Page 1

914G2/IT14G2

Compact Wheel Loader/

IntegratedToolcarrier

Engine Weights

Model Cat

Net Power – SAE J1349 71 kW 95 hp Operating Weight – IT14G2 8450 kg 18,632 lb

Net Power – ISO 9249/EEC 72 kW 97 hp Buckets

Net Power – ISO 9249 (DIN) 72 kW 98 hp Bucket Capacities 1.2-1.4 m

®

C4.4 Electronic Operating Weight – 914G2 7950 kg 17,530 lb

3

1.6-1.8 yd

3

Page 2

914G2/IT14G2 Features

Comfortable Cab

Spacious cab and easy to use controls deliver all

day comfort so you can concentrate on your work.

High Performance Power Train

Aggressive performance helps you get more done.

Loader Linkage

Loader design is built for strength and durability.

Work Tools

Do more jobs with one machine with the variety

of Cat Work Tools.

Contents

Operator Station ..................................................3

Power Train ..........................................................4

Loader ...................................................................4

Work Tools ............................................................5

Serviceability .......................................................6

Customer Support ...............................................6

914G2/IT14G2 Compact Wheel Loader/

Integrated Toolcarrier Specications .............7

914G2/IT14G2 Standard Equipment ................18

914G2/IT14G2 Optional Equipment .................19

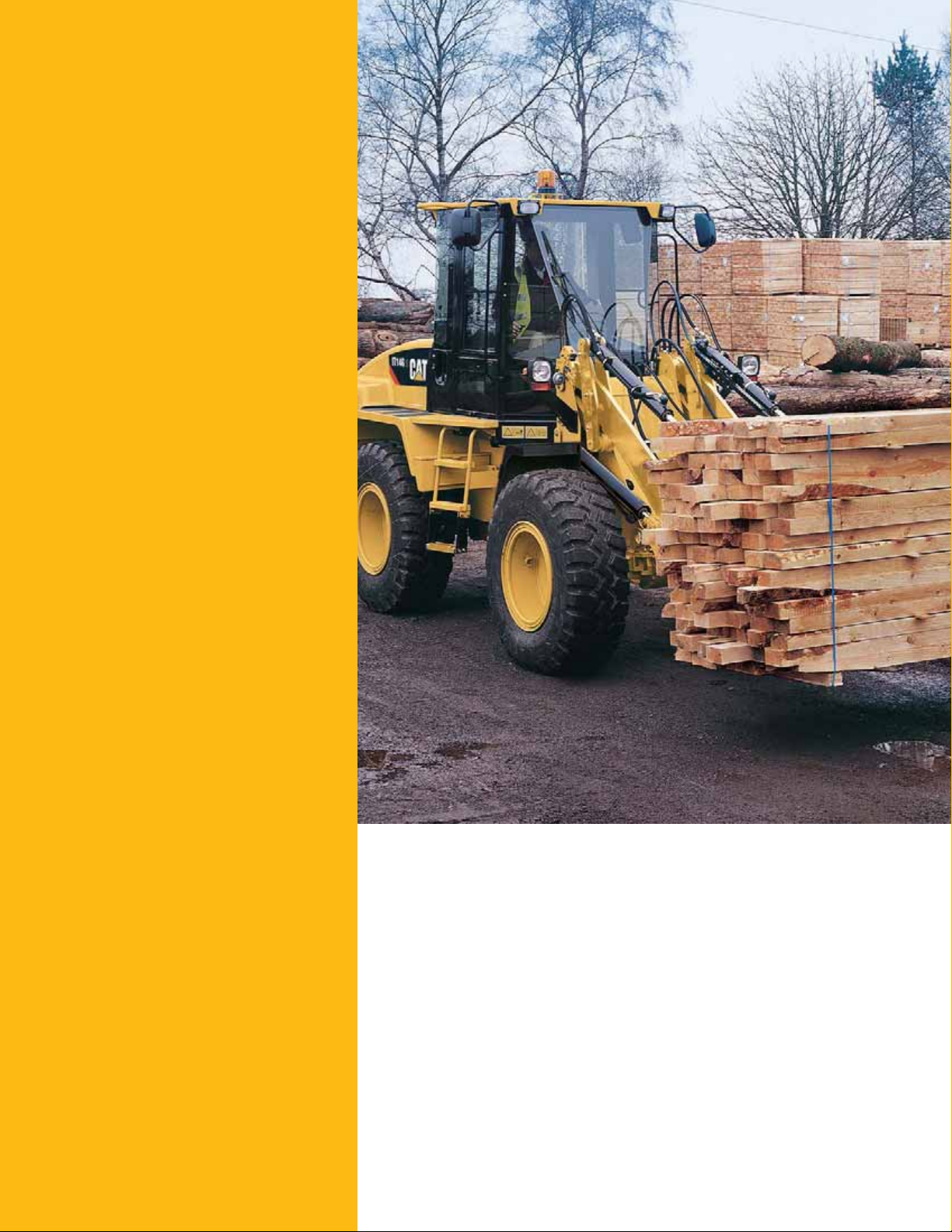

The Cat® 914G2/IT14G2 delivers strong performance, high

productivity and proven reliability. Spacious cab with

joystick control keeps you comfortable throughout the

work day, allowing you to get more done. Loader design

provides strength and durability with superior control.

Expand your business with the 914G2/IT14G2.

Page 3

Operator Station

Superior comfort keeps you productive, all day long.

