Page 1

Installationsplan / Installation plan

Installatietekening

Plan d`installation

Piano di installazione

Plano de instalación

Plano de instalação

Σχέδιο εγκατάστασης

Asennusohje

Installasjonsplan

Installationsplan

G

PM 1421 EL

Materialnummer / Mat. no.: 06 797 580

Änderungsstand / Version: 02

Datum Zeichnung / Drawing date: 29.03.2006

Datum Legende / Legend date: 29.03.2006

Page 2

Page 3

Page 4

Page 5

Page 6

Technical Datasheet

Flatwork ironers:

Heating:

PM 1421

Electric (EL)

Legend:

Circled, bold-type abbreviations:

Connection required

Abbreviations surrounded by broken circle:

Connection optional or required, depending on model

G

Optional extras:

BWR

Return feed kit Optional equipment to return ironed laundry to the front of the

machine for single-person operation.

Machine connections:

Electrical

connection

Fuse rating A 3 × 50

Supply lead (H 07 RN-F), min. cross-section mm² 5 × 10

with threaded cable connector M 40 x 1.5

1. Standard voltage (as supplied) V 3N AC 380-415

Frequency Hz 50 (60)

Rated load kW 23.7

Switched plug and socket connection in accordance with IEC

On-site vent connection (interior diameter) mm 75

Max. temperature °C 90

As relative humidity can be as high as 100%, suitable

If the machine fan is unable to transport air over the on-site

Machine connection (d

60309 and IEC 60947 recommended to facilitate electrical

safety tests.

Install mains isolator according to IEC 60947 on hard-wired

connection.

Wall socket or mains isolator must be accessible after

installation.

The use of an earth leakage circuit breaker (ELCB) is strongly

recommended.

If necessary, equipotential bonding with good galvanic contact

must be provided in accordance with all appropriate national

and local regulations.

For installation of supply lead in plasterwork Conduit

Nominal air throughput in vented mode m³/h 160 Vented

Permissible pressure attenuation Pa 100

measures must be taken to prevent a backflow of condensate

into the machine.

vent ducting distance, an additional fan with a suitable

capacity must be installed either in the ducting or at the point

of discharge to atmosphere.

× s × l) [DN 70] mm 75 × 2.0 × 58

ext

Sufficient air intake should be available to replace displaced

volume of air.

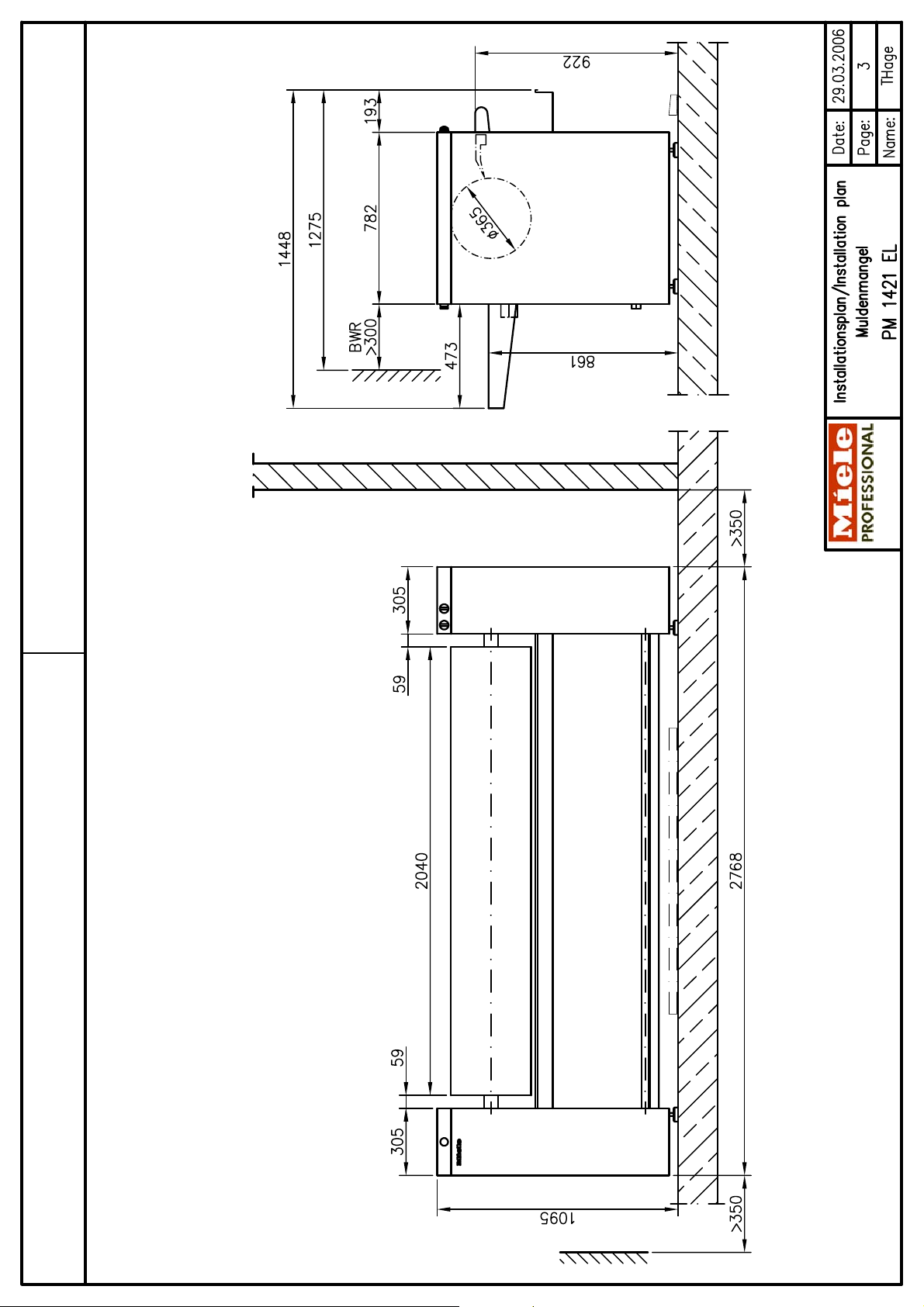

Installationsplan PM 1421 EL

Stand: 29.03.2006 Seite 6

Page 7

Floor bolts Fittings (supplied)

4 × rawl plugs (Ø × length) mm 10 × 50

Machine must be bolted to the floor!

Fixing materials for floating screed floor to be provided on site

Machine data Width mm 2768

Depth mm 1448

Height mm 1095

Min. access width to installation site mm 953

Minimum side wall gap mm 350

Minimum rear wall gap (when using BWR kit) mm 300

Net weight kg 441

Dynamic floor load, max. N 4571

Average heat dissipation

Acoustic power level (re1 pW) dB (A) not yet available

Sound pressure level dB (A) < 70

(measured at a distance of 1 m from the machine and at a

Installation should only be carried out by authorised fitters in accordance with valid regulations!

Observe installation instructions when installing machine! All rights reserved! Measurements in mm

4 × screws DIN 571 (Ø × length) mm 8 × 50

4 × safety claws

W 3800

(dependent on ambient room temperature and throughput)

height of 1.6 m)

Installationsplan PM 1421 EL

Stand: 29.03.2006 Seite 7

Loading...

Loading...