Page 1

User Guide

ScanMaker 1000XL features, scenarios, and information

Getting to Know Your ScanMaker 1000XL

The ScanMaker 1000XL is a tabloid-size scanner with a 12" x 17" scan bed, 6400 x

3200-dpi optical resolution, 4.0 maximum optical density, and dual FireW ire and HiSpeed USB interfaces. W ith the use of the TMA 1000XL Transparent Media Adapter

(available as either standard or optional equipment), you can also scan film and

transparencies – including X-rays – up to 12" x 16" in size.

Contents

Getting to Know Your ScanMaker 1000XL ..................................................... 1

Features of the ScanMaker 1000XL ................................................................. 2

Taking a Closer Look ........................................................................................ 3

Unlocking the Scanner .................................................................................... 4

Connecting to the FireWire Port .....................................................................5

How to Use the TMA 1000XL .......................................................................... 6

A. Unpacking TMA 1000XL ..................................................................... 6

B. Installing the TMA 1000XL .................................................................. 7

Unlocking the TMA 100 0XL .................................................................... 8

Positioning Transparent Film ................................................................. 9

A. Using the 35mm Slide Template .............................................. 10

B. Using the 35mm Filmstrip Template ....................................... 11

C. Using the 120 Film Template ..................................................... 12

D. Using the 4" x 5" Film Template ................................................ 13

E. Using the Film Alignment Ruler .............................................. 14

Positioning Multiple Templates ........................................................... 15

Copyright © 2005 Microtek International, Inc. http://www.microtek.com

I49-003868 A, January 2005

Positioning Reflective Originals ........................................................... 16

Scanning Scenarios ....................................................................................... 17

Scanning Regular, Non-Damaged Photos .......................................... 18

Scanning Damaged Photos ................................................................. 22

Scanning Positive Film ......................................................................... 25

Scanning Negative Film ........................................................................ 28

Using the Microtek Scanner ICC Profiler (MSP) .......................................... 31

Calibration Kit ........................................................................................ 31

MSP Installation .................................................................................... 31

Positioning the Target ........................................................................... 32

A. Positioning the Reflective Target ............................................. 32

B. Positioning the Transparent Target .......................................... 32

Calibration Setup ................................................................................... 33

Calibration and Profiling ....................................................................... 34

Loading a Profile ................................................................................... 35

Specifications / System Requirements ........................................................ 36

FCC Compliance Statement .......................................................................... 37

Page 2

Features of the ScanMaker 1000XL

The ScanMaker 1000XL comes with several important features, including the

following:

• Large 12" x 17" scan bed: The tabloid-size scan bed of the ScanMaker 1000XL lets

you easily scan oversized originals, contact sheets, large pieces of art, mechanical

blueprints, and X-rays.

• 6400 x 3200-dpi resolution: The exceptionally high resolution of the ScanMaker

1000XL lets you scan even postage-size images and enlarge them with amazing

clarity, with little loss of detail. The scanner's 4.0 maximum optical density allows it

to capture a wide range of tones approximating real-life color and hues.

• Microtek's PictuRescueTM system: This combined photo reconstruction and

restoration solution incorporates DIGIT AL ICE

TM

Photo Print T echnology and

ColoRescueTM.

– With DIGIT AL ICE Photo Print T echnology , the ScanMaker 1000XL can

automatically map, identify , and eliminate surface defects on your photos. Built

into the hardware and software, DIGIT AL ICE Photo Print T echnology removes

dust, scratches, rips, and tears, reconstructing your damaged photos and

restoring them to pristine, near-original quality .

– With ColoRescue, the ScanMaker 1000XL restores faded colors in photos and

film, bringing hues back to their original luster and brilliance for more vibrant

images. ColoRescue's one-click, automatic color recovery process is simple

and straightforward, involving no learning curve or hassle.

• Transparent Media Adapter: The TMA 1000XL is available as either standard

equipment or optional accessory (depending on the configuration of the

ScanMaker 1000XL that you purchased). W ith the use of the TMA 1000XL, you

can scan X-rays, positive transparencies, and negative film. The included

templates accommodate a variety of film sizes, including 35mm slides, 35mm

filmstrips, 4" x 5" film, and medium format film from 6 x 4.5-cm up to 6 x 17-cm

panoramic film.

• Microtek ScanWizard™ Pro scanning software: This is an advanced scanner

controller program that provides many powerful, professional-level features for

scanning. ScanWizard Pro includes the Microtek Scanner ICC Profiler (MSP)

program, which allows users to calibrate the scanner and generate the appropriate

ICC color profile to ensure color consistency and accuracy during the scanning

process. ScanWizard Pro also features two color spaces, allowing users to work in

the Native CMYK / RGB mode, as well as in the intuitive LCH (Lightness, Chroma,

Hue) mode.

2 ScanMaker 1000XL Supplement

Page 3

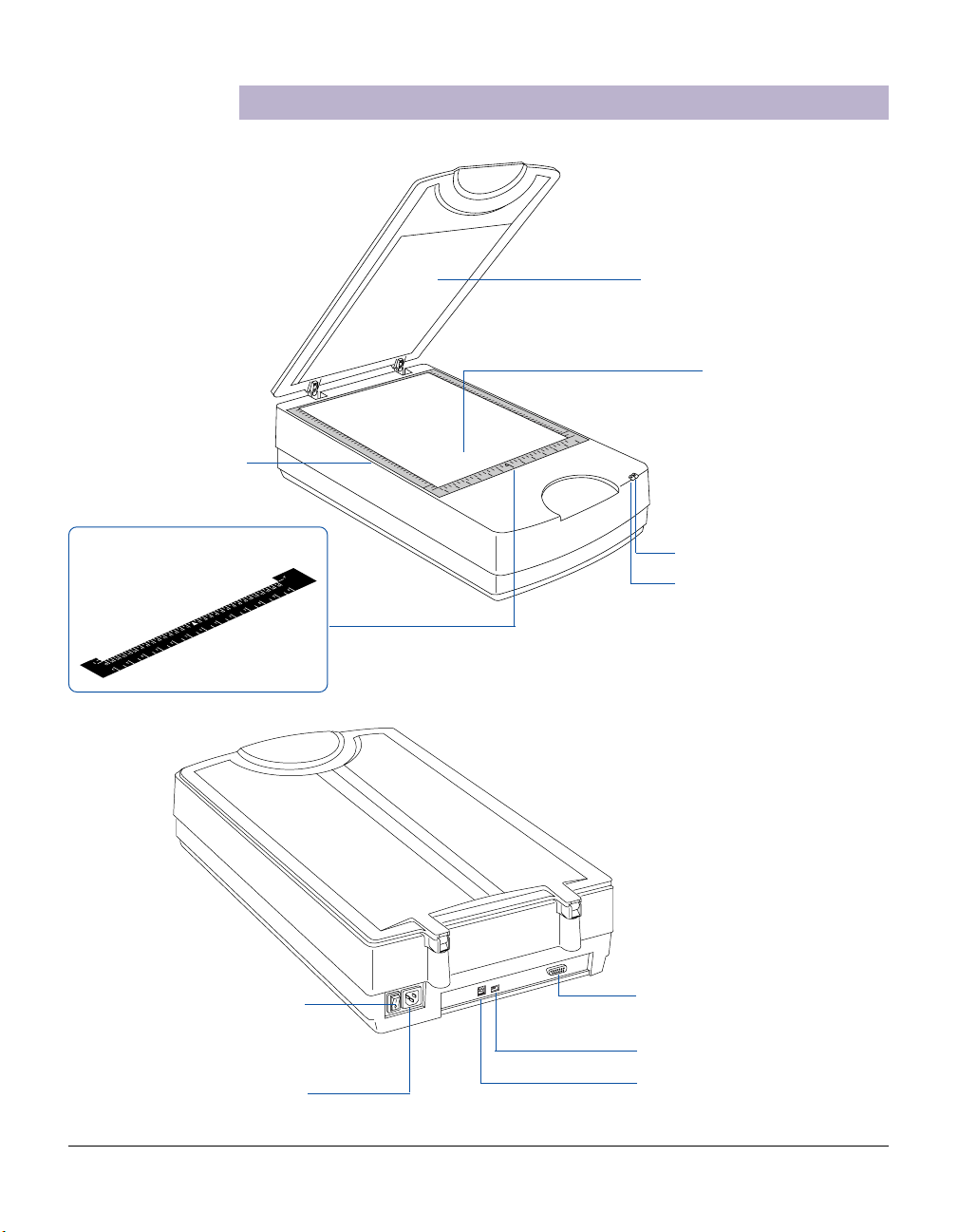

Vertical ruler

Taking a Closer Look

2

3

4

5

6

Scanner lid (or TMA 1000XL)

Glass surface

6

5

4

3

1

0

1

Horizontal ruler

(U-shaped ruler)

Power switch

Power connector

READY indicator (Green)

POWER indicator (Orange)

Accessory port (or with TMA

1000XL's connector securely

connected)

FireWire port (1)

Hi-Speed USB port (1)

