Operating and installation instructions

Cooker hoods

DA 196-2

DA 199-2

To avoid the risk of accidents or

damage to the appliance it is

essential to read these instructions

before it is installed or used for the first time.

GiWO

M.-Nr. 05 609 480

Contents

Caring for the environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warning and Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Description of the appliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation

Switching on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Selecting the power level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Switching off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Switching the lighting on and off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Brief description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cleaning and care

Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Grease filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Fitting / replacing the active charcoal filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Defective lighting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Appliance dimensions

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Assembly parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Retaining plates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Canopy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Motor unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Air extraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Recirculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Extension piece . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Fitting the tower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Connection for air extraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Condensate trap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

After sales service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Technische Daten. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2

Caring for the environment

Disposal of the packing mate

-

rial

The transport and protective packing

has been selected from materials which

are environmentally friendly for disposal

and can normally be recycled.

Ensure that any plastic wrappings,

bags etc. are disposed of safely and

kept out of the reach of babies and

young children. Danger of suffocation.

Rather than just throwing these materi

als away, please ensure that they are

recycled.

-

Disposal of your old appliance

Old appliances contain materials which

can be reclaimed or recycled. Please

contact your dealer, your local waste

collection centre or scrap merchant

about potential recycling schemes.

Ensure that the appliance presents no

danger to children while being stored

for disposal. See the appropriate sec

tion in the Warning and Safety instruc

tions.

-

-

3

Warning and Safety instructions

Any damage which may be caused by

This appliance complies with all rele

vant legal safety requirements. Inap

propriate use can, however, lead to

personal injury and damage to prop

erty.

Before installation and before using

for the first time, read the operating

instructions carefully. They contain

important information on safety, in

stallation, use and maintenance of

the appliance. This way you will

avoid the risk of accidents and dam

age to the appliance.

Keep these operating instructions in

a safe place and ensure that all users are familiar with the contents.

Pass them on to any future owner of

the appliance.

Correct usage

This appliance is intended for domestic use only.

It is not a toy! To avoid the risk of injury

do not let children play with it or use the

controls. Supervise its use by the el

derly or infirm.

The manufacturer cannot be held liable

for damage caused by improper or in

correct use of the appliance.

In countries where there are areas

which may be subject to infestation

by cockroaches or other vermin, pay

particular attention to keeping the appli

ance and its surroundings in a clean

condition at all times.

-

cockroaches or other vermin will not be

-

covered by the appliance guarantee.

-

Technical safety

the voltage and frequency details given

on the data plate correspond with the

-

-

on-site electricity supply; otherwise the

appliance could get damaged. Consult

a qualified electrician if in any doubt.

-

continuity is complete between the appliance and an effective earthing system which complies with local and national regulations. It is most important

that this basic safety requirement is

present and regularly tested. If in any

doubt, the electrical wiring in the home

should be checked by a qualified electrician. The manufacturer cannot be

held liable for the consequences of an

inadequate earthing system (e.g. elec

tric shock).

qualified and competent persons to en

sure safety. Repairs and other work by

unqualified persons could be danger

ous, and the manufacturer will not be

held liable.

Ensure power is not supplied to the ap

pliance until after any maintenance or

repair work has been completed.

-

Before connecting the appliance to

the mains supply, make sure that

The electrical safety of this appli

ance can only be guaranteed when

Installation work and repairs may

only be carried out by suitably

-

-

-

-

-

4

Warning and Safety instructions

This equipment is not designed for

maritime use or for use in mobile

installations such as caravans, aircraft

etc. However it may be suitable for

such usage subject to a risk assess

ment of the installation being carried

out by a suitably qualified engineer.

The appliance is only completely

isolated from the electricity supply

when:

it is switched off at the wall socket

–

and the plug removed (pull on the

plug, not the cable),

the fuse from the fused spur connec

–

tion unit is withdrawn, or

– the screw-out fuse is removed (in

countries where this is applicable).

Do not connect the appliance to

the mains electricity supply by an

extension lead.

Extension leads do not guarantee the

required safety of the appliance (e.g.

danger of overheating).

-

Use

Never use an open flame beneath

the cooker hood. To avoid the dan

ger of fire, do not flambé or grill over an

open flame under the cooker hood.

When switched on, the cooker hood

could draw flames into the filter. Fat

particles drawn into the cooker hood

present a fire hazard.

When using the cooker hood over

a gas hob, ensure that any burners

in use are always covered by a pan;

otherwise flames could be drawn up by

the suction of the cooker hood, parts of

-

which could then be damaged.

Always switch the cooker hood on

when a cooking zone is in use, otherwise condensation may collect in the

hood, which could cause corrosion.

When cooking with oil or fat, chip

pans and deep fat fryers etc, do

not leave the pans unattended. Never

leave an open grill unattended when

grilling. Overheated oil and fat can ig

nite and could set the cooker hood on

fire.

-

-

Do not use the cooker hood without

the grease filters in place. This way

you will avoid the risk of grease and dirt

getting into the appliance and hinder

ing its smooth operation.

The filters should be regularly

cleaned or changed as appropri

ate. Saturated filters are a fire hazard.

(See Cleaning and care).

Do not use a steam-cleaner to

clean this appliance. Pressurised

steam could reach the electrical com

ponents and cause a short circuit.

-

-

-

5

Warning and Safety instructions

Installation

The minimum safety distance be

tween the top of the cooker/hob

and the bottom of the cooker hood

should be at least:

– 450 mm above electric hobs and

cookers,

– 650 mm above gas hobs and cookers,

– 650 mm above an open grill

from our range

For non-Miele cooking appliances,

maintain the safety distance as recom

mended by the manufacturer in their In

stallation and Operating instructions.

If more than one appliance is fitted beneath the cooker hood, and they have

different minimum safety distances to

the cooker hood, select the greater distance.

Safety regulations prohibit the fitting of a cooker hood over solid

fuel stoves.

All ducting, pipework and fittings

must be of non-flammable material.

