Page 1

928Hz

Wheel Loader

Cat® C6.6 Engine with ACERT™ Technology

Net power (SAE J1249) 111 kW 149 hp

EPA Tier 3, EU Stage III Compliant

Weight

Operating Weight 12 564 kg 27,699 lb

Buckets

Bucket Capacity 2.0-2.3 m

3

2.6-3.0 yd

3

Page 2

928Hz Features

High Performance Power Train

Clean, quiet operation with superior power.

Powerful Hydraulic System

System senses work demand and adjusts

flow and pressure to match for precise,

efficient control.

Loader Linkage

Proven design delivers outstanding bucket

loading performance.

Comfortable Cab

Large, spacious cab and low-effort, ergonomic

joystick controls let you concentrate on

your work.

Buckets

Caterpillar® buckets deliver superior digging,

loading and carrying performance.

Contents

Power Train . . . . . . . . . . . . . . . . . . . . . . . . .3

Hydraulic System . . . . . . . . . . . . . . . . . . . .4

Loader Linkage . . . . . . . . . . . . . . . . . . . . . .4

Operator Station . . . . . . . . . . . . . . . . . . . . .5

Buckets. . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Serviceability. . . . . . . . . . . . . . . . . . . . . . . .7

Customer Support. . . . . . . . . . . . . . . . . . . .7

Specifications . . . . . . . . . . . . . . . . . . . . . . .8

Standard and Optional Equipment. . . . .14

The Cat® 928Hz Wheel Loader leads the industry in

operator comfort and performance. Size, power, and

performance make this machine ideal for a wide range

of jobs. Fast cycle times help you move more material.

Large spacious cab with joystick control keeps you

comfortable throughout the work day, allowing you to get

more done. Loader design delivers strength and durability

with superior control. Discover how much more you can

get done with the new 928Hz.

Page 3

Power Train

Delivers maximum rimpull to the ground and full power to loader hydraulics.

Cat Engine

The Cat® C6.6 engine provides cleaner, quieter operation while delivering superior performance and

durability. The 111 kW (149 hp) rated net power engine meets all worldwide emissions standards and features

flatter power curve for outstanding response in the working RPM range (1,900 to 2,300), noise reduction

technologies for up to 5 dB reduction, and patented ACERT™ Technology combined with common rail fuel

system, smart waste gate turbocharger and crossflow head design for reduced emissions.

Cat Axles

Heavy-duty axles feature hardened gears and bearings for durable performance. Rear axle oscillates up to

12 degrees to help assure four-wheel ground contact for optimum traction and stability. Optional front and

rear Limited Slip Differentials enable outstanding traction in poor underfoot conditions.

Cat Transmission

Rugged Cat transmission uses heavy-duty components for durable and reliable operation. The operator can

choose between manual shift and two autoshift modes, Performance or Economy. Performance mode provides

maximum acceleration while the economy mode increases fuel economy and improves operator comfort.

3

Page 4

Hydraulics

System provides high efficiency with low effort, precise control.

Proven Design

Time tested hydraulic system provides low effort operation and

superior control. Fast loader cycle times help you get more done.

Dual Hydraulic Pumps System

Load-sensing steering pump provides outstanding response

during heavy and light duty operations.

High output implement pump provides all the hydraulic power

required to move loads at all engine speeds.

Ride Control System

The optional Ride Control System provides a comfortable ride

and excellent material retention.

Nitrogen charged accumulator enables optimum cushioning over

uneven terrain for all loads and speeds.

The system operates in Automatic – as the loader ground speed

exceeds 5 km/h (3 mph) the system will activate, below 5 km/h

(3 mph) the system is off providing maximum lift power.

Loader Linkage

Strong design delivers superior

performance.

Z-Bar Design

Z-bar linkage generates excellent breakout force and good

rack back angle for better bucket loading and load retention.

Lift arms are solid steel, providing superior strength with an

excellent front end viewing area. The proven design offers

excellent dump clearance and reach for exceptional truck

loading performance.