ScanMaker 1000XL Supplement 3

Page 4

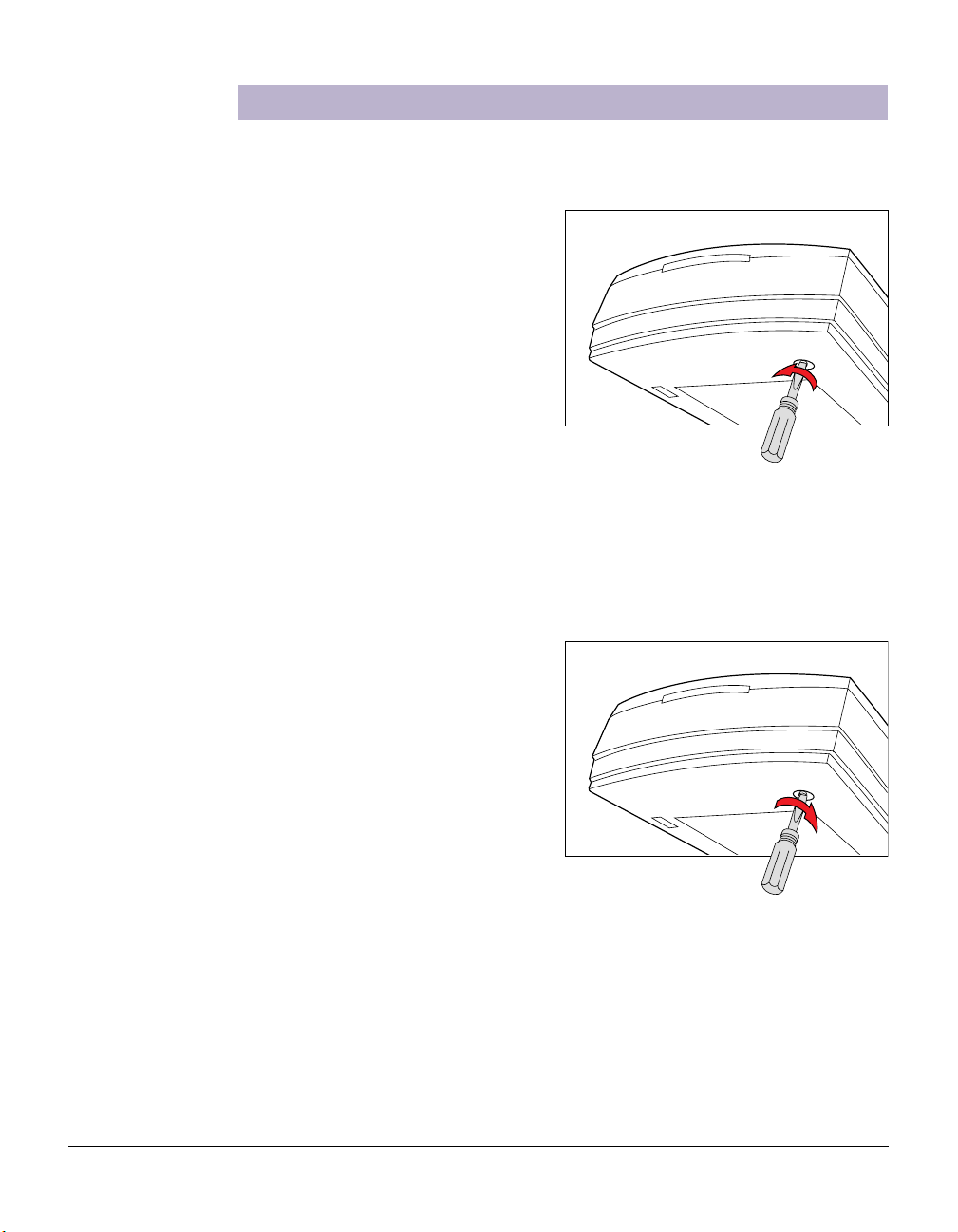

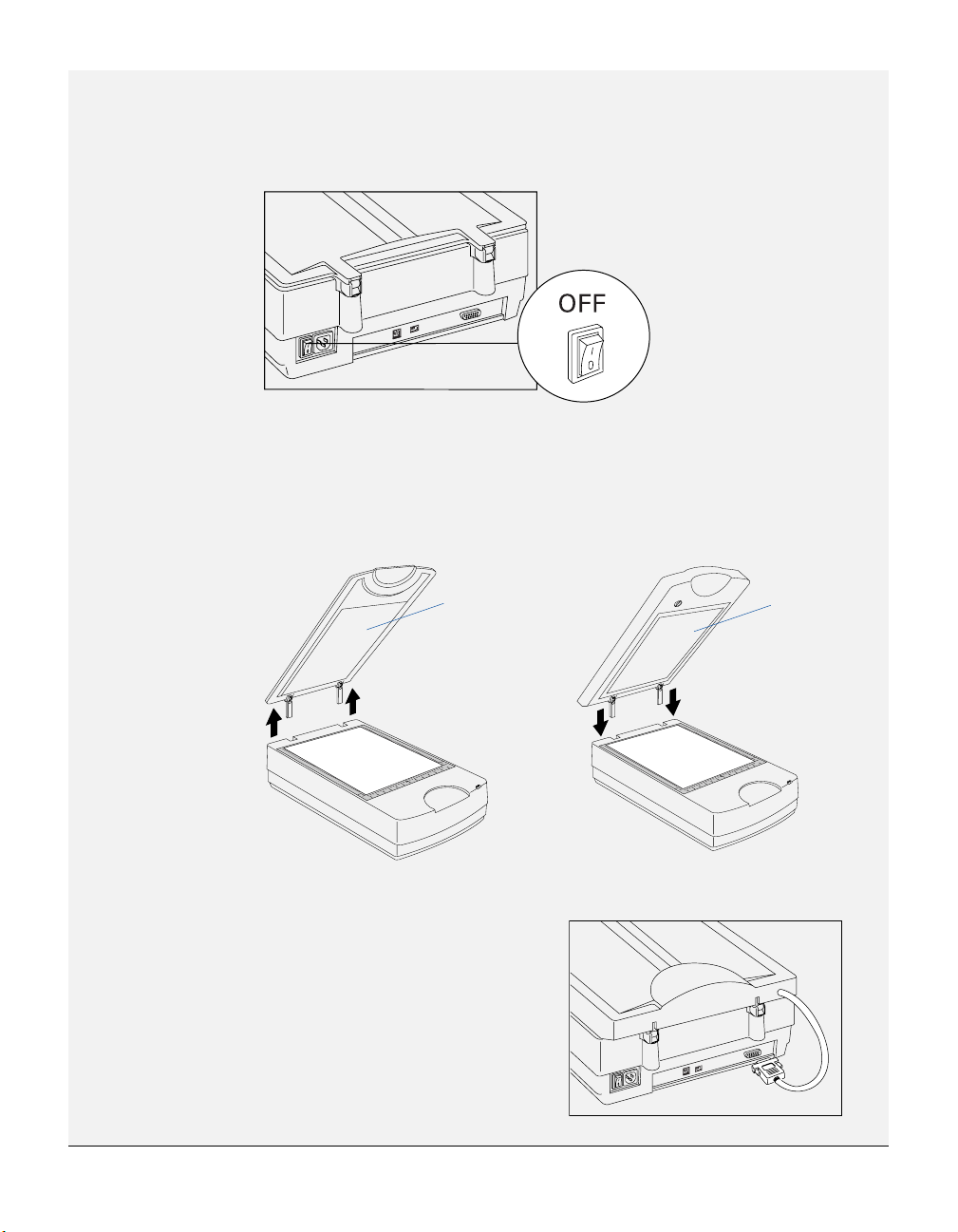

Unlocking the Scanner

Before you can operate the scanner, you will need to unlock the scanner. To unlock

the scanner, follow the steps below:

1 . Remove the yellow “Step 3” sticker

from your scanner.

2 . Look for the unlocking screw at the

bottom of the scanner.

3. Using a screwdriver, push and turn

the locking screw counterclockwise

to the unlock position.

When successfully unlocked, the

screw will push out a little,

protruding slightly from the bottom

of the scanner.

Shipping the Scanner

If you have to transport the scanner, you will need to lock the scanner back. Follow

the steps below:

1. Turn off the scanner if your scanner

is on.

2. Turn the scanner back on. The

scanner’s carriage will move to the

standby position in a few moments.

3. When the indicators on the front of

your scanner stop blinking, use a

screwdriver, and then push and turn

the locking screw clockwise to the

locked position.

When the screw has been

tightened, this indicates that your scanner is locked.