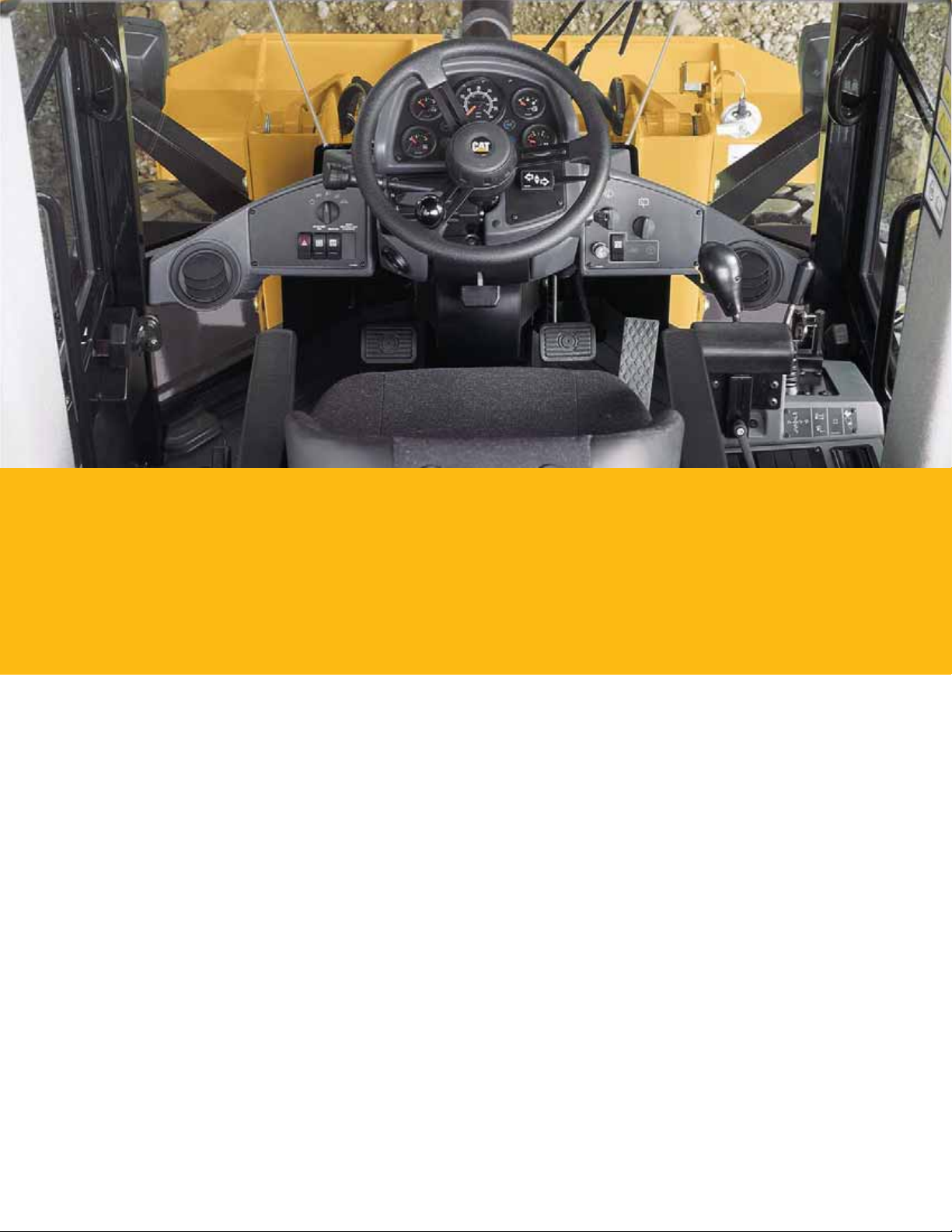

Cab

The ergonomic cab provides a comfortable work environment with large windows, spacious interior

room, generous storage areas and low interior sound levels. The two-door design allows easy entry

and exit. Both doors open fully and lock ush against the cab. Steps leading up to the cab are wide

and angled out for secure footing. The optional air suspension seat is designed for maximum comfort

and fully-adjustable support. Generous storage space includes a lockable compartment, coat hook

and compartments designed to hold a lunchbox/cooler, cup or can. A tool box is also provided.

Low Effort Controls

Hydraulic pilot controls provide easy operation of lift and tilt functions. A remote transmission control

option adds a forward/neutral/reverse control switch on the implement lever for easier operation and

enhanced productivity. Third and fourth function controls are also available for use with special work

tools. Hydrostatic, closed-center steering system with ow amplication provides fast or slow steering

response, depending on the operational requirement. With the optional Engine Speed Control, a speci c

engine RPM can be set and maintained with a switch in the cab. The creeper control option allows

variable function of travel speeds with full engine RPM.

Visibility

The loader arms have been designed to provide excellent visibility throughout the production cycle.

3

Page 4

Power Train

Designed for power, durability and performance.

Cat Engine

The Cat C4.4 Electronic engine has a proven reputation for rugged, reliable

operation while providing peak performance in a wide range of operating

conditions. Highhorsepower and torque help you get more work done in a day.

Transmission

The high-pressure closed-loop hydrostatic transmission delivers high performance

with a broad range of power to the ground.

Axles

Heavy-duty axle design features strong gears and bearings for durable

performance. The xed front, oscillating rear axle helps assure four-wheel ground

contact for optimum traction and stability. Patented Duo-Cone™ seals on the

axle and housing keep oil in and lock contaminants out. A choice of standard

conventional or Limited Slip Differentials adapts the machine to a wide range

of operating conditions.

Brakes

Hydraulically-actuated disc brakes are standard on both the front and rear axles

and provide low effort operation. The mechanical, shoe-type parking brake also

automatically neutralizes the transmission when applied.

Loader

Built for strength.

