Operating and installation instructions

ProLine deep fat fryer

To avoid the risk of accidents or damage to the appliance it is essential

to read these instructions before it is installed and used for the first time.

en-GB M.-Nr. 07 180 430

Contents

Warning and Safety instructions.......................................................................... 4

Caring for the environment ................................................................................ 13

Guide to the appliance........................................................................................ 14

Deep fat fryer......................................................................................................... 14

Indicators............................................................................................................... 15

Accessories supplied ............................................................................................ 15

Before using for the first time ............................................................................ 16

Cleaning the ProLine element for the first time..................................................... 16

Switching on the ProLine element for the first time .............................................. 16

Operation.............................................................................................................. 17

Fryer lid.................................................................................................................. 17

Rotary control........................................................................................................ 17

Switching on.......................................................................................................... 17

Switching off.......................................................................................................... 17

Residual heat indicator.......................................................................................... 18

Before frying.......................................................................................................... 18

Deep/shallow frying............................................................................................... 19

Tips for frying ........................................................................................................ 22

After frying............................................................................................................. 23

Safety features..................................................................................................... 24

Safety switch-off ................................................................................................... 24

Cleaning and care ............................................................................................... 25

Stainless steel frame/control panel and lid ........................................................... 26

Rotary controls...................................................................................................... 26

Frying basket......................................................................................................... 26

Oil reservoir ........................................................................................................... 27

Problem solving guide ........................................................................................28

Optional accessories ..........................................................................................29

After sales service............................................................................................... 30

Contact in case of malfunction ............................................................................. 30

Data plate .............................................................................................................. 30

Warranty ................................................................................................................ 30

Installation............................................................................................................ 31

Safety instructions for installation ......................................................................... 31

Safety distances.................................................................................................... 32

Installation notes ................................................................................................... 35

2

Contents

Building-in dimensions ......................................................................................... 36

Installing several ProLine elements ....................................................................... 37

Installation ............................................................................................................. 39

Electrical connection ............................................................................................. 43

3

Warning and Safety instructions

This deep fat fryer complies with all relevant safety requirements.

Inappropriate use can, however, lead to personal injury and damage to property.

To avoid the risk of accidents and damage to the deep fat fryer,

please read these instructions carefully before installation and before using it for the first time. They contain important notes on installation, safety, use and maintenance.

Miele cannot be held liable for damage caused by non-compliance

with these instructions.

Keep these instructions in a safe place and ensure that new users

are familiar with the content. Pass them on to any future owner.

4

Warning and Safety instructions

Correct application

This deep fat fryer is intended for use in domestic households and

similar environments including, for example:

– in kitchens used by employees in shops, offices and other com-

mercial settings

– by customers in hotels, motels and other residential settings

– in bed and breakfast accommodation

This deep fat fryer is not intended for outdoor use.

This deep fat fryer is intended for domestic use only to cook food.

Any other use is not supported by the manufacturer and could be

dangerous.

5

Warning and Safety instructions

Safety with children

Children between the ages of 0and8years old are not permitted

to use this deep fat fryer. Children 8years and older are permitted to

use this deep fat fryer but must be supervised at all times. This deep

fat fryer can be used by people with reduced physical, sensory or

mental capabilities or lack of experience and knowledge if they are

supervised at all times or if they have been shown how to use it in a

safe way and recognise and understand the consequences of incorrect operation. Children younger than 8years old must be kept away

from the appliance and its connection cable. Children must not be

allowed to carry out cleaning or maintenance work.

Please supervise children in the vicinity of the deep fat fryer and

do not let them play with it.

The deep fat fryer gets hot when in use and remains hot for a

while after being switched off. Keep children well away from the appliance until it has cooled down and there is no danger of burning.

Ensure that children cannot reach the drain tap where hot liquid

could be drained out.

Danger of burning.

Do not store anything which might arouse a child’s interest in storage

areas above or behind the deep fat fryer. Otherwise they could be

tempted into climbing onto the appliance with the risk of burning

themselves.

Danger of suffocation! Whilst playing, children may become en-

tangled in packaging material (such as plastic wrapping) or pull it

over their head with the risk of suffocation. Keep packaging material

away from children.

6

Warning and Safety instructions

Technical safety

Unauthorised installation, maintenance and repairs can cause

considerable danger for the user. Installation, maintenance and repairs must only be carried out by a Miele authorised technician.

A damaged deep fat fryer can be dangerous. Check it for visible

signs of damage. Do not use a damaged appliance.

Reliable and safe operation of the deep fat fryer can only be as-

sured if it has been connected to the mains electrical supply.

The electrical safety of this deep fat fryer can only be guaranteed

when correctly earthed. It is essential that this standard safety requirement is met. If in any doubt please have the electrical installation tested by a qualified electrician.

Before connecting the deep fat fryer to the mains supply, ensure

that the connection data on the data plate (voltage and frequency)

match the mains electricity supply.

This data must be checked before connecting the appliance. Consult

a qualified electrician if in any doubt.

Do not connect the deep fat fryer to the mains electricity supply

by a multi-socket unit or an extension lead. These do not guarantee

the required safety of the appliance (fire hazard).

For safety reasons, this deep fat fryer may only be used after it

has been built in.

This deep fat fryer must not be used in a non-stationary location

(e.g. on a ship).

Never open the casing of the deep fat fryer.

Touching or tampering with electrical connections or components

and mechanical parts is highly dangerous to the user and can cause

operational faults.

7

Warning and Safety instructions

While the deep fat fryer is under warranty, repairs should only be

undertaken by a Miele authorised service technician. Otherwise the

warranty is invalidated.

Miele can only guarantee the safety of the appliance when genu-

ine original Miele replacement parts are used. Faulty components

must only be replaced by Miele spare parts.

The deep fat fryer is not intended for use with an external timer

switch or a remote control system.

If the plug is removed from the connection cable or if the cable is

supplied without a plug, the deep fat fryer must be connected to the

electrical supply by a suitably qualified electrician.

