Metabo TKHS 315 M Operating Instructions Manual

0017_33_1v5IVZ.fm

TKHS 315 M

Originalbetriebsanleitung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Original operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Origineel gebruikaanwijzing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

115 169 3748 / 0516 - 3.3

www.metabo.com

1

2

4

5

6

10

11

12

13

14

15161718

19

7

8

3

9

21

22

23

20

I_0014en4A.fm 5.2.16 Original operating instructions

ENGLISH

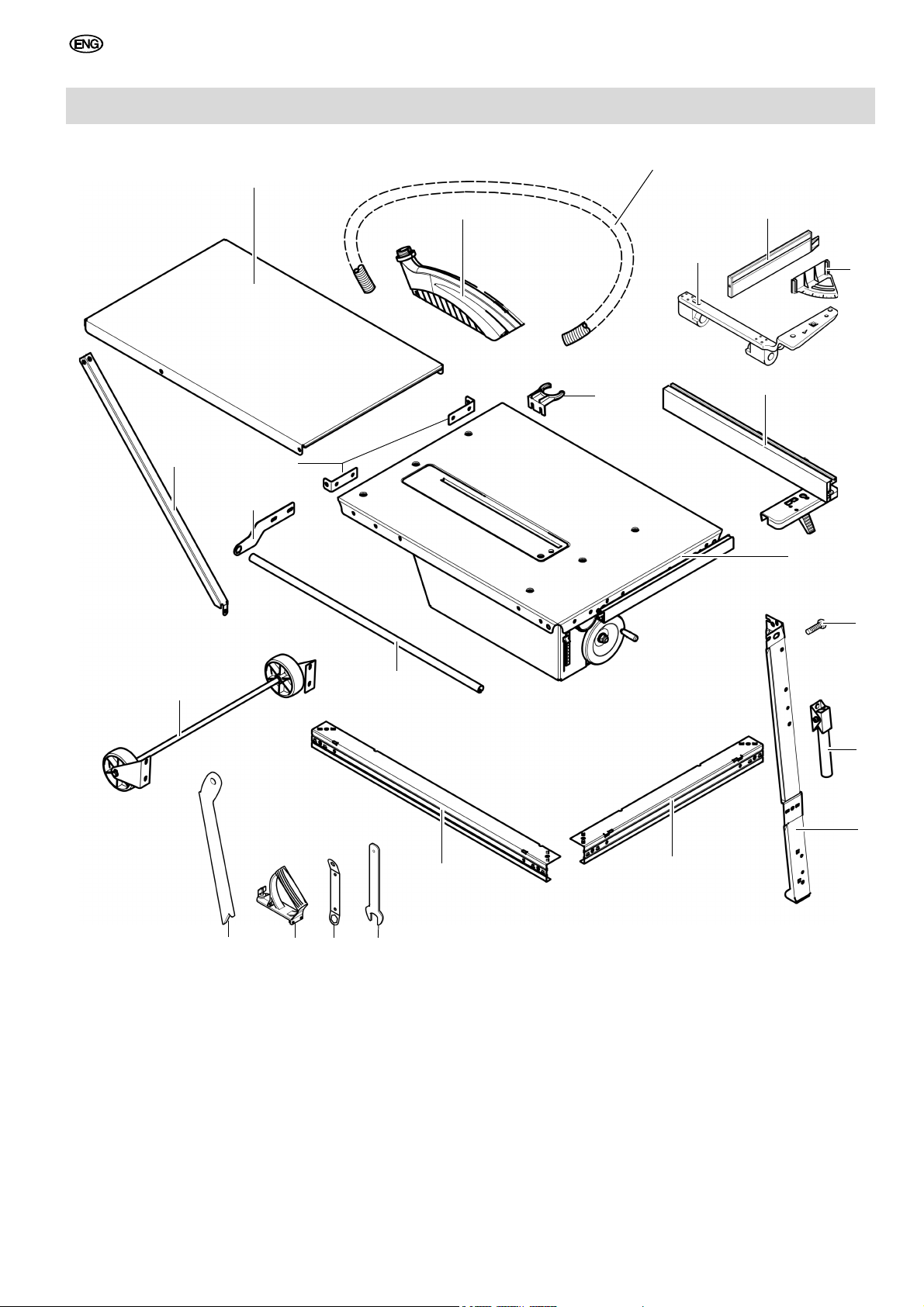

1. Scope of delivery

1 Plate, table rear extension

2 Blade guard

3 Suction hose

4 Fence carrier, lower

5 Fence extrusion, short

6 Fence carrier, upper

7 Rip fence

8 Hose carrier

9 Table panel, c/w with motor carrier

unit, motor, switch, saw blade, riving knife, dust extraction port

22

10 Accessory storage (2x)

11 Transport handle (2x)

12 Leg (4x)

13 Stanchion, short (2x)

14 Stanchion, long (2x)

15 Spanner for saw blade change

16 Spanner for saw blade change

17 Handle for push block

18 Push stick / feeding aid

19 Wheel set

20 Guide bar for mitre fence

21 Support (2x)

22 Mounting bracket (2x)

23 Bracket, for rear extension table

(2x)

