Page 1

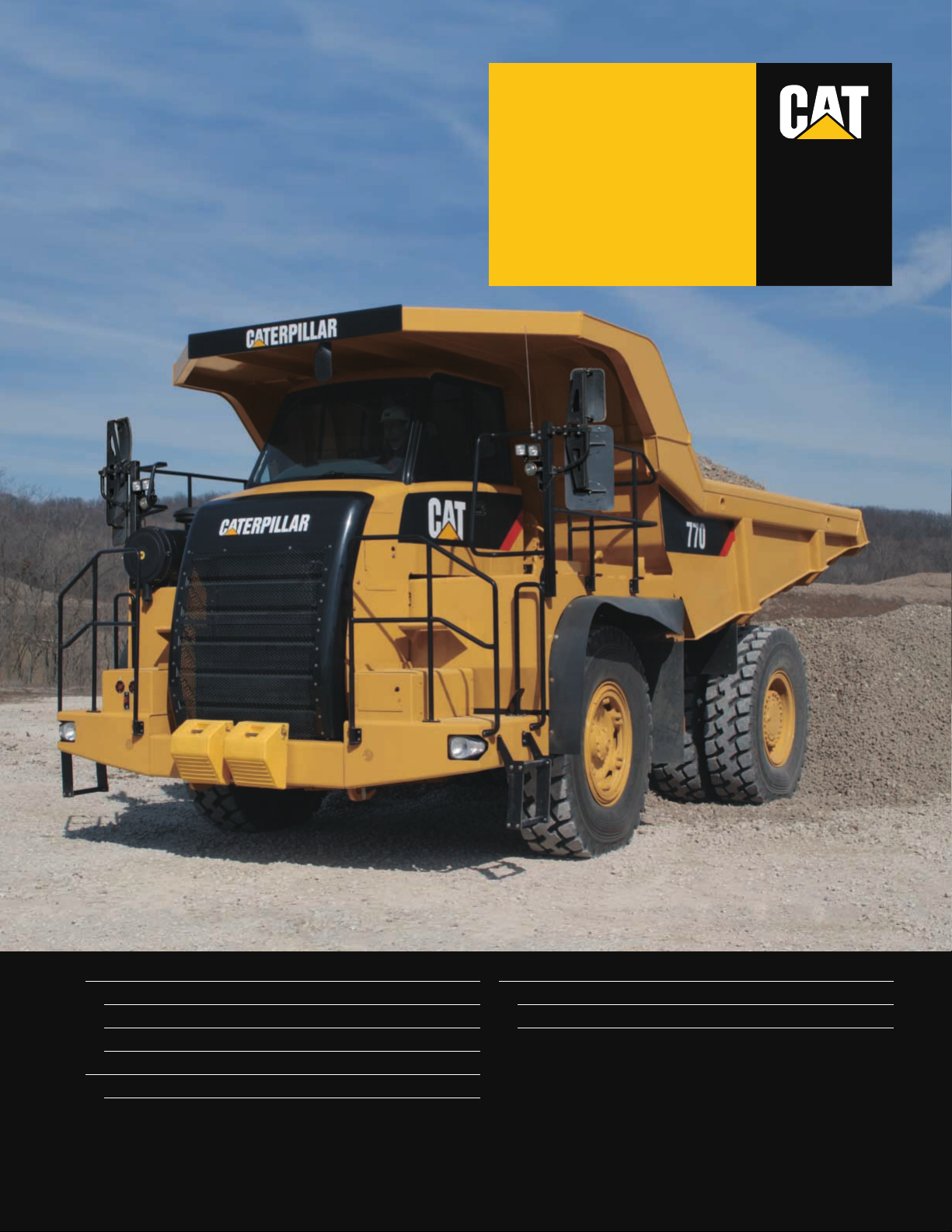

Engine

Engine Model Cat®C15 ACERT™

Gross Power – SAE J1995 381 kW 511 hp

Net Power – SAE J1349 355 kW 476 hp

Weights – Approximate

Target Gross Machine 71 214 kg 157,000 lb

Operating Weight

Operating Specifications

Nominal Payload Class 36.3 tonnes 40 tons

Body Capacity – SAE 2:1 25.1 m

3

32.9 yd

3

• Refer to the Caterpillar®10/10/20 Overload Policy

for maximum gross machine weight limitations.

• Capacity with flat floor body.

770

Off-Highway Truck

®

®

Page 2

2

770 Off-Highway Truck

Engineered for performance, designed for comfort, built to last.

Top Performance.

Developed specifically for construction,

mining, and quarry applications, the 770

optimizes demands for lower cost per ton,

challenges of finding skilled labor, and

overall health and safety.

Reliable, Durable, Dependable.

Rugged construction and easy maintenance

procedures ensure long life with low

operating costs.

Truck Body Systems

The 770 offers two body types with six

different body liner system selections

to accommodate almost any type of

application. These body liner systems

are designed to maximize strength and

durability while providing the lowest

cost per ton. pg. 16

✔

Serviceability

The 770 offers 500-hour engine service

intervals – 250 hours more than the 769D.

Simplified service and maintenance

features combined with improved

service access are designed to

reduce downtime. pg. 14

✔

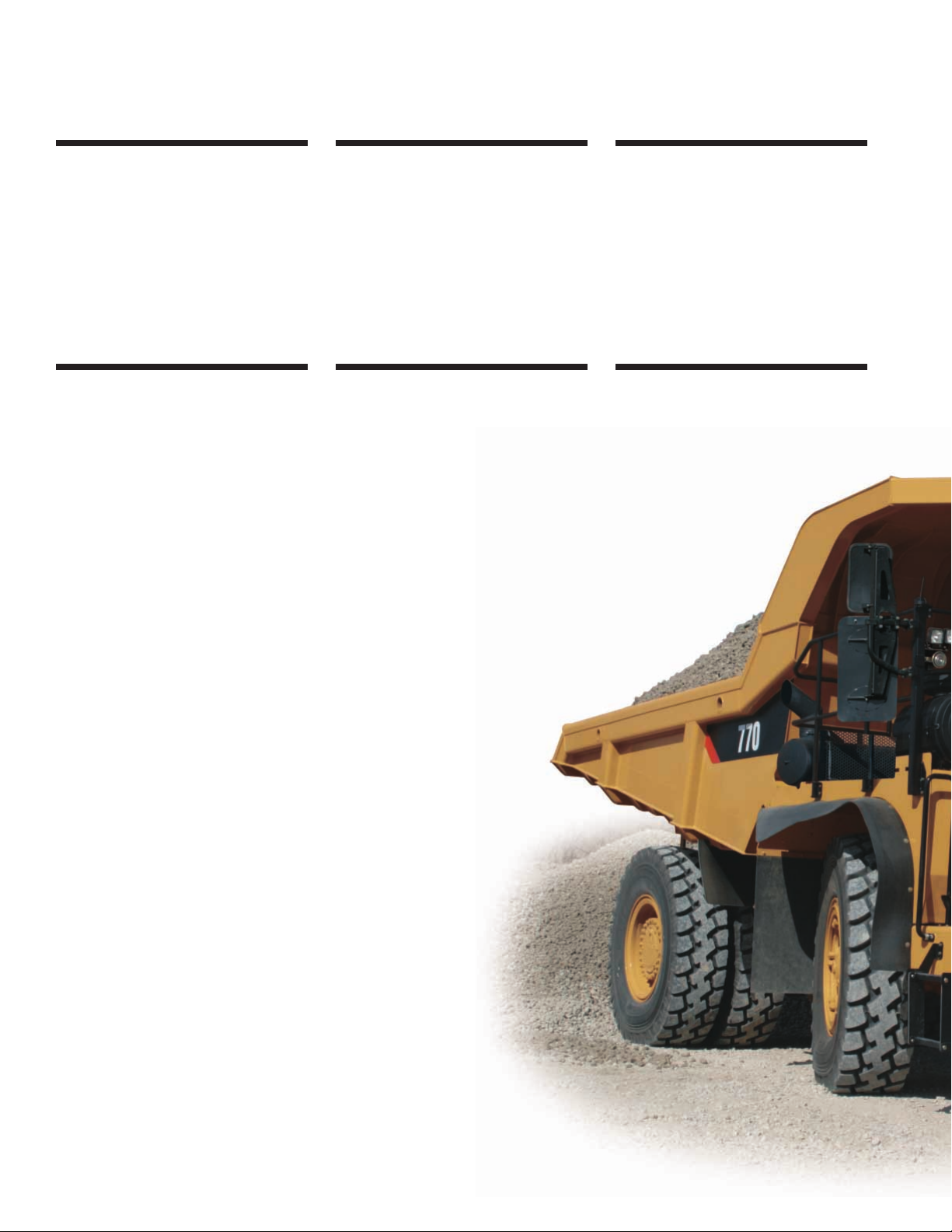

Structures

The 770 features a mild-steel, box-section

type frame to deliver durability and long

life with low operating costs. Castings and

forgings are strategically placed in highstress areas to evenly distribute stresses

and provide long fatigue life. pg. 8

✔

Power Train – Transmission

The Cat®seven-speed power shift

transmission matched with the Cat C15

engine with ACERT Technology provides

constant power and efficiency over a

wide operating speed range for optimal

power train performance. pg. 6

✔

Power Train – Engine

The Cat®C15 engine with ACERT™

Technology uses advanced engine

technology to reduce emissions

without after-treatment. The turbocharged,

aftercooled 6-cylinder engine has faster

response for superior performance in

demanding applications. pg. 4

✔

Information and Monitoring Systems

Standard on the 770, the Cat Messenger

system provides real-time engine

performance and operating data. pg. 18

✔

Page 3

✔ New Feature

3

Safety

Caterpillar sets the standard when

it comes to safety in the design and

manufacturing of heavy equipment.

