Page 1

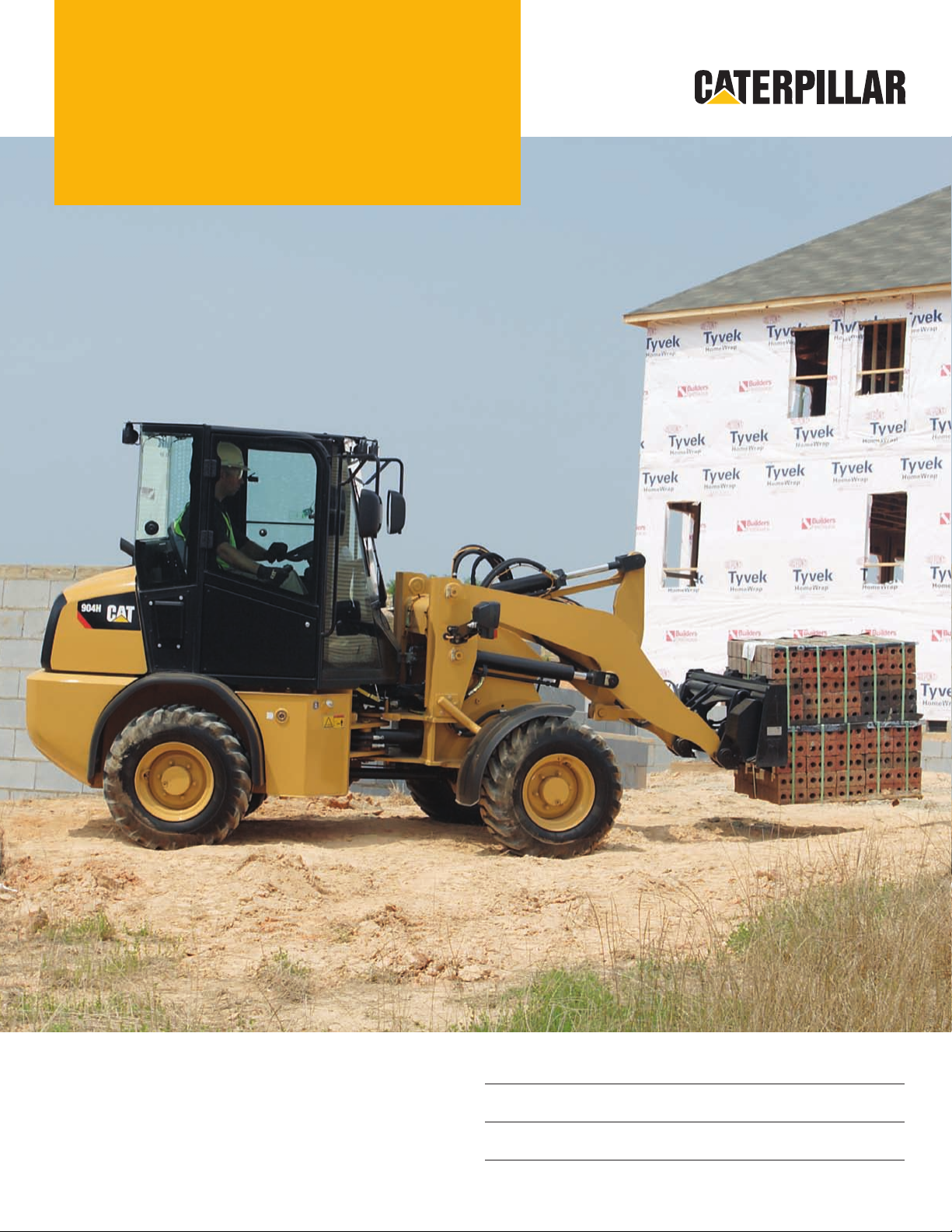

904H

®

Compact Wheel Loaders

Engine

Net Power 39 kW 52 hp

Weights

Operating Weight 4490 kg 9,900 lb

Buckets

Bucket Capacities 0.6 m3-1.0 m30.8 yd3-1.3 yd

3

Page 2

904H Features

Loader Linkage

Z-bar loader linkage is built for strength, visibility

and versatility.