These can be obtained from the Miele

Spare Parts department or from build

ers’ merchants.

The appliance must not be con

nected to a chimney or vent flue

which is in use. Neither should it be

connected to ducting which ventilates

rooms with fireplaces.

If exhaust air is to be extracted into

a chimney or ventilation duct no

longer used for other purposes, seek

professional advice.

-

-

-

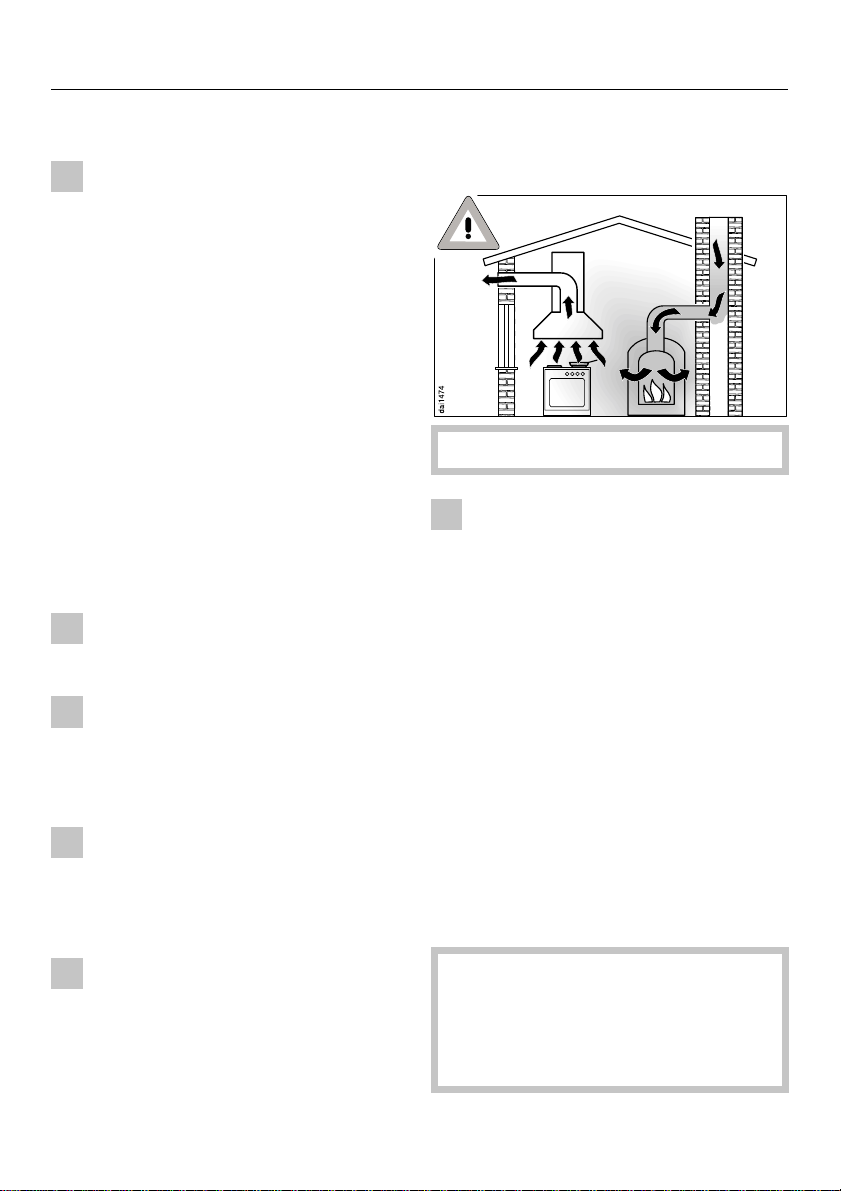

Using at the same time as other heat

ing appliances that depend on the air

from the room

-

Warning - danger of toxic fumes

Great care should be taken when

using the cooker hood at the same

time and in the same room or area of

the house as another heating appliance

which depends on the air in the room.

Such appliances include gas, oil, wood

or coal-fired boilers and heaters, continuous flow or other water heaters, gas

hobs, cookers or ovens which draw air

in from the room and duct exhaust

gases out through a chimney or extrac

tion ducting. When used in extraction

mode, the appliance draws air in from

the room in which it is installed and

from neighbouring rooms. If there is in

sufficient air an underpressure will oc

cur. The heating appliance may be

starved of oxygen, impairing combus

tion.

Harmful gases such as carbon mon

oxide could be drawn out of the

chimney or extraction ducting back

into the room with potentially fatal

consequences.

