Page 1

®

®

525C

Wheel Skidder

Engine

Engine Model Cat®C7 ACERT™

Gross Power – SAE J1995 146 kW 196 hp

Dimensions

Wheelbase 3534 mm 139.2 in

Weights

Est Operating Weight 17 711 kg 39,045 lb

• Operating weight includes enclosed cab, 30.5 tires,

decking blade, arch, bunching grapple, winch

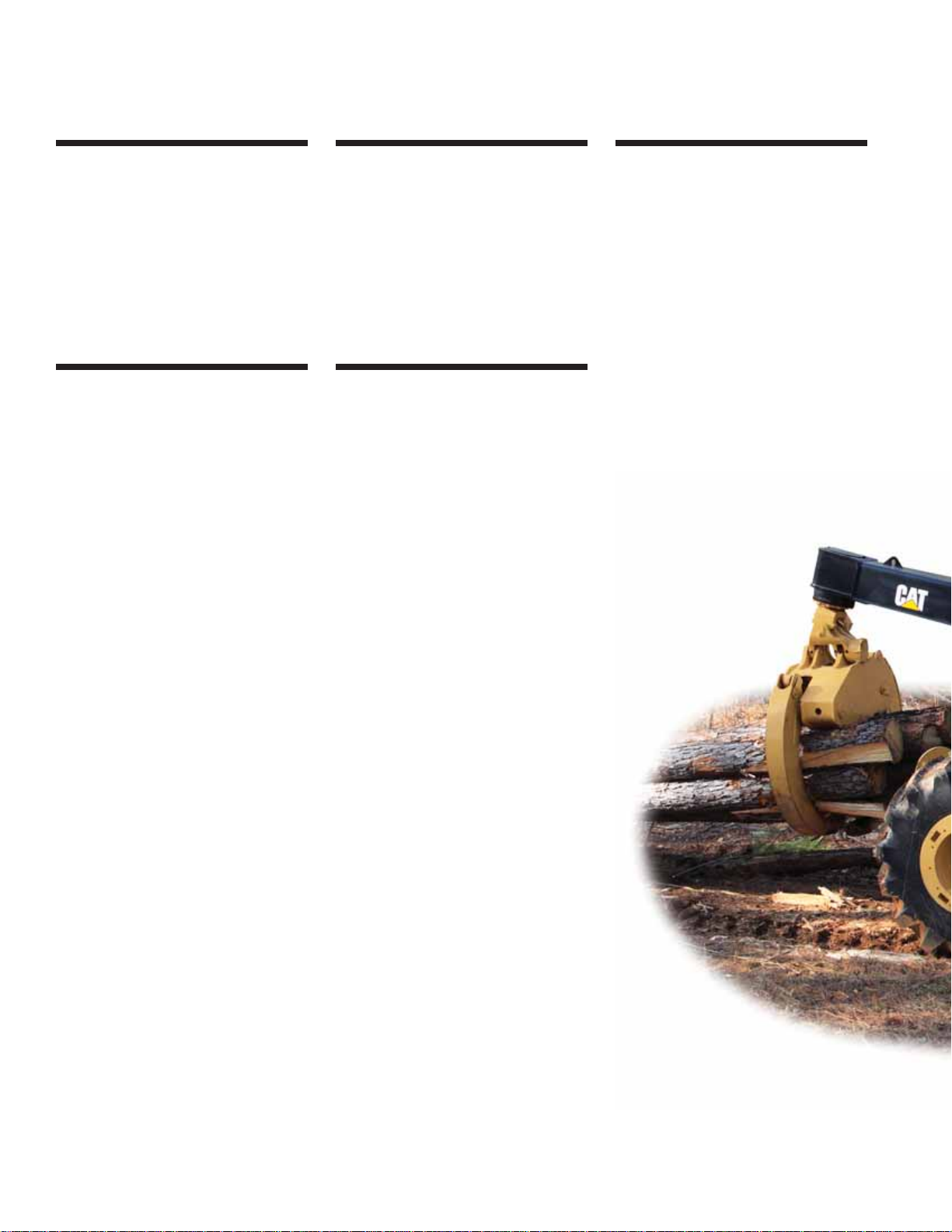

Grapple

Bunching Capacity 1.16 m

Thinning Capacity 1.34 m

2

2

12.5 ft

14.4 ft

2

2

Page 2

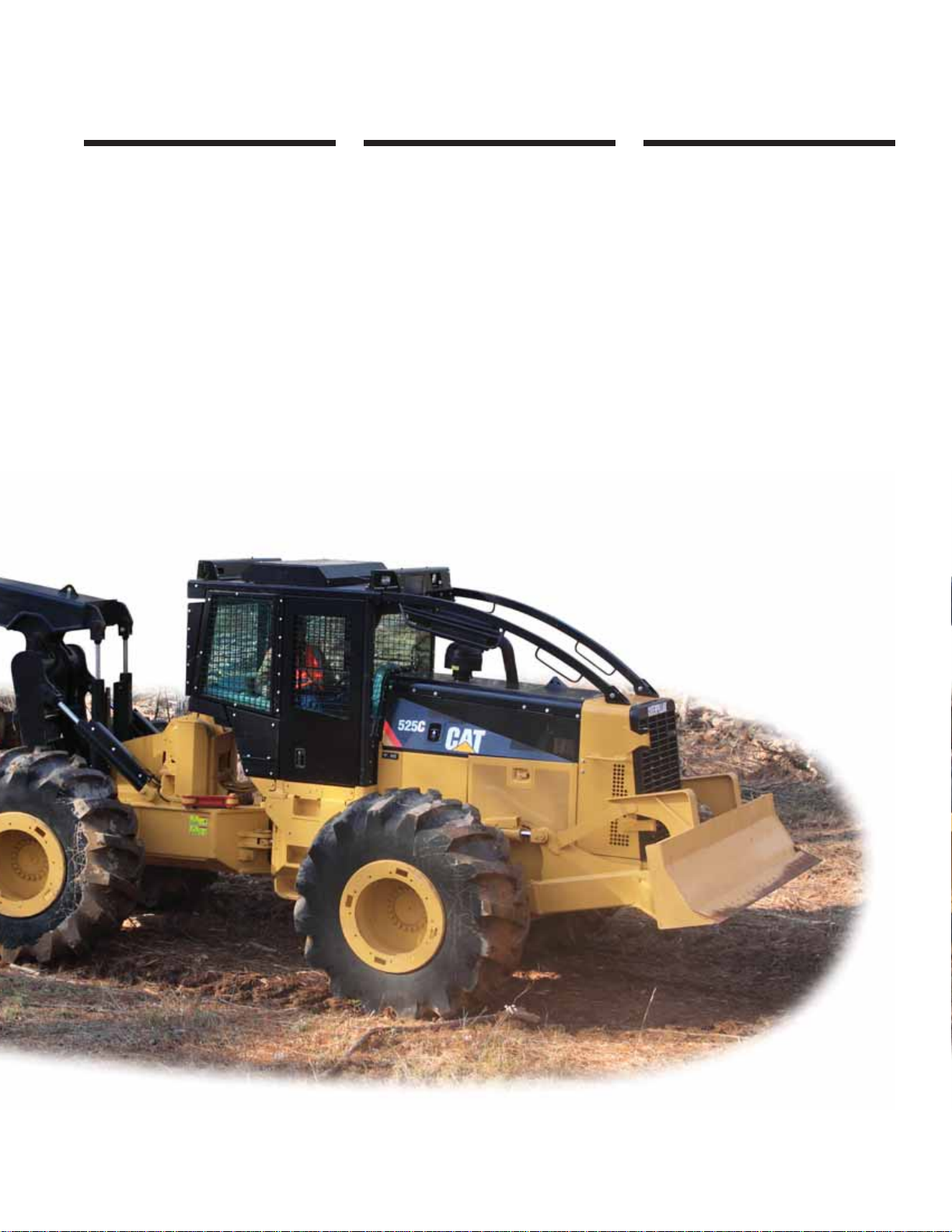

525C Wheel Skidder

The 525C wheel skidder sets the standard for productivity and durability.

Engine

The Cat®C7 engine with ACERT™

✔

technology is field proven and U.S.

EPA Tier 3 compliant. The industry

leading Caterpillar®lock up torque

converter automatically engages/

disengages direct drive for maximum

efficiency, performance and productivity.

pg. 4

Serviceability

The 525C is designed to make regular

✔

maintenance easier, extend service

intervals, and reduce the time required

for maintenance. pg. 11

Power Train

The field-proven Cat torque converter,

heavy-duty transmission and high

performance axles improve availability,

performance and productivity, while

minimizing fuel consumption. pg. 5

Customer Support

Your Cat dealer offers support you can

count on, from purchase options to

operator training, maintenance programs

and unmatched parts availability … all

to keep your Cat skidder up and running

when you need it. pg. 12

Hydraulics

The state-of-the-art closed-center,

variable displacement, pressure

compensating hydraulic system

provides power for braking, steering,

blade and grapple functions. pg. 6

Engineered to exceed customer expectations

in the toughest applications. Caterpillar

quality, improved serviceability and

productivity provide maximum uptime

and lower owning and operating costs.

2

Page 3

Structures

Operator Station

Work Tools

The 525C structures are Caterpillar

✔

designed and manufactured for the

most demanding logging conditions.

Durable box section mainframes and

decking blade provide superior strength.

pg. 7

Finger tip gear selection, 1/4 turn

✔

steering, improved ergonomic control

layout and reduced operator lever effort

contribute to the most comfortable

operator environment. pg. 8