Quick Coupler

The standard skid steer loader style quick coupler

allows the use of many popular hydromechanical

skid steer loader work tools.

High Performance Power Train

Aggressive performance helps you get more done.

Comfortable Cab

Spacious cab and easy to use controls deliver all

day comfort so you can concentrate on your work.

More Work Tools

Make your 904H the most versatile machine

on the job site with Caterpillar’s broad range

of work tools.

Contents

Operator Station ..................................................3

Power Train ..........................................................4

Linkage..................................................................4

Work Tools ............................................................5

Serviceability .......................................................6

Customer Support ...............................................6

904H Compact Wheel Loader

Specifications ......................................................7

904H Standard Equipment ...............................10

904H Optional Equipment .................................10

Notes ...................................................................11

2

The Cat® 904H Compact Wheel Loader delivers high

performance with outstanding versatility. Spacious cab

with joystick control keeps you comfortable throughout

the work day, allowing you to get more done. Loader design

delivers strength and durability with superior control.

Do more with one machine with the skid steer loader style

coupler. This coupler allows the use of Cat Skid Steer

and Multi Terrain Loader hydromechanical Work Tools

on the Cat Compact Wheel Loader for greater machine

versatility. Expand your business with the new 904H.

Page 3

Operator Station

Superior comfort keeps you productive, all day long.

Cab Comfort

Spacious, comfortable cab with increased oor space helps you stay productive. Canopy, cab with heat

or cab with heat and air conditioning are available. All cabs are pre-wired, making it easy to install future

options. A backlit LED display provides system information and is conveniently located in the operator’s

line of sight. Right side window opens fully for better ventilation or communication with workers.

Low Effort Controls

Pilot hydraulics for implement control and use with Cat Work Tools keep operator fatigue low.

No linkage to adjust or wear ensures consistent control over the life of the machine. The multi functional

joystick contains a 3-position Forward/Neutral/Reverse switch, an easy to control third function auxiliary

hydraulics switch, and (when equipped) optional bucket positioner (return to dig) switch.

Excellent Visibility

The loader arms have been designed with visibility to the work tool in mind. Wide cab glass area and

sloping rear hood provide both a 360 degree panorama and visibility within a few feet of the machine.

This makes for safer operation and reduces machine damage caused by collision with unseen obstacles.

3

Page 4

Power Train

Designed for power, durability and performance.

Engine

The MHI S4Q2 Turbo engine meets EPA Interim Tier 4 emissions requirements

and delivers superior power to help you get more done.

Chassis

Rear axle oscillation helps assure four wheel ground contact for optimum traction

and stability. Heavy duty axles with outboard planetary reduction gears are built

for durable performance. Optional differential lock is available in the front axle

only or both axles and can be easily engaged by a foot switch to the left of the

steering column to increase tractive effort in poor underfoot conditions.

Power Train

Two-speed closed loop hydrostatic transmission delivers smooth transition

from full rimpull to runout. Precise inching control and smooth acceleration

and deceleration minimize operator fatigue. Optional speed (creeper) control

and hand throttle are also offered.

Ride Control

The optional Ride Control System further enhances the already smooth road

handling of the machine, resulting in increased operator comfort and higher

productivity. It is suited for extreme applications where operators need to maintain

bucket material load or carry a heavy work tool and have a smooth ride.

Linkage

Built for strength.

Z-Bar Design

The high performance Z-bar

loader design is built for strength,

visibility and versatile attachment

usage. The Z-bar linkage gives the

operator a clear view to the work

tool and excellent dump clearance

while maintaining good cycle times.

