Milton CAT 430E IT User Manual

430E/430E IT

®

Backhoe Loaders

Engine

Engine Model Cat® C4.4 ACERT® DIT

Gross Power @ 2,200 rpm – SAE J1995 83 kW 111 hp

Net Power @ 2,200 rpm – SAE J1349 76 kW 102 hp

Net Peak Power @ 1,800 rpm – SAE J1349 77 kW 103 hp

Weights

Operating Weight – Nominal 7125 kg 15,708 lb

Operating Weight – Maximum 11 000 kg 24,251 lb

Backhoe

Dig Depth – Standard 4698 mm 15 ft 5 in

Dig Depth – E-Stick Extended 5951 mm 19 ft 6 in

430E/430E IT Features

World-Class Cab

Standard air suspension seat, extra legroom and

more visibility make you feel comfortable – for a

safer, more productive work day.

Easy Joystick Control

Ergonomic joystick controls provide smooth

operation and low operator effort.

Improved Power Train

Top travel speed of 25 mph/40 km/h so you can

get on and off the site faster.

More Work Tools

Do more jobs with one machine. The thumb lets

you grip, grab and sort virtually any material.

Contents

Operator Station ..................................................3

Controls.................................................................3

Hydraulics ............................................................4

Ride Control..........................................................4

Power Train ..........................................................5

Loader ...................................................................6

Backhoe................................................................7

Serviceability .......................................................8

Customer Support ...............................................8

Technology Products ..........................................9

Work Tools ..........................................................10

430E/430E IT Specifications.............................11

430E/430E IT Standard Equipment ..................26

430E/430E IT Optional Equipment ...................27

2

With standard pilot-operated joystick controls, a more

comfortable operator station, extendible stick design

and increased performance, the 430E/430E IT lets you

get more done with less effort.

