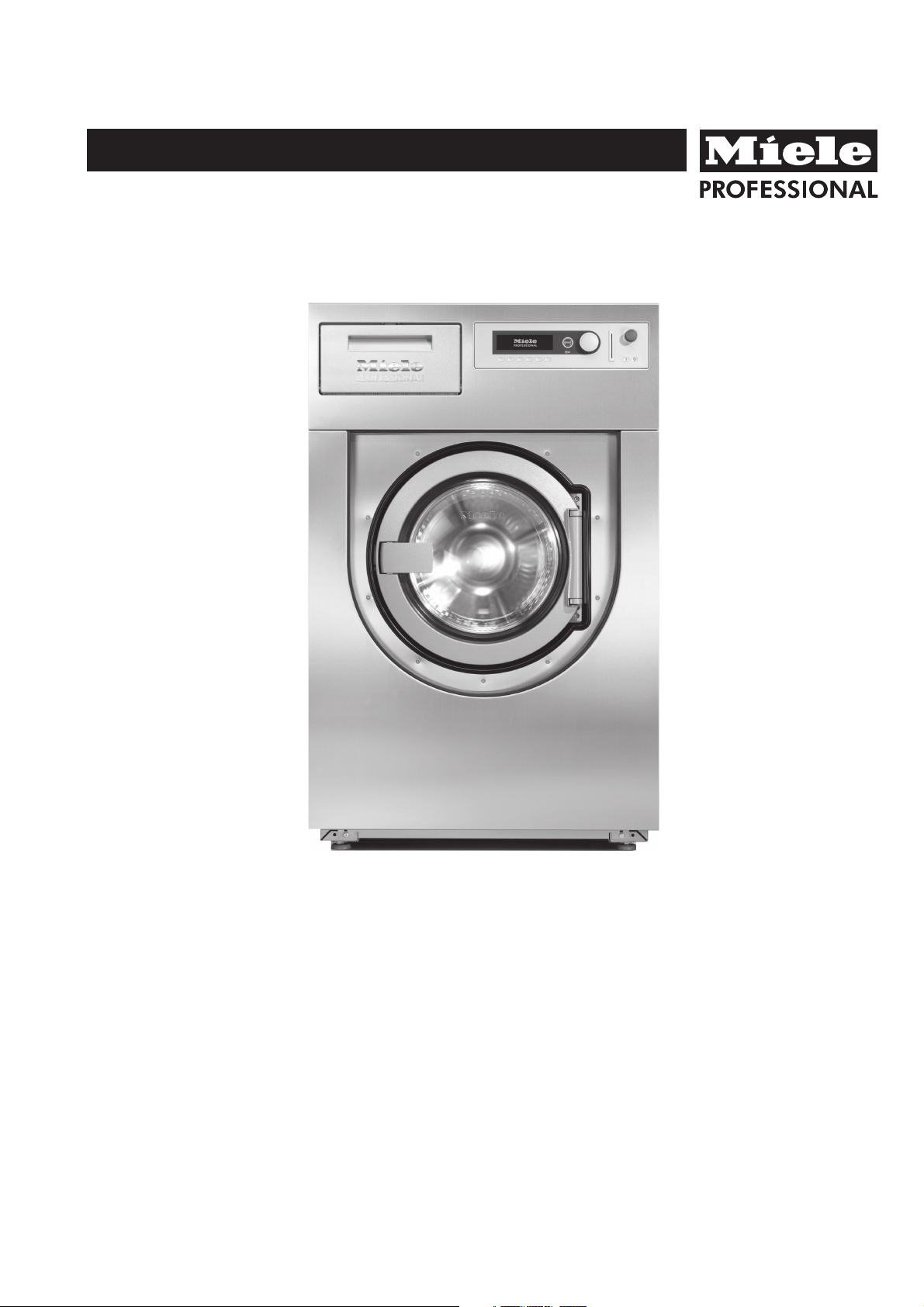

Miele PW 6107 EL Operating instructions

Operating Instructions

Washer

PW 6107

PW 6137

PW 6167

PW 6207

To prevent accidents

and machine damage

read these instructions

before

installation or use.

en, fr - US, CA

M.-Nr. 09 118 330

2

Contents

IMPORTANT SAFETY INSTRUCTIONS ..........................................................4

Guide to the machine ........................................................................7

Guide to the washer .........................................................................8

Operating panel .............................................................................8

Use ......................................................................................10

Turn on the washer ..........................................................................10

Sort and load the laundry .....................................................................10

Maximum dry laundry weights for standard programs .................................................10

Add detergent..............................................................................11

Select a program ...........................................................................12

Select wash options (if desired) ................................................................12

Adjust the program (if desired).................................................................13

End of program.............................................................................14

Chip card use .............................................................................15

Card operation .............................................................................15

Additional features .........................................................................16

Language selection .........................................................................16

Delay Start ................................................................................16

Program stop ..............................................................................17

Canceling a program ........................................................................17

Skipping program cycles .....................................................................18

Optional Module ...........................................................................19

Liquid dispensing system.....................................................................19

Peak load cut off ............................................................................21

Communication module ......................................................................21

Operating data .............................................................................21

Load module...............................................................................23

Frequently asked questions .................................................................24

Power failure - Emergency door release .........................................................24

Fault messages.............................................................................26

Cleaning and Care .........................................................................28

Help to protect the environment ..............................................................32

Installation Instructions .....................................................................33

Removing the shipping struts ..................................................................34

On-site connections .........................................................................35

Water connections ..........................................................................35

Plumbing..................................................................................35

Detergent connection at the mixing compartment of the liquid dispensing system ........................36

Electrical connection ........................................................................37

Technical Data.............................................................................39

3

IMPORTANT SAFETY INSTRUCTIONS

Explanation of safety instructions and

warnings on the washer

Read the operating instructions.

Read all the instructions, e.g. the

installation instructions.

Caution, hot surfaces.

Caution, voltage up to 1000 V

Grounding

Correct usage of the washer

Only use the washing machine to wash items which are

~

specified by the manufacturer to be machine washable on

the fabric care label. Any other applications may be

dangerous.

Persons who lack physical, sensory or mental abilities,

~

or experience with the appliance should not use it without

supervision or instruction by a responsible person.

This washer-extractor is only intended for laundry which

~

has not come in contact with flammable substances.

Dry cleaning solvents must not be used in this machine.

~

Such solvents could cause a fire or explosion.

Do not wash articles that have been previously cleaned,

~

washed, soaked or spotted with gasoline, dry-cleaning

solvents, organic oils or other flammable substances.

These articles give off vapors that could ignite or explode.

Do not add these items to the wash load.

CAUTION: Fire hazard!

~

Do not store or use gasoline, gasoline-based substances

or any easily flammable materials near the machine. Do not

use the top of the washer as a storage area.

READ AND SAVE THESE INSTRUCTIONS

,

Keep these operating instructions in a safe place

and pass them on to any future user.

Read all instructions before installation or use of the

washer to prevent injury and machine damage.

Installation, repair and maintenance work should be

performed by a Miele authorized service technician.

Work by unqualified persons could be dangerous.

This appliance complies with current safety

requirements. Improper use of the appliance can

lead to personal injury and material damage.

All personnel working with this machine must be

fully trained in all aspects of its use and safety.

Do not store any chemicals (liquid detergents, wash

~

aids) on the top of the washer. The chemicals could

damage the surface. Spilled chemicals must be

immediately washed off with a wet sponge.

Under certain conditions, hydrogen gas may be

~

produced in a hot water system that has not been used for

2 weeks or more. HYDROGEN GAS IS EXPLOSIVE. If the

hot water system has not been used for such a period, turn

on all hot water faucets and let the water flow from each for

several minutes before using the washing machine. This

will release any built-up hydrogen gas. Do not smoke or

use an open flame during this time, the gas is flammable.

Check the wash results when the laundry was soiled

~

with biological oils or grease. If the laundry is not

sufficiently cleaned, a spontaneous combustion might

occur when the laundry is dried in a dryer.

Use special detergents or wash programs.

If the washer is operated in a publicly accessible area,

~

the operator must ensure the safe use of the appliance.

Ensure that any one operating this machine is familiar

~

with these important safety instructions.

4

IMPORTANT SAFETY INSTRUCTIONS

Electrical Safety

Be certain this appliance is properly installed and

~

grounded by an authorized technician. For electrical safety

this machine must be grounded. It is imperative that this

basic safety requirement be tested by a qualified

electrician. Consult a qualified electrician if in doubt.

Repairs to electrical or steam appliances should only be

~

carried out by a Miele authorized technician in accordance

with local and national safety regulations. Unauthorized

repairs could cause injury or machine damage.

Do not repair of replace any part of the appliance or

~

attempt any servicing unless specifically recommended in

these operating instructions. Contact Miele’s Technical

Service Department for assistance.

Do not damage, remove, or bypass any of the safety

~

features and controls of the washer.

Do not operate the appliance if the control panel, wires

~

or cables are damaged.

Do not operate the washer when housing parts have

~

been removed and the moving or electrical parts are

exposed and accessible.

The washer is only completely isolated from the

~

electrical supply when the circuit breaker has been tripped

or the power main shut off.

Do not use force to open the washer drum door. The

~

door handle is equipped with an extra safety mechanism to

guarantee that the door remains locked.

Faulty components must only be replaced with genuine

~

Miele spare parts to guarantee the safe operation of this

machine.

Use

Do not let children play in, on or near the washer. Do not

~

let them play with the controls or operate the unit. Close

supervision of children is necessary when the appliance is

used near children.

Always close the door after loading or unloading the

~

washer, to prevent:

children from climbing into the washer, or hiding small

–

items in the washer.

small animals from climbing into the washer.

–

The drum door glass will be hot when washing at very

~

high temperatures. Do not touch the glass.

Do not reach into the appliance if the drum is moving.

~

Take care not to pinch or cut your fingers on the hinges

~

of the drum door or lint flap. Use the handles.

The area necessary to open the drum door completely

~

must not be obstructed by doors or other structures.

Do not drink washer water! Harmful residues could be

~

present.

Always follow the instructions of the chemical

~

manufacturer when using cleaning agents and special

application chemicals. Only use such chemicals for the

purpose and in the situation specified by the manufacturer.

This will prevent the danger of adverse chemical reactions

and material damage.

If in doubt, check with the manufacturer to be sure that the

product is suitable for use in this machine.

Dyes, dye removers and descaling agents may only be

~

used in this machine if the manufacturer states they are

suitable for use in a washing machine. Always observe the

manufacturer’s instructions carefully.

Fabric softeners may be used with this machine. Follow

~

the manufacturers instructions.

Do not use high pressure cleaners to hose down the

~

washer.

Check the hoses regularly for leaks to prevent water

~

damage.

Do not tamper with

~

the controls.

5

IMPORTANT SAFETY INSTRUCTIONS

Additional information

Disinfecting and cleaning agents often contain chlorides

~

(salts) which can cause steel surfaces to rust. To protect

the machine from rust damage, only use chloride free

disinfecting and cleaning agents for washing/disinfecting

and for cleaning the machine. If you are not sure about an

agent contact Miele’s Professional Department. If you

accidentally spill an agent containing chloride on the

machine it should be rinsed off with water and dried with a

soft cloth.

The manufacturer of the washer does not take

~

responsibility for the effect of the chemical on the laundry

or the machine when a chemical cleaning agent is

recommended on technical application grounds.

Keep the area around the machine clean and free of

~

debris.

Before the appliance is removed for service or

~

discarded, remove the door.

The interior of the machine should be cleaned

~

periodically by a qualified service agent.

Using accessories

Only use genuine Miele accessories. If other parts are

~

used, guarantee, performance and product liability claims

may become void.

Chlorine damage to components

How to handle chlorine bleach and perchloroethylene

(PCE)

Heavy use of chlorine products increases the risk of

~

damage to appliance components.

Depending on the chlorine concentration, the exposure

time, and the temperature, the use of liquid and powdered

chlorine-based bleaches can erode the stainless steel

protective layer and lead to corrosion of the appliance

components. Therefore, it is recommended that these

products not be used. Instead you can use oxygen-based

bleaches.

If you still need to use chlorine-based bleaches in special

cases, you will need to perform a neutralizing step each

time. Failure to do so can result in permanent and

irreversible damage to the washing machine and the

laundered items.

Chlorine neutralization

Chlorine neutralization must be done immediately following

the use of a chlorine-based bleach. For best results, use

hydrogen peroxide or an oxygen-based laundry soap or

bleach, without draining the tub.

