AND EXIT. A ladder with

aggressive tread pattern keeps debris

build-up to a minimum. The ladder is

at a 5° forward incline for easy entry

and exit.

The main cab door opens a full 180° and

latches in place to allow safe navigation

to the rear of the machine.

The right side door opens 10°, or

completely for secondary exit simply

by pulling a pin. A full-length ladder

on the right side facilitates safe exit

if needed.

Steering. Caterpillar’s low effort load

sensing steering directs power through

the steering system only when needed.

The new hand metering unit and priority

valve provide operators with full

steering and multi-function capability

a low engine RPM’s. The combined

steering column and instrument panel

tilt for maximum operator comfort.

Controls. Key machine controls are

conveniently located within arms reach

and allow better efficiency while

minimizing operator fatigue.

A variety of machine controls are also

contained within the Messenger display.

By accessing various menus, an operator

can tailor the machine to fit operating

style and application. For multi-shift

operations, personalized settings for

each operator can be established and

stored for maximum uptime and comfort.

SAFETY.CAT.COM™.

14

OPERATOR COMFORT

Work Comfortably and Efficiently

Page 15

15

938H Wheel Loader specifications

Transmission

Forward 1 8.1 km/h 5 mph

Forward 2 14.6 km/h 9.1 mph

Forward 3 25.5 km/h 15.8 mph

Forward 4 43.2 km/h 26.8 mph

Reverse 1 8.1 km/h 5 mph

Reverse 2 14.6 km/h 9.1 mph

Reverse 3 25.5 km/h 15.8 mph

• Maximum travel speeds with empty bucket and 20.5-R25 tires.

Hydraulic System

Steering System Pump Type Piston

Hydraulic Cycle Time – Raise 5.4 Seconds

Hydraulic Cycle Time – Dump 1.4 Seconds

Hydraulic Cycle Time – Lower, 2.7 Seconds

Empty, Float Down

Hydraulic Cycle Time – Total 9.5 Seconds

Pilot System – Pump Output 295 L/min 77.9 gal/min

• Implement System (Standard), Piston Pump – Rated at

2,100 rpm and 1,000 psi (6900 kPa).

• Cycle time with rated payload.

Brakes

Brakes Meets required

standards

• Meet OSHA, SAE J1473 Oct90 and ISO 3450-1985 standards.

Axles

Front Fixed front

Rear Oscillating ±12°

Maximum Single-Wheel 420 mm 17 in

Rise and Fall

Engine

Engine Model Cat®6.6 ACERT™

Gross Power – SAE J1995 147 kW 197 hp

Net Power – ISO 9249 134 kW 180 hp

Net Power – SAE J1349 128 kW 172 hp

Net Power – 80/1269/EEC 134 kW 180 hp

Peak Torque (Net) @ 1,400 rpm 840 N·m 620 ft-lb

Total Torque Rise 38 %

Bore 105 mm 4.1 in

Stroke 127 mm 5 in

Displacement 6.6 L 402.8 in

3

• Caterpillar engine with ACERT™ Technology – EPA Tier III,

EU Stage III Compliant.

• These ratings apply at 2,100 rpm when tested under the

specified standard conditions.

• Rating for net power advertised based on power available

when the engine is equipped with alternator, air cleaner,

muffler and on-demand hydraulic fan drive at maximum

fan speed.

Weights

Operating Weight 15 059 kg 33,190 lb

• For 2.8 m3(3.65 yd3) general purpose bucket with standard

20.5-R25 tires.

Buckets

Bucket Capacities 2.3 - 3.0 m33.0 - 4.0 yd

3

Max Bucket Capacity 3 m

3

4 yd

3

Operating Specifications

Static Tipping Load, Full Turn 10 076 kg 22,207 lb

Breakout Force 123 kN 27,576 lb

• For 2.8 m3(3.65 yd3) general purpose bucket with standard

20.5-R25 tires.

Page 16

16

938H Wheel Loader specifications

Service Refill Capacities

Fuel Tank – Standard 247 L 65.3 gal

Cooling System 36 L 9.5 gal

Crankcase 17.4 L 4.6 gal

Transmission 43 L 11.4 gal

Differentials and Final Drives 57 L 15.1 gal

– Front

Differentials and Final Drives 53 L 14 gal

– Rear

Hydraulic Tank 89 L 23.5 gal

Tires

Tires Choose from a variety

of tires to match your

application.

