Page 1

Installation Instructions

Gas-Hob

KM 404

IMPORTANT NOTICE

THIS APPLIANCE MUST ONLY BE INSTALLED OR SERVICED

BY AUTHORISED PERSONNEL

Note: The installation of this appliance must comply with the requirements of the National

Standard or AS 5601 (AG 601) Gas Installations.

It is essential to read these

operating instructions before

installing or using the machine,

to avoid the risk of accident

or damage to the machine. M.-Nr.05 667 660

r

Page 2

Contents

Contents

Warning and Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Building in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety distance above appliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Appliance dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Worktop cut-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Fitting the spacer bars and support brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Fixing the spacer bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Granite worktops. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Fixing the support brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Building in the gas hob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Gas connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Conversion to another type of gas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Jet table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Changing the jets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2

Page 3

Warning and Safety Instructions

Warning and Safety Instructions

Building in

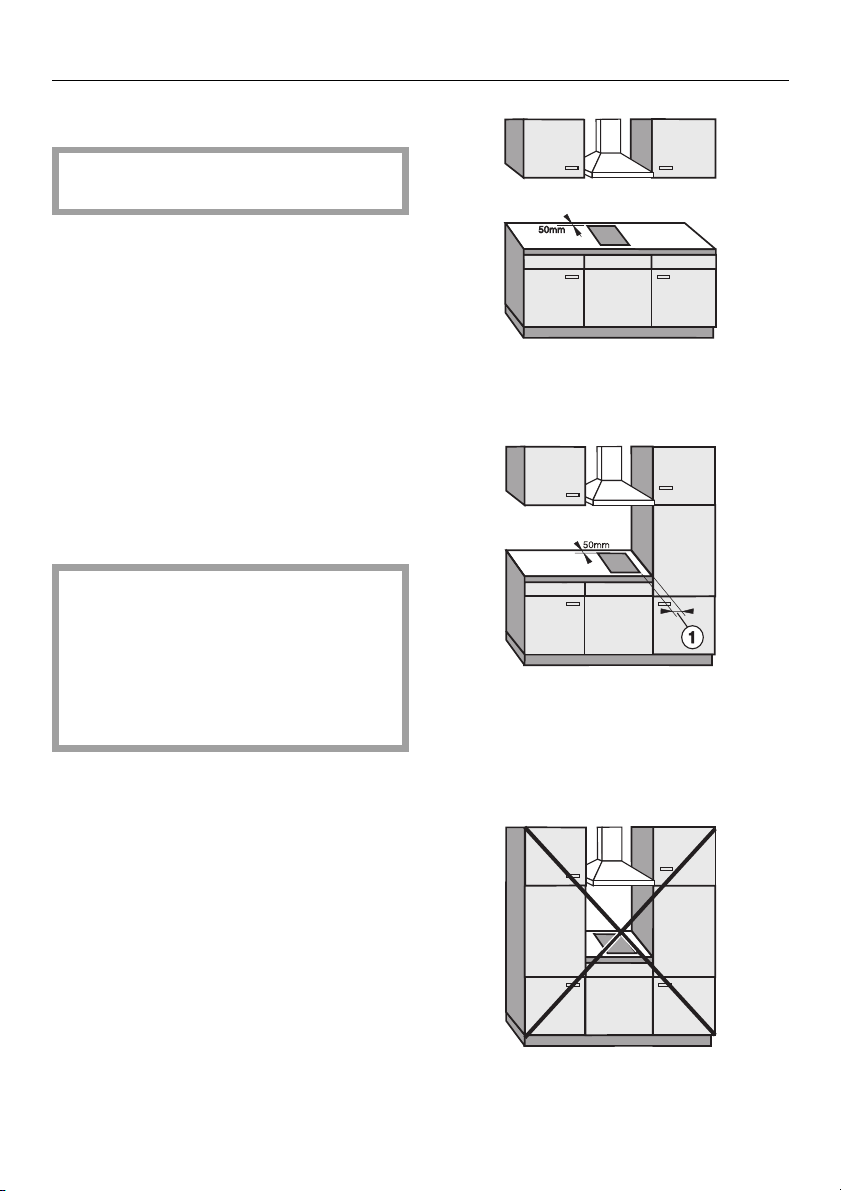

To avoid damage to the hob install

it after fitting any wall cabinets

The veneer or laminate coatings of

worktops (or adjacent kitchen units)

must be treated with 100°C heat-resistant adhesive which will not dissolve or

distort.

Any backmoulds must be of heat-resistant material.

