Page 1

IC equipment

Wall-Jet cell

Manual

8.110.8015EN / 2013-12-12

Page 2

Page 3

Metrohm AG

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

IC equipment

Wall-Jet cell

6.5337.0x0

8.110.8015EN / 2013-12-12

Manual

zst

Page 4

Teachware

Metrohm AG

CH-9100 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://documents.metrohm.com.

Page 5

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

1 Introduction 1

1.1 Description ............................................................................ 1

1.2 About the documentation ................................................... 1

1.2.1 Content and scope .................................................................. 1

1.2.2 Symbols and conventions ........................................................ 2

2 Overview 4

3 Installation 5

3.1 Inserting the working electrode .......................................... 5

3.2 Inserting the reference electrode ........................................ 6

3.3 Connecting the detector capillaries .................................... 8

3.4 Connecting the electrode cables ....................................... 10

Table of contents

4 Start-up 12

5 Operation and maintenance 13

5.1 Operation ............................................................................ 13

5.2 Maintenance ....................................................................... 13

5.2.1 Replacing the working electrode ............................................ 13

5.2.2 Replacing the reference electrode .......................................... 14

5.2.3 Replacing the spacer .............................................................. 15

5.2.4 Cleaning the measuring cell ................................................... 17

6 Technical specifications 20

6.1 General ................................................................................ 20

6.2 Wall-Jet cell for carbohydrate analysis ............................. 21

6.3 Wall-Jet cell for cyanide analysis ....................................... 21

6.4 Wall-Jet cell for anion analysis .......................................... 22

7 Accessories 23

Index 25

IC equipment Wall-Jet cell

■■■■■■■■

III

Page 6

Table of figures

Table of figures

Figure 1 Wall-Jet cell – Parts and connections ................................................. 4

Figure 2 Inserting the working electrode ......................................................... 5

Figure 3 Ag/AgCl reference electrode (6.1257.720) ......................................... 7

Figure 4 Disassembling the measuring cell .................................................... 16

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

IV

IC equipment Wall-Jet cell

Page 7

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

1.1 Description

The Wall-Jet cell is used for amperometric detection with the Amperometric Detector. The Wall-Jet cell applies the wall-jet principle, which means

that the inlet is positioned directly opposite the working electrode. A thin

vertical jet of eluate is directed onto the working electrode, thus enabling

an optimum measurement performance.

The IC equipment Wall-Jet cell is available in four versions:

■ Wall-Jet cell without electrodes (6.5337.000).

■ Wall-Jet cell Carb (6.5337.010), with one gold working electrode and

one palladium reference electrode for the analysis of sugars and amino

acids.

■ Wall-Jet cell Cyanide (6.5337.020), with one silver working electrode

and one palladium reference electrode for applications relating to environmental analysis, e.g. the determination of cyanide and sulfide.

■ Wall-Jet cell Anion (6.5331.030), with one glassy carbon working elec-

trode and one silver / silver chloride reference electrode for the analysis

of inorganic anions, e.g. nitrite, sulfite and iodide.

1 Introduction

A more detailed description of the specifications and areas of application

for the individual cells can be found in Chapter 6, page 20.

1.2 About the documentation

CAUTION

Please read through this documentation carefully before putting the

measuring cell into operation. The documentation contains information

and warnings which the user must follow in order to ensure safe operation of the instrument.

1.2.1 Content and scope

Content of this manual

This manual describes:

■ how to insert the working electrode in the Wall-Jet cell.

■ how to insert the reference electrode in the Wall-Jet cell.

■ how to connect the capillaries and the electrode cables.

■ how users can carry out maintenance work.

IC equipment Wall-Jet cell

■■■■■■■■

1

Page 8

1.2 About the documentation

■ the technical specifications of the Wall-Jet cell.

■ the supplied and the optional accessories.

Additional information

Detailed information concerning the insertion of the measuring cell into

the detector can be found in the manuals for the amperometric detector.

Information on the use, care and maintenance of the working electrodes

and reference electrodes can be found in the leaflets enclosed with the

electrodes.