-

-

-

-

-

-

6

Warning and Safety instructions

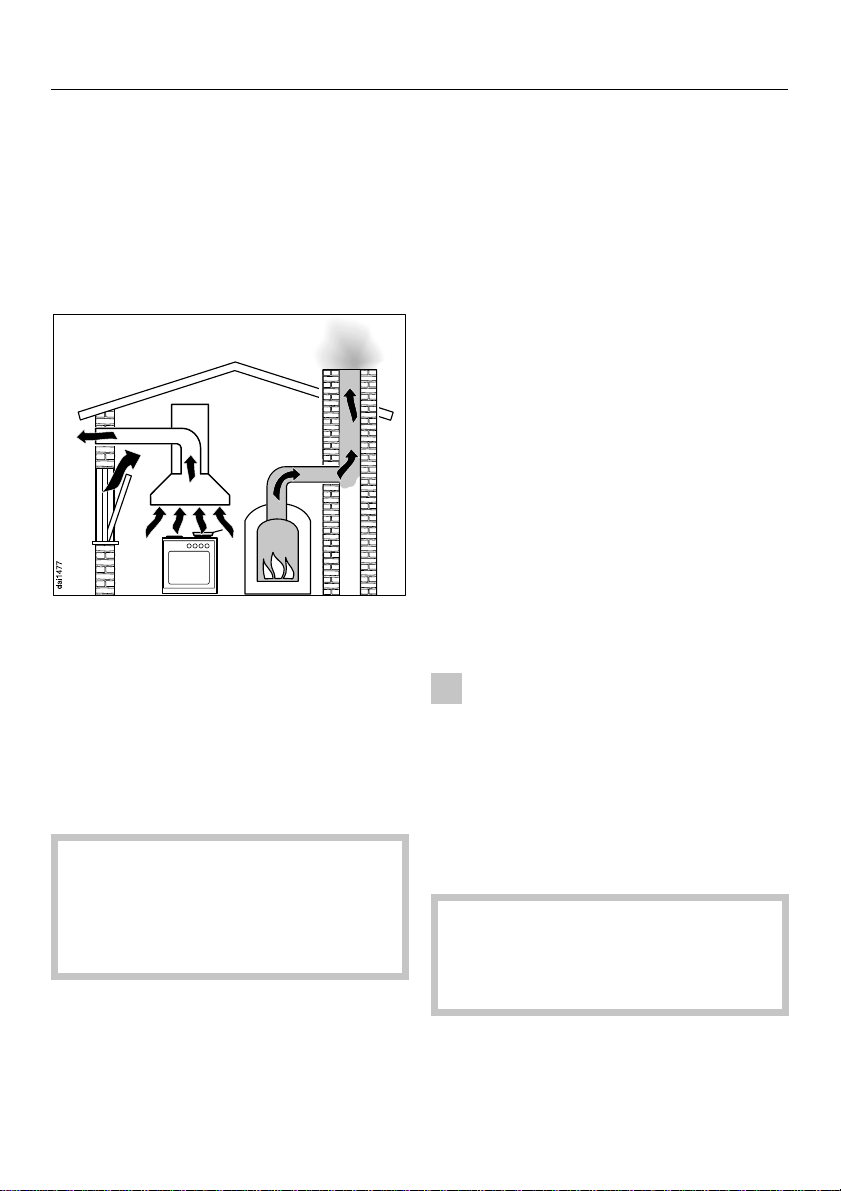

In order to ensure safe operation, and

to prevent gases given off by the heat

ing appliances from being drawn back

into the room when the extractor and

the heater are in operation simulta

neously, an underpressure in the room

of 0.04 mbar (4 pa) is the maximum

permissible.

Ventilation can be maintained by air inlets which cannot be blocked, in windows, doors and outside wall vents, or

by other technical measures, such as

ensuring that the extractor can only be

switched on when the heating appli

ance is switched off or vice-versa. A

ventilation brick alone is not generally

sufficient to ensure safe ventilation.

The overall ventilation condition of

the dwelling must be taken into ac

count. If in any doubt, the advice of

a competent builder or, for gas, a

"Corgi" installer, must be sought.

-

-

-

If adequate ventilation can only be

achieved through an open window, a

window contact switch must be fitted.

This ensures that the hood can only be

operated when the window is opened

wide enough.

The advice of a competent builder must

be sought. The cooker hood is then

ready for use. A window contact switch

kit is available from good builders mer

chants.

Take care when ventilating the room

through an open window that ventilation

is not impaired by a closed blind or cur

tain.

If the hood is being operated in

recirculation mode, the above restrictions do not apply.

Disposal of your old appliance

Before discarding an old appli-

ance, switch off and disconnect it

from the power supply. Cut off and ren

der any plug useless. Cut off the cable

directly behind the appliance to prevent

misuse.

This should be done by a competent

person.

The manufacturer cannot be held lia

ble for damage caused by non-com

pliance with these Warning and

Safety instructions.

