Page 1

Operating instructions

Washer-Extractor

PW 6107

PW 6137

PW 6167

PW 6207

To avoid the risk of accidents or damage to the machine it is

essential to read these instructions before installing,

commissioning and using it for the first time.

en, nl - GB, NL

M.-Nr. 09 105 050

Page 2

Gas-heated appliances

Safety precautions to take if you smell gas

Turn off the gas emergency control valve immediately.

^

This is usually located near the gas meter.

Eliminate all sources of ignition in a safe manner.

^

Do not smoke, light cigarette lighters or matches.

Do not operate electrical lights or switches, i.e. do not switch them "On" or "Off".

^

Open all doors and windows to ventilate the area.

^

If the smell of gas persists, evacuate the building.

^

In the UK you must now:

Call the Gas Emergency Contact Centre (Tel: 0 800 111 999)

^

For any gas work in the UK always use a Gas Safe registered engineer.

In other countries please follow relevant country specific procedures on gas.

2

Page 3

Contents

Warning and Safety instructions...............................................................4

Caring for the environment ...................................................................7

Description of the machine ...................................................................8

Control elements.............................................................................9

How to wash correctly ......................................................................11

Sort the laundry.............................................................................11

Maximum loads for the standard programmes.......................................................11

Add detergent..............................................................................12

Detergent dispensing ........................................................................13

Select a programme .........................................................................13

Open the door at the end of the programme ......................................................15

Card operation ............................................................................16

Card access operation .......................................................................16

Additional options .........................................................................17

Language selection .........................................................................17

Start date and time ..........................................................................17

Programme stop ............................................................................18

Programme cancellation......................................................................18

Changing the programme order................................................................19

Optional modules ..........................................................................20

Liquid dispensers ...........................................................................20

Peak load cut-out ...........................................................................22

Communication module ......................................................................22

Operating data .............................................................................22

Weighing system ...........................................................................24

Problem solving guide ......................................................................25

The door will not open .......................................................................25

Power cut during a wash programme - Emergency door release ......................................25

Error messages.............................................................................27

After sales service ..........................................................................28

Cleaning and care ..........................................................................29

Installation and connection ..................................................................32

Transit fittings ..............................................................................33

On-site connections .........................................................................34

Plumbing connections on the machine ..........................................................34

Liquid agent dispensing mixing box connections ..................................................35

Electrical connection ........................................................................36

Connecting the dispenser pumps ..............................................................37

Steam connection ...........................................................................37

Gas connection.............................................................................37

Technical data .............................................................................38

3

Page 4

Warning and Safety instructions

Explanation of the Warning and Safety

symbols on the machine

It is essential to read these operating

instructions.

When used in a commercial environment ensure

~

that all operators are trained to use the machine

correctly.

If the machine is used in a publically accessible

room, please ensure that operators are able to use it

safely.

This machine is not intended for outdoor use.

~

Please refer to specific instructions, e.g.

Installation instructions

Caution, hot surfaces.

Caution, voltage up to 1000 volts.

Earthing

To avoid the risk of accidents and damage to the

machine read the operating instructions carefully

before using it for the first time. They contain

important information about the installation, safety,

use and maintenance of the machine. Keep these

operating instructions in a safe place and ensure

that new users are familiar with the content. Pass

them on to any future owner of the machine.

Correct application

This machine is not designed for washing items

~

which have been treated with dangerous or

flammable substances.

Only use the machine to wash items which are

~

specified by the manufacturer to be

machine-washable on the wash-care label.

Any other applications may be dangerous. The

manufacturer is not liable for damage resulting from

improper use or operation.

Chemical dry cleaning agents must not be used in

~

this machine. Most dry cleaning agents, e.g. benzine,

pose a fire and explosion hazard.

Petrol, paraffin, or any easily flammable liquid

~

must not be stored or used near the machine. Do not

use the machine lid as a storage shelf.

Fire and explosion hazard.

Do not store any chemicals on the machine lid

~

(liquid detergent, fabric conditioners etc). They could

discolour the lid and also damage the surface finish.

If any chemicals should come in contact with the

surface, wipe them away immediately with clean

water. Then dry with a soft cloth.

Technical and electrical safety

The electrical safety of this machine can only be

~

guaranteed if connected to a correctly installed

earthing system on site. It is most important that this

basic safety requirement is present and tested

regularly, and where there is any doubt, the on-site

electrical wiring should be inspected by a qualified

electrician. The manufacturer cannot be held liable

for the consequences of an inadequate earthing

system (e.g. electric shock).

Do not damage, remove or bypass the safety

~

features, fixtures and control elements of this

machine.

Do not use a machine with damaged controls or

~

cables. These must be repaired before it is used

again.

Any removable outer panels must be back in

~

place, and all moving or electrical parts shielded

before the machine is switched on.

Connection should be made via a suitable isolator

~

which complies with local and national safety

regulations and which is easily accessible for

disconnecting the machine from the electricity

supply. Provision must be made on site to switch off

all poles.

The machine is only completely isolated from the

~

electricity supply either when it is switched off at the

isolator switch or the mains fuse has been withdrawn.

Repairs to electrical, gas or steam operated

~

machines may only be carried out by a suitably

qualified person in accordance with national and

local safety regulations, e.g. a Gas Safe registered

service technician in the U.K for gas-heated

machines.

Repairs and other work by unqualified persons could

be dangerous.

The manufacturer cannot be held liable for

unauthorised work.

Do not force the drum door open. The door handle

~

is fitted with an safety device to ensure that the door

lock functions correctly.

Faulty components must only be replaced by

~

genuine Miele original spare parts. Only when these

parts are fitted can the safety standards of the

machine be guaranteed.

4

Page 5

Warning and Safety instructions

The best materials are used in the manufacture of

~

this machine, and every care is taken to check all

parts. However, with time, deterioration of parts can

occur, especially with such components as hoses,

giving rise to leaks. Check the inlet hoses regularly

for signs of wear and tear. Change in good time to

avoid the risk of leaks and subsequent damage.

Local regulations regarding regular inspection and

~

maintenance of this machine must be observed. A

log book should be kept with the machine.

Gas-heated washer-extractors

Important After installation, maintenance, conversion,

repairs and before using for the first time it is

essential that a test for possible leakages is carried

out. All components which carry gas must be

checked, including the gas valve and burner jets.

Particular attention must be paid to the test nipple on

the gas valve.

Testing must be carried out with the burner switched

on and switched off.

Using the washer-extractor

This machine is not intended for use by people

~

reduced physical, sensory or mental capabilities, or

lack of experience and knowledge, unless they are

supervised whilst using it or have been shown how to

use it correctly by a person responsible for their

safety.

This machine is not a toy! To avoid the risk of

~

injury never allow children to play on or near the

machine, or to operate it themselves.

Remember that the porthole glass will be hot when

~

washing at very high temperatures. Do not let

children touch it.

Always close the door after use. This way you will

~

avoid the danger of:

–

children climbing onto or into the washer-extractor

or hiding things in it.

–

pets or other small animals climbing into it.

Always make sure that the drum is stationary

~

before reaching into the machine to remove laundry.

Reaching into a moving drum is extremely

dangerous.

If the washer-extractor is switched off and the

~

drum door is closed, you need to switch the machine

on before you can open the door.

If water comes out of the suds container when the

door is opened, close the door and switch the

washer-extractor on. Drain the water away before you

try and open the door.

It is the operator's responsiblity to ensure that the

~

standard of disinfection in thermal as well as chemo

thermal procedures is maintained (in accordance

with § 18 IFSG and national health and safety

regulations) by carrying out suitable validation tests.

These procedures should be checked on a regular

basis, either thermo-electrically using loggers, or

bacteriologically with bio indicators. The operator

must pay particular attention to maintaining the

correct parameters in the procedure, including

temperature and with chemo thermal programmes,

the chemical concentration used. Disinfection

programmes must not be interrupted, as this can

have a limiting effect on the disinfection result.

It is particularly important to observe

~

manufacturer's instructions when using a combination

of cleaning agents and special application products.

Only use the product for the application described by

the manufacturer, to avoid any material damage or

the occurrence of strong chemical reactions.

Confirm with the detergent manufacturer that their

product can be used in combination with another

type of product.

Only use dyes, colour run and dye removers

~

specified as being suitable for use in washing

machines. Always observe the manufacturer's

instructions carefully.

Laundry that was soiled with biological oils or fat

~

should be washed using a suitable detergent and /or

wash programme. It must also be inspected after

washing. If oils or fat are not sufficiently removed they

could cause the laundry to self ignite during the

drying process. This type of soiling should be

removed using specialist detergents and/or

programmes.

Do not use a pressure washer or hose to clean the

~

machine.

Take care in the area of the hinges of the drum

~

door. Danger of injury.

The drum door must be able to be opened to its

~

fullest extent. This area must not be restricted by

doors or structural features.

The water used for washing is a suds solution and

~

is not drinking water.

The suds solution must be drained away via an

appropriate drainage system.

The washer-extractor may only be operated

~

without supervision if there is a floor drain (gully) in

the immediate vacinity.

5

Page 6

Warning and Safety instructions

Further notes

Cleaning and disinfecting agents often contain

~

chlorine-based substances. Do not let such agents

dry out on stainless steel surfaces, as the chlorine

can have a corrosive effect. Use chlorine-free agents

for washing and disinfecting and also for cleaning

stainless steel surfaces to protect them from

corrosion.

If in doubt, confirm with the manufacturer that their

product is suitable. If any agent containing chlorine

comes into contact with the stainless steel surfaces,

wipe it away immediately with clean water. Then dry

with a soft cloth.

The manufacturer cannot be held liable for the

~

effect of a chemical cleaning agent on laundry or the

machine, even when the use of such agents is

recommended.

Please note that changes to the product which have

not been made known by the manufacturer can affect

the quality of the wash result.

Using accessories

Accessory parts may only be fitted when

~

expressly approved by Miele. Using spare parts or

accessories from other manufacturers will invalidate

the guarantee, and Miele cannot accept liability.

Anti-chlorine treatment

Anti-chlorine treatment has to be carried out

immediately after chlorine bleach has been used. The

use of hydrogen peroxide or an oxygen based

cleaning or bleaching agent is recommended and the

laundry should not be drained in between.

With thiosulfate, especially when used with hard

water, gypsum can form, which can lead to

incrustations on laundry or deposits in the machine.

The use of hydrogen peroxide is preferable as it aids

the chorline neutralising process.

The exact quantity of additives and the treatment

temperatures required must be set and tested on site

in accordance with the dosage recommendations of

the detergent and additive manufacturers. The

laundry must also be tested to check whether it

contains any active chlorine residues.

Disposing of your old machine

Before disposing of an old machine, first make the

~

door lock unusable. This way you will prevent

children from accidentally locking themselves in and

endangering their lives.

Any additional components used, e.g. suction

~

devices for liquid agents, electronic water meters or

dispenser monitors, must conform to Safety Class II.

If connected to an external PC, this must conform to

EN 60950-1:2001 (IEC 60950-1:2001).

Chlorine and component damage

Notes on using chlorine bleach and

perchlorethylene

Frequent use of chlorine increases the risk of

~

component damage.

The use of agents containing chlorine, such as

sodium hypochlorite and chlorine bleach in powder

form, can damage the protective upper surface of

stainless steel and cause corrosion to components.

Factors affecting this are chlorine concentration

levels, contact time and temperature. It is therefore

advisable to avoid the use of such agents. Oxygen

based bleaching agents should be used instead.

If, however, chlorine based bleaching agents have to

be used for particular types of soiling, then

anti-chlorine measures must also be carried out. If

this is not done irreparable damage can occur to

components in the machine and to laundry.

All personnel working with this machine must be

fully trained in all aspects of its use and safety.

Keep these instructions in a safe and accessible

place.