If thiosulfate is used (especially with hard water), lime

deposits can form, leading to residue on the laundered

items or a build-up in the washing machine. The preferable

alternative is to use hydrogen peroxide, because it helps

promote the neutralization of chlorine.

The exact amounts to be used, and at what temperature(s),

should be selected based on the recommendations of the

neutralizer manufacturer, then checked for efficacy. The

laundry will need to be tested to ensure that no active

chlorine remains behind after neutralization.

SAVE THESE

INSTRUCTIONS

6

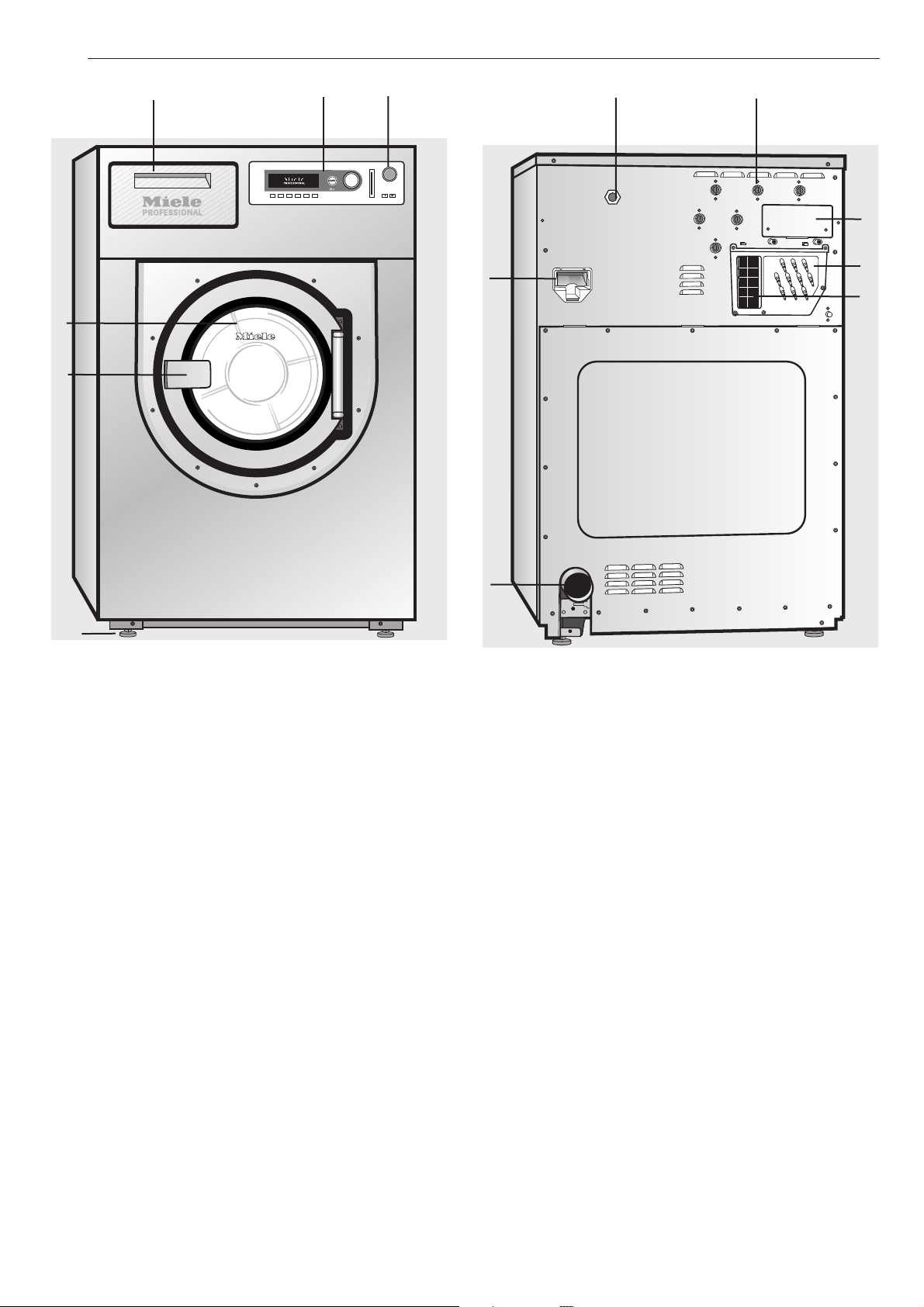

Guide to the machine

d

e

c

b

a

j

g

h

i

l

m

f

a Emergency Stop button

Pressing the red button turns the machine off.

b Control panel

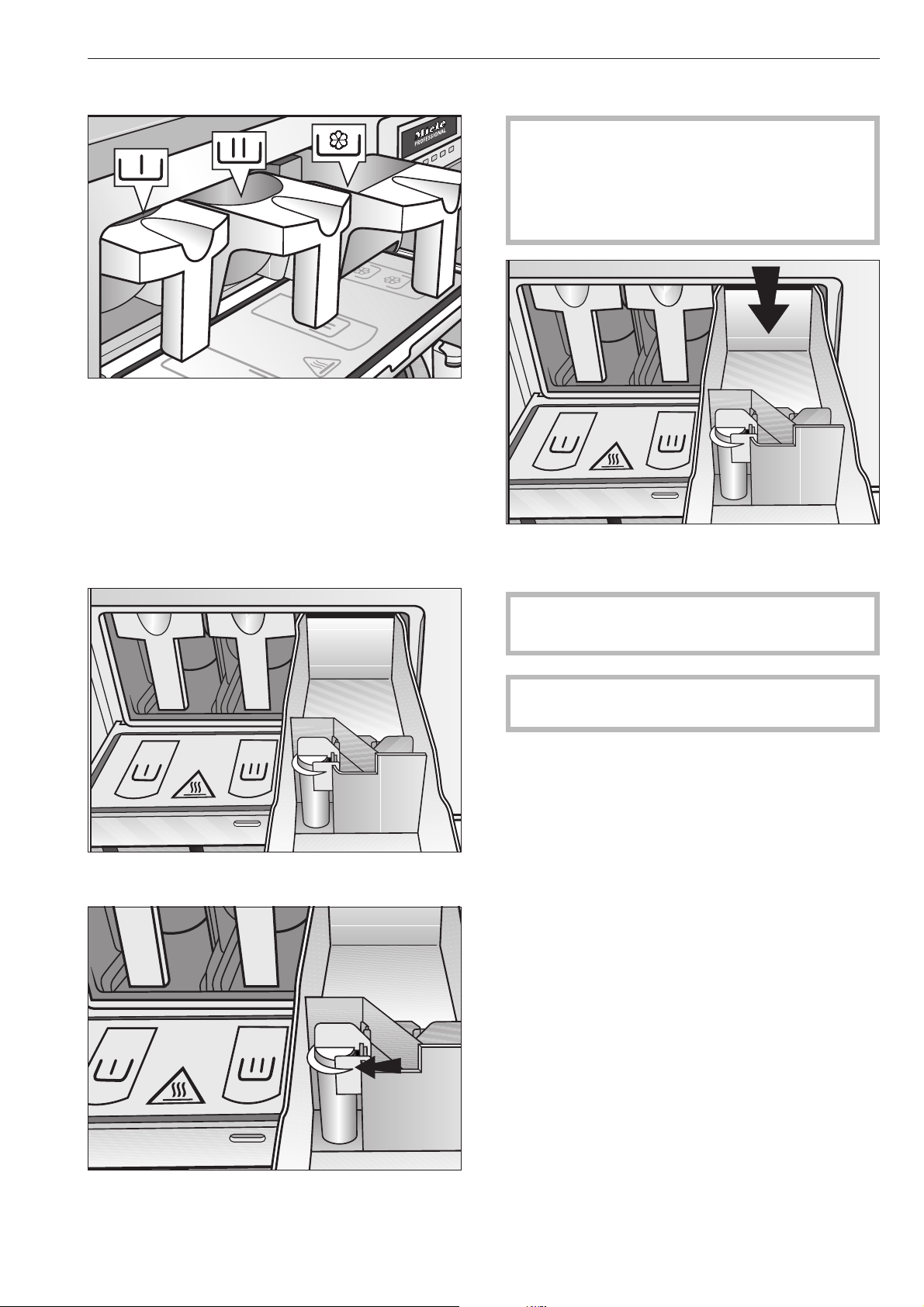

c Detergent compartments

Pull the handle to open the flap.

d Drum door

Pull the door handle to open the drum door.

Do not use force.

e Door handle

The door handle is equipped with an extra safety

mechanism to guarantee that the door remains

locked (see "Frequently asked questions").

f Four height adjustable feet

k

g Electrical connection

h Water connection

i Water recovery connections

j Communication module

k Drain pipe

l Connections for liquid dispensing

m Vapor vent

See "Installation"

7

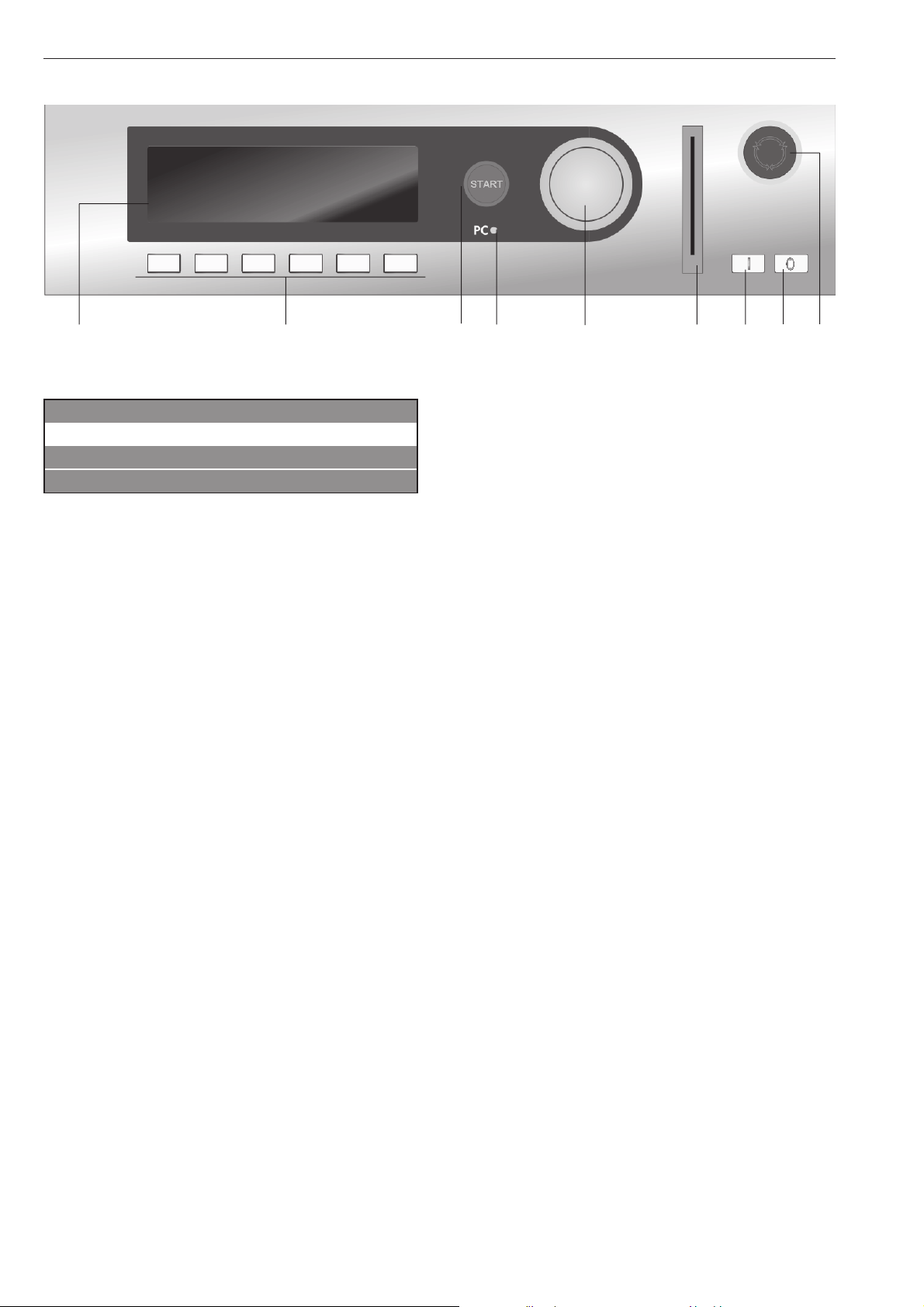

Guide to the washer

Operating panel

a b c d e f g h i

a Display*

1 Hot Wash 194 °F

2 Cottons 140 °F

3 Cottons Intensive 140 °F

i FC A

After turning the machine on, the display briefly

shows a welcome screen and switches to the

program list. The last started program is highlighted.

b Control keys

The control keys have different functions depending

on the machine status. The functions are shown in the

display above each button.