-

-

-

-

-

7

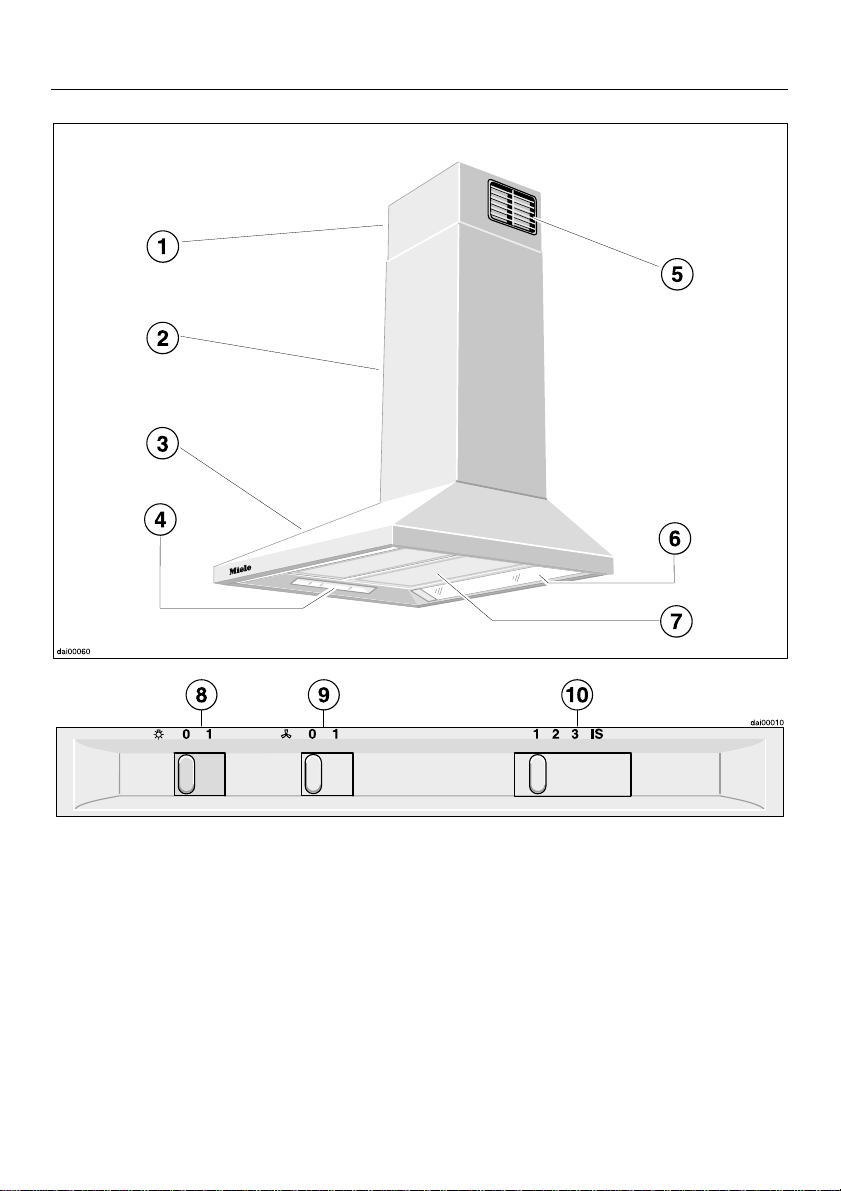

Description of the appliance

a Extension piece

b Tower

c Canopy

d Sliding switches

e Sliding switches

f Lighting for hob

g Grease filters

8

h Sliding switch for the lighting

i Sliding switch for the fan

j Sliding switch for the power setting

Operation

Switching on

Set the sliding switch for the fan i

^

to "1".

The cooker hood will run at the

powersetting most recently selected.

Selecting the power level

You can select one of four power levels

with the sliding switch j depending on

how much the air needs to be filtered.

Levels "1" to "3" are suitable for normal

use.

When frying or cooking food with a

strong aroma you can set the sliding

switch j to the Intensive "IS" setting for

a short period.

After cooking

If the air still needs to be cleared after

cooking, we recommend letting the

cooker hood continue to run for a further ten minutes.

Switching the lighting on and off

The hob lighting h can be switched on

and off independently of the fan.

"0" – lighting off

"1" – lighting off

Then switch the appliance off:

Switching off

^

Set the sliding switch for the fan i

to "0".

9

Brief description

The cooker hood works with

. . . air extraction:

The air is drawn in and cleaned by the

grease filters and directed outside.

If the on-site ventilation system does

not have a non-return flap, the non-re

turn flap supplied must be fitted.

The non-return flap is designed to pre

vent the exchange of room and outside

air taking place.

This flap is closed when the cooker

hood is switched off.

When the cooker hood is switched on,

the non-return flap opens for the cooking vapours to be blown directly outside.

. . . air recirculation:

The air is drawn in and cleaned first by

the grease filters and then by a char

coal filter. The cleaned air is then

recirculated back into the kitchen

-

through grilles in the top of the cooker

hood extension piece.

-

Charcoal filters are available to order

through your Dealer or the Miele Spare

Parts Dept (see back cover for contact

details and "Technical data" for model

number).

Before using the cooker hood in

recirculation mode, ensure that the

charcoal filter is in place, see

"Cleaning and care".

-

10

Before any cleaning or maintenance

work the cooker hood must be dis

connected from the mains supply.

Ensure that:

– it is switched off at the wall socket

and the plug has been withdrawn

(do not pull on the cable, only on the

plug), or

– the fuse has been withdrawn from

the fused spur connection unit, or

– the mains fuse is withdrawn, or

– the screw-out fuse is removed (in

countries where this is applicable).

-

Housing

Warning: The surfaces are susceptible to scratches and abrasion.

Please observe the following cleaning instructions:

^ All external surfaces and controls can

be cleaned using warm water with a

little washing up liquid applied with a

soft sponge.

^

Wipe dry using a soft cloth.

Avoid:

–

cleaning agents containing soda, ac

ids or chlorides,

–

abrasive cleaning agents, e.g. pow

der cleaners and cream cleaners,

–

abrasive sponges, e.g. pot scourers

or sponges which have been previ

ously used with abrasive cleaning

agents.

These would damage the surface.

-

-

Cleaning and care

Stainless steel

Stainless steel surfaces can be cleaned

using a proprietary non-abrasive clean

ing agent designed specifically for use

on stainless steel.

To help prevent re-soiling, proprietary

conditioning agents for stainless steel

can also be used.

Apply sparingly with an even pressure.

E-Cloth

A microfibre "E-Cloth" is available from

the Miele UK Spare Parts Department,

Part Number 98013530, which is suitable for cleaning surfaces such as

stainless steel, glass, plastic and

chrome.

If you are unsure about a particular

product or need further advice please

contact your nearest Miele Sales office. See back page for address.

Grease filters

The re-usable metal grease filters in the

appliance remove solid particles from

the kitchen vapours (grease, dust, etc)

preventing soiling of the cooker hood.

Clean the grease filters when they look

dirty, and avoid letting them become so

dirty that the filtering effect is inefficient.

The grease filters should be cleaned

regularly, at least every 3 or 4 weeks. to

avoid a build-up of fat.

An over saturated filter is a fire haz

ard.

-

-

11

Cleaning and care

To remove a grease filter, press the

^

locking clips towards the middle of

the filter.

^ Remove the filters.

^ Clean the filters:

by hand: with a nylon brush in warm

water with a little washing up liquid.

in a dishwasher: place the filters

with the short side upright in the

lower basket, ensuring the spray arm

is not obstructed.

Depending on the cleaning agent

used, cleaning the grease filters in a

dishwasher can cause permanent

discolouration to the surface of the

filters. However, this will not affect

the functioning of the grease filters in

any way.

^

After cleaning leave the filters to dry

for a while on an absorbent surface

before putting them back in place.

^

When removing the filters for clean

ing also clean off any residues of oil

or fat from the now accessible hous

ing to prevent the risk of these catch

ing fire.

When replacing the grease filters

^

make sure the locking clips are visi

ble facing down towards the hob.

Should the grease filters be put back

upside down:

insert a small screwdriver into the

slits to disengage them. Do not let

them drop on to the hob below.

Fitting / replacing the active

charcoal filters

If the cooker hood is connected for

recirculation two active charcoal filters

must be inserted in addition to the

grease filters. These filters absorb nor

mal kitchen odours.