6

Page 7

Caring for the environment

Disposing of the packing material

The packaging is designed to protect the machine

during transportation. The materials used are

environmentally friendly for disposal.

Rather than just throwing these materials away,

please ensure that they are recycled.

Packaging materials such as plastic film and

,

bags must be kept out of the reach of babies and

children. Danger of suffocation.

Disposing of your old machine

Electrical and electronic machines often contain

materials which, if handled or disposed of incorrectly

could be potentially hazardous to human health and

to the environment. They are, however, essential for

the correct functioning of your machine. Please do

not dispose of your old it with your general waste.

Tips on saving energy

To save energy and water, try to load the maximum

for the programme selected. Underloading is

uneconomical. Overloading gives a poorer quality of

wash result and may cause unnecessary creasing.

Make sure that your laundry is thoroughly spun

before drying. This saves time and energy.

Carrying out the final rinse with hot water helps to

reduce the residual moisture level, and the residual

heat in the laundry will help keep processing time

down in the dryer, thus saving energy.

Follow detergent manufacturer's advice regarding the

right amount of detergent to use.

This will depend on the size of the load, the water

hardness level and the amount of soiling in the

laundry.

Chose the correct programme (with pre-wash or

intensive options selected) and the correct

temperature.

Please dispose of it at your local community waste

collection/recycling centre.

Please contact your dealer, your local waste

collection centre or scrap merchant about recycling

schemes.

Please store it out of the reach of children whilst

awaiting disposal.

7

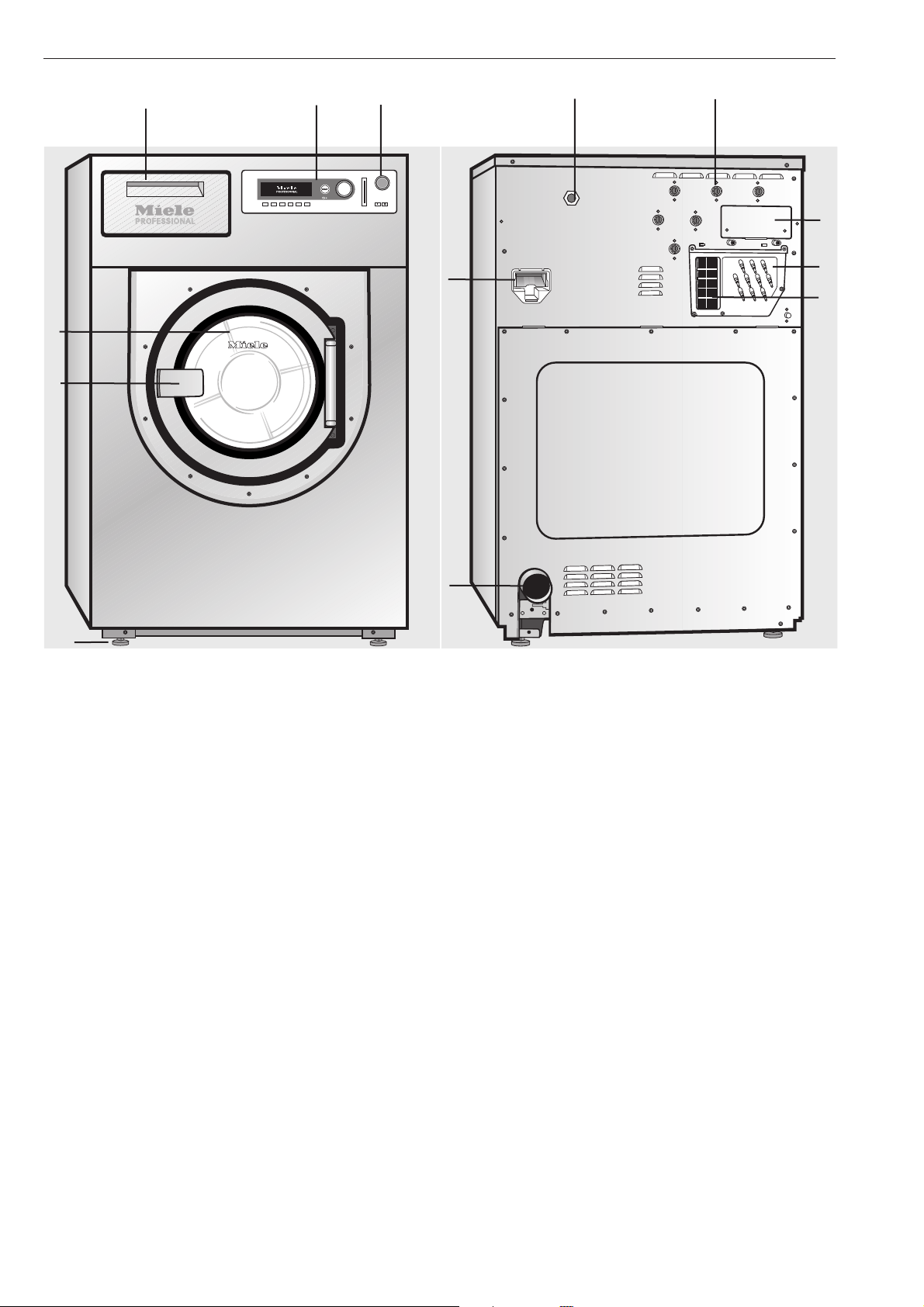

Page 8

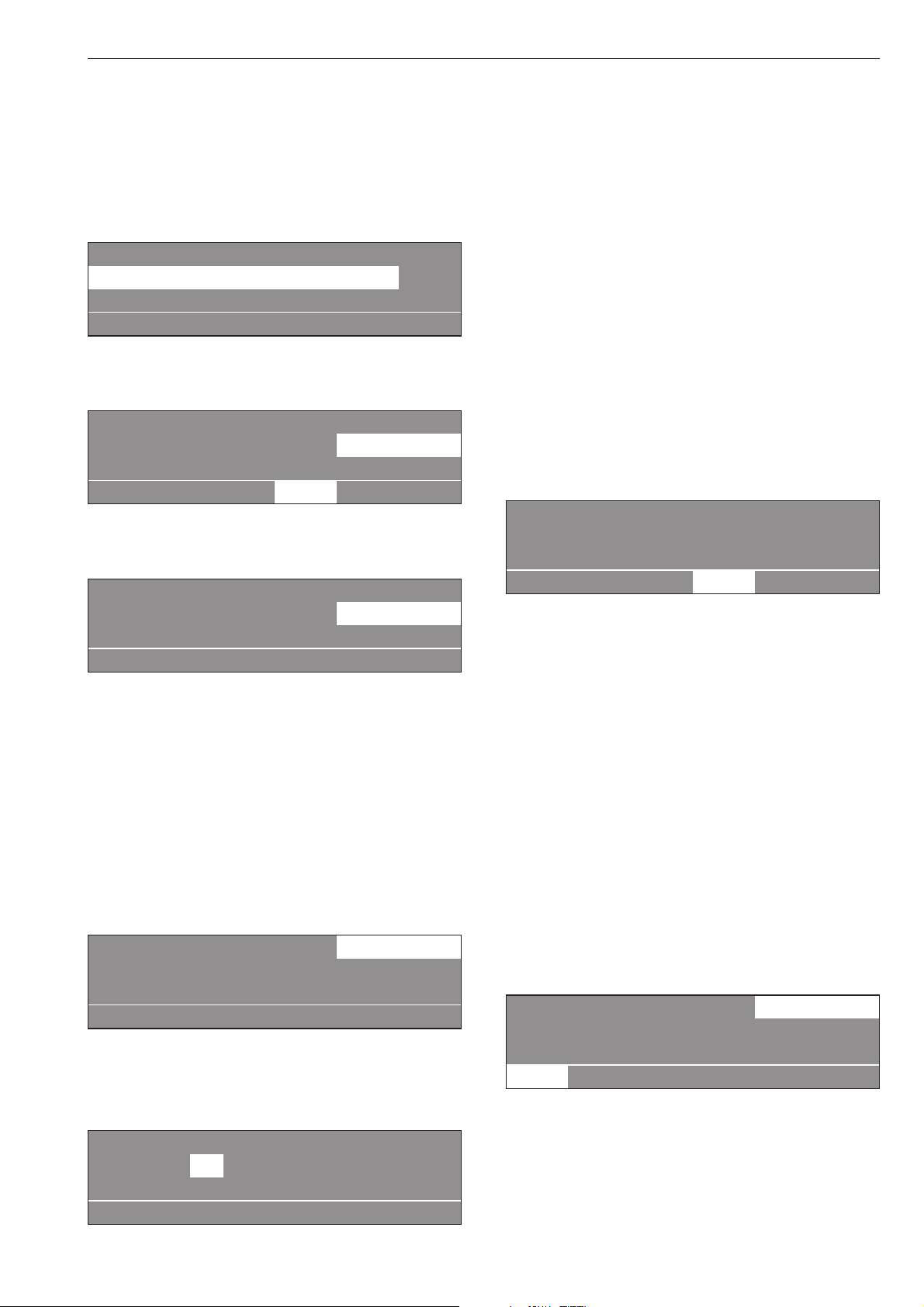

Description of the machine

d

e

c

b

a

j

g

h

i

l

m

f

a Emergency stop switch

Press the red button to switch the machine off.

b Control panel

c Detergent dispenser drawer

Pull the handle to open the compartment.

d Drum door

Pull the door handle to open the drum door. Do not

use force to open it.

e Door handle

The door handle is fitted with a safety device to

ensure that the door lock functions correctly (see

"Problem solving guide").

k

g Electrical connection

h Water inlet connections

i Water recycling connections

j Communication slot

k Water drainage

l Liquid agent dispensing connections

m Vapour extraction

See "Installation and connection"