Large Cat grapples maximize

✔

production with a new tong profile and

higher clamping forces. Raised edges

and wear resistant cast tips provide

added durability. The hydraulic winch

is ideal for self-retrieval and log truck

towing. pg. 10

✔ New Feature

3

Page 4

Engine

The Cat power train delivers top performance, power, and durability.

Cat C7 Engine. The Cat C7 uses

Caterpillar’s breakthrough ACERT™

Technology to meet exhaust emission

reduction standards. It features efficient

air management, fuel delivery and

electronic control for high productivity

and exceptional service life.

Engine Design. This four-stroke engine

provides efficient fuel combustion.

Precise engineering and thorough

testing assure durability, reliability and

plenty of power. Built-in serviceability

and excellent fuel economy lower

operating costs.

ACERT™ Technology. Caterpillar

optimizes engine performance while

meeting EPA Tier 3 regulations.

ACERT™ Technology reduces

emissions during the combustion

process by using advanced technology

in the air and fuel systems, in conjunction

with integrated electronics. Caterpillar

meets emission regulations at the

combustion source rather than

recycling exhaust gases.

ADEM A4 Control Module. Controls the

fuel injector solenoids to monitor fuel

injection. This system provides automatic

altitude compensation, and it will not

allow the engine to fire until it has oil

pressure, acting as cold start protection

and a form of pre-lube.

Turbocharger. The C7 features a waste

gate turbocharger that provides high

boost over a wider range, improving

engine response and peak torque, as

well as providing outstanding low-end

performance.

Maintenance. The C7 engine reduces

costs and downtime with a 500-hour oil

change interval. Extended service

intervals can save thousands of dollars

over the life of a machine. Machines are

equipped with Caterpillar high efficiency

oil filters, whose revolutionary design

doubles efficiency without increasing

the change interval.

Water Pump. A dual thermostat control

improves coolant flow and heat

dissipation, resulting in better durability.

Electronic Transfer Pump. The electric

fuel transfer pump is self-priming,

eliminating the need for a manual

priming pump.