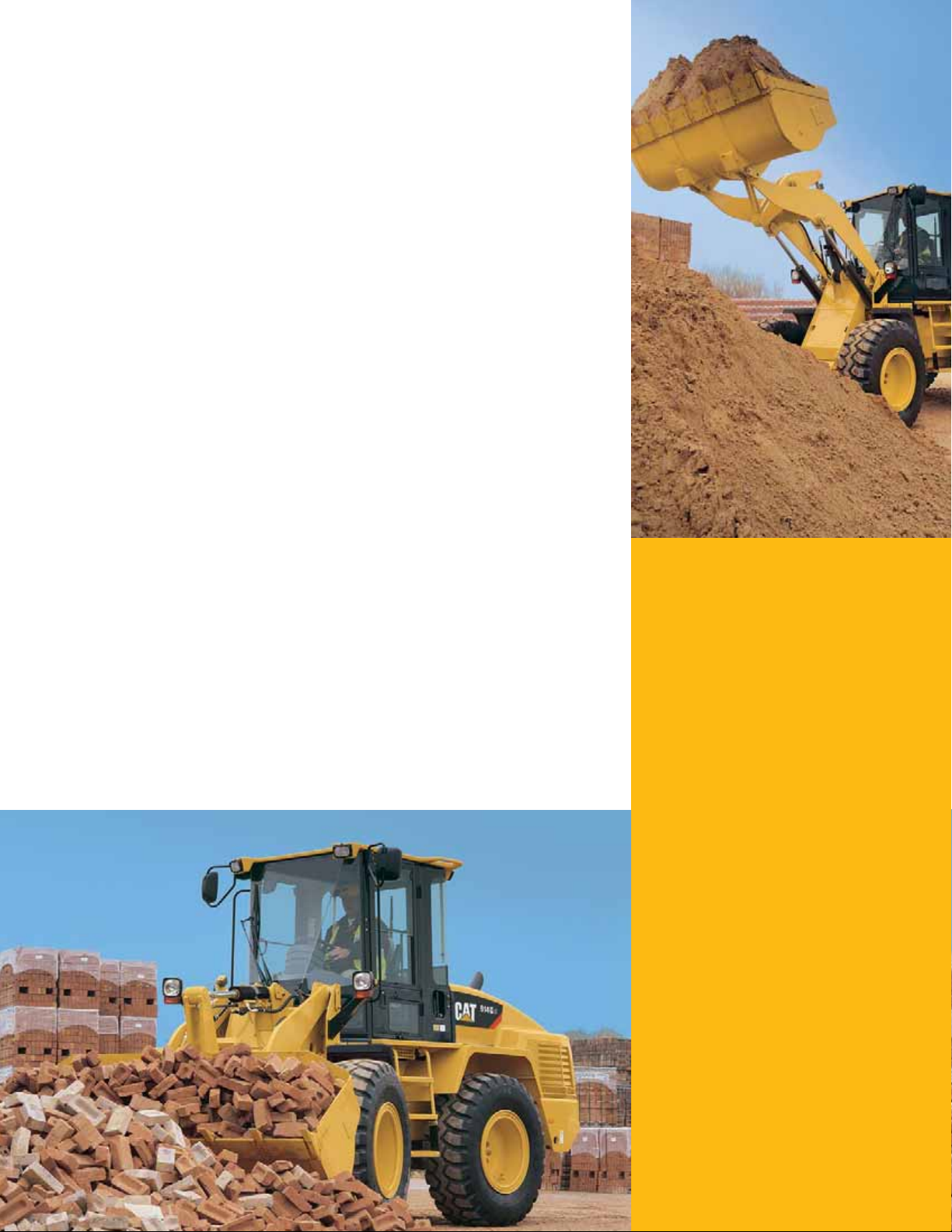

Z-Bar Linkage Design

The high performance Z-bar

loader linkage design on the 914G2

is built for strength, visibility and

versatile attachment usage.

8-Bar Parallel Linkage Design

The 8-bar parallel linkage on the

IT14G2 simplies keeping forks

level throughout the range of lift,

without adjustment. Longer lift

arms, taller front tower and higher

pivot points offer more lift, height

and reach than conventional loaders.

Having more tilt capacity than lift

in almost every position provides

superior load control.