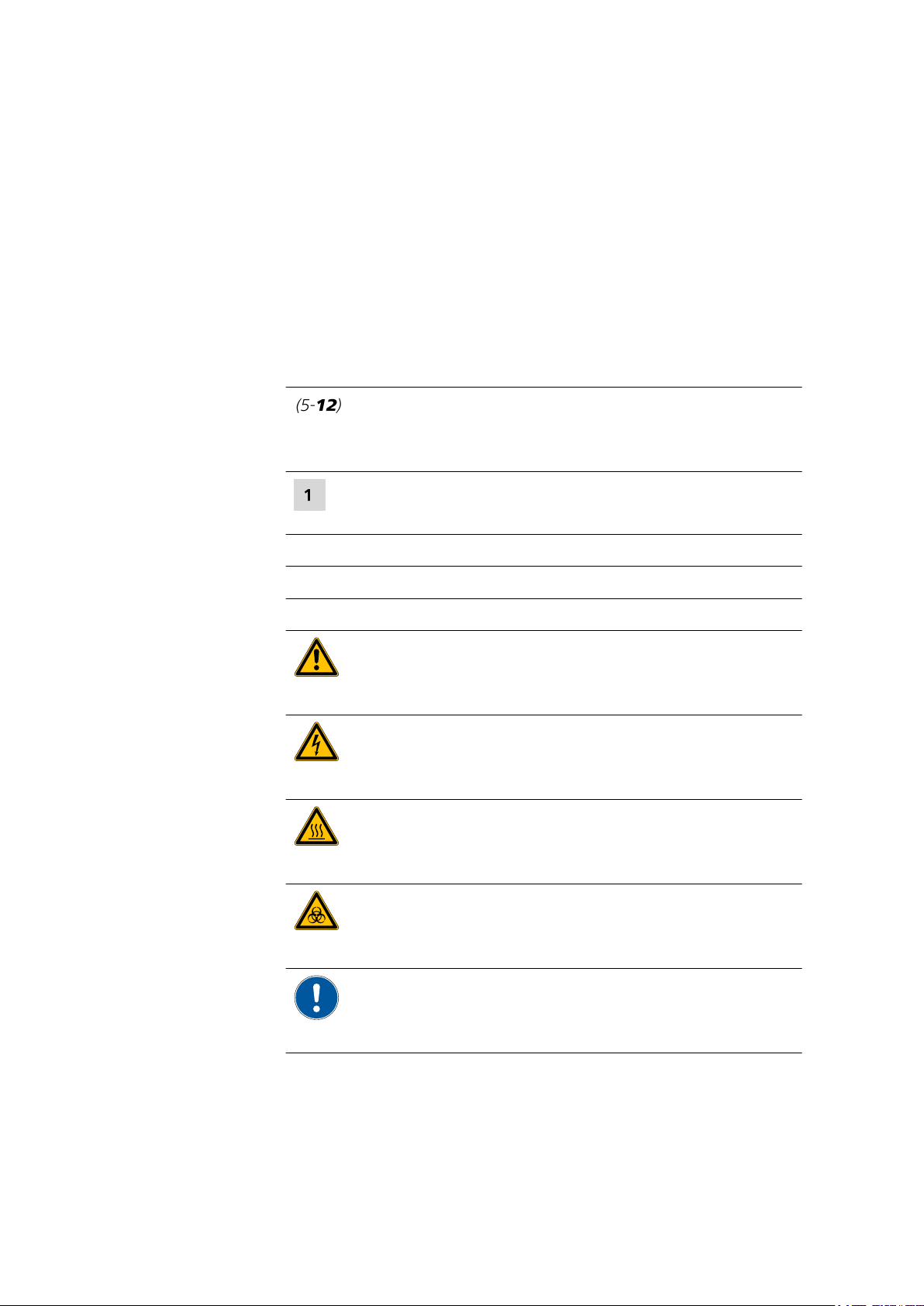

1.2.2 Symbols and conventions

The following symbols and formatting may appear in this documentation:

■■■■■■■■■■■■■■■■■■■■■■

Cross-reference to figure legend

The first number refers to the figure number, the second to the instrument part in the figure.

Instruction step

Carry out these steps in the sequence shown.

