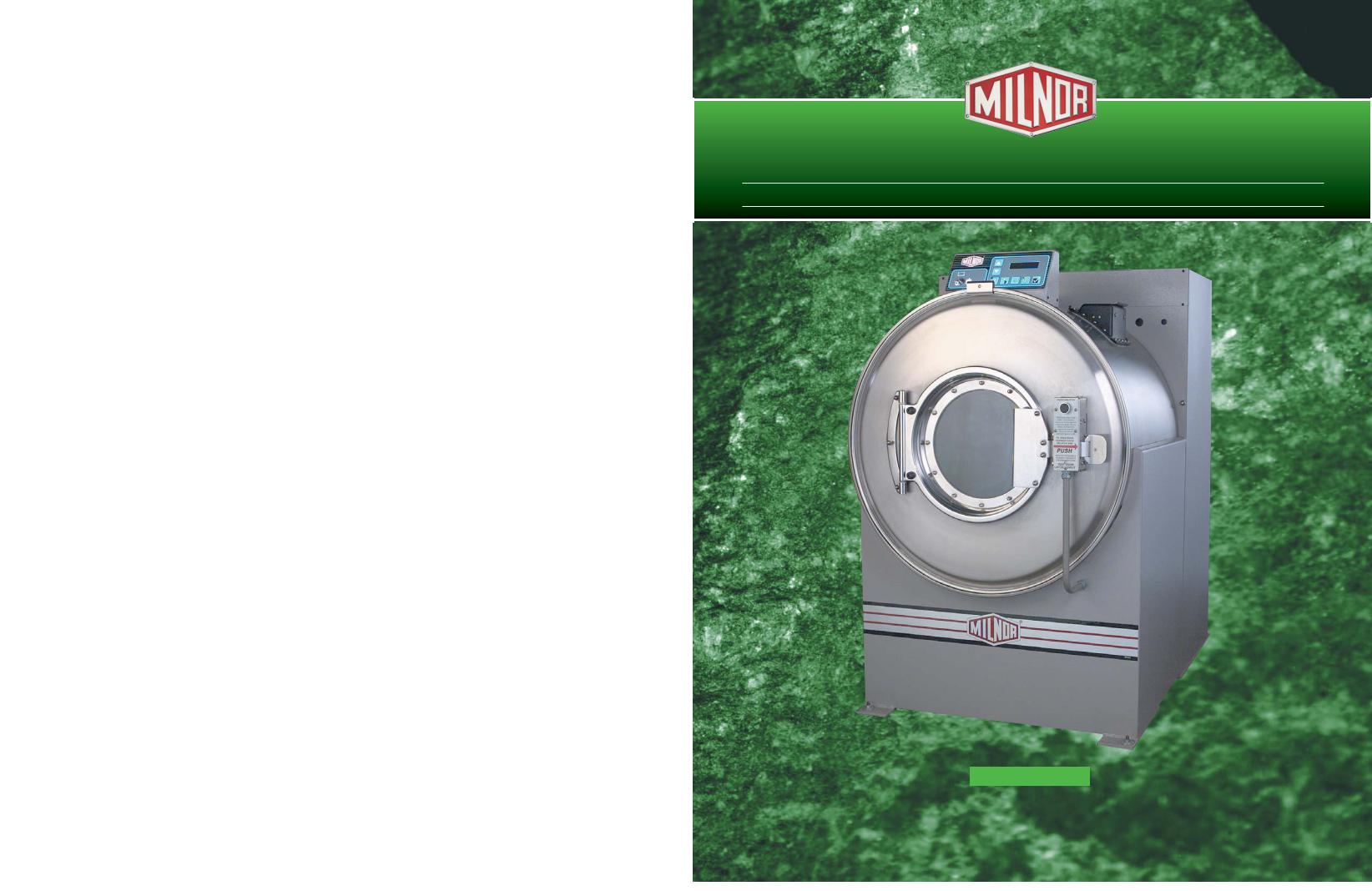

Milnor 30022 V6J Manual

40-160 LB. WASHER-EXTRACTORS

FLEXIBLE CONTROLS • SIX CAPACITY SIZES

Model 30022 V6J

TOP RESULTS.

The right cylinder design.

Milnor’s bigger cylinder perforations give:

•Better wash quality (promotes intense interchange of wash solutions with goods).

•Better rinsing (promotes interchange of solutions and goods and lets water drain freely).

•Better extraction (allows water to escape from goods easily, quickly).

Spacious wash cylinders also yield better results. There’s more room for lift-and-drop action,

and for goods to open up and absorb the washing solution (and rinse water).

