Milton CAT 325D FM User Manual

®

®

Engine

Engine Model Cat®C7 ACERT™

Net Flywheel Power 152 kW 204 hp

Weights

General Forestry (HW) 33 329 kg 73,478 lb

Log Loader (U/U) 37 807 kg 83,350 lb

Log Loader (O/U) 38 211 kg 84,241 lb

• Operating weight with front linkage, without bucket

or grapple.

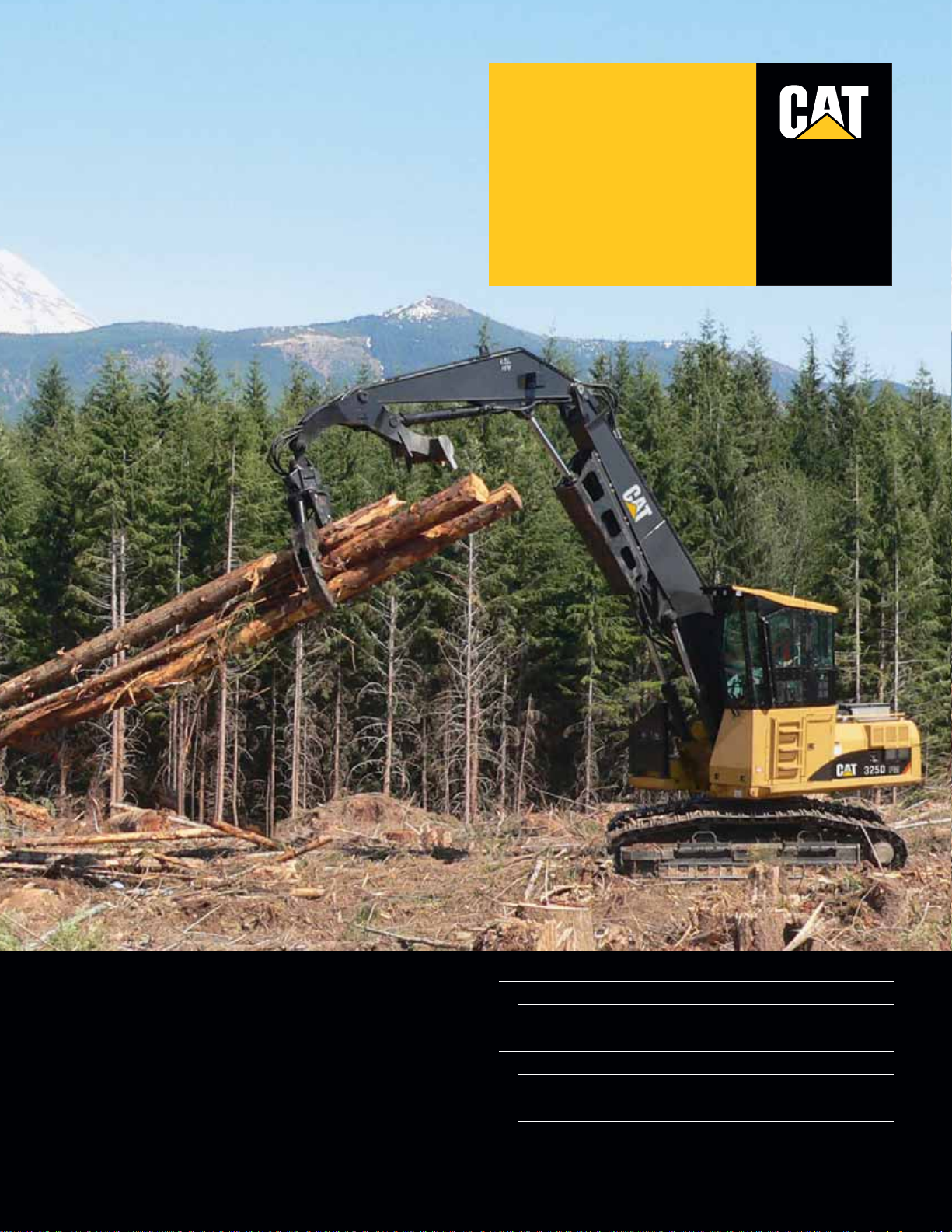

325D FM

Forest Machine

2

325D FM Forest Machine

The D Series incorporates innovations for improved performance, rugged durability

and maximum productivity.