Method Dialog text, parameter in the software

File ▶ New Menu or menu item

[Next] Button or key

WARNING

This symbol draws attention to a possible life-threatening hazard or risk of injury.

WARNING

This symbol draws attention to a possible hazard due

to electrical current.

WARNING

This symbol draws attention to a possible hazard due

to heat or hot instrument parts.

WARNING

This symbol draws attention to a possible biological

hazard.

CAUTION

■■■■■■■■

2

This symbol draws attention to possible damage to

instruments or instrument parts.

IC equipment Wall-Jet cell

Page 9

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

NOTE

This symbol highlights additional information and

tips.

IC equipment Wall-Jet cell

■■■■■■■■

3

Page 10

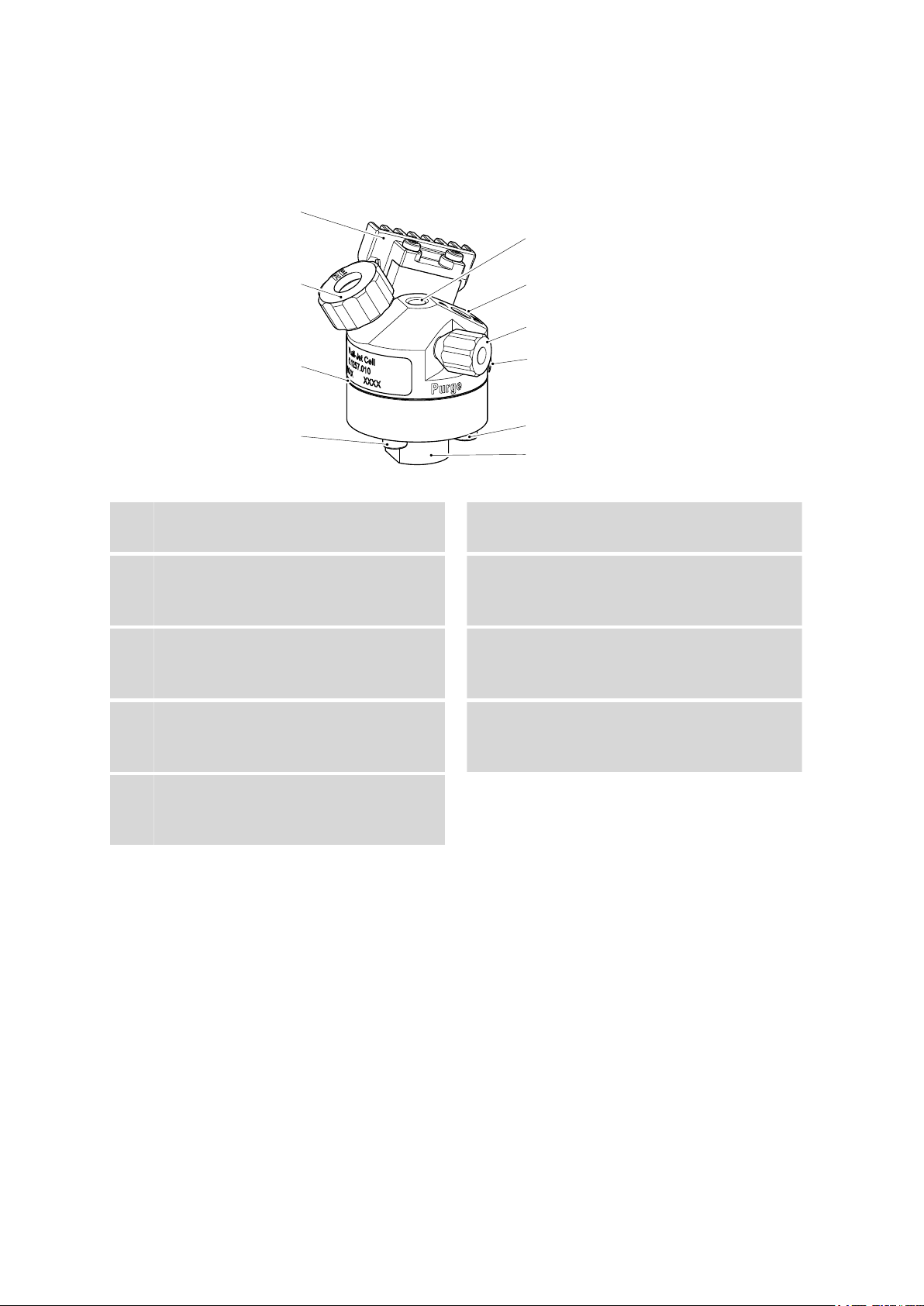

2 Overview

1

2

3

4

6

8

9

5

5

7

■■■■■■■■■■■■■■■■■■■■■■

Figure 1 Wall-Jet cell – Parts and connections

Eluent inlet

1

Labeled In.

Stopper

3

For deaeration opening.

Screws (4x)

5

For assembling the Wall-Jet cell.

Spacer

7

Standard: 50 µm (6.1257.810).

Chip

9

Intelligent. For hanging the Wall-Jet cell in

the detector.

Eluent outlet

2

Labeled Out.

Electrode cable connection socket

4

For the auxiliary electrode cable. Labeled

AE.

Pressure screw

6

For fixing the working electrode (WE) in

place.

Fastening screw

8

For fixing the reference electrode in place.

Labeled RE.

■■■■■■■■

4

IC equipment Wall-Jet cell

Page 11

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

CAUTION

Never switch on the measuring cell …

■ … if it is not simultaneously being rinsed by a conductive eluent; or

■ … if the electrode cables are not completely connected.

3.1 Inserting the working electrode

The measuring cell is supplied without electrodes. The working electrode

is either included in your equipment or you have ordered it separately.

Insert the working electrode as follows:

3 Installation

Inserting the working electrode

Figure 2

1

Inserting the working electrode

Unscrew the pressure screw on the base part of the cell and remove

it.

Insert the working electrode in the opening. The working electrode is

2

formed in such a way that it can be inserted into the measuring cell

in only one position.