If programmed to "Button allocation direct", the first 6

programs from the program list can be selected

directly with the control keys 1 to 6.

c "START" button

The circle illumination flashes if a selected program

can be started. To start a program press the "START"

button. Once a program has started the START

button can be pressed to show the original display.

* Contents in the display will vary with

program offering.

d Optical interface PC

The optical interface on the machine’s control panel

provides the connection point for data transfer

between the machine’s controls and a PC.

e Jog shuttle

Turn the jog shuttle to display selections and input

fields.

Press the jog shuttle to confirm display selections or

changes.

f Card reader

For card operation. Washing programs can be

uploaded and downloaded on the program card. The

programs on the card can be used to operate the

washer.

g I On button

Turns the machine on.

h 0 Off button

Turns the machine off.

i Emergency Stop button

Only use in case of an emergency.

^ Press the red button to turn the machine off. After

clearing the danger, turn the button clockwise to

unlock it.

^ Press "START" to continue the interrupted program.

8

Guide to the washer

Control keys

Press once to activate the function, press again to

^

deactivate the function.

i Manual operation

(Used by Miele Service Technicians)

See the Programming Manual.

FC Functions

Press this key to temporarily select another language

and/or access the Supervisor level.

A Back to the previous display

+ i Block plus

The respective program block, e.g. prewash, will be

added to the program.

m Starch Stop

Press this button to stop the program and allow

starch to be added to the laundry.

k Spin Stop

Press this button if a final spin is not required after the

final rinse.

m Delay start

Press this key to select a start time in the display.

e/- Following or previous line

S Save

See the Programming Manual.

$ Program locked

If a program is locked it cannot be stopped or ended

with the 0 "Off" button after 1 minute.

) Program unlocked

ß Dispensing

ä Dispensing not available

\ Operating data

->l<- Reset to 0 (zero)

To reset the load sensor to "00.0" when the drum is

empty and the display shows a load size.

D Data transfer

Operator Card

K Information

To show program information

f Stop/Finish

Press to stop a selected program or to end an

already stopped program.

q Drain

ü Skip

Cycles of a program in progress can be skipped or

repeated.

No programs are saved on this card. To transfer the

data from the control to the card and vice versa see

the Programming Manual.

30 programs containing 6 blocks each can be saved

on the card.

The rear side of the card can be labeled.

9

Use

The machine must be commissioned by a Miele

service technician or a dealer authorized by the

manufacturer before it is used for the first time.

Turn on the washer

Open the on-site water faucets (and the supply

^

faucets for steam, if relevant).

Turn on the electrical supply at the mains (on site).

^

Press l "On" to turn the washer on.

^

Miele

PROFESSIONAL

PW 6xx7

Welcome

The welcome screen shows.

1 Hot Wash 194 °F

2 Cottons 140 °F

3 Cottons Intensive 140 °F

i äFC A

Then the program list is shown. The last started

program is highlighted.

Only wash fabrics according to their wash care

label.

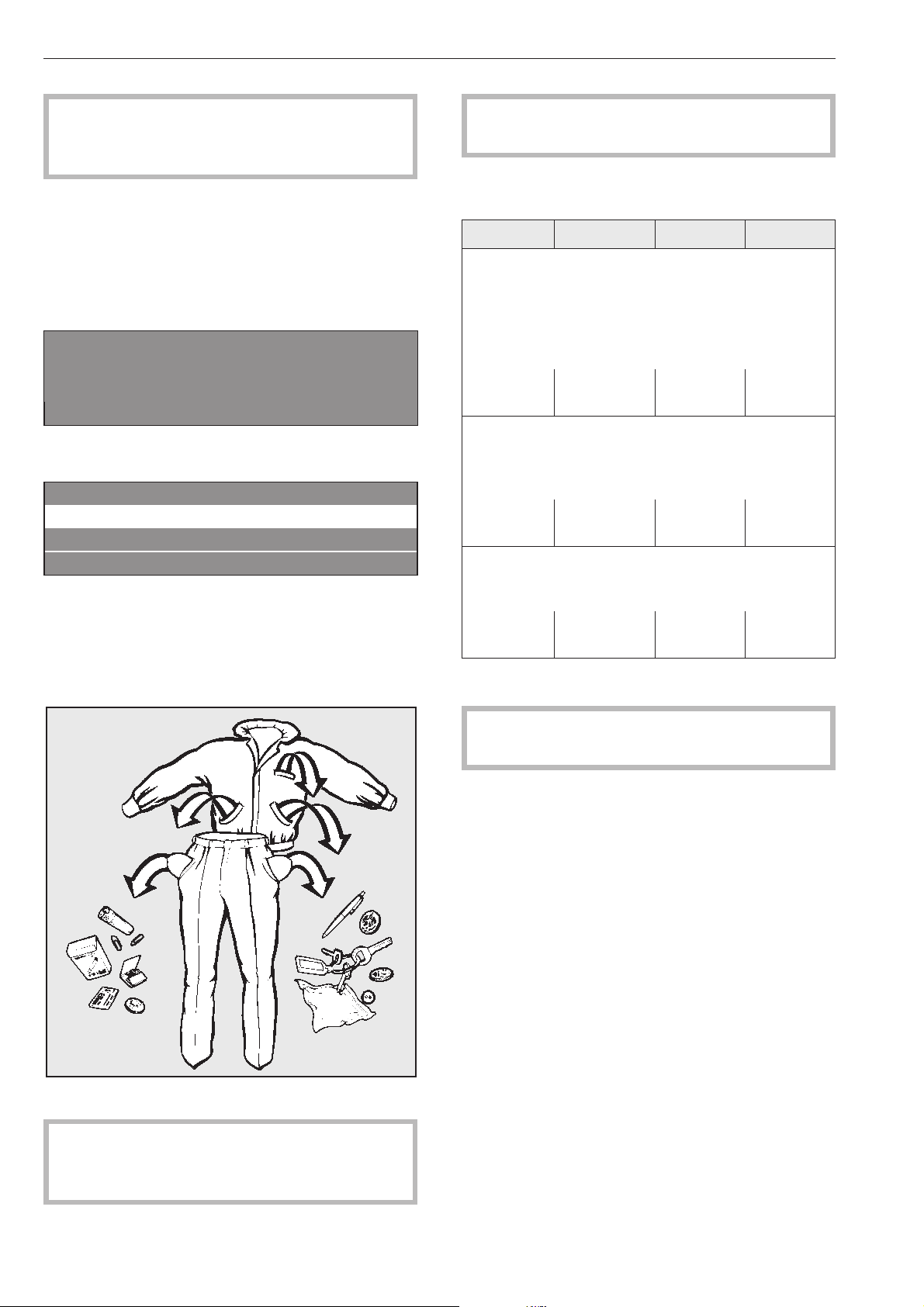

Maximum dry laundry weights for standard

programs

PW 6107 PW 6137 PW 6167 PW 6207

1 Hot Wash

2 Cottons

3 Cottons Intensive

4 Cottons

5 Cottons Intensive

6 Cottons Eco short

max. 22 lbs

(10 kg)

max. 11 lbs

(5 kg)

max. 9 lbs

(4 kg)

max. 29 lbs

(13 kg)

max. 35 lbs

(16 kg)

7 Permanent Press

8 Permanent Press Intensive

9 Permanent Press

10 Permanent Press Intensive

max. 14 lbs

(6.6 kg)

max. 17 lbs

(8 kg)

11 Delicates

12 Woolens

13 Handwash Woolens

max.11.5 lbs

(5.2 kg

max. 14 lbs

(6.4 kg)

max. 44 lbs

(20 kg)

max. 22 lbs

(10 kg)

max. 17 lbs

(8 kg)

Sort and load the laundry

^

Empty all pockets.

^ Load the laundry loosely into the drum.

To prevent fabric damage, check that laundry will

not be caught in the closed door.

^

Close the drum door with the handle.

Do not swing the door shut.

Foreign objects left in pockets (e.g. nails, coins,

paper clips, etc.) can cause damage to clothes

and the machine.

^

Sort the laundry.

10

Use

Add detergent

Open the detergent compartment flap,

^

pull out the respective containers and add

detergent.

j = Detergent for the main wash

i = Detergent for a Pre-Wash

p = Front compartment

1

(

/4of the total recommended amount

of detergent)

Fabric softener or liquid starch

Bleach

Only bleach items with the x symbol on the fabric

care label.

Liquid bleach can only be used in a program

designed for bleach.

Liquid bleach must only be filled in a programmed

detergent compartment. It will be automatically

added to the second rinse.

p = Rear compartment

Liquid additives e.g. bleach

A third rinse is necessary when using bleach (see

the Programming Manual).

,

With increased use of chlorine the possibility of

machine damage rises.

Fabric dye

Fabric dye and color aids must be suitable for use in

a washer. Always follow the instructions of the

manufacturer.

^

Do not exceed the maximum fill level (see arrow),

the excess will flow directly into the drum.

^

Close the detergent compartment.

11

Use

Detergent

Only use the correct amount of high efficiency low

sudsing detergent. Too much detergent will cause

over sudsing.

Dosage

Follow the instructions on the detergent packaging to

ensure the correct usage and dosage amount for

your water hardness.

Adjust the amount of detergent if the load is smaller

and more or less soiled than normal.

Water hardness

Water

hardness

levels

I soft 0 - 1.3 0 - 7

II moderate 1.3 - 2.5 7 - 14

III hard 2.5 - 3.8 14 - 21

IV very hard over 3.8 over 21

If you do not know the water hardness in your area

contact your local water authority.

Water

quality

Hardness

level in mmol/l

German

hardness

°d

Select wash options (if desired)

Press one of the wash option buttons.

^

To deselect the option, press it again.

+ i Block Plus

A pre-wash can be selected for heavily soiled laundry

in certain program. If a pre-wash is an option the

"+i" field is highlighted. If a pre-wash is not

available, the "+i" will not be shown.

m Starch Stop

Starch can be selected with all standard program

(excluding Extra Spin and Extra Drain). The m field

is highlighted in the display.

k Spin Stop

Spin Stop can be selected with all standard program

(excluding Extra Spin). The k field is highlighted in

the display.

If no additional changes need to be made to the

program:

^ Press "START" and the program will begin.

Select a program

^ Select a program by turning the jog shuttle (e.g.

Program 1 Hot Wash), see "Program guide".

The following will appear in the display:

18 Extra Drain

1 Hot Wash 194 °F

2 Cottons 140 °F

i äFC A

^

Confirm the selected program by pressing the

inner button of the jog shuttle.

The display shows:

1 Hot Wash 22.0 /22.0 lb

194 °F Main wash

Rinse 1200 rpm

+im k m A

12

Use

Adjust the program (if desired)

Laundry weight

The laundry weight can be manually selected.

1 Hot Wash 22.0 22.0 lb

104 °F Pre-wash

194 °F Main wash e

+im k m A

Turn the jog shuttle to "Laundry weight" and press

^

to confirm the selection.

The weight shown on the right side indicates the max.

weight.

Turn the jog shuttle to the desired laundry weight

^

and press to confirm the selection.

Temperature in 1° increments from 15 °C to max.

95 °C .

Turn the jog shuttle to "Temperature" (104 °F for

^

Pre-wash) and press to confirm the selection.

1 Hot Wash 22.0 / 22.0 lb

104 °F Pre-wash

194 °F Main wash e

+im k m A

^ Turn the jog shuttle to the desired temperature and

press it to confirm the selection.

Press "START" and the program will begin.

^

After starting the program the program sequence

appears in the display.

1 Hot Wash

104 °F Pre-wash 68 °F

Main wash Finish at 12:35

+im k mKf

The second line of the display here shows Pre-wash

and the current temperature.

1 Hot Wash

194 °F Main wash 140 °F

Rinse 1 Cold Finish at 12:35

+im k mKf

Once the Pre-wash ends, Main wash will appear in

the second row of the main program block. The

current temperature will appear next to it and the first

rinse cycle will appear below.

The Program End indicator will appear in the display

along with the program end time.

1 Hot Wash

194 °F Main wash 140 °F

Rinse 1 Cold Finish at 12:35

+im k m K f

Spin speed

The spin speed can be adjusted from 0 - 300 then in

25 rpm increments.

^

Turn the jog shuttle to "Spin speed" and press to

confirm the selection.