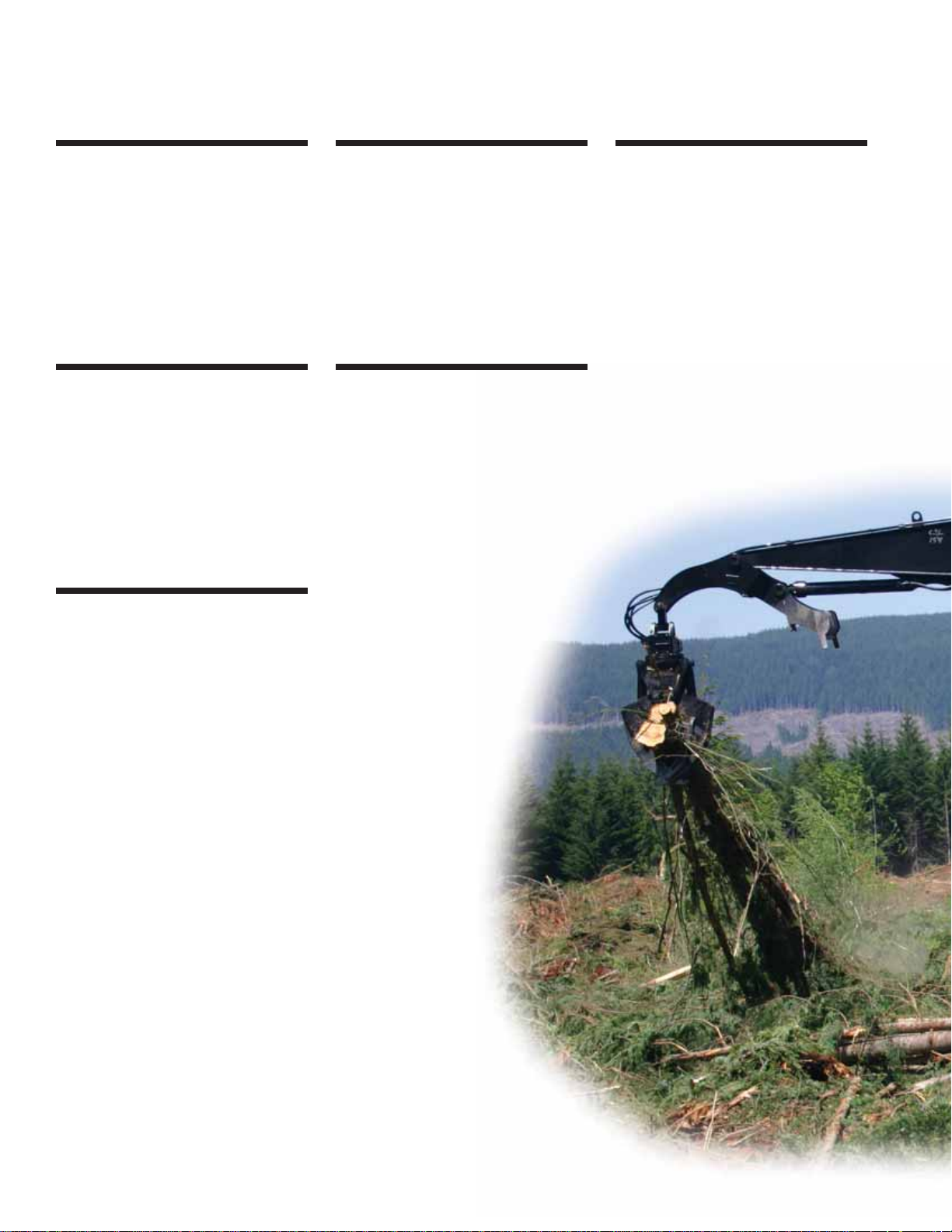

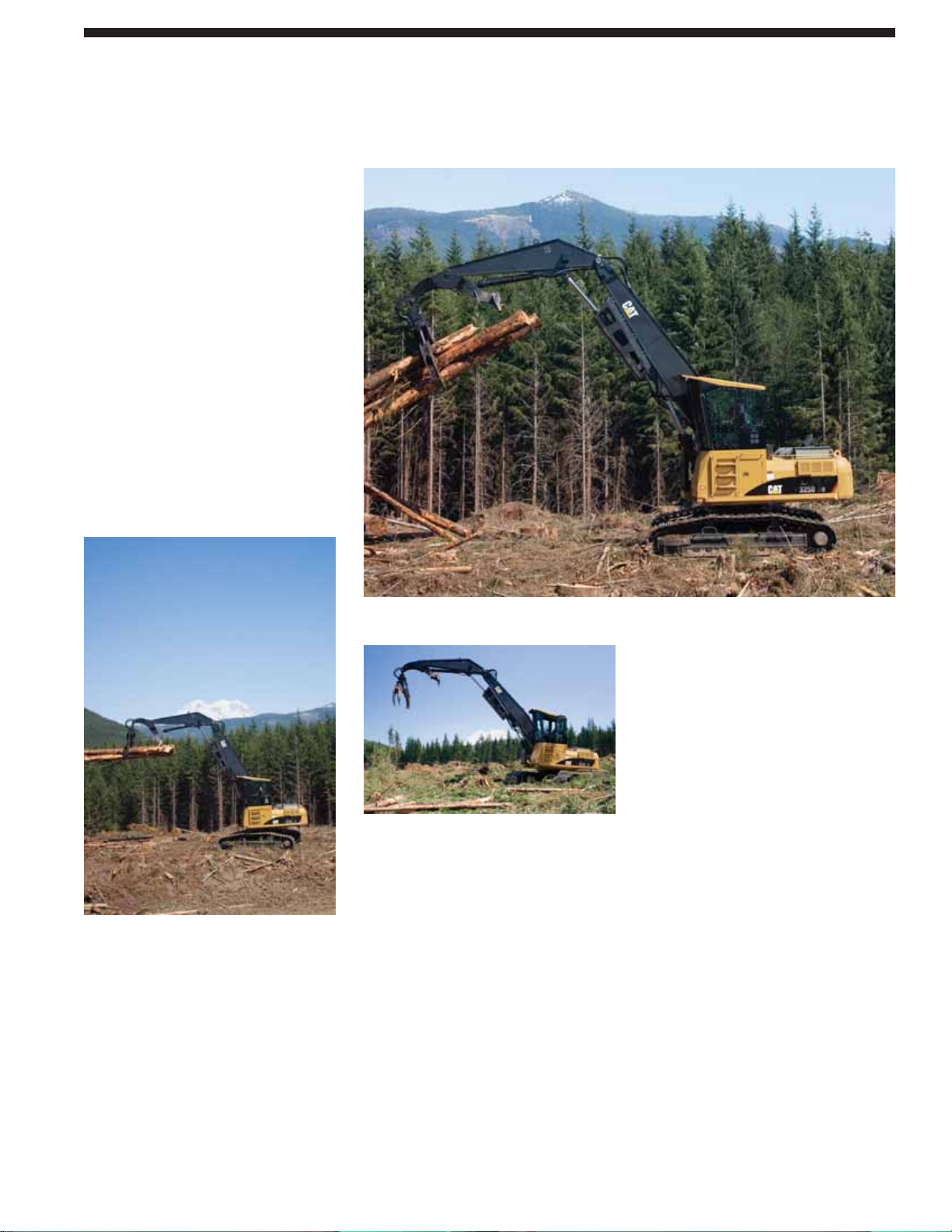

Caterpillar®Grapples

Cat®Log Loading Grapples combined

with Cat Forest Machines make the

325D FM flexible, versatile and efficient

enough, allowing you to maximize

productivity on your forestry job. pg. 12

Versatility

Designed and purpose-built to meet

diverse forestry applications, the

325D FM can help improve productivity

in various forestry and millyard

applications. pg. 11

Operator Comfort

Spacious purpose built forestry cab with

excellent sightlines to the work area

with 8 lights and all scratch resistant

polycarbonate windows. Certified FOPS

to ISO 8084 and SAE 1084, certified

OPS to ISO 8083 and SAE J231, certified

FOGS to ISO 10262 and SAE J1356,

certified TOPS to OR-OSHA code

437-007-0775 TOPS and WCBG602/

G603/G604/G608 compliant. pg. 6

Hydraulics

Forest Machine hydraulic systems

are designed to provide reliability,

outstanding controllability and proven

performance in various forestry

applications. pg. 5

Power Train

The Cat®C7 with ACERT™ Technology

gives the 325D FM exceptional power

and fuel efficiency unmatched in the

industry. The C7 meets U.S. EPA Tier 3

emissions requirements. pg. 4

Customer Focus

Down time is minimized by the utilization

of a worldwide computer network that

can help find in-stock parts and minimize

your down time. Your Cat dealer can

also offer a wide range of other services

that can be set up to meet your equipment

needs. The dealer will help choose the

plan that can cover everything from

machine and attachment selection to

replacement. pg. 15

3

Serviceability

The new FM cooling package provides

easy access to all radiator cores for

faster cleanouts. Regularly scheduled

maintenance extends machine service

life and lowers overall operating costs.