They are fitted in the canopy above the

grease filters.

Active charcoal filters can be ob

tained from your dealer or the Miele

Spare Parts Department.

Refer to the section "Technical data"

for type and reference number.

The filters are supplied with fitting instruc

-

tions. Ensure these are carefully followed.

Replace the filters when they no longer

-

absorb kitchen odours effectively.

-

They should, however, be replaced at

least every 6 months.

-

-

-

-

12

Defective lighting

If the lighting is not working the light

tube and/or starter may need changing.

Disconnect the cooker hood from

the mains supply. Ensure that:

– it is switched off at the wall socket

and the plug has been withdrawn

(do not pull on the cable, only on the

plug), or

– the fuse has been withdrawn from

the fused spur connection unit, or

– the mains fuse is withdrawn, or

– the screw-out fuse is removed (in

countries where this is applicable).

Cleaning and care

^ Replace the light tube or the starter.

^ Put the glass cover back into place

and secure with the glass cover holders.

^

Unscrew the fixing screw of either the

right or left hand holder for the glass

cover. When doing this, push the

glass cover upwards so that it does

not fall on the hob surface.

^

Take off the glass cover holder.

^

Take out the glass cover, guiding it

downwards at an angle.

^

When changing the light tube also

unscrew the second glass cover

holder.

13

Appliance dimensions

Safety regulations prohibit the fitting

of this cooker hood over a solid fuel

stove.

For safety reasons a minimum safe

distance must be maintained be

tween the top of the hob / cooker

and the bottom of the cooker hood:

– 450 mm above electric hobs /

cookers

– 650 mm above gas hobs / cookers

– 650 mm above an open grill

from our range.

See "Warning and Safety instruc

tions" for further information.

A distance of 650 mm may be preferable above electric hobs / cookers

to give more working space.

When deciding dimension S ensure

that the minimum specified safety distance between the hob / cooker and the

cooker hood is maintained. If the hood

is fitted flush to the ceiling make sure

that the remaining distance to the ceiling is not greater or less than appliance

height H.

-

-

14

Recirculation

H = 820 – 1110 mm

Extraction

H = 800 – 1020 mm with extraction

through the wall.

H = 730 – 1020 mm with extraction

through the ceiling.

To fit the tower, distance A between the

top of the tower and the ceiling must be

at least 20 mm.

The shaded area represents the

wall or ceiling area for the vent

cut-out, and for fitting the connection

socket.

(For recirculation mode the connection

socket may only be fitted in a wall area).

Connection for extraction C 125 mm

Appliance dimensions

15

Installation

Assembly parts

16

a 2 recirculation grilles

(for recirculation mode only)

Installation

b 2 protective sheets

for use when fitting the tower.

c 1 directional unit

(for recirculation mode only)

d 1 flexible aluminium hose for con

necting the directional unit to the ex

haust socket on the motor unit.

e 2 hose clips for securing the ex

haust ducting.

f 1 non-return valve for fitting into the

exhaust connection on the motor unit

(for extraction mode only).

g Upper retaining plate B for secur-

ing the extension piece.

h Middle retaining plate C for addi-

tional stability for the tower.

i Lower retaining plate A for secur-

ing the canopy and the motor unit.

-

-

12 large headed screws 5 x 40 mm

and

12, S 8 plugs for securing the retaining

plates and the canopy.

2, M 6 locking nuts for securing the

motor unit.

4 screws 3.9 x 7.5 mm for securing the

tower and the extension piece.

17

Installation

Retaining plates

There are three retaining plates A, B and

C for fixing the cooker hood to the wall.

First of all drill the holes for attaching the

canopy and for fitting retaining plate A.

^ Before fitting the retaining plate draw

a vertical line centrally above the hob

on the back wall.

^ Mark measurement S from the hob

surface upwards (see "Appliance dimensions"). This marks the height of

the lower rim of the cooker hood.

^

DA 196-2:

Drill an 8 mm C hole on the middle

line, 18 mm above the height marked

S. Insert an S8 plug into the hole.

18

^

DA 199-2:

Drill two 8 mm C holes, 18 mm above

the height marked S and 250 mm right

and left of centre. Insert S8 plugs.

Retaining plate A

^

Drill two 8 mm C holes, one at

S + 100 mm and one at S + 425 mm

on the centre line for the retaining

plate (see "Appliance dimensions").

Insert S8 plugs.

Lightly secure retaining plate A into

^

position using 5 x 40 mm screws

through the two holes and use the

notches to align with the middle line.

Installation

Retaining plate B

Hold retaining plate B to the wall and

^

push up until it is directly below the

ceiling. Use the notches and the mid

dle line to align it horizontally. Mark

the 4 drill holes on the wall.

Drill two C 8 mm holes into the wall,

^

and push the S8 plugs into the holes.

Screw on the retaining plate with two

^

5 x 40 mm screws.

Retaining plate C

-

^

Drill 4 more 8 mm C holes through

the now fitted retaining plate and

press S8 plugs into the holes.

^

Screw two 5 x 40 mm screws into the

upper two holes.

Retaining plate C only needs to be fit

ted if dimension Y is greater than

415 mm. It provides additional stability

for the extension piece.

-

19

Installation

At a maximum distance of 415 mm

^

from the ceiling hold retaining plate C

against the wall and use the notches

to align it with the middle line. Mark

the two drill holes.

Drill two C 8 mm holes into the wall,

^

and press the S8 plugs into the holes.

Screw on retaining plate C with two

^

5 x 40 mm screws.