– Operating instructions and spare

parts list

– Hardware bag

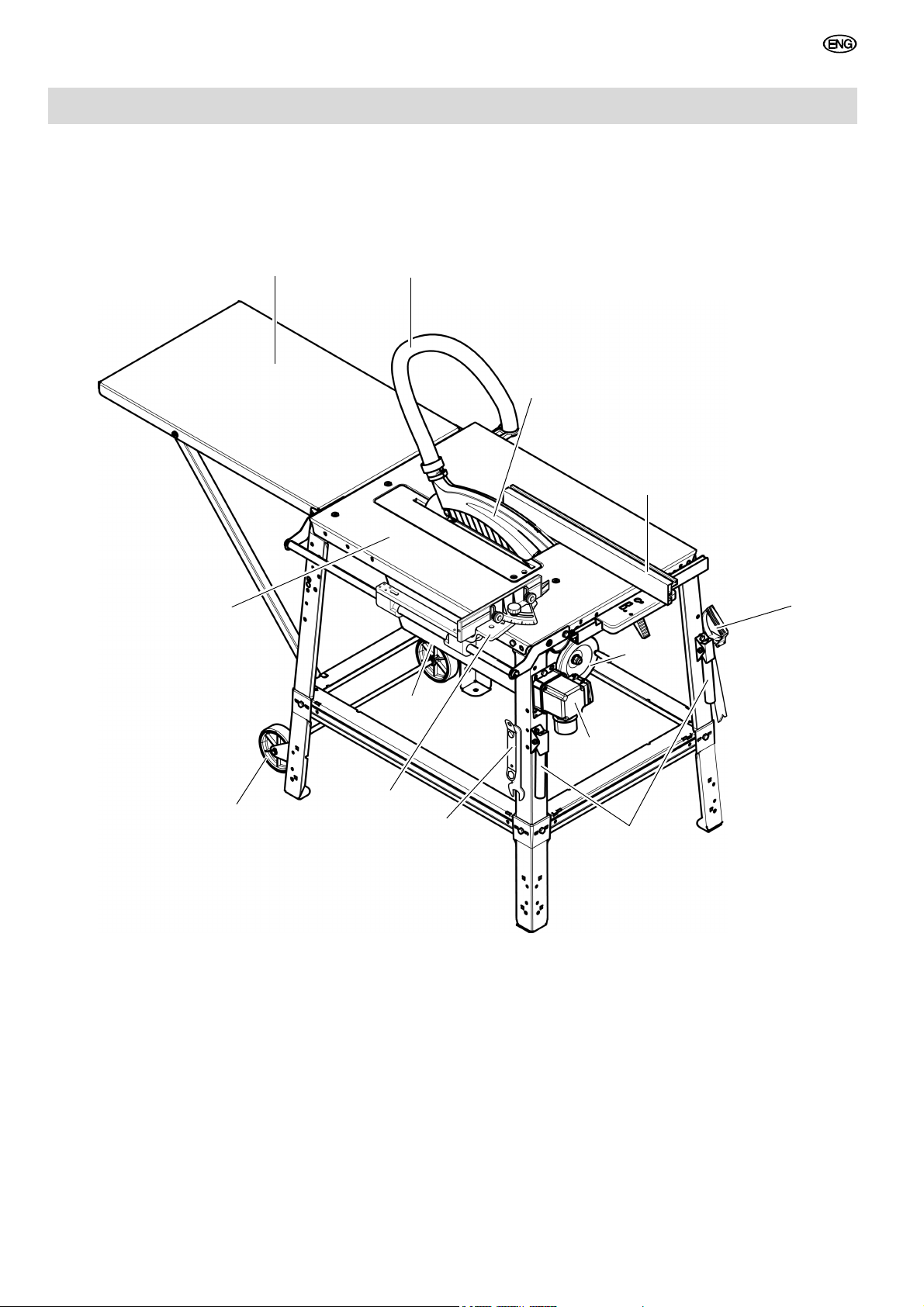

2. Machine overview

24

27

28

29

30

31

32

33

34

25

26

35

36

ENGLISH

24 Table extension

25 Suction hose

26 Blade guard

27 Rip fence

28 Accessory holders for push stick

/ feeding aid and push block

handle

29 Crank for cutting height setting,

stepless from 0 – 85 mm

30 ON/OFF switch

31 Transport handles

32 Accessory holder for saw blade

change wrenches

33 Mitre fence

34 Motor carrier unit – angle of incli-

nation steplessly adjustable from

0° through 47°

35 Wheel set

36 Table top

23

ENGLISH

Table of Contents

1. Scope of delivery...................22

2. Machine overview..................23

3. Please Read First!.................. 24

4. Safety Instructions ................ 24

4.1 Specified conditions of use ...... 24

4.2 General Safety Instructions ..... 24

4.3 Symbols on the machine ......... 26

4.4 Safety devices .........................26

5. Special Product Features...... 27

6. Operating elements ............... 27

7. Assembly................................ 28

7.1 Mains connection.....................32

7.2 Set-up ...................................... 32

8. Operation................................ 32

8.1 Dust collector ...........................33

8.2 Adjusting the cutting depth ...... 33

8.3 Setting the saw blade tilt..........34

8.4 Sawing with the rip fence......... 34

8.5 Sawing with the mitre fence..... 34

9. Tips and Tricks ......................35

10. Care and Maintenance........... 35

10.1 Changing the saw blade ..........35

10.2 Aligning the riving knife............36

10.3 Cleaning the saw blade's

height adjustment mechanism . 36

10.4 Storing the saw ........................ 37

10.5 Maintenance ............................ 37