Page 5

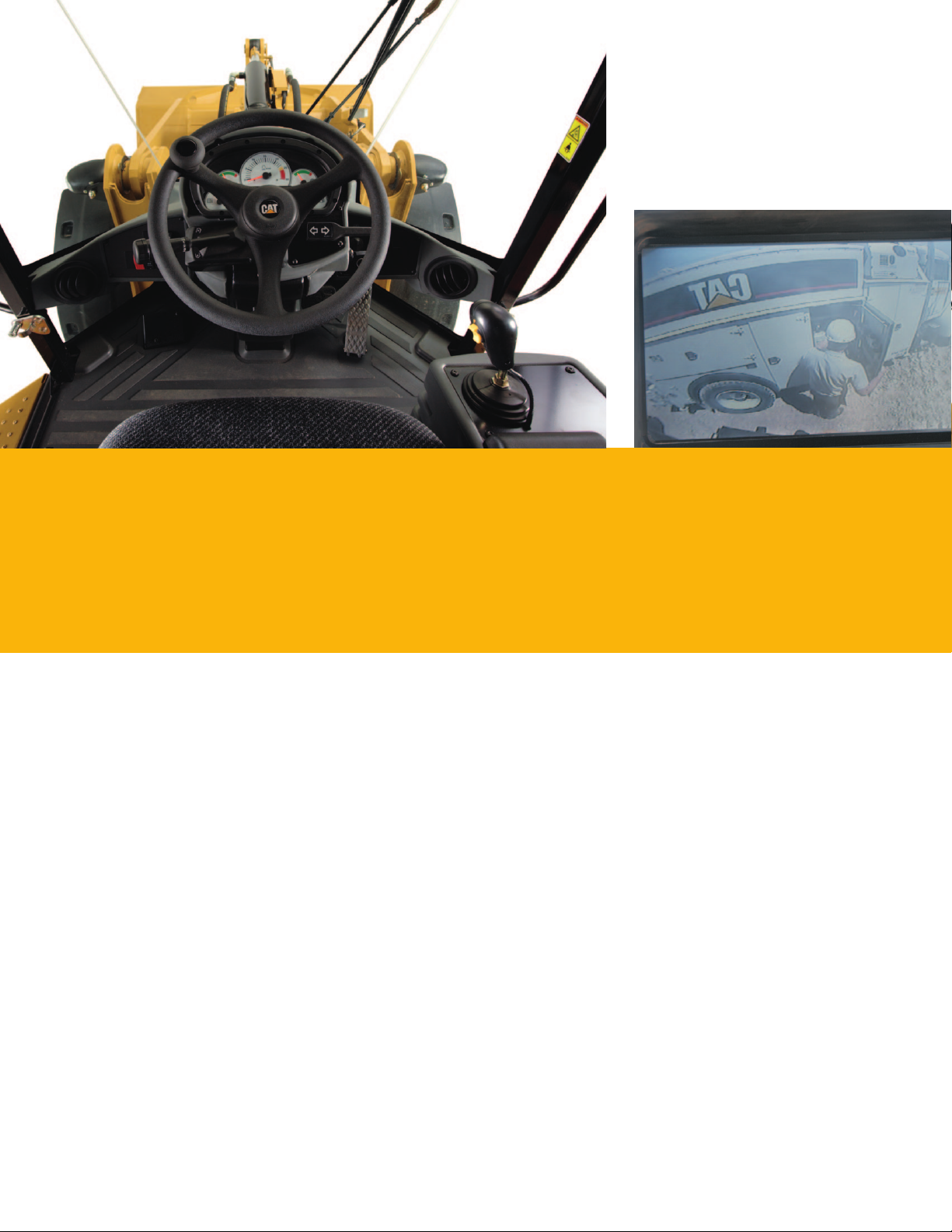

Operator Station

Superior comfort keeps you productive, all day long.

Experience comfort and convenience in the H-Series cab. The spacious interior and ergonomic controls

keep you comfortable throughout the work day. Choose the seat that meets your needs – the standard, fully

adjustable seat or the optional Cat Contour seat for added adjustment and air suspension. The two-door

design lets you enter and exit from either side of the machine and wide, serrated steps provide stable footing.