4

Page 5

Work Tools

Do more jobs with one machine with Cat Work Tools.

The Right Tool for the Job

Increase the machine’s versatility with the wide range of

Cat buckets, forks and hydraulically powered work tools.

Work tools can be changed quickly and easily with the

machine’s quick coupler system. Available work tools include:

Buckets and Forks

•

Augers

•

Blades (Angle/Dozer)

•

Brooms

•

Cold Planers

•

Grapple Buckets, Forks and Rakes

•

Landscape Rakes and Tillers

•

Material Handling Arm

•

Power Box Rakes

•

Snow Blowers

•

Stump Grinders

•

Trenchers

•

Vibratory Compactors

•

Consult your Cat dealer for a complete list.

Skid Steer Loader Style Coupler

The universal skid steer loader style coupler allows the use

of many Cat Skid Steer, Multi Terrain and Compact Track

Loader hydromechanical work tools. Standard ow auxiliary

lines and connectors are optional equipment.

Additional Options to Increase Productivity

The following options further increase your productivity:

Return to dig work tool positioner automatically returns

•

the bucket to level position after dumping.

Auxiliary hydraulic lines and ttings for a 3rd hydraulic

•

function when more than general bucket and fork work

is required, such as a broom.

Work tool wiring harness for fourth hydraulic function

•

such as broom angling.

Speed control (creeper) provides variable control

•

of ground speed while maintaining optimal

hydromechanical work tool speed.

Hand throttle control provides innitely variable means

•

of xing engine speed, ideal for steady operation of

hydromechanical work tools.

5

Page 6

Serviceability

Easy access and minimal maintenance requirements reduce downtime.

Convenient Service Features

Easy to lift engine hood provides easy access to all major

•

components and service points from ground level.

S•O•S valve is conveniently located in the engine bay for

•

analyzing hydraulic system cleanliness and pressure taps

for service analysis, prolonging machine life.

Two stage air cleaner with primary and secondary

•

element and a visual restriction indicator improves

service life.

Auxiliary fuses, relays and other electrical service points

•

are all located together behind a locked door for ease

of servicing.

Spin-on engine and hydraulic oil lters and fuel lter

•

with water separator are vertically mounted for easier

servicing.

Heavy-duty wiring increases electrical durability and

•

is multicolored to ease diagnosis and fault nding.

Water resistant sealed connectors prevent dust and

moisture from interfering with the electronics.

Wheels and tires are mounted on studs rather than

•

secured with bolts for easier wheel removal/installation.

Customer Support

Support you can count on.

Superior Dealer Service

Your Cat dealer is ready to assist you with your purchase

decision and everything after.

Make comparisons of machines, with estimates of

•

component life, preventative maintenance and cost

of production.

Financing packages are exible to meet your needs.

•

Your Cat dealer can evaluate the cost to repair,

•

rebuild and replace your machine, so you can make

the right choice.

For more information on Cat products, dealer services

•

and industry solutions, visit us at www.cat.com.

6

Page 7

904H Compact Wheel Loader Specifications

Engine

Model MHI S4Q2-T

Gross Power 41 kW 55 hp

Net Power 39 kW 52 hp

SAE J1349 Rating 39 kW 52 hp

ISO 9249 Rating 39 kW 52 hp

EEC 80/1269 Rating 39 kW 52 hp

Bore 88 mm 3.5 in

Stroke 103 mm 4 in

Displacement 2.505 L 153 in

Engine meets Interim Tier 4 emissions

•

regulations.

Rated power at 2,400 rpm.