Reliability Features. The C7 offers

maximum reliability and response

thanks to a range of features:

• Improved fuel injectors and pump

• Leak-free design

• Higher cylinder pressures

• Reinforced cylinder block

Leak-Free Design. Improved joints

throughout the engine reduce the chance

of leaks. The oil pan seal, timing

cover and block to flywheel housing

incorporate a leak-free design proven

in thousands of Cat on-highway truck

engines in the field.

4

Page 5

Power Train

The integrated Cat power train delivers dependable, relentless pulling power.

Five-Speed Transmission. The field

proven Cat power shift countershaft

transmission easily matches engine

power to the load size and ground

conditions. Electronic control makes

fingertip controls possible, reducing

operator fatigue and improving comfort.

Gear Application. Gear ratios are

carefully designed to maximize

productivity in specific cycle segments

and under specific loads.

• Gear 1 provides highest rimpull

capability for heavy load

applications.

• Gears 2, 3 for normal loads and

higher speed operations.

• Gears 4, 5 provide excellent empty

return and roading speeds.

Electronic Clutch Pressure Control.

The C-Series Skidders have an

additional transmission feature for

added performance and operator comfort

– the Electronic Clutch Pressure Control

(ECPC). This unique feature provides

smoother shifting and increases skidding

performance by regulating and modulating

the individual clutches based on current

operating conditions.

Torque Converter. The large, heavy-

duty torque converter maximizes the

productivity of the entire drive train.

The torque converter is matched to the

Cat C7 engine for excellent rimpull and

skidding performance. This lock-up

torque converter has proven its

durability over thousands of hours

of punishing loads.

Improved Productivity. The torque

multiplication capability of the torque

converter reduces the need for the

operator to continually shift the

transmission to maintain good skidder

performance, as is required on

competitive skidders. This reduces

operator effort and improves machine

productivity.

Lock-up Clutch. The integral lock-up

clutch allows the machine to operate in

converter drive for greater rimpull, or

direct drive for high efficiency hauling

and faster travel speeds. Direct drive

capability allows up to 15% higher

travel speeds when the lock-up clutch

is engaged.

Auto Lock-up. The lock-up clutch

automatically engages according

to ground speed and engine speed

conditions. This feature is handled

electronically and allows for increased

travel speeds in the same gear.

Reduced Operating Costs. Torque

converter direct drive capability,

combined with the lock-up differential,

reduces wheel slip. This minimizes

rutting and soil damage in straightahead pulls on weaker soil. In turn, it

minimizes tire wear, component stress

and fuel consumption, reducing total

operating costs.

Differential Locks. Normal operation is

with the differential locks in both axles

disengaged, meaning the all four wheels

are free to drive independently. Locking

a differential forces both wheels on an

axle to turn in sync with each other.

Both front and rear differential locks are

easily engaged and disengaged with a

conveniently located switch on the right

hand console. Hydraulically actuated

differential locks allow for on-the-go

engagement or disengagement.

Axles. Axles feature a full length oil sump

with splash lubrication for excellent

heat rejection and long component life.

The 525C is available with two axle

options – Standard Duty axles are used

for most applications and tire sizes up

to 30.5 ⳯ 32. A Wide Axle option is

available for use in moderate to severe

applications, or when using dual tires,

wide flotation tires or chains.

Front Axle. The front axle features a

pinion-mounted design and a heavy-duty

housing, eliminating the need for the

front axle guard.

Pivot Design. The oscillation pivot design

provides industry leading ride comfort.

• 15° oscillation absorbs minor shock

loads caused by stumps and holes

and helps isolate the cab from axle

movement for a smoother, more

comfortable ride.

• Front axle oscillation also provides

excellent fore-aft stability for large

capacity grapples and dual function

arches.

Brake Components. Brake components

are housed inside the axles, protecting

them from dirt, dust and wet ground

conditions. Inboard brakes allow for

splash lubrication and cooling. They are

virtually maintenance free, and provide

reliable brake performance in the most

demanding logging applications.

5

Page 6

Hydraulics

State-of-the-art hydraulic system provides dependable power and maximum efficiency.

Auto-Grab Feature. Auto-Grab,

engineered by Caterpillar, constantly

monitors tong pressure and adjusts as

needed to securely hold grapple loads

while skidding. It is easily activated

on demand by a switch located on the

right-hand control lever.

Load Sensing Hydraulics. A load

sensing variable displacement pump

and pressure compensating system

continually monitor hydraulic power

requirements, then provides power

based on demand.

Lower Power Consumption. The variable

displacement hydraulic pump draws

engine power only when braking,

steering, dozer or grapple actuation

demands flow or pressure. This conserves

engine horsepower and increases fuel

efficiency.

Cooling Demands. Load sensing

hydraulics provide flow only when

needed, saving fuel and generating

less heat, allowing the cooling system

to allocate more capacity to the engine,

transmission and torque converter.

Oil Cooler. The oil cooler is located

above the radiator for better hydraulic

oil cooling performance and to make

radiator cleanout easier.