Both doors lock open 180 degrees and feature sliding glass windows for better communication with workers

on the ground. Large flat glass windows provide excellent visibility all around the machine. The rear window

features a standard electric defroster.

Controls

Low effort, ergonomic joystick controls provide easy operation of lift and tilt functions. The standard

joystick features an integrated directional control switch for added convenience. The operator programmable

transmission neutralizer can be set in seconds optimizing brake effort for all applications.

Instrument Panel

The sealed instrument panel with easy to read white faced gauges and indicators keeps the operator informed

of system conditions. The large LED readout provides ground speed and other critical information.

Optional Rear View Camera

This work area visual enhancement system uses a closed circuit video monitoring system. Up to three cameras

can be mounted on the machine frame. Objects can be viewed on a color LCD monitor in the cab.

5

Page 6

Buckets

Cat® Buckets are built for high performance.

The Right Bucket for the Job

Caterpillar offers a variety of buckets to meet your specific job

requirements. Careful match of the bucket design and machine

operating characteristics provide the best digging, loading and

carrying performance.

General Purpose Buckets

Caterpillar general purpose buckets, available in 2.0 m3 (2.6 yd3)

and 2.3 m3 (3.0 yd3) capacities with bolt-on cutting edge, are

suitable for most general applications. Features include:

• Improved bucket design with longer floor and a larger radius

for easier flow of material into the bucket.

• Patented Two-Bolt Corner Guard Cutting Edge System

for superior wear resistance, better stability and a simple

bolt-on system.

• Built-in, replaceable heel wear plates for extended bucket life.

Sand and Gravel Bucket

This 2.5 m3 (3.5 yd3) heavy duty material handling bucket, built

with additional wear plates on the floor and sides, is engineered

for ready mix or batch plant applications with plant capacity of

200 tons per hour.

Ground Engaging Tools

Ground engaging tools include hardened steel cutting edges,

choice of short or long teeth and a variety of tooth adapters.

These tools optimize performance, improve load retention

and extend the useful life of Caterpillar buckets.

Versatility

For expanded machine versatility, factory installed quick

couplers and other special purpose buckets are also available.

Contact your Caterpillar dealer for details.

6

Page 7

Serviceability

Easy access and minimal maintenance requirements keep

your machine on the job.

Convenient service features make maintenance easy.

All service points are accessible from ground level on the

right side of the engine. Gull-wing doors with gas struts lift for

exceptional access to filters and service points. Extended service

intervals reduce service time and increase machine availability.

• Sight gauges let you easily check radiator coolant, hydraulic

oil and transmission oil levels as well as engine air filter

restriction without opening the air cleaner.

• Standard pressure taps allow quick diagnosis of the entire

hydraulic system.

• S•O•SSM ports make oil sampling quicker, cleaner and provide

the best oil sample for analysis.

• Spin-on filters for engine oil, transmission oil and hydraulic oil

are vertically mounted for easier servicing.

• 928Hz features a standard electronic fuel prime pump.

• Sequentially placed radiator and oil coolers are easy to access.

• Swing-out cooling fan allows quick and easy cleaning and

servicing of the radiator. The fan is hydraulically driven and

separate from the engine compartment for low noise operation.

• Optional reversing fan cleans screens without interrupting

machine operation.

Customer Support

Unmatched support makes

the difference

Your Cat dealer is ready to assist you with your

purchase decision and everything after.

• Make comparisons of machines, with estimates of

component life, preventative maintenance and cost

of production.

• Financing packages are flexible to meet your needs.

• Your Cat dealer can evaluate the cost to repair, rebuild and

replace your machine, so you can make the right choice.

• For more information on Cat products, dealer services and

industry solutions, visit us at www.cat.com.

Page 8

928Hz Wheel Loader Specifications

Engine

Rated net power 111 kW 149 hp

@ 2,300 rpm

Model Cat

®

C6.6

SAE J1349 111 kW 149 hp

ISO 9249 (1997) 112 kW 150 hp

EEC 80/1269 112 kW 150 hp

Max. net power 119 kW 160 hp

@ 2,000 rpm

SAE J1349 119 kW 160 hp

ISO 9249 (1997) 120 kW 161 hp

EEC 80/1269 120 kW 161 hp

Bore 105 mm 4.13 in

Stroke 127 mm 5 in

Displacement 6.6 L 403 in

3

Net torque 727 N·m 536 ft-lb

Peak torque 742 N·m 547 ft-lb

• Net Power ratings are tested at the reference

conditions for the specified standard.