•

Weights

Operating Weight 4490 kg 9,900 lb

Operating Specifications

Tire Size 12-16.5, 10PR

Rated Bucket Capacity 0.6 m30.8 yd

Breakout force 35.6 kN 8,003 lb

Rated operating load

@ full turn, bucket

Straight tipping load,

bucket

Full turn static tipping

load, bucket

3

Rackback, transport

position

Rated operating load 1600 kg 3,527 lb

@ full turn, forks

(EN 474-3:2006, rm and level ground,

500 mm (20 in) load center) (80% of FTSTL)

Rated operating load 1200 kg 2,646 lb

@ full turn, forks

(EN 474-3:2006, rough terrain, 500 mm

(20 in) load center) (60% of FTSTL)

Specications shown are for the 904H with

•

cab, 75 kg (165 lb) operator and general

purpose bucket.

1250 kg 2,756 lb

3000 kg 6,614 lb

2500 kg 5,511 lb

49 Degrees

Transmission

Cab

ROPS SAE J1040 MAY94,

3

FOPS SAE J/ISO 3449

ISO 3471:1994

APR98 Level I and II;

ISO 3449:1994 Level I

and II

Hydraulic System

Main relief 207 bar 3,000 psi

3rd valve ow 83 L/min 22 gal/min

Hydraulic cycle time

– lift

Hydraulic cycle time

– dump

Hydraulic cycle time

– lower, oat

4.5 seconds

0.8 seconds

3.2 seconds

Service Refill Capacities

Cooling System 8 L 2 gal

Fuel tank 83 L 22 gal

Hydraulic system 43 L 11 gal

Engine Oil 7.5 L 2 gal

Travel Speed 1 7 km/h 4.3 mph

Travel Speed 2 20 km/h 12.4 mph

Buckets

Bucket Capacities 0.6 m3-

1.0 m

0.8 yd3-

3

1.3 yd

3

7

Page 8

904H Compact Wheel Loader Specifications

Dimensions

All dimensions are approximate. Dimensions may vary with bucket. Refer to Operating Specifications.

1

Cab Height 2390 mm 7 ft 10 in

2

Ground Clearance 245 mm 9.6 in

3

Wheelbase 1900 mm 6 ft 3 in

4

Overall Length with Bucket 4695 mm 15 ft 5 in

5

Reach at Maximum Dump Height 665 mm 2 ft 2 in

6

Dig Depth 90 mm 3.6 in

7

Maximum Dump Height 2380 mm 7 ft 10 in

8

Load Over Height 2885 mm 9 ft 6 in

9

Hinge Pin at Maximum Height 3110 mm 10 ft 2 in

10

Departure Angle (degrees) 35°

11

Overall Length with Forks 5250 mm 17 ft 3 in

12

Reach at Ground Level 855 mm 2 ft 10 in

13

Maximum Reach 1380 mm 4 ft 6 in

14

Fork Depth Above Ground 95 mm 3.7 in

15

Fork Height at Maximum Reach 1450 mm 4 ft 9 in

16

Maximum Fork Height 3075 mm 10 ft 1 in

17

Fork Reach at Maximum Height 560 mm 1 ft 10 in

18

Turning Radius Over Bucket 3850 mm 12 ft 8 in

19

Turning Radius Inside Tire 1675 mm 5 ft 6 in

20

Width Over Bucket 1780 mm 5 ft 10 in

21

Tire Gauge 1330 mm 4 ft 4 in

22

Machine Width 1645 mm 5 ft 5 in

23

Articulation Angle 42°

24

Steering Angle – Left/Right 84°

25

Dump Angle at Maximum Height 44°

16

15

14

13

11

12

17

24

21

23

19

18

20

22

25

10

9

8

7

5

1

6

4

3

2

8

Page 9

Maximum Material Densities

Based on ISO 7546:1983 and rated operating loads at full turn.