f 4 adjustable screw feet

8

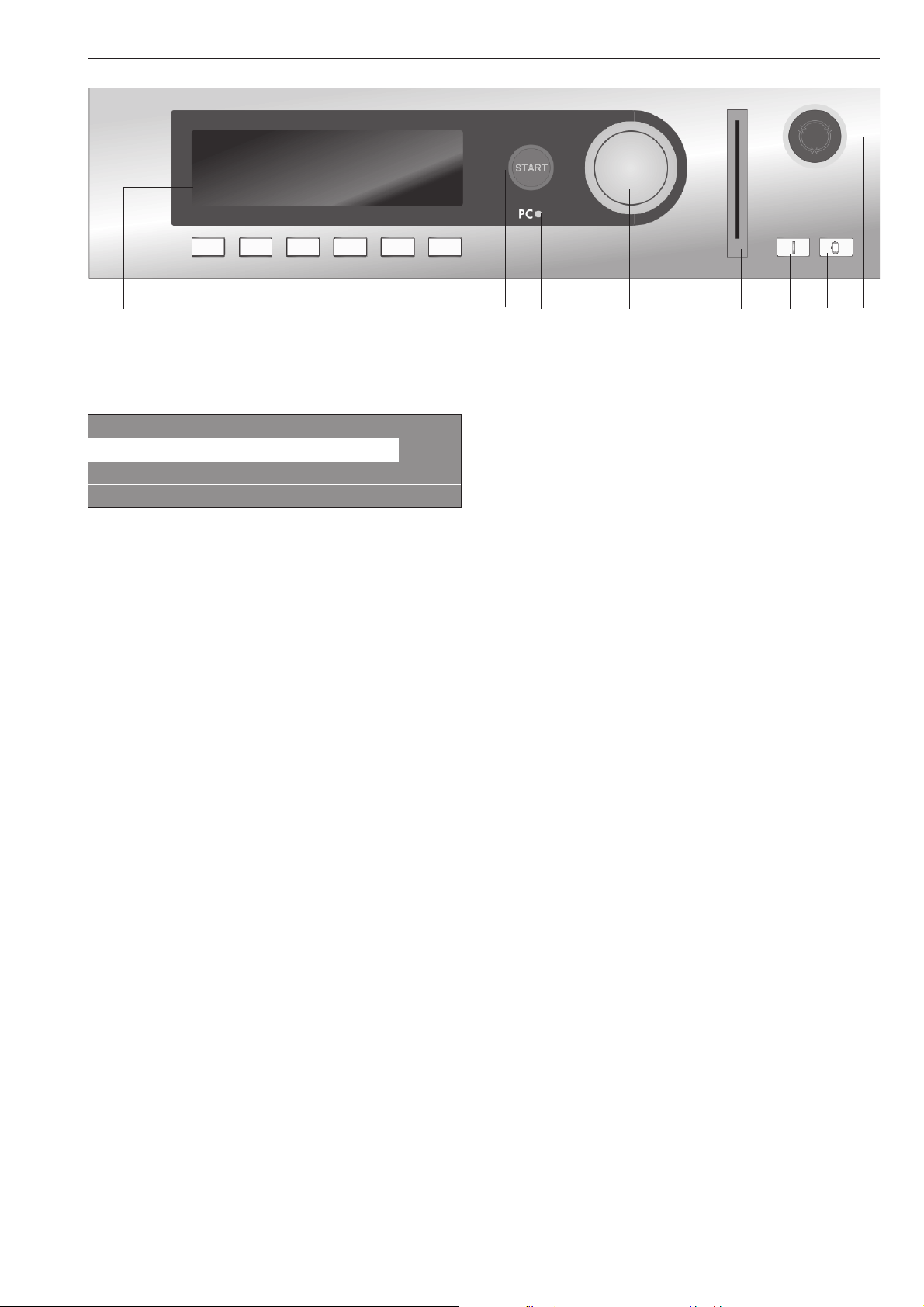

Page 9

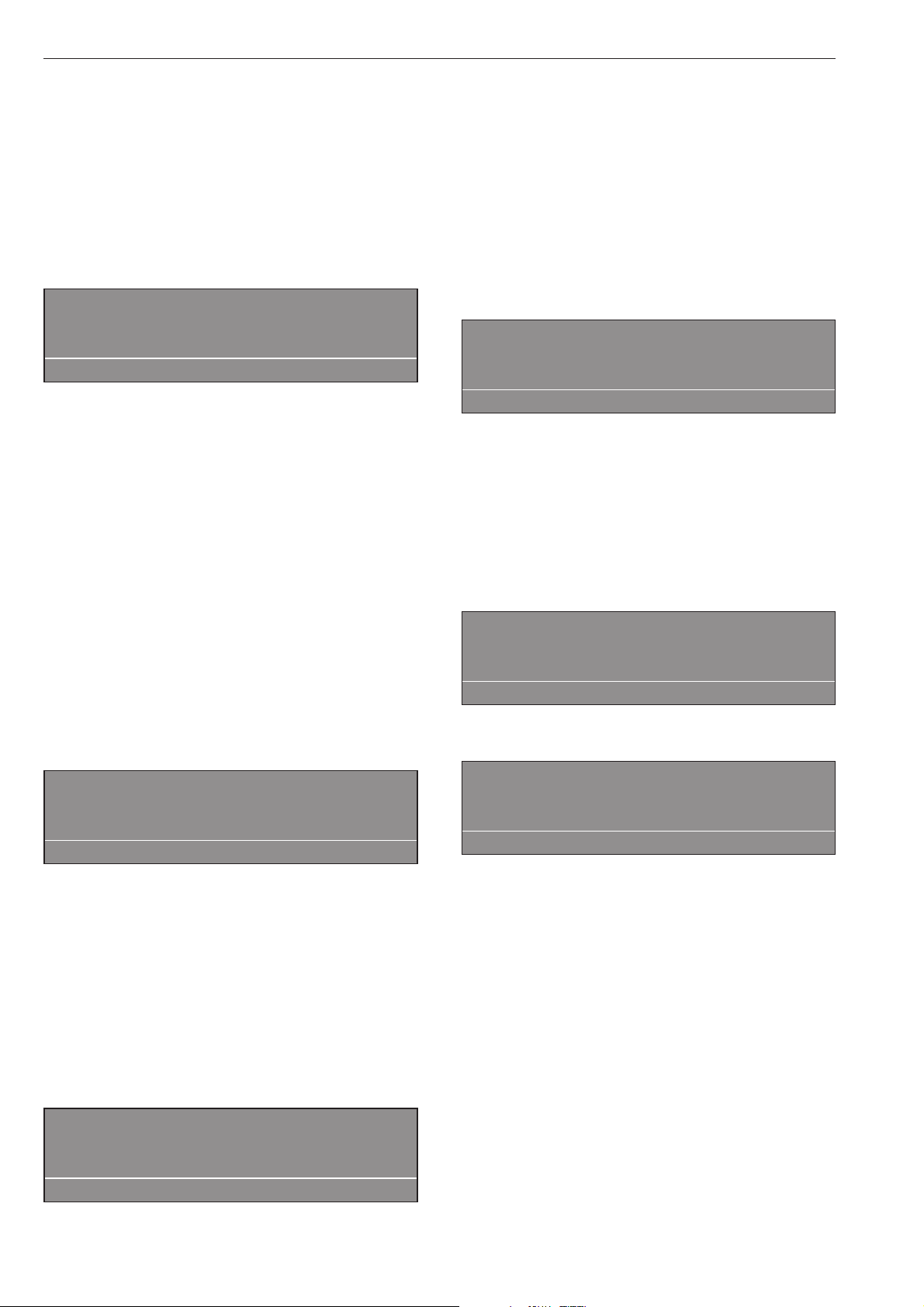

Description of the machine

a b c d e f g h i

Control elements

a Display

1 Cottons 90 °C

2 Cottons 60 °C

3 Cottons intensive 60 °C

i FC A

After switching on the "Welcome" display will appear

for a short time followed by the programme list. The

most recently used programme is highlighted.

b Function buttons

The six buttons underneath the display are the

function buttons. These buttons have specific

functions depending on the status of the machine.

These functions will be listed in the display above the

buttons and will be highlighted once selected.

If the machine is reprogrammed to "Direct button

allocation" the first 6 programmes listed in the display

can be selected directly via these buttons.

c START button

The lightring will flash when a selected programme

can be started. Pressing the Start button will start the

programme. After a programme has started, pressing

this button will show the display as it was before the

start of the programme.

d PC / Optical interface

This interface is used for transferring data to the

control unit from a PC and vice versa.

e Rotary selector

Turning the selector brings up options and menus in

the display.

Pressing the selector confirms your selection.

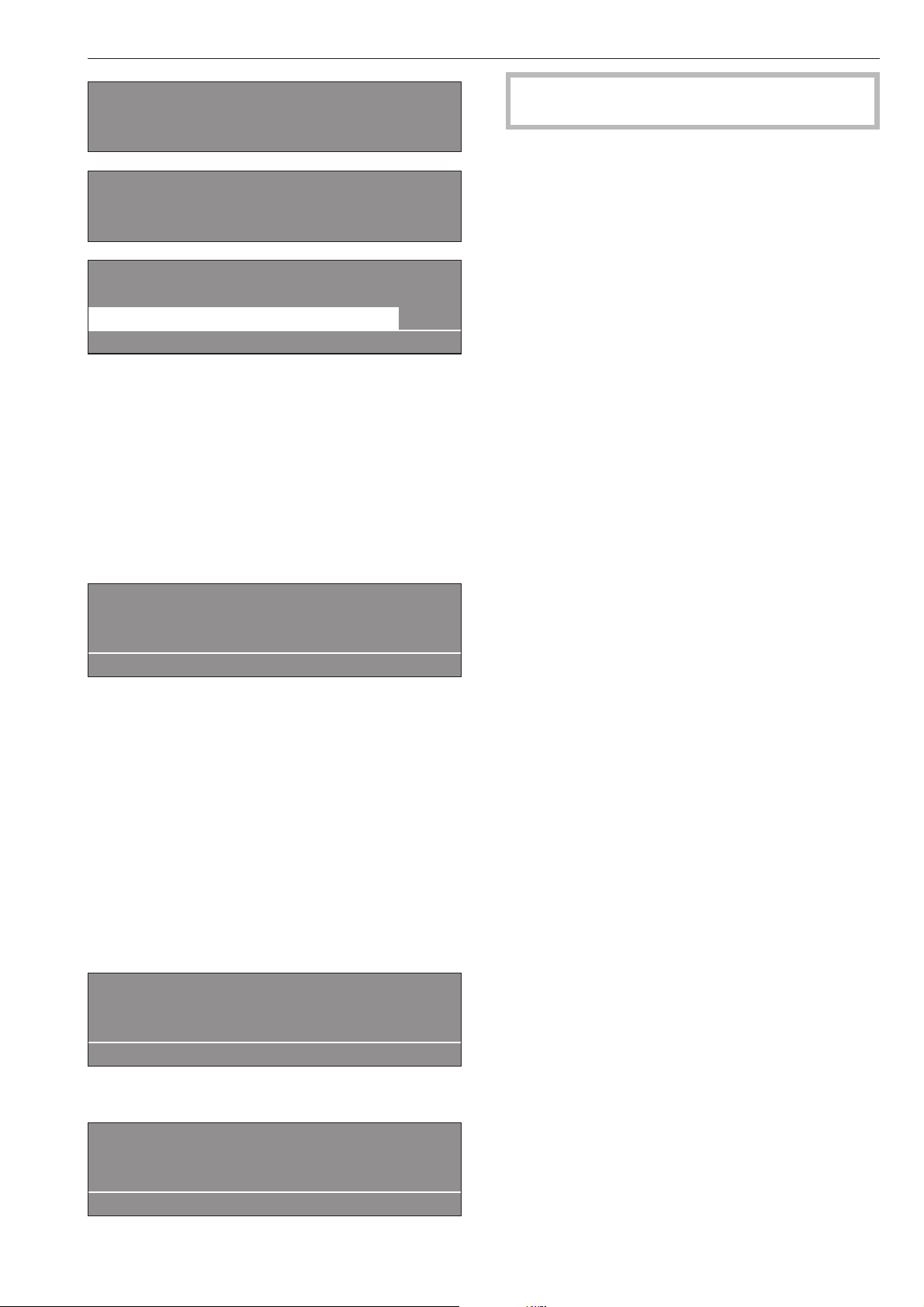

f Chip card reader

When a chip card is inserted, the programmes on the

chip card can be used.

Insert the card in the direction of the arrow (on the

card).

g I Mains on switch

Switches the machine on.

h 0 Mains off switch

Switches the machine off.

i Emergency stop switch

Only for use in an emergency.

Press the red button to switch the machine off. After

the problem has been resolved, turn the red dial

clockwise to release it. Then press the Start button to

continue the interrupted programme.

9

Page 10

Description of the machine

Function buttons

Pressing the button activates the function and

pressing the button again deactivates it.

f Stop/End

The function button on the right-hand side is used to

stop a programme after it has started.

Pressing it again finishes the programme.

+i Block plus

The relevant programme block (e.g. Pre-wash) is

added to the programme.

m Starch stop

Press this button if you wish to laundry to be

starched.

k Without spin

Press this button if you do not want the laundry to be

spun after being rinsed.

FC Settings

Press this button to switch to another language

temporarily.

m Start time

Press this button before the start of a programme to

display the message that a start time can be

selected.

Chip card operation

A chip card is available to order as an optional extra.

It is supplied without any programmes.

See the programming instruction booklet for

information on transferring data from the control unit

to the chip card and vice versa.

The chip card can store a maximum of 30

programmes, each with 6 blocks. The back of the

chip card can be labelled.

K Information

Press this button to call up programme information in

the display.

q Water drainage

i Manual control

See the programming instruction booklet.