If the mains connection cable is damaged, it must be replaced

with a special mains connection cable by a qualified electrician (see

“Electrical connection” in the “Installation” chapter).

During installation, maintenance and repair work, the deep fat

fryer must be completely disconnected from the mains electricity

supply. It is only completely isolated from the electricity supply

when:

– The mains fuse is disconnected.

– The screw-out fuse is removed (in countries where this is applic-

able).

– The plug (if present) is removed from the socket. To do this, pull

the plug and not the mains connection cable.

If the deep fat fryer is built in behind a furniture front (e.g. a door),

do not close the furniture door while the deep fat fryer is in use. Heat

and moisture can build up behind the door when closed. This can

result in damage to the deep fat fryer, the housing unit and the floor.

Do not close the furniture door until the residual heat indicators have

gone out.

8

Warning and Safety instructions

Risk of electric shock.

Do not use the deep fat fryer if it is damaged. If you detect a fault

during use switch it off immediately. Disconnect it from the mains

electricity supply. Contact Miele Service.

9

Warning and Safety instructions

Correct use

The deep fat fryer gets hot when in use and remains hot for some

time after being switched off. The risk of burning is present until the

residual heat indicators have gone out.

Do not use the deep fat fryer to heat up the room. Due to the high

temperatures radiated, objects left near the deep fat fryer could

catch fire.

Overheated fat and oil can ignite and catch fire. Never leave the

deep fat fryer unattended. Do not attempt to extinguish burning oil or

fat with water.

Switch the appliance off and carefully smother the flames with a fire

blanket or with the fryer lid.

Fire hazard.

Never use naked flames, e.g. an ignited lighter, near the deep fat

fryer.

Do not cover the deep fat fryer, e.g. with a cloth or protective foil.

The material could catch fire, shatter or melt if the appliance is

switched on by mistake or if residual heat is still present.

The frying basket must only be covered using the cover supplied

with the appliance.

You could burn yourself on the hot deep fat fryer. Protect your

hands with heat-resistant pot holders or gloves when handling hot

pots and pans. Do not let them get wet or damp, as this causes heat

to transfer through the material more quickly with the risk of scalding

or burning yourself.

When using an electrical appliance, e.g. a hand-held food blender,

near the deep fat fryer, ensure that the cable of the electrical appliance cannot come into contact with the hot deep fat fryer. The insulation on the cable could become damaged.

The heater element must be lowered before the deep fat fryer is

switched on.

10

Warning and Safety instructions

Do not pour hot fat from frying into plastic containers. These will

melt at high temperatures. Only use heat-resistant containers for hot

fat.

The deep fat fryer must only be used when it has been filled with

oil and without the cover on it.

Clean or change dirty oil or fat in good time. Oil or fat containing

impurities is liable to catch fire.

Do not dispose of used cooking oil down the sink. It can damage

pipework and cause blockages in the water pipes.

Dispose of it safely with your household food waste, or ask your

local authority about disposal schemes in your area.

Handling and cooking food correctly is essential for maintaining

good health. Please pay careful attention to the information provided

in “Tips for frying” in the “Operation” chapter.

Where several ProLine elements are installed side by side:

Hot objects can damage the seal on the spacer bars. Do not place

hot pans near or on the spacer bar.

11

Warning and Safety instructions

Cleaning and care

Do not use a steam cleaning appliance to clean this deep fat fryer.

The steam could reach electrical components and cause a short circuit.

12

Caring for the environment

Disposal of the packing material

The packaging is designed to protect

the appliance from damage during

transportation. The packaging materials

used are selected from materials which

are environmentally friendly for disposal

and should be recycled.

Recycling the packaging reduces the

use of raw materials in the manufacturing process and also reduces the

amount of waste in landfill sites.

Disposing of your old appliance

Electrical and electronic appliances often contain valuable materials. They

also contain specific materials, compounds and components, which were

essential for their correct function and

safety. These could be hazardous to human health and to the environment if

disposed of with your domestic waste

or if handled incorrectly. Please do not,

therefore, dispose of your old appliance

with your household waste.

Please dispose of it at your local community waste collection / recycling

centre for electrical and electronic appliances, or contact your dealer or

Miele for advice. You are also responsible (by law, depending on country) for

deleting any personal data that may be

stored on the appliance being disposed

of. Please ensure that your old appliance poses no risk to children while being stored prior to disposal.