4. Turn off your scanner. The scanner is now ready for transport.

4 ScanMaker 1000XL Supplement

Page 5

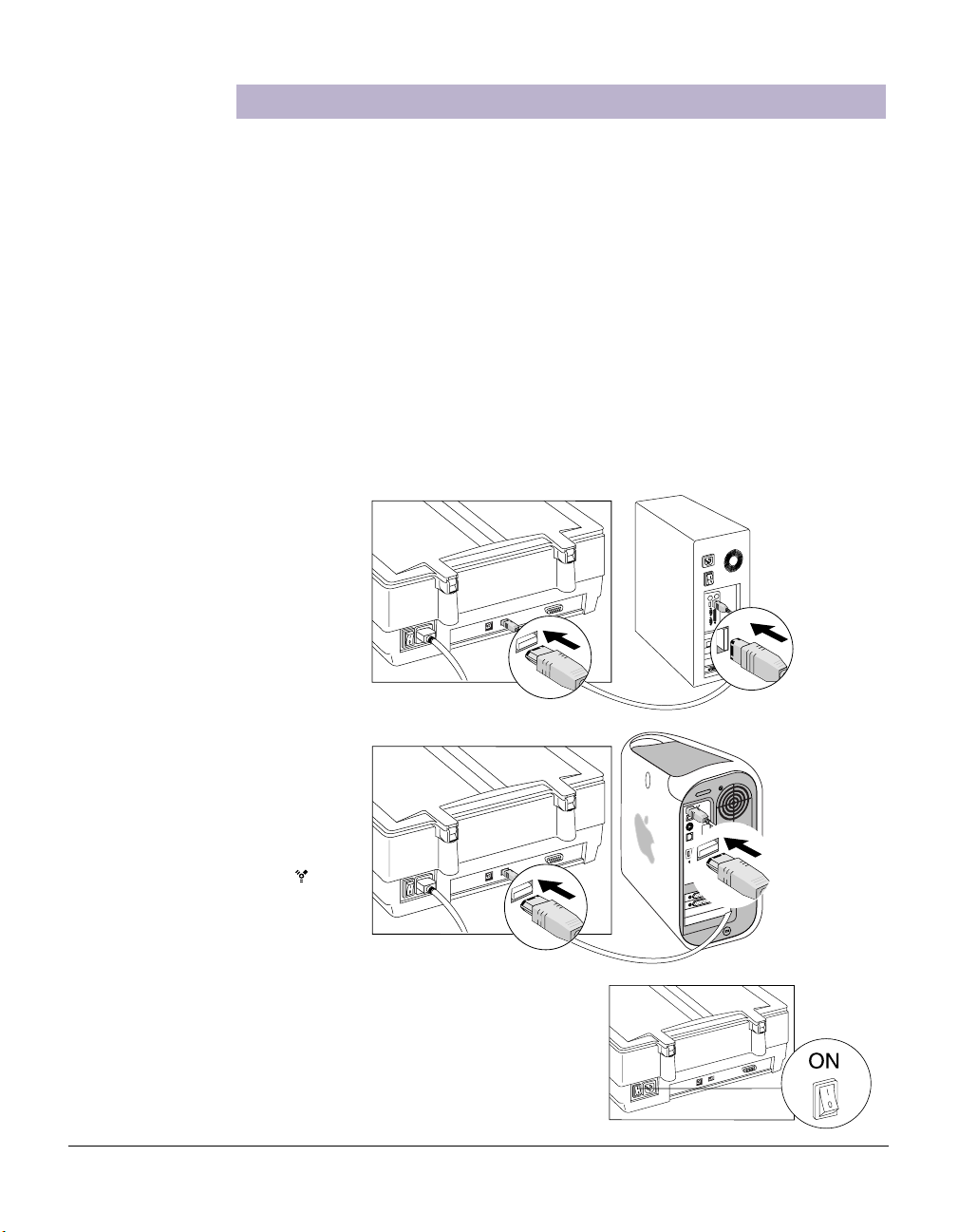

Connecting to the FireWire Port

The printed Start Here guide showed you how to connect your computer to the USB

port of the ScanMaker 1000XL. Here, the User Guide shows you how to connect the

computer to the scanner's alternate FireWire port.

Prior to connection, check first to see if your computer system has a FireWire port. If

FireWire is present, connect the FireW ire cable to the FireW ire port. If your computer

does not have a FireWire port, install a FireW ire card to make use of the FireW ire port.

For details on how to install a FireWire card in your computer , refer to the

documentation that came with the FireWire card.

Note: Your ScanMaker 1000XL does not include a FireWire card in the package.

Follow the steps below to perform the FireWire connection:

1. Connect one end of the FireWire cable to your computer, and connect the other

end of the cable to the scanner’s FireWire port.

(with a built-in FireWire port

or FireWire card installed)

(with a built-in FireWire port)

The latest Macintosh

computers (i.e., G3, G4, G5,

etc.) are equipped with a built-

in FireWire port, usually

labeled with the “ ” logo.

For PC users

For Mac users

2. Turn the Power switch on the back of the

scanner to “ On”, and wait for the lights to

stop blinking and stay on steady.

The scanner will be detected by your

system automatically.

ScanMaker 1000XL Supplement 5

Page 6

How to Use the TMA 1000XL

The Transparent Media Adapter (TMA 1000XL) is specially designed to scan slides,

transparencies, and negative film with the ScanMaker 1000XL scanner . The TMA

1000XL is available either as standard equipment or an optional accessory

(depending on the scanner configuration that you purchased).

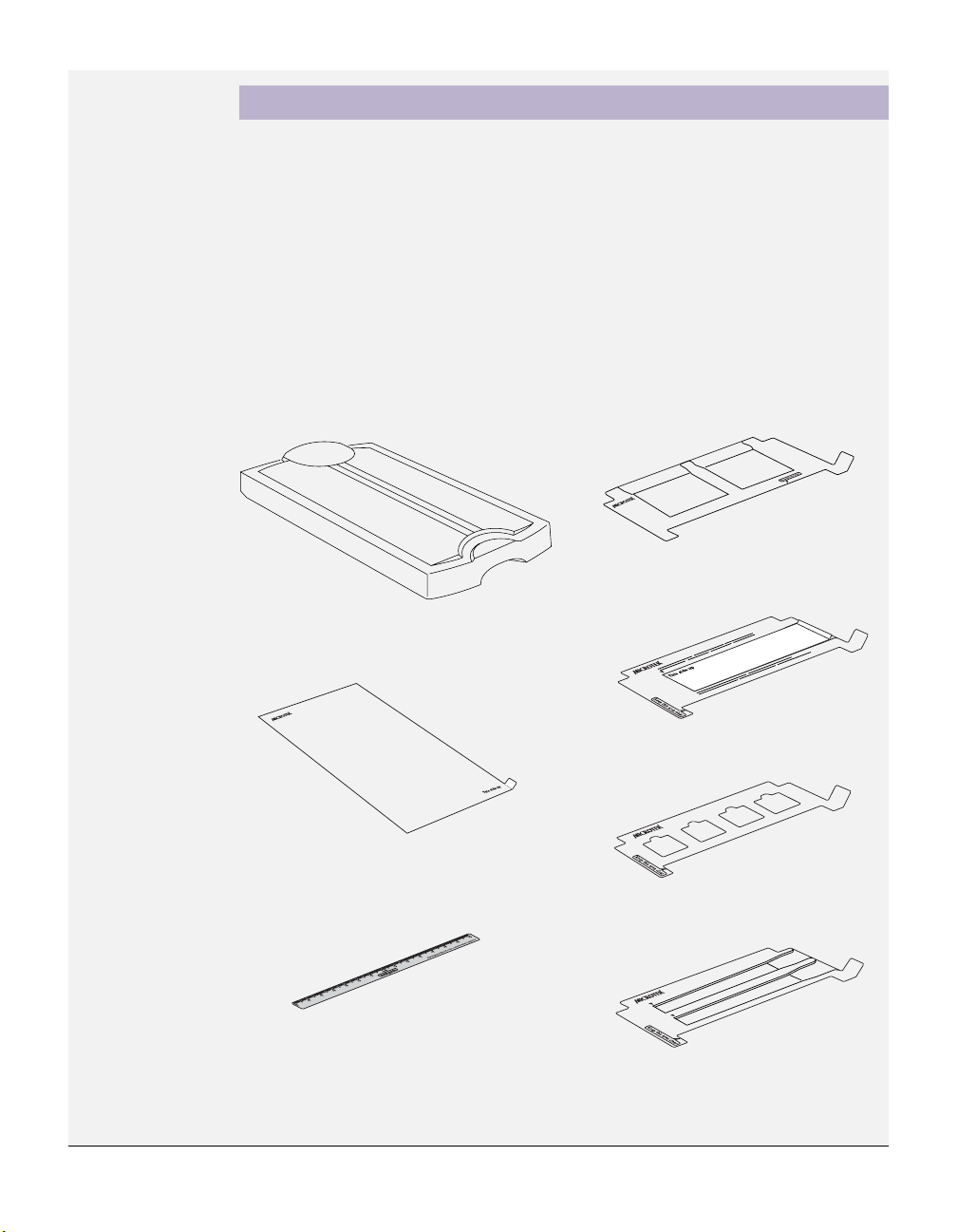

A. Unpacking the TMA 1000XL

The TMA 1000XL is packaged as an assembled unit. Make sure that the following

major components are included after unpacking your TMA 1000XL:

4" x 5" Film Template (2)

TMA 1000XL

(for scanning reflective media)

Film Alignment Ruler

(for scanning film without using templates)

6 ScanMaker 1000XL Supplement

120 Film Template with Black Plate (3)

Black Plate

35mm Slide Template (3)

35mm Filmstrip Template (3)

Page 7

B. Installing the TMA 1000XL

2

1

0

3

4

5

3

2

1

1

0

3

4

5

6

6

5

4

3

2

1

1 . Check to make sure that the scanner power is switched off.

2 . Remove the scanner lid, then attach the TMA 1000XL by sliding the posts at the

rear of the TMA 1000XL into the holes.

Scanner lid

6

5

4

3

1

0

1

2

3

4

5

6

TMA 1000XL

3. Plug the connector of the TMA

1000XL into the scanner’s

15-pin accessory port.