ü Change order

The order of the programme in progress can be

changed or programme blocks can be repeated.

A Back

Takes you back to the previous display.

e/- Indicates more information on the

next / previous line

S Save

See the programming instruction booklet.

$ Programme locked

Once a locked programme has been started, the End

button can only be used to stop and cancel it during

the first minute.

) Programme unlocked

ß Dispensing

ä Dispensing switched off

\ Operating data

I < 0- Setting (calibration)

If the display does not show 00.0 when the drum is

empty press this button to reset it.

Data transfer

10

Page 11

How to wash correctly

The machine must be commissioned by a Miele

service technician or a dealer authorised by the

manufacturer before it is used for the first time. For

gas heated machines in the U.K. this must be

carried out by a Gas Safe registered technician.

Open the on-site stopcocks for water and

^

depending on the type of heating, gas or steam.

Switch on the on-site mains switch.

^

Press the "On" I switch to switch the machine on.

^

PROFESSIONAL

PW 6xx7

Welcome

A "Welcome" message will appear in the display.

1 Cottons 90 °C

2 Cottons 60 °C

3 Cottons intensive 60 °C

i äFC A

This is followed by the programme list (with the most

recently used programme highlighted).

Foreign objects (e.g. nails, coins, paper clips, etc.)

can cause damage to garments and components

in the machine.

Maximum loads for the standard

programmes

(Dry weight of laundry)

PW 6107 PW 6137 PW 6167 PW 6207

1 Cottons 90°C

2 Cottons 60°C

3 Cottons intensive 60°C

4 Cottons 30°C

5 Cottons intensive 30°C

6 Cottons Eco short

max. 10 kg max. 13 kg max. 16 kg max. 20 kg

7 Minimum iron 60°C

8 Minimum iron intensive 60°C

9 Minimum iron 30°C

10 Minimum iron intensive 30°C

max. 5 kg max. 6.6 kg max. 8 kg max. 10 kg

11 Delicates

12 Woollens 30°C

13 Handwashable woollens 30°C

max. 4 kg max. 5.2 kg max. 6.4 kg max. 8 kg

Turn the selector dial to highlight the programme you

want. The programme can be then started by simply

pressing the START button.

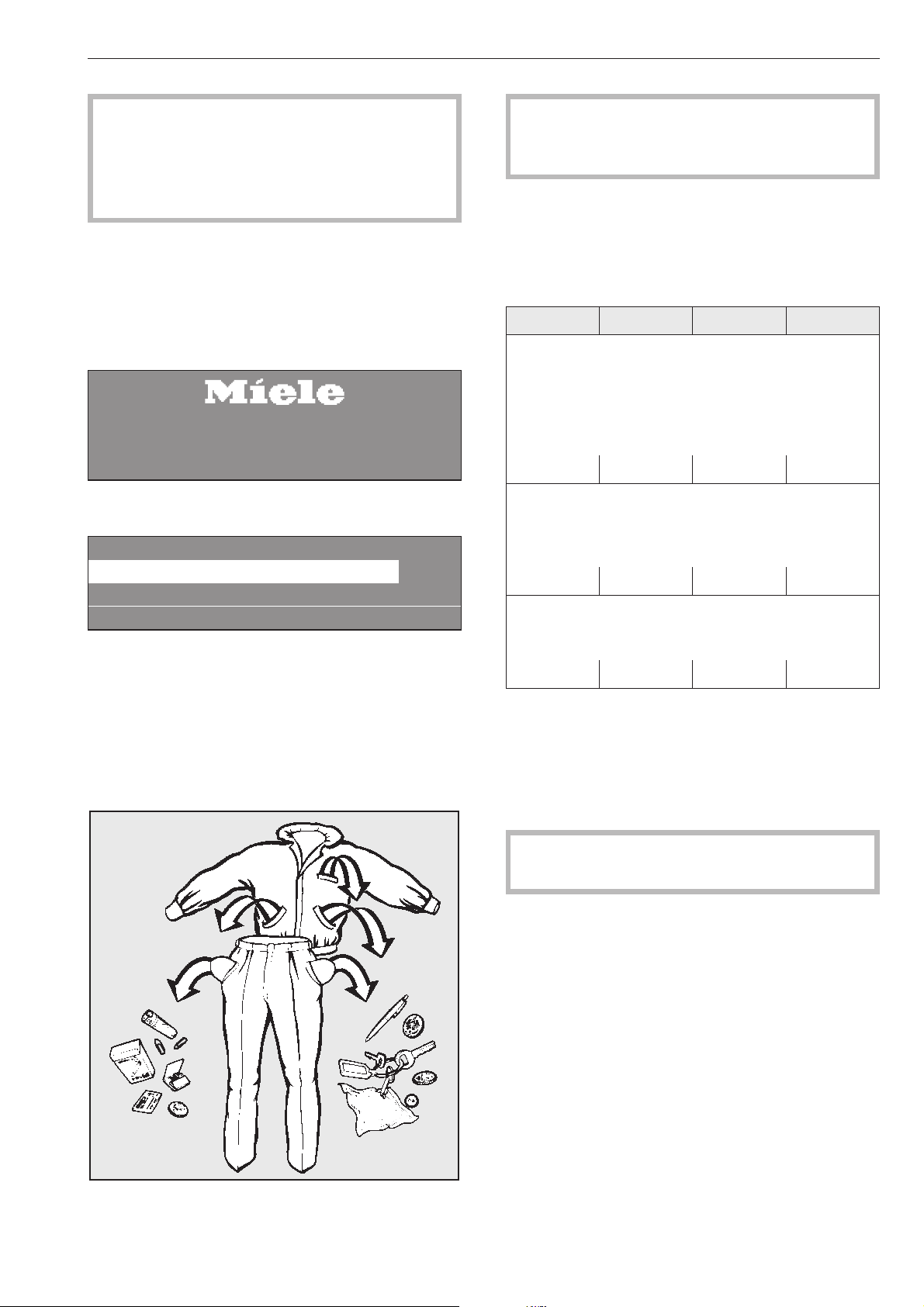

Sort the laundry

The maximum load for other programmes is given in

the relevant programme overview.

^

Load the laundry

^

Close the drum door with the door handle. Do not

slam it shut.

Make sure that no garments are caught between

the drum door and the drum opening.

^

Empty any pockets.

11

Page 12

How to wash correctly

Add detergent

With the standard programmes, place detergent for

^

the main wash in compartment j and if wished,

detergent for the Pre-wash in compartment i.

Place fabric conditioner in the front section of

compartment p

Bleaching agents

Only use bleaching agents on textiles with the x

symbol on the wash care label.

Liquid bleaching agents may only be placed in the

compartment designated for them. This is to ensure

that the agent is added automatically at the second

rinse. Liquid bleaching agents should only be used

with coloureds if the textile manufacturer's wash care

label states that the textile is colour fast and suitable

for bleaching.

^

Place other liquid washing additives, e.g. liquid

starch, in the rear section of the compartment p

(only if the machine has been programmed for this

function).

A 3rd rinse cycle must be programmed in if bleach

is to be used (see Profitronic programming

manual).

,

Frequent use of chlorine increases the risk of

component damage.

Only use dyes, colour run, dye removers and

descaling agents which are specified as being

suitable for use in washing machines. Always

observe the manufacturer's instructions carefully.

^

Do not exceed the level marker in compartment

p. Otherwise the agent will run through the siphon

into the suds container.

12

Page 13

How to wash correctly

Detergent dispensing

It is important to avoid adding too much detergent as

this causes excessive foam.

Do not use detergents which create a lot of foam.

–

Follow the detergent manufacturer's instructions for

–

use.

The right amount to dispense will depend on the

following:

The amount of laundry

–

The water hardness level

–

The soiling level of the laundry

–

The amount to dispense

Take the water hardness into account and follow the

detergent manufacturer's instructions on the

packaging.

Water hardness levels

Hardness

range

I soft 0 - 1.3 0 - 7

II medium 1.3 - 2.5 7 - 14

Water

properties

Hardness

level in

mmol/l

German

scale

°d

Select a programme

Turn the rotary dial to select a programme (e.g.

^

Programme 1 Cottons).

For this example, the following will appear in the

display:

16 Separate drain

1 Cottons 90 °C

2 Cottons 60 °C

i äFC A

Select the Pre-wash, Starch stop or Without spin

additional option

Confirm the selection of the programme by

^

pressing the rotary selector.

For this example, the following will appear in the

display:

1 Cottons 10.0 / 10.0 kg

90 °C Main wash

Rinses 1100 rpm

+im k m A

III hard 2.5 - 3.8 14 - 21

IV very hard above 3.8 above 21

Check with your local water supplier if you do not

know the hardness level in your area.

Gas heated machines

On gas heated machines the suds solution is

pumped around the heater elements. This additional

agitation of the suds solution creates foam. It is

therefore important to use a low-foaming detergent

and not to use too much detergent.

If over-foaming occurs use a reduced foam detergent

or call in a detergent application specialist.

^ If wished you can now select the Pre-wash

programme block, by pressing the +i function

button.

When the +i function button is pressed, the

following will appear in the display:

1 Cottons 10.0 / 10.0 kg

40 °C Pre-wash

90 °C Main wash 1100 rpm

+i mk m A

"+i" is highlighted.

Press the function button again to deselect the

function.

Press the m Starch stop button if the laundry is to

be starched.

Press the k Without spin button if you do not want

the laundry to be spun after being rinsed.

If you do not wish to make any further alterations to

the programme:

^

Press the START button. The programme will start.

13

Page 14

How to wash correctly

If you wish to make alterations before the start of

the programme, e.g. to the load size, temperature

or spin speed:

Load weight

You can enter the weight of the load manually before

the start of the programme.

1 Cottons 10.0 10.0 kg

40 °C Pre-wash

90 °C Main wash e

+im k m A

Turn the rotary dial until "Load" is highlighted. Press

^

the dial to confirm your selection. Turn the dial to

alter the weight and confirm your selection by

pressing it.

Temperature in 1 °C increments from cold, 15 to

max. 95 °C .

Turn the rotary dial to select the "Temperature" field

^

(40°C for pre-wash) and press it to confirm your

selection.

Once a programme has started the programme

sequence will appear in the display.

1 Cottons

40 °C Pre-wash 20 °C

Main wash Ready at 12:35

+im k mKf

In the 2nd line of the display, pre-wash in this

example, the actual suds temperature will also be

shown.

1 Cottons

90 °C Main wash 60 °C

Rinse 1 Cold Ready at 12:35

+im k mKf

Once the pre-wash programme block has finished

the programme block for the main wash will appear in

the 2nd line of the display together with the actual

suds temperature. Under that the following

programme block will be listed. Rinse 1 in this

example.

1 Cottons 10.0 / 10.0 kg

40 °C Pre-wash

90 °C Main wash e

+im k m A

^ Turn the rotary dial to alter the temperature value

and then press it to confirm your selection.

Spin speed in 25 rpm increments from 0, 300 to

maximum spin speed.

^

Turn the rotary dial to select the "Spin speed" field

(1100 rpm for the final spin) and press it to confirm

your selection.

1 Cottons 10.0 / 10.0 kg

90 °C Main wash

Rinses 1100 rpm

+im k m A

^

Turn the rotary dial to alter the spin speed and then

press it to confirm your selection.

Maximum spin speeds

PW 6107 PW 6137 PW 6167 PW 6207

The time that the programme will finish is shown on

the right hand side of the display.

1 Cottons

90 °C Main wash 60 °C

Rinse 1 Cold Ready at 12:35

+im k m K f

Pressing the K "Information" button will call up further

information about the programme e.g.:

1 Cottons

Start date and time: 10.7.2010

Start time: 9:47 e

A

Time after start: 0h 23 min

Time left: 0h 11min

Time after start: 0h 23 min e

Time left: 0h 11min

Repeat: No

Area 3: rinse e

1200 rpm 1100 rpm 1150 rpm 1100 rpm

^

Press the START button. The programme will start.