Page 5

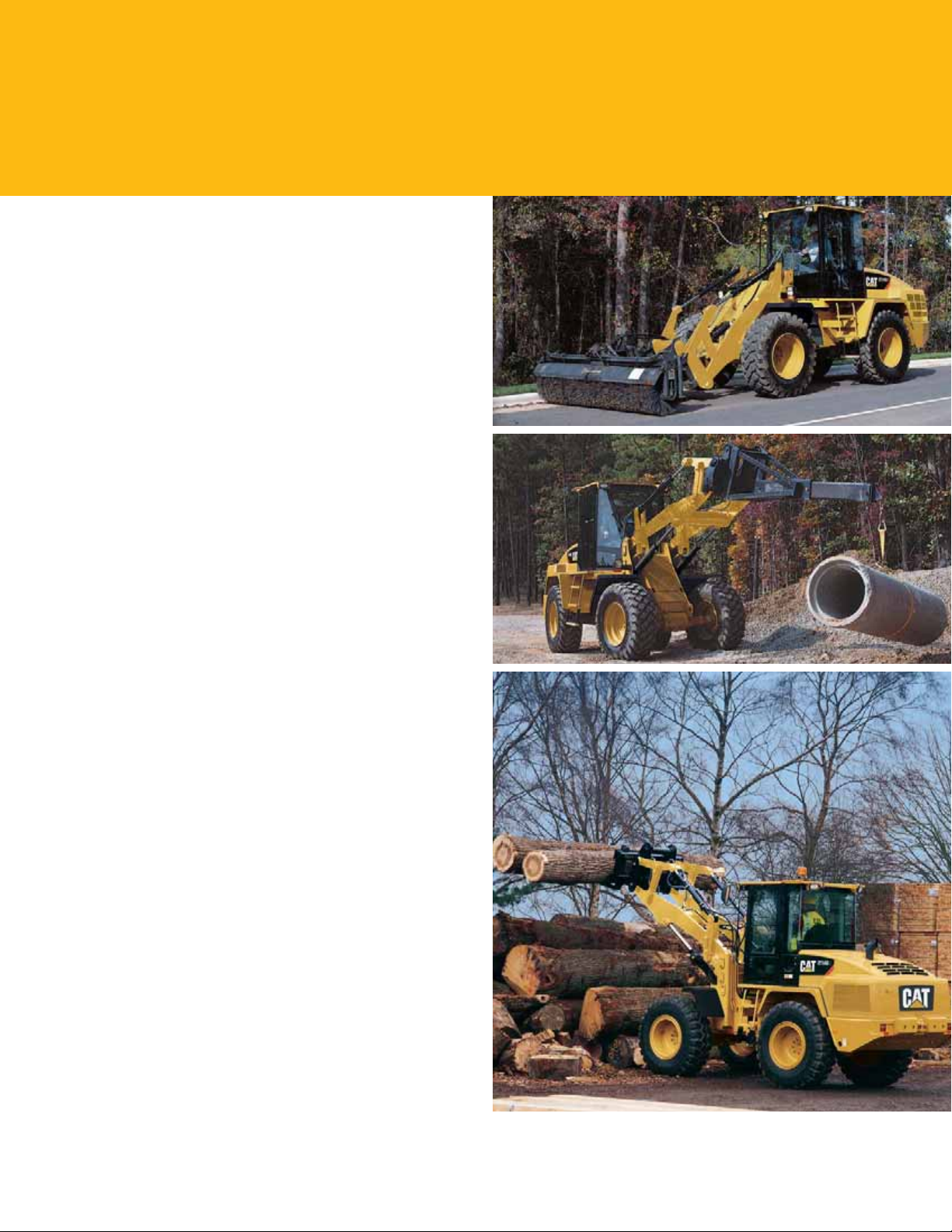

Work Tools

Do more jobs with one machine with Cat Work Tools.

The Right Tool for the Job

With a variety of Cat Work Tools, the 914G2/IT14G2 is

idealfor a wide range of applications. Work tool controls

feature pilot operated lift and tilt circuits with low effort

single-lever control.

Quick Coupler

Work Tools can be changed quickly and easily with the

integral quick coupler system, standard on the IT14G2

and optional on the 914G2. A switch in the IT14G2 cab

activates a hydraulic cylinder for positive tool engagement

ordisengagement.

Auxiliary Hydraulics

Optional 3rd (standard on the IT14G2) and 4th function

hydraulics are available for use with work tools that require

hydraulic power such as rotary brooms.

5

Page 6

Serviceability

Easy access and minimal maintenance requirements reduce downtime.

Convenient Service Features

One-piece engine enclosure hood with gas struts lifts for

exceptional access to lters and service points. All service

points are accessible from ground level.

• Radiator and oil coolers are easily accessible for cleaning.

• Easily check radiator coolant and hydraulic oil levels

with sight gauges.

• Swing-out oil cooler allows quick, easy cleaning and

service to the radiator.

• S•O•SSM ports are factory installed for improved access

to engine, transmission and hydraulic oils. S•O•S ports

make oil sampling quicker, cleaner and provide the best

oil sample for analysis.

• Spin-on lters for engine oil and hydraulic oil are

vertically mounted for easier servicing.

• Cat Extended Life Coolant/Antifreeze allows extended

operation (up to 6,000 hours) between changes.

Customer Support

Support you can count on.

Superior Dealer Service

Your Cat dealer is ready to assist you with your purchase

decision and everything after.

• Make comparisons of machines, with estimates of

component life, preventative maintenance and cost

of production.

• Financing packages are exible to meet your needs.

• Your Cat dealer can evaluate the cost to repair,

rebuild and replace your machine, so you can make

the right decision.

• For more information on Cat products, dealer services

and industry solutions, visit us at www.cat.com.

Page 7

914G2/IT14G2 Compact Wheel Loader/Integrated Toolcarrier Specications

Engine Operating Speci cations Hydraulic System

Model Cat® C4.4 Electronic Tire Size 17.5-25 Main Relief 245.5 bar 3,560 psi

Maximum Gross 75 kW 101 hp Rated Bucket 1.3 m

Power – ISO 14396 Capacity

Maximum Gross 75 kW 102 hp Breakout Force 62 kN 14,007 lb Time – Lift

Power – ISO 14396

(DIN)

Rated Net Power

@ 2,300 rpm –

SAEJ1349

Rated Net Power

@ 2,300 rpm –

ISO 9249/EEC

Rated Net Power

@ 2,300 rpm –

ISO 9249 (DIN)

• The Cat C4.4 Electronic engine meets

EUStage IIIA and U.S. EPA Tier 3

emission regulations.

71 kW 95 hp –IT14G2

72 kW 97 hp Bucket – 914G2

72 kW 98 hp Bucket – IT14G2

Engine Dimensions

Bore 105 mm 4.13 in

Stroke 127 mm 5 in

Displacement 4.4 L 268 in

Weights

Operating Weight

–914G2

Operating Weight

–IT14G2

Optional

Counterweight*

* Optional on 914G2. Standard on IT14G2.

• 914G2 with 1.4 m

with bolt-on cutting edge and optional

counterweight.

• IT14G2 with 1.4 m3 (1.8 yd3) bucket

with bolt-on cutting edge, quick coupler

and counterweight.

7950 kg 17,530 lb

8450 kg 18,632 lb

150 kg 330 lb

3

(1.8 yd3) bucket

–914G2

Breakout Force 77 kN 17,342 lb

Full Turn Static

Tipping Load,

Full Turn Static

Tipping Load,

Dump Height @

Full Lift – 914G2

Dump Height @ 2921 mm 9 ft 7 in Tilt Cylinder, 102 × 4.0 ×

Full Lift – IT14G2 Double Acting 400 mm 15.8 in

Articulation 40 degrees

Oscillation +/– 11 degrees

Transmission

Travel Speed 1

3

Travel Speed 2

–914G2

Travel Speed 2 32 km/h 20 mph

–IT14G2

Cab

ROPS SAE J394, SAE J1040,

FOPS SAE J231, ISO 3449

Sound 74 dB(A)

3

5323 kg 11,737 lb

4792 kg 10,566 lb

2659 mm 8 ft 9 in

9 km/h

35 km/h

ISO 3471

3

1.7 yd

5.6 mph

22 mph

Flow 90 L/min 23.8 gal/min

Hydraulic Cycle 5.6

Hydraulic Cycle

Time – Dump

Hydraulic Cycle

Time – Lower,

Float

Lift Cylinders,

Double Acting

–914G2

Lift Cylinders,

Double Acting

–IT14G2

–914G2

Tilt Cylinder,

Double Acting

–IT14G2

2.1

3.2

89 ×

672 mm

89 ×

795 mm

76 ×

805 mm

3.5 ×

26.5 in

3.5 ×

31.3 in

3.0 ×

31.7 in

Service Re ll Capacities

Cooling System 23 L 6.1 gal

Fuel Tank 150 L 39.6 gal

Hydraulic System 100 L 26.4 gal

Hydraulic Tank 70 L 18.5 gal

Buckets

Bucket Capacities 1.2-1.4 m3 1.6-1.8 yd

Brakes

• Meets SAE J1473 and ISO 3450 requirements.

