Page 1

Assembly/Operating Instructions

Site Saw BKS 400/BKS 450

Model No. 1001

3305 Stock-no. 115 107 8059

Page 2

Contents

1.0 Scope of Application

2.0 Specifications

3.0 User Responsibility

4.0 Standard Accessories

5.0 Optional Accessories

6.0 Assembly

7.0 Mitre Fence Assembly

8.0 Installation

9.0 Operation/Settings

10.0 Cutting

11.0 Saw Dust Collection (optional accessory)

12.0 Crane Lifting

13.0 Safety Rules

14.0 Care and Maintenance

15.0 Wiring Diagrams

16.0 Spare Parts List and Drawing

1.0 Scope of Application

This site saw model BKS 400/BKS 450 has been designed to perform rip and cross cuts in wood having a

square or rectangular cross section.

Cross cuts should only be performed with the help of the mitre fence.

Round stock or firewood should not be cut without an appropiate jig holding the work safely.

The maximum/minimum blade diameters are 400/350 mm for model BKS 400 and 450/350 mm for model

BKS 450.

2.0 Specifications

BKS 400/3.1 WNB BKS400/4.2 DNB BKS450/4.75DNB

Table size 1000 x 665 mm 1000 x 665 mm 1000 x 665 mm

Table height from floor 850 mm 850 mm 850 mm

Depth of cut 127 mm 127 mm 152 mm

Motor speed 50/60 Hz 2800/3360 rpm 2800/3360 rpm 2800/3360 rpm

Cutting speed 58.5 m/sec 58.5 m/sec 66 m/sec

Motor capacity P1 S6 40% 3.1 kW 4.2 kW 4,75 kW

Motor capacity P2 S1 100% 1.5 kW 2.1 kW 2.4 kW

Voltage 1~ 220/240V 3~ 380/440V 3~ 380/440V

Mains fuse 1 x 16A 3 x 16A 3 x 16A

Max. saw blade diameter 400 mm 400 mm 450 mm

Min. saw blade diameter 350 mm 350 mm 350 mm

Saw blade bore 30 mm dia. 30 mm dia. 30 mm dia.

Note: Saw blade 450mm diameter requires 4.75kW motor. Use of 450mm blades with 3.1kW and 4.2kW

motor voids factory warranty!

3.0 User Responsibility

This machine will perform in conformity with the description contained in the instructions provided. This machine must

be checked periodically. Defective equipment (including service leads) should not be used. Parts that are broken,

missing, plainly worn, distorted or contaminated, should be replaced immediately. Should such repair or replacement

become necessary, it is recommended that such repairs are carried out by qualified persons approved by the equipment

manufacturer or its representative. This machine or any of its parts should not be altered or changed from standard

specifications. The user of this machine shall have the sole responsibility for any malfunction which results from

improper repair by anyone other than qualified persons approved by the equipment manufacturer or its representatives.

Page 3

Note

Within the U.K., this machine falls under the Woodworking Machinery Regulations 1974, under which certain

operations, e.g. grooving, rebatting, tenoning and moulding are prohibited without special guards. For your own safety

it is recommended to follow the instructions given in the Health and Safety at Work booklet No.41, entitled “Safety in

the Use of Woodworking Machines” and “A Guide to Woodworking Machinery Regulations” HS(R)9. Both publications

are available from Her Majesty’s Stationary Office and other bookshops.

The information contained in this manual is intended to make the operator of this saw familiar with its safety features,

setting of guards and fences, and the safe performance of the different basic cutting operations normally carried out

with this type of saw. It does not teach the operator how to become an expert woodworker. Those persons interesting

in gaining a more intimate knowledge on the tasks which can be carried out on this type of saw are advised to refer to

commercially available literature on the subject.