• Choice of:

20.5R25 XTLA L2 Radial

20.5R25 XHA L3 Radial

20.5R25 GP2B L3 Radial

20.5R25 HRL L3 Radial

20.5R25 RL-2+ L3 Radial

650/65R-25 XLD L3 Radial (Low Profile)

20.5-25 SRG LD L3 Bias (16 PLY)

20.5-25 SRG LD L3 Bias (20 PLY)

20.5-25 RM 99 L3 Bias

• NOTE: In certain applications (such as load and carry)

the loader’s productive capabilities might exceed the tires’

tonnes-km/h (ton-mph) capabilities. Caterpillar recommends

that you consult a tire supplier to evaluate all conditions

before selecting a tire model. Other special tires are

available on request.

Cab

ROPS/FOPS Meets SAE and

ISO standards

• Caterpillar cab with Integrated Rollover Protective Structure

(ROPS) is standard in North America and Europe.

• ROPS meets SAE J1040 APR88 and ISO 3471:1994 criteria.

• Falling Objects Protective Structure (FOPS) meets SAE J231

Jan81 and ISO 3449:1992 Level II criteria.

• The operator sound pressure level measured according

to the procedures specified in ISO 6394:1998 is 75 dB(A) for

the cab offered by Caterpillar when properly installed and

maintained and tested with the doors and windows closed.

• Hearing protection may be needed when operating with an

open operator station and cab (when not properly maintained

or doors/windows open) for extended periods or in noisy

environment.

• The sound power level is 108 dB(A) measured according

to the dynamic test procedure and conditions specified in

ISO 6395:1998 for a standard machine configuration.

Page 17

17

938H Wheel Loader specifications

Operation Specifications

General Purpose Buckets

Rated capacity

Struck capacity

Width

Dump clearance at full lift and 45° discharge

Reach at full lift and 45° discharge

Reach with lift arms horizontal and bucket level

Digging depth

Overall length

Overall height with bucket at full raise

Loader clearance circle with bucket in carry position

Static tipping load, straight

Static tipping load, articulated at full 40° turn

Breakout force

Operating weight

Reach at 2134 mm (7'0") height, 45° dumped

Clearance at full raise and dump, on stops

Dump angle at full raise and dump, on stops

m

yd

m

yd

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

mm

ft/in

mm

ft/in

mm

ft/in

kg

kg

kN

kg

mm

ft/in

mm

ft/in

degrees

Bolt-on

edges

3

2.30 2.30 2.10 2.50 2.50 2.30

3

3.00 3.00 2.75 3.25 3.25 3.00

3

1.97 1.97 1.87 2.11 2.11 2.01

3

2.58 2.58 2.45 2.76 2.76 2.63

and

segments Teeth

Bolt-on

edges

Teeth

Teeth

and

segments Teeth

2700 2777 2777 2700 2777 2777

8'10" 9'1" 9'1" 8'10" 9'1" 9'1"

2890 2786 2786 2849 2744 2744

9'5" 9'1" 9'1" 9'4" 9'0" 9'0"

993 1098 1098 1019 1123 1123

3'3" 3'7" 3'7" 3'4" 3'8" 3'8"

2189 2336 2336 2239 2386 2386

7'2" 7'7" 7'7" 7'4" 7'9" 7'9"

50 50 25 50 50 25

in

1.9 1.9 0.9 1.9 1.9 0.9

7193 7351 7351 7243 7401 7401

23'7" 24'1" 24'1" 23'9" 24'3" 24'3"

5140 5140 5140 5188 5188 5188

16'10" 16'10" 16'10" 17'0" 17'0" 17'0"

11 946 12 105 12 105 11 971 12 131 12 131

39'2" 39'8" 39'8" 39'3" 39'9" 39'9"

11 834 11 737 11 959 11 755 11 658 11 878

lb

26,081 25,867 26,357 25,909 25,694 26,179

10 302 10 205 10 415 10 229 10 131 10 339

lb

22,706 22,492 22,954 22,544 22,329 22,787

141.9 141.1 152.7 134.9 134.2 144.7

lb

31,877 31,703 34,297 30,317 30,143 32,508

14 952 15 027 14 932 14 986 15 061 14 966

lb

32,955 33,120 32,911 33,028 33,194 32,984

1508 1563 1563 1516 1567 1567

4'11" 5'1" 5'1" 4'11" 5'1" 5'1"