1 Hot Wash 22.0 / 22.0 lb

194 °F Main wash

Rinse 1100 rpm

+im k m A

^

To change the spin speed turn the jog shuttle,

press to confirm the selection.

Max. spin speeds

PW 6107 PW 6137 PW 6167 PW 6207

1200 rpm 1100 rpm 1150 rpm 1100 rpm

By pressing the K "Information" button, further

information regarding the wash cycle can be shown,

for example:

1 Hot Wash

Delay start 7.10.2010

Start time: 9:47 e

A

Time after start: 0h 23 min

Time left: 0h 11min

Program end 12: 35 Clock e

Time left: 0h 11min

Repetition: No

Area 3: Rinse e

13

Use

Block 2: Rinse 2

Step: Wash time 1

Actual water level: 22 in e

Required water level 60 in

Actual temperature 95 °F

Rqurd. temp.: 140 °F e

1 Hot Wash

rpm: 40 rpm

Rhythm 12 / 3 -

Press A "Back" to return to the program.

^

End of program

A

The drum door is locked.

,

Do not use force!

Press the q "Drain" button or select the Drain Extra

^

program and press "START".

At the end of the program open the door.

^

Leave the drum door open to air dry the interior.

Turn the machine off with the 0 "Off" button.

^

Shut off the power supply (on-site).

^

At the end of the program, once the drum is

stationary and no water is in the machine the display

shows (for example):

1 Hot Wash

Program end

Door can be opened.

m FC A

At the same time a tone will sound for a short time to

signal the program end.

^ Pull the door handle to open the drum door.

Important: If the door cannot be opened, press

against the door handle then pull again.

Do not use force!

^

Remove the laundry.

If the program was stopped with water in the machine

or while spinning, the following is displayed:

1 Hot Wash

Program end - Water in the drum

qmFC A

or

1 Hot Wash

Program end - Drum rotates

m FC A

14

Chip card use

Chip cards are programmed to a machine type.

Empty cards can be used with any machine.

Press l "On" to turn the washer on.

^

The Welcome screen shows.

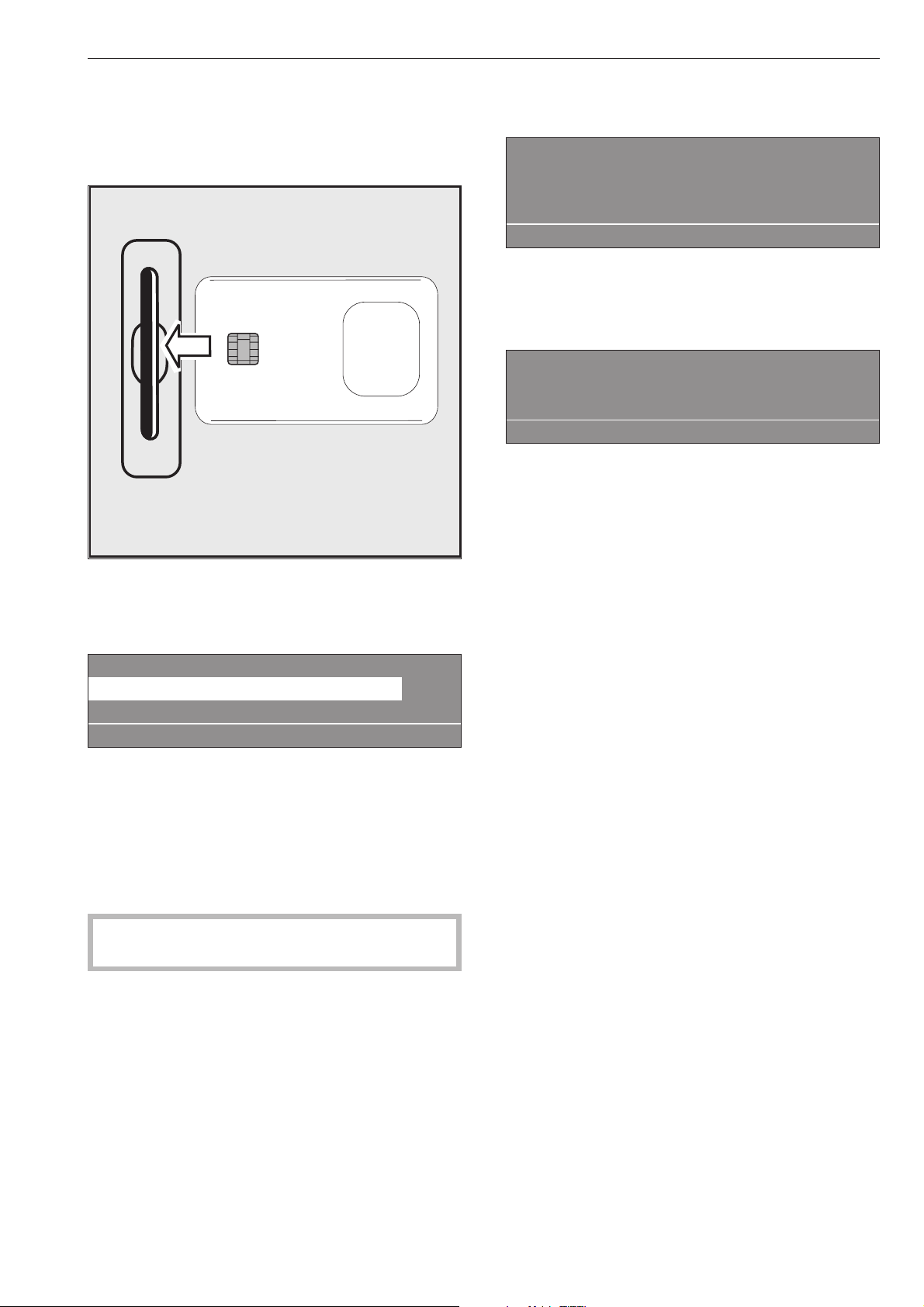

^ Insert the card, arrow first, into the card reader.

The display shows the list of programs on the card,

example:

Card operation

17 Fire department clothing 113 °F

18 Wrinkle-free 140 °F

i ßFC A

If the card was inserted the wrong way, the display

shows:

Card fault

§

Reinsert the card properly into the card reader.

^

If the card is not suitable for this type of machine, the

display shows:

Card operation

Programs on the card are only

suitable for machine type PW 6167

Insert a card suitable for this machine type.

^

Reinsert card correctly in card reader.

i ü f

A

Card operation

For laundry loads which need special wash

procedures, a single special program is written on a

card which is then used to run the program.

This function blocks all machine programs. The

washer runs only the program saved on the card.

The function "Load" can be activated in the supervisor

level. The machine will only accept cards in this

function.

^

Turn the jog shuttle to select a program. Press the

jog shuttle to confirm the selection.

^

Press the "START" button to begin the program.

^

Remove the card from the card reader.

Once the program is finished it will be deleted from

the machines memory.

,

Do not insert any items other than the card into

the card reader.

15

Additional features

Language selection

The language can be selected with the F flag

symbol. The language is set back to its original

setting 5 minutes after the program ends or when the

door is opened.

1 Hot Wash 194 °F

2 Cottons 140 °F

3 Cottons Intensive 140 °F

i FC A

Press the function button FC. The display shows:

Settings Back A

Main menu Language

Supervisor level

FC A

Turn then press the jog shuttle to select

^

"Language".

Settings Dansk

Language Deutsch

English

FC A

^ Turn the jog shuttle to select the desired language

and press to confirm the selection.

Delay Start

Use the m "Delay start" button to program the washer

to start automatically at a later time.

Press the "START" button to start the program at the

^

selected start time.

The following appears in the display:

1 Hot Wash 22.0 / 35.0 lb

194 °F Main wash

16:15 -4.2.2010 Start: 6:00 -4.3.2010

+im k m A

The display shows the current time of day, date and

the start time.

If the door is opened before the delay start time

^

has elapsed, press the "START" button again.

Canceling the Delay Start

Press m "Delay Start" again or the

^

A "Back" button to cancel the delay start

function.

With Pre-wash

For heavily soiled laundry a pre-wash can be

selected for Standard programs 1 to 10 by pressing

the+i "Block plus" button

Pressing the button again will deselect the function.

When the +i "Block plus" button is pressed the

display shows the following:

1 Hot Wash 31.0 / 35.0 lb

104 °F Pre-wash

Main wash e

+i mk m A

Setting the delay start

In the program selected, the display will show (for

example):

1 Hot Wash 22.0 / 35.0 lb

194 °F Main wash

Rinse 1000 rpm

+im k m A

^

Press m "Delay Start".

The following will appear in the display:

1 Hot Wash 10.0/16.0 lb

Start time: 16 : 10 Start date: 4.2.2010

After setting the delay start press Start.

A

The display shows the current time of day and date.

The entry field is highlighted for hours.

^

Press, then turn the jog shuttle to select the hour.

Press it to confirm the selection.

The "+i" field is highlighted.

^

Repeat with the minutes, day, month and year.

16

Additional features

Starch

In the detergent container

Starch can be selected for all standard programs

(except Extra Spin und Extra Drain) before starting

the program by pressing m "Starch Stop".

The field m is highlighted in the display.

By pressing the button again the function can be

deselected.

1 Hot Wash

Program stop - Starch stop

Door can be opened.

i ü f

"Starch Stop" flashes in the display.

Add starch, prepared according to the

^

manufacturer’s instructions, into compartment p.

The wash time is automatically extended by 4

minutes.

The program will continue by pressing "START".

In the drum

m

To continue the program with spinning, press the

^

"START" button.

Program stop

To stop the program, press f "End".

^

The program stops.

1 Hot Wash

Program stop

i ü f

To continue the program press "START".

^

Canceling a program

To cancel a program, press the f "End" button

^

twice.

If the program was canceled with water in the

machine or during spinning, the display shows:

1 Hot Wash

Program stop - Water in the drum

^ Once the program stops in "Starch Stop", open the

drum door and add starch to the laundry load

prepared according to the manufacturer’s

instructions.

^ Close the drum door.

The display shows:

1 Hot Wash

Program stop - Starch stop

Door can be opened.

i ü f

^

Press the "START" button to continue the program.

m

Without spin

Without spin can be selected for all standard

programs (except "Extra spin") Before starting the

program press k "Without spin".

"k" is highlighted in the display.

Pressing the button again will deselect the function.

1 Hot Wash

Program stop - W/o spin

k

i ü f

or:

1 Hot Wash

Program stop - Rotating drum

i ü f

^

Press the q "Water drain" button or select the

program Extra Spin, and press the "START" button.

i ü f

"Without spin" flashes in the display when the spin

cycle is reached.

^

Press the f "End" button.

^

The program ends without spinning.

17

Additional features

Canceling a locked program

Locked programs cannot be stopped or canceled.

1 Hot Wash

194 °F Main wash

LOCKED Finish at 12:35

)e

The display shows that the program is locked if the f

"End" button is pressed.

To unlock the program press the ) "Unlock"

^

button.

Enter the password, by turning the jog shuttle to the

^

desired character in the alpha numeric list and then

pressing the jog shuttle to confirm each selection.

After entering the password the display shows:

Unlock program?

S A

Press the S "Save" button to confirm. The normal

display shows and the program can be canceled.

1 Hot Wash

194 °F Main wash 140 °F

Rinse 1 Finish at 12:35

mKf

Skipping program cycles

Cycles of a program in progress can be skipped or

repeated.

Press the f "End" button to stop the program.

^

1 Hot Wash

Program stop

i ü f

Press the ü "Skip/Repeat" button. The display

^

shows the current area, block or step.

See also "Program structure" in the Programming

Manual.

Skip/Repeat -> Hot Wash

Area 2: Main wash e

S A

Area 2: Main wash

Block 1: Main wash

Step: Wash time 2 -

S A

^ Turn the jog shuttle to "Area" and press it to confirm

the selection.

Area: Select either 1 Pre-wash, 2 Main wash or 3

Rinse and confirm by pressing the jog shuttle.

^ Turn the jog shuttle to "Block" and press it to

confirm the selection.

Block: Select either Pre-wash 1-10, Main wash 1-10

or Rinse 1-10 and confirm by pressing the jog

shuttle.

^

Turn the jog shuttle to "Block" and press it to

confirm the selection. Select the desired program

step and confirm.

^

To start the new program step press S "Save" and

"START".

To go back without skipping a program cycle

^

Press the A "Back" button to go back to the

program stop.