3

7

Page 8

914G2/IT14G2 Compact Wheel Loader/Integrated Toolcarrier Specications

914G2 Operating Specifications

General

Purpose Buckets

Penetration

Buckets

With Bolt-On

With Bolt-On

Cutting Edge

Rated bucket capacity (§) m

Struck capacity (§) m3 1.1 1.2 1.1 1.2 1.0 1.1 1.1 1.2

3

1.3 1.4 1.3 1.4 1.2 1.3 1.3 1.4

3

yd

1.7 1.8 1.7 1.8 1.6 1.7 1.7 1.8

3

yd

1.4 1.5 1.4 1.5 1.3 1.5 1.5 1.5

Teeth and

Segments

With Bolt-On

Teeth

With Flush

Mounted Teeth

Width mm 2401 2401 2424 2424 2424 2424 2434 2434

ft/in 7'10.5" 7'10.5" 7'11.4" 7'11.4" 7'11.4" 7'11.4" 7'11.8" 7'11.8"

Dump clearance at full lift and 45° discharge (§) mm 2659 2623 2667 2632 2715 2680 2680 2680

ft/in 8'9" 8'7" 8'9" 8'7" 8'11" 8'10" 8'10" 8'10"

Reach at full lift and 45° discharge (§) mm 973 1008 964 1000 944 979 979 979

ft/in 3'2" 3'4" 3'2" 3'3" 3'1" 3'3" 3'3" 3'3"

Reach at 45° discharge and 2130 mm (7 ft)

clearance (§)

mm 1331 1348 1282 1297 1259 1275 1287 1249

ft/in 4'4" 4'5" 4'2" 4'3" 4'2" 4'2" 4'3" 4'1"

Reach with lift arms horizontal and bucket level mm 1980 2030 1970 2020 1920 1970 1970 1970

ft/in 6'6" 6'8" 6'6" 6'8" 6'4" 6'6" 6'6" 6'6"

Digging depth (§) mm 89 89 89 89 70 70 70 70

in 3.5" 3.5" 3.5" 3.5" 2.8" 2.8" 2.8" 2.8"

Overall length mm 6229 6279 6328 6378 6310 6360 6358 6438

ft/in 20'5" 20'7" 20'9" 20'11" 20'8" 20'10" 20'10" 21'1"

Overall height with bucket at full raise (§) mm 4390 4442 4390 4442 4390 4442 4442 4442

ft/in 14'5" 14'7" 14'5" 14'7" 14'5" 14'7" 14'7" 14'7"

Loader clearance circle with bucket

in carry position

m 10.34 10.37 10.42 10.45 10.42 10.45 10.44 10.49

ft/in 33'11" 34'0" 34'2" 34'4" 34'2" 34'4" 34'3" 34'5"

Static tipping load straight* (§) kg 6098 6069 6059 6029 6169 6166 6183 6011

lb 13,446 13,382 13,360 13,294 13,603 13,602 13,634 13,254

Static tipping load full 40° turn* (§) kg 5323 5295 5284 5256 5415 5387 5404 5232

lb 11,737 11,675 11,651 11,589 11,940 11,878 11,916 11,537

Breakout force (§) kg 6367 5971 6415 6010 6929 6469 6484 6374

lb 14,007 13,136 14,113 13,222 15,246 14,232 14,265 14,055

Operating weight* kg

7378 7391 7409 7422 7336 7349 7336 7500

16,262 16,297 16,337 16,366 16,176 16,205 16,176 16,538

lb

*Static tipping and operating weights shown are for high-speed version 914G2 and include lubricants, full fuel tank, ROPS cab, 80 kg

(176 lb) operator and 17.5-R25 (L2 equivalent) tires.

NOTE: Specifications and ratings conform to all applicable standards recommended by the Society of Automotive Engineers (SAE).

SAE Standards J732 and J742 govern loader rating, denoted in the text by (§).

8

Page 9

914G2 Dimensions with Bucket

All dimensions are approximate.

1

2

3

48°

60°

41°

46°

10

9

15.5-25, 12PR (L-2)

17.5-R25 (L-2 equivalent)

30°

4

8

5

6

7

mm ft/in

1 3100 10'2"

2 2255 7'5"

3 2080 6'10"

4 620 2'0"

5 1658 5'5"

6 1300 4'3"

7 2600 8'6"

8 374 1'3"

9 3236 10'7"

10 3435 11'3"

Dimensions vary with bucket. Refer to Operating

Specifications chart on previous page.

Change in Vertical

Dimensions

–42

–1.7

—

—

mm

in

mm

in

Tread Width

1800

70.9

1800

70.9

Width over Tires

2223

87.5

2258

88.9

Ground Clearance

414

16.3

456

18.0

9

Page 10

914G2/IT14G2 Compact Wheel Loader/Integrated Toolcarrier Specications

914G2 Supplemental Specifications

Air conditioner

Canopy, ROPS (less cab)

Counterweight, 150 kg (330 lb)

Ride control

Standard speed version machine

Secondary steering

Tires and rims, 15.5-25, 12PR (L-2)

Tires and rims, 15.5-25, 12PR (L-3)

Tires and rims, 17.5-25, 12PR (L-2)

Tires and rims, 17.5-25, 12PR (L-3)

Tires and rims, 17.5-R25, radial (L-3 equivalent)

Tires and rims, 17.5-R25, radial (L-2/L-3 equivalent)

