Installation plan

Vented dryer

PDR 507 EL

It is essential to read the operating and installation instructions before installation

and commissioning.

This prevents both personal injury and damage to the appliance.

en-GB

11 277 080/04

2 11 277 080/04

United Kingdom

Miele Co. Ltd.

Fairacres, Marcham Road

Abingdon, Oxon, OX14 1TW

Professional Sales, Tel.: 0845 365 6608

E-mail: professional@miele.co.uk

Website: www.miele.co.uk/professional

South Africa

Miele (Pty) Ltd

63 Peter Place, Bryanston 2194

P.O. Box 69434, Bryanston 2021

Tel.: (011) 875 9000, Fax: (011) 875 9035

E-mail: info@miele.co.za

Website: www.miele.co.za

Australia

Miele Australia Pty. Ltd.

ACN 005 635 398

ABN 96 005 635 398

1 Gilbert Park Drive, Knoxfield, VIC 3180

Tel.: 1300 731 411

Website: www.miele-professional.com.au

E-mail: info@miele-professional.com.au

New Zealand Miele

New Zealand Limited

IRD 98 463 631

Level 2, 10 College Hill

Freemans Bay, Auckland 1011, NZ

Tel.: 0800 464 353

Website: www.miele-professional.com.au

E-mail: info@miele-professional.com.au

United Arab Emirates

Miele Appliances Ltd.

Showroom 1, Eiffel 1 Building

Sheikh Zayed Road, Umm Al Sheif

P.O. Box 114782 - Dubai

Tel. +971 4 3044 999, Fax. +971 4 3418 852

800-MIELE (64353)

E-mail: info@miele.ae

Website: www.miele.ae

Singapore

Miele Pte. Ltd.

163 Penang Road

# 04–03 Winsland House II

Singapore 238463

Tel.: +65 6735 1191, Fax: +65 6735 1161

E-mail: info@miele.com.sg

Website: www.miele.sg

Malaysia

Miele Sdn Bhd

Suite 12–2, Level 12

Menara Sapura Kencana Petroleum

Solaris Dutamas No. 1, Jalan Dutamas 1

50480 Kuala Lumpur, Malaysia

Tel.: +603-6209-0288

Fax: +603-6205-3768

India

Miele India Pvt. Ltd.

Ground Floor, Copia Corporate Suites

Plot No. 9, Jasola

New Delhi – 110025

Tel.: 011-46 900 000, Fax: 011-46 900 001

E-mail: customercare@miele.in

Website: www.miele.in

Ireland

Miele Ireland Ltd.

2024 Bianconi Avenue

Citywest Business Campus, Dublin 24

Tel.: (01) 461 07 10, Fax: (01) 461 07 97

E-mail: info@miele.ie

Website: www.miele.ie

Miele (Hong Kong) Limited

41/F–4101, Manhattan Place

23 Wang Tai Road

Kowloon Bay, Hong Kong

Tel.: (852) 2610 1025, Fax: (852) 3579 1404

E-mail: customerservices@miele.com.hk

Website: www.miele.hk

China

Miele (Shanghai) Trading Ltd.

1–3 Floor, No. 82 Shi Men Yi Road

Jing’ an District, 200040 Shanghai, PRC

Tel.: +86 21 6157 3500, Fax: +86 21 6157 3511

E-mail: info@miele.cn

Website: www.miele.cn

Manufacturer:

Miele & Cie. KG

Carl-Miele-Straße 29

33332 Gütersloh, Germany

Key:

Connection required

Connection optional or required,

depending on model

AL

Exhaust air

KLZ

Cooling air intake

ASK

Condensate drain hose

PA

Equipotential bonding

B

Appliance anchoring

SLA

Peak-load connection

EL

Electrical connection

UG

Box plinth

F

Appliance feet, adjustable

UO

Open plinth

KG

Payment system

APCL

Washer-dryer stacking kit

KGA

Payment system connection

XKM

Communication module

KLA

Cooling air vent

ZL

Air intake

All rights reserved.12/19

PDR 507 EL en-GB

11 277 080/04 3

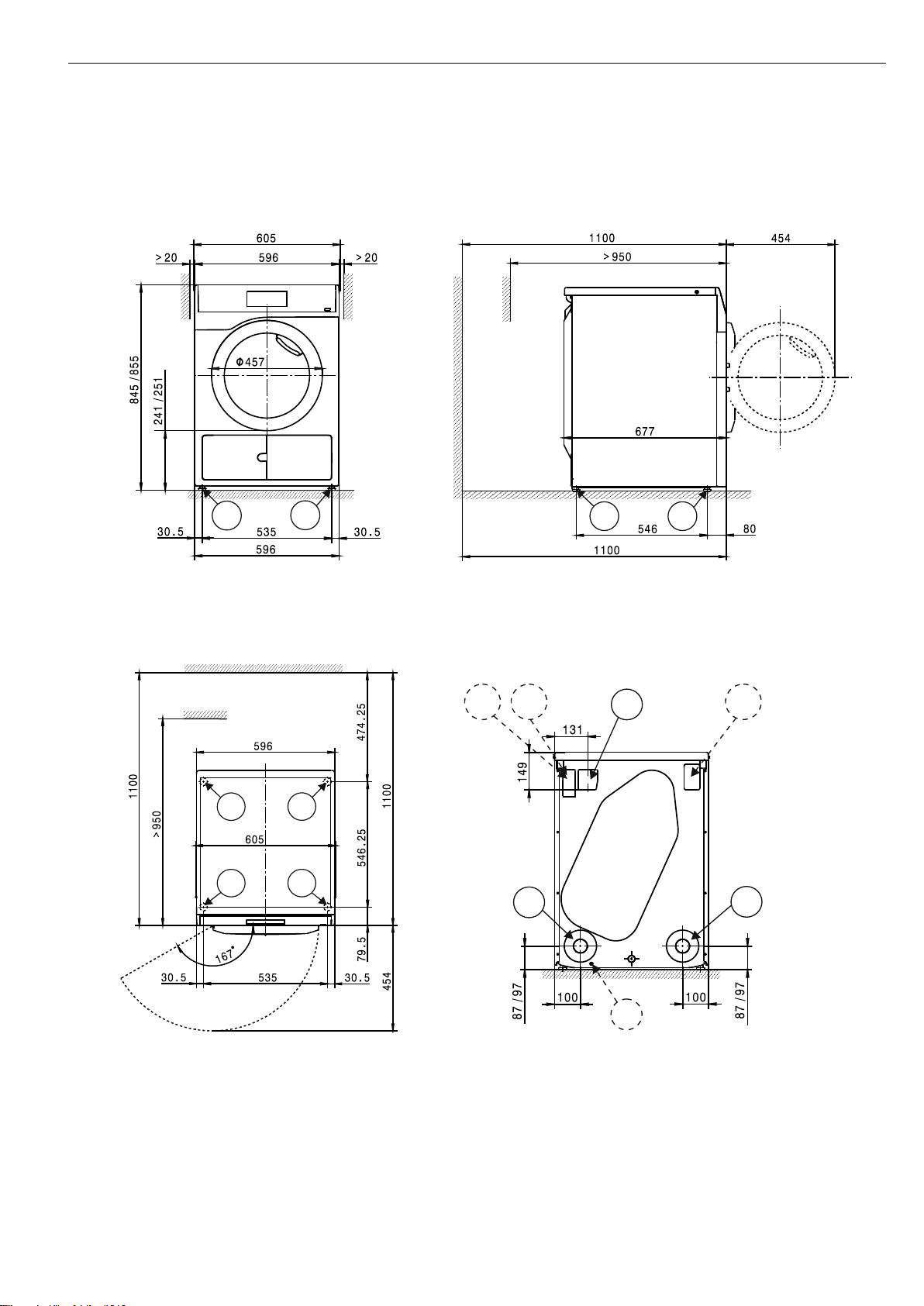

Appliance dimensions

F