• Net power shown is the power available at

the flywheel when the engine is equipped

with alternator, air cleaner, muffler and fan

at minimum speed.

• No derating required up to 3000 m

(9,843 ft) altitude. Auto derate protects

hydraulic and transmission systems.

• When the fan is at maximum speed,

Rated Net Power is 97 kW (130 hp) and

Maximum Net Power is 106 kW (142 hp)

at the flywheel per the SAE reference

conditions.

• The Caterpillar

®

C6.6 engine meets Tier 3

off-highway emission regulations.

Engine Torque

(ft-lb)

N·m

(800)

1085

(700)

949

(600)

813

(500)

678

(400)

542

(300)

407

Net Torque

(200)

271

(100)

136

(0)

0

800 1,000 1,100 1,200 1,400 1,600 1,800 2,000 2,200 2,300

Buckets

Bucket capacities 2.0 m3- 2.6 yd3-

2.3 m

3

3.0 yd

Weights

Operating weight 12 564 kg 27,699 lb

• Specifications shown are for 928Hz with

optional counterweight, standard lubricants,

full fuel tank, deluxe cab, Limited Slip rear

axle with heavy duty brakes, additional

guarding, 2.0 m

3

(2.6 yd3) bucket with

bolt-on cutting edge, 80 kg (176 lb) operator

and 20.5 R25 radial (L-3) XHA tires.

Steering

Steering 40° 40°

articulation

Minimum turning 5233 mm 206 in

radius (over tire)

Steering angle, 40° 40°

each direction

Steering cylinders, 70 mm 2.75 in

two, bore

Hydraulic output at 104 L/min 27 gal/min

2,300 engine rpm

and 6900 kPa

(1,000 psi)

Maximum working 20 700 kPa 3,000 psi

pressure

928Hz Net Torque

928Hz Net Power

(hp)

kW

(188)

140

(161)

120

(134)

100

(107)

80

(80)

60

40

20

0

RPM

Net Power

(54)

(27)

(0)

Loader Hydraulic System

3

Output at 151.5 L/min 40.3 gal/min

2,300 engine rpm

and 6900 kPa

(1,000 psi) with

SAE 10W oil at

65° C (150° F)

Hydraulic 10.1 Seconds

cycle time

Pump flow – 152 L/min 40.2 gal/min

implement pump

Relief pressure – 258.9 bar 3,755 psi

implement pump

Maximum working 25 900 kPa 3,755 psi

pressure

Hydraulic 10.1 Seconds

cycle time

Raise 6.1 Seconds

Dump 1.2 Seconds

Lower, empty, 2.8 Seconds

float down

Total 10.1 Seconds

Lift cylinders,

double acting:

Bore 120.6 mm 4.75 in

Stroke 685 mm 27 in

Tilt cylinder,

double acting:

Bore 127 mm 5 in

Stroke 550 mm 21.7 in

Service Refill Capacities

Fuel tank 225 L 59.4 gal

Cooling system 42 L 11.1 gal

Crankcase 15 L 4.0 gal

Transmission 34.5 L 9.1 gal

Differentials and

final drives:

Front 26 L 6.9 gal

Rear 25 L 6.6 gal

Hydraulic system 125 L 33 gal

(including tank)

Hydraulic tank 70 L 18.5 gal

8

Page 9

Transmission

Standard 37.7 km/h 23.4 mph

transmission

max travel speeds

Forward 1 7.9 km/h 4.9 mph

2 12.6 km/h 7.8 mph

3 25.8 km/h 16 mph

4 37.7 km/h 23.4 mph

Reverse 1 7.9 km/h 4.9 mph

2 12.6 km/h 7.8 mph

3 25.8 km/h 16 mph

Tires

Size 20.5 R25 L3 XHA

Tread width 2570 mm 8 ft 5 in

• Choice of:

• 17.5-25, 12PR (L-2)

• 17.5-25, 12PR (L-3)

• 17.5 R25, radial (L-2)

• 17.5 R25, radial (L-3)

• 20.5-25, 12PR (L-2)

• 20.5-25, 12PR (L-3)

• 20.5 R25, radial (L-2/L-3)

• 600/65 R25, radial (L-3)

• Other tire choices are available, contact your

®

Cat

Dealer for details.