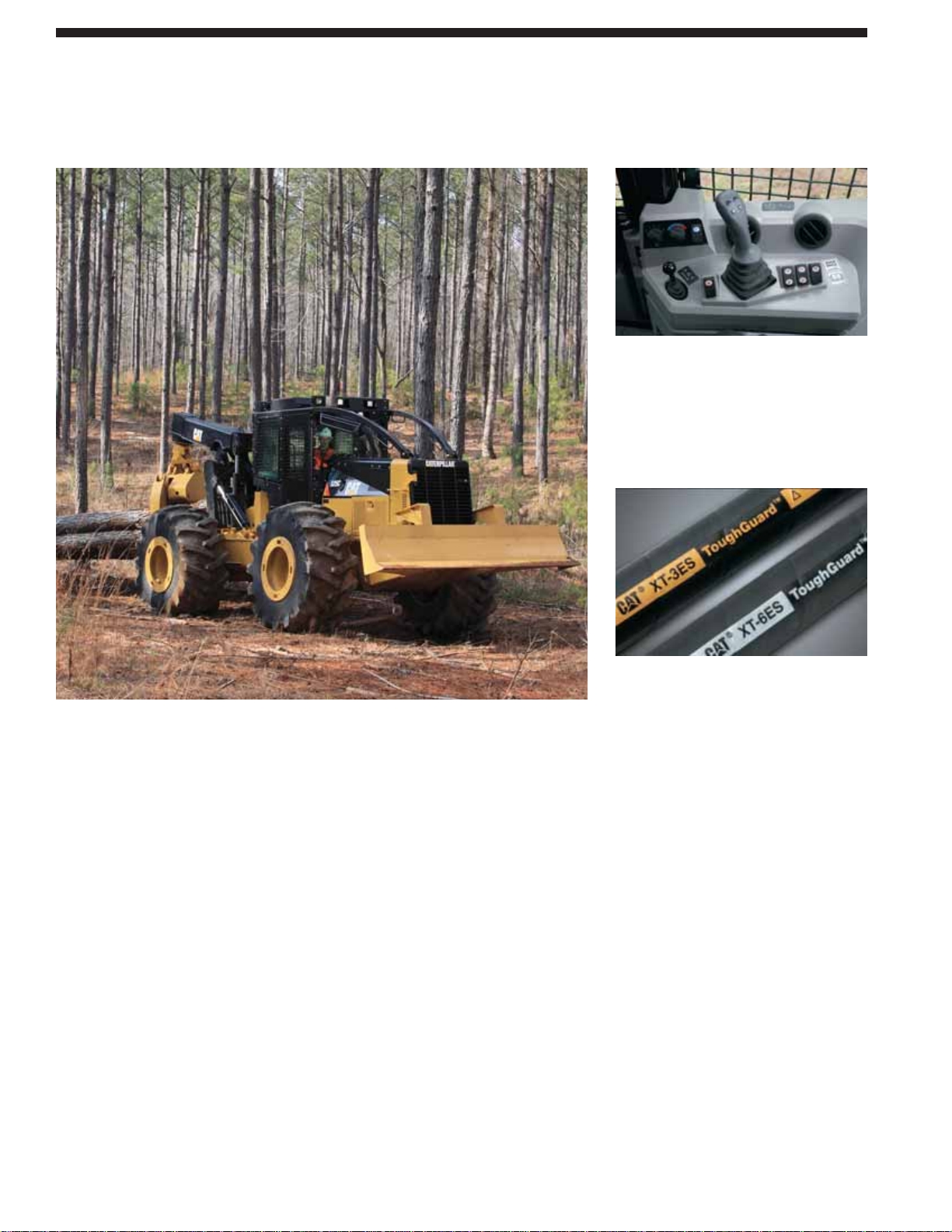

Cat ToughGuard™ Hoses. Caterpillar

®

XT

-3 ToughGuard™ hoses improve

hose life in the grapple, arch, boom

and across the hitch. ToughGuard hoses

have been very successful in reducing

early hour hose failures. O-ring face

seals assure rock-solid connections that

maintain pressure and reduce oil leaks.

Steering. Fully hydraulic control.

Meets the following standards:

SAE J1511 OCT90, ISO 5010-1992.

6

Page 7

Structures

The 525C mainframe, hitch and decking blade are designed and built to surpass the

expectations of the logging industry.

Box-Section Construction. Caterpillar

designed and manufactured box section

structures set the industry standard for

reliable, durable main frames. Extensive

computer analysis and field-testing

resulted in the design of the 525C.

Absorbs Twisting and Shock Loads.

Frames can absorb twisting and impact

forces to provide a sound foundation

and well-balanced system for the entire

structure.

Superior Balance. Low center of mass

and weight forward design create

excellent skidder balance.

Maneuverability. The 525C skidder

provides the tightest turning radius for

superior maneuverability while still

maintaining the excellent balance

required for high capacity skidding.

Caterpillar Manufacturing. The front

and rear frames are robotically welded

and manufactured by Caterpillar to

ensure the highest level of quality

and durability.

Hitch. A heavy-duty center section

features oversized plates and bosses to

disperse forces. A large double-tapered

roller bearing is used on the lower

hitch for reduced flexing stress and

maintaining tight joints.

Hitch Pins. The wide hitch pin spread

significantly reduces horizontal loading

on hitch pins and bearings for greater

durability and extended pin and bearing

life. The extra room also increases

hydraulic hose clearance and makes

hose routing easier.

Fenders. Rear frame fender options are

available for both grapple and cable

arrangements.

Arches and Booms. All Caterpillar

arches use box-section construction,

and are thoroughly tested to exceed

durability requirements.

Single Function Arch. This high strength

design is simple to operate and is ideally

suited for logging conditions where

maneuverability is not limited by ground

conditions. This arch is best suited for

use with the bunching head grapple.

Dual-Function Arch. The 525C is

available with a dual function arch and

compatible with a sorting or bunching

head. The dual-function arch offers

variable reach, which minimizes machine

maneuvering to pinpoint a load with the

grapple, and large grapple capacities.

Cable Arch. Allows outstanding line

skidding performance with a two-position

adjustable height fairlead to match site

conditions.

7

Page 8

Operator Station

Easy to operate, fingertip controls, less fatigue

Sound Insulation. With the optional

enclosed cab, ample sound insulation

keeps interior sound levels low.

Reduced sound levels meet operator

environment regulations and significantly

boost operator comfort, especially on

long shifts.

Cab Mounting. The modular ROPS/FOPS

cab is resiliently mounted to the skidder

frame, reducing vibration for greater

comfort and a quieter ride.

Comfortable Work Station. The work

station incorporates years of cab design

innovations to maximize operator

comfort and productivity.

Air Suspension Seat. Standard air

suspension seat swivels 30° to the right

for maximum comfort, while allowing

the operator to observe skidder and

grapple operations to the rear.