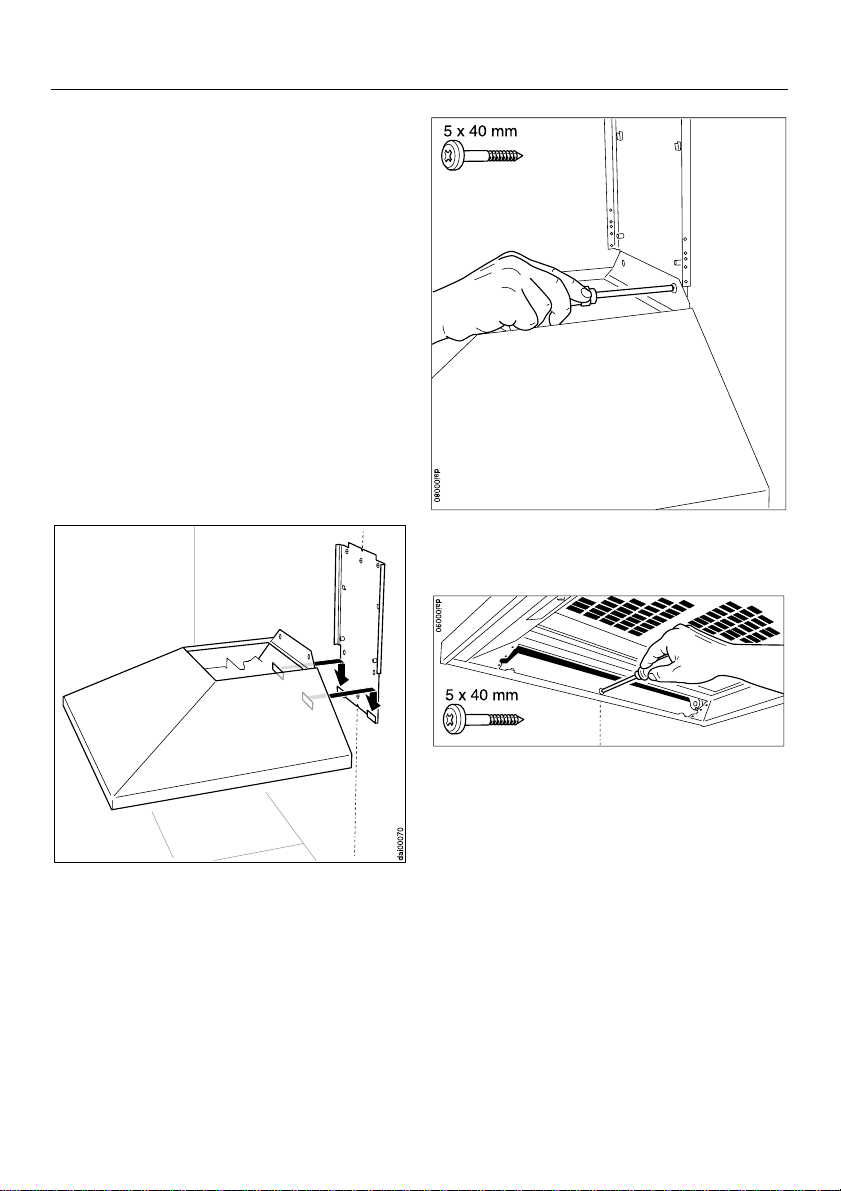

Canopy

Before fitting the canopy the glass

^

cover of the lighting tube must first

be removed (see relevant section in

"Cleaning and care").

^ Secure the canopy with 5 x 40 mm

screws into each drilled hole.

^

Hang the canopy on the angle brack

ets on retaining plate A.

20

^

DA 196-2:

Secure the canopy with a 5 x 40 mm

screw.

^

DA 199-2:

Secure the canopy with two5x40mm

screws.

^

Replace the glass cover.

Installation

Motor unit

First loosely screw the two self tap

^

ping nuts onto the threaded bolts on

retaining plate A.

Leave a gap of approx. 3 mm for

hanging the motor on afterwards.

Air extraction

If a non-return valve is not present in

^

the venting system the non-return

flap supplied must be fitted onto the

exhaust connection in the motor unit.

The flaps must open upwards.

-

^ For extraction connection secure a

flexible hose or an extraction pipe to

the exhaust connection on the motor

unit using a hose clip. Lead the top

end to the open air through the wall

or ceiling cut-out.

^

Fit the motor unit onto the hooks on

retaining plate A and slide down be

hind the nuts.

^

Tighten the nuts.

^

For further installation instructions

proceed to "Connection for air extrac

tion".

-

-

21

Installation

Recirculation

If site conditions are not suitable for the

cooker hood to be used for air extrac

tion the appliance must be connected

for recirculation.

^ Push the directional unit on to the top

retaining plate.

-

Electrical connection

First push the 6 pole plugs on the

^

canopy connection cable into the ter

minals on the motor unit.

^ Push the cable into the groove shown.

-

^

Secure the flexible hose supplied to

the directional unit and to the exhaust

connection on the motor unit using

hose clips.

^

Fit the charcoal filters (see "Cleaning

and Care").

22

^

Pass the connection cable up to the

left of the motor and through the ca

ble guide.

^

Connect the appliance to the mains

via a fused spur or fused socket as

appropriate.

Before connecting the appliance

read the safety notes in "Warning

and Safety Instructions" and in the

"Electrical connection" section.

-

Installation

Extension piece

An extension piece allows the cooker

hood to be fitted at varying distances

from the ceiling (see section "Appliance

dimensions").

The extension piece has an opening at

each side. These are needed for venti

lation when the appliance is being used

in recirculation mode.

Recirculation Extraction

For recirculation the extension piece is

fitted with the openings at the top.

For air extraction the openings are not

required. In this case the extension

piece is fitted with the openings at the

bottom. They are then covered by the

tower.

-

Before fitting the extension piece re

^

move the protective foil.

^ Bend the top hanging retainers

approx. 45° inwards. This makes fitting easier.

Recirculation Extraction

-

^

Pull the extension piece slightly out

wards and push over the upper re

taining plate.

-

-

23

Installation

For recirculation make sure that the

openings in the extension piece are po

sitioned at the same height as the air

outlets in the directional unit of the fan

motor.

-

The paper protective sheets protect the

extension piece from being scratched

when the tower is fitted. They are re

moved when fitting is complete.