• In certain applications, the loader’s productive

capabilities may exceed the tire’s tonneskm/h (ton-mph) capabilities. Caterpillar

recommends that you consult a tire supplier

to evaluate all conditions before selecting

a tire model.

Cab

ROPS SAE J1040 MAY94,

ISO 3471-1994

FOPS SAE J/ISO 3449 APR98

Level II, ISO 3449 1992

Level II

• Caterpillar cab and Rollover Protective

Structure (ROPS) are standard in North

America and Europe.

• When properly installed and maintained, the

cab offered by Caterpillar, when tested with

doors and windows closed as per work cycle

procedures specified in ANSI/SAE J1166

May 90, results in operator sound exposure

Leq (equivalent sound pressure level) of

74 dB(A).

Operating Specifications

Static tipping load 8658 kg 19,089 lb

(full turn)

Reach – full lift/ 927 mm 3 ft 0 in

45 degree

dump angle

Dump clearance – 2879 mm 9 ft 6 in

full lift/45 degree

dump angle

Articulation angle 40° 40°

9

Page 10

928Hz Wheel Loader Specifications

Dimensions

All dimensions are approximate. Dimensions may vary with bucket. Refer to Operating Specifications.

15

1

14

2

3

16

10

18

17

13

12

11

24

23

25

4

7

1 Height to top of ROPS/FOPS 3269 mm (10 ft 9 in)

5

8

9

6

20

19

21

22

2 Height to top of exhaust stack 3189 mm (10 ft 6 in)

3 Height to top of hood 2197 mm (7 ft 2 in)

4 Height to center of axle 685 mm (2 ft 3 in)

5 Ground clearance 408 mm (1 ft 4 in)

6 Overall length 7252 mm (23 ft 10 in)

7 Length – rear axle to bumper 1920 mm (6 ft 4 in)

8 Center line of front axle to hitch 1450 mm (4 ft 9 in)

9 Wheel base length 2900 mm (9 ft 6 in)

10 Dump clearance at maximum lift and 45° dump 2879 mm (9 ft 5 in)

11 Bucket clearance at maximum lift and level 3752 mm (12 ft 4 in)

12 Bucket pin height at maximum lift 3872 mm (12 ft 8 in)

13 Overall height – bucket raised 4971 mm (16 ft 4 in)

14 Reach at maximum lift and 45° dump 927 mm (3 ft 0 in)

15 Rack back angle at maximum lift 60°

16 Dump angle at maximum lift 45°

17 Rack back angle at ground 44°

18 Rack back angle at carry 47.8°

19 Carry height 449 mm (1 ft 6 in)

20 Digging depth 86 mm (3 in)

3

Dimensions listed are for 928Hz with 2.0 m

axles, heavy duty rear brakes, additional guarding, sound sppression, work tool, 80 kg (176 lb) operator and Michelin 20.5R25 L3 XHA tires.

(2.6 yd3) pin-on bucket with bolt-on cutting edge, cab with A/C, optional counterweights, limited slip

20.5 R25 (L-3) Tires 17.5-25 12PR (L-2) Tires

21 Width at tread center 1950 mm (6 ft 5 in) 1950 mm (6 ft 5 in)

22 Overall width over tires 2570 mm (8 ft 5 in) 2407 mm (7 ft 11 in)

23 Minimum turning radius over tires 5275 mm (17 ft 4 in) 5186 mm (17 ft 0 in)

24 Minimum turning radius over bucket at ground level 5794 mm (19 ft 0 in) 5795 mm (19 ft 0 in)

25 Steering angle – left/right 40° 40°

Change in vertical dimension no change no change –65 mm (–2.6 in)