Safety is not an afterthought at Caterpillar,

but an integral part of all machine and

systems designs. pg. 20

✔

Operator’s Station

The 770 features an all new operator

station with enhanced visibility,

increased operator space and

ergonomically designed controls that

set new industry standards for operator

comfort. All controls and gauges are

positioned for optimum efficiency

and total machine control. pg. 9

✔

Brake System

Front dry disc and rear oil-cooled,

multiple disc brakes are now hydraulically

controlled, reducing maintenance costs

and improving operator control and

modulation. They provide exceptional,

fade-resistant braking and retarding for

maximum performance and productivity

in all haul-road conditions. pg. 12

✔

Engine – Power Train Integration

The Cat Data Link electronically

combines engine, transmission,

brake and operational information

to optimize overall truck performance.

Stored diagnostic data can be accessed via

the Cat Electronic Technician (Cat ET)

service tool to improve troubleshooting

and reduce downtime. pg. 10

✔

Customer Support

Caterpillar®dealers provide unmatched

product support, anywhere in the world.

With industry-best parts availability and

a wide range of maintenance and service

options, Cat dealers have what it takes to

keep your hauling machines productive.

pg. 21

✔

Page 4

Cat®C15 Engine with ACERT™

Technology. Caterpillar optimizes engine

performance while meeting U.S. EPA

Tier 3 and European Union Stage IIIa

engine emission regulations. ACERT

Technology reduces emissions during the

combustion process by using advanced

technology in the air and fuel systems, in

conjunction with integrated electronics.

Caterpillar meets emission regulations

at the combustion source, rather than

recycling exhaust gases.

Block. The C15 block incorporates a onepiece, grey iron block, featuring generous

ribbing for stiffness and heavy bearing

bulkheads for rigidity and strength.

Caterpillar also has moved away from

pipe thread ports to straight-thread, o-ring

connection points, reducing the potential

for leaks. This new design supports the

engine’s higher compression ratios and

increased power density.

Cylinder Head. The new cross flow air

design routes air straight across the head

removing bends and turns that create

resistance to flow. By removing the

resistance to flow, parasitic loads are

reduced as pumping needs are lessened.

The cylinder head is a one piece, cast

iron component with a newly designed

graphite and steel composite head gasket

that seals the combustion chamber with

better rigidity and wear capability.

Overhead Cam. A single overhead cam

is driven by gears on the front of the

engine, which significantly reduce noise

and vibration. Caterpillar also has added

two pendulum absorbers, mounted at

the front of the camshafts to further

reduce noise and vibration.

Pistons, Connecting Rods, Cylinder Liners.

New design and material improvements

to the pistons, rods and liners have been

made to support the higher cylinder

pressures and the 18:1 compression

ratios associated with ACERT

Technology, while still providing

durability to engine overhaul.

A single-piece steel piston, pulsator-tested

to 25 560 kPa (4,000 psi), is matched to

a robust connecting rod to ensure long

component life. The piston’s steel skirt

increases its durability and results in

reduced thermal expansion, allowing

a tighter piston fit and reduced liner

vibration. The overall piston surface

area reduces friction and enhances

fuel economy.

The newly designed connecting rod

allows better lubrication and cooling and

is more securely fastened to the crankshaft

using two additional bolts. The new

improved rod bearings are made of steelbacked copper alloy with lead tin overlay.

This new metallurgy reduces flaking

and offers better fatigue strength.

Cylinder liners are wet liners made of

compacted graphite and iron for excellent

wear and strength characteristics. Also, the

tolerances between the pistons and the

wet cylinder liners have been tightened

to unprecedented levels for reduced

blow-by and higher efficiency.

4

The Cat®C15 engine with ACERT™ Technology is built for power, reliability and efficiency

for superior performance in the toughest applications.

Power Train – Engine

Page 5

Turbochargers. The single, waste-gated

turbocharger found on the C15 engine is

water-cooled to accommodate sudden hot

machine shutdowns. Water cools the

bearings during this event, preventing

bearing seizure. The C15 engine also

includes a new turbine housing and an

additional spacer bearing. The addition

of a spacer bearing eliminates snap rings

and, therefore, reduces complexity and

improves shaft motion.

The turbocharger uses an aluminum

compression wheel. Changes enable

the C15 to deliver longer life and lower

maintenance costs and contribute to good

fuel economy. The design also provides

high horsepower with improved response

time while keeping exhaust temperatures

low for long hours of continuous

operation. The waste-gate turbocharger

design improves engine response and

peak torque, while providing higher

boost over a wider range.

MEUI Fuel System. The Cat MEUI

fuel system combines the technical

advancement of electronic control with

the simplicity of direct mechanically

controlled unit fuel injection. This system

electronically controls injection pressure

by sensing the engine speed and load

conditions over the entire engine

operating speed range.

A low-pressure fuel transfer pump

provides fuel to the injectors, which

then increases the pressure to deliver

very fine, atomized fuel particles into

the combustion chamber with precise

timing and duration. The result is a

more complete fuel burn with lower

emissions and better engine response.

Oil Coolers. The 770 is equipped with

three oil coolers: an engine-mounted

engine oil cooler, an engine-mounted

transmission/torque converter oil cooler,

and a remote-mounted, brake, hoist and

hydraulic fan oil cooler. These coolers

allow major components to expel heat,

maintaining optimal operating

temperatures.

Fuel Filters. The C15 engine is equipped

with two fuel filters. The primary filter is

engine-mounted and features oil/water

separation and an electric priming pump.

The electric pump provides easier priming

and better contamination control than a

manual unit. The secondary fuel filter is

also engine-mounted, and has a switch

that monitors pressure changes and

provides pressure drop warnings to

the operator.

Advanced Diesel Engine Management

A4 Engine Controller. The ADEM™ A4

electronic control module provides

flexible fuel mapping, allowing the

engine to respond quickly to varying

application needs.

Next Generation Modular Radiator

(NGMR). The new modular cooling

system with a single-pass flow core

design uses brazed construction for

stronger joints, better leak prevention

and higher heat transfer. The simpler

design of the single-pass system, which

replaces the two-pass flow folded core

system enables coolant to enter one end

of the core and flow out the opposite end

for more efficient ambient cooling

capability and greater durability.

Hydraulic Demand Fan and Accessory

Drive. The 770 includes a standard,

variable-speed, on-demand fan. This fan

provides cooling airflow only when

necessary, resulting in reduced parasitic

losses, a reduction of fuel consumption

and fan-generated noise.

The C15 engine includes a Poly-V

accessory drive belt with an autotensioner, which is self adjusting.

5

Page 6

Mechanical Power Train. The Cat

mechanical drive power train and power

shift transmission provides unmatched

operating efficiency and control on steep

grades, in poor underfoot conditions, and

on haul roads with high rolling resistance.

Transmission. Pairing the Caterpillar

seven-speed planetary power shift

transmission with the C15 diesel engine

with ACERT Technology delivers

constant power over a wide range

of operating speeds.

• Transmission Chassis Control (TCC).

Transmission shifting is based on

Transmission Output Speed for optimum

performance efficiency and clutch life.

The TCC provides integrated functionality

to controlled throttle shifting, directional

shift management, neutral coast inhibitor,

body-up shift limiter and body-up

reverse neutralizer.

Throttle Lock. The operator can now

electronically lock the throttle pedal

at full throttle, to reduce fatigue on long

uphill hauls. The throttle can be locked

on by momentarily depressing the throttle

lock switch located on the operator

console, while depressing the pedal

fully. The throttle is released whenever

braking is applied or the throttle is again

depressed.

Lock-Up Torque Converter.

Combines maximum rimpull and

cushioned shifting of torque converter

drive with the efficiency and performance

of direct drive. The torque converter

includes an additional clutch plate to

maintain power train capability for

higher horsepower and top speed, as

well as a new torque converter adapter

that provides extra length to house the

additional clutch plate and enables the

converter components to be changed

without having to change the housing.

The lock-up torque converter engages

at approximately 8 km/h (5 mph),

delivering more power to the wheels.

Lock-Up Clutch. Quickly releases and

re-engages to reduce power train torque

loads for smoother shifting, long life

and a more comfortable ride.

New Differential and Proven Final Drives.

The new Cat differential works with

the proven final drives as a system to

deliver maximum power to the ground.

For improved serviceability, the pinion

gear is cantilever mounted, which allows

inspection of the differential without

pulling the rear-end. Visual inspection

of the pinion gear and bearings can be

performed in 1-2 hours versus 8 hours

on the previous models. In addition,

the differential bevel pinion gear set

is designed for improved adjustability,

which results in improved contact patterns

and life. The differential gear set also

provides enhanced bending life for

steeper grade applications.

New Differential Center Housing. A new,

ductile iron center housing improves

quality and reliability. The improved

stiffness allows for better main support

bearing life. The new housing also uses

bolts, reducing maintenance time.

This change also improves wheel

station bolted-joint life.

6

Cat power train delivers more to the ground for greater productivity and lower operating costs.

Power Train – Transmission

Page 7

New A-Frame. The new A-frame mounts

directly to the spindles. The new A-frame

eliminates the “king” bolt and includes

a pin and bushing style mounting,

consistent with the 777 and 793.