4.0 Standard Accessories

Saw blade

Riving knife DIN 38820 Gr. 50x3

Saw blade guard

Rip fence

Mitre fence

Lifting eyes

Push stick

Tool set

Operating instructions

-

5.0 Optional Accessories

For the metabo Site Saws BKS the following accessories are available at extra cost:

-

Sliding Carriage BKS/BKH Stock-no. 0910 00666 5

-

Extension Table BKS/BKH Stock-no. 0910 00667 3

-

Dust Extraction Adaptor BKS 100mm Stock-no. 0910 00874 9

-

Log Cutting Attachment BKS/BKH Stock-no. 0910 00886 2

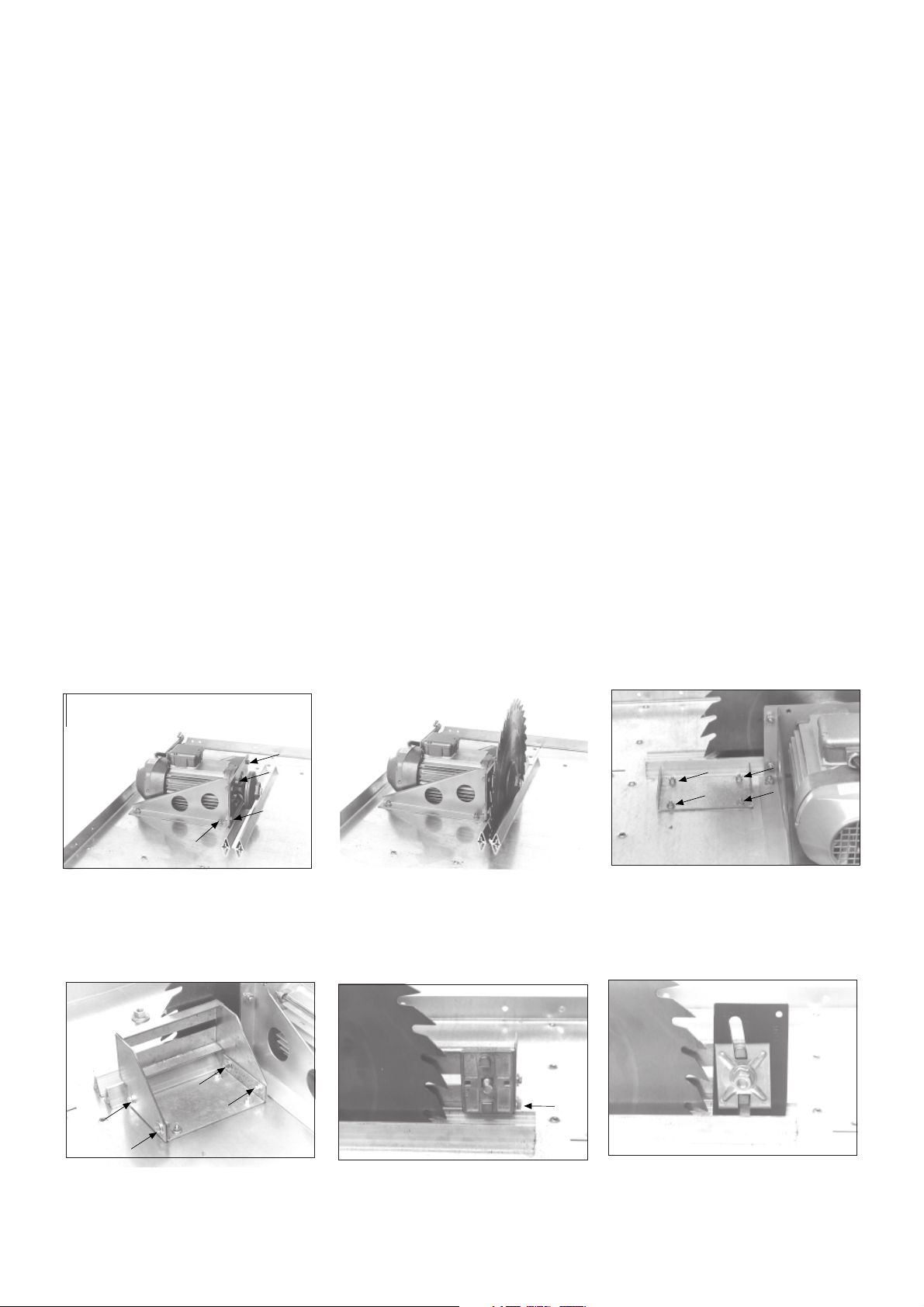

6.0 Assembly

Place table onto firm support (e.g. saw horses).

Attach table insert (aluminium extrusion) to table; use 10 pcs. countersunk flat-head screw 4.2x13. Bolt rip fence guide

extrusion to front of table.