Slide the pressure screw over the working electrode and screw it

3

tightly.

IC equipment Wall-Jet cell

■■■■■■■■

5

Page 12

3.2 Inserting the reference electrode

3.2 Inserting the reference electrode

The measuring cell is supplied without electrodes. The reference electrode

is either included in your equipment or you have ordered it separately.

Insert the reference electrode as follows:

Inserting the reference electrode

The reference electrode itself and one sealing ring are contained in the

packaging for the reference electrode.

Slide the sealing ring over the reference electrode.

1

■■■■■■■■■■■■■■■■■■■■■■

Unscrew the fastening screw on the RE connector and remove it.

2

Insert the reference electrode into the opening with the flat side fac-

3

ing downward.

Retighten the fastening screw.

4

Special case: Ag/AgCl reference electrode

The Ag/AgCl reference electrode (6.1257.720) is, in contrast to the other

reference electrodes, permanently connected to the reference electrode

cable.

■■■■■■■■

6

IC equipment Wall-Jet cell

Page 13

■■■■■■■■■■■■■■■■■■■■■■

1

2

4

5

3

3 Installation

Figure 3 Ag/AgCl reference electrode (6.1257.720)

Plug

1

Sealing screw

3

For sealing the storage vessel.

Storage vessel

5

For storing the Ag/AgCl reference electrode.

Insert the reference electrode as follows:

Inserting the Ag/AgCl reference electrode

Take the Ag/AgCl reference electrode out of the storage vessel. Pull

1

the sealing screw of the storage vessel over the plug and reseal the

storage vessel with it.

Reference electrode cable

2

Permanently mounted on the reference electrode.

Reference electrode

4

IC equipment Wall-Jet cell

■■■■■■■■

7

Page 14

3.3 Connecting the detector capillaries

Unscrew the fastening screw from the reference electrode holder.

2

Push the fastening screw over the cable of the Ag/AgCl reference

electrode.

Check whether the sealing ring is seated on the reference electrode

3

and insert the reference electrode into the reference electrode

holder.

Tighten the reference electrode to the reference electrode holder

4

with the fastening screw.

Further information regarding the correct handling of the Ag/AgCl reference electrode can be found in the leaflet for the Ag/AgCl reference electrode.