10

Page 11

Operating Specifications

Pin-on Buckets

With Bolt-On With Bolt-On With Bolt-On

Cutting Edge Teeth & Segments* Teeth*

Rated bucket capacity (§) m

yd

Struck capacity (§) m

yd

Bucket width mm 2549 2549 2549 2549 2549 2549

ft/in 8'4" 8'4" 8'4" 8'4" 8'4" 8'4"

10 Dump clearance at full lift and 45° discharge (§) mm 2879 2842 2766 2730 2766 2729

ft/in 9'5" 9'4" 9'1" 8'11" 9'1" 8'11"

14 Reach at full lift and 45° discharge (§) mm 927 964 1021 1058 1021 1058

ft/in 3'0" 3'2" 3'4" 3'6" 3'4" 3'6"

Reach at 45° discharge and 2130 mm (7'0") mm 1455 1474 1492 1509 1492 1509

clearance (§)

ft/in 4'9" 4'10" 4'11" 4'11" 4'11" 4'11"

Reach with lift arms horizontal mm 2253 2305 2399 2451 2399 2451

and bucket level

ft/in 7'5" 7'7" 7'10" 8'0" 7'10" 8'0"

20 Digging depth (§) mm 86 86 99 99 99 99

in 3.4" 3.4" 3.9" 3.9" 3.9" 3.9"

6 Overall length mm 7252 7304 7398 7450 7378 7430

ft/in 23'10" 24'0" 24'3" 24'5" 24'2" 24'5"

13 Overall height with bucket at full raise (§) mm 4971 5070 4971 5070 4971 5070

ft/in 16'4" 16'8" 16'4" 16'8" 16'4" 16'8"

24 Loader clearance radius with bucket mm 5781 5796 5845 5860 5845 5860

in carry position (§)

ft/in 19'0" 19'0" 19'2" 19'3" 19'2" 19'3"

Static tipping load straight (§) kg 9983 9911 9819 9746 9923 9851

lb 22,008 21,850 21,647 21,486 21,876 21,717

Static tipping load full 40° turn (§) kg 8654 8585 8490 8420 8594 8525

lb 19,079 18,928 18,718 18,564 18,948 18,795

Breakout force (§) kg 11 723 11 095 11 590 10 961 12 604 11 880

lb 25,844 24,460 25,552 24,165 27,787 26,191

Operating weight kg 12 564 12 618 12 669 12 753 12 614 12 668

lb 27,699 27,818 27,997 28,116 27,809 27,928

3

2.0 2.3 2.0 2.3 1.9 2.2

3

2.6 3.0 2.6 3.0 2.5 2.9

3

1.7 1.9 1.7 1.9 1.6 1.8

3

2.2 2.5 2.2 2.5 2.1 2.4

Specifications shown are for 928Hz with cab with A/C, optional counterweight, limited slip axles, heavy duty rear brakes, additional guarding,

sound supression, work tool, 80 kg (176 lb) operator and Michelin 20.5 R25 L3 XHA tires.

* Dimensions are measured to the tip of the bucket teeth to provide accurate clearance data. SAE standards specifies the cutting edge.

(

§)

Specifications and ratings conform to all applicable standards recommended by the Society of Automotive Engineers (SAE), including

SAE-Standards J732 JUN92 and J742 FEB85 governing ratings.

Other Ground Engaging Tools available, consult your Cat dealer.