2821 2706 2706 2786 2671 2671

9'3" 8'10" 8'10" 9'1" 8'9" 8'9"

51.2 51.2 51.2 50.5 50.5 50.5

yd3m

GP

3.00

GP

3.25

GP

3.65

GP

4.00

MH 2.8

3.65

Pin-On Bucket Selection Guide

3

3

2.3

2.5

2.8

3.0

1400

2,250 2,500 2,750 3,000 3,250 3,500 3,750 4,000 lb/yd

1600 1800 2000 2200 2400

kg/m

% = Bucket Fill Factor

115% 100% 95%

3

Material Density

Page 18

18

938H Wheel Loader specifications

2.80 2.80 2.70 3.00 3.00 2.85 2.80 2.80 2.70 2.40 2.40 2.30

3.65 3.65 3.50 4.00 4.00 2.75 3.65 3.65 3.50 3.15 3.15 3.00

2.41 2.41 2.30 2.66 2.66 2.55 2.42 2.42 2.32 2.02 2.02 1.92

3.15 3.15 3.01 3.48 3.48 3.34 3.17 3.17 3.03 2.64 2.64 2.51

2700 2777 2777 2700 2777 2777 2700 2777 2777 2700 2777 2777

8'10" 9'1" 9'1" 8'10" 9'1" 9'1" 8'10" 9'1" 9'1" 8'10" 9'1" 9'1"

2771 2664 2664 2702 2597 2597 2720 2607 2607 2774 2669 2669

9'1" 8'8" 8'8" 8'10" 8'6" 8'6" 8'11" 8'6" 8'6" 9'1" 8'9" 8'9"

1077 1179 1179 1102 1206 1206 1001 1096 1096 1017 1120 1120

3'6" 3'10" 3'10" 3'7" 3'11" 3'11" 3'3" 3'7" 3'7" 3'4" 3'8" 3'8"

2339 2486 2486 2397 2544 2544 2339 2486 2486 2285 2432 2432

7'8" 8'1" 8'1" 7'10" 8'4" 8'4" 7'8" 8'1" 8'1" 7'5" 7'11" 7'11"

50 50 25 110 110 85 50 50 25 109 109 84

1.9 1.9 0.9 4.3 4.3 3.3 1.9 1.9 0.9 4.3 4.3 3.3

7343 7501 7501 7450 7608 7608 7343 7502 7502 7337 7496 7496

24'1" 24'7" 24'7" 24'5" 24'11" 24'11" 24'1" 24'7" 24'7" 24'0" 24'7" 24'7"

5284 5284 5284 5195 5195 5195 5272 5272 5272 5075 5075 5075

17'4" 17'4" 17'4" 17'0" 17'0" 17'0" 17'3" 17'3" 17'3" 16'7" 16'7" 16'7"

12 024 12 185 12 185 12 106 12 267 12 267 12 024 12 185 12 185 12 009 12 165 12 165

39'5" 39'11" 39'11" 39'8" 40'2" 40'2" 39'5" 39'11" 39'11" 39'4" 39'10" 39'10"

11 593 11 494 11 711 11 488 11 388 11 602 11 514 11 416 11 627 11 655 11 558 11 773

25,551 25,333 25,811 25,320 25,100 25,571 25,376 25,160 25,625 25,688 25,474 25,947

10 076 9977 10 182 10 000 9901 10 103 10 008 9909 10 109 10 122 10 025 10 228

22,207 21,989 22,441 22,041 21,821 22,267 22,057 21,841 22,281 22,310 22,095 22,543

122.7 122.0 130.8 117.2 116.3 124.5 122.7 122.0 130.8 129.4 128.5 138.2

27,576 27,402 29,395 26,320 26,133 27,959 27,576 27,402 29,394 29,063 28,875 31,060

15 059 15 134 15 039 14 898 14 973 14 878 15 048 15 123 15 028 15 165 15 240 15 145

33,190 33,355 33,146 32,835 33,000 32,791 33,165 33,331 33,121 33,424 33,589 33,379

1535 1579 1579 1523 1566 1566 1433 1462 1462 1477 1523 1523

5'0" 5'2" 5'2" 4'11" 5'1" 5'1" 4'8" 4'9" 4'9" 4'10" 4'11" 4'11"