Ideally the hobs should be installed

with plenty of space on either side.

There may be a wall at the rear and

wall or tall units at one side. On the

other side however, no unit or divider

should stand higher than the hob.

A safety distance must be maintained between the hob and adjacent furniture, because of the heat

given off by the flames, and to allow

fumes to dissipate; with a tall unit

for example at least

100 mm with KM 404.

The gas hob must not be installed next

to an electric deep fat fryer, as the gas

flames could ignite the fat in the fryer.

It is essential to maintain a distance of

at least 288 mm between these two appliances.

Fig.1

recommended

Fig. 2

possible but not recommended

Measurement

(minimum distance)

at least 100 mm

b

The hob must not be installed over a

dishwasher, washing machine, tumble

dryer, refrigerator or freezer. The high

temperatures radiated by the hob

could damage the appliance below.

Fig 3

not allowed

3

Page 4

Warning and Safety Instructions

Safety distance above the appliance

Fig. 4

As a general rule there must be a

c

safety distance of at least 760 mm

between the appliance and any

flammable objects sited above, e.g.

wall units. If the manufacturer of the

said objects states a different figure,

either greater or smaller, then this

should be adhered to.

When two or more appliances are installed together, the maximum distance quoted between the cooker

hood and the appliance must always be observed. These measurements are given in the operating

and installation instructions for the

cooker hood.

Space required for gas appliances

Minimum requirements are more than

3

20 m

space where the appliance is installed, and a door or window which

can be opened to the outside air.

All dimesions in this instruction booklet

are given in mm.

Keep these instructions in a safe place

and pass them on to any future owner

of the appliance.