Change in Operating Weight

kg

+55

–199

+152

+32

–70

+30

–159

–78

–126

+12

+156

+95

lb

+121 +71 +156

–438 –174 –383

+334 +287 +631

+70 +6 +13

–154 –74 –163

+66 +44 +97

–350 –99 –218

–172 –48 –106

–277 –78 –172

+26 +7 +15

+343 +96 +211

+209 +58 +128

Change in Articulated

Static Tipping Load

kg lb

10

Page 11

Typical Material Densities – Loose

3

kg/m

Basalt

Bauxite, Kaolin broken

1960 3,305

1420 2,394

Clay crushed

natural bed Limestone

dry broken

wet crushed

1660 2,799

1480 2,495

1660 2,799

lb/yd

3

kg/m

3

lb/yd

3

Gypsum

1810 3,052

1600 2,698

1540 2,596

1540 2,596

Clay and gravel Sand

dry dry, loose

wet damp

1420 2,394

1540 2,596

Decomposed rock wet

75% rock, 25% earth Sand and clay

50% rock, 50% earth loose

25% rock, 75% earth Sand and gravel

1960 3,305

1720 2,900

1570 2,647

Earth dry

dry, packed wet

wet, excavated Sandstone

1510 2,546

1600 2,698

Granite Shale

broken Slag

1660 2,799

Gravel broken

pitrun Stone

dry crushed

dry, 6-50 mm (0.2-2 in)

wet, 6-50 mm (0.2-2 in)

1930 3,254

1510 2,546

1690 2,849

2020 3,406

1420 2,394

1690 2,849

1840 3,102

1600 2,698

1720 2,900

2020 3,416

1510 2,546

1250 2,107

1750 2,950

1600 2,698

914G2 Bucket Size Selector

Bucket Capacity

1400 1600 1800 2000 2200 2400 2600

3

m3 yd

1.2 1.6

1.3 1.7

1.4 1.8

2,400 2,700 3,000 3,300 3,600 3,900 4,200

Material Density

% = Bucket Fill Factor

kg/m

lb/yd

115% 100% 95%

3

3

11

Page 12

914G2/IT14G2 Compact Wheel Loader/Integrated Toolcarrier Specications

IT14G2 Operating Specifications

General

Purpose Buckets

Penetration

Buckets

With Bolt-On

With Bolt-On

Cutting Edge

Rated bucket capacity (§) m

Struck capacity (§) m3 1.1 1.2 1.0 1.1 1.1 1.2 1.1

3

1.3 1.4 1.2 1.3 1.3 1.4 1.3

3

yd

1.7 1.8 1.6 1.7 1.7 1.8 1.7

3

yd

1.4 1.5 1.3 1.5 1.4 1.5 1.5

With Bolt-On

Teeth

Teeth and

Segments

With Flush

Mounted Teeth

Width mm 2401 2401 2424 2424 2424 2424 2434

ft/in 7'10.5" 7'10.5" 7'11.4" 7'11.4" 7'11.4" 7'11.4" 7'11.8"

Dump clearance at full lift and 45° discharge (§) mm 2921 2886 2977 2942 2930 2895 2942

ft/in 9'7" 9'6" 9'9" 9'8" 9'7" 9'6" 9'8"

Reach at full lift and 45° discharge (§) mm 787 823 757 792 779 814 792

ft/in 2'7" 2'8" 2'6" 2'7" 2'7" 2'8" 2'7"

Reach at 45° discharge and 2130 mm (7 ft)

clearance (§)

mm 1426 1443 1351 1368 1375 1390 1380

ft/in 4'8" 4'9" 4'5" 4'6" 4'6" 4'7" 4'6"

Reach with lift arms horizontal and bucket level mm 2151 2201 2090 2140 2139 2189 2140

ft/in 7'1" 7'3" 6'10" 7'0" 7'0" 7'2" 7'0"

Digging depth (§) mm 174 174 155 155 174 174 155

in 6.9" 6.9" 6.1" 6.1" 6.9" 6.9" 6.1"

Overall length mm 6424 6474 6506 6556 6524 6574 6554

ft/in 21'1" 21'3" 21'4" 21'6" 21'5" 21'7" 21'6"

Overall height with bucket at full raise (§) mm 4802 4855 4802 4855 4802 4855 4855

ft/in 15'9" 15'11" 15'9" 15'11" 15'9" 15'11" 15'11"

Loader clearance circle with bucket

in carry position

m 10.40 10.42 10.47 10.50 10.47 10.50 10.49

ft/in 34'1" 34'2" 34'4" 34'5" 34'4" 34'5" 34'5"

Static tipping load straight* (§) kg 5541 5495 5637 5589 5503 5456 5605

lb 12,218 12,116 12,407 12,324 12,134 12,030 12,359

Static tipping load full 40° turn* (§) kg 4792 4750 4882 4840 4754 4712 4855

lb 10,566 10,474 10,765 10,672 10,483 10,390 10,705

Breakout force (§) kg 7865 7435 8456 7965 7920 7481 7979

lb 17,342 16,394 18,645 17,563 17,464 16,496 17,594

Operating weight* kg

8032 8044 7990 8003 8063 8076 7990

17,771 17,737 17,618 17,647 17,779 17,808 17,618

lb

*Static tipping and operating weights shown are for high-speed version IT14G2 and include lubricants, full fuel tank, ROPS cab, 80 kg

(176 lb) operator, standard 250 kg (550 lb) counterweight and 17.5-R25 (L2 equivalent) tires.

NOTE: Specifications and ratings conform to all applicable standards recommended by the Society of Automotive Engineers (SAE).

SAE Standards J732 and J742 govern loader rating, denoted in the text by (§).

12

Page 13

IT14G2 Dimensions with Bucket

All dimensions are approximate.

1

2

3

48°

57°

49°

54°

10

9

15.5-25, 12PR (L-2)

17.5-R25 (L-2 equivalent)

30°

4

5

6

8

7

mm ft/in

1 3100 10'2"

2 2255 7'5"

3 2080 6'10"

4 620 2'0"

5 1658 5'5"

6 1300 4'3"

7 2600 8'6"

8 374 1'3"

9 3565 11'8"

10 3798 12'6"

Dimensions vary with bucket. Refer to Operating

Specifications chart on previous page.