Bolt both support brackets to the motor. Use 4

each hex. head screw M8x16 hex. nut M8.

Attach the thus preassembled motor to the

table, but do not yet tighten fully. Use 4 each

countersunk screw M8x16

hex.nut M8

washer 8.4

Install saw blade onto motor, than align motor

so that the saw blade is centered in the table

insert’s slot.

When positioned correctly fully tighten the

motor on the table.

Attach mounting plate for the riving knife carrier bracket to the table.

Use 4 each

countersunk screw M6x16

hex. nut M6

Attach riving knife carrier bracket loosely to

mounting plate.

Use 4 each

hex. head screw M6x16

washer 6.4

hex. nut M6

top

Place carriage bolt M12x30 into slot of carrier

braand slide riving knife carrier onto bolt. The

imprint “Oben” must point towards the table.

Mount riving knife and secure in place with

pressure plate and self-locking hex. nut M12.

Align riving knife with saw blade, then fully tighten the screws ficing the riving knife carrier

bracket to the mounting plate.

Page 4

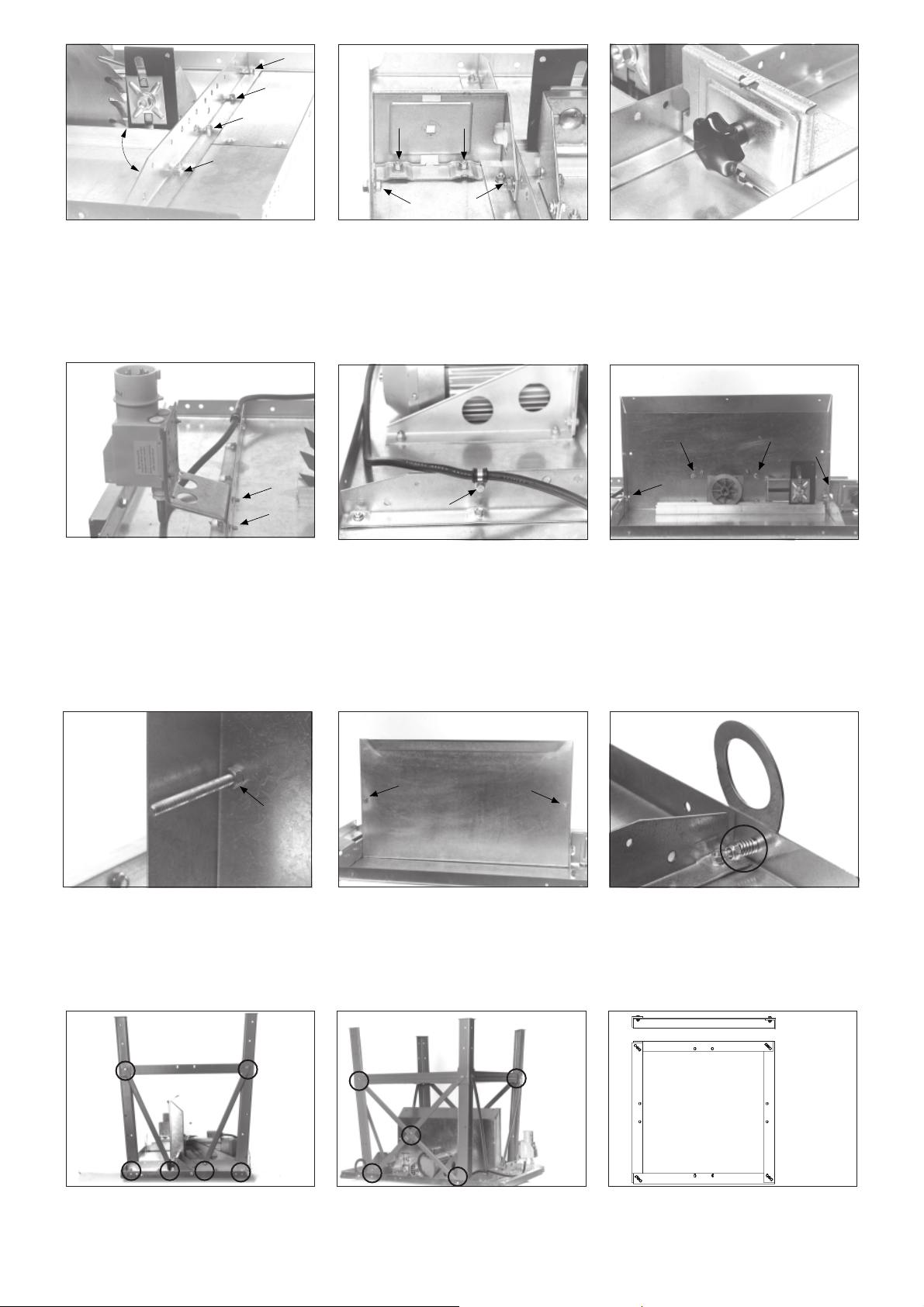

90°

Place both support struts onto the table, set

square with the slot of the table insert and bolt

to the table. Use 10 each

countersunk screw M6x16,

hex. nut M6

Bolt switch to front support strut. Use 2 each

hex. head bolt M6x16

torque type hex. nut M6

Install the guard support bracket without fully

tightening the screws.

Use 2 each

countersunk screw M6x16, hex. nut M6,

hex. head screw M8x16,

hex. nut M8

Attach strain relief clamp to support strut. Use

hex. head bolt M6x16

hex. nut M6

Attach gusset plate with carriage bolt M10x25,

washer 10.5 and starknob M10

Remove saw blade and bolt chip case to both

support struts and motor plate. Hardware:

4 ea. hex head screw M8x16

4 ea. hex. nut M8

2 ea. hex. head bolt M6x16

2 ea. washer 6.4

2 ea. hex. nut M6

Install both hex. head bolts M8x90 into chipcase, secure with hex. nuts M8

Install legs with struts and diagonal struts to table.

- Tighten all screws handtight only at this stage. - Install struts as shown in drawing “A”.

Hardware: 22 each hex. head bolt M8x16; 4 each hex. head bolt M8x20; 26 each hex. nut M8