pg. 14

Owning and Operating Costs

Proven fuel efficiency combined with

easier access and extended service

intervals maximize uptime, reduce

operating costs and maximize

productivity. pg. 13

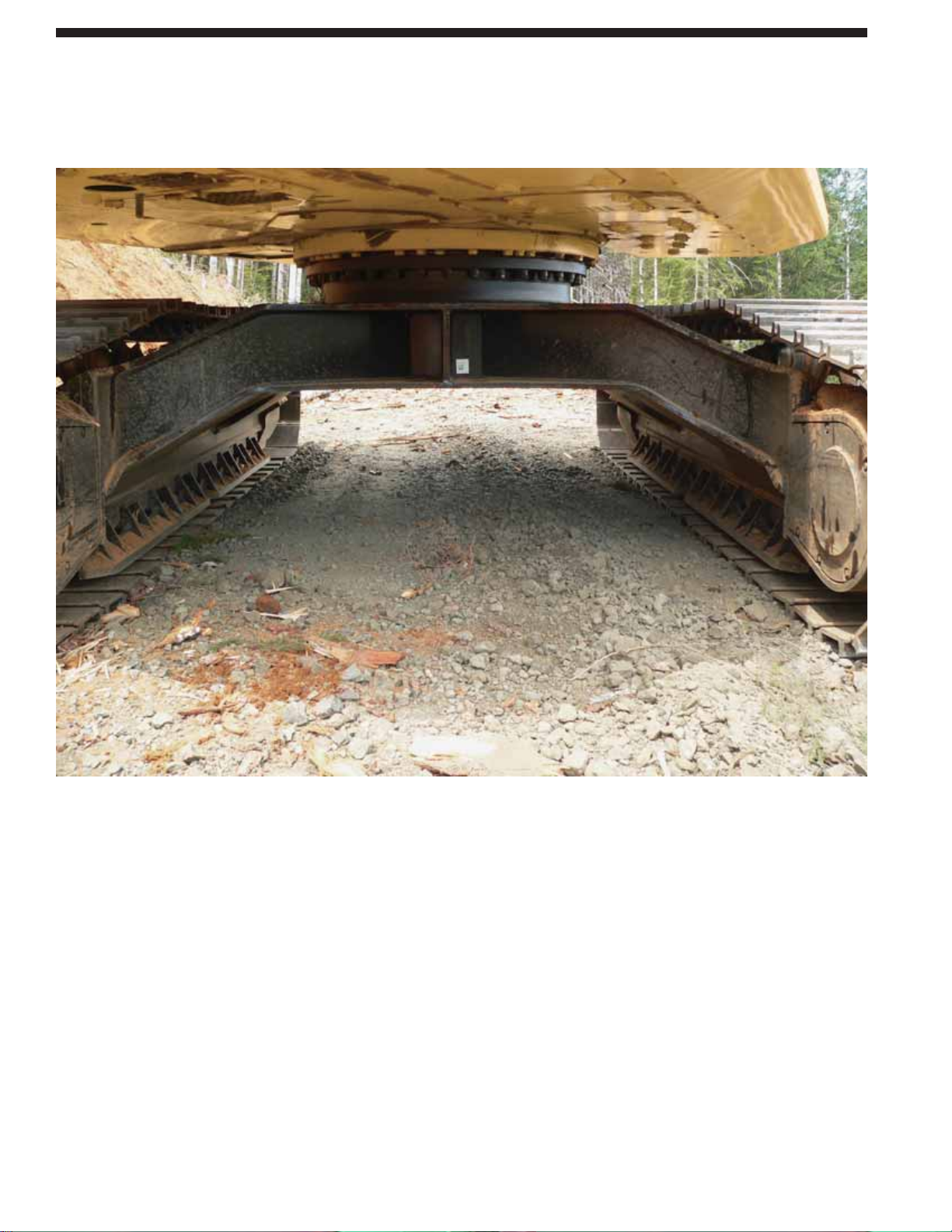

Undercarriage

Heavy Duty link assemblies provide

toughness and durability. The FM track