3.3 Connecting the detector capillaries

■■■■■■■■■■■■■■■■■■■■■■

The amperometric detector is equipped with a preheating capillary in its

interior to ensure that the eluent flows through the measuring cell at a

constant temperature.

Connecting the preheating capillary is optional. If the ambient conditions

are optimal or if the eluent is heated in the column, then the measuring

results can be sufficiently accurate, even without the use of the preheating

capillary.

CAUTION

The preheating capillary may not be connected if highly flammable liquids are analyzed!

In the event of a leak, the fluid might evaporate and ignite in the heating area.

If the preheating capillary is not used, proceed as follows:

Connecting capillaries to the measuring cell

1

Connecting the cell inlet

Use a pressure screw (6.2744.014) to fasten the detector input capillary to the In connector of the measuring cell.

■■■■■■■■

8

IC equipment Wall-Jet cell

Page 15

■■■■■■■■■■■■■■■■■■■■■■

2

Connecting the cell outlet

Use a pressure screw (6.2744.014) to fasten a piece of PEEK capillary

(6.1831.010) with a length of 1 to 1.5 m to the Out connector of

the measuring cell.

NOTE

This capillary must be tested with the IC instrument the first time

the detector is put into operation, see the chapter "Start-up" in

the manual for the detector.

If the preheating capillary is used, proceed as follows:

Connecting capillaries to the measuring cell

1

Connecting the preheating capillary

3 Installation

NOTE

The preheating capillary must be tested with the IC instrument the

first time the detector is put into operation, see the chapter "Start-

up" in the manual for the detector.

■ Use a pressure screw (6.2744.014) to connect the detector input

capillary to the Eluent in connector of the detector.

■ Use a pressure screw (6.2744.014) to fasten a piece of PEEK capil-

lary (6.1831.010) to the Eluent to cell connector of the detector.

2

Connecting the cell inlet

Use a pressure screw (6.2744.014) to fasten the other end of the

PEEK capillary (6.1831.010) to the In connector of the measuring

cell.

3

Connecting the cell outlet

Use a pressure screw (6.2744.014) to fasten a piece of PEEK capillary

(6.1831.010) with a length of 1 to 1.5 m to the Out connector of

the measuring cell.

IC equipment Wall-Jet cell

■■■■■■■■

9

Page 16

3.4 Connecting the electrode cables

NOTE

This capillary must be tested with the IC instrument the first time

the detector is put into operation, see the chapter "Start-up" in

the manual for the detector.

3.4 Connecting the electrode cables

CAUTION

The electrode cables may not be plugged or unplugged unless the measuring cell is switched off in the software.

NOTE

■■■■■■■■■■■■■■■■■■■■■■

The sockets and the plugs of the cables must be clean and dry.

Connecting the electrode cables to the detector

Prerequisites:

■ The measuring cell is switched off.

Plug the straight plug of the working electrode cable (red sleeve) into

1

the WE socket of the detector.

Plug the straight plug of the reference electrode cable (black sleeve)

2

into the RE socket of the detector.

Plug the straight plug of the auxiliary electrode cable (blue sleeve)

3

into the AE socket of the detector.

■■■■■■■■

10

IC equipment Wall-Jet cell

Page 17

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

Connecting the electrode cables to the measuring cell

Prerequisites:

■ The working electrode and the reference electrode are inserted into

the measuring cell.

Plug the angled plug of the working electrode cable (labeled WE)

1

into the working electrode socket.

Plug the angled plug of the reference electrode cable (labeled RE)

2

into the reference electrode socket.

Plug the angled plug of the auxiliary electrode cable (labeled AE) into

3

the socket (labeled AE).

IC equipment Wall-Jet cell

■■■■■■■■

11

Page 18

4 Start-up

■■■■■■■■■■■■■■■■■■■■■■

The measuring cell and the amperometric detector are set to work at the

same time. Additional information on this topic can be found in the manual for the detector.

■■■■■■■■

12

IC equipment Wall-Jet cell

Page 19

■■■■■■■■■■■■■■■■■■■■■■

5 Operation and maintenance

5.1 Operation

The measuring cell is operated together with the detector and the entire

IC system with the MagIC Net™ software.