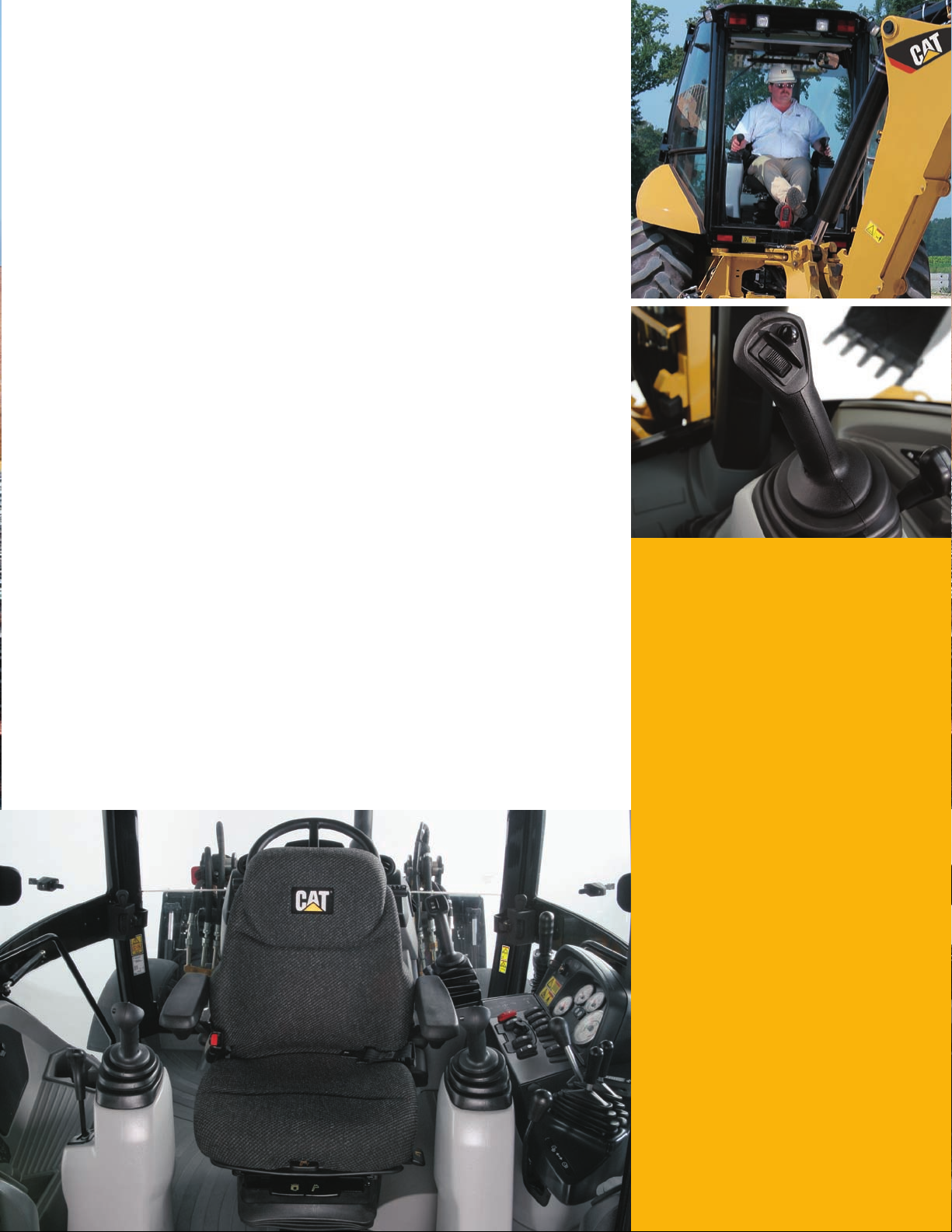

Operator Station

Comfort, visibility and style.

Experience a whole new level of comfort with the spacious E-Series operator

station. The ergonomic, automotive style enhances the operator environment.

A narrow front dash provides excellent visibility to the front bucket. Reduced

vibration keeps operator fatigue low. In-cab storage compartment and lockable

tool and battery box provides ample space for tools and belongings. The operator

station also features an easy-to-read gauge cluster and increased legroom.

Automatic Engine Speed Control

This new feature reduces engine speed when the backhoe is not in use to conserve

fuel and lower environmental noise.

Air Suspension Seat

The standard air suspension seat is adjustable for a greater operating range and

more comfortable ride. A switch allows the seat to be tailored to support differing

body weights. Adjustable seat height accommodates all operators. The deluxe

cab air suspension seat also has an adjustable back support, lumbar support, seat

cushion extension, seat cushion tilt and vertical and angle adjusting armrests.

Improved Air Conditioning

The improved air conditioning system features enhanced air distribution and

performance for a more comfortable work environment. A nearly 20% increase in

air ow combined with improved louver locations provide superior operator comfort.

Configurations

The 430E operator station is available in 5 options – ROPS Canopy, ROPS Canopy

Plus, Standard Cab, Deluxe Cab and Deluxe Cab with Air Conditioning. See Standard

and Optional Equipment for details.

Controls

Reduce fatigue.

Low effort, ergonomic excavatorstyle joystick controls provide smooth

modulation. Thumb rollers provide

convenient, ngertip control of

auxiliary functions, eliminating

pedals on the oor.

One-Touch Low Idle

Located on the right hand joystick,

this button reduces engine speed

to low idle. This new feature will

reduce fuel consumption and

improve communication with

ground crew.

Pattern Selector

The pattern selector switch, located

in the cab, allows the operator to

change from excavator to backhoe

control pattern simply by pressing

a button. This allows the operator

to use the pattern they are most

familiar with to get more done,

faster.

3

Hydraulics

Load-sensing system matches power to demand.

The 430E has a load-sensing, closed center hydraulic system,

which closely matches power and ow to the demand needed

by the implements. So whether you’re in full trenching mode,

or delicately digging around services, you are in control.

In applications such as production trenching, speed is

important and the system will match the ow needed to

get the job done quickly and efciently. The load-sensing

hydraulic system also delivers:

A cooler hydraulic system

•

Better fuel efciency

•

Quieter operation

•

Reduced wear on components

•

Cat XT-3 ES ToughGuard™ hoses combined with Cat

couplings and O-ring face seal ttings provide a leak-free

system. The 430E also features new ow-sharing hydraulic

valves, ensuring proportional ow of oil to all hydraulic

cylinders, providing greater control and improving multifunction performance.

Ride Control

Delivers even greater

operator comfort.

The optional Ride Control System smoothes the ride in

all conditions, including load and carry, highway roading,

or simply moving around the job site. It reduces machine

loping, providing a smooth and stable ride for increased

operator comfort and reduced operator fatigue. The Ride

Control option improves material retention in the loader

bucket for increased productivity and a cleaner job site.

The system is easily engaged by a switch on the front

console. The Ride Control switch has three positions, ON,

OFF and AUTOMATIC. In the automatic position, the

Ride Control engages automatically as the travel speed

increases. At low speed, the system disengages for loading,

grading or nishing applications.

4

Power Train

Built for performance, power, reliability and fuel efficiency.

Cat Engine

The 430E features the Cat® C4.4 DIT (Direct Injection

Turbocharged) engine with ACERT® technology and meets

all U.S EPA Tier 3/EU Stage IIIa emissions requirements.

The increased horsepower and torque rise deliver improved

loading and roading performance.

Electronic engine control provides precise fuel metering

•

for optimized power, response and fuel efciency.

The water separator service indicator ensures the

•

operator is alerted when service is necessary.