13

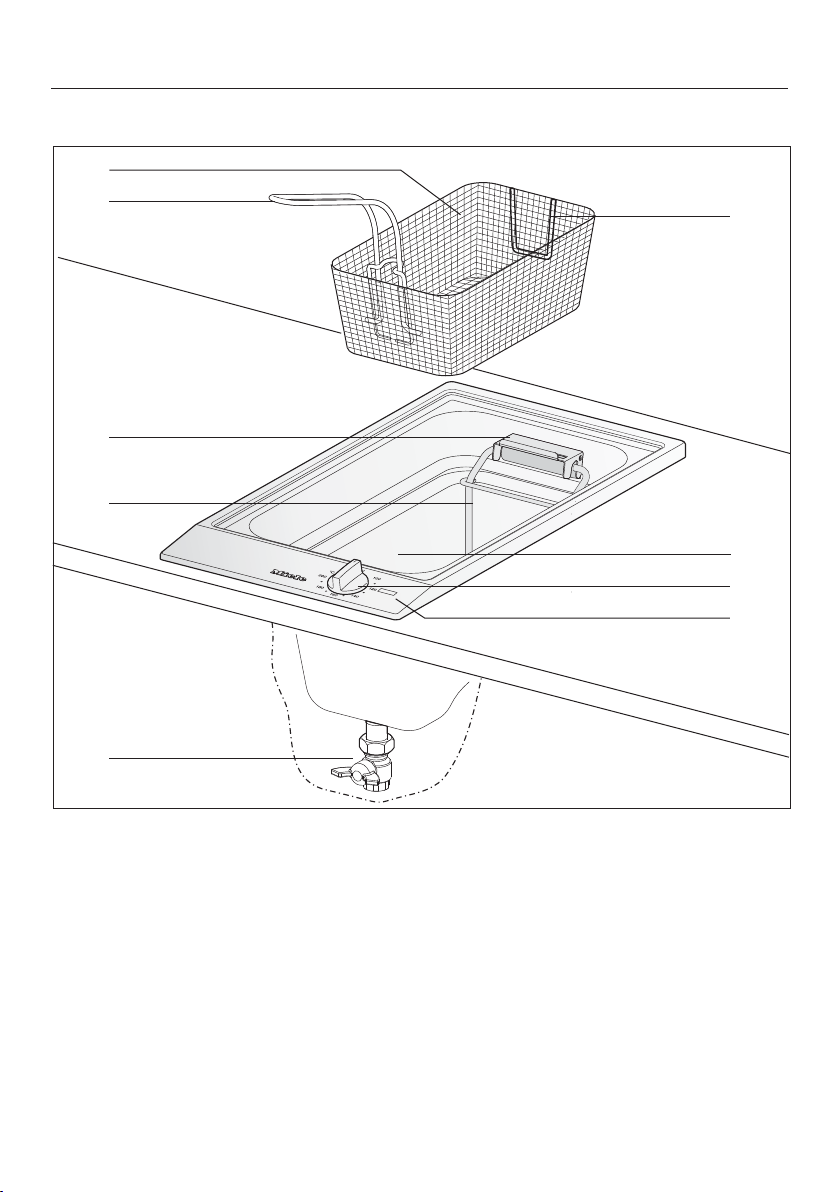

Guide to the appliance

a

b

d

e

f

i

h

c

g

Deep fat fryer

a

Frying basket

b

Handle (folds away, removable)

c

Hanging facility

d

Bracket for hanging the frying basket

on

e

Heating element (can be raised up)

14

f

Drain tap

g

Indicators

h

Control knob

i

Oil reservoir

Guide to the appliance

Indicators

j

In-operation indicator

k

Temperature indicator light

l

Residual heat indicator

Accessories supplied

The accessories supplied with your appliance as well as a range of optional

ones are available to order from Miele

(see “Optional accessories”).

Frying basket

Fryer lid

Cover to protect the oil reservoir after

use.

15

Before using for the first time

Please stick the extra data plate for

the appliance supplied with this documentation in the space provided in

the “After sales service” section of

this booklet.

Remove any protective wrapping and

stickers.

Cleaning the ProLine element for the first time

Fill the oil reservoir to the max.

marker with water (approx. 4litres)

and add a little washing-up liquid.

Turn the rotary control in a clockwise

direction to 130°C and bring the water briefly to the boil.

Switch the deep fat fryer off and drain

the water off into a heat-resistant

container (see “After frying” in the

“Operation” chapter).

Leave the appliance to cool down

and then raise the heating element.

Switching on the ProLine element for the first time

The metal components have a protective coating which when heated for the

first time will give off a slight smell and

possibly some vapours.

The smell and any vapours given off do

not indicate a faulty connection or appliance and they are not hazardous to

health.

Wipe the oil reservoir and all other

surfaces of the appliance with a

damp cloth and then dry them.

Close the drain tap.

16

Operation

Fryer lid

To remove the fryer lid press the

cover on the left or right hand side

with your finger.

Use your other hand to lift the cover

off the fryer.

Hot fat or oil.

Risk of burning due to hot fat or oil.

Do not replace the lid until the deep

fat fryer is cold.

Rotary control

Do not turn the control to “0” by

turning it past 200°C.

Switching on

Risk of fire with overheated food.

Unattended food can overheat and

catch alight.

Do not leave the deep fat fryer unattended when you are using it.

Do not switch the deep fat fryer on

when it is empty or with the heating

element raised up.

Turn the control clockwise to the re-

quired temperature.

The in-operation indicator and the temperature indicator will light up. The residual heat indicator will light up after a

certain temperature has been reached.

The temperature indicator light will

switch on and off intermittently in conjunction with the heating element. It

will only light up when the heating element is on.

Switching off

Turn the control anti-clockwise to the

0position.

17

Operation

Residual heat indicator

If the deep fat fryer is still hot, the residual heat indicator will light up after it

has been switched off.

The residual heat indicator remains on

until the deep fat fryer is cool enough to

touch.

Danger of burning due to hot

surfaces.

The surfaces will be hot after cook-

ing.

Do not touch the surfaces while the

residual heat indicators are on.

Before frying

Do not use the fryer lid when deep

fat frying.

Only use oil and fat that has a high

flash point. Liquid or solid fat can be

used.

Never mix different types of oil or fat

together.

The oil reservoir must be filled with sufficient oil or fat for frying (at least 3litres

or 3kg, maximum 4litres or 4kg).

Check that the drain tap is closed.

Fill the oil reservoir with oil or fat.

Solid fat should be cut up into small

pieces first.

When re-using fat that has solidified

in the reservoir, make a hole in the fat

as far as the heating element. This allows any water which has collected

under the fat to evaporate.

Turn the control to 100°C and wait

until the fat has melted.

18

Check the level in the reservoir. This

needs to be between the minimum

and maximum level markers at the

back of the reservoir.

Deep/shallow frying

Set the temperature required (see

chart) and wait until the temperature

indicator goes out for the first time.

The oil has now reached the set temperature.

Carefully lower the frying basket con-

taining the food to be fried into the

hot oil. If the oil froths a lot, lift the

basket out of the oil briefly and then

slowly lower it into the hot oil again.

When the food has cooked, lift the

basket out of the hot oil. Shake the

basket a little to remove any excess

oil, and then hang it on its bracket.

Do not leave food suspended over

the reservoir for too long as steam

from the oil can cause the food to

lose it crispness. Finally, place the

food onto kitchen paper towel to

soak up any excess oil.

Operation

Whilst frying food make sure you do

not touch the hot oil. Protect your

hands in particular, e.g. by wearing

heat-resistant oven gloves.