4

Page 5

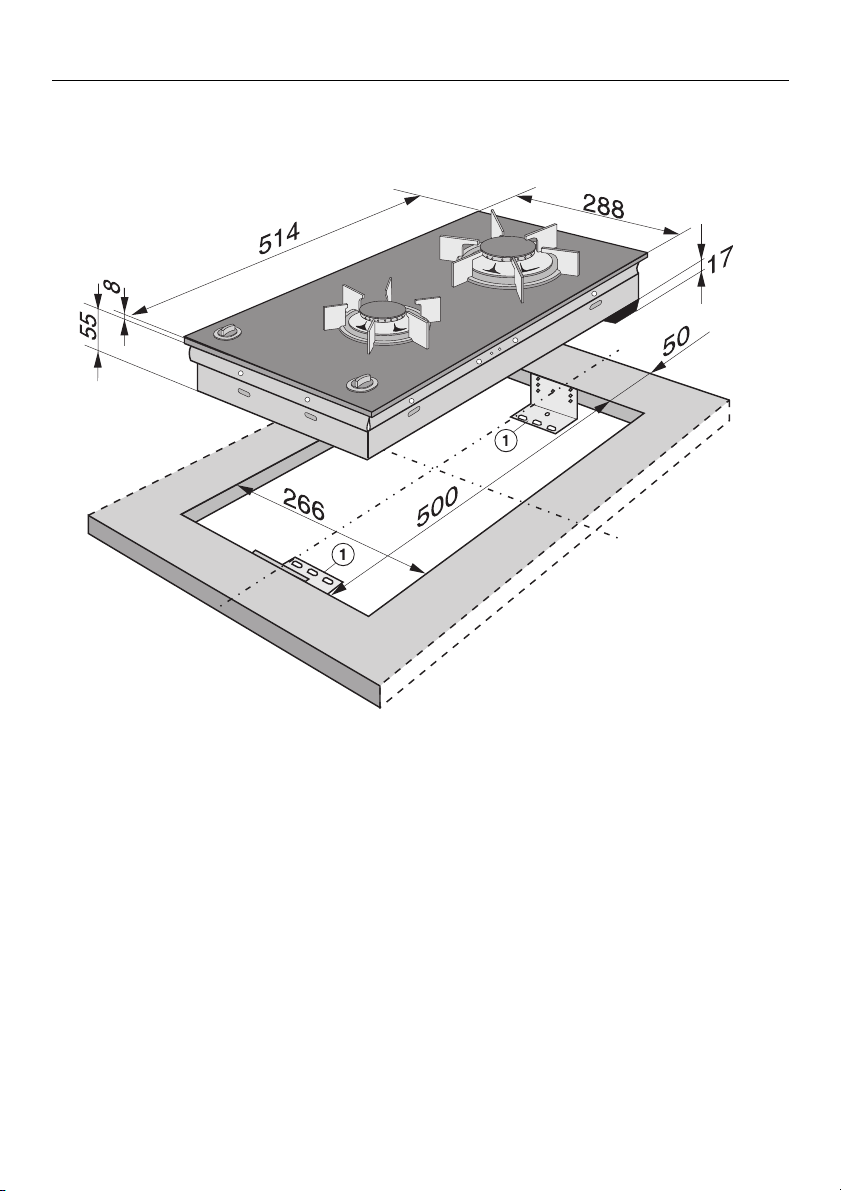

Appliance dimensions

KM 404

Appliance dimensions

Support bracket

b

Fig. 5

5

Page 6

Installation

Installation

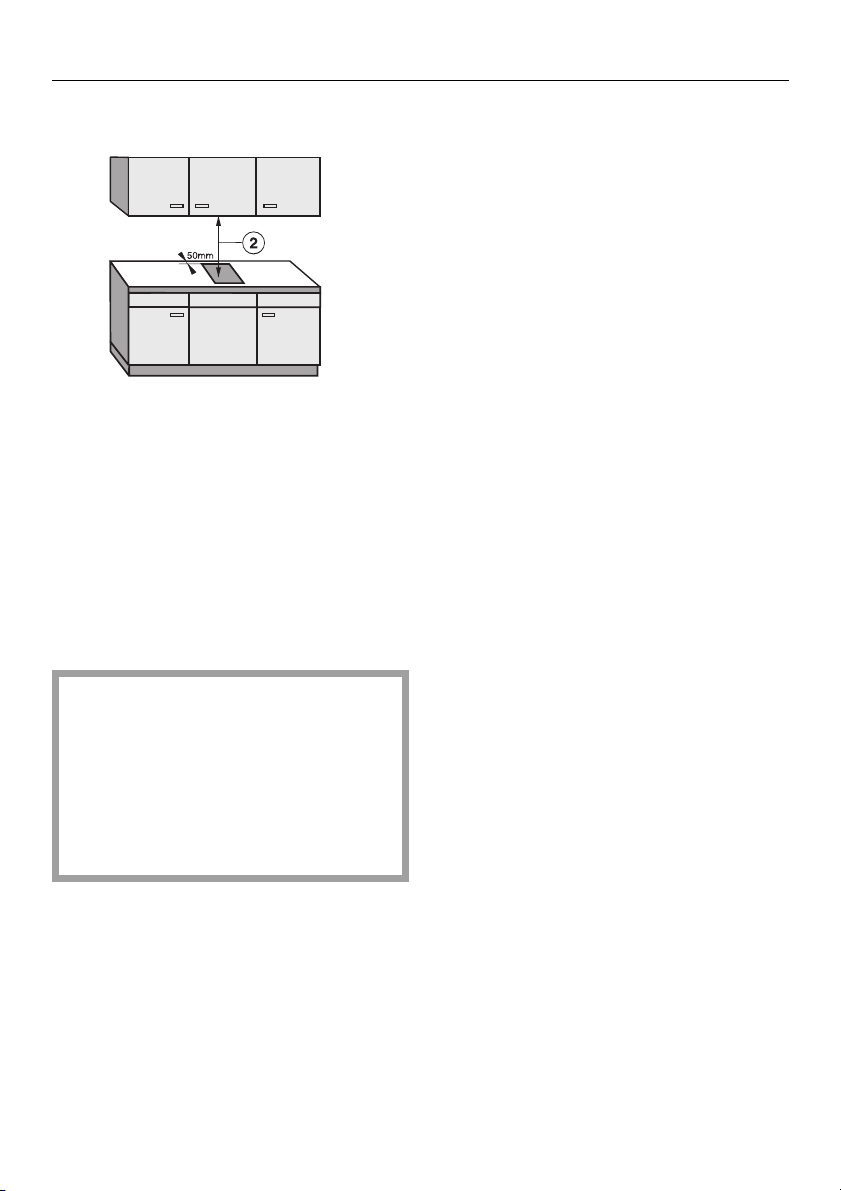

Cut-out for the worktop

Fig. 6

Make a cut-out for the hob in the

worktop, paying attention to the appliance depth. See Figures 5, 6,

and 7.

Dimension ‘B’ applies to a combination of appliances and is shown on

the chart.

There must be a minimum distance

of 50 mm between the hob and the

back wall and 100 mm distance from

a side wall to the right or left of the

hob.

See also ‘‘Warning and Safety Instructions’’.