will maximize undercarriage life and

minimize operating costs. pg. 10

Guarding

Factory forestry cab guarding, shoe

support guards and heavy-duty access

doors help extend component life,

reduces downtime and helps to protect

your forestry machine investment. pg. 9

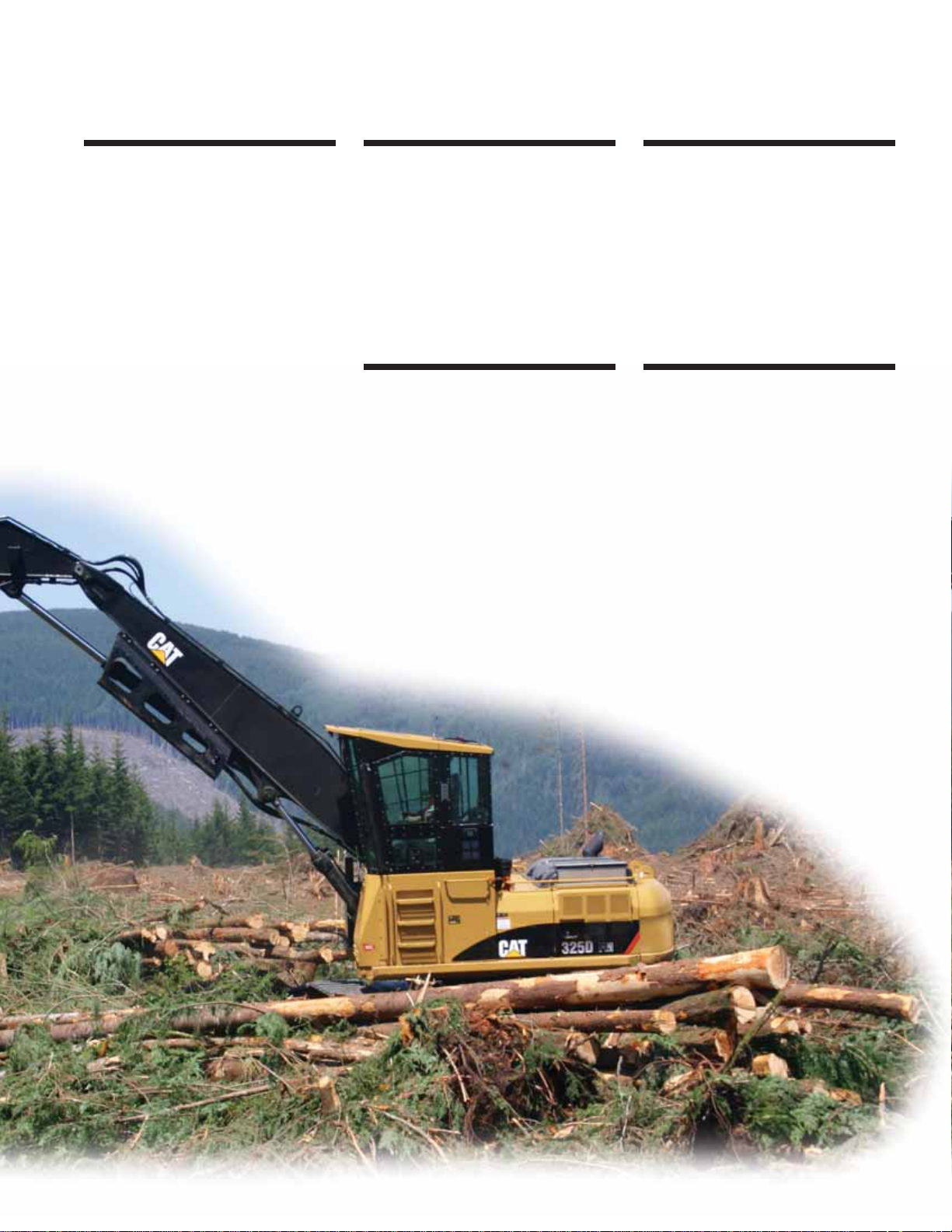

Structures