Bucket Type General Purpose Multi Purpose Light Material

Rated capacity m3 (yd3) 0.6 (0.8) 0.6 (0.8) 1.0 (1.3)

Dump height mm (in) 2380 (94) 2380 (94) 2205 (87)

Maximum material density kg/m3 (lb/yd3) 2095 (3,531) 1995 (3,362) 1195 (2,014)

Bucket width mm (in) 1780 (70) 1770 (70) 1880 (74)

Cab Features

Comfort Cab Canopy

Standard Cab Features

Left side door

•

Fixed steering column

• •

Vinyl static seat

• •

Left window – sliding top section

•

Heated rear window

•

Coat hook

• •

Cabin light

•

Internal mirror

• •

Heater

•

Storage tray and cup holder

• •

Right window with holdback latch

•

Optional Cab Features

Radio ready kit (wiring, speaker, antenna and grill)

•

Sun visor

• •

External mirrors (2)

• •

Air conditioning

•

Vinyl suspension seat

• •

Cloth suspension seat

•

9

Page 10

904H Standard Equipment

Standard equipment may vary. Consult your Caterpillar dealer for details

TRANSMISSION

Transmission, 20 km/h (12.4 mph) with

standard axles

Transmission inching function

Hydrostatic drive

LOADER

Skid steer loader quick coupler

Loader arm oat function

Connect under pressure hydraulic quick

connector

ENGINE

MHI S4Q2-T Interim Tier 4 emissions

compliant

Two stage air cleaner with visual indicator

Cat Extended Life Coolant

Lockable engine compartments

Easy quick release fuel lter/water

separator

Engine oil drain valve

ELECTRICAL

Battery, maintenance free, 650 CCA

Engine cold starter aid

Alternator, 90 amp

Roading lights

Back up alarm

GENERAL

Pressure test points

Recovery hitch pin ready

S•O•S ports

Fuel ller cap

OPERATOR ENVIRONMENT

Multifunction joystick with direction

control

Auxiliary control switch

Warning indicators for major systems

Wiper/washer front and rear (cab only)

Easy clean cab oor

Left side door (cab only)

Personal storage

Cup holder

Heated rear window

ROPS & FOPS

Wrist rest

Seat belt, 50 mm (2 in), retractable

Cabin light

Auxiliary power sockets

Coat hook

Heater with window, side, feet and defrost

vents

Sound suppression

Steering column, xed

Heavy duty oor mat

Seat, static, vinyl

Left sliding window (cab only)

Storage tray

Internal mirror

904H Optional Equipment

Optional equipment may vary. Consult your Caterpillar dealer for details

TRANSMISSION

Creeper control

Hand throttle

Ride control

100% Differential Lock on both axles

LOADER

Proportional auxiliary hydraulic circuit

Return to dig work tool positioner

ENGINE

Engine block heater, 120V

Cat extended life coolant, protects to

–50° C (–58° F)

Turbine style precleaner

ELECTRICAL

Rotating beacon

Work tool wiring harness

Working lights, two front and two rear

Battery, heavy duty, 880 CCA

GENERAL

Tire options including Flexport and

otation tires

Recovery hitch pin

Guard, overhead, FOPS II rating

WORK TOOLS

For all work tool options, consult your

Cat dealer

OPERATOR ENVIRONMENT

Air conditioning

Canopy

Cab, Comfort

Proportional auxiliary control

External mirrors (2)

Seat belt, 75 mm (3 in), retractable

Seat, adjustable suspension, vinyl

Seat, adjustable suspension, cloth

Radio ready kit including speakers

(cab only)

Sun visor

10

Page 11

Notes

11

Page 12

904H Compact Wheel Loader

For more complete information on Cat products, dealer services, and industry solutions, visit

us on the web at www.cat.com

© 2008 Caterpillar Inc.

All rights reserved

Materials and specifications are subject to change without notice. Featured machines in may

include additional equipment. See your Caterpillar dealer for available options.

CAT, CATERPILLAR, SAFETY.CAT.COM, their respective logos, “Caterpillar Yellow” and

the POWER EDGE trade dress, as well as corporate and product identity used herein,

are trademarks of Caterpillar and may not be used without permission.

12

AEHQ6016 (10-2008)

Replaces AEHQ5638-01

Loading...

Loading...