This new design is simpler to

maintain and service.

New Ductile Iron Spindles. A stressoptimized, ductile iron spindle is

splined to the rear brakes, reducing

brake pack rebuild time by up to two

hours. In addition, the spindles are longer

and wider with fewer seals for increased

strength and durability.

Brake Packs. A single-piece brake anchor

eliminates more than 200 fasteners and

a row of bolted joints. Rebuild time is

reduced by up to two hours. In addition,

the brake pack is removable without

taking the spindle off the truck.

Each of the two oil-cooled disc brakes on

the 770 rear axle features 24 brake discs.

The brake discs have increased in diameter

from 495.3 to 540.0 mm (19.5 to 21.3 in).

By increasing the diameter, Caterpillar

has improved the overall reliability and

durability of the brake packs and has also

designed the brake packs to improve the

OD/ID ratio. The new 770 brake pack

design, moves the braking forces to the

outer edge of the disc, thereby using

greater surface area for improved

braking forces and longer life,

improving reliability and lowering

maintenance cost.

Wheel Stations. The wheel stations now

integrate both the wheel and the hub.

The single-piece design reduces removal

and installation time, and the risk of

brake cooling oil leakage. The inner

Duo-Cone™ seal has been changed

from a formed type to a cast design.

Brake cooling flow and the Duo-Cone

seal has also been reversed for better

sealing performance and improved

seal life.

Wheel stations are now interchangeable,

reducing the number of replacement

parts: left and right wheel stations are

symmetric and can be interchanged.

In addition, the new design eliminates one

o-ring seal, which improves reliability

and simplifies the system and the wheel

bearings have been enhanced for longer

bearing life.

Tires. The 770 uses 18.00R33 tires

as the standard tire configuration.

• Steering System. Hydraulic steering

control system is designed for

exceptional smoothness and precise

control. A separate circuit prevents

cross contamination for long life.

• Battery Powered Supplemental

Steering. A battery powered

supplemental steering system uses

pressure accumulators and allows

up to three 90 degree turns in case

of engine failure.

• Wheels and Rims. Cast rear wheels and

Cat center-mount rims are mounted using

studs and nuts to minimize maintenance

and maximize durability.

7

Page 8

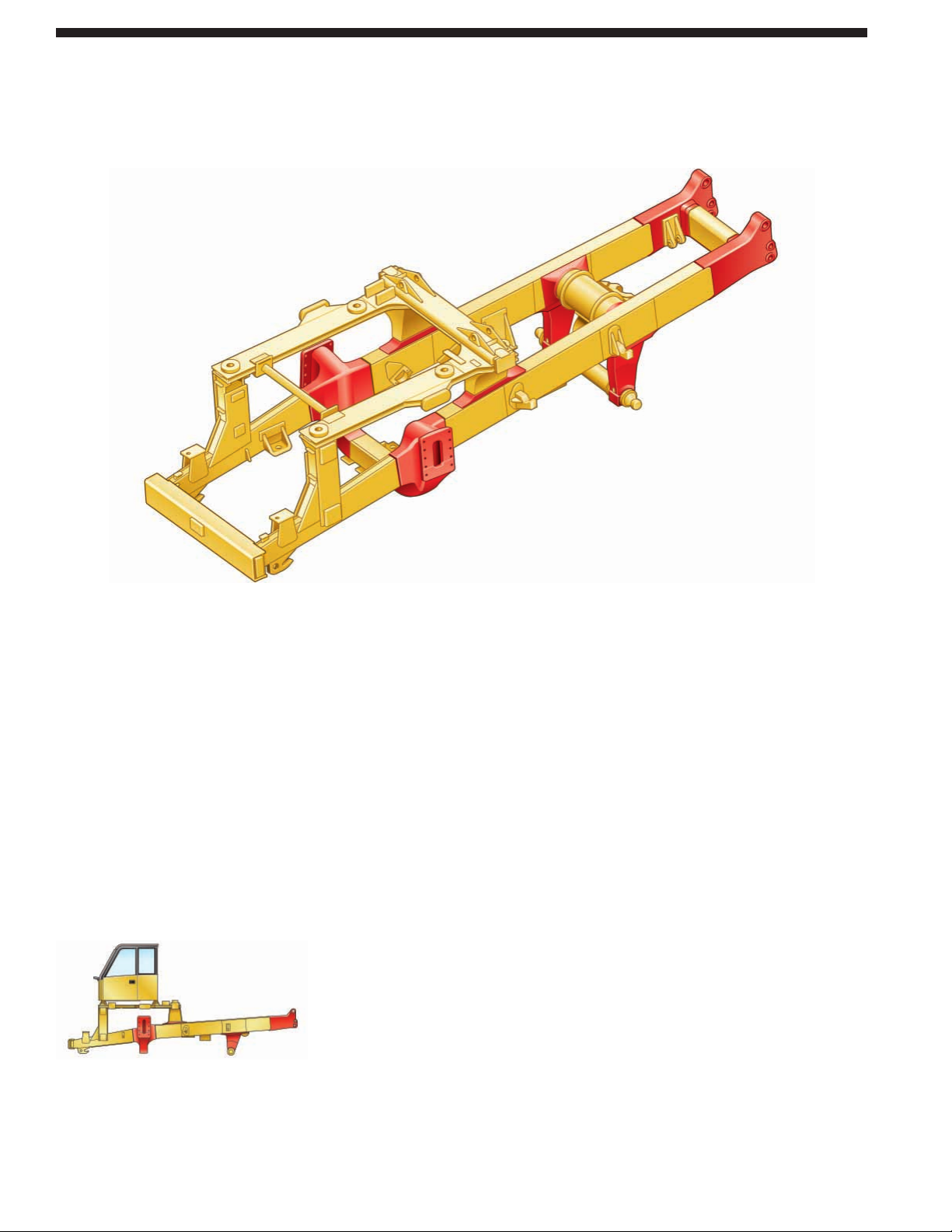

Box-Section Design. The 770 frame uses

a box-section design, incorporating two

forgings and 13 castings in high-stress

areas with deep penetrating and

continuous wrap-around welds to resist

damage from twisting loads without

adding extra weight.

• Steel Structures. Mild steel used

throughout the frame provides flexibility,

durability and resistance to impact loads,

even in cold climates and allows for easy

field repairs.

• Castings. Castings have large radii with

internal reinforcing ribs to dissipate stress

in areas of high stress concentration.

Castings move welds to lower stress

areas for greater frame life.

Integral Four-Post ROPS Cab.

Resiliently mounted to the main frame

with all-new cab mounts that reduce

vibration and sound, the integral ROPS

is designed as an extension of the truck

frame. The ROPS/FOPS structure

provides “five-sided protection”

for the operator.

Forgings and Castings.

• The 770 features a drop tube/casting

design and two forged steel mountings

for hoist cylinders, similar to the

design as found on the 773.

• A volcano casting that holds the center

tube is enhanced with thicker wall

dimensions for increased durability.

• New strut-mount castings have been

moved 254 mm (10 in) forward and

25.4 mm (1 in) outward on each side.

These thicker strut-mount castings

and their location improve ride

characteristics as well as durability.

• New steering casting (same as 773)

accommodates larger steering

cylinders and ball studs.

• New tail casting accommodates new

angled rail design.

Superior Weld Quality. Structural frame

welds are J-groove type, ensuring full

weld penetration for strength and

longevity. During fabrication, weld

integrity is further enhanced by rotating

the frames 360 degrees to provide

optimal, flat welding surfaces.

Technology Enhanced.

Caterpillar structures are tested using

System Structural Analysis (SSA) to

dynamically simulate operations in field

environments and identify potential

structural improvements in high stress

areas. With analysis of machine structures

and variables, such as haul road and

payload, structural improvements were

made to the frame to accommodate the

new cab, platform, engine and radiator.

Quality Control. A Coordinate

Measuring Machine (CMM) is used to

inspect truck frames for consistency in

the manufacturing process. In addition,

all critical welds receive testing to verify

weld penetration, which results in frame

durability.

8

Rugged Cat structures are the backbone of the 770 off-highway truck’s durability.

Structures

Page 9

9

All New Center-Mounted Cab. Center cab

positioning provides additional room and

creates a walk-in-style cab. The new

configuration allows the operator to

easily enter and exit the cab. The cab

environment offers a spacious

surrounding, giving the operator the

ability to stretch out and providing

superior comfort for an entire operating

shift. The operator seat is located on the

right hand side of the cab with the

trainer to the immediate left.

Ergonomic Layout. The 770 operator’s

station is ergonomically designed for

total machine control in a comfortable,

productive and safe environment.

All controls, levers, switches and gauges

are positioned to maximize productivity

and minimize operator fatigue.

New ISO Designed Cab Mounts.

Integral, sound-suppressed cab is

resiliently mounted to the frame to isolate

the operator from sound and vibration

for a quiet, secure and comfortable ride.

Viewing Area. Designed for excellent

all-around visibility and clear sight lines

to the haul road. The large viewing area,

with 52 percent more glass, enables the

operator to maneuver with confidence

for greater productivity.

Air Suspension Seat w/Three-Point

Operator Restraint. Ergonomically

designed, fully adjustable air suspension

seat with adjustable armrests provides

optimal driving comfort. A wide,

retractable 3-point seat/shoulder belt

provides a secure, comfortable restraint.

Hoist Lever. Four-position, low effort

electronic hoist control system is

positioned next to the gear selector

in the right-hand console.