18

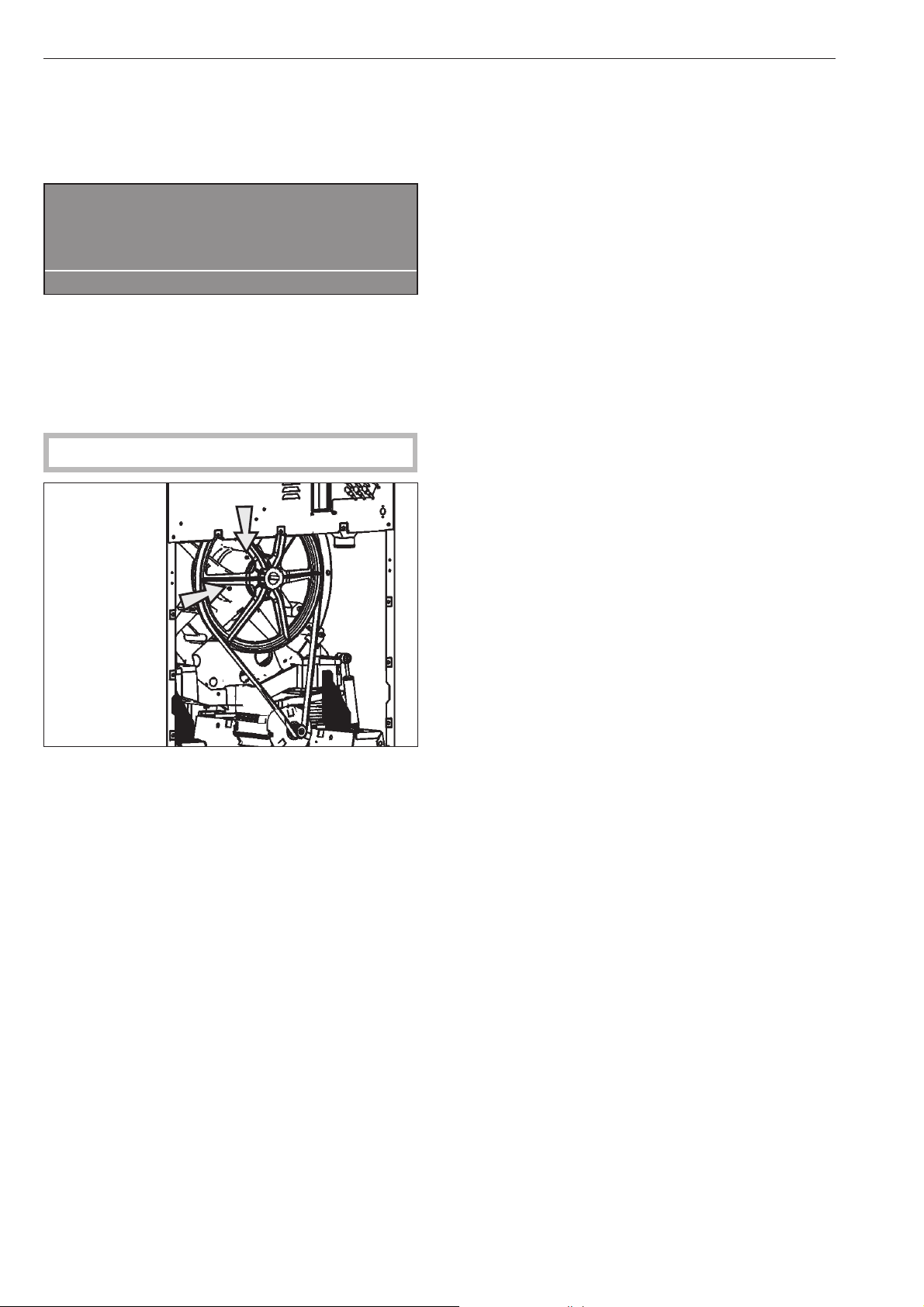

Optional Module

Liquid dispensing system

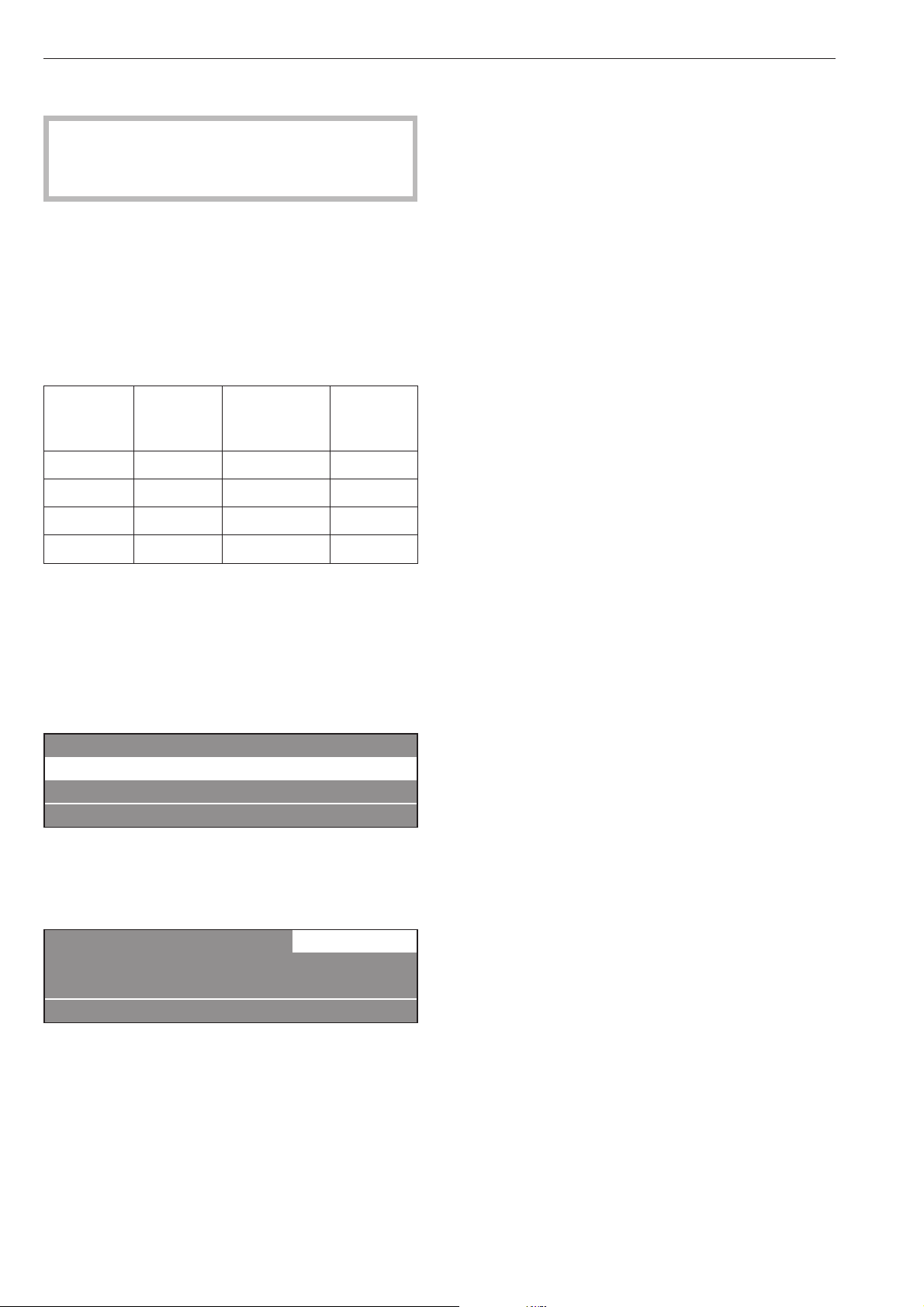

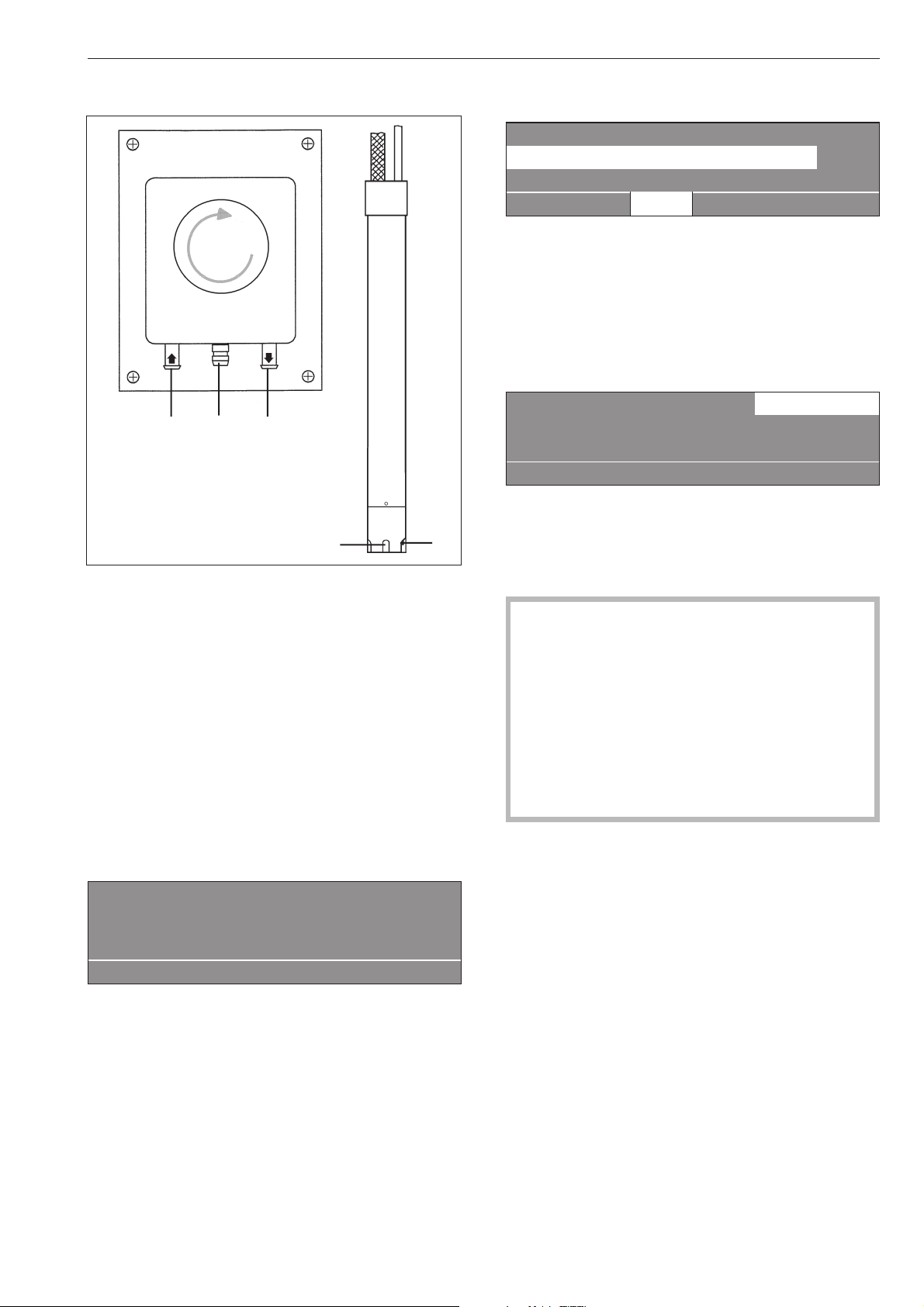

a

c

b

d

e

Deselecting the dispensing

1 Hot Wash 194 °F

2 Cottons 140 °F

3 Cottons Intensive 140 °F

i ä FC A

The liquid dispensing can be manually deselected

^

ä before a program start.

he liquid dispensing can be manually deselected

before a program start.

The dispensing pump is turned off.

The display shows:

1 Hot Wash 22.0/22.0 kg ä

194 °F Main wash

Rinse 1000 rpm

+im k m A

(Dispensing systems vary)

Priming the dispensing pumps

a Hose connection socket (in)

b Hose connection socket (out)

c Leakage outlet

d Suction inlet opening

e Level indicator

When the dispenser container is empty the pump and

the machine will shut off.

The display will indicate that the detergent dispenser

is empty.

Dispensing amount

Always follow the instructions of the chemical

,

manufacturer when using cleaning agents and

special application chemicals.

Only use such chemicals for the purpose and in

the situation specified by the manufacturer to

prevent the danger of adverse chemical reactions

and material damage.

If in doubt, check with the manufacturer that the

product is suitable for use in this machine.

Liquid detergent should stand at room temperature

before being used to ensure proper dispensing.

Dispensing system fault

ö

^

Refill the dispensing containers.

Fill dispensing container 1

Press Start.

if

^

Press "START" to continue the program.