-

^ Screw the extension piece firmly to

the upper retaining plate at each side

with two screws, 3.9 x 7.5 mm.

Note for recirculation:

^

Fit the recirculation grilles into the ex

tension piece and into the directional

unit behind so that the slats point

downwards.

^ Fold each protective sheet at the top.

^ Remove the protective foil from

around the sticking points.

^ Stick the protective sheet to the ex-

tension piece so that it is smooth at

the sides and flush at the bottom.

-

24

Fitting the tower

Before fitting the extension piece re

^

move the protective foil from the pro

tective sheets.

^ Hold the tower gently apart and fit it

over the extension piece.

Installation

-

-

Now secure the tower on both sides

^

with 2 screws 3.9 x 7.5 mm.

Remove the protective foil from the

^

canopy.

^ Then slide the tower downwards

approx. 2 cm into the vapour canopy.

^

Align the tower.

^

Remove the protective sheets.

^ Before using the appliance for the

first time take the grease filter out and

remove the protective foil from the fil

ter frame. Then replace the filter.

-

25

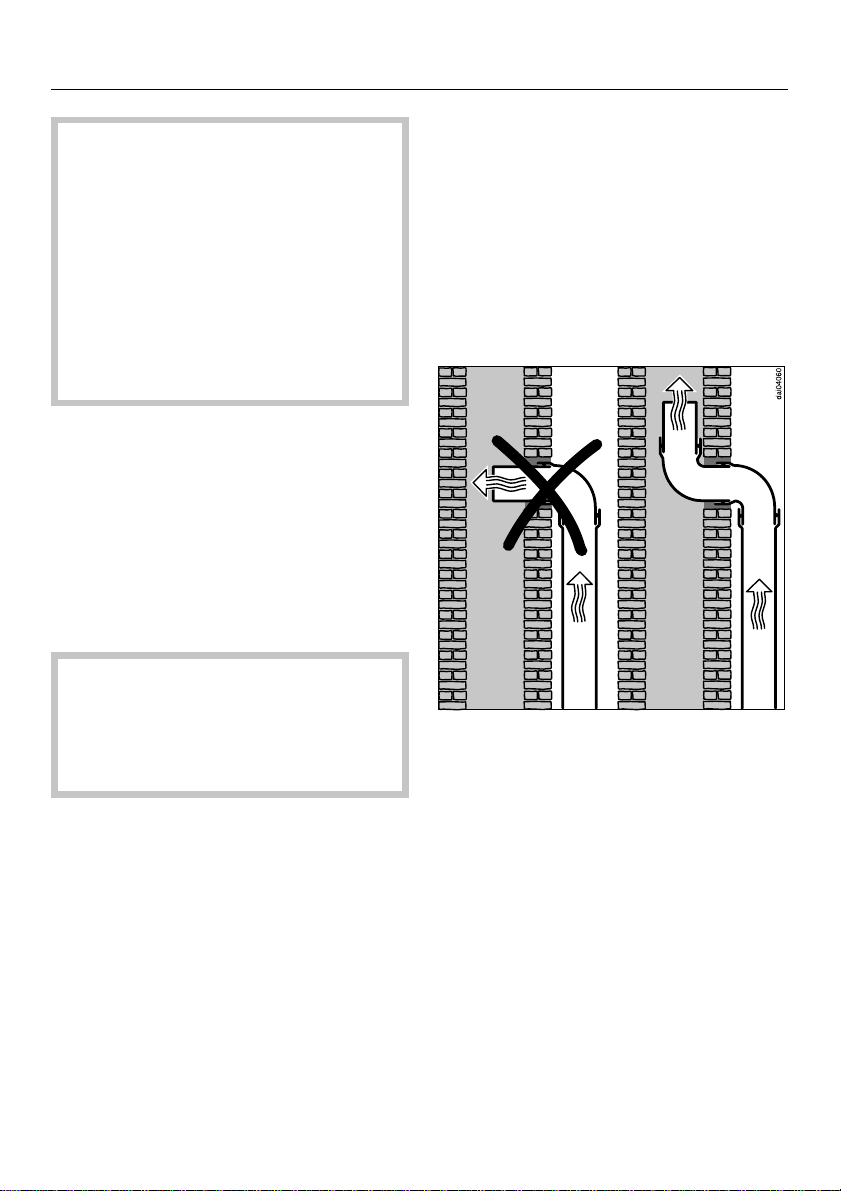

Connection for air extraction

Important: To avoid the danger of

toxic fumes please observe the

Warning and Safety instructions.

This is especially crucial when using

the cooker hood at the same time as

another heating appliance which re

lies on air from the same room.

The cooker hood should be installed

according to local building regula

tions. Seek approval from the build

ing inspector where necessary.

– All ducting, pipework and fittings

must be of non-flammable materials.

– The exhaust ducting should be as

short and straight as possible.

– To ensure efficient air extraction the

diameter of the exhaust ducting

should not be less than 125 mm.

-

-

-

Where ducting is horizontal, it must

–

be laid to slope away at at least 1 cm

per metre.

This is to ensure that condensate

cannot drain back into the cooker

hood.

If the exhaust air is to be ducted into

–

the open air, the installation of a tele

scopic wall vent is recommended.

-

If exhaust ducting with a diameter of

less than 125 mm or flat ducting

were used, the noise level of the

cooker hood would increase and ex

traction would be less efficient.

Only reduce the diameter of the

ducting if absolutely necessary, e.g.

where narrower ducting has already

been installed.

–

Only use wide radius bends. Tight

bends reduce the air throughput of

the cooker hood.

–

Only use smooth pipes or flexible

hoses made from non-flammable ma

terials for extraction connection.

26

–

-

If the exhaust air is to be ducted into

a vent flue, the ducting must be di

rected in the flow direction of the

flue.

-

-

Important:

If the exhaust ducting is to run through

rooms, ceiling space etc. where there

may be great variations in temperature

between the different areas, the prob

lem of condensation will need to be ad

dressed.The exhaust ducting will need

to be suitably insulated.