ScanMaker 1000XL Supplement 7

Page 8

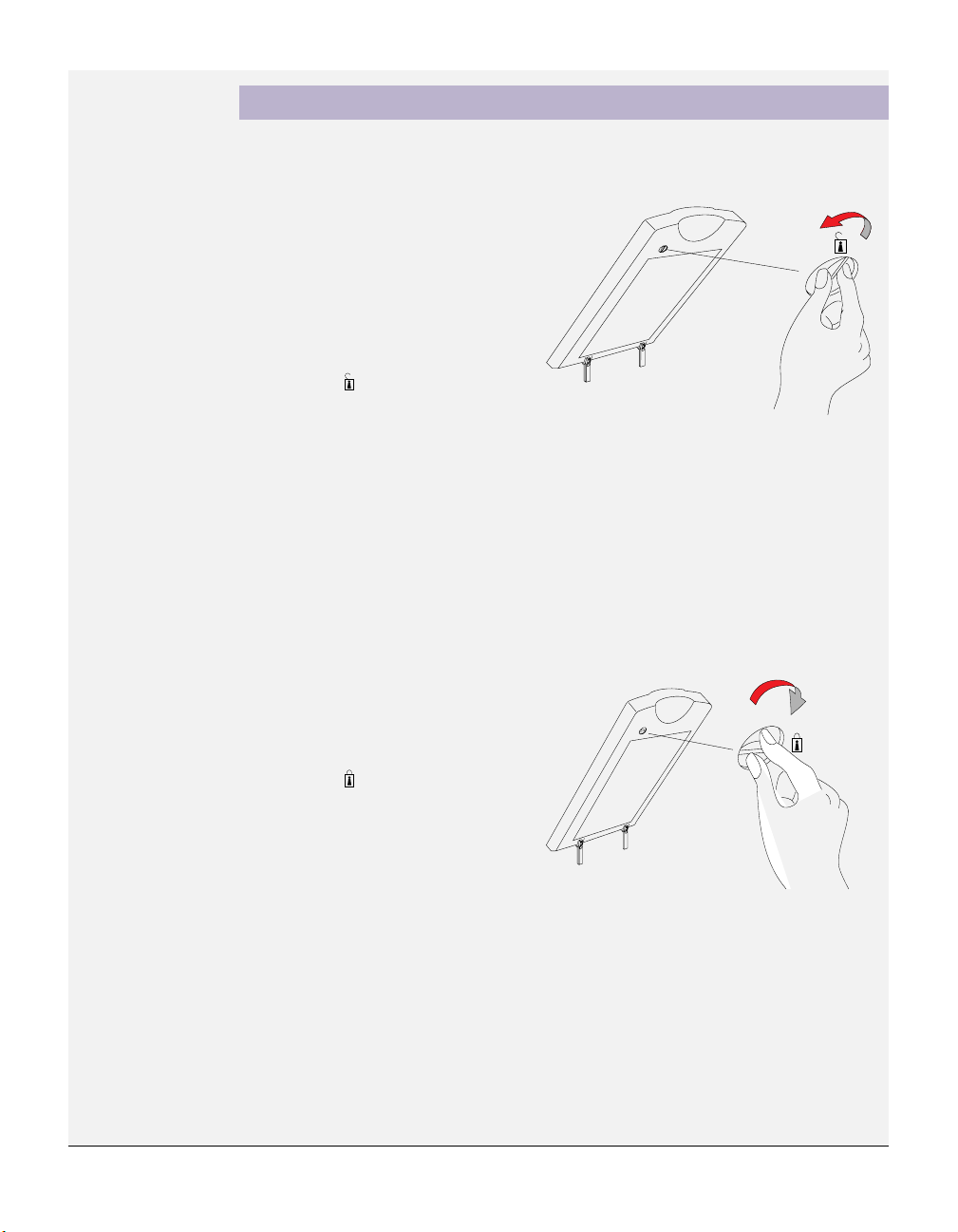

Unlocking the TMA 1000XL

Before you can operate the TMA 1000XL, you will need to unlock the TMA 1000XL.

Follow the steps below:

1 . Remove the yellow “Step 3” sticker

from the TMA.

2 . Look for the locking knob at the

base of the TMA 1000XL.

3 . Turn the locking knob

counterclockwise to the unlock

position “ ”.

Shipping the TMA 1000XL

If you have to transport the TMA 1000XL, you will need to lock the TMA 1000XL

back. Follow the steps below:

1. Make sure the TMA 1000XL is connected to the scanner, then turn off the

scanner if your scanner is on.

2 . Turn the scanner back on. The TMA 1000XL's carriage will move to the standby

position in a few moments.

3. When the indicators on the front

of your TMA 1000XL and scanner

stop blinking, turn the locking

knob clockwise to the lock

position “ ”.

4. Turn off your scanner and

disconnect the TMA 1000XL

connector from the scanner. The

TMA 1000XL is ready for

transport.

8 ScanMaker 1000XL Supplement

Page 9

Positioning Transparent Film

T o scan transparent film, use the templates or Film Alignment Ruler included with

your package. Use the templates to scan standard-size transparent film such as

35mm slides, 35mm filmstrips, 4" x 5" film, or 120 film (6 x 17 cm panoramic film). Use

the Film Alignment Ruler to scan non-standard-size transparent film such as 8" x

10" film, as well as medical and dental X-rays.

Included in the TMA 1000XL package are four types of templates – 35mm Slide

T emplate, 35mm Filmstrip T emplate, 120 Film T emplate, and 4" x 5" Film T emplate.

Use the template that correctly matches the film type to be scanned. The use of the

individual film templates and Film Alignment Ruler is explained in the succeeding

pages of the manual.

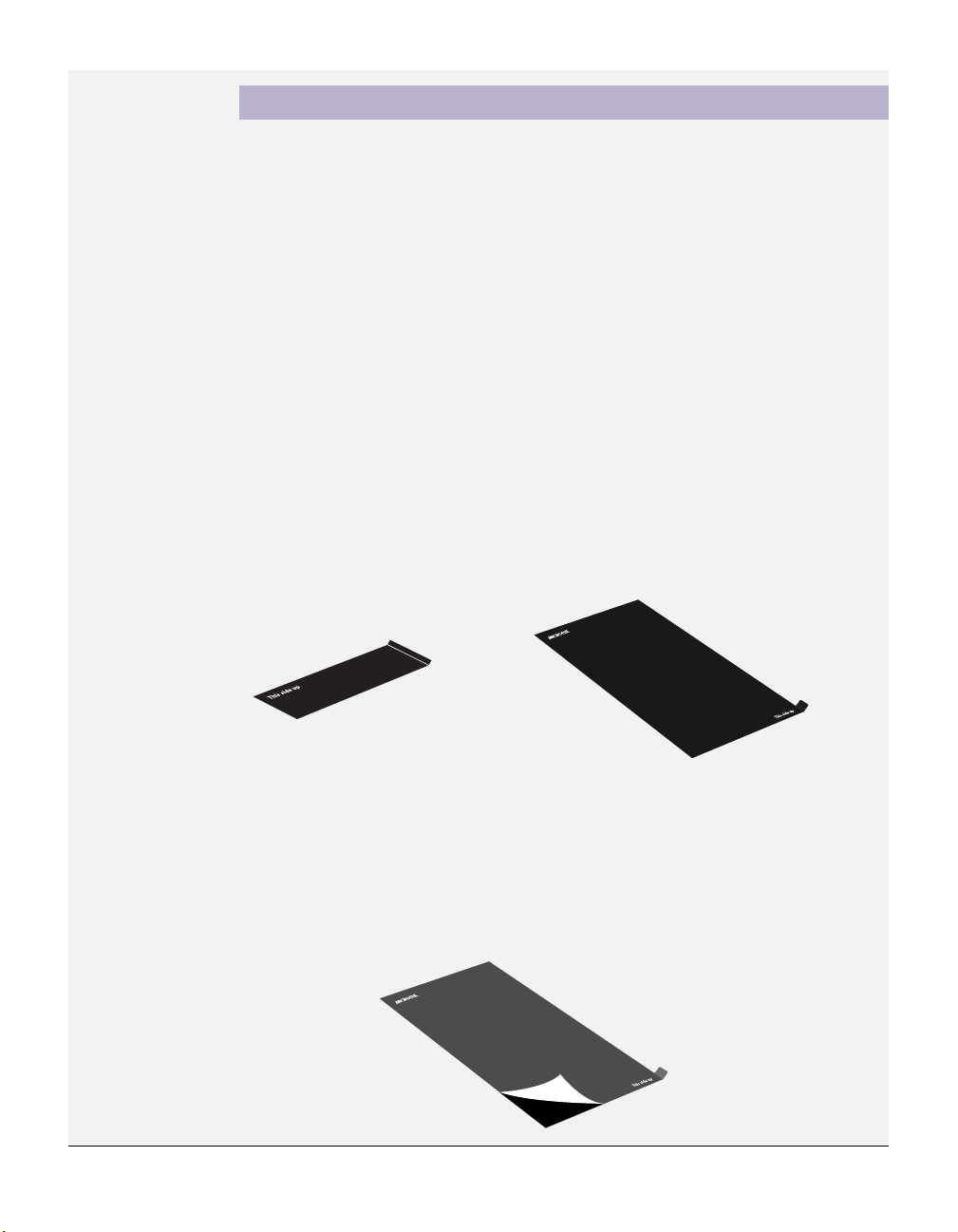

The Black Plate

Light from the TMA 1000XL and other ambient light during scanning may result in

overexposed images. The Black Plate is designed to work with 120 film and

reflective originals. T o ensure correct exposure and optimal image quality during

scanning, the Black Mat should be used to shield unwanted light out. Two Black

Plates are available with your TMA 1000XL package.

T ake note of the following before using the Black Plate.

1 . The Black Plate may become dirty over time and with prolonged use. To clean the

plate, use a white cotton cloth dipped in some water, and gently wipe the plate

surface. This ensures that the Black Plate is in optimal condition at all times.

2 . A protective film covers the Black Plate during shipping and prevents it from

being scratched. When peeling the film from the plate, be careful not to tear or

bend the Black Plate.