Secondary Brake Pedal. Conveniently

located on the floor for easy operator

control.

Steering Column. Comfortable steering

wheel with tilt and telescoping function

provides a comfortable driving position

for all operators.

Transmission Console. Ergonomic gear

shift lever with backlit gear indicators

provides easy operation. The parking

brake function is integrated into the

gear selector.

Trainer Seat. By moving the trainer seat

to the left of the operator, the trainer may

enter/exit the vehicle using the same

stairway door as the operator. When not

in use, the fold-down trainer seat creates

a working surface with cup holder.

Under seat storage is convenient

for stowing a lunch box.

Operator Controls. Easy to reach turn

signal, high beam, intermittent windshield

wiper and windshield washer controls are

located on the left side of the steering

column, and are designed for optimum

efficiency and comfort.

Radio Ready. Cab is prewired with power

converter, speakers, wiring harness,

antenna and necessities for add-on

communication systems.

Multiple Power Ports. Power ports are

conveniently located in three locations

in the cab: one in the right-hand console,

two behind the trainer seat, and one in

the dash.

Truck Production Management System

(TPMS) (Optional). TPMS provides

valuable payload and cycle time data,

which is viewed through Messenger.

Now the system provides 2,400 cycles,

as opposed to the previous 1,400 cycles,

and takes a second payload measurement

when the truck reaches second gear for

increased accuracy. Standard LED lamps

replace incandescent lamps on the TPMS,

extending lamp life by 25 times.

Ergonomically designed for operator comfort, superior control and high productivity.

Operator’s Station

Page 10

Cat Data Link. Electronically integrates

machine computer systems to optimize

overall power train performance, increase

reliability and component life, and reduce

operating costs. All the information from

these controls can be accessed through

a laptop computer with Cat ET.

Transmission Chassis Control (TCC).

TCC uses electronically transferred

engine rpm data to execute shifts at

preset points for optimum performance,

efficiency and clutch life.

Electronic Technician (Cat ET). Cat ET

service tool provides service technicians

with easy access to stored diagnostic data

through the Cat Data Link to simplify

problem diagnosis and increase machine

availability. Cat ET is beneficial because

of how it displays the status of all engine

parameters, including throttle position,

timing and fuel flow. Critical data from

the electronic engine and transmission

controls, including transmission shifting,

engine speed and fuel consumption,

provides service technicians with

enhanced diagnostic capability to

reduce downtime and operating costs.

Controlled Throttle Shifting. Regulates

engine rpm during shifting to reduce

power train stress and clutch wear

by controlling engine speed, torque

converter lock-up and transmission

clutch engagement for smoother shifts

and longer component life.

Directional Shift Management.

Regulates engine speed during directional

shifts to prevent damage caused by highspeed directional changes.

Neutral Coast Inhibitor. Prevents the

transmission from shifting to neutral

at speeds above 6.5 km/h (4 mph),

protecting the transmission from

operating with insufficient lubrication.

10

This system electronically combines critical power train components to work together more

intelligently to optimize overall truck performance.

Engine – Power Train Integration

1 Engine Control Module (ECM)

2 Sensors

3 Mechanical Electronic Unit Injector (MEUI)

4 Automatic Retarder Control (ARC)

Traction Control System (TCS)

Transmission/Chassis Control (TCC)

5 Transmission

6 Wheel Sensor

7 Brakes

8 CAT Data Link

9

Cat Messenger

6

9

4

ET

8

3

7

5

2

1

Page 11

Body-up Shift Limiter. Prevents the

transmission from shifting above a preprogrammed gear without the body

being fully lowered. This function

is programmable via Cat Electronic

Technician (Cat ET) and Messenger.

Body-up Reverse Neutralizer.

Automatically shifts the transmission to

neutral if the hoist lever is activated while

the transmission is shifted in reverse.

Overspeed Protection. The transmission

control electronically senses engine

conditions and automatically up-shifts

one gear to prevent overspeeding.

If overspeeding occurs in the top gear,

the lock-up clutch is disengaged, and

the brakes are applied.

Programmable Top Gear. Transmission

top gear maximum can be set using Cat

Messenger or the Cat ET service tool to

help the operator maintain speed limits.

Anti-Hunt Function. This function

minimizes shifting by not allowing

the transmission to up or down shift

immediately after a shift has occurred.

This prevents gear hunting when operating

near a shift point and minimizes

transmission shifting for increased

component life.

Downshift Inhibitor. Prevents engine

overspeeding by keeping the transmission

from downshifting until engine speed

reaches the downshift point.

Economy Shift Mode. Modifies engine

maps for better fuel economy.

Reverse Shift Inhibitor. Protects the

engine from abrupt directional changes

by slowing down the engine before

shifting the transmission into reverse.

Cat Messenger. Critical data from the

engine and transmission, including

transmission shifting, engine speed

and fuel consumption, provides service

technicians with enhanced diagnostic

capability, through Cat Messenger, to

reduce downtime and operating costs.

Traction Control System (TCS) (Optional).

TCS electronically monitors and controls

rear wheel slippage for greater traction

and enhanced truck performance in poor

underfoot conditions.

Hydraulic Power Management System.

The system reduces parasitic losses

in the power management system

components. The system is operated

by a variable displacement piston pump.

This pump primarily provides for the

steering and is independent of the brake

and hoist circuit.

11

Page 12

Full Hydraulic Service Brake. The 770

features a full hydraulic brake system,

which offers significant improvements

in reliability, response, control and

serviceability versus an air-over

hydraulic system. There are fewer

components (part by part comparison),

boosting reliability and streamlining

maintenance.

Hydraulic Accumulators. The brake

system is equipped with a primary

accumulator and a secondary accumulator,

which also provides back-up braking in

the event of a failure. The accumulators

automatically drain pressure after

shutdown, reducing the service time by

removing the need to drain the pressure off

the system and reducing the risk of highpressure exposure during maintenance.

The new brake system uses a pump that

is driven off the flywheel 100 percent

of the time and is only loaded when

hydraulic pressure falls below 11 024 kPa

(1,600 psi). The pump will cut out at

13 608 kPa (1,975 psi). In the new system,

oil in this circuit is also sent to the

hydraulic fan system. Any additional

oil is sent to the brake cooling system

along with the oil used in the drive fan.

Improved Reliability. Because oil is now

used to actuate the brakes, Caterpillar

has eliminated the need for two brake

master cylinders, two relay valves, an

air dryer and the retarder valve (found on

ARC trucks only) that were associated

with the air-over-hydraulic brake system.

The air system had complexity which

affected its reliability. The oil actuated

system is simpler and more reliable.

Oil-Cooled Multiple Disc Brakes.

Cat dry front and rear oil-cooled, multiple

disc brakes are now hydraulically

controlled, reducing maintenance costs.

The 770 brakes provide exceptional,

fade-resistant braking and retarding for

maximum performance and productivity

in all haul-road conditions.

Extended Life Multiple Disc Brakes

(Optional). Extended life friction material

has double the wear life of standard

brakes and is twice as resistant to

glazing for more consistent braking

power with less noise.

Brake Design. Cat rear oil-cooled disc

brakes are designed with large discs

and plates for reliable, adjustment-free

operation and performance. Rear brakes

are completely enclosed and sealed to

prevent contamination and reduce

maintenance.

Long Life. An oil film prevents direct

contact between the discs. This design

absorbs the braking forces by shearing

the oil molecules and carrying heat

away to extend brake life.

12

Reliable braking with superior control gives the operator the confidence to focus on productivity.

Brake System

Page 13

Pistons. The Caterpillar two-piece piston

design combines the service, secondary,

parking brake and retarding functions

in the same system. The primary piston

hydraulically actuates both service and

retarding functions. The secondary

piston is spring-applied and held in

the disengaged position by hydraulic

pressure. If hydraulic system pressure

drops below a specified level, the springapplied secondary piston automatically

applies the brakes.

Parking Brake. The 770 parking brake

function is provided by the spring-applied

function in each of the rear oil-cooled

disc brakes. The 770 parking brake is

capable of holding the machine with a

rated load on grades up to 15 percent.

Automatic Retarder Control (ARC).

Standard ARC electronically controls

braking on grade to maintain engine at

approximately 2,200 rpm (adjustable from

1,950-2,200 rpm in increments of 10).

ARC is deactivated when the operator

applies the brakes or throttle.

• Faster Speeds. ARC allows the operator

to maintain optimum engine speeds for

up to 15 percent faster downhill hauls

and greater productivity.

• Superior Control. Automatic brake

modulation offers a smoother ride and

better control in slippery conditions,

allowing the operator to concentrate

on driving.

• Ease of Operation. ARC increases

operating ease, resulting in greater

operator confidence with less fatigue.

• Engine Overspeed Protection.

Automatically activates ARC when

engine speed exceeds factory preset

levels, regardless of operator inputs,

to avoid potentially damaging

engine overspeeds.

Traction Control System (TCS) (Optional).

Electronically monitors and controls rear

wheel slippage for greater traction and

enhanced truck performance in poor

underfoot conditions. If slippage exceeds

a set limit, the oil-cooled disc brakes

engage to slow the spinning wheel.

Torque is then automatically transferred

to the wheel with better traction.

Compression Brake (Optional). Optional

Compression Brake is integrated with

Automatic Retarder Control (ARC) to

provide up to 35 percent higher downhill

travel speed and reduce wear on brake

components.