F

F F

F F

F F

PA

AL

EL

KGASLA

AL

XKM

PDR 507 EL en-GB

4 11 277 080/04

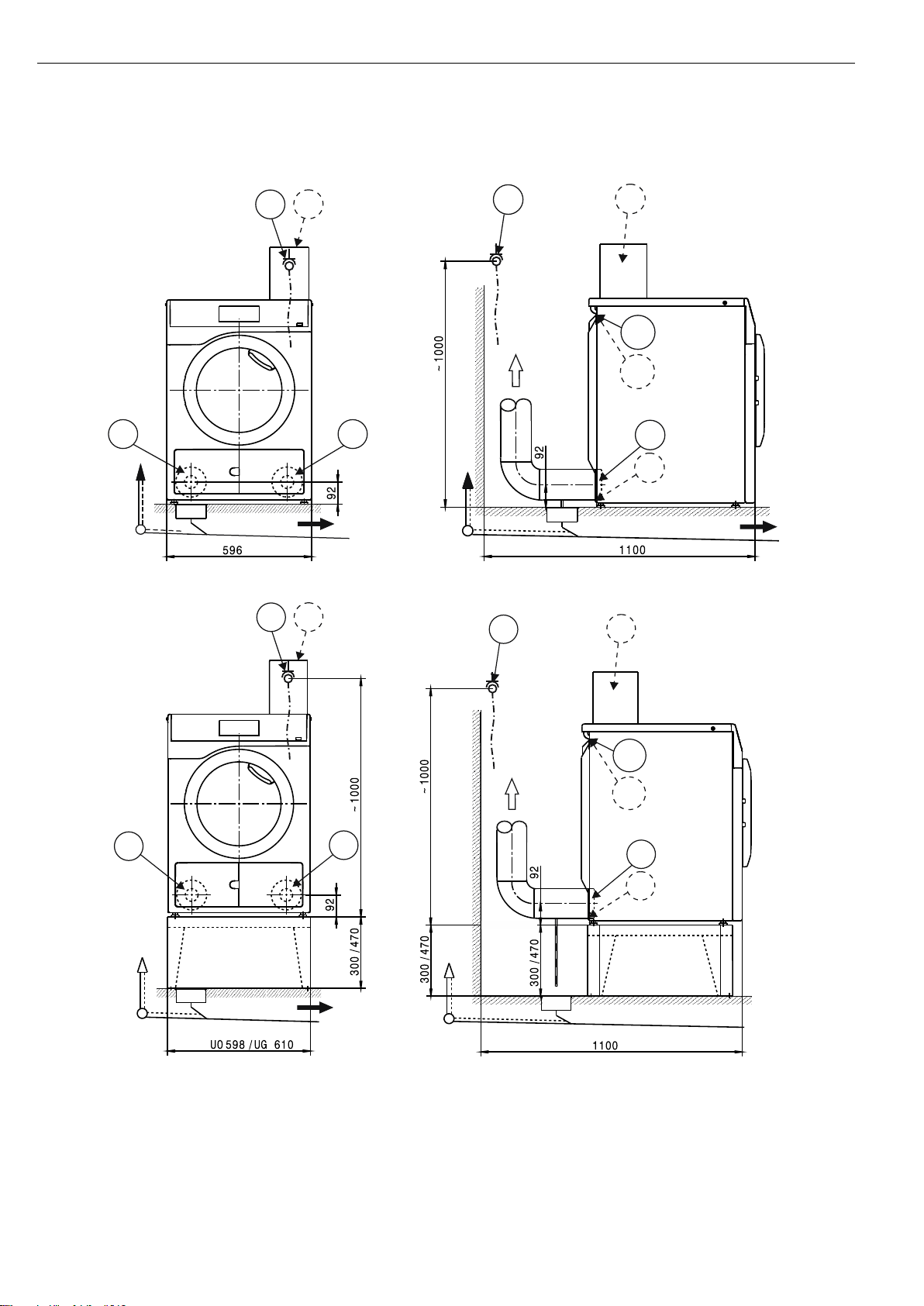

Installation

KGEL

ALAL

EL KG

AL

KGA

SLA

PA

KGEL

AL

AL

UO UG /

UO UG /

EL KG

AL

KGA

SLA

PA

PDR 507 EL en-GB

11 277 080/04 5

Washer-dryer stack

F F

FF

PDR 507 EL en-GB

6 11 277 080/04

Installation

PDR 507 EL en-GB

= standard, = optional, + = only on request, - not available

11 277 080/04 7

Technical data

PDR 507 EL

Drying system

Vented

Drum volume

l

130 Load capacity

kg

7.0 Door opening diameter

mm

370

Electrical connection (EL)