Dry-type axial seal air cleaner with automatic,

•

integrated dust ejection system for more efcient preseparation. Both air cleaner and precleaner functions are

incorporated into a single unit mounted under the hood.

Transmission

The Cat standard power shuttle transmission provides four

speeds forward and reverse. Hydraulically shifted clutches

allow on-the-go direction and travel speed shifts. The optional

auto-shift transmission matches gears with grade and load

conditions. Top gear is selected with the twist grip control

on the steering wheel.

Hydraulic proportional control valves smooth speed

•

and directional shifts.

Transmission Kick-Down Switch/Neutralizer allows

•

the operator to downshift through the gears to rst.

Standard Four Wheel Drive (4WD) improves mobility

•

and loader performance in poor underfoot and can

be activated on-the-go.

Maximum roading speed of 40 km/h (25 mph) for faster

•

travel between job sites.

Cat Rear Axles are designed specically for demanding

•

backhoe loader applications. Axles feature outboard

planetary gear sets for easy serviceability and brake

design improvements for longer service life.

Brake Mode Selector

The brake mode selector switch has three positions: two

wheel drive, two wheel drive with all wheel braking and four

wheel drive. Two wheel drive with all wheel braking provides

better tire life while roading and engages the front axle when

brakes are applied for improved braking performance.

5

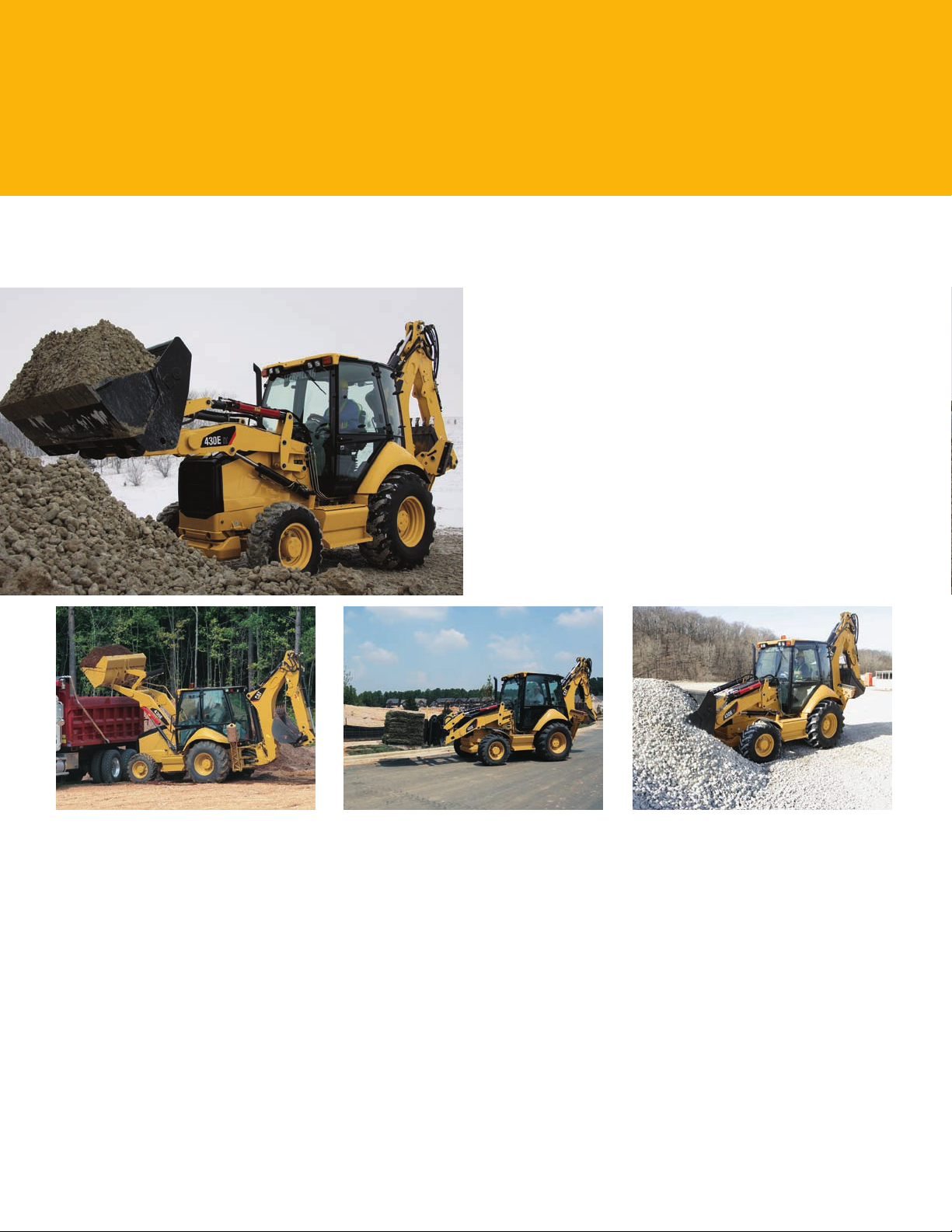

Loader

Choice of loader linkage to meet your needs.