Change in Vertical

Dimensions

–42

–1.7

—

—

mm

in

mm

in

Tread Width

1800

70.9

1800

70.9

Width over Tires

2223

87.5

2298

90.5

Ground Clearance

414

16.3

456

18.0

13

Page 14

914G2/IT14G2 Compact Wheel Loader/Integrated Toolcarrier Specications

IT14G2 Supplemental Specifications

Change in Operating Weight

kg

Air conditioner

Canopy, ROPS (less cab)

Ride control

Power train guard

Secondary steering

Tires and rims, 15.5-25, 12PR (L-2)

Tires and rims, 15.5-25, 12PR (L-3)

Tires and rims, 17.5-25, 12PR (L-2)

Tires and rims, 17.5-25, 12PR (L-3)

Tires and rims, 17.5-25, R25 (L-3 equivalent)

Tires and rims, 17.5-25, R25 (L-2/L-3 equivalent)

Static tipping load changes are for an IT14G2 with lubricants, full fuel tank, ROPS cab, 80 kg (176 lb) operator, standard 250 kg (550 lb)

counterweight, 17.5-R25 L-2 equivalent tires and a 1.3 m

3

(1.7 yd3) general purpose bucket with bolt-on cutting edge.

+55

–122

+28

+17

+30

–140

–76

–40

+32

+100

+76

lb

+121 +62 +137

–269 –89 –196

+62 +5 +11

+37 +15 +33

+66 +38 +84

–309 –84 –185

–168 –46 –101

–88 –21 –46

+71 +17 +37

+220 +54 +119

+168 +41 +90

Change in Articulated

Static Tipping Load

kg lb

14

Page 15

IT14G2 Dimensions with Forks

All dimensions are approximate.

mm ft/in

1

2

3

4

5

6

Dimensions vary with fork length.

Refer to Operating Specifications

chart below.

586 1'11"

1490 4'11"

745 2'5"

3708 12'2"

1808 5'11"

34 1.3"

1

2

4

3

6

5

IT14G2 Operating Specifications with Forks

Fork Tine Length 1050 mm (3'5") 1200 mm (3'11") 1350 mm (4'5")

Operating load:

Per SAE J1197 FEB91 kg 1927 1870 1810

(50% of full turn static tipping load)

Per CEN 474-3, rough terrain kg 2312 2244 2172

(60% of full turn static tipping load)

Per CEN 474-3, firm and level ground kg 3082 2992 2896

(80% of full turn static tipping load)

Overall length mm 6723 6873 7023

Load center mm 525 600 675

Static tipping load with level arms and forks, kg 4447 4309 4179

600 mm (23.6 in) load center, straight*

Static tipping load with level arms and forks, kg 3853 3734 3620

600 mm (23.6 in) load center, full 40° turn*

Operating weight* kg 7898 7915 7928

*Static tipping and operating weights shown are for an IT14G2 with lubricants, full fuel tank, ROPS cab, 80 kg (176 lb) operator, standard

250 kg (550 lb) counterweight and 17.5-R25 (L2 equivalent) tires.

Tipping load is defined by SAE J732.

lb 4,249 4,123 3,991

lb 5,098 4,948 4,789

lb 6,796 6,597 6,386

ft/in 22'1" 22'7" 23'1"

in 21" 24" 27"

lb 9,806 9,501 9,215

lb 8,496 8,233 7,982

lb 17,415 17,453 17,481

15

Page 16

914G2/IT14G2 Compact Wheel Loader/Integrated Toolcarrier Specications

IT14G2 Dimensions with Material Handling Arm

All dimensions are approximate.

10

11

12

13

14

15

16

mm ft/in

1

2

3

4

5

6

7

8

2522 8'3"

1962 6'5"

1402 4'7"

3179 10'5"

4178 13'8"

5178 17'0"

6840 22'5'

6012 19'9"

1

2

3

7

8

9

4

5

10

6

9

5185 17'0"

1585 5'2"

1874 6'2"

2670 8'9"

3468 11'5"

1514 4'11"

2116 6'11"

2719 8'11"

11

12

13

14

15

16

IT14G2 Operating Specifications with Material Handling Arm

Material Handling Arm Position Retracted Mid-Position Extended

Operating load at 40° full turn kg 1370 1076 888

lb 3,021 2,373 1,958

Static tipping load, straight* kg 3158 2484 2051

lb 6,963 5,477 4,522

Static tipping load, full 40° full turn* kg 2740 2153 1777

lb 6,042 4,747 3,918

Operating weight* kg 7770 7770 7770

lb 17,133 17,133 17,133

*Static tipping and operating weights shown include lubricants, full fuel tank, ROPS cab, 80 kg (176 lb) operator, standard 250 kg (550 lb)

counterweight and 17.5-R25 (L2 equivalent) tires.

NOTE: Machine stability and operating weights are affected by tire size, tire ballast and other attachments.

16

Page 17

Typical Material Densities – Loose

3

kg/m

Basalt

Bauxite, Kaolin broken

1960 3,305

1420 2,394

Clay crushed

natural bed Limestone

dry broken

wet crushed

1660 2,799

1480 2,495

1660 2,799

lb/yd

3

kg/m

3

lb/yd

3

Gypsum

1810 3,052

1600 2,698

1540 2,596

1540 2,596

Clay and gravel Sand

dry dry, loose

wet damp

1420 2,394

1540 2,596

Decomposed rock wet

75% rock, 25% earth Sand and clay

50% rock, 50% earth loose

25% rock, 75% earth Sand and gravel

1960 3,305

1720 2,900

1570 2,647

Earth dry

dry, packed wet

wet, excavated Sandstone

1510 2,546

1600 2,698

Granite Shale

broken Slag

1660 2,799

Gravel broken

pitrun Stone

dry crushed

dry, 6-50 mm (0.2-2 in)

wet, 6-50 mm (0.2-2 in)

1930 3,254

1510 2,546

1690 2,849

2020 3,406

1420 2,394

1690 2,849

1840 3,102

1600 2,698

1720 2,900

2020 3,416

1510 2,546

1250 2,107

1750 2,950

1600 2,698

IT14G2 Bucket Size Selector

Bucket Capacity

1400 1600 1800 2000 2200 2400 2600

3

m3 yd

1.2 1.6

1.3 1.7

1.4 1.8

2,400 2,700 3,000 3,300 3,600 3,900 4,200

Material Density

% = Bucket Fill Factor

kg/m

lb/yd

115% 100% 95%

3

3

17

Page 18

914G2/IT14G2 Standard Equipment

Standard equipment may vary. Consult your Cat dealer for details.