ScanMaker 1000XL Supplement 9

Page 10

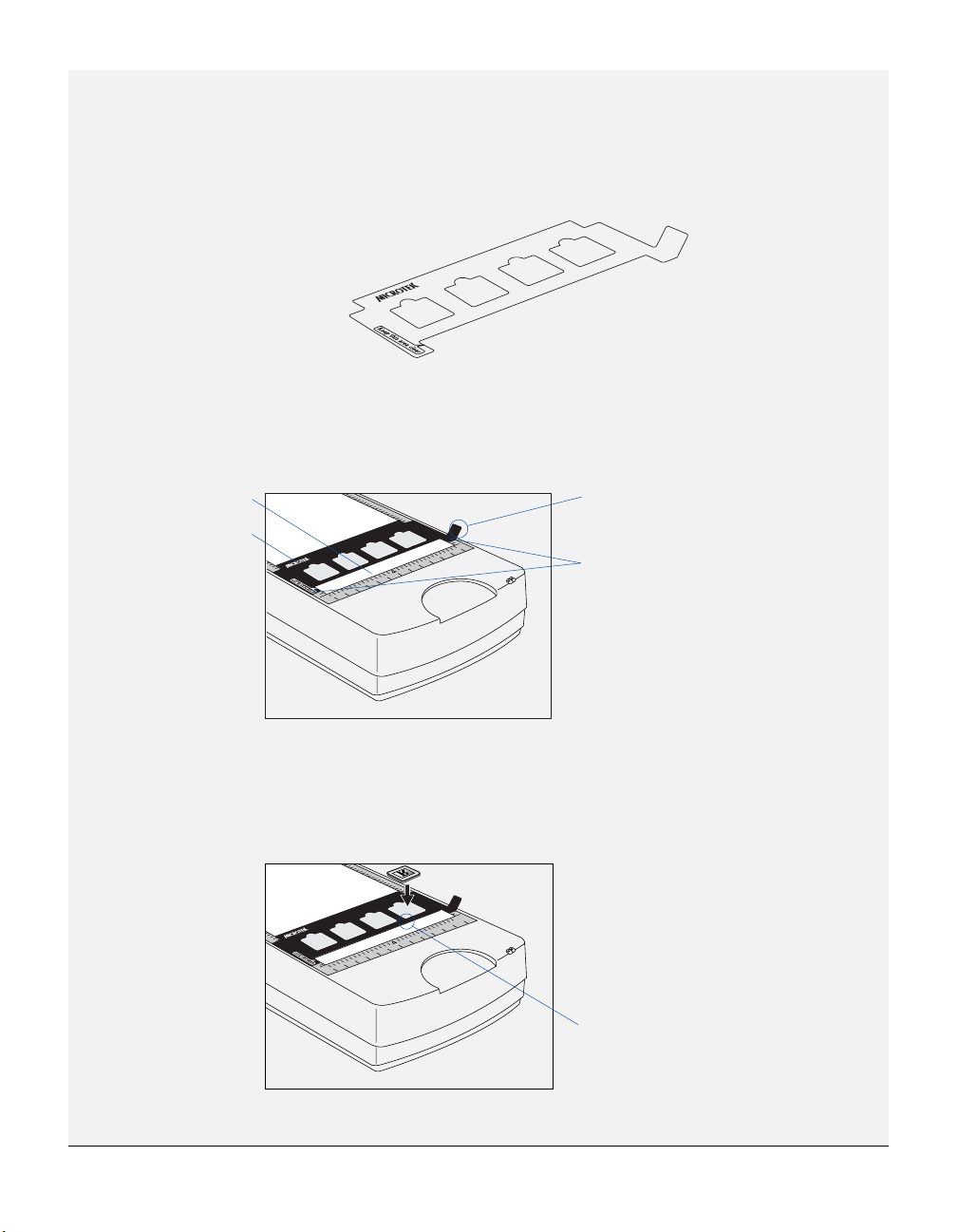

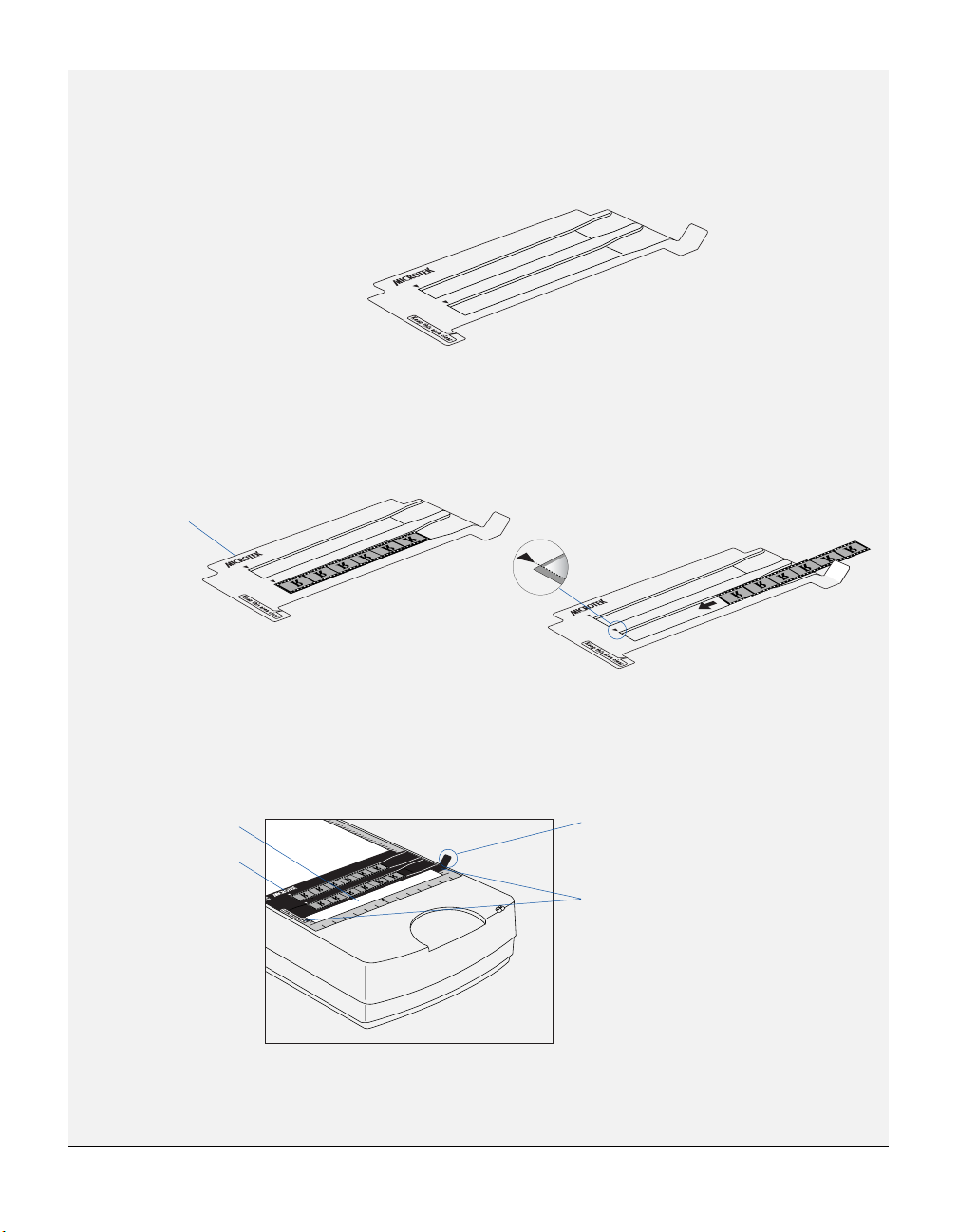

A. Using the 35mm Slide Template

T o scan 35mm slides, use the 35mm Slide T emplate, which can hold up to 4 mounted

35mm slides at a time.

1 . Place the 35mm Slide Template on the scanner glass surface. Make sure to orient

the template with the “Microtek” logo facing up.

Calibration strip

Microtek logo

The Grabber is used to remove the

template out of the scanner glass

surface.

6

5

4

3

2

1

0

1

2

3

4

5

6

Important: Align the template's

front corners firmly against the top

corners (left and right) of the

U-shaped ruler located at the front

of the scanner. During placement of

the template, make sure that the

calibration strip on the scanner

glass surface is kept clear and free

of obstruction at all times.

2 . Place the 35mm slides to be scanned inside the individual frames of the 35mm

Slide T emplate. The shiny base of the 35mm slide should be facing down, and

the emulsion side of the slide should be facing up.

6

5

4

3

2

1

0

1

2

3

4

5

6

Align the 35mm slide against the

bottom-left corner of the frame

10 ScanMaker 1000XL Supplement

Page 11

B. Using the 35mm Filmstrip Template

To scan 35mm filmstrips, use the 35mm Filmstrip T emplate, which can simultaneously

hold two strips of 6 frames each, or a total of 12 frames.

1 . Place the 35mm filmstrip to be scanned inside the frame of the 35mm Filmstrip

T emplate. The shiny base of the 35mm filmstrip should be facing down, and the

emulsion side of the filmstrip should be facing up.

Orient template with

"Microtek" logo facing up

2 . Place the 35mm Filmstrip T emplate containing the loaded filmstrip on the

Calibration strip

Microtek logo

Align the edge of the film frame

with the arrow mark of the template

scanner glass surface. Make sure to orient the template with the “Microtek”

logo facing up.

The Grabber is used to remove the

template out of the scanner glass

6

5

4

3

2

1

0

1

2

3

4

5

6

surface.

Important: Align the template's

front corners firmly against the top

corners (left and right) of the

U-shaped ruler located at the front

of the scanner. During placement of

the template, make sure that the

calibration strip on the scanner

glass surface is kept clear and free

of obstruction at all times.