Caterpillar offers a choice of single tilt or integrated

toolcarrier (IT) loader linkage to suit your application

requirements. The IT loader controls provide single lever

proportional control and ne modulation of the hydraulic

work tools. A thumb roller operates auxiliary hydraulic

functions such as the multi purpose bucket on the IT

machines.

Single Tilt

The standard single tilt loader linkage

features strong lift and breakout forces

for solid performance in backlling

and truck loading applications.

Integrated Toolcarrier

The optional integrated toolcarrier

(IT) loader linkage provides higher

breakout forces, as well as parallel

lift, for efcient loading and material

handling. Integrated toolcarriers are

highly versatile and can use a wide

range of Cat Work Tools for a variety

of applications.

Return-to-Dig

The return-to-dig system reduces

loading cycle times by bringing the

loader bucket back to the dig position

with an easy pull of the lever. By the

time the loader bucket is at ground

level, the bucket is angled correctly

for the next load or cut.

6

Backhoe

Boom and stick designed for high performance and easy service.

The E-Series backhoe delivers industry-leading digging forces. Serrated edges on the stick provide

improved material clamping for clearing and demolition applications. The single pin bucket linkage

contributes to best-in-class rotation of 205 degrees for all applications.

E-Stick Design

The optional extendible stick (E-stick) increases reach and dig depth by approximately 1.2 meters

(4 feet). The new design delivers increased life and easy in-eld adjustment with common hand tools.

Curved Boom

The excavator-style boom is built for optimum performance and durability. The curved design provides

additional clearance over obstacles while digging a trench or truck loading. The narrow boom enhances

the viewing area to the bucket and trench throughout the entire operating range.

Thumbs

Thumb mounting provisions are standard on every Cat Backhoe Loader for added machine versatility.

Hydraulic thumbs are available factory-installed. Mechanical thumbs are available through your

Cat Dealer.

7

Serviceability

Easy access and minimal maintenance requirements maximize uptime.

Convenient service features make maintenance easy, reducing

your downtime.

Tilt-up hood provides convenient access to all engine

•

check points.

Fill caps are color-coded for quick identication.

•

Electronic control modules store fault codes for easy,

•

efcient troubleshooting and maximum uptime.

S•O•SSM, Coolant Sampling and Technical Analysis help

•

you avoid unscheduled repairs.

Caterpillar is committed to providing you with a safe

•

work environment. For more information please visit

SAFETY.CAT.COM™.

Customer Support

Makes the difference.

Your Cat dealer is ready to assist you with your purchase

decision and everything after.

Financing packages are exible to meet your needs.

•

Your Cat dealer can evaluate the cost to repair,

•

rebuild and replace your machine, so you can make

the right choice.

Nearly all parts are available at your Cat dealer

•

parts counter.

See your dealer’s website or www.cat.com to customize

•

the machine that is right for you using the Build and

Quote applications. Also nd information on other

Cat products, dealer services and industry solutions.

8

Technology Products

Advanced technologies improve productivity and simplify serviceability.

AccuGrade™ System

The AccuGrade system for backhoe loaders improves digging

accuracy and site safety by eliminating the need for manual

grade measuring. Both the Site and Laser Reference Systems

save time and money in a variety of digging and trenching

applications.

Site Reference System

The Site Reference System allows the operator to excavate

to pre-determined coordinates. The intuitive software and

controls allow the operator to set target grades.

An in-cab display allows the operator to enter slope and dig

depth parameters. Easy to read grade indicator and elevation

display delivers all system information to the cab for easy

viewing by the operator. System includes rugged components

built to withstand the harshest environments:

In-cab display

•

Cylinder position sensors

•

Swing position sensor

•

Inclinometer

•

Wiring harnesses

•

Laser Reference System

The Laser Reference System works with laser transmitters to

accurately grade or excavate to a site plan without the use of

grade stakes. The Laser System includes all the components

of the Site Reference System with the addition of the

following:

Laser receiver

•

Electric mast and mount

•

Laser wiring harness

•

Note: Laser transmitter and tripod sold separately

Product Link

Product Link uses GPS technology to provide machine data,

including service hours, location, events and diagnostic

information, to you through a web-based application or

e-mail/pager notication.

Machine Security System

An optional Machine Security System (MSS) that utilizes

a programmable key system deters theft, vandalism and

unauthorized usage. MSS uses electronically coded keys

selected by the customer to limit usage by individuals or

time parameters.

9

Loading...

Loading...