19

Optional Module

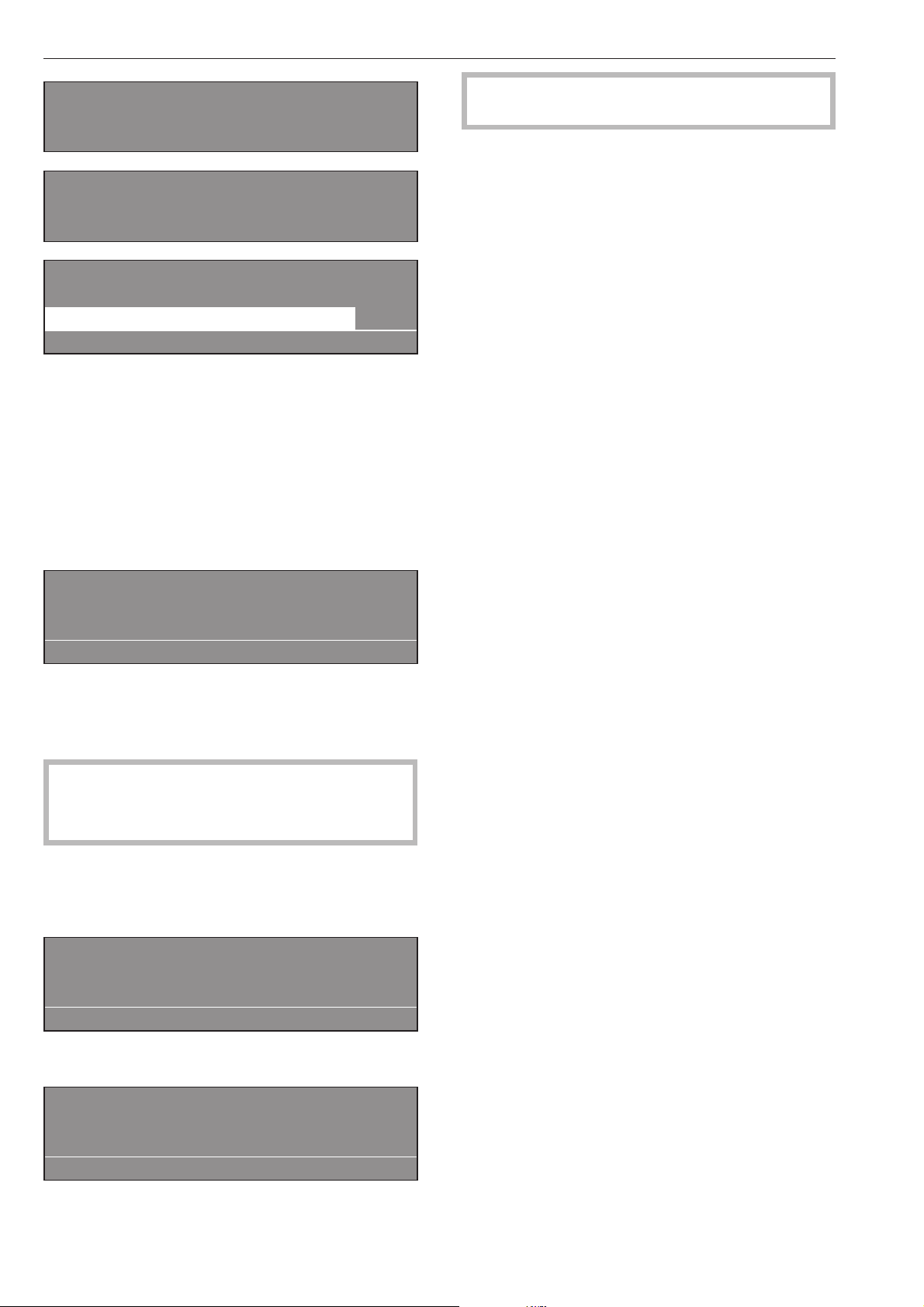

Priming the dispensing pumps

Use the calibration to get liquid detergent to the

pumphead. Once calibration is complete run an

empty program to get detergent to the machine

before actually washing a load of laundry in the

machine.

Dispensing calibration

The dispensing calibration is used to calculate the

flow rate of each dispensing pump.

For direct access to the dispensing calibration when

the machine is turned off:

Press and hold the 2

^

Turn the machine on and release the control key.

^

nd

control key from the left.

Dispensing calibration ~ Dispensing pump 1

V: 100ml t: 0s P: No

0/1 S A

The dispensing can be manually stopped by

^

pressing the 0/1 button or it will stop automatically

after 60 seconds.

Measure the pumped amount in the measuring

^

cup.

Dispensing calibration ~ Dispensing pump 1

V: 100ml t: 30s P: 200.0 ml/min

Dispensing calibration ~ Main menu

Dispensing pump 1

Dispensing pump 2 e

A

Dispensing pump 1 to 13

After selecting a dispensing pump the display shows:

Dispensing calibration ~ Dispensing pump 1

V: 100ml t: 0s P: No

0/1 S A

The dispensing amount can be adjusted in 1ml

increments from 0 to 999 ml.

^

Press the 0/1 control key, the dispensing hose fills.

Press the 0/1 button again to stop.

^

Point the hose of the dispensing pump to be

determined, in a measuring cup. Hold the cup high

enough so the liquid has to be pumped rather than

flowing out.

0/1 S A

Enter the measured amount in the "V:" field. The

^

flow rate P: in milliliter per minute is calculated by

the control.

Press S "Save" to allocate the measured values to

^

the dispensing pump.

^ Reconnect the hose.

Maintenance of the dispensing system

Rinse the dispensing system with hot water every 2

weeks, or before shutting down the dispenser pumps

for any length of time, to prevent the system from

clogging.

^ Rinse out the suction pipes with water.

^

Place the suction pipes in a container with warm

water, 104 - 122°F (40 - 50°C).

^

Select each pump by using the dispensing

calibration.

^

Turn on each pump until the dispensing system is

rinsed.

,

Avoid skin and eye contact, wear protective

clothing.

^

Press A to get back to the main menu.

Dispensing calibration ~ Main menu

Dispensing pump 1

Dispensing pump 2 e

^

Select the dispensing pump.

20

A

^

Check the connection points, hoses and washers

for leaks.

Optional Module

Peak load cut off

When activating the peak load cut off the heat is

turned off and the program is stopped. The display

shows:

If there is no more memory available in the operating

data module a message will appear after pressing

the "START" button to say that the operating data will

be overwritten.

If you press the A "Back button or do not press the

1 Hot Wash

Program stop - Peak load function

Program will continue.

if

When the peak load function ends the program will

continue automatically.

Communication module

The communication module makes it possible to

connect the machine to a PC (Personal Computer).

"START" button within 30 seconds the display will

revert to the way it was before starting the program.

Total data

Operating data module

Total data

Program data e

\ A

After selecting Total data the following (example) will

appear in the display:

The outlet for the module is on the back of the

machine.

This requires a special Editor Program which is

available from the Miele Professional Department.

Operating data module ~ Total data

Total time power on: 20,987 h

Operating hours: 123456 h e

\ A

Operating data

By pressing the \ "Operating data" button the

operating data module can be used to read or delete

operating data either before the start of a program, or

after it has finished.

1 Hot Wash 194 °F

2 Cottons 140 °F

3 Cottons Intensive 140 °F

i \ FC A

After pressing the \ button the following will

appear.

Other options:

Total time power on: 200,987 h

Operating hours: 123,456 h

Duration heating active: 73,456 h

Duration drive motor active: 93,456 h

Program starts: 23,456

Program stops: 567

Program cancellations: 67

Water volume: 1,234,567 l

Amount of laundry: 1,234,567 kg

Liquid agent: 2,345 l

Energy: 12,345,678 kWh

Operating data module

Total data

Program data e

\ A

Selection choice:

–

Total data

In this option all program data is collated and

summarized.

–

Program data

Program data contains all the data called up during a

program.

–

Delete data

–

Module (Total data including program data)

–

Total data (only delete total data)

–

Program data (only delete program data)

Pressing the button again deselects the \

"Operating data" option..

21

Optional Module

Program

Operating data module

Program data -

Delete data e

\ A

After selecting Program data the following (example)

will appear in the display:

Operating data module ~ Program data

1 Hot Wash 194 °F -

2 Cottons 140 °F e

\ A

Select the program you want from the list and press

the rotary dial to call up a list of all program starts

including date and start time for that program (Hot

Wash 90°C in the example).

Program data ~ 1 Hot Wash

Date: 05.21.2010 Start time: 11:30 -

Date: 05.21.2010 Start time: 12:30 e

\ A

Select the required program start from the list for

program 1 Hot Wash and confirm your choice by

pressing the rotary dial.

Program data ~ 1 Hot Wash

Date: 05.21.2010

Name: Miller e

\ A

Other options:

Town: Lehrte

Serial number: 12345678

Machine type: PW 6107

Amount of laundry: 29 lbs

+ Button: activated

Starch stop button: activated

Without spin button: not activated

Program start: 11:30

Program end: 12:05

Total operating time:0h35min

Electrical energy: 12.5 kWh

Gas energy: 0 kWh

Stem energy: 0 kWh

Total volume of water: 140 l

Max. water temperature: 203 °F

Max. drain temperature: 113 °F

Program change 2

pressing the jog shuttle only the last 3 stops and starts will

be displayed.)

Program fault: none (only the last 3 faults are saved)

(after making your selection and

Area 1: Pre-wash (after making your selection and

pressing the jog shuttle you can display the area or the

block.)

Block 1: Pre-wash

22

Holding time: 6 min

Water volume: 20 l

Dispensing phase 1: Amount ml (after making your

selection and pressing the jog shuttle 5 dispensing

are displayed.)

Max. Temperature: 54 °F

Holding time: 6 min

Dispensing phase 2: no

Delete data

Operating data module

Program data

Delete data e

\ A

After selecting Delete data the following message will

appear in the display:

Operating data module ~ Delete data

Module: 02.21.2010

Total data: 07.12.2010 e

\ A

The module menu option can be used to delete the

total data and program data from the operating data

memory.

The total data option can only be used to delete the

total data from the operating data. The program data

option can only be used to delete program data from

the operating data.

After making your selection and pressing the rotary

dial you will be prompted to enter your password.

Password:

ABCDEFGHIJKLMNOPQRSTUVWXYZ

0123456789

KSA

After keying in your password or inserting your

supervisor level key card in the reader the following

security prompt will appear in the display:

Delete operating data?

S A

After pressing the S button the data will be deleted.

Load module

If the machine is equipped with a load module, the

load weight will be displayed, in 0.5 lb increments,

while loading the laundry. The maximum laundry

weight is displayed next to the selected program.

Reset with the I "zero setting" if the weight display

^

does not show "00.0" when the drum is empty.

1 Hot Wash 00.0 / 35.0 lb

140 °F Main wash

Rinse e

+im k m ->I<- A

If there was still laundry in the drum when the weight

display was reset, the display shows:

1 Hot Wash - -.-/ 35.0 lb

140 °F Main wash

Rinse e

+im k m ->I<- A

Optional Module

Reset again with the I button.

^

If the machine is overloaded (wet laundry) the

machine calculates after the programs start with the

nominal value. This value is saved in the operating

data module.

At the end of a program, with the drum stationary, the

residual moisture of the laundry is displayed.