Sealed Cab. The pressurized cab is

sealed from exterior air (with windows

closed) for efficient heating and cooling.

Tight door and window casings also

keep out dust, fumes and insects.

Air Conditioning. Standard with the

enclosed, pressurized cab, air conditioning

helps the operator concentrate on work

rather than environmental distractions.

A dedicated cab filter assures clean air.

Windows. Tough polycarbonate

windows protect the operator, and are

large enough for an excellent side and

rear view, increasing operator confidence

and productivity. Sliding glass windows

protected by metal screens in both doors

provide fresh air and communication

outside the machine.

Machine Controls. The comfortable

operator environment uses ergonomically

designed and placed machine controls

to reduce fatigue and increase

productivity.

Steering. Column tilts and telescopes to

fit any size operator. The quarter-turn

steering wheel quickly and accurately

controls 90 degrees of machine

articulation delivering excellent

maneuverability and productivity.

Transmission Controls. Transmission

controls for forward, reverse and gear

range are located on the steering wheel

for easy fingertip control. The operator

can control machine functions with

minimal effort, allowing greater

concentration on skidding operations.

The result is higher productivity and

reduced operator fatigue.

8

Page 9

Governor Pedal. The governor pedal is

located to the right for more clearance

between the brake pedal, and for

improved operator comfort.

Single-lever Grapple Control. A single

four-function joystick control has top

mounted switches for grapple open

and close, tong rotate, and Auto-Grab

System activation. The control is

simple, convenient and easy to use.

Decking Blade Control. The decking

blade control is located on the right

side console. This location provides

for precise control for various decking

and clearing functions while reducing

operator fatigue.

Auto-Grab Switch. The Auto-Grab

system monitors and adjusts tong

pressure as needed to maintain a

secure grip on grapple loads.

Lock-up Torque Converter Drive.

When activated by a switch on the main

dashboard, the machine will automatically

switch between operation in fuel efficient

direct drive mode or torque converter

drive for maximum rimpull in tough

skidding applications.

Differential Lock Switch.

Ergonomically located rocker switch

allows quick engagement of differential

locks when needed.

Monitoring Controls. Conveniently

located and easy-to-see gauges and

displays make monitoring machine

systems as simple as possible.

Gauges. Four gauges indicate engine

coolant temperature, hydraulic oil

temperature, torque converter oil

temperature, engine rpm and fuel level.

Caterpillar Monitoring System.

Monitors fuel, temperatures, vital

electrical systems, gear speed and

direction. A three-level warning system

alerts the operator of potential problems.

Additional. The right hand console has

a standard 12V outlet for powering

auxiliary equipment. The cab is prewired and fitted for an entertainment

radio, and a CB type 2-way radio.

ROPS/FOPS. FOPS (Falling Object

Protection) and ROPS (Roll-Over

Protection) guards offer protection

to the operator and the machine.

9

Page 10

Work Tools

Move more wood with powerful, flexible Cat grapples and winches.

Reliable, Productive Grapples.

Caterpillar designed and manufactured

grapples use box section construction

for ultimate durability. The tong

curvature reduces the time it takes

to bundle the load, and higher clamp

forces deliver excellent load retention

for secure hauls to the landing.

Bunching Grapples. Bunching grapples

are designed for harvesting mid-to-large

diameter trees, usually felled by a

mechanical feller buncher. Its large tong

opening is designed to gather a large

number of these stems per cycle for

maximum loading. It is heavier than the

sorting grapple, but its large capacity

holds more stems for improved production

in smaller trees and large loads.

Thinning Grapples. Thinning grapples

are designed for harvesting small

diameter trees, usually felled by a

mechanical feller buncher. Its large tong

opening is designed to gather a large

number of these small stems per cycle

for maximum loading. Cat grapples

offer large capacity for maximum

performance and productivity.

Sorting Grapples. Sorting head grapples

are designed primarily for use in skidding

larger, inconsistent diameter timber.

The “scissor” action of the tongs is well

suited for gathering individual logs.

Grapple Snubber. Reduces grapple

swing, hydraulic hose stress and

improves component life.

Flow Divider. The high capacity flow-

divider delivers reliable operation and

maintains consistent tong sequencing.

Hydraulic Winch. The 525C features

an electronically controlled hydraulic

winch for grapple applications, replacing

the mechanical winch. The hydraulic

winch improves application flexibility

by allowing the tractive effort to be

used while winching, and eliminating

the continuously rotating driveshaft.

The high capacity winch has four

function controls: reel-in, reel-out,

brake-on, and free-spool. This winch

is driven and controlled by the main

implement hydraulic system.

Cable Winch. An electro-hydraulic

lever controls the winch hydraulic

control valve, located on the winch case.

The integrated software electronically

protects free-spool clutches.

The C-500 mechanical winch is

available on cable skidders where

higher line speeds and max drum pull

are important. Winch sump oil is used

for hydraulic control and lubrication.

Decking Blade. The decking blade

efficiently clears landings and roads,

and maintains log decks. It features box

section steel arms for superior strength

and durability. Decking blade pusharms

are mounted directly to the mainframe

for excellent strength, and set lower

and forward for efficient clearing of

slash and debris as well as log deck

maintenance. The electro-hydraulic

control improves operator comfort

and control of the decking blade.

• Heat-treated bolt-on edge and

• The 525 C is available with

maintenance-free pivot joints for

outstanding durability.

four blade options to allow it to be

customized to many different types

of operating conditions:

– No Blade – for industrial

applications

– Narrow Decking – 85" width for

general purpose applications.

– Wide Decking – 105.4" width

with bolt-on cutting edges –

for improved coverage of tires

and high decking blade usage.

– Extended Decking – 123.5" width

with bolt-on cutting edges –

for the fullest coverage of tires

and high decking blade usage.

10

Page 11

Serviceability

Ease of service increases productivity.

SM

S•O•S

Provides a fast, convenient way to

gather uncontaminated fluid samples,

which improves analysis reliability.