-

Condensate trap

In addition to insulating the exhaust

ducting, we recommend that a suitable

condensate trap is also installed to col

lect and evaporate any condensate

which may occur.

Condensate traps are available from

builders merchants.

When installing a condensate trap,

ensure that it is positioned vertically

and if possible directly above the exhaust connection.

Connection for air extraction

-

-

27

Electrical connection

All electrical work should be under

taken by a suitably qualified and

competent person in strict accor

dance with national and local safety

regulations.

Installation, repairs and other work

by unqualified persons could be

dangerous. The manufacturer can

not be held liable for unauthorised

work.

Ensure power is not supplied to the

appliance while installation or repair

work is being carried out.

U.K., IRL: The cooker hood is supplied

for connection to an a.c. 230 V single

phase 50 Hz supply.

AUS: The cooker hood is supplied for

connection to an a.c. single phase

240 V, 50 Hz supply.

The voltage, rated load and fusing are

given on the data plate. This is visible

when the grease filters have been removed. Ensure that these match the

household mains supply.

For U.K.: Connection should be made

either by a double pole fused spur con

nection unit, or a fused plug and a suit

able switched socket. The On-Off

switch should be easily accessible after

the appliance has been built in.

When switched off there must be an

all-pole contact gap of 3 mm in the

switch (including switch, fuses and re

lays according to EN 60 335).

If the socket is not accessible after in

stallation (depending on country) an

additional means of disconnection must

be provided for all poles.

-

-

-

-

For extra safety it is advisable to install

a residual current device (RCD) with a

trip current of 30 mA (in accordance

with DIN VDE 0664, VDE 0100 Sec

tion 739).

Do not connect via an extension lead.

Important UK

If the appliance is fitted with a

non-rewireable plug (BS 1363 UK) and

the socket outlets are not suitable for

the plug supplied, or if the existing plug

needs to be replaced by a new one, the

old plug will need to be cut off and an

appropriate plug fitted. The fuse carrier

and the fuse should be removed from

the old plug and disposed of. The old

plug should then be disposed of and

on no account inserted into any socket

elsewhere in the house (electric shock

hazard).

The fuse cover must be re-fitted when

changing the fuse and if the fuse cover

is lost the plug must not be used until a

suitable replacement is obtained.

The colour of the correct replacement

cover is that of the coloured insert in

-

the base of the plug or the colour that is

-

embossed in words in the base of the

plug (as applicable to the design of

plug fitted).

Replacement fuses should be ASTA ap

proved to BS 1362 and have the cor

rect rating.

Replacement fuses and fuse covers

may be purchased from your local elec

trical supplier.

-

-

-

-

28

Important

Electrical connection

The wires in the mains lead are col

oured in accordance with the following

code:

Green/yellow = earth

Blue = neutral

Brown = live

If the appliance is to be connected via

a plug and socket, please note the fol

lowing:

As the colours of the wires in the mains

lead of this appliance may not corre

spond with the coloured markings iden

tifying the terminals in your plug, proceed as follows:

^ The wire which is coloured green and

yellow must be connected to the terminal in the plug which is marked

with the letter E or by the earth symbol - or coloured green or green

and yellow.

^ The wire which is coloured blue must

be connected to the terminal which is

marked with the letter N or coloured

black.

-

-

-

-

^

For U.K., IRL: The wire which is col

oured brown must be connected to

the terminal which is marked with the

letter L or coloured red.

^

For Australia: The wire which is col

oured brown must be connected to

the terminal which is marked with the

letter A or coloured red.

WARNING:

THIS APPLIANCE MUST BE

EARTHED

-

-

29

After Sales Service

In the event of a fault which you cannot

correct yourself, or if the appliance is

under guarantee please contact:

Your Miele Dealer

–

or

The Service Department (see back

–

cover for address).

When contacting the Service Depart

ment, please quote the model and se

rial number of your appliance These are

shown on the data plate which is visible

when the grease filters are removed.

Please note that telephone calls may

be monitored and recorded to improve our service.

-

-

30

Technical data

Rated load

– DA 196-2 . . . . . . . . . . . . . . . . . 165 W

– DA 199-2 . . . . . . . . . . . . . . . . . 168 W

Motor

– DA 196-2, DA 199-2 . . . . . . . . . 150 W

Lighting

– DA 196-2. . . . . . . . . . . . . . . . . . . 15 W

– DA 199-2. . . . . . . . . . . . . . . . . . . 18 W

Voltage

UK, IRL, NZ . . . . . . . . . . . . . . . . . 230 V

AUS . . . . . . . . . . . . . . . . . . . . . . . 240 V

Frequency. . . . . . . . . . . . . . . . . ~ 50 Hz

Fuse rating (UK). . . . . . . . . . . . . . . 13 A

Fuse rating (IRL). . . . . . . . . . . . . . . 10 A

AUS, NZ:

Plug rating . . . . . . . . . . . . . . . . . . . 10 A

Test marks . . . . . . . . . . Electrical safety

. . . . . . . . . . . . . . . . . . . . . . C-Tick Mark

Fan performance

Extraction power according to EN 61591

Extraction system C 125 mm:

Levels 1-3. . . . . . . . . . . . 200 - 380 m

Intensive level IS . . . . . . . . . . . 485 m

Unrestricted. . . . . . . . . . . . . . . 560 m

3

3

3

Recirculation with charcoal filter:

Levels 1-3. . . . . . . . . . . . 180 - 340 m

Intensive level IS . . . . . . . . . . . 420 m

3

3

Charcoal filter:

Miele Active charcoal filter DKF 6

/h

/h

/h

/h

/h

Electrically suppressed

according to AS/NZS 1044

31

Änderungen vorbehalten / 0604

M.-Nr. 05 609 480 / V02

Dieses Papier besteht aus 100% chlorfrei gebleichtem Zellstoff und ist somit umweltschonend.

Loading...

Loading...