14

Page 15

Block 2: Rinse 2

Block step: Wash time 1

Actual level: 22 mm e

Rqrd. level: 60 mm

Actual temperature: 35 °C

Rqrd. temperature: 60 °C e

How to wash correctly

The machine door is locked. Never use force

,

to try and open the door.

Press the q "Water drainage" function button or

^

select the Separate spin programme and press the

START button.

Open the door at the end of the programme.

1 Cottons

Spin speed: 40 rpm

Rhythm: 12 / 3 -

A

Press the A "Back" button to return to the

^

programme sequence display.

Open the door at the end of the

programme

The following message will appear in the display at

the end of the programme as long as there is no

water in the machine and the drum is stationary:

1 Cottons

Programme finished

The door can be opened.

m FC A

At the same time an acoustic buzzer will sound for 5

seconds to let you know that the programme has

finished.

If no more laundry is to be processed:

Switch the machine off by pressing the "Off" 0

^

button and then switch off at the on-site mains

switch.

Close all stopcocks for water, gas and steam as

^

applicable.

^

Pull the door handle to open the drum door.

Important: If the door will not open press against it

and then pull on the handle again. Do not use force

to open it.

^

Unload the drum.

If the programme was interrupted with water in the

drum, or if the programme was stopped, for example,

during the spin the following message will appear in

the display:

1 Cottons

Programme finished. Water in the drum.

qmFC A

or

1 Cottons

Programme finished. Drum still rotating.

m FC A

15

Page 16

Card operation

Cards on which a programme has been saved can

only be used on the machine type for which they

have been written. Unwritten cards can be used

universally.

Press the "On" I button to switch the machine on.

^

The Welcome screen will appear.

If the card is inserted the wrong way round the

following message will appear in the display:

Card fault

§

Insert the card the right way round in the card

^

reader.

If the card is not the right one for the machine it is

being used in the following message will appear in

the display:

Card contents

Programmes on the card are

only suitable for machine type PW 6161.

Insert the correct card for the machine in the card

^

reader.

Card incorrectly inserted in card reader.

A

A

^ Insert the card in the reader.

The programmes listed on the card will appear in the

display.

Card operation

17 Masks 45 °C

18 Minimum iron 60 °C

i ßFC A

^

Use the rotary dial to highlight the programme you

want to use. Press the rotary dial to select the

programme you have highlighted.

^

Press the START button. The programme will start.

After pressing the START button you can remove the

card from the reader. The programme is deleted from

the machine's memory once it has finished.

,

Never insert any other type of card or object

into the card reader!

Card access operation

Programmes requiring special procedures are written

on to a card which is then used to run the

programme.

"Card access" has to be activated via the supervisor

level in the machine.

The machine will then only run programmes by using

a card (on which one programme has been saved).

Programmes in the machine's control unit cannot then

be accessed.

16

Page 17

Additional options

Language selection

The language shown in the display can be changed

briefly before starting a programme if you wish. To do

so use the button underneath the flag symbol.

The language will revert back to the default setting 5

minutes after the end of a programme with the door

open.

1 Cottons 90 °C

2 Cottons 60 °C

3 Cottons intensive 60 °C

i FC A

If you press the FC button the following will appear

in the display:

Settings Back <Main menu Language

Supervisor level

FC A

Press the rotary dial to confirm your selection of the

^

"Language" menu.

Settings deutsch

Language F english (GB)

español

FC A

^ Turn the rotary dial to highlight the language you

want and then press the dial to confirm your

selection.

Start date and time

If you want a programme to start at a later time use

the m button for "Start date and time".

The actual time and date will then appear. The input

field for hours will be highlighted.

Press the rotary dial to change the hour.

^

Turn the rotary dial to alter the hour and then press

it to confirm your selection.

Then turn the rotary dial to select the "Minutes" field

^

and press it to confirm your selection.

Turn the dial to alter the minutes and then press it

to confirm your selection.

Then turn the rotary dial to select the "Start date"

^

field and press it to confirm your selection.

Turn the dial to alter the date and then press it to

confirm your selection.

Do the same for the month and the year.

^

After setting the required start date and time:

Press the START button and the programme

^

selected will commence at the time specified.

The display will now contain the following information:

1 Cottons 10.0 / 16.0 kg

90 °C Main wash

16:15 -2.4.2010 Start 6:00 -3.4.2010

+im k m A

The current time and date as well as the start time will

be displayed.

^ If the door is opened again you will have to press

the START button again.

To cancel the start time and date function

Press the m "Start date and time" button again or

press the A"Back", and any changes will be

rejected.

With pre-wash

To set a date and time

After selecting your programme, e.g. Cottons in the

example here, the following will appear in the display:

1 Cottons 10.0 / 16.0 kg

90 °C Main wash

Rinses 1000 rpm

+im k m A

^

Press the m "Start date and time" button.

The following (example) will appear in the display:

1 Cottons 10.0 /16.0 kg

Start time: 16 : 10 Start date: 2.4.2010

After selection press the start button

A

For heavily soiled laundry the standard programmes

1 to 10, can have a pre-wash added. To do so press

the "Block+" button i.

Pressing the button again deselects the option.

When the "Blockplus" + i button is pressed, the

following will appear in the display:

1 Cottons 14.0 / 16.0 kg

40 °C Pre-wash

Main wash e

+i mk m A

The "+i" field will be highlighted in the display.

17

Page 18

Additional options

Starch

Starching via the dispenser drawer

Starch can be selected with all the standard

programmes (except for Separate spin and Separate

drain) before starting a programme by selecting the

m "Starch stop" option.

The m field will be highlighted in the display.

Pressing the button again deselects the option.

1 Cottons

Prog. stopped. Starch stop pressed.

The door can be opened.

i ü f

Once the "Starch stop" programme stage is reached

the words "Starch stop" will start flashing in the

display.

Make up the starch solution following the

manufacturer's instructions on the packaging and

then add it to the front section of compartment p.If

necessary dilute the starch with water. The wash time

is automatically increased by 4 minutes.

Press the START button to continue the programme.

m

Once the "Without spin" programme stage is reached

the words "Without spin" will start flashing in the

display.

To finish the programme without spinning and with

water left in the drum press the f button.

To continue with a spin press the START button.

Programme stop

To halt the programme press the f button.

The programme remains stationary.

1 Cottons

Programme stop

i ü f

To continue the programme press the START button.

Programme cancellation

Press the f button twice in succession to cancel a

programme.

If there is still water in the machine or if it was

cancelled during spinning the following (example) will

appear in the display:

Dispensing directly into the drum

Make the starch up following the manufacturer's

instructions on the packaging. Once the "Starch stop"

programme stage has been reached open the door

and add the starch. Close the drum door

The following message will appear in the display

again:

1 Cottons

Prog. stopped. Starch stop pressed.

The door can be opened.

i ü f

Press the START button and the programme selected

will commence

m

Without spin

"Without spin" can be selected with all the standard

programmes (except for Separate spin) before

starting a programme by selecting the k "Without

spin" option.

The k field will be highlighted in the display.

1 Cottons

Programme finished. Water in the drum.

i ü f

or:

1 Cottons

Programme stopped. Drum rotating.

i ü f

To open the door press the q "Water drainage"

button or select the Separate spin programme and

press the START button.

Pressing the button again deselects the option.

1 Cottons

Prog. stopped. Without spin pressed.

i ü f

18

k

Page 19

Additional options

Programme cancelled with a locked

programme

It is not possible to stop or cancel a programme if the

programme is locked.

1 Cottons

90 °C Main wash

Locked Ready at 12:35

)f

The display will show that the machine is locked if

you try to cancel the programme with the f button.

To cancel the programme you will first have to select

the ) "Unlocked" function and then enter a

password to unlock the programme.

After entering the password the following will show in

the display:

Unlock programme?

S A

Press the S "Save" button to return to the normal

display and the programme can now be cancelled.

Changing the programme order

The order of the programme in progress can be

changed or programme blocks can be repeated.

Press the f button and the programme will stop.

^

1 Cottons

Programme stop

i ü f

After pressing the ü button the current area,

^

block or step will appear in the display.

See also "Programme structure" in the Progamming

Manual.

Reorganise -> Cottons

Area 2: Main wash e

S A

Area: 2 Main wash

Block 1: Main wash

Step: Wash time 2 -

S A

1 Cottons

90 °C Main wash 60 °C

Rinse 1 Ready at 12:35

mKf

^ Turn the rotary dial to alter the area and then press

it to confirm your selection. Area: Select 1

Pre-wash, 2 Main wash or 3 Rinses and confirm

your selection.

^ Turn the rotary dial to alter the block and then

press it to confirm your selection. Block: Select

Pre-wash 1-10, Main wash 1-10 or Rinses 1-10 and

confirm your selection.

^

Turn the rotary dial to alter the step and then press

it to confirm your selection. Select the required

programme step and confirm your selection.

^

Press the S "Save" button and then press START to

reorganise the programme order or press the A

"Back" button to override the programme stop and

not change the programme order.