1 Hot Wash

Program end Residual moisture 60 %

Door can be opened.

m FC A

23

Frequently asked questions

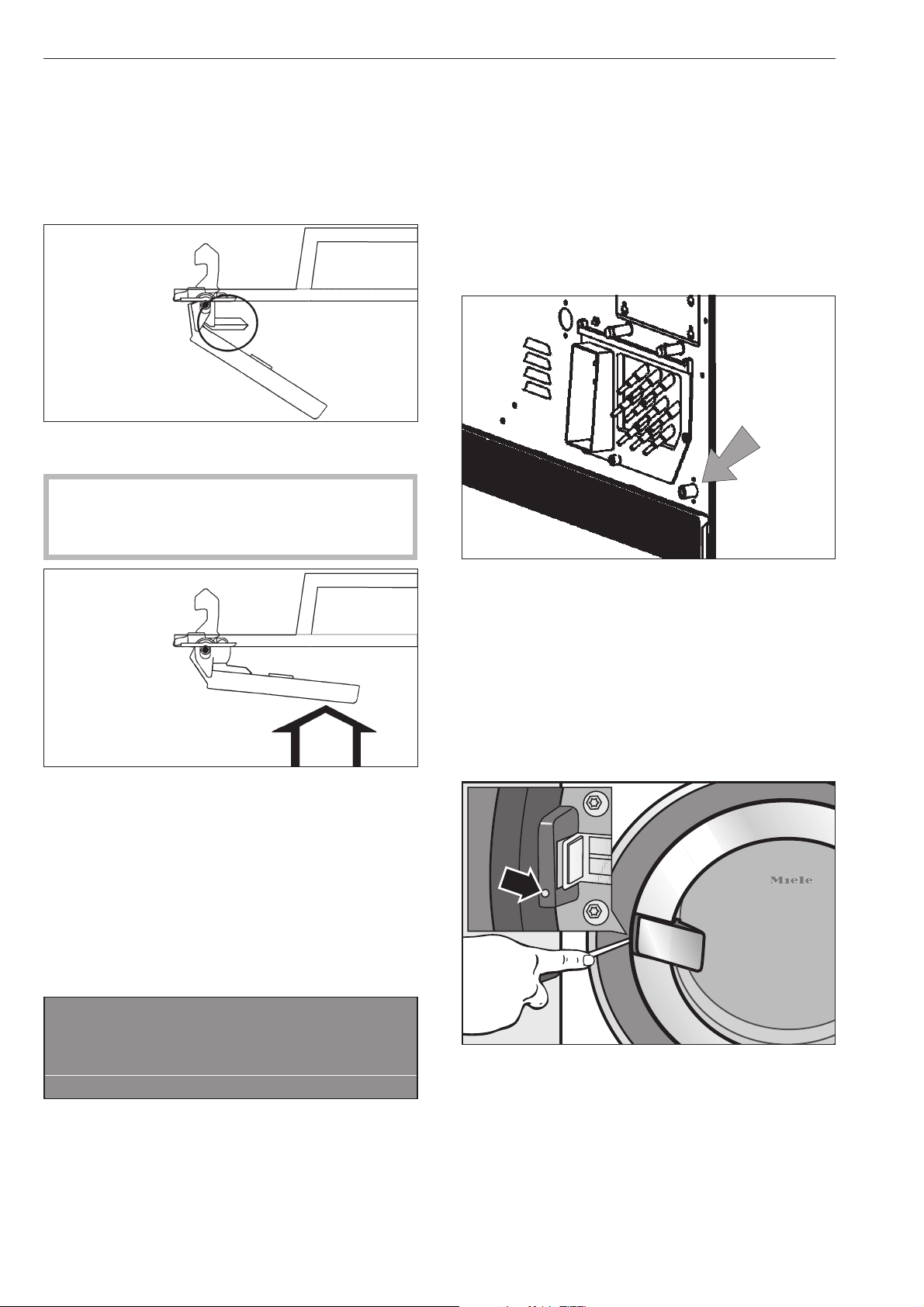

The drum door cannot be opened

Press against the door handle, turn the machine on

^

then off and pull on the door handle once more.

The safety mechanism of the door handle

is disengaged

The door handle has lost its function. The door cannot

be opened or closed.

The safety mechanism is designed to protect the

handle from damage, i.e. if too much force is

being used in an attempt to open the door.

Extended power failure

Turn the machine off.

^

Turn the electrical supply off at the main power

^

supply.

Close the valves (on-site).

^

The machine must be drained and the drum door

opened manually to unload the machine.

Draining the wash water

^

Firmly press against the door handle until you hear

the safety mechanism click.

The door can now be opened or closed provided

there is no water in the machine.

Power failure - Emergency door release

During a short power failure

The program remains in the last position. When

power is restored the following message appears in

the display:

Power failure

y

Program stop.

Press Start.

i ü f

^

Press "START" to continue the program.

^ Place a container under the manual drain at the

rear of the machine.

^ Open the drain by loosening the venting screw. Do

not take it completely out.

^ A small amount of water will drain from the

machine.

^ Tighten the venting screw again and test for leaks

by opening the water supply.

Open the door manually

^

Insert and hold a small screwdriver in the opening

next to the door lock.

^

Press against the door handle, then pull it towards

you to open the door.

Do not use force!

24

^

Remove the laundry.

Frequently asked questions

Reasons for over sudsing

Detergent type

Only use detergent formulated for use in

^

commercial washers. Detergents for domestic

machines are not suitable.

Too much detergent

^ Follow the detergent manufacturer’s instructions

and adjust the amount to the local water hardness.

Over sudsing detergent

^ Use a low sudsing detergent or contact Miele’s

detergent application specialists.

Very soft water

^ In areas with soft water, use less detergent.

Soiling level of laundry

^ For lightly soiled laundry use less detergent.

Residue, e.g. undissolved detergent on laundry

Large articles of laundry stretching

during the spin cycle

Large articles of laundry (e.g. table cloths) can

stretch during the spin cycle. This can generally be

prevented by reprogramming the machine.

Please contact the Miele Service Department.

^ Run a prewash without detergent and without

selecting a temperature.

^ Laundry which has been pre-treated in detergent

before washing must be thoroughly rinsed before

running a wash program.

Small loads

^ Reduce the amount of detergent accordingly.

Drum speed too high during a wash

(Profitronic-controls)

^ Reduce the drum speed and wash rhythm.

25

Frequently asked questions

Fault messages

Repairs to electrical or steam appliances

,

should only be carried out by a Miele authorized

technician in accordance with local and national

safety regulations. Unauthorized repairs could

cause injury or machine damage.

Faults that occur before or after the start of a program

flash in the display.

Heating system fault

§

Program stop. Press Start.

Program runs with cold water..

if

Press "START" to continue the program without

^

heating.

If the program has a "Thermostop" the program will

time out.

Contact Miele Technical Service.

^

Some programs may be canceled if this messages

^

shows.

Contact Technical Service.

If the display remains off, the washer has no power.

Check the plug, main switch and fuses on-site.

^

m

Power failure

y

Program stop.

Press Start.

f

^ Press "START".

This fault message can also indicate that the overload

cut-out of the drive motors has over heated.

^ Allow the motor to cool.

Water intake fault

M

Contact Technical Service

if restart w/o success.

if

^

Check the water supply and press "START".

^ Allow the motor to cool.

§

Large imbalance, the imbalance switch has

activated.

^

Turn the machine off and on again

^

Press "START".

Drive motor fault

Program stop. Press Start.

Motor temperature too high.

if

Imbalance fault

Contact Technical Service

if restart w/o success.

i A

Door lock fault.

a

Contact Technical Service

if restart w/o success.

if

^

Press the door handle so that it closes with a click,

press "START".

26

q

^

Check and clean the drain system and press

"START".

A defective drain valve should only be replaced by

an authorized service technician.

Drain valve fault

Contact Technical Service

if restart w/o success.

if

Frequently asked questions

Dispensing system fault

ö

Change/fill the dispensing container.

^

Fill dispensing container 1

Press Start.

if

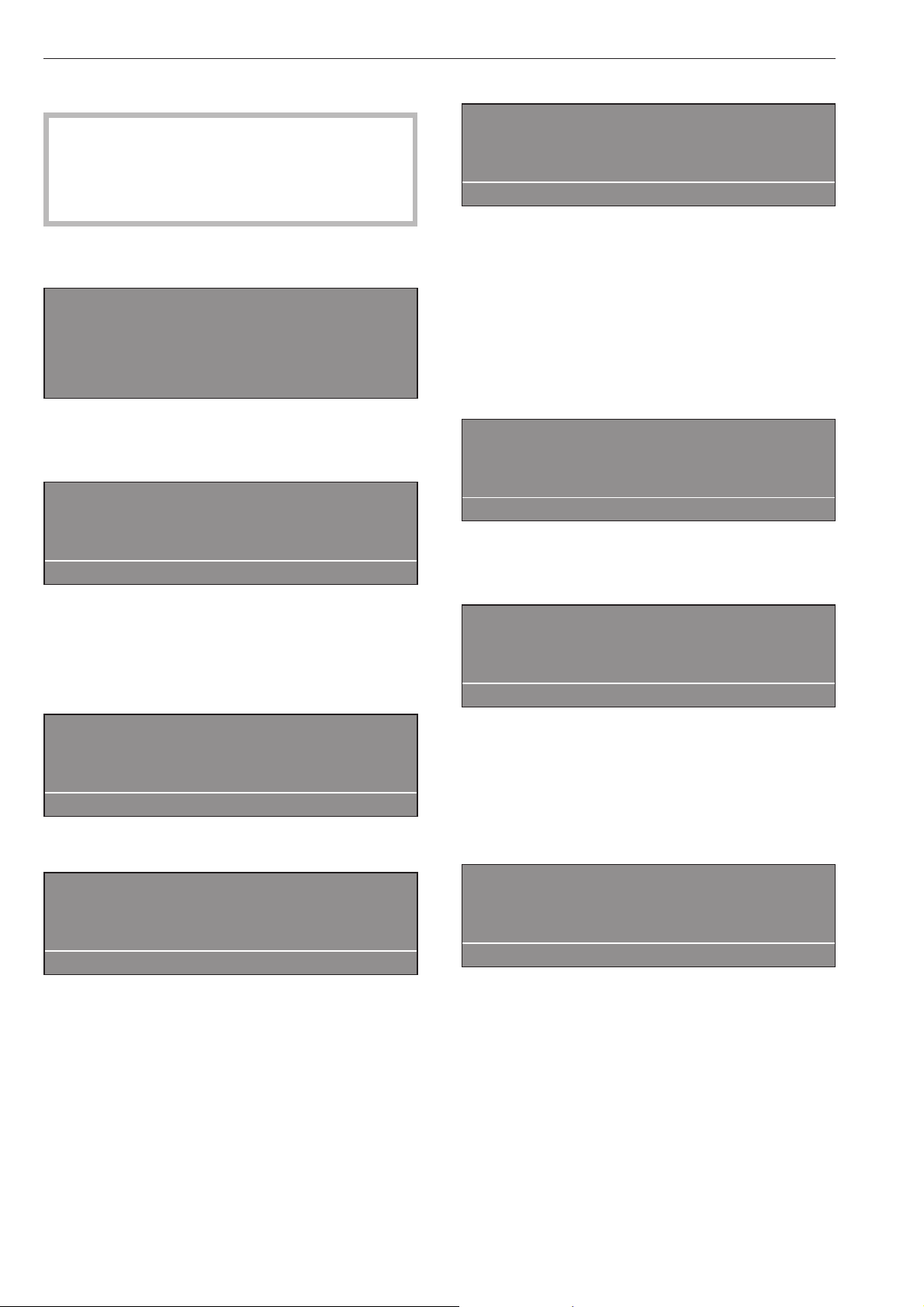

In the event of a fault which you cannot correct

^

yourself, please contact Technical Service.

When contacting Technical Service please quote

^

the model, serial number (SN) and part number

(M.-Nr.) of the machine.

Card fault

§

Insert the card properly into the card reader.

^

Reinsert card correctly in card reader.

A

They can be found on the data plate located at the

top of the door opening (when drum door is open) or

on the back of the machine at the top.

When contacting Technical Service report the fault

^

in the display.

Only use original Miele spare parts when performing

maintenance or repairs on this machine. When

ordering please quote the model, serial number (SN)

and part number (M.-Nr.) of the machine.