Standard voltage

3N AC 400 V

Frequency

Hz

50/60 Total rated load

kW

6.4 Fuse rating (B trip rating according to EN 60898)

A

3 x 10

Supply lead min. cross-section

mm²

5 x 1.5

Supply lead without plug

Length of supply lead

mm

2000

Alternative voltage (convertible by Miele Customer Service Department)

1N AC 230 V

Frequency

Hz

50/60 Total rated load

kW

3.24 Fuse rating (B trip rating according to EN 60898)

A

1 x 16

Supply lead min. cross-section

mm²

3 x 1.5

Alternative voltage (convertible by Miele Customer Service Department)

3 AC 230 V

Frequency

Hz

50/60 Total rated load

kW

6.4 Fuse rating (B trip rating according to EN 60898)

A

3 x 16

Supply lead min. cross-section

mm²

4 x 1.5

Non-standard voltages MAR 400/440/480 (Marine)

3 AC 400/440/480 V

Frequency

Hz

50/60 Total rated load

kW

4.5/5.4/6.4

Fuse rating (B trip rating according to EN 60898)

A

3 x 10

Supply lead min. cross-section

mm²

4 x 1.5

Supply lead without plug

Length of supply lead

mm

2000

Variations in the following countries:

Standard voltage 13 A (GB only)

3N AC 400 V

Frequency

Hz

50/60 Total rated load

kW

5.47 Fuse rating (B trip rating according to EN 60898)

A

3 x 13

Supply lead min. cross-section

mm²

5 x 1.5

Supply lead without plug

Length of supply lead

mm

2000

Standard voltage 13 A (GB only)

1N AC 220–230 V

Frequency

Hz

50/60 Total rated load

kW

2.76–2.99

Fuse rating (B trip rating according to EN 60898)

A

1 x 13

Supply lead min. cross-section

mm²

3 x 1.5

Supply lead with plug

Length of supply lead

mm

2000

Standard voltage 25 A (GB only)

1N AC 220–230 V

Frequency

Hz

50/60 Total rated load

kW

5.03–5.47

Fuse rating (B trip rating according to EN 60898)

A

1 x 25

Supply lead min. cross-section

mm²

3 x 2.5

Supply lead without plug

Length of supply lead

mm

2000

PDR 507 EL en-GB

= standard, = optional, + = only on request, - not available

8 11 277 080/04

Technical data

PDR 507 EL

Standard voltage (N only)

3 AC 230 V

Frequency

Hz

50/60 Total rated load

kW

6.4 Fuse rating (B trip rating according to EN 60898)

A

3 x 16

Supply lead min. cross-section

mm²

4 x 1.5

Supply lead without plug

Length of supply lead

mm

2000

Alternative voltage (convertible)

1N AC 230 V

Total rated load

kW

3.24 Fuse rating (B trip rating according to EN 60898)

A

1 x 16

Supply lead min. cross-section

mm²

3 x 1.5

Alternative voltage (convertible)

3N AC 400 V

Frequency

Hz

50/60

Total rated load

kW

6.4 Fuse rating (B trip rating according to EN 60898)

A

3 x 10

Supply lead min. cross-section

mm²

5 x 1.5

Vented (EL)

Connection (ext. diameter)

mm

100 Max. exhaust air temperature

°C

80

Electrical connection with 50 Hz/60 Hz

Max. permissible pressure loss

Pa

340 Max. flow rate w/o counterpressure (0 Pa) in vented mode

m³/h

285

Equipotential bonding (PA)

Appliance connection (with installation kit)

XCI box LG interface

Peak load/energy management (SLA)

Appliance connection (with XCI box LG)