2714 2599 2599 2631 2516 2516 2714 2599 2599 2710 2596 2596

8'10" 8'6" 8'6" 8'7" 8'3" 8'3" 8'10" 8'6" 8'6" 8'10" 8'6" 8'6"

49.5 49.5 49.5 50.5 50.5 50.5 45.5 45.5 45.5 50.6 50.6 50.6

Material Handling Buckets General Purpose Buckets

– Quick Coupler

Bolt-on

edges

Teeth

and

segments Teeth

Bolt-on

edges

Teeth

and

segments Teeth

Bolt-on

edges

Teeth

and

segments Teeth

Bolt-on

edges

Teeth

and

segments Teeth

Page 19

19

938H Wheel Loader specifications

Operation Specifications

Rated capacity

Struck capacity

Width

Dump clearance at full lift and 45° discharge

Reach at full lift and 45° discharge

Reach with lift arms horizontal

and bucket level

Digging depth

Overall length

Overall height with bucket at full raise

Loader clearance circle with bucket

in carry position

Static tipping load, straight

Static tipping load, articulated at full 40° turn

Breakout force

Operating weight

Reach at 2134 mm (7'0") height, 45° dumped

Clearance at full raise and dump, on stops

Dump angle at full raise and dump, on stops

m

yd

m

yd

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

mm

ft/in

mm

ft/in

mm

ft/in

kg

kg

kN

kg

mm

ft/in

mm

ft/in

degrees

General Purpose Buckets

– Quick Coupler

Bolt-on

edges

3

2.70 2.70 2.60 2.80 2.80 2.70 4.25

3

3.50 3.50 3.40 3.65 3.65 3.50 5.50

3

2.35 2.35 2.25 2.46 2.46 2.36 3.73

3

3.07 3.07 2.94 3.22 3.22 3.09 4.88

and

segments Teeth

Bolt-on

edges

Teeth

Teeth

and

segments Teeth

2700 2777 2777 2700 2777 2777 2738

8'10" 9'1" 9'1" 8'10" 9'1" 9'1" 8'11"

2708 2603 2603 2681 2575 2575 2501

8'10" 8'6" 8'6" 8'9" 8'5" 8'5" 8'2"

1077 1180 1180 1106 1210 1210 1142

3'6" 3'10" 3'10" 3'7" 3'11" 3'11" 3'8"

2374 2521 2521 2414 2561 2561 2594

7'9" 8'3" 8'3" 7'11" 8'4" 8'4" 8'6"

122 122 97 124 124 99 106

in

4.7 4.7 3.8 4.8 4.8 3.8 4.1

7436 7594 7594 7478 7636 7636 7643

24'4" 24'10" 24'10" 24'6" 25'0" 25'0" 25'0"

5149 5149 5149 5149 5149 5149 5541

16'10" 16'10" 16'10" 16'10" 16'10" 16'10" 18'2"

12 063 12 219 12 219 12 085 12 242 12 242 12 244

39'6" 40'1" 40'1" 39'7" 40'1" 40'1" 40'2"

11 400 11 302 11 513 11 455 11 356 11 566 9910

lb

25,126 24,909 25,375 25,246 25,028 25,493 21,841

9879 9780 9980 9937 9838 10 038 8526

lb

21,773 21,556 21,996 21,901 21,682 22,123 18,792

118.9 118.0 126.4 115.2 114.4 122.3 95.8

lb

26,702 26,512 28,394 25,891 25,700 27,478 21,512

15 326 15 401 15 306 15 227 15 302 15 207 15 725

lb

33,779 33,944 33,734 33,560 33,725 33,516 34,657

1501 1544 1544 1516 1557 1557 1441

4'11" 5'0" 5'0" 4'11" 5'1" 5'1" 4'8"

2640 2525 2525 2610 2495 2495 2493

8'7" 8'3" 8'3" 8'6" 8'2" 8'2" 8'2"

50.5 50.5 50.5 50.5 50.5 50.5 45.5

Refuse

Bucket

Bolt-on

edges

Page 20

20

938H Wheel Loader specifications

Dimensions

All dimensions are approximate and may vary with work tool.

Tires are 20.5R25 Michelin XHA.