Purpose-built carbody design uses the

most advanced manufacturing processes,

ensuring durability and reliability in the

most rugged forestry applications. pg. 8

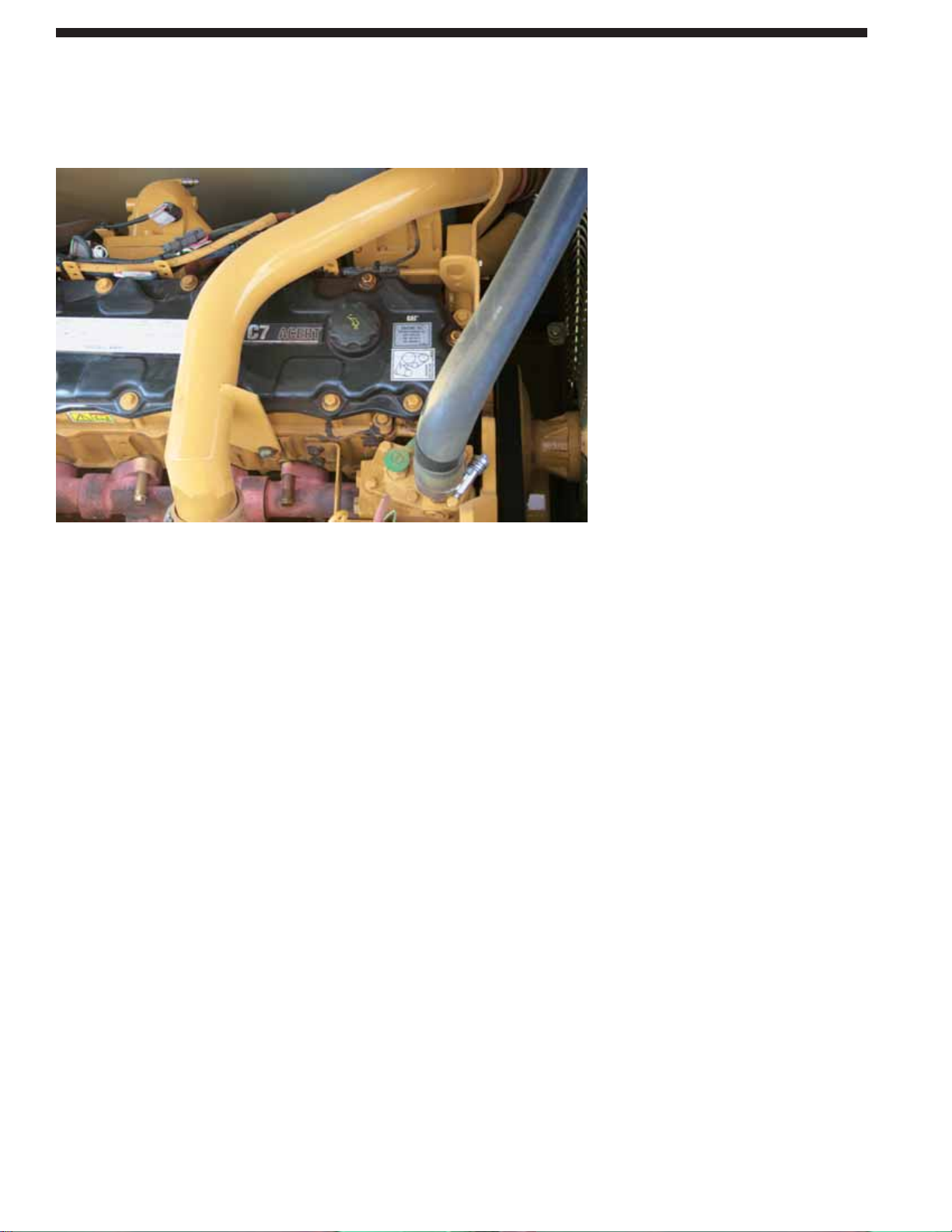

Cat C7 ACERT™. The Cat

®

C7 with

ACERT™ Technology gives the

325D FM exceptional power and fuel

efficiency unmatched in the industry.