19

Operation

Food, fresh Quantity [°C] [min]*

Doughnuts Qty4 170 6–8

Camembert 4 x 1/2 pieces 170 2–3

Raw battered vegetables 400g 170 7–9

Chicken quarters, breaded 2pieces, each

250g

Croquette potatoes 400g 170 pre-fry 2–4

Apple turnovers Qty 5 170 6–8

Parsley 180 1–2

Chips 400g 170 pre-fry 4–6

Turkey steaks, unbreaded 2pieces, each

250g

Escalopes 200g 180 5–7

Drop cookies Qty4 170 6–8

Banana fritters Qty 2 170 3–4

Temperature / Frying times in min.

*The frying times given in the chart are only a guide.

170 8–10

fry 3–5

fry 2–4

180 3–5

20

Operation

Food, frozen Quantity [°C] [min]*

Fish fingers 300g 170 4–6

Croquette potatoes 400g 170 pre-fry 1–2

fry 3–4

Chips 250g

400g

Plaice fillet, unbreaded 300g 170 3–5

Squid rings, unbreaded 250g 170 2–3

Temperature / Frying times in min.

*The frying times given in the chart are only a guide.

170 2–3

3–4

21

Operation

Tips for frying

Handling and cooking food correctly

is essential for maintaining good

health. Food should only be fried until golden, not dark brown.

Never add salt to hot fat. This will

cause the fat to boil over.

– The oil or fat needs to be hot enough

to seal the food quickly. If the temperature is too low the food will absorb too much fat making it difficult

to digest.

It is important to wait until the temperature indicator goes out (which

means that the set temperature has

been reached) before adding food to

the fryer.

– Best results are achieved by keeping

to the temperature guidelines given in

the chart. Only use temperatures

above 170°C where absolutely necessary (e.g. for fish and meat which

has not been coated in breadcrumbs

or pastry).

– Heating the oil for too long will speed

up its deterioration rate.

– Food should be as dry as possible for

frying, as moisture can cause frothing. Damp food should be dried using

paper towel. Remove any excess ice

and frost from deep frozen food.

– Lower the basket slowly, so that the

oil does not froth over.

– Rinsing freshly cut potatoes under

cold running water and then drying

them thoroughly with paper towel will

prevent them sticking together.

– Never season food before frying. Salt,

seasoning, icing sugar etc. should be

added after the food has been removed from the basket and drained

of excess oil.

– When frying deep frozen food, use

the lowest temperature quoted on the

manufacturer’s packaging.

– Keep frying times as short as pos-

sible.

– Select the correct ratio of food to fat/

oil. This should be between

1:10and1:15. You will need between

1and1.5litres of fat/oil to fry 100g of

chips, for example. More oil would

heat the food being fried to too high a

temperature; too much food would

cause the temperature of the fat/oil to

drop too low.

22

Operation

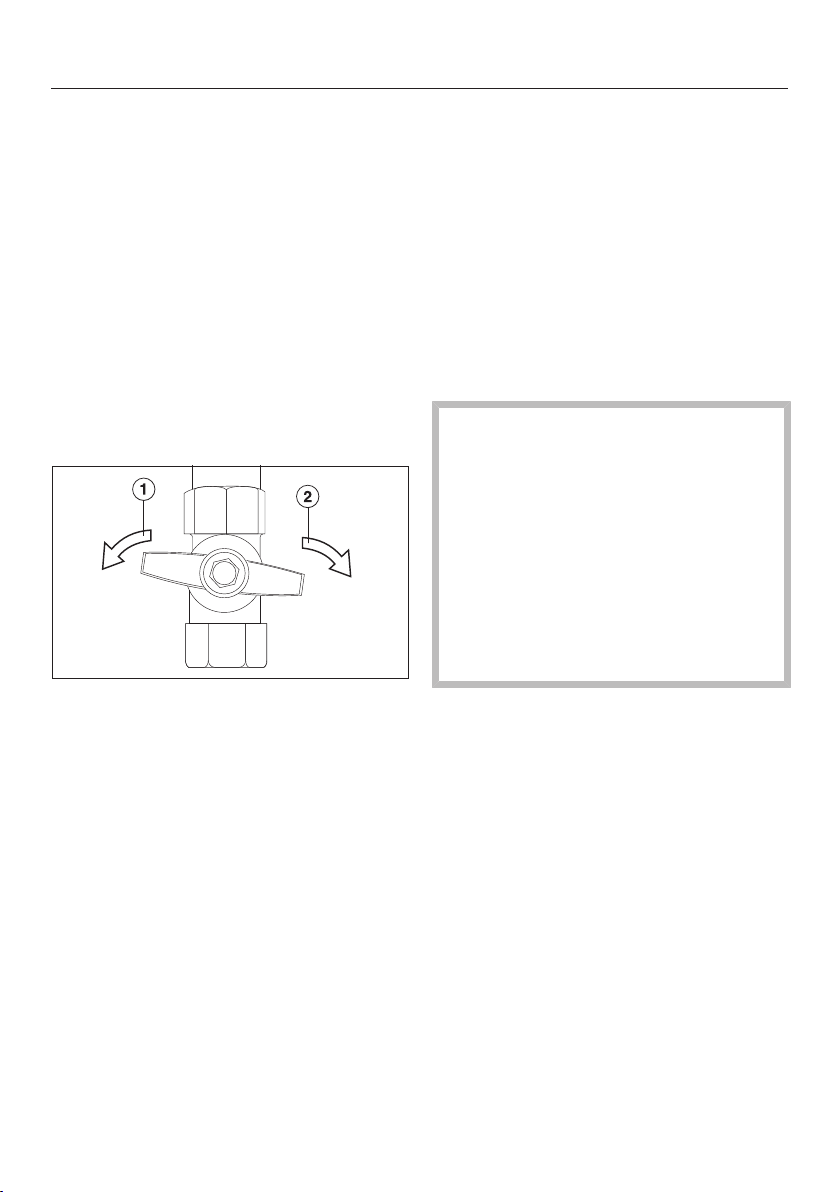

After frying

Switch the fryer off and filter the oil.