Re-install saw blade, be sure of correct direction of rotation. Install chip case lid. Use 2 each

torque type hex. nut M8

Bolt lifting eyes to table (at rear left and front

right). Place pressure spring onto bolt before

screwing on nut. Use 2 each

hex. bolt M8x35

pressure spring 9x20

torque type hex. nut M8

"A"

Turn saw over and stand onto its legs.

Align and fully tighten all screws.

Page 5

Place guard support into guard support brakket. Align with blade and riving knife and to

exact 90 against the table by moving the not

yet fully tightened guard support bracket. Tighten.

Note: An improperly set up guard support may

cause personal injury to the operator.

Install the hex. socket head screw holding the

push stick to the front left leg. Hardware:

1 hex. socket head screw M6x30

2 each hex. nut M6

Install bolt for holding the rip fence to front right

leg. Use hex. nut M8 and bolt M8

7.0 Mitre Fence Assembly

Cross cuts and mitre cuts must not be carried out without a suitable cross-cutting attachment (sliding carriage or

-

mitre fence).

If no mitre fence is installed use the Sliding Carriage stock-no. 091 000 06665.

Bolt guide rod brackets to front and rear of

table. Use 4 each

hex. head bolt M8x16

hex. nut M8

Screw vernier scale carrier to mitre fence carrier with raised countersunk head tapping screw

4.8x13

Slide both plastic guide bushes onto guide rod,

then bolt guide rod to brackets. Use 2 hex.

head bolts M8x20.

Screw vernier scale to vernier scale carier with

2 each raised countersunk head tapping screw

2.9x6.5

Bolt mitre fence carrier to guide bushes. Use 8

raised countersunk tapping screws 4.8x22.

Install adjustable backstop on mitre fence segment. Hardware:

1 hex. head bolt M6x20

2 hex. nut M6

1 washer 6.4

Place wave spring washer onto fitting bolt and

plastic glide piece into mitre fence carrier.

Place mitre fence segment onto carrier and

screw fitting bolt through segment into glide

piece.

Hardware:

fitting bolt SW 19x42

spring washer 12

plastic glide piece with threaded bush.

Attach mitre scale to segment using 3 each

tapping screw 3.9x9.5

washer 4.3

Page 6

7.1 Mitre Fence Setting

Place carriage bolt M10x30 from underneath

through carrier and slot of fence segment.