19

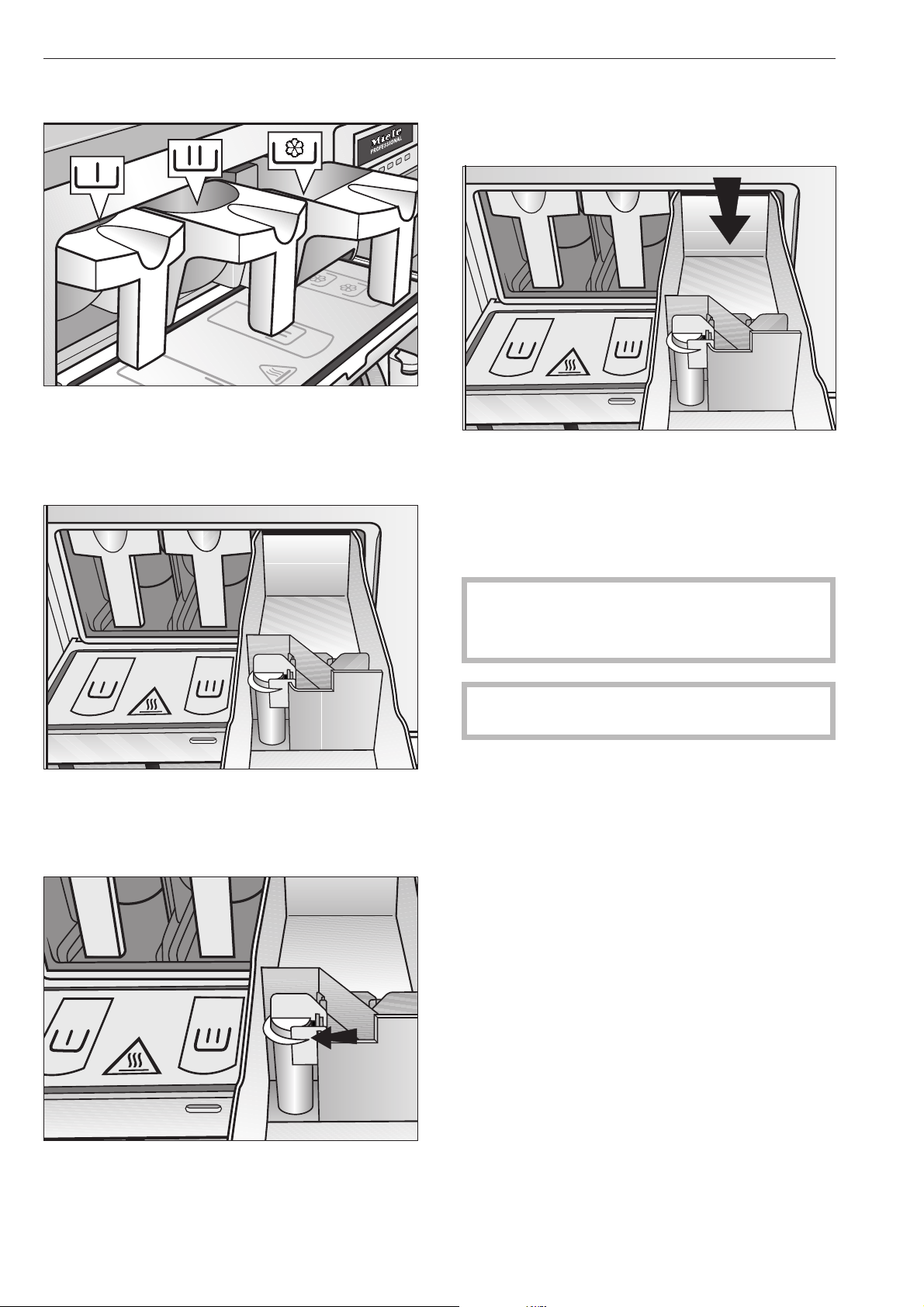

Page 20

Optional modules

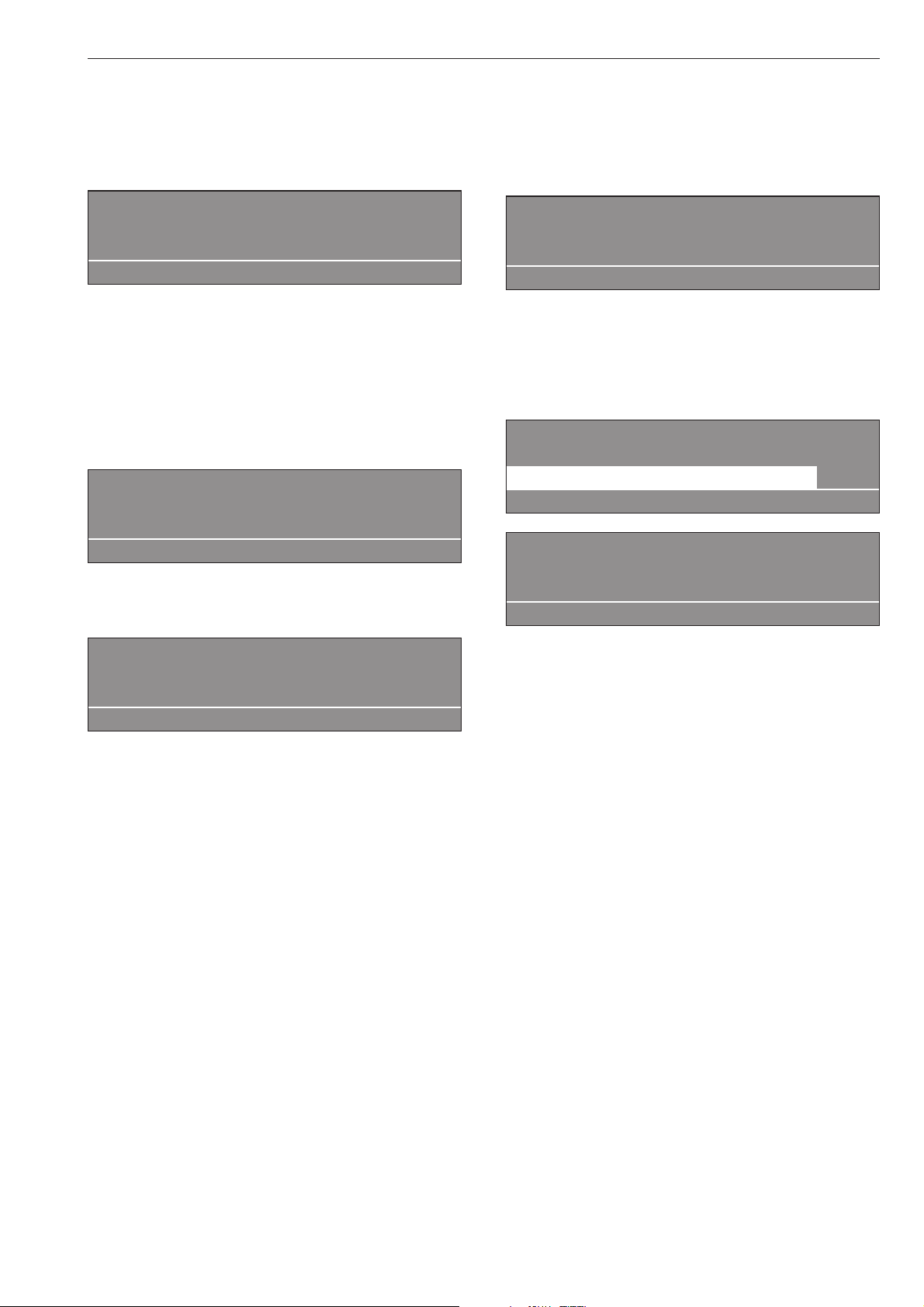

Liquid dispensers

Dispenser pump Suction pipe

a

c

b

To deselect the liquid dispensing system

1 Cottons 90 °C

2 Cottons 60 °C

3 Cottons intensive 60 °C

i ä FC A

You can switch off the liquid dispensing system

manually before starting a programme by setting the

ä "Dispensing" system to off.

Once the programme has started dispensing will not

take place via the dispenser pumps and the following

will appear in the display:

1 Cottons 10.0/10.0 kg ä

90 °C Main wash

Rinses 1000 rpm

+im k m A

Dispensing amount

d

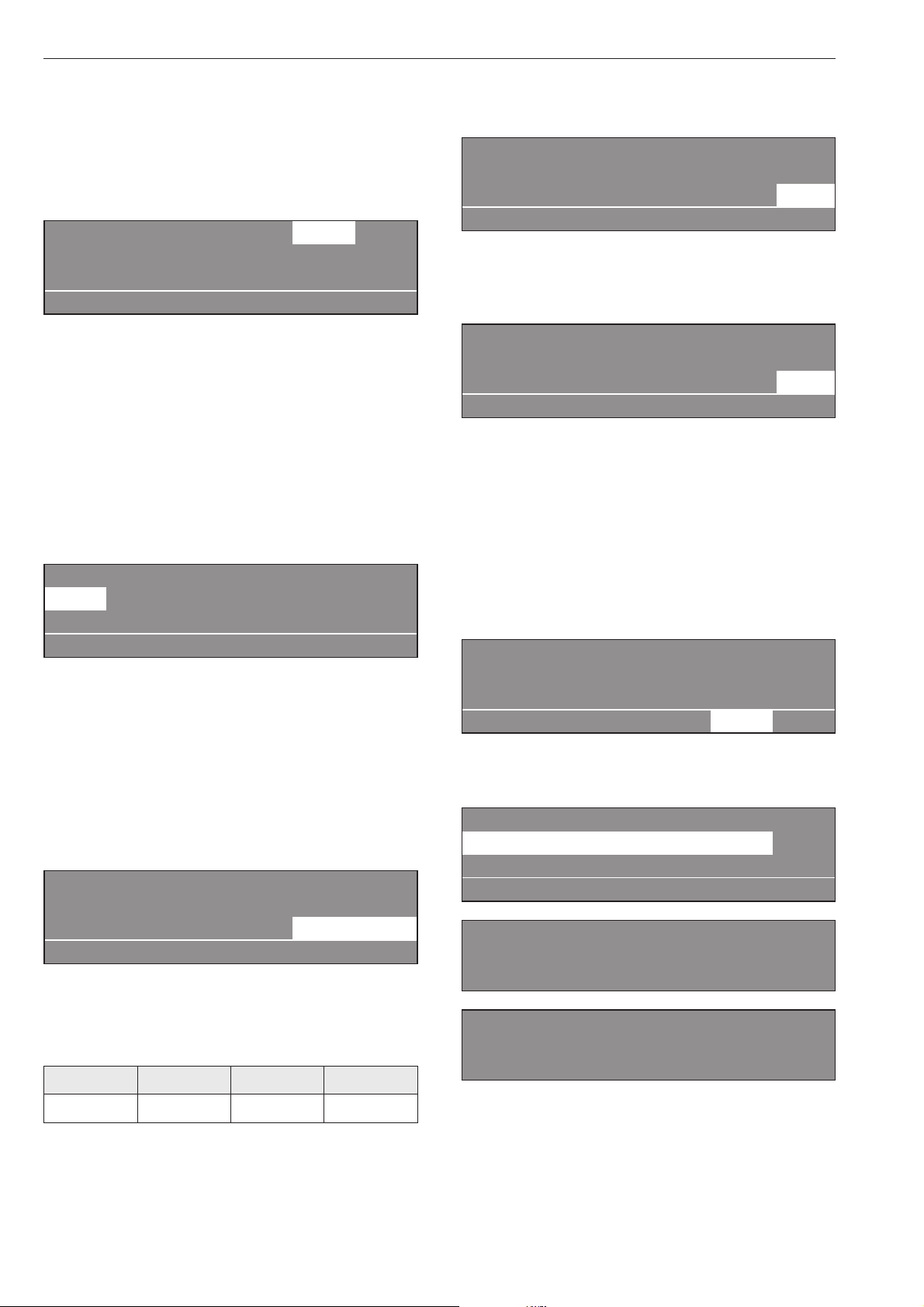

a Hose connection socket (suction side)

b Hose connection socket (pressure side)

c Leakage outlet (in case of damaged hose)

d Suction inlet

e Level checker for empty indicator. The pump and

the machine will switch off automatically if a liquid

agent container is empty.

e

Dispensing system fault

ö

The machine will warn you that the liquid dispensing

agent level is insufficient.

The programme can be restarted after refilling the

liquid agent container by pressing the START button.

Fill dispenser 1

Press the start button

if

Please follow the manufacturer's instructions on the

packaging for dispensing requirements.

,This is particularly important when using a

combination of cleaning agents and special

application products. Only use the product for the

application described by the manufacturer, to

avoid any material damage or the occurrence of

strong chemical reactions. Confirm with the

detergent manufacturer that their product can be

used in combination with another type of product.

Liquid agents should be allowed to settle to room

temperature before use to ensure that their viscosity

level is correct and thus ensure the correct amount is

dispensed.

20

Page 21

Commissioning the dispensing pumps

Before the liquid dispensing pumps can be used the

liquid agent must be drawn up into the system and

the amount to be dispensed set.

Dispenser calibration

Optional modules

Dispenser calibration ~ Main menu

Dispenser pump 1

Dispenser pump 2 e

A

The dispensers need to be calibrated to ensure the

dispenser pumps supply the correct amount of liquid

agent.

To calibrate the dispensers with the machine

switched off:

Press and hold the rotary dial in.

^

Then switch the machine on with the "On" switch.

^

Dispenser calibration ~ Main menu

Dispenser pump 1

Dispenser pump 2 e

A

Selection choice: Dispenser pumps 1 to 13

After selecting a dispenser pump the following

message will appear in the display:

Dispenser calibration ~ Dispenser pump 1

V: 100ml t: 0s P: no

0/1 S A

The amount to dispense can be set between 0 and

9999 ml in 1 ml increments.

Select dispenser pump.

^

Dispenser calibration ~ Dispenser pump 1

V: 100ml t: 0s P: no

0/1 S A

Press multi-function button 0/1.

^

To stop the pump press the 0/1 button again, or it

will switch off automatically after a period of 60

seconds.

Measure the amount collected in the measuring

^

flask.

Dispenser calibration ~ Dispenser pump 1

V: 100ml t: 30s P: 200.0 ml/min

0/1 S A

^ Enter this value in field "V:". Flow rate P in ml/min

will be calculated electronically.

^ Press the S "Save" button to save the values

measured in memory.