This not only removes impurities which

can affect the taste of the food, but will

help the oil last longer.

Allow the oil to cool down, but not to

solidify. If it has solidified it can be

melted by heating the fryer up to

100°C.

Place a heat-resistant container of a

suitable size, e.g. a metal pan, beneath the drain tap under the appliance.

Open the drain by turning the tap

anti-clockwise as far as it will go.

Filter the oil by pouring it through kit-

chen paper or a metal sieve lined with

kitchen paper or filter paper and store

it in a closed, heat-resistant container

until it is needed again.

The oil must be replaced if it:

– is very dark and thick

– smells unpleasant and froths

– begins to smoke at a temperature of

170°C or less

Make sure that the drain tap under

the appliance is always easy to access for draining.

Always wait until the oil has cooled

down before draining to avoid the

danger of being scalded. Make sure

that the container you use for draining the oil into is heat-resistant.

After using the fryer do not replace

the lid until the appliance has cooled

down.

After the oil has drained, close the tap

by turning it clockwise as far as it

will go.

23

Safety features

Safety switch-off

Your deep fat fryer is fitted with a safety

switch-off. It will switch the heating off

automatically if:

– The oil reservoir is not filled to at

least the lower level marker.

– The fryer is switched on when empty.

– The fryer is switched on when the

heating element has been raised (e.g.

for cleaning).

Turn the control to0 and wait until the

heating element has cooled down.

Use a pen or similar to press the

pin on the front right-hand side of

the appliance in. The deep fat fryer

can now be used again in the normal

way.

24

Cleaning and care

Danger of burning due to hot

surfaces.

The surfaces will be hot after cook-

ing.

Switch the grill off.

Allow the surfaces to cool down be-

fore cleaning the grill.

Risk of damage due to moisture

ingress.

The steam from a steam cleaning ap-

pliance could reach live electrical

components and cause a short circuit.

Do not use a steam cleaner to clean

the grill.

Abrasive cleaning agents and scouring sponges may only be used to

clean the heating element.

Allow the ProLine element to cool

down before cleaning.

Clean the ProLine element and ac-

cessories after each use.

Dry the ProLine element thoroughly

after cleaning it with water to avoid

limescale residue.

Unsuitable cleaning agents

To avoid damaging the surfaces of the

appliance, do not use:

– cleaning agents containing soda, am-

monia, acids or chlorides

– cleaning agents containing descaling

agents

– stain and rust removers

– abrasive cleaning agents, e.g.

powder cleaners and cream cleaners

– solvent-based cleaning agents

– dishwasher cleaner

– oven sprays

– glass cleaning agents

– hard, abrasive brushes or sponges,

(e.g. pot scourers, or sponges which

have been previously used with abrasive cleaning agents)

– melamine eraser blocks

25

Cleaning and care

Stainless steel frame/control panel and lid

Clean the frame, the control panel

and the lid with a solution of warm

water and a little washing-up liquid

applied with a soft sponge.

You can also use a ceramic and stainless steel cleaning agent. We recommend also using a stainless steel conditioning agent to help prevent resoiling

(see "Optional accessories).

Do not use ceramic and stainless

steel cleaner or stainless steel conditioning agent on the printing.

This would rub the printing off.

These areas should be only cleaned

with a solution of warm water and a

little washing-up liquid applied with a

soft sponge.

Rotary controls

Clean the rotary control(s) using a

solution of warm water and a little

washing-up liquid applied with a soft

sponge. Soften any stubborn soiling

beforehand.

Dry the control(s) with a clean cloth.

Frying basket

Clean the frying basket after each use

by hand in a solution of hot water

with a little washing-up liquid.

Do not clean the frying basket in the

dishwasher.

26

Oil reservoir

Drain the oil or water (if the fryer has

been used for cooking pasta) out of

the reservoir before cleaning (see

“After frying” in the “Operation”

chapter).

Then raise the heating element.

Cleaning and care

Use paper towel to remove any

coarse soiling.

Fill the reservoir to the maximum

marker with hot water and add a little

washing-up liquid.

Clean the oil reservoir.

Drain the dirty water away and clean

the drain with a bottle brush. Rinse

with hot water and then dry the oil

reservoir and the drain.

Do not use conditioning agents for

stainless steel in the reservoir.

27

Problem solving guide

Many malfunctions and faults that can occur in daily operation can be easily

remedied. Time and money will be saved because a service call will not be

needed.

The following guide may help you to find the reason for a malfunction or a fault,

and to correct it.

Problem Cause and remedy

The deep fat fryer does

not get hot.

The oil has an unpleasant odour.

The food is not crisp

and golden.

There is no mains power to the deep fat fryer.

The safety switch-off has been activated (see

“Safety switch-off” in the “Safety features”

chapter).

Check whether the fuse has tripped. Contact an

electrician or Miele Service (for the minimum fuse

rating, see data plate).

The oil is not suitable.

The oil needs changing.

Change the oil.

The oil was not hot enough.

Select a higher temperature.

The frying basket has been overloaded. Do not fry

so much at once.

Allow the food to fry for a sufficient time.

The frying time was not long enough.