13

1 2

4

3

5

8

6

6

7

7

TCSARC

1 Service Brake Sensor

2 Engine Sensor

3 ARC

4 ARC Switch

5 Brakes

6 Service Brakes

7 Axle Speed Sensor

8 TCS

2,500

2,000

1,500

1,000

Engine Speed (rpm)

500

10

20 30 40 50 60

Time (Seconds)

700

With Automatic Retarder Control

(average speed, 1,950 rpm)

With Manual Retarder Control

(average speed, 1,730 rpm)

Page 14

Ground-Level Access. All maintenance

points have convenient ground level or

platform access. Common engine service

points are grouped on the right side of

the engine for quick access. Two fuel

filters come standard with the machine

and the primary fuel filter includes a

water separator. These filters are easy to

change and are all spin-on/spin-off type.

Engine and torque converter oil check

and fill are accessed via the service

platform. The newly designed engine

oil dipstick is “rope-type” style, making

daily checks easier for the operator.

Service Switches. Machine switches

and an auxiliary start receptacle offer

easier access and expanded capabilities.

The battery disconnect switch, and

auxiliary start receptacles are now

combined into the same modular

assembly and relocated for ground

access.

Also, a new service panel on the LH

front of the machine provides:

• Engine Starter Lockout Switch.

Power is available to the machine,

but it cannot be started.

• Transmission, Hoist and Steering

Lockout Switch. The 770 features an

all-new transmission, hoist and steering

lockout mode. This feature disables

the steering, hoist and transmission

hydraulics, and sets the parking brake

while the engine is running, allowing

maintenance and trouble-shooting on

the truck. The operator can use this

feature to take S•O•SSManalysis samples.

• Electrical Breakers. Ground-level

access to circuit breakers are now

provided for engine control, alternator

and main electrical breakers.

Scheduled Oil Sampling. S•O•S sampling

valves speed sampling and analysis

reliability.

Pressure Test Points. Disconnect valves

are conveniently located throughout the

hydraulic systems for easy pressure

testing.

Air Filters. Radial seal air filters are

easy to change, reducing time required

for air filter maintenance.

Sealed Electrical Connectors. Electrical

connectors are sealed to lock out dust and

moisture. Harnesses are braided for

protection. Wires are color-coded for

easy diagnosis and repair.

Fuel Filters. The C15 engine is equipped

with two fuel filters. The primary filter

features 10-micron screening, and the

secondary filter is 2-micron.

Oil Filter. The 770 has one engine

oil filter on the right-hand side of the

engine. This filter is located for easy

serviceability. The oil filter is a 5-micron

filter and features a 500-hour oil change

interval.

14

Less time spent on maintenance means more time on haul roads.

Serviceability

Page 15

Electrical Access. The 770 features

a new configuration for fuses, circuit

breakers and rear cab-mounted relays,

enabling up to 50 percent faster servicing.

A 12-Volt and 24-Volt power port are

included. The automotive-style fuses,

which replace the screw-in type, are all

incorporated into a single enclosure that

is easily accessible from inside the cab.

10-amp and 15-amp spare fuses are also

included in the new design.

Cat Data Link. A Cat Data Link port

located near the fuse panel in the cab

can access all electronic controls for

obtaining monitoring and diagnostic

data. Excellent access to the ECM and

electrical panels improves the ability to

perform maintenance and trouble-shoot

the cab electronics.

Cat ET. Cat ET service tool provides

service technicians with easy access to

stored diagnostic data through the Cat

Data Link to simplify problem diagnosis

and increase machine availability.

Cat ET is beneficial because of how

it displays the status of all engine

parameters, including throttle position,

timing and fuel flow. Critical data from

the electronic engine and transmission

controls, including transmission shifting,

engine speed and fuel consumption,

provides service technicians with

enhanced diagnostic capability to

reduce downtime and operating costs.

Lincoln’s Quick Lube Automatic

Lubrication (Optional). This advanced

lubrication system is available as a

factory installed option. This system

provides optimal lubrication at preset

intervals during machine operation

significantly extends component life.

Clustered Grease Fittings (Optional).

Clustered grease fittings save time as all

lubrication points are mounted in three

main locations.

Oil Dipstick. New “rope-type” oil dipstick

improves serviceability by allowing easy

daily checks.

QuickEvac™ System and Prelube

System. Oil change labor time is reduced

by as much as 50 percent with this

standard on-board engine oil evacuation

and pre-lube system. This system

automatically fills engine oil filters and

galleries, which ensures components are

lubricated prior to starting the engine.

Extended Life Brake Discs (Optional).

The extended life brake discs are made

with a friction material that provides

longer service life and increased

heat resistance when compared to

Caterpillar’s standard brake offerings.

Discs use an innovative carbon paper for

braking and can be expected to double the

life of standard paper friction material

in most conditions. This is a significant

step forward, especially in long, downhillloaded hauling applications. The material

is also twice as resistant to glazing, which

is common during periods of hightemperature braking in moderate to severe

operating conditions. Resistance to glazing

leads to more consistent braking power.

15

Page 16

Increased Body Capacities. The 770

body capacity at 25.1 m3(32.9 yd3), has

increased 3.5 percent over the 769 at

24.2 m3(31.7 yd3). Payloads are based

on 1660 kg per LCM (2,800 lb per LCY)

material.

Electronic Hoist Control. Provides the

operator with better control of the load

when dumping, including over-center

load control and modulated control

throughout the operating range.

The automatic body snubbing feature

reduces impact on the frame, hoist

cylinders and operator.

1) Dual Slope Body 2) Flat Floor Body

Body Design. The new dual slope and

flat floor body systems will continue to

use fully fabricated, mild steel structures,

offering a strong, yet weldable underbody

structure. All interior, steel body surfaces

that come in contact with material are

fabricated from 400 BHN steel to provide

superior wear characteristics and

resistance to impact. Wide box-section

ribs provide excellent durability and

impact support in the floor, front-wall,

sidewall, and top rail areas. Full-length

stringer rails enhance strength and rigidity

throughout the body. Other new features

that further enhance durability of the

understructure include:

• Sidewall ribs are integrated into the

floor ribs, forming a belt to provide

increased strength in the sidewalls.

• Underbody ribs are increased

from seven to nine, enhancing

the underbody structural support.

• Front wall body rest supports are

integrated into the front wall structure

for enhanced durability.

• Full-length, single-piece stringer rails

are used, improving the structural

support in the body, especially in the

body pivot support area.

• Front wall is 400 BHN and

the thickness is increased from

10.2 mm (0.4 in) to 16.0 mm (0.63 in),

eliminating the need for additional

liners for impact resistance in most

applications.

Application Specific Body Systems.

With the introduction of the next

generation of trucks, Caterpillar will

build on the previous strengths and

provide differentiation through six

different body systems. Both dual slope

and flat floor bodies will be available in

the following configurations:

• Low Impact, Steel Body System

• Medium Impact, Steel Body System

• High Impact, Steel Body System

• Heavy Duty Impact, Steel Body

System

• High Impact, Rubber Body System

• Heavy Duty High Impact, Rubber

Body System

Steel-Lined Body System. The traditional

steel-lined system is well understood by

users worldwide. In the new 770 steel

body system, the unique design allows

the floor and liner to work together to

provide the impact and wear resistance.

The Medium Impact, Steel Body System

offers optimum combinations of wear and

impact resistance, while maximizing

performance. If the application dictates

higher impact or wear needs, the High

Impact, Steel Body System or the Heavy

Duty, High Impact, Steel Body System

provides more impact and wear resistance,

but at an increase in body weight versus

the Medium Impact, Steel Body System.

16

Cat designed and built for rugged performance and reliability in the toughest hauling applications.

Truck Body Systems

1 2

Page 17

Rubber-Lined Body System. A new

offering available from the factory is the

rubber-lined body system. For impact

resistance in hard-rock applications,

rubber liners offer a practical, durable

and cost-effective solution. They dissipate

impact energy, maximizing body life and

reduce noise, improving job site work

conditions inside and outside the cab.

These maintenance-free liners also

require minimal installation time.

The density of rubber is 20 percent of

the density of steel, yet its ability to

absorb impact is three times that of

steel. This gives rubber a high impact

strength-to-weight ratio. In addition,

truck operators enjoy a better operator

environment, without the hard impacts

felt during loading.

Body System Selection. Two primary

factors affect body selection:

• Impact. Impact is the energy that is

created by the material when it hits the

truck body. The condition and size of

material, combined with the height at

which it is dropped, greatly determines

the impact energy that the body must

absorb. The most measurable effect of

impact is structural bending, chipping,

cracking, and spalling. These conditions

can be created when the impact absorption

capability is exceeded by the impact of

the material itself. Generally speaking,

a high impact material might be basalt

or granite. A medium impact material

might be mixture of decomposed rock

(75 percent rock, 25 percent dirt), while

a low impact material might simply

be dry, packed dirt.

• Abrasion or Wear. The tendency of a

material to grind away the surface of a

body by means of friction is abrasion.

Abrasion occurs when a material’s

hardness is higher than the wear surface

that it slides on. A high abrasion material

could be any rock material containing a

high proportion of hard, angular minerals

such as quartz. Granite tends to be highly

abrasive. A moderate abrasion material

might contain a high proportion of

minerals such as calcite. Limestone is

most likely in the moderately abrasive

category. A low abrasion material could

be any material that contains minerals

such as talc.