ScanMaker 1000XL Supplement 11

Page 12

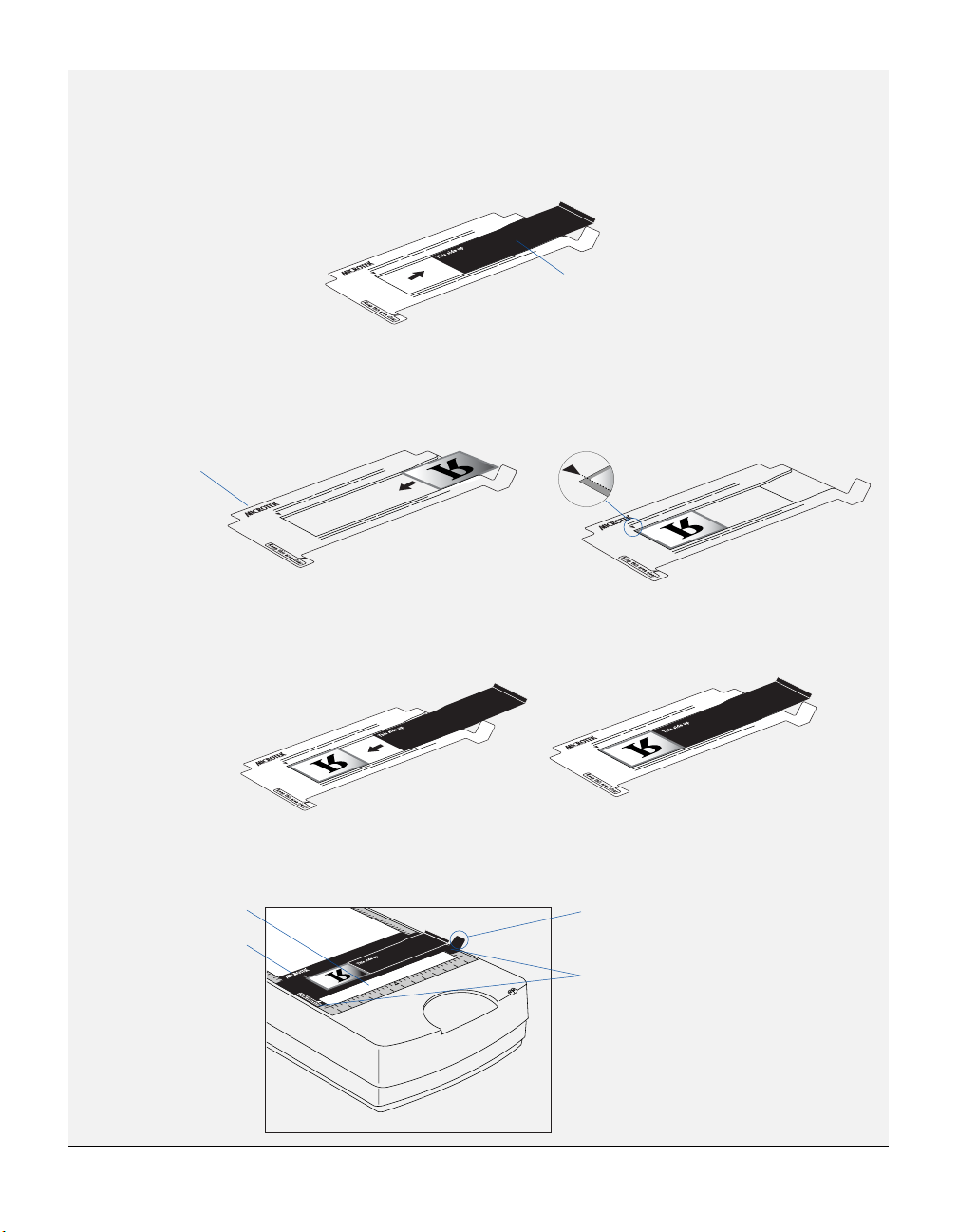

C. Using the 120 Film Template

T o scan 6 x 4.5 cm, 6 x 6 cm, 6 x 7 cm, 6 x 9 cm, and 6 x 17 cm panoramic film, use the

120 Film T emplate, which can hold up to 4 pieces of 6 x 4.5 cm film, 2 pieces of 6 x 9 cm

film, or a single piece of 6 x 17 cm panoramic film.

1 . Place the 120 film to be scanned inside the frame of the 120 Film T emplate. The

shiny base of the 120 film should be facing down, and the emulsion side of the

film should be facing up.

Orient template with

"Microtek" logo facing up

2 . Load the Black Plate into the template frame, with the side of the Black Plate that

reads “This side up” facing up. Slide the Black Plate until its edge is against the

film and completely covers the blank spaces of the template.

Remove the Black Plate from the 120 Film

Template before loading the 120 film

Align the edge of the film frame

with the arrow mark of the template

3 . Place the 120 Film T emplate containing the loaded film on the scanner glass

surface. Make sure to orient the template with the “Microtek” logo facing up.

Calibration strip

Microtek logo

12 ScanMaker 1000XL Supplement

The Grabber is used to remove the

template out of the scanner glass

6

5

4

3

2

1

0

1

2

3

4

5

6

surface.

Important: Align the template's

front corners firmly against the top

corners (left and right) of the

U-shaped ruler located at the front

of the scanner. During placement of

the template, make sure that the

calibration strip on the scanner

glass surface is kept clear and free

of obstruction at all times.

Page 13

D. Using the 4" x 5" Film Template

T o scan 4" x 5" film, use the 4" x 5" Film T emplate, which can hold up to 2 pieces of

4" x 5" film at a time.

1 . Place the 4" x 5" film to be scanned inside the frame of the 4" x 5" T emplate. The

shiny base of the 4" x 5" film should be facing down, and the emulsion side of the

film should be facing up.

Orient template with

"Microtek" logo facing up

Calibration strip

Microtek logo

2 . Place the 4" x 5" Film Template containing the loaded film on the scanner glass

surface. Make sure to orient the template with the “Microtek” logo facing up.

The Grabber is used to remove the

template out of the scanner glass

surface.

6

5

4

3

2

1

0

1

2

3

4

5

6

Important: Align the template's

front corners firmly against the top

corners (left and right) of the

U-shaped ruler located at the front

of the scanner. During placement of

the template, make sure that the

calibration strip on the scanner

glass surface is kept clear and free

of obstruction at all times.

ScanMaker 1000XL Supplement 13

Page 14

E. Using the Film Alignment Ruler

T o scan non-standard-size film such as 8" x 10" film, medical and dental X-rays, use

the Film Alignment Ruler , which allows you to scan film up to 14" x 17" in size.

1 . Place the Film Alignment Ruler* on the scanner glass surface.

Film Alignment Ruler

6

5

4

3

2

1

0

1

2

3

4

5

Calibration strip

2 . Place the film (X-ray or other non-

standard size) to be scanned on the

scanner glass surface, and center the

film along the Film Alignment Ruler on

the scanner.

Calibration strip

6

5

4

3

2

1

0

1

2

3

4

5

Important: Align the Film Alignment

Ruler firmly against the corners (left

and right) of the U-shaped ruler

located at the front of the scanner,

with the ruler oriented correctly and

with the correct side up. During

placement of the Ruler, make sure that

the calibration strip on the scanner

glass surface is kept clear and free of

obstruction at all times.

6

5

4

3

2

1

0

1

2

3

4

5

* Please note that the Film Alignment

Ruler should be removed from the

glass surface of the scanner if the

width of the film is larger than the

width of the scanner glass surface.

If the Film Alignment Ruler is not going

to be used, align the film to be

scanned against the top corners (left

and right) of the U-shaped ruler

located at the front of the scanner.

During placement of the film, make

sure that the calibration strip on the

scanner glass surface is kept clear and

free of obstruction at all times.

14 ScanMaker 1000XL Supplement

Page 15

Positioning Multiple Templates

At least two sets of each template are included in your TMA 1000XL package for

multiple placements of the templates on the scanner. The templates can be placed side

by side on the scanner glass surface, as shown in the illustration below.

6

5

4

3

2

1

0

1

2

3

4

5

6

ScanMaker 1000XL Supplement 15

Page 16

Positioning Reflective Originals

T o scan reflective originals such as photos, you can use the ScanMaker 1000XL

with or without the TMA 1000XL.

A. If you purchased your ScanMaker 1000XL without the TMA 1000XL, simply lift

the scanner lid, and place the reflective original to be scanned on the scanner

glass surface. Center the original along the U-shaped ruler on the scanner.

6

5

4

3

1

0

1

2

3

4

5

6

B . If you purchased your ScanMaker 1000XL with the TMA 1000XL, you will need

to use the Black Plate included with your TMA 1000XL package to shield

unwanted light.

1 . Place the reflective original face down on the scanner glass surface. Center

the original along the U-shaped ruler on the scanner.

2 . Peel the protective film from the Black Plate.

3 . Put the Black Plate on top of the reflective

photo to be scanned, so that the Plate covers

the photo. The side of the Black Plate that reads

“This side up” should be facing up.

4 . Gently lower the TMA 1000XL down onto the scanner glass surface.

16 ScanMaker 1000XL Supplement

6

5

4

3

1

0

1

2

3

4

5

6

Page 17

Scanning Scenarios

The following pages provide various scenarios for scanning with the ScanMaker

1000XL, including the following:

• Scanning regular, non-damaged photos: This scenario can also be your first scan

in order to familiarize yourself with scanning basics.

• Scanning damaged photos: This scenario utilizes DIGIT AL ICE for reconstructing

damaged photos.

• Scanning positive film: This scenario details the steps for scanning positive film,

such as 35mm mounted slides and X-rays.

• Scanning negative film: This scenario details the steps for scanning negative film,

such as 35mm filmstrips, 6 x 17 cm (120) panoramic film, and 4" x 5" / 6 x 9 cm film.

ScanMaker 1000XL Supplement 17

Page 18

Scanning Regular, Non-Damaged Photos

1 . Raise the scanner lid, and place the

photo to be scanned face down on the

scanner glass bed, towards the front of

the scanner. Center the top of the photo

along the U-shaped ruler on the scanner.

If the scanner has an installed TMA

2

3

4

5

6

1000XL, put the Black Plate on top of the

photo to cover it, with the side of the

Black Plate that reads “This side up”

facing up. Follow the procedures on

page 18 for positioning reflective originals to load the Black Plate.

2 . Launch ScanWizard Pro either as a standalone by clicking the program icon, or by

using the File-Import or File-Acquire command from your image-editing program

(such as Adobe Photoshop). Alternatively, you can start ScanWizard Pro from the

Applications folder in your Mac OS X system.

• The first time you launch ScanWizard Pro, you will be prompted to perform

color calibration for your scanner. (Dialog boxes below show appearance in

Windows XP and Mac OS X).

6

5

4

3

1

0

1

- Click the Skip button to exit the “Calibration Reminder” window. Clicking

the Skip button allows you to use the factory default ICC profile for your

scanner.

- Click the Calibrate button to run the Microtek Scanner ICC Profiler (MSP)

program to perform color calibration and to customize the ICC profile for

your scanner. After finishing with calibration, relaunch ScanW izard Pro.

18 ScanMaker 1000XL Supplement

Allows you to

specify how often

you wish to be

prompted to

calibrate the

scanner. The default

setting is 14 days

Page 19

Color Matching

features

Note: The MSP program should be installed before you perform color

calibration for your scanner. For details on how to install the MSP program

and how to use it to calibrate the scanner, refer to section of the manual

titled “Using the Microtek Scanner ICC Profiler”.

• Next, you will be prompted to set up color matching for your scanner. If you

are not sure about what to do, simply click the OK button to accept the

settings. You can always change the settings at a later time.

For more information, see the Color Matching Setup section in the

ScanWizard Pro Refer ence Manual in the Microtek CD.