Additional information on operation with MagIC Net™ can be found in

the "MagIC Net™ Tutorial" or in the MagIC Net™ online help.

5.2 Maintenance

The measuring cell must be taken out of the detector for the following

maintenance tasks.

CAUTION

5 Operation and maintenance

The electrode cables may not be unplugged unless the measuring cell is

switched off in the software!

Taking the measuring cell out of the detector

Switch off the measuring cell in the software.

1

Disconnect all three electrode cables.

2

On the measuring cell holder, push the Press button and remove the

3

measuring cell from the holder.

5.2.1 Replacing the working electrode

Depending on the application, the measuring cell can be operated with a

variety of different working electrodes. The different working electrodes

are available as accessories (see Chapter 7, page 23).

Replacing the working electrode

IC equipment Wall-Jet cell

Prerequisites:

■ The measuring cell is switched off.

■ The measuring cell has been removed from the detector.

■ The electrode cables are unplugged.

■■■■■■■■

13

Page 20

5.2 Maintenance

■■■■■■■■■■■■■■■■■■■■■■

No tool is required for replacing the working electrode.

Unscrew the pressure screw (1-6) on the base part of the cell and

1

remove it.

Take out the working electrode.

2

Insert the new working electrode. The working electrode is shaped in

3

such a way that it can be inserted into the measuring cell in only one

position.

Slide the pressure screw over the working electrode and tighten it.

4

5.2.2 Replacing the reference electrode

Depending on the application, the measuring cell can be operated with a

variety of different reference electrodes. The different reference electrodes

are available as accessories (see Chapter 7, page 23).

NOTE

These instructions apply analogously to the Ag/AgCl reference electrode.

Inserting the reference electrode

Prerequisites:

■ The measuring cell is switched off.

■ The measuring cell has been removed from the detector.

■ The electrode cables are unplugged.

No tool is required for replacing the reference electrode.

Slide the supplied sealing ring over the new reference electrode.

1

■■■■■■■■

14

IC equipment Wall-Jet cell

Page 21

■■■■■■■■■■■■■■■■■■■■■■

5 Operation and maintenance

Unscrew the fastening screw for the reference electrode and remove

2

it.

Take out the reference electrode.

3

Insert the new reference electrode.

4

Tighten the fastening screw again.

5

NOTE

Important: After an Ag/AgCl reference electrode has been

removed!

The Ag/AgCl reference electrode may not be allowed to dry out. Follow

the directions for storage contained in the leaflet for the Ag/AgCl reference electrode.

5.2.3 Replacing the spacer

Depending on the application, the measuring cell can be operated with a

variety of different spacers. The different spacers are available as accessories (see Chapter 7, page 23).

The measuring cell must be disassembled in order for the spacer to be

replaced. Proceed as follows to disassemble the measuring cell:

Disassembling the measuring cell

Prerequisites:

■ The measuring cell is switched off.

IC equipment Wall-Jet cell

■■■■■■■■

15

Page 22

5.2 Maintenance

1

2

3

4

■■■■■■■■■■■■■■■■■■■■■■

■ The measuring cell has been removed from the detector.

■ The electrode cables have been removed.

To disassemble the measuring cell, you need a 2.5 mm hex key.

Fastening screw (4x)

1

Spacer

3

6.1257.810 or 6.1257.830.

Figure 4 Disassembling the measuring cell

Base part

2

Measuring part

4

With auxiliary electrode.

Remove the reference electrode.

1

Remove the working electrode.

2

Unscrew the four screws on the base part of the measuring cell with

3

the hex key and remove them.

Remove the base part.

4

Remove the spacer.

5

Replace the spacer as follows:

■■■■■■■■

16

IC equipment Wall-Jet cell

Page 23

■■■■■■■■■■■■■■■■■■■■■■

5 Operation and maintenance

Replacing the spacer

Prerequisites:

■ The measuring cell is disassembled.

■ The new spacer is dry, clean and lint-free.

You will need a 2.5 hex key and a pair of tweezers to replace the spacer.

Wear latex gloves when replacing the spacer.