Install washer Ø 10.5 and ratched lever M10

female.

Install 0° (90°) setting screw into mitre fence

carrier.

Hardware:

1 set screw M8x20

2 hex. thin nut M8

A

To set mitre fence square with the blade turn

setting screw in or out, as required.

B

Make trial cut to verify setting.

C

Loosen mitre scale and adjust so that zero

mark corresponds with mark on vernier scale,

then retighten.

8.0 Installation

8.1 Setup

This saw must be placed on a firm and level ground. The work area must be kept clear of all waste to provide firm

footing for the operator.

8.2 Connection to Power Mains

Check if voltage of power mains matches with voltage stated on machine’s name plate. This machine must be

-

earthed while in use to protect the operator from electric shock.

Models BKS400/3.1 kW must be connected to an earthed outlet with a 3-conductor mains lead.

-

Models BKS 450/4.2 kW and 4.75 kW have to be connected to an earthed outlet with a 5-conductor mains lead.

-

A minimum conductor cross section of 1.5mm /16 AWG is required. For the 3.1kW single-phase motor extension

-

cords should have a conductor cross section of 2.5mm .

Use of an extension cord with too small a conductor cross section causes voltage drop and consequently starting

-

problems and excessive heat build-up in the motor.

8.3 Saw Blade Direction of Rotation

On single-phase machines the saw blade’s direction

of rotation does not need to be checked.

For three-phase machines start saw briefly with all

guards in place and check direction of rotation. If

incorrect interchange two phases by rotating two pins

in the switch by 180°. Remove plug, use screwdriver

with 6mm/1/4" blade to push lock down and turn pins.

To prevent unauthorized use the switch can be blok-

ked with a padlock.

Page 7

8.4 Switch/Motor Protection/Motor Brake

The magnetic switch does not engage if not connected

to power mains. It disengages in the event of a power

failure (no-volt release). When the power is restored the

machine has to be started again.

The built-in motor protection relay switches the motor off

in case it becomes too hot. If this has happened let motor

cool down for at least 10 minutes before starting again.

Three-phase motors are equipped with a mechanical

brake, which is designed for a long service life. If the

blade needs more than 10 sec. to come to a complete

standstill the brake has to be replaced. Check with your

metabo dealer for replacement.

An inoperative motor brake increases danger of injury!

9.0 Operation/Settings

9.1 Riving Knife Setting

Disconnect from power before servicing!

The riving knife prevents the work from closing behind the blade, thus stalling it and causing kickback.

Set riving knife as close as possible against the blade. The gap between riving knife and blade must not exceed

10mm/3/8 “. Do not set top of riving knife lower than 2mm-5/64” below the blade’s crown.

9.2 Blade Change

Disconnect from power before servicing!

Remove chip case lid and loosen arbor bolt. Remove

arbor bolt and counter flange, then take off blade.

Note: Arbor bolt has L.H. thread, turn clockwise to

loosen.

Before installing new blade clean blade seat and apply a light coat of oil to the arbor bolt.

Be sure that teeth are pointing in direction of rotation. Tighten arbor bolt carefully. Replace chip case lid and nuts

securing it in place.

Operation without chip case lid in place may cause personal injury!

Page 8

9.3 Rip Fence Setting/Adjusting

Set rip fence to required width of cut. Distance from blade

is shown on the rip fence scale.

Lock rip fence in position by pushing the cam-lock

lever down.

If rip fence is not required it can be hung to the bolt on

the right leg.

9.4 Saw Blade Guard

After loosening the starknob on the guard support brakket the complete guard assembly can be removed.

Risk of personal injury when saw is operated without blade guard in place!

Attention!

Remove/install blade guard only with blade at

complete standstill.

Danger of injury!

Loosen scale fixing screw to adjust rip fence scale to give

exact reading of width of cut.

Make trial cut to verify setting.

Loosen the ratched lever to adjust the blade guard position. Set blade guard about 8mm/3/8“ higher than the

workpiece’s thickness.

Attention! Set blade guard only with blade at complete standstill. Danger of injury!

Page 9

10.1 Ripping/Through Sawing

10.0 Cutting

Have riving knife and blade guard in

place - danger of injury.