11. Repairs....................................37

12. Transport ................................37

13. Available Accessories ........... 37

14. Environmental

Considerations.......................37

15. Troubleshooting .................... 37

16. Technical Data .......................38

3. Please Read First!

These instruction have been written in

a way which facilitates learning of how

to safely operate your saw. Here is a

guide on how you should read these instructions:

– Read these instructions before use.

Pay special attention to the safety

information.

– These instructions are intended for

persons with basic technical knowledge regarding the operation of a

device like the one described herein. Inexperienced persons are

strongly advised to seek competent

advise and guidance from an experienced person before operating this

machine.

– Keep all documents supplied with

this machine for future reference.

Retain proof of purchase in case of

warranty claims.

– This device must not be sold or lent

to someone else without being accompanied by these Operating Instructions and all other documents

supplied with the device.

– The equipment manufacturer is not

liable for any damage resulting from

neglect of these operating instructions.

Information in these instructions is designated as under:

ADanger!

Risk of personal injury or environmental

damage.

BRisk of electric shock!

Risk of personal injury by electric

shock.

cDrawing-in/trapping hazard!

Risk of personal injury by body parts or

clothing being drawn into the rotating

saw blade.

A Caution!

Risk of material damage.

3 Note:

Additional information.

– Numbers in illustrations (1, 2, 3

etc.)

– denote component parts;

– are consecutively numbered;

– relate to the corresponding num-

ber(s) in brackets (1), (2), (3) etc.

in the neighbouring text.