The C7 meets U.S. EPA Tier 3 emissions

requirements. The forestry designed

hydraulics give the 325D FM exceptional

power, efficiency and controllability

unequaled in the industry for consistently

high performance in all forestry

applications.

Performance. The 325D FM is

equipped with the C7 ACERT engine,

which provides 12% more horsepower

as compared to the 3126B ATAAC

HEUI engine.

Automatic Engine Speed Control.

The two-stage, one-touch control

maximizes fuel efficiency and reduces

sound levels.

ADEM™ A4 Engine Controller.

The ADEM A4 electronic control

module manages fuel delivery to get the

best performance per liter of fuel used.

The engine management system provides

flexible fuel mapping, allowing the

engine to respond quickly to varying

application needs. It tracks engine and

machine conditions while keeping the

engine operating at peak efficiency.

Electronic Control Module.

The Electronic Control Module (ECM)

works as the “brain” of the engine’s

control system, responding quickly to

operating variables to maximize engine

efficiency. Fully integrated with sensors

in the engine’s fuel, air, coolant, and

exhaust systems, the ECM stores and

relays information on conditions such

as RPM, fuel consumption, and

diagnostic information.

Fuel Delivery. The Cat C7 ACERT

features electronic controls that govern

the fuel injection system. Multiple

injection fuel delivery involves a high

degree of precision. Precisely shaping

the combustion cycle lowers combustion

chamber temperatures, generating fewer

emissions and optimizing fuel combustion.

This translates into more work output

for your fuel cost.

Cooling System. The cooling fan

is directly driven from the engine.

An optional programmable reversible

fan allows for radiator blowout, to

increase service intervals and to maintain

engine operational temperatures.

The optimum fan speed is calculated

based on the target engine speed, coolant

temperature, hydraulic oil temperature

and actual fan speed. The Cat C7 ACERT

delivered a completely new layout that

separates the cooling system from the

engine compartment.

Air Cleaner. The radial seal air filter

features a double-layered filter core for

more efficient filtration and is located in

a compartment behind the cab. A warning

is displayed on the monitor when dust

accumulates above a preset level.

Noise Reduction Technologies.

The engine mounts are rubber-isolating

mounts matched with the engine package.

Further noise reduction has been achieved

through design changes to the isolated

top cover, oil pan, multiple injection

strategy, insulated timing cover, sculpted

crankcase and gear train refinements.

4

Power Train

The Cat®C7 has exceptional power and fuel efficiency unmatched in the industry

for consistently high performance in both forestry and millyard applications.

Component Layout. The 325D FM

hydraulic system and component locations

have been designed to provide a high

level of system efficiency. The main

pumps, control valves and hydraulic

tank are located close together to allow

for shorter tubes and lines between

components that reduce friction loss and

pressure drops in the lines. The layout

further provides greater operator comfort

by placing the radiator on the cab side

of the upper structure.

This allows incoming air to enter the

engine compartment from the operator

side and hot air and corresponding engine

sound to exit on the opposite side away

from the operator. This reduces engine

compartment heat and sound being

transmitted to the operator.

Pilot System. The pilot pump is

independent from the main pumps

and controls the front linkage, swing

and travel operations.

Hydraulic Cross Sensing System.

The hydraulic cross sensing system

improves productivity with faster

implement speeds and quicker,

stronger pivot turns.

Boom and Stick Regeneration Circuit.

Boom and stick regeneration circuit

saves energy during boom-down

and stick-in operation which increases

efficiency, reduces cycle times and

pressure loss for higher productivity,

lower operating costs and increased

fuel efficiency.