1

Positioning the spacer

■ Hold the measuring part in your hand as shown in Figure 4, page

16.

■ Use tweezers to place the new spacer on the measuring part.

The straight side of the spacer must lie on the straight edge of the

measuring part and the four small holes in the spacer must be

aligned precisely to the boreholes.

Use your fingertips to hold the spacer in correct position.

2

Attaching the base part

■ Insert the four screws into the boreholes on the base part.

■ Carefully mount the base part of the measuring cell:

The straight edge of the base part must lie on the straight edge of

the measuring part and the four screws must fit precisely in the

four boreholes.

Take care to ensure that the boreholes on the base part, the spacer

and the measuring part are aligned precisely with one another.

3

Tightening the screws

Tighten the four screws evenly in crosswise sequence with the hex

key.

5.2.4 Cleaning the measuring cell

The auxiliary electrode can be readily cleaned when the working electrode

has been removed from the cell.

IC equipment Wall-Jet cell

■■■■■■■■

17

Page 24

5.2 Maintenance

■■■■■■■■■■■■■■■■■■■■■■

Cleaning the auxiliary electrode

Prerequisites:

■ The electrode cables are unplugged.

■ The reference electrode has been removed from the measuring cell.

■ The working electrode has been removed from the measuring cell.

1

NOTE

When cleaning the auxiliary electrode, the edges of the spacer

may get damaged.

The spacer must then be replaced.

■ Moisten a cotton swab with 2 mol/L of nitric acid.

■ Use this to carefully wipe the auxiliary electrode.

The edges of the spacer may be damaged when wiping the auxiliary electrode.

If the auxiliary electrode is tenaciously stained, we recommend

that the spacer be removed prior to cleaning the auxiliary electrode (see Chapter 5.2.3, page 15).

■■■■■■■■

18

Rinse off the measuring cell (except for the working electrode and

2

the reference electrode) under running water and dry with a lint-free

cloth.

NOTE

When you rinse off the measuring part, take care to ensure that

the chip in the cell holder does not get wet.

IC equipment Wall-Jet cell

Page 25

■■■■■■■■■■■■■■■■■■■■■■

5 Operation and maintenance

Cleaning the working electrode

Clean the working electrode in accordance with the directions con-

1

tained in the leaflet for the working electrode or polish it if necessary.

Reinsert the working electrode (see Chapter 3.1, page 5).

2

Inserting the reference electrode

Reinsert the reference electrode (see Chapter 3.2, page 6).

1

IC equipment Wall-Jet cell

■■■■■■■■

19

Page 26

6.1 General

■■■■■■■■■■■■■■■■■■■■■■

6 Technical specifications

6.1 General

Structure Flow-through cell with working, reference and auxiliary electrode.

Material Cell body made of PEEK.

Cell volume Dependent on the thickness of the spacer:

for 3 mm working electrode

and 50 µm

spacer

for 2 mm working electrode

and 25 µm

spacer

< 0.35 µL

< 0.1 µL

Maximum operating pressure

Cell recognition Intelligent cell with automatic identification and monitoring.

Auxiliary electrode

Type Installed

Material Stainless steel

Reference electrode

Type Replaceable

Material ■ Palladium solid-state electrode

0.4 MPa (100 psi)

■ Ag/AgCl gel electrode

■■■■■■■■

20

IC equipment Wall-Jet cell

Page 27

■■■■■■■■■■■■■■■■■■■■■■

6.2 Wall-Jet cell for carbohydrate analysis

Working electrode

Material Gold

Diameter 3 mm

6 Technical specifications

Reference elec-

Palladium solid-state electrode

trode

Applications Sugar and amino acids

■ Mono-, di-, oligo- and polysaccharides

■ Sugar alcohols

■ Amino sugars

■ Sugar acids

■ Amino acids

■ Antibiotics

Working range

Acidic medium

(pH 1)

Ag/AgCl refer-

–0.35 V - +1.10 V

ence electrode

Alkaline

medium (pH 13)