– Numbered steps must be carried

out in sequence.

– Instructions which can be carried

out in any order are indicated by a

bullet point (•).

– Listings are marked by a dash (–).

4. Safety Instructions

4.1 Specified conditions of

use

This machine is intended for ripping,

cross-cutting and cutting to size of solid

wood, particle board, fibreboard, plywood and these materials provided

they have plastic laminate surfaces or

edge trim or are veneered.

Round workpieces may not be sawed

as they can be twisted by the rotating

saw blade.

The tool must not be used for grooving.

Always have blade guard installed during operation.

Any other use is considered to be not

as specified and not permitted. The manufacturer is not liable for any damage

caused by unspecified use.

Reconstruction of this machine or use

of parts that have not been tested and

released by the manufacturer can lead

to unforeseen damage and dangers during operation.

4.2 General Safety Instructions

When using this machine observe

the following safety instructions to

minimise the risk of personal injury

or material damage.

Please also observe the special sa-

fety instructions in the respective

sections.

Where applicable, follow the legal

directives or regulations for the prevention of accidents pertaining to

the use of circular saws.

AGeneral hazards!

Keep your work area tidy – a messy

work area invites accidents.

Be alert. Know what you are doing.

Set out to work with reason. Do not

operate device while under the influence of drugs, alcohol or medication.

Consider environmental conditions.

Keep work area well lighted.

Avoid unnatural body positions.

Ensure firm footing and keep your

balance at all times.

Use suitable workpiece supports

when cutting long stock.

24

ENGLISH

Wedges may only be cut using a

wedge cutting jig, adapted to the

desired wedge thickness, length,

and taper:

– Install riving knife and blade

guard.

With your right hand push the

wedge cutting jig against the rip

fence, while at the same time feed it

into the saw blade. Secure workpiece with your left hand.

Do not operate the machine near in-

flammable liquids or gases.

The saw shall only be started and

operated by persons familiar with

circular saws and who are at any

time aware of the dangers associated with the operation of such

machine.

Persons under 18 years of age shall

use this tool only in the course of

their vocational training under the

supervision of an instructor.

Keep bystanders, particularly child-

ren, out of the danger zone. Do not

permit bystanders to touch the device or mains cable while it is running.

Do not overload device – use it only

within the performance range it was

designed for (see 'Technical Data').

BDanger! Risk of electric

shock!

Do not expose device to rain.

Do not operate device in damp or

wet environment.

Prevent body contact with earthed

objects such as radiators, pipes,

cooking stoves or refrigerators

when operating this device.

Do not use the mains cable for any

purpose it is not intended for.

Do not use any damaged mains ca-

ble.

A damaged mains cable may only

be replaced by the manufacturer, its

customer service or its service partner.

ARisk of personal injury and

crushing by moving parts!

Do not operate the machine without

installed guards.

Always keep sufficient distance to

the saw blade. Use suitable feeding

aids if necessary. Keep sufficient di-

stance to driven components when

operating the device.

Wait for the saw blade to come to a

complete stop before removing cutouts, waste wood etc. from the work

area.

Do not attempt to stop the saw bla-

de by pushing the workpiece

against its side.

Ensure the device is disconnected

from power before servicing.

When turning ON the machine (e.g.

after servicing) ensure that no tools

or loose parts are left on or in the

machine.

Turn power OFF if the machine is

not used.

ACutting hazard, even with the

cutting tool at standstill!

Wear gloves when changing cutting

tools.

Store saw blades in such a manner

that nobody can get hurt.

ARisk of kickback (workpiece is

caught by the saw blade and thrown

against the operator)!

Always work with a properly set ri-

ving knife.

Riving knife and saw blade used

must match: The riving knife should

be thinner than the kerf, but thicker

than the saw blade body.

Do not jam workpieces.

Make sure the saw blade is suitable

for the workpiece material.

Cut thin or thin-walled workpieces

only with fine-toothed saw blades.

Always use sharp saw blades.

If in doubt, check workpiece for in-

clusion of foreign matter (e.g. nails

or screws).