28

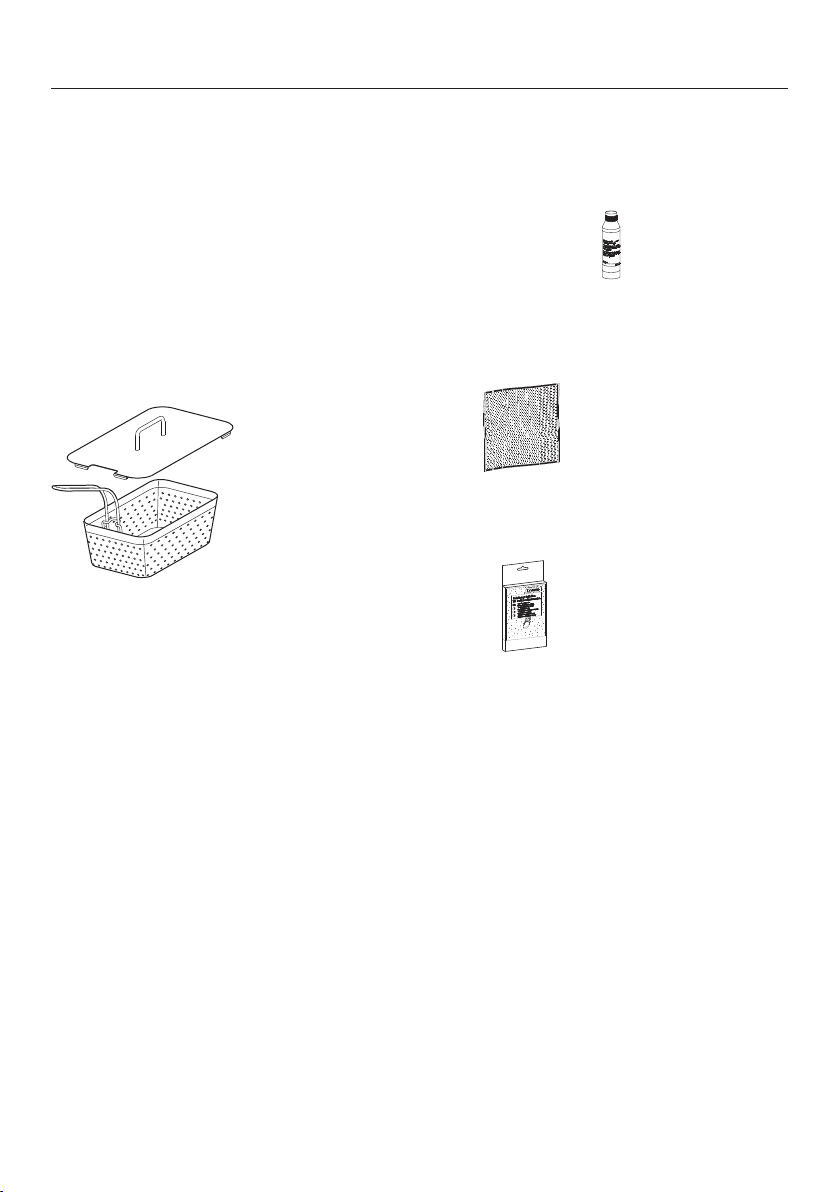

Optional accessories

Miele offer a comprehensive range of

useful accessories as well as cleaning

and conditioning products for your

Miele appliances.

These products can be ordered through

the Miele Webshop.

They can also be ordered from Miele

(see end of this booklet for contact details) or from your Miele dealer.

Pasta basket with lid

For cooking pasta

Cleaning and care products

Ceramic and stainless steel hob

cleaner 250ml

Removes heavy soiling, limescale deposits and aluminium residues

Microfibre cloth

Removes finger marks and light soiling

Descaling tablets- pack of 6

For descaling the oil reservoir.

29

After sales service

Contact in case of malfunction

In the event of any faults which you cannot remedy yourself, please contact your

Miele Dealer or Miele Service.

Contact information for Miele Service can be found at the end of this document.

Please note that telephone calls may be monitored and recorded for training purposes and that a call-out charge will be applied to service visits where the problem

could have been resolved as described in this booklet.

Please quote the model and serial number of your appliance when contacting

Miele. This information can be found on the data plate.

Data plate

Stick the extra data plate supplied with the appliance here. Make sure that the

model number matches the one specified on the back cover of this document.

Warranty

For information on the appliance warranty specific to your country please contact

Miele. See back cover for address.

In the UK, your appliance warranty is valid for 2 years from the date of purchase.

However, you must activate your cover by calling 0330 160 6640 or registering online at www.miele.co.uk.

30

-

I

N

S

T

A

L

L

A

T

I

O

N

-

Installation

Safety instructions for installation

Risk of damage from incorrect connection.

Incorrect installation can cause damage to the ProLine element.

The ProLine element must only be installed by a qualified person.

Damage from falling objects.

Take care not to damage the ProLine element when fitting wall units or a cooker

hood above it.

Fit the wall units and the cooker hood before the ProLine element.

The veneer or laminate coatings of worktops (or adjacent kitchen

units) must be treated with 100°C heat-resistant adhesive which will

not dissolve or distort. Any backmoulds must be of heat-resistant

material.

A deep fat fryer must not be installed directly next to a gas hob or

a wok burner as the gas flames could ignite the fat in the fryer. It is

essential to maintain a distance of at least 288mm between these

two appliances.

When installing the ProLine appliance, make sure that the mains

connection cable cannot come into contact with hot appliance parts.

After installation, the mains connection cable of the ProLine appli-

ance must not come into contact with any moving kitchen component (e.g. a drawer) or be subject to mechanical loads which could

damage it.

Observe carefully the safety clearances listed on the following

pages.

All dimensions are given in mm.

31

-

I

N

S

T

A

L

L

A

T

I

O

N

-

Installation

Safety distances

Safety distance above the ProLine element

The safety distance specified by the

manufacturer of the cooker hood must

be maintained between the ProLine element and the cooker hood above it. If

the cooker hood manufacturer's instructions are not available or if combustible objects are installed above the

ProLine element (e.g., cabinets, utensil

rail, etc.), a minimum safety distance of

at least 760mm must be maintained.

When two or more ProLine elements

which have different safety distances

are installed together below a cooker

hood, you should observe the

greatest safety distance.

32

-

I

N

S

T

A

L

L

A

T

I

O

N

-

Safety distances to the sides and back of the hob

The ProLine elements may be installed

with a wall at the rear and a tall unit or

wall to one side (right or left) (see illustrations).