Exhaust Routing. There are three

exhaust routing systems available for

the 770, depending on the customer’s

requirements for body heat and sound:

• Full-Time Body Routing. The standard

design provides full-time routing of

exhaust into the body to heat areas where

material gathers. This plays a crucial role

in preventing material from being retained

in the body during dumping. Not for use

with rubber liner body systems.

• Full-Time Muffler Routing. The second

option is the full-time routing of exhaust

through a muffler, which eliminates

exhaust in the body. This option

should be used for rubber-lined bodies or

applications that do not require body heat.

• Diverter Box Routing. The final

option provides a diverter box so that

the customer has the flexibility to

choose whether to route the exhaust

through the body or directly through

the muffler. Not for use with rubber

liner body systems.

Target Payload Strategy. Your Caterpillar

Dealer can help you manage to target

payload to maximize equipment use,

ensure safe operation, increase

productivity and lower cost-per-ton.

• Underloading increases costs

due to lost payloads, underutilizes

equipment, and increases cost-per-ton.

• Overloading causes excessive wear

on vehicle components, such as

brakes, tires and drive train, reducing

component life and increasing

maintenance costs and repairs.

Matched Systems. Designed to work as

an optimum pass/match system, the 770

is best sized to match the 988H Wheel

Loader, with a 4 pass/match, the 990H

Wheel Loader, with 3 pass/match, and

the 385C Hydraulic Excavator with a

6 pass/match.

17

Page 18

New Features.

• Standard Messenger Display replaces

Caterpillar Electronic Monitoring

System (CEMS) unit.

• Enhanced TPMS (Optional

Attachment) incorporates second

gear weighing capability and

increases to 2,400 cycles of

data storage for analysis.

Cat Messenger. Standard on the 770, Cat

Messenger provides real-time machine

performance and operating data, and

basic trip, maintenance and diagnostic

data using an LCD display. The viewable

LCD screen area of the Messenger

display is 22.5 mm 84.6 mm

(0.89 in 3.33 in).

Service Mode. This allows a technician

to change machine settings that are

typically changed via Cat ET through

the display. Service Mode can be a

password-protected feature to inhibit

the operator from changing these

settings. Settings that can be changed

via Service Mode are:

• Top Gear Limit

• Body Up Gear Limit

• Machine Overloaded Speed Limit

(if TPMS is installed)

• Machine Speed Limit

• Economy Shift Mode

• Desired Engine Retard Speed

• Target Payload (if TPMS is installed)

• Payload Overload Limit

(if TPMS is installed)

Real Time System Parameter Display.

This will show a real-time display of

various machine parameters related to

the engine, transmission, hoist, brake

and TPMS (if installed) systems.

• System Tests. The technician can

perform a transmission stall test and

a monitoring system self test.

• Machine Functionality. Records and

displays worst-case values for brake,

hoist and hydraulic fan oil temperature,

engine coolant temperature, tachometer,

transmission/torque converter temperature,

and fuel level since the last reset.

• System Information. Displays electronic

system information such as the ECM

part number, the software part number

and the software release date.

• Supports Multiple Languages.

Available in 47 languages. Please consult

with your salesman as to specific language

availability.

• Payload Calibration.

(if TPMS is installed)

18

Vital machine health and payload data keeps the 770 peforming at peak production levels.

Information and Monitoring Systems

1 Gauge Cluster

2 Messenger Display

3 Action Alarm

3

1

2

4 ADEM A4 Engine Control Module

5 CAT Data Link

6 Payload Lamps

7 Truck Production Management System

8 Diagnostic Connector (ET)

9 Automatic Retarder Control (ARC)

Traction Control System (TCS)

Transmission/Chassis Control (TCC) Module

6

4

7

8

5

9

Page 19

Truck Production Management System

(TPMS) (Optional). TPMS provides

valuable payload and cycle time

data to improve productivity.

• Uses strut pressure sensors and onboard microprocessor to determine

payload weight.

• Delivers consistent, accurate payloads

and improves efficiency by

minimizing overloading and

underloading.

• External lights signal loading tool

operator when payload is reached.

• On-board computer stores up to

2,400 cycles for analysis of payload

weight, cycle times, distances and

actual cycle dates and times.

• A second gear reweigh takes an

additional measurement once the

truck has reached second gear for

improved accuracy.

• System is accurate within ± 5 percent

under normal loading conditions

over a normal shift.

• Standard LED lamps replace

incandescent lamps on the TPMS,

extending lamp life by 25 times.

Product Link. Using satellite technology,

this optional wireless system automatically

reports information, including vital

machine health data, to Cat dealers

and customers via e-mail or pager.

It can streamline diagnostic efforts,

downtime, and maintenance scheduling

and costs. The standard configuration of

the 770 is Product Link (Level 1) ready.

Product Link PL321SR (Level 3) is

offered as a standard factory-installed

attachment.

Equipment Manager (Optional). Product

Link data can be delivered to a customer’s

desktop via this on-line, user-friendly

subscription service. Information is

organized and color-coded according

to priority. There are four levels of

Equipment Manager service available:

• Asset Watch. Provides alerts, location

and fuel levels and machine start and

stop times.

• Maintenance Watch. Provides all Asset

Watch data, plus repair and maintenance

information, such as PM maintenance due

or past due, and PM maintenance history.

• Health Watch. Provides all Maintenance

Watch data, and adds machine fault

information, performance trending

and S•O•S oil analysis reporting

with interpretation tools.

• Utilization and Productivity Watch.

Offers comprehensive customized usage

and monitoring reports.

19

Page 20

Product Safety. Caterpillar has been and

continues to be proactive in developing

machines that meet or exceed safety

standards. Safety is an integral part

of all machine and systems designs.

Integral ROPS Cab. Resiliently mounted

to the frame to reduce vibration and sound,

the integral ROPS structure, which

provides “five-sided protection” for the

operator, is designed as an extension of

the truck frame.

Payload Guidelines. Safety is integral to

maintaining the highest productivity in

mining machine operation. The Caterpillar

10/10/20 Payload Guidelines ensures

that steering and braking systems have

sufficient capacity to perform.

WAVS Camera (Optional). An optional

rear vision camera system provides

visibility to the rear of the machine

through an LCD monitor in the cab.

The monitor an be set to activate only

when the truck is in reverse, and the

display is equipped with a sensor to

detect ambient light, which automatically

brightens or dims the display.

Brake Systems. Cat hydraulically

controlled dry front and rear oil-cooled

multiple disc brakes provide exceptional,

fade-resistant braking and retarding for

maximum performance and productivity

in all haul-road conditions. The service

brakes and retarding system are actuated

by modulated hydraulic pressure, while

secondary and parking brake functions are

spring applied and hydraulic released.

This reliable and durable system ensures

braking in the event of complete

hydraulic failure.

Steering System. A twin, double-acting

cylinder steering system is designed to

deliver precise control under all loading

and underfoot conditions. The steering

hydraulic system is separate from the

main hydraulic system to prevent

crosscontamination and overheating.

Engine Shutoff Switch. A secondary

engine shutoff switch is located at

ground level.

Electrical System Disconnect. A battery

disconnect switch, located directly above

the front bumper, provides ground-level

lockout of the electrical system.

Ladder/Secondary Egress. Wide

stationary stairways and platforms on

both sides of the machine, allow easy

ingress and egress.

Standard Safety Features.

• Slip resistant surfaces

• 75 mm (3 in) wide three-point

operator restraint

• Heated, wide-angle mirrors

• Body raised indicator

• Guard rails

• Reverse neutralizer when dumping

• Low interior sound level

• Service platform level transmission,

hoist and steering disable switch

• Service platform level starter

disable switch

SAFETY.CAT.COM™.

20

Safety

Caterpillar®machines and systems are designed with safety as the first priority.

Page 21

21

Commitment Makes the Difference.

Cat dealers offer a wide range of

solutions, services and products that help

you lower costs, enhance productivity and

manage your operation more efficiently.

Support goes far beyond parts and service.

From the time you select a piece of

Cat equipment until the day you rebuild,

trade or sell it, the support you get from

your Cat dealer makes the difference

that counts.

Dealer Capability. Cat dealers provide the

level of support you need, on a global

scale. Dealer expert technicians have

the knowledge, experience, training and

tooling necessary to handle your repair

and maintenance needs, when and

where you need them.

Product Support. Cat dealers believe

superior products deserve superior

support. When Cat products reach the

field, they are supported by a worldwide

network of parts distribution facilities,

dealer service centers, and technical

training facilities to keep your equipment

up and running. Cat customers rely on

prompt, dependable parts availability

and expertise through our global dealer

network, ready to meet your needs 24/7.

Service Support. Every piece of Cat

equipment is designed and built to

provide maximum productivity and

operating economy throughout its

working life. Cat dealers offer a wide

range of service plans that will maximize

uptime and return on your investment,

including:

• Preventive Maintenance Programs

• Diagnostic Programs, such as

Scheduled Oil Sampling and

Technical Analysis

• Rebuild and Reman Options

• Customer Support Agreements

Application Awareness. Operating and

maintenance costs are influenced by

many application and site-specific factors,

such as material density, loading position,

payload, grades, speeds, haul road design

and maintenance. To optimize total cost

of ownership and productivity, your Cat

dealer can provide you with a fundamental

understanding of the effects application

characteristics and operating techniques

have on maintenance and operating costs.

Operation. With today’s complex

products, equipment operators must have

a thorough understanding of machine

systems and operating techniques to

maximize efficiency and profitability.