Cut only stock of dimensions that al-

low for safe and secure holding

while cutting.

Never cut several workpieces at the

same time – and also never cut

bundles containing several individual pieces. There is a risk of personal

injury if individual pieces are caught

by the saw blade in an uncontrolled

manner.

Remove small cut-outs, waste wood

etc. from the work area – when you

are doing so, the saw blade must be

at a complete standstill.

cDrawing-in/trapping hazard!

Ensure that no parts of the body or

clothing can be caught and drawn in

by rotating components (no ties, no

gloves, no loose-fitting clothes; contain long hair with hairnet).

Never attempt to cut any workpi-

eces which contain

– ropes,

– strings,

– bands,

– cables or

– wires or to which any of the

above are attached.

ADanger due to insufficient per-

sonal protection equipment!

Wear ear protection.

Wear safety goggles.

Wear dust mask.

Wear suitable work clothes.

When working outdoors wearing of

non-slip shoes is recommended.

ARisk of injury by inhaling

wood dust!

Some types of wood dust (e.g. oak,

beech, ash) may cause cancer

when inhaled. If working in a closed

room, always use a dust collector.

Make sure that as little as possible

wood dust can escape into the environment:

– install dust collector

– repair any leaks on the dust coll-

ector

– keep your work area well ventila-

ted at all times.

Operation without a dust collector is

only possible:

– outdoors;

– for short-term operation

(up to a maximum of 30 minutes); or

– if a dust respirator is worn.

25

ENGLISH

38

39

40

41 42

44

37

43

45 46

48 49 50

47

51 52

53

54

AHazard caused by modificati-

on of the machine or use of parts not

tested and approved by the manufacturer!

Strictly follow these instructions

when assembling the device.

Use only parts approved by the

equipment manufacturer. This applies particularly to:

– Saw blades (please see 'Availab-

le accessories' for order numbers);

– safety devices (see 'Spare parts

list' for stock numbers).

Do not change any parts.

AHazard generated by machine

defects!

Keep the machine and accessories

in good repair. Follow the maintenance instructions.

Before any use check machine for

possible damage: before operating

the machine all safety devices, protective guards or slightly damaged

parts need to be checked for proper

function as specified. Check to see

that all moving parts work properly

and do not jam. All parts must be

correctly installed and meet all requirements for proper operation of

the device.

Any damaged parts or protection

devices must be repaired or replaced by a qualified specialist.

Have damaged switches replaced

by a service centre. Do not operate

device if the switch cannot be turned ON or OFF.

Keep handles free of oil and grease.

4. Clear the blockage using a suitable

tool.

4.3 Symbols on the machine

Data on the nameplate

37 Manufacturer

38 Serial number

39 Machine designation

40 Motor data (see also 'Technical

Data')