^ Reconnect the hose.

^

Press the 0/1 multi-function button and the

dispenser hose will start to fill. Press the 0/1 button

again to stop filling the hose.

^

Direct the hose of the dispenser pump being

calibrated into a suitable measuring flask.

,

Avoid contact with the skin and eyes, and

wear suitable protective clothing.

^

Press the A "Back" button to return to the main

menu.

Cleaning and maintaining the dispensing system

The dispensing system should be flushed through

with clean warm water every two weeks and before

any longer down-times to prevent the risk of

blockages and corrosion.

^

The suction pipes should be cleaned through with

water.

^

Place the suction pipes in a container of hot water

(40 - 50°C).

^

Then use the dispenser calibration system to

operate each pump until the dispensing system is

thoroughly flushed through.

^

After reconnecting all parts check all connections,

hoses, dispensers and seals for leakages.

21

Page 22

Optional modules

Peak load cut-out

If the peak-load cut out function is activated the

heating will switch itself off and any programme

running will be stopped. The following message will

appear in the display:

- Total data (only delete total data)

- Programme data (only delete programme data)

Pressing the button again deselects the \

"Operating data" option.

If there is no more memory available in the operating

1 Cottons

Prog. stopped. Peak load cut-out.

Programme will continue

if

data module a message will appear after pressing

the START button to say that the operating data will

be overwritten.

If you press the A "Back" button or do not press the

START button within 30 seconds the display will

Once the peak load has finished the programme will

continue automatically as before.

revert to the way it was before starting the

programme.

Total data

Communication module

This machine can be linked to a PC via a

communication module.

The shaft for the communication module is located at

Operating data module

Total data

Programme data e

\ A

the rear of the machine.

After selecting Total data the following (example) will

appear in the display:

An editor programme is available from Miele.

Operating data module ~ Total data

Total time power on: 200,987 h

Operating data

By pressing the \ "Operating data" button the

Operating hours: 123456 h e

\ A

operating data module can be used to read or delete

operating data either before the start of a

Other options:

programme, or after it has finished.

Total time power on: 200,987 h

Operating hours: 123,456 h

Duration heating active: 123,456 h

1 Cottons 90 °C

2 Cottons 60 °C

3 Cottons intensive 60 °C

i \ FC A

Duration drive motor active: 93,456 h

Programme starts: 23,456

Programme stops: 567

Programme cancellations: 67

Water volume: 1,234,567 l

Amount of laundry: 1,234,567 kg

After pressing the \ button the following will appear

in the display:

Liquid agent: 2,345 l

Energy: 12,345,678 kWh

Operating data module

Total data

Programme data e

\ A

Selection choice:

–

Total data

In this option all programme data is collated and

summarised.

–

Programme data

Programme data contains all the data called up

during a programme.

–

Delete data

- Module (Total data including programme data)

22

Page 23

Optional modules

Programme data

Operating data module -

Programme data

Delete data e

\ A

After selecting Programme data the following

(example) will appear in the display:

Operating data module~ Programme data

1 Cottons 90 °C

2 Cottons 60 °C e

\ A

Select the programme you want from the list and

press the rotary dial to call up a list of all programme

starts including date and start time for that

programme.

Programme data ~ 1 Cottons

Date: 21.05.2010 Start time: 11:30

Date: 21.05.2010 Start time: 12:30 e

\ A

Select the required programme start from the list for

programme 1 Cottons and confirm your choice by

pressing the rotary dial.

Programme data ~ 1 Cottons

Date: 21.05.2010

Name: Smith e

\ A

Other options:

Town: Abingdon

Serial number: 12345678

Machine type: PW 6107

Amount of laundry: 13 kg

+ Button: Activated

Starch stop button: Activated

Without spin button: Not activated

Programme start: 11:30

Programme finished: 12:05

Total operating time:0h35min

Electrical energy: 12.5 kWh

Gas energy: 0 kWh

Steam energy: 0 kWh

Total volume of water: 140 l

Max. water temperature: 95 °C

Max. drain temperature: 45 °C

Programme change: 2

pressing the rotary dial only the last 3 stops and starts will

be displayed.)

(after making your selection and

Programme fault: None (only the last 3 faults are saved.)

Area 1: Pre-wash (after making your selection and

pressing the rotary dial you can display the area or the

block.)

Operating time: 6 min

Water volume: 20 l

Dispensing phase 1: Amount ml

selection and pressing the rotary dial 6 dispensings are

displayed.)

(after making your

Max. temperature: 12 °C

Holding time: 6 min

Dispensing phase 2: No

Delete data

Operating data module

Programme data

Delete data e

\ A

After selecting Delete data the following message will

appear in the display:

Operating data module~ Delete data

Module: 21.02.2010

Total data: 12.07.2010 e

\ A

The module menu option can be used to delete the

total data and programme data from the operating

data memory.

The total data option can only be used to delete the

total data from the operating data.

The programme data option can only be used to

delete programme data from the operating data.

After making your selection and pressing the rotary

dial you will be prompted to enter your password.

Password:____

ABCDEFGHIJKLMNOPQRSTUVWXYZ

0123456789

KSA

After keying in your password or inserting your

supervisor level key card in the reader the following

security prompt will appear in the display:

Delete operating data?

S A

After pressing the S button the data will be deleted!

23

Page 24

Optional modules

Weighing system

If the machine has been equipped with a weighing

system module the weight of the laundry in the

machine will be displayed in 0.2 kg increments. The

maximum load for the programme selected will show

next to the actual weight in the drum.

If when the drum is empty the load display is not

showing "00,0", you will need to press the ->I<-"to

reset it

1 Cottons 00,0/ 16.0 kg

60 °C Main wash

Rinses e

+im k m ->I<- A

If after calibrating the sensor to 0 there was still

laundry in the drum the following will appear in the

display:

1 Cottons - -,- / 16.0 kg

60 °C Main wash

Rinses e

+im k m ->I<- A

Press the ->I<-button again to set it to 0.

If there is too much laundry in the drum, e.g. because

it is wet, a nominal load will be calculated after

starting the programme and this value will also be

saved by the operating data module.

At the end of the programme when the drum has

stopped rotating the display will show the residual

moisture content of the laundry.

1 Cottons

Programme finished Residual moisture 60 %

The door can be opened

m FC A

24

Page 25

Problem solving guide

The door will not open

Press against the door handle and at the same time

^

switch the machine off and then on again. Then try

to open the door again.

If you still cannot open the door:

The door handle safety mechanism has disingaged

itself. The door handle cannot be opened or closed.

The safety mechanism is designed to protect the

handle and the lock from damage, for instance, if

too much force is being used in an attempt to

open the door.

With an extended power cut:

Switch the machine off.

^

Switch off the mains supply at the on-site mains

^

switch.

Close all stopcocks for water, gas and steam as

^

applicable.

To remove the laundry the drain valve will need to be

opened manually and the drum door unlocked

manually.

^ Open the drain valve by partially opening the

venting screw (spanner size 17 mm) at the rear of

the machine. Do not unscrew it completely. Drain

off the suds. Take care as some water will seep out

of the screw opening (approx. 100 mm). This

should be collected in a suitable container.

^

Press firmly against the door handle until you

clearly hear the safety mechanism engage.

You will now be able to open and close the door

again (as long as there is no water in the machine).

Power cut during a wash programme Emergency door release

With a short power cut:

The programme remains in the last position, and

when power is restored the following message

appears in the display:

Power cut

y

Programme stop

Press the start button.

i ü f

^ Tighten up the venting screw again and check that

there is no leak.

^

Insert a screwdriver (head approx. 4 mm) into the

opening beside the door lock so that the head

engages with the notch of the door release

mechanism. Turning the screwdriver slightly

anti-clockwise will unlock the door.

Never use force to open the door!

^

Remove the laundry

^

Press the START button and the programme

selected will continue.

25

Page 26

Problem solving guide

Possible reasons for increased levels of

foaming

Detergent type

–

Only use detergents formulated for commercial

^

washer-extractors. Domestic laundry detergents

are not suitable.

Using too much detergent

–

Follow the manufacturer's dosage

^

recommendations on the packaging and take local

water hardness levels into account.

Heavy foaming detergent

–

Use a low foaming detergent or contact your

^

detergent supplier for advice.

Very soft water

–

In areas with very soft water (hardness level 1)

^

dispense less detergent as specified by the

detergent manufacturer.

Soiling level of the laundry

–

For lightly soiled laundry dispense less detergent in

^

accordance with the detergent manufacturer's

instructions.

Large articles of laundry stretching

during the spin cycle

Large articles of laundry (e.g. table cloths) can

stretch during the spin cycle. This can generally be

prevented by reprogramming the machine.

Please contact the Miele Service Department.

Service interval

If after switching the machine on the following

message appears in the display the machine will

need to be serviced by the Miele Service

Department.

Service interval 1

§

The display will go out after 5 minutes.

Call the Service Department

A

– Residues e.g. detergent on the laundry

^ Run a pre-wash without detergent and without

selecting a temperature.

Laundry which has been soaked before washing

must be thoroughly rinsed before running a wash

programme.

– Small loads

^ Reduce the amount of detergent dispensed

according to the size of the load.

–

Drum speed too high during the wash

(Profitronic controls)

^

Reduce the drum speed and the wash rhythm.

–

Gas-heated washer-extractors

On gas heated machines the suds solution is

pumped around the heater elements. This additional

movement of the suds can produce extra foam.

^

Follow the dispensing instructions given above.

^

Use a low lather detergent.

^

On Profitronic controlled machines and in special

circumstances it is possible to reduce the drum

speed and the wash rhythm during the heating-up

phase.

26

Page 27

Error messages

Repairs to electrical, gas or steam operated

,

machines may only be carried out by a suitably

qualified person in accordance with national and

local safety regulations. In the U.K. repairs to gas

heated machines must only be carried out by a

Gas Safe registered technician.

A message will appear in the display if there is a

problem either before starting a programme or once it

has started:

The display remains dark.

There is no power to the machine.

Check the mains switch and the on-site fuses.

^

Problem solving guide

Heating system fault

§

Programme stopped. Press start.

Programme will continue without heat.

if

To continue the programme with heating press the

^

START button. If a disinfection programme was

running the programme will be cancelled if this

message appears.

Call the Service Department.

Drive motor fault

m

Allow the motor to cool down.

^

Programme stopped. Press the start button.

Motor overheating.

if

Power cut

y

Programme stop

Press the start button.

f

^ Once power has been restored press the START

button.

This error message can also indicate that the winding

on the motor has overheated.

^

Allow the motor to cool down.

§

The imbalance is too great and the imbalance switch

has been activated.

^ Switch the machine off and on again. Then press

the START button.

Imbalance fault

Call the Service Department

if restart does not work.

i A

Gas system fault

Water inlet fault

M

Call the Service Department

if restart does not work.

if

^

Check the stopcock and then press the START

button.

§

If this message appears before a programme has

been started:

^

Open the gas tap and then press the START

button.

Open the gas tap.

Press the start button.

if

Door lock fault

a

Call the Service Department

if restart does not work.

if

^

Push firmly on the door handle until you hear the

lock engaging. Confirm by pressing START.

If this message appears during a programme the

pressure in the gas supply has dropped because of

other gas heated appliances operating at the same

time.

^

Press the START button.

27

Page 28

Problem solving guide

After sales service

Gas system fault

§

Call the Service Department

if restart does not work.

if

If the programme still will not start please call the

^

Service Department.

Gas system fault

§

Clean the lint filter as described in "Cleaning and

care" and then press the START button.

On gas heated machines heavy foaming can lead to

a fault.

Clean the lint filter.

Press the start button.

if

In the event of any faults please contact your Dealer

or the nearest Service Department.

When contacting the Service Department, please

quote the Model, Serial number (SN) and Material

number (M.Nr) of your machine. These are shown on

the data plate.