3 . Go to the Preview window of

ScanWizard Pro, and choose

Reflective from the Scan Material

menu.

4 . Optional: If calibration has been

performed, go to the Settings window

in ScanWizard Pro. Choose the profile

you have just created in the Input

Profile / Scanner Profile menu.

For more details, see the section

“Loading a Profile” in the MSP

section of the manual.

ScanMaker 1000XL Supplement 19

Page 20

5 . Click the Overview button to perform a preliminary scan of the image, which will

appear in the Preview window .

6 . Select the Scan Frame tool from the Toolbar in the Preview window , and choose

the area to be scanned by dragging a rectangle around it. You will see a flashing

frame (marquee) around the selected area.

7 . Click the Prescan button to display a detailed image of area selected by the

Scan Frame tool. A thumbnail of the image appears as well in the Scan Job

Queue window .

8 . Specify your scanning requirements in the Settings window.

a) Select a desired image type.

b) Select a desired resolution.

c) Adjust the scan frame settings if necessary.

9. Adjust image quality if necessary, using the Advanced Image Correction (AIC) tools.

10. Click the Scan (or “Batch”) button in the Preview window to start scanning.

• If ScanWizard Pro was launched from an application program, the image is then

delivered to your application, where the image can be saved, printed, or edited.

Note: In Mac OS X, you will be prompted to specify the file attributes for the

scanned image before scanning takes place.

• If ScanWizard Pro was launched in standalone mode, you will be prompted to

specify the file attributes for the scanned image after the Scan or Batch

button is pressed, such as entering the file name, specifying a folder name of

your own, etc. When you have completed the settings, press the Done/Save

button, and the scanner will automatically scan and save your image based on

your settings.

20 ScanMaker 1000XL Supplement

Click the Folder icon to

specify a folder or file name

of your own.

Page 21

ScanMaker 1000XL Supplement 21

Page 22

Scanning Damaged Photos

1. Raise the scanner lid, and place the damaged photo to be scanned face down on

the scanner glass bed, towards the front of the scanner. Center the top of the

photo along the U-shaped ruler on the scanner.

Place photo here for

photo restoration

6

5

4

3

1

0

1

2

3

4

5

6

Direction of

Note: If the creases lie in the same

carriage moving

direction where the carriage is moving,

the creases may not be detected by the

scanner. To fix this problem, position

your photo slightly skewed (min. 10°,

2

3

4

5

6

6

5

4

3

1

0

1

max. 45°), so that none of the creases

are parallel to the direction of the

moving carriage.

If the scanner has an installed TMA 1000XL, put the Black Plate on top of the

photo to cover it, with the side of the Black Plate that reads “This side up” facing

up. Follow the procedures on page 18 for positioning reflective originals to load

the Black Plate.

2 . Launch ScanWizard Pro.

3 . Go to the Preview window and

choose Reflective from the Scan

Material menu.

4 . Optional: If calibration has been

performed, go to the Settings window

in ScanWizard Pro. Choose the profile

you have just created in the Input

Profile / Scanner Profile menu.

For more details, see the section

“Loading a Profile” in the MSP section

of the manual.

22 ScanMaker 1000XL Supplement

Page 23

5 . Click the Overview button to perform a preliminary scan of the image, which will

appear in the Preview window.

6 . Select the Scan Frame tool from the Toolbar in the Preview window , and choose

the area to be scanned by dragging a rectangle around it. You will see a flashing

frame (marquee) around the selected area.

7 . Specify your scanning requirements in the Settings window.

a) Select a desired image type.

b) Select a desired resolution. Recommended resolution for DIGITA L ICE is 800

or 1600 dpi.

c) Adjust the scan frame settings if necessary.

8. Adjust image quality if necessary, using the Advanced Image Correction (AIC) tools.

Important: The Descreen setting in the Settings window should be “None.”

Otherwise the “DIGIT AL ICE” option in the next step will be dimmed and will not

be available for selection.

9. To repair creases, tears, and other

surface defects from your photo,

choose the DIGIT AL ICE option

that works best for you in the

Settings window . Select from

Normal or Strong.

Note: DIGITAL ICE Photo Print Technology is designed to work with

continuous-tone reflective originals such as photos. It is not designed to work

with slides, negatives, transparencies, and printed matter.

10. If the colors in your photo are

faded and need restoring, check

the “Automatic Color

Restoration” box in the Settings

window.

ScanMaker 1000XL Supplement 23

Page 24

11. Click the Prescan button to display a detailed image of area selected by the Scan

Frame tool.

12. Click the Scan (or “Batch”) button in the Preview window to start scanning.

• If ScanWizard Pro was launched from an application program, the image is then

delivered to your application, where the image can be saved, printed, or edited.

Note: In Mac OS X, you will be prompted to specify the file attributes for the

scanned image before scanning takes place.

• If ScanWizard Pro was launched in standalone mode, you will be prompted to

specify the file attributes for the scanned image after the Scan or Batch

button is pressed, such as entering the file name, specifying a folder name of

your own, etc. When you have completed the settings, press the Done/Save

button, and the scanner will automatically scan and save your image based on

your settings.

Before

After

24 ScanMaker 1000XL Supplement

Page 25

Scanning Positive Film

1 . Select the film you wish to scan.

Follow the procedures for positioning

transparent film to load the film to be

scanned.

0

1

2

3

4

5

6

6

5

4

3

2

1

2 . Launch ScanWizard Pro.

3 . Go to the Preview window and

choose Positive / Positive Film from

the Scan Material menu.

If this is your first time to scan transparent media, you will be prompted to perform

color calibration for your scanner. A Calibration Reminder window appears.

Allows you to specify

how often you wish to

be prompted to calibrate

the scanner. The default

setting is 14 days

- Click the Skip button to exit the “Calibration Reminder” window. Clicking the

Skip button allows you to use the factory default ICC profile for your scanner.

- Click the Calibrate button to run the Microtek Scanner ICC Profiler (MSP)

program to perform color calibration and to customize the ICC profile for your

scanner. After finishing with calibration, relaunch ScanW izard Pro.

Note: For details on how to install the MSP program and how to use it to

calibrate the scanner, refer to section of the manual titled “Using the Microtek

Scanner ICC Profiler”.

ScanMaker 1000XL Supplement 25

Page 26

4 . Optional: If calibration has been

performed, go to the Settings

window in ScanWizard Pro.

Choose the profile you have

just created in the Input Profile

/ Scanner Profile menu.

For more details, see the

section “Loading a Profile” in the

MSP section of the manual.

5 . Click the Overview button to perform a preliminary scan of your original.

6 . Select the Scan Frame tool from the Toolbar in the Preview window , and choose

the area to be scanned by dragging a rectangle around it. You will see a flashing

frame (marquee) around the selected area.

7 . Specify your scanning requirements in the Settings window.

a) Select a desired image type.

b) Select a desired resolution.

c) Adjust the scan frame settings if necessary.

8. Adjust image quality if necessary, using the Advanced Image Correction (AIC) tools.

9. If the colors in your photo are

faded and need restoring, check

the “Automatic Color

Restoration” box in the Settings

window.

10. Click the Prescan button to display a detailed image. A thumbnail of the image

appears as well in the Scan Job Queue window.

11. Click the Scan (or “Batch”) button in the Preview window to start scanning.

• If ScanWizard Pro was launched from an application program, the image is then

delivered to your application, where the image can be saved, printed, or edited.

Note: In Mac OS X, you will be prompted to specify the file attributes for the

scanned image before scanning takes place.

• If ScanWizard Pro was launched in standalone mode, you will be prompted to

specify the file attributes for the scanned image after the Scan or Batch

button is pressed, such as entering the file name, specifying a folder name of

your own, etc. When you have completed the settings, press the Done/Save

button, and the scanner will automatically scan and save your image based on

your settings.

26 ScanMaker 1000XL Supplement

Page 27

For film scanning

using the template,

it is normal for a

blank strip to appear

in the preview

window after you

preliminary scan of

perform a

your original.

For film scanning using

the Film Alignment Ruler,

it is normal for a black

ruler to appear in the

preview window after you

perform a preliminary

scan of your original.

ScanMaker 1000XL Supplement 27

Page 28

Scanning Negative Film

1 . Select the film you wish to scan.

Follow the procedures for positioning

transparent film to be scanned.

0

1

2

3

4

5

6

6

5

4

3

2

1

.

2 . Launch ScanWizard Pro.

3 . Go to the Preview window and

choose Negative / Negative Film

from the Scan Material menu.

If this is your first time to scan transparent media, you will be prompted to perform

color calibration for your scanner. A Calibration Reminder window appears.

- Click the Skip button to exit the “Calibration Reminder” window. Clicking the

Skip button allows you to use the factory default ICC profile for your scanner.

- Click the Calibrate button to run the Microtek Scanner ICC Profiler (MSP)

program to perform color calibration and to customize the ICC profile for your

scanner. After finishing with calibration, relaunch ScanW izard Pro.

Note: For details on how to install the MSP program and how to use it to

calibrate the scanner, refer to section of the manual titled “Using the Microtek

Scanner ICC Profiler”.

28 ScanMaker 1000XL Supplement

Allows you to specify

how often you wish to

be prompted to calibrate

the scanner. The default

setting is 14 days

Page 29

4 . In the Settings window,

choose the film type you are

using from the Film Type

menu.

When the Film T ype menu appears the first time, the film type is blank because the

default film type has not yet been selected. You need to specify the film type

attributes setting in the Select Film T ype window below. For details on how to

select the film type, refer to a PDF document called “ScanWizard Pro Reference

Manual” in your Microtek software CD-ROM, and see the Addendum to

ScanWizard Pro section.

Note: The Film Type option is enabled only when negative film is your film type

selection. Otherwise, this option will not appear, and the option switches to the

Input Profile/Scanner Profile option for positive film scanning.

5 . Click the Overview button to perform a preliminary scan of your original.