High ribs provide excellent lifting action. They’re perforated, too (unlike some others), for fast interchange of goods and water.

RinSave® Water Saver Feature

Save Water

Save Energy

Save Time

The V-Series washer-extractors now feature RinSave™ water saver software which eliminates an entire rinse step.

This innovative process allows a precise high G-force to “sling” the wash liquor (including water chemistry and soil) out of the goods after a wash step. Slinging the wash liquor quickly acts like a rinse. A large basket open area combined with the proper and exact G-force is the key to making RinSave water saver work.

RinSave water saving feature means fewer cycles and faster turnaround with no compromise in wash quality. And you save...save...save...

MILNOR

POPULAR

COMPETITOR

Milnor’s cylinder has bigger perforations, allowing water to pass quickly through the goods.

The right speeds.

Efficient inverter drive produces the speeds you need – normal wash (plus reverse) for shirts and other cotton goods, gentle wash (plus reverse) for delicates and polyesters, pre-extract distribution (helps prevent unbalanced loads), a Rinsave™ speed, and three extract speeds. You get the best speeds for a wide variety of fabrics.

High-speed extraction is great for all-cottons. Lower speeds are available for polyesters (including 100% poly table linens). Combined with a big cylinder (which means a thinner layer of goods for water to pass through) and large perforations, this adds up to very effective moisture removal.

ExactXtract™ extraction optimizer control is a high speed extract option for the 36021V7J, 36026V7J, 42026V6J and the 42030V6J. Unlike competitive models, the ExactXtract control uses precision technology to measure physical vibration of a machine in high extract.

With this option, after achieving normal high speed extract (250 Gs for the 36” models and 215 Gs for the 42” models), ExactXtract control will allow the machine to continue increasing extraction speed until 300 Gs is reached, or until a certain vibration threshold is reached, at which point the extraction speed will be locked-in.

Competitive brands use the inverter to monitor load imbalance. If the load is not balanced to spin at the programmed spin speed, the machine will redistribute the load. After several unsuccessful attempts to lower the speed and speed up, the controller will limit the spin speed. By using the inverter to limit speed, valuable time is wasted as the machine cycles through distribution trying to find the maximum extract speed for the load.

ExactXtract™ high speed control SAVES VALUABLE TIME by not cycling through distribution continually to correct an out of balance. Along with our proper cylinder design and superior basket open area, it SAVES DRYER ENERGY by maximizing extract up to 300 Gs.

EASIER TO USE.

E-P Plus® microprocessor.

Formulas: Thirty total – all programmable – including ten pre-programmed specifically for each of eight markets (see list) … all formulas can be modified to suit needs … management may choose whether operator can manually skip to end of existing bath or extract.

Programming: Simple, two-button programming; display prompts each step … “help” screen makes it even easier … create new formulas, add/delete/modify steps, and/or delete an entire formula – all in one programming mode … move backward to make changes, then rapidly forward.

Display: Display uses real words (not codes) to tell operator what step is underway, what supply is being injected, time remaining, etc. … also: error messages, diagnostic information, formula counts.

Supply injection: Any supplies can be injected in any bath (up to two in one bath) – either with fill, at level-satisfied, or ten seconds after level and temperature (with temperature control option) are achieved … injection duration is programmable, too (1 to 255 seconds) … five injection signals (includes connectors for six liquid supply tubes).

Getting the most from personnel.

Efficient use of labor cuts overtime costs, prevents delays. And Milnor can help – with E-P Plus microprocessor formula counters. You can detect whether employees are running too many loads on long cycles – which leads to overtime.

Or too many short cycles – resulting in poor quality, excessive rewashes, and more overtime. All Milnor washer-extractors operate automatically, further enhancing the efficiency of personnel.

The right formulas.

Pre-programmed wash formulas in E-P Plus models are specifically tailored for each of eight different markets. They were developed with the help of laundry chemists. They’re not common-denominator formulas, as with other pre-programmed machines. And with the E-P Plus control, you can modify pre-programed formulas as needed, and add more.

Why they require less training.

The less judgment a machine calls for, the less training it takes. And that saves time and money. Quality is more consistent, too. E-P Plus microprocessor offers a wide variety of wash formulas – yet

formula selection is easy. Formulas were developed for specific types of goods (sheets, for example). So workers don’t have to guess whether these goods require “medium”

or “light” soil formulas, as with most other machines. Automatic supply injection also makes it simple.

Problem solvers.

These machines save time by helping solve problems. Error messages (such as “door open”) help prevent production delays. Thorough selfdiagnostics aid in troubleshooting if malfunctions occur. You can test inputs/outputs without even removing panels.

Loading...

Loading...