This is visible above the door aperture or at the back

of the machine.

Please let the Service Department know any error

message that has appeared in the display.

Should you require spare parts ensure that you only

use original Miele Spare Parts (and remember to let

the Spare Parts Department know the model, serial

number and material number of your machine).

Drain valve fault

q

Call the Service Department

if restart does not work.

if

^ Check the on-site drainage system and then press

the START button.

A defective drain valve must be repaired by a Miele

Service technician only.

Dispensing system fault

ö

Replace the empty container with a full one.

§

Fill dispenser 1

Press the start button

if

Card fault

Card incorrectly inserted in card reader.

if

^

Insert the card the right way round in the card

reader.

28

Page 29

The machine should be cleaned and checked over

immediately after use where possible.

Do not use a pressure washer or hose to clean

,

the machine.

The housing, control panel and any plastic

components should be cleaned using a suitable mild

cleaning agent, applied with a soft damp cloth. Rub

dry with a soft cloth after cleaning.

Do not use abrasive cleaning agents as they will

damage the surface material.

Parts of the housing made from stainless steel can be

cleaned using a suitable proprietary stainless steel

cleaning agent.

Any deposits on the door seals should be wiped off

using a damp cloth.

Cleaning and care

Pull the detergent dispenser flap out to a 45° angle to

allow cleaning of the drip channel and the siphons. If

a siphon is blocked a bottle brush can be used.

The grille over the cooling fan at the back of the

machine should be checked for soiling from time to

time and cleaned if necessary.

Clean the detergent dispenser, dispenser

compartments and siphons

The detergent dispenser, dispenser compartments

and siphons must be cleaned after each use with

warm water to thoroughly remove any residues of

detergents or other agents. If the machine is not

going to be used for a while the detergent dispenser

should be left open to air the compartment. The

siphon in the dispenser compartment for fabric

conditioner should also be cleaned.

Remove the siphon and clean with hot water. Then

put it back in place.

Superficial rust

The drum and suds container are manufactured from

rust free stainless steel.

Water with a very high iron content, or foreign objects

such as paper clips, metal buttons etc. which get into

the drum with the laundry can cause superficial

rusting in the drum and suds container.

To prevent this happening the drum and suds

container should be checked and cleaned regularly

and if rusting does occur it should be removed using

a proprietary cleaning agent for stainless steel.

The door seals should be checked for foreign objects

regularly and cleaned as described above.

Leave the door ajar after cleaning to allow the

machine to dry.

29

Page 30

Cleaning and care

The filters in the water inlet valve (1) and in the inlet

hoses (2) should be checked from time to time for

soiling and cleaned if necessary.

Clean the filter as follows:

Place a suitable 2 litre capacity container below the

^

filter.

Turn the lid a half to a full turn anti-clockwise to

^

open the filter.

Any water in the filter housing will then drain out.

Warning - the water may be hot.

When the machine is not in use

If the machine is not going to be used for a longer

period of time (4 weeks or more) the drum should be

rotated several times after the last use. The drum

should then be rotated every 4 weeks to prevent

damage to the bearings.

Cleaning the filter

This only applies to gas heated machines

The filter should be checked regularly for and

cleaned when necessary.

,

Carry out this check only after a programme

has finished and the suds container has been

emptied.

A blocked filter is indicated by a flashing fault

message in the display.

Gas system fault

§

Clean the filter.

Press the start button.

if

^ Empty the dish and repeat as many times as is

necessary.

^

When no more water runs out, unscrew the lid

completely. The filter is attached to the lid.

^

Clean the filter and the inner housing of the filter

compartment.

^

Replace the filter and tighten the lid making sure it

is secure.

30

Page 31

Cleaning and care

Drum bearings (PW 6167, PW 6207)

Once the service interval has been reached the

following message will appear in the display:

Lubricate drum bearings

§

Press the A"Back" button to get rid of the message

in the display. This message will appear in the

display each time you switch the machine on until the

service work has been carried out by the Miele

service technician.

,

Call the Service Department.

A

Disconnect the machine from the mains.

When the machine is not in use

If the machine is not going to be used for a longer

period of time (4 weeks or more) the drum bearings

should be lubricated (PW 6167, PW 6207) as

described above and the drum rotated a few turns.

The drum should then be rotated again every 4

weeks to prevent damage to the bearings.

The grease nipples on the drum bearings need to be

lubricated after approx. 1000 operating hours with

Arcanol L 100.

Gas-heated washer-extractors.

31

Page 32

Installation and connection

This machine must be installed by an authorised

technician only. In the UK any gas heated

machines must be installed by a Gas Safe

registered engineer.

This machine is not designed for washing

,

items which have been treated with dangerous or

flammable substances.

To avoid the risk of frost damage do not install this

machine in a room where there is a risk of frost

occurring.

Use a pallet lifter to move the machine around the

room.

Transport packaging must be carefully removed

using suitable tools.

Use a suitable lifting mechanism to lift the machine off

the transport pallet.

Do not install the machine on carpeted flooring as the

carpet pile can hinder the free flow of air into the

ventilation gaps at the bottom of the machine.

Securing the machine

Gas heated washer-extractors must be secured to

the floor. Fixings are supplied with the machine.

Installation on a plinth

The washer-extractor can be installed on a plinth or a

raised concrete plinth.

The plinth must be secured to the floor.

Concrete plinth / Floor Miele plinth

To ensure suitable access for future maintenance and

service work, please ensure that the minimum

distances between the machine and the wall

specified on the installation diagram are strictly

observed.

Minimum distance to wall for maintenance and

service work: approx. 400 mm

The washer-extractor must be perfectly level to

ensure that it functions correctly.

The screw feet can be adjusted to align it.

The machine must not be moved without all the

outer panels in place.

32

Page 33

Transit fittings

The transit fittings, 2 at the front and 2 at the back are

each secured in position with 3 hex screws. These

have to be removed on-site before the machine can

be commissioned.

Installation and connection

To do so the front panel and the rear panel of the

machine have to be removed. Unscrew the screws

from the bottom edge of the front panel and then take

the front panel off.

Unscrew the screws from the back panel and then

take the back panel off.

Store the transit fittings in a safe place for future

use. They will need to be refitted should the

machine ever be moved to another location.

33

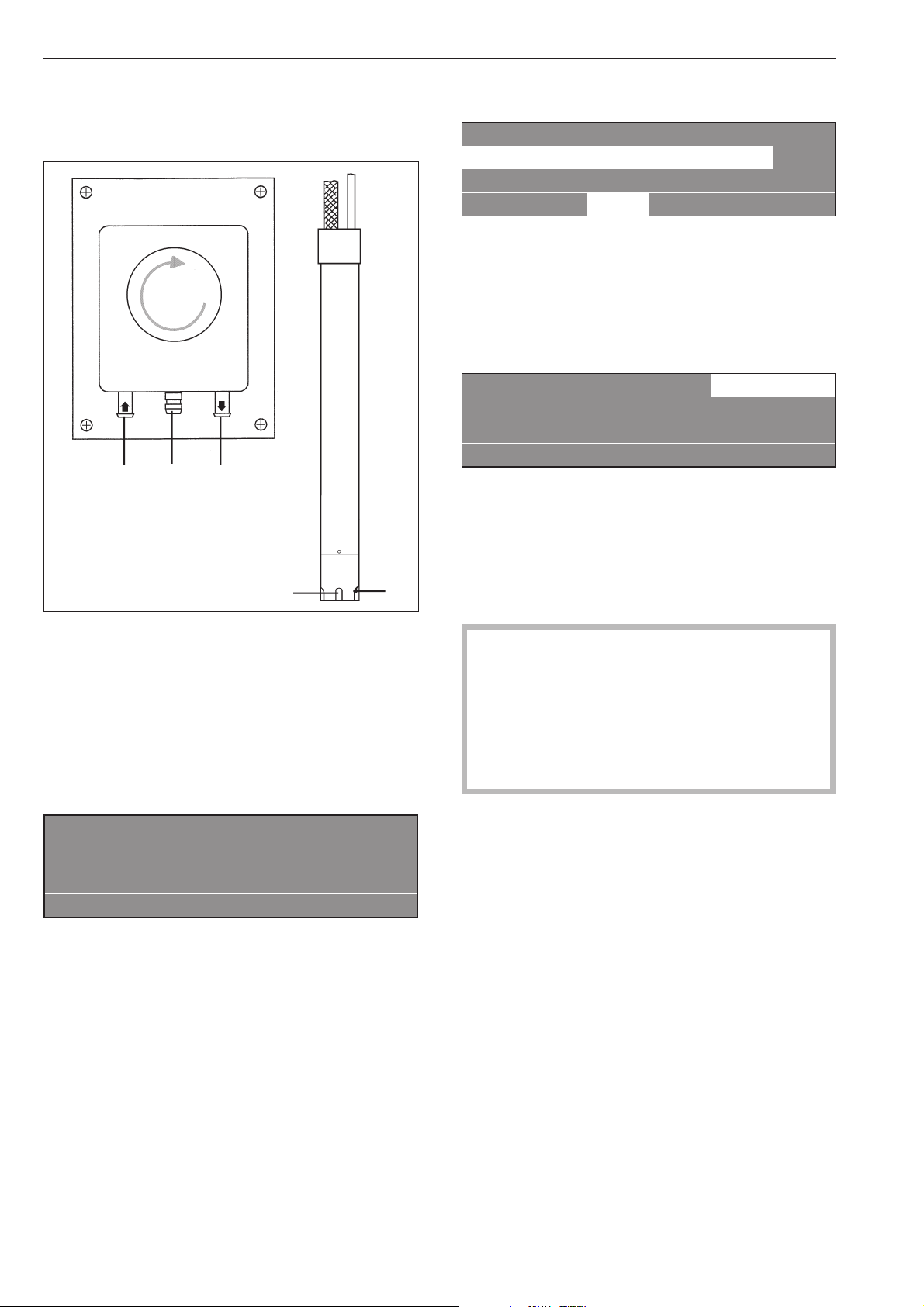

Page 34

Installation and connection

On-site connections

WW Hot water

KW Cold water

KWHHot and cold hard water

EL Electrical connection

AG Exhaust gas (gas heated machines)

G Gas connection (gas heated machines)

AV Drain

D Steam connection (steam heated machines)

K Condensate drain (steam heated machines)

Plumbing connections on the machine

Cold water Hot water Cold water

Hard water Liquid dispensers Hard water

Plumbing

Connection must be made to the water supply via a

stopcock which conforms to local and national

regulations. This work must be carried out by an

authorised person in strict accordance with local and

national regulations.

Water inlet / drainage

To ensure trouble free operation of the machine, the

flow pressure must be at least 100 kPa (1 bar) and

not exceed 1000 kPa (10 bar).

The inlet pressure tested hoses supplied with the

machine must be used for connection to the water

supply.

If replacing an inlet hose only use a hose tested to at

least 7000 kPa (70 bar) pressure, and for a water

temperature of at least 90 °C.

This also applies to all fittings. Genuine Miele original

parts fulfil these requirements.

Water taken into the machine must not exceed a

temperature of 70°C.

34

Page 35

Installation and connection

Cold water supply

1"

3/4"

A Y-piece connnector is supplied with the machine.

Liquid agent dispensing mixing box

connections

Connections 1 and 2 are for viscous agents only.

These connections are sealed and have to be drilled

open with an 8 mm drill bit.

Be careful to only drill through the first wall (1). There

is a second one located 10 mm behind it (2) to

deflect the agent and this must not be drilled into.

Any connections that have been drilled open must be

resealed if they are subsequently not required.

Connections 3 to 12 are for liquid agents only. These

connections are also sealed and have to trimmed to

the correct diameter for the hoses being used with a

suitable small saw.

Any connections that have been opened must be