ELECTRICAL

24V direct electric starting

Alarm, back-up

Alternator, 80-ampere

Batteries, two 900 CCA maintenance free

Battery disconnect switch

Glow plug starting aid

Horn, front, warning (electrical)

Ignition key start/stop switch

Lighting system: brake lights, interior

light, turn signals (front and rear), halogen

working lights (front and rear)

Power receptacles; internal and external

LOADER

Linkage, sealed Z-bar design loader

(914G2 only)

Linkage, 8-bar parallel lift linkage

with sealed pins (IT14G2 only)

Bucket/fork positioner, automatic

Lift kickout, automatic

Lift/tilt kickout neutralizer

HYDRAULICS

Hydraulic control, pilot-operated

implement, single lever, 2 valve

Hydraulics, third function

(standard on IT14G2 only)

Hydraulic oil cooler, tiltable

Hydraulic diagnostic connectors

•O•

SSM port – hydraulic oil

S

Standard hydraulic oil cooler

Steering, hydraulic

OPERATOR ENVIRONMENT

Bucket control, single lever, pilot

Cab, ROPS (sound suppressed

and pressurized)

• Adjustable steering column

• Cigar lighter

• Cup holder

• Ground level door release

• Heater/defroster

• Rearview mirrors, inside (2)

• Storage space, lockable

• Seat, adjustable fabric suspension

• Retractable seat belt

• Tinted safety glass

• Two doors

• Wiper and washer (front and rear),

front intermittent

Defroster, rear window, wired glass

Indicators:

• Air cleaner

• Air lter

• Brake charge pressure

• Engine oil pressure

• Electrical system voltage

• Hystat oil lter bypass

• Parking brake

• Primary steering

Instrumentation:

• Battery voltage gauge

• Engine coolant temperature gauge

• Fuel level gauge

• Digital hour meter

• Hydraulic oil level sight gauge

• Hydraulic oil temperature gauge

Single lever transmission control

POWER TRAIN

Air cleaner, radial seal

Antifreeze (protected to –36° C/–33° F)

Extended life coolant antifreeze

Brakes, Service – inboard, oil-immersed,

enclosed, wet-disc full hydraulic

Brakes, Parking – mechanical on drive line,

secondary

Differentials, conventional (front and rear)

Driveshaft, lubed for life

Electric fuel pump

Engine: Cat C4.4 Electronic diesel

turbocharged, EU Stage IIIA and

U.S.EPA Tier 3 emission compliant

Engine enclosure, lockable

Muf er

Radiator, serviceable unit core

Radiator expansion bottle

•O•

SSM port – engine oil

S

Suction fan

Transmission, hydrostatic

OTHER

Counterweight

(IT14G2 with quick coupler only)

Fenders (front/rear)

Hitch, drawbar

Pressure test points

Vandalism protection-locked service points

18

Page 19

Optional equipment may vary. Consult your Cat dealer for details.

914G2/IT14G2 Optional Equipment

ELECTRICAL

Electrical Accessories Package

(12Vconverter, accessory plug outlet, wiring)

Lighting, auxiliary front: 2 additional

cab-mounted halogen working lights

Machine Security System

Rotating beacon, magnetic

HYDRAULICS

Drain valves, ecological

Hydraulic third and fourth valves

(third valve standard on IT14G2)

Hydraulic quick disconnects (IT14G2 only)

Steering, secondary

OPERATOR ENVIRONMENT

Air conditioner (R-134a refrigerant)

Canopy, ROPS

Mirrors, two external

Radio prep package (12V) includes

speakers, antenna, converter and mounts

(radio not included)

Ride Control System

Seats:

• Heated, fabric, with parking brake alarm

• Cat Comfort Series, fabric, air suspension

Sliding door window

Speedometer

Sun screen, rear window

Sun visor

POWER TRAIN

Antifreeze (protected to –50° C/–58° F)

Creeper control, transmission

Differential, Limited Slip

(front and/or rear axle)

Engine air lter precleaner, cyclone

Engine Speed Control (ESC)

Forward/Neutral/Reverse (FNR) remote

transmission control

Starting aid, engine block heater, 120V

OTHER

Bottom guard, hystat

Counterweight, 150 kg/330 lb (914G2 only)

Fenders, roading

Guard, windshield (optional 914G2 only)

Ground engaging tools, bucket

Low sound package

“Blue Angel” low sound package

Quick coupler (standard on IT14G2)

Tires:

• Bias ply, 15.5 × 25 and 17.5 × 25

• Radial, 17.5 × R25

Tire rims, 1- and 3-piece

Tool box, lockable

Tool kit

19

Page 20

914G2/IT14G2 Compact Wheel Loader/Integrated Toolcarrier

For more complete information on Cat products, dealer services, and industry solutions,

visit us on the web at www.cat.com

© 2012 Caterpillar Inc.

All rights reserved

Materials and specications are subject to change without notice. Featured machines

in photos may include additional equipment. See your Cat dealer for available options.

CAT, CATERPILLAR, SAFETY.CAT.COM, their respective logos, “Caterpillar Yellow”

and the “Power Edge” trade dress, as well as corporate and product identity used herein,

are trademarks of Caterpillar and may not be used without permission.

AEHQ6617 (01-2012)

Loading...

Loading...