Pressure Taps. Conveniently located

for easy access to hydraulic system

pressure measurements.

Spin-on Oil Filters. Simplify maintenance

processes and shorten downtime.

Electronic Transfer Pump. Delivers the

proper fuel flow to the fuel system and

eliminates manual priming.

Fluid Sampling Valves.

Quick-Access Engine Doors. Large,

hinged engine enclosure doors make

regular maintenance as easy and fast as

possible. Easy access to daily service

points increases the likelihood that

maintenance will be done, and increases

machine service life. In addition, less

maintenance time means more working

time and greater productivity.

Ground Level Access. Most filters and

lube points are accessible from the

ground without special tools. Remote

lubrication points make daily attention

to hard-to-reach joints easy.

Rear Frame Access. Steps and grab

irons are located on the rear frame and

cab for easier access to the rear frame,

arch and boom.

Bolt-on Guards. Bolt-on guards offer

protection to critical components,

and are easily removable for servicing.

Removable floor plates and side plates

allow access to components under

the cab.

Radial Seal Air Filters. Hand access

makes them easy to change, reducing

air filter maintenance times.

Extended Oil Service Intervals. A 500-

hour oil change interval reduces

downtime for service and lowers

maintenance costs.

Ecology Drains. All major fluid

compartments (hydraulic tank, engine

oil pan, radiator, axles and transmission)

incorporate ecology drains to make

regular maintenance easier, and protect

the environment from accidental

oil spills.

Hitch Hoses. The grapple pilot lines,

pressure line and load-sense lines are

routed above the hitch and are bulkheaded

for easy hose replacement and fastest

service. The hitch hoses use the Cat

ToughGuard™ technology and have

excellent wear characteristics.

Electrical System. The 24V electrical

system delivers dependable electrical

power for engine cranking, additional

lighting, and engine diagnostics. Wiring

circuits are color coded, numbered and

protected by circuit breakers.

On-Board Diagnostic Systems.

The Caterpillar Monitoring System

continuously checks all critical machine

functions and components, and helps

locate faults quickly for faster repair.

Extremes are recorded, including fluid

temperatures, engine speed and

electrical system events.

Radiator. Cleanout access doors located

on both sides of the radiator help make

radiator cleanout faster. The radiator

features an all aluminum construction

with 8 fins per inch for easy cleanout.

Matched Set Hitch Bearings. Matched

set bearings come pre-assembled with

the correct pre-load from the supplier

to streamline the assembly process and

ensure a quality hitch joint every time.

No rolling torque measurement is

required, so the assembly process is

simplified. Matched set bearings also

reduce service time in the field.

11

Page 12

Customer Support

Cat dealer services help you operate longer with lower costs.

Product Support. You will find nearly

all parts at our dealer parts counter.

Cat dealers use a worldwide computer

network to find in-stock parts to minimize

machine down time. Save money with

genuine Cat Reman parts. You receive

the same warranty and reliability as new

products at substantial cost savings.

Product Link. Product Link enables

convenient monitoring of important

equipment information remotely to

help increase productivity and reduce

owning and operating costs.

This state-of-the-art satellite technologybased Product Link system enables

Caterpillar dealers and customers to keep

in touch with their machines. The system

provides a two-way information flow

between machine on-board systems

and Caterpillar dealers/customers

via the Cat Dealer Website and

EquipmentManager. Through the

subscriptions to Asset Watch

(hours, location, time and geo-fence),

Maintenance Watch (preventative

maintenance, repair scheduling, parts

ordering), and Health Watch (event and

diagnostic codes, fuel consumption) the

customer can manage their entire fleet.

Machine Selection. Make detailed

comparisons of the machines under

consideration before purchase. Cat dealers

can estimate component life, preventive

maintenance cost, and the true cost

of lost production.

Purchase. Look past initial price.

Consider the financing options available

as well as day-to-day operating costs.

Look at dealer services that can be

included in the cost of the machine

to yield lower equipment owning and

operating costs over the long run.

Customer Support Agreements.

Cat dealers offer a variety of product

support agreements, and work with

customers to develop a plan that best

meets specific needs. These plans can

cover the entire machine, including

attachments, to help protect the

customer’s investment.

Operation. Improving operating

techniques can boost your profits.

Your Cat dealer has videotapes,

literature and other ideas to help you

increase productivity, and Caterpillar

offers certified operator training classes

to help maximize the return on your

machine investment.

Maintenance Services. Talk to your

dealer about the range of available

maintenance services. Repair option

programs guarantee the cost of repairs

up front. Diagnostic programs such as

S•O•SSMAnalysis and Coolant Sampling

and Technical Analysis help avoid

unscheduled repairs.

Replacement. Repair, rebuild or

replace? Your Cat dealer can help you

evaluate the cost involved so you can

make the right choice.

SAFETY.CAT.COM™.

12

Page 13

Engine

Power Train

Engine Model Cat C7 ACERT™

Net Flywheel Power 136 kW 182 hp

Net Power – ISO 9249 136 kW 182 hp

Net Power – SAE J1349 136 kW 182 hp

Gross Power – SAE J1995 146 kW 196 hp

Displacement 7.2 L 439 in

3

Bore 110 mm 4.33 in

Stroke 127 mm 5 in

Number of Cylinders 6

Max Torque @ Rated Speed 896 N·m at 1,400 rpm

Derating Altitude 2285 m 7,500 ft

Air Cleaner Dry precleaner

Alternator 80 amp

Fan Speed 1,620 rpm

Fan Type Blower

Electrical System 24V

Battery – Quantity 2

Battery – Volts 12V

Battery – Capacity 950 CCA

Starting System Direct electric

• These ratings apply at 1,800 rpm when tested under the

specified standard conditions.

• Net power advertised is the power available at the flywheel

when the engine is equipped with fan, air cleaner, muffler

and alternator. No derating required up to 2285 m (7,500 ft)

altitude.