Your Cat dealer can arrange training

programs to help operator’s improve

productivity, decrease downtime,

reduce operating costs, enhance safety,

and improve return on the investment

you make in Cat products.

www.cat.com. For more complete

information on Cat products, dealer

services, and industry solutions,

visit us on the web at www.cat.com.

Customer Support

Caterpillar dealers have what it takes to keep trucks productive.

Page 22

22

770 Off-Highway Truck specifications

Transmission

Forward 1 12.1 km/h 7.5 mph

Forward 2 16.6 km/h 10.3 mph

Forward 3 22.5 km/h 14 mph

Forward 4 30.3 km/h 18.8 mph

Forward 5 40.9 km/h 25.4 mph

Forward 6 55.2 km/h 34.3 mph

Forward 7 74.8 km/h 46.5 mph

Reverse 15.9 km/h 9.9 mph

• Maximum travel speeds with standard 18.00R33 (E4) tires.

Final Drives

Differential Ratio 2.74:1

Planetary Ratio 4.80:1

Total Reduction Ratio 13.15:1

Brakes

Brake Surface – Front 1395 cm

2

216 in

2

Brake Surface – Rear 40 266 cm26,235 in

2

Brake Standards ISO 3450: 1996

• Target Gross Machine Operating Weight is up to 71 214 kg

(157,000 lb).

Body Hoists

Pump Flow – High Idle 515 L/min 136 gal/min

Relief Valve Setting – Raise 17 255 kPa 2,500 psi

Relief Valve Setting – Lower 3450 kPa 500 psi

Body Raise Time* 8.1 Seconds

Body Lower Time – Float 14.7 Seconds

Body Power Down – High Idle* 14.3 Seconds

* Without Sound Suppression Package

Capacity – Dual Slope – 100% fill factor

Struck 18.0 m

3

23.6 yd

3

Heaped 2:1 (SAE) 25.9 m

3

33.9 yd

3

Capacity – Flat Floor – 100% fill factor

Struck 17.1 m

3

22.4 yd

3

Heaped 2:1 (SAE) 25.1 m

3

32.9 yd

3

Engine

Engine Model Cat®C15 ACERT™

Rated Engine Speed 1,800 rpm

Gross Power – SAE J1995 381 kW 511 hp

Net Power – SAE J1349 355 kW 476 hp

Net Power – ISO 9249:1997 355 kW 476 hp

Net Power – 80/1269/EEC 355 kW 476 hp

Number of Cylinders 6

Peak Torque 2320 N•m 1,711 lb-ft

Bore 137 mm 5.4 in

Stroke 171 mm 6.7 in

Displacement 15.2 L 927.6 in

3

• Power rating applies at 1,800 rpm when tested under

the specified condition for the specified standard.

• Ratings based on SAE J1995 standard air conditions of 25° C

(77° F) and 100 kPa (29.61 Hg) barometer. Power based on

fuel having API gravity of 35 at 16° C (60° F) and an LHV of

42 780 kJ/kg (18,390 BTU/lb) when engine used at 30° C (86° F).

• No engine derating required up to 2286 m (7,500 ft) altitude.

• Compliant with U.S. Environmental Protection Agency Tier 3

emissions standards and European Union Stage IIIa

regulations.

Weights – Approximate

Target Gross Machine 71 214 kg 157,000 lb

Operating Weight

Chassis Weight 24 213 kg 53,380 lb

Body Weight 10 029 kg 22,110 lb

• Body weight varies depending on how body is equipped.

Shown above is the Flat Floor, Medium Impact, Steel

Body System.

Operating Specifications

Nominal Payload Class 36.3 tonnes 40 tons

Top Speed – Loaded 74.8 km/h 46.5 mph

Body Capacity – SAE 2:1 25.1 m

3

32.9 yd

3

Target Payload Capacity 36.3 tonnes 40 tons

• Refer to the Caterpillar 10/10/20 Overload Policy for maximum

gross machine weight limitations.

• Capacity with flat floor body.

Page 23

23

770 Off-Highway Truck specifications

ROPS

ROPS/FOPS Standards

• ROPS (Rollover Protective Structure) for cab offered

by Caterpillar meets ISO 3471:1994 ROPS criteria.

• FOPS (Falling Objects Protective Structure) meets

ISO 3449:1992 Level II FOPS criteria.

Sound

Sound Standards

• The operator sound pressure level measured according to

work cycle procedures specified in ANSI/SAE J919 APR95

is 79 dB(A) for cab offered by Caterpillar, when properly

installed and maintained and tested with doors and windows

closed, engine speed at high idle, and fan at medium settings.

• The exterior sound pressure level for the standard machine

measured at a distance of 15 m (49 ft) according to the test

procedures specified in SAE J88 APR95, mid-gear moving

operation is 84 dB(A).

• Hearing protection may be needed when operating with an

open operator station and cab (when not properly maintained

or doors/windows open) for extended periods or in a noisy

environment.

Steering

Steering Standards ISO 5010:1992

Steer Angle 40º

• Target Gross Machine Operating Weight is 71 214 kg

(157,000 lb).

• Turning circle as measured from the outside of the tire is

18.1 m (59.4 ft).

Weight Distributions – Approximate

Front Axle – Empty 48%

Front Axle – Loaded 34%

Rear Axle – Empty 52%

Rear Axle – Loaded 66%

Suspension

Effective Cylinder Stroke – Front 234 mm 9.2 in

Effective Cylinder Stroke – Rear 149 mm 5.9 in

Rear Axle Oscillation 8.9º

Service Refill Capacities

Fuel Tank 530 L 140 gal

Cooling System 114 L 30 gal

Crankcase 34 L 9 gal

Differentials and Final Drives 159 L 42 gal

Steering Tank 34 L 9 gal

Steering System (Includes Tank) 56 L 15 gal

Brake/Hoist/Fan Hydraulic Tank 155 L 35 gal

Brake/Hoist/Fan System (Tank) 277 L 73 gal

Transmission/Torque 53 L 14 gal

Converter Sump

Transmission/Torque Converter 95 L 25 gal

System (Includes Sump)

Tires

Standard Tire 18.00R33 (E4)

• Productive capabilites of the 770 truck are such that, under

certain job conditions, TKPH (TMPH) capabilities of standard

or optional tires could be exceeded and, therefore, limit

production.

• Caterpillar recommends the customer evaluate all job

conditions and consult the tire manufacturer for proper

tire selection.

Page 24

Dimensions

24

770 Off-Highway Truck specifications

All dimensions are approximate.

2

12

3

11

47.5°

1

10

9

7

5

4

8

6

17

14

13

15

16

18

19

20

1 Height to Top of ROPS 3911 mm 12 ft 10 in

2 Overall Body Length 8185 mm 26 ft 10 in

3 Inside Body Length 5549 mm 18 ft 3 in

4 Overall Length 9020 mm 29 ft 7 in

5 Wheelbase 3960 mm 13 ft

6 Rear Axle to Tail 2595 mm 8 ft 6 in

7 Ground Clearance 680 mm 2 ft 3 in

8 Dump Clearance 498 mm 1 ft 7 in

9 Loading Height – Empty 3158 mm 10 ft 4 in

10 Inside Body Depth – Max. 1326 mm 4 ft 5 in

11 Overall Height – Body Raised 8280 mm 27 ft 2 in

12 Operating Width 4780 mm 15 ft 8 in

13 Centerline Front Tire Width 3110 mm 10 ft 3 in

14 Engine Guard Clearance 673 mm 2 ft 3 in

15 Outside Body Width 3932 mm 12 ft 10 in

16 Inside Body Width 3698 mm 12 ft 2 in

17 Front Canopy Height 4195 mm 13 ft 9 in

18 Rear Axle Clearance 508 mm 1 ft 9 in

19 Centerline Rear Dual Tire Width 2536 mm 8 ft 4 in

20 Overall Tire Width 3693 mm 12 ft 2 in

Page 25

25

770 Off-Highway Truck specifications

Weight/Payload Calculation

(Example)

Flat Floor

Low Impact Medium Impact High Impact Heavy Duty High Impact Heavy Duty

Steel Body Steel Body Steel Body Steel Body Rubber Body Rubber Body

System System System System System System

8 mm (0.315 in) 16 mm (0.630 in) 20 mm (0.787 in) 25 mm (1.0 in) 102 mm (4.0 in) 102 mm (4.0 in)

Target Gross Machine Weight* kg (lb) 71 214 (157,000) 71 214 (157,000) 71 214 (157,000) 71 214 (157,000) 71 214 (157,000) 71 214 (157,000)

Empty Chassis Weight* kg (lb) 24 213 (53,380) 24 213 (53,380) 24 213 (53,380) 24 213 (53,380) 24 213 (53,380) 24 213 (53,380)

Body System Weight kg (lb) 8367 (18,446) 10 029 (22,110) 10 524 (23,202) 11 474 (25,296) 10 757 (23,714) 11 113 (24,499)

Empty Machine Weight kg (lb) 32 579 (71,826) 34 242 (75,490) 34 737 (76,582) 35 687 (78,676) 34 969 (77,094) 35 325 (77,879)

Attachments

Fuel Tank Size L (gal) 529 (140) 529 (140) 529 (140) 529 (140) 529 (140) 529 (140)

Fuel Tank – 100% fill kg (lb) 446 (983) 446 (983) 446 (983) 446 (983) 446 (983) 446 (983)

Empty Operating Weight** kg (lb) 33 026 (72,809) 34 688 (76,473) 35 183 (77,565) 36 133 (79,659) 35 415 (78,077) 35 771 (78,862)