➤

➤

➤

1

2

3

➤

➤

➤

➤

➤

➤

➤

8

➤

➤

11

1 Height to top of ROPS 3356 mm 11'0"

2 Height to top of exhaust pipe 3099 mm 10'2"

3 Height to top of hood 2415 mm 7'11"

4 Ground clearance/Standard tire

See Chart below for other tires 397 mm 1'3"

5 Lift arm clearance @ maximum lift 3435 mm 11'3"

6 Bucket pin height @ maximum lift 3843 mm 12'7"

Bucket pin height, optional high lift 4266 mm 13'11"

7 Overall height – bucket raised 5284 mm 17'4"

8 Center line of rear axle to edge

of counterweight 1869 mm 6'1"

➤

➤

12

➤

➤

➤

➤

13

➤

➤

➤

14

15

4

➤

9

➤

➤

➤

16

➤

➤

10

➤

➤

7

6

5

➤

➤

➤

9 Wheelbase 3020 mm 9'10"

10 Height to center line of axle 688 mm 2'3"

11 Center line of rear axle to hitch 1510 mm 4'11"

12 Rack back @ maximum lift 65°

13 Dump angle @ maximum lift 50°

14 Rack back @ carry 50°

15 Rack back @ ground 42°

16 Dump clearance @ maximum lift

and 45° dump 2771 mm 9'1"

Tires

Width over tires –

maximum

(loaded)

mm inches mm inches kg lb kg lb kg lb

20.5-R25 XTLA L2 Radial 2603 102 –16 –1 –170 –376 –120 –264 –104 –230

20.5-R25 XHA L3 Radial 2674 105 –0 –0 –0 –0 –0 –0 –0 –0

20.5 R25 GP2B L3 Radial 2619 103 +6 –0 –53 –116 –37 –81 –32 –71

20.5 R25 HRL L3 Radial 2618 103 +23 +1 –48 –107 –34 –75 –30 –65

20.5 R25 RL-2+ L3 Radial 2609 103 +12 –0 +13 +28 +9 +20 +8 +17

650/65R-25 XLD L3 Radial (Low Profile) 2733 108 –0 –0 +519 +1145 +364 +803 +318 +701

20.5-25 SRG LD L3 Bias (16 PLY) 2558* 101* +8 –0 –242 –533 –170 –374 –148 –326

20.5-25 SRG LD L3 Bias (20 PLY) 2556* 101* +11 –0 –174 –384 –122 –270 –107 –235

20.5-25 RM 99 L3 Bias 2540* 100* +8 –0 –58 –129 –41 –90 –36 –79

*Without bulge.

Change in

vertical

dimensions

Change in

operating weight

without ballast

Change in

static tipping

load – straight

Change in

static tipping

load – articulated

Page 21

21

938H Wheel Loader specifications

Standard Equipment

Standard equipment may vary. Consult your Caterpillar dealer for details.

Dual interior rearview mirrors

Dual exterior rearview mirrors

Interior operator lighting

Storage compartments

Lunchbox compartments

Beverage holder

Seat, KAB, cloth, adjustable

Seat belt, retractable, 51 mm (2") wide

Adjustable steering column/wheel

Forward/Neutral/Reverse switch by implement controls

LH door with sliding window

RH sliding window and emergency exit

Windshield wipers, front and rear

Interval function for front and rear wipers

Windshield washers, front and rear

POWER TRAIN

Brakes, full hydraulic enclosed wet-disc

Brake wear indicators with Integrated Braking System (IBS)

Front axle with locking differential

Drive line, extreme service

Engine, Cat C6.6 ACERT and ATAAC technology,

electronically controlled.

Fan, radiator, electronically controlled, hydraulically driven,

temperature sensing, on demand.

Filters, fuel, primary/secondary

Fuel priming pump (Electric)

Fuel/Water separator

Monitoring System, Axle Oil Temp.

Muffler, sound suppressed

Radiator, unit core (6 fpi) with ATAAC

Starting aid (Glow Plugs)

Trans, neutralizer lockout in messenger

Torque converter

Transmission, countershaft, automatic power shift (4F/3R)

Variable Shift Control (VSC), messenger

ELECTRICAL

Alarm, back-up, adjustable

Alternator, 24V/65A

Battery disconnect switch with removable key

Lighting:

Turn signals with flashing hazard function

Two halogen headlights with high/low beam

Parking lights

LED brake and tail lights

Two front and rear halogen work lights, cab mounted

Jumpstart receptacle

OPERATOR ENVIRONMENT

Air Conditioning

Bucket/Work tool lever lockout feature

Cab, ROPS/FOPS, pressurized and sound suppressed

Coat hook

Controls, lift and tilt functions

Radio ready including antenna, speakers, two 12V/5A

power outlets, includes cigar lighter

Electric horn, dual actuation (steering wheel, implement pod)