• Based on standard air conditions of 25° C (77° F) and 99 kPa

(29.32 in Hg) dry barometer. Used 35° API gravity fuel having

an LHV of 42 780 kJ/kg (18,390 BTU/lb) when used at 30° C

(86° F) [ref. A fuel density of 838.9 g/L (7.001 lb/gal)].

Travel Speed – Fwd. 1st 6.4 km/h 4 mph

Travel Speed – Fwd. 2nd 9 km/h 5.6 mph

Travel Speed – Fwd. 3rd 10.9 km/h 6.8 mph

Travel Speed – Fwd. 4th 15.3 km/h 9.5 mph

Travel Speed – Fwd. 5th 27.5 km/h 17.1 mph

Travel Speed – Rev. 1st 6.2 km/h 3.9 mph

Travel Speed – Rev. 2nd 10.5 km/h 6.5 mph

Travel Speed – Rev. 3rd 18.6 km/h 11.6 mph

Torque Converter – Type Lock-up clutch

Transmission 5 fwd/3 rev countershaft,

powershift

Transmission Cooler Type Plate

Steering, frame articulation ± 45°

Brakes – Service Type Single disc WET enclosed

Brakes – Parking Type Drum brake on rear output

of transmission drop box

Hydraulic System

Circuit Type Closed center,

variable flow

Pump Type Axial piston

Pump Output 174 L/min 46 gal/min

Relief Valve Setting 21 000 kPa 3,045 psi

Steering Valve Direct link, non-follow

Steering Cylinder – Bore 88.9 mm 3.5 in

Steering Cylinder – Stroke 437.5 mm 17.22 in

Steering Cylinder – Rod Diameter 50.8 mm 2 in

Dozer Valve Electro-hydraulic

Dozer Cylinder – Bore 101.6 mm 4 in

Dozer Cylinder – Stroke 470 mm 18.5 in

Dozer Cylinder – Rod Diameter 57.15 mm 2.25 in

Grapple Valve 4 or 5 stack, pilot

• Measured at 2,200 rpm.

Grapple

Bunching Capacity 1.16 m

Thinning Capacity 1.34 m

Sorting Capacity .83 m

525C Wheel Skidder specifications

2

2

2

12.5 ft

14.4 ft

2

9 ft

2

2

13

Page 14

Winch – Grapple Skidder

Service Refill

Max Line Pull – Bare Drum 175 kN 39,342 lb

Max Line Speed 40.2 m/min 132 ft/min

Drum Capacity 19.0 mm (3/4 in) 47 m 154 ft

Drum Capacity 22.2 mm (7/8 in) 30 m 97 ft

Drum capacity 25.4 mm (1 in) 28 m 91 ft

Drum Diameter 229 mm 9 in

Drum Width 279 mm 11 in

Winch – Cable Skidder

Max Line Pull – Bare Drum 183.5 kN 41,270 lb

Max Line Speed 110 m/min 360 ft/min

Drum Capacity 19.0 mm (3/4 in) 45 m 148 ft

Drum Capacity 22.2 mm (7/8 in) 32 m 105 ft

Drum capacity 25.4 mm (1 in) 25 m 82 ft

Drum Diameter 254 mm 10 in

Drum Width 279 mm 11 in

Fuel Tank 315 L 83.2 gal

Cooling System 56.7 L 15 gal

Differential, Final Drive – Front 52 L 13.7 gal

Differential, Final Drive – Rear 52 L 13.7 gal

Engine Oil 27 L 7.1 gal

Transmission, Torque Converter 54 L 14.2 gal

Mechanical Winch 24.5 L 6.5 gal

Hydraulic System – Tank 54 L 14.3 gal

Hydraulic System – Total 112 L 29.6 gal

Weights

Est Operating Weight 17 711 kg 39,045 lb

• Operating weight includes enclosed cab, 30.5 tires, decking

blade, single arch, bunching grapple, winch.

14

525C Wheel Skidder specifications

Page 15

1A

2

9

7

5A

3

4

8

6

10

12

11

9

7

5

3

4

8

1

2

Dimensions

Dimension

dual function 4103 mm (161.5 in)

single function 3760 mm (148 in)

2794 mm (110 in)

843 mm (33.2 in)

1798 mm (70.8 in)

3534 mm (139.2 in)

dual function 7626 mm (300.2 in)

single function 8369 mm (329.4 in)

6945 mm (273.4 in)

581 mm (22.9 in)

1381 mm (54.4 in)

456 mm (17.9 in)

3184 mm (125.4 in)

3138 mm (123.5 in)

2622 mm (103.2 in)

3398 mm (133.8 in)

6000 mm (236.2 in)

Cable

*With 30.5 x 32 tires

†

Add 188 mm (7.4 in) if equipped with optional lights or water tank

All dimensions are approximate

GrappleGrapple

†

Ground level to top boom (grapple)

Ground level to top roller (cable)

Ground level to axle center line*

Rear axle center line to pin

Wheel base

Overall length (grapple)

Overall length (cable)

Ground clearance

Decking blade lift height

Decking blade dig depth

Height to top of cab

Decking blade width

Tread width

Overall width

1

1A

2

3

4

5

5A

6

7

8

9

10

11

12

Turning radius over tires*

525C Wheel Skidder specifications

15

Page 16

525C Arch

Single Function Dual Function

1 Lift highest, retracted 2212 mm (87.1 in) 2623 mm (103.3 in)

2 Lift highest, farthest x 1944 mm (76.5 in)

3 Lift maximum reach x 1336 mm (52.6 in)

4 Lift lowest, retracted x 752 mm (29.6 in)

5 Lift lowest, farthest 600 mm (23.6 in) 259 mm (10.2 in)

6 Loaded tire radius* 843 mm (33.2 in) 843 mm (33.2 in)

7 Reach highest, retracted 1630 mm (64.2 in) 1513 mm (59.6 in)

8 Reach lowest, retracted x 1469 mm (57.8 in)

9 Reach lowest, farthest 2521 mm (99.3 in) 2488 mm (98 in)

10 Reach highest, farthest x 2765 mm (108.9 in)

11 Reach maximum x 2880 mm (113.4 in)

*With 30.5 x 32 tires

Single Function

Dual Function

6

5

7

9

1

7

8

9

10

11

6

1

4

3

2

5

16

525C Wheel Skidder specifications

Page 17

1

2

4

3

6

5

4

3

2

1

*Thinning grapple is intended only for use in thinning applications

525C Grapple — Continuous Rotation

Sorting Bunching Thinning*

1 Grapple capacity 0.83 m

2

(9 ft2) 1.16 m2 (12.5 ft2) 1.34 m2 (14.4 ft2)