Palladium refer-

–0.9 V - +0.75 V

ence electrode

6.3 Wall-Jet cell for cyanide analysis

Working electrode

Material Silver

Diameter 3 mm

Reference electrode

Applications Applications relating to environmental analysis

IC equipment Wall-Jet cell

Palladium solid-state electrode

■ Halogenides

■ Cyanide, sulfide

■ Thiosulfate

■ Pharmaceuticals

■■■■■■■■

21

Page 28

6.4 Wall-Jet cell for anion analysis

Working range

Acidic medium

(pH 1)

Ag/AgCl refer-

–0.55 V - +0.40 V

ence electrode

Alkaline

medium (pH 13)

Palladium refer-

–1.2 V - +0.1 V

ence electrode

6.4 Wall-Jet cell for anion analysis

Working electrode

Material Glassy carbon

Diameter 3 mm

■■■■■■■■■■■■■■■■■■■■■■

Reference elec-

Ag/AgCl gel electrode

trode

Applications Aromatics and amines

■ Catecholamines, aromatic amines

■ Inorganic anions (nitrite, sulfite, etc.)

■ Phenols

■ Vitamins

■ Some amino acids

Working range

Acidic medium

(pH 1)

Ag/AgCl refer-

–0.8 V - +1.3 V

ence electrode

Alkaline

medium (pH 13)

Ag/AgCl refer-

–1.5 V - +0.6 V

ence electrode

■■■■■■■■

22

IC equipment Wall-Jet cell

Page 29

■■■■■■■■■■■■■■■■■■■■■■

7 Accessories

Up-to-date information on the scope of delivery and optional accessories

for your instrument can be found on the Internet.

When you receive your new instrument, we recommend downloading

the accessories list from the Internet, printing it out and keeping it

together with the manual for reference purposes.

Instruments currently sold

If you do not know the article number of your instrument, proceed as follows:

Downloading the accessories list

7 Accessories

NOTE

Go to the Metrohm website http://www.metrohm.com/com.

1

2

Click on .

The Search webpage will be displayed.

Enter a search term relating to the instrument into the search field

3

and click on Find.

The search results will be displayed.

In the search results, select the Devices tab (if it is not already

4

selected) and then click on the Metrohm article number of the

required instrument (e.g. 2.852.0050).

The page with information pertaining to the searched article is displayed.

Select the Parts tab.

5

The complete list of accessories with the scope of delivery and the

optional accessories will be displayed.

6

Click on .

IC equipment Wall-Jet cell

■■■■■■■■

23

Page 30

■■■■■■■■■■■■■■■■■■■■■■

The Partslists webpage will be displayed.

Select the desired output language.

7

With the article number entered, click on the command Generate

8

PDF.

The PDF file with the accessories data will be created in the language

selected.

Direct access for all instruments

If you are unable to find your instrument using the search as described

above, this may be due to the instrument not being sold anymore. Using

the article number, you can download accessories lists for all instruments

as follows:

Downloading the accessories list

Type http://partslists.metrohm.com into your Internet browser.

1

The Partslists webpage will be displayed.

Select the desired output language.

2

Enter the article number and click on the Generate PDF command.

3

The PDF file with the accessories data will be created in the language

selected.

■■■■■■■■

24

IC equipment Wall-Jet cell

Page 31

■■■■■■■■■■■■■■■■■■■■■■

Index

Index

A

Auxiliary electrode

Cleaning ............................. 17

E

Electrode cable

Connect ............................. 10

I

Installation

Insert Ag/AgCl reference elec-

trode .................................... 7

Insert reference electrode ..... 6

Insert working electrode ....... 5

Measuring cell ...................... 5

M

Measuring cell

Cleaning ............................. 17

Connect capillaries ................ 8

Remove .............................. 13

Take out ............................. 13

R

Reference electrode

Installation ........................... 6

Replace .............................. 14

S

Spacer

Replace .............................. 15

T

Technical specifications ............ 20

W

Wall-Jet cell

Anion analysis .................... 22

Carbohydrate analysis ......... 21

Cyanide analysis ................. 21

Technical specifications . 21, 22

Working electrode .................... 17

Inserting ............................... 5

Replace .............................. 13

IC equipment Wall-Jet cell

■■■■■■■■

25

Loading...

Loading...