Minimum distance between the back

of the worktop cut-out and the rear

edge of the worktop:

50mm

Minimum distance between the

worktop cut-out and a tall unit or wall to

the right or left of it:

40mm CS 1212, CS 1212-1

CS 1221, CS 1221-1

CS 1234, CS 1234-1

CS 1223

CS 1222

Installation

Not allowed

Highly recommended

50mm CS 1112

CS 1122

CS 1134

CS 1326

CS 1327

CS 1411

100mm CS 1012, CS 1012-1

CS 1012-2

150mm CS 1421

CS 1312

CS 1322

200mm CS 1034, CS 1034-1

250mm CS 1011, CS 1011-1

CS 1021, CS 1021-1

CS 1018 G

Not recommended

Not recommended

33

-

I

N

S

T

A

L

L

A

T

I

O

N

-

Installation

Safety distance when installing the appliance near a wall with additional niche cladding

A minimum safety distance must be maintained between the worktop cut-out and

any niche cladding to protect it from heat damage.

If the niche cladding is made from a combustible material (e.g. wood) a minimum

safety distance of 50 mm must be maintained between the cut-out and the

cladding.

If the niche cladding is made from a non-combustible material (e.g. metal, natural

stone, ceramic tiles) the minimum safety distance between the cut-out and the

cladding will be 50 mm less the thickness of the cladding.

Example: 15 mm niche cladding

50mm - 15mm = minimum safety distance of 35mm

a

Masonry

b

Niche cladding dimension x = thickness of the niche cladding material

c

Worktop

d

Worktop cut-out

e

Minimum distance to

combustible materials 50mm

non-combustible materials 50mm - dimension x

34

-

I

N

S

T

A

L

L

A

T

I

O

N

-

Installation

Installation notes

Sealing between the ProLine Element and the worktop

The ProLine element and worktop

may be damaged if the ProLine element needs to be removed after it

has been sealed with a sealant. Do

not use any sealant between the ProLine element and the worktop.

The sealing strip under the edge of

the top part of the appliance

provides a sufficient seal for the

worktop.

Tiled worktop

Grout lines and the hatched area underneath the ProLine element frame

must be smooth and even. If they are

not, the ProLine element will not sit

flush with the worktop and the sealing

strip underneath the top part of the appliance will not provide a good seal

between the appliance and the worktop.

35

-

I

N

S

T

A

L

L

A

T

I

O

N

-

Installation

Building-in dimensions

a

Spring clamps

b

Front

c

Installation height

d

Casing depth including mains connection box with mains connection cable, L =

2000mm

e

Drain tap

36

-

I

N

S

T

A

L

L

A

T

I

O

N

-

Installing several ProLine elements

Example: 3 ProLine elements

Installation

a

Spring clamps

b

Spacer bars

c

Gap between spacer bars and worktop

d

Cover

e

ProLine element width less 8mm

f

ProLine element width

g

ProLine element width less 8mm

h

Worktop cut-out

37

-

I

N

S

T

A

L

L

A

T

I

O

N

-

Installation

Calculating the worktop cut-out

The frames of the ProLine elements overlap the worktop at the outside right and

left by 8mm on each side.

Add up the widths of the ProLine elements and subtract 16mm from this figure.

Example:

288mm+288mm+380mm=956mm-16mm=940mm

The ProLine elements are 288mm, 380mm or 576mm wide depending on the

ProLine elements (see “Building-in dimensions” in the “Installation” chapter).

Spacer bars

When installing several ProLine elements, an additional spacer bar must be fitted

in between the individual ProLine elements. The position for securing the spacer

bar will depend on the width of the ProLine element.

38

-

I

N

S

T

A

L

L

A

T

I

O

N

-

Installation

Preparing the worktop

Make the worktop cut-out as shown

in “Building-in dimensions” or as calculated (see “Installing several ProLine appliances” in the “Installation”

chapter). Remember to maintain the

minimum safety distances (see

“Safety distances” in the “Installation” chapter).

Wooden worktops

Seal any cut surfaces on wooden

worktops with a special varnish, silicone sealant or resin to prevent the

wood from swelling as a result of

moisture ingress. The sealant must

be heat-resistant.

Installation

Make sure that the sealant does not

come into contact with the top of the

worktop.

Position the spring clamps and the

spacer bars at the top edge of the

cut-out in the positions shown in the

illustrations.

Secure the spring clamps and

spacer bars with the 3.5x25 mm

wood screws supplied.

39

-

I

N

S

T

A

L

L

A

T

I

O

N

-

Installation

Natural stone worktops

You will need heavy duty double-sided

tape (not supplied) to secure the

spring clamps and spacer bars.

Stick the tape to the top edge of

the cut-out in the positions shown in

the diagram.

Position the spring clamps and

spacer bars on the top edge of the

cut-out and press them firmly into

place.

40

Apply silicone to the side and lower

edges of the spring clamps and

the spacer bars.

Then fill gap between spacer

bar and the worktop with silicone.

-

I

N

S

T

A

L

L

A

T

I

O

N

-

Installation

Fitting the ProLine element

Feed the mains connection cable

down through the cut-out.

Starting at the front, position the Pro-

Line appliance in the worktop cutout.

Using both hands, press down evenly

on the sides of the ProLine element

until it clicks into position. When doing this make sure that the seal of the

appliance sits flush with the worktop

on all sides. This is important to ensure an effective seal all round.

Do not use any additional sealant

(e.g. silicone) on the ProLine element.

If the seal does not meet the worktop

correctly on the corners, the corner radius (≤R4) can be carefully scribed to

suit.

Installing several ProLine elements

Push the built-in ProLine element to

the side until the holes in the spacer

bar can be seen.

Fit cover strip into the holes in

spacer bar .

Starting at the front, position the next

ProLine element in the worktop cutout.

Proceed as described previously.

41

-

I

N

S

T

A

L

L

A

T

I

O

N

-

Installation

Connecting the ProLine element

Connect the ProLine element(s) to the

mains electricity supply.

Check that each ProLine element is

working.