Fine Swing Control. Standard fine swing

control cushions start and stop for better

implement control.

Controllability. The hydraulic system

offers precise control to the 325D FM

reducing operator fatigue, improving

operator effectiveness and efficiency,

which ultimately translates into

enhanced performance.

Auxiliary Hydraulic Valve. The auxiliary

valve is standard on the 325D FM.

Control Circuits are available as

attachments, allowing for operation

of high and medium pressure tools

such as grapples.

Hydraulic Cylinder Snubbers.

Snubbers are located at the rod-end

of the boom cylinders and both ends

of the stick cylinders to cushion shocks,

reduce sound and increase cylinder life,

increasing uptime and productivity.

5

Hydraulics

Cat®hydraulics provide the power and control needed for a variety of applications.

Operator Station. The workstation

is spacious, quiet and comfortable,

assuring high productivity during a long

work day. Controls, joysticks and an

ergonomically designed seat reduces

operator fatigue.

Pre-Start Check. Prior to starting the

machine, the system will check for low

fluid levels for the engine oil, hydraulic

oil and engine coolant and warn the

operator through the monitor in the

event display area.

Monitor. The monitor is a full color

400

⳯ 234 pixels Liquid Crystal Display

(LCD) graphic display. The monitor

angle can be adjusted to minimize sun

glare and has the capability of displaying

information 27 different languages.

6

The purpose built forestry cab interior layout maximizes operator space, provides

exceptional comfort, provides excellent sightlines and reduces operator fatigue.

Operator Comfort

Gauge Display. Three analog gauges,

fuel level, hydraulic oil temperature

and coolant temperature, are displayed

in this area.

Event Display. Machine information

is displayed in this area with the icon

and language.

Multi-Information Display. This area

is reserved for displaying various

information which is convenient for the

operator. The “Cat” logo is displayed

when no information is available to

be displayed.

Seat. Seat provides a variety of

adjustments to suit the operator’s size

and weight including fore/aft, height

and weight. Wide adjustable armrests

and a retractable seat belt are also

included.

Joystick Control. Joystick controls

have low lever effort and are designed

to match the operator’s natural wrist

and arm position. The operator can

operate joystick controls with an arm

on the armrest and the horizontal and

vertical strokes have been designed

to reduce operator fatigue. Exclusive

proportional control and push buttons

are programmable to operator personal

preferences, allowing maximum

productivity.

Hydraulic Activation Control Lever.

For added safety, this lever must be

in the operate position to activate

the machine control functions.

Console. Redesigned consoles feature

a simple, functional design to reduce

operator fatigue, ease of switch operation

and excellent visibility.

Skylight. An enlarged skylight with

sunshade provides excellent upwards

visibility.

Viewing. Cab design optimizes

post structures, and scratch-resistant

polycarbonate window placement to

provide excellent operator visibility

to front, sides and rear. Forestry cab

is designed with heavy-duty guarding,

meeting FOPS/OPS/FOGS/TOPS

and CB requirements.

7

Rugged main frame design

maximizes durability.

• Outer frame utilizes curved side

rails, which are di-formed for

excellent uniformity and strength.

• Box-section channels improve upper

frame rigidity under the cab.

• Inverted U-channels span the width

of the main frame and are formed,

rather than fabricated, for superior

strength and reduced weight.

• Boom tower and main rails are

constructed of solid, high-tensile

strength, steel plates.

• Boom foot and engine mount areas

are reinforced for additional strength.

• Sheet metal supporting structure is

improved by integrating the mounting

into the upper frame structure.

Carbody Design. Advanced, reinforced,

purpose-built carbody design stands up

in the toughest forest applications.

Carbody Structure. Wide, tall, and thick

carbody structure provides operating

stability and durability while improving

operation’s effectiveness.

• Upper structure weight and stresses

are distributed evenly across the full

length of the track roller frame.

• Smooth transitions and long welds

help reduce stresses at the carbodyto-roller frame junctions for

excellent durability.

• Robot welding helps ensure consistent,

high-quality welds throughout the

manufacturing process.

8

Structures

Purpose-built forest applications with reinforced carbody, rugged swing bearing, heavy

doors and extra guarding.

Loading...

Loading...