6 . Select the Scan Frame tool from the Toolbar in the Preview window , and choose

the area to be scanned by dragging a rectangle around it. You will see a flashing

frame (marquee) around the selected area.

7. Specify your scanning requirements in the Settings window.

a) Select a desired image type.

b) Select a desired resolution.

c) Adjust the scan frame settings if necessary.

8. Adjust image quality if necessary, using the Advanced Image Correction (AIC) tools.

ScanMaker 1000XL Supplement 29

Page 30

9. If the colors in your photo are faded

and need restoring, check the

“Automatic Color Restoration” box in

the Settings window.

10. Click the Prescan button to display a

detailed image. A thumbnail of the

image appears as well in the Scan Job

Queue window .

11. Click the Scan (or “Batch”) button in the Preview window to start scanning.

• If ScanWizard Pro was launched from an application program, the image is then

delivered to your application, where the image can be saved, printed, or edited.

Note: In Mac OS X, you will be prompted to specify the file attributes for the

scanned image before scanning takes place.

• If ScanWizard Pro was launched in standalone mode, you will be prompted to

specify the file attributes for the scanned image after the Scan or Batch

button is pressed, such as entering the file name, specifying a folder name of

your own, etc. When you have completed the settings, press the Done/Save

button, and the scanner will automatically scan and save your image based on

your settings.

30 ScanMaker 1000XL Supplement

Page 31

Using the Microtek Scanner ICC Profiler (MSP)

The Microtek Scanner ICC Profiler (MSP) is a scanner calibration and profiling utility

program designed exclusively for Microtek scanners. Used together with the color

calibration target, the ICC Profiler determines the color attributes of your scanner

accurately, then generates an ICC profile tailored exclusively for the scanner that you

are using under ScanWizard Pro.

MSP and IT8 Calibration Data Installation

Before installing MSP, ScanWizard Pro needs to be installed on your system to

ensure that MSP function properly.

T o install MSP, take note of the following:

• For PC: MSP installation will automatically launch following installation of

ScanWizard Pro. Follow the on-screen instructions to install, and you will be

prompted to insert the IT8 Calibration Data CD included in your software kit.

Insert the IT8 Calibration Data CD to ensure that the MSP utility will have the

latest color profile targets.

• For Mac OS X: Double-click the MSP installer icon. After installing the software,

insert the IT8 Calibration Data CD, and double-click the IT8 installer icon. Follow

the on-screen instructions to install the IT8 Calibration Data to ensure that the

MSP utility will have the latest color profile targets.

• For Mac OS 9.x: Double-click the Scanner ICC Profiler folder, then double-click the

ICC Profiler installer icon.

Calibration Kit

The calibration kit for your MSP program may vary, depending on the configuration

of the ScanMaker 1000XL that you purchased.

• If you purchased a ScanMaker 1000XL without the TMA 1000XL, an industrystandard Reflective target (IT8, size 5" x 7") is included in the scanner package.

• If you purchased a ScanMaker 1000XL with the TMA 1000XL, two industrystandard color targets are included: a Reflective target (IT8, size 5" x 7"); and a

Transparency target (IT8, size 4" x 5").

The calibration targets are very delicate and must be handled carefully . Take note of

the following:

• Gently remove targets from their respective protective sleeves and avoid touching

the target image surface.

• When not in use, keep targets in their sleeves and keep away from light and heat.

ScanMaker 1000XL Supplement 31

Page 32

Note: To keep the colors in your scanner consistent, you should perform color

calibration on a regular basis. Professional photographers, graphic designers or

others who require extremely precise color may wish to calibrate the scanner every

time it is used.

Positioning the Target

Proper positioning of the target on the scanner is important for successful calibration.

Incorrect positioning of the target will result in an unsuccessful calibration.

A. Positioning the Reflective Target

1. Flip and place the target on the scanner glass surface, making sure that the target

is positioned correct side up toward the front panel of the scanner, with its edge

firmly aligned against the U-shaped ruler.

2. Using the U-shaped ruler as a point of reference, adjust the target so that it is

positioned at the center of the scanner glass bed.

Make sure the woman's

portrait lies towards the right

6

5

4

3

2

1

0

1

2

3

4

5

6

side of the scanner

Note: If your ScanMaker 1000XL is

equipped with the TMA 1000XL, put

the Black Plate on top of the target

to cover the target and shield

unwanted light.

B. Positioning the Transparent Target

1 . Load the target face down inside the slot of the 4" x 5" Film Template.

2 . Place the 4" x 5" Film T emplate with the loaded target on the scanner glass

surface, and orient the template with the “Microtek” logo facing up.

Important: Align the

template's front

corners firmly against

the top corners (left

and right) of the Ushaped ruler, located

at the front of the

scanner.

32 ScanMaker 1000XL Supplement

Make sure the woman's

6

5

4

3

2

1

0

1

2

3

4

5

6

portrait lies towards the

right side of the scanner

Keep calibration strip clear

and free of any obstruction

Page 33

Calibration Setup

With the target properly positioned on the scanner, turn on your scanner and

let it warm up for about five minutes. Launch the MSP program; the MSP main

window appears.

A

B

C

D

A. Choose the scanner model that you are calibrating.

B . Choose the correct target media. If you are calibrating the reflective target, select

Reflective. Otherwise, select Positive.

C. Select the date code and target type from the

drop-down list that matches your target. You can

verify this information by looking at the left and

right corners of the target’ s bottom mar gin.

Date code and target type

information

If the desired data file is not present in the drop-down menu, insert the IT8

Calibration Data CD to update the target profiles in your system.

D . When all the settings are done, click the Start button. The calibration window will

appear, and an initial preview of the target is performed.

ScanMaker 1000XL Supplement 33

Page 34

Calibration and Profiling

After the Preview, you are now ready to complete calibration and create a profile for

your scanner.

1. Scan the target. To do this, select the entire target by dragging a frame over it, and

then click the Next>> button.

2 . Align the registration marks of the target with your cursor (see inset at bottom

of page).

3 . Click the Create Profile button (PC) or Finish button (Mac) to create the scanner

ICC profile. At the end of the profiling process, a dialog box appears, prompting

you to enter a profile name and description.

Aligning the Registration Marks

A. Upper-left registration mark

Move the cursor to the target image

area; the pointer will change to a

horizontally flipped L mark (“ ”).

Align the cursor with the small upperleft registration mark.

34 ScanMaker 1000XL Supplement

B. Upper-right registration mark C. Bottom-right registration mark

After the upper left mark is aligned,

the upper right part of the target image

is displayed, and an instruction dialog

box prompts you to align the upper

right registration mark.

Move the cursor to the target image

area; the pointer will change to a

normal L mark (“ ”). Align the cursor

with the small upper-right registration

mark.

After the upper right mark is aligned,

the lower right part of the target

image is displayed, and an instruction

dialog box prompts you to align the

bottom-right registration mark.

Move the cursor to the target image

area; the pointer will change to a

vertically flipped L mark (“ ”). Align

the cursor with the small bottomright registration mark.

Page 35

Loading a Profile

Once the profile has been produced, follow the steps below to load the profile you

just created.

1 . Launch ScanWizard Pro.

2 . In the Preview window, click the Scan Material icon. Select the “Reflective”

option for reflective materials; select the “Positive” or “Positive Film” option for

transparencies and slides; or select the “Negative” or “Negative Film” option for

negative filmstrips.

3 . From the Settings window, click the Scanner Profile/Input Pr ofile list box, and

select the profile you have just created.

ScanMaker 1000XL Supplement 35

Page 36

Specifications

Scanning Modes Color, grayscale, and black-and-white in a single

scanning pass

True 48-bit color (approx. 281 billion colors)

16-bit grayscale (approx. 65,536 shades of gray)

Scanning Area Reflective: 12" x 17" (305 mm x 432 mm)

Transparent: 12" x 16" (305 mm x 405 mm)

Resolution Optical: 6400 dpi x 3200 dpi

Interpolated: 25,600 dpi x 25,600 dpi

Dynamic Range 4.0 Dmax

Interface Hi-Speed USB (USB 2.0) and FireWire (IEEE 1394

standard)

Dimensions (L x W x H) 24.7" x 14.8" x 5.1" / 627.5 x 375.9 x 129.5 mm;

24.7" x 14.8" x 7.1" / 627.5 x 375.9 x 180.5 mm

(with TMA 1000XL)

Weight 26.4 lbs / 12 kg; 35.4 lbs / 16.1 kg (with TMA 1000XL)

Voltage AC 100V to 240V,

1A max; 47-63 Hz

Power Consumption 44W max.

Environment Operating T emperature: 50° F to 104° F (10° C to 40° C)

Relative Humidity: 20% to 85%

System Requirements

General Requirements

• CD-ROM drive (for installing software)

• Color display with 24-bit color output capability

• 128MB RAM (256MB or more to use DIGIT AL ICE Photo Print T echnology)

PC and compatibles

• Pentium III PC or higher with USB, Hi-Speed USB (USB 2.0), or FireWire port

• Microsoft Windows 98SE, Me, 2000 or XP

Macintosh

• iMac or Mac G3/G4/G5 with built-in USB port or FireWire port

• Mac OS X 10.2 or later

Important

Specifications, bundles, and accessories are subject to change without notice.

36 ScanMaker 1000XL Supplement

Page 37

FCC Compliance Statement

This equipment (Model: MRS-6400A3 or TMA-6400) has been tested and found to

comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC

rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there

is no guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can

be determined by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Note: A shielded Hi-Speed USB interface cable with ferrite core installed on the

scanner connector and must be used with this equipment.

Caution: Changes or modifications not expressly approved by the manufacturer

responsible for compliance could void the user's authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) This device may not cause harmful interference, and (2)

this device must accept any interference received, including interference that may

cause undesired operation.

Responsible Party: Loi Han

Microtek Lab, Inc.

16941 Keegan A venue

Carson, CA 90746

USA

Phone: 310-687-5800

Fax: 310-687-5950

ScanMaker 1000XL Supplement 37

Loading...

Loading...