Removing a ProLine element

If the ProLine element cannot be accessed from below, you will need a

special tool to remove it.

If the ProLine element can be ac-

cessed from below, push it upwards

to remove it. Push the back of the appliance out first.

42

-

I

N

S

T

A

L

L

A

T

I

O

N

-

Installation

Electrical connection

We recommend that you connect the

ProLine element to the mains via a suitable switched electrical socket. This

makes it easier to perform servicing

work. The socket must be easily accessible after the ProLine element has

been installed.

Risk of damage from incorrect

connection.

Installation, repairs and other work

by unqualified persons could be dangerous. Miele cannot be held liable

for unauthorised work.

Miele cannot be held liable for damage or injury caused by the lack of or

inadequacy of an on-site earthing

system (e.g. electric shock).

This ProLine element must be connected to the electrical supply by a

qualified electrician.

The electrician must be familiar with

and comply with the national regulations and any additional regulations

of the local electricity provider (e.g.

BS 7671 in the UK).

After installation, ensure that all electrical components are shielded and

cannot be accessed by users.

Total power rating

See data plate

Connection data

The connection data is quoted on the

data plate. Please ensure these match

the household mains supply.

Residual current device

For extra safety, it is advisable to protect the appliance with a suitable residual current device (RCD) with a trip

range of 30 mA.

43

-

I

N

S

T

A

L

L

A

T

I

O

N

-

Installation

Disconnecting from the mains

Risk of electric shock.

There is a risk of electric shock if the

appliance is connected to the mains

supply during repair or service work.

After disconnection, ensure the appliance cannot be switched back on

by mistake.

To disconnect the appliance from the

mains power supply, do one of the following depending on installation:

Safety fuses

Completely remove fuses.

Automatic circuit breakers

Press the (red) test button until the

middle (black) button springs out.

Built-in circuit breakers

Circuit breakers at least type B or C:

Switch the lever from 1 (on) to 0 (off).

Replacing the mains connection cable

Risk of electric shock.

Incorrect connection to the power

supply may result in an electric

shock.

The mains cable must only be replaced by a qualified electrician.

When replacing the mains cable only

use cable type H05VV-F with a suitable cross section. A suitable connection cable is available to order from

Miele.

Residual current device (RCD)

Switch the main switch from 1 (on) to

0 (off) or press the test button.

44

United Kingdom

Miele Co. Ltd.

Fairacres, Marcham Road

Abingdon, Oxon, OX14 1TW

Tel: 0330 160 6600

Internet: www.miele.com

Australia

Miele Australia Pty. Ltd.

ACN 005 635 398

ABN 96 005 635 398

1 Gilbert Park Drive

Knoxfield, VIC 3180

Tel: 1300 464 353

Internet: www.miele.com.au

Miele (Shanghai) Trading Ltd.

1-3 Floor, No. 82 Shi Men Yi Road

Jing' an District

200040 Shanghai, PRC

Tel: +86 21 6157 3500

Fax: +86 21 6157 3511

E-mail: info@miele.cn,

Internet: www.miele.cn

China

41/F - 4101, Manhattan Place

23 Wang Tai Road

Kowloon Bay, Hong Kong

Tel: (852) 2610 1025

Fax: (852) 3579 1404

Email:

customerservices@miele.com.hk

Website: www.miele.hk

Miele (Hong Kong) Limited

Miele India Pvt. Ltd.

Ground Floor

Copia Corporate Suites

Plot No. 9, Jasola

New Delhi - 110025

Tel: 011-46 900 000

Fax: 011-46 900 001

E-mail: customercare@miele.in

Internet: www.miele.in

India

Miele Ireland Ltd.

2024 Bianconi Avenue

Citywest Business Campus

Dublin 24

Tel: (01) 461 07 10

Fax: (01) 461 07 97

E-Mail: info@miele.ie

Internet: www.miele.ie

Ireland

Malaysia

Miele Sdn Bhd

Suite 12-2, Level 12

Menara Sapura Kencana

Petroleum

Solaris Dutamas No. 1

Jalan Dutamas 1

50480 Kuala Lumpur, Malaysia

Phone: +603-6209-0288

Fax: +603-6205-3768

Miele New Zealand Limited

IRD 98 463 631

Level 2, 10 College Hill

Freemans Bay, Auckland 1011

New Zealand

Tel: 0800 464 353

Internet: www.miele.co.nz

New Zealand

Miele Pte. Ltd.

163 Penang Road

# 04 - 03 Winsland House II

Singapore 238463

Tel: +65 6735 1191

Fax: +65 6735 1161

E-Mail: info@miele.com.sg

Internet: www.miele.sg

Singapore

Miele (Pty) Ltd

63 Peter Place, Bryanston 2194

P.O. Box 69434, Bryanston 2021

Tel: (011) 875 9000

Fax: (011) 875 9035

E-mail: info@miele.co.za

Internet: www.miele.co.za

South Africa

Miele Appliances Ltd.

Gold & Diamond Park

Office No. 6-217

Sheikh Zayed Road

P.O. Box 11 47 82 - Dubai

Tel. +971 4 3044 999

Fax. +971 4 3418 852

800-MIELE (64353)

E-Mail: info@miele.ae

Website: www.miele.ae

United Arab Emirates

Manufacturer:

Miele & Cie. KG, Carl-Miele-Straße 29, 33332 Gütersloh, Germany

K.E. & Kingstone Co., Ltd.

6th Fl., No. 120, Sec. 2

Jianguo N. Rd.

Taipei, Taiwan

TEL: +886 2 2502-7256

FAX: +886 2 2502-3077

E-mail: kenk@kenk.com.tw

Website:

www.kenk.com.tw/ke/miele

Taiwan

Thailand

BHIRAJ TOWER at EmQuartier

43rd Floor Unit 4301-4303

689 Sukhumvit Road

North Klongton Sub-District

Vadhana District

Bangkok 10110, Thailand

CS1411

M.-Nr. 07 180 430 / 08en-GB

Loading...

Loading...