10.2 Through Cross/Mitre Cuts

Set blade guard to thickness of workpiece.

Important!

-

Have blade at complete standstill before making adjustments - Disconnect

machine from power before setting riving knife

-

If width of cut is less than 120mm-41/2” always use a push stick to feed the

work

Set rip fence to desired width of cut

and lock in position.

A - Have riving knife and blade guard

in place - danger of injury.

D - Push mitre and work forward to

feed into blade

B - Swing mitre fence onto table and

set to required angle

E - When cut is completed pull back

both mitre fence and work

C - Pull mitre fence back and place

work against it.

- Start machine

Page 10

10.3 Cutting Wedges

A - Place work firmly into wedge

cutting jig and set to desired angle.

- Start machine

B - Push mitre fence forward to feed

work into blade.

When cut is complete pull mitre fence

back.

11.0 Saw Dust Collection (optional accessory)

If this machine is operated in enclosed spaces it must be connected to a saw dust collection device.

The dust collection device must have a minimum air flow rate of 20 m/sec.

Connection to dust collector with 100 mm/4" diameter flexible suction hose.

-

12.0 Crane Lifting

For crane lifting swing both lifting eyes, attached to table, upwards.

13.0 Safety Rules

As with all power tools there is a certain amount of hazard involved with the

operator and his use of the machine. Using the machine with the respect and

caution demanded as far as safety precautions are concerned will considerably lessen the possibility of personal injury. If, however, normal safety precautions

are overlooked or completely ignored, personal injury to the operator can

develop.

1.

FOR YOUR OWN SAFETY; READ AND UNDERSTAND INSTRUCTION MANUAL BEFORE OPERATING THE

SAW:Learn the saw’s applications as well as the specific hazards peculiar to it.

2.

KEEP GUARDS IN PLACE and in working order.

3.

REMOVE ALL ADJUSTING KEYS AND WRENCHES: Form habit of checking to see that all keys and adjusting

wrenches are removed from tool before switching it “ON”.

4.

ALWAYS USE SAW BLADE GUARD AND RIVING KNIFE for every operation for which they can be used,

including through sawing. Through sawing operations are those when the blade cuts completely through the work

piece as in ripping or cross cutting.

5.

ALWAYS HOLD WORK FIRMLY AGAINST RIPFENCE OR MITRE FENCE.

6.

USE PUSH-STICK if distance between blade and rip fence is less than 120mm/5".

7.

NEVER PERFORM ANY OPERATION “FREE-HAND”.

8.

NEVER REACH BEHIND, OVER OR UNDER THE CUTTING TOOL WITH EITHER HAND FOR ANY REASON.

Keep hands away from saw blade; do not reach into area 120mm left and right of saw blade.

9.

DIRECTION OF FEED: Feed work into saw blade against direction of rotation only.

10.

AVOID KICKBACKS (work thrown back at you) by keeping the rip fence parallel to the blade, keeping riving knife

and guards in place and operating, by not releasing work before it is pushed all the way past the saw blade, and

by not ripping stock that is twisted or warped or does not have a straight edge to guide along the fence.

13.1 Problems

If saw blade is stalled by waste, or the discharge port of the chip case clogged, switch machine off and let blade come

to a complete standstill before attempting to remove obstruction.

Switch motor off immediately if blade has stalled. A dull blade is most often the cause for what appears to be a loss

of power of the motor.

An extremely dull blade leaves burn marks in the kerf. Replace or resharpen at once.

After a power failure the machine has to be switched on again.

-

14.0 Care and Maintenance

-

Always disconnect from power before servicing. Do not rely on switch alone.

-

This machine requires very little maintenance

-

When changing the saw blade apply a light coat of oil to the arbor bolt.

-

Regularly apply a light coat of oil to the mitre fence guide rod.

14.1 Tool Maintenance

Residue resin built-up on the saw blade(s) should be removed regularly. Immerse blade in a natrium carbonate solution

or in paraffin/kerosene or mineral turpentine for 24 hours. The residue resin is then easily wiped off with a rag.

Page 11

Page 12

U4BA_M1.FM

Achtung!

Diese Seite ersetzen durch „ More of metabo- tools “

Attention!

Please replace this page by „ More of metabo - tools “

Loading...

Loading...