2 Tip to tip height 2045 mm (80.5 in) 1920 mm (75.6 in) 1981 mm (78 in)

3 Tong opening 2540 mm (100 in) 3050 mm (120 in) 3124 mm (123 in)

4 Full open height 1590 mm (62.6 in) 1677 mm (66 in) 1832 mm (72.1 in)

5 Minimum stem diameter 76 mm (3 in) 155 mm (6 in) 190 mm (7.5 in)

6 Fully closed height 1829 mm (72 in) 1285 mm (50.6 in) 1371 mm (54 in)

Sorting Grapple

525C Wheel Skidder specifications

17

Page 18

Standard Equipment

Standard equipment may vary. Consult your Caterpillar dealer for details.

Electrical

24V electrical system

Alarm, back-up

Alternator, 80 amp

Batteries, maintenance free (2-1000CCA)

Lighting system, exterior lights (4 total)

Main disconnect switch

Starter, electric, heavy duty

Starting and charging system

Diagnostic connector

Horn, warning

Operator Environment

12V accessory power port

Seat, air suspension

30° swivel, 3 position locking

Seat belt

Beverage holder

Cab, ROPS/FOPS certified

Computerized Monitoring System

Instrumentation, Gauges:

Engine coolant temperature

Fuel level

Hydraulic oil temperature

Tachometer

Torque converter oil temperature

Instrumentation, Warning Indicators:

Autograb

Brake oil pressure

Differential locks

Engine

Engine oil pressure

Lockup clutch

Parking brake

Primary steer pressure

Secondary steer pressure (if equipped)

Starting aid

System voltage

Transmission filter bypass

Winch freespool (if equipped)

Work lights

Instrumentation, Digital Data

Computerized diagnostics and monitoring

Engine rpm

Gear and direction

Odometer

Service hour meter

Headliner, Floormat, and Domelight

Mirror, rear view

Steering wheel, tilt and telescoping

Electronic transmission mounted controls

Power Train

Air cleaner, 2-stage with precleaner

Brakes

Parking

Service, four-wheel enclosed disc

Differential locks (front, rear)

Driveline slipjoint, lubed for life

Engine, Cat C7, ACERT Technology, ATAAC

Fan, blower

Filters, fuel/engine air, primary/secondary

Final drives, inboard planetary

Fuel transfer pump (electric)

Fuel tank, high capacity

Lock-up torque converter

Muffler

Radiator with clean-out doors

Steering, variable flow-modulated 1/4 turn

Transmission, countershaft powershift (5F/3R)

Universal joints, lubed for life

Hydraulics

Closed center-load sensing system

Hitch hoses, Caterpillar ToughGuard™

Line filter, full flow return

Hydraulic oil cooler, Spin-on filters

Variable displacement piston pump, 46 gal/min

(174.1 L/min)

Other standard equipment

Articulation lock link

Brush sweeps, front

Ecology drains (engine, hyd tank, axles, transmission)

Engine enclosures, hinged

Guards, hinged – bottom and radiator

SOSSMsampling ports

Vandalism protection, lockable doors and cap locks

18

525C Wheel Skidder specifications

Page 19

Optional Equipment

Optional equipment may vary. Consult your Caterpillar dealer for details.

Power Train

Standard Gross Power – 146 kW (196 hp)

Dual Gross Power

1st gear – 146 kW (196 hp)

2nd-5th gears – 163 kW (218 hp)

Arch

Dual function

Single function

Cable skidding

Industrial arrangement

Axles

Heavy duty (wide tire/chains)

Standard duty

Blade

Narrow decking

Wide decking

Extended decking

Cab, enclosed, with window screens

ROPS, open

ROPS, enclosed with heat/AC

Window screens

Wipers, front and rear

Electrical

Converter, high capacity 12V, 10A continuous, 15A peak

Jump start receptacle

Fenders, heavy duty

Grapples – Cat Continuous Rotation

Bunching

Sorting

Thinning

Lights

Additional 8 (2 front, 2 rear, 2 per side)

Pre-cleaner, turbine

Starting aid package, cold weather

Steering, secondary

Tires and Tubes, set of four, logger (LS-2)

30.5L-32, 20PR

30.5L-32, 26PR

35.5L-32, 20PR

35.5L-32, 26PR

Dual ring capable

Narrow overall width options

Water tank

Winch

Grapple

Cable skidding

525C Wheel Skidder specifications

19

Page 20

525C Wheel Skidder

AEHQ5670-01 (02-10)

Replaces AEHQ5670

For more complete information on Cat products, dealer services,

and industry solutions, visit us on the web at www.cat.com

© 2010 Caterpillar

All Rights Reserved

Printed in U.S.A.

Materials and specifications are subject to change without notice.

Featured machines in photos may include additional equipment.

See your Caterpillar dealer for available options.

CAT, CATERPILLAR, SAFETY.CAT.COM, their respective logos, ACERT, ToughGuard,

“Caterpillar Yellow” and the “Power Edge” trade dress, as well as corporate and product

identity used herein, are trademarks of Caterpillar and may not be used without permission.

R

Loading...

Loading...