Depth

in mm

+

1 mm

Width

(=Dim. B)

in mm

+

1 mm

Worktop cut-out

1 hob

2 hobs

3 hobs

4 hobs

5 hobs

6 hobs

7 hobs

500

500

500

500

500

500

500

266

554

842

1130

1418

1706

1994

Important:

The maximum tolerance for the worktop

+

cut-out must not exceed

1 mm.

When building in several “combi”

hobs a spacer bar must be fitted between each unit.

See the following page.

Seal the cut surfaces with a suitable

sealant to avoid swelling caused by

moisture.

The materials used must be heat resistant.

6

Page 7

Fitting the spacer bars and

support brackets

Installation

Fig. 7

Support brackets

b

Spacer bars

c

Figure 7 shows an example for worktop

cut-out and fixing the spacer bars

and support brackets b for 3 appliances.

For more than 3 appliances, repeat

dimension 288 mm.

The worktop cut-out dimensions for several appliances are shown in the table

on the previous page.

c

Gap between spacer bar and

d

worktop.

Drilling for a granite worktop.

e

Fix the spacer bars c and the support brackets

sitions indicated. See also figures 8

and 9.

supplied to the po-

b

7

Page 8

Installation

Fixing the spacer bar

d

c

Fig. 8

Lay the spacer bars c on the top

edge of the cut-out in the positions

indicated (Fig. 7), as shown in Fig. 8,

and secure with the 3.5 x 25 mm

screws supplied.

Then fill in the gap d between the

bars and the worktop with silicone

from the tube supplied.

For granite worktops

With granite worktops the spacer bars

must be positioned and secured

c

with strong double-sided adhesive

tape. In addition, coat the edges with

silicone and fill in the gap

The screws are not necessary for granite tops.

d

.

8

Page 9

Installation

Fixing the support brackets

Fig. 9

Position the support brackets supplied

as shown in Fig. 9, flush with the top

edge of the worktop, and secure

with the 3.5 x 25 mm screws supplied.

2 screws are needed to secure the

support brackets.

The thickness of the worktop will

determine which drilled hole is used.

(2 pieces) (see also Fig. 7),

b

For granite worktops

A granite worktop must be prepared with a hole drilled

positions indicated to secure each

support bracket, (see Figs. 7 and 9).

Using a piece of double-sided

strong adhesive tape press the support brackets supplied

position indicated (Fig. 7), as shown

in Fig 9 , flush with the top edge of

the worktop and secure each

bracket with one screw.

at the

e

on to the

b

9

Page 10

Installation

Building in the gas hob

Lay the gas hob in the prepared cutout.

Draw the electricity connection cable

through the cut-out and connect.

Make the gas connection.

(see the following pages).

Secure the gas hob from below

through the middle elongated hole

(see Fig. 9) using the two screws

c

supplied. Gently adjust the hob if

necessary.

Fig. 10

On no account let sealant get in

between the hob frame and the

worktop.

This could lead to damage to the hob if

it needs to be taken out for servicing or

repair work. The seal provided underneath the hob edge provides a sufficient seal between the appliance and

the worktop.

10

Page 11

Other notes

Other notes

Electrical connection

Electrical work should be carried out by

a competent person, in strict accordance with national and local safety

regulations.

The voltage and rated load are given

on the data plate. Ensure that these

match the household mains supply.

After the appliance has been built in,

a check must be made that all electrical parts are shielded.

Connection for each appliance should

be made via a suitable isolator (rated

load above 3 kW) or a double pole

fused spur connection unit or fused

plug and switched socket (rated load

up to 3 kW) which complies with national and local safety regulations, and

which is accessible after the appliance

has been built in.

When switched off there must be an allpole gap of at least 3 mm in the isolator

switch. For extra safety it is advisable

to install a residual current device

(RCD) with a trip current of 30 mA.

Important

The wires in the mains lead are coloured in accordance with the following

code:

Green/yellow = earth

Blue = neutral

Brown = live

Disconnection from the power supply

will depend on the isolator, according

to country e.g.:

1. Safety fuse:

Completely remove the fuse links

from the fuse carrier. or:

2. Safety cut-outs (screw type):

Press the (red) test button until

the black centre button pops out.

or:

3. Built-in safety cut-outs (MCBs at

least type B or C):

Set rocker from 1 (On) to O (OFF) or:

4. FI-Safety switch (RCD)

Set main switch from 1 (ON) to

O (Off) or press the test button.

Technical Data

Fusing: See data plate.

For appliances up to 3 kW - 13 amps

For appliances above 3 kW - 20 amps

If the cable needs to be changed select either type H 05 RR-F (rubber insulated) or type H 05 VV-F (PVC-insulated).