27

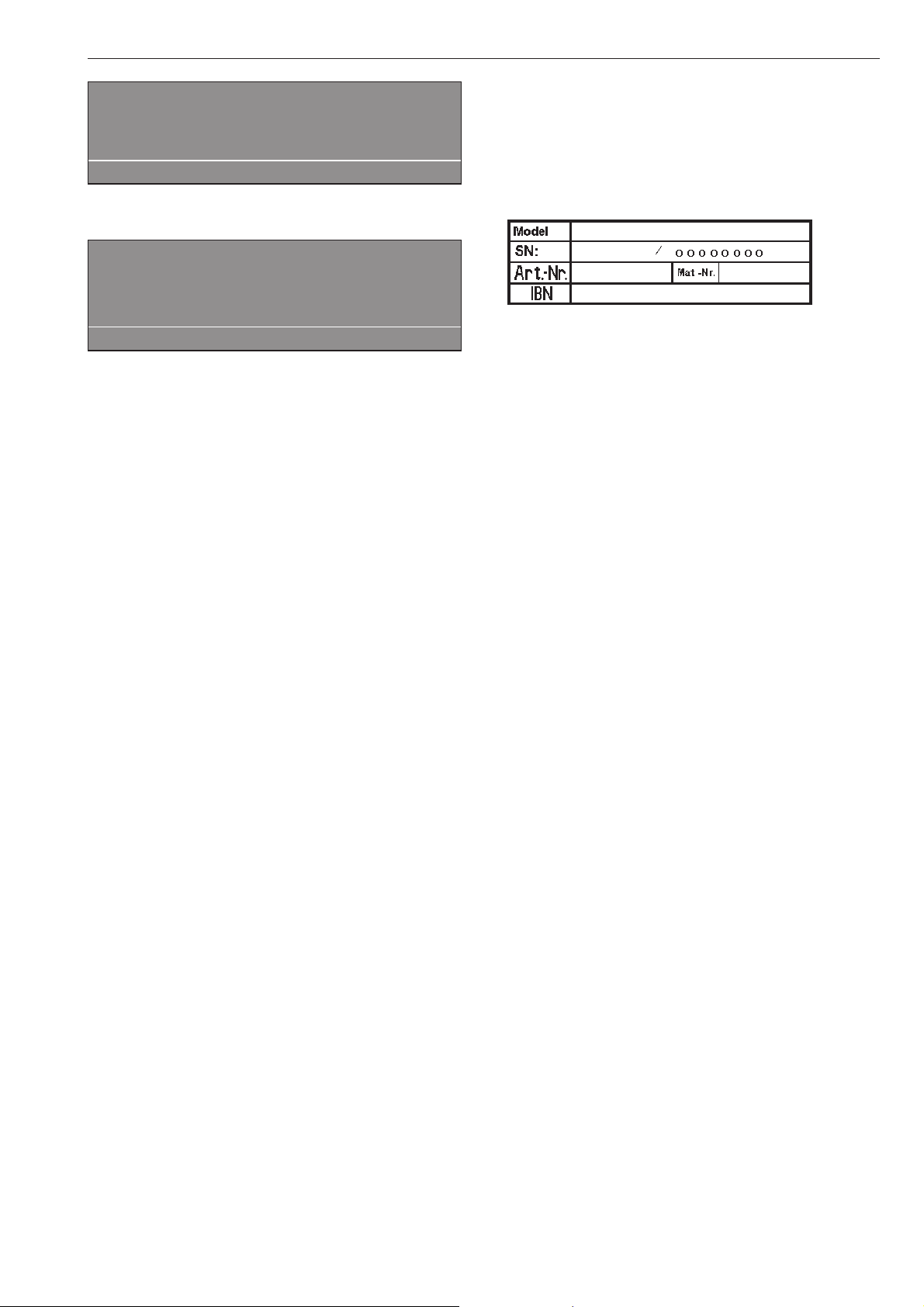

Cleaning and Care

After each use

Never use high pressure cleaners to hose down

the machine.

The machine should be cleaned immediately after

use.

^ After use do not shut the drum door, allow the

interior to air dry.

Cleaning the exterior

Never use abrasive cleaners, scouring pads,

,

steel wool or caustic cleaners on the machine.

They will damage the surface.

All surfaces can be cleaned with a solution of warm

water and liquid dish soap applied with a soft

sponge.

Door gasket

^ Clean any residues on the door gasket with a damp

cloth.

Stainless steel

Stainless steel surfaces can be cleaned using a

non-abrasive stainless steel cleaner.

To help prevent resoiling, a conditioner for stainless

steel can also be used.

^ Apply sparingly with even pressure.

Clean the detergent dispenser, dispenser

compartments and siphons

The detergent dispenser, dispenser compartments

and siphons must be cleaned after each use with

warm water to thoroughly remove any residues of

detergents or other agents. If the machine is not

going to be used for a while the detergent dispenser

should be left open to air the compartment.

To clean the drip channels and siphon in the

detergent dispenser, open the flap 45°. The siphon

can be cleaned with a bottle brush if necessary..

The grille over the cooling fan at the back of the

machine should be checked for soiling from time to

time and cleaned if necessary.

Rust

The drum itself and the wash water drum are made of

stainless steel. Water with a high iron content or items

like paper clips or iron buttons which are in the

laundry, can lead to rust in the drums.

^ To help prevent rust, a conditioner for stainless

steel can be used.

^ Check the door gasket for iron residue and clean

with stainless steel conditioner.

^ Clean regularly.

Leave the drum door open after use for the interior

to air dry.

The siphon in the dispenser compartment for fabric

conditioner should also be cleaned.

Remove the siphon and clean with hot water. Then

put it back in place.

28

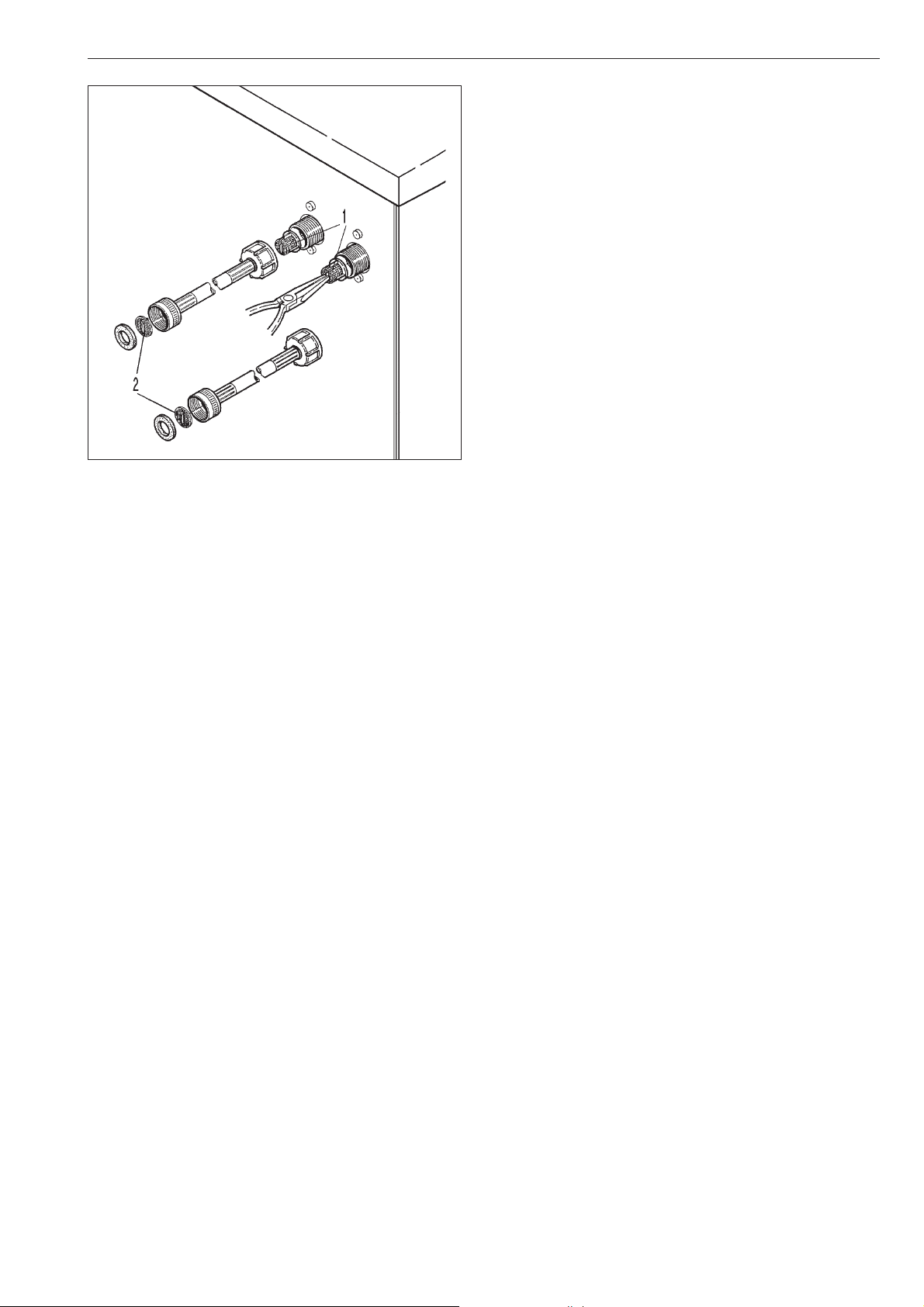

Regularly check and clean the filters in the water

^

intake faucets, 1, and the water intake hoses, 2.

Cleaning and Care

29

Cleaning and Care

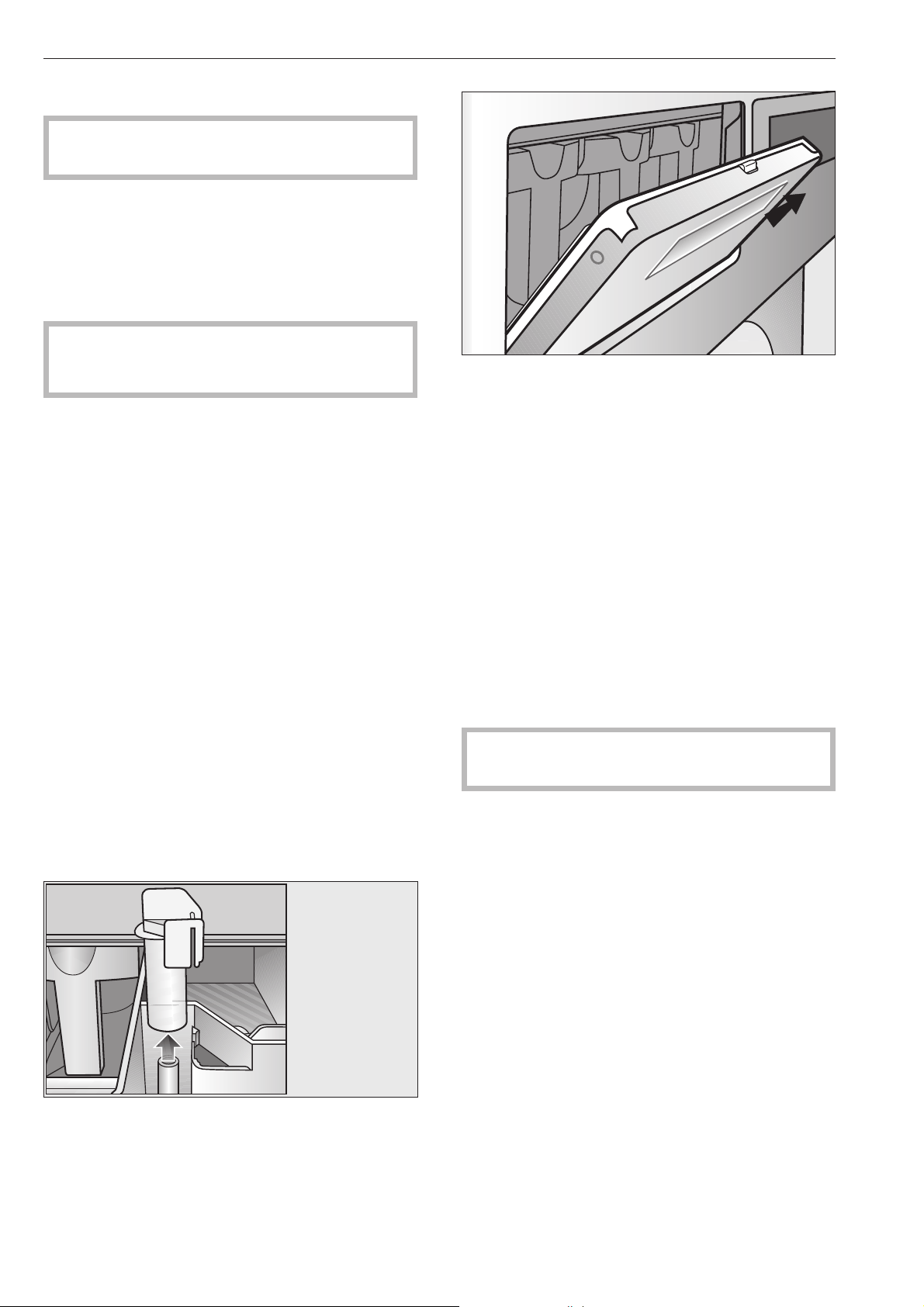

Drum bearing lubrication

(PW 6167 and PW 6207 only)

If the machine needs to be serviced the following

message shows:

Drum bearing lubrication

§

Press A "back" to delete the message.

^

The message will show each time the machine is

turned on, until a Service Technician has serviced the

machine.

,

Contact Technical Service.

A

Unplug the machine.

Maintenance during downtime

When the machine is not in use for an extended time

(4 weeks or more), the drum bearings must be

lubricated (before the downtime).

Lubricate the drum bearings according to the

^

warning message and turn the drum by hand a few

times.

Repeat every month to prevent bearing damage.

^

^

After about 1000 operating hours, lubricate the

drum journal bearings with the lubricating nipple

using Arcanol L 100 grease.

30

Loading...

Loading...