41 Date of manufacture

42 CE mark – This machine meets

the EC directives as per declaration of conformity

43 Waste disposal symbol – Device

can be disposed of by returning it

to the manufacturer

44 Dimensions of permissible saw

blades

Symbols on the machine

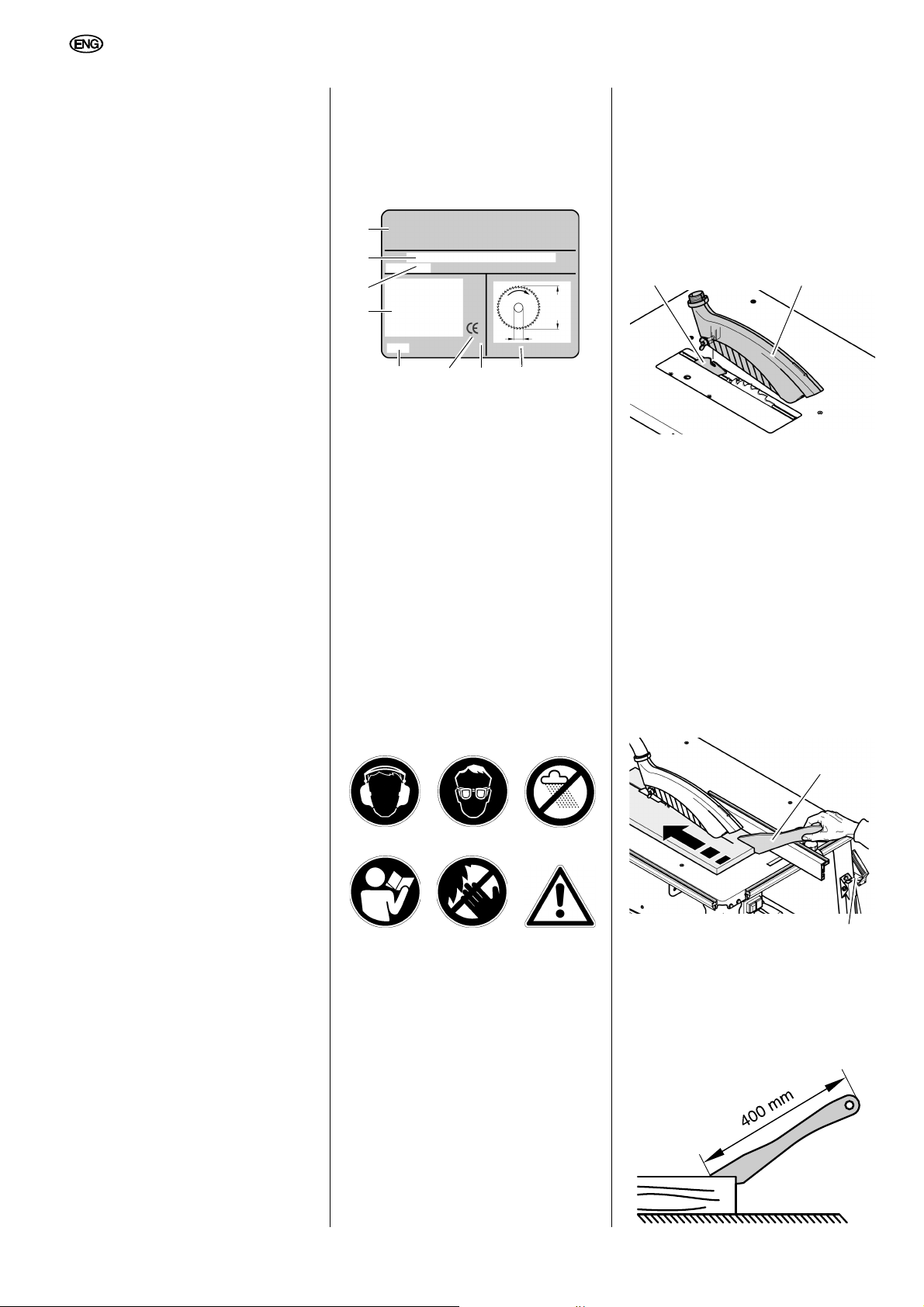

4.4 Safety devices

Riving knife

The riving knife (51) prevents the workpiece from being caught by the rising

teeth of the saw blade and being

thrown back against the operator.

Always have riving knife installed during operation.

Blade guard

The blade guard (52) protects against

unintentional contact with the saw blade and from chips flying about.

Always have the blade guard installed

during operation.

Push stick

The push stick (53) serves as an extension of the hand and protects against

accidental contact with the saw blade.

Always use the push stick if the distance between saw blade and rip

fence is less than 120 mm.

ARisk of injury by noise!

Wear ear protection.

Make sure the riving knife is not

bent. A bent riving knife will push

the workpiece against the side of

the saw blade, causing noise.

ADanger from blocking work-

pieces or workpiece parts!

If blockage occurs:

1. Switch machine OFF.

2. Unplug mains cable.

3. Wear gloves.

26

45 Wear ear protection

46 Wear eye protection

47 Do not operate tool in moist or

wet environment.

48 Read operating instructions

49 Do not reach into saw blade area

50 Hazardous area warning

Guide the push stick at an angle of 20

… 30 against the saw table's surface.

When the push stick is not used, it can

be hung to the holder (54) provided.

Replace the push stick if it is damaged.

Loading...

Loading...