See data plate for connection data.

Important

The manufacturer cannot be held responsible for the consequences of an

inadequate earthing system.

WARNING THIS APPLIANCE MUST

BE EARTHED

Ensure power is not restored to the

appliance while installation work is

being carried out.

The manufacturer can assume no responsibility for damage which is the direct or indirect result of incorrect installation or connection.

11

Page 12

Gas connection

Gas connection

Connection to the gas supply

should only be undertaken by an approved fitter, who is responsible for

correct functioning of the appliance

when installed. Every appliance

should have its own isolating valve.

Check with your local gas supplier

about the type of gas and its calorific value, and compare this information with the type of gas quoted

on the hob data plate.

The hob is supplied ready for connection to town gas.

Connection

Conversion to another type of gas is described under the relevant section.

The gas connection must be installed so that connection can be

made either from inside or outside

the kitchen unit, and the isolating

valve must be easily accessible and

visible (by opening one of the kitchen unit doors, if necessary).

12

Page 13

Technik

The gas connection must be in accordance with national and local

regulations.

Fig. 11

Gas connection

Town gas / LP gas

An appropriate rigid or flexible connection can be used.

The gas connection must be so sited

that it is not adversely heated when

the appliance is in operation.

When the gas hob has been installed it is essential to check that

neither the gas hose nor the electricity cable is in contact with hot

parts of the appliance or hot gas exhaust, otherwise heat damage to

the hose and cable could occur.

Connection for pressure gauge

b

Governor fitted for connection to

c

town gas. Inlet pressure 10-20 mbar/

1-2 kPa, burner pressure 10 mbar/

1 kPa.

A test for possible leakages should

be carried out after installation.

The relevant building regulations must

also be observed.

Note: Where a flexible connection (Hose Assembly) is used it must

(I) be of an adequate size and;

(II) comply with the National standard or AGA certification and;

(III) be suitable for the intended use.

13

Page 14

Conversion to another type of gas

Conversion to another type of gas

KM 404

When converting to LP gas, the

main jets and the small jets of all

burners must be changed.

Nominal rating at high setting

Normalburner

Fastburner

Gas type

Supply pressure

Towngas

10-20 mbar /

1-2 kPa

LP gas

30 mbar /

3 kPa

Towngas

10-20 mbar /

1-2 kPa

LP gas

30 mbar /

3 kPa

kW MJ/h

1.9

1.6

3.1

2.7

7.0

5.6

11.2

9.7

Screw in the new jets according to the

following table.

Jet table

Main-jet

Ø

Town gas

Normal burner

Fast burner

1.85

2.75

LP gas

30 mbar

Normal burner

Fast burner

0.65

0.85

The jet markings refer to 1/100 mm of

the jet orifice.

Total rating

Low

setting jet

Ø

0.74

0.88

0.27

0.36

Nominal rating at low setting

Normalburner

Fastburner

14

Gas type

Supply pressure

Towngas

10-20 mbar /

1-2 kPa

LP gas

30 mbar / 3 kPa

Towngas

10-20 mbar /

1-2 kPa

LP gas

30 mbar / 3 kPa

kW MJ/h

0.3

0.3

0.5

0.4

1.2

1.0

1.7

1.5

Towngas

LP gas

kW MJ/h

5.06

4.25

18.2

15.3

Page 15

Conversion to another type of gas

Changing the jets

Disconnect the gas hob from the

electricity supply. Depending on the

type of installation, either withdraw

the mains fuse, switch of at the

fused spur unit, or at the socket and

withdraw the plug.

Changing the main jets

Changing the low setting jet

Fig. 13

Guide a screwdriver throug the holes

in the lower casing of the hob and

loosen the low setting jets

Pull the jets out with a pair of pliers.

Put in the new jets and secure with a

screwdriver.

g

.

Fig. 12

Take off the pan support, the burner

cover

burner head

Using an (M7) socket spanbner inscrew the main jet

Change the main jet.

Reassemble the burner head, burner

ring and burner cover in the correct

order.

, the burner ring d and the

c

.

e

.

f

Fix the jets and air-setting with sealing-wax against accidental loosening.

At low setting the flame must not extinguish, even when the control

switch is turned fast from “High” to

“Low” setting.

At “High” setting the flame must burn

with a clearly visible core.

15

Page 16

Alteration rights reserved 00/3301

This paper consists of cellulose which has been bleached without the use of chlorine.

Loading...

Loading...