Target Payload* kg (lb) 38 190 (84,191) 36 526 (80,527) 36 031 (79,435) 35 081 (77,341) 35 799 (78,923) 35 443 (78,138)

Target Payload* tonnes (tons) 38.2 (42.1) 36.6 (40.3) 36.0 (39.7) 35.1 (38.7) 35.8 (39.5) 35.4 (39.1)

Dual Slope

Low Impact Medium Impact High Impact Heavy Duty High Impact Heavy Duty

Steel Body Steel Body Steel Body Steel Body Rubber Body Rubber Body

System System System System System System

8 mm (0.315 in) 16 mm (0.630 in) 20 mm (0.787 in) 25 mm (1.0 in) 102 mm (4.0 in) 102 mm (4.0 in)

Target Gross Machine Weight* kg (lb) 71 214 (157,000) 71 214 (157,000) 71 214 (157,000) 71 214 (157,000) 71 214 (157,000) 71 214 (157,000)

Empty Chassis Weight* kg (lb) 24 213 (53,380) 24 213 (53,380) 24 213 (53,380) 24 213 (53,380) 24 213 (53,380) 24 213 (53,380)

Body System Weight kg (lb) 8362 (18,436) 10 019 (22,088) 10 518 (23,188) 11 474 (25,295) 10 836 (23,889) 11 159 (24,602)

Empty Machine Weight kg (lb) 32 930 (71,816) 34 232 (75,468) 34 731 (76,568) 35 686 (78,675) 35 049 (77,269) 35 372 (77,982)

Attachments

Fuel Tank Size L (gal) 529 (140) 529 (140) 529 (140) 529 (140) 529 (140) 529 (140)

Fuel Tank – 100% fill kg (lb) 445 (983) 445 (983) 445 (983) 445 (983) 445 (983) 445 (983)

Empty Operating Weight** kg (lb) 33 021 (72,799) 34 688 (76,451) 35 177 (77,551) 36 132 (79,658) 35 495 (78,252) 35 817 (78,965)

Target Payload* kg (lb) 38 193 (84,201) 36 536 (80,549) 36 038 (79,449) 35 082 (77,342) 35 720 (78,748) 35 396 (78,035)

Target Payload* tonnes (tons) 38.2 (42.1) 36.6 (40.3) 36.0 (39.7) 35.1 (38.7) 35.7 (39.4) 35.4 (39.0)

* Refer to Caterpillar® 10/10/20 overload policy

** Includes weight of all attachments

Page 26

26

770 Off-Highway Truck specifications

Gradeability/Speed/Rimpull

To determine gradeability performance: Read from gross

weight down to the percent of total resistance. Total resistance

equals actual percent grade plus 1% for each 10 kg/t (20 lb/ton)

of rolling resistance. From this weight-resistance point, read

Direct Drive

Torque Converter Drive

E – Typical Field Empty Weight

L – Target Gross Machine Operating Weight 71 214 kg (157,000 lb )

Gross Weight

0 102030 40 5060 70 80

30

25

20

lb x

0 50 100 150

1000

60

50

1A

40

kg x

1000

horizontally to the curve with the highest obtainable gear, then

down to maximum speed. Usable rimpull will depend upon

traction available and weight on drive wheels.

kg x 1000

lb x 1000

LE

30%

25%

15

Rimpull

10

5

0

30

1B

20

10

0

0 5 10 15 20 25 30 35 40 45

0 10203040506070805 15253545556575

2

3

4

5

6

7

Speed

20%

15%

10%

5%

mph

km/h

al Resistance

t

To

(Grade Plus Rolling)

Page 27

27

770 Off-Highway Truck specifications

Retarding Performance

To determine retarding performance: Add lengths of all

downhill segments and, using this total, refer to proper

retarding chart. Read from gross weight down to the percent

effective grade. Effective grade equals actual % grade minus

1% for each 10 kg/t (20 lb/ton) of rolling resistance. From this

weight-effective grade point, read horizontally to the curve

with the highest obtainable gear, then down to maximum

descent speed brakes can properly handle without exceeding

With ARC Only

ARC and Engine Brake

E – Typical Field Empty Weight

L – Target Gross Machine Operating Weight 71 214 kg (157,000 lb)

Gross Weight

01020304050607080

05025 10075 125 150 175

cooling capacity. The following charts are based on these

conditions: 32° C (90° F) ambient temperature, at sea level,

with 18.00R33 tires.

NOTE: Select the proper gear to maintain engine rpm at the highest

possible level, without overspeeding the engine. If cooling oil

overheats, reduce ground speed to allow transmission to shift to

the next lower speed range.

kg x 1000

lb x 1000

30%

LE

25%

1

20%

2

15%

3

4

5

6

7

0 5 10 15 20 25 30 35 40 45

0 10203040506070805 15253545556575

10%

5%

Speed

Continuous Grade Length

Effective Grade

(Grade Minus Rolling Resistance)

mph

km/h

Page 28

28

770 Off-Highway Truck specifications

Retarding Performance

With ARC Only

E – Typical Field Empty Weight

L – Target Gross Machine Operating

Weight 71 214 kg (157,000 lb)

ARC and Engine Brake

01020304050607080

05025 10075 125 150 175

Gross Weight

kg x 1000

lb x 1000

With ARC Only

E – Typical Field Empty Weight

L – Target Gross Machine Operating

Weight 71 214 kg (157,000 lb)

ARC and Engine Brake

LE

30%

1

2

3

4

5

6

0 5 10 15 20 25 30 35 40 45

0 10203040506070805 15253545556575

7

25%

20%

15%

10%

5%

mph

km/h

Speed

Grade Distance – 450 m (1,500 ft)

Gross Weight

01020304050607080

05025 10075 125 150 175

kg x 1000

lb x 1000

Effective Grade

(Grade Minus Rolling Resistance)

1

2

3

4

0 5 10 15 20 25 30 35 40 45

0 10203040506070805 15253545556575

Speed

Grade Distance – 600 m (2,000 ft)

LE

30%

25%

20%

15%

5

6

7

10%

5%

Effective Grade

(Grade Minus Rolling Resistance)

mph

km/h

Page 29

29

770 Off-Highway Truck specifications

Retarding Performance

With ARC Only

E – Typical Field Empty Weight

L – Target Gross Machine Operating

Weight 71 214 kg (157,000 lb)

ARC and Engine Brake

01020304050607080

05025 10075 125 150 175

Gross Weight

kg x 1000

lb x 1000

With ARC Only

E – Typical Field Empty Weight

L – Target Gross Machine Operating

Weight 71 214 kg (157,000 lb)

ARC and Engine Brake

LE

30%

25%

1

2

3

4

5

6

0 5 10 15 20 25 30 35 40 45

0 10203040506070805 15253545556575

7

20%

15%

10%

5%

mph

km/h

Speed

Grade Distance – 900 m (3,000 ft)

Gross Weight

01020304050607080

05025 10075 125 150 175

kg x 1000

lb x 1000

Effective Grade

(Grade Minus Rolling Resistance)

LE

30%

25%

1

2

3

4

5

6

0 5 10 15 20 25 30 35 40 45

0 10203040506070805 15253545556575

7

15%

10%

5%

Speed

Grade Distance – 1500 m (5,000 ft)

20%

Effective Grade

(Grade Minus Rolling Resistance)

mph

km/h

Page 30

Standard Equipment

Standard equipment may vary. Consult your Caterpillar dealer for details.

POWER TRAIN

Cat C15 Engine with ACERT®Technology

6-cylinder diesel

Air-to-Air Aftercooler (ATAAC)

Air cleaner with precleaner (1)

Automatic cold mode idle control

Electric start

Quick Evac™ System with engine prelube

Turbocharger

Braking system:

Automatic Retarder Control (ARC)

(utlizes rear oil-cooled brakes)

Brake release motor (towing)

Caliper-disc (front)

Oil-cooled, multiple disc (rear)

Parking

Secondary

Service

Transmission:

7-speed automatic powershift

Body up shift inhibitor

Controlled throttle shifting

Directional shift management

Downshift inhibitor

Neutral start switch

Neutral coast inhibitor

Reverse shift inhibitor

Reverse neutralizer during dumping

Programmable top gear selection

ANTIFREEZE

Extended Life Coolant to –35° C (–30° F)

ELECTRICAL

Alarm, backup

Alternator, 95-amp

Auxiliary jump start receptacle

Batteries, maintenance-free, 12V (2), 190 amp-hour

Electrical system, 24V

Lighting system:

Backup light (halogen)

Directional signals/hazard warning, (front/rear LED)

Headlights, halogen with dimmer

Operator access courtesy lights

Side profile lights

Stop/tail lights LED

OPERATOR ENVIRONMENT

Air conditioning

Ashtray and cigarette lighter

Coat hook

Cup holders (4)

Diagnostic connection port, 24V

Entertainment Radio Ready

5 amp converter

Speakers

Antenna

Wiring harness

Gauges/indicators:

Air cleaner service indicator – electronic

Brake oil temperature gauge

Coolant temperature gauge

Engine overspeed indicator

Fuel level

Hour meter

Speedometer/odometer

Tachometer

Transmission gear indicator

Heater/defroster, 11 070 kCal (43,930 BTU)

Hoist lever

Horn, electric

Light, dome/courtesy

Messenger display unit

Mirrors

Power port, 12V

ROPS cab, insulated/sound suppressed

Seat, Caterpillar Comfort

Full air suspension

Retractable, 3-point seat belt with shoulder harness