Payment system connection (KGA)

Connection of payment systems (with XCI box LG)

Communication module (XKM)

Communication module XKM 3200 WL PLT

Installation on appliance feet (F)

No. of appliance feet

No. 4

Appliance foot, height-adjustable with thread

mm

± 5 Appliance foot diameter

mm

31.7

Anchoring (B)

Standard anchoring

Floor anchor kit (for 4 machine feet)

Wood screws according to DIN 571

mm

6 x 50

Rawl plugs (diameter x length)

mm

8 x 40

Anchoring of Miele plinths

Miele plinth installation (fasteners included)

Required anchor points

No. 4

Wood screws according to DIN 571

mm

8 x 65

Rawl plugs (diameter x length)

mm

12 x 60

PDR 507 EL en-GB

= standard, = optional, + = only on request, - not available

11 277 080/04 9

Technical data

PDR 507 EL

Plinth floor anchoring (to be provided on site)

Appliance installation on on-site plinth (concrete or masonry)

Min. plinth installation footprint (W/D)

mm

600/650

Wood screws according to DIN 571

mm

6 x 50

Rawl plugs (diameter x length)

mm

8 x 40

Appliance data

Overall appliance dimensions (H/W/D)

mm

850/605/717

Casing dimensions (H/W/D)

mm

850/596/677

Site-access dimensions (H/W)

Min. site-access opening (excl. packaging)

mm

900/605

Installation dimensions

Min. side gap

mm

20

Recommended side gap – washer-dryer stack

mm

300 Min. distance to opposite wall from appliance front

mm

950 Recommended distance to opposite wall from appliance front

mm

1100

Weights and floor loads

Appliance weight (net weight)

kg

50

Max. floor load in operation

N

670

Emissions

Sound pressure level (in accordance with EN ISO 11204/11203)

dB(A)

<70

Heat dissipation rate to installation site

W

200

PDR 507 EL en-GB

10 11 277 080/04

Installation and planning notes

Installation requirements

The tumble dryer should only be connected to a power supply

provided in accordance with all appropriate local and national

legislation and regulations.

In addition, all regulations issued by the appropriate utilities as well as

standards relating to occupational safety and all applicable valid

regulations and technical standards must be observed.

General operating conditions

Ambient temperature in installation room: +2 °C to +35 °C.

Electrical connection

Depending on the model, the tumble dryer is delivered with a supply

lead with/without a plug.

The appliance may only be connected to an electrical system that

conforms to the national and local codes and regulations (BS 7671 in

the UK). The installation must be performed by a qualified electrician.

The data plate indicates the nominal power consumption and the

appropriate fuse rating. Compare the specifications on the data plate

with those of the electrical power supply.

It is always recommended to connect the appliance via a plug and

socket so that electrical safety checks, e.g. during repair or service

work, can be carried out easily.

The appliance can either be hard-wired or connected using a plugand-socket connection in accordance with IEC 60309-1. If the

appliance is hard-wired, a dual circuit breaker must be provided on

site. When switched off there must be an all-pole contact gap of at

least 3 mm in the isolator switch (including circuit breakers, fuses and

contactors according to IEC/EN 60947).

The plug connector or isolator switch should be easily accessible at all

times. If the appliance is disconnected from the electricity supply, the

isolator must be lockable or the point of disconnection must be

monitored at all times.

The tumble dryer should never be connected by an extension

cable, e.g. power strips, to avoid the risk of fire.

New connections, modifications to the system or servicing of the

earthing conductor, including determining the correct fuse amperage,

must be carried out by a qualified electrician, as they are familiar with

the pertinent regulations and the specific requirements of the electric

utility company.

If converting the tumble dryer to an alternative voltage, observe the

instructions in the wiring diagram. Conversion must be performed

by the Miele Customer Service Department or by an authorised

Miele dealer. The heater rating must also be adapted.

The appliance must not be connected to devices such as timers which

would switch it off automatically.

References to cable cross-sections in the technical data refer only to

the required mains cable. Please consult relevant local and national

regulations when calculating any other wire gauges.