11

Page 12

928Hz Wheel Loader Specifications

Typical Material Densities – Loose

kg/m3 lb/yd

Basalt 1960 3,305

Bauxite, Kaolin 1420 2,394

Clay

natural bed 1660 2,799

dry 1480 2,495

wet 1660 2,799

Clay and gravel

dry 1420 2,394

wet 1540 2,596

Decomposed rock

75% rock, 25% earth 1960 3,305

50% rock, 50% earth 1720 2,900

25% rock, 75% earth 1570 2,647

Earth

dry, packed 1510 2,546

wet, excavated 1600 2,698

Granite

broken 1660 2,799

Gravel

pitrun 1930 3,254

dry 1510 2,546

dry, 6-50 mm (0.2-2") 1690 2,849

wet, 6-50 mm (0.2-2") 2020 3,406

3

kg/m

Gypsum

broken 1810 3,052

crushed 1600 2,698

Limestone

broken 1540 2,596

crushed 1540 2,596

Sand

dry, loose 1420 2,394

damp 1690 2,849

wet 1840 3,102

Sand and clay

loose 1600 2,698

Sand and gravel

dry 1720 2,900

wet 2020 3,416

Sandstone 1510 2,546

Shale 1250 2,107

Slag

broken 1750 2,950

Stone

crushed 1600 2,698

3

lb/yd

3

Bucket Selection – Pin-on Buckets

Bucket

Capacity

1500 1700 1900 2100 2300 2500

3

yd

3

m

2.0 2.6

2.3 3.0

Material Density

115% 100% 95%

% = Bucket Fill Factor

3

kg/m

3

3,500 4,0003,000

lb/yd

12

Page 13

Supplemental Specifications

Change in Change in Articulated Static Tipping Load

Operating Weight with Pin-On Bucket 2.0 m

3

(2.6 yd3)

kg lb kg lb

Canopy, ROPS (less cab) –198 –436 –181 –398

No optional counterweights –470 –1,034 –751 –1,652

Substitute 296 kg (653 lb) optional counterweight –174 –383 –278 –612

Without guard, crankcase –17 –37 –22 –48

Without guard, power train –58 –128 –56 –123

Without ride control system –41 –90 –28 –62

Without secondary steering –42 –92 –52 –114

Tires, 1-piece rims

17.5-25, 12PR (L-2) –661 –1,454 –410 –902

17.5-25, 12PR (L-3) –582 –1,280 –361 –794

17.5-25, radial (L-2/L-3) –519 –1,142 –322 –708

17.5-25, radial (L-2) –614 –1,351 –381 –838

17.5-25, radial (L-3) –458 –1,008 –284 –625

Tires, 3-piece rims

17.5-25, 12PR (L-2) –529 –1,164 –328 –722

17.5-25, 12PR (L-3) –457 –1,005 –283 –623

17.5-25, radial (L-2/L-3) –413 –909 –256 –563

17.5-R25, radial (L-2) –489 –1,076 –303 –667

17.5-R25, radial (L-3) –389 –856 –241 –530

20.5-25, 12PR (L-2) –240 –528 –149 –328

20.5-25, 12PR (L-3) –96 –211 –60 –132

20.5-25, radial (L-2/L-3) –52 –114 –33 –73

20.5 R25, radial (L-2) –172 –378 –107 –235

20.5 R25, radial (L-3) 0 0 0 0

600/65 R25, radial (L-3) Michelin +4 +9 +2 +4

13

Page 14

928Hz Standard Equipment

Standard equipment may vary. Consult your Caterpillar dealer for details.

ELECTRICAL

Alternator, 95-amp brushless

Alarm, back-up

Batteries, maintenance-free, 950 CCA, (2)

Directional signals (front & rear)

Starting and charging system, 24V

Halogen work lights (front & rear)

Ignition key start/stop switch

Roading lights

Starting aid, thermal

Switch, battery disconnect

OPERATOR ENVIRONMENT

Standard two door cab includes all of the

following items:

Air conditioner, heater/defroster

Sliding glass door windows

Radio ready

12 volt electrical accessory outlet

Sealed Instrument Gauge:

• Engine RPM

• Hydraulic oil temperature

• Engine coolant temperature

• Torque converter oil temperature

• Fuel level

• Digital LED speedometer, hour meter/

odometer

Indicator Lights:

• Turn signal

• Primary steering malfunction

• Hydraulic oil bypass

• Parking brake applied

• Brake charge pressure low

• Transmission oil temperature

• General warning

• Electrical system voltage low

• Fuel water separator

• Engine oil temperature

• Bright lights activated

Adjustable tilt steering column

Coat hook

Ground level door release

Horn, steering wheel mounted (electric)

Hydraulic control lever lockout

Interior light

Lighter

Lunch box storage with cup holder

Pilot hydraulic implement controls

Rear window defroster, electric

Rear view mirrors (2 inside)