Sun Visor, Front

Cab heating with fresh air inlet and defrosting function

Messenger System

Monitoring and logging of machine data

Clock

Operator keypad

Axle oil temperature

Product Link Ready (optional in some regions)

Operator display, Gauges:

Engine coolant temperature

Fuel level

Hydraulic oil temperature

Speedometer

Gear indicator

Tachometer

Transmission oil temperature

Operator display, Warning Indicators:

Glow Plugs

Electrical, alternator output

Engine inlet manifold temperature

Engine oil pressure

Fuel pressure

Hydraulic oil temperature

Parking brake

Primary steering oil pressure

Service brake oil pressure

Transmission filter bypass

Axle oil temperature

Page 22

22

938H Wheel Loader specifications

Standard Equipment (cont’d)

Standard equipment may vary. Consult your Caterpillar dealer for details.

HYDRAULICS

Load sensing implement system, pressure sensing

Load sensing steering system

Two function hydraulic valve (lift and tilt)

Two lever operator implement controls

TIRES, RIMS, & WHEELS

A tire must be selected from the mandatory attachments

section. Base machine price includes an allowance based

on a premium radial tire.

ANTIFREEZE

Premixed 50% concentration of Extended Life Coolant with

freeze protection to –34° C (–29° F).

OTHER STANDARD EQUIPMENT

Automatic bucket positioner

Counterweight

Couplings, Caterpillar O-ring face seal

Fenders, Extension, Platform, Rear

Guards, (bottom crankcase and fuel tank)

Hitch, drawbar with pin

Hood, non-metallic power tilting

Hoses, Caterpillar XT

Hydraulics, Load Sensing

Kickout, lift, automatic

Kickout, tilt, adjustable

Linkage, Z-bar, cast crosstube/tilt lever

Oil sampling valves

Remote Diagnostic Pressure Taps.

Sight Gauges: Engine coolant, hydraulic oil and

transmission oil level.

Steering, load sensing

Vandalism protection caplocks

Page 23

23

938H Wheel Loader specifications

Optional Equipment

Optional equipment may vary. Consult your Caterpillar dealer for details.

High Lift, three-valve with hydraulic horizontal pin

quick coupler

Hydraulics, three or four-valve

Joystick control, two, three or four valve

Ladder, cable

Lights, auxiliary cab lights

Lights, high intensity discharge (HID)

Lights, warning beacon

Machine Security System

Mirrors, heated external

Open canopy

Precleaner , turbine

Precleaner , turbine/trash

Quick Coupler, hydraulic horizontal pin

Quick Coupler ready lines

Radio, AM/FM CD player

Ride Control

Seat, air suspension

Seat, heated air suspension

Seatbelt, 76 mm (3") wide

Seatbelt, 76 mm (3") wide (KAB)

Steering, secondary

Sunscreen, rear

Toolbox

Alternator, heavy-duty

Antifreeze, –50° C (–58° F)

Autolube

Buckets and work tools

Bucket Ground Engaging Tools (GET) – see Cat dealer

for details

Camera, rear view

Coolant, extended life

Cooler, axle oil

Differential Lock, automatic front and rear

Drain, axle ecology

Ether Starting Aid

Fenders/Platforms, narrow

Fenders, roading

Guards, axle seal

Guard, front window, wide mesh

Guard, power train bolt-on

Guard, power train hinged

Guard, hitch area

Guard, front driveshaft

Guard, roading light, front and rear

Guard, tilt cylinder

Guard, transmission oil fill

Heater, engine coolant, 120- or 240-volt

High Lift, three-valve

Page 24

For more complete information on Cat products, dealer services,

and industry solutions, visit us on the web at www.cat.com

© 2008 Caterpillar

All Rights Reserved

Printed in U.S.A.

Materials and specifications are subject to change without notice.

Featured machines in photos may include additional equipment.

See your Caterpillar dealer for available options.

CAT, CATERPILLAR, SAFETY.CAT.COM, their respective logos, “Caterpillar Yellow,”

and the POWER EDGE trade dress, as well as corporate and product identity used

herein, are trademarks of Caterpillar and may not be used without permission.

AEHQ5911-01 (8-08)

Replaces AEHQ5911

938H Wheel Loader

R

Loading...

Loading...