Vent connection

Hot moist exhaust air should be vented to atmosphere along the

shortest possible route or connected to a suitable vent system.

Depending on the duct path, the moist exhaust air can condense on

the duct walls to a greater or lesser extent. For this reason it is

recommended to lay ducting with a downwards slope to the air exit.

If ducting slopes upwards, a condensate trap either with a drip tray or

a connection to a suitable on-site floor drain must be fitted in the

system at the lowest point.

Condensate must not flow back into the appliance.

It is permissible to vent exhaust air via an external wall. In this case,

measures must be taken to minimise the risk and annoyance to

neighbouring buildings.

The end of exhaust air ducting leading into the open should be

protected against the elements, e.g. using a suitable hood or with a

90° bend.

The cross-sectional area of the ducting must not be reduced or

obstructed by built-in parts. Filters and louvres must not be fitted in the

ducting.

Congestion in the line may lead to a drop in appliance performance or

to appliances being switched off to guarantee safety.

Proper functioning of the tumble dryer cannot be guaranteed if the

max. permissible pressure loss is exceeded in the on-site vent

ducting system.

When connecting several tumble dryers to a common duct, the crosssectional area of the duct must be increased accordingly.

Additionally, in such a case every tumble dryer must have its own

non-return valve to prevent dryers affecting others in the system. This

requires the provision of on-site additional parts.

In the event that exhaust air ducts from several tumble dryers are

merged into a common duct, a non-return device should be

installed in each separate line to prevent backflow.

With complex ducting with many bends and additional components, or

with the connection of several different tumble dryers to a common

duct, it is recommended that a detailed calculation is carried out by a

suitable specialist.

Air intake

The air supply for the tumble dryer is taken directly from the

installation site.

During operation, adequate ventilation of the installation site should be

guaranteed. Depending on the appliance version, it is necessary to

ensure an intake of fresh air to compensate for the volume of exhaust

air extracted in order to avoid the creation of a vacuum.

It should not be possible to close or otherwise obstruct air intake

grilles or alternative measures should be implemented to ensure that

an adequate supply of fresh air is available at all times during

appliance operation.

Equipotential bonding

If necessary, equipotential bonding with good galvanic contact must

be guaranteed in compliance with all applicable local and national

installation specifications.

Connection material for equipotential bonding must be provided on

site or using a kit available from the Miele Customer Service

Department.

Peak load/energy management

The appliance can be connected to a peak-load or energy

management system using an optional kit.

When the peak-load function is activated, the heating is deactivated.

A message appears in the display to inform you of this.

PDR 507 EL en-GB

11 277 080/04 11

Payment system

The tumble dryer can be fitted with a single-machine payment system

as an optional accessory using an optional kit (XCI box).

The programming required for connecting a payment system can be

carried out during the initial commissioning process. After initial

commissioning, changes may only be carried out by your Miele dealer

or the Miele Customer Service Department.

Interface

The appliance can be fitted with an XKM 3200 WL PLT

communication module.

This module can be used as a WiFi or LAN interface.

The LAN interface provided via the module complies with SELV

(Safety Extra Low Voltage) in accordance with EN 60950. Connected

appliances must also comply with SELV. The LAN connection uses a

RJ45 connector in accordance with EIA/TIA 568-B.

Installation and anchoring

The appliance must be installed on a perfectly smooth, level and firm

surface which is able to withstand the quoted loads.

The floor load created by the appliance is concentrated and

transferred to the installation footprint via the appliance feet.

The appliance should be levelled in both directions with the aid of the

adjustable feet.

Plinth installation

The tumble dryer can be installed on a plinth (open or box plinth,

available as an optional Miele accessory) or on a concrete plinth to be

provided on site.

The quality of the concrete and its strength must be assessed

according to the appliance load. Ensure that any raised concrete

plinth is adequately bonded to the floor below.

Washer-dryer stack

The tumble dryer can be installed as a washer-dryer stack together

with a Miele washing machine. A stacking kit (optional accessory) is

required for this.

Installation of the stacking kit must be performed by the Miele

Customer Service Department or an authorised Miele service

technician.

Loading...

Loading...