Seat, adjustable suspension, armrest

(fabric or vinyl)

Seat belt, 75 mm (3 in), retractable

Tinted safety glass, front

Tool box

Wet arm wiper/washer (front & rear),

front intermittent

POWER TRAIN

Engine, Cat C6.6 ACERT

• Low emission diesel engine

• Noise reduction technology

• Smart waste gate turbocharged

• Aftercooled

• Closed Circuit Breather

• Electronically controlled

Air cleaner, dry type

Axle seal guards, integrated

Brakes, enclosed wet-disc full hydraulic

Differentials, conventional (front/rear)

Driveshaft, lubed for life

Electric fuel prime pump

Engine speed control

Fuel/water separator

Muffler

Radiator, unit serviceable

S•O•S oil sampling port, engine oil

S•O•S oil sampling port, transmission oil

Torque converter

Transmission, 4F/3R, autoshift, single lever

control with F/N/R and kickdown button

Transmission neutralizer; operator

programmable

HYDRAULICS

Hydraulic diagnostic connectors

Heavy duty hydraulic oil cooler

Hydraulic control, 2-valve, 1-lever

with F/N/R

Hydraulics, third function

Load-sensing steering system

SM

oil sampling port, hydraulic oil

S•O•S

OTHER STANDARD EQUIPMENT

Antifreeze/coolant, extended-life protects to

–36° C (–33° F)

Automatic bucket positioner/fork positioner

Brakes, secondary and parking

Counterweight

Engine enclosure, lockable

Fenders, front

Hitch, recovery

Loader linkage, z-bar

Lift kickout, automatic

Machine Security System ready

Product Link ready

Remote grease lines

Steering stops, cushioned

Swing-out, hydraulically driven demand fan

Vandalism protection, lockable service points

Visual indicators:

• air cleaner service

• coolant level

• hydraulic oil

• transmission oil

14

Page 15

Optional equipment may vary. Consult your Caterpillar dealer for details.

928Hz Optional Equipment

Antifreeze/coolant, extended-life, protects to

–50° C (–58° F)

Axles:

• Front Limited Slip Differential

• Rear Limited Slip Differential

• Rear Limited Slip Differential, with heavy

duty brakes (axle oil cooler included)

Beacon light, rotating or strobe,

magnetic-mount

Buckets/ground engaging tools

Canopy, ROPS

Counterweight, additional, optional

Coupler controls and lines

Deluxe Cab arrangement includes:

• External heated mirrors

• Sunscreen

• Sun shade

• Flood lights, auxiliary, cab mounted

Fan, reversing

Fenders, roading, rear

Fenders, steel

Guards:

• Crankcase

• Driveshaft, front

• Power train

• Lights

• Windshield

• Radiator

Hydraulic control auxiliary, third valve

Load check valves (dealer installed)

Machine Security System

Material handling arm

Pallet forks, carriage

Product Link

Quick Coupler

Radiator, wide fin spacing, 5.5 fpi

Radio packages:

• Radio, AM/FM

• Radio, AM/FM with CD player

Rear-view camera system

Ride Control System

Seats:

• Cat Contour Seat, fabric, with adjustable

backrest and lumbar support

• Cat Contour Seat, fabric, electrically

adjustable with air suspension

Sound suppression package, available in

select markets

Starting aid, engine coolant heater, 120V

Steering, secondary

Tires:

• Bias ply, 17.5-25 and 20.5-25

• Radial, 17.5-R25, 20.5-R25 and 600/65 R25

15

Page 16

928Hz Wheel Loader

For more complete information on Cat products, dealer services, and industry solutions, visit us on

the web at www.cat.com

© 2007 Caterpillar Inc.

All rights reserved

Printed in the U.S.A.

Materials and specifi cations are subject to change without notice. Featured machines may include

additional equipment. See your Caterpillar dealer for available options.

CAT, CATERPILLAR, their respective logos, “Caterpillar Yellow” and the POWER EDGE trade dress,

as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be

used without permission.

AEHQ5907 (08-2007)

Replaces AEHQ5610-01

19

Loading...

Loading...